Page 1

DVP-S7700

RMT-D107E/D107P

SERVICE MANUAL

SPECIFICATIONS

AEP Model

Hong K ong Model

UK Model

MICROFILM

CD/DVD PLAYER

Page 2

SAFETY CHECK-OUT

WARNING!!

WHEN SERVICING, DO NO T APPR O A CH THE LASER

EXIT WITH THE EYE TOO CLOSELY. IN CASE IT IS

NECESSARY TO CONFIRM LASER BEAM EMISSION,

BE SURE TO OBSERVE FROM A DISTANCE OF

MORE THAN 25 cm FROM THE SURFACE OF THE

OBJECTIVE LENS ON THE OPTICAL PICK-UP BLOCK.

CAUTION:

The use of optical instrument with this product will increase eye

hazard.

CAUTION

Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous radiation exposure.

CLASS 3B LASER

LUOKAN 3B LASER

LASERKLASS 3B

SAFETY CHECK-OUT

After correcting the original service problem, perform the following

safety checks before releasing the set to the customer:

1. Check the area of your repair for unsoldered or poorly-soldered connections. Check the entire board surface for solder

splashes and bridges.

2. Check the interboard wiring to ensure that no wires are

“pinched” or contact high-wattage resistors.

3. Look for unauthorized replacement parts, particularly transistors, that were installed during a previous repair. Point them

out to the customer and recommend their replacement.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK ! OR DOTTED

LINE WITH MARK ! ON THE SCHEMA TIC DIAGRAMS

AND IN THE PARTS LIST ARE CRITICAL TO SAFE

OPERATION. REPLACE THESE COMPONENTS WITH

SONY PARTS WHOSE PART NUMBERS APPEAR AS

SHOWN IN THIS MANUAL OR IN SUPPLEMENTS PUBLISHED BY SONY.

4. Look for parts which, though functioning, show obvious signs

of deterioration. Point them out to the customer and recommend their replacement.

5. Check the B+ voltage to see it is at the values specified.

– 2 –

Page 3

TABLE OF CONTENTS

Section Title Page Section Title Page

Service Note ............................................................................ 4

1. GENERAL

This Player Can Play the Following Discs .................... 1-1

Getting Started .............................................................. 1-1

Basic Operations ........................................................... 1-2

Playing Discs in Various Modes .................................... 1-4

Setting and Adjustments ............................................... 1-9

Additional Information ................................................... 1-10

2. DISASSEMBLY

2-1. Upper Case Removal.................................................... 2-1

2-2. Front Panel Removal .................................................... 2-1

2-3. Door Open/Close Motor Removal................................. 2-1

2-4. MB-84 Board Removal.................................................. 2-1

2-5. AU-218 Board Removal ................................................ 2-2

2-6. MD Block Ass’y Removal .............................................. 2-2

2-7. TK-47 Board Removal................................................... 2-2

2-8. Tray Removal ................................................................ 2-2

2-9. Skew Motor (M903) Removal ....................................... 2-3

2-10. Sled Motor (M501) Removal ......................................... 2-3

2-11. Spindle Motor (M901) Removal .................................... 2-3

2-12. Optical Pick-up Removal............................................... 2-3

2-13. Internal Views ................................................................ 2-4

2-14. Circuit Boards Location ................................................. 2-5

3. BLOCK DIAGRAMS

3-1. Overall Block Diagram .................................................. 3 -1

3-2. RF/Servo Block Diagram .............................................. 3-3

3-3. Signal Process Block Diagram ..................................... 3-5

3-4. Video Block Diagram..................................................... 3-7

3-5. System Control Block Diagram ..................................... 3-9

3-6. Audio Block Diagram..................................................... 3-11

3-7. Mode Control Block Diagram ........................................ 3-13

3-8. Power Block Diagram.................................................... 3-15

4. PRINTED WIRING BOARDS AND SCHEMATIC

DIAGRAMS

4-1. Frame Schematic Diagram ........................................... 4-3

4-2. Printed Wiring Boards and Schematic Diagrams ......... 4-7

TK-47 Printed Wiring Board .......................................... 4-7

TK-47 (RF, Servo 1) Schematic Diagram ..................... 4-11

TK-47 (RF, Servo 2) Schematic Diagram ..................... 4-13

MB-84, FG-43 Printed Wiring Boards........................... 4-15

MB-84 (AV Decoder) Schematic Diagram .................... 4-19

MB-84 (Clock Generator) Schematic Diagram............. 4-21

MB-84 (DNR) Schematic Diagram................................ 4-23

MB-84 (Video Encoder) Schematic Diagram................ 4-25

MB-84 (Drive 1) Schematic Diagram ............................ 4-27

MB-84 (Drive 2), FG-43 Schematic Diagrams.............. 4-29

MB-84 (DSP 1) Schematic Diagram ............................. 4-31

MB-84 (DSP 2) Schematic Diagram ............................. 4-33

MB-84 (Bias) Schematic Diagram ................................ 4-35

MB-84 (IF µ-com) Schematic Diagram ......................... 4-37

MB-84 (L Gate Array) Schematic Diagram ................... 4-39

MB-84 (ARP, Decrypt) Schematic Diagram .................. 4-41

MB-84 (System µ-com) Schematic Diagram ................ 4-43

MB-84 (S Gate Array) Schematic Diagram .................. 4-45

AU-218 Printed Wiring Board ....................................... 4-47

AU-218 (Audio 1) Schematic Diagram ......................... 4-51

AU-218 (Audio 2) Schematic Diagram ......................... 4-53

AU-218 (Video Buffer) Schematic Diagram.................. 4-55

YS-19 Printed Wiring Board and

Schematic Diagram ....................................................... 4-57

ER-8 Printed Wiring Board............................................ 4-59

ER-8 (EURO AV 1) Schematic Diagram ....................... 4-63

ER-8 (EURO AV 2) Schematic Diagram ....................... 4-65

ER-8 (EURO AV 3) Schematic Diagram ....................... 4-67

HP-120 Printed Wiring Board and

Schematic Diagram ....................................................... 4-69

FP-75 Printed Wiring Board .......................................... 4-71

FP-75 Schematic Diagram............................................ 4-73

CN-113, DR-88, FL-108, FR-160, PW-120

Printed Wiring Boards ................................................... 4-75

CN-113, DR-88, FL-108, FR-160, PW-120

Schematic Diagrams ..................................................... 4-77

PS-421 Printed Wiring Board........................................ 4-79

PS-421 Schematic Diagram.......................................... 4-81

POWER BLOCK (HS-930SH) Printed Wiring Board.... 4-83

POWER BLOCK (HS-930SH) Schematic Diagram...... 4-85

5. IC PIN FUNCTION DESCRIPTION

5-1. Interface Control Pin Function (MB-84 Board IC604) .. 5-1

5-2 System Control Pin Function (MB-84 Board IC805) .... 5-2

6. TEST MODE

6-1. Starting up Test Mode ................................................... 6-1

6-2. Selection of Check Item ................................................ 6-1

6-2-1. Selected Item Check ................................................ 6-1

6-2-2. All Items Check ........................................................ 6-1

6-3. Error Display.................................................................. 6-2

6-4. General Description of Checking Method..................... 6-2

6-5. Drive Auto Adjustment .................................................. 6-8

6-6. Drive Manual Operation ................................................ 6-12

6-6-1. Drive Manual Operation Menu Screen .................... 6-12

6-6-2. Disc T ype.................................................................. 6-12

6-6-3. Manual Control 1...................................................... 6-12

6-6-4. Manual Control 2...................................................... 6-13

6-6-5. Manual Control 3...................................................... 6-13

6-6-6. Manual Adjust 1 ....................................................... 6-13

6-6-7. Manual Adjust 2 ....................................................... 6-14

6-6-8. Auto Adjust ............................................................... 6-14

6-6-9. Check ....................................................................... 6-14

6-6-10. EEPROM Data Screen Display................................ 6-15

6-7. Other Operation............................................................. 6-15

6-8. Emergency History ........................................................ 6-16

6-9. Error Code ..................................................................... 6-18

7. ELECTRICAL ADJUSTMENT

7-1. Power Supply Check ..................................................... 7-1

1. HS-930SH Board........................................................... 7-1

7-2. Adjustment of System Control ...................................... 7-2

1. System Clock 27 MHz Adjustment ................................ 7-2

7-3. Adjustment of Video System......................................... 7-2

1. Video Level Adjustment ................................................ 7-2

2. S-terminal Output Check............................................... 7-2

3. Checking Component Video Output B-Y...................... 7-2

4. Checking Component Video Output R-Y...................... 7-3

5. Checking Component Video Output Y .......................... 7-3

6. Checking RGB Output R............................................... 7-3

7. Checking RGB Output G ............................................... 7-3

8. Checking RGB Output B............................................... 7-4

9. Checking S Video Output S-C ...................................... 7-4

10. Checking S Video Output DC Level.............................. 7-4

7-4. Adjustment Related Parts Arrangement ....................... 7-6

8. REPAIR PARTS LIST

8-1. Exploded Views ............................................................. 8-1

8-1-1. Case Assembly ........................................................ 8-1

8-1-2. Front Panel Assembly .............................................. 8-2

8-1-3. Chassis Assembly.................................................... 8-3

8-1-4. DVD Mechanism Chassis Assembly (1) .................. 8-5

8-1-5. DVD Mechanism Chassis Assembly (2) .................. 8-6

8-2. Electrical Parts List........................................................ 8-7

– 3 –

Page 4

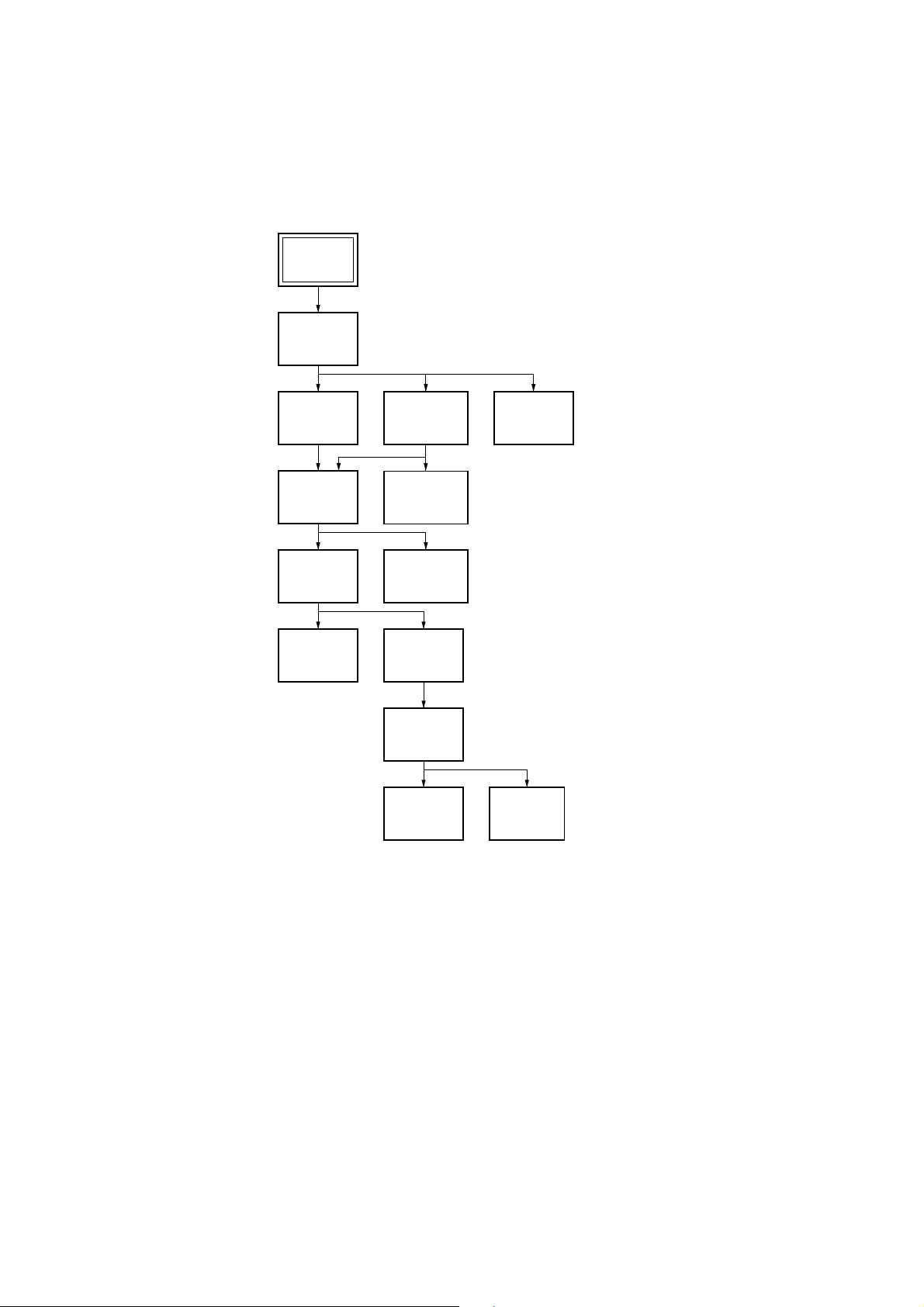

SERVICE NOTE

1. DISASSEMBLY

• This set can be disassembled in the order shown below.

Set

Upper Case

(Page 2-1)

MB-84

Board

(Page 2-1)

MD Block

Ass’y

(Page 2-2)

Tray

(Page 2-2)

Optical

Pick-up

(Page 2-3)

Front Panel

Section

(Page 2-1)

Door Open/

Close Motor

(Page 2-1)

TK-47

Board

(Page 2-2)

Skew

Motor

(Page 2-3)

Spindle

Base

(Page 2-3)

Spindle

Motor

(Page 2-3)

AU-218

Board

(Page 2-2)

Sled

Motor

(Page 2-3)

– 4 –

Page 5

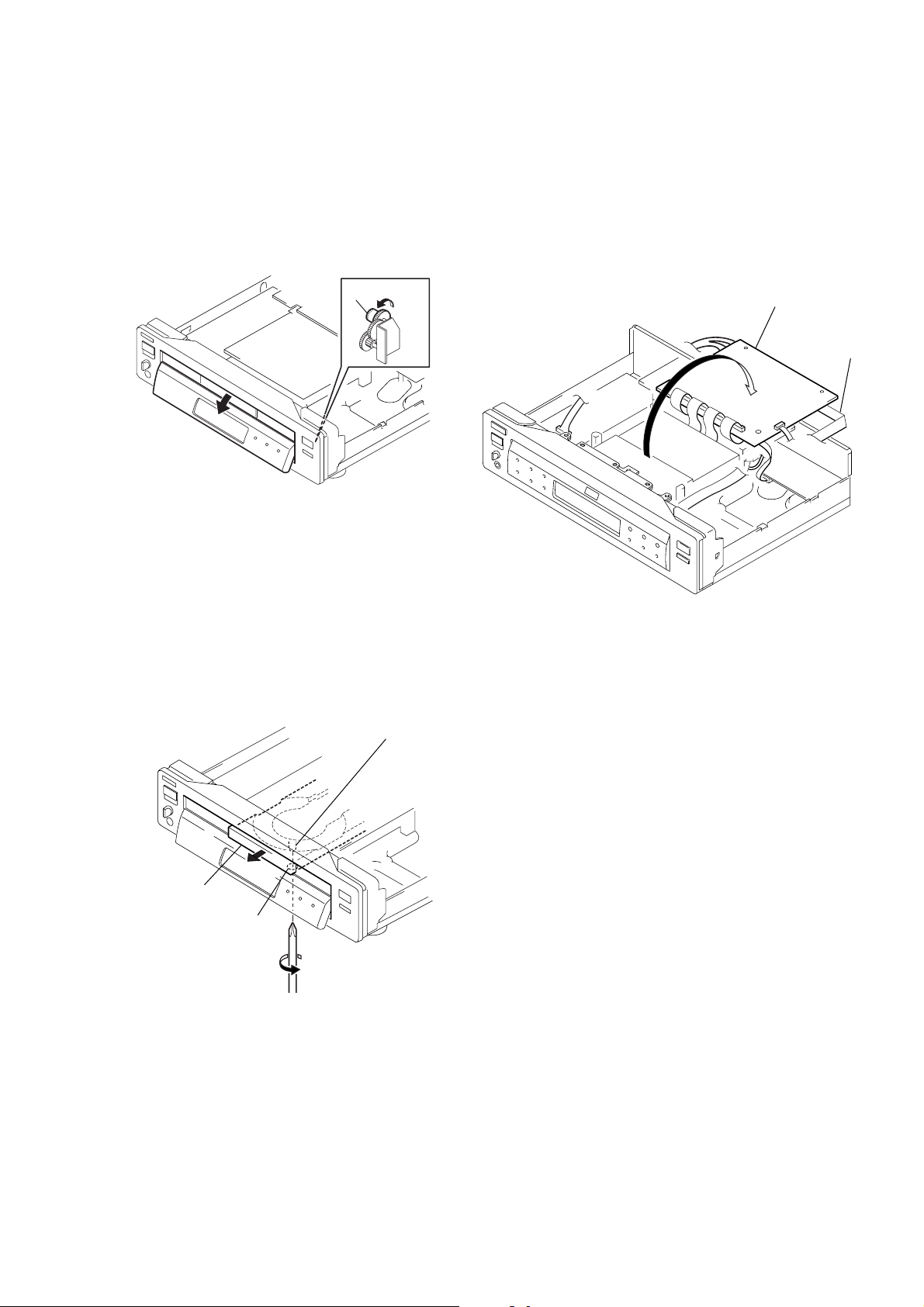

2. DISK REMOVAL PROCEDURE

(at POWER OFF)

2-1. How to Open the Door

1) With the top case removed, rotate the gear (D) 1 in direction

A to open the door. (See Fig. 1)

3. HOW TO SER VICE MB-84 (SIDE B) BO ARD

1) Remove the case from the set. (Refer to 2-1)

2) Remove the cover (upper). (Refer to 2-3)

3) Set the MB-84 board as shown in Fig. 3.

Note 1: Do not disconnect wiring.

Note 2: Spread a insulating material under the MB-84 board

and through down lest you should short.

4) Mount the extention cable (J-6090-079-A).

(MB-84 (CN601) ↔ FL-107 (CN153))

1 Gear (D)

A

Fig. 1

2-2. How to Draw out Tray

1) Insert a cross-tip screwdriver into a hole at the bottom, and

rotate the cam gear 2 in direction B. (See Fig. 2)

Note: To prevent a damage of cam g ear, rotate it in direction

B by 1/4 turn.

2) Draw out the tray 3 in direction C by hand, and remove a

disk. (See Fig. 2)

2 Cam gear

MB-84 board

Extention Cable

(J-6090-079-A)

Fig. 3

3 Tray

C

Hole

B

Fig. 2

– 5 –

Page 6

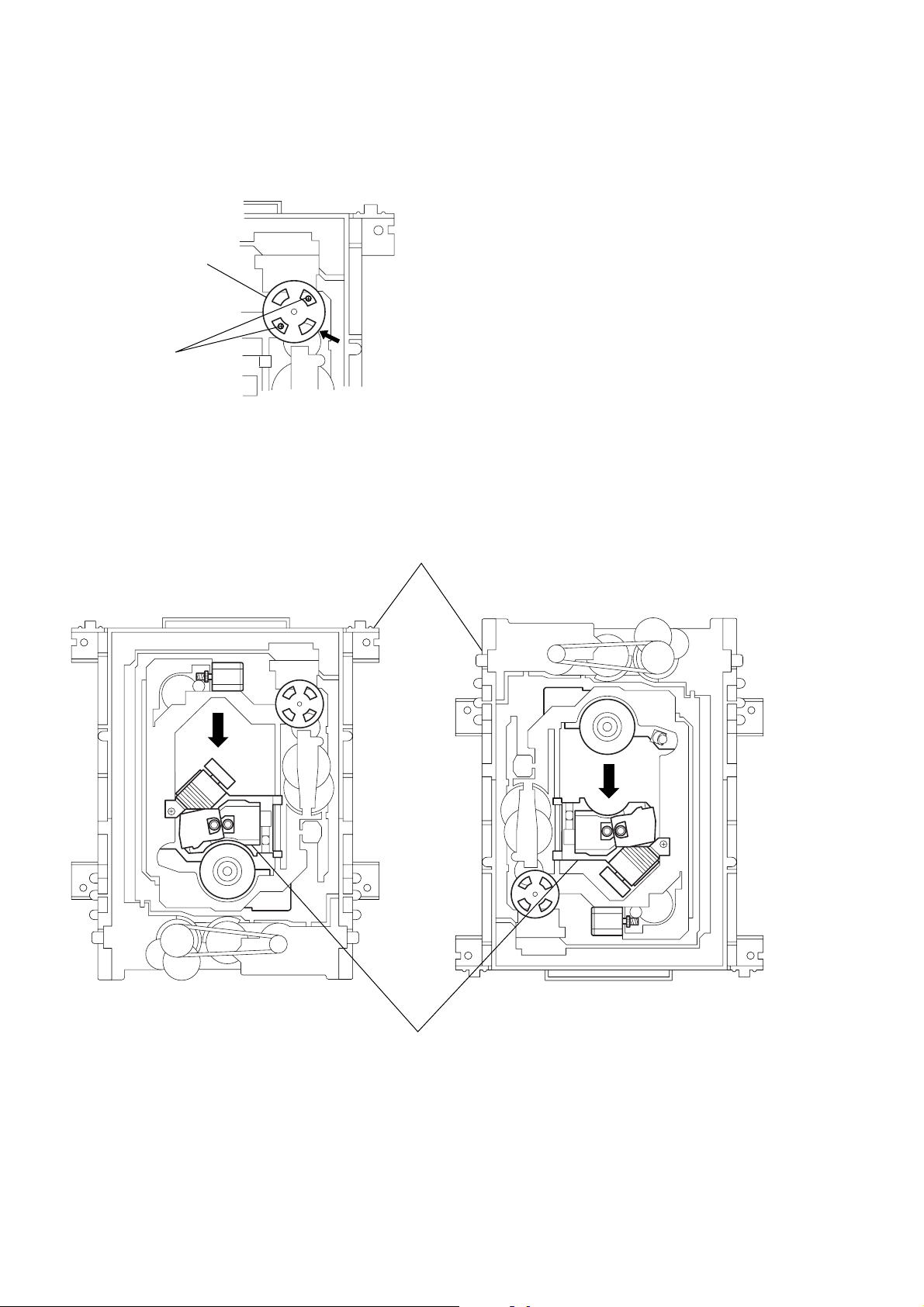

4. NOTE ON MOUNTEING SLED MOTOR

1) Push the sled motor ass’y 1 toward direction A. (See Fig. 4)

2) Tighten two screws 2 (M1.7 × 2.5).

