Sony HCDF-3-MD Service manual

HCD-F3MD

SERVICE MANUAL

HCD-F3MD is the Amplifier, CD player, MD

Deck and Tuner section in CMT-F3MD.

US and foreign patents licensed from Dolby

Laboratories.

CD

Section

MD

Section

E Model

Model Name Using Similar Mechanism HCD-MD373

CD Mechanism Type CDM55A-5SBD32

Base Unit Name BU-5SBD32

Optical Pick-up Name KSS-213BH/Z-NP

Model Name Using Similar Mechanism HCD-MD373

MD Mechanism Type MDM-5GA

Base Unit Name MBU-5A

Optical Pick-up Name KMS-260B/S1NP

Amplifier section

DIN power output (Rated):20 + 20 watts (6 ohms at 1 kHz,

Continuous RMS power output (Reference):

Peak Music Power Output:400 watts

Inputs

TAPE IN (phono jacks): voltage 250 mV, impedance

Outputs

TAPE OUT (phono jacks):voltage 250 mV, impedance

PHONES (stereo minijack):

SPEAKER: accepts impedance of 6 to 16

CD player section

System Compact disc and digital audio

Laser Semiconductor laser (λ=780 nm)

DIN, 240 V)

18 + 18 watts (6 ohms at 1 kHz,

DIN, 220 V)

25 + 25 watts (6 ohms at 1 kHz,

10% THD, 240 V)

23 + 23 watts (6 ohms at 1 kHz,

10% THD, 220 V)

47 kilohms

1 kilohm

accepts headphones of 8 ohms or

more.

ohms.

system

Emission duration: continuous

SPECIFICATIONS

Laser output Max. 44.6 µW*

Frequency response 2 Hz – 20 kHz

MD deck section

System MiniDisc digital audio system

Laser Semiconductor laser (λ=780 nm)

Laser output Max. 44.6 µW*

Sampling frequency 44.1 kHz

Frequency response 5 Hz –

T uner section

FM stereo, FM/AM superheterodyne tuner

FM tuner section

Tuning range 87.5 – 108.0 MHz

Aerial FM lead aerial

Aerial terminals 75 ohms unbalanced

Intermediate frequency 10.7 MHz

*This output is the value measured

at a distance of 200 mm from the

objective lens surface on the

Optical Pick-up Block with a

7 mm aperture.

Emission duration: continuous

*This output is the value measured

at a distance of 200 mm from the

objective lens surface on the

Optical Pick-up Block with a

7 mm aperture.

20 kHz

(50 kHz step)

COMPACT DISC DECK RECEIVER

AM tuner section

Tuning range 531 – 1,602 kHz

Aerial AM loop aerial

Intermediate frequency 450 kHz

General

Power requirements 110 – 120 V or 220 – 240 V

Power consumption 70 watts during normal operation

Dimensions (w/h/d) incl. projecting parts and controls

Mass

Design and specifications are subject to change

without notice.

(with the interval set at 9 kHz)

530 – 1,710 kHz

(with the interval set at 10 kHz)

External aerial terminals

AC, 50/60 Hz

Approx. 3 watts in standby mode

(clock displayed)

Approx. 1 watt in standby mode

(clock not displayed)

Approx. 215 × 150 × 335 mm

Approx. 4.9 kg

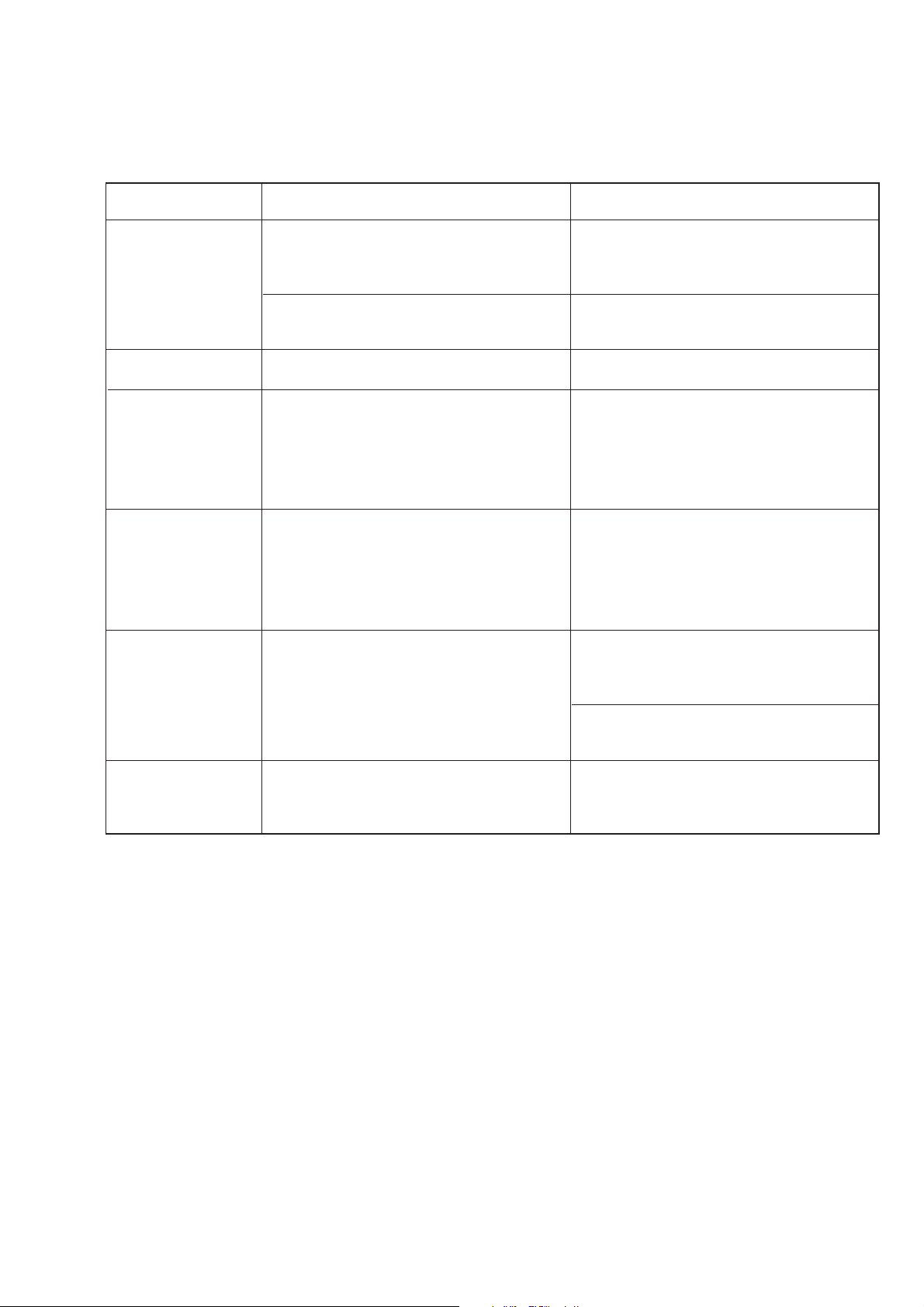

SELF-DIAGNOSIS FUNCTION

The self-diagnosis function consists of error codes for customers, which are displayed automatically when errors occur, and error codes,

which show the error history in the test mode during servicing. For details on how to view error codes for the customer, refer to the

following box in the instruction manual. For details on how to check error codes during servicing, refer to the following “Procedure for

using the Self-Diagnosis Function (Error History Display Mode)”.

C13/REC Error

Self-diagnosis Display

This system has a Self-diagnosis display function

to let you know if there is a system malfunction.

The display shows a code made up of three letters

and a message alternately to show you the

problem. To solve the problem refer to the

following list. If any problem persists, consult

your nearest Sony dealer.

C11/Protected

The MD is protected against erasure.

cRemove the MD and slide the tab to close the

slot (see page 24).

C12/Cannot Copy

You tried to record a CD or MD with a format

that the system does not support, such as a CDROM.

cRemove the disc and turn off the system once,

then turn it on again.

Recording could not be performed properly.

cMove the system to a stable place, and start

recording over from the beginning.

The MD is dirty or scratched, or the MD does

not meet the standards.

cReplace the MD and start recording over from

the beginning.

C13/Read Error

The MD deck cannot read the disc information

properly.

cRemove the MD once, then insert it again.

C14/Toc Error

The MD deck cannot read the disc information

properly.

cReplace the MD.

cErase all the recorded contents of the MD

using the All Erase function on page 38.

C41/Cannot Copy

The sound source is a copy of a commercially

available music software, or you tried to record

a CD-R (Recordable CD).

cThe Serial Copy Management System

prevents making a digital copy (see page 53).

You cannot record a CD-R.

PROCEDURE FOR USING THE SELF-DIAGNOSIS FUNCTION (ERROR HISTORY DISPLAY MODE)

Note 1: About “R”

As this unit has only a few buttons, some operations require the use of remote commander (RM-SF3MD/provided with unit: 1-476-068-11)

buttons. These operations are indicated as “R” in this manual.

Example: MENU/NO “R” ...Press the [MENU/NO] button of the remote commander.

Note 2: Incor rect operations may be performed if the MD test mode is not entered properly.

In this case, press the I/1 button to turn the power off, and retry to enter the MD test mode.

Note 3: Perform the self-diagnosis function in the “error history display mode” in the MD test mode. The following describes the least required

procedure. Be careful not to enter other modes by mistake. If you set other modes accidentally, press the MENU/NO “R” button to exit the

mode.

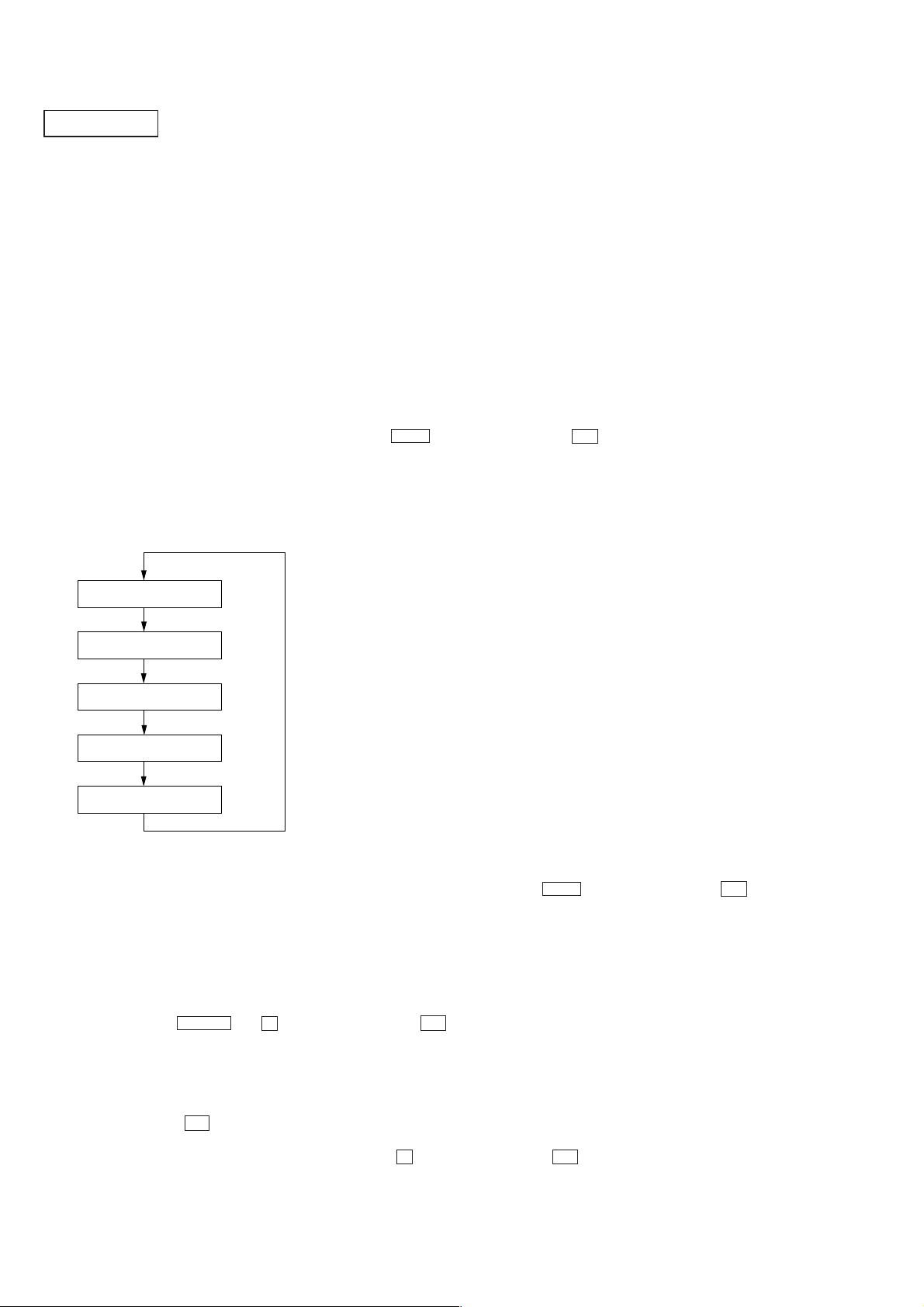

Procedure:

1. Press the I/1 button to turn the power on.

2. Press the [FUNCTION] button to set the MD function.

3. Press three buttons of s (MD) , zREC and I/1 simultaneously to enter the MD test mode and display “[Check]”.

4. Press the l m or M L button to display “[Service]”, and press the ENTER/YES “R” button.

5. Press the l m or M L button to display “ERR DP MODE”.

6. Press the ENTER/YES “R” button to enter the error history mode and display “total rec”.

7. Select the contents to be displayed or executed using the l m or M L button.

8. Press the [CD-MD SYNC] button will display or execute the contents selected.

9. Press the [CD-MD SYNC] button another time returns to step 7.

10. Press the MENU/NO “R” button displays “ERR DP MODE” and release the error history mode.

11. To release the MD test mode, press the [REPEAT] button to display “Initialize” and release the MD test mode.

2

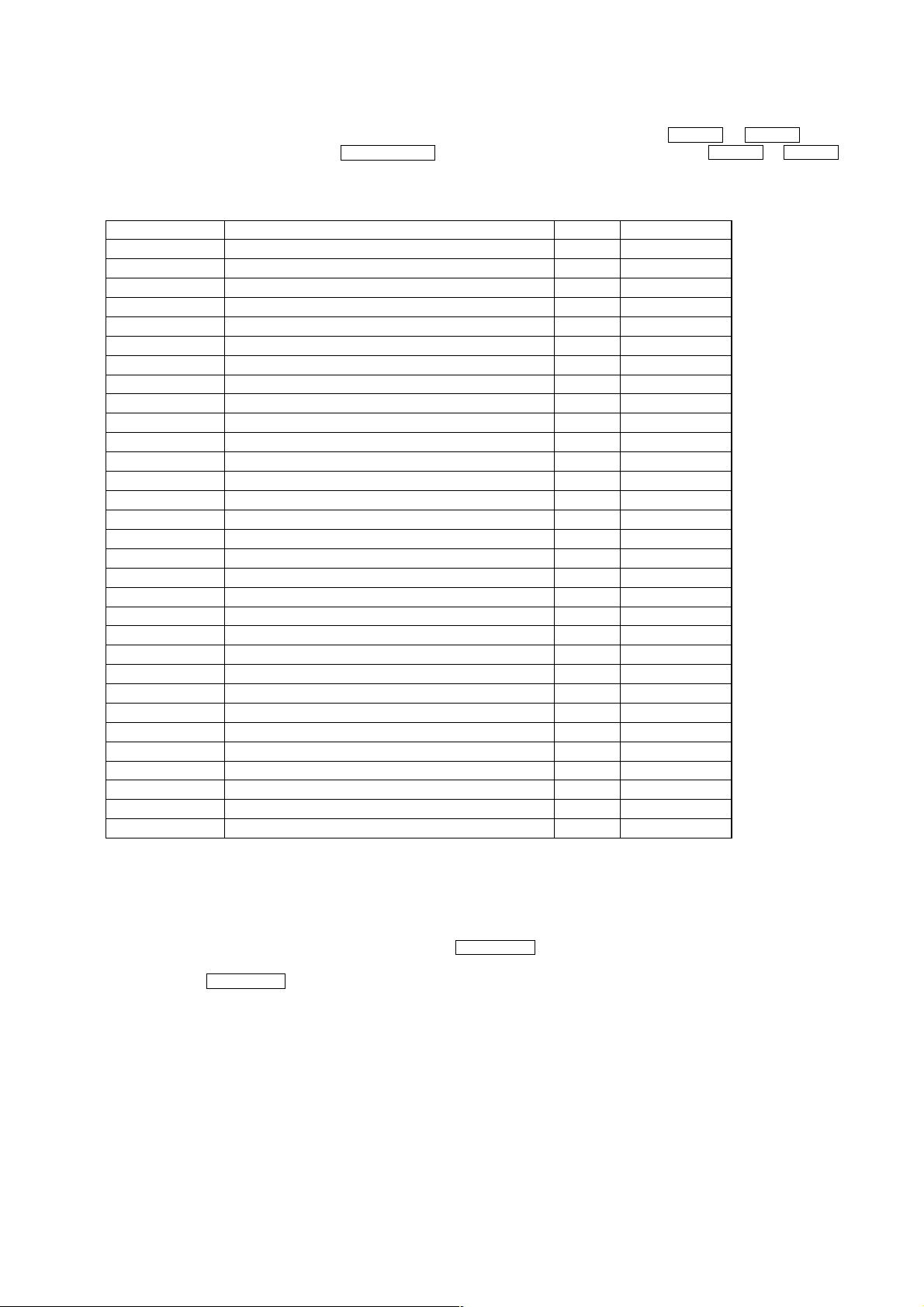

ITEMS OF ERROR HISTORY MODE ITEMS AND CONTENTS

Selecting the Test Mode

Display

total rec Displays the recording time.

