Page 1

ANALOG VIDEO DISTRIBUTION BOARD

BKPF-L703A

MAINTENANCE MANUAL

1st Edition (Revised 1)

Serial No. 10001 and Higher

Page 2

! WARNING

This manual is intended for qualified service personnel only.

To reduce the risk of electric shock, fire or injury, do not perform any servicing other than that

contained in the operating instructions unless you are qualified to do so. Refer all servicing to

qualified service personnel.

! WARNUNG

Die Anleitung ist nur für qualifiziertes Fachpersonal bestimmt.

Alle Wartungsarbeiten dürfen nur von qualifiziertem Fachpersonal ausgeführt werden. Um die

Gefahr eines elektrischen Schlages, Feuergefahr und Verletzungen zu vermeiden, sind bei

Wartungsarbeiten strikt die Angaben in der Anleitung zu befolgen. Andere als die angegeben

Wartungsarbeiten dürfen nur von Personen ausgeführt werden, die eine spezielle Befähigung

dazu besitzen.

! AVERTISSEMENT

Ce manual est destiné uniquement aux personnes compétentes en charge de l’entretien. Afin

de réduire les risques de décharge électrique, d’incendie ou de blessure n’effectuer que les

réparations indiquées dans le mode d’emploi à moins d’être qualifié pour en effectuer d’autres.

Pour toute réparation faire appel à une personne compétente uniquement.

BKPF-L703A

Page 3

Table of Contents

Manual Structure

Purpose of this manual ........................................................................................ 3 (E)

Related manuals................................................................................................... 3 (E)

Contents ............................................................................................................... 3 (E)

1. Service Overview

1-1. Notes on Repair Parts............................................................................1-1 (E)

1-2. IC Link Replacement ............................................................................1-1 (E)

1-3. Unleaded Solder ....................................................................................1-1 (E)

1-4. Name and Function of Switch/Indicator ...............................................1-2 (E)

2. Electrical Alignment

2-1. Electrical Alignment Overview.............................................................2-1 (E)

2-1-1. Required Equipment and Tools............................................2-1 (E)

2-1-2. Connection ...........................................................................2-2 (E)

2-2. Preparation for Adjustment ...................................................................2-3 (E)

2-3. +5 V Power Voltage Adjustment..........................................................2-3 (E)

2-4. CMR (Common Mode Rejection) Adjustment .....................................2-4 (E)

2-5. VIDEO OUT Level Adjustment ...........................................................2-4 (E)

2-6. VIDEO OUT Frequency Response Adjustment ................................... 2-5 (E)

2-7. VIDEO OUT Offset Adjustment ..........................................................2-5 (E)

2-8. Vector Waveform Check.......................................................................2-6 (E)

2-9. DP & DG Check....................................................................................2-6 (E)

BKPF-L703A

3. Spare Parts

4. Semiconductor Pin Assignments

5. Block Diagram

Overall ....................................................................................................................5-1

1 (E)

Page 4

6. Schematic Diagrams

CN-1982 ................................................................................................................. 6-1

VDA-56 ..................................................................................................................6-2

7. Board Layout

VDA-56 ..................................................................................................................7-1

2 (E)

BKPF-L703A

Page 5

Purpose of this manual

Related manuals

Manual Structure

This manual is the maintenance manual of Analog Video Distribution Board BKPFL703A.

This manual is intended for use by trained system and service engineers, and

describes the information for maintenance and detailed service.

The following manuals are prepared for BKPF-L703A.

..

. Installation Manual (Supplied with BKPF-L703A)

..

This manual describes the information on installing the BKPF-L703A.

..

. “Semiconductor Pin Assignments” CD-ROM (Available on request)

..

This “Semiconductor Pin Assignments” CD-ROM allows you to search for

semiconductors used in B&P Company equipment.

Semiconductors that cannot be searched for on this CD-ROM are listed in the

service manual for the corresponding unit. The service manual contains a complete list of all semiconductors and their ID Nos., and thus should be used together

with the CD-ROM.

Part number: 9-968-546-XX

Contents

This manual is organized by following sections.

Section 1 Service Overview

This section explains the notes on repair parts and IC link replacement.

Section 2 Electrical Alignment

This section explains the adjustment after replacing part.

Section 3 Spare Parts

This section describes the spare parts.

Section 4 Semiconductor Pin Assignments

This section describes the pin assignments of semiconductor.

Section 5 Block Diagram

This section describes the overall block diagram.

Section 6 Schematic Diagrams

This section describes the schematic diagrams of the VDA-56 and CN-1982 boards.

Section 7 Board Layouts

This section describes the board layout for the VDA-56 board.

BKPF-L703A

3 (E)

Page 6

Page 7

Section 1

Service Overview

1-1. Notes on Repair Parts

1. Safety Related Components Warning

w

Components marked ! are critical to safe operation.

Therefore, specified parts should be used in the case of

replacement.

2. Standardization of Parts

Some repair parts supplied by Sony differ from those

used for the unit. These are because of parts commonality and improvement.

Parts list has the present standardized repair parts.

3. Stock of Parts

Parts marked with “o” at SP (Supply code) column of

the spare parts list may not be stocked. Therefore, the

delivery date will be delayed.

n

For the replacement of the VDA-56 board, please buy

BKPF-L703A because VDA-56 mounted circuit board is

not prepared for spare parts.

1-2. IC Link Replacement

w

An IC link is critical parts to safe operation.

Replace this component with Sony parts whose part

numbers appear in this manual published by Sony.

If not, this may cause a fire or electric shock.

Be sure to use the specified component in this manual.

The IC link is mounted on the VDA-56 board. Be sure to

replace with the specified IC link as shown below after

removing the foreign substances that may cause the shorts.

VDA-56 Board

Ref No. (Address) Description Part No.

PS301 (J-3) IC link 2 A !1-533-282-21

1-3. Unleaded Solder

Boards requiring use of unleaded solder are printed with a

lead free mark (LF) indicating the solder contains no lead.

(Caution: Some printed circuit boards may not come

printed with the lead free mark due to their particular size.)

: LEAD FREE MARK

m

. Be sure to use the unleaded solder for the printed circuit

board printed with the lead free mark.

. The unleaded solder melts at a temperature about 40 dC

higher than the ordinary solder, therefore, it is recommended to use the soldering iron having a temperature

regulator.

. The ordinary soldering iron can be used but the iron tip

has to be applied to the solder joint for a slightly longer

time. The printed pattern (copper foil) may peel away if

the heated tip is applied for too long, so be careful.

BKPF-L703A

1-1 (E)

Page 8

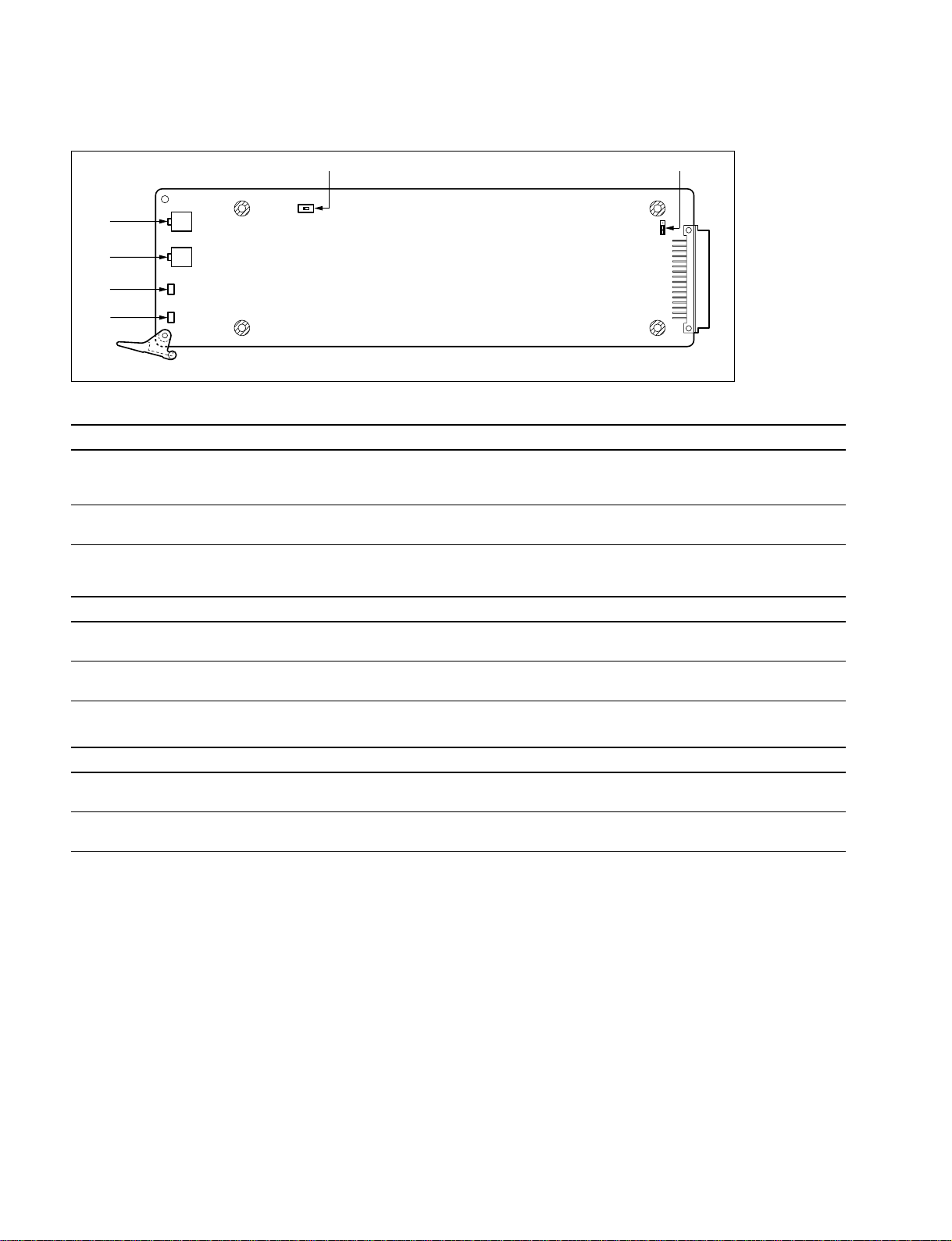

1-4. Name and Function of Switch/Indicator

1-4. Name and Function of Switch/Indicator

1

S101

5

6

3

4

RV102

RV103

D101

D302

Switches/Shorting plug (Factory default settings are indicated by a

No. Ref. No. Name Function

1 S101 CLAMP \ ON: Under normal operation

2 COR101 SINGLE/DIFFERENTIAL \ SINGLE: Under normal operation

OFFON

Main Board (VDA-56 Board: Side A)

OFF: When a signal containing no sync signal is input to the VIDEO IN

connector

DIFFERENTIAL: When a differential signal is input to the VIDEO IN connector

\\

\ mark)

\\

COR101

2

Indicators

No. Ref.No. Name Function

3 D101 VIDEO IN Lights in green: When an analog video signal is input to the VIDEO IN connector

4 D302 _5 V Lights in green: A power supply of _5 V is normal

Lights in red: When a signal is not input to the VIDEO IN connector

Lights in red: A power supply of _5 V is abnormal

Volumes

No. Ref.No. Name Function

5 RV102 EQ Corrects and adjusts the deterioration in the frequency characteristics of the video

signal input to the VIDEO IN connector

6 RV103 GAIN Corrects and adjusts the deterioration in the level of the video signal input to the

VIDEO IN connector

1-2 (E)

BKPF-L703A

Page 9

Section 2

Electrical Alignment

2-1. Electrical Alignment Overview

2-1-1. Required Equipment and Tools

Use the equipment listed below or the equivalent.

Item Model Remarks

Extension board EX-731 (Part No.A-8322-598-A) For the VDA-56 board extension

Analog video signal generator* Tektronix 1410 For 525 mode

Tektronix 1411 For 625 mode

Analog video signal generator* TSG-170A For 525 mode

TSG-271A For 625 mode

Audio signal generator* Tektronix SG505 (option 02 type)

Audio level meter*_

Oscilloscope* Tektronix 2465B

Interface unit Sony PFV-L10/L02

Composite video monitor Sony PVM-1444Q

Waveform/vector monitor* Tektronix 1780R For 525 mode

Tektronix 1781R For 625 mode

Digital voltmeter*_

Adjustment screwdriver*_ Insulation type

Resister (600 Z) _ within 1%

Terminal connector _ BNC type (Feed-through), 75 Z, 3 pcs

*: Use the equipment after calibration has been completed.

