Page 1

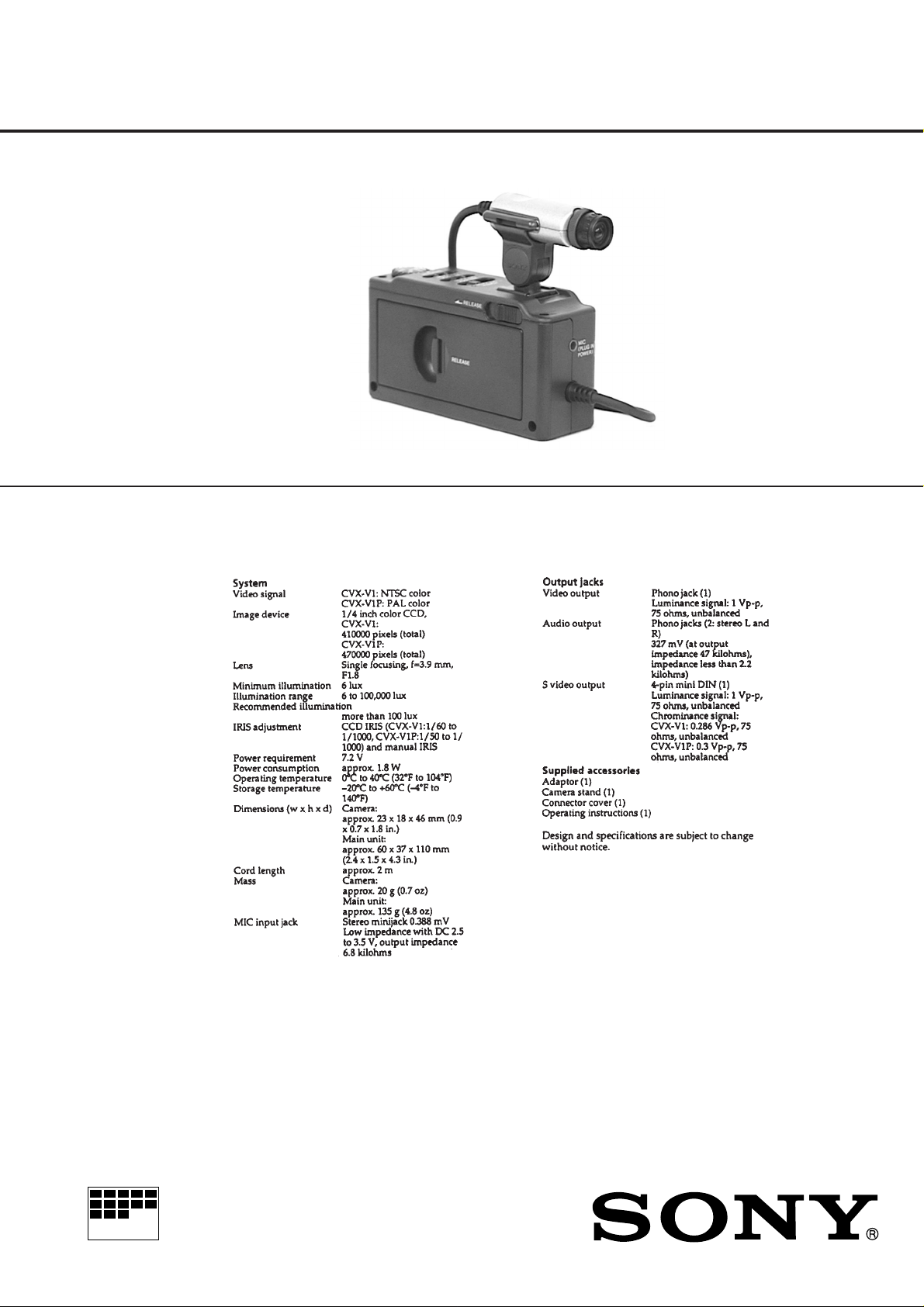

CVX-V1/V1P

SERVICE MANUAL

Photo: CVX-V1P

NTSC model: CVX-V1

PAL model : CVX-V1P

SPECIFICATIONS

US Model

Canadian Model

CVX-V1

AEP Model

UK Model

CVX-V1P

MICROFILM

COLOR VIDEO CAMERA

Page 2

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK ! OR DOTTED

LINE WITH MARK ! ON THE SCHEMATIC DIA GRAMS

AND IN THE PARTS LIST ARE CRITICAL TO SAFE

OPERATION. REPLACE THESE COMPONENTS WITH

SONY PARTS WHOSE PART NUMBERS APPEAR AS

SHOWN IN THIS MANU AL OR IN SUPPLEMENTS PUBLISHED BY SONY.

SAFETY CHECK-OUT

After correcting the original service problem, perform the following

safety checks before releasing the set to the customer.

ATTENTION AU COMPOSANT AYANT RAPPORT

À LA SÉCURITÉ!

LES COMPOSANTS IDENTIFIÉS P AR UNE MARQUE !

SUR LES DIAGRAMMES SCHÉMATIQUES ET LA LISTE

DES PIÈCES SONT CRITIQUES POUR LA SÉCURITÉ

DE FONCTIONNEMENT. NE REMPLACER CES COMPOSANTS QUE PAR DES PIÈCES SONY DONT LES

NUMÉROS SONT DONNÉS DANS CE MANUEL OU

DANS LES SUPPLÉMENTS PUBLIÉS PAR SONY.

1. Check the area of your repair for unsoldered or poorly soldered connections. Check the entire board surface for solder

splashes and bridges.

2. Check the interboard wiring to ensure that no wires are

“pinched” or contact high wattage resistors.

3. Look for unauthorized replacement parts, particularly transistors, that were installed during a previous repair. Point them

out to the customer and recommend their replacement.

4. Look for parts which, through functioning, show obvious signs

of deterioration. Point them out to the customer and recommend their replacement.

5. Check the B+ voltage to see it is at the values specified.

6. Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270 °C

during repairing.

• Do not touch the soldering iron on the same conductor of

the circuit board (within 3 times).

• Be careful not to apply force on the conductor when sol-

dering or unsoldering.

– 2 –

Page 3

TABLE OF CONTENTS

Section Title Page Section Title Page

1. GENERAL ................................................................... 1-1

2. DISASSEMBLY

2-1. Removal of Cabinet (Lower) Assembly ........................ 2-1

2-2. Removal of VA-103 Board............................................. 2-1

2-3. Removal of Camera Head Assembly,

CS-53 Board.................................................................. 2-1

2-4. Removal of Lens (CCD) Assembly ............................... 2-2

2-5. Circuit Boards Location ................................................. 2-2

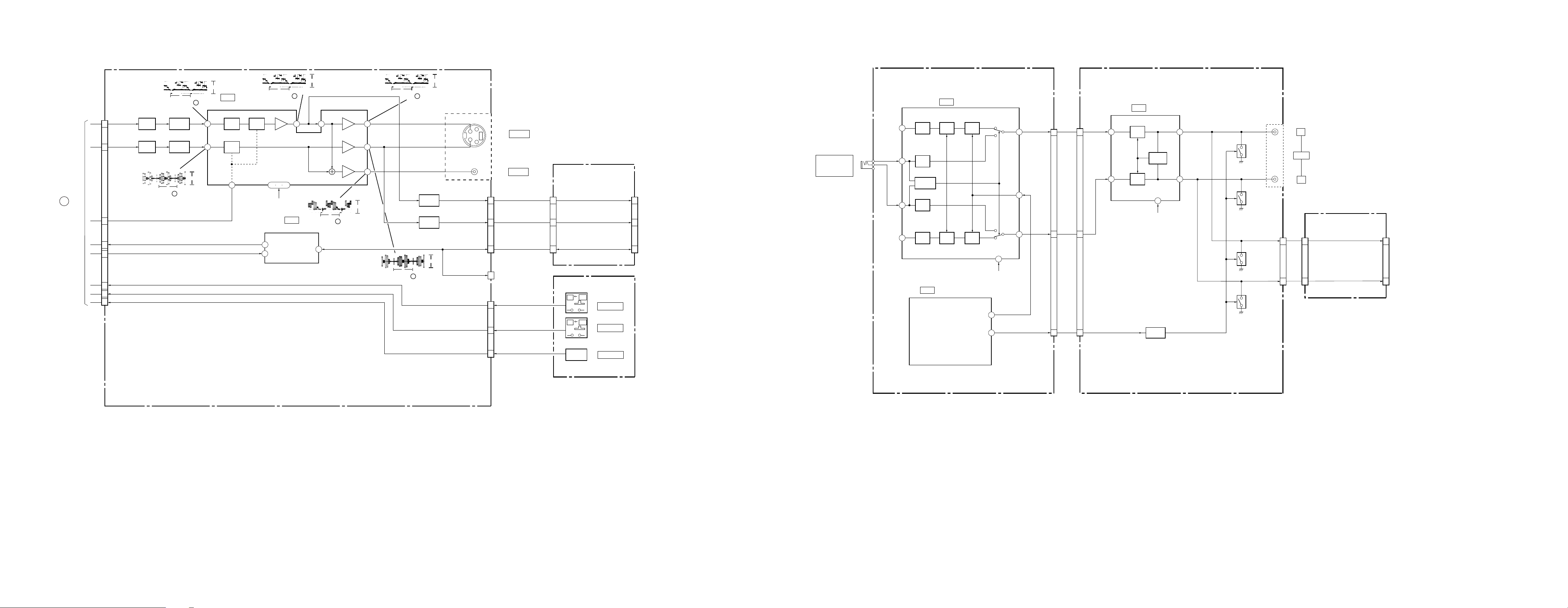

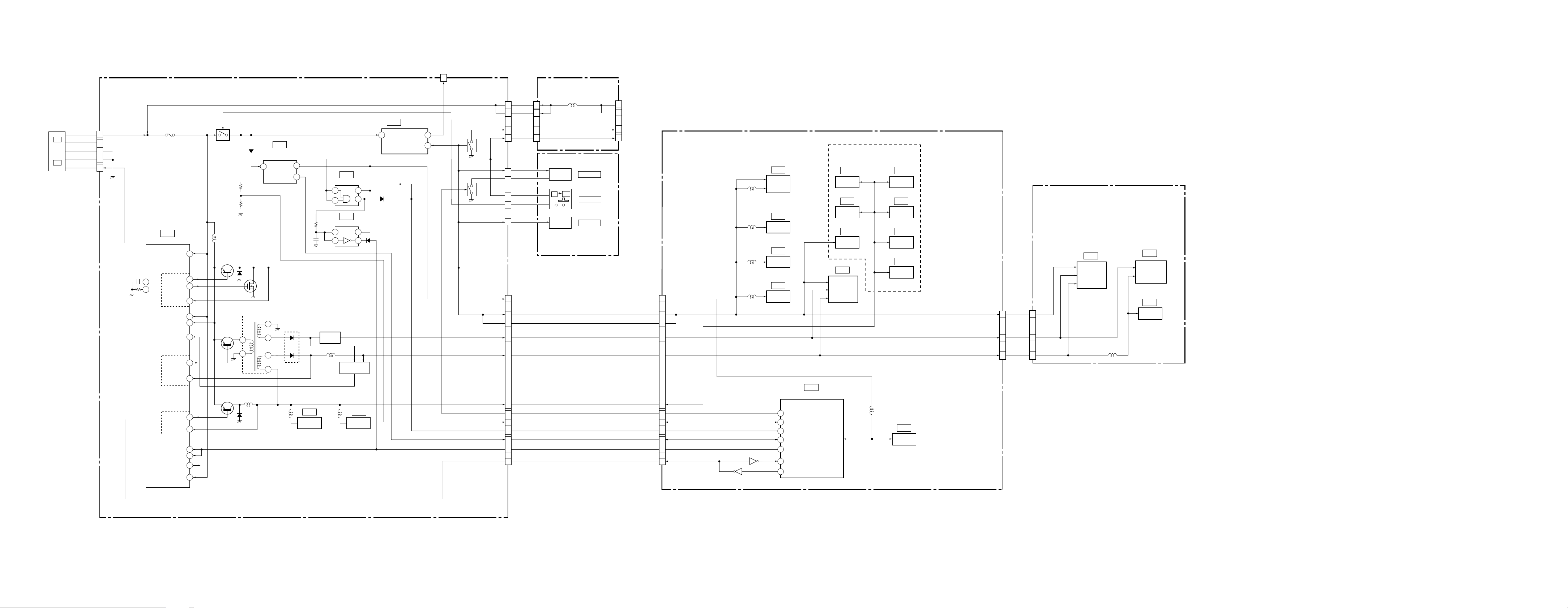

3. BLOCK DIAGRAMS

3-1. Overall Block Diagram................................................... 3-1

3-2. Camera (1) Block Diagram ........................................... 3-5

3-3. Camera (2) Block Diagram ........................................... 3-9

3-4. Audio Block Diagram..................................................... 3-11

3-5. Power Block Diagram.................................................... 3-13