Displayed as “rssssssh”.

The displayed time is the total time the laser is set to the high power state.

This is about 1/4 of the actual recording time.

The time is displayed in decimal digits from 0h to 65535h.

total play Displays the play time.

Displayed as “pssssssh”. The time displayed is the total actual play time. Pauses are not counted.

The time is displayed in decimal digits from 0h to 65535h.

retry err Displays the total number of retries during recording and number of retry errors during play.

Displayed as “rss pss”.

“r” indicates the retries during recording while “p” indicates the retry errors during play.

The number of retries and retry errors are displayed in hexadecimal digits from 00 to FF.

total err Displays the total number of errors.

Displayed as “total ss”.

The number of errors is displayed in hexadecimal digits from 00 to FF.

err history Displays the 10 latest errors.

Displayed as “0s E@@”.

s indicates the history number. The smaller the number, the more recent is the error. (00 is the latest).

@@ indicates the error code.

Refer to the following table for the details. The error history can be switched by pressing the

M L button.

er refresh Mode which erases the “retry err”, “total err”, and “err history” histories.

When returning the unit to the customer after completing repairs, perform this to erase the past error history.

After pressing the

erase the history.

“Complete!” will be displayed momentarily.

Be sure to check the following when this mode has been executed.

• The data has been erased.

• The mechanism operates normally when recording and play are performed.

tm refresh Mode which erases the “total rec” and “total play” histories.

These histories serve as approximate indications of when to replace the optical pick-up.

If the optical pickup has been replaced, perform this operation and erase the history.

After pressing the

erase the history.

“Complete!” will be displayed momentarily.

Be sure to check the following when this mode has been executed.

• The data has been erased.

• The mechanism operates normally when recording and play are performed.

[CD-MD SYNC] button and “er refresh?” is displayed, press the ENTER/YES “R” button to

[CD-MD SYNC] button and “tm refresh?” is displayed, press the ENTER/YES “R” button to

Details of History

l m or

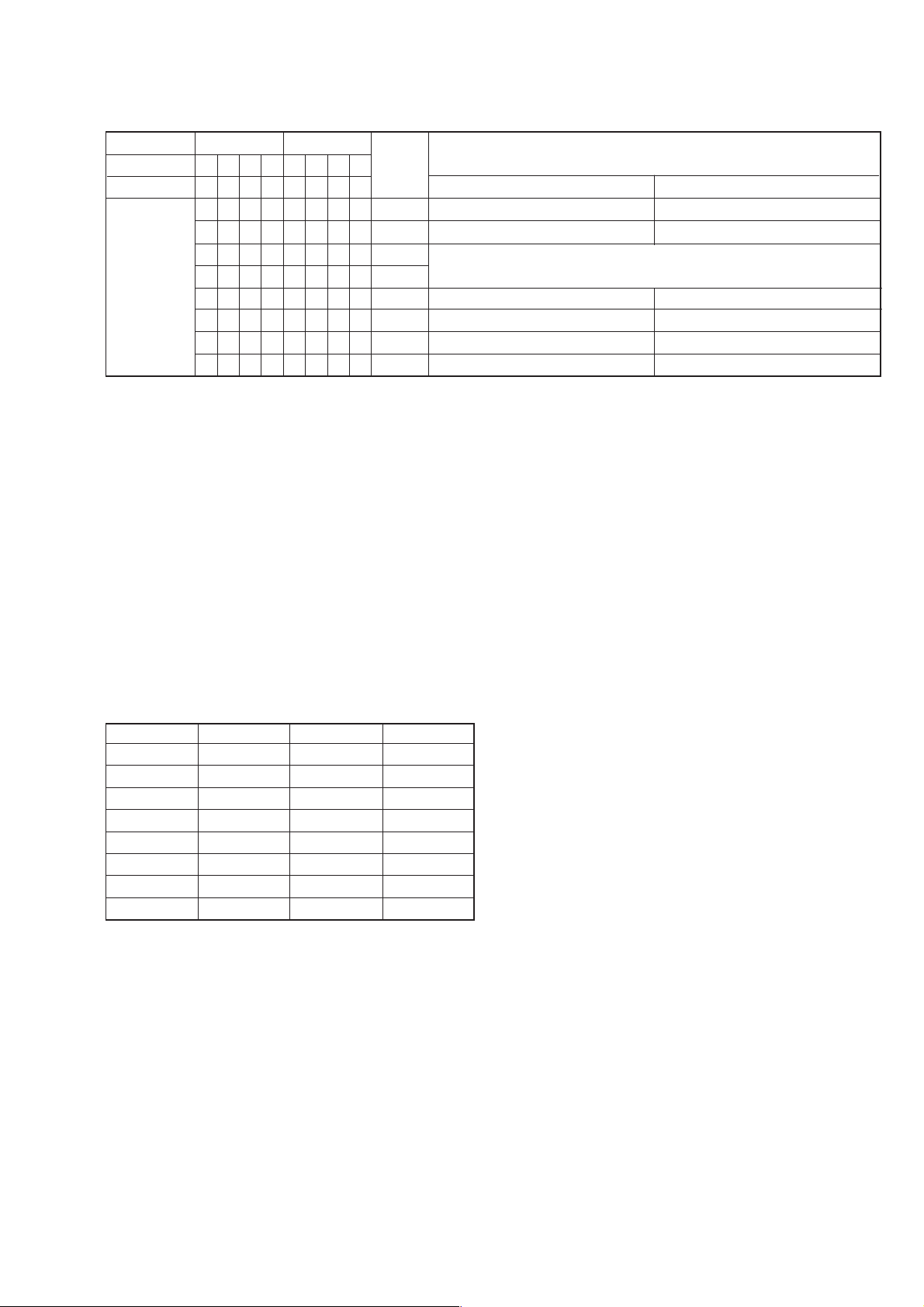

Table of Error Codes

Error Code Error Code Details of Error

E00 No error

E01 Disc error. PTOC cannot be read

(DISC ejected)

E02 Disc error. UTOC error

(DISC not ejected)

E03 Loading error

E04 Address cannot be read (Servo has deviated)

Details of Error

E05 FOK has deviated

E06 Cannot focus (Servo has deviated)

E07 Recording retry

E08 Recording retry error

E09 Playback retry error

(Access error)

E0A Playback retry error (C2 error)

3

TABLE OF CONTENTS

SELF-DIAGNOSIS FUNCTION..................................... 2

1. SERVICING NOTES ............................................... 5

2. GENERAL ................................................................... 16

3. DISASSEMBLY ......................................................... 18

4. TEST MODE ............................................................... 26

5. ELECTRICAL ADJUSTMENTS

MD Section ..................................................................... 30

CD Section ...................................................................... 38

6. DIAGRAMS

6-1. Block Diagram – CD SERVO Section – ....................... 39

6-2. Block Diagram – MD SERVO Section (1/2) – ............. 40

6-3. Block Diagram – MD SERVO Section (2/2) – ............. 41

6-4. Block Diagram – MAIN Section –................................ 42

6-5. Note for Printed Wiring Boards and

Schematic Diagrams ....................................................... 43

6-6. Printed Wiring Board – BD (CD) Board – .................... 44

6-7. Schematic Diagram – BD (CD) Board –....................... 45

6-8. Schematic Diagram – BD (MD) Board (1/2) –............. 46

6-9. Schematic Diagram – BD (MD) Board (2/2) –............. 47

6-10. Printed Wiring Board – BD (MD) Board – ................... 48

6-11. Schematic Diagram – BD SW (MD) Board – ............... 49

6-12. Printed Wiring Board – BD SW (MD) Board – ............ 49

6-13. Schematic Diagram – LOADING (CD) Board – .......... 49

6-14. Printed Wiring Board – LOADING (CD) Board – ....... 49

6-15. Printed Wiring Board – MD DIGITAL Board – ........... 50

6-16. Schematic Diagram – MD DIGITAL Board – .............. 51

6-17. Printed Wiring Board – MAIN Board – ........................ 52

6-18. Schematic Diagram – MAIN Board (1/3) – .................. 53

6-19. Schematic Diagram – MAIN Board (2/3) – .................. 54

6-20. Schematic Diagram – MAIN Board (3/3) – .................. 55

6-21. Printed Wiring Boards – AMP/SP Boards –.................. 56

6-22. Schematic Diagram – AMP/SP Boards – ...................... 57

6-23. Printed Wiring Board – PANEL Board – ...................... 58

6-24. Schematic Diagram – PANEL Board – ........................ 59

6-25. Printed Wiring Board – POWER Board –..................... 60

6-26. Schematic Diagram – POWER Board – ........................ 61

6-27. IC Pin Function Description ........................................... 70

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be dam-

aged by heat.

Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270 ˚C during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

CAUTION

Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous radiation exposure.

This appliance is classified as a CLASS 1 LASER product.

The CLASS 1 LASER PRODUCT MARKING is located on

the rear exterior.

Laser component in this product is capable of emitting radiation

exceeding the limit for Class 1.

The following caution label is located inside the unit.

7. EXPLODED VIEWS................................................ 80

8. ELECTRICAL PARTS LIST ............................... 86

4

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED

LINE WITH MARK 0 ON THE SCHEMATIC DIAGRAMS

AND IN THE PARTS LIST ARE CRITICAL TO SAFE

OPERATION. REPLACE THESE COMPONENTS WITH

SONY PARTS WHOSE PART NUMBERS APPEAR AS

SHOWN IN THIS MANUAL OR IN SUPPLEMENTS PUBLISHED BY SONY.

SECTION 1

SERVICING NOTES

NOTES ON HANDLING THE OPTICAL PICK-UP

BLOCK OR BASE UNIT

The laser diode in the optical pick-up block may suffer electrostatic break-down because of the potential difference generated

by the charged electrostatic load, etc. on clothing and the human

body.

During repair, pay attention to electrostatic break-down and also

use the procedure in the printed matter which is included in the

repair parts.

The flexible board is easily damaged and should be handled with

care.

For CD

NOTES ON LASER DIODE EMISSION CHECK

The laser beam on this model is concentrated so as to be focused

on the disc reflective surface by the objective lens in the optical

pick-up block. Therefore, when checking the laser diode emission, observe from more than 30 cm away from the objecti ve lens.

LASER DIODE AND FOCUS SEARCH OPERATION

CHECK

Carry out the “S curve check” in “CD section adjustment” and

check that the S curve waveforms is output three times.

For MD

NOTES ON LASER DIODE EMISSION CHECK

Never look into the laser diode emission from right above when

checking it for adjustment. It is feared that you will lose your sight.

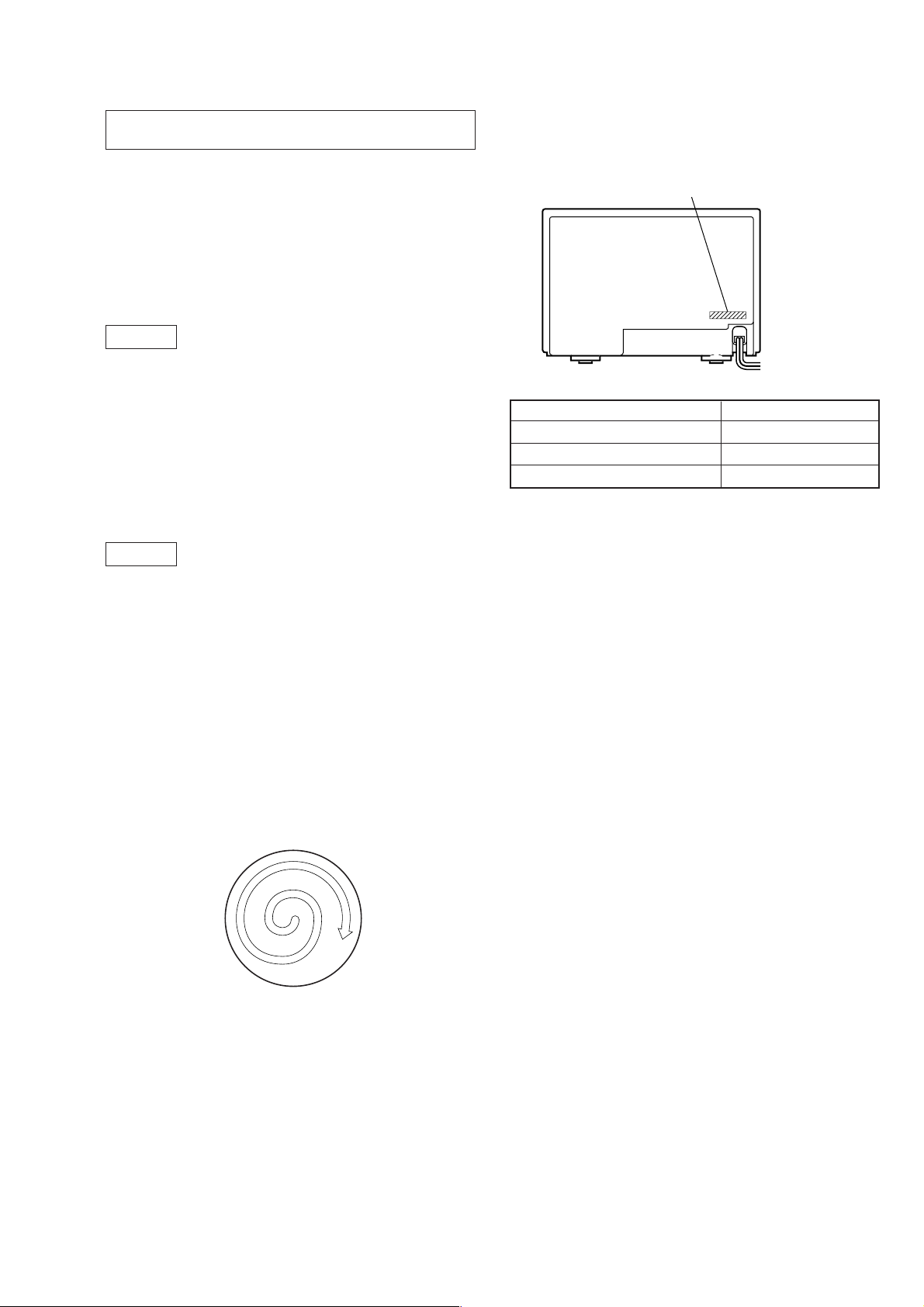

MODEL IDENTIFICATION

— Back panel —

PART No.

