Sony FWD-50PX1N Schematic

FLAT WIDE DISPLAY

FWD-50PX1

FWD-50PX1N

FLAT PANEL DISPLAY SPEAKER SYSTEM

SS-SP50FW

TV STAND

SU-50FW

SERVICE MANUAL

1st Edition

! WARNING

This manual is intended for qualified service personnel only.

To reduce the risk of electric shock, fire or injury, do not perform any servicing other than that

contained in the operating instructions unless you are qualified to do so. Refer all servicing to

qualified service personnel.

! WARNUNG

Die Anleitung ist nur für qualifiziertes Fachpersonal bestimmt.

Alle Wartungsarbeiten dürfen nur von qualifiziertem Fachpersonal ausgeführt werden. Um die

Gefahr eines elektrischen Schlages, Feuergefahr und Verletzungen zu vermeiden, sind bei

Wartungsarbeiten strikt die Angaben in der Anleitung zu befolgen. Andere als die angegeben

Wartungsarbeiten dürfen nur von Personen ausgeführt werden, die eine spezielle Befähigung

dazu besitzen.

! AVERTISSEMENT

Ce manual est destiné uniquement aux personnes compétentes en charge de l’entretien. Afin

de réduire les risques de décharge électrique, d’incendie ou de blessure n’effectuer que les

réparations indiquées dans le mode d’emploi à moins d’être qualifié pour en effectuer d’autres.

Pour toute réparation faire appel à une personne compétente uniquement.

Power cord plug should be pulled out from the wall before starting the service operation.

If power switch is turned OFF only, you may receive an electric shock, because the unit may have an

electric inside.

Therefore, you should pull out the power cord plug from the wall before starting the service operation.

FWD-50PX1

CAUTION

Danger of explosion if battery is incorrectly replaced.

Replace only with the same or equivalent type

recommended by the manufacturer.

Dispose of used batteries according to the

manufacturer’s instructions.

ADVARSEL!

Lithiumbatteri-Eksplosionsfare ved fejlagtig

håndtering.

Udskiftning må kun ske med batteri

af samme fabrikat og type.

Levér det brugte batteri tilbage til leverandøren.

ADVARSEL

Lithiumbatteri - Eksplosjonsfare.

Ved utskifting benyttes kun batteri som

anbefalt av apparatfabrikanten.

Brukt batteri returneres

apparatleverandøren.

Vorsicht!

Explosionsgefahr bei unsachgemäßem Austausch

der Batterie.

Ersatz nur durch denselben oder einen vom

Hersteller empfohlenen ähnlichen Typ. Entsorgung

gebrauchter Batterien nach Angaben des

Herstellers.

ATTENTION

Il y a danger d’explosion s’il y a remplacement

incorrect de la batterie.

Remplacer uniquement avec une batterie du même

type ou d’un type équivalent recommandé par le

constructeur.

Mettre au rebut les batteries usagées conformément

aux instructions du fabricant.

VARNING

Explosionsfara vid felaktigt batteribyte.

Använd samma batterityp eller en likvärdig typ

som rekommenderas av apparattillverkaren.

Kassera använt batteri enligt gällande

föreskrifter.

VAROITUS

Paristo voi räjähtää jos se on virheellisesti

asennettu.

Vaihda paristo ainoastaan laitevalmistajan

suosittelemaan tyyppiin.

Hävitä käytetty paristo valmistajan ohjeiden

mukaisesti.

FWD-50PX1

1 (P)

For the customers in the Netherlands

Voor de klanten in Nederland

Hoe u de batterijen moet verwijderen, leest u in de tekst

van deze handleiding.

Gooi de batterij niet weg maar lever deze in als klein

chemisch afval (KCA).

Für Kunden in Deutschland

Entsorgungshinweis: Bitte werfen Sie nur entladene

Batterien in die Sammelboxen beim Handel oder den

Kommunen. Entladen sind Batterien in der Regel dann,

wenn das Gerät abschaltet und signalisiert “Batterie

leer” oder nach längerer Gebrauchsdauer der Batterien

“nicht mehr einwandfrei funktioniert”. Um

sicherzugehen, kleben Sie die Batteriepole z.B. mit

einem Klebestreifen ab oder geben Sie die Batterien

einzeln in einen Plastikbeutel.

For the customers in the U.S.A. and Canada

RECYCLING LITHIUM-ION BATTERIES

Lithium-Ion batteries are recyclable.

You can help preserve our environment

by returning your used rechargeable

batteries to the collection and recycling

location nearest you.

For more information regarding recycling of rechargeable batteries, call toll free

1-800-822-8837, or visit http://www.rbrc.org/

Caution: Do not handle damaged or leaking Lithium-Ion

batteries.

2 (P)

FWD-50PX1

Table of Contents

1. Service Overview

1-1. Board Location............................................................................................1-1

1-2. Installing/Removing the Cabinet.................................................................1-2

1-2-1. Rear Cover Assembly ................................................................1-2

1-2-2. Bezel Assembly..........................................................................1-3

1-3. Replacing the Board ....................................................................................1-4

1-3-1. Q Board ......................................................................................1-4

1-3-2. B Board ...................................................................................... 1-5

1-3-3. SP Board.....................................................................................1-6

1-3-4. S Board .......................................................................................1-6

1-3-5. Y Drive Board ............................................................................1-7

1-3-6. X Drive Board ............................................................................1-8

1-3-7. Digital Video Board/Interface Board .........................................1-8

1-4. Replacing the Main Parts ............................................................................1-9

1-4-1. Power Unit/DC Fan (For Power Supply) ...................................1-9

1-4-2. DC Fan (For Q/B Mount).........................................................1-10

1-4-3. Plasma Display Panel ............................................................... 1-11

1-5. Service Position.........................................................................................1-12

1-5-1. Service Position of the B and Q Boards...................................1-12

1-6. Packaging of the Plasma Display Panel When It Is Shipped to

Pioneer Corporation ..................................................................................1-13

1-7. Backup Battery Replacement ....................................................................1-14

1-8. Unleaded Solder ........................................................................................ 1-14

1-9. Warning on Power Connection .................................................................1-14

FWD-50PX1

2. Electrical Adjustments

2-1. Equipment Required....................................................................................2-1

2-2. Electrical Adjustments Using the Service Mode ........................................ 2-1

2-3. White Balance Adjustment ....................................................................... 2-20

2-4. AD Calibration Adjustment ......................................................................2-20

2-5. Sub Color and Sub Hue Adjustments........................................................2-21

2-6. Video Decoder Adjustment.......................................................................2-21

2-7. Watch Error Adjustment ...........................................................................2-22

3. Troubleshooting

3-1. Judging Method When Image Does Not Appear ........................................3-1

3-2. Self Diagnosis Function ..............................................................................3-2

3-2-1. Overview ....................................................................................3-2

3-2-2. Abnormality Judgment Criterion ............................................... 3-2

1

4. Circuit Description

4-1. Outline.........................................................................................................4-1

4-2. Q Board .......................................................................................................4-1

4-3. B Board .......................................................................................................4-2

4-4. S Board........................................................................................................4-2

5. Semiconductors

6. Spare Parts

6-1. Notes on Repair Parts..................................................................................6-1

6-2. Exploded Views ..........................................................................................6-2

6-3. Electrical Parts List .....................................................................................6-8

6-4. Packing Materials & Supplied Accessories .............................................. 6-24

6-5. SS-SP50FW...............................................................................................6-24

7. Block Diagrams

B (1/3), Q (1/2), SP .....................................................................................7-1

B (2/3) .........................................................................................................7-2

B (3/3), Q (2/2), H1, H2, S.......................................................................... 7-3

8. Schematic Diagrams

B ..................................................................................................................8-2

H1, H2, SP.................................................................................................8-14

Q ................................................................................................................ 8-15

S.................................................................................................................8-20

U1 (FWD-50PX1) ..................................................................................... 8-21

Frame Wiring ............................................................................................8-22

9. Board Layouts

B ..................................................................................................................9-2

Q ..................................................................................................................9-4

H1 ................................................................................................................9-6

H2 ................................................................................................................9-6

S...................................................................................................................9-6

SP ................................................................................................................9-6

U1 (FWD-50PX1) .......................................................................................9-7

2

FWD-50PX1

(

)

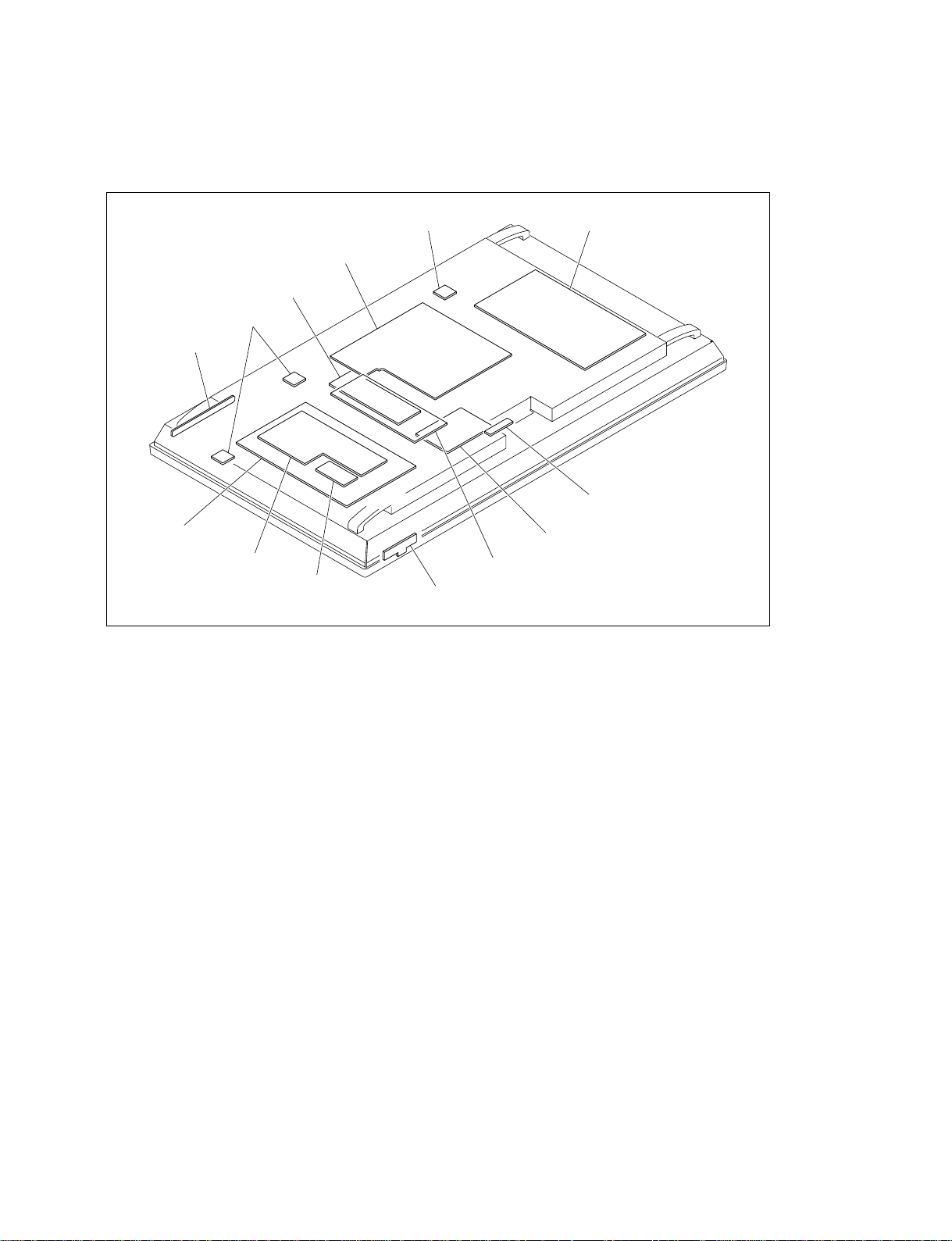

1-1. Board Location

Digital video board

S boards

H2 board

Section 1

Service Overview

X drive boardS board

Power unit board

SP board

Y drive board

Q board

U1 board

FWD-50PX1

Interface board

B board

H1 board

FWD-50PX1

1-1

1-2. Installing/Removing the Cabinet

n

When installing/removing the cabinet and replacing the board, place the unit on the conductive cushion.

