Page 1

DVP-S3000

RMT-D100E/D100U

SERVICE MANUAL

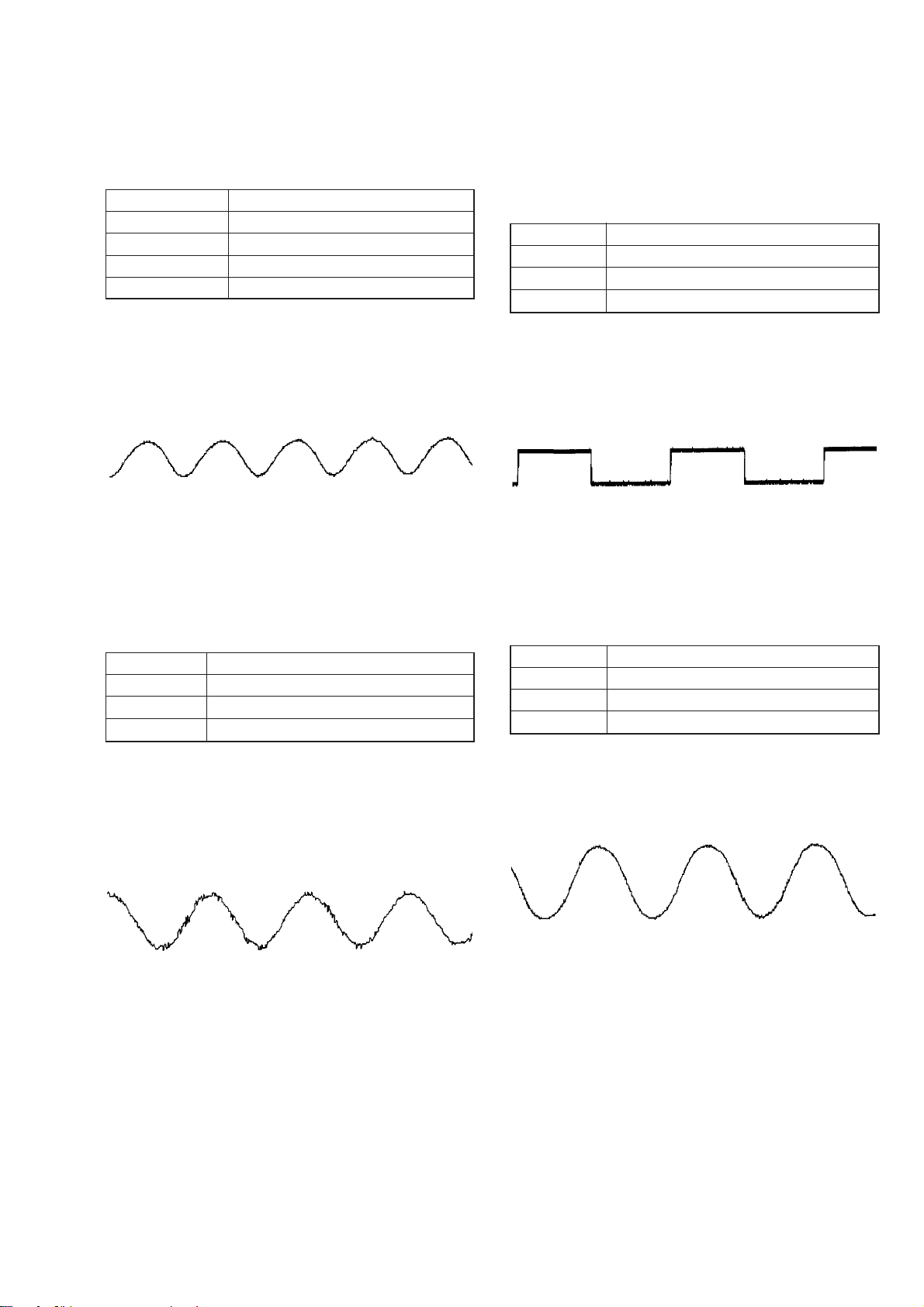

SPECIFICATIONS

US Model

Canadian Model

Chinese Model

Hong Kong Model

Singapore Model

• Audio/video/S-link connecting cord (1) (US, Canadian)

• Audio/Video connecting cord (1)

(Chinese, Hong Kong, Singapore)

• S video cable (1)

• Remote commander (remote) RMT -D100U (1) (US, Canadian)

• Remote commander (remote) RMT-D100E

(Chinese, Hong Kong, Singapore)

• sony R6 (size AA) batteries (2)

Design and specifications are subject to change without notice.

CD/DVD PLAYER

MICROFILM

Page 2

SAFETY CHECK-OUT

After correcting the original service problem, perform the following

safety checks before releasing the set to the customer:

1. Check the area of your repair for unsoldered or poorly-soldered connections. Check the entire board surface for solder

splashes and bridges.

2. Check the interboard wiring to ensure that no wires are

“pinched” or contact high-wattage resistors.

3. Look for unauthorized replacement parts, particularly transistors, that were installed during a previous repair. Point them

out to the customer and recommend their replacement.

4. Look for parts which, though functioning, show obvious signs

of deterioration. Point them out to the customer and recommend their replacement.

5. Check the line cord for cracks and abrasion. Recommend the

replacement of any such line cord to the customer.

6. Check the B+ voltage to see it is at the values specified.

7. Check the antenna terminals, metal trim, “metallized” knobs,

screws, and all other exposed metal parts for AC leakag e. Check

leakage as described below.

To Exposed Metal

Parts on Set

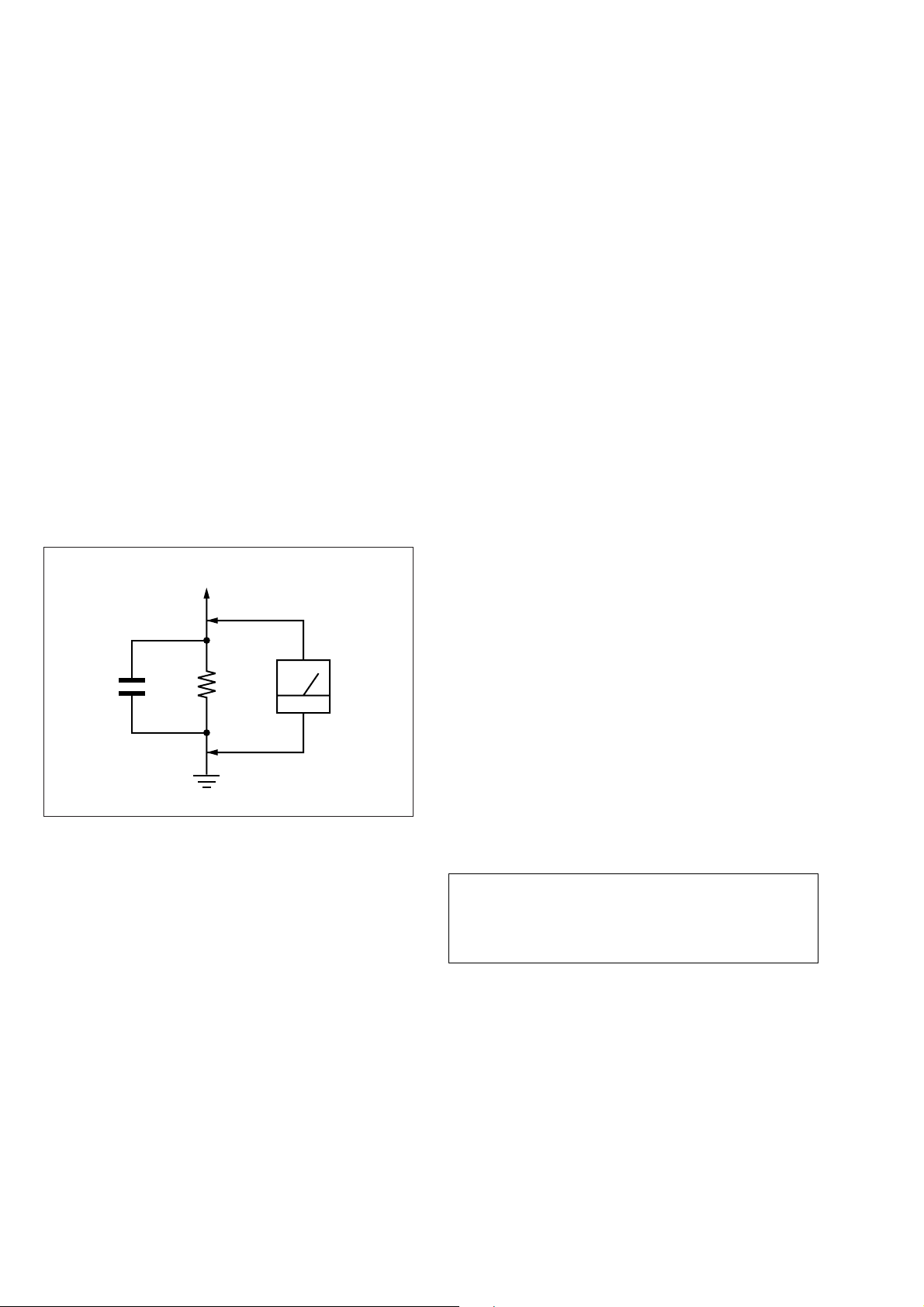

LEAKAGE TEST

The A C leakage from any exposed metal part to earth ground

and from all exposed metal parts to any exposed metal part having

a return to chassis, must not exceed 0.5 mA (500 microamperes).

Leakage current can be measured by any one of three methods.

1. A commercial leakage tester, such as the Simpson 229 or RCA

WT -540A. Follo w the manufacturers' instructions to use these

instruments.

2. A battery-operated A C milliammeter. The Data Precision 245

digital multimeter is suitable for this job.

3. Measuring the voltage drop across a resistor by means of a

VOM or battery-operated AC voltmeter. The “limit” indication is 0.75V, so analog meters must have an accurate lowvoltage scale. The Simpson 250 and Sanwa SH-63T rd are e xamples of a passive VOM that is suitable. Nearly all battery

operated digital multimeters that have a 2V AC range are suitable. (See Fig. A)

0.15 µF

1.5 k

Ω

Earth Ground

AC

Voltmeter

(0.75 V)

Fig. A Using AC voltmeter to check AC leakage

WARNING!!

WHEN SERVICING, DO NOT APPROACH THE LASER

EXIT WITH THE EYE TOO CLOSELY. IN CASE IT IS

NECESSARY TO CONFIRM LASER BEAM EMISSION,

BE SURE TO OBSER VE FROM A DISTANCE OF MORE

THAN 25 cm FROM THE SURFACE OF THE OBJECTIVE LENS ON THE OPTICAL PICK-UP BLOCK.

CAUTION:

The use of optical instrument with this product will increase eye

hazard.

CAUTION

Use of controls or adjustments or performance procedures other

than those specified herein may result in hazardous radiation

exposure.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK ! OR DOTTED LINE

WITH MARK ! ON THE SCHEMATIC DIAGRAMS AND IN

THE PARTS LIST ARE CRITICAL TO SAFE OPERATION.

REPLACE THESE COMPONENTS WITH SONY PAR TS WHOSE

P AR T NUMBERS APPEAR AS SHO WN IN THIS MANU AL OR

IN SUPPLEMENTS PUBLISHED BY SONY.

ATTENTION AU COMPOSANT AYANT RAPPORT

À LA SÉCURITÉ!

LES COMPOSANTS IDENTIFIÉS PAR UNE MARQUE ! SUR

LES DIAGRAMMES SCHÉMATIQUES ET LA LISTE DES

PIÈCES SONT CRITIQUES POUR LA SÉCURITÉ DE

FONCTIONNEMENT. NE REMPLACER CES COM- POSANTS

QUE PAR DES PIÈCES SONY DONT LES NUMÉROS SONT

DONNÉS DANS CE MANUEL OU D ANS LES SUPPLÉMENTS

PUBLIÉS PAR SONY.

– 2 –

Page 3

TABLE OF CONTENTS

Section Title Page

Service Note .............................................................................4

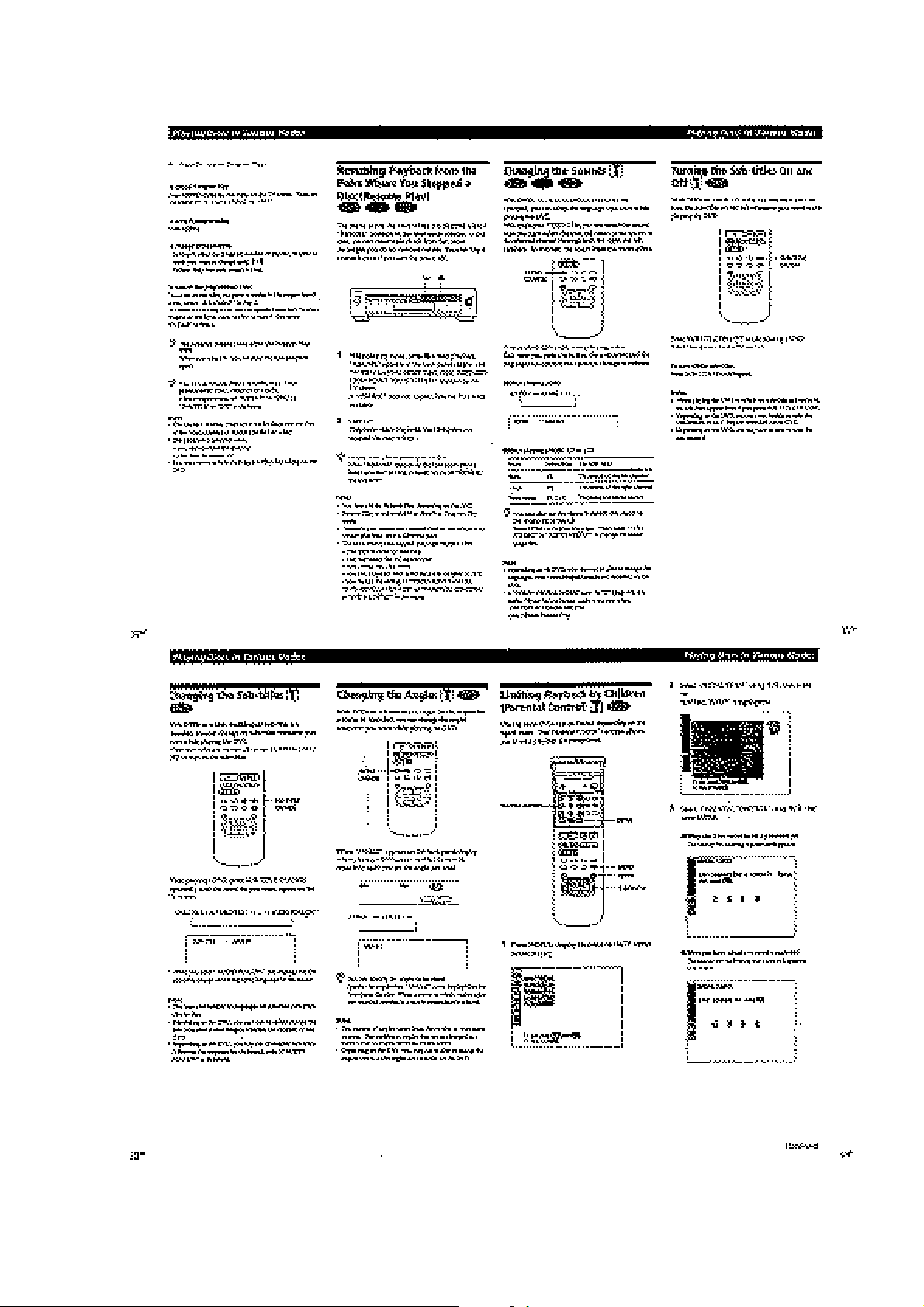

1. GENERAL

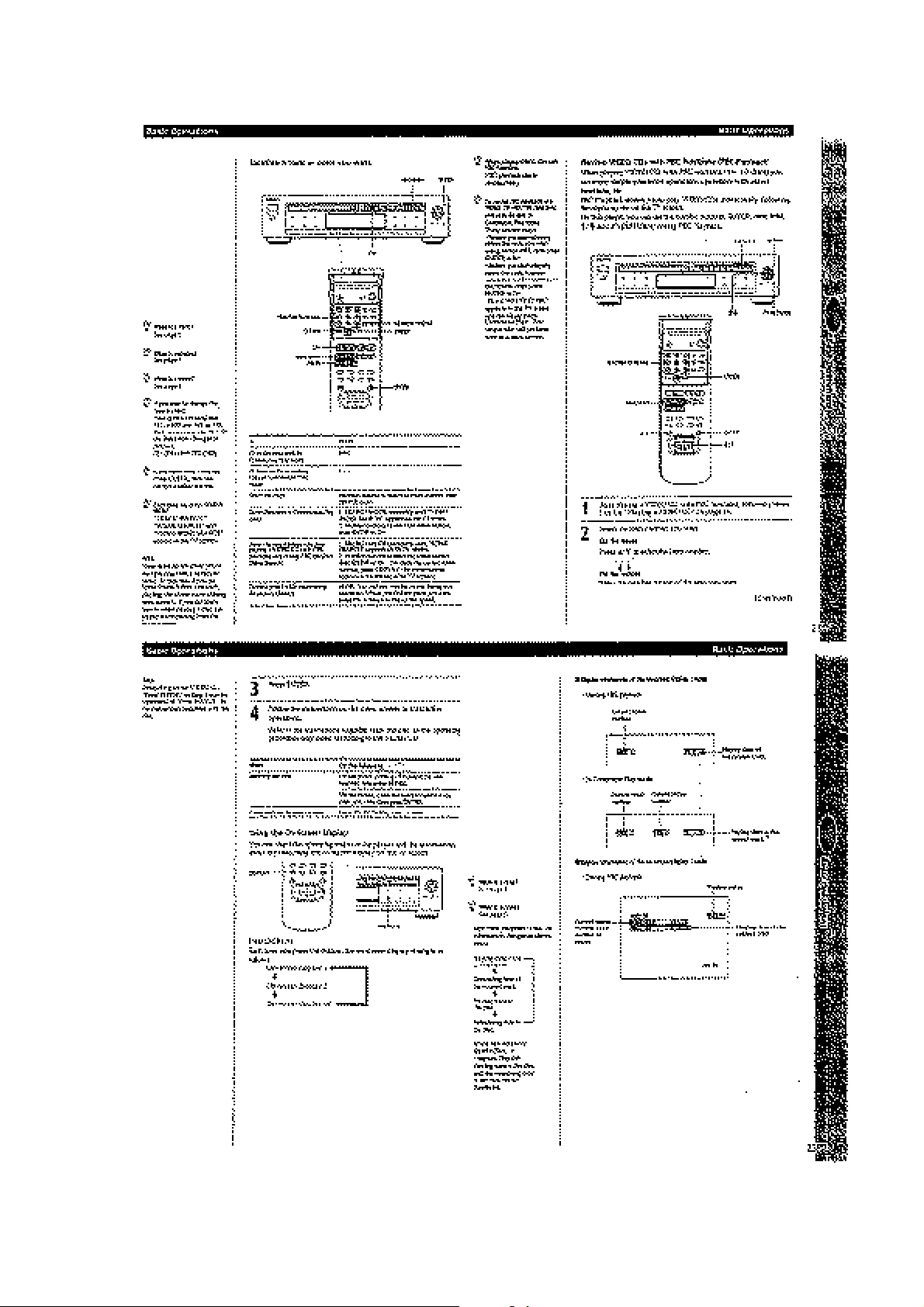

This Player Can Play the Following Discs.......................1-1

Getting Started ...............................................................1-1