4. PRINTED WIRING BOARDS AND

SCHEMATIC DIAGRAMS

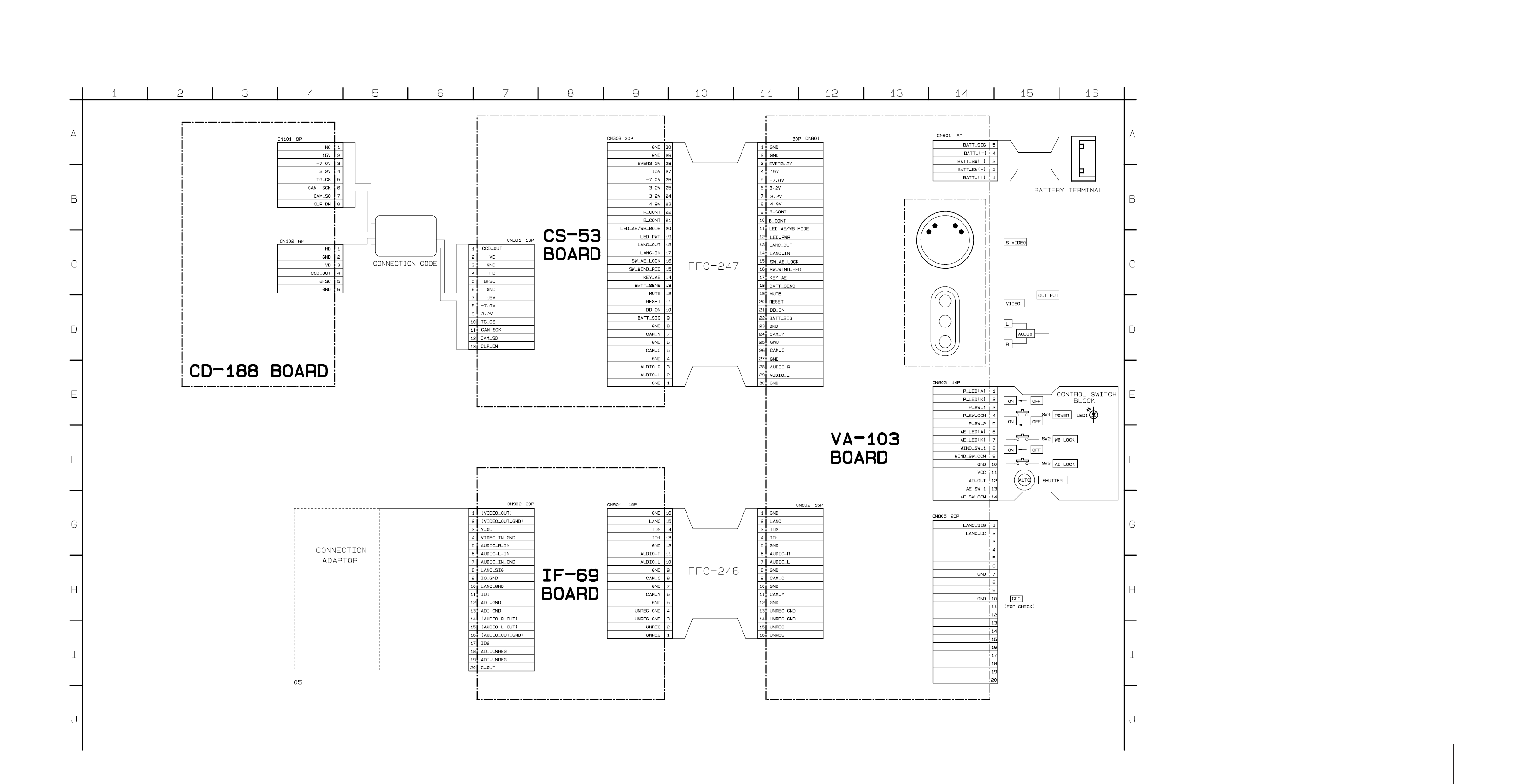

4-1. Frame Schematic Diagram............................................ 4-1

4-2. Printed Wiring Boards and Schematic Diagrams ......... 4-4

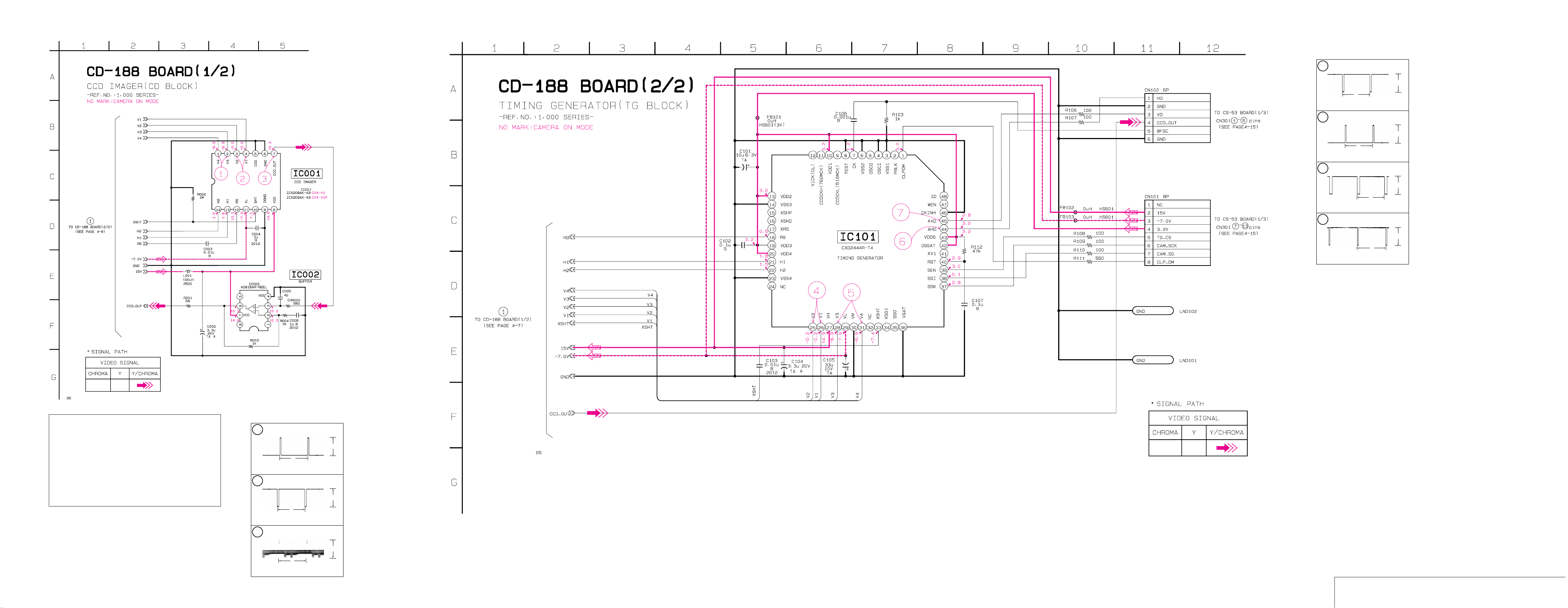

CD-188 (CCD Imager, Timing Generator)

Printed Wiring Board ..................................................... 4-5

CD-188 (CCD Imager), (Timing Generator)

Schematic Diagrams ..................................................... 4-7

CS-53 (Camera, Y/C Process, Mic Amp,

Mode Control) Printed Wiring Board............................. 4-11

CS-53 (Camera, Y/C Process)

Schematic Diagram ....................................................... 4-15

CS-53 (Mode Control) Schematic Diagram .................. 4-21

CS-53 (Mic Amp) Schematic Diagram .......................... 4-23

VA-103 (DC-DC Converter, Video/Audio I/O, LANC I/O),

IF-69 (Interface) Printed Wiring Boards........................ 4-28

VA-103 (DC-DC Converter) Schematic Diagram ......... 4-33

VA-103 (Video/Audio I/O) Schematic Diagram............. 4-36

VA-103 (LANC I/O), IF-69 (Interface)

Schematic Diagrams ..................................................... 4-39

1-3. Camera System Adjustments .................................. 5-9

1. 28 MHz Origin Oscillation Adjustment ..................... 5-9

2. Picture Frame Setting .............................................. 5-10

3. Color Reproduction Adjustment ............................... 5-11

4. Auto White Balance Reference Data Input.............. 5-12

5. Auto White Balance Adjustment .............................. 5-12

6. White Balance Check............................................... 5-13

7. Battery Down Adjustment......................................... 5-14

6. REPAIR PARTS LIST

6-1. Exploded Views ............................................................. 6-1

6-2. Electrical Parts List........................................................ 6-2

* The color reproduction frame is shown after the page

of ELECTRICAL PARTS LIST.

5. ADJUSTMENTS

5-1. Camera Section Adjustment ......................................... 5-1

1-1. Preparations Before Adjustment................................... 5-1

1-1-1. List of Service Tools ................................................. 5-1

1-1-2. Preparations ............................................................. 5-2

1-1-3. Precaution ................................................................ 5-3

1. Setting the Switch .................................................... 5-3

2. Order of Adjustment ................................................. 5-3

3. Subjects .................................................................... 5-3

1-1-4. Adjustment Remote Commander ............................ 5-4

1. Using the Adjustment Remote Commander ............ 5-4

2. Precaution Upon Using the Adjustment

Remote Commander................................................ 5-4

1-1-5. Data Process ............................................................ 5-5

1-2. Initialization of F Page Data.......................................... 5-6

1. Initializing the F Page Data ...................................... 5-6

2. Modification of F Page Data .................................... 5-6

3. F Page Table ............................................................ 5-6

– 3 –

Page 4

SECTION 1

GENERAL

CVX-V1/V1P

1-1

Page 5

1-2 E

Page 6

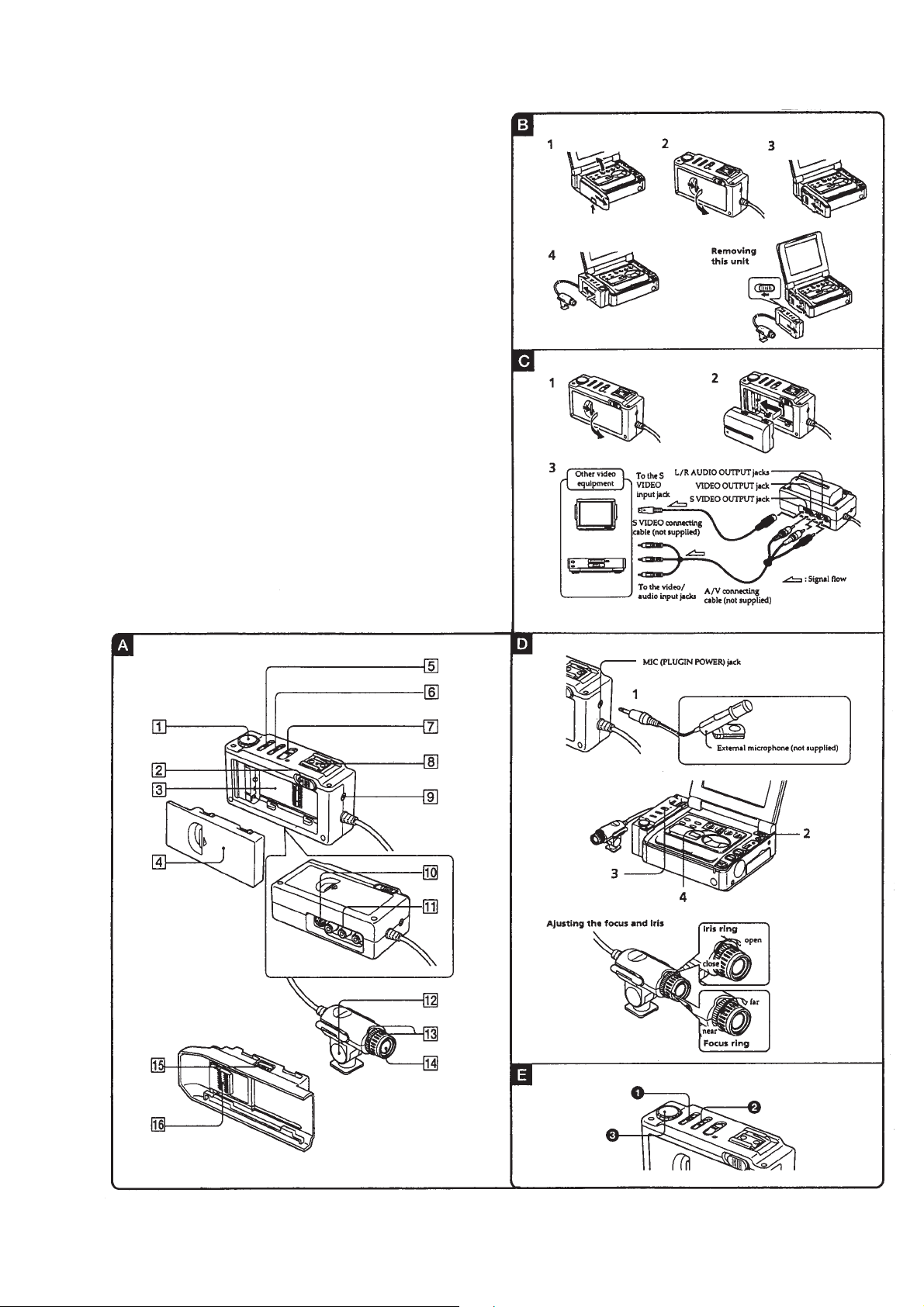

SECTION 2

DISASSEMBLY

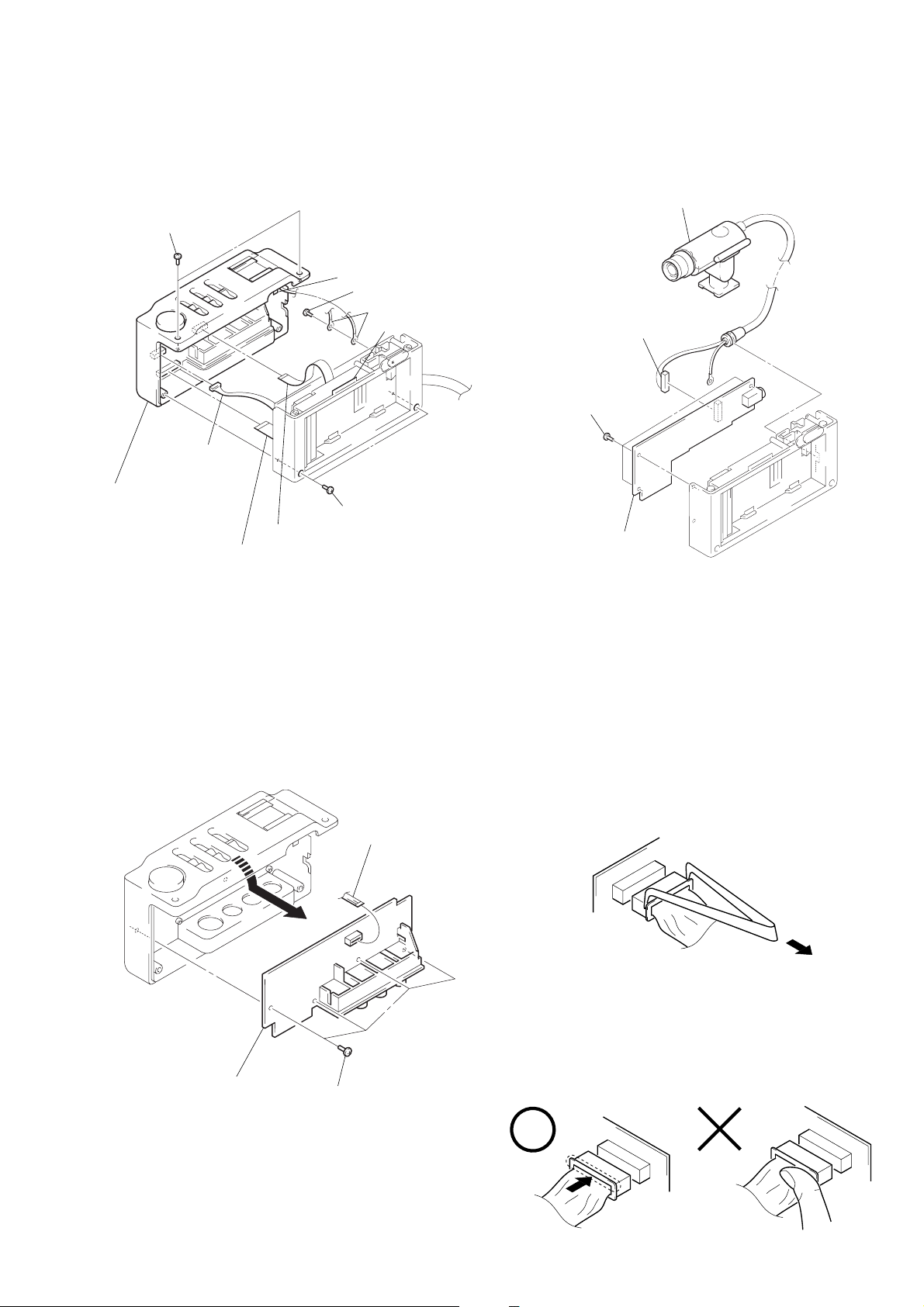

Note: Follow the disassembly procedure in the numerical order given.

