D-VM1

SERVICE MANUAL

Ver 1.0 2001. 12

SPECIFICATIONS

System

Laser Semiconductor laser

Signal format system

(monitor unit)

Signal format system

(AV output adaptor)

Audio characteristics (output signal from AV outpuadt

aptor when “SOUND MODE” is set to “NORMAL”)

Frequency response DVD (PCM 96 kHz): 4 Hz to 44 kHz (±1 dB)*

Signal-to-noise ratio (S/N ratio) 110 dB* (AUDIO OUT jack only)

Harmonic distortion 0.005%

Dynamic range DVD: 103 dB*

Wow and flutter Less than detected value (±0.001% W PEAK)

Maximum power output (at DC) 25 mW + 25 mW (16 ohms)

* The signals from AUDIO OUT jack are measured. When you play PCM sound tracks with

a 96 kHz sampling frequency, the output signal from the OPTICAL jack is converted to

48 kHz sampling frequency.

General

Power requirements DC 10 V

Battery life

When the cover of th e

monitor unit is open

When the cover of th e

monitor unit is closed

Power consumption 6 W

Dimensions (approx.) 150.2 × 31.8 × 167.7 mm (6 × 1 5/16 × 6 5/8 inches)

Mass (approx.) 332 g (11.7 oz) (player only), 571 g (1 lb 4 oz)

Operating temperature 5°C to 35°C

Operating humidity 25% to 80%

PAL/NTSC

VIDEO CD:

DVD: Disc’s color system

DVD (PCM 48 kHz): 4 Hz to 22 kHz (±1 dB)*

CD: 4 Hz to 20 kHz (±1 dB)*

CD: 99 dB*

Rechargeable battery (supplied, LIP-30, 7.4 V, 3000 mAh,

Lithium-ion)

Dry batteries (2 for the remote)

(width/height/depth)

(with rechargeable battery)

PAL, NTSC

about 4 hours

about 5 hours

Monitor unit

LCD screen 3.5-inch TFT monitor

AV output adaptor

OPTICAL jack Mini jack, Maximum output level -18 dBm,

AUDIO OUT jack Mini jack, Maximum output level 2 Vrms (50 kilohms),

VIDEO OUT jack Mini jack, Maximum output level 1.0 Vp-p,

S VIDEO OUT jack 4-pin mini DIN,

AC power adaptor

Power requirements 100 to 240 V A C, 50/ 60 Hz

Supplied accessories

Specifications and design ar e subject to change without no t ice.

Tourist Model

Hong Kong Model

Model Name Using Similar Mechanism NEW

CD Mechanism Type CDM-501

Load impedance Wave length 660 nm

Load impedance Over 10 kilohms

Load impedance 75 ohms, sync negative

Maximum output level:

Luminance signal:1.0 Vp-p, Load impedance 75 ohms,

sync negative

Color signal: 0.3 Vp-p (PAL), 0.286 Vp-p (N TSC), Load

impedance 75 ohms terminated

AC power adaptor (1)

AC power cord (mains lead) (1)

Rechargeable battery LIP-30 (1)

Headphones (1)

Remote commander (remote) (1)

Audio/video cord (miniplug x 2 y pinplug x 3) (1)

Monitor unit (1)

AV output adaptor (1)

Stand (1)

Carrying porch (1)

Strap for the monitor unit (1)

AC plug adaptor (1) (For the tourist models only)

PORTABLE CD/DVD PLAYER

9-873-411-01

2001L1600-1

© 2001.12

Sony Corporation

Personal Audio Company

Published by Sony Engineering Corporation

D-VM1

TABLE OF CONTENTS

1. SERVICING NOTE ·························································· 4

2. GENERAL ·········································································· 5

3. DISASSEMBLY ································································ 7

4. TEST MODE ··································································· 11

5. DIAGRAMS ······································································ 21

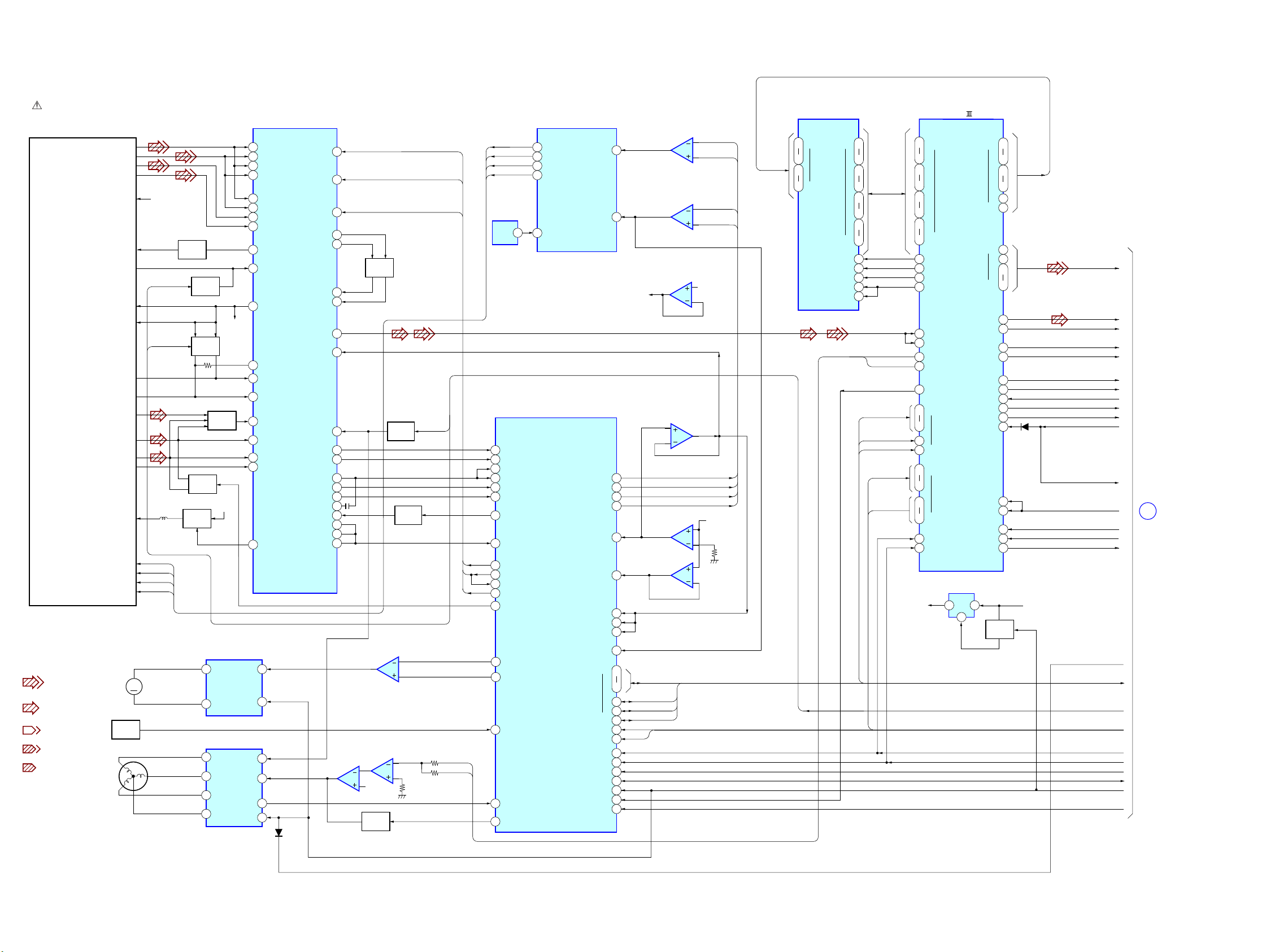

5-1. Block Diagram – RF/SERVO Section –····················· 22

– A/V, SYSCON Section – ·········································· 23

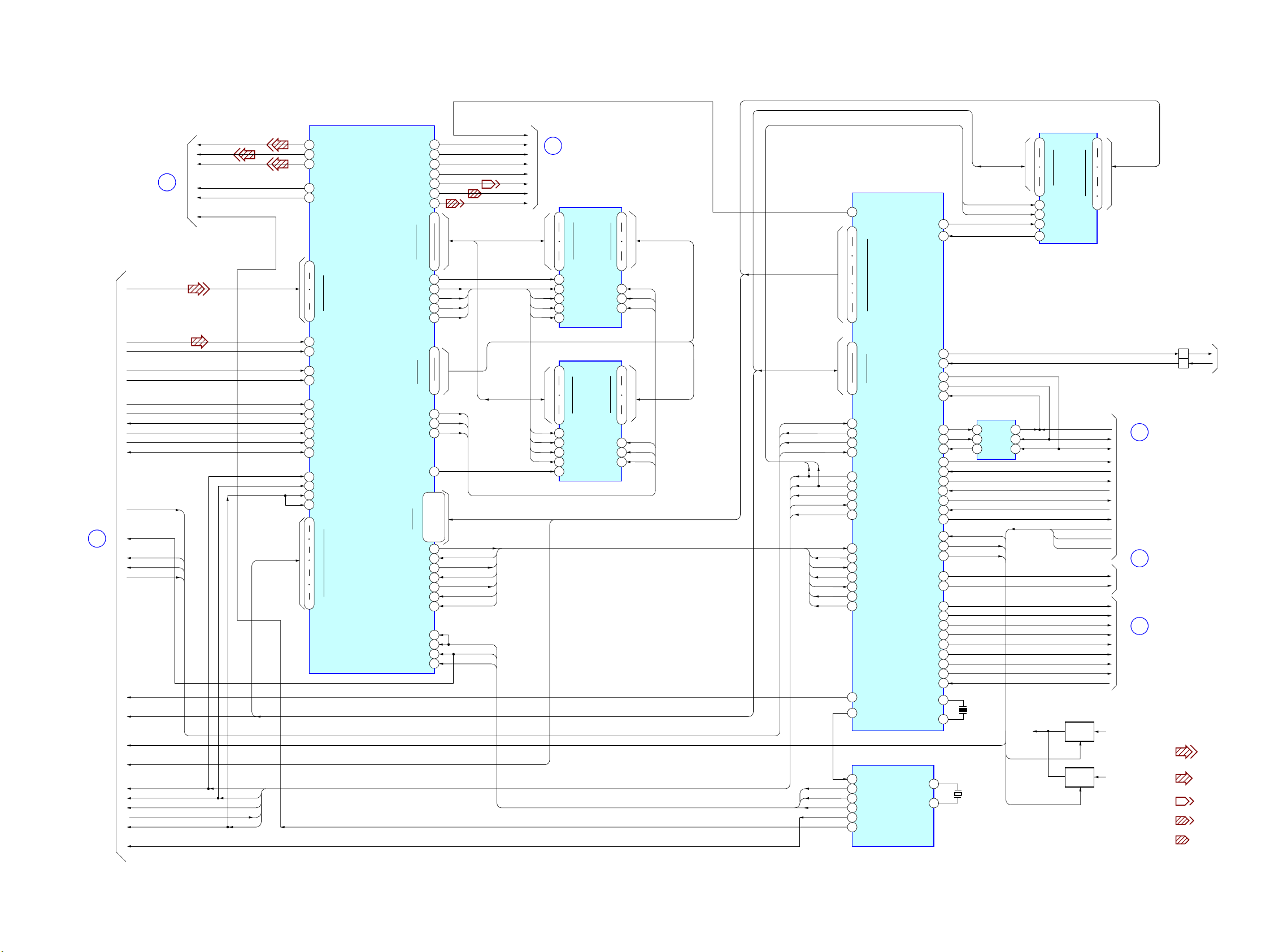

– AUDIO Section – ····················································· 24

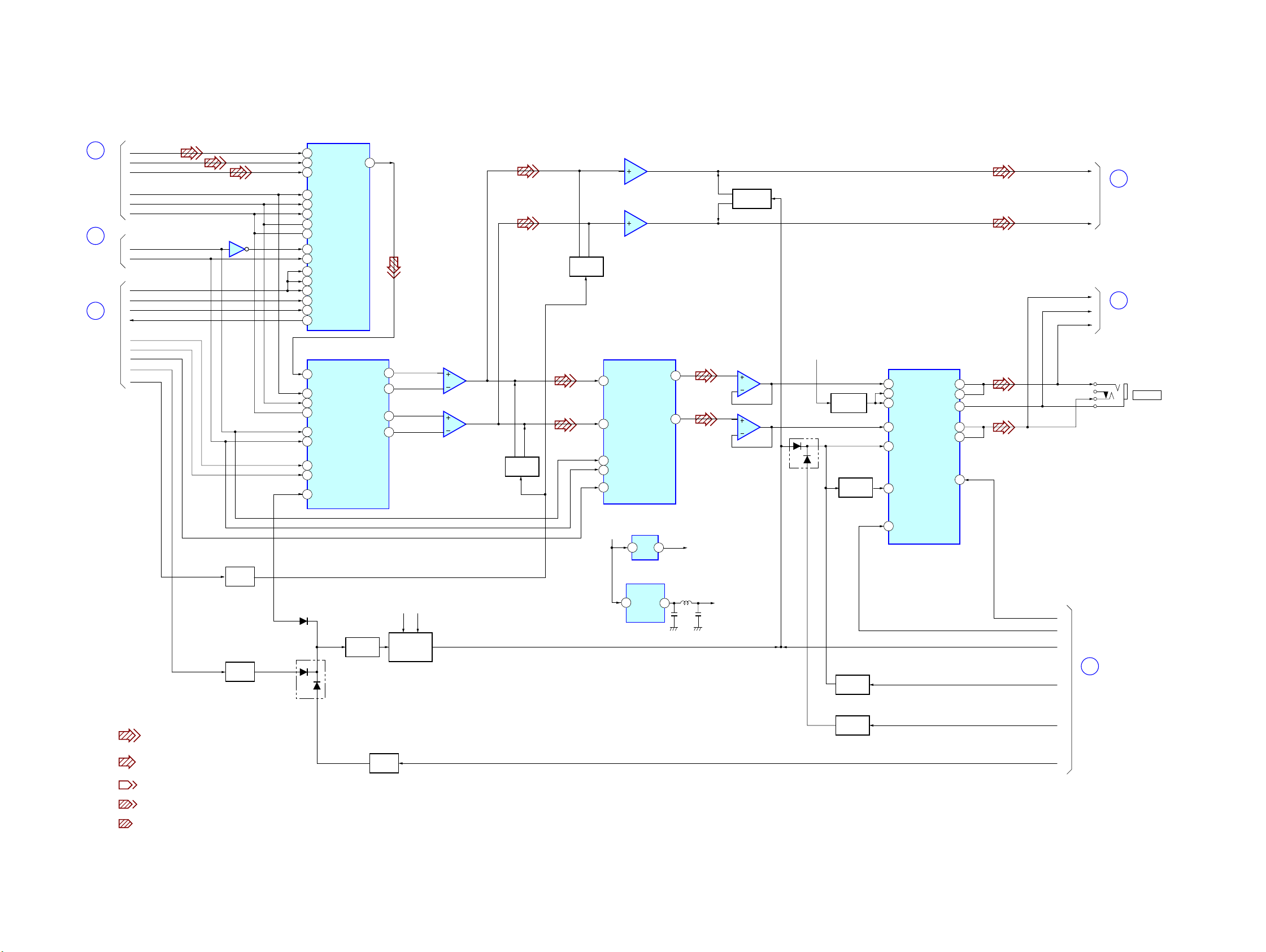

– VIDEO OUT Section – ············································ 25

– POWER Section – ···················································· 26

– TFT Section – ··························································· 27

5-2. Printed Wiring Board

– MAIN Section (Side A) (Over All View) – ·············· 28

5-3. Printed Wiring Board

5-4. Printed Wiring Board

5-5. Printed Wiring Board

5-6. Printed Wiring Board

5-7. Printed Wiring Board

– MAIN Section (Side B) (Over All View) – ·············· 33

5-8. Printed Wiring Board

5-9. Printed Wiring Board

5-10. Printed Wiring Board

5-11. Printed Wiring Board

5-12. Schematic Diagram – MAIN Section (1/11) – ·········· 38

5-13. Schematic Diagram – MAIN Section (2/11) – ·········· 39

5-14. Schematic Diagram – MAIN Section (3/11) – ·········· 40

5-15. Schematic Diagram – MAIN Section (4/11) – ·········· 41

5-16. Schematic Diagram – MAIN Section (5/11) – ·········· 42

5-17. Schematic Diagram – MAIN Section (6/11) – ·········· 43

5-18. Schematic Diagram – MAIN Section (7/11) – ·········· 44

5-19. Schematic Diagram – MAIN Section (8/11) – ·········· 45

5-20. Schematic Diagram – MAIN Section (9/11) – ·········· 46

5-21. Schematic Diagram – MAIN Section (10/11) – ········ 47

5-22. Schematic Diagram – MAIN Section (11/11) – ········ 48

5-23. Printed Wiring Board – TFT Section (Side A) –········ 49

5-24. Printed Wiring Board – TFT Section (Side B) –········ 50

5-25. Schematic Diagram – TFT Section (1/3) – ················ 51

5-26. Schematic Diagram – TFT Section (2/3) – ················ 52

5-27. Schematic Diagram – TFT Section (3/3) – ················ 53

5-28. IC Block Diagrams ····················································· 54

5-29. IC Pin Function Descriptions······································ 59

– MAIN Section (Side A) (1/4) – ·········

– MAIN Section (Side A) (2/4) – ·········

– MAIN Section (Side A) (3/4) – ·········

– MAIN Section (Side A) (4/4) – ·········

– MAIN Section (Side B) (1/4) – ·········

– MAIN Section (Side B) (2/4) – ·········

– MAIN Section (Side B) (3/4) –·········

– MAIN Section (Side B) (4/4) –·········

29

30

31

32

34

35

36

37

6. EXPLODED VIEWS ······················································ 63

7. ELECTRICAL PARTS LIST ······································· 66

This appliance is classified as a CLASS 1 LASER product.

