D-V55

SERVICE MANUAL

Ver 1.0 1999.05

SPECIFICATIONS

E Model

Chinese Model

Model Name Using Similar Mechanism NEW

CD Mechanism Type CDM-2901ABA

Optical Pick-up Type DAX-01A2

Two LR6 (size AA) batteries:3VDC

Battery case (External Batteries):

Two LR6 (size AA) batteries:3VDC

AC power adaptor (DC IN 6V jack):

220-230 V, 50/60Hz

220 V, 50Hz

220 V, 50/60Hz

MICROFILM

PORTABLE VIDEO CD PLAYER

TABLE OF CONTENTS

Specifications ........................................................................... 1

1. SERVICING NOTE....................................................... 3

2. GENERAL

Location and Function of Controls .................................... 4

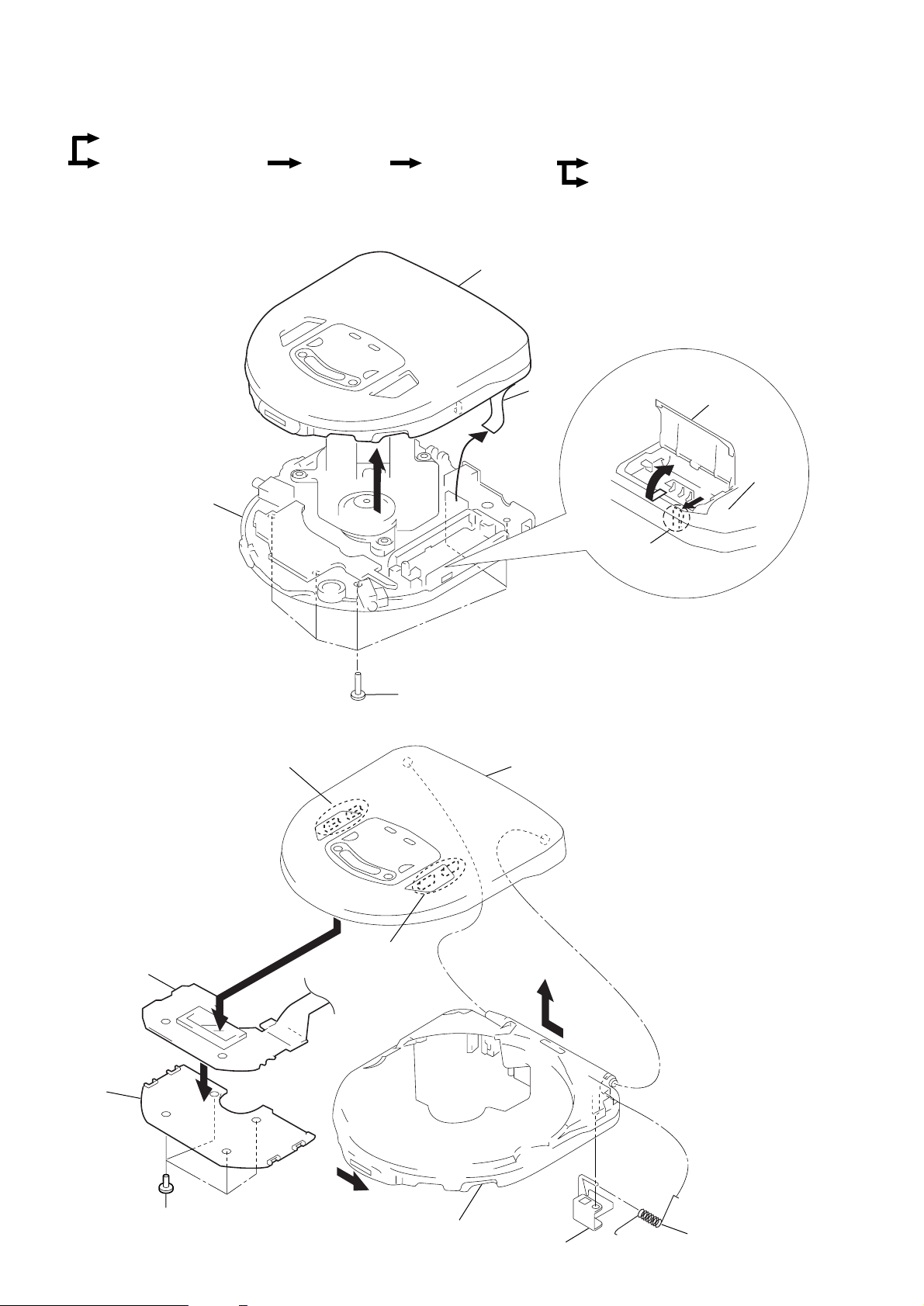

3. DISASSEMBLY

3-1. Cabinet (Lower) Sub ASSY ....................................... 6

3-2. Lid Sub ASSY, Switch Unit........................................ 6

3-3. MPEG Board .............................................................. 7

3-4. MD ASSY, IR Board .................................................. 7

3-5. Main Board ................................................................. 8

3-6.Turn Table Motor ASSY (Spindle) (M902),

Optical Pick-up (DAX-01A2),

Sled Motor ASSY (M901) .......................................... 8

4. SERVICE MODE (TEST MODE)

4-1. How to Enter the Test Mode ....................................... 9

4-2. How to Release the Test Mode ................................... 9

4-3. Each Key Function in Test Mode ............................... 9

5. ELECTRICAL ADJUSTMENTS

5-1. Precautions for Adjustment ...................................... 10

5-2. Before Beginning Adjustment .................................. 10

5-3. Tracking Balance Check........................................... 10

5-4. Focus Bias Check ......................................................11

6. DIAGRAMS

6-1. Explanation of IC Terminals..................................... 12

6-2. Block Diagram.......................................................... 19

6-3. Printed Wiring Boards (Main Section) ..................... 23

6-4. Schematic Diagram (Main Section) ......................... 27

6-5. Schematic Diagram (MPEG Section)....................... 34

6-6. Printed Wiring Boards (MPEG Section) .................. 37

7. EXPLODED VIEWS

7-1. Cabinet (Upper) Section ........................................... 42

7-2. Cabinet (Lower) Section........................................... 43

7-3. Optical Pick-up Section (CDM-2901ABA) ............. 44

8. ELECTRICAL PARTS LIST ................................45

Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270°C during

repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering or

unsoldering.

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be damaged by heat.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK ! OR DOTTED LINE WITH

MARK !ON THE SCHEMATIC DIAGRAMS AND IN THE PARTS

LIST ARE CRITICAL TO SAFE OPERATION.

REPLACE THESE COMPONENTS WITH SONY PARTS WHOSE

PART NUMBERS APPEAR AS SHOWN IN THIS MANUAL OR IN

SUPPLEMENTS PUBLISHED BY SONY.

DANGER

Invisible laser radiation when open and interlock failed or defeated.

Avoid direct exposure to beam.

CAUTION

Use of controls or adjustments or performance of procedures other than

those specified herein may result in hazardous radiation exposure.

This Compact Disc player is

classified as a CLASS 1 LASER

product.

The CLASS 1 LASER

PRODUCT label is located on the

bottom exterior.

– 2 –

SECTION 1

4

3

2

1

5

6

4

3

2

1

5

6

1

5

10

11

20

B

C

E

B

C

E

BCE

BCE

BCE

R532

C525

C526

R751

C518

D501

C516

R544

L506

R518

IC501

R520

R531

R522

R542

R514

C530

C507

R515

R513

R525

C522

C529

R512

R516

R543

C502

Q504

R510

Q506

Q502

R509

C509

R506

R554

R528

R507

R511

R521

R519

R517

R526

Q501

C519

R523

Q503

Q507

C508

R527

TP512

TP520

TP534

TP540

TP537

TP531

TP536

TP524

TP535(RFO)

TP522

(FE)

TP523

(TE)

TP508

(VC)

TP521

TP752

TP810

TP809

TP530

TP525

15

TP524

digital voltmeter

TP520

SERVICING NOTE

NOTES ON HANDLING THE OPTICAL PICK-UP

BLOCK OR BASE UNIT

The laser diode in the optical pick-up block may suffer electrostatic breakdown because of the potential difference generated by

the charged electrostatic load, etc. on clothing and the human

body. During repair, pay attention to electrostatic breakdown and

also use the procedure in the printed matter which is included in

the repair parts.

The flexible board is easily damaged and should be handled with

care.

NOTES ON LASER DIODE EMISSION CHECK

The laser beam on this model is concentrated so as to be focused

on the disc reflective surface by the objective lens in the optical

pick-up block. Therefore, when checking the laser diode emission, observe from more than 30cm away from the objective lens.

Before Replacing the Optical pick-up Block

Please be sure to check thoroughly the parameters as per the

“Optical pick-up Block Checking Procedure” (Part No. : 9-960027-11) issued separately before replacing the optical Pick-up

block.

Note and specifications required to check are given below.

• FOK output : IC601 ((£ pin (FOK).

When checking FOK, remove the lead wire to disc motor.

• S curve P-to-P value : 1.2 – 2Vp-p IC501 !§ pin.

When checking S curve P-to-P value, remove the lead wire to

disc motor.

• RF signal P-to-P value : 0.5 – 0.9Vp-p

• Traverse signal P-to-P value : 1.2 – 2.0Vp-p

• The repairing grating holder is impossible.

Laser Diode Checking Methods

During normal operation of the equipment, emission of the laser

diode is prohibited unless the upper panel is closed while turning

ON the S804 (push switch type).

The following two checking methods for the laser diode are

operable.

AC2211397

current value

A : less than 48 mA

year

month

date

shift No.

line No.

version

3. Connect a digital voltmeter as shown in Fig. 1-2

4. Press the fl key.

5. Calculate the current value by the reading of the digital

voltmeter.

Reading of the digital voltmeter V ÷ 4.7 Ω = current value (A)

(Example) Reading of the digital voltmeter of 0.2256 V :

0.2256 V ÷ 4.7 Ω = 0.048 (A) = 48 mA

6. Check that the current value is within the following range.

• Current value of the label -11 mA(25˚C)

+5

Variation by temperature : 0.4mA / ˚C

Current increases with temperature increased.

Current decreases with temperature decreased.

If the current is more than the range above, there is a trouble

in the automatic power control circuit or the laser diode is in

deterioration.

If less than the range, a trouble exists in the automatic power

control circuit or the optical pick-up.

