Sony DVP-C600D,RMT-D104A Service Manual

MICROFILM

SERVICE MANUAL

US Model

Canadian Model

Mexican Model

CD/DVD PLAYER

DVP-C600D

RMT-D104A

SPECIFICATIONS

– 2 –

LEAKAGE TEST

The AC leakage from any exposed metal part to earth ground

and from all exposed metal parts to any exposed metal part having

a return to chassis, must not exceed 0.5 mA (500 microamperes).

Leakage current can be measured by any one of three methods.

1. A commercial leakage tester, such as the Simpson 229 or RCA

WT -540A. Follow the manufacturers' instructions to use these

instruments.

2. A battery-operated A C milliammeter. The Data Precision 245

digital multimeter is suitable for this job.

3. Measuring the voltage drop across a resistor by means of a

VOM or battery-operated AC voltmeter. The “limit” indica-

tion is 0.75V, so analog meters must have an accurate low-

voltage scale. The Simpson 250 and Sanwa SH-63T rd are ex-

amples of a passive VOM that is suitable. Nearly all battery

operated digital multimeters that have a 2V A C range are suit-

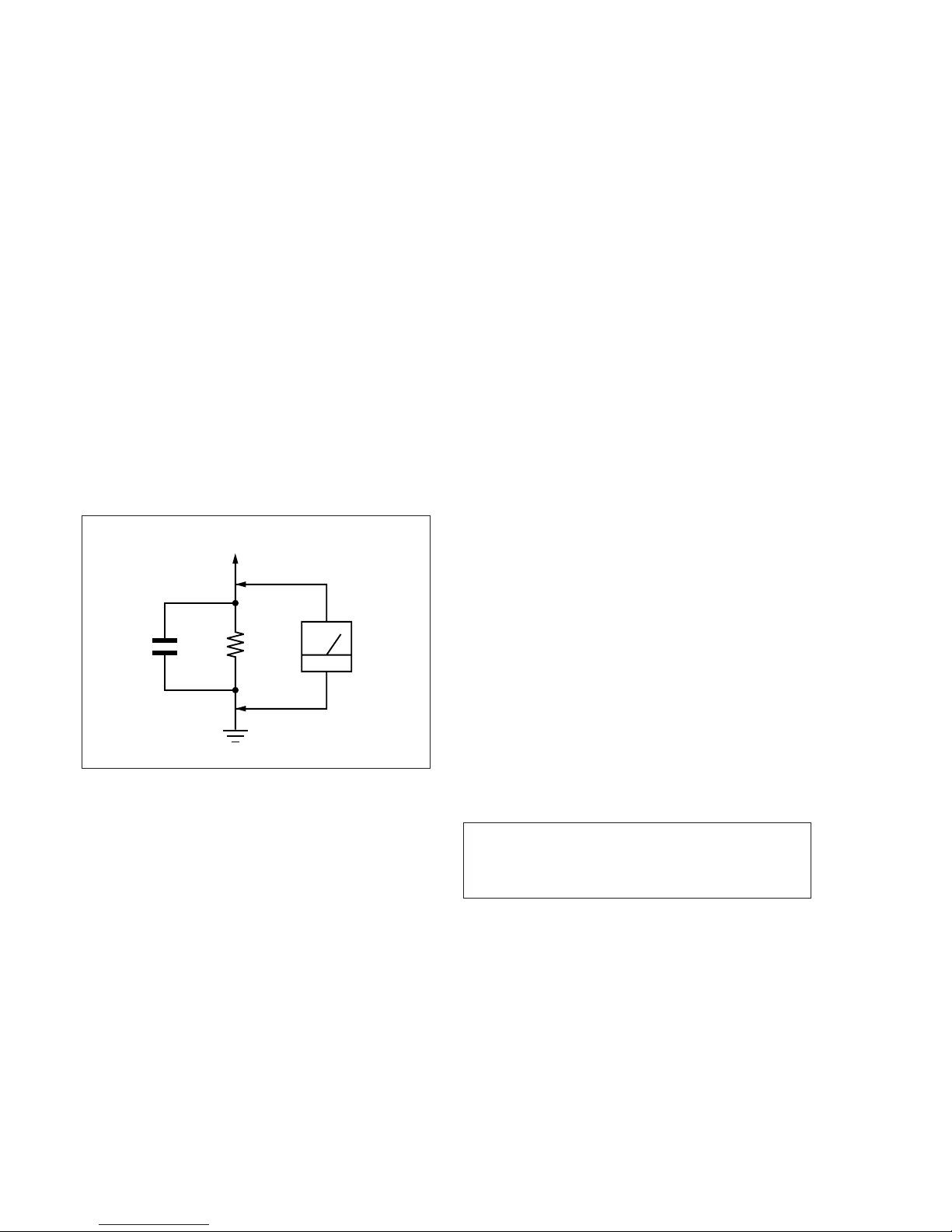

able. (See Fig. A)

Fig. A Using AC voltmeter to check AC leakage

1.5 k

Ω

0.15 µF

AC

Voltmeter

(0.75 V)

To Exposed Metal

Parts on Set

Earth Ground

WARNING!!

WHEN SERVICING, DO NO T APPR O A CH THE LASER

EXIT WITH THE EYE TOO CLOSELY. IN CASE IT IS

NECESSARY TO CONFIRM LASER BEAM EMISSION,

BE SURE TO OBSERVE FROM A DISTANCE OF

MORE THAN 25 cm FROM THE SURFACE OF THE

OBJECTIVE LENS ON THE OPTICAL PICK-UP BLOCK.

CAUTION:

The use of optical instrument with this product will increase eye

hazard.

ATTENTION AU COMPOSANT AYANT RAPPORT

À LA SÉCURITÉ!

LES COMPOSANTS IDENTIFIÉS P AR UNE MARQUE !

SUR LES DIAGRAMMES SCHÉMA TIQ UES ET LA LISTE

DES PIÈCES SONT CRITIQUES POUR LA SÉCURITÉ

DE FONCTIONNEMENT. NE REMPLACER CES COMPOSANTS QUE PAR DES PIÈCES SONY DONT LES

NUMÉROS SONT DONNÉS DANS CE MANUEL OU

DANS LES SUPPLÉMENTS PUBLIÉS PAR SONY.

1. Check the area of your repair for unsoldered or poorly-soldered connections. Check the entire board surface for solder

splashes and bridges.

2. Check the interboard wiring to ensure that no wires are

“pinched” or contact high-wattage resistors.

3. Look for unauthorized replacement parts, particularly transistors, that were installed during a previous repair. Point them

out to the customer and recommend their replacement.

4. Look for parts which, though functioning, show obvious signs

of deterioration. Point them out to the customer and recommend their replacement.

5. Check the B+ voltage to see it is at the values specified.

6. Check the B+ voltage to see it is at the values specified.

7. Check the antenna terminals, metal trim, “metallized” knobs,

screws, and all other exposed metal parts for AC leakage.

Check leakage as described below.

SAFETY CHECK-OUT

After correcting the original service problem, perform the following

safety checks before releasing the set to the customer:

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK ! OR DOTTED

LINE WITH MARK ! ON THE SCHEMATIC DIAGRAMS

AND IN THE PARTS LIST ARE CRITICAL TO SAFE

OPERATION. REPLACE THESE COMPONENTS WITH

SONY PARTS WHOSE PART NUMBERS APPEAR AS

SHOWN IN THIS MANUAL OR IN SUPPLEMENTS PUBLISHED BY SONY.

CAUTION

Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous radiation exposure.

– 3 –

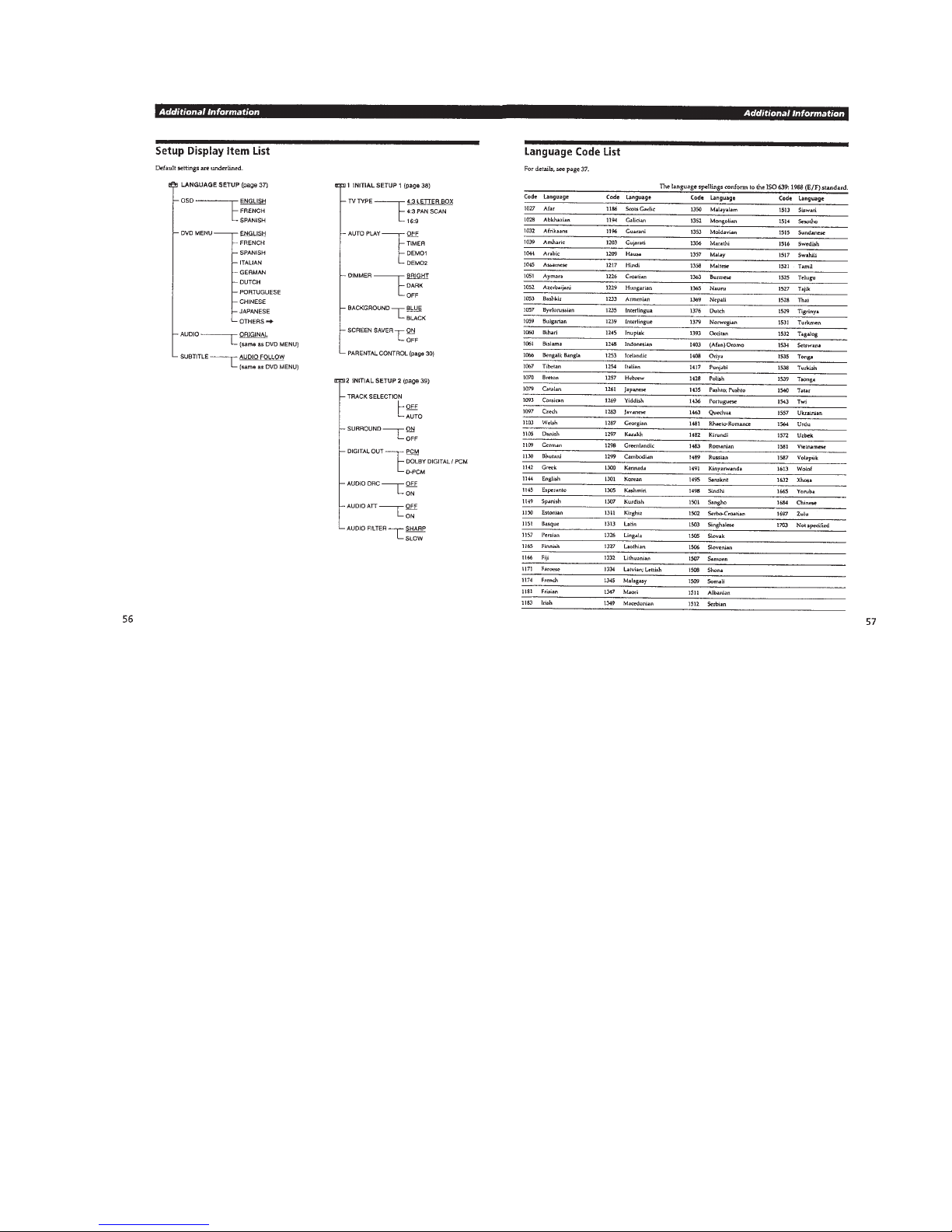

TABLE OF CONTENTS

Section Title Page Section Title Page

Service Note ............................................................................ 4

1. GENERAL

This Player Can Play the Following Discs .................... 1-1

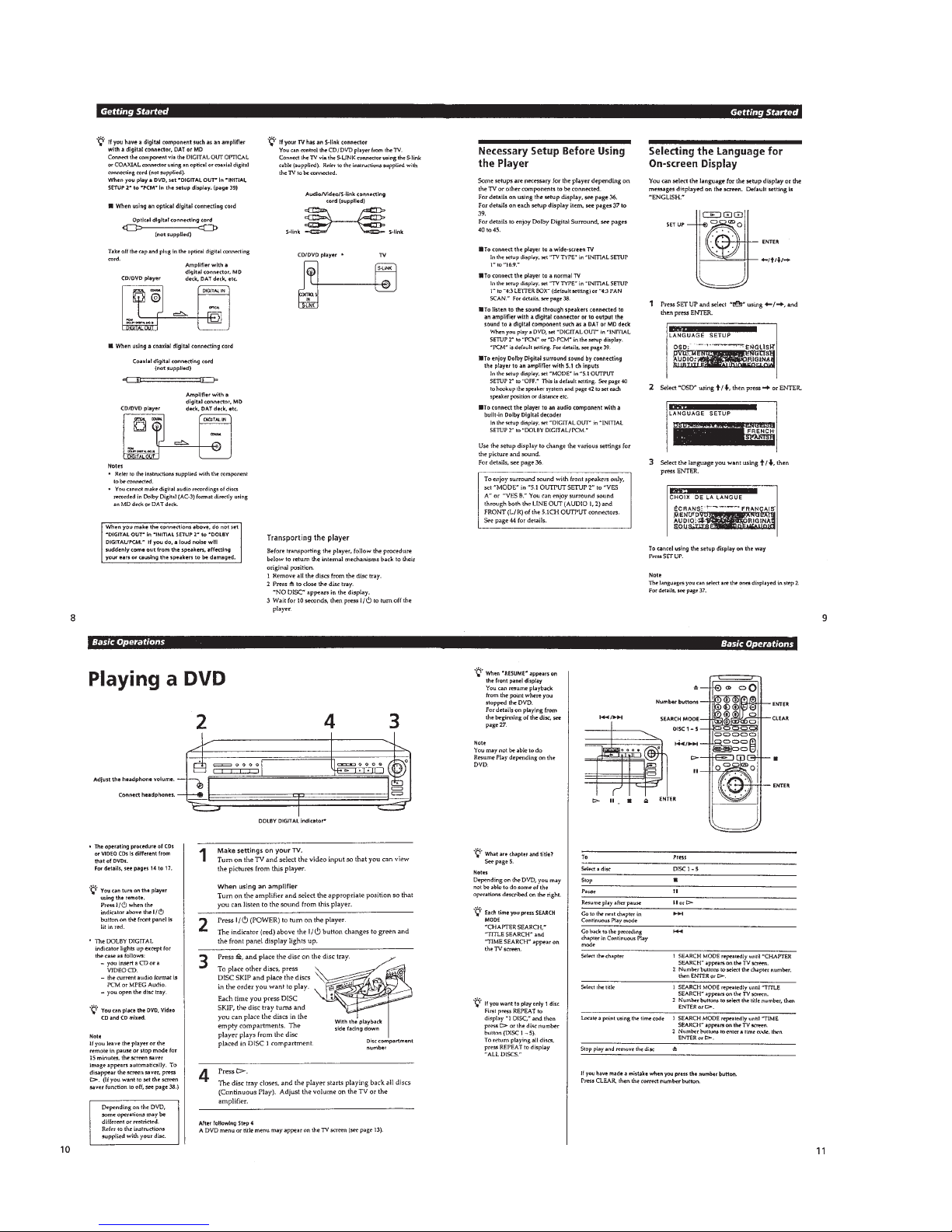

Getting Started .............................................................. 1-1

