Sony CX-LZP3 Schematic

CX-LZP3

SERVICE MANUAL

Ver. 1.2 2005.04

• CX-LZP3 is compact disc receiver

in AWP-ZP3.

AEP Model

UK Model

E Model

Australian Model

Model Name Using Similar Mechanism NEW

CD Mechanism Type CDM80BV-F4BD81

Base Unit Name BU-F4BD81B

Optical Pick-up Name KSM-215CFP

Amplifier section

AEP, UK model:

DIN power output (rated):

16 + 16 W

(6 ohms at 1 kHz, DIN)

Continuous RMS power output (reference):

20 + 20 W

(6 ohms at 1 kHz, 10%

THD)

Music power output (reference):

40 + 40 watts (6 ohms at

1 kHz, 10% THD)

Other models:

The following measured at 110 – 120, 220 – 240 V AC,

50/60 Hz

DIN power output (rated):

16 + 16 W

(6 ohms at 1 kHz, DIN)

Continuous RMS power output (reference):

20 + 20 W

(6 ohms at 1 kHz, 10 %

THD)

SPECIFICATIONS

Inputs

MD (RCA pin jacks): Sensitivity 500 mV,

impedance 47 kilohms

Outputs

PHONES (stereo mini jack):

Accepts headphones with

an impedance of 8 ohms or

more

SPEAKERS: Accepts impedance of

6 ohms

CD player section

System Compact disc and digital

audio system

Laser Semiconductor laser

(λ=780 nm)

Emission duration:

continuous

Frequency response 2 Hz – 20 kHz

– Continued on next page –

9-877-756-03

2005D04-1

© 2005.04

COMPACT DISC RECEIVER

Sony Corporation

Personal Audio Group

Published by Sony Engineering Corporation

1

CX-LZP3

Ver. 1.1

Tuner section

FM stereo, FM/AM superheterodyne tuner

FM tuner section

Tuning range 87.5 – 108.0 MHz

(50-kHz step)

Antenna FM lead antenna

Antenna terminals 75 ohms unbalanced

Intermediate frequency 10.7 MHz

AM tuner section

Tuning range

AEP, UK model: 531 – 1,602 kHz

(with the tuning interval

set at 9 kHz)

Other models: 530 – 1,710 kHz

(with the tuning interval

set at 10 kHz)

531 – 1,602 kHz

(with the tuning interval

set at 9 kHz)

Antenna AM loop antenna, external

antenna terminal

Intermediate frequency 450 kHz

General

Power requirements

AEP, UK model: 230 V AC, 50/60 Hz

Australian model: 230 – 240 V AC, 50/60 Hz

Korean model: 220 V AC, 60 Hz

Other models: 110 – 120, 220 – 240 V

AC, 50/60 Hz

Adjustable with voltage

selector

Power consumption

AEP, UK, Korean model:

40 W

0.3 W (in Power Saving

mode)

Other models: 45 W

Dimensions (w/h/d) Approx. 108 × 224.8 ×

327.1 mm

Mass Approx. 4.2 kg

Design and specifications are subject to change

without notice.

Notes on Chip Component Replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be

damaged by heat.

Flexible Circuit Board Repairing

• Keep the temperature of soldering iron around 270°C during

repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

UNLEADED SOLDER

Boards requiring use of unleaded solder are printed with the lead

free mark (LF) indicating the solder contains no lead.

(Caution: Some printed circuit boards may not come printed with

the lead free mark due to their particular size)

: LEAD FREE MARK

Unleaded solder has the following characteristics.

• Unleaded solder melts at a temperature about 40 °C higher than

ordinary solder.

Ordinary soldering irons can be used but the iron tip has to be

applied to the solder joint for a slightly longer time.

Soldering irons using a temperature regulator should be set to about

350 °C.

Caution: The printed pattern (copper foil) may peel away if the

heated tip is applied for too long, so be careful!

• Strong viscosity

Unleaded solder is more viscou-s (sticky, less prone to flow) than

ordinary solder so use caution not to let solder bridges occur such

as on IC pins, etc.

• Usable with ordinary solder

It is best to use only unleaded solder but unleaded solder may also

be added to ordinary solder.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED LINE

WITH MARK 0 ON THE SCHEMATIC DIAGRAMS AND IN

THE PARTS LIST ARE CRITICAL TO SAFE OPERATION.

REPLACE THESE COMPONENTS WITH SONY PARTS WHOSE

PART NUMBERS APPEAR AS SHOWN IN THIS MANUAL OR

IN SUPPLEMENTS PUBLISHED BY SONY.

2

CAUTION

Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous

radiation exposure.

NOTES ON HANDLING THE OPTICAL PICK-UP BLOCK

OR BASE UNIT

The laser diode in the optical pick-up block may suffer electrostatic

breakdown because of the potential difference generated by the

charged electrostatic load, etc. on clothing and the human body.

During repair, pay attention to electrostatic break-down and also

use the procedure in the printed matter which is included in the

repair parts.

The flexible board is easily damaged and should be handled with

care.

NOTES ON LASER DIODE EMISSION CHECK

The laser beam on this model is concentrated so as to be focused on

the disc reflective surface by the objective lens in the optical pickup block. Therefore, when checking the laser diode emission,

observe from more than 30 cm away from the objective lens.

CX-LZP3

Laser component in this product is capable

of emitting radiation exceeding the limit for

Class 1.

This appliance is

classified as a CLASS 1

LASER product. This

marking is located on the

rear exterior.

PLAYABLE DISCS

You can play back the following discs on this system. Other discs

cannot be played back.

List of playable discs

Format of discs Disc logo

Audio CDs

CD-R/CD-RW

(audio data/MP3 files)

3

CX-LZP3

TABLE OF CONTENTS

1. SERVICE POSITIONS

1-1. CDM Service Position ........................................................ 5

2. GENERAL

Main Unit ................................................................................ 6

Remote Control ....................................................................... 7

3. DISASSEMBLY

3-1. Case (Top) ........................................................................... 9

3-2. Front Panel Section ............................................................. 9

3-3. Rear Panel Section ............................................................ 10

3-4. Main Board ....................................................................... 10

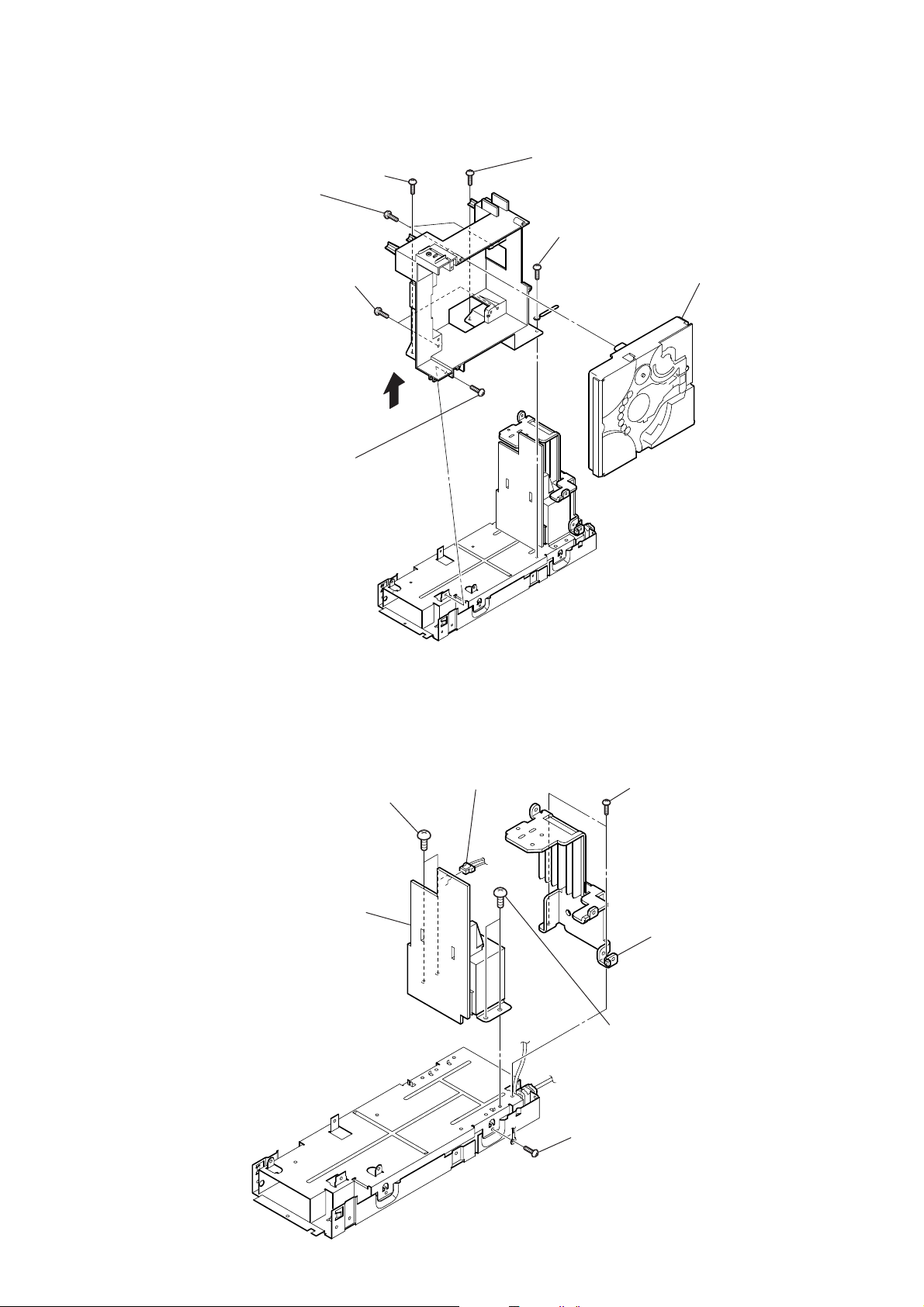

3-5. Mechanism Deck ............................................................... 11

