Sony ICFCD-830 Service manual

ICF-CD830/CD830L

SERVICE MANUAL

Ver 1.1 2001. 08

With SUPPLEMENT-1

Photo : ICF-CD830

SPECIFICATIONS

CD player section

System: Compact disc digital audio system

Laser diode properties: Material: GaAlAs

Wavelength: 780 nm

Emission duration: Continuous

Laser output: Less than 44.6 µW

(This output is the value measured at a

distance of about 200 mm from the objective

lens surface on the optical pick-up block

with 7 mm aperture.)

Frequency response: 20-20 000 Hz

Wow and flutter: Below measurable limit

Radio section

Frequency range:

ICF-CD830 ICF-CD830L

FM 87.5-108 MHz

America

AM 530-1 710 kHz

North and South

FM 87.5-108 MHz 87.5-108 MHz

AM(MW) 530-1 710 kHz 530-1 710 kHz

Other

countries

LW

–

+1

dB

–1.5

–

–

153-255 kHz

US Model

Canadian Model

Australian Model

E Model

ICF-CD830

AEP Model

ICF-CD830/CD830L

UK Model

ICF-CD830L

Model Name Using Similar Mechanism ICF-CD823

Optical Device Name KSM-213CDM

Optical Pick-UP Name KSS-213C

General

Time display:

North and South America, UK and

Australia: 12-hour system

Other countries: 24-hour system

Speaker:

66 mm (2

Power outputs:

1.2 W + 1.2 W

Power requirements:

North and South American model:

Australian model:

Other models:

Dimensions:

Approx. 273 × 94.5 × 194.5 mm (w/h/d)

(Approx. 10

projecting parts and controls

Mass:

Approx. 1 705 g (3 lb. 12 oz.)

ICF-CD830L (UK model):

Approx. 1 725 g (3 lb. 13 oz.)

Design and specifications are subject to change

without notice.

5

⁄8 inches) dia., 4 Ω

(at 10% harmonic distortion)

120 V AC, 60 Hz

240 V AC, 50 Hz

220-230 V AC, 50 Hz

3

⁄4 × 3 3⁄4 × 7 3⁄4 inches) incl.

9-873-107-12

2001H1600-1

© 2001.8

CD CLOCK RADIO

Sony Corporation

Personal Audio Company

Shinagawa Tec Service Manual Production Group

ICF-CD830/CD830L

r

TABLE OF CONTENTS

1. GENERAL ········································································ 4

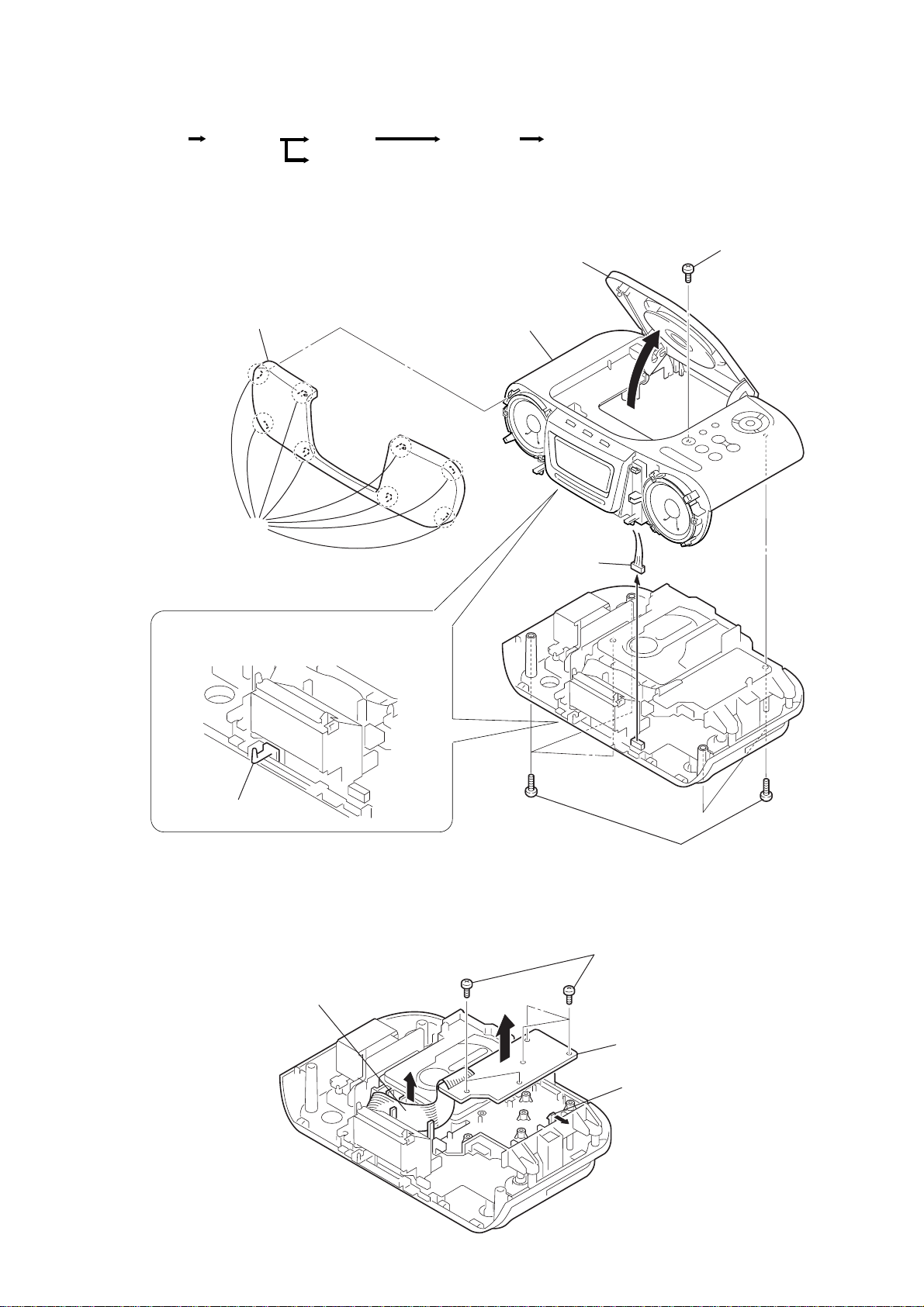

2. DISASSEMBLY

2-1. UPPER CASE ······························································· 5

2-2. KEY BOARD ································································ 5

2-3. TRANSFORMER BOARD··········································· 6

2-4. MAIN CHASSIS ··························································· 6

2-5. OPTICAL PICK-UP BLOCK (KSM-213CDM) ·········· 6

3. TEST MODE ·······························································7

4. ELECTRICAL ADJUSTMENTS ····························· 9

5. DIAGRAMS

5-1. CIRCUIT BOARDS LOCATION ······························· 10

5-2. BLOCK DIAGRAM (CD830) ···································· 11

5-3. BLOCK DIAGRAM (CD830L) ·································· 12

5-4. SCHEMATIC DIAGRAM

– TUNER SECTION (CD830) –································· 13

5-5. SCHEMATIC DIAGRAM

– TUNER SECTION (CD830L) – ······························ 14

5-6. SCHEMATIC DIAGRAM

– CD SECTION – ······················································· 15

5-7. SCHEMATIC DIAGRAM

– POWER SECTION – ··············································· 16

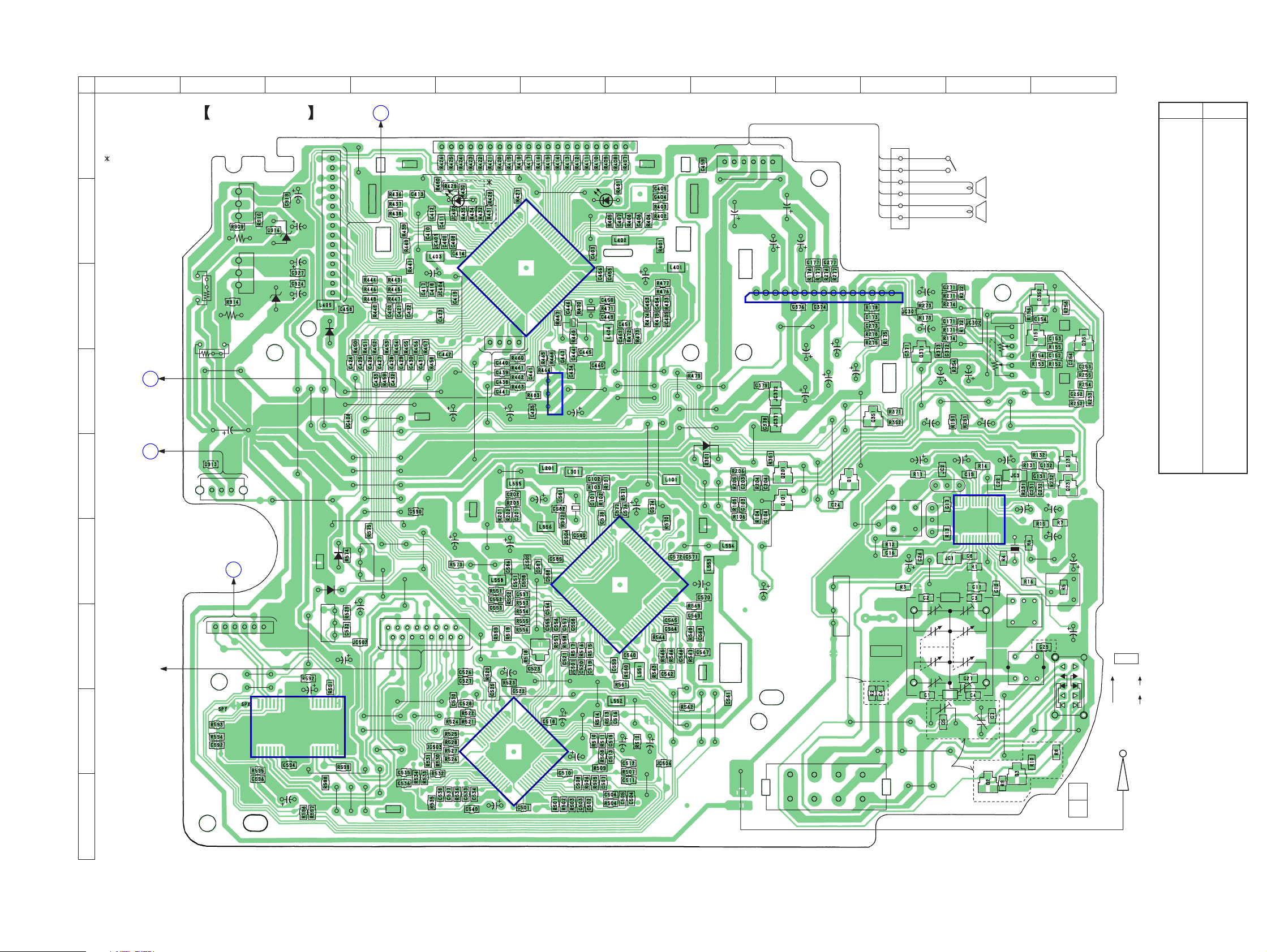

5-8. PRINTED WIRING BOARD

– MAIN SECTION – ·················································· 17

5-9. PRINTED WIRING BOARD

– KEY/POWER SECTION – ······································ 18

5-10.SCHEMATIC DIAGRAM

– KEY SECTION – ····················································· 19

5-11.IC BLOCK DIAGRAMS ············································ 20

5-12.IC PIN FUNCTION DESCRIPTION ························· 22

SAFETY CHECK-OUT

After correcting the original service problem, perform the following

safety check before releasing the set to the customer:

Check the antenna terminals, metal trim, “metallized” knobs, screws,

and all other exposed metal parts for AC leakage.