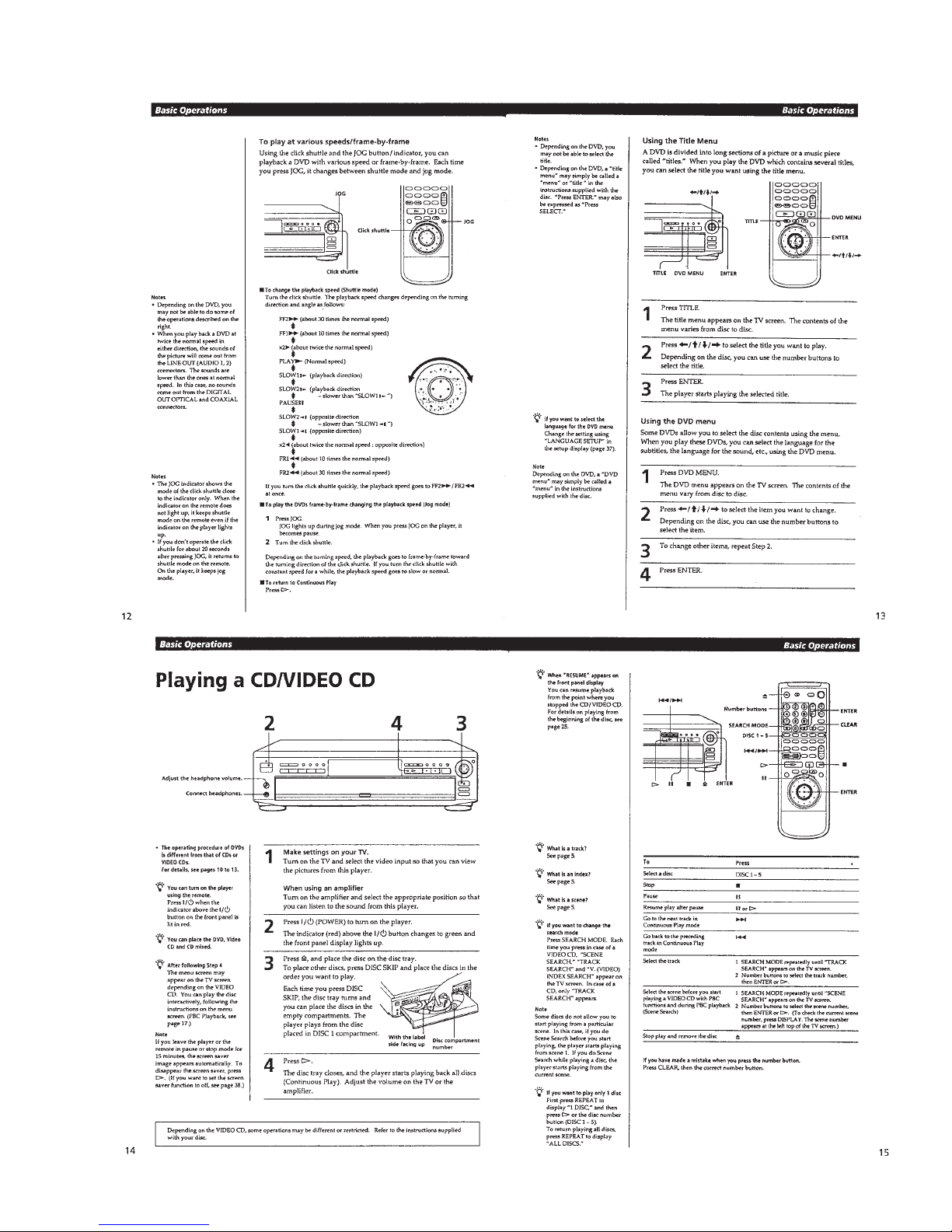

Basic Operations ........................................................... 1-2

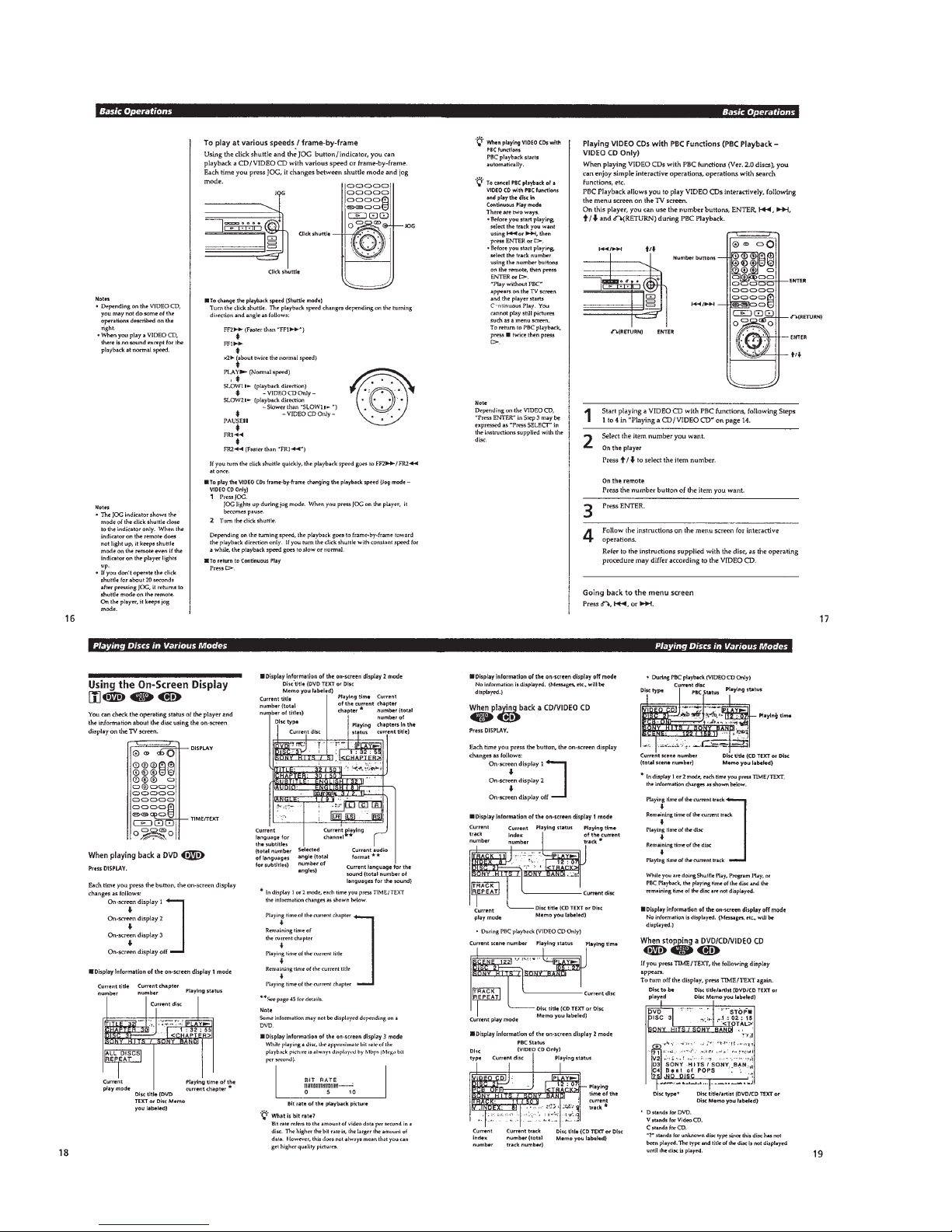

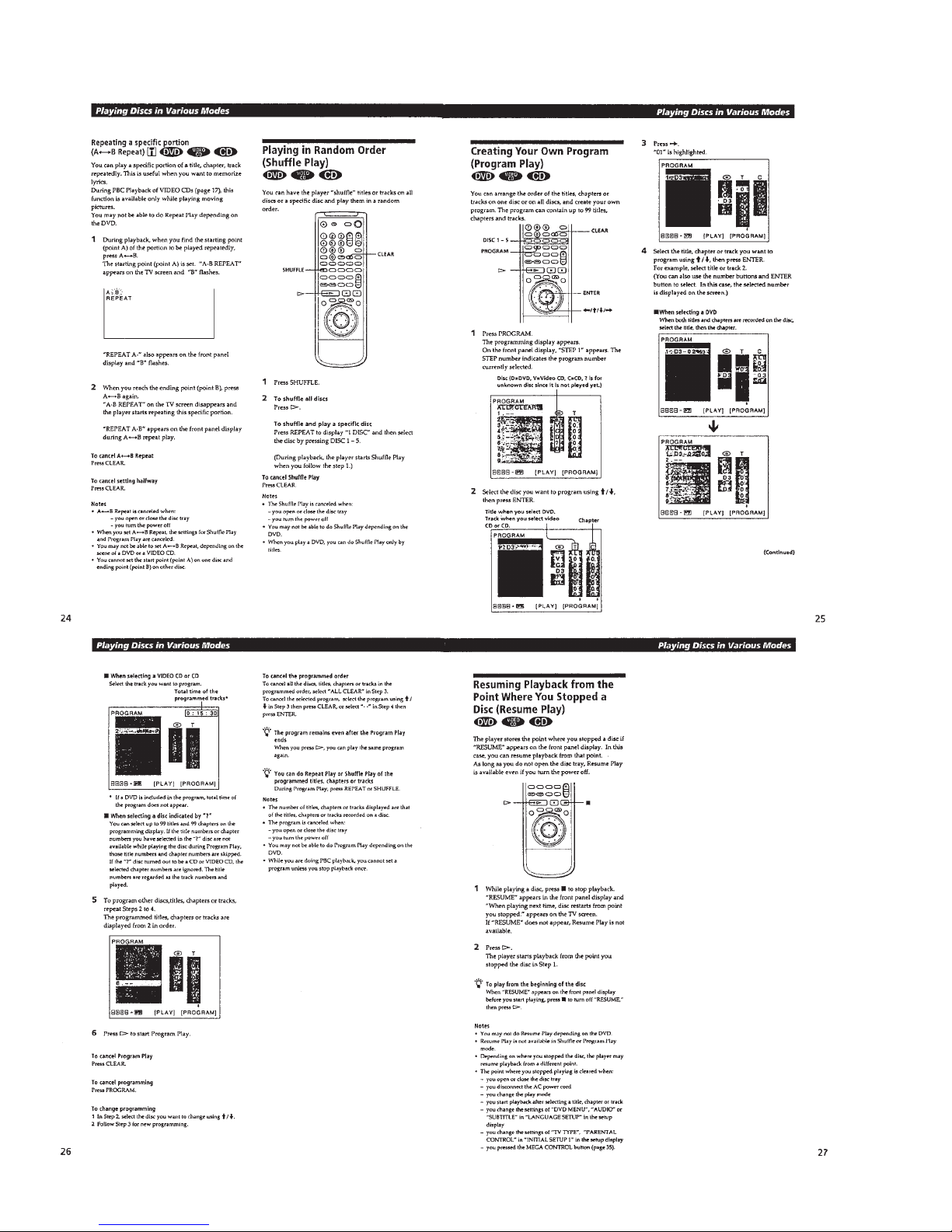

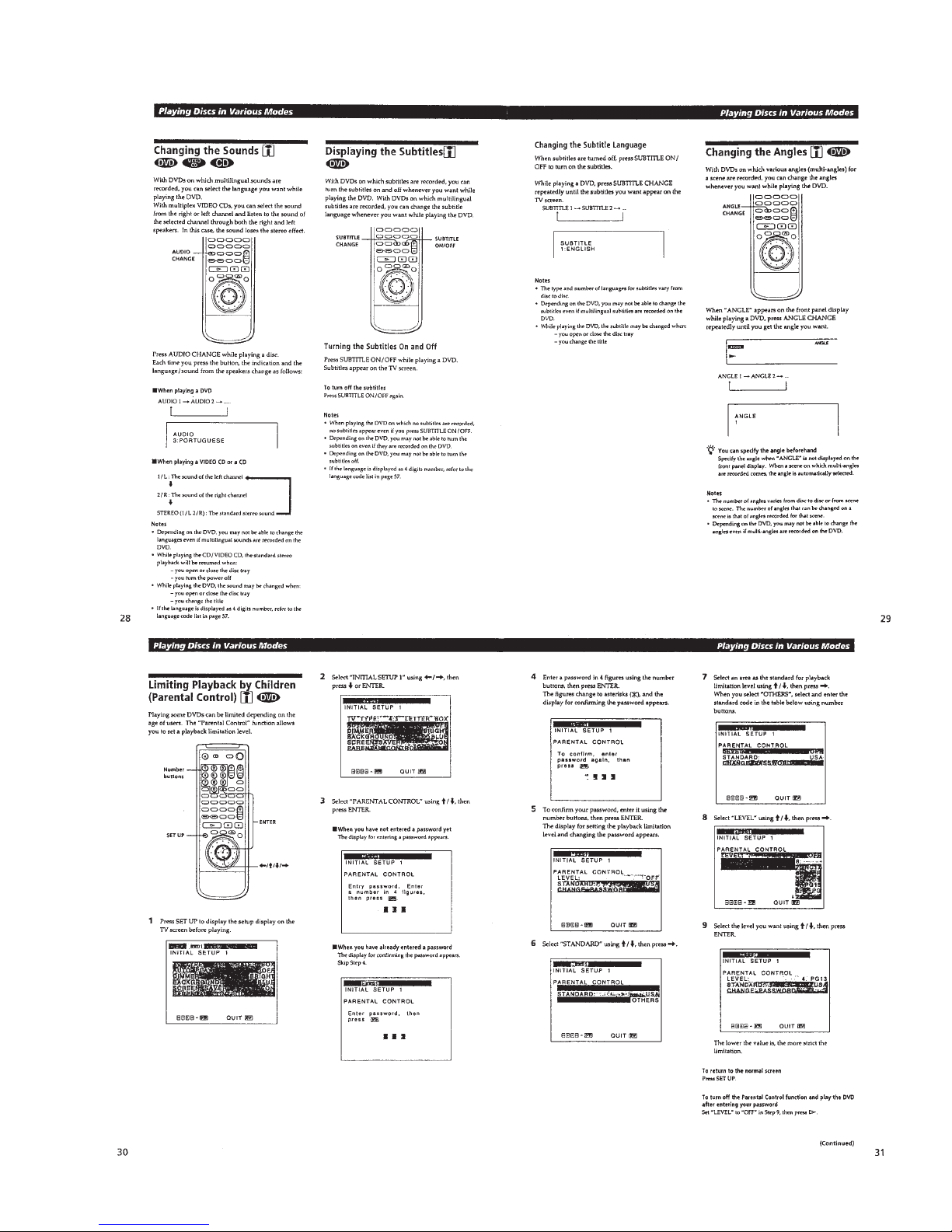

Playing Discs in Various Modes .................................... 1-4

Setting and Adjustments ............................................... 1-9

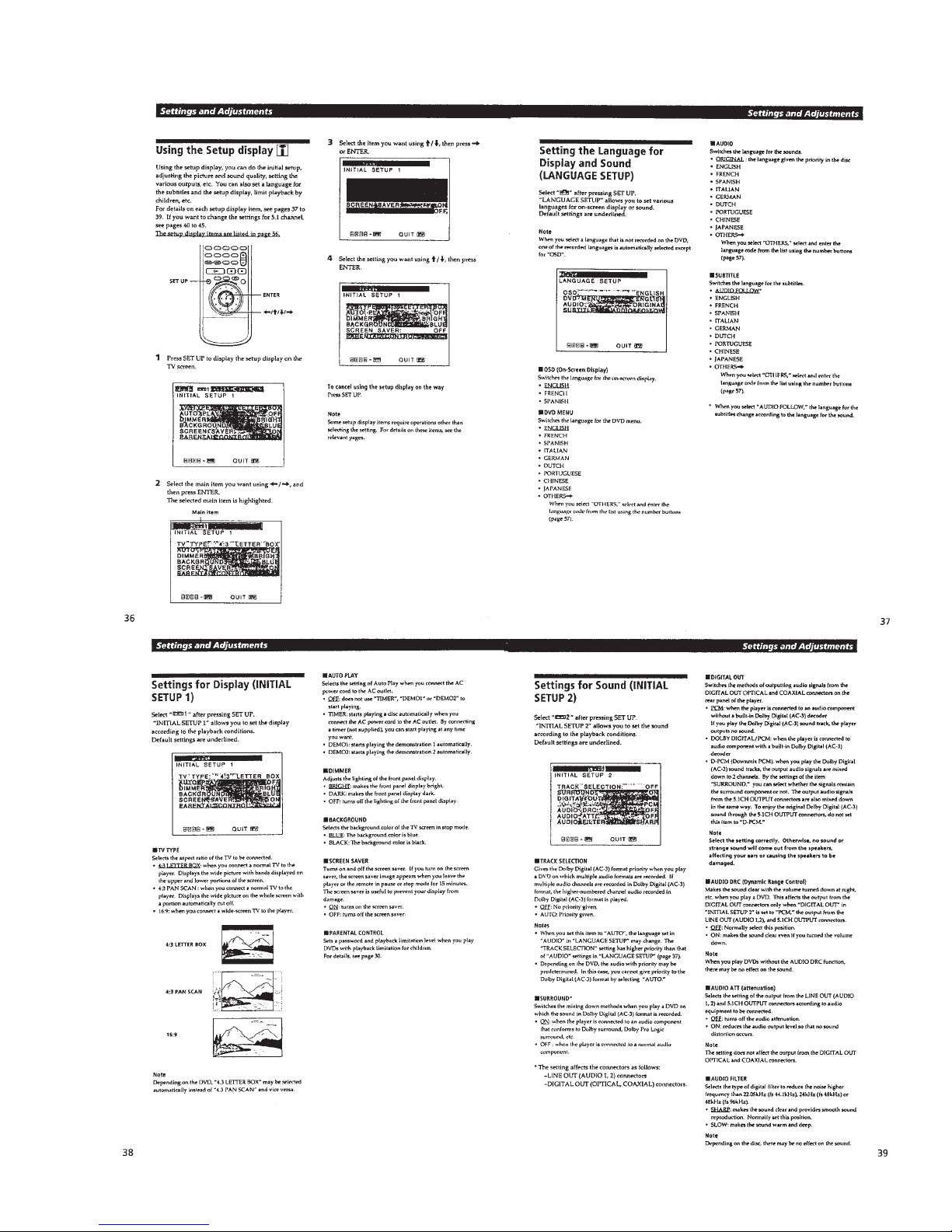

Dolby Digital Surround .................................................. 1-10

Additional Information ................................................... 1-11

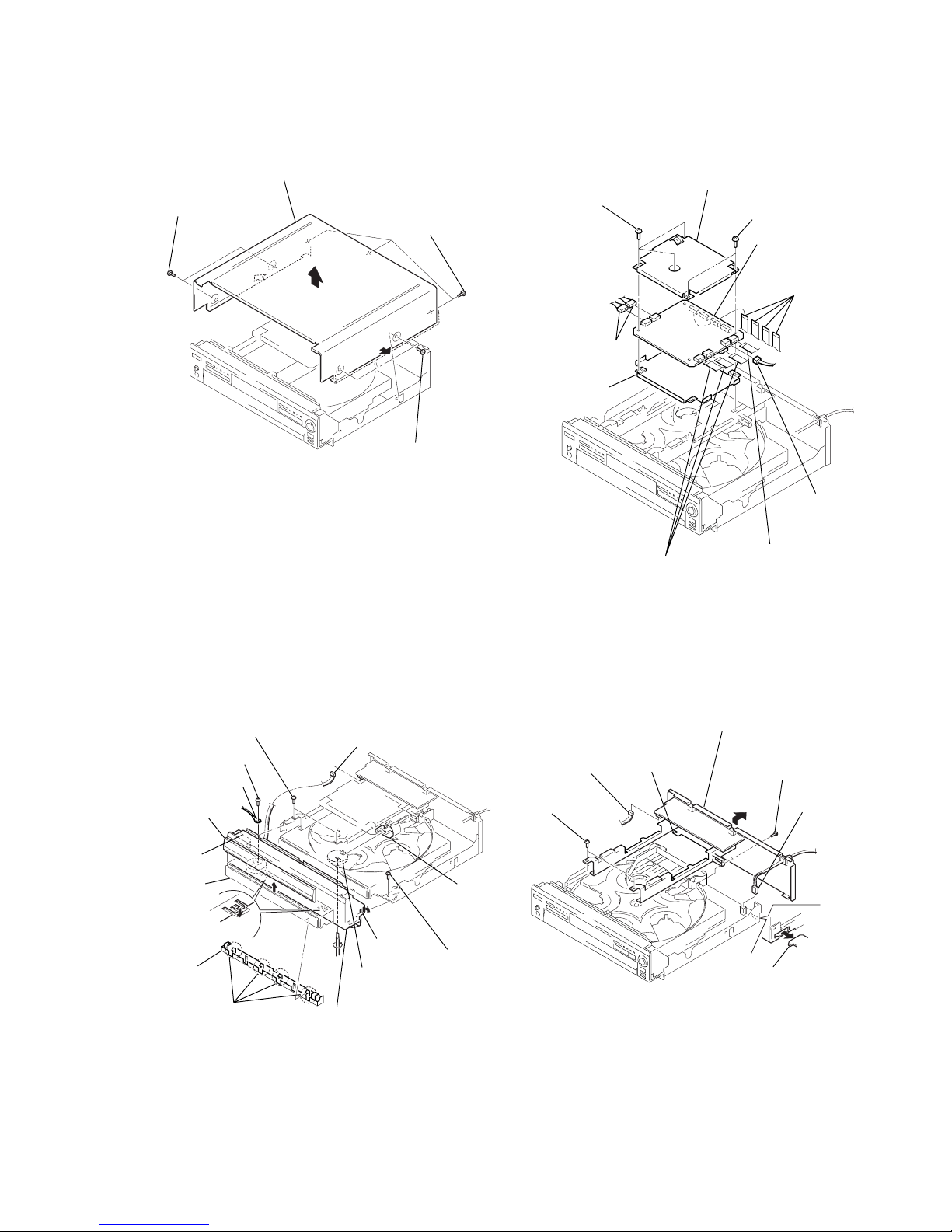

2. DISASSEMBLY

2-1. CASE REMOVAL ......................................................... 2-1

2-2. FRONT PANEL SECTION REMOVAL....................... 2-1

2-3. MB-83 BOARD REMOVAL .......................................... 2-1

2-4. REAR PANEL REMOVAL ........................................... 2-1

2-5. TABLE ASS’Y REMOVAL............................................ 2-2

2-6. ROTARY MOTOR ASS’Y (M951) REMOVAL ........... 2-2

2-7. CHASSIS ASS’Y REMOVAL ....................................... 2-2

2-8. LOADING MOTOR ASS’Y (M991) REMOVAL ......... 2-2

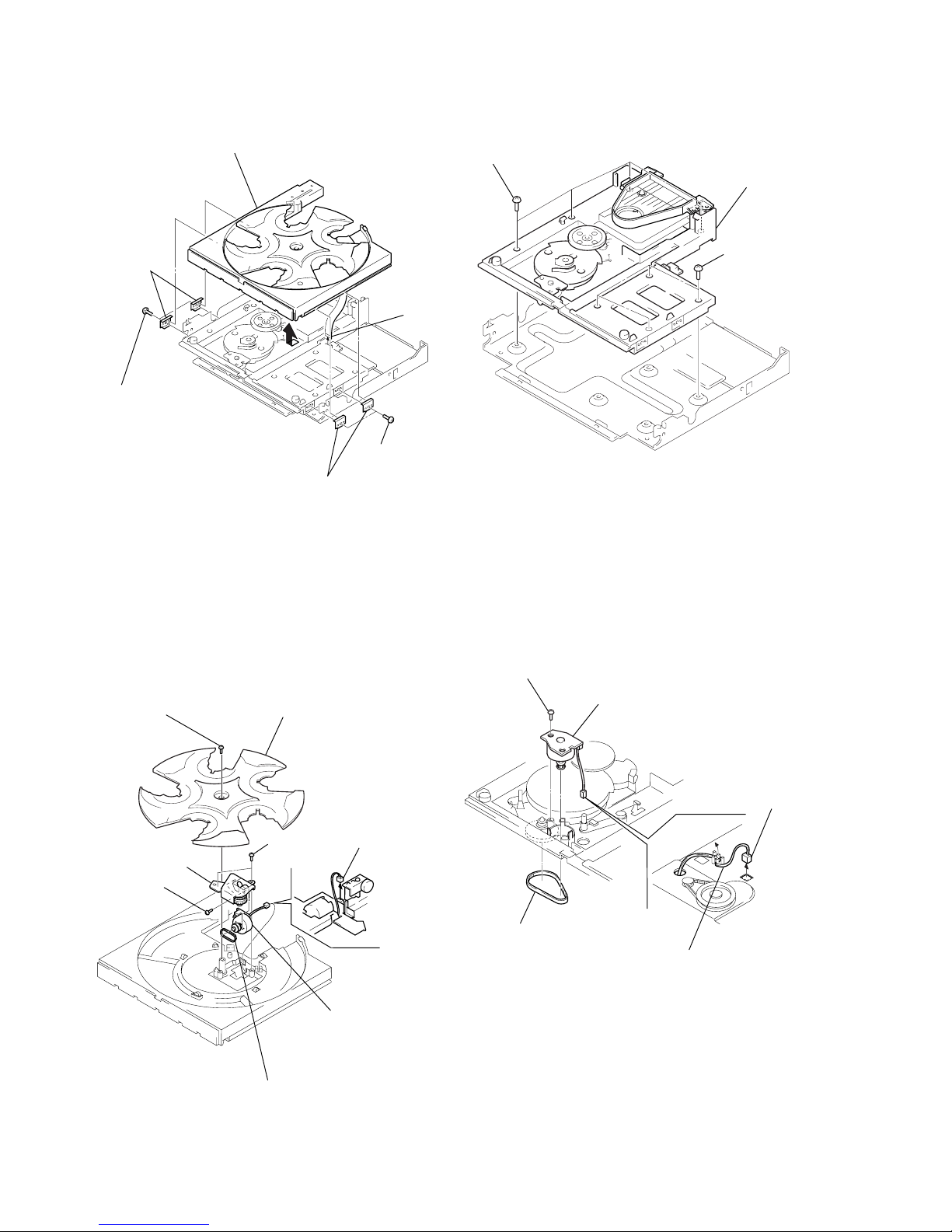

2-9. BU HOLDER ASS’Y REMOVAL ................................ 2-3

2-10. TK-48 BOARD REMOVAL .......................................... 2-3

2-11. SKEW MOTOR ASS’Y (M902) REMOVAL............... 2-3

2-12. SLED MOTOR ASS’Y (M501) REMOVAL ................ 2-3

2-13. SPINDLE MOTOR ASS’Y (M901) REMOVAL.......... 2-4

2-14. OPTICAL PICK-UP REMOVAL ................................... 2-4

2-15. INTERNAL VIEWS ....................................................... 2-4

2-16. CIRCUIT BOARDS LOCATION .................................. 2-5

3. BLOCK DIAGRAMS

3-1. Overall Block Diagram .................................................. 3-1

3-2. RF/Servo Block Diagram .............................................. 3-3

3-3. Signal Precess Block Diagram ..................................... 3-5

3-4. Video Block Diagram..................................................... 3-7

3-5. System Control Block Diagram ..................................... 3-9

3-6. Audio Block Diagram..................................................... 3-11

3-7. Mode Control Block Diagram ........................................ 3-13

3-8. Power Block Diagram.................................................... 3-15

4. PRINTED WIRING BOARDS AND SCHEMATIC

DIAGRAMS

4-1. Frame Schematic Diagram............................................ 4-1

4-2. Printed Wiring Boards and Schematic Diagrams ......... 4-5

TK-48 Printed Wiring Board .......................................... 4-5

TK-48 (RF, Servo 1) Schematic Diagram ..................... 4-7

TK-48 (RF, Servo 2) Schematic Diagram ..................... 4-9

MB-83 Printed Wiring Board ......................................... 4-11

MB-83 (AC-3 Decoder) Schematic Diagram ................ 4-15

MB-83 (M Gate Array) Schematic Diagram.................. 4-17

MB-83 (AV Decoder) Schematic Diagram.................... 4-19

MB-83 (Clock Generator) Schematic Diagram............. 4-21

MB-83 (Video Encoder) Schematic Diagram................ 4-23

FG-44 Printed Wiring Board.......................................... 4-26

MB-83 (Drive 1) Schematic Diagram ............................ 4-27

MB-83 (Drive 2), FG-44 Schematic Diagram .............. 4-29

MB-83 (DSP 1) Schematic Diagram ............................. 4-31

MB-83 (DSP 2) Schematic Diagram ............................. 4-33

MB-83 (Roulette), CK-78, LM-55, SE-70

Schematic Diagram ....................................................... 4-35

CK-78, LM-55, SE-70 Printed Wiring Boards ............... 4-37

MB-83 (Bias) Schematic Diagram ................................ 4-39

MB-83 (IF µ-com) Schematic Diagram ......................... 4-41

MB-83 (L Gate Array) Schematic Diagram ................... 4-43

MB-83 (ARP, Decrypt) Schematic Diagram .................. 4-45

MB-83 (System µ-com) Schematic Diagram ................ 4-47

MB-83 (S Gate Array) Schematic Diagram .................. 4-49

AU-198 Printed Wiring Board ....................................... 4-51

