SONY CD400 Service Manual

MVC-CD250/CD400

SERVICE MANUAL

Ver 1.0 2002. 04

Revision History

Revision History

Photo: MVC-CD400

Link

Link

SPECIFICATIONS

SPECIFICATIONS

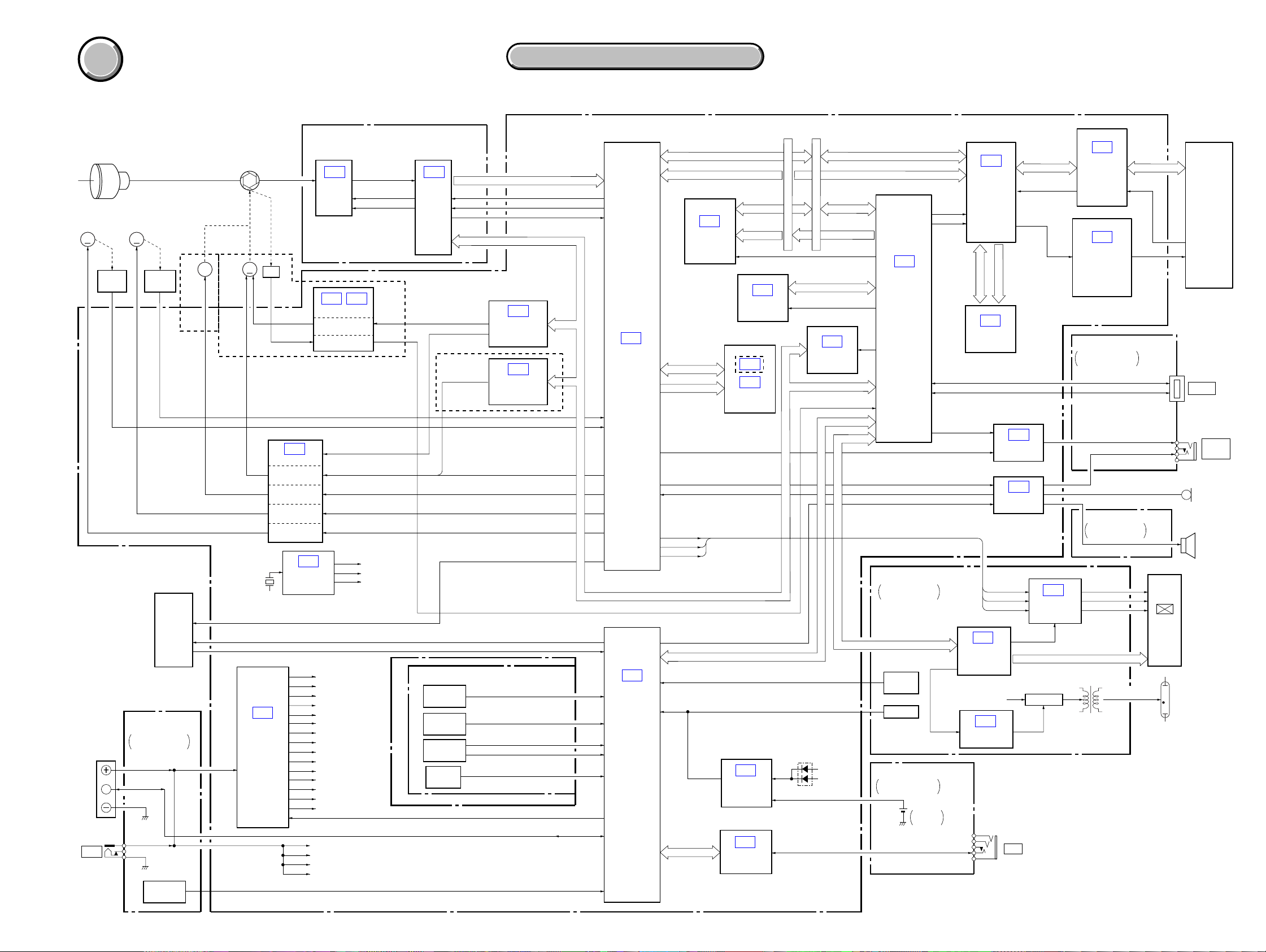

BLOCK DIAGRAMS

BLOCK DIAGRAMS

LEVEL 2

US Model

Canadian Model

E Model

Chinese Model

Australian Model

Japanese Model

MVC-CD250/CD400

AEP Model

UK Model

Korea Model

Tourist Model

MVC-CD400

PRINTED WIRING BOARDS

PRINTED WIRING BOARDS

SERVICE NOTE

SERVICE NOTE

DISASSEMBLY

DISASSEMBLY

•For INSTRUCTION MANUAL, refer to SERVICE MANUAL, LEVEL 1 (992996841.pdf).

• This service manual contains information for Japanese model as well.

•Table for differences of function of each model

On the SY-76 board

This service manual procides the information that is premised

the circuit board replacement service and not intended repair

inside the SY-76 board.

Therefore, schematic diagram, printed wiring board and

electrical parts list of the SY-76 board are not shown.

The following pages are not shown.

FRAME SCHEMATIC DIAGRAMS

FRAME SCHEMATIC DIAGRAMS

SCHEMATIC DIAGRAMS

SCHEMATIC DIAGRAMS

SY-76 board

Schematic diagram ......................... Pages 4-15 to 4-40

Printed wiring board ........................ Pages 4-57 to 4-60

Electrical parts list ........................... Pages 6-15 to 6-23

The above-described information is shown in service

manual Level 3.

ADJUSTMENTS

ADJUSTMENTS

REPAIR PARTS LIST

REPAIR PARTS LIST

DIGITAL STILL CAMERA

MVC-CD250/CD400

COVER

COVER

System

Image device

Total pixels number of camera

Lens MVC-CD400

Camera

Effective pixels number of camera

Exposure control

White balance

Data formats

Recording media

Flash MVC-CD400

MVC-CD400

8.98 mm (1/1.8 type) color CCD

Primary color filter

MVC-CD250

6.64 mm (1/2.7 type) color CCD

Primary color filter

MVC-CD400

Approx. 4 130 000 pixels

MVC-CD250

Approx. 2 110 000 pixels

3 × zoom lens

f = 7.0 – 21.0 mm (9/32 – 27/32 inches)

(34 – 102 mm (1 3/8 – 4 1/8 inches)

when converted to a 35 mm still camera)

F2.0 – 2.5

MVC-CD250

3 × zoom lens

f = 6.4 – 19.2 mm (9/32 – 25/32 inches)

(41 – 123 mm (1 5/8 – 4 7/8 inches)

when converted to a 35 mm still camera)

F3.8 – 3.9

MVC-CD400

Approx. 3 950 000 pixels

MVC-CD250

Approx. 1 980 000 pixels

MVC-CD400

Automatic exposure, Shutter speed

priority, A perture priority,Manual

exposure, Scene selection (4 modes)

MVC-CD250

Automatic exposure, Scene selection

(3 modes)

Automatic, Daylight, Cloudy,

Fluorescent, Incandescent, One-push*

* MVC-CD400 only

Moving images: MPEG1

Still images: JPEG, GIF (for Clip

Motion), TIFF

Audio with still image: MPEG1

(Monaural)

8 cm CD-R/CD-RW

Recommended distance (ISO set to

Auto): 0.5 m to 5.0 m (19 3/4 inches to

196 7/8 inches)

MVC-CD250

Recommended distance (ISO set to

Auto): 0.8 m to 3.5 m (31 1/2 inches to

137 7/8 inches)

SPECIFICATIONS

Drive

Readout Non-contact optical readout (using

semiconductor laser)

Laser Wavelength: 779 to 789 nm

Maximum output: 23 mW

Input and Output connectors

A/V OUT (MONO) (Monaural)

Minijack

Video: 1 Vp-p, 75 Ω, unbalanced,

sync negative

Audio: 327 mV (at a 47 kΩ load)

Output impedance 2.2 kΩ

ACC jack Mini-minijack (ø 2.5 mm)

USB jack mini-B

LCD screen

Used LCD panel

6.2 cm (2.5 type) TFT drive

Total number of dots

123 200 (560 × 220) dots

General

Used battery pack

NP-FM50 (supplied)

Power requirements

7.2 V

Power consumption (during shooting

with LCD backlight on)

MVC-CD400

3.0 W

MVC-CD250

2.5 W

Operating temperature

0°C to +40°C (32°F to +104°F)

Storage temperature

–20°C to +60°C (–4°F to +140°F)

Dimensions

MVC-CD400

Approx. 138 × 95 × 103 mm

(5 1/2 × 3 3/4 × 4 1/8 inches)

(W/H/D, excluding maximum

protrusions)

MVC-CD250

Approx. 138 × 95 × 101 mm

(5 1/2 × 3 3/4 × 4 inches)

(W/H/D, excluding maximum

protrusions)

Mass MVC-CD400

Approx. 638 g (1 lb 7 oz) (including

battery pack NP-FM50, disc, and lens

cap)

MVC-CD250

Approx. 608 g (1 lb 6 oz) (including

battery pack NP-FM50, disc, and lens

cap)

AC-L10A/L10B AC power adaptor

Power requirements

100 to 240 V AC, 50/60 Hz

Rated output voltage

DC 8.4 V, 1.5 A in operating mode

Operating temperature

0°C to +40°C (32°F to +104°F)

Storage temperature

–20°C to +60°C (–4°F to +140°F)

Dimensions

125 × 39 × 62 mm

(5 × 1 9/16 × 2 1/2 inches) (w/h/d,

excluding maximum protrusions)

Mass Approx. 280 g (10 oz)

NP-FM50 battery pack

Used battery

Lithium-ion battery

Maximum voltage

DC 8.4 V

Nominal voltage

DC 7.2 V

Capacity 8.5 Wh (1 180 mAh)

Operating temperature

0°C to +40°C (32°F to +104°F)

Dimensions

38.2 × 20.5 × 55.6 mm

(1 9/16 × 13/16 × 2 1/4 inches) (w/h/d)

Mass Approx. 76 g (3 oz)

Accessories

•AC-L10A/L10B AC power adaptor (1)

•Power cord (mains lead) (1)

•USB cable (1)

•NP-FM50 battery pack (1)

•A/V connecting cable (1)

•8 cm CD adaptor (1)

•Mavica disc (7) (CD-R (6), CD-RW (1))

•Shoulder strap (1)

•Lens cap (1)

•Lens cap strap (1)

• CD-ROM (SPVD-009) (1)

•Operating instructions (1)

Design and specifications are subject to change

without notice.

— 2 —

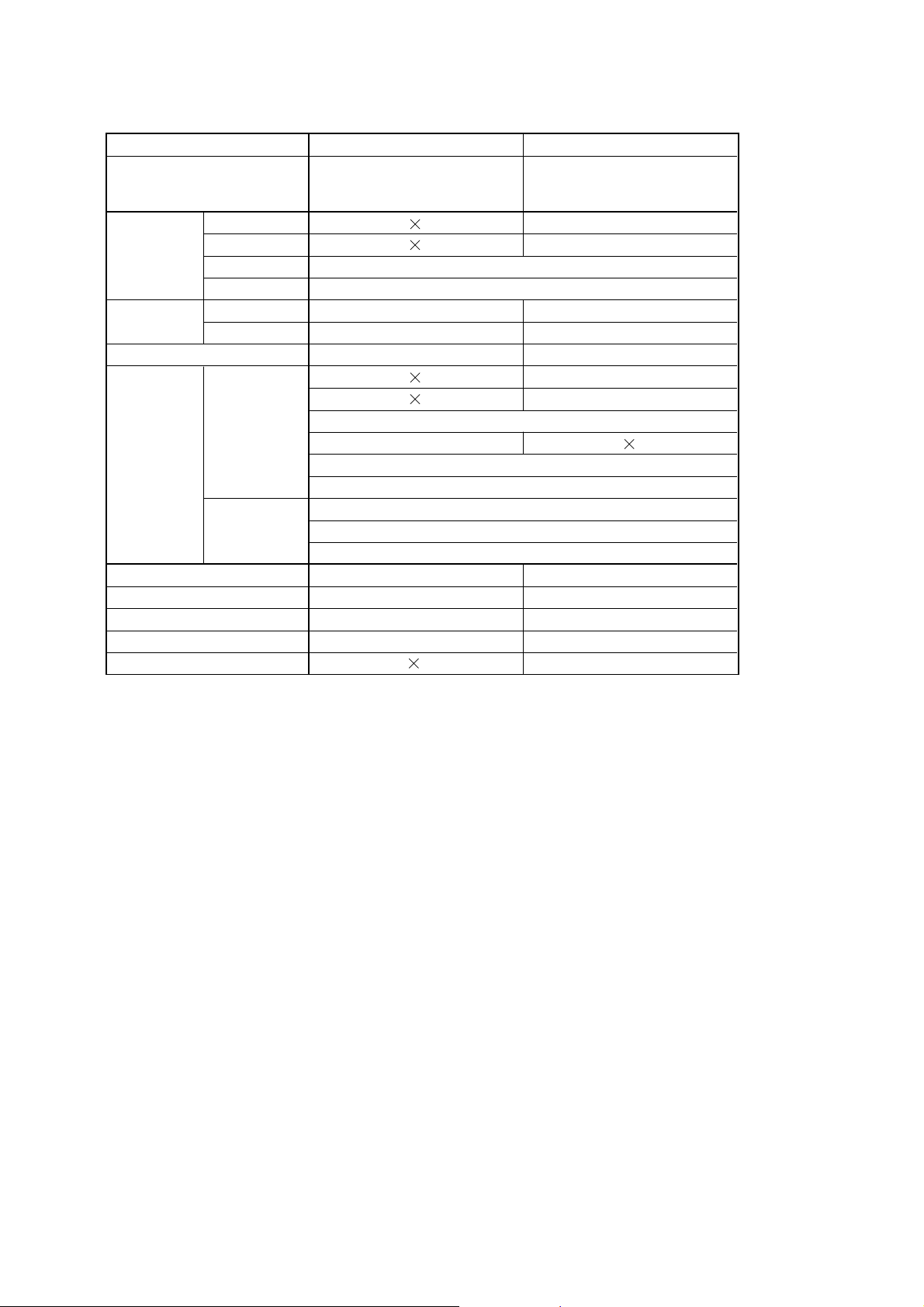

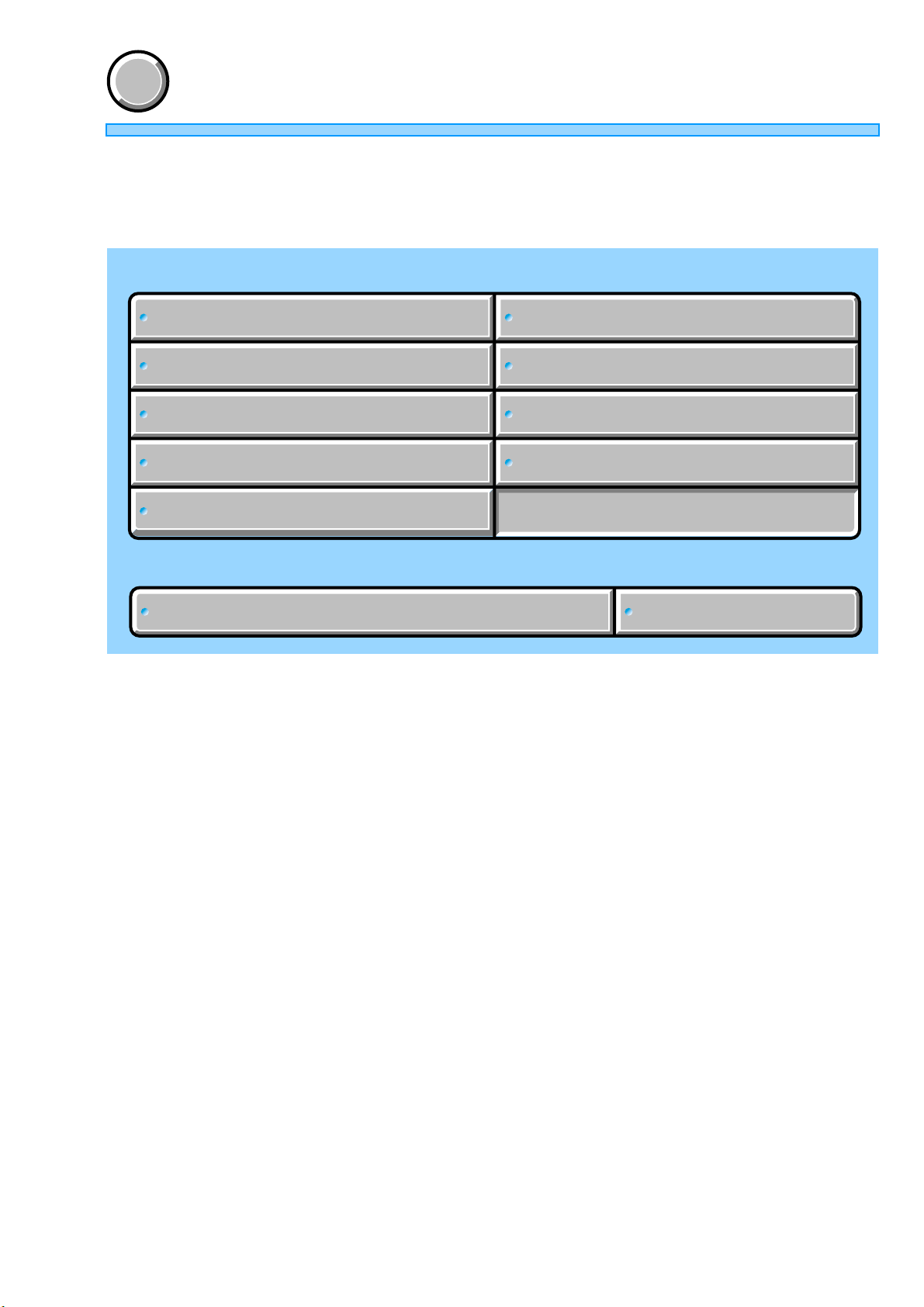

Table for differences of function

Model MVC-CD250 MVC-CD400

Destination

Carl Zeiss lens a

Lens

CCD imager

AF optical system AF illuminator (LED) Hologram AF (Laser diode)

Image size 1280 × 960

CD board CD-394 CD-393

FS board FS-85 FS-84

JK board JK-225 JK-224

PK board PK-66 PK-65

LS board LS-61

Movable lens a

Optical zoom 3 ×

Digital zoom 6 ×

Size 1/2.7 type 1/1.8 type

Pixels 2.1 mega 4.1 mega

Still

Movie 320 × 240

US, Canadian, E, Japanese,

Australian, Chinese

1600 × 1200

1600 (3:2)

640 × 480

320 (HQ)

160 × 112

US, Canadian, AEP, UK, E

Japanese, Australian, Chinese,

Korea, Tour ist

2272 × 1704

2272 (3:2)

MVC-CD250/CD400

,

— 3 —

MVC-CD250/CD400

WARNING!!

WHEN SERVICING, DO NOT APPROACH THE LASER

EXIT WITH THE EYE TOO CLOSELY. IN CASE IT IS

NECESSARY TO CONFIRM LASER BEAM EMISSION,

BE SURE T O OBSERVE FR OM A DIST ANCE OF MORE

THAN 30 cm FROM THE SURFACE OF THE

OBJECTIVE LENS ON THE OPTICAL PICK-UP BLOCK.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED LINE WITH

MARK 0 ON THE SCHEMATIC DIAGRAMS AND IN THE PARTS

LIST ARE CRITICAL TO SAFE OPERATION. REPLACE THESE

COMPONENTS WITH SONY PARTS WHOSE PART NUMBERS

APPEAR AS SHOWN IN THIS MANUAL OR IN SUPPLEMENTS

PUBLISHED BY SONY.

CAUTION:

The use of optical instrument with this product will increase eye

hazard.

CAUTION

Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous

radiation exposure.

ATTENTION AU COMPOSANT AYANT RAPPORT

À LA SÉCURITÉ!

LES COMPOSANTS IDENTIFÉS P AR UNE MARQUE 0 SUR LES

DIAGRAMMES SCHÉMA TIQUES ET LA LISTE DES PIÈCES SONT

CRITIQUES POUR LA SÉCURITÉ DE FONCTIONNEMENT. NE

REMPLACER CES COMPOSANTS QUE PAR DES PIÈSES SONY

DONT LES NUMÉROS SONT DONNÉS DANS CE MANUEL OU

DANS LES SUPPÉMENTS PUBLIÉS PAR SONY.

SAFETY CHECK-OUT

After correcting the original service problem, perform the following

safety checks before releasing the set to the customer.

1. Check the area of your repair for unsoldered or poorly-soldered

connections. Check the entire board surface for solder splashes

and bridges.

2. Check the interboard wiring to ensure that no wires are

"pinched" or contact high-wattage resistors.