The CLASS 1 LASER PRODUCT MARKING is located on

the rear exterior.

CAUTION

Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous

radiation exposure.

Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270 ˚C during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be damaged by heat.

Unleaded solder

Boards requiring use of unleaded solder are printed with the leadfree mark (LF) indicating the solder contains no lead.

(Caution: Some printed circuit boards may not come printed with

the lead free mark due to their particular size.)

: LEAD FREE MARK

Unleaded solder has the following characteristics.

• Unleaded solder melts at a temperature about 40°C higher than

ordinary solder.

Ordinary soldering irons can be used but the iron tip has to be

applied to the solder joint for a slightly longer time.

Soldering irons using a temperature regulator should be set to

about 350°C.

Caution: The printed pattern (copper foil) may peel away if the

heated tip is applied for too long, so be careful!

• Strong viscosity

Unleaded solder is more viscous (sticky, less prone to flow) than

ordinary solder so use caution not to let solder bridges occur such

as on IC pins, etc.

• Usable with ordinary solder

It is best to use only unleaded solder but unleaded solder may

also be added to ordinary solder.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED LINE WITH

MARK 0 ON THE SCHEMATIC DIAGRAMS AND IN THE PARTS

LIST ARE CRITICAL TO SAFE OPERATION. REPLACE THESE

COMPONENTS WITH SONY PARTS WHOSE PART NUMBERS

APPEAR AS SHOWN IN THIS MANUAL OR IN SUPPLEMENTS

PUBLISHED BY SONY.

2

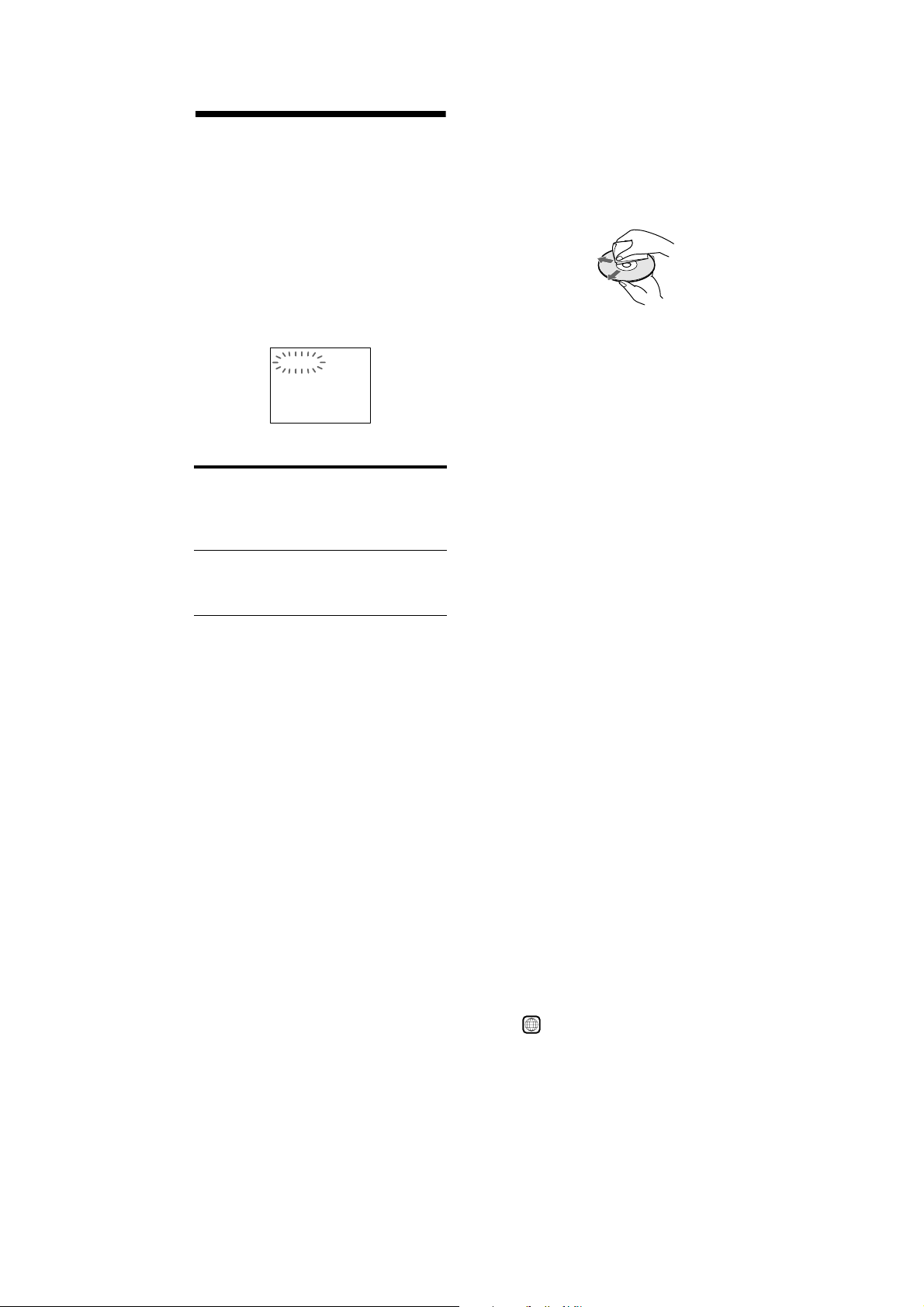

Self-diagnosis Function

(When letters/numbers appear in the

display)

When the self-diagnosis function is activ ated

to prevent the player from malfunctioning, a

five-character service number (e.g., C 13 00)

with a combination of a letter and digits

appears on the screen. In this case, check the

following table.

C:13:00

D-VM1

On cleaning

• Fingerprints or dust on a disc may cause

deteriorated image or sound quality. Leave

the disc clean.

• Wipe the disc with a soft cloth from the

center out.

• If the disc is very dirty, first wipe it with a

damp cloth, then wipe it again with a dry

cloth.

• Do not use solvents such as benzine,

thinner, commercially available cleaners, or

anti-static spray intended for vinyl LPs.

First three

characters

of the

service

number

C 13 The disc is dirty.

Cause and/or corrective

action

, Clean the dis c with a soft cloth

,

The player cannot play the

disc, etc.

The player cannot play the following discs:

xDVD

• DVD-ROM

• DVD-RAM

• DVD Audio discs

• DVD-RWs recorded in video recording

format (VR mode)

xCD

• CD-ROMs (PHOTO CDs included)

• All CD-Rs/RWs other than music format

and VCD format CD-Rs/RWs

• Data part of CD-Extras

• CDs recorded in DTS*

*

If you playback a CD recorded in DTS,

excessive noise may be heard from

headphones output or the AUDIO OUT

jack.

xSuper Audio CD

• The player, however, can play CD layer in

hybrid discs.

Also, the player ca nnot play the following

discs:

• A DVD with a different region code

Region Code

This system is used to protect copyrights. A

region number is allocated on each DVD

player or DVD disc according to the sales

region. Each region code is shown on the

player as well as on the disc packaging. The

player can play the discs that match its region

code. The player can also play discs with the

ALL

mark. Even when the region code is not

shown on the DVD, the region limit may still

be activated.

• A disc that has a non-standard shape (e.g.,

card, heart).

• A disc with paper or stickers on it.

• A disc that has the adhesive of cellophane

tape or a sticker still left on it.

3

D-VM1

SECTION 1

SERVICING NOTE

Note: If you are going to repair the monitor unit.

Do not touch the inverter unit and piezo-electric transformer that

are mounted on the TFT board both in the statuses of power-on and

power-off.

(Touching these components may damage them.)

INVERTER UNIT

piezo-electric transformer

TFT BOARD

NOTES ON HANDLING THE OPTICAL PICK-UP

BLOCK OR BASE UNIT

The laser diode in the optical pick-up block may suffer electrostatic

breakdown because of the potential difference generated by the

charged electrostatic load, etc. on clothing and the human body.

During repair, pay attention to electrostatic breakdown and also use

the procedure in the printed matter which is included in the repair

parts.

The flexible board is easily damaged and should be handled with

care.

NOTES ON LASER DIODE EMISSION CHECK

The laser beam on this model is concentrated so as to be focused on

the disc reflective surface by the objective lens in the optical pickup block. Therefore, when checking the laser diode emission,

observe from more than 30 cm away from the objective lens.

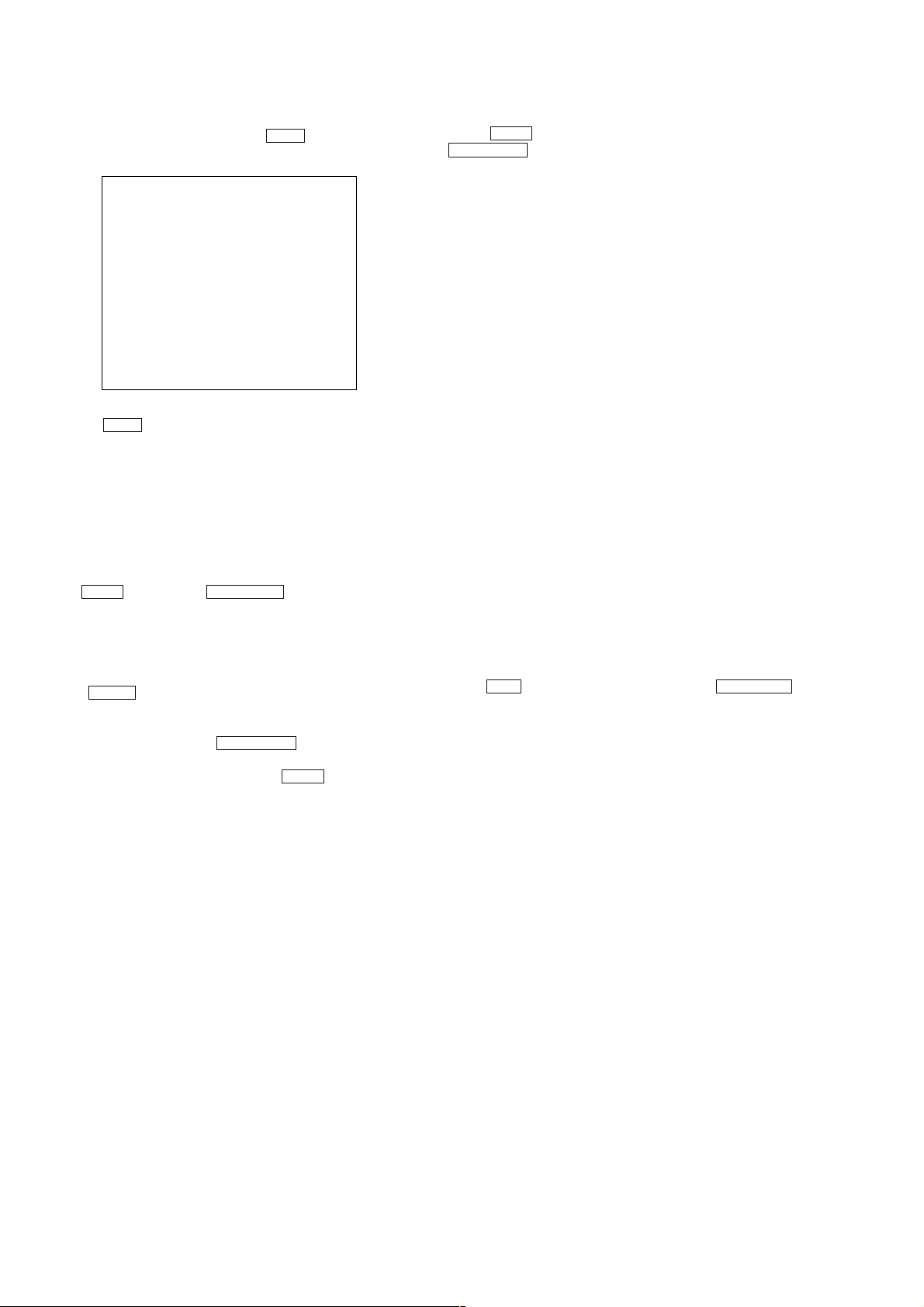

MONITOR UNIT

4

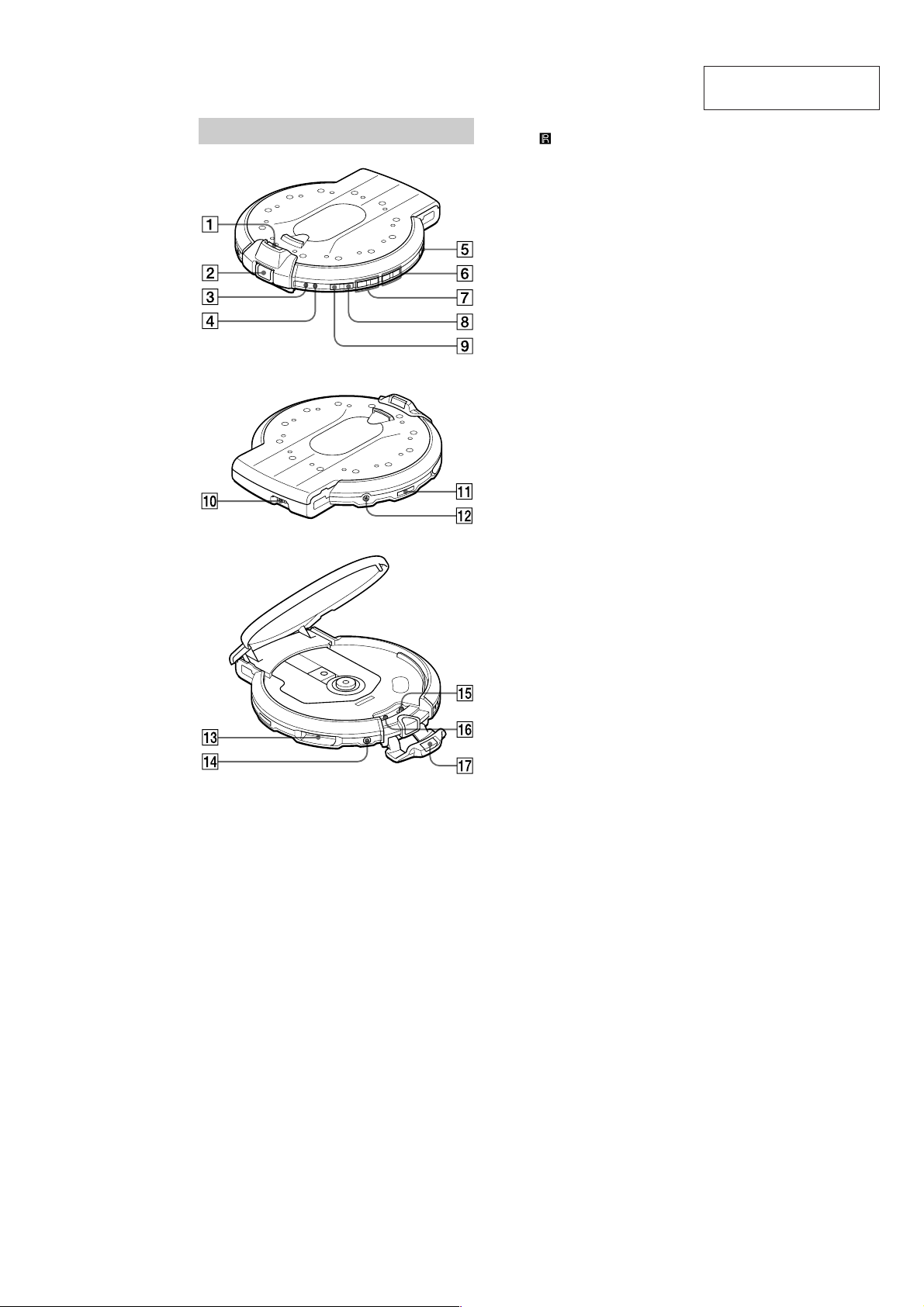

Player

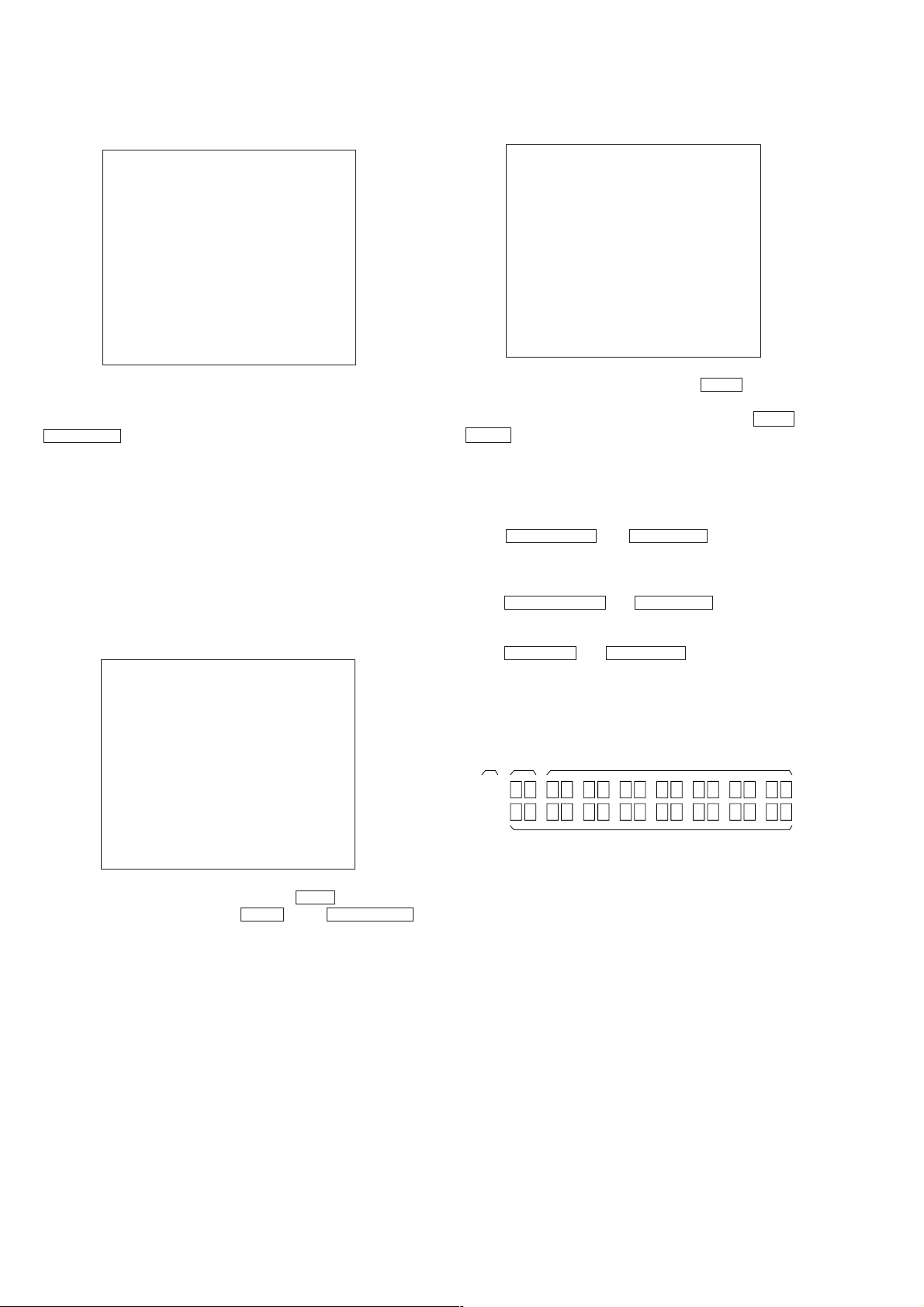

SECTION 2

GENERAL

A OPEN knob

B (remote sensor)