AU-198 (Audio 1) Schematic Diagram ......................... 4-55

AU-198 (Audio 2) Schematic Diagram ......................... 4-57

AU-198 (Audio 3) Schematic Diagram ......................... 4-59

AU-198 (Video Buffer) Schematic Diagram .................. 4-61

FL-89, LE-20 Printed Wiring Boards............................. 4-63

FL-89, LE-20 Schematic Diagrams............................... 4-65

FR-134, HP-97 Printed Wiring Boards ......................... 4-67

FR-134, HP-97 Schematic Diagrams ........................... 4-69

HS-934SU Printed Wiring Board .................................. 4-71

HS-934SU Schematic Diagram .................................... 4-73

5. IC PIN FUNCTION DESCRIPTION

5-1. Interface Control Pin Function (MB-83 Board IC604) .. 5-1

5-2 System Control Pin Function (MB-83 Board IC805) .... 5-2

6. TEST MODE

6-1. Starting up Test Mode ................................................... 6-1

6-2. Selection of Check Item ................................................ 6-1

6-2-1. Selected Item Check................................................ 6-1

6-2-2. All Items Check ........................................................ 6-1

6-3. Error Display.................................................................. 6-2

6-4. General Description of Checking Method..................... 6 -2

6-5. Drive Auto Adjustment................................................... 6-10

6-6. Drive Manual Operation ................................................ 6-14

6-6-1. Drive Manual Operation menu screen..................... 6-14

6-6-2. Disc Type .................................................................. 6-14

6-6-3. Manual Control 1...................................................... 6-14

6-6-4. Manual Control 2...................................................... 6-15

6-6-5. Manual Control 3...................................................... 6-15

6-6-6. Manual Adjust 1........................................................ 6-15

6-6-7. Manual Adjust 2........................................................ 6-16

6-6-8. Auto Adjust ............................................................... 6-16

6-6-9. Check ....................................................................... 6-16

6-6-10. EEPROM Data screen Display ................................ 6-17

6-7. Other Operation............................................................. 6-17

6-8. Emergency History ........................................................ 6-18

6-9. Error Code ..................................................................... 6-20

7. ELECTRICAL ADJUSTMENT

7-1. Power Supply Check ..................................................... 7-1

1. HS-934SU Board........................................................... 7-1

7-2. Adjustment of System Control ...................................... 7-2

1. System Clock 27 MHz Adjustment ................................ 7-2

7-3. Adjustment of Video System

1. Video Level Adjustment ................................................ 7-2

2. S-Terminal Output Check .............................................. 7-2

3. Checking Composite Video Output B-Y........................ 7-2

4. Checking Composite Video Output R-Y ....................... 7-3

5. Checking Composite Video Output Y ............................ 7-3

6. Checking S Video Output S-C....................................... 7-3

7. Checking S Video Output DC Level .............................. 7-3

7-4. Adjustment Related Parts Arrangement ....................... 7-4

8. REPAIR PARTS LIST

8-1. Exploded Views ............................................................. 8-1

8-1-1. Main Assembly ......................................................... 8-1

8-1-2. Front Panel Assembly .............................................. 8-2

8-1-3. Table Assembly ........................................................ 8-3

8-1-4. Chassis Assembly .................................................... 8-4

8-1-5. DVD Mechanism Chassis Assembly........................ 8-5

8-2. Electrical Parts List........................................................ 8-6