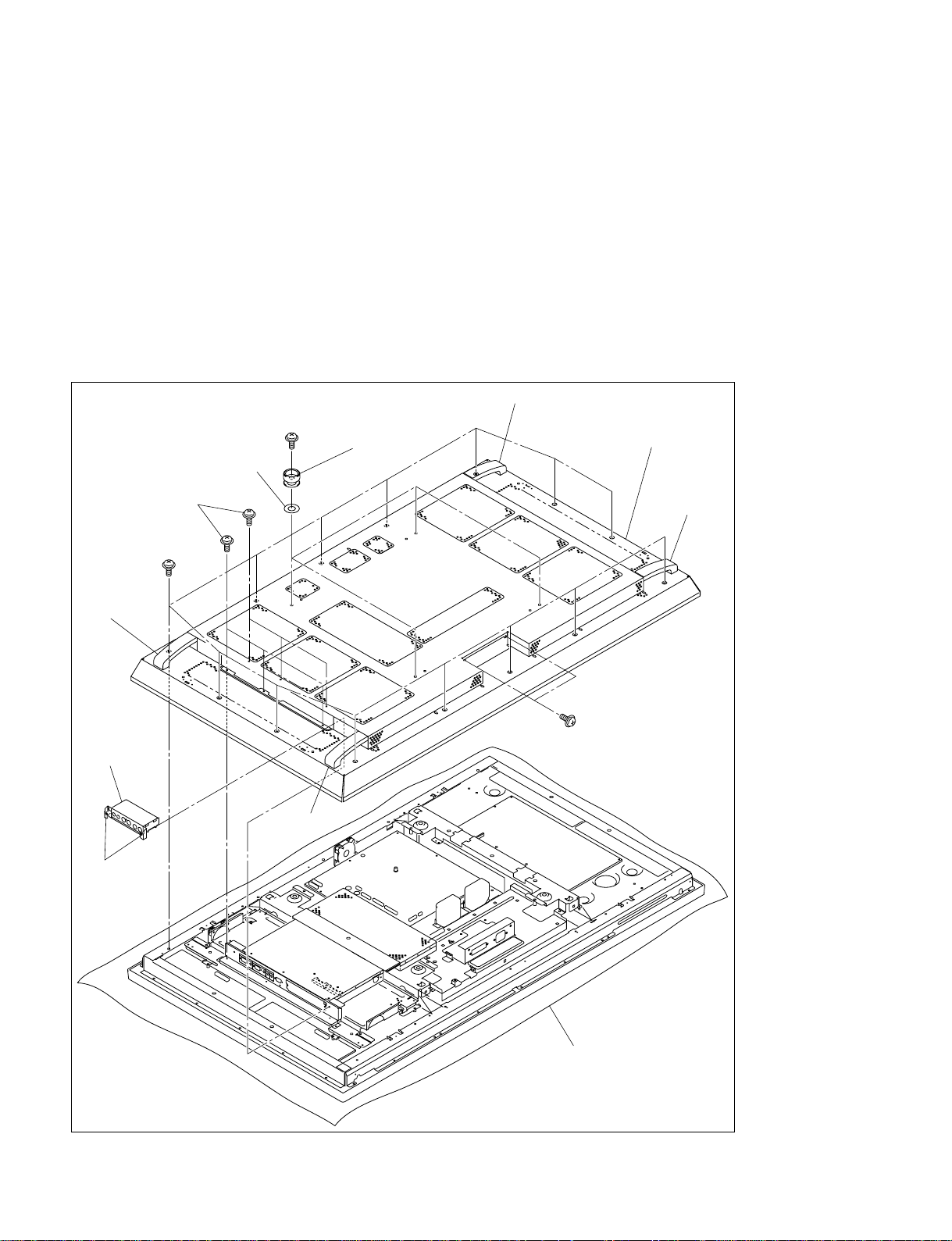

1-2-1. Rear Cover Assembly

1. Loosen the two panel securing screws, then remove the U1 block assembly. (FWD-50PX1 only)

2. Remove the four screws (PSW M6 x 20), then remove the four nylon washers and four knobs.

3. Remove the fourteen screws (PSW3 x 20) and eight screws (PSW3 x 8), then remove the rear cover

assembly while holding the handle.

Handle

PSW

M6 x 20

Knob

Nylon washer

Rear cover assembly

PSW

3 x 20

Handle

U1 block

assembly

(FWD-50PX1)

Panel securing

screws

PSW3 x 8

Handle

PSW3 x 8

Handle

4. Attach the rear cover assembly in the reverse order of steps 1 to 3.

1-2

Conductive cushion

FWD-50PX1

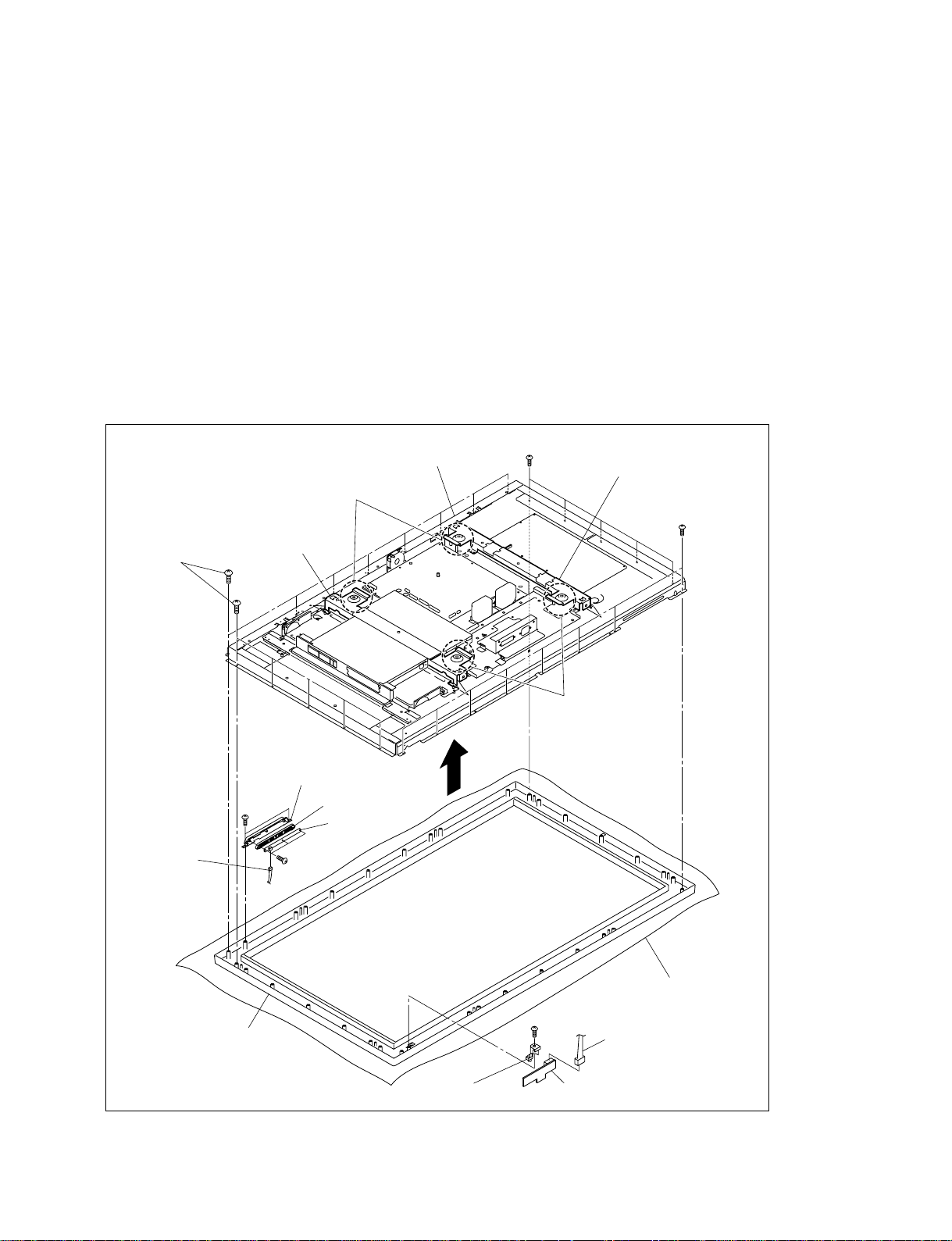

1-2-2. Bezel Assembly

m

. Be sure to remove the chassis assembly with more than two persons.

. Place the removed chassis assembly on the conductive cushion.