1 Sled motor ass’y

A

2 Two screws (M1.7 × 2.5)

Fig. 4

3) Raising the MD block ass’y 3 90 º with the side down.

confirm that the optical pick-up 4 falls by self weight.

(See Fig. 5)

4) Further, with the front side of MD block ass’y 3 up, confirm

that the optical pick-up falls by self weight.

3 MD block ass’y

Upper

Lower Front side

4 Optical pick-up

Upper

Lower

Front side

Fig. 5

– 6 –

Page 7

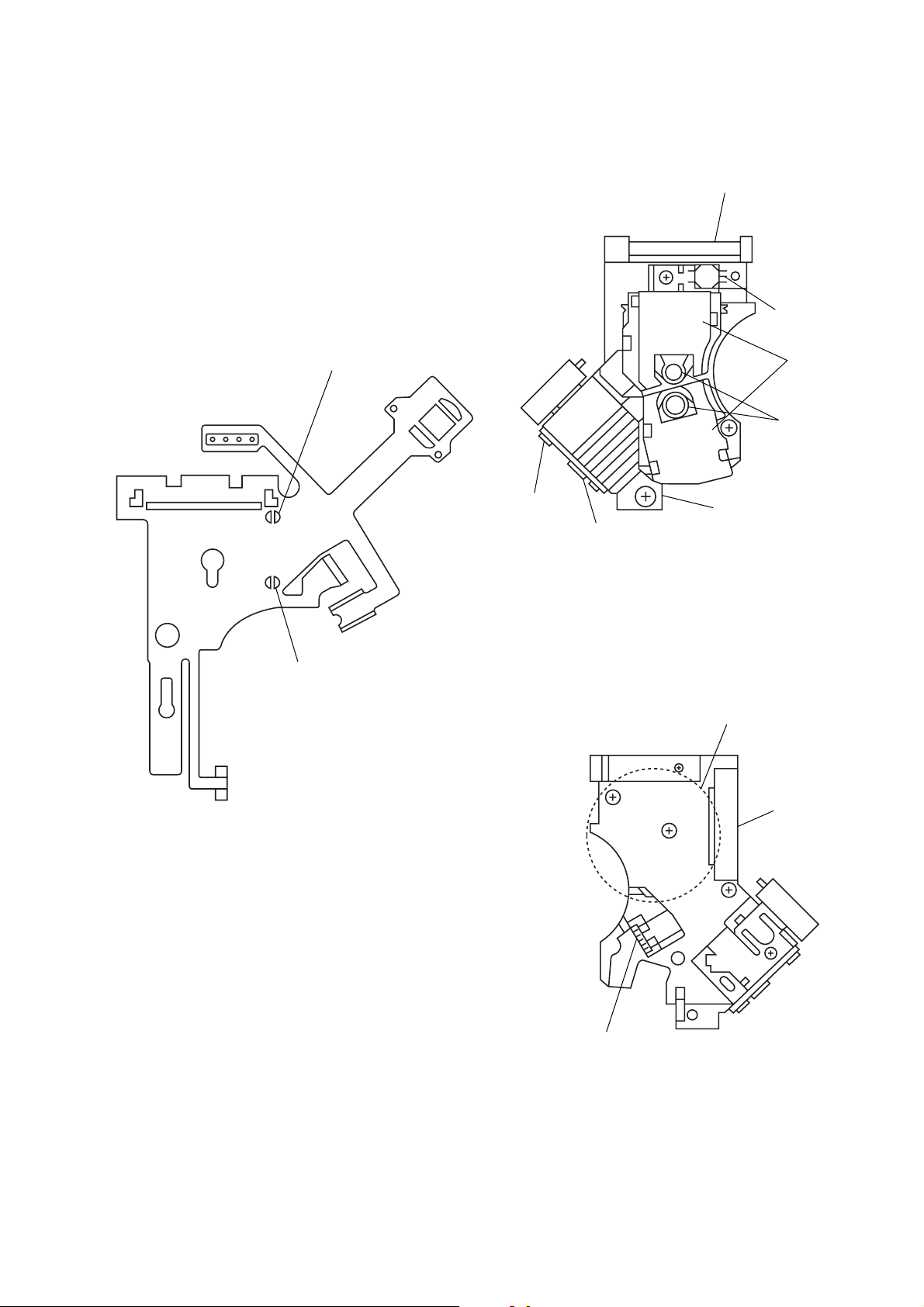

5. REPLACING OPTICAL PICK-UP

Slide base bearing

Skew sensor

Lens actuator

covers

Objective lenses

U-shaped guide

OEIC

Laser holder

5-1. Handling

1) A red laser diode for DVD requires more attention to static

electricity than general infrared laser diodes for CD.

Because its durability to static electricity is far weaker than

that of infrared laser diodes, always use an earth band when

handling the optical pick-up block as service parts.

2) As for the flexible board KHS-180A (RP) packed as service

parts, the short lands have been soldered to protect from static

electricity. Accordingly, remove solders when replacing optical pick-up. (See Fig. 6)

DVD short land

CD short land

3) In handling the KHS-180A (RP), do not touch inhibited parts

shown in Fig. 7, but grip the slide base bearing and U-shaped

guide.

Touch inhibited parts

• Objective lens

• Skew sensor

• Laser holder

• Laser coupler

• Flexible board

• OEIC

• Lens actuator covers

Fig. 6 Flexible board

Flexible board

Connector

Laser coupler

Fig. 7 KHS-180A (RP)

– 7 –

Page 8

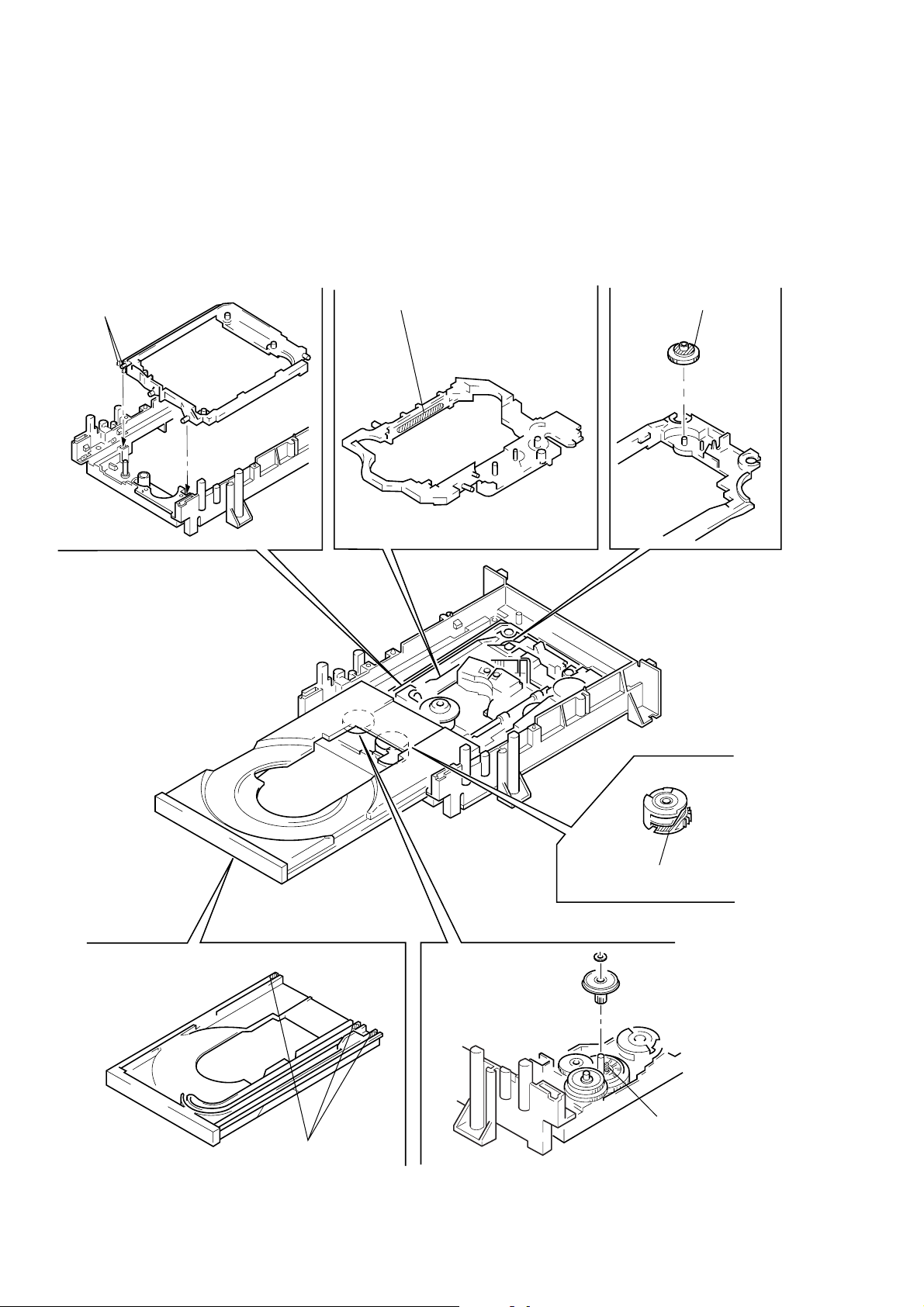

6. NOTE ON ASSEMBLING MECHANICAL DECK

6-1. Application of Grease

1) Grease must be applied if the following parts were replaced.

(See Fig. 8)

Note 1: Recommended grease is Foil KG-70MP.

Note 2: In applying grease, take care not to allow grease to

stick to other parts (particularly, rubber belt, spindle

motor, and optical pick-up)

Base unit holder

2 bosses

Slide base Skew cam

Tray 3 grooves

Note:Add grease if tray

moves slowly.

Cam gear

Loading pulley shaft

Note:Add grease if tray

generates noise

periodically.

Fig. 8

– 8 –

Page 9

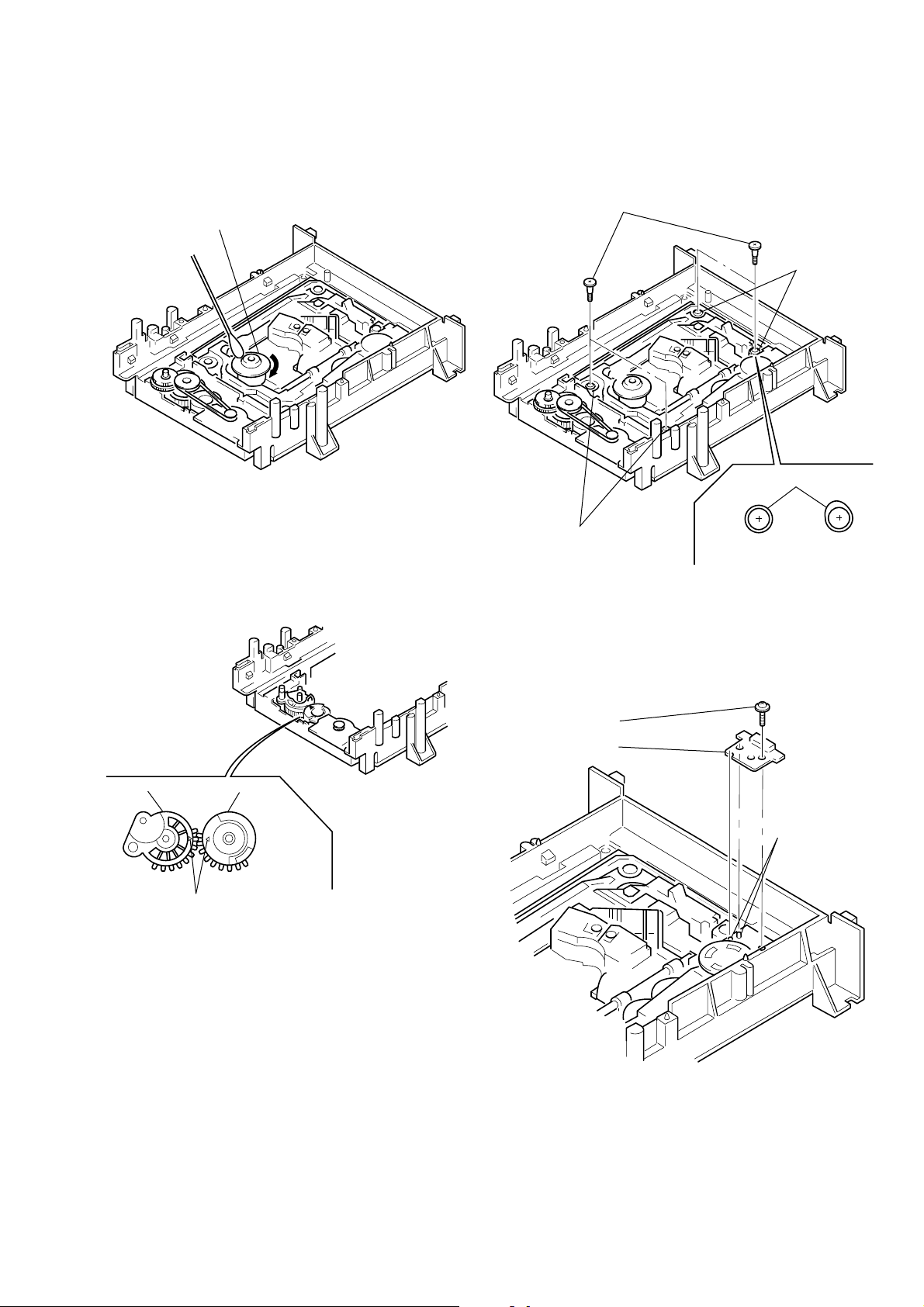

6-2. Cleaning Spindle Motor Turntable

1) Remove the tray. (Refer to 2-7)

2) Clean the spindle motor turntable if disc antiskid rubber (black)

is dirty. (See Fig. 9)

6-4. Deformation of Insulator

1) Assemble the spindle base into the base unit.

2) Loc k with 4 shoulder screws. (See Fig. 11)

3) Chec k if 4 insulators deformed. (See Fig. 11)

Spindle motor

Turntable

Fig. 9

6-3. Aligning Phase of Cam Gear and

Drive Gear

1) Align triangle marks when assembling the cam gear and drive

gear. (See Fig. 10)

Four step screws

Two insulators

Insulator

Two insulators

Good NG

Fig. 11

6-5. Note on Mounting FG-43 Board

1) Align two bosses. (See Fig. 12)

2) Fix the board securely with screws (PTPWH2 × 5). (The sen-

sor will not function normally if the board floats up.)

Drive gear Cam gear

Align triangle marks.

Screw

(PTPWH2 × 5)

FG-43 board

Two bosses

Fig. 10

Fig. 12

– 9 –

Page 10

6-6. Note on Mounting TK-47 Board

1) Align two bosses. (See Fig. 13)

2) Align four tabs. (See Fig. 13)

3) Fix the board securely with 3 screws (BV3 × 10). (The sensor

will not function normally if the board floats up.)

Three screws

TK-47 board

Two claws

(BV3 × 10)

Boss

Two claws

Boss

Fig. 13

6-7. Note on connecting OPT Harness

1) The optical pick-up could be destroyed unless the OPT harness is connected normally to the connector. (See Fig. 14)