C CHG (charge) indicator

D POWER indicator

E HOLD switch

F VOL (volume) +/– buttons

G ./> (previous/next) buttons

H NX (play/pause) button

I x/OFF (stop/power off) button

J Rechargeable battery terminal

K A/V OUT (aud io /video output) jack

L DC IN 10V jac k

M MONITOR jack

N i (headphones) jack

O AVLS (Automatic Volume Limiter

P NTSC/PAL switcha

Q Buckle (21)

D-VM1

This section is extracted

from instruction manual.

The VOL + button has a tactile dot.

The NX button has a tactile dot.

System) swi t ch

5

D-VM1

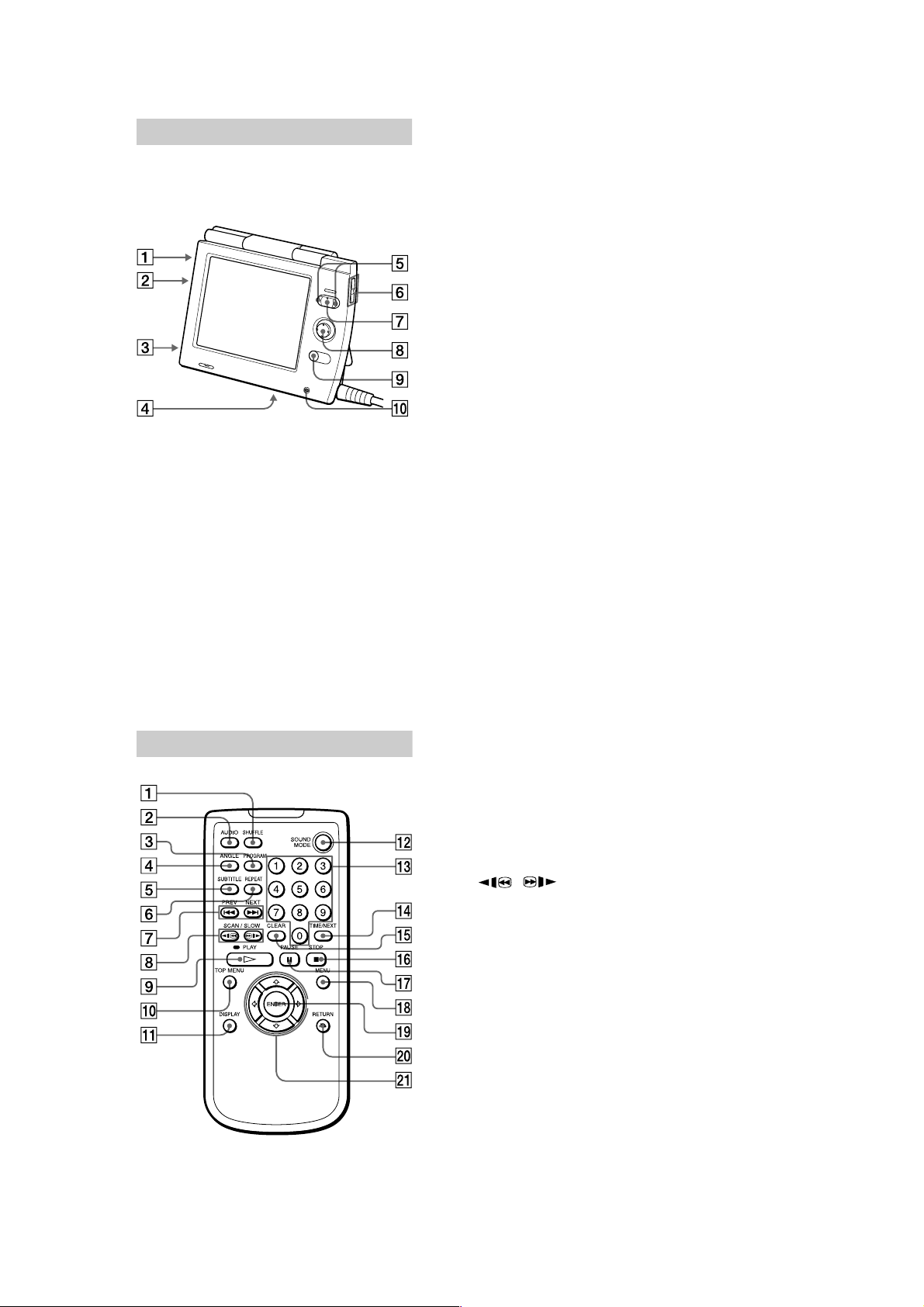

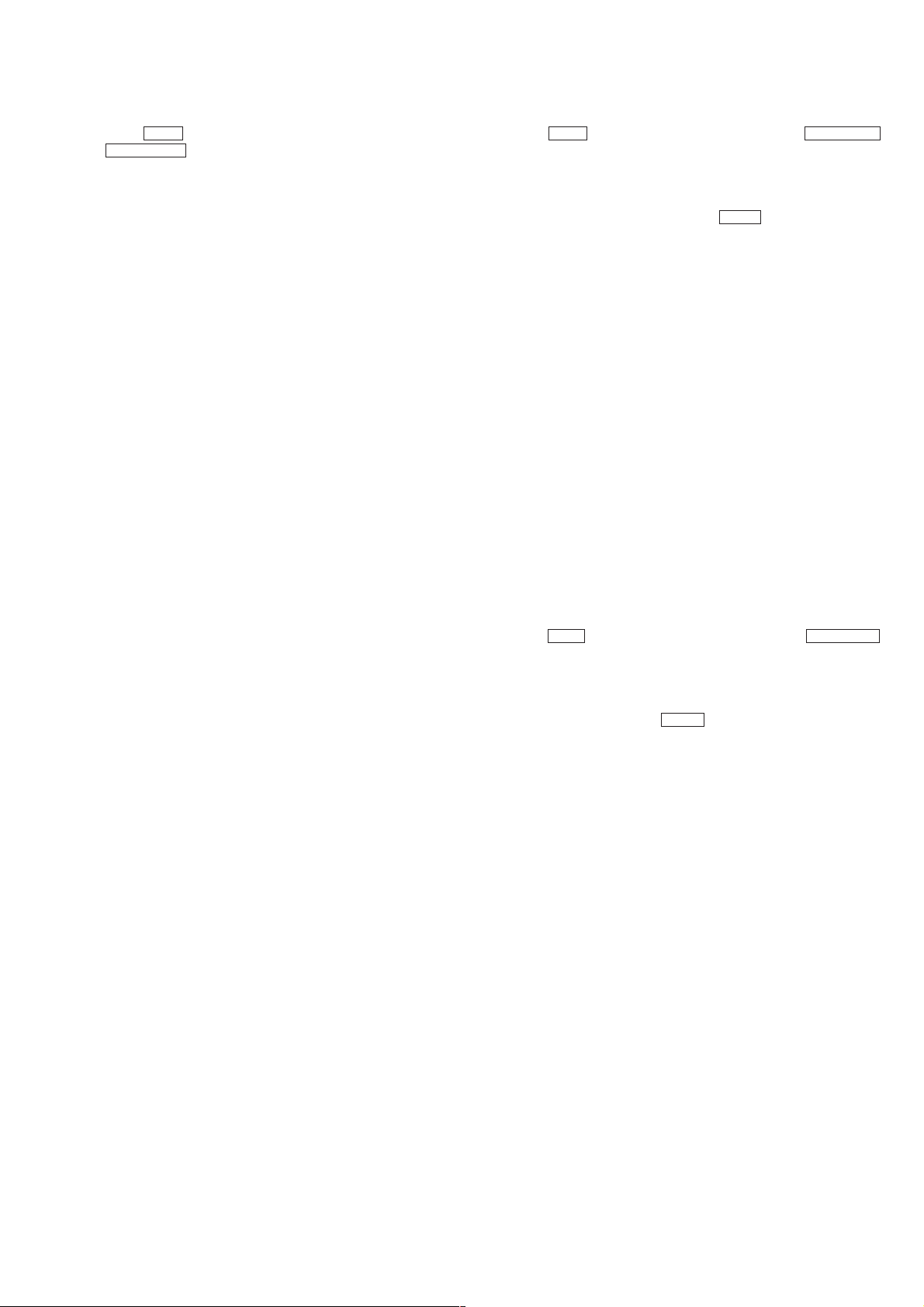

Monitor unit

The buttons on the monitor unit work

differently when they are operated with the

SHIFT button.

A SHIFT button

B BRIGHT knob

CDi (headphones) jack

HOLD switch

E ./> (previous/next ) buttons

When operated with SHIFT:

Slow motion/One fram e pla y ba c k

buttons

F VOL (volume) +/– bu ttons

The VOL + button has a tactile dot.

When operated with SHIFT:

+: TIME/TEXT button

–: CLEAR button

G NX (play/pause) button

The NX button has a tactile dot.

When operated with SHIFT:

SOUND MODE button

H b/v/V/B/ENTER buttons

When operated with SHIFT:

b: ORETURN button

v: MENU button

V: DISPLAY button

B: TOP MENU button

ENTER: TIMER button

I x/OFF (stop/power off) button

When operated with SHIFT:

Releases Resume Play or returns to PBC

playback.

