Page 1

DVP-S7000

DVD MECHANISM

OPERATION MANUAL

i

III

III lllll IIII

illil lllll lilii

392162751

illli

III1

ill1

llli

SONY@

Page 2

1.

Mainparts

2.

Operation ofparts

layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CONTENTS

3

.........................................................................................................

4

2-l. Operation of spindle base with loading motor..

1)

Tray

open ................................................................................................................ 4

2) Tray IN

2-2.

Operation of optical pick-up block with sled motor

2-3.

Operation of slide base with

3.

Tray close (Disc IN)

3-l. With disc (1)

With disc (2)

3-2.

Without disc..

4.

PB . . . . . . . . . . . . . . .

.................................................................................................................... 7

skew

motor

.....................................................................................................

.............................................................................................................

..............................................................................................................

............................................................. .:. ............................................ 25

*

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

*

. . . . .

*

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.......................................................... 4

.................................................

.................................................................

*

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..*.............

10

13

17

17

21

29

5. PB-PAUSE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.

PB-STOP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.

Tray open (Disc OUT)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

-2-

33

34

36

Page 3

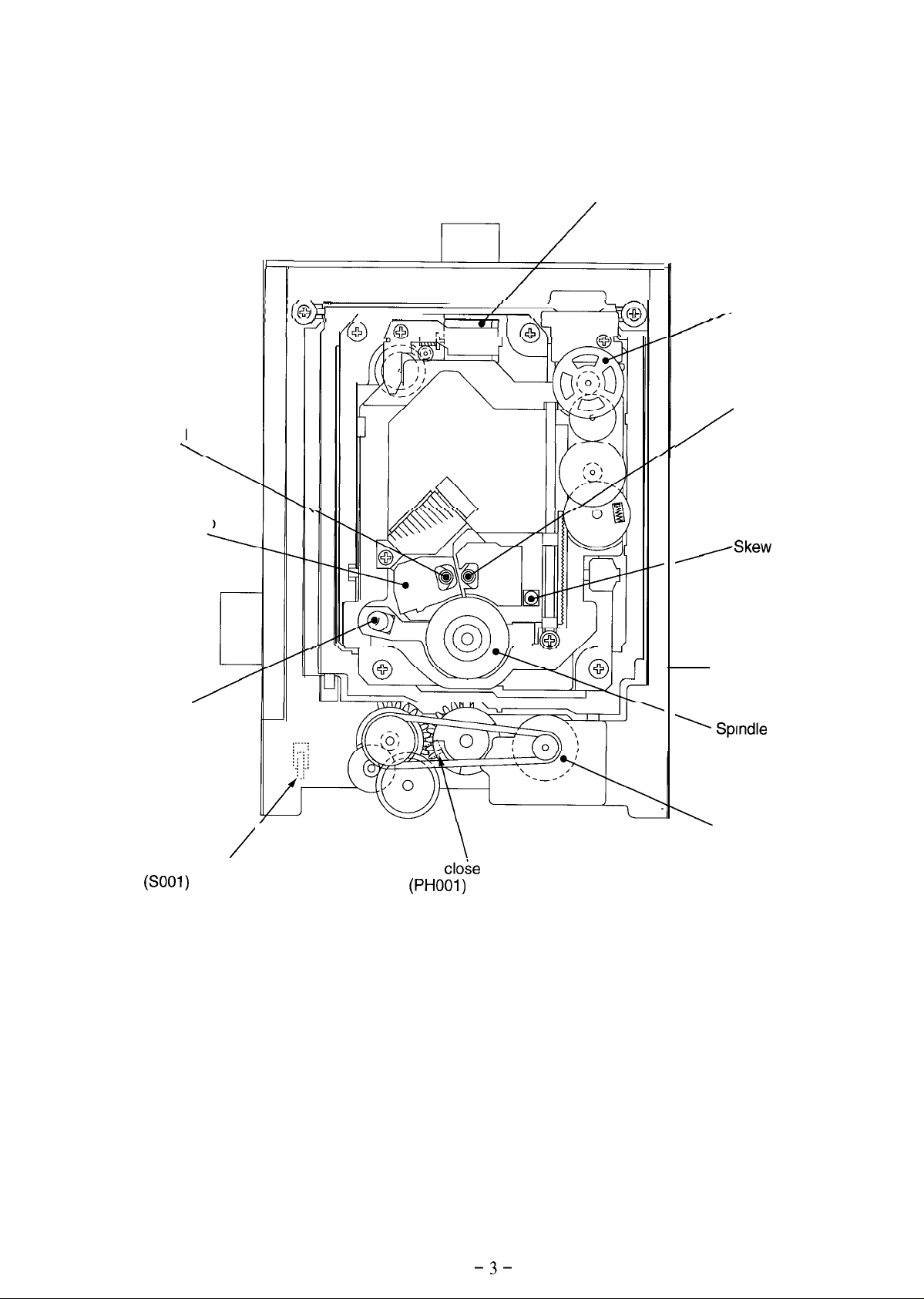

1. Main parts layout

!

\ I

I

CD optical

pick-up

.

