Sony ICFCD-837 Service manual

ICF-CD837

SERVICE MANUAL

Ver. 1.1 2005.07

Section

SPECIFICATIONS

US Model

Canadian Model

Australian Model

Model Name Using Similar Mechanism ICF-CD832

CD

CD Mechanism Type KSM-213CDP

Optical Pick-up Name KSS-213C

E Model

AUDIO POWER SPECIFICATIONS (US model)

POWER OUTPUT AND TOTAL HARMONIC DISTORTION

With 8-ohm loads, both channels driven from 100 – 10,000 Hz; rated

1.0 W per channel minimum RMS power, with no more than 10% total

harmonic distortion in AC operation.

CD player section

System:

Compact disc digital audio system

Laser diode properties:

Material: GaAlAs

Wav elength: 780 nm

Emission duration: Continuous

Laser output: Less than 44.6 µW

(This output is the value measured at a distance of

about 200 mm from the objective lens surface on

the optical pick-up block with 7 mm aperture.)

Frequency response:

20 – 20,000 Hz dB

Wow and flutter:

Below measurable limit

Radio section

Frequency range:

FM: 87.5 – 108 MHz

AM: 530 – 1,710 kHz

+1

–1.5

General

Time display:

12-hour system

Speaker:

66 mm (2 5 ⁄8 inches) dia., 8 Ω

Power outputs:

1 W + 1 W (at 10% harmonic distortion)

Power requirements:

120 V AC, 60 Hz (Except Australian model)

230 V AC, 50 Hz (Australian model)

Dimensions:

Approx. 246 × 96 × 210 mm (w/h/d)

(Approx. 9 3/4 × 3 7/8 × 8 3 ⁄8 inches) incl.

projecting parts and controls

Mass:

Approx. 1,750 g (3 lb. 86 oz.)

Design and specifications are subject to change without

notice.

9-879-522-02

2005G04-1

© 2005.07

FM/AM CD CLOCK RADIO

Sony Corporation

Personal Audio Group

Published by Sony Engineering Corporation

1

ICF-CD837

CAUTION

Use of controls or adjustments or performance of procedures other than those specified herein may result in hazardous radiation exposure.

Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270˚C during

repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

Notes on Chip Component Replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be dam-

aged by heat.

NOTES ON HANDLING THE OPTICAL PICK-UP BLOCK

OR BASE UNIT

The laser diode in the optical pick-up block may suffer electrostatic

breakdown because of the potential difference generated by the

charged electrostatic load, etc. on clothing and the human body.

During repair, pay attention to electrostatic breakdown and also use

the procedure in the printed matter which is included in the repair

parts.

The flexible board is easily damaged and should be handled with

care.

SAFETY CHECK-OUT

After correcting the original service problem, perform the following safety check before releasing the set to the customer:

Check the antenna terminals, metal trim, “metallized” knobs, screws,

and all other exposed metal parts for AC leakage.

Check leakage as described below.

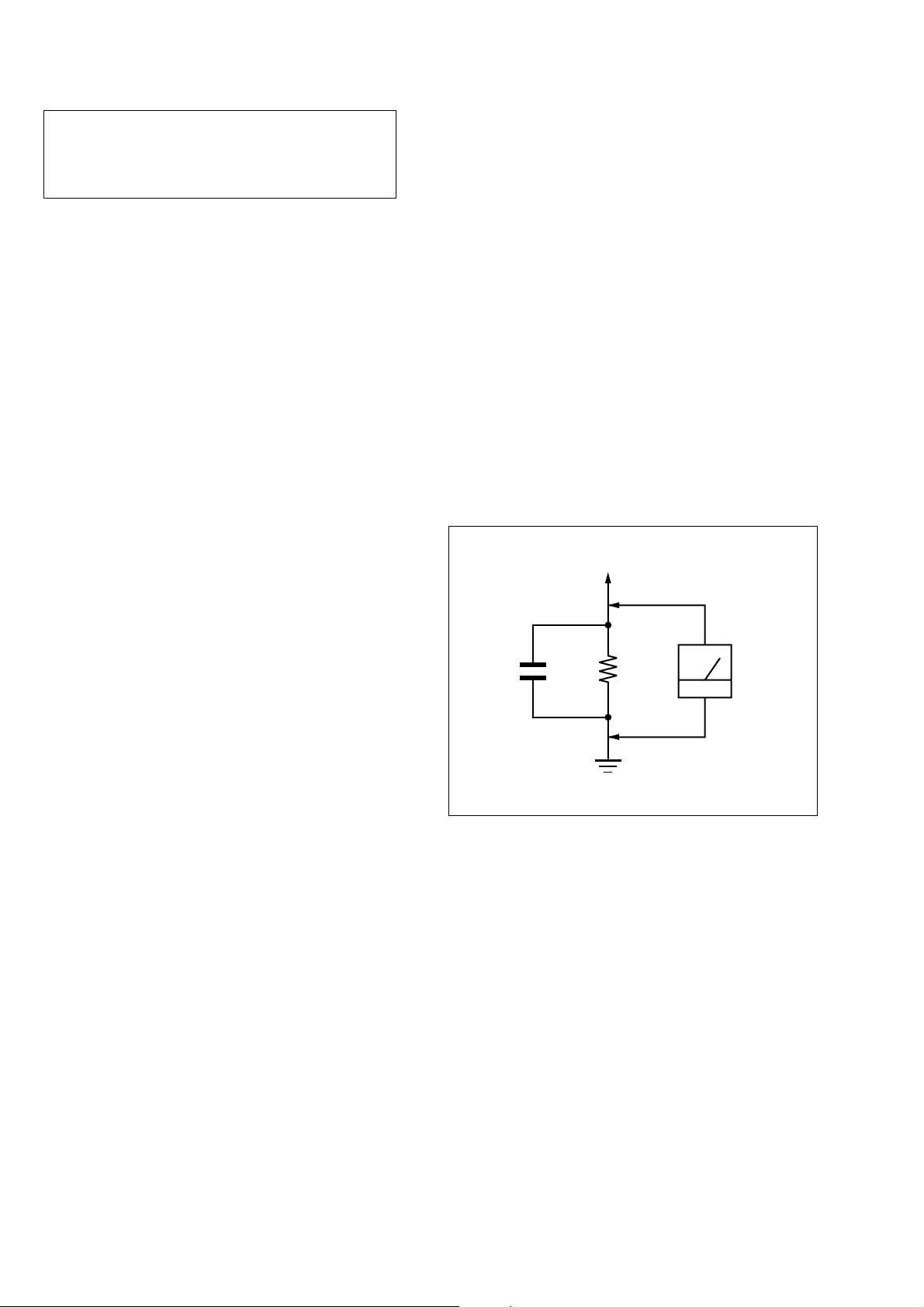

LEAKAGE TEST

The AC leakage from any exposed metal part to earth ground and

from all exposed metal parts to any exposed metal part having a

return to chassis, must not exceed 0.5 mA (500 microampers.).

Leakage current can be measured by any one of three methods.

1. A commercial leakage tester, such as the Simpson 229 or RCA

WT-540A. Follow the manufacturers’ instructions to use these

instruments.

2. A battery-operated AC milliammeter. The Data Precision 245

digital multimeter is suitable for this job.

3. Measuring the voltage drop across a resistor by means of a

VOM or battery-operated AC voltmeter. The “limit” indication is 0.75 V, so analog meters must have an accurate lowvoltage scale. The Simpson 250 and Sanwa SH-63Trd are examples of a passive VOM that is suitable. Nearly all battery

operated digital multimeters that have a 2 V AC range are suitable. (See Fig. A)

To Exposed Metal

Parts on Set

NOTES ON LASER DIODE EMISSION CHECK

The laser beam on this model is concentrated so as to be focused on

the disc reflective surface by the objective lens in the optical pickup block. Therefore, when checking the laser diode emission,

observe from more than 30 cm away from the objective lens.

