Page 1

2018/05/0404:12:02(GMT+09:00)

HISTORY INFORMATION FOR THE FOLLOWING MANUAL:

SERVICE MANUAL (COMMON)

GN4UN CHASSIS

ORIGINAL M ANUA L ISSUE DATE: 4/2018

Version Date Subject

1 4/2018 1st Issue

Segment : CHL

LCD TV

9-888-752-01

For SM - Unique , plea s e ref er :

9-888-752-Ax ( America )

9-888-752-Ex ( Europe )

9-888-752-Px (Asia)

SYSSET

Page 2

2018/05/0404:12:02(GMT+09:00)

SERVICE MANUAL (COMMON)

GN4UN CHASSIS

Segment : CHL

LCD TV

SYSSET

Page 3

2018/05/0404:12:02(GMT+09:00)

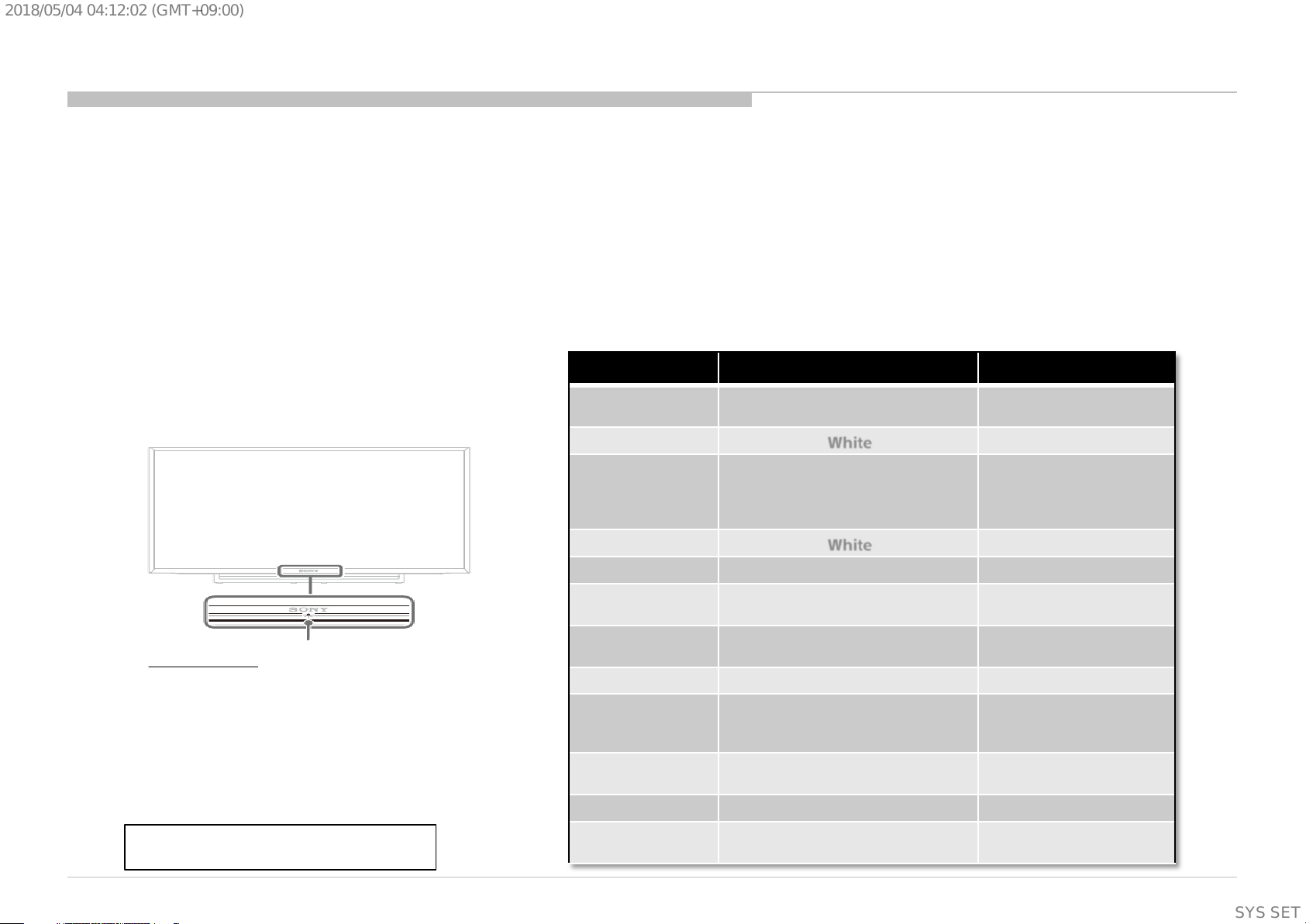

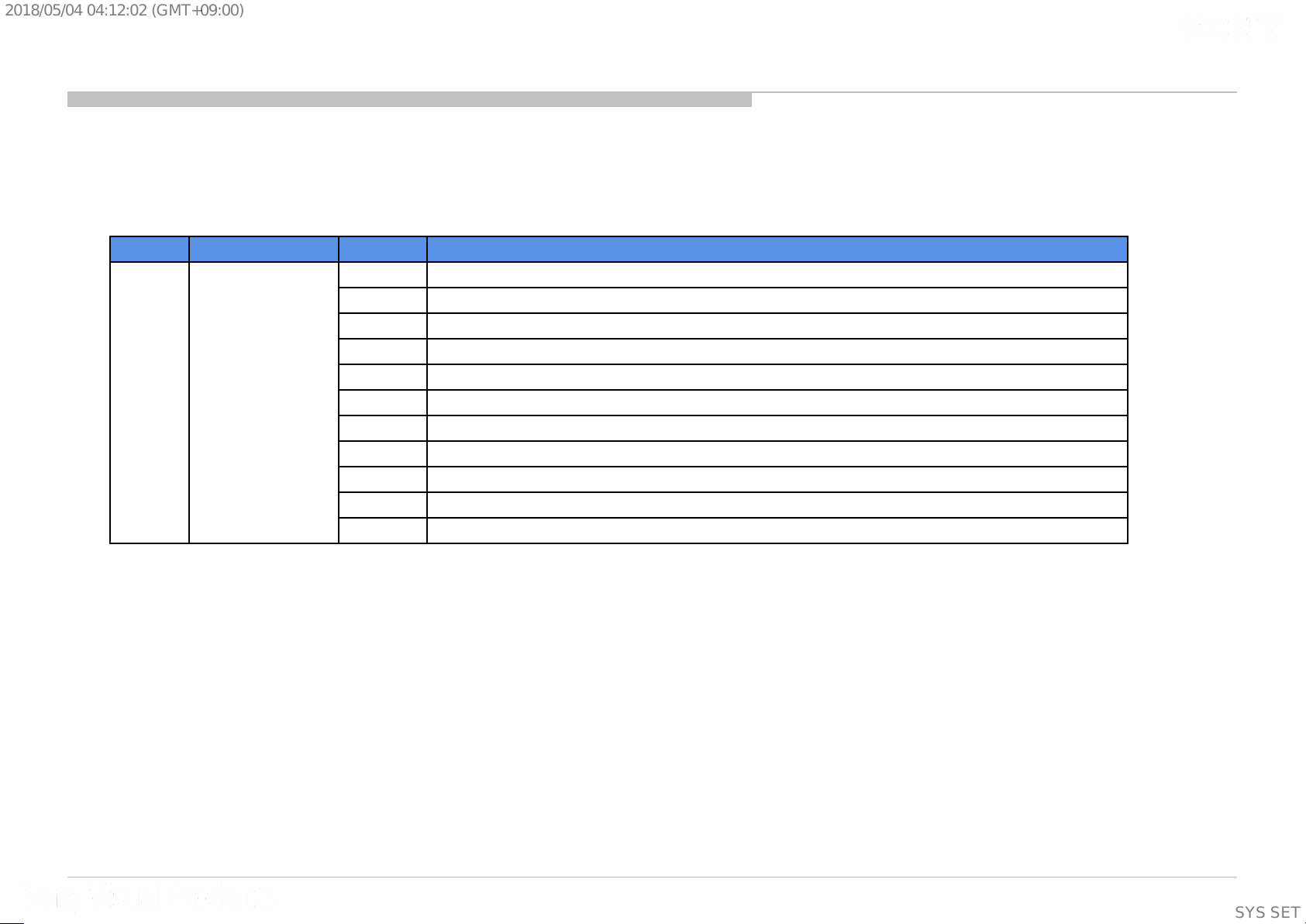

MODEL LIST

THIS SERVICE MANUAL CONTAINS COMMON INFORMATION FOR BELOW REGIONS AND MODELS:

REGION

ASIA AMERICA EUROPE

MODEL

KD-43X7*F

KD-43XF7*

KD-49X7*F

KD-49XF7*

KD-55X7*F

KD-55XF7*

KD-65X7*F

KD-65XF7*

SYSSET

Page 4

4. SERVICE ADJUSTMENTS

5. DIAGRAMS

2018/05/0404:12:02(GMT+09:00)

Section Title Page

1. SAFETY NOTES 5

2. SELF DIAGNOSTIC FUNCTION 12

3. TROUBLE SH OOTING 14

138

TABLE OF CONTE NTS

115

Please refer Service Manual – Unique for below information :

-Dissassy and Removal Caution

-Wire Dressing

-Circuit Board Location

-Exploded Views and Parts List

Note: Pictures provided in this Service Manual might have slight difference from the

actual sets.

4

SYSSET

Page 5

2018/05/0404:12:02(GMT+09:00)

1-1. Warnings and Caution

1) CAUTION :These servicing instructions are for use by qualified service

personnel only.

2) To reduce the risk of electric shock, do not perform any servicing other than

that contained in the operating instructions unless you are qualified to do so.

3) WARNING!! : An isolation transformer should be used during any service

to avoid possible shock hazard, because of live chassis. The chassis of this

receiver is directly connected to the ac power line.

SECTION 1

SAFETY NOTES

Whenever a TV Main board is replaced, the correct TV Model and Serial

number must be reinserted into m emor y.

This is a MANDATOR Y procedure that each ser vic e center must appl y.

Please refer to t he chapter of A DJUS TM ENT in this service manual to

find out how to set the model number and s erial number in serv ice mode.

1-2-1. Caution Handling of LCD Panel

The replaceable fuse could be in the neutral of the mai ns supply. When

replacing the fuse, t he mains shal l be disconnected for de-energi ze the phase

conductors.

(*Except AC ADAPTOR , Because i t does not carr y out replacing an i nternal

fuse.)

4) CARRYING THE TV : Be sure to follow these guidelines to protect your

property and avoid causing serious injury :

• Carry the TV with an adequate number of people; larger size TVs require

two or more people.

• Correct hand placement while carrying the TV is very important for

safety and to avoid damages.

5) SAFETY-RELATED COMPONENT WARNING!! : Components identified

by shading and ! mark on the exploded views, and in the parts list are critical

for safe operation. Replace these components with Sony parts whose part

numbers appear as shown in this manual or in supplements published by

Sony. Circuit adjustments that are critical for safe

this manual. Follow these procedures whenever critical components are

replaced or improper operation is suspected.

6) IMPORTANT REMINDER FOR TV MAINBOARD REPLACEMENT :

It is mandatory for s ervi ce center s to confirm the TV‘ s system inform ation after

each repair carr ied out w ith Mainboard replacement.

operation are identified in

When r epair ing the LCD Panel, make sure you are grounded w ith a wrist

band.

When r epair ing the LCD Panel on the wall, the panel must be secured

using the 4 mounting holes on the rear cover .

1) Do not pr ess the panel or frame edge to avoid the ri sk of electri c

shock.

2) Do not scratch or press on the panel wi th any sharp objects .

3) Do not leave the module i n high temperatur e or in areas of high

humidity for an extended peri od of time.

4) Do not expose the LC D panel to direct sunl ight.

5) Avoid c ontact wit h water. I t may cause short cir cuit within the module.

6) Disconnect the AC power when replacing t he backli ght ( CC FL) or

inverter c irc uit. ( High voltage oc curs at the inv erter cir cuit at 650Vrms)

7) Always clean the LCD panel with a soft cloth materi al.

8) Use care when handling t he wir es or connectors of the inver ter ci rcui t.

Damaging the wi res may cause a short cir cuit .

9) Protect the panel from ESD to avoid damagi ng the el ectroni c circuit

(C-MOS).

5

SYSSET

Page 6

2018/05/0404:12:02(GMT+09:00)

10) During the repair, D O NOT leave the Power On or Burn-in peri od for

more than 1 hour while the TV is face down on a cloth. Refer Figure 1 .

Figure 1.

1-2-2. Caution for OLED Panel

1) Handling

When repai r i ng the TV set, be sur e y ou ar e gr ounded by usi ng a w r is t band.

*Do not press on the panel or frame edge to avoid the ri sk of electric shock.

*Do not scratch or press on the panel wi th any sharp objects.

*Do not leave the module in high tem peratur es or in areas of high humidi ty

for an extended per iod of tim e.

*Do not expose the panel to dir ect sunli ght.

*Avoid contact wi th water. I t may cause a short cir cuit wit hin the module.

*Disconnec t the AC power when replacing.

*Always clean the panel wi th a soft cloth material .

*Use care when handling the wi res or connectors. D amagi ng the wir es may

cause a short.

*Protect the panel from ES D to avoid damaging the elect ronic cir cuit.

*Do not recommend power-on i n the conditions w hi ch l ai d face down the

panel, in repair acti vity. Refer F i gur e 1 .

*When transpor ting by hand, do not put stress on the panel and the frame

around the screen.

Refer to the panel handli ng chapter of each Ser vice manual ,

or the "Transpor ting" inform ation of the Referenc e Guide of eac h model for

how to hold i t.

2) OLED Screen

•Although the O LED scr een is made with high-preci sion technology and

99.99% or m or e of the pix els ar e effect i ve, blac k dots may appear or br i ght

points of light (white, red, bl ue, or green) m ay appear c onstantly on the

OLED screen. T his is a structural property of the OLED s creen and i s not a

malfunction.

•Do not push or scratch the front filt er, or place obj ects on top of thi s TV

set. The i m age m ay be unev en or the OLE D screen m ay be damaged.

•The screen and cabinet get w arm when this TV set is in use. This is not a

malfunction.

3) Precautio n s t o P ro t ect th e Scr een from Damage

Image retention

OLED TV’s ar e s usc epti bl e to image retention (bur n-i n) due to the

characteri stic s of the mat erial s used. I mage r etention may occur if images

are displayed in the same locati on on the screen repeatedl y or over

extended per iods of tim e. Thi s is not a malfunction of the TV. Avoi d

displaying images that may caus e i m age r etenti on.

The fol lowing are examples o f images that may cause i mage

retention:

•Content w ith black bars either on the top and bottom and/or the left and

right sides of the scr een. ( for exampl e, Letterbo xed , 4:3 sc reen, Standar d

definition)

•Static im ages such as photos.

•Video games that might hav e static content in some part of the scr een.

•On-screen menus, pr ogram guides, channel l ogos et c.

•Static content from appl ications.

•On-screen ti ckers , such as those used for new s and headlines.

6

SYSSET

Page 7

2018/05/0404:12:02(GMT+09:00)

To reduce the risk of image retention:

•Fill the screen by changing [Wide mode] to elim inate the bl ack bars.

Select [Wide mode] other than [Nor mal] .

•Turn off the OSD (On Sc r een Displ ay ) by press i ng the DISPLAY button,

and turn off the menus from connected equipment. For detail s, refer to

the instruct ion m anuals for the c onnected equi pment.

•Avoid displ ay i ng st ati c i m ages w it h br ight colours (includi ng w hi te) ,

clocks or l ogos on any por ti on of the s c reen.

•Set the pictur e settings based on the ambi ent c onditions . T he Standard

Picture is recommended for hom e use and when viewi ng content that

often displ ays the station logos , etc.

The TV has following features to hel p reduce/ pr event image r etention.

Press the HOME button, then select [Settings] – [Picture & Display] –

[Expert panel settings ] – the desir ed option.

Panel ref res h

Panel refresh wil l automatically run to adjust the uniformi ty of the TV

screen after i t has been in use for long periods of tim e.

Panel refresh can also be performed manual ly and s hould only be used if

image retenti on i s very noti c eable or y ou see t he follow i ng m es sage:

[Panel refresh did not finish...]

Caution:

•The Panel refresh function may affect the panel. As a reference, perfor m

the Panel refresh only once a year, do not per form it more than once a

year as it may affect the usable l ife of the panel.

•Panel refresh takes about one hour t o complete.

•A white line may be displayed on the scr een duri ng the Panel refresh,

this is not a malfunction of the TV.

•Panel refresh wil l only work when the room temper ature i s between 10

ºC and 40 ºC.

Pixel shift

Automatical ly moves the image on the screen to pr event i mage retent ion.

Other feature

The screen brightnes s i s automatic ally reduced when dis playi ng stil l

images, cl ocks, bri ght colours or l ogos etc .

IMPORTANT REMINDER FOR OLED PANEL REPLA C EMENT

When c arry ing out OLED panel r eplacem ent, i t is mandatory of a

service c enter to confirm and r ec or d Panel ON tim e & Panel

Refresh times.

It is because t hey ar e i ndi s pensabl e informati on i n or der to c l ar ify

responsibi lity for image retenti on after panel replacement.

Please refer to the chapter of SELF DI AGNOSI S FUN CTI ON in this

service manual to find out how to confirm the Panel ON time &

Panel Refresh times in ser v i ce m ode.

1-3. Caution About the Lithium Battery

1) Danger of explosion if battery is incorrectly replaced. Replace only with

the same or equi val ent type.

2) Outer case broken battery should not contact to water.

1-4. Safety Ch eck-Out

After correcting the original service problem, perform the following

safety checks before releasing the set to the customer:-

1) Check the area of your repair for unsoldered or poorly soldered

connections. Check the entire board surface for solder splashes and

bridges.

2) Check the inter board wiring to ensure that no wires are pinched or

contact high-wattage resistors.

3)Check all control knobs, shields, covers, ground straps and mounting

hardware have been replaced. Be absolutely certain you have replaced

all the insulators.

7

SYSSET

Page 8

2018/05/0404:12:02(GMT+09:00)

4) Look for unauthorized replacement parts, particularly transistors that

were installed during a previous repair. Point them out to the customer and

recommend their replacement.

5) Look for parts which, though functioning show obvious signs of

deterioration. Point them out to the customer and recommend their

replacement.

6) Check the line cords for cracks and abrasion. Recommend the

replacement of any such line cord to the customer.

7) Check the antenna terminals, metal trim, metalized knobs, screws and all

other exposed metal parts for AC leakage. Check leakage test as described

next.

8. For safety reasons, repairing the Power board and/or Inverter board is

prohibited.

1-5.Leakage Test

(To protect electr ic shock w hen customer touch t he termi nal.)

Leakage current c an be measured by V: Voltmeter or oscillosc ope (r.m.s. or

peak reading)

Stabilized pow er suppl y instr ument and isol ated voltage trans forme r:

Use too much current capaci ty and is olated vol tage trans former does not

need to use stabilized pow er suppl y equipment.