3-6. PT Board ........................................................................... 11

3-7. USB Board ........................................................................ 12

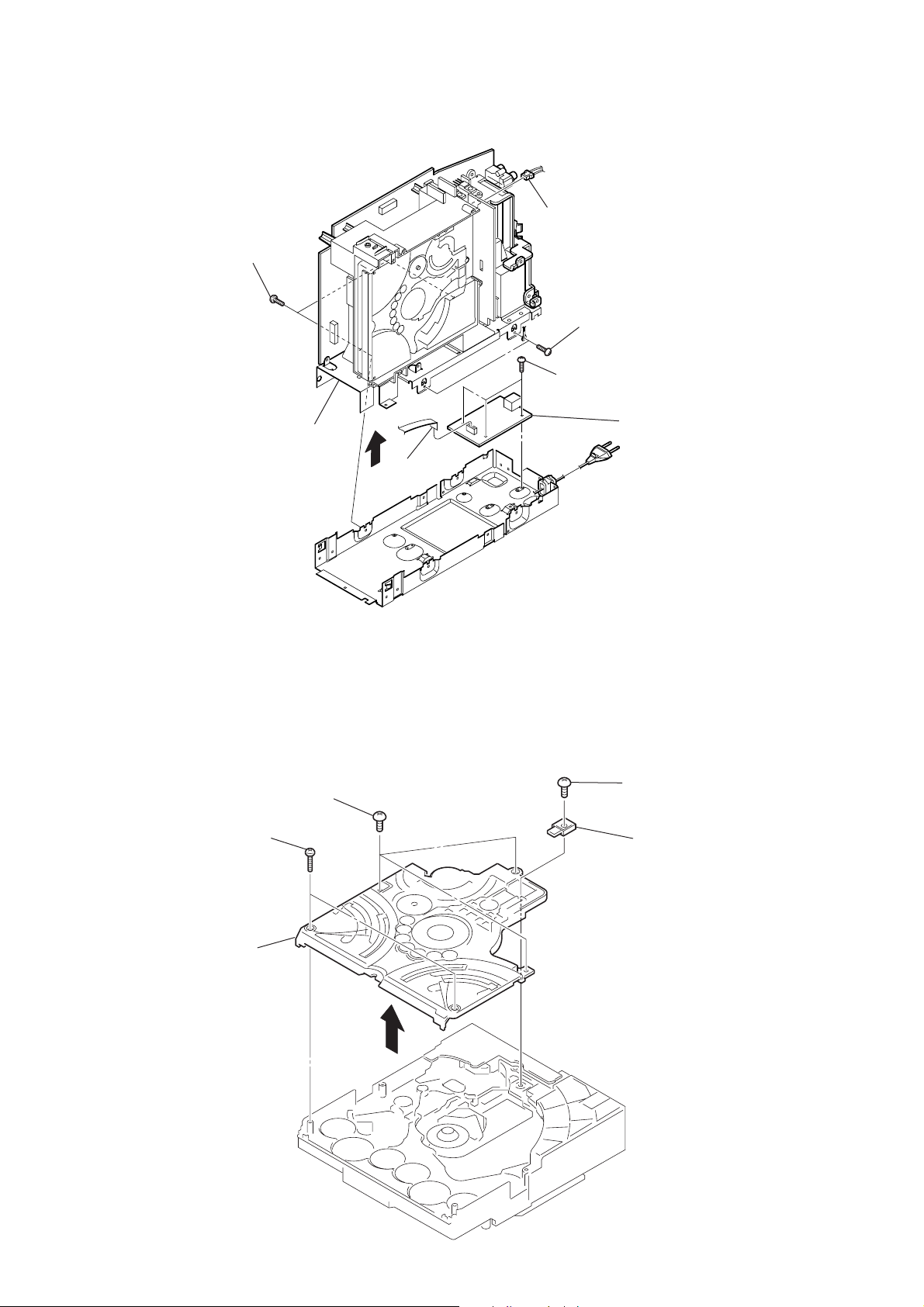

3-8. Chassis (Top) ..................................................................... 12

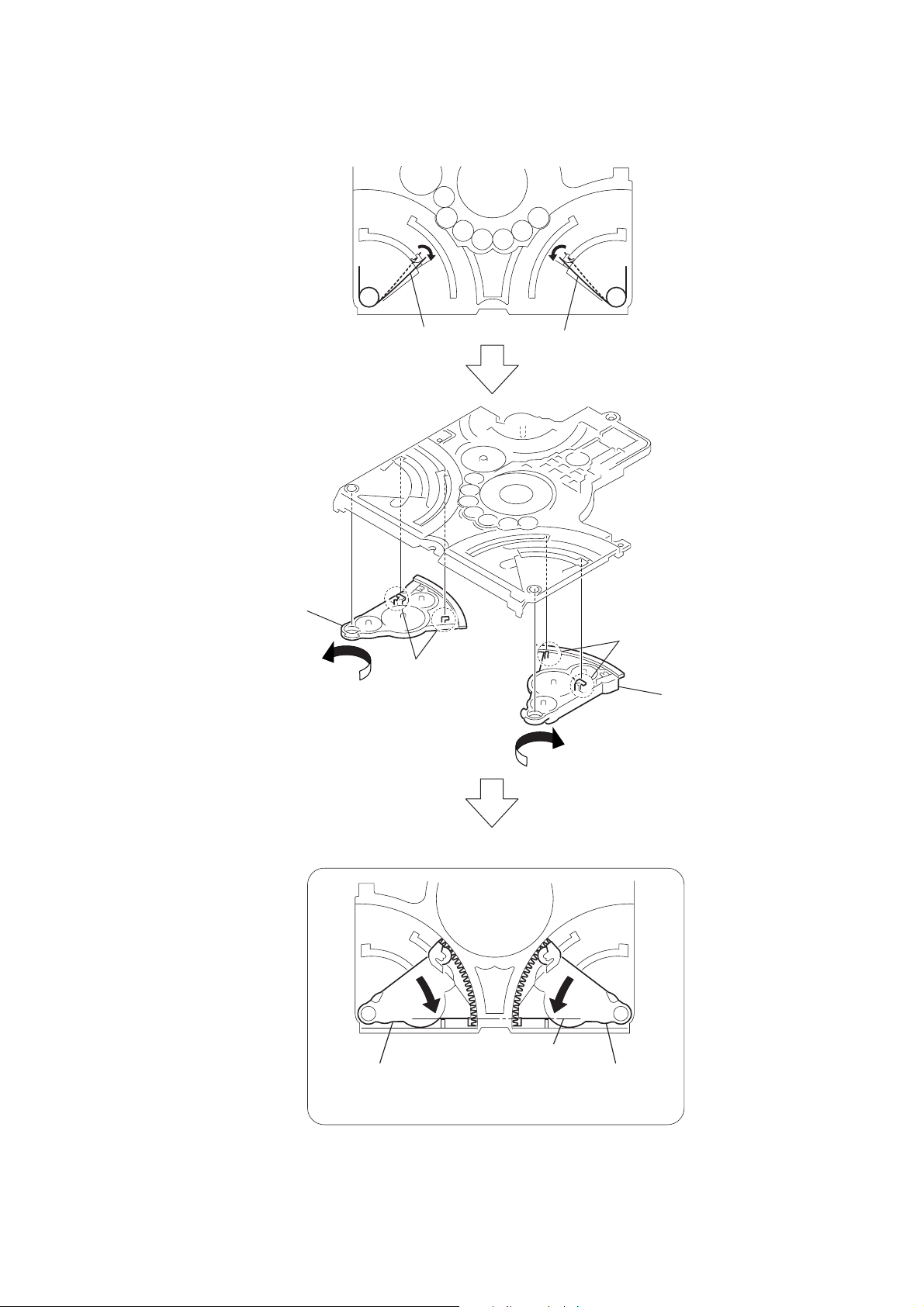

3-9. Lever (Loading R/L) ......................................................... 13