Check leakage as described below.

LEAKAGE TEST

The AC leakage from any exposed metal part to earth ground and

from all exposed metal parts to any exposed metal part having a

return to chassis, must not exceed 0.5 mA (500 microampers.).

Leakage current can be measured by any one of three methods.

1. A commercial leakage tester, such as the Simpson 229 or RCA

WT-540A. Follow the manufacturers’ instructions to use these

instruments.

2. A battery-operated AC milliammeter. The Data Precision 245

digital multimeter is suitable for this job.

3. Measuring the voltage drop across a resistor by means of a VOM

or battery-operated AC voltmeter. The “limit” indication is 0.75

V, so analog meters must have an accurate low-voltage scale.

The Simpson 250 and Sanwa SH-63Trd are examples of a

passive VOM that is suitable. Nearly all battery operated digital

multimeters that have a 2 V AC range are suitable. (See Fig. A)

To Exposed Metal

Parts on Set

AC

0.15 µF

1.5 k

Ω

voltmete

(0.75 V)

6. EXPLODED VIEWS

6-1. CABINET SECTION ·················································· 23

6-2. CHASSIS SECTION··················································· 24

6-3. OPTICAL PICK-UP SECTION

(KSM-213CDM) ························································· 25

7. ELECTRICAL PARTS LIST ································· 26

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK ! OR DOTTED LINE

WITH MARK ! ON THE SCHEMATIC DIAGRAMS AND IN

THE PARTS LIST ARE CRITICAL TO SAFE OPERATION.

REPLACE THESE COMPONENTS WITH SONY PARTS WHOSE

PART NUMBERS APPEAR AS SHOWN IN THIS MANUAL OR

IN SUPPLEMENTS PUBLISHED BY SONY.

ATTENTION AU COMPOSANT AYANT RAPPORT

À LA SÉCURITÉ!

LES COMPOSANTS IDENTIFIÉS PAR UNE MARQUE ! SUR

LES DIAGRAMMES SCHÉMATIQUES ET LA LISTE DES

PIÈCES SONT CRITIQUES POUR LA SÉCURITÉ DE

FONCTIONNEMENT. NE REMPLACER CES COM- POSANTS

QUE PAR DES PIÈCES SONY DONT LES NUMÉROS SONT

DONNÉS DANS CE MANUEL OU DANS LES SUPPLÉMENTS

PUBLIÉS PAR SONY.

Earth Ground

Fig. A. Using an AC voltmeter to check AC leakage.

Note on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be dam-

aged by heat.

2

ICF-CD830/CD830L

NOTES ON HANDLING THE OPTICAL PICK-UP

BLOCK OR BASE UNIT

The laser diode in the optical pick-up block may suffer electrostatic

break-down because of the potential difference generated by the

charged electrostatic load, etc. on clothing and the human body.

During repair, pay attention to electrostatic break-down and also

use the procedure in the printed matter which is included in the

repair parts.

The flexible board is easily damaged and should be handled with

care.

NOTES ON LASER DIODE EMISSION CHECK

The laser beam on this model is concentrated so as to be focused on

the disc reflective surface by the objective lens in the optical pickup block. Therefore, when checking the laser diode emission,

observe from more than 30 cm away from the objective lens.

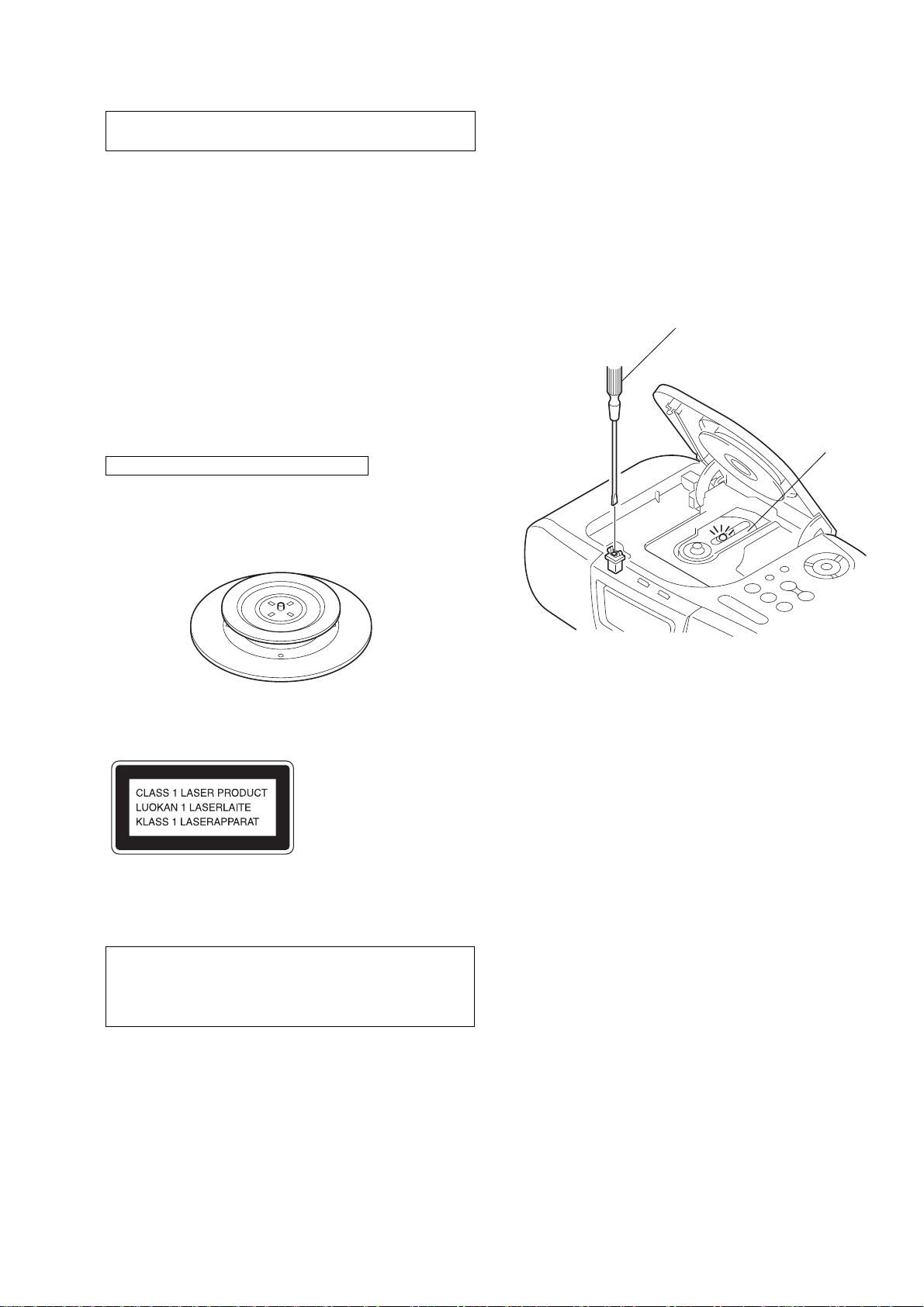

CHUCK PLATE JIG ON REPAIRING

On repairing CD section, playing a disc without the CD lid, use

Chuck Plate Jig.

• Code number of Chuck Plate Jig: X-4918-255-1

LASER DIODE AND FOCUS SEARCH

OPERATION CHECK

1. Open the CD lid.

2. Turn on S401 as following figure.

3. Confirm that the laser diode emission while observing the

objecting lens. When there is no emission, Auto Power Control

circuit or Optical Pick-up is broken.

Objective lens moves up and down once for the focus search.

Insert a precision

screwdriver and

push S401

laser diode

emission

This Compact Disc player is classified as a CLASS 1

LASER product.

The CLASS 1 LASER PRODUCT label is located on the

bottom exterior.

CAUTION

Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous

radiation exposure.

3

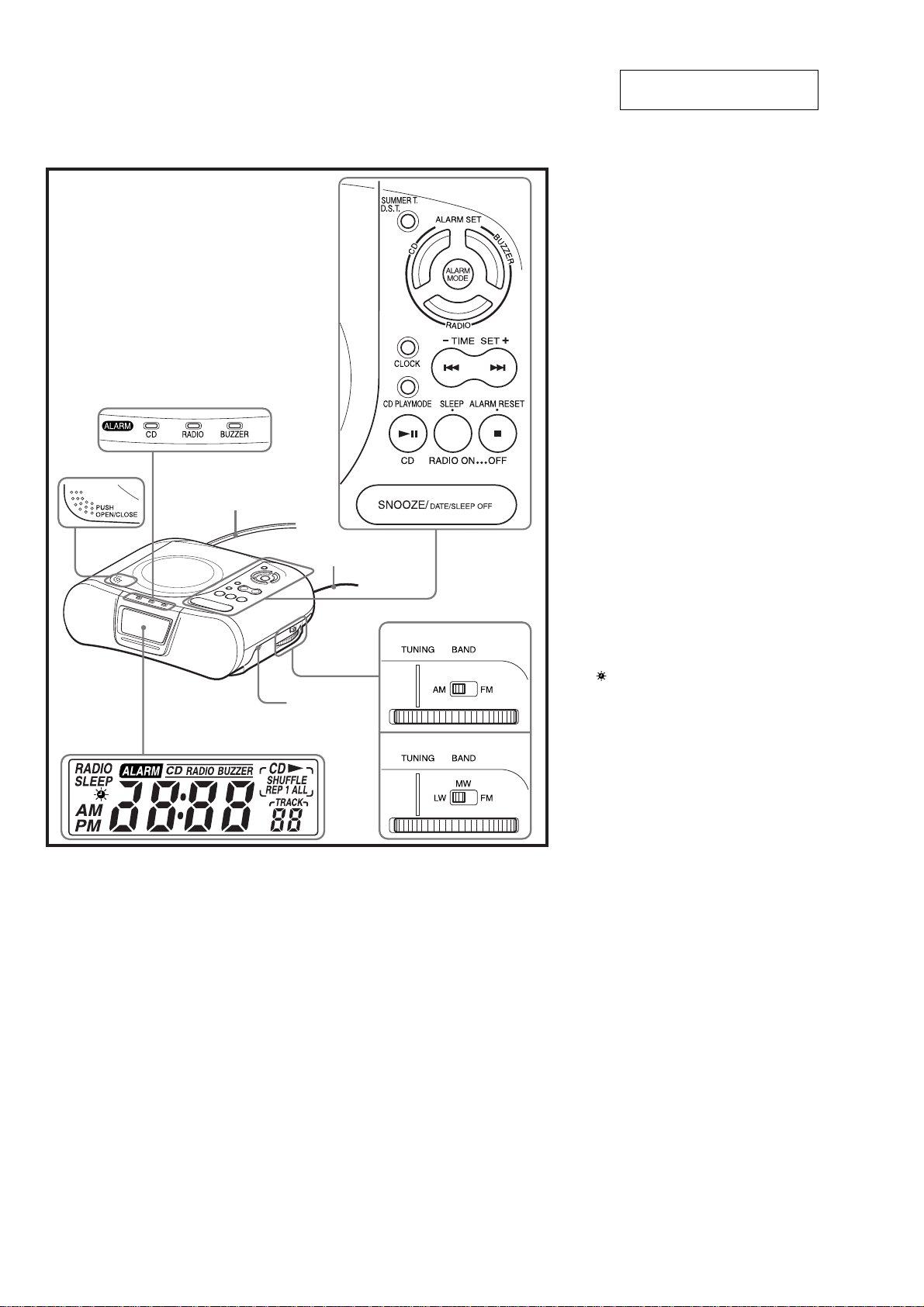

ICF-CD830/CD830L

AC power cord

Cordon d’alimentation

secteur

FM wire antenna

Antenne fil FM

VOLUME

SECTION 1

GENERAL

ICF-CD830

This section is extracted from

instruction manual.

