Sony DVPCX-985-V Service manual

DVP-CX985V

SERVICE MANUAL

Ver 1.1 2004.09

E

NERGY STARR is a U.S. registered mark.

As an

E

NERGY STARR Partner, Sony

Corporation has determin ed that this product

meets the

energy efficiency.

E

NERGY STARR guidelines for

US Model

Canadian Model

Model Name Using Similar Mechanism NEW

CD/DVD Mechanism Type CDM62-DVBU26

Base Unit Name DVBU26

Optical Pick-up Name KHM-290AAA

System

Laser: Semiconductor laser

λ = 780 nm for CD

λ = 650 nm for SA-CD and DV D

Emission duration: continuous

Signal format system: NTSC

Audio characteristics

Frequency response: DVD VIDEO (PCM

96 kHz): 2 Hz to 44 kHz (44 kHz: −2 dB

±1 dB), Super A udio CD: 2 Hz to

100 kHz (50 kHz: −3 dB ±1dB), CD:

2Hz to 20 kHz (±0.5 dB)

Signal-to-noise ratio (S/N ratio): 115 dB

(LINE OUT AUDIO L/R 1/2 jacks only)

Harmonic distortion: 0.003 %

Dynamic range: DVD VIDEO/Super Audio

CD: 103 dB, CD: 99 dB

Wow and flutter: Less than detected value

(±0.001% W PEAK)

SPECIFICATIONS

Outputs

(Jack name: Jack type/Output level/Load

impedance)

LINE OUT AUDIO L/R 1/2: Phono jack/

2Vrms/10 kilohms

DIGITAL OUT (OPTICAL): Optical

output jack/−18 dBm (wave lengt h:

660 nm)

DIGITAL OUT (COAXIAL): Phono jack/

0.5 Vp-p/75 ohms

5.1CH OUTPUT: Phono jack/2 Vrms/

10 kilohms

COMPONENT VIDEO OUT(Y, P

P

R/CR

): Phono jack/Y: 1.0 Vp-p/PB/CB,

P

R/CR

LINE OUT VIDEO 1/2: Phono jack/

S VIDEO OUPUT 1/2: 4-pin mini DIN/

: 0.7 Vp-p/75 ohms

1.0 Vp-p/75 ohms

Y: 1.0 Vp-p/C: 0.286 Vp-p /75 ohms

B/CB

,

General

Power requirements:

120V AC, 60 Hz

Power consumption: 20 W

Dimensions (approx.): 430 × 189 × 54 5 mm

Mass (approx.): 8.6 kg (18 lb 15 oz)

Operating temperature: 5

Operating humidity: 25 % to 80 %

Supplied accessories

• Audio/video cord (pinplug × 3 y pinplug × 3) (1)

• Remote commander (remote) (1)

• Size AA (R6) batteries (2)

Specifications and design are subject to

change without notice.

1

/

2

× 21

F to 95°F)

1

/

2

in .) (widt h/height/ depth)

(17 × 7

incl. projecting parts

(41

°

°

C to 35°C

9-961-042-02 Sony Corporation

2004I05-1 Audio Group

© 2004.09 Published by Sony Engineering Corporation

CD/DVD PLAYER

DVP-CX985V

SELF DIAGNOSIS FUNCTION

Self-diagnosis Function

(When letters/numbers appear in the

display)

When the self-d iagnosis fun ction i s activ ated

to prevent the player from malfunctioning, a

five-charact er service number (e.g., C 13 50)

with a combination of a letter and four d igits

appears on the screen and the fr ont panel

display. In this case, check the following

table.

C:13:50

First three

characters of

the service

number

C 13 The disc is dirty.

C 31 The disc is not inserted

C 32 The front cover

E XX

(xx is a number)

Cause and/or corrective

action

,Clean the disc with a soft

cloth

correctly.

,Re-insert the disc

correctly.

automatically opens and the

player enters standby mode .

,Check that there is

nothing wrong inside the

rotary table, such as a

fallen disc. After you

have checked the inside

of the rotary table and

resolved any possible

problems, press H.

To prevent a malf unction, the

player has performed the

self-diagnosis function.

,Contact your nearest

Sony dealer or local

authorized Sony service

facility and give the 5character ser vi ce number.

Example: E 61 10

Note: Refer to the “5. TEST MODE” (pa ge 23) for another self-diagnosis

function.

2

DVP-CX985V

r

Notes on chip component replacement

•Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be dam-

aged by heat.

Flexible Circuit Board Repairing

•Keep the temperature of the soldering iron around 270 ˚C dur-

ing repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

SAFETY CHECK-OUT

After correcting the original service problem, perform the following safety check before releasing the set to the customer:

Check the antenna terminals, metal trim, “metallized” knobs,

screws, and all other exposed metal parts for AC leakage.

Check leakage as described below.

LEAKAGE TEST

The AC leaka ge from an y exposed metal part to earth ground and

from all exposed metal parts to any exposed metal part having a

return to chassis, must not exceed 0.5 mA (500 microamperes.).

Leakage current can be measured by any one of three methods.

1. A commercial leakage tester, such as the Simpson 229 or RCA

WT -540A. Follo w the manufacturers’ instructions to use these

instruments.

2. A battery-operated AC milliammeter . The Data Precision 245

digital multimeter is suitable for this job.

3. Measuring the voltage drop across a resistor by means of a VOM

or battery-operated A C voltmeter . The “limit” indication is 0.75

V, so analog meters must have an accurate low-voltage scale.

The Simpson 250 and Sanwa SH-63Trd are examples of a passive VOM that is suitable. Nearly all battery operated digital

multimeters that have a 2 V A C range are suitable. (See Fig. A)

CAUTION

Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous radiation exposure.

UNLEADED SOLDER

Boards requiring use of unleaded solder are printed with the leadfree mark (LF) indicating the solder contains no lead.

(Caution: Some printed circuit boards may not come printed with

the lead free mark due to their particular size)

: LEAD FREE MARK

Unleaded solder has the following characteristics.

• Unleaded solder melts at a temperature about 40 ˚C higher than

ordinary solder.

Ordinary soldering irons can be used but the iron tip has to be

applied to the solder joint for a slightly longer time.

Soldering irons using a temperature regulator should be set to

about 350 ˚C.

Caution: The printed pattern (copper foil) may peel away if the

heated tip is applied for too long, so be careful!

• Strong viscosity

Unleaded solder is more viscou-s (sticky, less prone to flow)

than ordinary solder so use caution not to let solder bridges occur such as on IC pins, etc.

• Usable with ordinary solder

It is best to use only unleaded solder but unleaded solder may

also be added to ordinary solder.

To Exposed Metal

Parts on Set

1.5 k

0.15 µF

Fig. A. Using an AC voltmeter to check AC leakage.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED

LINE WITH MARK 0 ON THE SCHEMA TIC DIAGRAMS

AND IN THE PARTS LIST ARE CRITICAL TO SAFE

OPERATION. REPLACE THESE COMPONENTS WITH

SONY PARTS WHOSE PART NUMBERS APPEAR AS

SHOWN IN THIS MANUAL OR IN SUPPLEMENTS PUBLISHED BY SONY.

Ω

Earth Ground

AC

voltmete

(0.75 V)

ATTENTION AU COMPOSANT AYANT RAPPORT

À LA SÉCURITÉ!

LES COMPOSANTS IDENTIFIÉS P AR UNE MARQUE 0

SUR LES DIAGRAMMES SCHÉMATIQUES ET LA LISTE

DES PIÈCES SONT CRITIQUES POUR LA SÉCURITÉ

DE FONCTIONNEMENT. NE REMPLACER CES COMPOSANTS QUE PAR DES PIÈCES SONY DONT LES

NUMÉROS SONT DONNÉS DANS CE MANUEL OU

DANS LES SUPPLÉMENTS PUBLIÉS PAR SONY.

3

DVP-CX985V

This Player Can Play the

Following Discs

Format of discs

DVD VIDEO

DVD-RW

Super Audio CD

VIDEO CD

Music CD

“DVD VIDEO” and “DVD-RW” are

trademarks.

Region code

Your player has a region code printed on th e

back of the unit and will only play DVD

VIDEOs (playback only) labeled with

identical region codes . This sys tem is used to

protect copyrights.

DVD VIDEOs labeled will also play on

this player.

If you try to play any other DVD VIDEO, the

message “Playback pr ohibited by area

limitations.” will appear on the TV screen.

Depending on the DVD VIDEO, no region

code indication may be labeled even though

playing the DVD VIDEO is prohibited by

area restrictions.

Region code

ALL

X

Example of discs that the player

cannot play

The player cannot pl ay the following di scs:

•

All CD-ROMs (including PHOTO CDs)/

CD-Rs/CD-RWs other than thos e r ecorded

in the following formats:

−music CD format

−video CD format

−MP3 format t hat conforms to IS O 9660*

Level 1/Le vel 2, or its extended for mat,

Joliet

•

Data part of CD-Extras

•

DVD-ROMs

•

DVD Audios

*A logical format of files and folders on CD-

ROMs defined by ISO (International Standa rd s

Organization).

Also, the player cannot play the following

discs:

•

A DVD VIDEO with a different region

code.

•

A disc recorded in a color system other than

NTSC, such as PAL or SECAM (this player

conforms to the NTSC color system).

