Sony HCDG-2500 Service manual

Tuner section

FM stereo, FM/AM superheterodyne tuner

FM tuner section

Tuning range 87.5 – 108.0 MHz

Antenna FM lead antenna

Antenna terminals 75 Ω unbalanced

Intermediate frequency 10.7 MHz

AM tuner section

Tuning range

(2 band model)

North American model:

530 – 1,710 kHz

(with the tuning interval set at 10 kHz)

Other models: 531 – 1,602 kHz

(with the tuning interval set at 9 kHz)

530 – 1,710 kHz

(with the tuning interval set at 10 kHz)

(3 band model)

MW: 531 – 1,602 kHz

(with the tuning interval set at 9 kHz)

LW: 153 – 279 kHz

(with the tuning interval set at 3 kHz)

Antenna AM loop antenna

Antenna terminals External antenna terminal

Intermediate frequency 450 kHz

General

Power requirements

North American model:

120 V AC, 60 Hz

Mexican model: 120 V AC, 50/60 Hz

European model: 230 V AC, 50/60 Hz

Australian, South African and Thailand models:

220 – 240 V AC, 50/60 Hz

Other models: 110 – 120 V AC or 220 – 240 V AC,

50/60 Hz (adjustable with voltage selector)

Power consumption 130 W

Dimensions (w/h/d) incl. projecting parts and controls

Approx.355 × 423 × 440 mm

(14 × 16 3/4 × 17 3/8 in)

Mass Approx. 14.0 kg (30 lb 14 oz.)

Supplied accessories AM loop antenna (1)

Remote RM-SG5 (1)

FM lead antenna (1)

SERVICING NOTE

NOTES ON HANDLING THE OPTICAL PICK-UP BLOCK

OR BASE UNIT

The laser diode in the optical pick-up block may suffer electrostatic

break-down because of the potential difference generated by the

charged electrostatic load, etc. on clothing and the human body.

During repair, pay attention to electrostatic break-down and also

use the procedure in the printed matter which is included in the

repair parts.

The flexible board is easily damaged and should be handled with

care.

NOTES ON LASER DIODE EMISSION CHECK

The laser beam on this model is concentrated so as to be focused on

the disc reflective surface by the objective lens in the optical pickup block. Therefore, when checking the laser diode emission,

observe from more than 30 cm away from the objective lens.

Design and specifications are subject to change without notice.

CAUTION

Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous

radiation exposure.

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be

damaged by heat.

Flexible Circuit Board Repairing

• Keep the temperature of soldering iron around 270˚C

during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK ! OR DOTTED LINE WITH

MARK ! ON THE SCHEMATIC DIAGRAMS AND IN THE PARTS

LIST ARE CRITICAL TO SAFE OPERATION. REPLACE THESE

COMPONENTS WITH SONY PARTS WHOSE PART NUMBERS

APPEAR AS SHOWN IN THIS MANUAL OR IN SUPPLEMENTS

PUBLISHED BY SONY.

Laser component in this product is capable of emitting radiation

exceeding the limit for Class 1.

This appliance is classified as

a CLASS 1 LASER product.

The CLASS 1 LASER

PRODUCT MARKING is

located on the rear exterior.

This caution

label is located

inside the unit.

— 2 —

SAFETY CHECK-OUT

After correcting the original service problem, perform the following

safety checks before releasing the set to the customer:

Check the antenna terminals, metal trim, “metallized” knobs, screws,

and all other exposed metal parts for AC leakage. Check leakage as

described below.

LEAKAGE

The AC leakage from any exposed metal part to earth Ground and

from all exposed metal parts to any exposed metal part having a

return to chassis, must not exceed 0.5 mA (500 microampers).

Leakage current can be measured by any one of three methods.

1. A commercial leakage tester, such as the Simpson 229 or RCA

WT -540A. F ollow the manufactur ers’ instructions to use these

instruments.

2. A battery-operated AC milliammeter. The Data Precision 245

digital multimeter is suitable for this job.

3. Measuring the voltage drop across a resistor by means of a

VOM or battery-operated A C voltmeter . The “limit” indication

is 0.75 V, so analog meters must have an accurate low-v oltage

scale. The Simpson 250 and Sanwa SH-63Trd are e xamples of

a passive VOM that is suitable. Nearly all battery operated

digital multimeters that have a 2V AC range are suitable. (See

Fig. A)

T o Exposed Metal

Parts on Set

AC

0.15

µ

F

Fig. A. Using an A C v oltmeter to check A C leakage.

1.5 k

Ω

Earth Ground

Voltmeter

(0.75 V)

TABLE OF CONTENTS

1. GENERAL ········································································· 4

—FRONT PANEL— ·························································4

—BACK PANEL—····························································5

2. DISASSEMBLY

2-1. Top Cover ··········································································· 6

2-2. Front Panel Assy································································· 6

2-3. Main Board········································································· 7

2-4. Main Section······································································· 7

2-5. CD Mechanism Deck Section ············································ 8

2-6. Tape Mechanism Deck ······················································· 8

2-7. Cassette Door ····································································· 9

2-8. CD Door Assy ···································································· 9

2-9. Base Unit ··········································································10

2-10. Disc T able········································································· 10

3. MECHANICAL ADJUSTMENTS ····························· 11

4. ELECTRICAL ADJUSTMENTS ······························· 11

5. DIAGRAMS

5-1. Circuit Boards Location ··················································· 16

