Sony DVP-C650, DVP-C653D Service Manual

MICROFILM

SERVICE MANUAL

US Model

Canadian Model

E Model

DVP-C650D

PX Model

DVP-C653D

CD/DVD PLAYER

DVP-C650D/C653D

RMT-D112A

SPECIFICATIONS

CD/DVD player

Laser Semiconductor laser

Signal format system NTSC

Audio characteristics

Frequency response DVD (PCM 96 kHz): 2 Hz to 44 kHz

(±1 dB)*

DVD (PCM 48 kHz): 2 Hz to 22 kHz

(±0.5 dB)

CD: 2 Hz to 20 kHz (±0.5 dB)

Signal-to-noise ratio More than 115 dB (LINE OUT (AUDIO 1,

2) connectors only)

Harmonic distortion Less than 0.0025%

Dynamic range More than 100 dB (DVD)

More than 97 dB (CD)

Wow and flutter Less than detected value

(±0.001% W PEAK)

Outputs and inputs

Jack Output Load impedance

type level

LINE OUT Phono 2 Vrms Over 10 kilohms

(AUDIO 1, 2) jacks (at 50 kilohms)

DIGITAL OUT Optical –18 dBm Wave length: 660 nm

(OPTICAL) output

connector

DIGITAL OUT Phono 0.5 Vp-p 75 ohms terminated

(COAXIAL) jack

LINE OUT Phono 1.0 Vp-p 75 ohms,

(VIDEO 1, 2) jacks sync negative

S VIDEO OUT 4-pin Y: 1.0 Vp-p 75 ohms,

(1, 2) mini DIN sync negative

C: 0.286 Vp-p 75 ohms terminated

COMPONENT phono Y: 1.0 Vp-p 75 ohms,

VIDEO OUT jacks sync negative

(Y, PB/B-Y, PB/B-Y,

PR/R-Y) PR/R-Y:

0.7 Vp-p 75 ohms

PHONES Phone 12 mW 32 ohms

jack

5.1CH Phono 2 Vrms Over 10 kilohms

OUTPUT jacks (at 50 kilohms)

Jack Output Load impedance

type level

S-LINK Mini jack – –

MEGA Mini jack – –

CONTROL

AUDIO IN Phono 2 Vrms 47 kilohms

jack

General

Power requirements (indicated on the rear panel)

120 V AC, 60 Hz (C650D : US, Canadian)

110–240 V AC, 50/60 Hz

(C653D : E, C653D : PX)

Power consumption 18 W

Dimensions (approx.) 430 × 120 × 425 mm

(17 × 43/4 × 163/4 in.) (w/h/d)

incl. projecting parts

Mass (approx.) 6.1 kg (13 lb 7 oz)

Operating temperature 41°F to 95°F (5°C to 35°C)

Operating humidity 5% to 90%

Supplied accessories

• Audio/Video/S-link connecting cord (1) or Audio/Video connecting

cord (1)

• S video cord (1)

• Plug adaptor (1) (except for the USA/Canada models)

• Remote commander (remote) RMT-D112A (1)

• Size AA (R6) batteries (2)

* The signals from LINE OUT (AUDIO 1, 2) connectors and 5.1 ch L, R

connectors are measured. When you play the PCM sound tracks with

96 kHz sampling frequency, the output signals from the DIGITAL OUT

(OPTICAL, COAXIAL) are converted to 48 kHz (sampling frequency).

Design and specifications are subject to change without notice.

Photo: DVP-C650D

– 2 –

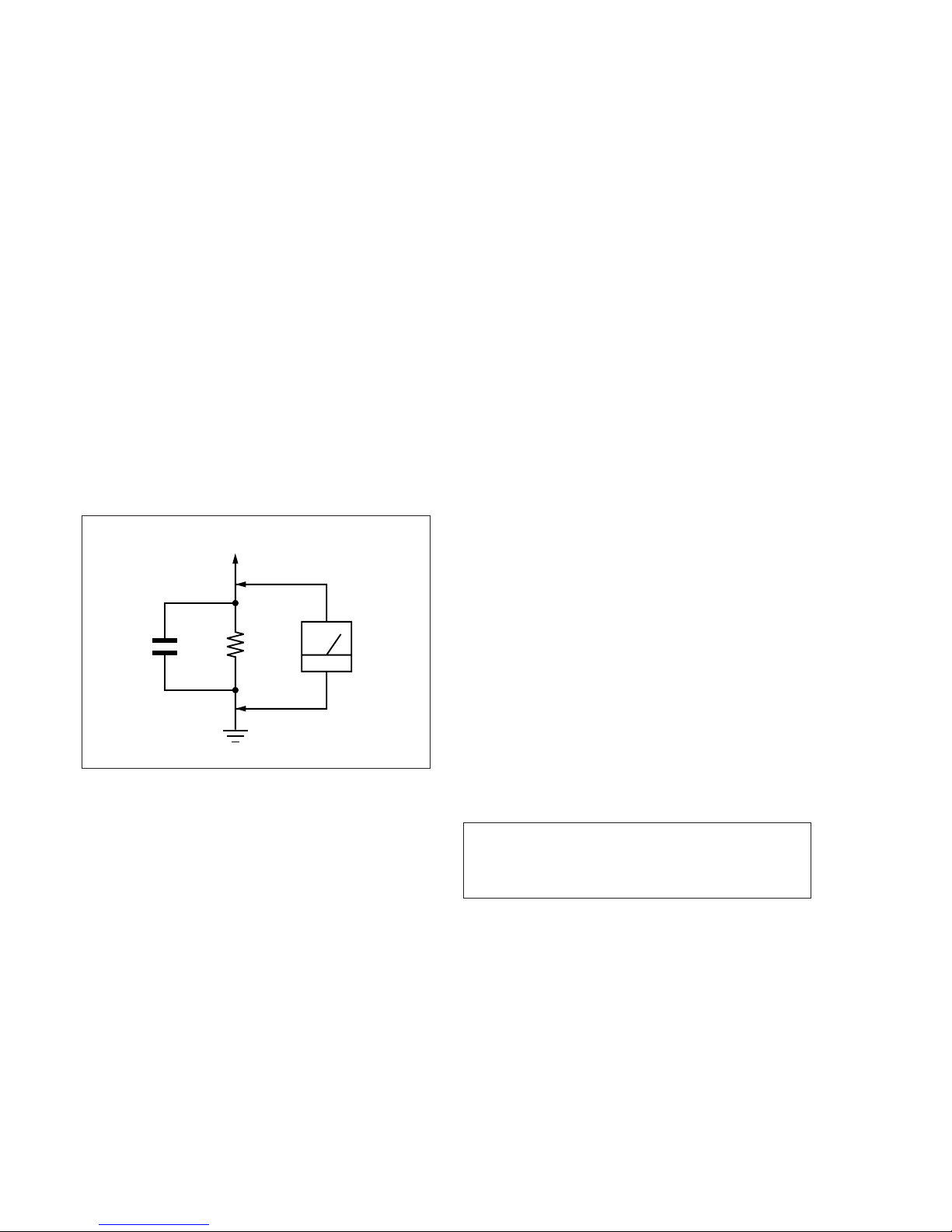

LEAKAGE TEST

The AC leakage from any exposed metal part to earth ground

and from all exposed metal parts to any exposed metal part having

a return to chassis, must not exceed 0.5 mA (500 microamperes).

Leakage current can be measured by any one of three methods.

1. A commercial leakage tester, such as the Simpson 229 or RCA

WT -540A. Follow the manufacturers' instructions to use these

instruments.

2. A battery-operated A C milliammeter. The Data Precision 245

digital multimeter is suitable for this job.

3. Measuring the voltage drop across a resistor by means of a

VOM or battery-operated AC voltmeter. The “limit” indica-

tion is 0.75V, so analog meters must have an accurate low-

voltage scale. The Simpson 250 and Sanwa SH-63T rd are ex-

amples of a passive VOM that is suitable. Nearly all battery

operated digital multimeters that have a 2V A C range are suit-

able. (See Fig. A)

Fig. A Using AC voltmeter to check AC leakage

1.5 k

Ω

0.15 µF

AC

Voltmeter

(0.75 V)

To Exposed Metal

Parts on Set

Earth Ground

WARNING!!

WHEN SERVICING, DO NO T APPR O A CH THE LASER

EXIT WITH THE EYE TOO CLOSELY. IN CASE IT IS

NECESSARY TO CONFIRM LASER BEAM EMISSION,

BE SURE TO OBSERVE FROM A DISTANCE OF

MORE THAN 25 cm FROM THE SURFACE OF THE

OBJECTIVE LENS ON THE OPTICAL PICK-UP BLOCK.

CAUTION:

The use of optical instrument with this product will increase eye

hazard.

ATTENTION AU COMPOSANT AYANT RAPPORT

À LA SÉCURITÉ!

LES COMPOSANTS IDENTIFIÉS P AR UNE MARQUE !

SUR LES DIAGRAMMES SCHÉMATIQUES ET LA LISTE

DES PIÈCES SONT CRITIQUES POUR LA SÉCURITÉ

DE FONCTIONNEMENT. NE REMPLACER CES COMPOSANTS QUE PAR DES PIÈCES SONY DONT LES

NUMÉROS SONT DONNÉS DANS CE MANUEL OU

DANS LES SUPPLÉMENTS PUBLIÉS PAR SONY.

1. Check the area of your repair for unsoldered or poorly-soldered connections. Check the entire board surface for solder

splashes and bridges.

2. Check the interboard wiring to ensure that no wires are

“pinched” or contact high-wattage resistors.

3. Look for unauthorized replacement parts, particularly transistors, that were installed during a previous repair. Point them

out to the customer and recommend their replacement.

4. Look for parts which, though functioning, show obvious signs

of deterioration. Point them out to the customer and recommend their replacement.

5. Check the line cord for cracks and abrasion. Recommend the

replacement of any such line cord to the customer.

6. Check the B+ voltage to see it is at the values specified.

7. Check the antenna terminals, metal trim, “metallized” knobs,

screws, and all other exposed metal parts for AC leakage.

Check leakage as described below.

SAFETY CHECK-OUT

After correcting the original service problem, perform the following

safety checks before releasing the set to the customer:

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK ! OR DOTTED

LINE WITH MARK ! ON THE SCHEMATIC DIAGRAMS

AND IN THE PARTS LIST ARE CRITICAL TO SAFE

OPERATION. REPLACE THESE COMPONENTS WITH

SONY PARTS WHOSE PART NUMBERS APPEAR AS

SHOWN IN THIS MANUAL OR IN SUPPLEMENTS PUBLISHED BY SONY.

CAUTION

Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous radiation exposure.