Setting the Clock

and Date

1

Plug in the clock radio.

The display will flash “AM 12:00” or “0:00”.

2

Press CLOCK for a few seconds.

You will hear a beep and the year will start to

flash in the display.

3

Press TIME SET + or – until the correct

year appears in the display.

4

Press CLOCK once.

5

Repeat steps 3 and 4 to set the month,

day, hour, and minute.

After setting the minute, press CLOCK to start

the counting of the seconds, and you will

hear two short beeps.

• To display the year and date, press SNOOZE/

DATE/SLEEP OFF once for the date, and within

2 seconds press it again for the year. The

display shows the date or year for a few

seconds and then changes back to the current

time.

• To set the current time rapidly, hold down

TIME SET + or –.

• The clock system varies depending on the

model you own.

12-hour system: “AM 12:00” = midnight

24-hour system: “0:00” = midnight

• In step 5, when you press CLOCK after the

minute setting to activate the clock, the seconds

start counting from zero.

To change the display to the

daylight saving time (summer time)

indication

Press D.S.T./SUMMER T.

“

” is displayed and the time indication

changes to summer time.

To deactivate the summer time function, press

D.S.T./SUMMER T. again.

ICF-CD830L

4

SECTION 2

d

)

DISASSEMBLY

• The equipment can be removed using the following procedure.

Set

Upper case

Note: Follow the disassembly procedure in the numerical order given.

Key board

Transformer board

2-1. UPPER CASE

Main chassis Optical pick-up block (KSM-213CDM

ICF-CD830/CD830L

Ver 1.1 2001.08

5 Screw (+P3 × 14)

4 Lid, CD

2 Panel (SP)

1 Eight claws

Precaution during installation

When installing the upper case to the main section,

move the pointer to the left-most end as shown.

7 Upper case

6 Connector

(CN371)

Pointer

2-2. KEY BOARD

3 Five screws (+P3 × 14)

1 Five screws

(+P3 × 10)

4 Wire

3 Key boar

2 Hook

5

ICF-CD830/CD830L

k

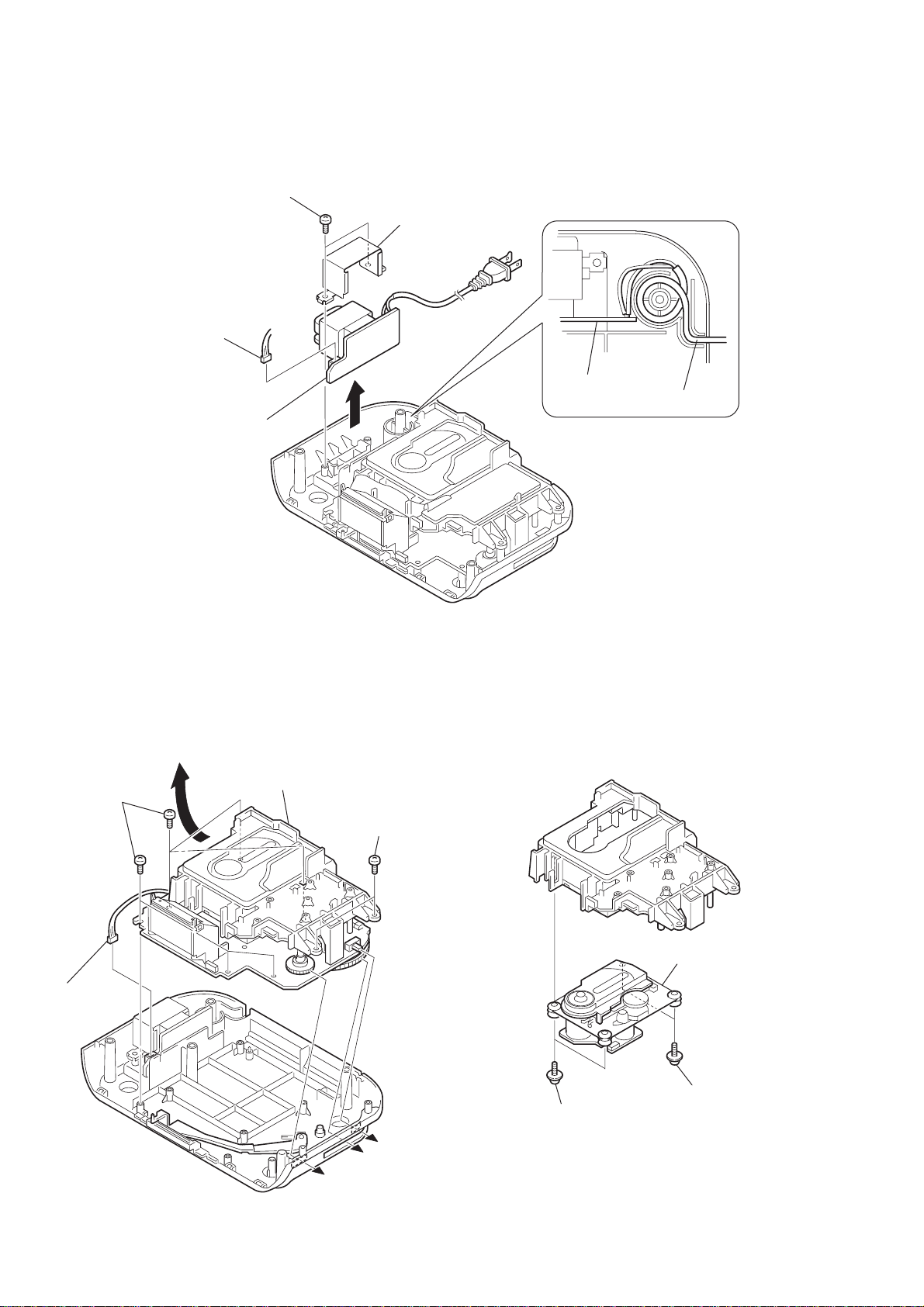

2-3. TRANSFORMER BOARD

2 Two screws

(+P3 × 10)

1 Connector

(CN901)

4 Transformer board

3 Bracket (Trans)

Transformer board

Power cord

2-4. MAIN CHASSIS

2 Six screws

(+P3 × 10)

3 Connector

(CN901)

4 Main chassis

1 Two screws

(+P3 × 10)

2-5. OPTICAL PICK-UP BLOCK (KSM-213CDM)

3 Optical pick-up bloc

(KSM-213CDM)

1 Two screws

2 Two screws

(2.6 × 10)

(2.6 × 10)

6

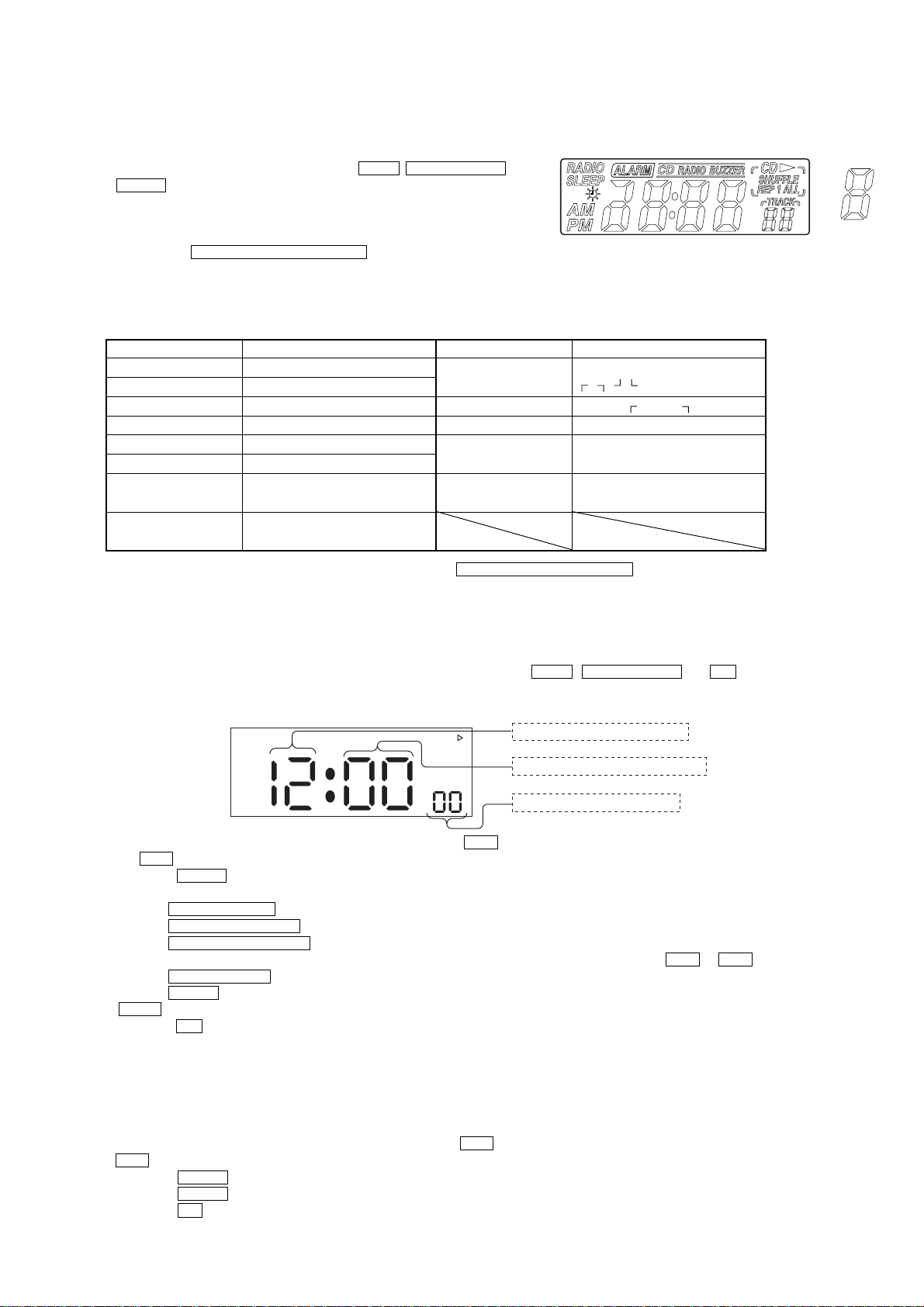

SECTION 3

TEST MODE

3-1. LCD Test Mode

• The LCD test mode is initiated by turning off the main power once then

back on or by resetting the machine while IC401 pin-60 terminal is

connected to GND, or while depressing the D.S.T. , ALARM MODE and

RADIO keys simultaneously.