Specificati on of RM S volt meter: Input r esis tance > 1 Mohm, Input

capacitance < 200 pF , F r equency range: 15 Hz – 1M Hz . Refer Figure 2.

Isolated ty pe volt -meter (FLUKE 8921A etc *1)

*1 Not use FLUKE 8920A that connected t o protecti ve earth by diode

# Leakage current of measurement instrument is less than 10μArms when

under test equipm ent AC plug is opened

# Set up the following condition and turn on the set. Appl ied vol tage:

Nominal input v oltage (D escr iption on N amepl ate)

# Measure the leakage current between one phase conductor and neutral

for terminal A and terminal B.

Read rms value, and then calculate to peak value PEAK VALUE =√2 RMS

VALUE

Comply with the following requirement

Class II equipment (2-pin plug) : for each term inal , the wor st value of

measurement must not exceed AC 350uA peak).

Note: including AC adaptor, AC adaptor/DC oper ated unit combinati on

Figure 2 – Measuring network

for Leakage Current

1-6. How to Find a Good Earth Ground

1) A cold-w ater pipe is a guaranteed earth gr ound; the cov er-plate

retaining sc rew on most AC outlet boxes is also at earth ground.

2) If the r etai ni ng screw is t o be used as your ear th gr ound, v er i fy that i t i s

at ground by m eas ur ing the r esi st ance between i t and a cold-water pipe

with an ohmmeter. The readi ng should be z ero ohms.

3) If a cold-w ater pi pe is not accessibl e, connect a 60- to 100-wat t troublelight (not a neon lamp) between the hot si de of the receptacl e and the

retaining sc rew. Try both slots, i f necessary , to locat e the hot side on the

line; the l am p s hould light at nor m al br i ll i anc e if the sc r ew i s at gr ound

potential (s ee Figure 3).

Figure 3. Checking for earth

ground.

8

SYSSET

Page 9

2018/05/0404:12:02(GMT+09:00)

1-7. Lead Free Information

The circui t boar ds us ed i n thes e models have been proc ess ed using

Lead Free Solder. The boards ar e identified by the LF logo located

close to the board designat ion.

The servicing of these boards requir es speci al precauti ons. I t is

strongly r ecomm ended to use Lead Free Sol der mater ial i n order to

Figure 4: LF Logo

Figure 5: LF logo on circuit board

guarantee optimal qualit y of new solder j oints.

9

SYSSET

Page 10

2018/05/0404:12:02(GMT+09:00)

1-8. FFC Handling Caution

10

SYSSET

Page 11

2018/05/0404:12:02(GMT+09:00)

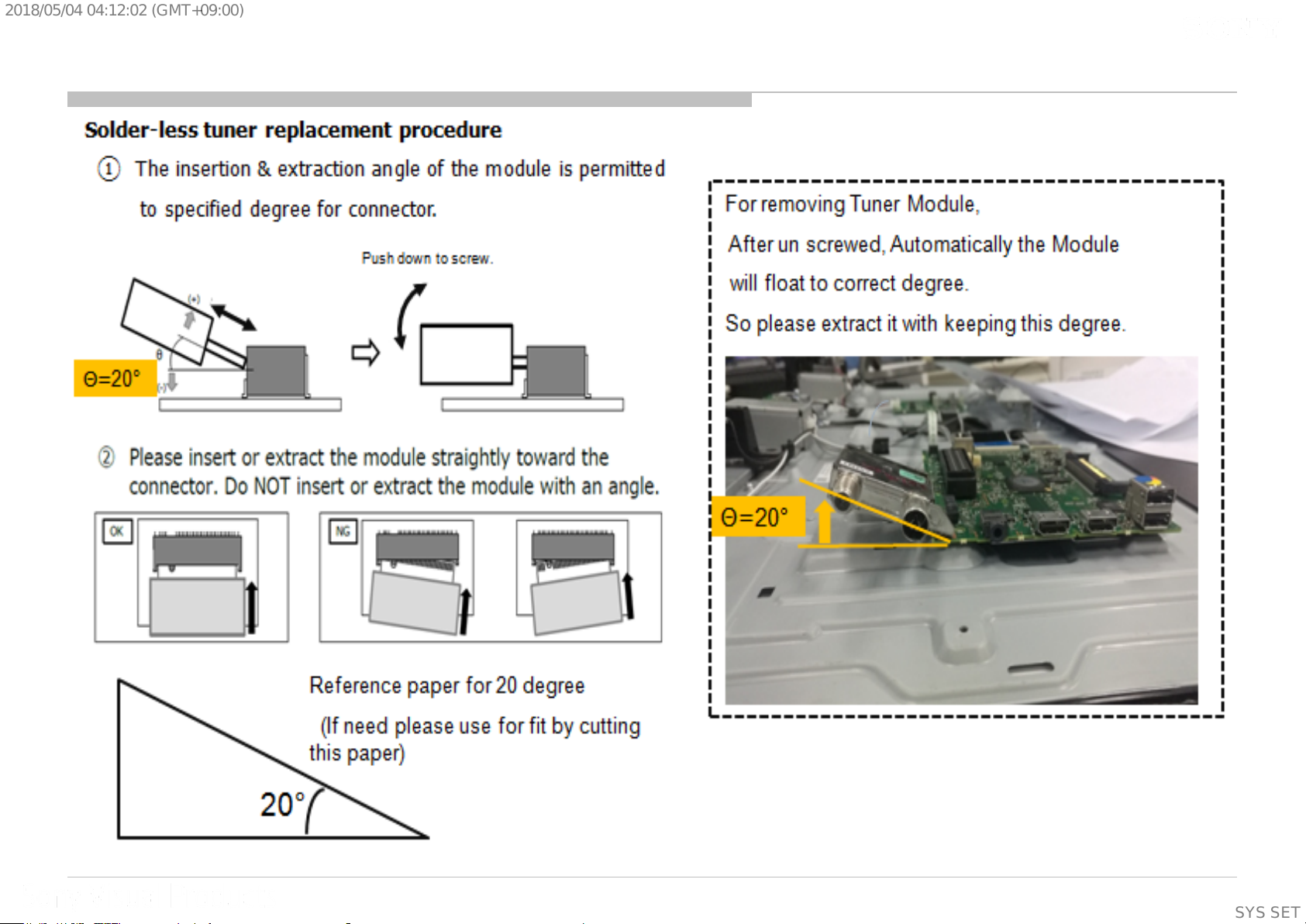

1-9. Solder-less Tuner Replacement

11

SYSSET

Page 12

2018/05/0404:12:02(GMT+09:00)

The units i n t his m anual cont ain a self-diagno sti c function. If an error oc cur s , the Smart C or e R ed LED w i ll automatical l y begin to flash.

The number of times the LED flashes tr anslates to a probable sour ce of the problem .

A definition of the Smar t Core Red LED flash indi cators is listed in the instr uction manual for the user’ s knowledge and reference.

If an error symptom cannot be reproduc ed, the rem ote com mander can be used to review the failure oc curr ence data stored i n memory to

reveal past problems and how often these problems occur .

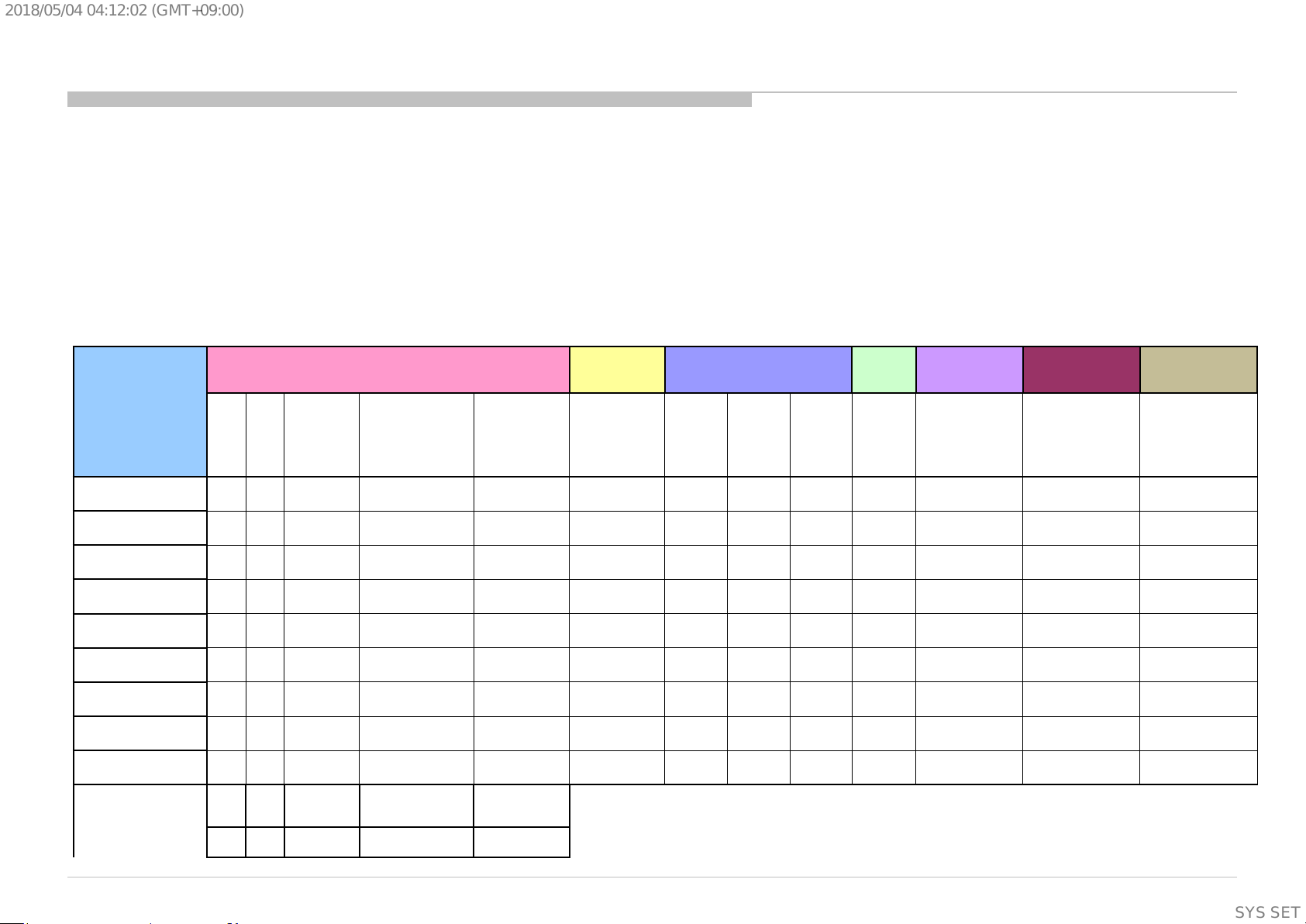

DIAGNOSTIC TEST INDICATORS

When an error occurs , the Smar t Cor e Red LED will flash a set number of times to indi cate the possi ble cause of the pr oblem.

If there is more than one err or, the LED wil l identify the first of the problem areas.

Result for all of the following diagnosti c item s are displ ayed on screen.

If the scr een di s play s a “0”, no er r or has occ ur r ed .

SECTION 2

SELF DIAGNOSTIC FUNCTION

Status

LED Colour

Remarks

LED Indicator

• Lights up in white when you select “Picture Off”.

• Lights up in amber when you set the timer or

“Photo Frame Mode”.

• Lights up in white when the TV is turned on.

• Flashes while the remote is being operated.

Amber = Red + Green

Power Off

( AC Off and *1)

Power On

Standby

( by remote control

off and Side Key

off)

Picture Off

Set "Sleep Timer"

Set "On Timer"

( Power On )

Set "On Timer"

( Standby )

Picture Frame

Failure

Error of panel ID

Software Updating

Software Updating

failure

OFF

White

OFF

White

Amber

Amber

Amber

Amber

Red Blinking

Amber / Green Blinking

Amber Blinking

Amber / Red Blinking

*1 power switch off (by

Side Key)

The number of LED

blinking indicates cause of

failure.

Blinking:0.5sec Amber/

0.5sec Green

Blinking: 1sec On / 1sec Off

Blinking:1 sec Amber/ 1sec

Red

12

SYSSET

Page 13

2018/05/0404:12:02(GMT+09:00)

Failure LED Display

The Number of Standby LED

(RED blinking)

2 Main Power Error

3 Audio Error Main Board

4 Panel Power Error Main Board

5 Panel I2C Communication Error Main Board or Source Board

6 Backlight Error Main Board

Error Detection Error Location

AC Adaptor or Power Supply

Unit

Tuner Demod Error do not go to Safety Shutdown and do not have RED blinking.

Error Detection Symptoms Error Location

Tuner Demod Error Cannot tune Digital RF/ Analog RF Main Board/Tuner Module

13

SYSSET

Page 14

Before you make the service call…

1. Confirm the symptom from the customer.

2. Select that symptom from the chart.

3. Bring all the boards and cables listed for that symptom .

4. Follow the troubleshooti n g charts in the technical guides to isolate the board.

5. Chart

RED

BLUE

BLACK

No White Power

LED & does not

Stationary

dots

2018/05/0404:12:02(GMT+09:00)

Triage Char t

Colour Code

DOT: Most likely defective part

TRIANGLE: Secondary possible defective part

TEXT: Board that may correct the symptom

SECTION 3

TROUBLESHOOTING

Symptoms - Shutdown. Power LED

blinking red diagnostics sequences

No

Power

Reference

2 3 4 5 6

B* Board

G* Board

H* Board

Speaker

Wifi Module

LD* Board

VBO FFC

Tcon/Source

Board

LCD Panel

Problem

Power Power

Audio

LD

Panel

(Communication)

Panel

(Backlight)

reponse to

remote (Dead

Set)

- missin g or distorte d

colored

lines o r

Video

No video

One of

Inputs

No video

all Inputs

Remote Network Audio Smart Core

No Remot e

Wireless

can't connect

No Audio

Smart Core no LED

(Se t is still a liv e)

14

SYSSET

Page 15

2018/05/0404:12:02(GMT+09:00)

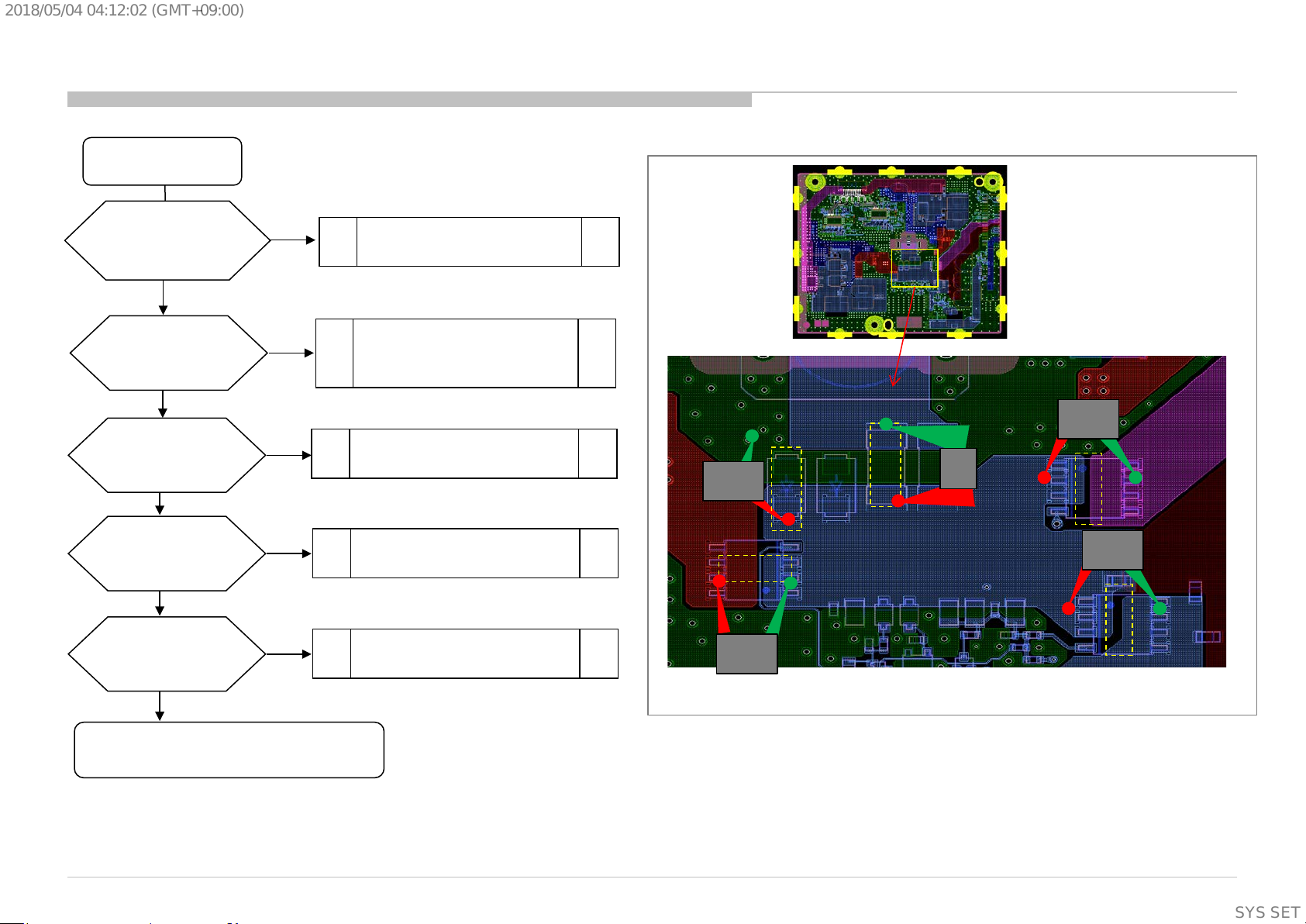

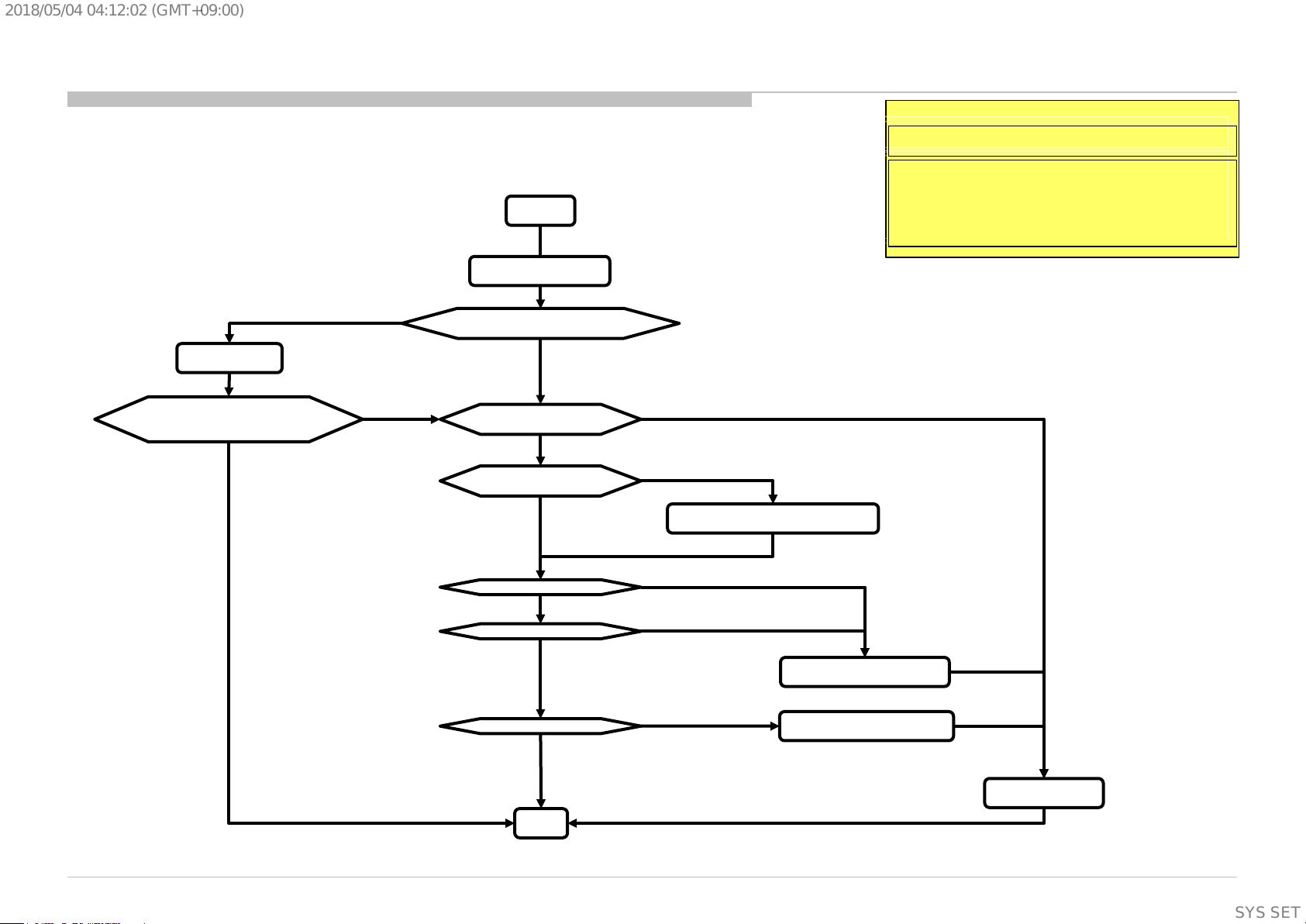

3.1 No power - LD board

START

LD board

1. Check fuse imped a n ce

F1001

Is < 1ohm ?

