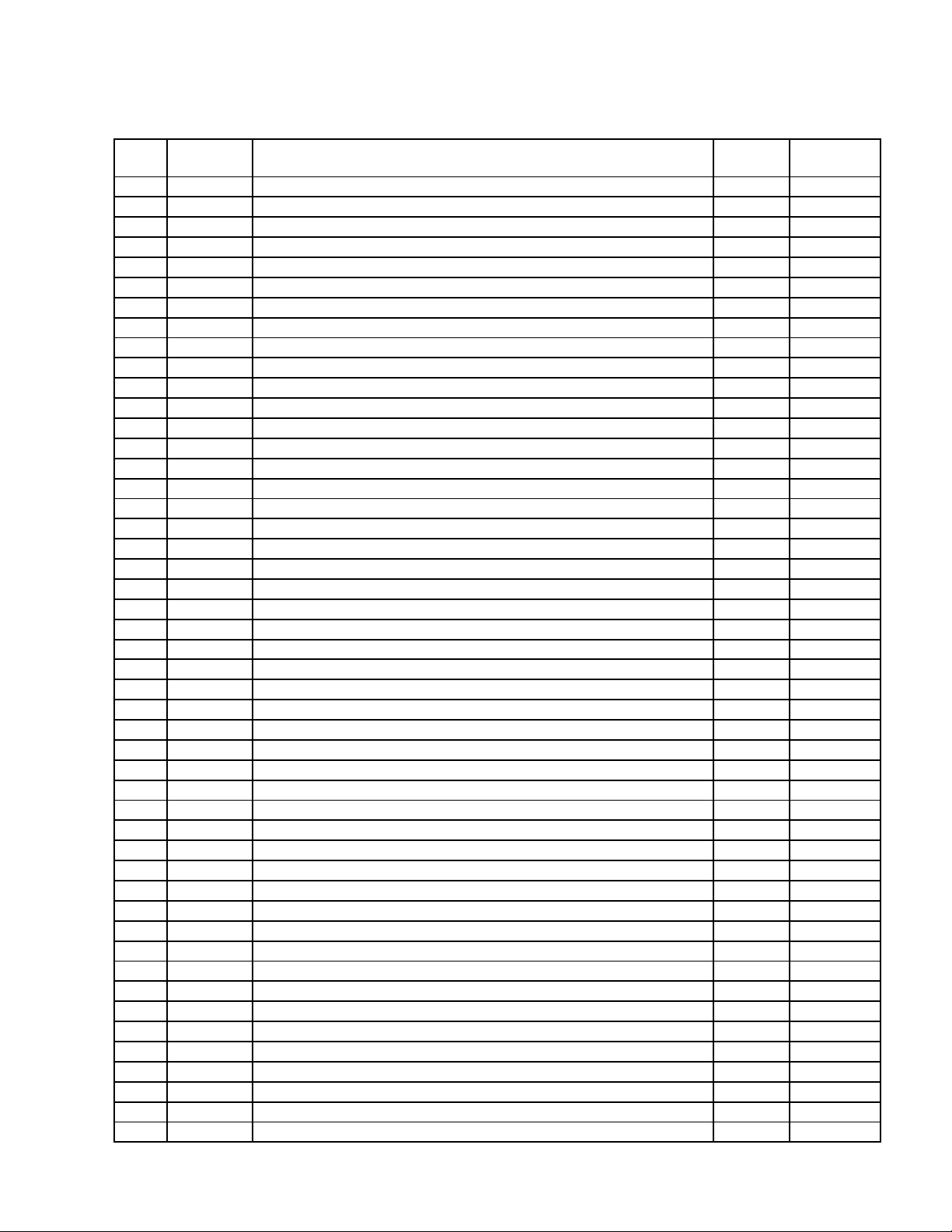

HISTORY INFORMATION FOR THE FOLLOWING MANUAL:

SERVICE MANUAL

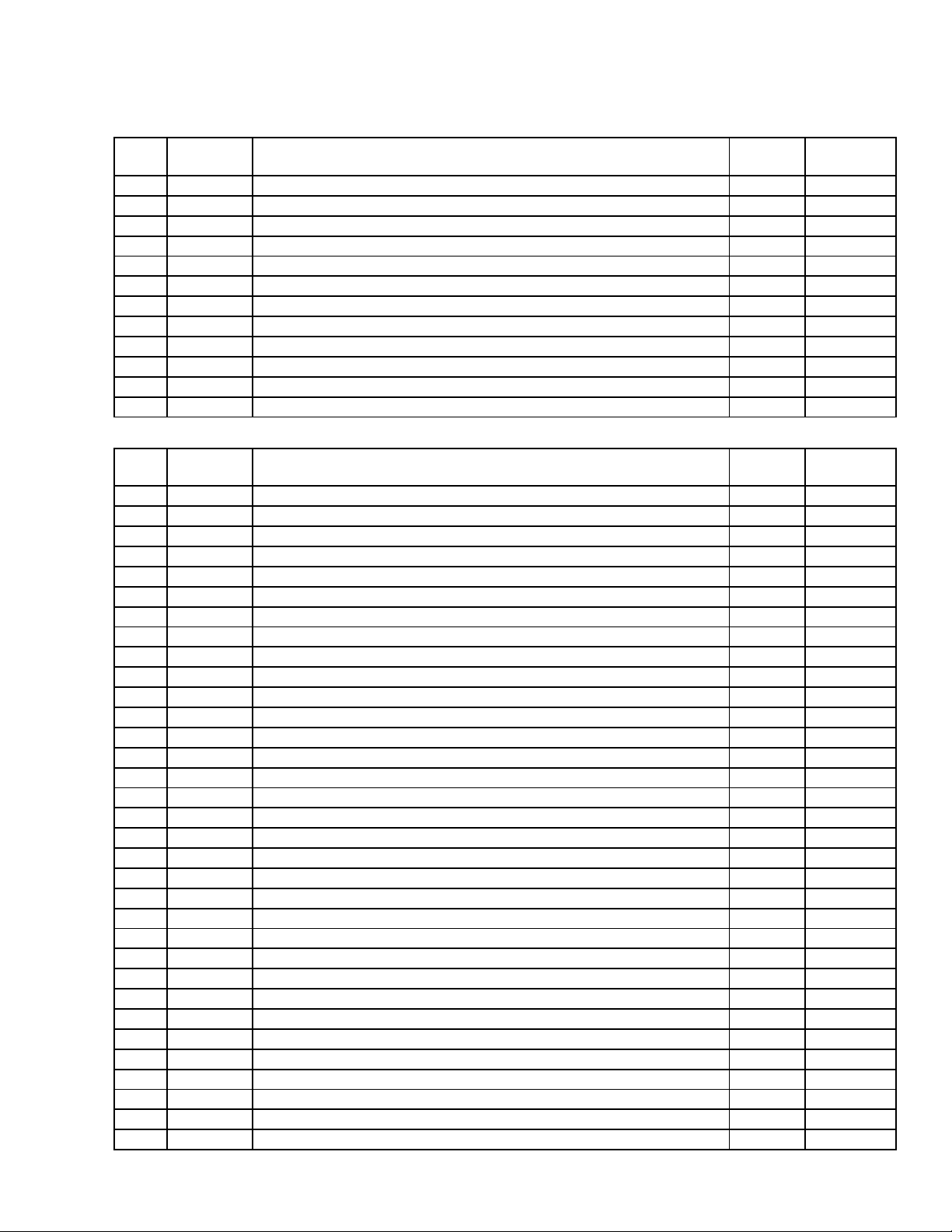

MODEL NAME REMOTE COMMANDER DESTINATION CHASSIS NO.

KV-20FS100

KV-20FS100

KV-20FV300

KV-20FV300

KV-21FM100

KV-21FM100

KV-21FS100

KV-21FS100

KV-21FV300

KV-21FV300

KV-24FV300

RM-Y173 US SCC-S61A-A

RM-Y173 CND SCC-S59A-A

RM-Y180 US SCC-S61B-A

RM-Y180 CND SCC-S59B-A

RM-Y172 LATIN NORTH SCC-S60E-A

RM-Y172 LATIN SOUTH SCC-S60F-A

RM-Y173 LATIN NORTH SCC-S60A-A

RM-Y173 LATIN SOUTH SCC-S60B-A

RM-Y180 LATIN SOUTH SCC-S60D-A

RM-Y180 LATIN NORTH SCC-S60C-A

RM-Y180 US SCC-S61C-A

BA-6

CHASSIS

KV-24FV300

KV-25FV300

KV-25FV300

RM-Y180 CND SCC-S59C-A

RM-Y180 LATIN NORTH SCC-S60G-A

RM-Y180 LATIN SOUTH SCC-S60H-A

ORIGINAL MANUAL ISSUE DATE: 2/2002

ALL REVISIONS AND UPDATES TO THE ORIGINAL MANUAL ARE APPENDED TO THE END OF THE PDF FILE.

REVISION DATE REVISION TYPE SUBJECT

2/2002 No revisions or updates are applicable at this time.

9-965-922-01

TRINITRON® COLOR TELEVISION

Self Diagnosis

Supported model

SERVICE MANUAL

MODEL NAME REMOTE COMMANDER DESTINATION CHASSIS NO.

KV-20FS100

KV-20FS100

KV-20FV300

KV-20FV300

KV-21FM100

KV-21FM100

KV-21FS100

KV-21FS100

KV-21FV300

KV-21FV300

KV-24FV300

RM-Y173 US SCC-S61A-A

RM-Y173 CND SCC-S59A-A

RM-Y180 US SCC-S61B-A

RM-Y180 CND SCC-S59B-A

RM-Y172 LATIN NORTH SCC-S60E-A

RM-Y172 LATIN SOUTH SCC-S60F-A

RM-Y173 LATIN NORTH SCC-S60A-A

RM-Y173 LATIN SOUTH SCC-S60B-A

RM-Y180 LATIN SOUTH SCC-S60D-A

RM-Y180 LATIN NORTH SCC-S60C-A

RM-Y180 US SCC-S61C-A

BA-6

CHASSIS

KV-24FV300

KV-25FV300

KV-25FV300

RM-Y180 CND SCC-S59C-A

RM-Y180 LATIN NORTH SCC-S60G-A

RM-Y180 LATIN SOUTH SCC-S60H-A

KV-24FV300

RM-Y180

9-965-922-01

TRINITRON® COLOR TELEVISION

KV-20FS100/20FV300/21FM100/21FS100/

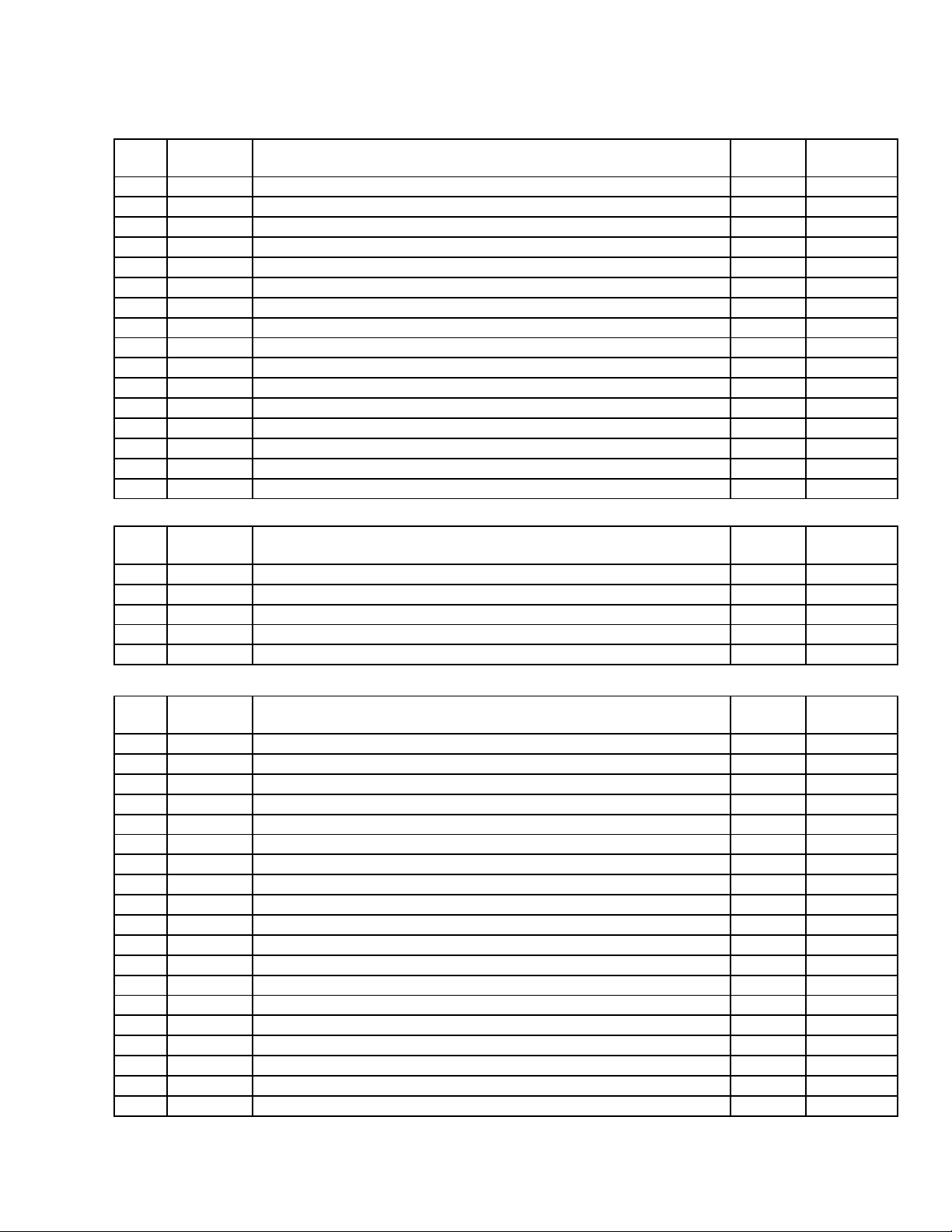

TABLE OF CONTENTS

SECTION TITLE PAGE

SpeciÞ cations........................................................................................................................................ 4

Warnings and Cautions ........................................................................................................................ 5

Safety Check-Out.................................................................................................................................. 6

Self-Diagnostic Function ....................................................................................................................... 7

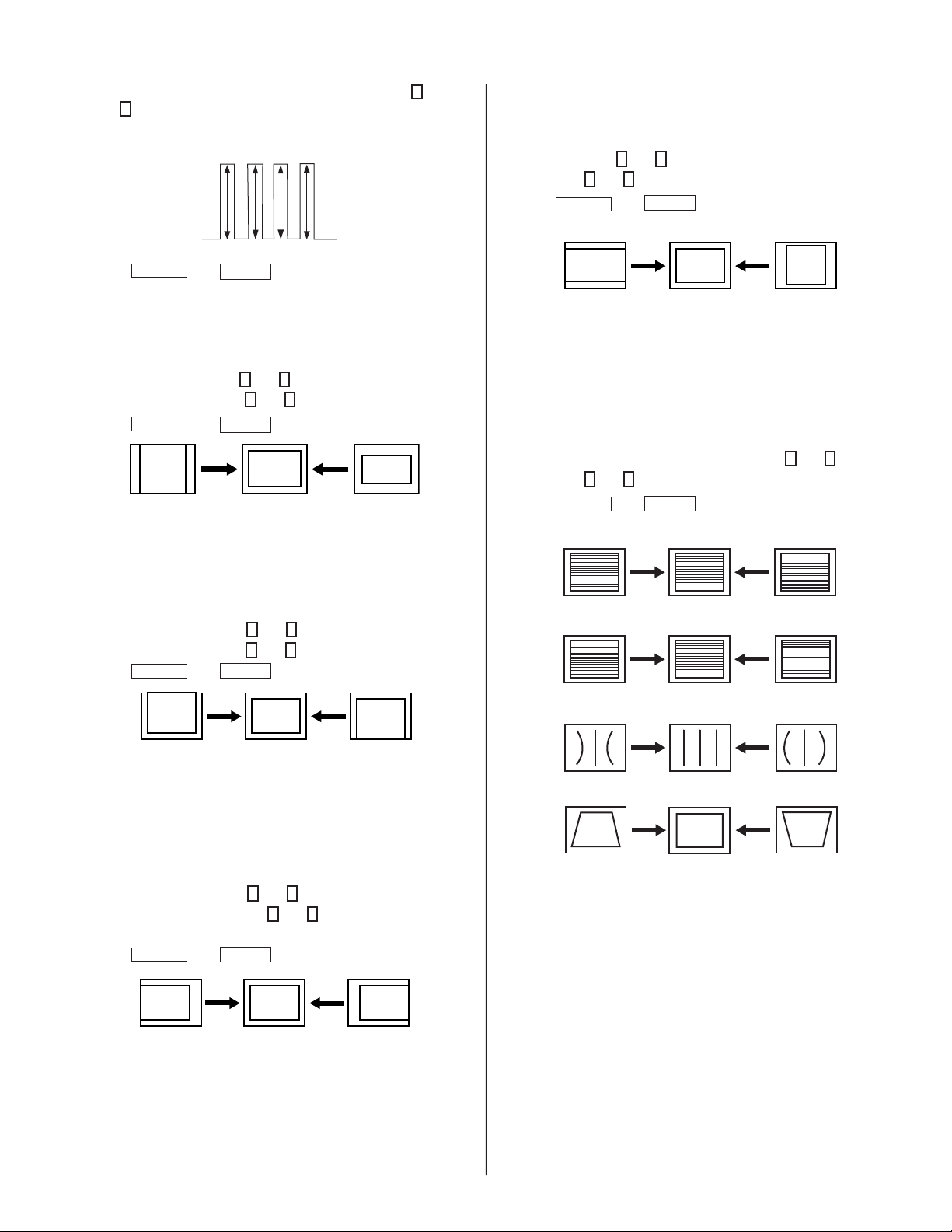

1. Disassembly

1-1. Rear Cover Removal...................................................................................................................... 9

1-2. Chassis Assembly Removal .......................................................................................................... 9

1-3. Service Position ............................................................................................................................. 9

1-4. Picture Tube Removal.................................................................................................................. 10

Anode Cap Removal Procedure.................................................................................................. 10

2. Set-Up Adjustments

2-1. Beam Landing.............................................................................................................................. 11

2-2. Convergence................................................................................................................................ 12

2-3. Focus ........................................................................................................................................... 13

2-4. Screen (G2) ................................................................................................................................. 13

2-5. Method of Setting the Service Adjustment Mode......................................................................... 14

2-6. White Balance Adjustments......................................................................................................... 14

21FV300/24FV300/25FV300

3. Safety Related Adjustments

3-1.