• The LCD test mode operations are listed in the following table.

• When the machine enters the LCD test mode, the version number of the

system control IC is displayed on the LCD.

• Pressing the SNOOZE/DATE/SLEEP OFF key turns on all segments of

LCD and LEDs.

• Pressing any key turns off the corresponding segment of the LCD.

Correspondence between the keys and segments of LCD are as follows.

ICF-CD830/CD830L

(LCD segment)

a

fgb

ce

d

1234 56

KEY

D.S.T.

ALARM MODE

ALARM SET CD

ALARM SET BUZZER

ALARM SET RADIO

CLOCK

TIME SET –

TIME SET +

s

ALARM CD RADIO BUZZER

ALARM-CD LED

ALARM-BUZZER LED

ALARM-RADIO LED

AM, PM,:

1a, 1b, 1c, 1d, 1e, 1f, 1g,

2a, 2b, 2c, 2d, 2e, 2f, 2g

3a, 3b, 3c, 3d, 3e, 3f, 3g,

4a, 4b, 4c, 4d, 4e, 4f, 4g

SEGMENT

KEY

CD PLAY MODE

CD

RADIO

OFF

SNOOZE/DATE/

SLEEP OFF

SEGMENT

REP, 1, ALL, SHUFFLE,

, , ,

CD, H, TRACK

RADIO, SLEEP

5a, 5b, 5c, 5d, 5e, 5f, 5g,

6a, 6b, 6c, 6d, 6e, 6f, 6g

• After all segments of LCD and LEDs turn off, pressing the SNOOZE/DATE/SLEEP OFF key ends the LCD test mode and resets the

machine.

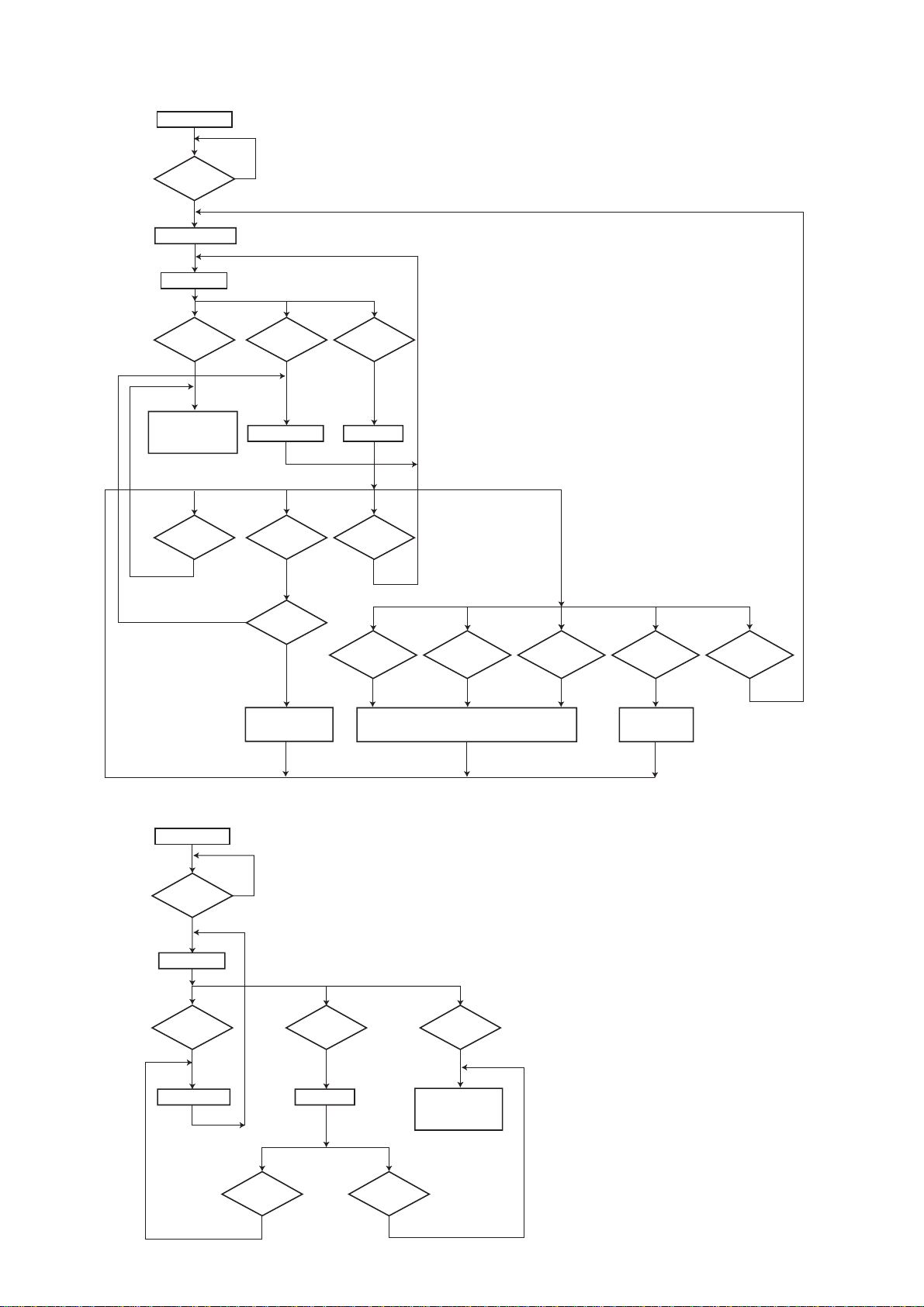

3-2. CD Test Mode

3-2-1. CD TEST-1 (AUTO)

• The CD TEST-1 (AUTO) mode is initiated by turning off the main power once then back on or by resetting the machine while IC401 pin59 terminal (RADIO LED) is connected to GND, or while depressing the D.S.T. , ALARM MODE and CD keys simultaneously.

• When the machine enters CD TEST-1 (AUTO) mode, it repeats the focus search until the focus becomes OK.

• After the focus becomes OK and the focus is automatically adjusted, rough servo is locked in and the adjustment value is displayed.

F-E BALANCE ADJUSTMENT

TRACKING GAIN ADJUSTMENT

FOCUS BIAS ADJUSTMENT

AM

CD

SHUFFLE

TRACK

• The sled can be moved to the innermost track by pressing the . button. The sled can be moved to the outermost track by pressing

the > button.

• When the RADIO button is pressed, the machine enters the CLVA (servo ON) and the mute is turned OFF if data is read successfully.

When the following button is pressed, the corresponding operations are performed.

a) ALARM SET CD Setting the 1 track jump

b) ALARM SET RADIO Setting the 10 track jump

c) ALARM SET BUZZER Setting the 100 track jump

Afterwards the desired track jump can be set by pressing the > or . button.

d) ALARM MODE TRACKING GAIN-UP

e) RADIO Rough servo

• D.S.T. restarts CD TEST-1 (AUTO) mode from the focus automatic adjustment

• When the CD button is pressed then, the track jumps to the second session and the machine exits the CD TEST-1 (AUTO) mode.

3-2-2. CD TEST-2 (MANUAL)

• The CD TEST-2 (MANUAL) mode is initiated by turning off the main power once then back on or by resetting the machine while IC401

pin-58 terminal (CD LED) is connected to GND.

• When the machine enters CD TEST-2 (MANUAL) mode, it repeats the focus search until the focus becomes OK.

• After the focus becomes OK, the machine enters the rough servo.

• The sled can be moved to the innermost track by pressing the . button. The sled can be moved to the outermost track by pressing the

> button.

• When the RADIO button is pressed, the machine enters the CLVA (servo ON) and the mute is turned OFF if data is read successfully.

When the RADIO button is pressed again, the machine enters the rough servo.

• When the CD button is pressed then, the track jumps to the second session and the machine exits the CD TEST-2 (MANUAL) mode.

7

ICF-CD830/CD830L

CD TEST-1

FOCUS

OK

Y

Auto adjustment

Rough servo

CD button

TEST MODE END

The second music

played back.

CD button

Y

N

± button

Sled movement

± button

Y : YES

N: NO

Servo ON

RADIO

button

YYY

RADIO

button

YY

CD TEST-2

FOCUS

OK

Y

Rough servo

± button

Y

jump has

been set?

N

Executes the

setting of jump.

N

Y

RADIO

button

ALARM SET

CD

Y

ALARM SET

RADIO

Y

YY Y Y

Sets the respective

setup values.

CD

button

Y

ALARM SET

BUZZER

ALARM

MODE

TRACKING

GAIN UP

D.S.T.

Sled movement

± button

Servo ON

CD

button

YY

TEST MODE END

The second music

played back.

8

SECTION 4

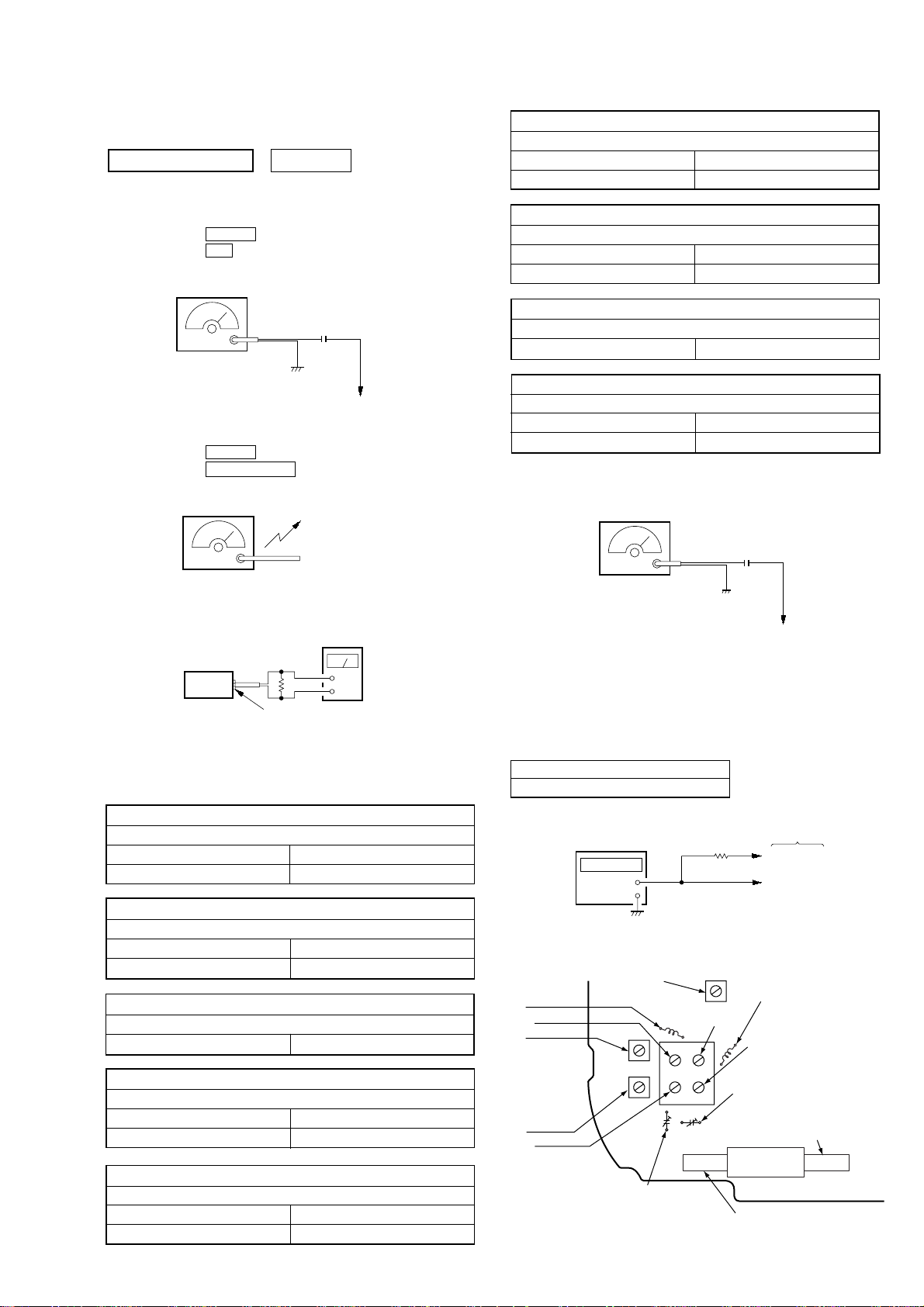

FM RF signal

generator

Carrier frequency: 98 MHz

Modulation: no modulation

Output level: 0.1 V (100 dB)

0.01 µF

FM lead wire antenna terminal

d

t

nt

ELECTRICAL ADJUSTMENTS

ICF-CD830/CD830L

PRECAUTION

• Adjustment should be performed in the order given.