•

A disc that has a non-standard shape (e.g.,

card, heart).

•

A disc with paper or stickers on it.

•

A disc that has the adhesive of cel lophane

tape or a sticker still left on it.

Notes

• Note about DVD-RWs/DVD-Rs, DVD+RWs/

DVD+Rs, or CD-Rs/CD-RWs.

Some DVD-RWs/DVD-Rs, DVD+RWs/

DVD+Rs, or CD-Rs/CD-RWs cannot be played

on this player due to the recording quality or

physical condition of the disc, or the

characteristics of the rec or din g dev ic e and

authoring software. Also, images in DVD-RWs

with CPRM* protection may not be played if they

contain a copy protection signal . “Cop yr ight

lock” appe ars on the screen. For m ore

information, see the operating instructions for the

recording device.

Note that discs created in the Packet Write format

cannot be played.

*CPRM (Content Protection for Recordable

Media) is a coding tech nology that protects

copyright for images.

• Music discs encoded with copyright prote ction

technologies

This product is designed to playback discs that

conform to the Compact Disc (CD) standard.

Recently, various music discs encoded with

copyright protection technologies are marketed

by some record companies. Please be aware that

among those discs, there are some that do not

conform to the CD standard and may not be

playable by this product.

Note on playback operations of

DVDs and VIDEO CDs

Some playback operations of DVDs and

VIDEO CDs may be intentionally set by

software producers. Since this player pla ys

DVDs and VIDEO CDs according to the disc

contents the software producers designed,

some playback features may not be available.

Also, refer to the instructions supplied with

the DVDs or VIDEO CDs.

Copyrights

This product inco rporates copyri ght

protection technology that is protected by

U.S. patents and other intelle ct ual property

rights. Use of this copyright protection

technology must be authorized by

Macrovision, and is intended for home and

other limited viewing uses only unless

otherwise authorized by Macrovision.

Reverse engineeri ng or disassembly is

prohibited.

4

TABLE OF CONTENTS

DVP-CX985V

SELF DIAGNOSIS FUNCTION.................................... 2

1. SERVICING NOTES ............................................... 6

2. GENERAL ................................................................... 10

3. DISASSEMBLY

3-1. Disassembly Flow ........................................................... 11

3-2. Case ................................................................................. 12

3-3. MB Board ........................................................................ 12

3-4. AV Board ......................................................................... 13

3-5. Bracket (L)/(R)................................................................ 13

3-6. Front Panel Section ......................................................... 14

3-7. Cover (PT)/(CDM).......................................................... 14

3-8. DVBU26 Assy ................................................................. 15

3-9. Power Block .................................................................... 15

3-10. Table (400) Assy ............................................................. 16

3-11. Door Block, Base (Door) Assy ....................................... 16

3-12. DC Motor (Door) (M603)............................................... 17

3-13. Holder (Table Sensor 400) .............................................. 17

3-14. D. SENS OUT Board, D. SENS IN Board..................... 18

3-15. Pop-up (400) Assy........................................................... 18

3-16. Door SW Board............................................................... 19

3-17. Lock SW Board, Loading SW Board ............................. 20

3-18. CD/DVD Mechanism Deck Block

(CDM62-DVBU26) ........................................................ 21

3-19. Motor (400) Assy (Loading) (M602)/(Table) (M601),

Loading Motor Board ..................................................... 21

3-20. Optical Pick-up (KHM-290AAA) .................................. 22

4. TEST MODE.............................................................. 23

5. MECHANICAL ADJUSTMENTS....................... 45

6. ELECTRICAL ADJUSTMENTS......................... 46

7. DIAGRAMS

7-1. Block Diagram – RF Section – ...................................... 50

7-2. Block Diagram – SERVO/CHANGER Section – ......... 51

7-3. Block Diagram – AUDIO Section – .............................. 52

7-4. Block Diagram – VIDEO Section – .............................. 53

7-5. Block Diagram

– PANEL/POWER SUPPLY Section – .......................... 54

7-6. Note for Printed Wiring Boards and

Schematic Diagrams ....................................................... 55

7-7. Printed Wiring Board

– MB Board (Component Side) –................................... 56

7-8. Printed Wiring Board

– MB Board (Conductor Side) –..................................... 57

7-9. Schematic Diagram – MB Board (1/14) – .................... 58

7-10. Schematic Diagram – MB Board (2/14) – .................... 59

7-11. Schematic Diagram – MB Board (3/14) – .................... 60

7-12. Schematic Diagram – MB Board (4/14) – .................... 61

7-13. Schematic Diagram – MB Board (5/14) – .................... 62

7-14. Schematic Diagram – MB Board (6/14) – .................... 63

7-15. Schematic Diagram – MB Board (7/14) – .................... 64

7-16. Schematic Diagram – MB Board (8/14) – .................... 65

7-17. Schematic Diagram – MB Board (9/14) – .................... 66

7-18. Schematic Diagram – MB Board (10/14) – .................. 67

7-19. Schematic Diagram – MB Board (11/14) – .................. 68

7-20. Schematic Diagram – MB Board (12/14) – .................. 69

7-21. Schematic Diagram – MB Board (13/14) – .................. 70

7-22. Schematic Diagram – MB Board (14/14) – .................. 71

7-23. Printed Wiring Board – DRIVER Board – .................... 72

7-24. Schematic Diagram – DRIVER Board –....................... 73

7-25. Printed Wiring Boards

– MOTOR/SWITCH Section –....................................... 74

7-26. Schematic Diagram – MOTOR/SWITCH Section – .... 75

7-27. Printed Wiring Boards – SENSOR Section –................ 76

7-28. Schematic Diagram – SENSOR Section – .................... 77

7-29. Printed Wiring Board

– AV Board (Component Side) – .................................... 78

7-30. Printed Wiring Board

– AV Board (Conductor Side) – ...................................... 79

7-31. Printed Wiring Board

– RS-232C Board – ......................................................... 80

7-32. Schematic Diagram – AV (1/3)/RS-232C Boards – ...... 81

7-33. Schematic Diagram – AV Board (2/3) –........................ 82

7-34. Schematic Diagram – AV Board (3/3) –........................ 83

7-35. Printed Wiring Board

– PANEL-L Board (Component Side) –......................... 84

7-36. Printed Wiring Board

– PANEL-L Board (Conductor Side) – .......................... 85

7-37. Schematic Diagram – PANEL-L Board (1/2) – ............ 86

7-38. Schematic Diagram – PANEL-L Board (2/2) – ............ 87

7-39. Printed Wiring Boards – PANEL Section – .................. 88

7-40. Schematic Diagram – PANEL Section – ....................... 89

7-41. Printed Wiring Board – POWER Board – ..................... 90

7-42. Schematic Diagram – POWER Board –........................ 91

7-43. IC Pin Function Description .......................................... 100

8. EXPLODED VIEWS

8-1. Overall Section............................................................... 124

8-2. Front Panel Section ........................................................ 125

8-3. Power Block Section ...................................................... 126

8-4. Table Section.................................................................. 127

8-5. Chassis Section ..............................................................128

8-6. Base (Door) Section ....................................................... 129

8-7. CD/DVD Mechanism Deck Section-1

(CDM62-DVBU26) ....................................................... 130

8-8. CD/DVD Mechanism Deck Section-2

(CDM62-DVBU26) ....................................................... 131

8-9. CD/DVD Mechanism Deck Section-3

(CDM62-DVBU26) ....................................................... 132

8-10. CD/DVD Mechanism Deck Section-4

(CDM62-DVBU26) ....................................................... 133

8-11. Optical Pick-up Section (DVBU26) .............................. 134

9. ELECTRICAL PARTS LIST ..............................135

5

DVP-CX985V

Ver 1.1

SECTION 1

SERVICING NOTES

NOTES ON HANDLING THE OPTICAL PICK-UP

BLOCK OR BASE UNIT

The laser diode in the optical pick-up block may suffer electrostatic break-down because of the potential difference generated

by the charged electrostatic load, etc. on clothing and the human

body.

During repair, pay attention to electrostatic break-down and also

use the procedure in the printed matter which is included in the

repair parts.

The flexible board is easily damaged and should be handled with

care.

NOTES ON LASER DIODE EMISSION CHECK

The laser beam on this model is concentrated so as to be focused

on the disc reflective surface by the objective lens in the optical

pick-up block. Therefore, when checking the laser diode emission, observe from more than 30 cm away from the objectiv e lens.

NOTE OF REPLACING THE MB BOARD

When replacing the MB board, since the adjustment value is not

set up correctly, “Drive Auto Adjustment” can’t be performed.

In this case, initialize Memory in the following procedures.

Procedure:

1. Set the test mode. (See page 23)

2. Press the [2] key of the remote commander, and set the “DRIVE

MANUAL OPERATION”. (See page 29)

3. Press the [6] key of the remote commander, and set the “2-6,

Memory Check”. (See page 32)

4. Press the [CLEAR] key of the remote commander, and initialize Memory.

CHECK OF POWER BOARD WITH THE POWER ON

It is possible to analyze the defect with only POWER board power

ON.

Procedure:

1. Set to power OFF state.

2. Remove the connector from CN201 on the POWER board.

3. Short between CN201 pin 1 (P-CONT) and CN201 pin qa

(EVER+3.3V) on the POWER board.