– 4 –

SERVICE NOTE

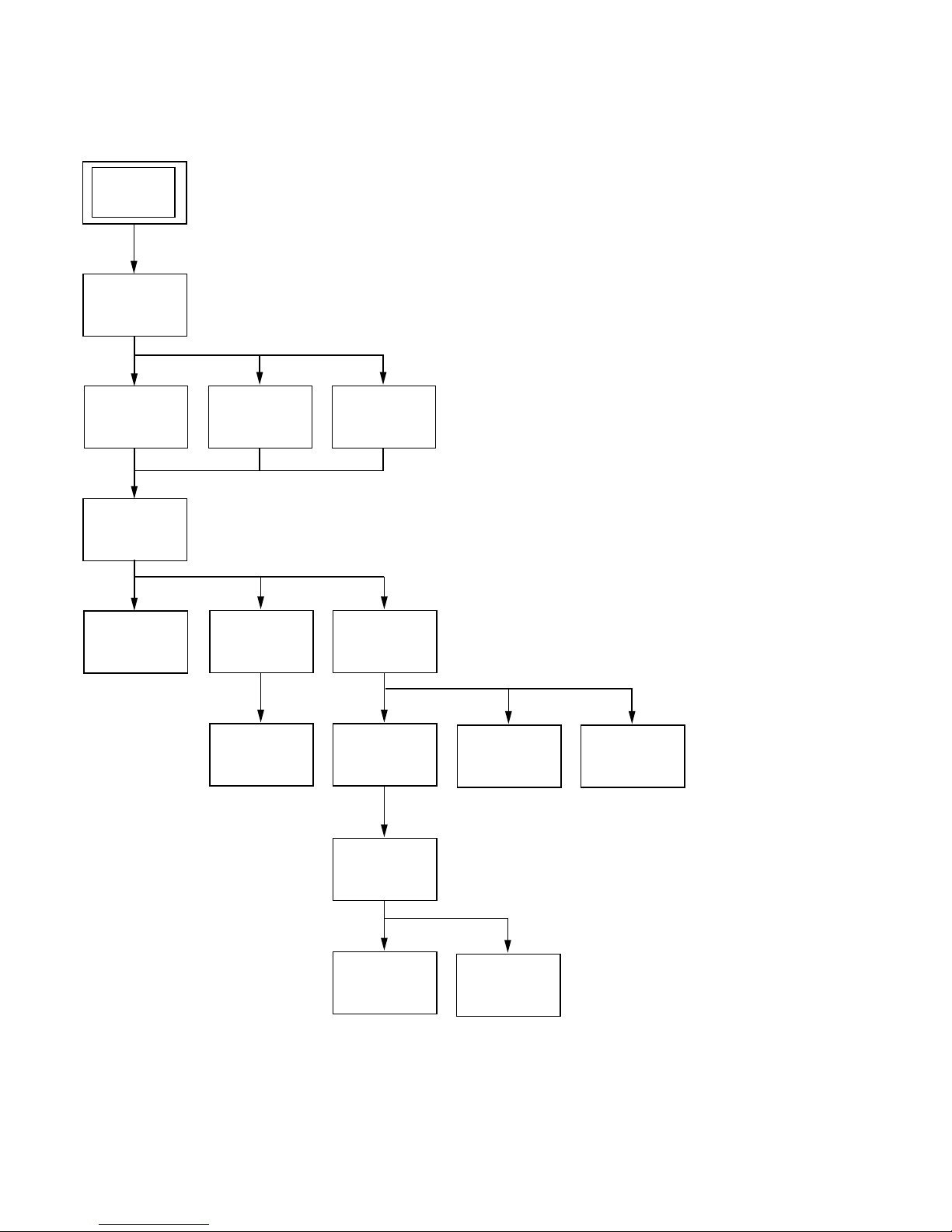

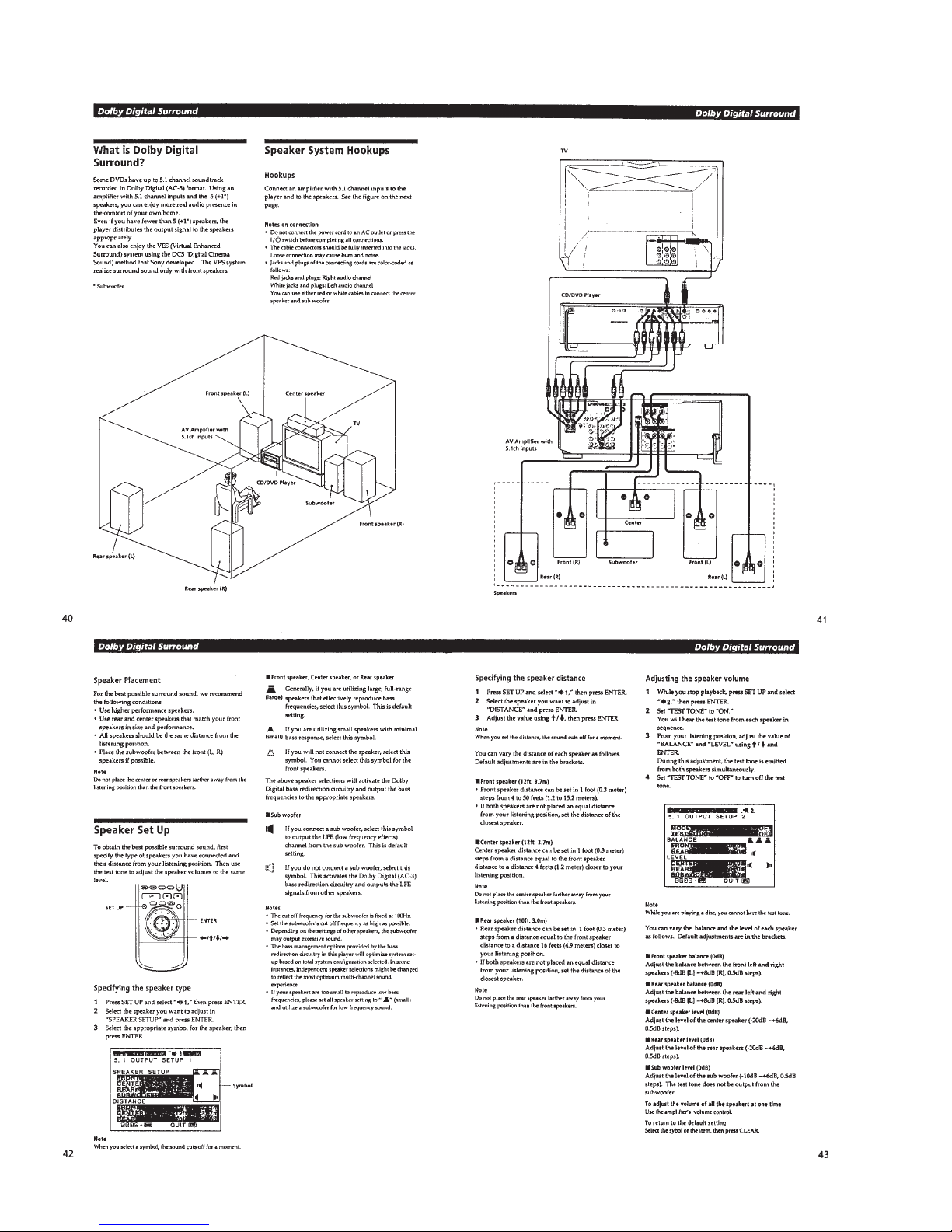

1. DISASSEMBLY

• This set can be disassembled in the order shown below.

Set

Case

(Page 2-1)

MB-83 board

(Page 2-1)

Table ass’y

(Page 2-2)

Chassis ass’y

(Page 2-2)

BU holder

ass’y

(Page 2-3)

Rotary motor

ass’y

(Page 2-2)

Loading motor

ass’y

(Page 2-2)

Skew motor

ass’y

(Page 2-3)

Sled motor

ass’y

(Page 2-3)

Spindle motor

ass’y

(Page 2-4)

TK-48 board

(Page 2-3)

Spindle base

(Page 2-3)

Optical pick-up

(Page 2-4)

Front panel

section

(Page 2-1)

Rear panel

(Page 2-1)

– 5 –

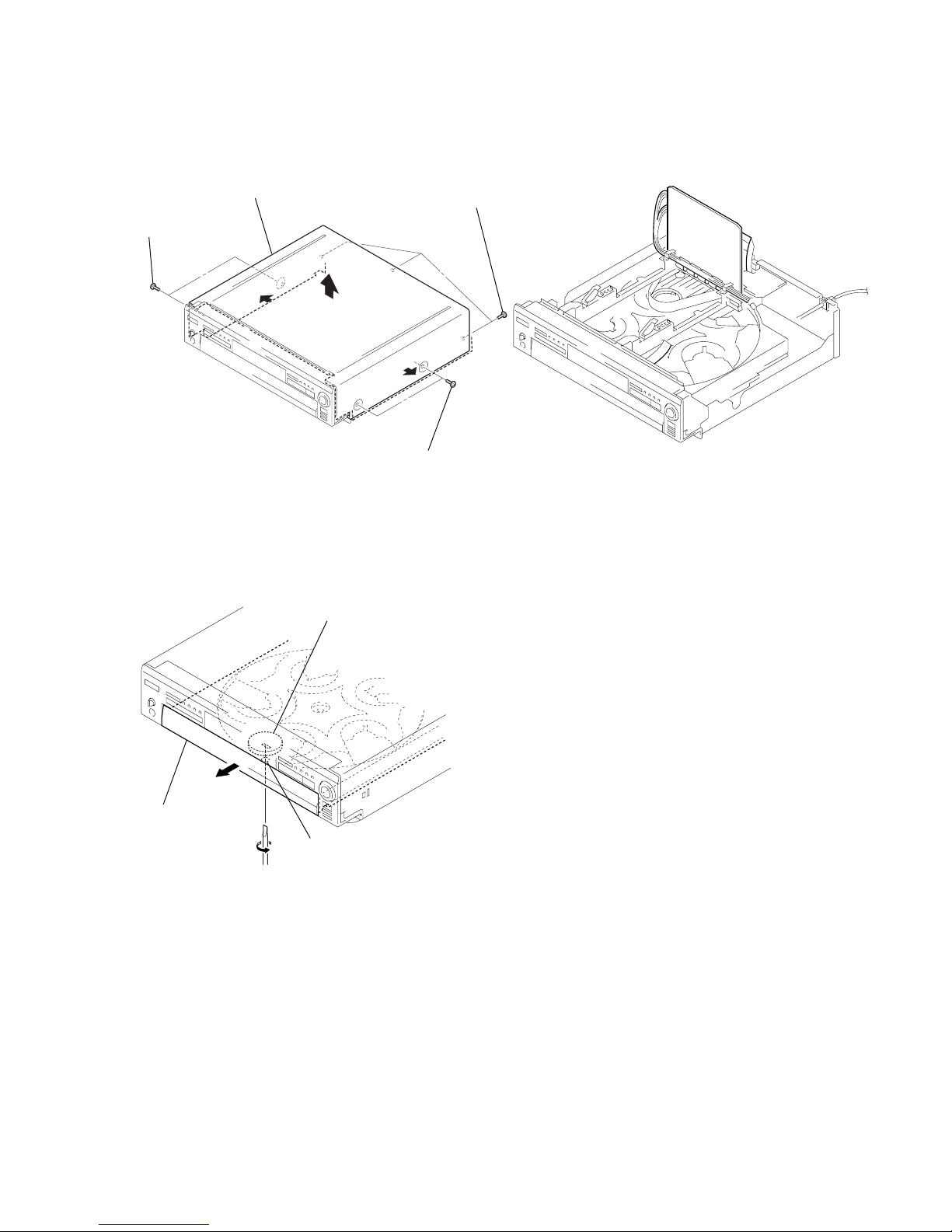

2. NOTE ON REMOVE THE CASE

1) Remove seven tapping screws. (See Fig. 1)

2) Open the side of case. (See Fig. 1)

3) Remove the case as lift straight. (See Fig. 1)

Fig. 1

3. DISK REMOVAL PROCEDURE

(at POWER OFF)

1) Insert a flat-blade screwdriver into a hole at the bottom, and

rotate the cam gear in direction A. (See Fig. 2)

Fig. 2

4. HOW TO SERVICE MB-83 BOARD

1) Remove the case from the set. (Refer to 2-1)

2) Remove the MB-83 board. (Refer to 2-3)

3) Set the MB-83 board as shown in Fig. 3.

Note: Do not disconnect wiring.

Fig. 3

Case

Two tapping screws

Three tapping screws

Two tapping screws

Table

Hole

Cam gear

A

– 6 –

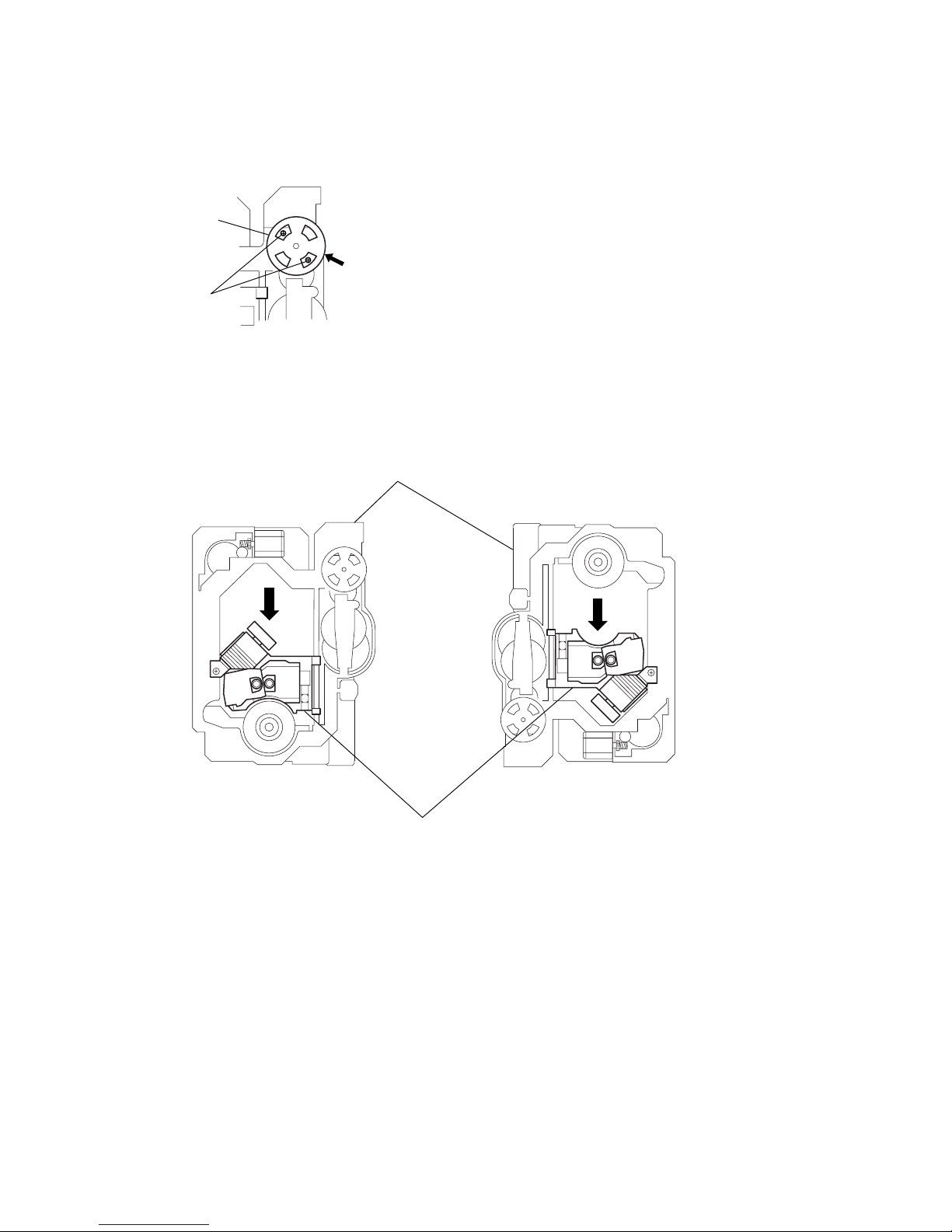

5. NOTE ON MOUNTING SLED MOTOR

1) Push the sled motor ass’y 1 toward direction A. (See Fig. 4)

2) Tighten two screws 2 (M1.7 × 2.5).