3. Look for unauthorized replacement parts, particularly

transistors, that were installed during a previous repair . Point

them out to the customer and recommend their replacement.

4. Look for parts which, through functioning, show obvious signs

of deterioration. Point them out to the customer and

recommend their replacement.

5. Check the B+ voltage to see it is at the values specified.

6. Flexible Circuit Board Repairing

•Keep the temperature of the soldering iron around 270˚C

during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

Unleaded solder

Boards requiring use of unleaded solder are printed with the leadfree mark (LF) indicating the solder contains no lead.

(Caution: Some printed circuit boards may not come printed with

the lead free mark due to their particular size.)

: LEAD FREE MARK

Unleaded solder has the following characteristics.

• Unleaded solder melts at a temperature about 40°C higher than

ordinary solder.

Ordinary soldering irons can be used but the iron tip has to be

applied to the solder joint for a slightly longer time.

Soldering irons using a temperature regulator should be set to

about 350°C.

Caution: The printed pattern (copper foil) may peel away if the

heated tip is applied for too long, so be careful!

• Strong viscosity

Unleaded solder is more viscous (sticky, less prone to flow) than

ordinary solder so use caution not to let solder bridges occur such

as on IC pins, etc.

• Usable with ordinary solder

It is best to use only unleaded solder but unleaded solder may

also be added to ordinary solder.

— 4 —

MVC-CD250/CD400

TABLE OF CONTENTS

Section Title Page Section Title Page

1. SERVICE NOTE

1-1. Note for Repair ································································1-1

1-2. Discharging of the FLASH unit’s Charging Capacitor ··· 1-1

1-2-1.Preparing the Short Jig ····················································1-1

1-2-2.Discharging the Capacitor ···············································1-1

1-3. Notes on Handling the Laser Diode

[Laser Unit (D9001: MVC-CD400) and

Base Unit (DDX-G3000)] ··················································1-2

1-3-1.Precautions for Checking Emission of Laser Diode

[Base Unit (DDX-G3000)] ··············································1-2

1-3-2.Soldering Conditions of Laser Unit

(D9001: MVC-CD400) ···················································1-2

1-4. Description on Self-diagnosis Display ····························1-3

1-5. Power Supplying Method ················································1-3

2. DISASSEMBLY .........................................................2-1

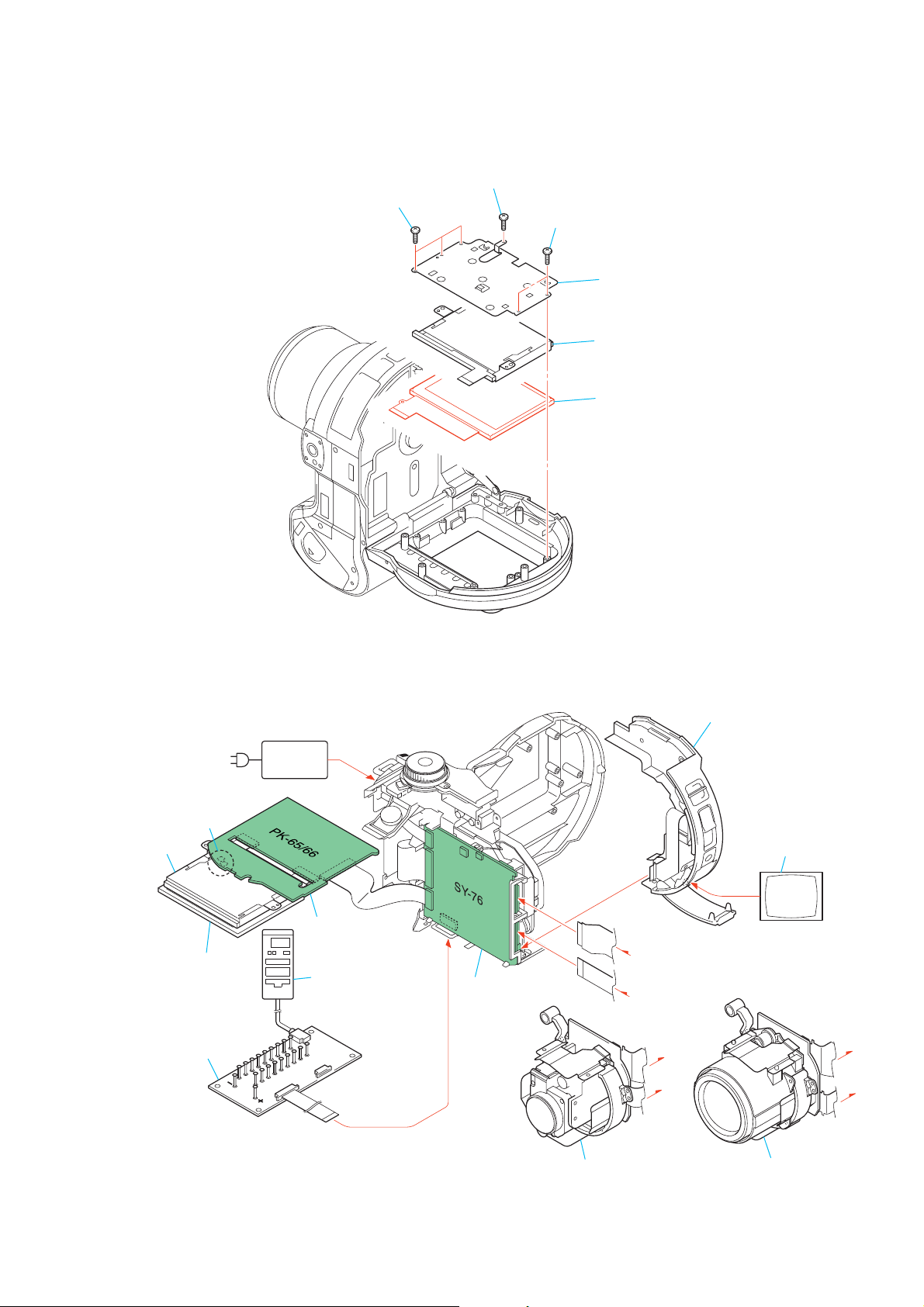

2-1. Side Cabinet Block Assembly ·········································2-2

2-2. Cabinet (Rear) Block Assembly······································2-2

2-3. Lens Block Assembly······················································2-3

2-4. Stroboscope Block Assembly··········································2-4

2-5. Flash Unit ········································································2-5

2-6. BT Holder Assembly·······················································2-5

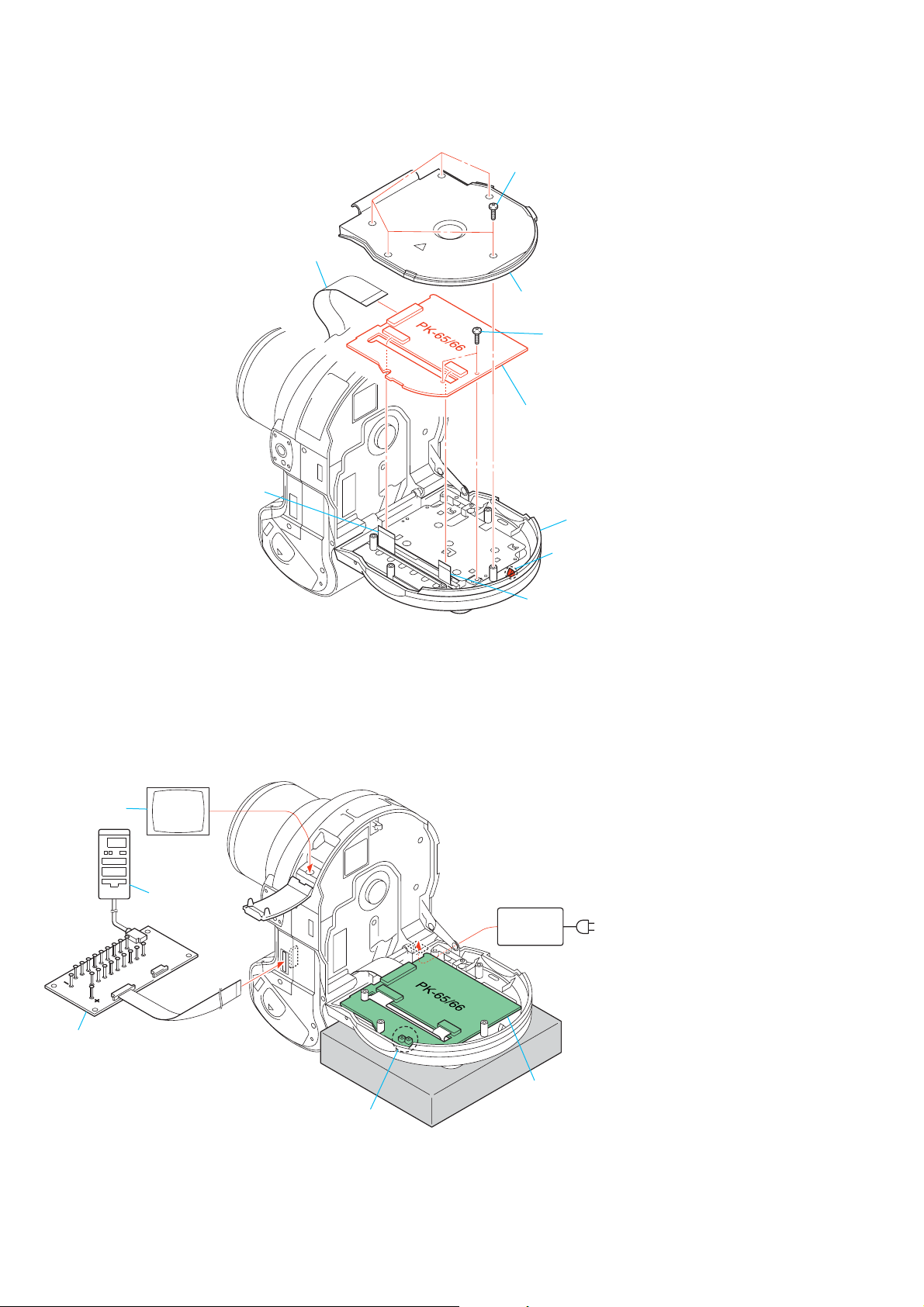

2-7. SY-76 Board ····································································2-6

2-8. DDX-G3000 Complete Assembly···································2-7

2-9. Base Unit ·········································································2-7

2-10. PK-65/66 Board·······························································2-8

2-11. LCD Module···································································· 2-9

2-12. Circuit Boards Locaion ·················································2-10

2-13. Flexible Boards Locaion ···············································2-11

3. BLOCK DIAGRAMS

3-1. Overall Block Diagram ···················································3-1

3-10. Power Block Diagram 1 ················································3-19

3-11. Power Block Diagram 2 ················································3-21

4. PRINTED WIRING BOARDS AND

SCHEMATIC DIAGRAMS

4-1. Frame Schematic Diagrams

Frame Schematic Diagram (1/2) ·····································4-1

Frame Schematic Diagram (2/2) ·····································4-3

4-2. Schematic Diagrams························································4-5

CD-393 (1/2) (CCD IMAGER)

(MVC-CD400)································································4-7

CD-393 (2/2) (CAMERA MODULE)

(MVC-CD400)································································4-9

CD-394 (1/2) (CCD IMAGER)

(MVC-CD250)······························································4-11

CD-394 (2/2) (CAMERA MODULE)

(MVC-CD250)······························································4-13

PK-65/66 (1/2)

(LCD DRIVE, TIMING GENERATOR) ·····················4-41

PK-65/66 (2/2) (BACK LIGHT DRIVE) ·····················4-43

FS-84/85 (DC IN, CONTROL SWITCH) ····················4-45

JK-224/225 (JACK) ······················································4-47

LS-61 (LENS CAP SWITCH) (MVC-CD400) ············4-49

CONTROL SWITCH BLOCK (ZK-860/880) ·············4-50

4-3. Printed Wiring Boards ···················································4-51

CD-393 (MVC-CD400) ················································4-53

CD-394 (MVC-CD250) ················································4-55

PK-65/66 ·······································································4-61

FS-84/85 ········································································4-65

JK-224/225 ····································································4-67

LS-61 (MVC-CD400) ···················································4-69

FP-482/489/490 ·····························································4-71

4-4. Waveforms·····································································4-73

4-5. Mounted Parts Location ················································4-78

5. ADJUSTMENTS

1-1. Adjusting Items when Replacing

Main Parts and Boards ····················································5-2

5-1. Camera Section Adjustments··········································· 5-3

1-1. Preparations Before Adjustment

1-1-1.List of Service Tools························································5-3

1-1-2.Preparations ·····································································5-4

1-1-3.Discharging of the Flashlight Power Supply···················5-4

1-1-4.Precaution

1. Setting the Switch ····························································5-6

2. Order of Adjustments ······················································5-6

3. Subjects ··········································································· 5-6

4. Preparing the Flash Adjustment Box·······························5-7

1-2. Initialization of A, B, D, E, F, 7, 9 Page Data

1-2-1.Initialization of A, D Page Data

1. Initializing A, D Page Data··············································5-8

2. Modification of A, D Page Data ······································5-8

3. A Page Table····································································5-8

4. D Page Table····································································5-8

1-2-2.Initialization of B, E, F, 7, 9 Page Data

1. Initializing B, E, F, 7, 9 Page Data ··································5-9

2. Modification of B, E, F, 7, 9 Page Data···························5-9

3. B Page Table···································································· 5-9

4. E Page Table ····································································5-9

5. F Page Table ··································································5-10

6. 7 Page Table···································································5-12

7. 9 Page Table···································································5-12

1-3. Video System Adjustment

1. Video Output Level Adjustment ····································5-13

1-4. Camera System Adjustments·········································5-14

Data Setting During Camera System Adjustments········5-14

Picture Frame Setting ····················································5-15

Check on the Oscilloscope ············································5-15

1. Hall Adjustment (MVC-CD250 only) ···························5-16

2. Flange Back Adjustment

(Using the minipattern box) ··········································5-17

3. Flange Back Adjustment

(Using the flange back adjustment chart

and subject more than 500 m away) ······························5-18

4. Flange Back Check ························································5-19

5. F No. Compensation ······················································5-19

6. Mechanical Shutter Adjustment ····································5-20

7. Light Value Adjustment·················································5-20

8. Mixed Color Cancel Adjustment ···································5-21

9. Auto White Balance 3200K Standard Data Input 1 ······5-21

10. Auto White Balance 3200K Standard Data Input 2 ······5-22

11. Auto White Balance 3200K Standard Data Input 3 ······5-22

12. Auto White Balance 3200K Check 1 ····························5-23

13. Auto White Balance 3200K Check 2 ····························5-24

14. Auto White Balance 3200K Check 3 ····························5-24

15. Auto White Balance 5800K Standard Data Input 1 ······5-25

16. Auto White Balance 5800K Standard Data Input 2 ······5-26

17. Auto White Balance 5800K Standard Data Input 3 ······5-26

18. Auto White Balance 5800K Check 1 ····························5-27

19. Auto White Balance 5800K Check 2 ····························5-28

20. Auto White Balance 5800K Check 3 ····························5-29

21. Color Reproduction Adjustment····································5-30

22. CCD White Defect Compensation ································5-31

23. CCD Black Defect Compensation································· 5-32

24. CCD Linearity Check ····················································5-33

25. Strobe White Balance Adjustment·································5-34

26. AF Illumination Check (MVC-CD250 only) ················5-36

1-5. LCD System Adjustments ·············································5-37

— 5 —

MVC-CD250/CD400

Section Title Page

1. LCD Initial Data Input (1) ·············································5-38

2. LCD Initial Data Input (2) ·············································5-38

3. Back Light Adjustment (PK-65/66 Board)····················5-39

4. VCO Adjustment (PK-65/66 Board) ·····························5-39

5. D Range Adjustment (PK-65/66 Board) ·······················5-40

6. Contrast Adjustment (PK-65/66 Board) ························5-40

7. V-COM Level Adjustment (PK-65/66 Board)···············5-41

8. V-COM Adjustment (PK-65/66 Board)·························5-41

9. White Balance Adjustment (PK-65/66 Board)··············5-42

1-6. System Control System Adjustments

1. Battery Down Adjustment ·············································5-43

2. Serial No. Input ·····························································5-44

5-2. Service Mode

2-1. Adjusting Remote Commander ·····································5-45

1. Used the Adjusting Remote Commander ······················5-45

2. Precautions upon Using the Adjusting

Remote Commander······················································5-45

2-2. Data Process ··································································5-46

2-3. Service Mode

1. Setting the Test Mode····················································5-47

2. Bit Value Discrimination ···············································5-47

3. Switch Check (1) ···························································5-48

4. Switch Check (2) ···························································5-48

5. Switch Check (3) (MVC-CD400 only) ·························5-48

6. Switch Check (4) ···························································5-49

7. Switch Check (5) ···························································5-49

8. Switch Check (6) ···························································5-49

9. LED Check ····································································5-50

10. Self Diagnosis Log Check·············································5-50

11. Record of Use Check·····················································5-50

6. REPAIR PARTS LIST

6-1. Exploded Vie ws ·······························································6-1

6-1-1.Overall Assembly ····························································6-1

6-1-2.Cabinet (Front) Block Assembly (MVC-CD250) ···········6-2

6-1-3.Cabinet (Front) Block Assembly (MVC-CD400) ···········6-3

6-1-4.Lens Block Assembly (MVC-CD250) ····························6-4

6-1-5.Lens Block Assembly (MVC-CD400) ····························6-5

6-1-6.Stroboscope Block Assembly··········································6-6

6-1-7.DDX-G3000 Complete Assembly···································6-7

6-1-8.Side Cabinet Assembly····················································6-8

6-1-9.Cabinet (Rear) Block Assembly ······································6-9

6-2. Electrical Parts List ·······················································6-10

* The color reproduction frame is shown on page 147.

— 6 —

MVC-CD250/CD400

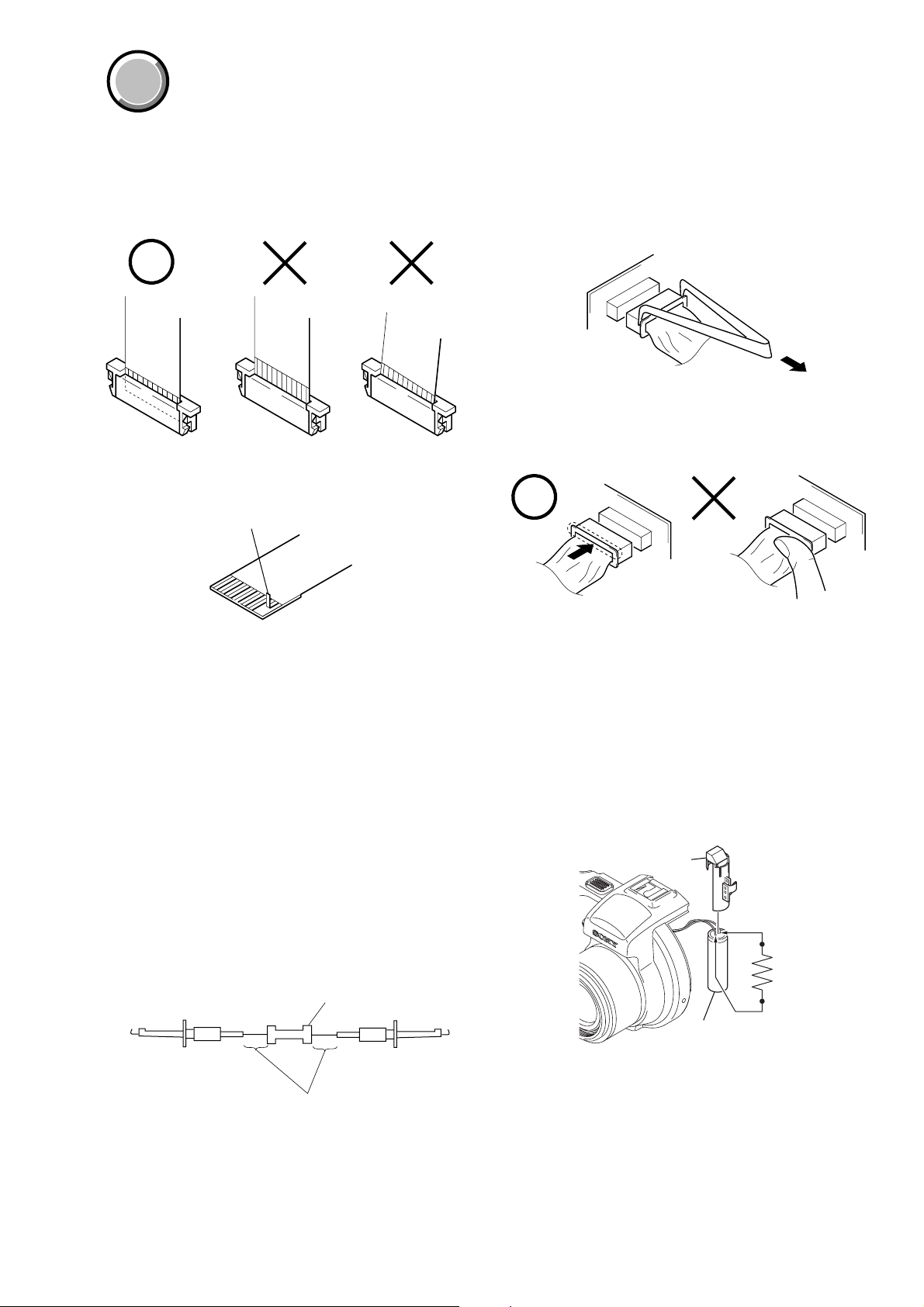

When installing a connector, don’t press down at wire of connector.