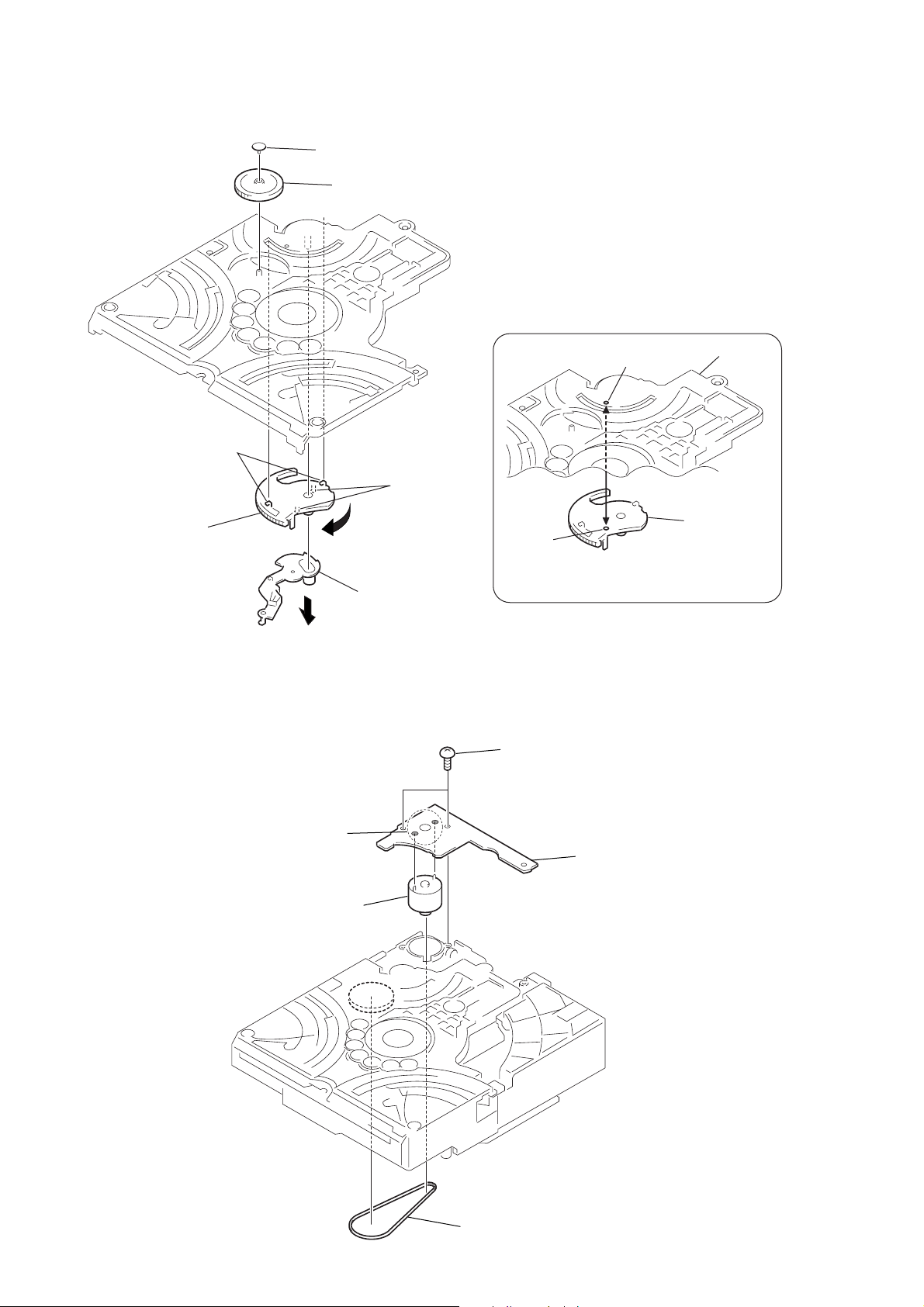

3-10. Disc Stop Lever, Disc Sensor Lever.................................. 14

3-11. Driver Board...................................................................... 14

3-12. BD Board .......................................................................... 15

3-13. Optical Pick-up ................................................................. 15

3-14. Base Unit ........................................................................... 16

3-15. Lever (BU Lock) ............................................................... 16

3-16. Close Lever ....................................................................... 17

3-17. DIR Lever, Gear (IDL-B) .................................................. 17

3-18. Gear (IDL-C) ..................................................................... 18

4. TEST MODE ...................................................................... 19

5. ELECTRICAL ADJUSTMENT.................................... 20

6. DIAGRAMS

6-1. IC Pin Description ............................................................. 21

6-2. Block Diagram –CD Section– ........................................... 27

6-3. Block Diagram –Main Section– ........................................ 28

6-4. Note for Printed Wiring Boards and

Schematic Diagrams .......................................................... 29

6-5. Circuit Boards Location .................................................... 29

6-6. Waveforms ......................................................................... 29

6-7. Printed Wiring Board –CD Section– ................................. 30

6-8. Schematic Diagram –CD Section– .................................... 31

6-9. Schematic Diagram –Main Section (1/2)– ........................ 32

6-10. Schematic Diagram –Main Section (2/2)– ........................ 33

6-11. Printed Wiring Boards –Main Section– ............................ 34

6-12. Printed Wiring Board –Driver Section– ............................ 35

6-13. Schematic Diagram –Driver Section– ............................... 35

6-14. Printed Wiring Board –USB (A) Section– ........................ 36

6-15. Schematic Diagram –USB (A) Section– ........................... 37

6-16. Printed Wiring Board –Front Section– .............................. 38

6-17. Schematic Diagram –Front Section– ................................ 39

6-18. Printed Wiring Board –Power Section– ............................ 40

6-19. Schematic Diagram –Power Section– ............................... 41

6-20. IC Block Diagrams ............................................................ 42

7. EXPLODED VIEWS

7-1. Rear Panel Section ............................................................ 44

7-2. Front Panel Section ........................................................... 45

7-3. Main Board Section .......................................................... 46

7-4. CD Mechanism Deck (1) Section ..................................... 47

7-5. CD Mechanism Deck (2) Section ..................................... 48

7-6. CD Mechanism Deck (3) Section ..................................... 49

7-7. Base Unit Section .............................................................. 50

8. ELECTRICAL PARTS LIST......................................... 51

4

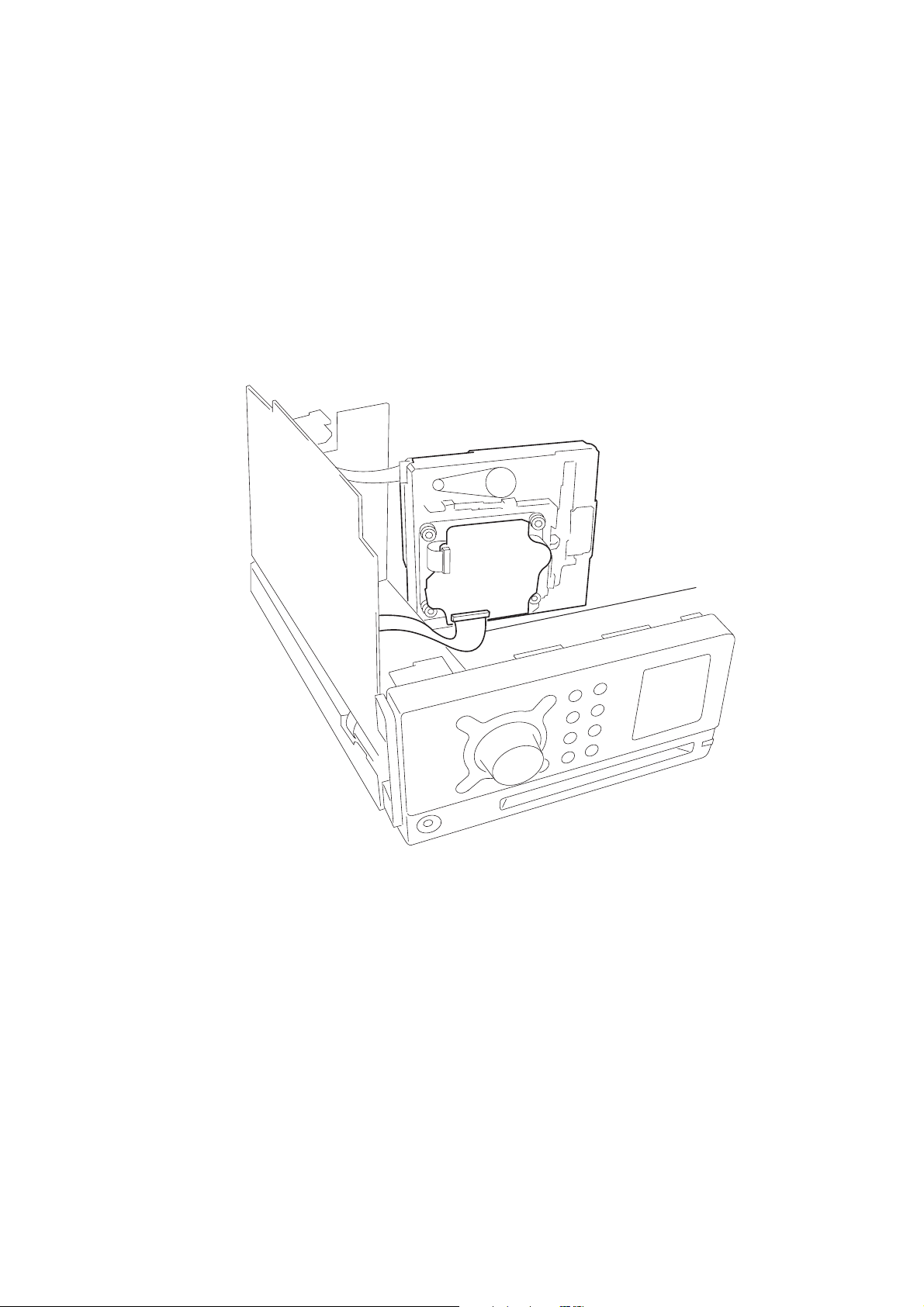

SECTION 1

A

SERVICE POSITIONS

1-1. CDM SERVICE POSITION

•The CDM is specified in vertical position and this is the standard position.