4. Turn the power ON.

5. Confirm that the voltage value of CN201 each pin on the

POWER board satisfy following value .

CN201 Pin Voltage Value

pin 2 (EVER–11V) –11V

pin 3 (SW–11V) –11V

pin 6, 7 (SW+11V) +11V

pin 8 (SW+3.3V) +3.3V

pin qa (EVER+3.3V) +3.3V

pin qs (SW+5V) +5V

pin qd (EVER+11V) +11V

– POWER Board (Conductor Side) –

13

CN201

1

6

DVP-CX985V

ALIGNMENT OF GEAR (CAM) PHASE WITH DOOR

ASS’Y

door assy

gear (cam)

Align a slit of door assy with a marking on

the bottom land of gear tooth when the gear

is rotated fully in arrow direction, as shown.

CLEANING OF OPTICAL PICK-UP

optical pick-up

pulley assy

Remove the pulley assy, and

clean the lens of optical pick-up

through this hole.

NOTE FOR INSTALLATION

It takes care that the cables doesn’t hang down.

cable

(AV board to panel-L board)

cable

(MB board to

led board)

– Front side –

AV board

MB board

cables

(MB board to

driver board,

sensor board)

AV board

cables

(MB board to

driver board,

sensor board)

locking wire

saddle

MB board

AV board

cables

(MB board to

driver board,

sensor board)

MB board

power block

7

DVP-CX985V

When installing the cables, it is made to make it crawl in a chassis.

cables

driver board

cables

It is made to contact and for there not to be a power block and cables.

AV board

MB board

power block

AV board

cables

power block

8

SERVICE POSITION

k

– MB board –

panel-L board

(CN1005)

DVP-CX985V

Connect the jig (J-2501-086-A) to

MB board (CN102) and

panel-L board (CN1005).

MB board (CN102)

– Optical pick-up block –

optical pick-up bloc

(DVBU26)

9

DVP-CX985V

SECTION 2

GENERAL

This section is extracted from

instruction manual.

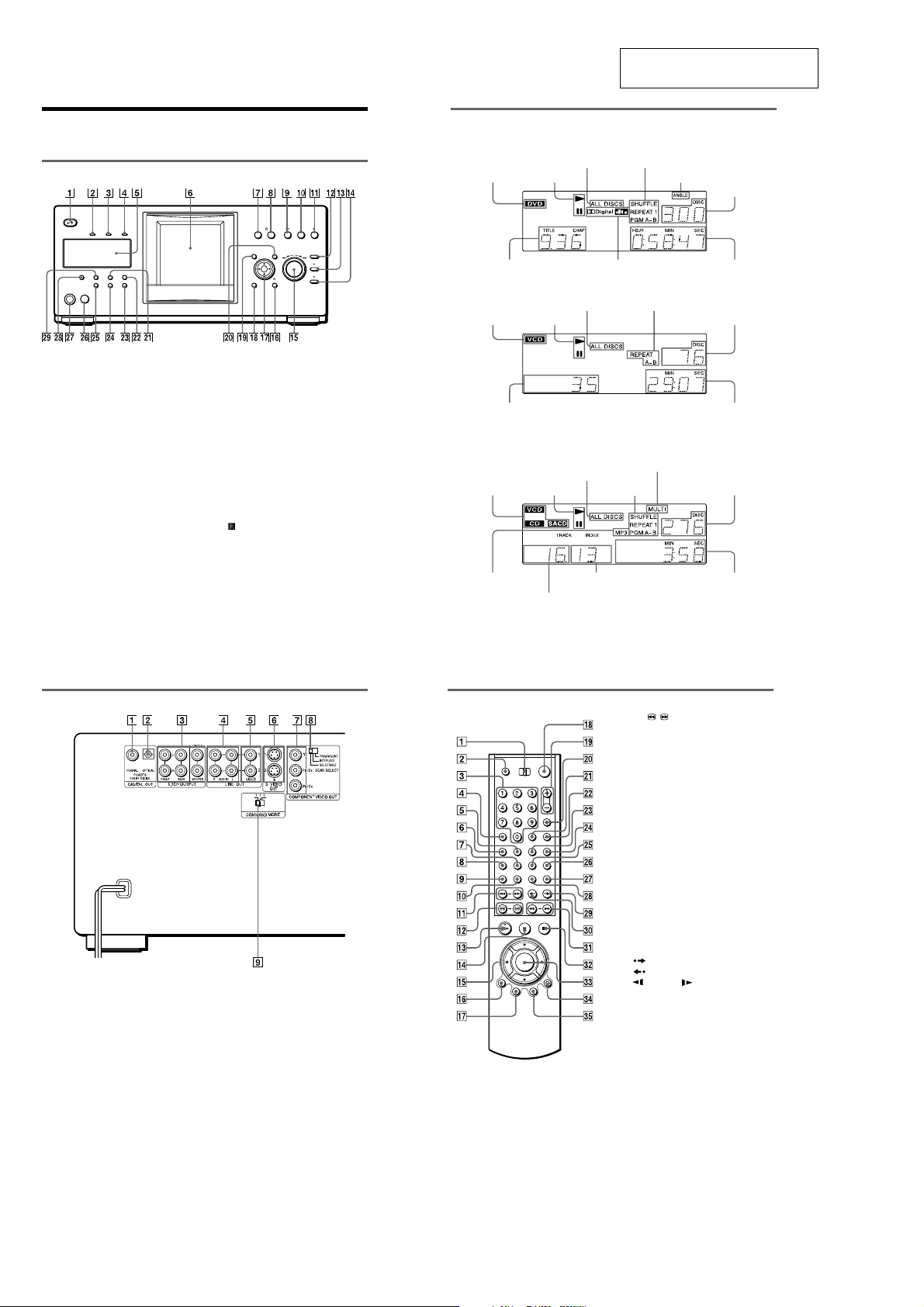

Index to Parts and Controls

For more information, see the pages in parentheses.

Front panel

A [/1 (on/standby) button

B PROGRESSIVE indicator

Lights up when the player outputs

progressive signals.

C SACD (Super Audio CD) indicator

Lights up when:

—playing a Super Audio CD.

— no disc is inserted.

D MULTI CHANNEL indicator

Lights up when:

—Playing a track or chapter that

contains three or more audio signal

channels.

—no disc is inserted.

E Front panel display

F Front cover

G OPEN/CLOSE button

H A DISC EJECT button

I H (play) button

J X (pause) button

K x (stop) butt on

L +1 00 button

M DISC CHANGE button/indicator

N DIRECT SEARCH button/indicator

O .–/>+/ENTER (p re vi ous/next/

enter) dial

O

RETURN button

P

Q C/X/x/c/ENTER buttons

R DISPLAY button

S TOP MENU button

T MENU button

U PICTURE MODE button

V SURROUND button

W ONE/ALL DISCS button

X FOLDER button

Y LOAD button

Z (remote sensor)

wj KEYBOARD jack

wk FL OFF button/indicator

wl TIME/TEXT button

Front panel display

When playing back a DVD VIDEO/DVD-RW

Disc type

Current title and chapter

When playing back a VIDEO CD with Playback Control (PBC)

Disc type

Current scene

When playing back a CD, Super audio CD, DATA CD (MP3 audio), or VIDEO CD (without

PBC)

Disc type

(“SACD” lights up

during HD playback)

Lights up when

playing MP3 audio

tracks

All discs mode

Playing status

Current audio signal

All discs mode

Playing status

All discs mode

Playing status Current disc

Current index (CD, Super Audio CD,

VIDEO CD) or track (DATA CD)

Current track (CD, Super Audio CD,

VIDEO CD) or album (DATA CD)

Current play

mode

Current play mode

Current play

mode

Lights up when you can

change the angle

Current disc

Playing time

Current disc

Playing time

Lights up when playing the multi-channel

playback area on Super Audio CDs

Playing time

Rear panel

A DIGITAL OUT (COAXIAL) jack

B DIGITAL OUT (OPTICAL) jack

C 5.1CH OUTPUT jacks

D LINE OUT AUDIO L/R 1/2 jacks

E LINE OUT VIDEO 1/2 jacks

F S VIDEO OUT 1/2 jacks

G COMPONENT VIDEO OUT (Y, P

, PR/CR) jacks

B

C

H COMPONENT VIDEO OUT/SCAN

SELECT switch

I COMM AND MODE switch

Remote

L c / C SEARCH/STEP

buttons

M H PLAY button

The H button has a tactile dot.*

N X PAUSE button

O C/X/x/c buttons

P DISPLAY/FILE button

Q TOP MENU/EDIT button

R [/1 (on/standby) button

S VOL (volume) +/– buttons

The + button has a tactile dot.*

T TV/VIDEO/DISC SKIP + button

U ENTER button

V WIDE MODE/DISC SKIP – button

W FOLDER button

X PICTURE MEMORY button

Y ANGLE button

Z TIME/TEXT button

wj SACD/CD (Super Audio CD/CD)

button

wk SACD MULTI/2CH (Super Audio CD

multi/2 channel) button

wl INSTANT SEARCH button

e; INSTANT REPLAY button

ea m/M SCAN/SLOW

B

/

A TV/DISC EXPLORER/DVD switch

B OPEN/CLOSE button

C Number buttons

The number 5 button has a tactile do t.*

D CLEAR button

E SUR (surround) button

F PICTURE MODE button

G SUBTITLE button

H AUDIO button

I PICTURE NAVI (picture navigation)

button

J REPEAT button

K ./> PREV/NEXT (previous/

next) buttons

buttons

es x STOP butto n

ed ENTER button

ef O RETURN button

eg MENU/SORT button

*Use the tactile dot as a reference when operating

the player.