yes

2. Check impedance

D1001 to GND

Is > 1kohm?

yes

3. Check MOSFET

Q1007

Is > 1kohm?

yes

4. Check MOSFET

Q1002

Is > 1kohm?

yes

5. Check MOSFET

Q1008

Is > 1kohm?

no

no

no

no

no

Fuse F1001 broken

Diode D1001 broken

MOSFET Q 1007 Brok en

MOSFET Q 1002 Brok en

MOSFET Q 1008 Brok en

2

Q1007

3

4

F1001

D1001

1

Q1002

5

Q1008

yes

Check B board

15

SYSSET

Page 16

2018/05/0404:12:02(GMT+09:00)

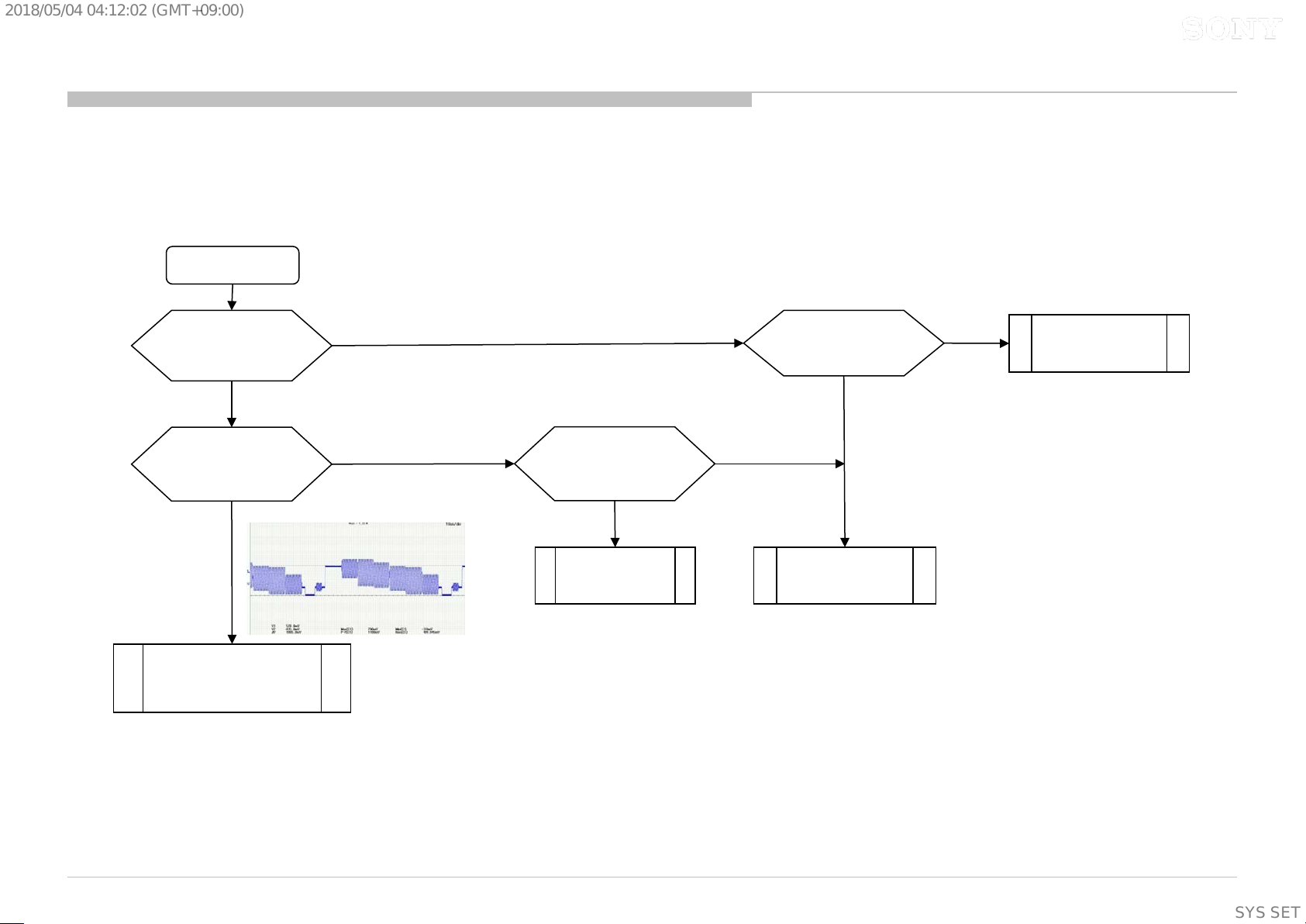

3.1 No power - LD board

12V DDCON check

START

Check fuse F1000

Is < 1ohm

yes

Check Input to GND

Is > 1k ohm?

yes

Check Input to Output

Is > 1k ohm?

yes

Check Output to GND

Is > 1k ohm?

yes

Check 12V

C1016 voltage

Is voltage <12V?

yes

Check EN POWER_ON

R1003 voltage

Is voltage >2.5V?

yes

Check Vcc

C1009 voltage

Is voltage >5.0V?

yes

no

no

no

no

≥ 12V

no

no

Fuse F1000 broken

DDC IC1000 broken

DDC IC1000 broken

DDC IC1000 broken

Check B-Board

Troubleshooting flow 1.2

IC1000 broken

12V_TCON check

yes

Check 12.5V_TCON

Is voltage > 12.0V?

no

Check TCON_O N

C1024

Is voltage > 3.0V?

yes

Check MOSFET

Q1006

Is > 1kohm?

yes

12V power OK

Check other troubleshooting flow

END

no

no

Main device failure

Q1006 broken

Check point on PWB refer next slide

16

SYSSET

Page 17

2018/05/0404:12:02(GMT+09:00)

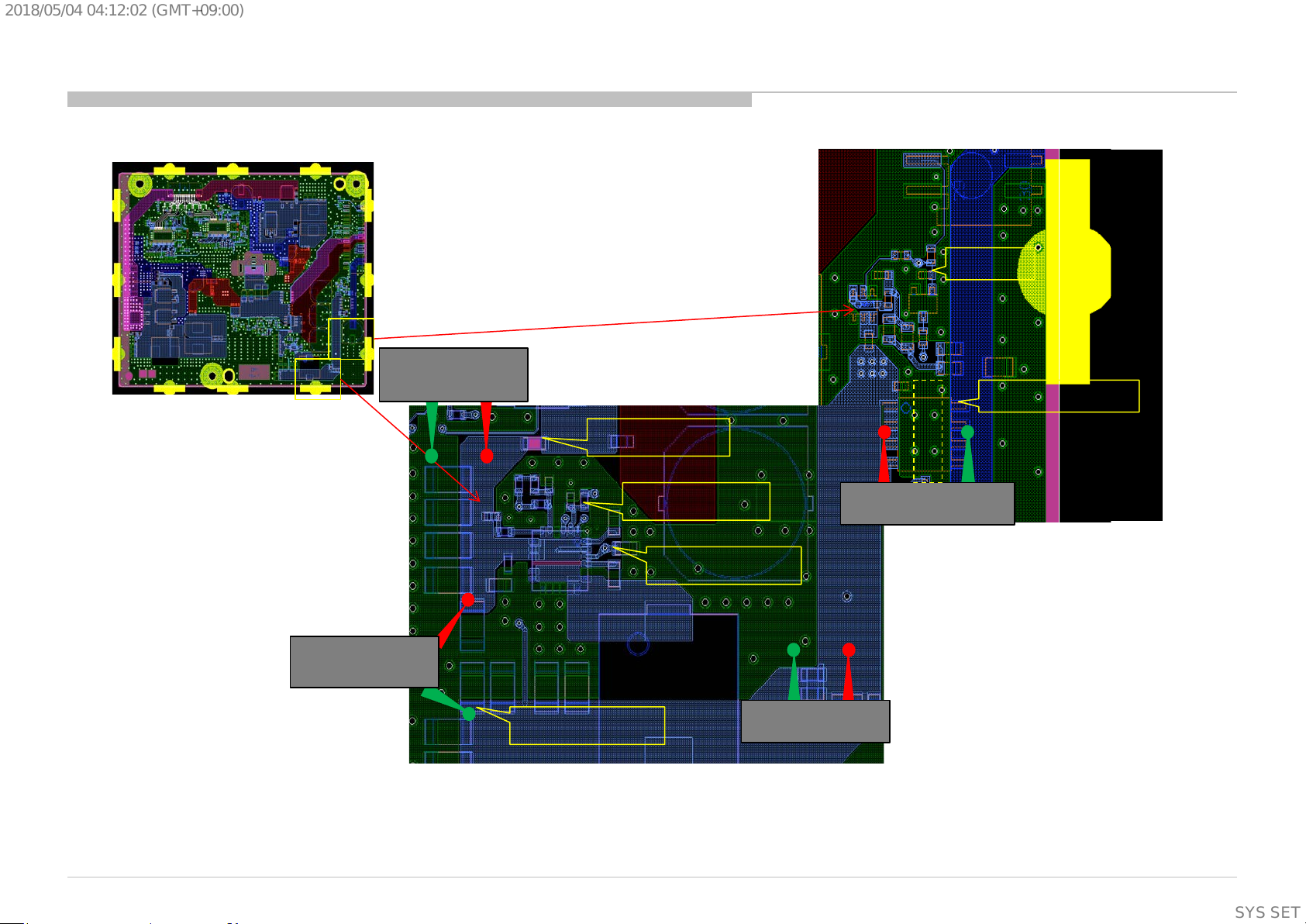

3.1 No power - LD board

Input t o G N D

Impedance check

C1024

+12.5V_TCON

Input t o O ut put

Impedance check

C1016

F1000

R1003

C1009

Q1006

Impedance check

Output to GND

Impedance check

17

SYSSET

Page 18

2018/05/0404:12:02(GMT+09:00)

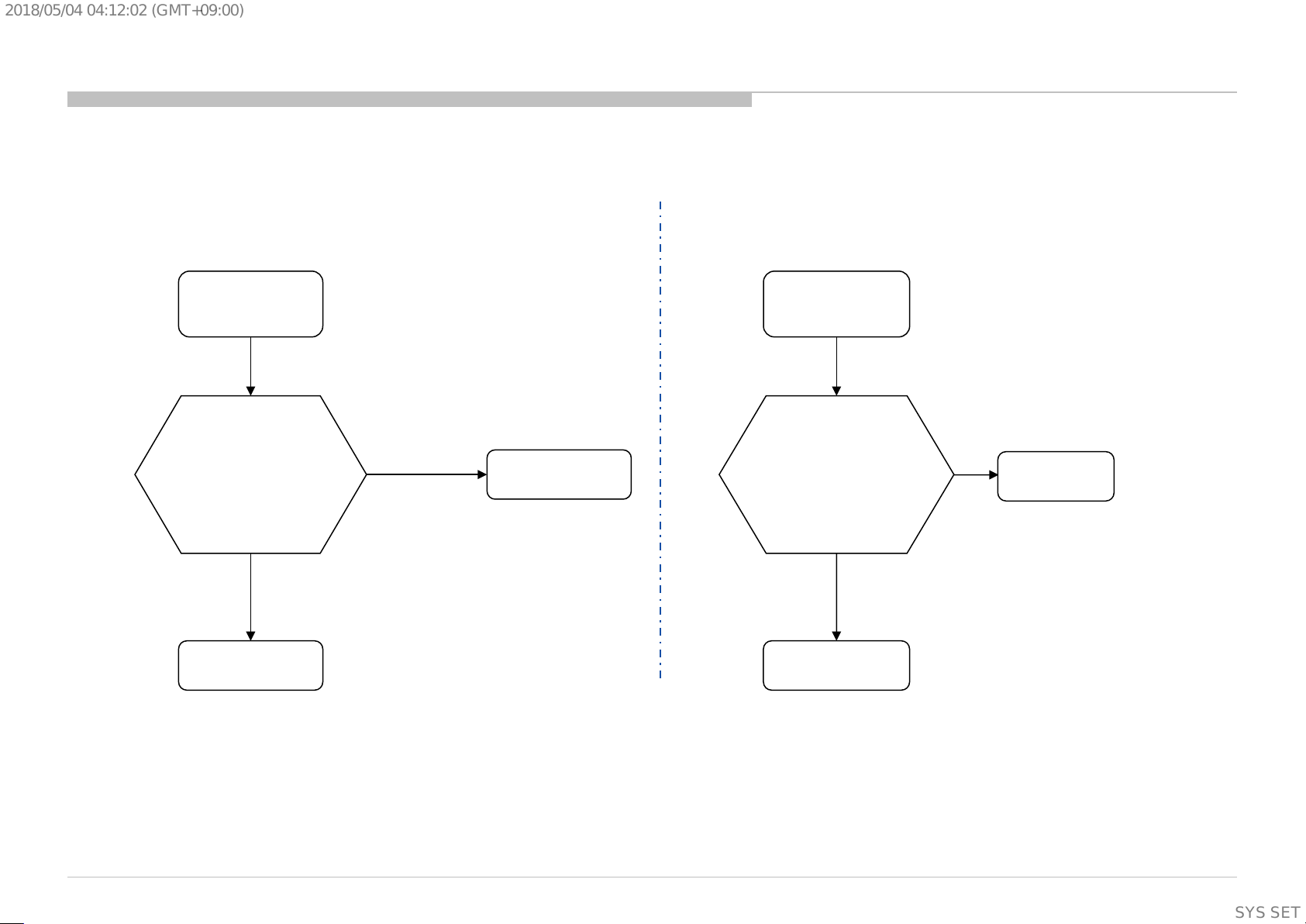

3.2 LED Blink ing: 2x (Main power E rror - Operating Chart )

BB9(G* Board mode l) BB9(AC adapter model)

23V

13.2V

12.2V

16.44V

18

SYSSET

Page 19

2018/05/0404:12:02(GMT+09:00)

3.2 LED Blink ing: 2x (Main power E rror)

BB9(G* Board model)

2-time blinking

Check “+19.5_12.5V_MAIN”

at pin 15/16 of CN 5500

on BB9 Board,

Voltage 12.2V -13.2V?

*Typical 12.7V*

No

Yes

G* Board

BB9(AC adapter model)

2-time blinking

Check “+19.5_12.5V_MAIN”

at pin 15/16 of CN 5500

on BB9 Board,

Voltage 16.44V – 23V ?

*Typical 19.5V*

No

Yes

LD Board

BB9 Board

BB9 Board

19

SYSSET

Page 20

2018/05/0404:12:02(GMT+09:00)

3.2 : 2x Blinking – Main Power Error

LD Board

2 times

Blinking

LD-Board

Check DC voltage at

Q1002

18V – 20V?

*Typical: 19.5V

Yes

Change LD-

board

No

Adaptor

Take out adaptor

and check the output voltage.

18V – 20V?

(Refer Figure 1)

*Typical: 19.5V

Yes

Change LD-

Board

No

Change

Adaptor

-ve

+ve

Ensure that +ve

probe is touching

the needle.

Figure 1: How to check adaptor’s output voltage.