Model Part No.

Hong Kong model 4-229-548-1[]

Korean model 4-232-128-0

Taiwan model 4-232-129-0

[]

[]

CLEANING OBJECTIVE LENS OF OPTICAL PICK-UP

• In cleaning the objective lens of optical pick-up, be sure the

following below.

1. In cleaning the lens, do not apply an excessive force.

As the optical pick-up is vulnerable, application of excessive

force could damage the lens holder.

2. In cleaning, do not use a cleaner other than exclusive cleaning

liquid (KK-91 or isopropyl alcohol).

3. Wipe the objective lens spirally from center toward outside.

(See Figure A)

(Figure A)

4. Eject the disk, if loaded.

5. Disconnect the power cord from the socket to shut off the po wer

supply.

6. When cleaning the objective lens of optical pick-up in CD,

refer to “HOLDER (BU) ASS’Y” on page 24 for removing

HOLDER (BU) ASS’Y.

5

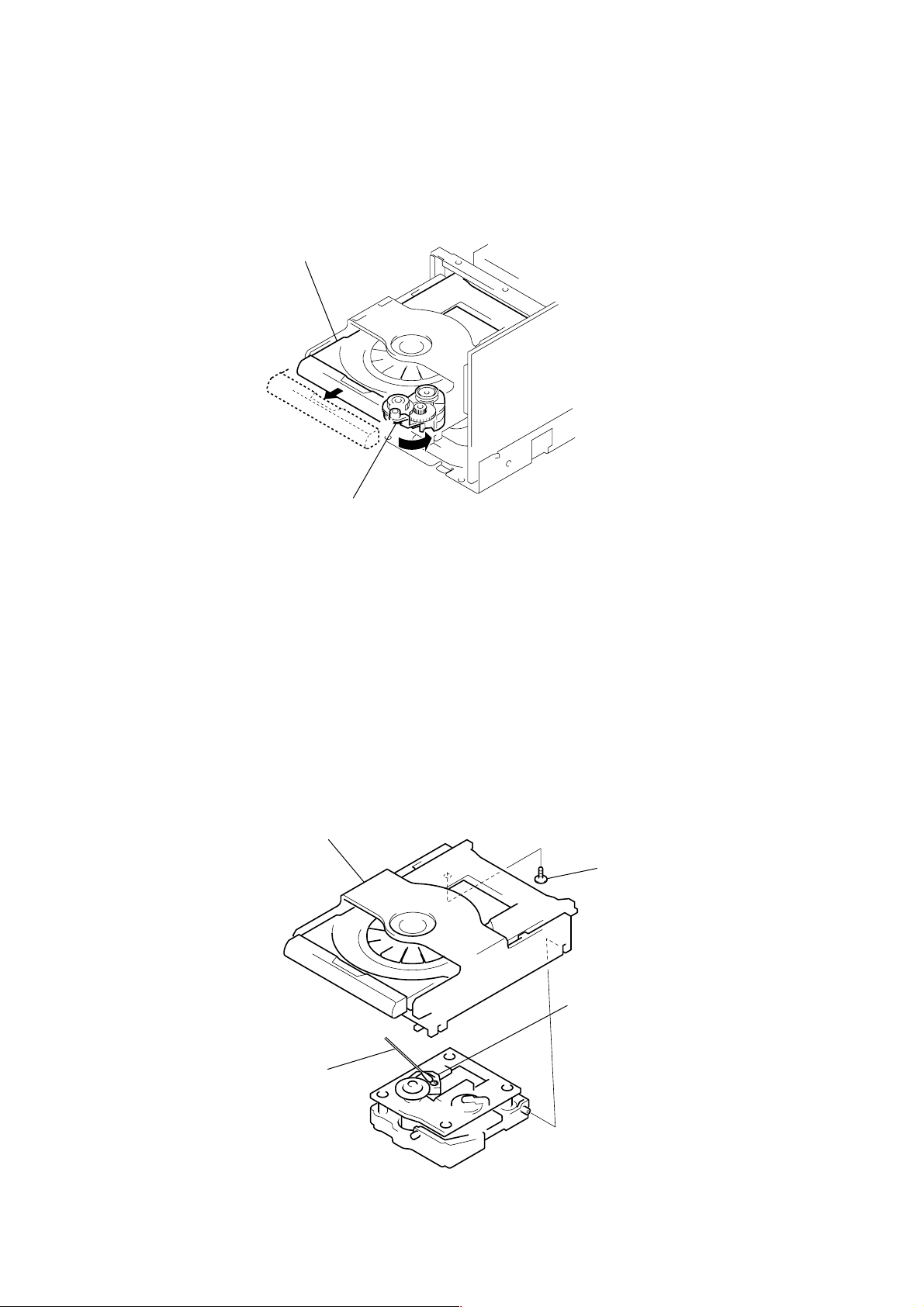

DRAWING OUT THE TRAY WHEN THE POWER IS OFF

tray (CDM)

A

Move the cam block in the direction

of arrow

A

with a finger.

CLEANING THE OPTICAL PICK-UP (CD PLAYER)

CD mechanism deck

Clean the lens block

with a cotton bud.

floating screw

(PTPWH M2.6)

optical pick-up block

6

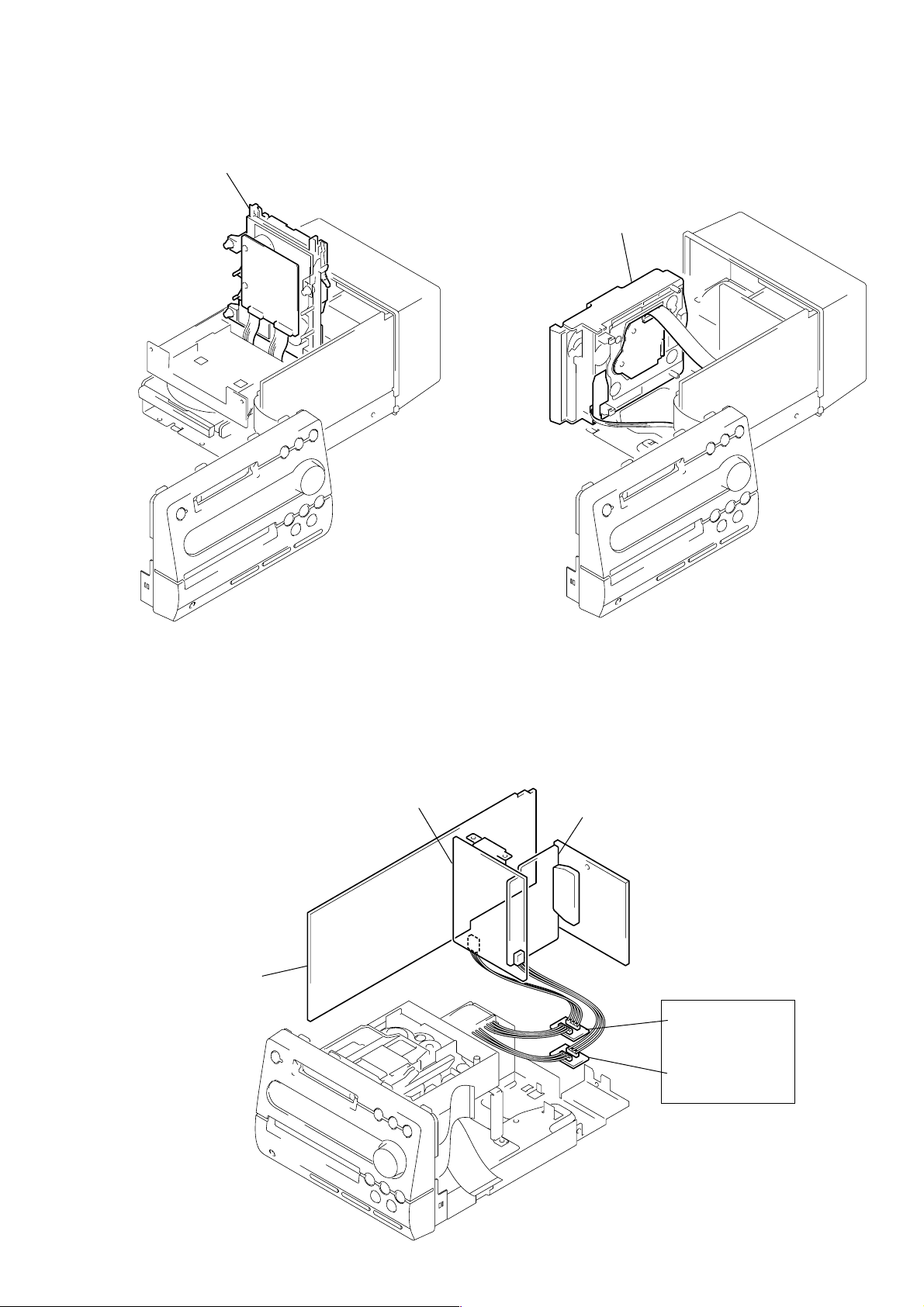

SERVICE POSITION OF THE MD MECHANISM

DECK

MD mechanism deck

SERVICE POSITION OF THE CD MECHANISM

DECK

CD mechanism deck

SERVICE POSITION OF THE POWER BOARD

POWER board

CN993

MAIN board

AMP board

CN802

Extension cable (4P)

(J-2501-042-A)

Extension cable (3P)

(J-2501-045-A)

7

MC COLD RESET

• The cold reset clears all data including preset data stored in the RAM to initial conditions. Execute this mode when returning the set to

the customer.

Procedure:

1. Press the I/1 button to turn the power on.

2. While pressing the [PLAY MODE/TUNING MODE] and s (CD) buttons, press the I/1 button.

3. The set is reset, and displays “COLD RESET”, then becomes standby status.

MC HOT RESET

• This mode resets the set with the preset data kept stored in the memory . The hot reset mode function is same as if the po wer cord is plugged

in and out.

Procedure:

1. Press the I/1 button to turn the power on.

2. While pressing the [PLAY MODE/TUNING MODE] and HS (CD) buttons, press the I/1 button.

3. The set is reset, and becomes standby state.

LED/FLUORESCENT INDICATOR TUBE AND KEY TEST

Procedure:

1. Press the I/1 button to turn the power on.

2. While pressing the [PLAY MODE/TUNING MODE] and A (CD) buttons, press the I/1 button.

3. LEDs and fluorescent indicator tube are all turned on.

4. Press the HS (MD) button to enter the key test mode, and display “Key0 Vol0”.

5. Each time a button is pressed, “Key” value increases. However, once a button is pressed, it is no longer taken into account.

“Vol” value increases like 0, 1, 2 ... if turn the [VOLUME] knob clockwise, or it decreases like 9, 8, 7 ... if turn the [VOLUME] knob

counterclockwise.

6. To release from this mode, press three buttons in the same manner as step 2, or disconnect the power cord.

Note: l m and M L buttons are no longer taken into account, if it pressed within for a second.

CHANGE-OVER THE AM TUNING INTERVAL

• The AM tuning interval can be changed over 9 kHz or 10 kHz.

Procedure:

1. Press the I/1 button to turn the power on.

2. Press the

3. Press the I/1 button to turn the power off.

4. When the power off, press the I/1 button while pressing the [PLAY MODE/TUNING MODE] button, and the display of fluorescent

indicator tube changes to “AM 9k STEP” or “AM 10k STEP”, and thus the tuning interval is changed over.

[FUNCTION] button to set the TUNER function, and press the [TUNER/BAND] button to select the band “AM”.

