Page 1

SERVICE MANUAL

AE-6D

CHASSIS

MODEL

KD-32NX100AEP

COMMANDER DEST CHASSIS NO.

RM-935 AEP SCC-Q85B-A

KD-32NX100AEP

- 1 -

RM-935

Page 2

TABLE OF CONTENTS

Section Title Page Section Title Page

Caution .................... 3

Specifications .................... 4

Connectors .................... 5

Self Diagnostic Software .................... 6

1. GENERAL

Automatically Tuning the TV .................... 9

Finding your Video Channel .................... 9

Viewing a Digital Text Service .................... 9

Using the Text Menu .................... 10

The Main Menu .................... 10

Manually Tuning Analogue

Signals .................... 12

Remote Control Configuration

for VCR/DVD .................... 12

Specifications .................... 13

Troubleshooting .................... 13

2. DISASSEMBLY

2-1. Rear Cover Removal (Step 1) .................... 14

2-2. Rear Cover Removal (Step 2) .................... 14

2-3. Rear Cover Removal (Step 3) .................... 14

2-4. Speaker Disconnection .................... 14

2-5. Chassis Removal .................... 15

2-6. Service Position .................... 15

2-7. D and G Board Removal .................... 15

2-8. G1 Bracket Removal .................... 16

2-9. F1 Board Removal .................... 16

2-10. H1 Board Removal .................... 16

2-11. Removal of N Board Shield .................... 16

2-12. Picture Tube Removal .................... 17

Bottom Plates .................... 18

Removing the Glass Panel .................... 19

3. SET-UP ADJUSTMENTS

3-1. Beam Landing .................... 20

3-2. Convergence .................... 21

3-3. Focus Adjustment .................... 23

3-4. Screen (G2), White Balance .................... 23

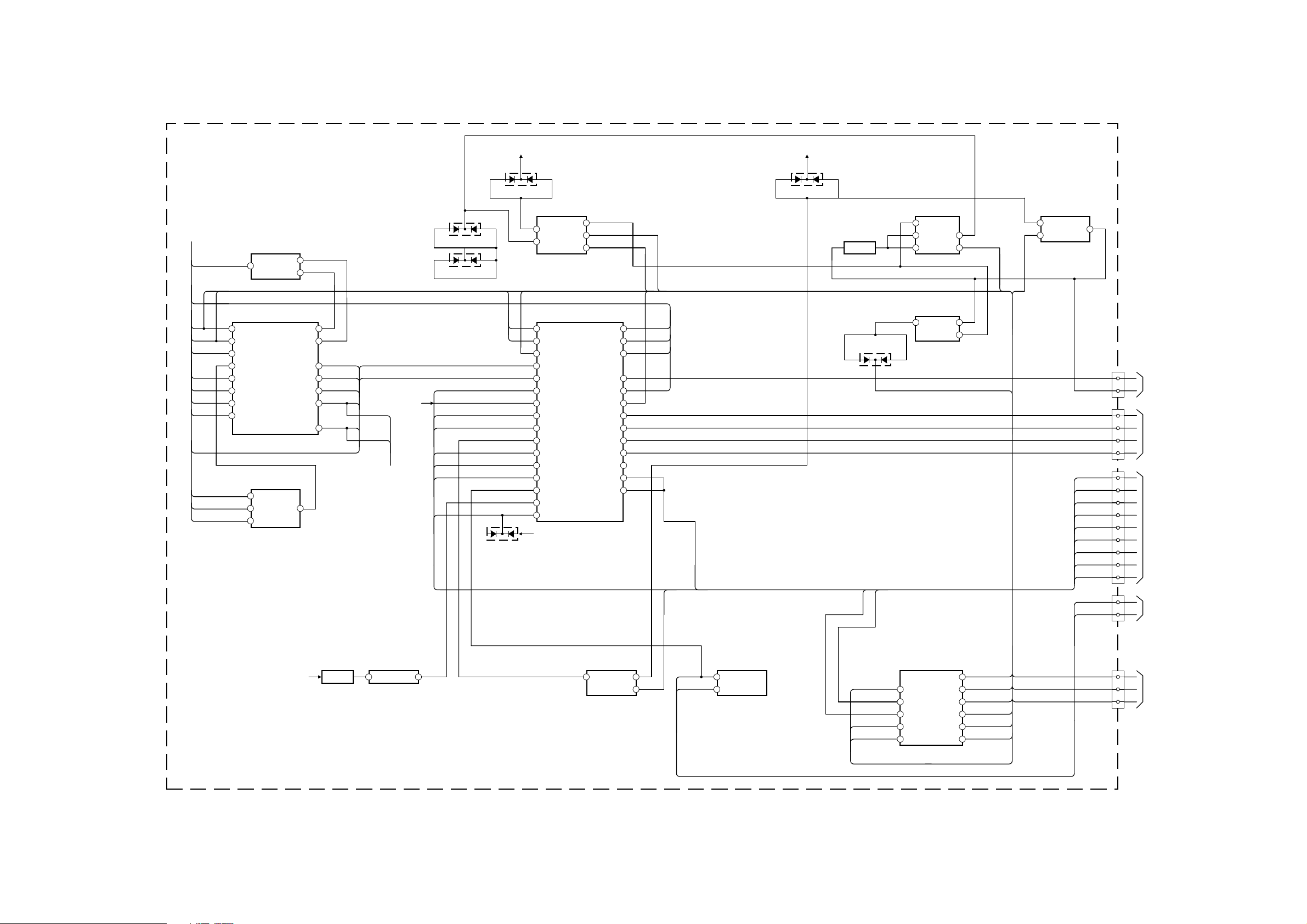

5. DIAGRAMS

5-1. Block Diagrams (1) .................... 29

Block Diagrams (2) .................... 30

Block Diagrams (3) .................... 31

Block Diagrams (4) .................... 32

Block Diagrams (5) .................... 33

Block Diagrams (6) .................... 34

Block Diagrams (7) .................... 35

Block Diagrams (8) .................... 36

5-2. Circuit Board Location .................... 37

5-3. Schematic Diagrams and

Printed Wiring Boards .................... 37

* A Board .................... 41

* M3 Board .................... 44

* C Board .................... 47

* N1 Board .................... 48

* L Board .................... 49

* J1 Board .................... 51

* B4 Board .................... 52

* F1 Board .................... 57

* H1 Board .................... 57

* H2 Board .................... 57

* H3 Board .................... 57

* G Board .................... 59

* D Board .................... 61

* G1 Board .................... 62

* VM Board .................... 62

5-4. Semiconductors .................... 64

5-5. IC Blocks .................... 67

6. EXPLODED VIEWS

6-1. Chassis .................... 69

6-2. Picture Tube ................. 70

6-3. Modem .................... 71

7. ELECTRICAL PARTS LIST .................... 72

4. CIRCUIT ADJUSTMENTS

4-1. Electrical Adjustments .................... 24

4-2. Volume Electrical Adjustments .................... 27

4-3. Test Mode 2 .................... 28

CAUTION

SHORT CIRCUIT THE ANODE OF THE PICTURE TUBE AND THE

ANODE CAP TO THE METAL CHASSIS, CRT SHIELD, OR THE

CARBON PAINTED ON THE CRT, AFTER REMOVAL OF THE

ANODE CAP.

WARNING !!

AN ISOLATION TRANSFORMER SHOULD BE USED DURING

ANY SERVICE WORK TO AVOID POSSIBLE SHOCK HAZARD

DUE TO LIVE CHASSIS, THE CHASSIS OF THIS RECEIVER IS

DIRECTLY CONNECTED TO THE POWER LINE.

SAFETY-RELATED COMPONENT WARNING !!

COMPONENTS IDENTIFIED BY SHADING AND MARKED

THE SCHEMATIC DIAGRAMS, EXPLODED VIEWS AND IN THE

PARTS LIST ARE CRITICAL FOR SAFE OPERATION. REPLACE

THESE COMPONENTS WITH SONY PARTS WHOSE PART

NUMBERS APPEAR AS SHOWN IN THIS MANUAL OR IN

SUPPLEMENTS PUBLISHED BY SONY.

ON

ATTENTION

APRES AVOIR DECONNECTE LE CAP DE’LANODE,

COURT-CIRCUITER L’ANODE DU TUBE CATHODIQUE ET

CELUI DE L’ANODE DU CAP AU CHASSIS METALLIQUE DE

L’APPAREIL, OU AU COUCHE DE CARBONE PEINTE SUR LE

TUBE CATHODIQUE OU AU BLINDAGE DU TUBE

CATHODIQUE.

ATTENTION !!

AFIN D’EVITER TOUT RISQUE D’ELECTROCUTION

PROVENANT D’UN CHÁSSIS SOUS TENTION, UN

TRANSFORMATEUR D’ISOLEMENT DOIT ETRE UTILISÈ LORS

DE TOUT DÈPANNAGE LE CHÁSSIS DE CE RÈCEPTEUR EST

DIRECTMENT RACCORDÈ Á L’ALIMENTATION SECTEUR.

ATTENTION AUX COMPOSANTS RELATIFS Á

LA SECURITÈ!!

LES COMPOSANTS IDENTIFIÈS PAR UNE TRAME ET PAR UNE

MARQUE SUR LES SCHÈMAS DE PRINCIPE, LES VUES

EXPLOSÈES ET LES LISTES DE PIECES SONT D’UNE IMPOR-

TANCE CRITIQUE POUR LA SÈCURITÈ DU FONCTIONNEMENT,

NE LES REMPLACER QUE PAR DES COMPSANTS SONY DONT

LE NUMÈRO DE PIÈCE EST INDIQUÈ DANS LE PRÈSENT

MANUEL OU DANS DES SUPPLÈMENTS PUBLIÈS PAR SONY.