J POWER indicator

Remote

A SHUF FLE button

B AUDIO button

CDPROGRAM button

ANGLE button

E SUBTITLE button

F REPEAT button

G ./> PREV (previous) /NEXT

buttons

H / SCAN/SLOW butt ons

I H PLAY button

J TOP MENU button

K DISPLAY button

L SOUND MODE button

M Number buttons

N TIME/TEXT button

O CLEAR button

P x STOP/power off button

Q X PAUS E button

R MENU button

S ENTER button

T ORETURN button

U C/X/x/c buttons

6

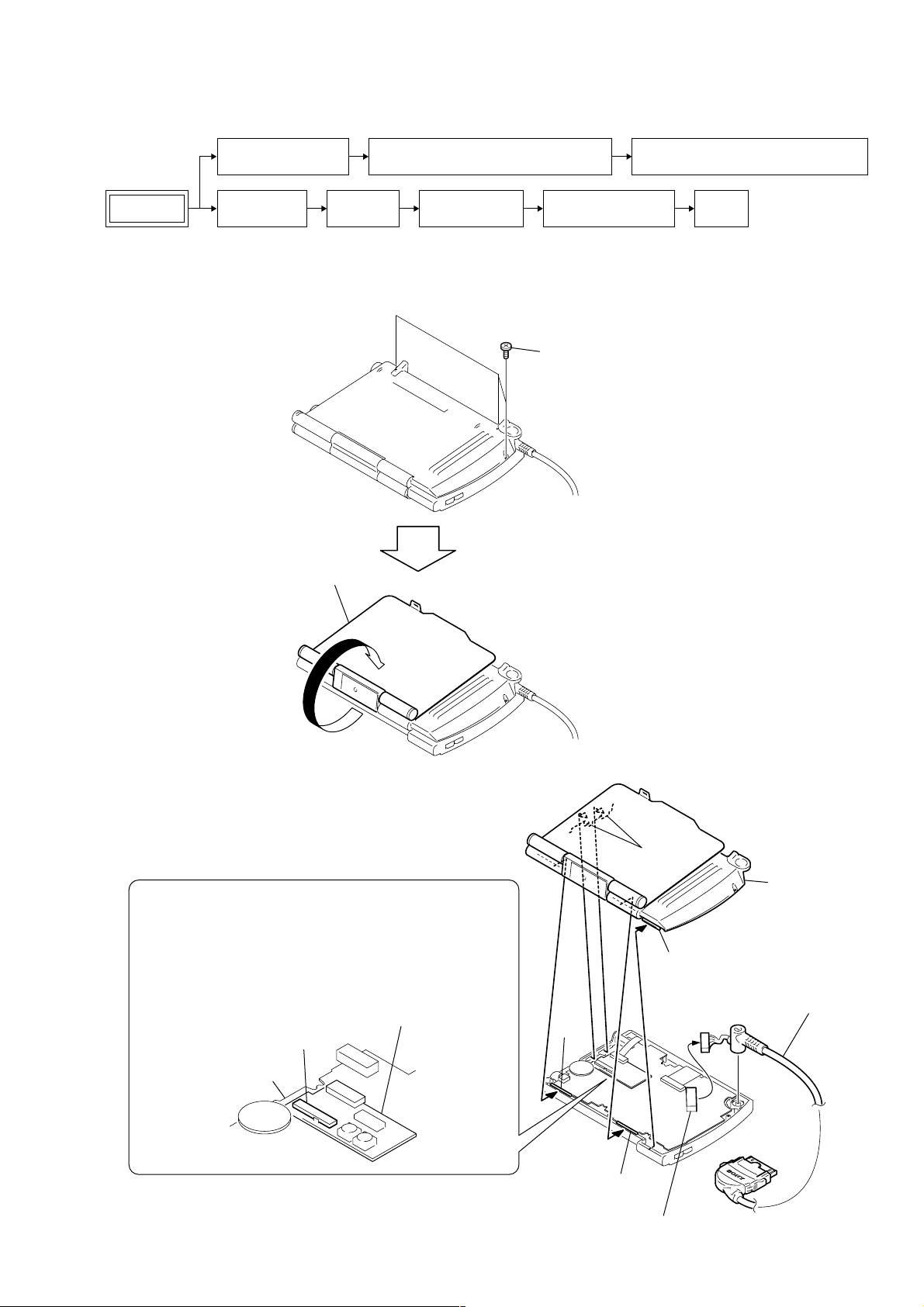

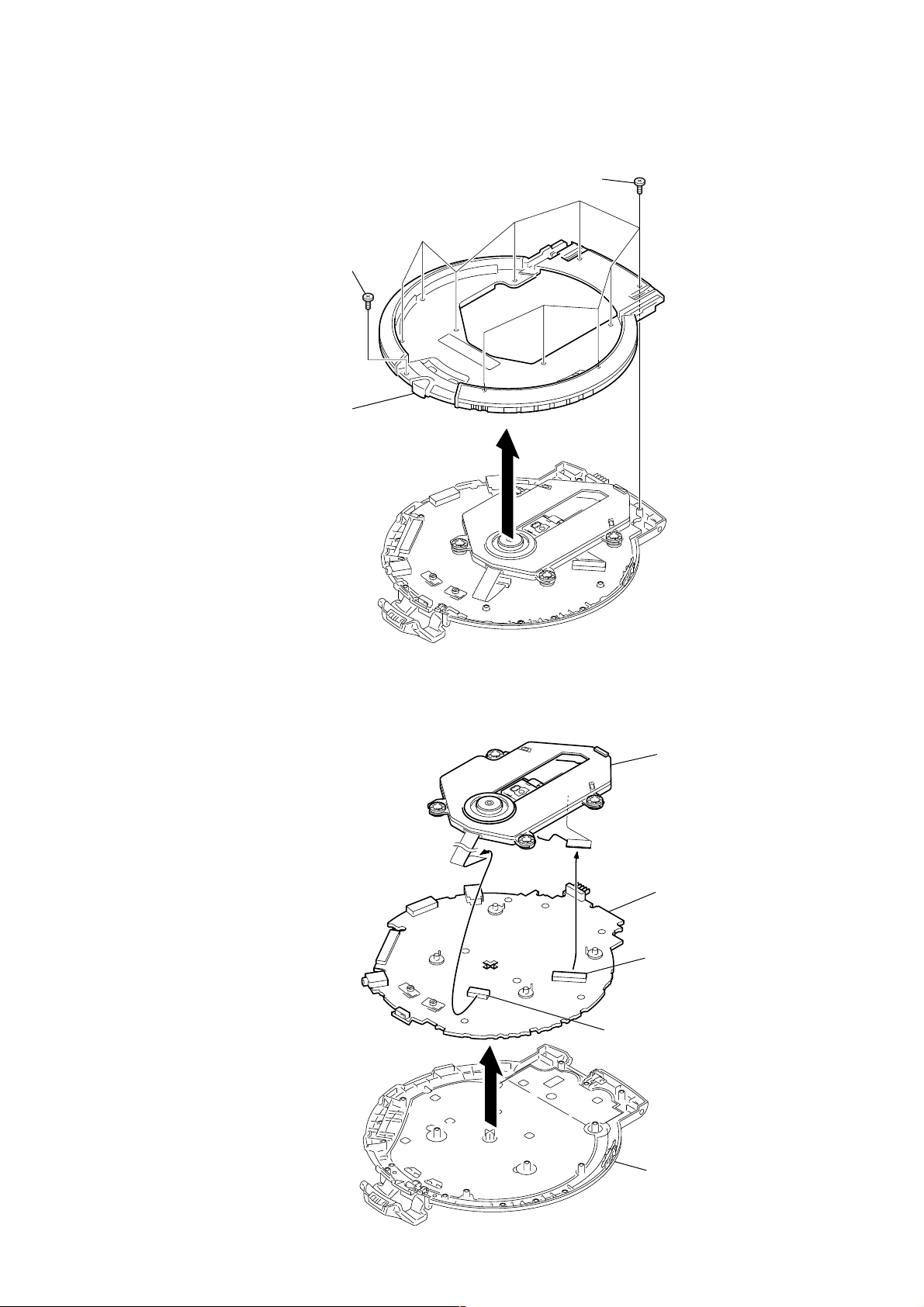

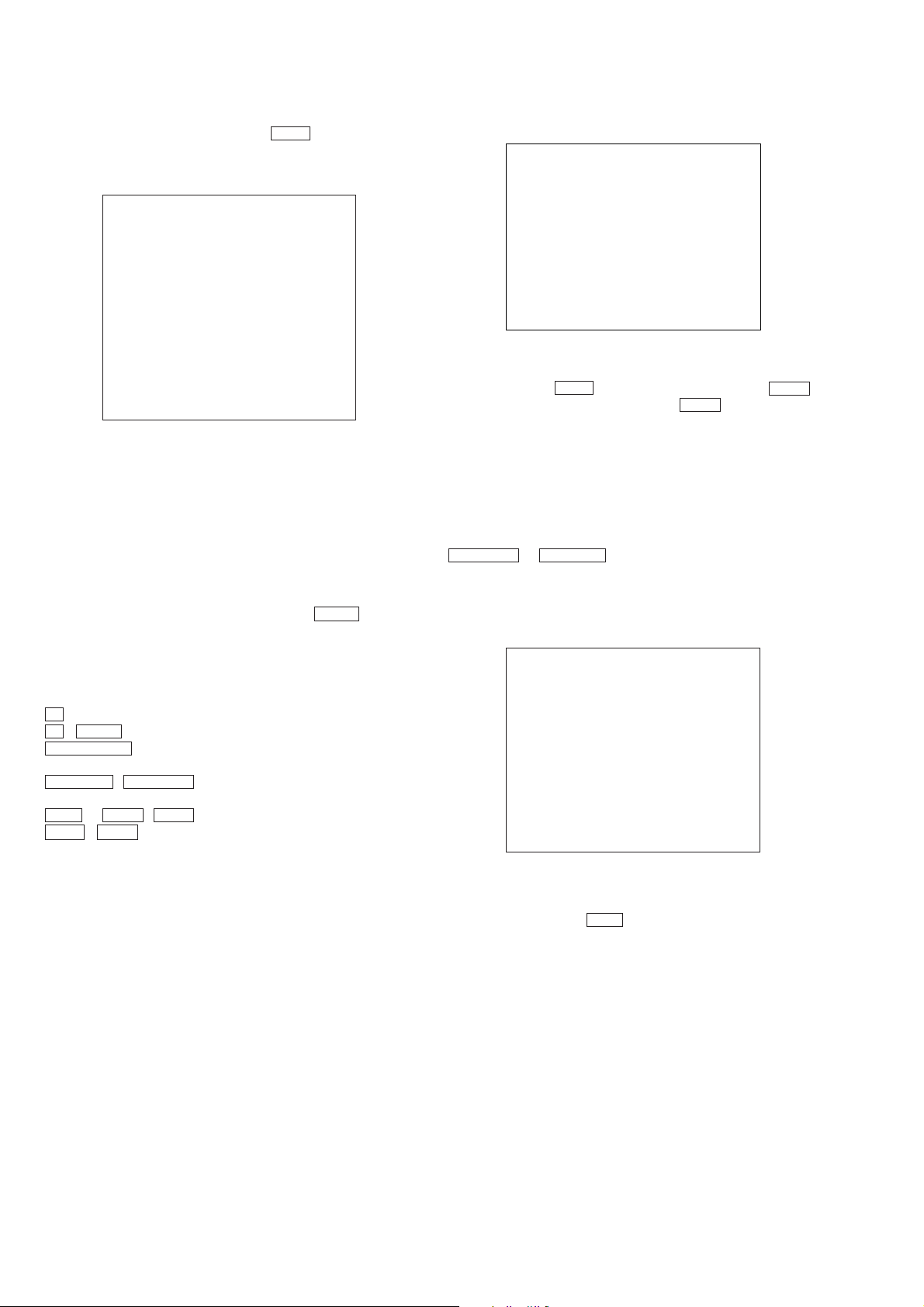

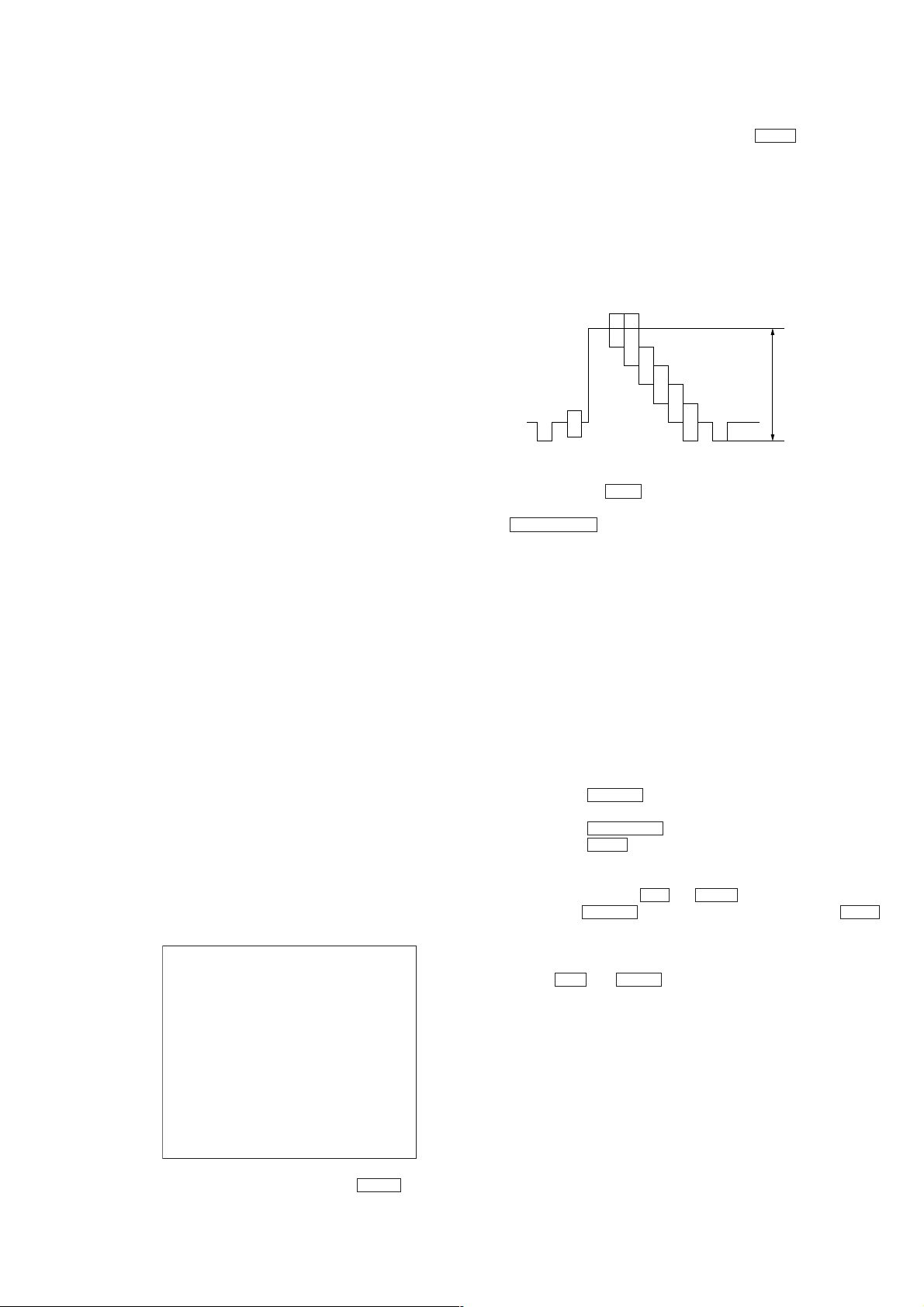

DISASSEMBLY

3

Release the claws in the direction of the arrow

in the order starting from step

A

to E.

6

Cord, connection (Monitor)

5

Connector, 30pin (CN1302)

A

B

C

D

E

Claw

Two claws

Claw

Claw

4

Cabinet

(Rear M)

TFT board, complete

Piezo-electric transformer

Inverter unit

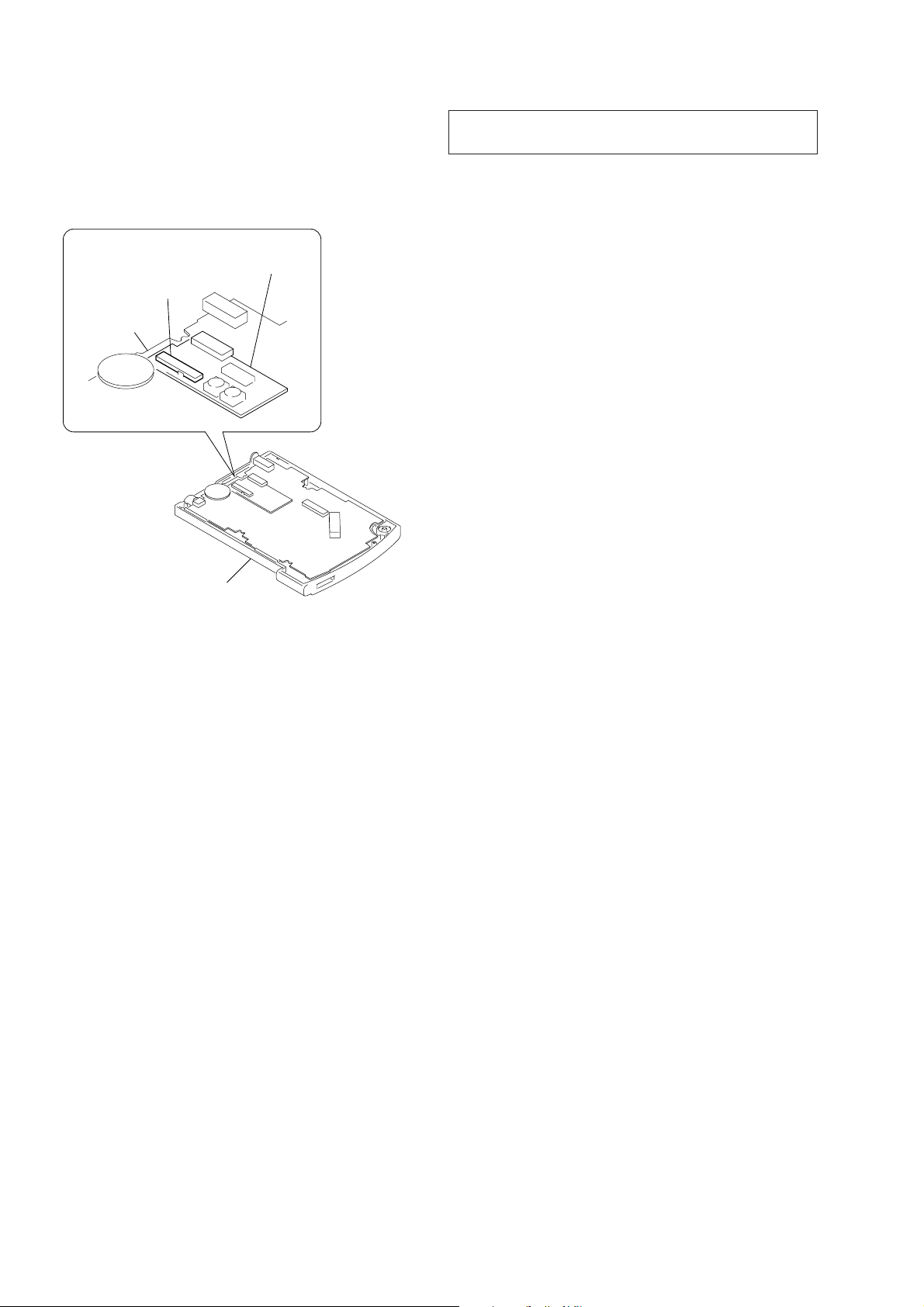

Note: If you are going to repair the monitor unit.

Do not touch the inverter unit and piezo-electric transformer

that are mounted on the TFT board both in the statuses

of power-on and power-off.

(Touching these components may damage them.)

Note : Disassemble the unit in the order as shown below.

D-VM1

SECTION 3

Monitor unit section

Set Lid (disc)

Main section

Cabinet (rear), Connection coard (monitor)

Cabinet (upper)

Note : Follow the disassembly procedure in the numerical order given.

3-1. CABINET (REAR), CONNECTION CORD (MONITOR)

Lid (LCD M)

Inverter unit,

Liquid crystal indicator display (LCD901)

CDM501, Main board

1

Three screws (+BM1.7 × 6)