5-2. Block Diagram —Deck Section— ··································· 17

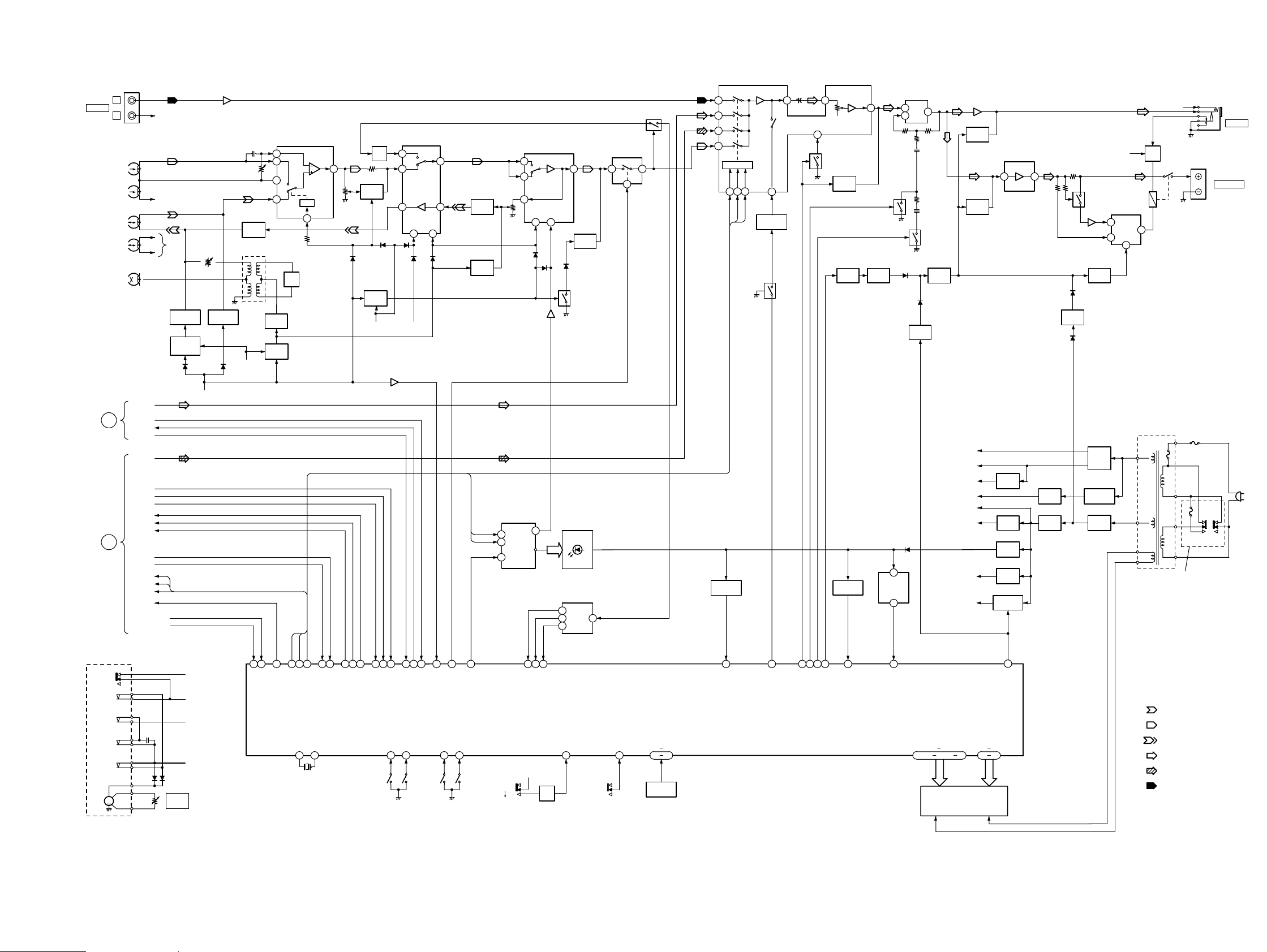

5-3. Block Diagram —Tuner/CD Section— ··························· 19

5-4. Schematic Diagram —Main Section (1/2)— ··················· 21

5-5. Schematic Diagram —Main Section (2/2)—

(US, AUS, MX model) ····················································· 25

5-6. Printed Wiring Board —Main Section—

(US, AUS, MX model) ····················································· 29

5-7. Printed Wiring Board —Main Section—

(AEP, UK, E, SP, MY, AR model)···································· 34

5-8. Schematic Diagram —Main Section (2/2)—

(AEP, UK, E, SP, MY, AR model)···································· 39

5-9. Schematic Diagram —Display Section— ························ 43

5-10. Printed Wiring Board —Display Section— ····················· 47

5-11. Printed Wiring Board —CD Section—···························· 52

5-12. Schematic Diagram —CD Section— ······························· 57

5-13. Schematic Diagram —Power Section— ·························· 60

5-14. Printed Wiring Board —Power Section— ······················· 63

5-15. IC Block Diagrams ··························································· 68

5-16. IC Pin Function Description············································· 71

— 3 —

6. EXPLODED VIEWS

6-1. Top Cover Section ···························································· 73

6-2. CD Door Section ······························································ 74

6-3. Panel Section ····································································75

6-4. Main Section····································································· 76

6-5. Cassette Button Section···················································· 77

6-6. Cassette Mechanism Deck Section··································· 78

6-7. CD Mechanism Deck Section ·········································· 79

6-8. Base Unit Section ····························································· 80

