Sony ICFCD-555-TV Service manual

ICF-CD555TV

SERVICE MANUAL

Ver. 1.3 2005.10

SPECIFICATIONS

US Model

Canadian Model

Model Name Using Similar Mechanism ZS-D10

Optical Pick-up Block Name KSM-900AAA

Optical Pick-up Name KSS-900A

AUDIO POWER

SPECIFICATIONS

(US model only)

POWER OUTPUT AND TOTAL HARMONIC

DISTORTION

With 6–ohm loads, both channels driven from 100 –

10,000 Hz; rated 1.4 W per channel-minimum RMS

power, with no more than 10 % total harmonic

distortion in AC operation.

TV section

Television system: American TV standard/NTSC

Channel coverage:

VHF: 2–13/UHF: 14–69/CATV: 1–125

Antenna:

75-ohm external antenna terminal for VHF/UHF

Display type: Wide LCD color monitor

Size: 7 inches

System: TFT active matrix

Number of pixel: 336,960 pixels

Input: 1 video, 1 audio

CD player section

System: Compact disc digital audio system

Laser diode properties: Material: GaAlAs

Wavelength: 780 nm

Emission duration: Continuous

Laser output: Less than 44.6 µW

(This output is the value measured at a distance of

about 200 mm from the objective lens surface on

the optical pick-up block with 7 mm aperture.)

Frequency response: 20 – 20,000 Hz

Wow and flutter: Below measurable limit

dB

Radio section

Frequency range:

FM: 87.5 – 108 MHz

AM: 530 – 1,710 kHz

General

Time display: 12-hour system

Speaker: 77 mm (3

Power outputs:

1.8 W + 1.8 W (at 10% harmonic distortion)

Power requirements: 120 V AC, 60 Hz

Dimensions:

Approx. 400 × 104 × 323 mm (w/h/d)

(Approx. 15

projecting parts and controls

Mass: Approx. 4.2 kg (9 lb 4.2 oz)

Supplied accessories:

Mounting screws (4), Template (1),

Spacers (4), Remote commander (1)

Design and specifications are subject to change

without notice.

1

⁄8 inches) dia, 6 Ω

3

⁄4× 4 1⁄8× 12 3⁄4 inches) incl.

9-877-644-04 Sony Corporation

2005J05-1 Personal Audio Group

© 2005.10 Published by Sony Engineering Corporation

LCD-TV CD KITCHEN CLOCK RADIO

ICF-CD555TV

r

Ver. 1.1

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be dam-

aged by heat.

Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270 °C dur-

ing repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

SAFETY CHECK-OUT

After correcting the original service problem, perform the following safety check before releasing the set to the customer:

Check the antenna terminals, metal trim, “metallized” knobs,

screws, and all other exposed metal parts for AC leakage.

Check leakage as described below.

LEAKAGE TEST

The AC leakage from any exposed metal part to earth ground and

from all exposed metal parts to any exposed metal part having a

return to chassis, must not exceed 0.5 mA (500 microamperes).

Leakage current can be measured by any one of three methods.

1. A commercial leakage tester, such as the Simpson 229 or RCA

WT -540A. Follo w the manufacturers’ instructions to use these

instruments.

2. A battery-operated AC milliammeter. T he Data Precision 245

digital multimeter is suitable for this job.

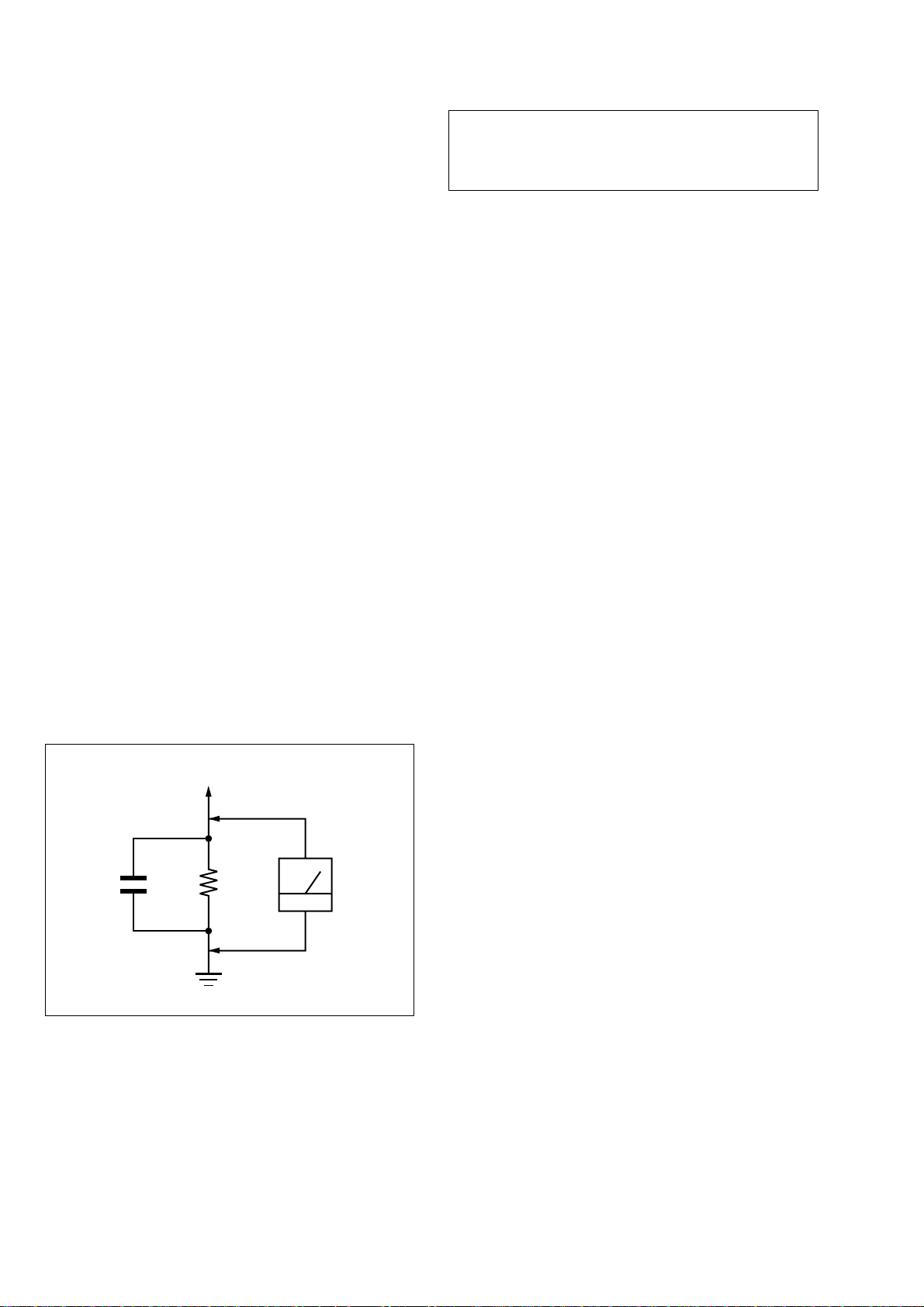

3. Measuring the voltage drop across a resistor by means of a

VOM or battery-operated AC voltmeter. The “limit” indication is 0.75 V, so analog meters must have an accurate lowvoltage scale. The Simpson 250 and Sanwa SH-63T rd are examples of a passive VOM that is suitable. Nearly all battery

operated digital multimeters that have a 2 V A C range are suitable. (See Fig. A)

CAUTION

Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous radiation exposure.

About CD-Rs/CD-RWs

This unit is compatible with CD-Rs/CD-RWs but

playback capability may vary depending on the

quality of the disc, the recording device and

application software.

To Exposed Metal

Parts on Set

AC

1.5 k

0.15 µF

Fig. A. Using an AC voltmeter to check AC leakage.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED

LINE WITH MARK 0 ON THE SCHEMATIC DIAGRAMS

AND IN THE PARTS LIST ARE CRITICAL TO SAFE

OPERATION. REPLACE THESE COMPONENTS WITH

SONY PARTS WHOSE PART NUMBERS APPEAR AS

SHOWN IN THIS MANU AL OR IN SUPPLEMENTS PUBLISHED BY SONY.

Ω

Earth Ground

voltmete

(0.75 V)

ATTENTION AU COMPOSANT AYANT RAPPORT

À LA SÉCURITÉ!

LES COMPOSANTS IDENTIFIÉS P AR UNE MARQUE 0 SUR

LES DIAGRAMMES SCHÉMATIQUES ET LA LISTE DES

PIÈCES SONT CRITIQUES POUR LA SÉCURITÉ DE

FONCTIONNEMENT. NE REMPLACER CES COM- POSANTS

QUE PAR DES PIÈCES SONY DONT LES NUMÉROS SONT

DONNÉS DANS CE MANUEL OU D ANS LES SUPPLÉMENTS

PUBLIÉS PAR SONY.

2

ICF-CD555TV

SECTION 1

SER VICING NOTES

TABLE OF CONTENTS

1. SERVICING NOTES .............................................. 3

2. GENERAL .................................................................. 4

3. DISASSEMBLY

3-1. Disassembly Flow ........................................................... 5

3-2. CD Lid, Cabinet (Upper) ................................................ 5

3-3. CD Tray Assy .................................................................. 6

3-4. CD Tray (Lower) ............................................................. 6

3-5. Optical Pick-up Block (KSM-900AAA) ........................ 7

3-6. Optical Pick-up (KSS-900A) .......................................... 7

3-7. DSP Case (Rear) ............................................................. 8

3-8. TV Board ......................................................................... 8

3-9. LCD Unit (LCD1) ........................................................... 9

3-10. The Cable Processing Method which Connects

a MAIN Board and TV Board ........................................ 9

4. TEST MODE............................................................. 10

5. ELECTRICAL ADJUSTMENTS

Tuner Section ................................................................. 13

CD Section ..................................................................... 15

Monitor Section.............................................................. 16

6. DIAGRAMS

6-1. Block Diagram – CD Section – .................................... 21

6-2. Block Diagram – TUNER Section – ............................ 22

6-3. Block Diagram – MONITOR Section – ....................... 23

6-4. Block Diagram – MAIN Section – ............................... 24

6-5. Note for Printed Wiring Boards and

Schematic Diagrams ....................................................... 25

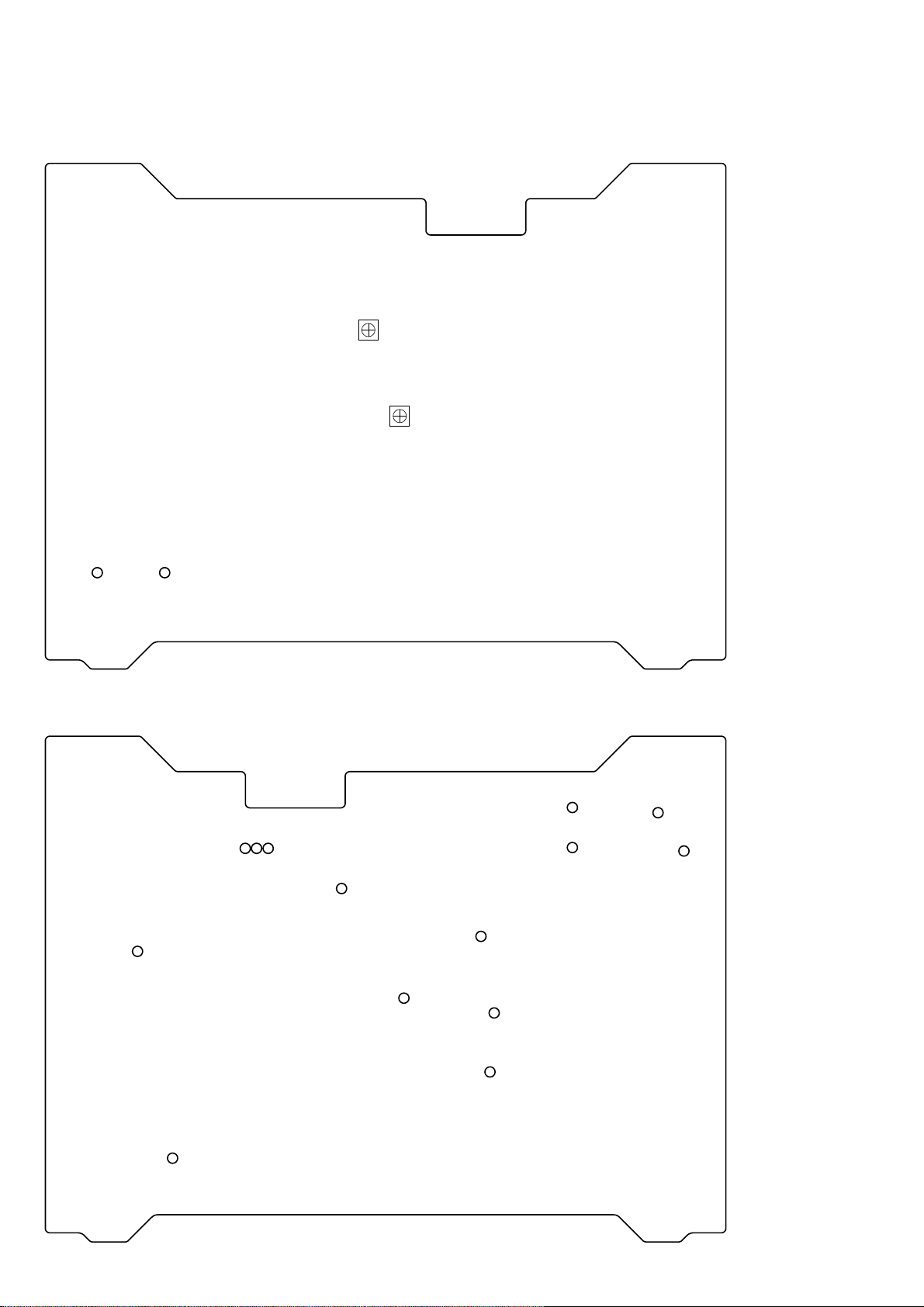

6-6. Printed Wiring Boards – CD Section – ........................ 26

6-7. Schematic Diagram – CD Section – ............................. 27

6-8. Printed Wiring Board – TUNER Section – .................. 28

6-9. Schematic Diagram – TUNER Section – ..................... 29

6-10. Printed Wiring Boards – MAIN Section – ................... 30

6-11. Printed Wiring Boards – PANEL Section – ................. 31

6-12. Schematic Diagram – MAIN Section (1/3) –............... 32

6-13. Schematic Diagram – MAIN Section (2/3) –............... 33

6-14. Schematic Diagram – MAIN Section (3/3) –............... 34

6-15. Schematic Diagram – MONITOR Section (1/3) –....... 35

6-16. Schematic Diagram – MONITOR Section (2/3) –....... 36

6-17. Schematic Diagram – MONITOR Section (3/3) –....... 37

6-18. Printed Wiring Board

– MONITOR Section (Component Side) – ................... 38

6-19. Printed Wiring Board

– MONITOR Section (Conductor Side) –..................... 39

6-20. Printed Wiring Boards

– AMP/POWER SUPPL Y Section – ............................. 40

6-21. Schematic Diagram

– AMP/POWER SUPPL Y Section – ............................. 41

NOTES ON HANDLING THE OPTICAL PICK-UP

BLOCK OR BASE UNIT

The laser diode in the optical pick-up block may suffer electrostatic break-down because of the potential difference generated

by the charged electrostatic load, etc. on clothing and the human

body.