TV Business Division

(Supplementary

information)

20

SYSSET

Page 21

2018/05/0404:12:02(GMT+09:00)

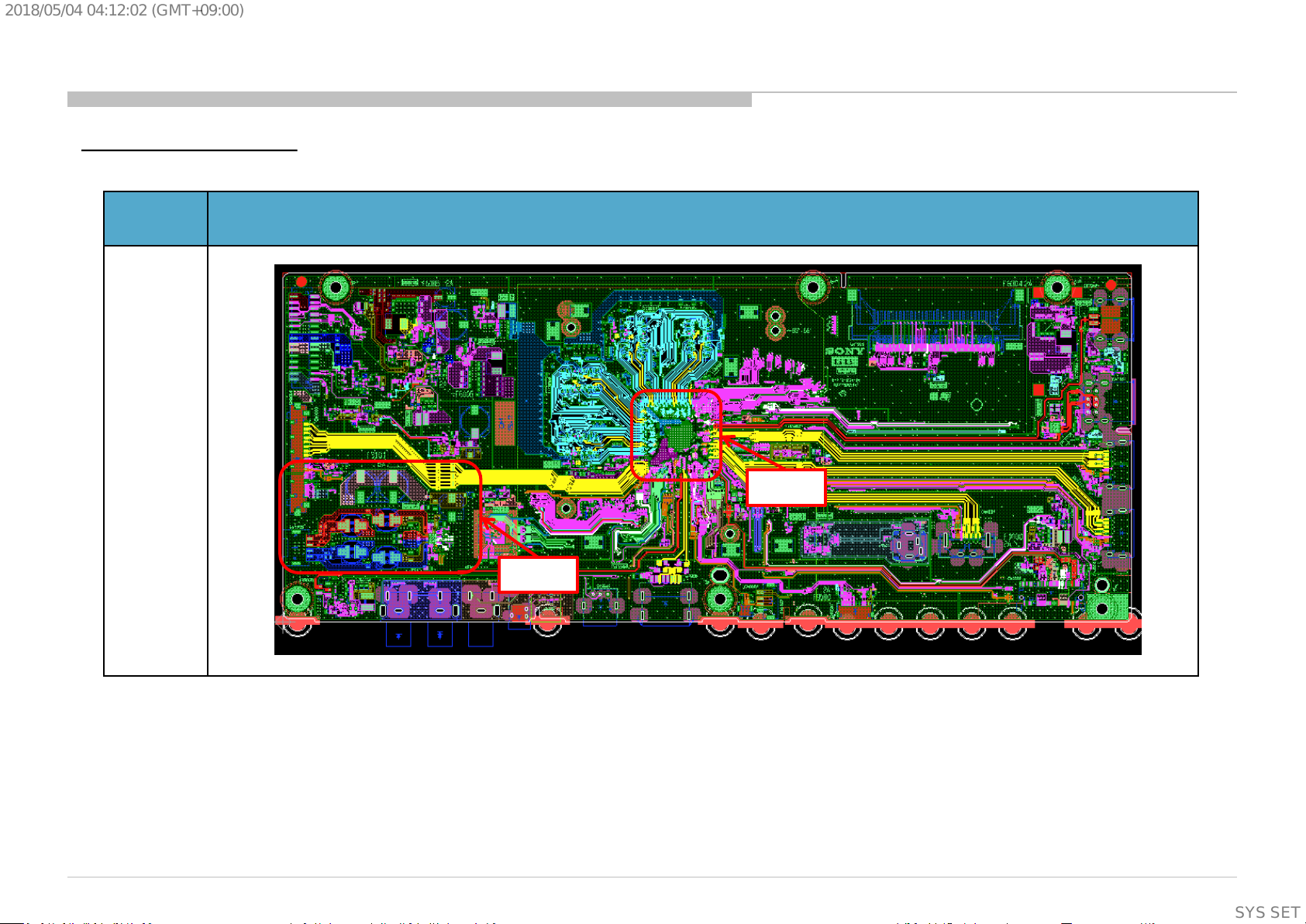

Check point LD1

Board

Name

LD1

(Q1002)

Board PWB (A side) Detail

Q1002

19.5V

(Supplementary

information)

21

SYSSET

Page 22

2018/05/0404:12:02(GMT+09:00)

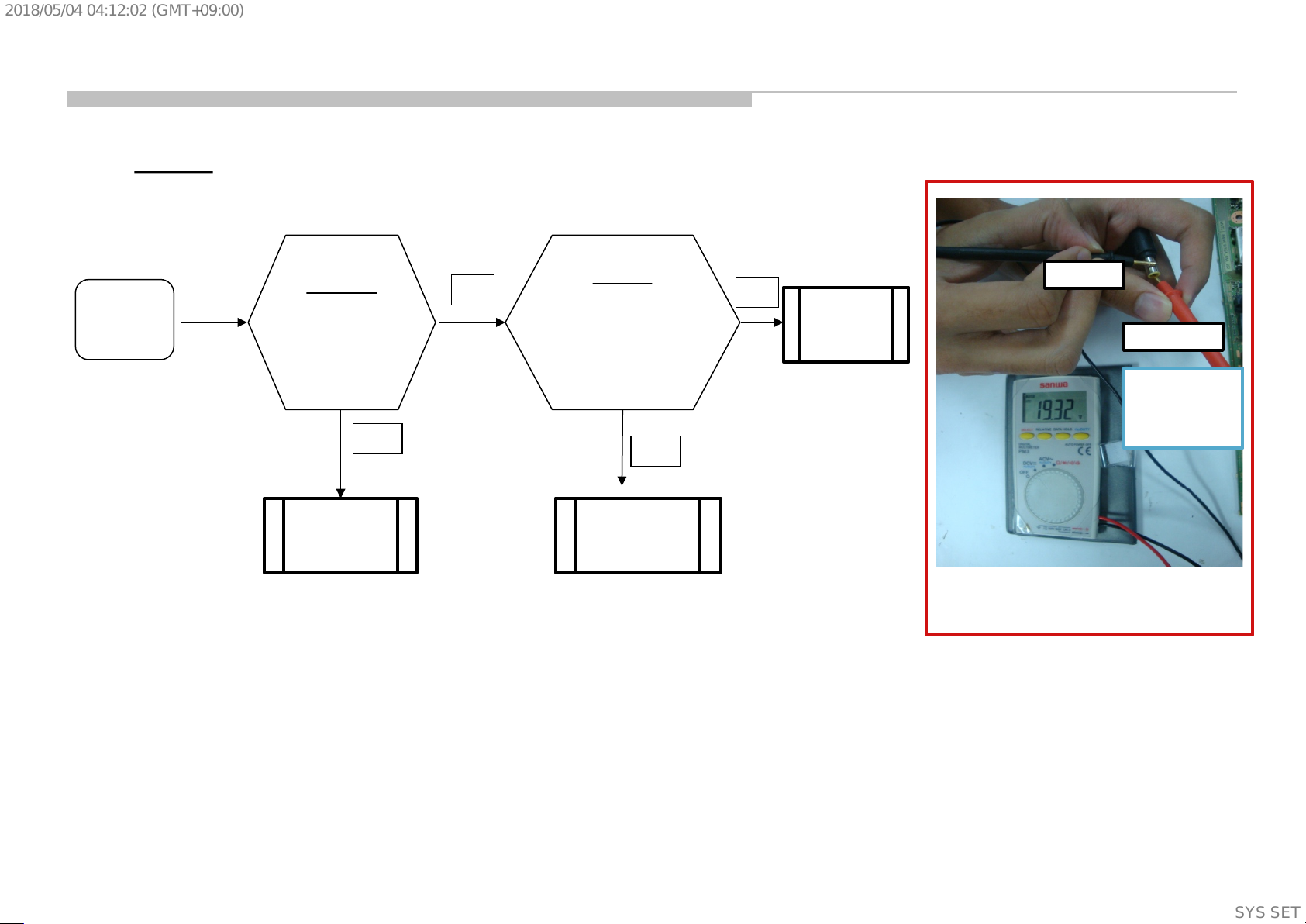

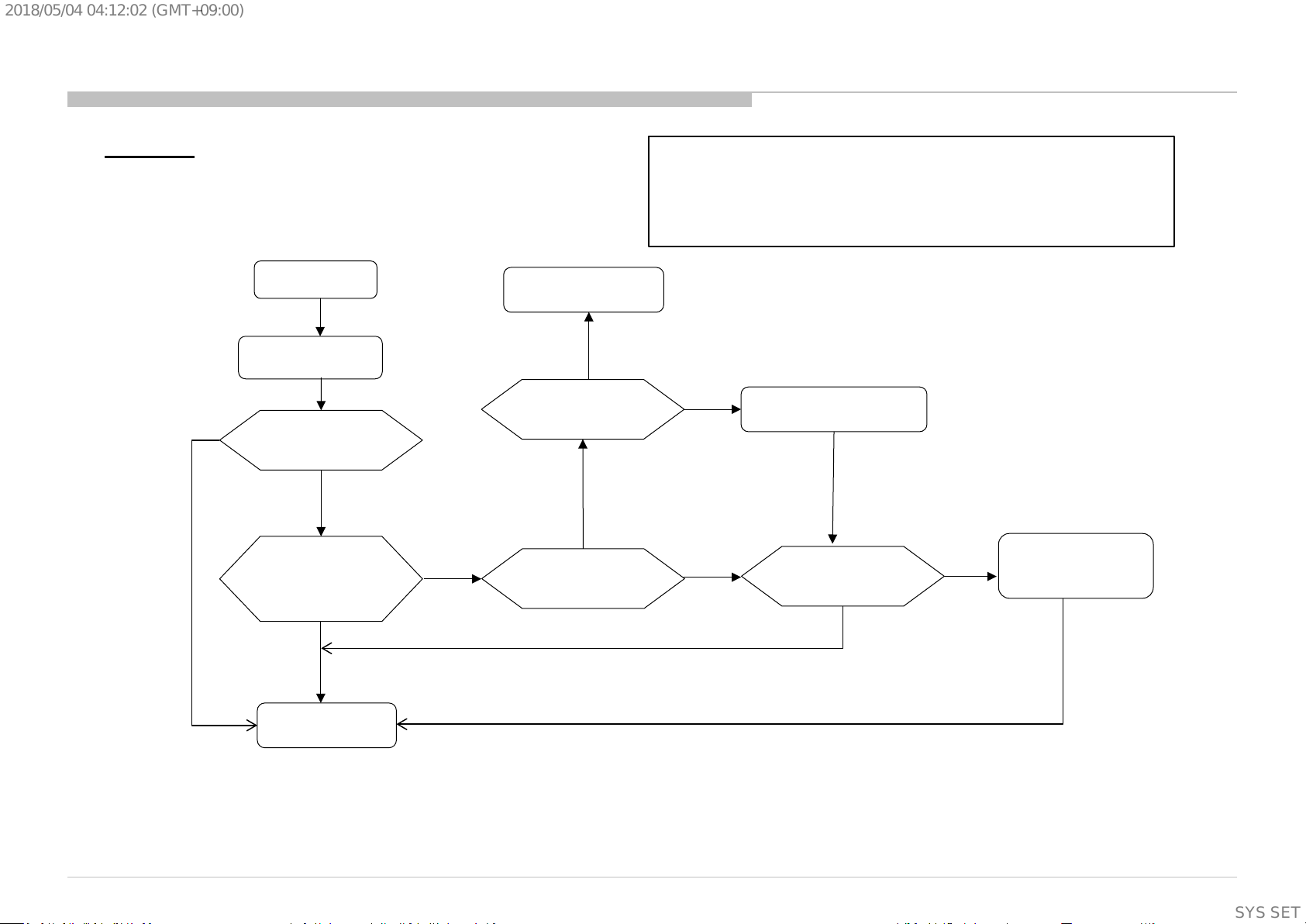

3.3 : 3x Blinking – Audio Error

B Board

B-board Audio Error pin

short to GND

No connectivity of F3101

F3101 broken,

Replace F3101

3x blinking & F3101 OK

START

3x blinking

Check correct Option bit is set?

Correct Option bit & 3x blinking

Disconnect pow er supply

and check Aud i o E rror p i n

Audio Error pin no short to GND

Remove Speaker Connecto r

at CN3109 and

perform AC OF F - ON

3x blinking

Check connecti vit y

of F3101

3x blinking & F3101 OK

Wrong Option bit

3x blinking

No 3x blinking

3x blinking

Important Note :

TV must be power OFF condition before

plug or unplug any of the

FFC/FPC/wire/cable from the board. ->

This is to prev en t possib ili ty c ir cu it

damage happen.

Set correct Option bit and

perform AC OF F - ON

Check Speaker harnes s and

Speaker impedance

Speaker harness

shorted

Change Speaker

Harness

No 3x blinking

Main Speaker

Impedance ≠ 6~8 Ω

Change Main

Speaker

No 3x blinking

#Audio IC (IC3101) problem

Change B-board

DONE

Connect back

Speaker Connector

to CN3109 and

perform AC OF F - ON

No 3x blinking

(Supplementary

information)

22

SYSSET

Page 23

2018/05/0404:12:02(GMT+09:00)

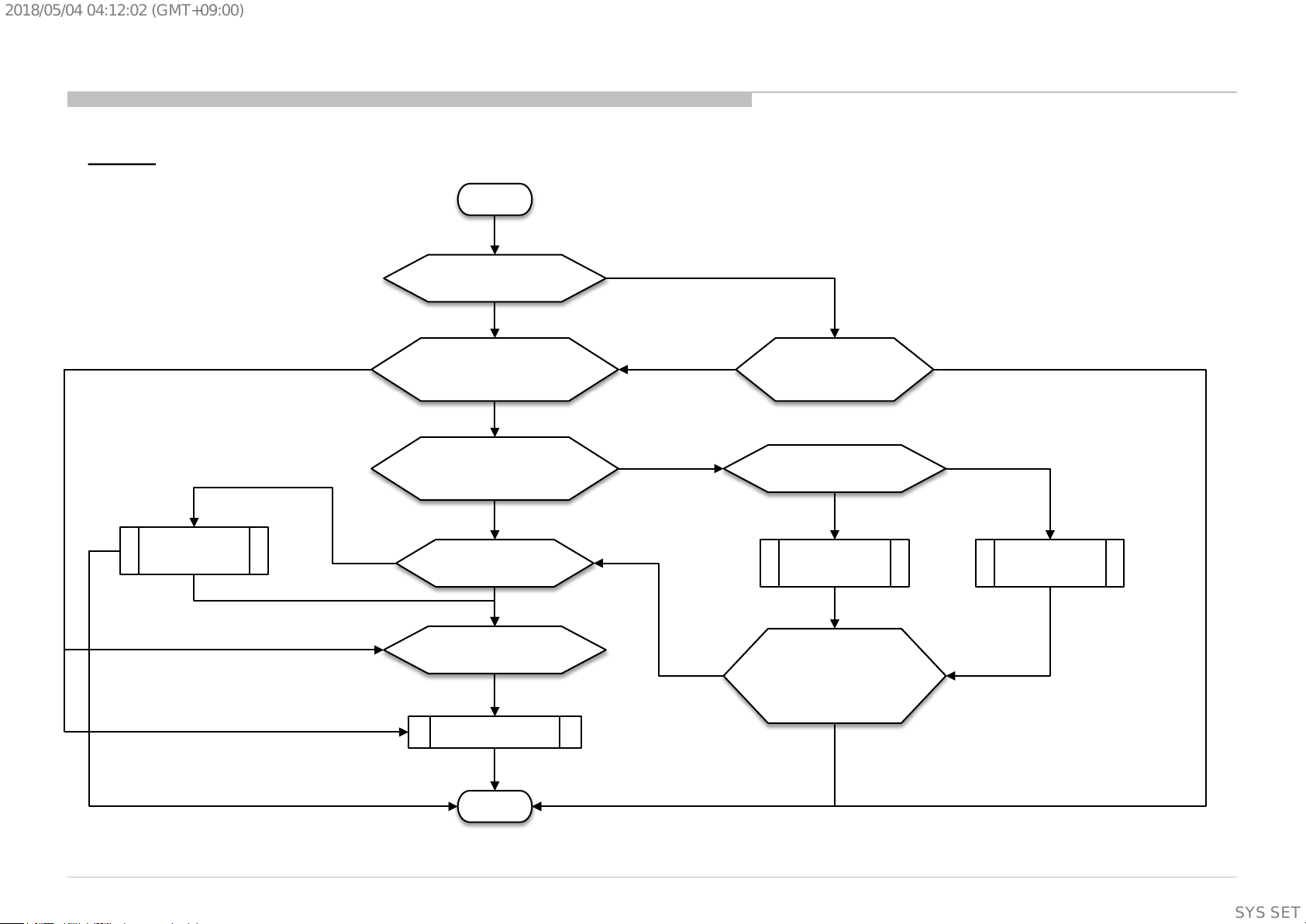

3.3 : 3x Blinking – Audio Error

B Board

(#Audio I C (I C 3 101) problem)

START

#Audio IC (IC3101) problem

3x blinking and F3101 OK

Check Audio IC pins and surrounding part,

Replace the NG part if have any

(For example, fuse broken, e.capacitor blow,

c.capacitor short connection,

inductor open connection and etc.)

3x blinking

Check have any burn mark on Audio IC,

If have burn mark, replace the NG Audio IC

Important Note :

TV must be power OFF condition before

plug or unplug any of the

FFC/FPC/wire/cable from the board. ->

This is to prev en t possib ili ty c ir cu it

damage happen.

No 3x blinking

No 3x blinking

3x blinking

Change B-board

DONE

(Supplementary

information)

23

SYSSET

Page 24

2018/05/0404:12:02(GMT+09:00)