7. ELECTRICAL PARTS LIST ······································ 81

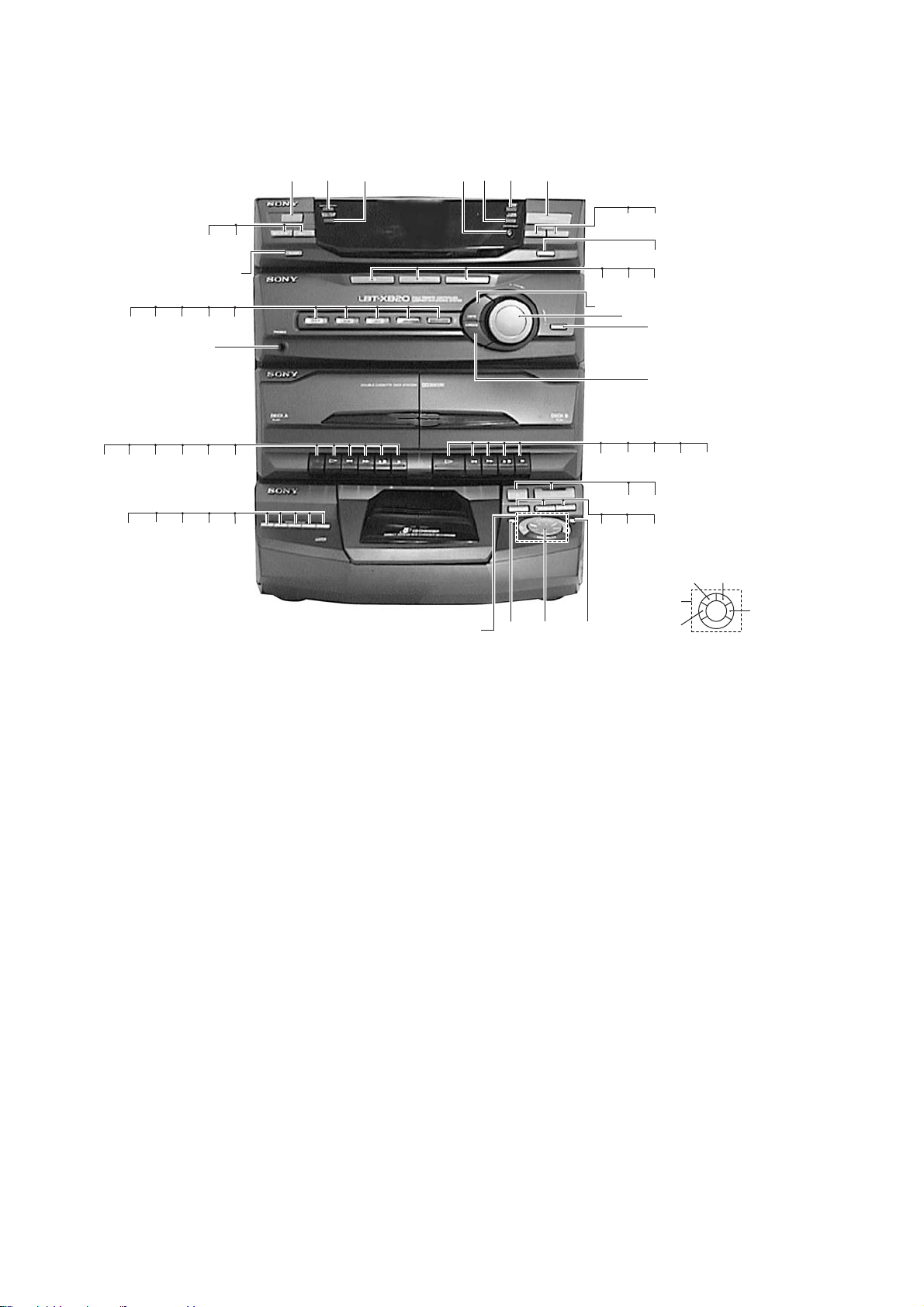

– FRONT PANEL –

SECTION 1

GENERAL

#§

#¶

#¡

$¢

$∞

#•

#ª

#™ #£

$ª

$§$£

$™

$º

#¢

%º

$•

$¶

$¡

#∞

1

2

3467

see

A

5

#º

@ª

@•

!¡

!¢

!•

@∞

89

!º

!™

!£

!∞

!§

!¶

!ª

@º

@¢

@£

@¶

@§

@¡

%¢ %¡

A

%£

@™

%™

1 I/u (POWER) button

2 DISPLA Y/DEMO button

3 SPECTRUM ANALYZER button

4 ENTER/NEXT button

5 TUNER MEMORY button

6 TUNING MODE button

7 TUNER/BAND button

8 TUNING – button

9 TUNING + button

0 STEREO/MONO button

!¡ TAPE button

!™ CD button

!£ PHONO button

!¢ DBFB button

!∞ VOLUME knob

!§ DOLBY NR button

!¶ SURROUND button

!• · button

!ª 0 button

@º ) button

@¡ 6p button

@™ P button

@£ 6 button

@¢ · button

@∞ DISC SKIP button

@§ P button

@¶ p button

@• ) button

@ª ≠ AMS ± button

#º 0 button

#¡ DISC1 button

#™ DISC2 button

#£ DISC3 button

#¢ DISC4 button

#∞ DISC5 button

#§ r button

#¶ · button

#• 0 button

#ª ) button

$º 6p button

$¡ P button

$™ PHONES jack

$£ ROCK button

$¢ POP button

$∞ JAZZ button

$§ SALSA button

$¶ FLAT button

$• SLEEP button

$ª t/CLOCK SET button

%º DAILY1 button

%¡ PLAY MODE button

%™ REPEAT button

%£ EDIT button

%¢ 1/ALL DISC button

— 4 —

– BACK PANEL –

1

2

1 ANTENNA terminal

2 PHONO jack

3 SPEAKER terminal

3

— 5 —

SECTION 2

DISASSEMBLY

Note : Follow the disassembly procedure in the numerical order given.