3-2. B+ Voltage ConÞ rmation and Adjustment .................................................................................... 15

4. Circuit Adjustments

4-1. Setting the Service Adjustment Mode.......................................................................................... 17

4-2. Memory Write ConÞ rmation Method ............................................................................................ 17

4-3. Remote Adjustment Buttons and Indicators ................................................................................ 17

Adjustment Items ........................................................................................................................ 18

4-4. ID Map Table................................................................................................................................ 26

4-5. A Board Adjustments ................................................................................................................... 26

5. Diagrams

5-1. Circuit Boards Location................................................................................................................ 29

5-2. Printed Wiring Board and Schematic Diagram Information ........................................................ 29

5-3. Block Diagram and Schematics ................................................................................................... 30

A Board Schematic Diagram....................................................................................................... 31

CV Board Schematic Diagram ....................................................................................................41

HR Board Schematic Diagram ....................................................................................................43

M3 Board Schematic Diagram ....................................................................................................44

5-4. Semiconductors ........................................................................................................................... 46

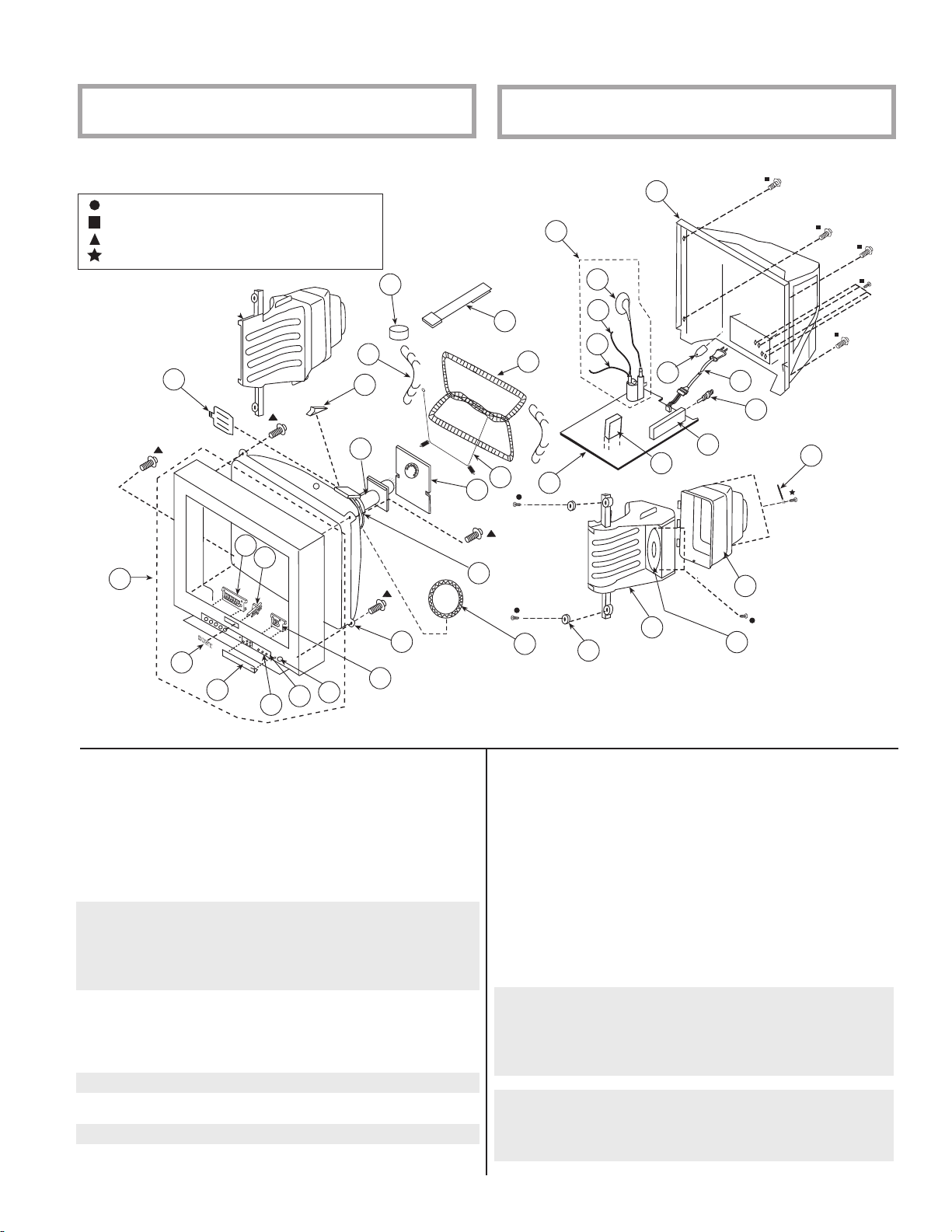

6. Exploded Views

6-1. Chassis (KV-21FM100 ONLY)..................................................................................................... 47

6-2. Chassis (KV-20FS100/21FS100 ONLY)...................................................................................... 48

6-3. Chassis (KV-20FV300/21FV300 ONLY)...................................................................................... 49

6-4. Chassis (KV-24FV300/25FV300 ONLY)...................................................................................... 50

X

R565 ConÞ rmation Method (HV Hold Down ConÞ rmation) and Readjustments.................... 15

7. Electrical Parts List ..................................................................................................................................... 51

— 3 —

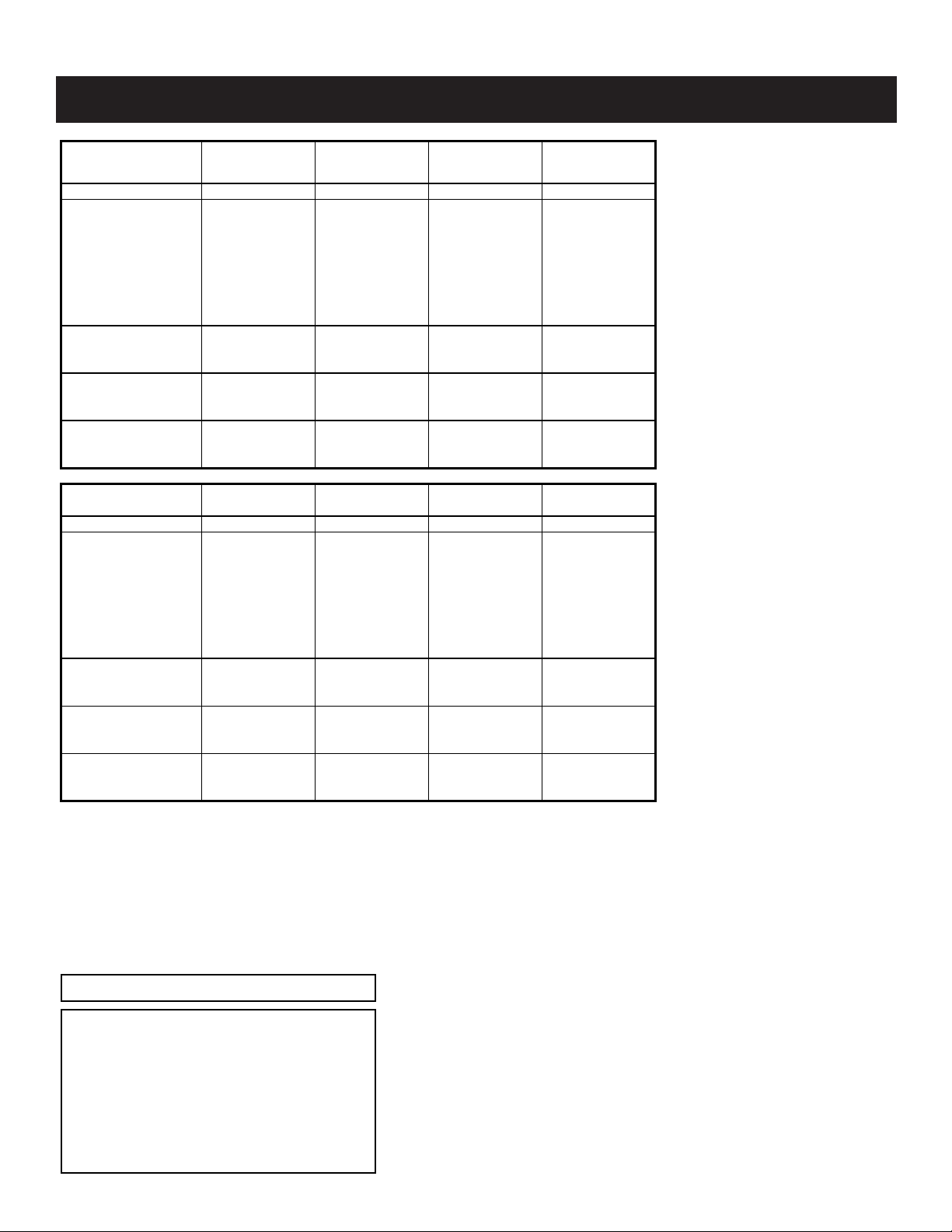

SPECIFICATIONS

KV-20FS100/20FV300/21FM100/21FS100/

21FV300/24FV300/25FV300

KV-21FM100 (N) KV-21FM100 (S) KV-21FS100 (S)

21FS100 (N)

Power requirements 120V, 60Hz 220V, 50/60Hz 220V, 50/60Hz 120V, 60Hz

KV-20FS100/

Number of Inputs/Outputs

Y,P

Audio Out

Speaker output (W) 3Wx2 3Wx2 5Wx2 5Wx2

Headphones

Video

S Video

B,PR

Audio

1)

2)

3)

4)

5)

5)

2222

0000

0011

2244

0000

1111

Power Consumption (W)

In use (Max) 115W 110W 115W 120W

In Standby 1W 1W 1W 1W

Dimensions(W/H/D)

mm 592 x 466 x 494 mm 592 x 466 x 494 mm 592 x 466 x 494 mm 592 x 466 x 494 mm

1/4

3/8

1/2

1/4

3/8

1/2

1/4

3/8

1/2

1/4

in 23

x18

x19

23

x18

x19

23

x18

x19

23

x18

3/8

x19

Mass

kg 24.8 kg 24.8 kg 24.8 kg 24.8 kg

54 lbs. 11 oz. 54 lbs. 11 oz. 54 lbs. 11 oz. 54 lbs. 11 oz.

lbs

KV-20FV300/

21FV300 (N) KV-21FV300 (S)

KV-24FV300/

25FV300 (N) KV-25FV300 (S)

Power requirements 120V, 60Hz 220V, 50/60Hz 120V, 60Hz 220V, 50/60Hz

Number of Inputs/Outputs

Y,P

Audio Out

Speaker output (W) 10Wx2 10Wx2 10Wx2 10Wx2

Headphones

Video

S Video

B,PR

Audio

1)

2)

3)

4)

5)

5)

2222

1111

1111

4444

1111

1111

Power Consumption (W)

In use (Max) 155W 155W 180W 180W

In Standby 1W 1W 1W 1W

Dimensions(W/H/D)

mm 609 x 463 x 502 mm 609 x 463 x 502 mm 762 x 625 x 570 mm 762 x 625 x 570 mm

in 24x18

1/4

x19

3/4

24 x 18

1/4

x19

3/4

30 x 22

7/16

x24

5/8

30 x 24

5/8

x22

Mass

kg 27 kg. 27 kg. 37 kg 37 kg

59 lbs. 8 oz. 59 lbs. 8 oz. 81 lbs. 9 oz. 81 lbs. 9 oz.

lbs

7/16

1/2

1)

1 Vp-p 75 ohms unbalanced, sync negative

2)

Y: 1 Vp-p 75 ohms unbalanced, sync negative

C: 0.286 Vp-p (Burst signal), 75 ohms

3) Y: 1.0 Vp-p, 75 ohms, sync negative; PB: 0.7 Vp-p, 75 ohms;

PR Vp-p, 75 ohms.

4)

500 mVrms (100% modulation), Impedance: 47 kilohms

5)

More than 408 mVrms at the maximum volume setting (variable)

More than 408 mVrms (Þ x); Impedance (output): 2 kilohms

Television system

Visible screen size

American TV Standard, NTSC

Channel coverage

VHF: 2-13/ UHF: 14-69/ CATV: 1-125

Actual screen size

Picture tube

FD Trinitron® tube

( • ) SRS (SOUND RETRIEVAL SYSTEM)

The ( • ) SRS (SOUND RETRIEVAL SYSTEM) is

manufactured by Sony Corporation under license

from SRS Labs, Inc. It is covered by U.S. Patent No.

4,748,669. Other U.S. and foreign patents pending.

The word ‘SRS’ and the SRS symbol ( • ) are

registered trademarks of SRS Labs, Inc.

BBE and BBE symbol are trademarks of BBE Sound,

Inc. and are licensed by BBE Sound, Inc. under U.S.

Patent No. 4,638,258 and 4,482,866.

20/21-20 inch picture measured diagonally

24/25-24 inch picture measured diagonally

20/21-21 inch measured diagonally

24/25-25 inch measured diagonally

— 4 —

Antenna

75 ohm external terminal for VHF/UHF

Supplied Accessories

Remote Commander:

RM-Y172

(KV-21FM100 ONLY)

RM-Y173

(KV-20FS100/21FS100 ONLY)

RM-Y180

(KV-20FV300/21FV300/24FV300/25FV300 ONLY)

Size AA (R6) batteries (2)

Antenna, Telescopic

(KV-21FM100/21FS100/21FV300/25FV300 ONLY)

Design and speciÞ cations are subject to change without notice.

KV-20FS100/20FV300/21FM100/21FS100/

21FV300/24FV300/25FV300

WARNINGS AND CAUTIONS

CAUTION

Short circuit the anode of the picture tube and the anode cap to the metal chassis, CRT shield, or carbon painted on the CRT,

after removing the anode.

WARNING!!

An isolation transformer should be used during any service to avoid possible shock hazard, because of live chassis. The chassis of

this receiver is directly connected to the AC power line.

! SAFETY-RELATED COMPONENT WARNING!!

Components identifi ed by shading and ! mark on the schematic diagrams, exploded views, and in the parts list are critical for

safe operation. Replace these components with Sony parts whose part numbers appear as shown in this manual or in supplements

published by Sony. Circuit adjustments that are critical for safe operation are identifi ed in this manual. Follow these procedures

whenever critical components are replaced or improper operation is suspected.

ATTENTION!!

Apres avoir deconnecte le cap de l’anode, court-circuiter l’anode du tube cathodique et celui de l’anode du cap au chassis metallique

de l’appareil, ou la couche de carbone peinte sur le tube cathodique ou au blindage du tube cathodique.

Afi n d’eviter tout risque d’electrocution provenant d’un chássis sous tension, un transformateur d’isolement doit etre utilisé lors de tout

dépannage. Le chássis de ce récepteur est directement raccordé à l’alimentation du secteur.

! ATTENTION AUX COMPOSANTS RELATIFS A LA SECURITE!!

Les composants identifi es par une trame et par une marque ! sur les schemas de principe, les vues explosees et les listes de

pieces sont d’une importance critique pour la securite du fonctionnement. Ne les remplacer que par des composants Sony dont

le numero de piece est indique dans le present manuel ou dans des supplements publies par Sony. Les reglages de circuit dont

l’importance est critique pour la securite du fonctionnement sont identifi es dans le present manuel. Suivre ces procedures lors de

chaque remplacement de composants critiques, ou lorsqu’un mauvais fonctionnement suspecte.

— 5 —

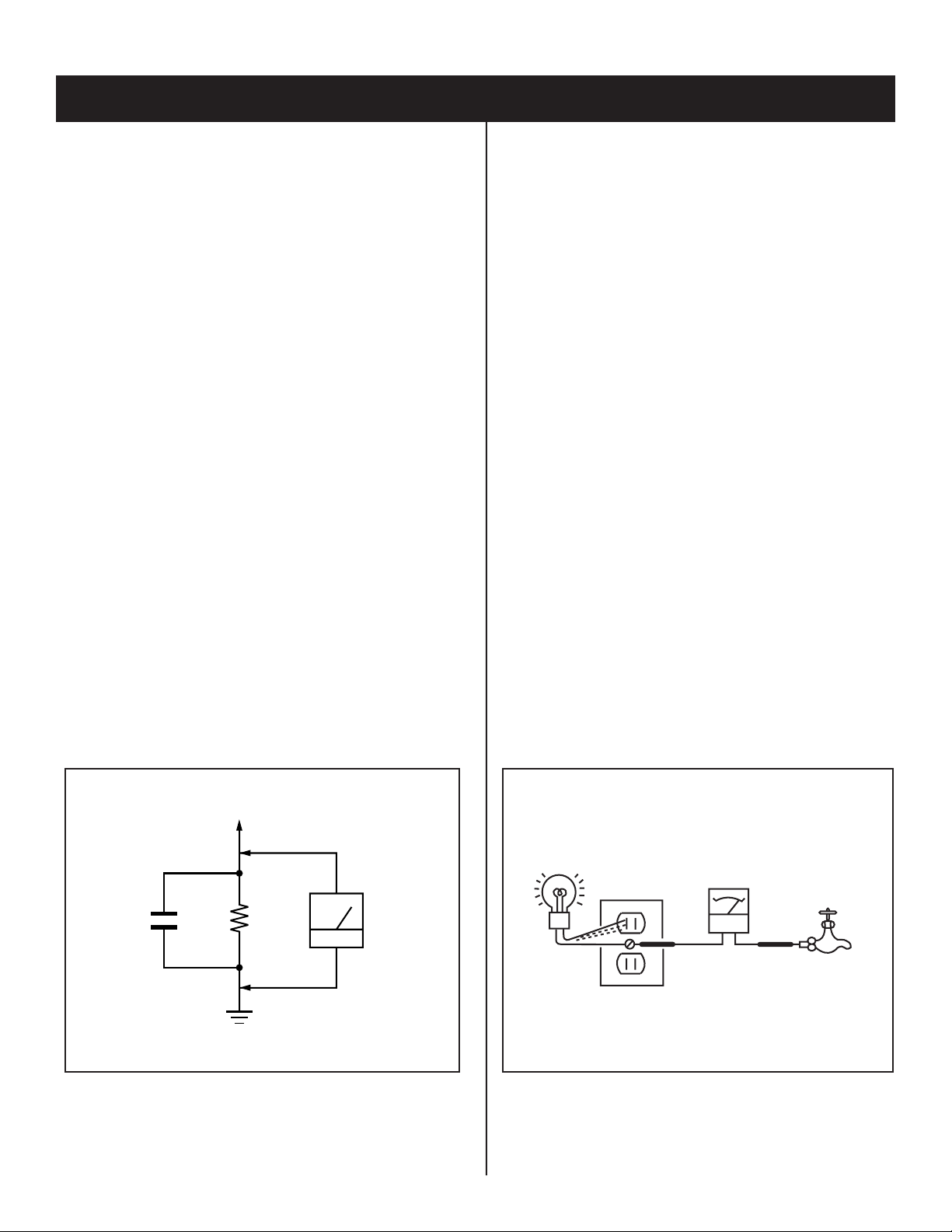

SAFETY CHECK-OUT

KV-20FS100/20FV300/21FM100/21FS100/

21FV300/24FV300/25FV300

After correcting the original service problem, perform the following

safety checks before releasing the set to the customer:

1. Check the area of your repair for unsoldered or poorly soldered

connections. Check the entire board surface for solder splashes and

bridges.

2. Check the interboard wiring to ensure that no wires are “pinched” or

touching high-wattage resistors.

3. Check that all control knobs, shields, covers, ground straps, and

mounting hardware have been replaced. Be absolutely certain that

you have replaced all the insulators.

4. Look for unauthorized replacement parts, particularly transistors, that

were installed during a previous repair. Point them out to the customer

and recommend their replacement.

5. Look for parts which, though functioning, show obvious signs of

deterioration. Point them out to the customer and recommend their

replacement.

6. Check the line cords for cracks and abrasion. Recommend the

replacement of any such line cord to the customer.

7. Check the B+ and HV to see if they are specifi ed values. Make sure

your instruments are accurate; be suspicious of your HV meter if sets

always have low HV.

8. Check the antenna terminals, metal trim, “metallized” knobs, screws,

and all other exposed metal parts for AC leakage. Check leakage as

described below.

Leakage Test

The AC leakage from any exposed metal part to earth ground and

from all exposed metal parts to any exposed metal part having a

return to chassis, must not exceed 0.5 mA (500 microamperes).

Leakage current can be measured by any one of three methods.

1. A commercial leakage tester, such as the Simpson 229 or RCA

WT-540A. Follow the manufacturers’ instructions to use these

instructions.

2. A battery-operated AC milliampmeter. The Data Precision 245

digital multimeter is suitable for this job.

3. Measuring the voltage drop across a resistor by means of a

VOM or battery-operated AC voltmeter. The “limit” indication is

0.75 V, so analog meters must have an accurate low voltage

scale. The Simpson’s 250 and Sanwa SH-63TRD are examples of

passive VOMs that are suitable. Nearly all battery-operated digital

multimeters that have a 2 VAC range are suitable (see Figure A).

How to Find a Good Earth Ground

A cold-water pipe is a guaranteed earth ground; the cover-plate

retaining screw on most AC outlet boxes is also at earth ground. If the

retaining screw is to be used as your earth ground, verify that it is at

ground by measuring the resistance between it and a cold-water pipe

with an ohmmeter. The reading should be zero ohms.

If a cold-water pipe is not accessible, connect a 60- to 100-watt

trouble- light (not a neon lamp) between the hot side of the receptacle

and the retaining screw. Try both slots, if necessary, to locate the hot

side on the line; the lamp should light at normal brilliance if the screw

is at ground potential (see Figure B).

To Exposed Metal

Parts on Set

Trouble Light

Ohmmeter

Cold-water Pipe

0.15 F

1.5 K Ω

AC Outlet Box

AC

Voltmeter

(0.75 V)

Earth Ground

Figure A. Using an AC voltmeter to check AC leakage. Figure B. Checking for earth ground.