OPT harness

Good NG

Connector

Fig. 14

– 10 –

Page 11

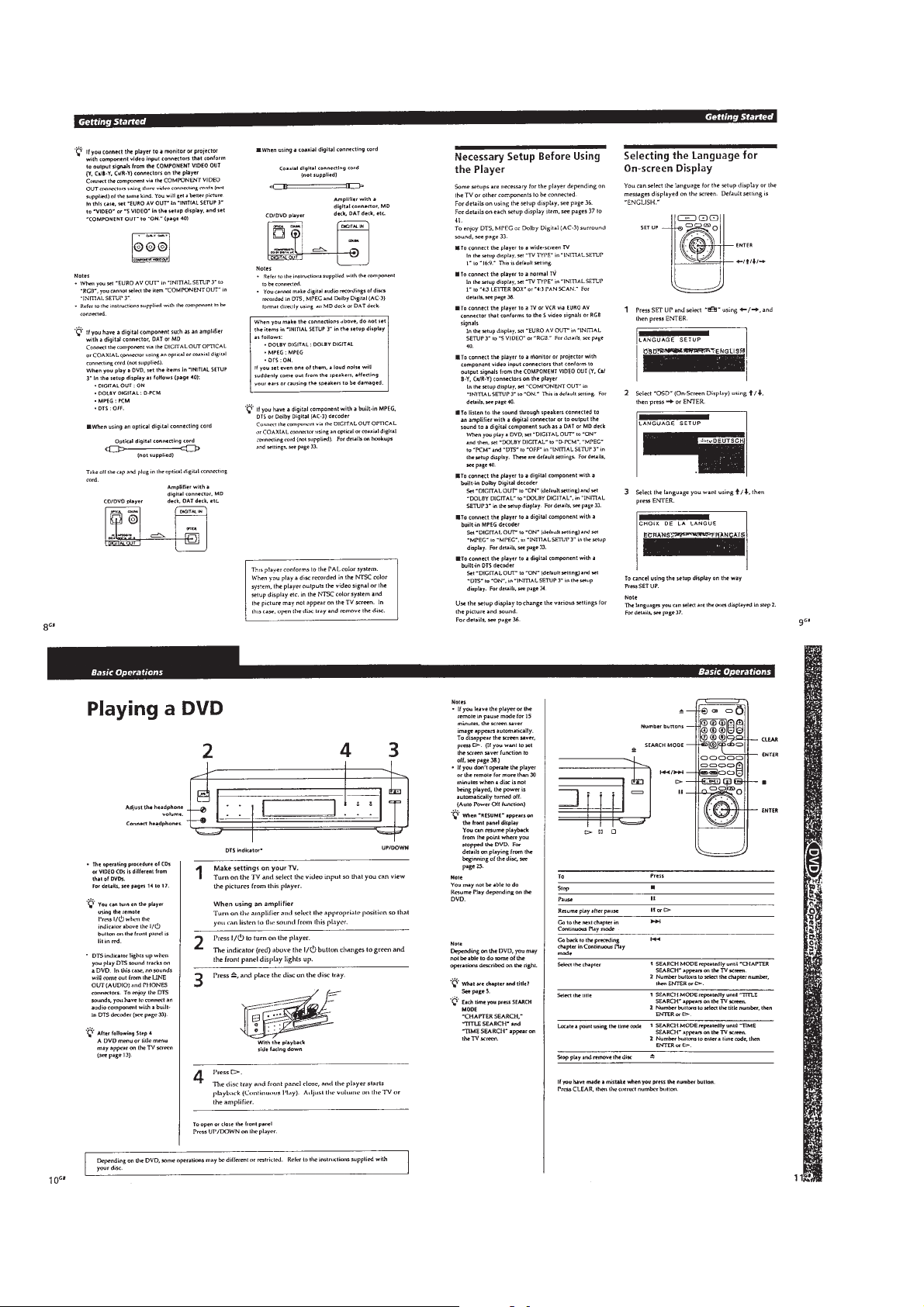

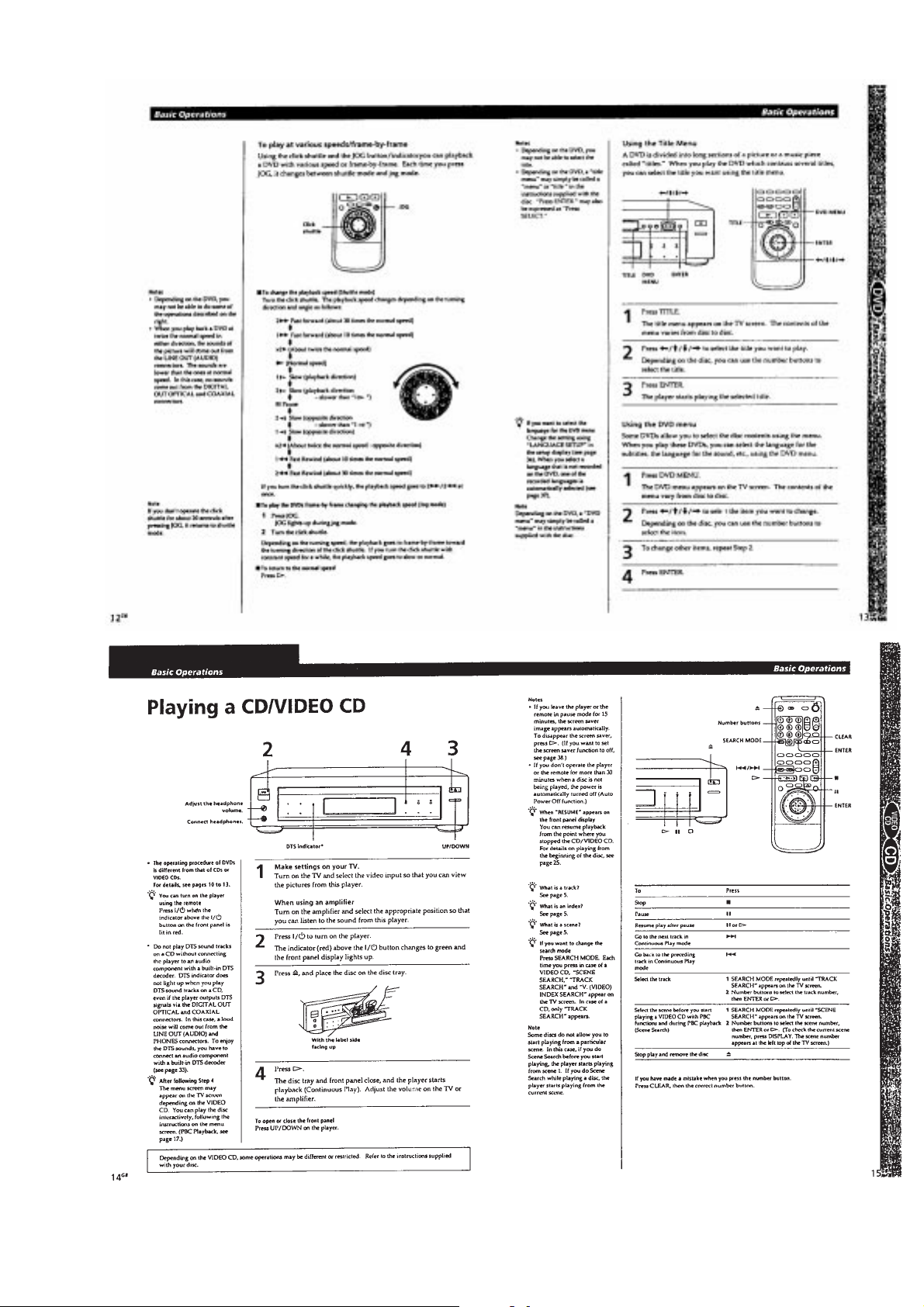

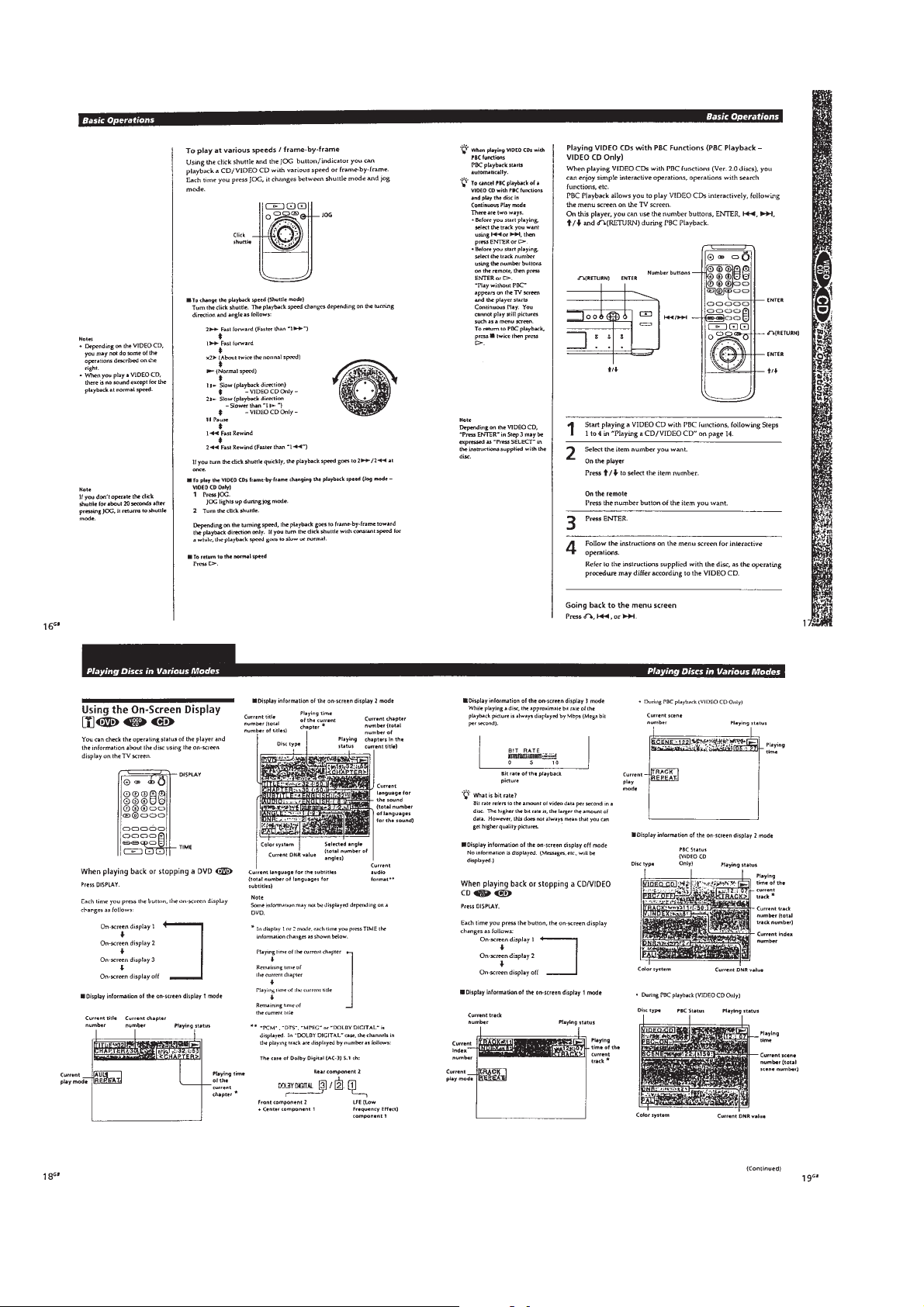

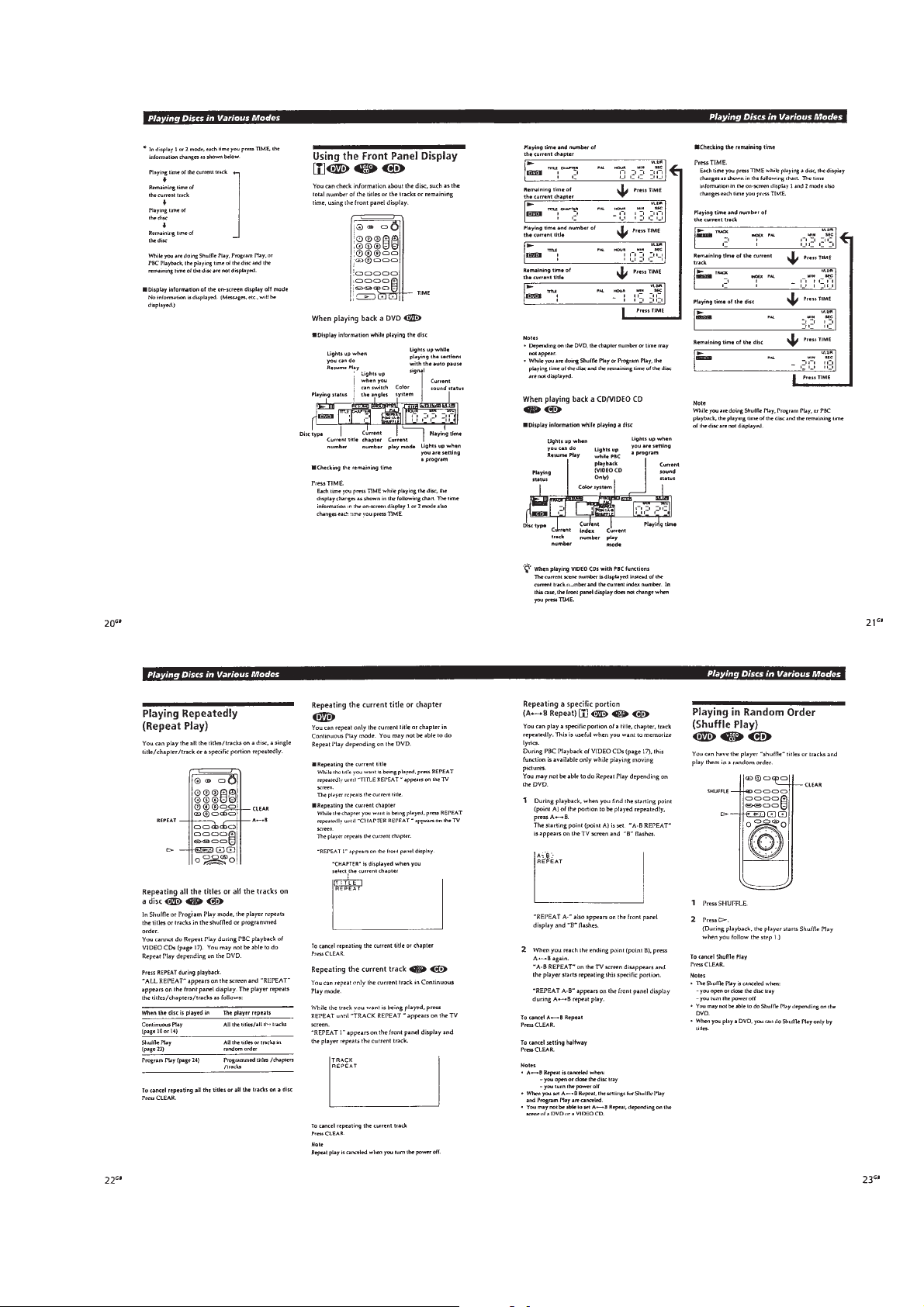

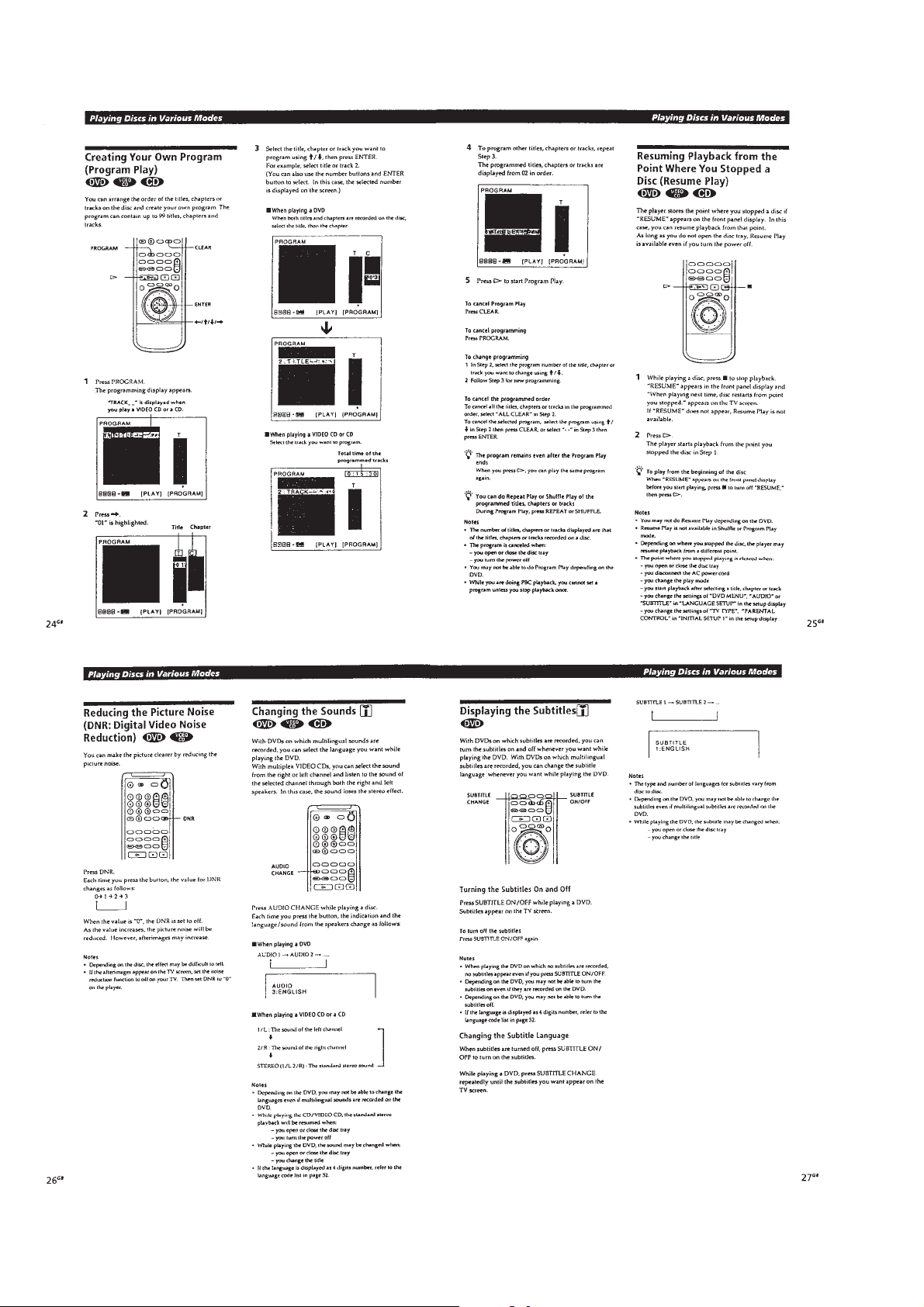

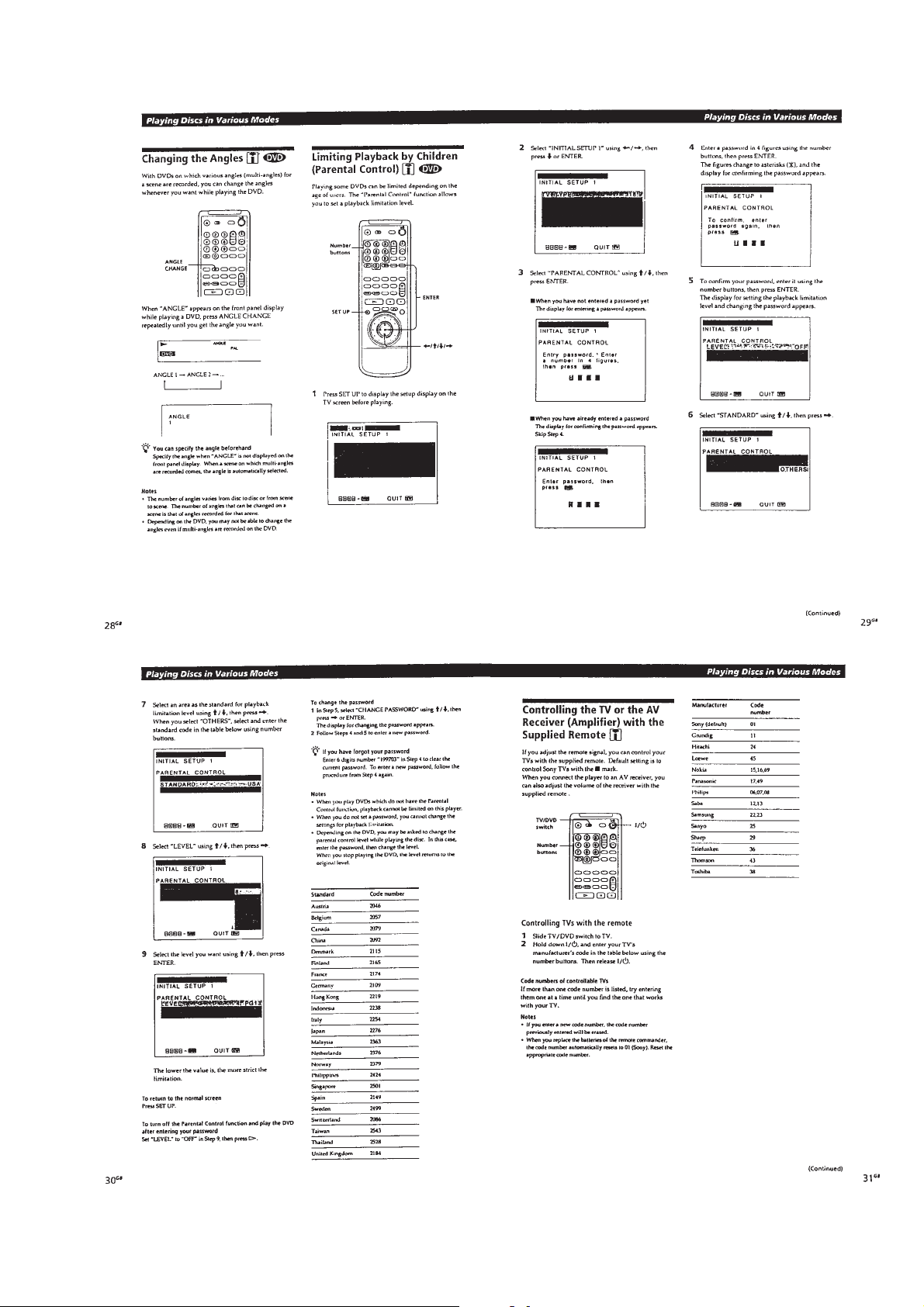

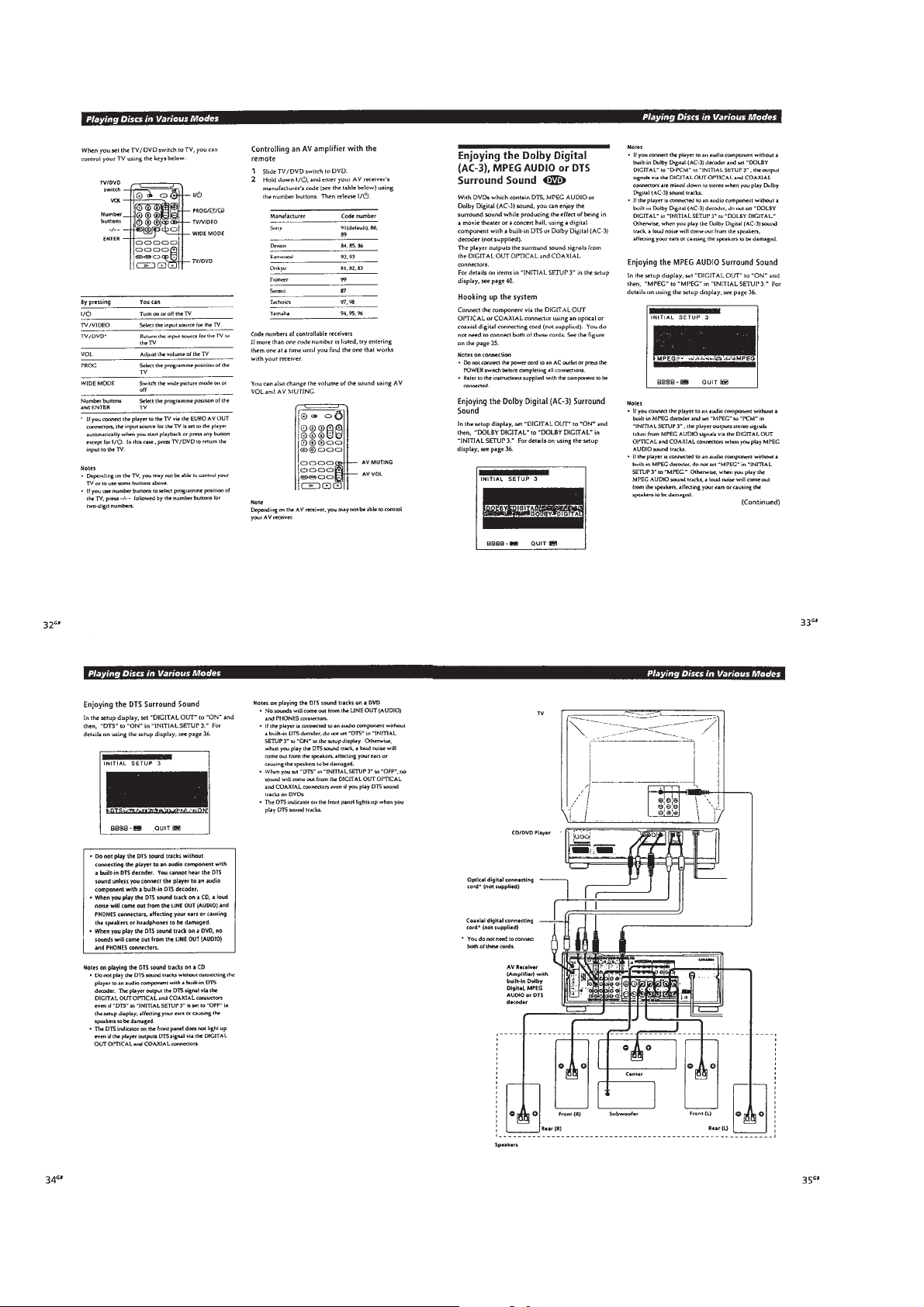

SECTION 1

GENERAL

DVP-S7700

This section is extracted from AEP, UK model

instruction manual (3-864-941-31).

1-1

Page 12

1-2

Page 13

1-3

Page 14

1-4

Page 15

1-5

Page 16

1-6

Page 17

1-7

Page 18

1-8

Page 19

1-9

Page 20

1-10

Page 21

1-11 E

1-11

Page 22

SECTION 2

DISASSEMBLY

Note: Follow the disassembly procedure in the numerical order given.