1. Remove the rear cover assembly. (Refer to Section 1-2-1.)

2. Remove the two screws (BVTP3 x 8), then remove the control button panel.

3. Disconnect the harness from the connector on the H2 board.

4. Remove the three screws (BVTP3 x 8), then remove the control button and H2 board.

5. Remove the screw (BVTP3 x 8), then remove the light tube and H1 board.

6. Disconnect the harness from the connector on the H1 board.

7. Remove the twenty-six screws (BVTP4 x 16).

8. Remove the chassis assembly while holding the portions A of the main bracket.

BVTP

4 x 16

Harness

Main bracket

Control button panel

BVTP

3 x 8

BVTP

3 x 8

Chassis assembly

Portions A

Control button

H2 board

BVTP4 x 16

Main bracket

BVTP4 x 16

Portions A

Bezel assembly

Light tube

9. Attach the bezel assembly in the reverse order of steps 1 to 8.

FWD-50PX1

BVTP

3 x 8

H1 board

Conductive

cushion

Harness

1-3

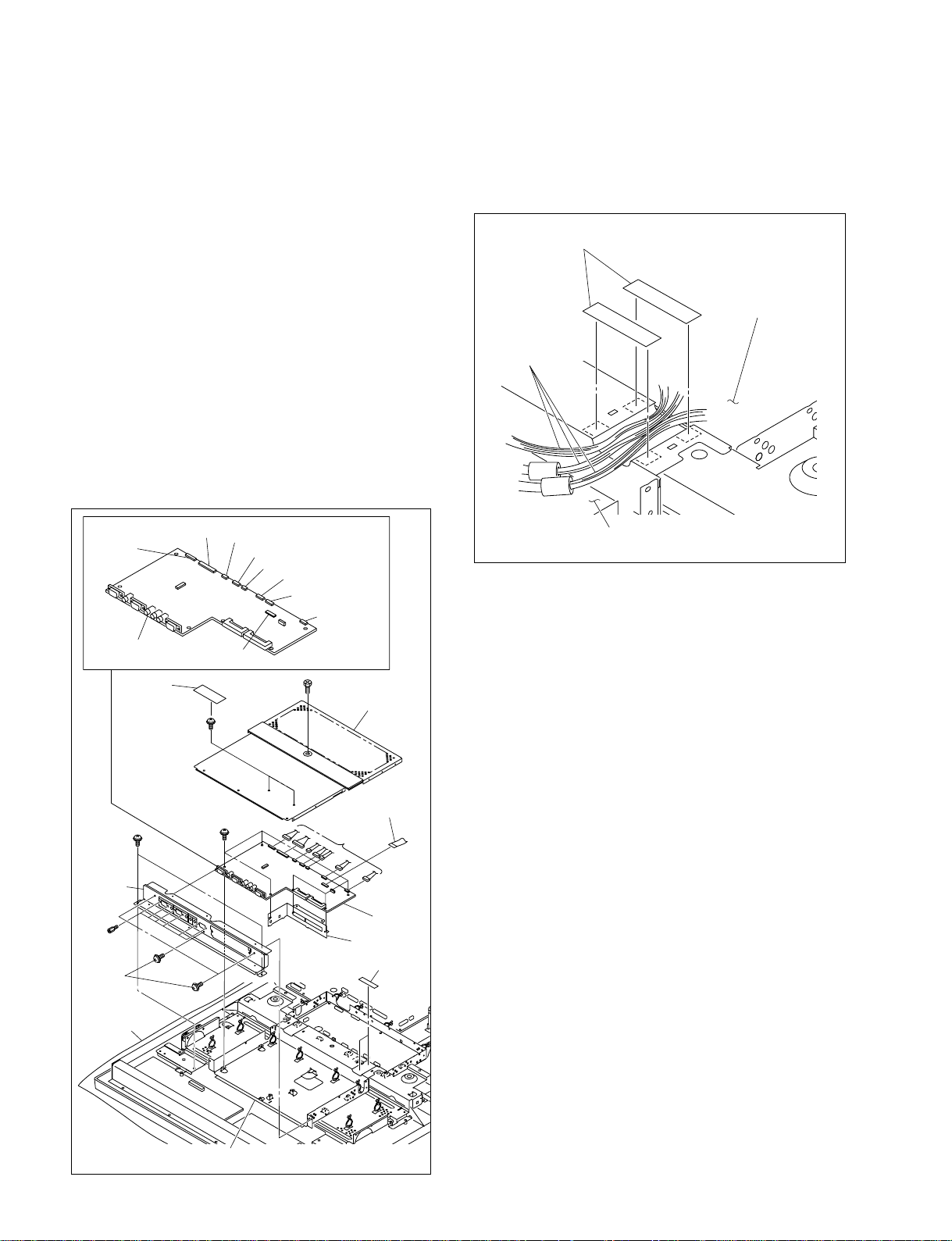

1-3. Replacing the Board

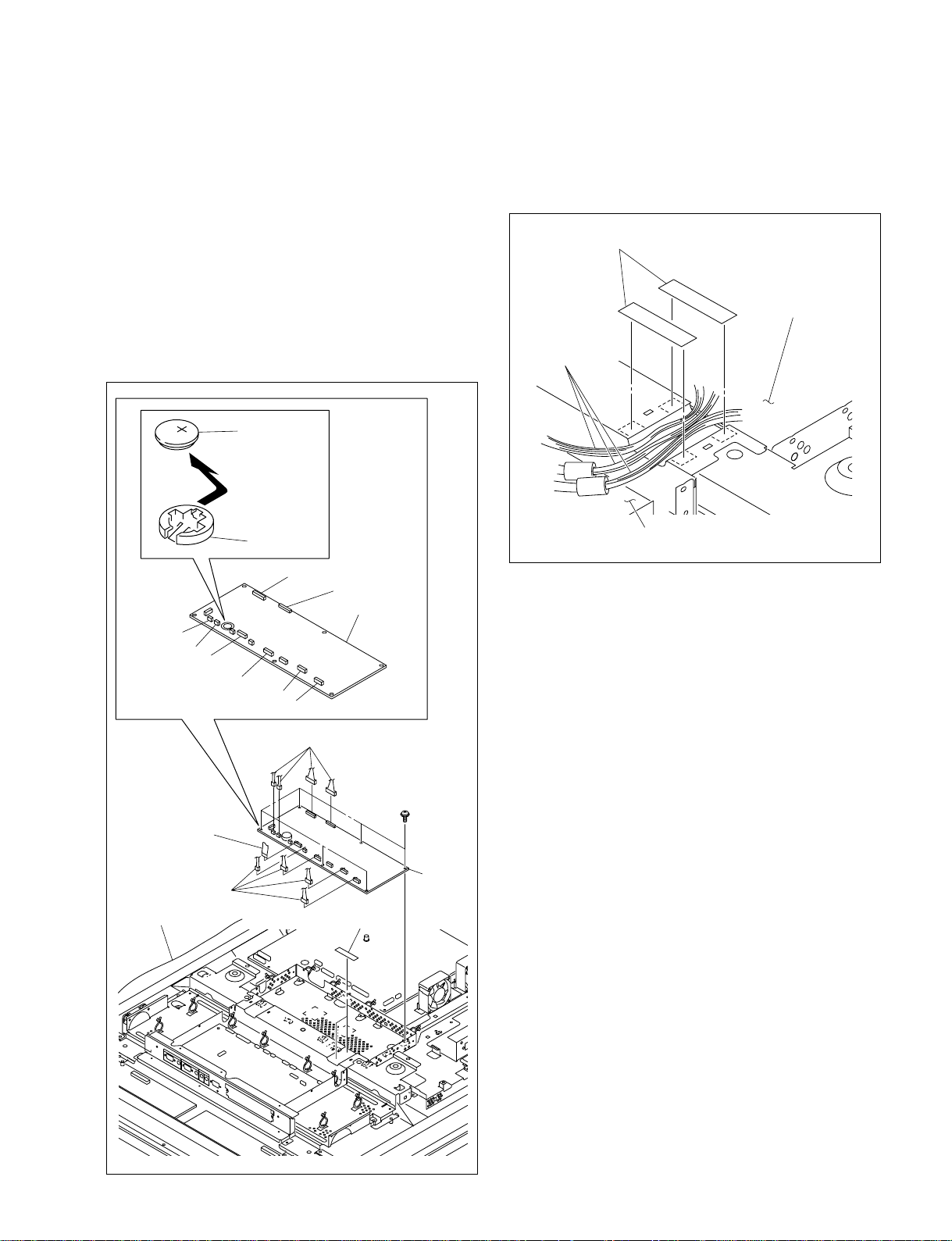

1-3-1. Q Board

1. Remove the rear cover assembly.

(Refer to Section 1-2-1.)

2. Remove the bolt, cushion (15x25), and two screws

(PSW3 x 8), then remove the Q/B shield cover.

3. Remove the two screws (PSW3 x 6), three screws

(PSW3 x 8) (black) and six hexagonal screws, then

remove the Q terminal plate.

4. Move the Q terminal plate slowly in the direction shown

by the arrow, then remove it from the copper foil tape.

5. Remove the two UL tapes, then disconnect the seven

harnesses and the flexible flat cable connected to the Q

board.

6. Remove the six screws, then remove the Q board and

partition Q.

7. Install the Q board in the reverse order of steps 1 to 6.

n

Place and fix the harnesses to connect the Q board and

B board as shown in the illustration.

UL tapes

B board

Harnesses

CN3007

Q board

PSW

3 x 6

Q terminal

plate

Hexagonal

screw

PSW

3 x 8

(black)

Conductive

cushion

Cushion

(15x25)

CN3005

PSW

3 x 6

PSW

3 x 6

CN3008

CN3002

CN3012

Q board

CN3011

CN3001

CN3006

CN3003

M8 x 16

Q/B shield cover

Flexible flat

cable

Harnesses

Q board

Partition Q

UL tapes

1-4

Copper foil tape

FWD-50PX1

1-3-2. B Board

1. Remove the rear cover assembly.

(Refer to Section 1-2-1.)

2. Remove the Q/B shield cover.

(Refer to step 2 of Section 1-3-1.)

3. Remove the two UL tapes, then disconnect the eight

harnesses and the flexible flat cable connected to the B

board.

4. Remove the six screws, then remove the B board.

5. Remove the lithium battery from the battery holder on

the B board.

Lithium battery

(CR1220)

6. Install the B board in the reverse order of steps 1 to 5.

n

Place and fix the harnesses to connect the Q board and

B board as shown in the illustration.

UL tapes

B board

Harnesses

CN1004

CN1005

Flexible flat

cable

Harnesses

Conductive

cushion

CN1001

CN101

Battery

holder

CN7002

CN401

CN402

Harnesses

CN7001

B board

UL tapes

PSW

3 x 6

B board

Q board

FWD-50PX1

1-5

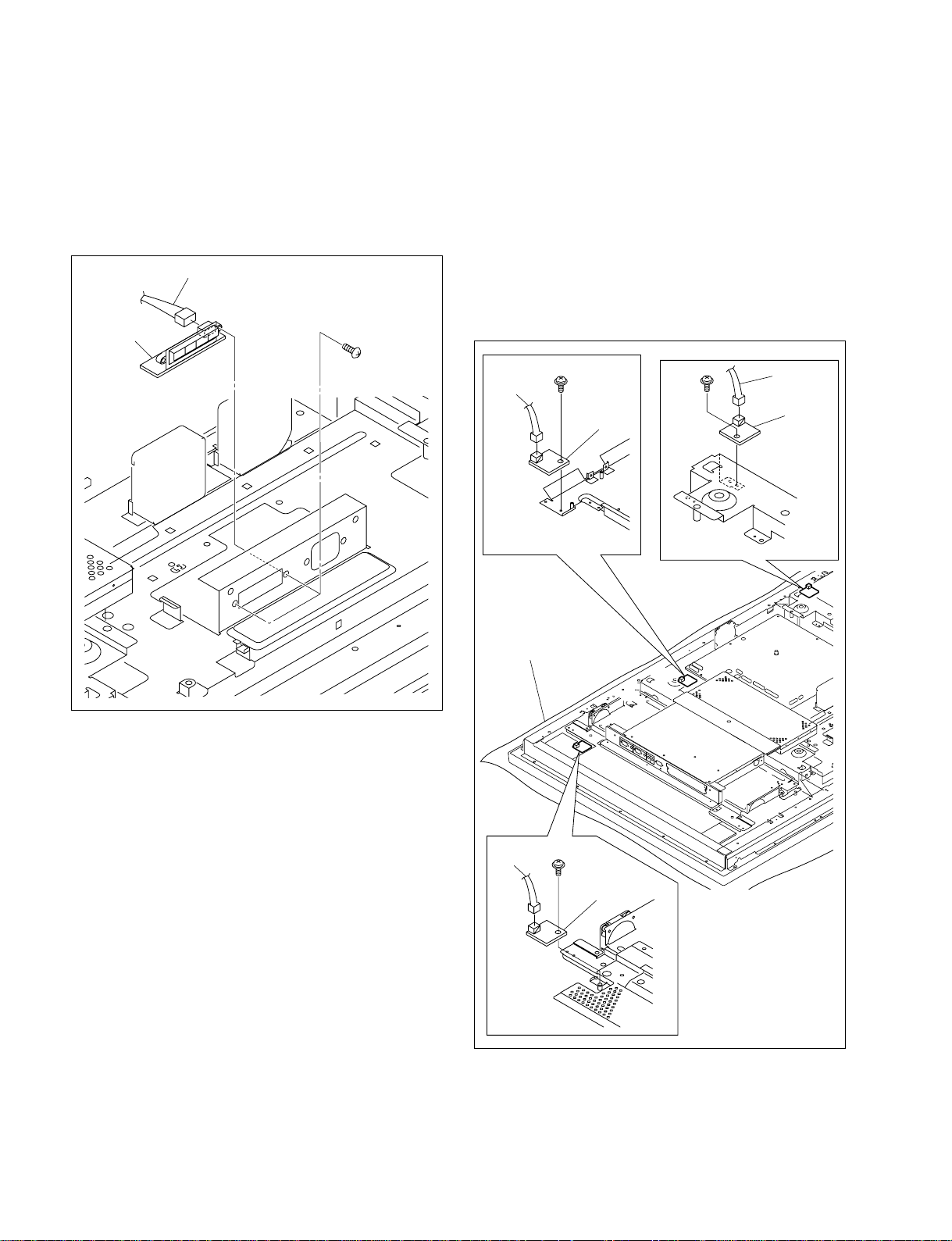

1-3-3. SP Board

1-3-4. S Board

1. Remove the rear cover assembly.

(Refer to Section 1-2-1.)

2. Remove the harness from the SP board.

3. Remove the two screws, then remove the SP board.

Harness

SP board

BVTP

3 x 8

n

The three S boards are installed in this unit. When

replacing them, remove/install in the same procedure.

1. Remove the rear cover assembly.

(Refer to Section 1-2-1.)

2. Disconnect the harness from the S board.

3. Remove the screw, then remove the S board.

Harness

PSW

3 x 6

S board

PSW

3 x 6

Harness

S board

4. Install the SP board in the reverse order of steps 1 to 3.

Conductive cushion

Harness

PSW

3 x 6

S board

4. Install the S board in the reverse order of steps 1 to 3.

1-6

FWD-50PX1

1-3-5. Y Drive Board

1. Remove the rear cover assembly.

(Refer to Section 1-2-1.)

2. Remove the five connectors.

3. Remove the harness from the eight clampers.

4. Remove the bolt (M8 x 16) and four screws (PSW3 x

6), then remove the QB block assembly in the

direction shown by the arrow.

5. Remove the three screws (PSW3 x 6), then remove

the side frame and board cover assembly.

Connectors

PSW

3 x 6

Clamper

M8 x 16

PSW

3 x 6

Connector

6. Remove the four screws, then remove the option case

bracket assembly.

7. Disconnect the harness and flexible flat cable from the

connectors on the Y drive board.

8. Remove the two connectors from the scan A board and

scan B board.

9. Remove the two screws [B], six screws [A], five

screws [C] and four board holders, then remove the Y

drive board.

PSW

3 x 6

Flexible flat cable

Option case bracket

assembly

Clampers

QB block

assembly

Connector

PSW

3 x 6

Clampers

Side frame

Board cover

assembly

Harness

Screw

[A]

Connectors

Conductive

cushion

Scan B board

Board holders

Scan A board

Screw

[B]

Screw

[C]

Y drive board

Board

holders

10. Install the Y drive board in the reverse order of steps 1

to 9.

FWD-50PX1

1-7

1-3-6. X Drive Board

1-3-7. Digital Video Board/Interface Board

1. Remove the rear cover assembly.

(Refer to Section 1-2-1.)

2. Disconnect the harness and flexible flat cable from the

connectors on the X drive board.

3. Remove the two screws [A], six screws [C], five

screws [B] and four board holders, then remove the X

drive board.

Screw [B]

Screw [A]

Screw [C]

X drive board

Board holders

Conductive cushion

1. Remove the rear cover assembly.

(Refer to Section 1-2-1.)

2. Remove the QB block assembly.

3. Remove the power unit.

(Refer to steps 2 and 3 of Section 1-4-1.)

4. Disconnect all harnesses and flexible flat cables from

the connectors on the digital board.

5. Remove the six board holders, then remove the digital

video board.

6. Disconnect all harnesses and flexible flat cables from

the connectors on the interface board.

7. Remove the six board holders, then remove the

interface board.

Flexible flat cable

Harnesses

Flexible flat cable

Flexible flat cables

Harnesses

Board holders

4. Install the X drive board in the reverse order of steps 1

to 3.

Flexible flat

cables

Digital video

board

Harness

Board holders

Interface board

Board holdersBoard holders

8. Install the digital video board and interface board in

the reverse order of steps 1 to 7.

1-8

FWD-50PX1

1-4. Replacing the Main Parts

1-4-1. Power Unit/DC Fan (For Power Supply)

n

When attaching the DC fan, make sure that the orientation

of imprinting is correct.

1. Remove the rear cover assembly.

(Refer to Section 1-2-1.)

2. Disconnect the nine harnesses from the connectors on

the power unit.

3. Remove the bolt (M8 x 16) and four screws (PSW3 x

6), then remove the QB block assembly.

4. Remove the four connectors [A].

5. Remove the three connectors [B].

6. Disconnect the three harnesses from the connectors on

the interface board.

7. Disconnect the harness from the connector on the SP

board.

8. Remove the harness from the four purse locks.

9. Remove the four screws, then remove the K board

bracket assembly.