CVX-V1/V1P

2-1. REMOVAL OF CABINET (LOWER)

ASSEMBLY

1 Two tapping

screws

3 Claw

9 Tapping screw

0 Two earth leads

4 Claw

6 Connector

(CN601)

5 Cabinet (lower)

assembly

8 Flexible flat cable (CN802)

7 Flexible flat cable (CN801)

2 Two tapping screws

2-3. REMOVAL OF CAMERA HEAD

ASSEMBLY, CS-53 BOARD

2 Camera head assembly

1 Connector (CN301)

(Note1, 2)

3 Three tapping

screws

CS-53 Board

4 CS-53 board

2-2. REMOVAL OF VA-103 BOARD

1 Flexible board

(CN803)

VA-103 Board

3 VA-103 board

2 Four tapping screws

Note 1: When remove a connector, don't pull at

wire of connector.

Be in danger of the snapping of a wire.

Note 2: When installing a connector, don't press

down at wire of connector.

Be in danger of the snapping of a wire.

2-1

Page 7

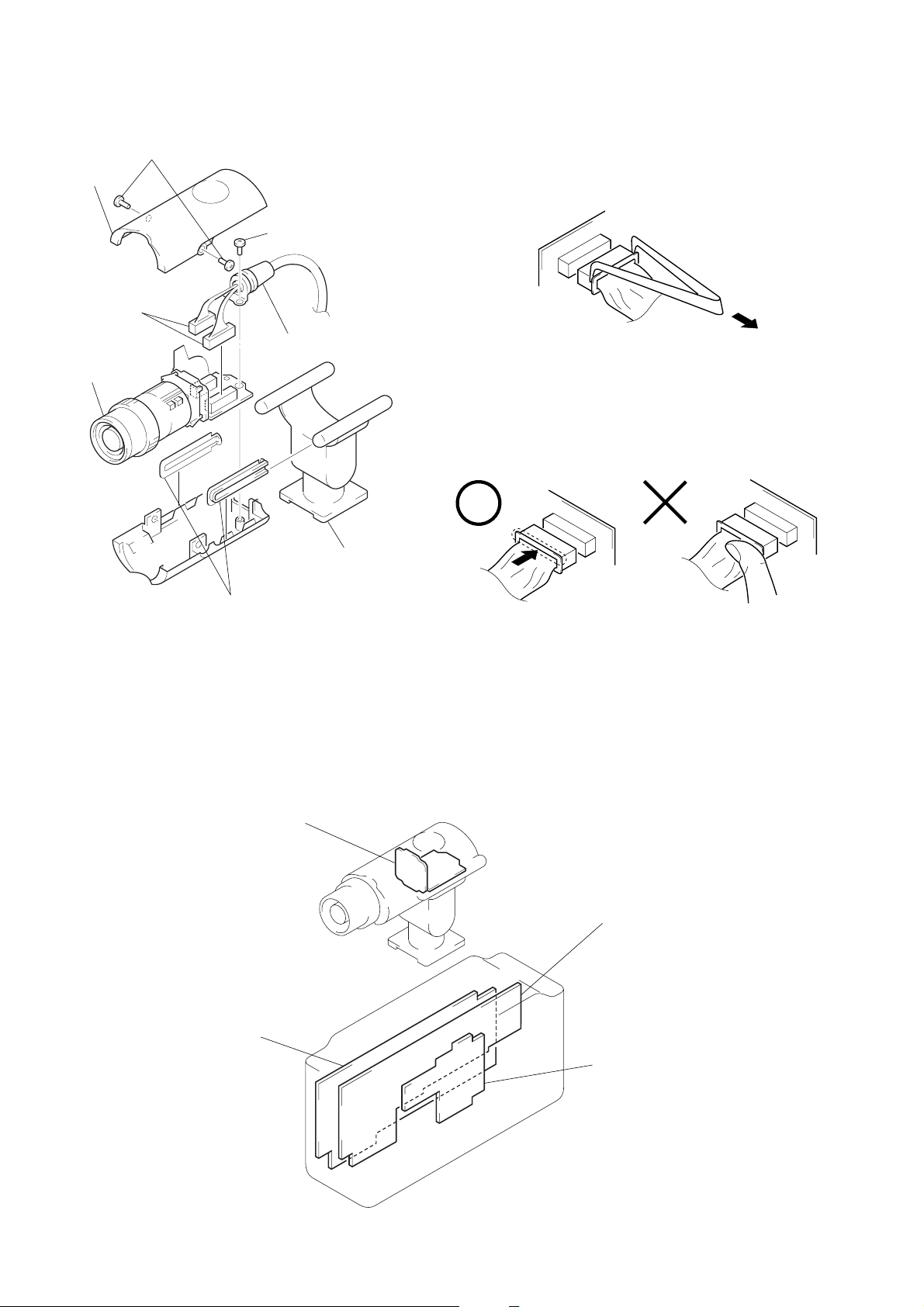

2-4. REMOVAL OF LENS (CCD) ASSEMBLY

3 Cabinet

(upper)

6 Two connectors

(CN101, 102)

(Note1, 2)

8 Lens (CCD)

assembly

2 Two screws (P2)

Note 1: When remove a connector, don't pull at

wire of connector.

Be in danger of the snapping of a wire.

5 Screw (M1.7 × 3)

7 Connection cord

Note 2: When installing a connector, don't press

down at wire of connector.

Be in danger of the snapping of a wire.

1 Y holder

assembly

4 Two guide holders

2-5. CIRCUIT BOARDS LOCATION

CD-188

CCD IMAGER,

()

TIMING GENERATOR

C

D

-1

B

8

o

8

ard

CS-53

CAMERA, Y/C PROCESS,

()

MIC AMP, MODE CONTROL

VA-103

VIDEO/AUDIO I/O,

DC-DC CONVERTER,

()

LANC I/O

IF-69

VA-103 Board

CS-53 Board

IF-69 Board

(INTERFACE)

2-2 E

Page 8

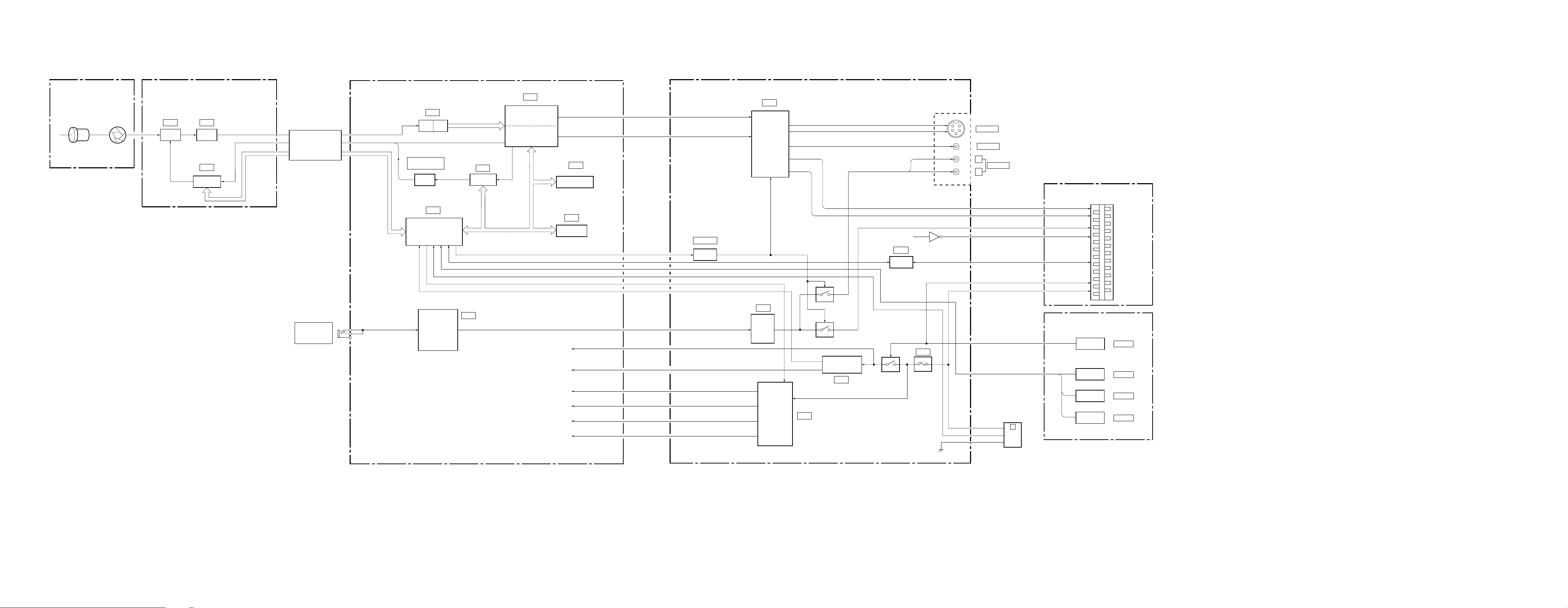

3-1. OVERALL BLOCK DIAGRAM

SECTION 3

BLOCK DIAGRAMS

CVX-V1/V1P

CVX-V1/V1P

LENS BLOCK

MANUAL

FOCUS

LENS

MANUAL

IRIS

CD-188 BOARD

(SEE PAGE 4-7 - 4-9)

H1, H 2

RG, XSHT

05

V1-V4

IC001

CCD

IMAGER

IC002

BUFFER

IC101

TIMING

GENERATOR

CCD OUT

HD

VD

8FSC

CLPDM

2m

CAMERA CABLE

CS-53 BOARD

(SEE PAGE 4-15 - 4-24)

CCD OUT

TG SO, SCKTG SO, SCK

IC302, 303, 309

310, 311, 312, 303

CLPDM

IC305

S/H

AGC

CONV.

PHASE

ADJUST

IC502

CAMERA/MODE

CONTROL

A/D

VA-103 BOARD

IC307

CAMERA

AD0-9

HD, VD

IC304

8FSC8FSC

TIMING

GENERATOR

CAM SI, SO, SCK

MUTE

LANC I/O

KEY AE, SW WIND RED, SW AE LOCK

BATT SIG

DD ON

RESET

Y

PROCESS

CAMERA

C

PROCESS

CAM Y

CAM C

IC306

EVR

(D/A CONVERTER)

IC501

EEPROM

(SEE PAGE 4-33 - 4-41E)

IC802, 803

MUTE

CONTROL

CAM Y

CAM C

MUTE

IC701

Y/C MIX

VIDEO AMP

S-Y

S-C

VIDEO

Y OUT

C OUT

S-Y

S-C

VIDEO

AUDIO L

AUDIO R

3.2V

IC801

LANC I/O LANC SIG

LANC

I/O

J701

S VIDEO

VIDEO

L

R

AUDIO

IF-69 BOARD

(SEE PAGE 4-41E)

AUDIO L

AUDIO R

LANC SIG

Y OUT

C OUT

ID2

ID1

UNREG

EASY

CONNECTOR

PLUG IN

(

POWER

MIC

IC702

IC401

EXT MIC L, R

MIC

AMP

AUDIO L, R

ALC

)

SW_UNREG

EVER 3.2V

15V

–7.0V

3.2V

4.9V

DD ON

DC-DC

CONVERTER

IC601

RESET

INITIAL RESET

BACKUP VCC

IC602

F601

KEYAE, SW WIND RED, SW AELOCK

BATTERY

TERMINAL

BATT (+)

BATT SIG

BATT (–)

CONTROL SWITCH BLOCK

SW 1

POWER SW

SW 2

WB SW

SW 3

AE SW

SHUTTER

DIAL

POWER

WB LOCK

AE LOCK

SHUTTER

3-1 3-2 3-3

Page 9

CVX-V1/V1P

3-2. CAMERA (1) BLOCK DIAGRAM

CD-188 BOARD

(SEE PAGE 4-7 - 4-9)

IC001

3

2

IC002

BUFFER

CN102

6

CCD OUT

4

CCD IMAGER

CCD OUT

7

IC101

TIMING GENERATOR

5

1

3

8

5

7

6

CN101

SHT

VDD

V1

4

3

V2

2

V3

1

V4

14

H2

13

H1

12

RG

10

VL

–7.0V

11

8

15V

–7.0V

15V

V1

V2

V3

V4

22

H2

H1

RG

XSHT

30

VM

VL

29

VH

27

AHD

AVD

CLPDM

SEN

SSI

SSK

RST

VDD

CK

726

4425

4528

131

3921

3818

3733

40

10

13

19

20

43

3.2V

05

CS-53 BOARD

(SEE PAGE 4-15 - 4-24)

CN301

1

8FSC

5

AHD

4

AVD

2

13

CS TG2

10

TG SO

12

TG SCK

11

LPF

MCK

2 10

3.2 Vp-p

83

ı

91

93

75

78

76

73

74

77

56

57

27

16

CLPI

CCDCKH

CCDCKL

PBLK

XVI

XSGI

ID

AHD

AVD

VREF Y

VREF C

IC307

CAM SCK

CAM SO

CAM SI

CAMERA

Y PROCESS

CAMERA

C PROCESS

CAMERA Y.C PROCESS

D/A

CONV.

D/A

CONV.

V

V=60 Hz: CVX-V1

V=50 Hz: CVX-V1P

IC307

51

IC501

EEPROM

2

SK

3

DI

4

DO

BUSY

3Vp-p

XCS

RST

IOY

IOC

OSC O

OSC I

VD

FLD

SYSV

VRI

SCK

SI

XCE

SO

XCLR

CS EEPROM

1

WEN EEPROM

6

BUSY EEPROM

7

8

3.2V

H

IC307

Q302

23

BUFFER

Q303

20

8

21

22

39

58

64

79

92

BUFFER

3.2V

63

X302

17.734475MHz

62

CVX-V1P

51

53

65

RST SG

55

CAM SCK

67

CAM SO

68

CS CAM

69

CAM SI

70

RST CAM

71

1.0 Vp-p

H

IC305

S/H, AGC, A/D CONVERTER

26

IC305

0.14 usec

IC305

Q301

LPF

BUFFER

PHASE ADJUST

IC302

1

4

2

2

1

IC310

7

PR

D

5

Q

3

Q

CK

CLR

2

1

6

IC312 IC311

7

PR

D

5

Q

3

Q

CK

CLR

IC313

1

2

6

7

PR

4

D

2

1

5

Q

3

Q

CK

CLR

6

CK CONT

DIN

26

PIN

27

CLPDM

23

XSHP

21

XSHD

22

S/H

VDD

12 17 33 43

3.2V

AGC

S/H

AGC CONT1 AGC CONT2

29 19 16 44

30

S/H BLK

PBLK

DRV

A/D

CONV.