TFT board,

Buckle

2

7

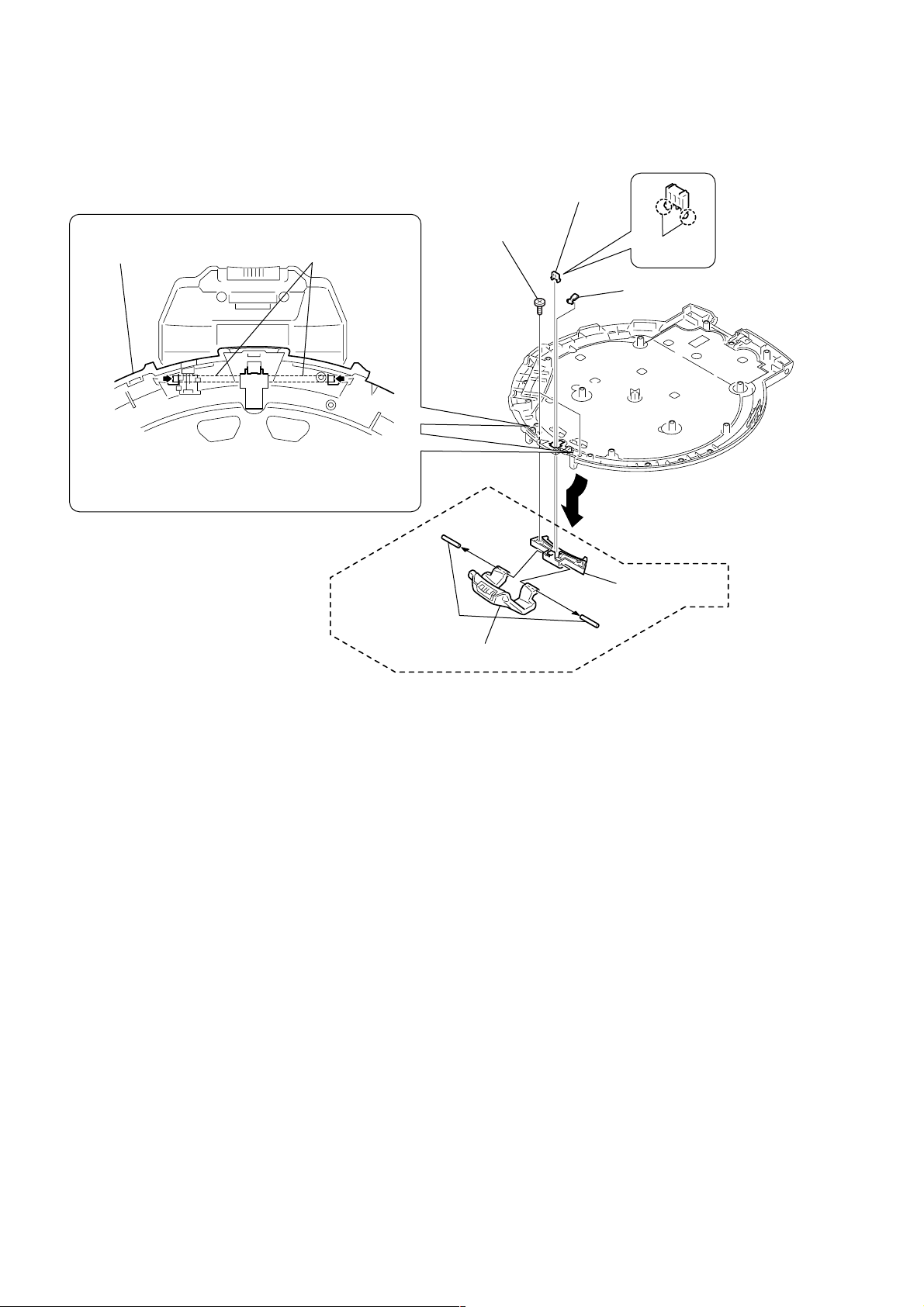

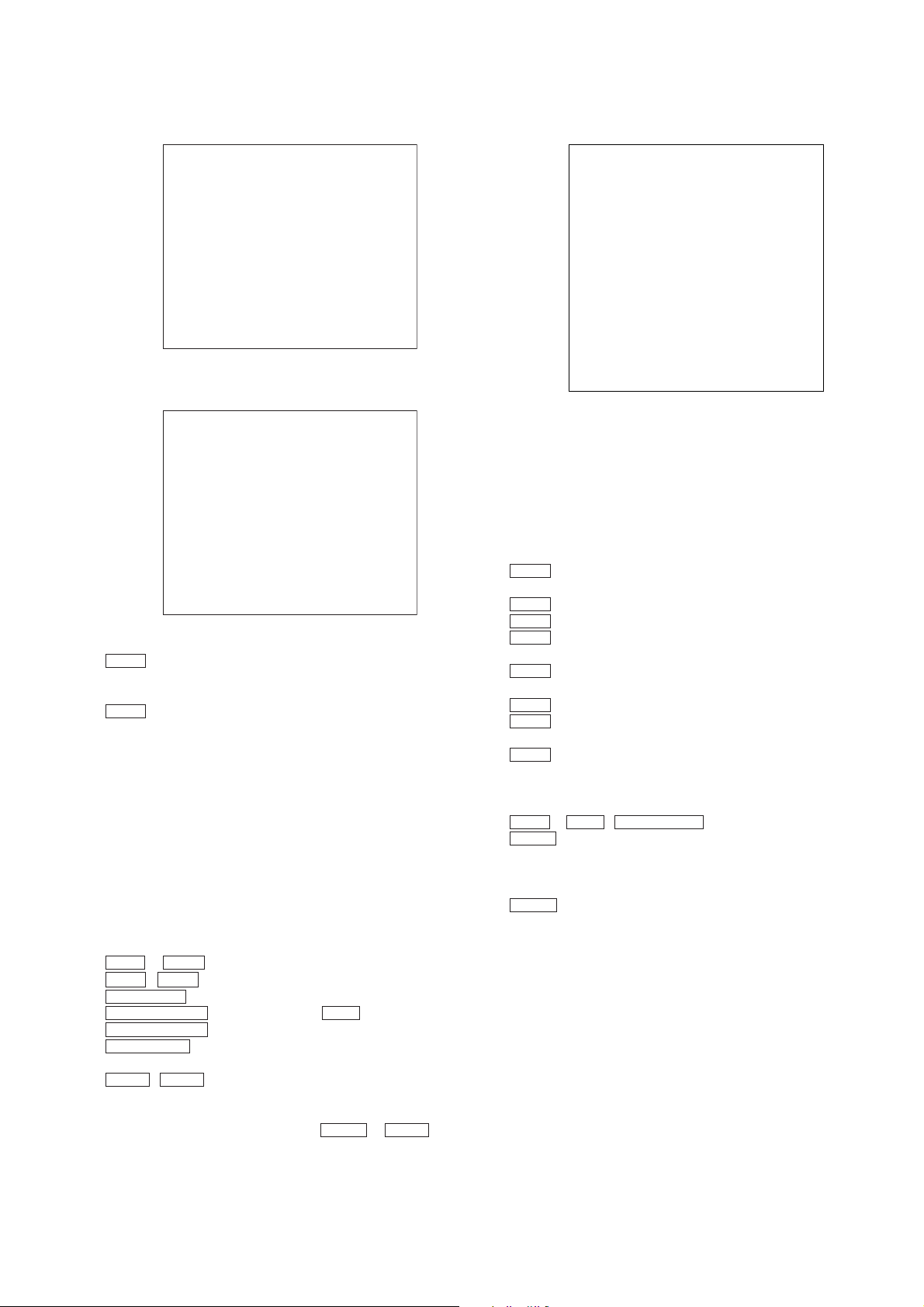

D-VM1

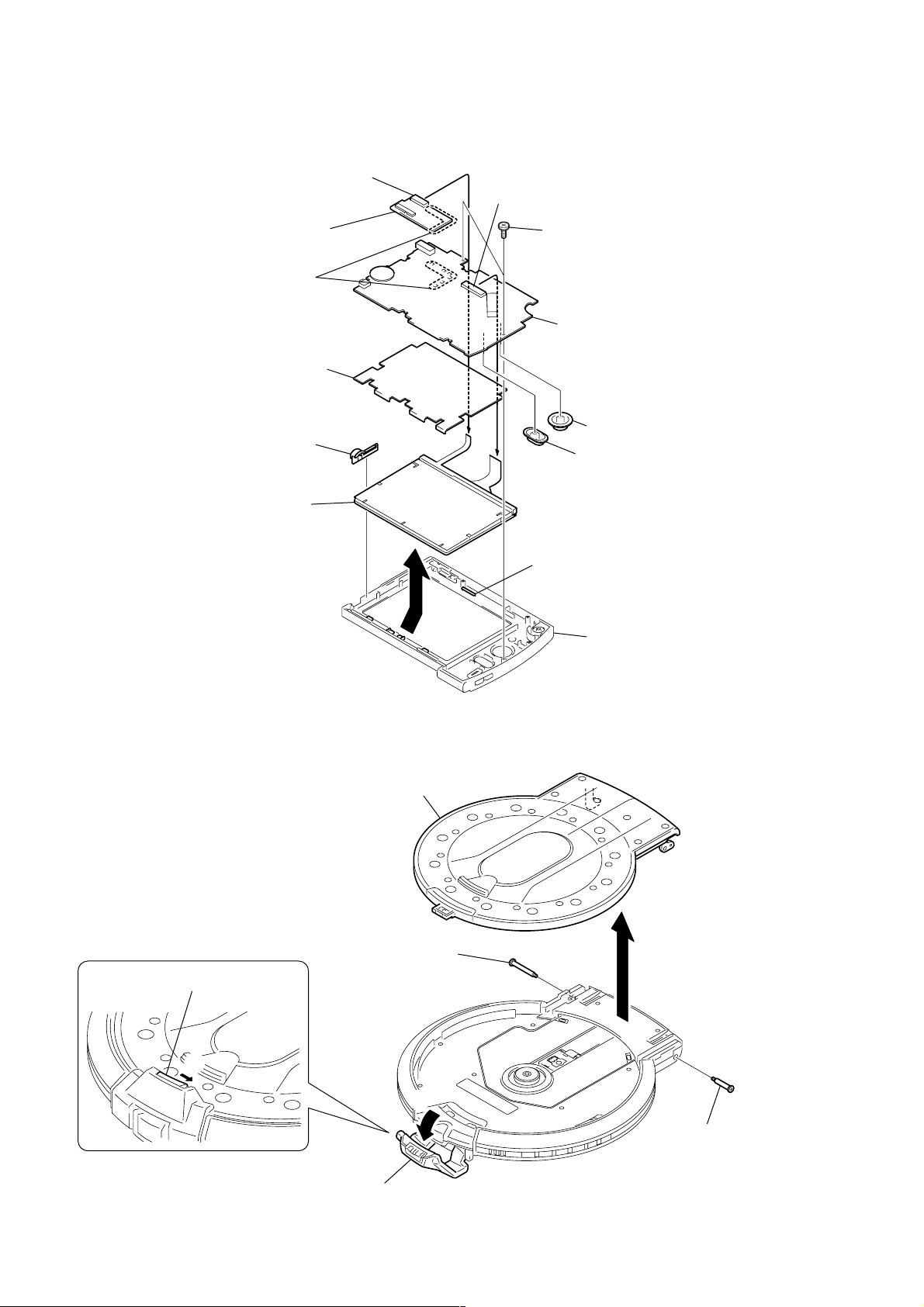

3-2. INVERTER UNIT, TFT BOARD, LIQUID CRYSTAL INDICATOR DISPLAY (LCD901)

Connector, 3pin

1

(Inverter unit)

5

Connector, 24pin (CN1401)

3

Inverter unit

2

Remove the six soldrings.

7

Spacer (M)

8

Button (Shift M)

4

Two screws (+BM1.7 × 6)

6

TFT board, complete

Knob (Direction key M)

Knob (Play M)

3-3. LID (DISC)

qa

Liquid crystal indicator

display (LCD901)

Knob (Open)

6

Lid (Disc)

3

Screw (M1.4), step

q;

9

Claw

Cabinet (Front M)

5

1

2

4

Screw (M1.4), step

Buckle

8

3-4. CABINET (UPPER)

)

4

Cabinet (Upper)

2

screw, tapping

1

Ten screws (+BM1.7 × 6)

3

D-VM1

3-5. CDM501, MAIN BOARD

3

CDM501

5

Main board, complete

1

Connector, 30pin (CN601

2

4

Connector, 8pin (CN1601)

Cabinet (Lower)

9

D-VM1

3-6. BUCKLE

Cabinet (Lower)

4

Press the two shafts (buckles) that are located in the

recessed areas in the right and left of the cabinet (lower)

in the direction of the arrows respectively.

Shaft (Buckle)

Stopper (Shaft)

2

1

Two screws, tapping

5

Two claws

3

Lever (Battery direction)

6

Shaft (Buckle)

8

Buckle

7

Base, buckle

10

SECTION 4

TEST MODE

Note : About “R”

As this unit has only a few buttons, some operations require the use of remote commander (RMT-DV20/provided with unit: 1-476-993-11)

buttons. These operations are indicated as “R” in this manual.

Example: ENTER “R” ...Press the ENTER button of the remote commander.

D-VM1

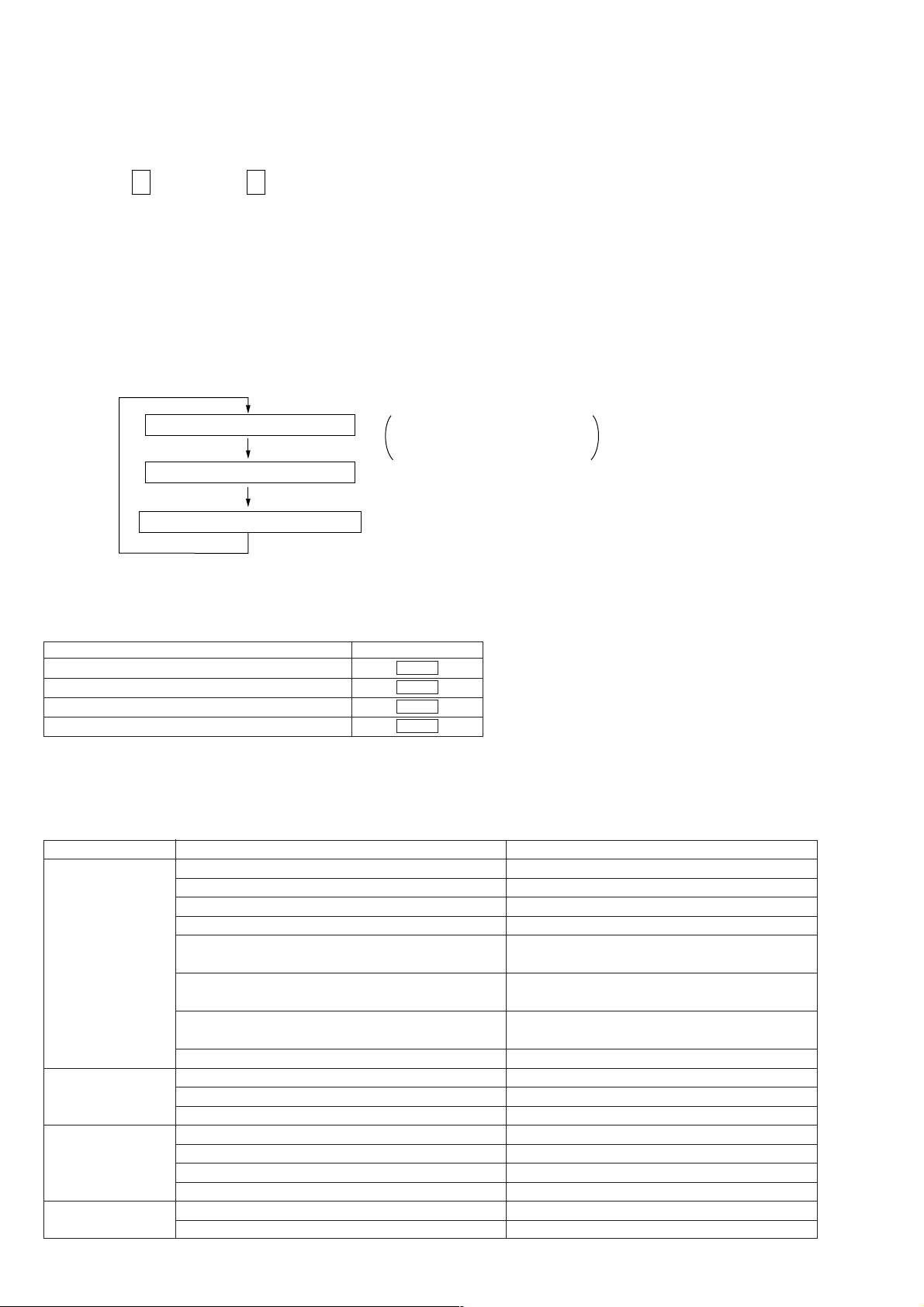

4-1. GENERAL DESCRIPTION

The T est Mode allows you to make diagnosis and adjustment easily using the remote commander and monitor TV. The instructions,

diagnostic results, etc. are given on the on-screen display (OSD).

4-2. STARTING TEST MODE

While the power of the main unit turns on, press the buttons of the

remote commander in the order starting from TIME/TEXT “R” ,

NEXT “R” , PAUSE “R” , 3 “R” and PLAY “R” buttons. The

test mode starts up and the following menu appears on the display

screen. At the bottom of the menu screen, the model name and

revision number are displayed. To execute each function, select

the desired menu and press its number on the remote commander.

To exit from Test Mode, press the SOUND MENU “R” button.

Test Mode Menu

0. Syscon Diagnosis

1. Drive Auto Adjustment

2. Drive Manual Operation

3. Mecha Aging

4. Emergency History

5. Version Information

6. Video Level Adjustment

7. EVR/MON Adjustment

Exit: Surround Key

_

Model : UVX-5xxx

Revision : 1.xxx

4-3. SYSCON DIAGNOSIS

The same contents as board detail check by serial interface can be

checked from the remote commander.

On the Test Mode Menu screen, press the 0 “R” key on the remote commandeer, and the following check menu will be displayed.

1. All (All items continuous check)

This menu checks all diagnostic items continuously. Nor mally , all

items are checked successively one after another automatically

unless an error is found, but at a certain item that requires judgment through a visual check to the result, the following screen is

displayed for the key entry.

### Syscon Diagnosis ###

Diag All Check

No. 2 Version

2-3. ROM Check Sum

Check Sum = xxxx

Press NEXT Key to Continue

Press PREV Key to Repeat

_

For the “ROM Check”, the checksum calculated by the Syscon is

output, and therefore you must compare it with the specified value

for confirmation. Following the message, press the NEXT “R”

key to go to the next item, or the PREV “R” key to repeat the

same check again. To quit the Syscon Diagnosis and return to the

Check Menu screen, press x “R” or ENTER “R” key. If an

error occurred, the diagnosis is suspended and the error code is

displayed as shown below.

### Syscon Diagnosis ###

### Syscon Diagnosis ###

Check Menu

0. Quit

1. All

2. Version

3. Peripheral

4. Servo

5. Supply

6. AV Decoder

7. Video

8. Audio

_

0. Quit

Quit the Syscon Diagnosis and return to the Test Mode Menu.

3-3. EEPROM Check

Error 03: EEPROM Write/Read N

Address : 00000001

Write Data : 2492

Read Data : 2490

Press NEXT Key to Continue

Press PREV Key to Repeat

_

Press the x “R” key to quit the Syscon Diagnosis, or PREV “R”

key to repeat the same item where an error occurred, or

NEXT “R” key to continue the check from the item next to faulty

item. Selecting 2 and subsequent items call the submenu screen

of each item. For example, if “5. Supply” is selected, the following submenu will be displayed.

11

D-VM1

### Syscon Diagnosis ###

Check Menu

No. 5 Supply

0. Quit

1. All

2. ARP Register Check

3. ARP to RAM Data Bus

4. ARP to RAM Address Bus

5. ARP RAM Check

_

0. Quit

Quit the submenu and return to the main menu.

1. All (All submenu items continuous check)

This menu checks 2 and subsequent items successively . At the item

where visual check is required for judgment or an error occurred,

the checking is suspended and the message is output for key entry .

Normally, all items are checked successively one after another

automatically unless an error is found. Selecting 2 and subsequent

items execute respective menus and output the results.

For the contents of each submenu, see “Check Items List”.

General Description of Checking Method

2. V ersion

(2-2)Revision

ROM revision number is displayed.

Error : Not detected.

The revision number defined in the source file of ROM

(IC1105) is displayed with four digits.

(2-3)ROM Checksum

Checksum is calculated.

Error : Not detected.

The data stored in the ROM (IC1105) are added and the result is displayed with 4-digit hexadecimal number. Error is

not detected. Compare the result with the specified value.

(2-4)Model Type

Model code is displayed.

Error : Not detected.

The model code is displayed with 2-digit hexadecimal number.

Model Type

D-VM1 (HK) 9 7

D-VM1 (JE) 9 7

(2-5)Region

Region code is displayed.

Error : Not detected.

The region code determined from the model code is displayed.

(4-3)DSP Driver Test

Test signal data → DSP Driver

Error : Not detected.