10. Remove the four screws (BVTT3 x 6), then remove

the G bracket.

11. Remove the two screws (PSW4 x 25), then remove

the DC fan.

12. Remove the four screws (PSW4 x 35), then remove

the two DC fans.

13. Remove the seven screws, then remove the power unit.

Power unit

Imprinting

DC fan

Purse lock

PSW

3 x 6

Imprinting

PSW

3 x 6

Connector [B]

Conductive

cushion

Connectors [A]

M8 x 16

QB block assembly

Connectors [B]

Harness

Harness

SP board

Harnesses

PSW

4 x 25

DC fan

G bracket

K board bracket

assembly

Conductive cushion

BVTT

3 x 8

DC fan

PSW

4 x 35

PSW

3 x 6

Purse

locks

14. Attach the power unit and DC fan in the reverse order

of steps 1 to 13.

FWD-50PX1

Interface board

1-9

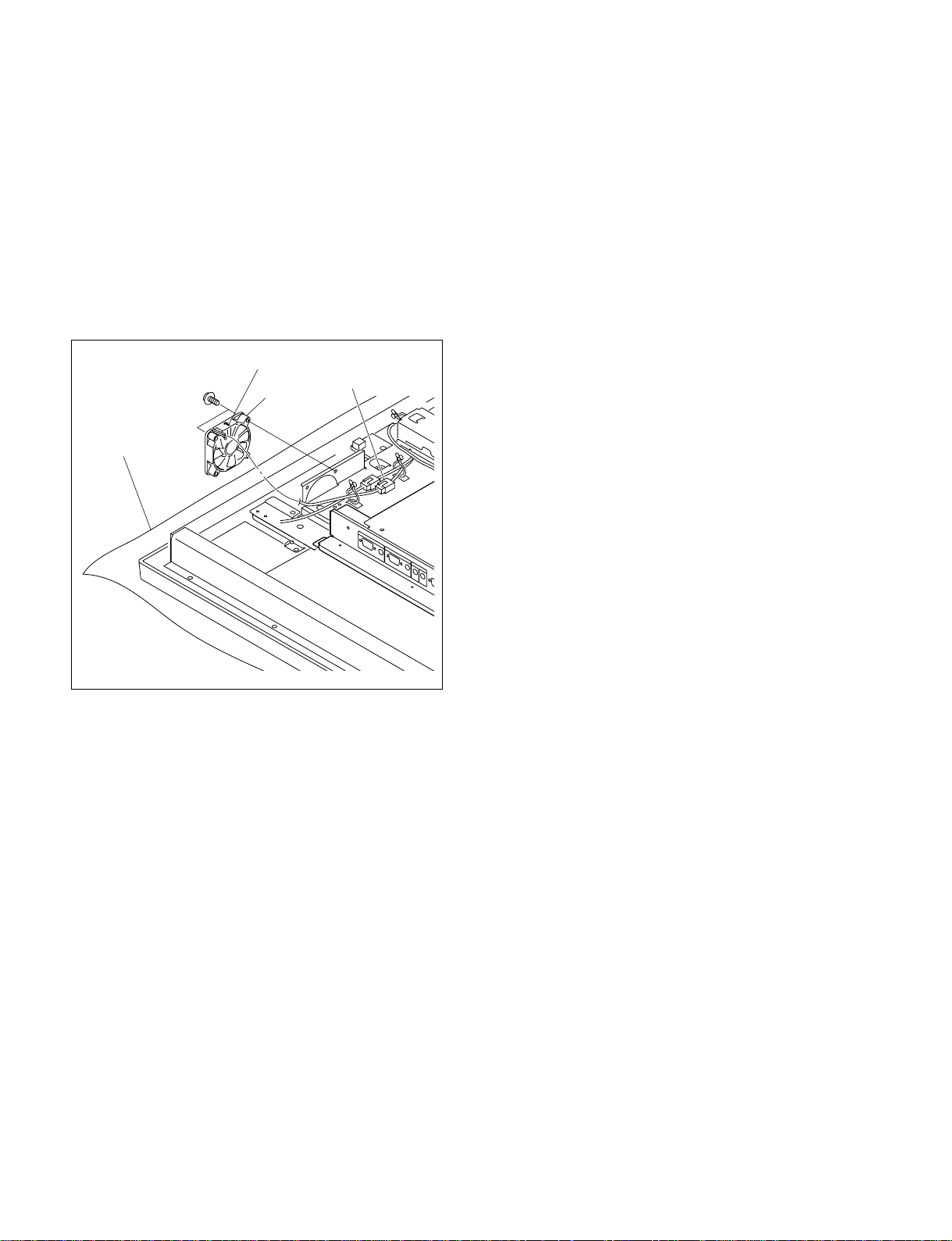

1-4-2. DC Fan (For Q/B Mount)

n

When attaching the DC fan, make sure that the orientation

of imprinting is correct.

1. Remove the rear cover assembly.

(Refer to Section 1-2-1.)

2. Remove the connector and two screws, then remove

the DC fan.

Imprinting

PSW

4 x 25

Conductive cushion

DC fan

Connector

3. Attach the DC fan in the reverse order of steps 1 and 2.

1-10

FWD-50PX1

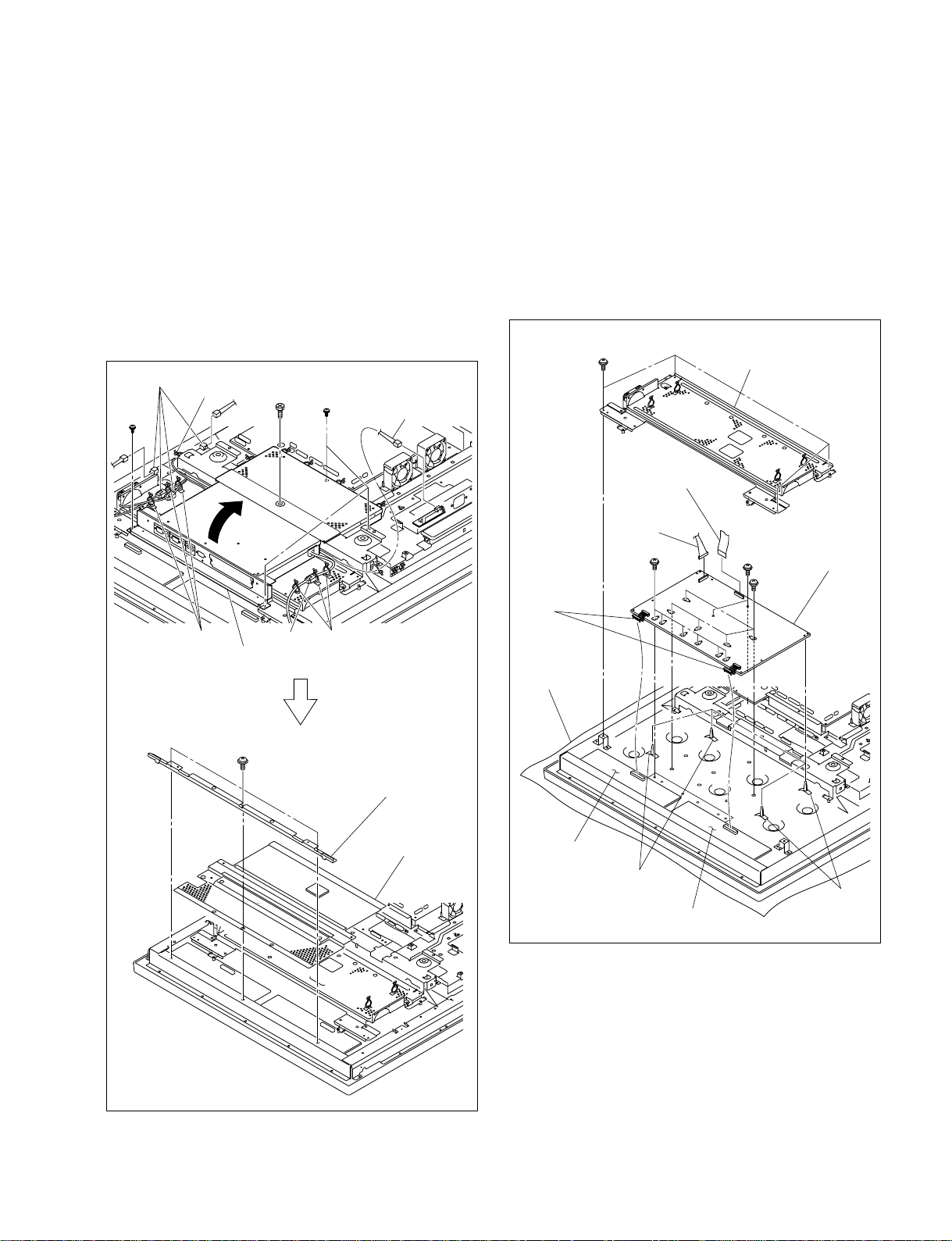

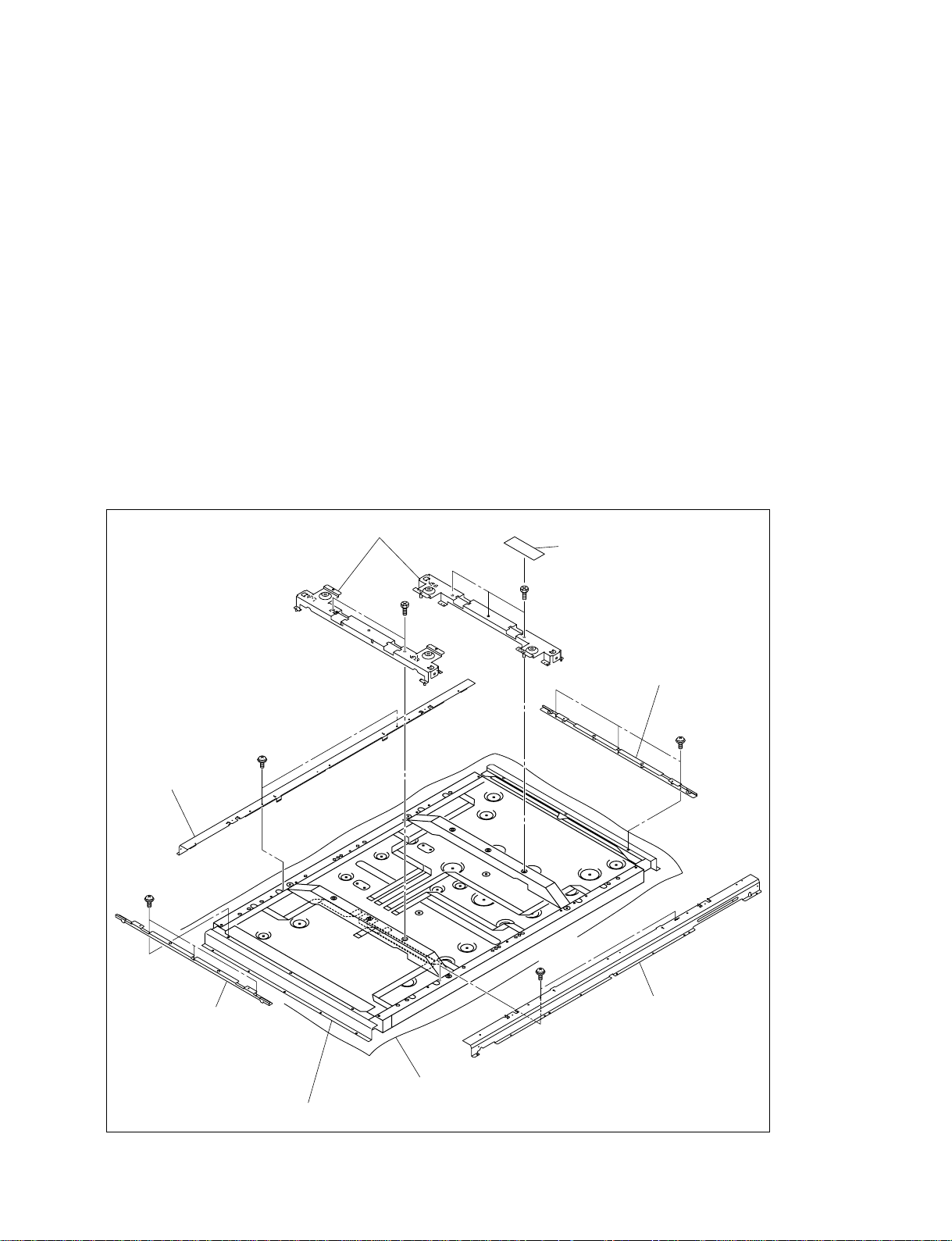

1-4-3. Plasma Display Panel

n

Be sure to replace the plasma display panel with two persons.

1. Remove the rear cover assembly. (Refer to Section 1-2-1.)

2. Remove the bezel assembly. (Refer to Section 1-2-2.)

3. Remove the QB block assembly. (Refer to Section 1-4-1.)

4. Remove the S board. (Refer to Section 1-3-4.)

5. Remove the Y drive board. (Refer to Section 1-3-5.)

6. Remove the X drive board. (Refer to Section 1-3-6.)

7. Remove the digital video board and interface board. (Refer to Section 1-3-7.)

8. Remove the power unit. (Refer to 1-4-1.)

9. Remove the cushions (15x25) attached to the heads of the three bolts on the right side as viewed

from backside.