10

SECTION 3

DISASSEMBLY

• This set can be disassembled in the order shown below.

3-1. DISASSEMBLY FLOW

Note 1: The process described in can be performed in any order.

Note 2: Without completing the process described in , the next process can not be performed.

Set

3-2. CASE

(Page 12)

DVP-CX985V

3-3. MB BOARD

(Page 12)

3-5. BRACKET (L)/(R)

(Page 13)

3-7. COVER (PT)/(CDM)

(Page 14)

3-8. DVBU26 ASSY

(Page 15)

3-18. CD/DVD MECHANISM

DECK BLOCK

(CDM62-DVBU26)

(Page 21)

3-19. MOTOR (400) ASSY

(LOADING) (M602)/(TABLE) (M601),

LOADING MOTOR BOARD

(Page 21)

3-4. AV BOARD

(Page 13)

3-9. POWER BLOCK

(Page 15)

3-20. OPTICAL

PICK-UP

(KHM-290AAA)

(Page 22)

3-17. LOCK SW

BOARD,

LOADING

SW BOARD

(Page 20)

3-6. FRONT PANEL SECTION

(Page 14)

3-10. TABLE (400) ASSY

(Page 16)

3-11. DOOR BLOCK,

BASE (DOOR) ASSY

(Page 16)

3-12. DC

MOTOR

(DOOR)

(M603)

(Page 17)

3-14. D. SENS

OUT

BOARD,

D. SENS IN

BOARD

(Page 18)

3-16. DOOR SW

BOARD

(Page 19)

3-15. POP-UP

(400)

ASSY

(Page 18)

3-13. HOLDER

(TABLE SENSOR 400)

(Page 17)

11

DVP-CX985V

)

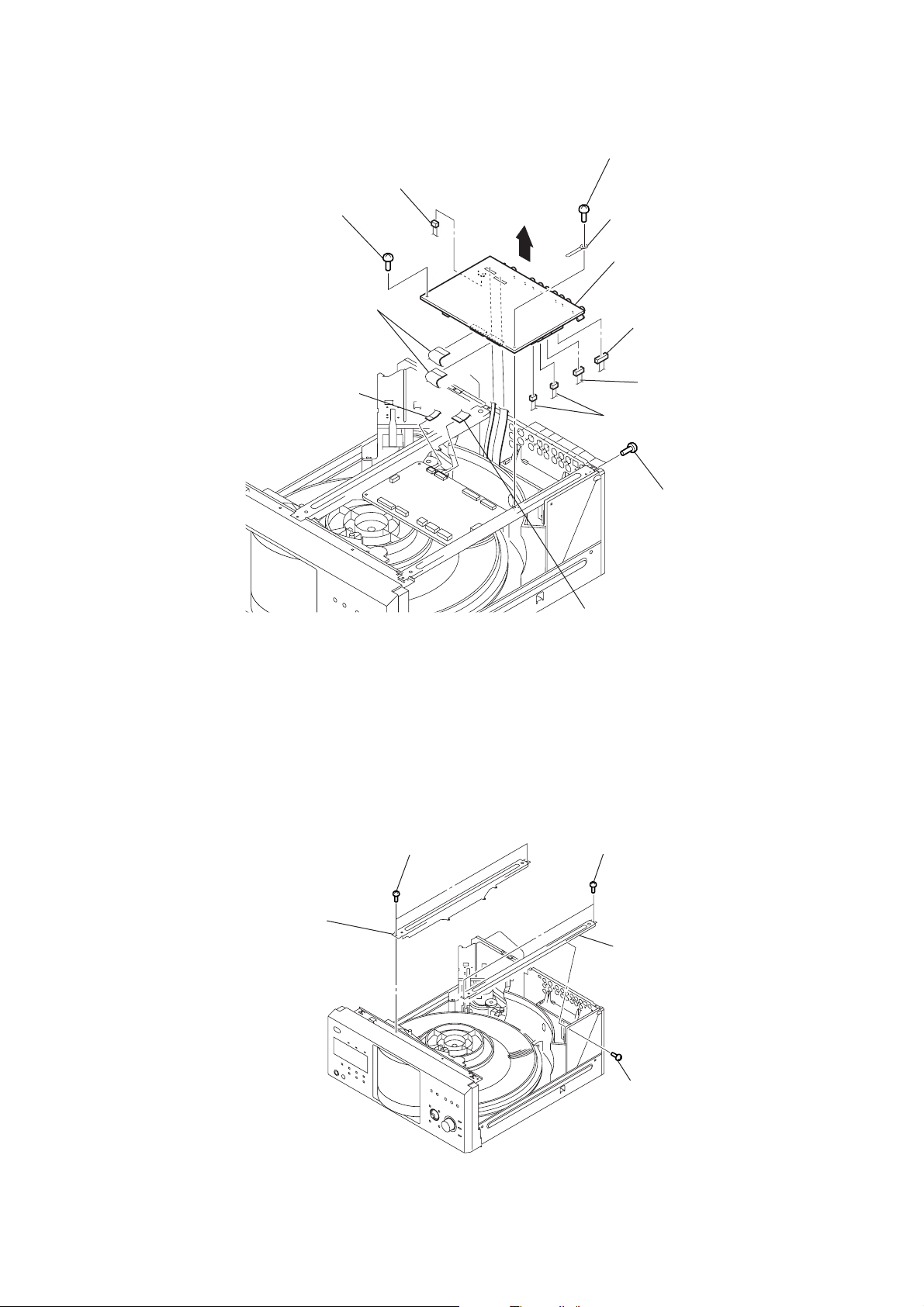

Note: Follow the disassembly procedure in the numerical order given.

3-2. CASE

5

case

4

two screws

(case 3 TP2)

1

two screws

(case 3 TP2)

3

three screws

(case 3 TP2)

3-3. MB BOARD

1

8

9

two harnesses

wire (flat type)

(19 core) (CN102)

two screws

(BVTP 3

2

two screws

(case 3 TP2

3

wire (falt type)

(9 core) (CN204)

2

qs

×

8)

MB board

wire (flat type)

(26 core) (CN203)

4

q;

two wires (flat type)

(23 core: CN601,

27 core: CN501)

two screws

(BVTP 3

×

8)

12

5

connector (CN105)

6

connector (CN103)

7

connector (CN106)

qa

connector (CN101)

)

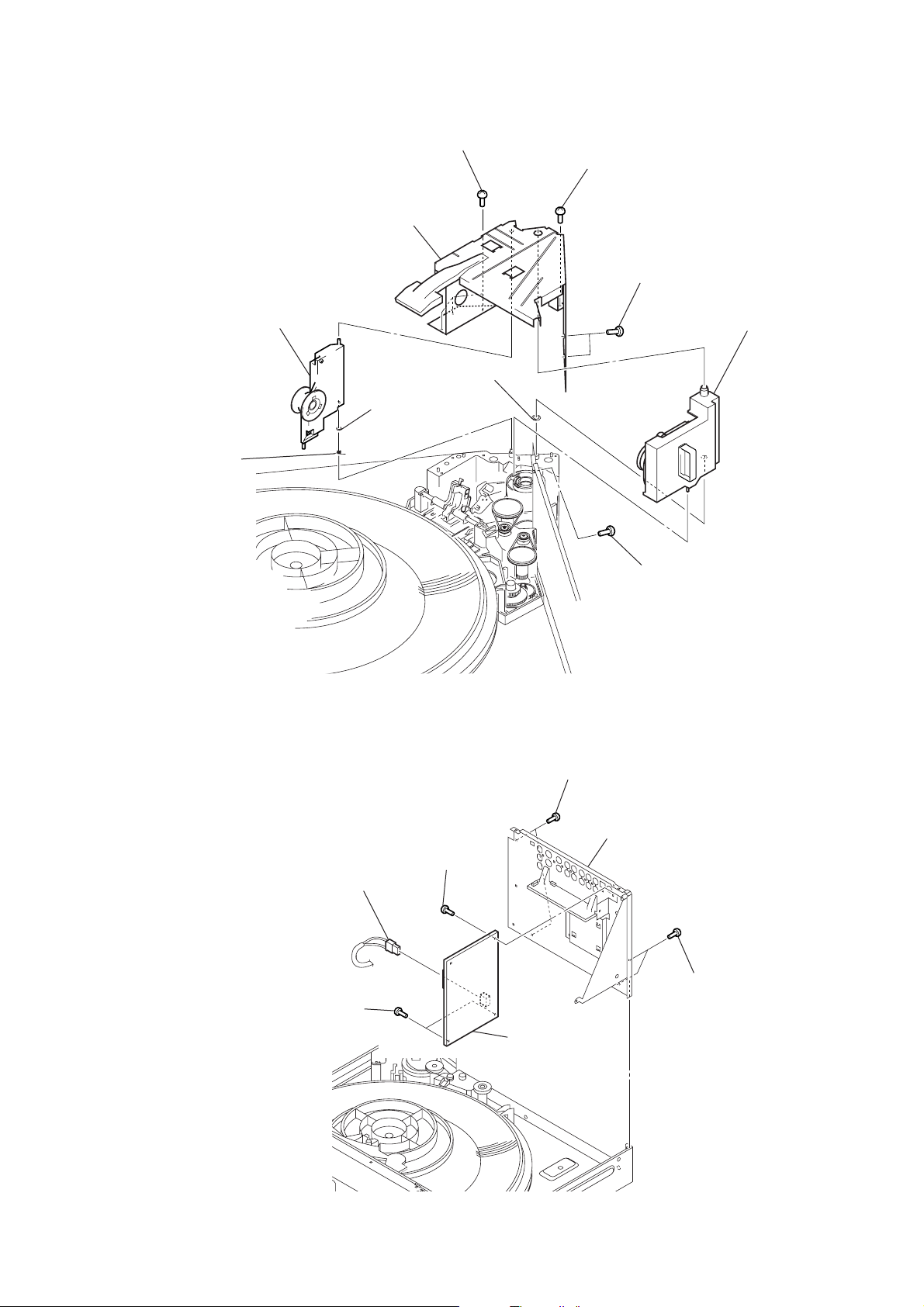

3-4. AV BOARD

4

screw (BVTP 3 × 8)