Fig. 4

3) Raising the MD block ass’y 3 90 º with the side down.

confirm that the optical pick-up 4 falls by self weight.

(See Fig. 5)

4) Further, with the front side of MD block ass’y 3 up, confirm

that the optical pick-up falls by self weight.

Fig. 5

A

1 Sled motor ass’y

2 Two screws

(M1.7 × 2.5)

Upper

Upper

Front side

Front side

Lower

Lower

3 MD block ass’y

4 Optical pick-up

– 7 –

6. REPLACING OPTICAL PICK-UP

6-1. Handling

1) A red laser diode for DVD requires more attention to static

electricity than general infrared laser diodes for CD.

Because its durability to static electricity is far weaker than

that of infrared laser diodes, always use an earth band when

handling the optical pick-up block as service parts.

2) As for the flexible board KHS-180A (RP) packed as service

parts, the short lands have been soldered to protect from static

electricity. Accordingly, remove solders when replacing optical pick-up. (See Fig. 6)

Fig. 6 Flexible board

3) In handling the KHS-180A (RP), do not touch inhibited parts

shown in Fig. 7, but grip the slide base bearing and U-shaped

guide.

Fig. 7 KHS-180A (RP)

Touch inhibited par ts

• Objective lens

• Skew sensor

• Laser holder

• Laser coupler

• Flexible board

• OEIC

• Lens actuator covers

DVD short land

CD short land

Slide base bearing

Skew sensor

Lens actuator

covers

Objective lenses

U-shaped guide

OEIC

Laser holder

Flexible board

Connector

Laser coupler

– 8 –

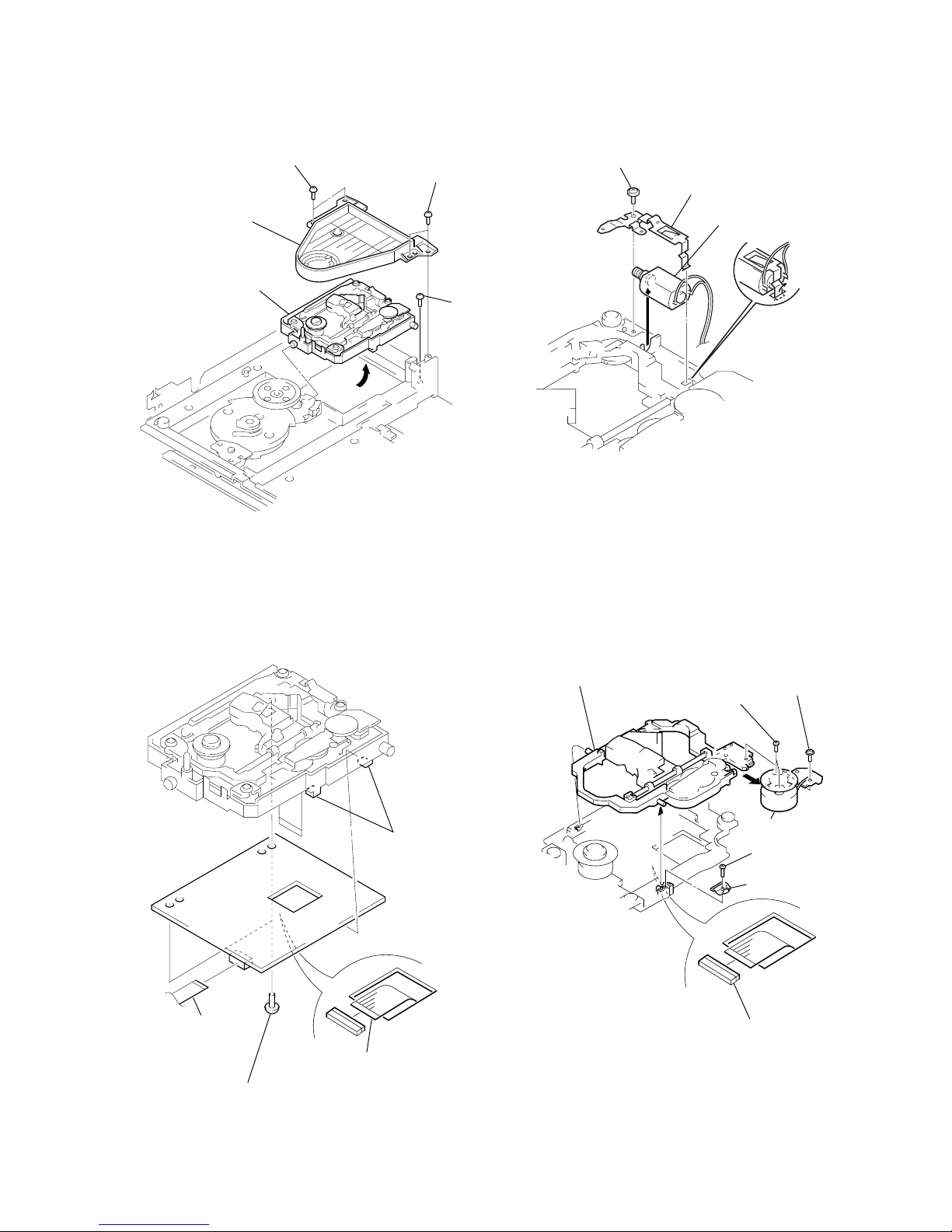

7. NOTE ON ASSEMBLING MECHANICAL DECK

Fig. 11

7-1. Cleaning Spindle Motor Turntable

1) Remove the BU holder ass’y. (Refer to 2-9)

2) Clean the spindle motor turntable if disc antiskid rubber (black)

is dirty. (See Fig.8)

7-2. Deformation of Insulator

1) Assemble the spindle base into the BU holder.

2) Lock with 4 shoulder screws. (See Fig.9)

3) Check if 4 insulators deformed. (See Fig.9)

7-3. Note on Mounting FG-44 Board

1) Align two bosses. (See Fig.10)

2) Fix the board securely with screws (PTPWH2 × 5). (The sen-

sor will not function normally if the board floats up.)

7-4. Note on connecting OPT Harness

1) The optical pick-up could be destroyed unless the OPT harness is connected normally to the connector. (See Fig.11)

Spindle motor

Turn table

Fig. 8

Fig. 9

Two step screws

Two step screws

Two insulators

Two insulators

Insulator

Good

NG

Screw

(PTPWH2 × 5)

FG-44 board

Two bosses

Good

NG

OPT harness

Connector

Fig. 10

– 9 –

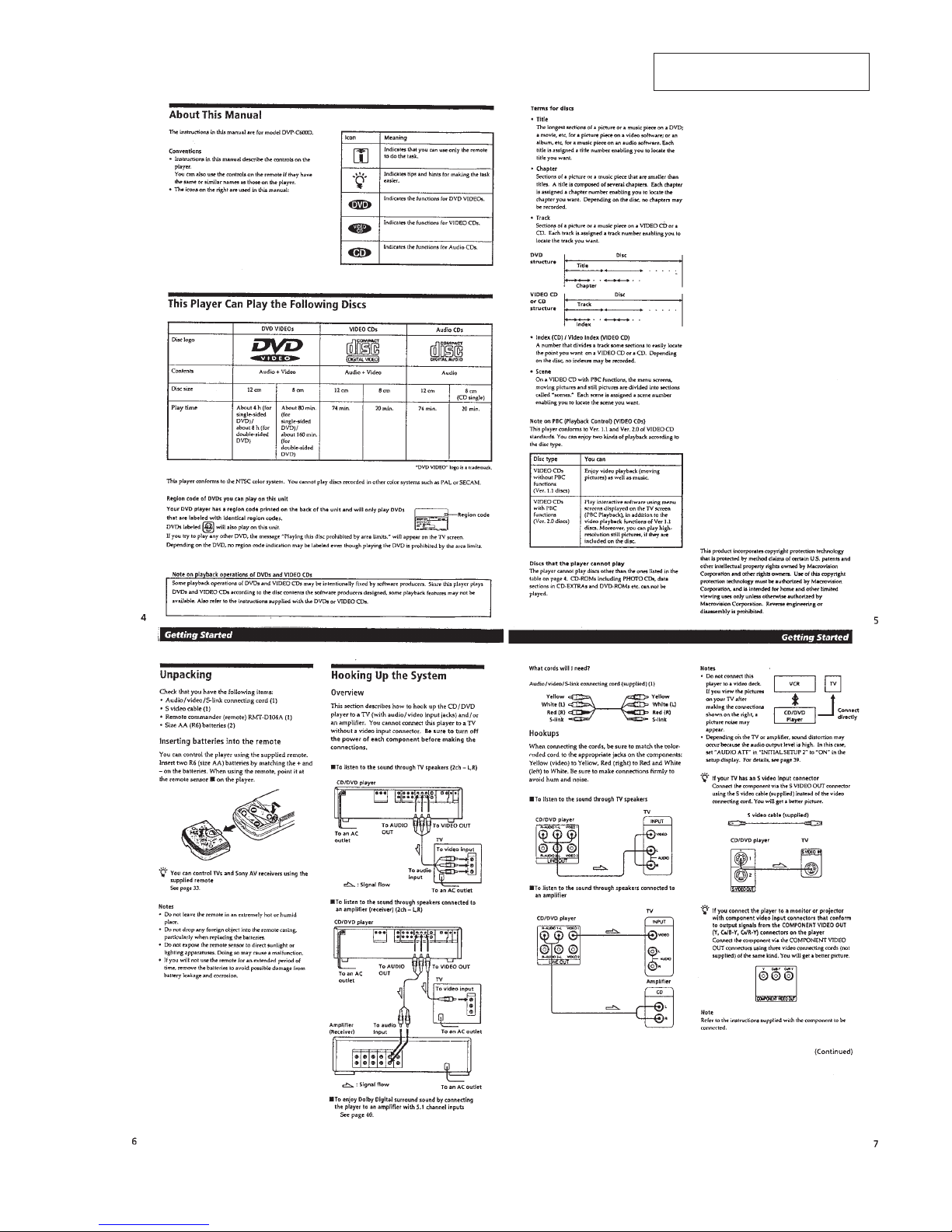

8. NOTE ON MOUNTING GEARS

1) Mount the gear (U/D). (See FIg.12.)

2) Rotate the gear (U/D) in the direction of the arrow.

(down position) (See Fig.12.)

3) Align triangle marks of the rotary encoder. (See Fig.13.)

4) Escape the set lever. (See Fig.13.)

5) Connect the boss of the gear (main) with the groove of the

rotary encoder and mount the gear (main). (See Fig.13.)

6) Mount the lock lever (See Fig.14.)

7) Mount the spring (lock lever). (See Fig.14.)

8) Rotate the gear (main) in the direction of the arrow A by 90°

turn. (Gear (U/D) is up position.) (See Fig.15.)

9) Mount the Gear (rev). (See Fig.15.)

10) Fix three stopper washers on the groove of shafts.

(See Fig.15.)

Gear (U/D)

Fig. 12

Fig. 14

Fig. 13

Fig. 15

Spring

(lock lever)

Spring

(lock lever)

Lock lever

Lock lever

Gear

(main)

Gear (main)

Set lever

Boss

Groove

Rotary encoder

Align triangle marks.

BU

Shaft

Stopper washer

Gear (rev)

Gear (main)

Gear (U/D)

Two stopper

washers

Groove

**

*

A

1-1

SECTION 1

GENERAL

This section is extracted from

US model instruction manual.

DVP-C600D

1-2

1-3

1-4

1-5

1-6

1-7

1-8

1-9

1-10

1-11

1-12

1-13

1-13 E

2-1

Note: Follow the disassembly procedure in the numerical order given.

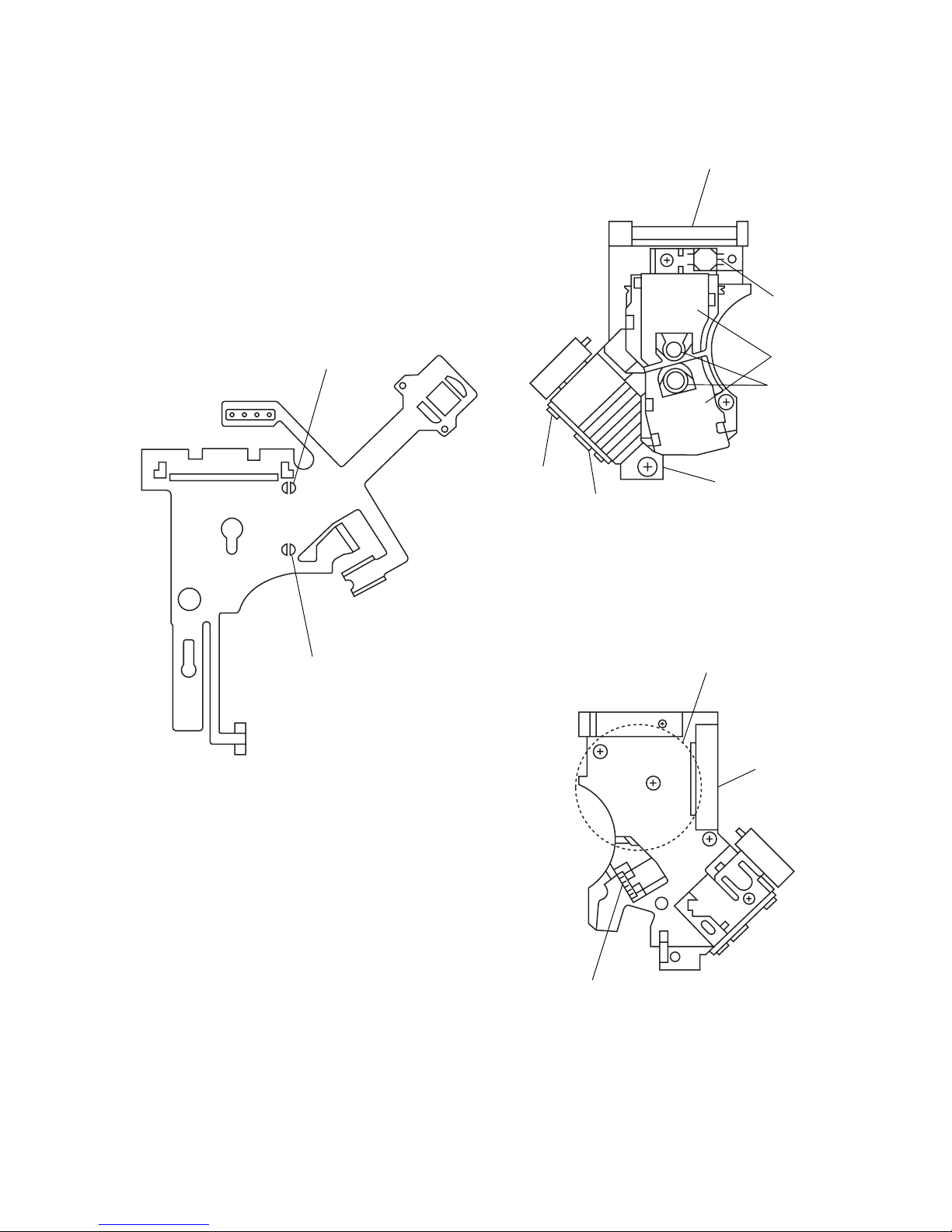

2-1. CASE REMOVAL 2-3. MB-83 BOARD REMOVAL

2-2. FRONT PANEL SECTION REMOVAL

2-4. REAR PANEL REMOVAL

SECTION 2

DISASSEMBLY

DVP-C600D

4 Case

3 Two tapping screws

1 Two tapping screws

2 Three tapping

screws

2 Connector

(CN205)

1 Flat wire

(CN601)

3 Rotate the cam gear

in the direction of

the arrow A.

0 Lug

!¢ Claw

!∞ Front panel section

!™ Claw

!£ Two Claws

!¡ Two screws (B3)

9 Screw (B3)

5 Tray cover

ass’y

8 Screw (B3)

4 Draw out

the table.