10. Remove the five bolts (M8 x 16), then remove the two main brackets.

11. Remove the four screws (PSW3 x 8), then remove the two frames (H).

12. Remove the six screws (PSW3 x 8), then remove the two side frames.

Frame (H)

PSW3 x 6

PSW3 x 6

Main brackets

M8 x 16

Cushion

(15x25)

M8 x 16

(Right side as viewed from backside)

Side frame

PSW3 x 6

PSW

3 x 6

Side frame

Conductive cushion

Plasma display panel

13. Attach the plasma display panel in the reverse order of steps 1 to 12.

FWD-50PX1

Frame (H)

1-11

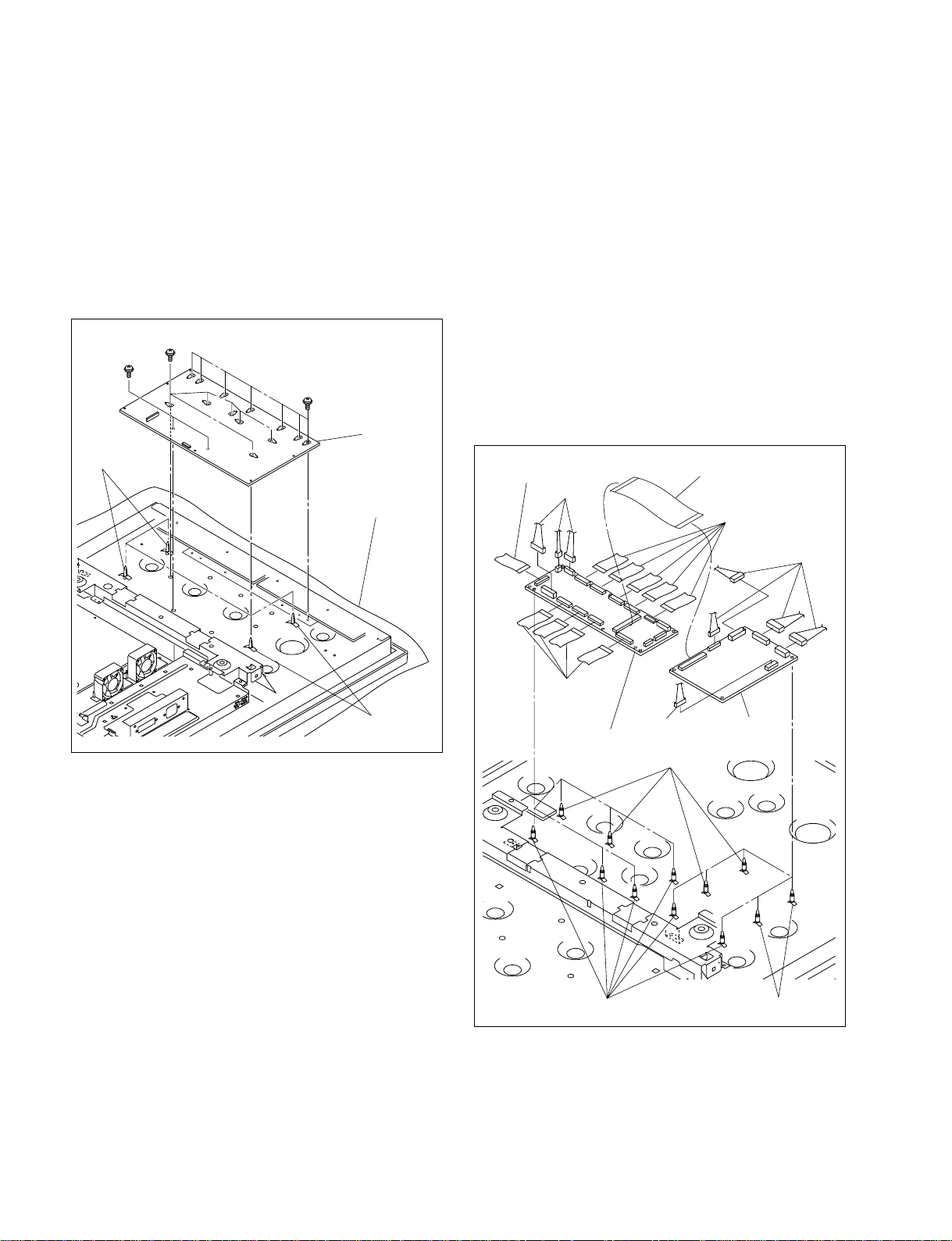

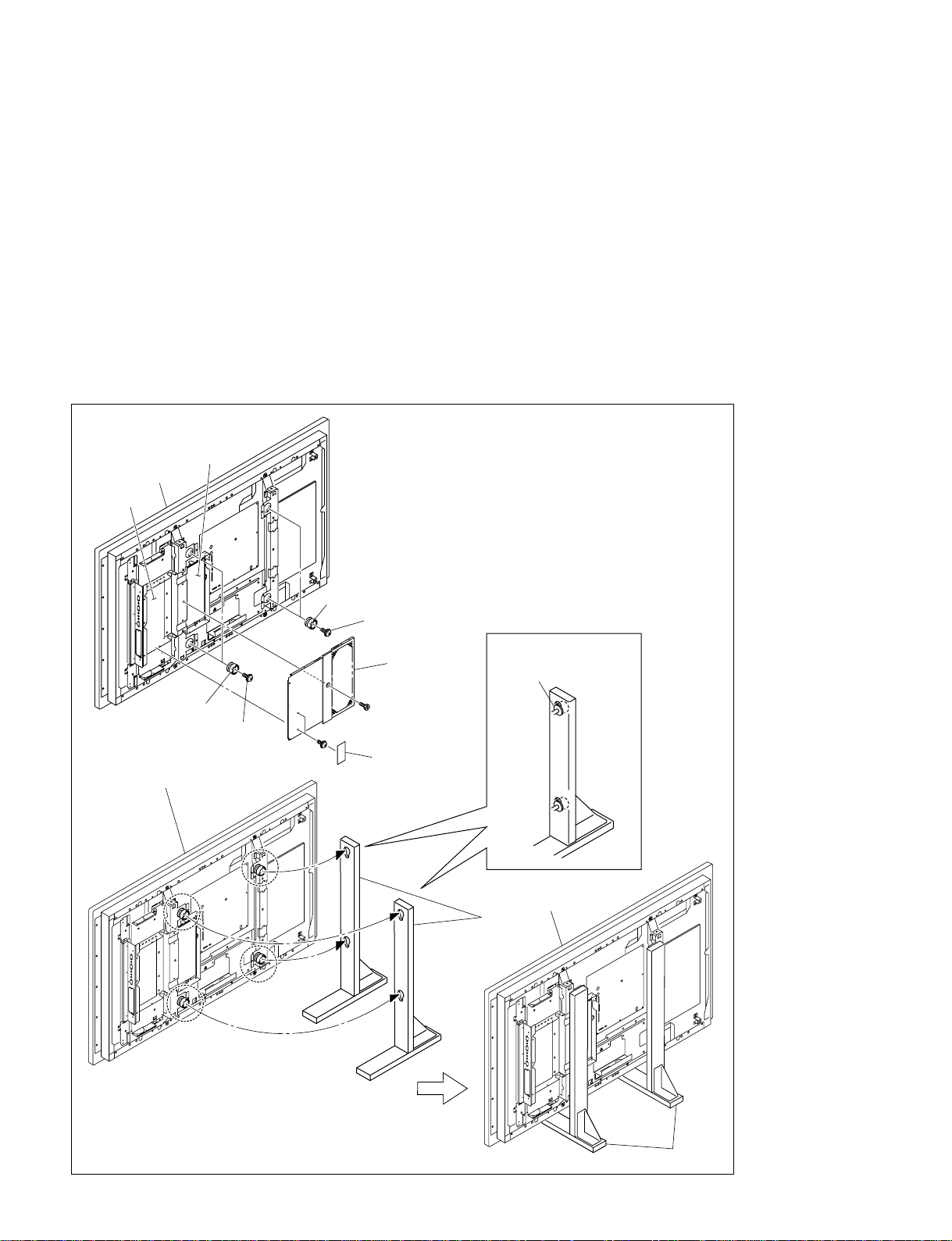

1-5. Service Position

1-5-1. Service Position of the B and Q Boards

m

. Be sure to attach the stand with more than two persons.

. When attach the stand to the unit, check that four knobs are attached to the holes of the stand.

1. Remove the rear cover assembly. (Refer to Section 1-2-1.)

2. Remove the two cushions (15x25) attached to the two screws.

3. Remove the bolt (M8 x 16) and two screws, then remove the QB shield assembly.

4. Attach the four knobs to the unit by the four screws.

5. Attach the four knobs to the holes of the each stand.

B board

Unit

Q board

Unit

Knobs

PSW

M6 x 20

PSW

3 x 6

Knobs

PSW

M6 x 20

Q/B shield

cover

Bolt

(M8 x 16)

Cushion

(15x25)

Atacch the two knobs

to the each stand.

Unit

Stands

1-12

Stands

FWD-50PX1

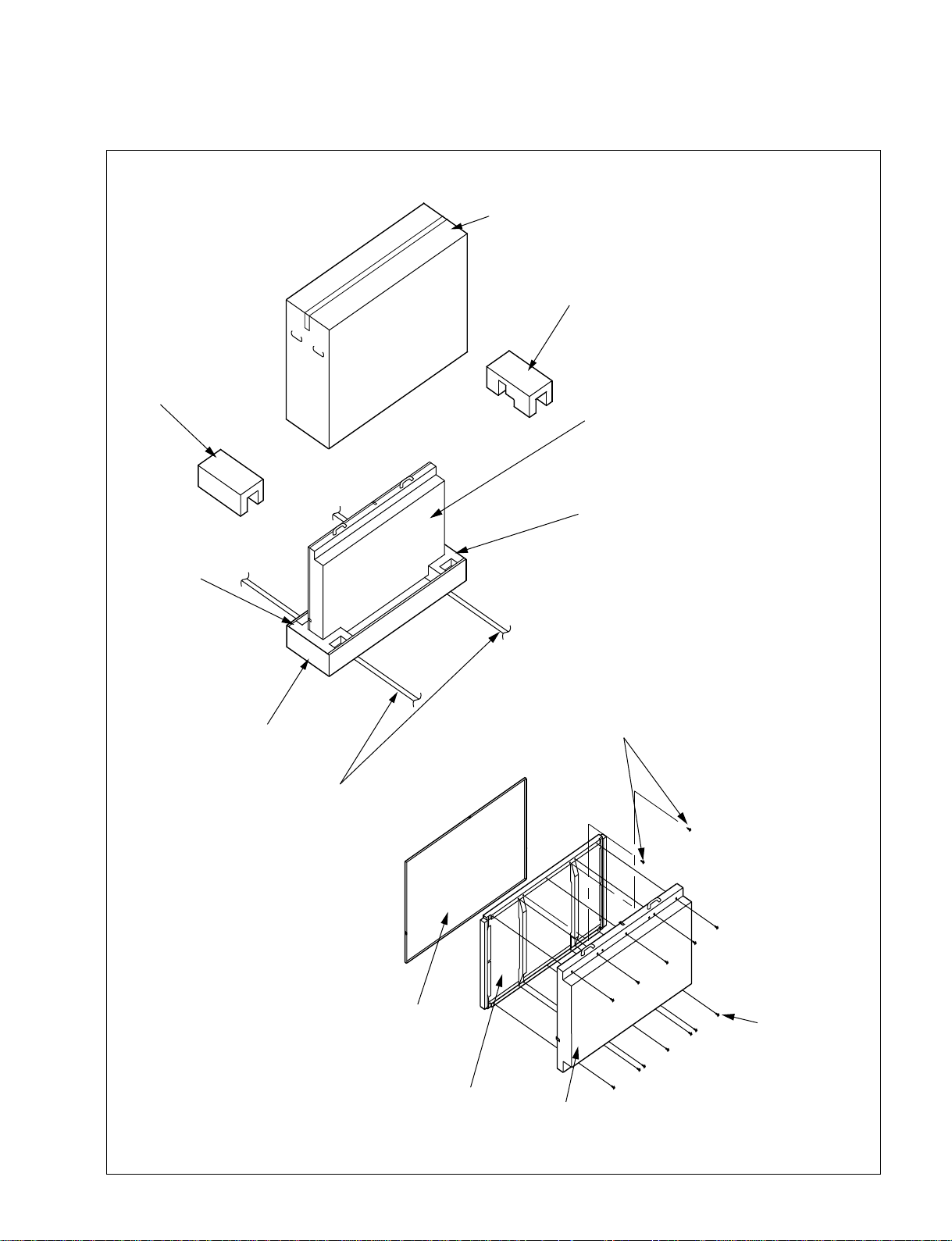

1-6. Packaging of the Plasma Display Panel When It Is Shipped to Pioneer Corporation

Carton (Upper)

Pad R (Upper)

Pad L (Upper)

Individual inner case

Pad R (Under)

Pad L (Under)

Carton (Under)

PP bands

FRONT LID

SERVICE

MODULE

POSITIONING

SCREWS

Screws (12 pcs)

Individual inner case

FWD-50PX1

1-13

1-7. Backup Battery Replacement

1-8. Unleaded Solder

The B board contain the lithium battery for the clock.

c

When replacing the part, be sure to use the specified one

below.