0.15 µF

1.5 k

Ω

Earth Ground

AC

voltmeter

(0.75 V)

Fig. A. Using an AC voltmeter to check AC leakage.

(Fig. A)

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED LINE

WITH MARK 0 ON THE SCHEMATIC DIAGRAMS AND IN

THE PARTS LIST ARE CRITICAL TO SAFE OPERATION.

REPLACE THESE COMPONENTS WITH SONY PARTS WHOSE

PA RT NUMBERS APPEAR AS SHOWN IN THIS MANUAL OR

IN SUPPLEMENTS PUBLISHED BY SONY.

2

ATTENTION AU COMPOSANT AYANT RAPPORT

À LA SÉCURITÉ!!

LES COMPOSANTS IDENTIFIÉS PAR UNE MARQUE 0 SUR LES

DIAGRAMMES SCHÉMATIQUES ET LA LISTE DES PIÈCES

SONT CRITIQUES POUR LA SÉCURITÉ DE FONCTIONNEMENT.

NE REMPLACER CES COMPOSANTS QUE PAR DES PIÈCES

SONY DONT LES NUMÉROS SONT DONNÉS DANS CE MANUEL

OU DANS LES SUPPLÉMENTS PUBLIÉS PAR SONY.

ICF-CD837

UNLEADED SOLDER

•

Boards requiring use of unleaded solder are printed with the leadfree mark (LF) indicating the solder contains no lead.

(Caution: Some printed circuit boards may not come printed with

the lead free mark due to their particular size.)

: LEAD FREE MARK

Unleaded solder has the following characteristics.

• Unleaded solder melts at a temperature about 40°C higher than

ordinary solder.

Ordinary soldering irons can be used but the iron tip has to be

applied to the solder joint for a slightly longer time.

Soldering irons using a temperature regulator should be set to

about 350°C.

Caution: The printed pattern (copper foil) may peel away if

the heated tip is applied for too long, so be careful!

• Strong viscosity

Unleaded solder is more viscous (sticky, less prone to flow)

than ordinary solder so use caution not to let solder bridges

occur such as on IC pins, etc.

• Usable with ordinary solder

It is best to use only unleaded solder but unleaded solder may

also be added to ordinary solder.

TABLE OF CONTENTS

1. SERVICING NOTES

1-1. Cord Dressing (Power Cord) ............................................... 5

1-2. Pointer Alignment ............................................................... 5

2. GENERAL............................................................................ 6

3. DISASSEMBLY

3-1. Cabinet (Upper) Assy .......................................................... 8

3-2. Front Panel Assy ................................................................. 8

3-3. Power Board ........................................................................ 9

3-4. Main Board Section ............................................................ 9

3-5. Main Board, CD Block Assy............................................. 10

3-6. CD Mechanism Deck ........................................................ 10

3-7. CD Board .......................................................................... 11

3-8. Optical Pick-up ................................................................. 11

3-9. Lid (CD) ............................................................................ 12

3-10. LED Holder Assy .............................................................. 12

3-11. LED Indicator Element Unit ............................................. 13

3-12. Indicator Board, Drive Board ............................................ 13

4. ELECTRICAL ADJUSTMENTS

Tuner Section......................................................................... 14

CD Section ............................................................................ 15

5. DIAGRAMS

5-1. Block Diagram – CD Section – ......................................... 17

5-2. Block Diagram – Main Section – ...................................... 18

5-3. Circuit Boards Location .................................................... 19

5-4. Printed Wiring Board – CD Section – ............................... 20

5-5. Schematic Diagram – CD Section – .................................. 21

5-6. Printed Wiring Boards – Main Section – .......................... 22

5-7. Schematic Diagram – Main Section – ............................... 23

5-8. Printed Wiring Boards – Display Section – ...................... 24

5-9. Printed Wiring Board – Key Section – .............................. 25

5-10. Schematic Diagram – Display Section – ........................... 26

5-11. Printed Wiring Board – Power Supply Section – .............. 27

5-12. Schematic Diagram – Power Supply Section – ................. 28

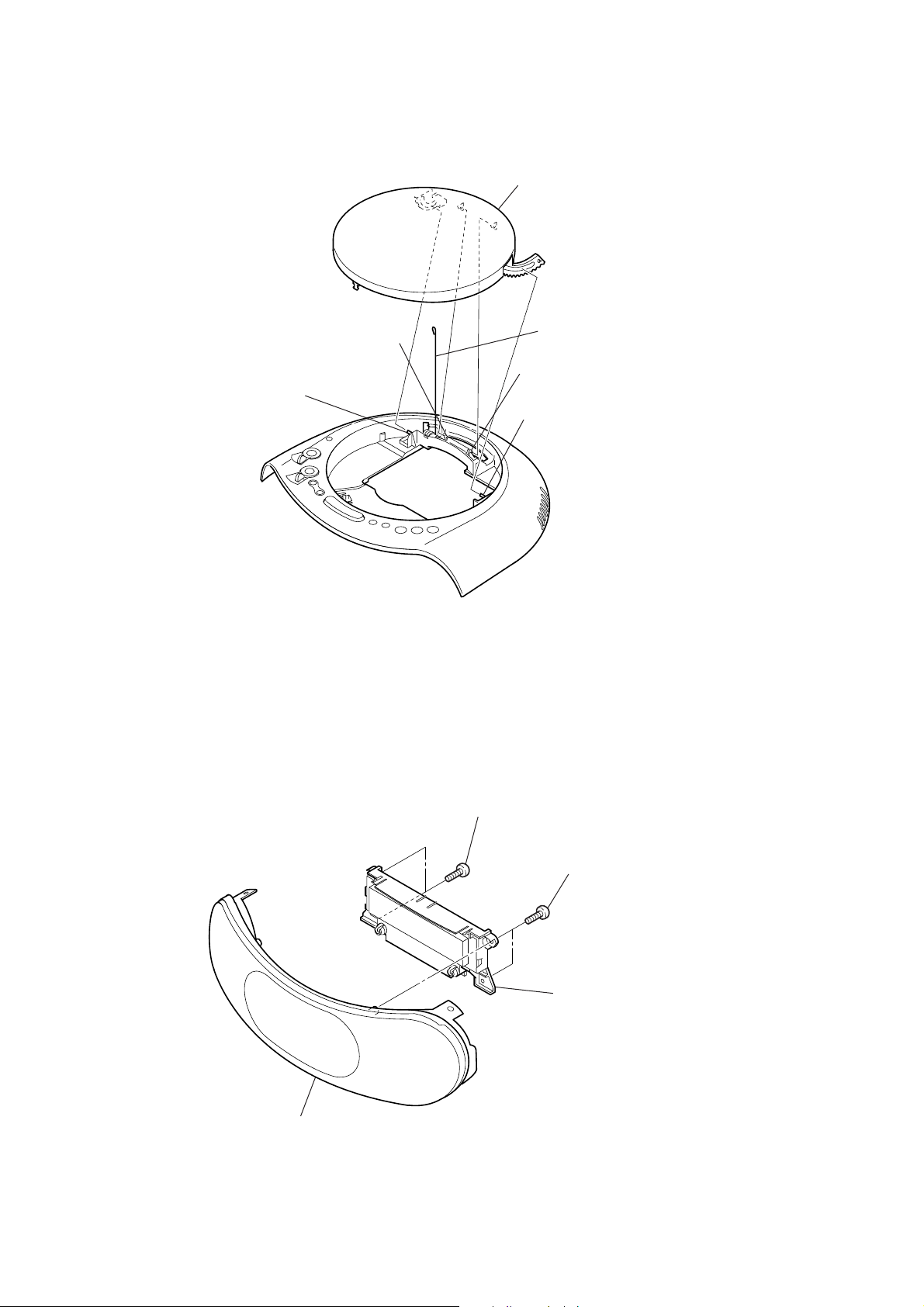

6. EXPLODED VIEWS

6-1. Cabinet Section ................................................................. 32