A

6 Four claws

7 Tray guard

9 Four flat wires

(CN101, 302,

452, 252)

2 Three flat wires

(CN301, 601, 701)

3 Flat wire

(CN251)

6 Two screws (B3)

5 Three screws

(B3)

4 Connector

(CN361)

1 Two connectors

(CN001, 002)

0 Cover (lower)

7 Cover (upper)

8 MB-83 board

1 Connector

(CN101)

2 Connector

(CN205)

6 Claw

7 Rear panel

5 Claw

3 Two screws

(B3)

4 Tapping screw

2-2

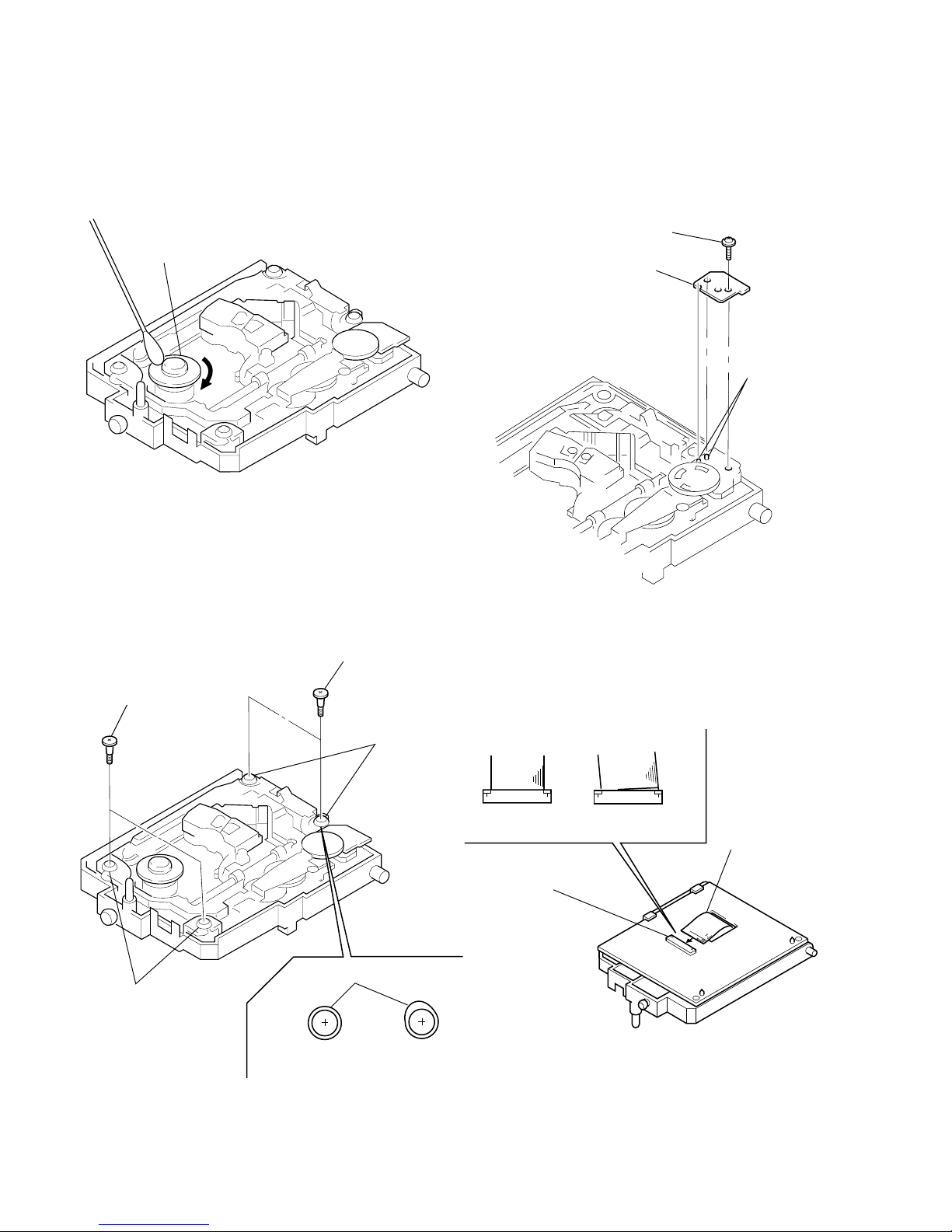

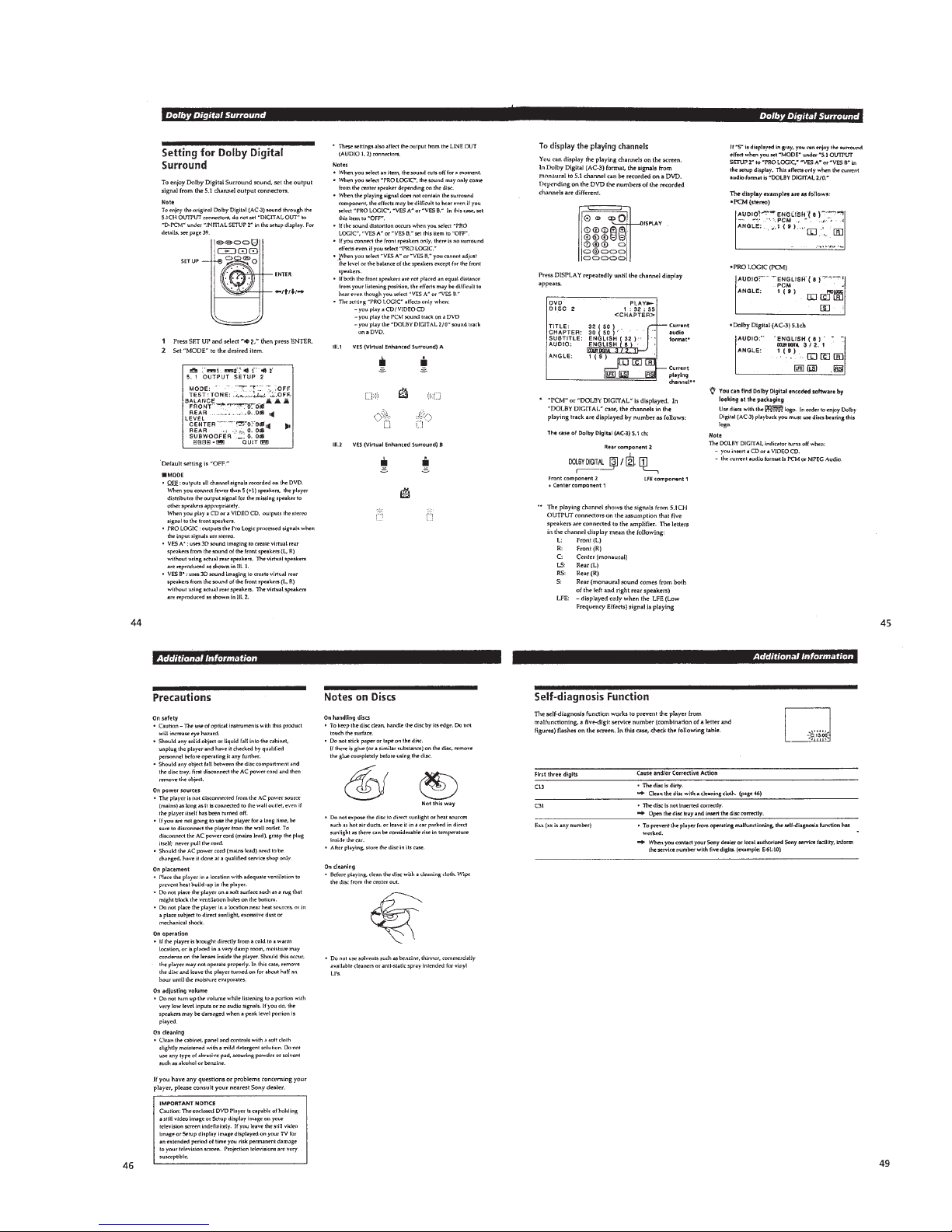

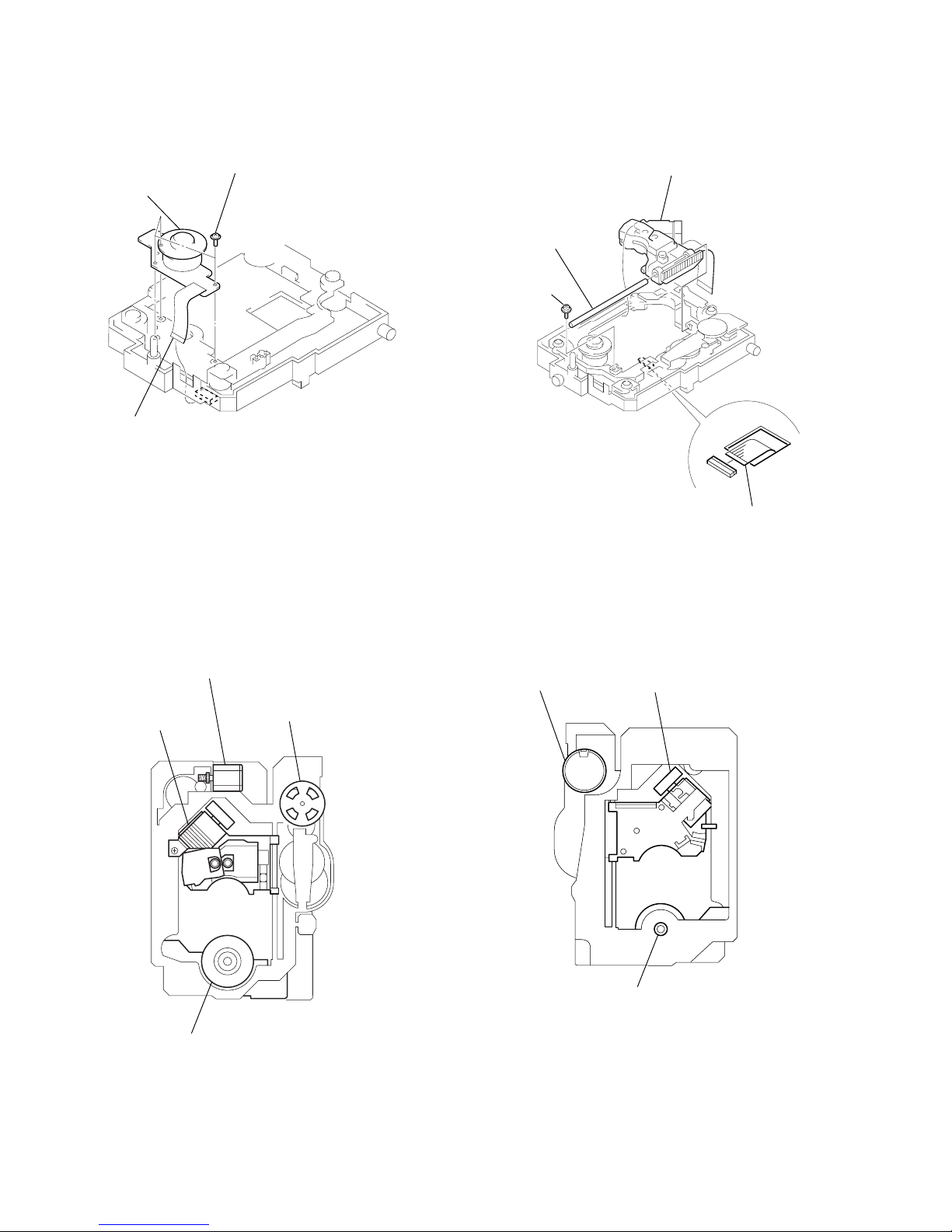

2-5. TABLE ASS’Y REMOVAL 2-7. CHASSIS ASS’Y REMOVAL

2-6. ROTARY MOTOR ASS’Y (M951)

REMOVAL

2-8. LOADING MOTOR ASS’Y (M991)

REMOVAL

6 Flat wire

(CN602)

1 Two screws

(B3)

2 Two brackets

(guide B1)

4 Two brackets

(guide B1)

3 Two screws

(B3)

5 Table ass’y

4 Two screws

(B3)

7 Two screws

(B2.6 × 3)

1 Tapping screw

(M3 × 12)

5 Bracket (RM) ass’y

6 Belt (RM)

2 Table (rotary)

3 Connector

(CN701)

8 Rotary motor ass’y

1 Four screws

(B3)

2 Four screws

(B3)