During repair, pay attention to electrostatic break-down and also

use the procedure in the printed matter which is included in the

repair parts.

The flexible board is easily damaged and should be handled with

care.

NOTES ON LASER DIODE EMISSION CHECK

The laser beam on this model is concentrated so as to be focused

on the disc reflective surface by the objective lens in the optical

pick-up block. Therefore, when checking the laser diode emission, observe from more than 30 cm away from the objectiv e lens.

UNLEADED SOLDER

Boards requiring use of unleaded solder are printed with the leadfree mark (LF) indicating the solder contains no lead.

(Caution: Some printed circuit boards may not come printed with

the lead free mark due to their particular size)

: LEAD FREE MARK

Unleaded solder has the following characteristics.

• Unleaded solder melts at a temperature about 40 °C higher than

ordinary solder.

Ordinary soldering irons can be used but the iron tip has to be

applied to the solder joint for a slightly longer time.

Soldering irons using a temperature regulator should be set to

about 350 °C.

Caution: The printed pattern (copper foil) may peel away if the

heated tip is applied for too long, so be careful!

• Strong viscosity

Unleaded solder is more viscou-s (sticky, less prone to flow)

than ordinary solder so use caution not to let solder bridges occur such as on IC pins, etc.

• Usable with ordinary solder

It is best to use only unleaded solder but unleaded solder may

also be added to ordinary solder.

7. EXPLODED VIEWS

7-1. Cabinet (Upper) Section ................................................. 53

7-2. Cabinet (Front) Section ................................................... 54

7-3. Cabinet (Lower) Section-1.............................................. 55

7-4. Cabinet (Lower) Section-2.............................................. 56

7-5. TV Assy Section.............................................................. 57

7-6. MAIN Board Section ...................................................... 58

7-7. CD Tray Assy Section..................................................... 59

7-8. Optical Pick-up Section (KSM-900AAA) ..................... 60

8. ELECTRICAL PARTS LIST .............................. 61

3

ICF-CD555TV

SECTION 2

GENERAL

This section is extracted from

instruction manual.

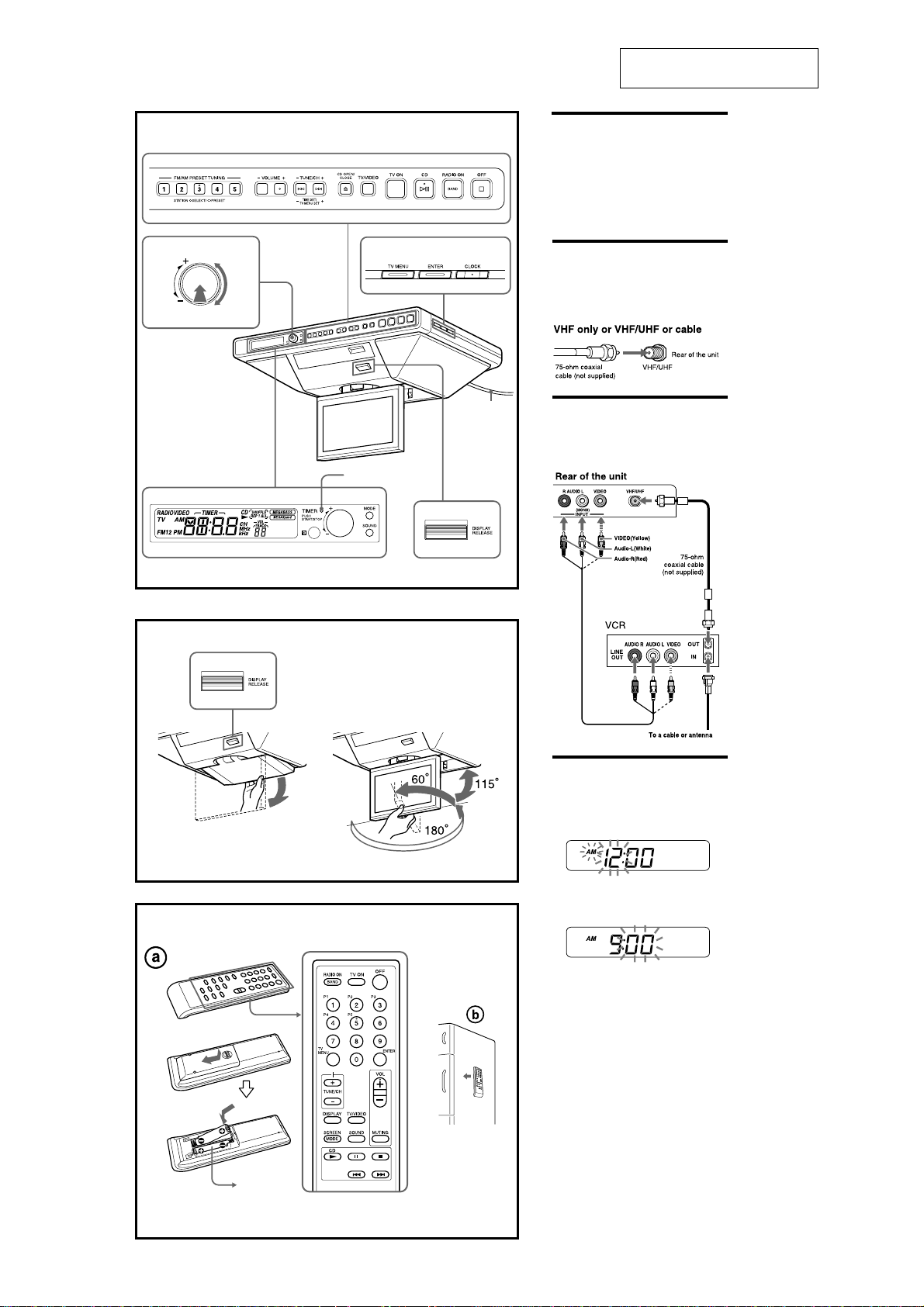

The preset 3, CLOCK, VOLUME + and CD u buttons have a tactile dot.

Turn

Push

TIMER indicator

AC power cord

Features

¥ Super Slim under the counter LCD-TV

¥ 7" wide-screen LCD Color panel display

¥ TV/Cable Tuner

¥ TV stereo/Auto SAP Function

¥ MEGA Xpand function to get the effect of

expansion of the sound field

¥ Easy Set, One Touch Cooking Timer

¥ Magnetic Remote Commander

Basic Connections

(Connecting Cable

TV or Antenna)

Connecting directly to cable or an antenna

Connecting a VCR

and TV

Use this hookup if you subscribe to a cable TV

System that does not require a cable box.

B

C

Setting the Clock

1

Plug in the kitchen clock radio.

The display will flash AM 12:00.

2

Press CLOCK for a few seconds.

You will hear a beep and the hour will start to

flash in the display.

3

Press TIME SET + or — until the correct

hour appears in the display.

4

Press CLOCK once.

The minutes will flash.

5

Repeat steps 3 and 4 to set the minutes.

After setting the minutes, press CLOCK to start

the counting of the seconds, and you will hear two

short beeps.

To set the current time quickly, hold down TIME

SET + or —.

12-hour system: AM 12:00 = midnight

In step 5, when you press CLOCK after the minute

setting to activate the clock, the seconds start

counting from zero.

Size AAA

(R03) × 2

The number 5 and the VOL +

buttons have a tactile dot.

4

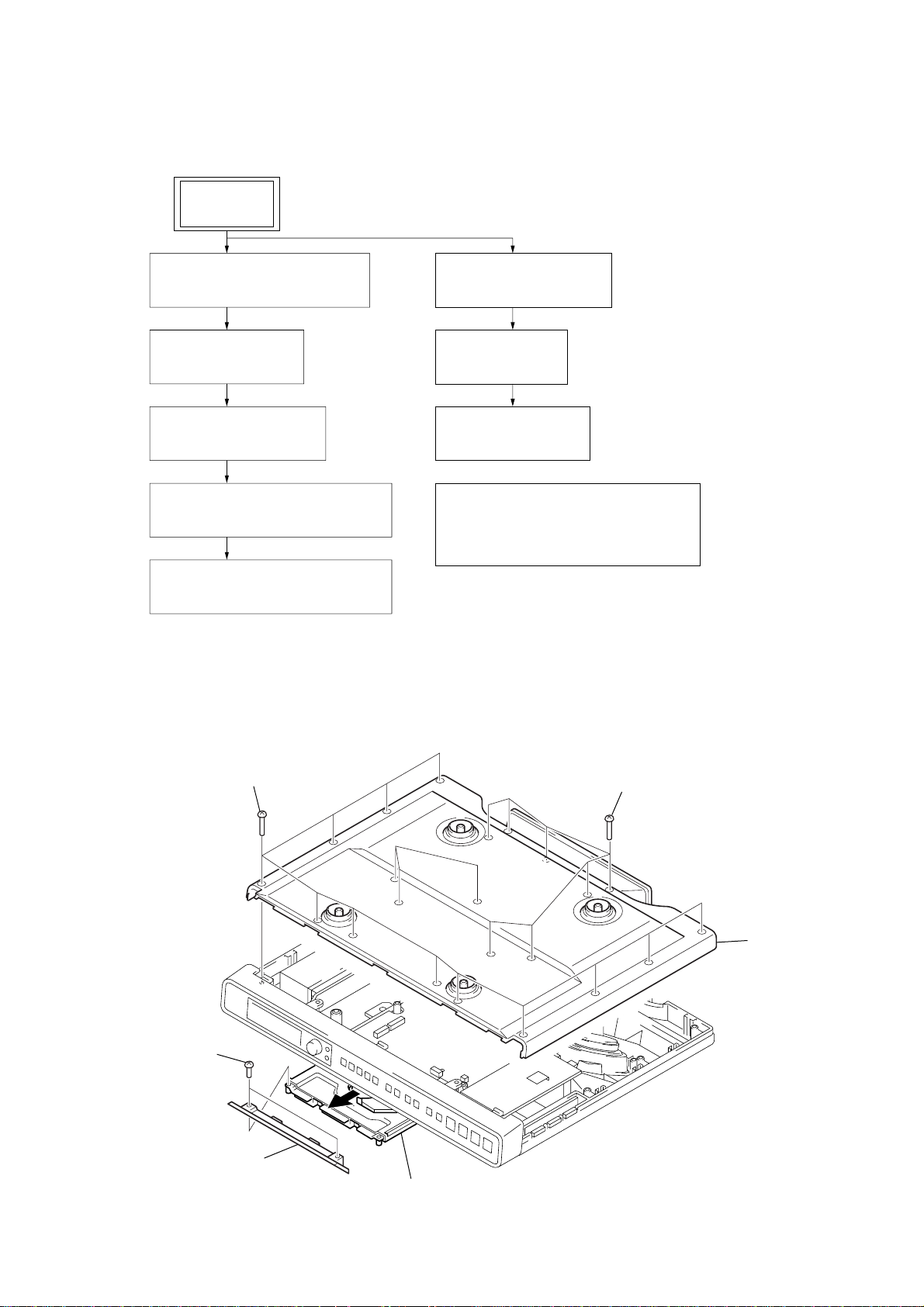

• This set can be disassembled in the order shown below.

3-1. DISASSEMBLY FLOW

SET

ICF-CD555TV

SECTION 3

DISASSEMBLY

3-2. CD LID, CABINET (UPPER)

(Page 5)

3-3. CD TRAY ASSY

(Page 6)

3-4. CD TRAY (LOWER)

(Page 6)

3-5. OPTICAL PICK-UP BLOCK

(KSM-900AAA) (Page 7)

3-6. OPTICAL PICK-UP (KSS-900A)

(Page 7)

Note: Follow the disassembly procedure in the numerical order given.

3-7. DSP CASE (REAR)

3-8. TV BOARD

3-9. LCD UNIT (LCD1)

3-10.THE CABLE PROCESSING METHOD

3-2. CD LID, CABINET (UPPER)

(Page 8)

(Page 8)

(Page 9)

WHICH CONNECTS A MAIN BOARD

AND TV BOARD

(Page 9)

2

two screws

4

twelve BV tapping screws

(B3)

3

CD lid

1

Open the CD tray.