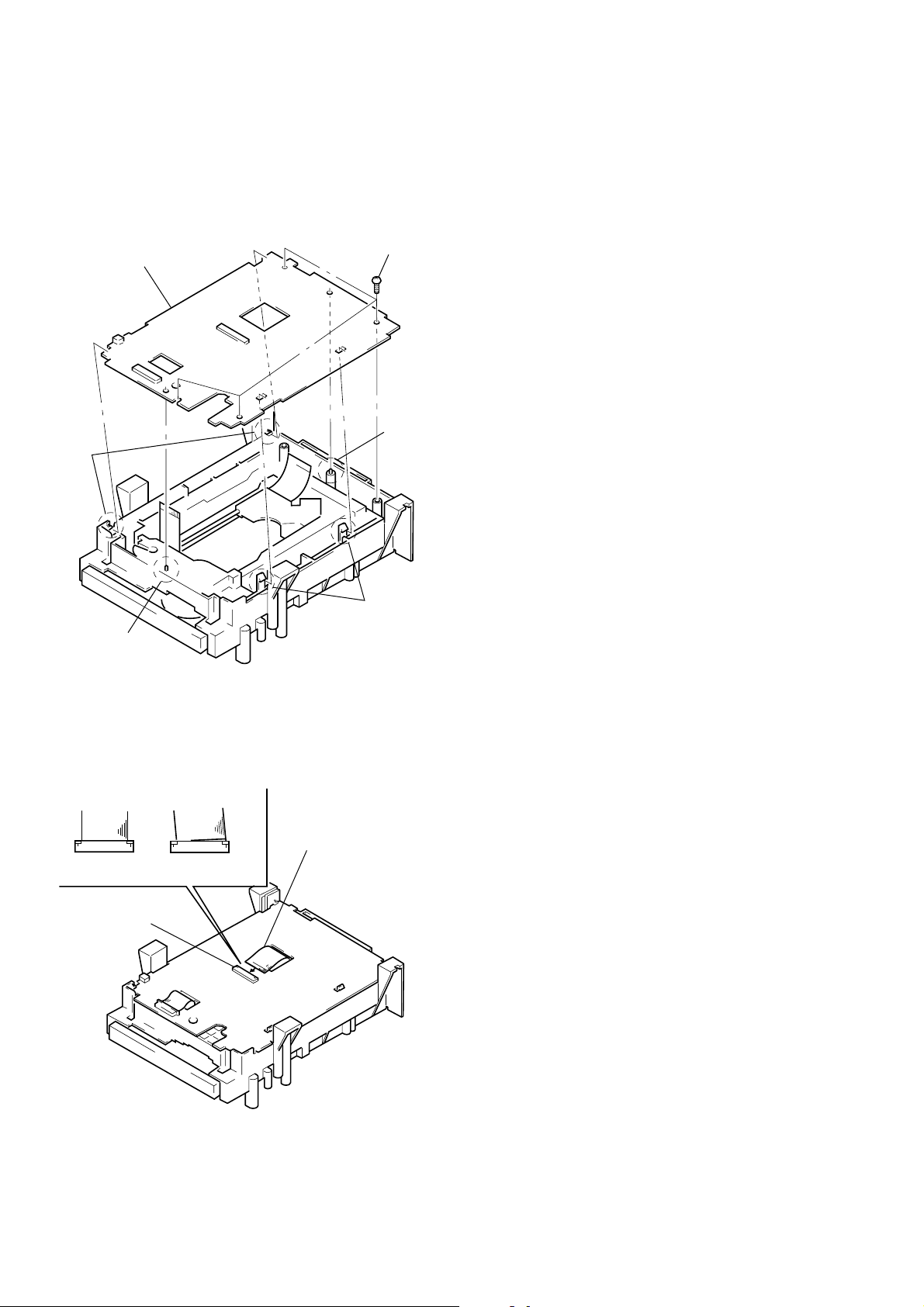

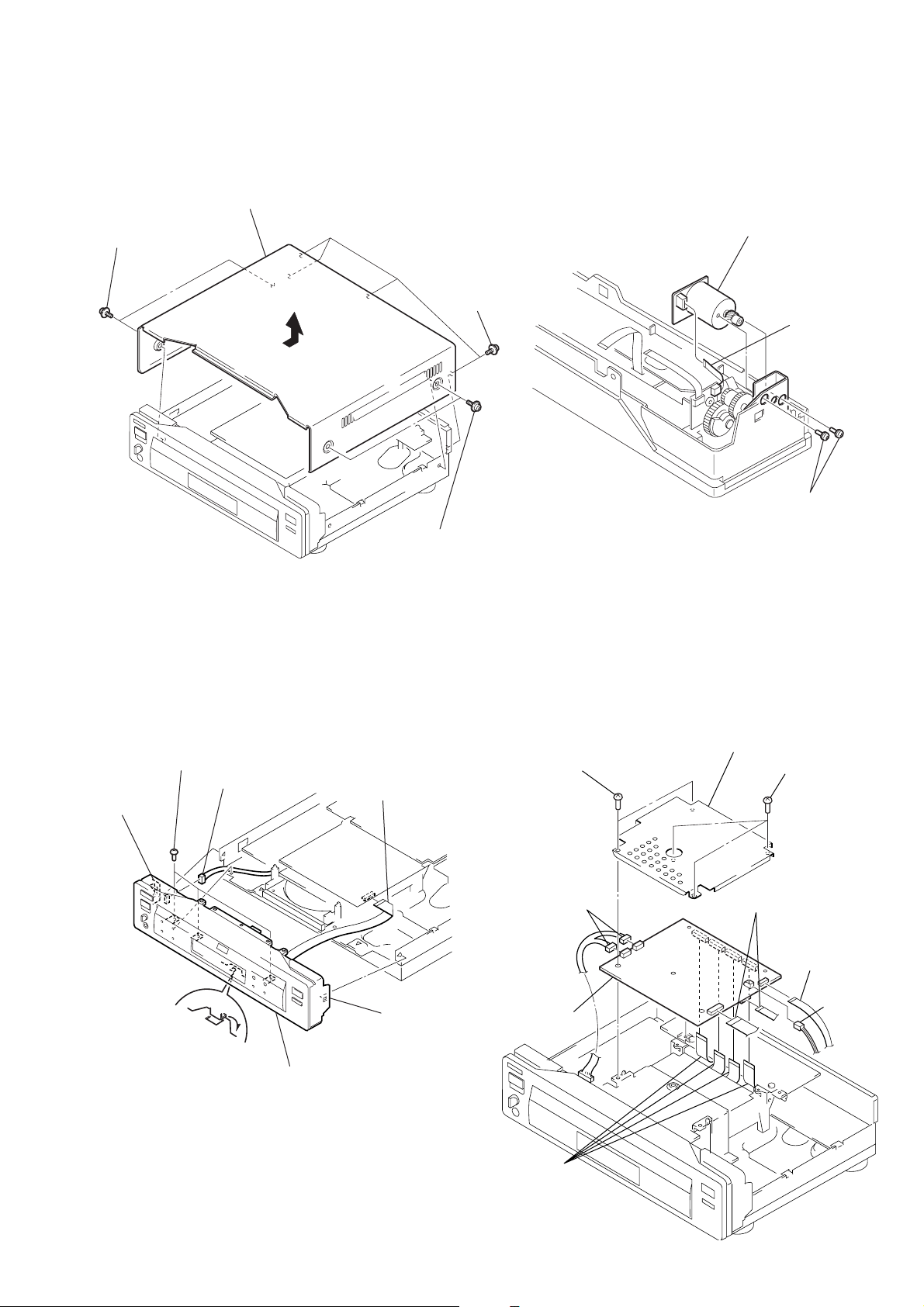

2-1. UPPER CASE REMOVAL 2-3. DOOR OPEN/CLOSE MOTOR

REMOVAL

DVP-S7700

1 Two tapping

screws

4 Upper case

3 Door open/close motor

CN-112 board

2 Four tapping

screws

1 Flat cable

(CN451)

2 Two screws

(PS3 × 4)

3 Two tapping

screws

2-2. FRONT PANEL REMOVAL

3 Three screws

(B3)

2 Connector

4 claw

5 Claw

(CN002)

7 Front panel

1 Font cable

(CN601)

6 Claw

2-4. MB-84 BOARD REMOVAL

7 Cover (upper)

5 Two screws

(B3)

1 Two connectors

(CN001, 002)

8 MB-84

board

2 Two flat cables

(CN301, 601)

6 Three screws

(B3)

3 Flat cable

(CN251)

4 Connector

(CN361)

9 Four flat cables

(CN101, 252, 302, 452)

2-1

Page 23

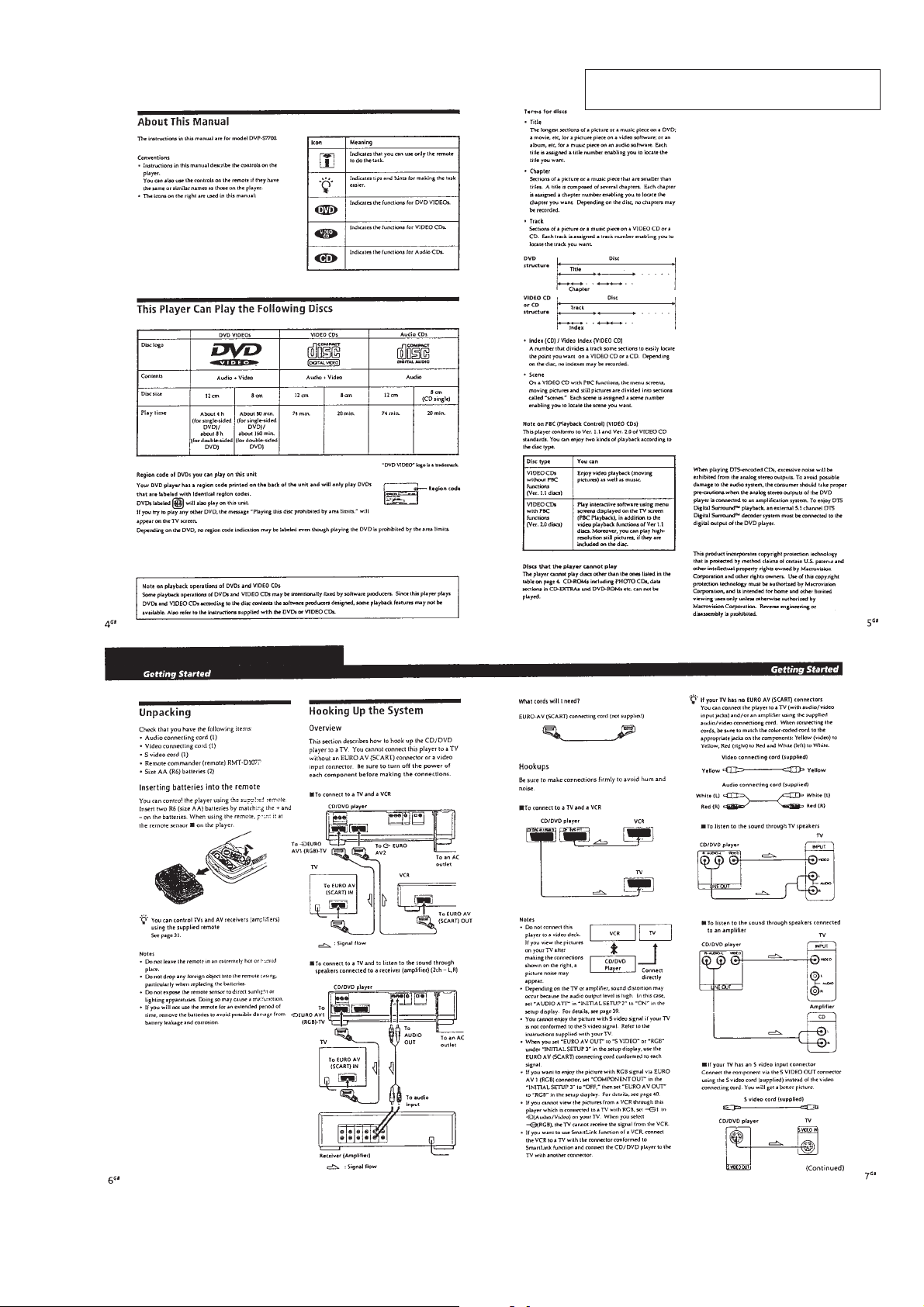

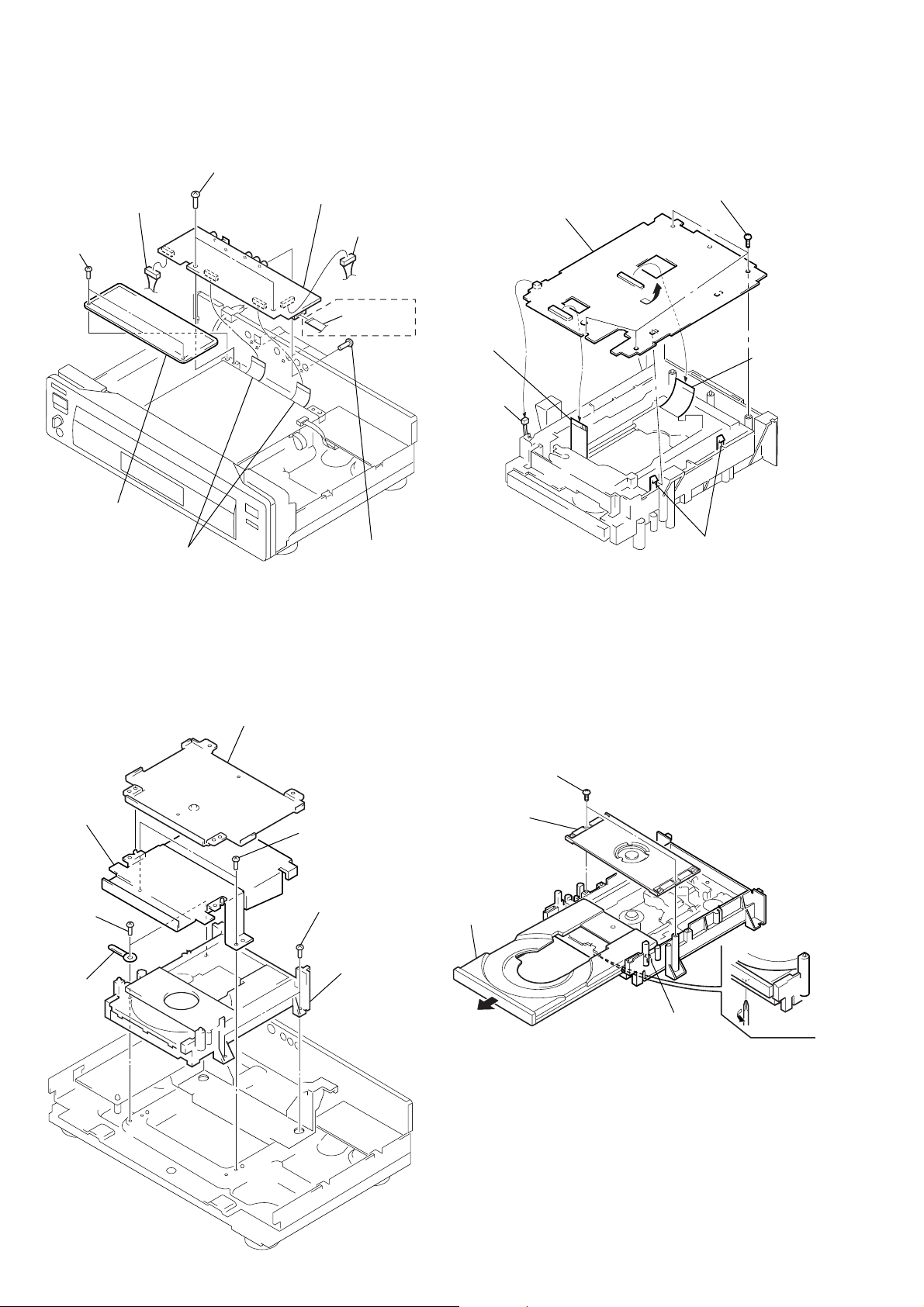

2-5. AU-218 BOARD REMOVAL

7 Two screws

3 Connector

(CN205)

1 Two screws

(B3)

(B3)

8 AU-218 board

4 Connector

(CN204)

2-7. TK-47 BOARD REMOVAL

4 Four screws

(BVTP3 × 10)

6 TK-47 board

2 Copper leaf plate

9 Two flat cables

(CN201, 203)

AEP, UK

5 Flat cable

(CN202)

6 Four screws

(BV/RING)

2 Flat cable

(spindle

motor)

(CN002)

1 Connector

(CN004)

2-6. MD BLOCK ASS’Y REMOVAL 2-8. TRAY REMOVAL

1 Cover (lower)

3 OP-15

flexible

board

(CN001)

5 Two claws

3 Chassis

bracket (B)

5 Two screws

(B3)

6 Clamp

2 Two screws

(B3)

4 Two screws

(B3)

7 MD block

ass’y

1 Two screws

(BVTP3 × 10)

2 Press pully bracket

4 Pull the tray.

6 Remove the

tray.

A

5 Claw

3 Rotate the cam gear

in direction A.

2-2

Page 24

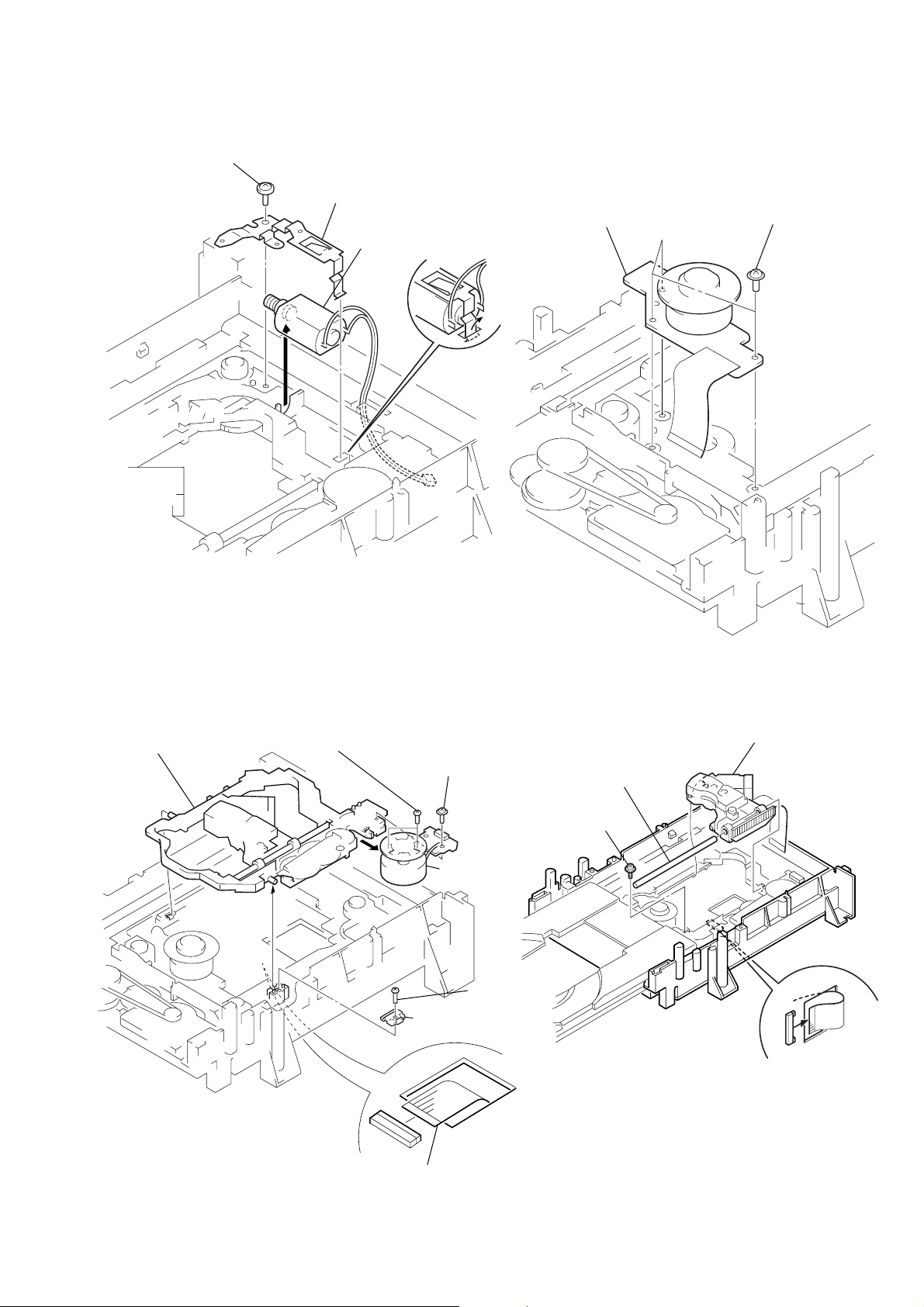

2-9. SKEW MOTOR (M903) REMOVAL

1 Three screws

(PTTWH2 × 5)

2 Spindle motor

(M901)

1 Screw

(PT WH2 × 5)

3 Skew gear retainer

4 Skew motor

(M903)

2-11. SPINDLE MOTOR (M901) REMOVAL

2 Claw

2-10. SLED MOTOR (M501) REMOVAL 2-12. OPTICAL PICK-UP REMOVAL

4 Spindle base

6 Two screws

(P1.7 × 2.5)

5 Screw

(PTTWH2 × 5)

3 Skew shaft

4 Optical pick-up

3 Main shaft

2 Screw

(PTTWH2 × 5)

7 Sled motor

(M501)

2 Screw

(P2 × 8)

stopper

1 OP-15 flexible board

(CN001)

1 OP-15 flexible

board

(CN001)

