ICF-CD2000/CD2000S

SERVICE MANUAL

Ver 1.0 1999. 10

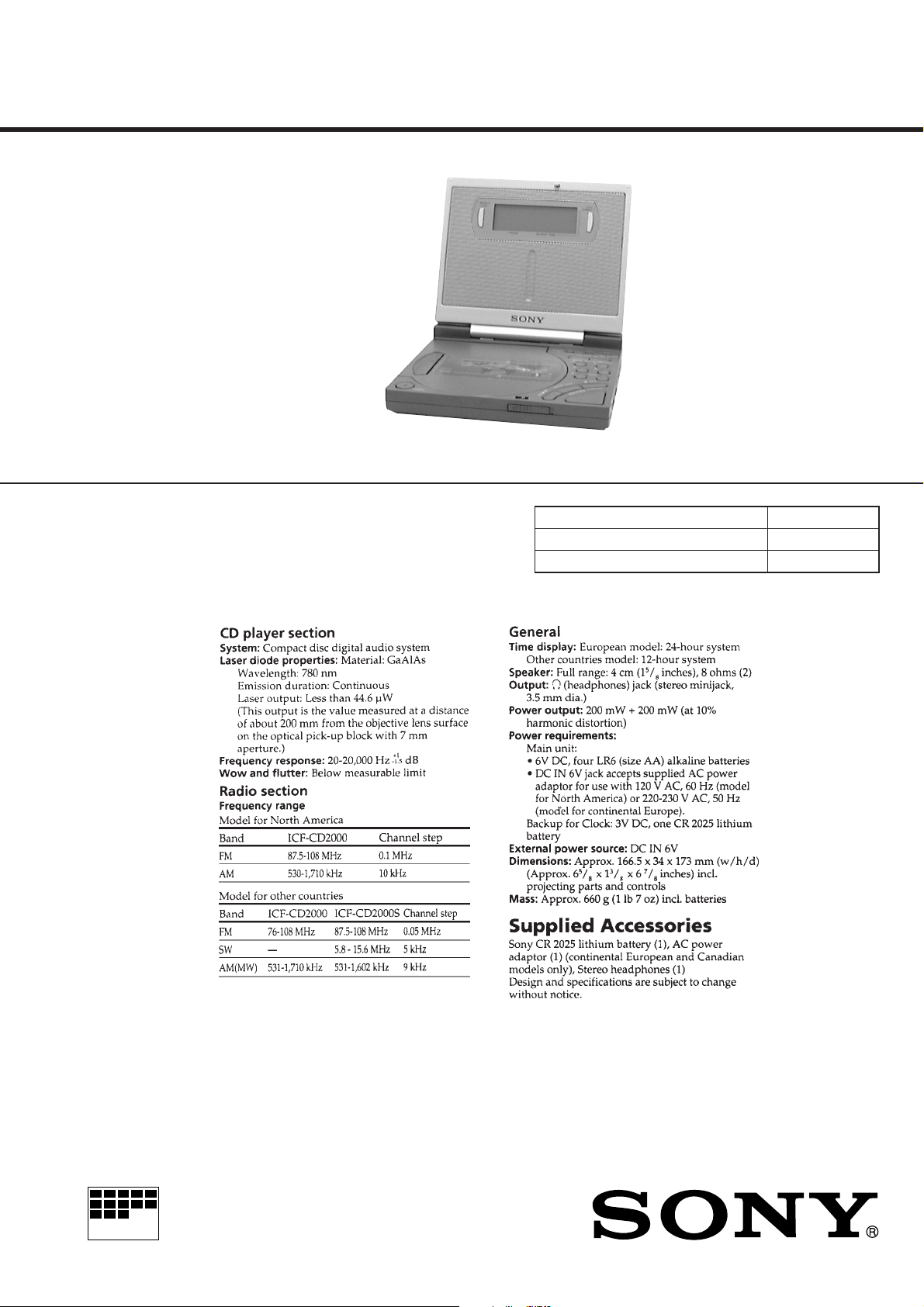

Photo: ICF-CD2000 (US model)

SPECIFICATIONS

US Model

Canadian Model

E Model

Tourist Model

ICF-CD2000

AEP Model

UK Model

ICF-CD2000S

Model Name Using Similar Mechanism D-E551

Optical Device Name CDM-2911EBA

Optical Pick-Up Name DAX-11E

MICROFILM

ICF-CD2000

FM/AM CD CLOCK RADIO

ICF-CD2000S

FM/SW/MW CD CLOCK RADIO

TABLE OF CONTENTS

1. SERVICING NOTES ................................................ 3

2. GENERAL ................................................................... 5

3. DISASSEMBLY ......................................................... 8

CAUTION

Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous radiation exposure.

4. SERVICE MODE...................................................... 11

5. TEST MODE.............................................................. 12

6. ELECTRICAL ADJUSTMENTS......................... 15

7. DIAGRAMS

7-1. IC Pin Function Description........................................... 21

7-2. Block Diagram – CD Section – ..................................... 23

7-3. Block Diagram – Main Section – ................................... 27

7-4. Printed Wiring Boards – MAIN/JACK Boards – .......... 31

7-5. Schematic Diagram – MAIN/JACK Boards – .............. 35

7-6. Printed Wiring Boards – LCD/KEY Boards – .............. 40

7-7. Schematic Diagram – LCD/KEY Boards –................... 45

8. EXPLODED VIEWS ................................................ 53

9. ELECTRICAL PARTS LIST ............................... 57

This appliance is classified as a CLASS 1 LASER product.

The CLASS 1 LASER PRODUCT MARKING is located on

the rear exterior.

Laser component in this product is capable of emitting radiation

exceeding the limit for Class 1.

Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270 ˚C during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be damaged by heat.

HOW TO CHANGED THE CERAMIC FILTERS

This model is used two ceramic filters of CF1 and CF3.

You must use same type of color marked ceramic filters in order

to meet same specifications.

Therefore, the ceramic filter must be changed two pieces together

since it’s supply two pieces in one package as a spare parts.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED

LINE WITH MARK 0 ON THE SCHEMATIC DIA GRAMS

AND IN THE PARTS LIST ARE CRITICAL TO SAFE

OPERATION. REPLACE THESE COMPONENTS WITH

SONY PARTS WHOSE PART NUMBERS APPEAR AS

SHOWN IN THIS MANU AL OR IN SUPPLEMENTS PUBLISHED BY SONY.

ATTENTION AU COMPOSANT AYANT RAPPORT

À LA SÉCURITÉ!

LES COMPOSANTS IDENTIFIÉS P AR UNE MARQUE 0

SUR LES DIAGRAMMES SCHÉMATIQUES ET LA LISTE

DES PIÈCES SONT CRITIQUES POUR LA SÉCURITÉ

DE FONCTIONNEMENT. NE REMPLACER CES COMPOSANTS QUE PAR DES PIÈCES SONY DONT LES

NUMÉROS SONT DONNÉS DANS CE MANUEL OU

DANS LES SUPPLÉMENTS PUBLIÉS PAR SONY.

– 2 –

SECTION 1

SERVICING NOTES

NOTES ON HANDLING THE OPTICAL PICK-UP

BLOCK OR BASE UNIT

The laser diode in the optical pick-up block may suffer electrostatic breakdown because of the potential difference generated by

the charged electrostatic load, etc. on clothing and the human body .

During repair, pay attention to electrostatic breakdown and also

use the procedure in the printed matter which is included in the

repair parts.

The flexible board is easily damaged and should be handled with

care.

Before Replacing the Optical Pick-Up Block

Please be sure to check thoroughly the parameters as par the “Optical Pick-Up Block Checking Procedures” (Part No.: 9-960-027-

11) issued separately before replacing the optical pick-up block.