- 2 -

Page 3

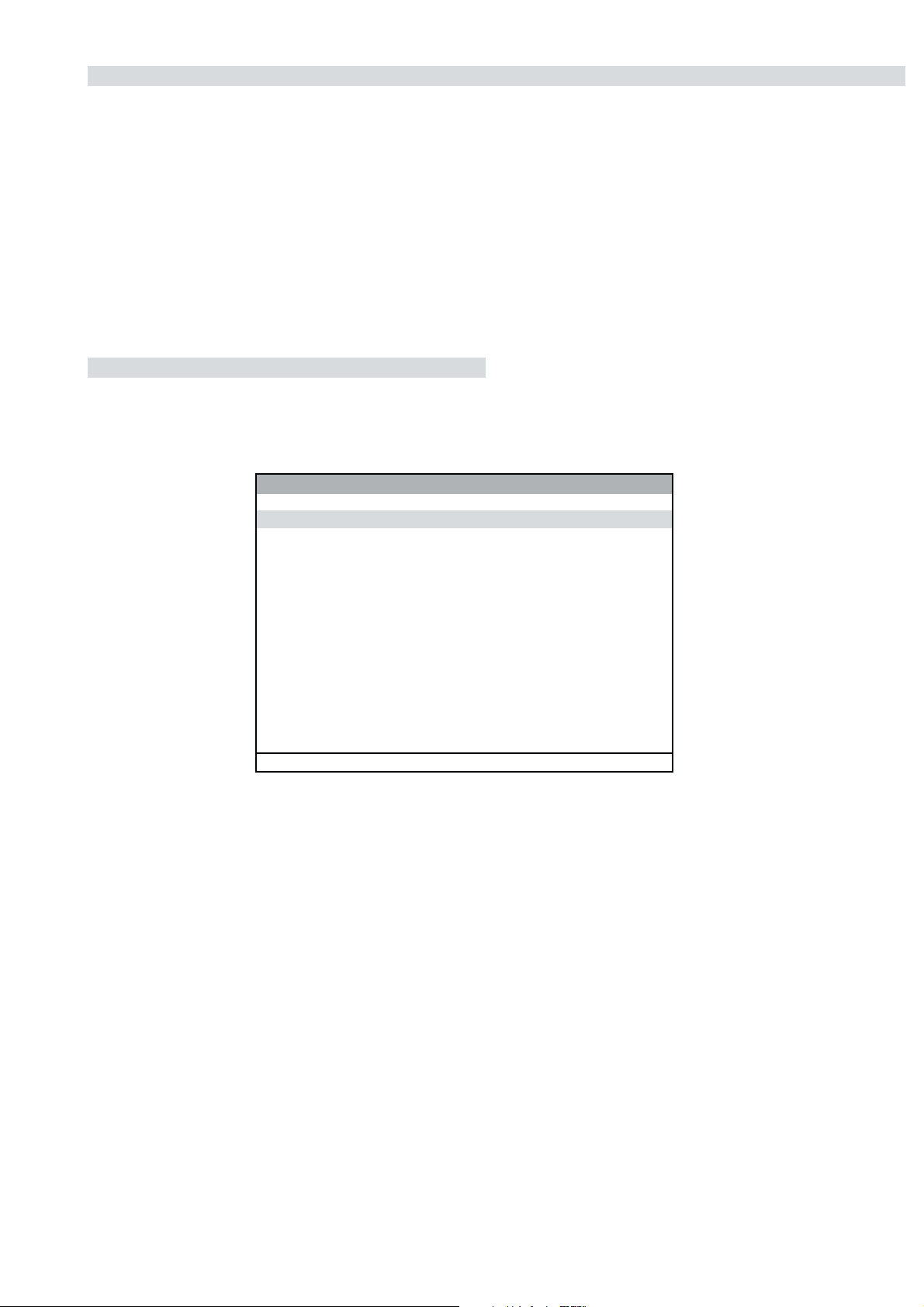

CAUTION

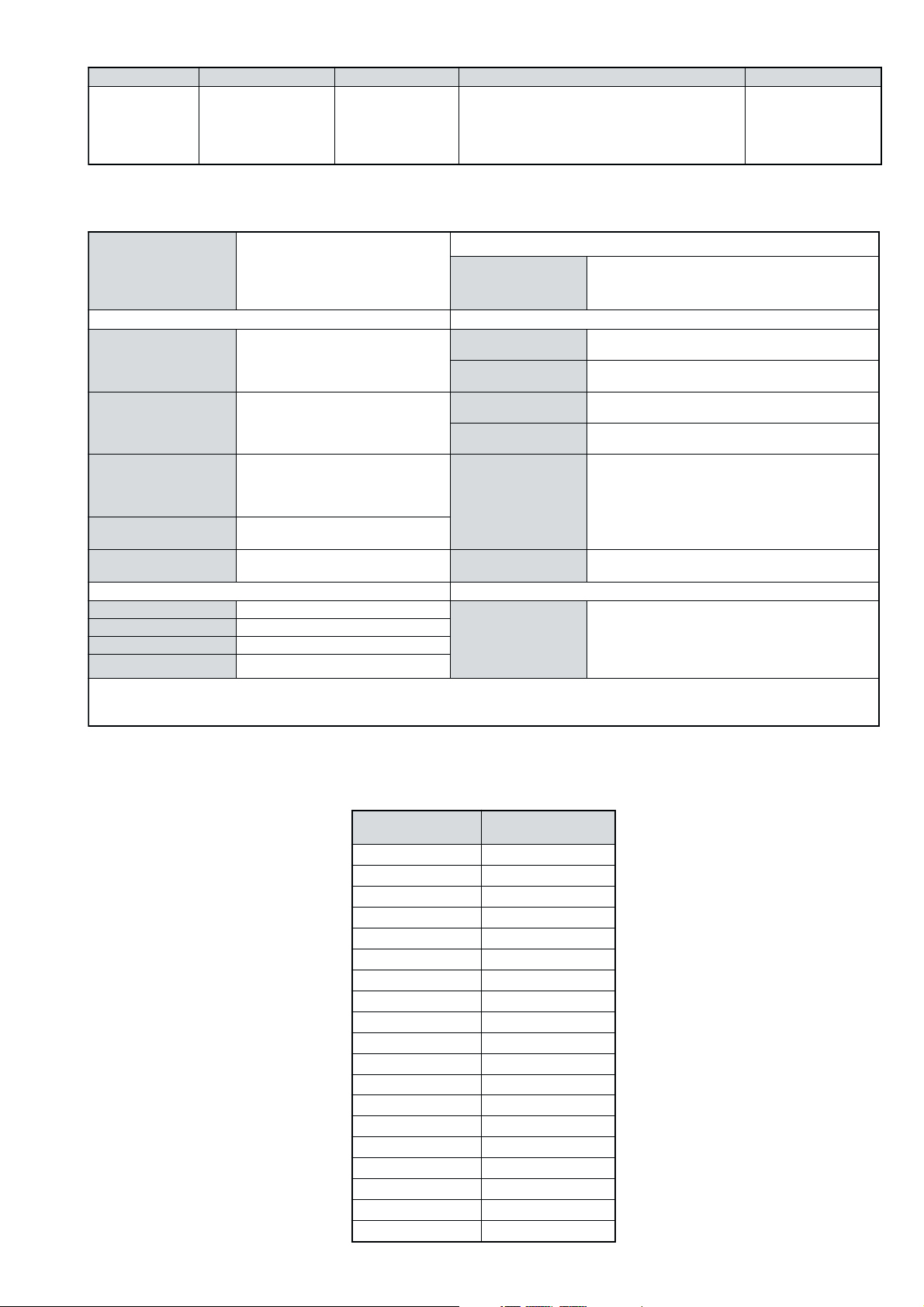

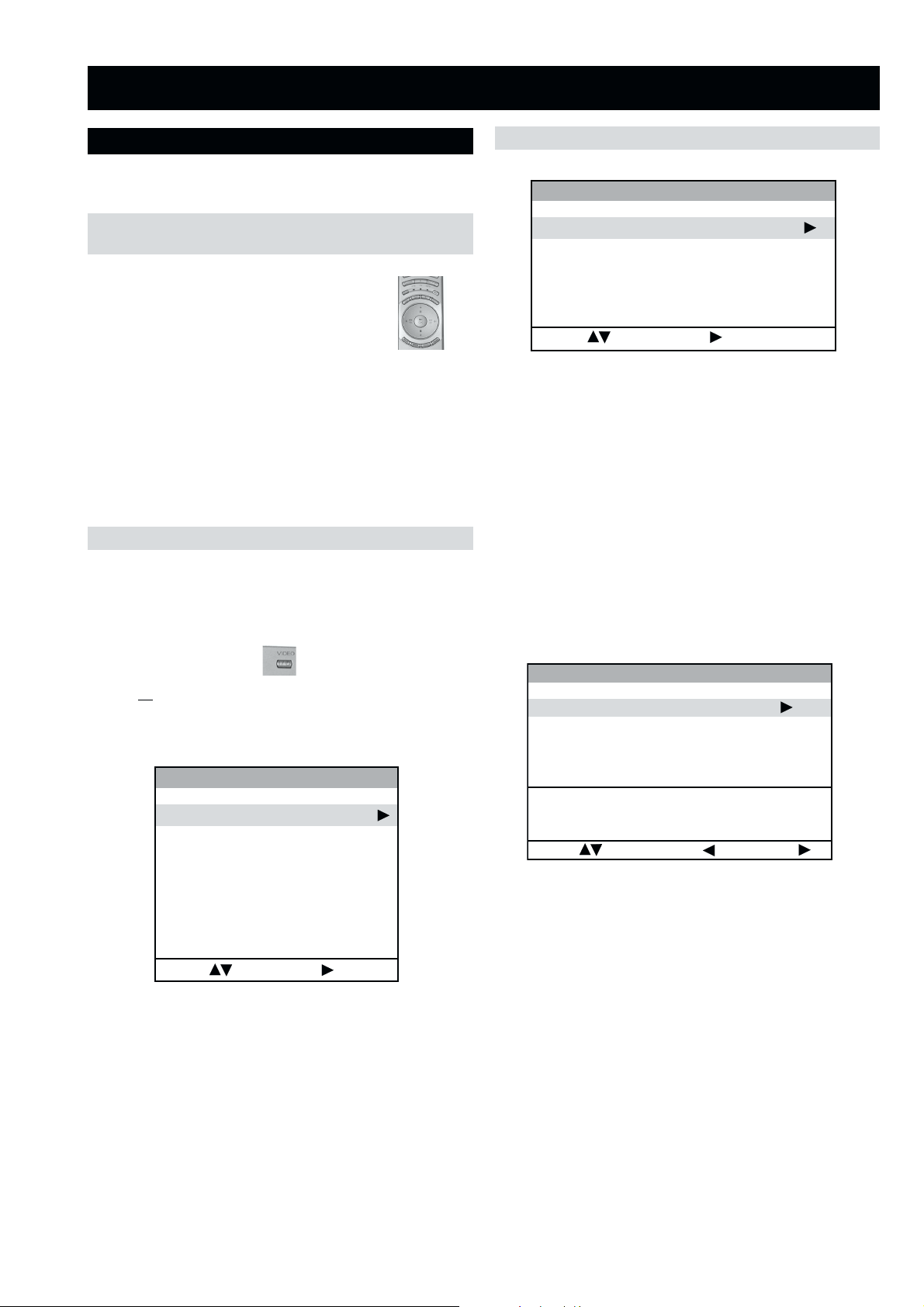

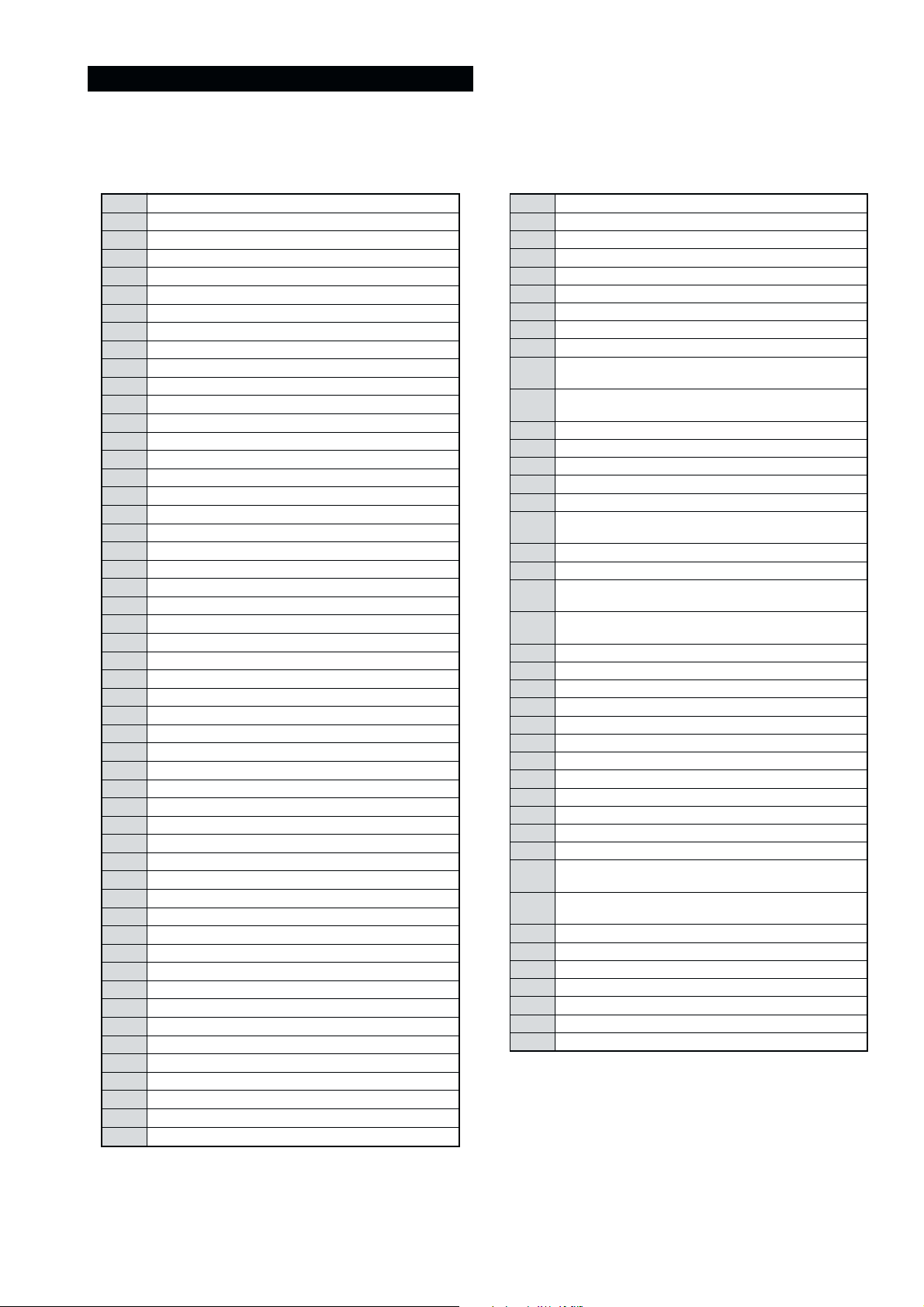

Lead Free Soldered Boards

The circuit boards listed below [Table 1] used in these models

may have been processed using Lead Free Solder. The boards are

identified by the LF logo located close to the board designation

e.g. F1, H1 etc [ see examples ]. The servicing of these boards

requires special precautions to be taken as outlined below.

Table 1

draoB noitcnuF

CevirDTRCB,G,R

1FtupnICA

1HonohPdnaSHVS

2HscriS

3HrekaepS

MVnoitaludoMyticoleV

example 1

example 2

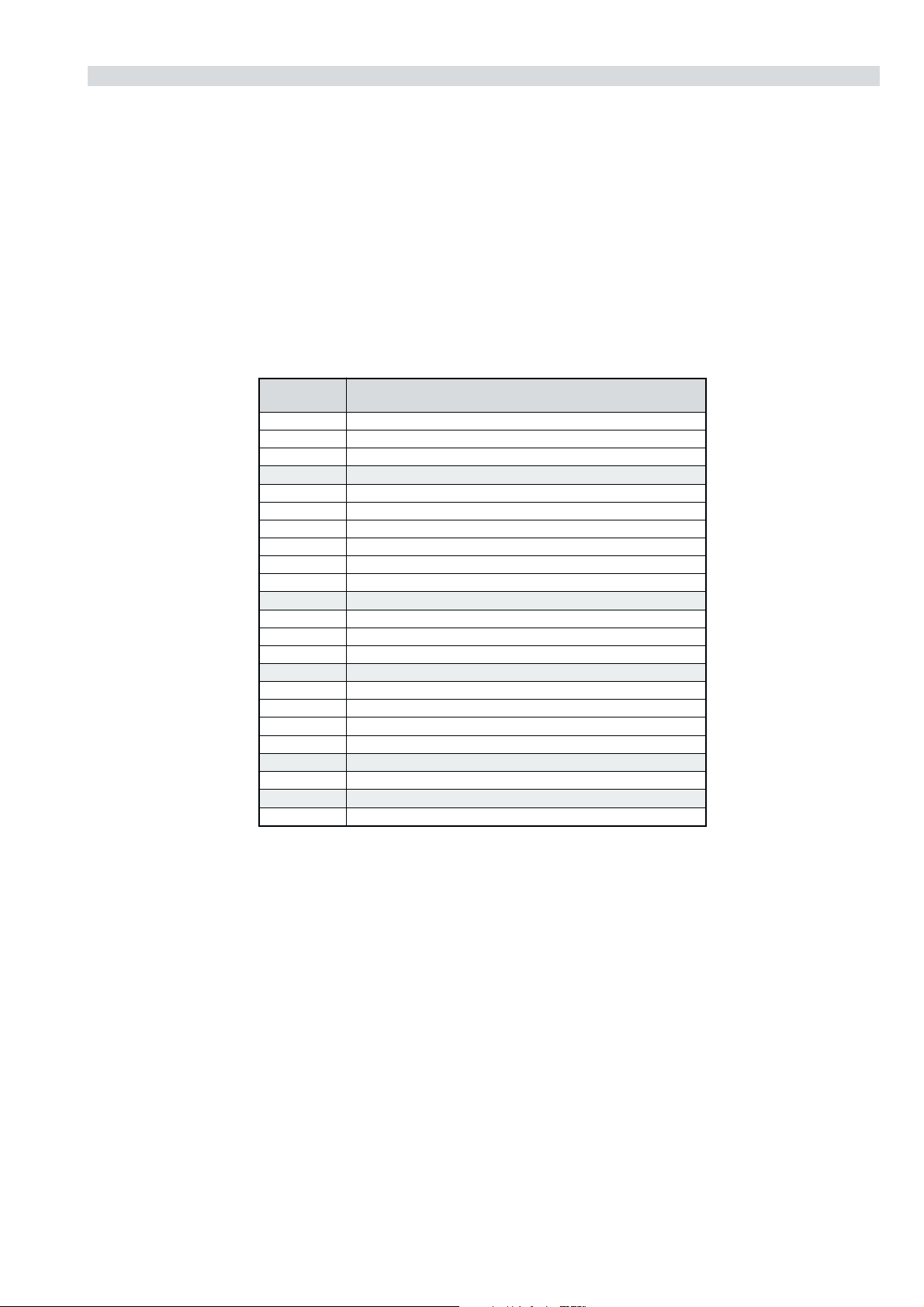

It is strongly recommended to use Lead Free Solder material in order to guarantee optimal quality of new solder joints. Lead Free Solder is

available under the following part numbers :

rebmuntraP retemaiD skrameR

91-500-046-7mm3.0gK52.0

02-500-046-7mm4.0gK05.0

12-500-046-7mm5.0gK05.0

22-500-046-7mm6.0gK52.0

32-500-046-7mm8.0gK00.1

42-500-046-7mm0.1gK00.1

52-500-046-7mm2.1gK00.1

62-500-046-7mm6.1gK00.1

Due to the higher melting point of Lead Free Solder the soldering iron tip temperature needs to be set to 370 degrees centigrade. This

requires soldering equipment capable of accurate temperature control coupled with a good heat recovery characteristics.

For more information on the use of Lead Free Solder, please refer to http://www.sony-training.com

- 3 -

Page 4

LEDOMMETI metsySnoisiveleT metsySoeretS egarevoClennahC metsySroloC

PEA

,L,I,K/D,H/G/B

T-BVD

MACIN/NAMREG

oeretS

14S-12S:REPYH

01F-2F,21R-10R,21E-20E:FHV

96B-12B,96F-12F,96R-12R,96E-12E:FHU

Q-B,02S-10S:VTELBAC

MACES,LAP

,34.4CSTN

85.3CSTN

,)NIOEDIV(

LM@PM2GEPM

nortinirTDF

ebuTerutciP

rotcennocoruEnip-12:1

)dradnatsCELENEC(

rotcennocoruEnip-12:2

rotcennocoruEnip-12:3

skcaJonohP

tekcoSAICMCPeludoMsseccAlanoitidnoC serutaeFrehtO

kcajenohpdaeHkcajinimoerets

stupnioiduAskcajonohp

stupnioediVskcajonohp

tupnioediVSNIDnip4

)yllanogaid

]RAER[slanimreTtuptuO/tupnI snoitacificepSlareneG

.BGRrofstupnI

.slangis

.BGRrofstupnI

.slangis

)elbatceles(

slangiS

]EDIS[slanimreTtuptuO/tupnI lortnocderarfnI:metsyslortnocetomeR

)sehcni23(mc28xorppA

noitcelfedeerged°201

oiduAdnaoediVVTfostuptuO

oiduAdnaoediVVTfostuptuO

.oediVSrofstupnI

tuptuOdnuoS

derusaemerutcipmc67xorppA(

refoowbuS

.slangisoediVdnaoiduArofstupnI

.slangisoediVdnaoiduArofstupnI

.slangisoediVdnaoiduArofstupnI

slangisoiduAdnaoediVrofstuptuO

oiduArofelbairavsrotcennoCtuptuO

snoisnemiDmm685x465x5.779xorppA

thgieWgk47xorppA

rekaepstfeLdnathgiR

stnemeriuqeRrewoPV042-022

noitpmusnoCrewoPW641

seirosseccAdeilppuS

stnemeriuqerrewoP

etomeR539-MRrednammoC

elbachguorhtpooLFR

)09.V(medoMlanretxE

ybloDlautriV

cdV3

noitangisedCEIseirettab2

)AAezis(6R

)SMR(W01x2)rewoPcisuM(W02x2

)SMR(W51x1)rewoPcisuM(W03x1

)2(yrettab6RdetangisedCEI

,kniltramS,txeteleT,CRD,erutcipzH001

metI

emaNledoM

bmoClaPNO

PIPFFO

ytiroirPBGRNO

xoBrefooWNO

1tracSNO

2tracSNO

3tracSNO

)4(nitnorFNO

rotcejorPFFO

edom9:61niBKANO

G/BmroNNO

ImroNNO

K/DmroNNO

SUAmroNFFO

LmroNNO

TASmroNNO

MmroNFFO

txeteleTNO

oeretSmaciNNO

.ecitontuohtiwegnahcottcejbuserasnoitacificepsdnangiseD

PEA001XN23-DK

- 4 -

Page 5

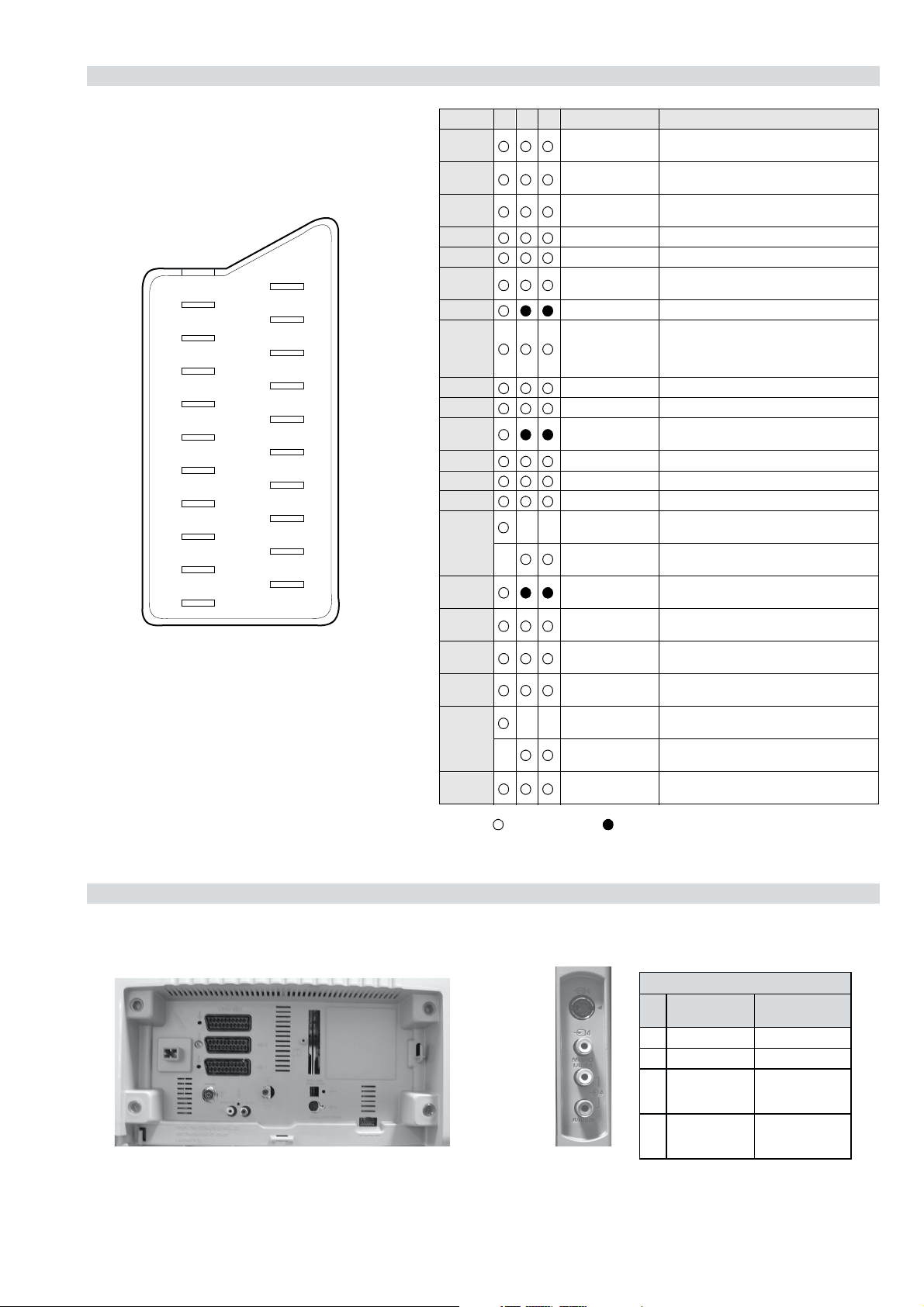

21 pin connector

21

19

17

15

13

11

9

7

5

3

1

20

18

16

14

12

10

4

2

Pin No 1 2 4 Signal Signal level

1 Audio output B

2

3

4 Ground (audio)

5 Ground (blue)

6 Audio input A

7 Blue input 0.7 +/- 3dB, 75 ohms positive

8 Function select

9 Ground (green)

10 Open

11 Green Green signal : 0.7 +/- 3dB, 75 ohms,

8

6

12 Open

13 Ground (red)

14 Ground (blanking)

15

16 Blanking input

17 Ground (video

18 Ground (video

19 Video output 1V +/- 3dB, 75ohms, positive sync 0.3V

20

21 Common ground

3

(right)

Audio input B

(right)

Audio output A

(left)

(left)

(AV control)

_ _ Red input 0.7 +/- 3dB, 75 ohms, positive

_ (S signal Chroma

input)

(Ys signal)

output)

input)

_ _ Video input 1V +/- 3dB, 75ohms, positive sync 0.3V

_ Video input

Y (S signal)

(plug, shield)

Standard level : 0.5V rms

Output impedence : Less than 1kohm*

Standard level : 0.5V rms

Output impedence : More than 10kohm*

Standard level : 0.5V rms

Output impedence : Less than 1kohm*

Standard level : 0.5V rms

Output impedence : More than 10kohm*

High state (9.5-12V) : Part mode

Low state (0-2V) : TV mode

Input impedence : More than 10K ohms

Input capacitance : Less than 2nF

positive

0.3 +/- 3dB, 75 ohms, positive

High state (1-3V) Low state (0-0.4V)

Input impedence : 75 ohms

(-3+10dB)

(-3+10dB)

1V +/- 3dB, 75ohms, positive sync 0.3V

(-3+10dB)

Connected Not Connected (open) * at 20Hz - 20kHz

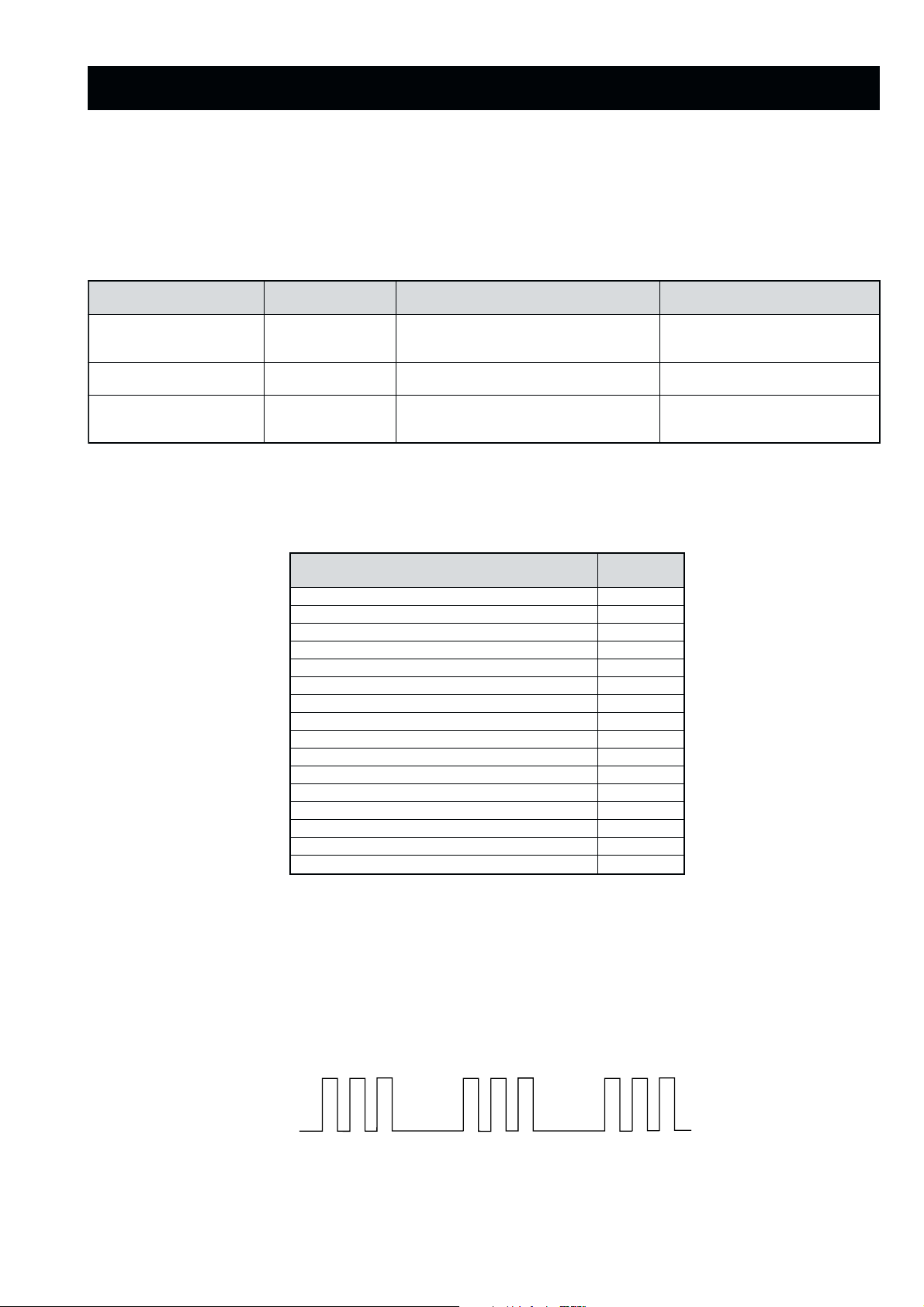

Rear Connection Panel Side Connection Panel

S-Video

socket

niP

oN

1dnuorG-

2dnuorG-

3tupni)langisS(Y,mho57Bd3-/+V1

4tupni)langisS(CBd3-/+V3.0

langiS leveLlangiS

noitarugifnocniptekcosoediVS

V3.0.cnySevitisop

Bd01+3-

evitisop,mho57

.cnyS

- 5 -

Page 6

AE-6D SELF DIAGNOSTIC SOFTWARE

The identification of errors within the AE-6D chassis is triggered in one of two ways :- 1: Busy or 2: Device failure to respond to IIC. In the

event of one of these situations arising the software will first try to release the bus if busy (Failure to do so will report with a continuous

flashing LED) and then communicate with each device in turn to establish if a device is faulty. If a device is found to be faulty the relevant

device number will be displayed through the LED (Series of flashes which must be counted) See table 1., non fatal errors are reported using this

method.