9

connector (CN201)

5

+BV sumitite (B3)

6

harness

DVP-CX985V

8

2

wire (flat type)

(9 core) (CN204)

3-5. BRACKET (L)/(R)

two wires (flat type)

(23 core: CN202,

27 core: CN203)

7

qd

AV board

qs

connector (CN205)

qa

q;

two connectors

(CN206, 207)

1

wire (flat type)

(26 core) (CN203)

connector (CN208

3

eight screws

(BVTP 3

×

8)

2

bracket (L)

1

two screws

(BVTP 3

3

×

8)

two screws

(BVTP 3

5

bracket (R)

4

screw

(BVTP 3

×

8)

×

8)

13

DVP-CX985V

3-6. FRONT PANEL SECTION

3

two screws

(BVTP 3

×

8)

2

screw

(BVTP 3

5

claw

×

8)

4

claw

1

five screws

(BVTP 3

3-7. COVER (PT)/(CDM)

1

screw

(BVTP 3

3

cover (PT)

6

front panel section

×

8)

4

×

8)

2

screw

(BVTP 3

8

bracket (CDM)

×

8)

7

three screws

(BVTP 3

×

8)

six screws

(BVTP 3

×

8)

5

three screws

(BVTP 3

×

8)

14

6

cover (CDM)

DVP-CX985V

y

)

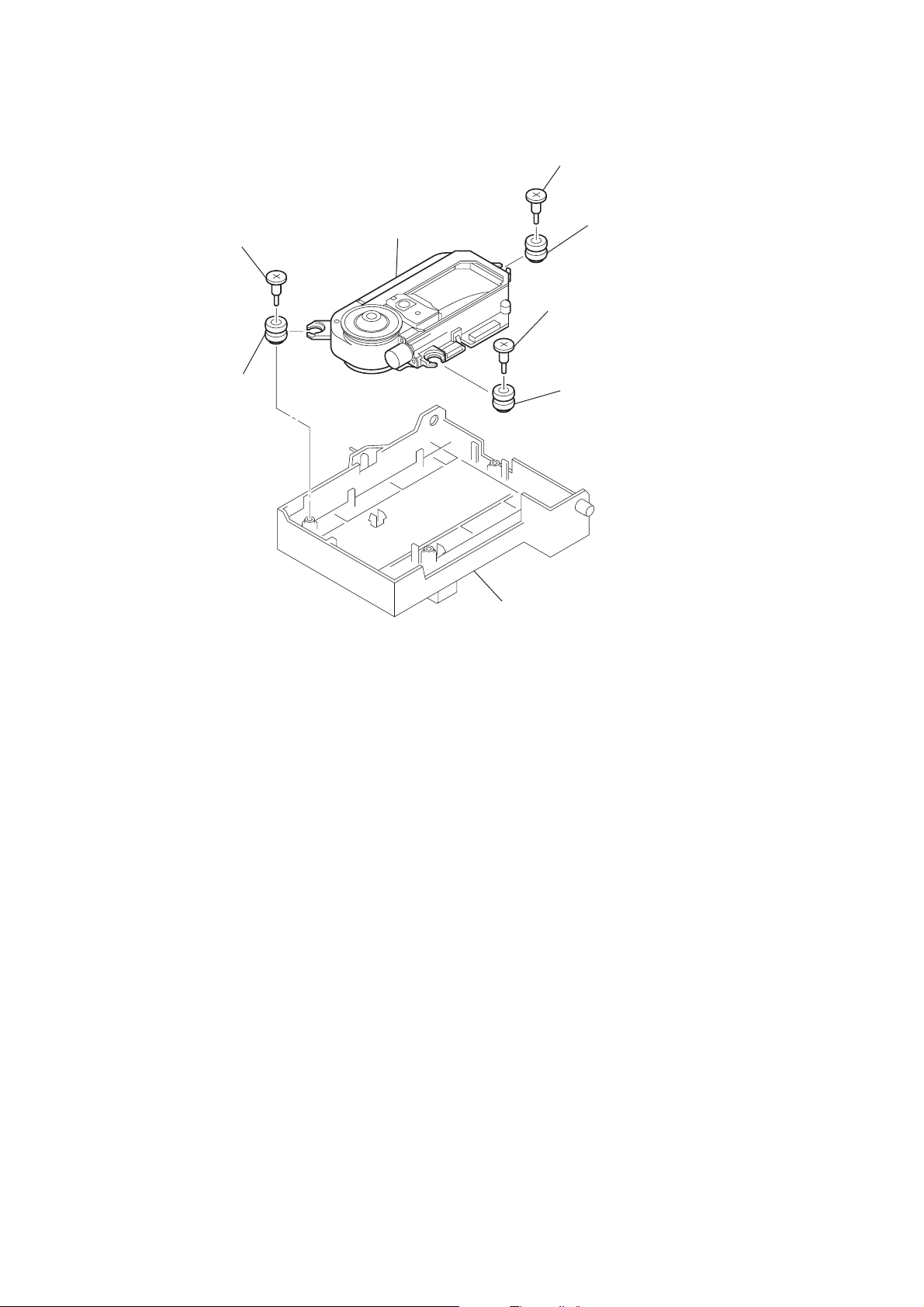

3-8. DVBU26 ASSY

6

torsion holder

(magnet) block

8

torsion spring

(MG)

5

bracket (top 400) block

7

washer

1

three screws

(BVTP 3

q;

8 washer

×

8)

2

screw (BVTP 3 × 8)

3

two screws

(BVTP 3

×

8)

9

DVBU26 ass

3-9. POWER BLOCK

4

6

two screws

(BVTP 3

connector

(CN101)

×

8)

5

screw

(BVTP 3

4

screw

(BVTP 3

1

two screws

(BVTP 3

×

8)

×

8)

3

rear panel block

×

8)

2

two screws

(BVTP 3

×

8

7

power block

15

DVP-CX985V

)

)

3-10. TABLE (400) ASSY

1

2

guide (door)

Note for installation

When installing the guide (door),

align the positions as shown.

screw (M 3 × 14)

3

table (400) assy

3-11. DOOR BLOCK, BASE (DOOR) ASSY

2

3

cover (table)

three screws (BVTP 3 × 8)

7

base (door) assy

4

washer

1

connector (CN904

16

4

door assy

5

two screws (BVTP 3 × 8)

6

eight screws (BVTP 3 × 8

3-12. DC MOTOR (DOOR) (M603)

d

1

belt

3

Remove two

solderings.

5

DC motor (door) (M603)

4

DVP-CX985V

door motor boar

3-13. HOLDER (TABLE SENSOR 400)

2

connector

(CN83)

5

screw

(PTTWH 3

6

×

6)

two claws

1

four screws

(BVTP 3

4

×

8)

sensor board

3

two connectors

(CN81, CN82)

6

claw

2

two screws (BVTP 3 × 8)

7

holder

(table sensor 400)

17

DVP-CX985V

)

3-14. D. SENS OUT BOARD, D. SENS IN BOARD

6

screw

4

screw

(PSW 3

5

D. sens out board

×

8)

1

screw

(PTTWH 3

(PTTWH 3

×

6)

×

6)

7

D. sens in board

2

two step screws (T1)

3

bracket (sensor 400

3-15. POP-UP (400) ASSY

2

step screw

3

pop-up (400) assy

18

1

screw (PTPWH 3 × 6)

3-16. DOOR SW BOARD

1

screw (PTPWH 2.6 × 8)

2

gear (cam)

3

screw (PTPWH 2.6 × 8)

4

gear (B)

5

two screws

(BVTP 2.6

6

door SW board

DVP-CX985V

×

8)

Precaution during the gear (cam) installation

1

Move the slider (pop-up) and the lever (pu joint) fully

in the direction of the arrow

slider (pop-up)

The levers of the two rotary switches on the door SW board

are shown in the illustration below.