Note and specifications required to check are given below.

• FOK output: IC501 ts pin

• S curve P-to-P value: 1.2 Vp-p IC501 wa pin

When checking S curve P-to-P value, remove the lead wire to

disc motor.

• RF signal P-to-P value: 0.8 to 1.3 Vp-p

• Traverse signal P-to-P value: 0.7 to 1.8 Vp-p

• The repairing grating holder is impossible.

Precautions for Checking Emission of Laser Diode

Laser light of the equipment is focused by the object lens in the

optical pick-up so that the light focuses on the reflection surface

of the disc. Therefore, be sure to keep your eyes more then 30 cm

apart from the object lens when you check the emission of laser

diode.

Laser Diode Checking Methods

During normal operation of the equipment, emission of the laser

diode is prohibited unless the upper panel is closed while turning

ON the S423. (push switch type)

However, in the service mode, the laser diode always emits light

even if S423 is not turned on.

The following two checking methods for the laser diode are operable.

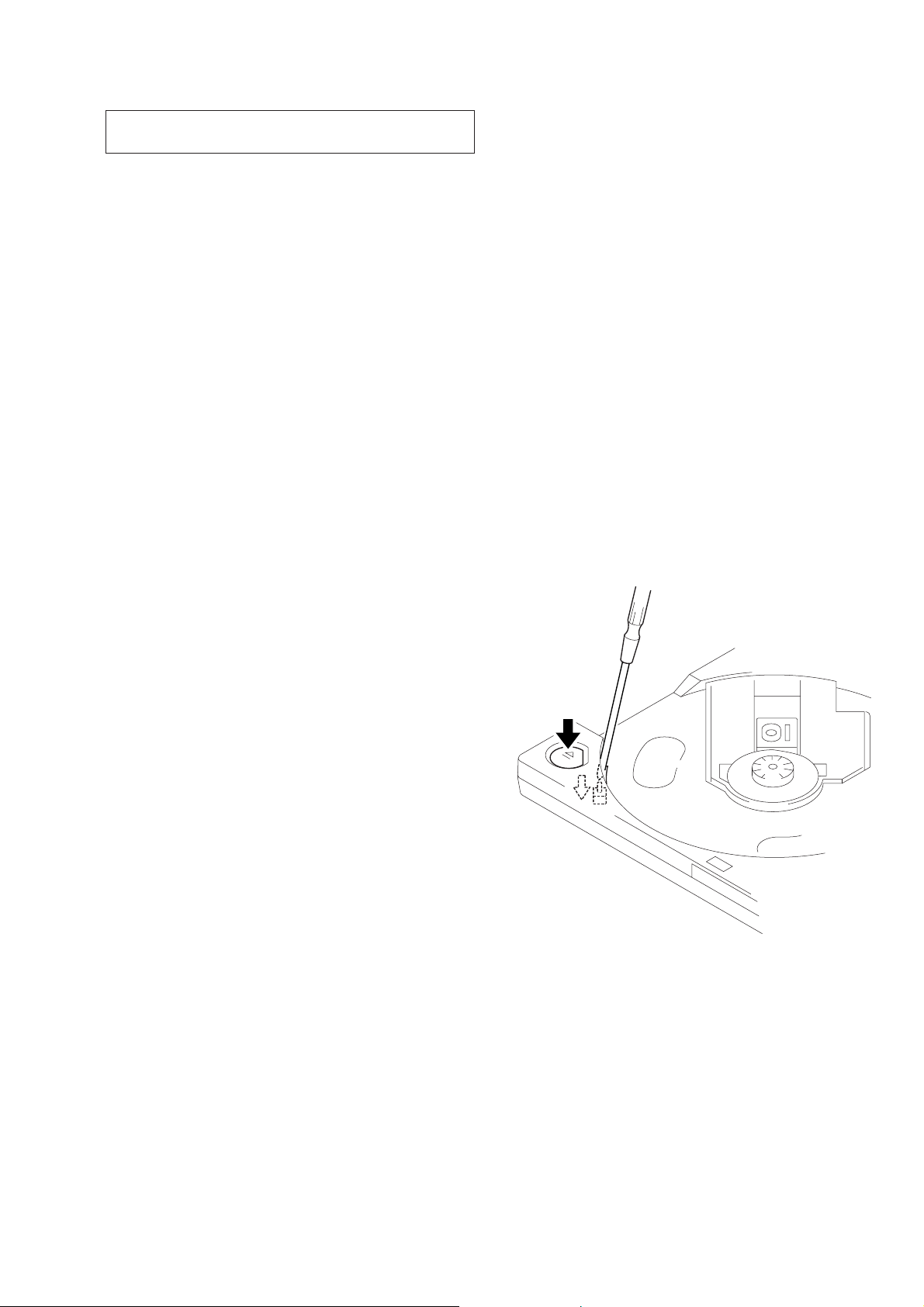

• Method-1 (In the service mode or normal operation):

Emission of the laser diode is visually checked.

1. Open the upper lid.

2. Push the S423 as shown in Fig. 1.

(Unnecessary in the service mode)

3. Press the

4. Check the object lens for confirming normal emission of the

laser diode. If not emitting, there is a trouble in the automatic

power control circuit or the optical pick-up.

During normal operation, the laser diode is turned ON about

2.5 seconds for focus searching.

u

[CD ] key.