TUNER SECTION 0 dB=1 µV

[FM]

Setting:

Function switch : RADIO

BAND switch : FM

FM RF signal

generator

0.01 µF

75 kHz frequency deviation

by 1 kHz signal.

Output level: as low as possible

[AM (MW/LW) ]

Setting:

Function switch : RADIO

BAND switch : AM (MW/LW)

AM RF signal

generator

FM lead wire antenna terminal

Put the lead-wire

antenna close to

the set.

MW FREQUENCY COVERAGE ADJUSTMENT (CD830L)

Adjust for a maximum reading on level meter

L4 515 kHz

CT4 1,750 kHz

MW TRACKING ADJUSTMENT (CD830L)

Adjust for a maximum reading on level meter

L1-1 600 kHz

CT1 1,400 kHz

LW FREQUENCY COVERAGE ADJUSTMENT (CD830L)

Adjust for a maximum reading on level meter

CT6 145 kHz

LW TRACKING ADJUSTMENT (CD830L)

Adjust for a maximum reading on level meter

L1-2 160 kHz

CT5 240 kHz

FM VCO Adjustment

Procedure:

• Repeat the procedures in each adjustment several times, and the

frequency coverage and tracking adjustments should be finally

done by the trimmer capacitors.

AM FREQUENCY COVERAGE ADJUSTMENT (CD830)

30% amplitude modulation by

400 Hz signal.

Output level: as low as possible

level meter

4 Ω

set

SPEAKER OUT

FM FREQUENCY COVERAGE ADJUSTMENT

Adjust for a maximum reading on level meter

L3 86.5 MHz (87.35 MHz)

CT3 109.5 MHz (108.25 MHz)

FM TRACKING ADJUSTMENT

Adjust for a maximum reading on level meter

L2 86.5 MHz (87.35 MHz)

CT2 109.5 MHz (108.25 MHz)

AM IF ADJUSTMENT

Adjust for a maximum reading on level meter

T1 455 kHz

Adjust for a maximum reading on level meter

L4 515 kHz (516.5 kHz)

CT4 1,750 kHz (1,631.5 kHz)

AM TRACKING ADJUSTMENT (CD830)

Adjust for a maximum reading on level meter

L1 600 kHz

CT1 1,400 kHz

+

–

( ) : AEP Model

1. Connect the frequency counter to 4 and 7 pins of IC1 as shown

the figure right.

2. Tune the set to 98 MHz.

3. Adjust RV1 for 76 kHz reading on frequency counter.

Specification V alue:

Frequency counter

75,950 – 76,050 Hz

Connection:

frequency counter

+

–

33 k Ω

MAIN Boar

IC1 Pin 7

IC1 Pin 4

Adjustment Location:

[MAIN BOARD] (Component Side)

T1

L3

CT3

L3

FM Frequency

Coverage

Adjustment

L4

CT4

AM Frequency

Coverage Adjustment

MW Frequency

Coverage Adjustment

AM IF

Adjustment

CT6

LW Frequency

Coverage

Adjustment

CT2

L2

FM Traking

Adjustment

CT1

AM Tracking Adjustmen

MW Tracking Adjustme

CT5

LW Traking Adjustment

L1-2

LW Traking Adjustment

L1, L1-1

AM Tracking Adjustment

MW Tracking Adjustment

9

ICF-CD830/CD830L

SECTION 5

DIAGRAMS

Note on Printed Wiring Board:

• X : parts extracted from the component side.

• : Pattern from the side which enables seeing.

Note on Schematic Diagrams:

• All capacitors are in µF unless otherwise noted. pF: µµF

50 WV or less are not indicated except for electrolytics

and tantalums.

• All resistors are in Ω and 1/

specified.

¢

•

• 2 : nonflammable resistor.

• C : panel designation.

• H : adjustment for repair.

• A : B+ Line.

• Voltages and waveforms are dc with respect to ground

Note:

The components identified by mark ! or dotted

line with mark ! are critical for safety.

Replace only with part

number specified.

• Voltages are taken with a VOM (Input impedance 10 MΩ).

• Signal path.

• Abbreviation

: internal component.

under no-signal (detuned) conditions.

no mark : FM

( ) : AM (MW/LW)

< > : CD

Voltage variations may be noted due to normal production tolerances.

F : FM

f : AM (MW/LW)

J : CD

AUS : Australian model

CND : Canadian model

IT : Italian model

SP : Singapore model

4

W or less unless otherwise

Note:

Les composants identifiés par

une marque ! sont critiques

pour la sécurité.

Ne les remplacer que par une

piéce portant le numéro

spécifié.

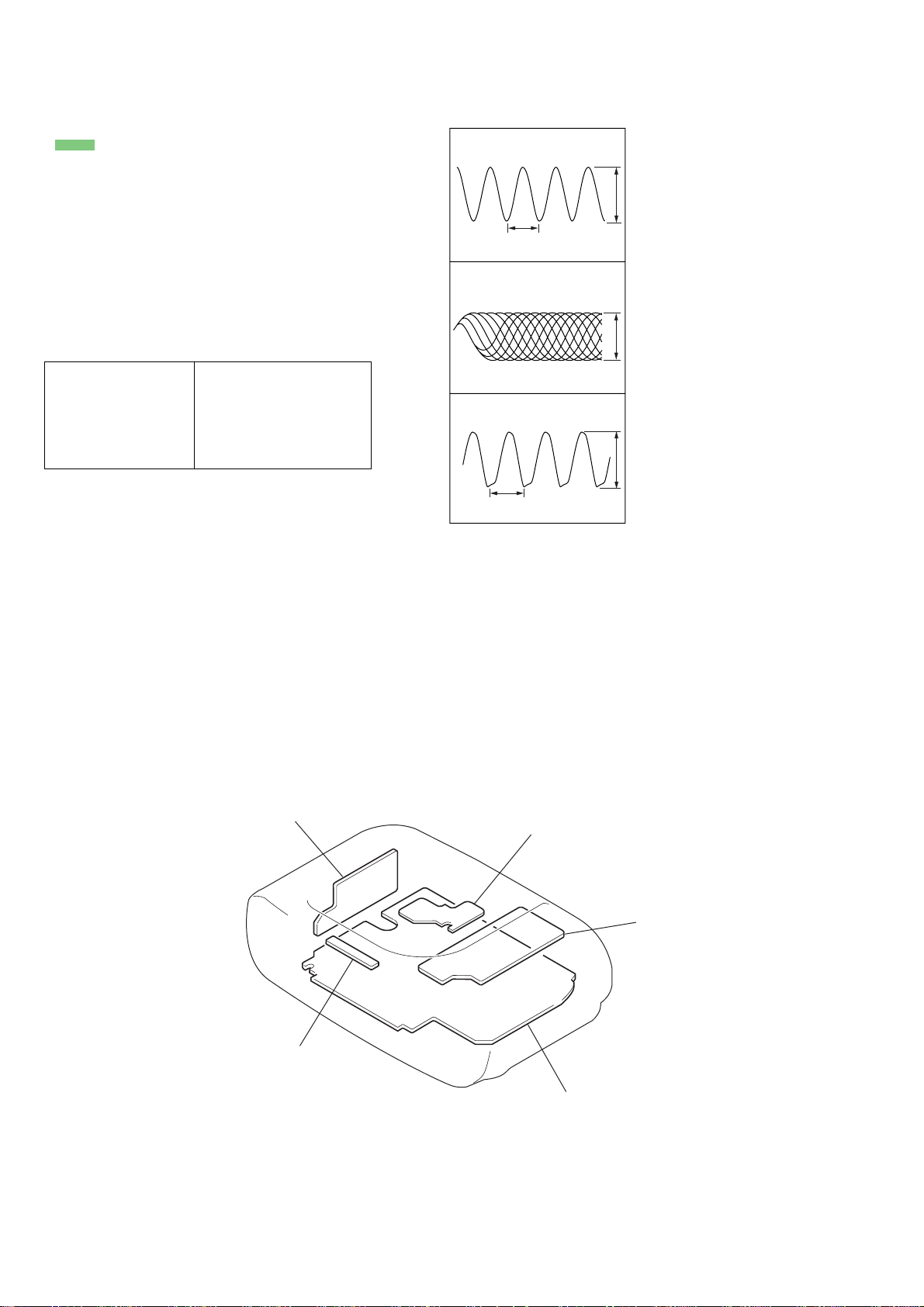

• Waveforms

1

IC401 ud (XT1)

31 ms

1.0 V/DIV, 20 ms/DIV

2

IC501 ed (RF0)

(PLAY MODE)

0.2 V/DIV, 500 ns/DIV

3

IC551 ua (XTA0)