8

MD SECTION

r

3

5

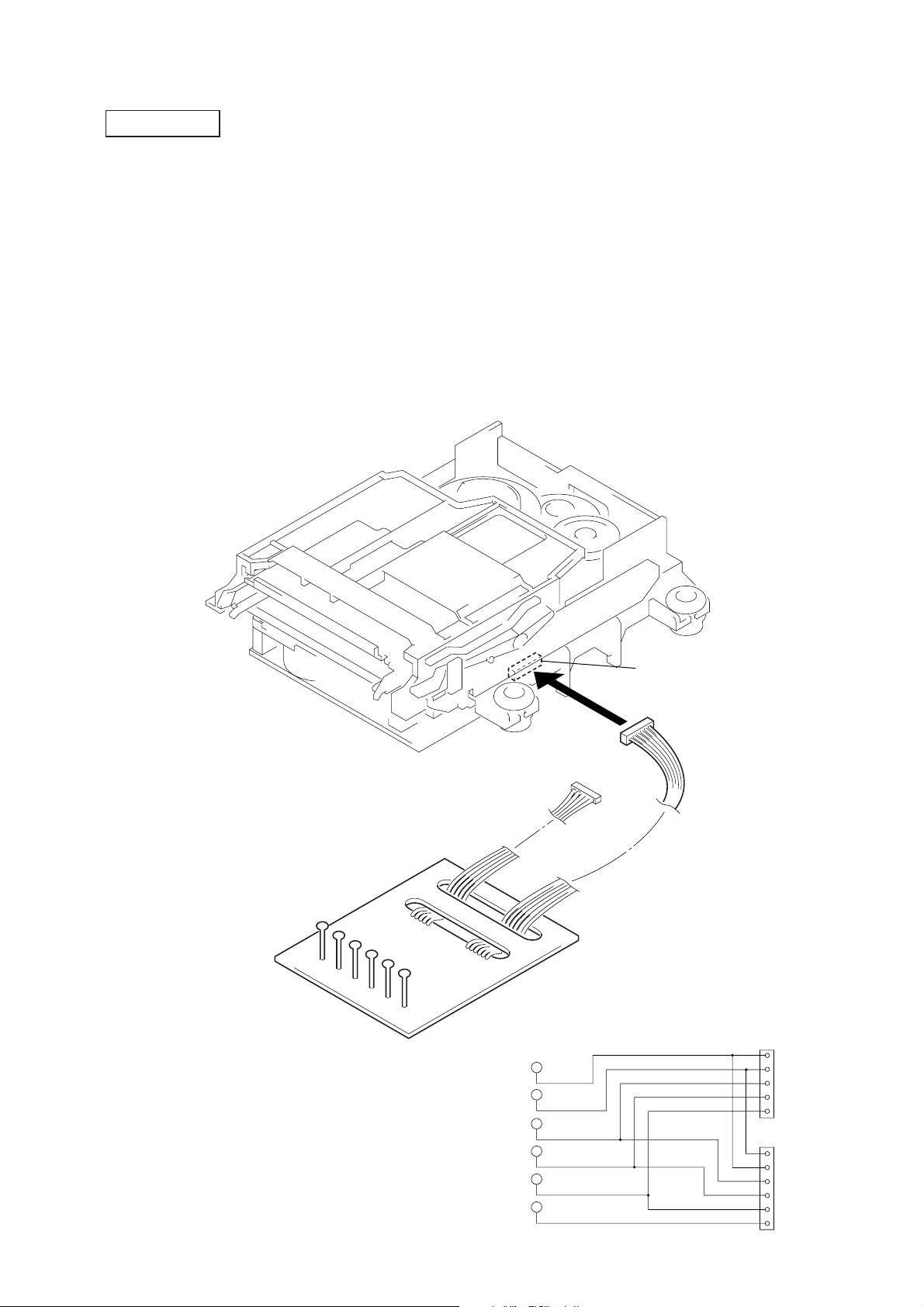

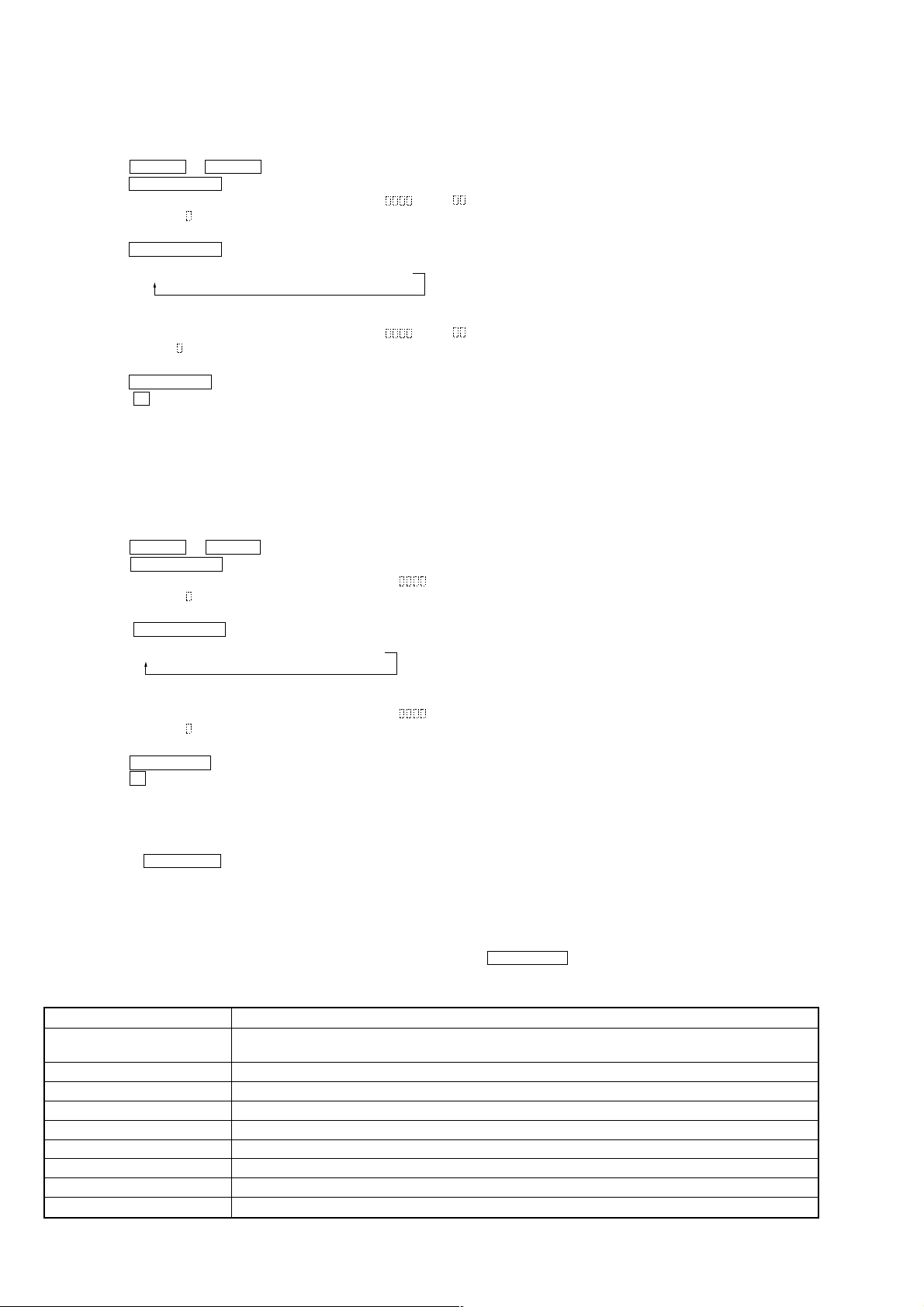

JIG FOR CHECKING BD (MD) BOARD WAVEFORM

The special jig (J-2501-149-A) is useful for checking the waveform of the BD (MD) board. T he names of terminals and the checking items

to be performed are shown as follows.

GND: Ground

I+3V : For measuring IOP (Check the deterioration of the optical pick-up laser)

IOP : For measuring IOP (Check the deterioration of the optical pick-up laser)

TEO : Tracking error signal (Traverse adjustment)

VC : Reference level for checking the signal

RF : RF signal (Check jitter)

Mechanism deck

RF

VC

TEO

IOP

I+3V

GND

RF

VC

TEO

5P connector

CN110

6P connecto

1

RF

VC

for

TEO

MDM-

IOP

I+3V

5

1

IOP

I+3V

GND

VC

RF

for

TEO

IOP

MDM-

I+3V

6

GND

9

Note : About “R”

As this unit has only a few buttons, some operations require the use of remote commander (RM-SF3MD/provided with unit: 1-476-068-11)

buttons. These operations are indicated as “R” in this manual.

Example: MENU/NO “R” ...Press the [MENU/NO] button of the remote commander.

IOP DATA RECORDING AND DISPLAY WHEN OPTICAL PICK-UP AND NON-VOLATILE MEMORY (IC171 ON THE BD

(MD) BOARD) ARE REPLACED

The IOP value labeled on the optical pick-up can be recorded in the non-volatile memory. By recording the value, it will eliminate the need

to look at the value on the label of the optical pick-up. When replacing the optical pick-up or non-v olatile memory (IC171 on the BD (MD)

board), record the IOP value on the optical pick-up according to the following procedure.

Record Procedure:

1. Press the I/1 button to turn the power on.

2. Press the [FUNCTION] button to set the MD function.

3. While pressing the s (MD) and zREC buttons, press the I/1 button to enter the MD test mode and display “[Check]”.

4. Press the l m or M L button to display “[Service]”, and press the ENTER/YES “R” button.

5. Press the l m or M L button to display “Iop Write”, and press the ENTER/YES “R” button.

6. The display becomes “Ref=@@@.@” (@ is an arbitrary number) and the numbers which can be changed will blink.

7. Input the IOP value written on the optical pick-up.

To select the number : Press the l m or M L button.

To select the digit : Press the [SYNC REC] button.

8. When the ENTER/YES “R” button is pressed, the display becomes “Measu=@@@.@” (@ is an arbitrary number).

9. As the adjustment results are recorded for the step7 value. Leave it as it is and press the ENTER/YES “R” button.

10. “Complete!” will be displayed momentarily. The value will be recorded in the non-volatile memory and the display will become “Iop

Write”.

11. Press the [REPEAT] button to complete. “Standby” will be displayed.

Display Procedure:

1. Press the I/1 button to turn the power on.

2. Press the [FUNCTION] button to set the MD function.

3. While pressing the s (MD) and zREC buttons, press the I/1 button to enter the MD test mode and display “[Check]”.

4. Press the l m or M L button to display “[Service]”, and press the ENTER/YES “R” button.

5. Press the l m or M L button to display “Iop Read”, and press the ENTER/YES “R” button.

6. “@@.@/##.#” is displayed and the recorded contents are displayed.

@@.@: indicates the Iop value labeled on the pick-up.

##.# : indicates the Iop value after adjustment

7. To release, press the [CD-MD SYNC] button or MENU/NO “R” button to display “Iop Read”. Then press the [REPEAT] button to

display “Standby”.

10

CHECKS PRIOR TO PARTS REPLACEMENT AND ADJUSTMENTS

Before performing repairs, perform the following checks to determine the faulty locations up to a certain extent.

Details of the procedures are described in “5 Electrical Adjustments”.

Laser power check

(5-6-2 : See page 32)

Traverse check

(5-6-3 : See page 32)

Focus bias check

(5-6-4 : See page 33)

C PLAY check

(5-6-5 : See page 33)

Self-recording/playback

check

(5-6-6 : See page 33)

Temperature

compensation

offset check

(5-6-1 : See page 32)

Criteria for Determination

(Unsatisfactory if specified value is not satisfied)

• 0.9 mW power

Specified value : 0.84 to 0.92 mW

• 7.0 mW power

Specified value : 6.8 to 7.2 mW

lop (at 7mW)

• Labeled on the optical pickup

Iop value ± 10mA

• Traverse waveform

Specified value : Below 10% offset

• Error rate check

Specified value : For points A, B

C1 error : About 200

AD error : Below 2

For point C

C1 error : Below 50

AD error : Below 2

• Error rate check

Specified value:

a. When using test disc (MDW-74/AU-1)

C1 error : Below 80

AD error : Below 2

b. When using check disc (TDYS-1)

C1 error : Below 50

• CPLAY error rate check

Specified value:

C1 error : Below 80

AD error : Below 2

• Unsatisfactory if displayed as T=@@ (##) [NG”

NG

(@@, ## are both arbitrary numbers)

• Clean the optical pick-up

• Adjust again

• Replace the optical pick-up

• Replace the optical pick-up

• Replace the optical pick-up

• Replace the optical pick-up

• Replace the optical pick-up

If always unsatisfactory:

• Replace the overwrite head

• Check for disconnection of the circuits around the

overwrite head

If occasionally unsatisfactory:

• Check if the overwrite head is distorted

• Check the mechanism around the sled

• Check for disconnection of the circuits around

D101 (BD (MD) board)

• Check the signals around IC101, IC121, CN102,

CN103 (BD (MD) board)

Measure if unsatisfactory:

Note:

The criteria for determination above is intended merely to determine if satisfactory or not, and does not serve as the specified value for adjustments.

When performing adjustments, use the specified values for adjustments.

11

RETRY CAUSE DISPLAY MODE

• In this test mode, the causes for retry of the unit during recording can be displayed on the fluorescent indicator tube. During playback,

the “track mode” for obtaining track information will be set.

This is useful for locating the faulty part of the unit.

• The following will be displayed :

During recording and stop: Retry cause, number of retries, and number of retry errors.

During playback : Information such as type of disc played, part played, copyright.

These are displayed in hexadecimal.

Procedure:

1. Load a recordable disc whose contents can be erased into the unit.

2. Press the MENU/NO “R” button. When “Edit Menu” is displayed on the fluorescent indicator tube, press the l m or M L

button to display “All Erase?”.

3. Press the ENTER/YES “R” button.

4. When “All Erase??” is displayed on the fluorescent indicator tube, the music calendar number blinks.

5. Press the ENTER/YES “R” button to display “Complete!!”, and press the s (MD) button immediately. Wait for about 10 seconds

while pressing the button.

6. When the “TOC” displayed on the fluorescent display tube goes off, release the s (MD) button.

7. Press the zREC button to start recording. Then press the HS (MD) button and start recording. If recording cannot be performed,

press the [FUNCTION] button and set a different function.

8. To check the “track mode”, press the HS (MD) button to start play.

9. To release the test mode, press the I/1 button, and turn the power off. When “TOC” disappears, disconnect the power plug from the

outlet. If the test mode cannot be released, refer to “MC COLD RESET” on page 8).

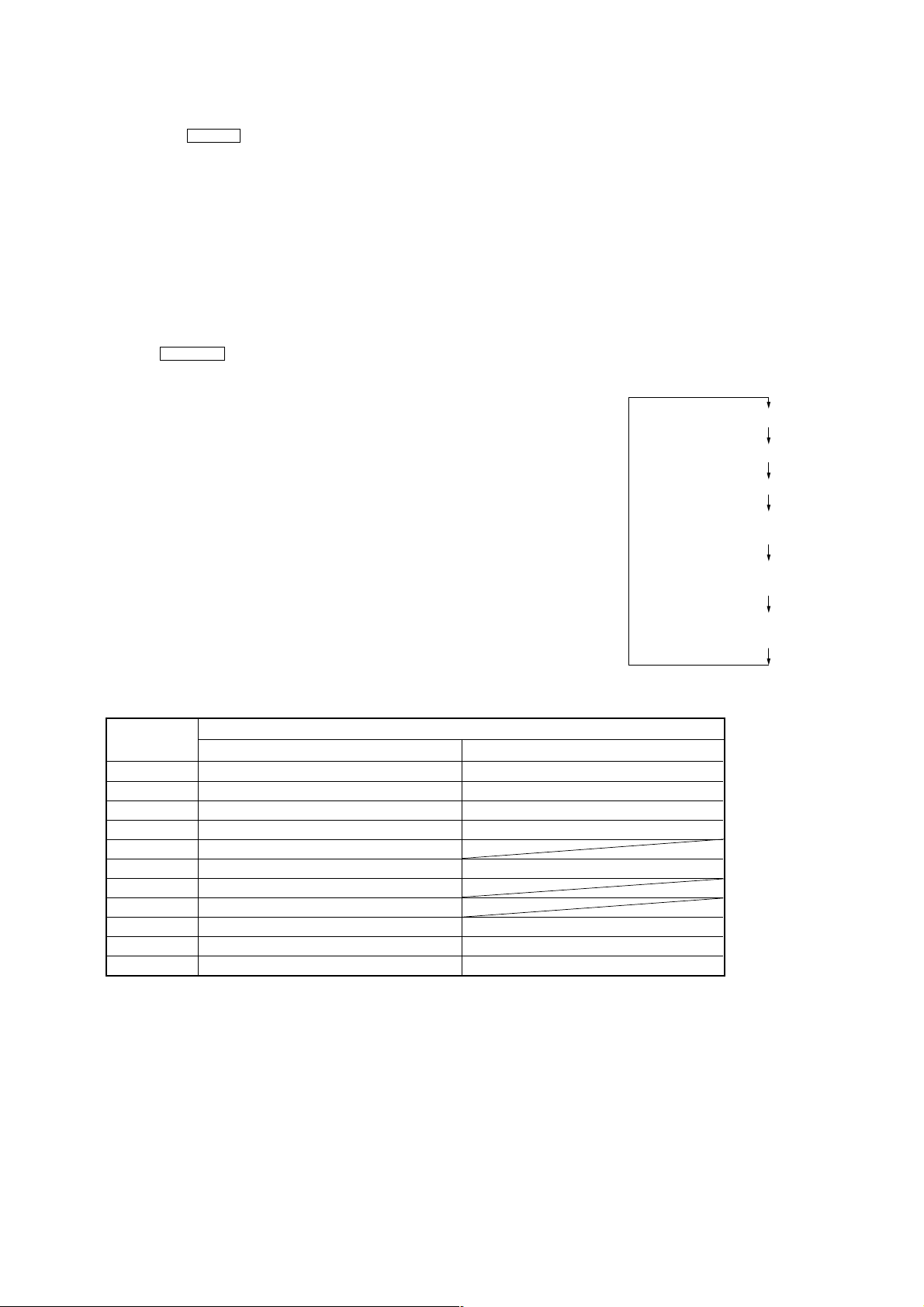

Fig. 1 Reading the Test Mode Display

(During recording and stop)

RTs@@c##e

Fluorescent indicator tube display

@@ : Cause of retry

## : Number of retries

: Number of retry errors

**

Reading the Retry Cause Display

Higher Bits Lower Bits

Hexadecimal

Bit

Binary

84218421

b7 b6 b5 b4 b3 b2 b1 b0

00000001

00000010

00000100

00001000

00010000

00100000

01000000

10000000

**

Hexa-

decimal

01

02

04

08

10

20

40

80

Cause of Retry

shock

ader5

Discontinuous address

DIN unlock

FCS incorrect

IVR rec error

CLV unlock

Access fault

Fig. 2 Reading the Test Mode Display

(During playback)

@@ ###

Fluorescent indicator tube display

@@ : Parts No. (name of area named on TOC)

## : Cluster

: Sector

**

$$ : Track mode (Track information such as copy-

right information of each part)

When track jump (shock) is detected

When ADER was counted more than five times

continuously

When ADIP address is not continuous

When DIN unlock is detected

When not in focus

When ABCD signal le v el e xceeds the specified range

When CLV is unlocked

When access operation is not performed normally

Address

Occurring conditions

**

$$

Reading the Display:

Convert the hexadecimal display into binary display. If more than two causes, they will be added.