– 3 –

Fig. 1 Method to push the S423

9

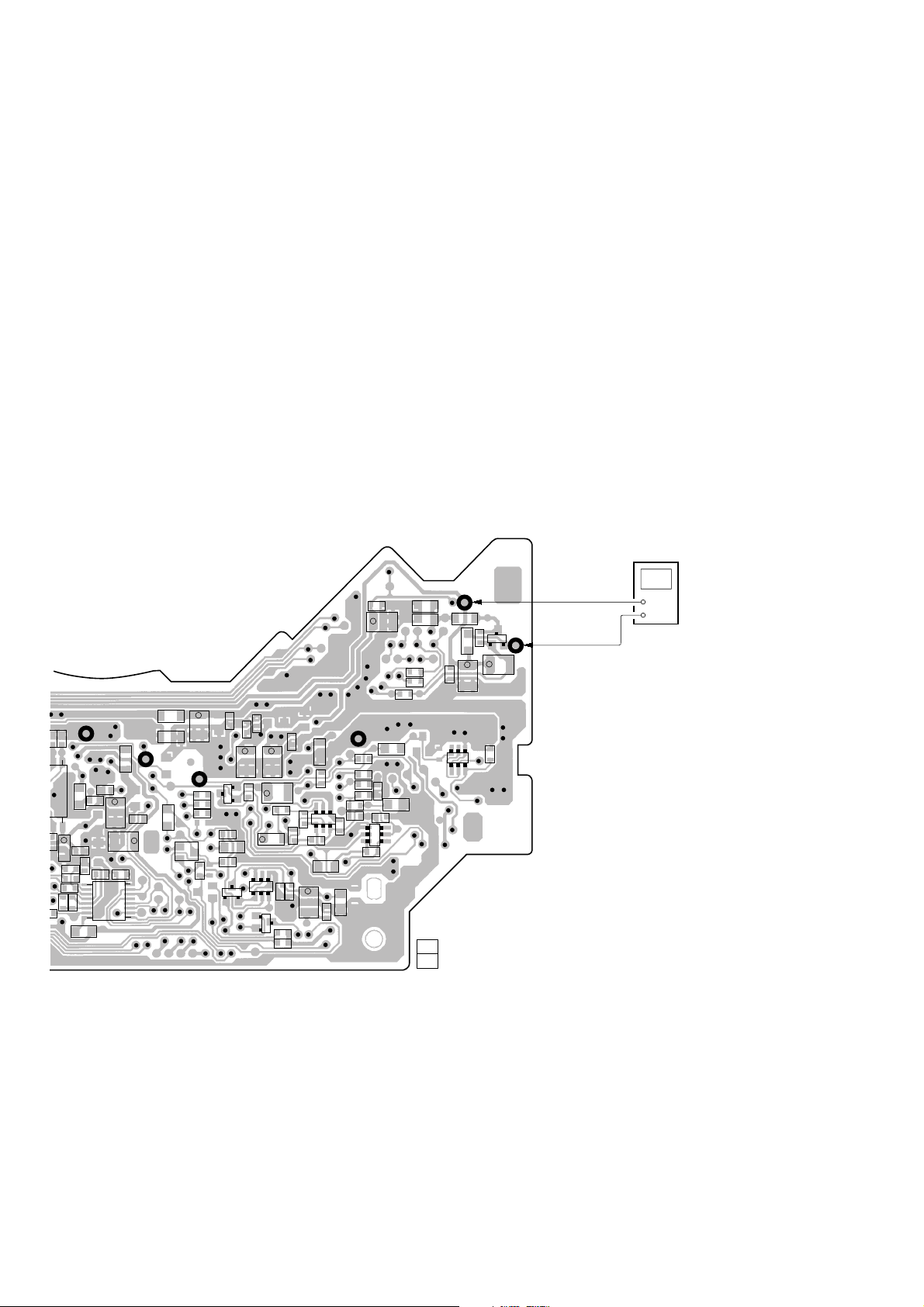

• Method-2 (In the service mode or normal operation):

Check the value of current flowing in the laser diode.

1. Remove the upper panel.

2. Connect a digital voltmeter as show in Fig. 2.

3. Press the [CD ] key.

u

4. Calculate current v alue by the reading of the digital v oltmeter .

Reading of the digital voltmeter (V) ÷ 2.2 (Ω) = current value

(A)

(Example) Reading of the digital voltmeter of 0.082 V:

0.082 V÷2.2 Ω= 0.037 (A) = 37 mA

Current value of the specified: 16 to 18 mA

5. Check that the current value is within the following range.

• Current value of the specified mA (25 ˚C)

+5

–11

Variation by temperature: 0.4 mA/˚C

Current increases with temperature increased.

Current decreases with temperature decreased.

If the current is more than the range above, there is a trouble

in the automatic power control circuit or the laser diode is in

deterioration.

If less than the range, a trouble exists in the automatic power

control circuit or the optical pick-up.

– MAIN Board (Conductor Side) –

digital voltmeter

(DC3 V range)

TP

(GND)

C586

14

13

+

C585 C587

C551

C595

C494

R476

R477

C495

R478

9

16

FB401

R539

9

C545

C493

C565

IC404

C568

L511

+

C569

C564

+

C419R483

8

1

TP

(RF)

D512

L508

L515

AK

D504

+

C533

R535

Q505

R549

R591

Q514

C552

BCE

C536

C542

+

+

C543

C535

+

C561

R567

BCE

R501

R851

+

C515

C555

2C1B 1E

Q503

C516

R524

2E2B 1C

BCE

R576

R575

Q507

C534

TP

(TE)

C807

C806

C805

A

K

A

R844

Fig. 2 Digital voltmeter connecting location

2C1B 1E

Q502

2E2B1C

R558

+

C520

C553

C502

C505

R525

R584

C504

C559

C506

R566

R854

2E

C554

2B

1C

C519

1-673-930-

(VC)

R557

TP

(IOP 1)

R568

C541

R565

Q501

C803

2C

1B

1E

C801

R631

D501

AK

C510

R552

R553

1C

Q513

C609

L501

2B 2E

1B 2C1E

R632

+

C610

C619

Q601

BCE

+

R850

C608

TP

(IOP 0)

C540

+

TP

+

–

11

(11)