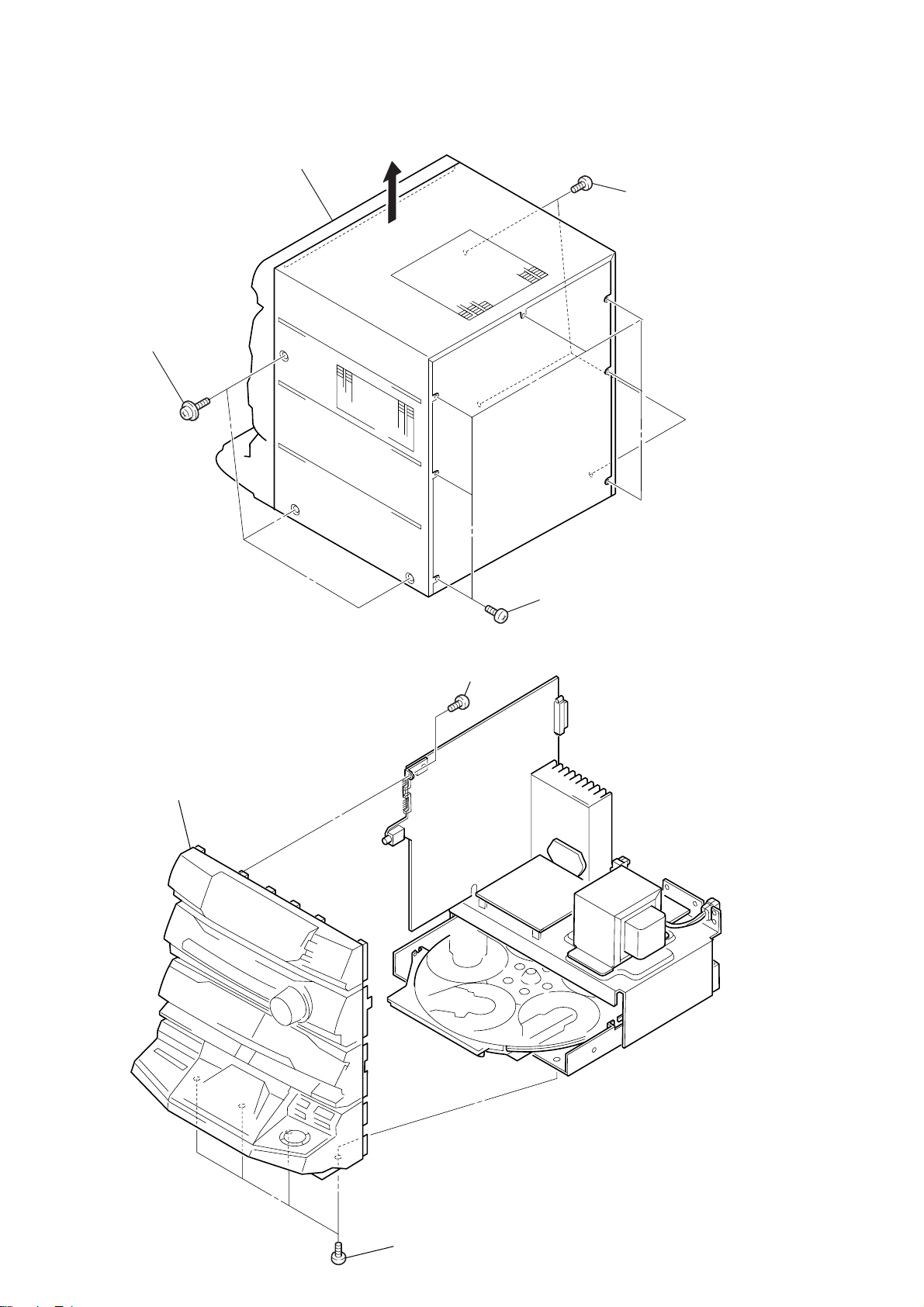

2-1. TOP COVER

1

Three screws

3

Top cover

2

Seven screws

1

Three screws

2-2. FRONT PANEL ASSY

3

Front panel assy

1

Screw

2

Four screws

— 6 —

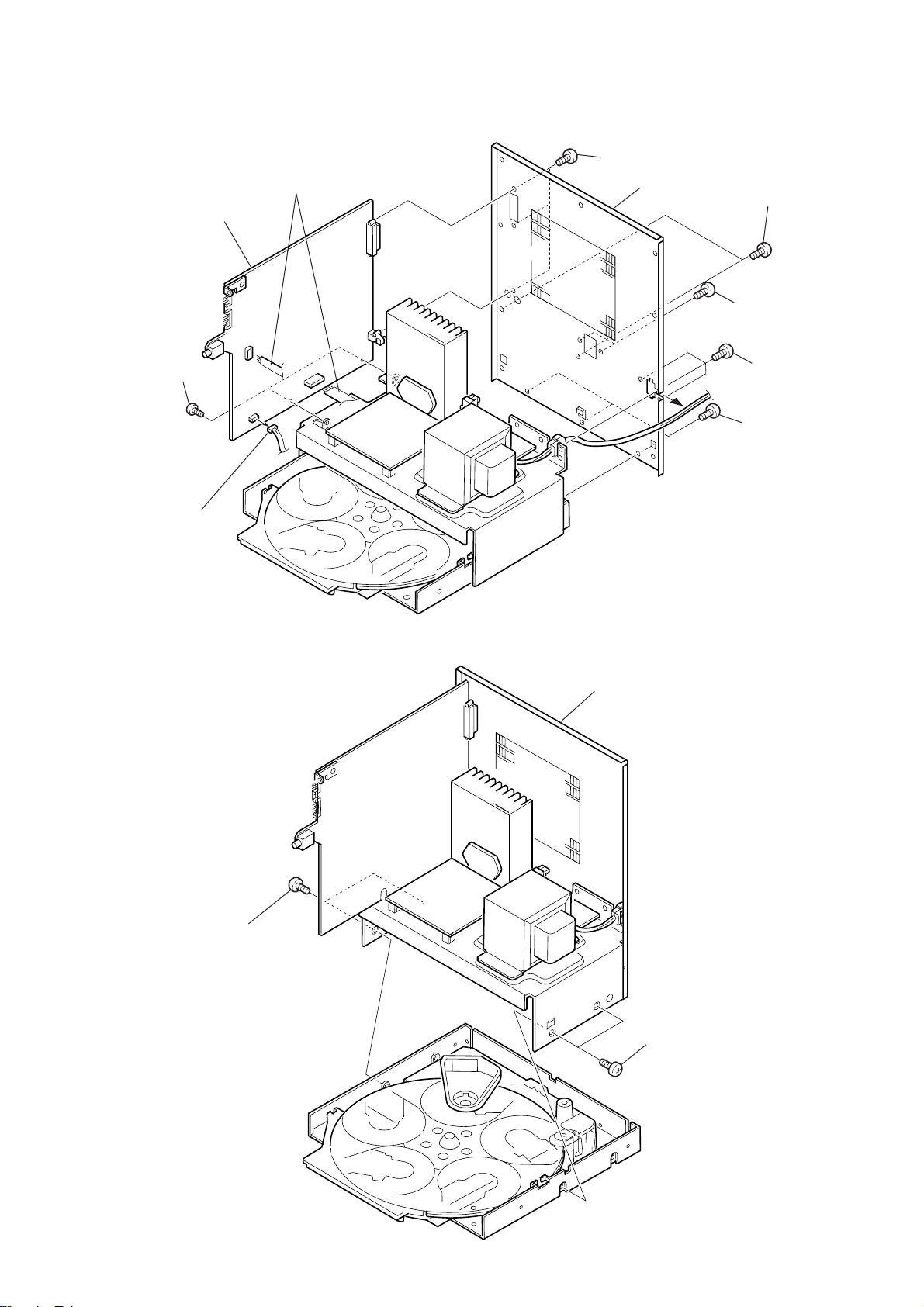

2-3. MAIN BOARD

1

Two screws

2

Three screws

2

Three screws

2

Two screws

1

Three screws

3

Rear panel

7

MAIN board

6

Two screws

5

Two flat wires

4

Connector

2-4. MAIN SECTION

1

Two screws

2

Main section

1

Two screws

— 7 —

2-5. CD MECHANISM DECK SECTION

3

Five screws

(BVTP 3 × 8)

4

CD mechanism

deck section

2

Flat wire and

lead wire

2-6. TAPE MECHANISM DECK

1

Open the clamp.

1

Six screws

2

Tape mechanism deck

— 8 —

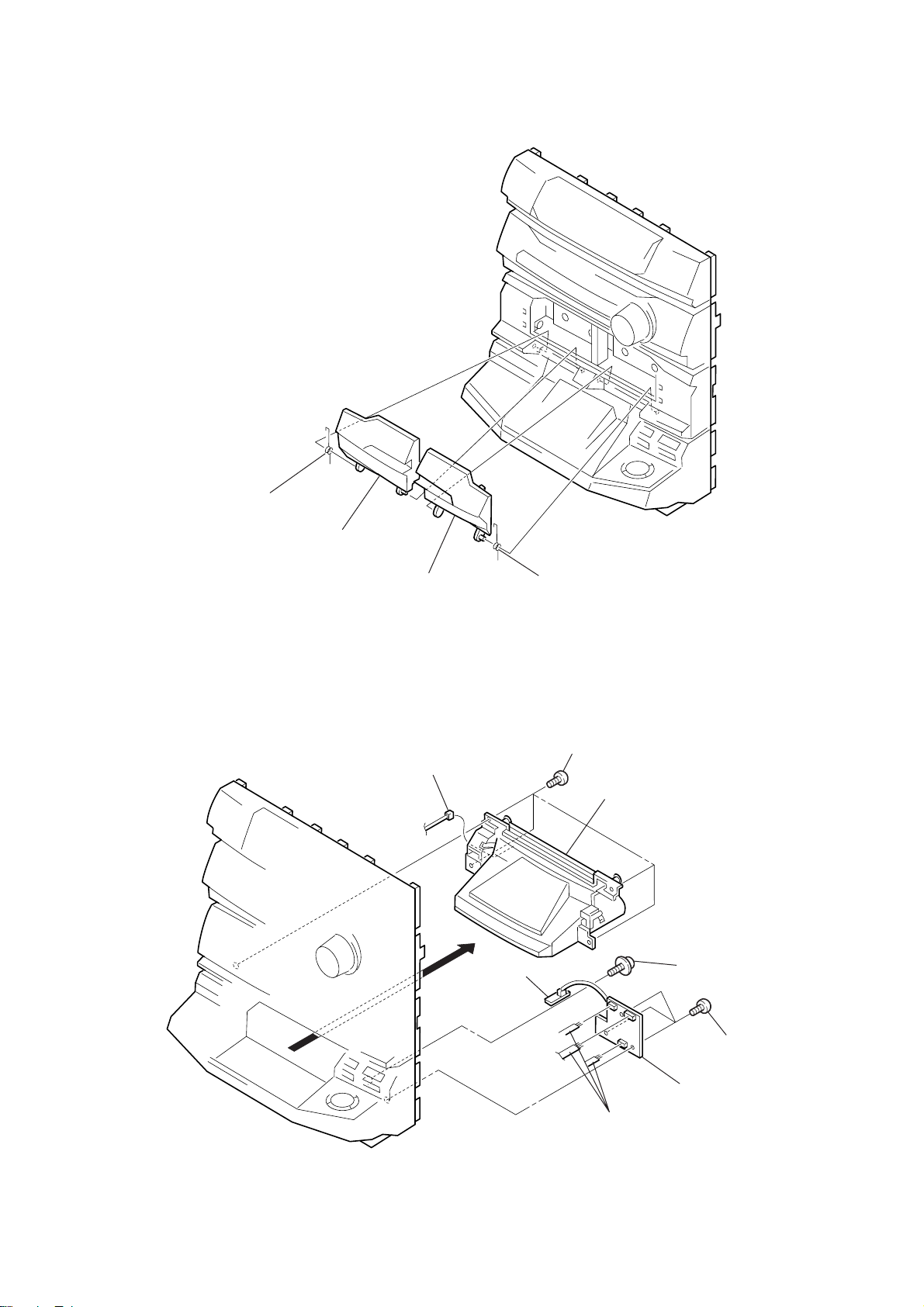

2-7. CASSETTE DOOR

3

Door spring

2

Cassette door (L)

2-8. CD DOOR ASSY

1

Cassette door (R)