Replacement with a part other than the specified part will

result in fire hazards and electric hazards.

Replacement part

Part description: Lithium battery (CR1220)

Part No.: ! 1-756-157-11

Replacement

1. For removing the lithium battery, refer to steps 1 to 5

in Section 1-5-3.

2. Attach the lithium battery in the reverse order of steps.

1-9. Warning on Power Connection

Boards requiring use of unleaded solder are printed with a

lead free mark (LF) indicating the solder contains no lead.

(Caution: Some printed circuit boards may not come

printed with the lead free mark due to their particular size.)

: LEAD FREE MARK

m

. Be sure to use the unleaded solder for the printed circuit

board printed with the lead free mark.

. The unleaded solder melts at a temperature about 40 dC

higher than the ordinary solder, therefore, it is recommended to use the soldering iron having a temperature

regulator.

. The ordinary soldering iron can be used but the iron tip

has to be applied to the solder joint for a slightly longer

time. The printed pattern (copper foil) may peel away if

the heated tip is applied for too long, so be careful.

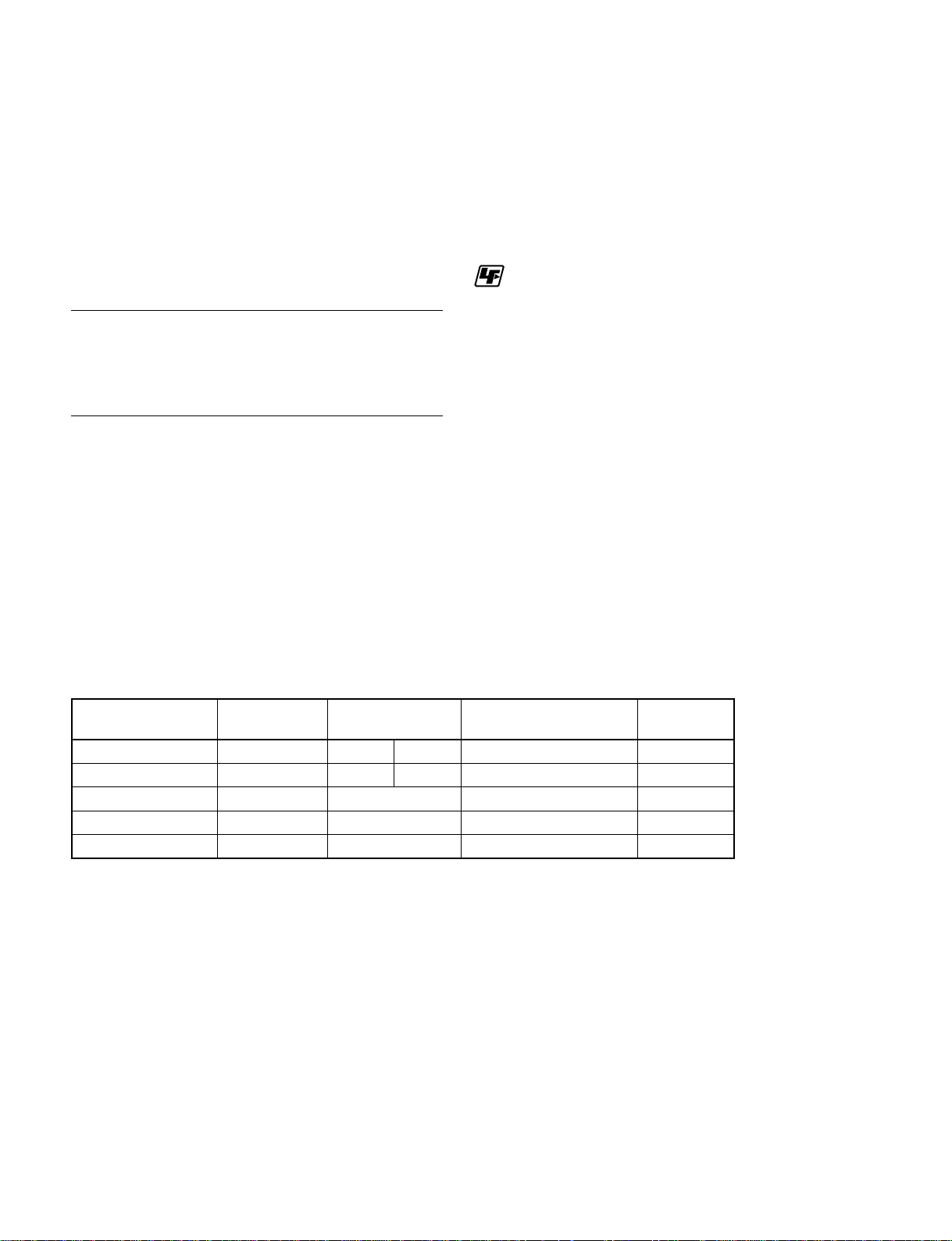

Use the proper power cord for your local power supply.

FWD-50PX1

United States, Continental United Kingdom, Ireland, Japan

Canada Europe Australia, New Zealand

Plug type VM0233 COX-07 636 _ a) VM1296

Female end VM0089 COX-02 VM0310B VM0303B VM1313

Cord type SVT H05VV-F CEE (13) 53rd (O.C) HVCTF

Minimum cord set rating 10A/125V 10A/250V 10A/250V 10A/125V

Safety approval UL/CSA VDE VDE DENAN-HO

a) Note : Use an appropriate rating plug which is applied to local regulations.

1-14

FWD-50PX1

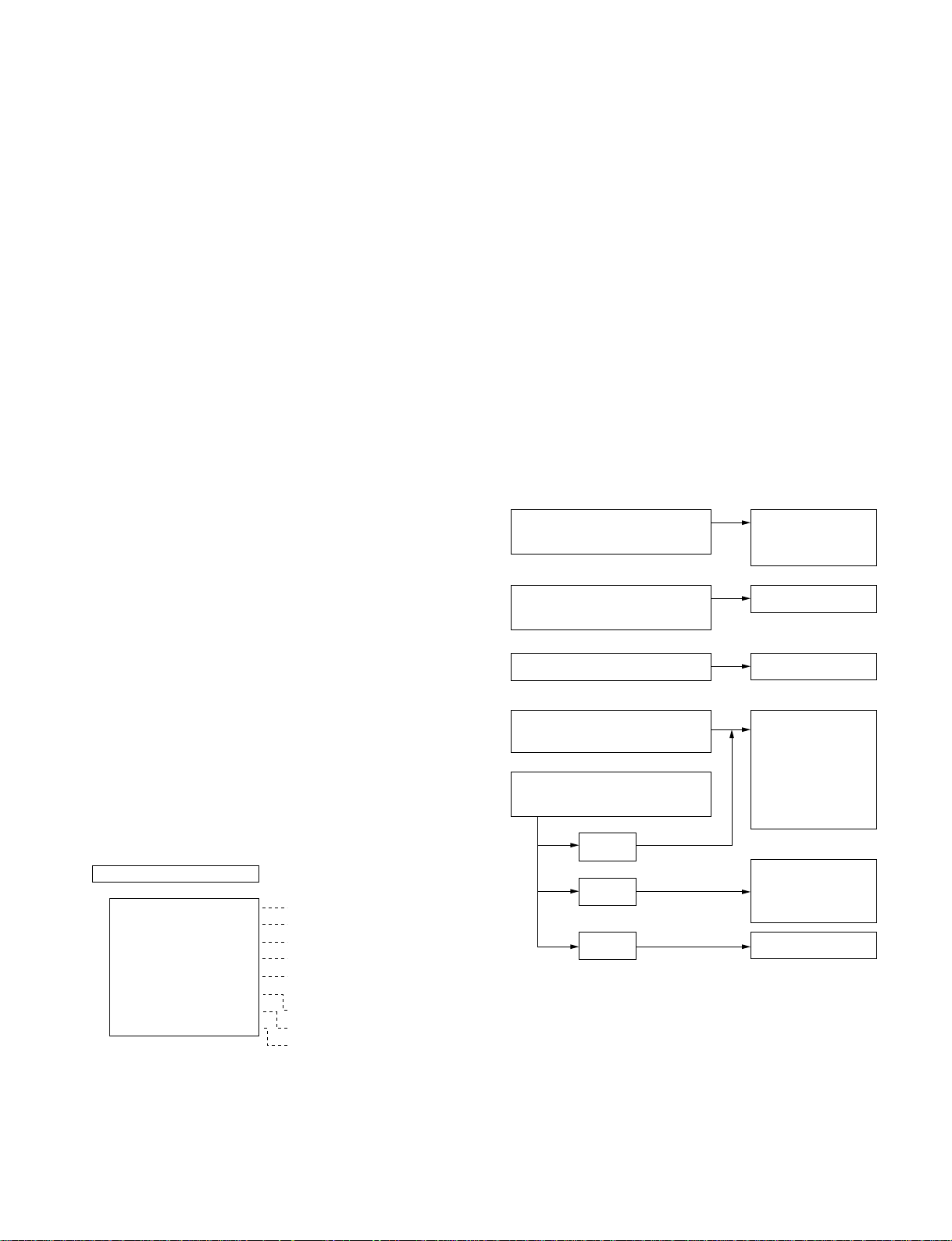

Section 2

Chroma Decoder

AD Converter

White Balance

When IC403/B board and its

peripheral part is replaced.

AD Converter

When PDP is replaced.

White Balance

When memory (IC1007) on the

B board is replaced.

EEPROM Initialize

Chroma Decoder

AD Converter

White Balance

General

Service Status

When any of the circuit boards

below is replaced.

B board

Q board

S board

Chroma Decoder

AD Converter

Service Status

Service Status

When any repair related to picture

quality is executed.

Operation check only

Electrical Adjustments

2-1. Equipment Required

. Oscilloscope

Tektronix 2465 or equivalent

(band width : 350 MHz or more)

. VG (Programmable video signal generator)

VG814 or equivalent

. Frequency counter

Advantest TR5821AK or equivalent

. Digital voltmeter

Advantest TR6845 or equivalent

. Potential transformer

. Regulated DC power supply

. Remote commander (RM-980C)

n

Perform the following adjustments at least 5 minutes after

turning on the power.

2-2. Electrical Adjustments Using the

Service Mode

Press the [STBY] key once and back on to enter the STANDBY state or turn off the main power to exit the Service Mode.

..

. Operation of remote commander in the Service

..

Mode

The six keys of MENU, ENTER, ←, →, ↑ and ↓ are the

basic operation keys in the same manner as in the user

adjustment. The other keys can be operated in the same

manner as in the user adjustment.

..

. The electrical adjustments using the Service

..

Mode become necessary in the following cases.

When one of the following adjustments is made,

adjustment using the service mode becomes necessary.

The electrical adjustments can be performed using the remote

commander RMremote commander has the Service Mode. Select the Service

Mode to perform the electrical adjustments as listed below.

..

. Service Mode

..

When the machine enters the service mode, the “Service

Mode” submenu is displayed in addition to the ordinary

user menu. The electrical adjustment is executed using the

“Service Mode” submenu.

Service Mode

EEPROM Initialize Initializes the EEPROM

Chroma Decoder Chroma decoder adjustment

AD Converter A/D converter adjustment

White Balance White balance adjustment

General Other adjustments and the

Manual Control functions required for check

Preset Edit Factory check menu (Not used in service)

Service Status Editing the preset signal

How to enter the Service Mode using the RM-980C :

In the STAND-BY state, press the keys in the following

order.