5. Supply

Caution : Do not conduct this check with a mechanical deck connected.

An access is made to the stream supply and servo control IC

(IC1002) and external RAM (IC1003) using check data. If

mechanical deck is connected, the motor and optics could be

damaged. This check is also executed by the “All” menu item.

Supplement: How to disconnect mechanical deck

Disconnect flat cables connected to the CN601 and CN1601

of MAIN board.

(5-2)ARP Register Check

Data write → read, and accord check

Error 08 : ARP register write, and read data disaccord

(5-3)ARP to RAM Data Bus

Data write → read, and accord check

Error 09: ARP ← → RAM data bus error

Data 0x0001 to 0x8000 where one bit each is set to 1 are

written to the address 0 of RAM (IC1003) connected to the

ARP (IC1002) through the bus, then they are read and

checked. In case of discord, written bit pattern and read data

are displayed. If data where multiple bits are 1 are read, the

bits concerned may touch each other. Further, if data wher e

certain bit is always 1 or 0 regardless of written data, the line

could be disconnected or shorted.

(5-4)ARP to RAM address Bus

Data write → other address read discord check

Error 10: ARP ← → RAM address bus error

Caution : Address and data display in case of an error is different from

the display of other diagnosis (described later). Before starting the test, all addresses of RAM (IC1003) are cleared to

0x0000. First, 0xA55A is written to the address 0x00000, and

the address data are read and checked from addresses 0x00001

to 0x80000 while shifting 1 bit each. Next, the data at that

address is cleared, and it is written to the address 0x00001,

and read and checked in the same manner. This check is repeated up to the address 0x80000 while shifting the address

data by 1 bit each.

If data other than 0 is read at the addresses except written

address, an error is given because all addresses were already

cleared to 0. In this check, the error display pattern is different from that of other diagnosis; read data, written address,

and read address are displayed in this order. However, the

message uses same template, and accordingly exchange Address and Data when reading. The following display, for example, shows the data 0xA55A was read from address

0x00080000 though it was written to the address 0x00000000.

This implies that these addresses are in the form of shadow.

Also, if the read data is not 0xA55A, another error will be

present.

### Syscon Diagnosis ###

3. Peripheral

(3-2)EEPROM Check

Data write → read, and accord check

Error 03 : EEPROM write/read discord

Before writing, the data are saved, then after checking, they

are written to restore the contents of EEPROM.

4. Servo

(4-2)Servo DSP Check

Data write → read, and accord check

Error 12 : Read data discord

12

5-4. ARP to RAM Address Bus

Error 10: ARP - RAM Address B

Address : 0000A55A

Write Data : 00000000

Read Data : 00080000

Press NEXT Key to Continue

Press PREV Key to Repeat

_

D-VM1

(5-5)ARP RAM Check

Data write → read, and accord check

Error 11 : ARP RAM read data discord

The program code data stored in ROM are copied to all areas

of RAM (IC1003) connected to the ARP (IC1002) through

the bus, then they are read and checked if they accord. If the

detail check was selected initially, the data are written to all

areas and read, then the same test is conducted once again

with the data where all bits are inverted between 1 and 0. If

discord is detected, faulty address, written data, and read data

are displayed following the error code 11, and the test is suspended.

6. AV Decoder

(6-2)1933 RAM

Data write → read, and accord check

Error 13 : AVD RAM read data discord

The program code data stored in ROM (IC1105) are copied

to all areas of RAM (IC901, IC903) connected to the AVD

(IC902) through the bus, then they are read and checked if

they accord. Further, the same test is conducted once again

with the data where all bits are inverted between 1 and 0. If

discord is detected, faulty address, written data, and read data

are displayed following the error code 13, and the test is suspended.

(6-3)1933 SP

ROM → AVD RAM → Video OUT

Error: Not detected

The data including sub picture streams in ROM (IC1105)

are transferred to the RAM (IC901, IC903) in AVD (IC902),

and output as video signals from the AVD (IC902). They are

output from all video terminals (Composite, Y/C).

7. Video

(7-2)Color Bar

AVD color bar command write → Video OUT

Error : Not detected.

The command is transferred to the AVD, and the color bar

signals are output from the video terminals. They are output

from all video terminals (Composite, Y/C).

8. Audio

(8-2)ARP → 1933

Error 14 : ARP → 1933 video NG

15 : ARP → 1933 audio NG

(8-3)Test Tone

Pink noise is output from the AVD (IC902) to both of the

optical/co-axial digital output and the analog audio connector.

Error : Not detected.

All channels → left 2 channels → right 2 channels

Check Items List

2. Version (Version Display)

(2-2)Revision

(2-3)ROM Checksum

(2-4)Model Type

(2-5)Region

3. Peripheral

(3-2)Gate Array Check

(3-3)EEPROM Check

4. Servo

(4-2)Servo DSP Check

(4-3)DSP Driver Test

5. Supply

(5-2)ARP Register Check

(5-3)ARP to RAM Data Bus

(5-4)ARP to RAM Address Bus

(5-5)ARP RAM Check

6. AV Decoder

(6-2)1933 RAM

(6-3)1933 SP

7. Video

(7-2)Color Bar

8. Audio

(8-2)ARP → 1933

(8-3)Test Tone

Error Codes List

00 : Error not detected

01 : RAM write/read data discord

02 : Gate array NG

03 : EEPROM NG

04 : Flash memory erase error

05 : Flash memory write error

06 : Flash memory read data discord

08 : ARP register read data discord

09 : ARP ← → RAM data bus error

10 : ARP ← → RAM address bus error

11 : ARP RAM read data discord

12 : Servo DSP NG

13 : 1933 SDRAM NG

14 : ARP → 1933 video NG

15 : ARP → 1933 audio NG

16 : 1939 UCODE download NG

17 : System call error (function not supported)

18 : System call error (parameter error)

19 : System call error (illegal ID number)

20 : System call error (time out)

21 : NAND FLASH defective blocks are more than 10.

90 : Error occurred

91 : User verification NG

92 : Diagnosis cancelled

13

D-VM1

4-4. DRIVE AUTO ADJUSTMENT

On the Test Mode Menu screen, press 1 “R” key on the remote

commander, and the dri ve auto adjustment menu will be displayed.

## Drive Auto Adjustment ##

Adjustment Menu

0. ALL (adj:SL/CD/DL)

1. DVD-SL

2. CD

3. DVD-DL

4. SACD

5. CD-RW

Exit: RETURN

Normally , 0 “R” is selected to adjust DVD (single layer), CD and

DVD (dual layer) in this order. But, individual items can be adjusted for the case where adjustment is suspended due to an error.

In this mode, the adjustment can be made easily through the operation following the message displayed on the screen.

The disc used for adjustment must be the one specified separately .

Howev er, for SACD disc or CD-RW disc, use the player with initial data if the disc is not available.

0. All

Select 0 “R” and press the ENTER “R” key, and the servo set

data in EEPROM will be initialized. Then, 1. D VD-SL disc, 2. CD

disc and 3. DVD-DL disc are adjusted in this order . Each time one

disc was adjusted, the message of disc replacement stand-by appears on the screen. Eject the disc and replace it with the specified

disc following the message. You can finish the adjustment if pressing the x “R” button. The system prompts you to confirm the

“S”-figure characteristics level, RF level and jitter value in the

middle of adjustment. If these characteristics levels are satisfied

and confirmed OK, press the ENTER “R” key to continue the

adjustment. If you cannot confirm that these characteristics lev els

are satisfied and confirmed NG, press the x “R” button. Be sure

to measure the respective test discs to use in order to identify the

disc types before starting the adjustments of any disc type because

the automatic adjustment does not judge the disc type unlike conventional models. Take care not to insert the discs of wrong types.

Before adjustment, be sure to place the player horizontally level

with the player placed in a horizontal posture. Do not give a shock

during adjustment.

1. DVD-SL (single layer)

Select 1 “R” and insert DVD single layer disc, and press the

ENTER “R” key, and the adjustment will be made through the

following steps, then the adjusted values will be written to the

EEPROM.

DVD Single Layer Disc Adjustment Steps

1. SLED TILT Reset

2. Disc Check Memory SL

3. Wait 500 msec

4. Set Disc Type SL

5. LD ON

6. Spdl Start

7. Wait 1 sec

8. Focus Servo ON 1

9. CLVA ON

10. Wait 500 msec

11. Auto Track Offset Adjust

12. Tracking ON

13. CLVA ON

14. Wait 1 sec

15. Sled ON

16. Check CLV Lock

17. Auto LFO Adjust

18. FSGain (Focus Balance) Adjust

19. Auto Focus Gain Adjust

20. Auto Focus Offset Adjust

21. EQ Boost Adjust

22. Auto LFO Adjust

23. Auto Track Gain Adjust

24. All Servo Stop

25. Eep Copy Loop Filter Offset

2. CD

Select 2 “R” , insert the CD disc, and press the ENTER “R” key,

and the adjustment will be made through the following steps, then

adjusted values will be written to the EEPROM.

CD Adjustment Steps

1. Sled Rest

2. Disc Check Memory CD

3. Wait 500 msec

4. Set Disc Type CD

5. LD ON

6. Spdl Start

7. Wait 1 sec

8. Focus Servo ON 1

9. CLVA ON

10. Wait 500 msec

11. Auto Track Offset Adjust

12. Tracking ON

13. (TC Display Start)

14. CLVA ON

15. Wait 1 sec

16. Jitter Display Start

17. Sled ON

18. Check CLV ON

19. Auto LFO Adjust

20. Auto Focus Offset Adjust

21. Auto Focus Gain Adjust

22. Auto Focus Offset Adjust

23. Eq Boost Adjust

24. Auto LFO Adjust

25. Auto Track Gain Adjust

26. All Servo Stop

27. Rewrite the CD adjustment value over the original value .

14

D-VM1

3. DVD-DL (dual layer)

Select 3 “R” , insert the DVD dual layer disc, and press the

ENTER “R” key, and the adjustment will be made through the

following steps, then adjusted values will be written to the

EEPROM.

DVD Dual Layer Disc Adjustment Steps

1. Sled Reset

2. Disc Check Memory DL

3. Wait 500 msec

4. Set Disc Type DL

5. LD ON

6. Spdl Start

7. Wait 1 sec, Layer 1 Adjust

8. Focus Servo ON 1

9. Clva ON

10. Wait 500 msec

11. Auto Track Offset Adjust

12. Tracking ON

13. Wait 1 sec

14. Sled ON

15. Check CLV Lock

16. Auto Loop Filter Offset Adjust

17. FSGain (Focus Balance) Adjust

18. Auto Focus Gain Adjust

19. Auto Focus Offset Adjust

20. Eq Boost Adjust

21. Auto Loop Filter Offset

22. Auto Track Gain Adjust

23. Fj (L1 → L0)

24. Clva ON

25. Wait 500 msec

26. Auto Track Offset Adjust L0

27. Tracking ON

28. Wait 1 sec

29. Sled ON

30. Check CLV Lock

31. Auto Loop Filter Offset Adjust

32. FSGain (Focus Balance) Adjust

33. Auto Focus Gain Adjust

34. Auto Focus Offset Adjust

35. Eq Boost Adjust

36. Auto Loop Filter Offset

37. Auto Track Gain Adjust

38. All Servo Stop

4. SACD (SACD hybrid layer)

Select 4 “R” , insert the SACD disc, and press the ENTER “R”

key , and the adjustment will be made through the follo wing steps,

then adjusted values will be written to the EEPROM. However, if

the SACD hybrid layer disc is not available, use the player with

initial data, skipping the SACD adjustment. In this case, you can

finish the adjustment if pressing the x “R” button.

SACD Adjustment Steps

1. Sled Reset

2. Set Disc Type SACD (Hybrid Layer)

3. LD ON

4. Spdl Start

5. Wait 1 sec

6. Focus Servo ON 1

7. Auto track Offset Adjust

8. Tracking ON

9. CLVA ON

10. Wait 1 sec

11. Sled ON

12. Check CLV ON

13. Auto LFO Adjust

14. Auto Focus Offset Adjust

15. Auto Focus Gain Adjust

16. Auto Focus Offset Adjust

17. Eq Boost Adjust

18. Auto LFO Adjust

19. Auto Track Gain Adjust

20. All Servo Stop

5. CD-RW (CD-RW)

Select 5 “R” , insert the CD-RW disc, and press the ENTER “R”

key , and the adjustment will be made through the follo wing steps,

then adjusted values will be written to the EEPROM. However, if

the CD-RW disc is not available, use the player with initial data,

skipping the CD-RW adjustment. In this case, you can finish the

adjustment if pressing the x “R” button.

CD-RW Adjustment Steps

1. Sled Rest

2. Disc Check Memory CD-RW

3. Wait 500 msec

4. Set Disc Type CD-RW

5. LD ON

6. Spdl Start

7. Wait 1 sec

8. Focus Servo ON 0

9. CLVA ON

10. Wait 500 msec

11. Auto Track Offset Adjust

12. Tracking ON

13. (TC Display Start)

14. CLVA ON

15. Wait 1 sec

16. Jitter Display Start

17. Sled ON

18. Check CLV ON

19. Auto LFO Adjust

20. Auto Focus Offset Adjust

21. Auto Focus Gain Adjust

22. Auto Focus Offset Adjust

23. Eq Boost Adjust

24. Auto LFO Adjust

25. Auto Track Gain Adjust

26. All Servo Stop

15

D-VM1

4-5. DRIVE MANUAL OPERATION

On the Test Mode Menu screen, select 2 “R” , and the Manual

operation menu will be displayed. For the Manual operation, each

servo on/off control and adjustment can be executed manually.

## Drive Manual Operation ##

1. Disc type

2. Servo Control

3. Track/Layer Jump

4. Manual Adjustment

5. Auto Adjustment

6. Memory Check

9. Disc Speed Change

0. Disc Check Memory

Operation Menu

In using the Manual operation menu, take care of the following

points. These commands do not provide protection, thus requiring

correct operation. The sector address or time code field is displayed when a disc is loaded.

1. Set correctly the disc type to be used on the Disc Type screen.

The disc type must be set after a disc was loaded. The set disc

type is cleared when the tray is opened.

2. After power ON, if the Drive Manual Operation was selected,

first perform Reset SLED TIL T by opening 1. Disc T ype screen.

3. In case of an alarm, immediately press the x “R” button to

stop the servo operation, and turn the power OFF.

Basic operation (controllable from front panel or remote

commander)

x (by pressing and holding) Power OFF

“R” Servo stop

x , x

RETURN “R” Return to Operation Menu or Test

Mode Menu

NEXT “R” , PREV “R” Transition between sub modes of

menu

1 “R” to 9 “R” , 0 “R” Selection of menu items

“R” , ↓ “R” Increase/Decrease in manually ad-

↑

justed value

0. Disc Check Memory

Disc Check

1. SL Disc Check

2. CD Disc Check

3. DL Disc Check

4. Disc EX

0. Reset SLED TILT

On this screen, the mirror time is measured to judge the disc and it

is written to the EEPROM. 4. Disc Ex is not used. First load D VDSL disc and press 1 “R” , next load CD disc and press 2 “R” ,

and finally load DVD-DL disc and press 3 “R” .

The adjustment must be executed more than once after default

data were written. External vibration or shock to the player must

not be given. Reference value for DVD is from 28 to 3f, and for

CD, from 50 to 6F.

Check that the value of CD is larger than that of DVD .

When those values are beyond a range, perform this adjustment

again.

From this screen, you can go to another mode by pressing the

NEXT “R” or PREV “R” key, but you cannot enter this mode

from another mode. You can enter this mode from the Operation

Menu screen only.

1. Disc Type

1. Disc Type Auto Check

[DVD SL] 2.

[DVD DL] 3.

[CD] 4.

[SACD] 5.

[CD-RW] Up.

[DVD-R] Ag.

[DVD RW] ST.

[DRW-HG] L.

0. Reset SLED TILT

DVD SL 12 cm

12 cm

12 cm

12cm

12 cm

12 cm

12 cm

12 cm

12 cm

SA. ------ SI. -- EMG. 00

6.

7.

8.

9.

Dw.

Pg.

Rp.

R.

8 cm

8 cm

8 cm

8 cm

8 cm

8 cm

8 cm

8 cm

16

On this screen, select the disc type. To select the disc type, press

the number of the loaded disc. The selected disc type is displayed

at the bottom. Selecting 1 “R” automatically selects and displays

the disc type. Note that the DVD-R and DVD-RW disc types are

displayed as the DVD-SL type by the disc type auto check. If any

disc type other than DVD-R and DVD-RW is not displayed correctly , retry Disc Check Memory . If you try the Manual operation,

be sure to specify the disc type. Never select the DRW-HG disc

type. If the DRW-HG mode is selected from any other disc types

other than DRW-HG while the LD (laser diode) turns on, it may

cause damage of LD (laser diode) in the worst case. Once the disc

type has been selected, the sector address or time code display

field will appear as shown belo w . These values are displayed when

PLL is locked.

D-VM1

Display when DVD SL 12cm disc was selected

1. Disc Type Auto Check

[DVD SL] 2.

[DVD DL] 3.

[CD] 4.

[SACD] 5.

[CD-RW] Up.

[DVD-R] Ag.

[DVD RW] ST.

[DRW-HG] L.

0. Reset SLED TILT

DVD SL 12 cm

12 cm

12 cm

12cm

12 cm

12 cm

12 cm

12 cm

12 cm

SA. ------ SI. -- EMG. 00

6.

7.

8.

9.

Dw.

Pg.

Rp.

R.

8 cm

8 cm

8 cm

8 cm

8 cm

8 cm

8 cm

8 cm

Display when CD 12cm disc was selected

1. Disc Type Auto Check

[DVD SL] 2.

[DVD DL] 3.