ADCLK REFSLOW

MCK

11

D0-D9

20 80

CLPOB

10 10

ı

2

I MUTE

2.3 Vp-p

16

D/A CONVERTER

VREF C

CLK

VDD

4

5

STBY DA

15

LD

DI

CAM SCK

16

CAM SO

17

10

11

3.2V

IC303

2

4

X301

28.636MHz: CVX-V1

28.375MHz: CVX-V1P

28.636 MHz: CVX-V1

28.375 MHz: CVX-V1P

4

IC304

3.2V

–7.0V

15V

0.8 Vp-p

TIMING GENERATOR

CK

7

OSCO

5

OSCI

4

10

13

19

VDD

20

43

29

VL

27

VH

30

VM

IC304

CLPDM

XSHP

XSHD

PBLK

CCDCLKH

XSG1

XV1

AHD

AVD

SSK

SSI

SEN

RST

VSK

VSI

VEN

IC309

4

2

AHD

14.318 MHz: CVX-V1

14.187 MHz: CVX-V1P

IC305

1

15

16

2

MCK

11

32

41

48

ID

44

14.318 MHz: CVX-V1

14.187 MHz: CVX-V1P

IC304

45

37

38

39

40

CAM SCK

CAM SO

CS CAM

RST CAM

1.8 Vp-p

IC306

11

AGC CONT1 VREF Y

12

AGC CONT2

13

FRQ

18

33

34

35

23

0.9 Vp-p

H

IC307

17.734475 MHz

IC307

Q503

CN303

CAM Y

CAM C

0.6 Vp-p

20

2.3 Vp-p

63

IC502

7

5

CAMERA/MODE CONTROL

1

62

CAM VD

63

FLD

SOFTV

55

4

RST CAM

7

RST SG

STBY DA

97

98

CS CAM

CAM SI

33

34

CAM SO

35

CAM SCK

26

WEN EEPROM

CS EEPROM

29

BUSY EEPROM

31

99

CS TG2

45

TG SO

TG SCK

46

FLIP

59

25

CK CONT

I MUTE

50

20 MHz

20 MHz

IC502

41

41

IC502

32 kHz

32 kHz

LANC IN

LANC OUT

WB MODE

SW AE LOCK

0.2 Vp-p

32KHz IN

32KHz OUT

52

52

MUTE

KEY AE

XTAL

EXTAL

0.7 Vp-p

VDD

60

1

2

18

15

82

40

41

52

53

42

51

77

86

87

MUTE

LANC IN

LANC OUT

SW WIND RED

SW AE LOCK

KEY AE

X502

20MHz

X501

32.768KHz

3.2V

12

17

18

15

16

14

CAMERA BLOCK 2

VA-103 BOARD

CN801

(SEE PAGE 3-9)

3-5 3-6 3-7 3-8

AVREF

75

76

Page 10

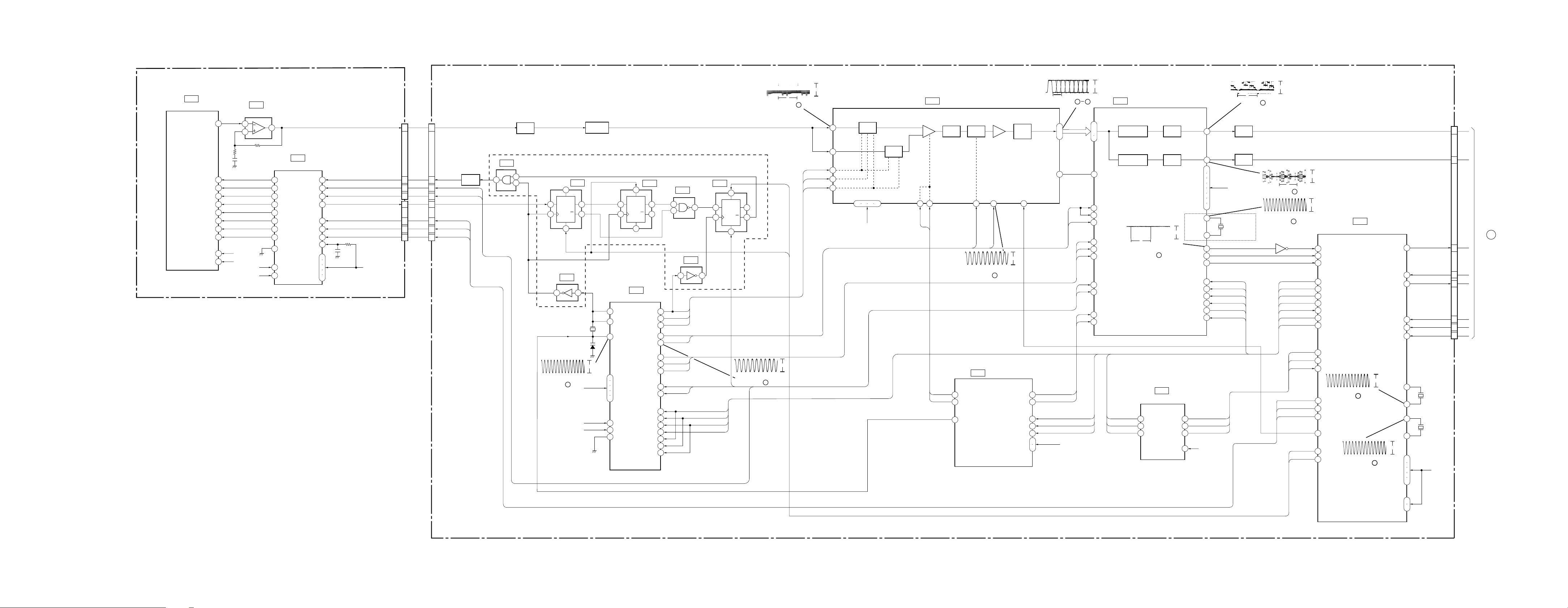

3-3. CAMERA (2) BLOCK DIAGRAM 3-4. AUDIO BLOCK DIAGRAM

CVX-V1/V1P

1

CAMERA BLOCK 1

CS-53 BOARD

CN303

(SEE PAGE 3-8)

VA-103 BOARD

(SEE PAGE 4-33 - 4-41E)

CN801

CAM Y

24

CAM C

26

MUTE

19

LANC IN

14

LANC OUT

13

SW WIND RED

16

SW AE LOCK

15

KEY AE

17

0.46 Vp-p

H

IC701

22

Q708FL701

LPF BUFFER CLAMP

Q707

BPF BUFFER

0.5 Vp-p

H

IC701

16

Y/C MIX, VIDEO AMP

22

16

IC701

MUTE

13

MUTE

10

12

H

IC701

6dB

10 27 30

4.9V

DATA

DATA

31

IC801

LANC I/O

1.1 Vp-p

LANC SIG

H

IC701

11

J401

CS-53 BOARD

(SEE PAGE 4-21,4-23)

6

2

29

24

IC401

MIC AMP

EQ

EQ

EX MIC

DETECT

EQ

EQ HPF

L/R

MIX

L/R

MIX

IC502

CAMERA/MODE CONTROL

WIND RED

HPF

MUTE

INT

13 13

EXT

25

EXT

17

INT

7

4.9V

91

60

AUDIO L

AUDIO R

CN303

2

3

1.8 Vp-p

H

IC701

9

J701

6dB

6dB

91831

14

S-Y

S-C

1

43

2

S VIDEO

MIC

6dB

6

6

Q703

BUFFER

2.1 Vp-p

Q704

BUFFER

VIDEO

CAM Y

CAM C

CN802

VIDEO

11

9

IF-69 BOARD

(SEE PAGE 4-41E)

CN901

6

9

Y OUT

C OUT

CN902

3

20

EASY

PLUG IN

(

POWER

)

CONNECTOR

IC701

H

14

WIND SW1

SW AE LOCK

1.0 Vp-p

LANC SIG

LANC SIG

CN805

CN803

2

(FOR CHECK)

1

8

13

2

CONTROL SWITCH BLOCK

SW2

ON

OFF

SW3

ON

OFF

LANC SIG

WB LOCK

AE LOCK

8

VA-103 BOARD

(SEE PAGE 4-37)

CN801

29

28

1912

IC702

ALC

J701

AMP

LEVEL

DETECT

9

AMP

5

4.9V

Q709

MUTE

CONTROL

1

7

AUDIO L

Q706

AUDIO R

Q705

AUDIO L

Q702

AUDIO R

Q701

CN802

L

AUDIO

R

IF-69 BOARD

(SEE PAGE 4-41E)

CN901 CN902

7

10

6

11

AUDIO L

AUDIO R

6

5

EASY

CONNECTOR

KEY AE

05

12

SHUTTER

DIAL

SHUTTER

05

3-9 3-10 3-11 3-12

Page 11

CVX-V1/V1P

3-5. POWER BLOCK DIAGRAM

BATTERY

TERMINAL

BATT (+)

BATT SW (+)

BATT SW (–)

BATT (–)

BATT SIG

CN601

1

2

3

4

5

VA-103 BOARD

(SEE PAGE 4-33 - 4-41E)

F601

IC601

DC-DC CONVERTER

22

21

OUTPUT-4

CT

MOSGATE-4

RT

OUTPUT VCC13

OUTPUT VCC24

OUTPUT-3

OUTPUT-2

OUTPUT VCC56

VCC

FB4

FB3

FB2

STBY3

SYBT

VREF

(FOR CHECK)

2

LANC DC

UNREG

IC801

LANC I/O

1

UNREG

Q604

D604

BATT SENS

L601

28

37

60

18

43

31

13

CO

36

34

50

35

29

30

37

63

Q603

SWITCHING

Q605

SWITCHING

Q601

SWITCHING

Q602

SWITCHING

D602

T601

3

1

L602

D601

IC602

INITIAL RESET

BACKUP VCC

VIN

7

2

6

4

3

VOUT

RESET

L701

D603

6

5

IC701

Y/C MIX

VIDEO AMP

Q607-610

–7.0V

REG

L605

L702

IC802

MUTE CONTROL

VCC

2

IC803

MUTE CONTROL

VCC

2

EMERGENCY

DETECT

Q606

IC702

ALC

51

4

51

4

D802

MUTE

D803

DD ON

LANC DC

VCC

14

8

CN805

Q803

Q801

EVER3.2V

LED PWR

BATT SENS

RESET

DD ON

BATT SIG

3.2V

–7.0V

15V

4.9V

MUTE

CN802

15

16

3

4

CN803

1

2

3

5

11

CN801

3

6

7

5

4

8

12

18

19

20

21

22

IF-69 BOARD (SEE PAGE 4-41E)

CN901

2

1

14

13

UNREG

L901

ID2

ID1

CONTROL SWITCH BLOCK

LED 1

POWER

LED

SW 1

SHUTTER

DIAL

POWER

OFFON

POWER

SHUTTER

CN902

18

19

17

11

EASY

CONNECTOR

28

25

24

26

27

23

19

13

12

11

10

9

CN303

EVER3.2V

3.2V

–7.0V

15V

4.9V

LED PWR

BATT SENS

MUTE

RESET

DD ON

BATT SIG

CS-53 BOARD

(SEE PAGE 4-15 - 4-24)

Q502

L303

L302

L301

L401

Q501

IC307

CAMERA

Y.C

PROCESS

IC306

EVR

D/A CONV.

IC305

S/H AGC

A/D CONV.

IC401

MIC AMP

CAMERA/MODE CONTROL

LED PWR

89

BATT SENS

71

MUTE

60

RESET

38

DD ON

37

48

BATT SI

49

BATT SO

IC502

PHASE ADJUST

IC302

IC304

IC309

IC304

TIMING

GENERATOR

3.2V

4.9V

–7.0V

15V

L501

IC310

IC311

IC312

IC313

IC501

EEPROM

CN301

3.2V

–7.0V

15V

CD-188 BOARD

(SEE PAGE 4-7 - 4-9)

IC101

TIMING

GENERATOR

CN101

3.2V

9

8

7

4

–7.0V

3

15V

2

L001

IC001

CCD

IMAGER

IC002

BUFFER

05

3-13 3-14 3-15 3-16 E

Page 12

PRINTED WIRING BOARDS AND SCHEMATIC DIAGRAMS

4-1. FRAME SCHEMATIC DIAGRAM

CVX-V1/V1P

SECTION 4

4-1 4-2 4-3

FRAME

Page 13

CD-188 (CCD IMAGER), (TIMING GENERATOR) SCHEMATIC DIAGRAM

CVX-V1/V1P

CD-188 BOARD (2/2)

4

7 Vp-p

H

IC101 @∞, @§

5

7 Vp-p

H

IC101 @•, #¡

6

3 Vp-p

H

IC101 $¢

7

Precautions for Replacement of CCD Imager

• The CD-188 board mounted as a repair part is not equipped

with a CCD imager.

When replacing this board, remove the CCD imager from the

old one and mount it onto the new one.

• If the CCD imager has been replaced, carry out all the

adjustments for the camera section.

• As the CCD imager may be damaged by static electricity from

its structure, handle it carefully like for the MOS IC.

In addition, ensure that the receiver is not covered with dusts

nor exposed to strong light.

3 Vp-p

V

IC101 $∞

CD-188 BOARD (1/2)

1

7 Vp-p

H

IC001 1, 2

2

7 Vp-p

H

IC001 3, 4

3

1.0 Vp-p

H

IC001 7

4-7 4-8 4-9

4-10

CCD IMAGER/TIMING GENERATOR

CD-188 (1/2) CD-188 (2/2)

Page 14

CVX-V1/V1P

CS-53 (CAMERA, Y/C PROCESS, MIC AMP, MODE CONTROL) PRINTED WIRING BOARD

– Ref. No.: CS-53 board; 1,000 series –

• For printed wiring board.

• CS-53 board is 4-layers print board. However, the patterns of

layers 2 to 3 have not been included in the diagram.

• Chip transistor

C

EB

There are few cases that the part isn't mounted in this model is printed on this diagram.