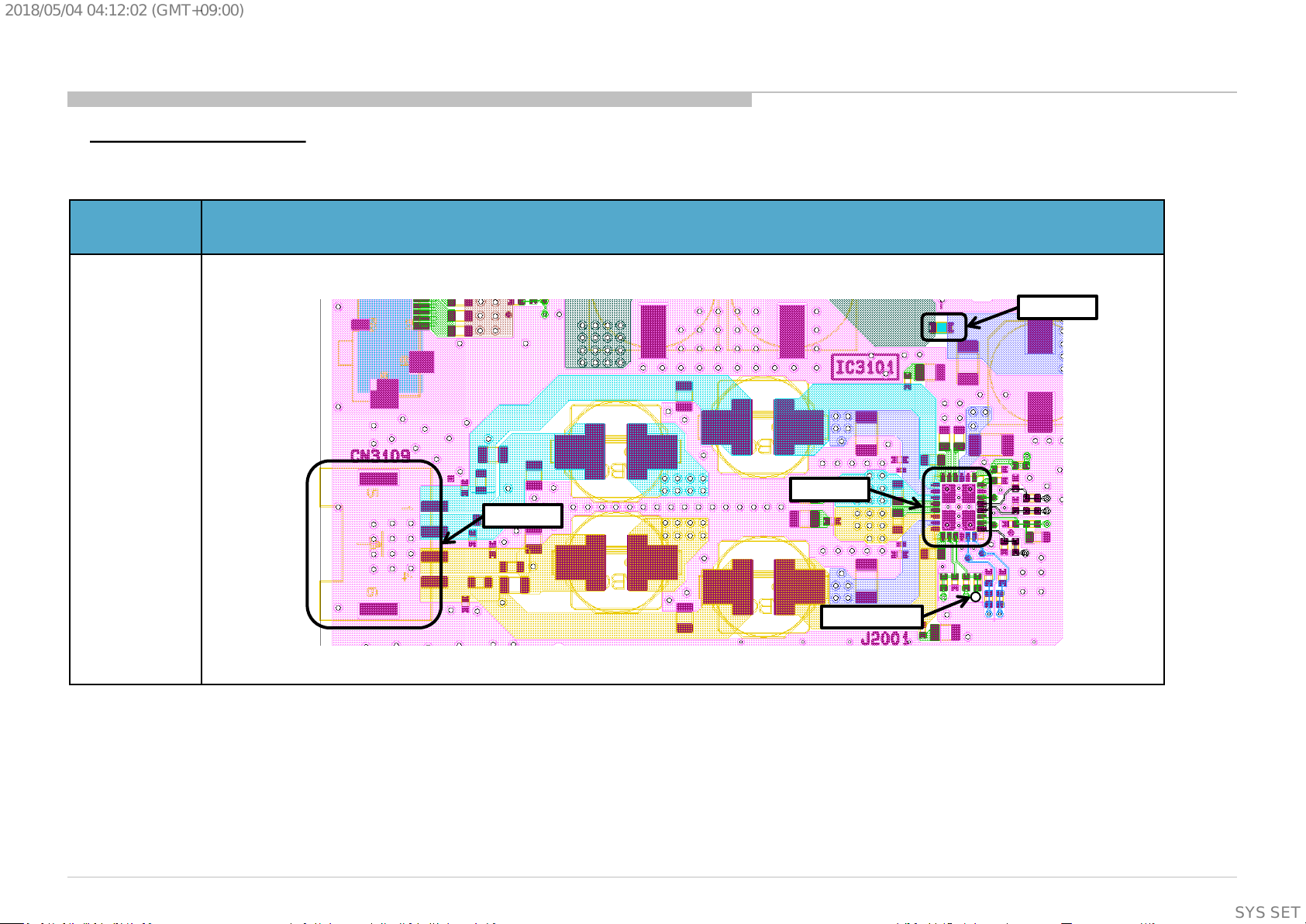

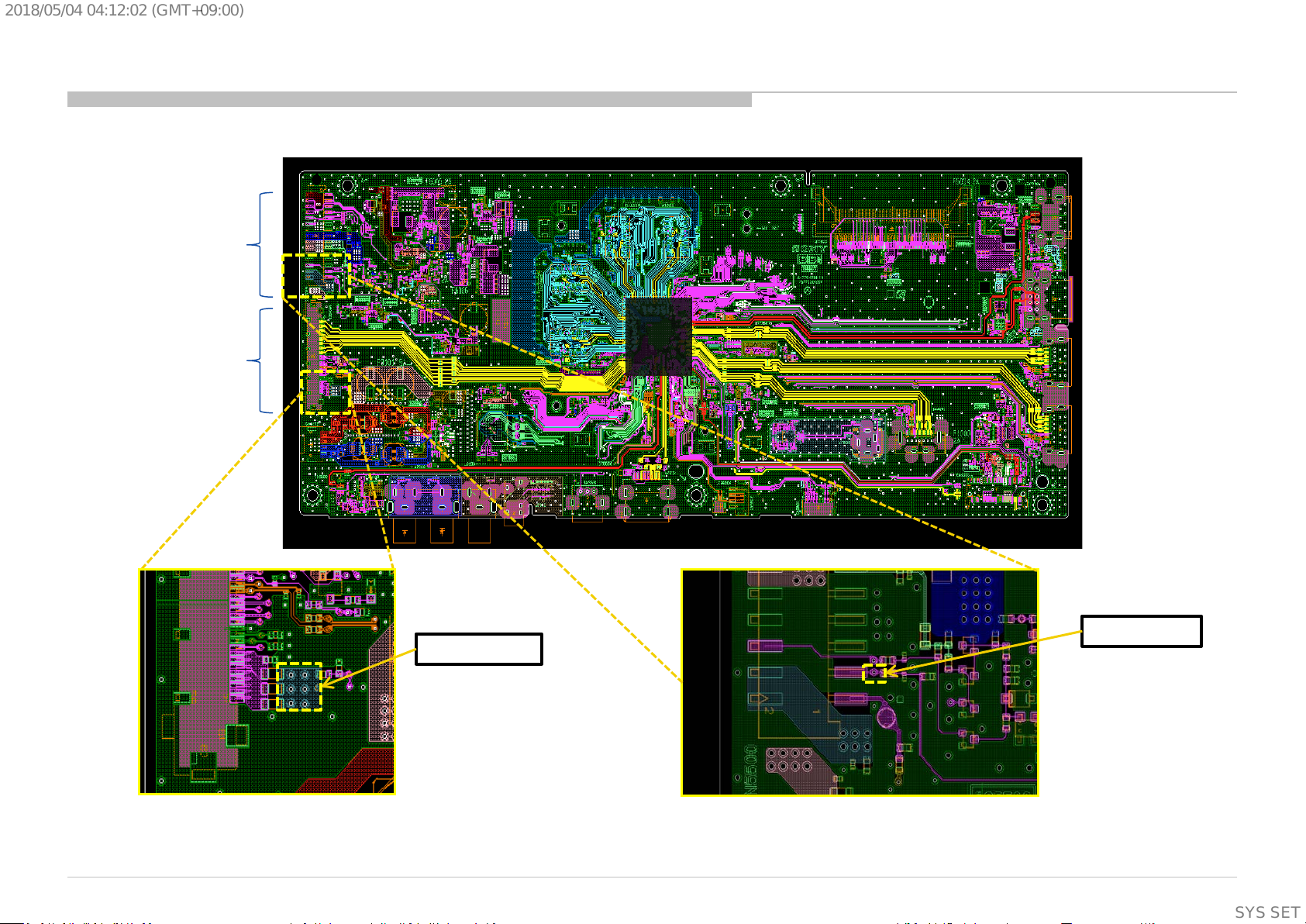

3.3 : 3x Blinking – Audio Error

B Board (Checking Point)

Board PWB

(A side)

Purpose :

Checking Audio

Error pin not

short to GND

Checking fuse

condition

Change Audio IC

if need

Audio IC each pin

checking, please

refer to “Audio

No Sound”

BB9 (CHL) - Audio A mp circuit

F3101

IC3101

CN3109

Audio Erro r pi n

(Supplementary

information)

24

SYSSET

Page 25

2018/05/0404:12:02(GMT+09:00)

3.3 : 3x Blinking – Audio Error (Back up)

B Board (Checking Point)

Board PWB

(A side)

BB9 (CHL)

Main IC

(IC5000)

Audio Amp

circuit

(Supplementary

information)

25

SYSSET

Page 26

2018/05/0404:12:02(GMT+09:00)

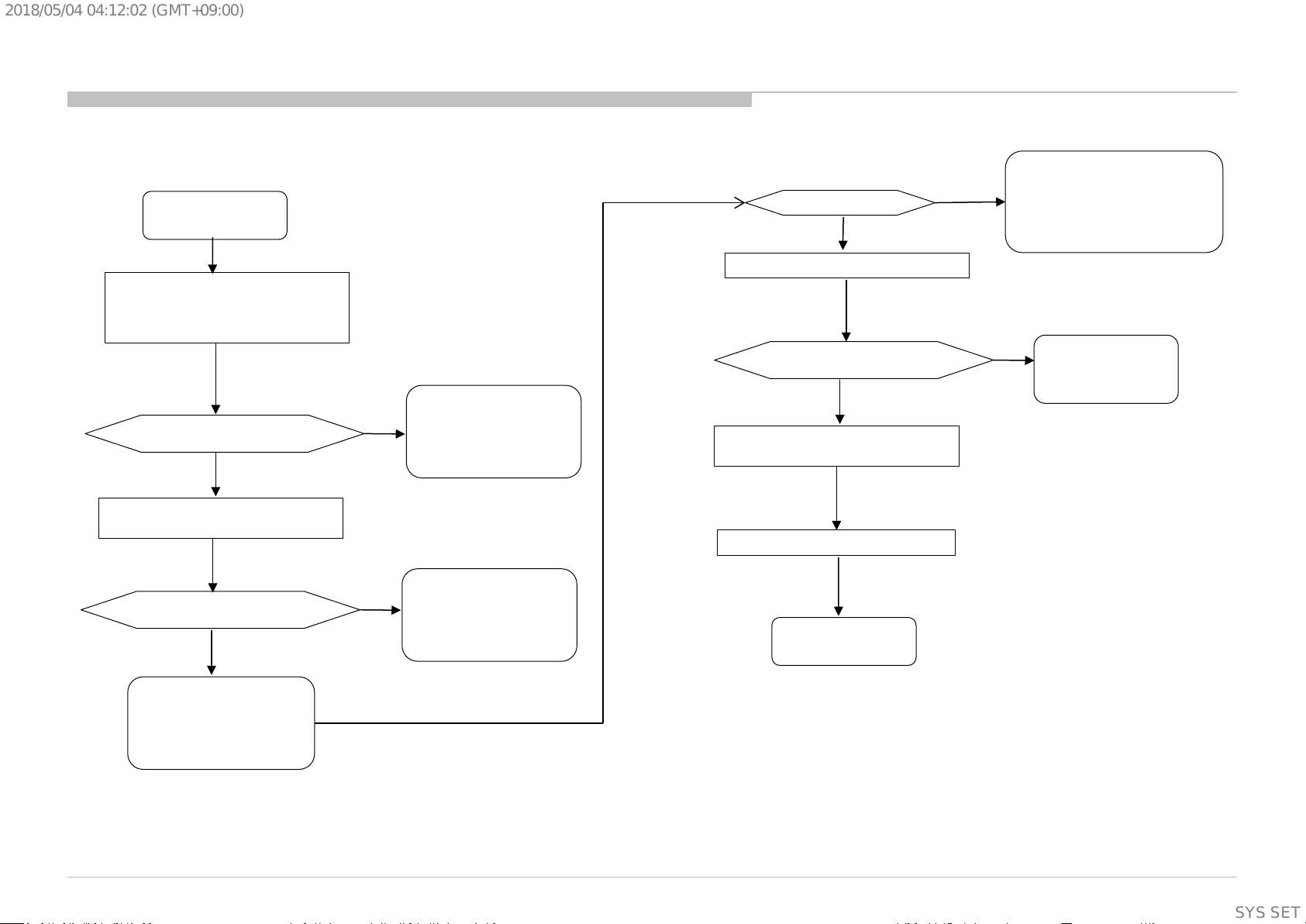

3.4 : 4x Blinking – Panel Power Error

BB9 Board

Yes

Start

*Check Adaptor /

G board connection

TV boot up normally?

No

Check voltag e at

+12.5V_TCON

10.8V-13.2V

No

RC ON

Yes

TV in standby mode?

No

Check PANE L_PWR

3.00V-3.33V?

*Check Adaptor / G-board connection

CHL 43/49 = LD board & Adaptor

CHL 55/65 = G-board

Adaptor: Remove and reinsert Harness from LD board Main board

G-board: Remove and reinsert Harness from Gboard Main board

No

Replace Main IC / B-Board

Yes

Check +12.5V_TCON

10.8V-13.2V?

No

Suspected LD board / G

Board side issue.

Replace PSU uni t board

Yes

End

(Supplementary

information)

26

SYSSET

Page 27

2018/05/0404:12:02(GMT+09:00)

BB9 layout

30pin PSU/LD

Connector

51pin LVDS C onnec tor

SoC

+12.5V_TCON

TV Business Division

PANEL_PWR

27

SYSSET

Page 28

2018/05/0404:12:02(GMT+09:00)

3.5 : 5x Blinking – P anel I2C Error

START

Reinsert LVDS 51pin Flat

Flexible Cable (FFC) at B-Boar d and

Panel Side. Make sur e F FC is t aped

properly.

5 Times Blinking happen?

YES

Replace LV DS 51 pin Flat Flexible

Cabl e (FFC )

5 Times Blinking happen?

YES

No

No

TV set is OK now

NG Symptom:

Incorrect FFC Ins ertion

TV set is OK now

NG Symptom:

LVDS Cable NG

Is 10.8 – 13. 2V available?

YES

Replace B-Board

5 Times Blinking happen?

YES

Replace

O-Cell* or Panel M odule*

TV Boots Up Normally

END

NO

TV set is OK now

NG sympton:

LD board/ G board

no +12.5V_TCON supply

No

TV set is OK now

NG Symptom:

B-Board Is su e NG

* O-Cell or Panel

Module replacement

depends on ser v ice

capabilities

Check voltage at +12.5V_T CO N

28

SYSSET

Page 29

2018/05/0404:12:02(GMT+09:00)

BB9 layout

30pin PSU/LD

Connector

51pin LVDS C onnec tor

SoC

+12.5V_TCON

29

SYSSET

Page 30

2018/05/0404:12:02(GMT+09:00)