– 4 –

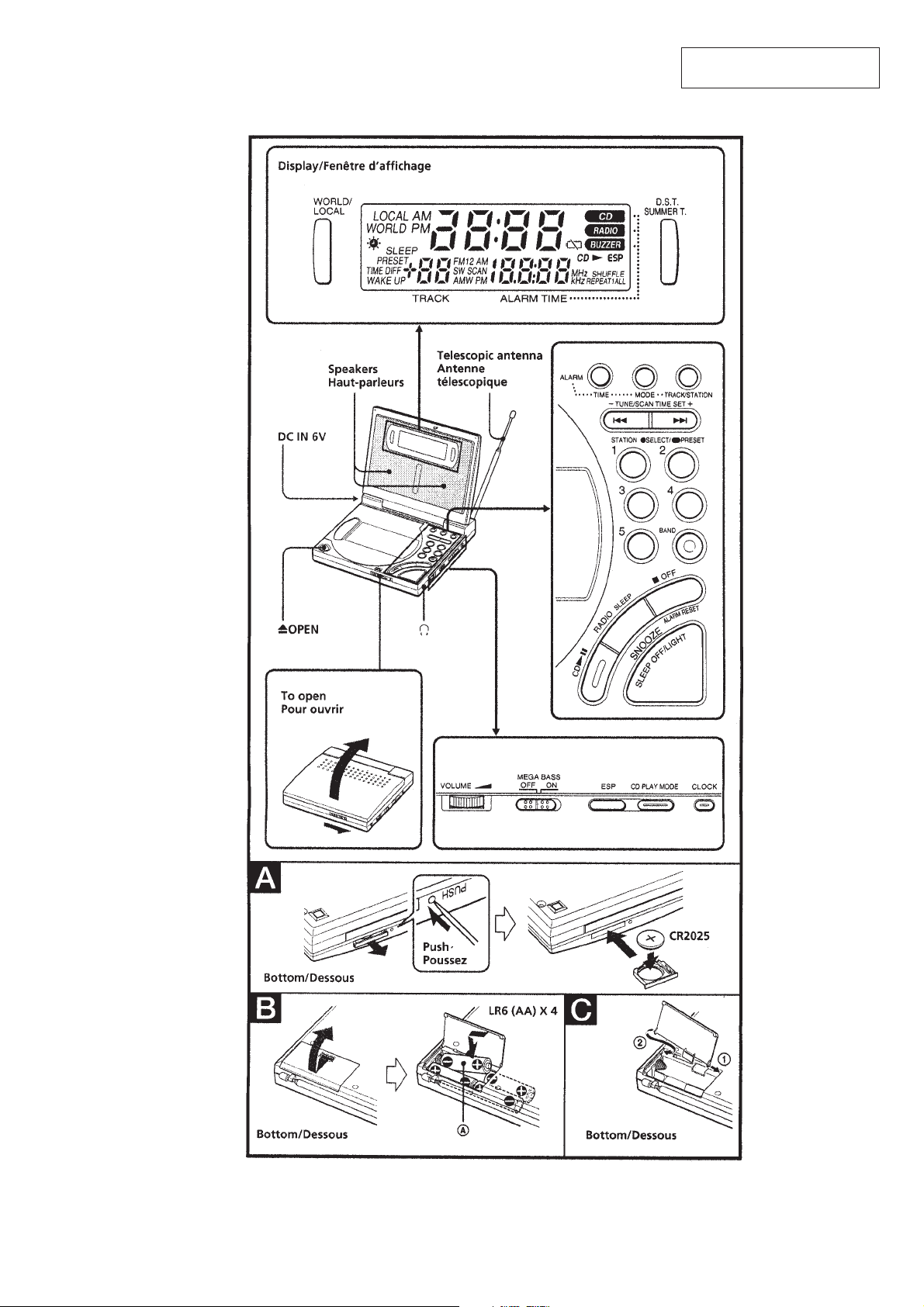

SECTION 2

GENERAL

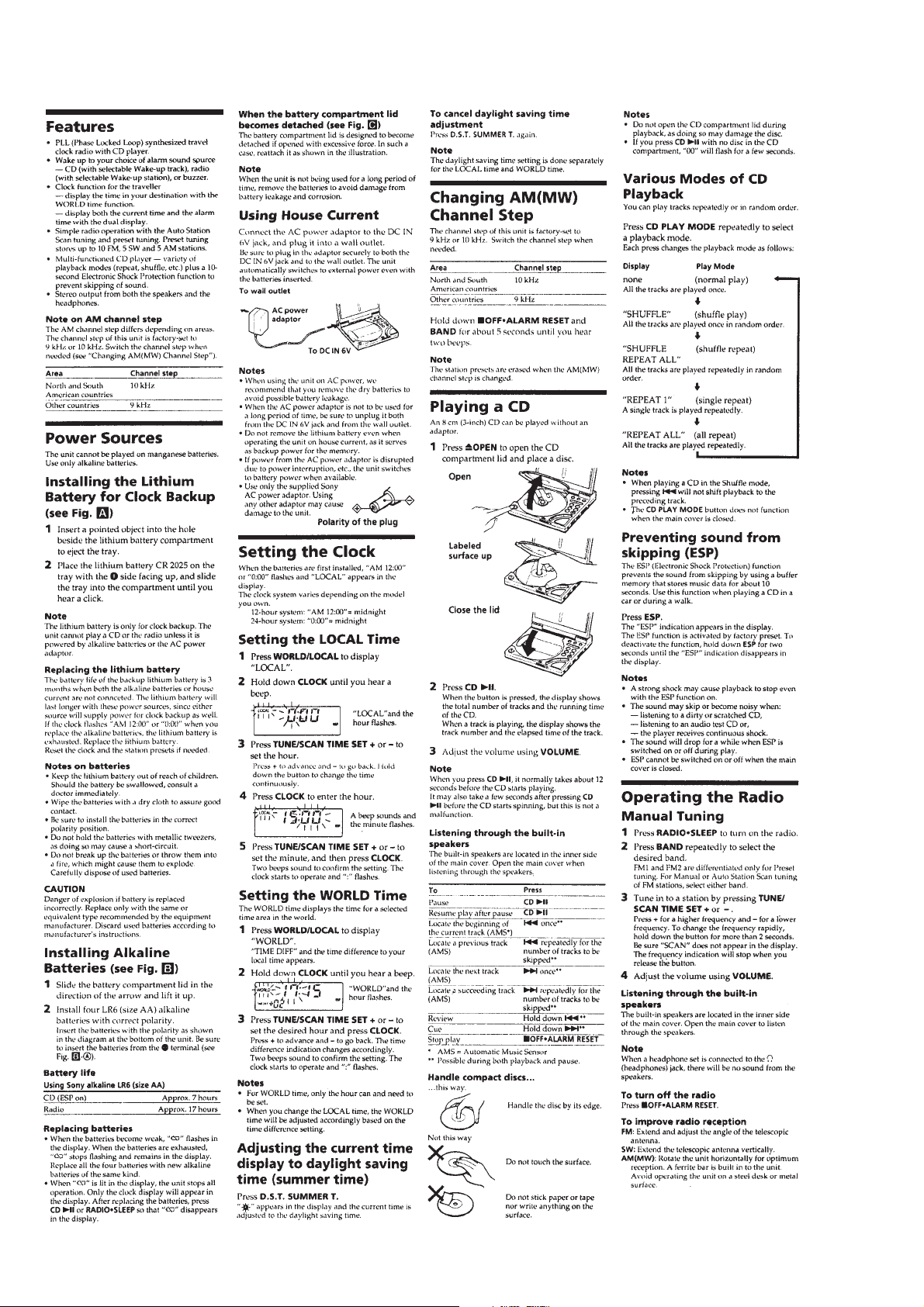

This section is extracted from

instruction manual.