BKPF-L703A

2-1 (E)

Page 10

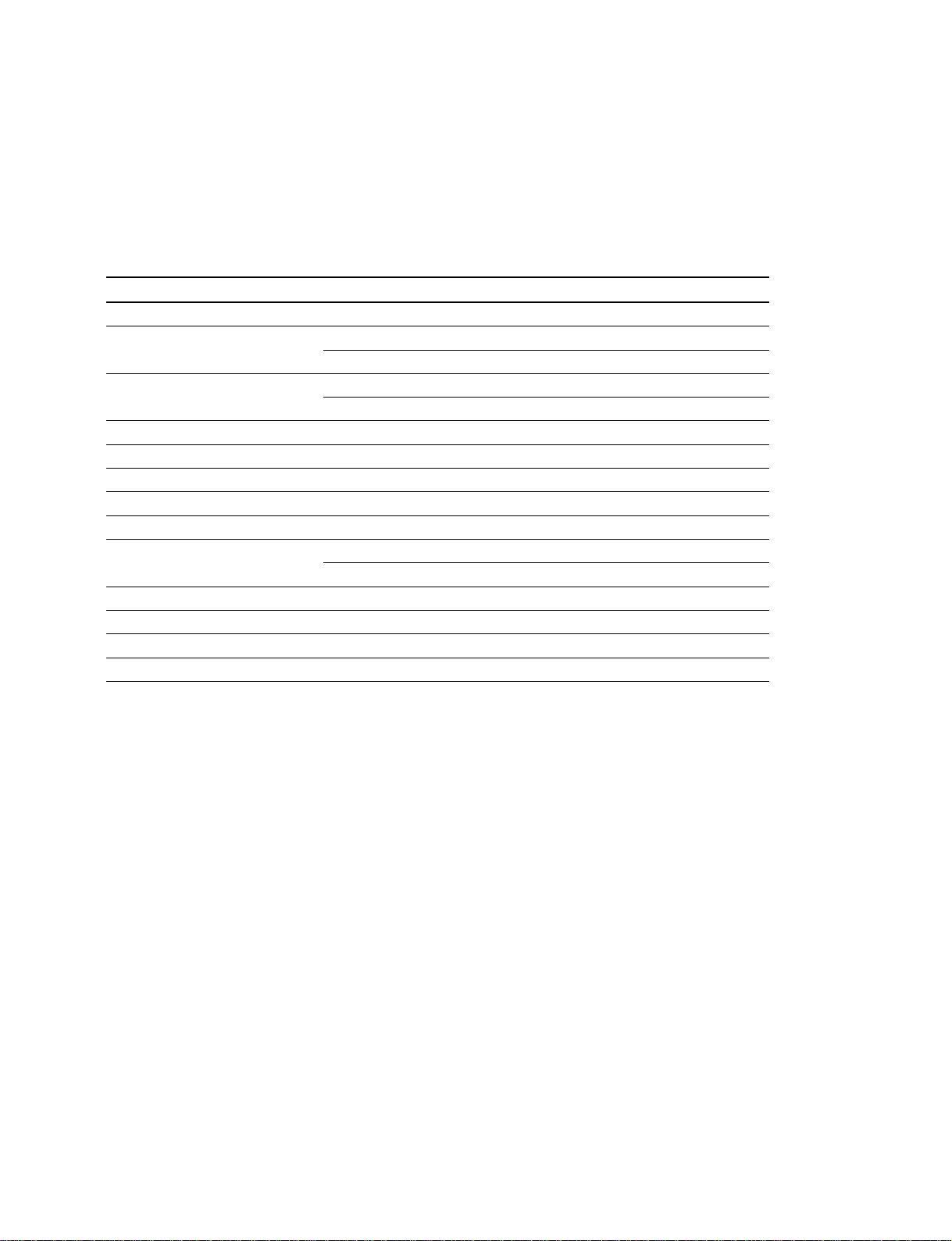

2-1. Electrical Alignment Overview

2-1-2. Connection

n

The interface unit in the connection diagram shown below uses PFV-L10.

VDA-56 board

PFV-L10 (Side)

PFV-L10 (Rear)

Extension board EX-731

Signal generator (TSG-170A/271A)

VIDEO IN

75 Z terminator

VIDEO OUT

BKPF-L703A

75 Z terminator

Waveform/vector monitor

(1780R/1781R)

Signal generator (1410/1411)

75 Z terminator

Composite video monitor

(PVM-1444Q)

Digital voltmeter

+

CH-A

_

m

. To the loop-through output connector, be sure to insert a 75 Z terminator.

. Use a cable of about 1 m in length to connect between a signal generator (TSG-170A/271A) and the

VIDEO IN connector of BKPF-L703A.

. Obtain the output signal of signal generator 1410/1411 from pin 6 of the MODULE OUTPUTS

connector on the connector panel.

Oscilloscope (2465B)

CH1

PIX OUT

When performing the CMR (Common Mode Rejection) adjustment (Section 2-4)

VDA-56 board

Audio signal generator (SG505)

OUTPUT

COM

Audio level meter

INPUT

PFV-L10 (Side)

Extension board EX-731

+

_

+

600 Z

_

PFV-L10 (Rear)

VIDEO IN

1

3

5

7

BKPF-L703A

VIDEO OUT

75 Z terminator

2

4

6

8

L703A

2-2 (E)

BKPF-L703A

Page 11

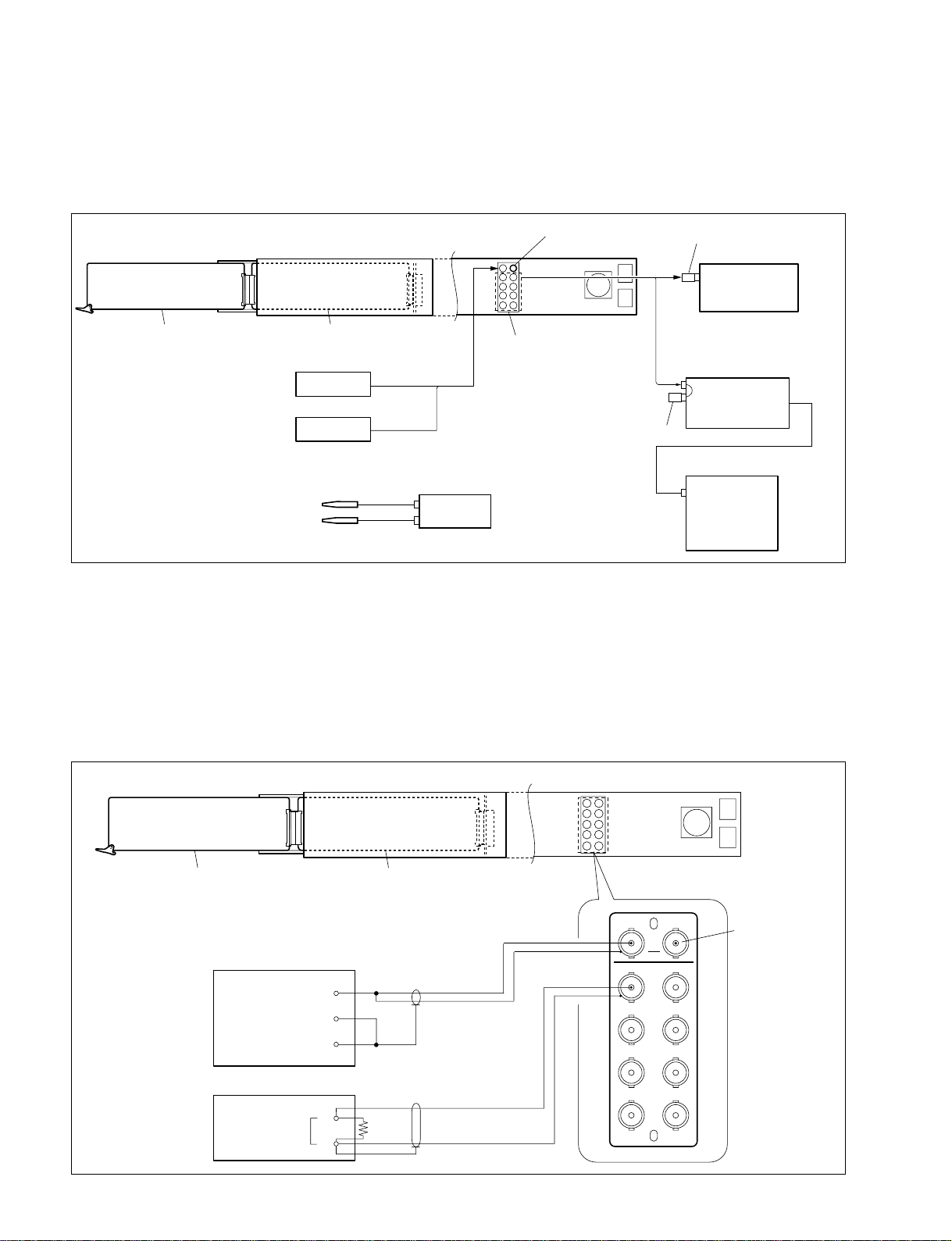

2-2. Preparation for Adjustment

2-3. +5 V Power Voltage Adjustment

2-2. Preparation for Adjustment

1. Extend the VDA-56 board with the extension board

EX-731.

2. Set the switch and variable resistors (RV) on the

VDA-56 board as shown below.

Ref.No. (Address) Initial setting

S101 (C-1) ON

RV102 (A-1) Counterclockwise 3 fully

RV103 (A-2) Counterclockwise 3 fully

3. Turn on the power of the PFV-L10/L02 and warm up

the unit for about 10 minutes.

S101

1

1

RV102

RV103

E1

OFFON

2-3.

++

+5 V Power Voltage Adjustment

++

n

Be sure to perform the “+5 V Power Voltage Adjustment”

before performing other adjustments.

Measuring equipment: Digital voltmeter

1. Set the digital voltmeter as follows:

Range: AUTO

Mode: DC V

2. Connect the probe of the digital voltmeter as follows:

+: TP301/VDA-56 (C-3)

_: E1/VDA-56 (C-1)

3. Adjust the voltage.

Adjustment point: 1RV301/VDA-56 (C-3)

Specification: 5.00 ±0.05 V dc

COR101

1

1

RV104

RV103

TP301

1

RV301

VDA-56 board (Side A)

BKPF-L703A

2-3 (E)

Page 12

2-4. CMR (Common Mode Rejection) Adjustment

2-5. VIDEO OUT Level Adjustment

2-4. CMR (Common Mode Rejection)

Adjustment

n

Perform “2-3. +5 V Power Voltage Adjustment” in

advance.

Measuring equipment: Audio level meter

1. Turn off switch S101 on the VDA-56 board and set

shorting plug COR101 to DIFFERENTIAL.

2. Connect an audio signal generator and audio level

meter to the connector of BKPF-L703A. (Refer to

Section 2-1-2.)

3. Set the output level of the audio signal generator to

+5 dBm, 60 Hz.

4. Adjust so that specification A is satisfied.

Measurement point: VIDEO OUT 1

(BKPF-L703A connector panel)

Adjustment point: 1RV104/VDA-56 (J-1)

Specification: A < _65 dBm

5. Turn on switch S101 and return shorting plug COR101

to SINGLE.

2-5. VIDEO OUT Level Adjustment

n

Perform “2-3. +5 V Power Voltage Adjustment” in

advance.

Measuring equipment: Waveform/vector monitor

1. Supply 75% color bars signal from the signal generator

(TSG-170A/271A) to the VIDEO IN connector.

2. Connect and set the waveform/vector monitor.

CH-A: VIDEO OUT 1 (BKPF-L703A connector panel)

MODE: WAVEFORM

INPUT: CH-A

REF: INT

3. Adjust 1RV103 (A-2) so that the level A satisfies the

specifications.