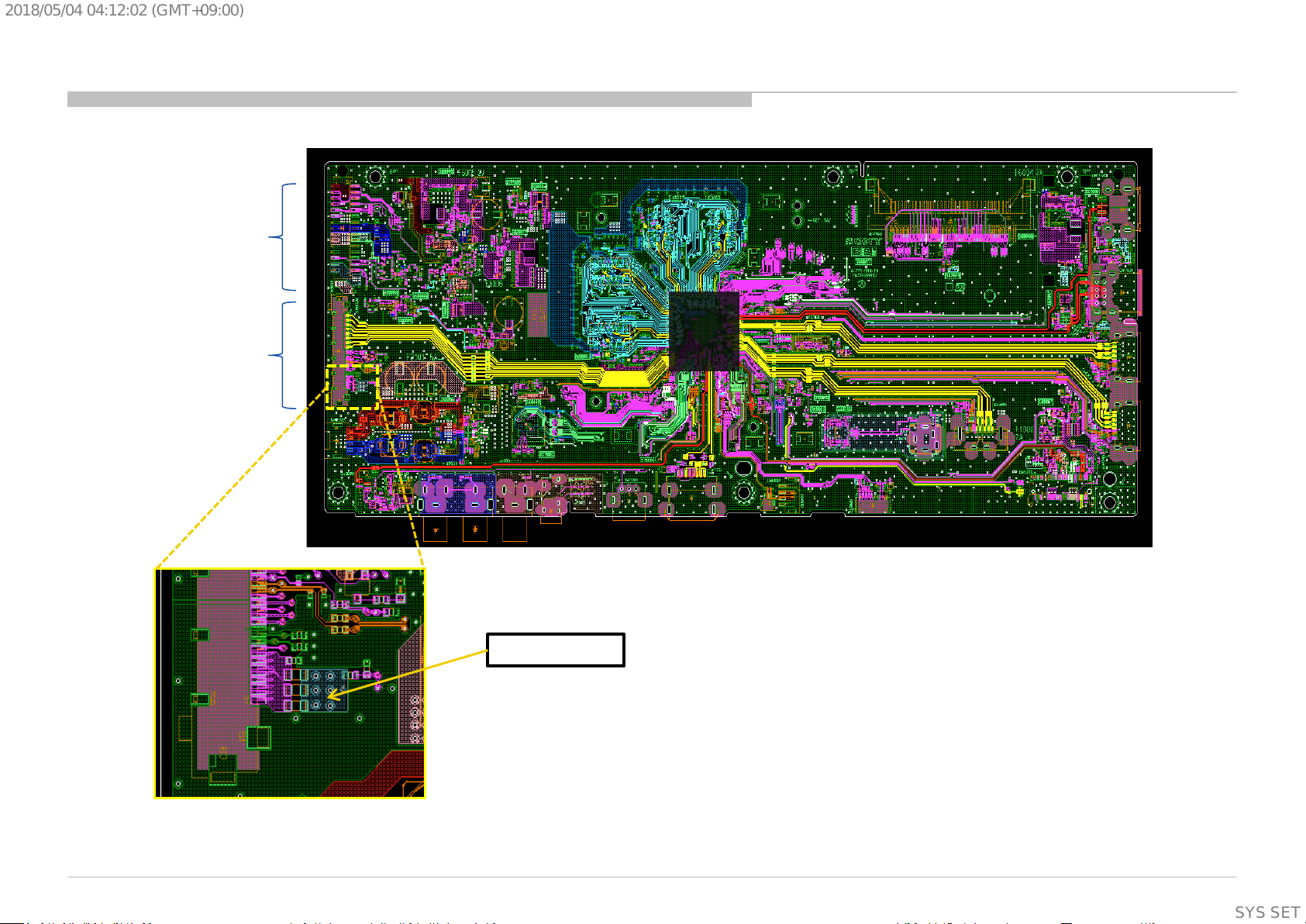

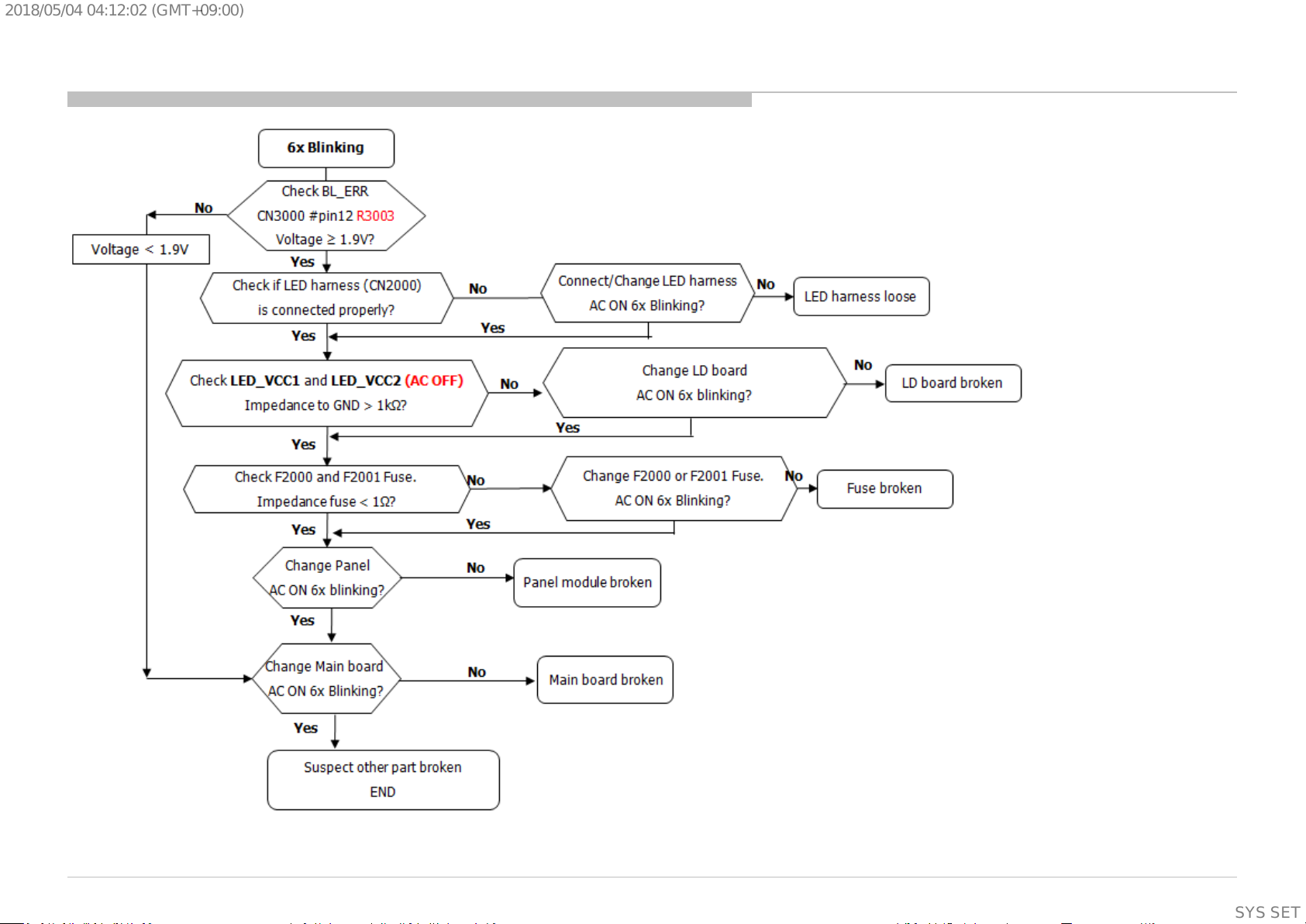

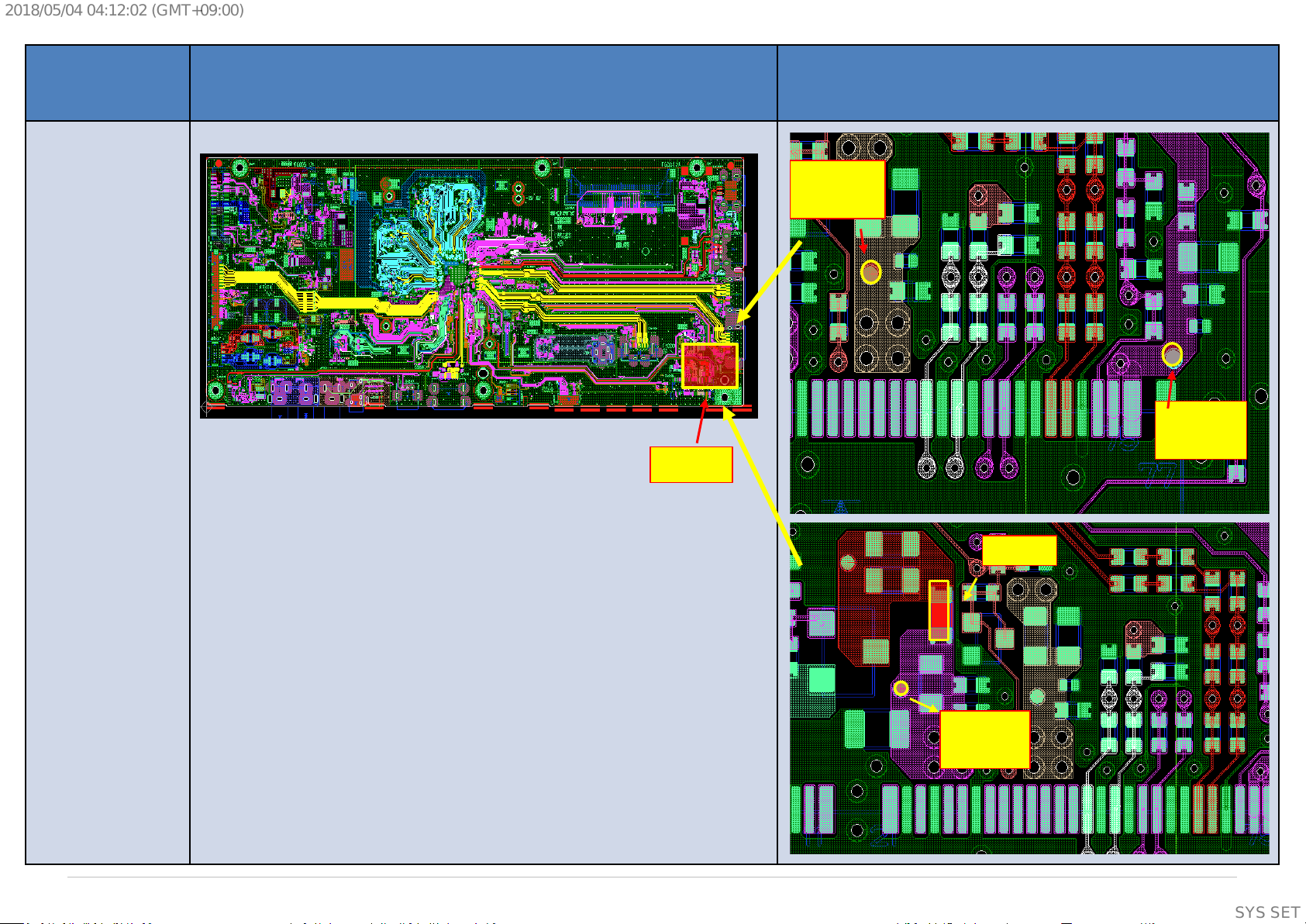

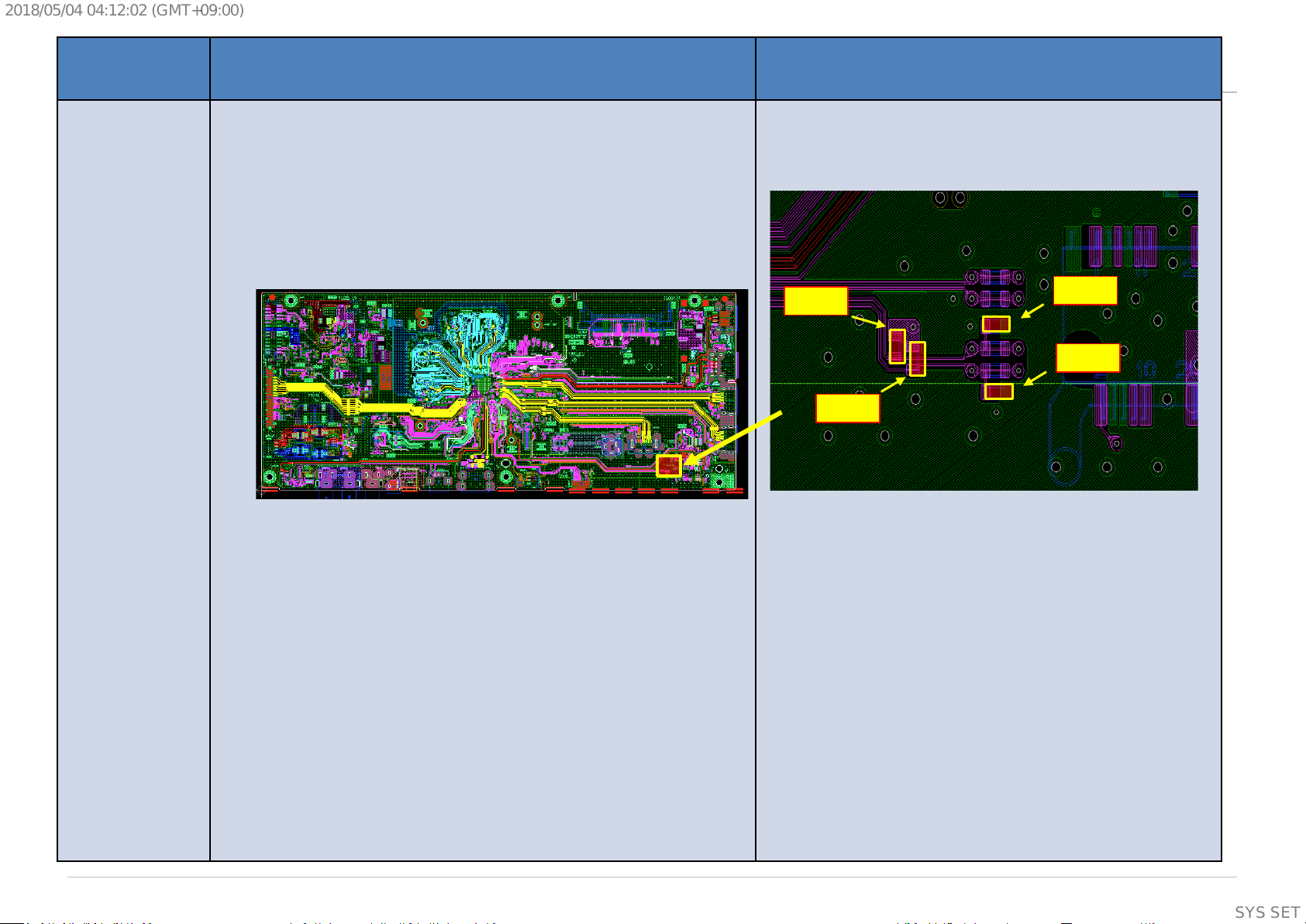

3.6 6x Blinki ng back l ight error

Check point on PWB refer next slide

30

SYSSET

Page 31

2018/05/0404:12:02(GMT+09:00)

3.6 6x Blinking backlight error

31

SYSSET

Page 32

2018/05/0404:12:02(GMT+09:00)

3.7 Blank Screen, Backlight Visible

No Picture

Got Any Abnormal

Display?

Yes

Check Other

Portion:

Tuner - No Picture

Check Smart Core

LED Indication

No

Troubleshoo ting manual

Ext. Video Input -

No Picture

HDMI - No Picture

(5x Blinking)

Refer 5x Blinking

Yes

No

Replace

the V by One FFC

Harness

OK

V by One FFC

Harness NG

NG

Replace

the main Board

OK

Main board NG

NG

Replace

LD/G Board

NG

LCD Panel

(T-CON) NG

OK

LD/G Board NG

32

SYSSET

Page 33

2018/05/0404:12:02(GMT+09:00)

3.8.1 NO PICTURE: TUNER (for Analogue , Digital and Satel li te)

RF input no picture / noisy picture

Check RF source cable

and antenna, OK?

OK

Check Tuner power line:

3.3V at CL1000 = 3.3V?

1.8V at CL1001= 1.8V?

OK

Tuning for Analog, Dig ital or

Satellite?

NG

NG

Change RF cable and antenna

For 1.8V Please refer DDCON

troubleshooting (2a)

For 3.3V Please refer DDCON

troubleshooting ( 2a)

Satellite

NG

Check fuse F1000 continuity.

Part broken?

YES

Change part

F1000

Problem solved?

NG

Change Tuner Module EU-T2S2

(SUT-CE251ZP)

(Please refer page Assemble and

Dissemble Tuner Module)

Please refer DDCON 12V LNB

Voltage troubleshooting (2a)

NO

OK

Done (End)

Refer Analog Tuning

Digital

For TW-DVB ,

AM-ATSC, LA-ISDB & EUDVB only.

Refer Digital Tun ing 1

Check Tuner power line

12V line at CL1006 = 12V?

OK

For EU-T2S2, PA-T2,

HK-DTMB, LA-T2

& PA-ISDB only.

Refer Digital Tun ing 2

Problem solved?

NG

Change B-board

OK

Done (End)

33

SYSSET

Page 34

2018/05/0404:12:02(GMT+09:00)

Board Name Board PWB (A side) Detail

BB9 board

(A side)

(3.3V)

CL1000

(1.8V)

CL1001

(12V)

CL1006

F1000

BB9 board

(A side)

CL1001

(1.8V)

CL1000

(3.3V)

Detail

F1000

CL1006

(12V)

(Supplementary

information)

34

SYSSET

Page 35

2018/05/0404:12:02(GMT+09:00)

3.8.2 For Anal ogue Tuning Failed ( All destination)

Analog Tuning

For Other

destination

Channel can be lock?

OK

Picture quality is noisy?

Not Noisy

Noisy

NG

For LA-ISDB,

PA_ISDB &

LA-T2

Confirm Antenna or Cable connection

Check part mounting condition for

digital control line

“M_SCL,M_SDA”

OK

Check part mounting condition

for analog control line

“IFOUTN1, IFOU TP1,

IFAGC1”

OK

Notes:

- Parts for IFOUTN1 line: FB1000,C1005,C1012

- Parts for IFOUTP1 line: R1030, FB1001, C100 6,C10 13

- Parts for IFAGC1 line: C1014, R1010

-Parts for M_SCL line: C1004,R1049

-Parts for M_SDA line: C1003,R1048

NG

NG

Done (End)

OK

Please r e-

upgrade

Firmware (PK G),

Check again

Picture quality?

NG

Change Tuner Module

(Please refer page Assemble and Dissemble Tuner Module)

OK

Problem solved?

NG

Change B-board

35

SYSSET

Page 36

2018/05/0404:12:02(GMT+09:00)

Board Name Board PWB (A side) Detail

BB9 board

(A side)

(IFOUTN1)

FB1000

C1005

C1012

(IFOUTP1)

R1030

FB1001

C1006

C1013

C1012

C1006

C1005

FB1001

R1030

FB1000

C1013

36

SYSSET

Page 37

2018/05/0404:12:02(GMT+09:00)

Board

Name

BB9 board

(A side)

(IFAGC1)

C1014

R1010

Board PWB (A side) Detail

C1014

R1010

37

SYSSET

Page 38

2018/05/0404:12:02(GMT+09:00)

Board

Name

BB9 board

(A side)

(M-SCL)

C1004

R1049

(M-SDA)

C1003

R1048

Board PWB (A side) Detail

R1049

C1004

C1003

R1048

38

SYSSET

Page 39

2018/05/0404:12:02(GMT+09:00)

3.8.3 FOR DIGITAL TUNING 1: For TW-DVB , AM-ATSC,LA-ISDB , EU-DVB only

Digital Tuning 1

Notes:

- Parts fo r IFOUTN1 line: FB1000,C1005,C1012

- Parts for IFOUTP1 line: R1030,

FB1001,C1006,C1013

- Parts fo r IFAGC1 line: C1014, R1010

-Parts for M_SCL line: C1004,R104 9

-Parts for M_SDA line: C1003 ,R10 48

Channel can be lock?

OK

OK (but no picture)

Sound is normal?

No sound

Confirm UEC of digital RF by Service mode

If UEC > 0

Check part mounting conditio n for digital data line

“IFOUTN1, IFOUTP1, IFAGC1”

OK

Please re-upgrade Firmware (PKG),

Check again Picture quality?

OK

NG

If UEC = 0

NG

NG

Check part mounting conditio n for

digital control line

“M_SCL,M_SDA”

OK

Check IC 5000(SoC)

(Change B-board)

Change NG parts

(Please refer page Assemble and Dissemble Tuner Module)

NG

Change NG parts

Problem

solved?

NG

Change Tuner Module

OK

Done (End)

Done (End)

OK

Problem solved?

NG

Change B-board

39

SYSSET

Page 40

2018/05/0404:12:02(GMT+09:00)

Board

Name

BB9 board

(A side)

(IFOUTN1)

FB1000

C1005

C1012

(IFOUTP1)

R1030

FB1001

C1006

C1013

Board PWB (A side) Detail

C1012

C1006

C1005

FB1001

R1030

FB1000

C1013

40

SYSSET

Page 41

2018/05/0404:12:02(GMT+09:00)

Board

Name

BB9 board

(A side)

(IFAGC1)

C1014

R1010

Board PWB (A side) Detail

C1014

R1010

41

SYSSET

Page 42

2018/05/0404:12:02(GMT+09:00)

Board Name Board PWB (A side) Detail

BB9 board

(A side)

(M-SCL)

C1004

R1049

(M-SDA)

C1003

R1048

R1049

C1004

C1003

R1048

42

SYSSET

Page 43

2018/05/0404:12:02(GMT+09:00)

3.8.4 FOR DIGITAL TUNING 2: For EU-T2S2, PA-T2, LA-T2 ,HK-DTMB & PA-ISDB only.

Digital Tuning 2

For LA-T2 For EU-T2S2

Confirm ANT or Cable connection

Channel can be lock?

Sound is normal?

No sound

Confirm UEC of digital RF by Service mode

If UEC > 0

Check part mounting conditio n for digital data line

“DEMOD_TSCL K, DEMOD_TS DATA”

OK

For EU-T2,

PA-T2,

and HK-DTMB

Confirm ANT or Satellite connection

NG

OK

If UEC = 0

Check part mounting conditio n for

NG

digital control line

“M_SDA,M_SCL”

5000(SoC)

(Change B-board)

Change NG parts

NG

Check IC

Notes:

-Parts for M_SCL line: C1004,R1049

-Parts for M_SDA line: C1003,R1048

-Parts for DEMOD_TSCLK line: R1020

- Parts for DEMOD_TSDATA line: R1019

OK

Change NG parts

Problem

solved?

OK

Done (End)

OK

Please re-upgrade Firmware (PKG),

Check again Picture quality?

OK

OK

Done (End)

NG

NG

Change Tuner Module

(Please refer page Assemble and Dissemble Tuner Module)

Problem solved?

NG

Change B-board

43

SYSSET

Page 44

2018/05/0404:12:02(GMT+09:00)

Board

Name

BB9 board

(A side)

(M-SCL)

C1004

R1049

(M-SDA)

C1003

R1048

Board PWB (A side) Detail

R1049

C1004

C1003

R1048

44

SYSSET

Page 45

2018/05/0404:12:02(GMT+09:00)

Board Name Board PWB (A side) Detail

BB9 board

(A side)

(DEMOD_TSCLK)

R1020

(DEMOD_TSDATA

0)

R1019

R020

R1019

45

SYSSET

Page 46

2018/05/0404:12:02(GMT+09:00)

3.8.5 EWBS – (for PA-ISDB Only)

If TV unable to output audible tone /wakeup during standby after received EWBS signal– General Checking

Start

Connection Failed

Check region settin g

OK

NG: Wrong region

setting

TV does not triggered

Due to region

Miss matched

EWBS UI: ON

OK

Does any

RF signal stored

from RF Antenna?

OK

Does Tuning RF

Antenna

OK?

OK

Check mount

Part at EWBS lin e

R5066

OK

NG: Tuner power is OFF

NG: Tuner power is OFF

NG: Cannot locked

any signals

NG: Part missing

EWBS Feature is

Not Enable

During standby

EWBS Feature is

Not Enable

during standby

Refer to

2f.3.1 No Picture Tuner

Trouble shooting

flow

Replace board

END

(Supplementary

information)

46

SYSSET

Page 47

2018/05/0404:12:02(GMT+09:00)

3.8.6 – NO SOUND

No Sound with normal picture

NO

Only RF tuner input?

YES

Change B-board

Please refer Aud io

troubleshooting

(Supplementary

information)

47

SYSSET

Page 48

2018/05/0404:12:02(GMT+09:00)

3.9.1 USB Port 1

3.9.1 USB Port 1– No Detection / Cannot Play / No pict ur e / N o Sound – General Checki ng

TV turn ON condition:

START

Do a Fac t or y S et ti ng

Chan ge t o ON

Detec ti on OK

and

Picture and Sound O K

OK

OFF

NG

*1 Confirm USB Auto Start is

ON or OFF

ON

Check 5V at C7012

(USB port1)

Have 5 V bu t No d et ec ti o n

*2 Confirm U SB file

format

OK

NG

Change to supported USB format

Remarks:

*1 Confirm USB AutoStart at Set-up Menu.

*2 Confirm with OSD on bottom pane l, if

playback not suppor t.

Please refer to IM for detail supported U SB

format.