4

ten BV tapping screws

(B3)

5

cabinet (upper)

5

ICF-CD555TV

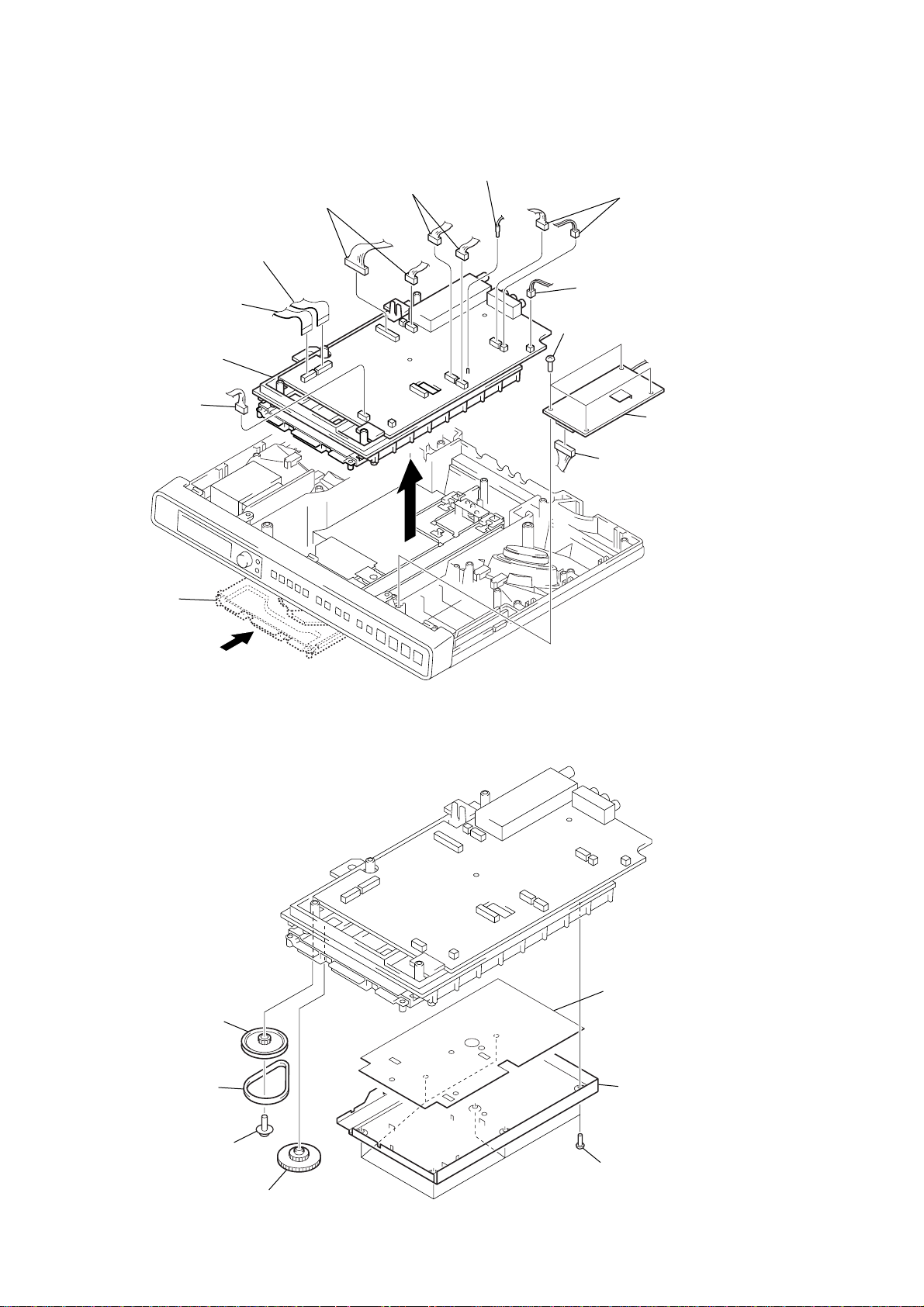

3-3. CD TRAY ASSY

5

flexible flat (17 core) cable

(CN403)

6

flexible flat (16 core) cable

(CN410)

9

CD tray assy

7

connector

(CN406)

7

two connectors

(CN302, CN303)

7

two connectors

(CN501, CN504)

8

terminal

(CN304)

7

two connectors

(CN502, CN503)

7

connector

(CN409)

2

four BV tapping screws

(B3)

3

4

connector

(CNP1)

Lift up the TUNER board.

1

Close the CD tray.

3-4. CD TRAY (LOWER)

3

pulley

7

insulating sheet (CD tray)

1

2

PWH tapping screw

(B2.6)

belt

4

gear

6

CD tray (lower)

5

seven P tapping screws

(B2.6)

6

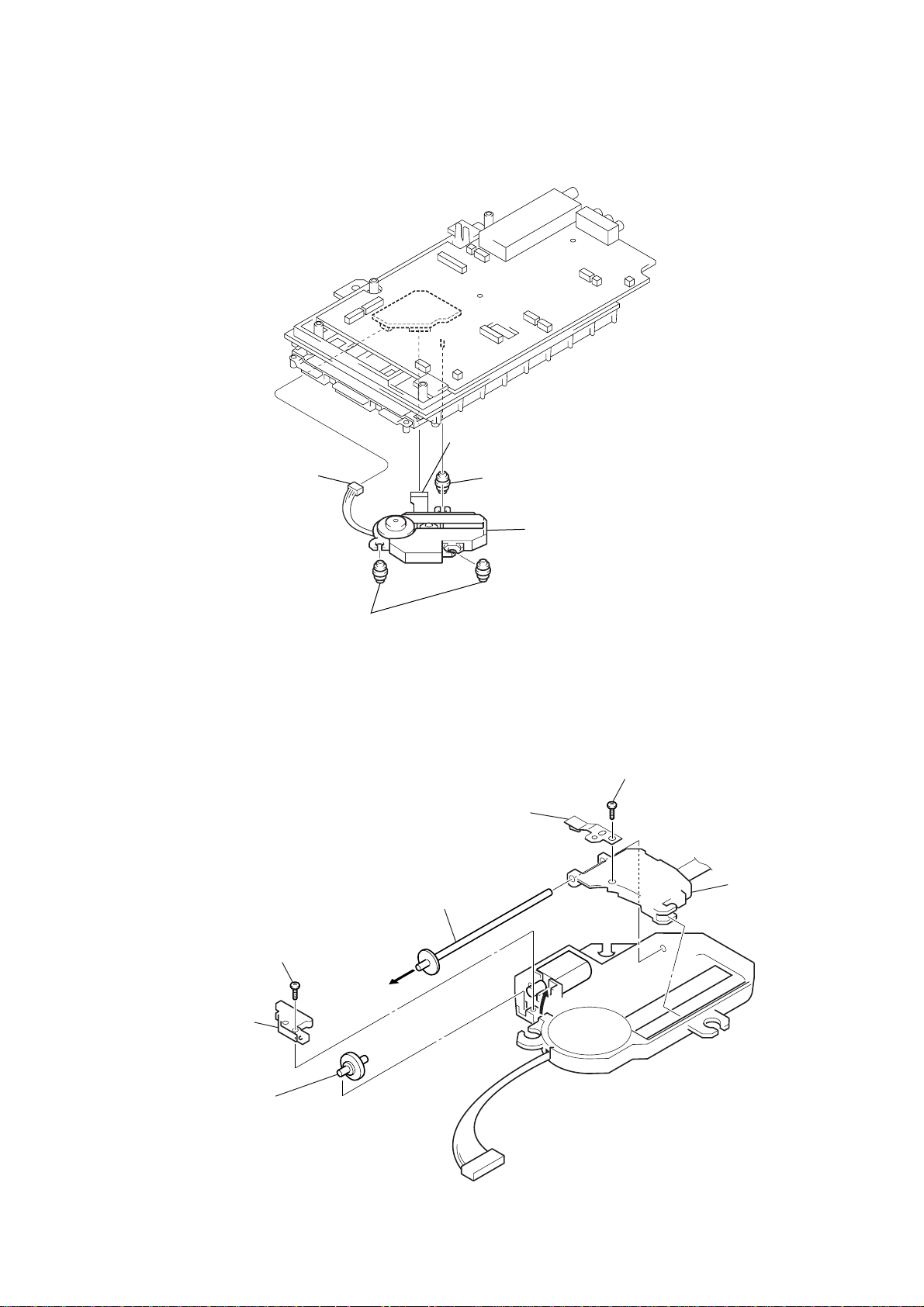

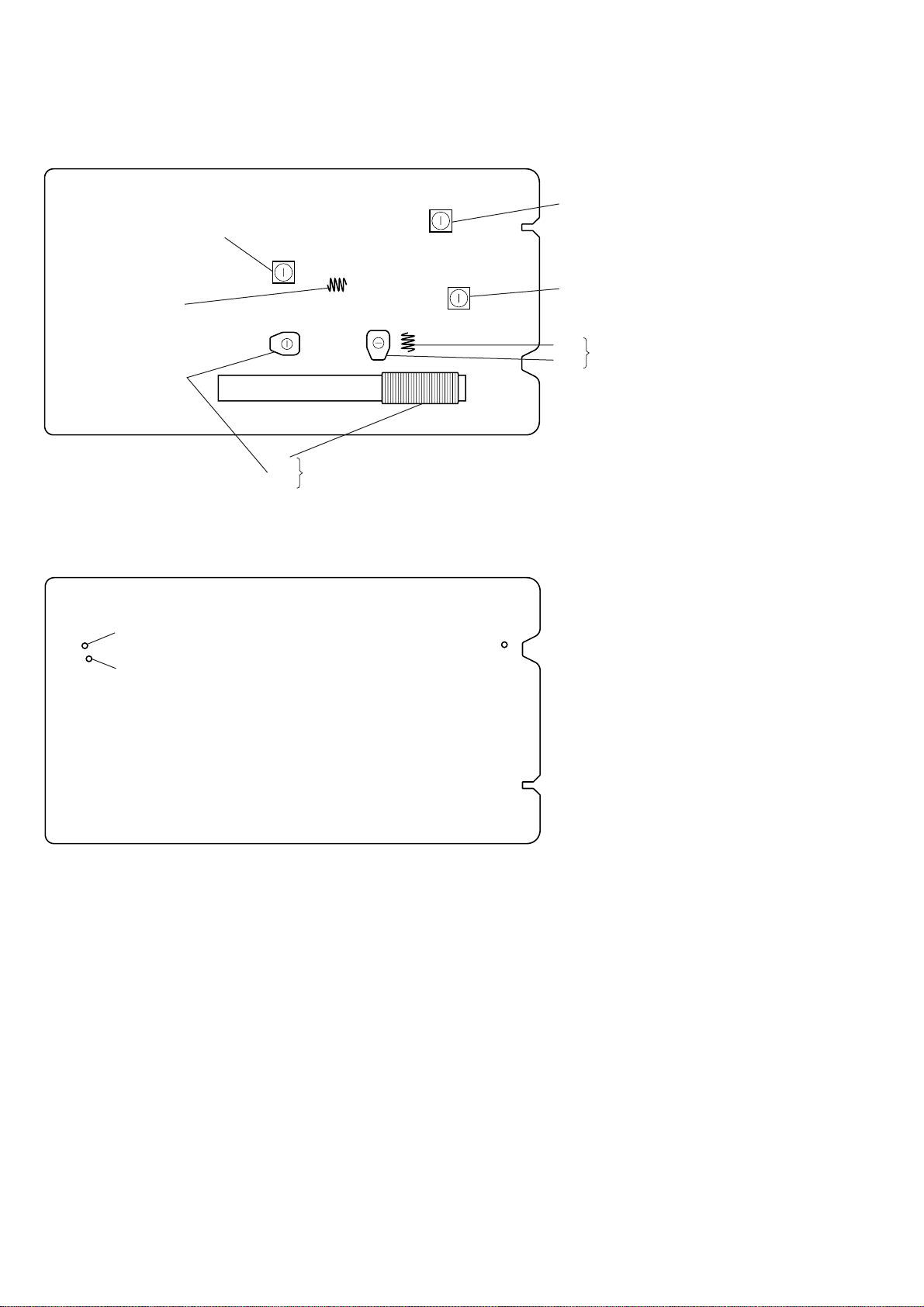

3-5. OPTICAL PICK-UP BLOCK (KSM-900AAA)

2

1

connector

(CNP706)

OP flexible board

(CNP705)

3

insulator

ICF-CD555TV

3

two insulators

3-6. OPTICAL PICK-UP (KSS-900A)

7

sled screw assy (780E)

1

screw

(2

×

8)

5

rack spring (780C)

4

optical pick-up block (KSM-900AAA)

4

screw

×

4)

(B1.7

8

optical pick-up

(KSS-900A)

2

holder (780C)

3

gear B (780C)

6

7

ICF-CD555TV

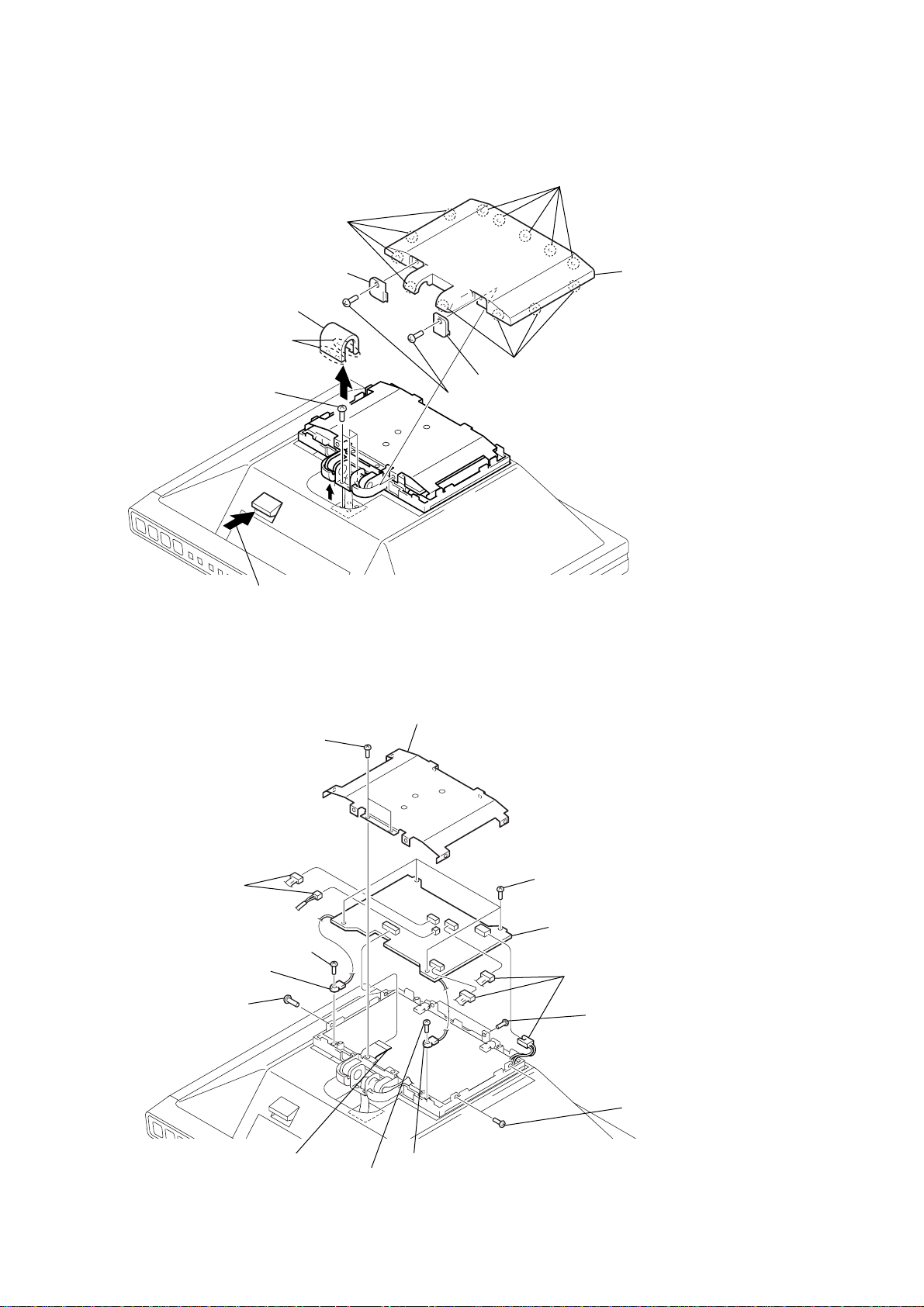

3-7. DSP CASE (REAR)

2

1

3

four screws

7

0

slider (DSP) (R)

case (shaft)

four claws

four claws

5

9

6

two screws

7

7

four claws

slider (DSP) (L)

five claws

8

DSP case (rear)

3-8. TV BOARD

3

two connectors

(CN1402, CN1404)

7

bracket (DSP)

1

two screws

4

Push the button (release).

