Page 1

Training Manual

KDL46S3000

WAX3 Direct-View LCD Television Chassis

Circuit Description and Troubleshooting Guide

MODELS: KDL-26S3000 KDL-32XBR4

KDL-32S3000 KDL-32SL130

KDL-40S3000 KDL-40SL130

KDL-46S3000

Course : CTV-41

Page 2

Table of Contents

Chapter 1 – Features and Circuit Descriptions ................. 2

Introduction ...................................................................... 2

Features .......................................................................... 2

New Customer Menu .............................................................. 2

Internet Video Linking ............................................................. 2

HDMI 1.3 Support ................................................................... 2

Bravia™ Theater Sync ............................................................ 3

1080p Input ............................................................................. 3

Circuit Description ........................................................... 4

Overall Block Diagrams ................................................... 4

26 and 32-inch S-Line Models ............................................. 4

Backlight Inverter .................................................................... 4

Power Supply .......................................................................... 4

BU1 Board .............................................................................. 4

40 and 46-inch S Line Models ............................................. 6

Backlight Power ...................................................................... 6

Power Supply .......................................................................... 6

32” XBR and 40D3000 Models ............................................ 6

Video Processing ........................................................... 10

New Trident Processor .......................................................... 10

Video Switching ..................................................................... 10

Digital Tuner .......................................................................... 10

HDMI Inputs .......................................................................... 10

Audio Processing ........................................................... 13

Analog Audio ......................................................................... 13

Digital Audio .......................................................................... 13

Power Supply and Protection ............................................ 15

BU1 Board Protection ........................................................ 19

Onboard Regulator Protect ................................................... 19

Thermal Protect .................................................................... 19

Panel Protect ........................................................................ 19

Audio Protect ........................................................................ 19

Communications Errors ..................................................... 20

Trident Video Process Failure ............................................... 20

BH Board Communication Error ........................................... 20

BU1 to Panel (S series models) or BU1 to BH (XBR4 and

D3000 series) Communication Error .............................. 20

Protect Table ...................................................................... 22

Chapter 2 – Service and Troubleshooting ....................... 23

Overview ........................................................................ 23

Circuit Board Locations ................................................. 23

Protection ........................................................................... 30

Diagnostics History ............................................................ 31

Clearing the Diagnostics History ........................................... 31

Digital Signal Status ........................................................... 32

New Remote Control Commands ...................................... 32

Service Mode ................................................................. 34

Data Handling .................................................................... 34

Saving (Writing) Data ............................................................ 34

Reading Back of Data ........................................................... 34

Factory Reset ........................................................................ 34

White Balance Adjustments ............................................... 34

QM Service Page ............................................................... 36

Troubleshooting ............................................................. 38

CTV-41 i

Page 3

Table of Contents (Continued)

Triage Worksheets ............................................................. 38

Troubleshooting Flowcharts ............................................... 38

Initial Contact Flowchart A ..................................................... 45

No Power Flowchart B .......................................................... 46

Protect ModeFlowchart C ..................................................... 47

26/32" Inverter Error Flowchart D ......................................... 48

40/46" Inverter Error Flowchart E .......................................... 49

No Video Flowchart F ............................................................ 50

Video Distortion Flowchart G ................................................ 51

Audio Flowchart H ................................................................. 52

Service Test Points ........................................................ 53

Chapter 3 - Disassembly ................................................... 58

Overview ........................................................................ 58

Inverter Board Removal (26 and 32” Models) ............... 58

26” LCD Panel Removal ................................................ 61

46” Panel Removal ........................................................ 67

CTV-41 ii

Page 4

Chapter 1 – Features and Circuit Descriptions

Introduction

The WAX3 chassis is one of several LCD Flat Panel designs introduced for

the Bravia™ 2007 model year. It provides for introductory and intermediate

level televisions for the customer to choose from. The following models

utilize the WAX3 chassis:

KDL26S3000

KDL32S3000

KDL32SL130

KDL32XBR4

KDL40S3000

KDL40SL130

KDL40D3000

KDL46S3000

Features

LCD Panels

New Customer Menu

The customer Graphics User Interface (GUI) has been improved to make

navigation of the setup features easier. Icons (similar to those found on

the PSP2) are used extensively. It is known as XMedia Bar™ (pronounced

cross media bar) or XMB for short.

Internet Video Linking

Yet another first for Sony, the Bravia™ model lineup will include a Digital

Media Exchange (DMEX) interface. By attaching an optional interface

device, known as Bravia Internet Video Link™, customers will have the

ability to access internet video entertainment via a broad-band connection.

Local news, weather and traffic along with access to selected digital media

streaming can be viewed on the television independent of a computer.

A special DMEX USB port on the rear of the television will allow bidirectional communication with the Bravia Internet Video Link™ device

via the Xross Media Bar™ feature included in the television. Sony will

partner with selected channels on the internet and these will automatically

appear on the screen for the customer to select.

All LCD panel sizes will be 1280 X 768 (WXGA) resolution. 32” and up

utilizes the Wide Color Gamut Cold-Cathode Fluorescent (WCG-CCFL)

backlighting for increased color uniformity and accurate grey-scales. The

26” model uses conventional fluorescent lights.

The 26 and 32-inch models (with the exception of the 32XBR4) utilize 8-bit

LCD panels. The 40 and 46-inch panels receive 10-bit RGB information.

All panel sizes (except the 32” XBR) are 60FPS refresh rate.

Exclusive to the KDL32XBR4 and KDL40D3000 is Sony’s introduction

of Motionflow™. An additional circuit is included to double the 60HZ

frame resolution from the video process circuits to 120HZ for clear picture

reproduction during rapid moving scenes. In this manual this feature will

be referred to as High Frame Rate (HFR).

CTV-41 2

Page 5

HDMI 1.3 Support

HDMI version 1.3 has added several features to enhance picture and

audio quality along with bi-directional communication between HDMI

equipped devices. The added features that apply to display products are

as follows:

Speed: Single link bandwidth is increased from 4.9GBS to 10.2GBS

Deep Color™: Increases RGB and component sample level from 24-bit

to 30, 36, and 48 bit.

xvYCC: Removes previous color space limitations to allow for the

reproduction of every color perceivable by the human eye.

CEC: Short for Consumer Electronics Control. Allows communication

among HDMI devices for control. Uses the industry standard A/V link

protocol. For example: Equipment can be set up so that when a DVD disc

is inserted into a player, the television will turn on with the proper input

setting along with the audio equipment turning on and being set for the

proper input and audio format.

The WAX3 model lineup only supports the CEC feature of HDMI 1.3.

Chapter 1 - Features and Circuit Descriptions

Bravia™ Theater Sync

A feature incorporated within the television to utilize the CEC feature of

HDMI 1.3

1080p Input

Unit can receive 1080p source content via the HDMI inputs only. The

1080p signal is scaled to the WXGA panel resolution.

NOTE: Only the 32” XBR and D3000 model will support 24-frame

sources. The S series models support 30-frame only.

CTV-41 3

Page 6

Chapter 1 - Features and Circuit Descriptions

Circuit Description

Various differences in circuitry occur in the WAX3 chassis line based on

panel size and display features. Virtually all video processing is the same

among the different designs and centers around the BU1 board. From this

point it becomes a matter of what LCD panel size is used, HDMI versus

analog front video inputs and the design of the power supply dedicated to

that model.

The circuit descriptions to follow will differentiate between the models

based primarily on LCD panel size since this will determine what type of

power supply and backlight inverter boards will be used. The KDL32XBR4

and KDL40D3000 are the only models in this chassis line that has an

upgrade in video features including a third HDMI input and High Frame

Rate circuits and panel. This will be described in a separate block

diagram.