Optical pick-up

block

Skew motor

/

/Skew

Sled motor

DVD optical

pick-up

sensor

CD sensor

/

Tray open sensor switch

(SOOl)

r

1

’

Splndle motor

\

Loading motor

Tray

close

sensor

(PHOOl)

Fig. l-l

-3-

Page 4

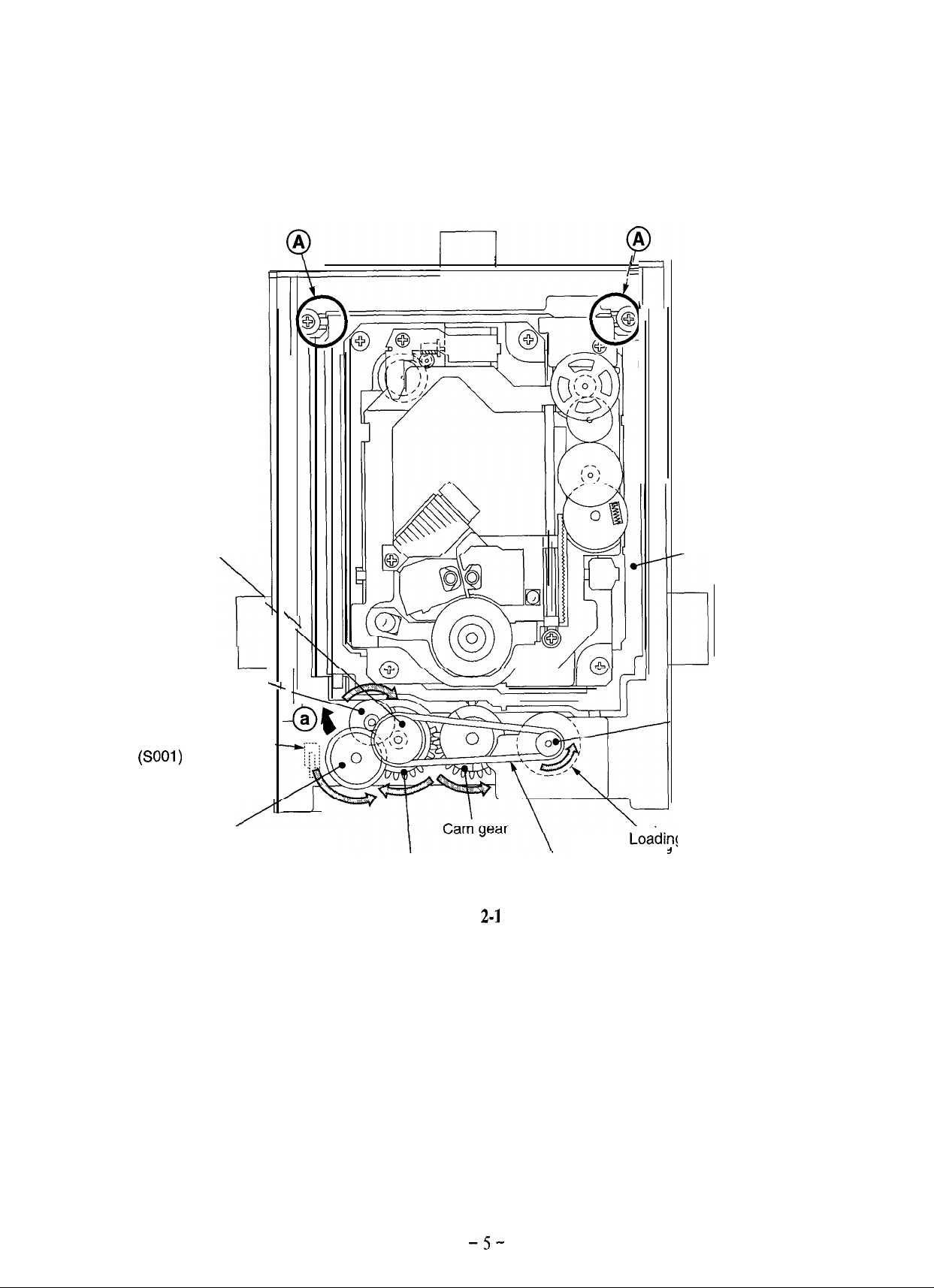

2. Operation of parts

2-l. Operation of spindle base with loading motor

1) Tray open

Press open/close button.

Loading motor rotates in the direction of arrow mark.

I

Loading (midway) gear rotates in the direction of arrow mark

through belt and loading pulley.

I

Tray driving gear rotates in the direction of arrow mark.

+

Tray driving gear meshed with tray rack unit, and loading

(midway) gear both move in the direction of arrow mark @.

I

Drive gear rotates in the direction of arrow mark to rotate cam

gear in the direction of arrow mark.

1

I

1

Spindle base moves down in the direction of arrow mark

centering around the fulcrum@, and the gap between press

pulley and spindle motor becomes large.

* Disc is released from chucking.

Tray driving gear further rotates and tray is pushed out in

the direction of arrow mark.

* Disc can be set.

Tray open sensor switch

motor stops.