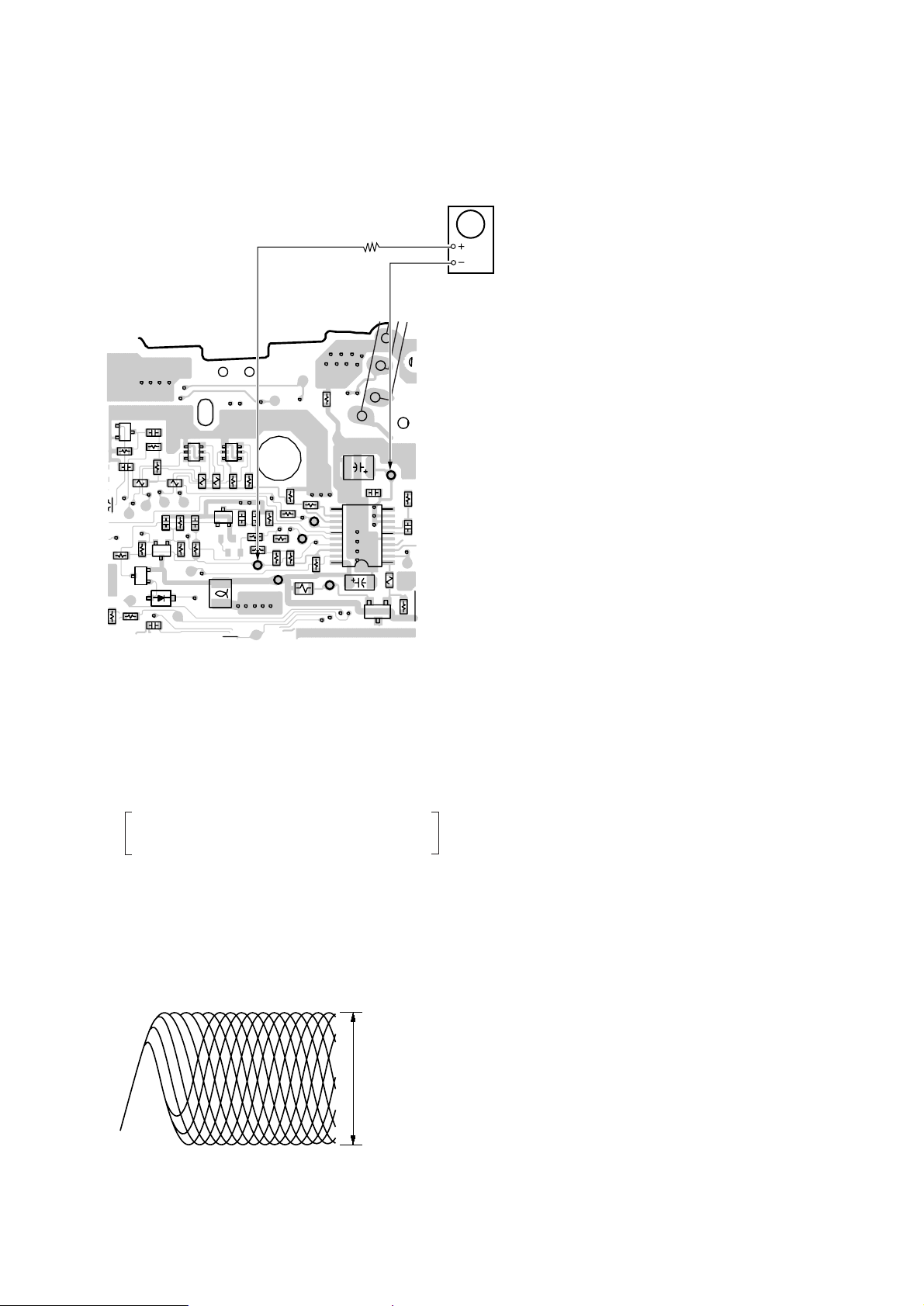

[MAIN BOARD] (SIDE B)

Method-1 (In the service mode or normal operation) :

Emission of the laser diode is visually checked.

1. Open the upper lid.

2. Push the S804 as shown in Fig. 1-1.

3. Press the fl key.

4. Check the object lens for confirming normal emission of the

laser diode. If not emitting, there is a trouble in the automatic

power control circuit or the optical pick-up. During normal

operation, the laser diode is turned ON about 2.5 seconds for

focus searching.

S804

Fig.1-1 Method to push S804

Method-2 (In the service mode or normal operation) :

Check the value of current flowing in the laser diode.

1. Remove the upper panel.

2. Read the current printed on the rear side of the optical pick-up.

(Print on the rear side of the optical pick-up)

Fig. 1-2 Digital Voltmeter Connecting Location

– 3 –

LOCATION AND FUNCTION OF CONTROLS

SECTION 2

GENERAL

This section is extracted from

instruction manual.

– 4 –

– 5 –

SECTION 3

DISASSEMBLY

r

The equipment can be removed using the following procedure.

Lid sub ASSY, Switch unit

Set Main board

Cabinet (Lower) sub ASSY

Note : Follow the disassembly procedure in the numerical order given.

3-1. CABINET (LOWER) SUB ASSY

Cabinet (lower) sub ASSY

MPEG board

MD ASSY, IR board

4

Lid sub ASSY

5

Flexible

board

Turn table motor ASSY (Spindle)

(M902), Optical pick-up (DAX-01A2),

Sled motor ASSY (M901)

2

Battery lid

3

3-2. LID SUB ASSY, SWITCH UNIT

6

Claws

Switch unit

8

1

Screws (B2x10)

6

Claws

Claw

Lid sub ASSY

Cover, lid

7

5

Screws (1.7x4)

1

OPEN

Cabinet (upper) sub ASSY

– 6 –

3

Bracket (spring)

2

4

Spring, torsion

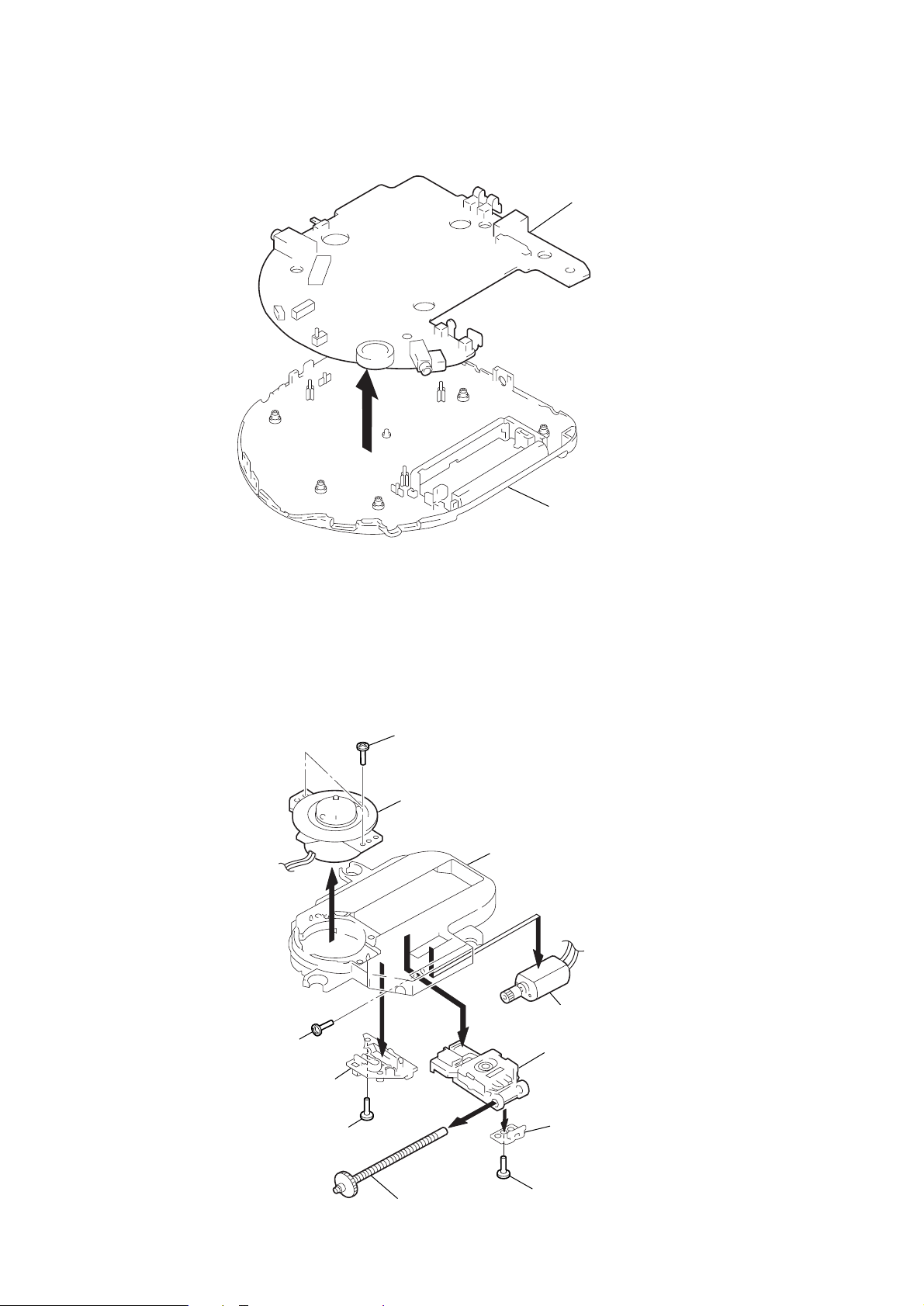

3-3. MPEG BOARD

Y

Y

3-4. MD ASSY, IR BOARD

MPEG board

Cabinet (lower) sub ASS

1

CN601

6

IR board

2

CN502 (white)

1

Flexible board

CN501

3

CN503 (green)

4

CN504 (black)

MD ASSY

5

Cabinet (lower) sub ASS

– 7 –

3-5. MAIN BOARD

Y

Main board

1

Cabinet (lower) sub ASS

3-6. TURN TABLE MOTOR ASSY (SPINDLE) (M902), OPTICAL PICK-UP (DAX-01A2),

SLED MOTOR ASSY (M901)

1

Screws (B1.7)

Turn table motor ASSY (Spindle) (M902)

Chassis

2

!º

Sled motor ASSY

(M901)

Optical pick-up

(DAX-01A2)

Rack

9

Screws

(+P1.4x2.5)

Spring, sled

3

Screw (B1.7x6)

4

8

5

7

Screw ASSY, Feed

– 8 –

6

Screw

SECTION 4

TAP801

(TEST)

CN801

CN501

Monitor IN

Video monitor

Video OUT (J901)

J901

SERVICE MODE (TEST MODE)

• In this set, there are two test modes; CD-DA Test Mode and

VIDEO CD Test Mode.

4-1. How to Enter the Test Mode

1. Disconnect external power (no current is applied to the set).

2. Bridge the TAP801 (TEST) on the MAIN Board with a solder.

(IC801 (∞ (TEST) pin is shorted to the ground.)

3. Connect the external power.

4. The CD-DA Test Mode is activated. (LCD display varies in 5ways, and its 5-way display is repeated.)

5. Before connecting external power in step 3, if π (STOP) key

was pressed, the mode is switched to VIDEO CD Test Mode.

(On the LCD, all segments are displayed, and the video monitor

becomes 100% white.)

4-2. How to Release the Test Mode

1. Always disconnect external power, and break the solder bridge

of TAP801 (TEST) on the MAIN Board.

2. Thus, the set become ready for normal operation.

4-3. Each key Function in Test Mode

1. CD-DA Test Mode

Switches Description

π Stop processing

Press once: Initialize, Average Correct

fl

(PLAY/PAUSE)

SELECT

±

(NEXT)

≠

(PREV)

ˆ

(RETURN)

ESP

REPEAT/

ENTER

+

MENU Raise K23** by one step after Tracking

–

MENU Lower K23** by one step after Tracking

* Coefficient of Focus Gain

** Coefficient of Tracking Gain

Press twice: Auto Focus

Press 3 times: Focus Auto Gain

Press 4 times: Tracking Auto Gain

Press 5 times: All Servo ON, Mute OFF

Repeat once more the processing currently

selected with fl (PLAY/PAUSE) key.