metIcitsongaiD

noitpircseD

nonruttonseodrewoPthgiltonseoD

)PCO(tnerrucrevOB+semit2

deppotsnoitcelfeDlacitreVsemit4

ybdnatSsemitfooN

sehsalFDEL

.tiucricneposiesuF

egasseMrorrE

rorreoN00

devreseR10

)noitcetorPtnerruCrevO(PCO20

)noitcetorPegatloVrevO(PVO30

noitcetorPlacitreV40

noitcetorPlatnoziroH60

noitcetorPrekaepS70

rorre0subC2I80

redoceD-txeT-eleTB-M90

MVN,23C42TSB-M01

redoceDruoloCniaM,0239ADTB-J11

dnekcaBQ0512AXCB-A21

rossecorPdnuoS,D0143PSMB-A31

orciMlatigiDAMMEB-N41

MARlanretxE81

esuacelbaborP

noitacoL

.nideggulptonsidrocrewoP

)draoBA(detrohssi1071CI

)sces03retfastratskcehc(BKAelbatsnU50

smotpmySdetceteD

noemoctonseodrewoP

VTehtotdeilppussirewopoN

ytluafsiylppusrewopCA

.)draoBD(detrohssi)4088/3088Q(TUO.H

.)draoBD(detrohssi)6088Q(TEFytiraeniL

)draoBD(nepo5388RdeilppustonsiV51+

)draoBD(nepo4388RdeilppustonsiV51-

DEL

edoC

noemoctonseodrewoP

detrohssahenilrewopnodaoL

deppotssaheslupnoitcelfedlacitreV

detrohssahenilrewoP

Flash Timing Example : e.g. error number 3

StBy LED

ON

OFF

ON ON

- 6 -

OFF

Page 7

Error Detection Monitor

Device acknowledge is used to check IIC errors. Device acknowledge is checked by sending an IIC start sequence during CRT power on. Each

device is checked three times, if there is no acknowledge after each attempt, it will be regarded as an error.

There are three steps to check for errors.

1. IIC line 0

If all devices except the NVM have errors, IIC line 0 error is displayed.

2. Board check

If all devices mounted on one board have errors, board error is displayed.

3. Each device check

If IIC line error and board error are not detected then the device with the error is displayed.

The detected errors can be displayed as follows :

1. Error Monitor Menu.

2. Error Reader.

1. Error Monitor Menu

rotinoMrorrE

FFONOFFOSRORREERONGI.1

:srorrEderotS

derruccOrorrEoN.1

derruccOrorrEoN.2

derruccOrorrEoN.3

derruccOrorrEoN.4

derruccOrorrEoN.5

:rorrEtnerruC

ecneuqeSrorrEtratS

:uneMtsaL:metIretnE

nim54h922000:emiTgnitarepO

- 7 -

Page 8

2. Error Reader Display

The error reader display is connected to the service connector to read actual error codes. The part number for the error reader display is

S-188-900-10. Once an error has been detected it will then be displayed on the two digit error reader. The errors displayed refer to the following

table.

rorrE

edoC

h000derruccororreoN

h1000CII,rorresuB

h2001CII,rorresuB

h001 draoB-A

h101rednapxEtroP,5781AXCB-A

h201renuTniaM,6231UTB-A

h401FIniaM,6889ADTB-A

h601dnekcaB,Q0512AXCB-A

h70114188BMB-A

h801CTR,3958FCPB-A

h004 draoBPB

h104XDIMroDIMB-PB

h304yarrAetaGamaronaPB-4B

h404CRDB-3B

h007 draoBJ

h307redoceDruoloCniaMB-J

h507dnuoS-buS,5781AXCB-J

h607rossecorPdnuoS,D0143PSMB-J

h807hctiwSVA,9X12AXCB-J

h008 draoBM

h108MVN,23C43TSB-M

h009 draoB-N

h109orciMlatigiDAMMEB-N

egasseMrorrE

- 8 -

Page 9

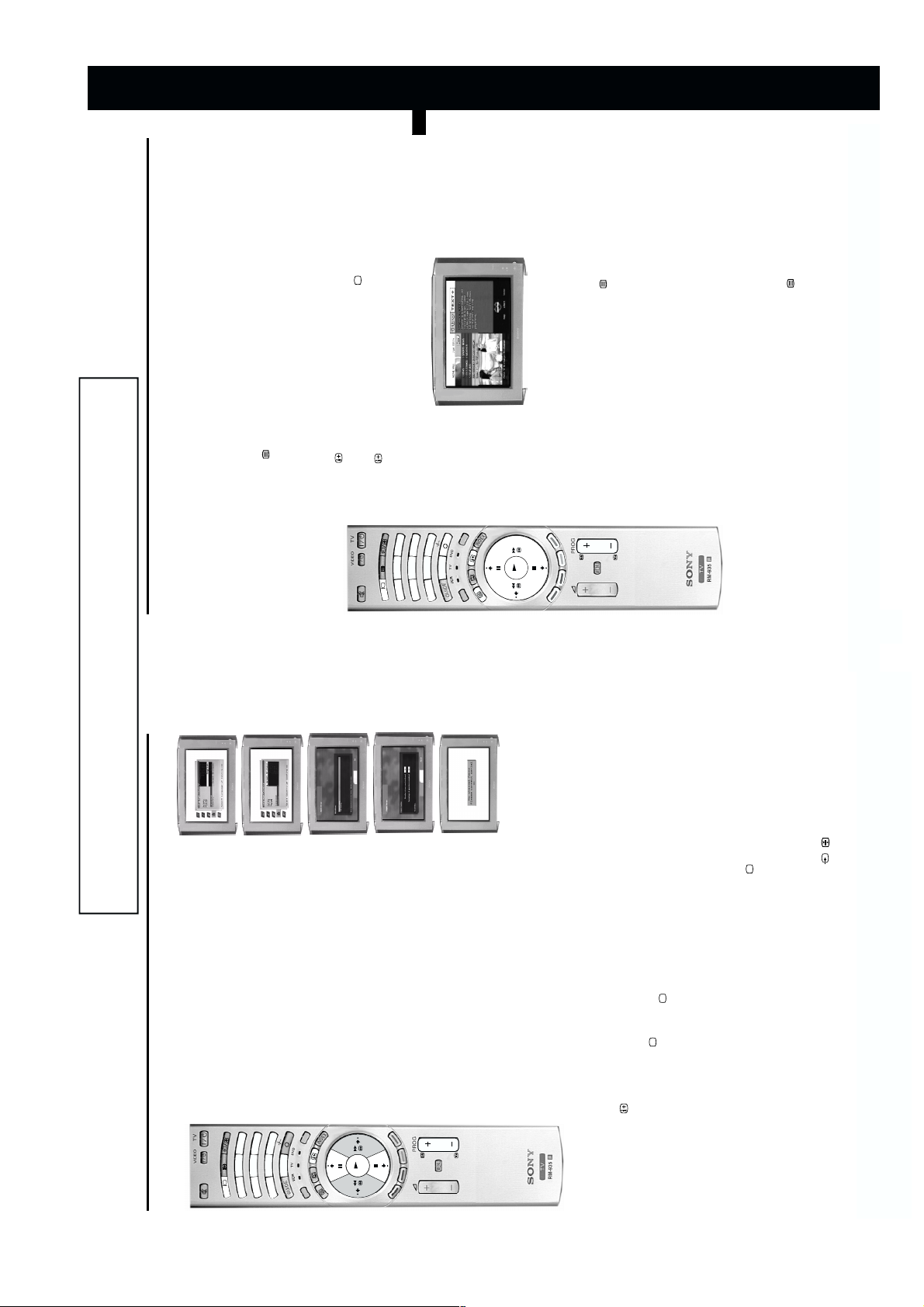

Teletext

Viewing a Digital text service

SECTION 1 GENERAL

GB

9

viewing the text pages, press the OK button.

Digital programme an Info display appears on screen providing brief details for the current and next

programme. If the display does not appear, press the Digital/ button to switch to Digital mode.

that is broadcasting the dedicated Digital text channel by using the numbered buttons on the remote

control. If you do not know the channel number of a dedicated Digital text channel, you can use the

Most Digital TV c hannels broadcast i nformation via thei r text service. This Digital service includes high

quality text and graphics along with advanced navigation options. Additionally, this TV has access to

dedicated text channels transmitted by the broadcasting authorities.

The appearance, content and navigation methods of all Digital text services are decided by the

broadcaster. For example, the RTL Digital text service may look different to ZDF’s Digital text. Most of the

Digital text services currently available use simple navigation methods based on the following buttons:

The four coloured buttons (to access shortcuts).

The text button to load up the Digital text,

The V, v, B and b buttons (to move around the screen),

Selecting a dedicated Digital text channel

1. Press the button on the remote control to check if you are in Digital mode. If you are watching a

2. Press the button to remove the Info display from the TV screen. Select the programme number

258

DIGITAL

DIGITAL

EC

3

6

1

4

R

9

0

7

E

D

O

M

The OK button or the numbered buttons (to select items on screen),

‘Channel Index menu’ to find one. (Please refer to the ‘Channel index menu’ section of this manual .)

Note: On some pages the TV programme may also be displayed on the text screen. On-screen instructions will

inform you how to change the displayed programme.

3. Once the text page is displayed, follow the on-screen instructions to obtain your required selection.

OK

4. If you are instructed to pr ess ‘OK’ or ‘Select’ when viewing the text pages, press the OK button.

5. When you have finished viewing the text service, press the button to exit.

Selecting a text service from other Digital channels

information.

Normal text services may also be available on other Digital channels. This is sometimes indicated by a

small symbol on your TV screen, superimposed on the programme you are watching.

2. Alternatively, you may be instructed to use the numbered or coloured buttons on your remote control

1. Press the V, v, B, or b buttons to select the symbol, then press the OK button to display the chosen

buttons, the coloured buttons and/or the numbered buttons on the remote control.

to display the various pages of text information. If you are instructed to press ‘OK’ or ‘Select’ when

3. Once the text information is disp layed, you can access required i nformation by using the V, v, B, or b

4. When you have finished viewing the text service, press the button to exit.

as in the manual.

The operating instructions mentioned here are partial abstracts from the ‘Operating

Instruction Manual’. The page numbers of the ‘Operating Instruction Manual’ remain

Getting started

/

choose the country in which you wish to operate the TV, then press

the OK button to confirm.

An autotune prompt appears on screen. Press the OK button to select

‘Yes’. A menu is displayed giving you two options to choose from:

Quick tuning: Tunes in the recommended signals for your location.

Full tuning: Tunes in all the available signals.

Use the V or v buttons to make your choice then press the OK button.

A display appears asking you to press the OK button to begin tuning.

As the Digital tuning procedure may take some time, a menu is

displayed to show you the tuning progress.

When the on screen display informs you that the tuning is succesfully

finished, press the BLUE button repeatedly to remove all menus from

the screen.The Analogue tuning procedure then begins.

If no Digital and no Analogue signals are found, a display appears

asking you to confi rm your aerial is connected. Check your aer ial is

connected, then p ress the OK button to repeat the tuning procedure.

menu appears on screen with the word ‘English’ highlighted. Press

require then press the OK button to confirm.

the V or v buttons on the remote control to choose the language you

1. When you switch on this TV for the first time, the Language/Country

L

A

AL

IT

IT

IG

D

DIG

3

6

258

1

4

2. The word Country is now highlighted. Press the V or v buttons to

REC

9

0

7

E

OD

M

OK

Once all signals have been captured and stored, the TV returns to

normal operation and displays the Digital programme captured on

programme number 1 is displayed.

programme number 1.

Note: If no Digital signals are captured, then the Analogue programme stored on

buttons on the remote control.

3. To view programmes, press the PROG+/- button or the numbered

5. Automatically tuning the TV

button on the remote control. If you are watching a Digital

Switching between Digital and Analogue

programmes

To check if you are watching a Digital or Analogue programme press the

programme, an Info display appears on screen providing brief details for

the current and next programme. To change to Analogue programmes

press the Digital/ button. When you wish to return to Digital

programmes, press the Digital/ button once more.

on the remote control.

aerial instructions’, you now need to find your video channel.

1. First ensure the TV is in Analogue mode. If not press the Digital/ button

If you have connected a VCR to your TV when following the ‘Connecting your

6. Finding your video channel

2. Press the PROG+/- button on the remote control until the picture from the

the ‘Rearranging your channels’ section of this manual.

If you have connected your VCR using a scart lead, you can press the

button repeatedly on the remote control until the picture from the pre-recorded

pre-recorded tape appears on screen.

tape appears on the TV screen.

Notes: If you wish to move your video channel to a different programme number, refer to

6

- 9 -

Page 10

Installation

This option allows you to tune in programmes automatically or manually and to change the order of the

‘Status’ to indicate searching is taking place. If no Digital services are found on your chosen

Full Tuning

Quick Tuning

menu.

stored programmes.

1. Press the button, then press the BLUE button on the remote control to display the Main Menu.

2. Press the V or v buttons to select ‘Installation’ then press the OK button to display the Installation

display the relevant sub menu.

3. Press the V or v buttons to select your chosen item on the menu screen then press the OK button to

showing the tuning progress.

This option will tune in all the recommended signals for your location.

This option will tune in all the signals available. As this option may take some time a menu is displayed

channel using the buttons 0 - 9. Press the OK button to confirm.

Manual Tuning

With this option you can manually add channels to your TV.

1. With the ‘Manual Tuning’ menu on display, enter the new programme number for your chosen

buttons 0 - 9. Press the b button to make the ‘Select Search’ box active.

Press OK to confirm and display the Search menu.

channel number of your choice, press the V or v button or enter the number directly using the

2. The Manual Tuning programme list is displayed with your chosen programme number highlighted.

4. Press the V or v button to begin the search process. ‘Searching ...’ appears alongside the word

3. The search will begin from the channel number shown highlighted. If you wish to change this to a

selected in Step 1, then press the OK button to return to the Manual Tuning programme list display.

channel, the channel number changes up or down automatically and the search continues. Once all

the services allocated to the channel have been found, they are displayed in the ‘Services Found’

box.

5. Press the V or v button to highlight the service you wish to allocate to the programme number

the chosen programme number, then press the OK button to return to the Manual Tuning programme list display.

button to display the full service list for the channel. Press the V or v button to select the service you require on

Note: Manual tuning allows you to add another service from the same channel to a different programme number.

then press OK. Now repeat steps 3 to 5.

To do this, select a new programme number from the display using the V or v button, then press the YELLOW

6. If you wish to tune in more channels, highlight a new programme number using the V or v button,

the YELLOW button. Use the numbered buttons on your remote control to enter the new programme

number for your chosen channel then press the OK button to confirm. Repeat this procedure to move

other channels.

displayed on the screen, press the V or v buttons to highlight the channel you wish to move then press

Programme Sorting

Use this option to change the order of the stored channels. With the ‘Programme Sorting’ menu

Once you have made all the changes you require in the Installation menu, press the BLUE button

repeatedly to remove all menus from the TV screen.

Digital features

Teletext

The Main menu

DIGITAL

DIGITAL

DIGITAL

3

3

6

6

258

258

1

1

4

4

REC

9

9

0

0

7

7

E

OD

M

OK

16

GB

11

button to enlarge the upper half of the page or v to enlarge the bottom half. Press

the OK button to return the page to normal size. Press the B button to return to

the Teletext menu.

Once the page has been found, a blue symbol appears in the top left corner

of the screen. Press the button to view the page.

displayed at a set time. When selecte d, the ‘Time Page’ sub menu is displayed.

Feature Function

4. Press the MENU button to remove the text menu from the screen.

You can access more features by using the text menu:

1. Press the button on your remote control to enter text mode.

2. With the text display on screen, press the MENU button to display the ‘Te le t ex t ’ menu.

REC

9

0

7

E

D

O

M

L

L

A

A

IT

IT

IG

IG

D

D

3

6

258

1

4

The following table explains each feature and its function.

3. Press the V or v button to highlight your desired feature, then press the b button to select.

OK

Top/Bottom/Full This feature allows you to enlarge sections of the displayed page. Press the V

Text Clear Use this feature to view the TV programme whilst text is searching for a page.

Reveal Select this to reveal hidden information on the page (such as answers to a quiz).

Time Page This feature allows a time-coded text page (such as an alarm page), to be

Note: This feature is dependent on the broadcaster’s transmission.

Enter the desired page number and the time you want the page to appear using

the remote control buttons 0 - 9, then press the OK button to confirm the settings.

The TV then exits text mode and the time is displayed in the top left corner of the

screen.

TOP-Text pages are divided into two columns. The first column shows ‘block s’ of

Page Overview

(Only for TOPText

broadcasts)

‘block’ of pages. Press the OK button to display the chosen pages.

the desired column, then press the V or v button to select the relevant ‘group’ or

pages and the second shows ‘groups’ of pages. Press the b or B button to select

Using the text menu

- 10 -

Page 11

CAM and viewing

card

Note: A door was supplied with the stand assembly to cover the rear sockets of this TV. If you have already

attached this cover, you will have remove it to gain access to the CAM socket.

CA Set-up

This feature allows you to access a pay per view service once you have obtained a Conditional Access

Digital features

The Main Menu

when inserting.

Module (CAM) with a viewing card. Please contact your nearest pay-per-view supplier for details.

1. Switch off the TV and unplug from the mains.

2. Insert the CAM into the socket on the rear of the TV as shown. Take care not to damage the CAM

REC

0

L

L

ITA

ITA

ITAL

IG

IG

D

D

DIG

MODE

OK

3. Insert your viewing card into the CAM.

4. Connect the TV to the mains and switch on.

up menu.

Set-up menu.

For further information regarding the available services, please contact your pay per view supplier.

7. Press the V or v button to highlight ‘CA Set-up’, then press the OK button to display the supplier’s set

5. Press the button, then the BLUE button on the remote control to display the Main Menu.

6. Press the V or v button to highlight ‘Detailed Set-up’, then press the OK button to display the Detailed

Personal Information

Information menu.

Use this option to enter personal information such as your e-mail name and address.

1. Press the button, then the BLUE button on the remote control to display the Main Menu.

2. Press the V or v button to highlight ‘Personal Information’, then press OK to display the Personal

then press the OK button to display the letter/number in the name box. Repeat this procedure until the

chosen option then press the OK button to display a keyboard. Press the RED button to clear the

existing name or address. Press the V, v, B and b buttons to select the letter or number you require

3. If you wish to change your user name, address or e-mail, press the V or v button to highlight your

existing font size, then press the OK button to confirm.

Applications Font Size’ then press the OK button to confirm. Press the V or v button to change the

button to return to the ‘Personal Information’ menu.

new name is complete, then after using the V, v, B and b buttons to highlight DONE, press the OK

4. If you wish to change the MHP Applications Font Size, press the V or v button to highlight ‘MHP

5. Press the BLUE button repeatedly to remove all menus from the TV screen.

18

GB

17

Digital features

Detailed set-up

Set-up menu.

Use this option to change your PIN number, modem settings and languages etc.

1. Press the button, then the BLUE button on the remote control to display the Main Menu.

2. Press the V or v button to highlight ‘Detailed Set-up’, then press the OK button to display the Detailed

3

3

6

6

9

9

258

258

L

L

1

1

A

4

A

4

7

AL

IT

IT

7

IT

IG

IG

D

D

DIG

chosen item then press the OK button to display the relevant sub menu.