Adjustment point: 1RV103/VDA-56 (A-2)

Specification: 140 ±2 IRE

4. Make sure that VIDEO OUT 2 thru 8 connectors

satisfy the specification.

A

2-4 (E)

BKPF-L703A

Page 13

2-6. VIDEO OUT Frequency Response Adjustment

2-7. VIDEO OUT Offset Adjustment

2-6. VIDEO OUT Frequency Response

Adjustment

n

Perform “2-3. +5 V Power Voltage Adjustment” in

advance.

Measuring equipment: Waveform/vector monitor

1. Supply 6 MHz SWEEP signal from the signal

generator (1410/1411) to the VIDEO IN connector.

2. Connect and set the waveform/vector monitor.

CH-A: VIDEO OUT 1 (BKPF-L703A connector panel)

MODE: WAVEFORM

INPUT: CH-A

3. Adjust an amplitude of 1 to 5 MHz with an amplitude

of 500 kHz as the reference (100%).

Adjustment point: 1RV102/VDA-56 (A-1)

Specification: A = 0 ±3.5% (0 ±0.3 dB)

4. Make sure that the output signal in the VIDEO OUT 2

thru 8 connectors satisfy the specifications.

2-7. VIDEO OUT Offset Adjustment

n

Perform “2-3. +5 V Power Voltage Adjustment” in

advance.

Measuring equipment: Oscilloscope

1. Supply 75% color bars signal from the signal generator

(TSG-170A/271A) to the VIDEO IN connector.

2. Connect and set the waveform/vector monitor.

CH1: VIDE O O U T 1 (BKPF-L703A connector panel)

CH1: 10 mV/DIV DC

TIME: 20 us/DIV

TRIG: CH1

3. Adjust 1RV101 (G-1) so that the level A satisfies the

specifications.

Adjustment point: 1RV101/VDA-56 (G-1)

Specification: The pedestal level is 0 ±20 mV DC.

4. Make sure that the output signal in the VIDEO OUT 2

thru 8 connectors satisfy the specifications.

500 k (Reference)

A

1 M 2 M 3 M 4 M 5 M

A

Pedestal level

A

GND

DC 0 V

BKPF-L703A

2-5 (E)

Page 14

2-8. Vector Waveform Check

2-9. DP & DG

*

Check

2-8. Vector Waveform Check

2-9. DP & DG

**

*

**

Check

n

Perform “2-3. +5 V Power Voltage Adjustment” in

advance.

Measuring equipment: Waveform/vector monitor

1. Supply 75% color bars signal from the signal generator

(TSG-170A/271A) to the VIDEO IN connector.

2. Connect and set the waveform/vector monitor.

CH-A: VIDEO OUT 1 (BKPF-L703A connector panel)

MODE: VECTOR

INPUT: CH-A

3. Confirm that each luminance point is located in “4”

when the burst level is adjusted to the reference.

4. Make sure that the output signal in the VIDEO OUT 2

thru 8 connectors satisfy the specifications.

R

M

G

Y

L

B

n

Perform “2-3. +5 V Power Voltage Adjustment” in

advance.

Measuring equipment: Waveform/vector monitor

1. Supply ramp signal (with chroma) from the signal

generator (TSG-170A/271A) to the VIDEO IN

connector.

2. Connect and set the waveform/vector monitor.

CH-A: VIDEO OUT 1 (BKPF-L703A connector panel)

MODE: VECTOR

DP & DG measuring

INPUT: CH-A

m

To change to the DP & DG measuring display, push

the measure button and touch DP & DG item on the

display (the display is a touch panel).

3. Confirm that the specification below is satisfied.

Specification: DP < 0.5d

DG < 0.5%

4. Make sure that the output signal in the VIDEO OUT 2

thru 8 connectors satisfy the specifications.

G

Cr

DP

DG

* DP: Differential Phase

DG: Differential Gain

2-6 (E)

BKPF-L703A

Page 15

------------CN-1982 BOARD

------------ Ref. No.

or Q'ty Part No. SP Description

Section 3

Spare Parts

-----------------------VDA-56 BOARD ;Suffix -12

----------------------- Ref. No.

or Q'ty Part No. SP Description

1pc A-8327-449-A o MOUNTED CIRCUIT BOARD, CN-1982

1pc 1-680-193-11 o PRINTED WIRING BOARD, CN-1983

5pcs 7-621-775-10 s SCREW +B2.6X4

CN1+CN2 1-793-325-11 s CONNECTOR, COAXIAL (BNC TYPE)

CN3+CN4 1-793-325-11 s CONNECTOR, COAXIAL (BNC TYPE)

CN5+CN6 1-793-325-11 s CONNECTOR, COAXIAL (BNC TYPE)

CN7+CN8 1-793-325-11 s CONNECTOR, COAXIAL (BNC TYPE)

CN9+CN10 1-793-325-11 s CONNECTOR, COAXIAL (BNC TYPE)

1pc 1-562-579-11 s RESEPTACLE,CONNECTOR

1pc 3-179-084-01 s LEVER(R),PRINTED C,BOARD

2pcs 7-685-547-14 s SCREW +BTP 3X10(EP-FE/CU,NI,CR

C101 1-164-346-11 s CAPACITOR CHIP CERAMIC 1MF/16V

C102 1-163-239-11 s CAPACITOR,CHIP CERAMIC33PF/50V

C103 1-115-153-11 s CAPACITOR,ELECT 4.7MF/16V(BP)

C104 1-163-038-91 s CAPACITOR,CHIP CERAMIC 0.1MF

C105 1-163-038-91 s CAPACITOR,CHIP CERAMIC 0.1MF

C106 1-164-346-11 s CAPACITOR CHIP CERAMIC 1MF/16V

C107 1-163-243-11 s CAPACITOR CHIP CERAMIC 47PF/50

C108 1-126-391-11 s CAPACITOR ELECT 47MF/6.3V(105)

C109 1-163-038-91 s CAPACITOR,CHIP CERAMIC 0.1MF

C110 1-163-251-11 s CAPACITOR CERAMIC 100PF/50V

C111 1-163-224-11 s CAPACITOR,CHIP CERAMIC 7PF(M-)

C112 1-163-038-91 s CAPACITOR,CHIP CERAMIC 0.1MF

C113 1-163-038-91 s CAPACITOR,CHIP CERAMIC 0.1MF

C114 1-163-243-11 s CAPACITOR CHIP CERAMIC 47PF/50

C115 1-163-239-11 s CAPACITOR,CHIP CERAMIC33PF/50V

C116 1-126-391-11 s CAPACITOR ELECT 47MF/6.3V(105)

C117 1-126-391-11 s CAPACITOR ELECT 47MF/6.3V(105)

C118 1-163-275-11 s CAPACITOR CERAMIC 1000PF/50V

C119 1-163-233-91 s CAPACITOR,CHIP CERAMIC 18PF/50

C120 1-163-239-11 s CAPACITOR,CHIP CERAMIC33PF/50V

C121 1-163-245-11 s CAPACITOR CERAMIC 56PF/50V

C122 1-163-249-11 s CAPACITOR CERAMIC 82PF/50V

C123 1-163-257-11 s CAPACITOR CERAMIC 180PF/50V

C124 1-163-038-91 s CAPACITOR,CHIP CERAMIC 0.1MF

C125 1-163-038-91 s CAPACITOR,CHIP CERAMIC 0.1MF

C126 1-163-038-91 s CAPACITOR,CHIP CERAMIC 0.1MF

C127 1-163-038-91 s CAPACITOR,CHIP CERAMIC 0.1MF

C128 1-126-391-11 s CAPACITOR ELECT 47MF/6.3V(105)

C129 1-126-391-11 s CAPACITOR ELECT 47MF/6.3V(105)

C130 1-163-222-11 s CAPACITOR. CHIP CERAMIC 5.0PF

C131 1-163-220-11 s CAPACITOR, CHIP CERAMIC 3.0PF

C132 1-163-038-91 s CAPACITOR,CHIP CERAMIC 0.1MF

C133 1-126-391-11 s CAPACITOR ELECT 47MF/6.3V(105)

C134 1-163-220-11 s CAPACITOR, CHIP CERAMIC 3.0PF

C135 1-126-391-11 s CAPACITOR ELECT 47MF/6.3V(105)

C136 1-163-038-91 s CAPACITOR,CHIP CERAMIC 0.1MF

C137 1-163-038-91 s CAPACITOR,CHIP CERAMIC 0.1MF

C138 1-163-038-91 s CAPACITOR,CHIP CERAMIC 0.1MF

C139 1-163-038-91 s CAPACITOR,CHIP CERAMIC 0.1MF

C140 1-126-392-11 s CAPACITOR,CHIP ELECT100MF/6.3V

C141 1-126-392-11 s CAPACITOR,CHIP ELECT100MF/6.3V

C142 1-163-038-91 s CAPACITOR,CHIP CERAMIC 0.1MF

C143 1-163-038-91 s CAPACITOR,CHIP CERAMIC 0.1MF

C144 1-126-392-11 s CAPACITOR,CHIP ELECT100MF/6.3V

C145 1-126-392-11 s CAPACITOR,CHIP ELECT100MF/6.3V

C146 1-163-227-11 s CAPACITOR CERAMIC 10PF/50V(CH)

C147 1-163-227-11 s CAPACITOR CERAMIC 10PF/50V(CH)

C148 1-163-227-11 s CAPACITOR CERAMIC 10PF/50V(CH)

C149 1-163-227-11 s CAPACITOR CERAMIC 10PF/50V(CH)

C150 1-163-227-11 s CAPACITOR CERAMIC 10PF/50V(CH)

C151 1-163-227-11 s CAPACITOR CERAMIC 10PF/50V(CH)

C152 1-163-227-11 s CAPACITOR CERAMIC 10PF/50V(CH)

C153 1-163-227-11 s CAPACITOR CERAMIC 10PF/50V(CH)

C154 1-163-038-91 s CAPACITOR,CHIP CERAMIC 0.1MF

C155 1-126-396-11 s CAPACITOR,ELECT 47MF/16V(CHIP)

BKPF-L703A

3-1

Page 16

(VDA-56 BOARD ;Suffix -12)

(VDA-56 BOARD ;Suffix -12)

Ref. No.

or Q'ty Part No. SP Description

C156 1-126-396-11 s CAPACITOR,ELECT 47MF/16V(CHIP)

C157 1-126-396-11 s CAPACITOR,ELECT 47MF/16V(CHIP)

C158 1-126-396-11 s CAPACITOR,ELECT 47MF/16V(CHIP)

C159 1-164-004-11 s CAPACITOR,CERAMIC 0.1MF/25V

C160 1-164-004-11 s CAPACITOR,CERAMIC 0.1MF/25V

C161 1-164-004-11 s CAPACITOR,CERAMIC 0.1MF/25V

C162 1-164-004-11 s CAPACITOR,CERAMIC 0.1MF/25V

C163 1-164-004-11 s CAPACITOR,CERAMIC 0.1MF/25V

C301 1-128-400-11 s CAPACITOR, ELECT 47MF/25V

C302 1-109-892-11 s CAPACITOR ERECT 47MF/25V(105C)

C303 1-163-038-91 s CAPACITOR,CHIP CERAMIC 0.1MF

Ref. No.

or Q'ty Part No. SP Description

L101 1-410-802-11 s CHIP INDUCTOR 0.039UH (3225)

L102 1-410-389-31 s INDUCTOR,CHIP 47UH (3225)

L103 1-410-658-31 s INDUCTOR,CHIP 220UH (3225)

L301 1-424-643-11 s COIL, CHOKE 10UH

L302 1-424-643-11 s COIL, CHOKE 10UH

L303 1-424-643-11 s COIL, CHOKE 10UH

L304 1-410-381-11 s INDUCTOR,CHIP 10UH (3225)

L305 1-410-381-11 s INDUCTOR,CHIP 10UH (3225)

L306 1-410-381-11 s INDUCTOR,CHIP 10UH (3225)

L307 1-410-381-11 s INDUCTOR,CHIP 10UH (3225)

PS301 ! 1-533-282-21 s CIRCUIT PROTECTOR 2A (3225)