(SOOl)

detects “tray open” when loading

I

I

@

-4-

Page 5

I

I

I

I

I

r’l

i

Loading pulley

‘p

Loading

(midway) gear,

Tray open

sensor switch ---

(SOOl)

Tray driving

L

gear

\

.,

-0’

, Spindle base

\,

a

Loabint

Drive’ gear

Fig.

2-1

Belt

, Motor pulley

motor

-5-

Page 6

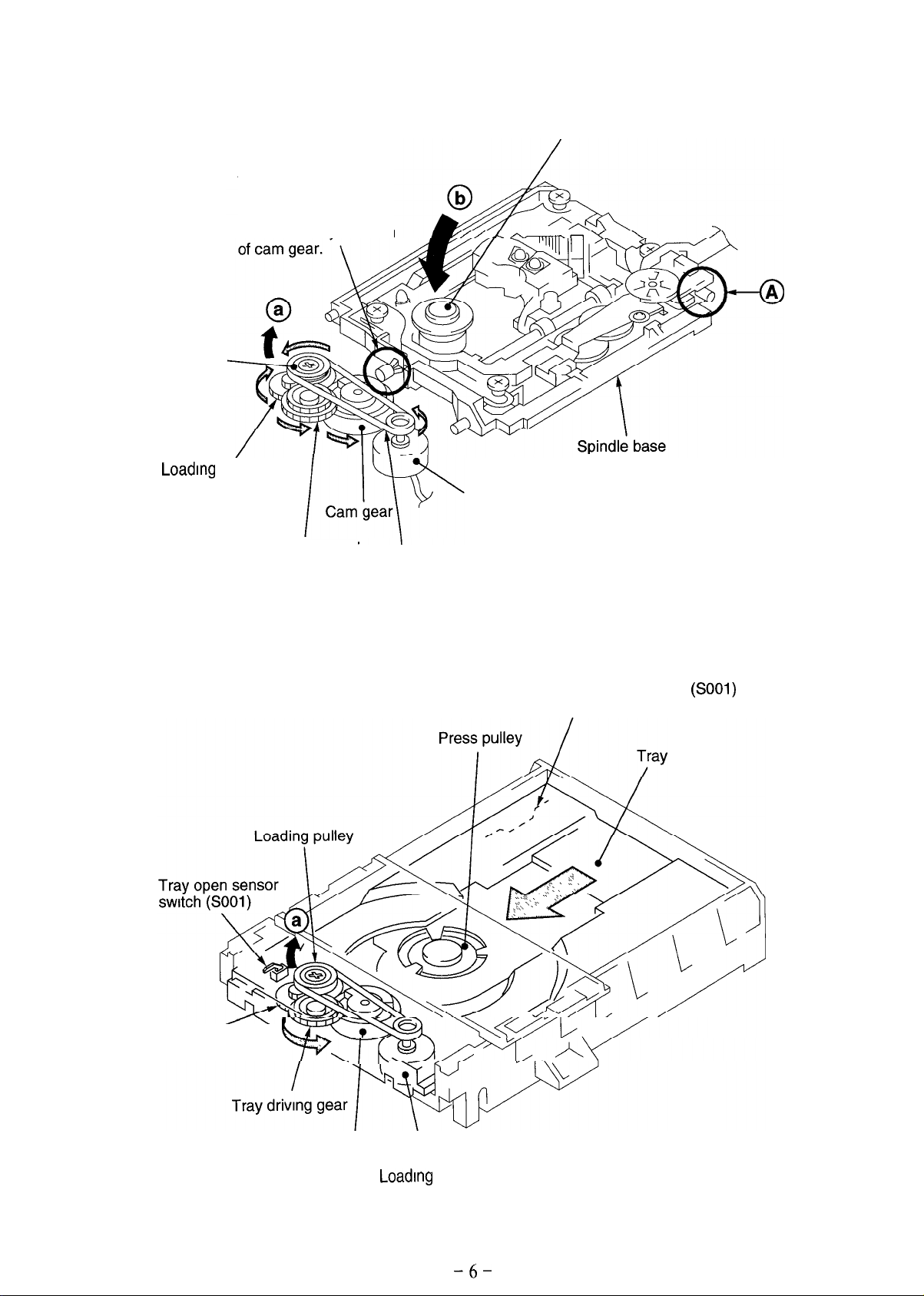

Loading pulley

Loading (midway)

gear

This portion touches

the cam gear, allowing

the spindle base to

move down

by the cam

Spindle motor

Loading motor

Tray driving gear

Belt

Fig. 2-2

Tray open sensor switch

to ON by the projection under the tray.

(SOOl)

IS set

Loading (midway)

gear

.