— 6 —

KV-20FS100/20FV300/21FM100/21FS100/

21FV300/24FV300/25FV300

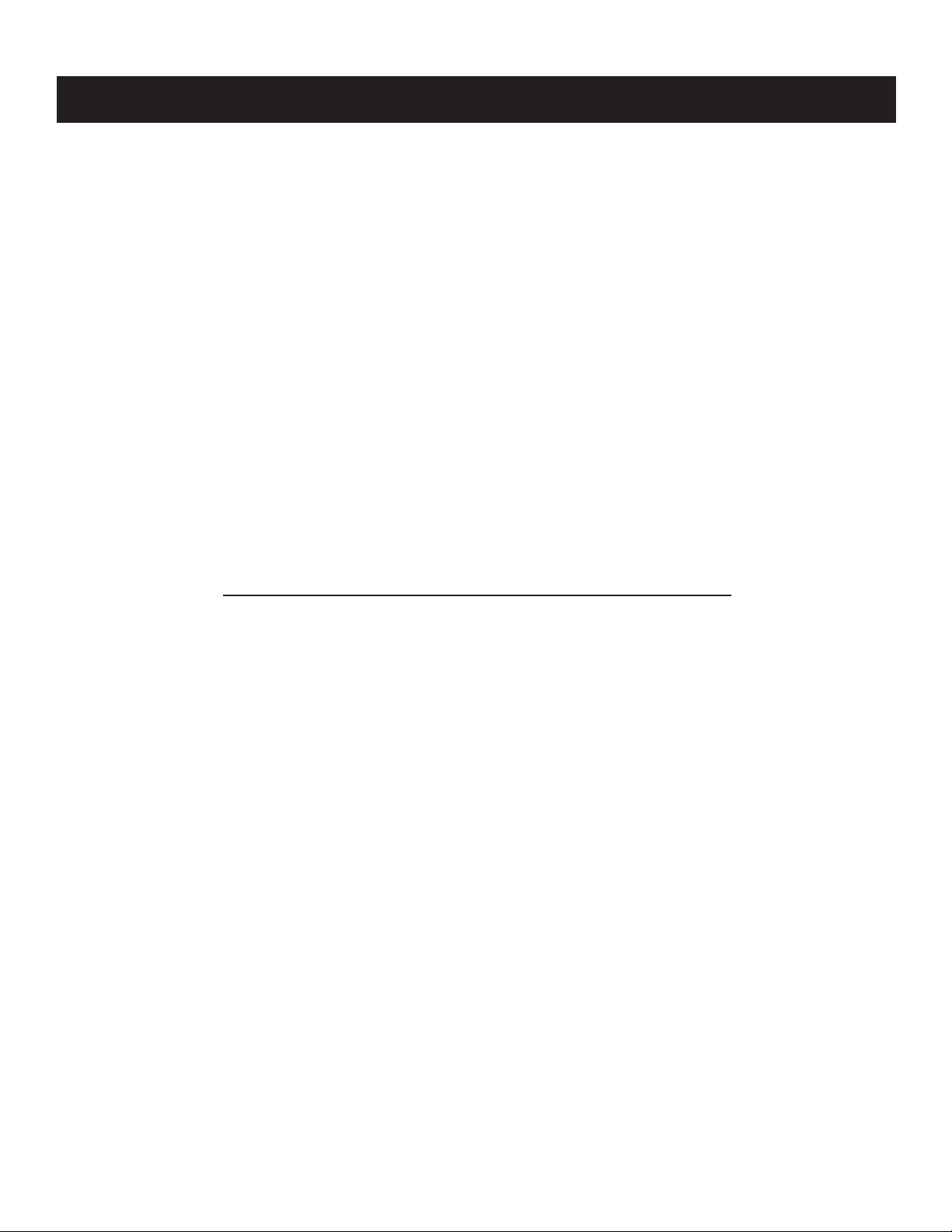

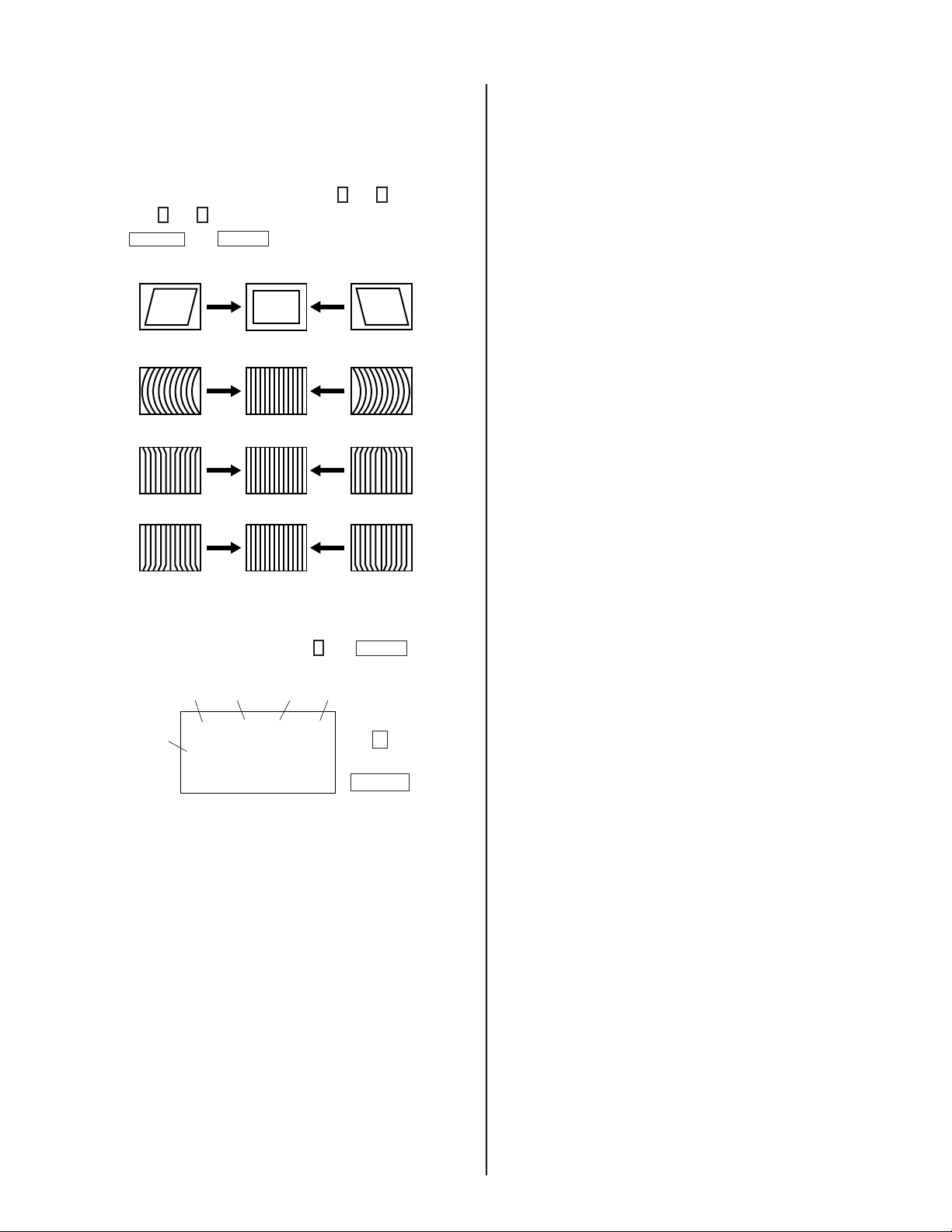

SELF-DIAGNOSTIC FUNCTION

Self Diagnosis

Supported model

The units in this manual contain a self-diagnostic function. If an error occurs, the STANDBY/TIMER LED will automatically begin to fl ash. The number

of times the LED fl ashes translates to a probable source of the problem. A defi nition of the STANDBY/TIMER LED fl ash indicators is listed in the

instruction manual for the user’s knowledge and reference. If an error symptom cannot be reproduced, the Remote Commander can be used to review

the failure occurrence data stored in memory to reveal past problems and how often these problems occur.

Diagnostic Test Indicators

When an error occurs, the STANDBY/TIMER LED will fl ash a set number of times to indicate the possible cause of the problem. If there is more than

one error, the LED will identify the fi rst of the problem areas.

Results for all of the following diagnostic items are displayed on screen. No error has occurred if the screen displays a “0”.

Diagnostic Item

Description

Power does not turn on

+B overcurrent (OCP)*

I-Prot

IK (AKB)

No. of times

STAN DBY/ TIMER

lamp fl ashes

Does not light

2 times

4 times

5 times

Self-Diagnositc

Display/

Diagnostic Result

2:0 or 2:1

4:0 or 4:1

5:0 or 5:1

Probable Cause Location

• Power cord is not plugged in.

• Fuse is burned out (F601). (A Board)

• H.OUT (Q505 OR Q506) is shorted.

(A Board)

• IC1751 is shorted. (CV Board)

• +13V is not supplied. (A Board)

• IC1545 is faulty. (A Board)

• Viedo OUT (IC1545) is faulty.

(A Board)

• IC001 is faulty. (A Board)

• Screen (G2) is improperly adjusted.**

Detected Symptoms

• Power does not come on.

• No power is supplied to the TV.

• AC Power supply is faulty.

• Power does not come on.

• Load on power line is shorted.

• Has entered standby state after horizontal raster.

• Vertical defl ection pulse is stopped.

• Power line is shorted or power supply is stopped.

• No raster is generated.

• CRT Cathode current detection reference pulse

output is small.

*If a +B overcurrent is detected, stoppage of the vertical defl ection is detected simultaneously. The symptom that is diagnosed fi rst by the

mircrocontroller is displayed on the screen.

**Refer to Screen (G2) Adjustments in Section 2-4. of this manual.

Display of Standby/Timer LED Flash Count

U U

U U

U

Standby/Timer LED

Diagnostic Item Flash Count*

+B Overcurrent 2 times

I-Prot 4 times

IK (AKB) 5 times

*One fl ash count is not used for self-diagnostic.

Stopping the Standby/Timer LED Flash

Turn off the power switch on the TV main unit or unplug the power cord from the outlet to stop the STANDBY/TIMER LAMP from fl ashing.

— 7 —

KV-20FS100/20FV300/21FM100/21FS100/

21FV300/24FV300/25FV300

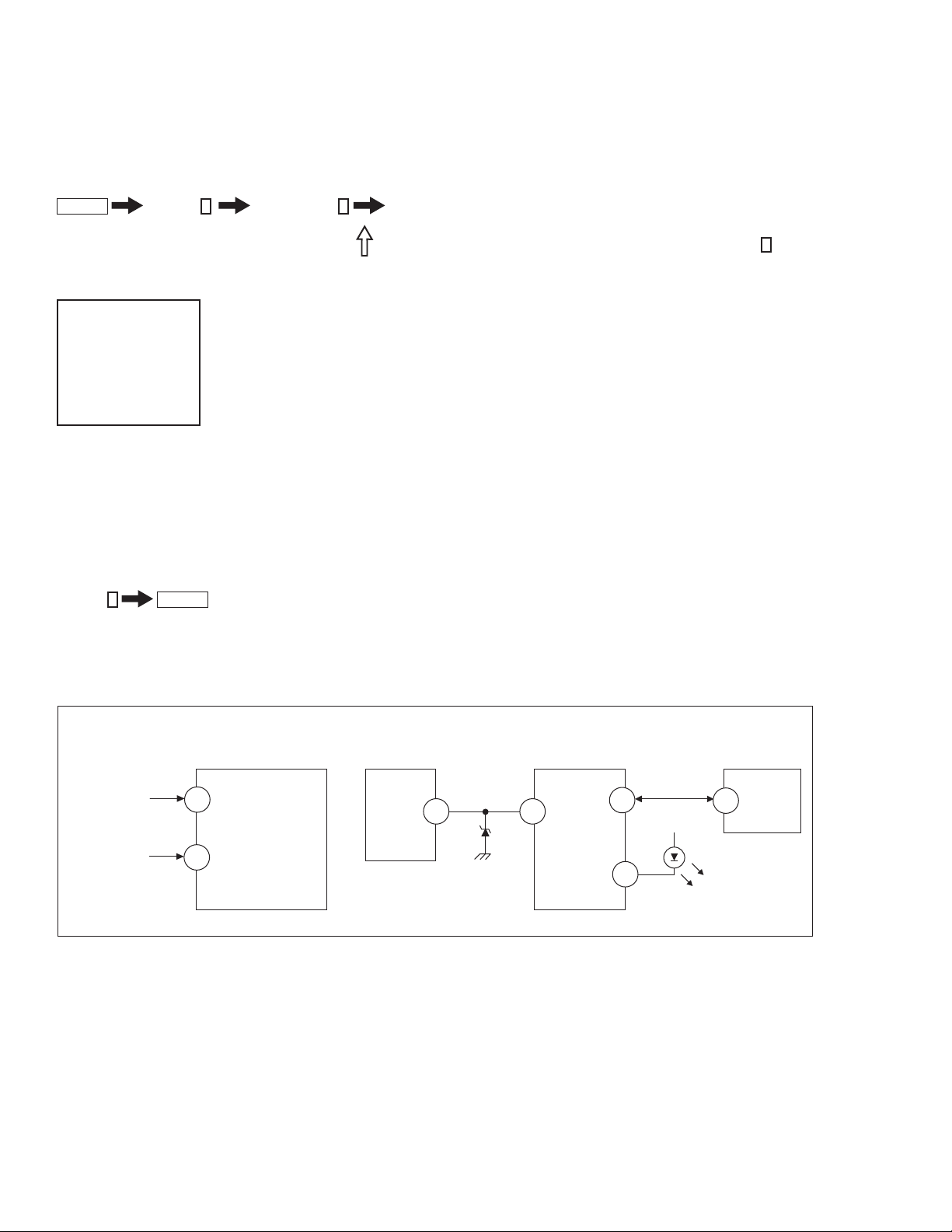

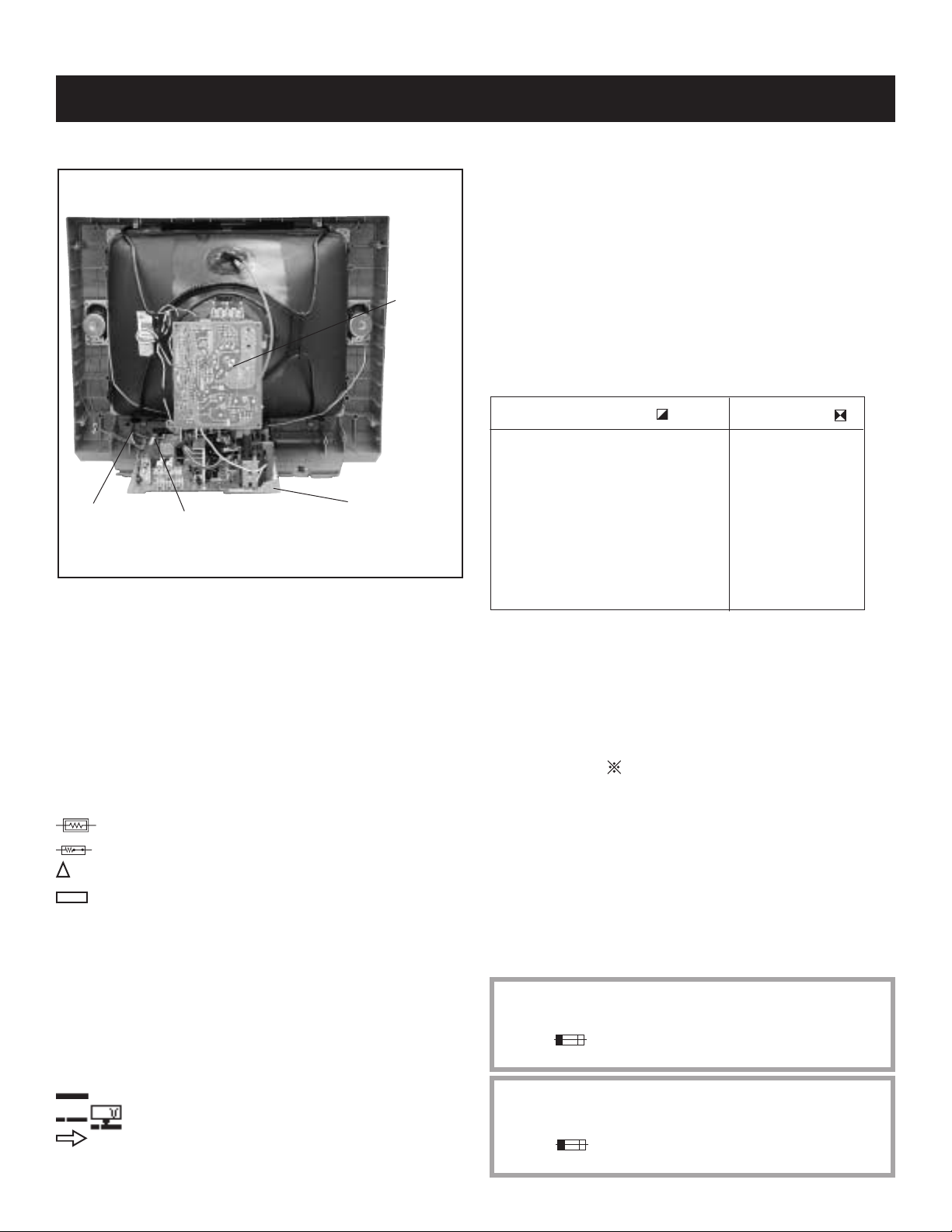

Self-Diagnostic Screen Display

For errors with symptoms such as “power sometimes shuts off” or “screen sometimes goes out” that cannot be confi rmed, it is possible to bring up

past occurrences of failure on the screen for confi rmation.

To Bring Up Screen Test

In standby mode, press buttons on the Remote Commander sequentially, in rapid succession, as shown below:

Display

Self-Diagnostic Screen Display

Handling of Self-Diagnostic Screen Display

Since the diagnostic results displayed on the screen are not automatically cleared, always check the self-diagnostic screen during repairs. When you

have completed the repairs, clear the result display to “0”.

Unless the result display is cleared to “0”, the self-diagnostic function will not be able to detect subsequent faults after completion of the repairs.

Clearing the Result Display

To clear the result display to “0”, press buttons on the Remote Commander sequentially when the diagnostic screen is displayed, as shown below:

Channel

Quitting the Self-Diagnostic Screen

To quit the entire self-diagnostic screen, turn off the power switch on the Remote Commander or the main unit.

Channel

SELF DIAGNOSTIC

2: 000

3: N/A

4: 000

5: 001

101: N/A

8

ENTER

5

Sound Volume - Power ON

Note that this differs from entering the Service Mode (Sound Volume

Numeral “0” means that no fault was detected.

Numeral “1” means a fault was detected one time only.

+

).

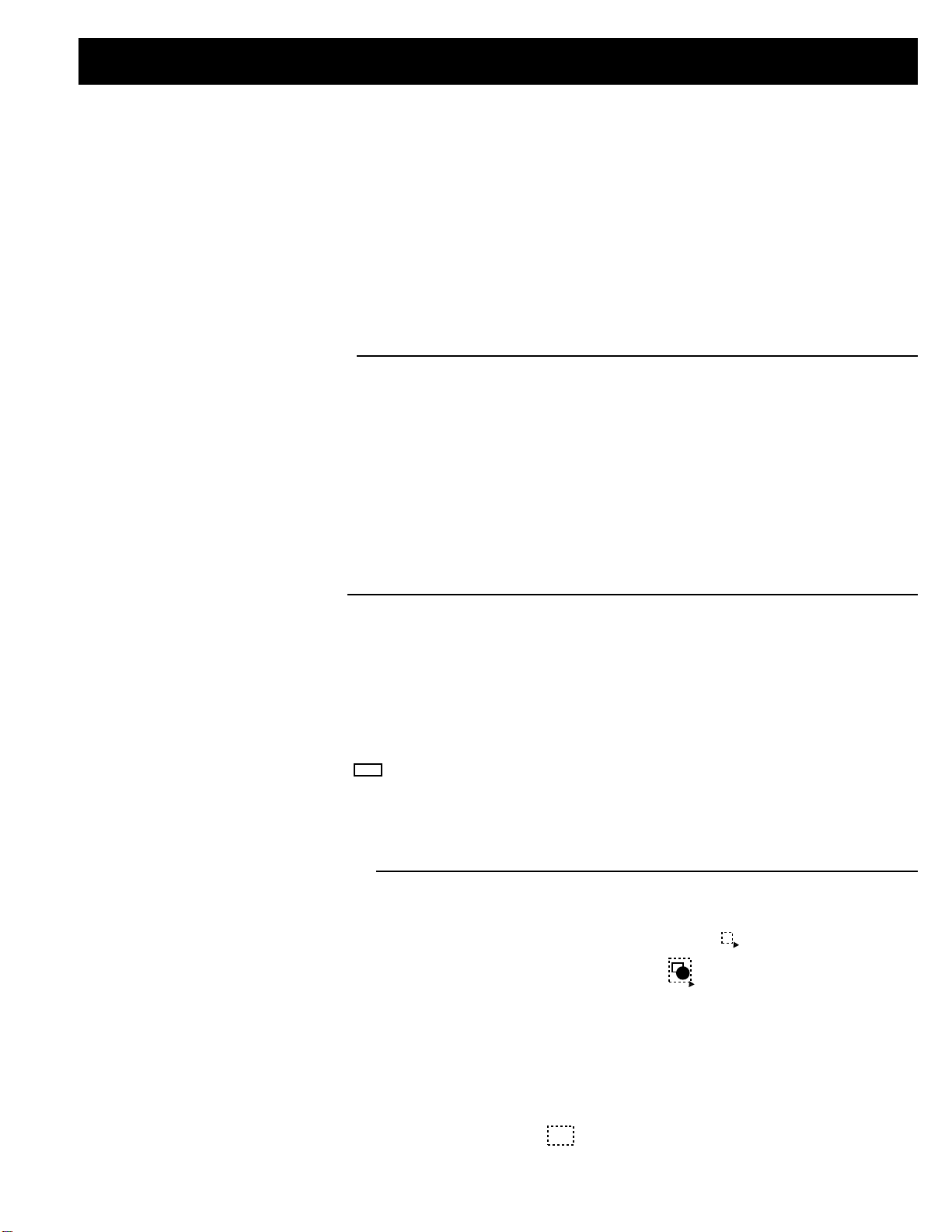

Self-Diagnostic Circuit

FROM

CV BOARD

IC1751 PIN 5

A BOARD

IC001

Y/CHROMA JUNGLE

51

IK-AKBIN

A BOARD

IC545

V. OUT

REF

3

A BOARD

IC001

SYSTEM

IO-BDAT

78

I-Prot

53

A BOARD

IC002

MEMORY

5

BDA

A BOARD

72

FROM

IC561

PIN 7

+B overcurrent (OCP)

Occurs when an overcurrent on the +B (135V) line is detected by pin 72 of IC001 (A Board). If the voltage of pin 72 of IC001 (A Board) is less than 1V

when V.SYNC is more than seven verticals in a period, the unit will automatically turn off.