No 5V

Detec ti on OK

OK

Picture OK

OK

Sound OK

OK

END

US B for m at OK b u t N o detec ti on

Picture NG

Main IC (IC 5000) problem

Sound NG

Audio IC (IC3101) problem

Chan ge B-Board

(Supplementary

information)

48

SYSSET

Page 49

2018/05/0404:12:02(GMT+09:00)

3.9.2 USB Port 2

3.9.2 USB Port 2– No Detection / Cannot Play / No pict ur e / N o Sound – General Checki ng

TV turn ON condition:

START

Do a Fac t or y S et ti ng

Chan ge t o ON

Detec ti on OK

and

Picture and Sound O K

OK

OFF

NG

*1 Confirm USB Auto Start is

ON or OFF

ON

Check 5V at C7029

(USB port2)

Have 5 V bu t No d et ec ti o n

*2 Confirm U SB file

format

OK

NG

Change to supported USB format

Remarks:

*1 Confirm USB AutoStart at Set-up Menu.

*2 Confirm with OSD on bottom pane l, if

playback not suppor t.

Please refer to IM for detail supported U SB

format.

No 5V

Detec ti on OK

OK

Picture OK

OK

Sound OK

OK

END

US B for m at OK b u t N o detec ti on

Picture NG

Main IC (IC 5000) problem

Sound NG

Audio IC (IC3101) problem

Chan ge B-Board

(Supplementary

information)

49

SYSSET

Page 50

2018/05/0404:12:02(GMT+09:00)

3.9.3 USB Port 3

3.9.3 USB Port 3– No Detection / Cannot Play / No pict ur e / N o Sound – General Checki ng

TV turn ON condition:

START

Do a Fac t or y S et ti ng

Chan ge t o ON

Detec ti on OK

and

Picture and Sound O K

OK

OFF

NG

*1 Confirm USB Auto Start is ON

or O FF

ON

Check 5V at C7037

(USB port3)

Have 5 V bu t No d et ec ti o n

*2 Confirm U SB file

format

OK

Detec ti on OK

OK

Picture OK

Change to supported USB format

US B for m at OK b u t N o detec ti on

Remarks:

*1 Confirm USB AutoStart at Set-up Menu.

*2 Confirm with OSD on bottom pane l, if

playback not suppor t.

Please refer to IM for detail supporte d USB

format.

No 5V

NG

Picture NG

OK

Sound OK

OK

END

Sound NG

Main IC (IC 5000) problem

Audio IC (IC3101) problem

Chan ge B-Board

(Supplementary

information)

50

SYSSET

Page 51

2018/05/0404:12:02(GMT+09:00)

3.9.4 USB Port 1 or 3

3.9.4 USB Port 1 or 3 – No D etect ion / Cannot Play / No pi c tur e / N o Sound – Checking Point

USB ( B -board Checking) – Checking 5V Points [USB Port 1 or 3]

Board

Name

BB9

Board PWB (A side) Detail

Have 5V?

C7012

C7037

(Supplementary

information)

51

SYSSET

Page 52

2018/05/0404:12:02(GMT+09:00)

3.9.5 USB Port 2

3.9.5 USB Port 2 – No Detection / Cannot Play / N o pictur e / N o Sound – Checking Point

USB ( B -board Checking) – Checking 5V Points [USB Port 2]

Board

Name

BB9

Board PWB (A side) Detail

Have 5V?

C7029

(Supplementary

information)

52

SYSSET

Page 53

2018/05/0404:12:02(GMT+09:00)

3.10 Ethernet

3.10 Ethernet – No Connect – General Checking

TV turn ON condition:

START

Check if TV has good

cab le conn ecti on

Set-up Network setup

Failed

Check if the Ethernet

cable is good

NG

Chan g e a good c ab l e

Check TV has connection O K

Set-up Network setup

OK

OK

OK

Failed

Check if any abnormal

or broken point on

Ethernet Connector and parts

(J7000/L7000/RB7000/C7002)

No

Check if TV has MAC Address

Set-up Network setup

Failed

Invalid MAC Address

Chan ge B Boar d

Yes

Yes

Connector (J 7000) and parts N G

Chan ge B Boar d

T7000 or T7001 or Main IC (IC5000)

NG

Chan ge B Boar d

53

END

53

SYSSET

Page 54

2018/05/0404:12:02(GMT+09:00)

3.10 Ethernet

3.10 Ethernet – No Connect – General Checking

Ethernet (B-board Che c k ing) – Checking parts broken or knock off

Board

Name

BB9

Board PWB (A side) Detail

Check any

parts broken

T7000

or knock off?

RB7000

C7002

L7000

T7001

J7000

54

SYSSET

Page 55

2018/05/0404:12:02(GMT+09:00)

3.11 CI Slot

3.11 CI Slot – Cannot Play / No picture / No Sound – General Checki ng

TV turn ON condition:

START

*1 Insert Good CICAM and

Check if TV can detect CICAM

Channel Setup Digital Setup

Yes

CA Module

No

No

Insert CICAM and

Check CI 5V

at PIN 17/18/51/52

Change B Board

Check CI or CI+ case

CI+

Check service menu for

CI+ Credentials CI+ Key

Invalid key

Invalid Key

Change B Board

CI

Valid key

Check any pin on

CI Slot is bend or

broken.

Connector NG

Change B Board

No

IC7003 NG

Remarks:

*1 Im por t an t : P leas e us e a kn own G ood C I C AM f or tes t in g

*2 Both CI Detection at Pin 36/67 s hould be 3. 3V before

CICAM insert and 0v when CICAM inserted.

*3 Con fi rm thes e 6 resi st ors par t are mou nt p roper l y.

Yes

Yes

*2 Insert CICAM and

Check CI Detection

at Pin 36/67

No

Yes

*3 Check Resistor

Part mounting

Yes

END

Power 3.3V NG

Change B Board

NG

Part Knock Off

Change B Board

Picture and

55

Sound OK

NG

Main IC (IC5000) NG

Change B Board

Yes

55

SYSSET

Page 56

2018/05/0404:12:02(GMT+09:00)

3.11 CI Slot

3.11 CI Slot – Cannot Play / No picture / No Sound – Checking Point

CI Slot (B-board Checking) – Checkin g 5V Point s [1/3]

Board

Name

BB9

Board PWB (A side) Detail

CI 5V at PIN

17/18/51/52

56

SYSSET

Page 57

2018/05/0404:12:02(GMT+09:00)

3.11 CI Slot

3.11 CI Slot – Cannot Play / No picture / No Sound – Checking Point

CI Slot (B-board Checking) – Checking CI Detection Pin Points [2/3]

Board

Name

BB9

Board PWB (A side) Detail

Card Detect 2 – PIN 67

Card Detect 1 – PIN 36

TV Business Division

Remark:

Both CI Detection Pin should be 3.3V before CICAM insert and 0 v when CICAM inserted.

(Supplementary

information)

57

SYSSET

Page 58

2018/05/0404:12:02(GMT+09:00)

3.11 CI Slot

3.11 CI Slot – Cannot Play / No picture / No Sound – Checking Point

CI Slot (B-board Checking) – Checking Resistor Part Mounting Points [3/3]

Board

Name

Board PWB (A side) Detail

BB9

Ref. No. Location Ref. No. Location

RB7003 1 RB7012 6

RB7004 2 RB7020 7

RB7005 3

RB7010 4

2

1

3

5

6

Remark:

Confirm these 6 resistors part are mount properly or not.

4

TV Business Division

(Supplementary

information)

58

SYSSET

Page 59

2018/05/0404:12:02(GMT+09:00)

Troubleshooting manual summary – No Picture

Section

3

Problem/Issue

No Picture

Symptom:

1. No Red LED

Blinking

2. White LED

3.12

3.12.1

3.12.2

3.12.3

3.12.4

3.12.5

3.12.6

HDMI No Picture

- HDCP Failure Analysis

- +5V Power Failure Analysis

- HPD Failure Analysis

- I2C Failure Analysis

- TMDS Failure Analysis

- Bravia Sync (CEC) not function- HDMI

Title

TV Business Division

(Supplementary

information)

59

SYSSET

Page 60

2018/05/0404:12:02(GMT+09:00)

3.12 HDMI No Picture

3.12 HDM I – No picture – General Ch ecking

HDMI No Picture

Verify with laptop /

Computer

[NG] No picture

Verify with other

HDMI player /cable

[NG] No picture

Factory reset

HDMI source & re-verify

[NG] No picture

Physical appearance check

On HDMI connector

[OK] Appearance OK

[OK] Picture recovered

[OK] Picture recovered

[OK] Picture recovered

[NG] Connector abnormal

[NG] No picture

Checking condition:

- TV ON & HDMI Source ON except if the flow men tione d is AC OFF.

- TV HDMI input connected to HDMI source (Player etc.)

- TV Input Selection: HDMI

Go to

"HDCP Failure Analysis“

Page

HDMI player/

cable problem

TV

setting problem

HDMI Connector Broken.

Replace & Re-verify

END

[OK] Picture recovered

Check voltage of +5V Power

HDMI1: CN4001 – Pin 18

HDMI2: CN4002 – Pin 18

HDMI3: CN4000 – Pin 18

[OK] V5V = 4.8 ~ 5.3V

Check voltage of HPD

HDMI1: CN4001 – Pin 19

HDMI2: CN4002 – Pin 19

HDMI3: CN4000 – Pin 19

[OK] V

HPD = 2.4 ~ 5.3V

Continue Next Page

TV Business Division

[NG] V

[NG] V

5V ≠ 4.8 ~ 5.3V

HPD ≠ 2.4 ~ 5.3V

Go to

“+5V Power Failure Analysis“

Page

Go to

“HPD Power Failure Analysis“

Page

(Supplementary

information)

60

SYSSET

Page 61

2018/05/0404:12:02(GMT+09:00)

3.12 HDMI No Picture

3.12 HDM I – No picture – General Checking (Continued)

Continue..

Check impedance of series

resistor at SCL&SDA during AC OFF

[OK] Impedance ≈ 100

[OK] VI2C = 3.5 ~ 5.5V

HDMI1: CN4001 – Pin1,3,4,6,7,9,10,12

HDMI2: CN4002 – Pin1,3,4,6,7,9,10,12

HDMI1: R4004 & R4007 (I2C)

HDMI2: R4005 & R4008 (I

HDMI3: R4003 & R4006 (I

Ω±5%

Check voltage o f SCL&SDA line

HDMI1: CN4001 – Pin 15 & 16

HDMI2: CN4002 – Pin 15 & 16

HDMI3: CN4000 – Pin 15 & 16

Check voltage of TMDS line

HDMI3: CN4000 – Pin1,3,4,6,7,

9,10,12

2C)

2C)

[NG] V

[NG] VTMDS ≠ 2.6 ~ 3.5V

[NG] Impedance ≠

100

Ω±5%

[NG] No picture

I2C ≠ 3.5 ~ 5.5V

Checking condition:

- TV ON & HDMI Source ON except if the flow men tione d is AC OFF.

- TV HDMI input connected to HDMI source (Player etc.)

- TV Input Selection: HDMI

Series Resistor Brok en.

Replace → Re-verify

Go to

“I2C Failure Analysis“

Page

Go to

“TMDS Failure Analysis“

Page

[OK] Picture recovered

END

[OK] V

TMDS = 2.6 ~ 3.5V

Replace B-board &

re-verify

Escalate this issue to

R&D team

TV Business Division

END

(Supplementary

information)

61

SYSSET

Page 62

2018/05/0404:12:02(GMT+09:00)

3.12 HDMI No Picture

3.12.1 HDC P Failu re Anal ysi s

Checking condition:

- TV ON & HDMI Source ON except if the flow men tione d is AC OFF.

- TV HDMI input connected to HDMI source (Player etc.)

- TV Input Selection: HDMI

HDCP

Failure Analysis

[OK] Compatible

Verify HDMI Source

device compatibilitie s for

HDCP version 2.2

[NG] Not Com pat i bl e

[NG] Not Com pat i bl e

HDMI Source incompatib le

for HDCP1.4 and HDCP 2.2

TV Business Division

Verify HDMI Source

device compatibilitie s for

HDCP version 1.4

[OK] Compatible

HDCP1.4 Issues

Replace B-Board and Re-verify

[OK] Pict ure recovered

END

HDCP2.2 Issues

[NG] No pict ure

HDCP key corrupted

Escalate this issue to

R&D team

(Supplementary

information)

62

SYSSET

Page 63

2018/05/0404:12:02(GMT+09:00)

3.12 HDMI No Picture

3.12.2 +5V Po w er Failure Analysis – HDMI1 and HDMI3

Checking condition:

- TV ON & HDMI Source ON except if the flow men tione d is AC OFF.

- TV HDMI input connected to HDMI source (Player etc.)

- TV Input Selection: HDMI

+5V Power

Failure Analysis

[OK] Impedance ≈ 1K Ω

[NG] Impedance ≠ 100kΩ ±5%

[OK] Picture recovered

Check impedance of

Resistor durin g AC OFF

HDMI1: R4025

HDMI3: R4024

Check impedance of

Varistor during AC OFF

HDMI1:

VR4010

HDMI3:

VR4009

Replace Broken Varistor

and Re-verify

END

[NG] Impedance ≠ 1K Ω

[NG] No picture

[OK] Impedance ≈ 100kΩ ±5%

[NG] No picture

Replace Broken Resistor

[OK] Picture recovered

and Re-verify

Go to

“HPD Power Failure Analysis“

Page

TV Business Division

(Supplementary

information)

63

SYSSET

Page 64

2018/05/0404:12:02(GMT+09:00)

3.12 HDMI No Picture

3.12.2 +5V Po w er Failure Analysis – HDMI2

Checking condition:

- TV ON & HDMI Source ON except if the flow men tione d is AC OFF.

- TV HDMI input connected to HDMI source (Player etc.)

- TV Input Selection: HDMI

+5V Power

Failure Analysis

Check impedance of

Resistor durin g AC OFF

HDMI2:

[OK] Impedance ≈ 22 Ω

Check impedance of

Varistor during AC OFF

HDMI2:

[NG] Impedance ≠ Open (High Z)

Replace Broken Varistor

and Re-verify

[OK] Picture recovered

R4044

VR4011

[NG] Impedance ≠ 22 Ω

Replace Broken Resistor

and Re-verify

[NG] No picture

[OK] Impedance ≈ Open ( Hi gh Z)

“HPD Power Failure Analysis“

[NG] No picture

[OK] Picture recovered

Go to

Page

TV Business Division

END

(Supplementary

information)

64

SYSSET

Page 65

2018/05/0404:12:02(GMT+09:00)

3.12 HDMI No Picture

3.12.3 HPD Failure Analysis – HDMI1 and HDMI3

[NG] Any of the part as below

R4021, R4022≠ 4.7KΩ

R4015,R4016, R4018, R4019≠ 1KΩ

HPD

Failure Analysis

Check impedance of

Resistor durin g AC OFF

HDMI1: R4016, R4019 and R4022

HDMI3: R4015, R4018 and R4021

Checking condition:

- TV ON & HDMI Source ON except if the flow men tione d is AC OFF.

- TV HDMI input connected to HDMI source (Player etc.)

- TV Input Selection: HDMI

[OK] All part as below

R4021, R4022 ≈ 4.7KΩ

R4015,R4016, R4018, R4019 ≈ 1KΩ

Check HPD GPIO Line

[OK] Impedance ≈ 100kΩ ±5%

impedance to Ground

during AC OFF

[NG] Impedance ≠ 100kΩ ±5%

HDMI1: R4019*

HDMI3: R4018*

Replace Broken

Resistor and Re-verify

[OK] Picture recovered

END

[NG] No Picture

Internal Main IC (SoC)

Broken (IC5000)

Replace B-Board

and Re-Verify

*Please refer page 67 for actual measuring points

Go to

“I2C Failure Analysis“

Page

(Supplementary

information)

65

SYSSET

Page 66

2018/05/0404:12:02(GMT+09:00)

3.12 HDMI No Picture

3.12.3 HPD Failure Analysis – HDMI2

HPD

Failure Analysis

Check impedance of

Resistor durin g AC OFF

HDMI2: R4043

[NG] Resistance ≠4.7 Ω

Replace Broken

Resistor and Re-verify

[OK] Picture recovered

[OK] Resistance

[NG] No Picture

≈ 4.7 Ω

Checking condition:

- TV ON & HDMI Source ON except if the flow men tione d is AC OFF.

- TV HDMI input connected to HDMI source (Player etc.)

- TV Input Selection: HDMI

Check HPD GPIO Line

impedance to Ground

during AC OFF

HDMI2: R4043*

[NG] Impedance not Open (High Z)

Internal Main IC (SoC)

Broken (IC5000)

Replace B-Board

and Re-Verify

[OK] Impedance ≈ Open (High Z)

Go to

“I2C Failure Analysis“

Page

END

TV Business Division

*Please refer page 67 for actual measuring points

(Supplementary

information)

66

SYSSET

Page 67

2018/05/0404:12:02(GMT+09:00)

3.12 HDMI No Picture

3.12.3 HPD Failure Analysis – Measuring poi nt for H PD GPI O l i ne referenc e s to ground

R4019*

Only meas ure t hi s p o int

reference to GND

HDMI2

R4043*

Only meas ure t hi s p o int

reference to GND

HDMI3

HDMI1

TV Business Division

R4018*

Only meas ure t hi s p o int

referenc e to GND

(Supplementary

information)

67

SYSSET

Page 68

2018/05/0404:12:02(GMT+09:00)

3.12 HDMI No Picture

3.12.4 I2C Fail ure Analy si s

I2C

Failure Analysis

Check impedance of

Resistor during AC OFF

HDMI1: RB4001

HDMI2: RB4002

HDMI3: RB4000

[NG] Impedance

[OK] Picture recovered

≠ 47kΩ

Replace Broken

Resistor and Re-verify

[OK] Impedance

[NG] No Picture

≈ 47kΩ

[NG] HDMI1 Impedance ≠ 140kΩ ±5%

[NG] HDMI2 Impedance not Open (High z)

[NG] HDMI3 Impedance ≠ 140kΩ ±5%

Check I2C GPIO Li ne

impedance to Ground

during AC OFF

HDMI1: CN4001 – Pin15&16

HDMI2: CN4002 – Pin15&16

HDMI3: CN4000 – Pin15&16

Internal Main IC (SoC)

Broken (IC5000)

Replace B-Board

and Re-Verify

Checking condition:

- TV ON & HDMI Source ON except if the flow men tione d is AC OFF.

- TV HDMI input connected to HDMI source (Player etc.)

- TV Input Selection: HDMI

[OK] HDMI1 Impedance ≈ 140kΩ ±5%

[OK] HDMI2 Impedance Open (High Z)

[OK] HDMI3 Impedance ≈ 140kΩ ±5%

Go to

“TMDS Failure Analysis“

Page

END

TV Business Division

68

(Supplementary

information)

68

SYSSET

Page 69

2018/05/0404:12:02(GMT+09:00)

3.12 HDMI No Picture

3.12.5 TMDS Fail ure Anal ysi s

Failure Analysis

Checking condition:

- TV ON & HDMI Source ON except if the flow men tione d is AC OFF.

- TV HDMI input connected to HDMI source (Player etc.)