Overall Block Diagrams

26 and 32-inch S-Line Models

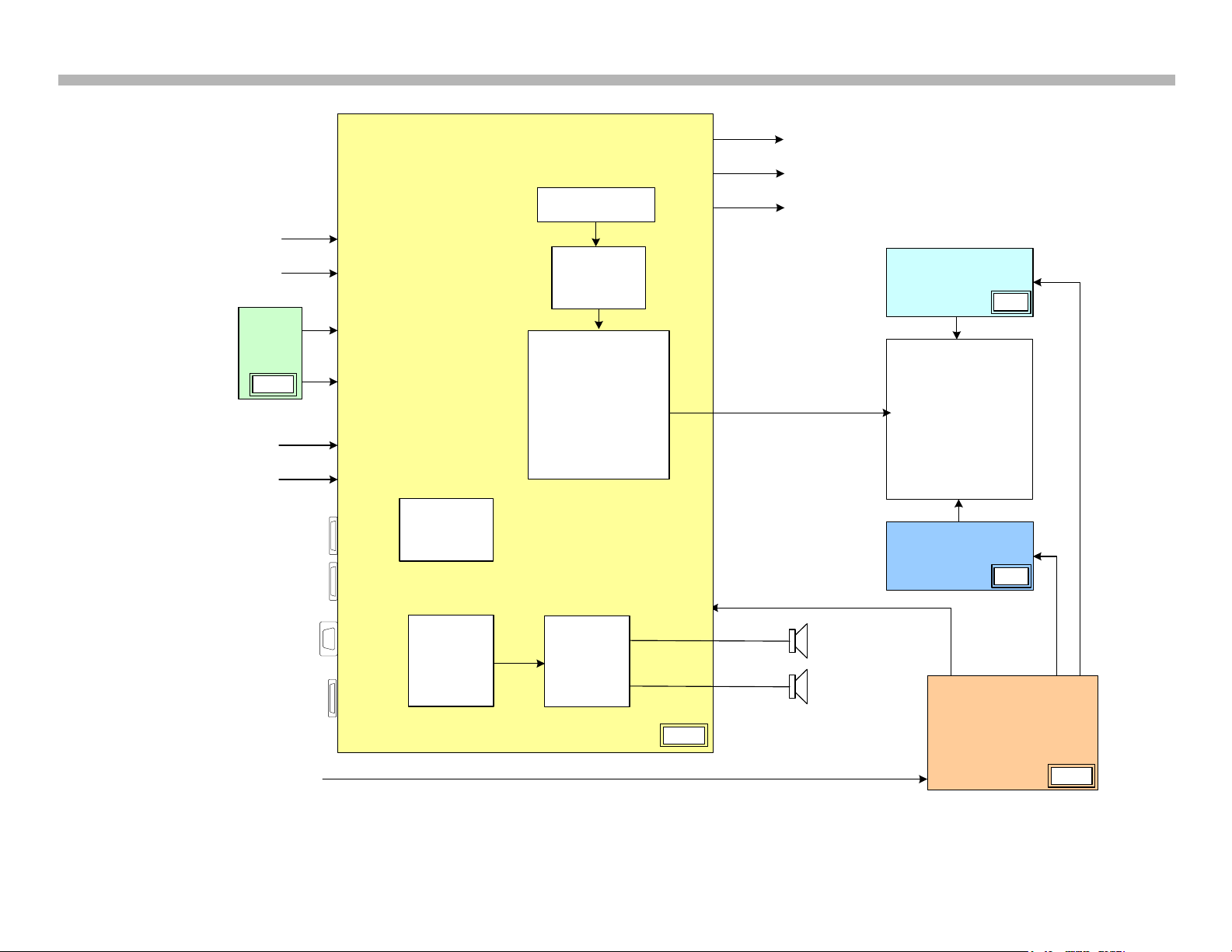

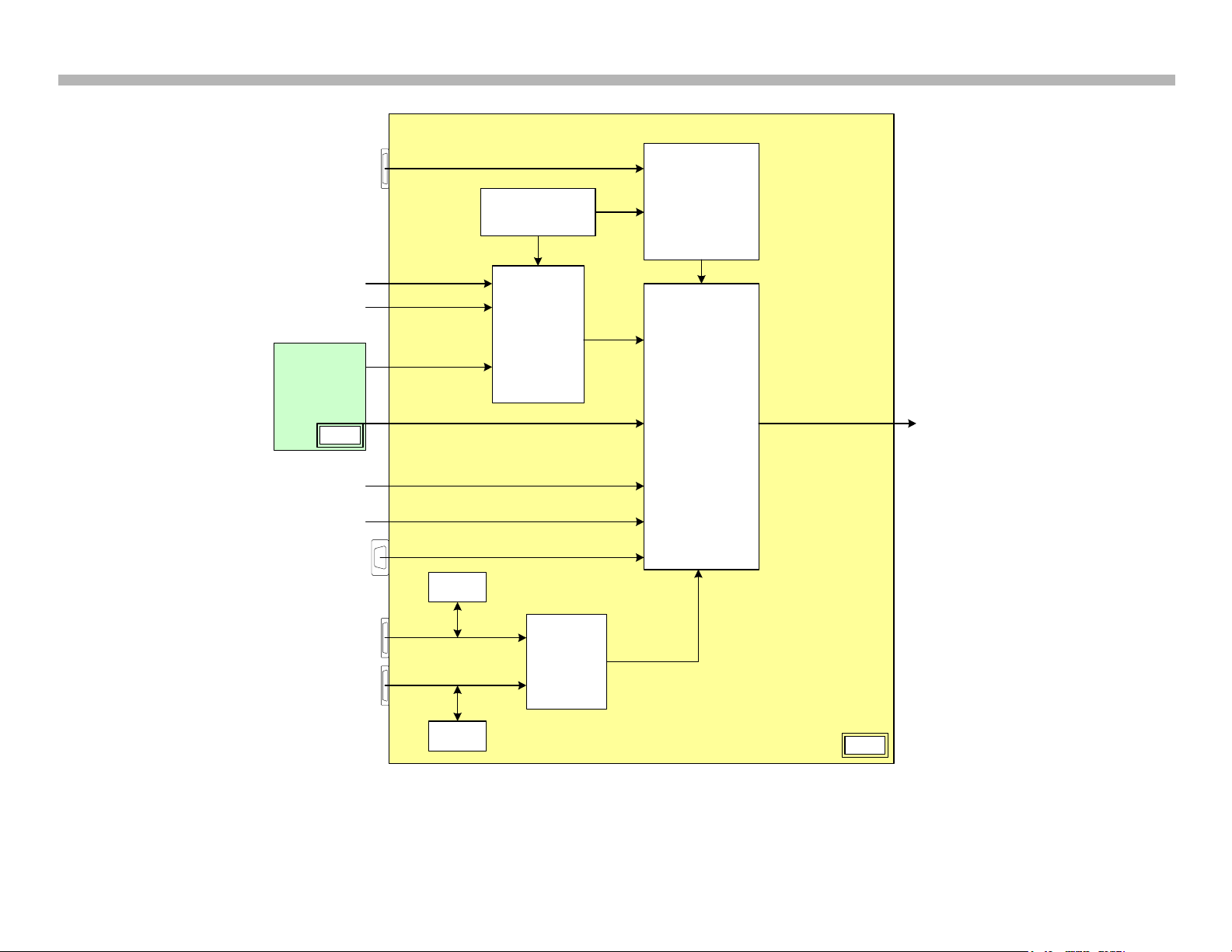

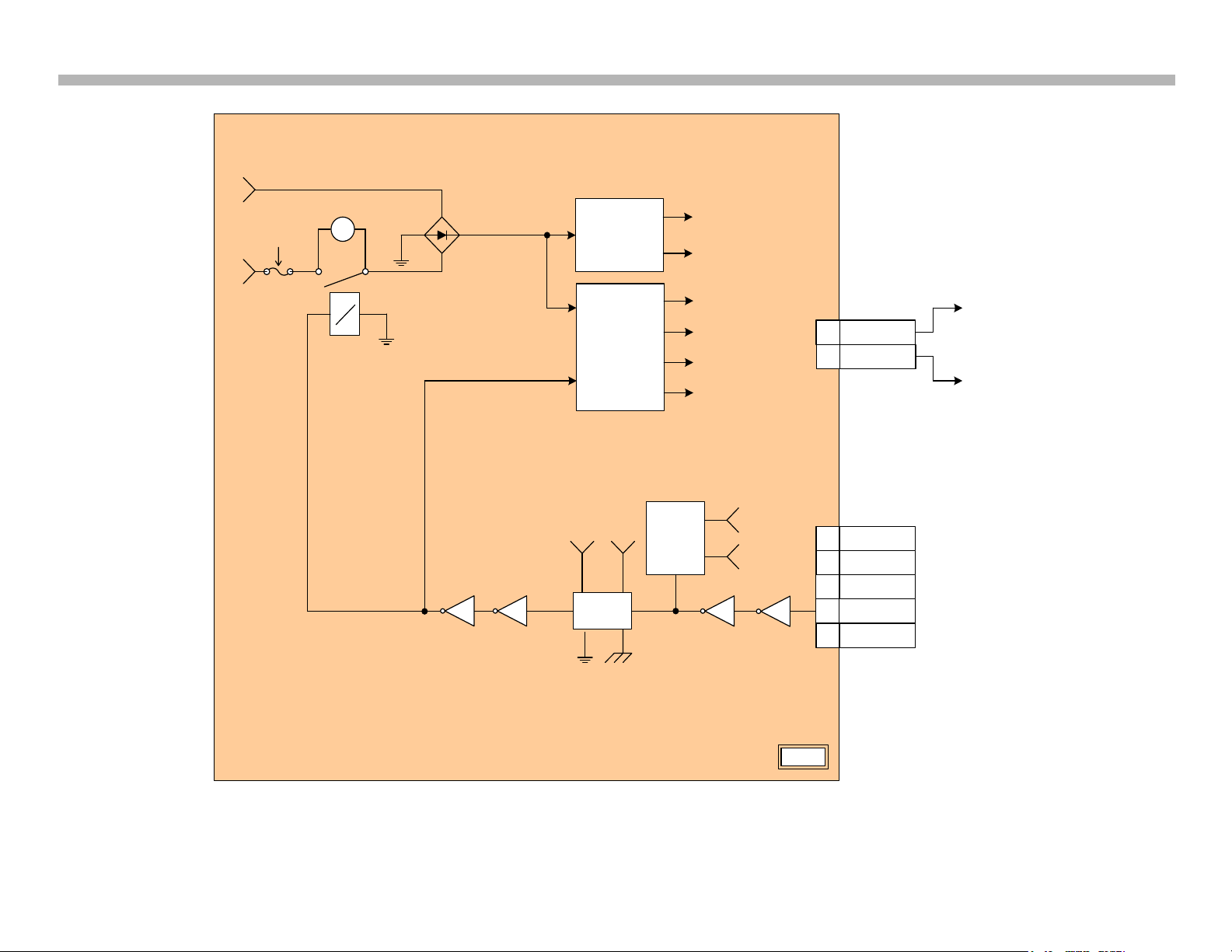

In Figure 1-1 the overall block diagram of the circuit layout utilized in the

KDL26A3000 and KDL32S3000 is shown. A brief description for each of

the major circuit boards will be given.

each individual backlight lamp. If a lamp were to fail or weaken with age,

or if one or more of the inverters were to fail, an error command will be

detected by the Main Micro on the BU1 board and shut the unit down and

blink the front power LED in groups of 6.

Power Supply

2 power supplies reside on the G board. The 23” model power supplies

are designated G1D whereas the 32” is G1H. Both supplies are relatively

the same aside from current capacity and layout of their protect circuits. A

standby supply runs constantly whenever AC power is applied to provide

12VDC for the main relay and power for the main switching supply.

Standby 3.3 volts is also generated to power the Main Micro on the BU1

board and other circuits that are required to run constantly such as the

remote IR receiver. The main switching regulator provides the majority of

the voltages used within the unit. Further details of the power supplies will

be discussed later in this chapter.

BU1 Board

This board has been redesigned to take on virtually all of the circuits that

were found on 3 boards in last year’s chassis designs. The tuner and ATI

Micro were on separate boards in previous designs but have now been

integrated on the same board with the video process circuits.

Backlight Inverter

These smaller panels use a single inverter/balancer assembly that is part

of the LCD panel in order to provide ballast control for the fluorescent

backlights. 24VDC is provided by the power supply (G1D for the 26” or

G1H for the 32”). This 24 volt source powers the individual inverters to

generate the high voltage (4.5KV to 5KV) necessary to light the fluorescent

backlight lamps. Additional lines for on/off control and inverter failure

feedback are on the same DC voltage connector from the power supply

and are routed to the BU1 board for control and monitoring by the Main

Micro.

The inverter board also contains circuits to monitor the current draw of

Other than the front video inputs applied to the U1 board, all analog and

HDMI input connectors are part of the BU1 board. The Main TV Micro

resides on this board and is responsible for virtually all of the operational

functions of the unit.

Audio switching, digital signal processing and amplification are also

located here. The audio exits the BU1 board to drive the speakers, optical

output, L/R analog out and headphones. Another important feature of the

audio circuits is that all audio sources selected will be output from the

optical transmitter. This was not true in previous Sony designs in which

the optical out only functioned when a digital tuner signal was received.

CTV-41 4

Page 7

Chapter 1 - Features and Circuit Descriptions

LCD PANEL

(WXGA)

INVERTER

AC IN

OPTICAL OUT

VIDEO 1

COMPOSITE

_Y/C IN

VIDEO 3

COMPOSITE IN

L

R

HDMI 1 IN

HDMI 2 IN

PC IN

VIDEO PROCESS

A/V SWITCH ING

MAIN TV MICRO

AUD IO PR OCESS

/AMP

HDMI MICRO

TUNER

ATI MICRO

IC4500

TRID ENT

VIDEO PROCESSOR

IC7300

ATI

IC2009

AUD IO AMP

BU1

USB FOR DMEX

AND SOFTWARE

UPGRADE

FRONT

INPUTS

U1

VIDEO 2

COMPOSITE IN

COMPONENT 2 IN

ATSC/NTSC

TUNER

COMPONENT 1 IN

COMPONENT 3 IN

IC3001

MAIN TV

MICRO

POWER SU PPLY

G1H

G1D

26"

32

"