A

B

C

CS-53

BOARD(SIDE A)

6

4

5

10

7

8

9

CS-53

BOARD(SIDE B)

J401

A

MIC

PLUG IN

()

POWER

G

B

13

G

S

D

C

12

11

1

2

05

1

23456 78

4-11

CAMERA, Y/C PROCESS, MIC AMP, MODE CONTROL

CS-53

CS-53 BOARD (SIDE A)

< CAPACITOR >

C302 C-5

C309 B-5

C310 B-6

C312 B-6

C315 B-5

C317 C-5

C319 C-5

C320 C-5

C321 C-5

C322 C-5

C323 C-6

C324 C-5

C325 C-5

C326 C-6

C327 C-6

C328 C-6

C331 B-6

C332 C-7

C333 C-7

C334 B-7

C335 C-7

C336 C-7

C337 B-7

C338 C-7

C339 B-7

C340 B-8

C341 C-7

C342 C-8

C343 C-8

C403 B-3

C404 B-4

C405 C-2

C406 C-3

C407 C-4

C408 C-3

C409 C-4

C410 C-4

C411 C-4

C412 C-3

C413 C-3

C414 C-4

C415 C-4

C416 C-4

C417 C-3

3

1-669-612-

C418 B-3

C419 B-4

C420 B-3

C421 B-4

C422 B-3

C423 B-4

C424 B-3

< DIODE >

D302 A-7

D501 C-8

< FERRITE BEAD >

FB316 B-6

< IC >

IC305 C-6

IC307 C-7

IC309 C-5

IC310 C-3

4-12 4-13 4-14

IC312 C-4

IC313 C-3

IC401 C-4

< COIL >

L301 B-6

L303 C-6

L401 B-4

< TRANSISTOR >

Q301 C-5

Q502 C-8

< RESISTOR >

R310 B-5

R313 B-6

R324 B-7

R325 B-7

R326 B-7

R327 C-7

R328 B-7

R329 B-7

R330 C-7

R331 B-7

R332 C-7

R334 C-8

R335 B-8

R350 B-7

R401 C-3

R402 C-3

R405 C-4

R406 C-4

R407 C-4

R408 C-4

R409 C-3

R410 B-3

R411 C-3

R412 C-3

R413 C-4

R414 B-4

R415 B-3

R416 C-3

R417 B-4

12

R418 B-4

R419 B-3

R420 B-3

R421 B-3

R422 B-4

R508 B-8

R509 B-8

R510 B-8

R517 C-8

< VIBRATOR >

X302 B-6

X501 C-8

05

1

CD-188

CCD IMAGER,

()

TIMING GENERATOR

CD-188

Board

VA-103

VIDEO/AUDIO I/O,

DC-DC CONVERTER,

()

LANC I/O

VA-103 Board

CS-53 Board

IF-69 Board

23456 78

CS-53

CAMERA, Y/C PROCESS,

()

MIC AMP, MODE CONTROL

IF-69

(INTERFACE)

CS-53 BOARD (SIDE B)

< CAPACITOR >

C301 B-5

C305 C-4

C306 B-4

C308 B-4

C311 C-5

C313 C-5

C314 C-5

C316 C-5

C318 C-6

C330 B-3

C347 C-6

C501 B-1

C502 C-1

C503 C-2

C504 C-3

C505 C-2

C506 C-3

C509 C-1

C510 C-1

C511 B-3

C512 C-3

< CONNECTOR >

CN301 C-7

CN303 A-2

< FERRITE BEAD >

FB301 C-7

FB302 C-7

FB303 C-7

FB313 B-4

FB314 C-5

FB315 C-6

FB401 C-8

FB402 C-8

FB403 C-7

< FILTER >

FL301 C-6

FL302 B-6

< IC >

IC302 C-6

IC303 C-6

IC304 C-4

IC306 C-3

IC311 C-6

IC501 B-1

IC502 B-2

< JACK >

J401 C-8

< COIL >

L302 B-3

L501 C-3

< TRANSISTOR >

Q302 B-3

Q303 B-3

Q501 C-1

< RESISTOR >

R302 C-6

R303 C-6

R304 C-6

R305 B-6

R306 C-6

R307 C-6

R308 B-5

R312 C-5

R314 C-5

R316 C-4

R317 C-5

R338 A-2

R339 A-3

R423 B-7

R424 B-7

R501 B-1

R502 B-1

R503 A-2

R504 B-1

1-669-612-

R505 B-2

R506 B-2

R507 B-2

R511 B-1

R514 C-1

R515 C-1

R516 C-1

R518 C-1

R519 C-2

R520 C-1

R522 C-1

R523 C-2

R524 C-2

R526 B-1

R528 B-2

R529 B-2

R530 B-2

R531 C-2

< VARIST OR >

VDR401 C-8

VDR402 C-8

< VIBRATOR >

X301 C-5

X502 C-1

12

Page 15

CS-53 (CAMERA, Y/C PROCESS) SCHEMATIC DIAGRAM

CS-53 BOARD (1/3)

1

CVX-V1/V1P

6

1.8 Vp-p

14.318 MHz: NTSC

14.187 MHz: PAL

IC304 !¡

2

28.636 MHz

7

0.8 Vp-p

IC304 5

3

28.636 MHz: NTSC

28.375 MHz: PAL

8

0.8 Vp-p

IC304 4

4

14.318 MHz: NTSC

14.187 MHz: PAL

9

0.9 Vp-p

IC305 !§

5

0.14usec

IC305 2 – 0

10

3.2 Vp-p

H

IC305 @§

V=60Hz: NTSC

V

V=50Hz: PAL

IC307 %¡

H

IC307 @º

H

IC307 @£

PAL

17.734475 MHz

IC307 ^£

1.0 Vp-p

3 Vp-p

0.6 Vp-p

0.9 Vp-p

2.3 Vp-p

NTSC model: CVX-V1

PAL model : CVX-V1P

4-15 4-16 4-17 4-18

CAMERA, Y/C PROCESS

CS-53 (1/3)

Page 16

CVX-V1/V1P

CVX-V1/V1P

CS-53 BOARD (2/3)

11

V

V=60Hz: NTSC

V=50Hz: PAL

IC502 ^™

12

32.768 kHz

IC502 %™

13

20 MHz

IC502 $¡

NTSC model: CVX-V1

PAL model : CVX-V1P

CS-53 (MODE CONTROL) SCHEMATIC DIAGRAM • See page 4-11 for CS-53 BOARD printed wiring board.

3 Vp-p

0.7 Vp-p

0.2 Vp-p

MODE CONTROL

CS-53 (2/3)

4-20 4-21 4-22

Page 17

CS-53 (MIC AMP) SCHEMATIC DIAGRAM • See page 4-11 for CS-53 BOARD printed wiring board.

CVX-V1/V1P

CVX-V1/V1P

4-23 4-24

MIC AMP

CS-53 (3/3)

Page 18

CVX-V1/V1P

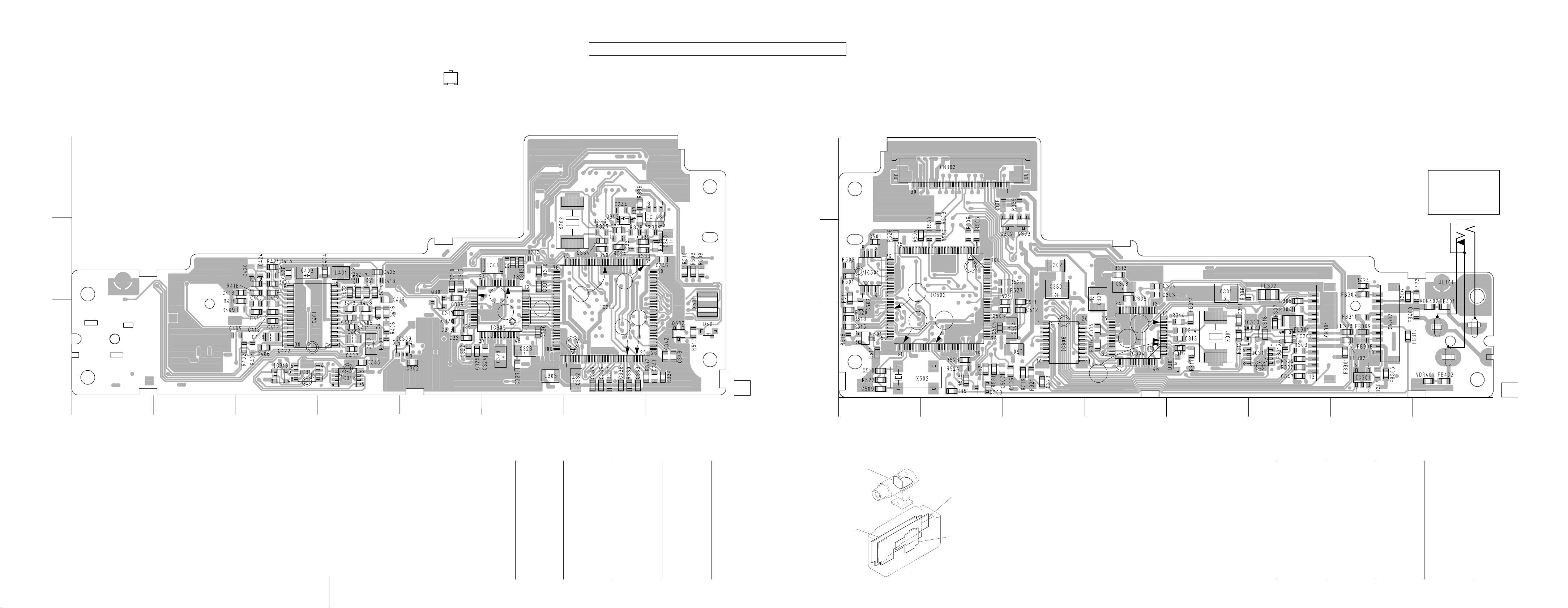

VA-103 (DC-DC CONVERTER, VIDEO/AUDIO I/O, LANC I/O), IF-69 (INTERFACE) PRINTED WIRING BOARDS

– Ref. No.: VA-103 board; 1,000 series, IF-69 board; 1,000 series –

• For printed wiring boards.

• VA-103 board is 4-layers print board. However, the patterns of

layers 2 to 3 have not been included in the diagram.

• Chip transistor

C

EB

There are few cases that the part isn't mounted in this model is printed on this diagram.

OUTPUT

S VIDEO

A

B

VA-103

BOARD(SIDE A)

A

B

VA-103

D

BOARD(SIDE B)

C

Y

GG

VIDEO

L

AUDIO

R

IF-69

A

B

BOARD (SIDE A)

IF-69

A

B

BOARD (SIDE B)

5

C

05

VA-103

VIDEO/AUDIO I/O,

DC-DC CONVERTER,

()

LANC I/O

DC-DC CONVERTER, VIDEO/AUDIO I/O, LANC I/O/INTERFACE

1

CD-188

CCD IMAGER,

()

TIMING GENERATOR

CD-188

Board

VA-103 Board

CS-53 Board

IF-69 Board

23456 78

VA-103 BOARD (SIDE A)

4-28

< CAPACITOR >

CS-53

CAMERA, Y/C PROCESS,

()

MIC AMP , MODE CONTROL

IF-69

(INTERFACE)

C625 B-7

C627 B-6

C628 B-7

C701 B-2

C702 B-3

C713 C-3

C714 C-2

C716 B-5

C718 B-4

C720 C-2

C721 C-2

C724 C-2

C725 C-3

C729 B-2

C730 B-2

C733 B-5

C735 C-4

C738 C-2

C739 B-2

< CONNECTOR >

CN601 C-8

CN801 A-7

CN802 C-5

CN803 C-4

CN805 C-1

< DIODE >

D603 B-7

< FUSE >

F601 C-8

< FILTER >

FL701 C-4

VA-103 IF-69

C

1

1-669-614-

13

< COIL >

L601 C-6

L602 C-6

L603 C-6

L605 B-7

L702 C-3

< LINE FILTER >

LF601 C-8

< IC >

IC702 C-2

< TRANSISTOR >

Q606 B-7

Q607 B-7

Q608 B-7

Q609 B-8

4-29 4-30

Q610 B-8

Q701 B-1

Q702 B-3

Q704 B-6

Q708 C-5

Q709 B-3

Q801 C-4

< RESISTOR >

R620 B-7

R621 B-7

R622 B-7

R623 B-7

R624 B-7

R625 B-8

R626 B-8

R627 B-8

R702 B-6

R703 C-2

R704 C-3

R710 C-2

R713 B-2

R715 C-3

R716 C-3

R717 C-2

R718 C-2

R719 C-2

R720 C-2

R721 C-2

R722 B-5

R723 B-6

R726 C-4

R727 C-4

R729 C-4

R733 C-4

R735 C-2

R736 C-3

R737 C-3

R738 C-2

R739 B-2

R804 C-3

R805 C-4

R806 C-4

R809 C-6

R810 C-6

R815 C-5

< TRANSFORMER >

T601 C-7

< VARISTOR >

VDR601 B-8

VDR602 C-8

05

1

23456 78

2

4

3

VA-103 BOARD (SIDE B)

< CAPACITOR >

C602 A-2

C603 B-2

C604 A-2

C605 B-2

C606 B-2

C607 B-2

C608 B-1

C609 B-1

C610 B-1

C611 B-1

C612 C-2

C613 C-2

C614 C-2

C618 C-3

C619 B-1

C620 C-3

C621 C-3

C622 C-3

C623 C-3

C624 C-2

7

C626 C-1

C629 B-1

C703 C-4

C704 C-5

C705 C-5

C706 B-4

C707 C-4

C708 C-4

C709 C-4

C710 C-4

C711 C-4

C712 B-4

C715 B-4

C717 B-4

C719 C-5

C734 C-3

C736 B-3

C737 B-3

C801 C-6

C802 C-6

C803 C-6

C805 A-1

6

< DIODE >

D601 C-2

D602 C-2

D604 C-1

D801 C-6

D802 A-2

D803 A-2

< FERRITE BEAD >

FB701 B-4

FB702 B-4

FB703 B-3

FB704 B-5

FB705 B-6

FB706 B-7

FB707 B-6

< IC >

IC601 B-2

IC602 C-1

IC701 C-5

IC801 C-6

IC802 A-1

IC803 A-2

< JACK >

J701 A-5

< COIL >

L604 C-2

L606 C-2

L701 C-4

L703 B-3

< TRANSISTOR >

Q601 C-2

Q602 C-2

Q603 C-2

1-669-614-

Q604 C-1

Q605 C-2

Q703 C-4

Q705 B-7

Q706 B-6

Q707 B-4

Q803 B-4

< RESISTOR >

R601 B-2

R602 A-2

R603 B-2

R604 B-2

R606 B-2

R607 B-1

R608 B-1

R609 B-3

R610 B-1

R611 B-1

R612 C-2

R613 C-2

C

D

1-669-613-

11

C

D

13

123

IF-69 BOARD (SIDE A)

R614 C-1

R615 C-1

R616 C-1

R618 C-1

R619 C-1

R701 B-3

R705 B-6

R706 B-6

R707 B-5

R708 B-5

R709 B-4

R711 B-4

R712 B-5

R724 C-4

R725 C-4

R728 B-3

R730 B-4

R731 B-3

R732 B-4

R801 C-6

R802 C-6

R803 C-6

R811 A-2

R812 A-2

R813 A-2

R814 A-2

< VARIST OR >

VDR701 B-5

VDR702 B-4

VDR703 B-4

VDR704 B-7

VDR705 B-6

4-31 4-32

< CONNECTOR >

CN902 A-2

1-669-613-

11

123

IF-69 BOARD (SIDE B)

< CONNECTOR >

CN901 C-2

< FERRITE BEAD >

FB901 B-2

FB902 B-2

FB903 B-2

FB905 B-2

FB906 B-2

< COIL >

L901 C-3

< RESISTOR >

R901 B-2

< VARISTOR >

VDR901 C-2

VDR902 C-2

VDR903 C-2

VDR904 C-2

VDR905 C-2

VDR906 C-2

VDR907 D-2

Page 19

VA-103 (DC-DC CONVERTER) SCHEMATIC DIAGRAM

CVX-V1/V1P

VA-103 BOARD (1/3)

1

13 Vp-p

2.0 µsec

Q601 C

4-33 4-34 4-35

DC-DC CONVERTER

VA-103 (1/3)

Page 20

CVX-V1/V1P

VA-103 (VIDEO/AUDIO I/O) SCHEMATIC DIAGRAM • See page 4-28 for VA-103 BOARD printed wiring board.