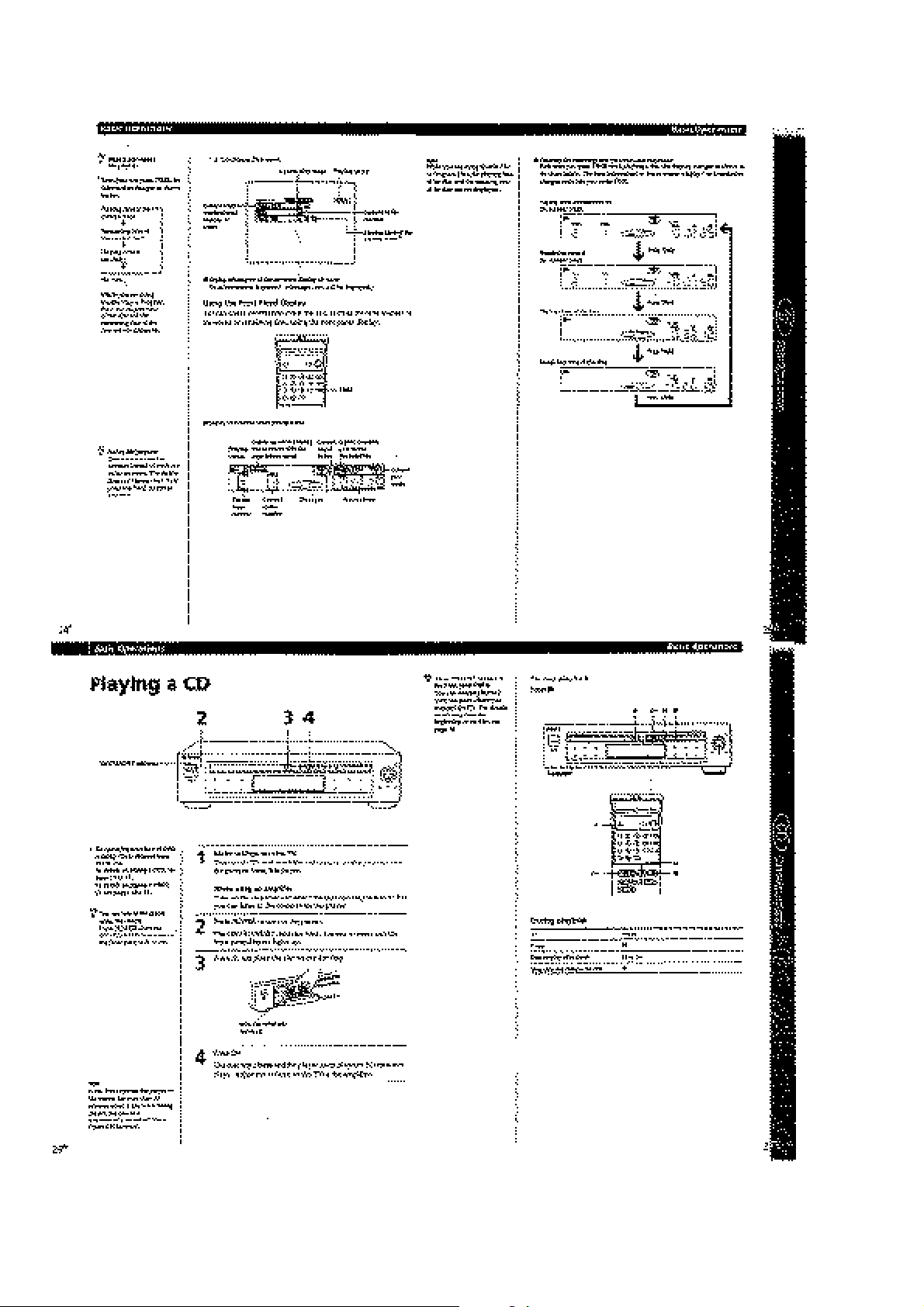

Basic Operations ............................................................1-2

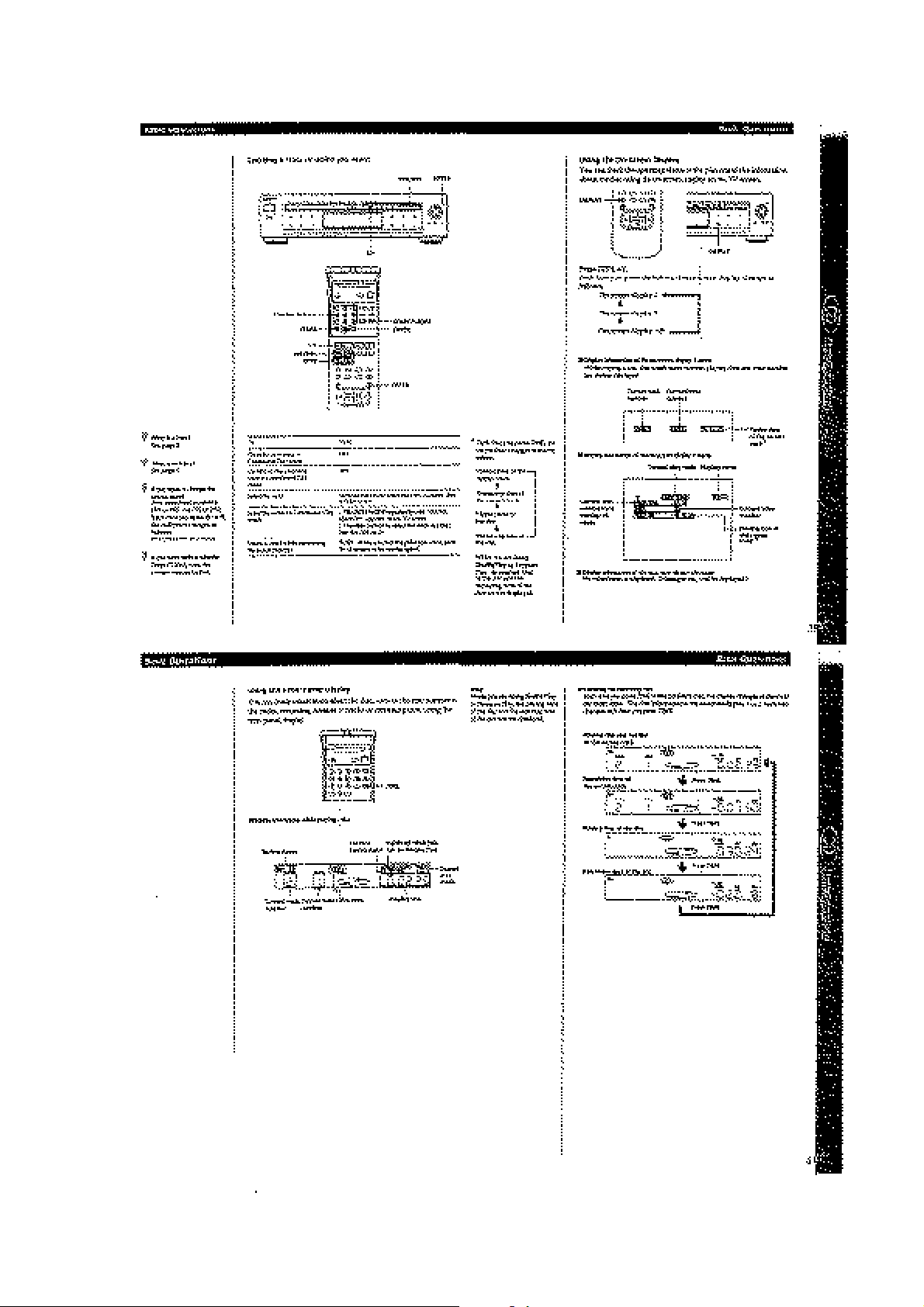

Playing Discs in Various Modes ......................................1-8

Setting and Adjustments .................................................1-10

Additional Information .....................................................1-12

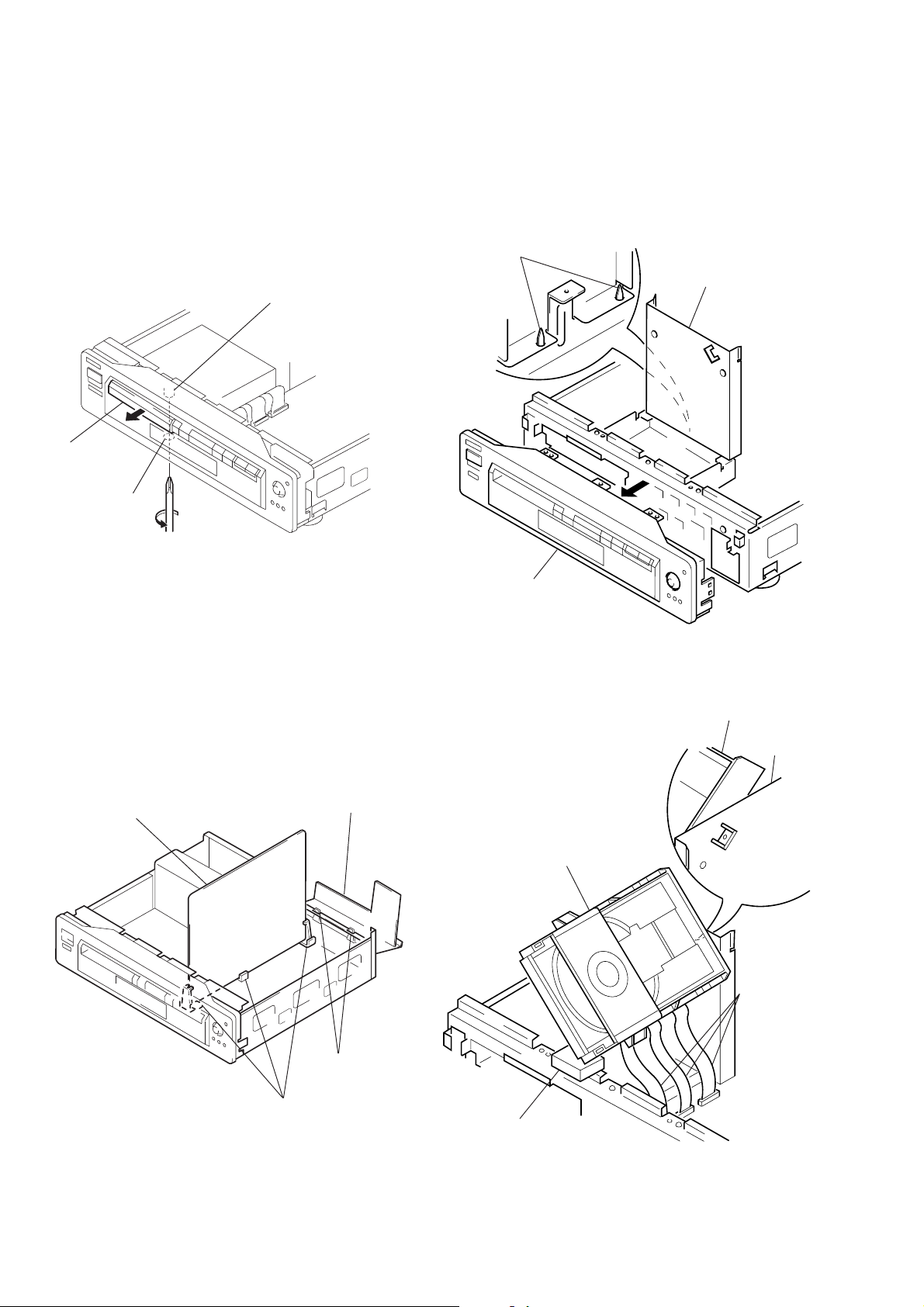

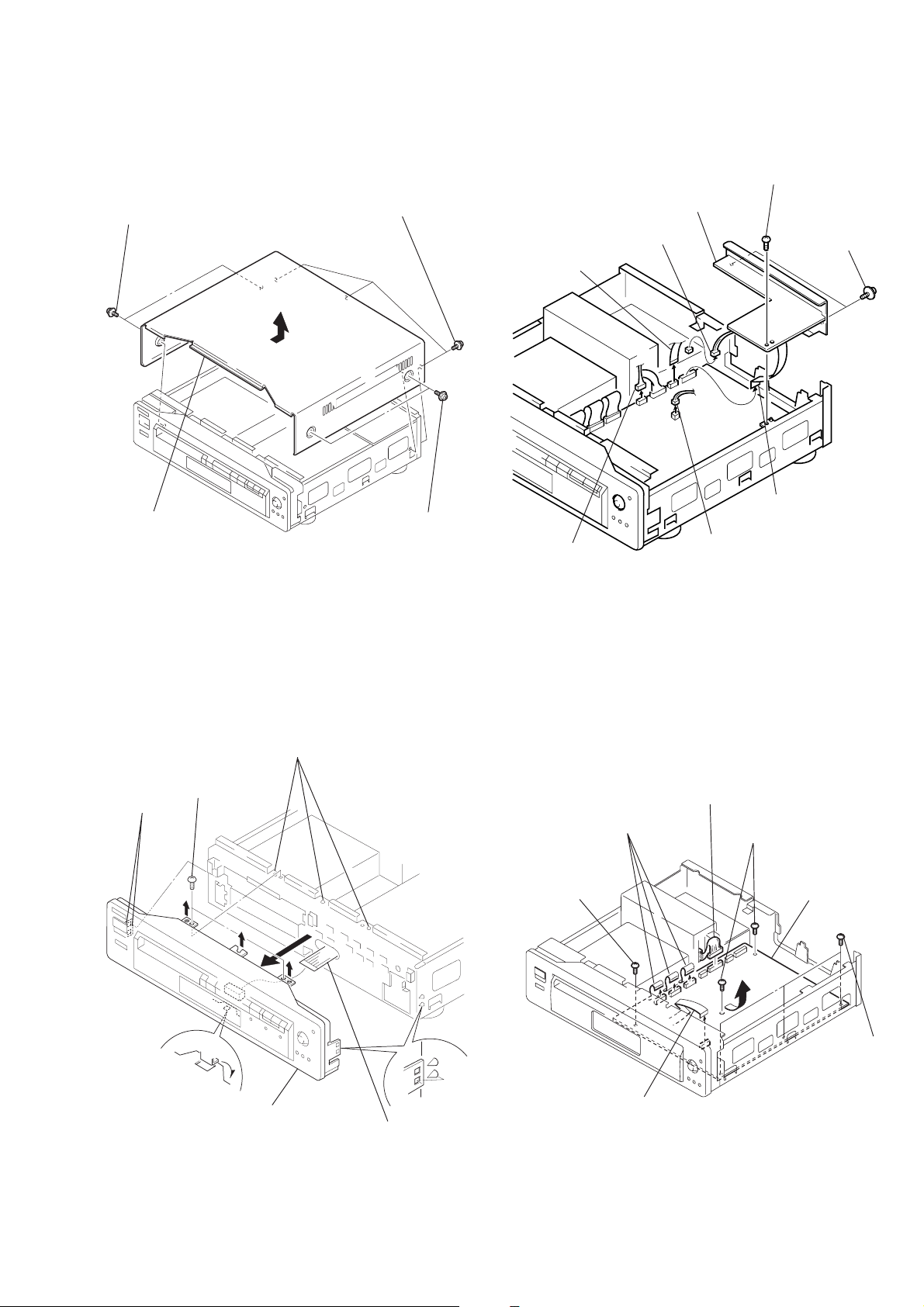

2. DISASSEMBLY

2-1. Top Case Removal..........................................................2-1

2-2. Front Panel Removal ......................................................2-1

2-3. AU-201, 203 Board Removal ..........................................2-1

2-4. MB-80 Board Removal....................................................2-1

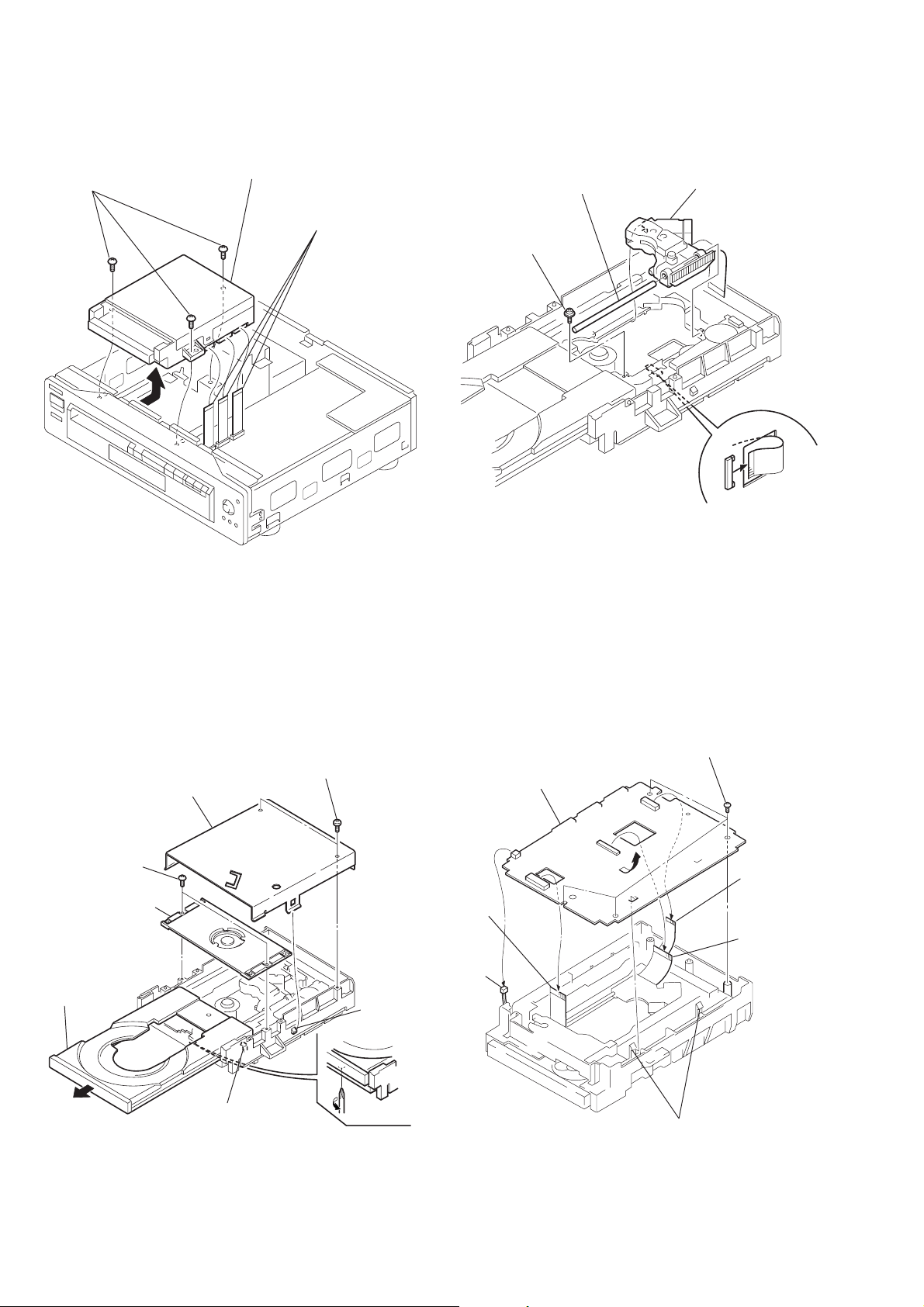

2-5. MD Block Ass’y Removal................................................2-2

2-6. Try Removal....................................................................2-2

2-7. Optical Pick-up Removal.................................................2-2

2-8. TT-40 Board Removal .....................................................2-2

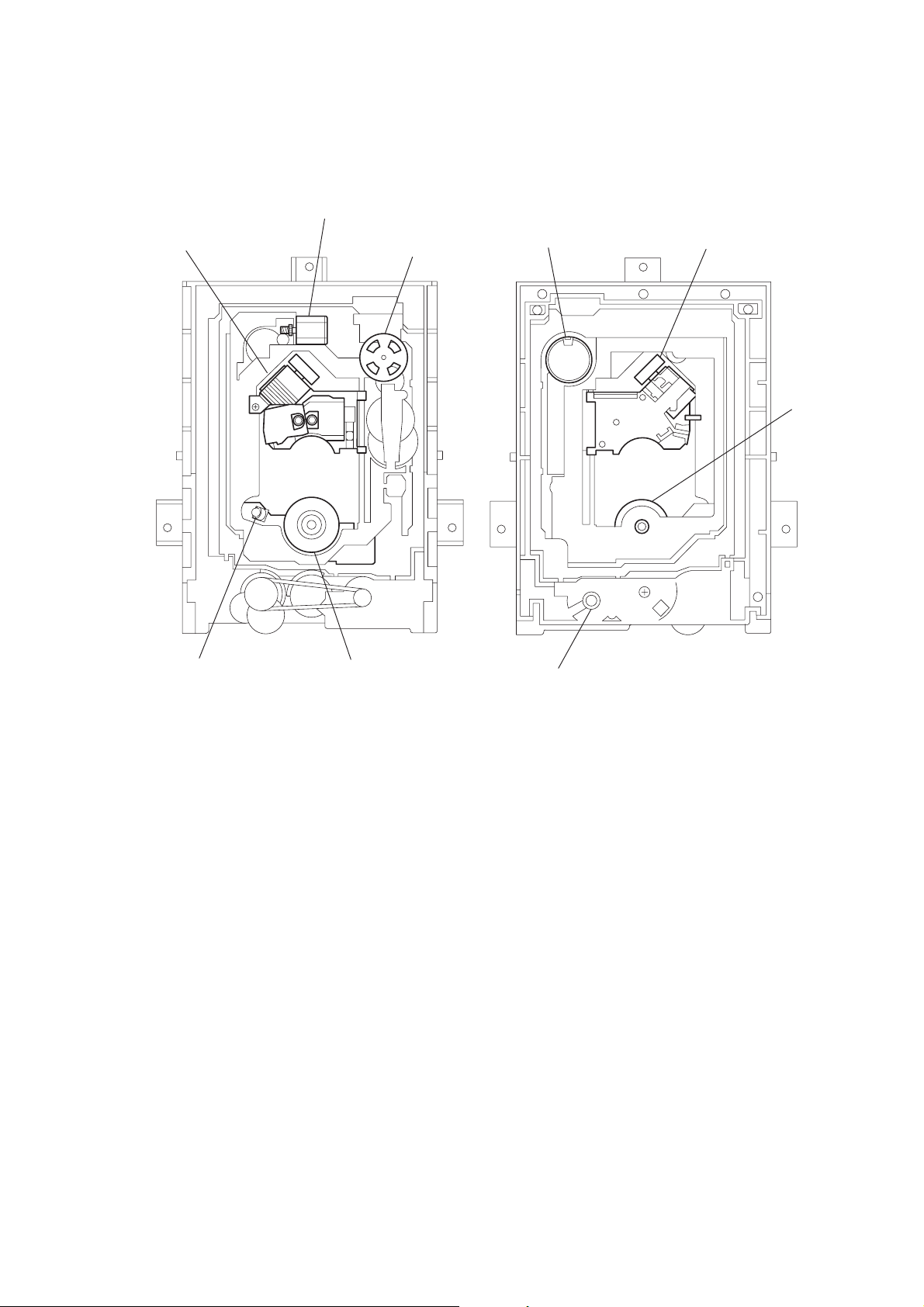

2-9. Internal Views .................................................................2-3

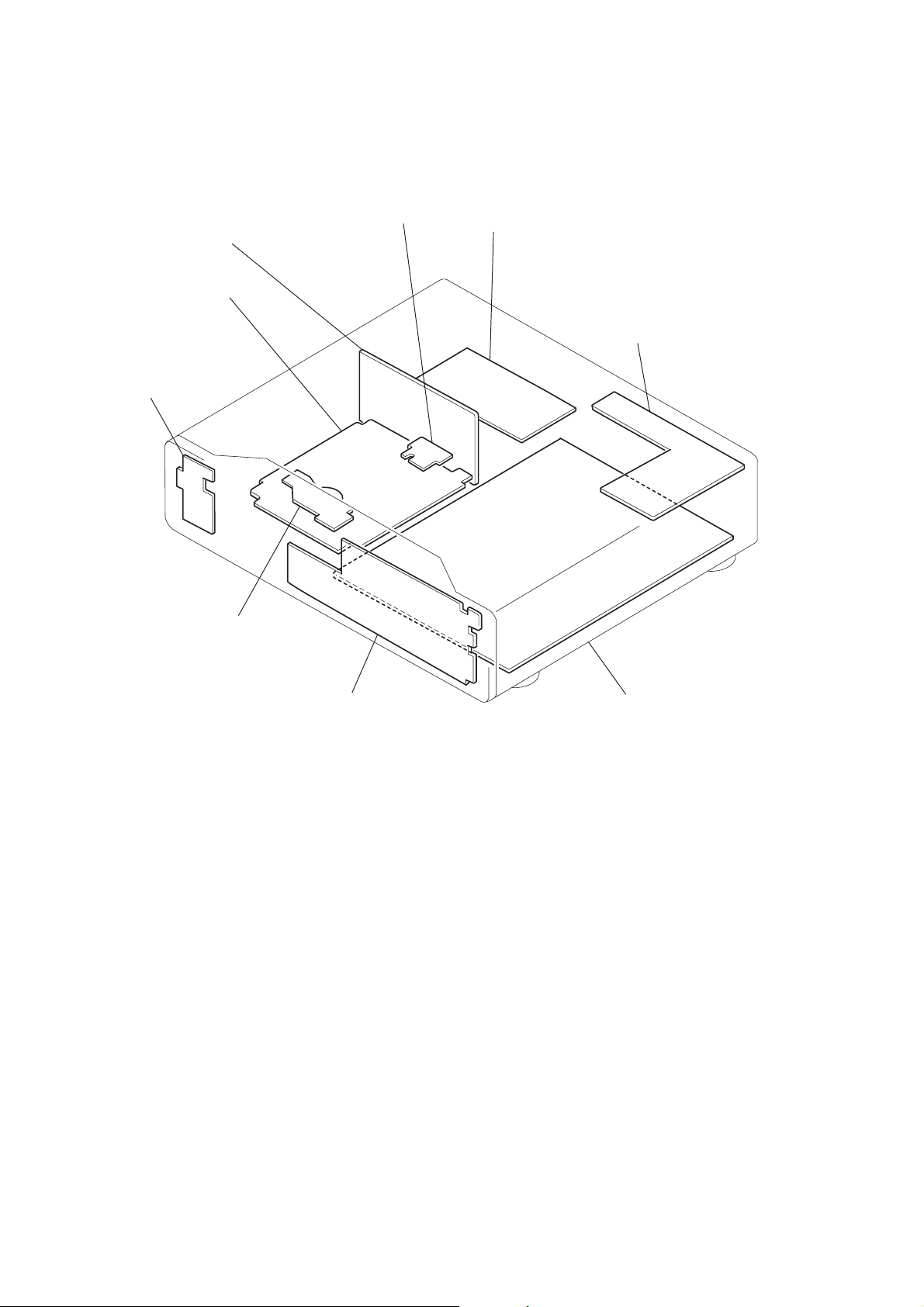

2-10. Circuit Boards .................................................................2-4

3. BLOCK DIAGRAMS

3-1. Overall Block Diagram 1 (RF, Servo, Audio Power) ........ 3-1

3-2. Overall Block Diagram 2 (Signal Process)......................3-6

3-3. RF/Servo Block Diagram ................................................3-11

3-4. Data Process Block Diagram ..........................................3-14

3-5. Video Block Diagram ......................................................3-16

3-6. System Control Block Diagram .......................................3-21

3-7. Audio Block Diagram ......................................................3-24

3-8. Mode Control Block Diagram ..........................................3-27

3-9. Power Supply Block Diagram..........................................3-30

4. PRINTED WIRING BOARDS AND SCHEMATIC

DIAGRAMS

4-1. Frame Schematic Diagram .............................................4-1

4-2. Printed Wiring Boards and Schematic Diagrams............4-5

TT-40, LM-56 Printed Wiring Boards...............................4-5

TT-40, LM-56 Schematic Diagram ..................................4-7

MB-80 Printed Wiring Board ...........................................4-12

MB-80 (Interface) Schematic Diagram............................4-17

MB-80 (CPU) Schematic Diagram ..................................4-21

MB-80 (Drive Control) Schematic Diagram.....................4-25

MB-80 (DVD Data Process) Schematic Diagram............4-28

MB-80 (CD ROM Decode) Schematic Diagram..............4-31

MB-80 (MPEG Video Decode) Schematic Diagram........4-35

MB-80 (Video EQ, Letter Box, Sub Picture)

Schematic Diagram ........................................................4-39

MB-80 (Audio Decode) Schematic Diagram ...................4-42

MB-80 (Video) Schematic Diagram ................................4-45

MB-80 (Digital Servo) Schematic Diagram .....................4-51

MB-80 (RF Block) Schematic Diagram ...........................4-55

MB-80 (Drive) Schematic Diagram .................................4-59

FP-611/619, PW-116/117 Printed Wiring Boards............4-63

FP-611/619, PW-116/117 Schematic Diagram................4-65

AU-201/203, PS-408/413 Schematic Diagram ...............4-67

AU-201/203, PS-408/413 Printed Wiring Boards............4-71

SR-740, SUB Printed Wiring Boards and

Schematic Diagram.........................................................4-74

SR-745, SUB Printed Wiring Boards and

Schematic Diagram.........................................................4-77

Section Title Page

5. IC PIN FUNCTION DESCRIPTION

5-1. Interface Control Pin Function (MB-75 Board IC021) .....5-1

5-2. Drive Control Pin Function (MB-75 Board IC136)...........5-2

5-3. Extended Output Port 0 (MB-75 Board IC147) ...............5-3

5-4. Extended Output Port 1 (MB-75 Board IC148) ...............5-3

5-5. Extended Output Port 2 (MB-75 Board IC149) ...............5-3

5-6. Extended Output Port 3 (MB-75 Board IC150) ...............5-3

5-7 D/A Converter (MB-75 Board IC722)..............................5-3

5-8 System Control Pin Function (MB-75 Board IC090) .......5-4

6. TEST MODE

6-1. Starting up Test Mode .....................................................6-1