It is possible that a wire is snapped.

COVER

COVER

SECTION 1

SERVICE NOTE

1-1. NOTE FOR REPAIR

Make sure that the flat cable and flexible board are not cracked of

bent at the terminal.

Do not insert the cable insufficiently nor crookedly.

Cut and remove the part of gilt

which comes off at the point.

(Be careful or some

pieces of gilt may be left inside)

When remove a connector, don’t pull at wire of connector.

It is possible that a wire is snapped.

1-2. DISCHARGING OF THE FLASH UNIT’S CHARGING CAPACITOR

The charging capacitor of the Flash unit is charged up to the

maximum 300 V potential.

There is a danger of electric shock by this high voltage when the

battery is handled by hand. The electric shock is caused by the

charged voltage which is kept without discharging when the main

power of the unit is simply turned off. Therefore, the remaining

voltage must be discharged as described below.

1-2-1. Preparing the Short Jig

To preparing the short jig, a small clip is attached to each end of a

resistor of 1 kΩ /1 W (1-215-869-11).

Wrap insulating tape fully around the leads of the resistor to prevent

electrical shock.

1 kΩ/1 W

Wrap insulating tape.

1-2-2. Discharging the Capacitor

Short-circuit between the positive and the negative terminals of

charged capacitor with the short jig about 10 seconds.

Capacitor retainer

R: 1 kΩ/1 W

(Part code:

1-215-869-11)

Capacitor

1-1

MVC-CD250/CD400

1-3. NOTES ON HANDLING THE LASER DIODE

[LASER UNIT (D9001: MVC-CD400) AND BASE UNIT (DDX-G3000)]

The laser diode may suffer electrostatic breakdown because of the

potential difference generated by the charged electrostatic load, etc.

on clothing and the human body.

During repair, pay attention to electrostatic breakdown and also use

the procedure in the printed matter which is included in the repair

parts.

The flexible board is easily damaged and should be handled with

care.

1-3-1. Precaution for Checking Emission of Laser

Diode [Base Unit (DDX-G3000)]

Laser light of the equipment is focused by the object lens in the

optical pick-up so that the light focuses on the reflection surface of

the disc. Therefore, be sure to keep your eyes more then 30 cm

apart from the object lens when you check the emission of laser

diode.

Optical pick-up

(Laser diode)

1-3-2. Soldering Conditions of Laser Unit

(D9001: MVC-CD400)

Temperature of

the Soldering Iron

Time to Solder 3 seconds

Interval to Solder

Laser unit

(D9001)

350 °C

Next terminal is soldered after

waiting for 1 second

[MVC-CD400]

1-2

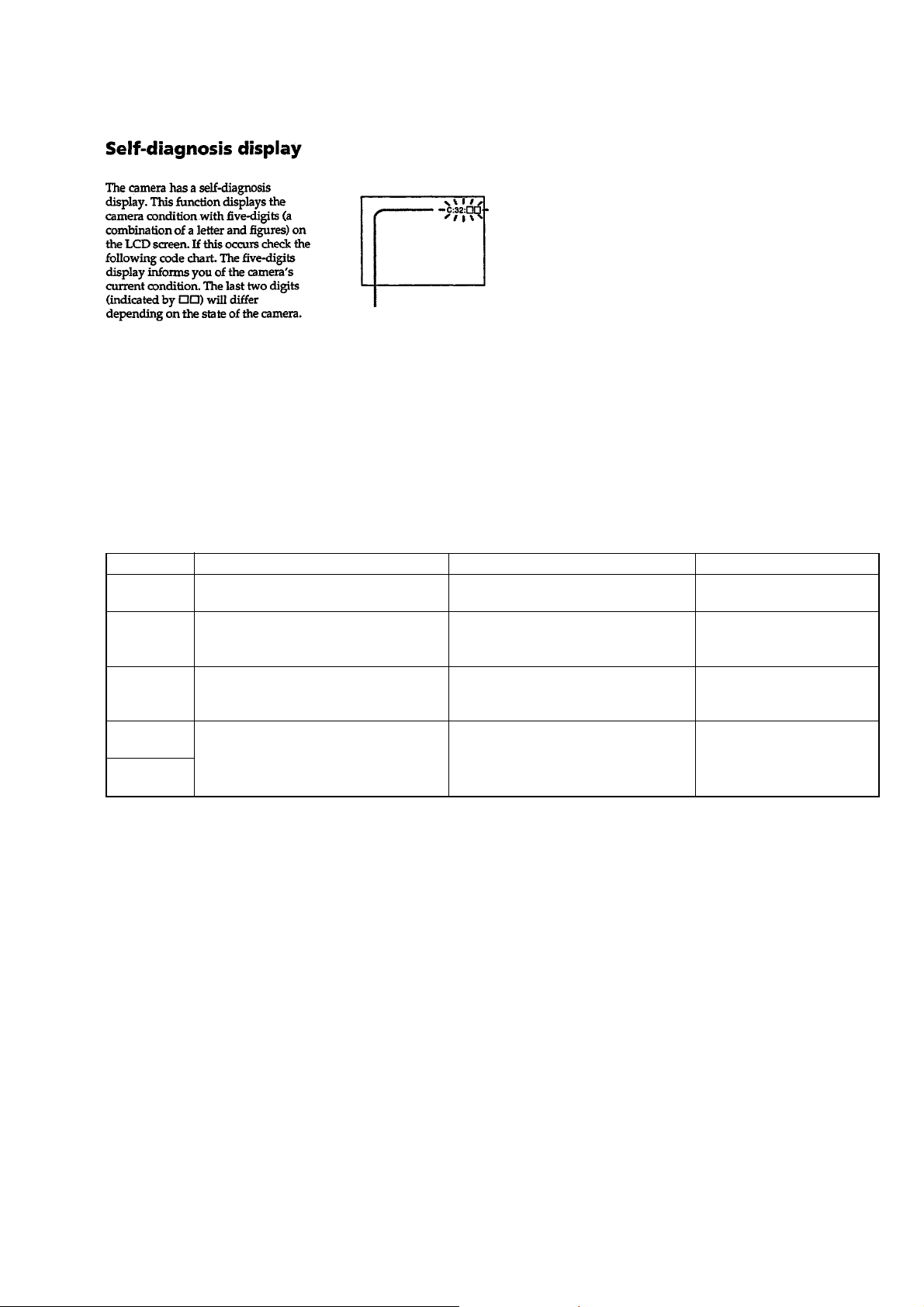

1-4. DESCRIPTION ON SELF-DIAGNOSIS DISPLAY

Self-diagnosis display

• C: ss: ss

You can reverse the camera

malfunction yourself. (However,

contact your Sony dealer or local

authorized Sony service facility

when you cannot recover from the

camera malfunction.)

• E: ss: ss

Contact your Sony dealer or local

authorized Sony service facility.

MVC-CD250/CD400

Display Code

C:32:01

C:13:01

E:91:01

*1

E:61:00

*1

E:61:10

Note: The error code is cleared if the battery is removed.

*1 : The error display is given in two ways.

Change the disk and turn off the main

power then back on.

Replace the CD-R/RW disk.

Checking of flash unit or replacement of

flash unit

Checking of lens drive circuit

Countermeasure

Cause

Defective base unit.

• The type of CD-R/RW disk that cannot

be used by this machine, is inserted.

• Data is damaged.

Abnormality when flash is being

charged.

When failed in the focus initialization.

1-5. POWER SUPPLYING METHOD

Use the AC power adaptor (AC-L10A/L10B) when supplying the power to this set.

Caution Display During Error

DRIVE ERROR

DISK ERROR

Flash LED

Flash display

Flashing at 3.2 Hz

—

1-3E

1-3

MVC-CD250/CD400

COVER

COVER

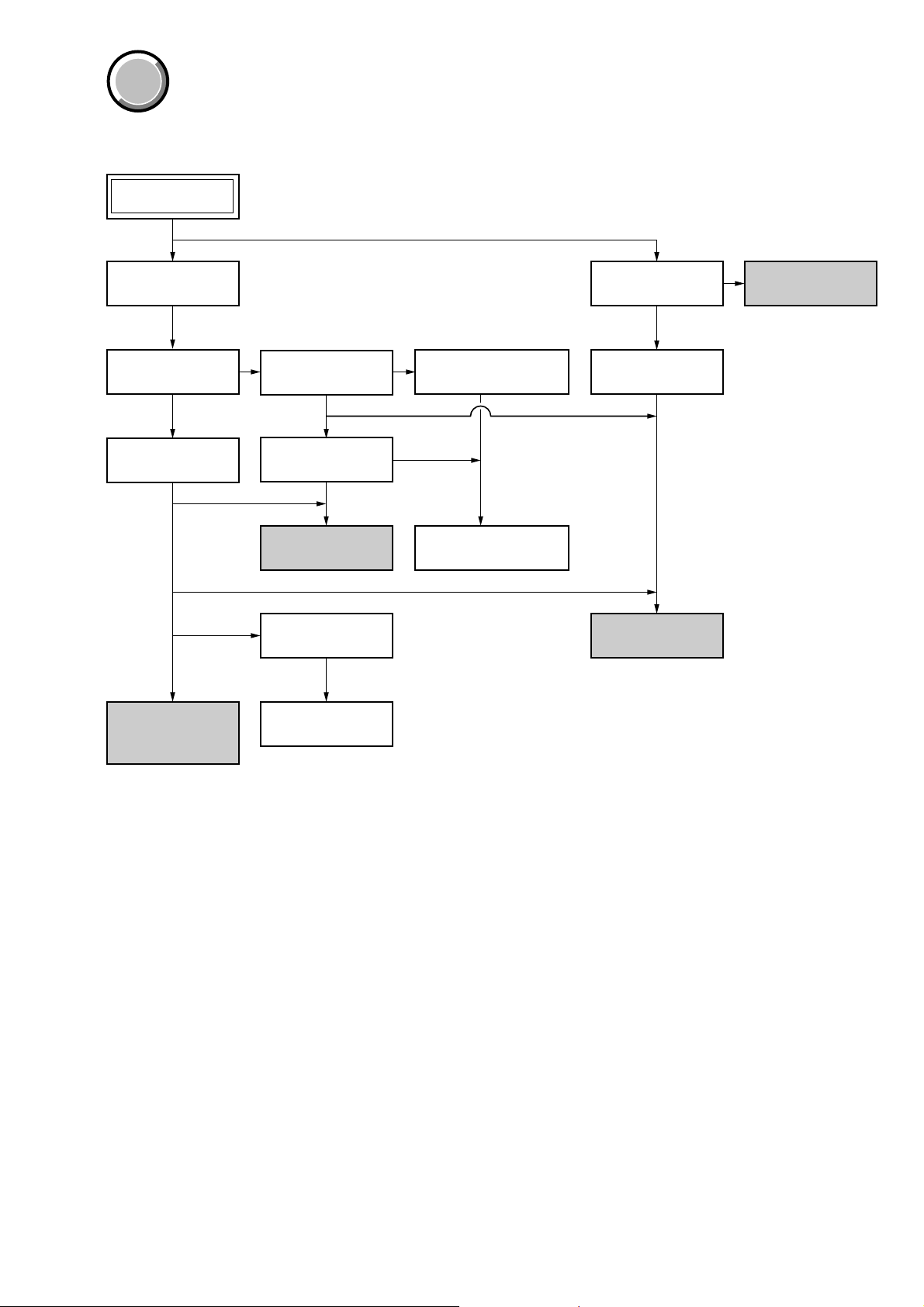

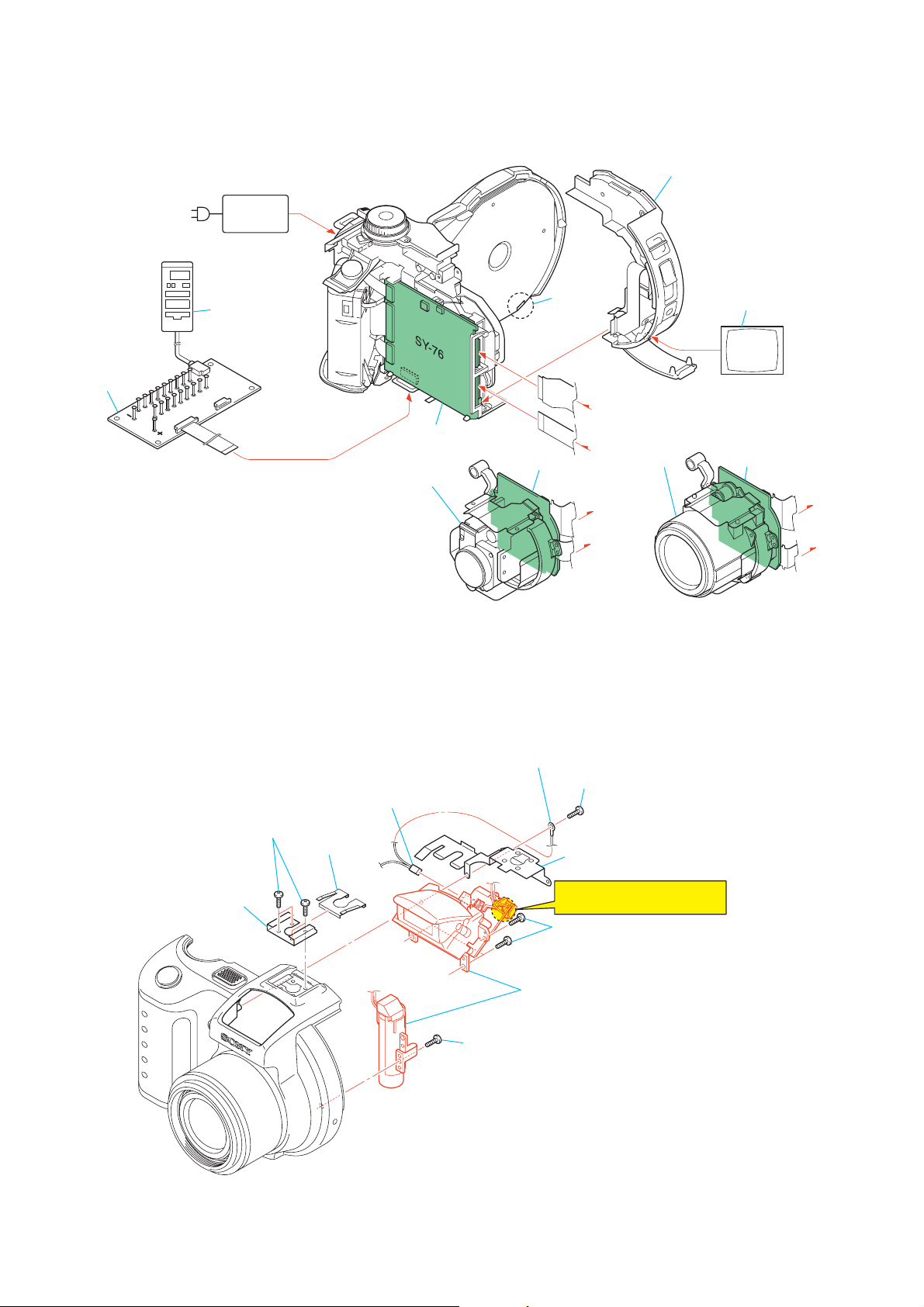

• This set can be disassembled in the order shown below.

MVC-CD250/CD400

2-1. SIDE CABINET

BLOCK ASSEMBLY

(Page 2-2)

2-2. CABINET (REAR)

BLOCK ASSEMBLY

(Page 2-2)

2-3. LENS BLOCK

ASSEMBLY

(Page 2-3)

2-6. BT HOLDER

ASSEMBLY

(Page 2-5)

2-7. SY-76 BOARD

(Page 2-6)

SECTION 2

DISASSEMBLY

2-8. DDX-G3000 COMPLETE

ASSEMBLY

(Page 2-7)

2-10.PK-65/66 BOARD

(Page 2-8)

2-11.LCD MODULE

(Page 2-9)

SERVICE POSITION

(PK-65/66 BOARD:

SIDE A) (Page 2-8)

SERVICE POSITION

(CD-393/394 BOARD,

SY-76 BOARD: SIDE A)

(Page 2-4)

SERVICE POSITION

(SY-76 BOARD: SIDE B)

(Page 2-6)

2-4. STROBOSCOPE

BLOCK ASSEMBLY

(Page 2-4)

2-5. FLASH UNIT

(Page 2-5)

2-9. BASE UNIT

(Page 2-7)

SERVICE POSITION

(PK-65/66 BOARD:

SIDE B) (Page 2-9)

2-1

MVC-CD250/CD400

Note: Follow the disassembly procedure in the numerical order given.

2-1. SIDE CABINET BLOCK ASSEMBLY

3 Open the CD cabinet.

4 Two screws (M2)

5 Side cabinet block assembly

Note:Remove it while taking care as

the flexible board is connected.

6 FP-482 flexible board

(CN718)

1 Screw (M2)

2-2. CABINET (REAR) BLOCK ASSEMBLY

6 Cabinet (rear) block assembly

3 Two screws (M2)

8 Harness (microphone)

(CN702)

2 Screw (M2)

7 Harness (SS-084)

(CN719)

1 FP-484 flexible board

(CN724)

4 Screw

(M2)

5 Open the battery lid.

2-2

2 FP-485/FP-486 flexible board

(CN651)

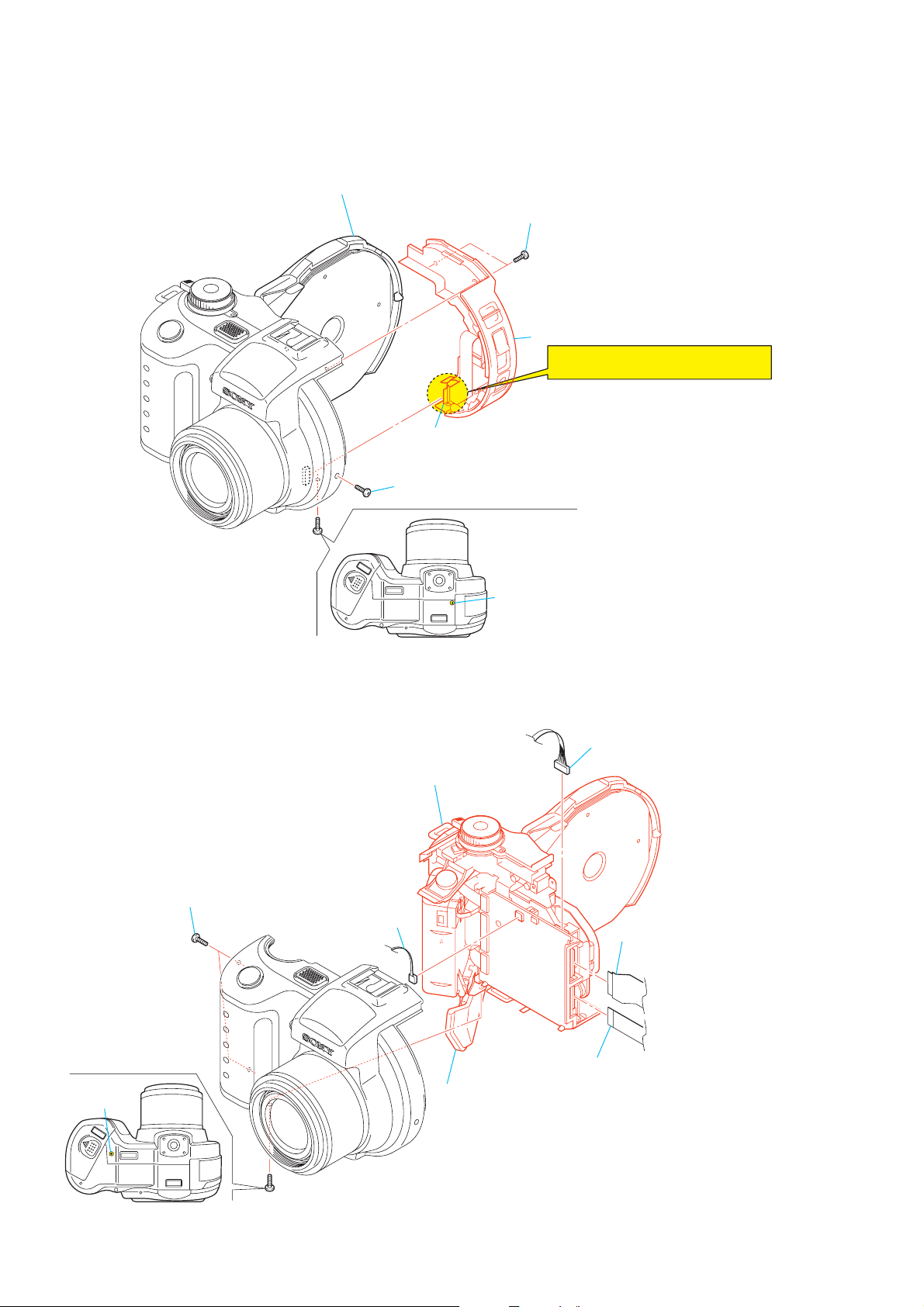

2-3. LENS BLOCK ASSEMBLY

(MVC-CD250)

MVC-CD250/CD400

1 FP-489 flexible board

(CN502)

5 Capacitor

3 AF/self timer illuminator

6 Screw

(M1.7

× 5)

8 Lens block assembly

4 Screw

(M1.7

× 5)

2 Two screws

(M1.7 × 5)

7 Two screws

(M1.7

× 5)

(MVC-CD400)

1 FP-490 flexible board

(CN502)

4 Screw

6 Screw

(M1.7

3 Laser unit

(M1.7 × 5)

8 Lens block assembly

× 5)

2 Two screws

(M1.7 × 5)

7 Two screws

(M1.7

× 5)

5 Capacitor

2-3

MVC-CD250/CD400

[SERVICE POSITION (CD-393/394 BOARD, SY-76 BOARD: SIDE A)]

Side cabinet block assembly

DC-IN

CPC-9 jig

(J-6082-393-C)

(Note 1, 2)

1

Note 1: Don’t use the 12 pin flexible board of CPC-9 jig.