– 5 –

– 6 –

– 7 –

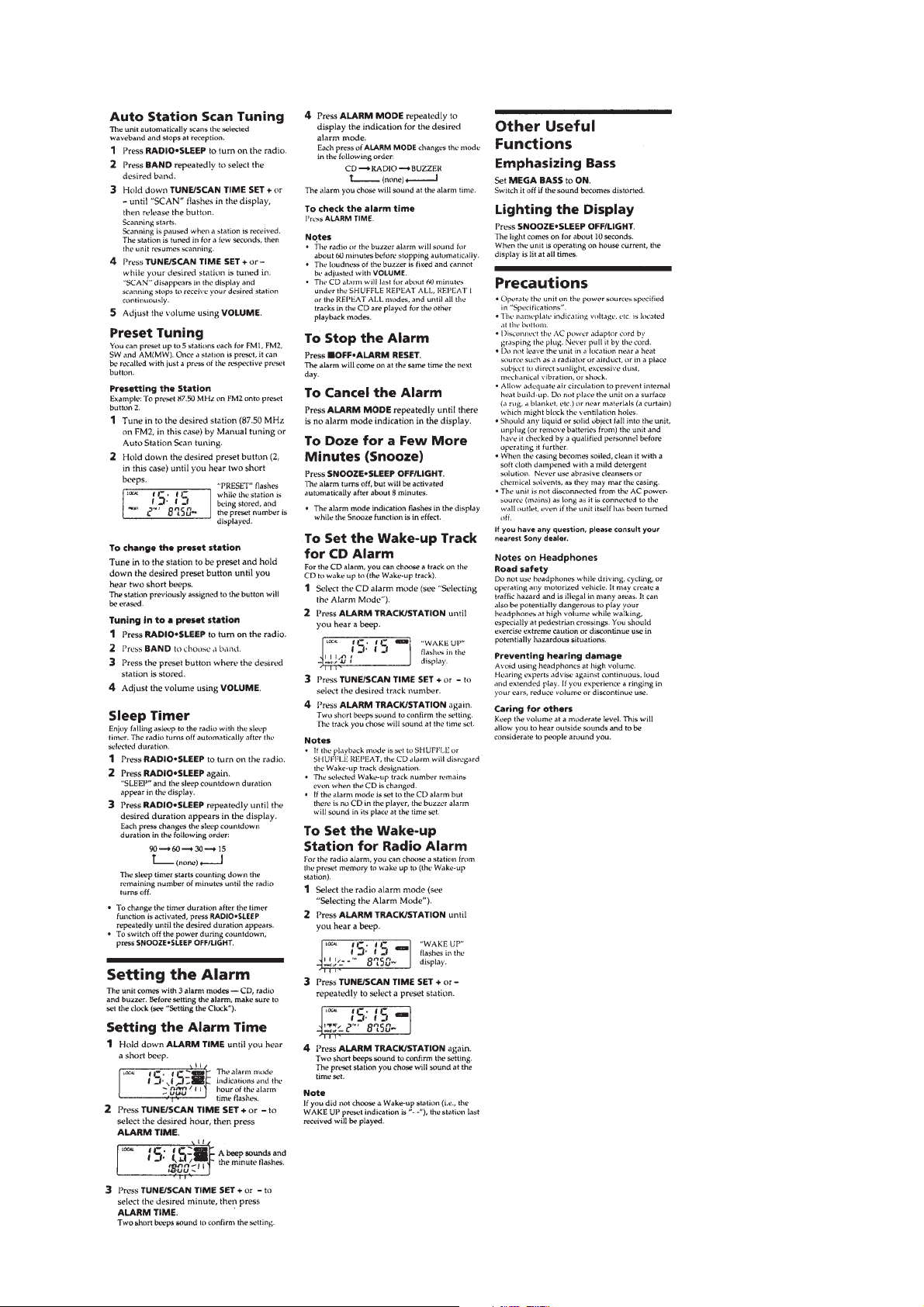

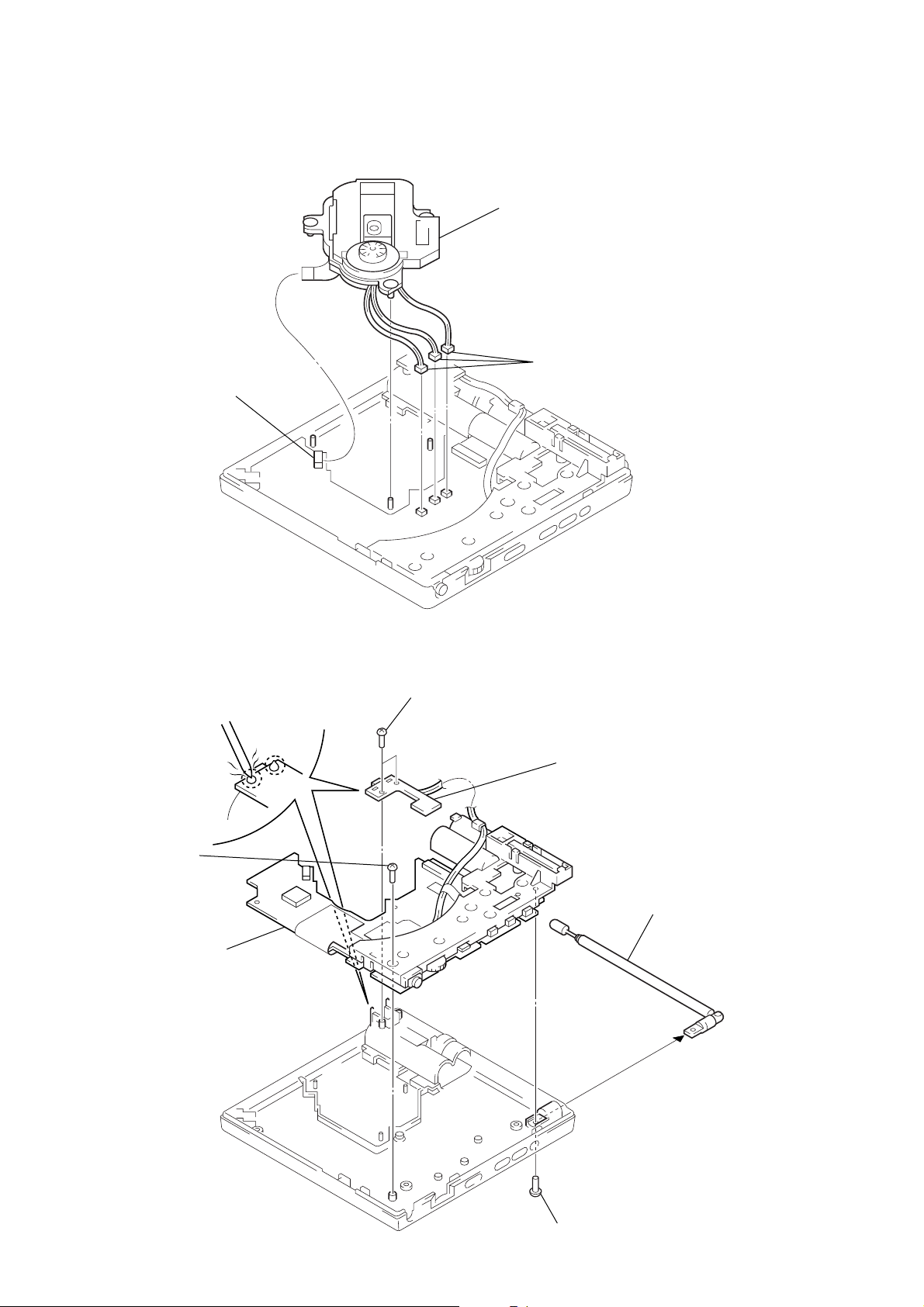

• This set can be disassembled in the order shown below.

SECTION 3

DISASSEMBLY

Cabinet (lower) assy

Set

Optical pick-up

(CDM-2911EBA)

Note: Follow the disassembly procedure in the numerical order given.

Cabinet (upper)

Main board

CABINET (LOWER) ASSY

5

cabinet (upper) assy

Cabinet (front) sub assy

4

flat wire (CN301)

1

Open the battery case lid.

3

four claws

2

five screws

(2

3

two claws

6

cabinet (lower) assy

3

×

8)

3

two claws

two claws

– 8 –

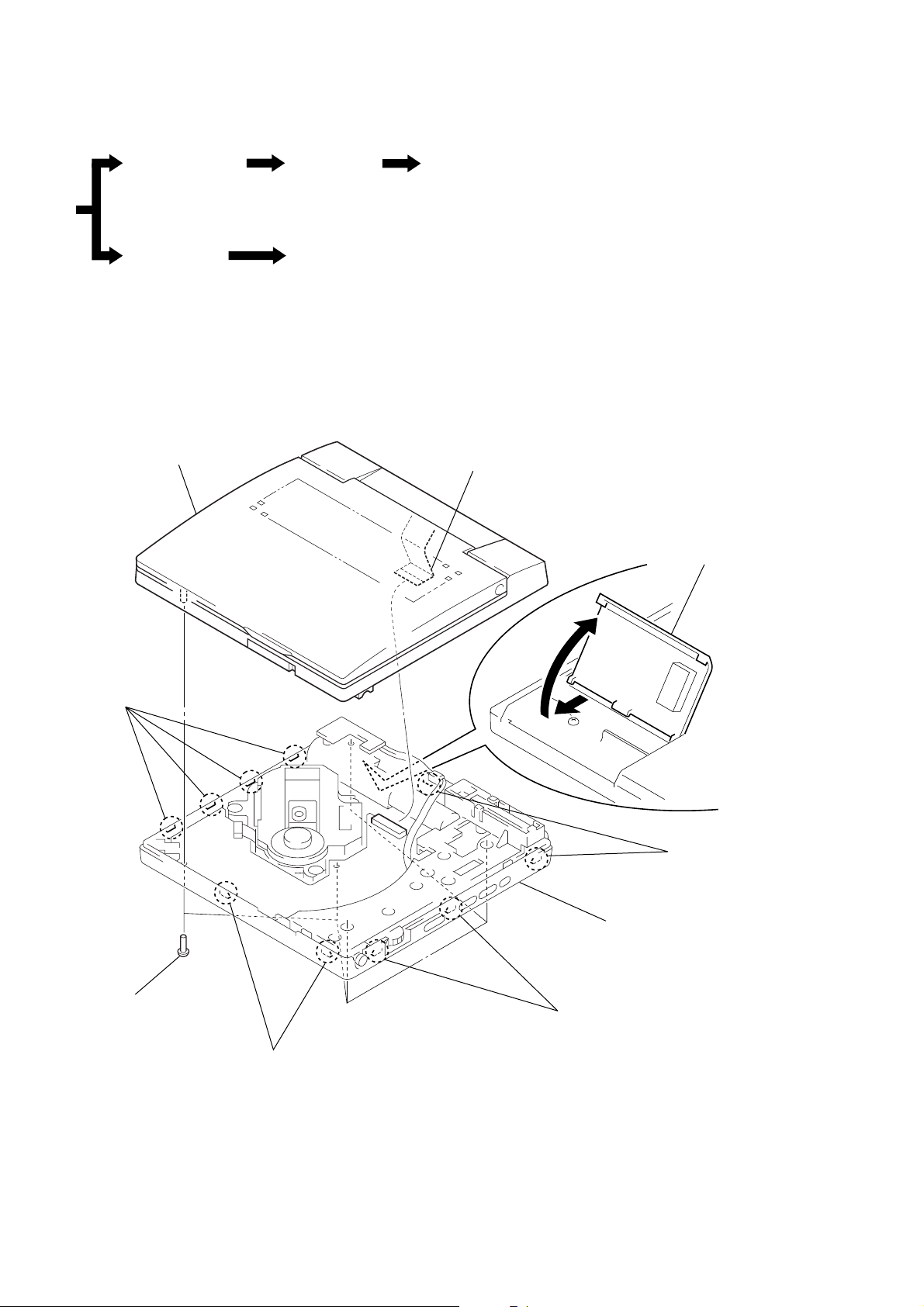

CABINET (UPPER)

e

2

four claws

3

cabinet (upper)

1

screw (2 × 8)

2

two claws

2

three claws

1

screw (2 × 8)

CABINET (FRONT) SUB ASSY

4

Pull out two flat wires.