I-Prot

Occurs when an absence of the vertical defl ection pulse is detected by pin 78 of IC001 (A Board). Power supply will shut down when waveform

interval exceeds 2 seconds.

IK (AKB)

If the RGB levels* do not balance within 2 seconds after the power is turned on, this error will be detected by IC001 (A Board). TV will stay on,

but there will be no picture.

*(Refers to the RGB levels of the AKB detection Ref pulse that detects 1K).

I-HLDWN

O-LED

79

DISPLAY

— 8 —

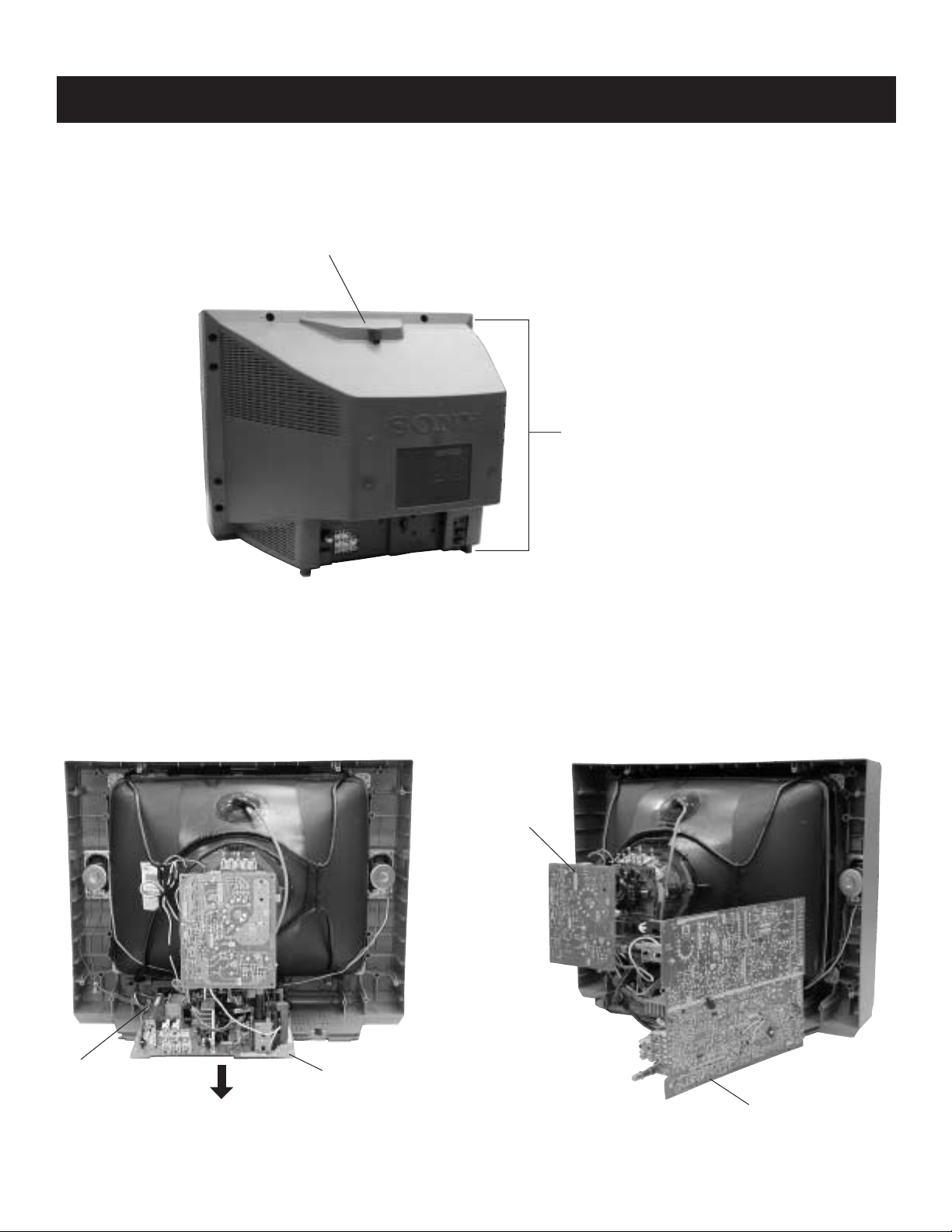

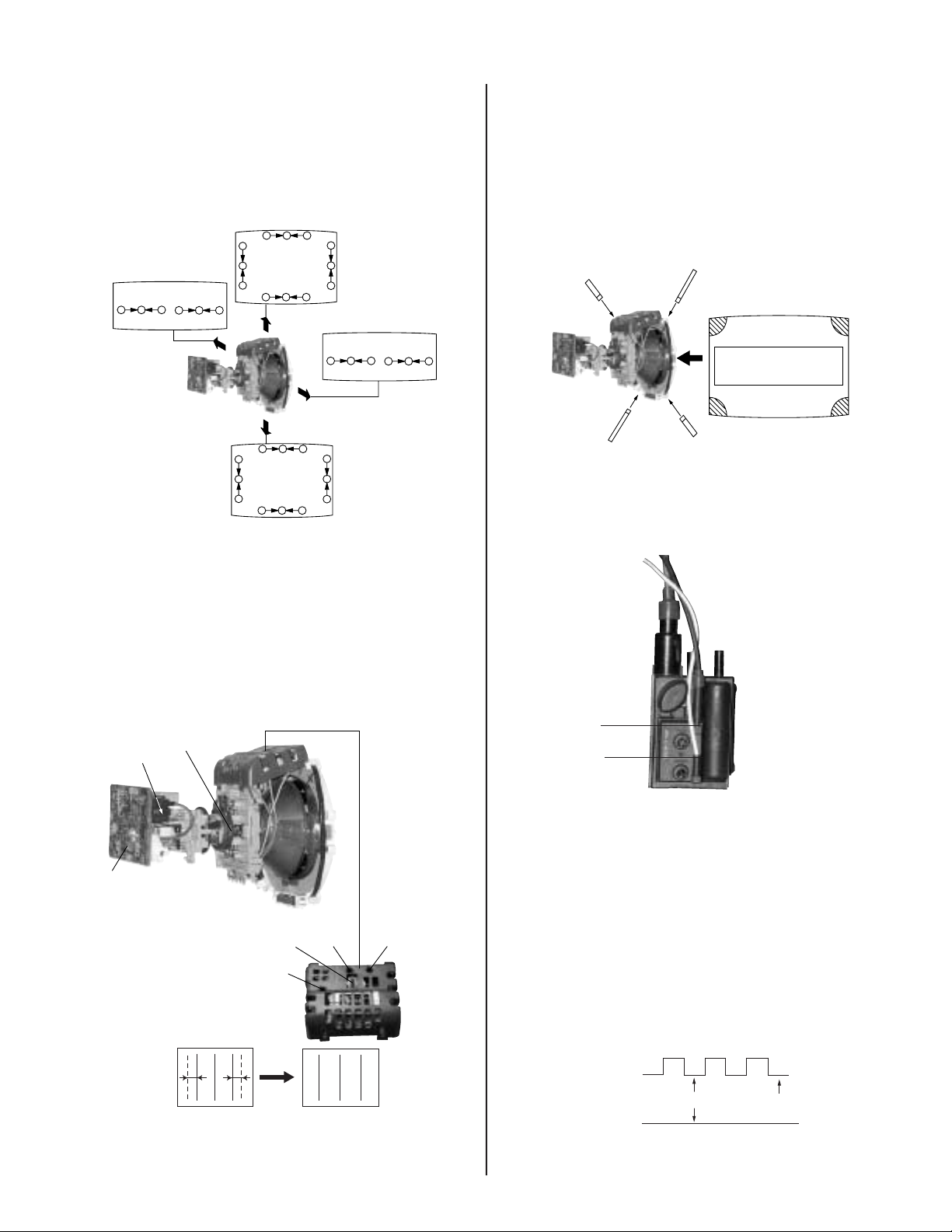

1-1. REAR COVER REMOVAL

Rear Cover

KV-20FS100/20FV300/21FM100/21FS100/

21FV300/24FV300/25FV300

SECTION 1: DISASSEMBLY

KV-20FS100/21FS100/21FM100 - 4 Screws +BVTP 4x16

KV-20FV300/21FV300 - 5 Screws +BVTP 4x16

KV-24FV300/25FV300 - 6 Screws +BVTP 4x16

1-2. CHASSIS ASSEMBLY REMOVAL 1-3. SERVICE POSITION

CV Board

Claw

Chassis Assembly

A Board

— 9 —

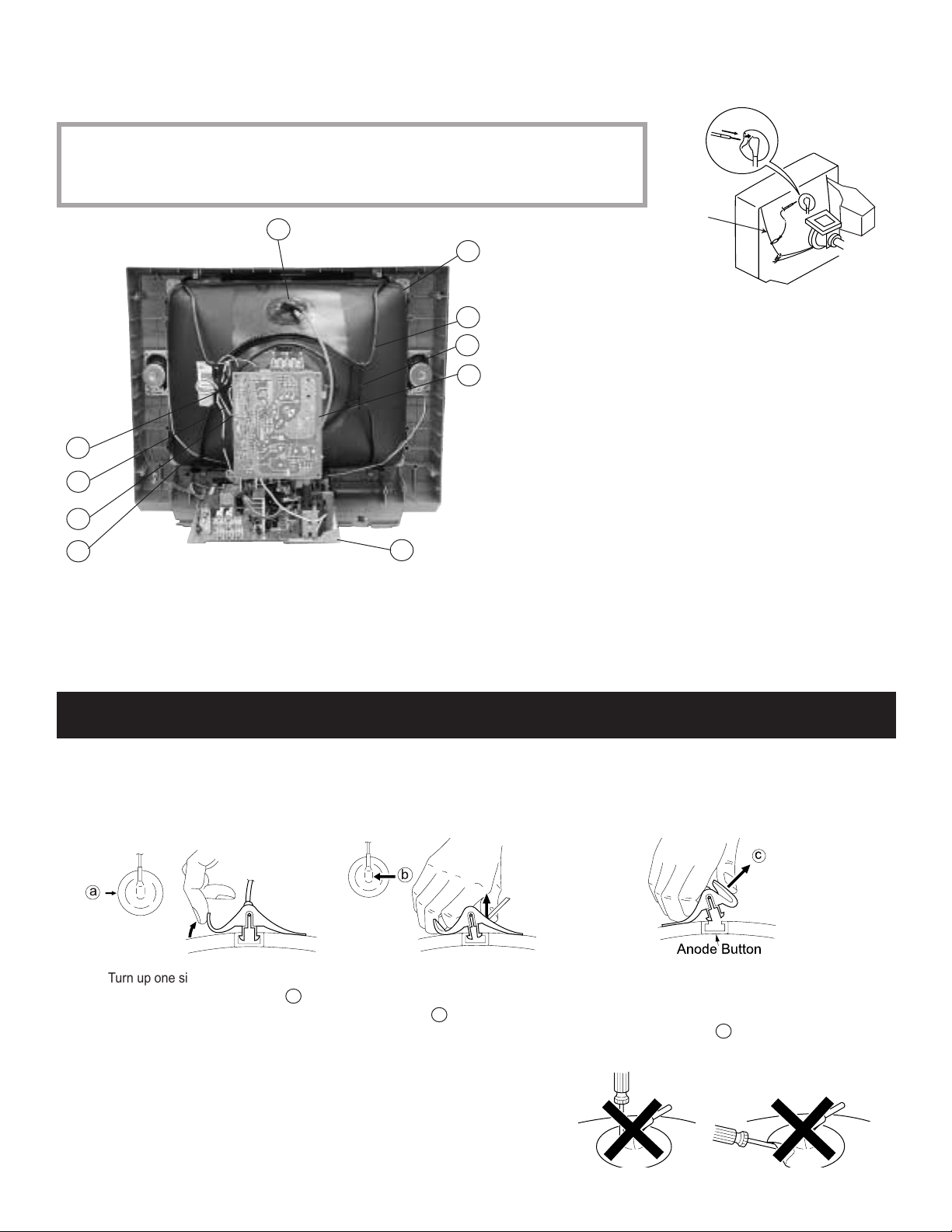

1-4. PICTURE TUBE REMOVAL

WARNING: BEFORE REMOVING THE ANODE CAP

High voltage remains in the CRT even after the power is disconnected. To avoid electric shock,

discharge CRT before attempting to remove the anode cap. Short between anode and CRT

coated earth ground strap.

1

10

1. Discharge the anode of the CRT and remove the anode cap.

8

7

3

6

2

5

9

4

2. Unplug all interconnecting leads from the defl ection yoke, neck

assembly, degaussing coils and CRT grounding strap.

3. Remove the CV Board from the CRT.

4. Remove the chassis assembly.

5. Loosen the neck assembly fi xing screw and remove.

6. Loosen the defl ection yoke fi xing screw and remove.

7. Place the set with the CRT face down on a cushion and remove

the degaussing coil holders.

8. Remove the degaussing coils.

9. Remove the CRT grounding strap and spring tension devices.

10. Unscrew the four CRT fi xing screws [located on each CRT

corner] and remove the CRT [Take care not to handle the CRT

by the neck].

KV-20FS100/20FV300/21FM100/21FS100/

21FV300/24FV300/25FV300

Coated

Earth

Ground

Strap

ANODE CAP REMOVAL PROCEDURE

WARNING: High voltage remains in the CRT even after the power is disconnected. To avoid electric shock, discharge CRT before attempting to

remove the anode cap. Short between anode and coated earth ground strap of CRT.

NOTE: After removing the anode cap, short circuit the anode of the picture tube and the anode cap to either the metal chassis, CRT shield, or

carbon painted on the CRT.

c

b

a

Anode Button

Turn up one side of the rubber cap in

the direction indicated by arrow

a

.

HOW TO HANDLE AN ANODE CAP

1. Do not use sharp objects which may cause damage to the surface of the anode

cap.

2. To avoid damaging the anode cap, do not squeeze the rubber covering too hard.

A material fi tting called a shatter-hook terminal is built into the rubber.

3. Do not force turn the foot of the rubber cover. This may cause the shatter-hook

terminal to protrude and damage the rubber.

Use your thumb to pull the rubber

cap fi rmly in the direction indicated

by arrow

.

b

When one side of the rubber cap separates from

the anode button, the anode cap can be removed

by turning the rubber cap and pulling it in the

direction of arrow

.

c

— 10 —

SECTION 2: SET-UP ADJUSTMENTS

KV-20FS100/20FV300/21FM100/21FS100/

21FV300/24FV300/25FV300

The following adjustments should be made when a complete

realignment is required or a new picture tube is installed.

These adjustments should be performed with rated power supply

voltage unless otherwise noted.

Set the controls as follows unless otherwise noted:

VIDEO MODE: Standard

PICTURE CONTROL: Normal

BRIGHTNESS CONTROL: Normal

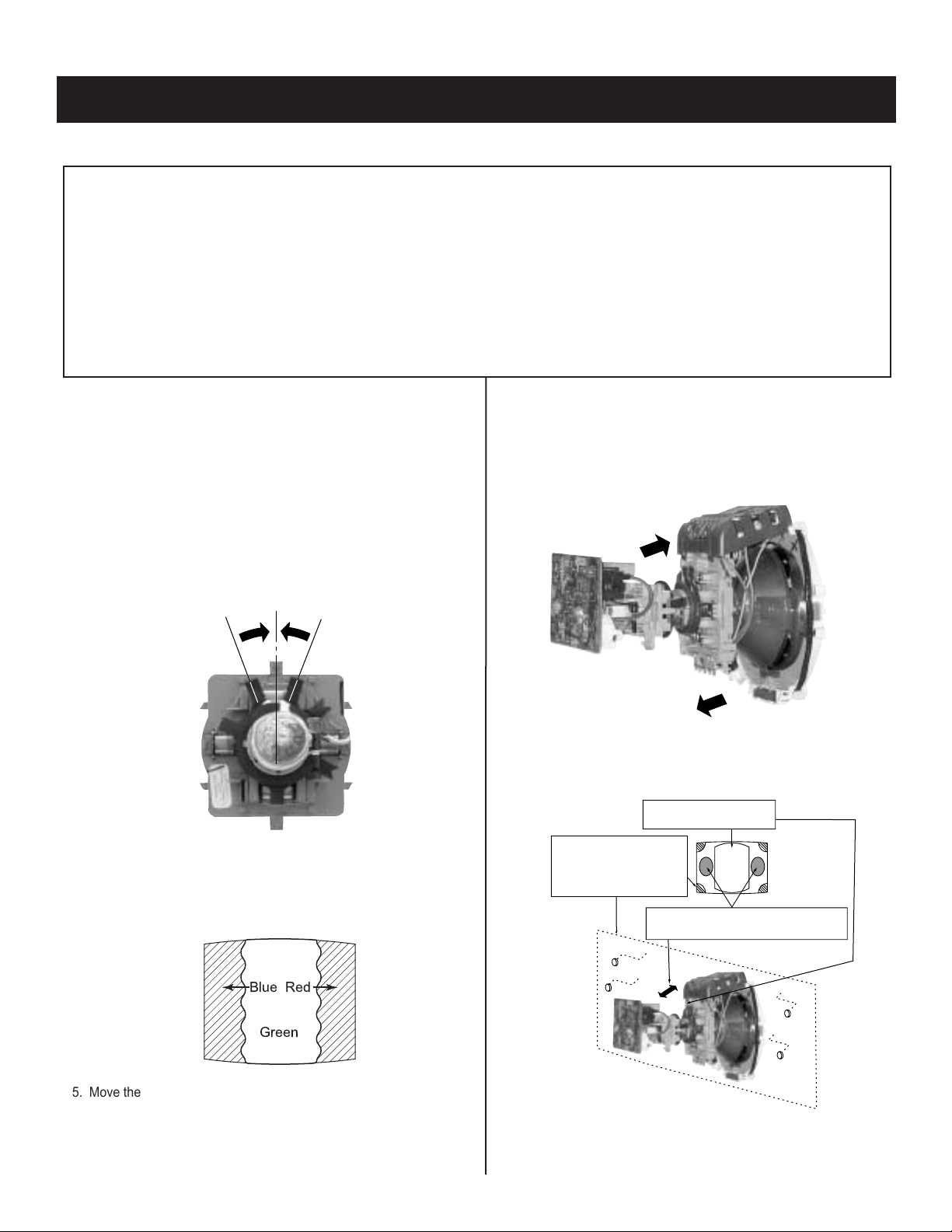

2-1. BEAM LANDING

Before beginning adjustment procedure:

1. Degauss the entire screen.

2. Feed in the white pattern signal.

ADJUSTMENT PROCEDURE

1. Input a raster signal with the pattern generator.

2. Loosen the defl ection yoke mounting screw, and set the purity control

to the center as shown below:

Purity Control

Perform the adjustments in order as follows:

1. Beam Landing

2. Convergence

3. Focus

4. Screen (G2)

5. White Balance

Note Test Equipment Required:

1. Color Bar Pattern Generator

2. Degausser

3. DC Power Supply

4. Digital Multimeter

6. Switch over the raster signal to red and blue and confi rm the

condition.

7. When the position of the defl ection yoke is determined, tighten it with

the defl ection yoke mounting screw.

8. If landing at the corner is not right, adjust by using the disk magnets.

3. Turn the raster signal of the pattern generator to green.

4. Move the defl ection yoke backward, and adjust with the purity control

so that green is in the center and red and blue are even on both

sides.