It causes damage to the unit.

Note 2: The old CPC-9 jig (Parts code: J-6082-393-B) Cannot be used,

because it cannot operate the adjustment remote commander.

Note 3: Must be pressed lid open/close detect switch (S307, S308 on

PK-65/66 board) when using the CD-R/RW drive unit.

AC power

adaptor

Adjustment remote

commander

18

1

18

SY-76 board

Lens block assembly

(MVC-CD250)

S307, S308

(Note 3)

CD-394 board

A

B

Lens block assembly

(MVC-CD400)

A

B

Monitor

CD-393 board

A

B

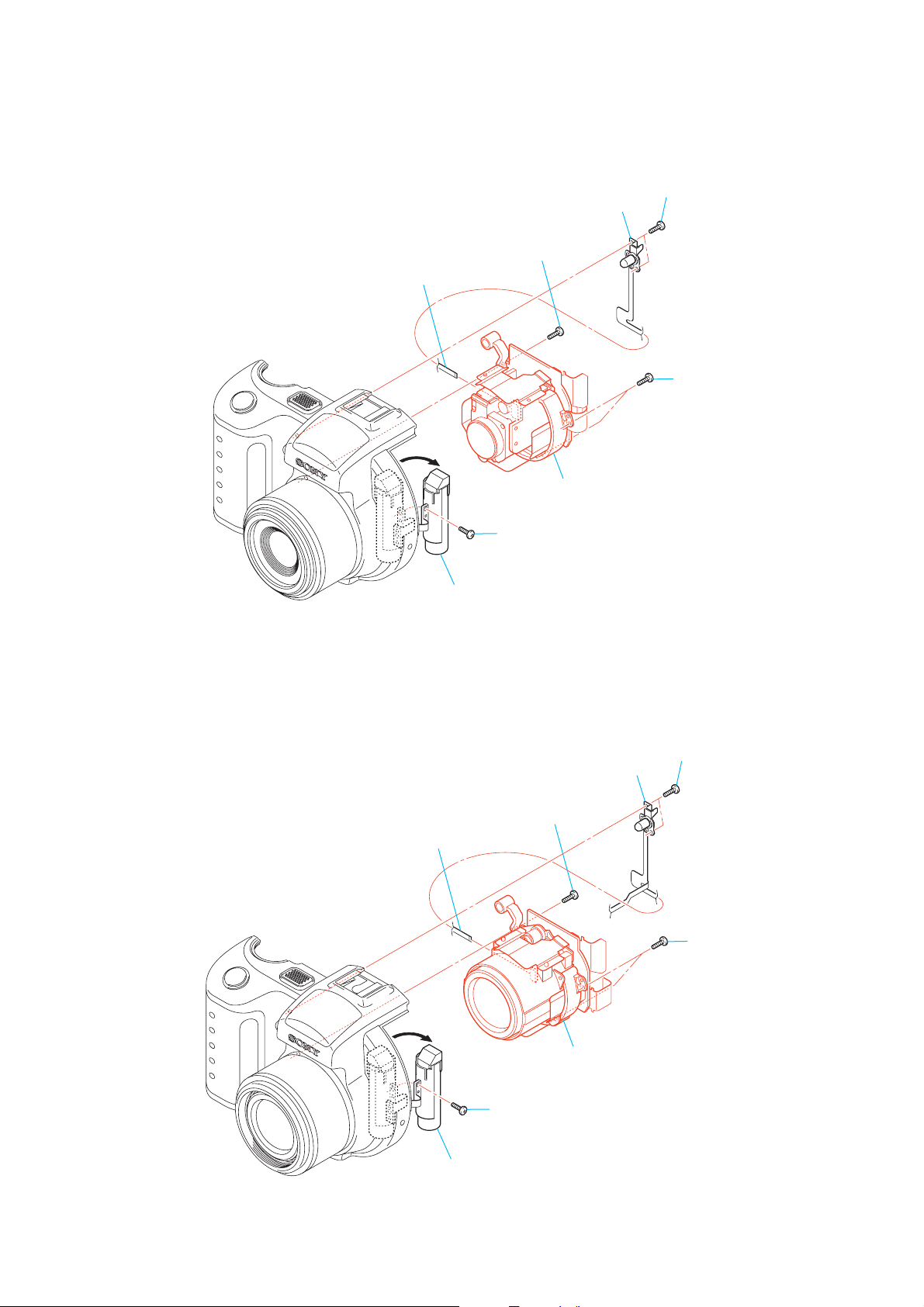

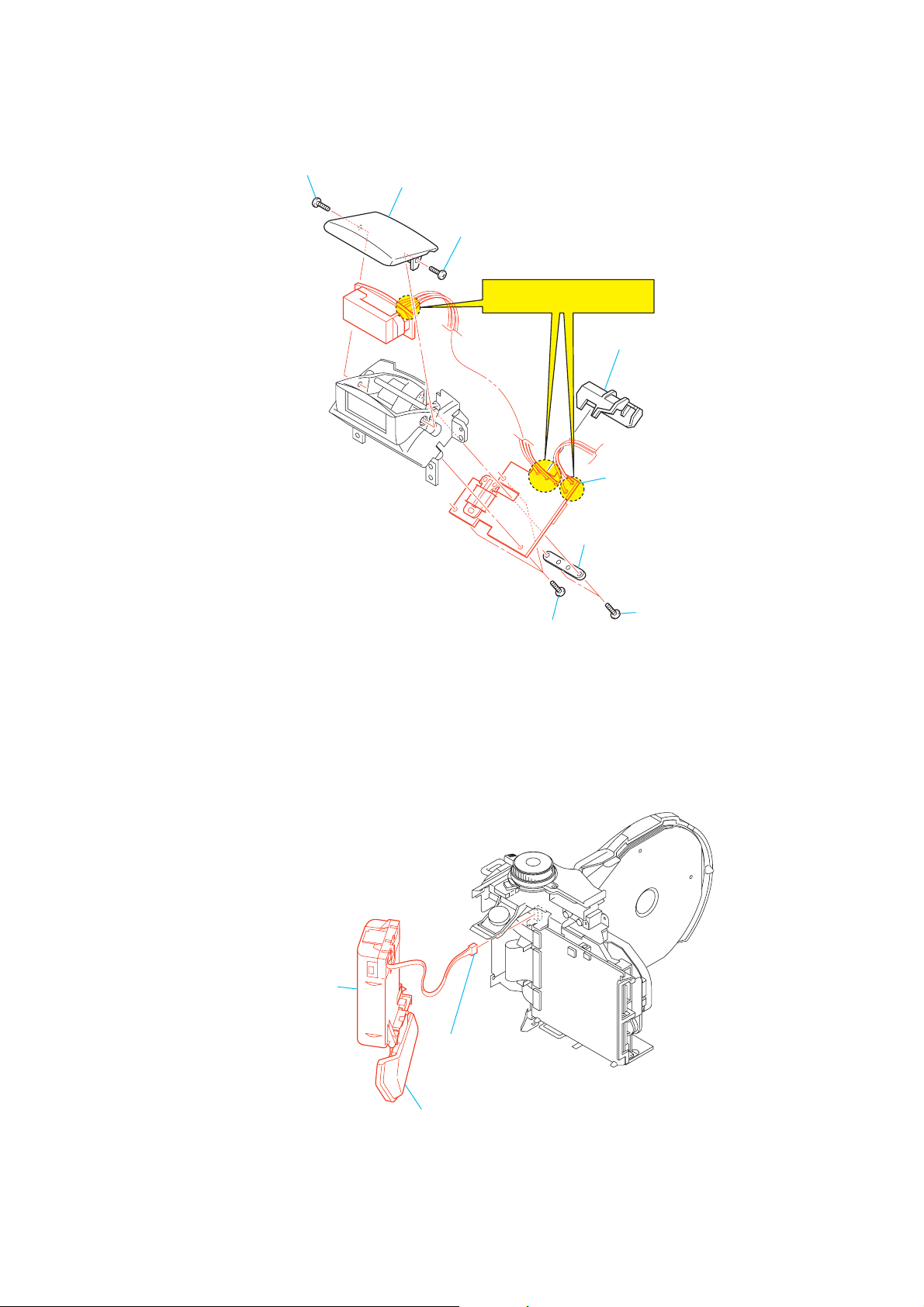

2-4. STROBOSCOPE BLOCK ASSEMBLY

4 Stroboscope terminal conector

(MVC-CD400 only)

2 Four screws

(M1.7)

1 Shoe spring

3 Shoe

6 Earth lug

(MVC-CD400 only)

0 Stroboscope block

8 Screw

(M1.7

×

5)

5 Screw

(M1.7

×

5)

7 Shoe stiffner

Note:High-voltage cautions.

(See page 1-1)

9 Three screws

(M1.7

×

5)

assembly

2-4

2-5. FLASH UNIT

1 Screw

(M1.7

MVC-CD250/CD400

×

4)

3 St roof cover

2 Screw

×

4)

(M1.7

Note:High-voltage cautions.

(See page 1-1)

6 Three screws

(M1.7

×

4)

7 Harness cover

8 Flash unit

5 ST solenoid cover

4 Two screws

(M1.7

×

4)

2-6. BT HOLDER ASSEMBLY

2 BT holder assembly

3 Connector

(CN003)

1 Open the battery lid.

2-5

MVC-CD250/CD400

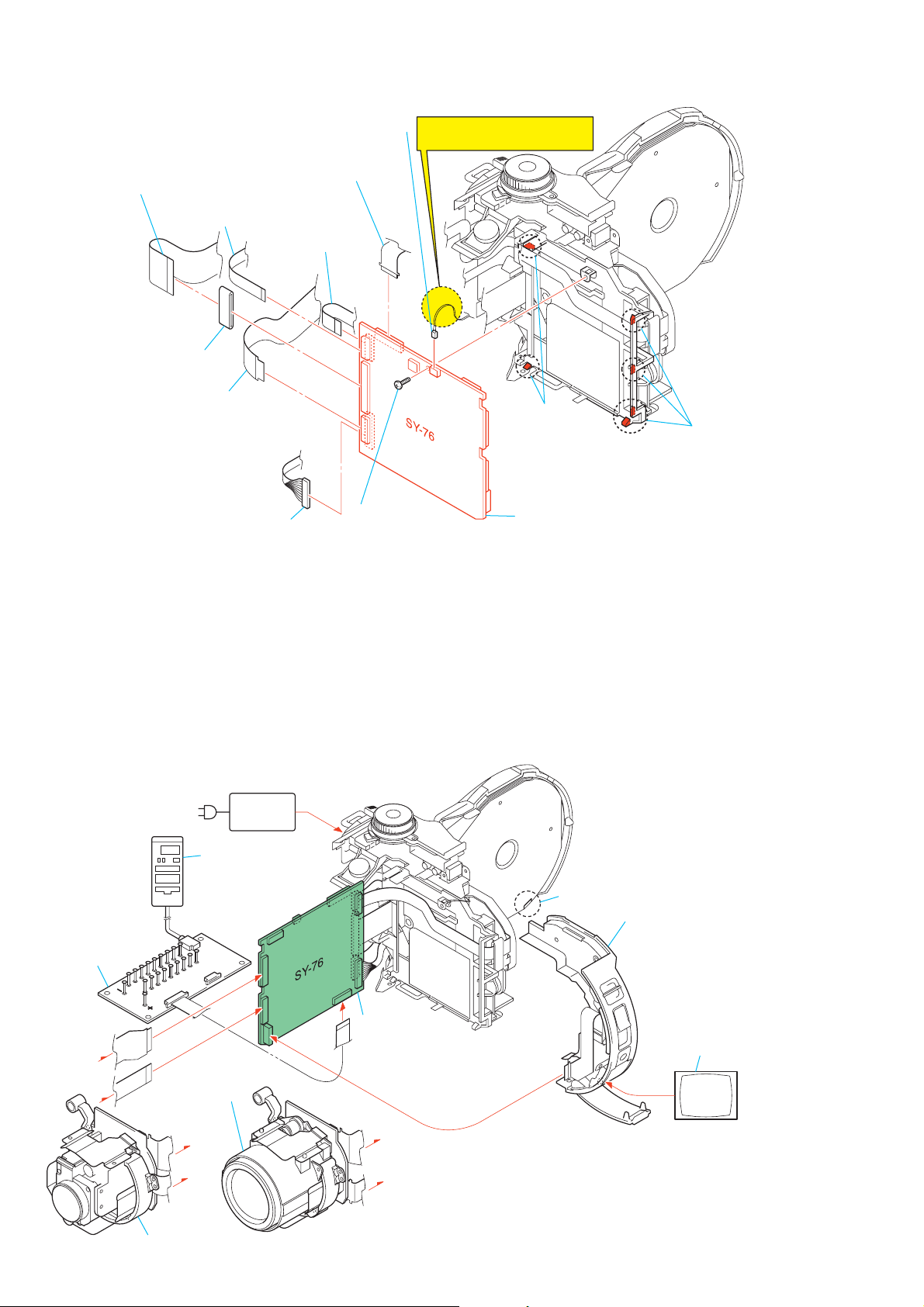

2-7. SY-76 BOARD

5 FP-488 flexible board

(CN901)

2 FP-481 flexible board

(CN721)

6 Ferrite core

3 FP-483 flexible board

(CN717)

4 FS-141 harness

(CN001)

7 Harness (microphone)

(CN902)

1 Control switch block

(CN720)

qs Flexible board

(base unit) (CN902)

Note:Don't pull at harness of

8 Screw (M2)

connector.

9 Two claws

0 Four claws

qa SY-76 board

[SERVICE POSITION (SY-76 BOARD: SIDE B)]

Setting the "Forced Power ON mode"

[Forced CAMERA mode]

1) Select page: 0, address: 01, and set

data: 01.

2) Select page: D, address: 2F, set data:

00, and then press the PAUSE button

of adjustment remote commander.

3) Select page: D, address: 21, set data:

07, and then press the PAUSE button

of adjustment remote commander.

4) Turn the power off, then on again.

DC-IN

CPC-9 jig

(J-6082-393-C)

(Note 1, 2)

18

1

A

AC power

adaptor

Adjustment remote

commander

[Forced PLAY mode]

1) Select page: 0, address: 01, and set

data: 01.

2) Select page: D, address: 2F, set data:

00, and then press the PAUSE button

of adjustment remote commander.

3) Select page: D, address: 21, set data:

08, and then press the PAUSE button

of adjustment remote commander.

4) Turn the power off, then on again.

18

1

SY-76 board

Exiting the "Forced Power ON mode"

1) Select page: 0, address: 01, and set

data: 01.

2) Select page: D, address: 2F, set data:

E0, and then press the PAUSE button

of adjustment remote commander.

3) Select page: D, address: 21, set data:

00, and then press the PAUSE button

of adjustment remote commander.

4) Select page: 0, address: 01, and set

data: 00.

S307, S308

(Note 3)

Side cabinet block assembly

Monitor

B

Lens block assembly

(MVC-CD400)

Lens block assembly

(MVC-CD250)

A

B

A

B

Note 1: Don't use the 12 pin flexible board of CPC-9 jig.

It causes damage to the unit.

Note 2: The old CPC-9 jig (Parts code: J-6082-393-B) Cannot be used,

because it cannot operate the adjustment remote commander.

Note 3: Must be pressed lid open/close detect switch (S307, S308 on

PK-65/66 board) when using the CD-R/RW drive unit.

2-6

2-8. DDX-G3000 COMPLETE ASSEMBLY

MVC-CD250/CD400

2 FP-481 flexible board

3 FP-483 flexible board

(CN717)

5 Two screws

2-9. BASE UNIT

(CN721)

(M1.7

× 5)

4 FS-141 harness

(CN001)

1 Control switch block

(CN720)

7 DDX-G3000 complete assembly

6 Screw (M2)

3 Tape

4 Three special

head screws

5 Base unit

1 Screw (M2)

2 Flexible board

2-7

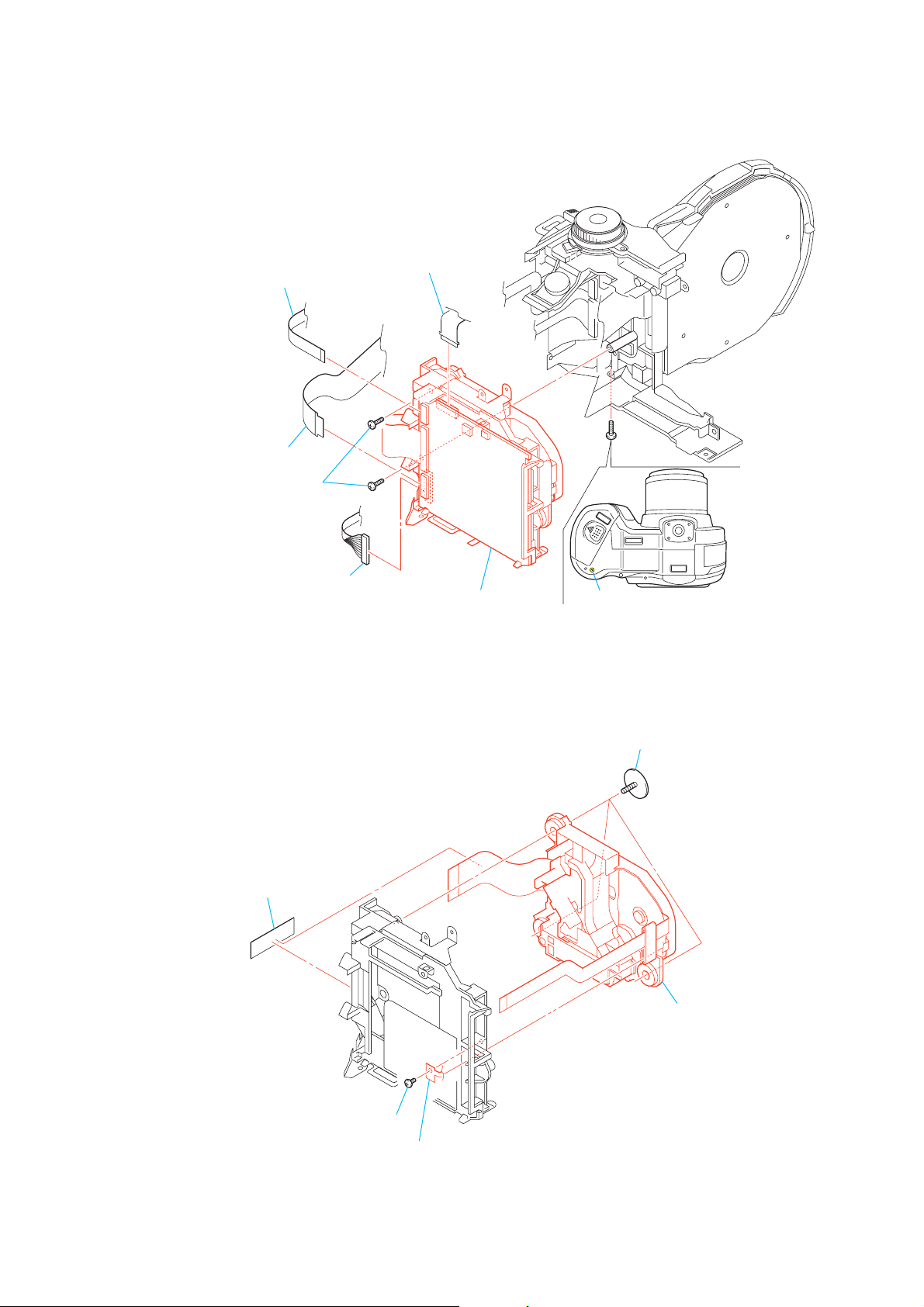

MVC-CD250/CD400

2-10.PK-65/66 BOARD

2 Five screws

(M1.7 × 5)

5 FP-483 flexible board

(CN303)

4 CD cabinet lid assembly

6 LCD flexible board

(CN302)

[SERVICE POSITION (PK-65/66 BOARD: SIDE A)]

Note 1: Don’t use the 12 pin flexible board of CPC-9 jig.