6-2. Syscon Diagnosis ...........................................................6-1

6-3. Drive Auto Adjustment ....................................................6-10

6-4. Drive Manual Operation ..................................................6-13

6-4-1. Drive Manual Operation wnu creen ...........................6-13

6-4-2. Disc Type ...................................................................6-13

6-4-3. Manual Control 1 .......................................................6-13

6-4-4. Manual Control 2 .......................................................6-14

6-4-5. Manual Control 3 .......................................................6-14

6-4-6. Manual Adjust 1 .........................................................6-15

6-4-7. Manual Adjust 2 .........................................................6-15

6-4-8. Auto Adjust ................................................................6-15

6-4-9. Check.........................................................................6-16

6-5. Emergency History .........................................................6-18

6-6. Other Checks ..................................................................6-18

7. ELECTRICAL ADJUSTMENT

7-1. Power Supply Check.......................................................7-1

1. PS-408/413 Board ..........................................................7-1

2. MB-80 Board...................................................................7-1

7-2. +5.2 V Adjustment...........................................................7-1

7-3. Adjustment of System Control ........................................7-2

1. 27 MHz Free Run............................................................7-2

2. 22 MHz Adjustment ........................................................7-2

3. 33 MHz Check ................................................................7-2

4. 33 MHz Lock Check........................................................7-2

5. 24 MHz Adjustment ........................................................7-3

6. 36 MHz Check ................................................................7-3

7. 36 MHz Lock Check........................................................7-3

8. 16 MHz Check ................................................................7-3

7-4. Adjustment of Video System

1. Video Level Adjustment ..................................................7-4

2. S-Terminal Output Check................................................7-4

3. Checking Composite Video Output B-Y..........................7-4

4. Checking Composite Video Output R-Y..........................7-5

5. Checking Composite Video Output Y ..............................7-5

6. Checking S Video Output S-C ........................................7-5

7. Checking S Video Output DC Level ................................7-5

7-5. Adjustment Related Parts Arrangement .........................7-6

8. REPAIR PARTS LIST

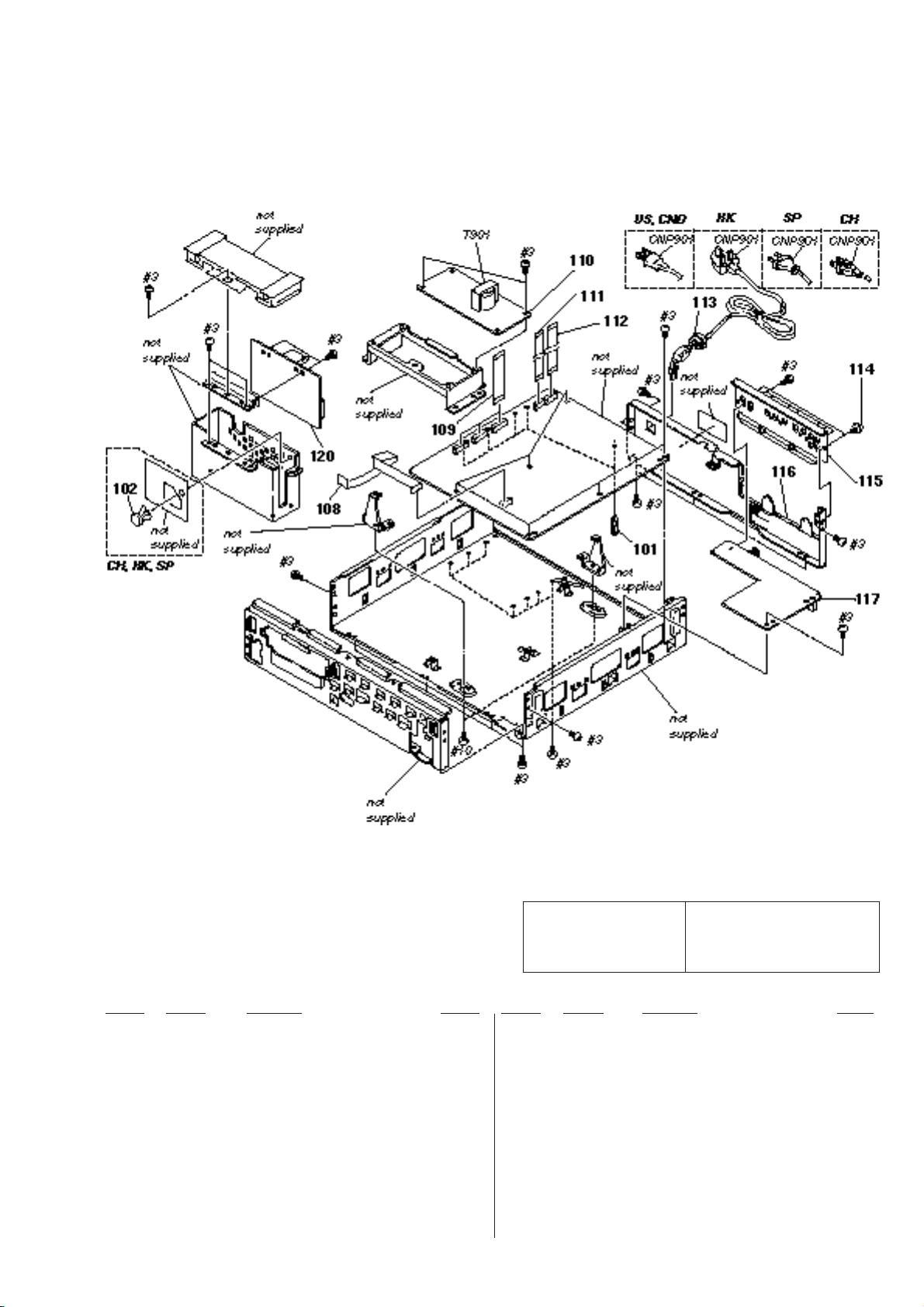

8-1. Exploded Views ..............................................................8-1

8-1-1. Case Assembly ..........................................................8-1

8-1-2. Front Panel Assembly ................................................8-2

8-1-3. Chassis Assembly .....................................................8-3

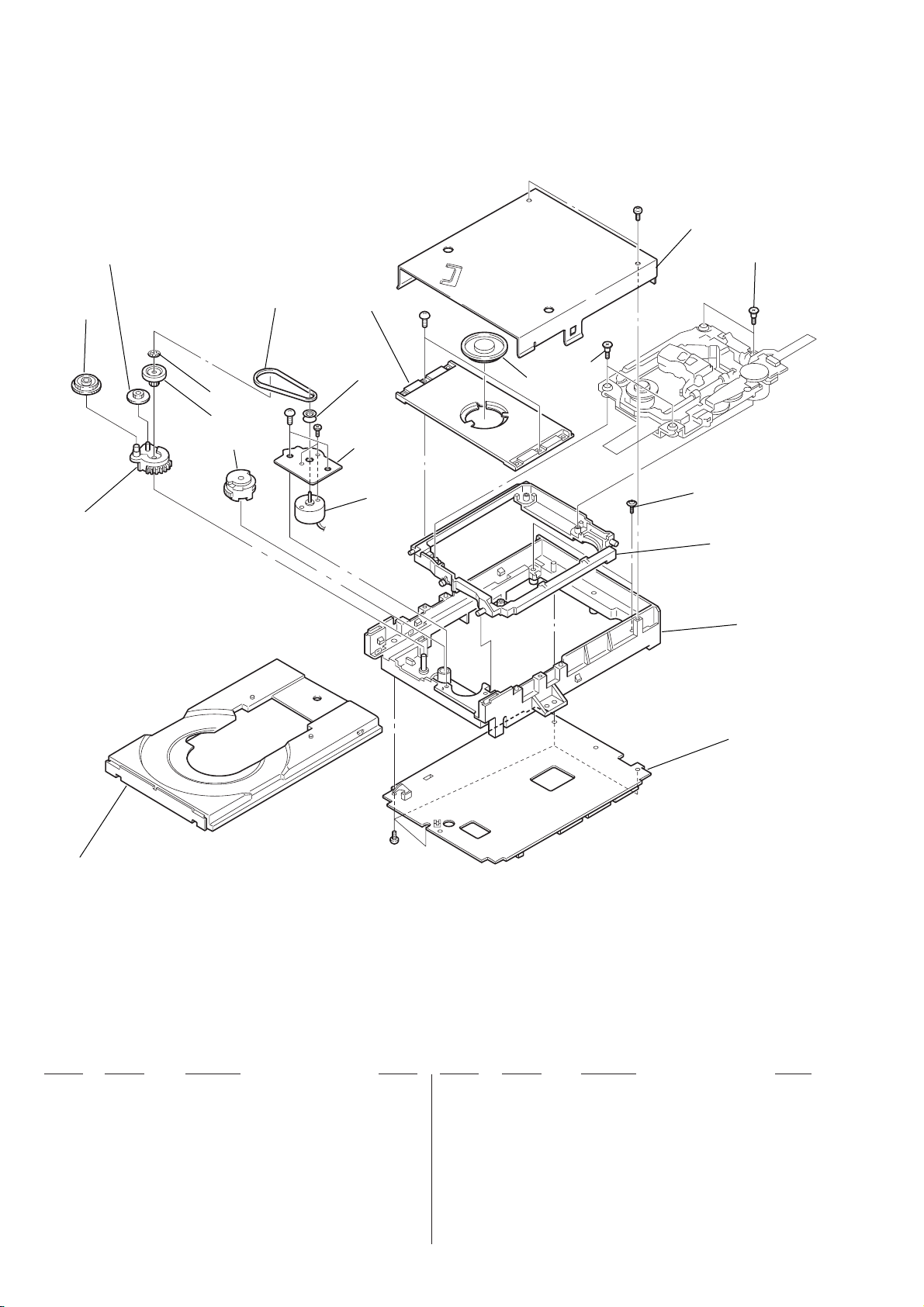

8-1-4. DVD Mechanism Chassis Assembly (1) ....................8-4

8-1-5. DVD Mechanism Chassis Assembly (2) ....................8-5

8-2. Electrical Parts List .........................................................8-6

– 3 –

Page 4

SER VICE NOTE

1. DISK REMOVAL PROCEDURE

(at POWER OFF)

1) Insert a cross-tip screwdriver into a hole at the bottom, and

rotate the cam gear 1 in direction A. (See Fig. 1)

Note: To prevent a damege of cam gear, rotate it in direction

A by 1/4 turn.

2) Draw out the tray 2 in direction B by hand, and remove a

disk. (See Fig. 1)

1

Cam gear

B

2 Tr a y

Hole

A

Fig. 1

2. HOW T O SER VICE AU-201, 203 AND MB80 BOARDS

1) Remove the top case from the set. (Refer to 2-1)

2) Remove the AU-201, 203 board. (Refer to 2-3)

Note: Do not disconnect wiring.

3) Remove the MB-80 board. (Refer to 2-4)

Note: Do not disconnect wiring.

4) Erect MB-80 board on three circuit board holders. (See. Fig. 2)

5) Erect AU-201, 203 board on two claws. (See Fig. 2)

AU-201 board

(US, Canadian model)

AU-203 board

MB-80 board

(Chinese, Hong Kong, Singapore model)

3. HOW T O SERVICE THE MD BLOCK ASS’Y

1) Remove the top case from the main unit. (Refer to 2-1)

2) Remove the front panel. (Refer to 2-2)

Note: Do not disconnect wiring.

3) Remove the MD block ass’y. (Refer to 2-5)

4) Remove the MD upper cover, and mount as shown in Fig. 3.

Claws

MD upper cover

Front panel

Fig. 3

5) Install the MD block ass’y as shown in Fig. 4.

Note: Place a cushion at the position A.

6) Connect three flexible flat cables.

MD block ass’y

MD upper

cover

Three circuit board

holders

Fig. 2

MD block ass’y

Three flexible

flat cable

Two claws

A

Fig. 4

– 4 –

Page 5

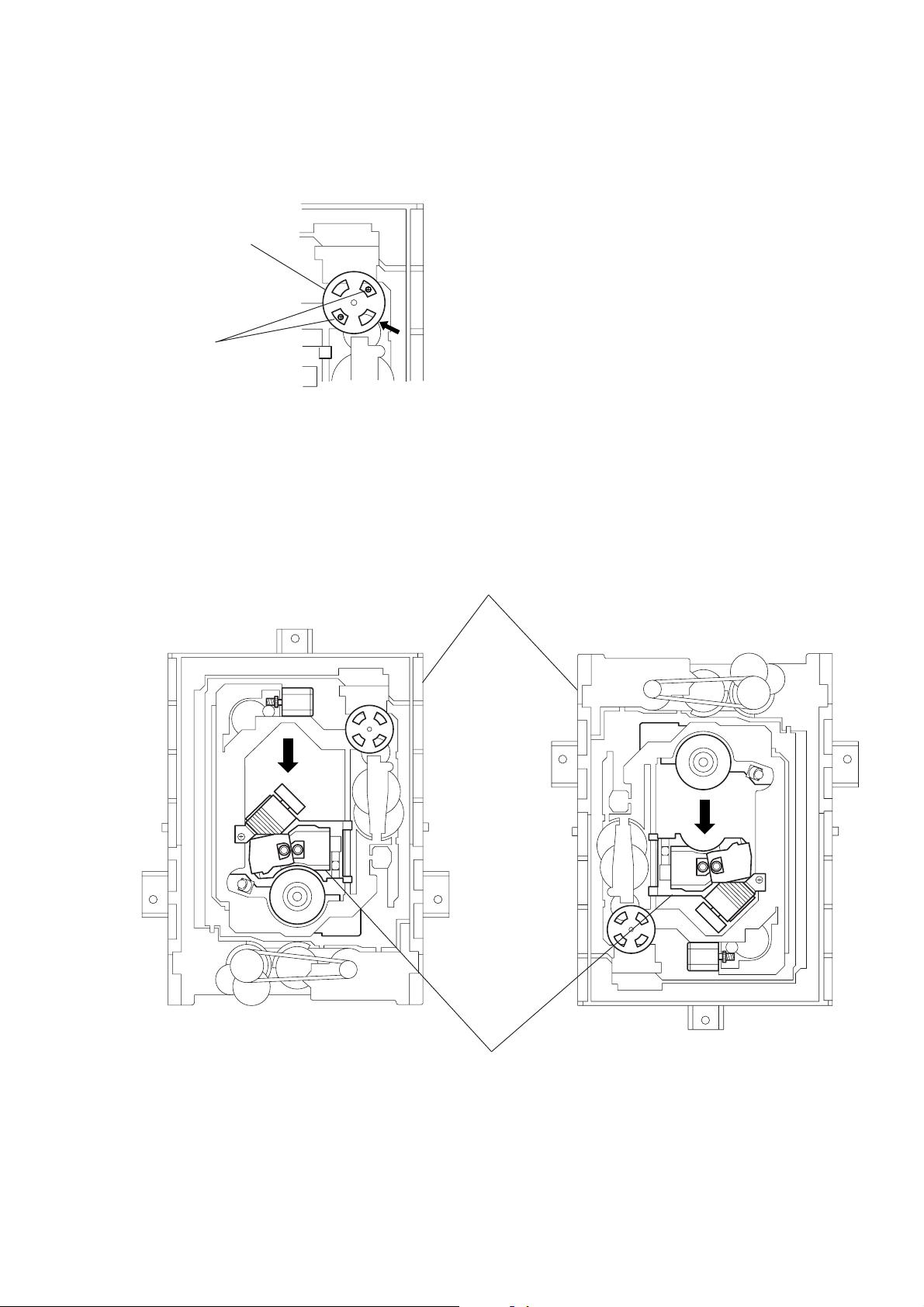

4. NOTE ON MOUNTEING SLED MOTOR

1) Push the sled motor assy 1 toward direction A. (See Fig.5)

2) Tighten two screws 2 (M1.7 × 2.5).

1 Sled motor ass’y

A

2 Two screws (M1.7 × 2.5)

Fig. 5

3) Raising the MD block assy 3 90 º with the side down.

confirm that the optical pick-up 4 falls by self weight.

(See Fig. 6)

4) Further, with the front side of MD block assy 3 up, confirm

that the optical pick-up falls by self weight.

Lower

Upper

Front side

3 MD block ass’y

4 Optical pick-up

Upper

Lower

Front side

Fig. 6

– 5 –

Page 6

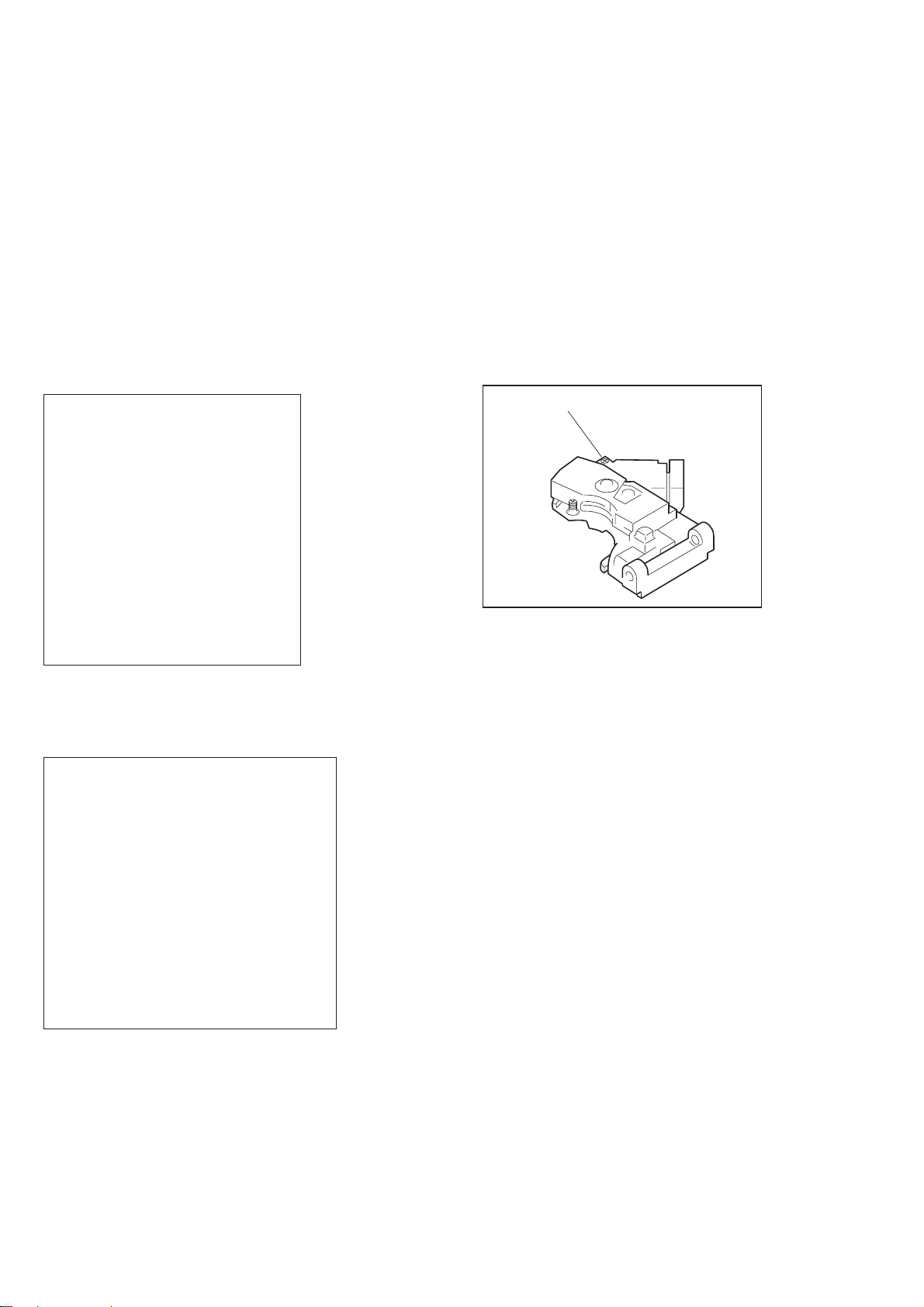

5. REPLACING OPTICAL PICK-UP

5-1. Handling

1) A red laser diode for DVD requires more attention to static

electricity than general infrared laser diodes for CD.

Because its durability to static electricity is far weaker than

that of infrared laser diodes, always use an earth band when

handling the optical pick-up block as service parts.

2) As for the flexible board KHS-180A (RP) packed as service

parts, the short lands have been soldered to protect from static

electricity. Accordingly, remove solders when replacing optical pick-up. (See Fig. 7)

DVD short land

3) In handling the KHS-180A (RP), do not touch inhibited parts

shown in Fig. 8, but grip the slide base bearing and U-shaped

guide.

Slide base bearing

Skew sensor

Lens actuator

covers

Objective lenses

Laser holder

U-shaped guide

OEIC

CD short land

Fig. 7 Flexible board

Touch inhibited parts

• Objective lens

• Skew sensor

• Laser holder

• Laser coupler

• Flexible board

• OEIC

• Lens actuator covers

Flexible board

Connector

– 6 –

Laser coupler

Fig. 8 KHS-180A (RP)

Page 7

6. NOTE ON ASSEMBLING MECHANICAL DECK

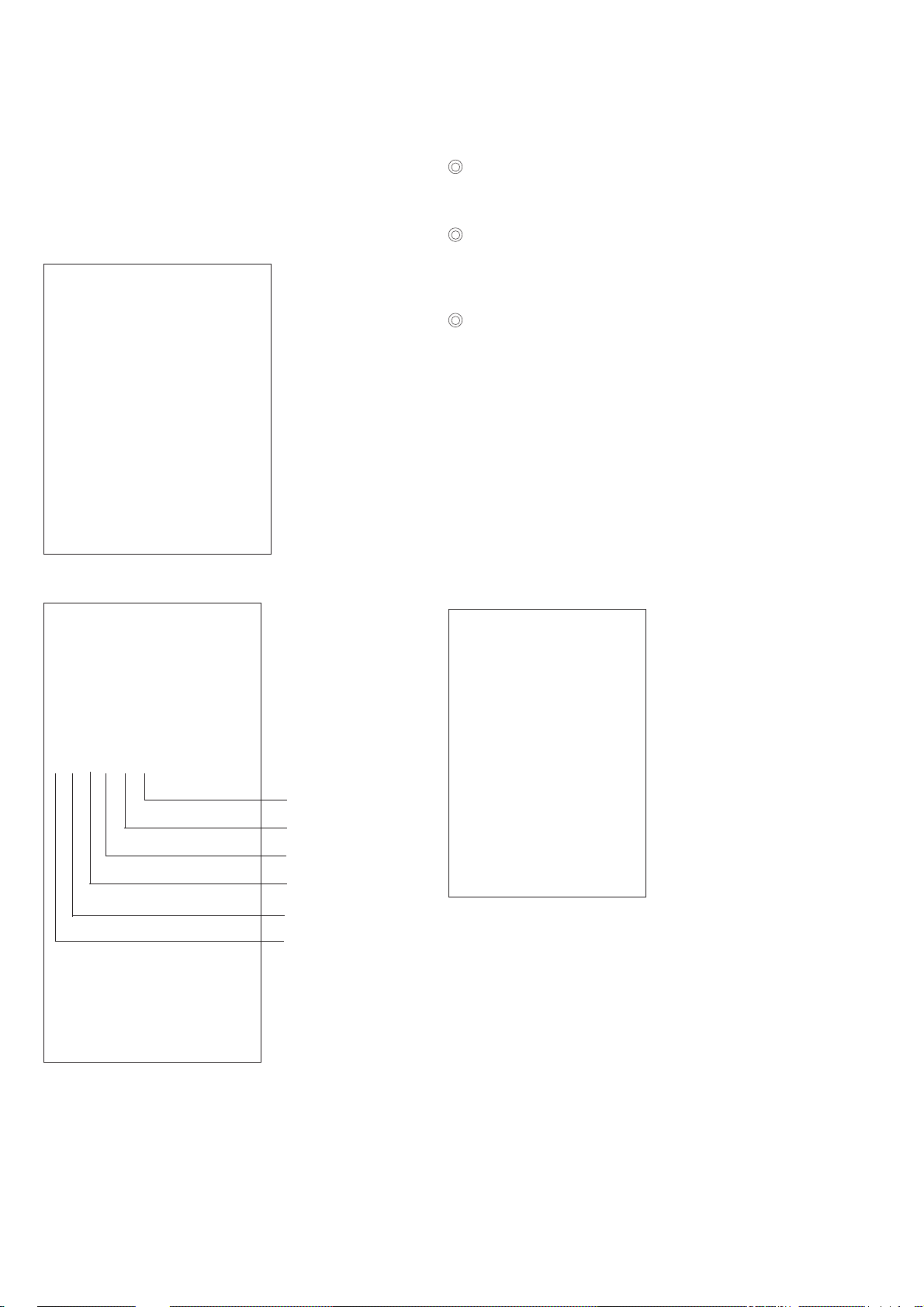

6-1. Application of Grease

1) Grease must be applied if the following parts were replaced.