1

two screws

6

screw

2

shield (DSP)

5

four screws

8

TV board

3

three connectors

(CN1401, CN1403, CN1801)

1

two screws

1

two screws

4

LCD flexible board

(CN1802)

6

screw

7

bracket (DSP)

8

3-9. LCD UNIT (LCD1)

1

two screws

2

two brackets (DSP)

3

insulating sheet (DSP)

4

LCD unit (LCD1)

ICF-CD555TV

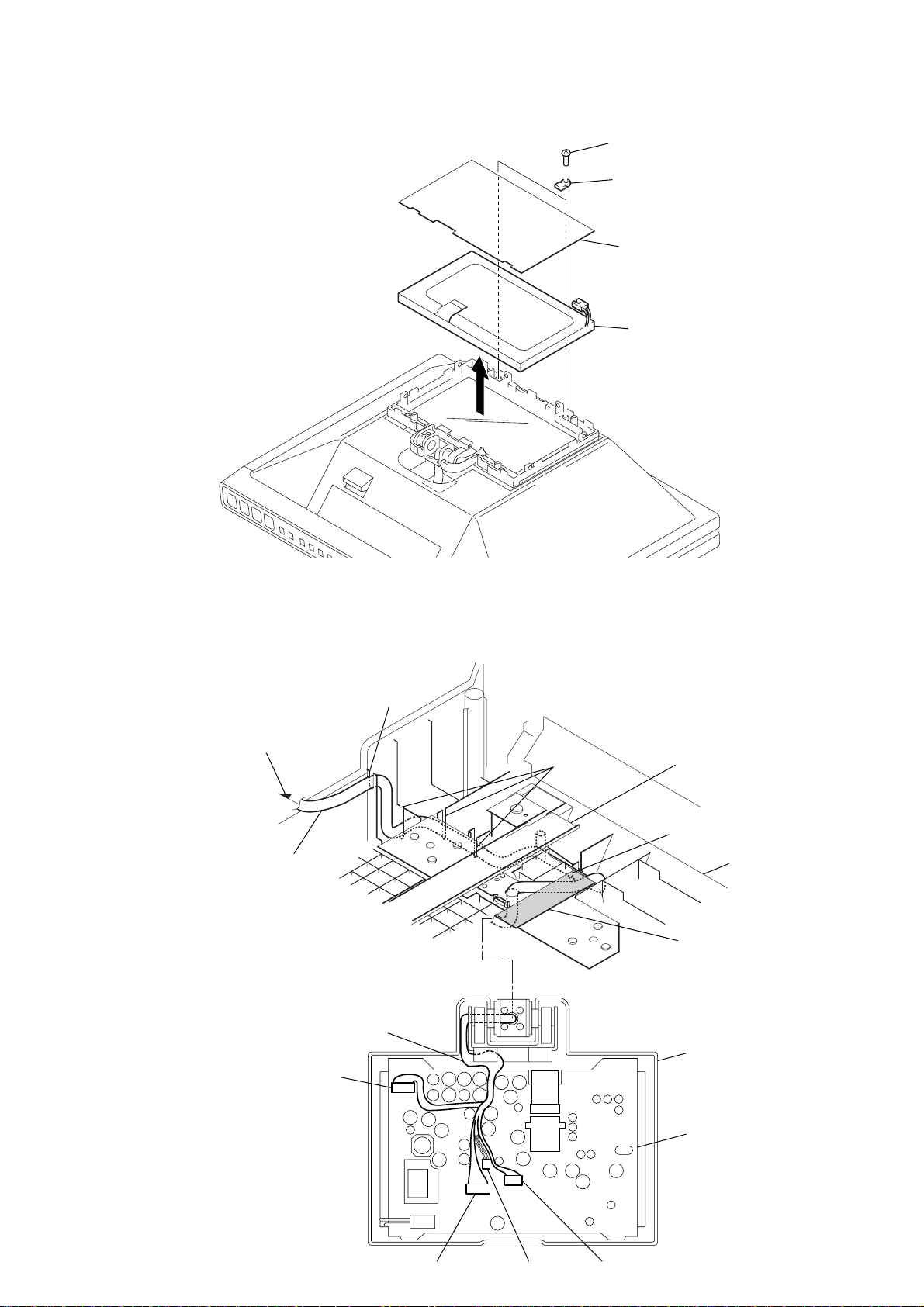

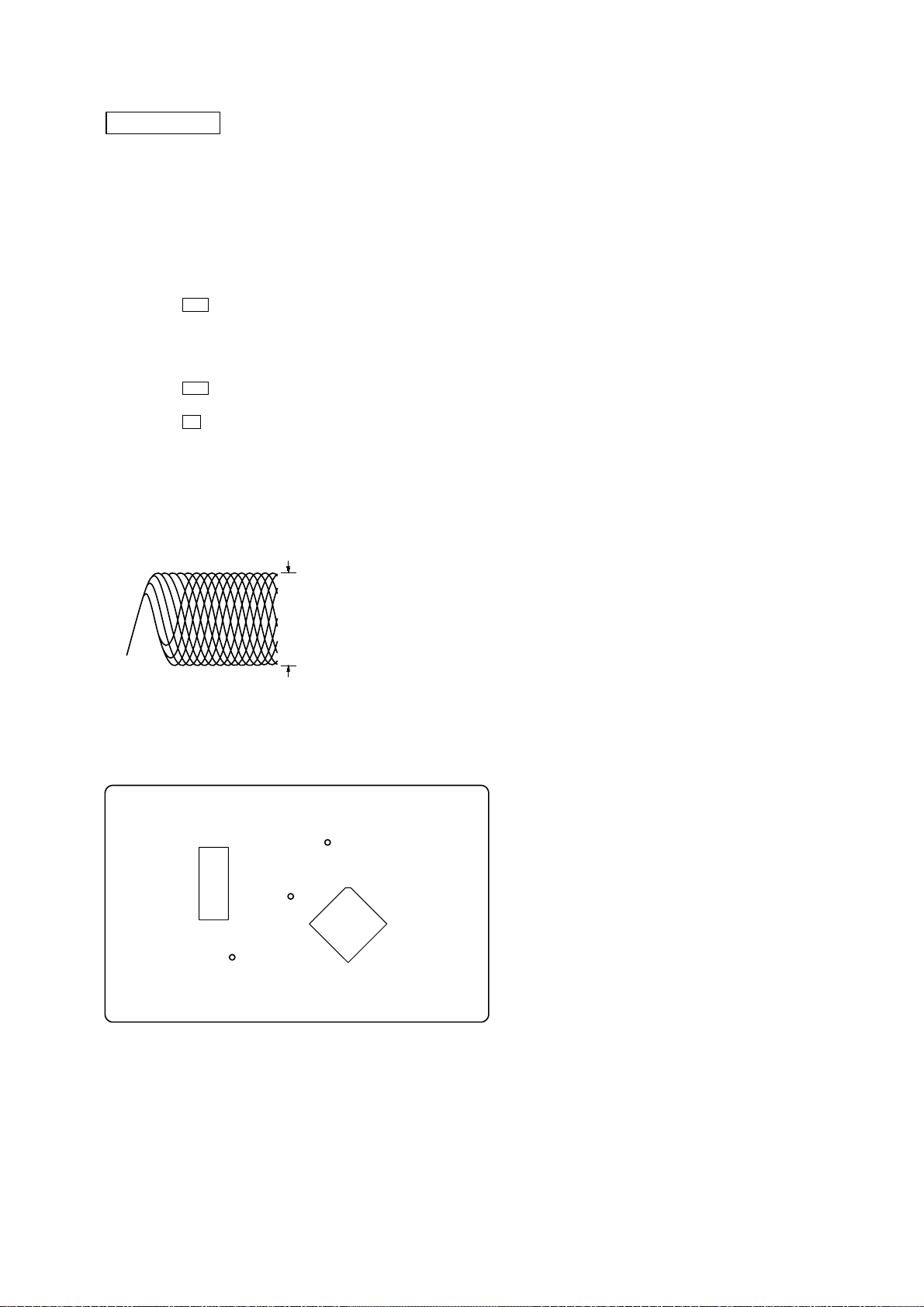

3-10. THE CABLE PROCESSING METHOD WHICH CONNECTS A MAIN BOARD AND TV BOARD

Note: When connecting cable, set it as shown in the figure.

ditch

MAIN board

(CN501, CN502, CN503, CN504)

ditch

CABLE

CABLE

CN1401

arm (release)

ditch

cabinet (lower)

adhesive tape

case (front)

TV board

CN1404CN1402CN1403

9

ICF-CD555TV

SECTION 4

TEST MODE

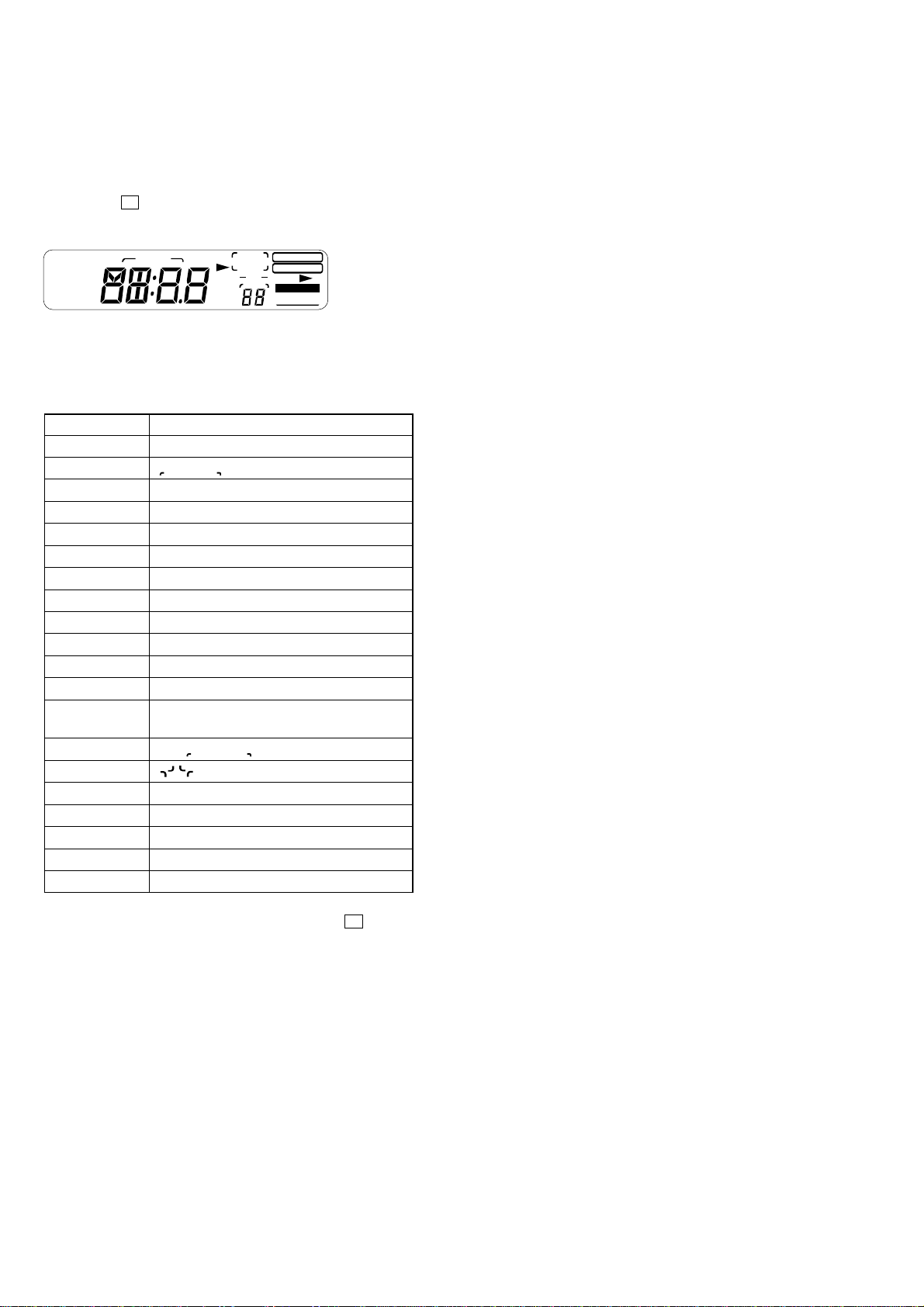

LCD TEST MODE

Procedure:

1. Turn the power ON while pressing simultaneously three keys

of [2], [VOLUME --] and [TV/VIDEO].

2. The microprocessor version will be displayed on the LCD.

3. Press the Z key. The LCD display will become as follows.

LCD display

SHUFFLE

REP 1 ALL

VOL

TRACK

MEGABASS

MEGAXpand

REC

MESSAGE

1 2 3 4 5

RADIOVIDEO TIMER

TV AM

WEATHER

FM12 PM

CD

CH

MHz

kHz

4. The display corresponding to a key is turned off, if a key on

the set is pressed.

Key Corresponding Table

Key Segment

CLOCK AM, PM, : (colon),

TIMER TIMER , TIMER LED

1 1a, 1d, 1e, 1f, 1g

2 2c, 2f

3 3e, 3f

4 4a, 4d, 4e

5 5b, 5e

VOLUME – – VOL –

VOLUME + . (dot), MHz, kHz, CH

. 6b

> 6a, 6c, 6d, 6e, 6f, 6g

BAND RADIO, WEATHER, FM1, FM2

s 1b, 1c, 2a, 2b, 2d, 2e, 2g, 3a, 3b, 3c, 3d, 3g,

4b, 4c, 4f, 4g, 5a, 5c, 5d, 5f, 5g

7 CD, TRACK , H

MODE , SHUFFLE, REP, 1, ALL

TV/VIDEO VIDEO

TV ON TV

SOUND MEGA B ASS, MEGA EXPAND

TV MENU REC, MESSAGE, MB number underline

ENTER 1, 2, 3, 4, 5, N

5. After all keys on the set were pressed, press the Z key, and

the test mode will be released.

10

ICF-CD555TV

CD TEST MODE

Procedure:

1. Connect 120 kΩ and 47 kΩ resistors in parallel to the TP604 on the SIDE-KEY board, and short another end of resistors to the GND,

and the CD TEST MODE will be activated.

2. Insert a CD disc.

3. Turn the power ON. Press the 7 key.

4. The following shows the state transition table for each key operation in respective sub modes of CD TEST MODE.

5. Turn the power OFF to release the CD TEST MODE.

State T ransition T able

If each key is pressed in respective sub modes, the mode will transit to the sub modes listed in table.

Mode Description LCD Key

Main Sub

INT State when TEST MODE is activated.