IC2002

AUD IO SW

AUD IO DSP

L/R AUDIO OUT

HEADPHONES OUT

CTV-41 5

FIGURE 1-1

26/32” S SERIES OVERALL BLOCK DIAGRAM

Page 8

Chapter 1 - Features and Circuit Descriptions

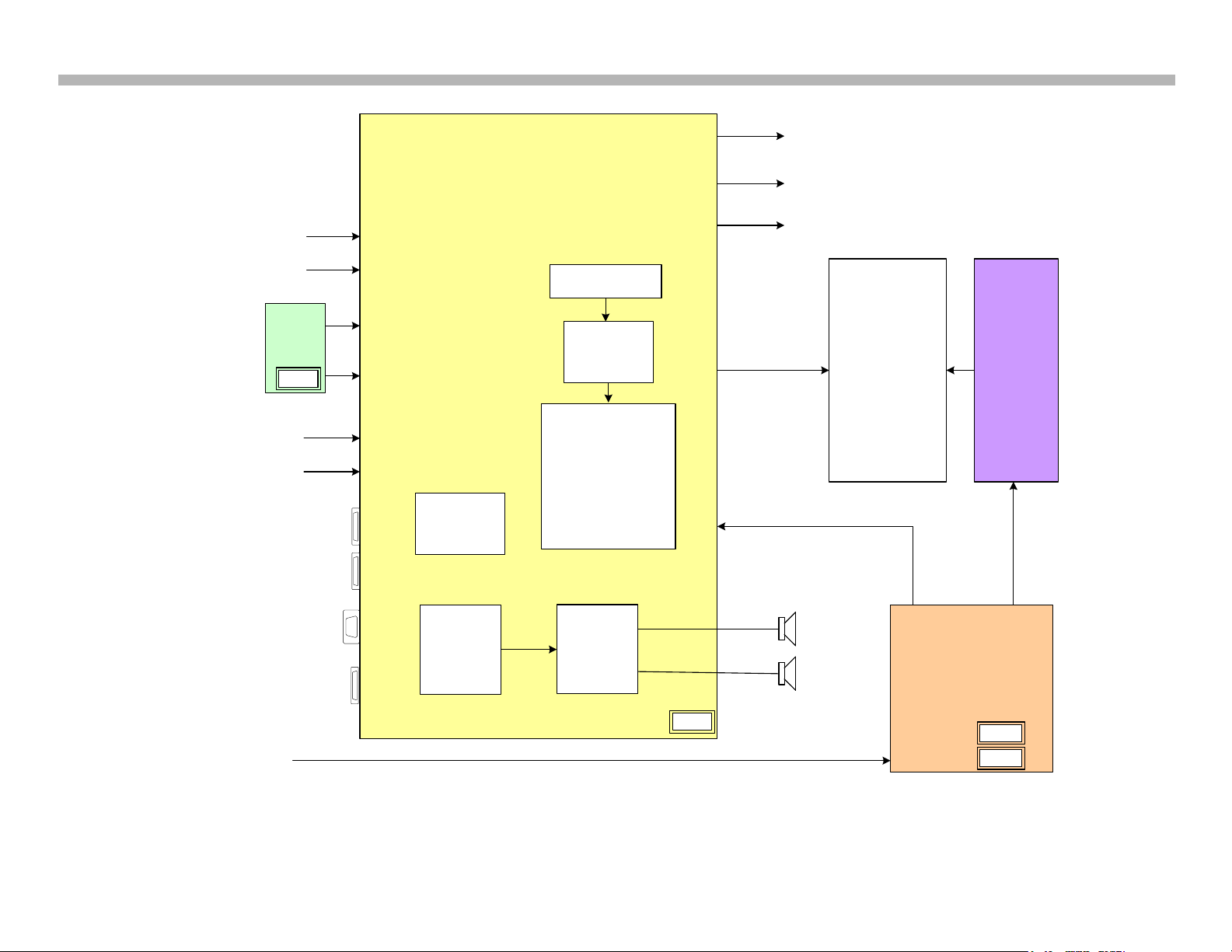

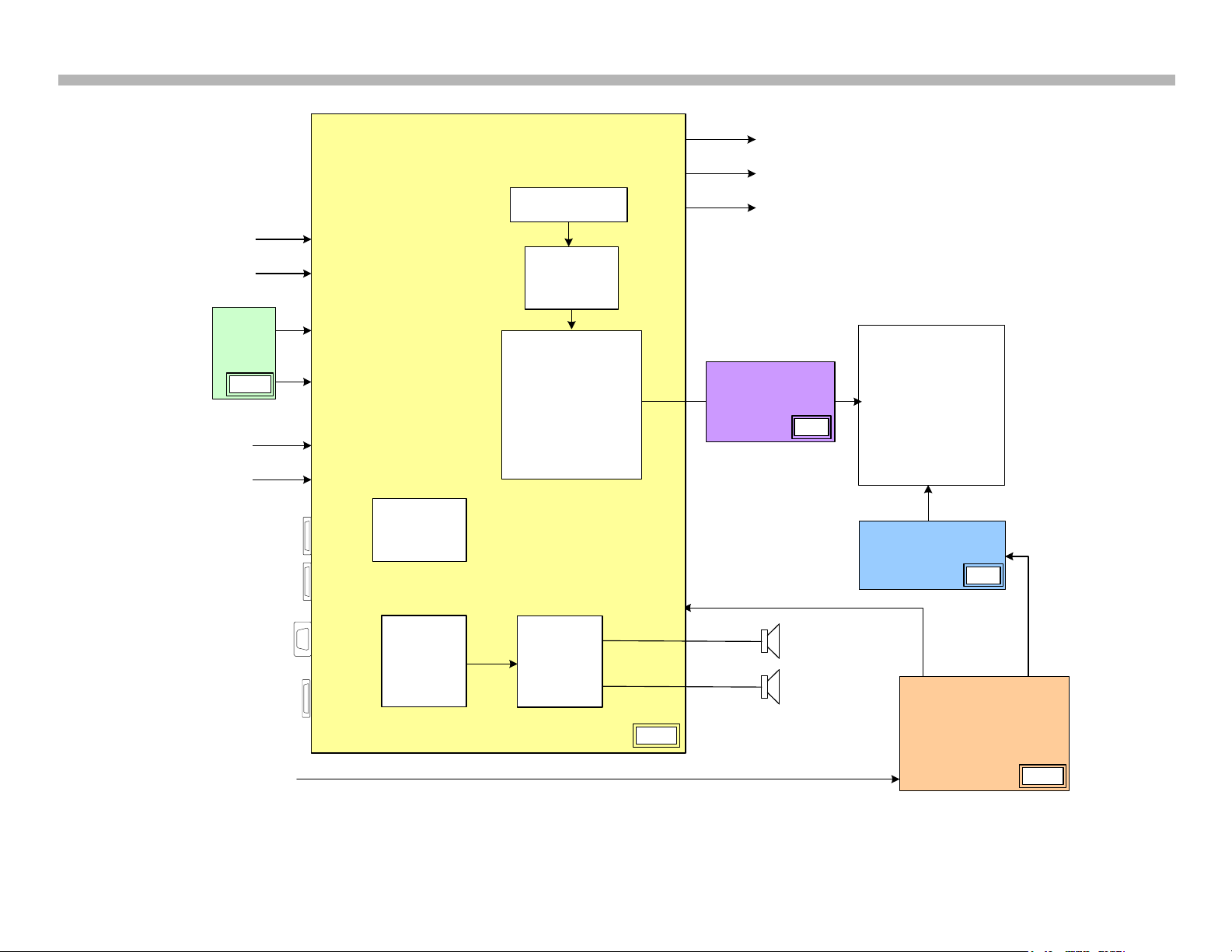

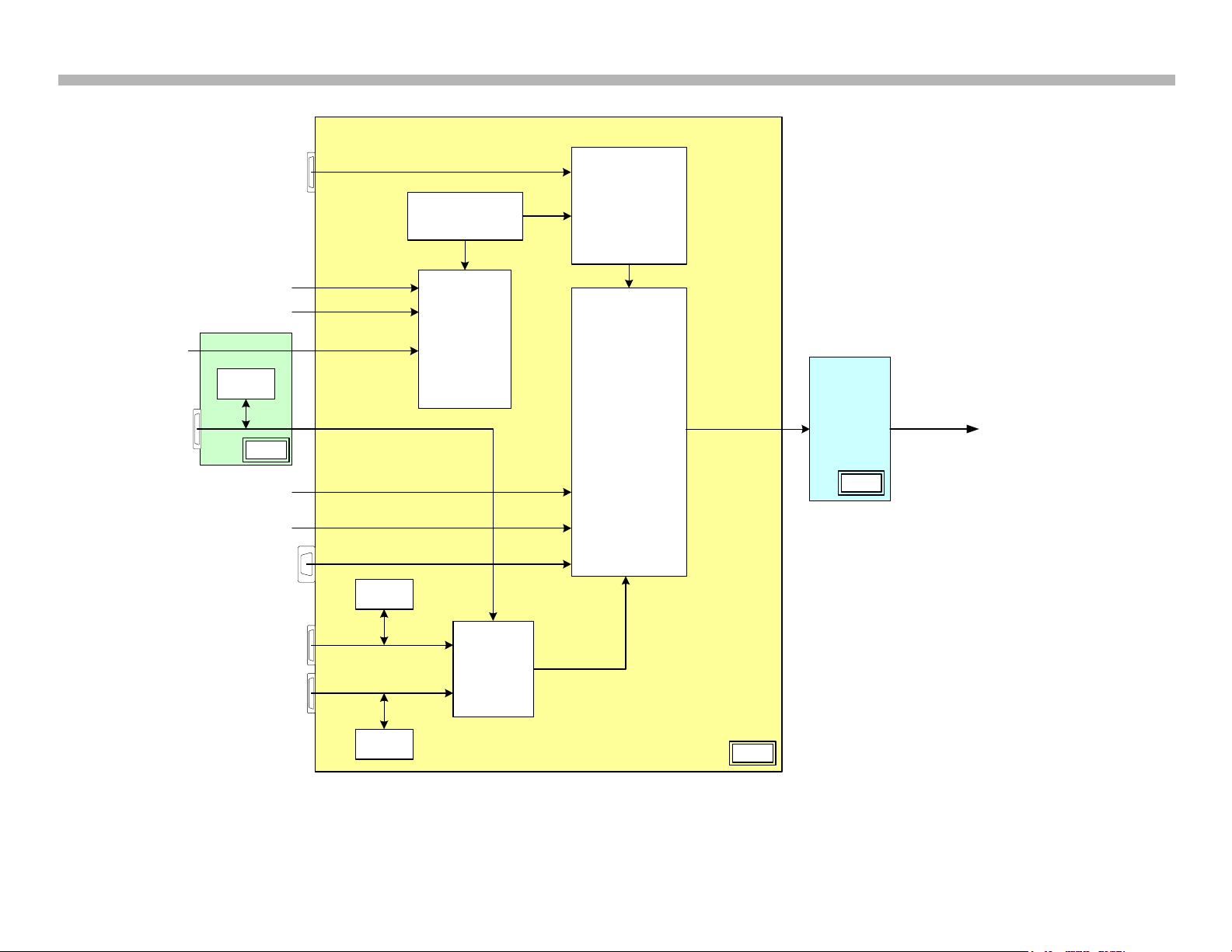

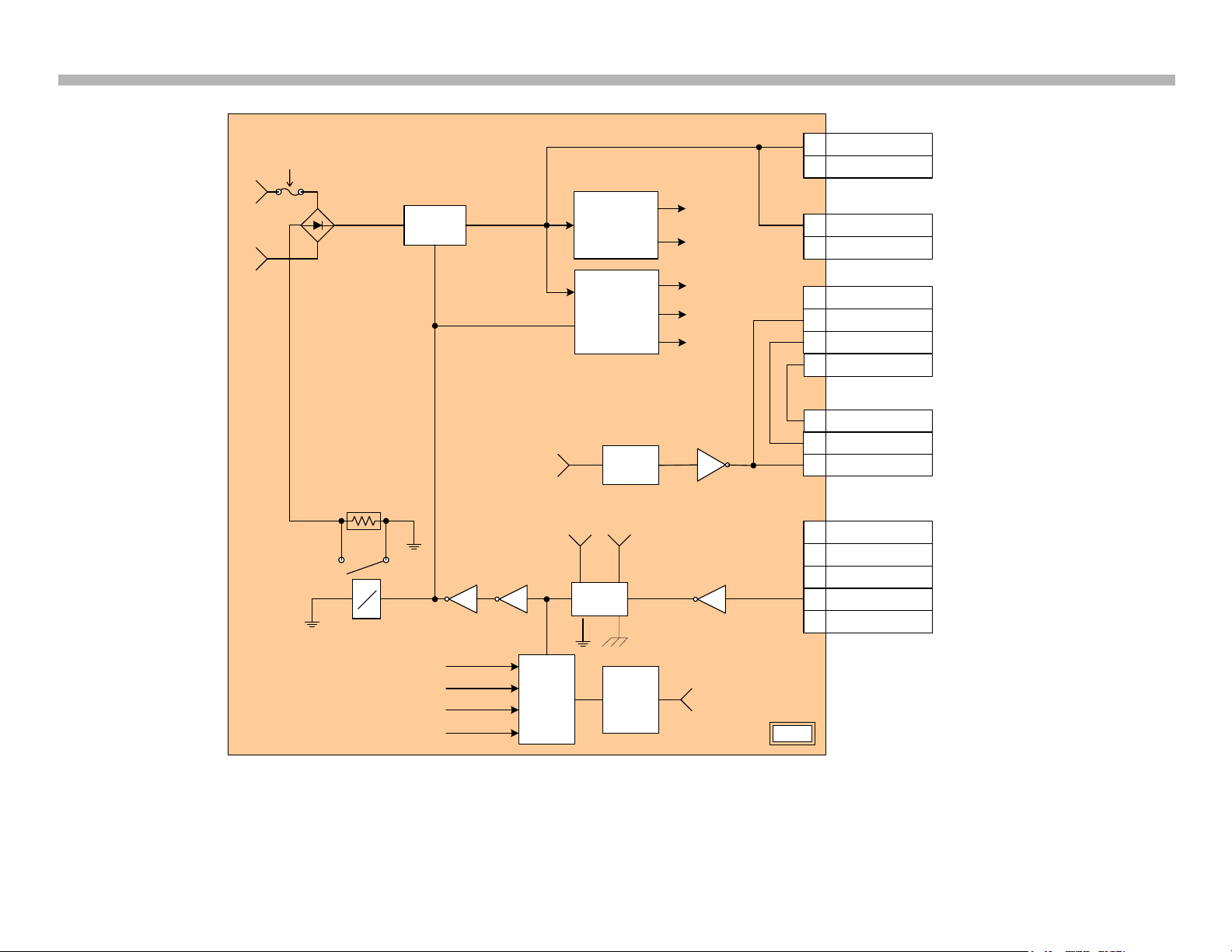

40 and 46-inch S Line Models

In Figure 1-2 it is seen that most of the circuits found in the 26/32” models

is the same. Therefore, only the differences will be explained here.

Backlight Power

Separate circuits are used to supply high voltage to the backlight lamps.

These circuits only generate the high voltage needed. Balancer circuit

boards are mounted on the panel to distribute the high voltage and monitor

the current level to each lamp.

The 40” model uses a single D1 board to generate high voltage of

approxiamtely 4.5 to 5KV. The 46” however, requires the use of 2 high

voltage boards due to the longer fluorescent tubes. In this case a D1 and

D2 board is used to supply voltage to both ends of the fluorescent lamps.

This is important to remember when troubleshooting a lamp protection

shutdown problem. If one board fails you will notice that one side of the

screen is lighter that the other before the unit shuts down. The side that is

darker indicates which board is at fault.

IMPORTANT: Even though the 40 and 46” models both use a D1 board,

they are not interchangeable. The D1 board part numbers are different for

the 40 and 46”.