PIN Set-up

If you wish to change any of the settings on the menu screen, press the V or v button to select your

This allows you to exercise parental control over programme viewing. Enter your existing PIN and

press OK. Use the numbered buttons on your remote control to enter your new number, then enter

again to confirm. Press the OK button then the BLUE button to return to the Detailed Set-up menu.

Modem

This allows you to set up the supplied modem. Press the V or v button to select your chosen item on

the screen then press the OK button to confirm. Press the V or v button to change the setting then

press the OK button to store. Press the BLUE button to return to the Detailed Set-up menu.

C

E

R

0

0

MODE

OK

buttons, select the first letter or number you require. Press the OK button to display the letter or number

in the name box. Repeat the procedure until the name is complete then, after using the V, v, B or b

buttons to highlight DONE, press the OK button. Finally, press the BLUE button to return to the Detailed

Set-up menu.

display the keyboard*. Press the RED button to clear any existing name then, using the V, v, B or b

Press the V or v buttons to select your chosen item on the menu screen then press the OK button to

Return Channel

input your new settings. Once complete, press the OK button to confirm.

* If you select ‘Default ISP’ or ‘DNS IP Address’ you need to use the numbered buttons on your remote control to

MHP Applications Rights

This allows you to set your preferences and also limit some MHP Applications. Press the V or v buttons

to select your chosen item on the screen, then press the OK button to confirm. Press the V or v button

to change the setti ng as desired, then p ress the OK button to sto re the new setting. Pres s the BLUE

and store the new setting. Press the BLUE button to return to the Detailed Set-up menu.

button to return to the Detailed Set-up menu.

Manufacturer information

Languages

Press the V or v button to select the Audio Language you want, then press the OK button to confirm

This is an information screen only and confirms the signal strength and which versions of hardware and

software are available. Press the BLUE button to return to the Detailed Set-up menu.

operating software is automatically downloaded when released. We recommend this option is set to

‘Ye s ’.

Software Upgrade

This allows the TV to automatically upgrade its software when a new version is transmitted. Press the V

Factory settings

or v buttons to set to ‘Yes ’ or ‘No ’ then press the OK butt on to store. When set to ‘Ye s ’, any new

repeatedly to remove all menus from the TV screen.

Press the OK button to select ‘Clear Personal Settings’ (this returns all your Digital settings to their

factory pre-set levels).

3. Once you have made all the changes you require in the Detailed Set-up menu, press the BLUE button

Note: The CA Set-up option is explained on the following page.

The Main Menu

- 11 -

Page 12

or the DVD green ligh t

Additional information

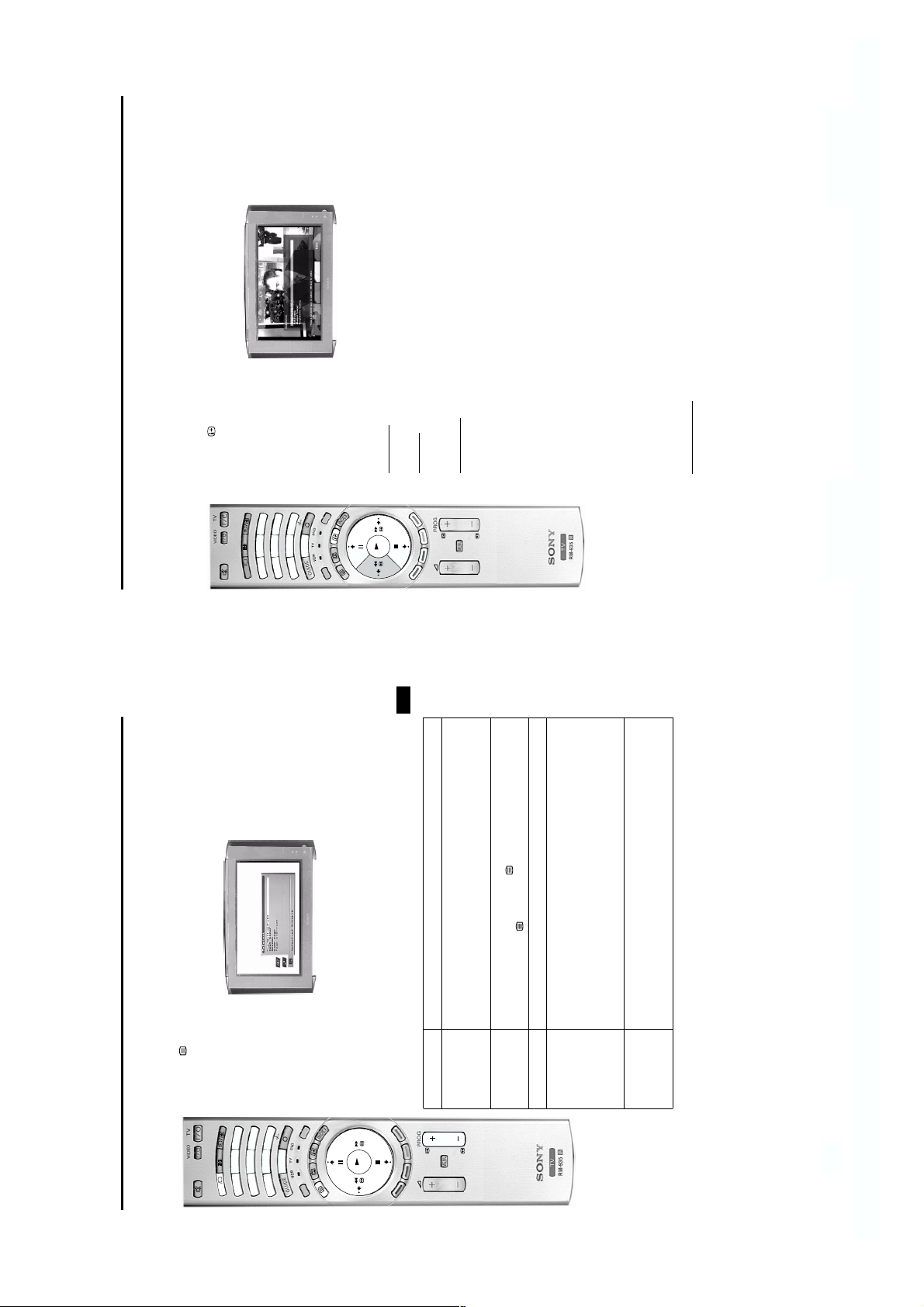

Remote control configuration for VCR/DVD

LOEWE 009, 028, 023, 024, 016. 003

354, 348, 349

is illuminated.

approximately 6 seconds, until the light starts to flash.

lights will illuminate momentarily.

steps 2 - 4 and enter the next 3 digit code allocated to your brand of VCR or DVD.

green light illuminates. Don’t forget you must select VCR or DVD using the MODE button every time

to it, make a note of the first code only at this stage.

3. Whilst the required green light is illuminated, press and ho ld down the YELLOW button for

This remote control has been configured to operate not only Sony DVDs and VCRs but also those made

by other manufacturers. To operate other brands of DVD and VCR using this remote control, complete the

following procedure:

1. Find the 3 digit code for your brand from the list below. If your brand has more than one code allocated

4. Enter the 3 digit code for your DVD or VCR. Once a correct number has been entered, all three green

2. Press the MODE button on the remote control until either the VCR green light

3

3

6

6

258

258

1

1

4

4

ITAL

ITAL

ITAL

DIG

DIG

DIG

you wish to operate your VCR or DVD with this remote control.

5. Turn on your DVD or VCR and check that the remote control operates the main functions. If not, repeat

6. When you wish to use the remote control to operate the TV again, press the MODE button until the TV

Note: The brand codes you set may be lost if weak batteries are not replaced immediately. Should this

happen, use the above procedure to reset the code. A small label has been attached to the inside of the

battery cover for you to make a note of your brand codes.

C

E

R

9

9

0

0

7

7

E

OD

M

Not all brands and models of DVDs or VCRs are covered in this list. However, Sony will endeavour to

VCR Brand List DVD Brand List

Brand Code Brand Code

SONY (VHS) 301, 302, 303, 309 SONY 001

SONY (BETA) 301, 302, 303, 309 AIWA 021

SONY (DVD) 304, 305, 306 DENON 018, 027, 020, 002

AIWA 325, 331, 351 GRUNDIG 009, 028, 023, 024, 016. 003

AKAI 326, 329, 330 HITACHI 025, 026, 015, 004

DAEWOO 342, 343 JVC 006, 017

GRUNDIG 358, 355, 360, 361, 320, 351 KENWOOD 008

HITACHI 327, 333, 334 LG 015, 014

JVC 314, 315, 322, 344, 352, 353,

LG 332, 338 MATSUI 013, 016

LOEWE 358, 355, 360, 361, 320, 351 ONKYO 022

update the software periodically, so please refer to the code table provided with your remote control.

MATSUI 356, 357 PANASONIC 018, 027, 020, 002

SAMSUNG 011, 014

358, 359

ORION 328 PHILIPS 009, 028, 023, 024, 016. 003

PANASONIC 321, 323 PIONEER 004

PHILIPS 311, 312, 313, 316, 317, 318,

SAMSUNG 339, 340, 341, 345 SANYO 007

SANYO 335, 336 SHARP 019, 027

SHARP 324 THOMSON 012

THOMSON 319, 350 TOSHIBA 003

TOSHIBA 337 YAMAHA 018, 027, 020, 002

32

GB

29

TV menu system

Manually tuning Analogue signals

menu.

Manual Programme Prese t menu.

L

ITAL

ITAL

ITA

ITAL

IG

IG

DIG

D

D

DIG

3. Press the v button to highlight ‘Manual Se t Up’ then press the b button to display the Manual Set U p

3

3

258

258

1

1

4. Press the v button to highlight ‘Manual Programme Preset’ then press the b button to display the

C

E

6

6

4

4

R

9

9

0

0

7

7

E

D

O

M

OK

You can manually add channels one by one to your TV using the following guidelines. Manual tuning also

allows you to select inputs from the scart sockets (VCRs etc.) so that they can be viewed on the

programme number of your choice. First, check you are in Analogue mode by pressing the button on

your remote control. If an Info display appears on screen providing brief details of both the current and

next programme, you are in Digital mode. Switch to Analogue mode by pressing the Digital/ button then

proceed as follows:

1. Press the MENU button to display the main menu.

2. Press the v button to highlight the icon, then press the b button to highlight ‘Auto Tuning ’.

highlight the SKIP column.

6. Press the V or v button to set to OFF, then press the b button to highlight SYS column.

5. Press the V or v button to highlight the programme number you require, then press the b button to

MENU

If you selected a TV broadcast system:

broadcasts or ‘EXT’ if you wish to view signals from your VCR or other equipment you have connected

to the scart sockets (AV1, AV2 etc.). Press the b button to confirm your choice.

broadcast. If the broadcast found is not the one you desire, press the V or v button to repeat t he

search.

If you have selected EXT:

Press the V or v button to select the AV socket whose input you wish to view on the programme

If you know the channel number or frequency number you require, use the buttons 0 - 9 on the remote

control to enter the number, otherwise press the V or v button to search for the next available

frequency input, then press the b button to confirm your choice.

Press the V or v button to select ‘C’ for terrestrial channels, ‘S’ for cable channels or ‘F’ for direct

number chosen in step 5.

7. Press the V or v button to select your system requirement. For example, choose ‘B/G’ for t he TV

MENU button to remove the menu from the screen.

8. Press the OK button to store.

9. Repeat steps 5 - 8 if you wish to tune in broadcasts to other programme numbers, then press the

- 12 -

Page 13

•Power off.

/

• TV in standby.

• Aerial disconnected.

• Picture preset level adjustment.

• No Digital transmissions in your area.

• No Digital transmissions from the transmitter you are currently using.

• Weak signal.

• Unsuitable aer ial.

• Scrambled/subscription-only channel.

• Programme used only for data (no picture or sound).

• Programme not being transmitted.

• Digital mode Timer Record active (regular flash).

• Fault (irregular flash).

• Volume control.

• Wrong external mode selected on an RGB video source.

• Colour level setting.

• Batteries low.

• Inputs from external equipment not switched off.

the remote control.

• Plug in the TV.

• Press the button on the front of the TV.

• If the indicator is on press the button or a numbered button on

colour levels.

Analogue signals’ instruction in this manual, then contact a local installer

to find out when Digital transmissions begin in your area.

pointing your aerial at.

(Contact a local installer)

• Check the aerial connection.

• Select ‘Picture Adjustment’ menu then adjust the brightness, picture and

• Tune in the Analogue channels available using the ‘Manually tuning

• Contact a local installer to find out which transmitter you should be

equipment).

• Change your aerial to cover the channels used by Digital programmes.

• Ensure aerial is correctly aligned to transmitter.

• Ensure aerial is plugged directly into the TV (not through other

• Upgrade to a higher gain aerial.

• Subscribe to pay-per-view broadcaster.

• See ‘Skipping a programme’ section.

• See ‘Re-arranging your channels’ section.

control.

• Do not open the cabinet, refer to qualified personnel.

• Contact your nearest Sony Service Centre.

on screen.

• Press the + button on the remote control.

• If is displayed on the screen, press the button on the remote

• Press the button repeatedly until the RGB symbol is displayed

• Select ‘Picture Adjustment’ menu then adjust the colour setting.

Additional information

Troubleshooting

Additional information

Problem Cause

No picture, no sound.

Poor or no picture (screen is dark), but goo d sound.

No picture on any channel after Digital tu ning.

Some channels are blank.

Standby indicator flashing.

Good picture, no sound.

Poor picture quality.

No colour on colour programmes.

Remote control does not function.

Distorted picture when changing progr ammes or

selecting Teletext.

Power off.

TV in standby.

Aerial disconnected.

Picture level adjustment.

No Digital transmissions i n your area.

No Digital transmissions from the transmitter you

are currently using.

Unsuitable aerial.

Weak signal.

Scrambled/subscription-only cha nnel.

Programme information without picture or sound.

Fault.

Volume control.

Here are some simple solutions to problems which may affect the picture and sound.

Cause Solution

Wrong external mode selected.

the Sony UK Digital Helpline on 0870 600 1717.

Colour level setti ng.

• If you continue to have these problems, have your TV serviced by qualified personnel or you can contact

34

• NEVER open the casing yourself.

GB

33

RGB input, TV audio/video output

S-video input, selectable audio/video output.

RGB input, TV audio/video output.

3

3

s

s

1

3

3

2

socket: S-Video input (4pin DIN)

socket: Audio inputs - phono jacks

socket: Headphone output - stereo minijack

4

4

4

s

RM-935 remote control (1)

IEC designated size AAA battery (2)

Modem

RF Loopthrough cable

Design and specification are subject to change without notice

Side terminals socket: Video input - phono jack

Accessories

supplied

Receivable Channels Channel Displays

Channel Display Table

B/G/H E2.12, 21...69 C02.C12, C21...C69

M1...M10 S01...S10

U1...U10 S11...S20

KABEL-TV (1) S1..S41 S01...S41

KABEL-TV (2) S01..S05 S42...S46

ITALIEN A, B.H, H1, H2 C13, C14.C20, C11, C12

S01...S05 S42...S46

D/K R01.R12, R21.R69 C01...C12, C21...C69

L F2.F10, F21...F69 C01...C12, C21...C69

I B21...B69 C21...C69

NTSC 3.58/4.43 (only Video in)

MPEG2 MP@ML

TV system L/I, B/G/H, DK, DVB-T

Colour system PAL, SECAM

Specifications

Channel coverage See the ‘Channel Display Table’ below

socket: RCA connectors (variable output for audio signals).

socket: Conditional Access Module.

AV3 socket : 21-pin Euro connector (CENELEC standard) including audio/video input,

AV2 socket : 21-pin Euro connector (CENELEC standard) including audio/video input,

Weigh t Approx. 74Kg

Sound output Left/Right 2 x 20W (music power) Sub Woofer 30W (music power)

Power consumption 146W

Picture tube 82cm (32inches) FD Trinitron WIDE 102° deflection

Dimensions 977.5mm x 564mm x 586mm (W x H x D)

Rear terminals AV1 socket : 21-pin Euro connector (CENELEC standard) including audio/video input,