C304 1-163-038-91 s CAPACITOR,CHIP CERAMIC 0.1MF

C305 1-126-392-11 s CAPACITOR,CHIP ELECT100MF/6.3V

C306 1-126-392-11 s CAPACITOR,CHIP ELECT100MF/6.3V

C307 1-163-038-91 s CAPACITOR,CHIP CERAMIC 0.1MF

Q101 8-729-120-28 s TRANSISTOR 2SC1623-L5L6

Q102 8-729-928-36 s TRANSISTOR DTA114EE

Q103 8-729-112-48 s TRANSISTOR 2SA1462-T1Y33

Q104 8-729-105-68 s TRANSISTOR 2SC3356-K

C308 1-128-391-11 s CAPACITOR,ELECT 330MF/6.3V

Q105 8-729-120-28 s TRANSISTOR 2SC1623-L5L6

C309 1-163-038-91 s CAPACITOR,CHIP CERAMIC 0.1MF

C310 1-126-396-11 s CAPACITOR,ELECT 47MF/16V(CHIP)

C313 1-163-038-91 s CAPACITOR,CHIP CERAMIC 0.1MF

C314 1-100-118-21 s CAPACITOR,ELECT 82MF 16V (8X7)

Q106 8-729-105-68 s TRANSISTOR 2SC3356-K

Q107 8-729-112-48 s TRANSISTOR 2SA1462-T1Y33

Q108 8-729-105-68 s TRANSISTOR 2SC3356-K

Q109 8-729-112-48 s TRANSISTOR 2SA1462-T1Y33

C315 1-100-118-21 s CAPACITOR,ELECT 82MF 16V (8X7)

Q301 8-729-928-90 s TRANSISTOR DTC114EE

C316 1-100-118-21 s CAPACITOR,ELECT 82MF 16V (8X7)

C317 1-100-118-21 s CAPACITOR,ELECT 82MF 16V (8X7)

C318 1-164-506-11 s CAPACITOR,CERAMIC 4.7MF/16V

Q302 8-729-120-28 s TRANSISTOR 2SC1623-L5L6

Q303 8-729-928-36 s TRANSISTOR DTA114EE

C319 1-164-506-11 s CAPACITOR,CERAMIC 4.7MF/16V

R101 1-208-782-11 s RESISTOR,CHIP 1K 1/10W (2012)

C320 1-164-506-11 s CAPACITOR,CERAMIC 4.7MF/16V

C321 1-164-506-11 s CAPACITOR,CERAMIC 4.7MF/16V

R102 1-208-782-11 s RESISTOR,CHIP 1K 1/10W (2012)

R103 1-208-790-11 s RESISTOR,CHIP 2.2K 1/10W(2012)

R104 1-211-960-11 s RESISTOR,CHIP 22 1/10W (2012)

CN101 1-506-746-11 s PIN,DIN CONNECTOR (DIP) 48P

R105 1-211-960-11 s RESISTOR,CHIP 22 1/10W (2012)

COR101 1-564-948-11 o PIN,CONNECTOR 3P

R106 1-208-822-11 s RESISTOR,CHIP 47K 1/10W (2012)

R107 1-208-782-11 s RESISTOR,CHIP 1K 1/10W (2012)

CT101 1-141-423-61 s TRIMMER CAPACITOR 20PF (CHIP)

CT102 1-141-422-11 s CAPACITOR TRIMER 10PF (CHIP)

R108 1-208-850-11 s RESISTOR,CHIP 680K 1/10W(2012)

R109 1-208-814-11 s RESISTOR,CHIP 22K 1/10W (2012)

R110 1-211-960-11 s RESISTOR,CHIP 22 1/10W (2012)

D101 8-719-027-84 s LED CL-155UR/G-D

D102 8-719-104-34 s DIODE 1S2836

D103 8-719-159-06 s DIODE RD4.7SB-T2

D104 8-719-159-06 s DIODE RD4.7SB-T2

D105 8-719-800-76 s DIODE 1SS226

R111 1-208-782-11 s RESISTOR,CHIP 1K 1/10W (2012)

R112 1-216-639-11 s RESISTOR,CHIP 330 1/10W (2012)

R113 1-208-784-11 s RESISTOR,CHIP 1.2K 1/10W(2012)

R114 1-216-646-11 s RESISTOR,CHIP 620 1/10W (2012)

R115 1-216-675-11 s RESISTOR,CHIP 10K 1/10W(2012)

D301 8-719-036-94 s DIODE RD5.6SB-T1

D302 8-719-027-84 s LED CL-155UR/G-D

D303 8-719-048-98 s DIODE RB160L-40TE25

R116 1-216-295-91 s CONDUCTOR, CHIP (2012)

R117 1-211-960-11 s RESISTOR,CHIP 22 1/10W (2012)

R118 1-216-639-11 s RESISTOR,CHIP 330 1/10W (2012)

DD301 1-475-610-11 s CONVERTER UNIT, DC-DC

R119 1-208-774-11 s RESISTOR,CHIP 470 1/10W (2012)

R120 1-218-760-11 s RESISTOR,CHIP 220K 1/10W(2012)

E1 1-535-877-22 s CHIP,CHECKER (TEST POINT)

E2 1-535-877-22 s CHIP,CHECKER (TEST POINT)

E3 1-535-877-22 s CHIP,CHECKER (TEST POINT)

R121 1-216-603-11 s RESISTOR,CHIP 10 1/10W(2012)

R122 1-208-800-11 s RESISTOR,CHIP 5.6K 1/10W(2012)

R123 1-208-750-11 s RESISTOR,CHIP 47 1/10W (2012)

IC101 8-752-052-82 s IC CXA1432M

IC102 8-759-239-55 s IC TC74HC123AF

R124 1-216-623-11 s RESISTOR,CHIP 68 1/10W(2012)

R125 1-216-649-11 s RESISTOR,CHIP 820 1/10W (2012)

IC105 6-704-406-01 s IC LM1881MX/NOPB

IC106 8-759-271-04 s IC LT1252CS8

IC107 8-759-271-04 s IC LT1252CS8

R126 1-208-793-11 s RESISTOR,CHIP 3K 1/10W (2125)

R127 1-208-801-11 s RESISTOR,CHIP 6.2K 1/10W(2012)

R128 1-208-822-11 s RESISTOR,CHIP 47K 1/10W (2012)

IC108 8-759-271-04 s IC LT1252CS8

IC109 8-759-035-87 s IC SC7S00F

R129 1-208-758-11 s RESISTOR,CHIP 100 1/10W (2012)

R130 1-216-622-11 s RESISTOR,CHIP 62 1/10W (2012)

IC110 8-759-271-04 s IC LT1252CS8

IC111 8-759-271-04 s IC LT1252CS8

IC301 8-759-492-38 s IC LM2941CSX

R131 1-208-782-11 s RESISTOR,CHIP 1K 1/10W (2012)

R132 1-216-633-11 s RESISTOR,CHIP 180 1/10W (2012)

R133 1-216-295-91 s CONDUCTOR, CHIP (2012)

IC303 8-759-579-74 s IC LM2665M6X

IC304 8-749-014-79 s IC LM2664M6X

R134 1-211-960-11 s RESISTOR,CHIP 22 1/10W (2012)

R135 1-216-646-11 s RESISTOR,CHIP 620 1/10W (2012)

3-2

BKPF-L703A

Page 17

(VDA-56 BOARD ;Suffix -12)

(VDA-56 BOARD ;Suffix -12)

Ref. No.

or Q'ty Part No. SP Description

R136 1-216-635-11 s RESISTOR,CHIP 220 1/10W (2012)

R137 1-216-639-11 s RESISTOR,CHIP 330 1/10W (2012)

R138 1-208-814-11 s RESISTOR,CHIP 22K 1/10W (2012)

R139 1-208-782-11 s RESISTOR,CHIP 1K 1/10W (2012)

R140 1-216-641-11 s RESISTOR,CHIP 390 1/10W(2012)

R141 1-216-646-11 s RESISTOR,CHIP 620 1/10W (2012)

Ref. No.

or Q'ty Part No. SP Description

RV101 1-237-039-11 s RESISTOR,ADJ,CERMET 100K

RV102 1-230-746-21 s RESISTOR, ADJ, CERMET 500

RV103 1-230-744-11 s RESISTOR,ADJ,CERMET 100

RV104 1-237-029-11 s RESISTOR,ADJ,CERMET 50

RV301 1-237-031-11 s RESISTOR,ADJ,CERMET 200

S101 1-771-709-31 s SWITCH, SLIDE

R142 1-208-758-11 s RESISTOR,CHIP 100 1/10W (2012)

R143 1-216-295-91 s CONDUCTOR, CHIP (2012)

R144 1-211-960-11 s RESISTOR,CHIP 22 1/10W (2012)

R145 1-208-814-11 s RESISTOR,CHIP 22K 1/10W (2012)

TP101 1-535-877-22 s CHIP,CHECKER (TEST POINT)

TP104 1-535-877-22 s CHIP,CHECKER (TEST POINT)

TP105 1-535-877-22 s CHIP,CHECKER (TEST POINT)

TP301 1-535-877-22 s CHIP,CHECKER (TEST POINT)

R146 1-208-758-11 s RESISTOR,CHIP 100 1/10W (2012)

TP303 1-535-877-22 s CHIP,CHECKER (TEST POINT)

R147 1-208-758-11 s RESISTOR,CHIP 100 1/10W (2012)

R148 1-208-782-11 s RESISTOR,CHIP 1K 1/10W (2012)

R149 1-208-782-11 s RESISTOR,CHIP 1K 1/10W (2012)

R150 1-208-822-11 s RESISTOR,CHIP 47K 1/10W (2012)

R151 1-211-960-11 s RESISTOR,CHIP 22 1/10W (2012)

R152 1-211-960-11 s RESISTOR,CHIP 22 1/10W (2012)

R153 1-216-603-11 s RESISTOR,CHIP 10 1/10W(2012)

R154 1-216-298-00 s RESISTOR,CHIP 2.2 1/10(2012)

R155 1-216-298-00 s RESISTOR,CHIP 2.2 1/10(2012)

R156 1-216-603-11 s RESISTOR,CHIP 10 1/10W(2012)

R157 1-211-960-11 s RESISTOR,CHIP 22 1/10W (2012)

R158 1-211-960-11 s RESISTOR,CHIP 22 1/10W (2012)

R159 1-216-603-11 s RESISTOR,CHIP 10 1/10W(2012)

R160 1-216-603-11 s RESISTOR,CHIP 10 1/10W(2012)

R161 1-208-755-11 s RESISTOR,CHIP 75 1/10W (2012)

R162 1-208-755-11 s RESISTOR,CHIP 75 1/10W (2012)

R163 1-208-755-11 s RESISTOR,CHIP 75 1/10W (2012)

R164 1-208-755-11 s RESISTOR,CHIP 75 1/10W (2012)

R165 1-208-755-11 s RESISTOR,CHIP 75 1/10W (2012)

R166 1-208-755-11 s RESISTOR,CHIP 75 1/10W (2012)

R167 1-208-755-11 s RESISTOR,CHIP 75 1/10W (2012)

R168 1-208-755-11 s RESISTOR,CHIP 75 1/10W (2012)

R169 1-216-298-00 s RESISTOR,CHIP 2.2 1/10(2012)

R170 1-216-298-00 s RESISTOR,CHIP 2.2 1/10(2012)

R171 1-216-308-00 s RESISTOR,CHIP 4.7 1/10W(2012)

R172 1-216-308-00 s RESISTOR,CHIP 4.7 1/10W(2012)

R173 1-216-308-00 s RESISTOR,CHIP 4.7 1/10W(2012)

R174 1-216-308-00 s RESISTOR,CHIP 4.7 1/10W(2012)

R175 1-208-782-11 s RESISTOR,CHIP 1K 1/10W (2012)

R176 1-208-782-11 s RESISTOR,CHIP 1K 1/10W (2012)

R177 1-208-782-11 s RESISTOR,CHIP 1K 1/10W (2012)

R178 1-208-782-11 s RESISTOR,CHIP 1K 1/10W (2012)

R179 1-216-607-11 s RESISTOR,CHIP 15 1/10W(2012)

R180 1-208-830-11 s RESISTOR,CHIP 100K 1/10W(2012)

R181 1-216-675-11 s RESISTOR,CHIP 10K 1/10W(2012)

R182 1-208-782-11 s RESISTOR,CHIP 1K 1/10W (2012)

R183 1-208-782-11 s RESISTOR,CHIP 1K 1/10W (2012)

R184 1-208-782-11 s RESISTOR,CHIP 1K 1/10W (2012)

R185 1-208-818-11 s RESISTOR,CHIP 33K 1/10W (2012)

R301 1-208-782-11 s RESISTOR,CHIP 1K 1/10W (2012)

R302 1-208-790-11 s RESISTOR,CHIP 2.2K 1/10W(2012)

R303 1-208-778-11 s RESISTOR,CHIP 680 1/10W (2012)

R304 1-216-675-11 s RESISTOR,CHIP 10K 1/10W(2012)

R306 1-216-681-11 s RESISTOR,CHIP 18K 1/10W (2012)

R307 1-208-782-11 s RESISTOR,CHIP 1K 1/10W (2012)

R308 1-208-782-11 s RESISTOR,CHIP 1K 1/10W (2012)

R309 1-208-782-11 s RESISTOR,CHIP 1K 1/10W (2012)

R310 1-216-639-11 s RESISTOR,CHIP 330 1/10W (2012)

BKPF-L703A

3-3

Page 18

-----------------------VDA-56 BOARD ;Suffix -11

(VDA-56 BOARD ;Suffix -11)

----------------------- Ref. No.