VA-103 BOARD (2/3)

2

0.46 Vp-p

H

IC701 @™

3

0.5 Vp-p

H

IC701 !§

4

1.0 Vp-p

H

IC701 !¢

5

1.8 Vp-p

H

IC701 9

6

2.1 Vp-p

H

IC701 6

7

1.1 Vp-p

H

IC701 #¡

VIDEO/AUDIO I/O

VA-103 (2/3)

4-36 4-37 4-38

Page 21

VA-103 (LANC I/O), IF-69 (INTERFACE) SCHEMATIC DIAGRAM • See page 4-28 for VA-103 BOARD and IF-69 BOARD printed wiring boards.

CVX-V1/V1P

4-39 4-40 4-41 E

LANC I/O/INTERFACE

VA-103 (3/3) IF-69

Page 22

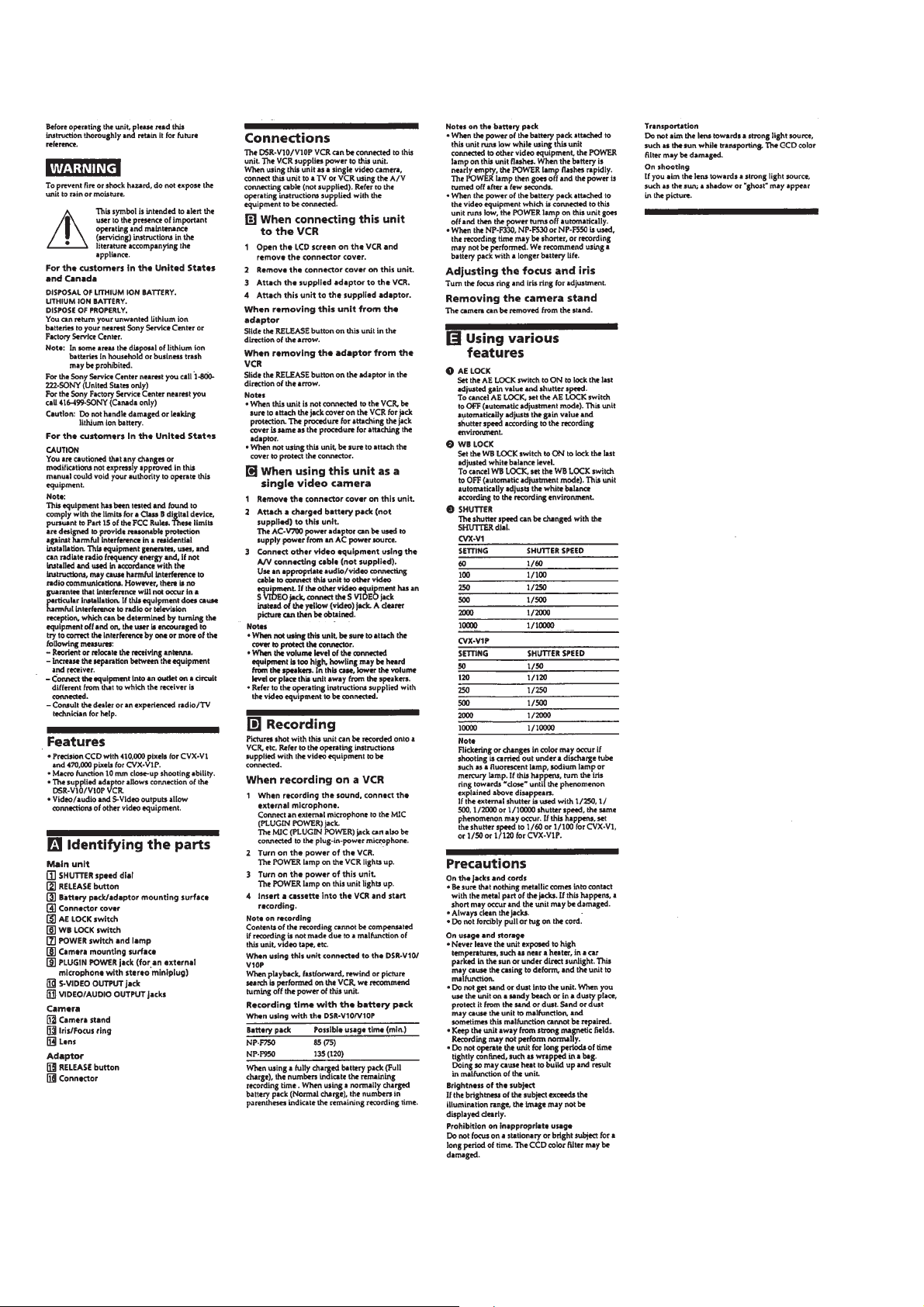

SECTION 5

ADJUSTMENTS

5-1. CAMERA SECTION ADJUSTMENT

NTSC model : CVX-V1

PAL model : CVX-V1P

1-1. PREPARATIONS BEFORE ADJUSTMENT

1-1-1. List of Service Tools

• Oscilloscope • Regulated power supply • Vectorscope • Frequency counter

• Color monitor • Digital voltmeter

CVX-V1/V1P

Ref. No.

J-1

Filter for color temperature correction (C14)

ND filter 1.0

J-2

ND filter 0.3

J-3

Pattern box PTB-450

J-4

Color chart for pattern box

Adjustment remote commander

J-5

(RM-95 upgraded). Note

J-6

Clear chart for pattern box

J-7

CPC-5 jig

Note: If the microprocessor IC in the adjustment remote commander is not the new microprocessor (UPD7503G-C56-12), the pages

cannot be switched.

In this case, replace with the new microprocessor (8-759-148-35).

J-1 J-2

J-6

J-7

Name

J-3

Parts Code

J-6080-058-A

J-6080-808-A

J-6080-818-A

J-6082-200-A

J-6020-250-A

J-6082-053-B

J-6080-621-A

J-6082-351-A

Usage

Auto white balance adjustment/check

White balance adjustment/check

White balance check

White balance check

For adjusting the video section

J-4 J-5

Fig. 5-1-1

5-1

Page 23

1-1-2. Preparations

d

Note 1: For details of how remove the cabinet and boards, refer

to “2. DISASSEMBLY”.

1) Connect the equipment for adjustments according to Fig. 5-1-3.

2) Connect the adjustment remote commander to the CN805 on

the VA-103 board via CPC-5 (J-6082-351-A).

Pattern box

L

Front side of the lens

L = About 40 cm

Fig. 5-1-2

Audio (L)

Audio (R)

Regulated power supply

(8.4 V

±

0.1 Vdc)

Adjustment remote comander

(RM-95)

(J-6082-053-B)

CPC-5jig

(J-6082-351-A)

CN805

VA-103

board

CN803

CN802

CN801

Remote

terminal

Video

Video/Audio

output

terminal

Color monitor Vectorscope

Camera head

CN301

CS-53

board

CN303

75

Ω

terminate

Note 2: In changing data, wait for more than

5 seconds after the set was turned

on, then change the data.

CN601

Fig. 5-1-3

5-2

Page 24

1-1-3. Precaution

1. Setting the Switch

Unless otherwise specified, set the switches as follows and perform adjustments.

1. POWER switch (Control switch block) .............. ON

2. AE LOCK switch (Control switch block) ...........OFF

2. Order of Adjustments

Basically carry out adjustments in the order given.

H

Electronic beam scanning frame

Yellow

AB B

Cyan

Green

A=B

White

Magenta

Red

Blue

A

Enlargement

Fig. a (Video output terminal

output waveform)

B

3. Subjects

1) Color bar chart (Standard picture frame).

When performing adjustments using the color bar chart, adjust the picture frame as shown in Fig. 5-1-4. (Standard picture frame)

2) Clear chart (Standard picture frame)

Remove the color bar chart from the pattern box and insert a

clear chart in its place. (Do not perform zoom operations

during this time.)

0

±

0.1msec

Red

Cyan

White

Green

Yellow

V

Blue

Magenta

CRT picture frame

Fig. b (TV monitor picture)

Difference in level

Direct the camera toward the subject and place the

A

subject with the distance (about 40 cm) from camera

until the specified picture frame fills the monitor display as shown in Fig. a and Fig. b.

Fig. 5-1-4

5-3

Page 25

1-1-4. ADJUSTMENT REMOTE COMMANDER

The adjustment remote commander is used for changing the calculation coefficient in signal processing, EVR data, etc. The adjustment remote commander performs bi-directional communication with the unit using the remote commander signal line (LANC).

The resultant data of this bi-directional communication is written

in the non-volatile memory.

1. Using the Adjustment Remote Commander

1) Connect the adjustment remote commander to the CN805

on the VA-103 board via CPC-5 (J-6082-351-A).

2) Set the HOLD switch of the adjustment remote commander

to “HOLD” (SER VICE position). If it has been properly connected, the LCD on the adjustment remote commander will

display as shown in Fig. 5-1-5.

Address

Page

Data

Fig. 5-1-5

2. Precautions Upon Using

The Adjustment Remote Commander

Mishandling of the adjustment remote commander may erase the

correct adjustment data at times. T o prev ent this, it is recommended

that all adjustment data be noted down before beginning adjustments and new adjustment data after each adjustment.

3) Operate the adjustment remote commander as follows.

• Changing the page

The page increases when the EDIT SEARCH+ button is pressed,

and decreases when the EDIT SEARCH– button is pressed.

There are altogether 16 pages, from 0 to F.

Hexadecimal

notation

LCD Display

Decimal notation

conversion value

0123456789ABCDEF

0123456789AbcdEF

0 1 2 3 4 5 6 7 8 9 101112131415

Table. 5-1-1

• Changing the address

The address increases when the FF ()) button is pressed, and

decreases when the REW (0) button is pressed. There are

altogether 256 addresses, from 00 to FF.

• Changing the data (Data setting)

The data increases when the PLAY (() button is pressed, and

decreases when the STOP (p) button is pressed. There are altogether 256 data, from 00 to FF.

• Writing the adjustment data

The P A USE button must be pressed to write the adjustment data

(F page) in the nonvolatile memory. (The new adjusting data

will not be recorded in the nonvolatile memory if this step is not

performed.)

4) After completing all adjustments, turn off the main power

supply (8.4V) once.

5-4

Page 26

1-1-5. DATA PROCESS

The calculation of the DDS display and the adjustment remote

commander display data (hexadecimal notation) are required for

obtaining the adjustment data of some adjustment items. In this

case, after converting the hexadecimal notation to decimal notation, calculate and convert the result to hexadecimal notation, and

use it as the adjustment data. Indicates the hexadecimal-decimal

conversion table.

Hexadecimal-decimal Conversion Table

Lower digit of

hexadecimal

Upper digit

of hexadecimal

0

1

2

3

4

5

6

7

8

9

A (

)

A

)

B (

1

b

C (

)

c

D (

)

d

E (

)

E

)

F (

F

Note: The characters shown in the parenthesis ( ) shown the display on the adjustment remote commander.

(Example) If the DDS display or the adjustment remote commander shows BD (

0123456789A

0

0

)B(b)C(c)D(d)E(

(

A

0123456789101112131415

16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31

32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47

48 49 50 51 52 53 54 55 56 57 58 59 60 61 62 63

64 65 66 67 68 69 70 71 72 73 74 77 76 77 78 79

80 81 82 83 84 85 86 87 88 89 90 91 92 93 94 95

96 97 98 99 100 101 102 103 104 105 106 107 108 109 110 111

112 113 114 115 116 117 118 119 120 121 122 123 124 125 126 127

128 129 130 131 132 133 134 135 136 137 138 139 140 141 142 143

144 145 146 147 148 149 150 151 152 153 154 155 156 157 158

176

192 193 194 195 196 197 198 199 200 201 202 203 204 205 206 207

208 209 210 211 212 213 214 215 216 217 218 219 220 221 222 223

224 225 226 227 228 229 230 231 232 233 234 235 236 237 238 239

240 241 242 243 244 245 246 247 248 249 250 251 252 253 254 255

Because the upper digit of the adjustment number is B (

“189” of 1 and 2 in the above table is the corresponding decimal number.

178 179 180 181 182 183 184 185 186 187 188 189 190 191

177

);

bd

), and the lower digit is D (d), the meeting point

b

2

E

174

F

)

)

(

F

159

175160 161 162 163 164 165 166 167 168 169 170 171 172 173

Table. 5-1-2

5-5

Page 27

1-2. INITIALIZATION OF F PAGE DATA

3. F Page T able

1. Initializing the F Page Data

Note: If the F page data has been initialized, “Modification of F

PAGE Data” and the camera system adjustments need to

be performed again.

Adjustment page F

Adjustment Address 00 to FF

Initializing Method:

1) Select page: 6, address: 02, and check that the data is “00”.

2) Select page: 0, address: 01, and set data: 01.

3) Select page: 3, address: 00, set data: 2D (NTSC) or data: 2F

(PAL), and press the PAUSE button of the adjustment remote commander.

4) Select page: 3, address: 01, set data: 2D (NTSC) or data: 2F

(PAL), and press the PAUSE button of the adjustment remote commander.

5) Select page: 6, address: 02, and check that the data is “01”.

6) Select page: 3, address: 00, set data: 00, and press the P A USE

button of the adjustment remote commander.

7) Select page: 3, address: 01, set data: 00, and press the P A USE

button of the adjustment remote commander.

8) Select page: 0, address: 01, and set data: 00.

9) Perform “Modification of F Page Data”.

2. Modification of F PAGE Data

If the F PAGE data has been initialized, change the data of the

“Fixed data-2” address shown in the following tables by manual

input.

Modifying Method:

1) Before changing the data, select page: 0, address: 01, and set

data: 01.

2) New data for changing are not shown in the tables because

they are different in destination. When changing the data,

copy the data built in the same model.

Note: If copy the data built in the different model, the camcorder

may not operate.

3) When changing the data, press the PAUSE button of the adjustment remote commander each time when setting new data

to write the data in the non-volatile memory.

4) Check that the data of adjustment addresses is the initial value.

If not, change the data to the initial value.

5) After changing the data, select page: 0, address: 01, and set

data: 00.

Note: Fixed data-1 : Initialized data. ( Refer to “1. Initializing

the F Page Data”.)

Fixed data-2 : Modified data. (Refer to “2. Modification of

F PAGE Data”.)