- 13 -

Page 14

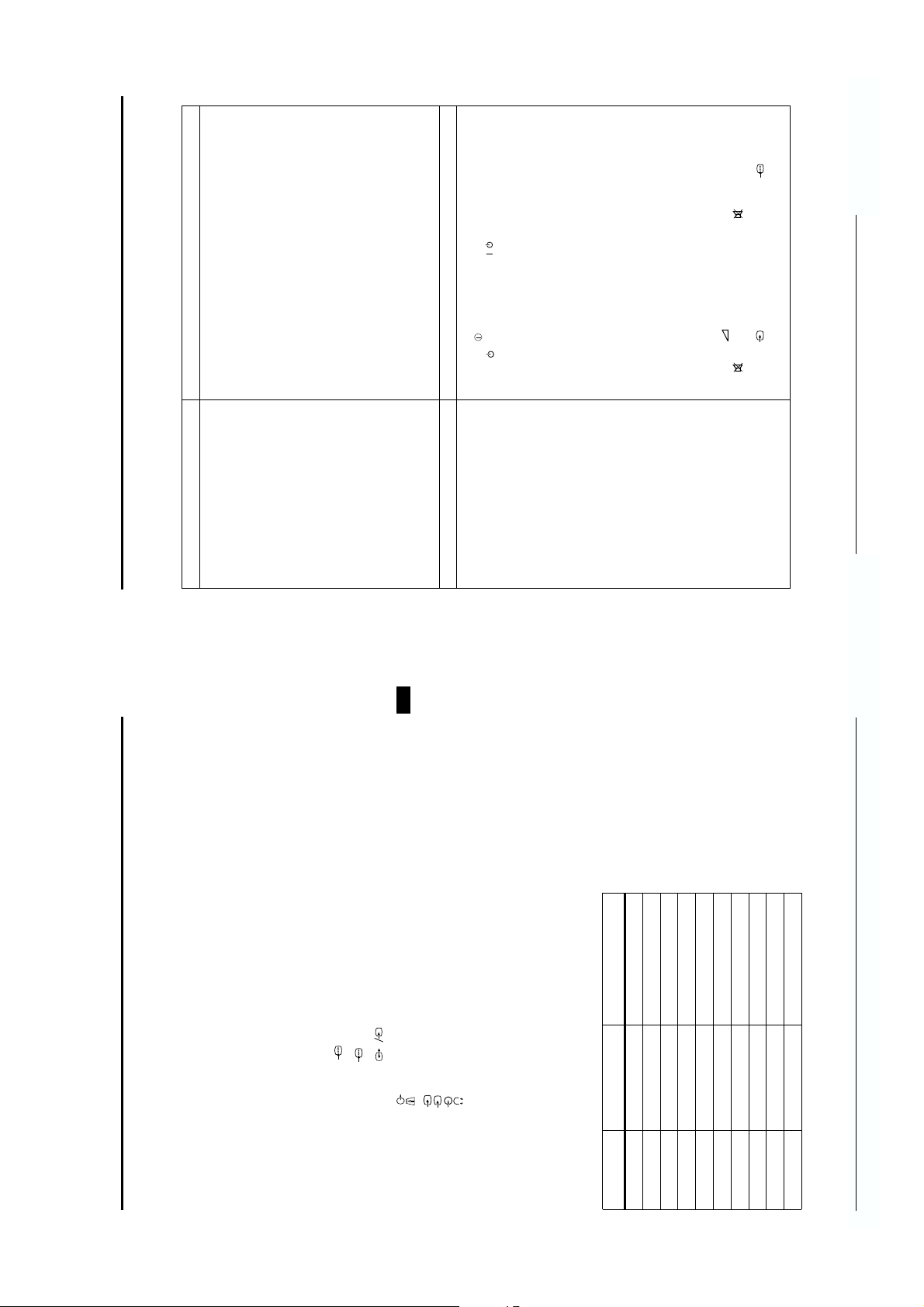

SECTION 2 DISASSEMBLY

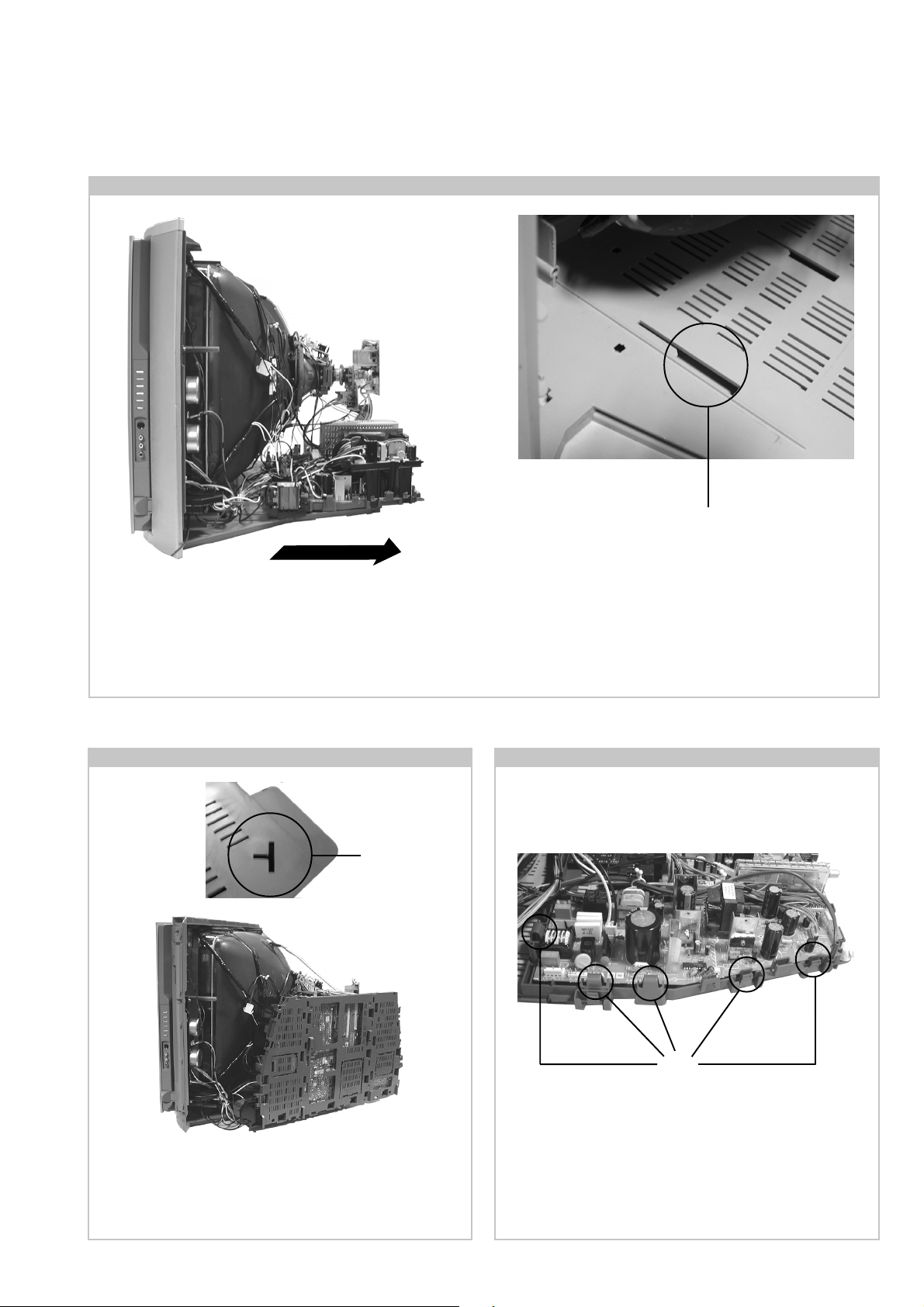

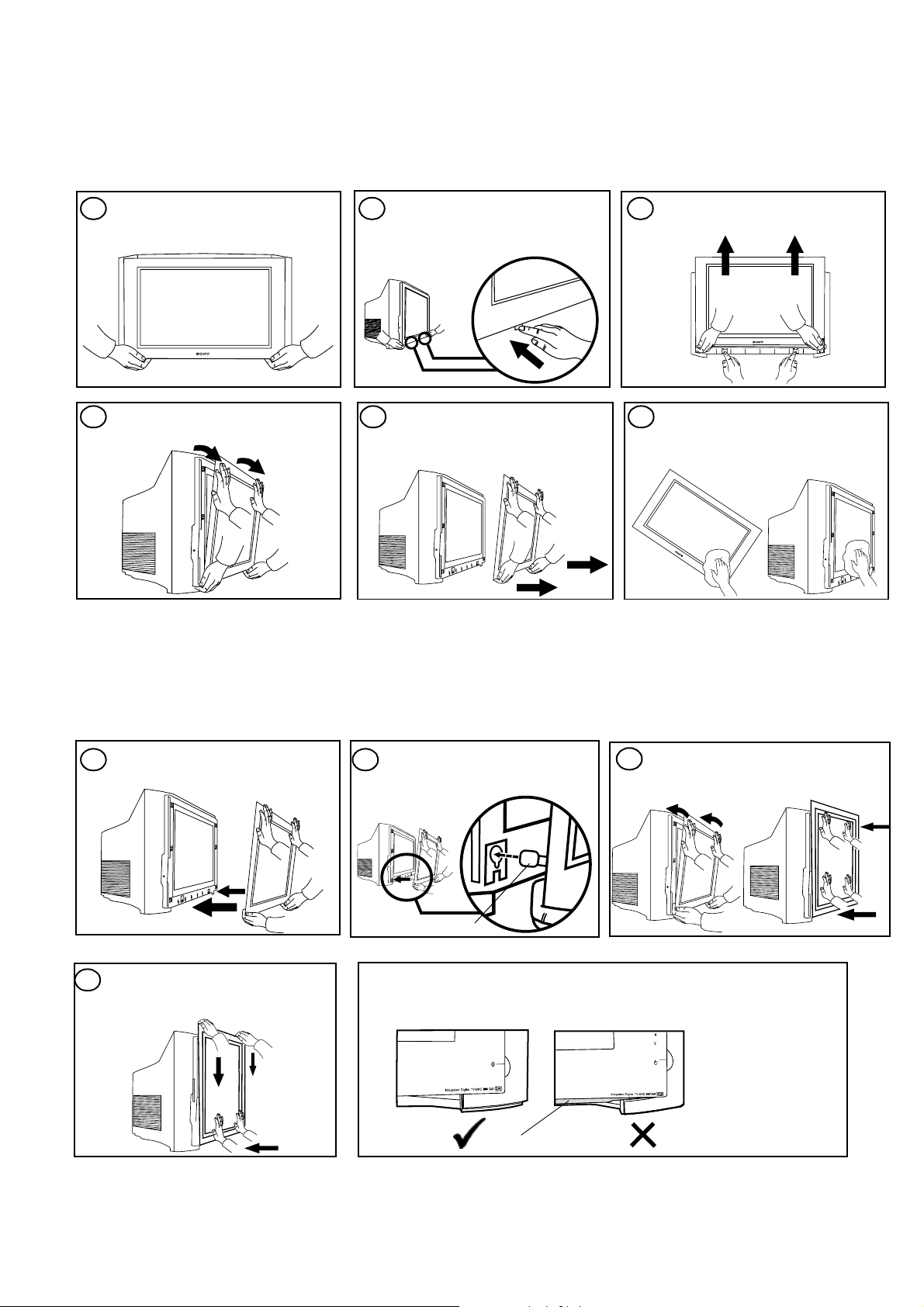

2-1. Rear Cover Removal (Step 1)

Screws

Using a narrow blade screwdriver lever off the 4 screw

covers from the rear of the set. Remove the 12 speaker grill

and rear cover fixing screws. (See 2-3.)

2-2. Rear Cover Removal (Step 2)

Speaker

Grill

Ornamental

Plate

Screws

Remove the speaker grills by holding top and bottom and

sliding away from the set. Remove the ornamental plate

from the top front of the beznet by sliding to the right.

Remove the 5 screws indicated from the top front of the set.

2-3. Rear Cover Removal (Step 3) 2-4. Speaker Connector Disconnection

=>

=>

Remove the rear cover by sliding backwards away from the

picture tube. Take care when removing the rear cover not to

damage the speaker cables [Disconnect the speaker

connector] as speakers are fitted inside the rear cover.

=>

=>

=>

=>

=>

=>

=>

=>

=>

=>

Before completely removing the rear cover disconnect the

speaker connector which is located on the inside of the rear

cover.

- 14 -

Page 15

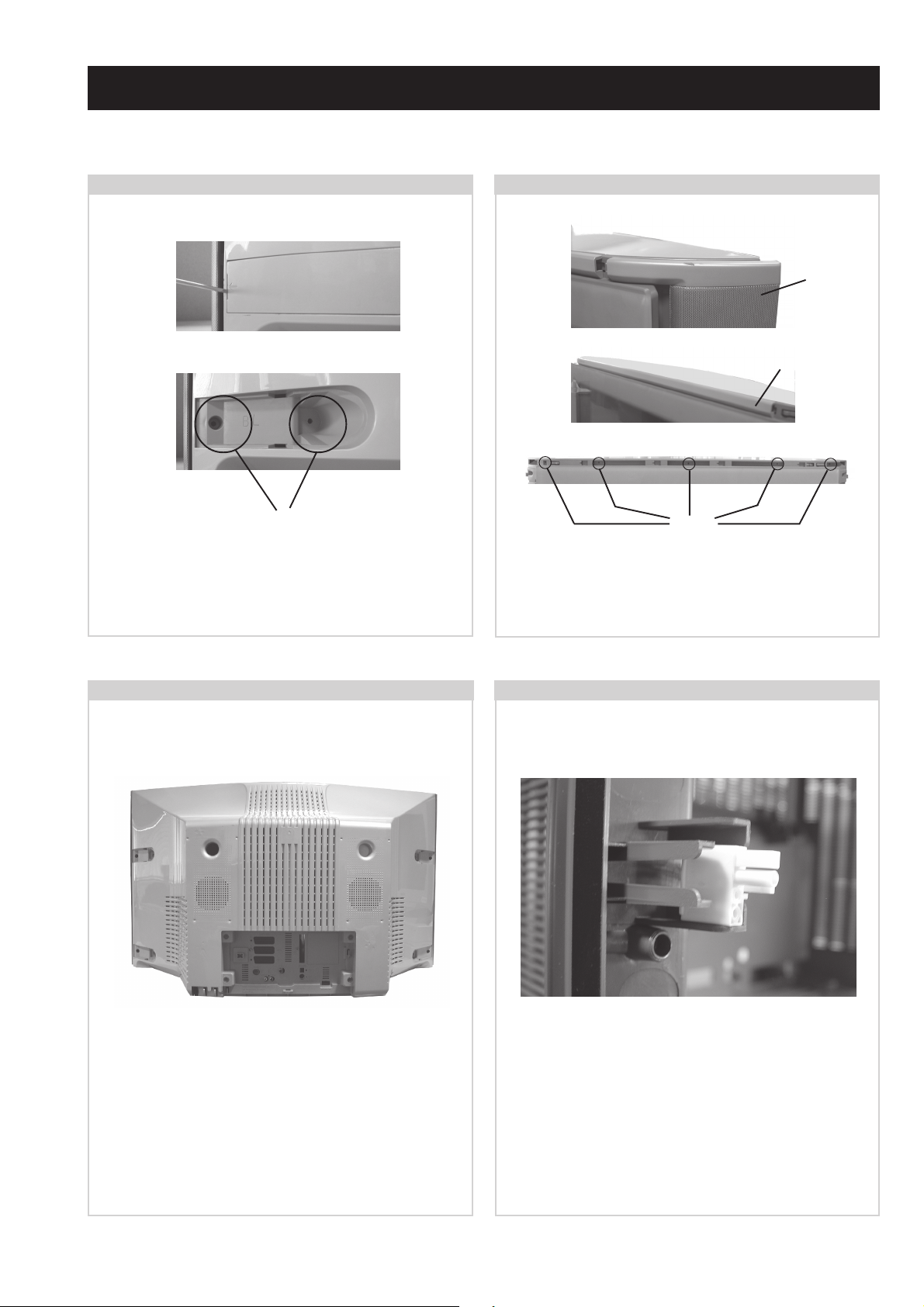

2-5. Chassis Removal and Refitting

T o remove lift the main bracket rear slightly and slide the

chassis away from the beznet. Ensure that the interconnecting

leads are released from their purse locks to prevent damage

being caused.

When refitting the chassis ensure that the main bracket is

located in the beznet guide slots before sliding the chassis

forwards. Refit the interconnecting leads in their respective

purse locks.

2-6. Service Position

Slot

Using the slot on the rear left of the beznet position the

chassis as indicated to access the solder side. T o gain access

to the underside of the boards follow the instructions on

page 18. [Removal and Replacement of the main bracket

bottom plates ].

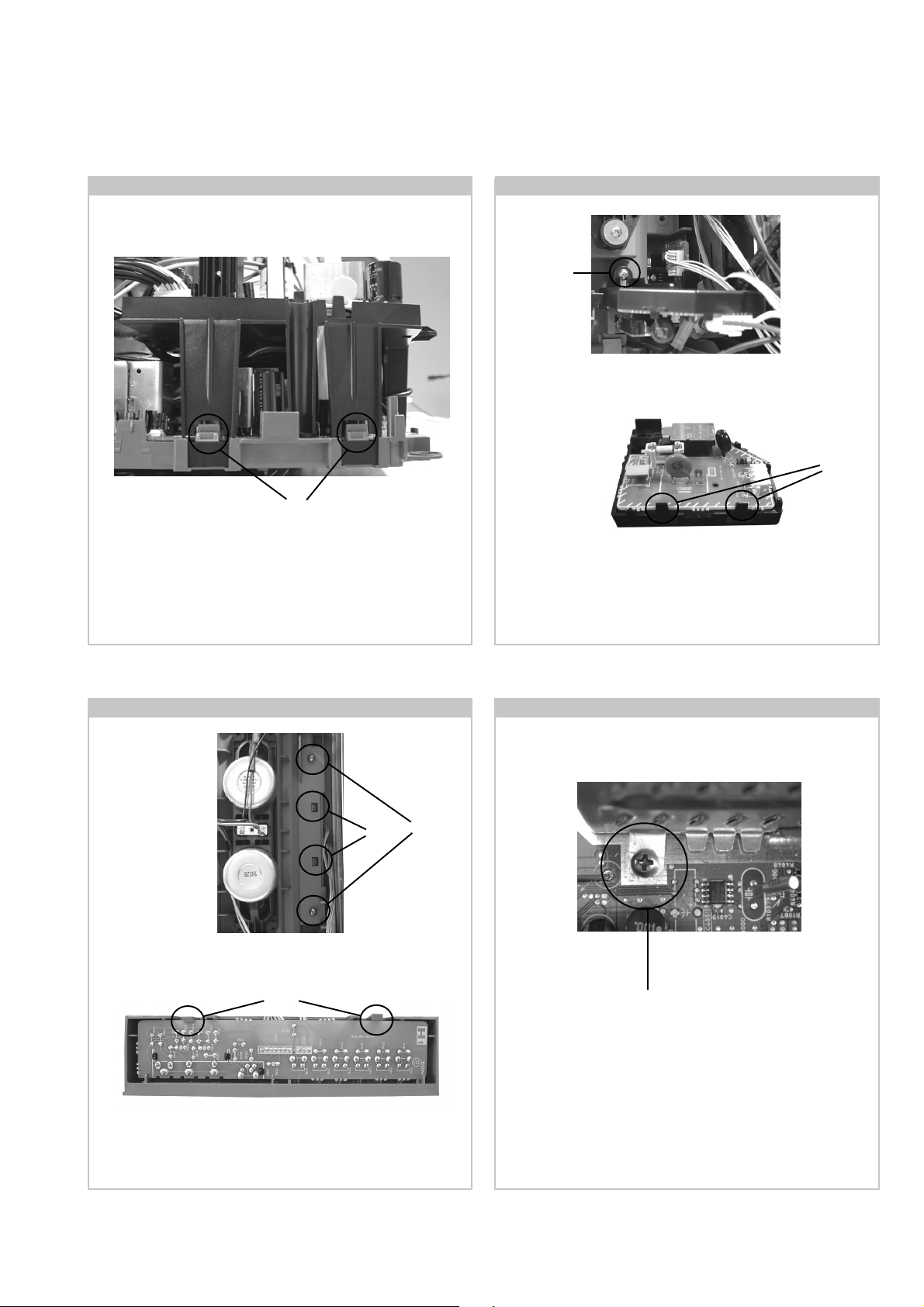

2-7. D and G Board Removal

Clips

T o remove the G Board release the clips circled and ease the

board gently away from the support bracket. Removal of the

D Board follows the same procedure.

- 15 -

Page 16

2-8. G1 Bracket Removal

Clips

T o remove the G1 Brack et release the four clips (two on each

side of the bracket) and carefully lift away from the chassis.

2-9. F1 Board Removal

Screw

Remove the F1 bracket by removing the screw indicated and

sliding the bracket away from the beznet.

Clips

T o remove the F1 board release the tw o clips circled and ease

the board gently away from the support bracket.

2-10. H1 Board Removal 2-11. Removal of N Board Shield

Screws

Clips

Remove the H1 bracket by removing the screws indicated.

Release the two clips circled and ease the bracket out of its slot

in the beznet.

Clips

Screw

T o remov e the N Board shield, release the two f ixing scre ws

and lift the shield vertically until it is clear of the chassis.

T o remove the H1 board release the two clips circled and ease

the board gently away from the support bracket.

Note : Removal of the H3 Board follows the same procedure.

- 16 -

Page 17

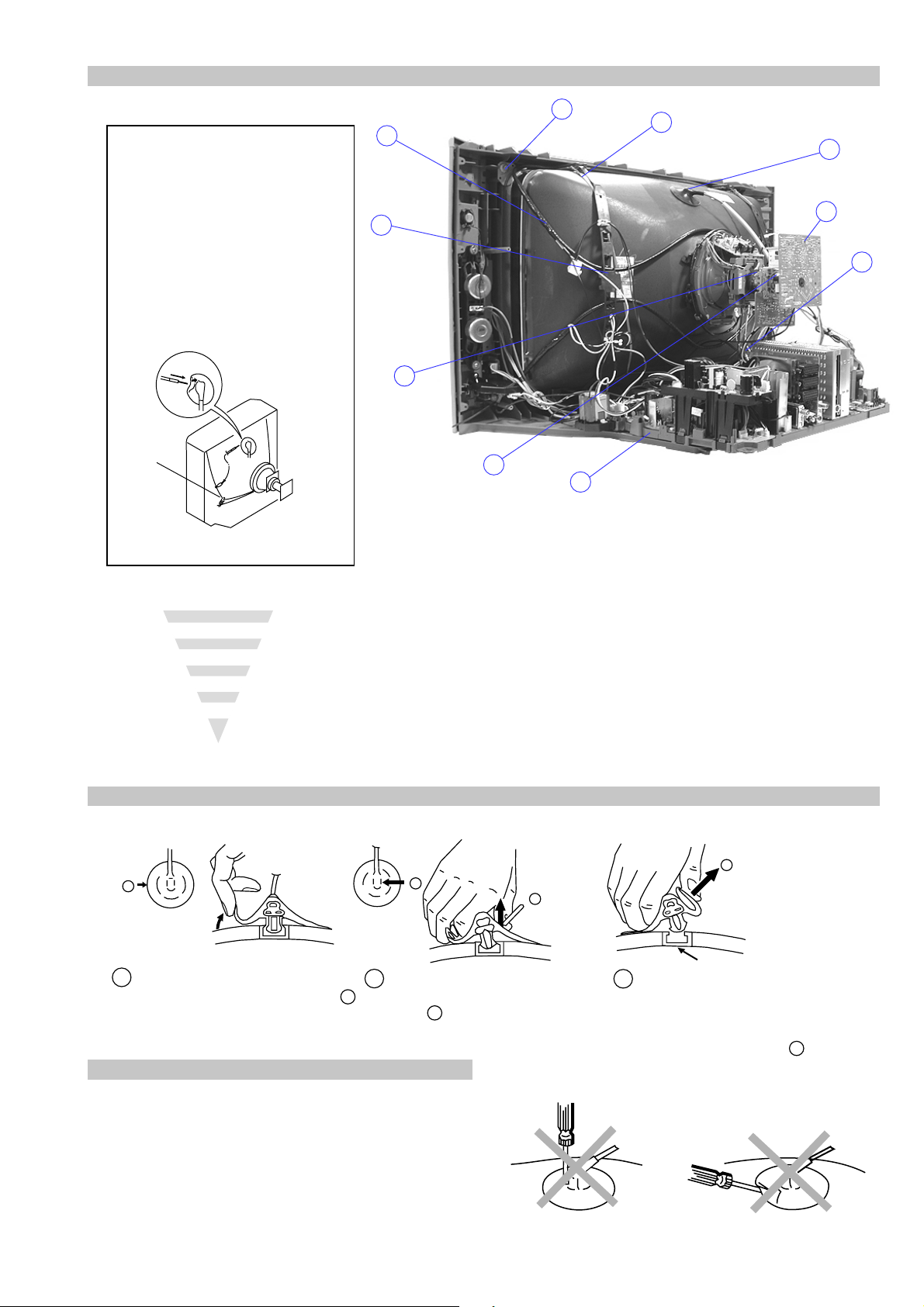

2-12. Picture Tube Removal

WARNING:

BEFORE REMOVING

THE ANODE CAP

High voltage remains in the CRT even

after the power is disconnected. To

avoid electric shock, discharge CRT

before attempting to remove the anode

cap. Short between anode and CRT

coated earth ground strap.