3 Chassis ass’y

4 Screw (B3)

5 Loading motor ass’y

1 Belt (timing)

3 Harness

2 Connector

2-3

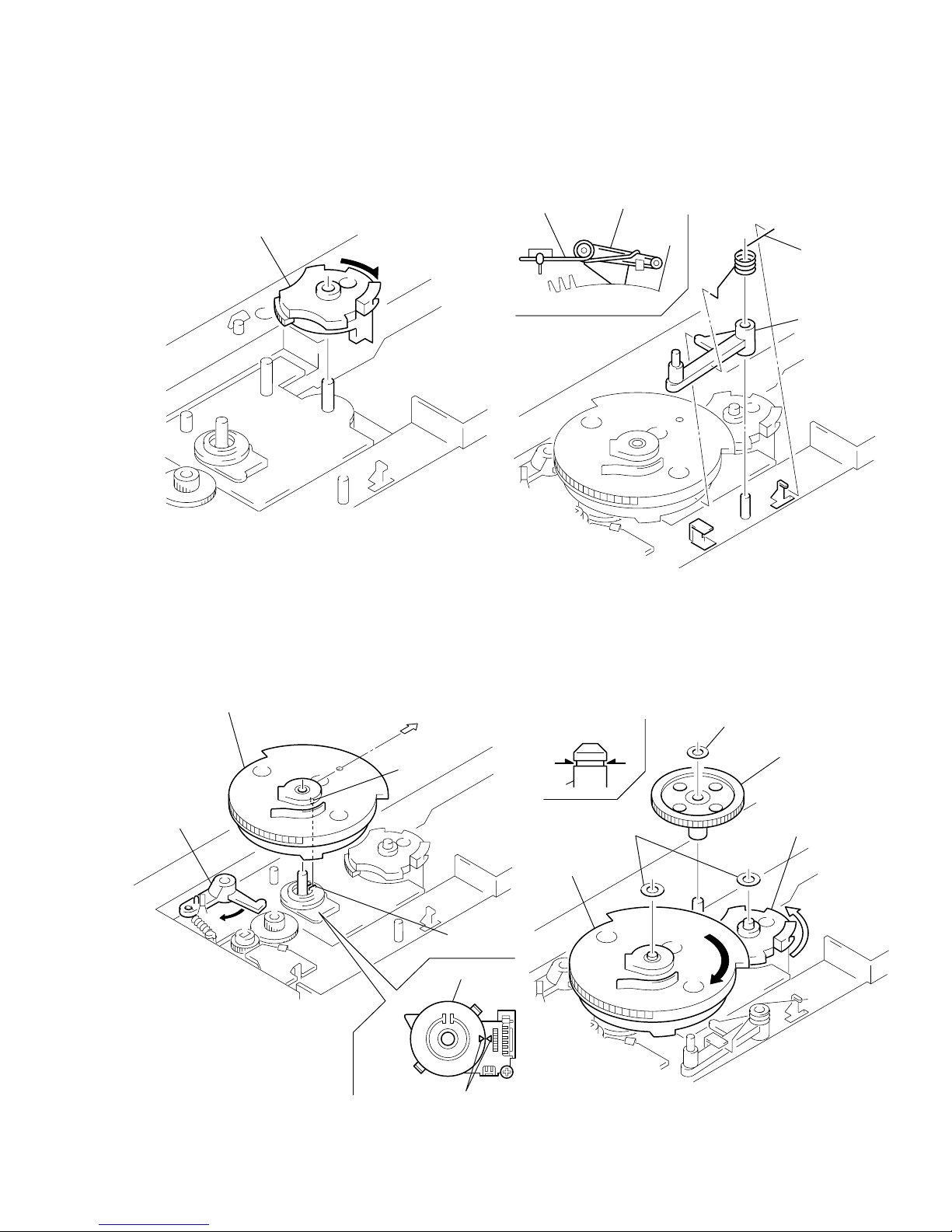

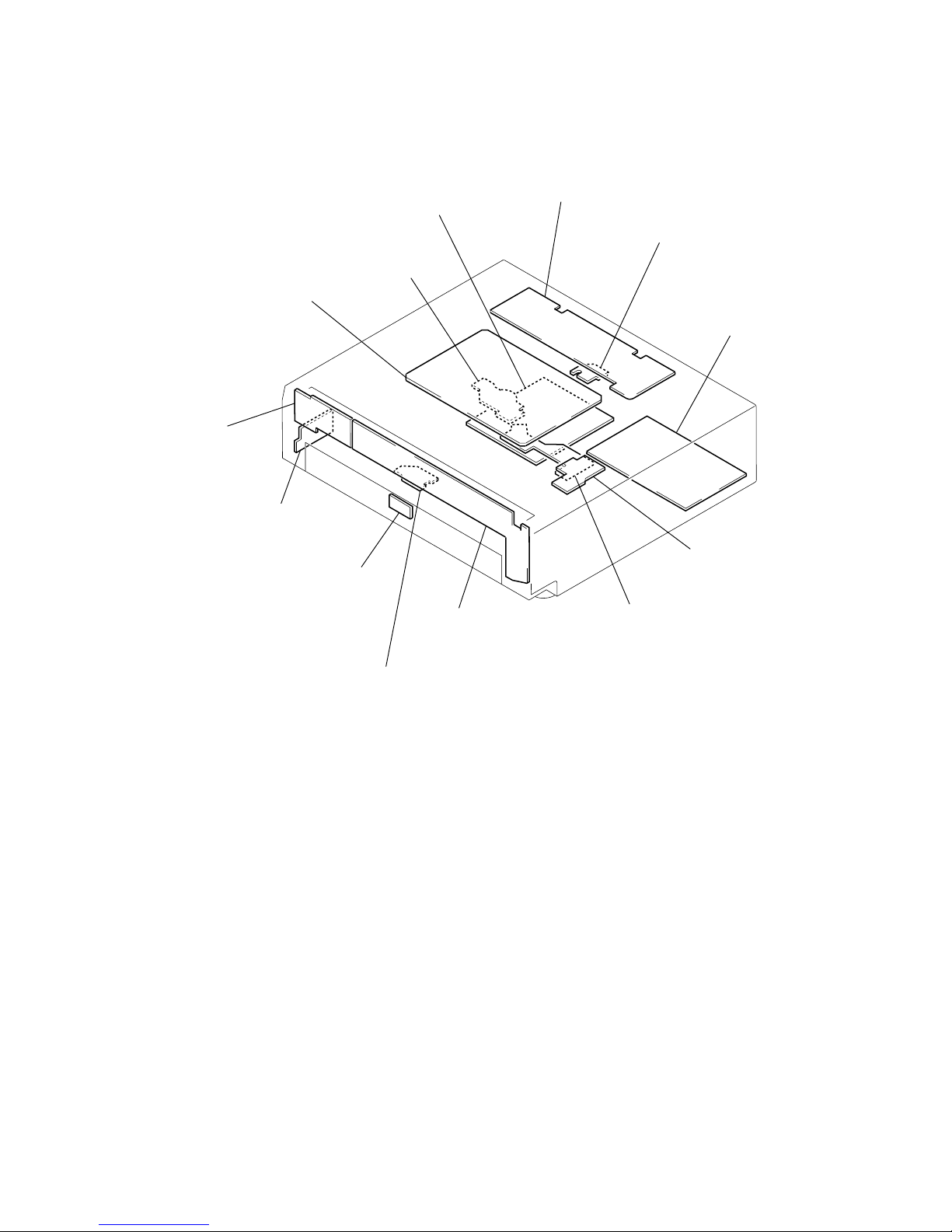

2-9. BU HOLDER ASS’Y REMOVAL 2-11. SKEW MOT OR ASS’Y (M902) REMOVAL

2-10. TK-48 BOARD REMOVAL

2-12. SLED MOTOR ASS’Y (M501) REMOVAL

1 Two screws

(B3)

2 Two screws

(B3)

4 Screw

(B3)

3 Bracket (CP)

5 BU holder ass’y

3 Two screws

(B3)

4 Two claws

2 OP-15 flexible board

(CN001)

1 Flat wire

(CN002)

TK-48 board

2 Claw

3 Skewgear retainer

4 Skewgear motor ass’y

(M902)

1 Screw

(PTTWH2 × 5)

3 Skew shaft stopper

7 Sled motor ass’y

(M501)

5 Screw

(PTTWH2 × 5)

4 Spindle base

1 OP-15 flexible board

(CN001)

2 Screw

(P2 × 8)

6 Two screws

(P1.7 × 2.5)

2-4

2-15. INTERNAL VIEWS

2-13. SPINDLE MOTOR ASS’Y (M901)

REMOVAL

2-14. OPTICAL PICK-UP REMOVAL

3 Spindle motor ass’y

(M901)

2 Three screws

(PTTWH2 × 5)

1 Flat wire

(CN002)

4 Optical pick-up

3 Main shaft

2 Screw

(PTTWH2 × 5)

1 OP-15 flexible board

(CN001)

Skew motor ass’y (M902)

X-3947-138-1

Sled motor ass’y (M501)

X-3947-137-1

Optical pick-up

(KHS-180A/J1N)

8-820-005-02

DC motor (spindle) (M901)

1-763-131-11

Sled motor ass’y (M501)

X-3947-137-1

Optical pick-up

(KHS-180A/J1N)

8-820-005-02

DC motor (spindle)

1-763-131-11

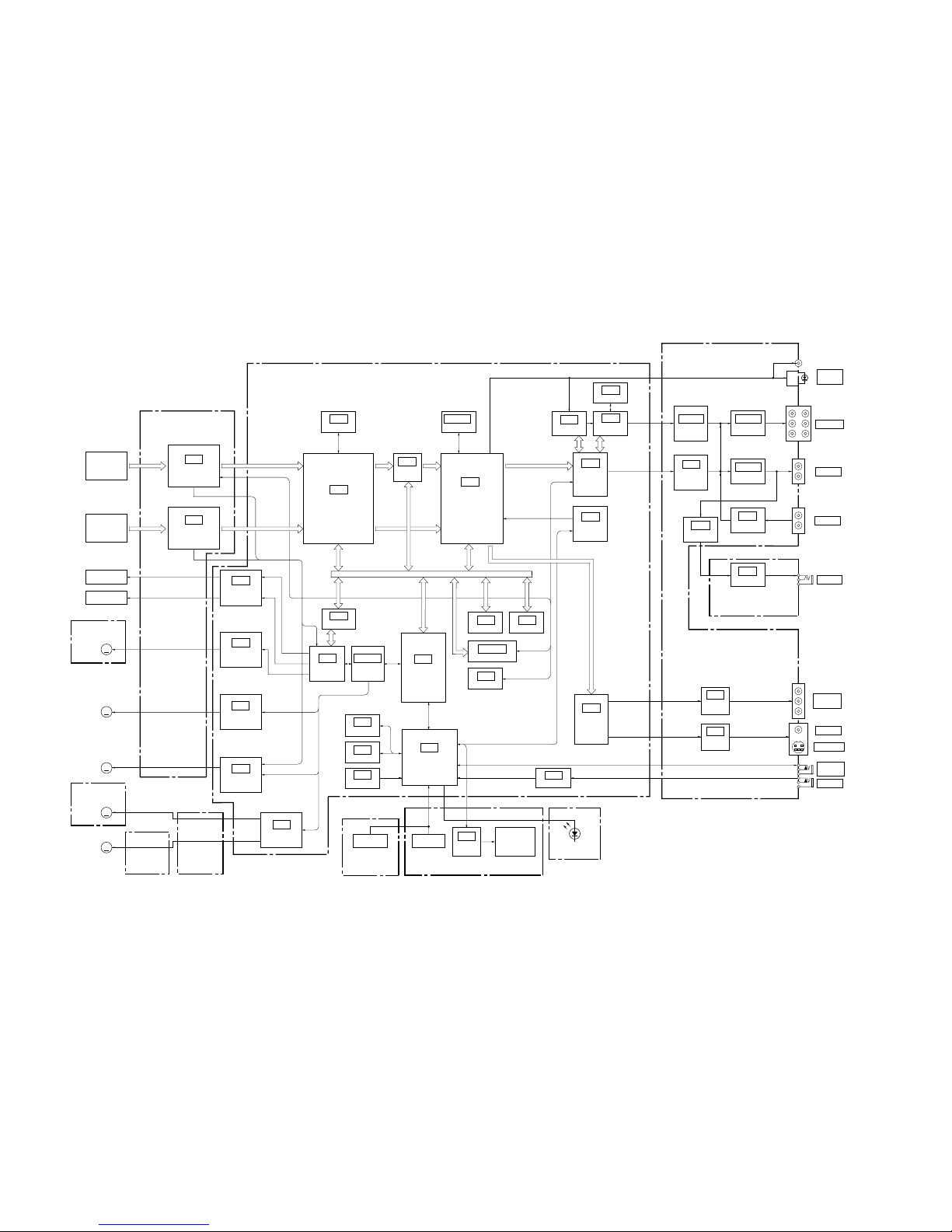

2-5

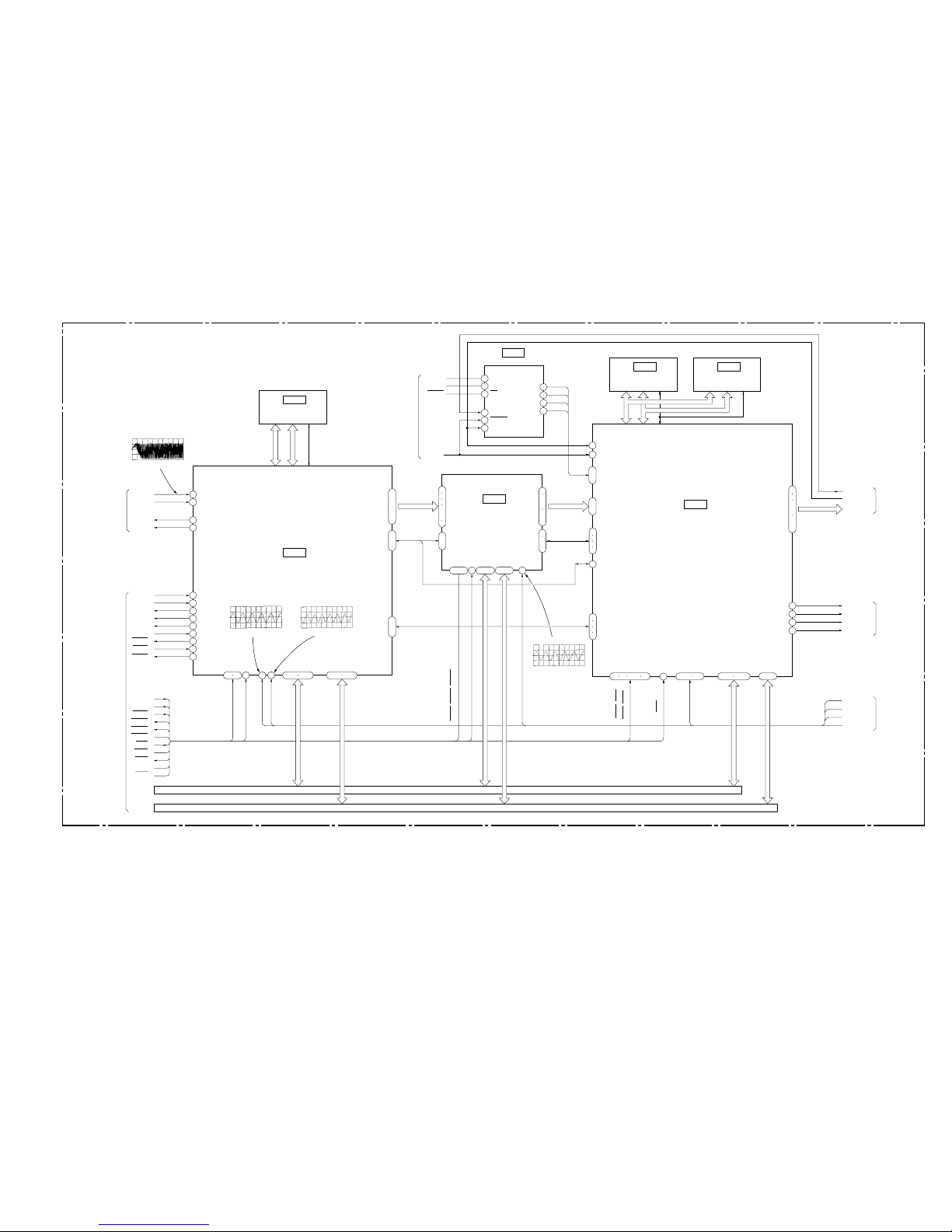

2-16. CIRCUIT BOARDS LOCATION

AU-198

(AUDIO)

FG-44

(SLED)

POWER BLOCK

(HS-934SU)

(POWER SUPPLY)

CK-78

(CONNECTION)

SE-70

(SENSOR)

LM-55

(LOADING MOTOR)

LE-20

(LED)

HP-97

(HEAD PHONE)

FR-134

(FUNCTION

SWITCH)

MB-83

(SIGNAL PROCESS)

DC MOTOR

(SPINDLE)

TK-48

(RF/SERVO)

FL-89

FL DRIVER/

FUNCTION SWITCH

(

)

2-5 E

DVP-C600D

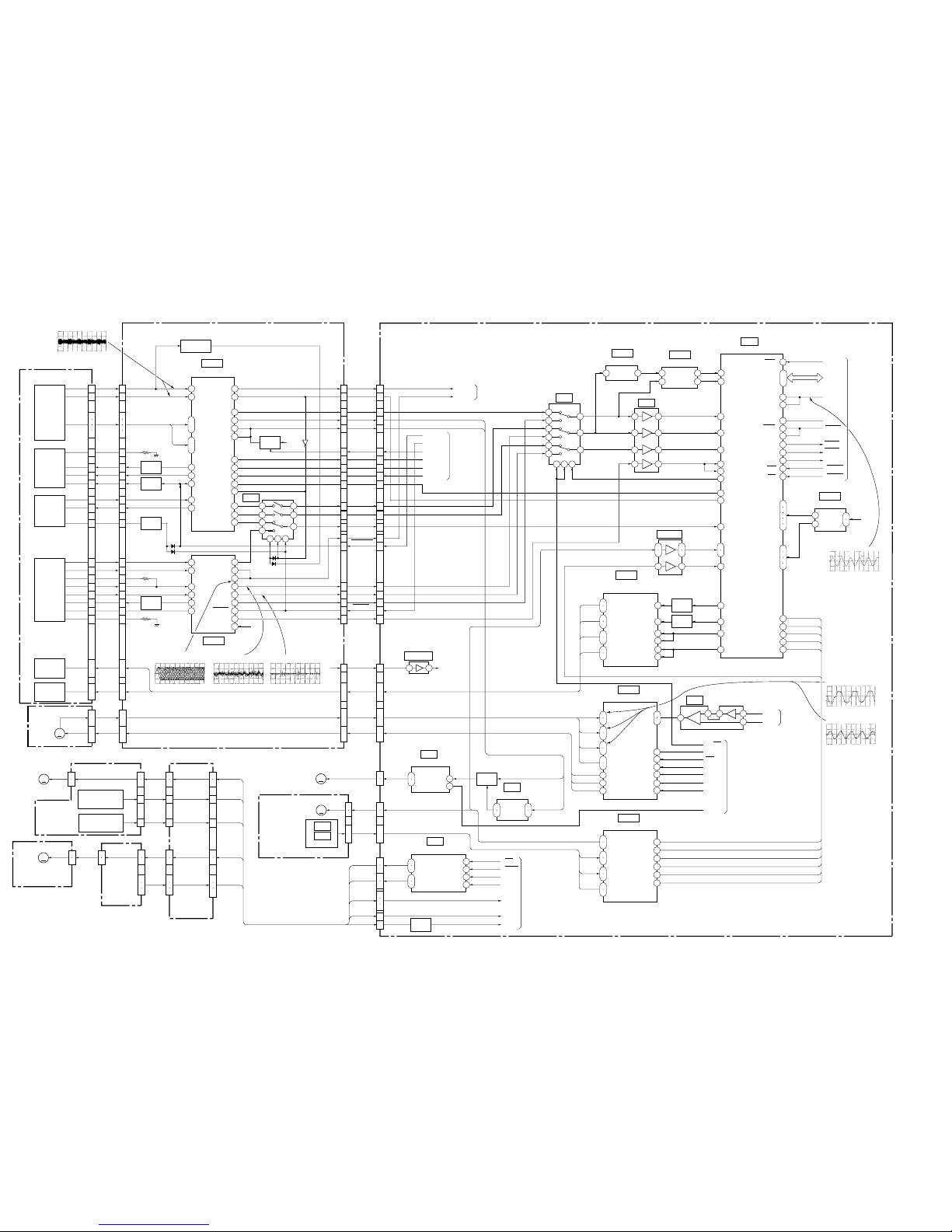

3-1 3-2

SECTION 3

BLOCK DIAGRAMS

3-1. OVERALL BLOCK DIAGRAM

SE-70 BOARD

(SEE PAGE 4-36)