– 3 –

TABLE OF CONTENTS

Section Title Page Section Title Page

Service Note ............................................................................ 4

1. GENERAL

This Player Can Play the Following Discs .................... 1-1

Getting Started .............................................................. 1-1

Playing Discs ................................................................. 1-3

Using Various Functions with the Control Menu ........... 1-6

Settings and Adjustments ............................................. 1-12

Additional Information ................................................... 1-16

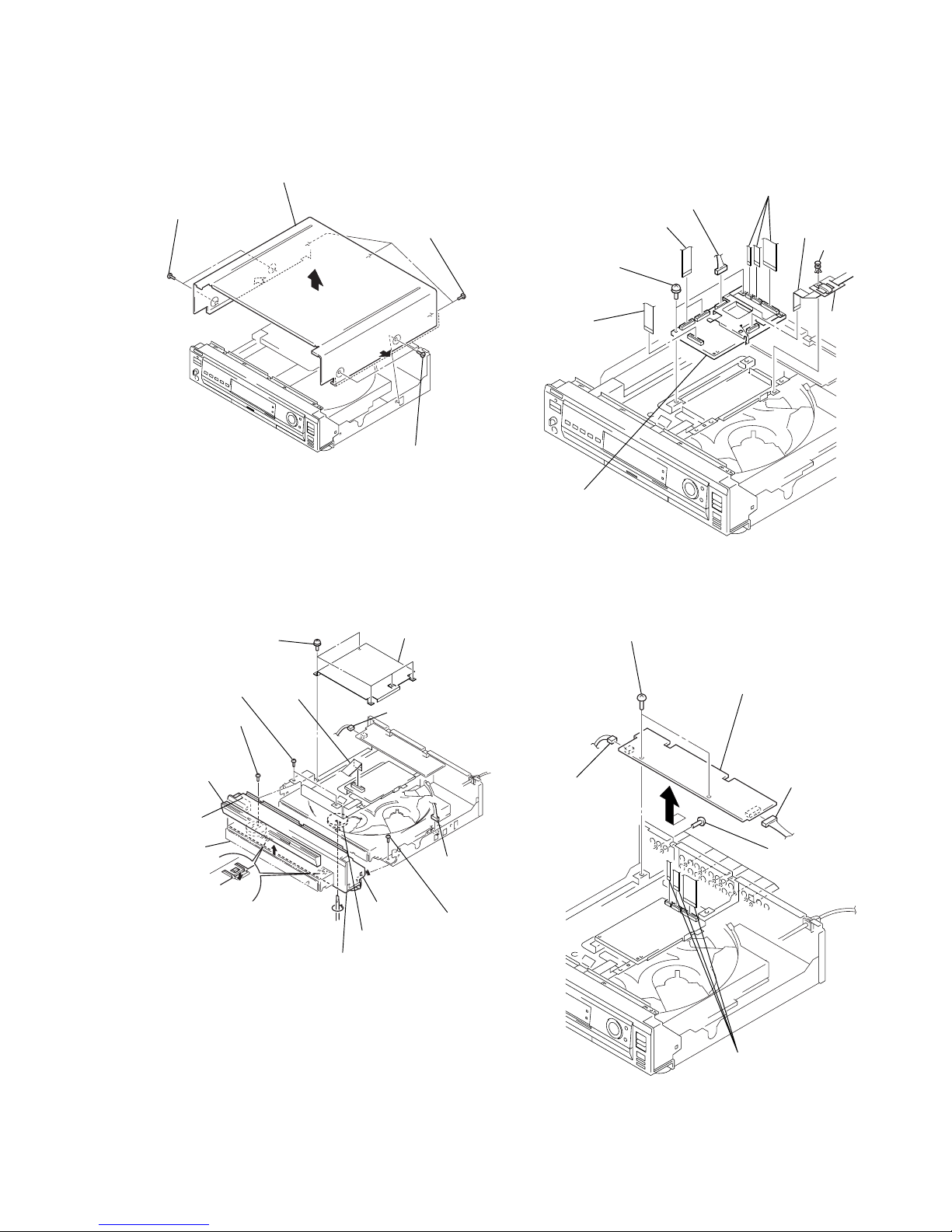

2. DISASSEMBLY

2-1. Case Removal ............................................................... 2-1

2-2. Front Panel Section Removal........................................ 2-1

2-3. MB-85 Board Removal .................................................. 2-1

2-4. AU-215 Board Removal ................................................ 2-1

2-5. Rear Panel Section Removal ........................................ 2-2

2-6. Table Ass’y Removal ..................................................... 2-2

2-7. Rotary Motor Ass’y (M951) Removal ............................ 2-2

2-8. Chassis Ass’y ................................................................ 2-2

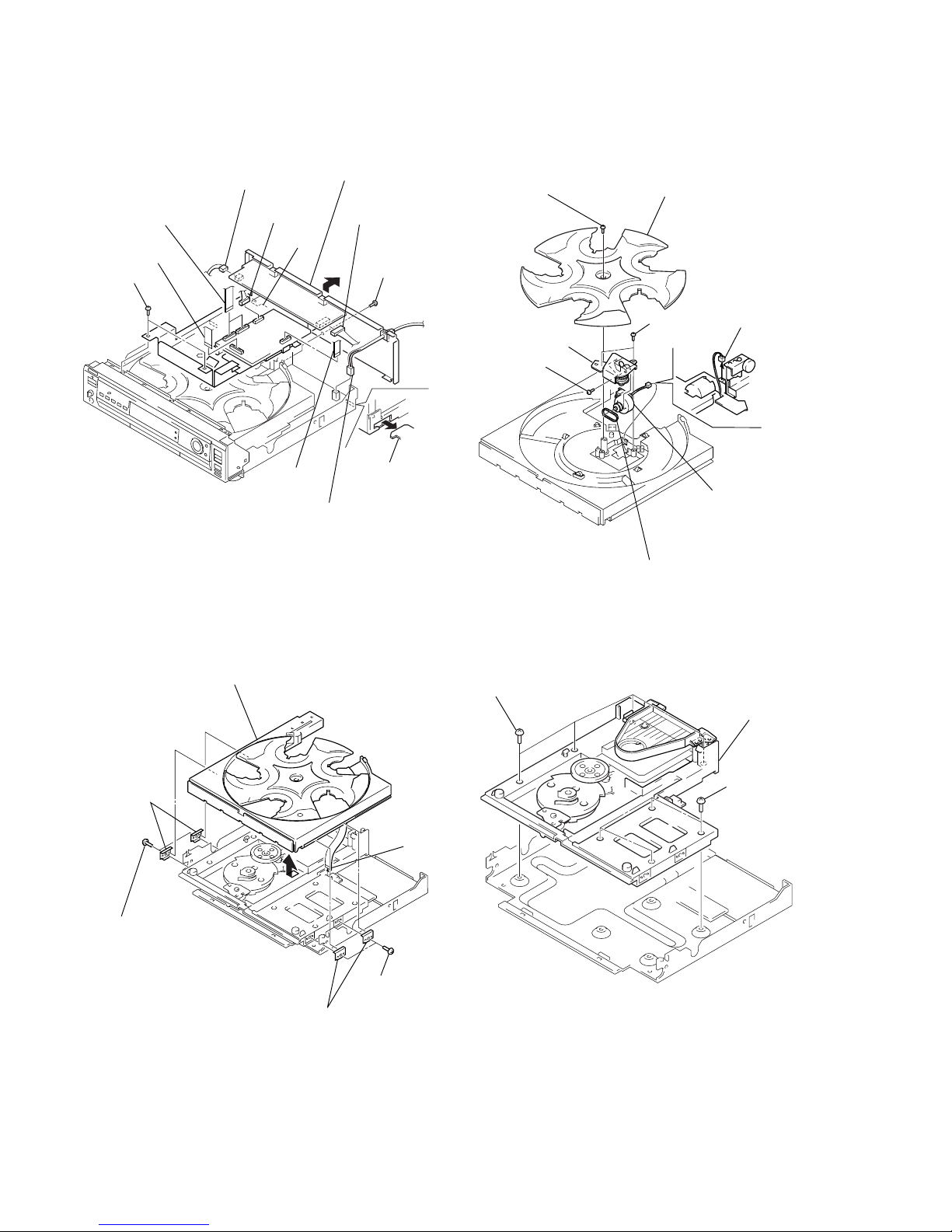

2-9. Loading Motor Ass’y (M991) Removal.......................... 2-3

2-10. BU Holder Ass’y Removal............................................. 2-3

2-11. TK-53 Board Removal................................................... 2-3

2-12. Optical Pick-up Removal............................................... 2-3

2-13. Internal View.................................................................. 2-4

2-14. Circuit Boards Location................................................. 2-5

3. BLOCK DIAGRAMS

3-1. Overall Block Diagram .................................................. 3-1

3-2. RF/Servo Block Diagram .............................................. 3-3

3-3. Signal Process/Video Block Diagram ........................... 3 - 5

3-4. System Control Block Diagram ..................................... 3-7

3-5. Audio (1) Block Diagram ............................................... 3-9

3-6. Audio (2) Block Diagram ............................................... 3-11

3-7. Interface Control Block Diagram ................................... 3-13

3-8. Power Block Diagram .................................................... 3-15

4. PRINTED WIRING BOARDS AND SCHEMATIC

DIAGRAMS

4-1. Frame Schematic Diagram ........................................... 4-3

4-2. Printed Wiring Boards and Schematic Diagrams ......... 4-7

TK-53 (RF/SERVO) Printed Wiring Board .................... 4-7

TK-53 (RF/SERVO) Schematic Diagra m ...................... 4-11

SE-91 (SENSOR), LE-24 (LED)

Printed Wiring Boards and Schematic Diagram ........... 4-13

MB-85 (SIGNAL PROCESS)

Printed Wiring Board ..................................................... 4-15

MB-85 (AV DECODER) Schematic Diagram................ 4-19

MB-85 (SDRAM) Schematic Diagram .......................... 4-21

MB-85 (SERVO DSP) Schematic Diagra m ................... 4-23

MB-85 (DRIVE) Schematic Diagram ............................ 4-25

MB-85 (ARP) Schematic Diagram ................................ 4-27

MB-85 (SYSTEM CONTROL)

Schematic Diagram ....................................................... 4-29

MB-85 (HGA) Schematic Diagram................................ 4-31

MB-85 (CLOCK GENERATOR/AUDIO DSP/

V EQ/NR) Schematic Diagram...................................... 4-33

MB-85 (DAC) Schematic Diagram ................................ 4-35

MB-85 (BIAS) Schematic Diagram ............................... 4-37

AU-215 (AUDIO/VIDEO BUFFER)

Printed Wiring Board ..................................................... 4-39

AU-215 (AUDIO) Schematic Diagram ........................... 4-43

AU-215 (VIDEO BUFFER) Schematic Diagram ........... 4-45

FL-104 (FUNCTION SWITCH/IF CON), SW-321

(FUNCTION SWITCH) and CK-88 (CONNECTION)

Printed Wiring Boards ................................................... 4-47

FL-104 (FUNCTION SWITCH), SW-321 (FUNCTION

SWITCH) and CK-88 (CONNECTION)

Schematic Diagram ....................................................... 4-51

FL-104 (IF CON) Schematic Diagram .......................... 4-53

FR-154 (IR/POWER SWITCH)

Printed Wiring Boards and Schematic Diagram ........... 4-55

HP-114 (HEADPHONE) Printed Wiring Boards

and Schematic Diagram................................................ 4-57

LM-59 (LOADING MOTOR), CK-81 (DRIVE)

Printed Wiring Boards ................................................... 4-59

LM-59 (LOADING MOTOR), CK-81 (DRIVE)

Schematic Diagram ....................................................... 4-61

HS-034SF (SWITCHING REGULATOR)

Printed Wiring Board ..................................................... 4-63

HS-034SF (SWITCHING REGULATOR)

Schematic Diagram ....................................................... 4-65

HS-034SU (SWITCHING REGULATOR)

Printed Wiring Board ..................................................... 4-67

HS-034SU (SWITCHING REGULATOR)

Schematic Diagram ....................................................... 4-69

5. IC PIN FUNCTION DESCRIPTION

5-1. System Control Pin Function

(MB-85 Board IC202) .................................................... 5-1

6. TEST MODE

6-1. General Description ...................................................... 6-1

6-2. Starting Test Mode ........................................................ 6-1

6-3. Syscon Diagnosis .......................................................... 6-1

6-4. Drive Auto Adjustment .................................................. 6-5

6-5. Drive Manual Operation ................................................ 6-7

6-6. Mecha Aging ................................................................. 6-9

6-7. Emergency History ........................................................ 6-9

6-8. Version Information ....................................................... 6-10

6-9. Video Level Adjustment ................................................ 6-10

7. ELECTRICAL ADJUSTMENTS

7-1. Power Supply Adjustment ............................................. 7-1

1. Power Supply Check

(HS-034SF/034SU BOARD) ......................................... 7-1

7-2. Adjustment of Video System ......................................... 7-2

1. Video Level Adjustment (MB-85 BOARD) .................... 7-2

2. S-terminal Output Check (MB-85 BOARD) .................. 7-2

3. Checking Component Video Output B-Y

(MB-85 BOARD)............................................................ 7-2

4. Checking Component Video Output R-Y

(MB-85 BOARD)............................................................ 7-2

5. Checking Component Video Output Y

(MB-85 BOARD)............................................................ 7-3

6. Checking S Video Output S-C (MB-85 BOARD) .......... 7-3

7-3. Adjustment Related Parts Arrangement ....................... 7-4

8. REPAIR PARTS LIST

8-1. Exploded Views ............................................................. 8-1

8-1-1. Main Assembly ......................................................... 8-1

8-1-2. Front Panel Assembly .............................................. 8-2

8-1-3. Table Assembly ........................................................ 8-3

8-1-4. Chassis Assembly.................................................... 8-4

8-2. Electrical Parts List ....................................................... 8-5