- TV Input Selection: HDMI

TMDS

Check impedance of Resistor,

CMF (Filter)du r ing AC OFF

HDMI1:RB4007,RB4008,L4002,L4003

HDMI2:RB4003,RB4004,L4004,L4005

HDMI3:RB4005,RB4006,L4000,L4001

[NG] Impedance ≠ 0Ω

Replace Broken

Resistor and Re-verify

[OK] Picture recovered

END

[OK] Impedance ≈ 0±5Ω

[NG] No Picture

Check I2C GPIO Line impedance

to Ground during AC OFF

HDMI1: CN4001 – Pin1,3,4,6,7,9,10,12

HDMI2: CN4002 – Pin1,3,4,6,7,9,10,12

HDMI3: CN4000 – Pin1,3,4,6,7,9,10,12

[NG] Impedance ≠ Open (High-Z)

Internal Main IC (SoC)

Broken (IC5000)

Replace B-Board

and Re-Verify

[OK] Impedance = Open (High-Z)

TV Business Division

69

(Supplementary

information)

69

SYSSET

Page 70

2018/05/0404:12:02(GMT+09:00)

3.12 HDMI No Picture

3.12.6 HDMI Bravia Sync (CEC) Not function

[OK] Source Support CEC &

CEC Source function Normally

Bravia Sync (CEC)

Not Function

Confirm Source (Play er)

CEC Condition/Capability

[NG] Source Not Support CEC /

CEC Source not function Normally

[NG] CEC not functioning

Checking condition:

- TV ON & HDMI Source ON except if the flow men tione d is AC OFF.

- TV HDMI input connected to HDMI source (Player etc.)

- TV Input Selection: HDMI

Change to CEC

Compatible source

[OK] CEC functioning

(CEC) TV setting

[OK] CEC Setting On

Factory Reset &

Change Proven OK

[NG] CEC not functioning

appearance Check On

HDMI connector

[OK] Connector no abnormality

Check impedance

Of R4015 Resistor

during AC OFF

[OK] R4031 ≈ 100Ω ±5%

Bravia Sync

HDMI cable

Physical

[NG] CEC setting Off

[NG] CEC not functioning

[OK] CEC functioning

[NG] Connector abnormal

[NG] CEC not functioning

[NG] R4031 ≠ 100Ω

[NG] CEC not functioning

Turn TV Bravia Sync

HDMI Connector Broken.

Replace & Re-verify

Resistor Broken .

Replace & Re-verify

Replace B-Board

And Re-verify

[OK] CEC functioning

[OK] CEC functioning

[OK] CEC functioning

END

TV Business Division

70

(Supplementary

information)

70

SYSSET

Page 71

2018/05/0404:12:02(GMT+09:00)

3.12 HDMI No Picture

HDMI No picture– Checking Poi nt

R4022

R4019

R4016

VR4010

Zoom 1 :

HDMI1

Pin 19

R4025

L4003

Zoom 4

RB4001

L4002

Pin 1

CN4001

Zoom 1

R4007

R4004

Zoom 2

Zoom 3

R4005

L4005

RB4002

R4044

R4008

L4004

Pin 1

R4043

Zoom 2 :

HDMI2

CN4002

VR4011

Pin 19

TV Business Division

More on the next slide…

(Supplementary

information)

71

SYSSET

Page 72

2018/05/0404:12:02(GMT+09:00)

3.12 HDMI No Picture

HDMI No picture-Checking point ( continued)

Zoom 4

R4031

RB4003

Zoom 4

RB4004

Zoom 3

RB4006

RB4005

RB4008

RB4007

R4036

R4003

RB4000

R4006

R4024

R4021

R4018

R4015

L4001

L4000

Pin 1

Zoom 3 :

HDMI3

VR4009

CN4000

Pin 19

TV Business Division

(Supplementary

information)

72

SYSSET

Page 73

2018/05/0404:12:02(GMT+09:00)

3.12 HDMI No Picture

HDMI No picture– Part List

No Ref No Part No Description

L4000,L4001, L4002, L4003, L4004, L4005 1-460-795-11 COMMON MODE CHOKE COIL

1

RB4003, RB4004, RB4005, RB4006, RB4007,

2

RB4008

1-257-559-21 CONDUCTOR, NETWORK (1005X4)

3

4

5

6

7

8

9

10

11

RB4000, RB4001, RB4002 1-257-548-21 RES, NETWORK 47K (1005X4)

R4043 1-220-803-81 RES, CHIP 4.7 (1005)

R4044 1-218-933-81 RES, CHIP 22 (1005)

R4003, R4004, R4005, R4006, R4007, R4008,

R4031

1-218-941-81 RE S, CHIP 100 (1005)

R4036 1-218-944-81 RE S, CHIP 180 (1005)

R4015,R4016 1-218-953-81 RES, CHIP 1.0K (1005)

R4018,R4019, R4024, R4025 1-250-495-11 RES,METAL FILM CHIP 1.0K(1005)

R4021, R4022 1-218-961-81 RES, CHIP 4.7K (1005)

VR4009, VR4010, VR4011 1-811-656-11 SURGE ABSORBER

TV Business Division

(Supplementary

information)

73

SYSSET

Page 74

2018/05/0404:12:02(GMT+09:00)

3.13 W IFI

3.13 WIFI – Cannot searc h device / Connec tion Fail ed – Gener al C hecki ng

Start

Connection Failed

Check Built-In WiFi

UI

OK

Check WiFi Direct

UI

OK

Check STBY_5V

IC6016

OK

Check Harness

Connection

CN9500

OK

Check TP-VCC

DNUR-SY3

NG: Built-In WiFi Off

NG: WiFi Direct Off

NG: DC Voltage not 5V

NG: Harne ss

Connection Not Ok

NG: DC Voltage is

not 5V

WiFi Feature is

Not Enable

WiFi Direct Feature is

Not Enable

DDCON IC6016

Broken

(Change B*Board)

Harness not in

Good Condition

(Change Harness)

WiFi Module

DNUR-SY3 Broken

(Change WiFi Module)

Check AP/Device

OK

Change B*Board /

WiFi Module

OK

END

Connection Success

NG: Signal Strength

Low

AP Device

Problem

(Change AP/Device)

OK

TV Business Division

(Supplementary

information)

74

SYSSET

Page 75

2018/05/0404:12:02(GMT+09:00)

3.13 W IFI

3.13 WIFI – Cannot searc h device / Connec tion Fail ed – Checking Point

Board Name Board PWB (A si de) Detail

BB9 (IC6016)

IC6016

IC6016

75

SYSSET

75

Page 76

2018/05/0404:12:02(GMT+09:00)

3.13 W IFI

3.13 WIFI – Cannot searc h device / Connec tion Fail ed – Checking Point

76

SYSSET

Page 77

2018/05/0404:12:02(GMT+09:00)

3.14.1 Video Analog Si gnal Path – No Picture – WW Destination

3.14.1 Video Analog Signal Path – No Picture – Gen eral C hecki ng - WW Destination (BB9)

Video

No Picture

Check if input on OSD

is GREY OUT?

(not selectable)

No

Check waveform

before C2006.

Is it Vpp : 1V?

Yes

IC5000 Problem.

(Refer IC troubleshooting

manual)

No

Yes

Check all parts

at CVBS0P signal path.

[VR2000,R2004,

C2000, R2017]

No

Parts Broken.

(Change Part)

Check R2021 voltage.

Is it 3.3V?

No

Yes

J2002 Connector

Problem.

(Change connector)

Yes

J2002 Connectivi ty

Problem.

77

SYSSET

77

Page 78

2018/05/0404:12:02(GMT+09:00)

3.14.1 Video Analog Si gnal Path – No Picture – WW Destination

3.14.1 Video Analog Signal Path – No Picture – Checking Point - WW Destination (BB9)

Board Name Board PWB (A si d e) Details

BB9 (WW)

J2002

VR2000

R2021

R2004

C2000

Details

BB9 (WW)

C2006

R2017

J2002

Details

R2021

VR2000

R2004

C2000

C2006

R2017

TV Business Division

(Supplementary

information)

78

SYSSET

Page 79

2018/05/0404:12:02(GMT+09:00)

3.14.2 Video Analog Signal Path – No Pi cture – UC Destination

3.14.2 Video Analog Signal Path – No Picture – Gen eral C hecki ng - No Picture UC Destination (BB9)

CHL UC

Video

No Picture

Check waveform

before C2006?

Is it Vpp : 1V?

Yes

Check all parts

at CVBS0P signal path.

[VR2000,R2004,

C2000, R2017]

No

No

No Picture or

Abnormal Pictu re

Reinsert Mini Plug

Video Adaptor

until hear

“click” sound

IC5000 Problem

(Refer IC

troubleshooting

manual)

Parts Broken.

(Change Part)

1) Y : 1V

Mini Plug Video Adaptor

Component

No Picture

Check Vpp waveform

at 1) C2003 for Y : 1V?

2) C2008 for Pb :0.7V?

3) C2009 for Pr :0.7V?

Yes

Check all parts.

Y: VR2000,R20 0 4, C2000,

R2014

PB: VR2001, R2005, C2001, R2018

PR: VR2002, R2006, C2002,

R2019

2) Pb : 0.7V

No

No

IC5000 Problem

(Refer IC

troubleshooting

manual)

3) Pr : 0.7V

Parts Broken.

(Change Part)

J2000 connector

Problem.

(Change connector)

TV Business Division

J2000 connector

Problem.

(Change connector)

(Supplementary

information)

79

SYSSET

Page 80

2018/05/0404:12:02(GMT+09:00)

3.14.2 Video Analog Signal Path – No Pi cture – UC Destination

3.14.2 Video Analog Signal Path – No Picture – Checking Point - No Picture UC Destination (BB9)

Board Name Board PWB (A si d e) Details

BB9 (UC)

J2000

R2004

R2005

R2006

C2000

C2001

C2002

VR2000

VR2001

VR2002

BB9 (UC)

C2003

C2006

C2008

C2009

R2014

R2017

R2018

R2019

This image cannot currently be displayed.

This image cannot currently be displayed.

Details

J2000

Details

This image cannot currently be displayed.

VR2002

VR2001

This image cannot currently be displayed.

C2008

C2003

R2014

VR2000

R2018

C2001

R2019

C2002

C2000

R2004

R2006

R2005

C2009

C2006

R2017

TV Business Division

(Supplementary

information)

80

SYSSET

Page 81

2018/05/0404:12:02(GMT+09:00)

3.15 No Power DDCON /LDO

Reference Points

IC Ref Voltage Supply Fuse Enable Output Input

IC6009 5V_DDC_OUT F6004 R6074 C6072 C6066

5V_Main - Q6006(pin2) Q6007(pin1) Q6007(pin3)

IC6010 3.3V_DDC_OUT & STBY F6005 R6089 C6093 C6086

3.3V_Main - Q6008(pin2) Q6009(pin1) Q6009(pin3)

IC6007 1.8V_TU - R6162 C6058 C6055

DDCON

IC6017 1.0V_M3 F6006 R6114 C6146 C6106

IC6004 1.5V_DDR - C6153 C6042 C6040

IC6014 1.05V_M3_A - R6120 C6134 C6130

IC6016 5V_WIFI - R6167 C6141 C6136

IC6018 1.8V_EMMC - IC Pin3 C6125 C6124

LDO

IC6005 1.05V_STBY - IC Pin3 C6050 C6049

TV Business Division

(Supplementary

information)

81

SYSSET

Page 82

2018/05/0404:12:02(GMT+09:00)

Block Diagram

43”

49”

B Board Adaptor /PSU

1.05V LDO

55”

65”

LD

G-Board

19.5V

12.7V

3.3V

DDC

1.0V

DDC

5.0V

DDC

1.5V DDC

1.05V DDC

5V DDC

(WIFI)

1.8V LDO

1.8V DDC

(TUNER)

TV Business Division

(Supplementary

information)

82

SYSSET

Page 83

2018/05/0404:12:02(GMT+09:00)

3.15 No Power DDCON /LDO

DC-DC Converter Overall Check

START

Check C6093 Voltage.

Is the vol ta ge 3.3V?

yes

Check C6042 Voltage.

Is the vol ta ge 1.5V?

yes

Check C6072 Voltage.

Is the vol ta ge 5V?

yes

Check C6141 Voltage.

Is the vol ta ge 5V?

no

no

no

no

DDC: +3.3V_DDC_OUT check

DDC: +1.5V_DDR check

DDC: +5.0V_DDC_OUT check

DDC: +5V_WIFI check

Check C6146 Voltage.

Is the vol ta ge 1V?

yes

Check C6134,

C6050 is it

1.05V?

yes

Check C6058 is

it 1.8V?

yes

Check C6125 is

it 1.8V?

yes

Check 3.3V_MAIN

C6130 Voltage.

Is the vol ta ge 3.3V?

no

no

no

no

no

DDC: +1.0V_M3 check

LDO: +1.05V_M3_xx check

DDC: +1.8V_TU check

DDC: +1.8V_EMMC check

SW: +3.3V_MAIN check

yes

TV Business Division

yes

END (DDCON/LDO working normal)

(Supplementary

information)

83

SYSSET

Page 84

2018/05/0404:12:02(GMT+09:00)

3.15 No Power DDCON /LDO

DDC: +3.3V_DDC_OUT check

START

LD-Board model

Check input

F6005 voltage

Is voltage >1 9 . 0 V?

yes

Check fu se

F6005

Is fuse OK?

yes

yes

no

Check EN signa l

R6088 voltage

Is voltage >2 .9V?

yes

Check Vcc

C6082 voltage

Is voltage >5 .3V?

Is voltage >1 2 . 0 V?

yes

no

Change F6005

G-Board model

Check input

F6005 voltage

no

no

G-Board/LD-Board

no

Change IC 6010

TV Business Division

END

yes

CHL 55”/65”= G-Board model (PSU)

CHL43”/49”=LD-Board model (ADP)

(Supplementary

information)

84

SYSSET

Page 85

2018/05/0404:12:02(GMT+09:00)

3.15 No Power DDCON /LDO

DDC: +1.5V_DDR check

START

no

Check IC6009 Vcc voltage

C6066

Is voltage >19.5V?

yes

Check Vcc voltage

C6040

Is voltage >=5V?

yes

Is IC6004 mounted?

yes

Check Enable

IC6019 #pin1

Is voltage >2.5V?

yes

no

no

no

Check Vcc voltage

C6040

Is voltage >3.3V?

yes

Check

D6002

Is diode ok?

yes

Change IC6019

no

no

Check

D6001

Is diode ok?

no

yes

Change D6002

Check +5V_MAIN DDCON (IC6009)

Change D6001

Check +3.3V_STBY.

G board or IC6010

Change DDCON

IC6004

TV Business Division

(Supplementary

information)

85

SYSSET

Page 86

2018/05/0404:12:02(GMT+09:00)

3.15 No Power DDCON /LDO

SW: +5V_MAIN check

START

Check VG signa l

Q6007 #pin 1

Is voltage > 4.9V?

yes

Check VB signal

Q6006 #pin 2

Is voltage > 1.9V?

no

Other Issue

no

yes

Change Q6007

Change Q6006

TV Business Division

86

(Supplementary

information)

86

SYSSET

Page 87

2018/05/0404:12:02(GMT+09:00)

3.15 No Power DDCON /LDO

DDC: +5.0V_DDC_OUT check

START

Check fu se

F6004

Is fuse OK?

LD-Board model G-Board model

Check input

F6004 voltage

Is voltage >1 9 . 0 V?

yes

yes

no

Check input

F6004 voltage

Is voltage >1 2 . 0 V?

no

yes

Check EN signa l

R6073 voltage

Is voltage >2 .5V?

yes

no

yes

Check Vcc

C6062 voltage

Is voltage >5 V?

no

Change F6004

no

G-Board/LD-Board

G-Board/LD-Board

Change IC 6009

TV Business Division

END

yes

CHL 55”/65”= G-Board model (PSU)

CHL 43”/49”= L D -Board model (ADP)

87

(Supplementary

information)

87

SYSSET

Page 88

2018/05/0404:12:02(GMT+09:00)

3.15 No Power DDCON /LDO DDC: +1.0V_M3 check

START

Check fu se

F6006

Is fuse OK?

LD-Board model G-Board model

Check input

F6006 voltage

Is voltage >1 9 . 0 V?

yes

yes

no

Check input

F6006 voltage

Is voltage >1 2 . 0 V?

no

yes

Check EN signa l

R6114 voltage

Is voltage >1 .9V?

yes

no

yes

Check Vcc

C6102 voltage

Is voltage >5 .3V?

no

yes

Change F6006

no

G-Board/LD-Board

MTK IC damag e

Change IC 6017

END

TV Business Division

CHL 55”/65”= G-Board model (PSU)

CHL43”/49”=LD-Board model (ADP)

88

(Supplementary

information)

88

SYSSET

Page 89

2018/05/0404:12:02(GMT+09:00)

3.15 No Power DDCON /LDO

LDO: +1.05V_M 3_STBY

+1.05V_M3_STBY

START

yes

Check input

C6049 voltage

Is voltage >3.0V?

yes

Check EN signal

IC6005 #pin3

Is voltage >3.0V?

yes

no

no

DDC: 3.3V_DDC_OUT check

DDC: 3.3V_DDC_OUT check

LDO: +1.8V_EM M C

+1.8V_EMMC

START

yes

Check input

C6124 voltage

Is voltage >3.0V?

yes

Check EN signal

IC6018 #pin3

Is voltage >3.0V?

yes

no

DDC: 3.3V Switching check

no

DDC:3.3V Switching check

Change IC6005

TV Business Division

Change IC6018

89

(Supplementary

information)

89

SYSSET

Page 90

2018/05/0404:12:02(GMT+09:00)

3.15 No Power DDCON /LDO

DDC: + 1.8V_TU chec k

START

Check voltage

C6055

Is voltage >5.0V?

yes

Check EN si gnal

R6162

Is voltage >1.6V?

yes

Change IC6007

no

no

Check

D6011

Is diode ok?

yes

Check

D6009

Is diode ok?

yes

no

no

Change D6011

Check +5.0V_DD C _OU T

Change D6009

MTK IC damage

TV Business Division

90

(Supplementary

information)

90

SYSSET

Page 91

2018/05/0404:12:02(GMT+09:00)

3.15 No Power DDCON /LDO

DDC: 1.05V_M3_A check

START

Check voltage

C6130

Is voltage >3.0V?

yes

Check EN si gnal

R6120

Is voltage >3.0V?

yes

Change IC6014

no

DDC: 3.3V switchi ng check

no

DDC: 3.3V switchi ng check

TV Business Division

91

(Supplementary

information)

91

SYSSET

Page 92

2018/05/0404:12:02(GMT+09:00)

3.15 No Power DDCON /LDO

DDC: 5.0V_WIFI check

START

Check voltage

C6136

Is voltage >3.0V?

yes

Check EN si gnal

R6167

Is voltage >3.0V?

yes

Change IC6016

no

no

Check +3.3V_STBY.

G board or IC6010

MTK IC damage

TV Business Division

92

(Supplementary

information)

92

SYSSET

Page 93

2018/05/0404:12:02(GMT+09:00)

3.15 No Power DDCON /LDO

SW: +3.3V_MAIN check

START

Check VG signal

Q6009 #pin1

Is voltage > 3.0V?

yes