-l-L

Cam ‘gear

\

Loading motor

Fig. 2-3

-6-

Page 7

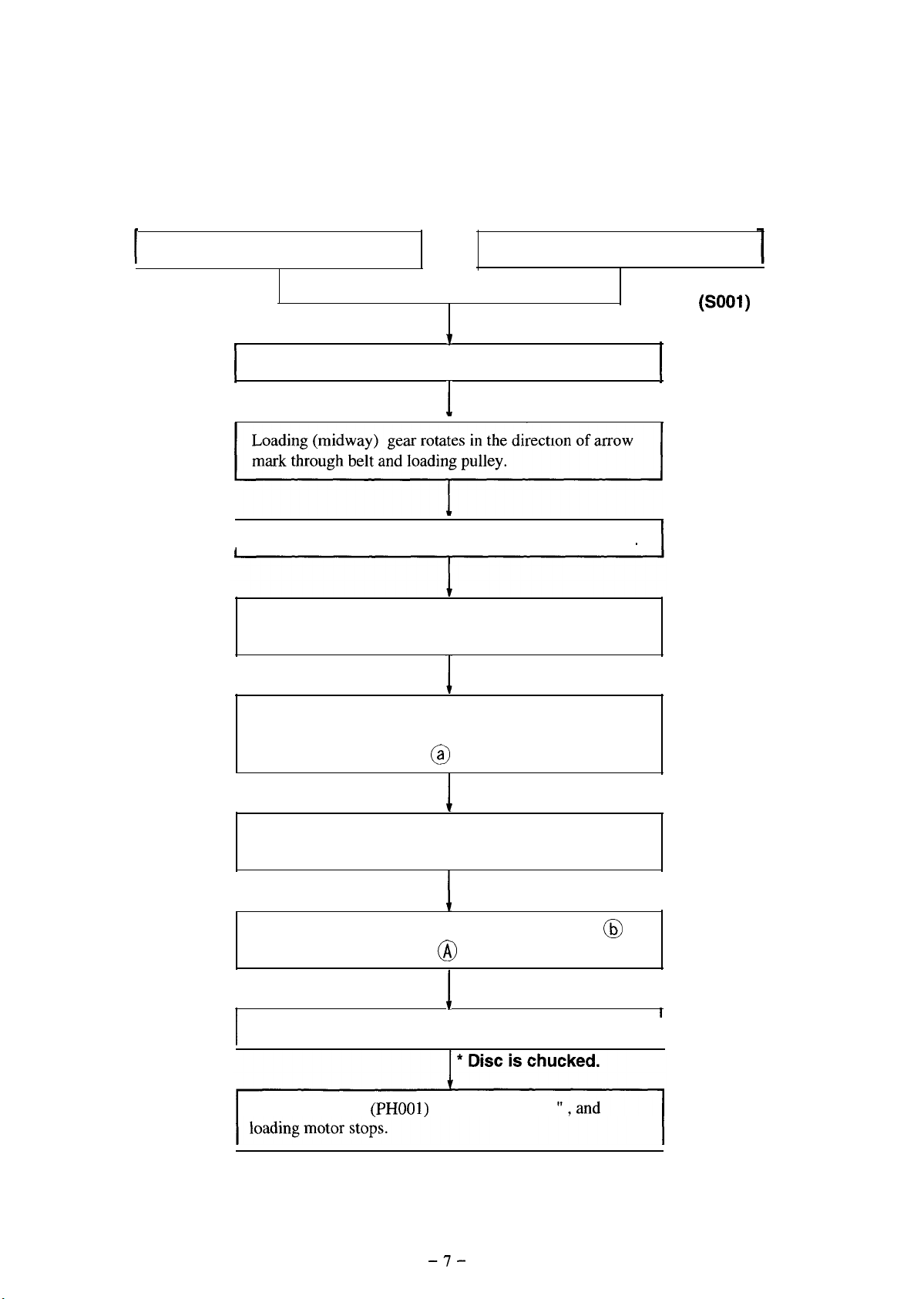

2) Tray IN

I

Press open/close button. Slightly push in the tray with hand.

* Tray open sensor

switch (SOOl) OFF

I

Loading motor rotates in the direction of arrow mark.

I

I

Loading (midway) gear rotates in the direction of arrow

mark through belt and loading pulley

*

I

I

1

I

I

Tray driving gear rotates in the direction of arrow mark.