6-2. Front Panel Section ........................................................... 33

6-3. Upper Cabinet Section ...................................................... 34

6-4. Lower Cabinet Section ...................................................... 35

6-5. CD Block Section .............................................................. 36

6-6. CD Mechanism Section .................................................... 37

7. ELECTRICAL PARTS LIST......................................... 38

3

ICF-CD837

SECTION 1

SERVICING NOTES

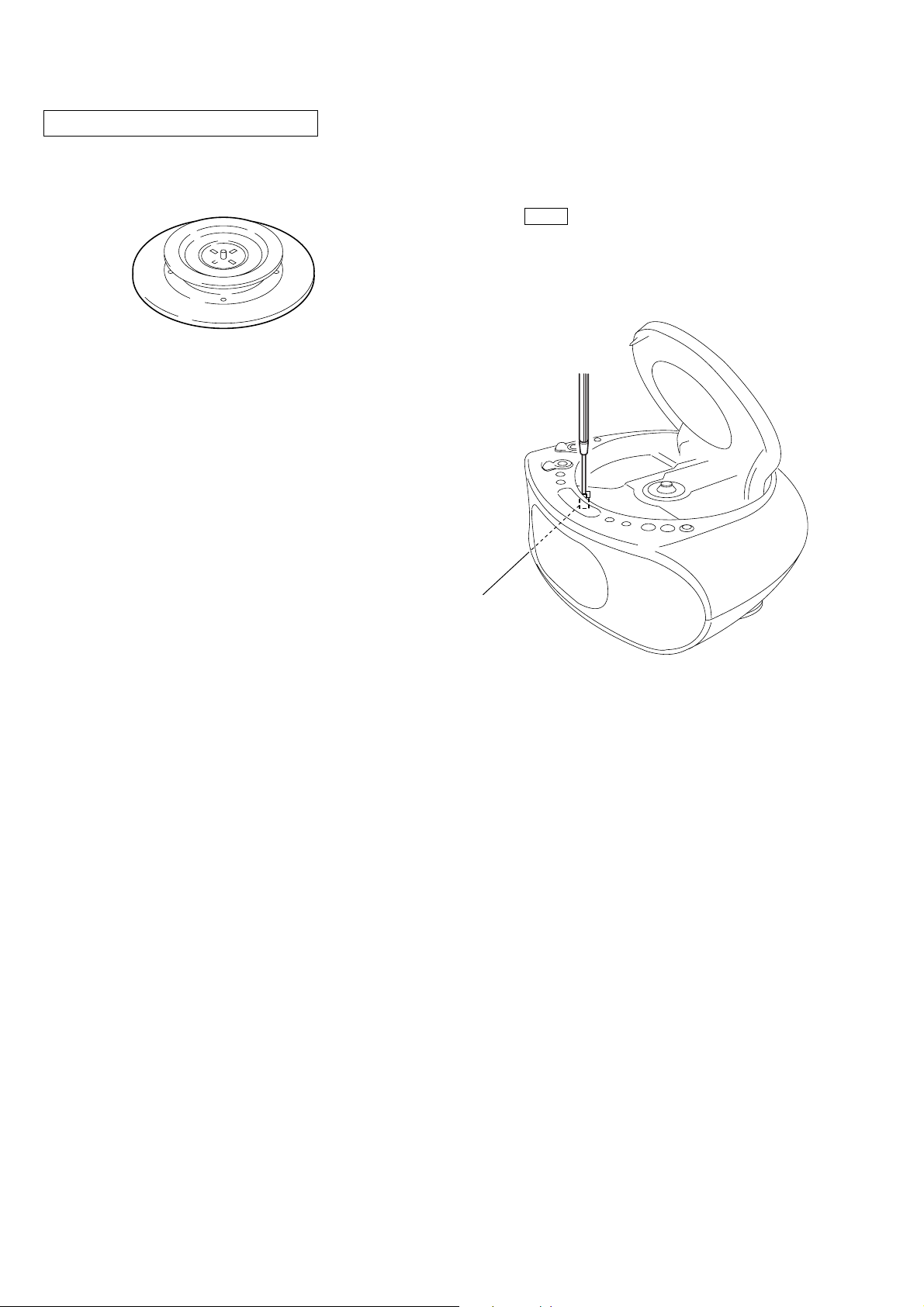

CHUCK PLATE JIG ON REPAIRING

On repairing CD section, playing a disc without the lid (CD), use

Chuck Plate Jig.

• Code number of Chuck Plate Jig: X-4918-255-1

LASER DIODE AND FOCUS SEARCH OPERATION

CHECK

1. Turn ON the [POWER] button and press [CD] button to CD

position.

2. Open the CD lid.

3. Turn on S401 with screwdriver, etc. as following figure.

4. Press the N X (CD) button.

5. Confirm the laser diode emission while observing the objecting

lens. When there is no emission, Auto Power Control circuit or

Optical Pick-up is broken.

Objective lens moves up and down three times for focus search.