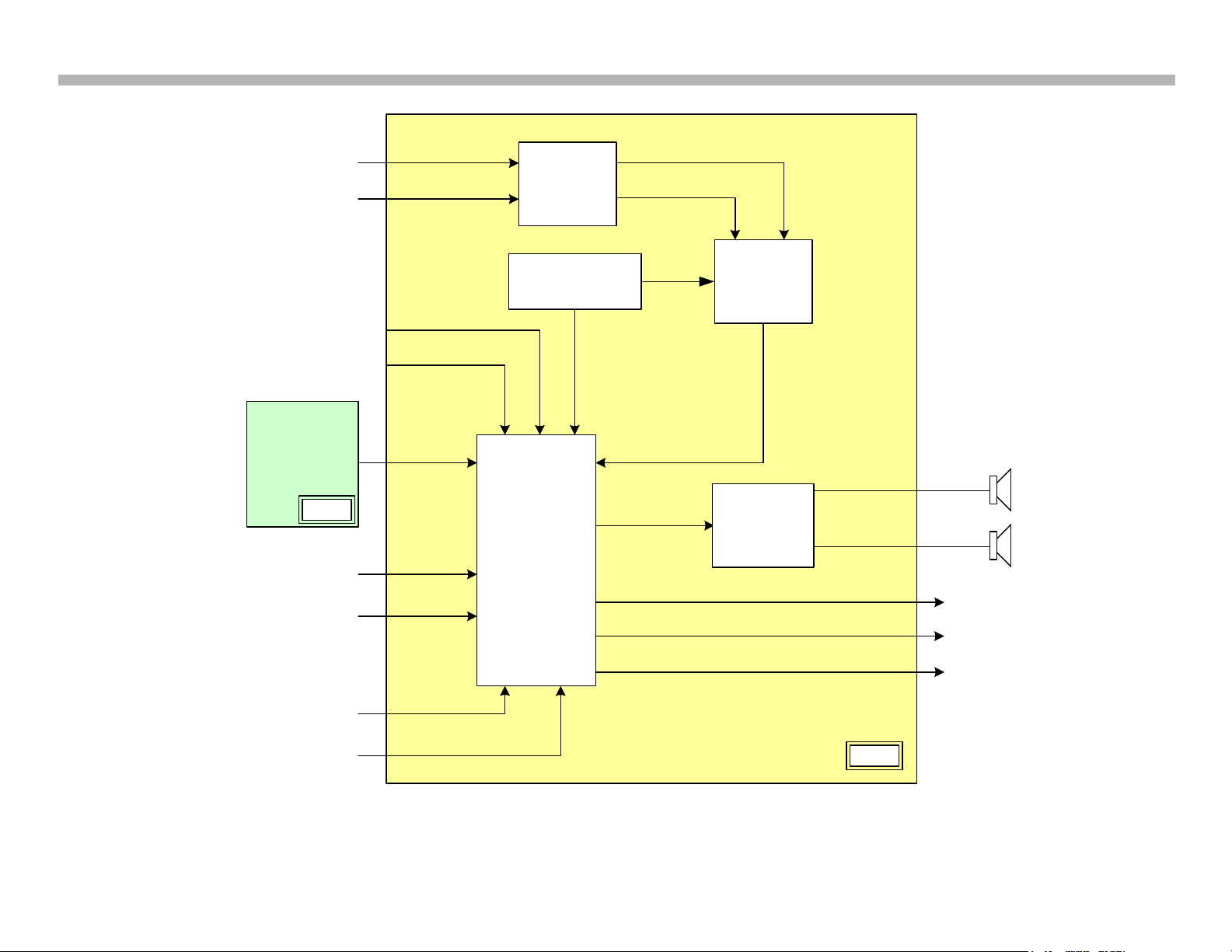

32” XBR and 40D3000 Models

All of the circuitry in these models are the same as their respective S

series models except for the addition of the BH and U2 boards as

illustrated in Figures 1-3 and 1-4. The circuitry on the BH board captures

the 60HZ frame rate video exiting BU1 board, analyzes the difference

between adjacent fields and generates additional fields in between to

double the frame rate to 120HZ. The end result is a dramatic reduction of

the smearing or “comet tailing” that is inherent to LCD displays during fast

moving video content.

The front video input U2 board provides an additional HDMI input not

found on the S series models. One analog component input was removed

to accommodate the additional HDMI so only HDMI and composite video

are accepted at these inputs.

Power Supply

A G3 board is used and uses a Power Factor Control circuit to generate

the 390VDC required by the D1 and D2 circuits. The on-board protect

circuits are slightly more sophisticated than the G1D and G1H boards but

the end result is to stop the power supply if certain over voltage and current

conditions arise. These items will be discussed later in this chapter.

CTV-41 6

Page 9

Chapter 1 - Features and Circuit Descriptions

LCD PANEL

(WXGA)

AC IN

OPTICAL OUT

BACKLIGHT POWER

46" ONLY

D2

BACKLIGHT POWER

40

/46"

D1

POWER SU PPLY

G3

VIDEO 1

COMPOSITE

_Y/C IN

VIDEO 3

COMPOSITE IN

L

R

HDMI 1 IN

HDMI 2 IN

PC IN

VIDEO PROCESS

A/V SWITCH ING

MAIN TV MICRO

AUD IO PR OCESS

/AMP

HDMI MICRO

TUNER

ATI MICRO

IC4500

TRID ENT

VIDEO PROCESSOR

IC7300

ATI

IC2009

AUD IO AMP

BU1

USB FOR DMEX

AND SOFTWARE

UPGRADE

FRONT

INPUTS

U1

VIDEO 2

COMPOSITE IN

COMPONENT 2 IN

ATSC/NTSC

TUNER

COMPONENT 1 IN

COMPONENT 3 IN

IC3001

MAIN TV

MICRO

IC2002

AUD IO SW

AUD IO DSP

L/R AUDIO OUT

HEADPHONES OUT

WXGA 60FPS

CTV-41 7

FIGURE 1-2

40/46” S SERIES OVERALL BLOCK DIAGRAM

Page 10

Chapter 1 - Features and Circuit Descriptions

LCD PANEL

(WXGA)

INVERTER

AC IN

VIDEO 1

COMPOSITE

_Y/C IN

VIDEO 3

COMPOSITE IN

L

R

OPTICAL OUT

HDMI 1 IN

HDMI 3 IN

PC IN

VIDEO 2

COMPOSITE IN

VIDEO PROCESS

A/V SWITCH ING

MAIN TV MICRO

AUD IO PR OCESS

/AMP

HDMI MICRO

TUNER

ATI MICRO

ATSC/NTSC

TUNER

IC4500

TRID ENT

VIDEO PROCESSOR

IC7300

ATI

IC2009

AUD IO AMP

BU1

POWER SU PPLY

G1H

HFR

(High Frame

Rate

)

BH

FRONT

INPUTS

U2

HDMI 2 IN

USB FOR DMEX

AND SOFTWARE

UPGRADE

COMPONENT 1 IN

COMPONENT 2 IN

IC3001

MAIN TV

MICRO

L/R AUDIO OUT

HEADPHONES OUT

IC2002

AUD IO SW

AUD IO DSP

CTV-41 8

FIGURE 1-3

32XBR4 OVERALL BLOCK DIAGRAM

Page 11

Chapter 1 - Features and Circuit Descriptions

LCD PANEL

(WXGA)

AC IN

OPTICAL OUT

POWER SU PPLY

G3

VIDEO 1

COMPOSITE

_Y/C IN

VIDEO 3

COMPOSITE IN

L

R

HDMI 1 IN

HDMI 3 IN

PC IN

VIDEO PROCESS

A/V SWITCH ING

MAIN TV MICRO

AUD IO PR OCESS

/AMP

HDMI MICRO

TUNER

ATI MICRO

IC4500

TRID ENT

VIDEO PROCESSOR

IC7300

ATI

IC2009

AUD IO AMP

BU1

USB FOR DMEX

AND SOFTWARE

UPGRADE

ATSC/NTSC

TUNER

COMPONENT 1 IN

COMPONENT 3 IN

IC3001

MAIN TV

MICRO

IC2002

AUD IO SW

AUD IO DSP

L/R AUDIO OUT

HEADPHONES OUT

HFR

BH

FRONT

INPUTS

U2

BACKLIGHT POWER

D1

CTV-41 9

FIGURE 1-4

40D3000 OVERALL BLOCK DIAGRAM

Page 12

Chapter 1 - Features and Circuit Descriptions

Video Processing

An overall block diagram of the video process circuits is illustrated in Figure

1-5 for the S series models and in Figure 1-6 for the 32”XBR 40” D3000

models. Processing of the video is the same except for the additional

HDMI input available via the U2 board and frame doubling on the BH

board.

New Trident Processor

IC4500 has been designed to handle many of the tasks once done by

separate components. It has eliminated a separate CCP processor, HDMI

Micro, DRC and Wega Engine. It is capable of handling video resolutions

from 480i all the way up to 1080p (via the HDMI inputs only). All signals

exit Trident as 720p 60FPS.

Video Switching

Only composite and Y/C signals are switched by IC4800. Component,

HDMI, and PC inputs are routed directly to Trident IC4500 where they are

selected internally. Only video input 1 accepts a Y/C signal source.

Display Information Data (EDID) to provide display capability information

to the device connected to the input. In the XBR model an additional EDID

IC250 (not shown) is located on the U2 board.

Digital Tuner

If a digital tuner source is selected, the signal is sent directly to the ATI

Micro IC7300 where the signal will be demodulated and decoded to

extract the audio and video information. The video digital stream is then

sent to Trident video processor IC4500 and audio data is input to Audio

DSP IC2002 (not shown).

HDMI Inputs

Note the lack of an HDMI Microprocessor. This is now integrated within

the Trident processor IC4500. HDMI sources pass through HDMI EQ

IC550 for impedance matching and into IC4500 for processing of the

audio and video information. IC5501 and IC5502 contain the Enhanced

CTV-41 10

Page 13

IC4500

TRIDENT VIDEO

PROCESSOR

IC7300

ATI MICRO

ATSC/NTSC

TUNER

IC4800

VIDEO

SWITCH

Y/C_COMPOSITE 1

COMPOSITE

3

BU1

COMPOSITE 2

COMPONENT

2

U1

COMPONENT 1

COMPONENT

3

HDMI 1

HDMI

2

PC

IC5501

EDID

IC5503

EDID

IC5500

HDMI EQ

TO LCD PANEL

DMEX USB

WXGA 60FPS

Chapter 1 - Features and Circuit Descriptions

CTV-41 11

FIGURE 1-5

S SERIES VIDEO PROCESS BLOCK DIAGRAM

Page 14

IC4500

TRIDENT VIDEO

PROCESSOR

IC7300

ATI MICRO

ATSC/NTSC

TUNER

IC4800

VIDEO

SWITCH

Y/C_COMPOSITE 1

COMPOSITE

3

BU1

COMPONENT 1

COMPONENT

3

HDMI 1

HDMI

3

PC

IC5501

EDID

IC5503

EDID

IC5500

HDMI EQ

TO LCD

PANEL

DMEX USB

WXGA 60FPS

HFR

BH

WXGA

120FPS

U1

IC250

EDID

Chapter 1 - Features and Circuit Descriptions

CTV-41 12

XBR AND D SERIES VIDEO PROCESS BLOCK DIAGRAM

FIGURE 1-6

Page 15

Chapter 1 - Features and Circuit Descriptions

Audio Processing

Figure 1-7 illustrates the overall block diagram for the audio processing.

All of this is accomplished on the BU1 board.

Analog Audio

All analog audio sources are switched by the Audio DSP IC2002. The L/R

audio signals are A/D converted within IC2002 for processing by DSP

and exit as analog L/R to IC2009. The analog L/R audio is converted

to PWM by IC2009 and amplified by the class-D amplifier within the IC.

All selected analog sources are output in SPDIF format for the optical

out transmitter. Analog L/R outputs are also provided for the audio output

jacks on the rear of the unit and the headphone jack on the front input U1

board. On the 32” XBR series the front input board is the U2 board.

Digital Audio

Digital audio sources are available via the HDMI inputs or digital channels

received by the tuner. HDMI audio is extracted by Trident IC4500 and sent

to the ATI Micro. Digital audio from the tuner is sent directly to ATI. The

audio information is then sent to Audio DSP IC2002 in digital format. At

this point audio process is the same as analog signals.

Optical Out

If an ATSC compliant digital channel is received by cable TV (QAM) or

terrestrial (8VSB) and a Digital Dolby® audio signal is embedded in the

content, the optical out will pass this signal for use with a surround-sound

amplifier that is compatible with Digital Dolby® 5.1 standards. Table 3-1

offers an overall view of what is output from the optical jack based on input

selection.

AUDIO SOURCE OPTICAL OUTPUT

DIGITAL TUNER 5.1 5.1 OR 2CH PCM

DVD HDMI 5.1 2CH PCM

The optical output jack at the rear of the unit will pass all selected audio

sources except for Super Audio CD (SACD) or DVD audio sources

hooked up to the HDMI inputs (for obvious copyright protection reasons).