*a:[Lot No. 0A3-223]

or Q'ty Part No. SP Description

*b:[Lot No. 224-]

C153 1-163-227-11 s CAPACITOR CERAMIC 10PF/50V(CH)

Ref. No.

or Q'ty Part No. SP Description

C154 1-163-038-00 s CAPACITOR, CERAMIC 0.1MF/25V

C155 1-126-396-11 s CAPACITOR,ELECT 47MF/16V(CHIP)

C156 1-126-396-11 s CAPACITOR,ELECT 47MF/16V(CHIP)

1pc 1-562-579-11 s RESEPTACLE,CONNECTOR

C157 1-126-396-11 s CAPACITOR,ELECT 47MF/16V(CHIP)

1pc 3-179-085-01 s LEVER(L),PRINTED C.BOARD

2pcs 7-685-547-14 s SCREW +BTP 3X10

C158 1-126-396-11 s CAPACITOR,ELECT 47MF/16V(CHIP)

C159 1-164-004-11 s CAPACITOR,CERAMIC 0.1MF/25V

C101 1-164-346-11 s CAPACITOR CHIP CERAMIC 1MF/16V

C102 1-163-239-11 s CAPACITOR,CHIP CERAMIC33PF/50V

C103 1-115-153-11 s CAPACITOR,ELECT 4.7MF/16V(BP)

C160 1-164-004-11 s CAPACITOR,CERAMIC 0.1MF/25V

C161 1-164-004-11 s CAPACITOR,CERAMIC 0.1MF/25V

C162 1-164-004-11 s CAPACITOR,CERAMIC 0.1MF/25V

C104 1-163-038-00 s CAPACITOR, CERAMIC 0.1MF/25V

C105 1-163-038-00 s CAPACITOR, CERAMIC 0.1MF/25V

C163 1-164-004-11 s CAPACITOR,CERAMIC 0.1MF/25V

C301 1-128-400-11 s CAPACITOR, ELECT 47MF/25V

C106 1-164-346-11 s CAPACITOR CHIP CERAMIC 1MF/16V

C107 1-163-243-11 s CAPACITOR CHIP CERAMIC 47PF/50

C108 1-126-391-11 s CAPACITOR ELECT 47MF/6.3V(105)

C302 1-109-892-11 s CAPACITOR ERECT 47MF/25V(105C)

C303 1-163-038-00 s CAPACITOR, CERAMIC 0.1MF/25V

C304 1-163-038-00 s CAPACITOR, CERAMIC 0.1MF/25V

C109 1-163-038-00 s CAPACITOR, CERAMIC 0.1MF/25V

C110 1-163-251-11 s CAPACITOR CERAMIC 100PF/50V

C305 1-126-392-11 s CAPACITOR,CHIP ELECT100MF/6.3V

C306 1-126-392-11 s CAPACITOR,CHIP ELECT100MF/6.3V

C111 1-163-224-11 s CAPACITOR,CHIP CERAMIC 7PF(M-)

C112 1-163-038-00 s CAPACITOR, CERAMIC 0.1MF/25V

C113 1-163-038-00 s CAPACITOR, CERAMIC 0.1MF/25V

C307 1-163-038-00 s CAPACITOR, CERAMIC 0.1MF/25V

C308 1-128-391-11 s CAPACITOR,ELECT 330MF/6.3V

C309 1-163-038-00 s CAPACITOR, CERAMIC 0.1MF/25V

C114 1-163-243-11 s CAPACITOR CHIP CERAMIC 47PF/50

C115 1-163-239-11 s CAPACITOR,CHIP CERAMIC33PF/50V

C310 1-126-396-11 s CAPACITOR,ELECT 47MF/16V(CHIP)

C313 1-163-038-00 s CAPACITOR, CERAMIC 0.1MF/25V

C116 1-126-391-11 s CAPACITOR ELECT 47MF/6.3V(105)

C117 1-126-391-11 s CAPACITOR ELECT 47MF/6.3V(105)

C118 1-163-275-11 s CAPACITOR CERAMIC 1000PF/50V

C314 1-127-518-11 s CAPACITOR,ELECT 100MF/16V

C315 1-127-518-11 s CAPACITOR,ELECT 100MF/16V

C316 1-127-518-11 s CAPACITOR,ELECT 100MF/16V

C119 1-163-233-11 s CAPACITOR,CHIP CERAMIC 18PF/50

C120 1-163-239-11 s CAPACITOR,CHIP CERAMIC33PF/50V

C317 1-127-518-11 s CAPACITOR,ELECT 100MF/16V

C318 1-164-506-11 s CAPACITOR,CERAMIC 4.7MF/16V

C121 1-163-245-11 s CAPACITOR CERAMIC 56PF/50V

C122 1-163-249-11 s CAPACITOR CERAMIC 82PF/50V

C123 1-163-257-11 s CAPACITOR CERAMIC 180PF/50V

C319 1-164-506-11 s CAPACITOR,CERAMIC 4.7MF/16V

C320 1-164-506-11 s CAPACITOR,CERAMIC 4.7MF/16V

C321 1-164-506-11 s CAPACITOR,CERAMIC 4.7MF/16V

C124 1-163-038-00 s CAPACITOR, CERAMIC 0.1MF/25V

C125 1-163-038-00 s CAPACITOR, CERAMIC 0.1MF/25V

CN101 1-506-746-11 s PIN,DIN CONNECTOR (DIP) 48P

C126 1-163-038-00 s CAPACITOR, CERAMIC 0.1MF/25V

COR101 1-564-948-11 o PIN,CONNECTOR 3P

C127 1-163-038-00 s CAPACITOR, CERAMIC 0.1MF/25V

C128 1-126-391-11 s CAPACITOR ELECT 47MF/6.3V(105)

C129 1-126-391-11 s CAPACITOR ELECT 47MF/6.3V(105)

CT101 1-141-423-61 s TRIMMER CAPACITOR 20PF (CHIP)

CT102 1-141-422-11 s CAPACITOR TRIMER 10PF (CHIP)

C130 1-163-222-11 s CAPACITOR. CHIP CERAMIC 5.0PF

D101 8-719-027-84 s LED CL-155VR/G-D

C131 1-163-220-11 s CAPACITOR, CHIP CERAMIC 3.0PF

C132 1-163-038-00 s CAPACITOR, CERAMIC 0.1MF/25V

C133 1-126-391-11 s CAPACITOR ELECT 47MF/6.3V(105)

C134 1-163-220-11 s CAPACITOR, CHIP CERAMIC 3.0PF

D102 8-719-104-34 s DIODE 1S2836

D103 8-719-159-06 s DIODE RD4.7SB-T2

D104 8-719-159-06 s DIODE RD4.7SB-T2

D105 8-719-800-76 s DIODE 1SS226

C135 1-126-391-11 s CAPACITOR ELECT 47MF/6.3V(105)

D301 8-719-158-15 s DIODE RD5.6SB

C136 1-163-038-00 s CAPACITOR, CERAMIC 0.1MF/25V

C137 1-163-038-00 s CAPACITOR, CERAMIC 0.1MF/25V

D302 8-719-027-84 s LED CL-155VR/G-D

D303 8-719-048-98 s DIODE RB160L-40TE25

C138 1-163-038-00 s CAPACITOR, CERAMIC 0.1MF/25V

C139 1-163-038-00 s CAPACITOR, CERAMIC 0.1MF/25V

DD301 1-475-610-11 s CONVERTER UNIT, DC-DC

C140 1-126-392-11 s CAPACITOR,CHIP ELECT100MF/6.3V

IC101 8-752-052-82 s IC CXA1432M

C141 1-126-392-11 s CAPACITOR,CHIP ELECT100MF/6.3V

C142 1-163-038-00 s CAPACITOR, CERAMIC 0.1MF/25V

C143 1-163-038-00 s CAPACITOR, CERAMIC 0.1MF/25V

C144 1-126-392-11 s CAPACITOR,CHIP ELECT100MF/6.3V

IC102 8-759-239-55 s IC TC74HC123AF

IC105 8-759-987-27 s IC LM1881M

IC106 8-759-271-04 s IC LT1252CS8

IC107 8-759-271-04 s IC LT1252CS8

C145 1-126-392-11 s CAPACITOR,CHIP ELECT100MF/6.3V

IC108 8-759-271-04 s IC LT1252CS8

C146 1-163-227-11 s CAPACITOR CERAMIC 10PF/50V(CH)

C147 1-163-227-11 s CAPACITOR CERAMIC 10PF/50V(CH)

C148 1-163-227-11 s CAPACITOR CERAMIC 10PF/50V(CH)

C149 1-163-227-11 s CAPACITOR CERAMIC 10PF/50V(CH)

IC109 8-759-035-87 s IC SC7S00F

IC110 8-759-271-04 s IC LT1252CS8

IC111 8-759-271-04 s IC LT1252CS8

IC301 8-759-492-38 s IC LM2941CSX

C150 1-163-227-11 s CAPACITOR CERAMIC 10PF/50V(CH)

IC303 8-759-579-74 s IC LM2665M6X

C151 1-163-227-11 s CAPACITOR CERAMIC 10PF/50V(CH)

IC304 8-749-014-79 s IC LM2664M6X

C152 1-163-227-11 s CAPACITOR CERAMIC 10PF/50V(CH)

3-4

BKPF-L703A

Page 19

(VDA-56 BOARD ;Suffix -11)

(VDA-56 BOARD ;Suffix -11)

Ref. No.

or Q'ty Part No. SP Description

L101 1-410-802-11 s CHIP INDUCTOR 0.039UH (3225)

L102 1-410-389-31 s INDUCTOR,CHIP 47UH (3225)

L103 1-410-658-31 s INDUCTOR,CHIP 220UH (3225)

L301 1-424-643-11 s COIL, CHOKE 10UH

L302 1-424-643-11 s COIL, CHOKE 10UH

L303 1-424-643-11 s COIL, CHOKE 10UH

L304 1-410-381-11 s INDUCTOR,CHIP 10UH (3225)

L305 1-410-381-11 s INDUCTOR,CHIP 10UH (3225)

L306 1-410-381-11 s INDUCTOR,CHIP 10UH (3225)

L307 1-410-381-11 s INDUCTOR,CHIP 10UH (3225)

PS301 ! 1-533-282-21 s CIRCUIT PROTECTOR 2A (3225)

Ref. No.

or Q'ty Part No. SP Description

R136 1-216-635-11 s RESISTOR,CHIP 220 1/10W (2012)

R137 1-216-639-11 s RESISTOR,CHIP 330 1/10W (2012)

R138 1-216-683-11 s RESISTOR,CHIP 22K 1/10W (2012)

R139 1-216-651-11 s RESISTOR,CHIP 1K 1/10W(2012)

R140 1-216-641-11 s RESISTOR,CHIP 390 1/10W(2012)

R141 1-216-646-11 s RESISTOR,CHIP 620 1/10W (2012)

R142 1-216-627-11 s RESISTOR,CHIP 100 1/10W (2012)