(See Fig. 9)

NOTE 1: Recommended grease is Foil KG-70MP.

NOTE 2: In applying grease, take care not to allow grease to

stick to other parts (particularly, r ubber belt, spindle

motor, and optical pick-up)

Base unit holder

2 bosses

Slide base

Skew cam

Tray 3 grooves

NOTE: Add grease if tray

moves slowly.

Cam gear

Loading pulley shaft

NOTE: Add grease if tray

generates noise

periodically.

Fig. 9

– 7 –

Page 8

6-2. Cleaning Spindle Motor Turntable

1) Remove the tray. (Refer to 2-6)

2) Clean the spindle motor turntable if disc antiskid rubber

(black) is dirty. (See Fig.10)

Spindle motor

Turntable

6-4. Deformation of Insulator

1) Assemble the spindle base into the base unit.

2) Lock with 4 shoulder screws. (See Fig.12)

3) Check if 4 insulators deformed. (See Fig.12)

Four step screws

Two insulators

Insulator

Two insulators

Good NG

Fig. 10

6-3. Aligning Phase of Cam Gear and

Drive Gear

1) Align triangle marks when assembling the cam gear and

drive gear. (See Fig.11)

Drive gear Cam gear

Fig. 12

6-5. Note on connecting OPT Harness

1) The optical pick-up could be destroyed unless the OPT

harness is connected normally to the connector. (See Fig.13)

OPT harness

Good

Connector

NG

Align triangle marks.

Fig. 11 Fig. 13

– 8 –

Page 9

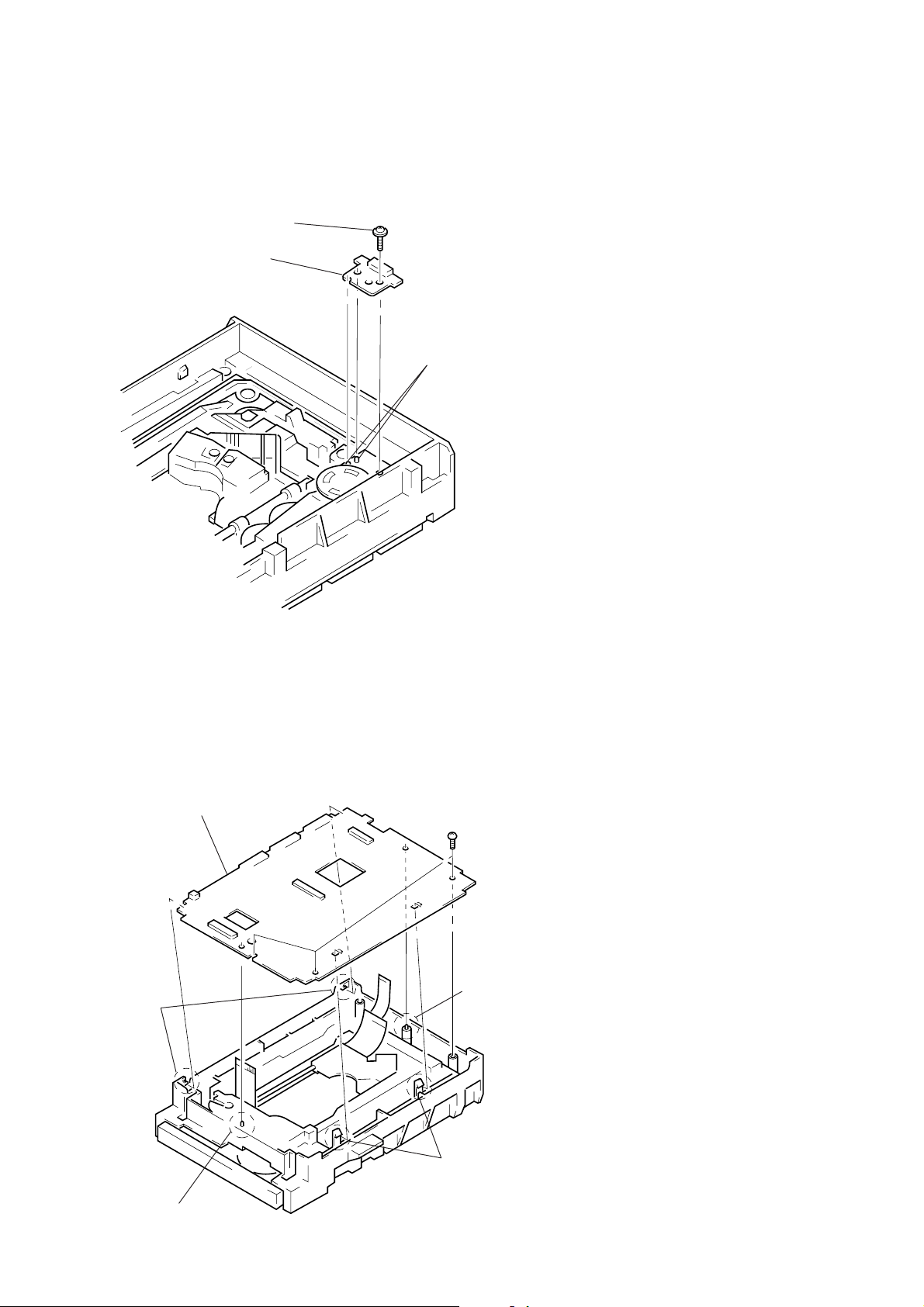

6-6. Note on Mounting LM-51 Board

1) Align two bosses. (See Fig.14)

2) Fix the board securely with screws (PTPWH 2 × 5). (The

sensor will not function normally if the board floats up.)

Screw

(PTPWH2 × 5)

LM-56 board

Two bosses

Fig.14

6-7. Note on Mounting TT-701 Board

1) Align two bosses. (See Fig.15)

2) Align four tabs. (See Fig.15)

3) Fix the board securely with 3 screws (BV 3 × 10). (The

sensor will not function normally if the board floats up.)

TT-40 board

Two claws

Three screws

(BV3 × 10)

Boss

Boss

Two claws

Fig.15

– 9 –

Page 10

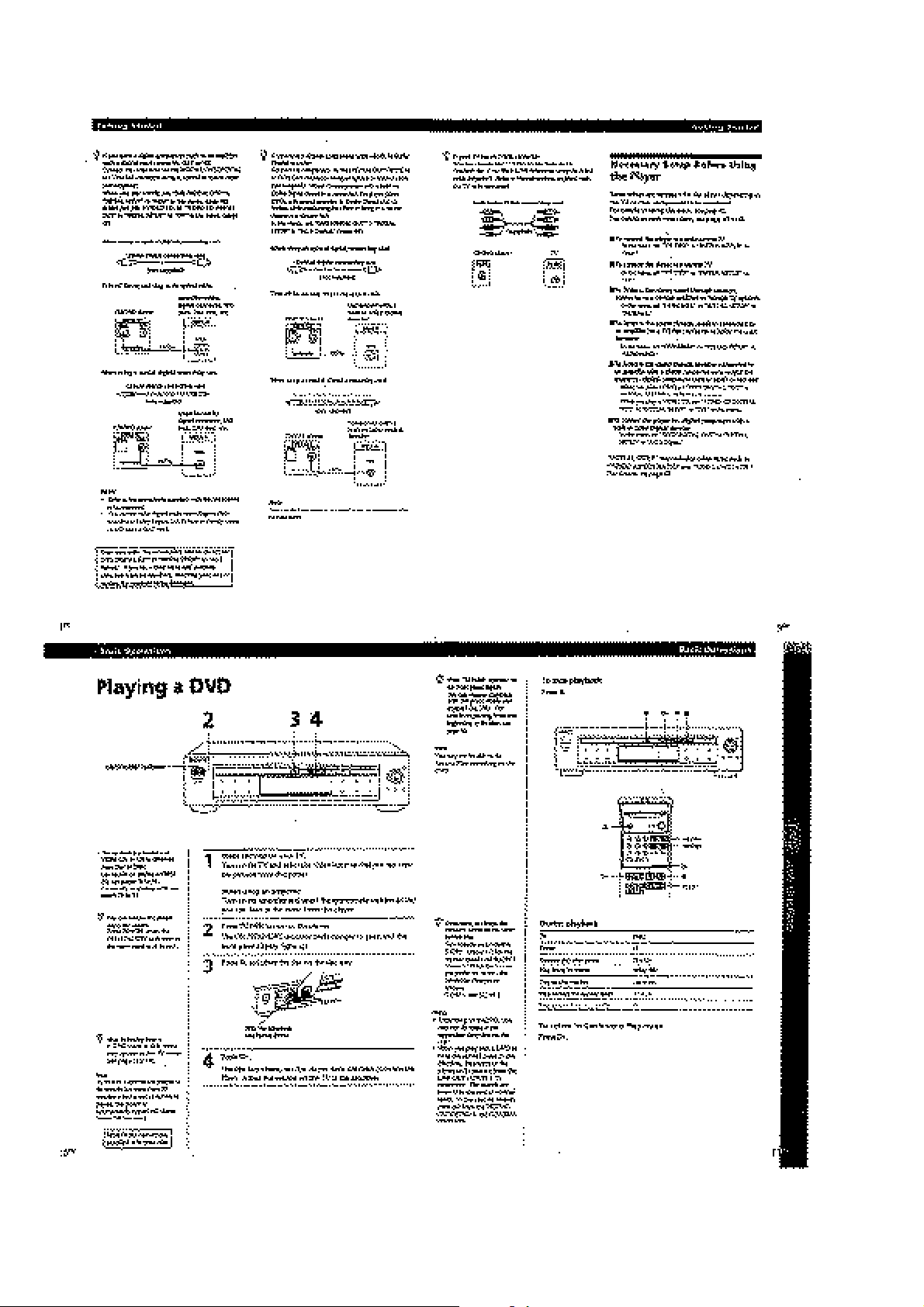

DVP-S3000

SECTION 1

GENERAL

This section is extracted from

US model instruction manual.

1-1

Page 11

1-2

Page 12

1-3

Page 13

1-4

Page 14

1-5

Page 15

1-6

Page 16

1-7

Page 17

1-8

Page 18

1-9

Page 19

1-10

Page 20

1-11

Page 21

1-12

1-12 E

Page 22

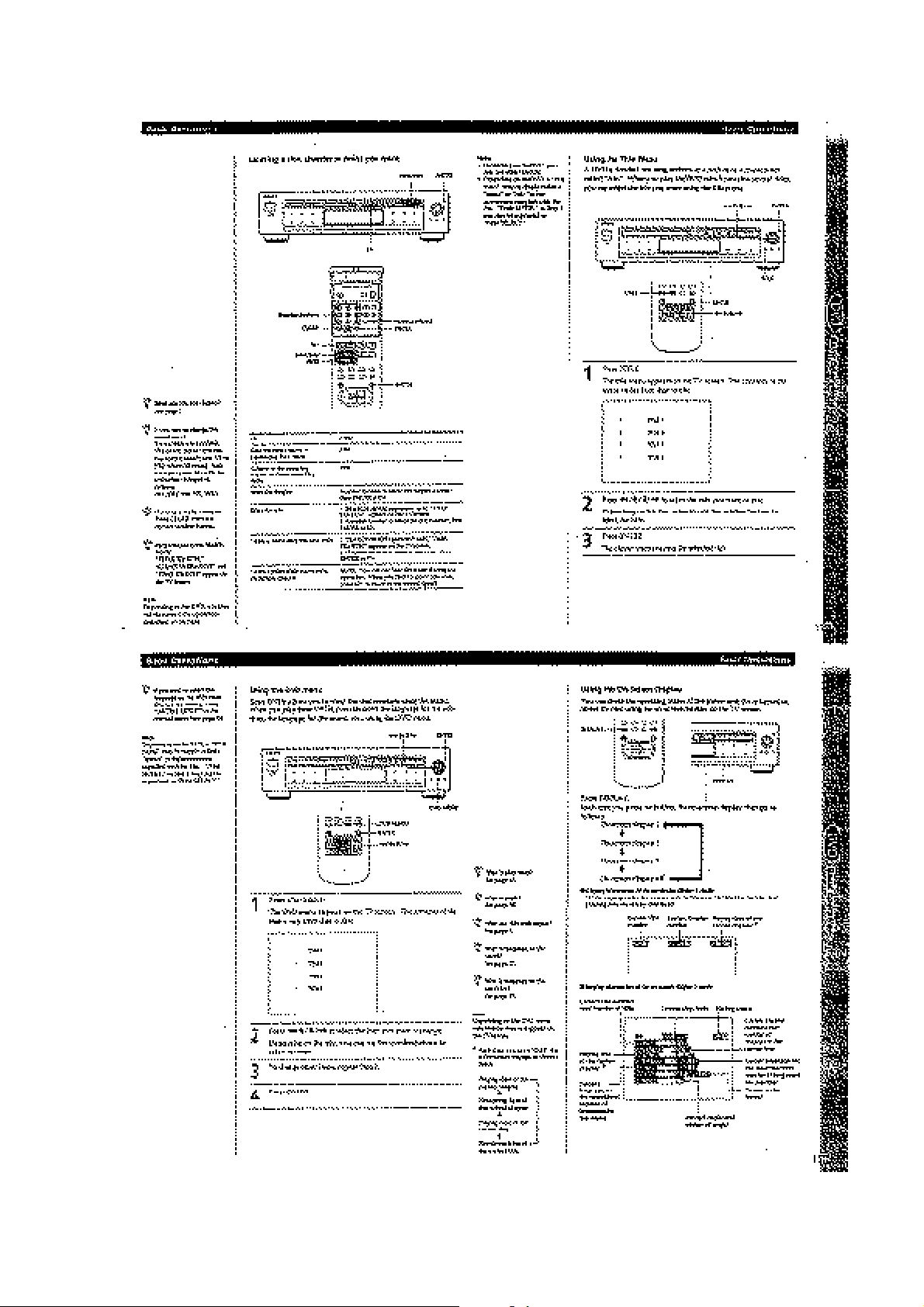

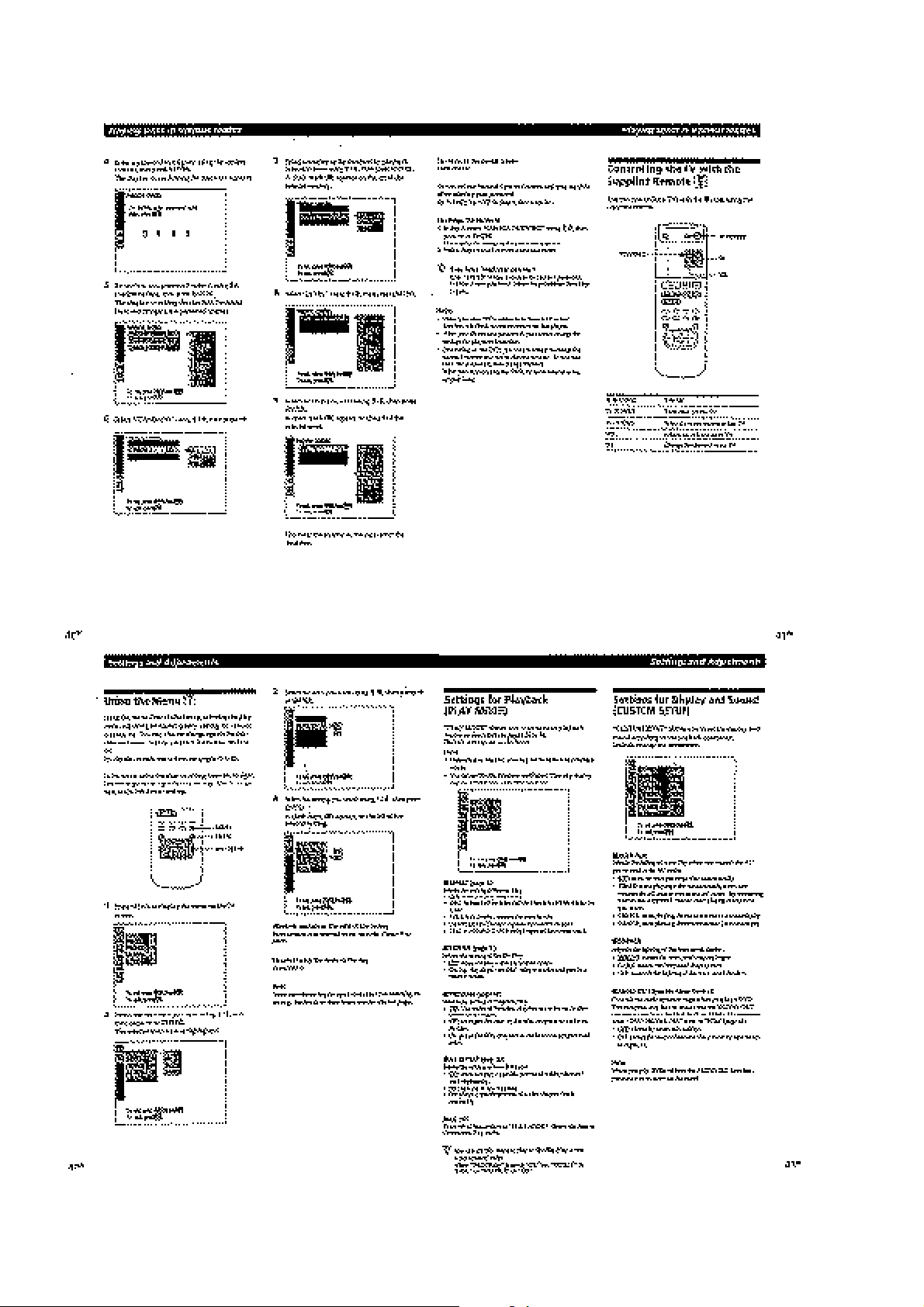

DVP-S3000

SECTION 2

DISASSEMBLY

Note: Follow the disassembly procedure in the numerical order given.

2-1. TOP CASE REMOVAL 2-3. AU-201, 203 BOARD REMOVAL

8 AU-201 board

1 Two tapping screws

2 Three tapping screws

(US, Canadian model)

AU-203 board

(Chinese, Hong Kong, Singapore

model)

2 Connector (CN954)

1 Flexible flat

cable (FAM-5)

(CN381)

7 Screw (BV3 × 10)

6 Two tapping screws

4 Top case

2-2. FRONT PANEL REMOVAL

2 Three bosses

1 Two screws

(BV3 × 10)

3 Two claws

3 Two tapping screws

3 Connector

(CN011)

5 Connector

(CN382)

2-4. MB-80 BOARD REMOVAL

1 Three flexible flat

cables (FTM-3)

(CN885/886/980)

4 Screw

(BV3 × 10)

2 Connector

(CN001)

5 Two screws

4 Flexible flat

cable (FAM-6)

(CN005)

(BV3 × 10)

7 MB-80 board

5 claw

6 Front panel

4 Two claws

7 Flexible flat

cable (FTT-4)

(CN101)

6 Three screws

(BV3 × 10)

3 Flexible flat

cable (FTT-4)

(CN009)

2-1

Page 23

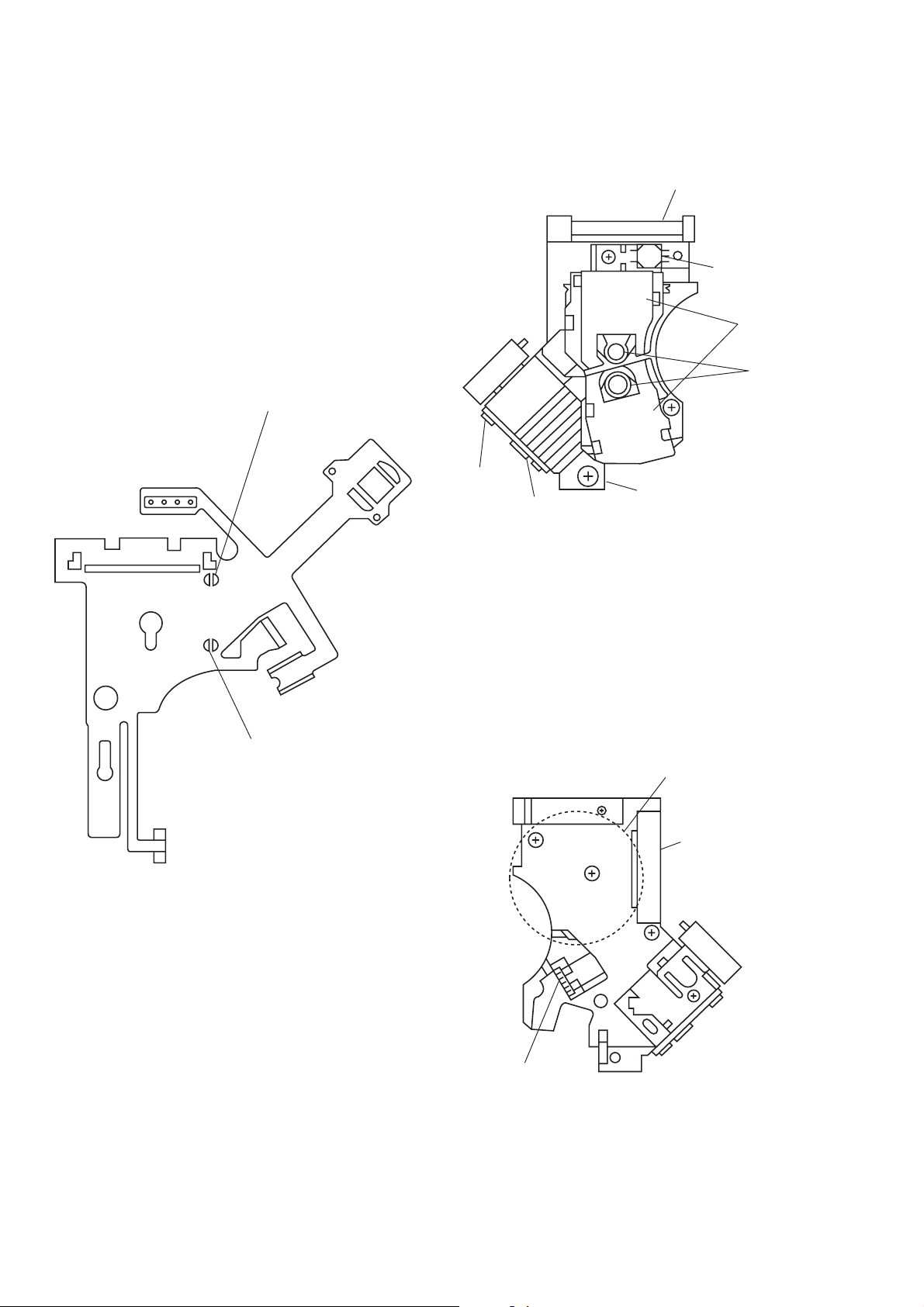

2-5. MD BLOCK ASS’Y REMOVAL 2-7. OPTICAL PICK-UP REMOVAL

2 Three screws

(BV3 × 10)

3 MD block ass’y

1 Three flexible flat

cables (FTM-3)

(CN005/006/007)

3 Main shaft

2 screw (PTTWH2 × 5)

4 Optical pick-up

1 OP-15 flexible board

(CN001)

2-6. TRAY REMOVAL

3 MD upper cover

4 Two screws

(BV3 × 10)

5 Press pully bracket

7 Pull the tray to direction

of the arrow B.

9 Remove

the tray

B

8 claw

1 Two screws (BV3 × 10)

2 claw

A

6 Rotate the cam gear to

direction of the arrow A .