5

6

cabinet (front) sub assy

cover

knob (open)

A

2

Slide the knob (open)

in the direction of the

arrow A, and open th

cabinet front assy.

cabinet (front) assy

3

connector (CN701)

– 9 –

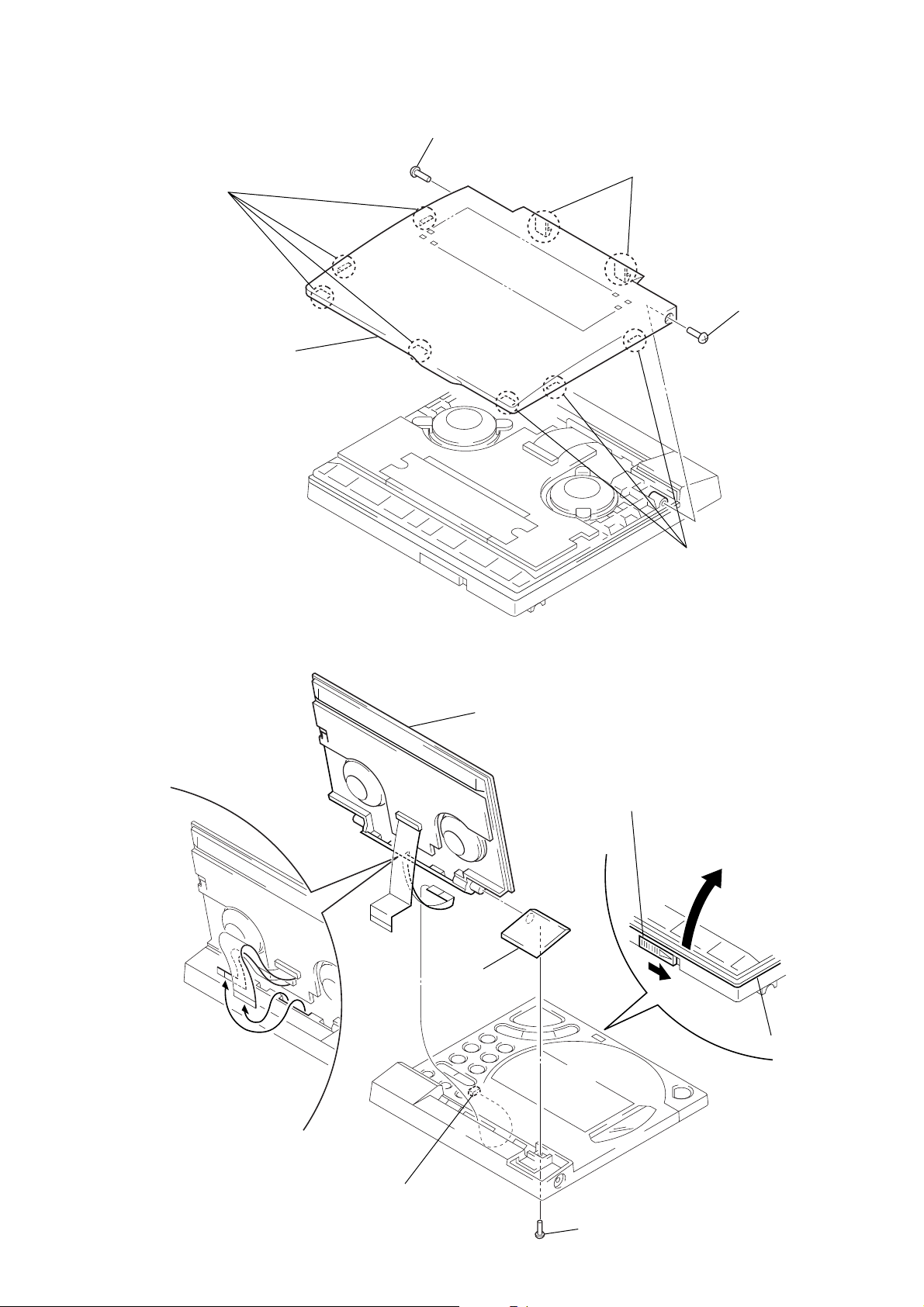

1

screw (2 × 8)

OPTICAL PICK-UP (CDM-2911EBA)

)

1

connector (CN501)

3

optical pick-up

(CDM-2911EBA)

2

three connectors

(CN601, 602, 603

MAIN BOARD

6

screw (2 × 8)

4

Remove two solders.

7

main board

3

two screws

(B1.7 × 5)

5

jack board

2

telescopic antenna

– 10 –

1

screw (B3 × 6)

SECTION 4

SERVICE MODE

Service Mode (Service program)

The equipment is provided with a service program built in the

microcomputer, like conventional models.

Service program operation methods are described in the following.

• Step 1 (Service mode setting methods)

1. Connect TP447 (CD TEST 2) to the TP444 (GND).

2. Turn ON the S423 (CD OPEN switch).

3. Insert external power supply.

4. Connect TP453 (RESET) to the TP444 (GND) to make open.

(Reset)

• Step 2 (Operation in the service mode)

1. Once the service mode is effected, the LCD displays 18 indications each of which is repeatedly displayed.

2. By pressing the > or . key , the optical pick-up is movable inwardly or outwardly . Howe ver, if this is acti vated, tracking servo and sled servo are turned OFF, so it can be turned

ON by pressing the [BAND] key if required.

3. Without disk, focus searching is repeated continuously.

4. By pressing the

CLV-A (servo in PLAY) are turned ON. Then playing begins.

No muting is ON in the service mode.

[BAND] key, tracking servo, sled servo and

• Step 3 (Resetting of service mode)

1. Remove external power supply.

2. Disconnect TP447 (CD TEST 2) and TP444 (GND), and also

TP453 (RESET) and TP444 (GND).