A

A

.

lever (pu joint)

two rotary switches

door SW board

2

Install the gear (cam) in the direction shown

in the illustration and rotate it fully

in the direction of the arrow

3

When the gear (cam) happens to go too deep,

return it to the original position

in the direction of the arrow

B

.

gear (cam)

C

.

B

C

19

DVP-CX985V

)

3-17. LOCK SW BOARD, LOADING SW BOARD

2

screw

(BVTP3

×

8)

A

B

1

Rotate the pulley (400) in the

direction of the arrow A fully.

3

Rotate the pulley (400) in the

direction of the arrow B fully.

Note for installation

When installing the

loading SW board and

lock SW boards,

align the leads position as shown.

loading SW board

lock SW board

leads

position

claws

9

8

screw

(BVTP 3 × 8)

lock SW

board

7

gear (center)

5

tapping screw

4

6

pulley (400

0

screw

(BVTP 2.6 × 8)

qa

loading SW

board

belt

20

3-18. CD/DVD MECHANISM DECK BLOCK

(CDM62-DVBU26)

6

CD/DVD mechanism deck block (CDM62-DVBU26)

5

seven screws

(BVTP 3 × 8)

DVP-CX985V

1

connector

(CN905)

2

connector

(CN903)

3

screw (PSW 3 × 8)

4

four screws

(BVTP 3 × 8)

3-19. MOTOR (400) ASSY (LOADING) (M602)/(TABLE) (M601), LOADING MOTOR BOARD

1

two belts (400)

4

motor (400) assy (loading)

(M602)

6

motor (400) assy (table)

(M601)

2

three screws

(PTPWH 2.6

3

Remove two

solders.

7

loading motor

board

5

Remove two

solders.

×

8)

21

DVP-CX985V

3-20. OPTICAL PICK-UP

(KHM-290AAA)

3

step screw (M)

7

insulator

8

optical pick-up (KHM-290AAA)

1

step screw (M)

5

2

step screw (M)

6

insulator

insulator

4

holder (BU) block

22

SECTION 4

TEST MODE

DVP-CX985V

4-1. GENERAL DESCRIPTION

The T est Mode allo ws you to mak e diagnosis and adjustment easily using the remote commander and monitor TV. The instructions,

diagnostic results, etc. are given on the on-screen display (OSD).

4-2. STARTING TEST MODE

Press the [TOP MENU], [CLEAR], I/1 keys on the remote commander in this order with the power of main unit in OFF status,

and the Test Mode starts, then “DIAG START” will be displayed

on the fluorescent display tube and the menu shown below will be

displayed on the TV screen. At the bottom of menu screen, the

model name and revision number are displayed. Last Off at the

lower right of screen indicates the information code concerning

the last power off. To execute each function, select the desired

menu and press its number on the remote commander. To exit from

the Test Mode, press the I/1 key.

Test Mode Menu

0. Syscon Diagnosis

1. Drive Auto Adjustment

2. Drive Manual Operation

3. Mecha Aging

4. Emergency History

5. Version Information

6. Video Level Adjustment

Exit: POWER Key

Model :TTX-15xxxx

Revision:x.xxx Last Off: xx

Power Off Information Code List

00: Primary Power Off

01: Power Off Request from SYSTEM CONTROL

02: Power Off by Emergency Power Off Command from SYS-

TEM CONTROL

(if information is sent from SYSTEM CONTROL)

03: IF CON Judged that SYSTEM CONTROL is Faulty

04: Power Off from Diagnosis Mode of IF CON

05: Forced Power Off by the User

06: Power Off by Power Supply Voltage Monitor

4-3. SYSCON DIAGNOSIS

The same contents as board detail check by serial interface can be

checked from the remote commander. On the Test Mode Menu

screen, press [0] key on the remote commander , and the following

check menu will be displayed.

### Syscon Diagnosis ###

Check Menu

0 . Quit

1 . All

2 . Version

3 . Peripheral

4 . Servo

5 . Supply

6 . AV Decoder

7 . Video

8 . Audio

_

0. (Quit)

Quit the Syscon Diagnosis and return to the Test Mode Men u.

1. (All items continuous check)

This menu checks all diagnostic items continuously. Normally, all

items are checked successively one after another automatically

unless an error is found, but at a certain item that requires judgment through a visual check to the result, the following screen is

displayed for the key entry.

### Syscon Diagnosis ###

Diag All Check

No. 2 Version

2-3. ROM Check Sum

Check Sum = xxxx

Press NEXT Key to Continue

Press PREV key to Repeat

For the ROM Check, the check sum calculated by the Syscon is

output, and therefore you must compare it with the specified value

for confirmation.

Following the message, press > key to go to the next item,

or . key to repeat the same check again.

23

DVP-CX985V

To quit the diagnosis and return to the Check Menu screen,

press x or [ENTER] key. If an error occurred, the diagnosis is

suspended and the error code is displayed as shown below.

### Syscon Diagnosis ###

3-2. EEPROM Check

Error 03 : EEPROM Write/Read N

Address : 00000001

Write Data: 2492

Read Data : 2490

Press NEXT Key to Continue

Press PREV key to Repeat

_

Press x key to quit the diagnosis, or . key to repeat the same

item where an error occurred, or > key to continue the check

from the item next to faulty item.

* In “All item continuous check”, pressing stop or enter will not

quit the diagnosis.

Selecting [2] and subsequent items call the submenu screen of

each item. When “———” is displayed in the submenu, it means

that the test is not supported in the model.

For example, if “5. Supply” is selected, the following submenu

will be displayed.

### Syscon Diagnosis ###

Check Menu

No. 5 Supply

0. Quit

1. All

2. ARP Register Check

3. ARP to RAM Data Bus

4. ARP to RAM Address Bus

5. ARP RAM Check

0. (Quit)

Quit the submenu and return to the main menu.

1. (All submenu items continuous check.)

This menu checks 2 and subsequent items successively . At the item

where visual check is required for judgment or an error occurred,

the checking is suspended and the message is output for key entry .

Normally, all items are checked successively one after another

automatically unless an error is found.

Selecting [2] and subsequent items executes respective menus and

outputs the results.

For the contents of each submenu, see “General Description of

Checking Method” and “Check Items List”.

General Description of Checking Method

2. V ersion

(2-2) Revision

ROM revision number is displayed.

Error: Not detected.

The revision number defined in the source file is displayed

with four digits.

(2-3) ROM Check Sum

Check sum is calculated.

Error: Not detected.

8-bit data are added up to the ROM address 0x000F0000 to

0x002EFFFF , and the result is displayed with 4-digit hexadecimal number. Error is not detected. Compare the result

with the specified value.

(2-4) Model Type

Model code is displayed.

Error: Not detected.

The model code read from the EEPROM is displayed with

2-digit hexadecimal number.

(2-5) Region

Region code is displayed.

Error: Not detected.

The region code determined from the model code is displayed.

(2-6) M’t Check

Mount resistance is checked.

Error 22: The region code does not accord.

Check whether the region code that is deduced from model

resistance and destination resistance accords with the region code that is deduced from region resistance value.

3. Peripheral

(3-2) EEPROM Check

Data write t read, and accord check

Error 03: EEPROM write/read discord

0x9249, 0x2942 and 0x4294 are written to the address 0x00

to 0xFF of the EEPROM and then read for checking. Before writing, the data are saved, then after checking, they

are written to restore the contents of EEPROM.

(3-3) Gate Array Check

Data write → read, and accord check

Error 02: Gate Array write/read discord

Data of 0x00 to 0xFF is written sequentialy to the address

0xF and then read for checking.

(3-4) NAND FLASH Check

Data delete → write → read, and accord check

Error 04: delete error

Error 05: write error

Error 06: read data discord

Error 21: more than ten blocks are defective

Deleting, writing and checking read data are executed to

the zeroth block of Flash memory.

If any detective block is found, the address is displayed.

When more than ten blocks are defective, it is considered

as an error.

24

(3-5) SACD Check

Device reset t internal organs RAM check.

Error 50: Write and read data discord.

DVP-CX985V

(3-6) VENC Check

Data write t read, and accord check

Error 52: Write/read data discord

Error may occur due to defect of access with syscon.

(3-7) —————

Check no support.

(3-8) EX RAM Check

Test Data write t read, and accord check

Error 02: The external RAM used in the system control is

checked.

4. Servo

(4-2) Servo DSP Check

Data write t read, and accord check

Error 12: Read data discord

0x9249, 0x2942 and 0x4294 are written to the RAM address 0x602 of the Servo DSP and then read for checking.

(4-3) —————

Check no support.

(4-4) RF Amp (SSI) W/R Check

Data write t read, and accord check

Error 13: RF Amp register write, and read data discord

Implement 8-bit shift operation of the 0x01 to the readable/writable register of the RF Amp. If once write data do

not accord with read data, it is NG.

5. Data Supply System

(5-2) ARP Register Check

Data write t read, and accord check

Error 08: ARP register write, and read data discord

Data 0x00 to 0xFF is written sequentially to the ARP TMAX

register (address 0xC6) and then read for checking.

(5-3) ARP to RAM Data Bus

Data write t read, and accord check

Error 09: ARP Tt RAM data bus error

Data 0x0001 to 0x8000 where one bit each is set to 1 are

written to the address 0 of RAM (IC303) connected to the

ARP (IC301) through the bus, then they are read and

checked. In case of discord, written bit pattern and read

data are displayed. If data where multiple bits are 1 are

read, the bits concerned may touch each other. Further, if

data where certain bit is always 1 or 0 regardless of written

data, the line could be disconnected or shorted.