Address Initial Remark

value

NTSC PAL

00 Fixed data2

01

02

03 Fixed data1

04 (Initialized data)

05

06

07

08

09

0A

0B

0C

0D

0E

0F

10

11

12

13

14 Fixed data2

15

16 Fixed data1

17 Fixed data2

18 Fixed data1

19 Fixed data2

1A Fixed data1

1B (Initialized data)

1C

1D

1E

1F

20

21

22

23 Fixed data2

24 Fixed data1

25 (Initialized data)

26

27

28

29

2A

2B

2C

2D

2E

2F

5-6

Page 28

Address Initial Remark

value

NTSC PAL

30 18 18 Auto White Balance

31 3D 3D Reference Data Input

32 21 21

33 39 39

34 24 24

35 Fixed data1

36 00 30 Picture Frame Setting

37 21 23

38 Fixed data1

39 (Initialized data)

3A

3B

3C

3D Fixed data2

3E Fixed data1

3F 20 20 28MHz Origin Oscillation Adj.

40 Fixed data1

41 (Initialized data)

42 Fixed data2

43 Fixed data1

44 1B 1B Color Reproduction Adj.

45 Fixed data1

46 42 42 Color Reproduction Adj.

47 Fixed data1

48 (Initialized data)

49

4A 89 89 Auto White Balance Adj.

4B 59 59

4C Fixed data2

4D

4E

4F

50

51 Fixed data1

52 (Initialized data)

53

54

55

56

57

58 94 94 Battery Down Adj.

59 9B 9B

5A B3 B3

5B C8 C8

5C D3 D3

5D Fixed data1

5E (Initialized data)

5F

60

61

62

63

64

65

66

Address Initial Remark

value

NTSC PAL

67 Fixed data1

68 (Initialized data)

69

6A

6B

6C

6D

6E

6F

70

71

72

73

74

75

76

77

78

79

7A

7B

7C

7D

7E

7F

80

81

82

83

84

85

86

87

88

89

8A

8B

8C

8D

8E

8F

90

91

92

93

94

95

96

97

98

99

9A

9B

9C

9D

5-7

Page 29

Address Initial Remark

value

NTSC PAL

9E Fixed data2

9F

A0 Fixed data1

A1 (Initialized data)

A2

A3

A4

A5

A6

A7

A8

A9

AA FD FE Color Reproduction Adj.

AB F6 F4

AC Fixed data2

AD

AE Fixed data1

AF (Initialized data)

B0

B1

B2

B3 Fixed data2

B4 Fixed data1

B5 (Initialized data)

B6 Fixed data2

B7 Fixed data1

B8 (Initialized data)

B9

BA

BB

BC

BD

BE

BF Fixed data2

C0 Fixed data1

C1 Fixed data2

C2 Fixed data1

C3 Fixed data2

C4 Fixed data1

C5 (Initialized data)

C6

C7

C8

C9

CA

CB

CC

CD

CE

CF

D0

D1

D2

D3

D4

Address Initial Remark

value

NTSC PAL

D5 Fixed data1

D6 (Initialized data)

D7

D8

D9

DA

DB

DC

DD

DE

DF

E0

E1

E2

E3

E4

E5

E6

E7

E8

E9

EA

EB

EC

ED

EE

EF

F0

F1

F2

F3

F4

F5

F6

F7

F8

F9

FA

FB

FC

FD

FE

FF Fixed data2

Table. 5-1-3

5-8

Page 30

1-3. CAMERA SYSTEM ADJUSTMENTS

1. 28 MHz Origin Oscillation Adjustment

(CS-53 board)

Set the frequency of the clock for synchronization. If deviated, the

synchronization will be disrupted and the color will become inconsistent.

Subject Not required

Measurement Point Pin !™ of IC304

Measuring Instrument Frequency counter

Adjustment Page F

Adjustment Address 3F

Specified Value

Adjusting method:

1) Select page: 0, address: 01, and set data: 01.

2) Select page: F , address: 3F, change the data and set the clock

frequency (f) to the specified value.

3) Press the PAUSE button of the adjustment remote commander.

4) Select page: 0, address: 01, and set data: 00.

f=14318181 ± 68 Hz (NTSC)

f=14187500 ± 69 Hz (PAL)

• PARTS LOCATION DIAGRAM FOR 28 MHz ORIGIN OSCILLATION ADJUSTMENT

CS-53 BOARD (SIDE B)

24

IC304

37

13

12

1

48

25

36

5-9

Page 31

2. Picture Frame Setting

t=0 ± 0.1msec

V

e

Subject

Color bar chart standard picture frame

(40 cm from the front of the lens)

Measurement Point Video output terminal

Measuring Instrument Oscilloscope and TV monitor

Adjustment page F

Adjustment address 36, 37

Specified Value A = B, C = D, t = 0 ± 0.1 msec

Setting method:

1) Select page: 0, address: 01, and set data: 01.

2) Select page: F, address: 36, and set data: 00, and press the

PAUSE button of the adjustment remote commander.

3) Select page: F, address: 37, and set data: 40, and press the

PAUSE button of the adjustment remote commander.

4) Adjust the camera direction, and set to the specified position.

5) Mark the position of the picture frame on the monitor display, and adjust the picture frame to this position in following adjustments using “Color bar chart standard picture

frame”.

Processing after Completing Adjustments:

1) Select page: F, address: 37, and set data: 21 (NTSC) or set

data: 23 (PAL), and press the PAUSE button of the adjustment remote commander.

2) Select page: F, address: 36, and set data: 00 (NTSC) or set

data: 30 (PAL), and press the PAUSE button of the adjustment remote commander.

3) Select page: 0, address: 01, and set data: 00.

Check on the oscilloscope

1. Horizontal period

A=B

BC

A

Fig. 5-1-6

2. Vertical period

C=D

D

Color on the TV monitor

Color bar chart picture frame

Fig. 5-1-7

TV monitor picture fram

Fig. 5-1-8

5-10

Page 32

3. Color Reproduction Adjustment

R-Y

B-Y

M

G

R

Y

L

G

C

Y

B

Burst position

Adjust the color Separation matrix coefficient so that proper color

reproduction is produced.

Subject

Measurement Point Video output terminal

Measuring Instrument Vectorscope

Adjustment Page F

Adjustment Address 44, 46, AA, AB

Specified Value All color luminance points should

Color bar chart standard picture

frame

settle within each color reproduction frame.

For NTSC model

Y

R-Y

M

R

L

G

B-Y

B

Adjusting method:

1) Select page: 0, address: 01, and set data: 01.

2) Select page: 2, address: 01, set data: 3D, and press the P A USE

button of the adjustment remote commander.

3) Select page: F , address: 1A, set data: 3F , and press the PAUSE

button of the adjustment remote commander.

4) Adjust the GAIN and PHASE of the vectorscope, and adjust

the burst luminance point to the burst position of the color

reproduction frame.

5) Change the data of page: F , address: 44, 46, AA and AB, and

settle each color luminance point in each color reproduction

frame.

Note: Be sure to press the PAUSE button of the adjustment re-

mote commander before changing the addresses. If not,

the new data will not be written to the memory.

6) Press the PAUSE button of the adjustment remote commander.

Processing after Completing Adjustments:

1) Select page: 2, address: 01, and set data: 00, and press the

PAUSE button of the adjustment remote commander.

2) Select page: 0, address: 01, and set data: 00.

Burst position

For PAL mode

Y

G

C

Fig. 5-1-9

5-11

Page 33

4. Auto White Balance Reference Data Input

Subject

Adjustment Page F

Adjustment Address 30 to 34

Note 1: Perform “Color Reproduction Adjustment” before this

adjustment.

Note 2: Check that the data of page: 2, address: 02 is 00. If not,

turn the power of the unit OFF/ON.

Adjusting method:

1) Select page: 0, address: 01, and set data: 01.

2) Select page: 2, address: 40, set data: 02, and press the P A USE

button of the adjustment remote commander.

3) Select page: 2, address: 41, set data: 01, and press the P A USE

button of the adjustment remote commander.

4) Shoot the clear chart with the color bar standard picture frame,

and wait for 2 seconds.

5) Select page: 2, address: 01, set data: 11, and press the P A USE

button of the adjustment remote commander.

6) Select page: 2, address: 01, set data: 0D, and press the P A USE

button of the adjustment remote commander.

(When the standard data is take in, the data will be automatically input to page: F, address: 30 to 34.)

7) Select page: 2, address: 02, and check that the data is “01”.

Processing after Completing Adjustments:

1) Select page: 2, address: 01, and set data: 00, and press the

PAUSE button of the adjustment remote commander.

2) Select page: 2, address: 41, and set data: 00, and press the

PAUSE button of the adjustment remote commander.

3) Select page: 2, address: 40, and set data: 00, and press the

PAUSE button of the adjustment remote commander.

4) Select page: 0, address: 01, and set data: 00.

5) Perform “Auto White Balance Adjustment”.

Clear chart

(Color bar standard picture frame)

5. Auto White Balance Adjustment

Adjust to the proper auto white balance output data.

If it is not correct, auto white balance and color reproducibility

will be poor.

Subject

Filter

Measurement Point

Measuring Instrument

Adjustment Page F

Adjustment Address 4A, 4B

Specified Value

Note 1: Perform “Auto White Balance Reference Data Input”

before this adjustment.

Note 2: The right four digits of the page 1 displayed data of the

adjustment remote commander.

01 XXXX

Adjusting method:

1) Place the C14 filter for color temperature correction on the

lens.

2) Select page: 0, address: 01, and set data: 01.

3) Select page: 2, address: 40, set data: 02, and press the P A USE

button of the adjustment remote commander.

4) Select page: 2, address: 41, set data: 01, and press the P A USE

button of the adjustment remote commander.

5) Select page: 2, address: 01, set data: 3F , and press the P A USE

button of the adjustment remote commander.

6) Select page: 0, address: 03, and set data: 04.

7) Select page: F, address: 4A, change the data and adjust the

average value of the page 1 displayed data (Note 2) to the R

ratio specified value.

8) Press the PAUSE button of the adjustment remote commander.

9) Select page: 0, address: 03, and set data: 05.

10) Select page: F, address: 4B, change the data and adjust the

average value of the page 1 displayed data (Note 2) to the B

ratio specified value.

11) Press the PAUSE button of the adjustment remote commander.

Clear chart

(Color bar standard picture frame)

Filter C14 for color temperature

correction

Page 1 displayed data of the

adjustment remote commander

(Note 2)

R ratio: 2B40 to 2BC0

B ratio: 5E40 to 5EC0

Object data

Processing after Completing Adjustments:

1) Select page: 2, address: 01, set data: 00, and press the P A USE

button of the adjustment remote commander.

2) Select page: 2, address: 41, set data: 00, and press the P A USE

button of the adjustment remote commander.

3) Select page: 2, address: 40, set data: 00, and press the P A USE

button of the adjustment remote commander.

4) Select page: 0, address: 03, and set data: 00.

5) Select page: 0, address: 01, and set data: 00.

5-12

Page 34

6. White Balance Check

Y

R-Y

B-Y

1.0mm

1.0mm

3mm

3mm

R-Y

B-Y

3mm

3mm

2.0mm

1.0mm

Subject

Clear chart

(Color bar standard picture frame)

Filter C14 for color temperature

Filter

correction

ND filter 1.0 and 0.3

Measurement Point Video output terminal

Measuring Instrument Vectorscope

Specified Value Fig. 5-1-10. (A) to (C)

R-Y

2mm

B-

2mm

Checking method:

1) Check that the lens is not covered with either filter.

2) Select page: 0, address: 01, and set data: 01.

3) Select page: 2, address: 40, set data: 02, and press the P A USE

button of the adjustment remote commander.

4) Select page: 2, address: 41, set data: 01, and press the P A USE

button of the adjustment remote commander.

5) Select page: 2, address: 01, set data: 0F , and press the P A USE

button of the adjustment remote commander.

6) Check that the center of the white luminance point is within

the circle shown Fig. 5-1-10 (A).

7) Select page: 2, address: 01, set data: 00, and press the P A USE

button of the adjustment remote commander.

8) Select page: 2, address: 01, set data: 23, and press the P A USE

button of the adjustment remote commander.

9) Place the C14 filter on the lens.

10) Check that the center of the white luminance point settles in

the circle shown Fig. 5-1-10 (B).

11) Remove the C14 filter, and place the ND filter 1.3 (1.0 +

0.3) on the lens.

12) Check that the white luminance point stopped moving, and

then remove the ND filter 1.3.

13) Check that the center of the white luminance point settles

within the circle shown Fig. 5-1-10 (C).

Processing after Completing Adjustments:

1) Select page: 2, address: 41, set data: 00, and press the P A USE

button of the adjustment remote commander.

2) Select page: 2, address: 40, set data: 00, and press the P A USE

button of the adjustment remote commander.

3) Select page: 2, address: 01, set data: 00, and press the P A USE

button of the adjustment remote commander.

4) Select page: 0, address: 01, set data: 00.

Fig. 5-1-10 (A)

Fig. 5-1-10 (B)

Fig. 5-1-10 (C)

5-13

Page 35

7. Battery Down Adjustment

Set the battery end voltage.

Mode Camera on

Subject Arbitrary

Measurement Point

LCD display of the adjustment

remote commander.

Measuring Instrument Not required

Adjustment Page F

Adjustment Address 58 to 5C

Connection

1) Connect the regulated power supply and the digital voltmeter to the battery terminal as shown in Fig. 5-1-11.

Digital voltmeter

11) Select page: F , address: 5B, set data: X3, and press the P A USE

button of the adjustment remote commander.

12) Select page: F , address: 5C, set data: X4, and press the P A USE

button of the adjustment remote commander.

13) Select page: 0, address: 01, and set data: 00.

Regulated power supply

(6.1

±

0.1Vdc)

Battery terminal

Fig. 5-1-11

Adjusting method:

1) Adjusting the output voltage fo the regulated power supply

so that the digital voltmeter display is 6.1 ± 0.1 Vdc.

2) Select page: 0, address: 01, and set data: 01.

3) Decrease the output voltage of the regulated power supply

so that the digital voltmeter display is 5.30 ± 0.01 Vdc.

4) Select page: 3, address: 0D, read the data, and this data is

named X0.

5) Convert X0 to decimal notation, and obtain X0'.

(Refer to “Table 5-1-2. Hexadecimal-decimal conversion

table”.)

6) Calculate X1', X2', X3', and X4' using follwing equations (decimal calculation).

Address: 59 X1' = X0' + 8

Address: 5A X2' = X0' + 32

Address: 5B X3' = X0' + 53

Address: 5C X4' = X0' + 64

7) Convert X1', X2', X3' and X4' to hexadecimal notation, and

obtain X1, X2, X3 and X4.

8) Select page: F , address: 58, set data: X0, and press the P AUSE

button of the adjustment remote commander.

9) Select page: F , address: 59, set data: X1, and press the P AUSE

button of the adjustment remote commander.

10) Select page: F , address: 5A, set data: X2, and press the P A USE

button of the adjustment remote commander.

5-14 E

Page 36

SECTION 6

REPAIR PARTS LIST

CVX-V1/V1P

6-1. EXPLODED VIEWS

NOTE:

• -XX and -X mean standardized parts, so they may

have some difference from the original one.