– 4 –

SERVICE NOTE

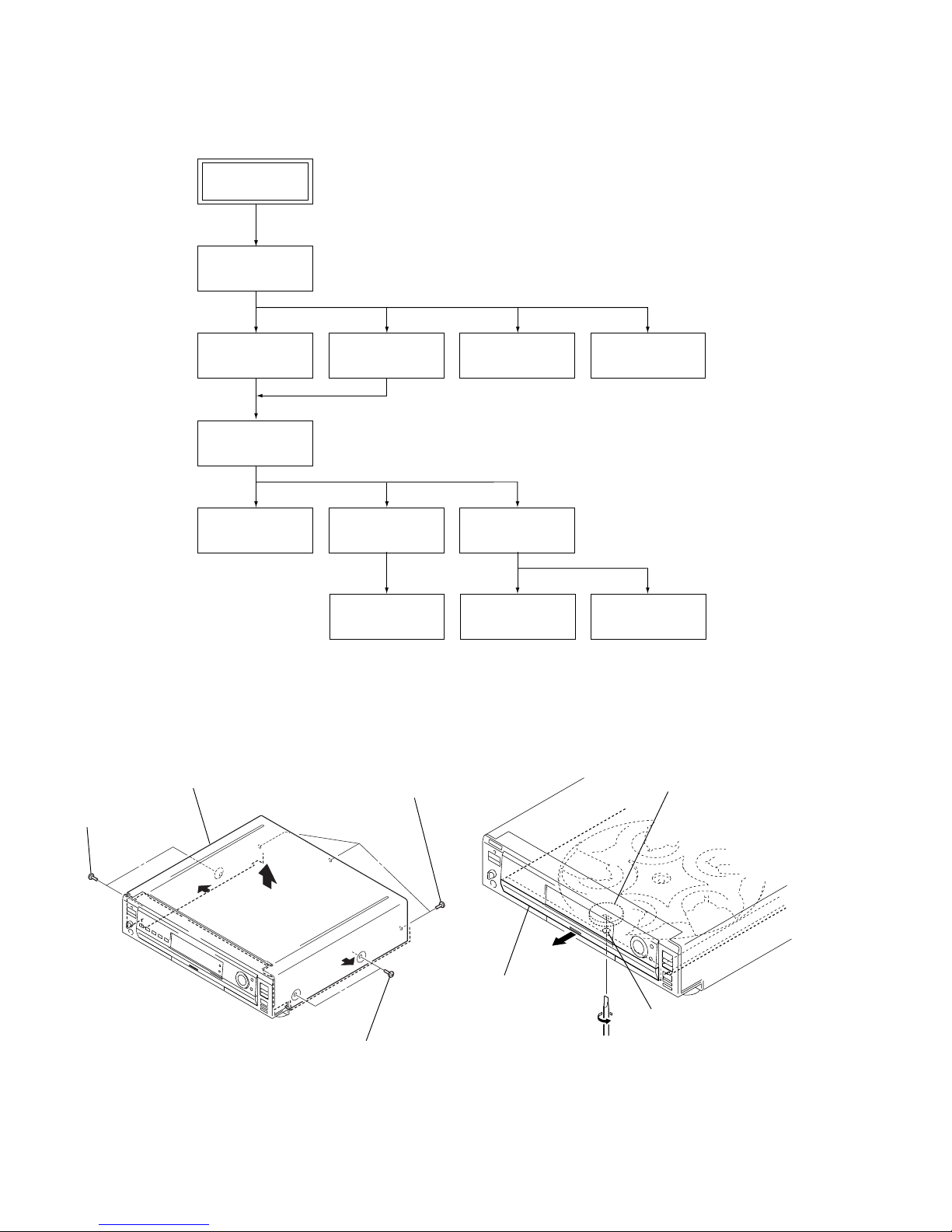

1. DISASSEMBLY

• This set can be disassembled in the order shown below.

2. NOTE ON REMOVE THE CASE

1) Remove seven tapping screws. (See Fig. 1)

2) Open the side of case. (See Fig. 1)

3) Remove the case as lift straight. (See Fig. 1)

Set

Case

(Page 2-1)

Front panel section

(Page 2-1)

Table ass’y

(Page 2-2)

Rear panel section

(Page 2-2)

MB-85 board

(Page 2-1)

AU-215 board

(Page 2-1)

Rotary motor ass’y

(M951) (Page 2-2)

Chassis ass’y

(Page 2-2)

BU holder ass’y

(Page 2-3)

TK-53 board

(Page 2-3)

Loading motor ass’y

(M991) (Page 2-3)

Optical pick-up

(Page 2-3)

3. DISC REMOVAL PROCEDURE

(at POWER OFF)

1) Insert a flat-blade screwdriver into a hole at the bottom, and

rotare the cam gear in direction A. (See Fig. 2)

Table

Hole

Cam gear

A

Case

Two tapping screws

Three tapping screws

Two tapping screws

Fig. 1

Fig. 2

– 5 –

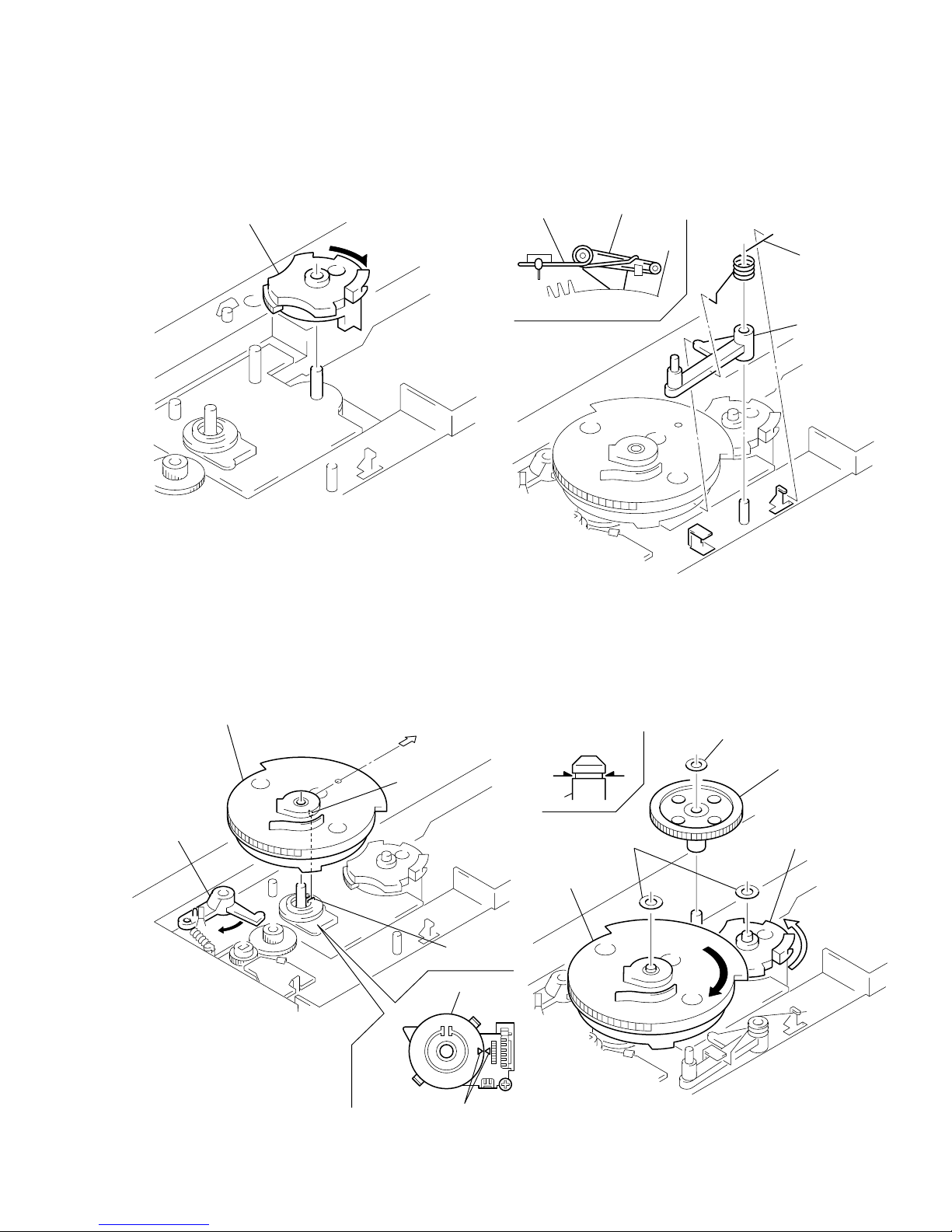

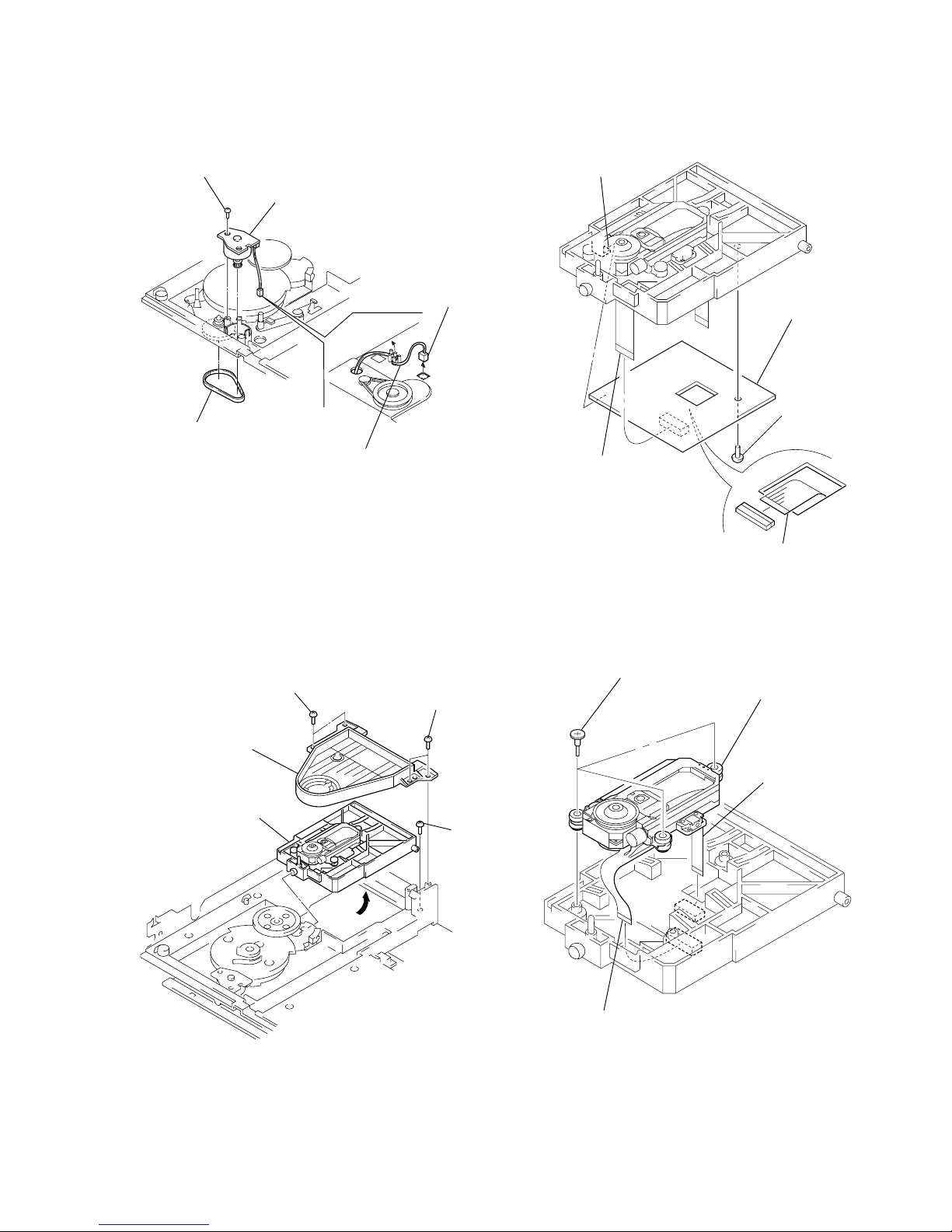

4. NOTE ON MOUNTING GEARS

1) Mount the gear (U/D). (See Fig. 3.)