Blue Red

Green

5. Move the defl ection yoke forward, and adjust so that the entire

screen becomes green.

— 11 —

Purity control

corrects this area.

Disk magnets

or rotatable disk

magnets correct

these areas (a-d).

Deflection yoke positioning

b

d

b

a

cd

corrects these areas.

a

c

KV-20FS100/20FV300/21FM100/21FS100/

21FV300/24FV300/25FV300

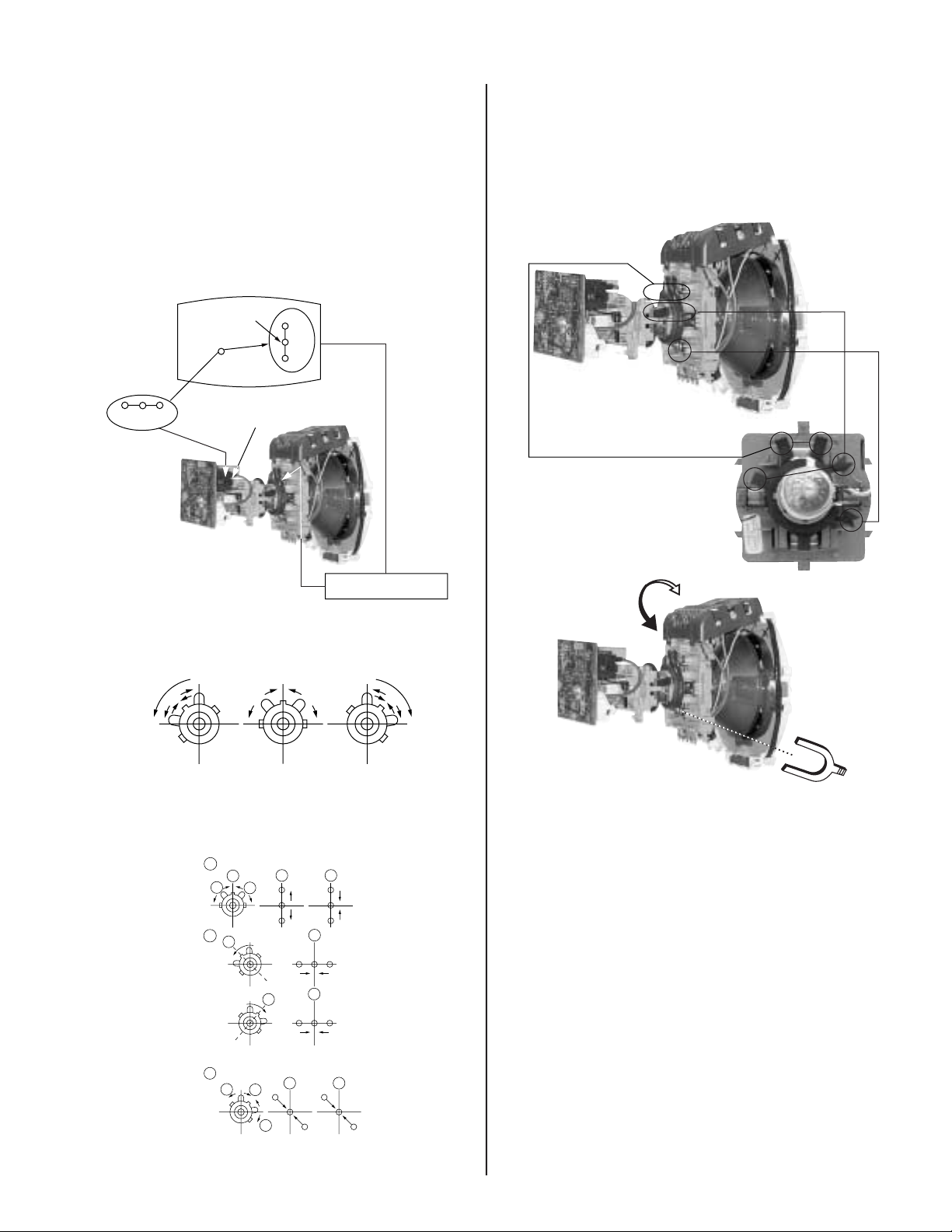

2-2. CONVERGENGE

Before starting convergence adjustments:

1 Perform FOCUS, VLIN and VSIZE adjustments.

2. Set BRIGHTNESS control to minimum.

3. Feed in dot pattern.

VERTICAL STATIC CONVERGENCE

1. Adjust V. STAT magnet to converge red, green and blue dots in the

center of the screen (Vertical movement adjust S V.STAT RV1750

to converge).

Center dot

RV1750

R

B

G

V.STAT

R

G

B

HORIZONTAL STATIC CONVERGENCE

If the blue dot does not converge with the red and green dots, peform

the following:

1. Move BMC magnet (a) to correct insuffi cient H.Static convergence.

2. Rotate BMC magnet (b) to correct insuffi cient V.Static convergence.

3. After adjusting the BMC magnet, repeat Beam Landing Adjustment.

V. STAT

BMC MAGNET

PURITY

V.STAT magnet

2. Tilt the V. STAT magnet and adjust static convergence to open or

close the V. STAT magnet.

When the V. STAT magnet is moved in the direction of arrow a and

b, red, green, and blue dots move as shown below:

1

a

b

2

a

a

b

B

G

R

b

b

B

G

R

a

RGB

b

BGR

b

BMC magnet

a

3

b

a

a

R

G

b

b

B

G

B

R

— 12 —

KV-20FS100/20FV300/21FM100/21FS100/

21FV300/24FV300/25FV300

DYNAMIC CONVERGENCE ADJUSTMENT

Before performing this adjustment, perform Horizontal and Vertical

Static Convergence Adjustment.

1. Slightly loosen defl ection yoke screw.

2. Remove defl ection yoke spacers.

3. Move the defl ection yoke for best convergence as

shown below:

G

B

R

R

G

B

BGR

B

G

R

R

R

B

G

R

B

B

G

R

B

G

BGR

B

G

R

G

B

R

G

R

GB

4. Adjust XCV core to balance X axis.

5. Adjust YCH VR to balance Y axis.

6. Adjust vertical red and blue convergence with V.TILT (TLV VR.)

Note: Perform adjustment 3-6 while tracking items 1 and 2.

SCREEN-CORNER CONVERGENCE

1. Affi x a permalloy assembly corresponding to the misconverged

areas:

b

a

ba

a-d: screen-corner

misconvergence

c

d

c

d

2-3. FOCUS

1. Adjust FOCUS control for best pictures.

4. Tighten the defl ection yoke screw.

5. Install the defl ection yoke spacers.

TLH PLATE ADJUSTMENT

1. Input crosshatch pattern.

2. Adjust PICTURE QUALITY to standard, PICTURE and

BRIGHTNESS to 50%, and OTHER to standard.

3 Adjust the Horizontal Convergence of red and blue dots by tilting

the TLH plate on the defl ection yoke.

RV1750

V. S TAT

CV

Board

TLH Plate

XCV

(TLV)

YCH

TLV

Focus (FV)

Screen (G2)

2-4. SCREEN (G2)

1. Input a dot pattern.

2. Set the PICTURE and BRIGHTNESS controls at minimum and

COLOR control at normal.

3. Adjust SBRT, GCUT, BCUT in service mode with an oscilloscope as

shown below so that voltages on the red, green, and blue cathodes

are 170 ± 2VDC.

B R R B

(R)(B) (B)(R)

TLH+

TLH-

— 13 —

Ground

170 ± 2VDC

Pedestal

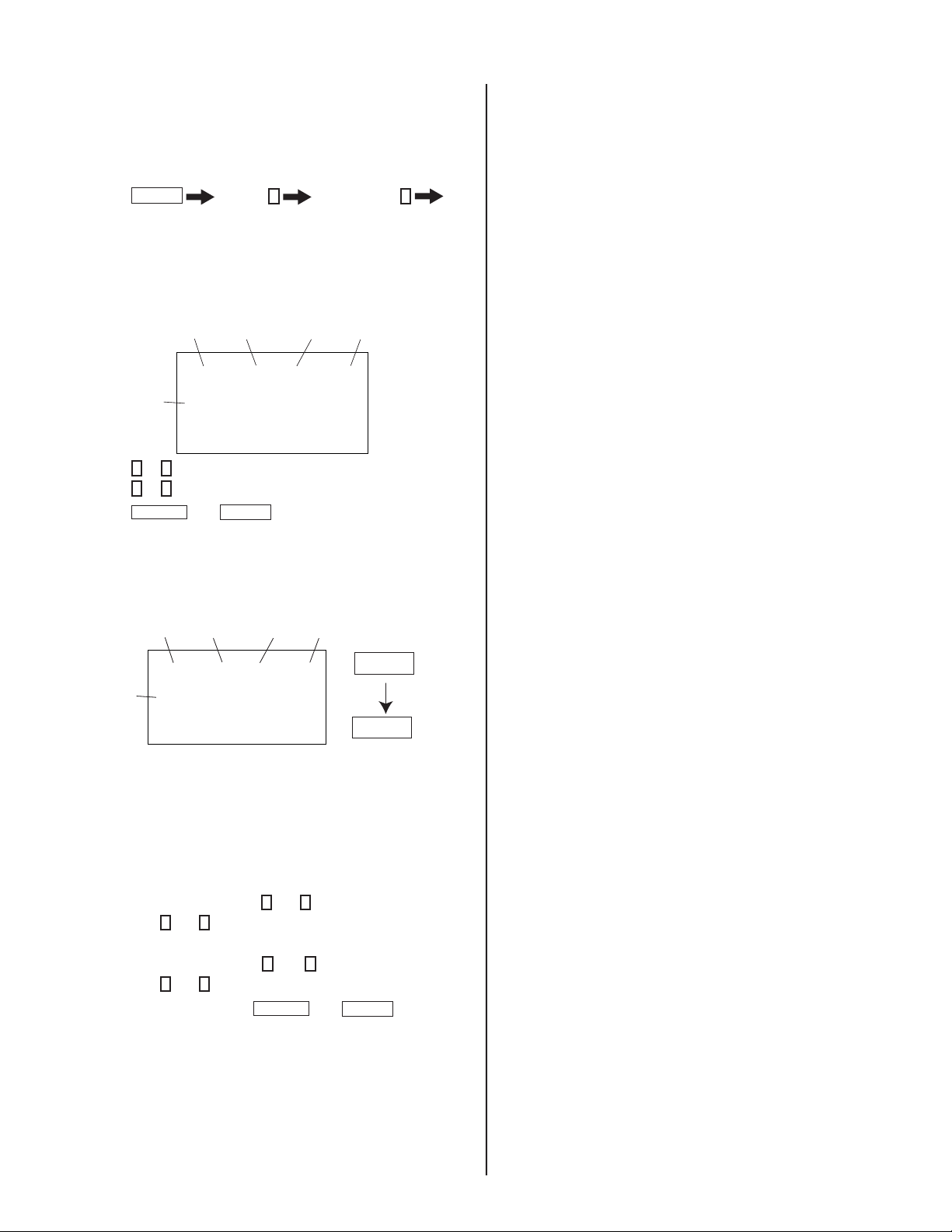

2-5. METHOD OF SETTING THE SERVICE ADJUSTMENT MODE

SERVICE MODE PROCEDURE

1. Standby mode (power off).

2. Press

Display

Channel 5 Sound Volume + Power

on the Remote Commander (press each button within a second).

SERVICE ADJUSTMENT MODE ON

1. The CRT displays the time being adjusted.

KV-20FS100/20FV300/21FM100/21FS100/

21FV300/24FV300/25FV300

2. Press

3. Press

4. Press

Display

defl

hsiz 16

00000000

to save into the memory.

service

ntsc

vchp

then

Category

ENTER

Mode

Signal

Type

1

or 4 on the Remote Commander to select the time.

3

or 6 on the Remote Commander to change the data.

MUTING

Item

00000000

Display

Item

SERVICE ADJUSTMENT MODE MEMORY

Turn the set off then on to exit Service Adjustment Mode.

Signal

Type

Category

Mode

service defl hsiz 16

ntsc

vchp 00000000 00000000

Display

Item

write

Item

Data

MUTING

ENTER

Green

Red

2-6. WHITE BALANCE ADJUSTMENTS

1. Input an entire white signal with burst.

2. Set to Service Adjustment Mode.

3. Set the PICTURE and BRIGHTNESS to minimum.

4. Adjust with SBRT if necessary.

5. Select GCUT and BCUT with

6. Adjust with

3

and 6 for the best white balance.

7. Set the PICTURE and BRIGHTNESS to maximum.

8. Select GDRV and BDRV with

9. Adjust with

3

and 6 for the best white balance.

10. To write into memory, press

1

and 4 .

1

and 4.

MUTING

then

ENTER

.

— 14 —

SECTION 3: SAFETY RELATED ADJUSTMENTS

KV-20FS100/20FV300/21FM100/21FS100/

21FV300/24FV300/25FV300

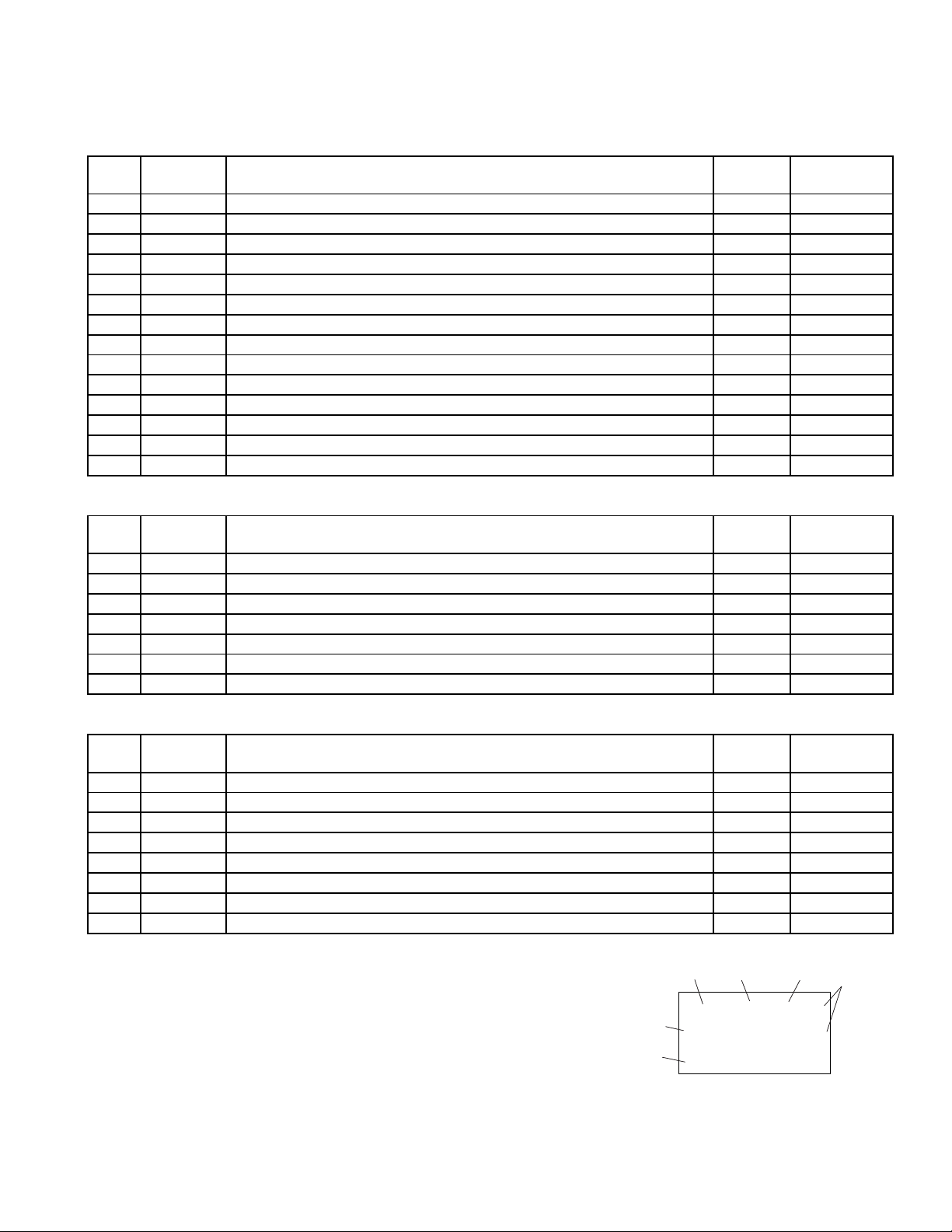

3-1. X R565 CONFIRMATION METHOD

(HV HOLD-DOWN CONFIRMATION) AND

READJUSTMENTS

The following adjustments should always be performed when

replacing the following components which are marked with

schematic diagram:

Part Replaced ( )

DY, T585, CRT, IC001, IC561,

C507, C508, C506, T511, L510,

Adjustment ( )

HV HOLD-DOWN

R565

Y

on the

C588, L588, C566, C561, C563,

D567, D568, D566, R567, R568,

R565, R566, R562, R563, R561,

R528....................A Board

PREPARATION BEFORE CONFIRMATION

1. Using a Variac, apply AC input voltage: 120 ±2 VAC.

2. Turn the POWER switch ON.

3. Input a white signal and set the PICTURE and BRIGHTNESS

controls to maximum.

4. Confi rm that the voltage between C566 (+) or TP30 and ground is

more than 97.0 VDC.

HOLD-DOWN OPERATION CONFIRMATION

1. Connect the current meter between Pin 11 of the FBT (T585) and

the PWB land where Pin 11 would normally attach (See Figure 1

on the next page).

2. Input a dot signal and set PICTURE and BRIGHTNESS to

minimum: IABL = 100 ± 100µA.

3. Confi rm the voltage of A Board TP-23 is 135.6 ± 1V.

4. Connect the digital voltmeter and the DC power supply via Diode

1SS119 to C566 (+) and ground (See Figure 1 on next page).

5. Increase the DC power voltage gradually until the picture blanks

out.

6. Turn DC power source off immediately.

7. Read the digital voltmeter indication (standard < 117VDC).

8. Input a white signal and set PICTURE and BRIGHTNESS to

maximum: IABL = 1350 ± 100µA.

9. Repeat steps 4 to 7.

HOLD-DOWN READJUSTMENT

If the setting indicated in Step 2 of Hold-Down Operation Confi rmation

cannot be met, readjustment should be performed by altering the

resistance value of R565 component marked with

X

.

T585

FBT

amPmeter

3.0 mA DC

range

ABL

+

-

A

IABL

3-2. B+ VOLTAGE CONFIRMATION AND ADJUSTMENT

Note: The following adjustments should always be performed when

replacing the following components, which are marked with

schematic diagram on the A Board:

A BOARD: IC600, PH602

1. Using a Variac, apply AC input voltage: 130 + 2.0 / - 0.0 VAC.

2. Input a DOT pattern at Q.C.

3. Set the PICTURE and the BRIGHTNESS controls to minimum.

4. Confi rm the voltage of A Board between TP-23 & Ground is <136.6

VDC.

5. If step 4 is not satisfi ed, replace the components listed above, then

repeat Steps 1 – 3.

Y

on the

— 15 —

KV-20FS100/20FV300/21FM100/21FS100/

(

)

21FV300/24FV300/25FV300

DIGITAL

MULTIMETER

+

-

X

R565

R

5

3

1

0

4

S

P

R

5

1

1

J

R

1

R

4

3

7

0

6

R

C

4

5

1

C

5

D

5

6

5

2

R

5

8

9

T

2

P

4

2

9

L

3

7

0

1

5

6

C

1

5

T

2

8

6

2

R

5

3

2

L

3

7

1

1

1

5

C

R

2

1

5

C

1

1

5

L

1

C

5

3

1

5

L

0

2

B

T

2

P

5

R

5

0

2

4

R

5

3

3

C

5

4

0

5

S

5

6

5

C

I

C

5

3

0

6

2

5

D

5

2

5

L

5

1

0

6

2

5

C

3

1

5

C

4

1

5

C

H

5

Q

B

5

2

5

C

L

5

1

5

R

5

3

7

R

5

6

2

2

R

5

2

2

E

C

5

2

7

R

5

4

9

R

5

1

5

6

5

7

C

5

6

1

R

5

4

6

5

4

5

D

6

R

5

4

8

C

5

4

5

R

9

0

R

5

4

0

0

D

2

7

C

R

5

4

7

6

0

6

1

5

L

R

5

C

5

4

8

1

J

R

5

0

POWER

SUPPLY

+

1SS119

C566

Q

4

0

2

R

4

0

8

R

4

1

1

.

H

P

O

R

T

R

5

P

0

T

3

6

6

5

D

R

5

2

9

C

5

6

2

C

5

2

9

1

6

5

C

I

C

5

4

4

2

C

5

9

7

1

T

P

1

V

.