Coated Earth

Ground Strap

10

9

8

1

3

7

2

6

5

4

1. Discharge the anode of the CRT and remove the anode cap.

2. Unplug all interconnecting leads from the Deflection yoke, neck

assy, de gaussing coils and CRT grounding strap.

3. Remove the C Board from the CRT .

4. Remove the chassis assembly.

5. Loosen the Neck assembly fixing screw and remove.

6. Loosen the Deflection yoke fixing screw and remove.

7. Place the set with the CRT face down on a cushion and remov e

the Degaussing Coil holders.

8. Remove the Degaussing Coils.

9. Remove the CRT grounding strap and spring tentioners.

10. Unscrew the four CR T fixing screws [ located on each CRT

corner ] and remove the CR T .

[T ake care not to handle the CR T by the neck.]

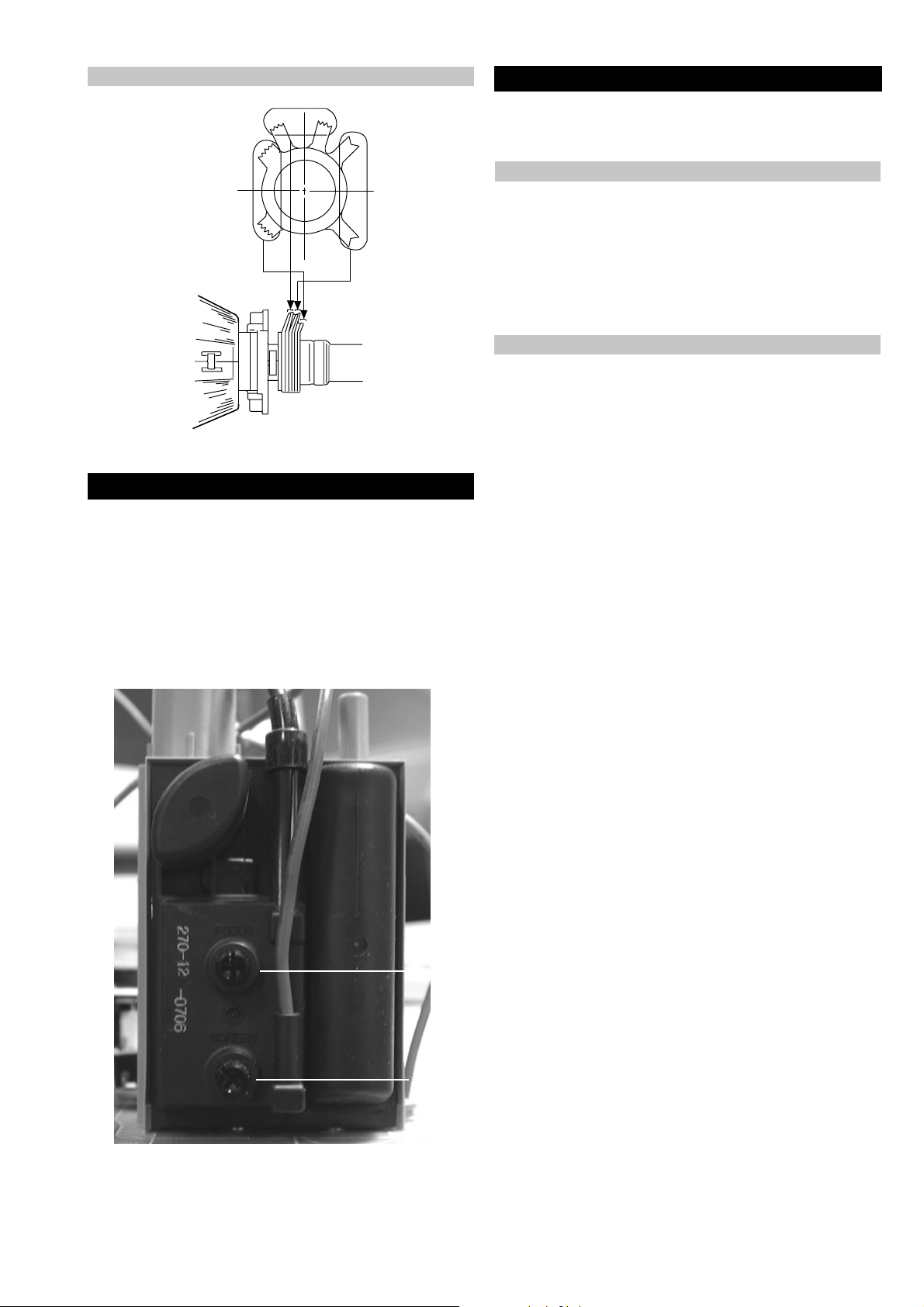

Removal of the Anode-Cap

* REMOVING PROCEDURES.

a

1

Turn up one side of the rubber cap in

the direction indicated by the arrow a

b

2 Using a thumb pull up the rubber cap

firmly in the direction indicated by the

arrow b

How to handle the Anode-Cap

1. To prevent damaging the surface of the anode-cap do not use

sharp materials.

2. Do not apply too great a pressure on the rubber, as this may cause

damage to the anode connector.

3. A metal fitting called a shatter hook terminal is fitted inside the

rubber cap.

4. Do not turn the rubber foot over excessively, this may cause

damage if the shatter hook sticks out.

c

b

Anode button

3 When one side of the rubber cap is

separated from the anode button, the

anode-cap can be removed by turning

up the rubber cap and pulling it up in

the direction of the arrow c

- 17 -

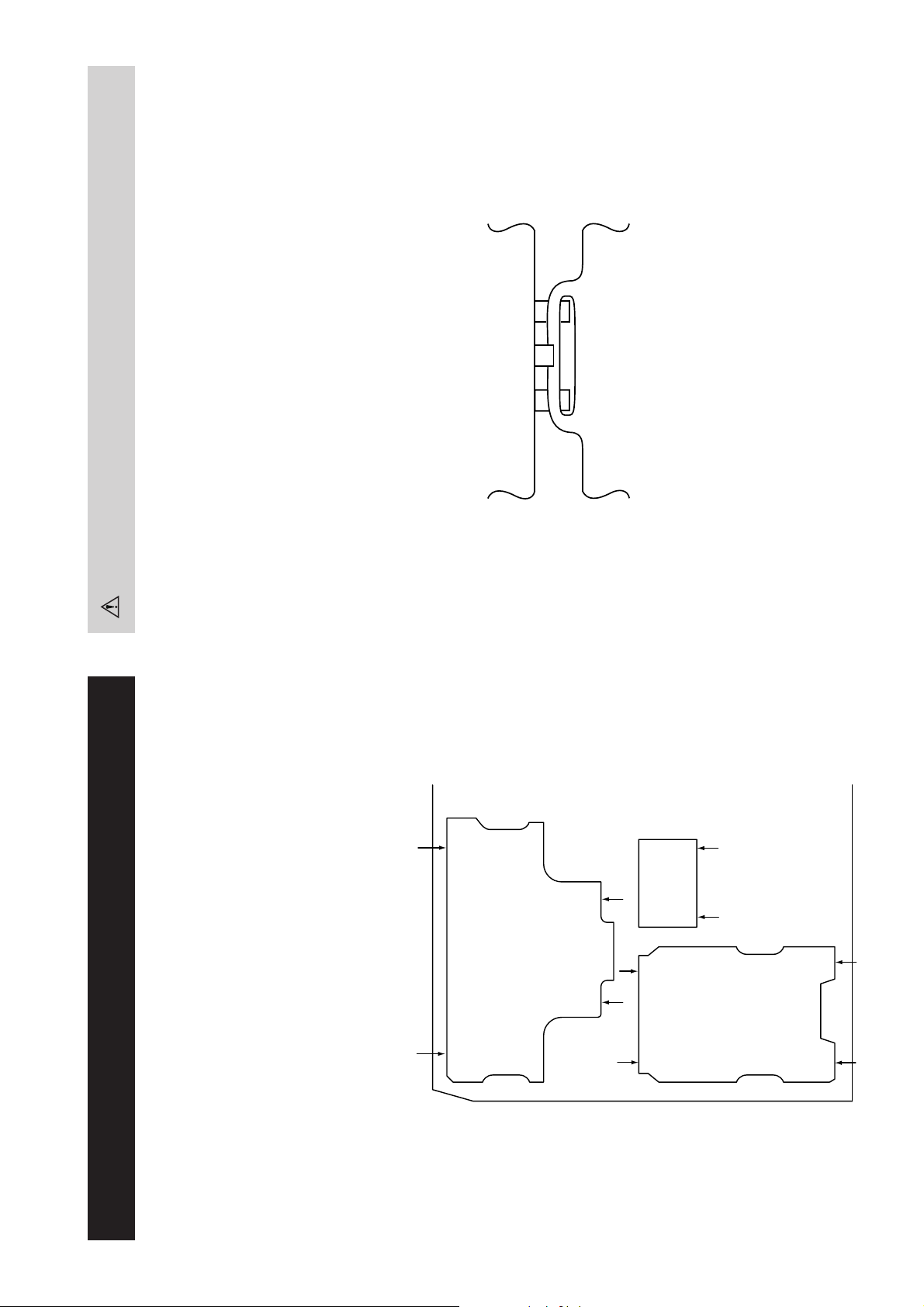

Page 18

Catch

For safety reasons, on no account should the plates be removed

and not refitted after servicing.

Because the plates differ in size it is important that the correct plates are refitted in their original

location.

Please note that the plates need to be rotated 180 degrees from their cut position to allow the

(2) REFITTING THE PLATES

tabs to be fitted into their catch positions.

Ta b

REMOVAL AND REPLACEMENT OF THE MAIN-BRACKET

BOTTOM PLATES.

Only remove the necessary plate to gain access to the printed wiring board.

In the event of servicing being required to the solder side of some of the printed wiring boards,

the bottom plates fitted to the main chassis bracket require to be removed.

This is performed by cutting the gates with a sharp wire cutter at the locations indicated by the

arrows.

(1) REMOVING THE PLATES

Note : There are 3 plates fitted to the main bracket and secured by3 gates.

- 18 -

Page 19

From time to time dust particles or condensation may get trapped between the glass panel and the TV screen. These instructions will

guide you through the steps required to both remove and re-fit the glass panel safely.

Removing the glass panel

NEVER attempt to remove the glass panel on your own - for safety reasons Sony recommends that two people carry out the

following procedure at all times.

Support the bottom of the glass

1

panel as shown AT ALL TIMES.

Trinitron

Supporting the glass panel, tilt it

away from the TV.

Push the clips located on the

2 3

underside o f the TV , as shown , to

release the glass panel.

Carefully remove the glass panel

and place it safely in an upright

position. To avoid injury or damage,

do not leave it on the floor.

Whilst pushing the release clip,

slide the glass panel up.

Clean both sides of the glas s and the

654

TV screen. Use a soft, damp, lin t free

cloth. Do not use any chemical

solutions or abrasive cleaners.

Re-fitting the glass panel

NEVER attempt to re-fit the glass panel on your own - for safety reasons Sony recommends that two people carry out the following

procedure at all times.

Lift the glass, and move toward

1

the TV.

While still maintaining forward

4

pressure to the bottom of the glass,

carefully slide the glass down until it

locks.

Insert the bot tom locating pins of

2

the glass panel into the keyhole

slots on the TV.

Locating pin

CAUTION

Before removing your hands check that you are unable to move the glass.

When correctly fi tted, th e pla stic rib sh own in the draw ing b elow s hould not b e

visible.

Tilt the glass panel forwards at the

3

top to engage all the locating pins,

then push forward firmly to secure.

Plastic rib

Safety No te

The glass panel suppl ied complies with all relevan t safety regul ations. How ever, should the glass becom e damaged at

any time, it is strongly recommended that a replacement is obtained from an authorised Sony dealer.

- 19 -

Page 20

SECTION 3 SET -UP ADJUSTMENTS

• When complete readjustment is necessary or a new picture

tube is installed, carry out the following adjustments.

• Unless there are specific instructions to the contrary, carry

out these adjustments with the rated power supply .

• Unless there are specific instructions to the contrary, set the

controls and switches to the following settings :

Contrast .................... 80% [or remote control normal]

Brightness................... 50%

Preparation:

1. In order to reduce the influence of geomagnetism on the

set’s picture tube, face it in an easterly or westerly direction.

2. Switch on the set’s power and degauss with the degausser .

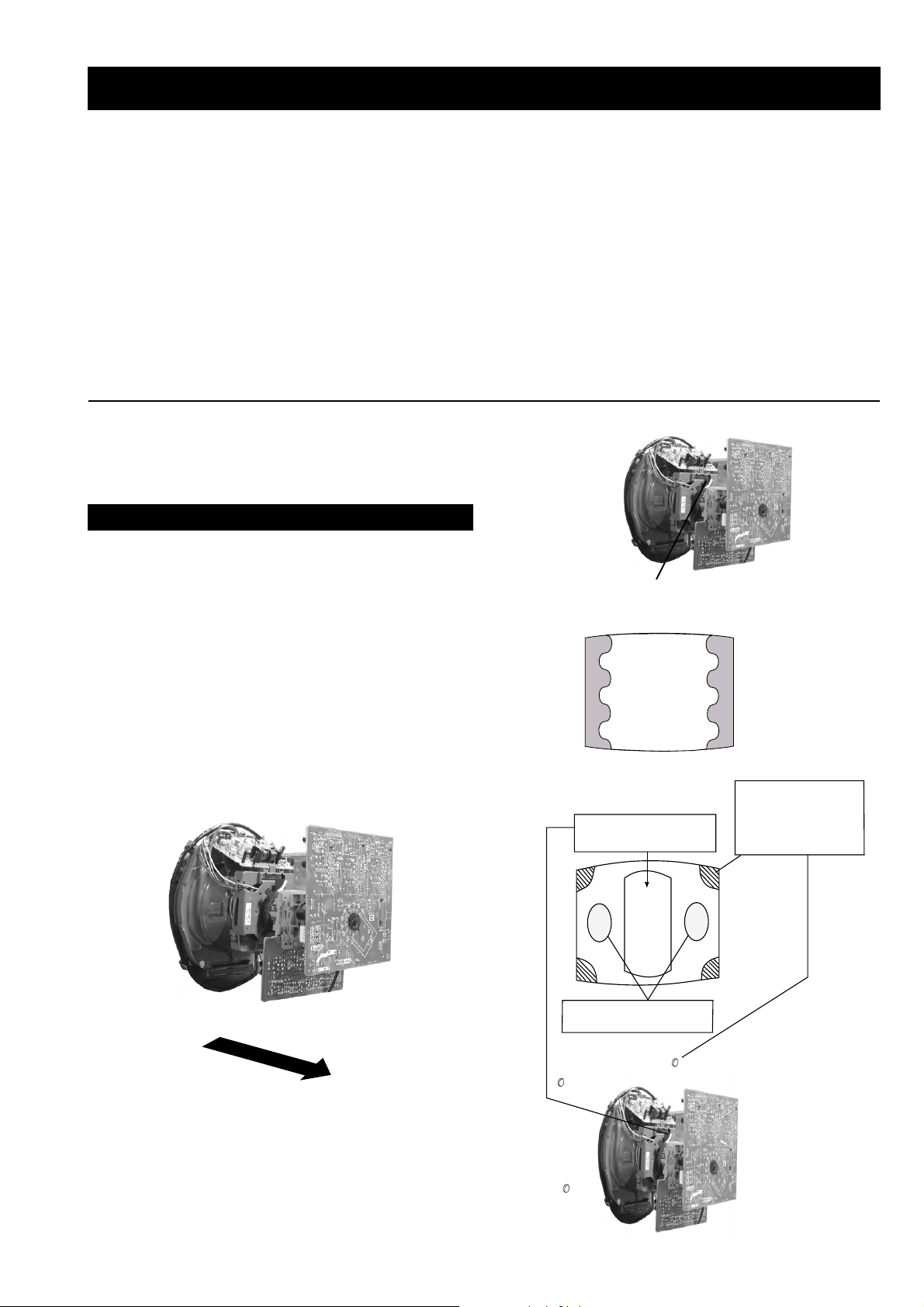

3-1. Beam Landing

1. Input an all white signal from the pattern generator. Set the

Contrast and Brightness to normal.

2. Set the pattern generator raster signal to Red.

3. Move the deflection yoke forward and adjust with the

purity control so that the Red is at the centre and the Blue

and Green take up equally sized areas on each side of the

screen. [See Fig.3-1 - 3-3].

4. Move the deflection yoke backwards and adjust so that the

entire screen becomes Red. [See Fig.3-1]

5. Switch the raster signal to Blue, then to Green and verify

the condition.

6. When the position of the deflection yoke has been

determined, fasten the deflection yoke with the screws.

7. If the beam does not land correctly in all the corners, use a

magnet to correct it. [See Fig.3-4]

Carry out the adjustments in the following order :

3-1. Beam Landing.

3-2. Convergence.

3-3. Focus.

3-4. White Balance.

Note : Test equipment required.

1. Color bar/pattern generator.

2. Degausser.

3. Oscilloscope.

4. Digital multimeter.

Fig. 3-2.

Purity

Fig. 3-3.

GREEN

RED

BLUE

Disk magnets or

rotatable disk

Purity control corrects

this area

magnets correct

these areas (a-d)

Fig. 3-1.

Caution :

High voltages are present on the Deflection yoke terminals

- take care when handling the Deflection yoke whilst carrying

out adjustments.