S401

4

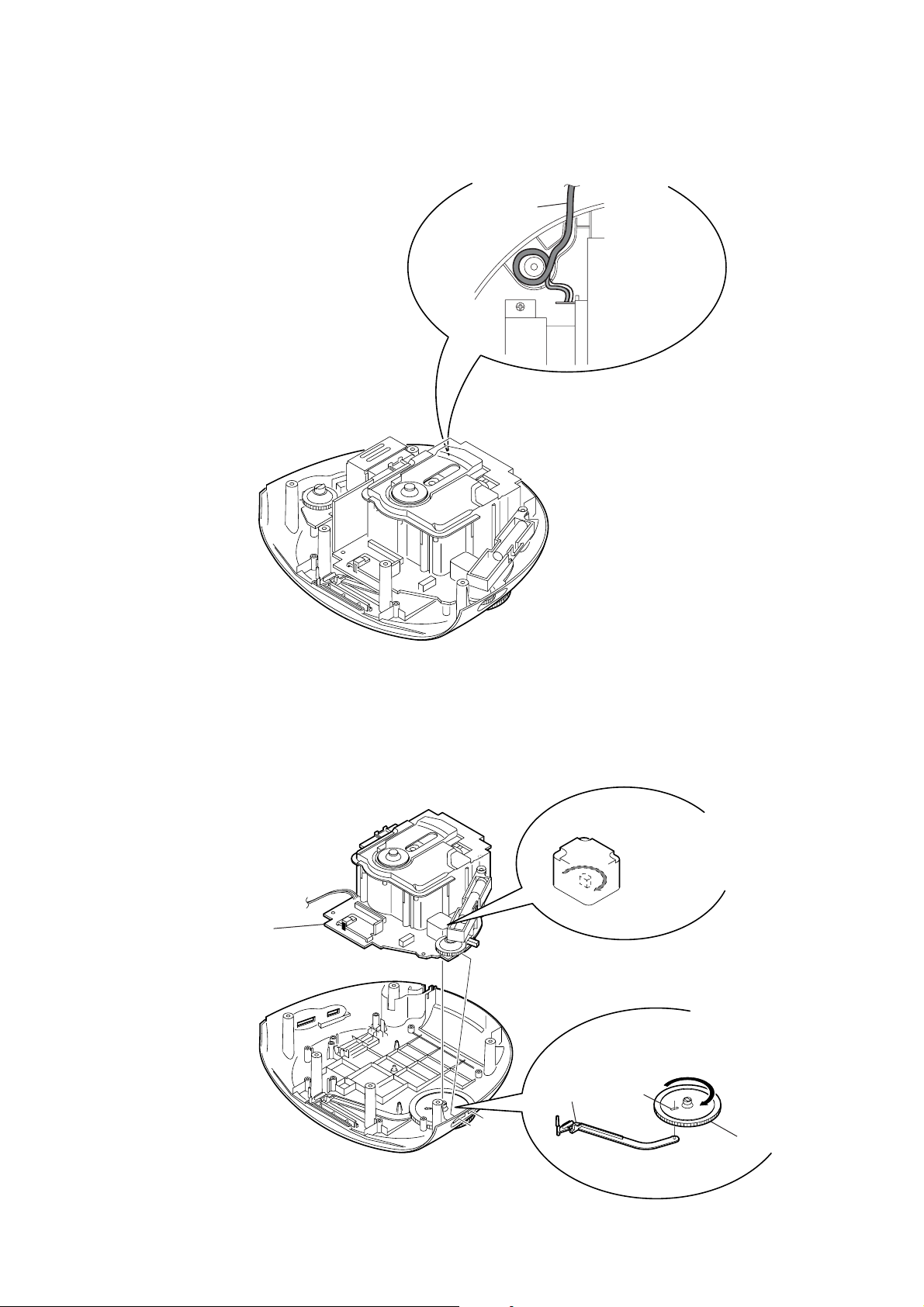

1-1. CORD DRESSING

(POWER CORD)

1) Set the power cord as shown in the figure.

ICF-CD837

power cord

1-2. POINTER ALIGNMENT

MAIN board section

1

Tu rn this in the arrow direction

until stopped.

3

of the knob (tune) with the

direction of CV1.

pointer

2

pointer in the hole A.

A

Fit the protrusion on the

Align the notch on the boss

knob (tune)

5

ICF-CD837

CLOCK

TRACK

SET/

ALARM SET A

A

A

L

A

R

M

S

E

E

R

T

B

ALARM SET B

TIME SET

B

U

Z

R

Z

A

D

IO

C

D

O

F

F

A

L

A

R

M

M

O

D

E

ALARM MODE selector

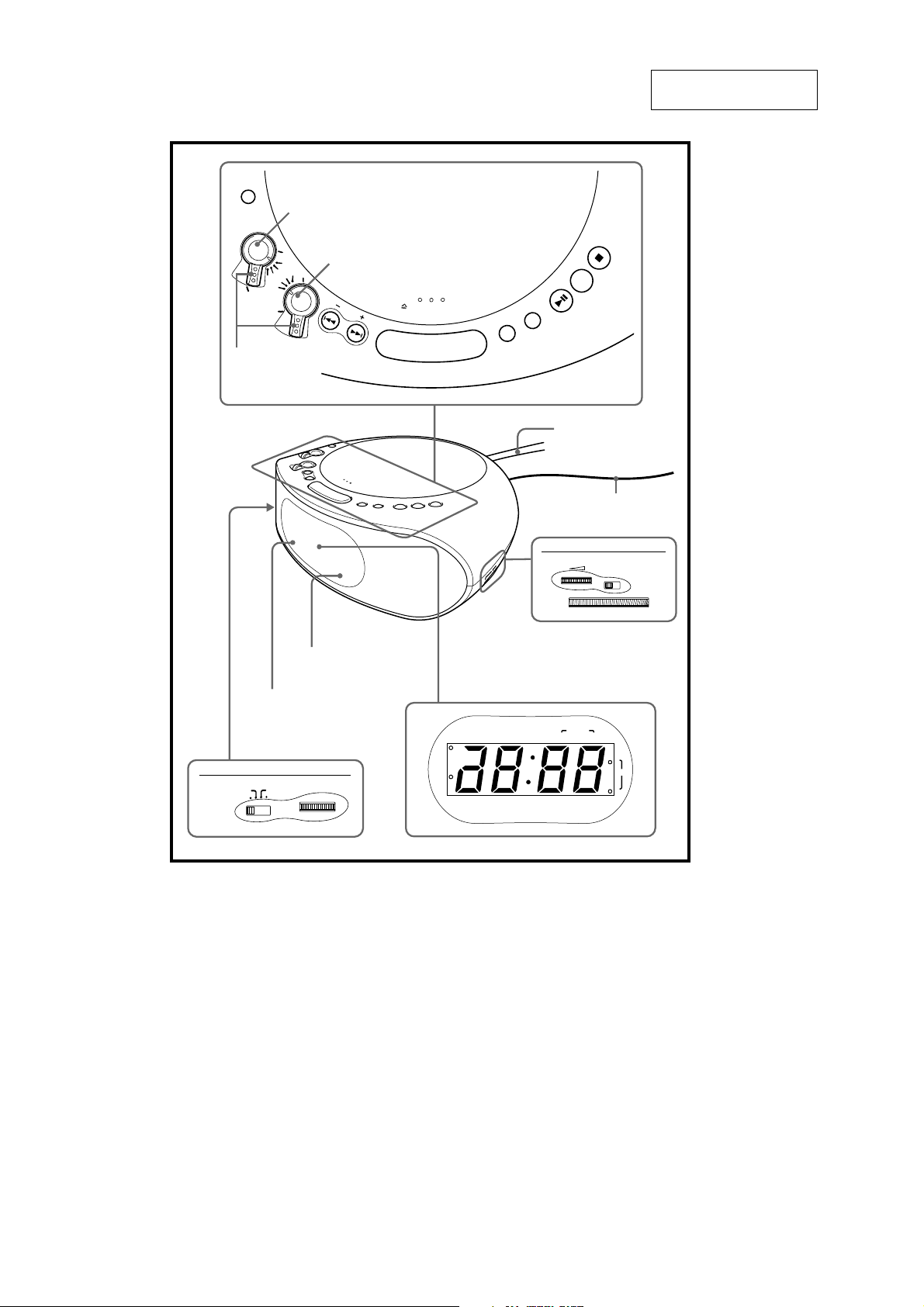

SECTION 2

GENERAL

E

S

P

U

O

L

S

C

H

/

N

O

E

P

S

N

O

O

Z

F

O

P

E

E

L

S

E

/

This section is extracted

from instruction manual.

T

E

S

E

R

M

R

A

L

A

F

F

O

RADIO

ON

D

C

NAP

SLEEP

F

The CD button has a tactile dot.

CD/RADIO

indicator

NAP indicator

REPEAT

NORMAL

BRIGHTNESS

HIGH

LOW

CD PLAY MODE

SHUFFLE

SHUFFLE REPEAT

AC power cord

FM wire antenna

VOLUME

BAND

AM

FM

TUNING

There is a tactile dot

beside volume to show

the direction to turn up

the volume.