2-3

Page 25

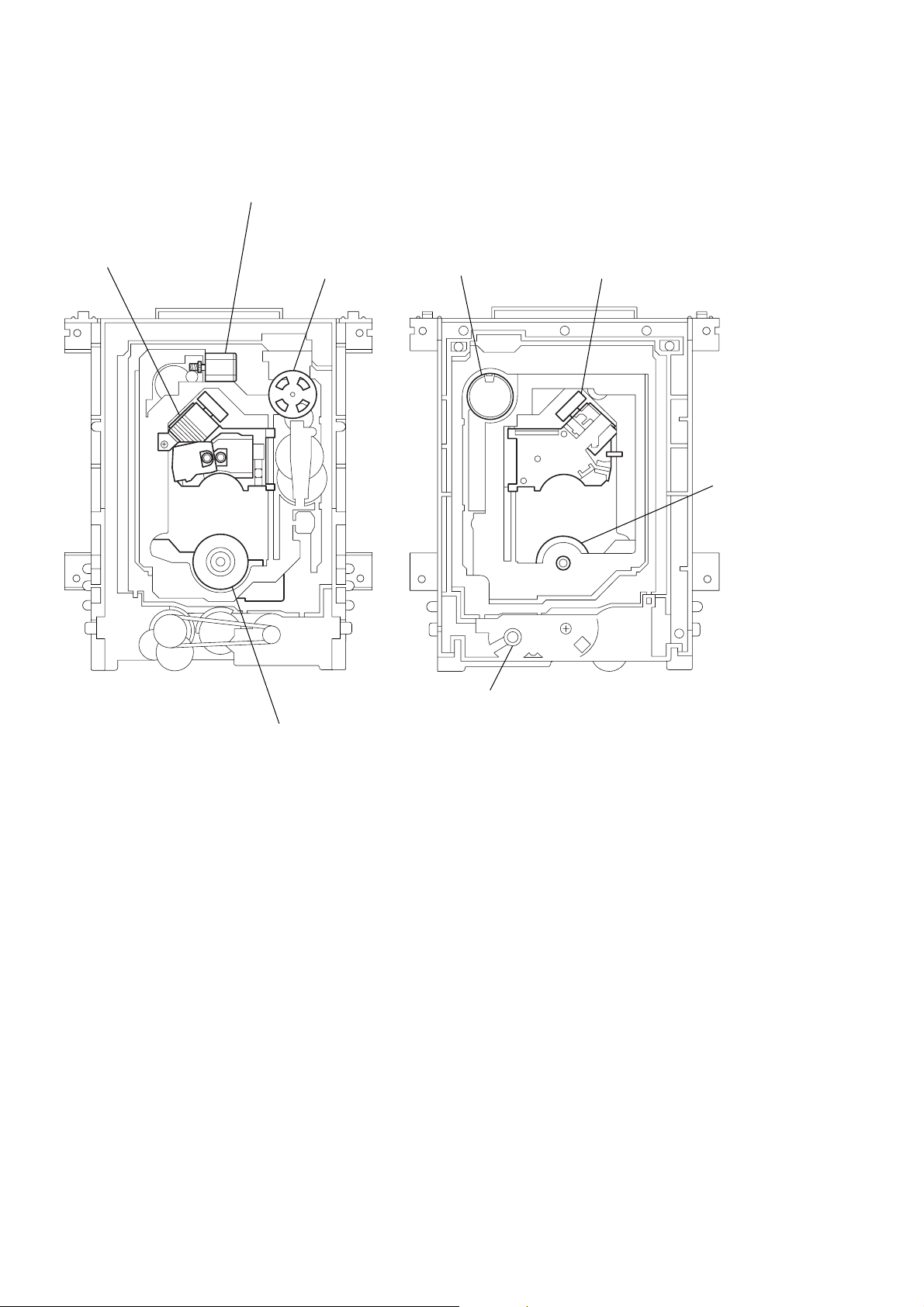

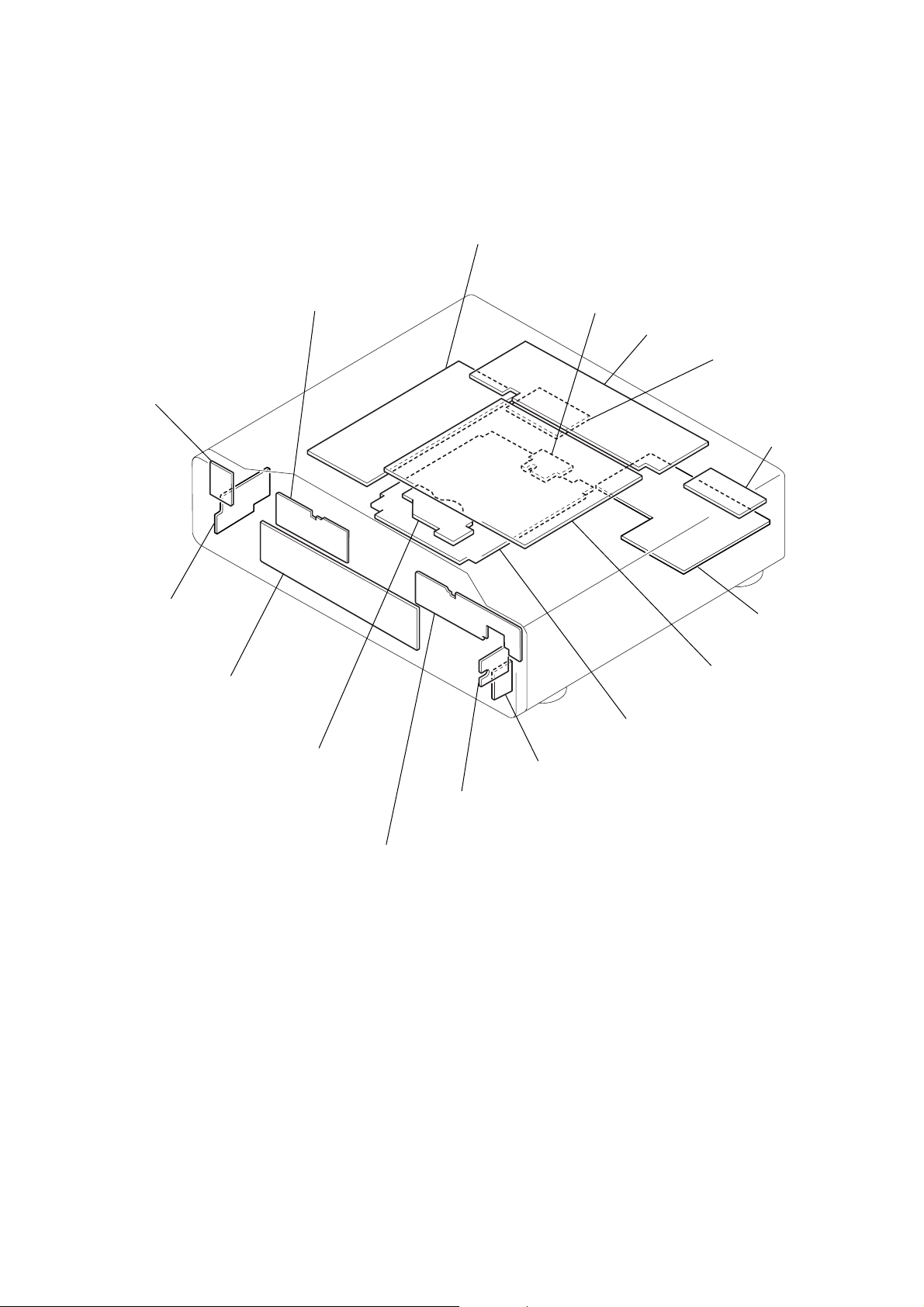

2-13. INTERNAL VIEWS

Skew motor ass’y (tilt)

X-3947-138-1

Optical pick-up

(KHS-180A/J1N)

8-820-005-02

Sled motor ass’y

X-3947-137-1

Sled motor ass’y

X-3947-137-1

Optical pick-up

(KHS-180A/J1N)

8-820-005-02

DC motor

(spindle)

1-698-944-11

DC motor (spindle)

1-698-944-11

Motor (loading)

1-698-942-21

2-4

Page 26

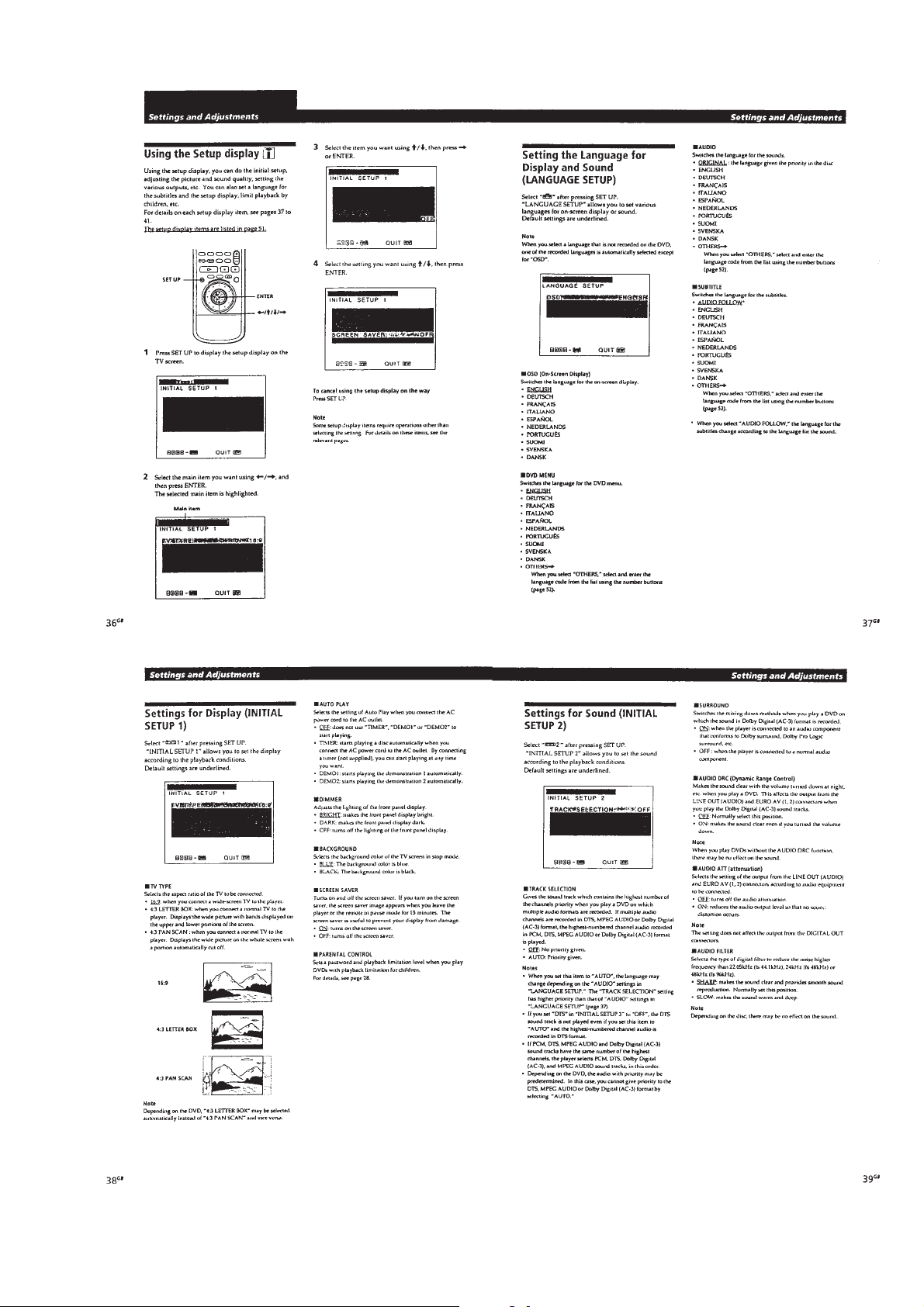

2-14. CIRCUIT BOARDS LOCATION

POWER BLOCK

(HS-930SH)

(SWITCHING REGULATOR)

FR-160

(FUNCTION SWITCH)

PW-120

(IR/POWER SWITCH)

HP-120

(HEAD PHONE)

FP-75

(FL DRIVER)

DC MOTOR

(SPINDLE)

DR-88

(DOOR SENSOR)

FL-108

(FUNCTION SWITCH)

FG-43

(SLED)

AU-218

(AUDIO)

TK-47

(RF/SERVO)

CN-113

(DOOR MOTOR)

PS-421

(AUDIO POWER)

YS-19

(COMPONENT

VIDEO)

ER-8 (AEP, UK)

(EURO AV)

MB-84

(SIGNAL PROCESS/

SERVO)

2-52-5 E

Page 27

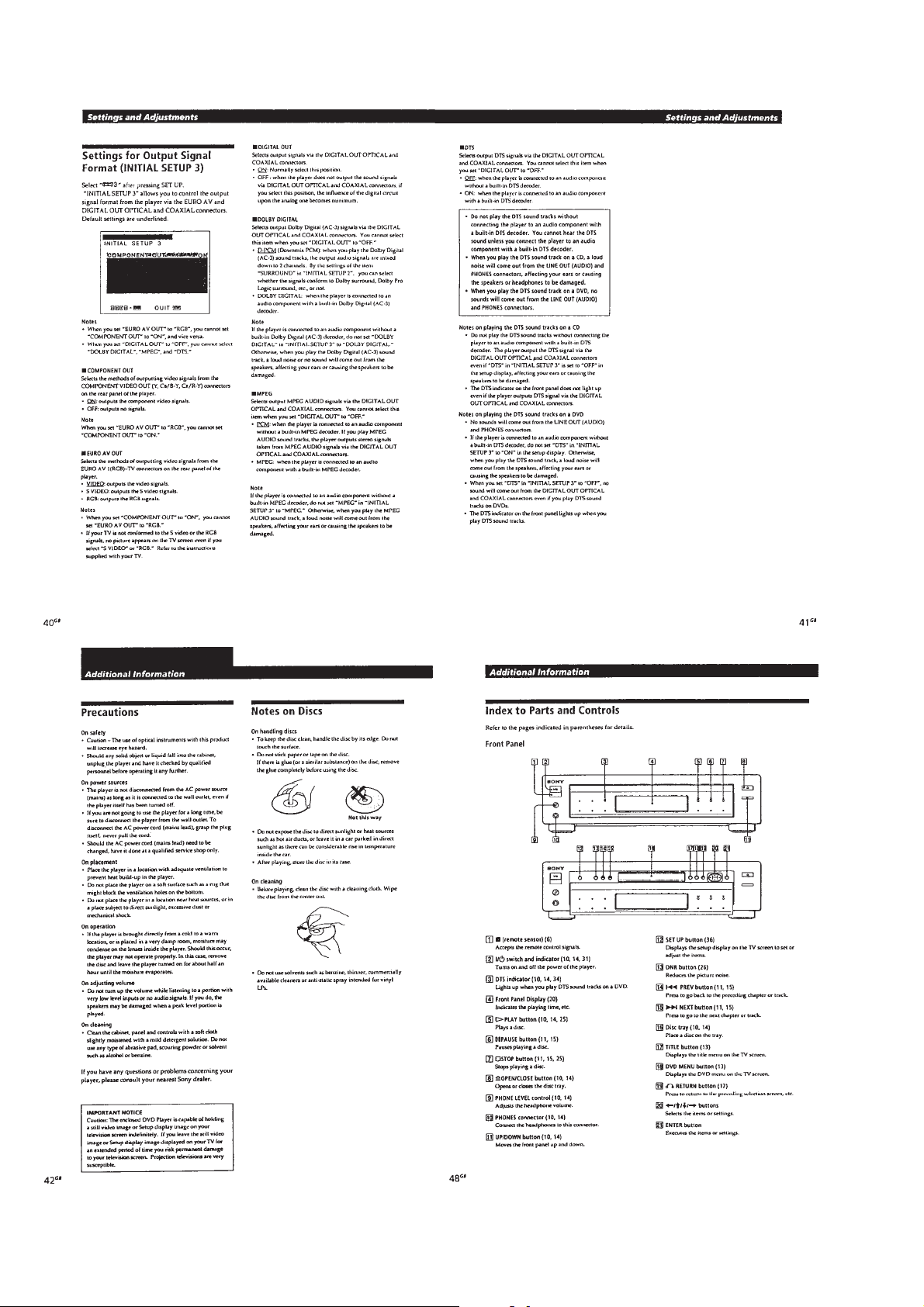

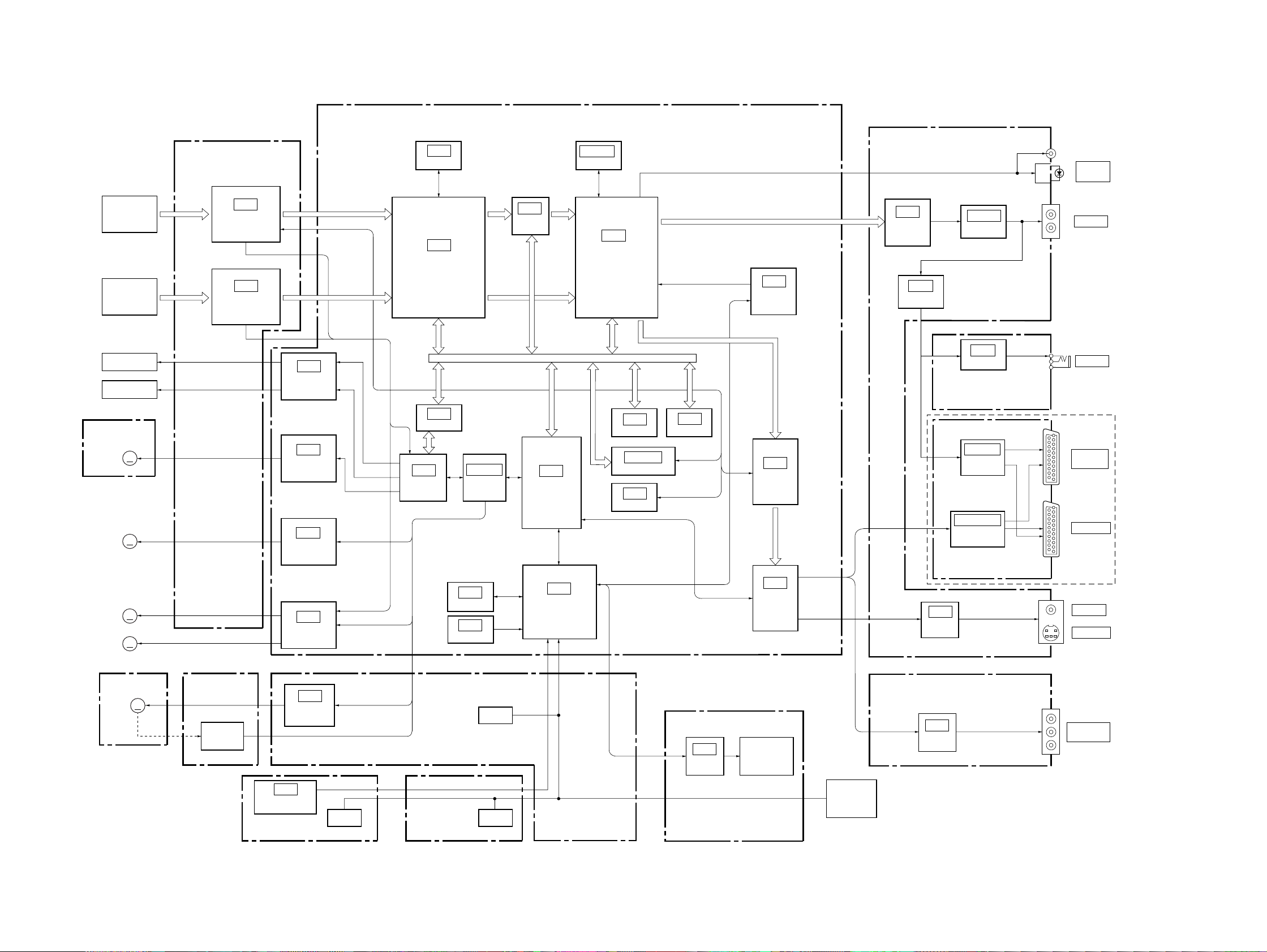

3-1. OVERALL BLOCK DIAGRAM

TK-47 BOARD

(SEE PAGE 4-11~4-14)

SECTION 3

BLOCK DIAGRAMS

MB-84 BOARD

(SEE PAGE 4-19~4-46)

IC810

16M DRAM

IC201, 202

16M SRAM

SPDIF

AU-218 BOARD

(SEE PAGE 4-51~4-56)

DIGITAL

OUT

DVP-S7700

DVD OPT

CD OPT

FOCUS COIL

TRACKING COIL

FG-43 BOARD

(SEE PAGE 4-30)

M503

M

SLED

MOTOR

M901

MOTOR

M902

MOTOR

M903

TILT

MOTOR

M

M

M

SPINDLE

LOADING

IC006

DVD RF AMP,

SERVO

IC005

CD RF AMP,

SERVO

IC363

FOCUS/TRACKING

COIL DRIVE

IC302

SLED MOTOR

DRIVE

IC303

SPINDLE MOTOR

DRIVE

IC361

TILT/LOADING

MOTOR DRIVE

DVD RF

CD RF

S GATE ARRAY

IC506

SERVO DSP

IC806

ARP

IC807

HA0-21, HD0-15

IC804 (1/2)

LGATE

ARRAY

IC603

ROM

IC605

RESET

SD0-7

CD_BCK,

CD_LRCK,

CD_DATA,

SPDIF

IC811

DECRYPT

SYSTEM µ-COM

DCRSD

IC851

IC604

IF µ-COM

0-7

IC203

AV DECODER

IC802

1M SRAM

IC804 (2/2)

L GATE ARRAY

IC801

EEPROM

AV_DATA, AV_BLK, AV_LRCK

YC0-7

IC803

8M ROM

IC207

OSD

IC251

DNR

IC252

VIDEO

ENCODER

Y0-7

C0-7

IC204

AUDIO 2CH

DAC

IC208

BUFFER

HP-120 BOARD

(SEE PAGE 4-70)

IC601-603, 607

SW, BUFFER

ER-8 BOARD

(SEE PAGE 4-63~4-68)

IC209

VIDEO

BUFFER

IC206, 207

FILTER AMP

BUFFER

IC001

HP AMP

IC604, 608

BUFFER

AUDIO

PHONE

AEP,UK

EURO AV1

(RGB)-TV

EURO AV2

VIDEO

S VIDEO

05

CN-113 BOARD

(SEE PAGE 4-77)

M451

M

DOOR

MOTOR

DR-88 BOARD

(SEE PAGE 4-77)

PH101, 102

DOOR

SWITCH

DOOR MOTOR

FL-108 BOARD

(SEE PAGE 4-77)

IC301

REMOTE CONTROL

RECEIVER

PW-120 BOARD

(SEE PAGE 4-78)

IC151

DRIVE

YS-19 BOARD

(SEE PAGE 4-57)

SWITCH

SWITCH

FR-160 BOARD

(SEE PAGE 4-78)

SWITCH

IC201

FL DRIVER

FP-75 BOARD

(SEE PAGE 4-73 )

ND201

FLUORESCENT

INDICATOR TUBE

TOUCH

SWITCH

BLOCK

3-1 3-2

IC851

VIDEO

DRIVER

COMPONENT

VIDEO

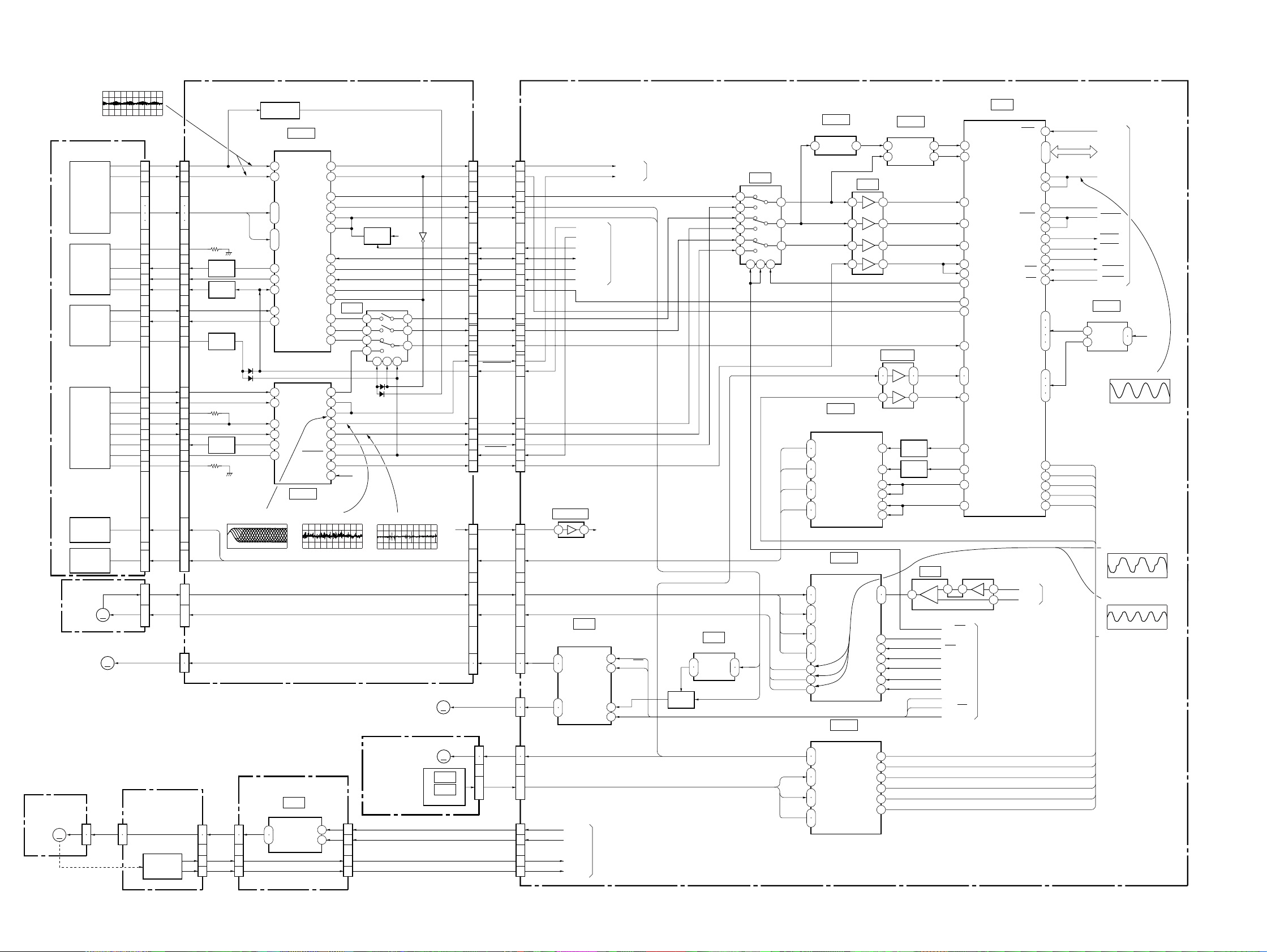

Page 28

DVP-S7700

3-2. RF/SERVO BLOCK DIAGRAM

OPTICAL DEVICE

SPINDLE

MOTOR

LOADING

MOTOR

CN-113 BOARD

(SEE PAGE 4-77)