All analog sources (including that from the NTSC tuner) are output as

2-channel 48KHZ PCM. DVD players hooked up to the HDMI inputs will

output 2-channel PCM regardless of what the HDMI audio output on

the DVD player is set to. The internal speakers will output DVD audio

regardless of what the HDMI audio of the DVD player is set to (unlike

previous year’s models).

ALL ANALOG AUDIO INPUTS 2CH PCM

NTSC TUNER 2CH PCM

SACD VIA HDMI NO OUTPUT

DVD AUDIO VIA HDMI NO OUTPUT

TABLE 3-1

OPTICAL OUTPUT TRUTH TABLE

CTV-41 13

Page 16

ATSC/NTSC

TUNER

IC7300

ATI MICRO

Y/C_COMPOSITE 1

COMPOSITE

3

COMPOSITE

2

COMPONENT

2

COMPONENT 1

COMPONENT

3

HDMI

1

PC

IC2002

AUDIO SW

DSP

L

R

IC2009

CLASS D

AUDIO AMP

HDMI 2

HDMI 1 ANALOG

IC4500

TRIDENT

OPTICAL OUT

HEADPHONES OUT

U1

BU1

L/R AUDIO OUT

Chapter 1 - Features and Circuit Descriptions

FIGURE 1-7

AUDIO PROCESS BLOCK DIAGRAM

CTV-41 14

Page 17

Chapter 1 - Features and Circuit Descriptions

Protection

Several circuits on the WAX3 chassis are utilized to monitor voltage and

current conditions. Should a problem develop in any of these monitored

circuits the unit will shut down in most cases and blink the power LED red

in varying sets of sequences in order indicate what is likely causing the

failure. Protect circuits are located on the power supply, BU1 board and

the back light inverters.

Power Supply and Protection

3 different power supplies are used in the WAX3 chassis and these are

shown in Figures 1-8, 1-9, and 1-10. The 26” units use a G1D board, the

32” a G1H board and the 40/46” models use the G3 board. The G1D and

G1H boards are very similar in design with current capacity being their

primary difference and the presence of a PFC circuit on the G1H while

one is not used on the G1D. They both generate 24VDC to supply the

inverter circuits on the panel.

The G3 board uses the PFC circuit to directly drive the D1 and D2 inverter

boards for the 40 and 46” panels. All 3 power supplies contain overvoltage, under-voltage and over-current monitoring. The D3 power supply

contains additiona circuits to monitor the temperature of the PFC switching

transistors and the in-rush current limit resistor R6009 as shown in figure

1-10. If either of these circuits is activated the power supply will be turned

off. The Main Micro located on the BU1 board monitors the regulated 12

volt line generated by all 3 boards. If this voltage is no longer generated

the Main Micro will flash the power LED in sequences of 2 assuming the

standby power supply is still operating.

would be no diagnostics indication from the power LED.

In figure 1-9, note the PFC detection line consisting of PH6301 and Q6403

which is unique to the 40/46” models. If the PFC circuit were to cease

operating the DC voltage, which is normally around 390 volts, would drop

to less than half (rectified AC only). This would put a strain on the D1 and

D2 boards since they would attempt to keep the lamps lit but would require

extra current due to the drastic voltage drop. In this event Q6403 will pull

the control signal (which is normally high) low, turning off the inverter(s).

The symptom would be a unit that has no backlights operating but there

CTV-41 15

Page 18

STBY

3.3V

STBY

12

V

IC305

AC

IN

AC

IN

Q302

Q902

Q901

STANDBY

POWER

SUPPLY

STBY

3.3V

STBY

12

V

PRIMARY

POWER

SUPPLY

AU

13

V

12V

6V

NTC

1

RY6101

PFC

Q304

SCR

LATCH

12V

OVP

340VDC

CN

3

TO CN 4001

BU1

BOARD

24V

POWER_ON

11

AU 13V

8

6V

4

AU GND

7

STBY 3.3V

13

REG 12V

3

24V

9

CN2

TO CN 4002

BU1

BOARD

TO

INVERTER

BD1

24V

OVP

G1D

Q303

F1

4A

T

Chapter 1 - Features and Circuit Descriptions

FIGURE 1-8

G1D BOARD PROTECTION (26” MODELS)

CTV-41 16

Page 19

STBY

3.3V

STBY

12V

PH6103

AC

IN

AC

IN

PFC

Q6201

Q6108

Q6107

IC6103

PFC

OVP

Q6105

Q6106

LATCH

STANDBY

POWER

SUPPLY

STBY

3.3V

STBY

12

V

PRIMARY

POWER

SUPPLY

AU

13

V

12V

6V

PFC OCP

R6101

RY6101

PFC

Q6202

Q6203

LATCH

12V

OVP

343VDC

CN6201

TO CN 4001

BU1

BOARD

PH6300

24V

POWER_ON

11

AU 13V

8

6V

4

AU GND

7

STBY 3.3V

13

REG 12V

3

24V

9

CN6202

TO CN 4002

BU1

BOARD

TO

INVERTER

D6101

F6102

4A

24V

OVP

G1H

ON = 3.3V

Chapter 1 - Features and Circuit Descriptions

CTV-41 17

G1H BOARD PROTECTION (32” MODELS)

FIGURE 1-9

Page 20

INV_ERR

4

REG 12V

6

BACK_LIGHT

3

INV_ERR

9

BACKLIGHT_ON

10

STBY

3.3V

STBY

12

V

PH6300

AC

IN

AC

IN

PFC

Q6407

Q6304

Q6303

1C6300

PFC

OVP

Q6300

Q6301

LATCH

STANDBY

POWER

SUPPLY

STBY

3.3V

STBY

12

V

PRIMARY

POWER

SUPPLY

AU

13

V

12V

6V

PFC OCP

PFC OTP

R6009 OTP

R6009

RY6000

PFC

PH6301

Q6403

PFC DET

PFC OUT

1

PRI GND

3

PFC OUT

1

PRI GND

3

390VDC

POWER_ON

10

AU 13V

7

6V

3

AU GND

5

STBY 3.3V

12

CN6202

CN6203

CN6004

CN6502

CN6501

TO D1

BOARD

TO D2

BOARD

TO D1

BOARD

FROM BU1

BOARD

TO BU1

BOARD

D6000

F6000

6.3A

G3

BALANCE_ERR

7

BALANCE_ERR

7

12V OVP

Chapter 1 - Features and Circuit Descriptions

CTV-41 18

G3 BOARD PROTECTION (40” AND 46” MODELS)

FIGURE 1-10

Page 21

Chapter 1 - Features and Circuit Descriptions

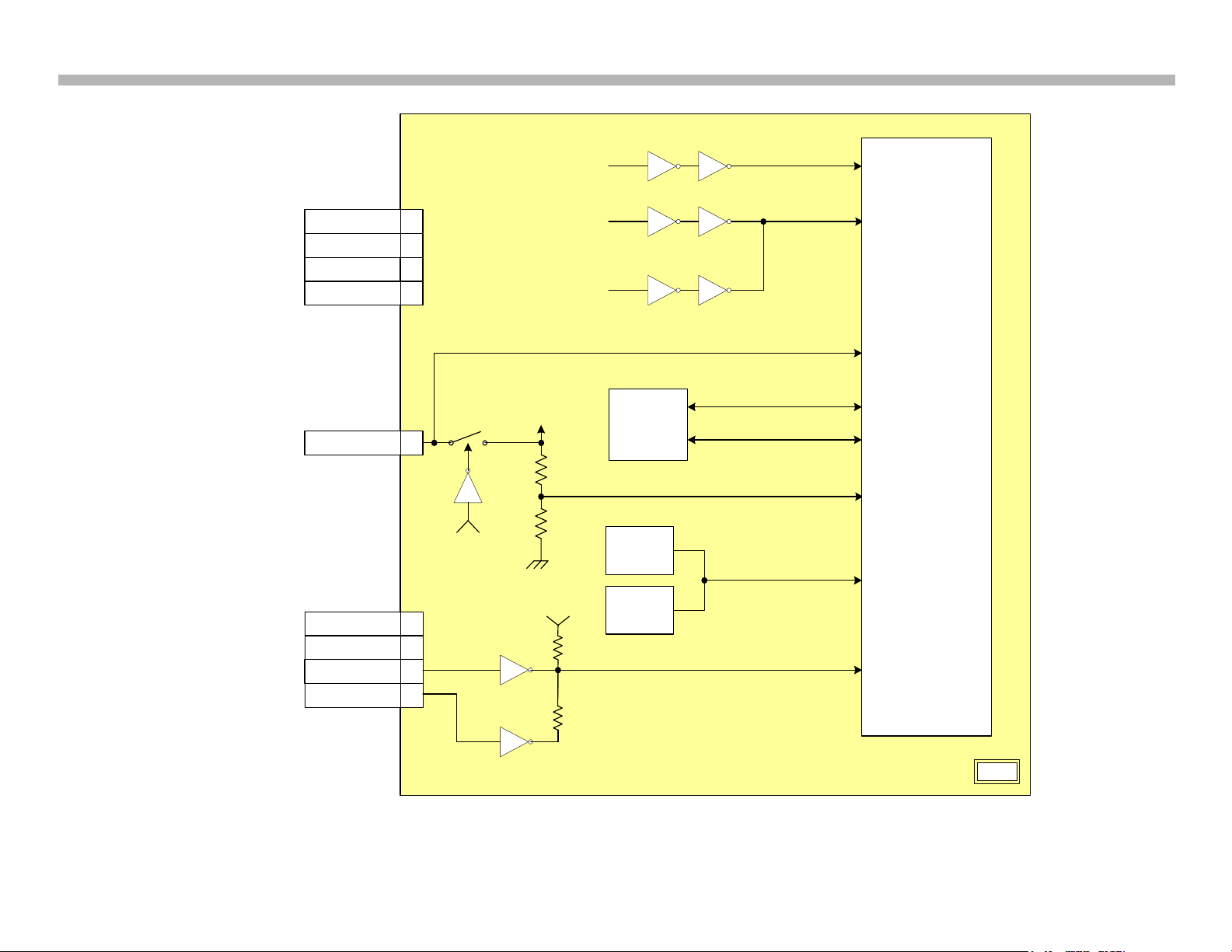

BU1 Board Protection

The BU1 board has several protect monitoring circuits for its own DC

voltage regulators. Monitoring of temperature, speaker protection and an

inverter failure are also included. A block diagram of these protect circuits

is illustrated in Figure 1-11

Onboard Regulator Protect

The regulated 2.5 volts for Trident IC4500 is monitored. If this voltage fails

A DC_ALERT 1 high will occur on pin 163 of the Main Micro IC3001. The

unit will shut down and the power LED will flash in groups of 3.

Similarly, if the D1.0V or D1.8V sources (generated on the BU1 board)

fails a high will be placed on pin 153 and the unit will shut down generating

groups of 4 blinks.

The regulated 12V is the only outside voltage monitored. It sources from

the power supply and will keep a specified high on pin 82 of the Main

Micro. If the voltage fails or falls below this specified limit, the unit will shut

down and blink the power LED in groups of 2. Note that this 12V line is

also the source for the Panel 12V which is switched by the main micro.

This voltage is also monitored by Main Micro at pin 154 (DC_ALERT_3).

If the 12V from the power supply is OK but failed on the Panel_12V line,

the unit will shut down and blink the power LED in groups of 5.

Thermal Protect

running hot. Shutdowns after extended periods would warrant checking

the location of the unit for proper ventilation.

Panel Protect

If the high voltage generated by the inverter were to fail, or if abnormal

current conditions are detected on the balancer circuits, a high would be

applied on pin 81 of the Main Micro. The unit will shut down and blink the

power LED in groups of 6.

Audio Protect

If any DC is detected on the left or right speaker channels the unit will shut

down and blink the power LED in groups of 8. This symptom is usually

caused by a failed audio amp and would require the replacement of the

BU1 board.

Balancer Protect

Along with a Panel Protect line, a Balancer Error line is connected to pin

81 of the Main Micro. Working in conjunction with panel protection, both

lines connect to a voltage divider. The voltage at pin 81 is normally 3.3

volts. If an inverter error is detected, the line (normally low) will go high

and the inverter transistor will pull the voltage down to zero. A balancer

error would complete the divider network and pull the voltage down to

about one-half (1.8 volts). This is how IC3001 is able to tell which type of

error has occured.

IC3007 is a digital thermometer that can be programmed to send data to the

Main Micro when a specified temperature level is reached. The purpose of

the thermal sensing is to monitor the unit for excessive temperature within

the unit during operation. If the temperature rises above the specified

threshold the unit will shut down and display groups of 6 blinks from the

power LED.