R143 1-216-295-00 s CONDUCTOR, CHIP (2012)

R144 1-216-611-11 s RESISTOR,CHIP 22 1/10W (2012)

R145 1-216-683-11 s RESISTOR,CHIP 22K 1/10W (2012)

R146 1-216-627-11 s RESISTOR,CHIP 100 1/10W (2012)

R147 1-216-627-11 s RESISTOR,CHIP 100 1/10W (2012)

Q101 8-729-120-28 s TRANSISTOR 2SC1623-L5L6

Q102 8-729-027-23 s TRANSISTOR DTA114EKA-T146

Q103 8-729-112-65 s TRANSISTOR 2SA1462

R148 1-216-651-11 s RESISTOR,CHIP 1K 1/10W(2012)

R149 1-216-651-11 s RESISTOR,CHIP 1K 1/10W(2012)

R150 1-216-691-11 s RESISTOR,CHIP 47K 1/10W(2012)

Q104 8-729-107-31 s TRANSISTOR 2SC3545

Q105 8-729-120-28 s TRANSISTOR 2SC1623-L5L6

R151 1-216-611-11 s RESISTOR,CHIP 22 1/10W (2012)

R152 1-216-611-11 s RESISTOR,CHIP 22 1/10W (2012)

Q106 8-729-105-68 s TRANSISTOR 2SC3356-K

Q107 8-729-112-65 s TRANSISTOR 2SA1462

Q108 8-729-105-68 s TRANSISTOR 2SC3356-K

R153 1-216-603-11 s RESISTOR,CHIP 10 1/10W(2012)

R154 1-216-298-00 s RESISTOR,CHIP 2.2 1/10(2012)

R155 1-216-298-00 s RESISTOR,CHIP 2.2 1/10(2012)

Q109 8-729-112-65 s TRANSISTOR 2SA1462

Q301 8-729-900-53 s TRANSISTOR DTC114EK

R156 1-216-603-11 s RESISTOR,CHIP 10 1/10W(2012)

R157 1-216-611-11 s RESISTOR,CHIP 22 1/10W (2012)

Q302 8-729-120-28 s TRANSISTOR 2SC1623-L5L6

Q303 8-729-027-23 s TRANSISTOR DTA114EKA-T146

R158 1-216-611-11 s RESISTOR,CHIP 22 1/10W (2012)

R159 1-216-603-11 s RESISTOR,CHIP 10 1/10W(2012)

R160 1-216-603-11 s RESISTOR,CHIP 10 1/10W(2012)

R101 1-216-651-11 s RESISTOR,CHIP 1K 1/10W(2012)

R102 1-216-651-11 s RESISTOR,CHIP 1K 1/10W(2012)

R103 1-216-659-11 s RESISTOR,CHIP 2.2K 1/10W(2012)

R104 1-216-611-11 s RESISTOR,CHIP 22 1/10W (2012)

R105 1-216-611-11 s RESISTOR,CHIP 22 1/10W (2012)

R161 1-216-624-11 s RESISTOR,CHIP 75 1/10W(2012)

R162 1-216-624-11 s RESISTOR,CHIP 75 1/10W(2012)

R163 1-216-624-11 s RESISTOR,CHIP 75 1/10W(2012)

R164 1-216-624-11 s RESISTOR,CHIP 75 1/10W(2012)

R165 1-216-624-11 s RESISTOR,CHIP 75 1/10W(2012)

R106 1-216-691-11 s RESISTOR,CHIP 47K 1/10W(2012)

R107 1-216-651-11 s RESISTOR,CHIP 1K 1/10W(2012)

R108 1-218-772-11 s RESISTOR,CHIP 680K 1/10W(2012)

R109 1-216-683-11 s RESISTOR,CHIP 22K 1/10W (2012)

R110 1-216-611-11 s RESISTOR,CHIP 22 1/10W (2012)

R166 1-216-624-11 s RESISTOR,CHIP 75 1/10W(2012)

R167 1-216-624-11 s RESISTOR,CHIP 75 1/10W(2012)

R168 1-216-624-11 s RESISTOR,CHIP 75 1/10W(2012)

R169 1-216-298-00 s RESISTOR,CHIP 2.2 1/10(2012)

R170 1-216-298-00 s RESISTOR,CHIP 2.2 1/10(2012)

R111 1-216-651-11 s RESISTOR,CHIP 1K 1/10W(2012)

R112 1-216-639-11 s RESISTOR,CHIP 330 1/10W (2012)

R113 1-216-653-11 s RESISTOR,CHIP 1.2K 1/10W(2012)

R114 1-216-646-11 s RESISTOR,CHIP 620 1/10W (2012)

R115 1-216-675-11 s RESISTOR,CHIP 10K 1/10W(2012)

R171 1-216-308-00 s RESISTOR,CHIP 4.7 1/10W(2012)

R172 1-216-308-00 s RESISTOR,CHIP 4.7 1/10W(2012)

R173 1-216-308-00 s RESISTOR,CHIP 4.7 1/10W(2012)

R174 1-216-308-00 s RESISTOR,CHIP 4.7 1/10W(2012)

R175 1-216-651-11 s RESISTOR,CHIP 1K 1/10W(2012)

R116 1-216-295-00 s CONDUCTOR, CHIP (2012)

R117 1-216-611-11 s RESISTOR,CHIP 22 1/10W (2012)

R118 1-216-639-11 s RESISTOR,CHIP 330 1/10W (2012)

R119 1-216-643-11 s RESISTOR,CHIP 470 1/10W (2012)

R120 1-218-760-11 s RESISTOR,CHIP 220K 1/10W(2012)

R176 1-216-651-11 s RESISTOR,CHIP 1K 1/10W(2012)

R177 1-216-651-11 s RESISTOR,CHIP 1K 1/10W(2012)

R178 1-216-651-11 s RESISTOR,CHIP 1K 1/10W(2012)

R179 1-216-607-11 s RESISTOR,CHIP 15 1/10W(2012)

R180 1-216-699-11 s RESISTOR,CHIP 100K 1/10W(2012)

R121 1-216-603-11 s RESISTOR,CHIP 10 1/10W(2012)

R122 1-216-669-11 s RESISTOR,CHIP 5.6K 1/10W(2012)

R123 1-216-619-11 s RESISTOR CHIP 47 1/10W(2012)

R124 1-216-623-11 s RESISTOR,CHIP 68 1/10W(2012)

R125 1-216-649-11 s RESISTOR,CHIP 820 1/10W (2012)

R181 1-216-675-11 s RESISTOR,CHIP 10K 1/10W(2012)

R182 1-216-651-11 s RESISTOR,CHIP 1K 1/10W(2012)

R183 1-216-651-11 s RESISTOR,CHIP 1K 1/10W(2012)

R184 1-216-651-11 s RESISTOR,CHIP 1K 1/10W(2012)

R185 *b 1-215-457-00 s RESISTOR,METAL FILM 33K 1/4W

R126 1-216-662-11 s RESISTOR,CHIP 3K 1/10W (2012)

*a 1-215-421-00 s RESISTOR,METAL FILM 1K 1/4W

R127 1-216-670-11 s RESISTOR,CHIP 6.2K 1/10W(2012)

R128 1-216-691-11 s RESISTOR,CHIP 47K 1/10W(2012)

R129 1-216-627-11 s RESISTOR,CHIP 100 1/10W (2012)

R130 1-216-622-11 s RESISTOR,CHIP 62 1/10W (2012)

R301 1-216-651-11 s RESISTOR,CHIP 1K 1/10W(2012)

R302 1-216-659-11 s RESISTOR,CHIP 2.2K 1/10W(2012)

R303 1-216-647-11 s RESISTOR,CHIP 680 1/10W (2012)

R304 1-216-675-11 s RESISTOR,CHIP 10K 1/10W(2012)

R131 1-216-651-11 s RESISTOR,CHIP 1K 1/10W(2012)

R306 1-216-681-11 s RESISTOR,CHIP 18K 1/10W (2012)

R132 1-216-633-11 s RESISTOR,CHIP 180 1/10W (2012)

R133 1-216-295-00 s CONDUCTOR, CHIP (2012)

R134 1-216-611-11 s RESISTOR,CHIP 22 1/10W (2012)

R135 1-216-646-11 s RESISTOR,CHIP 620 1/10W (2012)

R307 1-216-651-11 s RESISTOR,CHIP 1K 1/10W(2012)

R308 1-216-651-11 s RESISTOR,CHIP 1K 1/10W(2012)

R309 1-216-651-11 s RESISTOR,CHIP 1K 1/10W(2012)

R310 1-216-639-11 s RESISTOR,CHIP 330 1/10W (2012)

BKPF-L703A

3-5

Page 20

(VDA-56 BOARD ;Suffix -11)

Ref. No.

or Q'ty Part No. SP Description

RV101 1-237-039-11 s RESISTOR,ADJ,CERMET 100K

RV102 1-230-746-21 s RESISTOR, ADJ, CERMET 500

RV103 1-230-744-11 s RESISTOR,ADJ,CERMET 100

RV104 1-237-029-11 s RESISTOR,ADJ,CERMET 50

RV301 1-237-031-11 s RESISTOR,ADJ,CERMET 200

S101 1-553-977-00 s SWITCH,SLIDE (2-1-2)

3-6

BKPF-L703A

Page 21

Section 4

Semiconductor Pin Assignments

The following describes the semiconductor types used in

this unit.

For semiconductors marked with page numbers in the

index, refer to the corresponding pages in this section.

However, in some cases incompatible types are also listed,

therefore, when a part is to be replaced, also refer to the

Spare Parts section.

In addition, for semiconductors with ID Nos., refer to the

separate CD-ROM titled “Semiconductor Pin Assignments”

(Sony Part No. 9-968-546-xx) that allows searching for

parts by semiconductor type or ID No.

The semiconductors in the manual or on the CD-ROM are

listed by equivalent types. Thus the external view or the

index mark indication may differ from the actual type.

Pin assignments and block diagrams are based on the IC

manufacturer’s data book.

Index

DIODE Page or ID No.

1S2835-T1 ....................................................................... DC001-02

1S2836............................................................................. DC001-02

1SS123-T1 .......................................................................DC001-01

1SS226 ............................................................................ DC001-01

RB160L-40TE25 .............................................................. DC007-01

RD4.7SB-T1..................................................................... DC008-04

RD4.7SB-T2..................................................................... DC008-04

RD5.6SB ..........................................................................DC008-04

RD5.6SB-T1..................................................................... DC008-04

LED Page or ID No.

CL-155UR/G-D ................................................................ LC009-03

CL-155UR/G-DT .............................................................. LC009-03

TRANSISTOR Page or ID No.

2SA1462 .......................................................................... TC001-01

2SA1462-T1Y33Y34 ........................................................ TC001-01

2SC1623-L5L6 ................................................................. TC001-02

2SC1623-T1-L5L6 ........................................................... TC001-02

2SC3356-K ...................................................................... TC001-02

2SC3356-T1K .................................................................. TC001-02

2SC3545-T1T43T44 ........................................................ TC001-02

2SC3545-T43................................................................... TC001-02

IC Page or ID No.