2-8. TT-40 BOARD REMOVAL

2 Flat cable

(spindle motor)

(CN002)

1 Connector

(CN004)

5 Four screws

(BV3 × 10)

7 TT-40 board

3 LT-31 flexible

board

(CN003)

4 OP-15 flexible

board

(CN001)

6 Two claws

2-2

Page 24

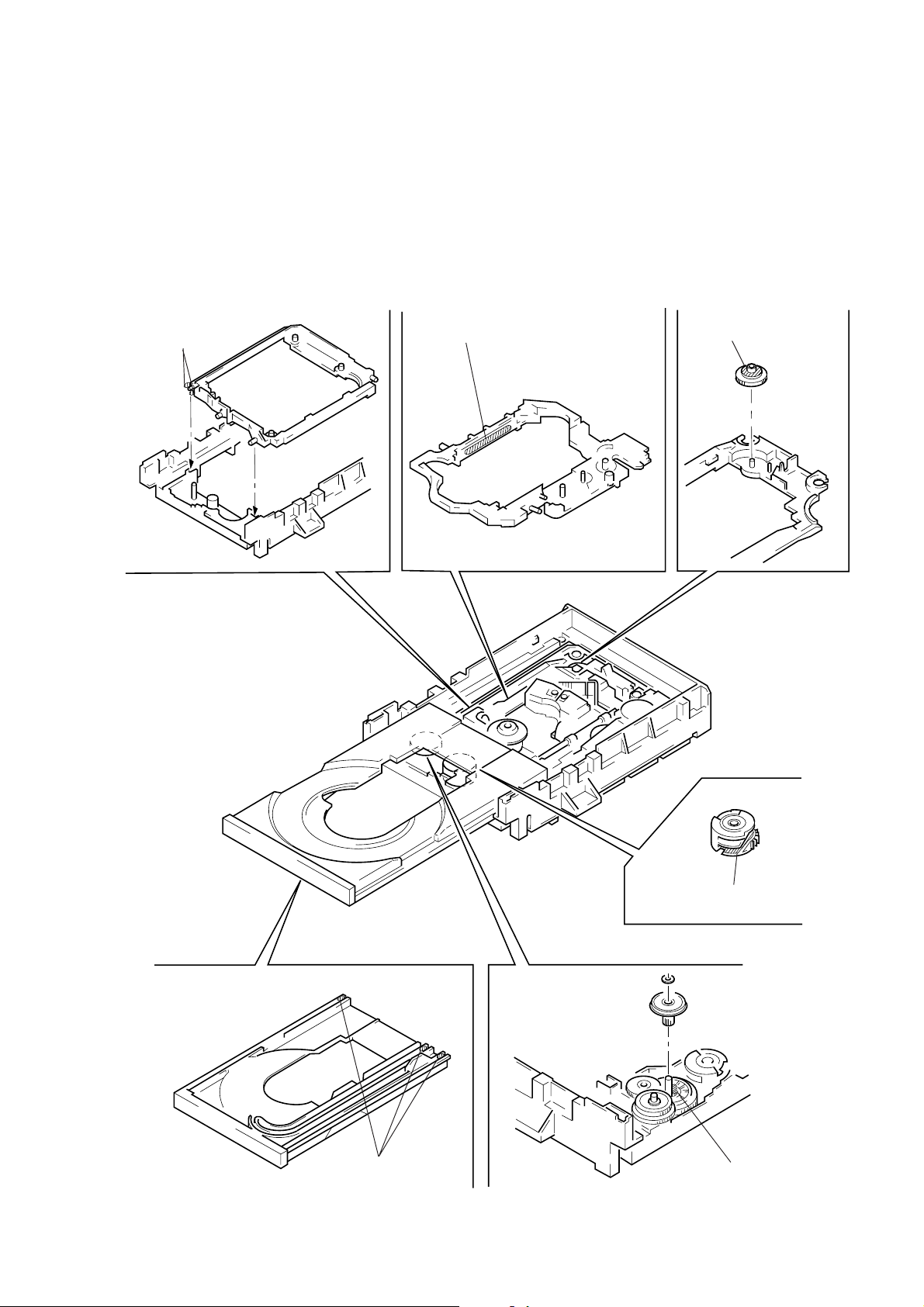

2-9. INTERNAL VIEWS

Optical pick-up (KHS-180A/J1N)

8-820-005-02

Skew motor ass’y

X-3947-138-1

Sled motor ass’y

X-3947-137-1

Sled motor ass’y

X-3947-137-1

Optical pick-up (KHS-180A/J1N)

8-820-005-02

DC motor (spindle)

1-698-944-11

KU160 (CD sensor)

8-749-013-33

DC motor (spindle)

1-698-944-11

Motor (loading)

1-698-942-21

2-3

Page 25

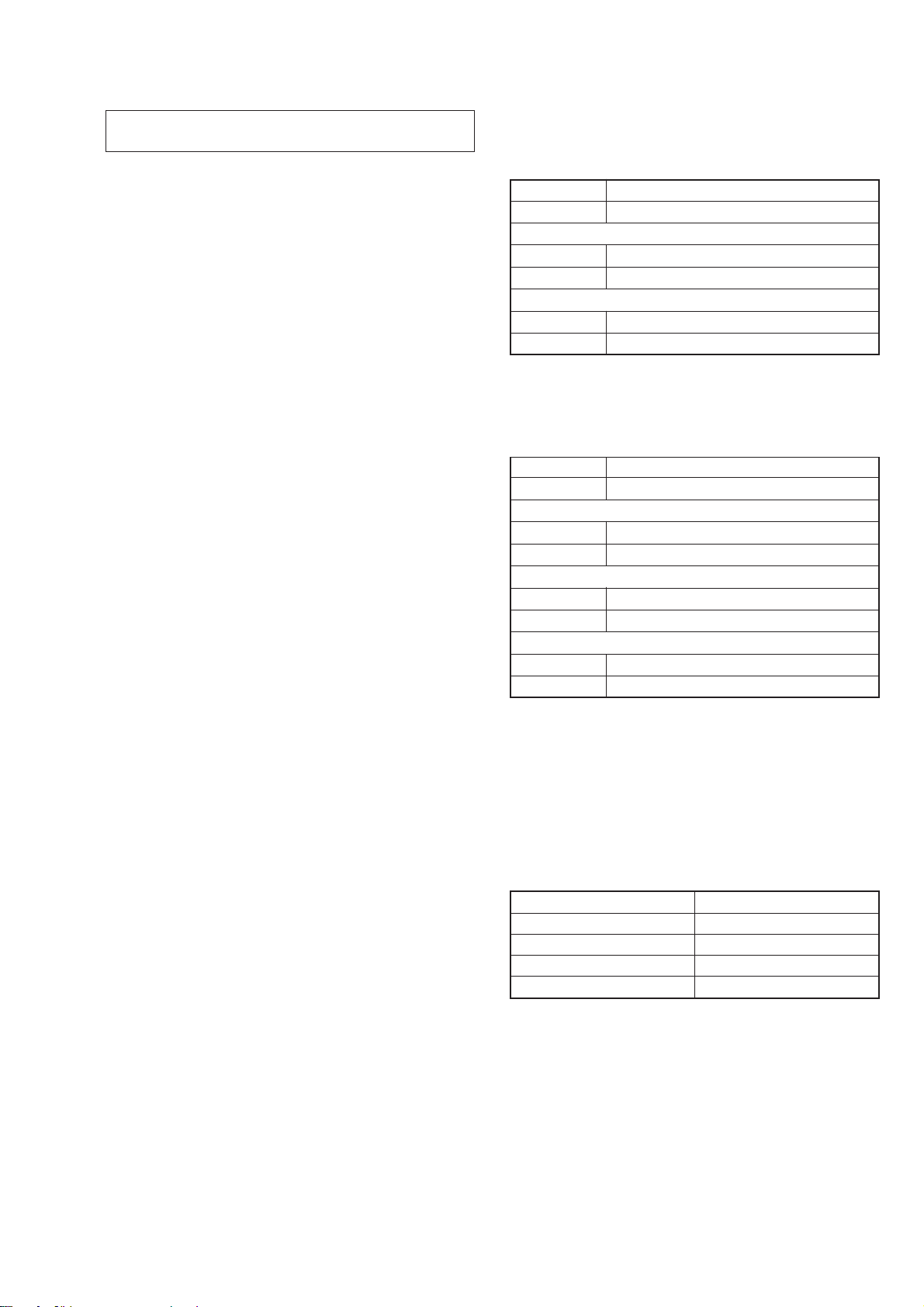

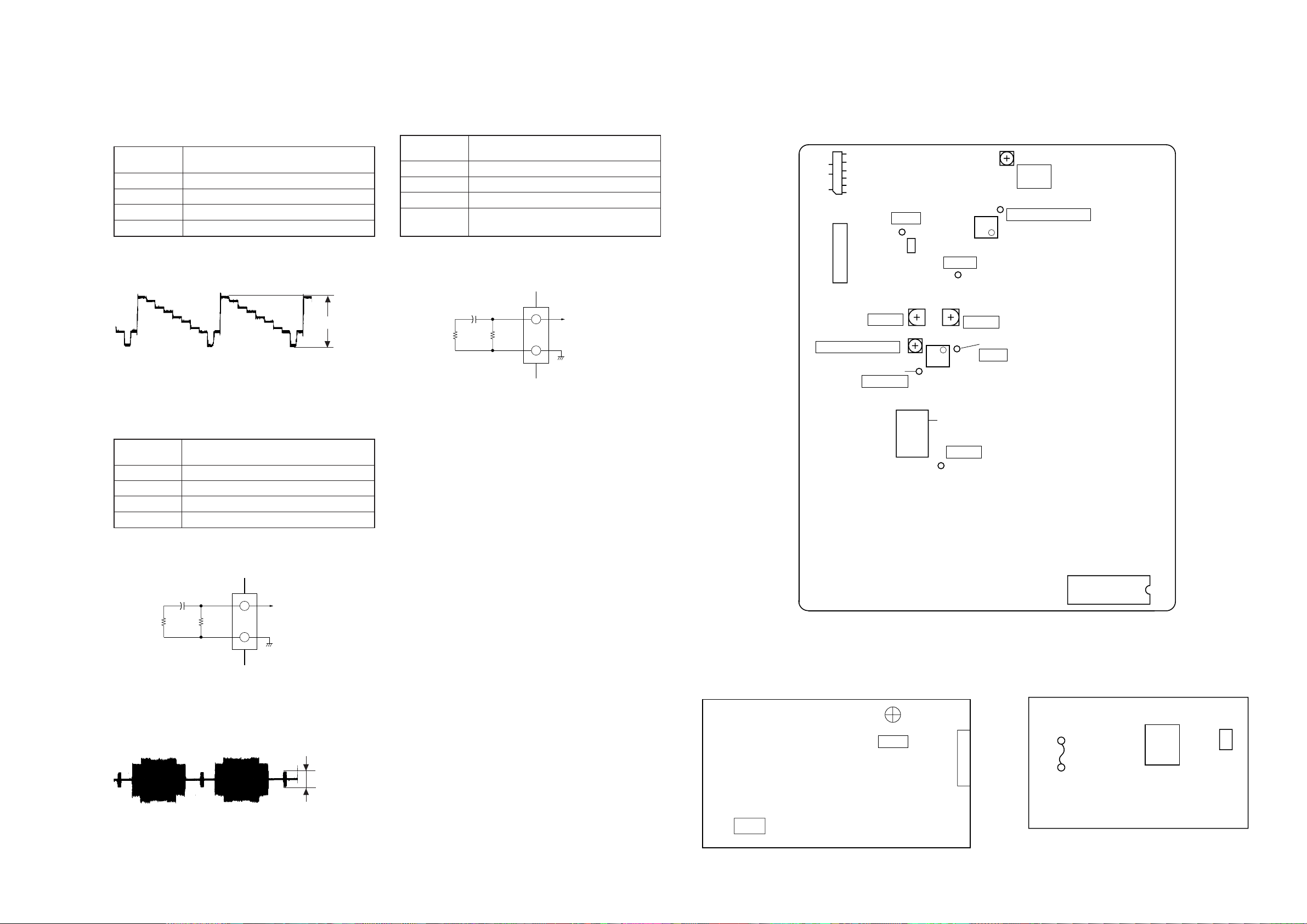

2-10. CIRCUIT BOARD LOCATION

SR-740

(US, Canadian model)

SR-745

(Chinese, Hong Kong, Singapore model)

SWITCHING

REGULATOR

TT-40

(RF/SERVO)

PW-116

(US, Canadian model)

PW-117

(Chinese, Hong Kong, Singapore model)

(IR/POWER SWITCH)

LM-56

(SLED)

PS-408

(US, Canadian model)

PS-413

(Chinese, Hong Kong, Singapore model)

(POWER)

AU-201

(US, Canadian model)

AU-203

(Chinese, Hong Kong, Singapore model)

(AUDIO)

DC MOTOR

(SPINDLE)

FP-611

(US, Canadian model)

FP-619

(Chinese, Hong Kong, Singapore model)

(FL DRIVER/FUNCTION SWITCH)

MB-80

(SIGNAL PROCESS/SERVO)

2-4

2-4 E

Page 26

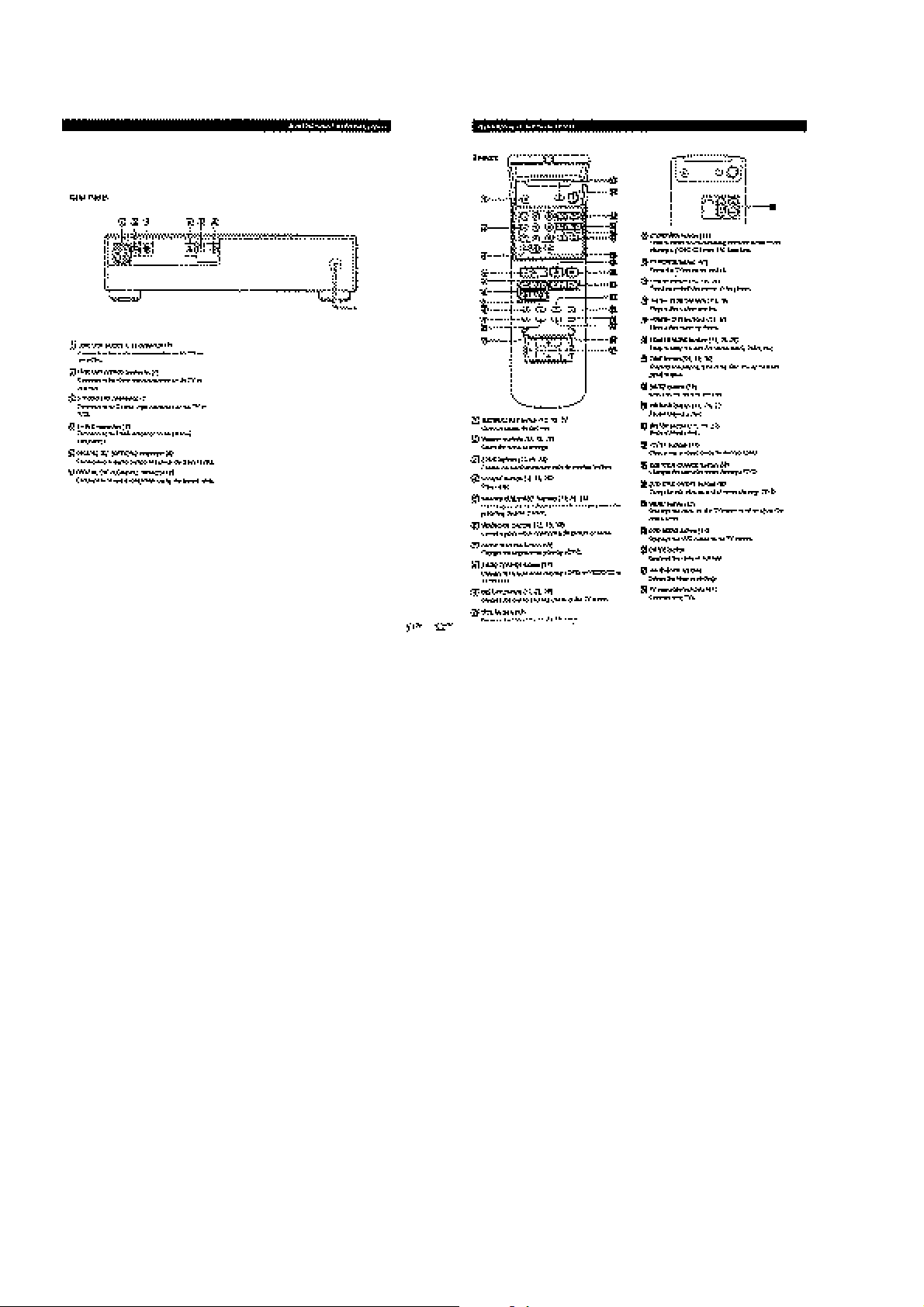

5-1

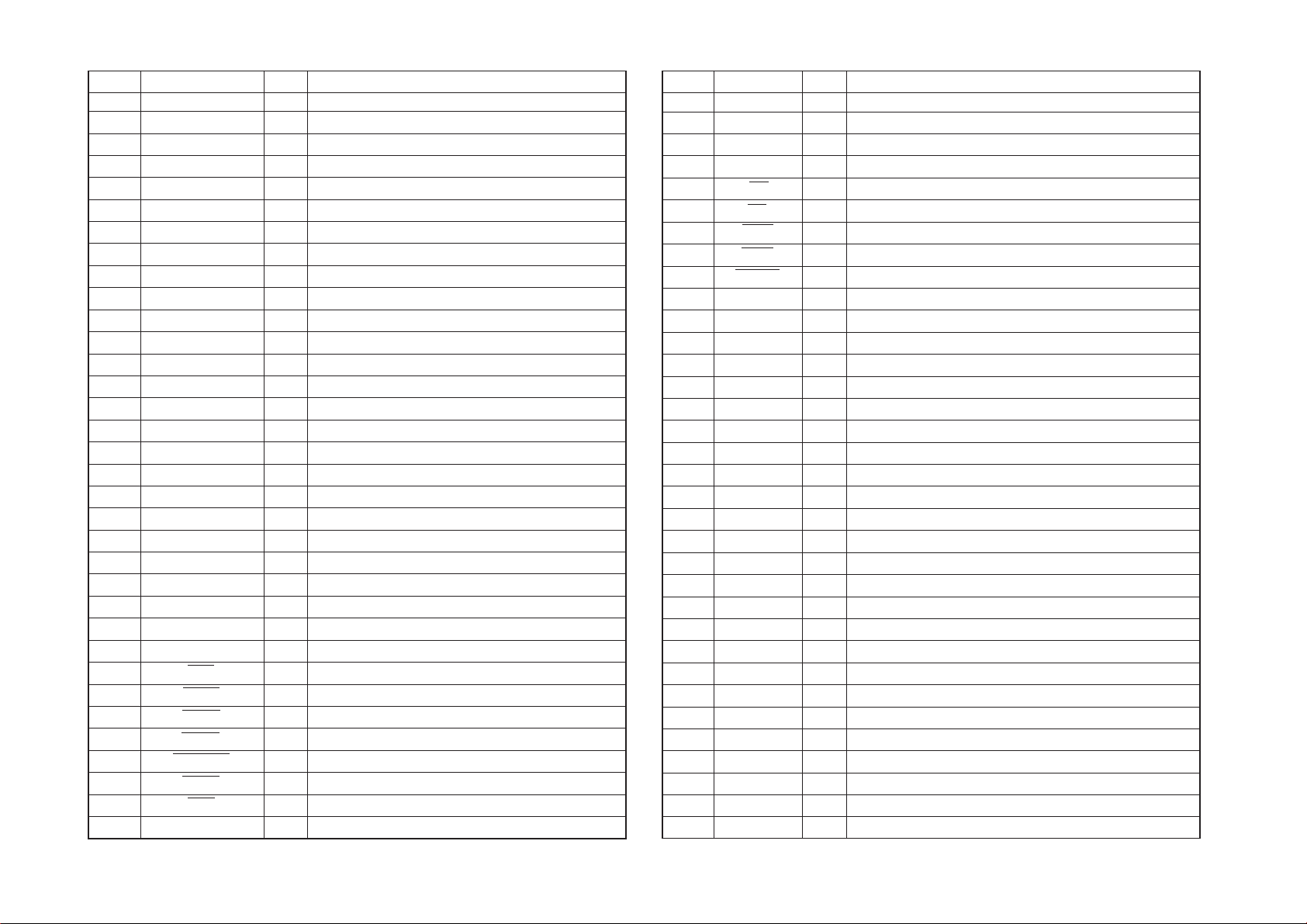

5-1. INTERFACE CONTROL PIN FUNCTION (IC021 on MB-80 Board (1/12))

Pin No. Pin Name I/O Function Pin No. Pin Name I/O Function

1,2 CL1, 0 I Input of sub clock (32kHz)

3,4 GND – Ground

5,6 X0–1 I Input of main clock (8MHz)

7 GND – Ground

8 RST I Input of RESET signal

9 RESET O SRESET (SYSCON)

10 INTMS O XINTM S (SYSCON)

11 AUDIO MUTE O SAUDIO MUTE (L)

12 IFDIAG I DIAG (H)

13 NITSC O NTSC (H) /PAL (L)

14,15 N.C. – Not used

16 FLCS O XFLCS (FL)

17 REF V I XREF-V (VSYNC)

18 INTSM I XINTSM (SYSCON)

19-24 N.C. – Not used

25 POWER CONT O POWER-CONT (H)

26 DA TA BOUND O DATA-BOUND

27 N.C. – Not used

28 CMOD I CMOD

29 P.FAIL O Power fail

30 CGSO O CGSO (FL & OSDC)

31 CGCLK O CGCLK (FL & OSDC)

32 WSIRCS I WSIRCS

33 CGCS O CGCS (OSDC)

34 V MUTE O Video mute

35 STATUS O STATUS (H)

36 N.C. – TSEL (OSDC) Not used

37 STATUS O FSEL (OSDC)

38 N.C. – TRE (OSDC) Not used

39-48 N.C. – Not used

49 VCC – Power supply

50-57 N.C. – Not used

58 GND – Ground

59-66 N.C. – Not used

67 VCC – Power supply

68-75 N.C. – Not used

76 CS I CS (SYSCON)

77 SI I SI (SYSCON)

78 SO O SO (SYSCON)

79 CLK I CLK (SYSCON)

80-82 N.C. – Not used

83 GND – Ground

84-87 AD0–3 I Analog input

88 TEST 1 I Input of TEST 1 signal

89 TEST 2 I Input of TEST 2 signal

90 N.C. – Not used

91 N.C. – Not used

92 VCC – Power supply

93 POWER-FAIL I Input of POWER-FAIL (AD INPUT)

94 N.C. – Not used

95 CGRA 16 I CGRA16 Character generator font ROM address 16

96 CGRA 17 I CGRA17 Character generator font ROM address 17

97 CGRA 18 I CGRA18 Character generator font ROM address 18

98 N.C. – Not used

99 N.C. – Not used

100 VCC – Power supply

5. IC PIN FUNCTION DESCRIPTION

DVP-S3000

Page 27

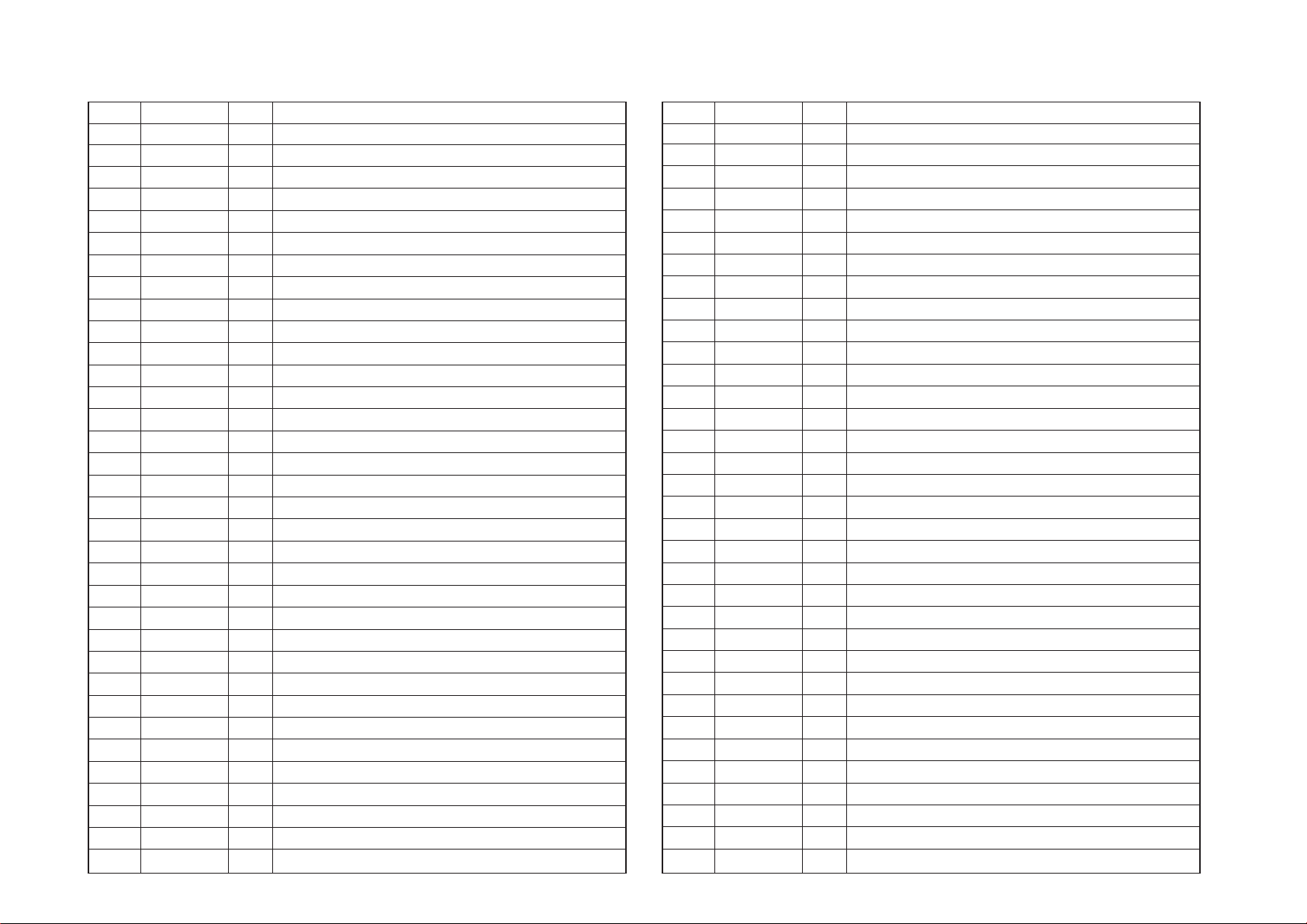

5-2

5-2. DRIVE CONTROL PIN FUNCTION (IC136 on MB-80 Board (3/12))