7

Connector

5

3

Door spring

DOOR SW board

6

Four screws

8

CD door assy

4

Screw

— 9 —

3

Three flat wires

1

Three screws

2

PLAY SW board

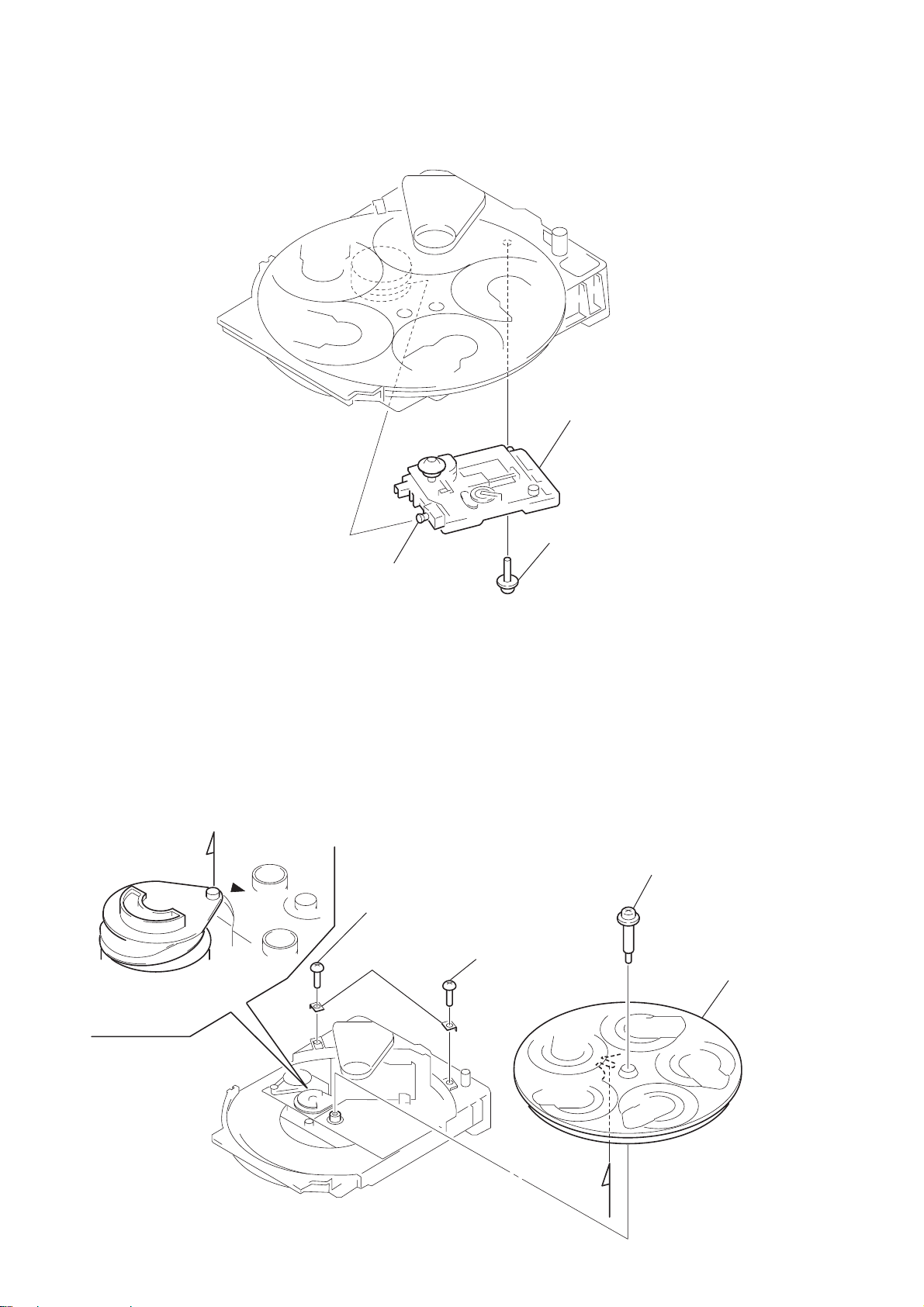

2-9. BASE UNIT

t

3

Base unit

1

Yoke bracke

2-10. DISC TABLE

Note:

When the disc table is installed, adjust the positions

of roller cam and mark z as shown in the figure,

then set to the groove of disc table.

A

2

1

Screw

(BVTP 3 × 8)

2

Bracket (BU)

Boss

1

Screw

(BVTP 3 × 8)

3

Step screw

4

Disc table

— 10 —

A

SECTION 3

MECHANICAL ADJUSTMENTS

SECTION 4

ELECTRICAL ADJUSTMENTS

Precaution

1. Clean the following parts with a denatured alcohol-moistened

swab:

record/playback head pinch rollers

erase head rubber belts

capstan idlers

2. Demagnetize the record/playback head with a head

demagnetizer.

3. Do not use a magnetized screwdriver for the adjustments.

4. After the adjustments, apply suitable locking compound to the

parts adjusted.

5. The adjustments should be performed with the rated power

supply voltage unless otherwise noted.

Torque Measurement

Torque

FWD

FWD

back tension

FF/REW

Torque meter

CQ-102C

CQ-102C

CQ-201B

Meter reading

40 to 70 g • cm

(0.56 - 0.97 oz • inch)

1 to 5 g • cm

(0.01 - 0.07 oz • inch)

55 to 140 g • cm

(0.76 - 1.94 oz • inch)

DECK SECTION 0 dB=0.775V

1. Demagnetize the record/playback head with a head

damagnetizer.

2. Do not use a magnetized screwdriver for the adjustments.

3. After the adjustments, apply suitable locking compound to the

parts adjusted.

4. The adjustments should be performed with the rated power

supply voltage unless otherwise noted.

5. The adjustments should be performed in the order given in this

service manual. (As a general rule, playback circuit adjustment

should be completed before performing recording circuit

adjustment.)

6. The adjustments should be performed for both L-CH and RCH.

Tape

P-4-A100

WS-48B

Record/Playback Head Azimuth Adjustment

(Deck A, Deck B)

Note: Perform this adjustments for both decks.

Procedure:

1. Mode : Playback

test tape

P-4-A100

(10kHz, –10dB)

Signal

10 kHz, –10 dB

3 kHz, 0 dB

SPEAKER

terminal (JK703)

Used for

Azimuth Adjustment

Tape Speed Adjustment

level meter

set

+

–

— 11 —

2. Turn the adjustment scre w and check output peaks. If the peaks

do not match for L-CH and R-CH, turn the adjustment screw

so that outputs match within 2 dB of peak.

L-CH

peak

screw

position

R-CH

peak

output

level

within

2dB

L-CH

peak

R-CH

peak

within 2dB

screw

position

4. After the adjustments, apply suitable locking compound to the

parts adjusted.

Adjustment Location:

Remove the cassette lid before adjustment (See page 9)

Adjustment screws

REC/PB head (deck A)

or PB head (deck B)

3. Mode: Playback

test tape

P-4-A100

(10kHz, –10dB)

in phase 45˚ 90˚ 135˚ 180˚

SPEAKER

terminal (JK703)

(L-CH)

L

set

R

SPEAKER

terminal (JK703)

(R-CH)

Waveform of oscilloscope

good

wrong

Tape Speed Adjustment (Deck A)

Procedure:

1. Mode: Playback

test tape

WS-48B

(3kHz, 0dB)

set

SPEAKER

terminal (JK703)

frequency counter

+

–

2. Adjust the SFR809 so that the frequency counter reads 3,000

Hz ± 90Hz.