M451

DOOR

MOTOR

CN451

M

IC006 ^£ – ^¢ (DVD play)

DVD PD IC

DVD LD

MODULE

SKEW

SENSOR

CD LASER

COUPLER

CD FOCUS

TRACKING

COIL

DVD FOCUS

TRACKING

COIL

M901

M

M902

M

D_MTR

1

3

800 mVp-p (V)

9

10

6

13

14

18

5

3

4

2

41

42

38

28

29

19

27

20

23

26

25

30

ı

33

34

ı

37

1

ı

8

9

ı

11

LDMT

DR-88 BOARD

(SEE PAGE 4-77)

CN101

1

3

RFP

RFN

A-D

VR

DVD LD

PD

VLD

SKEW IN

SKEW OUT

LED

PD1

PD2

AL

CD_E

CD_F

CD_LD

MON

VR

CD FCS,

CD TRK

DVD FCS,

DVD TRK

U IN,

V IN,

W IN,

SPVH

U OUT,

V OUT,

W OUT

PH101, 102

DOOR

SWITCH

TK-47 BOARD

(SEE PAGE 4-11~4-14)

CN001

9

10

6

13

14

18

5

3

SWITCH

4

2

SWITCH

41

42

38

28

29

19

27

20

23

SWITCH

26

25

30

ı

33

34

ı

37

CN002

1

ı

8

9

ı

11

CN004

1

2

CN102

D_MTR

4

5

D_SW1

2

D_SW2

1

Q004

Q005

Q001

LD ON

Q007

IC005 @™ (CD play)

500 mV/DIV 1 µs/DIV

FL-108 BOARD (1/2)

(SEE PAGE 4-77)

CN151

4

5

2

1

Q009, IC004

RF DET

IC006

DVD RF AMP, SERVO

63

RFP

HOLD1

64

RFN

10

A

ı

ı

7

D

1

A2

ı

ı

4

D2

SDATA

18

LD

17

PD

16

XLDON

FDCHG

20

TI-A

21

TI-B

3

PD1

4

PD2

5

E

6

F

1

LD

2

PD

APC_ON

IC005

CD RF AMP, SERVO

IC005 !£ (CD play)

500 mV/DIV 1 ms/DIV

IC151

DOOR MOTOR DRIVE

7

OUT1,2

9

SIGO

SCLK

ADEN

TIOFS

MIRR

MIRR

RF02

RF01

TE_C

IN1

IN2

RFO

MB-84 BOARD (1/6)

(SEE PAGE 4-27~4-34)

IC508

FILTER

2 1 6 7

CN005

CN008

CN501

26

9

23

10

11

3

19

18

17

4

20

22

27

16

21

13

14

15

12

2

1

16

ı

23

3

ı

10

11

ı

13

14

15

DVD_RF+

DFCTS

DVD_PI

TI-ERR

SCKG3

DVD_FE

DVD LDON

CDRFDC

CD LDON

TEATT

DVDFCS,

DVDTRK

CDFCS,

CDTRK

LDMT

TIMT

1

2

3

ı

8

TTLT/H

SSSD

SDEN

TIOFS

MIRR

CD TE

CD FE

57

47

37

PI

26

TIE

TII

23

TI–

24

43

44

45

19

33

TE

FE

30

19

21

22

13

TE

15

FE

32

25

12

VC

16

CN153

2

4

IC011

19

18

5

6

VC

DFWD

DRVS

DSW1

DSW2

SWITCH

SWITCH

338

139

13

12

FG-43 BOARD

(SEE PAGE 4-30)

Q008

10

9 11

IC005 !∞ (CD play)

500 mV/DIV 10 ms/DIV

VC

4

15

14

M903

TILT MOTOR

M501

SLED MOTOR

Q009

VC

M

M

IC501

IC502

HOLE SENSOR

TIE

DPD

CDRF

SVC

U IN,

V IN,

W IN,

SPVH

U OUT,

V OUT,

W OUT

SLDMT

HA, HB,

SLVH

2

19

18

17

25

9

10

11

24

8

6

1

12

7

15

14

13

16

26

27

12

5

25

18

17

15

13

14

1

2

7

8

1

6

19

18

5

ı

ı

ı

ı

5

6

CN452

CN302

CN361

CN301

CN601

IC502 (1/2)

3 1

TILT/LOADING

MOTOR DRIVE

8

DOUT2

9

5

DOUT1

6

DFWD

DRVS

DSW1

DSW2

DVD LDON

CD LDON

TILT/H

SSSD

SCKG3

SDEN

IC361

MUTE2

IN2–

IN1+

MUTE1

SYSTEM CONTROL

(SEE PAGE 3-9)

SYSTEM

CONTROL

(SEE PAGE 3-9)

VC

TRAY_FREE

13

OPN/CLS

17

21

S12VOFF

2

DVD RF

CD RF

TI_ERR

SIGNAL PROCESS

(SEE PAGE 3-5)

TIE

Q452

SWITCH

IC452

13

12

1

2

3

5

IC455

COMP

1

7

OUT

3

IN

5

TI_ERR

14

15

4

109 11

CD TRK

CDFCS

DVDFCS

DVDTRK

TIE

IN OUT

3 1

6 7

10 8

12 14

IC363

IC363

FOCUS/TRACKING

COIL DRIVER

11

DO2

12

13

DO1 MUTE2

14

15

DO4

16

17

DO3

18

SPINDLE MOTOR DRIVER

30

U IN

31

32

V IN

33

34

W IN

1

28

VH

29

23

U OUT

22

V OUT

19

W OUT

SLED MOTOR DRIVER

2

SLDMT

5

33

HA

34

29

HB

30

22

SLVH

23

MUTE1

IC303

Z1, Z2

SPCTRL1

SPCTRL0

SPGC2

SPGC1

IC302

IC503

IN2–

IN3–

IN1–

IN4–

HFG

NS+

DV–

DVI

DVO

TKC

CTRL

A+

IC501

COMP

IN2 OUT2

3 1

IN1 OUT1

IC502 (2/2)

5

10

12 14

Q371

9

MUTE

Q372

20

MUTE

6

23

3

26

14

15

27

7

8

9

10

11

8

12

13

18

25

32

PISW

7

8

IC301

19

20

–

671 2

+

CD/DVD

HFG

NST

SPCTRL1

SPCTRL0

SPGC2

SPGC1

TRAY_FREE

OPN/CLS

S12VOFF

89

TRIN

7

DFCTA

21

AIN5

AIN2

24

26

AIN0

GIO3

11

GIO2

12

8

GIO8

73

PWM2

99

TRREF

88

AIN6, 7

AIN8

18

2

GIO11

1

GIO12

49

AOUT0

AOUT1

46

IC506

SERVO DSP

HCK/HLDB

HDO-7

CLKIN

GIO10

MRST

GIO15

GIO13

HFD/HWR

HR/HRD

AOUT3

AOUT2

PWM1

PWM0

5

SYSTEM CONTROL

(SEE PAGE 3-9, 10)

TCK

IRS

GIO9

VTOP

VBTM

GIO0

MDS0

MDP0

72

56

ı

63

65

79

3

84

94

98

4

100

71

70

28

37

42

45

50

36

43

44

51

38

41

74

14

75

SIGNAL

PROCESS

(SEE PAGE 3-5)

HYCNTR

SDCNT

SOUT

SLOFS

TKC

HYCNTR

HYDET

SDCNT

SOUT

SLOFS

TKC

HYDET

IA1

IDO-7

27M_DSP

ACK

SYSTEM CONTROL

(SEE PAGE 3-9, 10)

SDPRST

ERROR

BUSY2

FON

SDSPWR

SDSPRD

IC507

POWER SUPPLY

7

OUT2

3

IN

5

OUT1

1

IC506 ^∞

3.6 Vp-p 27 MHz

IC303 !ª, @™, @£ (DVD play)

5.2 Vp-p 160Hz

IC303 !ª, @™, @£ (CD play)

1.84 Vp-p 45Hz

VC

05

3-3 3-4

Page 29

3-3. SIGNAL PROCESS BLOCK DIAGRAM

MB-84 BOARD (2/6)

(SEE PAGE 4-19, 4-41)

IC806 0

1.5 Vp-p

RF IN1DVD RF

10

RF IN2CD RF

RF/SERVO

(SEE PAGE 3-3, 4)

12

MDS0MDS0

43

MDP0MDP0

48

MA0-9

IC810

16M DRAM

MD00-15

IC806

ARP

XMWR, XCAS,

XRAS, XOE

SYSTEM CONTROL

(SEE PAGE 3-9, 10)

96

ı

99

SD0-7

101

ı

106

SDCK, XSHD,

106

XSRO, XSAK, SDEF

ı

109

IC207

OSD

SCLK

SO

SCLKO

CGCSO

OH SYNC

1

SD0-7 DCRSD0-7

3

74

77

DTI0-7

ı

79

80

4

ı

8

43-47 26-31 34-41

24

SIN

25

CS

26

EVEN

11

H SYVC

12

V SYNC

13

IC811

DECRYPT

XRST

54 51

SHA0-5

SHD0-7

R OUT

G OUT

B OUT

I OUT

DTO0-7

MCK

20

19

18

17

62

64

ı

66

68

ı

74

56

59

ı

61

AREQ, ALALID,

ERROR, TOS

VS

69

HS

70

88

ı

EX_OSD_0-3

91

12

ı

CH-DATA0-7

19

21

24

26

30

DCK

28

16M SDRAM

AVA0-11

AVID

IC201

0-15

SDQM, WE, CAS, RAS, CS1, CS2, SDQM, SDCLK

IC203

AV DECODER

IC202

16M SDRAM

PD0-7

DVP-S7700

73

74

76

ı

78

82

ı

84

FID

V SYNC

YC0-7

VIDEO

(SEE PAGE 3-7)

MUTE

MD2

DFCT

NORF

LOCK

FWON

ARPINT

ARPCS

ARPWT

SYSTEM CONTROL

(SEE PAGE 3-9, 10)

05

XWR

XRD

DCRCS

DCRINT

DCRWT

AVDRQ

AVCS

AVINT

AVWT

XRST

MRST

IA0-8

ID0-7

MUTE

110

MD2

112

DFCT

50

NORF

51

LOCK

53

FWON

55

XINT

80

XCS

81

83

XWAT

IC806 `⁄¤¤

3.4 Vp-p 27 MHz

XRST

84 122

XWR, XRD

XRST

MCKI

SCKI

124

33M

27M_DSP

70-73 75-7856 57

IA0-7

IC806 `⁄¤›

3.0 Vp-p 33 MHz

A0-7

56-62 64-67

ID0-7

D0-7

CD_LRCK, CD_BCK,

CD_DATA, SPDIF

106

ı

109

XRST

XWR, XRD,

DCRCS, DCRINT, DCRWT

IA0-5

ID0-7

27M_DNR

IC811 %¡

3.4 Vp-p 27 MHz

98

99

101

102

58 59 63-65 68 94-96 100 34-39 43-45 47-54

XWR, XRD,

AVDRQ, AVCS,

AVINT, AVWT

KESET_B

57

MRST

384FS

IA0-8

A_0-8

SPDIF_OUT

BCLK

LRCLK

ASDATA

D_0-7

ID0-7

111

105

106

107

SPDIF

AV_BCK

AV_LRCK

AV_DATA

384FS

27M_DNR

27M_DSP

33M

AUDIO

(SEE PAGE 3-11)

SYSTEM CONTROL

(SEE PAGE 3-10)

3-5 3-6

Page 30

DVP-S7700

3-4. VIDEO BLOCK DIAGRAM

MB-84 BOARD (3/6)

(SEE PAGE 4-23~4-26)

SIGNAL

PROCESS

(SEE PAGE 3-6)

SYSTEM

CONTROL

(SEE PAGE 3-9, 10)

MODE

CONTROL

(SEE PAGE 3-13)

05

YC0-7

FID

V SYNC

OHSYNC

27M_DNR

DCS

SCKG3

SOG3

AVCNT

E_V/RGB

YUV_RGB

AEP,UK

H SYNC

V SYNC

27M_VE

MRST

13.5M

VCS

AVCK

SOG2

VSI

VS

V SYNC

V MUTE

E_V/Y

EURO_V/Y

AV_CONT

E_V/RGR

YUY_RGB

OHSYNC

27M_DNR

DCS

SCKG3

SOG3

11

ı

GI 0-7

18

98 H SYNCI

9 BIO (27MHz)

29 XCS

30 XSCLK

31 SDI

IC251

DNR

XRST

DCLKI (13.5MHz)

93 100 97

MRST

13.5M

V SYNCI

G00-07

R00-07

AEP,UK:RGB output mode

IC252 &¢

0.7 Vp-p (H)

0.7 Vp-p (H)

IC252

VIDEO ENCODER

19

60

ı

67

51

ı

58

ı

22

PD0-7

24

ı

27

33

ı

36

PD8-15

38

ı

41

FID

14

V SYNC

15

16

H SYNC

PDCLK

XCS/SA

SCK/SCL

SI/SDASOVREF

XRST

SYSCLK

27M_VE

MRST

13.5M

4847 55454411108

VCS

AVCK

SOG2

VSI

IC252 %§

1.0 Vp-p

B-Y/R OUT

Y/G OUT

R-Y/B OUT

CPOUT

YOUT

COUT

RV251

VIDEO

LEVEL

ADJ

IC252 &™

74

72

66

56

64

58

IC252 ^¢

0.7 Vp-p (H)

IC252 ^§

0.7 Vp-p (H)

IC252 ^§IC252 &™IC252 &¢

0.7 Vp-p (H)1.0 Vp-p (H)

AV_CONT

Q638

VIDEO_B

EURO_V/Y

Hong Kong

VIDEO_R

VIDEO_G

6

Q601, 621, 624

AV CONT

Q639

BUFFER

Y

B-Y

R-Y

V MUTE

4

6

28

Q642

AV CONT L

AV CONT H

4

6

8

Hong Kong

V MUTE

2

EURO_V/Y

2

AV_CONT

3

E_V/RGB

9

YUV_RGB

1

AEP,UK

CN252 CN201

14

10

12

V MUTE

8

7

IC252 %•

0.7 Vp-p1.0 Vp-p

AEP,UK

E_V/RGB

YUV_RGB

178249

ER-8 BOARD (1/2)

(SEE PAGE 4-63~4-68)

CN603 CN604

B-Y

R-Y

V MUTE

VIDEO_V

VIDEO Y

VIDEO C

V MUTE

Q641

Y

VS

YS-19 BOARD

(SEE PAGE 4-57)

CN851CN251

4

6

8

2

12

16

14

18

19

14 15 5 3 1

VS

2 1 11 13 15

IC602

SWITCH

Q630

Q627

VIDEO C

V_MUTE

1

3

Q643,644

SWITCH

CONTROL

VIDEO Y

IC601

SWITCH

2

SWITCH

VIDEO V

CN602 (1/2)

AV CONT H

AV CONT L

Q632

IC851

VIDEO BUFFER

4 13

7

2

1

AU-218 BOARD (1/2)

(SEE PAGE 4-55)

Q218

BIFFER

CN202 (1/2)

3

1

2

7 4

7

4

AUDIO

(SEE PAGE 3-11)

Q215

INVERTER

5

IC851 !£

10

15

VIDEO BUFFER

2 15

4 13

7 10

1

VIDEO BUFFER

4 13

1

0.7 Vp-p (H)

IC209

VIDEO BUFFER

2 15

4

7

1

IC209 !£

1.0 Vp-p (H)

IC603

MUTE

IC607

107

MUTE

IC851 0

13

10

1.0 Vp-p (H)

Q214

VS

RY601

7

6

RY602

7

6

IC851 !∞

CB/B-Y

Y

CR/R-Y

IC209 0

8

5 1

RELAY DRIVE

58

RELAY DRIVE

0.7 Vp-p (H)

0.7 Vp-p (H)

Q628

1

Q629

J851

COMPONENT

VIDEO OUT

Y

C

Y

C

10

3

10

3

VIDEO 1

VIDEO 2

Hong Kong

S VIDEO 1

S VIDEO 2

Hong Kong

IC209 !∞

J202 (1/2)

LINE OUT

1.1 Vp-p (H)

Q602, 636

SWITCH

Q635, 637

SWITCH

20

19

15

11

7

16

8

20

19

15

11

7

16

8

V/Y IN

V/Y OUT

R/C

CNJ602 (1/2)

G

B

I

AV CONT OUT

V/Y IN

V/Y OUT

R/C

G

CNJ601 (1/2)

B

I

AV CONT IN

EURO AV1

(RGB)-TV

EURO AV2

3-7 3-8

Page 31

3-5. SYSTEM CONTROL BLOCK DIAGRAM

DVP-S7700

MB-84 BOARD (4/6)

(SEE PAGE 4-21, 4-39, 4-43,4-45)

AUDIO

(SEE PAGE 3-11)

RF/SERVO

(SEE PAGE 3-3, 4)

POWER

(SEE PAGE 3-16)

SIGNAL

PROCESS

(SEE PAGE 3-5)

MODE

CONTROL

(SEE PAGE 3-13)

SCKG3

SOG3

D2LT

DVDLDON

CDLDON

TILT/H

SSSD

SCKG3

SDEN

CD/DVD

NST

SPCTRL1

SPCTRL0

SPGC2

SPGC1

S12VOFF

TRAY_FREE

OPN/CLS

DFWD

DRVS

DSW1

DSW2

ERROR

BUSY2

FON

SDSPWR

SDSPRD

S12VOFF

MUTE

MD2

DFCT

NORF

LOCK

FWON

ARPINT

ARPCS

ARPWT

XRD

XWR

DCRCS

DCRINT

DCRWT

AVCS

AVWT

OHSYNC

XIFBSY

IFSI

IFSO

DIAG

XSHINT

IC801

EEPROM

SCKG3

SOG3

MLT

OHSYNC

EBSY, ECS,

EESI, EWC

46

47

117

50

2

3

13

52

48

4

7

8

9

10

22

19

18

5

112

142

111

12

15

14

17

77

58

104

103

105

106

16

102

60

59

61

56

57

62

63

64

65

66

140

132

44

109

125

133

SCKG3

SOG3

D2LT

MLT

DVDLDON

CDLDON

TILT/H

SSSD

SDEN

CD/DVD

NST

SPCTRL1

SPCTRL0

SPGC2

SPGC1

S12VOFF

TRAY_FREE

OPN/CLS

DFWD

DRVS

DSW1

DSW2

ERROR

BUSY2

FON

SDSPWR

SDSPRD

MUTE

MD2

DFCT

NORF

LOCK

FWON

ARPINT

ARPCS

ARPWT

IRD

IWR

DCRCS

DCRINT

DCRWT

AVCS

AVWT

OHSYNC

XIFBSY

IFSI

IFSO

DIAGN

XSHINT

IC804

L GATE ARRAY

HA0-7, 19-21

HD0-7

MRST

27M_VE

SCKG2

DOUTCTL

DCS

AVCNT

E_V/RGB

YUV_RGB

HSYNC

PDCLK

VCS

AVCK

VSI

IC807

1

ı

3

5

ı

8

ı

CGCS

SCLK

SI

SCKG1

SRST

HA0-8

HD0-7

CSI

SCKI

SDI

S GATE ARRAY

MODE

CONTROL

(SEE PAGE 3-13)

IC206 8

3.28 Vp-p 27 MHz

44

ı

50

IA0-8 IA1

52

53

33

ı

36

ID0-7

38

ı

41

57

SCO

56

SCKO

SDO

55

61

CK

384FS

33M

27M_DNR

27M_DSP

384FS_2CH

27M_DSP

IC204

716 2

SIGNAL

PROCESS

(SEE PAGE 3-6)

AUDIO

(SEE PAGE 3-11)

RF/SERVO

(SEE PAGE 3-4)

27M_DNR

27M_VE

ID0-7

IA0-8

ID0-7

CGCSO

SCLKO

SO

RF/SERVO

(SEE PAGE 3-4)

SIGNAL

PROCESS

(SEE PAGE 3-5)

VIDEO

(SEE PAGE 3-7)

IC802

1M SRAM

75

HA0-7, 19-21

76

83

ı

91

HD0-7

92

ı

99

HA0-21

23-30 32-39 41 42 44-47 4-11 13 14 16-21

RD, WR, CS0, CS1

RD, WR

73

74

XIRQ3, XIRQ7,

67

XCS6, XWAIT

68

71

72

SIG1, 2

69

70

108

123

115

113

158

49

150

149

151

148

127

118

36

114

37

152

VS

SOG1

48

49

57

59

2

55

56

69

107

109

108

54

MRST

SCK1

TXD1

PA11

112 110

65

PA0/CS4

53 64

A0-11

SYSTEM µ-COM

IC805 &£

PA10

IC804 `⁄⁄fi

3.3 Vp-p 27 MHz

IC805

4.4 Vp-p 20 MHz

A MUTE

MA MUTE

DOUTCTL

OHSYNC

SCKG3

SOG3

SOG3

DCS

E_V/YE_V/Y

AVCNT

E_V/

YUV_RGB

HSYNC

13.5M

VCS

AVCK

SOG2

VSI

VS

RGB

IC803

8M FLASH

HD0-15

AD0-15

AIDIO

(SEE PAGE 3-11)

AEP,UK

VIDEO

(SEE PAGE 3-7)

PB0

PB14/IRQ9

PA9

IRQ2

IRQ1

IRQ0

PB1

EXTAL

XTAL

SCK0

RES

HA0-8

HD0-7

97

1

63

68

67

66

98

73

74

111

79

MLT

SCKG3

SOG3

X201

27MHz

SYSCLK

(27MHz)

20MHz

CT201

ADJ

IC804 `⁄⁄°

X801

7

8

9

1

24

HFG

RF/SERVO

ACK

(SEE PAGE 3-4)

SDPRST

VIDEO

VSYNC

(SEE PAGE 3-7)

AVDRQ

SIGNAL

PROCESS

AVINT

(SEE PAGE 3-5)