Move optical pick-up toward outside track

Move optical pick-up toward inside track

Turn off the Mute

Turn on/off the ESP (fast speed play, when

ON)

Tracking Gain up/normal switching

Raise K13* by one step after Focus Auto

Gain

Auto Gain

Lower K13* by one step after Focus Auto

Gain

Auto Gain

2. VIDEO CD Test Mode

Switches Description

π Go to CD-DA Test Mode

SELECT

– MAIN Board – (Side A)

Video system reset (return to 100% white

screen)

Fig.4-1 Test terminal location and connecting position

– 9 –

SECTION 5

A

ELECTRICAL ADJUSTMENTS

5-1. Precautions for Adjustment

1. Before beginning adjustment, set the equipment to service

mode.

After the completion of adjustment, be sure to reset the

service mode.

For more information, see “Service Mode (Test Mode)” on

page 9.

2. Perform adjustments in the order given.

3. Use YEDS-18 disc (Part No.: 3-702-101-01) unless otherwise

indicated.

4. Power supply voltage requirement: DC6 V

HOLD switch: OFF

VOLUME control: Minimum

RESUME switch: OFF

5-2. Before Beginning Adjustment

Set the equipment to service mode (See page 9) and check the

following. If there is an error, repair the equipment.

• Checking of the sled motor

1. Open the upper lid.

2. Press the ± and ≠ keys and check that the optical pickup can move smoothly without sluggishness or abnormal

noise in innermost periphery n outermost periphery n

innermost periphery.

± : The optical pick-up moves outwardly.

≠ : The optical pick-up moves inwardly.

• Checking of the Focus serching

1. Open the upper lid.

2. Press the fl key twice. (Focus searching operation is

activated continuously.)

3. Check the object lens of the optical pick-up for smooth up/

down motion without sluggishness or abnormal noise.

4. Press the π key.

Check that focus searching operation is deactivated. If not,

again press the π key slightly longer.

5-3. Tracking Balance Check

Condition:

• Hold the set in horizontal state.

Connection:

oscillscope

(DC range)

TP523(TE)

TP508(VC)

MAIN board (Side B)

B

C

E

C518

BCE

Q506

TP540

R522

R521

TP536

TP531

R554

R532

C522

C530

6

R528

5

4

TP525

R544

BCE

Q507

D501

Q503

R519

R526

R527

TP530

TP535(RFO)

R543

TP537

TP534

C525

1

2

3

C529

R542

L506

6

5

4

BCE

C526

Q502

R515

R518

Q504

1

2

3

C519

R525

R520

R531

C516

TP524

R513

R517

R523

TP809

TP810

R516

R511

R514

R510

R751

R512

TP520

TP523

TP522

C509

R509

11

(TE)

15

(FE)

20

TP521

C508

TP752

C502

IC501

E

5

1

R507

C

TP508

(VC)

10

B

Q501

R506

C507

TP512

Checking Method:

1. Connect the oscilloscope to TP523 (TE) and TP508 (VC) on

the MAIN board.

2. Set the equipment to service mode stop state. (See page 9.)

3. Press the fl key once.

4. Move the optical pick-up to the center by pressing the ±

and ≠ keys.

5. Put the disc (YEDS-18).

6. Press the fl key twice.

From focus searching, focus is turned ON while entering CL V

drawing-in mode. Tracking and sled are turned OFF.

7. Confirm that a waveform on the oscilloscope is vertically

symmetric against 0 V.

Note: Take long sweep time

for easy monitoring.

A

0 V

1.2 – 2 Vp-p

B

0 V

B

A=B A=B

8. Stop removing of the disc motor by pressing the π key.

9. After the completion of check, reset service mode. (See page

9.)

– 10 –

5-4. Focus Bias Check

Condition:

• Hold the set in horizontal state.

8. Stop revolving of the disc motor by pressing the π key.

9. After the completion of check, reset service mode.

(See page 9.)

Connection:

MAIN board (Side B)

C522

B

C

E

C518

BCE

Q506

TP540

R521

TP536

TP531

R554

R532

R522

C530

R528

TP525

R544

BCE

Q507

D501

6

5

4

R519

R543

C525

Q503

R526

R527

TP530

TP537

TP534

1

2

3

C529

R542

TP535(RFO)

L506

6

5

4

BCE

C526

TP535 (RFO)

Q502

1

2

3

R515

R518

Q504

C516

C519

R525

R520

TP524

R531

R513

R517

R523

TP809

TP810

R516

R510

TP508 (VC)

R751

C509

R511

(TE)

TP523

(FE)

TP522

R512

R514

TP520

TP521

R509

11

15

20

2k

TP752

C502

C508

Ω

5

IC501

1

R507

C

E

TP508

(VC)

10

B

Q501

C507

TP512

oscillscope

(AC range)

R506

Checking Method:

1. Connect the oscilloscope to TP535 (RFO) and TP508 (VC)

on the MAIN board.

2. Set the equipment to service mode stop state. (See page 9.)

3. Press the fl key once.

4. Move the optical pick-up to the center by pressing the ±

and ≠ keys.

5. Put the disc (YEDS-18).

6. Press the fl key four times.

From focus searching, focus is turned ON while

entering CLV drawing-in mode. Both tracking and

sled are turned ON.

7. Check the oscilloscope waveform is as shown below.

A good eye pattern means that the diamond shape (≈) in the

center of the waveform can be clearly distinguished.

RF SIGNAL REFERENCE WAVEFORM (EYE PATTERN)

VOLT/DIV : 200 mV (With the 10:1 probe in use)

TIME/DIV : 500 ns

RF level

0.5 – 0.9 Vp-p

To watch the eye pattern, set the oscilloscope to AC range and increase the vertical sensitivity of the oscilloscope for easy watching.

– 11 –

SECTION 6

DIAGRAMS

6-1. EXPLANATION OF IC TERMINALS

• MAIN BOARD (1/2) IC601 CXD2545Q

(DIGITAL SIGNAL PROCESSOR, FOCUS/TRACKING/SLED SERVO, EFM COMPARATOR)

Pin No. Pin name I/O Description

1 SRON O Sled servo drive PWM signal output terminal. Not used (open)

2 SRDR O Sled servo drive PWM signal (-) output to the MPC17A51VMEL (IC502).

3 SFON O Sled servo drive PWM signal output terminal. Not used (open)

4 TFDR O Tracking servo drive PWM signal (-) output to the MPC17A51VMEL (IC502).

5 TRON O Tracking servo drive PWM signal output terminal. Not used (open)

6 TRDR O Tracking servo drive PWM signal (+) output to the MPC17A51VMEL (IC502).

7 TFON O Tracking servo drive PWM signal output terminal. Not used (open)

8 FFDR O Focus servo drive PWM signal (+) output to the MPC17A51VMEL (IC502).

9 FRON O Focus servo drive PWM signal output terminal. Not used (open)

10 FRDR O Focus servo drive PWM signal (-) output to the MPC17A51VMEL (IC502).

11 FFON O Focus servo drive PWM signal output terminal. Not used (open)

12 VCOO O Oscillator circuit output terminal for analog PLL of the playback EFM.

13 VCOI I Oscillator circuit input terminal for analog PLL of the playback EFM.

14 TEST I Input terminal for the test (fixed at “L”).

15 DVSS – Ground terminal (digital system).

16 TES2 I Input terminal for the test (fixed at “L”).

17 TES3 I Input terminal for the test (fixed at “L”).

18 PDO O Charge-pump output terminal for analog PLL of the playback EFM. Not used (open)

19 VPCO O PLL charge-pump output terminal for the variable pitch. Not used (open)

20 VCKI I Master clock signal (16.9344 MHz) input from the D/A converter (IC322) for the variable pitch.

21 AVD2 – Power supply terminal (+3.3V) (analog system).

22 IGEN I Power supply terminal (+3.3V) (for operational amplifier).

23 AVS2 – Ground terminal (analog system).

24 ADIO I Input terminal for the A/D converter. Not used (open)

25 RFC O Output terminal of the operational amplifier. Not used (open)

26 RFDC I RF signal (DC level) input terminal for the digital servo process.

27 TE I Tracking error signal input from the CXA1791N (IC501).

28 SE I Sled error signal input from the CXA1791N (IC501).

29 FE I Focus error signal input from the CXA1791N (IC501).

30 VC I Middle point voltage (+1.65V) input from the CXA1791N (IC501).

31 FILO O Filter output terminal for master clock of the playback master PLL.

32 FILI I Filter input terminal for master clock of the playback master PLL.

33 PCO O Phase comparison output terminal for master clock of the playback EFM master PLL.

34 CLTV I Internal VCO control voltage input of the playback master PLL.

35 AVS1 – Ground terminal (analog system).

36 RFAC I RF signal (AC level) input terminal for the EFM demodulator.

37 BIAS I Constant current input terminal of the playback EFM asymmetry circuit.

38 ASYI I Playback EFM asymmetry comparator voltage input terminal.

39 ASYO O Playback EFM full-swing output terminal.

40 AVD1 – Power supply terminal (+3.3V) (analog system).

41 DVDD – Power supply terminal (+3.3V) (digital system).

42 ASYE I Playback EFM asymmetry circuit on/off selection input terminal (fixed at “H”).

43 PSSL I Audio data output mode selection input terminal (fixed at “L”).

44 WDCK O Word clock signal (88.2 kHz) output terminal. Not used (open)

45 LRCK O

L/R sampling clock signal (44.1 kHz) output to the D-RAM controller (IC681) and

MPEG audio/video decoder (IC701).

– 12 –

Pin No. Pin name I/O Description

DA16 output when PSSL=“H”, 48-bit slot serial data output when PSSL=“L”

46 DATA O

47 BCLK O

48 64 DATA O

49 64 BCLK O

50 64 LRCK O

51 GTOP O

52 XUGF O

53 XPLCK O

54 GFS O

55 RFCK O

56 C2PO O

57 XRAOF O

58 MNT3 O

59 MNT2 O

60 MNT1 O

61 MNT0 O

62 XTAI I Master clock signal (16.9344 MHz) input from the D/A converter (IC322).

63 XTAO O Master clock output terminal (16.9344 MHz). Not used (open)

64 XTSL I Master clock selection input terminal (fixed at “L”).

65 DVSS – Ground terminal (digital system).

66 FSTI I 2/3 divider input terminal of pins ^™ (XATI) and ^£ (XTAO).

67 FSTO O 2/3 divider output terminal of pins ^™ (XATI) and ^£ (XTAO).

68 C4M O 4.2336 MHz clock signal output terminal. Not used (open)

69 C16M O 16.9344 MHz clock signal output terminal. Not used (open)

70 MD2 I Digital out on/off control signal input terminal Fixed at “H” in this set.

71 DOUT O Digital signal (for coaxial out and optical out) output terminal. Not used (open)

72 EMPH O Emphasis control signal output terminal. Not used (open)

73 WFCK O Write frame clock signal output terminal. Not used (open)

74 SCOR O

75 SBSO O Sub-code P-W serial data output terminal. Not used (open)

(PSSL (pin $£)=fixed at “L”) Serial data output to the D-RAM controller (IC681) and

MPEG audio/video decoder (IC701).