Pin No. Pin Name I/O Function Pin No. Pin Name I/O Function

1 VCC – Power supply

2 MRST O Peripheral circuits reset signal (L: Reset)

3 12 RST O 12V system power control signal

4 CD DET I Input of DVD/CD discriminate sensor

5 TRAY OUT I Tray out end (H: End)

6 CHUCK I Chucking down end (H: End)

7 LOCK I Good Frame Sync dat (H: OK, L: NG)

8 XPNM I RF Pro PLL Mode (L: Normal)

9 FOK I Focus OK (H: OK, L: NG)

10 N.C. – Not used

11 VSS – Ground

12 CPDTO O Serial data output to each IC

13 SDCS (SO) O Serial data output to jig

14 CPDTI I Serial data input from each IC

15 SDSC (SI) I Serial data input from jig

16 CPCK O Serial clock to each IC

17 SCKCS O Serial clock to jig

18–21 D0–3 I/O Data bus 0–3

22 VSS – Ground

23–25 D4–6 I/O Data bus 4–6

26–34 D7–15 I/O Data bus 7–15

35 VCC – Power supply

36–43 A0–7 O Address bus 0–7

44 VSS – Ground

45–50 A8–13 O Address bus 8–13

51–56 A14–19 O Address bus 14–19

57 VSS – Ground

58 WAIT I WAIT signal (fixed to “H”)

59 BREQ I Input of bus request

60 BACK O Output of bus ACK

61 SYS CLK O Output of system clock (for check)

62 STBY I Fixed to “H”

63 RES I Input of Reset by SH (L: Reset)

64 NMI I Fixed to “L”

65 VSS – Ground

66 EXTAL I Input of 16.9MHz

67 XTAL I Input of 16.9MHz

68 VCC – Power supply

69 AS O Address strobe

70 RD O Read

71 HWR O H_Write

72 LWR O L_Write

73–75 MD0–2 I Operation mode setting (Mode 2)

76 A VCC – Power supply

77 VREF – Reference voltage

78 N.C. – Not used

79 HYDET1 I Input of sled FG2

80 P FAIL I Power down pre signal

81 PI I Input of pull–in signal

82 SLD2– I Input of sled offset

83 SLD2+ I Input of sled offset

84 VCOM I Input of VCO adjustment

85 JIG BUSY I Serial busy signal from Jig

86 A VSS – Ground

87 SCOR I CXD2545 address storing request signal

88 INT-SC I Serial data

89 SOINT I Jitter storing request signal

90 SYS_INT I Interrupt request signal from Syscon

91 ROM BUSY I EEPROM Ready/Busy signal

92 VSS I Ground

93 TKC I Input of sled FG count

94 FCMPL I FEZC Low det

95 FCMPH O FEZC High det

96 SENS I Input of SENS signal

97 HFG I Input of spindle FG

98 DVDLDON O LD ON/OFF control for DVD

99 CDLCON O LD ON/OFF control for CD

100 LT MUTE O

Page 28

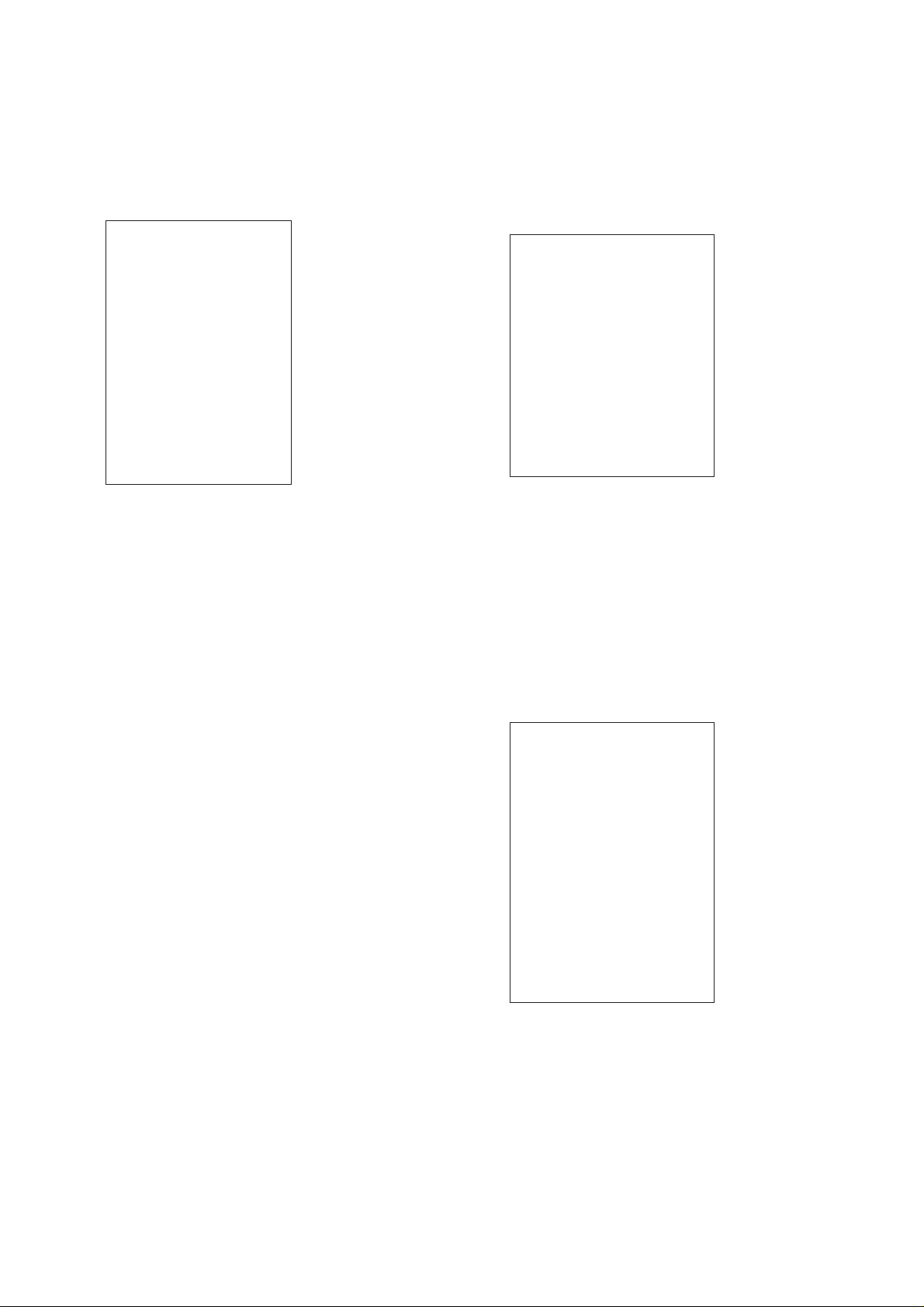

5-3. EXTENDED OUTPUT PORT0 (IC147 on MB-80 Board (3/12))

5-6. EXTENDED OUTPUT PORT3 (IC150 on MB-80 Board (3/12))

5-3

Pin No. Pin Name I/O Function

2 SQCK MSK O SubQ Read Clock Mask

5 ROM CS O Chip Select for EEPROM

6 DA XLD O Load Signal for D/A

9 SUBQ XOE O SubQ Output Enable

12 XLAT O Latch Signal for CXD2545

15 SDEN O Serial Output Enable For SSI3720

16 SLD MODE O Sled Control change

19 INT CS O Serial data forward request

5-4. EXTENDED OUTPUT PORT1 (IC148 on MB-80 Board (3/12))

Pin No. Pin Name I/O Function

2 XLT O Latch Signal for RF Pro

5 SOEN O Serial Output Enable for RF Pro

6 SCK MSK O Serial command transfer clock master

9 SCLK O SENS reading clock

12 FJUMP- O Focus Jump Pulse

15 FJUMP+ O Focus Jump Pulse

16 DRV BUSY O Communication inhibit request from system controller

19 LOCK MON O Spindle LOCK Monitor Out

5-5. EXTENDED OUTPUT PORT2 (IC149 on MB-80 Board (3/12))

Pin No. Pin Name I/O Function

2 DRV INT O Interrupt request to system controller

5 NST O Spindle forced stop (L: Stop) Active only at out of control

6 FHOLD O Focus Hold

9 FDWN O Focus Gain Down (L: Normal)

12 LOAD ON O Loading/Unloading Moter ON/OFF

15 DET ON O CD Det Sensor LED ON/OFF

16 LP ON O VCO Control

19 MUTE O Date output (CXD2545) control

Pin No. Pin Name I/O Function

2 TILT/H O Tilt Filter change

5 SPGC1 O Selection of low band boost (H: 12 cm, L: 8 cm)

6 CD/DVD O DVD/CD (H: DVD, L: CD)

9 Q4 – Not used

12 SPCTL0 O Spindle Control [SPCTL0: SPCTL1]

15 SPCTL1 O

16 CLVH O Spindle CLVH Control

19 Q8 – Not used

[0: 0] = control, [0: 1] = not control, [1: 0] = acceleration,

[1: 1] = deceleration

5-7. D/A CONVERTER (IC722 on MB-75 Board (10/12))

Pin No. Pin Name I/O Function

1 VSS – Ground

2 HYCNTR O Adjustment of hall element output

3 SDCNTR O Target sled speed

4 TI OFFSET O Tilt sensor offset output

5 LOAD/UNLOAD O Loading/Unloading Control

6 TI DRIVE O For tilt forced movement

7 SDINIT O Offset adjusting signal of sled motor drive

8 VDD – Power supply

9 VCC – Power supply

10 A08 – Not used

11 DO O Serial Data Output

12 LD I Serial Data Load

13 CLK I Serial Clock Input

14 DI I Serial Data Input

15 AVCO O For VCO adjustment

16 GND – Ground

Page 29

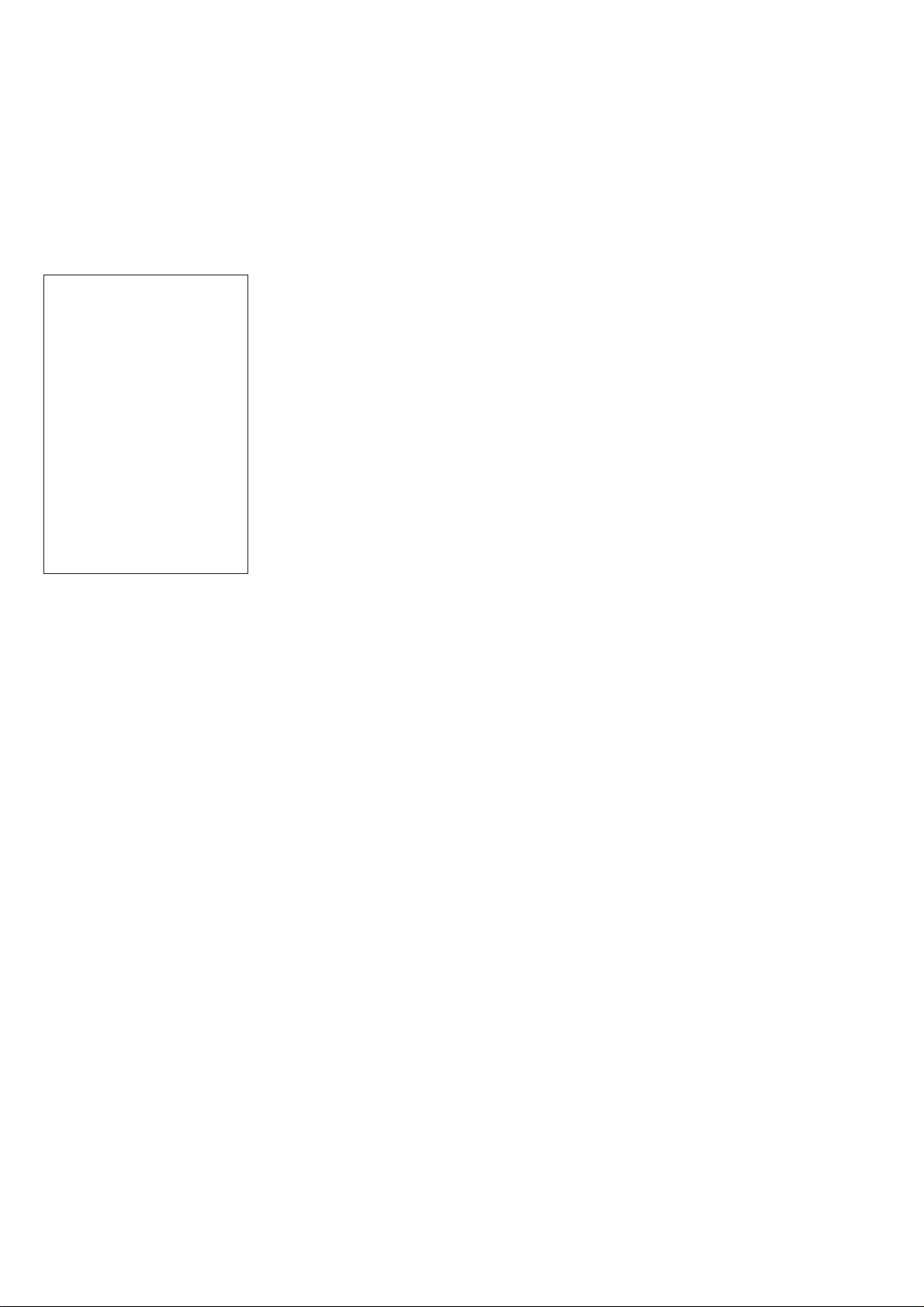

5-4

5-8. SYSTEM CONTROL PIN FUNCTION (IC090 on MB-80 Board (2/12))