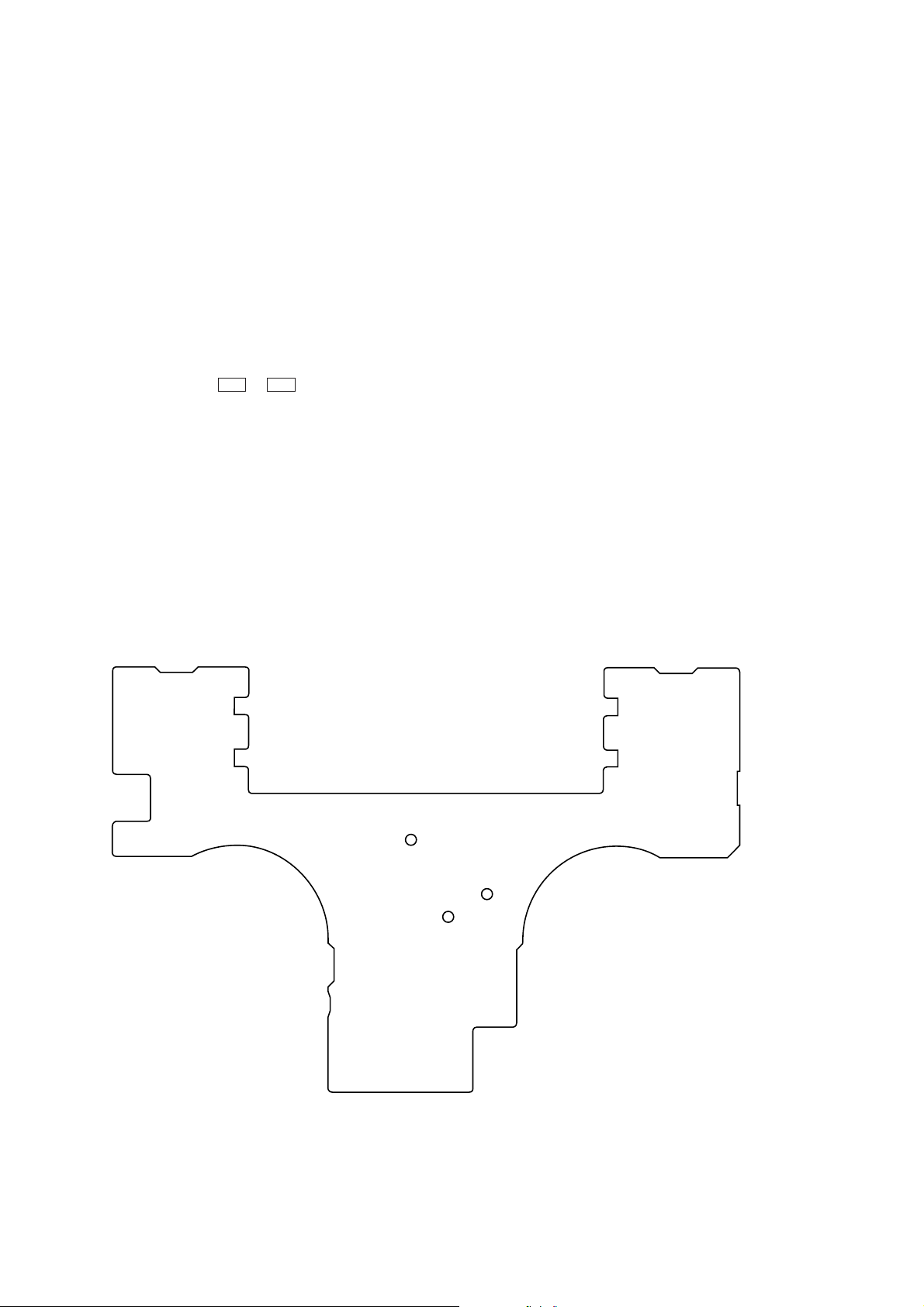

– LCD Board (Component Side) –

TP444

(GND)

(CD TEST 2)

TP453

(RESET)

TP447

Fig. 3 Location of CD TEST terminal

– 11 –

SECTION 5

TEST MODE

[Test Mode 1]

• Step1 (Test mode 1 setting methods)

1. Connect TP445 (CD TEST 1) to the TP444 (GND).

2. Insert external power supply.

• Step2 (Operation in the test mode 1)

1. The CD auto adjustment is not performed, but LCD test mode

is displayed. Also, ESP is placed in OFF state and it does not

turn ON.

2. The sled is operating while the > or . key is pressed.

At this time, the spindle and tracking servos turn OFF.

3. The focus search is performed until the focus becomes OK,

if the [CD ] key is pressed. At this time, the spindle and

tracking servos turn OFF. Also, when the focus becomes OK,

the optical pick-up moves to almost center of 12 cm disc.

4. The spindle and tracking servos turn ON when the [BAND]

key is pressed. Also, the mute turns OFF if the data is correct.

• Step3 (Resetting of test mode 1)

1. Remove external power supply.

2. Disconnect TP445 (CD TEST 1) and TP444 (GND).

[Test Mode 2]

• Step1 (Test mode 2 setting methods)

1. Connect TP447 (CD TEST 2) to the TP444 (GND).

2. Insert external power supply.

u

[Test Mode 3]

• Step1 (Test mode 3 setting methods)

1. Connect TP448 (CD TEST 3) to the TP449 (GND).

2. Insert external power supply.

• Step2 (Operation in the test mode 3)

1. The same operation as in test mode 2 is performed. However,

the LCD test mode is displayed same as in test mode 1.

• Step2 (Operation in the test mode 2)

1. The CD auto adjustment is performed. Also, the ESP can be

turned ON or OFF.

2. The sled is operating while the > or . key is pressed.

At this time, the spindle and tracking servos turn OFF.

3. The focus search is performed until the focus becomes OK,

u

[CD ] key is pressed. At this time, the spindle and

if the

tracking servos turn OFF. Also, when the focus becomes OK,

the optical pick-up moves to almost center of 12 cm disc.

4. The spindle and tracking servos turn ON when the [BAND]

key is pressed. Also, the mute turns OFF if the data is correct.

5. The pickup jumps by one track if > or . key is pressed

when the spindle and tracking servos turn ON, or it jumps

continuously if the key is kept pressed. Also, if the [PRESET]

key is pressed, the following operation is performed.

[PRESET 1] 1 track jump

[PRESET 2] 4 track jump

[PRESET 3] 16 track jump

[PRESET 4] 32 track jump

[PRESET 5] 256 track check

6. The pickup jumps to the second music and the test mode

is released, if [CD ] key is pressed when the spindle and

tracking servos turn ON.