DA15 output when PSSL=“H”, 48-bit slot bit clock signal output when PSSL=“L”

(PSSL (pin $£)=fixed at “L”) Bit clock signal (2.8224 MHz) output to the D-RAM

controller (IC681) and MPEG audio/video decoder (IC701).

DA14 output when PSSL=“H”, 64-bit slot serial data output when PSSL=“L”

(PSSL (pin $£)=fixed at “L”). Not used (open)

DA13 output when PSSL=“H”, 64-bit slot bit clock signal output when PSSL=“L”

(PSSL (pin $£)=fixed at “L”). Not used (open)

DA12 output when PSSL=“H”, 64-bit slot L/R sampling clock signal output when

PSSL=“L” (PSSL (pin $£)=fixed at “L”). Not used (open)

DA11 output when PSSL=“H”, GTOP signal output when PSSL=“L”

(PSSL (pin $£)=fixed at “L”). Not used (open)

DA10 output when PSSL=“H”, XUGF signal output when PSSL=“L”

(PSSL (pin $£)=fixed at “L”). Not used (open)

DA09 output when PSSL=“H”, XPLCK signal output when PSSL=“L”

(PSSL (pin $£)=fixed at “L”). Not used (open)

DA08 output when PSSL=“H”, GFS (guard frame sync) signal output when PSSL=“L”

(PSSL (pin $£)=fixed at “L”). Not used (open)

DA07 output when PSSL=“H”, RFCK (read frame clock) signal output when PSSL=“L”

(PSSL (pin $£)=fixed at “L”). Not used (open)

DA06 output when PSSL=“H”, C2PO signal output when PSSL=“L”

(PSSL (pin $£)=fixed at “L”) C2PO signal output to the D-RAM controller (IC680)

and MPEG audio/video decoder (IC901).

DA05 output when PSSL=“H”, XRAOF (RAM over flow) signal output when PSSL=“L”

(PSSL (pin $£)=fixed at “L”). Not used (open)

DA04 output when PSSL=“H”, MNT3 (monitor 3) signal output when PSSL=“L”

(PSSL (pin $£)=fixed at “L”). Not used (open)

DA03 output when PSSL=“H”, MNT2 (monitor 2) signal output when PSSL=“L”

(PSSL (pin $£)=fixed at “L”). Not used (open)

DA02 output when PSSL=“H”, MNT1 (monitor 1) signal output when PSSL=“L”

(PSSL (pin $£)=fixed at “L”). Not used (open)

DA01 output when PSSL=“H”, MNT0 (monitor 0) signal output when PSSL=“L”

(PSSL (pin $£)=fixed at “L”). Not used (open)

Sub-code sync (S0+S1) detection signal output to the D-RAM controller (IC681) and

system controller (IC801).

– 13 –

Pin No. Pin name I/O Description

76 EXCK I Sub-code P-W serial data reading clock signal input terminal. Not used (fixed at “L”)

77 SUBQ O Sub-code Q data signal output to the system controller (IC801).

78 SQCK I Sub-code Q data reading clock signal input from the system controller (IC801).

79 MUTE I Mute signal input terminal. Fixed at “L” in this set

80 SENS O Internal status (SENSE) signal output to the system controller (IC801).

81 XRST I

______

82 DIRC I 1-track jump mode input terminal Not used (fixed at “H”)

83 SCLK I Sense serial data reading clock signal input from the system controller (IC801).

84 DFSW I Defect on/off select signal input terminal. Not used (fixed at “L”)

85 ATSK I Input terminal for the anti-shock. Not used (fixed at “L”)

86 DATA I Serial data input from the system controller (IC801).

87 XLAT I Serial data latch pulse signal input from the system controller (IC801).

88 CLOK I Serial data transfer clock signal input from the system controller (IC801).

89 COUT O Track number count signal output terminal. Not used (open)

90 DVDD – Power supply terminal (+3.3V) (digital system).

91 MIRR O Mirror detection signal output terminal. Not used (open)

92 DFCT O Defect signal output terminal. Not used (open)

93 FOK O Focus OK signal output terminal. Not used (open)

94 FSW O Selection signal output terminal of the output filter for spindle motor. Not used (open)

95 MON O Spindle motor on/off control signal output terminal. Not used (open)

96 MDP O Spindle servo control signal output.

97 MDS O Spindle servo control signal output.

98 LOCK O GFS is sampled by 460 Hz. “H” output when GFS is “H” Not used (open)

99 SSTP I

100 SFDR O Sled servo drive PWM signal (+) output to the MPC17A51VMEL (IC502).

Reset signal input from the system controller (IC801) “L”: reset

For several hundreds msec. after the power supply rises,“L” is input, then it changes to “H”

Detection input from the sled limit-in detect switch (S901). The optical pick-up is inner

position when “H”

– 14 –

• MAIN BOARD IC801 MSM65354-418GS-BK4 (SYSTEM CONTROLLER, LCD DRIVER, KEY CONTROL)

Pin No. Pin name I/O Description

1-4 COM1-4 O Common drive signal output to the liquid crystal display.

5-19 SEG0-14 O Segment drive signal output to the liquid crystal display.

20-36 NC – Not used (open).

37 AGND – Ground terminal (analog system).

38 DC IN JACK I DC IN 6V jack (J801) detection input terminal. “L”: plug in

39 DOOR OPEN I

40 KEY IN1 I Key input terminal (A/D input).

41 XRM KEY IN I Remote control key input terminal (A/D input).

42 DC CHK I DC in voltage detection input terminal (A/D input) Also used for DC IN detection

43 NTSC/PAL I Video system select switch (S803) input terminal “L”: NTSC, “H”: PAL

44 BATT CHK I Battery check terminal.

45 KEY IN2 I Key input terminal (A/D input).

46 VRH I Reference voltage input terminal (+3.3V) (for A/D converter).

47 AVDD – Power supply terminal (+3.3V) (analog system).

48 DBB CTL1 O

49 AU-MUTE O Analog line mute control signal output terminal . “H”: mute on

50 XAU-RESET O Reset signal output to the CXD2545Q (IC601) and D-RAM controller (IC681). “L”: reset

51 XV-RESET O

52 HOLD I HOLD switch (S802) input terminal. “L”: hold off, “H”: hold on

53 RESUME I RESUME switch (S801) input terminal. “L”: resume off, “H”: resume on

54 XDSPLT O Serial data latch pulse signal output to the CXD2545Q (IC601).

55 XDACLT O Serial data latch pulse signal output to the D/A converter (IC322).

56 V-POWER O Video CD system power supply on/off control signal output terminal. “L”: power on

57 AU-POWER O Audio CD system power supply on/off control signal output terminal. “L”: power on

58 ESP-POWER O Control signal output to the ESP (Electronic Shock Protection) circuit.

59 TRVCTL O Tracking gain control signal output terminal.

60 TRV3 O

61 TRV2 O

62 TRV1 O

63 TRV0 O

64 XSOE O Serial data output enable signal output to the D-RAM controller (IC681).

65 DSP-SUBQ I Sub-code Q data signal input from the CXD2545Q (IC601).

66 DSP-SBQCLK O Sub-code Q data reading clock signal output to the CXD2545Q (IC601).

67 REMOTE I Sircs remote control signal input from the remote control receiver (IC1).

68 DSP-DATA O Serial data output to the CXD2545Q (IC601) and D/A converter (IC322).

69 DSP-SENS I Internal status (SENSE) signal input from the CXD2545Q (IC601).

70 DSP-CLK O Serial data transfer clock signal output to the CXD2545Q (IC601) and D/A converter (IC322).

71 DSP-SNSCLK O Sense serial data reading clock signal output to the CXD2545Q (IC601).

72 VDD – Power supply terminal (+3.3V) (digital system).

73 BEEP O Beep sound drive signal output terminal.

74 C2PO O C2PO signal control output to the D-RAM controller (IC681). “L”: stop mode, “H”: searching

75 ESP-CLK O Serial data transfer clock signal output to the D-RAM controller (IC681).

____________

__________

______

CD lid open/close detection switch (S804) input terminal The stop status is reset with the

falling edge of input signal. “H”: CD lid open, “L”: CD lid close

MEGA BASS on/off control signal output to the BA3574BFS (IC361).

“L”: MEGA BASS on (level-1 and level-2)

Reset signal output to the MPEG audio/video decoder (IC701) and video encoder (IC721).

“L”: reset

Tracking balance control signal output terminal.

– 15 –

Pin No. Pin name I/O Description

76 ESP-DATA O Serial data output to the D-RAM controller (IC681).

77 ESP-LT O Serial data latch pulse signal output to the D-RAM controller (IC681).

78 ESP-SENSE I Sense serial data input from the D-RAM controller (IC681).

79 XLASERCTL O Laser diode on/off control signal output to the CXA1791N (IC501). “L”: laser on

80 DSP-SCOR I Sub-code sync (S0+S1) detection signal input from the CXD2545Q (IC601).

81 OSC1 O Main system clock output terminal (4.19 MHz).

82 OSC0 I Main system clock input terminal (4.19 MHz).

83 GND – Ground terminal (digital system).

84 XT I Sub system clock input terminal. Not used (fixed at “L”)

85 XTO O Sub system clock output terminal. Not used (open)

86 A-SELECT O

87 XIRCTL O Power supply on/off control signal for the remote control receiver (IC1). “L”: power on

88 SYS XMT RQ O Communication request signal output to the MPEG audio/video decoder (IC701).

89 SYS RCV RDY O Ready signal output to the MPEG audio/video decoder (IC701).

90 MPG XMT RQ I Communication request signal input from the MPEG audio/video decoder (IC701).

91 ESS-DATAO O Serial data output to the MPEG audio/video decoder (IC701).

92 ESS-DATAI I Serial data input from the MPEG audio/video decoder (IC701).

93 ESS-CLK O Serial data transfer clock signal output to the MPEG audio/video decoder (IC701).

94 RESET I

95 TEST I

96 DBB CTL2 O

97 VDDL –

98 VDD1 –

99 VDD2 –

100 VDD3 –

____________

______

_____

Selection signal output to the DATA, BCLK, LRCK signal select switch (IC321) .

“L”: CD play, “H”: video CD play

System reset signal input from the reset signal generator (IC802). “L”: reset

For several hundreds msec. after the power supply rises, “L” is input, then it changes to “H”

Service mode setting terminal. The stop status is reset with the falling edge of input signal

“L”: service mode, Normally: “H”

MEGA BASS level control signal output to the BA3574BFS (IC361) .

“L”: MEGA BASS level-1, “H”: MEGA BASS level-2

Power supply output for the liquid crystal display bias.

– 16 –

• MPEG BOARD IC701 ES3210 (MPEG AUDIO/VIDEO DECODER)

Pin No. Pin name I/O Description

1 VCC – Power supply terminal (+3.3V).

2 DRAS B O Row address strobe signal output to the D-RAM (IC703) . “L” active

3 DWE B O Write enable signal output to the D-RAM (IC703). “L” active

4 – 12 MA0 – 8 O Address signal output to the D-RAM (IC703).

13 – 28 DBUS0 – 15 I/O Two-way data bus with the D-RAM (IC703).