TRACK

AM

PM

A

ALARM

B

6

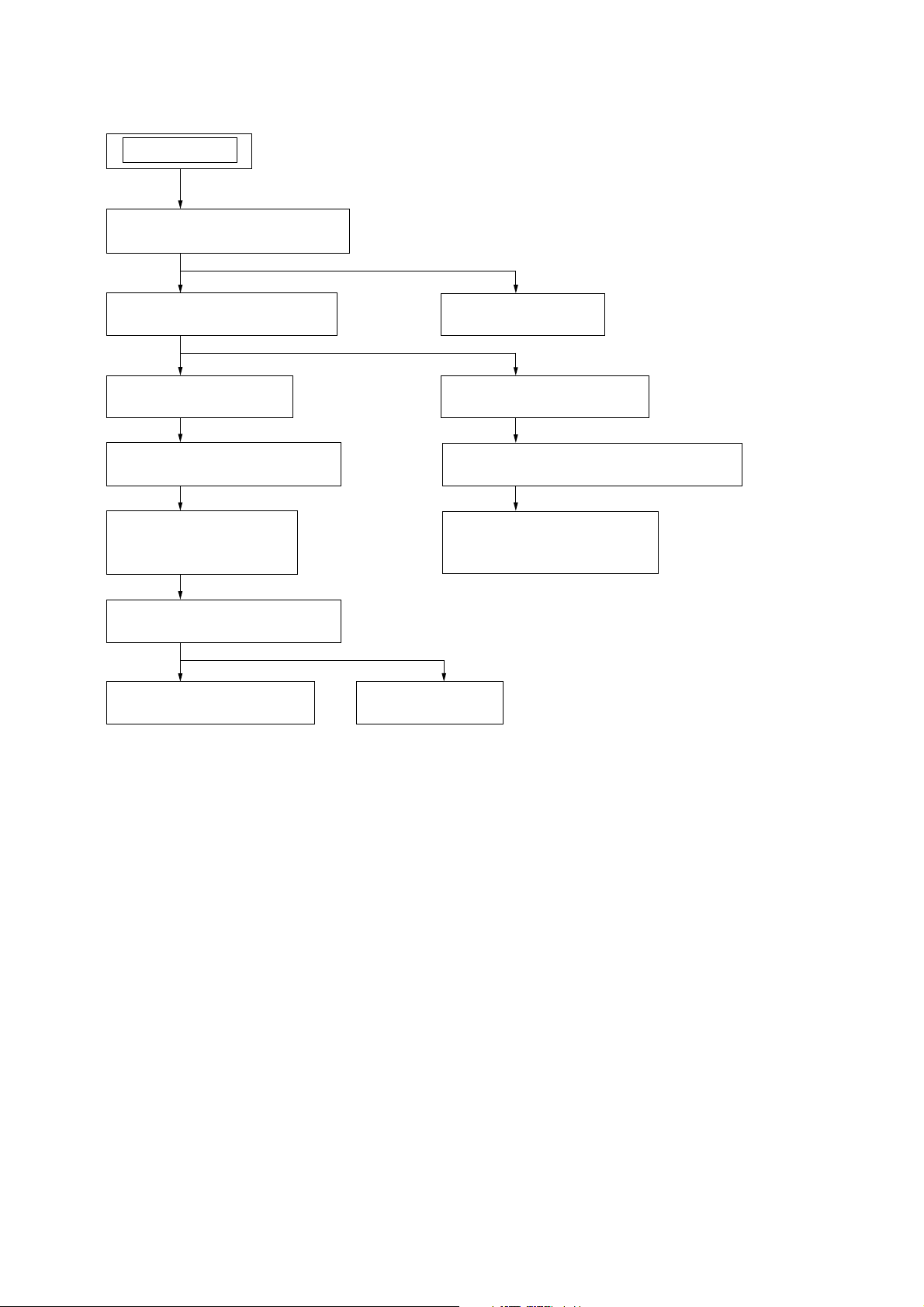

SECTION 3

DISASSEMBLY

• The equipment can be removed using the following procedure.

SET

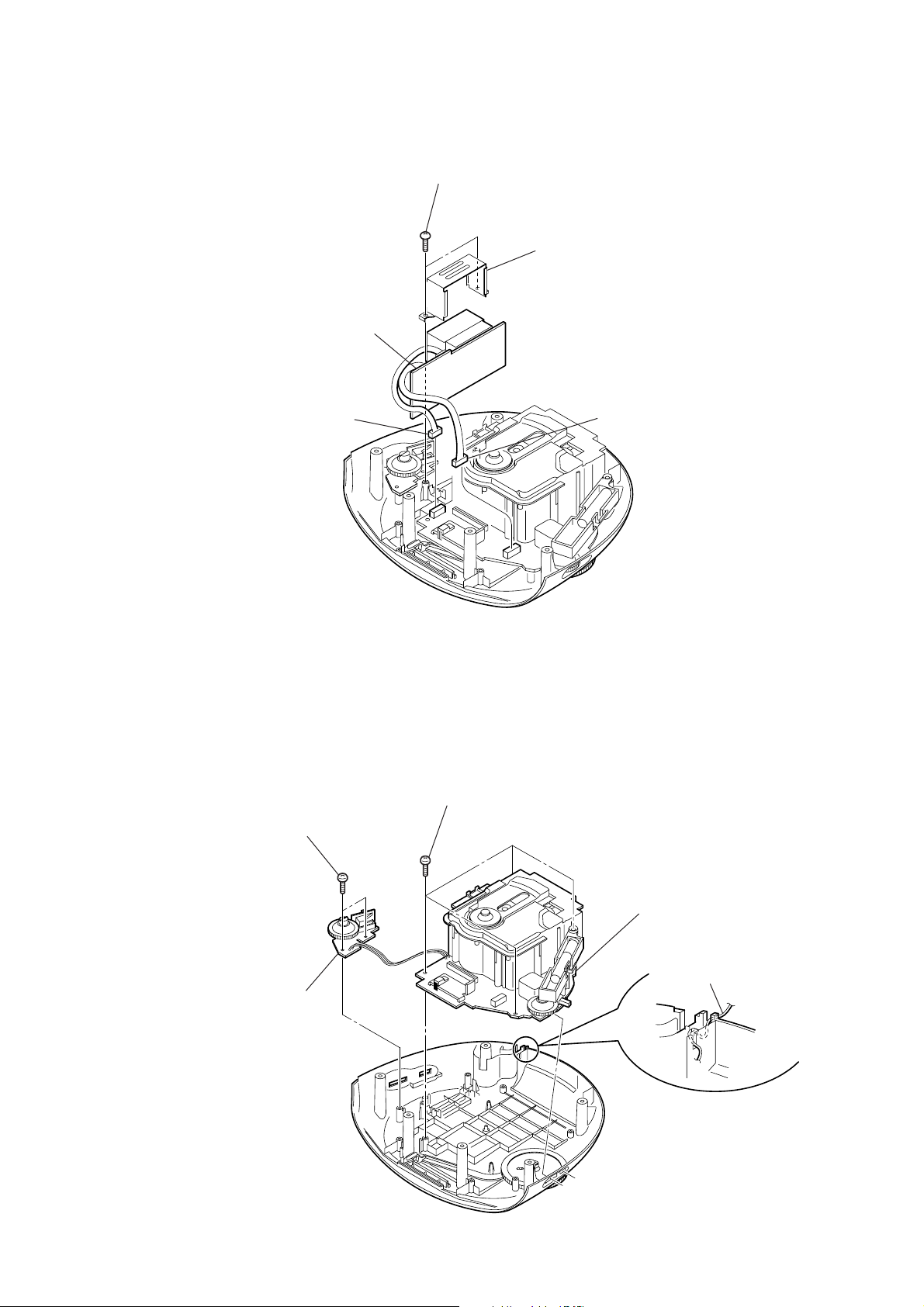

3-1. CABINET (UPPER) ASSY

(Page 8)

ICF-CD837

3-2. FRONT PANEL ASSY

(Page 8)

3-3. POWER BOARD

(Page 9)

3-4. MAIN BOARD SECTION

(Page 9)

3-5. MAIN BOARD,

CD BLOCK ASSY

(Page 10)

3-6. CD MECHANISM DECK

(Page 10)

3-8. OPTICAL PICK-UP

(Page 11)

3-9. LID (CD)

(Page 12)

3-10. LED HOLDER ASSY

(Page 12)

3-11. LED INDICATOR ELEMENT UNIT

(Page 13)

3-12. INDICATOR BOARD,

DRIVE BOARD

(Page 13)

3-7. CD BOARD

(Page 11)