It causes damage to the unit.

Note 2: The old CPC-9 jig (Parts code: J-6082-393-B) Cannot be used,

because it cannot operate the adjustment remote commander.

Monitor

Note 3: Must be pressed lid open/close detect switch (S307, S308 on

PK-65/66 board) when using the CD-R/RW drive unit.

8 Two screws

9 PK-65/66 board

7 Back light flexible board

(CN201)

× 4)

(M1.7

1 Open the CD cabinet.

3 Claw

18

1

CPC-9 jig

(J-6082-393-C)

(Note 1, 2)

Adjustment remote

commander

1

18

S307, S308

(Note 3)

2-8

AC power

adaptor

PK-65/66 board

DC-IN

2-11.LCD MODULE

2 Three screws

(M1.7

×

4)

1 Screw

(M1.7 × 5)

3 Two screws

(M1.7

×

4)

4 BL retainer

5 Back light unit

6 LCD module

MVC-CD250/CD400

[SERVICE POSITION (PK-65/66 BOARD: SIDE B)]

DC-IN

S307, S308

(Note 3)

Back light unit

LCD module

CPC-9 jig

(J-6082-393-C)

(Note 1, 2)

AC power

adaptor

PK-65/66 board

18

1

Adjustment remote

commander

18

1

SY-76 board

A

B

Side cabinet block assembly

A

B

Monitor

A

B

Note 1: Don’t use the 12 pin flexible board of CPC-9 jig.

It causes damage to the unit.

Note 2: The old CPC-9 jig (Parts code: J-6082-393-B) Cannot be used,

because it cannot operate the adjustment remote commander.

Note 3: Must be pressed lid open/close detect switch (S307, S308 on

PK-65/66 board) when using the CD-R/RW drive unit.

2-9

Lens block assembly

(MVC-CD250)

Lens block assembly

(MVC-CD400)

MVC-CD250/CD400

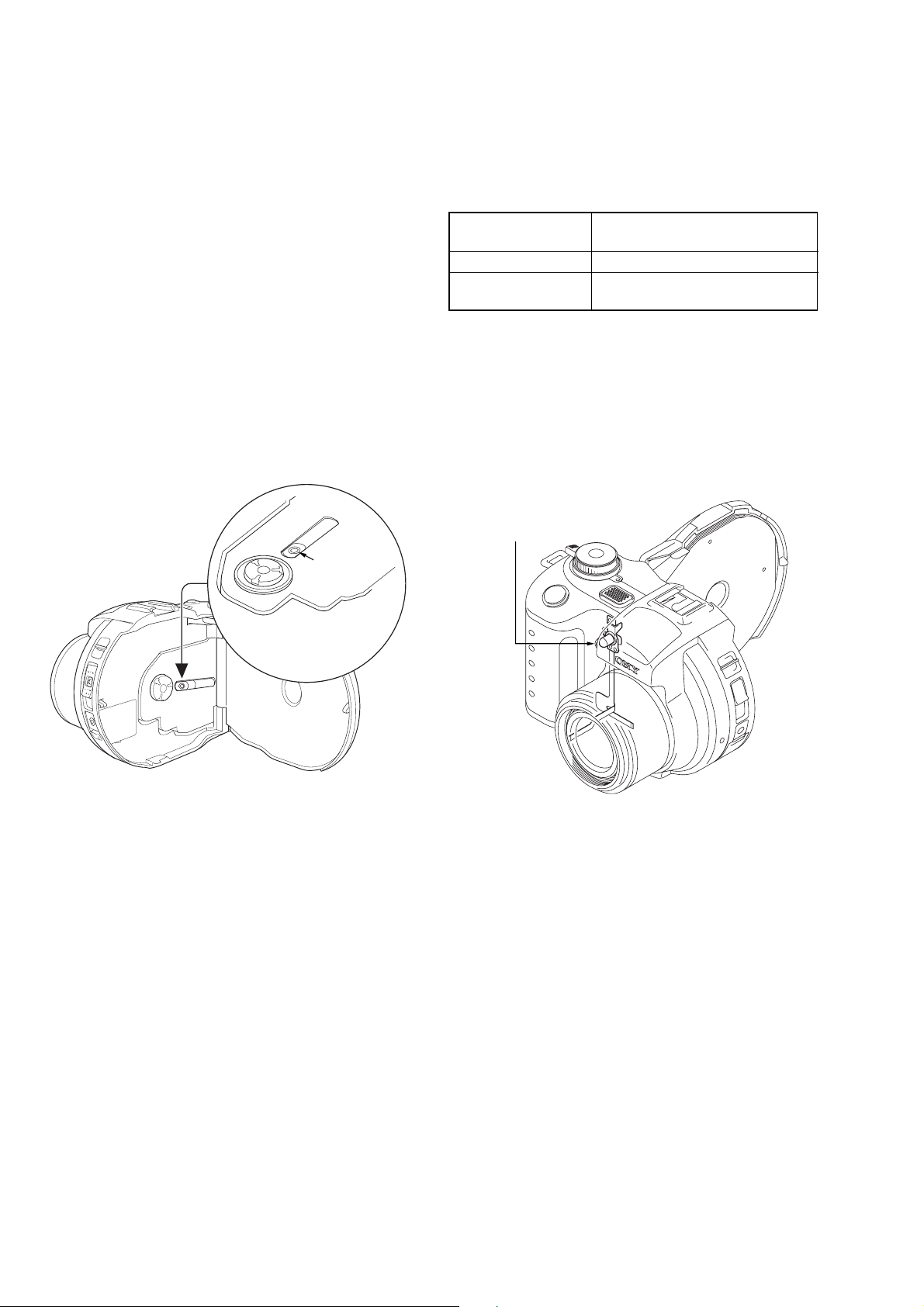

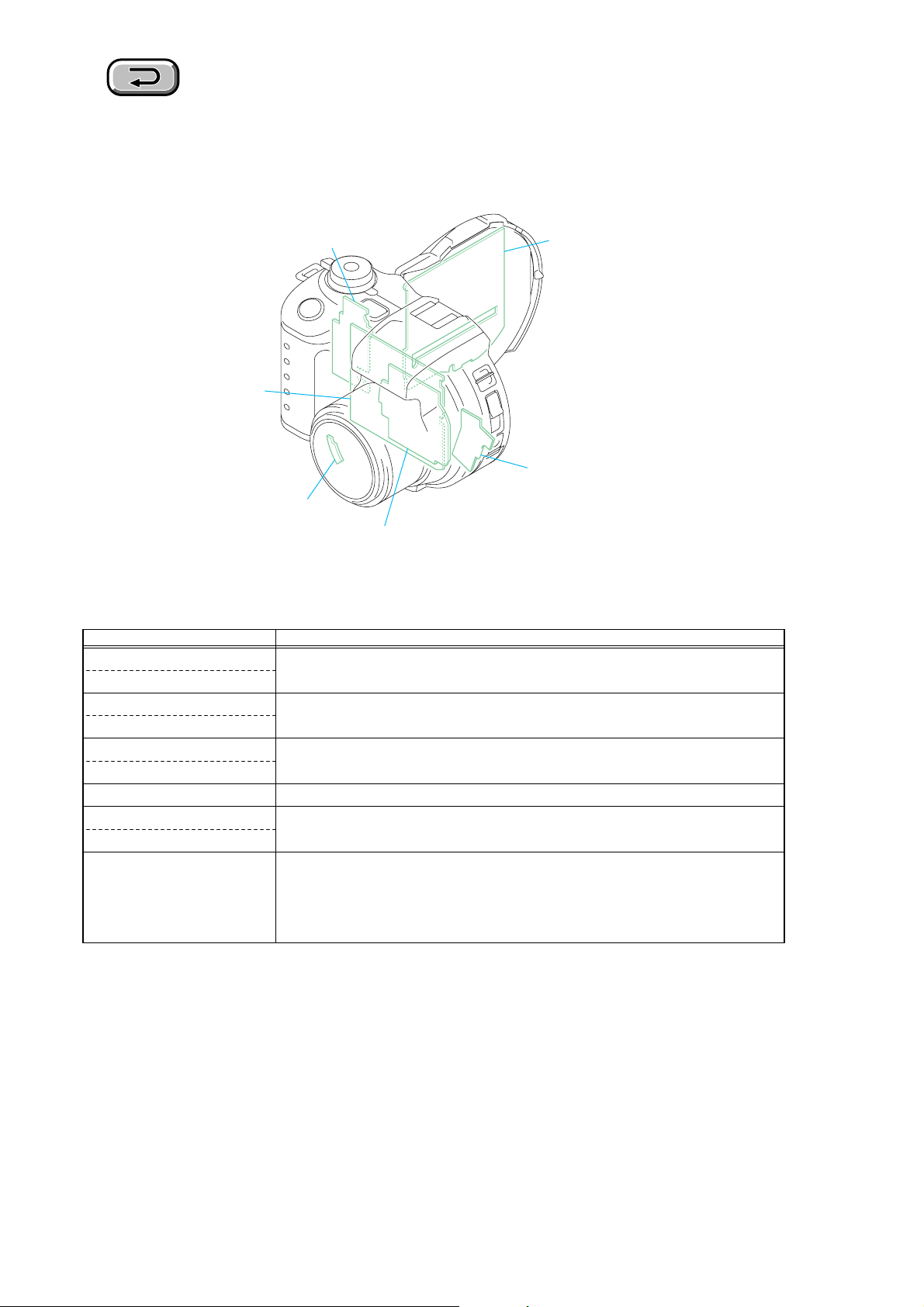

2-12.CIRCUIT BOARDS LOCATION

FS-84 (MVC-CD400)

FS-85 (MVC-CD250)

SY-76

LS-61 (MVC-CD400)

PK-65 (MVC-CD400)

PK-66 (MVC-CD250)

JK-224 (MVC-CD400)

JK-225 (MVC-CD250)

CD-393 (MVC-CD400)

CD-394 (MVC-CD250)

Board Name Function

CD-393 (MVC-CD400) CCD IMAGER, CAMERA PROCESS

CD-394 (MVC-CD250)

FS-84 (MVC-CD400) DC IN, CONTROL SW

FS-85 (MVC-CD250)

JK-224 (MVC-CD400) JACK

JK-225 (MVC-CD250)

LS-61 (MVC-CD400) LENS CAP SWITCH

PK-65 (MVC-CD400) LCD DRIVE, TIMING GENERATOR, BACK LIGHT DRIVE

PK-66 (MVC-CD250)

SY-76 CAMERA DSP, VIDEO, MEMORY, LENS DRIVE, SH DSP,

CD-R/RW SIGNAL PROCESS, CD DRIVE, CD DRIVE DSP,

AUDIO, LASER/IR LED DRIVE, HI CONTROL,

DC/DC CONVERTER

2-10

2-10E

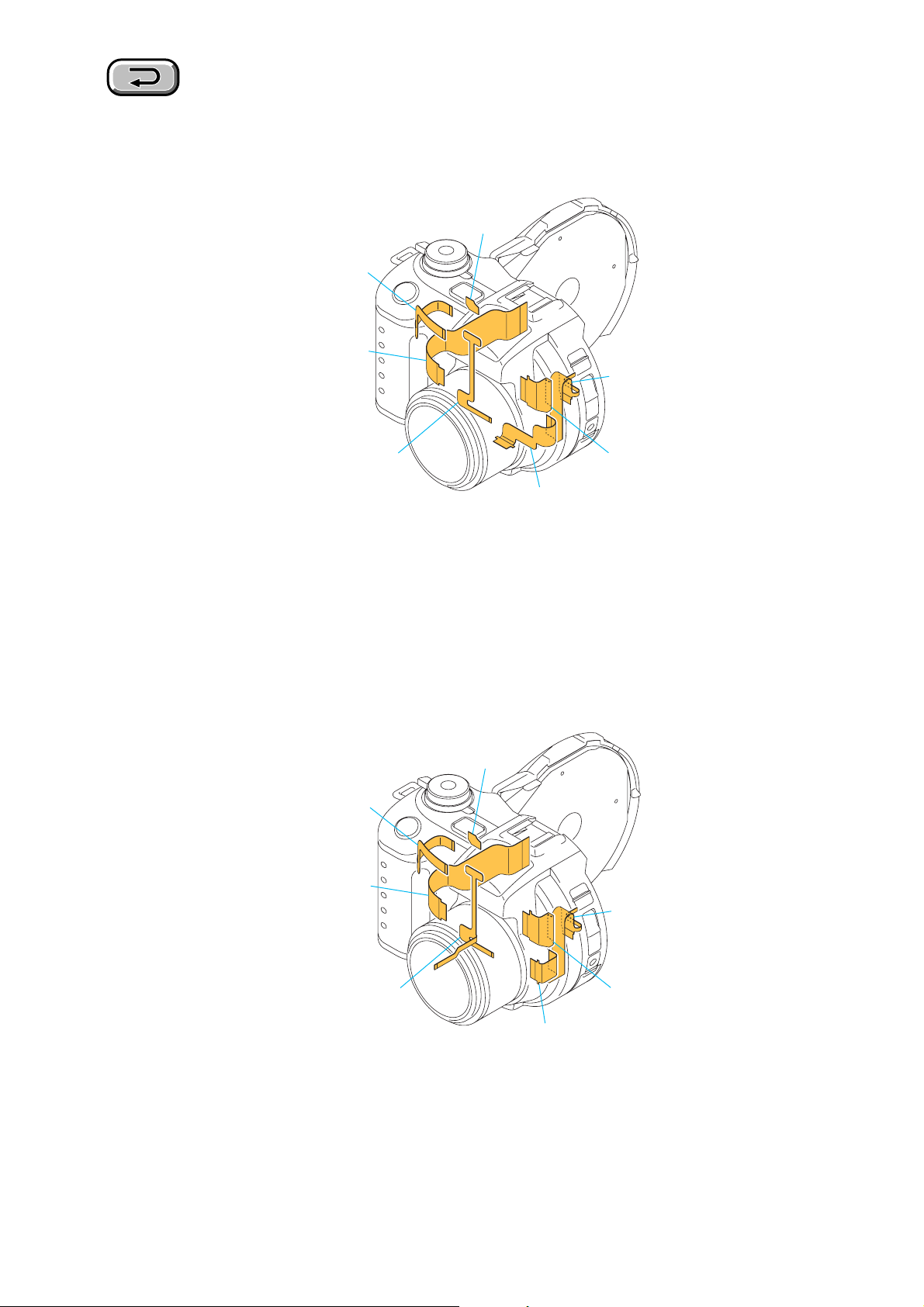

2-13.FLEXIBLE BOARDS LOCATION

(MVC-CD250)

FP-481

FP-483

MVC-CD250/CD400

FP-248

FP-482

(MVC-CD400)