29 RESET B I Reset signal input from the system controller (IC801). “L”: reset

30 VSS – Ground terminal.

31 VCC – Power supply terminal (+3.3V).

32 – 39 YUV0 – 7 O

40 VSSCN B O Vertical synchronous signal output to the video encoder (IC721).

41 HSSCN B O Horizontal synchronous signal output to the video encoder (IC721).

42 CLK I System clock signal input terminal Not used (open).

43 PCLK2XSCN I System clock signal (27 MHz) input from the video encoder (IC721).

44 PCKLQSCN O Pixel clock qualifier output for the screen video interface Not used (open).

45 AUX0 O Sub control signal output terminal Not used (open).

46 AUX1 I Serial data input from the system controller (IC801).

47 AUX2 O Serial data output to the system controller (IC801).

48 AUX3 O NTSC/PAL mode selection signal output to the video encoder (IC721). “L”: NTSC, “H”: PAL

49 AUX4 I C2PO signal input from the CXD2545Q (IC601).

50 VSS – Ground terminal.

51 VCC – Power supply terminal (+3.3V).

52 AUX6 O Communication request signal output to the system controller (IC801).

53 AUX5 I Ready signal input from the system controller (IC801).

54 AUX7 I Communication request signal input from the system controller (IC801).

55 – 62 LD0 – 7 I Data input from the program ROM (IC702).

63 LWR B O Write enable signal output terminal. “L” active Not used

64 LOE B O Output enable signal output to the program ROM (IC702). “L” active

65 LCS3 B O Chip select signal output to the program ROM (IC702). “L” active

66 LCS1 B I Serial data transfer clock signal input from the system controller (IC801). “L” active

67 LCS0 B O Chip select signal output terminal. “L” active Not used (open)

68 – 79 LA0 – 11 O Address signal output to the program ROM (IC702).

80 VSS – Ground terminal.

81 VPP – Power supply terminal (+5V) (digital system).

82 – 87 LA12 – 17 O Address signal output to the program ROM (IC702).

88 AUDIOCLK I Audio master clock signal (16.9344 MHz) input from the D/A converter (IC322).

89 AOUT O Audio interface serial data output to the D/A converter (IC322).

90 TBCK O Bit clock signal (2.8224 MHz) output to the D/A converter (IC322).

91 ATFS O L/R sampling clock signal (44.1 kHz) output to the D/A converter (IC322).

92 DOE B O Output enable signal output to the D-RAM (IC703). “L” active

93 AIN I Audio interface serial data input terminal. Not used (open)

94 RBCK I Audio interface bit clock signal (2.8224 MHz) input terminal. Not used (open)

95 ARFS I Audio interface L/R sampling clock signal (44.1 kHz) input terminal. Not used (open)

96 TDMCLK I Bit clock signal (2.8224 MHz) input from the CXD2545Q (IC601).

97 TDMDR I Serial data input from the CXD2545Q (IC601).

98 TDMFS I L/R sampling clock signal (44.1 kHz) input from the CXD2545Q (IC601).

99 DCAS B O Column address strobe signal output to the D-RAM (IC703). “L” active

100 VSS – Ground terminal.

_______

_______

________

Video data output to the video encoder (IC721).

(YUV; Y: luminance signal, UV: Screen video interface chrominance data bus)

______

_______

_______

_______

_______

______

_______

– 17 –

• MPEG BOARD IC721 TC90A07U (VIDEO ENCODER)

Pin No. Pin name I/O Description

1 MIFH I Horizontal synchronous signal input from the MPEG audio/video decoder (IC701).

2 MIFFL I Vertical synchronous signal input from the MPEG audio/video decoder (IC701).

3 MIFFR O Frame synchronous signal output terminal. Not used (open)

4 VBLNKI I Video blanking signal input terminal. “L”: blanking

5 VDD – Power supply terminal (+3.3V) (digital system).

6 GND – Ground terminal (digital system).

7 YCDI0 I 8 bit pixel data (LSB) input from the MPEG audio/video decoder (IC701).

8- 13 YCDI1 – YCDI6 I 8 bit pixel data input from the MPEG audio/video decoder (IC701).

14 YCDI7 I 8 bit pixel data (MSB) input from the MPEG audio/video decoder (IC701).

15 MODE I

16 VBLNKO O Video blanking signal output terminal.

17 VDD – Power supply terminal (+3.3V) (digital system).

18 GND – Ground terminal (digital system).

19 CLPF I

20 BF O Burst flag pulse output terminal. Not used (open)

21 BLK O Blanking signal output terminal. Not used (open)

22 FLD O

23 BIAS2 – Connect a capacitor for the D/A converter bias.

24 BIAS1 – Connect a capacitor for the D/A converter bias.

25 VREF I Reference voltage input terminal (for D/A converter).

26 AGND – Ground terminal (analog system for D/A converter).

27 YOUT O Analog Y signal (luminance signal) output terminal. Not used (open)

28 AVCC – Power supply terminal (+3.3V) (analog system for D/A converter).

29 COUT O Analog C signal (chroma signal) output terminal. Not used (open)

30 AGND – Ground terminal (analog system for D/A converter).

31 CVOUT O Analog composite video signal output terminal.

32 AVCC – Power supply terminal (+3.3V) (analog system for D/A converter).

33 CSYNC O Composite synchronous signal output terminal. Not used (open)

34 HSYNC O Horizontal synchronous signal output terminal. Not used (open)

35 VSYNC O Vertical synchronous signal output terminal. Not used (open)

36 TMS3 I Mode setting terminal. Normally fixed at “H”

37 VDD – Power supply terminal (+3.3V) (digital system).

38 CK27I I System clock input terminal (27 MHz).

39 XO O System clock output terminal (27 MHz).

40 GND – Ground terminal (digital system).

41 TMS2 I Mode setting terminal. Normally fixed at “H”

42 CK27O O System clock signal (27 MHz) output to the MPEG audio/video decoder (IC701).

43 TMS1 I Reset signal input from the system controller (IC801) . “L”: reset

44 TMS0 I Video output mode setting terminal. “L”: normal output mode, “H”: color bar output mode

NTSC/PAL mode selection signal input from the MPEG audio/video decoder (IC701).

“L”: NTSC, “H”: PAL

Low-pass filter on/off control signal input for the internal CbCr. “L”: on, “H”: off

Fixed at “L” in this set

Field discrimination signal output terminal. “L”: odd number field, “H”: even number field

Not used (open)

– 18 –

6-2. BLOCK DIAGRAM

D-V55

– 19 – – 20 – – 22 –– 21 –

• Signal path.

J : CD

L : VIDEO

D-V55

r

Semiconductor Location

Ref. No. Location Ref. No. Location

D101 B-17

D102 G-16

D201 B-17

D202 H-16

D301 H-16

D302 H-16

IC601 C-12

IC602 E-17

IC681 C-17

IC682 D-3

IC801 F-13

IC802 D-13

D351 E-17

D361 F-17

D401 F-11

D402 G-11

Q101 C-17

Q201 C-17

Q351 E-17

D404 E-12

D405 F-9

Q352 E-17

Q353 E-17

D411 E-4

D412 E-16

D421 F-16

Q361 F-17

Q362 G-16

Q363 G-16

D422 F-4

D501 C-14

Q412 E-4

Q413 F-9

D601 D-12

D681 D-18

D682 D-16

Q421 F-4

Q422 F-4

Q501 C-15

D801 E-12

Q502 B-14

Q503 B-14

IC1 A-1

IC321 D-18

IC322 E-18

IC361 F-17

IC411 F-16

IC421 F-16

IC501 B-15

IC502 C-15

Q504 B-14

Q505 B-13

Q506 C-14

Q507 C-14

Q601 D-12

Q801 E-14

Q802 F-14

Q812 E-13

IC503 C-14

IC504 D-14

Note:

• X : parts extracted from the component side.

®

•

: Through hole.

• b : Pattern from the side which enables seeing.

(The other layers' patterns are not indicated.)

Caution:

Pattern face side: Parts on the pattern face side seen from the

(Side B) pattern face are indicated.

Parts face side: Parts on the parts face side seen from the

(Side A) parts face are indicated.

6-3. PRINTED WIRING BOARDS (MAIN SECTION)

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19

[IR BOARD]

A

B

(SIDE A)

C1

1

2

IC1

4

3

1-674-189-

11

(11)

S802

HOLD

[IR BOARD]

(SIDE B)

C

D

E

F

G

H

I

M901

SLED

MOTOR

S901

(LIMIT)

MPEG

BOARD

CN901

(page 38)

M902

SPINDLE

MOTOR

02

TP2

M

A

M

TP3

TP1

1-674-189-

ORG

BLK

GRY

GRY

BLK

RED

11

(11)

TAP802

C752

RED

WHT

CN802

C330

BLK

RED

1

WHT

BLK

14

FB804

C619

C364

J901

[MAIN BOARD] (SIDE A)

S801

RESUME

OFF

TP529

TP518

OFF

ON

BLK

Q412

TAP501

TP519

12

GRY

GRY

D

C429

T421

CN504

S

R429

C426

CN501

1

BLK

12

CN503

D422

SDG

6

5

RED

Q422

TP526

C683

913

18

20

C366

10

15

C328

24

23

IC682

22

5

5

L411

C414

2

1

C418

C423

TP528

ORG

1

12

CN502

26

D411

R426

C428

G

C417

B

C

E

R425

Q421

10

1

C427

TAP502

TP527

TP532

14

ON

OPTICAL PICK-UP

BLOCK

DAX-01A2

SWITCH UNIT

LIQUID CRYSYAL DISPLAY

PLAY MODE

REPEAT/

TAP801

(TEST)

EXTERNAL

BATTERY

DRY BATTERY

SIZE “AA”

(IEC DESIGNATION LR6)

2PCS‚ 3V

J401

DC IN 6V

CN801

1

5

15

23

C809

2

C808

10

20

24

D405

BCE

Q413

TP405

ENTER

ESP

MEGA

BASS

RETURN MENU- MENU+ SELECT

1-674-190-

11

(11)

TP301

[MAIN BOARD] (SIDE B)

50

TP625

TP623

TP613

D401

55

TP622

TP618

TP616

TP612

TP611

D404

C605

C602

TP825

C401

51

60

65

70

75

80

81

TP403

TP817

Q601

FB805

TP815

FB802

TP827

TP835

TP620

L402

TP624

TP621

TP619

TP617

TP615

TP614

TB402

TB401

L401

D402

C613

45

85

R602

TP603

BCE

X801

TP404

R804

TP826

TP833

R803

TP831

C601

C801

TAP602

TAP601

40

IC601

90

TP602

TP604

TP802

TP816

R801

R824

TP830

C616

R607

TP605

C802

FB801

TP801

TP818

100

R802

C612

35

R608

95

TP606

TP607

R601

D601

C603

81

85

90

TP803

95

TP821

TP822

TAP603

R610

C615

R609

C609

C611

R605

R604

R613

R614

R616

R618

C806

C604

R621

C608

C606

R611

R617

R551

C534

R546

4

1

C816

L601

L602

C607

R615

C617

R541

R556

R548

R823

C805

R820

R612

R539

C528

R825

Q812

R530

TP538

C527

C533

TP517

BCE

C535

R550

C804

TP609

80

31

R606

25

20

15

10

100

TP601

C803

L801

5

R620

TP608

5

8

D801

30

1

TP610

R603

IC802

R619

IC801

511015202530

TP829

TP823

TP824

TP828

TP832

TP837

TP839

Q505

R524

C518

R536

1

4

1

4

55 5160657075

B

C

E

R553

Q506

R537

R805

R826

R521

R557

R519

TP536

TP531

R554

BCE

TP540

R532

IC503

IC504

R806

C522

R522

C530

BCE

50

45

40

35

31

TP838

6

5

R528

4

TP525

Q507

D501

8

5

8

5

Q503

R526

R527

R544

R543

TP537

TP534

C525

R535

R540

R549

TP804

R811

R813

C807

TP834

Q802

Q502

6

1

5

2

4

3

R515

R518

Q504

TP530

BCE

C529

R558

R529

R542

TP535(RFO)