Note: IC3007 is constantly polled by the Main Micro. If the IC were to

fail or the data line on the I²C to open the unit would shut down within

approximately 10 seconds. It is important to beware of this. If a unit shuts

down immediately, it can be safely assumed that the television is not

NOTE: The 26” and 32” models do not have a balancer error line from the

inverter board. Only the 40” and 46” models have this feature.

CTV-41 19

Page 22

Communications Errors

Another feature of the WAX 3 chassis is the monitoring of communications

between specific devices. Not shown on the previous block diagrams are

the following protect events that could occur.

Main Micro Communication Error

The unit will shut down and the power LED will blink in groups of 10. The

BU1 board must be replaced to rectify this.

Trident Video Process Failure

The unit will shut down and the power LED will blink in groups of 11 The

BU1 board must be replaced to rectify this.

BH Board Communication Error

Unique to the KDL32XBR4 and KDL40D3000 that utilize frame rate

doubling, the communication between the BH board and the LCD panel

TCON is monitored and the unit will shut down if this communication fails.

The power LED will blink in groups of 12.

Chapter 1 - Features and Circuit Descriptions

BU1 to Panel (S series models) or BU1 to BH (XBR4 and D3000 series) Communication Error

If either of these events occurs, the power LED will blink at one-half second

intervals continuously. The unit will not shut down. The backlights will be

lit but there will be no video display (including OSD graphics). This can be

caused by an unplugged LVDS cable or a failure of BU1 or BH board or a

defective panel (TCON failure).

CTV-41 20

Page 23

Chapter 1 - Features and Circuit Descriptions

AU 13V

5

STBY 3.3V

1

POWER_ON

3

AU GND

REG 12V

7

1

CN4001

CN4002

PANEL 12V DETECT

INV_ERR

5

DIMMER

1

BACKLIGHT

3

BALANCER_ERR

7

DC ALERT 1

(3X)

Q4014

Q4015

INVERTER ER ROR (6X)

CN4003

Q4017 Q4016

Q4001 Q4002

Q4018 Q4019

TRIDENT

DDR 2.5V

DC ALERT 3

(5X)

D1.0V

D1.8V

DC ALERT 2

(4X)

IC3007

TEMP

SENSE

SCL

SDA

163

153

154

81

26

Q2012

Q2017

DC

_DET R

Q2013

Q2018

DC

_DET L

SPEAKER PROT

8X

118

119

IC3001

MAIN MIC RO

BU1

FROM

CN

3 (G1D)

CN6201

(G1H)

CN6202

(G3)

FROM

CN

2 (G1d)

CN6202 (G1H)

CN6203

(G3)

FROM INVERTER

(26/32") OR G3

BOARD

(40/46")

3.3V

POWER_3

PANEL

12V TO

LCD

PANEL

BALANCER ERROR (13X)

MAIN POWER FAILURE (2x)

82

TEMP

ERR OR

(7X)

CTV-41 21

BU1 BOARD PROTECTION

FIGURE 1-11

Page 24

Protect Table

The various protect alarms are shown in Table 1-1

# OF RED LED

BLINKS EVENT POSSIBLE CAUSE NOTES

2 REG 12V FAILURE POWER SUPPLY BOARD PAGE 1 OF DIAGNOSTICS

3 2.5V FAILURE TO TRIDENT IC BU1 BOARD PAGE 1 OF DIAGNOSTICS

4 D 1.OV FAILURE BU1 BOARD PAGE 1 OF DIAGNOSTICS

5 PANEL 12V BU1 BOARD BU1 TO PANEL TCON 12V

Chapter 1 - Features and Circuit Descriptions

6 INVERTER ERROR

7 TEMPERATURE ERROR

8 SPEAKER PROTECT BU1 BOARD PAGE 2 OF DIAGNOSTICS

9 FAN ERROR NOT USED

10 MAIN MICRO COM ERROR BU1 BOARD PAGE 2 OF DIAGNOSTICS

11 TRIDENT IC FAILURE BU1 BOARD PAGE 2 OF DIAGNOSTICS

12 BU1 TO BH COM ERROR

13 BALANCER ERROR LCD PANEL

INVERTER (26/32")

D1, D2 BOARDS (40/46")

BU1 BOARD (S MODELS)

BH BOARD (D/XBR MODELS) PAGE 2 OF DIAGNOSTICS

BU1 BOARD OR BH BOARD

(32XBR AND 40D3000 ONLY) PAGE 2 OF DIAGNOSTICS

LISTED AS "BACK _LIGHT" IN

DIAGNOSTICS PAGE 1

NOT USED BUT APPEARS IN

PAGE 2 OF DIAGNOSTICS

NOT USED IN 26/32" MODELS

PAGE 1 OF DIAGNOSTICS

TABLE 1-1

WAX3 PROTECTION TABLE

CTV-41 22

Page 25

Chapter 2 – Service and Troubleshooting

Overview

Due to the reduced number of circuit boards and the requirement that

repairs be performed at board level, troubleshooting the WAX3 chassis

consists of observations of symptoms and customer information more

than actual signal tracing and voltage checks. This chapter will assist

in this process by providing illustrations of the circuit board locations,

troubleshooting flowcharts and various tips on determining what failure

may be causing the symptom.

Circuit Board Locations

The location of the major circuit boards is illustrated in Figures 2-1 through

2-4. They are as follows:

Figure 2-1; KDL26/32S3000 and KDL32S30L1

Figure 2-2: KDL32XBR4

Figure 2-3: KDL40S3000 and KDL40S30L1

Figure 2-4: KDL46S3000

Figure 2-5: KDL40D3000

Note the left and right support brackets that are visible when the rear

cover is removed. These may be removed at any time during service in

order to remove circuit boards more easily. If both brackets are removed

(necessary if LCD panel is replaced) attention must be paid as to which

side of the units the brackets came from. Each bracket is marked “L” and

“R”. These left and right markings are set when viewing the FRONT of

the television, not the rear. Locater pins are also located at the tops of

the brackets and are not in the same offset location. If the brackets are

installed incorrectly they will not sit flush and cause problems when trying

to install the screws for a wall mount bracket. Proper bracket installation

is shown in Figure 2-6.

CTV-41 23

Page 26

INVERTER

G1D 26"

G1H 32"

BU1

U1

TCON

Chapter 2 - Service and Troubleshooting

FIGURE 2-1

26” AND 32” S SERIES CIRCUIT BOARD LOCATIONS

CTV-41 24

Page 27

Chapter 2 - Service and Troubleshooting

INVERTER

G1H

BU1

U2

TCON

BH

FIGURE 2-2

32XBR CIRCUIT BOARD LOCATIONS

CTV-41 25

Page 28

BALANCER

G3

BU1

U1

TCON

D1

Chapter 2 - Service and Troubleshooting

FIGURE 2-3

40S3000 CIRCUIT BOARD LOCATIONS

CTV-41 26

Page 29

BALANCER

G3

BU1

U1

TCON

D1

D2

BALANCER

Chapter 2 - Service and Troubleshooting

FIGURE 2-4

46S3000 CIRCUIT BOARD LOCATIONS

CTV-41 27

Page 30

BALANCER

G3

BU1

U2

TCON

D1

BH

Chapter 2 - Service and Troubleshooting

FIGURE 2-5

46D3000 CIRCUIT BOARD LOCATIONS

CTV-41 28

Page 31

NOTE DIFFEREN CE IN LOCATION

OF PIN BOSSES

BRACKETS AR E LABELED AS

VIEWED FROM FRONT OF UNIT

Chapter 2 - Service and Troubleshooting

FIGURE 2-6

LEFT AND RIGHT WALL MOUNT BRACKETS

CTV-41 29

Page 32

Chapter 2 - Service and Troubleshooting

Protection

The protect circuits are described in detail in Chapter 1 of this manual.

Table 2-1 lists the protect events that could possibly occur and suggested

locations for their causes. Troubleshooting flowcharts are also located later

in this chapter to assist the technician in isolating the cause of a protect

event. Although the self-diagnostics feature is helpful in troubleshooting

a unit, they are not 100% reliable and may be caused by more than 1

component.

# OF RED LED

BLINKS EVENT POSSIBLE CAUSE NOTES

2 REG 12V FAILURE POWER SUPPLY BOARD PAGE 1 OF DIAGNOSTICS

2.5V FAILURE TO

3

4 D 1.OV FAILURE BU1 BOARD PAGE 1 OF DIAGNOSTICS

5 PANEL 12V BU1 BOARD BU1 TO PANEL TCON 12V

6 INVERTER ERROR

7 TEMPERATURE ERROR

TRIDENT IC BU1 BOARD PAGE 1 OF DIAGNOSTICS

INVERTER (26/32")

D1, D2 BOARDS (40/46")

BU1 BOARD (S MODELS)

BH BOARD (D/XBR MODELS) PAGE 2 OF DIAGNOSTICS

NOTE: Whenever the unit shuts down due to a protect event the

remote commander will not function. In previous Sony chassis

designs the remote could be used to cycle the unit back on. The unit

would shut down again, of course, if the problem still existed. In the

WAX3 chassis the power must be cycled by using the manual power

button.

LISTED AS "BACK_LIGHT" IN

DIAGNOSTICS PAGE 1

8 SPEAKER PROTECT BU1 BOARD PAGE 2 OF DIAGNOSTICS

9 FAN ERROR NOT USED

MAIN MICRO COM

10

11 TRIDENT IC FAILURE BU1 BOARD PAGE 2 OF DIAGNOSTICS

12 BU1 TO BH COM ERROR

13 BALANCER ERROR LCD PANEL

ERROR BU1 BOARD PAGE 2 OF DIAGNOSTICS

BU1 BOARD OR BH

BOARD PAGE 2 OF DIAGNOSTICS

NOT USED BUT APPEARS IN

PAGE 2 OF DIAGNOSTICS

NOT USED IN 26/32" MODELS

PAGE 1 OF DIAGNOSTICS

TABLE 2-2

SELF-DIAGNOSTICS TABLE

CTV-41 30

Page 33

Diagnostics History

USE “1” AND “4” KEY ON

REMOTE COMMANDER TO

TOGGLE BETWEEN PAGES

Certain protect events are monitored by the Main Micro on the BU1 board.

Those that are monitored are stored into NVM for retrieval. Each time a

monitored protect event occurs, a running count is kept and displayed.

This feature is very useful in locating the cause of intermittent failures.

The diagnostics history page is retrieved by turning the unit off and

pressing the following buttons on the remote commander in sequence:

“DISPLAY”, “5”, “VOL-”, and “POWER”. The unit will turn on and you may

have to wait several seconds for the display to appear once the backlights

have turned on. This feature is illustrated in Figure 2-7.

Note also that due to the large number of diagnostic events monitored,

there are 2 pages of lists. Toggling between the pages is performed using

the 1 and 4 keys on the remote.

Clearing the Diagnostics History

Once the diagnostics page has been viewed for a history of protect events

(and there are any present) the failure counts must be cleared to be useful

at a later time. This is accomplished by pressing the “8” followed by the “0”

key on the remote (not “8”, “ENTER” as in past models).

Chapter 2 - Service and Troubleshooting

FIGURE 2-7

DIAGNSTICS HISTORY PAGE

CTV-41 31

Page 34

Chapter 2 - Service and Troubleshooting

New Remote Control Commands

The button sequnces to perform read, write and initialize commands

has changed. The table below shows the correct buttons to press for the

various tasks.

OPERATION COMMAND BUTTONS

"7"

INITIALIZE DATA

"MUTE"

"0"

CUSTOMER

SETTINGS RESET

"8"

"MUTE"

"0"

READ NVM DATA

"9"

"0"

SERVICE PAGE

DISPLAY

INIINI-EXE

INI-EXE

RSTRST-EXE

RST-EXE

READ

READ

Digital Signal Status

If the customer is experiencing intermittent picture loss, freezing, or tiling,

the signal level of the cable or OTA signal can be checked in the service

mode or within the customer menu. The customer menu is easier to

access and is specific to those signal levels with pleasing graphics so it is

suggested to use this feature as opposed to the pages located within the

QM service graphics.

Figure 2-8 illustrates this feature. Signal readings can only be obtained for

digital sources at the antenna inputs. Analog signals will only display the

channel frequency and the fact that it is detected and locked.

The two important items to view are the AGC and Signal-To-Noise ratio

numbers. If the signal decreases, the numbers increase and vice versa.

Acceptable ranges for AGC are 18 to 54. SNR ranges are 16 to 22 for

ATSC and 29 to 38 for 256QAM.