FP-481

FP-483

FP-489

FP-484

FP-486

FP-248

FP-482

FP-490

FP-484

FP-485

2-11E

COVER

COVER

Link

Link

MVC-CD250/CD400

3. BLOCK DIAGRAMS

OVERALL BLOCK DIAGRAM

OVERALL BLOCK DIAGRAM

POWER BLOCK DIAGRAM-1

POWER BLOCK DIAGRAM-1

POWER BLOCK DIAGRAM-2

POWER BLOCK DIAGRAM-2

MVC-CD250/CD400

COVER

COVER

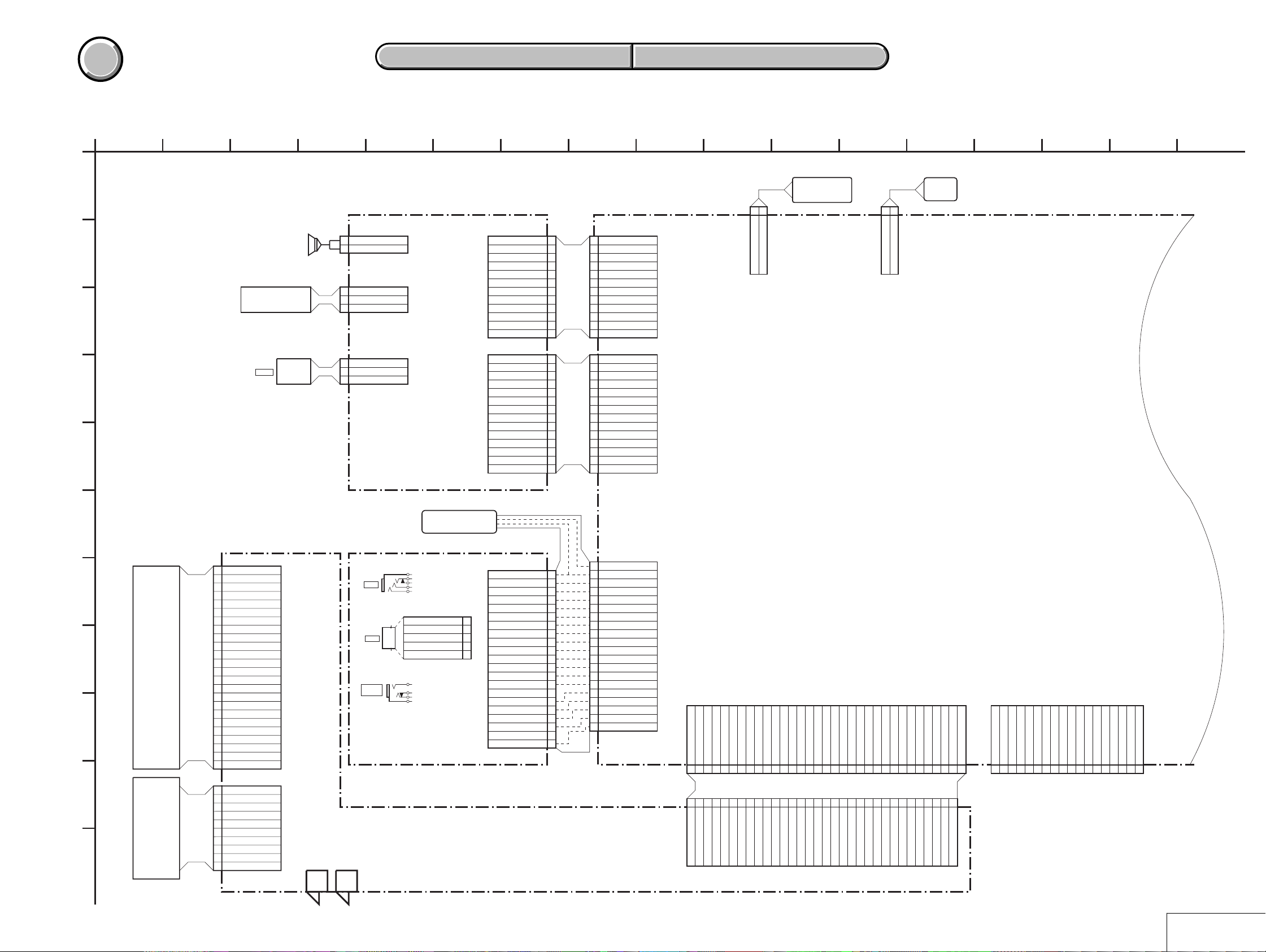

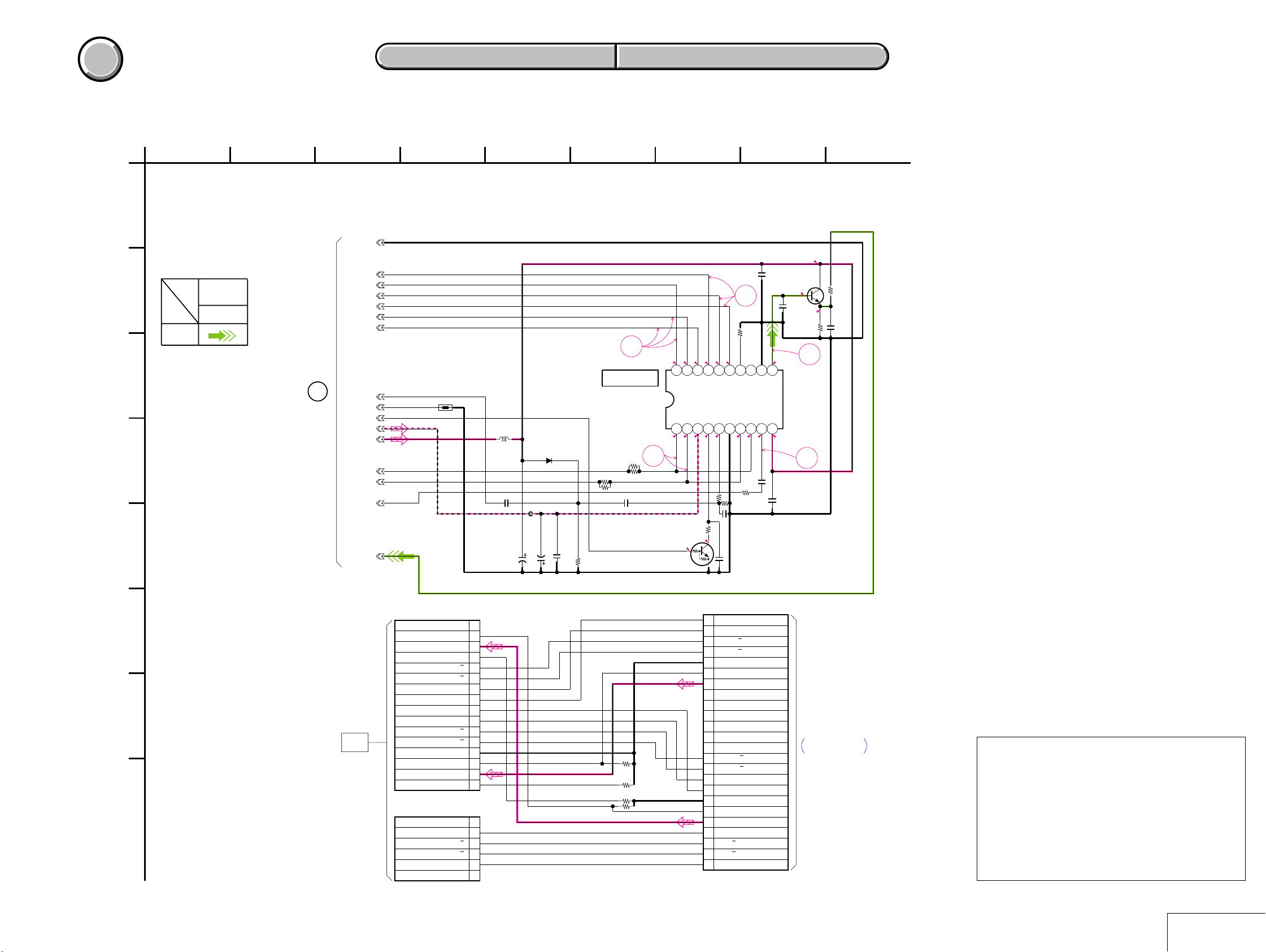

3-1. OVERALL BLOCK DIAGRAM

FOCUS

MOTOR

J9001

DC IN

LENS

FOCUS

SENSOR

BT9001

BATTERY

TERMINAL

S

05

ZOOM

MOTOR

MM

ZOOM

SENSOR

FLASH

UNIT

FS-84/85 BOARD

(1/2)

FS-84:MVC-CD400/

FS-85:MVC-CD250

BATT SIG

FUNCTION

KEY

CD400

IRIS

METER

(SHUTTER)

IRIS

METER

STRB ON

STB CHARGE

XSTB FULL

IRIS

MM

X601

CONTROL

(13/13)

H

SHUTTER DRIVE

IC001

DC

DRIVE−

HALL+

IC101

(3/13)

IRIS

IRIS MOTOR

DRIVE

ZOOM MOTOR

DRIVE

FOCUS MOTOR

DRIVE

SECTION 3

3. BLOCK DIAGRAMS

3. BLOCK DIAGRAMS

BLOCK DIAGRAMS

( ) : Number in parenthesis ( ) indicates the division number of schematic diagram where the component is located.

CD-393/394 BOARD

(CD-393:MVC-CD400/CD-394:MVC-CD250)

IC401

CCD OUT

CCD

IC601

CLOCK GEN.

(5/13)

MT UNREG

BL UNREG

ST UNREG

BATT UNREG

IMAGER

(1/2)

IC102 IC106

IRIS DRIVE

HALL AMP

Z SENS RST

F SENS RST

D 1.5V

D 2.5V

D 3.1V

A 3.1V

A 4.9V

4.6V

M 4.6V

PANEL 4.9V

PANEL 13.5V

PANEL –15.3V

CAM 5V

CAM P 5V

CAM 3.1V

CAM 15V

CAM −7.5V

(3/13)

H1, H2

V1A, V1B, V2, V3A,

V3B, V4, VSHT, RG

HALL AD

TG CLK

MC CLK1

USB CLK

IC501

CAMERA

MODULE

(2/2)

CD250

CD400

HALL AD

CONTROL SWITCH BLOCK

ZOOM

SWITCH

SHUTTER

SWITCH

MODE

DIAL

POWER

ON/OFF

CAM SO, XCAM SCK

DIR0A, DIR0B

XPWR ON

SY-76 BOARD

DATA BUS 14

CA HD

CA FD

MCK12

IC108

EVR

(D/A CONVERTER)

(3/13)

IC105

IRIS CONTROL

(3/13)

MSHUT EN, MSHUT ON

IRIS EN

HR EN1,

HR DIR1A, HR DIR1B

HR EN0,

HR DIR1A, HR DIR0B

STRB ON

STB CHARGE

XSTB FULL

KEY AD 3

XSHTR ON, XAE LOCK SW

MODE DIAL

XPB ON

KEY AD 0, 1

CAM SI, CAM SO, XCAM SCK

SYS DD ON

BATT SIG

IC301

CAMERA

DSP

(1/13)

CAM SI, CAM SO, XCAM SCK

IC402

HI

CONTROL

(12/13)

DATA BUS 32

ADDRESS BUS 14

CV OUT

AU AINL AU AINL

AU AOUT AU AOUT

PANEL R

PANEL G

PANEL B

BEEP, BEEP ON

FR SO, FR SI, XFR SCK

KEY AD2

LANC DATA

16

25

32M FLASH

IC503

(5/13)

16

21

IC805

EEPROM

(9/13)

CD400

IC302

IC303

128M SDRAM

(2/13)

FR XRESET

IC403

INITIAL RESET,

BACK UP VCC

(12/13)

IC401

LANC DRIVER

(12/13)

DATA BUS

ADDERESS BUS

CDC SI, CDC SO, CDC SCK

EEPROM

CAM SI, CAM SO, XCAM SCK

D403

UNREG

UNREG

16

25

IC504

(5/13)

HALL AD

LCD SO, LCD SCK

FR SO, FR SI, XFR SCK

BATT

ACV

16

16

MC XRD

MC XWE1

IC501

MC CAM,

SH DSP

(4/13)

USB D+ D+

USB D– D–

VAMP ON

BEEP, BEEO ON

PK-65/66 BOARD

PK-65:MVC-CD400/

PK-66:MVC-CD250

LCD SO, LCD SCK

FUNCTION

KEY

RESET

BL LEV

JK-224/225 BOARD (2/2)

JK-224:MVC-CD400/

JK-225:MVC-CD250

BT101

LITHIUM

BATTERY

LANC SIG

IC807

CD DRIVVE

DSP

(8/13)

DATA BUS 16

IC803

SRAM

(9/13)

CV OUT

PANEL R

PANEL G

PANEL B

IC302

TIMING

GENERATOR

(1/2)

BL UNREG

IC201

DC/DC CONTROL

(2/2)

CD-R/RW DATA

ADDRESS BUS 17

IC201

VIDEO AMP

(2/13)

IC251

AUDIO DSP

(10/13)

Q206

SWITCHING

J101

ACC

IC905

CD-R/RW

SIGNAL

PROCESS

(6/13)

IC904

TRACKING/FOCUS/

SLED MOTOR/

SPINDLE MOTOR

DRIVE

(7/13)

JK-224/225 BOARD (1/2)

JK-224:MVC-CD400/

JK-225:MVC-CD250

AU OUT

FS-84/85 BOARD (2/2)

FS-84:MVC-CD400/

FS-85:MVC-CD250

IC301

LCD

DRIVE

(1/2)

T201

INVERTER

TRANS

V OUT

VR

VG

VB

BL HIGH

CD-R/RW DATA

LCD9001

COLOR

LCD

MONITOR

ND9001

BASE UNIT

(DDX-G3000)

CN102

USB

J102

A/V OUT

(MONO)

MIC9001

MICROPHONE

SP9001

SPEAKER

3-1 3-2

MVC-CD250/CD400

COVER

COVER

3. BLOCK DIAGRAMS

3. BLOCK DIAGRAMS

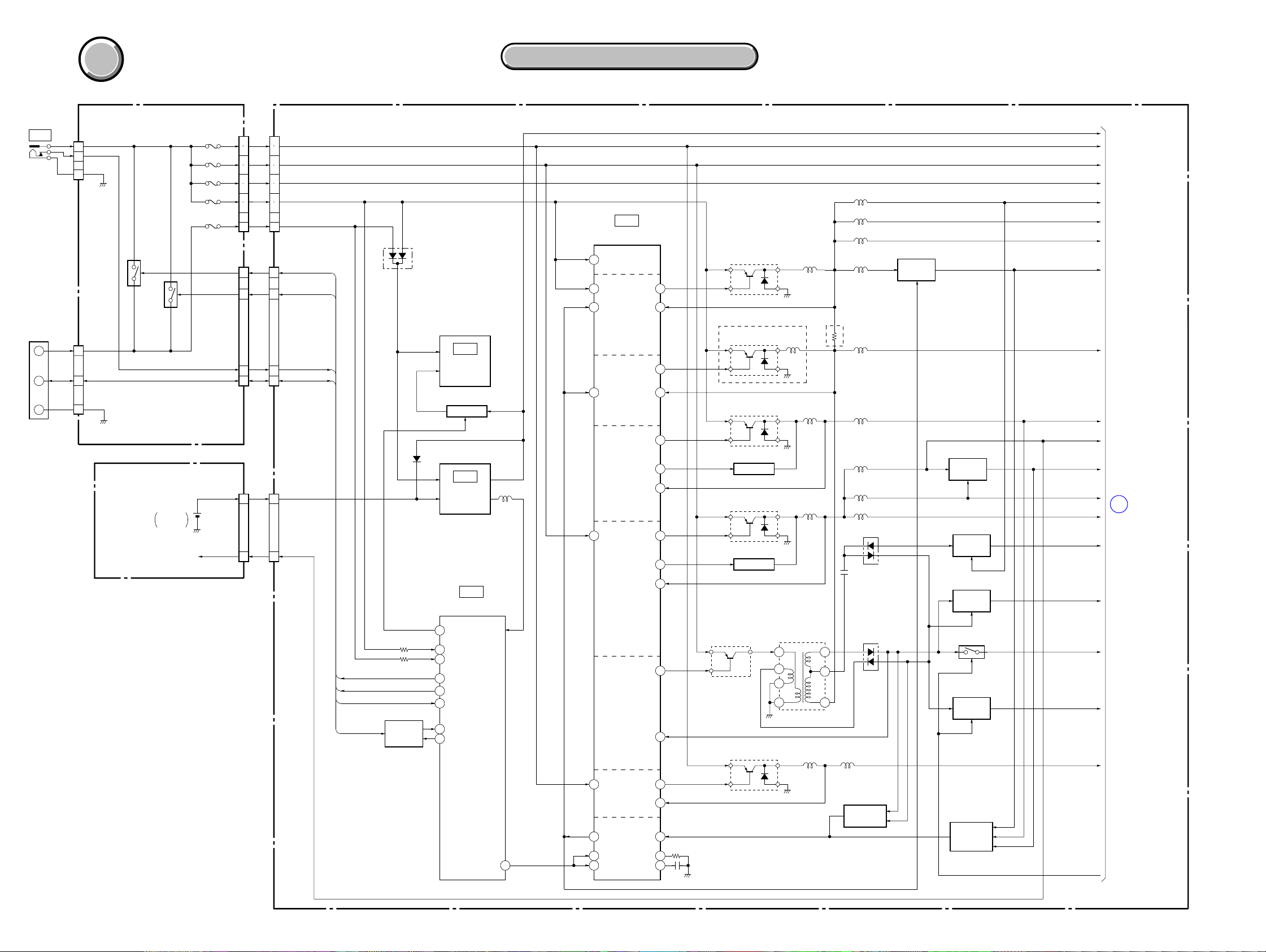

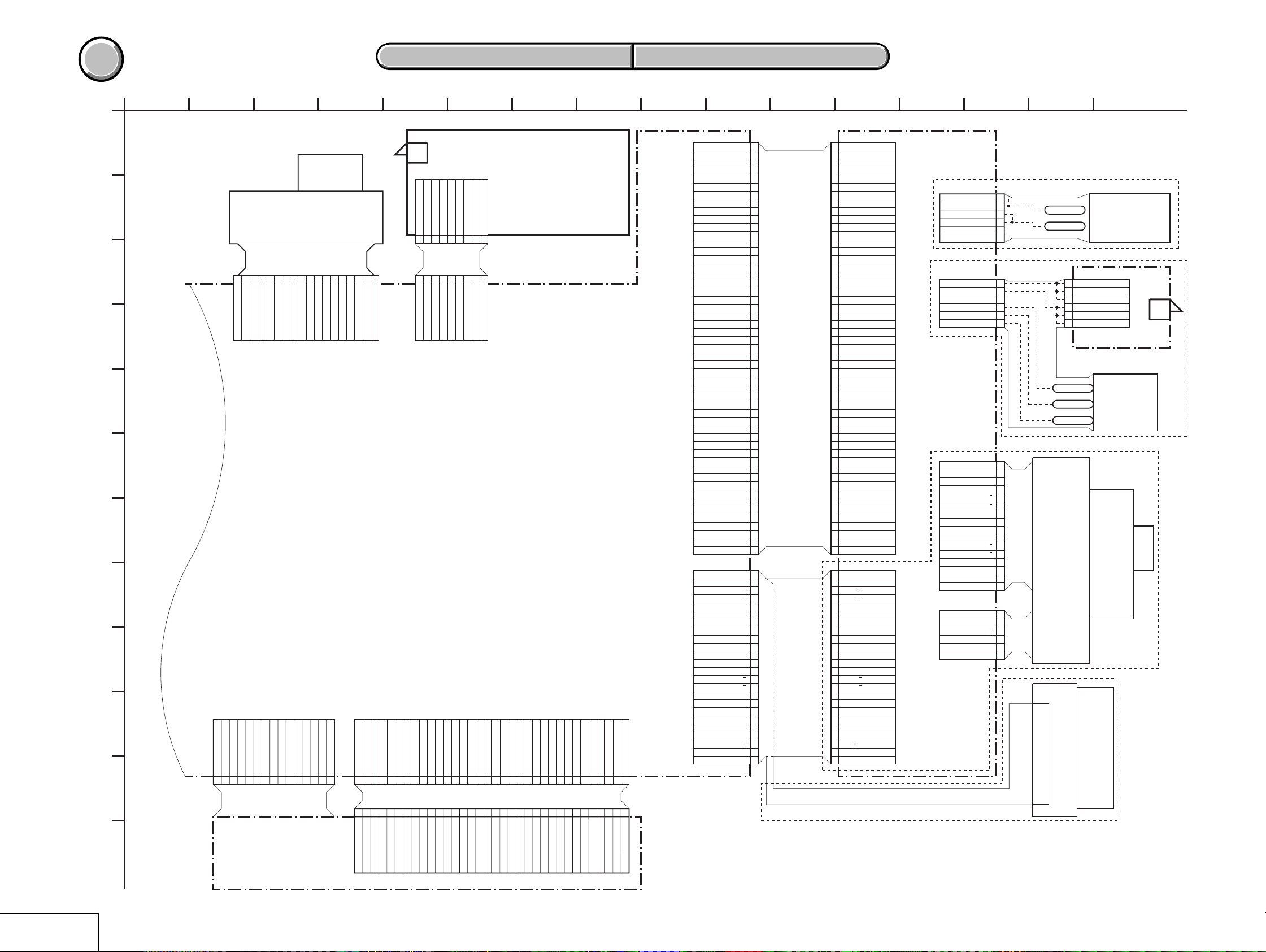

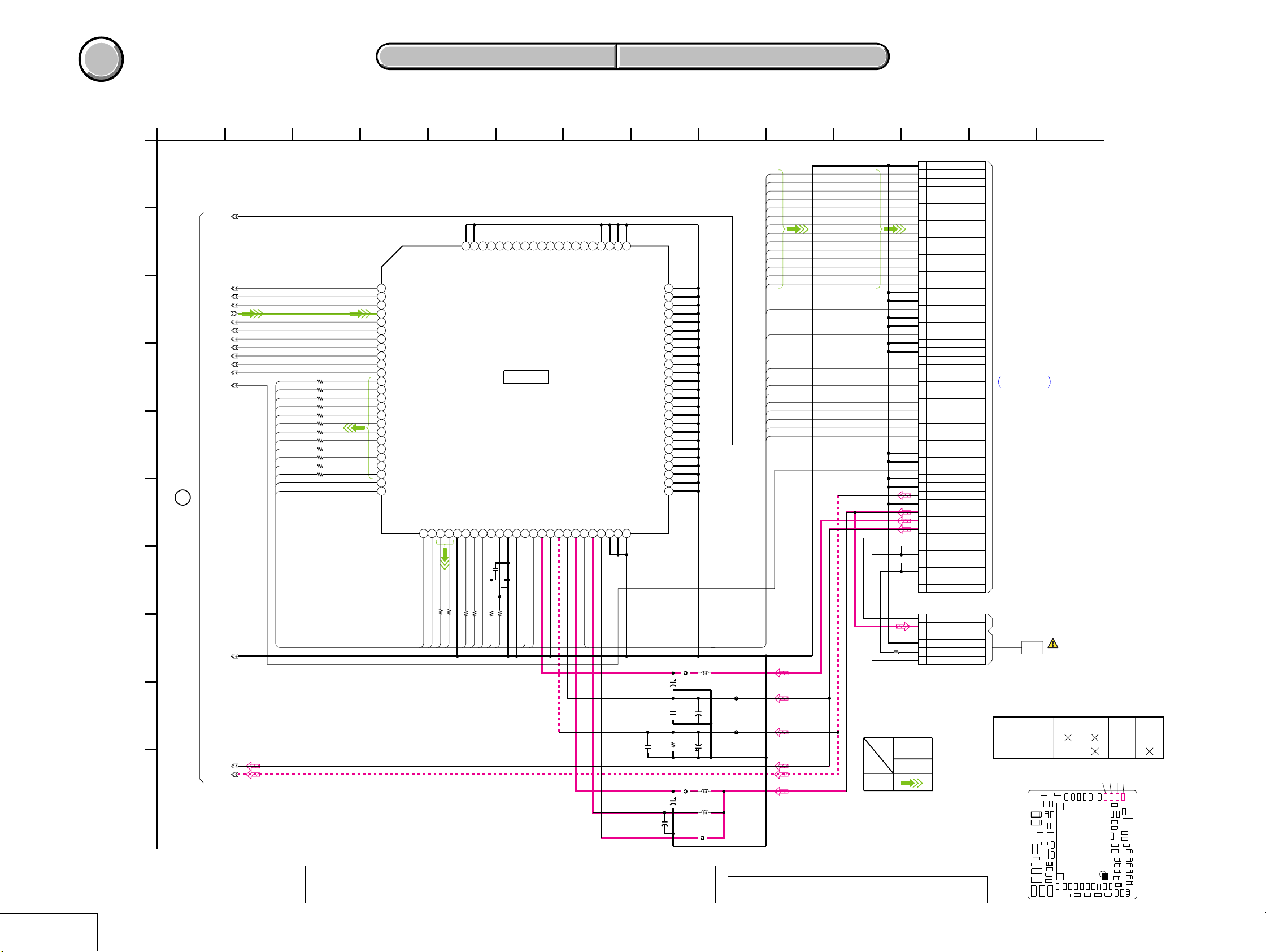

3-10.POWER BLOCK DIAGRAM 1

FS-84/85 BOARD

J9001

DC IN

BT9001

BATTERY

TERMINAL

+

S

–

(FS-84:MVC-CD400/FS-85:MVC-CD250)

CN002

ACV UNREG

1

BATT/XEXT

3

ACV GND

2

Q001, 002

Q003, 004

CN003

1

2

3

BATT

UNREG

BATT SIG

BATT GND

CHARGE

CONTROL

CN004

F001

F002

F004

F003

F005

CN005 CN721

( ) : Number in parenthesis ( ) indicates the division number of schematic diagram where the component is located.