- 20 -

Disk Magnets

Fig.3-4

a

cd

Deflection yoke positioning

corrects these areas

b

Page 21

GBR

GBR

GBR

G

B

R

GBR

G

B

R

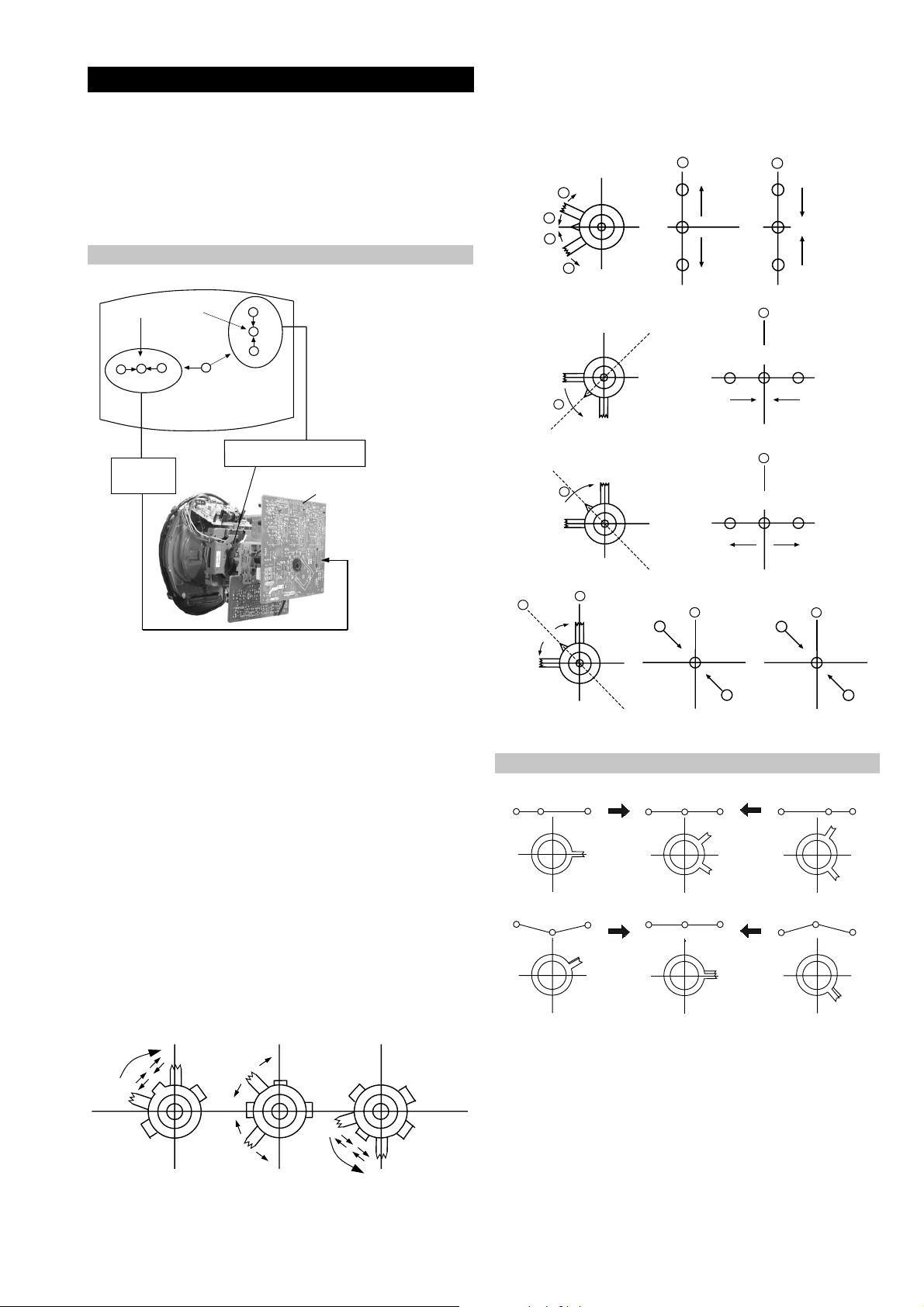

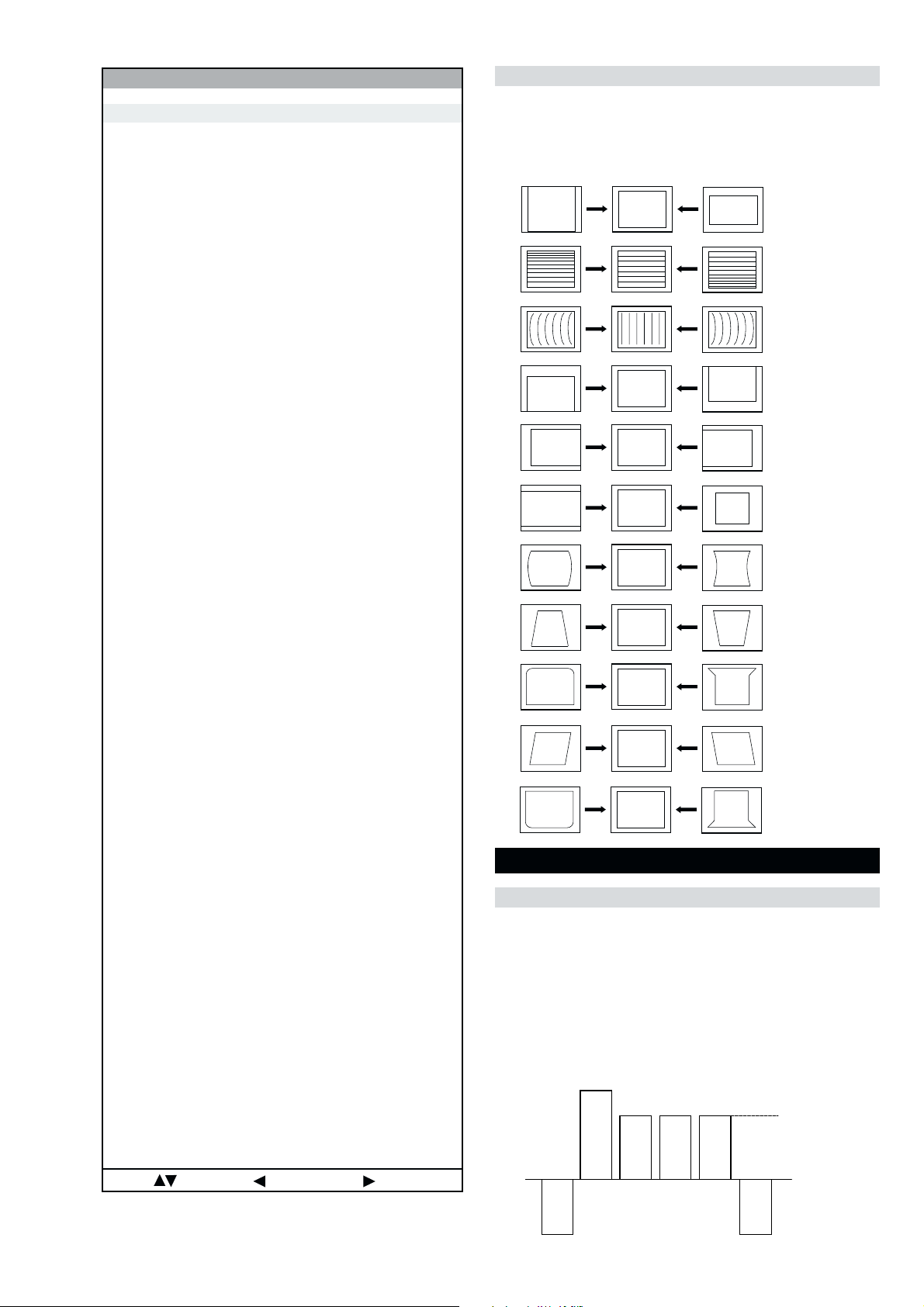

3-2. Con vergence

B

G

R

a

b

R

G

B

b

a

Preparation:

4. If the V.ST AT magnet is mov ed in the direction of the (a)

and (b) arrows, the Red, Green and Blue points move as

indicated below .

• Before starting this adjustment, adjust the focus, horizontal

size and vertical size.

• Minimize the Brightness setting.

• Input a dot pattern from the pattern generator.

Horizontal and Vertical Static Convergence

Center dot

R

G

B

H STAT

convergence

control

R

G

B

V.STAT Vertical Static Magnet

C Board

RV5375 (H STAT)

H STAT Convergence

(on mount side)

a

b

a

a

b

B

G

R

R

a

b

R

b

B

G

R

a

B

G

b

B

G

Fig.3-5

1. [Moving horizontally], adjust the H.ST AT control so that

the Red, Green and Blue points are on top of each other at

the centre of the screen.

Operation of the BMC (Hexapole) magnet.

2. [Moving vertically], adjust the V.ST AT magnet so that the

Red, Green and Blue points are on top of each other at the

centre of the screen.

3. If the H.STAT v ariable resistor is unable to bring the Red,

Green and Blue points together at the centre of the screen,

adjust the horizontal convergence with the H.STAT variable

resistor and the V.STAT magnet in the manner indicated

below.

[In this case, the H.ST AT variable resistor and the V.ST AT

magnet influence each other].

• Tilt the V.ST AT magnet and adjust the static con vergence by

opening or closing the V.STA T magnet.

The movement of the magnets interact with each other and so

the respective dot position should be monitored while carrying

out this adjustment.

Use the H.STA T VR to adjust the Red, Green and Blue dots so

that they coincide at the centre of the screen

(by moving the dots in the horizontal direction).

- 21 -

Page 22

+

YCH VR

Deflection Yoke

+

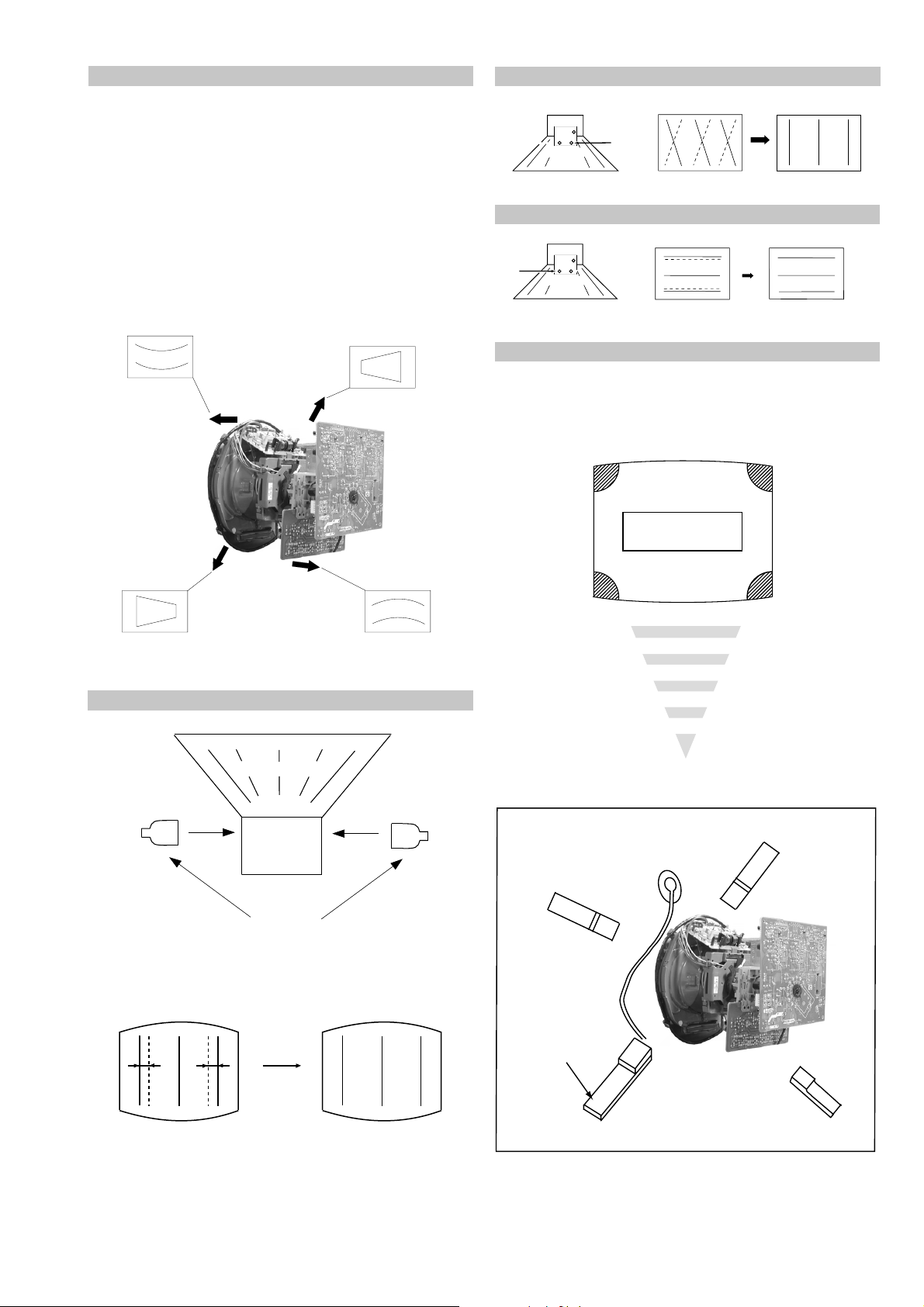

+

Geometry Adjustment.

Preparation:

Before starting this adjustment, adjust the horizontal and

vertical static convergence.

1. Remove the deflection yoke spacer.

2. Tilt the deflection yoke as indicated in the figure below and

optimise the geometry.

Tilting the D Y Up and Down will balance the upper and

lower pin adjustment.

Tilting the D Y Left and Right will balance the H-Trap

adjustment.

3. Re-install the deflection yoke spacer.

YCH Adjustment

TL V Adjustment

+

+

TLV VR

+

Deflection Yoke

Screen Corner Convergence

If you are unable to adjust the corner conver gence properly ,

this can be corrected with the use of permalloy magnets.

HTIL Adjustment

Deflection Yoke

TLH pieces

a

a-d: screen-corner

convergence defect

c

Install the permalloy assembly

for the area that needs correcting.

b

b

d

a

HTIL correction can be performed by adding a TLH correction

assembly to the Deflection yoke.

- 22 -

Permalloy Assy

X-4387-214-1

d

Convergence adjustment with permalloy

c

Page 23

Layout of each control

V.STAT

Purity

BMC (Hexapole)

3-3. Focus Adjustment

1. Receive a television broadcast signal.

2. Normalize the picture setting.

3. Adjust the focus control located on the flyback transformer

to obtain the best focus at the centre of the screen.

Bring only the centre area of the screen into focus, the

magenta-ring appears on the screen. In this case, adjust the

focus to optimize the screen uniformly.

3-4. Screen (G2), White Balance

[Adjustment in the service mode using the remote

commander]

G2 adjustment

1. Input a dot signal from the pattern generator.

2. Set the Picture, Brightness and Colour to minimum.

3. Apply 175V DC from an external power supply to the R,G and

B cathodes of the CRT.

4. Whilst watching the picture, adjust the G2 control [SCREEN]

located on the Flyback Transformer to the point just before the

flyback return lines disappear.

White balance adjustment for TV mode

1. Input an all-white signal from the pattern generator.

2. Program the Remote Commander for operation in Service Mode.

[ See Page 24 ]

3. Enter into the ‘Service Mode’ by pressing ‘VIDEO’, ‘VIDEO’

and ‘MENU’ ‘MENU’ on the Remote Commander.

4. Select ‘Device Register Setting’ > ‘Backend’ from the on screen

menu display .

5. Set the ‘Contrast’ to MAX.

6. Set the ‘R-Drive’ to 25.

7. Adjust the ‘G-Drive’ and the ‘B-Drive’ so that the white

balance becomes optimum.

8. Press the ‘OK’ button to write the data for each item.

9. Set the ‘Contrast’ to MIN.

10. Adjust the ‘G-Cutoff’, and the ‘R-Cutoff’ with the left and

right buttons on the remote commander so that the white

balance becomes optimum.

11. Press the ‘OK’ button to write the data for each item.

Focus

Screen

- 23 -

Page 24

SECTION 4 CIRCUIT ADJUSTMENTS

4-1. Electrical Adjustments

Service adjustments to this model can be performed using the

supplied remote Commander RM-935.

Programming the Remote Commander for Operation in Service Mode

1. Press the VCR/TV/DVD button until the TV

LED lights.

2. Press and hold the yellow button for approx. 5

seconds until the TV LED flashes quickly.

3. Press 99999. All three LED’s should light.

The remote commander is now set to Service Mode.

4. To return the remote commander to normal operation mode

repeat steps 1. and 2. then press 00000. All three LED’s

should light.

The remote commander is now set to normal mode.

Setting the TV into Service Mode

1. Program the remote commander for operation in Service

Mode as described above.

2. Turn on the TV main power switch.

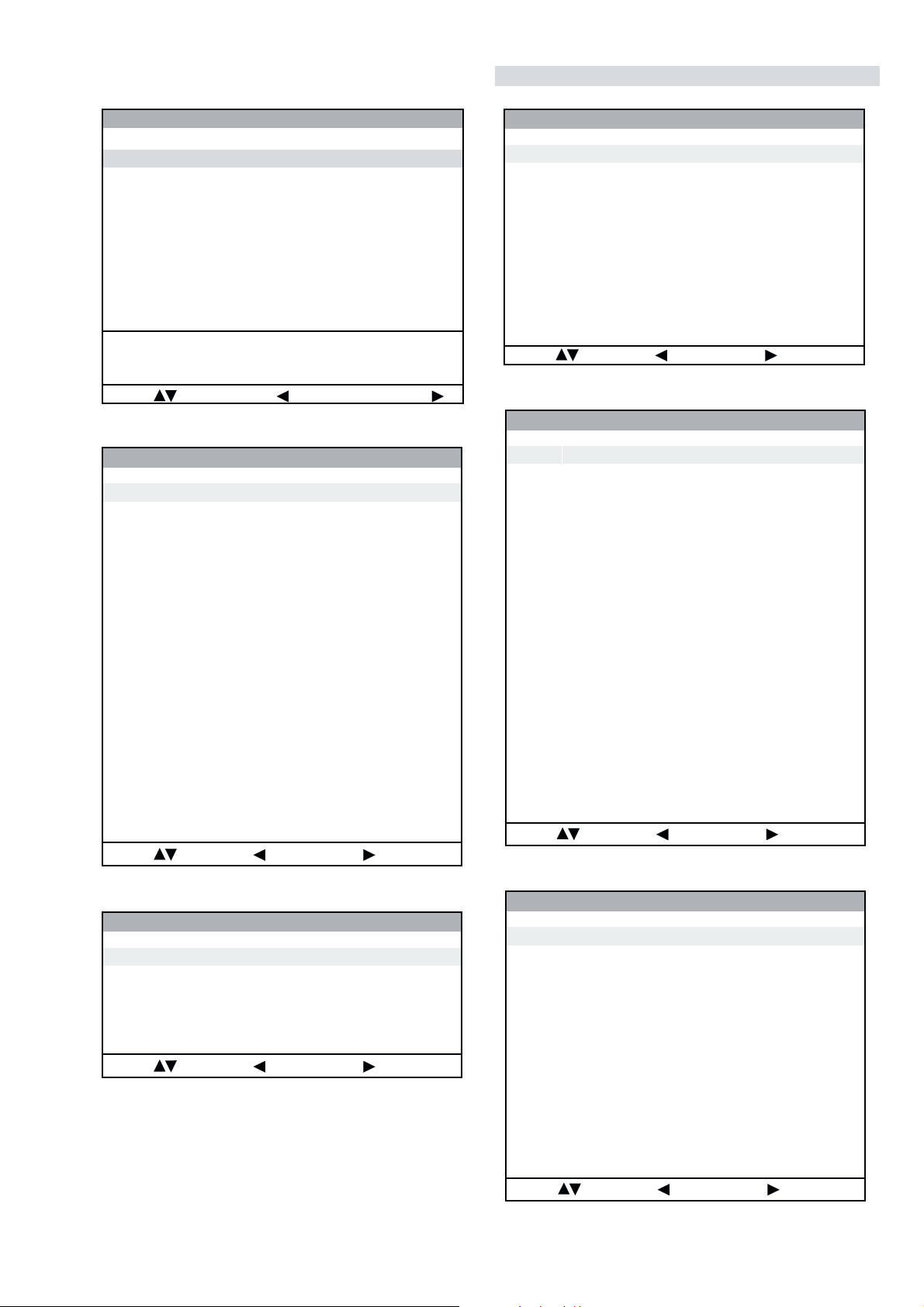

Initialising Menu

gnisilaitinI

gnitteSledoM

gnitteSnoitanitseD

gnitteScisaB

gnitteSerutaeF

:tceleS:unemtxeN

Model Setting

The menu contains a list with all the available models of this

software to set up the TV set in an easy way. The selection

of a model is setting data for its features and hardware

resources which cannot be detected by the automatic power

on H/W detection as well as a special model byte to get an

unique model identification for models which cannot be

differed by features and hardware resources

(e.g. KD-32DX100U and KD-32NX100U).

Before data is set, the user will be asked if he really wants to

set a new model. If the user agrees, the destination setting

menu is automatically shown.

3. Press the ‘VIDEO’ button on the remote commander

twice.

‘TT ’ will appear in the upper right corner of the screen.

4. Press the ‘MENU’ button on the remote commander twice

to obtain the following menu on the screen.

T094v,100212peS,D6EAecivreS

gnisilaitinI

seciveDteseR

gnirotinoM

gnitteSretsigeReciveD

tnemtsujdAlaicepS

:tceleS:unemtxeN

5. Move to the corresponding adjustment item using the

up or down arrow buttons on the Remote Commander.

6. Press the right arrow button to enter into the required menu item.

7. Press the ‘Menu’ button on the Remote Commander to quit the

Service Mode when all adjustments have been completed.

Note :

• Before performing any adjustments ensure that the correct model

has been selected in the ‘Model Setting’ menu.

• After carrying out the service adjustments, to prevent the

customer accessing the ‘Service Menu’ switch the TV set

OFF and then ON.

gnitteSledoM

teseR001XN23-DK

001SN23-DK

001XD82-DK

001XD23-DK

ytimrofnoCoN=KCALB

ledoMelbitapmoC=NEERG

atadllarofytimrofnoC=DER

:tceleS:unemtsaL:ledoMteS

Indication of Model Compatibility.

Black:

If any data does not match to specific model, the model name

is displayed in black.

Green:

All data which is checked by model setting menu concurs to

model except model byte.

Red:

All data which is checked by model setting menu concurs to

model including model byte.

Note:

After selecting a model, it may be necessary to reset some

devices to get the correct data. (Treble/Bass Offset of Sound,

deflection adjustments, ...)