Check signals such as RF waveform in this position.

• Extension of this flexible cable increases workability.

1mm pitch/29-pin/L300

Jig No.J-2501-103-A

CX-LZP3

J-2501-103-

5

CX-LZP3

Illustrati

1

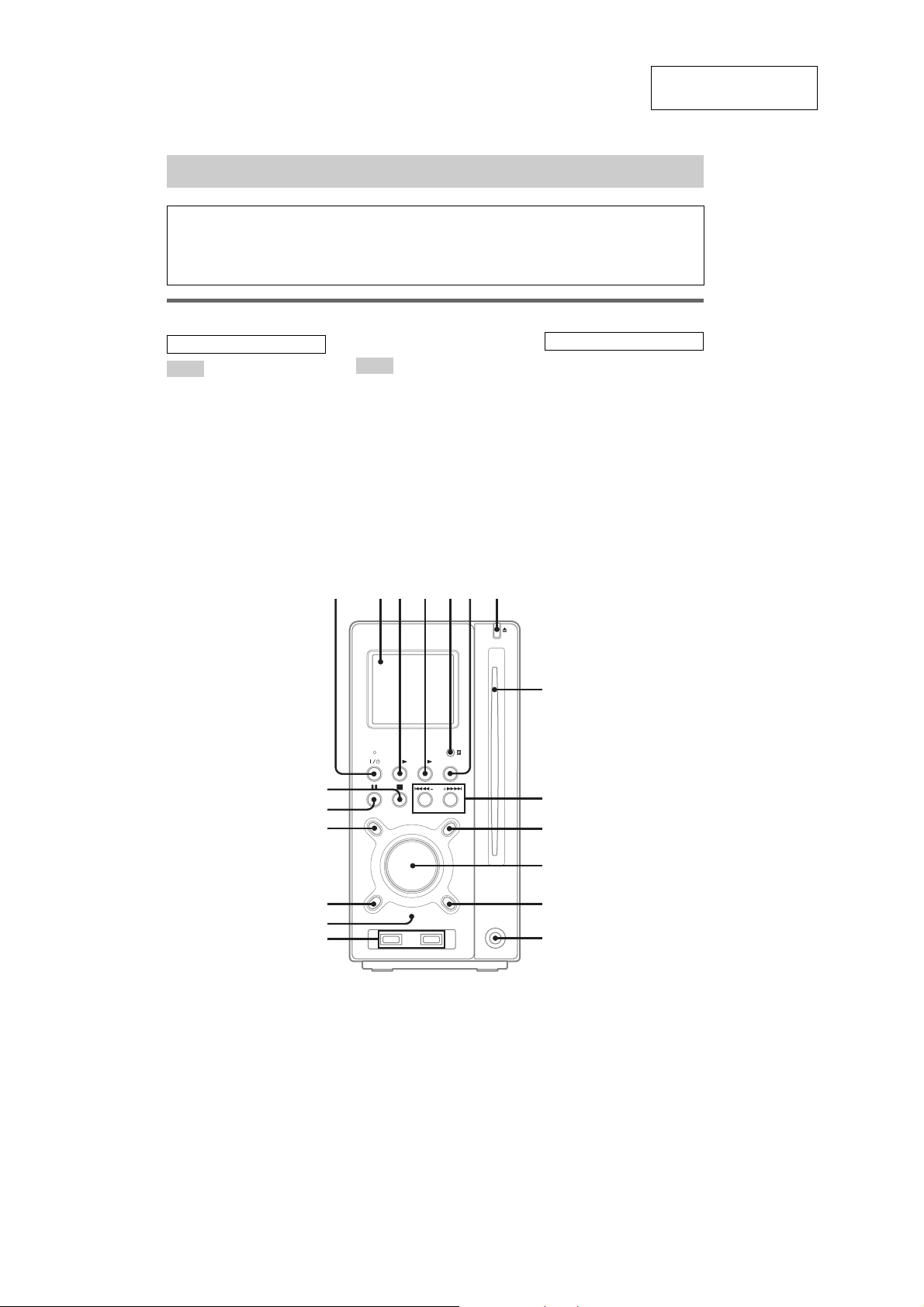

SECTION 2

GENERAL

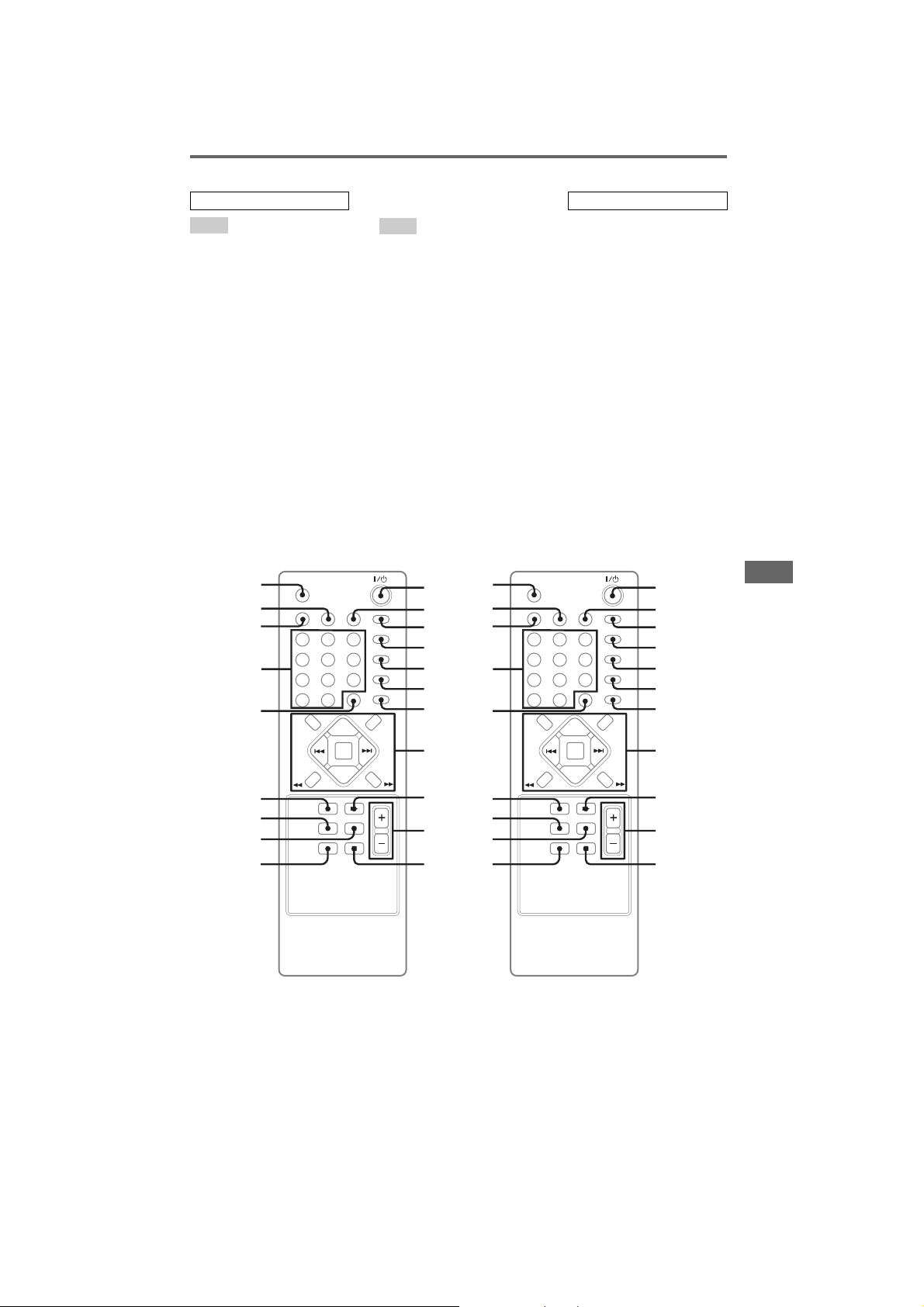

List of button locations and reference pages

This section is extracted

from instruction manual.

How to use this page

Use this page to find the location of buttons and other

parts of the system that are mentioned in the text.