r

~~~

~~

~~ ~ ~~

Tray meshed with tray dnving gear is pulled in the

direction of arrow mark.

When tray is pulled in and reaches the given position, both

the tray driving gear and loading (midway) gear move in

the direction of arrow mark @ .

I

Drive gear rotates in the direction of arrow mark to rotate

cam gear in the direction of arrow mark.

I

Spindle base moves up in the direction of arrow mark

centering around the fulcrum @ .

I I

Disc is set between press pulley and spindle motor.

I

Tray close sensor (PHOOl) detects “tray close

I

@

I

-7-

Page 8

Loading pulley

‘r\

Tray close

sensor

(PHOOl)

/

Loading

(midway) gear,

Tray driving gear

L-

-

a

O

Drive gear

I

Cam gear

Fig. 2-4

\

Belt

’

\

Loading motor

Spindle base

-8-

Page 9

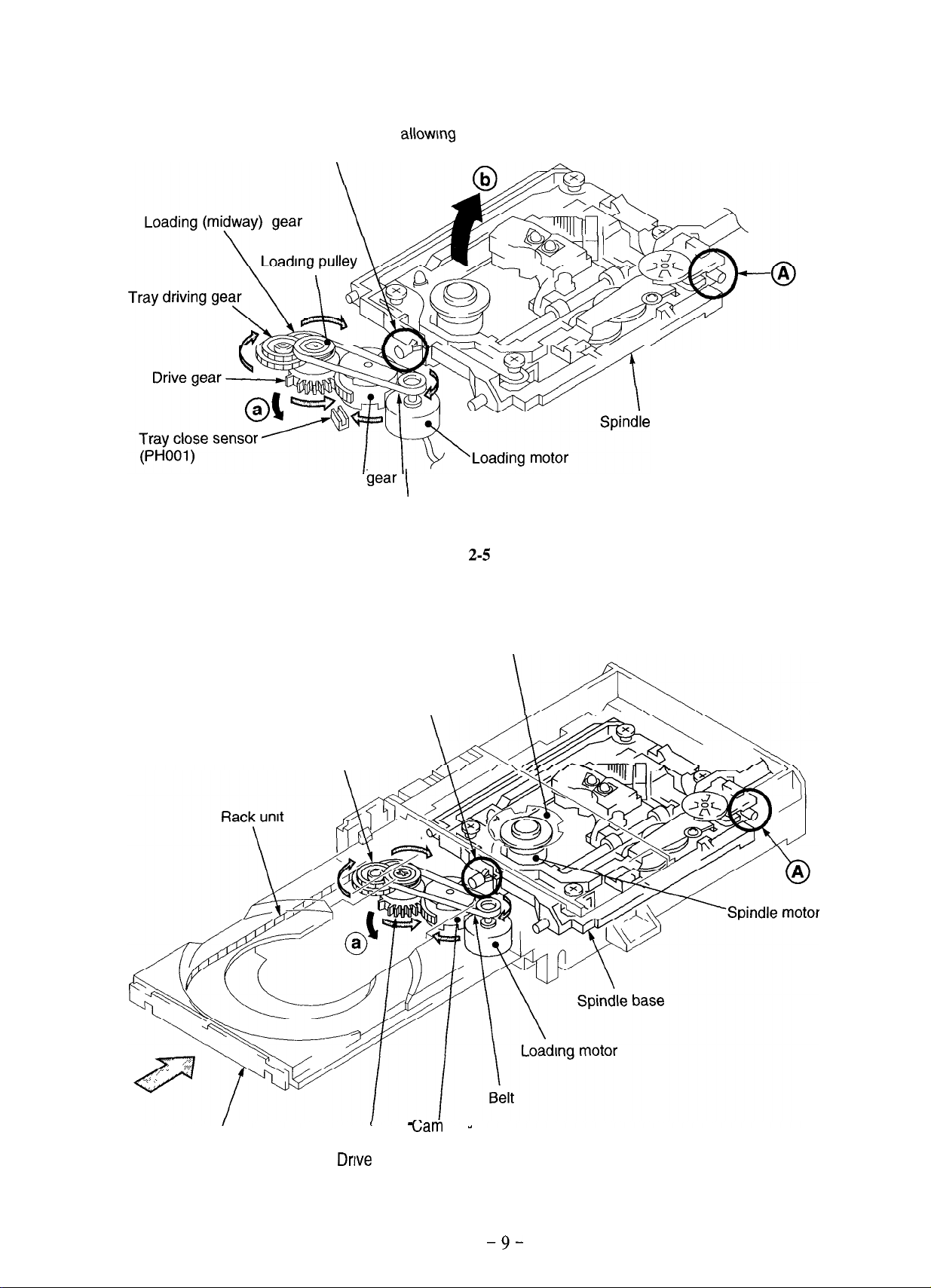

The portion touches cam gear, allow\ng spindle

base to move up by the cam of cam gear.

base

Cam bear

This portion touches

cam gear.

Tray driving gear

\

I

Belt

Fig.

2-5

Press pulley

\

Tray

I

Drive gear

Gam

gear

Fig. 2-6

-9-

Page 10

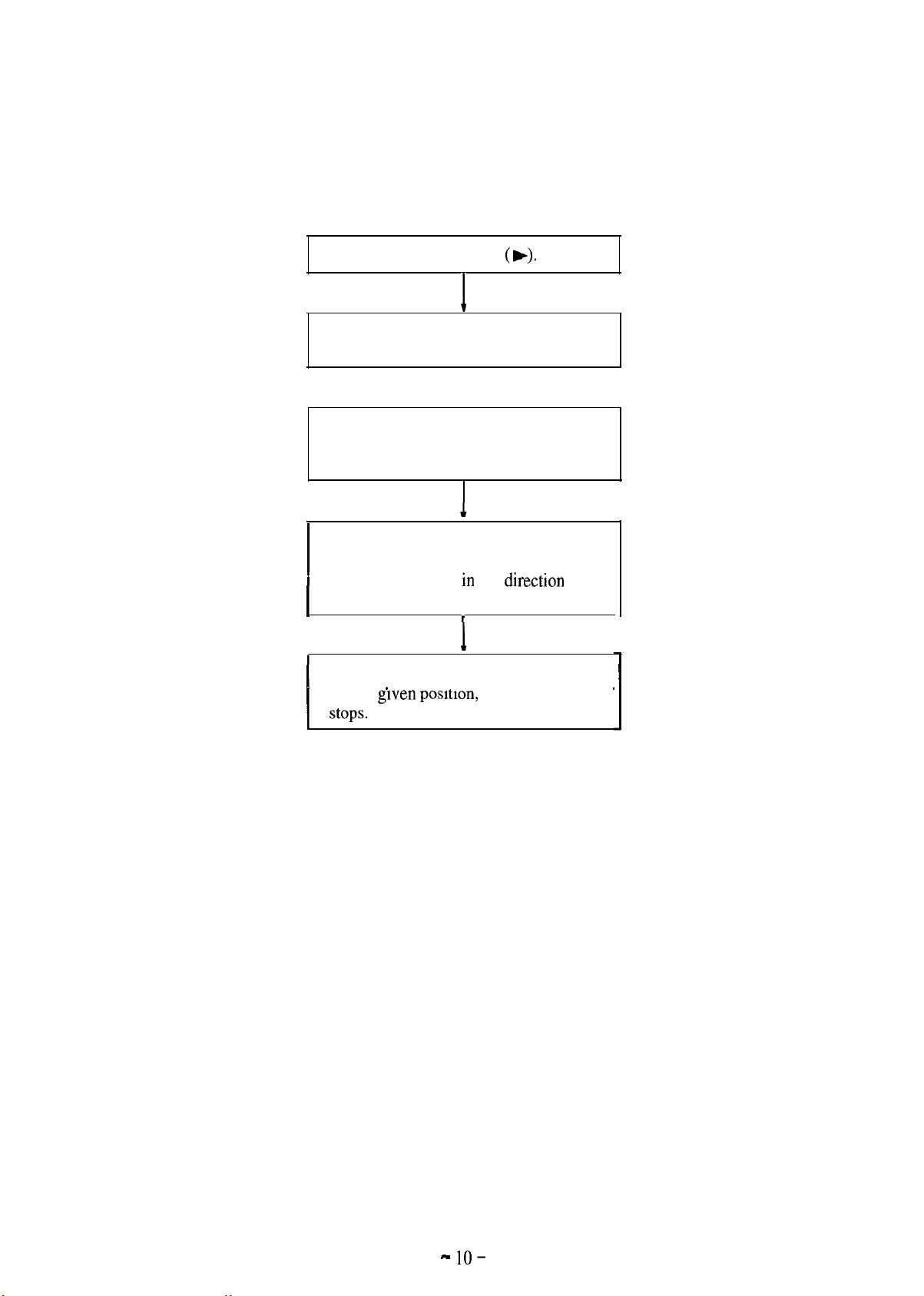

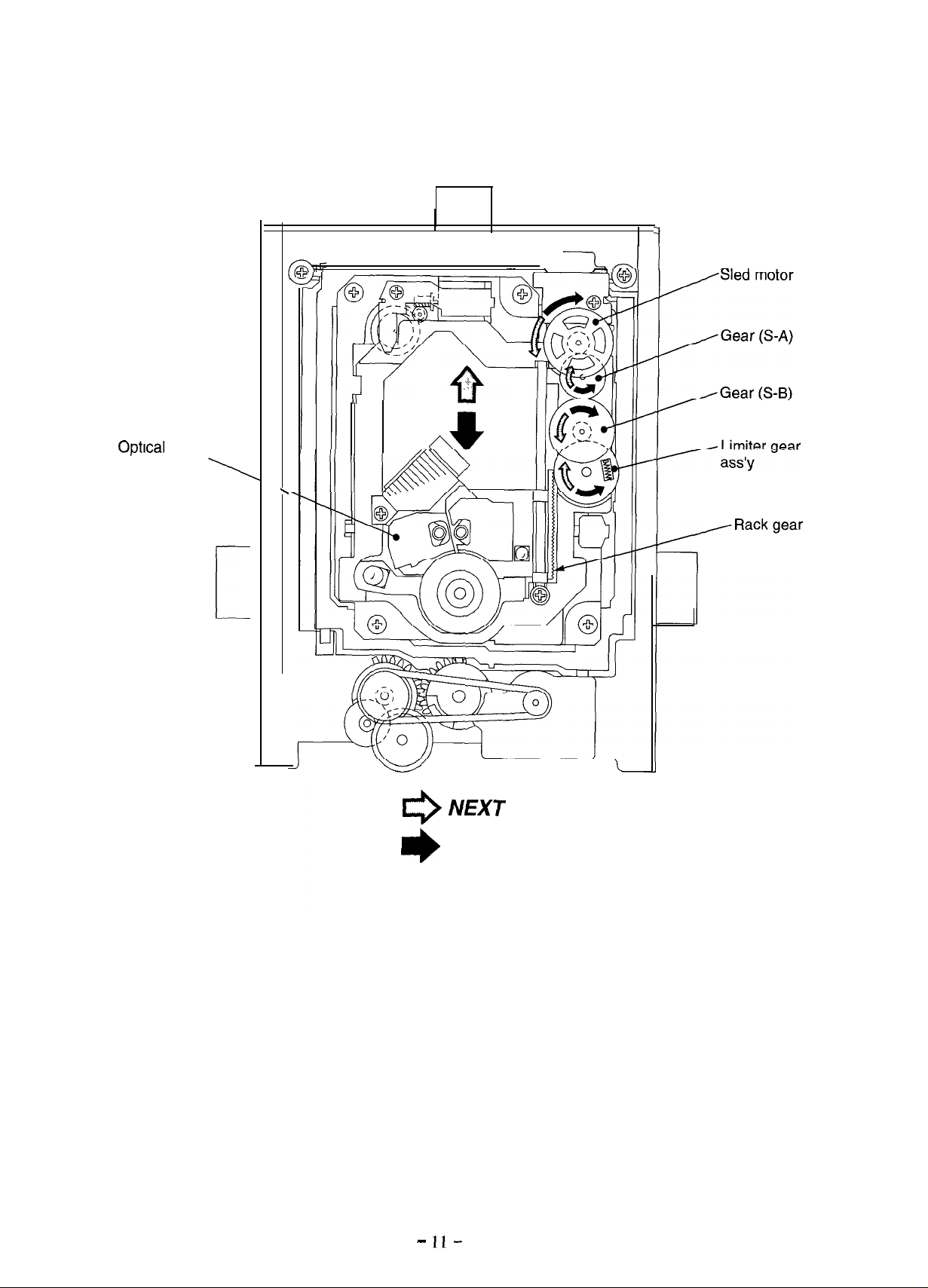

2-2. Operation of optical pick-up block with sled motor

Press PB button

Sled motor rotates in the direction of gray

arrow mark.

Limiter gear ass’y rotates in the direction

of gray arrow mark through gear (S-A) and

gear (S-B).

Limiter gear ass’y is meshed with the rack

gear of optical pick-up block and optical

pick-up block moves m the

1

gray arrow mark.

’

.

I

I

i

(b).

drrectron

of

I

When optical pick-up block is moved and

reaches given posmon, and sled motor

( stops. .

.

.

* Sled motor detects FG.

* The gray arrow mark indicates the movement of optical

pick-up block from inner to outer surface of disc (NEXT).

* The black arrow mark indicates reverse movement (PREV).

- lo-

Page 11

OptIcal

block

1

:

pick-up

.

1

0

*

Fig. 2-7

- ll-

NEXT

PREV

Page 12

C---m,-.

Sled motor

Spindle motor

Optical

Rack gear

pick-up block

\

Limiter gear ass’y

\

Fig. 2-8

Rack gear

I

Sled motor

\

V

I

Spindle motor \

-

\

Limiter gear ass’y

Fig. 2-9

- 12-

Geat

(S-B)

Page 13

2-3. Operation of slide base with skew motor

The purpose of this operation is to ensure that the detecting beam of optical pick-up block always

makes a right angle with disc. When the skew sensor detects the inclination, the skew motor

starts running to eliminate the inclination.

Skew motor rotates in the direction of arrow mark.

Skew gear rotates in the direction of arrow mark to

rotate the skew cam in the direction of arrow mark.

I

When skew cam rotates, the slide base is tilted in

the direction of arrow mark @centering around

the fulcrum

@.

I

Skew sensor detects the inclination, and skew motor

stops.

I

l