Example

When 42 is displayed:

Higher bit: 4 = 0100 t b6

Lower bit : 2 = 0010 t b1

In this case, the retry cause is combined of “CLV unlock” and “ader5”.

When A2 is displayed:

Higher bit: A = 1010 t b7+b5

Lower bit : 2 = 0010 t b1

The retry cause in this case is combined of “access fault”, “IVR rec error”, and “ader5”.

12

Reading the Retry Cause Display

Higher Bits

Hexadecimal

Bit

Binary

Reading the Display:

Convert the hexadecimal display into binary display. If more than two causes, they will be added.

Example When 84 is displayed:

Higher bit: 8 = 1000 t b7

Lower bit : 4 = 0100 t b2

In this case, as b2 and b7 are 1 and others are 0, it can be determined that the retry cause is combined of “emphasis OFF”, “monaural”,

“original”, “copyright exists”, and “write allowed”.

Example When 07 is displayed:

Higher bit: 0 = 0000 t All 0

Lower bit : 7 = 0111 t b0+b1+b2

In this case, as b0, b1, and b2 are 1 and others are 0, it can be determined that the retry cause is combined of “emphasis ON”, “stereo”,

“original”, “copyright exists”, and “write prohibited”.

84218421

b7 b6 b5 b4 b3 b2 b1 b0

00000001

00000010

00000100

00001000

00010000

00100000

01000000

10000000

Lower Bits

Hexa-

decimal

01

02

04

08

10

20

40

80

When 0

Emphasis OFF

Monaural

This is 2-bit display. Normally 01.

01:Normal audio. Others:Invalid

Audio (Normal)

Original

Copyright

Write prohibited

Details

When 1

Emphasis ON

Stereo

Invalid

Digital copy

No copyright

Write allowed

Hexadecimal t Binary Conversion Table

Hexadecimal Binary Hexadecimal Binary

0 0000 8 1000

1 0001 9 1001

2 0010 A 1010

3 0011 B 1011

4 0100 C 1100

5 0101 D 1101

6 0110 E 1110

7 0111 F 1111

13

CD SECTION

CD TEXT DISPLA Y

• This unit displays CD text.

Text is displayed for the first 50 tracks only and will not be displayed from the 51st track onwards. Do not suspect a fault in this case.

In some cases, some special characters will not be displayed and may be replaced by other characters. Do not suspect a fault in this case.

AGING MODE

• Mode for repeating operations of the CD player automatically.

When errors occur:

Aging stops and a message indicating that an error has occurred such as “CD MEC ERR” is displayed.

(For details of errors, refer to “Error History Display Mode”)

When no errors occur:

Aging is repeatedly performed.

Procedure:

1. Load any CD disc.

2. Press the [FUNCTION] button to set the CD function.

3. While pressing the [PLAY MODE/TUNING MODE] and HS (MD) buttons, press the I/ 1 button.

4. “AGING” is displayed on the fluorescent display tube briefly.

5. When the aging mode is set, it starts aging automatically.

6. Operations are performed in the following sequence during aging.

Aging mode sequence:

TOC read

Playback track 1

Playback last track

CD disc tray open

CD disc tray open

7. To release from this mode, while pressing the

(Hot reset is executed)

Error History Display Mode

Mode for checking the history of errors which have occurred in the CD player.

Execute this mode after ending the aging mode.

Procedure:

1. Press the [FUNCTION] button to set the CD function.

2. While pressing the M L and s (MD) buttons, press the I/1 button.

3. “EMC@@EDC**” is displayed.

@@ : Number of mechanism errors (Past 3 errors)

: Number of errors (NO DISC ERROR) which occurred after chucking (Past 3 errors)

**

4. To check the history of mechanism errors, press the [PLAY MODE/TUNING MODE] button, and to check BD errors, press the

[PLAY MODE/TUNING MODE] and HS (CD) buttons, press the I/1 button.

[REPEAT] button, and switch the display.

5. To release, press the I/1 button and turn the power off.

6. To erase the error history, perform COLD reset.

(While pressing the [PLAY MODE/TUNING MODE] and s (CD) buttons, press the I/1 button)

14

• Reading the Mechanism Error History Display

(To switch the history, press the [PLAY MODE/TUNING MODE] button)

Display

E@@M

@@ : Error number. 00 is the latest

*

# : Load in operations related

$ : Load out operations related

• Reading the BD Error History Display

(To switch the history, press the [REPEAT] button)

E@@D##$$%

@@ : Error number. 00 is the latest

## : Error details

$$ : Retry performed/not performed

% : State when determined as NO DISC

*

**#*$*

: Invalid

D : Operations stopped due to problems other than mechanism related during CLOSE

E : Operations stopped due to problems other than mechanism related during OPEN

C : Operations stopped due to problems other than mechanism related during chucking up

1 : Operations stopped during chucking up

2 : Operations stopped during chucking down

Display

*

01: Focus error

02: GFS error

03: Setup error

00: Determined as NO DISC without chucking retry

02: Determined as NO DISC after chucking retry

1 : When stopped

2 : During setup

3 : During TOC READ

4 : During access

5 : During playback

6 : During PAUSE

7 : During manual search (during playback)

8 : During manual search (during pause)

: Invalid

15

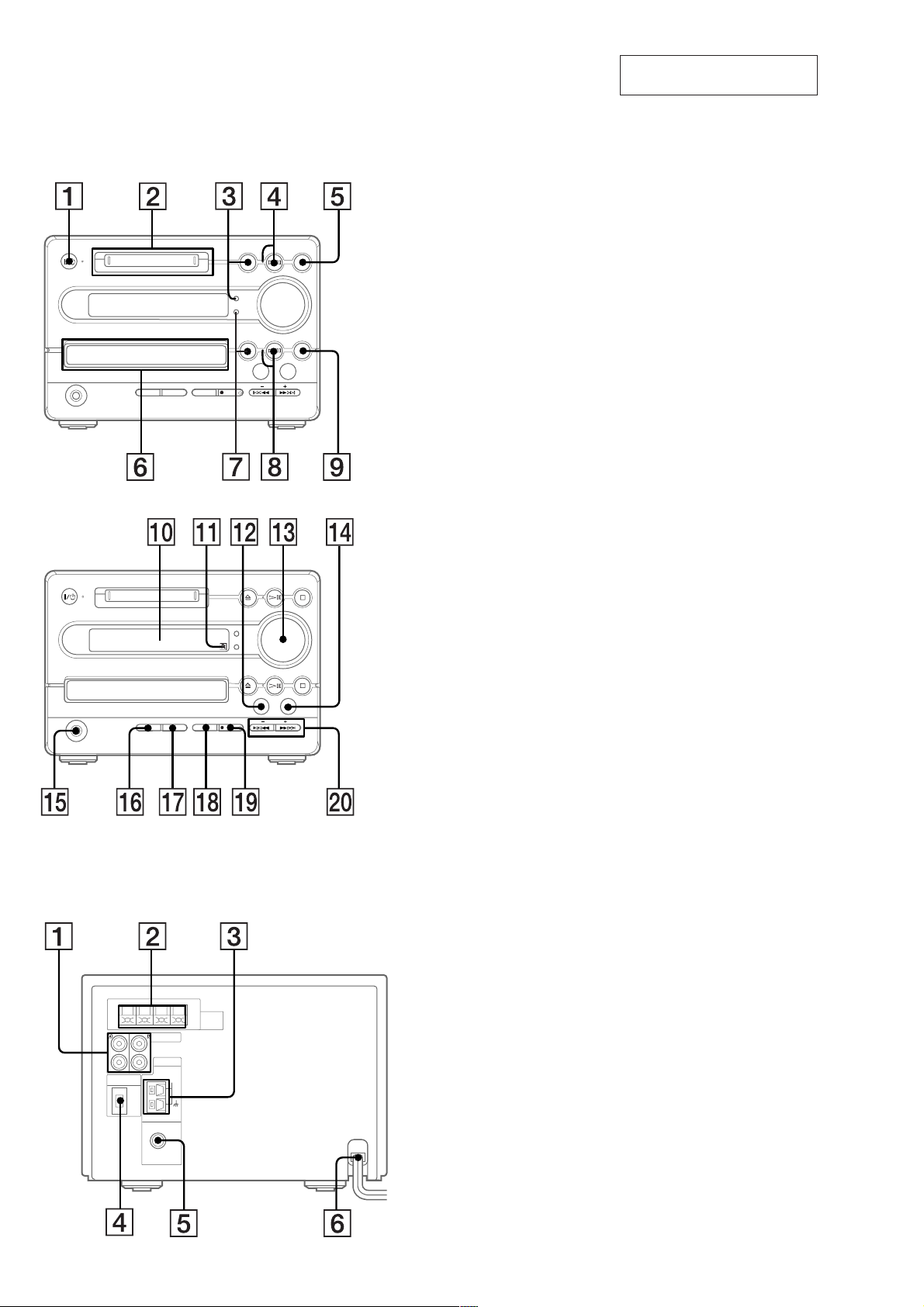

LOCATION OF CONTROLS

• Front View

SECTION 2

GENERAL

1 I/1 button and indicator

2 MD disc slot

3 MD A button and MD disc indicator

4 MD H S button and indicator

5 MD s button

6 CD disc tray

7 CD A button and CD disc indicator

8 CD H S button and indicator

9 CD s button

This section is extracted from

instruction manual.

• Rear View

0 Fluorescent indicator tube

qa Remote sensor

qs TUNER/BAND button

qd VOLUME knob

qf FUNCTION button

qg PHONES jack

qh PLAY MODE, TUNING MODE button

qj REPEAT, STEREO/MONO button

qk CD-MD SYNC button

ql zREC button and indicator

w; MD/CD l m/M L, TUNUNG +/– buttons

1 TAPE IN/OUT jacks

2 SPEAKER IMPEDANCE 6-16 Ω terminals

3 AM ANTENNA terminals

4 TAPE CONTROL jack

5 FM 75 Ω COAXIAL jack

6 AC power cord

16

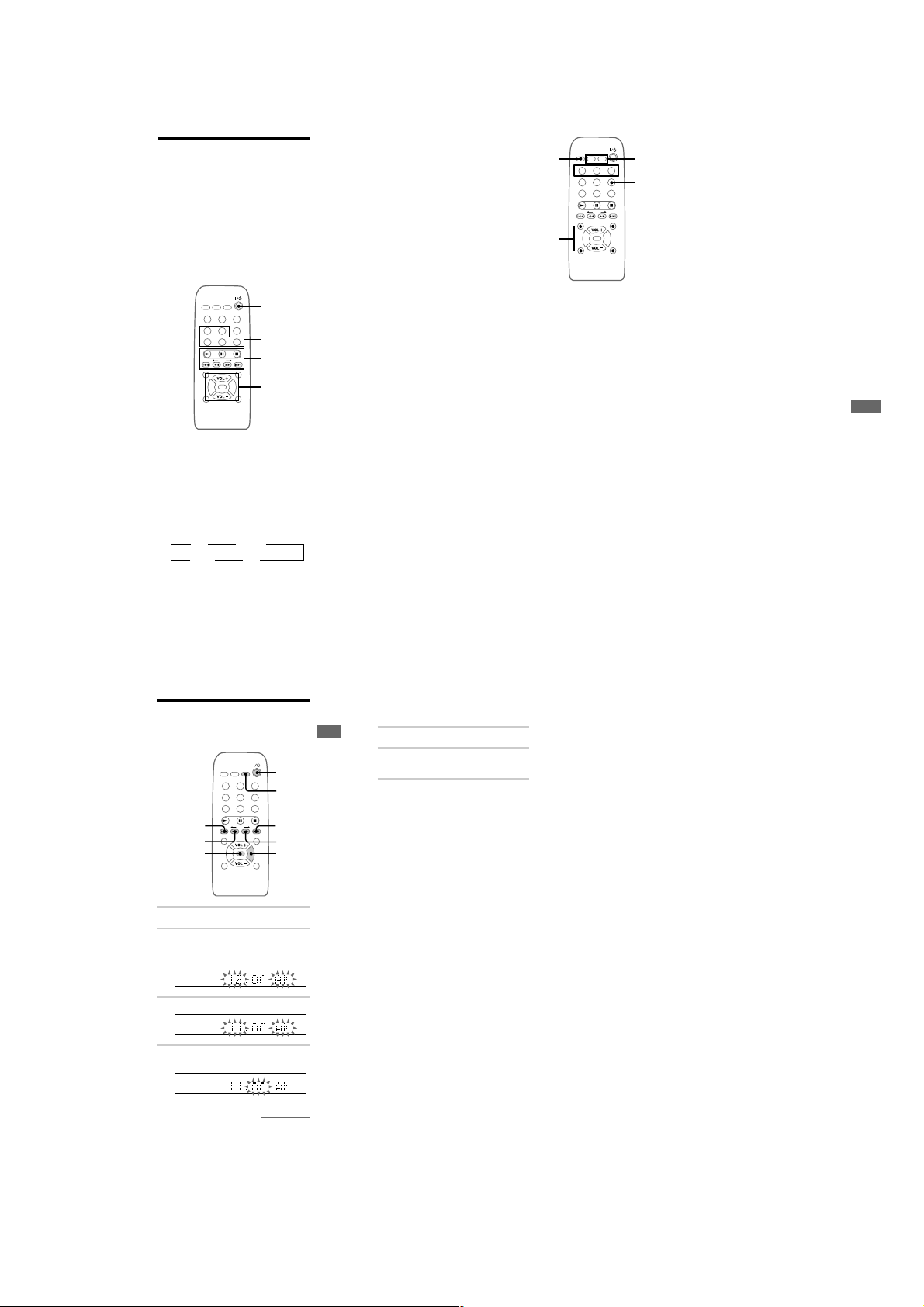

Parts descriptions for

the remote

You can use the supplied remote to control the

system.

Note

You cannot perform the following operations with the

remote;

— TUNING MODE setting for the tuner

— STEREO/MONO setting for the tuner

— Removing discs

— Recording on the MD

— One Touch Play

1

2

3

4

1 ?/1 (power) switch

2 The sound source buttons

MD button

CD button

TAPE button

FUNCTION button

Press to switch the sound source.

Each time you press this button, the sound source

changes as follows;

t

t

CD

TUNER

T

TAPE

TUNER/BAND button

Press to select the tuner for the sound source, or

to select the FM or AM band.

MD

T

3 N (play) button

X (pause) button

x (stop) button

CURSORT/t, m/M buttons

Press to label a CD, MD and preset station, or to

set the clock. (pages 5, 18, 35, 45)

./> (AMS: Automatic Music

Sensor) buttons

4 VOL +/– buttons

Press to adjust the volume.

MENU/NO button

Press to set Programme Play, or to label a CD,

MD and preset station.

ENTER/YES button

Press to set the clock, Programme Play and to

label a CD, MD and preset station, or to enter the

settings in “Edit Menu” or “Setup Menu”.

DISP button

Press to show the various information. (pages 17

and 23)

5

6

7

5 SLEEP button

Press to set Sleep Timer. (page 46)

6 PLAY MODE button

Press to select normal play, Shuffle Play or

Programme Play. (pages 15, 16, 21, 25)

REPEAT button

Press to play a track or all the tracks repeatedly

(pages 15 and 20).

MUSIC MENU button

Press to select the type of the preset equalizer.