Main unit

ALPHABETICAL ORDER

A – O

ALBUM + qs (11, 12, 27)

ALBUM – qh (11, 12, 27)

Disc slot 8 (10)

Display window 2

FUNCTION qj (8, 10, 12, 13, 15,

23, 26, 27, 30)

i-Bass 0 (17, 33)

1)

MD

6 (30)

P – Z

2)

3 (23, 26, 27)

PC

PHONES jack qd

Remote sensor 5

TUNER/BAND 4

TUNING +/– 9 (13, 15)

USB hub ports

USB STATUS lamp

VOLUME control qa (26, 27)

2

3)

3 4 5 76

1)

6 (13, 15)

qf (28, 29)

3)

qg (28)

on number

r

TUNER/BAND 41)6 (13, 15)

Name of button/part Reference page

RR

BUTTON DESCRIPTIONS

?/1 (power) 1 (8, 14, 23, 33)

3)

(play) 3 (27)

PC N

CD N (play) 3

Z (eject) 7 (8, 10)

.m (go back/rewind) 9

(11, 14, 27)

M> (fast forward/go

forward) 9 (8, 11, 14, 15, 27)

X (pause) qk (11)

x (stop) ql (11, 14)

1)

AWP-ZP1 only

2)

AWP-ZP3 only

3)

AWP-ZP5 only

1)

4 (11)

38

8

ql

qk

qj

9

0

qa

qh

qs

qg

qf

GB

qd

6

Remote control

CX-LZP3

ALPHABETICAL ORDER

A – H

ALBUM +/– 8 (11, 12, 27)

CD qf (10, 12, 14, 15)

CLEAR qh (13)

CLOCK/TIMER SELECT ql

(19)

CLOCK/TIMER SET 2 (9, 18)

DISPLAY qk (16, 20, 27)

ENTER 8 (9, 12, 14, 18)

EQ 8 (17)

FM MODE 6 (16)

FUNCTION w; (10, 12, 13, 15,

23, 26, 27, 30)

AWP-ZP5/ZP3 AWP-ZP1

w;

ql

qk

qj

qh

I – Z

i-Bass 8 (17)

Number buttons qj (11, 27)

PC* qg (23, 26, 27)

PC MIXING* 4 (17)

PLAY MODE 7 (11, 12, 27)

REPEAT 6 (12, 27)

SLEEP 3 (18)

TUNER BAND qs (13, 15)

TUNER MEMORY 5 (14)

TUNING MODE 7 (13, 15)

TUNING +/– 8 (13, 15)

VOLUME +/– 0 (18, 26, 27)

1

2

3

3

ql

qk

4

5

qj

6

7

qh

BUTTON DESCRIPTIONS

?/1 (power) 1 (8, 14, 18, 23,

33)

./> (go back/go forward)

8 (9, 11, 14, 18, 27)

m/M (rewind/fast forward)

8 (11, 27)

N (play) 9 (11, 27)

x (stop) qa (11, 14, 27)

X (pause) qd (11, 27)

*This button is not available for

AWP-ZP1.

1

2

7

6

5

6

7

Additional Information

qg

qf

qd

qs

8

9

0

qa

qf

qs

qd

w;

8

9

0

qa

39

GB

7

CX-LZP3

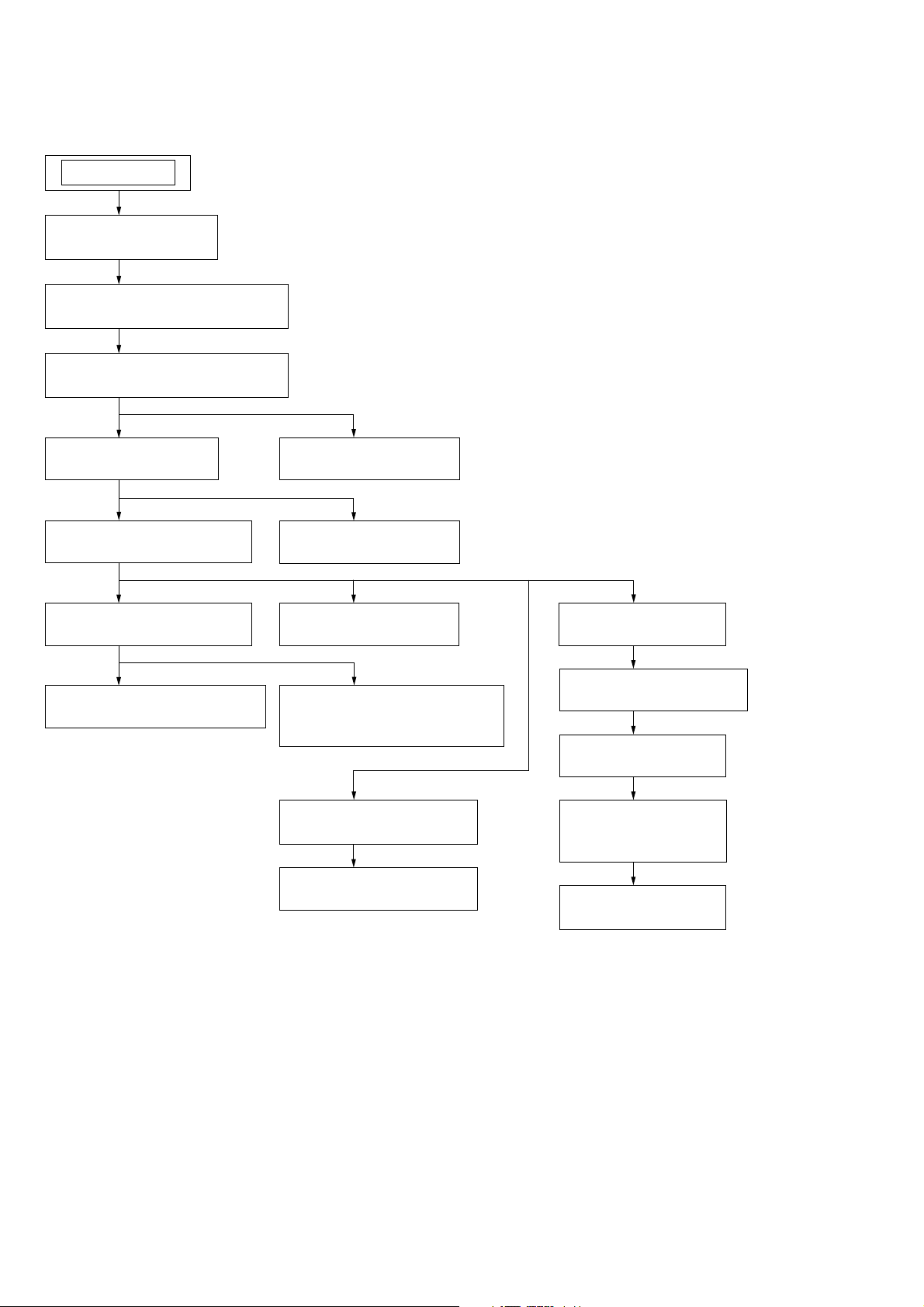

Note : Disassemble the unit in the order as shown below.

SET

3-1. CASE (TOP)

(Page 9)

3-2. FRONT PANEL SECTION

(Page 9)

3-3. REAR PANEL SECTION

(Page 10)

SECTION 3

DISASSEMBLY

3-4. MAIN BOARD

(Page 10)

3-5. MECHANISM DECK

(Page 11)

3-8. CHASSIS (TOP)

(Page 12)

3-9. LEVER (LOADING R/L)

(Page 13)

3-7. USB BOARD

(Page 12)

3-6. PT BOARD

(Page 11)

3-11. DRIVER BOARD

(Page 14)

3-10. DISC STOP LEVER,

DISC SENSOR LEVER

(Page 14)

3-12. BD BOARD

(Page 15)

3-13. OPTICAL PICK-UP

(Page 15)

3-14. BASE UNIT

(Page 16)

3-15. LEVER (BU LOCK)

(Page 16)

3-16. CLOSE LEVER

(Page 17)

3-17. DIR LEVER,

GEAR (IDL-B)

(Page 17)

3-18. GEAR (IDL-C)

(Page 18)