The rotating direction of the skew motor varies with

the direction of inclination.

* Skew gear retainer holds slide base so that it

always touches the skew cam.

-

13

-

Page 14

Skew gear retainer

Slide base

Skew cam

\

\ I

Skew gear

I

I

/

I

/

Skew motor

Skew sensor

Fig. 2-10

- 14-

Page 15

Skew gear

Spindle’motor

Skew cam

\

Fig. 2-11

Skew motor

Skew sensor

- 15-

Page 16

1

Memo

1

............................................................................................................................................ .....

............................................................................................................................................ .....

............................................................................................................................................ .....

............................................................................................................................................

............................................................................................................................................

............................................................................................................................................

............................................................................................................................................

............................................................................................................................................

............................................................................................................................................

............................................................................................................................................

............................................................................................................................................ .....

..................................................................................................................................................

..................................................................................................................................................

..................................................................................................................................................

..................................................................................................................................................

.....

.....

.....

.....

.....

.....

.....

..................................................................................................................................................

..................................................................................................................................................

..................................................................................................................................................

..................................................................................................................................................

..................................................................................................................................................

..................................................................................................................................................

..................................................................................................................................................

..................................................................................................................................................

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..........................

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..........................

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..........................

- 16-

Page 17

Page 18

Sled

rriotor

Gear (S-A)

Optical pick-up

block

\

Spindle motor

\

Loading pulley

T

Loading (midway)

gear

Tray driving gear

-

Drive

/

gear

Gear (S-B)

A

Limiter gear

ass’y

-

DVD optical

pick-up

Spindls

base

3

Tray ck

y

sensor

bse

(PHOOl)

-

\

Loading motor

Belt

Fig. 3-1

-

19-

Page 19

Press pulley

I

DVD optical

pick-up

/

Tray close sensor

(PHOOl)

I

Spindle motor

Cam.gear

Fig. 3-2

DVD optical pick-up

‘\

Rack gear

Ge$

(S-B)

\

Limiter gear ass’y

Fig. 3-3

-

20

-

Page 20

Page 21

Sled motor

Gear (S-A)

Optical pick-up

block

\

Spindle motor

\

Loading

Loading (midway)

gear

Tray driving gear

puyey

Drive

Gear (S-B)

, Limiter gear

ass’y

-

,

y

-

g&ar

DVD

optical

pick-up

Spindle base

Tray close

sensor

(PHOOl)

Fig. 3-4

-

23

-

Page 22

Press pulley

I

DVD optical pick-up

Tray

Tray close sensor

/

(PHOOl)

Cam’gear

Fig. 3-5

-

24

-

Page 23

Page 24

Optical pick-up

block

A

?

-

T

I

-

-

Spindle motor

Loading pulley

Loading

gear

Tray driving gear

(mldway)

l--f

/

Drive gear

\

\

.

\

c

Belt

-

3

, Tray close

DVD optical

pick-up

Splndle base

sensor

(PHOOl)

motor

Fig. 3-6

-

27

-

Page 25

Press pulley

DVD optical pick-up

I

Tray

/

Tray close sensor

(PHOOl)

Cam gear

Fig. 3-7

-

28

-

Page 26

Page 27

Skew cam

Skew gear

Slide

base

DVD optical

pick-up

CD optical

pick-up

OptIcal

pick-up

block

@.\

I

\

(

\

I

/

/

Skew motor

I-

\

\

-

,I ^

e

*

Fig. 4-1

NEXT

PREV

-3l-

Page 28

CD optical pick-up