XRST

SIGNAL PROCESS,

MRST

VIDEO, AUDIO

(SEE PAGE 3-5, 7, 11)

IC209

PLL

RSTB 384FS

ML

MC

MD

XT1

XT2

IC209 1

1.4 Vp-p 27 MHz

33M

27M

2010

21

63

64

11

14

16

19

23

24

25

IC205

BUFFER

5 6

2 3

12 11

IC206

BUFFER

24 3

5 6

12 11

9 8

225 mVp-p 13.5 MHz

05

3-9 3-10

Page 32

DVP-S7700

3-6. AUDIO BLOCK DIAGRAM

MODE CONTROL

(SEE PAGE 3-13)

SYSTEM CONTROL

(SEE PAGE 3-9)

SIGNAL PROCESS

(SEE PAGE 3-6)

SYSTEM CONTROL

(SEE PAGE 3-9,10)

MB-84 BOARD (5/6)

(SEE PAGE 4-21,4-23)

05

PMUTE

AUDIO MUTE

MA MUTE

AMUTE

SCKG3

D2LT

SOG3

SPDIF

AV_LRCK

AV_BCK

AV_DATA

DOUTCTL

384FS-2CH

MRST

CN252 (2/2)

IC208

CN101

20

AUDIO MUTE

17

19

18

16

5

4

5

3

1

8

MAMUTE

SCKG3

D2LT

SOG3

SPDIF OUT

DAC LRCK

DAC BCK

DAC DATA

384FS-2CH

MRST

AU-218 BOARD (2/2)

(SEE PAGE 4-51~4-56)

CN201 (2/2)

6

9

7

8

10

21

CN203

22

21

23

25

18

POWER

(SEE PAGE 3-15)

1

3

2

26

28

5

22

LRCIN

BCLK IN

D IN

ı

XTI

RSTB

PFAIL

FILTER SWITCH

IC204

AUDIO 2CH DAC

V_OUT L

ZEROR

V_OUT R

Q209

DRIVE

ZERO

HP_L

HP_R

COAXIAL

L

R

L

R

2

4

6

J201

OPTICAL

AUDIO1

AUDIO2

Hong Kong

PHONE

CN002

HP-120 BOARD

(SEE PAGE 4-70)

RV001

LEVEL

DIGITAL

OUT

J202 (2/2)

LINE

OUT

IC001

HP AMP

5 7

3 1

Q001, 002

MUTE

J001

PHONES

Q216

BUFFER

IC210

1

DIN

IC207

BUFFER

16

21

17

IC206

BUFFER

13

Q203

FILTER SWITCH

Q204

FILTER SWITCH

2 16 7

6 72 1

Q211

MUTE

Q210

MUTE DRIVE

Q217

MUTE DRIVE

Q212

MUTE

Q205

MUTE

IC208

HEAD PHONE AMP

3 1

5 7

CN205

5

3

PMUTE

1

AEP,UK

ER-8 BOARD (2/2)

(SEE PAGE 4-63,4-67)

VIDEO

(SEE PAGE 3-8)

AV CONT L

AV CONT H

CN202 (2/2)

CN602 (2/2)

MUTE_CTL

Q606, 640, 612

MUTE CTL

11 913

AU_R (X)

AU_L (X)

573

Q622, 623

MUTE

Q604, 605

MUTE

IC608

BUFFER

3 1

5 7

Q625, 626

MUTE

IC604

BUFFER

3 1

5 7

Q633, 634

MUTE

Q614, 615

MUTE

3

A (L) OUT

1

A (R) OUT

6

A (L) IN

2

A (R) IN

3

A (L) OUT

1

A (R) OUT

6

A (L) IN

CNJ602 (2/2)

EURO AV1

(RGB)-TV

CNJ601 (2/2)

EURO AV2

Q607, 608

MUTE

3-11 3-12

2

A (R) IN

Page 33

3-7. MODE CONTROL BLOCK DIAGRAM

MB-84 BOARD (6/6)

(SEE PAGE 4-37)

IC604

I/F µ-COM

VIDEO

SEE PAGE

3-7

POWER

SEE PAGE

3-16

AUDIO

SEE PAGE

3-11

SYSTEM

CONTROL

SEE PAGE

3-9, 10

VSYNC

VMUTE

P_CONT

IC605

RESET

PMUTE

AUDIO MUTE

XIFBSY

SCKGI

IFSI

IFSO

CGCS

SI

SCLK

DIAG

XSHINT

3OUT

SI

SCLK

53

REFV

27

VIDEO MUTE

33

P CONT

77

RESET IN

26

AUDIO MUTE

31 RESETSRST

16

INTMS

20

SCK

19

TX

18

RX

28

CGCS

32

PPG6

54 IFCS

SCLK

FLCS

AD6

AD4

AD3

X IN

X OUT

55

SO

22

24

30

25BZ

45

43

41

59IR

83

82

X601

4MHz

SI

SCLK

IC604 *™

5.6 Vp-p 4 MHz

ST-BY CONT 1 OUT1 IN1

A00–019 AD00–07

ALE, OE, WE

IC606

COMP

DVP-S7700

FP-75 BOARD

(SEE PAGE 4-73)

3

CN601

SI

10

SCKL

11

FLCS

12

BZ

13

AD6

17

AD4

16

IR

8

AD3

15

FL-108 BOARD (2/2)

(SEE PAGE 4-77)

CN153

10

11

12

13

17

16

8

15

Q151

BUFFER

DRIVE

RETURN

DVD

MENU

CN152

6

7

8

3

CN154

6

S155 S401

2

4

CN202

SI

6

SCLK

7

FLCS

8

D201

DTS

AD6

3

CN401

AD4

1

S404 S403 S402S159 S157

IR IR

5

AD3

3

FR-160 BOARD

(SEE PAGE 4-78)

IC 201

FL DRIVER

6

SI

8

SCLK

9

FLCS

dts

48

44

ı

G1–7 G1–7

38

15

ı

32

S1–19

•

35

49

PAUSE

50

PLAY

SEP UP

DNRPREVNEXTTITLE

CN402

4

2

ND201

FLUORESCENT

INDICATOR TUBE

5

ı

11

43

S1–19

ı

25

AD3

PAUSE_LED

PLAY_LED

PW-120 BOARD

(SEE PAGE 4-78)

CN301

2

EVER

5V

REG5V

4

CN201

2

6

AD6

3

IC301

REMOTE CONTROL

RECEIVER

1

Q301

LED

DRIVER

TOUCH

SWITCH

BLOCK

IC601

LATCH

05

IC603

ROM

S160

OPEN/

CLOSE

S158

PANEL

S156

ENTER

S154

RIGHT

S153UPS152 S151

DOWN

LEFT

S301

POWER

D303

ON/STANDBY

3-13 3-14

Page 34

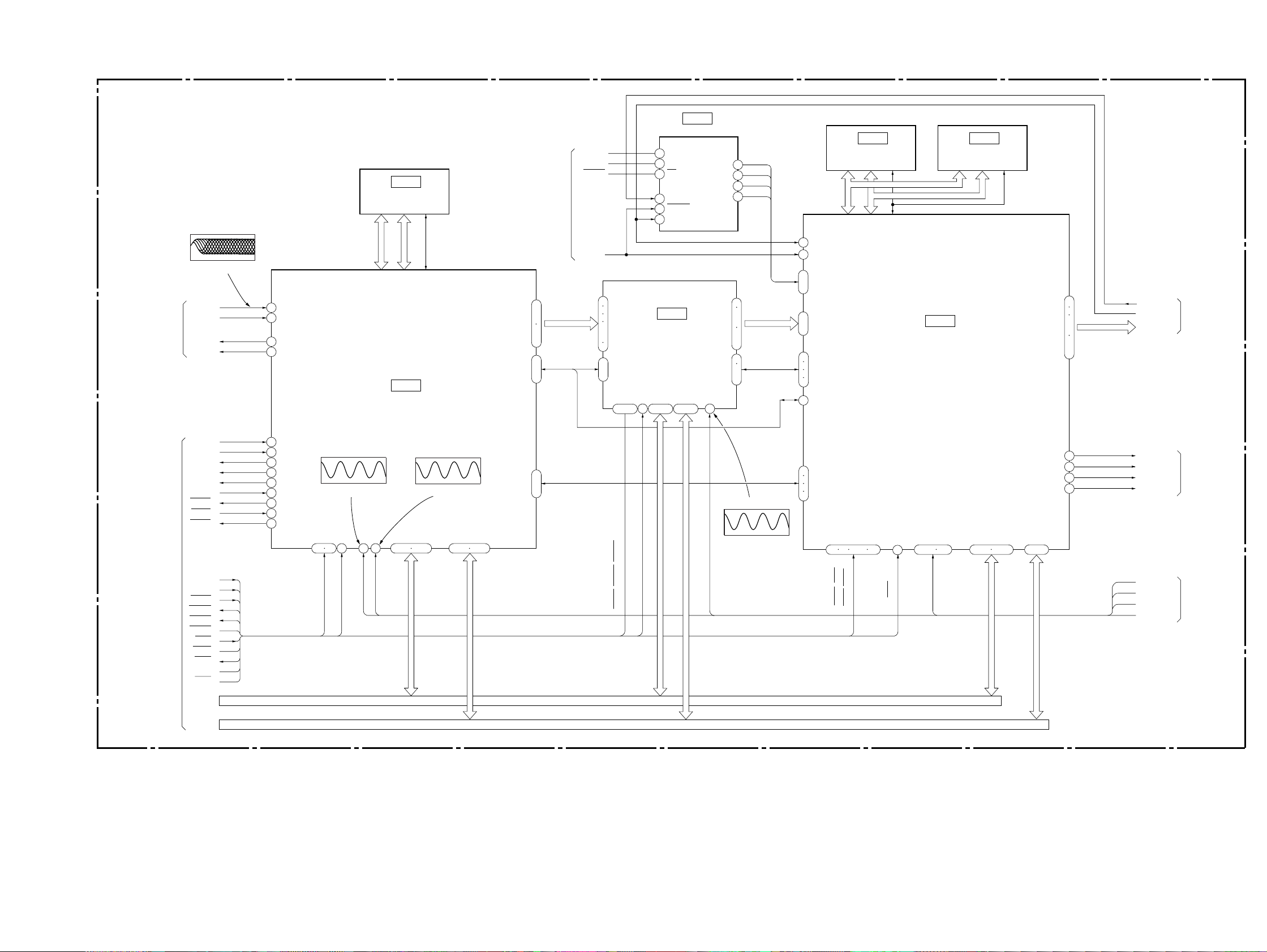

DVP-S7700

3-8. POWER BLOCK DIAGRAM

AC IN

HS-930SH BOARD

(SEE PAGE 4-85)

CN101

F101

1

•

2

CN902

1

•

2

CN901

1

•

3

CN903

1

•

2

CN904

1

•

4

PS-421 BOARD

(SEE PAGE 4-81)

F901

D901, 902,

904, 905

D903

L101

LFT

RY901

CONT

Q951, 952

SWITCH

A+12V

AU–12V

P.FAIL

AU+12V

TK-47 BOARD

(SEE PAGE 4-11~4-14)

24

•

25

F004

F003

F002

F001

SYSTEM CONTROL

(SEE PAGE 3-9)

IC302

IC303

IC361

IC363

IC004 IC005

IC006 IC011

CN001

VCC

22

OPTICAL

DEVICE

D101

LF901

LFT

Q101–103

SWITCH

PC101

PHOTO

COUPLER

T101

CN202

3 1

Q311

5.2V REG

IC611

3.3V REG

Q211

12V REG

Q511

-12V REG

AEP,UK

P311

P312

P211

Q312

POWER

CONTROL

P511

Q512

-12V SWITCH

CN201 CN001

1

REG+5.2V

•

2

EVER+5.3V

6

REG+3.3V

4

P-CONT

8

AU+12V

9

M+12V

14

AU-12V

11

–12V

12

MB-84 BOARD

(SEE PAGE 4-19~4-46)

F006

7

F005

•

8

FL002

3

5

FL006

1

CN002

7

2

5

4

FL004

P_CONT

FL008

FL005

FL001

FL007

FL003

EVER+5.3V

MODE CONTROL

(SEE PAGE 3-13)

DP+5V

A+5V

AU+5V

S+5V

D+5V

EVER+5V

D+3.3V

IC301 IC452 IC455

IC501 IC502 IC503

IC506 IC507 IC508

CN302 CN008

3

•

4

IC802

IC801 IC803

IC804 IC805

IC807 IC811

Q001, 002

SWITCH

S12V OFF

IC812

LPF

S+5V

IC806

ER-8 BOARD (SEE PAGE 4-63~4-68)

IC202

+5V REG

Q213

+5V REG

CN601

1

IC604

IC608

3

CN602

CN202

IC204

IC206 IC207

IC208

IC602

IC601

IC607

IC603

CN604

9

8

A+5V

EVER 5V

78

E 12V

CN905

A+12V

1

Q202

+9V REG

Q201

–9V REG

P.FAIL

HP-120 BOARD

(SEE PAGE 4-70)

IC001

CN002

51

AU–9V

26

CN205

AUDIO

(SEE PAGE 3-11)

AU–12V

4

P.FAIL

5

AU+12V

7

CN204

Q206-208

1

SWITCH

4

5

7

AU-218 BOARD

05

(SEE PAGE 4-51~4-56)

E-12V

AU+9V

9

A+5V

IC209

IC210

Q205, 209

210, 211

YS-19 BOARD

(SEE PAGE 4-57)

IC851

CN851

1

CN201

11

17

22

5

1

HongKong

A+5V

EVER 5V

A+5V

D+5V

AU+12V

AU+5V

CN251

1

CN252

15

9

4

21

25

CN601

IC201 IC202 IC203

IC208 IC810

IC251

IC252

IC204 IC205 IC206

IC207 IC209

IC601 IC602 IC603

IC604 IC605 IC606

EVER+5V

1

D+5V

2

–10V

4

FL-108 BOARD

(SEE PAGE 4-77)

CN153

1

2

4

F151

DR-88 BOARD

(SEE PAGE 4-77)

PH101, 102

CN102

6

6

CN151

IC151

FR-160 BOARD

(SEE PAGE 4-78)

EVER 5V

D+5V

D+5V

–10V

CN401 CN402

1

5

FP-75 BOARD

(SEE PAGE 4-73)

CN202

2

4

IC201

Q202 ,203

DC-DC

CONVERTER

1

5

+F, -F

EVER 5V

D+5V

ND201

1

5

CN154 CN301

1

5

CN152

2

4

PW-120 BOARD

(SEE PAGE 4-78)

IC301

Q301

3-15 3-16 E

Page 35

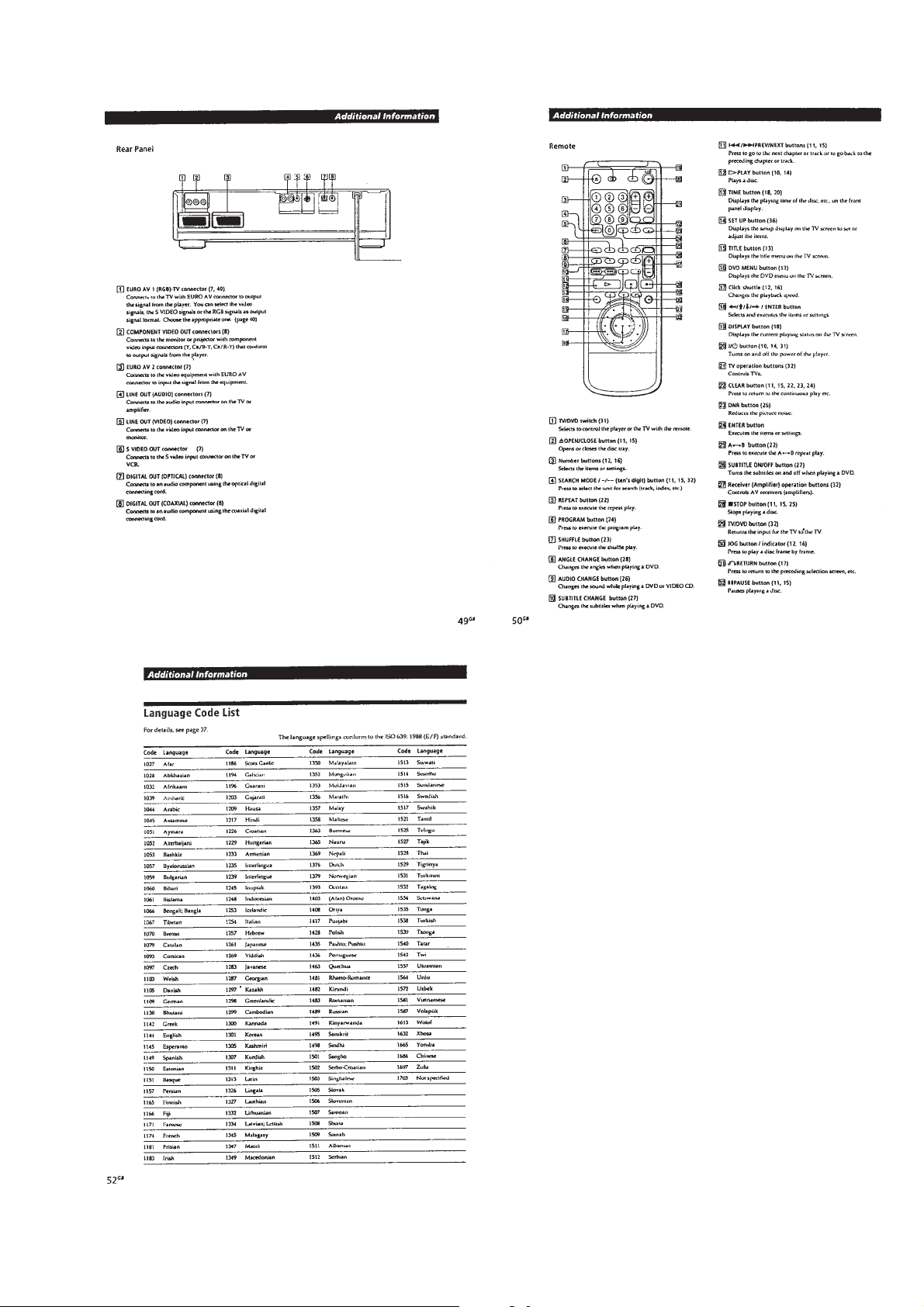

SECTION 4

PRINTED WIRING BOARDS AND SCHEMATIC DIAGRAMS

DVP-S7700

THIS NOTE IS COMMON FOR PRINTED WIRING

BOARDS AND SCHEMATIC DIAGRAMS.

(In addition to this, the necessary mote is printed

in each block.)

For printed wiring boards:

• X : indicates a lead wire mounted on the component

side.

• x : indicates a lead wire mounted on the printed side.

• ® : Through hole.

• p : Parts mounted on the conductor side.

• b : Pattern from the side which enables seeing.

(The other layers’ patterns are not indicated.)

Caution:

Pattern face side: Parts on the pattern face side seen from

(Side B) the pattern face are indicated.

Parts face side: Parts on the parts face side seen from

(Side A) the parts face are indicated.

For schematic Diagram:

• Caution when replacing chip parts.

New parts must be attached after removal of chip.

Be careful not to heat the minus side of tantalum capacitor,

because it is damaged by the heat.

• All resistors are in ohms, 1/

unless otherwise specified.

kΩ : 1000Ω, MW : 1000kΩ.

• All capacitors are in µF unless otherwise noted. pF : µµF

50V or less are not indicated except for electrolytics and

tantalums.

• All variable and adjustable resistors have characteristic curve

B, unless otherwise noted.

• 2 : nonflammable resistor.

• 5 : fusible resistor.

• C : panel designation.

• ¢ : internal component.

• C : adjustment for repair.

• U : B+ Line.

• V : B– Line.

• Circled numbers refer to waveforms.

• Voltages are dc betw een measurement point.

• Readings are taken with a color-bar signals on DVD reference disc and when playing CD reference disc.

• Readings are taken with a digital multimeter (DC 10MW).

• Voltage variations may be noted due to normal production

tolerances.

Note: The components identified by mark ! or dotted line

with mark ! are critical for safety.

Replace only with part number specified.

4

W (Chip resistors : 1/

10

W)

When indicating parts by reference

number, please include the board

name.