Pin No. Pin Name I/O Function Pin No. Pin Name I/O Function

1 IRQ6 I Input of interrupt from CXD1186, CXD8663Q, CXD8669Q

2 IRQ7 I Input of interrupt from CXD1900

3 VSS – Digital ground

4–11 AD0–7 I/O Data bus AD0-AD7

12 VSS – Digital ground

13,14 AD8–9 I/O Data bus AD8, AD9

15 VCC – Digital power supply

16–21 AD10–15 I/O Data bus AD10-AD15

22 VSS – Digital ground

23–30 A0–7 O Address bus A0-A7

31 VSS – Digital ground

32–39 A8–15 O Address bus A8-A15

40 VSS – Digital ground

41,42 A16–17 O Address bus A16, A17

43 VCC – Digital power supply

44–47 A18–21 O Address bus A18-A21

48 CS0 O Chip select signal for external ROM

49 CS1 O Chip select signal for external RAM

50 CS2 – Not used

51 CS3 O Chip select signal for RAM common to drive controller

52 VSS – Digital ground

53 PA0 O Not used

54 PA1 O Output of squeeze mode

55 CS6 O Output of chip select signal to external device

56 WAIT I Input of wait signal

57 WR O Output of write signal

58 PA5 O Output of IF controller serial data control

59 RD O Output of read signal

60 PA7 O Not used

61 VSS – Digital ground

62 PA8 O Output of serial select signal to L chip

63 PA9 O Output of serial select signal to CXD1914

64 PA10 O Output of serial select signal to audio DAC

65 PA11 O Output of error free signal

66 IRQ0 I Input of interrupt signal from SP, BFD, drive controller

67 DREQ0 I Input of DMA request from CK

68 IRQ2 I Input of VSYNC (FID) interrupt signal

69 IRQ3 I Input of interrupt signal from CK, DSP5600

70 VCC – Digital power supply

71 CK O Output of internal clock

72 VSS – Digital ground

73 EXTAL – 20MHz crystal connection pin

74 XTAL – 20MHz crystal connection pin

75 VCC – Digital power supply

76 NMI – Not used

77 VCC – Digital power supply

78 WDTOVF – Not used

79 RES I Input of reset signal

80 MD0 I Input of mode select 0 (fixed to “1”)

81 MD1 I Input of mode select 1 (fixed to “0”)

82 MD2 I Input of mode select 2 (fixed to “0”)

83,84 VCC – Digital power supply

85 AVCC – Analog power supply

86 AVREF – Reference power supply

87 PC0 I Input of DIAG mode select signal

88 PC1 I Input of EMPH signal from CXD2545

89 PC2 I Input of request from drive controller

90 PC3 I Input of request from DSP56000

91 AVSS – Analog ground

92 PC4 I Input of FID signal from CXD1914

93 PC5 I Input of request from I/F controller

94 PC6 I Input of control 1

95 PC7 I Input of control 2

96 VSS – Digital ground

97 PB0 O Output of request to I/F controller

98 PB1 O Output of request to drive controller

99 VCC – Digital power supply

100 PB2 O Output of clock system switching (DVD/CD)

Page 30

5-5

5-5 E

Pin No. Pin Name I/O Function

101 PB3 O Output of reset signal to audio DAC

102 PB4 O Output of reset signal to peripheral device

103 PB5 O Output of serial select signal to DSP56000

104 PB6 O Output of HREQ signal latch reset to DSP56000

105 PB7 O Output of serial select signal to video equalizer

106 VSS – Digital ground

107 RxD0 I Input of serial data from other than CXD1914

108 TxDO1 O Output of serial data to other than CXD1914

109 RxD1 I Input of serial data from CXD1914

110 TxD1 O Output of serial data to CXD1914

111 SCK0 O Output of serial clock to other than CXD1914

112 SCK1 O Output of serial clock to CXD1914

Page 31

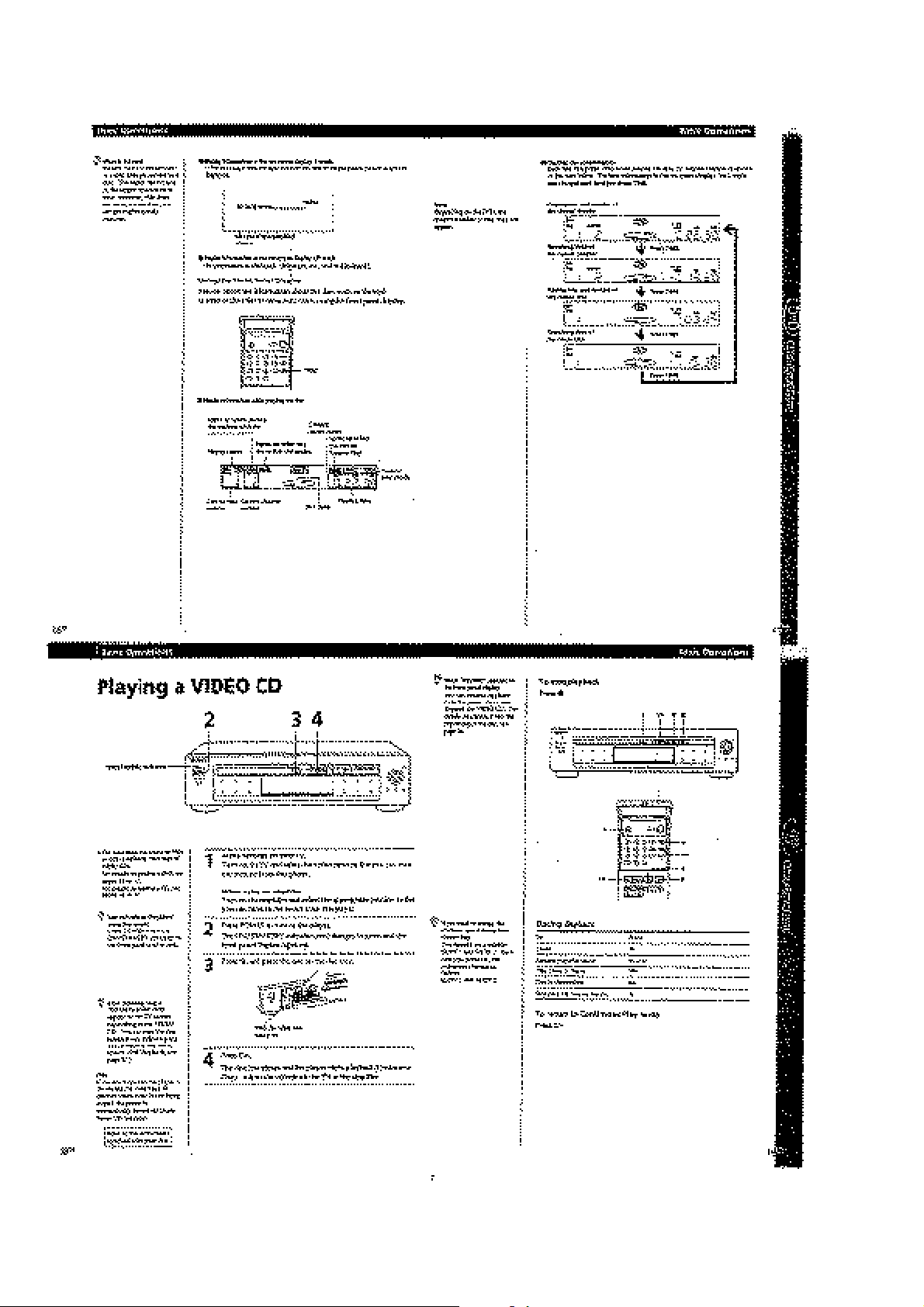

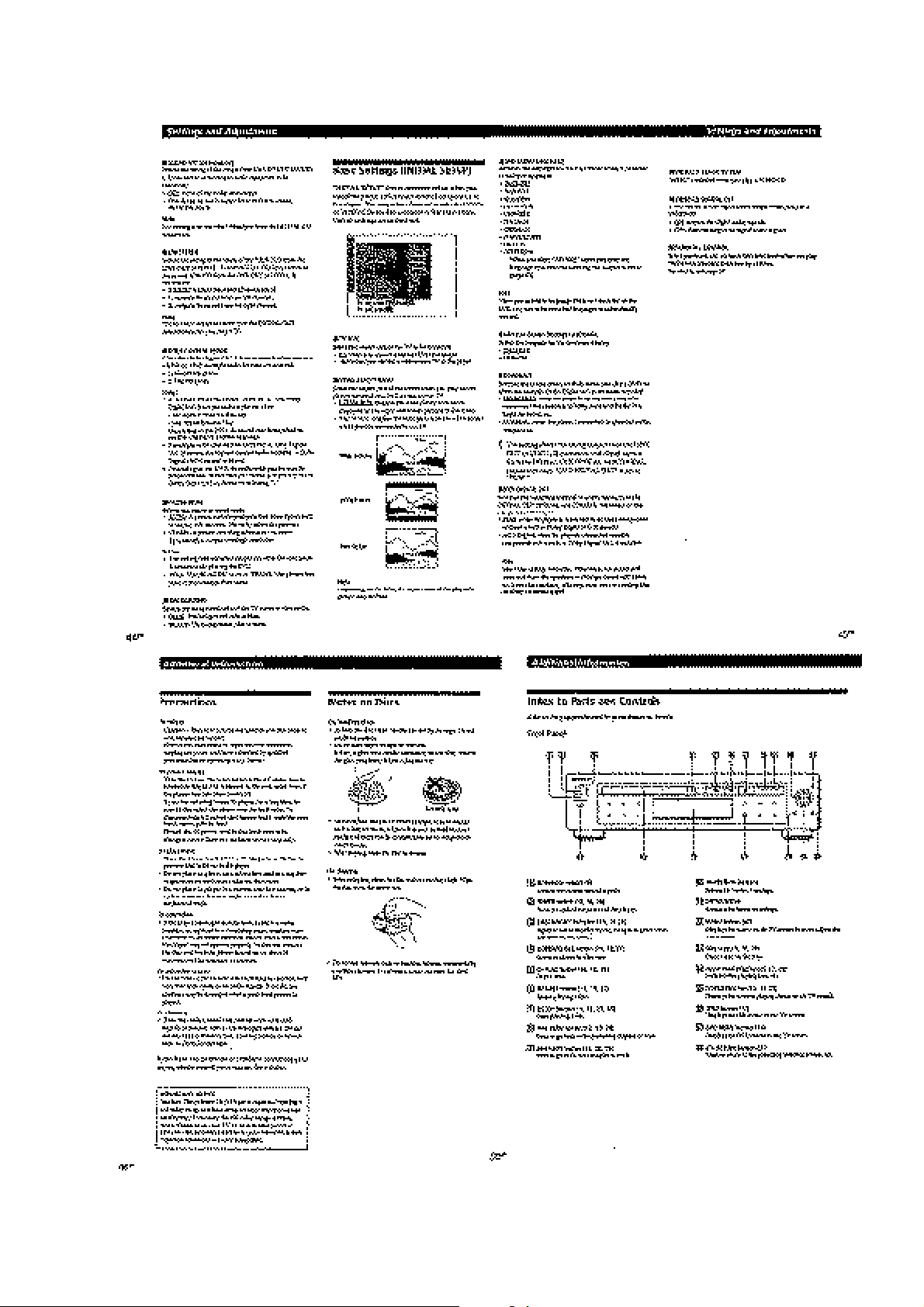

SECTION 6

TEST MODE

DVP-S3000

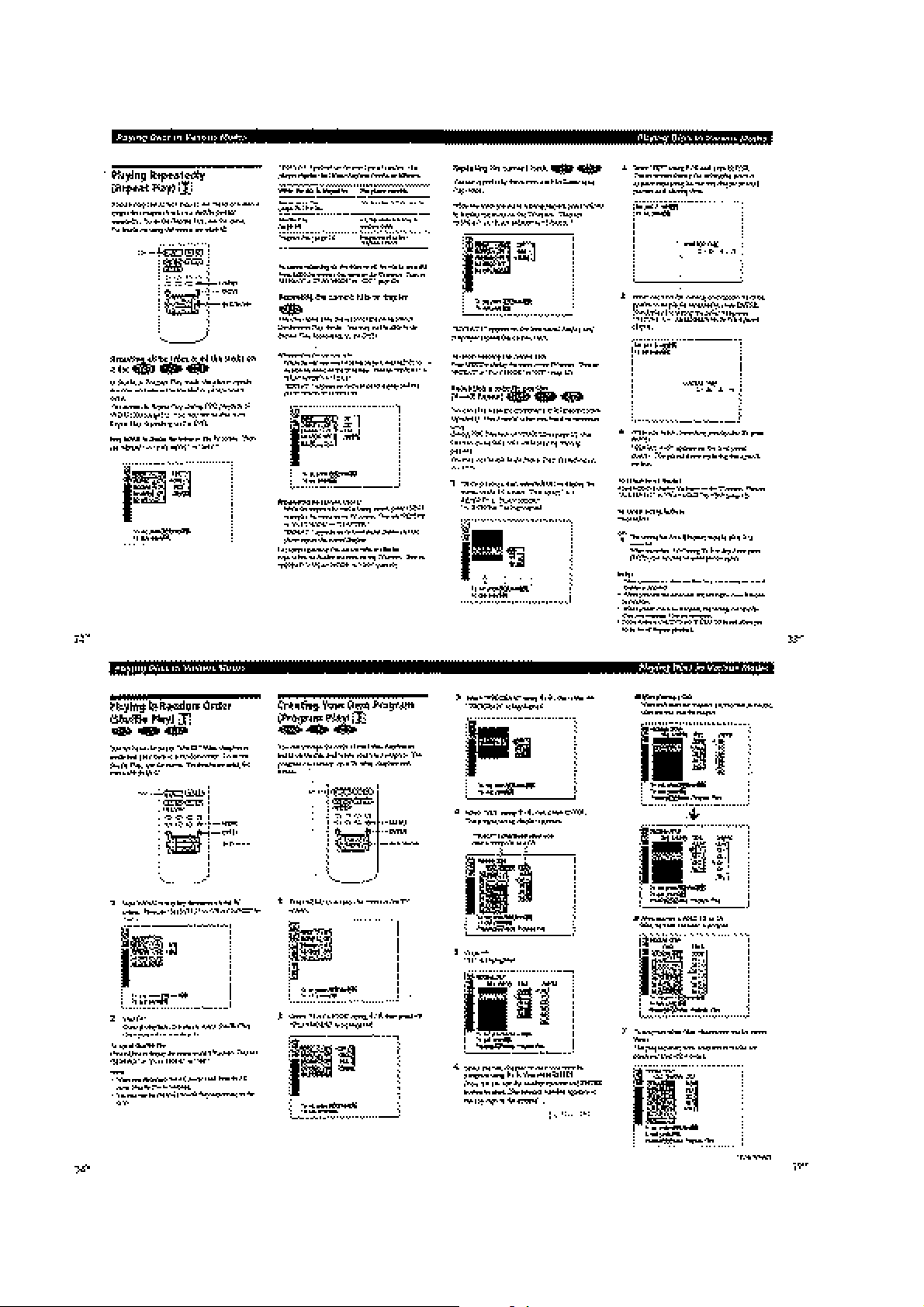

6-1. Starting up Test Mode

With the DVP-S3000 in standby status, press [TIME], [CLEAR],

and [POWER] keys on the standard commander in this order. And,

the Test mode starts up and the initial menu shown in Figure 1 appears on the video display.

Test Mode Menu

0. Syscon Diagnosis

1. Drive Auto Adjustment

2. Drive Manual Operation

3. Emergency History

4.OtherChecks

Exit: POWER Key

Figure 1 Initial menu

In the Test mode, necessary operations are all done with the keys

on standard commander or operation panel.

The test mode can be finished and the set returns to the power off

status when the [POWER] key is pressed whichever mode, except

during checking of Syscon Diagnosis, you are working in now.

6-2. Syscon Diagnosis

In the Syscon Diagnosis, intermittent blocks such as 0-ff, 500-5ff,

a00-aff, f00-fff, 1400-14ff, etc. (address) are checked. All of the

operation are done with standard commander keys, and a menu cannot be selected but all items are checked. After result display, you

can only select either “continue to next item” or “cancel”, and continue and retry in case of written data error are not available.

If [0] key on standard commander is pressed during initial menu

display, the Diagnosis screen as sho wn in Figure 2 is displayed, and

a checking starts from the top of diagnosis check items list sequentially. After a checking started, standard commander keys are accepted while a message or title is blinking, so that you can go to the

next job.

Syscon Diagnosis

IF con Ver.x.xx (xxxx)

SYScon Ver.x.xx (0000)

DRVcon Ver.0.00 (0000)

ROM Check

SIRCS:ff KEY:ff RATE: 29

Figure 2

In this mode, ROM revision number (Ver. No.) of each control IC

(MPU) and its checksum are displayed. However , Syscon checksum

and Drvcon value are obtained in the process of diagnosis check,

and therefore they are initially 0.

On the fifth line, an item is displayed, and IF control information is

displayed at the bottom though it is not related to a checking of

each item.

If Syscon Diagnosis is selected, a checking starts immediately, and

the result of initial ROM check and Syscon ROM checksum are

displayed as shown in Figure 3.

Syscon Diagnosis

IF con Ver.x.xx (xxxx)

SYScon Ver.x.xx (xxxx)

DRVcon Ver.0.00 (0000)

N Data in ( ) indicates

Syscon checksum

ROM Check

★★ Press Remocon Key★★

SIRCS:ff KEY:ff RATE: 29

Figure 3

6-1

Page 32

Confirm the result, and to cancel checking, press [RETURN],

[MENU], or [POWER]. Or, to continue next checking, press other

than these keys.

The ROM revision and checksum of Drvcon are displayed when

executing “DrvCon Data Exchange” and “DrvCon EPROM” respectively.

Also, in case of an error, the error code and information are displayed as shown in Figure 4.

Syscon Diagnosis

IF con Ver.x.xx (xxxx)

SYScon Ver.x.xx (xxxx)

DRVcon Ver.x.xx (xxxx)

CXD 1900BQ DRAM

Error Code: 05

Address: 000abcde

Write Data: fb

Read Data: ff

SIRCS:ff KEY:ff RATE: 29

Figure 4

N Name of item checked

N Error code

N Error address

N Written data (2/4 digits)

N Read data (2/4 digits)

(2-3) Syscon RAM (IC094) check

IC093 (Syscon ROM) n IC094 (Syscon RAM) collating check

Checking range: 0x01000000 - 0x0101ffff

IC093 (Syscon ROM) data (program codes) are transferred in DMA

mode in the unit of 64 bytes to the IC094 (Syscon RAM), then they

are read every 1 byte and compared with data in IC093. As the

Syscon RAM check is made by saving the data into internal RAM

(DMA transfer), the data are written and read every 64 bytes, and

interruption during that time is completely masked.

If compared data are not same, a checking is suspended, and error

code 05, its address, written data, and read data are displayed. Select the subsequent processing by pressing a key. As this check is

made through DMA transfer, if Repeat is selected, the data are transferred in DMA mode again to the block where this error occurred

and a checking is continued from the error address.

(3) Clock

(3-2) Audio clock system output switching (CD side)

I/O output

The audio clock system is switched to the CD side. In this check,

the Syscon itself does not detect an error. Observe output signals

with an instrument.

(3-3) Audio clock system output switching (DVD side)

Except error code “05” (write/read data mismatch error), the address and data fields show “0”. When a checking is over or cancelled, “Diag OK” or “Diag Error End” message blinks. If a key is

pressed here, the test mode initial menu is resumed. The “Diag

Error End” is displayed only when the Syscon detects an error, and

visual inspection result is out of the display.

6-2-1. General description of checking method

This section describes briefly a checking method for each item in

the order of menus.

Numbers in ( ) for respective items are diagnosis item numbers.

(2) Memory

(2-2) Syscon ROM (IC093) check

Calculation of checksum

Calculation range: 0x00000000 - 0x000fffff (at commercial products, 8Mbit ROM)

All 8bit data from address 0 to ROM size are added (checksum),

and output as 4-digit hexadecimal number.

In this check, the IC090 (Syscon) itself does not detect an error.

The result is displayed on the screen. Compare it with original ROM

checksum.

I/O output

The audio clock system is switched to the DVD side. In this check,

the Syscon itself does not detect an error. Observe output signals

with an instrument.

(4) Drvcon

(4-2) Drvcon (IC136) reset check

Hard Reset n DR V B USY response input

The Hard Reset signal is output, and after cancelling the reset,

whether DRV BUSY signal changes from “low” to “high” is

checked. The detection timing of DRV BUSY “low” is about 250

msec after the reset is cancelled. Also, whether the signal becomes

“high” later is checked.

After confirming “high” or “low” of DRV BUSY signal 250 msec

after reset was cancelled, if the signal does not go “high” though

about 300 msec elapsed, the reset error 02 is output.

6-2

Page 33

(4-3) Drvcon common RAM (IC138) check

(4-6) Drvcon SRAM check

IC093 (Syscon ROM) n IC138 (common RAM) collating check

Checking range: 0x03000001 - 0x03000fff

After confirming that the RAM areas common to Drvcon are not

occupied by Drvcon (namely, the contents of common RAM addresses are true), the IC093 (Syscon RAM) codes are copied to the

IC138 (common RAM) areas from address 1, then the data are read

for checking. If all are same, the IC093 code bits are inverted and

checked again. If compared data are not same, a checking is suspended, and error code 05, its address, written data, and read data

are displayed.

After checking, reset the Drvcon because irregular values are written to the IC138.

If common RAM areas are occupied by Drvcon and they are not

opened even after about 2 seconds, the write error 03 is output.

(4-4) Drvcon data exchange check

IC090 (Syscon) n IC136 (Drvcon), IC136 (Drvcon) n IC090

(Syscon) command path check

The path check command is sent from IC090 (Syscon) to IC136

(Drvcon), and as a result, whether the data same as sent data is

returned to the IC138 (common RAM) is checked. In the Syscon

Diagnosis, only the ROM revision is displayed. If no response is

returned from Drvcon or the data are not same, the error code 73 is

output.

(4-5) Drvcon interrupt line check

IC136 (Drvcon) n IC090 (Syscon), IC090 (Syscon) n IC136

(Drvcon) interrupt line check

If CXD8663Q check command is sent from IC090 to IC136, the

IC136 returns IC181 (CXD8663Q) register read/write command.

Receiving this command, the IC090 outputs a response signal implying that the interrupt signal was received, then the IC136 confirms this signal input and writes the Command Done to the IC138

(common RAM).

When the Command Done is not returned even after 1 second, the

error code 70 (DRV INT is not detected) is output if the interrupt

signal has not been received, or the error code 71 (Drvcon does not

recognize SYS INT) is output if the interrupt signal has been received.

Also, upon detection of an error in IC181 (CXD8663Q) by this

command, the error code 30 is output.

If DRV INT signal is kept “low”, the Syscon repeats an interrupt

processing continuously, thus making error displa y impossible. For

this reason, only for this command, the Drvcon returns the DRV

INT signal to “high” even if SYS INT is not detected. (The Syscon

makes judgment whether Command Done is returned or not.)

Here, if the Syscon makes no response, the DRV INT signal itself

will be faulty.

IC090 (Syscon) n IC136 (Drvcon) check request command

The SRAM check command is sent from IC090 to IC136, and its

response result is displayed.

In case of an error, the error information of Drvcon is read, then the

error code 05, error address, written data, and read data are displayed.

(4-7) EEPROM check

IC090 (Syscon) n IC136 (Drvcon) check request command

The EEPROM check command is sent from IC090 to IC136, and

its response result is displayed.

The error code 74 when IC139 (EEPROM) write signal is not ready ,

or error code 05 when written data and read data are not same, error

address, written data, and read data are displayed.

(4-8) RF Processor check

IC090 (Syscon) n IC136 (Drvcon) check request command

The RF processor check command is sent from IC090 to IC136,

and its response result is displayed.

In case of an error in IC770 (RF processor), the error code 76 is

output.

(4-9) CXD2545 RAM check

The CXD2545 check command is sent from IC090 to IC136, and

its response result is displayed.

In case of an error in IC717 (CXD2545), the error code 75 is output.

(4-10) Drvcon ROM check

IC090 n IC136 check request command

The EPROM check command is sent from IC090 to IC136.

The Drvcon calculates checksum of IC140 (EPROM), and returns

its result and the checksum value is displayed, if there is no error.

Compare the result displayed on the screen with the checksum of

original EPROM.

(4-11) VCO offset automatic adjustment

IC090 n IC136 check request command

The VCO offset automatic adjust command is sent from IC090 to

IC136.

If automatic adjustment failed, the error code 77 is output.

(5) Data supply system

(5-2) IC217 (CXD8598R) reset check

Write to register n Hard reset n Read from register

Registers to be checked: TSC2 (0x06200011)

TSC1 (0x06200012)

TSC0 (0x06200013)

Data other than 0 are written to readable and writable registers in

IC217 (CXD8598R), and they are read after hard reset, then the

error code 02 is output if they are not cleared to 0.

6-3

Page 34

(5-3) IC217 (CXD8598R) register check

Register write n Register read collating check

As SERR signal from IC181 (CXD8663Q) to IC217 (CXD8598R)

is not initialized, this signal line is shut off and fixed to “high” before checking.

Registers to be checked: TSC2 (0x06200011)

TSC1 (0x06200012)

TSC0 (0x06200013)

Incrementing 1 each starting from 0, data are written to readable

and writable registers, then they are read for checking. Incrementing

initial value by 1 each, a check is repeated 256 times.

If compared data are not same, a checking is suspended, and error

code 05, its address, written data, and read data are displayed.

(5-4) IC181 (CXD8663Q) reset check

Write to register n Hard reset n Read from register

Register to be checked: INTRMASK (0x22)

Data other than 0 are written to readable and writable register in

IC181 (CXD8663Q), and they are read after hard reset, then the

error code 02 is output if they are not cleared to 0.

(5-5) IC181 (CXD863Q) register check

Register write n Register read collating check

Register mask data to be checked

0x20 0xbf

0x22 0xff

0x25 0xff

0x26 0xff

0x27 0xff

Incrementing 1 each starting from 0, data are written to readable

and writable registers, then they are read for checking. Incrementing

initial value by 1 each, a check is repeated 256 times. However,

some bits that cannot be written are masked.

If compared data are not same, a checking is suspended, and error

code 05, its address, written data, and read data are displayed.

(5-6) IC181 (CXD8663Q) DRAM check

ROM n IC181 (CXD8663Q) n DRAM n IC181 (CXD8663Q)

read collating check

Checking range: 0x00000000 - 0x0007ffff

ROM pattern is copied to all areas to be checked. Each time 256

bytes are copied, 255 bytes of original (ROM) address are returned.

A reading check is made after data are written to all areas.

If compared data are not same, a checking is suspended, and error

code 05, its address, written data, and read data are displayed.

(5-7) IC181 (CXD8663Q) interrupt line check

(5-8) IC181 (CXD8663Q) to IC217 (CXD8598R) connection check

IC093 (Syscon ROM) n IC181 (CXD8663Q) n IC217

(CXD8598R)

DVD bit stream data stored in IC093 are transferred to the IC182

(external DRAM of IC181), and IC217 (CXD8598R) transfer end

interruption is checked, which occurs by flowing data to the IC217

(CXD8598R). If the transfer end interruption is not detected, the

error code 21 is output.

As SERR signal from IC181 (CXD8663Q) to IC217 (CXD8598R)

is not initialized, this signal line is shut off and fixed to “high” before checking.

(5-9) IC184 (CXD8669AQ) reset check

Write to register n Hard reset n Read from register

Register to be checked: SYSINI (0xe1)

Data other than 0 are written to readable and writable register in

IC184 (CXD8669AQ), and they are read after hard reset, then the

error code 02 is output if they are not cleared to 0.

(5-10) IC184 (CXD8669AQ) register check

Register write n Register read collating check

Register mask data to be checked

0xe0 0x80

0xe1 0xff

0xe4 0xc0

0xe5 0xc0

0xe6 0xf8

Incrementing 1 each starting from 0, data are written to readable

and writable registers, then they are read for checking. Incrementing

initial value by 1 each, a check is repeated 256 times. However,

some bits that cannot be written are masked.

If compared data are not same, a checking is suspended, and error

code 05, its address, written data, and read data are displayed.

(5-11) IC216 (CXD1186) reset check

Write to register n Hard reset n Read from register

Registers to be checked: DADRC_L (0x06380007)

DADRC_H (0x06380008)

HXFRC_L (0x06380009)

HXFRC_H (0x0638000A)

HADRC_L (0x0638000B)

HADRC_H (0x0638000C)

IC093 (Syscon ROM) n IC181 (CXD8663Q) n IC217

(CXD8598R)

DVD bit stream data stored in IC093 are transferred to the IC182

(external DRAM of IC181), and the SD bus sector header detect

interruption is checked, which occurs by flowing data to the IC217

(CXD8598R).

If the header of SD bus sector in IC181 (CXD8663Q) is not

detected, the error code 31 is output.

Data other than 0 are written to readable and writable register in

IC216 (CXD1186), and they are read after hard reset, then the error

code 02 is output if they are not cleared to 0.

6-4

Page 35

(5-12) IC216 (CXD1186) register check

Register write n Register read collating check

Registers to be checked: DADRC_L (0x06380007)

DADRC_H (0x06380008)

HXFRC_L (0x06380009)

HXFRC_H (0x0638000A)

HADRC_L (0x0638000B)

HADRC_H (0x0638000C)

Incrementing 1 each starting from 0, data are written to readable

and writable registers, then they are read for checking. Incrementing

initial value by 1 each, a check is repeated 256 times.

If compared data are not same, a checking is suspended, and error

code 05, its address, written data, and read data are displayed.

(5-13) IC216 (CXD1186) SRAM check

IC093 (Syscon ROM) n IC216 (CXD1186) n IC215 (SRAM)

n IC216 read collating check

Checking range: 0x00000000 - 0x00007fff

IC093 ROM pattern is copied to all areas to be checked. Each time

256 bytes are copied, 255 bytes of original (ROM) address are returned. A reading check is made after data are written to all areas.

After SRAM write addresses are set, error code 03 when writing is

not ready, or after read addresses are set, error code 04 when reading is not ready is output, then a check is finished.

Also, if compared data are not same, a check is suspended, and

error code 05, its address, written data, and read data are displayed.

(5-14) IC216 (CXD1186) to IC217 (CXD8598R) connection check

IC093 (ROM) n IC216 (CXD1186) n IC217 (CXD8598R)

VCD bit stream data stored in IC093 are transferred to the IC215

(external SRAM of IC216), and IC217 (CXD8598R) transfer end

interruption is checked, which occurs by flowing data to the IC217

(CXD8598R).

If the transfer end interruption is not detected, the error code 21 is

output.

Further, SCR is read to check its value. If the v alue is not the one in

sector transferred, the error code 22 is output.

Incrementing 1 each starting from 0, data are written to readable

and writable register, then the y are read for checking. Incrementing

initial value by 1 each, a check is repeated 256 times. However,

some bits that cannot be written are masked.

If compared data are not same, a checking is suspended, and error

code 05, its address, written data, and read data are displayed.

(6-4) IC281 (CXD1900BQ) DRAM check

IC093 (ROM) n IC281 n IC280, IC282 n NIC284 (DRAM)

n IC281 read collating check

Checking range: 0x00000000 - 0x0003fff f (data bus width = 64bits)

IC093 ROM pattern is copied to all areas to be checked. Because of

large DRAM capacity , each time 256 bytes are copied, 255 bytes of

original (IC093) address are returned. A reading check is made

after data are written to all areas.

The error code 03 when writing is not ready, or error code 04 when

reading is not ready is output, then a check is finished.

Also, if compared data are not same, a check is suspended, and

error code 05, its address, written data, and read data are displayed.

However, the data are displayed every 8 bits, though the b us width

of IC281 (CXD1900BQ) is 64 bits. Namely, actual address is the

displayed value shifted by 3 bits to the right where lower 3 bits

indicate the byte position.

For example, in the case of display shown below:

IC281 (CXD1900BQ) DRAM

Error Code: 05

Address: 000abcde

Write Data: fb

Read Data: ff

If displayed value 0 0 0 A B C D E is expressed with binary number, 0000 0000 0000 1010 1011 1100 1101 1110.

If it is shifted by 3 bits to the right, 0000 0000 0000 0001 0101 0111

1001 1011 110. That is, assuming that the top of address 0 0 0 1 5

7 9 B in hexadecimal notation is 0th byte, the 6th byte is erroneous

such as FB n FF (as for the bit position in the same manner, the

53rd bit is 0 n 1, assuming that MSB is 0th and LSB is 63rd).

(6-5) CXD1914 VSync check

IC475 (CXD1914Q) VSync interrupt cycle measurement

(6) Video Decoder

(6-2) IC281 (CXD1900BQ) reset check

Write to register n Hard reset n Read from register

Register to be checked: PLYMOD (0x06080002)

Data other than 0 are written to readable and writable register in

IC281 (CXD1900BQ), and they are read after hard reset, then the

error code 02 is output if they are not cleared to 0.

(6-3) IC281 (CXD1900BQ) register check

Register write n Register read collating check

Register to be checked: PLYMOD (0x06080002)

The VSync interruption is enabled for about 160msec, and the number of VSync interruption from NTSC encoder is counted. The operation is normal if the count is more than 9 times and less than 11

times. If out of this range, the error code 41 is output.

The SCI1 interruption is also enabled, as the NTSC encoder processing is required due to VSync interruption.

(6-6) IC281 (CXD1900BQ) VSync interrupt line check

IC281 (CXD1900BQ) VSync interrupt detection check

The VSync interruption of IC281 (CXD1900BQ) is enabled and

whether interruption is made is checked. If no interruption is made

though 2 seconds elapsed, the error code 41 is output.