u

– 12 –

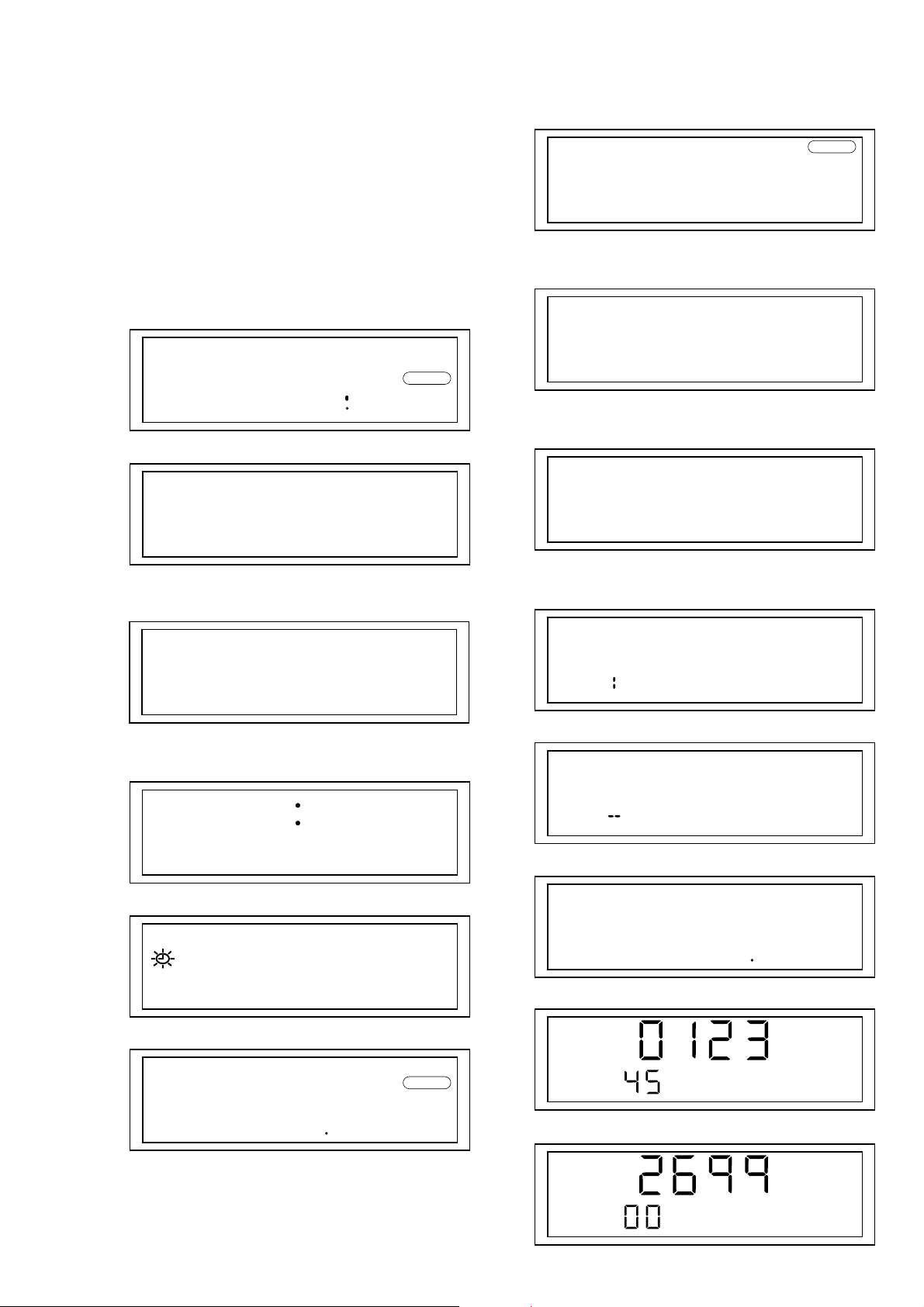

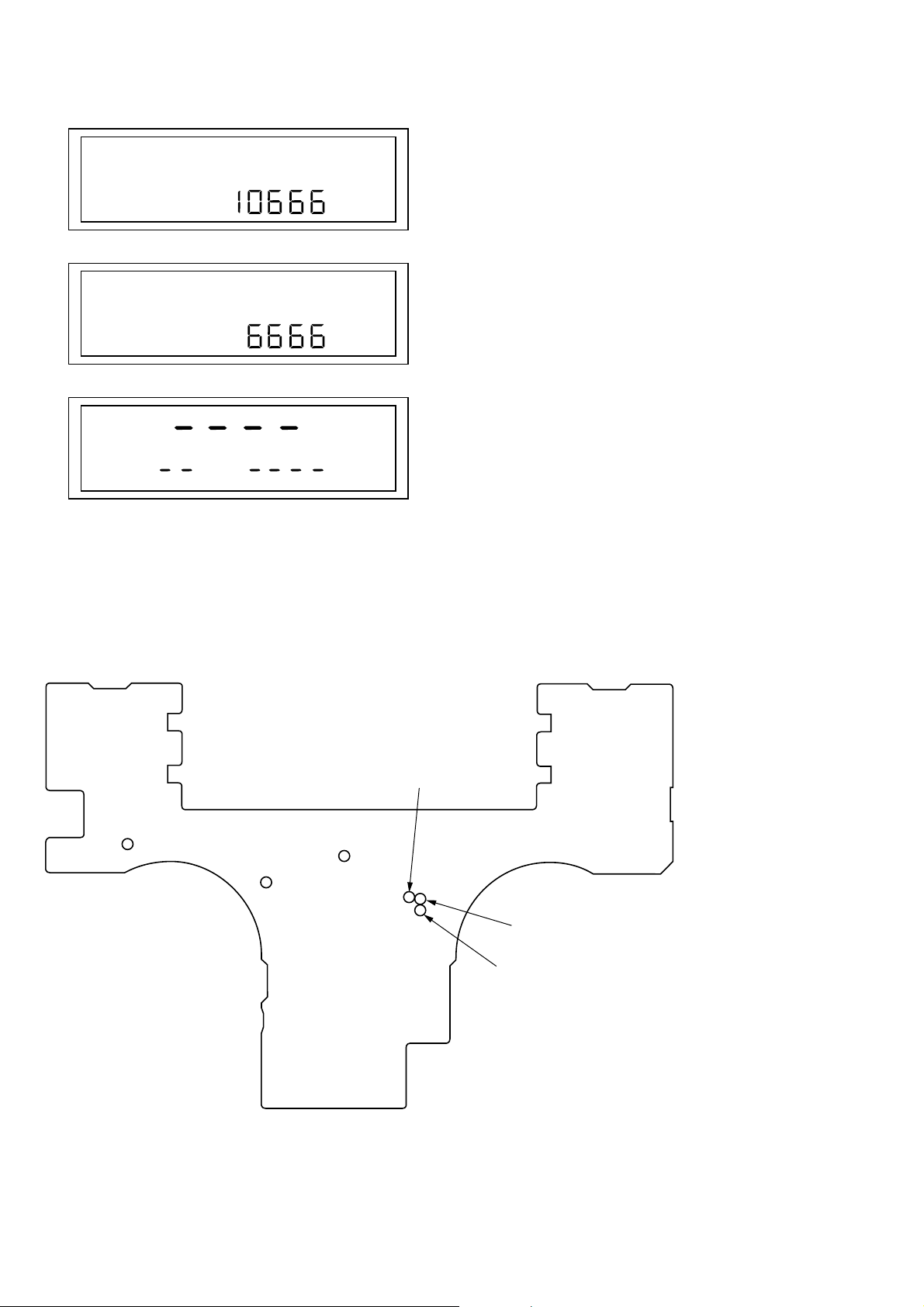

[LCD Display Check Mode]

• Step1 (LCD display check mode setting metyods)

1. Connect TP446 (TUNER TEST) to the TP444 (GND).

2. Insert external power supply.

• Step2 (Operation in the LCD display check mode)

1. All segments of LCD light up if the LCD display check mode

is activated.

2. If each key is pressed, the LCD display is as shown below. At

the same time, for some keys, the following operation is performed.

[CLOCK]:

WORLD

AM

BUZZER

TIMEDIF

[ESP]:

[ALARM TIME]:

AM

Buzzer sound OFF

[SNOOZE]:

FM 2

MW

LED ON

[ALARM TRACK/STATION]:

E

CD

CD

N

Beep sound ON

[CD PLAY MODE]:

Beep sound OFF

[WORLD/LOCAL]:

LOCAL

PM

[D.S.T SUMMER T.]:

PRESET

ESP

INTROSCAN

REPEAT ALL

SHUFFL

REPEAT1

SLEEP

WAKEUP

LED OFF

>

[ ]:

.

[ ]:

[BAND]:

[PRESET 1]:

FM1

AM

MHz

kHz

[ALARM MODE]:

Buzzer sound ON

RADIO

SW

PM

[PRESET 2]:

– 13 –

[PRESET 3]:

[PRESET 4]:

[PRESET 5]:

x

[ OFF, ALARM RESET]: All lit

• Step3 (Resetting of LCD display check mode)

1. Remove external power supply.

2. Disconnect TP446 (TUNER TEST) and TP444 (GND).

Connecting Location:

– LCD Board (Conductor Side) –

TP448

(CD TEST 3)

TP449

(GND)

TP445

(CD TEST 1)

TP444

(GND)

TP446

(TUNER TEST)

TP447

(CD TEST 2)

– 14 –