[DISPLAY] → [5] → [VOL+] → [

FWD-50PX1

980C

supplied with the FWD-50PX1. The

Internal status check

POWER|ON

]

2-1

Service Mode

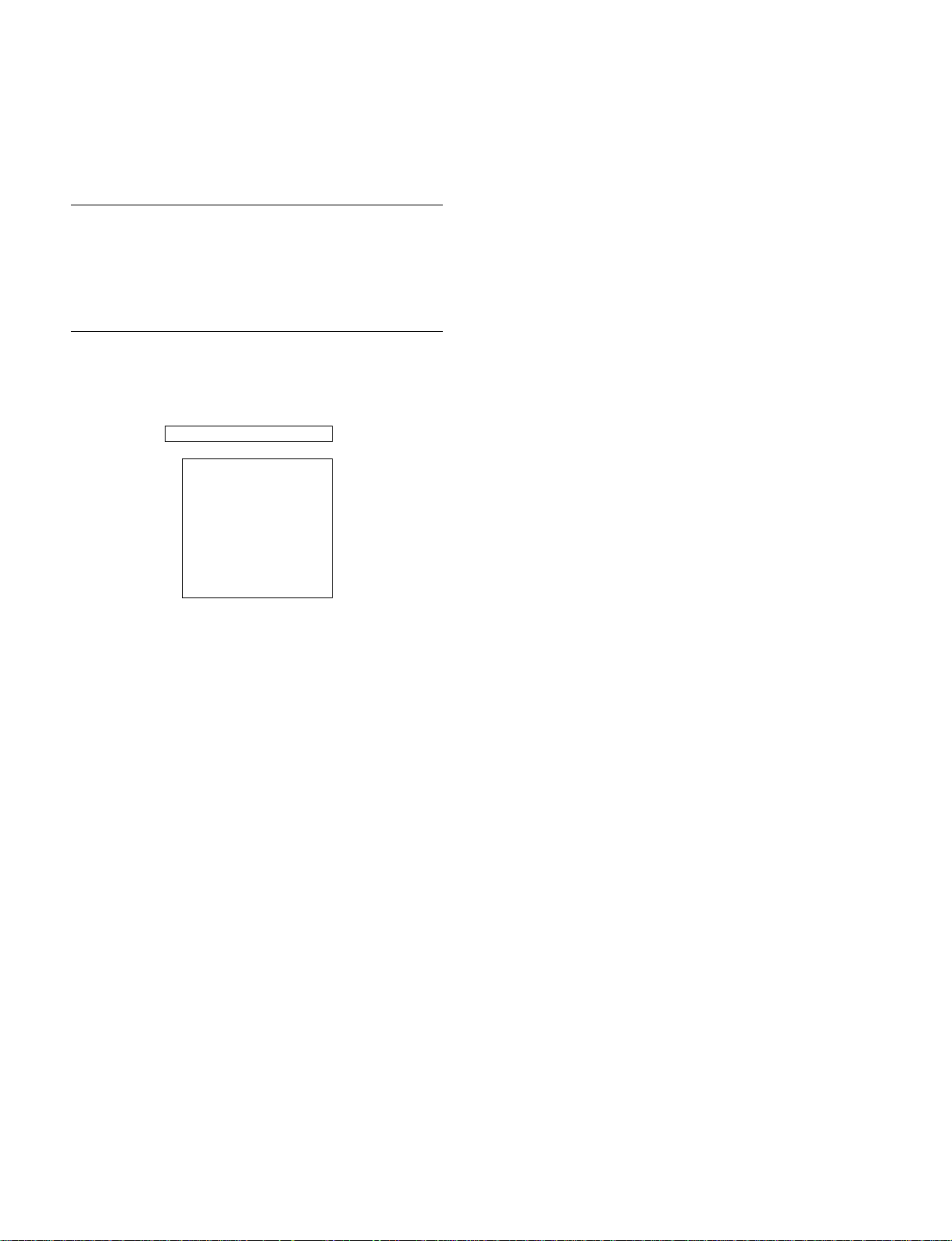

1. EEPROM Initialize

EEPROM Configuration

Table 1 (page 2-13) shows the configuration of EEPROM.

The entire area or the respective areas of the EEPROM can

be separately initialized.

Menu Structure

Select the desired area of EEPROM to be initialized using

the following menu.

Service Mode

EEPROM Initialize

Whole Area

Common

White Balance

Prog. Gamma

Prog. Preset

Last Memory

User Memory

Factory

To initialize the desired area, firstly select the desired item

from the EEPROM RESET menu. Change the selected

item from “CANCEL” to “OK”. Then press “ENTER”.

a) Whole Area

It initializes whole area of EEPROM.

This command is identical to carrying out the all items

of “Common”, “White Balance”, “Prog. Gamma”,

“Prog. Preset”, “Last Memory”, “User Memory” and

“Factory”.

Execute this command only when the memory

(IC1007) on the B board is replaced.

b) Common

It initializes “Common (1)”, “Common (2)” and

“Common (3)” of the “COMMON DATA AREA”

shown in Table 1.

It initializes the data unique to the machine and the

common data (various setup values of the user menu).

Do not carry out this command because it initializes

the serial number and accumulative operation hours.

c) White Balance

It initializes “Color Temp (1)” and “ Color Temp (2)”

of the “COMMON DATA AREA” shown in Table 1.

It initializes the color temperature “High”, “Mid” and

“Low”, and all data of user setup 1 to 3 to 00.

It also initializes the user name to “User1”, “User2”

and “User3”.

d) Prog. Gamma

This command is not used in this machine.

e) Prog. Preset

It initializes the “PRESET DATA AREA” (page 2-13)

shown in Table 1.

It resets the backup preset area.

f) Last Memory

It initializes “LAST MEMORY AREA” (pages 2-13,

14) shown in Table 1.

It initializes the last memory data that user has adjusted for each signal.

g) User Memory

This command is not used in this machine.

h) Factory

It resets the EEPROM to the factory default status.

All of the EEPROM areas except the following are

initialized by this command.

Items that are not initialized by the “FACTORY”

RESET function.

In the COMMON DATA AREA

1 Index Number stored in the Common (1) [General]

2 Watch Error and Serial Number data stored in the

Common (2) [General]

3 Service (1) [AD Converter] (Adjustment data of 2-4.

AD Calibration Adjustment)

4 Service (2) [Chroma Decoder] (Adjustment data of 2-

5. Sub Color, Sub Hue adjustment and 2-6. Video

Decoder Adjustment)

5 Adjustment data in Color Temp (1) [Data & Name] at

the factory except user adjustment value. (Adjustment

data of 2-3. White Balance Adjustment)

2-2

FWD-50PX1

2. Chroma Decoder

Menu structure

Hue and color of the video signal are adjusted.

Service Mode

Chroma Decoder

Hue

Sub Contrast : 8

Sub Color

Sharp Gain : 8

Sharp f0 : 3

Y Out Level : 18

C Out Level : 10

Y Delay

Cb Offset : 8

Cr Offset : 8

By Adj (SECAM) : 8

Ry Adj (SECAM) : 8

a) Hue

To adjust NTSC signal hue, adjust “Hue (NTSC)” in

the lower layer below this sub menu.

To adjust NTSC4.43 signal hue, adjust “Hue (NT443)”

in the lower layer below this sub menu.

Adjustment range is from 0 to 63.

b) Sub Contrast

Adjustment range is from 0 to 63.

Fixed value : 8

c) Sub Color

Adjust “Col (NTSC)”, “Col (PAL)” and “Col (SECAM)” for the respective signals of NTSC, PAL and

SECAM.

Adjustment range is from 0 to 15.

Fixed value for Col (NTSC) only : 6

d) Sharp Gain

Adjustment range is from 0 to 15.

Fixed value : 8

e) Sharp f0

Adjustment range is from 0 to 3.

Fixed value : 3

f) Y Out Level

Adjustment range is from 0 to 63.

Fixed value : 18

g) C Out Level

Receive the NTSC signal and adjust color. The color

adjustment of PAL and SECAM signals are performed

in c) Sub Color upon completion of the NTSC signal

adjustment.

Adjustment range is from 0 to 63.

h) Y Delay

Y delay for the respective signals can be adjusted by

“YDL (NTSC)”, “YDL (PAL)”, “YDL (SECAM),

“YDL (NT443)”, “YDL (PALM)” and “YDL

(PALN)”.

Adjustment range is from 0 to 15.

Fixed value : 5

i) Cb Offset

Adjustment range is from 0 to 15.

Fixed value : 8

j) Cr Offset

Adjustment range is from 0 to 15.

Fixed value : 8

k) By Adj (SECAM)

The blue offset when receiving the SECAM signal is

adjusted.

Adjustment range is from 0 to 15.

l) Ry Adj (SECAM)

The red offset when receiving the SECAM signal is

adjusted.

Adjustment range is from 0 to 15.

Sub Color and Sub Hue Adjustments

Refer to Section “2-5. Sub Color and Sub Hue Adjustment”.

Video Decoder Adjustment

Refer to Section “2-6. Video Decoder Adjustment”.

FWD-50PX1

2-3

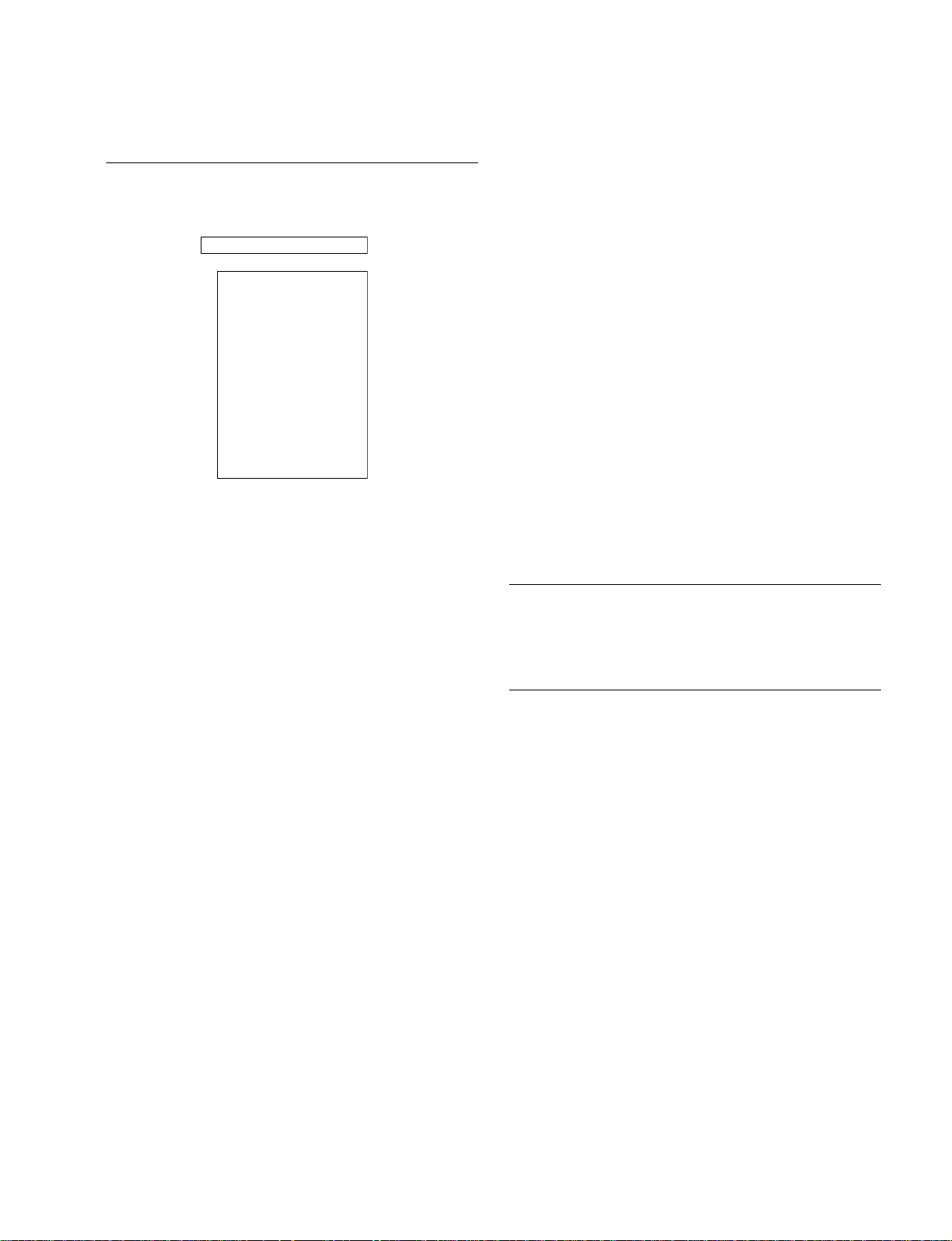

3. AD Converter

Service Mode

White Balance

Window : Off

Color T emp . : High

Red Gain llllllllll

Green Gain llllllllll

Blue Gain llllllllll

4. White Balance

Menu structure

This adjustment corrects non-uniformity among RGB (or

YCbCr) channels of AD converter (IC403).

Service Mode

AD Converter

Cal Mode : off

RGB Calibration

YUV Calibration

Video Calibration

a) Cal Mode

Set to “On” to enter the calibration mode.

Off : Normal operation

On : Calibration mode

b) RGB Calibration

The RGB signals are calibrated.

The RGB signals are calibrated by “Sub Cont RGB”,

“Red Gain”, “Green Gain”, “Blue Gain”, “Red Bias”,

“Green Bias” and “Blue Bias” that are located in the

lower layer below this sub menu.

Adjustment range is from 0 to 255 in each adjustment

item.

c) YUV Calibration

The component video signal is calibrated.

The component video signal is calibrated by “Sub

Cont YUV”, “Sub Brt YUV”, “Cb Offset YUV” and

“Cr Offset YUV” that are located in the lower layer

below this sub menu.

Adjustment range is from 0 to 255 for “Sub Cont

YUV” and “Sub Brt YUV”, and from 0 to 63 for “Cb

Offset YUV” and “Cr Offset YUV”.

d) Video Calibration

The composite video signal is calibrated.

The composite video signal is calibrated by “Sub Cont

Video”, “Sub Brt Video”, “Cb Offset Video” and “Cr

Offset Video” that are located in the lower layer below

this sub menu.