7

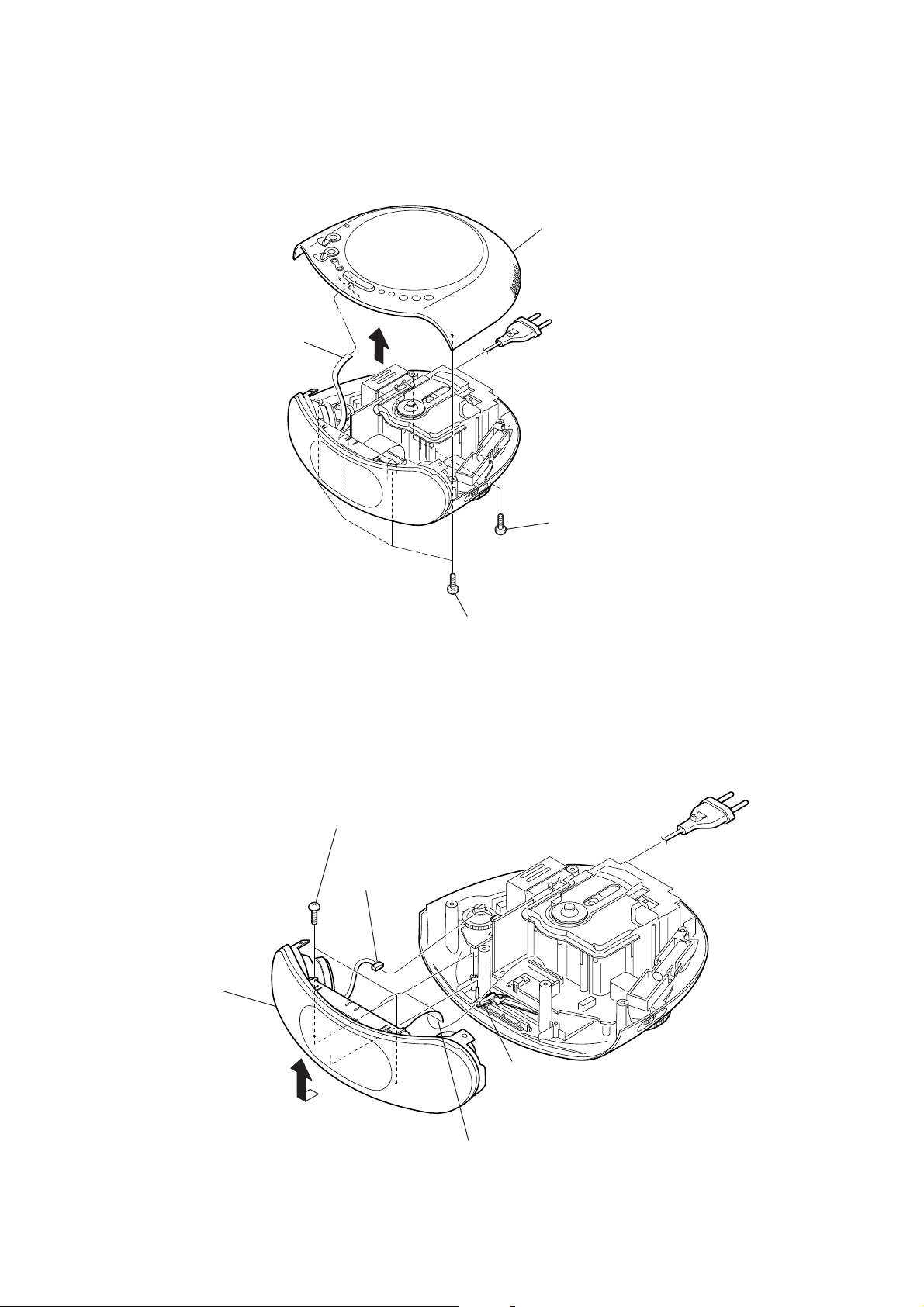

ICF-CD837

)

Note : Follow the disassembly procedure in the numerical order given.

3-1. CABINET (UPPER) ASSY

3

4

CNP602

5

cabinet (upper) assy

3-2. FRONT PANEL ASSY

3

two

screws

((+) BV tapping (B3))

1

CNP302

2

two

((+) BV tapping (B3)

1

four

screws

((+) BV tapping (B3))

screws

5

front panel assy

4

2

pointer

CNP402

8

3-3. POWER BOARD

3

two

screws

((+) BV tapping (B3))

4

bracket (trans)

5

POWER board

1

CNP901

2

CNP303

ICF-CD837

3-4. MAIN BOARD SECTION

1) Set the FM wire antenna as shown in the figure.

1

two

screws

((+) BV tapping (B3))

2

BRIGHTNESS board

3

four

screws

((+) BV tapping (B3))