O

U

T

5

4

7

5

4

5

C

I

4

1

C

5

9

5

P

7

T

1

R

9

0

1

5

1

2

C

2

2

8

D

5

2

8

D

5

6

R

5

8

3

2

8

5

C

P

T

3

3

Q

5

2

1

5

7

5

R

C

5

7

1

R

5

6

8

D

5

6

8

6

7

R

5

7

0

D

5

6

R

R

2

8

5

L

9

5

2

6

R

5

6

9

5

7

4

D

6

3

0

6

0

1

2

0

6

C

6

1

0

0

2

4

TP23

8

9

5

E

R

5

0

R

5

9

3

3

0

5

R

C

5

9

0

1

9

5

R

B

0

9

5

Q

R

5

9

4

T

P

1

3

4

2

6

E

C

6

C

P

3

T

2

1

6

C

8

4

0

4

2

6

D

4

5

0

5

C

H

-

O

Q

5

C

5

0

4

1

6

5

0

5

R

U

T

E

0

5

6

0

5

C

6

0

5

D

3

4

R

5

0

6

C

5

1

T

2

P

2

0

C

4

1

5

R

2

1

5

R

H

D

T

5

0

5

T

H

B

5

8

8

R

8

5

L

T

U

O

6

0

5

Q

6

G

2

0

0

V

8

N

/

C

V

D

Y

+

P

T

2

1

V

D

Y

-

T

2

P

7

H

D

Y

-

P

T

2

8

H

D

Y

-

H

D

Y

+

T

P

H

D

Y

+

3

1

H

-

O

2

9

1

5

5

N

C

D

R

5

9

8

T

1

P

9

H

E

A

T

E

R

N

D

5

V

U

T

-

1

3

V

G

G

N

D

G

N

D

N

D

5

5

T

+

1

3

V

N

/

C

A

B

L

T

2

P

0

R

5

8

8

F

B

T

1

AMMETER

3mA dc range

A

+

-

Figure 1

— 16 —

KV-20FS100/20FV300/21FM100/21FS100/

j

SECTION 4: CIRCUIT ADJUSTMENTS

ELECTRICAL ADJUSTMENTS BY REMOTE COMMANDER

Use the Remote Commander (RM-Y172, RM-Y173, RM-Y180) to perform the circuit adjustments in this section.

Test Equipment Required: 1. Pattern generator 2. Frequency counter 3. Digital multimeter 4. Audio oscillator

21FV300/24FV300/25FV300

4-1. SETTING THE SERVICE ADJUSTMENT MODE

1. Standby mode (Power off).

2. Press the following buttons on the remote commander within a

second of each other:

Display

Channel 5 Sound Volumne + Power

SERVICE ADJUSTMENT MODE ON

1. The CRT displays the item being adjusted.

2. Press

3. Press

4. Press

Category

Mode

service defl hsiz 16

Signal

Type

1

3

MUTING

ntsc

vchp 00000000 00000000

or 4 on the Remote Commander to select the item.

or 6 on the Remote Commander to change the data.

then

ENTER

Display

to write into memory.

Item

Item

Data

SERVICE ADJUSTMENT MODE MEMORY

Display

on the Remote Commander to initialize.

Display

Item

write

Signal

Type

1. Press

Mode

Signal

Type

Category

Mode

service defl hsiz 16

ntsc

vchp 00000000 00000000

8

ENTER

then

Category

service defl hsiz 16

ntsc

vchp 00000000 00000000

2. Turn set off then on to exit Service Adjustment Mode.

Item

Item

Data

MUTING

write

ENTER

Item

Data

MUTING

ENTER

Carry out Step 1 when adjusting

IDs 0-6 and when replacing and

ad

usting IC002

Green

Red

Green

Red

4-2. MEMORY WRITE CONFIRMATION

METHOD

1. After adjustment, pull out the plug from the AC outlet, then replace

the plug in the AC outlet again.

2. Turn the power switch ON and set to Service Mode.

3. Call the adjusted items again to confi rm they were adjusted.

4-3. REMOTE ADJUSTMENT BUTTONS AND INDICATORS

MUTING

(Enter into

memory)

1

Disp. (Item up)

2

(Device Item Up)

4

Disp. (Item down)

8

(Initialize)

VOLUME (+)

(Service Mode)

RM-Y180

POWER

(Service Mode)

DISPLAY

(Service Mode)

3

Item

(Data up)

6

Item

(Data down)

5

(Device item

down)

ENTER

(Enter into

memory)

0

(Remove from

memory)

— 17 —

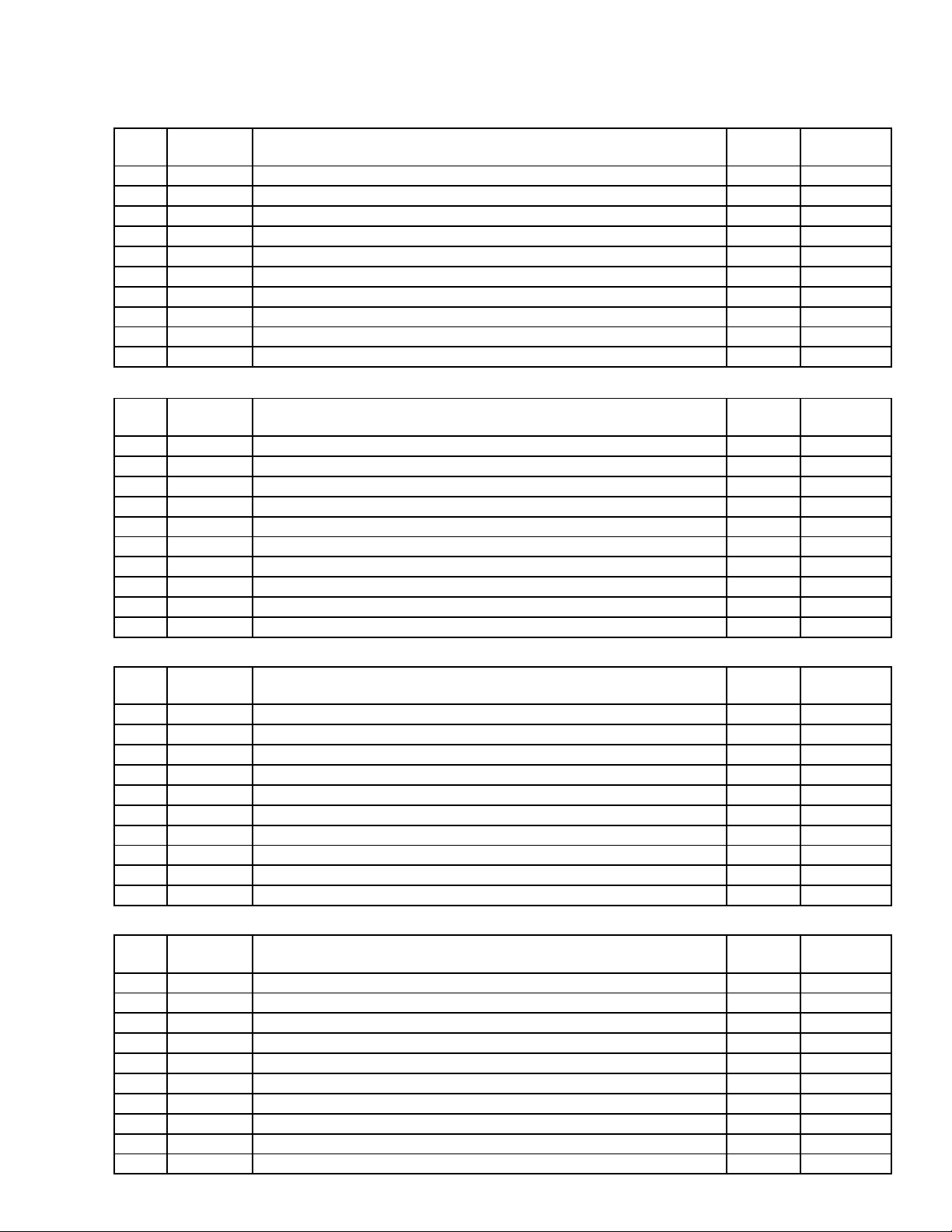

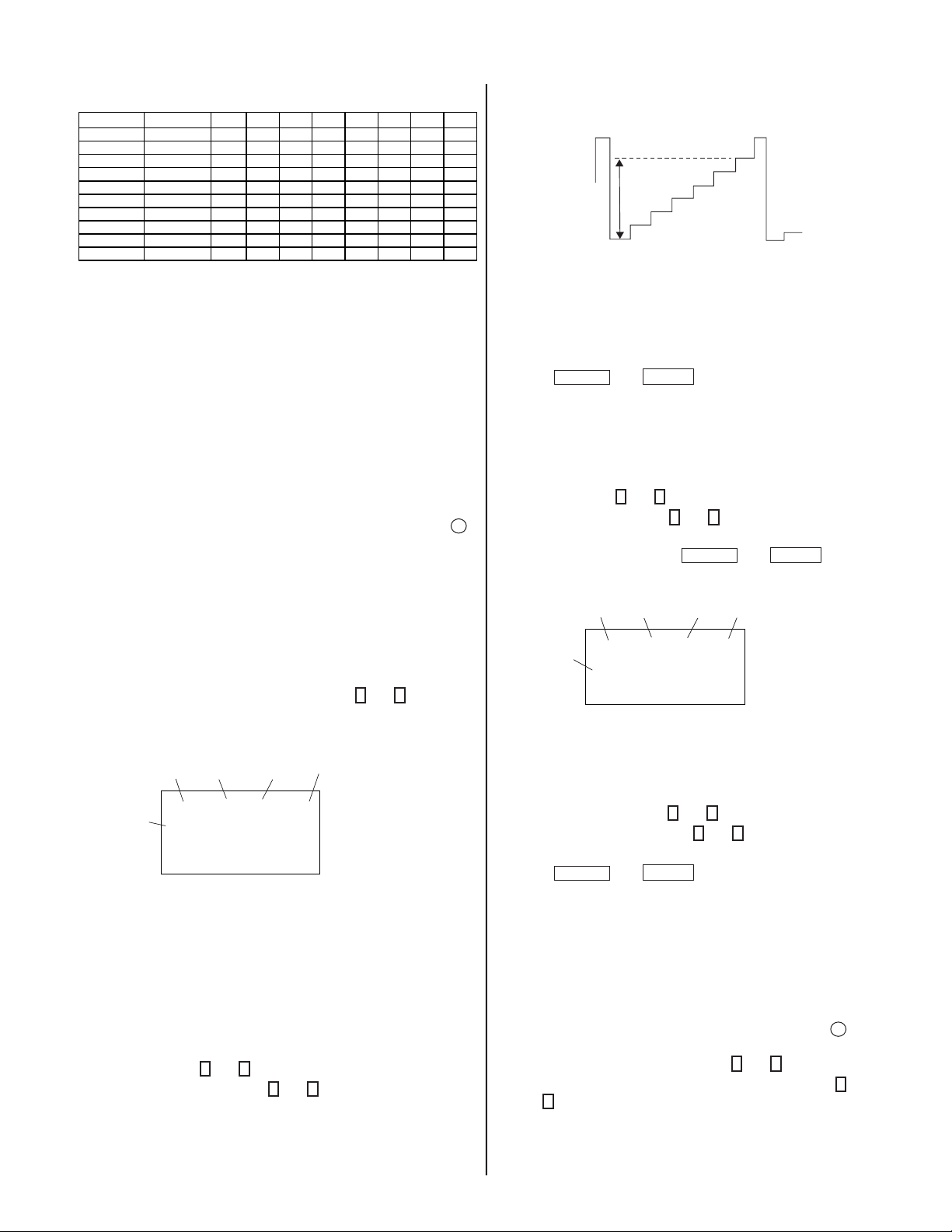

ADJUSTMENT ITEMS (1 OF 8)

DEVICE "DEF"

Item# OSD DETAIL

1 HSIZ H SIZE(EW DC) 00-63 25

2 HPOS H POSITION 00-63 41

3 VSIZ V RAMP SIZE 00-63 25

4 VPOS V POSITION(RAMP DC)not useful 00-63 34

5 VLIN V LINEARITY 00-63 36

6 SCOR S CORRECTION 00-63 39

7 VBOW BOW 00-63 36

8 VANG ANGLE 00-63 35

9 TRAP EW TRAPESIUM 00-63 29

10 PAMP EW PIN 00-63 39

11 UPIN UPPER PIN 00-63 28

12 LPIN LOWER PIN 00-63 29

13 TROT TROT 00-255 128

14 HBLK H BLK mode select 00-01 0

15 LBLK HBLK front timing 00-63 5

16 RBLK HBLK rear timing 00-15 31

17 VBLK V BLK width 00-03 0

18 HMSK TOP VEND(when MACROVISION)prevent OFF 00-01 0

19 HDW H PULSE WIDTH(25u/19u) 00-01 1

20 AFC AFC GAIN 00-01 0

21 AFC1 AFC1 TIME CONSTANT 00-07 3

22 AFCW AFC1 PULL IN WIDE 00-01 1

23 CDMD V DET WINDOW SW TIMING 00-03 1

24 HSS SYNC SLICE LEVEL(H sepa) 00-03 0

25 VSS SYNC SLICE LEVEL(V sepa) 00-03 3

26 SLDN Auto Slice level DOWN 00-03 0

27 SLUP Auto Slicelevel UP 00-01 0

28 JPSW Jump SW 00-01 0

29 HOSC H VCO fo ADJUST 00-255 5

30 EHT EHT 00-15 6

31 EHTG EHT MODE 00-01 0

Range

(DEC)

KV-20FS100/20FV300/21FM100/21FS100/

21FV300/24FV300/25FV300

Initial Data

DEVICE "16:9"

Item# OSD DETAIL

1 PAMP EW PIN 00-63 59

2 UPIN UPPER PIN 00-63 15

3 LPIN LOWER PIN 00-63 21

4 ACLV ACL VTH 00-03 0

5 ABLV ABL VTH 63-00 58

DEVICE "VP1"

Item# OSD DETAIL

1 RDRV R DRIVE 00-127 55

2 GDRV G DRIVE when Color Temp. is "Cool" and "Neutral" 00-127 38

3 BDRV B DRIVE when Color Temp. is "Cool" and "Neutral" 00-127 47

4 RCUT 00-1023 130

5 GCUT 00-1023 90

6 BCUT 00-1023 72

7 SCON CONTRAST LEVEL 00-127 20

8 SHUE TINT 00-127 8

9 SCOL COLOR LEVEL 00-127 17

10 SBRT BRIGHT 00-255 35

11 RON R OUTPUT MUTE 00-01 1

12 GON G OUTPUT MUTE 00-01 1

13 BON B OUTPUT MUTE 00-01 1

14 BLLV BLUE STRETCH(00:no <-> 11:deep) 00-03 1

15 MTRX MATRIX RATIO SELECT 00-03 2

16 AXIS R-Y PHASE OFFSET 00-63 48

17 SSHO SHARPNESS GAIN(OVER) 00-63 17

18 SSHP SHARPNESS GAIN(PRE) 00-63 26

19 SHPF SHRPNESS fo(00:2 CLK <-> 11:5 CLK) 00-03 1

Range

(DEC)

Range

(DEC)

Initial Data

Initial Data

— 18 —

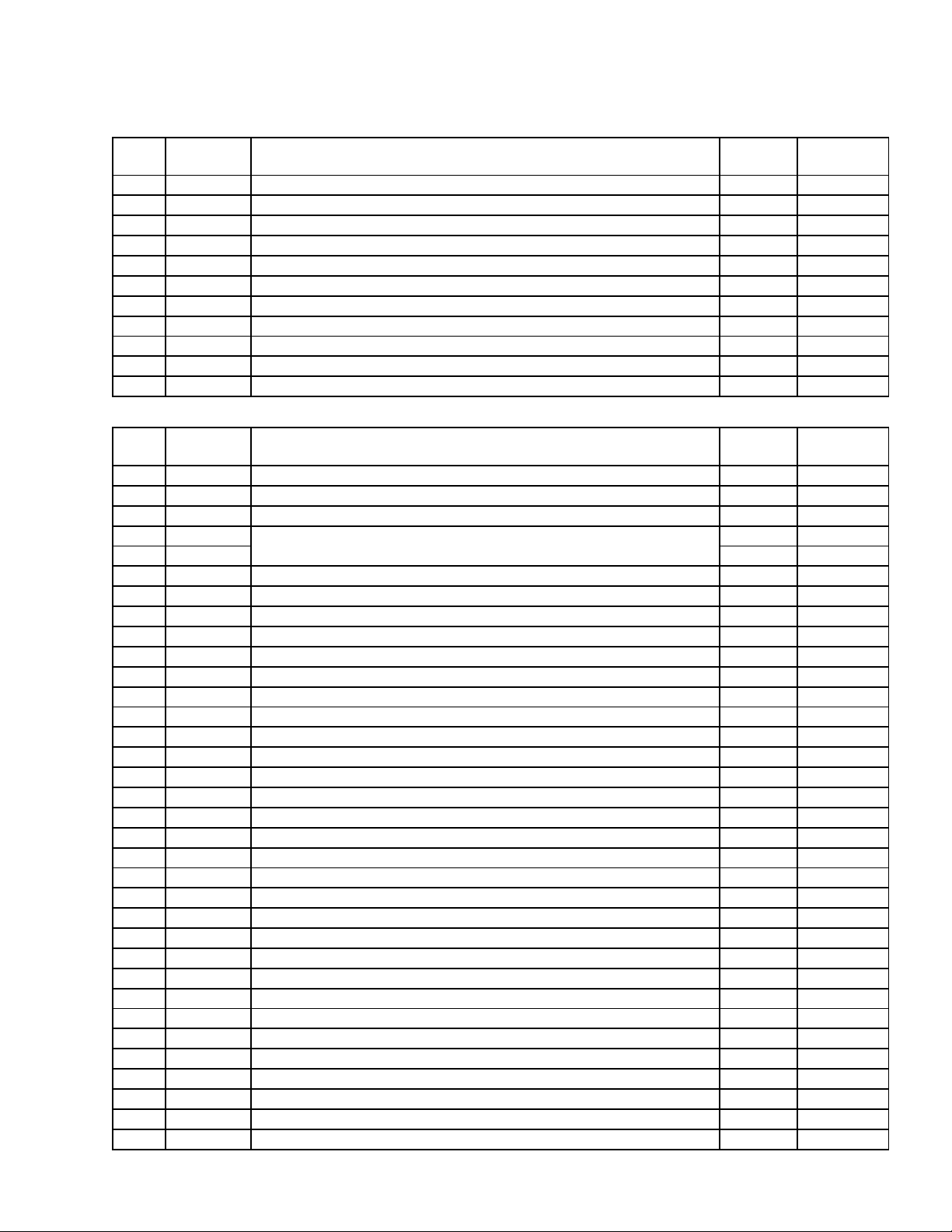

ADJUSTMENT ITEMS (2 OF 8)

DEVICE "VP1"

Item# OSD DETAIL

20 SHCL SHARPNESS CPRING LEVEL 00-15 0

21 SHMX SHARPNESS LIMITTER LEVEL 00-15 15

22 ACLV ACL VTH 00-03 0

23 ABLV ABL VTH 00-63 0

24 AKBD AKB Self Diagnostic Counter(@1sec) 00-07 7

25 AKBS AKB H/W S/W Switch 00-02 1

26 REFP AKB REFPLS timing 00-01 1

27 YNRC YNR LIMITER LEVEL 00-15 15

28 BKON BLACK STRETCH ON 00-01 1

29 BKTH BLACK STRETCH DETECTOR TRESH LEVEL 00-255 22

30 BKAR BLACK STRETCH DETECTOR TRESH AREA 00-03 1

31 BKSP BLACK STRETCH START POINT 00-03 1

DEVICE "VP2"