59 ns

2.0 V/DIV, 40 ns/DIV

3.4 Vp-p

0.9 – 1.3 Vp-p

5.6 Vp-p

5-1. CIRCUIT BOARDS LOCATION

TRANSFORMER board

LED board

MOTOR (6P) board

KEY board

MAIN board

10

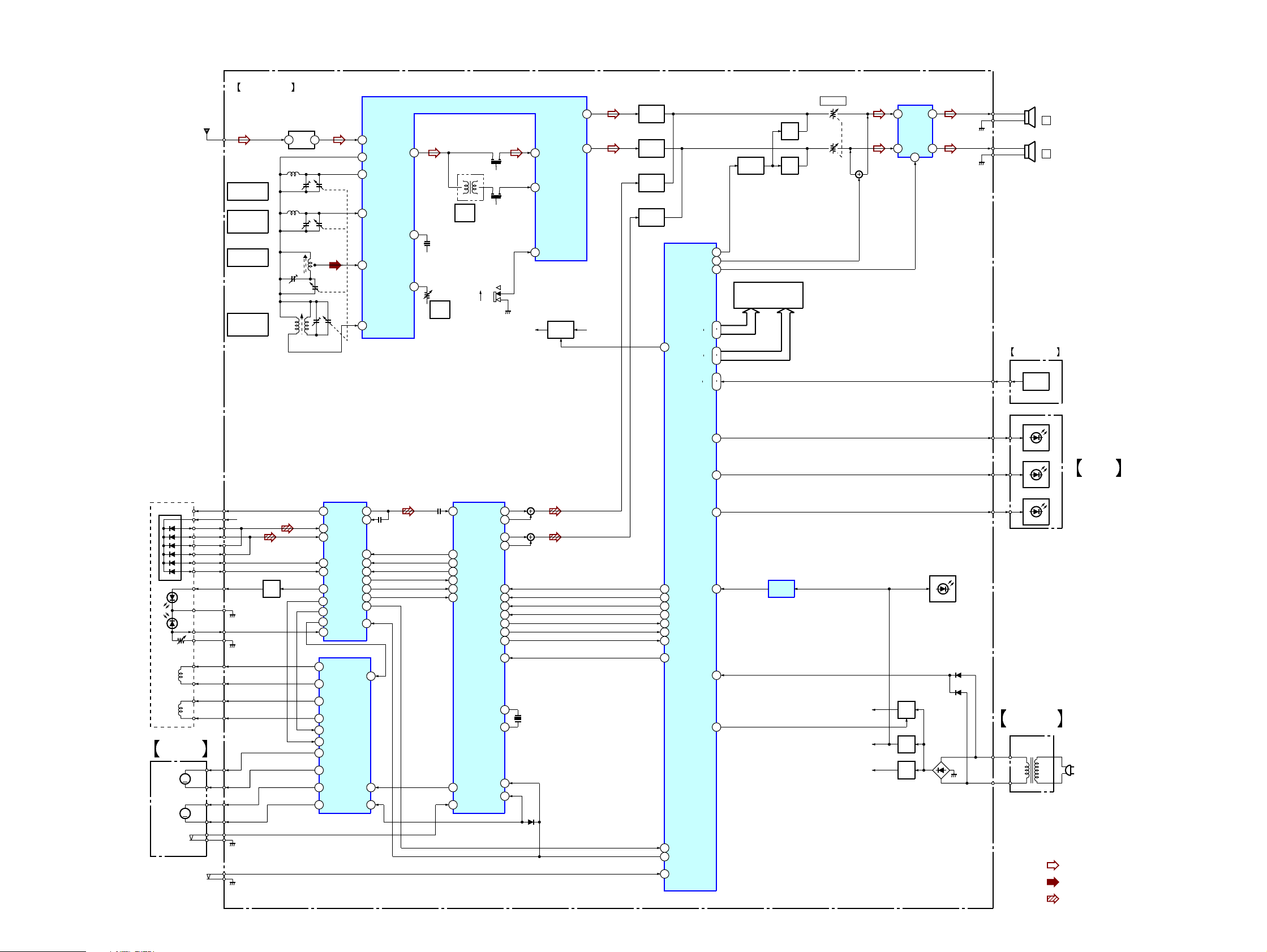

5-2. BLOCK DIAGRAM (CD830)

ANT1

(FM ANTENNA)

TRACKING

FREQUENCY

COVERAGE

TRACKING

FREQUENCY

COVERAGE

MAIN BOARD

FM

FM

AM

AM

AM OSC

BPF1

B.P.F

1

L2

CT2 CV1-2

FM RF

L3

CT3

FM OSC

L1

AM FERRITE-ROD

ANTENNA

CT1

L4

CT4

3

CV1-3

CV1-1

CV1-4

18

21

20

22

19

24

FRONT- END

FM RF IN

REG

FM RF OUT

FM OSC

AM RF

AM OSC

FM/AM

IC1

MIX OUT

DISCRI

VCO

ICF-CD830/CD830L

RV351

L OUT

6

CF3

AM IFT

AM

IF

10.7MHz

T1

CF2

455kHz

S1

FM

AM

13

14

15

16

26

CF1

27

RV1

FM

VCO

FM IF

AM IF

BAND

+B SW

Q1

R OUT

5

+5VTU +B

BUFFER

Q131

BUFFER

Q231

BUFFER

Q101

BUFFER

Q201

SYSTEM CONTROL

IC401

POWER ON

80

RADIO ON

A MUTE

BUZZER

SEG0

SEG15

COM0

COM3

KEY0

KEY12

MUTE

Q151

MUTE

CONT

Q351

77

53

79

LIQUID CRYSTAL

11

26

7

10

33

47

LCD401

DISPLAY PANEL

MUTE

Q251

VOLUME

11

POWER AMP

IC371

12

3

5

8

SP101

SP201

L

(SPEAKER)

R

KEY BOARD

S601-613

FUNCTION

KEY

OPTICAL PICK-UP

BLOCK

(KSS-213C)

VC

A

B

C

D

E

F

LD

GND

PD

VR

F+

FOCUS

COIL

F-

T+

TRACKING

COIL

T-

MOTOR(6P)

BOARD

M571

SLED

M

MOTOR

M572

SPINDLE

M

MOTOR

D653

ALM-CD LED

58

D652

DIGITAL SERVO

RF AMP

IC501

51

RFO

+5V

Q501

LD

DRIVE

VC

38

PD1

39

PD2

42

E

41

F

36

LD

16

SLO

13

TAO

6

FEO

37

PD

MOTOR/COIL DRIVE

26

F+

27

F-

17

T+

18

T-

19

T IN

3

SL IN

2

SL+

1

SL-

12

SP+

11

SP-

IC591

DATA

COUT

RFI

CLK

XLT

FOK

F IN

SP IN

MUTE

33

32

22

20

21

27

24

25SENS1

26SENS2

23XRST

25

15

7

DIGITAL SIGNAL PROC.

D/A CONV.

IC551

35

L OUT1

RF

A OUT1

L OUT2

A OUT2

12

DATO

14

CLKO

13

XLTO

18

FOK

11

10

21

15

CIN

SEIN

MDP

XLON MUTE

SPOA(LIMIT)

DATA

SENS

SMUTE

XTAI

XTAO

XRST

67

65

74

76

7

9CLK

8XLAT

4SQCK

57SCOR

5SQSO

6

62

71

X551

16.9344MHz

72

79

17

ALM-RADIO LED

ALM-BUZZER LED

56

C DATA

54

C CLOCK

55

C LATCH

62

C SQCK

52

C SCOR

61

C SQSO

50

C SENS

63

C MUTE

RESET

CD ON

59

D651

60

D401-402

67

49AC IN

57

RESET

IC402

IC402

CD +B

M +6V

D903

D905-908

D904

TRANSFORMER

BOARD

T901

POWER

TRANSFOMER

+B SW

Q551

+5V

REG

Q901

REG

Q903

AC

IN

LED

BOARD

S570

LIMIT

SW

S401

DOOR SW

51

64

75

C SENS2

C RST

DOOR IN

• Signal Path

: FM

: AM

: CD

1111

ICF-CD830/CD830L

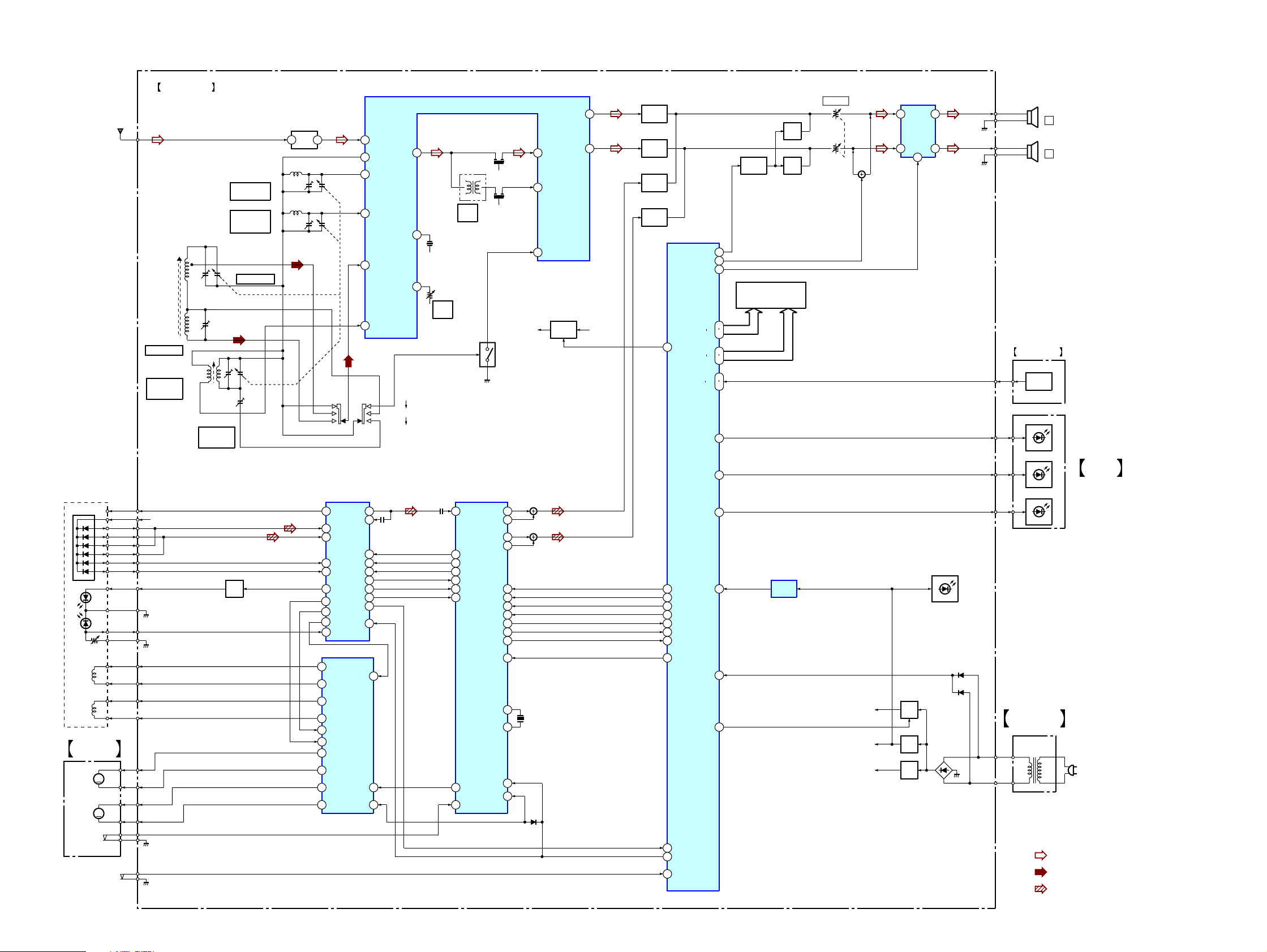

5-3. BLOCK DIAGRAM (CD830L)

MAIN BOARD

ANT1

(FM ANTENNA)

L1

MW/LW FERRITE-ROD

ANTENNA

L1-1

(MW)

L1-2

(LW)

L1-2,CT5

LW TRACKING

L4,CT4

MW

FREQUENCY

COVERAGE

OPTICAL PICK-UP

BLOCK

(KSS-213C)

VR

FOCUS

COIL

TRACKING

COIL

MOTOR(6P)

BOARD

M571

SLED

MOTOR

M572

SPINDLE

MOTOR

VC

A

B

C

D

E

F

LD

GND

PD

M

M

F+

F-

T+

T-

+5V

MW/LW

OSC

CT1

L4

FREQUENCY

COVERAGE

CT2,L2

FM

TRACKING

L3,CT3 CV1-3

FM

FREQUENCY

COVERAGE

CV1-1

L1-1,CT1

MW TRACKING

CT5

CV1-4

CT4

CT6

CT6

LW

Q501

LD

DRIVE

1

L2 CT2

FM RF

L3 CT3

FM OSC

BPF1

B.P.F

3

CV1-2

S1-1

RF AMP

IC501

51

VC

38

PD1

39

PD2

42

E

41

F

36

LD

16

SLO

13

TAO

6

FEO

37

PD

MOTOR/COIL DRIVE

IC591

26

F+

27

F-

17

T+

18

T-

19

T IN

3

SL IN

2

SL+

1

SL-

12

SP+

11

SP-

DATA

COUT

RFO

RFI

CLK

XLT

FOK

F IN

SP IN

MUTE

18

21

20

22

19

24

S1-2

FM RF IN

REG

FM RF OUT

FM OSC

AM RF

AM OSC

33

32

22

20

21

27

24

25SENS1

26SENS2

23XRST

25

15

7

FM/AM

FRONT- END

IC1

MIX OUT

DISCRI

VCO

RV351

L OUT

6

CF3

16

26

CF1

27

RV1

FM

VCO

FM

MW

LW

35

12

14

13

18

11

10

21

15

10.7MHz

T1

AM IFT

CF2

455kHz

AM

IF

Q2,Q3

DIGITAL SERVO

DIGITAL SIGNAL PROC.