(page 44)

7 NAME EDIT buttons

CHARACTER button

Press to display the text input screen and to select

the type of characters to be input. (pages 19, 35,

45)

SPACE button

Press to enter a space directly when labelling a

CD, MD and preset stion. (pages 19, 36, 46)

8 CLOCK/TIMER SELECT button

Press to check timer settings, or to set the timer

on/off. (pages 48 and 49)

CLOCK/TIMER

Press to set the clock and timer functions. (pages

5, 47, 48)

SET button

8

9

0

qa

9 DBFB button

Press to reinforce the bass sound. (page 44)

0 SCROLL button

Press to display the disc title or track title

scrolling. (pages 19, 23, 36)

qa CLEAR button

Press to cancel the selection. (pages 16, 18, 21,

35, 45)

Additional Information

60

Step 2: Setting the time

You must set the time beforehand to use the timer

functions.

3,5

CURSORT

DISP

1

Turn on the system.

2

Press CLOCK/TIMER SET.

The clock appears and the hour indication

flashes.

3

Press . or > to set the hour.

4

Press ENTER/YES or CURSORt .

The minute indication flashes.

1

2

3,5

4

4,6

Getting Started

Step 2: Setting the time

(continued)

5 Press . or > to set the minute.

6 Press ENTER/YES.

The clock starts.

If you made a mistake

Press CURSORT or t repeatedly until the

incorrect item flashes, then set it again.

To change the preset time

You can change the preset time while the system

is off.

1 Press DISP to display the clock.

2 Press CLOCK/TIMER SET.

3 Repeat steps 3 to 6 of “Setting the time”.

Tip

The upper dot of the colon flashes for the first 30

seconds, and the lower dot flashes for the last 30

seconds of each minute.

61

continued

5

6

17

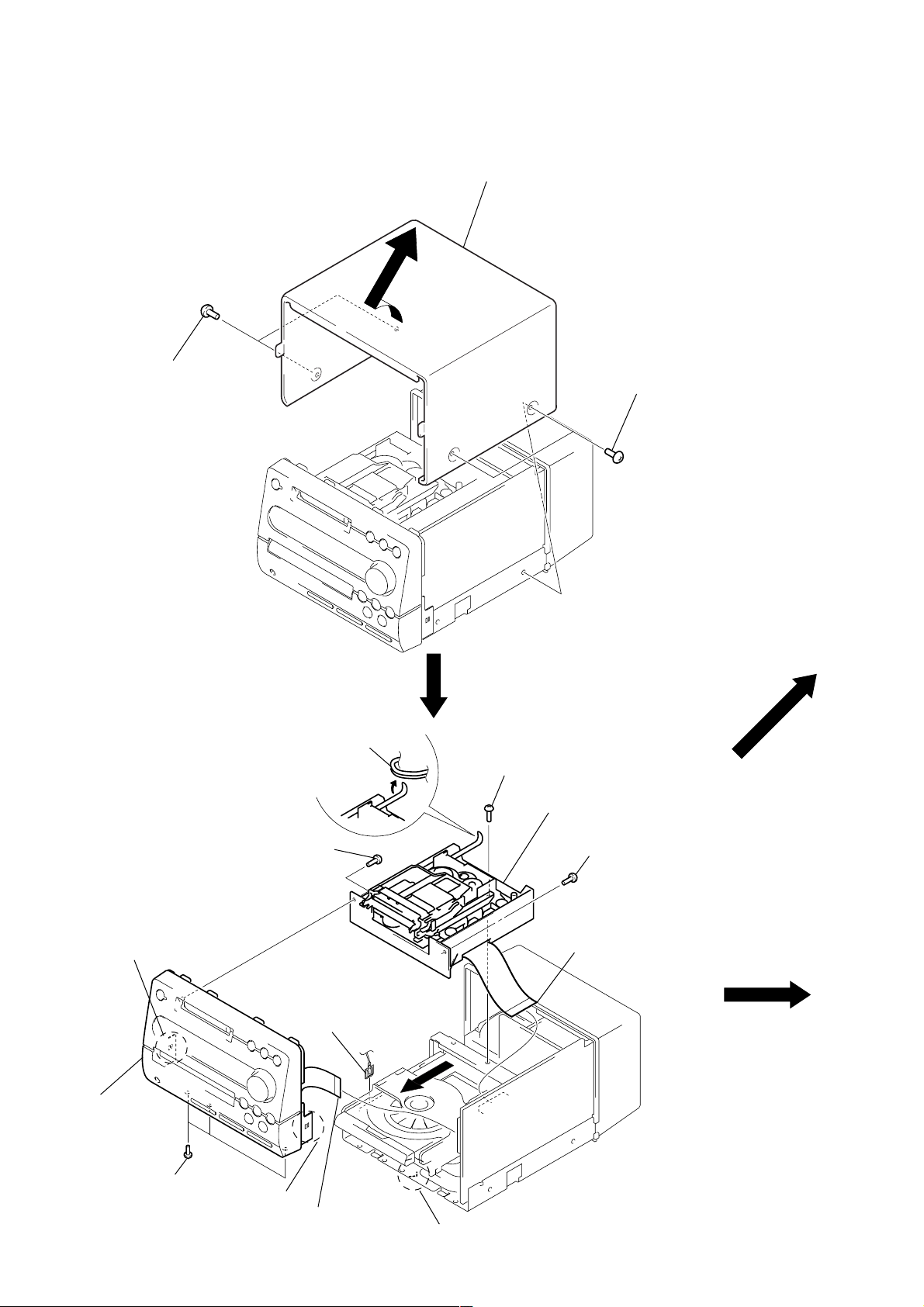

SECTION 3

)

)

DISASSEMBLY

Note: Follow the disassembly procedure in the numerical order given.

CASE

1

two screws

(case3 TP2)

2

case

1

two screws

(case3 TP2

FRONT PANEL SECTION

6

claw

q;

front panel section

8

screw

(BVTP2.6

3

Remove the cord.

×

8)

2

ground wire

7

5

screw (BVTT3 × 6)

9

MD mechanism deck section

8

screw (BVTP2.6 × 8)

1

wire (flat type) (25 core

(CN107)

BACK PANEL ASS’Y

(Page 22)

18

4

three screws

(BVTT3 × 6)

6

claw

1

wire (flat type)

(29 core) (CN11)

6

claw

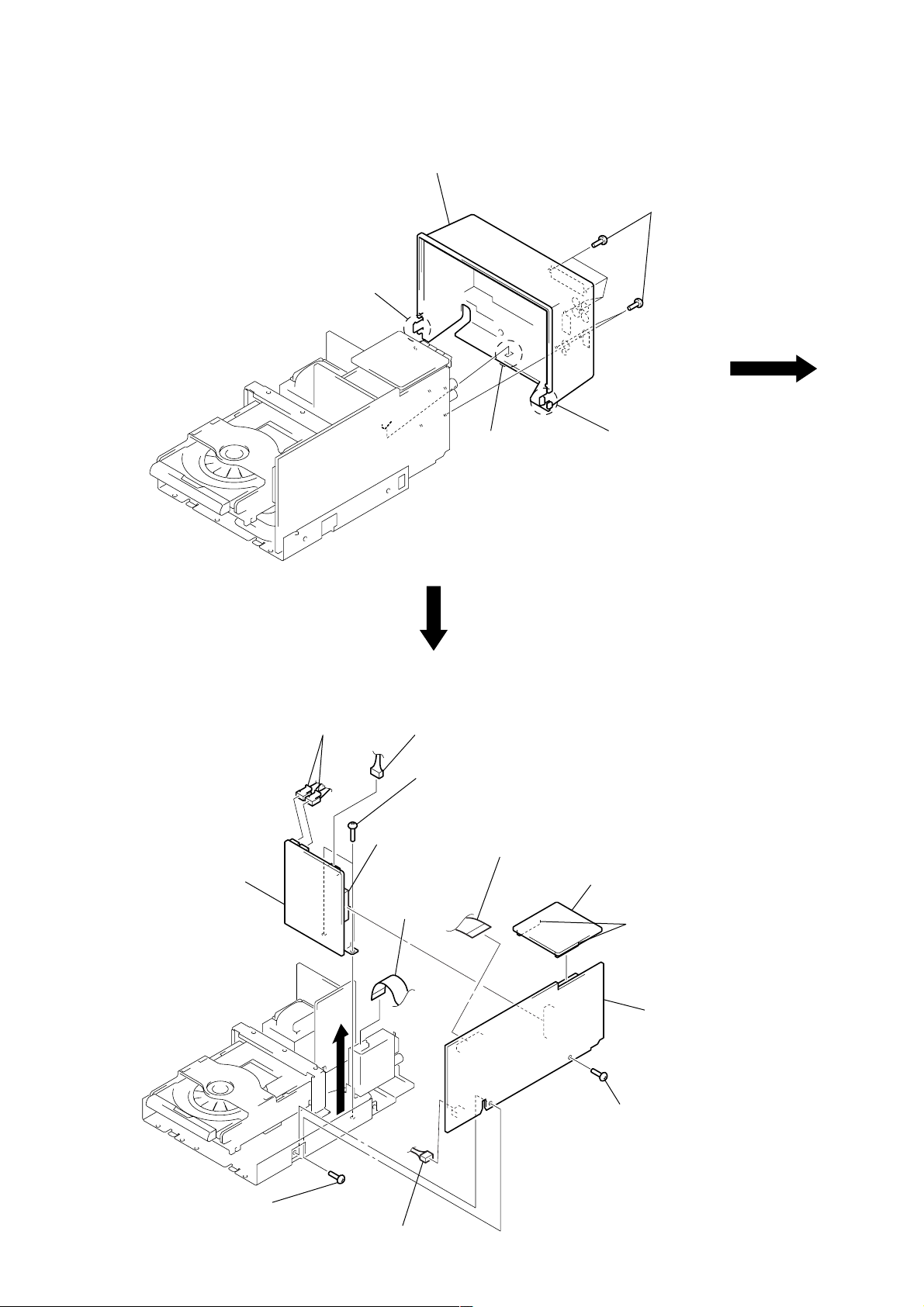

MD MECHANISM DECK (MDM-5GA)

)

2

four step screws

(BVTPWH M3)

6

MD mechanism deck

(MDM-5GA)

3

1

connector (CN601)

4

wire (flat type) (21 core)

(CN102)

4

wire (flat type) (23 core

(CN103)

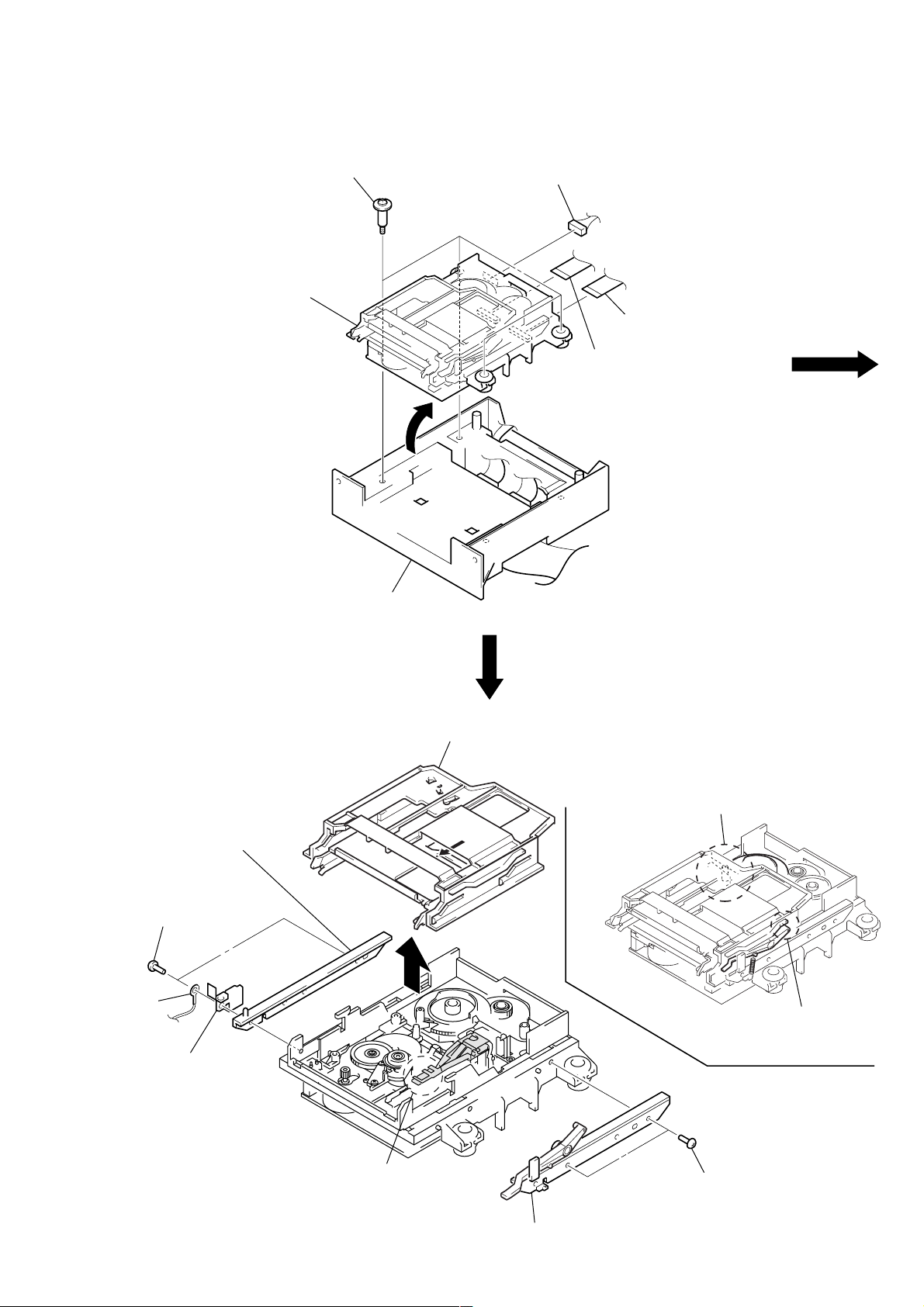

SLIDER (CAM)

3

1

two screws

(DIA2.6)

2

ground

wire

4

leaf spring

(electrostatic)

bracket (guide L)

bracket (MDM)

5

7

slider (cam)

A

•

NOTE FOR INSTALLATION

OF SLIDER (CAM)

Set the shaft of cam gear to be

at the position in the figure.

Set the shaft of lever

(O/C) to be at the position

in the figure.

When attaching the slider (cam),

this part of the over write head

should be inside arrow

A

.