4

MAIN board section

FM wire antenna

9

ICF-CD837

d

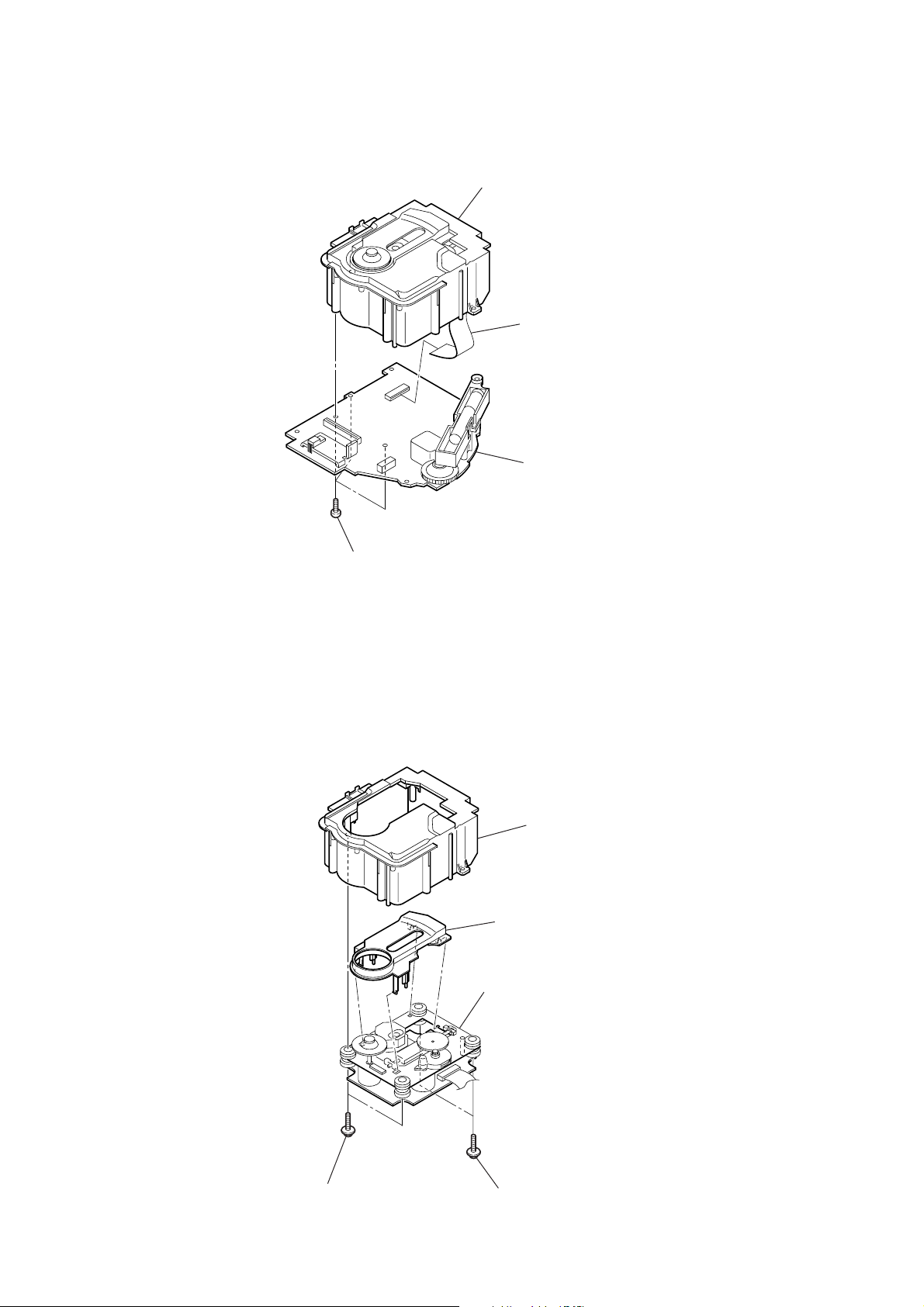

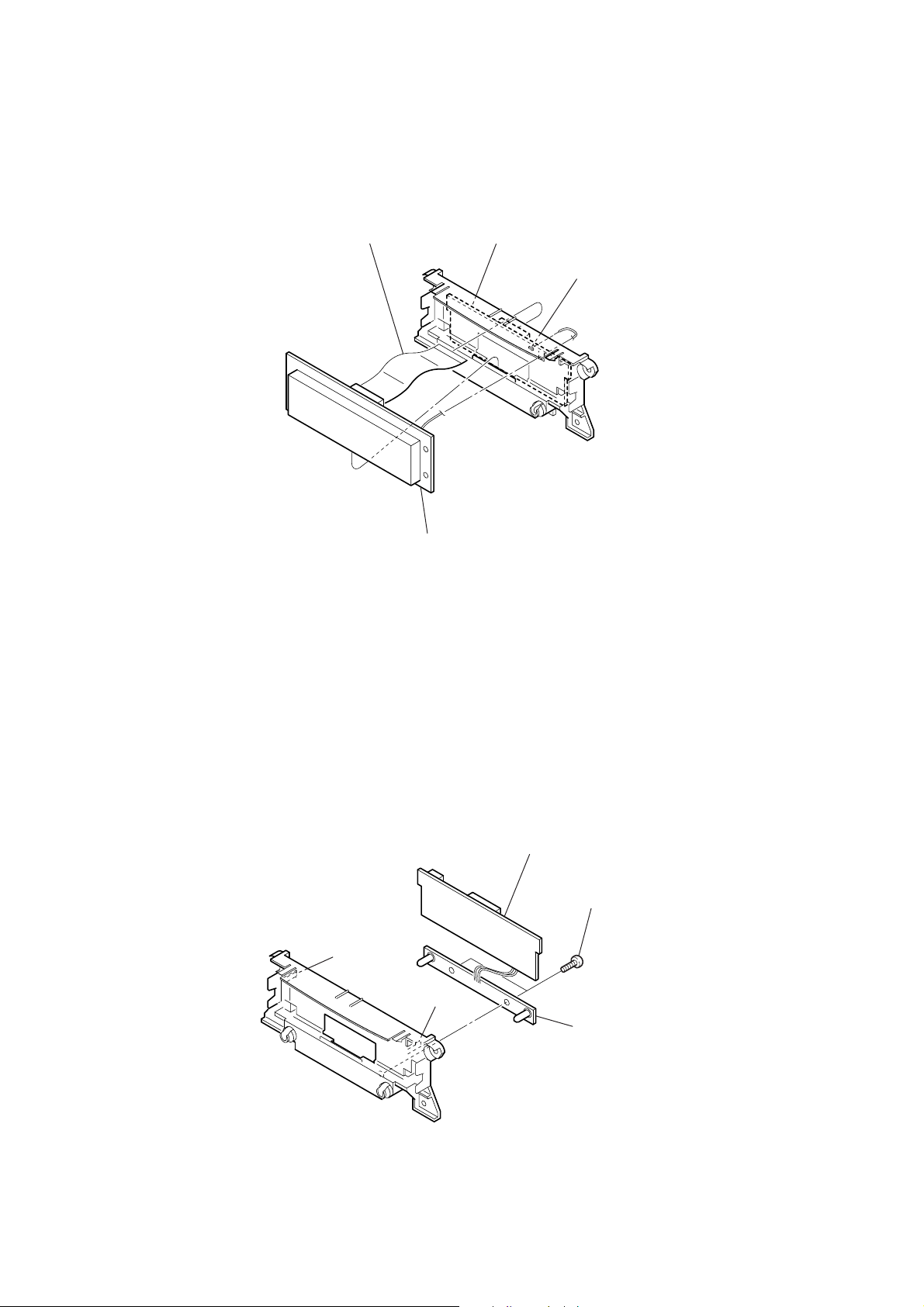

3-5. MAIN BOARD, CD BLOCK ASSY

3

CD block assy

2

4

CNP703

MAIN boar

3-6. CD MECHANISM DECK

1

three

((+) BV tapping (B3))

screws

3

chassis

4

CD cover

5

CD mechanism deck

10

2

two

screws

((+) PWH tapping (B2.6))

1

two

screws

((+) PWH tapping (B2.6))