WRITE DATA

TO NVM

"MUTE"

"0"

WRITE

WRITE

CTV-41 32

Page 35

Chapter 2 - Service and Troubleshooting

ATSC DIGITAL RECEPTIONQAM DIGITAL RECEPTION

NTSC ANALOG RECEPTION

ACCEPTABLE DIGITAL

SIGNAL READINGS

AGC

: 18-54

SNR

: ATSC 16-22

QAM256 MINIMUM 29

64 QAM MINIMUM 22

PEAK LEVEL RESETS

WHEN CHANNEL IS

CHANGED

FIGURE 2-8

SIGNAL LEVEL CHECK

CTV-41 33

Page 36

Chapter 2 - Service and Troubleshooting

Service Mode

The service mode in the WAX3 chassis is accessed in the traditional way

by starting with the unit turned off and pressing “DISPLAY”, “5”, “VOL+”,

and “POWER” in sequence. The TV will power up and the initial service

graphics shown in Figure 2-9 should appear. A white field from an external

generator was input to the television to make the picture more printerfriendly and to keep the video input graphic from displaying.

Service adjustment availability is extremely limited in this chassis as

compared to other Sony television products. Note that the firmware

versions of the Trident (Digital) and Main Micro (BE for back-end) are

displayed for viewing to see if the unit is loaded with the latest version.

Data Handling

A couple of procedures have changed with the new software installed in

the WAX3 chassis.

Saving (Writing) Data

The traditional method of saving data in Sony televisions was to press

“MUTE”, followed by “ENTER” on the remote commander. This is now

performed by pressing “MUTE” and then the “0” (zero) key. Just remember

that the “0” key on the remote is now what used to be the “ENTER” key.

If the key entry was successful, the word “WRITE” should appear on the

upper right portion of the screen as soon as the mute button is pressed

and turn red (indicating data writing) when the zero key is depressed.

The method for returning the unit to “out of box” condition has changed.

Traditionally, this was performed by pressing “8” followed by “ENTER” on

the remote commander while in the service mode. The new procedure is

to point the remote at the receiver while the unit is turned on. Press the

joystick “UP” and hold it there while turning the unit off with the manual

power button. The screen should go dark but the green power LED will

remain lit. The unit will then cycle and should turn back on to channel 3

and ask what language you would like to use.

White Balance Adjustments

Note that the first service item is a white balance adjustment for the green

drive. The only adjustments that can be performed in this group is white

balance and there is a drive and background adjustment for each of the

3 colors. White balance adjustments will probably not be required even if

the LCD panel or the BU1 board is replaced based on experience with the

WAX2 chassis from last year. These adjustments will only be required if

the customer requests it or if someone else has changed the values.

TIP: If someone changes the white balance adjustments to where it

is noticeable the white balance can be restored to a reasonable level

(assuming the backlights have not aged to the point of significant color

shift) by setting the data values for the red, green and blue drive to 100

and the background for each color to 200.

Reading Back of Data

When performing adjustments there comes a time where things may

appear to be getting out of control or you may be trying an adjustment

and forgot what the data value was. Pressing “9” followed by “0” will read

back the last stored data from NVM. Unplugging the unit from AC power

will also cause a read-back from NVM.

Factory Reset

CTV-41 34

Page 37

Chapter 2 - Service and Troubleshooting

FIGURE 2-9

MAIN TV MICRO SERVICE PAGE

CTV-41 35

Page 38

QM Service Page

The QM service page is accessed by pressing the “JUMP” button on the

remote commander once the service mode has been accessed. This

switches service data to the ATI Micro also located on the BU1 board.

Although various adjustments are available within this group most of them

are related to customer graphics display properties and are not usually

in need of adjustment. What is important is the availability of test pattern

graphics that can be useful in troubleshooting video issues, especially

those that involve distortion in the video signal.

Once in the QM service group, the initial page will be labeled “INFO”.

Use the “1” key to scroll to the next page labeled “TPNS”. The data value

default is “zero”. By changing the data value with the “3” button, various

test patterns in 4 different resolutions can be displayed on the screen with

the initial color bar pattern shown in Figure 2-10. There are 20 sets of

patterns for the 4 resolutions. They are as follows:

1-20 1080i

21-40 480i

Chapter 2 - Service and Troubleshooting

41-60 480p

61-80 720p

Since these patterns are generated by the ATI Micro which is located on

the BU1 board along with the video process circuits, they do not provide

much assistance in isolating video problems as past chassis designs in

which the ATI Micro was located on a separate board. They do, however,

provide a clean, stable video source to assist in closer examination of

the screen display. This is especially useful when trying to determine if a

distortion problem is being caused by the LCD panel.

CTV-41 36

Page 39

Chapter 2 - Service and Troubleshooting

DATA SETTING

CHANGES

GRAPHICS

PAGE 1 BRINGS UP

QM GRAPHICS

FIGURE 2-10

QM (ATI MICRO) SERVICE GRAPHICS

CTV-41 37

Page 40

Chapter 2 - Service and Troubleshooting

Troubleshooting

The WAX3 chassis is serviced at board level. Warranty repairs require

mandatory board level repair unless a specific bulletin is issued calling

for the replacement of an individual component. Because of this,

troubleshooting flowcharts will be utilized in this manual to assist in

diagnosing and repairing the unit. The preferred method is to “triage” the

unit by listening to the customer’s description of the symptoms when a

service request is made. This can be done by technical or non-technical

staff by utilizing the triage worksheet included in this section.

Once the correct part (or parts) is identified during the triage procedure, the

technician can use the flowcharts in the field to perform further diagnosis

of the unit. This is especially useful when more than one part is suspected

as being the cause. The flowcharts are designed to use visual checks, the

use of internal graphic patterns, and in the worst case, the use of a DVM to

check voltages or resistance levels. These quick checks are much quicker

than trying to repair the unit using the “shotgun” method.

Triage Worksheets

The triage worksheets in the following pages are an example of a useful

tool to aid in determining what part(s) may be needed to be brought to the

repair site to complete a repair. Based on a description of the symptom

by the customer, one can simply go down the column that best fits the

description of the failure and locate what is needed for the repair.

the field on what part is more likely to repair the problem. Always visit

the Sony service website to obtain the latest triage worksheet that will be

constantly updated and to view any service bulletins or repair tips to assist

in the repair.

Troubleshooting Flowcharts

The flowcharts in the remainder of this chapter are designed for the

technician who is servicing the unit in the field. They are particularly useful

when more than one part is brought to the location. Visual checks, use

of internal graphics patterns and voltage checks will assist in determining

which part is likely to complete the repair. As with the triage worksheet,

please check the Sony service website to see if the flowcharts have been

updated with new information to assist in the diagnosis of the unit. The

triage worksheets on the website will always have the latest flowcharts

included.

The part that is most likely to repair the failure is marked with a dot. In

some cases there may be more than one part with a dot. In this situation

it is highly recommended to bring both parts to the repair location. Parts

marked with a triangle may also be the cause and the decision on whether

to bring them will need to be determined based on various situations such

as distance to the repair site and the size of the unit (can it easily be

brought to the shop if needed).

Bear in mind that the worksheet illustrated is updated with correct part

numbers and suggested parts as of the writing of this manual but may

be updated as part numbers change due to production changes in the

product and the suggestion list may change as feedback is received from

CTV-41 38

Page 41

Chapter 2 - Service and Troubleshooting

Sony KDL26S3000 Technical Triage Summary Sheet

1. Confirm the symptom from the customer.

CHASSIS: WAX32. Select that symptom from the chart.

3. Bring all the boards listed for that symptom.

4. Follow the troubleshooting charts in the technical guides to isolate the board.

5. Chart Color Code

RED DOT: Most likely defective part

BLUE Triangle: Possible defective part LAST UPDATED: 7/16/07

BLACK TEXT: Board and Part # that may correct the symptom

7) The Troubleshooting Flowchart required to determine the actual defective part is listed for each column in the last row of each table.

Reference

BU1 BOARD

G1D BOARD

U1 BOARD

INVERTER

TCON LVDS CABLE

LCD Panel

Flowchart Reference

Problem

Symptoms - Shutdown. Power LED

blinking red diagnostics sequences

2 3 4 5 6 7** 8 10 11 13

▲

▲ ▲ ▲

▲

C C C C D C C C C N/A

POWER POWER POWER POWER INV TEMP AUDIO COMM COMM

**ONLY IF TEMPERATURE ERROR OCCURS IMMEDIATELY

No

Power Video - missing or distorted

No Green

Power LED

(Dead Set)

N/A

N/A

N/A

N/A

N/A

N/A

N/A

Stationary

colored

lines or

dots

Video 2

0nly

▲ ▲

▲ ▲ 1-834-155-11

▲ 1-802-368-11

B F F D H

No video

all Inputs

No Audio

Part #

A-1268-869-A

1-474-056-21

A-1220-504-C

1-789-780-11

CTV-41 39

Page 42

Chapter 2 - Service and Troubleshooting

Sony KDL32S3000/SL130 Technical Triage Summary Sheet

1. Confirm the symptom from the customer.

CHASSIS: WAX32. Select that symptom from the chart.

3. Bring all the boards listed for that symptom.

4. Follow the troubleshooting charts in the technical guides to isolate the board.

5. Chart Color Code

RED DOT: Most likely defective part

BLUE Triangle: Possible defective part LAST UPDATED: 7/19/07

BLACK TEXT: Board and Part # that may correct the symptom

7) The Troubleshooting Flowchart required to determine the actual defective part is listed for each column in the last row of each table.

Reference

BU1 BOARD

G1H BOARD

U1 BOARD

INVERTER

TCON LVDS CABLE

LCD Panel

Flowchart Reference

Problem

Symptoms - Shutdown. Power LED

blinking red diagnostics sequences

2 3 4 5 6 7** 8 10 11 13

▲

▲ ▲ ▲ ▲

▲

B C C C D C C C C N/A

POWER POWER POWER POWER INV TEMP AUDIO COMM COMM

**ONLY IF TEMPERATURE ERROR OCCURS IMMEDIATELY

No

Power Video - missing or distorted

No Green

Power LED

(Dead Set)

N/A

N/A

N/A

N/A

N/A

N/A

N/A

Stationary

colored

lines or

Video 2

0nly

dots

▲ ▲

▲ ▲ 1-834-157-11

▲ 1-802-380-11

B G F F H

No video

all Inputs

No Audio

Part #

A-1257-244-A

1-474-052-11

A-1220-504-C

1-789-780-11

CTV-41 40

Page 43

Chapter 2 - Service and Troubleshooting

Sony KDL32XBR4 Technical Triage Summary Sheet

1. Confirm the symptom from the customer.

CHASSIS: WAX32. Select that symptom from the chart.

3. Bring all the boards listed for that symptom.

4. Follow the troubleshooting charts in the technical guides to isolate the board.

5. Chart Color Code

RED DOT: Most likely defective part

BLUE Triangle: Possible defective part LAST UPDATED: 7/16/07

BLACK TEXT: Board and Part # that may correct the symptom

7) The Troubleshooting Flowchart required to determine the actual defective part is listed for each column in the last row of each table.

Reference

BU1 BOARD

BH BOARD

G1H BOARD

U2 BOARD

INVERTER

BU1/BH LVDS CABLE

BH/TCON LVDS

LCD Panel

Flowchart Reference

Problem

Symptoms - Shutdown. Power LED

blinking red diagnostics sequences

2 3 4 5 6 7** 8 10 11 12 13

▲

▲ ▲ ▲

▲

B C C C D C C C C D N/A

POWER POWER POWER POWER INV TEMP AUDIO COMM COMM

**ONLY IF TEMPERATURE ERROR OCCURS IMMEDIATELY

No

Power Video - missing or distorted

No Green

Power LED

(Dead Set)

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

Stationary

colored

lines or

Video 2

0nly

dots

▲ ▲

▲ ▲ 1-834-188-21

▲ 1-802-411-11

B G F F H

No video

all Inputs

No Audio

Part #

A-1268-671-A

▲ A-1236-654-A

1-474-052-11

A-1289-342-A

1-789-795-11

1-833-964-11

CTV-41 41

Page 44

Chapter 2 - Service and Troubleshooting

Sony KDL40S3000/SL130 Technical Triage Summary Sheet

1. Confirm the symptom from the customer.

CHASSIS: WAX32. Select that symptom from the chart.

3. Bring all the boards listed for that symptom.

4. Follow the troubleshooting charts in the technical guides to isolate the board.

5. Chart Color Code

RED DOT: Most likely defective part

BLUE Triangle: Possible defective part LAST UPDATED: 7/16/07

BLACK TEXT: Board and Part # that may correct the symptom

7) The Troubleshooting Flowchart required to determine the actual defective part is listed for each column in the last row of each table.