CXA1432M..................................................................... CXA1432M

CXA1432M-T4 ............................................................... CXA1432M

LM1881M ..........................................................................LM1881N

LM1881MX........................................................................LM1881N

LM1881MX/NOPB ............................................................LM1881N

LM2664M6X................................................................................ 4-2

LM2665M6X................................................................................ 4-2

LM2941CSX................................................................. LM2941CSX

LT1252CS8................................................................... LT1252CS8

LT1252CS8-E2 ............................................................. LT1252CS8

SC7S00F ..........................................................................TC7S00F

TC74HC123AF ..........................................................TC74HC123P

TC74HC123AF(EL).................................................... TC74HC123P

TC7S00F(TE85R) .............................................................TC7S00F

DTA114EE ....................................................................... TC001-04

DTA114EE-TL.................................................................. TC001-04

DTA114EKA-T146 ........................................................... TC001-04

DTC114EE ....................................................................... TC001-03

DTC114EE-TL ................................................................. TC001-03

DTC114EKA-T146 ........................................................... TC001-03

BKPF-L703A

4-1

Page 22

IC

[|IC|]

LM2664M6X (NS)

SWITCHED-CAPACITOR VOLTAGE CONVERTER

—TOP VIEW—

6

1

GND

2

OUT

3

CAP_

INPUTS

: SHUTDOWN CONTROL

SD

V+

: POSITIVE VOLTAGE SUPPLY

OUTPUT

OUT

: NEGATIVE VOLTAGE

OTHERS

CAP+

: CHARGE-PUMP CAPACITOR, POSITIVE TERMINAL

CAP_

: CHARGE-PUMP CAPACITOR, NEGATIVE TERMINAL

56

V+

OSC

– 2

CAP+

5

V+

4

SD

CAP+

3

CAP_

2

OUT

LM2665M6X (NS)

SWITCHED-CAPACITOR VOLTAGE CONVERTER

—TOP VIEW—

6

1

V+

2

GND

3

CAP_

INPUTS

SD

: SHUTDOWN CONTROL

V+

: POSITIVE VOLTAGE SUPPLY

OUTPUT

OUT

: POSITIVE VOLTAGE

OTHERS

CAP+

: CHARGE-PUMP CAPACITOR, POSITIVE TERMINAL

CAP_

: CHARGE-PUMP CAPACITOR, NEGATIVE TERMINAL

16

V+

– 2

OSC

CAP+

5

OUT

4

SD

CAP+

3

CAP_

5

OUT

4-2

BKPF-L703A

Page 23

Section 5

Block Diagram

OverallOverall

VDA-56

VIDEO IN

LOOP THROUGH OUT

CN1

CN2

CN101 IC110,IC111

1C 1C

1A 1A

1B

1B

2B

2B

2C

2C

CN-1982

(1/2)

DIFF

AMP

RV104

1

CMR

COR101

SINGLE

DIFFERENTIAL

S101

IC101

CLAMP

RV101

1

OFFSET

CLAMP

ON-OFF

IC106

PRE

AMP

ELEMENT

EQ

RV102

1

EQ

RV103

1

GAIN

IC107 IC108

EQ

AMP

CLAMP PULSE

IC105

SYNC

SEP

IC102

MONO

MULTI

PRE

DRIVER

Q103

Q104

NORMAL:H

Q106

Q107

D101

VIDEO IN

Q108

Q109

NORMAL:H

IC109,Q105

CN101

CN101

3C

3C

4A 4A

5C 5C

6A 6A

7C 7C

8A9C8A

9C

10A 10A

CN-1982

(2/2)

CN101

14C 14C

DIAG

CN3

CN4

CN5

CN6

CN7

CN8

CN9

CN10

VIDEO

VIDEO

VIDEO

VIDEO

VIDEO

VIDEO

VIDEO

VIDEO

OUT 1

OUT 2

OUT 3

OUT 4

OUT 5

OUT 6

OUT 7

OUT 8

BKPF-L703A

+5.1V

+5.1V

+5.1V

13A

13B

13C

CN101

13A

13B

13C

IC301

+5V

REG.

DD301

-5V

DC-DC CON.

RV301

1

+5V

(+5.0V)

5V

-5V

NG

DETECT

D301,Q301

D302

-5V

NORMAL:H

Overall

5-1 5-1

Page 24

Page 25

Section 6

10B

7B

9A 15C

6A

8B

2C

3C

5C

8A

14C

5B

5A

8C

1A

12C

2A

16C

1C

9B

13C

12A

15B

4B

4C

2B

9C

1B

14A

7A

10A

6C

10C

3B

14B

13B

13A

6B

11B

4A

16A

11A

15A

16B

12B

7C

3A

11C

(16/48)

CN101

(32/48)

CN101

(35/48)

CN101

(34/48)

CN101

CN7

(40/48)

CN101

(26/48)

CN101

(30/48)

CN101

(45/48)

CN101

(3/48)

CN101

(43/48)

CN101

(29/48)

CN101

(21/48)

CN101

(28/48)

CN101

(24/48)

CN101

(17/48)

CN101

GND

(18/48)

CN101

(25/48)

CN101

(46/48)

CN101

(22/48)

CN101

(5/48)

CN101

(20/48)

CN101

CN9

(6/48)

CN101

GND

(42/48)

CN101

(10/48)

CN101

GND

(13/48)

CN101

(12/48)

CN101

(1/48)

CN101

GND

CN3

(11/48)

CN101

(9/48)

CN101

(2/48)

CN101

(33/48)

CN101

(27/48)

CN101

CN1

(44/48)

CN101

(37/48)

CN101

(23/48)

CN101

(31/48)

CN101

CN5

(38/48)

CN101

(14/48)

CN101

(7/48)

CN101

(36/48)

CN101

(15/48)

CN101

(19/48)

CN101

(4/48)

CN101

(48/48)

CN101

(39/48)

CN101

GND

(8/48)

CN101

(41/48)

CN101

(47/48)

CN101

VIDEO_OUT4

GND

NC

NC

6

5

4

1

2

3

NC

GND

GND

NC

VIDEO_IN(+)

NC

GND

VIDE_OUT5

VIDEO_OUT8

GND

GND

GND

GND

NC

VIDEO_OUT6

VIDEO_IN(-)

GND

6

5

4

1

2

3

VIDEO_IN(-)

NC

VIDEO_OUT2

GND

GND

VIDEO_IN(-)

6

5

4

1

2

3

GND

VIDEO_OUT1

VIDEO_IN(-)

GND

VIDEO_OUT7

6

5

4

1

2

3

NC

NC

GND

GND

6

5

4

1

2

3

NCGND

GND

NC

VIDEO_OUT3

GND

NC

NC

NC

GND

NC

NC

CN-1982

Schematic Diagrams

Index

Board Name Function Page

CN-1982 Connector Board 6-1

VDA-56 Analog Video Distribution Board 6-2

BKPF-L703A (SY) : S/N 10001 and Higher

1

2

3

4

BKPF-L703A

A BCDEFGH

5

CN-1982

BOARD NO. 1-680-192-11, 12

LOT NO. 0A3-

6-1 6-1

Page 26

VDA-56 (1/2)

SUFFIX: -12

VDA-56 (1/2)

SUFFIX: -12

1

R161

75

C146

10pF

R162

75

C147

10pF

Q106

2SC3356-T1K

Q103

2SA1462-T1Y33Y34

0

C134

3pF

R145

C133

47uF

6.3V

6

0.1uF

22k

R146

100

R147

100

C136

0.1uF

C137

R148

1k

+5V

R143

2

C103

4.7uF

R106

47k

R107

1k

IC105

C104

0.1uF

C102

33pF

C105

0.1uF

R185

33k

1

3

8

9

10

+5V

2

-5V

(1/3)

16V

+5V

VCC

VDIN

FVIN

SENS

PEDE

CPIN

VEE

1

RV101

100k

3

-5V

R108

680k

1

2

R104

22

C101

1uF

16V

14

EOUT

VOUT

TP12

TP5

11

R105

22

2

7

12

4

C106

1uF

16V

R111

1k

R112

330

R113

1.2k

C112

0.1uF

R114

C113

0.1uF

3

2

620

RV1:OFFSET ADJ

C110

100pF

+5V

R110

C108

22

47uF

C109

6.3V

0.1uF

8

1

VCC2

CSYNC

VIN

3

VSYNC

6

RSET

47pF

14

C

C107

RD

GND

3

4

+5V

CR

Q

Q

B/B

O/E

R109

22k

15

13

4

5

7

+5V

+5V

R116

7

+

4

R117

-5V

L103

220uH

C111

7pF

0

22

R115

C116

47uF

6.3V

C117

47uF

6.3V

C115

33pF

+5V

10k

C114

47pF

IC106

LT1252CS8-E2

TP101

R121

R118

330

R119

470

C118

0.001uF

6

C

RD

11

C119

18pF

C120

33pF

C121

56pF

C122

82pF

C123

180pF

C124

0.1uF

+5V

7

CR

Q

Q

10

R120

220k

5

12

6

9

10

2SC1623-T1-L5L6

+5V

16

VCC

GND

8

TC74HC123AF(EL)

EQ

3

2

RV102

CT101

20pF

R123

47

R124

68

R125

820

R126

3k

R127

6.2k

R128

47k

R122

5.6k

IC102

TC74HC123AF(EL)

Q101

C125

0.1uF

500

1

3

R129

100

RV103

100

1

R130

GAIN

62

R132

180

RV2:EO

RV3:GAIN

(2/3)

+5V

G

R

D101

CL-155UR/G-DT

VIDEO IN

(3/3)IC102

R131

1k

2

21

43

C126

0.1uF

3

2

C127

0.1uF

+5V

+

-

-5V

R134

R137

330

R133

0

CT102

C128

10pF

47uF

6.3V

7

IC107

6

LT1252CS8-E2

R135

4

620

C129

47uF

6.3V

22

Q102

DTA114EE-TL

+9V

R171

CN101

(1/48)

1A

(2/48)

1B

(3/48)

1C

(4/48)

2A

(5/48)

2B

(6/48)

2C

3

GND

GND

VIDEO_IN

N.C.

GND

GND

SINGLE

DIFFERENTIAL

L101

39nH

COR101

1

2

3

GND

D103

RD4.7SB-T1

D104

RD4.7SB-T1

GND

GND

R180

100k

R181

10k

GND

4

4.7

C159

0.1uF

R182

GND

1k

3

2

R172

C161

4.7

0.1uF

-9V

+9V

R173

4.7

C160

0.1uF

GND

R183

1k

3

R179

2

15

R177

1k

C163

0.1uF

R178

1k

R174

4.7

GND

IC111

LT1252CS8-E2

IC110

LT1252CS8-E2

7

GND

+

6

4

C156

47uF

16V

GNDGND

C157

47uF

16V

7

GND

+

6

4

C158

47uF

16V

GND

-9V

C155

47uF

16V

2

GND

R175

1k

1

RV104

50

CMR

3

R176

1k

C162

0.1uF

R101

1k

D105

1SS123-T1

S101

CLAMP OFF ON

5

IC101

CXA1432M-T4

3

R184

1k

2

GND

1

E1

LM1881MX/NOPB

R102

1k

R103

2.2k

L102

47uH

IC102

TC74HC123AF(EL)

C132

0.1uF

IC108

LT1252CS8-E2

R139

1k

R140

390

C130

5pF

R136

220

R138

22k

R141

620

+5V

5

1

VCC 4

B

Y

2

A

GND

3

IC109

TC7S00F(TE85R)

3

7

+

2

4

R142

100

C135

47uF

C131

3pF

6.3V

R144

22

Q104

2SC3356-T1K

C154

0.1uF

+5V

R153

10

R151

22

R154

2.2

R155

2.2

R152

22

R149

1k

R156

10

2SA1462-T1Y33Y34

R150

47k

Q105

2SC1623-T1-L5L6

C140

C138

100uF

0.1uF

6.3V

R157

22

R158

22

C141

100uF

6.3V

C139

0.1uF

-5V

2SA1462-T1Y33Y34

Q107

3

2

D102

1S2835-T1

1

R159

10

C142

0.1uF

Q108

2SC3356-T1K

R169

TP104

2.2

R170

2.2

R160

10

C143

0.1uF

Q109

POWER DOWN L

NORMAL L

NORMAL_H

C144

100uF

6.3V

C145

100uF

6.3V

R163

75

C148

10pF

R164

75

C149

10pF

R165

75

C150

10pF

R166

75

C151

10pF

R167

75

C152

10pF

R168

75

C153

10pF

E2

TP105

DCDC_NG

VIDEO_EXIST

GND

GND

EO_OUT1

EO_OUT2

GND

GND

GND

GND

EO_OUT3

EO_OUT4

GNE

GND

GND

GND

EO_OUT5

EO_OUT6

GND

GND

GND

GND

EO_OUT7

EO_OUT8

GND

GND

DIAG

CN101

(7/48)

3A

(8/48)

3B

(9/48)

3C

(10/48)

4A

(11/48)

4B

(12/48)

4C

(13/48)

5A

(14/48)

5B

(15/48)

5C

(16/48)

6A

(17/48)

6B

(18/48)

6C

(19/48)

7A

(20/48)

7B

(21/48)

7C

(22/48)

8A

(23/48)

8B

(24/48)

8C

(25/48)

9A

(26/48)

9B

(27/48)

9C

(28/48)

10A

(29/48)

10B

(30/48)

10C

2/2

2/2

CN101

(42/48)

14C

VDA-56 (1/2)

BOARD NO. 1-680-191-12

6-2 (b)6-2 (b)

BKPF-L703A

ABCDEFGH

Page 27

VDA-56 (2/2)

SUFFIX: -12

VDA-56 (2/2)

SUFFIX: -12

+5V

1

(37/48)

(38/48)

(39/48)

(31/48)

(32/48)

(33/48)

(45/48)

(47/48)

(41/48)

(40/48)

(46/48)

(48/48)

CN101

13A

13B

13C

11A

11B

11C

15C

16B

14B

14A

16A

16C

5.1V

5.1V

5.1V

GND

GND

GND

GND

GND

LOAD

N.C.