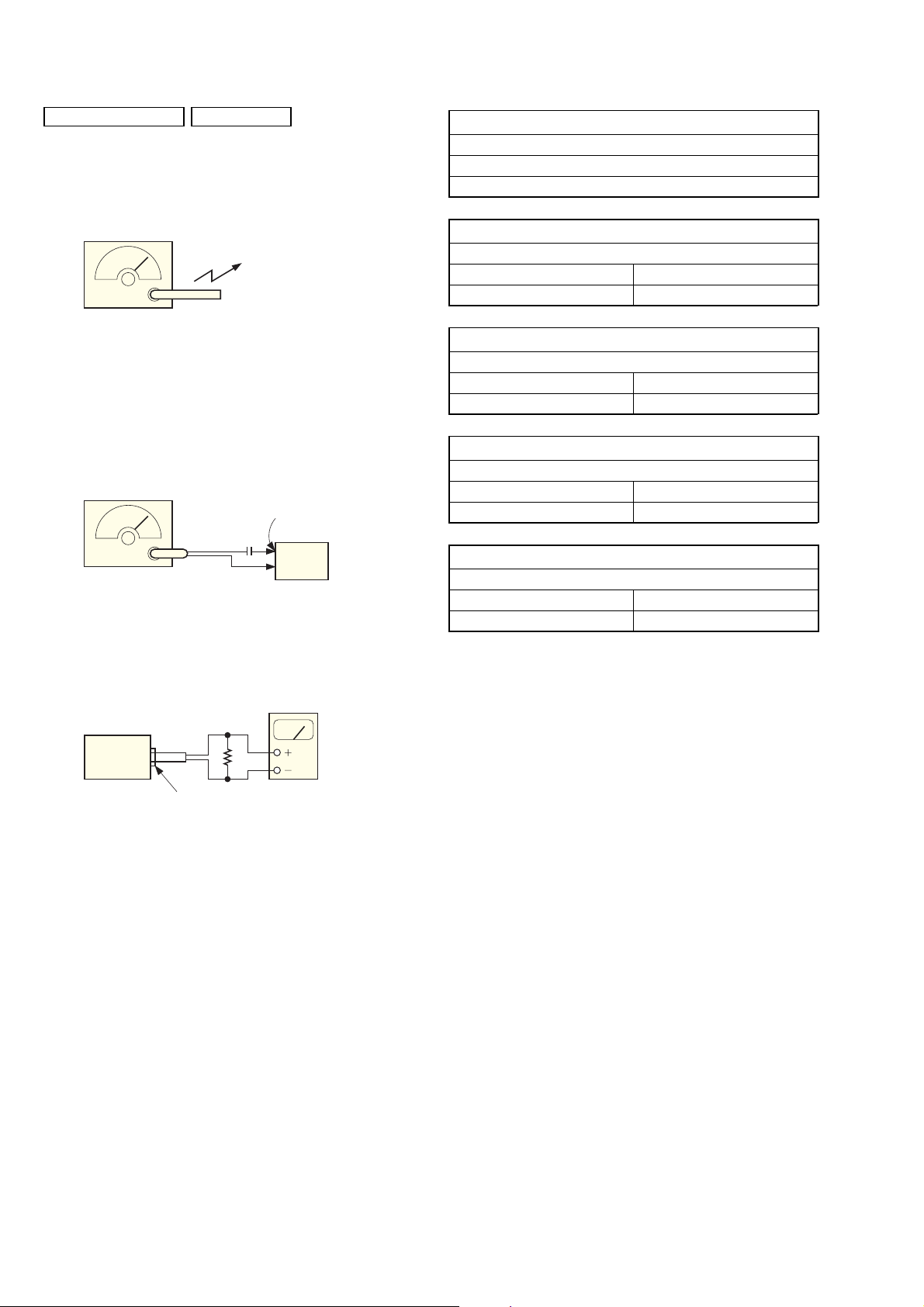

3-7. CD BOARD

4

CNP701

3

Remove the two solders of motor.

5

CD board

ICF-CD837

Ver. 1.1

3-8. OPTICAL PICK-UP

5

optical pick-up

1

screw

(+BVTT 2 × 6 (S))

1

gear (A)

2

Remove the two solders of motor.

3

2

claw

4

sled shaft

11

ICF-CD837

)

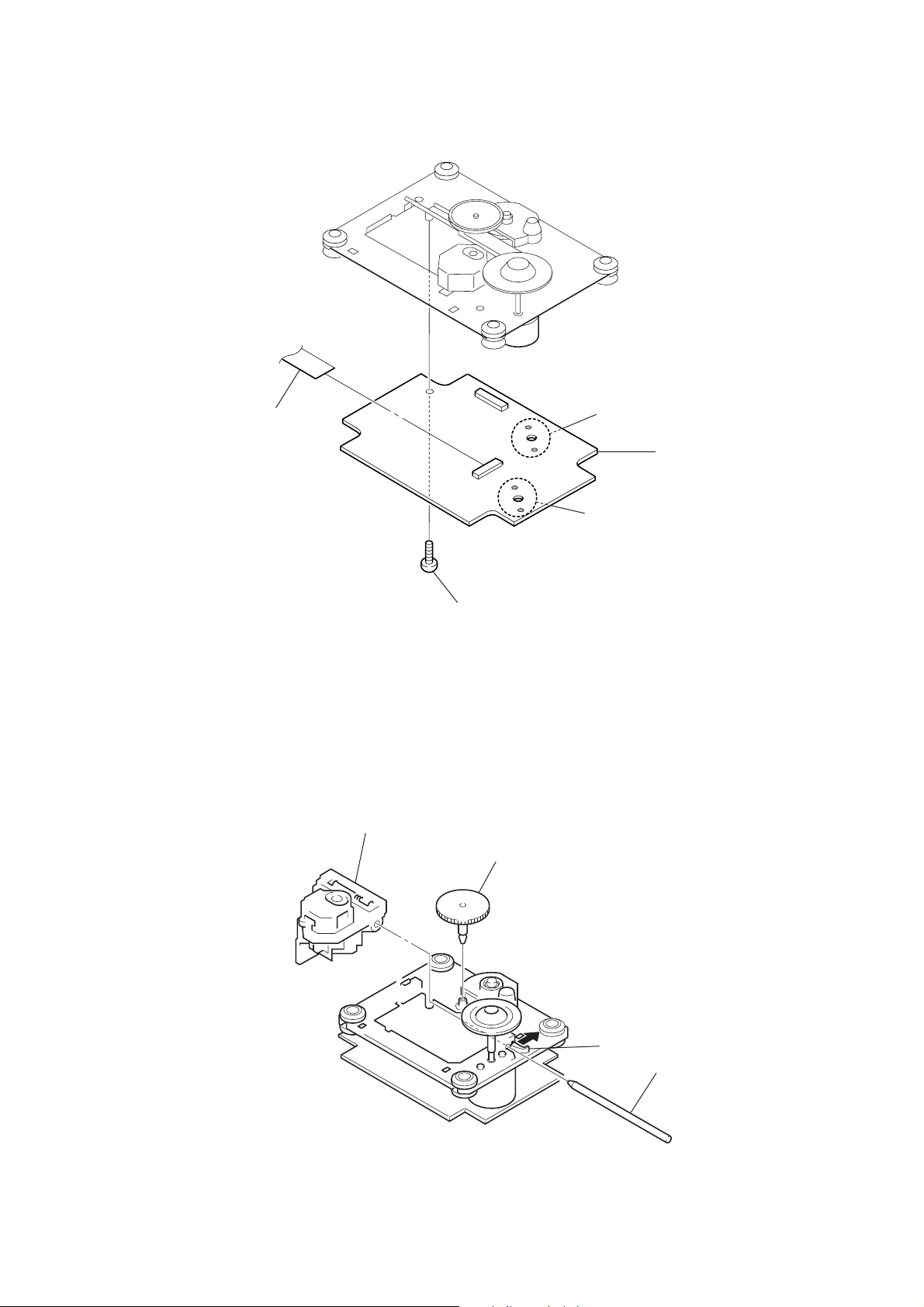

3-9. LID (CD)

5

lid (CD)

3-10. LED HOLDER ASSY

3

boss

4

boss

spring (CD)

2

boss

1

boss

panel (front) sub assy

1

two

screws

((+) BV tapping (B3))

2

two

((+) BV tapping (B3)

3

LED holder assy

screws

12

3-11. LED INDICATOR ELEMENT UNIT

1

CNP502

3

LED indicator element unit

2

Remove the solder.

DRIVE board

)

ICF-CD837

3-12. INDICATOR BOARD, DRIVE BOARD

4

claw

3

claw

5

DRIVE board

1

two

screws

((+) BV tapping (B2.6)

2

INDICATOR board

13

ICF-CD837

l

SECTION 4

ELECTRICAL ADJUSTMENTS

TUNER SECTION 0 dB = 1 µV

• AM Section

Setting:

BAND switch: AM

VOLUME control: MIN

AM RF signal

generator

30% amplitude

modulation by

400 Hz signal

• FM Section

Setting:

BAND switch: FM

VOLUME control: MIN

FM RF signal

generator

75 kHz frequency

deviation by 1 kHz signal

output level : as low as possible

Put the lead-wire

antenna close to

the set.

0.01

µ

F

FM lead wire

antenna termina

set

AM IF ADJUSTMENT

Adjust for a maximum reading on level meter.

T1

455 kHz

AM FREQUENCY COVERAGE ADJUSTMENT

Adjust for a maximum reading on level meter.

L4 CT4

520 kHz 1,750 kHz

AM TRACKING ADJUSTMENT

Adjust for a maximum reading on level meter.

L1 CT1

600 kHz 1,400 kHz

FM FREQUENCY COVERAGE ADJUSTMENT

Adjust for a maximum reading on level meter.

L5 CT3

86.5 MHz 109.5 MHz

FM TRACKING ADJUSTMENT

Adjust for a maximum reading on level meter.

L2 CT2

86.5 MHz 109.5 MHz

• Connecting Level Meter (FM and AM)

level meter

(range: 0.5–5 V ac)

Ω

16

set

speaker terminal

CNP302 (POWER Board)

•Repeat the procedures in each adjustment several times, and the

frequency coverage and tracking adjustments should be finally

done by the trimmer capacitors.

Adjustment Location: See page 15.

14

Loading...

Loading...