(6-7) IC217 (CXD8598R) to IC281 (CXD1900BQ) connection

6-5

Page 36

check

IC093 n IC216 n IC215 n IC216 n IC217 n IC281 n

IC280,

IC282 ~ NIC284

IC093 (ROM) n IC312 (CXD8600R) n IC313, IC319 (SRAM)

n IC312 read collating check

Checking range: 0x00000001 - 0x0003ff000

VCD bit stream data stored in IC093 are transferred via IC216

(CXD1186) to the IC215 (SRAM), and the sequence header interruption and transfer end interruption from IC281 are checked, which

occur by flowing data to the IC281 (CXD1900BQ) via IC216

(CXD1186) and IC217 (CXD8598R).

The error code 21 when transfer end interruption for transferred

sectors is not detected, or error code 42 when sequence header interruption is not detected is output.

(7) Subpictures

(7-2) IC312 (CXD8600R) reset check

Write to register n Hard reset n Read from register

Register to be checked: WRITE_READ_TOP (0x06000050)

Data other than 0 are written to readable and writable register in

IC312 (CXD8600R), and they are read after hard reset, then the

error code 02 is output if they are not cleared to 0.

(7-3) IC312 (CXD8600R) register check

Register write n Register read collating check

Registers to be checked: VB_LUMINANCE (0x06000050)

VB_LUMINANCE+1

VB_LUMINANCE+2

VB_LUMINANCE+3

VB_LUMINANCE+4

VB_LUMINANCE+5

VB_LUMINANCE+6

VB_LUMINANCE+7

VB_LUMINANCE+8

VB_LUMINANCE+9

VB_LUMINANCE+A

VB_LUMINANCE+B

VB_LUMINANCE+C

VB_LUMINANCE+D

VB_LUMINANCE+E

VB_LUMINANCE+F

The IC312 (CXD8600R) cannot designate read/write address of

SRAM. Internal pointer manages the addresses automatically. Accordingly, the reading order is same as the writing order.

IC093 pattern is copied to all areas to be checked. Each time 256

bytes are copied, 255 bytes of original (IC093) address are returned.

A reading check is made after data are written to all areas. As the

Syscon Diagnosis is a simplified check, actual check range is 1/5 of

the above mentioned checking range.

Unlike other RAM checks, the addresses are not skipped. The address 0 in each area has specific meaning, and therefore arbitrary

data cannot be written.

After the fixed data is written to address 0, a check starts from address 1, and the last 255 bytes are not checked because of a complicated program.

If compared data are not same, a check is suspended, and error code

05, its address, written data, and read data are displayed.

However, IC312 (CXD8600R) cannot designate an address, and

the repeat check is ignored.

Also, in case of an error in VB, 0x10000000 is added to the address

for explicit discrimination.

(7-5) IC217 (CXD8598R) to IC312 (CXD8600R) connection check

IC093 (ROM) n IC181 (CXD8663Q) n IC217 (CXD8598R)

n IC312 (CXD8600R)

The bit stream data including subpictures stored in IC093 (ROM)

are transferred to the IC182 (external DRAM of IC181). Then, SP

Arrive signal from IC312 is checked, which is generated by flowing the data to the IC312 (CXD8600R) via IC217 (CXD8598R).

The error code 61 is output when data arrival cannot be confirmed

though 2 seconds elapsed after data transfer request was sent to the

IC181 (CXD8663Q).

As SERR signal from IC181 (CXD8663Q) to IC217 (CXD8598R)

is not initialized, this signal line is shut off and fixed to “high” before checking.

When an error occurred, confirm (5-8) IC181 (CXD8663Q) to IC217

(CXD8598R) connection check.

(7-6) IC312 (CXD8600R) interrupt line check

The values written to the registers in IC312 (CXD8600R) are read

from the same address WRITE_READ_TOP in an y registers. Therefore, the Diagnosis function cannot read data after data were written to all registers. A checking is made by reading every register.

If compared data are not same, a check is suspended, and error code

05, its address, written data, and read data are displayed.

(7-4) IC312 (CXD8600R) SRAM check

IC093 (ROM) n IC181 (CXD8663Q) n IC217 (CXD8598R)

n IC312 (CXD8600R)

The bit stream data including subpictures stored in IC093 (ROM)

are transferred to the IC182 (external DRAM of IC181). Then, the

PTS interrupt is checked, which occurs by flowing the data to the

IC312 (CXD8600R) via IC217 (CXD8598R).

The error code 62 is output when an interruption cannot be confirmed though 2 seconds elapsed after data transfer request was

sent to the IC181 (CXD8663Q).

As SERR signal from IC181 (CXD8663Q) to IC217 (CXD8598R)

is not initialized, this signal line is shut off and fixed to “high” before checking.

When an error occurred, confirm (5-8) IC181 (CXD8663Q) to IC217

(CXD8598R) connection check.

(8) Video Related

6-6

Page 37

(8-2) Video encoder check (color bar output)

I/O output

The color bar is turned on for the NTSC encoder color bar enable

command IC475 (NTSC encoder).

In this check, the Syscon itself does not detect an error.

Confirm the video display screen.

(8-3) Video output check

IC093 (ROM) n IC216 (CXD1186) n IC217 (CXD8598R) n

IC281 (CXD1900BQ) n Video signal output

The bit stream data of still picture stored in IC093 (ROM) are transferred to the IC215 (SRAM of IC216), then the picture is displayed

on the video screen by flowing data to the IC281 (CXD1900BQ)

via IC217 (CXD8598R). If an error is present in any path, that code

is output and a checking is finished.

If no error is found, the controller waits for key entry.

Check the video display screen.

(8-4) IC310 (CXD8602Q) check (letter box output)

IC093 (ROM) n IC216 (CXD1186) n IC217 (CXD8598R) n

IC281 (CXD1900BQ) n IC310 (CXD8602Q) n Video signal

output

The bit stream data of still picture stored in IC093 (ROM) are transferred to the IC215 (SRAM of IC216), then the picture is displayed

on the video screen by flowing data to the IC281 (CXD1900BQ)

via IC217 (CXD8598R). In such a case, the letter box on command

is output on the IC310 (CXD8602Q).

If no error is found, the controller waits for key entry.

Check the video display screen.

(8-5) Video equalizer check (brightness control)

IC093 (ROM) n IC216 (CXD1186) n IC217 (CXD8598R) n

IC281 (CXD1900BQ) n IC317 (CXD8664Q) n Video signal

output

The bit stream data of still picture stored in IC093 (ROM) are transferred to the IC215 (SRAM of IC216), then the picture is displayed

on the video screen by flowing data to the IC281 (CXD1900BQ)

via IC217 (CXD8598R).

If no error is found, the brightness change command is sent to the

IC317 (CXD8664Q). The controller waits for key entry after changing the brightness twice.

Confirm that the brightness of video display screen changes.

(8-6) Subpicture output check

IC093 (ROM) n IC181 (CXD8663Q) n IC217 (CXD8598R)

n IC312 (CXD8600R) n Video signal output

The bit stream data including subpicture stored in IC093 (ROM)

are transferred to the IC312 (CXD8600R) via IC181 (CXD8663Q)

and IC217 (CXD8598R), and the picture is displayed on the video

screen unless an error is found.

Check the video display screen.

Make S-terminal output potential 0V.

In this check, the Syscon itself does not detect an error.

Observe the potential at the S-terminal with an instrument.

(8-8) S-terminal output check (5V)

I/O output

Make S-terminal output potential 5V.

In this check, the Syscon itself does not detect an error.

Observe the potential at the S-terminal with an instrument.

(8-9) S-terminal output check (2.5V)

(9) Audio Related

(9-2) IC380 (CXD8603R) reset check

Write to register n Hard reset n Read from register

Register to be checked: RAADRS (0x06100004)

Data other than 0 are written to readable and writable register in

IC380 (CXD8603R), and they are read after hard reset, then the

error code 02 is output if they are not cleared to 0.

Though this register has 16-bit length, MSB is always 0.

(9-3) IC380 (CXD8603R) register check

Register write n Register read collating check

Register to be checked: RAADRS (0x06100004)

Incrementing 1 each starting from 0, data are written to readable

and writable register, then the y are read for checking. Incrementing

initial value by 1 each, a check is repeated 32768 times.

If compared data are not same, a checking is suspended, and error

code 05, its address, written data, and read data are displayed. Because of 16-bit length, 4-digit data is displayed (however, MSB is

always 0).

(9-4) IC380 (CXD8603R) SRAM check

IC093 (ROM) n IC380 (CXD8603R) n IC383 (SRAM) n

IC380 read collating check

Checking range: 0x00000000 - 0x00007fff

IC093 (ROM) pattern is copied to all areas to be checked. Each

time 256 bytes are copied, 255 bytes of original (IC093) address

are returned. A reading check is made after data are written to all

areas.

The data write/read to IC383 (SRAM) are executed every 256 bytes

using the direct access function of the IC380 (CXD8603R). If compared data are not same, a checking is

suspended, and error code 05, its address, written data, and read

data are displayed.

(8-7) S-terminal output check (0V)

(9-5) IC217 (CXD8598R) to IC380 (CXD8603R) connection check

6-7

Page 38

IC093 (ROM) n IC216 (CXD1186) n IC217 (CXD8598R) n

IC380 (CXD8603R) SRAM read collating check

(CXD8603R) is read for checking.

The error code 10 is output if the data are not same as original bit

stream data.

The bit stream data of MPEG-AUDIO stored in IC093 (ROM) are

transferred by only one sector to the IC215 (external SRAM of

IC216), then they are flown to the IC380 (CXD8603R) via IC217

(CXD8598R).

If no error is found, the data are transferred to the SRAM in IC380

(CXD8603R) and compared with original ROM data.

The first 512 bytes in code buff er are read from IC380 (CXD8603R)

SRAM into internal RAM of CPU, and whether 256 byte pattern

after 12th bytes in effectiv e area of MPEG-AUDIO bit stream data

stored in ROM is contained is searched. If not found, the pattern to

be searched is shifted one byte each, and a searching is repeated

maximum 256 times. The check passed if 256 bytes are same successively.

If same pattern is not found, the error code 10 is output.

(9-6) Audio decoder boot check

AC-3 codes are downloaded to the audio decoder.

The error code 50 if download is not terminated successfully, or

error code 51 if AC-3 codes downloading failed is output.

When an error occurred here, the subsequent audio related diagnosis may be rejected, resulting in unconditional output of error code

50.

(9-7) IC380 (CXD8603R) interrupt line check

IC093 (ROM) n IC181 (CXD8663Q) n IC217 (CXD8598R) n

IC380 (CXD8603R)

The bit stream data including Navi Pack stored in IC093 (ROM)

are transferred to the DRAM of IC181 (CXD8663Q). Then, the

Navi Ready interruption is checked, which occurs by flowing the

data to the IC380 (CXD8603R) via IC217 (CXD8598R).

The error code 55 is output when an interruption cannot be confirmed though 2 seconds elapsed after data transfer request was

sent to the IC181 (CXD8663Q).

As SERR signal from IC181 (CXD8663Q) to IC217 (CXD8598R)

is not initialized, this signal line is shut off and fixed to “high” before checking.

When an error occurred, confirm (5-8) IC181 (CXD8663Q) to IC217

(CXD8598R) connection check.

(9-8) DREQ/NCST check

(9-9) MPEG audio digital output check

IC093 (ROM) n IC216 (CXD1186) n IC217 (CXD8598R) n

IC380 (CXD8603R) n Digital Audio I/F audio signal output

The bit stream data of MPEG-Audio stored in IC093 (ROM) are

transferred to the IC216 (CXD1186). Then, the data are flown to

the Digital Audio Interface via IC217 (CXD8598R) and CK to regenerate audio signals.

For the data, audio frequencies are different between left and right

channels. Using left and right channels mixing function, the same

stream is checked three times in the order of left channel, right channel, and both channels on.

In this diagnosis, the kind of expected errors is many because of

complicated paths, but the diagnosis is finished upon detection of

an error.

Confirm the content of error from the error code list.

If no error is detected, a sound is generated three times, then a message is output and the controller waits for key entry.

(9-10) MPEG audio analog output check

IC093 (ROM) n IC216 (CXD1186) n IC217 (CXD8598R) n

CK n Analog Audio I/F audio signal output

The bit stream data of MPEG-Audio stored in IC093 (ROM) are

transferred to the IC216 (CXD1186). Then, the data are flown to

the Analog Audio Interface via IC217 (CXD8598R) and CK to regenerate audio signals.

For the data, audio frequencies are different between left and right

channels. Using left and right channels mixing function, the same

stream is checked three times in the order of left channel, right channel, and both channels on.

In this diagnosis, the kind of expected errors is many because of

complicated paths, but the diagnosis is finished upon detection of

an error.

Confirm the content of error from the error code list.

If no error is detected, a sound is generated three times, then a message is output and the controller waits for key entry.

(9-11) Audio attenuator check

IC093 (ROM) n IC216 (CXD1186) n IC217 (CXD8598R) n

IC380 (CXD8603R) n Analog Audio I/F audio signal output

IC093 (ROM) n IC181 (CXD8663Q) n IC217 (CXD8598R) n

IC380 (CXD8603R) read data pattern check

The bit stream data including Navi Pack stored in IC093 (ROM)

are transferred to the DRAM of IC181 (CXD8663Q). Then, the

data are flown to the IC380 (CXD8603R) via IC217 (CXD8598R).

The error code 55 is output when Navi Ready interruption cannot

be confirmed though 2 seconds elapsed after data transfer request

was sent to the IC181 (CXD8663Q).

As SERR signal from IC181 (CXD8663Q) to IC217 (CXD8598R)

is not initialized, this signal line is shut off and fixed to “high” before checking.

When an error occurred, confirm (5-8) IC181 (CXD8663Q) to IC217

(CXD8598R) connection check.

If no error is found, the Navi Pack transferred to the SRAM in IC380

The bit stream data of MPEG-Audio stored in IC093 (ROM) are

transferred to the IC216 (CXD1186). Then, the data are flown to

the Analog Audio Interface via IC217 (CXD8598R) and IC380

(CXD8603R) to regenerate audio signals.

In such a case, DAC attenuation value is set to 1/4 of normal value

to lower the volume.

For the data, audio frequencies are different between left and right

channels. Using left and right channels mixing function, the same

stream is checked three times in the order of left channel, right channel, and both channels on.

In this diagnosis, the kind of expected errors is many because of

complicated paths, but the diagnosis is finished upon detection of

an error.

Confirm the content of error from the error code list.

If no error is detected, a sound is generated three times, then a mes-

6-8

Page 39

sage is output and the controller waits for key entry.

Check if the volume level becomes lower (about half) than that in

(9-10).

(9-12) AC-3 audio output check

IC093 (ROM) n IC181 (CXD8663Q) n IC217 (CXD8598R) n

IC380 (CXD8603R) n Audio signal output

The bit stream data including AC-3 audio stored in IC093 (ROM)

are transferred to the DRAM of IC181 (CXD8663Q). Then, the

data are flown to the IC380 (CXD8603R) via IC217 (CXD8598R)

to regenerate audio signals.

As SERR signal from IC181 (CXD8663Q) to IC217 (CXD8598R)

is not initialized, this signal line is shut off and fixed to “high” before checking.

This diagnosis turns on all channels to turn on both analog and

digital outputs.

If no error is detected, a sound is generated, then a message is output and the controller waits for key entry.

g Diagnosis Error code list

01: A mode not supported was selected

02: Reset error

03: Data write error

04: Data read error

05: Written and read data are not same

91: Check of this item is cancelled by key entry

92: Check of all items is cancelled by key entry

99: Other errors

10: Data transfer error between chips

12: Stop by time out

21: IC217 (CXD8598R) transfer end interrupt is not detected

22: IC217 (CXD8598R) SCR not same

30: Drvcon detects an error in IC181 (CXD8663Q)

31: IC181 (CXD8663Q) SD bus sector header is not detected

41: Vsync interrupt is not detected

42: Sequence header is not detected

50: Audio related chips initialize error

51: Audio stream change error

52: Audio decoder is not in play mode

53: Audio decoder is not in stop mode

54: IC380 (CXD8603R) chip PTS is not detected

55: IC380 (CXD8603R) chip NAVI is not detected

56: No data arrives at IC380 (CXD8603R) chip code buffer

57: No data in IC380 (CXD8603R) chip code buffer is consumed

61: No sub-picture data arrives

62: Sub-picture PTS is not detected

70: DRV INT is not detected

71: Drvcon does not recognize SYS INT

72: Drvcon does not make a response

73: Drvcon communication data error

74: Drvcon EEPROM busy time out

75: Drvcon CXD2545 NG

76: Drvcon RF processor NG

77: Drvcon VCO preset NG

90: Error judged by inspector

6-9

Page 40

6-3. Drive Auto Adjustment

The drive can be automatically adjusted, except disc change and

tangential skew adjustment. For a disc, use the disc for adjustment.

In case of abnormality, press the [stop] key to stop adjustment.

If the drive does not stop, prevent secondary failure by taking proper

action such as disconnection of the power cable. This adjustment

should be made after repair is finished and no trouble is present in

the drive.

A trouble, if present, causes NG and the adjustment to be aborted.

As the secondary failure could occur, perform automatic adjustment after the drive is completely repaired.

With the initial menu displayed, press [1] on standard commander,

and the screen as shown in Figure 5 will appear.

The tray opens after the ENTER key is pressed and the initialization is finished. Then, place the D VD_SL disc for adjustment. Press

the ENTER key to start adjustment. During adjustment, the tangential skew adjustment screen is displayed. Make this adjustment only

when the pickup was replaced.

As for adjustment, rotate the T -SKEW adjusting screw on the pic kup

so that the displayed jitter becomes minimum (CCW makes jitter

smaller). Avoid extreme rotation or interference of screwdriver with

the disc. After adjustment, a message to apply a scre w locking agent

will be displayed if jitter value is within the specification. Then,

apply a drip of locking agent to the recess of screw . Hence, change

discs following the given messages on OSD, and the adjustment is

finished if there is no problem.

Note that if “All” is selected, the data of previous adjustment are

erased and initial values are set.

Drive Auto Adjustment

SA.00000 SI.00 EMG.OO

Select No.

0: All 3: CD

2: DVD SL 4: DVD-DL

STOP: Press STOP Key

Figure 5

If “All” is selected, the screen shown in Figure 6 is displayed.

Drive Auto Adjustment

SA.00000 SI.00 EMG.OO

N Blinking

T-SKEW adjusting screw

Figure 7

0: Adjustment ALL

0: All 2: CD

2: DVD SL 3: DVD-DL

START: Press ENTER Key

STOP: Press STOP Key

Figure 6

N Blinking

6-10

Page 41

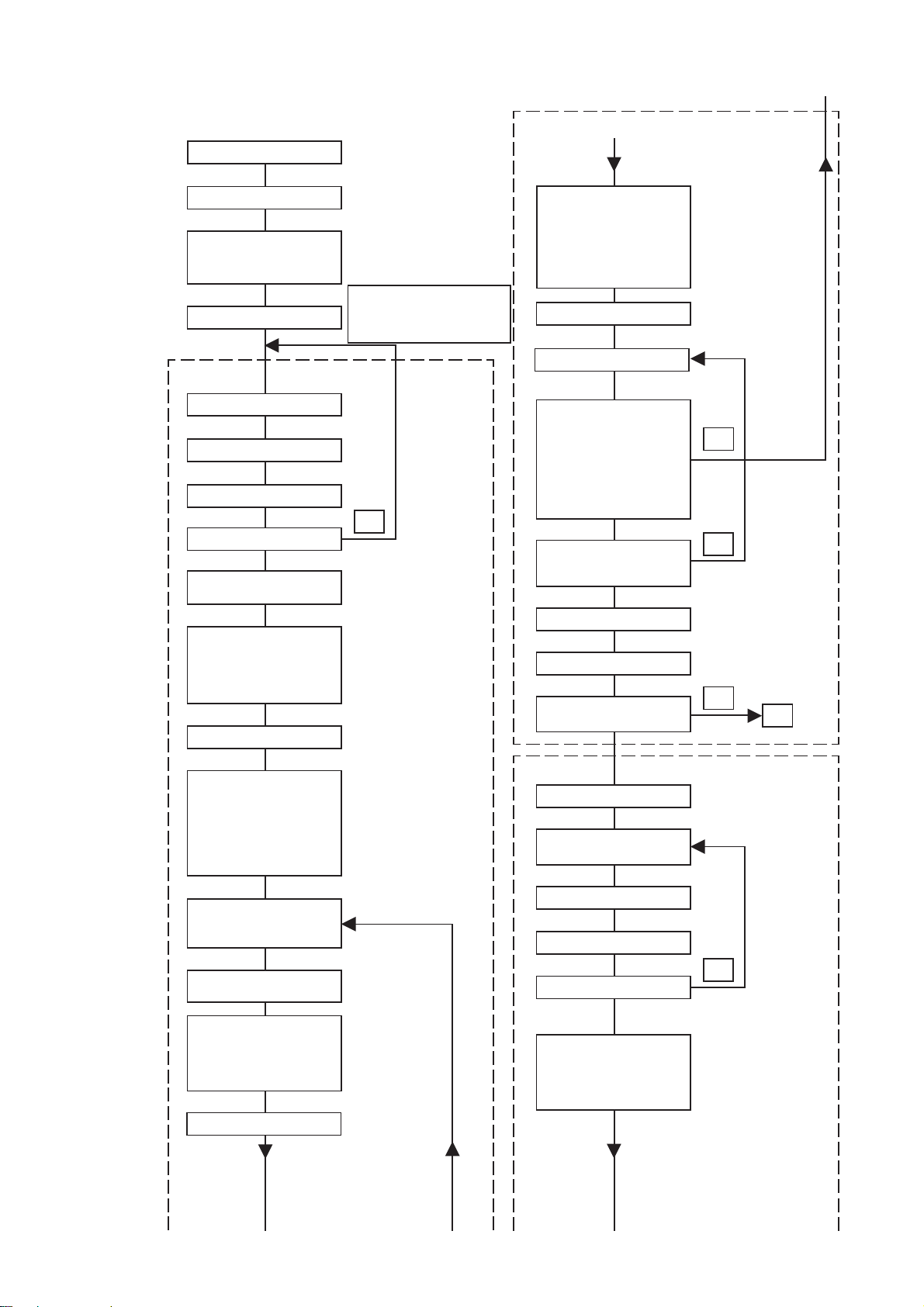

Drive Automatic Adjustment Flowchart

Service Mode ON

Loading

HYDET init

sled init

HOME Position

Adj. disc selection

DVD_SL

adjustment

Eject

Place DVD_SL disc for adj.

Loading

disc type check

EEPROM Default set

(Only if selecting ALL)

LDON

SP ON

Tilt ON

Focus ON

CLVS

Auto Tracking Offset

Note:If selecting other than ALL,

adjustment routine for

selected disc only is

executed

NG

Brake ON

FOK check

Tracking ON

Sled ON

Brake OFF

AGC ON

CLVA

JITTER ON

Tangential skew adjustment

Jitter OFF

Auto Focus Offset

Auto Tilt Offset

Auto Focus Offset

Auto Focus Gain

Auto Tracking Gain

Auto EQ

Pull in Memory

Jitter ON

Jitter Check

Jitter OFF

Servo Stop

Screw locking agent

search check

stop

NG

NG

NG

stop

Brake ON

FOK check

Tracking ON

Sled ON

Brake OFF

AGC ON

CLVA

Auto Focus Offset

Auto Tilt Offset

Auto Focus Offset

Servo Stop

Home Position

LDON

SP ON

Tilt ON

Focus ON

CLVS

Tan-Position

CD adjustment

Eject

Disc change

DVD_SLnCD

Loading

Go to Home Position

NG

disc type check

LDON

SP ON

Tilt ON

Focus ON

CLVS

(to next page)

6-11

Page 42

Auto Tracking Offset

Layer0 check

NG

Brake ON

FOK check

Tracking ON

Sled ON

Brake OFF

Auto Focus Offset

Auto Focus Gain

Auto Tracking Gain

Pull in Memory

Jitter ON

Jitter check

Jitter OFF

search check

DVD_DL

adjustment

Disc change

CD n DVD_DL

Loading

disc type check

Focus ON

Auto Focus Offset

CLVA

stop

Eject

LDON

SP ON

Tilt ON

CLVS

NG

NG

NG

stop

stop

Servo stop

Jitter ON

Jitter check

Jitter OFF

CLVS

F_Jump(0 n 1)

Auto Tracking Offset

Brake ON

FOK check

Tracking ON

Sled ON

Brake OFF

CLVA

Layer1 check

Auto Focus Offset

Auto Focus Gain

Auto Tracking Gain

Auto EQ

Pull in Memory

Jitter ON

Jitter check

Jitter OFF

search check

(incl. layer Jump)

stop

Auto VCO

NG

stop

NG

stop

NG

stop

NG

stop

NG

stop

Brake ON

FOK check

Tracking ON

Sled ON

Brake OFF

ACG ON

CLVA

Auto Focus Offset