8

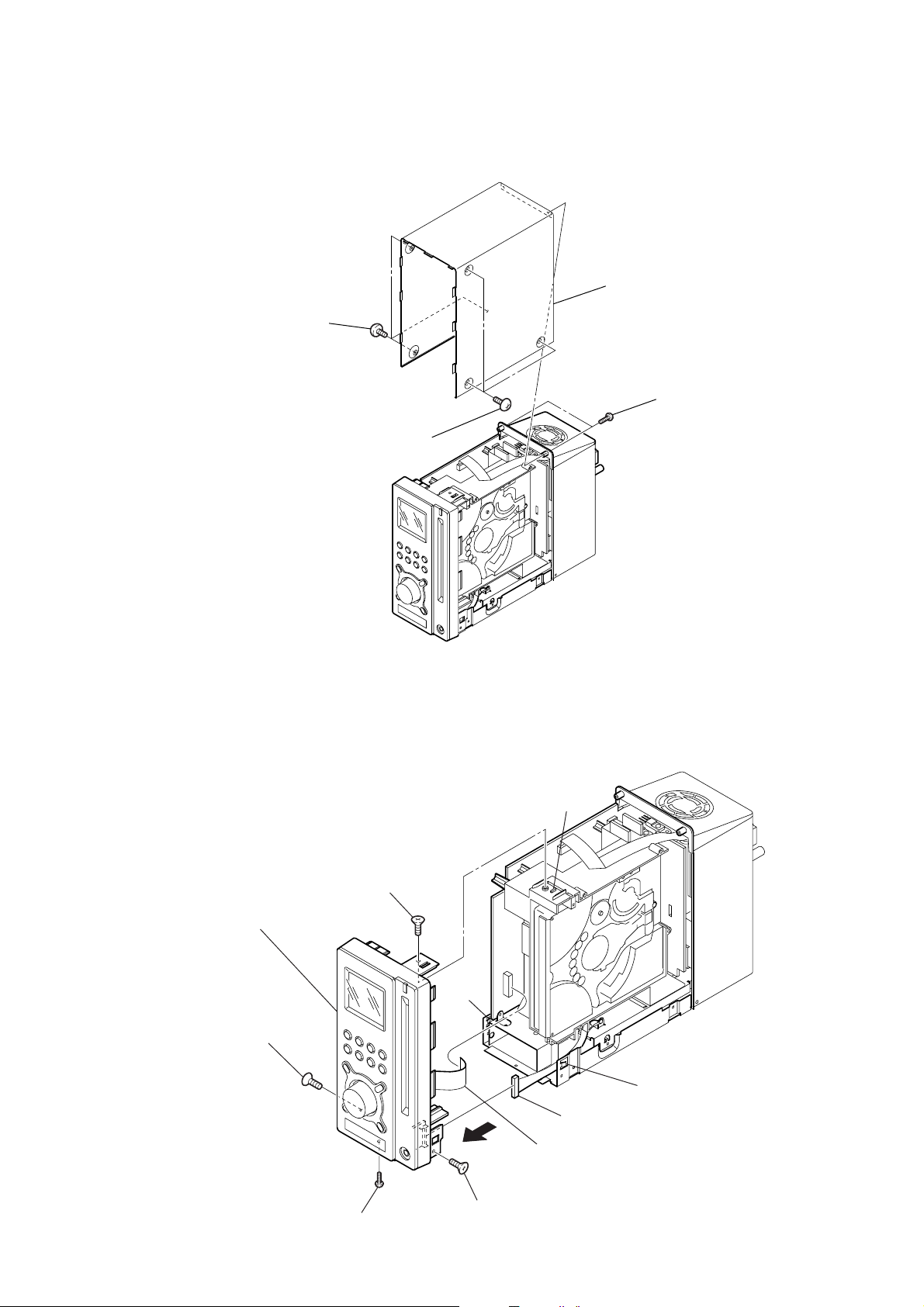

Note : Follow the disassembly procedure in the numerical order given.

)

3-1. CASE (TOP)

2

three screws

(case 3

TP2

)

1

three screws

(case 3

TP2

)

4

case (top)

3

two

screws

(+BVTP 3

x

CX-LZP3

8

3-2. FRONT PANEL SECTION

8

front panel section

3

screw

(+KTP 3

x

8)

screw

2

(+KTP 3

x

claw

8)

claw

5

6

CN602

7

CN700

claw

4

screw

(+BVTP 3

x

8)

1

screw

(+KTP 3

x

8)

9

CX-LZP3

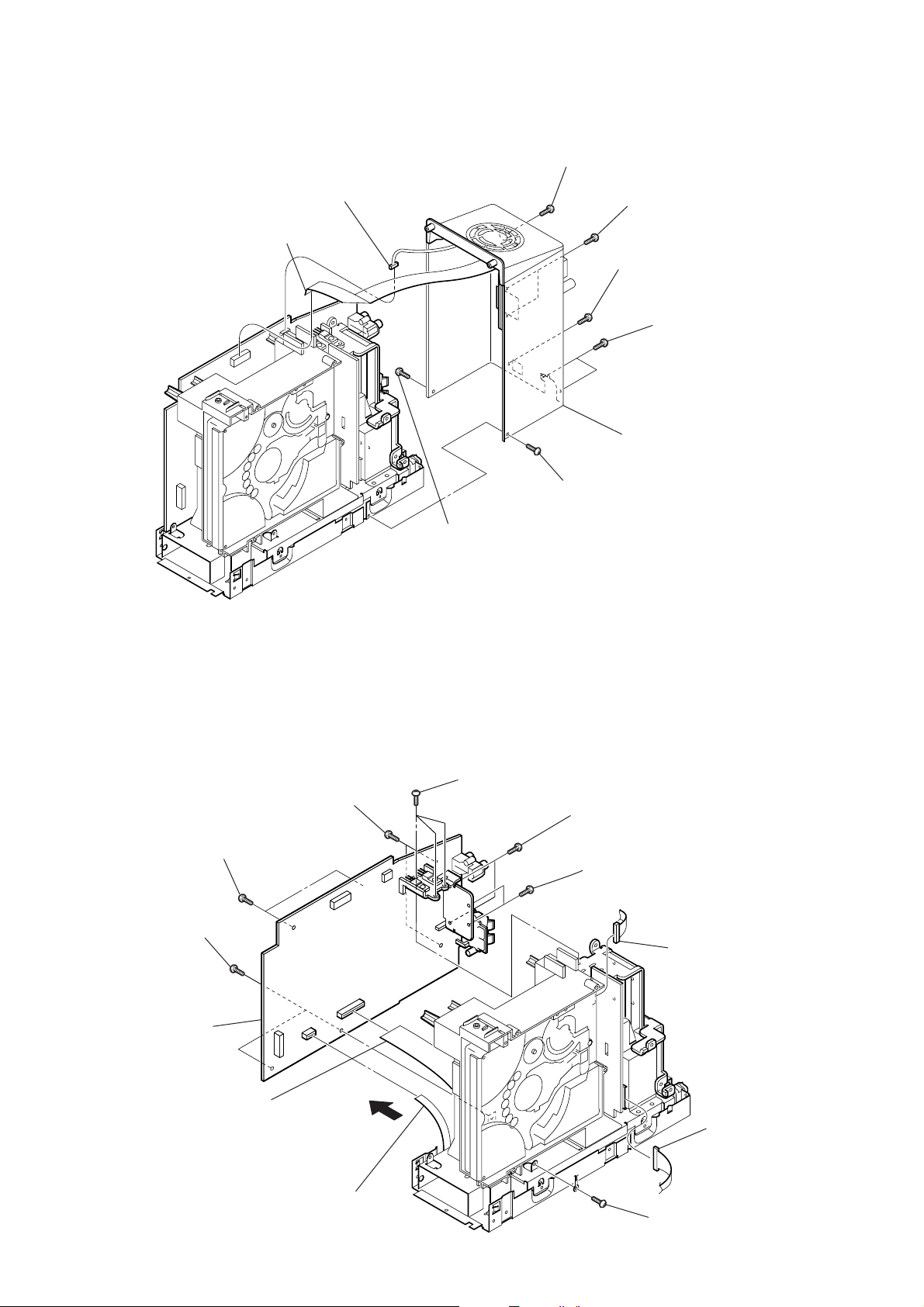

)

3-3. REAR PANEL SECTION

2

CN601

1

CN451

5

screw

(+BVTP 3

7

(+BVTP 3

9

3

screw

(+BVTP 3

x

8)

6

two

screws

(+BVTP 3

screw

rear panel section

x

8)

x

x

8

two

screws

(+BVTP 3

8)

8)

x

8

3-4. MAIN BOARD

9

two

(+BVTP 3

8

two

screws

(+BVTP 3

screws

x

8)

x

8)

7

two

screws

(+BVTP 3

x

4

screw

(+BVTP 3

4

8)

(+BVTP 3

three

x

8)

screws

x

8)

5

(+BVTP 3

two

screws

x

6

two

screws

(+BVTP 3

x

8)

8)

1

CN701

10

qd

MAIN board

qs

CN701

0

qa

CN802

2

CN101

3

screw

(+BVTP 3

x

8)

3-5. MECHANISM DECK

k

y

6

two

(+BVTP 3

2

screw

(+BVTP 3

screws

x

10)

7

two

screws

(+BVTP 3

x

8)

x

10)

5

4

screw

(+BVTP 3

x

CX-LZP3

1

screw

(+BVTP 3

8)

x

8)

3

screw

(+BVTP 3

x

8)

8

mechanism dec

3-6. PT BOARD

7

PT board

6

two

screws

(+BV 4

x

4

8)

CN102

1

(+BVTP 3

5

(+BV 4

screw

2

two

screws

(+BVTP 3

3

heat sink ass

two

screws

x

8)

x

8)

x

8)

11

CX-LZP3

d

)

Ver. 1.1

3-7. USB BOARD

3

two

screws

(+BVTP 3

5

chassis section

x

1

CN102

8)

2

two

screws

4

6

CN801

(+BVTP 3

7

three

(+BV3 (3-CR))

screws

8

x

8)

USB boar

3-8. CHASSIS (TOP)

5

4

three screws

(+BVTP 2.6

3

two screws

(+P 2

chassis (top)

×

10)

1

×

8)

screw

(+BVTP 2.6

2

lever (CL UP2

×

8)

12

3-9. LEVER (LOADING R/L)

)

CX-LZP3

5

lever (loading-R)

1

spr-T (loading-L) spr-T (loading-R)

4

two hooks

1

2

two hooks

3

lever (loading-L

PRECAUTION DURING LEVER (LOADING R / L) INSTALLATION

Align the horizontal position.

lever (loading-L)

Install the

both levers so that they move symmetrically.

lever (loading-R)

13

CX-LZP3

d

Ver. 1.1

3-10. DISC STOP LEVER, DISC SENSOR LEVER

1

gear (cap)

2

gear (IDL-L)

PRECAUTION DURING DISC STOP LEVER INSTALLATION

5

two hooks

6

disc stop lever

3-11. DRIVER BOARD

3

two claws

4

disc sensor lever

hole

hole

Install the disc stop lever so that the both holes

are aligned.