2) Rotate the gear (U/D) in the direction of the arrow.

(down position) (See Fig. 3.)

3) Align triangle marks of the rotary encoder. (See Fig. 4.)

4) Escape the set lever. (See Fig. 4.)

5) Connect the boss of the gear (main) with the groove of the

rotary encoder and mount the gear (main). (See Fig. 4.)

6) Mount the lock lever (See Fig. 5.)

7) Mount the spring (lock lever). (See Fig. 5.)

8) Rotate the gear (main) in the direction of the arrow A by 90°

turn. (Gear (U/D) is up position.) (See Fig. 6.)

9) Mount the Gear (rev). (See Fig. 6.)

10) Fix three stopper washers on the groove of shafts.

(See Fig. 6.)

Gear (U/D)

Fig. 3

Fig. 5

Fig. 4

Fig. 6

Spring

(lock lever)

Spring

(lock lever)

Lock lever

Lock lever

Gear

(main)

Gear (main)

Set lever

Boss

Groove

Rotary encoder

Align triangle marks.

BU

Shaft

Stopper washer

Gear (rev)

Gear (main)

Gear (U/D)

Two stopper

washers

Groove

**

*

A

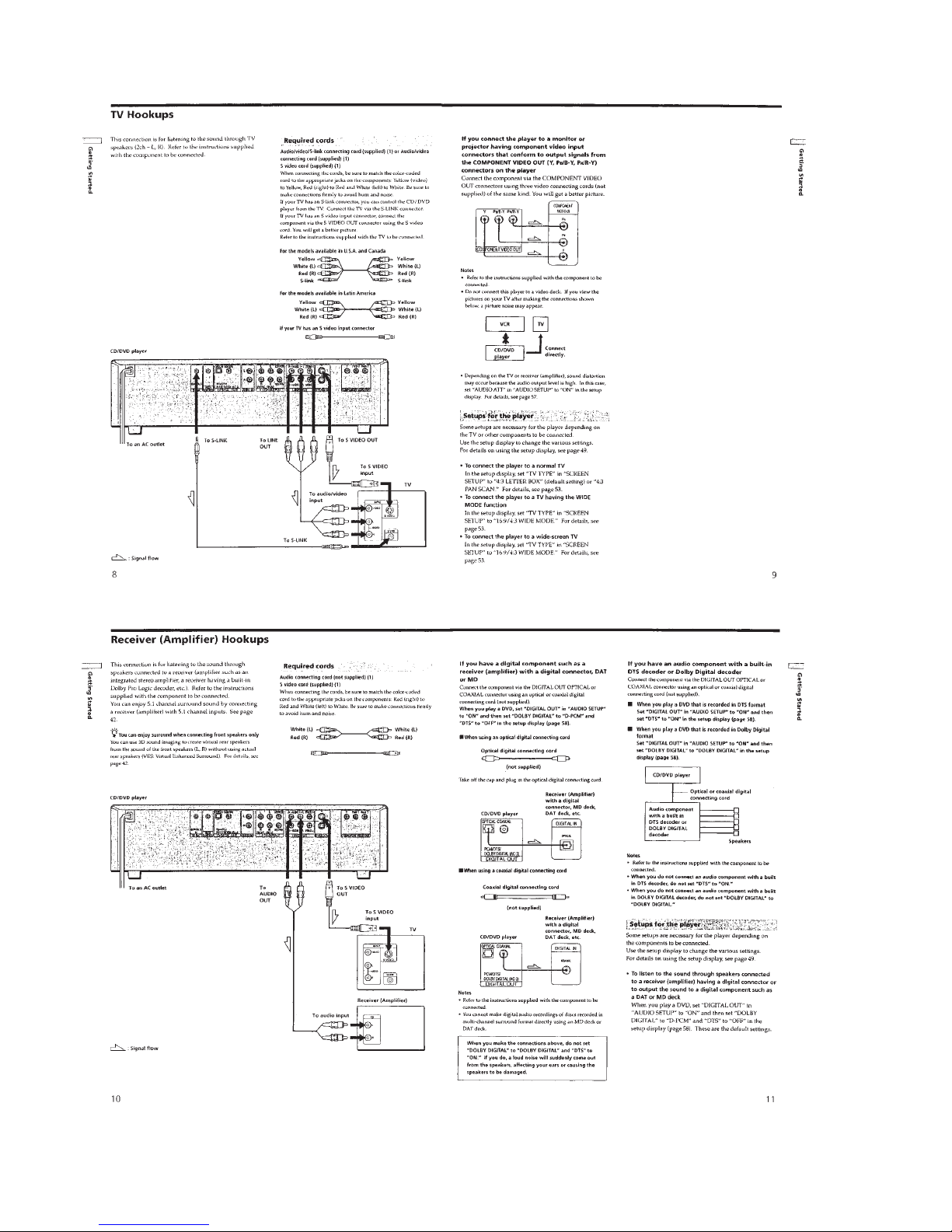

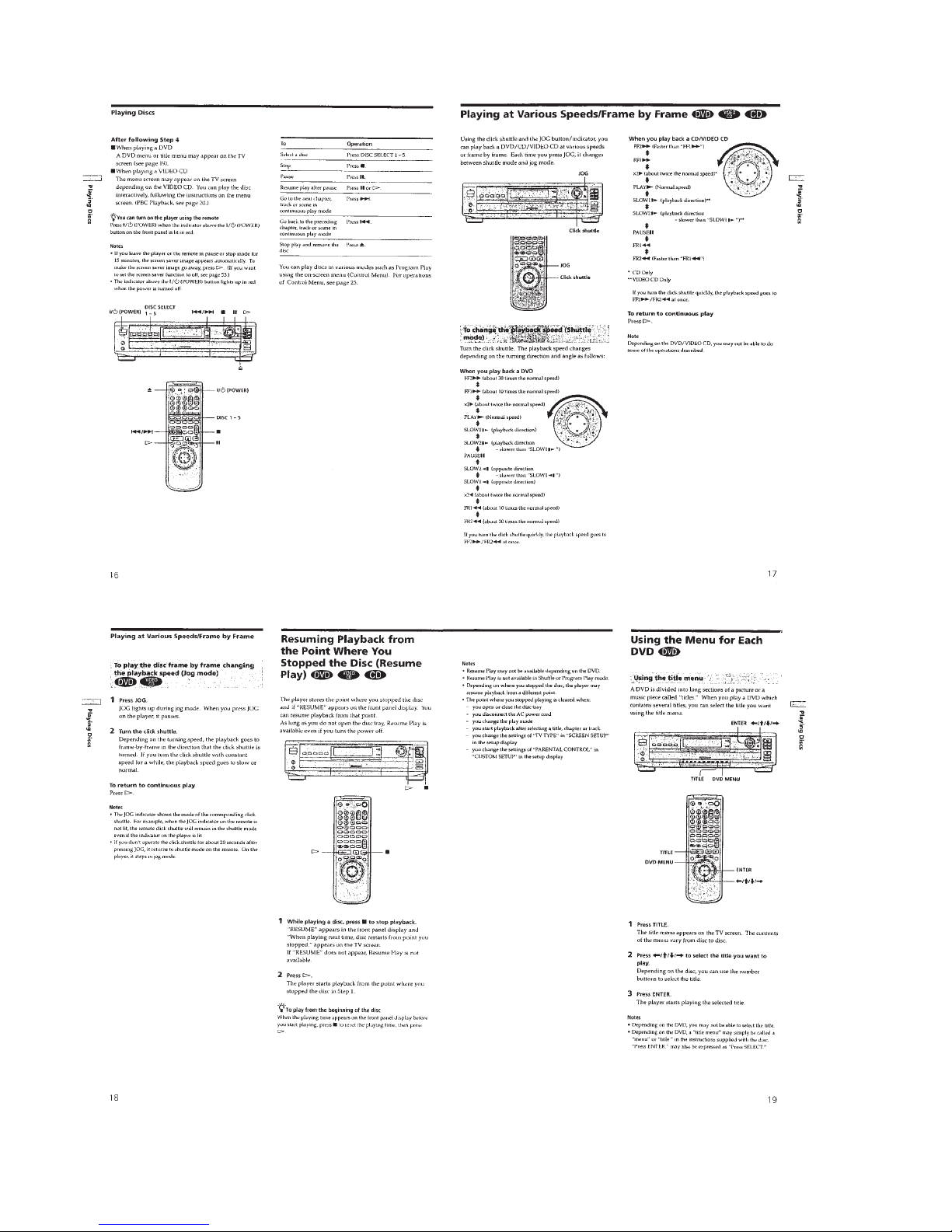

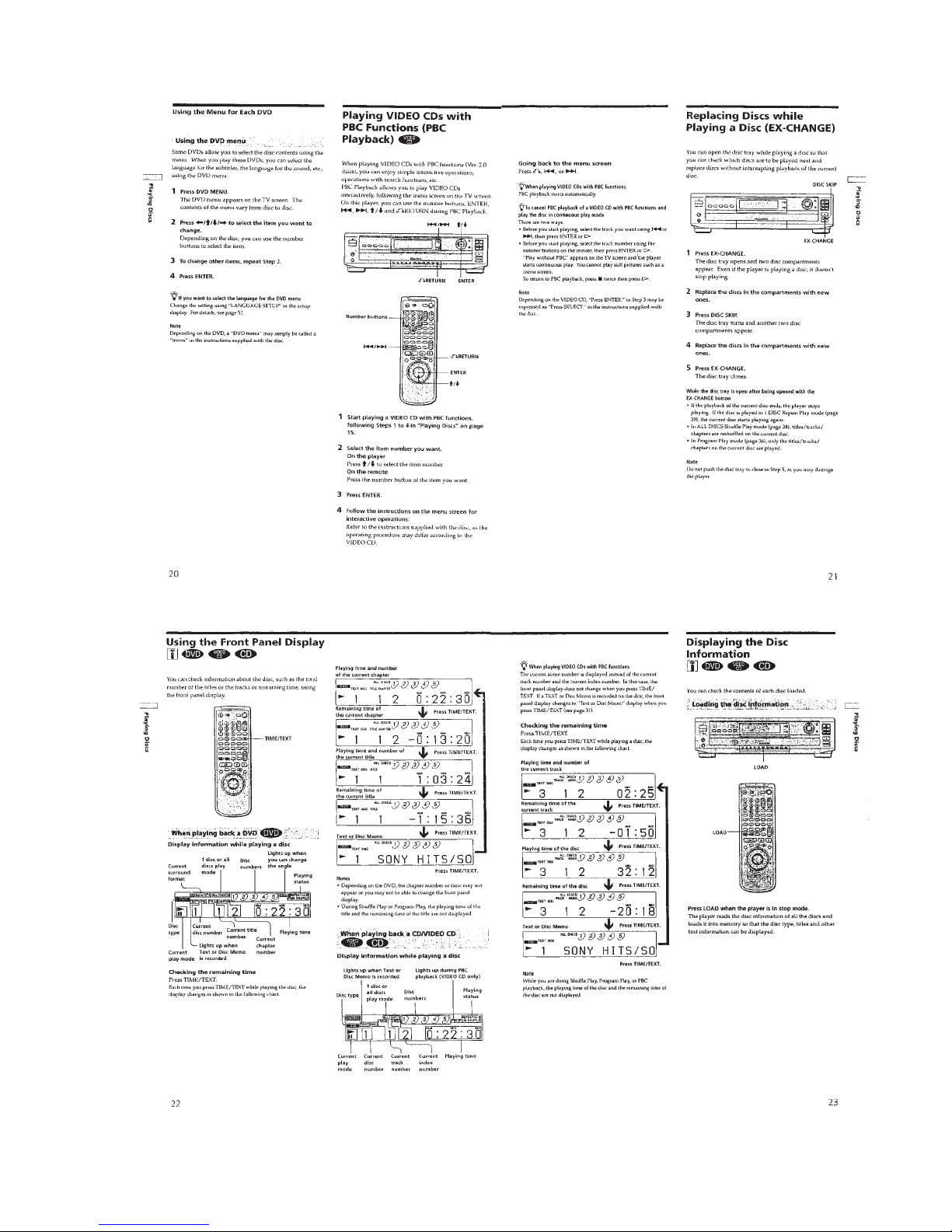

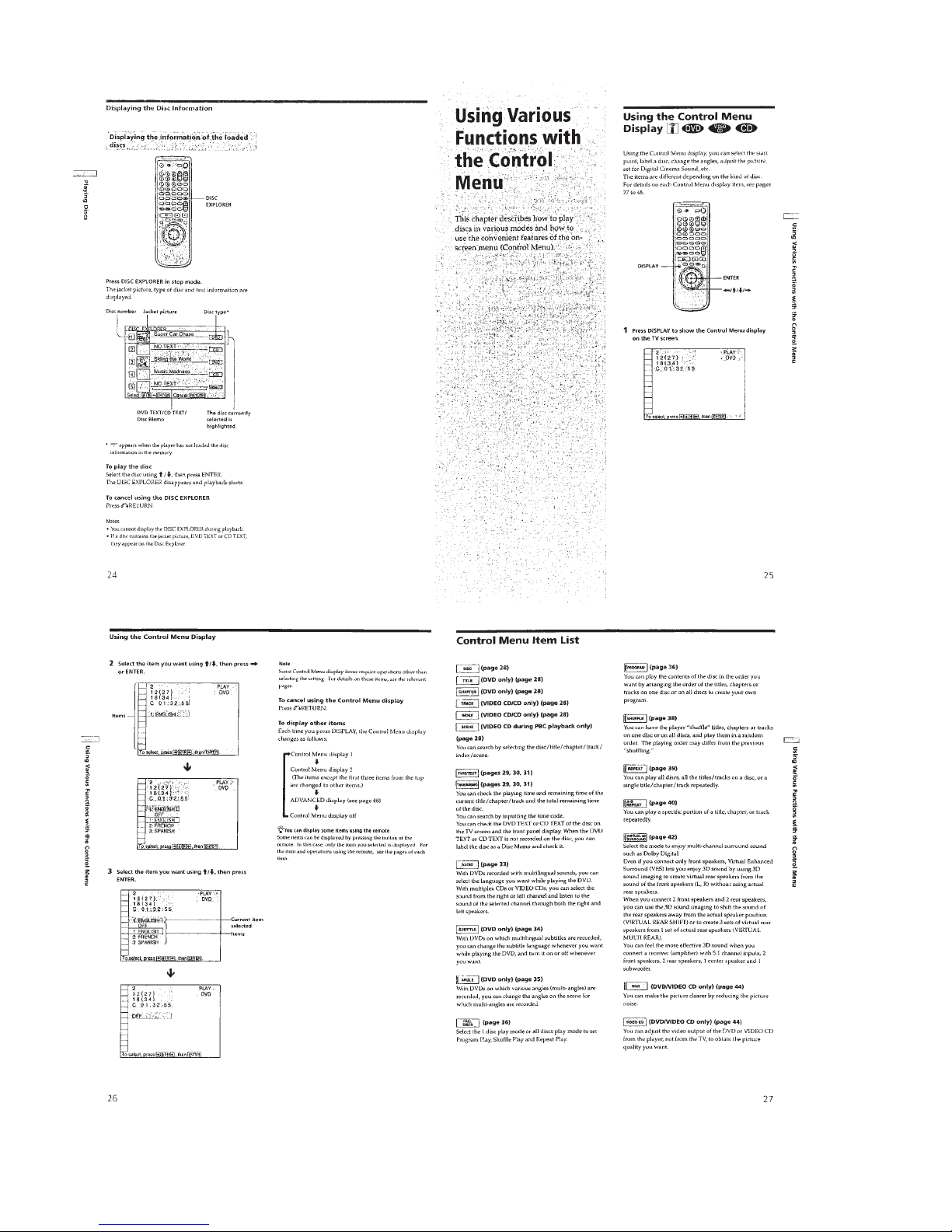

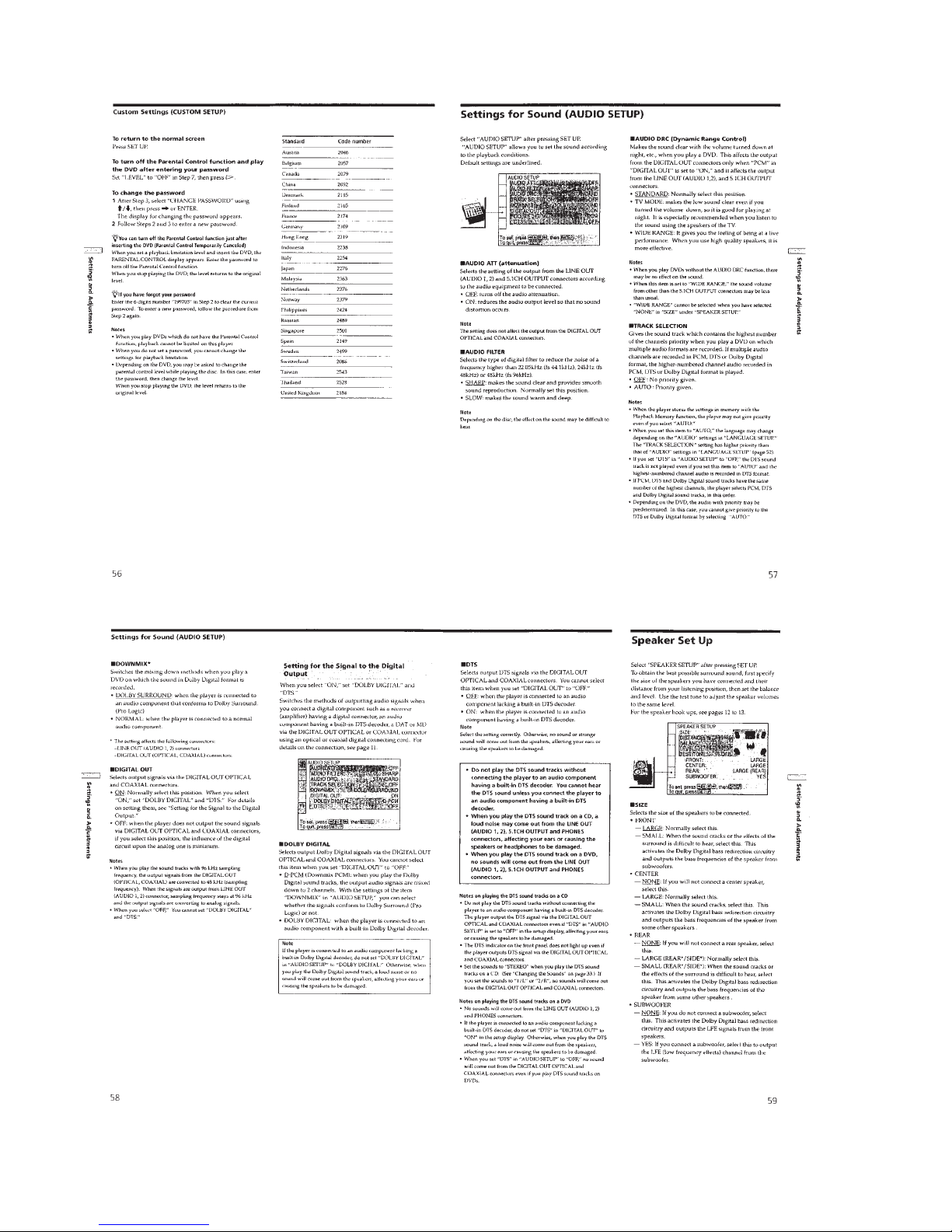

1-1

SECTION 1

GENERAL

This section is extracted from instruction

manual (3-867-237-11)

DVP-C650D/C653D

1-2

1-3

1-4

1-5

1-6

1-7

1-8

1-9

1-10

1-11

1-12

1-13

1-14

1-15

1-16

1-17

1-17 E

2-1

Note: Follow the disassembly procedure in the numerical order given.

2-1. CASE REMOVAL 2-3. MB-85 BOARD REMOVAL

2-2. FRONT PANEL SECTION REMOVAL 2-4. AU-215 BOARD REMOVAL

SECTION 2

DISASSEMBLY

DVP-C650D/C653D