D/A CONV.

IC551

L OUT1

RF

A OUT1

L OUT2

A OUT2

DATO

CLKO

XLTO

FOK

DATA

CIN

SEIN

SENS

SMUTE

XTAI

XTAO

XRST

MDP

XLON MUTE

SPOA(LIMIT)

13

14

15

67

65

74

76

7

9CLK

8XLAT

4SQCK

57SCOR

5SQSO

6

62

71

X551

16.9344MHz

72

79

17

FM IF

AM IF

BAND

+B SW

Q1

R OUT

5

+5VTU +B

BUFFER

Q131

BUFFER

Q231

BUFFER

Q101

BUFFER

Q201

SYSTEM CONTROL

IC401

POWER ON

80

RADIO ON

ALM-CD LED

ALM-RADIO LED

ALM-BUZZER LED

56

C DATA

54

C CLOCK

55

C LATCH

62

C SQCK

52

C SCOR

61

C SQSO

50

C SENS

63

C MUTE

A MUTE

BUZZER

SEG0

SEG15

COM0

COM3

KEY0

KEY12

RESET

CD ON

MUTE

Q151

MUTE

CONT

Q351

77

53

79

LIQUID CRYSTAL

11

26

7

10

33

47

58

59

60

67

49AC IN

57

LCD401

DISPLAY PANEL

RESET

IC402

IC402

MUTE

Q251

VOLUME

CD +B

M +6V

11

POWER AMP

IC371

12

3

5

8

SP101

SP201

L

(SPEAKER)