STOP STOP0 State when s key is pressed once from initial state.

STOP Automatically adjusted value is held.

FOCUS FOCUS0 Auto focus transfer mode

FOCUS Focus servo ON state.(CLV-S, tracking/sled, servo OFF)

It will be referred to as LPC ON if focus carries out on.

F.LPC OFF LPC OFF in focus state.

ALL ALSV State where all servo systems are turned ON.

SERVO ALPC OFF State where all servo systems are turned ON.(LPC OFF)

TGUP State with tracking gain up in all servo systems are turned ON.(LPC ON)

AUTO Mode in which automatic adjustment is made at once.

SLED SLDF Sled is fed outward in stop state.

SLDR Sled is fed inward in stop state.

F.SLED FCSF Sled is fed outward in focus state.

FCSR Sled is fed inward in focus state.

s7 .> BAND TV ON .> Processing

0STOP0 FOCUS0

1 FOCUS0 SLDR SLDF EF Normal

2STOP0 FOCUS0 SLDR SLDF Normal

3STOP FOCUS

4STOPF.LPC FCSR FCSF EF AUTO

5STOP ALSV FCSR FCSF SCURVE

7STOP ALPC OFF FCSR FCSF EF AUTO

8STOP TGUP FCSR FCSF

9STOP ALSV FCSR FCSF

b

cSTOPSTOPSTOPSTOPSTOP SLDF

dSTOPSTOPSTOPSTOPSTOP SLDR

E FOCUS FOCUS FOCUS FOCUS FOCUS FCSF

F FOCUS FOCUS FOCUS FOCUS FOCUS FCSR

OFF

Long pressed

end

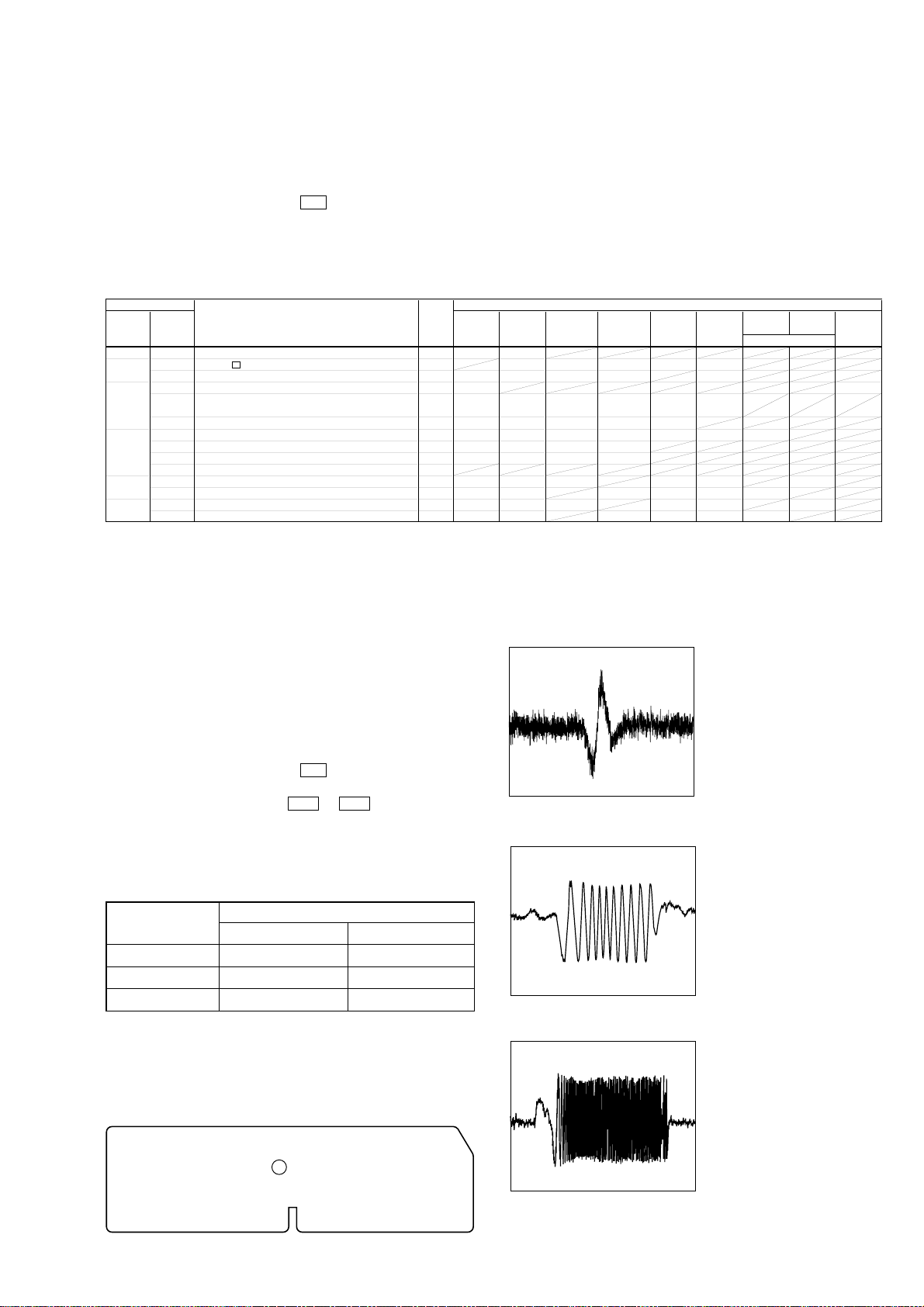

CD-JUMP TEST MODE

Procedure:

1. Connect the oscilloscope to TP (TE) and TP (VREF) on the

CD board.

Connecting Location: CD board (See page 13)

2. Connect 270 kΩ and 47 kΩ resistors in parallel to the end of

TP604 on the SIDE-KEY board, and short another end of resistors to the GND, and the CD-JUMP TEST MODE will be

activated.

3. Insert a CD disc.

4. Turn the power ON. Press the

5 . If the [MODE] key is pressed, you can jump in fast feed or fast

reverse direction with the > or . key by the jump

amount set in table 1.

6. Turn the power OFF to release the CD-JUMP TEST MODE.

Table 1

LCD

REP ALL TRACK + 1 TRACK - 1

SHUFFLE TRACK + 10 TRACK - 10

SHUFFLE, REP TRACK + 100 TRACK - 100

Waveform of TP (TE) and TP (VREF) output in each mode is as

follows.

7 key.

Key

>.

REPEAT – ALL mode

500 µs/div

SHUFFLE mode

1 ms/div

SHUFFLE – REPEAT mode

10 ms/div

Connecting Location:

– SIDE-KEY BOARD (Conductor Side) –

TP604

11

ICF-CD555TV

TV TEST MODE

Procedure:

1. Turn the power ON while pressing simultaneously two keys

of [2] and [VOLUME --].

2. When the TV test mode is activated, the TV monitor will become as follows.

SR7570 TEST MODE MENU

1. INITIAL MENU

2. FOR FACTORY

3. LCD SETTING

4. LOAD DEFAULT

5. TUNER TEST

Ver.7570S100

3. Five items can be changed over by pressing the [TV MENU]

key.

4. The selected item is displayed in red and the items not selected

are displayed in cyan. (“Ver. 7570S100” is displayed in red.)

5. You can enter the selected item by pressing the [ENTER] key.

6. Also, an item can be selected directly with the [1] to [5] keys

on the set or remote commander (RMT-CCD555A).

1. INITIAL MENU (TV MENU PRESET)

• TV menu item is initialized.

Procedure:

1. Press the [TV MENU] key to select the “INITIAL MENU” on

the main screen.

2. Each item of TV menu can be initialized, if pressing the

[ENTER] key.

2. FOR FACTORY (FOR ADJUSTMENT)

• It is used at the time of adjustment.

Procedure:

1. Press the [TV MENU] key to select the “FOR FACTORY” on

the main screen.

2. A changing between setting item and “EXIT” is possible by

pressing the [TV MENU] key. (The selected item is displayed

in red)

3. If the [ENTER] key is pressed when the setting item has been

selected, settable items can be changed over, and the value of

the selected item can be adjusted by pressing the . /

> keys. (For details, refer to VIDEO BUS ADJUSTMENT

(See page 17))

4. The main screen comes back if the [ENTER] key is pressed

when “EXIT” has been selected.

Note: The same operation is also carried out by pressing the keys on the

remote commander.

3. LCD SETTING

This mode is not used in servicing.

4. LOAD DEFAULT

• It carries out, only when EEPROM (IC1451) is exchanged.

Procedure:

1. Press the [TV MENU] key to select the “LOAD DEFAULT”

on the main screen.

2. All settings can be initialized, if pressing the [ENTER] key.

(In addition to the “INITIAL MENU”, set value of RGB

decoder (IC1501) and tuner N value)

5. TUNER TEST

This mode is not used in servicing.

12

r

SECTION 5

ELECTRICAL ADJUSTMENTS

ICF-CD555TV

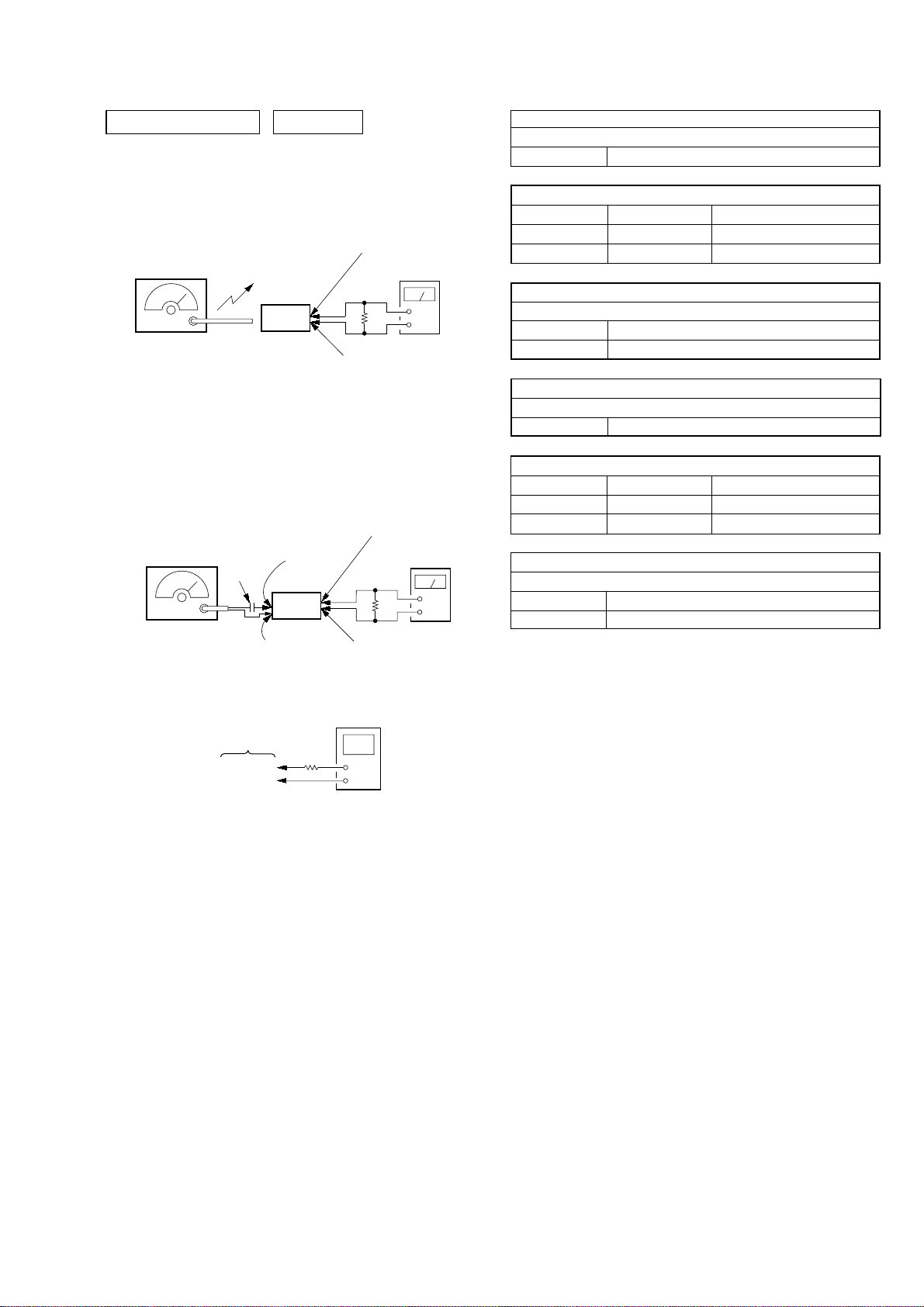

TUNER SECTION 0 dB=1 µV

[AM]

Setting:

Function: RADIO

Band: AM

AM RF signal

generator

30% amplitude

modulation by

400 Hz signal

Output level:

as low as possible

[FM]

Setting:

Function: RADIO

BAND button: FM

FM RF signal

generator

22.5 kHz frequency

deviation by 400 Hz

signal

Output level:

as low as possible

Put the lead-wire

antenna close to

the set.

set

TUNER board

TP (ANT)

0.01 µF

set

TUNER board

TP (GND)

AMP board

CN301 pin

6

Ω

AMP board

CN301 pin

AMP board

CN301 pin

6

Ω

AMP board

CN301 pin

1

level meter

+

–

2

1

level meter

+

–

2

AM IF ADJUSTMENT

Adjust for a maximum reading on level meter

T1 450 kHz

AM VCO VOLTA GE ADJUSTMENT

Adjustment Part Frequency Display Reading on Digital Voltmeter

L4 530 kHz 1.0 ± 0.1 V

Confirmation 1,710 kHz 5.3 ± 0.7 V

AM TRACKING ADJUSTMENT

Adjust for a maximum reading on level meter

L3 580 kHz

CT3 1,490 kHz

FM IF ADJUSTMENT

Adjust for a minimum reading on level meter

T2 10.7 MHz

FM VCO VOLTA GE ADJUSTMENT

Adjustment Part Frequency Display Reading on Digital Voltmeter

L2 87.5 MHz 1.3 ± 0.3 V

Confirmation 108 MHz 3.0 ± 0.2 V

FM TRACKING ADJUSTMENT

Adjust for a maximum reading on level meter

L1 87.5 MHz

CT1 108 MHz

Adjustment and Connecting Location:

TUNER board (See page 14)

digital voltmete

TUNER board

TP (VT)

TP (GND)

100 kΩ

• Repeat the procedures in each adjustment several times, and the

tracking adjustments should be finally done by the trimmer capacitors.