4 Case

3 Two tapping screws

1 Two tapping screws

2 Three tapping

screws

4 Three flat cables

(CN004, 005, 007)

5 Flat cable

(CN009)

3 Connector

(CN001)

2 Two flat cables

(CN002, 003)

8 Two screws

(B3) (with ring)

1 Flat cable

(CN006)

6 Rivet

7 Holder

9 MB-85 board

7 Connector

(CN401)

6 Flat cable

(CN006)

3 Rotate the cam gear

in the direction of

the arrow A.

!¢ Claw

!∞ Front panel section

!™ Claw

!£ Two Claws

!¡ Two screws

(B3)

1 Five screws

(B3) (with ring)

2 Shield case

0 Screw (B3)

5 Tray cover

ass’y

9 Screw (B3)

4 Draw out

the table.

A

8 Connector

(CN902)

1 Connector

(CN401)

3 Three flat cables

(CN004, 005, 007)

2 Connector

(CN304)

5 Two screws

(B3)

4 Nine screws

(B3)

6 AU-215 board

2-2

2-5. REAR PANEL SECTION REMOVAL

2-6. TABLE ASS’Y REMOVAL 2-8. CHASSIS ASS’Y

2-7. ROTARY MOTOR ASS’Y (M951)

REMOVAL

3 Connector

(CN401)

5 Connector

(CN304)

9 Screw

(B3)

4 Connector

(CN001)

!™ Rear panel section

!º Claw

!¡ Claw

2 Two flat cables

(CN002, 003)

1 Flat cable

(CN006)

6 Flat cable

(CN009)

7 Connector

(CN101)

8 Two screws

(B3)

4 Two screws

(B3)

7 Two screws

(B2.6 × 3)

1 Tapping screw

(M3 × 12)

5 Bracket (RM) ass’y

6 Belt (RM)

2 Table (rotary)

3 Connector

(CN801)

8 Rotary motor ass’y

(M951)

6 Flat wire

(CN656)

1 Two screws

(B3)

2 Two brackets

(guide B1)

4 Two brackets

(guide B1)

3 Two screws

(B3)

5 Table ass’y

1 Four screws

(B3)

2 Four screws

(B3)

3 Chassis ass’y

2-3

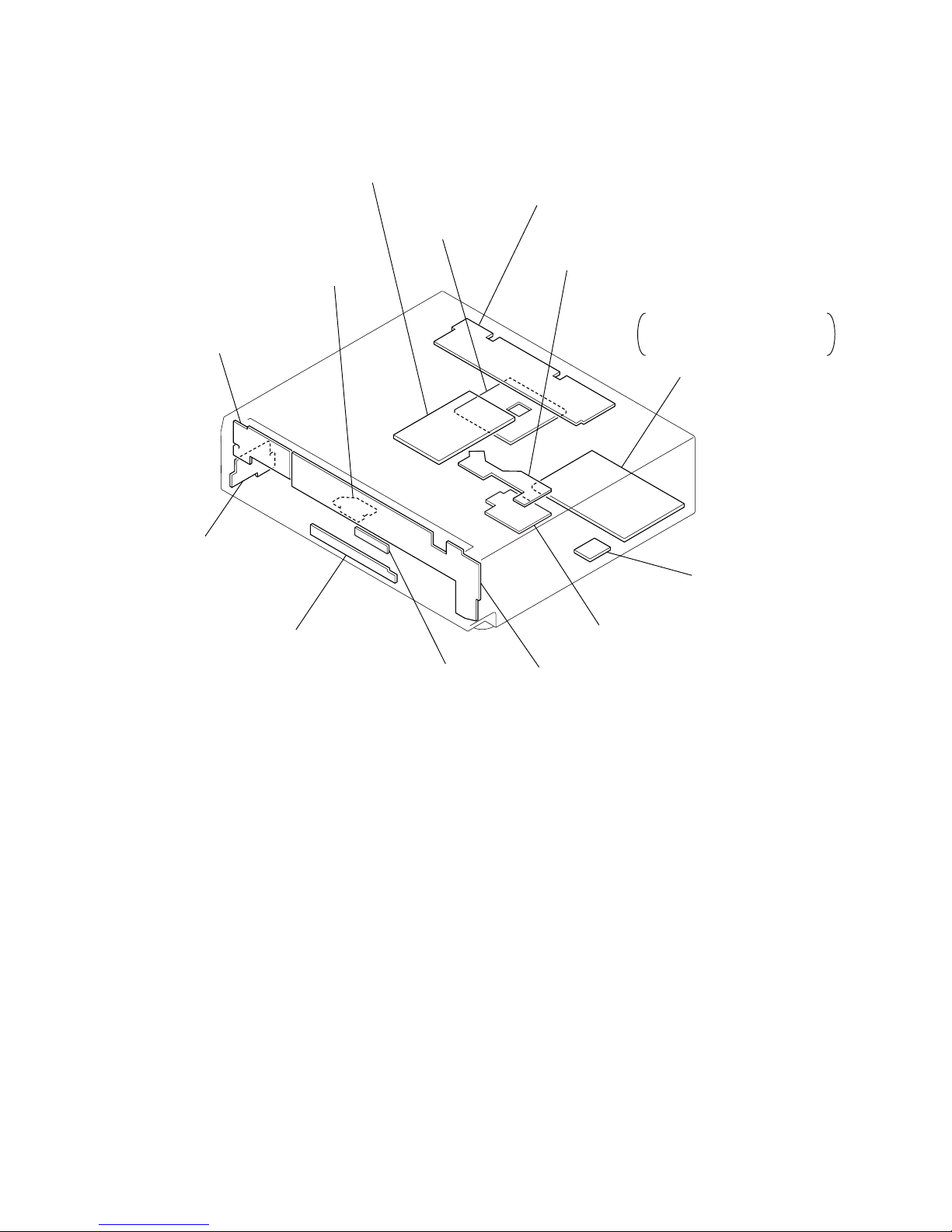

2-9. LOADING MOTOR ASS’Y (M991)