- 24 -

Page 25

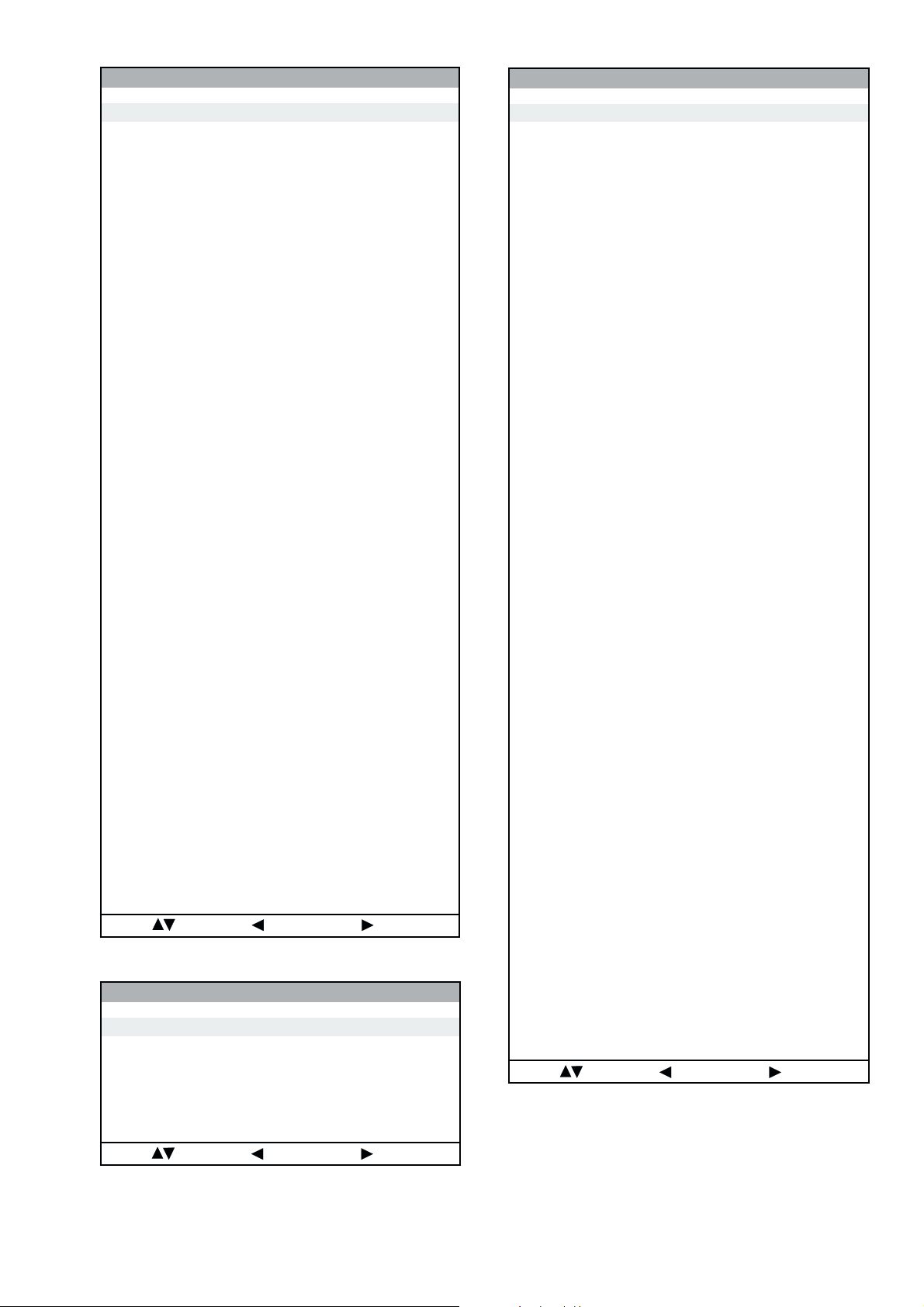

gnitteSretsigeReciveD

dnekcaB

noitcelfeD

noitcelfeDtxE

ecnegrevnoCcimanyD

1redoceDruoloC

hctiwSoediV/oiduA

X-diM

X-diMLLPlanretxE

pihCyarrAetaG

dnuoS

:metIretnE:unemtsaL:tceleS

gnitteSnoitanitseD

A

B

D

E

K

R

U

ytimrofnoCoN=KCALB

ledoMelbitapmoC=NEERG

:tceleS:unemtsaL:ledoMteS

Device Register Setting

teseRitluM

atadllarofytimrofnoC=DER

hctiwSoediV/oiduA

gnitteScisaB

oN rcseD niM xaM ataD

1G/B.sySFFONONO

2K/D.sySFFONONO

3L.sySFFONONO

4)KU(I.sySFFONONO

5)LRI(I.sySFFONOFFO

6noitpo.taNTXT143

7TRC9:61FFONONO

8refoow-buSFFONONO

9yb-dnatsotuAFFONONO

01retlif-bmoCFFONONO

11tedCYotuAFFONONO

21tedbmocotuAFFONONO

31elbaliavA2VAFFONONO

41elbaliavA3VAFFONONO

51elbaliavA4VAFFONONO

61raer&rF3VAFFONOFFO

71epaTMACESFFONONO

81etuMdnuoS1VAFFONOFFO

:metIretnE:unemtsaL:tceleS

gnitteSerutaeF

oN rcseD niM xaM ataD

1PAPFFONOFFO

2TAPFFONOFFO

3XEDNIFFONOFFO

4GPEFFONONO

:metIretnE:unemtsaL:tceleS

oN rcseD feD niM xaM ataD

11TUOVC0090

22TUOVC2092

3WS1DGFFOFFONOFFO

4WS2DGFFOFFONOFFO

51TUOCY0070

62TUOCY1071

7LRTC0OLFFOFFONOFFO

8LRTC1OLFFOFFONOFFO

91TUOA3073

012TUOA3073

11ETUM3TUOAFFOFFONOFFO

21WSDCZNOFFONONO

313TUOA3073

41LEDPUORG5101351

51R/L3TUOA0030

61FLOV3TUOA0070

71CLOV3TUOA3073

811CNYS1011

912CNYS1011

oN rcseD feD niM xaM ataD

1TRAMSFFOFFONOFFO

2evruCMOR0010

3DPCADFFOFFONOFFO

41LLITSV0010

51S0010

60S0010

7LCDV1011

8WSFF1011

9IKP1011

01HF1011

11VF1011

21tesFFOH051-510

- 25 -

:metIretnE:unemtsaL:tceleS

pihCyarrAetaG

:metIretnE:unemtsaL:tceleS

Page 26

1redoceDruoloC

dnekcaB

oN rcseD feD niM xaM ataD

1no-RNOFFONONO

2no-GNOFFONONO

3no-BNOFFONONO

4loc-D0030

5wS-bWFFOFFONOFFO

6L-ammaGFFOFFONOFFO

7tsartnoC0403604

8mottoB-KLB3033

9euH8203682

01sixA-ruoloC1031

11ruoloC1303613

21leveL-ITC2032

31ssenthgirB5203652

41lbA-S0030

51ssenprahS5203652

61leveL-ITL0030

71evirD-R5303653

81lvL-timiLP0030

91evirD-G1403602

02edoM-LBA0030

12evirD-B1403602

22edoM-ITC0032

32thgirBbuS603631

42ammaG0031

52ffotuC-R1303613

62edom-ITL1031

72ffotuC-G7203652

82leveL-CIPD1032

92ffotuC-B1303603

03narT-CD1031

13tnoC-buS805151

23lvL-2BGRL80518

33lbA-P5105151

43HT-LBA00510

53tesffo-BC5203652

63W-gnigAFFOFFONOFFO

73B-gnigAFFOFFONOFFO

83tesffo-RC5203652

93metsyS1031

04tesffo-Y70517

14leveL-MV1031

24OFprahSNOFFONONO

34ffO-DCFFOFFONOFFO

44DCprahS2032

541FprahS0030

64revO/erP2032

74roC-MV0031

840F-MV2032

94timiL-MV3033

05yaleD-MV2032

15ruoloCbuS08-80

:metIretnE:unemtsaL:tceleS

oN rcseD feD niM xaM ataD

1tniT1303613

2wGN/PFFOFFONOFFO

3DIN/PFFOFFONOFFO

4ruoloCbuS70517

5rtnoCbuS80518

6OFprahS1031

7QEprahS2032

8niaGprahS90518

9veLtuO-Y5303653

01tnioPSB0030

11veLtuO-C5403654

21tseRCD0030

31OFFPB1031

41QFPB1031

51wSretliFFFOFFONOFFO

61wSparT-C1010

71parTD-SNOFFONONO

81FPLNOFFONONO

91LD-Y80018

02bmoC-NNOFFONONO

12leSoediV00510

22leSBGR0030

32enoTflaHFFOFFONOFFO

421.FFOrC70517

521.FFObC70517

622.FFOrC70517

722.FFObC70517

82qerFDCV3073

92edoMDCV1031

03SNESCFA1031

13MVMFFOFFONOFFO

23jdAY-RS60516

33jdAY-BS40514

43FPH/LLEB2032

53OFLLEBFFOFFONOFFO

63PGS0030

73DISFFOFFONOFFO

83BNE1BGRFFOFFONOFFO

93HP-SH0010

04WSotuA1011

14DI-C1010

14HP-PV0010

24OITARN/S3033

:metIretnE:unemtsaL:tceleS

noitcelfeD.txE

oN rcseD feD niM xaM ataD

1esahPFD5810552581

2esahPPQD5210552521

3raeniLdiM5310552651

4pmacaPQD2310552231

5lvLcdPQD6210552621

:metIretnE:unemtsaL:tceleS

- 26 -

Page 27

noitcelfeD

Deflection System Adjustment

1. Program the Remote Commander for operation in Service Mode.

oN rcseD feD niM xaM ataD

1eziS-H1403615

2noitisoP-H9203642

3eziS-V6403634

4noitisoP-V7203682

5pmA-niP1203672

6nipC-pU7203613

7nipC-oL2303614

8woB-CFA2303623

9elgnA-CFA3203692

01esahP-niP3203671

11niL-V70518

21rroC-S50517

311-noitatoR1031

412-noitatoR5105151

51parT-H101341

61raeniLH58055275

71pmA-raP-CH8303683

81pmA-raP-PM70517

91sixAniPpU3033

02sixAniPoL3033

12niaGniPpU3033

22niaGniPoL2032

32miT-BKA5101351

42ffO-KLBFFOFFONOFFO

52ffO-BKAFFOFFONOFFO

62klB-pU00510

72klB-oL00510

82nO-VNOFFONONO

92cD-wEFFOFFONOFFO

03loP-cUFFOFFONOFFO

13wS-klbVFFOFFONOFFO

23esahP-cnyS0030

33edoM-CFA2032

43wS-tsRFFOFFONOFFO

53klB-tfeL2503625

63esahP-plC3033

73klB-thgiR0303684

83etaG-plCFFOFFONOFFO

93wS-klbHNOFFONONO

04tcepsA-V00360

14wS-mooZFFOFFONOFFO

24wS-pmJFFOFFONOFFO

34llorcS-V1303613

44qerF-V2032

54nilV-pU00510

64nilV-oL00510

74pmoC-V60516

84pmoC-H00510

94cD-1waSV70517

05pmoC-niP4075

15pmA-1waSV00130

25pmoC-CFA0070

35cD-raP-PM20512

45cD-raP-CH1303613

55wS-psAFFOFFONOFFO

65wS-vrDVFFOFFONOFFO

75ahP-raP-CH1303613

[ See Page 24 ] and enter into ‘Service Mode’ by pressing

‘VIDEO’ button twice. Enter into the ‘Device Register Setting’

then ‘Deflection’ service menu.

2. Select and adjust each item in order to obtain the optimum image.

4-2. Volume Electrical Adjustments

Sub Colour Adjustment

1. Input a PAL colour bar signal.

2. Connect an oscilloscope to CN5400 pin 5 located on the C

Board.

3. Program the Remote Commander for operation in Service Mode.

[ See Page 24 ] and enter into ‘Service Mode’ by pressing

‘VIDEO’ button twice. Enter into the ‘Device Register Setting’

then ‘Backend’ service menu.

4. Adjust ‘Sub Colour’ data so that the right sides of the waveform

are of equal height.

V SIZE

V LIN

AFC BOW

V POSITION

H POSITION

H SIZE

PIN AMP

PIN PHASE

UP-CPIN

AFC ANGLE

LO-CPIN

Same Level

:metIretnE:unemtsaL:tceleS

B-Out Waveform

- 27 -

Page 28

4-3. TEST MODE 2:

Test Mode 2 is available by programming the remote commander for operation in service mode (see page 24) and pressing the ‘VIDEO’ button

twice, OSD ‘TT’ appears. The functions described below are available by selecting the two numbers. To release the ‘Test mode 2’, press ‘0’

twice or switch the TV set into Stand-by mode.

00

10

20

30

40

50

60

70

80

01

11

21

31

41

51

61

71

81

91

02

12

22

32

42

52

62

72

82

03

13

23

33

43

53

63

73

83

93

04

14

24

34

44

54

64

74

84

94

05

15

25

35

ffoedom'TT'

mumixamerutciP

muminimerutciP

)enohpdaeh/rekaeps(%03=emuloV

)enohpdaeh/rekaeps(%05=emuloV

)enohpdaeh/rekaeps(%56=emuloV

)enohpdaeh/rekaeps(%08=emuloV

edomgniegA

noitidnoCgnippihS

noitcnufoN

45

55

65

75

85

95

06

16

26

36

tnemtsujdaerutcipbuS

tnemtsujdaruolocbuS

noitarugifnoctesVTdnanoisreverawtfosyalpsiD

noitcnufoN

tsetnoitatoRerutciP

%05levelerutciP

noetumoiduA

noitcnufoN

tnemtsujdassenthgirbbuS

noitcnufoN

AnoitanitseD

LnoitanitseD

EnoitanitseD

UnoitanitseD

DnoitanitseD

BnoitanitseD

KnoitanitseD

RnoitanitseD

noitcnufoN

1tnemtsujdAyrtemoeG

2tnemtsujdAyrtemoeG

rotinomrorrE

noitcnufoN

sutatsVTyalpsiD;9:61><3:4TRC

hctiwsnoitceted32eniL

tset)MV(noitaludoMyticoleV

noitcnufoN

noitcnufoN

noitcnufoN

kcehcedomneercS

)99margorp(yrtemoegesilaitini-eR

noitcnufoN

001CRD

05CRD

rednammocrelaedrofdevreseR

)99margorp(MVNesilaitini-eR

nigrivnonsaMVNteS

46

56

76

86

96

07

17

27

37

47

57

67

77

87

18

28

38

48

58

68

78

88

09

19

29

39

49

59

69

79

89

99

noitcnufoN

noitcnufoN

noitcnufoN

noitcnufoN

rotcennocecivresotatadMVNdneS

rotcennocecivresmorfatadMVNteS

noitcnufoN

edomecivreS

edomnoitcudorP

ehtotniMORmorfatadteser-erutcipehtypoC

MVNfonoitacolteser-erutcip

ehtotniMVNmorfataderutcipjdalautcaehtypoC

MVNfonoitacolteser-erutcip

sedocrorreteseR

teserdraobN

nosrorreerongI

ffosrorreerongI

noitcnufoN

lanretxe/AMARONAPfosetadtluafedypoC

MVNotniMORmorfXDIM/DIM/LLP

tsetknilVA

slebalnoitatslladna5-1tpecxesemmargorpllaraelC

,DIMrofniPrenroCreppU/pmANIProftnemtsujdA

edom10521dnaGPE

,DIMrofdiozeparT/niPrenroCrewoLroftnemtsujdA

edom10521dnaGPE

edom10521rofniPMroftnemtsujdA

kcehcretsooBerutciP

FFOetumoediV

edomyalpsidREB

edomrotinomVA

ffO/nOraBruoloClanretnIAMME

raelcMORPEE

tamrof-ermetsyseliF

srehto/d2EF

teserDIlanosreP

gnippihslatigiD

noitcnufoN

htiw)noitcelfeD.txE/esahPsucoF(tnemtsujdasucoF

nottubkcitsyojthgirdnatfel

.txE/esahPsucoFleveLCD(tnemtsujdasucoF

nottubkcitsyojthgirdnatfelhtiw)noitcelfeD

ylnopuorgerawtfosrofdevreseR

00ybdesaeler,dnammoctsetedomXEDNI

FFO/NOetumDSO

eludomIChguorhtssapST

dnammoctsetTTlatigiD

elbasid/elbaneyrevocerAMME

00ybdesaeler,kcehcrekaepS

nigrivsaMVNteS

noitcnufoN

noitcnufoN

noitcnufoN

noitcnufoN

- 28 -

Page 29

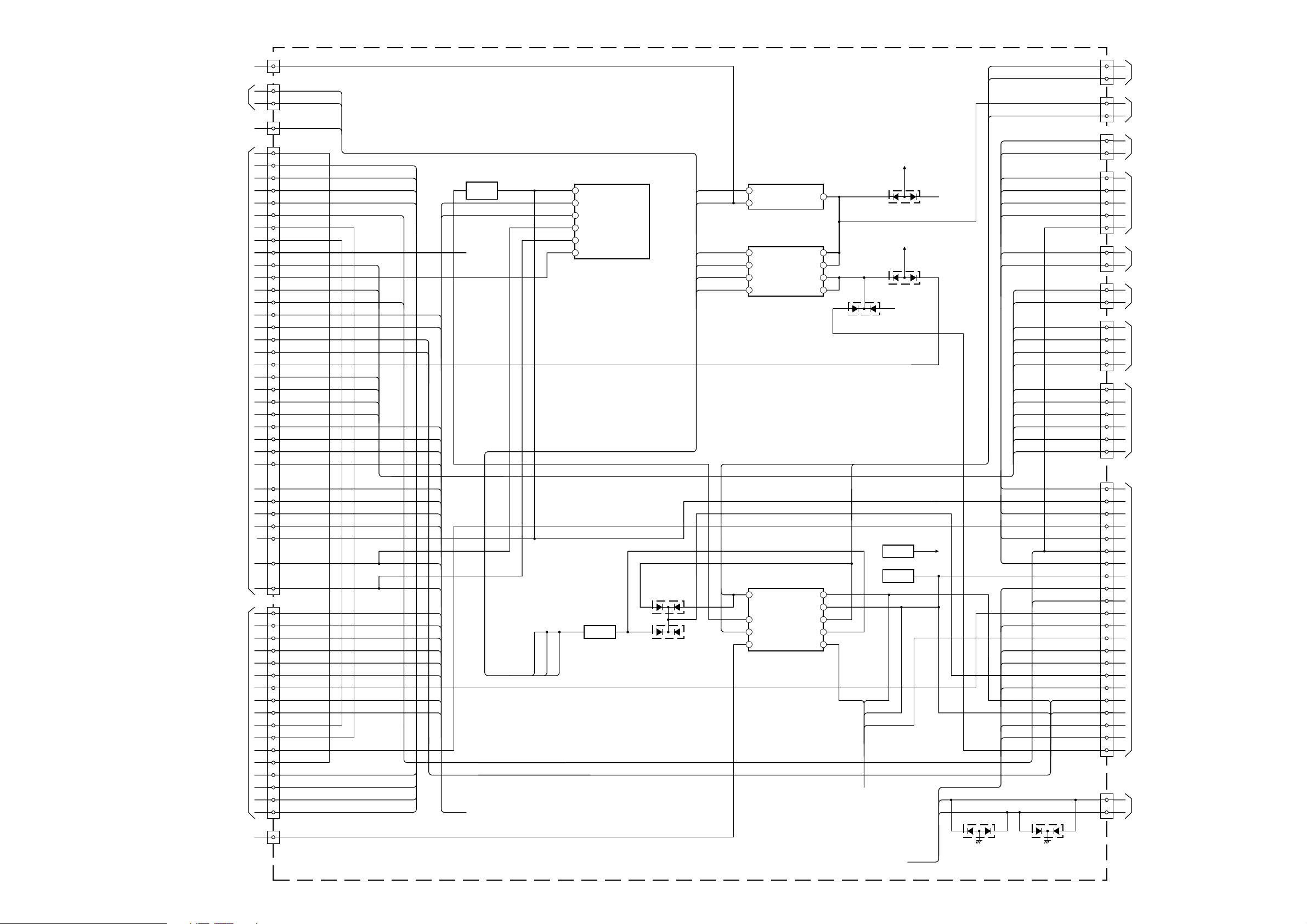

5-1. BLOCK DIAGRAMS (1)

RIGHT SP

A 1/3 (

)

PIC/SOUND

CN2000

1 15

IC1008

I/O EXPANDER

OCP

TO G BOARD

CN6006

12

13

OVP

CN1602

MAIN RY

TO G BOARD

CN6008

1

2

DGC RY

CN1703

KEY 2/SCL 3.3

TO FRONT

CONTROL

(3 PIN)

1

3

KEY 1/SDA 3.3HM(2)

HM(1)

CN1706

KEY 2/SCL 3.3

1

3

KEY 1/SDA 3.3HM(2)

HM(1)

5

SIRCS/AV INTHM(4)

6

RESP LED/RESETHM(3)

7

AV LINK

CN1702

SIRCS

TO H6 BOARD CN7100

(KD-32DX100)

TO H2 BOARD CN7150

(KD-32NS100/32NX100)

3

4

LEDHM(3)

HM(4)

CN7107

HEADPHONE R OUT

TO H3 BOARD

CN7104

1

3

HEADPHONE L OUTHP L

HP R

CN7108

AV4 CHROMA IN

TO H1 BOARD

CN7103

1

3

AV4 LUMINANCE INAV4 Y

AV4 C

AV4 LEFT IN

5

AV4 L