(5-4) ARP to RAM Address Bus

Data write t other address read discord check

Error 10: ARP Tt RAM address bus error

Caution: Address and data display in case of an error is

different from the display of other diagnosis (described

later).

Before starting the test, all addresses of RAM (IC303) are

cleared to 0x0000.

First, 0xA55A is written to the address 0x00000, and the

address data are read and checked from addresses 0x00001

to 0x80000 while shifting 1 bit each. Next, the data at that

address is cleared, and it is written to the address 0x00001,

and read and checked in the same manner. T his check is

repeated up to the address 0x80000 while shifting the address data by 1 bit each.

If data other than 0 is read at the addresses except written

address, an error is given because all addresses were already cleared to 0. In this check, the error display pattern is

different from that of other diagnosis; read data, written

address, and read address are displayed in this order. Ho wever, the message uses same template, and accordingly exchange Address and Data when reading. T he following display, for example,

### Syscon Diagnosis ###

5-4. ARP to RAM Address Bus

Error 10: ARP - RAM Address B

Address : 0000A55A

Write Data : 00000000

Read Data : 00080000

Press NEXT Key to Continue

Press PREV key to Repeat

_

shows the data 0xA55A was read from address 0x00080000

though it was written to the address 0x00000000. This implies that these addresses are in the form of shadow. Also,

if the read data is not 0xA55A, another error will be present.

(5-5) ARP RAM Check

Data write t read, and accord check

Error 11: ARP RAM read data discord

The program code data stored in ROM are copied to all

areas of RAM (IC303) connected to the ARP (IC301)

through the bus, then they are read and checked if they accord. If the detail check was selected initially, the data are

written to all areas and read, then the same test is conducted

once again with the data where all bits are inverted between

1 and 0. If discord is detected, faulty address, written data,

and read data are displayed following the error code 11,

and the test is suspended.

25

DVP-CX985V

6. AV Decoder

(6-2) 1935 RAM

Data write t read, and accord check

Error 14: AVD RAM read data discord

The program code data stored in ROM (IC106) are copied

to all areas of RAM (IC404, 405) connected to the AVD

(IC403) through the bus, then they are read and checked if

they accord. Further, the same test is conducted once again

with the data where all bits are inverted between 1 and 0. If

discord is detected, faulty address, written data, and read

data are displayed following the error code 14, and the test

is suspended.

During the test, OSD display becomes blank as the OSD

area is also checked.

(6-3) 1935 SP

ROM t AVD RAM t Video OUT

Error: Not detected.

The data including sub picture streams in ROM (IC106)

are transferred to the RAM (IC404, 405) in AVD (IC403),

and output as video signals from the AVD (IC403).

Though OSD display becomes blank, the output of video

signals continues until the key is pressed.

7. Video Output

(7-2) Color Bar

AVD color bar command write t Video OUT

Error: Not detected.

The command is transferred to the AVD, and the color bar

signals are output from video terminals.

(7-3) Composite Out

AVD color bar command write t Video (Composite, Y/C)

OUT

Error: Not detected.

The command is transferred to the AVD, and the color bar

signals are output from video terminals.

(7-4) Y/C Out

AVD color bar command write → Video (Composite, Y/C)

OUT

Error: Not detected.

The command is transferred to the AVD, and the color bar

signals are output from video terminals.

They are output from all video terminals (Composite, Y/C,

Component).

(7-5) —————

Check no support.

8. Audio Output

(8-2) ARP t 1935

Data flow from supply system DRAM to SDRAM of AV

Decoder is tested.

Error 15: ARP t 1935 video NG

16: ARP t 1935 audio NG

(8-3) —————

Check no support.

(8-4) Test T one

Pink noise output

Error: Not detected.

In the models without DD output, the test tone is output

from L and R of 2-channel only, and in the models with

DD output, the test tone is output from L and R of 2-channel, and all channels of 5.1 output.

After turning on all outputs, each time the > key is

pressed, the output channel is switched for individual channel checking.

Diagnosis Check Items List

2. V ersion Display

(2-2) Revision

(2-3) ROM Check Sum

(2-4) Model Type

(2-5) Region

(2-6) M’t Check

3. Peripheral

(3-2) EEPROM Check

(3-3) Gate Array Check

(3-4) NAND FLASH Check

(3-5) SACD Check

(3-6) VENC Check

(3-7) ———— (Function not supported)

(3-8) EX RAM Check

4. Servo

(4-2) Servo DSP Check

(4-3) ———— (Function not supported)

(4-4) RF Amp (SSI) W/R Check

5. Data Supply System

(5-2) ARP Register Check

(5-3) ARP to RAM Data Bus

(5-4) ARP to RAM Address Bus

(5-5) ARP RAM Check

(7-6) Component Out

AVD color bar command write t Video (Component, Y/

C) OUT

Error: Not detected.

The command is transferred to the AVD, and the color bar

signals are output from video terminals.

(7-7) —————

Check no support.

26

6. AV Decoder

(6-2) 1935 RAM

(6-3) 1935 SP

7. Video Output

(7-2) Color Bar

(7-3) Composite Out

(7-4) Y/C Out

(7-5) ———— (Function not supported)

(7-6) Component Out

(7-7) ———— (Function not supported)

8. Audio Output

(8-2) ARP t 1935

(8-3) ———— (Function not supported)

(8-4) Test Tone

DVP-CX985V

Error Codes List

00: Error not detected

01: RAM write/read data discord

03: EEPROM NG

04: Flash memory clear error

05: Flash memory write error

06: Flash memory read data discord

08: ARP register read data discord

09: ARP Tt RAM data bus error

10: ARP Tt RAM address bus error

11: ARP RAM read data discord

12: Servo DSP NG

13: RF Amp NG

14: 1935 SDRAM NG

15: ARP t 1935 video NG

16: ARP t 1935 audio NG

1A:System call error (Function not supported)

1B:System call error (Parameter error)

1C:System call error (Illegal ID number)

20: System call error (Time out)

22: Resistor installation error

50: SACD Decoder W/R NG

52: Video Encoder W/R NG

55: External RAM W/R NG

90: Error occurred

91: User verification NG

92: Diagnosis cancelled

4-4. DRIVE AUTO ADJUSTMENT

DVD reference disc

Single Layer

HLX-503 (J-6090-069-A) (NTSC) OR

HLX-504 (J-6090-088-A) (NTSC)

Dual Layer

HLX-501 (J-6090-071-A) (NTSC) OR

HLX-505 (J-6090-089-A) (NTSC)

CD reference disc

YEDS-18 (3-702-101-01) OR

PATD-012 (4-225-203-01)

On the T est Mode Menu screen, press [1] key on the remote commander, and the drive auto adjustment menu will be displayed.

## Drive Auto Adjustment ##

Adjustment Menu

0. ALL

1. DVD-SL

2. CD

3. DVD-DL

4. LCD

_

Exit: RETURN

Normally, [0] is selected to adjust DVD (single layer), CD, and

DVD (dual layer) in this order. But, individual items can be adjusted for the case where adjustment is suspended due to an error.

In this mode, the adjustment can be made easily through the operation following the message displayed on the screen. Which disc

is currently adjusted is displayed on the fluorescent display tube.

0. ALL

You will be asked if EEPROM data are initialized or not, and for

this prompt, select

setting data in EEPROM, Emergency History and Hour Meter are

cleared to initialize. Then, [1] DVD-SL disc, [2] CD disc, and [3]

DVD-DL disc are adjusted in this order . Because the changer model

can accept multiple discs in advance of adjustment, adjustments

can be continued by exchanging discs automatically whenever an

adjustment is completed following the instruction on screen. You

can exit the adjustment by pressing the x button. In adjusting

each disc, the mirror time is measured to check the disk type. In

the auto adjustment, whether the disc type is correct is not checked

unlike conventional models, and accordingly, take care not to insert a different type of disc.

Three kinds of discs can be set in advance. In this case, set discs in

order to the displayed number with following the massage. Every

time after adjusting a disc, the disc is replaced and adjustment is

continued automatically.

[0] and press the [ENTER] key. First, the servo

Set Disc

Disc slot number 1: DVD-SL

Disc slot number 2: CD

Disc slot number 3: DVD-DL

27

DVP-CX985V

1. DVD Single Layer Disc

Select [1], insert DVD single layer disc, and press [ENTER] key,

and the adjustment will be made through the following steps, then

adjusted values will be written to the EEPROM. T he disc slot No.

1 is used in the changer type model. If there is no disc on the disc

slot No. 1, the tray will be open to wait for closing. If there is a

disc on the table, the adjustment starts immediately. If y ou put a

disc prior to adjustment, confirm that the SL disc is set on the disc

slot 1.