SY-76 BOARD (1/2)

IC001

DC CONTROL

(13/13)

EVER 3.2V

MT UNREG

BL UNREG

ST UNREG

ACV UNREG

OUT-6

IN(C)6

OUT-5

IN(C)5

4

9

64

1415 +IN(E)5

6

7

8

9

12

13

10

11

14

8

9

7

5

CN001

8

M 4.6V

9

TRANS/3.1V

6

7

ST UNREG

2

3

5V

5

4

BATT UNREG

1

FAST CHARGE

8

9

7

5

INIT CHARGE

BATT/XEXT

BATT SIG

D403

IC401

LANC DRIVER

(12/13)

Q401

SWITCHING

28

VCC

63 VCC4, 5, 6

10

+IN(E)6

CD400

Q004

SWITCHING

Q005

SWITCHING

Q001

SWITCHING

L002

L001

CD250

L009

L010

L011

L012

L013

L014L004

Q020 - 022

4.6V

REG

EVER

MT UNREG

BL UNREG

ST UNREG

PANEL 4.9V

CAM 5V

A 4.9V

4.6V

CAM P 5V

D 1.5V

JK-224/225 BOARD

(JK-224:MVC-CD400/JK-225:MVC-CD250)

BT101

LITHIUM

BATTERY

D 3.1V

CN103 CN718

21 1

12 8

VL 3V

D 3.1V

FAST CHARGE

INIT CHARGE

BATT/EXT

BATT SIG

Q408

BATTERY

CHARGE

DETECTOR

D407

IC403

INITIAL RESET,

BACK UP VCC

(12/13)

IC402

HI CONTROL

(12/13)

18 XLANC ON

68

ACV SENS

67 BATT SENS

48

FAST CHARGE

47

INIT CHARGE

8

BATT/XEXT

43

BATT SI

42

BATT SO

L401

42 VCC1, 3

OUT-4

MOS-GATE-4

OUT-1

MOS-GATE-1

OUT-3

IN(C)3

57

Q009, 011

2.5V

REG

Q014, 017

–15.3V

REG

Q013, 016

13.5V

REG

Q018, 019

Q012, 015,

024, 025

–7.5V

REG

60

18IN(C)4

46

43

40IN(C)1

56

34

SWITCHING

SWITCHING

Q003

SWITCHING

Q007

Q002

SWITCHING

Q008

Q006

SWITCHING

T001

DC/DC CONV.

TRANS

4

3

2

1

L003

L005 L015

L008

L007

L006

D001

RECT

D003

RECT

5

6

8

D 3.1V

D 2.5V

A 3.1V

CAM 3.1V

PANEL –15.3V

PANEL 13.5V

CAM 15V

CAM –7.5V

M 4.6V

A

(PAGE 3-21)

POWER 2

SCP

50OUT-2

37IN(C)2

13

21

RT

2276SYS DD ON

CT

EMERGENCY

51 VCC2

27

V REF

29

CTL2

30

CTL1

05

3-19 3-20

Q023

DETECT

VREF

D 3.1V

Q010

EMERGENCY

DETECT

CAM DD ON

COVER

COVER

3. BLOCK DIAGRAMS

3. BLOCK DIAGRAMS

MVC-CD250/CD400

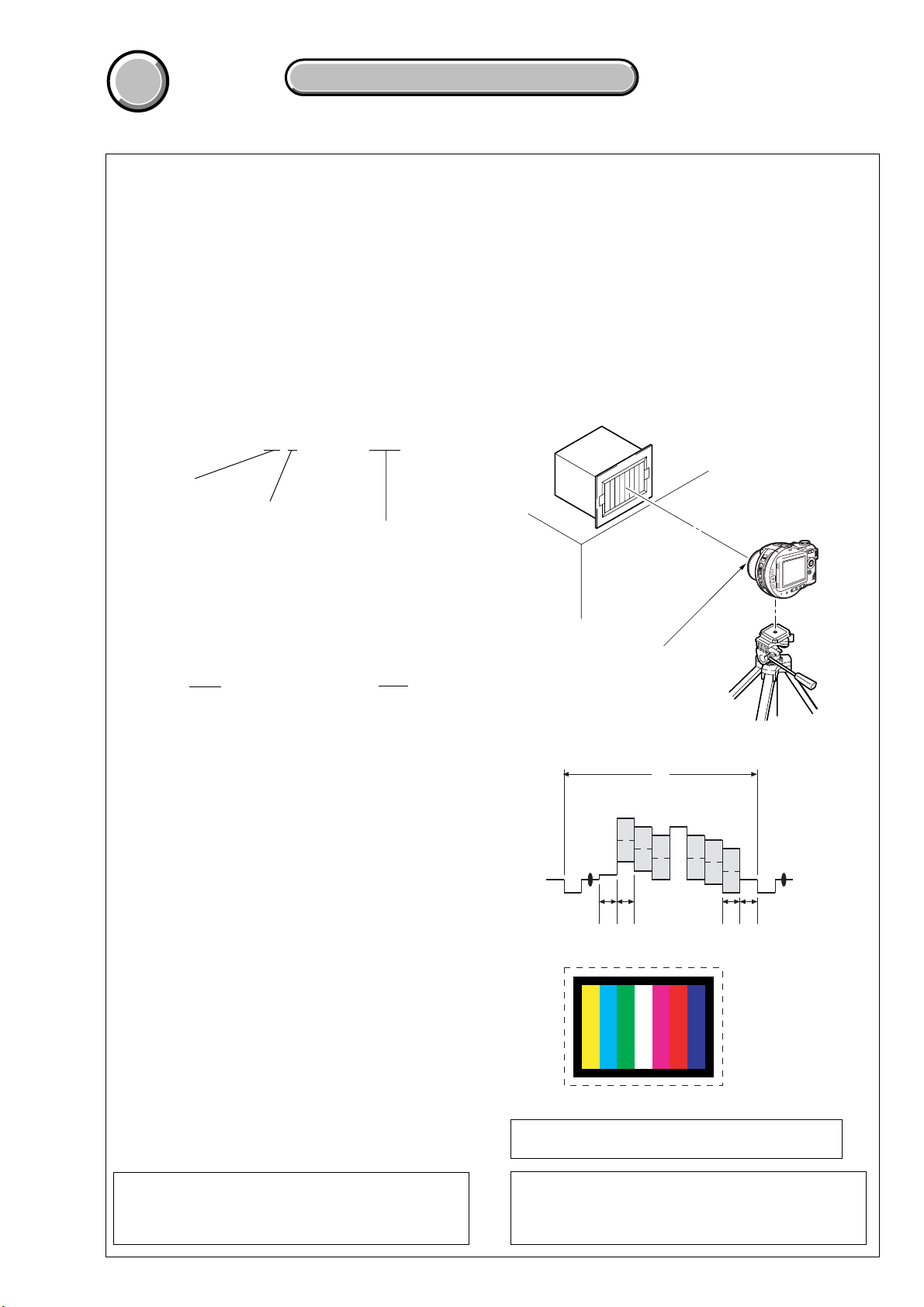

3-11.POWER BLOCK DIAGRAM 2

SY-76 BOARD (2/2)

CN717

EVER

D 3.1V

A 3.1V

PANEL 13.5V

PANEL –15.3V

PANEL 4.9V

BL UNREG

CN714

BL DC

MT UNREGMT UNREG

D 3.1V

CN720

D 3.1V

D 3.1V

D 3.1V

POWER 1

(PAGE 3-20)

05

A

EVER

A 3.1V

D 3.1V

ST UNREG

CAM DD ON

D 1.5V D 1.5V

D 3.1V

A 3.1V

A 4.9V

CAM P 5V

CAM 5V

CAM 3.1V

CAM 15V

CAM –7.5V

FB801

EVER

D 2.5V

4.6V

M 4.6V

FB802

( ) : Number in parenthesis ( ) indicates the division number of schematic diagram where the component is located.

PK-65/66 BOARD

(PK-65:MVC-CD400/PK-66:MVC-CD250)

CN303

EVER

3

3

D 3.1V

27

27

14

12

11

13

10

4

13

10

18

9

14

16

IC807

CD DRIVE DSP

(8/13)

PANEL 3.1V

14

PANEL 13.5V

12

PANEL –15.3V

11

PANEL 4.9V

13

BL UNREG

10

BL DC

4

CPC

CONTROL SWITCH BLOCK

IC906

AND

(6/13)

D801

(ZK-880)

(ZK-860)

D 3.1V

D 3.1V

D 3.1V

FB303

D 3.1V

IC803

SRAM

(9/13)

: CD400

: CD250

CD250

IC302

128M SDRAM

(2/13)

Q801

D303

FLASH

/CHG

D302

ACCESS

Q701, 702

CD400

Q304

FB304

L201

L303

CN719

128M SDRAM

IC805

EEPROM

(9/13)

L301

IC303

(2/13)

IC301

LCD DRIVE

(1/2)

L304

Q203, 206

SWITCHING

FLASH

UNIT

A 4.9V

UNREG

24

IC804

AND

(9/13)

L302

CD400

IC302

TIMING

GENERATOR

(1/2)

CURRENT

DETECT

D 3.1V

D 3.1V

A 3.1V

A 4.9V

CAM P 5V

CAM 5V

CAM 3.1V

CAM 15V

CAM –7.5V

IC202

(2/2)

IC806

AND

(9/13)

CD250

L203L202

L601

FB504

FB501

FB502

L501

CD250

CD400

Q307

IC201

DC/DC

CONTROL

(2/2)

T201

INVERTER

TRANS

CLOCK GEN.

EEPROM

32M FLASH

198

PTM(6)

MC CAM,

IC601

(5/13)

IC504

(5/13)

IC503

(5/13)

IC501

SH DSP

(4/13)

CN302

VDD/VGLAC

VDD/VSH3V

VGH

VGL

VDD/VSH5V

Q210Q201, 202

CN201

LED

BL HIGH

L301

FB302

IC904

TRACKING/FOCUS/

SLED MOTOR/

SPINDLE MOTOR

DRIVE

(7/13)

Note : CN302 Pin name A/B

4

23

1

3

24

2

10

IC201

VIDEO AMP

(2/13)

IC251

AUDIO DSP

(10/13)

IC301

CAMERA DSP

(1/13)

FB301 L302

SWITCH

A : CD250

B : CD400

PANEL UNIT

MONITOR

ND9001

L252

IC911

(6/13)

LCD9001

COLOR

LCD

LED

BACK

LIGHT

L201

L253

L251

IC912

SWITCH

(7/13)

CD-394 BOARD

IC501

CAMERA

MODULE

(2/2)

CD-393 BOARD

IC501

CAMERA

MODULE

(2/2)

Note : CN724 Pin name A/B

A : CD400

B : CD250

CD250

IC102

IRIS DRIVE

(3/13)

IC106

IRIS DRIVE

HALL AMP

HALL BAIS CONTROL

HALL GAIN CONTROL

(3/13)

IC108

EVR

(D/A CONVERTER)

(3/13)

IC101

7CH LENS DRIVER

(3/13)

L102 L104 L105

IC903

COMPARATOR

(6/13)

L902

FB505 FB401

FB504

FB503

L502

L501FB501

L503FB502

CN503

48 49

FB505 FB401

FB504

FB503

L502

L501FB501

L503FB502

CN501

48 49

CN724

LD OUT/CAM P 5V

L101

L103

D 3.1V

CAM P 5V

CAM P 5V

IC905

CD-R/RW

SIGNAL PROCESS

(6/13)

L901

43

CAM 5V

IC901

AND

(6/13)

CAM 15V

CAM 3.1VCAM 3.1V

404442

40404444424243

CAM –7.5V

D 3.1V

L401

L401

CD400

FB101

Q101

Q151, 152

IC401

CCD

IMAGER

(1/2)

CN502

CAM P 5V

IC401

CCD

IMAGER

(1/2)

CN502

CAM 3.1V

F SENS VCC

Z SENS VCC

IC103

XOR

(3/13)

IC104

XOR

(3/13)

IC107

D-FF

(3/13)

IC105

IRIS

CONTROL

(3/13)

IC151

MULTI

VIBRATOR

(11/13)

D302

(SELF TIMER)

IC152

COMPARATOR

(11/13)

FB901

FP-489 FLEXIBLE BOARD

1

2

FP-490

FLEXIBLE

BOARD

5

CN651 CN703

20

20

7

7

BASE UNIT

(DDX-G3000)

CN901

LDVCC

11

12

FPDO

15

PDVCC

17

D9002

(AF/SELF TIMER)

LS-61

BOARD

CN801

1

CAM 3.1V

ı

3

F SENS VCC

Z SENS VCC

FOCUS

SENSOR

ZOOM

SENSOR

CN701

CD250

CD250

CD400

FOCUS

14

SENSOR

ZOOM

2

SENSOR

3-21 3-22E

COVER

COVER

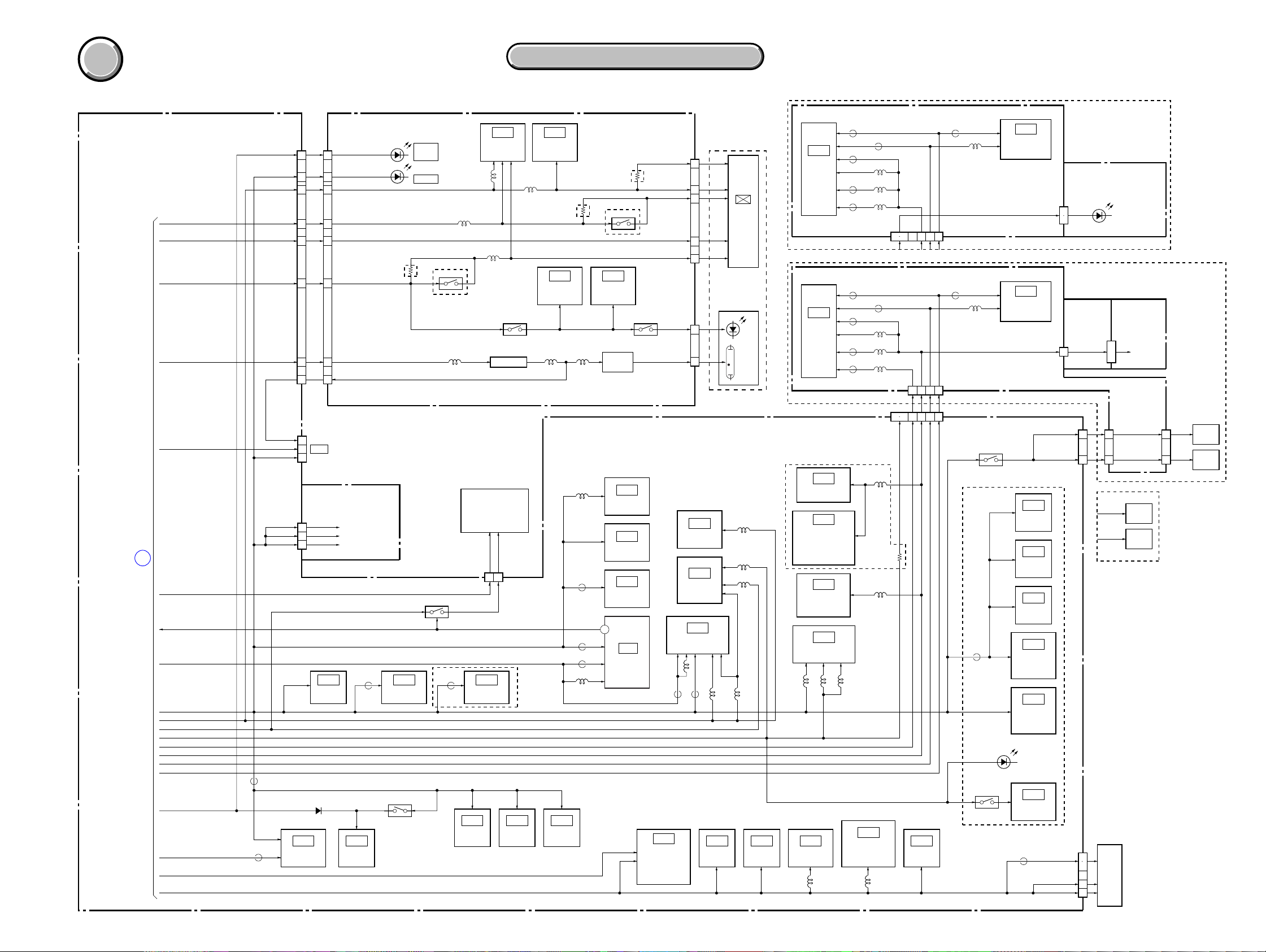

PRINTED WIRING BOARDS AND SCHEMATIC DIAGRAMS

4-1. FRAME SCHEMATIC DIAGRAMS

SECTION 4

4-2. SCHEMATIC DIAGRAMS 4-3. PRINTED WIRING BOARDS

4-2. SCHEMATIC DIAGRAMS 4-3. PRINTED WIRING BOARDS

MVC-CD250/CD400

1

FRAME SCHEMATIC DIAGRAM (1/2)

A

B

C

D

E

3

SP9001

BT9001

BATTERY TERMINAL

J9001

DC IN

DC JACK

CN006

SP-

2

SP+

1

3BATT_GND

2BATT_SIG

1BATT_UNREG

3BATT/XEXT

2 ACV_GND

1 ACV_UNREG

FS-84 BOARD

:CD400

FS-85 BOARD

:CD250

5

2P

3PCN003

3PCN002

684 172

CN005

REG_GND

REG_GND

BATT_SIG

REG_GND

BATT/XEXT

FAST_CHARGE

INIT_CHARGE

REG_GND

KEY_AD0

KEY_AD1

CN004

REG_GND

REG_GND

REG_GND

REG_GND

REG_GND

M_4.6V

M_4.6V

TRANS/3.1V

TRANS/3.1V

ST_UNREG

ST_UNREG

BATT_UNREG

7

12P

1

SP+

2

SP-

3

4

5

6

7

8

9

10

11

12

14P

1

2

3

4

5

6

7

8

9

10

5V

5V

11

12

13

14

FS-141 HARNESS FP-481 FLEXIBLE

1

2

3

4

5

6

7

8

9

10

11

12

14

13

12

11

10

9

8

7

6

5

4

3

2

1

SP+

SP-

REG_GND

REG_GND

BATT_SIG

REG_GND

BATT/XEXT

FAST_CHARGE

INIT_CHARGE

REG_GND

KEY_AD0

KEY_AD1

CN001

REG_GND

REG_GND

REG_GND

REG_GND

REG_GND

M_4.6V

M_4.6V

TRANS/3.1V

TRANS/3.1V

5V

5V

ST_UNREG

ST_UNREG

BATT_UNREG

12PCN721

14P

91411 12 16

DS-116

HARNESS

1

2PCN707

DEW_SENS

2

REG_GND

FP-248 FLEXIBLE

DEW SENSOR

2P

CN702

1

MIC_SIG

2

MIC_GND

13

MIC9001

MIC

1510

SY-76 BOARD (1/2)

CONTINUED ON

PAGE 4-3

PL9001

4

1

5

2

3

J102

DOOR LOCK

CN102

5P

VCC

1

D-

2

D+

3

4

ID

5

GND

PK-65 BOARD

PK-66 BOARD

CN103

EXT_STROB_ON

XLANC_JACK_IN

XUSB_JACK_IN

AV_JACK_IN

:CD400

:CD250

REG_GND

LANC_SIG

REG_GND

LANC_DC

USB_GND

USB_D+

USB_D-

REG_GND

D_3.1V

REG_GND

REG_GND

AU_OUT

REG_GND

V_OUT

REG_GND

REG_GND

VL_3V

21P

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

FP-482

FLEXIBLE

21pin - 20pin

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

DOORLOCK

REG_GND

LANC_SIG

REG_GND

LANC_DC

EXT_STROB_ON

XLANC_JACK_IN

USB_GND

USB_D+

USB_D-

REG_GND

XUSB_JACK_IN

D_3.1V

AV_JACK_IN

REG_GND

AU_OUT

REG_GND

V_OUT

REG_GND

VL_3V

20PCN718

33PCN717

XLID_OPEN

BL_DC

VG

EVER

3EVER

4BL_DC

HSY

5VG

6HSY

CHARGE_LED

123456789

1XLID_OPEN

2CHARGE_LED

32P

CN303

PANEL_COM

BL_GND

BL_GND

PANEL_3.1V

PANEL_4.9V

PANEL_13.5V

REG_GND

PANEL_-15.3V

BL_UNREG

1011121314151617181920212223242526272829303132

PANEL_B

PANEL_G

PANEL_R

REG_GND

REG_GND

XHD

XSYS_RST

LCD_SO

LCD_SCK

XVD

FP-483 FLEXIBLE

7PANEL_COM

8BL_GND

9BL_GND

10BL_UNREG

11PANEL-15.3V

12PANEL_13.5V

13PANEL_4.9V

14PANEL_3.1V

15REG_GND

16PANEL_B

17PANEL_G

18PANEL_R

19REG_GND

20REG_GND

21XSYS_RST

22XHD

23XVD

24LCD_SO

25LCD_SCK

XCS_LCD

26XCS_LCD

D_3.1V

27D_3.1V

KEY_AD2

28KEY_AD2

REG_GND

29REG_GND

FR_XRESET

REG_GND

30FR_XRESET

31REG_GND

ACCESS_LED

32ACCESS_LED

18P

CN714

DECEFM

MPXO

N.C

33

FMDT

123456789

REG_GND

XLID_OPEN

N,C

HSY

PANEL_COM

(FOR CHECK)

LANC_OUT

LANC_IN

BL_DC

MS_SCLK

MS_BS

VG

MT_UNREG

101112131415161718

CPC

MS_DIO

D_3.1V

N.C

F

24PCN302

VDD/VSH5V

24

23

VDD/VSH3V

22

G

H

LCD9001

PANEL UNIT

I

J

ND9001

BACK LIGHT

K

VSS/GND

21

VB

VG

20

19

VR

18

HCNT/SPD

17

MCLK/CLD

16

CLR/CTR

15

OE/PSS2

14

SRT/PSS1

13

STBYB/RES

12

VBC/CLS

11

VCOM

10

RESET/EX2

9

STBYB/PSG

8

GSRT/MO2

7

GPCK/MO1

6

GRES/EX1

5

N.C./SPS

4

VDD/VGLAC

3

VGL

2

VSS/GND

1

VGH

10PCN201

BL_HIGH

10

N.C.