2

two screws

(+BVTP 2.6

×

8)

chassis (top)

disc stop lever

3

Remove soldering

from the two points.

4

motor (pully) assy

1

belt (MOT)

5

DRIVER boar

14

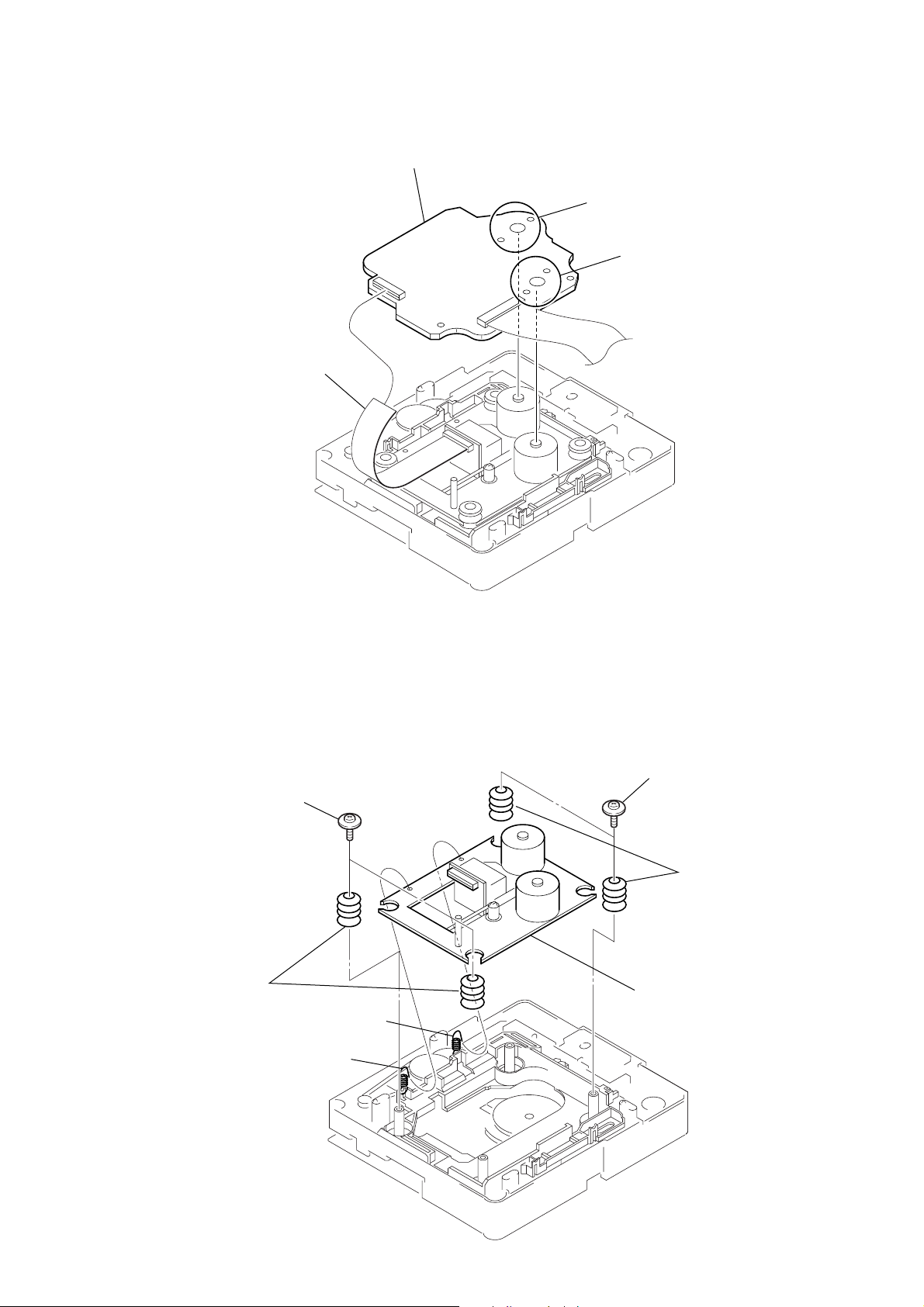

3-12. BD BOARD

s

1

CN101

4

BD board

3

Remove the two solderings.

2

Remove the two solderings.

CX-LZP3

3-13. OPTICAL PICK-UP

3

two floating screws

(+PTPWHM 2.6)

6

two insulators

2

1

tension spring (F-1)

tension spring (F-2)

4

two floating screws

(+PTPWHM 2.6)

5

two insulator

7

optical pick-up

15

CX-LZP3

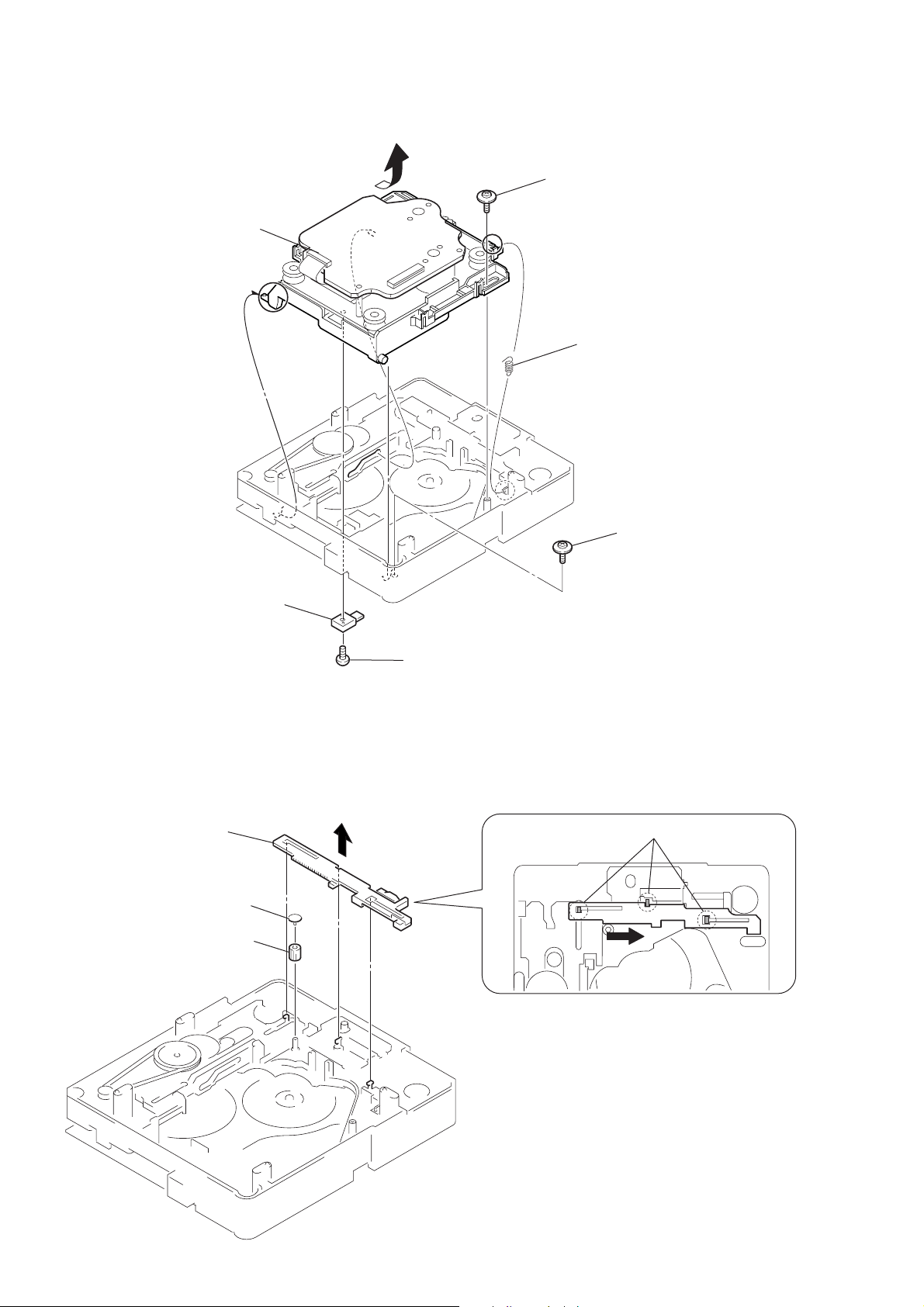

3-14. BASE UNIT

6

base unit

4

floating screw

(+PTPWHM 2.6)