Item# OSD DETAIL

1 VMLO VM LEVEL at "Low" Setting 00-15 10

2 VMHI VM LEVEL at "High" Setting 00-15 15

3 VMDL VM DELAY 00-15 6

4 VMPL VM PORALITY 00-01 0

5 VMWD VM WIDTH 00-03 0

6 VMCL VM CORING LEVEL 00-15 0

7 VMMX VM LIMITER LEVEL 00-15 15

8 CKLV COLOR KILLER VTH 00-127 1/YUV:0

9 CKON FORCE KILLER 00-01 0

10 ALFA ADAPTIVE DET SENSITIVITY 00-03 2

11 YCMD YC SEPA FORCE SELECT(00:ADAPTIVE 01:H 10:V 11:HV) 00-03 0

12 VACL V APERTURE CORING LEVEL 00-15 0

13 VAGA V APERTURE GAIN LEVEL 00-15 Soft Cont'l

14 VAMX V APERTURE LIMITER LEVEL 00-15 3

15 GAMM GANMA(00:no <-->11:deep) 00-03 Soft Cont'l

16 YDLY Y DELAY TIME 00-03 3/YUV:3

17 CDLY C DELAY 00-03 2/YUV:2

18 YOFF Y OUTPUT MUTE 00-01 0

19 CBPF C BPF fo HI 00-01 0/YUV:0

20 CLIM C OUTPUT LIMITTER 00-15 15

21 YFSL Y BAND WIDTH 00-03 0

22 CFSL C BAND WIDTH 00-03 0

23 BGPP BGP(for C DECODER)TIMING 00-31 8

24 NRCH NOISE DET TIME CONSTANT 00-03 0

25 NRCL NOISE DET TIME CONSTANT 00-255 8

26 NRVL NOISE DET VTH 00-255 16

27 NRVH NOISE DET VTH 00-255 0

28 GDOF G DRIVE 00-31 18

29 BDOF B DRIVE 00-31 31

30 GCOF G CUTOFF 00-31 02

31 BCOF B CUTOFF 00-31 00

32 DCTV DCTRANSFER VTH 00-127 5

33 DCTG DCTRANSFER GAIN 00-31 Soft Cont'l

KV-20FS100/20FV300/21FM100/21FS100/

21FV300/24FV300/25FV300

Range

(DEC)

Range

(DEC)

Initial Data

Initial Data

— 19 —

ADJUSTMENT ITEMS (3 OF 8)

DEVICE "VIVID"

Item# OSD DETAIL

1 VPIC Picture(VIVID) 00-63 63

2 VBRI Brightness(VIVID) 00-63 31

3 VCOL Color(VIVID) 00-63 37

4 VHUE Hue(VIVID) 00-63 31

5 VSHA Sharpness(VIVID) 00-63 31

6 VVM VM(VIVID) 00-02 2

7 VTRI Color Temp(VIVID) 00-02 0

8 VAPA Aperture G(VIVID) 00-15 7

9 VGMA Gamma(VIVID) 00-03 3

10 DCTG DCT LV(VIVID) 00-03 16

DEVICE "STD"

Item# OSD DETAIL

1 VPIC Picture(STANDARD) 00-63 50/FEFS:63

2 VBRI Brightness(STANDARD) 00-63 37/FEFS:31

3 VCOL Color(STANDARD) 00-63 31/FEFS:37

4 VHUE Hue(STANDARD) 00-63 31/FEFS:31

5 VSHA Sharpness(STANDARD) 00-63 31/FEFS:31

6 VVM VM(STANDARD) 00-02 1/FEFS:2

7 VTRI Color Temp(STANDARD) 00-02 1/FEFS:0

8 VAPA Aperture G(STANDARD) 00-15 7/FEFS:7

9 VGMA Gamma(STANDARD) 00-03 3/FEFS:3

10 DCTG DCT LV(STANDARD) 00-03 16/FEFS:16

KV-20FS100/20FV300/21FM100/21FS100/

21FV300/24FV300/25FV300

Range

(DEC)

Range

(DEC)

Initial Data

Initial Data

DEVICE "MOVIE"

Item# OSD DETAIL

1 VPIC Picture(MOVIE) 00-63 31

2 VBRI Brightness(MOVIE) 00-63 51

3 VCOL Color(MOVIE) 00-63 25

4 VHUE Hue(MOVIE) 00-63 31

5 VSHA Sharpness(MOVIE) 00-63 31

6 VVM VM(MOVIE) 00-02 0

7 VTRI Color Temp(MOVIE) 00-02 2

8 VAPA Aperture G(MOVIE) 00-15 7

9 VGMA Gamma(MOVIE) 00-03 3

10 DCTG DCT LV(MOVIE) 00-03 16

DEVICE "SPORTS"

Item# OSD DETAIL

1 VPIC Picture(SPORTS) 00-63 63

2 VBRI Brightness(SPORTS) 00-63 31

3 VCOL Color(SPORTS) 00-63 40

4 VHUE Hue(SPORTS) 00-63 31

5 VSHA Sharpness(SPORTS) 00-63 31

6 VVM VM(SPORTS) 00-02 2

7 VTRI Color Temp(SPORTS) 00-02 0

8 VAPA Aperture G(SPORTS) 00-15 7

9 VGMA Gamma(SPORTS) 00-03 3

10 DCTG DCT LV(SPORTS) 00-03 16

Range

(DEC)

Range

(DEC)

Initial Data

Initial Data

— 20 —

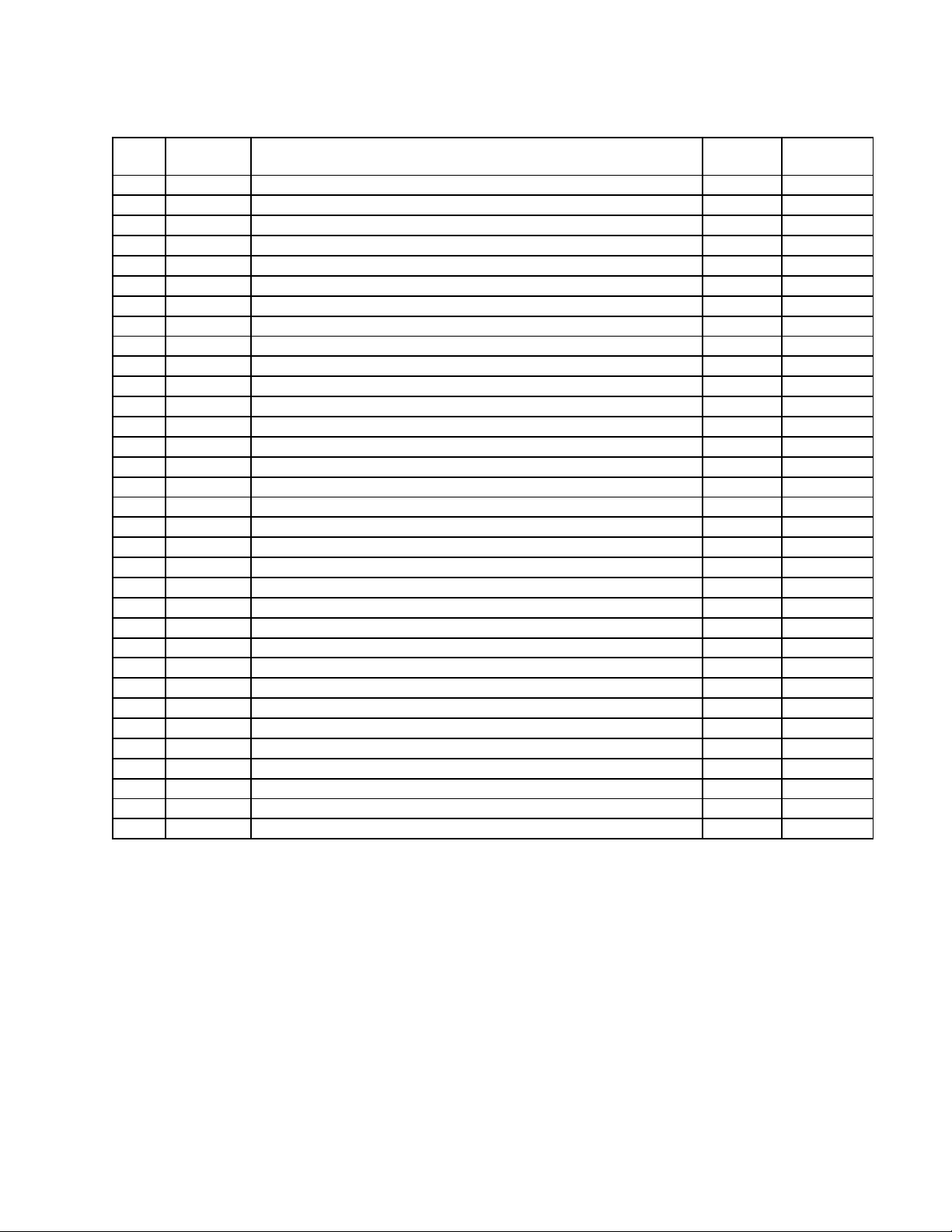

ADJUSTMENT ITEMS (4 OF 8)

DEVICE "Y"

Item# OSD DETAIL

1 COFI 0:4 Linedelaies 1:2 Linedelaies 00-01 0

2 YNRS YNR ON 00-01 0

3 YTHR Y SIGNAL GENERATE from 2DYCS 00-01 0

4 Y2D Y SIGNAL GENERATE from 2DYCS 00-01 0

5 2DFX C SIGNAL GENELATE from H/V BPF only 00-01 1

6 CLPS Y CLAMP TIME CONSTANT 00-01 1

7 VLPF Y_LPF(ANALOG) fo Ajust 00-03 3

8 CLPF C_LPF(ANALOG) fo Ajust 00-03 3

9 BKHS BLACK STRETCH HYSTERISYS 00-31 1

10 BPFB YCS HBPF SELECT(BACK) 00-03 1

11 BPFF YCS HBPF SELECT(FRONT) 00-01 1

DEVICE "C"

Item# OSD DETAIL

1 FORG CHROMA DECODER PHASE SELECT 00-03 0

2 FSEL CHROMA DECODER CLK SELECT 00-01 0/YUV:0

3 ACTL ANALOG ACC AMP MAX GAIN 00-03 3

4 A1FL 00-255 34

5 A1FH 00-01 0

6 A1ON ANALOG ACC AMP ON LEVEL 00-127 12

7 MV MACROVISION(BURST) DET TRESH 00-15 0

8 MV1S MACROVISION(BURST) DET ON 00-01 1

9 MV2S MACROVISION(BURST) DET POSITION 00-01 1

10 ACCS ACC ON/OFF 00-01 0/YUV:1

11 KILS KILLER DET SELECT 00-01 0/YUV:1

12 AASL C DECODER TIME CONSTANT(32,16,8,1H) 00-03 3

13 BASL ACC TIME CONSTANT 00-03 0

14 ATIM ANALOG ACC HISTERISYS SELECT 00-03 0

15 VMSK ACC V BLK OFF WIDTH 00-07 0

16 A3ON ACC MAX GAIN 00-01 0

17 INTE C DECODER INTRGRATOR ENABLE 00-01 0

18 SIN C DECODER PHASE V ENABLE 00-01 0

19 CKVT PLL STOP BURST LEVEL 00-03 1

20 XFFR VCXO FORCE FREERUN 00-01 0/YUV:1

21 ACCV C DECODER PHASE V ENABLE 00-01 1

22 BWSL KILLER DET SELECT 00-01 1/YUV:1

23 BWDT PLL KILLER VTH 00-03 0/YUV:3

24 A23E AMP2,3 ON/OFF ENABLE(0 FIX) 00-01 1

25 A2ON ABL VTH 00-127 12

26 A3ON ACL VTH 00-127 12

27 A2FL AMP2 OFF LEVEL lower 00-255 34

28 A2FH AMP2 OFF LEVEL upper 00-01 0

29 A3FL AMP3 OFF LEVEL lower 00-255 34

30 A3FH AMP3 OFF LEVEL upper 00-01 0

31 AXTH AXS HYS 00-63 30

32 ACTH ROM HYS 00-63 10

33 AVAV AVE SEL AV 00-03 3

34 B2TH B2COMP 00-127 0

ANALOG ACC hysteresis

KV-20FS100/20FV300/21FM100/21FS100/

21FV300/24FV300/25FV300

Range

(DEC)

Range

(DEC)

Initial Data

Initial Data

— 21 —

ADJUSTMENT ITEMS (5 OF 8)

DEVICE "RGB"

Item# OSD DETAIL

1 AMUT RGB POWER ON MUTE 00-01 0

2 PMUT RGB MUTE(EXCEPT OSD) 00-01 1

3 VBLK 00-01 0

4 CORL R CUTOFF lower 00-255 100

5 CORH R CUTOFF upper 00-01 1

6 COGL G CUTOFF lower when Color Temp. is "Cool" and "Neutral" 00-255 125

7 COGH G CUTOFF upper when Color Temp. is "Cool" and "Neutral" 00-01 1

8 COBL B CUTOFF lower when Color Temp. is "Cool" and "Neutral" 00-255 125

9 COBH B CUTOFF upper when Color Temp. is "Cool" and "Neutral" 00-01 1

10 ABLS ABL SELECT (ON:00, OFF:01) 00-01 0

11 ACLS ACL ON (ON:00, OFF:01) 00-01 1

12 ALSP ACL SPEED 00-03 1

13 ALRS ACL RECOVER SPEED 00-15 2

14 ALAS ACL ATACK SPEED 00-15 9

15 ABLG ABL GAIN 00-15 15

16 ALS2 ACL ATACK SPEED(2) 00-03 2

17 AKBS AKB MODE 00-01 1

18 AKBP AKB PULSE HEIGHT 00-63 40

19 OSDL OSD LIMMIT SELECT 00-01 0

20 MPXS UV MULTIPLEX ON 00-01 0/YUV:0

21 CXUV YC/YUV SELECT 00-01 0/YUV:1

22 UVIN U/V INVERT 00-01 0/YUV:0

23 UVOS UV OFFSET CANCELER ON 00-01 0/YUV:0

24 ACL SOFT ACL CONTROLE 00-63 63

25 HBLS H BLK OFF 00-01 0

26 VENS V-latch OFF 00-01 0

27 UOFS U IN OFFSET 00-15 4

28 VOFS V IN OFFSET 00-15 9

29 AABL ANALOG ABL THRESHOLD LEVEL CONTROL 00-15 0

30 AABG ANALOG ABL GAIN CONTROL 00-01 0

31 AALG ANALOG ACL GAIN CONTROL 00-01 0

32 AABS ANALOG ABL ON/OFF CONTROL (ON:01, OFF:00) 00-01 0

33 AALS ANALOG ACL ON/OFF CONTROL (ON:01, OFF:00) 00-01 1

KV-20FS100/20FV300/21FM100/21FS100/

21FV300/24FV300/25FV300

Range

(DEC)

Initial Data

— 22 —

ADJUSTMENT ITEMS (6 OF 8)

DEVICE "DEFD"

Item# OSD DETAIL

1 VSTP V OUTPUT STOP 00-01 0

2 HFFR AFC1 FORCE FREERUN 00-01 0

3 HFUP H FREERUN FREQUENCY UP(700Hz) 00-01 0

4 VPHA V PHASE(V POSITION ADJUST) 00-15 0

5 JSWW Jump Pulse Width 00-01 0

6 EWG EWV AD OUTPUT LEVEL(6db) 00-01 0

7 EWCL EW/VRAMP DA CLOCK SELECT 00-03 2/YUV:2

8 EWDI EW/VRAMP DA DITHER 00-01 0

9 XF0A VCXO FREERUN ADJUST 00-15 0

10 BGST BGP(for PLL) TIMING 00-63 17

11 SKWI Skew correcter refernce phase 00-01 0/YUV:0

12 XPHA VCXO PHASE ADJUST 00-15 10

13 SKEW Skew correcterphase controle 00-07 0/YUV:3

14 HRMP AFC2 TIME CONSTANT 00-03 0

15 RPLU REF PLL TIME CONSTANT 00-07 3

16 RPLB REF PLL TIME CONSTANT 00-01 1

17 XF0B VCXO Fo ADJUST 00-03 0

18 RPLS REF VCO FB LOOP SELECT 00-01 0

19 SSM SyncSepaMasking CONTROL 00-01 0

20 VSAG V-SAG prevent ON 00-01 0

21 AFC2 AFC2 GAIN CONTROL 00-03 0

22 VRFL V RAMP FILTER SWITCHING OFF 00-01 0

23 SSLP LPF pre SYNC SEPA ON/OFF 00-01 0

24 IMTS I.M. TEST 00-01 0

25 XPLU ACP TIME CONSTANT 00-01 0

26 8FSC 8fscCLK Skew OFF 00-01 1/YUV:1

27 4FS2 4fscCLK Skew OFF 00-01 1/YUV:1

28 EWVR DSDAC V RESET Enable 00-01 0

29 VLOF IIC V Latch OFF(for TEST) 00-01 0

30 1WIN FORCE 1Window 00-01 1

31 BGPC ANGLE Return current up 00-01 0

32 MHDL ANGLE Return current up timing 00-01 1

33 BFRE force V FREERUN 00-01 0

34 ANGG ANGLE Retun current up 00-01 1

35 ANGT ANGLE Retun current up timing 00-01 0

36 DOSD Digital OSD ON 00-01 0

37 ANGS AFC2 ANGLE/BOW INHIBIT 00-01 0

38 HRPP FRAMP RRAMP H OUT CONTROL RANGE 00-15 8

39 VF50 FORCE V FREERUN 50Hz 00-01 0

40 CLKS TBC clock system select 00-03 0

41 VBHK V BLK HALF KILL 00-01 0

42 DSYC CVBS INPUT CONTROL 00-01 0

43 VPW V Pulse Wide 00-01 1

44 QSW MODULATOR FEEDBACK GAIN CONTROL 00-01 0

45 ADTY CLOCK DUTY CONTROL at IIC QSWITCH=ON 00-01 0

46 DTH DITHER THRESHOLD LEVEL CONTROL at IIC AUTOD=ON 00-03 1

47 HBSW HBLK REFERENCE AFC1/AFC2 00-01 0

48 DSCS •DAC CLOCK ON/OFF CONTROL 00-01 0

KV-20FS100/20FV300/21FM100/21FS100/

21FV300/24FV300/25FV300

Range

(DEC)

Initial Data

— 23 —

ADJUSTMENT ITEMS (7 OF 8)

DEVICE "OTHER"

Item# OSD DETAIL

1 PCLP SYNC TIP/PEDESTAL CLAMP SELECT 00-01 0

2 VRT ADC REFERENCE (00:1.15Vpp 01:1.25Vpp 10:1.35Vpp 11:1.45Vpp) 00-03 1/YUV:1

3 AM INTERIGENT MONITOR OUTPUT SELECT(analog) 00-15 0

4 DME INTERIGENT MONITOR OUTPUT SELECT(degital) 00-01 0

5 DM INTERIGENT MONITOR OUTPUT SELECT(degital) 00-31 0

6 14HI 4fsc(Skew)CLK POLARITY 00-01 0

7 14HD 4fscCLK(Skew)CLK DELAY ADJUST 00-03 1

8 28I 8fscCLK POLARITY 00-01 1

9 28D 8fscCLK DELAY ADJUST 00-03 1

10 ADCD ADC CLK DELAY ADJUST 00-03 1/YUV:0

11 CLKS AD/LOGIC CLK SWAP 00-01 0/YUV:0

12 HDSL HD OUT(for MCU)SELECT 00-01 1

13 CPSL PLL CP LATCH ON 00-01 0

14 CPCL PLL CP LATCH CLOCK 00-01 0

15 CPCP PLL CP LATCH POLARTY 00-01 0

16 DUMY DUMMY 00-0F 1

KV-20FS100/20FV300/21FM100/21FS100/

21FV300/24FV300/25FV300

Range

(DEC)

Initial Data

DEVICE "OSD"

Item# OSD DETAIL

1 HT HALF TONE LEVEL 00-03 0

2 OSLR R OSD LEVEL 00-63 27

3 OSLG G OSD LEVEL 00-63 27

4 OSDC 00-03 0

5 OSDB B OSD LEVEL 00-63 27

DEVICE "S/W ADKB"

Item# OSD DETAIL

1 SRIL S/W AKB RED OUTPUT Lower 00-255 Soft Cont'l

2 SRIH S/W AKB RED OUTPUT Upper 00-01 Soft Cont'l

3 SGIL S/W AKB GREEN OUTPUT Lower 00-255 Soft Cont'l

4 SGIH S/W AKB GREEN OUTPUT Upper 00-01 Soft Cont'l

5 SBIL S/W AKB BLUE OUTPUT Lower 00-255 Soft Cont'l

6 SBIH S/W AKB BLUE OUTPUT Upper 00-01 Soft Cont'l

7 SLM1 S/W AKB LIMIT DATA 1 00-255 4

8 SLM2 S/W AKB LIMIT DATA 2 00-255 29

9 SLM3 S/W AKB LIMIT DATA 3 00-255 130

10 SAD1 S/W AKB ADD DATA 1 00-255 1

11 SAD2 S/W AKB ADD DATA 2 00-255 1

12 SBIT S/W AKB BIT SHIFT DATA 00-05 0

13 SNOP S/W AKB POWER ON NOP TIMER COUNTER DATA 00-FF 1

14 SERL S/W AKB BIT ERROR JUDGE LEVEL 01-80 124

15 SPWC S/W AKB ERROR JUDGE COUNTER DATA 01-FF 2

16 SLMC S/W AKB LIM2/LIM3 JUDGE COUNTER DATA 01-FF 10

17 SPWL S/W AKB POWER ON MUTE OFF JUDGE LEVEL 01-80 30

18 SPMT S/W AKB POWER ON MUTE EXIT TIMER DATA(@100ms) 00-FF 120

19 SEEP S/W AKB INITIAL DATA EEPROM WRITE TIMER(@1sec) 00-FF 20

Range

(DEC)

Range

(DEC)

Initial Data

Initial Data

— 24 —

KV-20FS100/20FV300/21FM100/21FS100/

21FV300/24FV300/25FV300

ADJUSTMENT ITEMS (8 OF 8)

DEVICE "AUDIO PROCESSOR"

Item# OSD DETAIL

1 SBAL Sub Balance 00-07 4

2 SBAS Sub Bass 00-07 0

3 STRE Sub Treble 00-07 0

4 SRL Surround Level 00-01 0

5 BBOL Surround Off-BBE Low 00-15 0

6 BBOH Surround Off-BBE High 00-15 3

7 BBSL Simulate BBE Low 00-15 0

8 BBSH Simulate BBE High 00-15 0

9 BBGL WOW Game BBE Low 00-15 7

10 BBGH WOW Game BBE High 00-15 3

11 BBTL SRS BBE Low 00-15 0

12 BBTH SRS BBE High 00-15 2

13 VFIX Audio output fix data 00-255 240

14 AGCL AGC level 00-03 2

Range

(DEC)

Initial Data

DEVICE "MICROPROCESSOR"

Item# OSD DETAIL

Range

(DEC)

1 DISP OSD horizontal offset 00-127 78

2 CCHP Closed Caption Horizontal Position 00-7E 80

3 HRLW Low limit of H-pulse counting window (RF) 00-255 16

4 HRHG High limit of H-pulse counting wondow (RF) 00-255 64

5 HSLW Low limit of H-pulse counting window (S-Video) 00-255 16

6 HSHG High limit of H-pulse counting wondow (S-Video) 00-255 64

7 HSDT H-pulse Detection(S-Video) 00-255 8

DEVICE "FEATURE"

Item# OSD DETAIL

Range

(DEC)

ID0 Language related 00-255 SEE ID MAP

ID1 Video ralated 00-255 SEE ID MAP

ID2 Audio related 00-255 SEE ID MAP

ID3 Miscellaneous 00-255 SEE ID MAP

ID4 Miscellaneous 00-255 SEE ID MAP

ID5 Miscellaneous 00-255 SEE ID MAP

ID6 Miscellaneous 00-255 SEE ID MAP

ID7 Miscellaneous 00-255 SEE ID MAP

Notes:

Range (DEC) shows the range of possible setting for each Adjustment Mode.