N.C.

N,C.

PS301

2A

C310

47uF

16V

R304

10k

R306

18k

C313

0.1uF

GND

E3

L301

10uH

L303

10uH

GND

C301

47uF

25V

GND

C302

47uF

25V

C303

0.1uF

GND

GND

DD301

1

+VIN

2

-VIN

C304

0.1uF

+VOUT

-VOUT

5

6

4

3

C305

100uF

6.3V

GND

GND

L302

10uH

C306

100uF

6.3V

GND

IC301

LM2941CSX

4

IN

2

SW

GND

3

OUT

ADJ

FIN

6

5

1

GND

GND

C307

0.1uF

R301

1k

-5V

TP303

-5V

R302

2.2k

+5V

R307

1k

R308

1k

D301

RD5.6SB-T1

RV301

200

R303

680

5V

+5V

R309

GND

TP301

C308

330uF

6.3V

GND

1k

DCDC_NG

Q301

DTC114EE-TL

L304

C318

4.7uF

16V

GND

+5V

C309

0.1uF

GND

GND

GND

IC304

LM2664M6X

5

V+

CAP+

4

SD

CAP-

GND

1

RB160L-40TE25

1

C319

4.7uF

16V

V+

4

SD

Q302

2SC1623-T1-L5L6

1/2

GND

C314

82uF

16V

L306

C317

82uF

16V

OUT

D303

GND

2

6

3

OUT

CAP+

CAP-

2

5

6

3

C316

82uF

16V

G

R

D302

CL-155UR/G-DT

43

21

GND

+9V

-5V

C320

4.7uF

16V

C321

4.7uF

16V

GND

C315

82uF

16V

R310

330

-9V

L307L305

Q303

DTA114EE-TL

2

3

BKPF-L703A

1/2

VIDEO_EXIST

IC302

PCF8574AT

NM

NORMAL L

C311

47uF

6.3V

NM

4

5

6

7

9

10

11

12

+5V

16

VDD

P015SDA

P1

SCL

P2

A2

P3

A1

P4

A0

P5

P6

INT

P7

VSS

8

C312

1uF

16V

NM

14

3

2

1

13

NORMAL L

+5V

R305

100k

NM

GND

IC303

LM2665M6X

87

65

43

21

RB301

100k

NM

CN101

SCL

SDA

CARD_ADRS0

CARD_ADRS1

CARD_ADRS2

15A

15B

CN101

12A

12B

12C

(43/48)

(44/48)

(34/48)

(35/48)

(36/48)

GNDGND

VDA-56 (2/2)

BOARD NO. 1-680-191-12

6-3 (b) 6-3 (b)

GND

4

5

A BCDEFGH

Page 28

VDA-56 (1/2)

SUFFIX: -11

1

C103

4.7uF

R106

47k

2

R107

1k

LM1881MX

C104

0.1uF

C102

33pF

C105

0.1uF

*

1

33k

16V

1

VDIN

3

FVIN

8

SENS

9

PEDE

10

CPIN

+5V

1

RV101

100k

3

-5V

IC105

R108

680k

(1/3)

1

2

+5V

R104

22

C101

VCC

VEE

-5V

2

6

1uF

16V

14

EOUT

VOUT

TP12

TP5

11

R105

22

C108

47uF

6.3V

VIN

RSET

C

C112

0.1uF

2

R111

1k

7

12

4

C106

1uF

16V

R112

330

R113

1.2k

3

2

R114

620

C113

0.1uF

RV101:OFFSET ADJ

C110

100pF

+5V

R110

22

C109

0.1uF

8

1

VCC

CSYNC

3

VSYNC

5

B/B

7

O/E

GND

4

+5V

R109

22k

C107

47pF

14

15

13

CR

Q

4

Q

RD

+5V

3

+5V

R116

7

+

4

R117

22

-5V

L103

220uH

C111

7pF

0

C116

47uF

6.3V

C117

47uF

6.3V

C115

33pF

+5V

R115

10k

C114

47pF

IC106

LT1252CS8-E2

6

9

10

2

(1/48)

(2/48)

(3/48)

(4/48)

(5/48)

(6/48)

CN101

1A

1B

1C

2A

2B

2C

GND

GND

VIDEO_IN

N.C.

GND

GND

SINGLE

DIFFERENTIAL

1

2

3

GND

L101

39nH

COR101

R180

100k

C159

0.1uF

R182

C161

0.1uF

3

0.1uF

R183

D103

RD4.7SB-T1

D104

RD4.7SB-T1

GND

GND

R181

10k

0.1uF

GND

R179

C163

4

MARK LOT NO.

*

5

1

CHANGED INFORMATION

R185 1k →33k 224-

+9V

R171

4.7

GND

1k

3

7

+

2

4

R172

4.7

-9V

GNDGND

+9V

R173

4.7

C160

GND

1k

3

7

+

2

15

-

R177

4

1k

C158

47uF

1k

R174

4.7

-9V

IC111

16V

R178

GND

LT1252CS8-E2

IC110

LT1252CS8-E2

C155

47uF

16V

R175

1k

1

RV104

50

2

CMR

3

RV104:CMR

R176

1k

C157

47uF

16V

C162

0.1uF

GND

R101

1k

1SS123-T1

S101

CLAMP

GND

C156

47uF

GND

GND

6

16V

6

D105

CXA1432M-T4

3

2

1

ON

2

1

3

OFF

R102

1k

R103

2.2k

IC101

R184

1k

GND

E1

L102

47uH

R185

IC102

TC74HC123AF(EL)

VDA-56 (1/2)

SUFFIX: -11

TP101

R121

10

CT101

R118

330

R119

470

C118

0.001uF

6

C

RD

11

TC74HC123AF(EL)

20pF

C119

R123

18pF

47

C120

R124

33pF

68

GAIN

C121

R125

56pF

820

C122

R126

82pF

3k

C123

R127

180pF

6.2k

C124

R128

0.1uF

47k

R122

5.6k

+5V

R120

220k

IC102

7

TC74HC123AF(EL)

5

CR

Q

12

Q

Q101

2SC1623-T1-L5L6

+5V

C125

0.1uF

16

VCC

GND

8

(3/3)IC102

EQ

3

2

RV102

C126

500

0.1uF

1

3

R131

1k

RV103

1

100

R130

2

62

R132

180

C127

0.1uF

R129

100

RV102:EQ

RV103:GAIN

(2/3)

+5V

G

21

43

R

D101

CL-155UR/G-DT

VIDEO IN

R136

+5V

R133

3

7

+

2

4

-5V

R134

22

DTA114EKA-T146

R137

330

220

0

CT102

C128

10pF

47uF

6.3V

IC107

6

LT1252CS8-E2

R135

620

C129

47uF

6.3V

Q102

R143

0

C132

0.1uF

IC108

LT1252CS8-E2

R139

1k

3

7

+

R140

390

2

-

C130

5pF

R138

22k

R141

620

+5V

VCC 4

1

B

2

A

GND

IC109

TC7S00F(TE85R)

4

C134

3pF

R142

100

C135

47uF

C131

3pF

6.3V

R144

22

Q104

2SC3545-T1T43T44

C154

0.1uF

5

Y

3

2SC3356-T1K

Q103

2SA1462-T1Y33Y34

R151

22

R152

22

R149

1k

R153

R154

2.2

R155

2.2

R156

10

47uF

6.3V

6

C133

R146

100

R147

100

C136

0.1uF

R148

1k

2SA1462-T1Y33Y34

+5V

C137

0.1uF

R145

22k

R150

47k

2SC1623-T1-L5L6

Q106

+5V

10

-5V

Q107

3

1

Q105

R159

10

C142

C140

C138

0.1uF

R157

R158

0.1uF

2

D102

1S2835-T1

0.1uF

100uF

6.3V

Q108

2SC3356-T1K

22

R169

2.2

R170

2.2

22

R160

10

C141

C143

100uF

0.1uF

6.3V

C139

Q109

2SA1462-T1Y33Y34

POWER DOWN L

NORMAL L

NORMAL_H

R162

R163

C144

100uF

R164

6.3V

TP104

C145

100uF

6.3V

TP105

75

75

75

R165

75

R166

75

R167

75

75

E2

R161

75

C146

10pF

C147

10pF

C148

10pF

C149

10pF

C150

10pF

C151

10pF

C152

10pF

R168

C153

10pF

GND

GND

EO_OUT1

EO_OUT2

GND

GND

GND

GND

EO_OUT3

EO_OUT4

GNE

GND

GND

GND

EO_OUT5

EO_OUT6

GND

GND

GND

GND

EO_OUT7

EO_OUT8

GND

GND

DCDC_NG

VIDEO_EXIST

DIAG

VDA-56 (1/2)

BOARD NO. 1-680-191-11

2/2

2/2

CN101

3A

3B

3C

4A

4B

4C

5A

5B

5C

6A

6B

6C

7A

7B

7C

8A

8B

8C

9A

9B

9C

10A

10B

10C

CN101

14C

(7/48)

(8/48)

(9/48)

(10/48)

(11/48)

(12/48)

(13/48)

(14/48)

(15/48)

(16/48)

(17/48)

(18/48)

(19/48)

(20/48)

(21/48)

(22/48)

(23/48)

(24/48)

(25/48)

(26/48)

(27/48)

(28/48)

(29/48)

(30/48)

(42/48)

6-2 (a)6-2 (a)

BKPF-L703A

ABCDEFGH

Page 29

VDA-56 (2/2)

SUFFIX: -11

VDA-56 (2/2)

SUFFIX: -11

(37/48)

(38/48)

(39/48)

(31/48)

(32/48)

(33/48)

(45/48)

(47/48)

(41/48)

(40/48)

(46/48)

(48/48)

CN101

13A

13B

13C

11A

11B

11C

15C

16B

14B

14A

16A

16C

5.1V

5.1V

5.1V

GND

GND

GND

GND

GND

LOAD

N.C.

N.C.

N,C.

PS301

2A

C310

47uF

16V

R304

10k

R306

18k

C313

0.1uF

GND

E3

L301

10uH

L303

10uH

GND

GND

C301

47uF

25V

C302

47uF

25V

C303

0.1uF

GND

GND

DD301

1

+VIN

2

-VIN

C304

0.1uF

+VOUT

-VOUT

5

6

4

3

C305

100uF

6.3V

GND

GND

L302

10uH

C306

100uF

6.3V

GND

IC301

LM2941CSX

4

2

IN

SW

GND1

OUT

ADJ

GND2

3

6

5

1

GND

GND

C307

0.1uF

R301

1k

-5V

TP303

-5V

R302

2.2k

+5V

R307

1k

R308

1k

D301

RD5.6SB-T1

RV301

200

R303

680

+5V

R309

1k

Q301

DTC114EKA-T146

GND

L304

RV301:+5V ADJ

TP301

5V

330uF

6.3V

GND

GND

+5V

C308

GND

C318

4.7uF

16V

C309

0.1uF

DCDC_NG

GND

GND

IC304

LM2664M6X

5

V+

CAP+

4

SD

CAP-

GND

1

RB160L-40TE25

1

C319

4.7uF

16V

V+

4

SD

Q302

2SC1623-T1-L5L6

1/2

OUT

D303

GND

2

6

3

OUT

CAP+

CAP-

2

C316

100uF

16V

5

6

3

L306

C317

100uF

16V

GND

C314

100uF

16V

+5V

G

R

D302

CL-155UR/G-DT

43

21

GND

+9V

-5V

C320

4.7uF

16V

C321

4.7uF

16V

R310

GND