13

ICF-CD555TV

t

Adjustment and Connecting Location:

– TUNER BOARD (Component Side) –

AM VCO Voltage Adjustment

L4

L2

FM VCO Voltage Adjustment

CT3

– TUNER BOARD (Conductor Side) –

TP

(VT)

L3

AM T rac king Adjustment

TP

(ANT)

T2 FM IF Adjustment

T1 AM IF Adjustment

L1

FM T rac king Adjustmen

CT1

TP

(GND)

14

CD SECTION

Perform all CD section check in the test mode.

FOCUS BIAS CHECK

Procedure:

1. Connect the oscilloscope to TP (RF) and TP (VREF) on the

CD board.

2. Set the CD TEST MODE. (Refer to CD TEST MODE (See

page 9))

3. Insert the test disc (YEDS-18). (Part No. 3-702-101-01) (CD)

4. Press the 7 key. (LPC ON)

5. Confirm that the oscilloscope waveform is as shown in the

figure below. (eye pattern)

A good eye pattern means that the diamond shape (◊) in the

center of the waveform can be clearly distinguished.

6. Press the 7 key. (LPC OFF)

7. Perform confirmation in the same manner as step 5.

8. Press the s key.

9. Change the test disc (TCD-W082L). (Part No. J-2502-063-2)

(CD-RW)

10. Perform confirmation in the same manner as step 4 to 7.

ICF-CD555TV

• RF signal reference waveform (eye pattern)

VOLT/DIV: 0.2 V (with the 10: 1 probe in use.)

TIME/DIV: 500 ns

CD:

1.1

±

0.2 Vp-p (LPC ON)

1.1

±

0.3 Vp-p (LPC OFF)

CD-RW:

1.0 ± 0.2 Vp-p (LPC ON)

0.9 ± 0.3 Vp-p (LPC OFF)

When observing the eye pattern, set the oscilloscope

for AC range and raise vertical sensitivity.

Connecting Location:

– CD BOARD (Conductor Side) –

TP

IC702

(RF)

TP

(TE)

IC701

TP

(VREF)

15

ICF-CD555TV

)

)

)

)

)

)

)

MONITOR SECTION

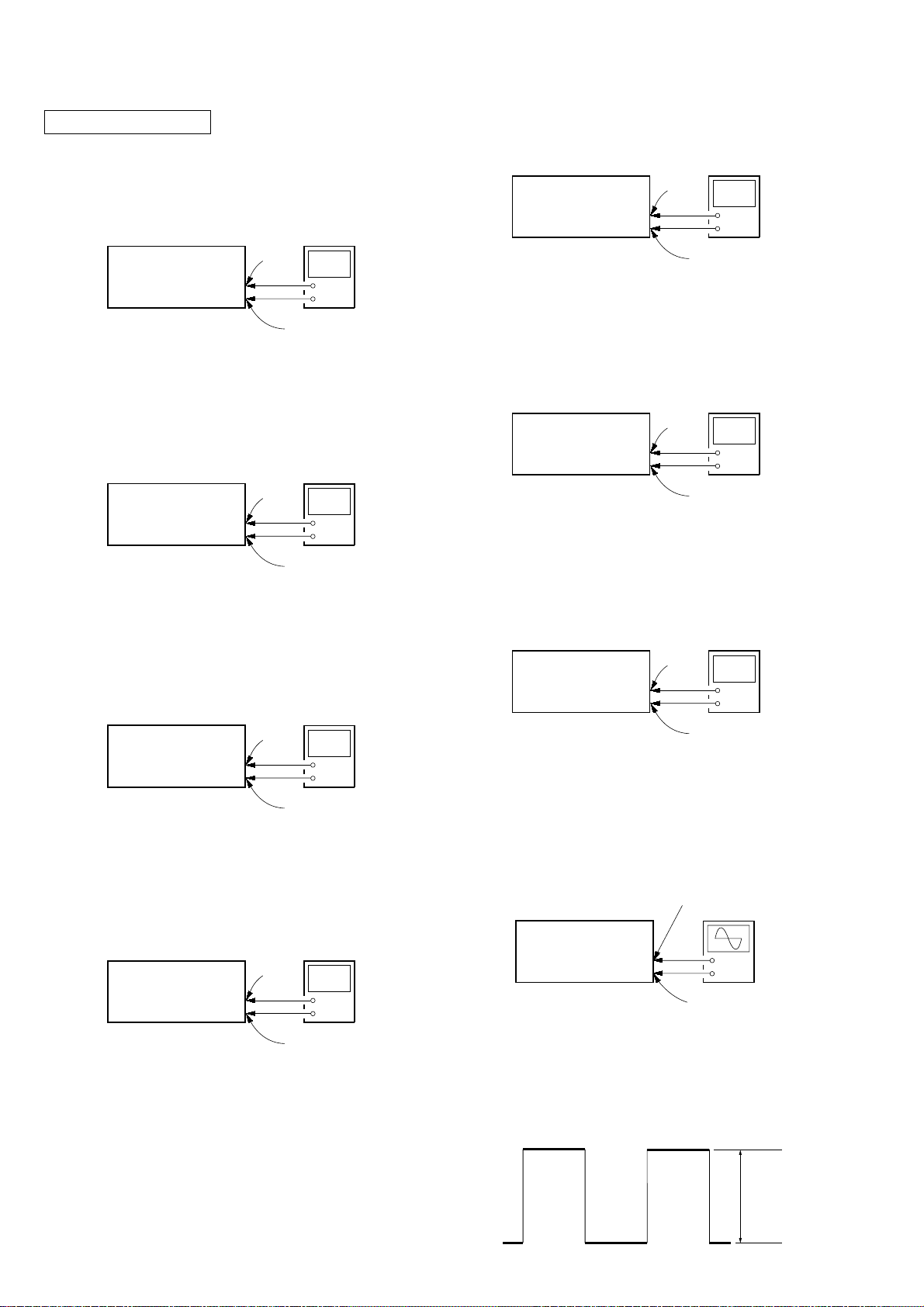

5-1. VOLTAGE CHECK

5-1-1. VDD (3.3V) CHECK

Connection:

digital

voltmeter

TP1904

set

Checking Procedure:

1. Connect a digital voltmeter to the TP1904 on the TV board.

2. Check that the reading of digital voltmeter is 3.3 ± 0.2 V.

5-1-2. VGH (17.0V) CHECK

Connection:

TP1912

set

Checking Procedure:

1. Connect a digital voltmeter to the TP1912 on the TV board.

2. Check that the reading of digital voltmeter is 17.5 ± 0.5 V.

5-1-3. VSS (–13.0V) CHECK

Connection:

TP1911

set

Checking Procedure:

1. Connect a digital voltmeter to the TP1911 on the TV board.

2. Check that the reading of digital voltmeter is –12.5 ± 0.5 V.

5-1-4. 13.5V CHECK

Connection:

TP1401

set

Checking Procedure:

1. Connect a digital voltmeter to the TP1401 on the TV board.

2. Check that the reading of digital voltmeter is 11.5 ± 0.5 V.

+

–

TP1403 (GND

digital

voltmeter

+

–

TP1403 (GND

digital

voltmeter

+

–

TP1403 (GND

digital

voltmeter

+

–

TP1403 (GND

5-1-5. 3.9V CHECK

Connection:

digital

voltmeter

TP1411

set

+

–

TP1403 (GND

Checking Procedure:

1. Connect a digital voltmeter to the TP1411 on the TV board.

2. Chec k that the reading of digital voltmeter is 3.85 ± 0.2 V.

5-1-6. 7.5V CHECK

Connection:

digital

voltmeter

TP1907

set

+

–

TP1403 (GND

Checking Procedure:

1. Connect a dig ital voltmeter to the TP1907 on the TV board.

2. Chec k that the reading of digital voltmeter is 7.3 ± 0.2 V.

5-2. PLL ADJUSTMENT

Connection:

digital

voltmeter

TP1651

set

+

–

TP1403 (GND

Adjusting Procedure:

1. Connect a dig ital voltmeter to the TP1651 on the TV board.

2. Adjust the RV1651 so that the reading of digital voltmeter is

2.2 ± 0.15 V.

5-3. V COM ADJUSTMENT

Connection:

TP1955

osclloscope

set

Adjusting Procedure:

Connect an oscilloscope to the TP1955 on the TV board.

5-3-1. VOLTAGE SET UP ADJUSTMENT

Adjust the set so that the A level of the waveform on the

oscilloscope is 6.6 ± 0.1 Vp-p. (Refer to the 5-7. video bus adjustment (See page 17))

+

–

TP1403 (GND)

16

A

ICF-CD555TV

V

V

V

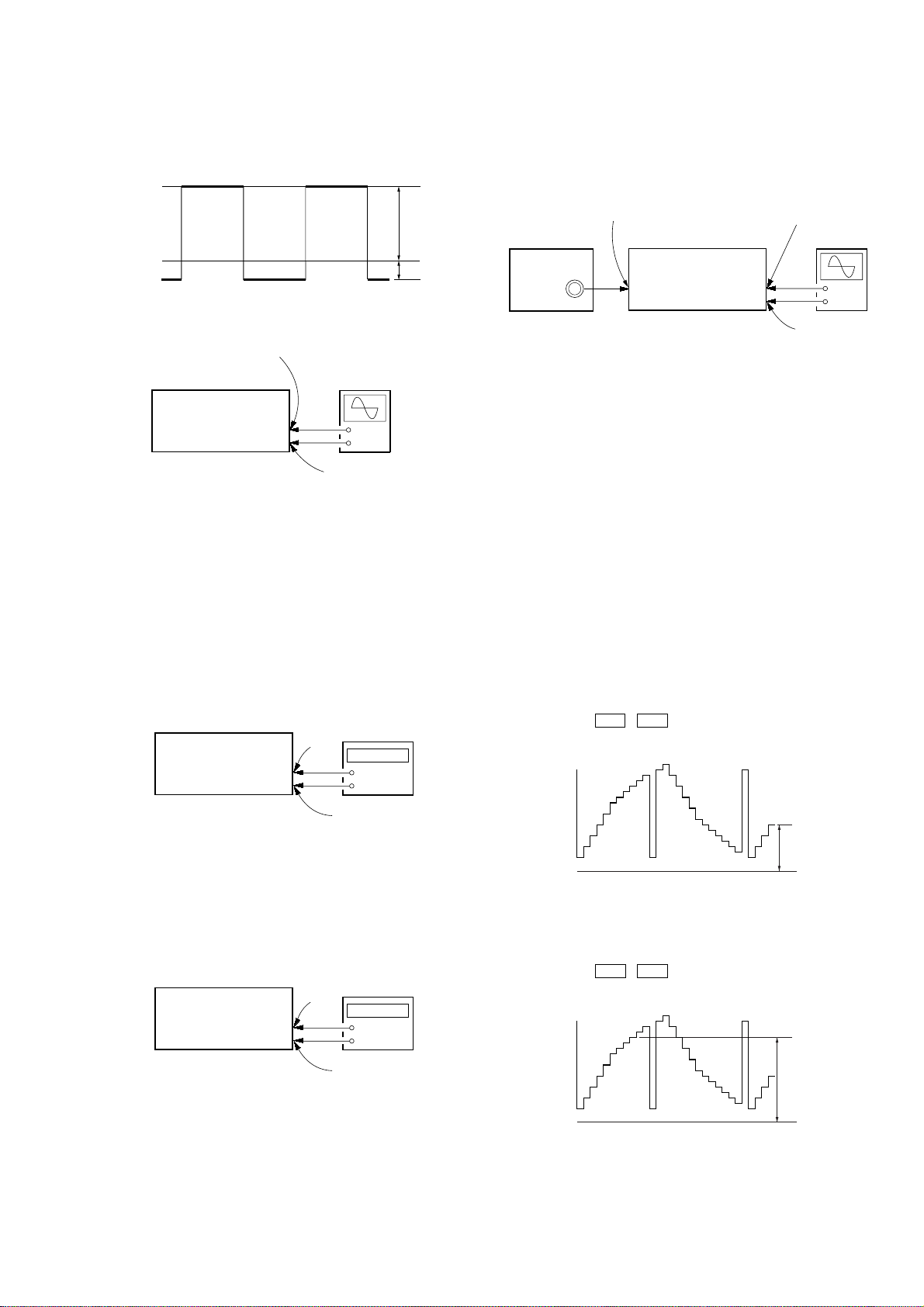

5-3-2. POSITION SET UP ADJUSTMENT

Check the B level of the waveform on the oscilloscope is 4.2 ±

0.1 Vp-p and adjust the R V1551 so that the C level of the wav eform

on the oscilloscope is –2.4 ± 0.1 Vp-p.

B

0

C

5-4. INVERTER HIGH VOLTAGE CHECK

Connection:

Checking Procedure:

Connect an oscilloscope to the TP1805 and TP1806 on the TV

board.

5-4-1. HIGH VOLTAGE CHECK

Check that the reading of oscilloscope is 550 ± 150 V (rms).

5-4-2. FREQUENCY CHECK

Check that the reading of oscilloscope is 70 ± 3 kHz.

set

TP1805

osclloscope

(high resistance probe)

+

–

TP1806

5-7. VIDEO BUS ADJUSTMENT

Connection: (5-7-1 to 5-7-9)

INPUT VIDEO jack

(JK301)

NTSC pattern

generator

set

Condition: (5-7-1 to 5-7-9)

Input the NTSC video signal (10 step (no burst)) (1 Vp-p 75 Ω) to

the INPUT VIDEO jack (JK301) on the MAIN board from NTSC

pattern generator.

Adjusting Procedure:

1. Set the TV test mode (Refer to TV TEST MODE (See page

12).

2. Press the [TV MENU] key to select “LOAD DEFAULT”, and

press the [ENTER] key to write initial v alues to the EEPR OM.

Note: It carries out, only when EEPROM (IC1451) is exchanged.

3. Press the [TV MENU] key to select “FOR FACTORY”, and

press the [ENTER] key to enter the adjustment mode.

4. If entering the adjustment mode, press the [TV MENU] key to

select item, and press the [ENTER] key to execute all

adjustment items mentioned below.