R

KEY BOARD

S601-613

FUNCTION

KEY

D653

D652

D651

D401-402

D903

D905-908

D904

TRANSFORMER

BOARD

T901

POWER

TRANSFOMER

+B SW

Q551

+5V

REG

Q901

REG

Q903

AC

IN

LED

BOARD

S570

LIMIT

SW

S401

DOOR SW

• Signal Path

51

64

75

C SENS2

C RST

DOOR IN

: FM

: MW/LW

: CD

1212

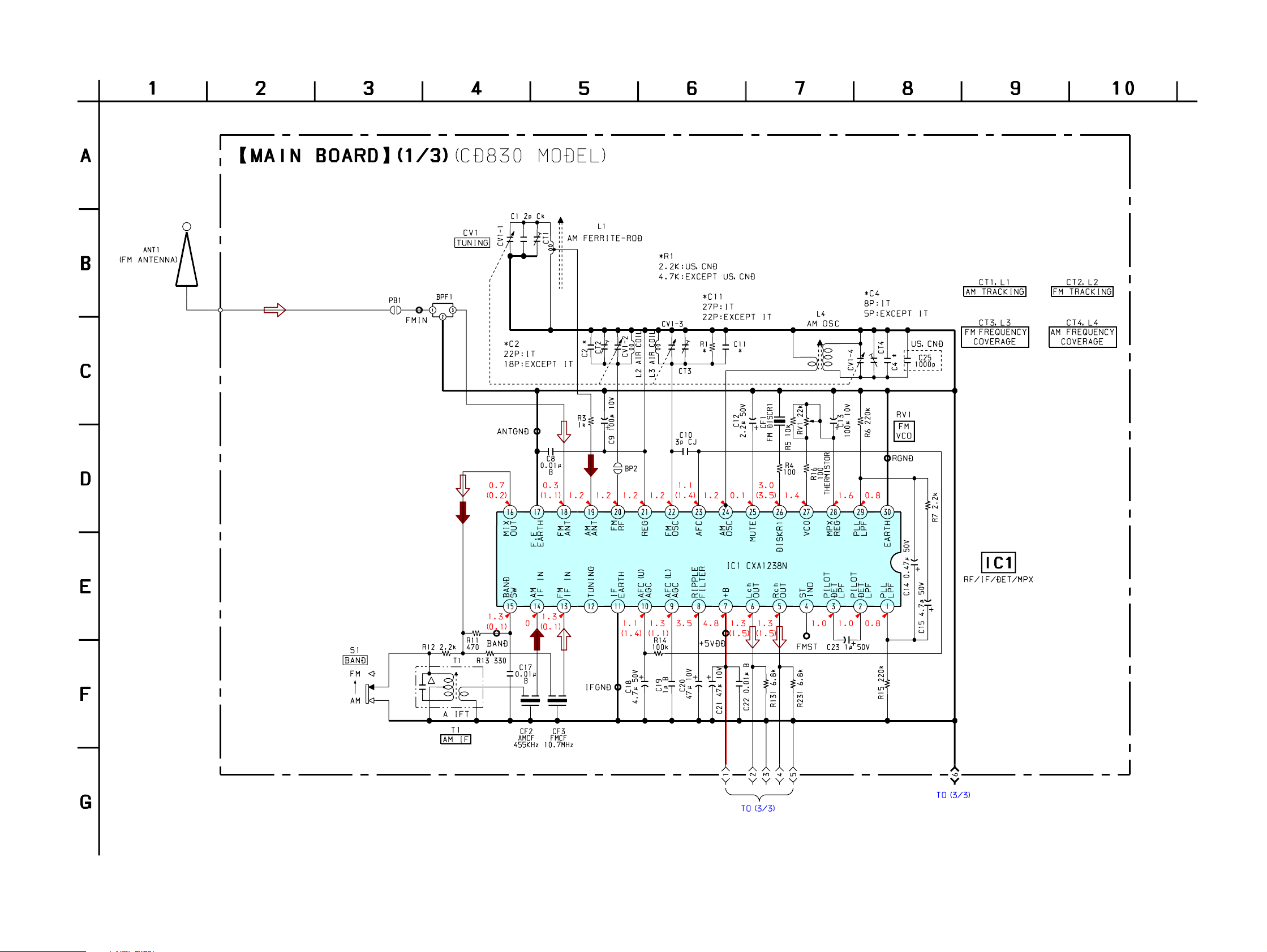

5-4. SCHEMATIC DIAGRAM – TUNER SECTION (CD830) –

ICF-CD830/CD830L

1313

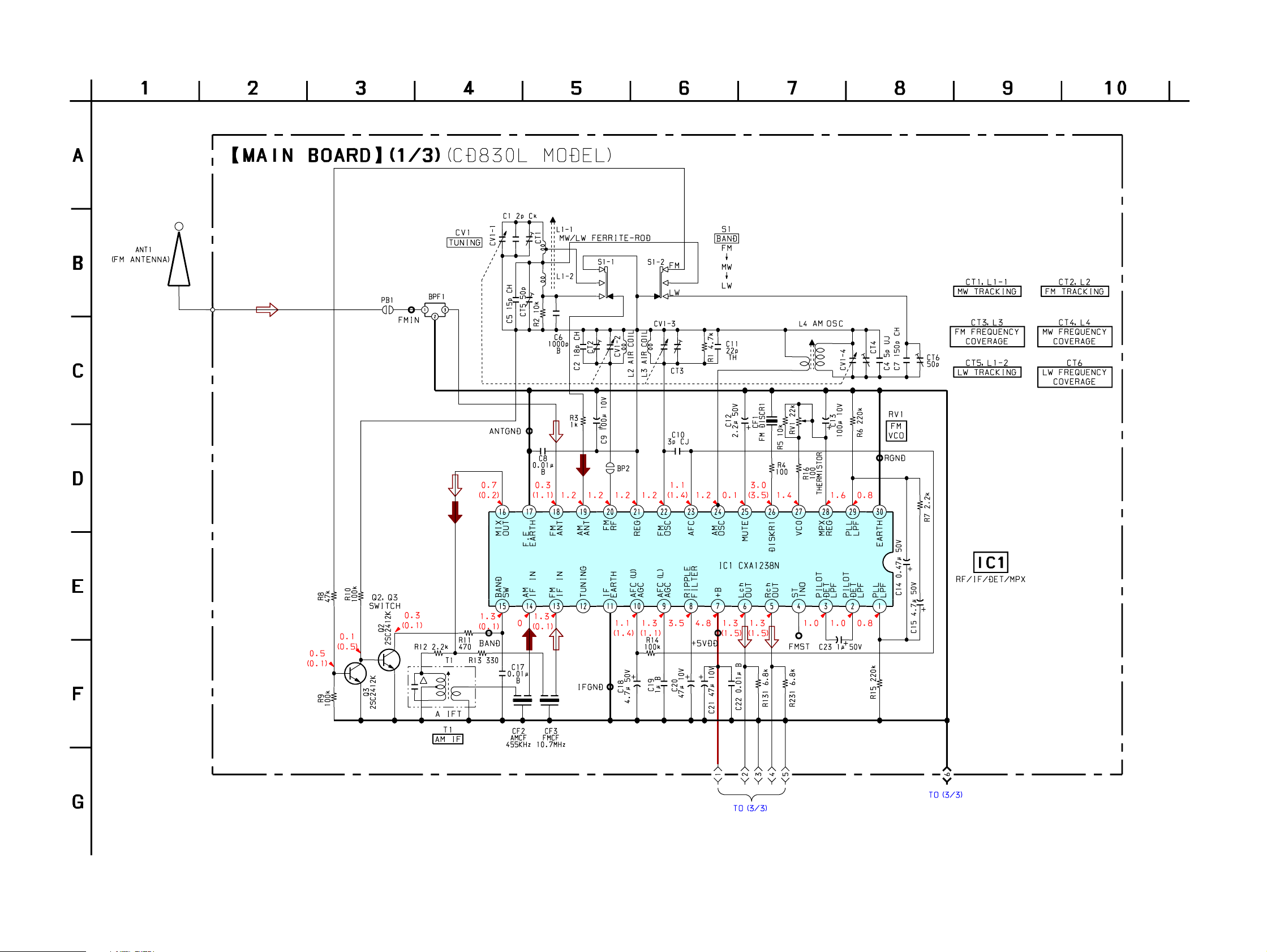

ICF-CD830/CD830L

5-5. SCHEMATIC DIAGRAM – TUNER SECTION (CD830L) –

1414

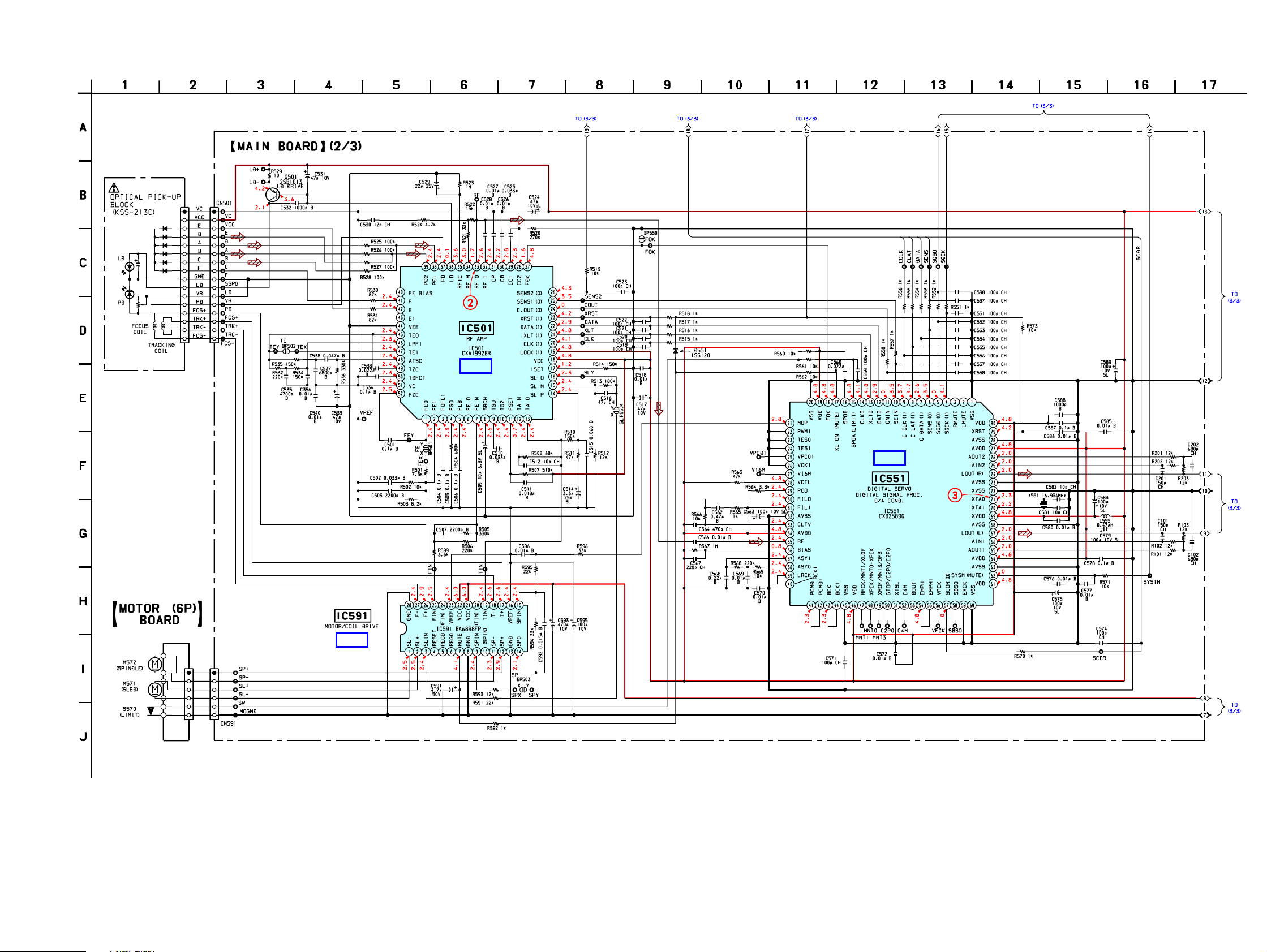

ICF-CD830/CD830L

5-6. SCHEMATIC DIAGRAM – CD SECTION –

• Refer to page 10 for Waveforms. • Refer to page 20, 21 for IC Block Diagrams.

IC B/D

IC B/D

IC B/D

1515

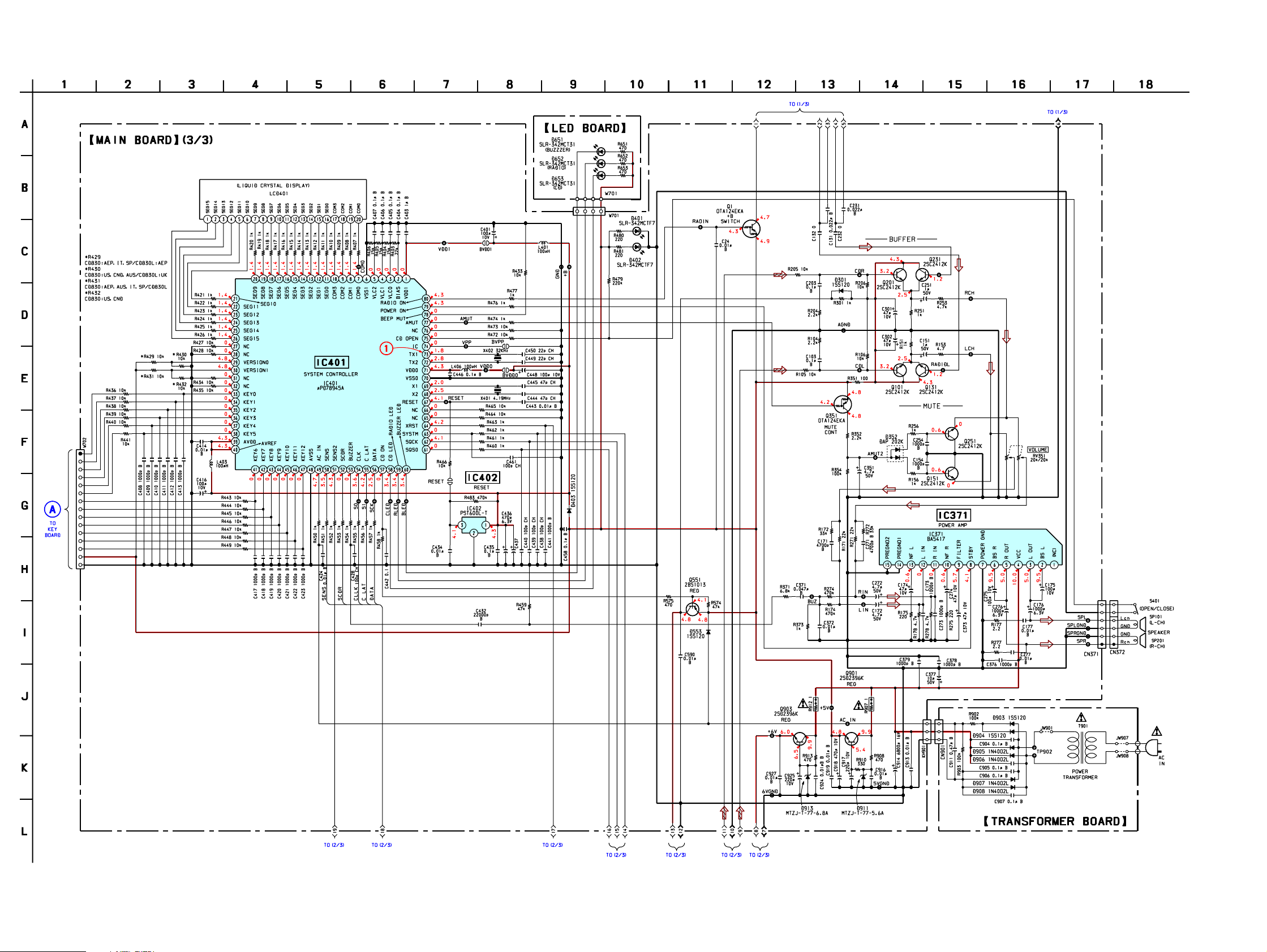

ICF-CD830/CD830L

5-7. SCHEMATIC DIAGRAM – POWER SECTION –

• Refer to page 10 for Waveforms. • Refer to page 22 for IC Pin Function Description.

(Page 19)

1616

ICF-CD830/CD830L

5-8. PRINTED WIRING BOARD – MAIN SECTION –

12

3 4 5 6 7 8 9 101112

MAIN BOARD

A

1

R429:

CD830:AEP,IT,SP/CD830L:AEP

R430:

CD830:US,CND,AUS/CD830L:UK

R431:

CD830:AEP,AUS,IT,SP/CD830L

B

R432:

CD830:US,CND

C

D

E

D

TO

LED

BOARD

C

TO

TRANSFORMER

BOARD

F

G

TO

OPTICAL PICK-UP

BLOCK (KSS-213C)

H

I

R908

R907

R912

MOTOR (6P)

1

Q901

E

Q903

E

D913

R913

C914

KH901

TO

BOARD

B

6

CN591

14

15 28

D911

C591

C595

W702

1

C918

C917

C926

16

C925

D553

D551

Q501

E

IC591

D403

1

• Refer to page 10 for Circuit Board Location.

TO

A

KEY

E

C593

C531

BOARD

1

D401

Q551

CN501

16

15

LCD401 (LIQUID CRYSTAL DISPLAY)

1

21

40

C416

41

C437 C436

C589

2

1

39

40

W701

C539

C579

C529

IC501

52

IC401

2627

1

20

6160

C583

X401

1

3

IC402

C517

14

13

80

X551

80

1

C509

• Semiconductor

Location

Ref. No. Location

D301 E-8

S401

20

D402

1

X402

C448

IC551

20 21

C514

C401

D301

C575

6061

41

40

C524

C563

CN371

16

C176

C276

C175

C275

115

IC371

C274

C375

C174

C373

C377

E

E

E

C301

BPF1

CN372

E

3

1

CV1

TUNING

CD830L

L1

(OPEN/CLOSE)

6

1

C272

C172

E

C351

C302

C20 C21

T1

C9

CT1

C18

CF3

15

16 30

CT2

CV1-2

CV1-3

CV1-1 CV1-4

CT5

CD830L

SP101

(L-CH)

(R-CH)

SP201

RV351

VOLUME

C251C151

CF2

IC1

CT3

CT4

CT6

E

1-680-415-

SPEAKER

C23

1

CF1

L3

CD830:US,CND

L4

E

E

E

E

C15

E

C14

C13

RV1

C12

S1

S1

BAND

AM

FM

(CD830)

(CD830L)

ANT1

(FM ANTENNA)

11

(11)

D352 C-12

D401 B-5

D402 B-6

D403 C-3

D551 F-3

D553 F-3

D911 B-3

D913 C-3

IC1 F-11

IC371 C-9

IC401 C-6

IC402 D-6

IC501 H-5

IC551 F-7

IC591 H-3

Q1 E-9

Q2 I-11

Q3 I-11

Q101 E-9

Q131 E-12

Q151 C-12

Q201 E-9

Q231 E-12

Q251 C-12

Q351 D-10

Q501 G-3

Q551 F-4

Q901 B-2

Q903 C-2

LW

MW

FM

1717

Loading...

Loading...