6

bracket (guide R)

5

two screws

(DIA.2.6)

19

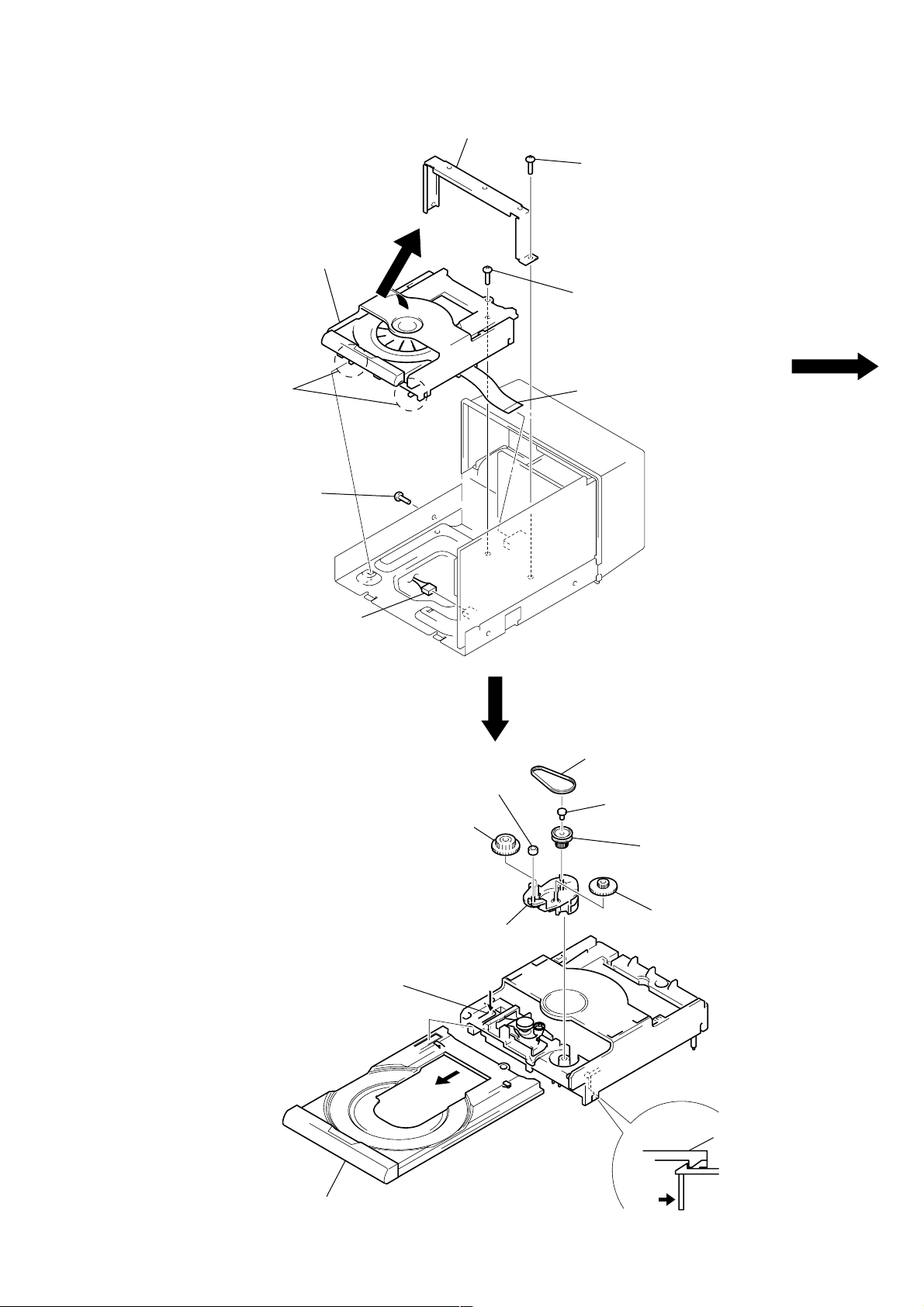

BD (MD) BOARD, BASE UNIT (MBU-5A)

)

5

two flexible boards

(CN101, 104)

7

base unit (MBU-5A)

CN103 CN102

1

Remove two solders

of spindle motor leads

(M901).

6

BD (MD)

board

4

screw (M1.7)

OVER WRITE HEAD (HR901)

3

three screws

(DIA.2.6)

3

over write head

(HR901)

2

Remove two solders

of sled motor leads (M902).

2

screw (P1.7 × 6

20

1

flexible board

(CN104)

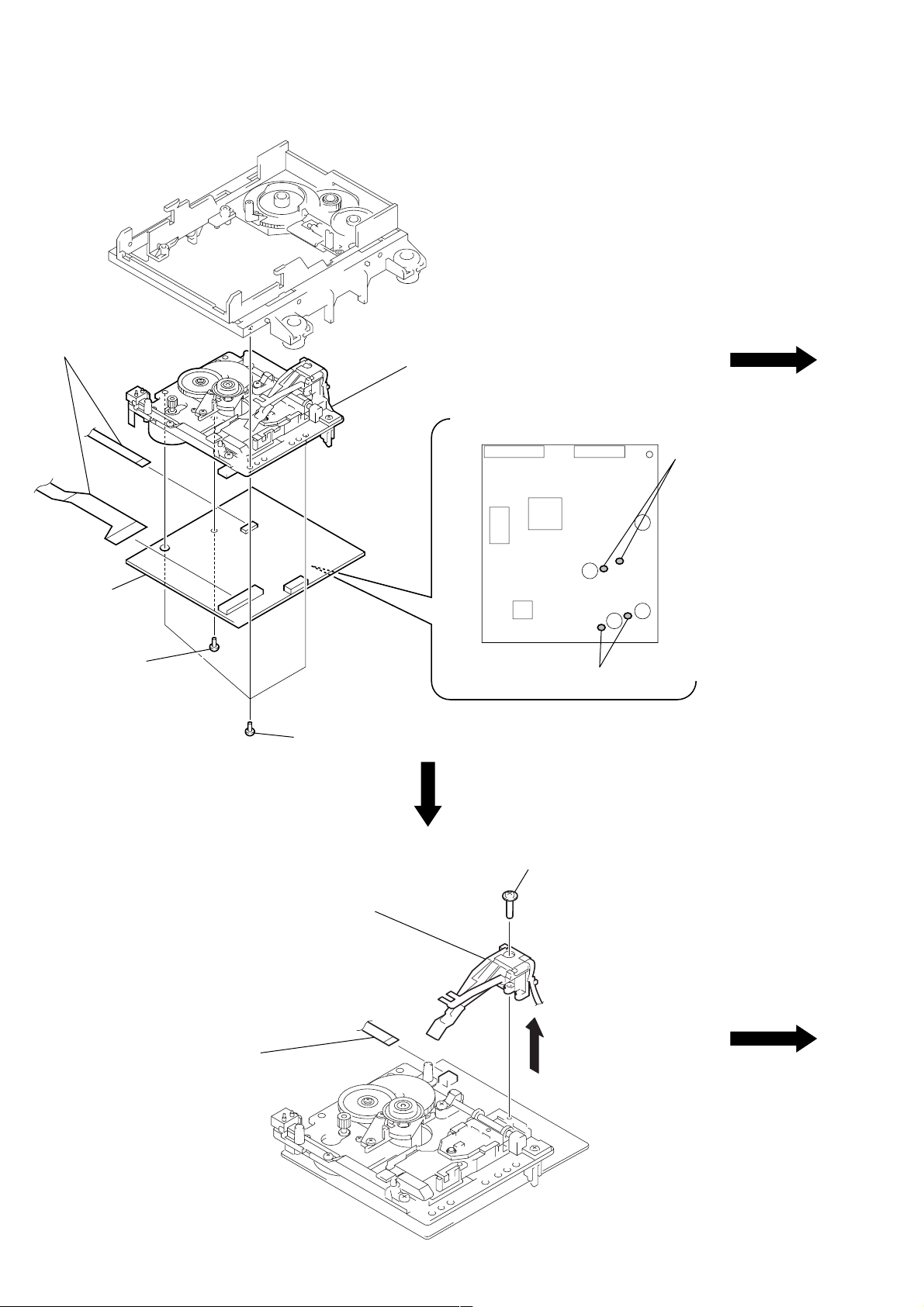

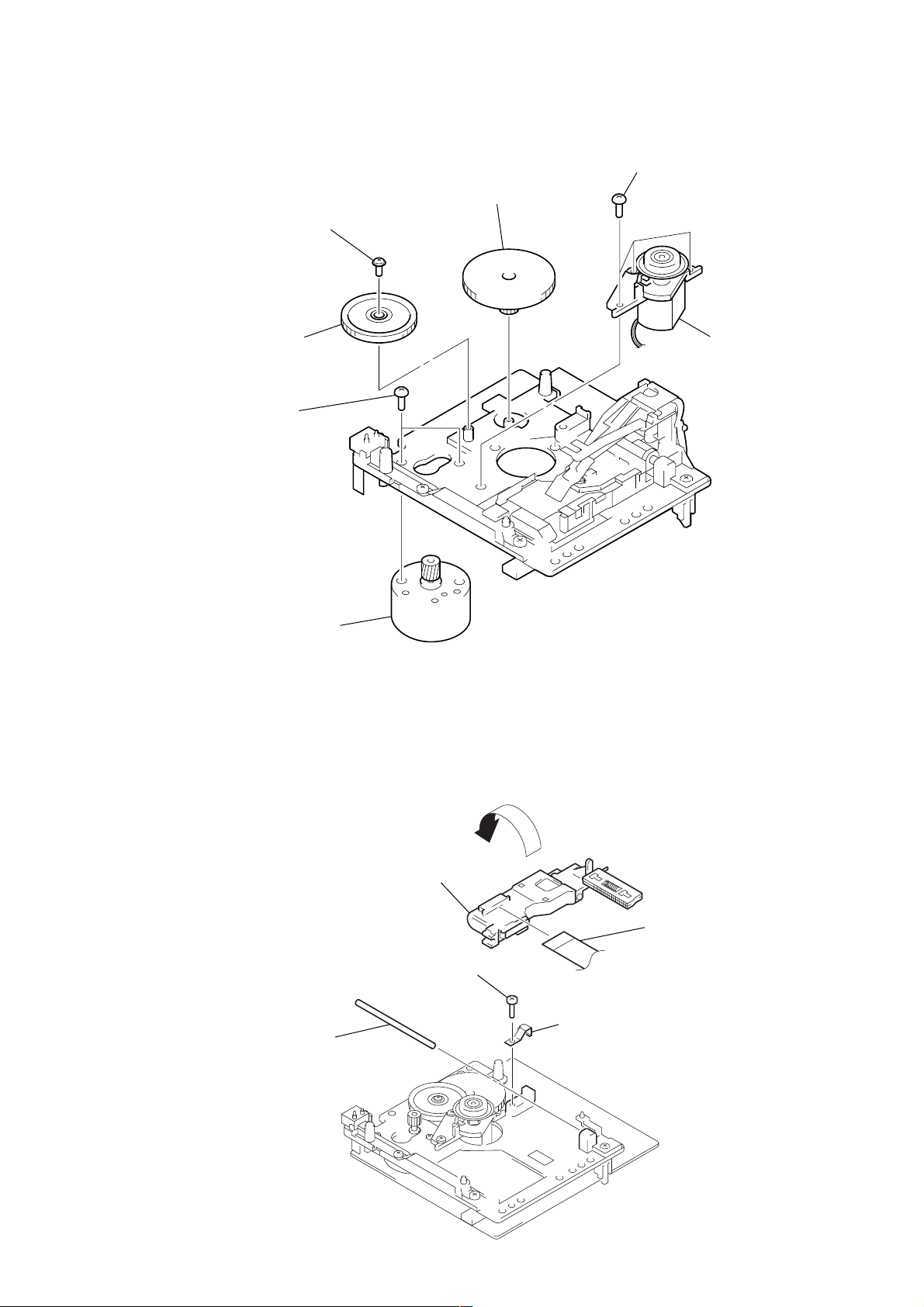

SPINDLE MOTOR ASS’Y (M901), SLED MOTOR ASS’Y (M902)

y

d

3

gear

(SL-B)

1

screw (M1.7)

2

gear (SL-A)

6

two screws

(P1.7 × 2.5)

4

three screws

(B2

×

5)

5

spindle motor ass’

(M901)

7

sled motor ass’y

(M902)

OPTICAL PICK-UP OF MD (KMS-260B/S1NP)

6

optical pick-up

(KMS-260B/S1NP)

1

screw (B2 × 8)

3

main shaft

4

Turn over the optical pick-up.

5

flexible boar

2

leaf spring (shaft)

21

BACK PANEL ASS’Y

)

d

3

4

back panel ass’y

claw

2

claw

1

six screws

(BVTP3

3

claw

×

10

SP BOARD, POWER BOARD AND MAIN BOARD

4

two connectors

(CN991, 992)

9

POWER board

7

4

5

8

connector

(CN994)

3

wire (flat type)

(15 core)

connector (CN993)

two screws (BVTT3 × 6)

3

wire (flat type) (25 core)

(CN109)

2

SP board

1

6

screw (BVTT3 × 6)

two connectors

(CN881, 882)

q;

MAIN boar

22

6

screw (BVTT3 × 6)

4

connector (CN110)

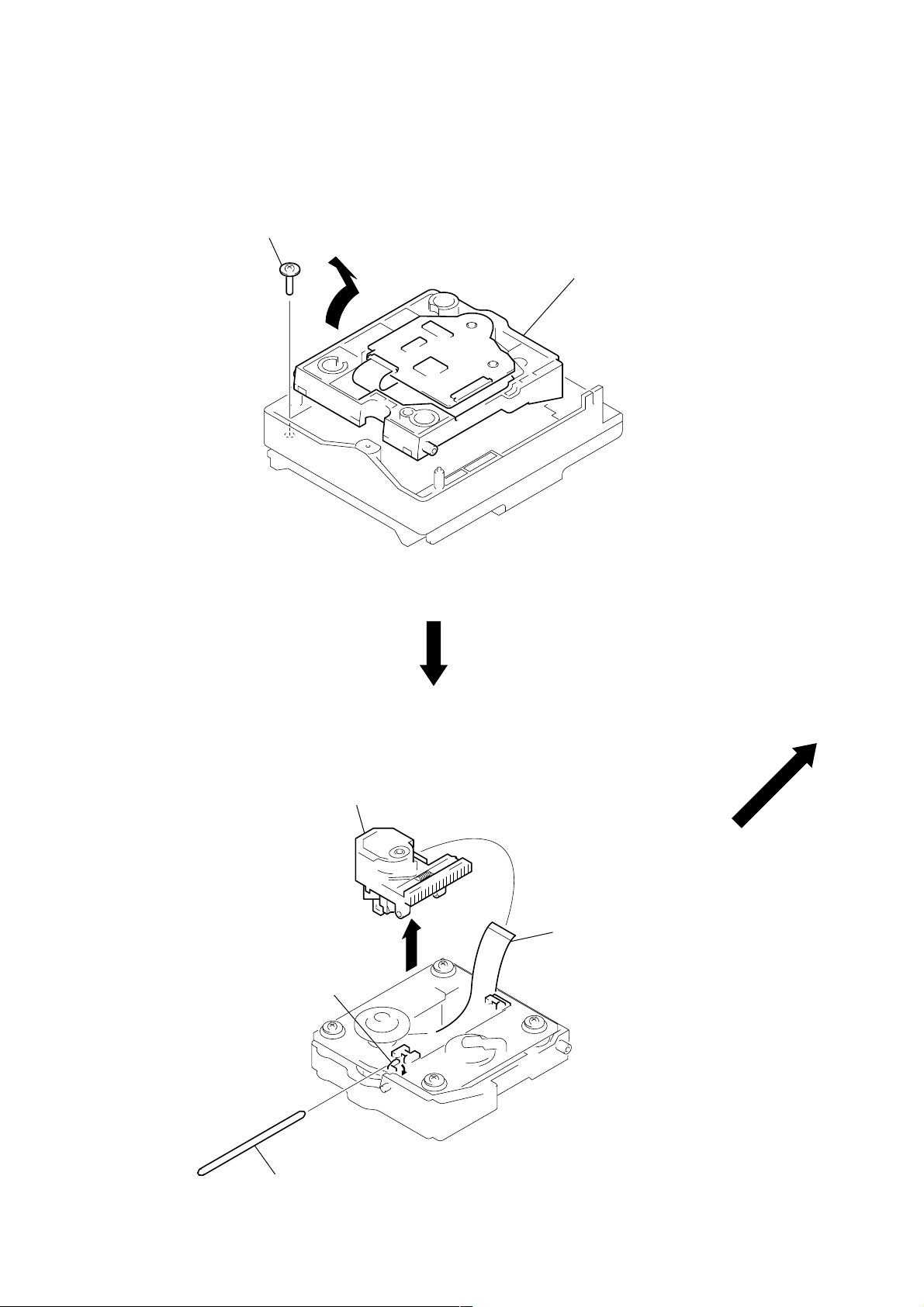

CD MECHANISM DECK (CDM55A-5SBD32)

)

7

CD mechanism deck

(CDM55A-5SB32)

6

two claws

3

screw

(BVTT3

×

6)

4

holder (MDM)

3

screw (BVTT3 × 6)

5

screw (BVTT3 × 6)

1

wire (flat type) (19 core

(CN109)

2

connector

(CN110)

TRAY (CDM), GEAR AND CAM (CDM55)

Note: when drawing out the tray (CDM), refer to

service notes DRAWING OUT THE TRAY

WHEN THE POWER IS OFF on page 6 .