CK-78 BOARD

(SEE PAGE 4-36)

FR-134 BOARD

(SEE PAGE 4-69)

FL-89 BOARD

(SEE PAGE 4-65)

LE-20 BOARD

(SEE PAGE 4-65)

LM-55 BOARD

(SEE PAGE 4-36)

FG-44 BOARD

(SEE PAGE 4-27)

TK-48 BOARD

(SEE PAGE 4-7~4-10)

MB-83 BOARD

(SEE PAGE 4-15~4-50)

IC006

DVD RF AMP,

SERVO

IC005

CD RF AMP,

SERVO

IC363

FOCUS/TRACKING

COIL DRIVE

IC302

SLED MOTOR

DRIVE

IC303

SPINDLE MOTOR

DRIVE

IC361

TILT MOTOR

DRIVE

IC701

ROULETE

SWITCH

SWITCH

IC604

IC606

IF µ-COM

IC101

FL DRIVER

ND101

FLUORESCENT

INDICATOR TUBE

IC608

256K SRAM

IC605

RESET

IC603

ROM

IC506

SERVO DSP

IC804 (1/2)

LGATE

ARRAY

IC807

S GATE ARRAY

IC802

1M SRAM

YC0-7

IC804 (2/2)

L GATE ARRAY

IC801

EEPROM

IC803

8M ROM

IC806

ARP

IC810

4M DRAM

IC203

AV DECODER

IC201, 202

16M SRAM

IC104

AC-3

DECODER

IC105

256K SRAM

SPDIF

IC102

DIR

IC101

M GATE

ARRAY

AV_DATA, AV_BLK, AV_LRCK

IC215

AUDIO 2CH

DAC

IC851

VIDEO

BUFFER

IC351

VIDEO

BUFFER

IC203-205

DAC

IC208-213

5.1OUTPUT

AUDIO 1, 2

AUDIO IN

PHONE

COMPNENT

VIDEO OUT

MEGA

CONTROL

VIDEO 1, 2

S VIDEO 1, 2

S-LINK

DIGITAL

OUT

MIX AMP

BUFFER

IC206, 207

MIX AMP

BUFFER

IC301

BUFFER

IC214

BUFFER

IC001

HP AMP

IC207

OSD

IC252

VIDEO

ENCODER

IC811

DECRYPT

IC851

SYSTEM µ-COM

DVD OPT

DVD RF

CD RF

HA0-21, HD0-15

CD OPT

FOCUS COIL

TRACKING COIL

M

M

M

M

M

M951

ROTARY

MOTOR

M991

LOADING

MOTOR

M903

TILT

MOTOR

M901

SPINDLE

MOTOR

M503

SLED

MOTOR

S-LINK COMP

SD0-7

CD_BCK,

CD_LRCK,

CD_DATA,

SPDIF

DCRSD

0-7

HP-97 BOARD

(SEE PAGE 4-69)

AU-198 BOARD

(SEE PAGE 4-55~4-62)

05

DVP-C600D

3-3 3-4

3-2. RF/SERVO BLOCK DIAGRAM

IC363

FOCUS/TRACKING

COIL DRIVER

63

64

57

47

20

9

10

TK-48 BOARD

(SEE PAGE 4-7~4-10)

MB-83 BOARD (1/6)

(SEE PAGE 4-27~4-36)

DVD PD IC

DVD LD

MODULE

SKEW

SENSOR

CD LASER

COUPLER

CD FOCUS

TRACKING

COIL

DVD FOCUS

TRACKING

COIL

Q004

SWITCH

Q008

SWITCH

Q005

SWITCH

Q001

LD ON

Q007

SWITCH

Q009, IC004

RF DET

OPTICAL DEVICE

6

13

14

18

5

41

3

4

2

TI-A

21

42

TI-B

38

16

XLDON

17

PD

18

LD

RFN

RFP

3

338

37

26

23

24

43

44

45

19

33

139

13

4

15

14

30

12

10

28

PD1

4

29

PD2

19

5

27

E

6

20

F

1

23

LD

2

26

PD

19

21

22

13

15

32

25

12

16

25

30

ı

33

34

ı

37

1

ı

8

9

ı

11

9

10

6

13

14

18

5

41

3

4

2

42

38

28

29

19

27

20

23

26

25

30

ı

33

34

ı

37

1

ı

8

9

ı

11

3

ı

10

11

ı

13

26

9

19

3

18

17

4

20

1

22

27

16

21

16

ı

23

25

ı

18

17

ı

15

27

12

ı

5

MIRR

RF02

RF01

TE

FE

RFO

SCLK

SDATA

ADEN

TIOFS

PI

TIE

SIGO

HOLD1

TII

TI–

FDCHG

TE

FE

MIRR

TE_C

VC

9 11

IC006

DVD RF AMP, SERVO

IC011

SWITCH

TTLT/H

10

23

11

14

13

15

12

2

2

19

9

25

10

11

24

8

6

1

12

7

18

5

17

CDRF

14

15

13

16

26

M

M

M

M

M

10

ı

7

A

ı

D

1

ı

4

A2

ı

D2

IC005

CD RF AMP, SERVO

2

4

5

6

5

3

1

2

7

9

11

12

1

2

1

2

PH701

DISK PRESENCE

DETECTION SENSOR

PH702

ROULETTE POSITION

DETECTION SENSOR

3

4

6

1

2

3

4

6

1

2

3

4

6

1

2

11

12

3

4

6

1

2

121

2

ENCODER

ROTARY

(LOADING)

M991

LOADING

MOTOR

SE-70 BOARD

(SEE PAGE 4-36)

LM-55 BOARD

(SEE PAGE 4-36)

CK-78 BOARD

(SEE PAGE 4-36)

FG-44 BOARD

(SEE PAGE 4-27)

1

2

3

ı

8

7

8

1

ı

6

7

9

11

13

5

6

173

5

14

16

4

21

3 1

2

5

22

21

IC701

IC501

M503

SLED MOTOR

M903

TILT MOTOR

IC502

ROULETE

IC361

IC502 (1/2)

TILT MOTOR DEVICE

IC455

COMP

OUT

IN

HALL SENSOR

Q701

BUFFER

Q452

SWITCH

13

12

1

14

4

15

2

109 11

3

5

IC452

89

7

2 1 6 7

3 1

72

TRIN

DFCTA

AIN5

AIN2

AIN0

GIO3

PISW

GIO2

GIO8

PWM2

GIO10

HDO-7

CLKIN

TCK

IRS

VTOP

VBTM

AOUT3

AOUT2

PWM1

GIO0

PWM0

GIO15

GIO9

GIO13

ACK

IA1

IDO-7

27M_DSP

FON

TRREF

AIN6, 7

AIN8

GIO12

AOUT0

AOUT1

IN OUT

IN2 OUT2

IN1 OUT1

IC506

SERVO DSP

IC508

FILTER

IC501

COMP

3 1

6 7

10 8

12 14

21

24

26

11

12

8

73

99

IC503

9

20

6

23

3

1

GIO11

2

88

7

1

49

46

26

IC502 (2/2)

11

12

5107

8

13

14

15

16

17

18

23

22

19

8

9

27

7

10

11

30

31

14

15

32

33

34

1

28

29

75

14

74

41

38

8

12

13

18

25

32

2

5

33

34

29

30

22

23

Q371

MUTE

Q372

MUTE

+

–

IC363

IC303

IC301

SPINDLE MOTOR DRIVE

IC302

SLED MOTOR DRIVE

19

20

3

5

65

79

3

98

4

100

71

70

84

94

56

ı

63

28

37

42

45

50

36

43

44

51

M901

SPINDLE

MOTOR

M951

ROTARY

MOTOR

CN991

LM LM

S1-S3

LM

S1-S3

CN701

CN702

CN603

TM

DSENS

TSENS

TM

DSENS

TSENS

CN602

CN601

TIMT

SLDMT

CN501

CN301

CN361

HA, HB,

SLVH

LM

TM

S1-S3

TSENS

DSENS

CN701

OUT1 +, –

DOUT

FIN1

IN1+

MUTE1

RIN1

FIN2

RIN2

TBLL

TBLR

S1-S3

TSENS

DSENS

OUT2 +, –

SYSTEM CONTROL

(SEE PAGE 3-9)

LDIN

LDOUT

CD FCS,

CD TRK

DVD FCS,

DVD TRK

U IN,

V IN,

W IN,

SPVH

U OUT,

V OUT,

W OUT

U IN,

V IN,

W IN,

SPVH

U OUT,

V OUT,

W OUT

APC_ON

Q009

VC

VC

VC

VC

DVD_RF+

DFCTS

DVD_PI

RFP

CN001

RFN

A-D

VR

DVD LD

PD

VLD

SKEW IN

SKEW OUT

LED

PD1

PD2

AL

CD_E

CD_F

CD_LD

MON

VR

TI-ERR

TIE

SSSD

SCKG3

SDEN

TIOFS

DPD

DVD_FE

MIRR

DVD LDON

CD TE

CD FE

CDRFDC

TEATT

CD LDON

SVC

DVDFCS,

DVDTRK

CDFCS,

CDTRK

TIE

TI_ERR

DVD RF

CD RF

TIE

TI_ERR

DVD LDON

CD LDON

TILT/H

SSSD

SCKG3

SDEN

SYSTEM

CONTROL

(SEE PAGE 3-9)

SIGNAL PROCESS

(SEE PAGE 3-5)

12 14

DO2

CD TRK

CDFCS

DVDFCS

DVDTRK

MUTE1

DO1 MUTE2

DO4

IN2–

DO3

IN1–

IN3–

IN4–

U IN

V IN

W IN

VH

Z1, Z2

U OUT

SPCTRL0

SPCTRL1

NS+

HFG

V OUT

SPGC2

W OUT

SPGC1

SPCTRL0

SPCTRL1

HFG

MDP0

MDS0

SPGC2

SPGC1

S12VOFF

SLDMT

DV–

HA

DVI

HB

DVO

SLVH

TKC

CTRL

A+

SDCNT

SOUT

SLOFS

TKC

HYCNTR

HYDET

SYSTEM CONTROL

(SEE PAGE 3-9, 10)

671 2

5

SIGNAL

PROCESS

(SEE PAGE 3-5)

NST

18

HCK/HLDB

MRST

HR/HRD

HFD/HWR

SDPRST

ERROR

BUSY2

SDSPWR

SDSPRD

OUT2

OUT1

IN

VC

IC507

POWER SUPPLY

SYSTEM CONTROL

(SEE PAGE 3-9, 10)

SDCNT

SOUT

SLOFS

TKC

HYCNTR

HYDET

CN002

CN008

CN302

CN005

CN452

CD/DVD

05

IC006 ^£ – ^¢ (DVD play)

800 mVp-p (V)

IC005 @™ (CD play)

500 mV/DIV 1 µs/DIV

IC005 !£ (CD play)

500 mV/DIV 1 ms/DIV

IC005 !∞ (CD play)

500 mV/DIV 10 ms/DIV

IC506 ^∞

3.6 Vp-p 27 MHz

IC303 !ª, @™, @£ (DVD play)

5.2 Vp-p 160Hz

IC303 !ª, @™, @£ (CD play)

1.84 Vp-p 45Hz

DVP-C600D

3-5 3-6

3-3. SIGNAL PROCESS BLOCK DIAGRAM

IC806

ARP

IC811

DECRYPT

IC207

OSD

IC203

AV DECODER

IC810

4M DRAM

10

RF IN1DVD RF

12

RF IN2CD RF

69

VS

70

HS

DCK

EX_OSD_0-3

CH-DATA0-7

OH SYNC

43

MDS0MDS0

48

MDP0MDP0

110

MUTE

112

MD2

50

DFCT

51

NORF

53

LOCK

55

FWON

80

XINT

81

XCS

83

84 122

XWAT

XRST

XWR, XRD

XRST

27M_DSP

33M

MCKI

SCKI

A0-7

D0-7

MUTE

MD2

DFCT

NORF

LOCK

FWON

XWR

XRD

XRST

IA0-8

ID0-7

05

24

SCLK

SO

25

SIN

SCLKO

26

20

19

18

17

R OUT

G OUT

B OUT

I OUT

11

EVEN

12

13

V SYNC

MA0-9

MD00-15

XMWR, XCAS,

XRAS, XOE

124

70-73 75-7856 57

43-47 26-31 34-41

56-62 64-67

106

ı

109

106

ı

109

96

ı

99

101

ı

106

4

ı

8

56

59

ı

61

88

ı

91

12

ı

19

1

3

74

77

ı

79

80

62

64

ı

66

68

ı

74

DCRCS

DCRINT

DCRWT

AVDRQ

AVCS

AVINT

AVWT

MRST

RF/SERVO

(SEE PAGE 3-3, 4)

SYSTEM CONTROL

(SEE PAGE 3-9, 10)

IA0-7

ID0-7

IA0-8

ID0-7

SD0-7

SD0-7 DCRSD0-7

AREQ, ALALID,

ERROR, TOS

DTI0-7

DTO0-7

SDCK, XSHD,

XSRO, XSAK, SDEF

CD_LRCK, CD_BCK,

CD_DATA, SPDIF

54 51

28

111

105

106

107

SYSTEM CONTROL

(SEE PAGE 3-9, 10)

CGCSO

CS

IC201

16M SDRAM

AVA0-11

AVID

0-15

IC202

16M SDRAM

SDQM, WE, CAS, RAS, CS1, CS2, SDQM, SDCLK

A_0-8

D_0-7

21

24

26

30

98

99

101

102

XRST

384FS

IA0-5

ID0-7

27M_DNR

XWR, XRD,

DCRCS, DCRINT, DCRWT

KESET_B

58 59 63-65 68 94-96 100 34-39 43-45 47-54

57

XWR, XRD,

AVDRQ, AVCS,

AVINT, AVWT

MRST

SPDIF_OUT

BCLK

LRCLK

ASDATA

SPDIF

AV_BCK

AV_LRCK

AV_DATA

YC0-7

FID

V SYNC

73

74

76

ı

78

82

ı

84

PD0-7

AUDIO

(SEE PAGE 3-11)

VIDEO

(SEE PAGE 3-7)

384FS

27M_DNR

27M_DSP

33M

SYSTEM CONTROL

(SEE PAGE 3-10)

MB-83 BOARD (2/6)

(SEE PAGE 4-19, 4-45)

XRST

SHA0-5

SHD0-7

MCK

H SYVC

ARPWT

ARPINT

ARPCS

IC806 0

1.5 Vp-p

IC806 `⁄¤¤

3.4 Vp-p 27 MHz

IC806 `⁄¤›

3.0 Vp-p 33 MHz

IC811 %¡

3.4 Vp-p 27 MHz

Loading...

Loading...