DVD optical

pick-up

Rack gear

Fig. 4-2

Slide

base

Spindle’motor

Skew cam

Fig. 4-3

Skew gear

A

b

I Skew motor

Skew sensor

-

32

-

Page 29

5, PB -

The unit is set in PAUSE mode by performing the following operation during PB mode.

Spindle motor continues to rotate. Sled motor stops.

PAUSE

Press PAUSE button ( II).

I

I

Gear (S-A), gear (S-B) and limiter

gear

ass’y

stop rotating.

Optical pick-up block stops moving.

Optical pick-up

block

Sled motor

Fig. 5-l

-

33

\i\

Spindle motor

-

Page 30

6. PB - STOP

Press STOP button (H

I

).

I

1 1

Spindle motor stops. Sled motor rotates in the direction of arrow mark.

Gear (S-A) and gear (S-B) rotate in the

;I

Limiter gear

:

ass’y

rotates in the direction of arrow

* When STOP button (m) is

pressed, the optical pick-up

block moves and reaches the

inner surface of disc.

‘I

Sled motor stops.

Optical pie:-up block

I

Spindle motor

Rack gear

I

\

Limiter gear

Fig. 6-1

-

34

-

Sled motor

Gea\r (S-B)

a&y

Page 31

I

I

Sled motor

/

Optical pick-up

block

Gear (S-A)

/

Gear (S-B)

Limiter gear

k

ass’y

, Spindle motor

Fig. 6-2

-

35

-

Page 32

7. Tray open (Disc OUT)

Press open/close button.

Loading motor rotates in the direction of

arrow mark.

i

Loading (midway) gear rotates in the

direction of arrow mark through belt and

loading pulley.

I

Tray driving gear rotates in the direction

of arrow mark.

i

Tray driving gear meshed with rack unit of

tray and loading (midway) gear both move in

the direction of arrow mark

Drive gear rotates in the direction of arrow

mark to rotate cam gear in the direction of

arrow mark.

Spindle base moves down in the direction of

arrow mark @centering around the fulcrum

@

, and the space between press pulley and

spindle motor becomes large.

@.

I

c

Sled motor rotates in the direction of arrow

I

I

1

Limiter gear ass’y rotates in the direction of

arrow mark through gear (S-A) and gear

IBi.

Optical pick-up block moves in the

(

direction

1

o~~f:I.,,.

,

I

I

(S-

)

I

Tray driving gear further rotates, and the tray

is pushed out in the direction of arrow mark.

t

Tray open sensor switch

“tray open” and loading motor stops.

* Disc can be ejected.

(SOOl)

detects

-

36

-

Page 33

\

1

\

A

0

I

/I I

Sled motor

Optical pick-up

block

Cam gear

\

Drive gear

4

Tray open

sensor switch

(SO01 )

Gear (S-A)

Gear (S-B)

, Limiter gear

ass’ y

/Spindle base

, Motor pulley

-

/

Tray driving gear

Fig.

-

37

Loading motor

7-1

-

Page 34

Tray open sensor

to ON by the projection under the tray.

/

switch (SOOl)

is set

Loading motorLoading motor

Fig. 7-2

Tray open sensor

switch

(SOOl)

Press pulley

Tray

Fig. 7-3

-

38

-

Page 35

DVP-S700

Q-921

-627-51

Loading...

Loading...