[CD] 4.

[SACD] 5.

[CD-RW] Up.

[DVD-R] Ag.

[DVD RW] ST.

[DRW-HG] L.

0. Reset SLED TILT

CD 12cm

12 cm

12 cm

12cm

12 cm

12 cm

12 cm

12 cm

12 cm

TC.--:--:-- EMG. 00

6.

7.

8.

9.

Dw.

Pg.

Rp.

R.

8 cm

8 cm

8 cm

8 cm

8 cm

8 cm

8 cm

8 cm

Select the desired disc type with the following buttons.

0 “R” Reset SLED TILT Resets the Sled to the initial position.

(When the Manual operation menu is selected, perform

this first.)

1 “R” Disc Type Check Judges automatically the loaded

disc. As the judged result is displayed

at the bottom of screen, make sure

that it is correct. Note that the DVDR and DVD-RW disc types are displayed as the DVD-SL type by the

disc type auto check.

If Disc Check Memory menu has not

been executed after EEPROM default

setting, be careful because the disc

type cannot be judged. In this case,

return to the initial menu and make a

check for three types of discs (SL,

DL, CD).

2 “R” to 9 “R” ,

↑ “R” , ↓ “R” ,

ANGLE “R” (Ag),

PROGRAM “R” (Pg),

Select the loaded disc. The adjusted

value is written to the address of selected disc. No further entry is nec-

essary if 1 “R” was selected.

SUB TITLE “R” (ST),

REPEAT “R” (Rp)

← “R” , → “R” If you make any mistake in opera-

tion, LD may be damaged. Do not

select the DRW-HG disc type by

pressing ← “R” or → “R” . Do not

select it.

2. Servo Control

1. LD Off R.Sled FWD

2. SP Off L.Sled REV

3. Focus Off

4. TRK. Off

5. Sled Off 0.Reset

6. CLVA Off

7. FCS. Srch

8. FCS GU.Off

9. TRK GU. on

SHF. Sld Im on

DVD SL 12 cm

Servo Control

SLED Pos

Off

SA. ------ SI. -- EMG. 00

On this screen, the servo on/off control necessary for replay is

executed. Normally, turn on each servo from 1 sequentially and

when CL VA turns on, the usual trace mode becomes active. In the

trace mode, DVD sector address or CD time code is displayed.

This is not displayed where the spindle is not locked.

The spindle could run overriding the control if the spindle system

is faulty or RF is not present. In such a case, do not operate CL VA.

Buttons used in servo control

0 “R” Reset SLED TILT Resets the Sled and Tilt to the

initial position.

1 “R” LD Turns ON/OFF the laser.

2 “R” SP Turns ON/OFF the spindle.

3 “R” Focus Searches the focus and turns on

the focus.

4 “R” TRK. Turns ON/OFF the tracking

servo.

5 “R” Sled Turns ON/OFF the sled servo.

6 “R” CLVA Turns ON/OFF the normal

servo of the spindle servo.

7 “R” FCS. Srch Applies the same voltage as

that of the focus search to the

focus drive to check the focus

drive system.

8 “R” to 9 “R” , SHUFFLE “R” Do not use them.

→

“R” Sled FWD Moves the sled in the direction

of the outer circumference.

Perform this operation with the

tracking servo turned off.

←

“R” Sled REV Moves the sled in the direction

of the inner circumference.

Perform this operation with the

tracking servo turned off.

The following menus are normally not used.

3. Track/Layer Jump

4. Manual Adjustment

5. Auto Adjustment

The persons who do not know well about these menus should not

use them.

17

D-VM1

2

6. Memory Check

EEPROM Data1 -– CD –- -–

ID No.XX

Fcs Gain

TRK. Gain xx xx xx

Fcs Offset xx xx xx

TRK. Offset xx xx xx

L. F. Offset xx xx xx

Alog FRSW xx xx xx

PLL DAC-G xx xx xx

EQ Boost xx xx xx

Jitter xx xx xxxx xx xx

Mirr Time xx xxxx

_ CLEAR: Default Set

SCD RW SL L0 L1

xx xx xx

xx xx xx

xx xx xx

xx xx xx

xx xx xx

xx xx xx

xx xx xx

xx xx xx

DVD –-

xx xx xx

This screen displays current servo adjusted data stored in the

EEPROM. Though the adjusted data can be initialized with the

CLEAR “R”

key, they cannot be restored after initialization.

So, before clearing, make a note of the adjusted data.

For reference, the drive has been designed so that the gain center

value is 20 and the offset value is 80. Other values will be in a

range of 10 to 80. If an extreme value such as 00 or FF is set,

adjustment will be faulty . In such a case, check for disc scratch or

cable disconnection, then perform adjustment again.

9. Disc Speed Change

The persons who do not know well about these menus should not

use them.

4-7. EMERGENCY HISTORY

### EMG. History ###

Laser Hours

Temperature

1. 00 00 00 00 00 00 00 00

00 00 00 00 00 00 00 00

2. 00 00 00 00 00 00 00 00

00 00 00 00 00 00 00 00

Select: 1 – 9 Scroll: UP/DOWN

(1: Last EMG.) Exit: RETURN

On the Test Mode Menu screen, selecting 4 “R” displays the

information such as servo emergency history. The history information from last 1 up to 10 can be scrolled with the ↑ “R” key

or ↓ “R” key. Also, specific information can be displayed by

directly entering that number with ten keys. The upper two lines

display the laser ON total hours. Data below minutes are omitted.

Clearing History Information

• Clearing laser hours

Press DISPLAY “R” and CLEAR “R” keys in this order.

Both CD and DVD data are cleared.

• Clearing emergency history

Press TOP MENU “R” and CLEAR “R” keys in this order.

CD xxxxxxxh

DVD xxxxxxxh

x

4-6. MECHA AGING

### Mecha Aging ###

0. Exec.Times.. 0

1. Sled Move1..

2. Sled Move2..

3. Spdl Slowdouwn

4. Err Cancel

Play or ENTER:aging start

On the Test Mode Men u Screen, selecting 3 “R” executes the

aging of the mechanism. Press the x “R” key or RETURN “R”

key to return to the Test Mode Menu. The persons who do not

know well about these menus should not use them.

MENU

on

on

on

on

45000

Exit:RETURN

• Initializing set up data

Press MENU “R” and CLEAR “R” keys in this order.

The data have been initialized when “Set Up Initialized” message is displayed. The EMG. History screen will be restored

soon.

How to see Emergency History

1

3

2

1.

1 : Emergency Code

2 : Do not care

These codes are used for verification of software designing.

3 : Historical order 1 to 9

18

D-VM1

1.0 ± 0.02 Vp-p

Emergency Codes List

10: Communication to IC001 (RF-240 board) failed.

11: Each servo for focus, tracking, and spindle is unlocked.

12: Communication to EEPROM and IC1102 failed.

13: Writing of hours meter data to EEPROM and IC1102 failed.

14: Communication to Servo DSP and IC701 failed, or Servo DSP

is faulty.

20: Initialization of tilt servo and sled servo failed. They are not

placed in the initial position.

21: Tilt servo operation error

22: Syscon made a request to move the tilt servo to wrong posi-

tion.

23: Sled servo operation error

24: Syscon made a request to move the sled servo to wrong posi-

tion.

30: Tracking balance adjustment error

31: Tracking gain adjustment error

32: Focus balance adjustment error

33: Focus bias adjustment error

34: Focus gain adjustment error

35: Tilt servo adjustment error

36: RF equalizer adjustment error

37: RF group delay adjustment error

38: Jitter value after adaptive servo operation is too large.

40: Focus servo does not operate.

41: With a dual layer (DL) disc, focus jump failed.

50: CLV (spindle) servo does not operate.

51: Spindle does not stop.

60: With a DVD disc, Syscon made a request to seek nonexistent

address.

61: With a CD disc, Syscon made a request to seek nonexistent

address.

62: With a CD disc, Syscon made a request to seek nonexistent

track No.

63: With a DVD disc, seeking of target address failed.

64: With a CD disc, seeking of target address failed.

65: With a CD disc, seeking of target index failed.

70: W ith a DVD disc, ph ysical information data could not be read.

71: With a CD disc, TOC data could not be read.

80: Disc type judgment failed.

81: As disc type judgment failed, retry was repeated.

82: As disc type judgment failed, a measurement error occurred.

83: Disc type could not be judged within the specified time.

84: Illegal command code was received from Syscon.

85: Illegal command was received from Syscon.

90: EEPROM checksum error

A0: Power was turned off due to temperature rise.

4-8. VERSION INFORMATION

4-9. VIDEO LEVEL ADJUSTMENT

On the Test Mode Menu screen, selecting 6 “R” displays color

bars for video level adjustment. During display of color bars, OSD

disappears but the menu screen will be restored if pressing any

key.

Measurement point : VIDEO OUT terminal (75Ω terminating

resistance)(AV output adapter)

Measuring instrument : Oscilloscope

Adjustment device : RV901 on MAIN board

Specified value : 1.0 ± 0.02 Vp-p

4-10. EVR/MON ADJUSTMENT

When you select 7 “R” on the Test Mode Menu screen, the screen

displays the 3.5/5-inch monitor adjustment menu. Press the

RETURN “R” key to return to the Test Mode Men u screen.

4-11. Power (Charge) Test Mode

4-11-1. ITEMS THAT CAN BE CONFIRMED BY THE

POWER (CHARGE) TEST MODE

• Battery voltage level

• DC IN voltage level

• Battery chargeable voltage or non-chargeable voltage judgment

status

• Charge end memory status

4-11-2. HOW TO START THE POWER (CHARGE) TEST

MODE

Conditions : DC IN status

Power off status

OPEN B knob is in the CLOSE status

(Close the disc lid.)

HOLD . switch is in the ON status

AVLS switch is in the LIMIT status

Operations :

1. While pressing the u and V OL+ buttons at the same time,

slide the OPEN B knob to open the lid, and change the AVLS

switch to NORMAL.

## Version Information ##

IF con. Ver: x. xxx (xxxx)

Group 00

SYScon. Ver: x. xxx (xxxx)

Model xx

Region 0x

Servo DSP Ver:1.XXX

Exit: RETURN

On the Test Mode Menu screen, selecting 5 “R” displays the

ROM version and region code.

The parenthesized hexadecimal number in version field is

checksum value of ROM.

2. If the Test Mode star ts once, you do not need to keep pressing

the u and VOL+ buttons. You may close the lid of the

disc.

4-11-3. HOW TO CANCEL POWER (CHARGE) TEST

MODE

Turning off the power (turning off the DC IN) cancels the power

test mode.

19

D-VM1

)

4-11-4. START-UP CONFIRMATION DISPLAY OF POWER (CHARGE) TEST MODE

• Main unit LED display :

CHG

(Orange LED)

POWER

(Green LED or Red LED

• On the CHG LED (orange LED)

While detecting the charging status (6 hours or 1 minutes) : LED turns on.

While detecting the request of the non-chargeable voltage display : LED flashes at every second

(turns on 0.5 seconds and flashes for 0.5 seconds).

While detecting the charge-display-end status and detecting : LED flashes every 0.2 seconds indicating that the system is in the charg

the non-charge status at the same time ing (power) status check mode (turns on 0.1 second and turns off 0.1

second).

• About POWER LED

Green LED turns on (for 1 second).

Red LED turns on (for 1 second).

POWER LED turns off (for 1 second).

Repeats flashing indicating that

the system is in the stand by status.

4-11-5. DISPLAY OF CHECK ITEMS

• Contents of the display item can be checked by pressing the following buttons after the power (charge) test mode has started up.

Table 1. Button operations and corresponding display items

Display items Button operation

Battery voltage level check

DC IN voltage level check

Battery voltage chargeability non-judgment status check VOL

Charge completion memory status check VOL

Note: Each button must be kept pressing while the display is shown on screen.

>

.

+

–

• Status of the machine corresponding to each display item can be known from the LED display.

• The display of CHG LED (orange LED) is the same as the aforementioned.

Table 2. Machine status corresponding to the display item and the Power LED display of main unit

Display item

Battery voltage level

check

DC IN voltage level

check

Battery chargeable

voltage or nonchargeable voltage

judgment status check

Charge-display-end

memory status check

Machine status corresponding to the display item

High battery voltage (9.5 V or higher)

Operation is possible (from 8.10 V or higher to less than 9.50 V)

Operation is possible (7.75 V or higher to less than 8.10 V)

Operation is possible (7.45 V or higher to less than 7.75 V)

Operation is possible (7.00 V or higher to less than 7.45 V)

Operation is possible (6.40 V or higher to less than 7.00 V)

Low battery voltage STOP (6.00 V or higher to less than 6.40 V)

Low battery voltage (less than 6.00 V)

High DC IN voltage (less than 11.50 V)

Charge is possible (8.60 V or higher to less than 11.50 V)

Low DC IN and unable to charge (less than 8.60 V)

High battery voltage (8.70 V or higher)

Under charging (6.00 V or higher to less than 8.70 V)

Charge stand-by (6.00 V or higher to less than 8.70 V)

Low battery voltage (less than 6.00 V)

Charge end memory status non-memorized status

Charge end memory status memorized status

Main unit power LED display

Red LED turns on.

Green LED turns on.

Green LED turns on 0.5 seconds and turns off 0.5 seconds.

Green LED turns on 0.1 seconds and turns off 0.1 seconds.

Green LED turns on 0.5 seconds and red LED turns on 0.5

seconds.

Green LED turns on 0.1 seconds and red LED turns on 0.1

seconds.

Green LED turns on 0.1 seconds. Red LED turns on 0.1

seconds and turns off 0.1 seconds.

Red LED turns on 0.5 seconds and turns off 0.5 seconds.

Red LED turns on.

Green LED turns on.

Red LED turns on 0.5 seconds and turns off 0.5 seconds.

Red LED turns on.

Green LED turns on.

Green LED turns on 0.5 seconds and turns off 0.5 seconds.

Red LED turns on 0.5 seconds and turns off 0.5 seconds.

Green LED turns on 0.5 seconds and turns off 0.5 seconds.

Green LED turns on.

20

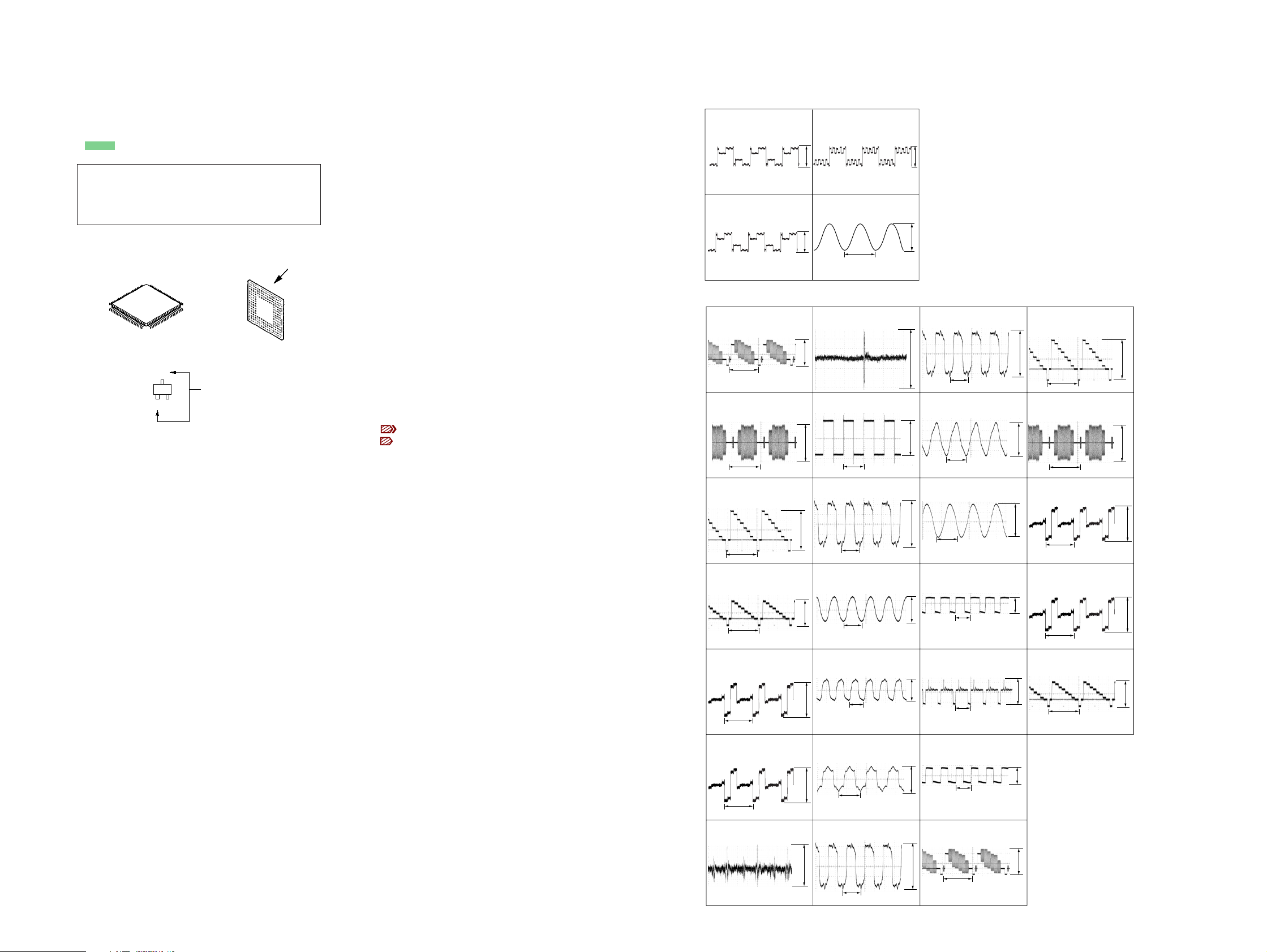

SECTION 5

DIAGRAMS

NOTE FOR PRINTED WIRING BOARDS AND SCHEMATIC DIAGRAMS • WAVEFORMS

TFT BOARD

Note on Printed Wiring Board

• X : parts extracted from the component side.