Adjustment Location: MAIN board (See page 14)

Sample Value of Wow and flutter

W. RMS (JIS) within 0.3%

(test tape: WS-48B)

— 12 —

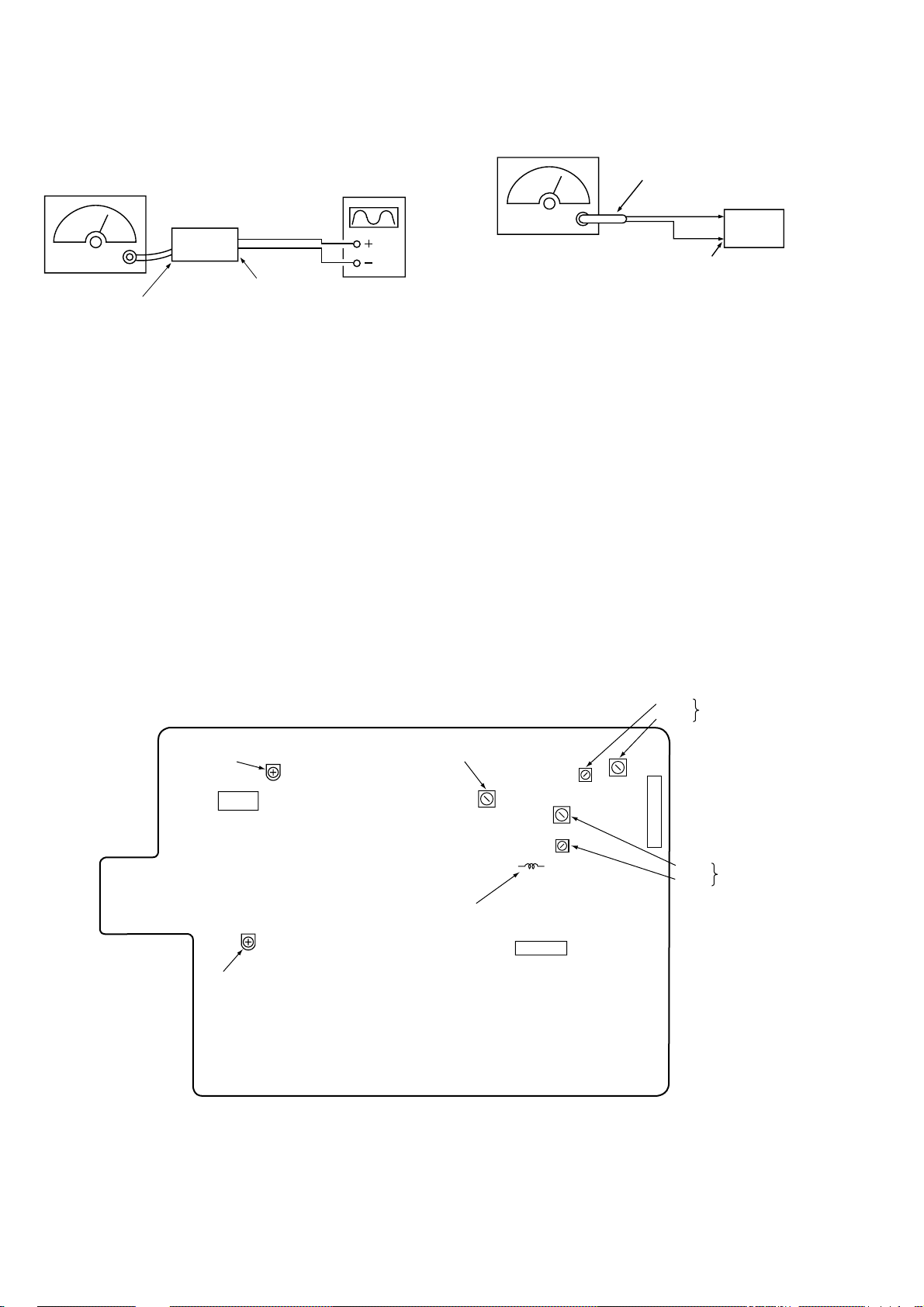

TUNER SECTION 0 dB=1µV

AM Tuning Voltage Adjustment

Main board

TP1

F

G

VT

DC voltmeter

+

–

Procedure:

1. Set the reception frequency of the unit to 530 kHz.

2. Adjust L105 for 1.2 ± 0.05 V reading on the DC voltmeter.

3. Set the reception frequency of the unit to 1,710 kHz.

4. Confirm that the voltage reading on the DC voltmeter is within

8.0 ± 0.5 V.

Adjustment Location: MAIN board (See page 14)

AM Tracking Adjustment

loop antenna

AM RF SSG

loop antenna

(Supplied accessories)

set

30% amplitude

modulation by

400 Hz signal

60 cm

Field strength dB (

µ

V/m) =SSG output level dB (µV/m) –26 dB.

Procedure:

1. Tune the set to 600 kHz.

2. Set the output of AM RF SSG so that the input le vel of the set

will become 60 dB (µV/m).

3. Adjust L104 so that when the waveform on the oscilloscope is

maximum, no noise appears.

4. Tune the set to 1,400 kHz.

FM Tuning Voltage Adjustment (US, Australian, Mexican model)

Main board

TP1

IF

G

VT

DC voltmeter

+

–

Procedure :

1. Set the reception frequency of the unit to 87.5 MHz.

2. Adjust L103 for 1.2 ± 0.05V reading on the DC voltmeter.

3. Set the reception frequency of the unit to 108 MHz.

4. Confirm that the voltage reading on the DC voltmeter is within

7.8 ± 0.5V.

AM ANTENNA

terminal (TM1)

5. Adjust TC102 so that when the waveform on the oscilloscope

is maximum, no noise appears.

• Repeat the procedures in each adjustment several times, and the

tracking adjustment should be finally done by the trimmer

capacitors.

Adjustment Location: MAIN board (See page 14)

Adjustment Location: MAIN board (See page 14)

— 13 —

FM Tracking Adjustment

)

(US, Australian, Mexican model)

Procedure:

FM RF SSG

set

SPEAKER terminal (JK703)

FM ANTENNA terminal (JK101)

Carrier frequency : 90 MHz, 106 MHz

Modulation : AUDIO 1kHz, 75kHz deviation (100%)

Output level : 20 dB (at 75 Ω open)

oscilloscope

1. Tune the set to 90 MHz.

2. Adjust L102 so that when the waveform on the oscilloscope is

maximum, no noise appears.

3. Tune the set to 106 MHz.

4. Adjust TC101 so that when the waveform on the oscilloscope

is maximum, no noise appears.

• Repeat the procedures in each adjustment several times, and the

tracking adjustment should be finally done by the trimmer

capacitors.

Adjustment Location: MAIN board

FM Tuned Level Adjustment

FM RF SSG

Ω

coaxial

75

set

Carrier frequency : 98 MHz

Modulation : AUDIO 1 kHz, 75 kHz

Output level : 28 dB (at 75

deviation (100%)

Ω

open)

FM ANTENNA terminal

(JK101)

Procedure:

1. Supply a 28 dB 98 MHz signal from the ANTENN A terminal.

2. Tune the set to 98 MHz.

3. Adjust SFR101 to the point (moment) when the TUNED

indicator will change from going off to going on.