Reference

BU1 BOARD

D1 BOARD

G3 BOARD

U1 BOARD

INVERTER

LVDS CABLE

LCD Panel

Flowchart

Problem

Symptoms - Shutdown. Power LED

blinking red diagnostics sequences

2 3 4 5 6 7** 8 10 11 13

▲

▲ ▲ ▲

▲ A-1236-528-A

▲ ▲ ▲ 1-802-410-11

B C C C E C C C C E

POWER POWER POWER POWER INV TEMP AUDIO COMM COMM PANEL

**ONLY IF TEMPERATURE ERROR OCCURS IMMEDIATELY

No

Power

No Green

Power LED

(Dead Set)

▲ ▲

Video - missing or

distorted

Stationary

colored

lines or

Video 2

0nly

dots

No video

all Inputs

B G F F H

▲ ▲ 1-834-158-11

No Audio

Part #

A-1257-243-A

A-1236-537-C

A-1220-504-C

1-789-771-11

CTV-41 42

Page 45

Chapter 2 - Service and Troubleshooting

Sony KDL46S3000 Technical Triage Summary Sheet

1. Confirm the symptom from the customer.

CHASSIS: WAX32. Select that symptom from the chart.

3. Bring all the boards listed for that symptom.

4. Follow the troubleshooting charts in the technical guides to isolate the board.

5. Chart Color Code

RED DOT: Most likely defective part

BLUE Triangle: Possible defective part LAST MODIFIED: 716/2007

BLACK TEXT: Board and Part # that may correct the symptom

7) The Troubleshooting Flowchart required to determine the actual defective part is listed for each column in the last row of each table.

Symptoms - Shutdown. Power LED

blinking red diagnostics sequences

Reference

2 3 4 5 6 7** 8 10 11 13

BU1 BOARD

D1 BOARD

D2 BOARD

G3 BOARD

U1 BOARD

INVERTER (RIGHT)*

INVERTER (LEFT)*

LVDS CABLE

LCD Panel

Flowchart Reference

Problem

POWER POWER POWER POWER INV TEMP AUDIO COMM COMM PANEL

▲

▲

▲

▲ ▲ ▲ 1-802-409-11

C C C C E C C C C E

* AS VIEWD FROM REAR OF UNIT

**ONLY IF TEMPERATURE ERROR OCCURS IMMEDIATELY

No

Power

No Green

Power LED

(Dead Set)

Video - missing or

distorted

Stationary

colored

lines or

Video 2

0nly

dots

No video

all Inputs

▲ ▲

B G F F H

▲ ▲ 1-834-159-11

No Audio

Part #

A-1257-242-A

A-1236-531-A

A-1247-497-A

A-1236-537-C

A-1220-504-C

1-789-788-11

1-789-787-11

CTV-41 43

Page 46

Start

No

Yes

Is Timer LED

Flashing Red

?

No

No

No

No

Yes

Yes

Yes

GO TO

Power Supply

Troubleshooting

Flowchart B

GO TO

Protection Mode

Troubleshooting

Flowchart C

GO TO

No Video

Troubleshooting

Flowchart F

GO TO

Video Distortion

Troubleshooting

Flowchart G

GO TO

Audio

Troubleshooting

Flowchart H

Done

Does unit

turn ON

?

Is video

distorted

?

Is audio

present

?

A

Distorted

No

Yes

Is video

present

?

Yes

Initial Contact Flowchart A

Chapter 2 - Service and Troubleshooting

CTV-41 44

Page 47

Unit Does

Not Turn On

No

Yes

No

Protection

Go to Flowchart C

Timer LED goes

to Flashing Red

?

Yes

Audio Present ?

Video problem

Go to flowchart D

Yes

No

Green Power

LED Lit?

3.3VDC

CN4001-1 on

BU1 Board

?

No

Yes

Remains Green ?

Video problem

Go to flowchart D

No

Standby Supply Failure

G1D Board (26")

G1H Board (32")

G3 Board 40/46")

High (>2.5V)

CN4001

-3 on

BU1 Board

?

No

BU1 Board

G1D Board (26")

G1H Board (32")

G3 Board 40/46")

Yes

Yes

B

No Power Flowchart B

Chapter 2 - Service and Troubleshooting

CTV-41 45

Page 48

Red Standby

LED Flashing

No

No

Yes

Yes

2X

12V Main

3X

Trident

3.3V

Yes

4X

Reg 5V

No

G1D Board (26")

G1H Board (32")

G3 Board (40/46")

12VDC

CN4002-1 on

BU1 Board

?

Yes

No

BU1 Board

BU1 Board

No

Yes

Go To Inverter

Troubleshooting

Flowchart D

(26/32")

Flowchart E (40/46")

7X

Temperature

Yes

Immediately ?

Check for possible

ventilation problem

BU1 Board

Yes

No

8X

Speaker

Protect

BU1 Board

Yes

12X

HFR (32XBR

Only

)

Yes

BH Board

13X

Balancer

No

No

Yes

Go To Inverter

Troubleshooting

Flowchart D

(26/32")

Flowchart E

(40/46")

No

6X

Inverter Fail

5X

Panel 12

V

Yes

C

10X or 11X?

No

Yes

Protect ModeFlowchart C

Chapter 2 - Service and Troubleshooting

CTV-41 46

Page 49

Inverter Error

6X (26/32")

D

Backlights turn

on before

shutdown?

Yes

No

High at pins 3

or 5 of CN4003

BU1 Board

?

Yes

No

Inverter or LCD

Panel

BU1 Baord

24VDC

CN001 pins

1~5

Inverter Board

?

Inverter

G1D Board

G1H board

No

Yes

26/32" Inverter Error Flowchart D

Chapter 2 - Service and Troubleshooting

CTV-41 47

Page 50

Inverter Error

6X (40/46")

E

Backlights turn

on before

shutdown

?

Yes

No

40" or 46" Model?

LCD Panel

390VDC

across pins 1 & 3

CN6600

D1

Board

?

Check cable from G 3

board. Replace G 3

board if OK

No

Yes

CN6707 pin 3

D1 Board (high?

No

BU1 Board

CN6707 pin

3 or 7 high?

No

BU1 Board

Yes

Yes

Unplug

CN6707 from

D1 Board

CN6707 pin

3 or 7 still high?

D1 Board

No

Yes

D2 Board

Check LCD panel for

damage. If OK

replace D1 Board

40" or 46" Model?

46"

40

"

40"

46

"

Screen lit evenly

across

?

Yes

LCD Panel

No

Observe which

side of s creen is

darker before

shutdown

Left or right side?

Right

Left

D2 Board

D1 Board

40/46" Inverter Error Flowchart E

Chapter 2 - Service and Troubleshooting

CTV-41 48

Page 51

No Picture

Yes

Backlights on?

No picture all

input sources

?

Yes

No

No

F

Check LVDS connector

from BU1 Board to LCD

Panel. If OK replace BU1

Board

No picture front

inputs

?

No

Yes

Done

26/32" or

40

/46"

Model?

Check connection

from Power Supply to

Inverter. If OK

Go to Flowchart D

26/32"

40

/46"

Approx

390VDC across

pins 1 & 3 CN6600

D1 Board?

No

G3 Board

Yes

High at

CN6707

-3 D1

Board

?

No

Yes

D1 Board

D2 Board

See Flowchart E

BU1 Board

U1 Board (S Models )

U2 Board (XBR Models)

No Video Flowchart F

Chapter 2 - Service and Troubleshooting

CTV-41 49

Page 52

Video Distortion Flowchart G

Distorted

Picture

Yes

Stationary lines

or spots

All input

sources

?

Yes

No

No

G

Check LVDS connector

from BU1 Board to LCD

Panel. If OK replace BU1

Board

Front inputs?

No

Done

Single colored

vertical line

?

Multiple colored

lines evenly

spaced?

No

Yes

Pixel stuck on

or off

No

Yes

Pixel Failure. Contact

Technical Support for

assistance

U1 Board (S Models )

U2 Board (XBR Models)

Yes

LCD Panel

No

Yes

Done

LVDS

Connectors from

BU1 Board to

Panel OK

?

No

Yes

LCD Panel

LVDS Cable

Chapter 2 - Service and Troubleshooting

CTV-41 50

Page 53

No or Distorted

Audio

Yes

All Sources?

Analog Tuner ?

Yes

No

No

H

Front Inputs

only

?

No

U1 Board (S Models)

U2 Board (XBR Models)

Yes

BU1 Board

All C hannels?

Yes

BU1 Board

No

Check “SAP” is not

turned on in customer

setup menu

HDMI Only?

Done

No

Check that connected

device is set for PCM

audio output

Yes

Audio Flowchart H

Chapter 2 - Service and Troubleshooting

CTV-41 51

Page 54

Service Test Points

Due to heavy shielding of the BU1 board, voltage and signal test points

are virtually inaccessible. Since all video processing is performed on

this board it is not necessary to view signals. Video issues are resolved

by observation of what appears (if anything) on the LCD screen. The

important test points are located on the power supply boards. Inverter

error test points for the 26/32” models are located on the inverter board.

Inverter drive and error lines for the 40/46” models can be checked on

the power supply board. Figures 2-11 through 2-14 provide illustrations of

the voltage test points of the 3 different power supplies and inverter test

points used in the WAX3 chassis.

Chapter 2 - Service and Troubleshooting

CTV-41 52

Page 55

Chapter 2 - Service and Troubleshooting

CN2

1,2 GROUND

3,4 12V

5~8 GROUND

9~12 24V

CN3

1~3 GROUND

4,5 6.5V

7,8 AUDIO GROUND

8,9 AUDIO 13.5V

10 AC

_OFF_ DET (NORM LOW)

11 POWER ON

(ON = 2.8V)

12 GROUND

13 STBY 3.3V

FIGURE 2-11

26” G1D BOARD TEST POINTS

CTV-41 53

Page 56

Chapter 2 - Service and Troubleshooting

CN6202

1~4 – REG 24V

5~8 – GROUND

9,10 – REG 12V

11,12 – GROUND

CN6201

1

– STBY 3.3V

2 – GROUND

3 – POWER ON

4

– AC DETECT

5,6 – AUDIO 13V

7,8 – AUDIO GROUND

9,10 – UNREG 6V

FIGURE 2-12

32” G1H BOARD TEST POINTS

CTV-41 54

Page 57

CN001 (SHOWN WITH SHIELD

REMOVED)

1~5 24V

6~10 GROUND

11 INV

_ERROR (NORM LOW)

12 BACKLIGHT ON

(3.3V = ON)

14 DIMMER

(1.2~2.8VDC)

Chapter 2 - Service and Troubleshooting

FIGURE 2-13

26/32” INVERTER TEST POINTS

CTV-41 55

Page 58

CN6501, CN6502

ONE USED IN 40

"

BOTH USED IN 46"

1

– PFC 380 V

3 – PFC GND

CN6004

1

– GROUND

2 – DIMMER

3

– BACKLIGHT ON

4 – INVERTER ERROR

6

– REG 12V

7

– BALANCER ERROR

CN6203

1~3 – GROUND

4~6 – REG 12V

7 – BALANCER ERROR

6

– REG 12V

7

– BALANCER ERROR

9 – INVERTER ERROR

10

– BACKLIGHT ON

11 – DIMMER

CN6202

1,2 – GROUND

3,4 – 6V

5,6 – AUDIO GROUN D

7,8 – AUDIO 13V

9 – AC OFF DET

10

– POWER ON

12

– STBY 3.3V

Chapter 2 - Service and Troubleshooting

CTV-41 56

40/46” G3 BOARD TEST POINTS

FIGURE 2-14

Page 59

Chapter 3 - Disassembly

Overview

Disassembly of the WAX3 chassis models is relatively straight forward.

The rear cover is removed by locating and screws marked by an arrow.

Most of the screws will be 4mm self-tap (particularly those around the

perimeter of the cover) with a couple of smaller 3mm self-tap and machine

screws in the area where the HDMI and A/V input jacks are located. The

only large machine screws for the rear cover will be attached to the wall

mount brackets.

Once the rear cover is removed, the wall mount brackets may be removed

(even while the unit is mounted to its pedestal) since they are not part of

the panel bracing. This is illustrated in Figure 3-1 During the disassembly

procedures described in this chapter, all references to right and left

pertaining to the wall mount brackets will be made as viewing from the

front of the unit.

For demonstration purposes in this manual the disassembly all the way

to LCD panel removal will be illustrated using a 32” and 46” model. Even

though different boards are used with the various sizes, removal of the

LCD panel is relatively the same. Any connectors that are attached to the

panel (such as LVDS to TCON) or circuit boards attached to the bezel

(IR receiver and function buttons) will need to be unplugged. The main

screws securing the panel are located at the top and bottom of the wall

mount brackets along with 2 to 4 additional screws along the bottom edge

of the chassis. The wall mount brackets will be left intact to provide a

gripping area for the removal. The panel can then be easily lifted out and

transferred to another flat cushioned surface for removal of the circuit

boards and additional hardware to transfer to the new panel.

Inverter Board Removal (26 and 32” Models)

Replacement of the inverter board begins with removal of the shield as

shown in Figure 3-2. Once the shield is removed, the power and control

connector is unplugged and the board pulled out from the lamp socket

connectors.