L506

C526

R555

C532

R547

R810

BCE

BCE

TP808

R821

TP807

TP836

PAL

1

2

3

C519

R525

R531

R538

TP539

TP806

R812

AUDIO/VIDEO

OUT

TP809

TP810

R751

R511

C516

R516

R513

R517

R520

TP524

R534

S803

S803

R545

R807

R817

R822

R512

R514

R523

TP520

R510

TP533

R814

RECHARGEABLE BATTRY

C512

C536

L504

L502

C503

Q801

TP805

NTSC

DRY BATTERY

SIZE “AA”

(IEC DESIGNATION LR6)

2PCS‚ 3V

(NICKEL-CADMIUM)

BP-DM10/DM20

2.4V

C509

R509

11

(TE)

TP523

15

(FE)

20

TP522

C514

C520

C510

TP521

19

20

25

30

35

36

TP401

TP752

C502

C508

TP508

(VC)

5

IC501

1

R507

C

E

IC502

10

C507

B

Q501

R508

TP422

R506

TP512

TP411

IC421

R505

R501

18

15

10

5

1

R402

R401

R421

TP513

TP505

R404

C416

C424

4

D421

TP509

2

TP507

TP514

R504

R503

TP511

R502

C506

C511

TP504

TP501

TP503

C515

C513

L505

C523

C504

TP642

R415

C413

C411

R403

2

1

R418

C415

IC411

5

4

R428

C430

C422

R423

1

5

C421

R427

R424

TB404

1-674-190-

TP510

TP506

C505

TP502

TP516

C517

R413

TAP411

C425

TP365

TB403

C521

D412

D202

(11)

R815

L503

C501

TP626

TP414

TP421

TP412

R422

TAP421

Q363

BCE

TP303

11

TP101

FB101

FB751

TP201

FB201

R816

FB803

L501

TP515

FB682

TP644

C412

R414

R416

R417

C206

R362

BCE

D102

R753

C810

34

TP683

35

40

44

C684

Q351

TP351

C351

C106

R207

10

R365

FB202

D301

D302

FB806

TP751

C101

R101

R754

D201

C201

TP812

R201

R105

TP811

TP813

R205

TP682

TP681

33 30 25 23

IC681

5

1

D682

TP629

TP631

TP639

TP637

C352

R352

3

BCE

R351

2

D351

R353

2

1

3

Q361

6

5

R107

4

C365

C375

1

IC361

5

C372

C371

C370

R363

R364

Q362

TP364

FB301

R819

C812

FB807

FB808

R818

TP819

D101

BCE

BCE

1

TP635

TP633

5

7

R354

4

D361

FB102

C751

R752

Q101

Q201

10

TP632

Q352

5

1

B

C

E

TP352

20

C205

11

C369

TP363

TP820

11

TP643

TP634

C353

Q353

C368

C367

15

C105

TP684

22

20

15

12

TP641

IC602

C329

L324

TP102

TP685

TP627

C618

14

10

8

L322

TP326

C362

R106

TP202

R104

R204

C682

TP686

FB681

TP630

FB683

L323

C102

C361

R206

TP304

IC322

R323

C327

R102

TP302

R681

TP636

8

9

TP638

TP322

101251

R103

R203

J301

PHONES/

REMOTE

C685

5

12

R322

C325

C202

R202

C104

D681

TP640

IC321

X321

13152024

C323

C103

1

16

C204

C324

C331

TP325

TP324

C203

FB321

C326

RV301

VOLUME

TP628

C322

L321

TP323

R321

TP840

C321

R809

C811

S804

(OPEN SW)

– 25 – – 26 –– 23 – – 24 –

6-4. SCHEMATIC DIAGRAM (MAIN SECTION)

r

Refer to page 39 for IC Block Diagrams. r Refer to page 32 for Waveforms.

D-V55

Note:

• All capacitors are in µF unless otherwise noted. pF: µµF

50 WV or less are not indicated except for electrolytics

and tantalums.

• All resistors are in Ω and 1/

specified.

¢

•

Note: The components identified by mark ! or dotted

• A : B+ Line.

• Power voltage is dc 6 V and fed with regulated dc power

• Voltages and waveforms are dc with respect to ground

• Voltages are taken with a V OM (Input impedance 10 MΩ).

• Waveforms are taken with a oscilloscope.

• Circled numbers refer to waveforms.

• Signal path.

: internal component.

line with mark ! are critical for safety.

Replace only with part number specified.

supply from external power voltage jack (J401).

under no-signal conditions.

no mark : VIDEO CD PLAY

( ) : AUDIO CD PLAY

Voltage variations may be noted due to normal production tolerances.

Voltage variations may be noted due to normal production tolerances.

J : CD

L : VIDEO

4

W or less unless otherwise

– 27 – – 28 – – 30 –– 29 – – 31 –

D-V55

p

p

p

p

p

p

p

p

p

r

Waveforms – MAIN Section –

r

Waveforms – MPEG Section –

6-5. SCHEMATIC DIAGRAM (MPEG SECTION)

r

Refer to page 41 for IC Block Diagram.

1

IC501 !¶ (RFO)

2

IC501 !§ (FE)

3

IC501 !¢ (TE)

4

0.5 -0.9

Vp-p

VOLT/DIV : 200 mV AC

TIME/DIV : 500 ns

Approx.

120 mVp-p

VOLT/DIV : 50 mV AC

TIME/DIV : 5 ms

Approx.

500 mVp-p

VOLT/DIV : 200 mV AC

TIME/DIV : 5 ms

8

91.6 ns

IC601 ^§ (FSTI)

9

22.9 µs

IC681 !∞ (LRCK)

10

488 ns

IC681 !¢ (BCLK)

11

1.6 Vp-p

VOLT/DIV : 0.5 V AC

TIME/DIV : 50 ns

3.3 Vp-p

VOLT/DIV : 2 V AC

TIME/DIV : 10 µs

3.2 Vp-p

VOLT/DIV : 1 V AC

TIME/DIV : 200 ns

15

22.9 µs

IC322 @¢ (LRCK)

16

4.19 MHz

IC801 *¡ (OSC1)

17

11.5 µs

IC502 @¶ (OUT)

18

3.3 Vp-p

VOLT/DIV : 1 V AC

TIME/DIV : 10 µs

1.5 Vp-p

VOLT/DIV : 0.5 V AC

TIME/DIV : 100 ns

3.1 Vp-

VOLT/DIV : 1 V AC

TIME/DIV : 2 µs

1

472 ns

IC701 (º (TBCK)

2

22.7 µs

IC701 (¡ (ATFS)

3

27 MHz

IC701 $£

(PCLK2XSCN)

3.2 Vp-p

VOLT/DIV : 1 V AC

TIME/DIV : 200 ns

3.2 Vp-p

VOLT/DIV : 1 V AC

TIME/DIV : 10 µs

5.2 Vp-

VOLT/DIV : 2 V AC

TIME/DIV : 1 ms

5

27 MHz

IC721 #ª (XO)

6

27 MHz

IC721 $™ (CK270)

7

H

IC723 1 (OUT)

4.2 Vp-p

VOLT/DIV : 2 V AC

TIME/DIV : 20 ns

3.9 Vp-

VOLT/DIV : 2 V AC

TIME/DIV : 20 ns

2.0 Vp-

VOLT/DIV : 500 mV AC

TIME/DIV : 20 µs

940 mVp-p

16.9344 MHz

IC601 @º (VCKI)

VOLT/DIV : 0.5 V AC

TIME/DIV : 20ns

5

3.5 Vp-

23.15 µs

IC601 $∞ (LRCK)

VOLT/DIV : 1 V AC

TIME/DIV : 5 µs

6

3.2 Vp-p

483 ns

IC601 $¶ (BCLK) VOLT/DIV : 1 V AC

TIME/DIV : 0.1 µs

7

940 mVp-

16.9344 MHz

IC601 ^™ (XTAI)

VOLT/DIV : 0.5 V AC

TIME/DIV : 20 ns

940 mVp-

16.9344 MHz

IC681 9 (CLK)

VOLT/DIV : 0.5 V AC

TIME/DIV : 20 ns

12

0.6 Vp-p

16.9344 MHz

IC322 !£ (CKO) VOLT/DIV : 0.2 V AC

TIME/DIV : 20 ns

13

3.7 Vp-p

16.9344 MHz

IC322 !§ (XTLO)

VOLT/DIV : 2 V AC

TIME/DIV : 20 ns

14

3.2Vp-p

488 ns

IC322 @£ (BCLK)

VOLT/DIV : 1 V AC

TIME/DIV : 0.1 µs

28 kHz

IC411 1 (EXT)

19

IC421 5 (EXT)

20

3.8 kHz

IC802 8 (LX)

21

5.78

µ

sec

Q421 C

VOLT/DIV : 2 V AC

TIME/DIV : 1 µs

180 kHz

VOLT/DIV : 1 V AC

TIME/DIV : 2 µs

VOLT/DIV : 1 V AC

TIME/DIV : 0.1 ms

VOLT/DIV : 1 V AC

TIME/DIV : 2 µs

5.9 Vp-

3.2 Vp-p

4.3 Vp-p

3.6 Vp-p

4

IC721 #¡

(CVOUT)

H

VOLT/DIV : 500 mV AC

TIME/DIV : 20 µs

1.0 Vp-

Note:

• All capacitors are in µF unless otherwise noted. pF: µµF

50 WV or less are not indicated except for electrolytics

and tantalums.

• All resistors are in Ω and 1/

specified.

• A : B+ Line.

• Power voltage is dc 6 V and fed with regulated dc power

supply from external power voltage jack (J401).

• Voltages and waveforms are dc with respect to ground

under no-signal conditions.

no mark : VIDEO CD PLAY

( ) : AUDIO CD PLAY

• Voltages are taken with a V OM (Input impedance 10 MΩ).

Voltage variations may be noted due to normal production tolerances.

• Waveforms are taken with a oscilloscope.

Voltage variations may be noted due to normal production tolerances.

• Circled numbers refer to waveforms.

• Signal path.