REMOVAL

2-10. BU HOLDER ASS’Y REMOVAL

2-11. TK-53 BOARD REMOVAL

2-12. OPTICAL PICK-UP REMOVAL

4 Screw (B3)

5 Loading motor ass’y

(M991)

1 Belt (timing)

3 Harness

2 Connector

1 Flexible board

(CN002)

2 Flexible board

(CN001)

3 Screw

(B3)

5 TK-53 board

4 Claw

1 Two screws

(B3)

2 Two screws

(B3)

4 Screw

(M3 × 12)

3 Bracket (CP)

5 BU holder ass’y

2 Flexible board

(CN001)

4 Optical pick-up

3 Three step screws

1 Flexible board

(CN002)

2-4

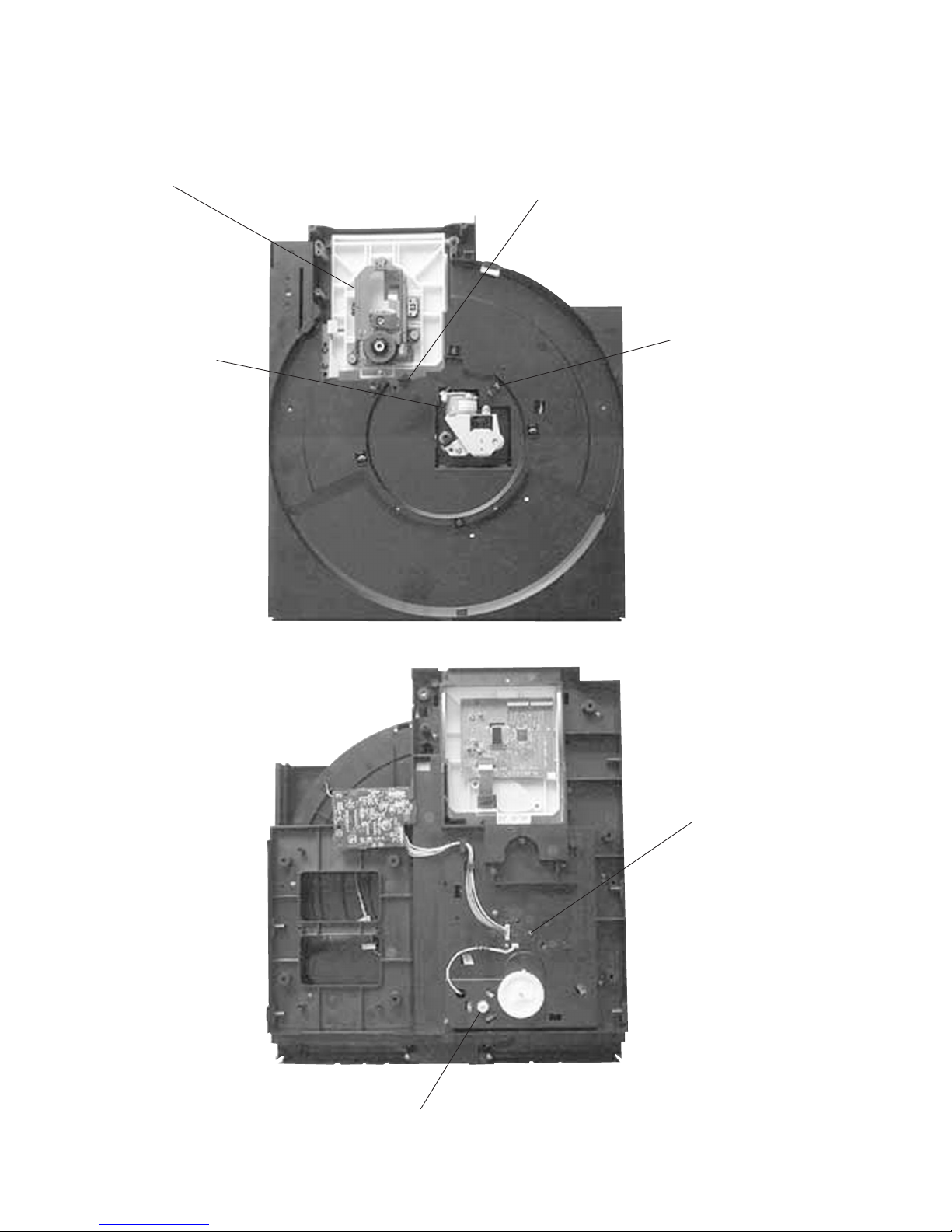

2-13. INTERNAL VIEWS

Optical pick-up (KHM-220AAA/J1RP)

8-820-081-03

PH801

Disc presence detection sensor

8-749-924-30

M951

Rotary motor ass’y

(turn table)

A-6062-080-A

PH802

Turn table position

detection sensor

8-749-924-18

Rotary encoder

(loading)

1-466-996-21

M991

Loding motor ass’y

A-4604-834-A

2-52-5 E

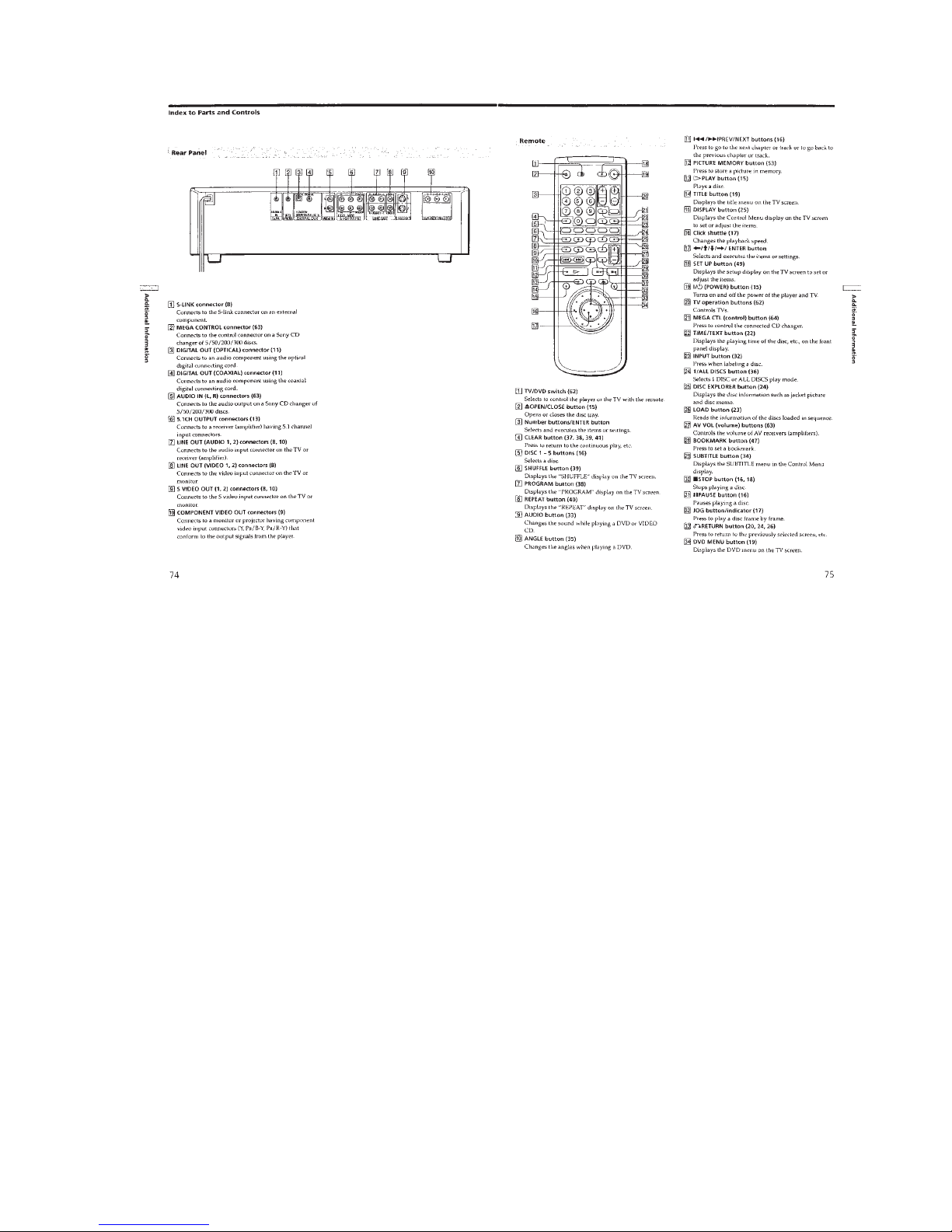

2-14. CIRCUIT BOARDS LOCATION

TK-53

(RF/SERVO)

AU-215

(AUDIO/VIDEO BUFFER)

SE-91

(SENSOR)

CK-88

(CONNECTION)

CK-81

(DRIVE)

FL-104

(FUNCTION SWITCH/IF CON)

LE-24

(LED)

SW-321

(FUNCTION SWITCH)

HP-114

(HEADPHONE)

FR-154

(IR/POWER SWITCH)

LM-59

(LOADING MOTOR)

MB-85

(SIGNAL PROCESS/SERVO)

POWER BLOCK

HS-034SU: US, Canadian

HS-034SF: E, PX

(SWITCHING REGULATOR)