• Color Indication of Appearance Parts

Example:

KNOB, BALANCE (WHITE) . . . (RED)

• Items marked “*” are not stocked since they are

seldom required for routine service. Some delay

should be anticipated when ordering these items.

↑↑

Parts Color Cabinet's Color

25

24

*

IC001

28

21

19

20

11

11

not

supplied

• The mechanical parts with no reference number in

the exploded views are not supplied.

• Accessories are given in the last of the electrical

parts list.

27

29

26

11

not

supplied

29

32

25

30

CVX-V1

22

33

17

11

11

16

not

supplied

4

5

IF-69

18

2

14

The components identified by mark

! or dotted line with mark ! are criti-

cal for safety.

Replace only with part number specified.

Les composants identifiés par une

marque ! sont critiquens pour la

sécurité.

Ne les remplacer que par une pièce

portant le numéro spécifié.

15

12

VA-103 Board

10

9

11

8

7

6

11

13

23

31

CS-53 Board

*Be sure to read “Precautions for

Replacement of CCD Imager” on

page 4-7 when changing the CCD

imager.

1 A-7073-693-A CS-53 BOARD, COMPLETE (CVX-V1P)

1 A-7073-696-A CS-53 BOARD, COMPLETE (CVX-V1)

2 1-694-076-21 TERMINAL BOARD, BATTERY

3 1-783-522-11 CABLE, FLEXIBLE FLAT (FFC-246)

4 1-783-523-11 CABLE, FLEXIBLE FLAT (FFC-247)

5 A-7073-694-A IF-69 BOARD, COMPLETE (CVX-V1P)

5 A-7073-697-A IF-69 BOARD, COMPLETE (CVX-V1)

6 3-989-171-21 CABINET (UPPER)

7 3-989-179-01 SPRING, COMPRESSION

8 3-989-173-01 SWITCH, RELEASE

9 3-989-174-01 LOCK, BATTERY

10 3-989-181-02 SPRING, TORSION

11 3-948-339-01 SCREW, TAPPING

12 A-7073-692-A VA-103 BOARD, COMPLETE (CVX-V1P)

12 A-7073-695-A VA-103 BOARD, COMPLETE (CVX-V1)

13 X-3949-036-1 CABINET (LOWER) ASSY (CVX-V1)

13 X-3949-037-1 CABINET (LOWER) ASSY (CVX-V1P)

14 3-989-177-01 SHOE

15 3-989-178-01 SPRING, SHOE LEAF

16 1-783-521-22 CORD, CONNECTION

1

CVX-V1

34

3

Ref. No. Part No. Description RemarkRef. No. Part No. Description Remark

17 1-475-734-11 SWITCH BLOCK, CONTROL (VC)

* 18 2-277-426-01 CLAMP

19 3-050-944-11 CABINET (LOWER)

20 1-758-186-11 LENS, VIDEO (VCL-3901VB)

21 1-758-157-11 FILTER BLOCK, OPTICAL

22 3-050-798-01 SPACER (VC)

* 23 3-052-339-01 CUSHION (A)

24 3-050-869-01 SPRING, SNAP

25 3-968-729-81 SCREW (M2), LOCK ACE, P2

26 3-050-943-11 CABINET (UPPER)

27 A-7029-292-A Y HOLDER ASSY

28 3-050-868-01 RUBBER, SEAL

29 3-050-945-11 HOLDER, GUIDE

30 A-7073-609-A CD-188 BOARD, COMPLETE

31 3-989-676-11 COVER, VC (CONNECTOR COVER)

32 2-646-027-01 SCREW (M1.7X3)

* 33 3-704-367-01 LABEL (CVX-V1)

* 34 3-704-437-01 LABEL, CAUTION, FUSE REPLACEMENT

IC001 8-752-616-03 IC ICX208AK-43 (CCD IMAGER) (CVX-V1)

IC001 8-752-616-11 IC ICX209AK-43 (CCD IMAGER) (CVX-V1P)

11

(CVX-V1)

6-1

Page 37

CD-188 CS-53

6-2. ELECTRICAL PARTS LIST

NOTE:

• Due to standardization, replacements in the

parts list may be different from the parts specified in the diagrams or the components used

on the set.

• -XX and -X mean standardized parts, so they

may have some difference from the original

one.

• RESISTORS

All resistors are in ohms.

METAL: Metal-film resistor.

METAL OXIDE: Metal oxide-film resistor.

F: nonflammable

Ref. No. Part No. Description Remark Ref. No. Part No. Description Remark

A-7073-609-A CD-188 BOARD, COMPLETE

***********************

< CAPACITOR >

C002 1-107-687-11 TANTAL. CHIP 3.3uF 20% 20V

C003 1-164-943-11 CERAMIC CHIP 0.01uF 10% 16V

C004 1-109-982-11 CERAMIC CHIP 1uF 10% 10V

C005 1-164-844-11 CERAMIC CHIP 4PF 0.25PF 16V

C006 1-109-982-11 CERAMIC CHIP 1uF 10% 10V

C101 1-135-259-11 TANTAL. CHIP 10uF 20% 6.3V

C102 1-107-826-11 CERAMIC CHIP 0.1uF 10% 16V

C103 1-163-021-91 CERAMIC CHIP 0.01uF 10% 50V

C104 1-107-687-11 TANTAL. CHIP 3.3uF 20% 20V

C105 1-113-682-11 TANTAL. CHIP 33uF 20% 10V

C106 1-164-937-11 CERAMIC CHIP 0.001uF 10% 16V

C107 1-125-777-11 CERAMIC CHIP 0.1uF 10% 10V

< CONNECTOR >

• Items marked “*” are not stocked since they

are seldom required for routine service.

Some delay should be anticipated when ordering these items.

• SEMICONDUCTORS

In each case, u: µ, for example:

uA. . : µA. . uPA. . : µPA. .

uPB. . : µPB. . uPC. . : µPC. .

uPD. . : µPD. .

• CAPACITORS

uF: µF

• COILS

uH: µH

R107 1-218-941-11 RES,CHIP 100 5% 1/16W

(Ref.No.:1,000 Series)

R108 1-218-941-11 RES,CHIP 100 5% 1/16W

R109 1-218-941-11 RES,CHIP 100 5% 1/16W

R110 1-218-941-11 RES,CHIP 100 5% 1/16W

R111 1-218-950-11 RES,CHIP 560 5% 1/16W

R112 1-218-973-11 RES,CHIP 47K 5% 1/16W

A-7073-696-A CS-53 BOARD, COMPLETE (CVX-V1)

A-7073-693-A CS-53 BOARD, COMPLETE (CVX-V1P)

C301 1-104-913-11 TANTAL. CHIP 10uF 20% 16V

C302 1-162-923-11 CERAMIC CHIP 47PF 5% 50V

C305 1-107-826-11 CERAMIC CHIP 0.1uF 10% 16V

C306 1-107-826-11 CERAMIC CHIP 0.1uF 10% 16V

C308 1-135-201-11 TANTALUM CHIP 10uF 20% 4V

******************************

*******************************

< CAPACITOR >

The components identified by

mark ! or dotted line with mark

! are critical for safety.

Replace only with part number

specified.

Les composants identifiés par une

marque ! sont critiquens pour la

sécurité.

Ne les remplacer que par une pièce

portant le numéro spécifié.

When indicating parts by reference

number, please include the board.

(Ref.No.:1,000 Series)

CN101 1-779-806-21 CONNECTOR 8P

CN102 1-785-125-21 CONNECTOR 6P

< FERRITE BEAD >

FB101 1-414-228-11 INDUCTOR CHIP 0UH

FB102 1-414-228-11 INDUCTOR CHIP 0UH

FB103 1-414-228-11 INDUCTOR CHIP 0UH

< IC >

IC002 8-759-197-89 IC AD818AR-REEL

IC101 8-752-386-72 IC CXD2444R

< COIL >

L001 1-412-963-11 INDUCTOR 100uH

< RESISTOR >

R001 1-218-939-11 RES,CHIP 68 5% 1/16W

R002 1-218-989-11 RES,CHIP 1M 5% 1/16W

R003 1-218-953-11 RES,CHIP 1K 5% 1/16W

R004 1-218-953-11 RES,CHIP 1K 5% 1/16W

R005 1-218-950-11 RES,CHIP 560 5% 1/16W

R103 1-218-953-11 RES,CHIP 1K 5% 1/16W

R106 1-218-941-11 RES,CHIP 100 5% 1/16W

C309 1-107-826-11 CERAMIC CHIP 0.1uF 10% 16V

C310 1-107-826-11 CERAMIC CHIP 0.1uF 10% 16V

C311 1-162-964-11 CERAMIC CHIP 0.001uF 10% 50V

C312 1-107-826-11 CERAMIC CHIP 0.1uF 10% 16V

C313 1-162-964-11 CERAMIC CHIP 0.001uF 10% 50V

C314 1-162-917-11 CERAMIC CHIP 15PF 5% 50V

C315 1-165-176-11 CERAMIC CHIP 0.047uF 10% 16V

C316 1-162-964-11 CERAMIC CHIP 0.001uF 10% 50V

C317 1-165-176-11 CERAMIC CHIP 0.047uF 10% 16V

C318 1-107-826-11 CERAMIC CHIP 0.1uF 10% 16V

C319 1-162-970-11 CERAMIC CHIP 0.01uF 10% 25V

C320 1-162-970-11 CERAMIC CHIP 0.01uF 10% 25V

C321 1-107-826-11 CERAMIC CHIP 0.1uF 10% 16V

C322 1-162-970-11 CERAMIC CHIP 0.01uF 10% 25V

C323 1-135-091-00 TANTALUM CHIP 1uF 20% 16V

C324 1-107-826-11 CERAMIC CHIP 0.1uF 10% 16V

C325 1-107-826-11 CERAMIC CHIP 0.1uF 10% 16V

C326 1-107-826-11 CERAMIC CHIP 0.1uF 10% 16V

C327 1-107-826-11 CERAMIC CHIP 0.1uF 10% 16V

C328 1-135-259-11 TANTAL. CHIP 10uF 20% 6.3V

C330 1-110-569-11 TANTAL. CHIP 47uF 20% 6.3V

C331 1-107-826-11 CERAMIC CHIP 0.1uF 10% 16V

C332 1-135-259-11 TANTAL. CHIP 10uF 20% 6.3V

C333 1-107-826-11 CERAMIC CHIP 0.1uF 10% 16V

6-2

Page 38

CS-53

Ref. No. Part No. Description Remark Ref. No. Part No. Description Remark

C334 1-162-917-11 CERAMIC CHIP 15PF 5% 50V

(CVX-V1P)

FB313 1-414-228-11 INDUCTOR CHIP 0UH

FB314 1-500-284-21 INDUCTOR CHIP 0UH

C335 1-107-826-11 CERAMIC CHIP 0.1uF 10% 16V

C336 1-162-970-11 CERAMIC CHIP 0.01uF 10% 25V

C337 1-162-964-11 CERAMIC CHIP 0.001uF 10% 50V

(CVX-V1P)

C338 1-107-826-11 CERAMIC CHIP 0.1uF 10% 16V

C339 1-107-826-11 CERAMIC CHIP 0.1uF 10% 16V

(CVX-V1P)

C340 1-107-688-11 TANTAL. CHIP 1.5uF 20% 10V

(CVX-V1P)

C341 1-107-826-11 CERAMIC CHIP 0.1uF 10% 16V

C342 1-162-970-11 CERAMIC CHIP 0.01uF 10% 25V

C343 1-107-826-11 CERAMIC CHIP 0.1uF 10% 16V

C347 1-162-915-11 CERAMIC CHIP 10PF 0.5PF 50V

C403 1-135-259-11 TANTAL. CHIP 10uF 20% 6.3V

C404 1-107-826-11 CERAMIC CHIP 0.1uF 10% 16V

C405 1-107-826-11 CERAMIC CHIP 0.1uF 10% 16V

C406 1-107-826-11 CERAMIC CHIP 0.1uF 10% 16V

C407 1-107-826-11 CERAMIC CHIP 0.1uF 10% 16V

C408 1-109-982-11 CERAMIC CHIP 1uF 10% 10V

C409 1-109-982-11 CERAMIC CHIP 1uF 10% 10V

C410 1-135-259-11 TANTAL. CHIP 10uF 20% 6.3V

C411 1-162-970-11 CERAMIC CHIP 0.01uF 10% 25V

C412 1-162-970-11 CERAMIC CHIP 0.01uF 10% 25V

C413 1-107-826-11 CERAMIC CHIP 0.1uF 10% 16V

C414 1-107-826-11 CERAMIC CHIP 0.1uF 10% 16V

C415 1-164-227-11 CERAMIC CHIP 0.022uF 10% 25V

C416 1-162-967-11 CERAMIC CHIP 0.0033uF 10% 50V

C417 1-162-967-11 CERAMIC CHIP 0.0033uF 10% 50V

C418 1-164-227-11 CERAMIC CHIP 0.022uF 10% 25V

C419 1-165-176-11 CERAMIC CHIP 0.047uF 10% 16V

C420 1-165-176-11 CERAMIC CHIP 0.047uF 10% 16V

C421 1-165-176-11 CERAMIC CHIP 0.047uF 10% 16V

C422 1-165-176-11 CERAMIC CHIP 0.047uF 10% 16V

C423 1-165-176-11 CERAMIC CHIP 0.047uF 10% 16V

C424 1-165-176-11 CERAMIC CHIP 0.047uF 10% 16V

C501 1-107-826-11 CERAMIC CHIP 0.1uF 10% 16V

C502 1-162-970-11 CERAMIC CHIP 0.01uF 10% 25V

C503 1-162-970-11 CERAMIC CHIP 0.01uF 10% 25V

C504 1-107-685-11 TANTAL. CHIP 15uF 20% 6.3V

C505 1-107-826-11 CERAMIC CHIP 0.1uF 10% 16V

C506 1-162-970-11 CERAMIC CHIP 0.01uF 10% 25V

C509 1-162-917-11 CERAMIC CHIP 15PF 5% 50V

C510 1-162-919-11 CERAMIC CHIP 22PF 5% 50V

C511 1-162-970-11 CERAMIC CHIP 0.01uF 10% 25V

C512 1-162-970-11 CERAMIC CHIP 0.01uF 10% 25V

FB315 1-414-228-11 INDUCTOR CHIP 0UH

FB316 1-414-228-11 INDUCTOR CHIP 0UH

FB401 1-414-228-11 INDUCTOR CHIP 0UH

FB402 1-414-228-11 INDUCTOR CHIP 0UH

FB403 1-414-228-11 INDUCTOR CHIP 0UH

< FILTER >

FL301 1-233-512-21 FILTER, EMI

FL302 1-233-512-21 FILTER, EMI

< IC >

IC302 8-759-058-62 IC TC7S08FU(TE85R)

IC303 8-759-058-60 IC TC7SU04FU(TE85R)

IC304 8-752-384-70 IC CXD2486R

IC305 8-759-462-43 IC AD9800JCSTRL

IC306 8-759-426-25 IC MB88346LPFV-G-BND-E