J : CD

L : VIDEO

: Impossible to measure

∗

4

W or less unless otherwise

– 34 – – 35 –– 32 – – 33 – – 36 –

6-6. PRINTED WIRING BOARDS (MPEG SECTION)

1 2 3 4 5 6 7 8 9

A

IC451

1

2

3

C455

C454

4

C453

IC722

C731

L724

C738

R726

35 26

90

TP717

R701

R704

C709

5

1

2

3

L723

R724

C734

R725

30

95

C702

1

5

33

100

34

35

40

44

1

TAP701

Q453

6

5

4

C451

C706

50

C452

R452

L722

C732

C736

L702

C705

45

80

C714

1

2

3

C733

TP703

40

IC701

85

R454

R453

B

Q452

SDG

Q451

L725

C739

S

D

G

L701

C707

C

32

30

25

IC702

D

5

1

R451

C735

C459

20

17

51

55

60

65

70

75

15

10

16

76

E

C703

C458

R456

L721

C728

30

IC721

5

25

20

15

10

5

1

TAP451

C721

44

40

[MPEG BOARD]

(SIDE A)

R458

R457

R722

C725

25

23

11

10

C704

12

22

20

15

R459

R721

C726

C724

C722

1

2

3

R460

IC452

C460

[MPEG BOARD]

(SIDE B)

C457

R723

C729

3

4

D451

IC723

TP701

X720

TP905

C456

2

1

TP722

TP724

Q454

G

D

S

C730

2

1

TP904

TP718

R455

TP902

5

TP711

D452

TP909

TP723

TP907

10

TP710

TP901

L451

15

TP744

TP911

20

23

TP709

TP910

24

TP705

TP908

CN901

TP706

TP453

TP903

TP906

MAIN BOARD

A

CN601

(page 23)

r

Semiconductor

Location

Ref. No. Location

D451 B-6

D452 B-6

IC451 A-2

IC452 B-4

IC701 D-2

IC702 D-1

IC703 E-3

IC721 C-3

IC722 B-2

IC723 B-6

Q451 C-1

Q452 B-2

Q453 B-2

Q454 B-6

D-V55

C713

10

C712

C711

F

C710

IC703

1520

22

G

35

30

25

23

1-674-188-

11

(11)

C715

1-674-188-

11

(11)

Note:

• X : parts extracted from the component side.

®

•

: Through hole.

• b : Pattern from the side which enables seeing.

(The other layers' patterns are not indicated.)

Caution:

02

Pattern face side: Parts on the pattern face side seen from the

(Side B) pattern face are indicated.

Parts face side: Parts on the parts face side seen from the

(Side A) parts face are indicated.

– 37 – – 38 –

r

LOW VOLTAGE

DETECTOR

CHAGE

PUMP

SAW

GEN

ERR 1

C2H

C1H

C1L

C2L

VCG

VIN34

VIN34

OUT 3 A

PGND3

OUT 3 B

OUT 4 B

PGND4

OUT 4 A

VIN34

CF4

CLV

TED

CF3

AGND

C11

VR

OE

SAWTOOTH

PSB

OUT 1 A

OUT 1 B

ERR 2

OUT 2 B

VR

VR

OE

OE

SAWTOOTH

SAWTOOTH

PSB

PSB

VR

OE

SAWTOOTH

PSB

OUT 2 A

OUT 4 B

C14

ERR 4

OUT 4 A

OUT 3 A

OUT 3 B

ER R3

C 13

C 12

MOTOR DRIVER

CH 1

MOTOR DRIVER

CH 2

MOTOR DRIVER

CH 3

MOTOR DRIVER

CH 4

VLG VG

VLG

VG

VCG

VIN12

VLG VG VIN12

VLG VG VIN34

VLG VG VIN34

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

36

35

34

33

32

31

30

29

28

27

26

25

24

23

22

21

20

19

VG

DGND

CLK

OE

VCC

VIN12

VIN12

OUT 1 A

PGND1

OUT 1 B

OUT 2 B

PGND2

OUT 2 A

VIN12

CF2

SLD

FED

CF1

VC

IC Block Diagrams (MAIN SECTION)

IC322 TC9434AFNEL

IC501 CXA1791N

IC361 BA3574BFS

IC321 TC74VHC157FT

LRCK

INTERFASE

CIRCUIT

DINAMIC

BASS BOOST

CIRCUIT

TEST

CIRCUIT

1

DVDD

DATA

2

BCLK

TEST

3

DATA

SPSL

DBB

SDATA

21222324

OUTPUT

CIRCUIT

ANALOG

FILTER

4

AVDD

SHCK

MICRO COMPUTER

INTERFASE

CIRCUIT

DIGITAL FILTER CIRCUIT

DEEMPHASIS FILTER CIRCUIT

ATTENUATER OPERATIONAL CIRCUIT

Σ-∆ MODULATION CIRCUIT

5

6

RO

AGND

181920

7

DACLT

VREF

17

8

XVDD

AGND

16

GENERATOR

OUTPUT

CIRCUIT

ANALOG

FILTER

9

XTLO

TIMING

LO

OSC

111

11

1

PD1

PD2

VEE

LD

APC

VREF

APC

PD AMP

+

2

PD

3

4

5

6

F

7

E

8

VR

9

VC

10

NC

–

–

+

VC

RF

IV AMP1

–

+

VC

RF

IV AMP2

–

+

VC

VC

VC

F

IV AMP

–

+

E

IV AMP

1.25V

LD AMP

+

–

VC

VC

VC

VC

VC BUFFER

VC

VCC

–

+

VC

SUMMING AMP

–

+

FOCUS

ERROR AMP

VC

–

+

TRACKING

ERROR AMP

VCC

+

–

20

VCC

19

LDON

18

RFI

17

16

15

14

13

12

11

RFO

FE

FE BIAS

TE

EI

EO

NC

RF

XTLI

XGND

14

11

MUTE-0

CKO

13

12

DGND

15

10

AVDD

MUTE SW

PW SW

IN 1

IN 2

BIAS OUT

BIAS IN

RF OUT

RF IN

BEEP IN

12

P.SW

13

14

15

16

17

RIPPLE

FILTER

18

19

20

V

CC

IC502 MPC17A51VMEL

MUTE

BB SW

AVC DET

BEEP

10

9

8

7

6

5

4

3

2

1

MUTE

LP

MUTE SW

AVC

AVC IN

MIX OUT

OUT 1

VREF

OUT 2

GND

SELECT

INPUT

OUTPUT

INPUT

OUTPUT

GND

2

1A

1A

3

1B

1B

4

1Y

1Y

5

2A

2A

6

2B

2B

7

2Y

2Y

8

16

V

S

3Y

CC

15

STROBE

G

4A

14

4A

4B

4Y

3A

3B

INPUT

4B

13

12

11

4Y

OUTPUT

3A

11

INPUT

3B

10

3Y

OUTPUT

9

IC601 CXD2545Q

SRON

SRDR

SFON

TFDR

TRON

TRDR

TFON

FFDR

FRON

FRDR

FFON

VCO0

VCO1

TEST

DVSS

TES2

TES3

PDO

VPCO

VCKI

AVDD

IGEN

AVSS

ADIO

RFC

SFDR

100

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

SLED PWM

GENERATOR

TRACKING PWM

GENERATOR

FOCUS PWM

GENERATOR

PWM GENERATOR

MIRR

DFCT

FOK DETECTOR

A/D

CONVERTER

SWITCH

&

BUFFER

26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41

TE

SE

RFDC

SERVO DSP

FE

SERVO

TRACKING

SERVO

FOCUS

SERVO

VC

SSTP

SLED

3

4

FILO

MDP

MDS

LOCK

CLV

PROCESSOR

NOISE

SHAPER

18-TIMES

OVER SAMPLING

FILTER

DIGITAL

PLL

VARI-PITCH

DOUBLE SPEED

FILI

PCO

– 39 – – 40 –

CLTV

MON

FSW

AVSS

FOK

93949596979899

ASYMMETRY

INTERFACE

CORRECTION

BIAS

RFAC

DFCT

CPU

MIRR

ASYI

GENERATOR

INTERFACE

INTERFACE

CORRECTOR

INTERFACE

GENERATOR 2

INTERFACE

ADD

ADDRESS

CPU

PRIORITY

CPU

ENCODER

ERROR

CPU

TIMING

CPU

COUT

INTERFACE

INTERFACE

SEQUENCER

SERVO

MICRO PROGRAM

INTERFACE

INTERFACE

DEMODULATOR

MUX

CLOK

CPU

CPU

SERVO

AUTO

32K RAM

CPU

EFM

XLAT

DATA

REGISTER

ASYO

ATSK

AVDD

DFSW

42

ADD

SCLK

DIRC

PROCESSOR

ASYE

XRST

D/A

DIGITAL

MUTE

SENS

7980818292 91 90 89 88 87 86 85 84 83

DETECTOR

PROCESSOR

PEAK

SQCK

SUBCODE

Q

PARALLEL

PROCESSOR

43 44 45

SERIAL

PSSL

SQSO

WDCK

EXCK

767778

SUBCODE

P-W

PROCESSOR

TIMING

GENERATOR 1

SYNC

PROTECTOR

DIGITAL

OUT

CLOCK

GENERATOR

46 — 50

LRCK

DA16|DA12

SBSO

75

SCOR

74

WFCK

73

EMPH

72

D OUT

71

70

MD2

C16M

69

68

C4M

67

FSTO

FSTI

66

DVSS

65

XTSL

64

XTAO

63

62

XTAI

61

DA01

|

|

51

DA11

r

IC Block Diagram (MPEG SECTION)

IC721 TC90A07U

CSYNC

AVCC

33

32 31 30 29 28 27 26 25 24 23

CVOUT

AGND

COUT

AVCC

YOUT

AGND

VREF

BIAS1

BIAS2

HSYNC

VSYNC

TMS3

VDD

CK27I

GND

TMS2

CK270

TMS1

YMS0

C LEVEL

ALIGNMENT

DAC

C

Y

34

35

36

37

38

39

XO

40

41

42

43

44

SYNC GENERATOR

142

MIFH

+

C SIGNAL GENERRATE

+

3

MIFFL

X

ROM

MIFFR

INTERPO-

LATE

INTERPO-

X

LATE

DAC

DAC

C SYNC

ADD

BURST FLAG

BLANKING

Cd

LEVEL

ALIGNMENT

5 6 7 8 9 10 11

VDD

VBLNKI

GND

Y LEVEL

ALIGNMENT

LOW-PASS

FILTER

LOW-PASS

FILTER

YCDI0

YCDI1

YCDI2

YCDI3

Y

Cb

SEPARATOR

Cr

GENERATOR

YCDI4

CLK

GENERATE

YCdCr

COLOR BAR

22

21

20

19

18

17

16

15

14

13

12

FLD

BLK

BF

CLPF

GND

VDD

VBLNKO

MODE

YCDI7

YCDI6

YCDI5

– 41 –

NOTE :

• -XX, -X mean standardized parts, so they

may have some difference from the original

one.

• Items marked “ * ”are not stocked since they

are seldom required for routine service. Some

delay should be anticipated when ordering

these items.