DVP-C650D/C653D

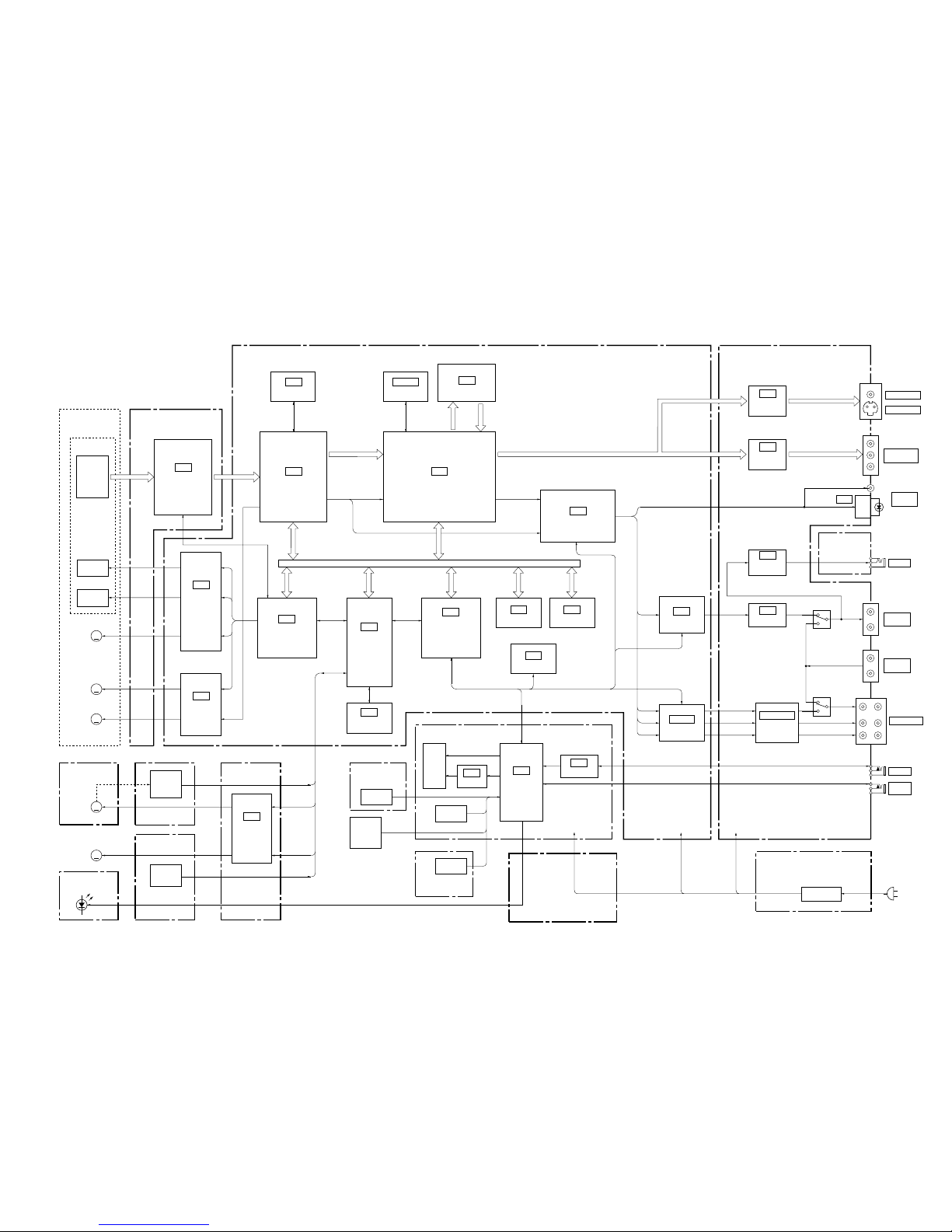

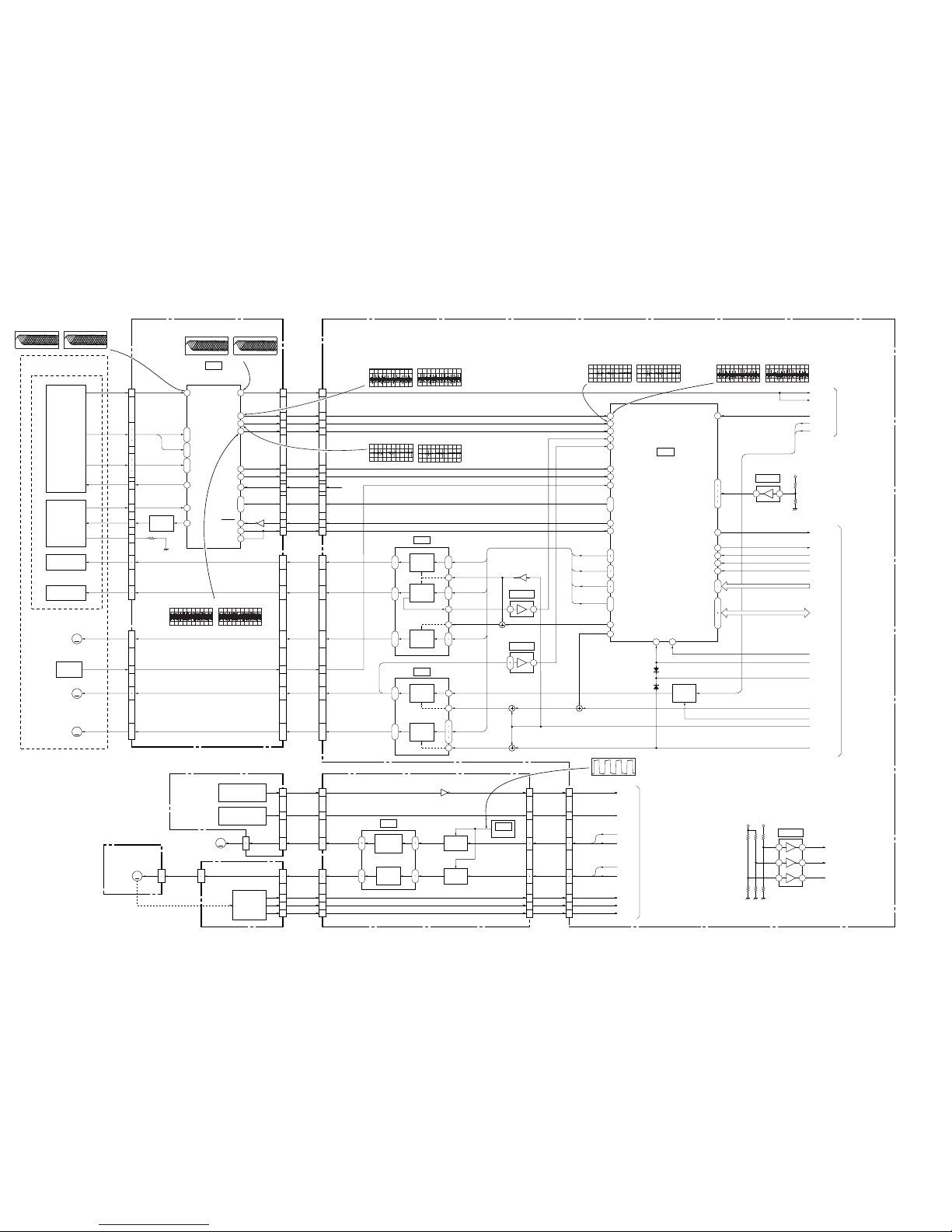

3-1 3-2

SECTION 3

BLOCK DIAGRAMS

3-1. OVERALL BLOCK DIAGRAM

TK-53 BOARD

(SEE PAGE 4-11)

BASE UNIT

KHM-220AAA

MB-85 BOARD

(SEE PAGE 4-21 to 35)

AU-215 BOARD

(SEE PAGE 4-43,45)

HP-114 BOARD

(SEE PAGE 4-58)

HS-034SF BOARD

(SEE PAGE 4-65)

HS-034SU BOARD

(SEE PAGE 4-67)

FL-104 BOARD

(SEE PAGE 4-51,53)

LM-59 BOARD

(SEE PAGE 4-61)

CK-81 BOARD

(SEE PAGE 4-61)

LE-24 BOARD

(SEE PAGE 4-14)

SE-91 BOARD

(SEE PAGE 4-14)

FR-154 BOARD

(SEE PAGE 4-55)

SW-321 BOARD

(SEE PAGE 4-51)

CK-88 BOARD

(SEE PAGE 4-51)

05

DVD RF,

CD RF

DVD/CD

PDIC

OPTICAL DEVICE

SPINDLE

MOTOR

M

TILT

MOTOR

M

M991

LOADING

MOTOR

M

SLED

MOTOR

M

M951

TURN TABLE

MOTOR

M

TRACKING

COIL

FOCUS

COIL

IC001

DVD/CD RF AMP

DIGITAL SERVO

IC801

FOCUS COIL/

TRACKING COIL/

TILT MOTOR

DRIVE

IC601

HGA

IC602

16M NAND-F

Serial BUS

JOG UNIT

SW REG

+5V

–12V

EVER5V

+3.3V

+5V

A+12V

M+12V

+3.3V

+5V

+12V

–12V

EVER5V

SWITCH

SWITCH

SWITCH

ND201

IC201

IF CON

IC203

S-LINK

IC205

FL DRIVER

IC701

IC202

IC802

SPINDLE/SLED/

MOTOR DRIVE

IC652

TURN TABLE/

LOADING

MOTOR DRIVE

ROTARY

ENCODER

LOADING)

PH801, 802

SENSOR

CDDOUT, CDDATA,

CDBCK, CDLRCK

IC303

ARP2

SD 0-7

RF

IC401

AV DECODER

IC304

16M DRAM

IC402, 403

16M SDRAM

IC502

V EQ/NR

IC204

1M SRAM

IC201

4K EEP ROM

IC205

16M FLASH

IC902

AUDIO 2CH DAC

SPDIF

Parallel BUS

PDO 0-7

PDI 0-7

VIDEO V,

VIDEO Y,

VIDEO C

VIDEO G/Y,

VIDEO R/B-Y,

VIDEO B/R-Y

ACH12,ACH34,

ACH56,

BCK, LRCK

IC905-907

AUDIO 5.1CH DAC

IC501

AUDIO DSP

VIDEO

BUFFER

LPF

RY301

RY302

HEADPHONE

AMP

AUDIO LT,

AUDIO RT

LPF

AUDIO L, R

AUDIO LS, RS

AUDIO C, LFE

VIDEO

BUFFER

IC321

IC303

IC505

IC401

IC431

VIDEO 1, 2

S VIDEO 1, 2

5.1CH OUTPUT

PHONES

S-LINK

MEGA

CONTROL

COMPONENT

VIDEO

DIGITAL

OUT

AUDIO

OUT1, 2

AUDIO

IN

SERVO DSP

SYSTEM CONTROL

IC502, 541, 571

DVP-C650D/C653D

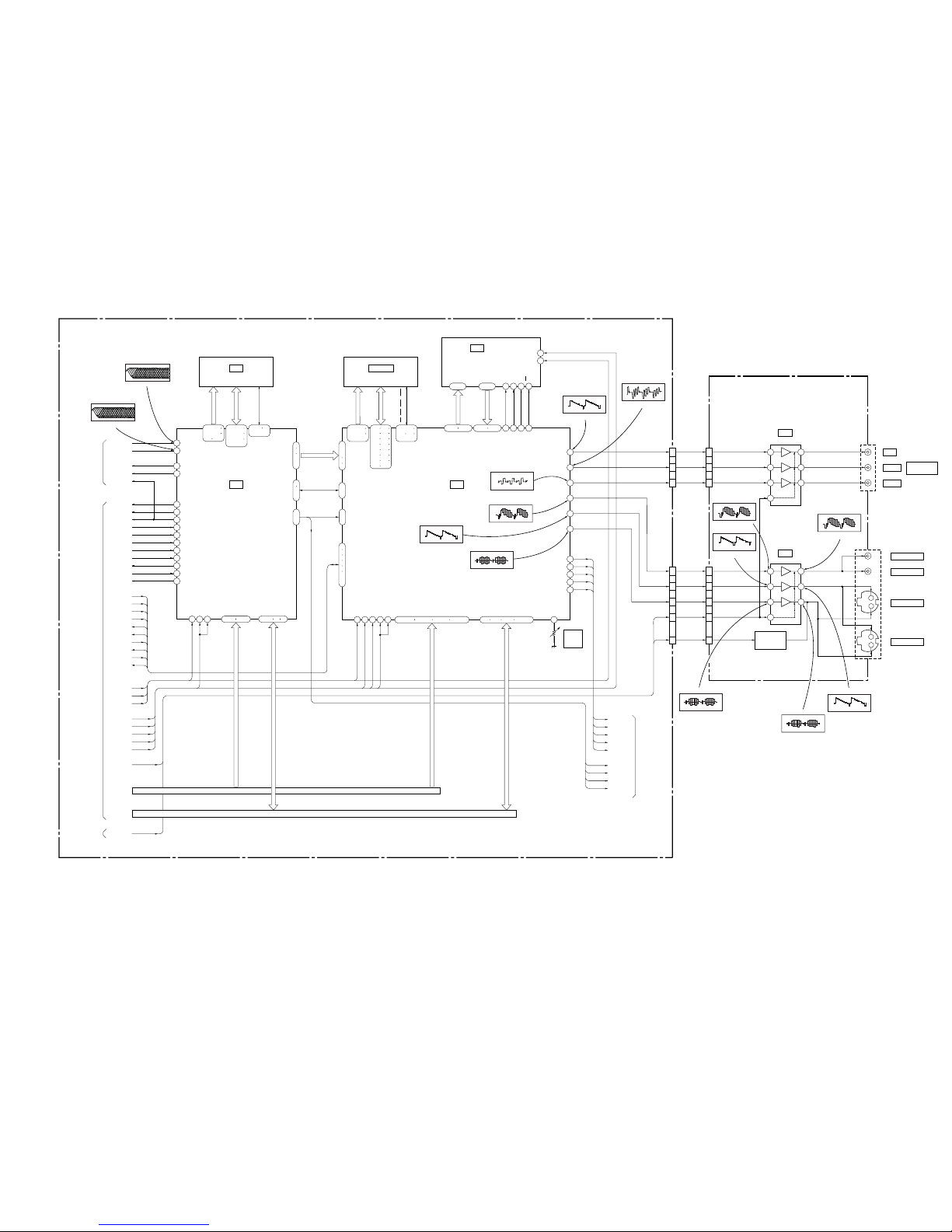

3-3 3-4

3-2. RF/SERVO BLOCK DIAGRAM

INLIMIT

SENSOR

TK-53 BOARD

(SEE PAGE 4-11)