9

N.C.

8

N.C.

7

N.C.

6

N.C.

5

N.C.

4

BL_LOW

3

LED

2

LED_GND

1

Note:CN302 Pin

Name A/B

A:CD250

B:CD400

J101

ACC

STROB JACK

USB

A/V OUT

(MONO)

AV JACK

JK-224 BOARD

:CD400

JK-225 BOARD

:CD250

05

4-1 4-2

FRAME (1/2)

MVC-CD250/CD400

COVER

COVER

4-2. SCHEMATIC DIAGRAMS 4-3. PRINTED WIRING BOARDS

4-2. SCHEMATIC DIAGRAMS 4-3. PRINTED WIRING BOARDS

1

FRAME SCHEMATIC DIAGRAM (2/2)

A

B

C

123456789

18P

XSHTR_ON

CN720

D

E

F

CONTINUED ON

PAGE 4-2

G

H

I

J

15PCN902

1 SLED+

2 SLED-

3 VH-

K

L

05

3

CONTROL SWITCH

BLOCK

(ZK-880):CD400

N.C

N.C

XPB_ON

XSET_UP

MODE_DIAL

XPOWER_ON

XAE_LOCK_SW

4W-

5W+

6V+

7V-

8U+

9U-

10 VH+

BASE

UNIT

(DDX-G3000)

:CD250(ZK-860)

101112131415161718

N.C

N.C

GND

11 XLMT

D_3.1V

12 LEDGND

D_3.1V

KEY_AD3

13 U

14 V

15 W

D_3.1V

XPOWER_LED

34P

CN901

1

34P

FCS+

5

DIAL_A

DIAL_B

SY-76 BOARD (2/2)

TRK-32TRK+33FCS-34FCS+

28 D

29 G

30 - (OP_TEMP)

31

2

3

4

5

6G7D8C9

FCS-

TRK-

TRK+

- (OP_TEMP)

UNREG

A_4.9V

UNREG_GND

HARNESS

A_4.9V

UNREG_GND

25 RFSUM

10

RFSUM

SS-084

UNREG

24 SW

11SW12

PDGND

XSTB_FULL

STROB_ON

STROB_ON

XSTB_FULL

PDVC23PDGND

22

13

PDVC

STB_CHARGE

123456789

123456789

9P

CN719

STB_CHARGE

26E27 C

E

6842

PLUNGER_ON

EXT2_STRB_ON

XSTB_POPUP

XSTB_POPUP

PLUNGER_ON

EXT2_STRB_ON

19 A

20B21 F

FP-488 FLEXIBLE

14F15B16A17H18

PDVCC

FLEXIBLE

FP-490

FP-489

LND001

LND002

LENS

BLOCK

1510

6

XLENSCAP_ON

5

XLENSCAP_ON

4

XLENSCAP_ON

3

CAM_3.1V

2

CAM_3.1V

1

CAM_3.1V

LS-061 BOARD

LND003

LND002

LND001

LENS BLOCK

CD250

D9002

AF/

SELF TIMER

ILLUMINATOR

6PCN801

D9001

LASER

UNIT

CD400

CD250

7

FLASH

UNIT

MODAMP

13 FPDVC

VWDC110VRDC11LDVCC12LDVCC

8 VWDC2

9

FPDGND

FPDVCC16FPDO17PDVCC18H

14

15

ENBL3OSCEN4WE25WE16LDGND7LDGND

1

2

91411 12 16

CN724

CD_GND

CA_AD10

CA_AD11

CA_AD12

CA_AD13

CD_GND

CD_GND

CD_GND

CD_GND

CD_GND

CD_GND

XGCAM_CS

CAM_SO

XCAM_SCK

TG_WEN

XCAM_RESET

VSUB_CONT

CD_GND

CD_GND

CCD_TEMP

CD_GND

CD_GND

CAM_-7.5V

REG_GND

CAM_3.1V

CAM_5V

CAM_15V

XLENSCAP_ON

PD_OUT/PRELAMP_LED

PD_OUT/PRELAMP_LED

LD_OUT/CAM_P_5V

LD_OUT/CAM_P_5V

CN651

ZOOM_B

ZOOM_A

ZOOM_B

ZOOM_A

Z_SENS_GND

Z_SENS_RST

Z_SENS_VCC

FOCUS_B

FOCUS_A

FOCUS_B

FOCUS_A

F_SENS_GND

F_SENS_RST

F_SENS_VCC

CA_AD0

CA_AD1

CA_AD2

CA_AD3

CA_AD4

CA_AD5

CA_AD6

CA_AD7

CA_AD8

CA_AD9

TG_CLK

MCK12

XTG_CS

CLPDM

CLPOB

CA_FD

CA_HD

BIAS+

HALL+

BIAS-

HALL-

DRIVE+

DRIVE-

IRIS-B

IRIS-A

IRIS-B

IRIS-A

51P

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

FP-484

26

FLEXIBLE

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

Note:CN724,CN503

Pin Name A/B

48

A:CD400

B:CD250

49

50

N.C.

51

N.C.

24P

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

FP-485

FLEXIBLE

CN501:CD400

CN503:CD250

CD_GND

1

CA_AD0

2

CA_AD1

3

CA_AD2

4

CA_AD3

5

CA_AD4

6

CA_AD5

7

CA_AD6

8

CA_AD7

9

CA_AD8

10

CA_AD9

11

CA_AD10

12

CA_AD11

13

CA_AD12

14

CA_AD13

15

CD_GND

16

CD_GND

17

TG_CLK

18

CD_GND

19

CD_GND

20

MCK12

21

CD_GND

22

CD_GND

23

XGCAM_CS

24

CAM_SO

25

XCAM_SCK

26

XTG_CS

27

TG_WEN

28

CLPDM

29

CLPOB

30

CA_FD

31

CA_HD

32

XCAM_RESET

33

VSUB_CONT

34

CD_GND

35

CD_GND

36

CCD_TEMP

37

CD_GND

38

CD_GND

39

CAM_-7.5V

40

REG_GND

41

CAM_3.1V

42

CAM_5V

43

CAM_15V

44

XLENSCAP_ON

45

46

PD_OUT/PRELAMP_LED

PD_OUT/PRELAMP_LED

47

LD_OUT/CAM_P_5V

48

LD_OUT/CAM_P_5V

49

N.C.

50

N.C.

51

CN703

ZOOM_B

1

ZOOM_A

2

3

ZOOM_B

4

ZOOM_A

Z_SENS_GND

5

Z_SENS_RST

6

Z_SENS_VCC

7

BIAS+

8

HALL+

9

BIAS-

10

HALL-

11

DRIVE+

12

DRIVE-

13

FOCUS_B

14

FOCUS_A

15

FOCUS_B

16

FOCUS_A

17

F_SENS_GND

18

F_SENS_RST

19

F_SENS_VCC

20

IRIS-B

21

IRIS-A

22

IRIS-B

23

IRIS-A

24

51P

24P

24pin-20pin

19FPDO

20

21FPDGND

22

23

24LDVCC

25VRDC

26

27VWDC2

28LDGND

29LDGND

30

32

33

34

WE131WE2

FPDVCC

FPDVC

LDVCC

VWDC1

OSCEN

ENBL

MODAMP

13

CD-393 BOARD

:CD400

CD-394 BOARD

:CD250

CD400

TEMP_COM_(GND)

FP-486 FLEXIBLE

CN502

CAM_P_5V

CAM_P_5V

PRELAMP_LED

PRELAMP_LED

CN502

XLENSCAP_ON

CAM_3.1V

REG_GND

LD_OUT

PD_OUT

CN701

F_SENS_RST

F_SENS_VCC

F_SENS_GND

ZOOM_B

ZOOM_A

ZOOM_A

ZOOM_B

FOCUS_A

FOCUS_B

FOCUS_A

FOCUS_B

Z_SENS_RST

Z_SENS_VCC

Z_SENS_GND

CN702

IRIS-B

IRIS-A

IRIS-B

IRIS-A

6P

1

2

3

4

5

N,C

6

N,C

6P

FLEXIBLE

6

5

N,C

4

3

2

1

16P

16

N.C

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

6P

N.C

6

5

4

3

2

N.C

1

FRAME (2/2)

4-3 4-4

4-2. SCHEMATIC DIAGRAMS

COVER

COVER

4-2. SCHEMATIC DIGARAMS

4-2. SCHEMATIC DIAGRAMS

THIS NOTE IS COMMON FOR SCHEMATIC DIAGRAMS

(In addition to this, the necessary note is printed in each block)

MVC-CD250/CD400

(For schematic diagrams)

• All capacitors are in µF unless otherwise noted. pF : µ

µF. 50 V or less are not indicated except for electrolytics

and tantalums.

• Chip resistors are 1/10 W unless otherwise noted.

kΩ=1000 Ω, MΩ=1000 kΩ.

• Caution when replacing chip parts.

New parts must be attached after removal of chip.

Be careful not to heat the minus side of tantalum

capacitor, Because it is damaged by the heat.

• Some chip part will be indicated as follows.

Example C541 L452

22U 10UH

TA A 2520

Kinds of capacitor

Temperature characteristics

External dimensions (mm)

• Constants of resistors, capacitors, ICs and etc with XX

indicate that they are not used.

In such cases, the unused circuits may be indicated.

•Parts with ★ differ according to the model/destination.

Refer to the mount table for each function.

• All variable and adjustable resistors have characteristic

curve B, unless otherwise noted.

• Signal name

XEDIT→ EDIT PB/XREC → PB/REC

• 2: non flammable resistor

• 5: fusible resistor

• C: panel designation

• A: B+ Line

• B: B– Line

• J : IN/OUT direction of (+,–) B LINE.

• C: adjustment for repair.

• A: VIDEO SIGNAL (ANALOG)

• A: AUDIO SIGNAL (ANALOG)

• A: VIDEO/AUDIO SIGNAL

• A: VIDEO/AUDIO/SERVO SIGNAL

• A: SERVO SIGNAL

• Circled numbers refer to waveforms.

(Measuring conditions voltage and waveform)

•Voltages and waveforms are measured between the

measurement points and ground when camera shoots

color bar chart of pattern box. The y are reference v alues

and reference waveforms.

(VOM of DC 10 MΩ input impedance is used)

•Voltage values change depending upon input impedance

of VOM used.)

1. Connection

Pattern box

About 34cm (MVC-CD250)

About 28cm (MVC-CD400)

Front of the lens

2. Adjust the distance so that the output wavef orm of Fig.

a and the Fig. b can be obtain.

AABBA=B

Fig. a (Video output terminal output waveform)

H

Yellow

Cyan

White

Magenta

Green

Red

Blue

Note : The components identified by mark 0 or

dotted line with mark 0 are critical for safety.

Replace only with part number specified.

Fig.b (Picture on monitor TV)

When indicating parts by reference number, please

include the board name.

Note : Les composants identifiés par une marque

0 sont critiques pour la sécurité.

Ne les remplacer que par une pièce portant

le numéro spécifie.

4-5

COVER

COVER

Link

Link

MVC-CD250/CD400

4-2. SCHEMATIC DIAGRAMS

CD-393 BOARD (1/2)

CD-393 BOARD (1/2)

CD-393 BOARD (2/2)

CD-393 BOARD (2/2)

CD-394 BOARD (1/2)

CD-394 BOARD (1/2)

CD-394 BOARD (2/2)

CD-394 BOARD (2/2)

PK-65/66 BOARD (1/2)

PK-65/66 BOARD (1/2)

(LCD DRIVE, TIMING GENERATOR)

(LCD DRIVE, TIMING GENERATOR)

(CCD IMAGER)

(CCD IMAGER)

(CAMERA MODULE)

(CAMERA MODULE)

(CCD IMAGER)

(CCD IMAGER)

(CAMERA MODULE)

(CAMERA MODULE)

PK-65/66 BOARD (2/2)

PK-65/66 BOARD (2/2)

FS-84/85 BOARD

FS-84/85 BOARD

JK-224/225 BOARD

JK-224/225 BOARD

LS-61 BOARD

LS-61 BOARD

(DC IN, CONTROL SW)

(DC IN, CONTROL SW)

(JACK)

(JACK)

(LENS CAP SWITCH)

(LENS CAP SWITCH)

WAVEFORMSCOMMON NOTE FOR SCHEMATIC DIAGRAMS

WAVEFORMSCOMMON NOTE FOR SCHEMATIC DIAGRAMS

(BACK LIGHT DRIVE)

(BACK LIGHT DRIVE)

COVER

COVER

For Schematic Diagram

• Refer to page 4-53 for printed wiring board.

• Refer to page 4-73 for waveforms.

4-2. SCHEMATIC DIAGRAMS CD-393 PRINTED WIRING BOARD

4-2. SCHEMATIC DIAGRAMS CD-393 PRINTED WIRING BOARD

MVC-CD250/CD400

1

2

CD-393 BOARD (1/2)

A

B

CCD IMAGER(4M CCD BLOCK)

XX MARK:NO MOUNT

NO MARK:REC/PB MODE

R:REC MODE

P:PB MODE

SIGNAL PATH

VIDEO

SIGNAL

Y/CHROMA

REC

3

4

(MVC-CD400)

GND

V2

V4

V1A

V1B

V3A

V3B

C

1

(2/2)

D

E

VSHT

CCD_TEMP

VSUB_CONT

CAM_-7.5V

CAM_15V

CCD_OUT

TH401

H2

H1

RG

L401

22uH

1uC401

C402

3.3u

35V

5

FB401

D401

MA111-(K8).S0

C403

C404

22u

16V

0.1u

R401

100k

R403

1

IC401

CCD IMAGER

IC401

ICX406AQ-13

R412

10

10

10

R413

C405

0.1u

R-7.1/P0

R2.3/P0

5

10R402

76

R-7.1/P0

R-7.1/P0

1

2

V4

V3A3V3B

H2

18VL19H120

R2.7/P0

R-7.5/P0

R404

2700

R10.1/P0

0

Q401

UN9213J-(K8).SO

SWITCH

R-0.3/P0

4V25

R10.1/P0

R405

R-0.3/P0

R-0.3/P0

V1A6V1B

R10.1/P0

0

0.1u

C407

R2.7/P0

R406

1M

C406

2200p

C408

0.1u

2

R407

7

TEST8TEST

R408

47

XX

R2.3/P0

C409

0.1u

9

10

GND

11

R13.1/P0

8

2SC4178-

F13F14-T1

BUFFER

R11.7/P0

11.7

VOUT

VDD12RG13H214H115GND16SUB17CSUB

R14.6/P0

C410

0.1u

R14.6/P0

Q402

C411

10p

R11/P0

R409

3300

4

9

R410

0

C412

XX

3

CN701

16P

N.C

ZOOM_B

ZOOM_A

ZOOM_A

ZOOM_B

FOCUS_A

FOCUS_B

FOCUS_A

FOCUS_B

IRIS-B

IRIS-A

IRIS-B

IRIS-A

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

N.C

6

5

4

3

2

1

N.C

R702

R703

56k

R701

180

180

R704

56k

F

F_SENS_RST

F_SENS_VCC

F_SENS_GND

G

LENS

BLOCK

H

05

CN702

TEMP_COM_(GND)

Z_SENS_RST

Z_SENS_VCC

Z_SENS_GND

6P

4-7 4-8

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

24PCN703

ZOOM_B

ZOOM_A

ZOOM_B

ZOOM_A

Z_SENS_GND

Z_SENS_RST

Z_SENS_VCC

BIAS+

HALL+

BIAS-

HALL-

DRIVE+

DRIVE-

FOCUS_B

FOCUS_A

FOCUS_B

FOCUS_A

F_SENS_GND

F_SENS_RST

F_SENS_VCC

IRIS-B

IRIS-A

IRIS-B

IRIS-A

SY-76 (3/13)

CN651

THROUGH THE

FP-485 FLEXIBLE

(PAGE 4-19)

Precautions for Replacement of CCD Imager

• The CD-393 board mounted as a repair part is not equipped

with a CCD imager.

When replacing this board, remove the CCD imager from the

old one and mount it onto the new one.

• If the CCD imager has been replaced, carry out all the

adjustments for the camera section.

• As the CCD imager may be damaged by static electricity from

its structure, handle it carefully like for the MOS IC.

In addition, ensure that the receiver is not covered with dusts

nor exposed to strong light.

CD-393 (1/2)

MVC-CD250/CD400

COVER

COVER

For Schematic Diagram

• Refer to page 4-53 for printed wiring board.

4-2. SCHEMATIC DIAGRAMS CD-393 PRINTED WIRING BOARD

4-2. SCHEMATIC DIAGRAMS CD-393 PRINTED WIRING BOARD

1

CD-393 BOARD (2/2)

A

CAMERA MODULE(MOJYUURU BLOCK)

XX MARK:NO MOUNT

VSUB_CONT

B

H1

H2

C

D

E

1

(1/2)

F

G

H

I

J

05

CCD_OUT

CCD_TEMP

CAM_15V

CAM_-7.5V

VSHT

RG

V1A

V1B

V2

V3A

V3B

V4

GND

D3

D4

D5

D6

D7

D8

D9

D10

D11

D12

D13

XTG_CS

XGCAM_CS

3

5

7

91411 126842

(MVC-CD400)

7677787980818283848586878889909192939495

12345678910111213141516171819202122232425

R505

150

R506

150

R507

150

R508

150

R509

150

R510

150

R511

150

R512

150

R513

150

R514

150

R515

150

R516

150

26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50

XCAM_SO

XCAM_SCKD1D0

Note:The voltage and waveform of CSP(chip size package)

cannot be measured,because its lead layout is different

form that of conventional IC.

150

150

XX

R518

R517

R524XXR523

CLPOB

CLPDM

XX

C508

220

R519

XCAM_RESET

CA_HD1

IC501

CAMERA MODULE

IC501

(CH-111 BOARD)

XX

C509

220

R520

CA_FD1D2MCK12

TG_CLK

TG_WEN

51 52 53 54 55 56 57 58 59 60 61 62 63 64 65 66 67 68 69 70 71 72 73 74 75

L503

47uH

FB502

C504

33u

10V

C506

C505

6.8u

0.1u

35V

C507

R502

C501

100k

0.1u

C503

6.3V

22u

16V

FB501

C502

47u

6.3V

47u

FB503

FB504

FB505

L501

47uH

L502

47uH

D0

D1

D2

D3

D4

D5

D6

D7

D8

D9

D10

D11

D12

D13

TG_CLK

MCK12

XGCAM_CS

XCAM_SO

XCAM_SCK

XTG_CS

TG_WEN

CLPDM

CLPOB

CA_FD1

CA_HD1

XCAM_RESET

10

R530 10

SIGNAL PATH

Y/CHROMA

REC

VIDEO

SIGNAL

CN501

10

11

12

13

14

15

16

17

18

19

20

21

22