DVD Single Layer Disc Adjustment Steps

1. Sled Reset

2. Disc Check Memory SL

3. Set Disc Type SL

4. Spindle Start

5. Laser Diode ON

6. Focus Error Check

7. Focus ON 0 with PI Level measure

8. Auto Track Offset Adjust L0

9. Try Level Check

10. Tracking ON

11. CLVA ON

12. Sled ON

13. Auto Focus Balance Adjust

14. Auto Loop Filter Offset Adjust

15. Auto Focus Gain Adjust L0

16. Auto Focus Balance Adjust L0

17. EQ Boost Adjust

18. Auto Loop Filter Offset Adjust

19. Auto Track Gain Adjust

20. RF Level Measure

21. Jitter measure

22. Eep Copy Loop Filter Offset

23. All Servo Off

2. CD Disc

[2], insert CD disc, and press [ENTER] key, and the adjust-

Select

ment will be made through the following steps, then adjusted values will be written to the EEPROM. The disc slot No. 2 is used in

the changer type model. If there is no disc on the disc slot No. 2,

the tray will be open to wait for closing. If there is a disc on the

table, the adjustment starts immediately. If you put a disc prior to

adjustment, confirm that the CD is set on the disc slot 2.

CD Adjustment Steps

1. Sled Reset

2. Disc Check Memory CD

3. Set Disc Type CD

4. Spindle Start

5. Laser Diode ON

6. Focus Error Check

7. Focus ON 0 with PI Level measure

8. Auto Track Offset Adjust L0

9. Try Level Check

10. Tracking ON

11. CLVA ON

12. Sled ON

13. Auto Focus Balance Adjust

14. Auto Loop Filter Offset Adjust

15. Auto Focus Gain Adjust L0

16. Auto Focus Balance Adjust L0

17. EQ Boost Adjust

18. Auto Loop Filter Offset Adjust

19. Auto Track Gain Adjust

20. Copy Adjustment Data to LCD

21. RF Level Measure

22. Jitter measure

23. All Servo Off

3. DVD Dual Layer Disc

Select

[3], insert DVD dual layer disc, and press [ENTER] key,

and the adjustment will be made through the following steps, then

adjusted values will be written to the EEPROM. The disc slot No.

3 is used in the changer type model. If there is no disc on the disc

slot No. 3, the tray will be open to wait for closing. If there is a

disc on the table, the adjustment starts immediately. If you put a

disc prior to adjustment, confirm that the DL disc is set on the disc

slot 3.

DVD Dual Layer Disc Adjustment Steps

1. Sled Reset

2. Disc Check Memory DL

3. Set Disc Type DL

DVD DL Layer 1 Adjust

4. Spindle Start

5. Laser Diode ON

6. Focus ON 0 with PI Level measure

7. Auto Track Offset Adjust L1

8. Tracking ON

9. ClVA ON

10. Sled ON

11. Auto Focus Balance Adjust

12. Auto Loop Filter Offset Adjust

13. Auto Focus Gain Adjust L1

14. EQ Boost Adjust L1

15. Auto Track Gain Adjust L1

16. Jitter measure

DVD DL Layer 0 Adjust

17. Focus Jump (L1 t L0)

18. Auto Track Offset Adjust L0

19. Tracking ON

20. ClVA ON

21. Sled ON

22. Auto Focus Balance Adjust

23. Auto Focus Gain Adjust L0

24. Auto Focus Balance Adjust L0

25. EQ Boost Adjust L0

26. Auto Track Gain Adjust L0

27. Jitter measure

28. All Servo Stop

4. LCD

LCD disc is not adjusted because the adjusted data of CD are reflected, and SACD (hybrid disc) is not adjusted because the adjusted data of CD and DVD-DL are reflected.

28

DVP-CX985V

4-5. DRIVE MANUAL OPERATION

On the T est Mode Menu screen, select [2], and the manual oper ation menu will be displayed. For the manual operation, each servo

on/off control and adjustment can be executed manually.

## Drive Manual Operation ##

1. Disc type

2. Servo Control

3. Track/Layer Jump

4. Manual Adjustment

5. Auto Adjustment

6. Memory Check

7. Changer Manual Move

8. Changer Mecha Check

0. Disc Check Memory

_

Operation Menu

Exit: RETURN

In using the Manual Operation menu, take care of the following

points. These commands do not provide protection, thus requiring

correct operation. The sector address or time code field is displayed when a disc is loaded.

1. Set correctly the disc type to be used on the Disc Type

setting screen.

The Disc T ype setting must be performed after a disc was

loaded.

The set Disc Type is cleared when the tray is opened.

2. After power ON, if the Manual Operation was selected,

first perform “Reset SLED TIL T” by opening 1. Disc T ype

screen.

3. In case of an alarm, immediately press the x button to

stop the servo operation, and turn the power OFF.

Basic operation (controllable from front panel or remote commander)

I/1 :Power OFF

x : Servo stop

A (DISC EJECT) : Stop+Eject/Loading

O (RETURN) : Return to Operation Menu or Test Mode

Menu

> , . :Transition between sub modes of menu

[1] to [9], [0] : Selection of menu and items

Cursor [Q]/[q] : Increase/Decrease in manually adjusted value

0. Disc Check Memory

Disc Check

1. SL Disc Check

2. CD Disc Check

3. DL Disc Check

0. Reset SLED TILT

_

On this screen, the mirror time is measured and written to the

EEPROM to check the disc type. First, set a DVD SL disc and

press [1], then set a CD disc and press [2], and finally set a DVD

DL disc and press [3]. The measured mirror time is displayed respectively.

The adjustment must be executed more than once after default

data were written.

From this screen, you can go to another mode by

pressing > or . key, but you cannot enter this mode from

another mode. You can enter this mode from the Operation Menu

screen only.

1. Disc Type

Disc Type

1. Disc Type Auto Check

2. DVD SL 12cm

3. DVD DL 12cm

4. CD 12cm

5. LCD 12cm

6. DVD SL 8cm

7. DVD DL 8cm

8. CD 8cm

9. LCD 8cm

0. Reset SLED TILT

_ EMG. 00

0. Reset SLED TIL

On this screen, select the disc type. To select the disc type, pr ess

the number of the loaded disc. The selected disc type is displayed

at the bottom. Selecting [1] automatically selects and displays the

disc type. In case of wrong display, retry “Disc Check Memory”.

Also, opening the tray causes the set disc type to be cleared. In

this case, set the disc type again after loading.

In performing manual operation, the disc type must be set.

29

DVP-CX985V

Once the disc type has been selected, the sector address or time

code display field will appear as shown below. These values are

displayed when PLL is locked.

Disc Type

1. Disc Type Auto Check

2. DVD SL 12cm

3. DVD DL 12cm

4. CD 12cm

5. LCD 12cm

6. DVD SL 8cm

7. DVD DL 8cm

8. CD 8cm

9. LCD 8cm

0. Reset SLED TILT

_ SA.------ SI.-- EMG.00

DVD SL 12cm Jitter FF

Display when DVD SL 12cm disc was selected

Disc Type

1. Disc Type Auto Check

2. DVD SL 12cm

3. DVD DL 12cm

4. CD 12cm

5. LCD 12cm

6. DVD SL 8cm

7. DVD DL 8cm

8. CD 8cm

9. LCD 8cm

0. Reset SLED TILT

_ TC.--:--:-- EMG.00

CD 12cm Jitter FF

Display when CD 12cm disc was selected

[0] Reset SLED TILT : Reset the Sled and Tilt to initial position.

(Reset the Sled only to initial position because the Tilt mechanism is not available

in this model.)

[1] Disc Type Check : Judge automatically the loaded disc. As

the judged result is displayed at the bottom of screen, make sure that it is correct.

If Disc Check Memory menu has not been

executed after EEPROM default setting,

the disc type cannot be judged. In this case,

return to the initial menu and make a check

for three types of discs (SL, DL, CD).

[2] to [9] : Select the loaded disc. The adjusted value

is written to the address of selected disc.

No further entry is necessary if [1] was

selected.

2. Servo Control

Servo Control

1. LD Off R. Sled FWD

2. SP Off L. Sled REV

3. Focus Off

4. TRK. Off

5. Sled Off

6. CLVA Off

7. FCS. Srch Off

0. Reset SLED TILT

_ SA.------ SI.-- EMG.00

DVD SL 12cm Jitter FF

On this screen, the servo on/off control necessary for replay is

executed. Normally, turn on each servo from 1 sequentially and

when CLVA is turned on, the usual tr ace mode becomes activ e . In

the trace mode, DVD sector address or CD time code is displayed.

This is not displayed where the spindle is not locked.

The spindle could run overriding the control if the spindle system

is faulty or RF is not present. In such a case, do not operate CL VA.

[0] Reset SLED TILT : Reset the Sled and Tilt to initial position.

(Reset the Sled only to initial position because the Tilt mechanism is not available

in this model.)

[1] LD : Turn ON/OFF the laser.

[2] SP : Turn ON/OFF the spindle.

[3] Focus : Search the focus and turn on the focus.

[4] TRK. : Turn ON/OFF the tracking servo.

[5] Sled : Turn ON/OFF the sled servo. When PLL

is not locked (cannot be locked), the sled

servo is not turned ON. The display keeps

OFF.)

[6] CLVA :Turn ON/OFF normal servo of spindle

servo.

[7] FCS. Srch : Apply same voltage as that of focus search

to the focus drive to check the focus driv e

system.

5 Sled FWD : Move the sled outward. Perform this op-

eration with the tracking servo turned off.

% Sled REV :Move the sled inward. Perform this opera-

tion with the tracking servo turned off.

30

Loading...

Loading...