BASE UNIT

KHM-220AAA

MB-85 BOARD(1/6) (SEE PAGE 4-23,25,31)

2

10

12

16

4

15

CN002CN003

CN001

RF+

FE

TE

PI

MIRR

TZC

2VC

2VC

SSDFCT

SSDFCTI

RF

A-D

E-H

VC

PD

LD

VR

FCSFOCUS

COIL

DVD/CD

LD MODULE

DVD/CD

PDIC

OPTICAL DEVICE

TRACKING

COIL

TRK

11

14

13

17

9

7

3

15

4

8

5

6

CN003

M

SLED

MOTOR

M

SPINDLE

MOTOR

M

TILT

MOTOR

1 54

FE

40

TE

39

PI

29

MIRR

26

TZC

32

27

HOLD2

42

DFT

31

VCI

33

43

ı

46

9

ı

12

17

19

20

5

ı

8

13

ı

16

Q002

Q801

SSCK, SSWD,

SSRD, SSCS

TRK

TIA, TIB

INLIM

SPM

SLA, SLB

TIA, TIB

INLIM

SPM

SLA, SLB

05

FCS

CN004

CN002

8

9

10

ı

13

4

ı

7

2

11

ı

14

5

ı

8

FDCHG

SIGO

A-D

RF IP

A2-D2

E-H

VC

SCLK

SWD

SRD

SDEN

PD

LD

Q001

LD DRIVE

69

22

41

ı

44

ADC0

68

ADC1

67

ADC2

66

ADC3

65

ADC4

FCSON

XSDPIT

XSDPRD

XSDPWR

XSDPCS

HA0, 1

HD8-15

N27MSDP

XSDPRST

X3VRST

DVD RF

CD RF

MDP0

LOCK

MDS0

SERVO DSP

20

TRREF

21

TRIN

23

FGIN

38 GIO 11

28

DFCTI

128

HINT

39

GIO 10

VRBA,

VRB 0-3

FG REF

1

HRD

2

HWR

3

HCS

EA 0, 1

HD 0-7

46

GIO 4

RS

X2/CLKIN

50

26 108

GIO 0

GIO 5-8

DAB 0, 1

DAB 2,3

GIO 1, 2

PWM 0-2

TRD

TILT MUTE

FGMODE

FCD

TLTA,TLTB

117

ı

120

122

ı

125

74

81

84

93

96

15

ı

18

13

14

2

3

23

26

FOCUS

COIL

DRIVE

TILT

MOTOR

DRIVE

Q802, 803

GAIN

CONTROL

TRD

FCD

TLTA, TLTB

7

9

20

IC801

IC701

IC702 (1/2)

11

ı

14

15

16

SPINDLE

MOTOR

DRIVE

SLED

MOTOR

DRIVE

SLDA, SLDB,

STVC

+3.3V

2.5VC

2VC

1.6VC

+5V

20

26

IC802

3 1

IC702 (2/2)

+3.3V

7 5

IC803 (1/2)

IC803 (2/2)

14

12

13

9

2

3

5

6

SLDA, SLDB,

STVC

7

ı

9

80

85

92

97

48

49

4

5

SPDLSTOP

SPGAIN

XDRV MUTE

LDMM/DMM

10

8

3 1

5 7

SYSTEM

CONTROL

(SEE PAGE 3-7,8)

SIGNAL PROCESS,

VIDEO

(SEE PAGE 3-5)

SYSTEM

CONTROL

(SEE PAGE 3-8)

500mV/DIV 50ms/DIV

IC001#ª(DVD play)

592mVp-p

200mV/DIV 500ms/DIV

IC001@ª(DVD play)

100mV/DIV 50ms/DIV

180mVp-p

IC001$º(DVD play)

500mV/DIV 50ms/DIV

860mVp-p

1.3Vp-p

IC001$º(CD play)

500mV/DIV 200ms/DIV

IC001#ª(CD play)

1.7Vp-p

448mVp-p

200mV/DIV 20ms/DIV

IC001@ª(CD play)

536mVp-p

200mV/DIV 100ns/DIV

IC0011(DVD play)

500mV/DIV 100ns/DIV

IC001%¢(DVD play)

1.5Vp-p

500mV/DIV 500ns/DIV

1.5Vp-p

IC001%¢(CD play)

880mVp-p

500mV/DIV 500ns/DIV

IC0011(CD play)

500mV/DIV 50ms/DIV

IC701^ª(DVD play)

1.4Vp-p

1.7Vp-p

500mV/DIV 200ms/DIV

IC701^ª(CD play)

860mVp-p

500mV/DIV 50ms/DIV

IC701^•(CD play)

100mV/DIV 5ms/DIV

180mVp-p

IC701^•(DVD play)

TRACKING

COIL

DRIVE

11

12

6

7

13

14

15

ı

18

9

ı

12

8

12

13

5

6

1

ı

4

7

ı

10

11

14

15

5

6

7

13

19

20

21

22

5

2

4

9

10

16

17

8

11

15

18

4

5

DVD/CD RF AMP

DIGITAL SERVO

IC001

M

B651

LMLM

M991

LOADING

MOTOR

S2

S3

1

2

1

2

ROTARY

ENCODER

(LOADING)

S1

SE-91 BOARD

(SEE PAGE 4-14)

CK-81 BOARD

(SEE PAGE 4-61)

LM-59 BOARD

(SEE PAGE 4-61)

M

CN656

CN802

TM

M951

TURN TABLE

MOTOR

DSENS

TSENS

6

1

2

CN801

1

2

B991

1

2

1

2

4

2

6

7

4

PH801

DISC PRESENCE

DETECTION SENSOR

PH802

TURN TABLE POSITION

DETECTION SENSOR

11

13

4

5

21

22

14

16

LOADING

MOTOR

DRIVE

TURN TABLE

MOTOR

DRIVE

IC652

3

6

4

CKSW2

OCSW1

8

9

CKSW1

CN651

CN009

DSW1

TSW1

TRMP, TRMM

CKMP, CKMM

CKSW2

OCSW1

CKSW1

DSW1

TSW1

TRMM

CKMM

TRMP

CKMP

1

6

7

11

4

2

3

5

6

13

7

8

3

10

12

11

3

6

4

Q656

Q653, 654

SWITCH

Q651, 652

SWITCH

IC651

OSC

11.6Vp-p (H)

IC6510

DVP-C650D/C653D

3-5 3-6

3-3. SIGNAL PROCESS/VIDEO BLOCK DIAGRAM

MB-85 BOARD(2/6)

(SEE PAGE 4-19,21,27,33,35)

AU-215 BOARD(1/3)

(SEE PAGE 4-43,45)

1

1

54

58

93

100

IC304

16M DRAM

IC303

ARP2

IC401

AV DECODER

IC502

V EQ/NR

CLK27I

XRST

PB/B-Y

PR/R-Y

VIDEO OUT1

VIDEO OUT2

S VIDEO OUT1

S VIDEO OUT2

Y

IC303

VIDEO BUFFER

IC321

VIDEO BUFFER

J505

55

56

58

59

DFCT

NORF

49

52

MDS0

MDP0

17

19

RFIN1

RFIN2

MDS0

MDP0

DVD RF

CD RF

LOCK

FWON

113

121

123

111

60

61

MD2

MUTE

XWR

XRD

83

84

86

XINT

XCS

XWAT

DFCT

NORF

LOCK

FWON

MD2

MUTE

XARPWR

XARPRD

XARPIT

XARPCS

XARPWT

XCS2

XCS3

XRD

XWRH

XAVDIT

XAVDWT

DACK0

DREQ0

DACK1

DREQ1

XARPRST

XAVDRST

X57RST

33MARP

256FS30

33M30

27M30

27M57

VS

V MUTE

05

HD 0-15

HA 0-21

87

SCKI

MD 00-15

MA 0-9

XMWR, XCAS,

XRAS, XOE

XARPRST

33MARP

HA 0-7

HD 8-15

A 0-7

D 0-7

MCKI

XRST

103 19 36

CRPCLKI

ACLKI

SCLKIN

HAD 0-21 I

HD 0-15

CLKI

RSTIN

256FS30

XAVDRST

27M30

33M30

160 163

VREFI

70

73-76 79-82

154-157

159-162

164-167

169-172

136-139

141-144

146 147

134 135

137 138

140 141

143 144

146 147

149 150

152 153

155 156

105-108

110-113

115-118

120-123

125 127

129-132

148

150-152

63-68 70 71

HA 0-21

HD 0-15

X57RST

27M57

IC402, 403

16M SDRAM

DDT 0-15

DAD 0-11

107

ı

110

29

ı

32

47

ı

51

91

93

ı

96

97

98

100

ı

105

SD 0-7

SD 0-7

DT 0-7 I

SDCK, SDEF,

XSHD, XSAK, XSRQ

CDDOUT, CDDATA,

CDBCK, CDLRCK

CDDOUT, CDDATA, CDBCK, CDLRCK

38

ı

43

45

46

166

167

193

194

196

198

ı

202

168-170 172-178 180-187 189-192 2-5 7-10 12-15 205-208

97 98

HSYNCI

VSYNCI

YO 0-7

YI 0-7

SDI

SENO

SDOUT

HSYNCO

FLDO

NR-SENO

NR-SDOUT

HSYNCON

FLDO

PDI 0-7

PDO 0-7

PDI 0-7

PDO 0-7

31 29

72 73 98 99

60-6711-18

75-78 80-8386-89 91-94

21

22

23

ACH12

ACH34

ACH56

LRCK

BCK

CDDOUT

CDDATA

CDBCK

CDLRCK

ACH12O

G/Y OUT

R/B-Y OUT

B/R-Y OUT

COMP OUT

Y OUT

C OUT

ACH34O

ACH56O

25

26

LRCKO

BCKO

LOCK

CLK, CKE,

DQML, DQMU,

CS, WE, CAS, RAS

CS

VIDEO

LEVEL

ADJ

RV401

SYSTEM

CONTROL

(SEE PAGE 3-7,8)

INTERFACE

CONTROL

(SEE PAGE 3-14)

RF, SERVO

(SEE PAGE 3-4)

AUDIO 1

(SEE PAGE 3-XX)

4

CN005

CN004

2

6

1

3

5

8

6

4

VIDEO V

VIDEO Y

VIDEO C

V MUTE

VS

CN303

J303

CN301

VIDEO G/Y

VIDEO R/B-Y

VIDEO B/R-Y

6

2

28

26

24

21

23

4

13

2 15

7 10

2

15

7 10

4 13

COMPONENT

VIDEO OUT

C

Y

C

Y

DC ON/OFF

Q321, 322

500mV/DIV 100ns/DIV

1.6Vp-p

IC303!¶(DVD play)

1.0Vp-p(H)

IC401%•

500mV/DIV 200ns/DIV

1.6Vp-p

IC303!ª(CD play)

720mVp-p(H)

IC401%¢

1,1Vp-p(H)

IC401^¡

816mVp-p(H)

IC401^™

728mVp-p(H)

IC401%¶

61

1.1Vp-p(H)

IC3212

57

1.2Vp-p(H)

IC401^∞

62

65

1.2Vp-p(H)

IC3214

860mVp-p(H)

IC3217

1.8mVp-p(H)

IC3210

2.4 Vp-p(H)

IC321!£

2.0Vp-p(H)

IC321!∞

Loading...

Loading...