Adjustment Location: MAIN board

Adjustment Location

[MAIN BOARD] — Component side —

SFR101

(FM Tuned Level)

IC103

SFR809

(Tape speed)

L105

(AM Tuning

Voltage)

L103

(FM Tuning

Voltage)

IC301

JK101

TC102

L104

L102

TC101

(AM

Tracking)

(FM

Tracking

— 14 —

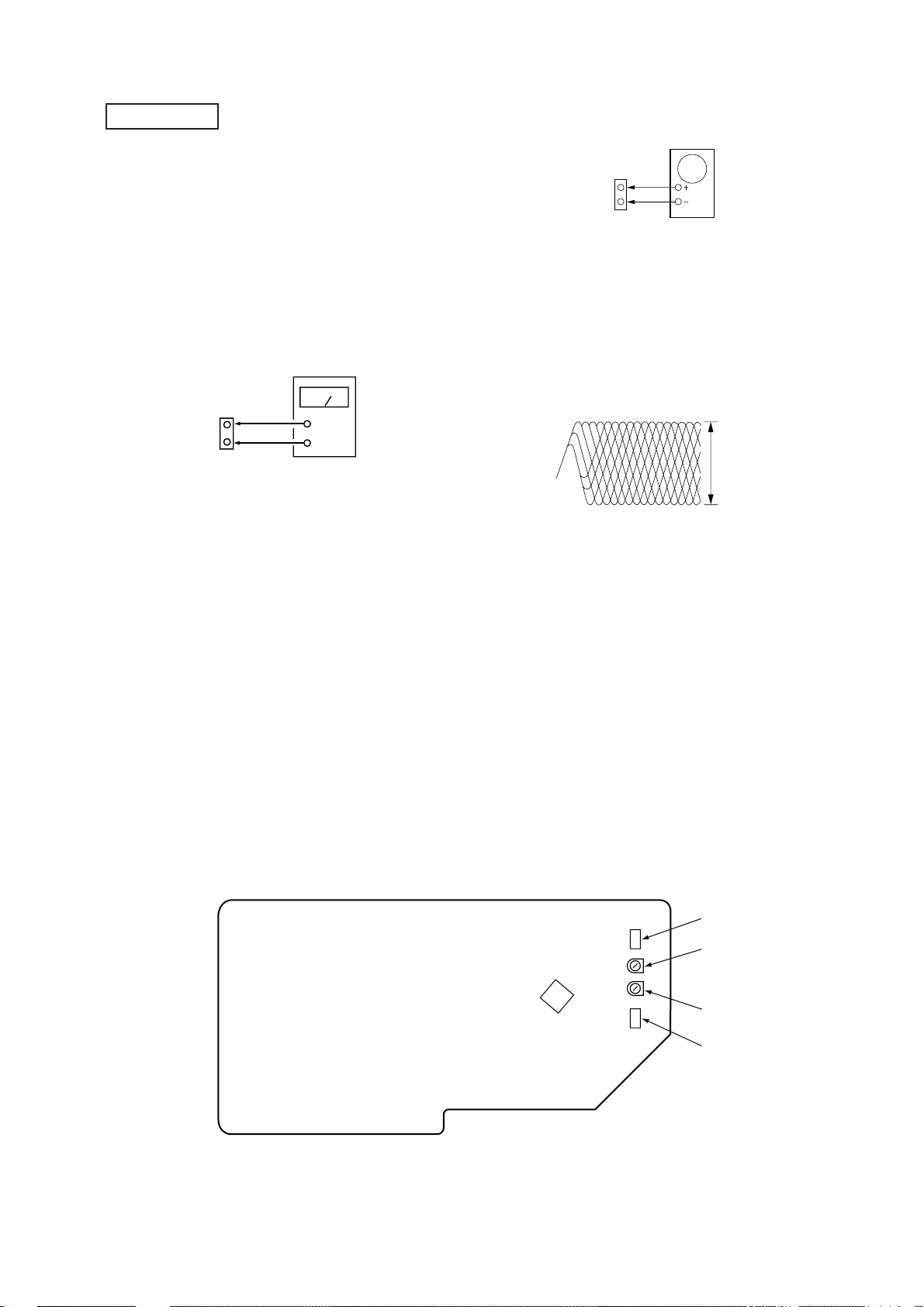

CD SECTION

)

Note:

1. CD Block is basically constructed to operate without

adjustment. Therefore, check each item in order given.

2. Use YEDS-18 disc (3-702-101-01) unless otherwise indicated.

3. Use an oscilloscope with more than 10MΩ impedance.

4. Clean the object lens by an applicator with neutral detergent

when the signal level is low than specified value with the

following checks.

5. Adjust the focus bias adjustment when optical block is replaced.

Focus Bias Adjustment

CD DECODER

board

TP02

FEO

VC

Procedure:

1. Connect DC voltmeter to test point TP02 on CD DECODER

board.

2. Turned Power switch on.

3. Put disc (YEDS-18) in and stop.

4. Adjust VR01 so that the DC voltmeter reading is 0 ± 20 mV.

DC voltmeter

+

–

RF Level Check

CD DECODER

board

TP01

RF

VC

oscilloscope

Procedure :

1. Connect oscilloscope to test point TP01 on CD DECODER

board.

2. Turned Power switch on.

3. Put disc (YEDS-18) in and playback.

4. Confirm that oscilloscope waveform is clear and check RF

signal level is correct or not.

Note: Clear RF signal waveform means that the shape “◊” can be

clearly distinguished at the center of the waveform.

VOLT/DIV: 200 mV

TIME/DIV: 500 nS

level: 1.0 Vp-p

+0.3

–0.2

Adjustment Location: CD DECODER board

Adjustment Location: CD DECODER board

Focus Gain Adjustment (VR02)

This gain has a margin, so even if it is slightly off.

There is no problem.

Therefore, do not perform this adjustment.

Please note that it should be fixed to mechanical center position

when you moved and do not know original position.

Adjustment Location

[CD DECODER BOARD] — Component side —

TP01

VR01

(Focus Bias)