2

Push the claw in the

direction of arrow

8

gear (B)

q;

A

.

7

roller

cam (CDM55)

A

4

belt (CDM55)

5

bushing

6

pulley (LDG)

9

gear (A)

3

Drawing out the tray (CDM).

1

tray (CDM)

2

Release the lock while pressing

this claw in the arrow direction.

23

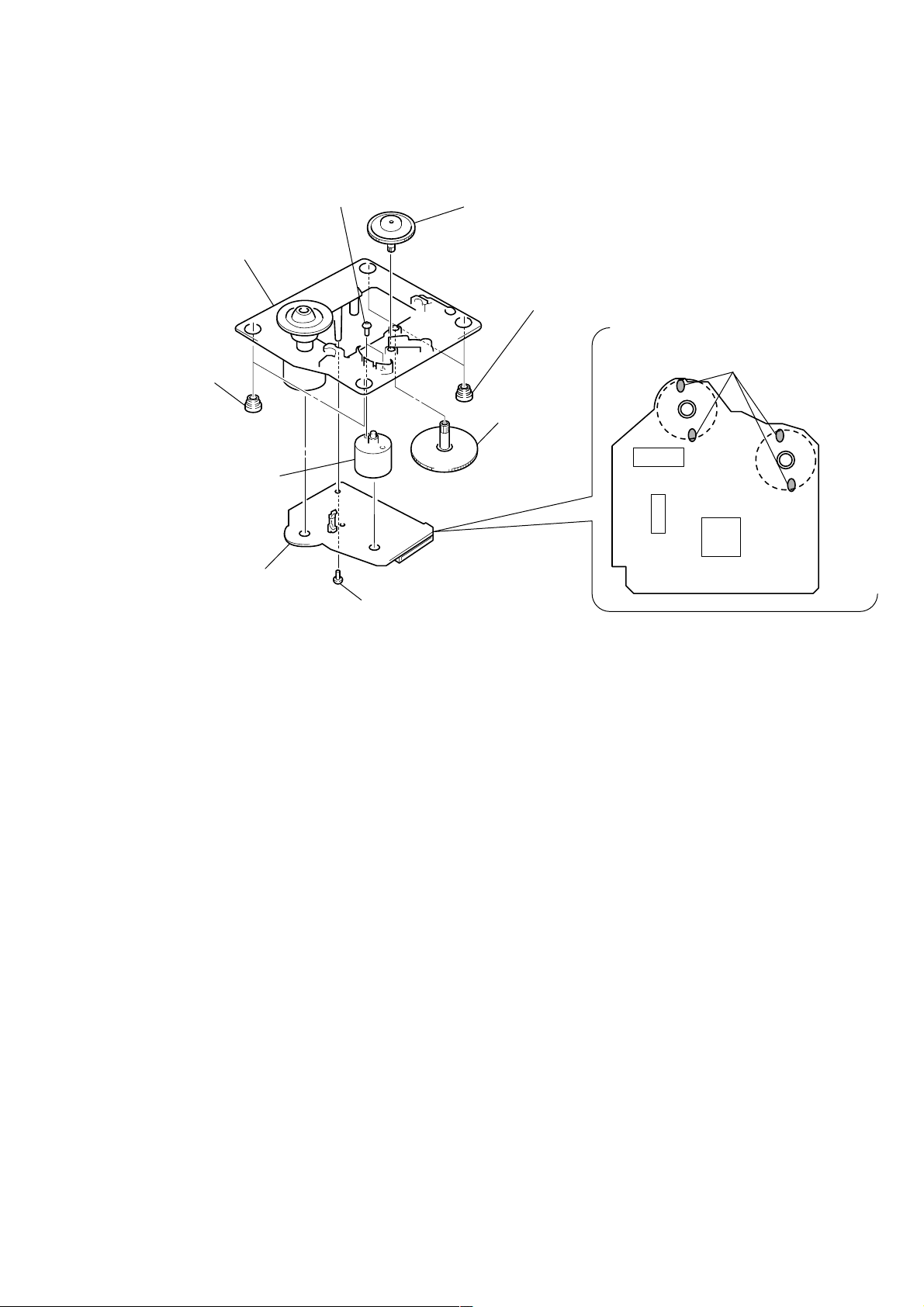

HOLDER (BU) ASS’Y

y

1

floating screw

(PTPWH M2.6)

2

Remove the holder (BU) ass’

in the direction of the arrow.

OPTICAL PICK-UP OF CD (KSS-213BH/Z-NP)

5

optical pick-up

(KSS-213BH/Z-NP)

1

Release the lever in the

direction of arrow

A

3

wire (flat type) (16 core)

4

.

A

24

2

sled shaft

BD (CD) BOARD, BASE (BU-5S) ASS’Y (M101) AND SLED MOTOR ASS’Y (M102)

4

two screws

×

4)

9

base (BU-5S) ass’y (M101)

8

two insulators (BU)

5

sled motor ass’y

(M102)

(B2

6

gear (M)

7

flatness gear

(P)

8

two insulators (BU)

2

Remove the four solders.

M101

M102

3

BD (CD) board

1

screw (BVTP2.6 × 8)

25

SECTION 4

TEST MODE

Note : About “R”

As this unit has only a few buttons, some operations require the use of remote commander (RM-SF3MD/provided with unit: 1-476-068-11)

buttons. These operations are indicated as “R” in this manual.

Example: MENU/NO “R” ...Press the [MENU/NO] button of the remote commander.

4-1. PRECAUTIONS FOR USE OF TEST MODE

• As loading related operations will be performed regardless of the test mode operations being performed, be sure to check that the disc

is stopped before setting and removing it.

Even if the A (MD) button is pressed while the disc is rotating during continuous playback, continuous recording, etc., the disc will

not stop rotating.

Therefore, it will be ejected while rotating.

Be sure to press the A (MD) button after pressing the MENU/NO “R” button and the rotation of disc is stopped.

4-1-1. Recording laser emission mode and operating buttons

• Continuous recording mode (CREC MODE)

• Laser power check mode (LDPWR CHECK)

• Laser power adjustment mode (LDPWR ADJUST)

• Traverse (MO) check (EF MO CHECK)

• Traverse (MO) adjustment (EF MO ADJUST)

• When pressing the zREC button.

4-2. SETTING THE TEST MODE

The following are two methods of entering the test mode.

Procedure 1: 1. Press the I/1 button to turn the power on.

2. Press the [FUNCTION] button to set the MD function.

3. While pressing the s (MD) and zREC buttons, press the I/1 button to enter the MD test mode and display “[Check]”.

When the test mode is set, “[Check]” will be displayed. Press the l m or M L button switches between the

following four groups; ···y [Check] y [Adjust] y [Service] y [Develop] y ···.

Procedure 2: 1. Press the I/1 button to turn the power on.

2. Press the [FUNCTION] button to set the MD function.

3. While pressing the s (MD) and [CD-MD SYNC] buttons, press the I/1 button to enter the MD test mode and display

“TEMP CHECK”.

By setting the test mode using this method, only the “Check” group of method 1 can be executed.

4-3. RELEASING THE TEST MODE

Press the [REPEAT] button.

4-4. BASIC OPERATIONS OF THE TEST MODE

All operations are performed using the l m or M L button , ENTER/YES “R” button, and MENU/NO “R” button.

The functions of these buttons are as follows.

Function name Function

l m , M L buttons Changes parameters and modes

ENTER/YES “R” button Proceeds onto the next step. Finalizes

MENU/NO “R” button Returns to previous step. Stops

input

operations

26

4-5. SELECTING THE TEST MODE

There are 31 types of test modes as shown below. The groups can be switched by pessing the l m or M L button. After

selecting the group to be used, press the ENTER/YES “R” button. After setting a certain group, press the l m or M L button

switches between these modes.

Refer to “Group” in the table for details can be selected.

All items used for servicing can be treated using group S. So be carefully not to enter other groups by mistake.

Display

TEMP CHECK

LDPWR CHECK

EF MO CHECK

EF CD CHECK

FBIAS CHECK

Scurve CHECK

VERIFYMODE

DETRK CHECK

TEMP ADJUST

LDPWR ADJUST

EF MO ADJUST

EF CD ADJUST

FBIAS ADJUST

EEP MODE

MANUAL CMD

SVDATA READ

ERR DP MODE

SLED MOVE

ACCESS MODE

0920 CHECK

HEAD ADJUST

CPLAY2 MODE

CREC2 MODE

ADJ CLEAR

AG Set (MO)

AG Set (CD)

Iop Read

Iop Write

INFORMATION

CPLAY MODE

CREC MODE

Contents

Temperature compensation offset check

Laser power check

Traverse (MO) check

Traverse (CD) check

Focus bias check

S letter check

Non-volatile memory check

Detrack check

Temperature compensation offset adjustment

Laser power adjustment

Traverse (MO) adjustment

Traverse (CD) adjustment

Focus bias adjustment

Non-volatile memory control

Command transmission

Status display

Error history display, clear

Sled check

Access check

Outermost circumference check

Head position check

Same functions as CPLAY MODE

Same functions as CREC MODE

Initialization of non-volatile memory of adjustment value

Auto gain output level adjustment (MO)

Auto gain output level adjustment (CD)

IOP data display

IOP data write

Microprocessing version display

Continuous playback mode

Continuous recording mode

Mark

(X)

(X)

(X)

(X) (!)

(X)

(X)

(X)

(X)

(X)

(X)

(X)

(X)

Group (*)

C: Check

S: Service

Group (*)

CS

CS

CS

CS

CS

C

C

C

AS

AS

AS

AS

AS

D

D

D

S

D

D

D

D

D

D

AS

AS

AS

CS

AS

CS

CASD

CASD

A: Adjust

D: Develop

• For details of each adjustment mode, refer to “5. Electrical Adjustments”.

For details of “ERR DP MODE”, refer to “Self-Diagnosis Function” on page 2.

• If a different mode has been selected by mistake, press the MENU/NO “R” button to release that mode.

• Modes with (X) in the Mark column are not used for servicing and therefore are not described in detail. If these modes are set accidentally, press the MENU/NO “R” button to release the mode immediately. Be especially careful not to set the modes with (!) as they will

overwrite the non-volatile memory and reset it, and as a result, the unit will not operate normally.

27

4-5-1. Operating the Continuous Playback Mode

1. Entering the continuous playback mode

(1) Set the disc in the unit. (Whichever recordable discs or discs for playback only are available.)

(2) Press the

(3) Press the

l m or M L button and display “CPLAY MODE”.

ENTER/YES “R” button to change the display to “CPLAY MID”.

(4) When access completes, the display changes to “C1 = AD = ”.

Note: The numbers “ ” displa yed show you error rates and ADER.

2. Changing the parts to be played back

(1) Press the ENTER/YES “R” button during continuous playback to change the display as below.

“CPLAY MID” t “CPLAY OUT” t “CPLAY IN”

When pressed another time, the parts to be played back can be moved.

(2) When access completes, the display changes to “C1 = AD = ”.

Note: The numbers “ ” displayed show you error rates and ADER.

3. Ending the continuous playback mode

(1) Press the MENU/NO “R” button. The display will change to “CPLAY MODE”.

(2) Press the A (MD) button and take out the disc.

Note: The playback start addresses for IN, MID, and OUT are as follows.

IN : 40h cluster

MID : 300h cluster

OUT: 700h cluster

4-5-2. Operating the Continuous Recording Mode (Use only when performing self-recording/palyback check.)

1. Entering the continuous recording mode

(1) Set a recordable disc in the unit.

(2) Press the l m or M L button and display “CREC MODE”.

(3) Press the ENTER/YES “R” button to change the display to “CREC MID”.

(4) When access completes, the display changes to “CREC ( )” and [ REC] indicator lights up.

Note: The numbers “ ” display ed shows you the recording position addresses.

z

2. Changing the parts to be recorded

(1) When the ENTER/YES “R” button is pressed during continuous recording, the display changes as below.

“CREC MID” t “CREC OUT” t “CREC IN”

z

When pressed another time, the parts to be recorded can be changed.

(2) When access completes, the display changes to “CREC ( )” and [ REC] indicator lights up.

Note: The numbers “ ” display ed shows you the recording position addresses.

[ REC] indicator goes off.

z

3. Ending the continuous recording mode

(1) Press the MENU/NO “R” button. The display changes to “CREC MODE” and [ REC] indicator goes off.

z

(2) Press the A (MD) button and take out the disc.

Note 1: The recording start addresses for IN, MID, and OUT are as follows.

IN : 40h cluster

MID : 300h cluster

OUT: 700h cluster

Note 2: The MENU/NO “R” button can be used to stop recording anytime.

Note 3: Do not perform continuous recording for long periods of time above 5 minutes.

Note 4: During continuous recording, be careful not to apply vibration.

4-5-3. Non-Volatile Memory Mode (EEP MODE)

This mode reads and writes the contents of the non-volatile memory.

It is not used in servicing. If the unit entered this mode accidentally, press the MENU/NO “R” button immediately to release it.

4-6. FUNCTIONS OF OTHER BUTTONS

Function

H S (MD)

s (MD)

M L

l m

CLEAR “R”

PLAY MODE/TUNING MODE

DISP “R”

A (MD)

REPAET

Sets continuous playback when pressed in the STOP state. When pressed during continuous playback, the tracking

servo turns ON/OFF

Stops continuous playback and continuous recording

The sled moves to the outer circumference only when this is pressed

The sled moves to the inner circumference only when this is pressed

Switches between the pit and groove modes when pressed

Switches the spindle servo mode (CLV-S y CLV-A)

Switches the displayed contents each time the button is pressed

Ejects the disc

Releases the test mode

Contents

28

4-7. TEST MODE DISPLAYS

Each time the DISP “R” button is pressed, the display changes in the following order.

1. Mode display

Displays “TEMP ADJUST”, “CPLAYMODE”, etc.

2. Error rate display

Displays the error rate in the following way.

C1 = ssss AD = ss

C1 = Indicates the C1 error.

AD = Indicates ADER.

3. Address display

The address is displayed as follows. (MO: recordable disc, CD: playback only disc)

Press the CLEAR “R” button to switches between the groove display and pit display.

h = ssss s = ssss (MO pit and CD)

h = ssss a = ssss (MO groove)

h = Indicates the header address.

s = Indicates the SUBQ address.

a = Indicates the ADIP address.

Note: “–” is displayed when servo is not imposed.

4. Auto gain display (Not used in servicing)

The auto gain is displayed as follows.

AG = ss/ss[ss]

Mode display

Error rate display

Address display

Auto gain display

(Not used in servicing)

5. Detrack check display (Not used in servicing)

The detrack is displayed as follows.

ADR = sssssss

6. IVR display (Not used in servicing)

The IVR is displayed as follows.

[ss][ss][ss]

MEANINGS OF OTHER DISPLAYS

Display

H (MD)*

S (MD)*

zREC*

SYNC

L.SYNC

OVER

1

REPEAT

DISC

SHUF

MONO

During continuous playback (CLV: ON)

Tracking servo OFF

Recording mode ON

CLV low speed mode

ABCD adjustment completed

Tracking offset cancel ON

Tracking auto gain OK

Focus auto gain OK

High reflection

CLV-S

CLV LOCK

When Lit

* : Indicate by LED.

Detrack check display

(Not used in servicing)

IVR display

(Not used in servicing)

Contents

When Off

STOP (CLV: OFF)

Tracking servo ON

Recording mode OFF

CLV normal mode

Tracking offset cancel OFF

Low reflection

CLV-A

CLV UNLOCK

29

Loading...

Loading...