TP1958 or

TP1959 or

TP1960

osclloscope

+

–

TP1403 (GND)

5-5. OSD DOT CLOCK CHECK

Connection:

frequency counter

(high impedance probe)

TP1554

set

+

–

TP1403 (GND)

Adjusting Procedure:

1. Connect an frequency counter to the TP1554 on the TV board.

2. Check that the reading of frequency counter is 6.5 ± 0.2 MHz.

5-6. NTSC SUB CARRIER CHECK

Connection:

frequency counter

(high impedance probe)

TP1508

set

Checking Procedure:

1. Connect an frequency counter to the TP1508 on the TV board.

2. Check that the reading of frequency counter is 3.579545 ±

0.0001 MHz.

+

–

TP1403 (GND)

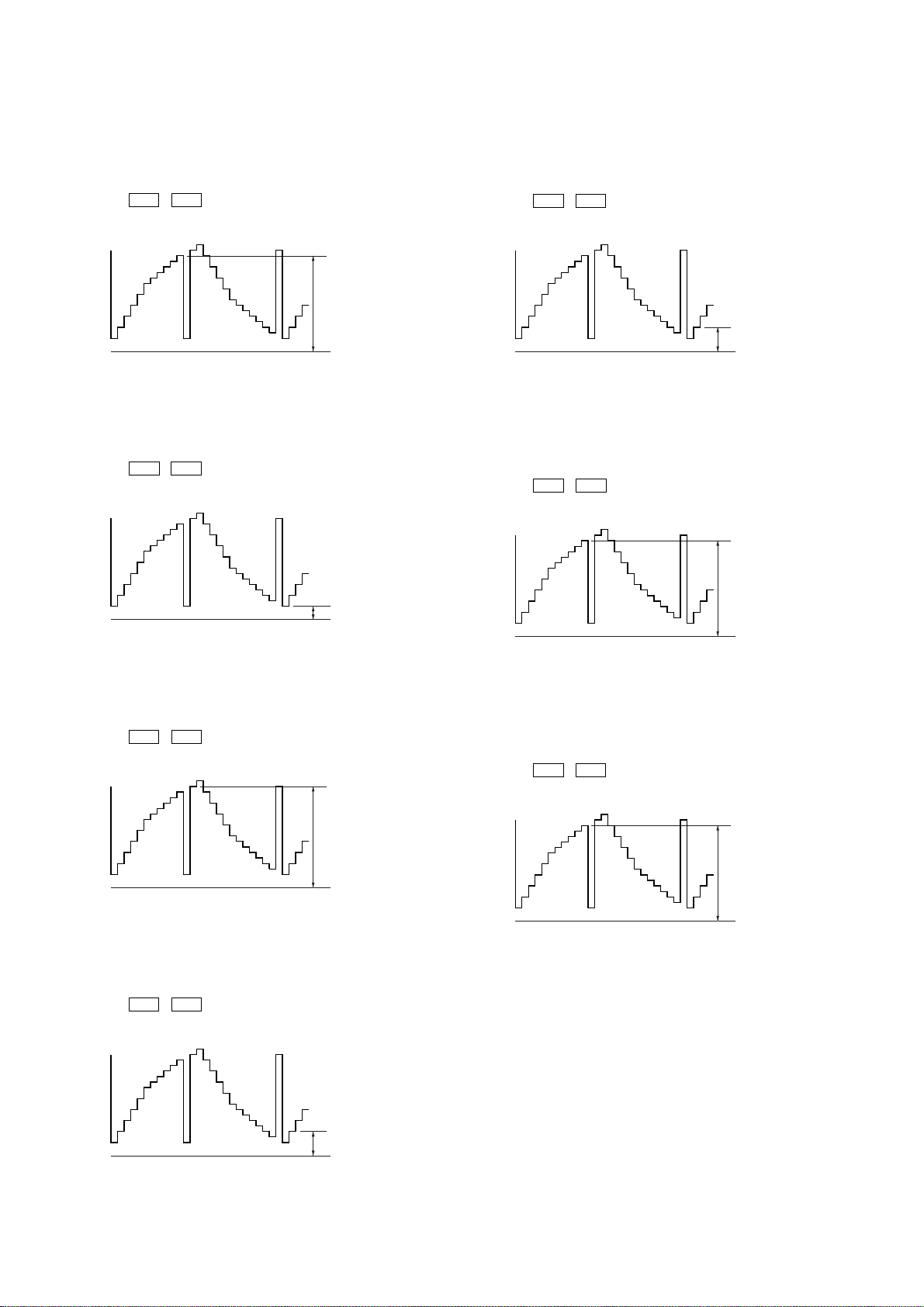

5-7-1. GAMMA 1 ADJUSTMENT

Adjusting Procedure:

1. Connect an oscilloscope to the TP1959 on the TV board.

2. Adjust the . / > keys so that the H level of the wave-

form on the oscilloscope is 2.1 ± 0.1 Vp-p.

H

0

5-7-2. GAMMA 2 ADJUSTMENT

Adjusting Procedure:

1. Connect an oscilloscope to the TP1959 on the TV board.

2. Adjust the . / > keys so that the J level of the wave-

form on the oscilloscope is 3.0 ± 0.1 Vp-p.

J

0

17

ICF-CD555TV

V

V

V

V

V

V

V

5-7-3. Y GAIN (LUMINANCE SIGNAL CONTRAST

LEVEL) ADJUSTMENT

Adjusting Procedure:

1. Connect an oscilloscope to the TP1959 on the TV board.

2. Adjust the . / > keys so that the D level of the wave-

form on the oscilloscope is 3.25 ± 0.1 Vp-p.

D

0

5-7-4. BLACK LIMIT (BLACK LIMITER LEVEL)

ADJUSTMENT

Adjusting Procedure:

1. Connect an oscilloscope to the TP1959 on the TV board.

2. Adjust the . / > keys so that the E level of the wave-

form on the oscilloscope is 1.0 ± 0.1 Vp-p.

5-7-7. B-SUB BRT (B-CH SUB BRIGHT) ADJUSTMENT

Adjusting Procedure:

1. Connect an oscilloscope of 1 step voltage to the TP1960 on

the TV board.

2. Adjust the . / > keys so that the G level of the wave-

form on the oscilloscope is 1.0 ± 0.1 Vp-p.

G

0

5-7-8. R-SUB CONT (R-CH SUB CONTRAST)

ADJUSTMENT

Adjusting Procedure:

1. Connect an oscilloscope of 10 step voltage to the TP1958 on

the TV board.

2. Adjust the . / > keys so that the D level of the wave-

form on the oscilloscope is 3.25 ± 0.1 Vp-p.

D

0

5-7-5. WHITE LIMIT (WHITE LIMITER LEVEL)

ADJUSTMENT

Adjusting Procedure:

1. Connect an oscilloscope to the TP1959 on the TV board.

2. Adjust the . / > keys so that the F level of the wave-

form on the oscilloscope is 3.9 ± 0.05 Vp-p.

F

0

5-7-6. R-SUB BRT (R-CH SUB BRIGHT) ADJUSTMENT

Adjusting Procedure:

1. Connect an oscilloscope of 1 step voltage to the TP1958 on

the TV board.

2. Adjust the . / > keys so that the G level of the wave-

form on the oscilloscope is 1.0 ± 0.1 Vp-p.

D

0

5-7-9. B-SUB CONT (B-CH SUB CONTRAST)

ADJUSTMENT

Adjusting Procedure:

1. Connect an oscilloscope of 10 step voltage to the TP1960 on

the TV board.

2. Adjust the . / > keys so that the D level of the wave-

form on the oscilloscope is 3.25 ± 0.1 Vp-p.

D

0

18

G

0

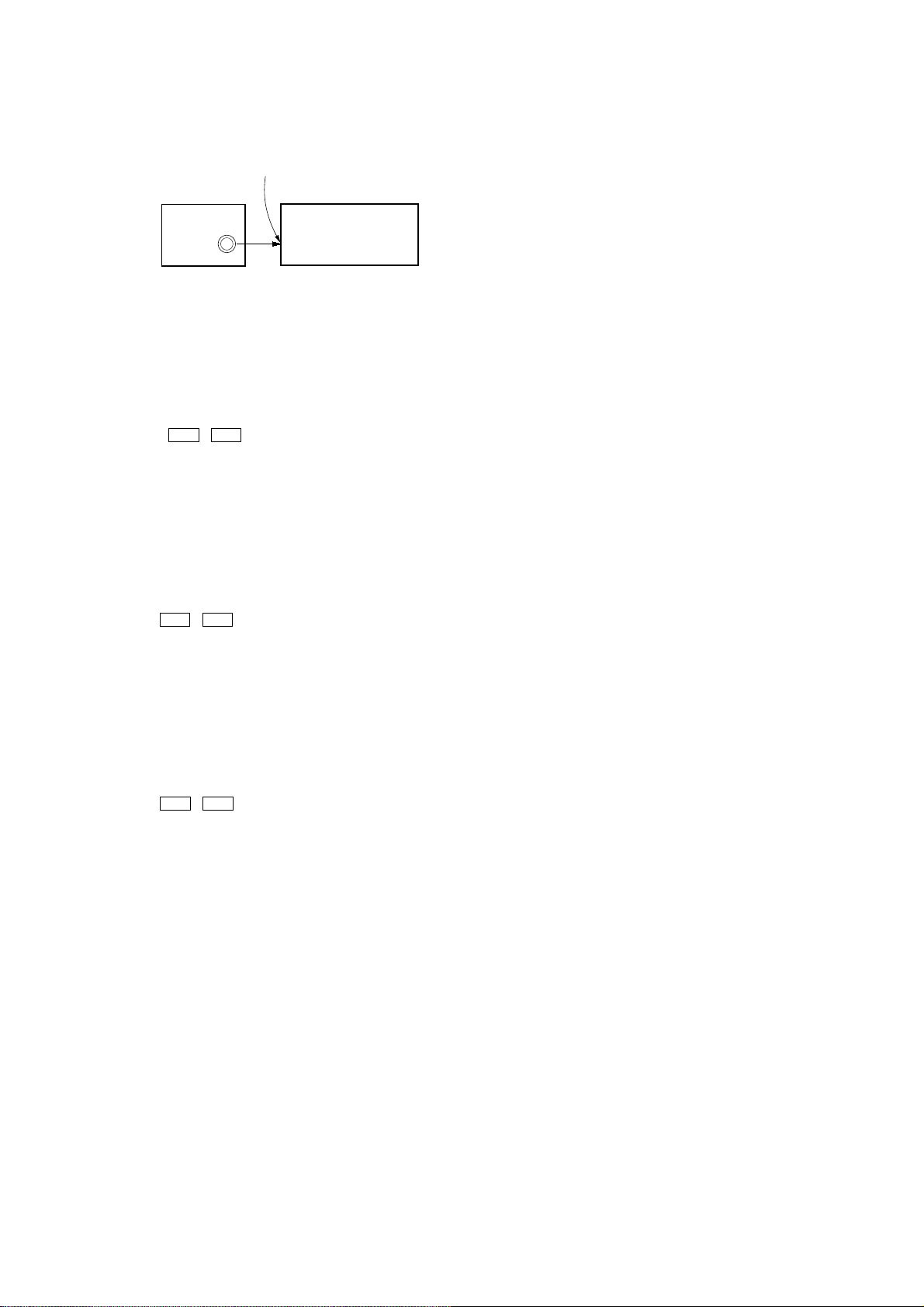

Connection: (5-7-10 to 5-7-12)

INPUT VIDEO jack

(JK301)

NTSC pattern

generator

set

5-7-10. VCO FREE RUN ADJUSTMENT

Condition:

Input the NTSC video signal (10 step (no burst)) (1 Vp-p 75 Ω) to

the INPUT VIDEO jack (JK301) on the MAIN board from NTSC

pattern generator.

Adjusting Procedure:

Adjust the . / > keys so that a screen on the monitor may

become normal.

5-7-11. PLL/V POS ADJUSTMENT

ICF-CD555TV

Condition:

Input the NTSC video signal (monoscope) (1 Vp-p 75 Ω) to the

INPUT VIDEO jack (JK301) on the MAIN board from NTSC

pattern generator.

Adjusting Procedure:

Press the . / > keys to adjust so that the position of screen

on the monitor becomes vertically symmetric.

5-7-12. H POS ADJUSTMENT

Condition:

Input the NTSC video signal (monoscope) (1 Vp-p 75 Ω) to the

INPUT VIDEO jack (JK301) on the MAIN board from NTSC

pattern generator.

Adjusting Procedure:

Press the . / > keys to adjust so that the position of screen

on the monitor becomes horizontally symmetric.

19

ICF-CD555TV

Connecting and Adjustment Location:

– TV BOARD (Component Side) –

RV1551

V COM Adjustment

RV1651

PLL Adjustment

TP1805 TP1806

– TV BOARD (Conductor Side) –

TP1959

TP1958 TP1960

TP1508

TP1955

TP1651

TP1904

TP1907

TP1912

TP1911

TP1403

TP1401

20

TP1411

TP1554

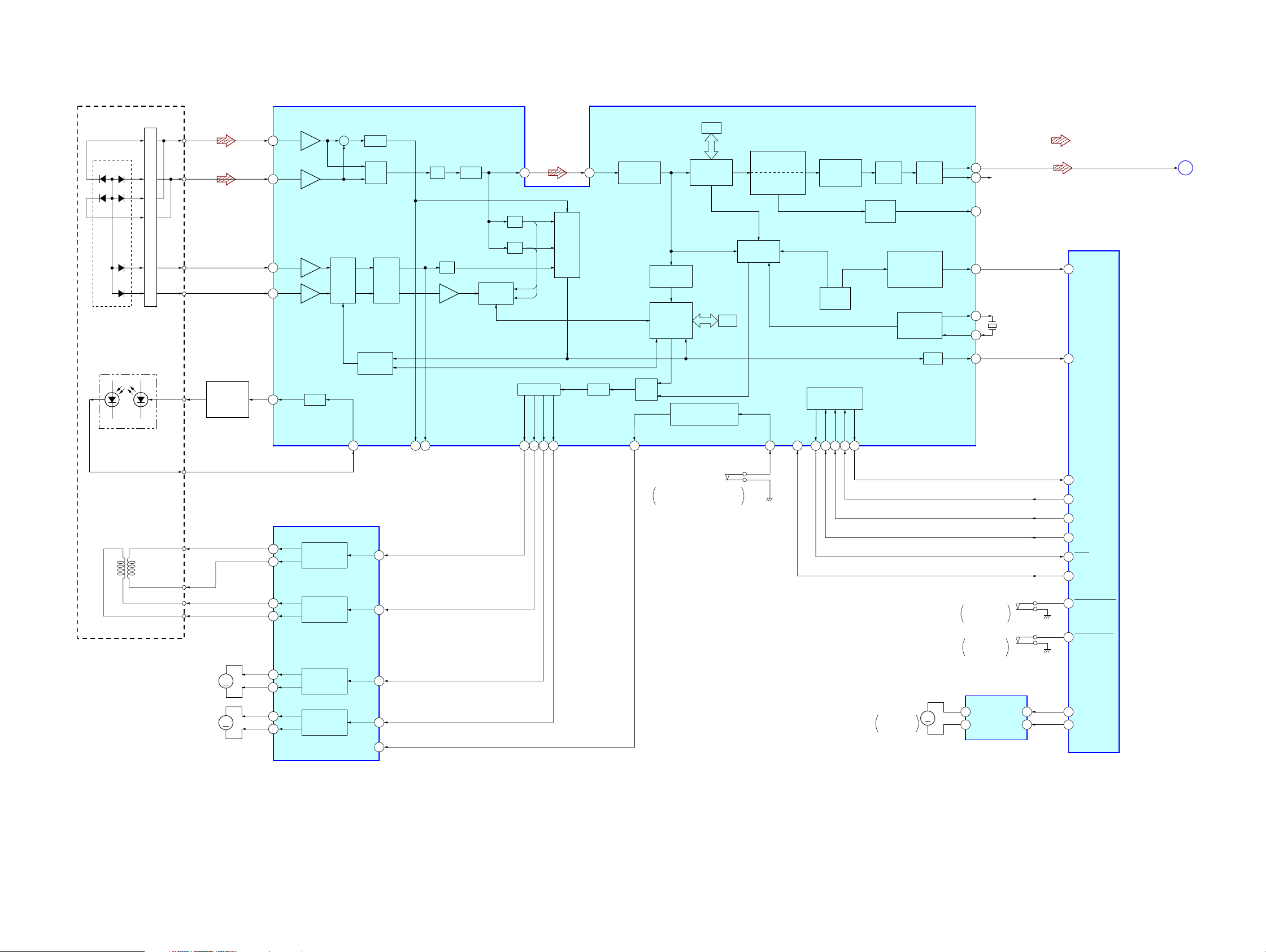

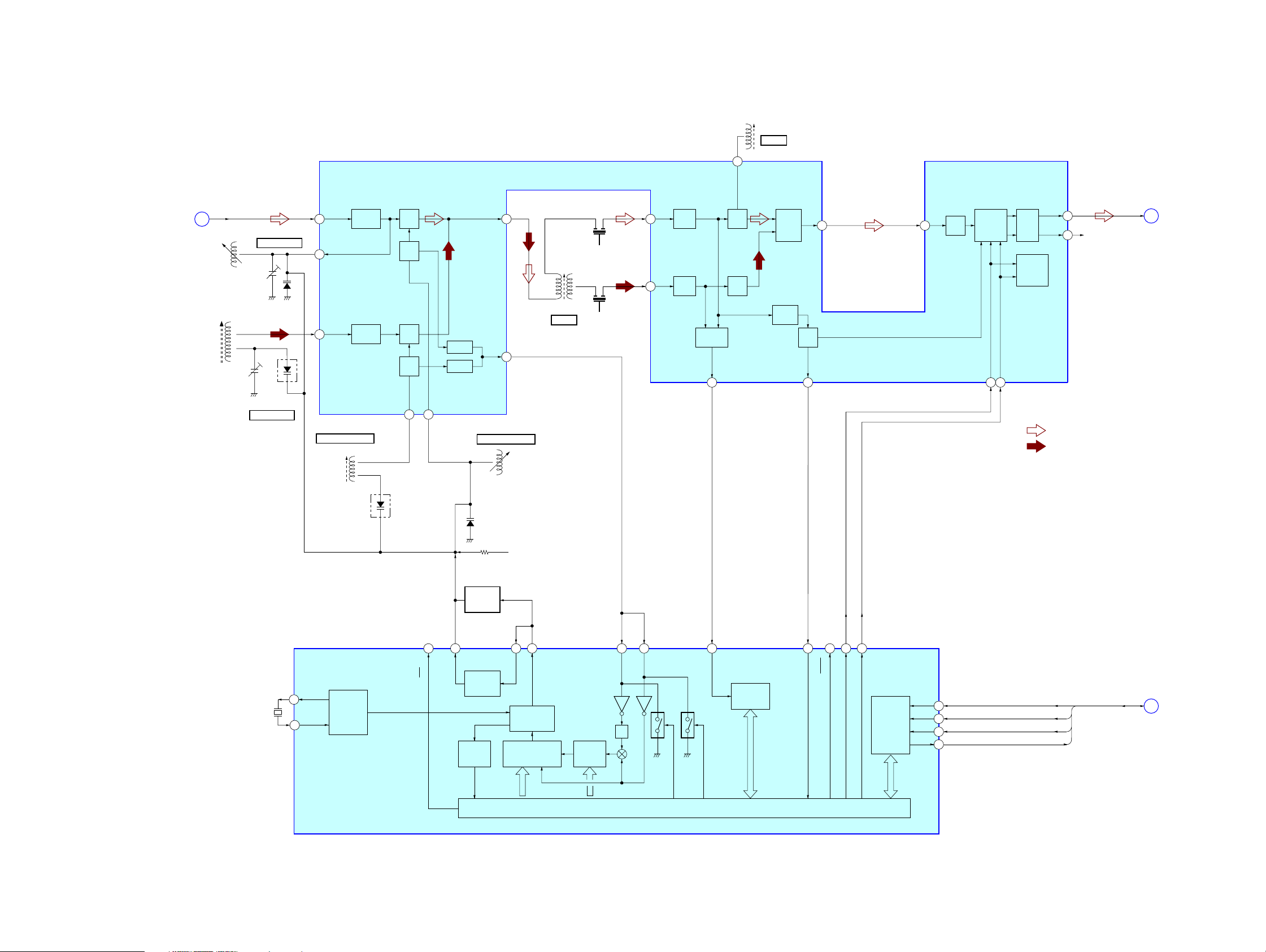

6-1. BLOCK DIAGRAM – CD Section –

ICF-CD555TV

SECTION 6

DIAGRAMS

DETECTOR

A

D

C

B

F

E

OPTICAL PICK-UP

BLOCK

(KSM-900AAA)

LASER DIODE

PD

RF AMP, FOCUS/TRACKING SERVO,

DIGITAL SIGNAL PROCESSOR, CLV SERVO,

PD1

PD2

I-V AMP

F

E

LD

LD

AUTOMATIC

POWER

CONTROL

Q701

FIN2

8

FIN1

7

TIN2

10

TIN1

9

LDD

80

TBAL

APC

LPF

+

MIX

AUDIO

ADJUST

LDS

79

DIGITAL FILTER, D/A CONVERTER

LPF

TE

13FE15

IC701

A/D

3

EFMIN

D/A

SLISE LEVEL

CONTROL

SW

CONT4

25

RUPTURE

DETECT

SERVO

PROCESSOR

RF

EQ

AGC

SW

TRACK

JUMP

4

PH

BH

S/H

TDO21FDO23SLDO22SPDO

20

RAM

ERROR

CORRECTION

AUDIO CD

RAM

GENERAL PURPOSE

PORTS

INTERPOLATION

MUTE

ATTENUATION

DEEMPHASIS

CLV, CAV

CONTROL

CONT1

72

8FS

DIGITAL

FILTER

PLL

VCEC

COMMAND

INTERFACE

RES

WRQ

∗

∗

66

65

61CE62CL63DI64

1 BIT

DAC

AUDIO

OUT

FRAME SYNC

DETECT,

PROTECT, INSERT,

EFM DECODE

CLOCK

GENERATOR

DO

LPF

DRF

LCHO

RCHO

DOUT

FSEQ

XOUT

DRF

XIN

42

R-CH

45

39

31

48

49

67

X701

16.9344MHz

• R-ch is omitted due to same as L-ch.

• SIGNAL PATH

: CD PLAY

CD LCH

39 FSEQ

57 DRF

SYSTEM

CONTROLLER

IC401

(1/2)

A

(Page 24)

2-AXIS

DEVICE

(FOCUS)

(TRACKING)

PD

T+

T–

F+

F–

M701

(SLED)

M702

(SPINDLE)

S701

(LIMIT)

When the optical pick-up

ON :

FOCUS/TRACKING COIL DRIVE,

SPINDLE/SLED MOTOR DRIVE

T+

12

T–

11

F+

17

F–

18

SL+

M

M

27

SL–

26

SP+

2

SP–

1

IC702

TRACKING

COIL DRIVE

FOCUS

COIL DRIVE

SLED

MOTOR DRIVE

SPINDLE

MOTOR DRIVE

TIN

SLIN

SPIN

9

FIN

19

25

3

7MUTE

is inner position

M301

CD TRAY

OPEN/CLOSE

S702

CD TRAY

CLOSE DETECT

S703

CD TRAY

OPEN DETECT

CD TRAY OPEN/CLOSE

MOTOR DRIVE

IC305

A OUT

M

8

B OUT

7

A IN

B IN

3

2

53 CD DATA IN

54 CD DATA

55 CD CLK

56 CD CE

50 WRQ

58 XRST

42 CD CLOSE DET

61 CD OPEN DET

CD CLOSE

51

CD OPEN

60

2121

ICF-CD555TV

6-2. BLOCK DIAGRAM – TUNER Section –

T2

FM IFT

T2

FM IF

(Page 24)

ANT

B

L1

FM RF

L3

AM FERRITE-ROD

ANTENNA

CT3

AM TRACKING

CT1, L1

FM TRACKING

CT1

D3

(1/2)

CT3, L3

FM/AM RF AMP, MIX, OSC,

2

24

D1

22

AM VCO VOLTAGE

L4

AM OSC

FM/AM IF AMP, DET, MPX

IC1

FM

RF IN

FM

RF AMP

FM

RF OUT

AM

RF IN

AM

RF AMP

L4

FM

MIX

FM

OSC

AM

MIX

AM

OSC

AM OSC

20 21

FM OSC

BUFFER

BUFFER

MIX OUT

4 7

T1

AM IFT

T1

AM IF

OSC

OUT

19

L2

FM VCO VOLTAGE

L2

FM OSC

CF2

CF4

10

QUAD

FM

IF IN

FM IF

AMP

AM

IF IN

AM IF

6

AMP

FM

DET

AM

DET

IF

BUFFER

IF OUT

17 18

AF

BUFFER

LEVEL

DET

DET

OUT

ST

IND

ST IND

MPX

IN

AF

16

15

AMP

MPX

LPF1/BAND

LPF2/MO-ST

13

14

MUTE

STEREO/

MONO,

FM/AM

L-OUT

R-OUT

12

11

TU LCH

R-CH

C

(Page 24)

• R-ch is omitted due to same as L-ch.

• SIGNAL PATH

: FM

: AM

X1

75kHz

20

19

FM/AM PLL

IC2

XOUT

XIN

(2/2)

REFERENCE

DIVIDER

D3

D2

VT B+

LOW-PASS

FILTER

6

FM/AM

LP-OUT

UNLOCK

DETECT

LOW-PASS

FILTER

PD

LP-IN

PHASE

DETECTOR/

CHARGE PUMP

12 BIT

PROGRAMMABLE

DIVIDER

SWALLOW

COUNTER

111218

FMIN

AMIN

1/2

SHIFT REGISTER & LATCH

10 9

IF IN

UNIVERSAL

COUNTER

ST-IND

BAND

7

BAND

13817 16

MO/ST

CCB

INTERFACE

PLL DATA, PLL CLK,

DI

2

CL

3

CE

1

DO

4

PLL DATA

PLL CLK

PLL CE

COUNT

PLL CE, COUNT

D

(Page 24)

2222

6-3. BLOCK DIAGRAM – MONITOR Section –

ICF-CD555TV

JK301

INPUT

VHF/UHF

VIDEO

TV ANT

R

TU501

TV TUNER UNIT

L

AUDIO

R-CH : R-ch is omitted due to same as L-ch.

SIGNAL PATH

: TV

: VIDEO

: AUX IN (AUDIO)

: AUX IN (VIDEO)

SDATA, SCK,

LATCH, RESET

E

(Page 24)

R-CH

TV/VIDEO

SELECT SWITCH

IC304

12

25 13L OUT

R-CH

24R OUT

5

16DET OUT

99V (MPX)

25V (TU)

145V (F)

265V (D/D)

4SDA

3SCL

15AFT OUT

22MUTE

13RF AGC

20MODE

21F MONO 79 T-FMONO

+9V

TV+5V

AUDIO MODE

SELECT SWITCH

AUDIO MODE

SELECT SWITCH

AGC

Q502

Q503

Q504

S701

DISPLAY

RELEASE

3

SDATA

SCK

LATCH

RESET

14

11

4

9

77

32 T-SDATA

33 T-SCL

46 T-AFT

31 T-MUTE

30 T-AGC

78 T-MODE

37 TFT OPEN

56 TV DATA-SI

58 TV DATA-CLK

57 TV DATA-SO

76 RESET

TV/VIDEO

MUTING

Q104

34

T-A MUTE

D104

R-CH

VIDEO AMP

Q350

SYNC

SEPARATOR

Q1504, 1505

X1501

3.579545MHz

63

VXO-NTSC

52 54 26

57 CIN

46 34

CTRAPOUT

YIN

CSYNCOUT

CSYNCIN

SDATA

SCLK47HSYNCLOCK

48

SYNC DET

Q1502, 1503

66

67 65

SCL

SDA

HDOUT

VDOUT

39

53

32

31

HSYNCLOCK

TRAP

RGB DECODER

IC1501

BUFFER

Q1501

52

VSYNC

CTRAPIN

VDIN35

VD

HD

EEPROM

IC1451

SDA

5

49

EEPROM-SDA

VCOMOUT

R-OUT

G-OUT 21

B-OUT 19

BLAK

36

18

POL

BLAK

SCL

6

50

EEPROM-SCL

R-IN2

G-IN2

B-IN2

YS 17

POL

TV SYSTEM CONTROLLER

OSC

RV1651

PLL

V COM AMP

IC1552

PHASE

COMPARATOR

IC1651

HD

VD

BLAK

POL

28

R

G

B

14

15

16

X1401

4.19MHz

74 64

75

X1

X2

IC1401

16

VR

17

VG

18

VB

BLK

15

HSYNCIN20

VSYNCIN19

OSD DRIVER

IC1551

OSC OUT

OSC IN 8

DATA

SCLK1CSN

3

2

54 55 53

OSD-CLK

OSD-DATA

7

OSD-CS

V COM BIAS

Q1551 – 1553

LCD CONTROLLER

IC1601

33

PD

36

VCO1

37

VCO0

2

HSYNCIN

5

VDBIN

BLACK

8

14

POL

ZOOMZOOM

12

61 62 63

JUST4SIDE1

31

JUST

RV1551

V COM

STV1

STV2

STH1

STH2

CPH1

CPH2

CPH3

CPV

OEV1

OEV2

OEV3

OEH

3

SIDE1

VGH17V

VEE5V

SIDE2

SIDE2

TV LCH

F

TFT-ON

(Page 24)

(Page 24)

G

H

(Page 24)

LIQUID CRYSTAL

DISPLAY MODULE

LCD1

VCOM

VCOM

R

G

B

20

26

23

24

29

27

25

16

19

18

17

80MONITOR ON

60TFT-ON

RED

GREEN

BLUE

VGON (17V)

VDD (3.3V)VDD3V

VEE (5.0V)

VB (2.5V)

VSS (–13.0V)VSS–13V

STV1

STV2

STH1

STH2

CLK1

CLK2

CLK3

CPV

OEV1

OEV2

OEV3

CPV21

MONITOR ON

2323

Loading...

Loading...