IC01

VR02

(Focus Gain

TP02

— 15 —

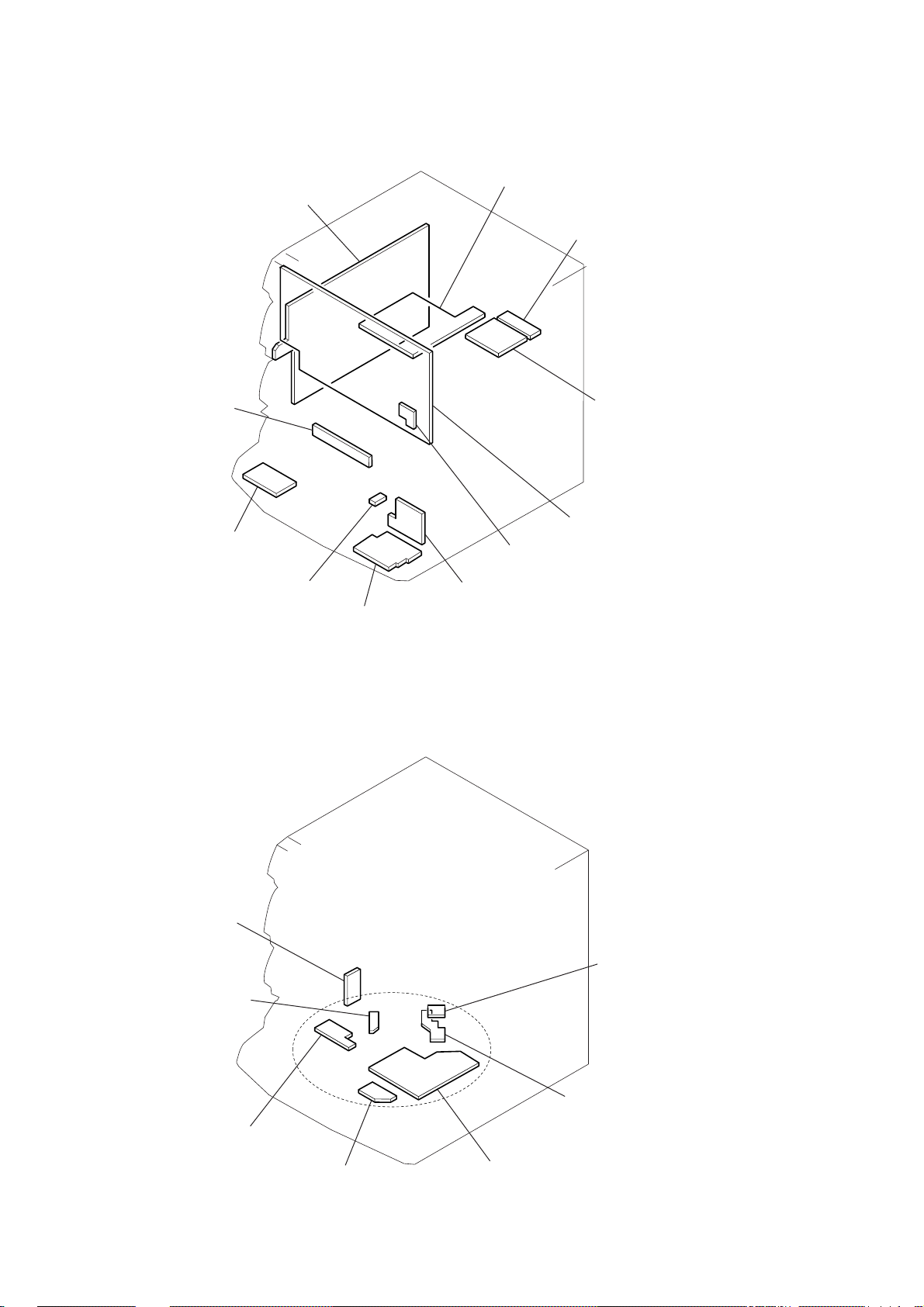

5-1. CIRCUIT BOARDS LOCATION

MAIN board

SECTION 5

DIAGRAMS

AMP board

POWER SELECT board

LED board

DISC board

DOOR SW board

POWER SUPPLY

board

FRONT board

VR board

PLAY SW board

JOG board

R/P SWITCH board

TABLE SENSOR board

MOTOR board

CONNECTOR board

— 16 —

DISC NO LED board

MOTOR (6P)(C) board

CD DECODER board

5-2. BLOCK DIAGRAM — DECK SECTION —

PHONO

TAPE B

TAPE A

HRP901

REC/PB

SECTION

SECTION

MECHANISM

BLOCK

SW201

S804

S804

S803

S802

S801

16

HP901

PB

HEAD

HEAD

HE901

ERASE

HEAD

A

TUNER

B

CD

M

JK301

L

R

TU MUTE

TABLE SENSOR

TU L

ST IND

CD L

SCOR

SENS

SQSO

XLAT

SQCK

DATA

COUNT

FOK

CLK

STB

DO

CE

DI

UP SW

R CH

R CHR CH

Q803,805

R CH

PLAY/REC

CONTROL

Q823

PLAY/REC

CONTROL

D803

SFR809

TAPE

SPEED

DRIVE

SFR807

SFR807

Q801

D802

REC +B

REC +B

A MOTOR +B

B PLAY +B

MOTOR +12V

IC402

PLAY/REC

CONTROL

SFR801

BIAS OSC

+12V

L805

BIAS

TRAP

L809

Q818

Q809

78

77

UP SW

TABLE SENSOR

6

5

9

7

Q816,817

BIAS

SWITCH

MUTE

CONT

91

STB

BIAS

OSC

CE

93CE97

EQ AMP

IC801

PB OUT

A/B

CLK

98

CLK

16

12

X601

6MHz

2

SFR803

3

DO

76

28

SO

FOK

COUNT

X217X1

Q803

10

MPX

14

Q807

REC

MUTE

MUTE

13

D805

D804

D801 D806

Q825,826

MUTE

CONT

B PLAY +B A MOTOR +B

Q819

95

97

34

96

75

27

XLAT

DATA

SQCK

SQSO

A

SENS

SCOR

81

VR601

VOLUME

VR UP

REC AMP

MUTE

15 1

89

3

SI

VR DOWN

82

B

PB/REC

AMP

IC802

D807

73

TU MUTE

FM ST IND

11

12

10

74

CD SYNC

FUNCTION TAPE

CD ENCODER A83CD ENCODER B

84

A

B

VR602

CD

ENCODER

BUFFER

CLK

98

ALATCH

Q811

Q813

MUTE

DI

SFR805

2

3

4

SW101

10k

9k

14

16

D808

LED DRIVE

IC602

+5.6V

HCD-G2500/XB20/XB22

SELECTOR

IC301

11

Q602

Q602

9

10

12

CONTROL

RESET

SWITCH

12

DI

RESET

CLK14DI15CE

CLK

16

CE

Q301

DOLBY

AMP

IC803

IC803

11

9

12

5

Q815

PB

MUTE

MUTE

D810

D809

Q820

Q822

LED601-609

16

SPANA

IC603

1

8

26

25

24

SPANA 3

SPANA 2

SPANA 1

Q605,606

SW

SYSTEM CONTROLLER/

MODE

68

S641

DOOR

514

FLD DRIVER

IC601

23

IC302

K 0

89

6

K1 K4

22 19

KEY

MATRIX

S601-624

S601-624

S626-640

LT COM

4

Q307

SURROUND

CONTROL

Q310

7

3 2

SURROUND

8

FLAT

ROCK

8

Q303

5

6

DBFB HIGH

DBFB NORMAL

Q311

MUTE

Q603

MUTE

SWITCH

Q601

Q601

POWER

DOWN DET

2

13

SYSTEM MUTE

1

POWER DOWN

Q604

MUTE

RM601

Q305

HIGH

Q308

NORMAL

3

REMOTE

CONTROL

RECEIVER

2

29

REMOTE

LINE AMP

4

3

D302

D602

IC303

Q402

POWER

MUTE

45

.

D303

47 50

2

Q410

MUTE

DRIVE

P1 P21

+30V

-30V

-12V

-27V

+12V

CD +7.5V

+12V

M +12V

.

52 67

FLD601

FLD DISPLAY

HP AMP

IC401

3

Q407

MUTE

Q709

MUTE

1

G1 G15

30 44

POWER AMP

IC701

3 11

Q401

-12V

REG

Q702

+7.5V

REG

Q409

+5.6V

REG

Q403

FILTER

Q405,406

SITCHING

1

POWER

Q703

-27V

REG

Q701

+12V

REG

Q712

P MUTE

CONT

D719

D714

Q706

Q708

Q711

AC OFF

DET

D701

RECT

D731,732

VOLTAGE

DOUBLER

D705-708

RECT

R CH

Q404

IC702

SP

RELAY

DRIVE

4

AC3.4V

AC3.4V

SP

DET

6

PT301

• RCH is omitted

• Signal Path

RL701

F702

F703

E, SP, MY, AR MODEL

: PB (DECK A)

: PB (DECK B)

: REC (DECK A)

: FM

: CD

+12V

1

2

SW401

JK401

PHONES

JK703

SPEAKER

AC

IN

: PHONO

— 17 — — 18 —

Loading...

Loading...