3

holder down spring

2

lever (CL UP2)

3-15. LEVER (BU LOCK)

4

lever (BU lock)

1

gear (cap)

2

gear (BU lock)

1

screw

(+BVTP 2.6

5

floating screw

(+PTPWHM 2.6)

×

8)

3

three hooks

2

16

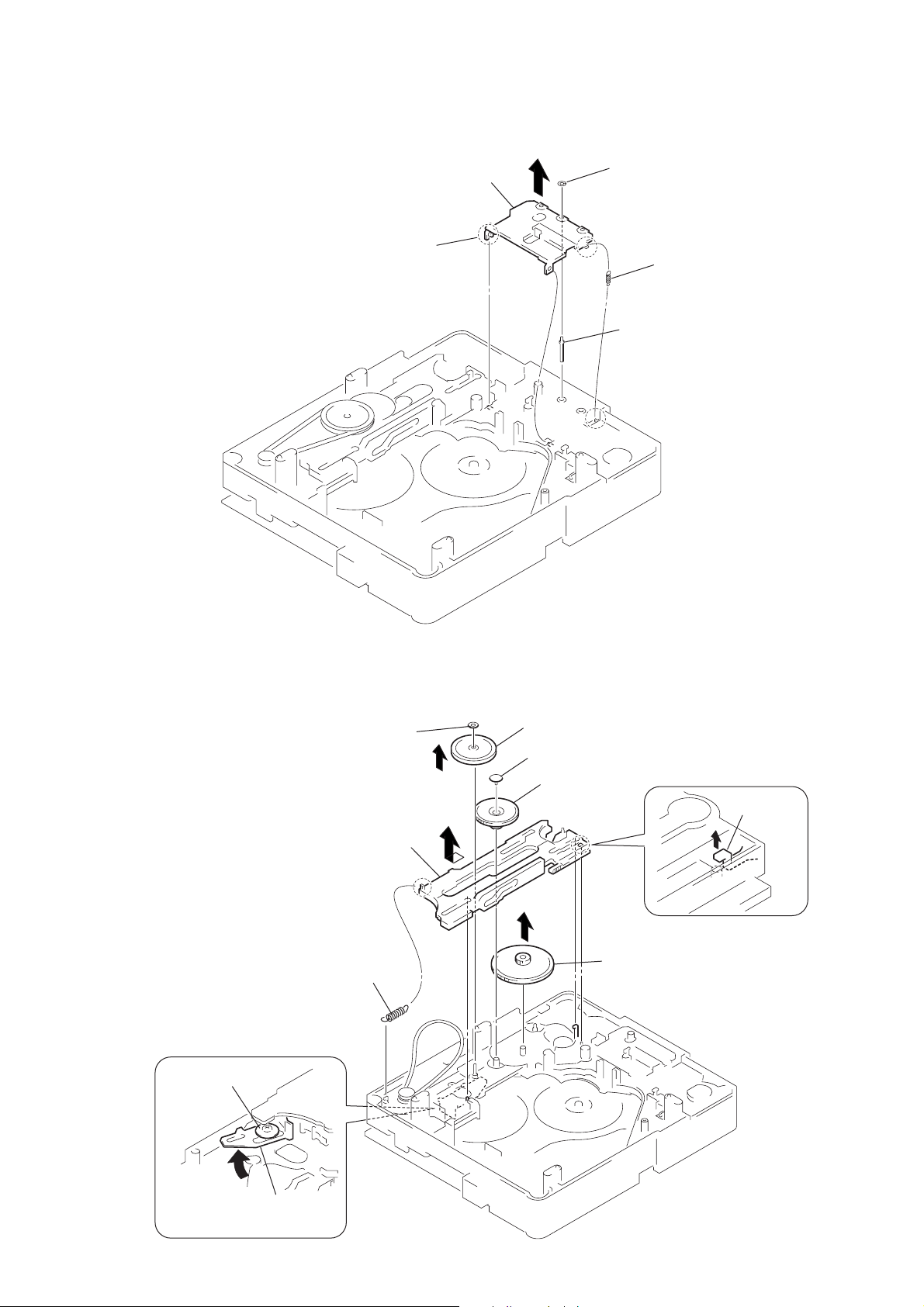

3-16. CLOSE LEVER

g

3

claw

5

close lever

1

washer (3-1-0.4)

2

close lever sprin

4

shaft disc stop

CX-LZP3

3-17. DIR LEVER, GEAR (IDL-B)

2

capstan retaining ring

1

6

Loosen the screw.

9

DIR lever

DIR spring-E

3

gear puley

4

gear (cap)

5

gear (IDL-A)

0

gear (IDL-B)

8

stoper

7

Hold the release lever

and change the direction.

17

CX-LZP3

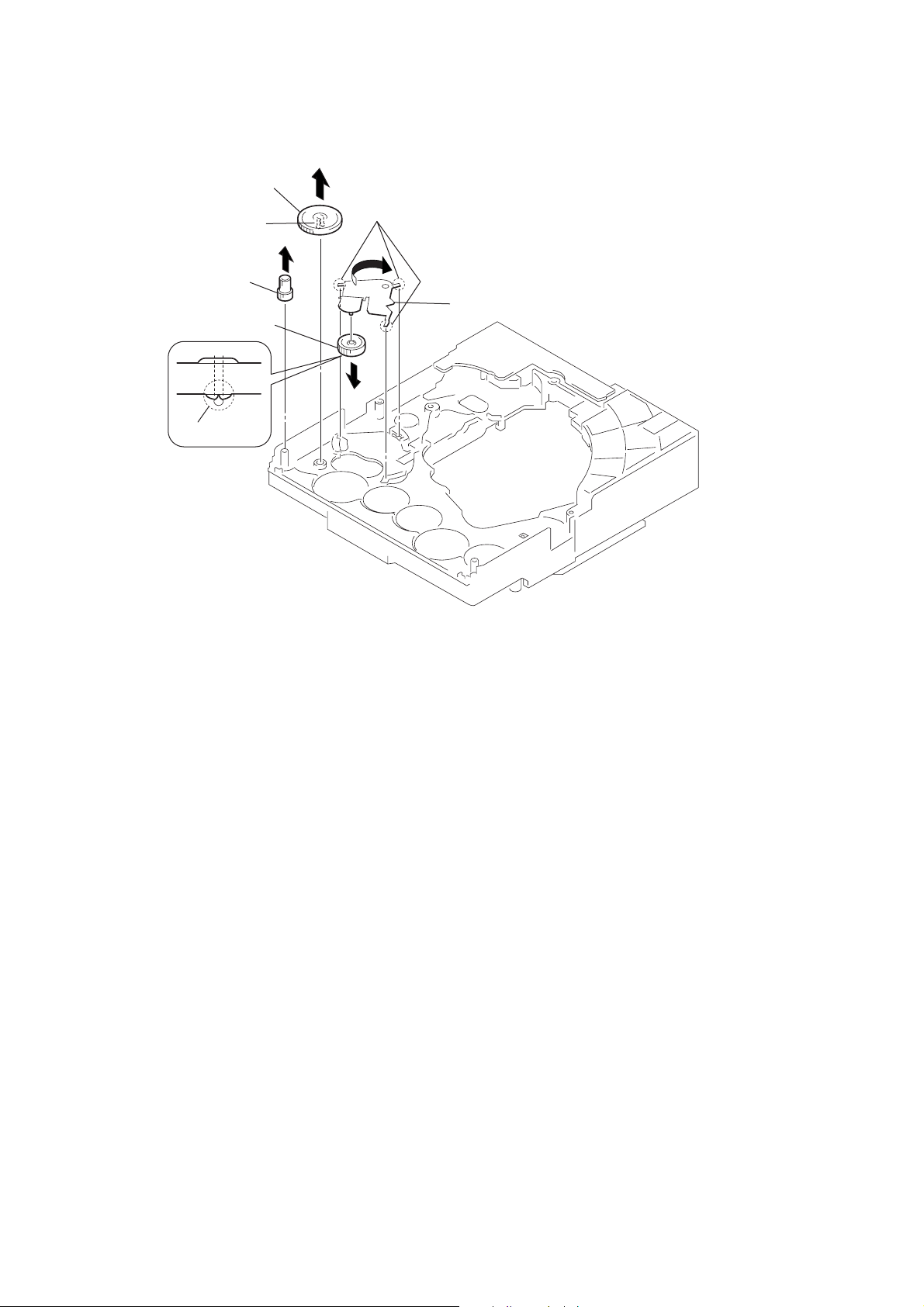

3-18. GEAR (IDL-C)

1

3

gear (IDL-D)

2

two claws

gear (IDL-F)

7

gear (IDL-C)

6

claw

4

three hooks

5

gear loading lever

18

Loading...

Loading...