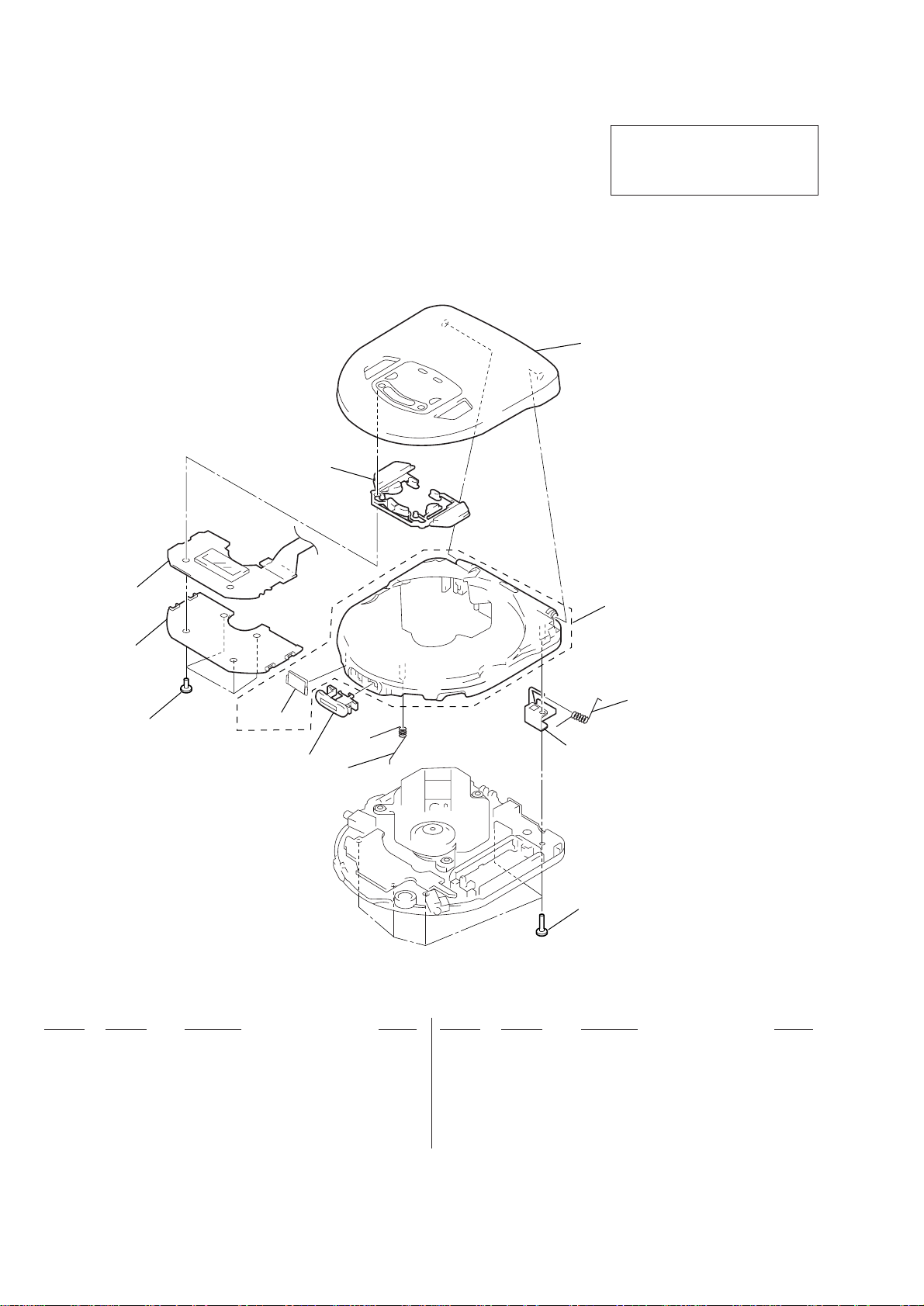

7-1. CABINET (UPPER) SECTION

SECTION 7

EXPLODED VIEWS

• The mechanical parts with no reference

number in the exploded views are not

supplied.

• Accessories and packing materials are given

in the last of this parts list.

6

The components identified by mark !

or dotted line with mark ! are critical

for safety.

Replace only with part number specified.

7

5

8

4

9

3

not supplied

10

1

2

11

Ref. No. Part No. Description Remark Ref. No. Part No. Description Remark

1 4-984-847-01 SPRING, TORSION

2 4-984-748-01 KNOB (OPEN)

3 3-318-382-71 SCREW (1.7X4), TAPPING

4 4-984-866-01 COVER, LID

5 1-418-438-11 SWITCH UNIT

6 4-217-534-01 BUTTON (CONTROL)

7 X-4951-142-1 LID SUB ASSY, UPPER

8 X-4951-143-1 CABINET (UPPER) SUB ASSY

9 4-984-849-01 SPRING, TORSION

10 4-984-848-01 BRACKET (SPRING)

11 3-336-395-01 SCREW (B2X10) (G), TAPPING

– 42 –

7-2. CABINET (LOWER) SECTION

56

55

54

CDM-2901ABA

56

62

53

52

60

63

61

53

57

59

58

51

Ref. No. Part No. Description Remark Ref. No. Part No. Description Remark

51 4-962-025-21 FOOT, RUBBER

52 X-4951-144-1 CABINET (LOWER) SUB ASSY

53 4-984-747-01 KNOB (H-R)

54 A-3321-971-A MAIN BOARD, COMPLETE

55 A-3321-973-A MPEG BOARD, COMPLETE

56 4-993-138-01 INSULATOR

57 4-978-696-01 TERMINAL BOARD (RELAY), BATTERY

58 4-984-750-11 LID, BATTERY CASE

* 59 1-674-189-11 IR BOARD

60 1-793-139-11 LEAD (WITH CONNECTOR)

61 4-978-695-01 PLATE, TERMINAL, BATTERY

62 4-984-850-01 TERMINAL BOARD (BATTERY CASE)

63 4-984-851-01 TERMINAL BOARD, BATTERY

– 43 –

7-3. OPTICAL PICK-UP SECTION

(CDM-2901ABA)

M902

106

107

not supplied

M901

109

105

S901

108

110

103

111

102

104

101

The components identified by mark ! or dotted

line with mark ! are critical for safety.

Replace only with part number specified.

Ref. No. Part No. Description Remark Ref. No. Part No. Description Remark

101 A-3320-684-A SCREW ASSY, FEED

102 3-318-203-11 SCREW (B1.7), TAPPING

103 4-972-163-04 SPRING, SLED

104 1-783-093-11 LEAD (WITH CONNECTOR)

105 7-627-850-17 SCREW,PRECISION +P 1.4X2.5

106 3-719-401-11 SCREW (B1.7), TAPPING

* 107 4-984-320-01 CHASSIS

108 4-974-003-01 GEAR (B)

109 1-667-512-11 SLIDE FLEXIBLE BOARD

! 110 X-4950-060-1 OPTICAL PICK-UP (DAX-01A2 RP)

111 4-972-165-01 RACK

112 4-973-631-01 SCREW

M901 A-3328-115-A MOTOR ASSY, SLED (SLED)

M902 A-3328-114-A MOTOR ASSY, TURN TABLE (SPINDLE)

S901 1-571-099-21 SWITCH (1 KEY) (LIMIT)

112

(INCLUDING GEAR)

– 44 –

SECTION 8

ELECTRICAL PARTS LIST

NOTE :

• Due to standardization, replacements in the

parts list may be different from the parts

specified in the diagrams or the components

used on the set.

• -XX, -X mean standardized parts, so they

may have some difference from the original

one.

• RESISTORS

All resistors are in ohms

METAL : Metal-film resistor

METAL OXIDE :Metal oxide-film resistor

F : nonflammable

• Items marked “ * ”are not stocked since

they are seldom required for routine service.

Some delay should be anticipated when

ordering these items.

Ref. No. Part No. Description Remark Ref. No. Part No. Description Remark

* 1-674-189-11 IR BOARD

********

• SEMICONDUCTORS

In each case, u : µ , for example :

uA.... : µ A.... , uPA.... : µ PA....

uPB.... : µ PB.... , uPC.... : µ PC....

uPD.... : µ PD....

• CAPACITORS

uF : µ F

• COILS

uH : µ H

C351 1-164-156-11 CERAMIC CHIP 0.1uF 25V

C352 1-109-982-11 CERAMIC CHIP 1uF 10% 10V

The components identified by mark !

or dotted line with mark ! are critical

for safety.

Replace only with part number specified.

When indicating parts by reference number, please include the board.

MAINIR

1-793-139-11 LEAD (WITH CONNECTOR)

< CAPACITOR >

C1 1-104-851-11 TANTAL. CHIP 10uF 20% 10V

< IC >

IC1 8-749-015-96 IC GP1UC10J

**************************************************************

A-3321-971-A MAIN BOARD, COMPLETE

*********************

4-978-695-01 PLATE, TERMINAL, BATTERY

4-984-850-01 TERMINAL BOARD (BATTERY CASE)

4-984-851-01 TERMINAL BOARD, BATTERY

< CAPACITOR >

C101 1-162-964-11 CERAMIC CHIP 0.001uF 10% 50V

C102 1-107-686-11 TANTAL. CHIP 4.7uF 20% 16V

C103 1-162-964-11 CERAMIC CHIP 0.001uF 10% 50V

C104 1-109-982-11 CERAMIC CHIP 1uF 10% 10V

C105 1-162-927-11 CERAMIC CHIP 100PF 5% 50V

C106 1-115-467-11 CERAMIC CHIP 0.22uF 10% 10V

C201 1-162-964-11 CERAMIC CHIP 0.001uF 10% 50V

C202 1-107-686-11 TANTAL. CHIP 4.7uF 20% 16V

C203 1-162-964-11 CERAMIC CHIP 0.001uF 10% 50V

C204 1-109-982-11 CERAMIC CHIP 1uF 10% 10V

C205 1-162-927-11 CERAMIC CHIP 100PF 5% 50V

C206 1-115-467-11 CERAMIC CHIP 0.22uF 10% 10V

C353 1-104-851-11 TANTAL. CHIP 10uF 20% 10V

C361 1-164-156-11 CERAMIC CHIP 0.1uF 25V

C362 1-104-847-11 TANTAL. CHIP 22uF 20% 4V

C364 1-124-779-00 ELECT CHIP 10uF 20% 16V

C365 1-115-156-11 CERAMIC CHIP 1uF 10V

C366 1-126-395-11 ELECT 22uF 20% 16V

C367 1-115-156-11 CERAMIC CHIP 1uF 10V

C368 1-164-156-11 CERAMIC CHIP 0.1uF 25V

C369 1-164-677-11 CERAMIC CHIP 0.033uF 10% 16V

C370 1-107-826-91 CERAMIC CHIP 0.1uF 10% 16V

C371 1-115-156-11 CERAMIC CHIP 1uF 10V

C372 1-115-156-11 CERAMIC CHIP 1uF 10V

C375 1-115-565-11 CERAMIC CHIP 2.2uF 10% 10V

C401 1-109-982-11 CERAMIC CHIP 1uF 10% 10V

C411 1-164-156-11 CERAMIC CHIP 0.1uF 25V

C412 1-115-416-11 CERAMIC CHIP 1000PF 5% 25V

C413 1-164-156-11 CERAMIC CHIP 0.1uF 25V

C414 1-119-764-11 ELECT 47uF 20% 4V

C415 1-115-156-11 CERAMIC CHIP 1uF 10V

C416 1-115-156-11 CERAMIC CHIP 1uF 10V

C417 1-128-416-11 ELECT CHIP 100uF 20% 16V

C418 1-119-764-11 ELECT 47uF 20% 4V

C421 1-162-967-11 CERAMIC CHIP 0.0033uF 10% 50V

C422 1-164-156-11 CERAMIC CHIP 0.1uF 25V

C423 1-119-764-11 ELECT 47uF 20% 4V

C424 1-115-156-11 CERAMIC CHIP 1uF 10V

C425 1-107-826-91 CERAMIC CHIP 0.1uF 10% 16V