Initial Data shows the standard settings for each Adjustment Mode.

Signal

Type

Chip

Version

Function

Mode

service id's id5 19

ntsc

M37280MK-00SP VERB.O

Number

00010011

Initial Data

Initial Data

ID

Data

— 25 —

4-4. ID MAP TABLE

Mode l De stinati on ID-O ID-1 ID-2 I D-3 ID-4 I D-5 ID-6 ID -7

KV-20FS100 US 89 7 65 33 128 48 0 150

KV-20FS100 CND 89 7 65 49 128 48 0 150

KV-20FV300 US 89 23 231 35 128 48 0 150

KV-20FV300 CND 89 23 231 51 128 48 0 150

KV-21FS100 E 81 7 81 129 160 48 0 214

KV-21FM100 E 81 3 64 129 160 16 0 198

KV-21FV300 E 81 23 231 131 160 48 0 214

KV-24FV300 US 89 23 231 35 128 48 0 150

KV-24FV300 CND 89 23 231 51 128 48 0 150

KV-25FV300 E 81 23 231 131 160 48 0 214

4-5. A BOARD ADJUSTMENTS

H. FREQUENCY (FREE RUN) CHECK

1. Input a TV mode (RF) with no signal.

2. Connect a frequency counter to base of Q502

(TP-25 H. DRIVE) on the A Board.

3. Check H. Frequency for 15735 ± 200 Hz.

V. FREQUENCY (FREE RUN) CHECK

1. Select video 1 with no signal input.

2. Set the conditions for a standard setting.

3. Connect the frequency counter to TP-27 (V OUT) or CN515 pin

6

(V DY+) and ground on the A Board .

4. Check that V. Frequency shows 60 ± 4 Hz.

DRIVE (SCON)

1. Input a color-bar signal and set the level to 75%.

2. Set in Standard mode.

3. Activate the Service Adjustment Mode.

4. Set AALS, ABLS, GON and BON items. Using

the following values. Leave RON set to “1”.

3

and 6 set each to

KV-20FS100/20FV300/21FM100/21FS100/

21FV300/24FV300/25FV300

86 ± 3Vpp for 20 inch and

96 ± 3Vpp for 24 inch.

8. Reset AALS, ABLS, GON and BON values to “1”.

AALS: ON (1)

ABLS: ON (0)

R ON: ON (1)

G ON: ON (1)

B ON: ON (1)

9. Press

MUTING

then

ENTER

to save into the memory.

DISPLAY POSITION ADJUSTMENT (DISP)

1. Input a color-bar signal.

2. Set to Service Adjustment Mode.

3. Select DISP with

4. Adjust values of DISP with

1

and 4 .

3

and 6 to adjust characters to the

center.

5. Write to memory by pressing

MUTING

then

ENTER

.

6. Check to see if the text is displayed on the screen.

Mode

Category

service micro disp 48

Signal

Type

ntsc

vchp

Display

00000000 00000000

Item

Item

Data

SUB BRIGHT ADJUSTMENT (SBRT)

1. Input a monoscope signal.

2. Activate the Service Adjustment Mode.

3. Set the PICTURE and BRIGHTNESS to minimum.

4. Select the SBRT item with

5. Adjust the values of SBRT with

Mode

service video rdrv

Signal

Type

ntsc

vchp

Category

Display

00000000 00000000

Item

26

Item

Data

6. Press

AALS: OFF (0)

ABLS: OFF (1)

SUB HUE, SUB COLOR ADJUSTMENT

(SHUE, SCOL)

R ON: ON (1)

G ON: OFF (0)

B ON: OFF (0)

1. Input color-bar signal at 75%.

2. Activate the Service Adjustment Mode.

3. Set (PIC) to Max and (COL) to 50%.

5. Connect an oscilloscope probe to CV Board, J1751Pin 12 (KR) (Red

4. Connect an oscilloscope probe to CV Board, CN301Pin

Out) .

6. Select SCON with

7. Adjust the value of SCON with

1

and 4 .

3

and 6 for

5. Select the SHUE and SCOL item with

6. While showing the SHUE item, adjust the waveform with

86 ± 3Vpp for 20/21 inch and 96 ± 3Vpp for 24/25 inch.

— 26 —

1

and 4 .

3

and 6 to obtain a faintly visible

crosshatch.

MUTING

then

ENTER

to save into the memory.

Out.

1

and 4 .

4

and

until the second and third bars show the same level

(V2 = V3 < 0.15Vp-p). Set Sub Hue -2 Step.

4

1

Blue

KV-20FS100/20FV300/21FM100/21FS100/

21FV300/24FV300/25FV300

7. While showing the SCOL item, adjust the waveform with

6

and

until the fi rst and fourth bars show the same level

(V1 = V4 < 0.15Vp-p). Set Sub Col +2 Step.

8. Press

MUTING

then

V1

ENTER

V2 V3

V4

to save into the memory.

3

V. SIZE ADJUSTMENT (VSIZ)

1. Input a crosshatch signal.

2. Activate the Service Adjustment Mode.

3. Select the VSIZ item with

4. Adjust value of VPOS with

5. Press

MUTING

then

1

and 4 .

1

and 4 for the best vertical center.

to save into the memory.

ENTER

V. CENTER ADJUSTMENT (VPOS)

Perform this adjustment after performing H. Frequency

(Free Run) Check.

1. Input a crosshatch signal.

2. Activate the Service Adjustment Mode.

3. Select the VPOS item with

4. Adjust value of VPOS with

5. Press

MUTING

then

1

and 4 .

3

and 6 for the best vertical center.

ENTER

to save into the memory.

H. SIZE ADJUSTMENT (HSIZ)

1. Input a monoscope signal.

2. Activate the Service Adjustment Mode.

1

3. Select HSIZ with

4. Adjust with

5. Press

MUTING

and 4 .

3

and 6 for the best horizontal size.

ENTER

then

to save into the memory.

V. LINEARITY (VLIN), V. CORRECTION

(SCOR), PIN AMP (PAMP), AND

HORIZONTAL TRAPEZOID (HTRP)

ADJUSTMENTS

1. Input a crosshatch signal.

2. Activate the Service Adjustment Mode.

3. Select VLIN, SCOR, PAMP, and HTRP with with

4. Adjust with

5. Press

3

and 6 for the best horizontal size.

then

MUTING

V LINEARITY (VLIN)

V CORRECTION (SCOR)

ENTER

to save into the memory.

1

and 4.

H. CENTER ADJUSTMENT (HPOS)

Perform this adjustment after performing H. Frequency

(Free Run) Check.

1. Input a crosshatch signal.

2. Activate the Service Adjustment Mode.

3. Select the HPOS item with

4. Adjust the value of HPOS with

center.

5. Press

MUTING

then

1

and 4 .

3

and 6 for the best horizontal

ENTER

to save into the memory.

PIN AMP (PAMP)

HORIZONTAL TRAPEZOID (HTRP)

— 27 —

V. ANGLE (VANG), V. BOW (VBOW), UPPER

PIN (UPIN) AND LOW PIN (LPIN)

ADJUSTMENTS

1. Input a crosshatch signal.

2. Activate the Service Adjustment Mode.

3. Select VANG, VBOW, UPIN, and LPIN with

4. Adjust with

5. Press

3

and 6 for the best picture.

ENTER

MUTING

then

V ANGLE (VANG)

V BOW (VBOW)

UPPER PIN (UPIN)

to save into the memory.

1

and 4.

KV-20FS100/20FV300/21FM100/21FS100/

21FV300/24FV300/25FV300

LOW PIN (LPIN)

SERVICE ADJUSTMENT MODE MEMORY

ENTER

0

Item

then

Item

Data

7

.

Green

0

Red

ENTER

1. After completing all adjustments, press

Read From Memory

Mode

Signal

Type

Category

service defl vbow

ntsc

vchp

Display

00000000 00000000

— 28 —

SECTION 5: DIAGRAMS

KV-20FS100/20FV300/21FM100/21FS100/

21FV300/24FV300/25FV300

5-1. CIRCUIT BOARDS LOCATION

HR Board

M3 Board

A Board

CV Board

The components identifi ed by X in this basic schematic diagram have

been carefully factory-selected for each set in order to satisfy regulations

regarding X-ray radiation. Should replacement be necessary, replace

only with the value originally used.

When replacing components identifi ed by

Y

, make the necessary

adjustments as indicated. If the results do not meet the specifi ed value,

change the component identifi ed by

X

and repeat the adjustment until

the specifi ed value is achieved. (Refer to Safety Related Adjustments

on Page 15.)

When replacing the parts listed in the table below, it is important to

perform the related adjustments.

Part Replaced ( )

DY, T585, CRT, IC001, IC561,

C507, C508, C506, T511, L510,

Adjustment ( )

HV HOLD-DOWN

R565

C588, L588, C566, C561, C563,

D567, D568, D566, R567, R568,

R565, R566, R562, R563, R561,

R528....................A Board

5-2. PRINTED WIRING BOARD AND SCHEMATIC DIAGRAM INFORMATION

All capacitors are in µF unless otherwise noted. pF : µµF 50WV or less

are not indicated except for electrolytics and tantalums.

All electrolytics are in 50V unless otherwise specifi ed.

All resistors are in ohms. k=1000, M=1000k

Indication of resistance, which does not have one for rating electrical

power, is as follows: Pitch : 5mm Rating electrical power :

1

/

W in resistance, 1/

4

W and 1/

10

W in chip resistance.

8

: nonfl ammable resistor.

: fusible resistor.

: internal component.

: panel designation and adjustment for repair.

All variable and adjustable resistors have characteristic curve B, unless

otherwise noted.

Readings are taken with a color-bar signal input.

Readings are taken with a 10M digital multimeter.

Voltages are DC with respect to ground unless otherwise noted.

Voltage variations may be noted due to normal production tolerances.

All voltages are in V.

S : Measurement impossibillity.

: B+line.

: B-line. (Actual measured value may be different).

: signal path. (RF)

Circled numbers are waveform references.

1

/

W

4

REFERENCE INFORMATION

RESISTOR : RN METAL FILM

: RC SOLID

: FPRD NONFLAMMABLE CARBON

: FUSE NONFLAMMABLE FUSIBLE

: RW NONFLAMMABLE WIREWOUND

: RS NONFLAMMABLE METAL OXIDE

: RB NONFLAMMABLE CEMENT

: ADJUSTMENT RESISTOR

COIL : LF-8L MICRO INDUCTOR

CAPACITOR : TA TANTALUM

: PS STYROL

: PP POLYPROPYLENE

: PT MYLAR

: MPS METALIZED POLYESTER

: MPP METALIZED POLYPROPYLENE

: ALB BIPOLAR

: ALT HIGH TEMPERATURE

: ALR HIGH RIPPLE

The components identiÞ ed by shading and ! symbol are critical for safety. Replace

only with part number speciÞ ed.

The symbol indicates a fast operating fuse and is displayed on the component

side of the board. Replace only with fuse of the same rating as marked.

Les composants identiÞ es per un trame et une marque

securite. Ne les remplacer que par une piece portant le numero speciÞ e.

Le symbole indique une fusible a action rapide. Doit etre remplace par une

fusible de meme yaleur, comme maque.

!

sont critiques pour la

— 29 —

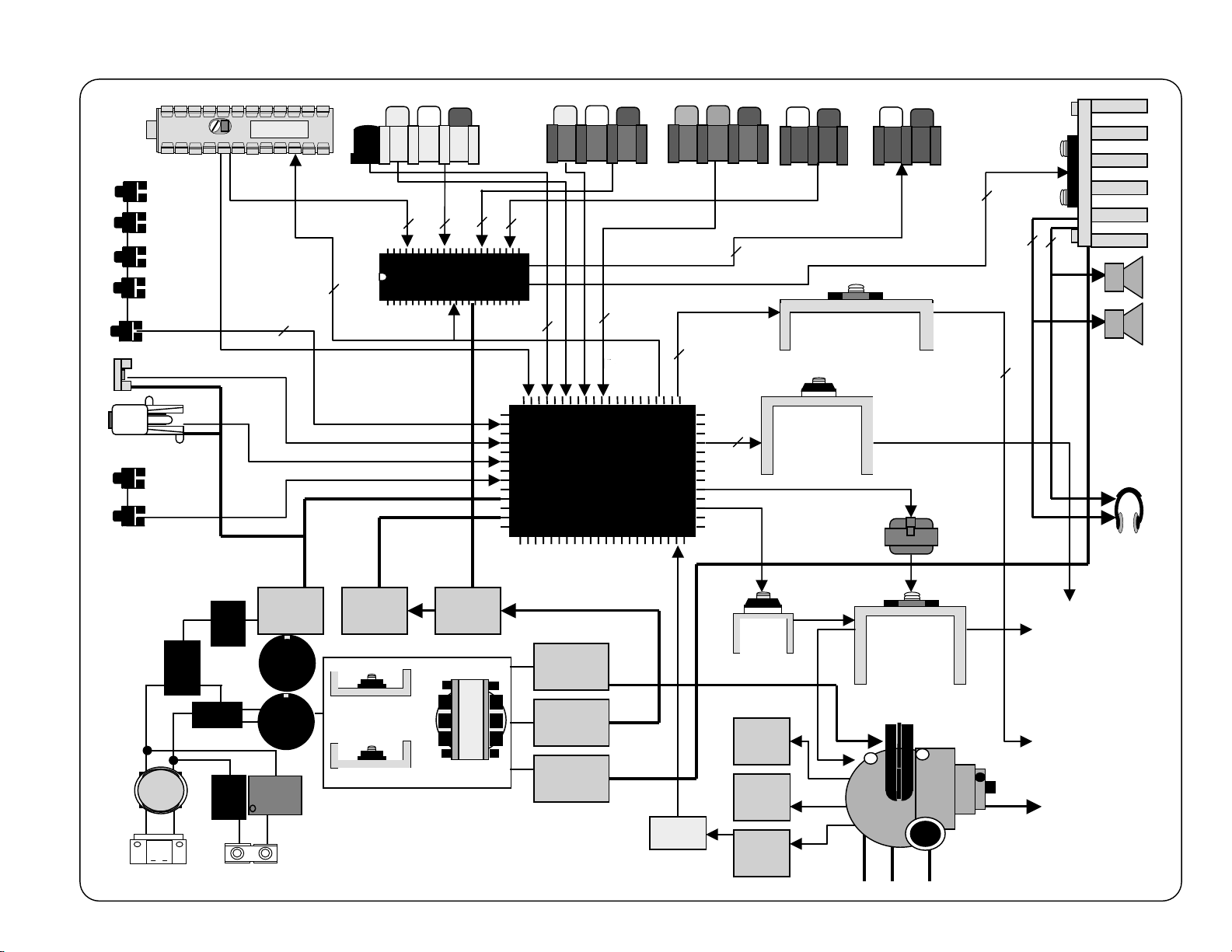

5.3 BLOCK DIAGRAM AND SCHEMATICS BLOCK DIAGRAM

KV-21FS100/21FM100/21FV300/20FV300/

20FS100/24FV300/25FV300

Tuner FRONT

I.R.

L.E.D.

Menu

CTRL

Energy Star

5VDC

TV-8

DEC

Det-Out

2

5V

STBY

S

REAR

V1 LR

2

2

2

V2 LR

Y/C

2

Y UV

AudioProcessor

2

I2C Bus

NJW1134

2

3

3 RGB

One-ChipIC

M65582MF-XXXFP

-Micro

-YCJ

Vd

YUV AUDIOYUV

LR

2

RGB Driver

TDA6108

V-Out

TDA8172

2

Hp

AUDIO OUT

Audio Amplifier

LR

AN7522 7.5W

AN1725 10W

2

2

2

R

L

Speakers

3RGB

-3LCombFilter

3.3V

Reg.

9V

Reg.

SRT

B+

Rect.

135V

E/W

Pin

Out

KC4370A

H-Out

2SD2627

H.Drive

Horiz.

Vert.

To DY

Head

phones

L.F.T

AC Line

Rect.

Relay

THP

D.G.C.

Power Mosfet

2SK2876

Power Supply

Low B

Rect.

Audio

Rect.

12.5V

14V

— 30 —

OCP

200v

Rect.

+13v

Rect.

-13v

Rect.

G2

FBT

HV

To CRT

To CRT

FBT

Focus

A BOARD SCHEMATIC DIAGRAM

1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 | 17 | 18 | 19 | 20 | 21 | 22 |

KV-21FS100/21FM100/21FV300/20FV300/

20FS100/24FV300/25FV300

A

—

B

—

C

—

D

—

E

—

F

—

G

—

H

—

I

—

J

—

K

—

L

—

M

—

N

—

O

T

T

C

U

G

O

A

D

L

V

O

N

O

M

E

O

T

E

S

R

0

1

P

0

T

V

3

.

6

R

F

-

C

A

G

4

7

0

C

0

1

8

0

0

L

5

7

0

C

0

7

4

2

0

P

T

6

V

9

0

3

6

D

D

0

3

-

7

7

-

T

-

J

Z

T

M

0

6

P

3

T

V

5

C

N

0

0

2

*

D

R

A

O

B

R

H

O

T

1

0

0

3

N

C

1

D

L

E

R

M

T

E

I

P

M

N

G

S

T

S

I

P

O

C

A

N

I

C

G

D

C

G

D

2

D

E

W

L

R

D

3

5

Y

V

B

4

C

S

R

5

N

E

O

R

W

6

I

C

0

4

0

*

S

I

R

C

S

123

2

7

0

R

k

7

.

4

N

C

6

0

0

2

P

N

I

C

2

A

1

N

I

C

A

0

0

6

R

0

M

2

.

2

0

*

6

W

2

/

1

R

D

V

2

0

*

6

1

0

6

F

*

0

N

5

1

C

2

P

1

C

G

D

C

D

G

C

2

2

S

C

D

C

1

5

5

W

J

*

8

0

5

L

)

m

m

0

.

5

(

W

J

3

2

5

*

1

0

5

Y

R

1

0

5

D

X

T

-

1

1

1

A

M

P

I

H

C

:

0

5

1

Q

3

1

1

A

Q

-

R

S

T

A

3

G

C

I

D

R

V

E

R

A

S

V

C

0

D

V

9

V

9

:

A

5

S

3

S

A

L

V

D

S

C

V

0

S

A

S

5

3

7

0

1

R

0

0

1

P

I

H

C

:

R

8

0

1

R

0

0

1