• Y : parts extracted from the conductor side.

• : Pattern from the side which enables seeing.

(The other layers' patterns are not indicated.)

Caution:

Pattern face side: Parts on the pattern face side seen from

(Side A) the pattern face are indicated.

Parts face side: Parts on the parts face side seen from

(Side B) the parts face are indicated.

* Replacement of IC902, IC1002 used in this set requires a special

tool.

• Lead Layouts

Lead layout of

conventional IC

C

Q

B

E

• MAIN board and TFT board consist of multiple layers.

However, only the sides (layers) A and B are shown.

CSP (chip size package)

These are omitted.

surface

Note on Schematic Diagram:

• All capacitors are in µF unless otherwise noted. pF: µµF 50

WV or less are not indicated except for electrolytics and

tantalums.

• All resistors are in Ω and

fied.

• % : indicates tolerance.

f

•

• 5 : fusible resistor.

• C : panel designation.

• A : B+ Line.

• Power voltage is dc 10 V and fed with regulated dc power

• Voltages and waveforms are dc with respect to ground in play-

• Voltages are taken with a VOM (Input impedance 10 MΩ).

• Waveforms are taken with a oscilloscope.

• Circled numbers refer to waveforms.

• Signal path.

* Replacement of IC902, IC1002 used in this set requires a

• The voltage and waveform of CSP (chip size package) can-

: internal component.

supply from DC IN jack (J401).

back mode.

no mark : DVD PLAY

: Impossible to measure

∗

Voltage variations may be noted due to normal production

tolerances.

Voltage variations may be noted due to normal production

tolerances.

J : CD

c : DVD

a : Y

: B-Y

: R-Y

special tool.

not be measured, because its lead layout is different from

that of conventional IC.

1

4

/

W or less unless otherwise speci-

1

IC1404 eh (G OUT)

[Test Mode Color Bar]

2

IC1404 ef (R OUT)

[Test Mode Color Bar]

MAIN BOARD

1

TP1049 (V OUT)

[Test Mode Color Bar]

H

2

TP1050 (C OUT)

[Color Bar]

H

3

TP1051 (Y OUT)

[Color Bar]

870 mVp-p

9.9 Vp-p

9.9 Vp-p

1.3 Vp-p

3

IC1404 es (B OUT)

[Test Mode Color Bar]

4

IC1404 wa (CKO)

44 Ns

8

TP629 (TE)

9

IC1602 3 (CLK)

5.4

µ

sec

q;

IC1101 4 (MO3)

10 Vp-p

3.9 Vp-p

1.3 Vp-p

3.2 Vp-p

qg

IC1101 wf (MO2)

37 ns

qh

IC1104 td (X1)

80 nsec

qj

IC2002 wl (XOUT)

4.6 Vp-p

3.9 Vp-p

ws

TP502 (S1)

H

wd

TP503 (S2)

wf

TP530 (R-Y)

D-VM1

2.4 Vp-p

2.0 Vp-p

H

H

H

4

TP1052 (Y-G)

[Test Mode Color Bar]

H

5

TP1053 (CR-B)

[Test Mode Color Bar]

H

6

TP1054 (CB-R)

[Test Mode Color Bar]

H

7

TP628 (FE)

1.1 Vp-p

1.1 Vp-p

800 mVp-p

800 mVp-p

37 nsec

qa

IC1101 9 (XO)

37 nsec

qs

IC1101 qs (SO1)

30 nsec

qd

IC1101 qh (SO3)

41 nsec

qf

IC1101 w; (SO2)

5.7 Vp-p

4.0 Vp-p

3.9 Vp-p

4.3 Vp-p

238 nsec

qk

TP405 3 (OUT-4)

2.2

µ

sec

ql

IC405 eh (OUT-1)

2.2 µsec

w;

IC405 ra (OUT-2)

2.2 µsec

wa

TP501 (C OUT)

3.4 Vp-p

750 mV

1.3 Vp-p

740 mV

H

wg

TP514 (B-Y)

H

wh

TP537 (Y)

740 mVp-p

740 mVp-p

390 mVp-p

H

2.7 Vp-p

330 mVp-p

54 ns

4.1 Vp-p

H

2121

D-VM1

5-1. BLOCK DIAGRAM – RF/SERVO SECTION –

OPTICAL PICK-UP BLOCK

B(DVD)

A(DVD)

D(DVD)

C(DVD)

DVDLD

PDDVDPD

• Signal Path

: DVD

: CD

: Y

: B-Y

: R-Y

M901

SLED

MOTOR

SPINDLE

MOTOR

SWITCH

VCC

V/2

V/2

E(CD)

F(CD)

C(CD)

B(CD)

A(CD)

CDPD

CDLD

TR–

TR+

FE–

FE+

INLIM

IC1602(1/2)

IC601

RF

SSCK

SSWD

SSRD

SSCS

PWM0

PWM1

FO+

FOTO+

TO-

IC1601

OSC

27

26

19

21

22

23

41

34

45

46

47

48

39

73

72

44

32

55

5

MIRR

TZC

PI_AVE

PI

FE

TE

SSDFCT

SSDFCTI

SSCK

SSWD

SSRD

SSCS

PICAN

SLDA

SLDB

INLIM

FGIN

FGMODE

B

13

A

14

D

11

C

12

6

A5V

SLD–

APCHG

CD-RW

L605

TOTO+

FOFO+

Q602

LD

SWITCH

SWITCH

SWITCH

SWITCH

Q603

CD-LD

DRIVE

Q610

Q601

Q609

28

Q608

AMP

CD-RWDSP

A5V

IC1602(2/2)

SLED MOTOR

DRIVE

OUT 3B

B2

5

A2

D2

8

C2

7

DVDLD

22

DVDPD

21

26

VC

VC

CDTE

17

16

E

15

F

CDRF

63

PD2

4

3

PD1

23

CDPD

CDLD

24

21

ERR3

M

SLD+

30

OUT 3A

IC1603

SPINDLE DRIVE

45

UOUT

43

VOUT

41

WOUT

2

COM

OE

BRAKE

VCONT

FG

S/S

4

13

14

18

12

XRST

XRST

D1601

XDRIVEMUTE

SCLK

SDATA

SDEN

ATOP

ATON

AIN

AIP

SIGO

VC1

LDON

MIRR

TZC

MIN

FDCHG

DFT

HOLD2

HOLD1

XRST

PI

FE

TE

46

47

48

62

61

60

59

57

27

25

29

39

36

42

41

35

32

37

45

49

IC603(2/2)

7

Q604,606

BUFFER

1

6

VR

5

Q1601

MUTE

IC1606(1/2)

7

IC1606(2/2)

Q605

LDON

SWITCH

Q607

6

5

2

3

CLVMUTE

INV

SSCK

SSDATA

SSCS

XDOPEN

MDP0

MDSO

FOCUS/TRACKING

COIL DRIVE

7

OUT1A

9

OUT1B

12

OUT2A

OUT1B

10

CLK

3

IC701

SDSP

ERR1

ERR2

FCD–

FCD+

TRD–

TRD+

VRTA

VRBA

VC

ADC6

MDP

SE

HD8

HD15

HA0

HA1

XSDPRD0

XSDPWR0

XSDPCS

XSDPIT

XRST

LOCK

N27MSDP

IC1605(1/2)

2

FCD–

FCD+

3

6

TRD–

TRD+

5

1

D3V

3

2VC

1

FCD–

FCD+

TRD–

TRD+

VC

3

2

5

6

MA0-9

VR

3VC

1VC

HD8-HD12

HD13

HD14

HD15

1

IC1605(2/2)

7

IC702

4

IC603(1/2)

3

2

IC602

1

7

16

15

1

3

5

7

9

13

16

17

18

20

90

86

84

83

82

81

80

79

78

77

76

68

31

95

IC1003

DRAM ARP

A0

21

24

27

32

DQ1

2

5

7

A9

DQ16

XWE

XOE

XRAS

XCASH

XCASL

10

41

44

46

49

17

33

18

34

35

MD00-15

MDP0

MDS0

HD8-HD13

HD14

HD15

HA0-HA3

HA4-HA7

154

157

159

162

164

167

169

172

148

152

151

150

17

19

52

49

58

63

68

70

71

73

76

79

82

61

60

VCC

MD0

MD15

XMWR

XOE

XRAS

XCAS

RFIN1

RFIN2

MDP0

MDS0

LOCK

D0

D7

A0

A7

XRD

IC1002

IC1004

RIPPLE FILTER

5

1

3

MA0

MA9

SD0

SD7

DATA

DOUT

BCLK

LRCK

SDEF

XSAK

XSRQ

XSHD

SDCK

XWAT

SCKI

MCKI

XRST

XCS

XINTXWR

136

139

141

144

146

147

97

98

100

105

107

110

108

109

96

95

94

93

91

86

123

121

87

84

83

Q1001

SWITCH

MA0-9

D1101

XRST

A3V

APCHG, CD-RW, XDOPEN

SD0 - 7

CDDATA

CDDOUT

CDBCK

CDLRCK

SDEF

XSAK

XSRQ

XSHD

SDCK

AVWT

AVWT

33MARP

XARPRST

XARPCS

XARPIT

XDRIVEMUTE

HD8-HD15

HA0-HA7

RD

WRH

XSDSPCS

XSDPIT

XRST

27MSDP

A

TO

A/V DEC.

SYSTEM CONTROL

BLOCK

2222

– A/V, SYSCON SECTION –

D-VM1

TO

RF,

SERVO

BLOCK

IC902

A/V DEC.

ACH12

ACH34

ACH56

TO

AUDIO

C

BLOCK

SD0 - 7

CDDATA

CDDOUT

CDBCK

CDLRCK

SDEF

XSAK

XSRQ

XSHD

SDCK

AVWT

AVWT

A

33MARP

XARPRST

XARPCS

XARINT

XDRIVEMUTE

HD8-HD15

APCHG, CD-RW, XDOPEN

HA0-HA7

RD

WRH

XSDSPCS

XSDPIT

XRST

27MSDP

SCLK

LRCK

384FS

HD0-HD15

14

15

16

19

18

31

34

36

39

23

22

25

26

43

45

46

44

41

224

220

221

122

231

232

235

237

240

2

5

7

10

ACH12

ACH34

ACH56

BCK0

LRCK0

DTI0

DTI7

CDIN1I

CDIN2I

CDBCKI

CDLRCKI

IERRI

IVALI

IREQ0

ISTARTI

ICLKI

HWAIT

HCSB

HRWB

TRST

RSTB

HD0

HD15

COMPOUT

YOUT

COUT

G OUT

B OUT/R-Y

R OUT/B-Y

SDD0

SDD15

SDCSO

SDDQMO

SDWEO

SDCASO

SDRASO

SAD0

SAD11

SDDQM1

SDCLK0

SDCK0

SDCS1

HA0

HA21

DMREQ0

DMACK0

DMREQ1

DMACK1

HIREQ0

HA22

HA23

SCLKI

CLKI

CRPCLKI

ACLK

80

74

77

20

D0

69

66

63

157

177

144

155

152

151

147

124

140

154

149

146

143

192-193

195-198

200-203

205-208

210-213

215-218

229

228

227

226

223

191

190

182

180

29

12

HD0-HD15

LDQM

XWE

XCAS

XRAS

UDQM

CLK

CKE

HA0-HA21

DREQ1

DACK1

DREQ0

DACK0

AVINT

XAVDCS3

XAVDCS2

27MAVD

33MAVD

512FSAVD

WIDE

V_OUT

Y_OUT

C_OUT

SPDIF1

Y-G

CR-B

CB-R

DT0-DT15

AD0-AD11

DT0-DT15

TO

VIDEO OUT,IF-COM

B

BLOCK

DO0

2

12

39

49

DO15

18

XCS

LDQM

14

XWE

15

16

XCAS

17

XRAS

2

DO0

12

39

DO15

49

LDQM

14

XWE

15

16

XCAS

17

XRAS

18

XCS

IC901

SDRAM

IC903

SDRAM

A11

UDQM

CLK

CKE

A11

UDQM

CLK

CKE

HD0-HD15

IC1104

SYSTEM CONTROL

WRH

EEPROM

8

XWC

3

XCS

1

R/XB

XDOPEN

APCHG

CD_RW

X1101

IC1102

RD

DO

DI

XSK

6

5

4

IC1104

VCC

XFRON

XSLPWR

WIDE

DREQ1

DACK1

DREQ0

DACK0

AVINT

XAVDCS3

XAVDCS2

8

HA0

102

109

111

118

120

1

5

HA21

HD0

85

100

HD15

79

XWAIT

22

XARPRST

69

CS4X

26

INT1

82

RD

83

WRH

18

XSDPCS

32

INT7

16

XRST

DREQ1

46

DACK1

47

DREQ0

43

DACK0

44

25

INT0

68

CS3X

67

CS2X

23

XDRIVEMUTE

61

44.1/48K

23

FSEL

24

MO2

12

SO1

SO3

16

MO3

4

SO2

20

IC1101

PLL

CS0X

INT6

SO2

SI2

SCLKFR

SIFR

SOFR

EWC

ECS

INT3

XIFCS

INT4

(RAS0)

XFRST

FPSLP

FRWAKE

INT2

XDOPEN

APCHG

CD_RW

SO1

SC1

VPCS

XDACRST

CHMOD

VRCS

MAMUTE

VPMODE

XDACCS

XVPRST

INT5

XO

XO

XI

65

31

41

40

36

35

33

48

49

28

45

29

56

74

7

17

27

20

63

21

38

39

50

51

59

60

62

42

57

58

30

53

XI

12.5MHz

54

9

X1102

27MHz

8

19

A0

24

27

32

36

35

34

19

A0

24

27

32

36

35

34

AD0-AD11

AD0-AD11

HA0-HA21

HD0-HD15

AVWT

XARPRST

CS4XINT3

XARPIT

XSDPIT

XRST

XSDPCS

27MAVD

33MAVD

512FSAVD

384FS

IC1105

16M FLASH MEMORY

29

D0

A1

36

38

45

D15

XWE

11

28

XOE

26

XCE

15

A17

RY

SCLKFR

XIFREQ

XFRST

FPSLP

FRWAKE

XVOLEMG

XDOPEN

XSLPWR

XFRON

XDACRST

CHMOD

MAMUTE

VPMODE

XDACCS

XVPRST

Q1101

SWITCH

Q1102

SWITCH

SOFR

SIFR

XIFCS

IMTR

SO1

SC1

VPCS

VRCS

INT5

25

16

9

1

48

CN1101

TXD

RXD

FOR

DIAG

JIG

1

2

F

TO

VIDEO OUT

IF-COM

BLOCK

E

TO VIDEO OUT,

IF-COM BLOCK,

AUDIO BLOCK

D

TO

AUDIO

BLOCK

D3V

EV3V

• Signal Path

: DVD

: CD

: Y

: B-Y

: R-Y

2323

D-VM1

– AUDIO SECTION –

TO

A/V DEC.

SYSTEM CONTROL

BLOCK

TO

A/V DEC.

SYSTEM CONTROL

BLOCK

TO

A/V DEC.

SYSTEM CONTROL

BLOCK

C

E

D

ACH12

ACH34

ACH56

384FS

LRCK

SCLK

SC1

SO1

CHMOD

VPCS

XVPRST

INT5

XDACCS

XDACRST

VRCS

MAMUTE

VPMODE

IC1202

24

20

19

18

34

5

7

4

6

26

24

1

3

16

23

29

27

3

1

4

2

7

8

6

5

15

IC1201

AUDIO DSP

SDI0

SDI1

SDI2

EXTAL

FSR

SCKR

FST

SCKT

SCK

MOSI

MODD

MODA

PC10

SS

XRESET

HREQ

DATA

MCLK

LRCK

SCLK

SC1

SO1

DACCS

DACRST

MUTE

SD00

IC301

AUDIO DAC

IC304

LINE AMP

14

Q101,

201

SW

IC303

AMP

R+

10

R–

9

L+

12

L–

11

5

7

6

3

1

2

Q102,

202

SW

5

7

Q103,203

MUTE

3

1

IC305

EVR

5

7

H0

10

H1

13

CLK

12

DATA

3

XRST

W0

W1

8

5

6

3

2

IC306

BUFFER

A3V

7

1

D304

Q310,311

VCC

SWITCH

Q307

SWITCH

22

20

23

21

17

13

IC308

HP AMP

INR

VCC1

VCC2

INL

MUTESW

C-AMPSW

OUT-R

BEEPOUT-R

OUT-C

OUT-L

BEEPOUT-L

PWSW

1

24

4

6

7

18

LINER

LINEL

HPL

HPCOM

HPR

I

TO

VIDEO OUT,

IF-COM

BLOCK

H

TO

VIDEO OUT,

IF-COM

BLOCK

J302

PHONES

• Signal Path

: DVD

: CD

: Y

: B-Y

: R-Y

Q302

INV.

Q301

INV.

D301

D303

Q304

SW

Q303

INV.

D3V IR3V

MUTE SW

Q305

A5V

IC309

RIPPLE FILTER

1

IC302

–5V SUPPLY

V+

5

OUT

5

2

IC301,IC303,304

VCC

L303

-5V

Q308

SW

Q306

SW

16

BEEPIN

HPCNT

BEEP

RSTMUTE

BEEPON

XHPMUTE

XAMUTE

G

TO

VIDEO OUT,

IF-COM

BLOCK

2424

Loading...

Loading...