4-1

Page 36

DVP-S7700

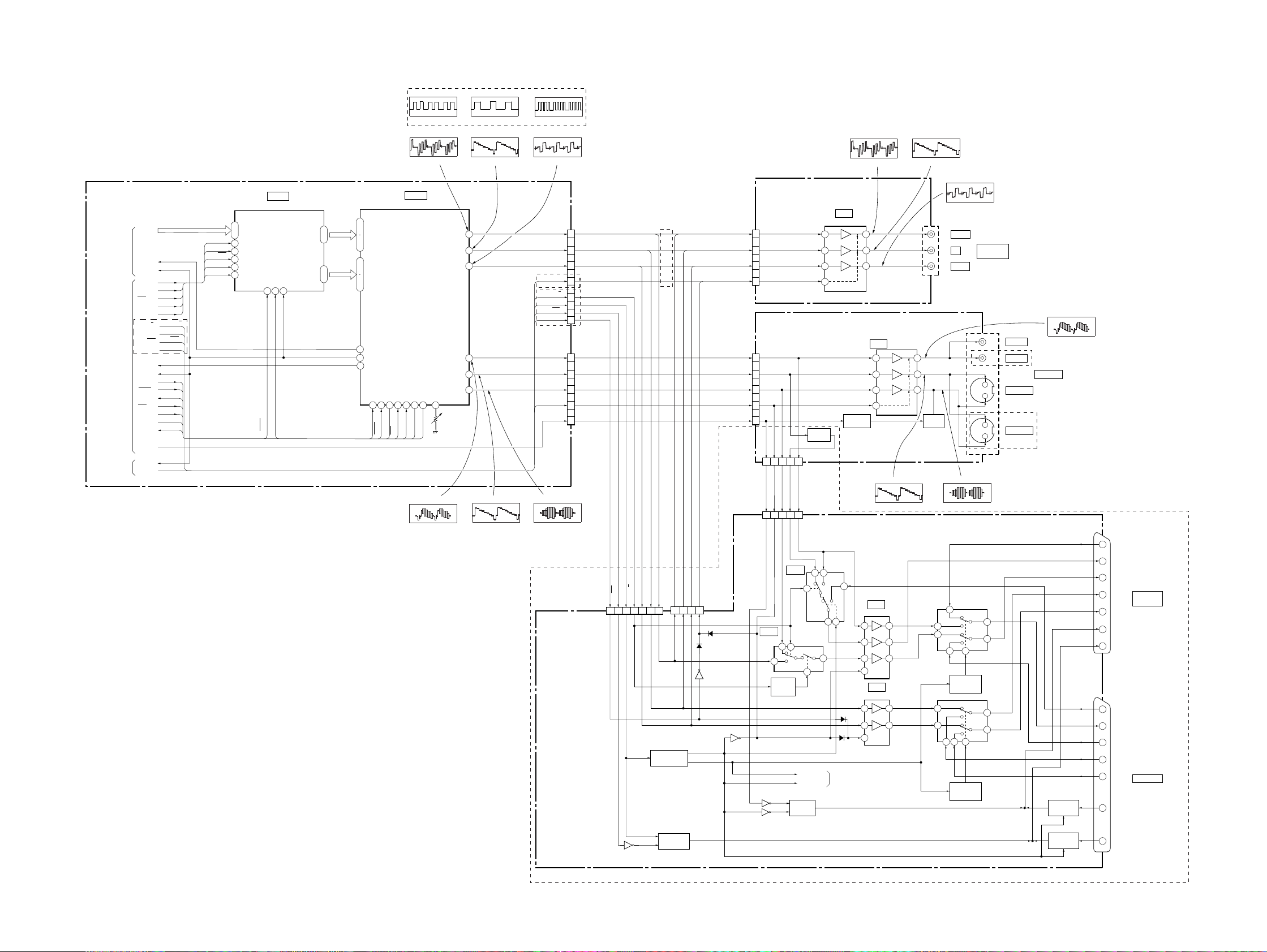

4-1. FRAME SCHEMATIC DIAGRAM (1/2)

FRAME (1/2)

4-3 4-4

Page 37

FRAME SCHEMATIC DIAGRAM (2/2)

DVP-S7700

4-5 4-6

FRAME (2/2)

Page 38

DVP-S7700

1-669-298-

05

(13)

13

TK-47

BOARD(SIDE A)

A

B

C

D

E

F

G

H

123456

48

33

32

17

16

1

64

49

48

25

32

1

8

9

16

17

24

4-2. PRINTED WIRING BOARDS AND SCHEMATIC DIAGRAMS

TK-47 (RF, SERVO) PRINTED WIRING BOARD

– Ref. No.: TK-47 board; 3,000 series –

TK-47 BOARD (SIDE A)

CN001 D-3

CN002 H-2

CN004 G-1

CN005 B-4

CN008 B-3

D003 C-4

D004 E-2

D006 F-5

IC004 C-4

IC005 D-4

IC006 F-3

IC011 E-5

Q001 E-2

Q004 E-2

Q005 E-2

Q007 D-4

Q008 F-3

Q009 F-3

Q010 D-3

There are few cases that the part isn't mounted in this model is printed on this diagram.

POWER BLOCK

(HS-930SH)

(SWITCHING REGULATOR)

PW-120

(IR/POWER SWITCH)

FR-160

(FUNCTION SWITCH)

FG-43

(SLED)

AU-218

(AUDIO)

PS-421

(AUDIO POWER)

YS-19

(COMPONENT

VIDEO)

HP-120

(HEAD PHONE)

FP-75

(FL DRIVER)

DC MOTOR

(SPINDLE)

DR-88

(DOOR SENSOR)

FL-108

(FUNCTION SWITCH)

TK-47

(RF/SERVO)

CN-113

(DOOR MOTOR)

ER-8 (AEP, UK)

(EURO A V)

MB-84

(SIGNAL PROCESS/

SERVO)

RF/SERVO

TK-47

4-7 4-8

Page 39

A

B

TK-47

BOARD(SIDE B)

DVP-S7700

DVP-S7700

C

D

E

F

G

H

05

123456

1-669-298-

13

(13)

RF/SERVO

4-9

TK-47

Page 40

DVP-S7700

• Waveforms

TK-47 (RF, SERVO 1) SCHEMATIC DIAGRAM

– Ref. No.: TK-47 board; 3,000 series –

1 IC006 %¡ – %™ (DVD play)

270 mVp-p (V)

2 IC006 ^¡ – ^™ (DVD play)

1.2 Vp-p (V)

3 IC006 ^£ – ^¢ (DVD play)

4 IC005 !£ (CD play)

500 mV/DIV 1 ms/DIV

5 IC005 !∞ (CD play)

500 mV/DIV 10 ms/DIV

6 IC005 @™ (CD play)

800 mVp-p (V)

500 mV/DIV 1 µs/DIV

Note:The components identified by mark ! or dotted line

with mark ! are critical for safety.

Replace only with part number specified.

DVD_FE

R018

22k

D006

MA151WA-TX

RF, SERVO 1

TK-47 (1/2)

4-11 4-12

Page 41

TK-47 (RF, SERVO 2) SCHEMATIC DIAGRAM

– Ref. No.: TK-47 board; 3,000 series –

DVP-S7700

4-13 4-14

RF, SERVO 2

TK-47 (2/2)

Page 42

DVP-S7700

IC803

1-671-899-

05

11

MB-84 BOARD(SIDE A)

A

B

C

1

2

3

4

5

6

7

8

D

E

F

1

7

18

R830

FG-43 BOARD

MB-84 BOARD (SIDE A)

CN001 F-1

CN002 E-1

CN251 A-8

CN303 A-5

CN361 B-8

CN451 A-3

CN601 E-8

CN801 F-5

D102 A-3

D801 F-6

IC203 D-2

IC205 C-6

IC206 D-6

IC251 B-2

IC252 A-2

IC301 A-6

IC303 A-6

IC455 C-3

IC501 A-5

IC506 C-4

IC508 B-5

IC603 F-6

IC604 E-7

IC803 F-4

IC804 E-6

IC805 E-3

IC806 B-4

Q371 C-3

Q372 C-4

Q501 A-5

MB-84 (SIGNAL PROCESS), FG-43 (SLED) PRINTED WIRING BOARDS

– Ref. No.: MB-84 board; 2,000 series, FG-43 board; 1,000 series –

There are few cases that the part isn't mounted in this model is printed on this diagram.

PW-120

(IR/POWER SWITCH)

HP-120

(HEAD PHONE)

FP-75

(FL DRIVER)

FR-160

(FUNCTION SWITCH)

DC MOTOR

(SPINDLE)

FL-108

(FUNCTION SWITCH)

POWER BLOCK

(HS-930SH)

(SWITCHING REGULATOR)

FG-43

(SLED)

CN-113

DR-88

(DOOR SENSOR)

(DOOR MOTOR)

AU-218

(AUDIO)

TK-47

(RF/SERVO)

PS-421

(AUDIO POWER)

YS-19

(COMPONENT

VIDEO)

ER-8 (AEP, UK)

(EURO A V)

MB-84

(SIGNAL PROCESS/

SERVO)

SIGNAL PROCESS, SLED

MB-84, FG-43

4-15 4-16

Page 43

1

24

25

40

41

64

65

80

1-671-899-

05

11

MB-84

BOARD(SIDE B)

A

B

C

1

2

3

4

5

6

7

8

D

E

F

1

7

18

R834

13

1

14

25

R911

1

2

2

1

DVP-S7700

MB-84 BOARD (SIDE B)

CN101 A-2

CN252 A-6

CN301 B-1

CN302 A-4

CN452 A-5

D002 E-8

D101 D-6

D103 D-6

D502 C-4

D503 C-4

D802 F-4

D803 F-2

IC201 C-7

IC202 D-8

IC204 B-6

IC207 B-7

IC208 C-7

IC209 D-2

IC302 B-2

IC361 C-2

IC363 C-5

IC452 A-4

IC502 B-4

IC503 B-4

IC507 C-4

IC601 F-2

IC602 F-3

IC605 E-2

IC606 F-1

IC801 E-3

IC802 F-4

IC807 F-6

IC810 B-5

IC811 D-7

IC812 B-6

Q001 E-7

Q002 E-7

Q452 C-5

4-17 4-18

SIGNAL PROCESS

MB-84

Page 44

DVP-S7700

MB-84 (AV DECODER) SCHEMATIC DIAGRAM • See page 4-15 to 4-18 for printed wiring board.

– Ref. No.: MB-84 board; 2,000 series –

AV DECODER

MB-84 (1/14)

4-19 4-20

Page 45

MB-84 (CLOCK GENERATOR) SCHEMATIC DIAGRAM • See page 4-15 to 4-18 for printed wiring board.

– Ref. No.: MB-84 board; 2,000 series –

DVP-S7700

• Waveforms

1 IC206 8

3.28 Vp-p 27 MHz

2 IC209 1

1.4 Vp-p 27 MHz

4-21 4-22

CLOCK GENERATOR

MB-84 (2/14)

Page 46

DVP-S7700

MB-84 (DNR) SCHEMATIC DIAGRAM • See page 4-15 to 4-18 for printed wiring board.

– Ref. No.: MB-84 board; 2,000 series –

DNR

MB-84 (3/14)

4-23 4-24

Page 47

DVP-S7700

MB-84 (VIDEO ENCODER) SCHEMATIC DIAGRAM • See page 4-15 to 4-18 for printed wiring board.

– Ref. No.: MB-84 board; 2,000 series –

• Wavef orms

1 IC252 &¢

0.7 Vp-p (H)

1 IC252 &¢

(AEP, UK model: RGB output mode)

0.7 Vp-p (H)

3 IC252 ^§

(AEP, UK model: RGB output mode)

0.7 Vp-p (H)

4 IC252 ^¢

1.0 Vp-p (H)

2 IC252 &™

1.0 Vp-p (H)

2 IC252 &™

(AEP, UK model: RGB output mode)

0.7 Vp-p (H)

3 IC252 ^§

5 IC252 %•

0.7 Vp-p (H)

6 IC252 %§

1.1 Vp-p (H)

0.7 Vp-p (H)

4-25 4-26

VIDEO ENCODER

MB-84 (4/14)

Page 48

DVP-S7700

• Wavef orms

1 IC303 !ª, @™, @£ (DVD play)

5.2 Vp-p 160 Hz

2 IC303 !ª, @™, @£ (CD play)

MB-84 (DRIVE 1) SCHEMATIC DIAGRAM • See page 4-15 to 4-18 for printed wiring board.

– Ref. No.: MB-84 board; 2,000 series –

1.84 Vp-p 45 Hz

DRIVE 1

MB-84 (5/14)

4-27 4-28

Page 49

MB-84 (DRIVE 2), FG-43 (SLED) SCHEMATIC DIAGRAMS • See page 4-15 to 4-18 for printed wiring boards.

– Ref. No.: MB-84 board; 2,000 series, FG-43 board; 1,000 series –

DVP-S7700

4-29 4-30

DRIVE 2, SLED

MB-84 (6/14), FG-43

Page 50

DVP-S7700

MB-84 (DSP 1) SCHEMATIC DIAGRAM • See page 4-15 to 4-18 for printed wiring board.

– Ref. No.: MB-84 board; 2,000 series –

DSP 1

MB-84 (7/14)

4-31 4-32

Page 51

MB-84 (DSP 2) SCHEMATIC DIAGRAM • See page 4-15 to 4-18 for printed wiring board.

– Ref. No.: MB-84 board; 2,000 series –

DVP-S7700

• Wavef orm

1 IC506 ^∞

3.6 Vp-p 27 MHz

4-33 4-34

DSP 2

MB-84 (8/14)

Page 52

DVP-S7700

MB-84 (BIAS) SCHEMATIC DIAGRAM • See page 4-15 to 4-18 for printed wiring board.

– Ref. No.: MB-84 boards; 2,000 series –

BIAS

MB-84 (9/14)

Note:The components identified by mark ! or dotted line

with mark ! are critical for safety.

Replace only with part number specified.

4-35 4-36

Page 53

MB-84 (IF µ-COM) SCHEMATIC DIAGRAM • See page 4-15 to 4-18 for printed wiring board.

– Ref. No.: MB-84 board; 2,000 series –

DVP-S7700

• Wavef orm

1 IC604 *™

5.6 Vp-p 4 MHz

4-37 4-38

IF µ-COM

MB-84 (10/14)

Page 54

DVP-S7700

• Wavef orms

MB-84 (L GATE ARRAY) SCHEMATIC DIAGRAM • See page 4-15 to 4-18 for printed wiring board.

– Ref. No.: MB-84 board; 2,000 series –

1 IC804 `⁄⁄°

225 mVp-p 13.5 MHz

2 IC804 `⁄⁄fi

3.3 Vp-p 27 MHz

3 IC806 0

4 IC806 `⁄¤›

3.0 Vp-p 33 MHz

5 IC806 `⁄¤¤

3.4 Vp-p 27 MHz

6 IC811 %¡

1.5 Vp-p

3.4 Vp-p 27 MHz

L GATE ARRAY

MB-84 (11/14)

4-39 4-40

Page 55

MB-84 (ARP, DECRYPT) SCHEMATIC DIAGRAM • See page 4-15 to 4-18 for printed wiring board.

– Ref. No.: MB-84 board; 2,000 series –

DVP-S7700

4-41 4-42

ARP, DECRYPT

MB-84 (12/14)

Page 56

DVP-S7700

MB-84 (SYSTEM µ-COM) SCHEMATIC DIAGRAM • See page 4-15 to 4-18 for printed wiring board.

– Ref. No.: MB-84 board; 2,000 series –

SYSTEM µ-COM

MB-84 (13/14)

4-43 4-44

Page 57

MB-84 (S GATE ARRAY) SCHEMATIC DIAGRAM • See page 4-15 to 4-18 for printed wiring board.

– Ref. No.: MB-84 board; 2,000 series –

DVP-S7700

• Waveform

1 IC805 &£

4.4 Vp-p 20 MHz

4-45 4-46

S GATE ARRAY

MB-84 (14/14)

Page 58

DVP-S7700

AU-218 (AUDIO) PRINTED WIRING BOARD

– Ref. No.: AU-218 board; 3,000 series –

AU-218 BOARD(SIDE A)

There are few cases that the part isn't mounted in this model is printed on this diagram.

11

05

POWER BLOCK

(HS-930SH)

(SWITCHING REGULATOR)

FR-160

(FUNCTION SWITCH)

PW-120

(IR/POWER SWITCH)

HP-120

(HEAD PHONE)

FP-75

(FL DRIVER)

DC MOTOR

(SPINDLE)

DR-88

(DOOR SENSOR)

FL-108

(FUNCTION SWITCH)

FG-43

AU-218

(SLED)

(AUDIO)

TK-47

CN-113

(DOOR MOTOR)

(RF/SERVO)

1-671-910-

PS-421

(AUDIO POWER)

YS-19

(COMPONENT

VIDEO)

ER-8 (AEP, UK)

(EURO A V)

MB-84

(SIGNAL PROCESS/

SERVO)

(11)

AUDIO

AU-218

4-47 4-48

Page 59

DVP-S7700

AU-218

BOARD(SIDE B)

COAXIAL

DIGITAL OUT

OPTICAL

S VIDEO OUT

VIDEO

LINE OUT

L

AUDIO

R

A

B

C

1-671-910-

05

1

2

3 4

AU-218 BOARD (SIDE B)

CN201 C-4

CN202 B-9

CN203 C-8

CN204 B-9

CN205 C-1

D201 C-8

D202 A-9

D203 A-9

D204 A-3

D205 A-3

D206 C-8

D207 A-3

D208 A-4

D209 C-8

D210 B-8

D211 B-8

D214 A-9

D216 A-7

IC202 B-8

IC204 C-6

IC205 A-8

IC206 B-7

IC207 B-4

IC208 B-1

IC209 B-2

IC210 A-2

Q201 B-8

Q202 A-9

Q203 B-5

Q204 B-6

Q205 B-8

Q206 A-10

Q207 A-10

Q208 A-10

Q209 B-7

Q210 B-7

Q211 B-5

Q212 B-6

Q213 A-7

Q214 B-3

Q215 B-3

Q216 A-1

Q217 B-7

Q218 C-4

5 6 7 8 9

11

(11)

4-49 4-50

AUDIO

AU-218

Page 60

DVP-S7700

AU-218 (AUDIO 1) SCHEMATIC DIAGRAM • See page 4-47 to 4-50 for printed wiring board.

– Ref. No.: AU-218 board; 3,000 series –

AUDIO 1

AU-218(1/3)

4-51 4-52

Page 61

AU-218 (AUDIO 2) SCHEMATIC DIAGRAM • See page 4-47 to 4-50 for printed wiring board.

– Ref. No.: AU-218 board; 3,000 series –

DVP-S7700

4-53 4-54

AUDIO 2

AU-218 (2/3)

Page 62

DVP-S7700

AU-218 (VIDEO BUFFER) SCHEMATIC DIAGRAM • See page 4-47 to 4-50 for printed wiring board.

– Ref. No.: AU-218 board; 3,000 series –

• Wavef orms

1 IC209 !∞

1.1 Vp-p (H)

2 IC209 !£

3 IC209 0

1.0 Vp-p (H)

0.7 Vp-p (H)

VIDEO BUFFER

AU-218 (3/3)

4-55 4-56

Page 63

DVP-S7700

YS-19 (COMPONENT VIDEO) PRINTED WIRING BOARD AND SCHEMATIC DIAGRAM

– Ref. No.: YS-19 board; 1,000 series –

YS-19

05

BOARD(SIDE A)

1-671-915-

There are few cases that the part isn't mounted in this model is printed on this diagram.

(11)

YS-19

11

05

BOARD(SIDE B)

POWER BLOCK

(HS-930SH)

(SWITCHING REGULATOR)

FR-160

COMPONENT VIDEO OUT

Y

B

/B-Y

C

CR/R-Y

1-671-915-

PW-120

(IR/POWER SWITCH)

HP-120

(HEAD PHONE)

11

(11)

(FUNCTION SWITCH)

FP-75

(FL DRIVER)

DC MOTOR

(SPINDLE)

DR-88

(DOOR SENSOR)

FL-108

(FUNCTION SWITCH)

FG-43

AU-218

(SLED)

(AUDIO)

TK-47

(RF/SERVO)

CN-113

(DOOR MOTOR)

PS-421

(AUDIO POWER)

YS-19

(COMPONENT

VIDEO)

ER-8 (AEP, UK)

(EURO A V)

MB-84

(SIGNAL PROCESS/

SERVO)

• Waveforms

1 IC851 !∞

2 IC851 !£

3 IC851 0

0.7 Vp-p (H)

0.7 Vp-p (H)

4-57 4-58

1.0 Vp-p (H)

COMPONENT VIDEO

YS-19

Page 64

DVP-S7700

ER-8 (EURO AV) PRINTED WIRING BOARD

– Ref. No.: ER-8 board; 1,000 series –

– AEP, UK –

There are few cases that the part isn't mounted in this model is printed on this diagram.

ER-8 BOARD (SIDE A)

D601 B-4

D607 A-5

D608 A-5

D609 A-6

D610 A-6

D616 A-2

D617 A-3

D618 A-3

D619 A-3

D620 A-4

D622 A-2

D623 A-2

D625 C-4

D626 C-2

D627 C-5

D628 B-2

D633 C-3

D634 C-3

IC603 B-2

IC604 B-4

IC607 B-3

IC608 B-5

Q601 C-4

Q602 C-6

Q604 B-4

Q605 B-4

Q607 A-4

Q608 B-4

Q612 C-5

Q614 A-5

Q615 B-5

Q622 B-5

Q623 B-5

Q625 A-5

Q626 B-5

Q633 A-6

Q634 B-6

Q635 C-5

Q636 A-4

Q637 C-5

Q638 C-4

Q639 C-4

Q643 C-3

Q644 C-3

A

B

C

ER-8

BOARD(SIDE A)

1-671-916-

11

(11)

FR-160

(FUNCTION SWITCH)

PW-120

(IR/POWER SWITCH)

HP-120

(HEAD PHONE)

FP-75

(FL DRIVER)

DC MOTOR

(SPINDLE)

POWER BLOCK

(HS-930SH)

(SWITCHING REGULATOR)

DR-88

(DOOR SENSOR)

FL-108

(FUNCTION SWITCH)

FG-43

AU-218

(SLED)

(AUDIO)

TK-47

CN-113

(DOOR MOTOR)

(RF/SERVO)

PS-421

(AUDIO POWER)

YS-19

(COMPONENT

VIDEO)

ER-8 (AEP, UK)

(EURO A V)

MB-84

(SIGNAL PROCESS/

SERVO)

D

05

1

2

3 4

5 6

EURO AV

ER-8

4-59 4-60

Page 65

ER-8

BOARD(SIDE B)

EURO AV2

DVP-S7700

EURO AV1

(RGB)-TV

A

B

C

1

2

2

9

21

20

1

1

2

21

20

ER-8 BOARD (SIDE B)

CN601 C-1

CN602 D-4

CN603 C-2

CN604 D-5

D602 A-3

D603 A-3

D604 A-2

D605 A-2

D606 A-1

D611 A-6

D612 A-6

D613 A-5

D614 A-5

D615 A-4

D621 A-2

D624 A-3

D631 B-5

D632 B-4

D635 D-5

D636 D-5

IC601 C-5

IC602 B-4

Q606 C-1

Q621 C-3

Q624 C-3

Q627 C-2

Q628 B-5

Q629 B-4

Q630 C-2

Q632 C-2

Q640 C-2

Q641 C-1

Q642 D-5

D

2

9

05

1

2

3 4

5

1

1-671-916-

6

11

(11)

4-61 4-62

EURO AV

ER-8

Page 66

DVP-S7700

ER-8 (EURO AV 1) SCHEMATIC DIAGRAM • See page 4-59 to 4-62 for printed wiring board.

– Ref. No.: ER-8 board; 1,000 series –

– AEP, UK –

EURO AV 1

ER-8 (1/3)

4-63 4-64

Page 67

ER-8 (EURO AV 2) SCHEMATIC DIAGRAM • See page 4-59 to 4-62 for printed wiring board.

– Ref. No.: ER-8 board; 1,000 series –

– AEP, UK –

DVP-S7700

4-65 4-66

EURO AV 2

ER-8 (2/3)

Page 68

DVP-S7700

ER-8 (EURO AV 3) SCHEMATIC DIAGRAM • See page 4-59 to 4-62 for printed wiring board.

– Ref. No.: ER-8 board; 1,000 series –

– AEP, UK –

EURO AV 3

ER-8 (3/3)

4-67 4-68

Page 69

HP-120 (HEAD PHONE) PRINTED WIRING BOARD AND SCHEMATIC DIAGRAM

1-671-918-

(12)

12

HP-120 BOARD(SIDE A)

05

– Ref. No.: HP-120 board; 1,000 series –

There are few cases that the part isn't mounted in this model is printed on this diagram.

DVP-S7700

HP-120

05

PHONES

BOARD(SIDE B)

PHONE

LEVEL

12

(12)

1-671-918-

FR-160

(FUNCTION SWITCH)

PW-120

(IR/POWER SWITCH)

HP-120

(HEAD PHONE)