Adjustment range is from 0 to 255 for “Sub Cont

Video” and “Sub Brt Video”, and from 0 to 63 for “Cb

Offset Video” and “Cr Offset Video”.

Menu structure

White balance of PDP panel is adjusted.

a) Window

This machine has the built-in window signal for white

balanced adjustment. Select large window for suitable

adjustment.

Off : Window is not displayed.

Small : Small window is displayed.

Large : All white is displayed.

b) Color Temp.

Select the desired color temperature that you want to

adjust located in the lower layer below this submenu.

Select the desired color temperature from “High”,

“Mid”, “Low”, “User 1”, “User 2” and “User 3”.

n

“User 1”, “User 2” and “User 3” can be adjusted from

the user menu, therefore they are not adjusted here.

c) Red Gain

Red gain of the selected “Color Temp.” is adjusted.

Adjustment range is from 0 to 255.

d) Green Gain

Green gain of the selected “Color Temp.” is adjusted.

Adjustment range is from 0 to 255.

e) Blue Gain

Blue gain of the selected “Color Temp.” is adjusted.

Adjustment range is from 0 to 255.

White Balance Adjustment

Refer to Section “2-3. White Balance Adjustment ”.

AD Calibration Adjustment

Refer to Section “2-4. AD Calibration Adjustment”.

2-4

FWD-50PX1

Service Mode

General

Fan Status

Fan Control : Manual

Ref Voltage : 8.0[V]

F/B Voltage : 8.0[V]

Drive Data 2B5F

P/S Temp : 43[dC]

Temp1 : 43[dC]

Temp2 : 43[dC]

Temp3 : 43[dC]

5. General

g) Fan Status

Menu structure

The data unique to the machine and the fan control are

checked.

Service Mode

General

Blue Only : 0

AGC Wide : 14

AGC Narrow : 13

32k Clock Out: Off

Watch Error : 32.76800

Serial Number: 2000001

Fan Status

Vs/Va Setting

a) Blue Only

When “1” is set, all colors of RGB displayed on the

PDP become blue data level.

b) AGC Wide

This command is not used in this machine.

c) AGC Narrow

This command is not used in this machine.

d) 32k Clock Out

The clock signal that is used for the Watch Error

adjustment is output.

Off : Not output.

On : Output

e) Watch Error

It corrects error of the built-in watch.

Set the measurement value of the frequency counter

connected.

Adjustment range is from 32.76180 to 32.77420 kHz.

f) Serial Number

It sets serial number.

Menu structure

Fan Control : You can set the 8.0 to 12.0 V to the fan

drive voltage using [Ref Voltage]. Use this

command for checking operation of the fan

drive circuit.

(Factory default setting: 8.0 V)

Ref Voltage : You can set the any desired voltage to the

fan drive voltage. Range of setting is from

8.0 V to 12.0 V, the setting value is saved.

F/B Voltage : It indicates the fan drive voltage. The

voltage that is actually driving the fan is

displayed as the setting voltage is being

supplied.

Drive Data : It indicates the fan drive data.

P/S Temp : It indicates the temperature that is measured

by the temperature sensor built in the power

board.

Temp1 : It indicates the temperature that is measured

by the S board attached on top of the BQ

block assembly.

Temp2 : It indicates the temperature that is measured

by the S board attached on top of the power

board.

Temp3 : It indicates the temperature that is measured

by the S board attached on the right side as

viewed from backside.

FWD-50PX1

2-5

6. Manual Control

Service Mode

Preset Edit

Original Data Select

Data Edit

Save Area Select

7. Preset Edit

This submenu is used in factory for operation checks.

Do not operate this function.

Preset data structure

You can add the preset signals in addition to the default

preset data.

The additional preset data are stored in [PROGRAM1] to

[PROGRAM12] of [PRESET DATA AREA]. [PROGRAM13] to [PROGRAM30] are not used.

Menu structure

Editing procedure

An independent memory area (editing RAM) is assigned for

data editing inside the system controller as shown below.

First, copy the source data for editing to the editing RAM.

Then modify the data on the editing RAM and save the

editing contents to the specified preset area of EEPROM.

In addition to the default preset data that has been set

already when shipped from the factory, you can edit the

various data from the already saved data in EEPROM or

the signal data that is being input at this moment.

(The following example shows the case the data stored in

the EEPROM preset area No.2 is used for editing and the

edited data is stored in the area No.11.)

2-6

EEPROM

preset data area

PROGRAM1

PROGRAM2

PROGRAM3

PROGRAM4

PROGRAM5

PROGRAM6

PROGRAM7

PROGRAM8

PROGRAM9

PROGRAM10

PROGRAM11

PROGRAM12

System controller

Editing RAM

Editing

FWD-50PX1

a) Original Data Select

Menu structure

You can select the original data that is used for editing and

copy the selected original data to the editing RAM.

Service Mode

Preset Edit

Original Data Select

Current Data Select (1) The signal data that is being

Table input at this moment, is used

as the original data for editing.

(2) The data stored in the preset

area is used for editing.

(1) Current Data Select

When you select the signal data that is being input at

this moment for editing, move the cursor to this item

and press ENTER.

The selected data is copied to the editing RAM.

This mode is prepared for the case that the signal

specification is unknown, and you can make editing by

checking the image on screen.

Select the respective adjustment items and change the

data as desired using the ↑/↓ key or the ←/→ key. The

changed data are reflected on screen.

(If you press the ENTER key again, the screen returns

to the previous menu.)

Among the adjustment items, the three types of

adjustment [H Freq], [V Freq] and [Sync Pol] cannot

be modified.

(2) Table

When you select the data stored in the preset area,

move the cursor to this item and press ENTER. Select

the desired data using the ↑/↓ key. The selected data is

copied to the editing RAM.

This mode is prepared for the case that the signal

specification is already known. You can make adjustment and edit data of all items but the modified data

are not reflected to the actual picture images.

FWD-50PX1

2-7

Sync Pol : N/N

Horizontal sync polarity

Vertical sync polarity

b) Data Edit

Menu structure

You can edit the data contents of the editing RAM.

Service Mode

Preset Edit

Data Edit

H Freq : 031.469[kHz] (1) Horizontal frequency

V Freq : 059.94[Hz] (2) Vertical frequency

Sync Pol : N/N (3) Sync signal polarity

H. Total Pixel : 800 (4) Total number of dots within horizontal

H. Active Pixel : 640 (5) Horizontal resolution power

H. Sync Pixel : 96 (6) Number of dots of horizontal sync signal

H. BP Pixel : 48 (7) Number of dots during the horizontal back porch

V. total Line : 525 (8) Total number of vertical lines

V. Active Line : 480 (9) Vertical resolution power (number of lines)

V. Sync Line : 2 (10) Total number of lines of vertical sync signal

V. BP Line : 33 (11) Number of lines during the vertical back porch

Clamp Posi : 60 (12) Clamp pulse position

Clamp Width : 8 (13) Clamp pulse width (number of dots)

Format Flag (14) Format flag

Picture Mode : Standard (15) Picture quality mode

Color Matrix : 12 (16) Color difference matrix

Zoom Mode : 4/3 (17) Wide selection

(1) H Freq

It sets the horizontal frequency.

n

When “Current Data Select” is selected in the Original

Data Select, this item cannot be modified because the

presently entered signal is selected for editing.

(2) V Freq

It sets the vertical frequency.

n

When “Current Data Select” is selected in the Original

Data Select, this item cannot be modified because the

presently entered signal is selected for editing.

(3) Sync Pol

It sets the sync signal polarity. Sync polarities are

displayed in the order of “Horizontal/Vertical”.

When you set the sync signal polarity, set it as shown

below.

Negative polarity :N

Positive polarity : P

SOG : SOG

n

When “Current Data Select” is selected in the Original

Data Select, this item cannot be modified because the

presently entered signal is selected for editing.

(4) H. Total Pixel

It sets the total number of dots within a single horizontal cycle.

This setup value becomes the default value of the user

menu “Total H Pixel”.

n

You should set in a way that number of H. Total Pixels

is equal or more than sum of (H. Active Pixel +H.

Sync Pixel +H. BP Pixel).

2-8

FWD-50PX1

(5) H. Active Pixel

It sets the horizontal resolution power.

(6) H. Sync Pixel

It sets the number of dots of horizontal sync signal.

(7) H. BP Pixel

It sets the number of dots during the horizontal back

porch.

(8) V. total Line

It sets the total number of vertical lines.

n

You should set in a way that number of V. Total Line

is equal or more than sum of (V. Active Line + V.

Sync Line + V. BP Line).

(9) V. Active Pixel

It sets the vertical resolution power.

(10)V. Sync Line

It sets the total number of lines of vertical sync signal.

(11)V. BP Pixel

It sets the number of lines during the vertical back

porch.

(12)Clamp Posi

It sets clamp pulse position.

The clamp pulse position is set starting (when data is

0) from the trailing edge of the horizontal sync signal.

When this value is increased, picture moves toward the

picture area.

The clamp pulse generation position Tcp is given by

the equation below starting from the trailing edge of

sync signal.

Tcp = Clamp Posi/(Horizontal sync frequency x H.

Total Pixel) [seconds]

(13)Clamp Width

It sets the clamp pulse width.

The clamp pulse width increases starting from the

position that is set by the Clamp Posi. When this value

is increased, the clamp pulse width is widened in the

direction toward picture area.

The clamp pulse width Wcp is given by the equation

below.

Wcp = Clamp Width/(Horizontal sync frequency x H.

Total Pixel) [seconds]

(14)Format Flag

It sets ON/OFF of the following respective items in

units of bit.

00000000 1 : ON

1234 0 : OFF

Upper 4 bits are not used.

1 Setting the IP converter

Set to OFF during normal operation.

2 Setting interlace

It sets the interlace input.

ON : When the input signal is the interlaced signal.

OFF : When the input signal is the progressive signal.

3 Setting to enable the “dot adjustment”

It enables or disables the “dot adjustment” in the user

menu.

ON : The “dot adjustment” is enabled in the user

menu.

OFF : The “dot adjustment” is disabled in the user

menu.

If the actual input signal specification is different from

the setups of “H. Total Pixel” and “H. Active Pixel”

due to fetching the interlace, set this item to OFF.

4 Frame synchronization setting

It sets synchronization setting of the picture input to

scan converter.

ON : Vertical sync of PDP panel synchronizes with

the input signal.

OFF : The PDP panel display signal is no more

synchronized with the input signal. When the

motion picture is going to be displayed, set this

item to ON.

n

This item can be set to ON only when the vertical

frequency of input signal is in the range from 50 to 60

Hz.

(15)Picture Mode

It sets the picture quality mode. Select the desired

mode from “Standard”, “Vivid”, “User1”, “User2” or

“User3”.

This setting becomes the default value of the “Picture

Mode” of user menu.

FWD-50PX1

2-9

(16)Color Matrix

Service Mode

Service Status

Signal/Sync

Power Supply

Fan & Temp Status

Warning Status

Operation Time :

*****H

Software Version:*.**

PLD Version :

***

It sets the color difference matrix when the color

difference component signal is input.

Either “12” or “13” can be set.

12 : In the case when the signal conforms to

SMPTE293M.

13 : In the case when the signal conforms to

SMPTE274M.

(17)Zoom Mode

It sets the wide selection. Select the desired mode from

“Expd. 4/3”, “Letterbx”, “Restore”, “Subtitle” or “4/

3”.

This setting becomes the default value of the “Zoom

Mode” of user menu.

c) Save Area Select

Menu structure

It saves the data of the editing RAM to the preset area.

Service Mode

Preset Edit

Save Area Select

Save Are : 1 (1) Selects the preset data area

Data Save that stores the data.

(2) Executes saving of the data.

8. Service Status

Menu structure

You can check the internal status of this unit.

a) Signal/Sync

Menu structure

Service Mode

Service Status

Signal/Sync

Format : 640 x 480/60 Signal specification

H Freq :

V Freq : 059.94[Hz] Vertical frequency

Sync Pol : N/N Sync signal polarity

Condition : Stable Sync signal status

031.469[kHz]

Horizontal frequency

(1) Save Area

It selects the preset data area that saves contents of the

editing RAM.

Select the desired area from “PROGRAM1” to

“PROGRAM12”.

(2) Data Save

It carries out saving of the data into the area that is

selected by the Save Area.

Change the menu item from [Cancel] to [OK] and

press [ENTER].

n

You can judge coincidence of the preset data with the input

signal using the sync signal polarity of horizontal/vertical

frequencies.

If the same sync signal data exists within a preset area, the

specification that has the smaller preset number has

priority.

2-10

The sync signal status of the input signal is displayed.

Format : The preset signal name for the input signal is

displayed.

H Freq : Horizontal frequency of the input is displayed

in 6 digits.

V Freq : Vertical frequency of the input is displayed in

5 digits.

Sync Pol : Sync signal polarity is displayed.

Horizontal sync signal/Vertical sync signal

N: NEGA

P: POSI

Conditions : Sync signal status is displayed.

Stable : Stable

Insecure : Unstable

No Sync : Sync signal does not exist.

FWD-50PX1

Loading...

Loading...