Page 1

HISTORY INFORMATION FOR THE FOLLOWING MANUAL:

Self Diagnosis

Supported model

SERVICE MANUAL

CONFIDENTIAL

ELECTRICAL SERVICE MANUAL

INTERNAL ONLY

ORIGINAL MANUAL ISSUE DATE: 3/2012

REVISION DATE SUBJECT

3/29/2012 Original Manual Release Date

AZ3TK

CHASSIS

LEVEL

CONFIDENTIAL

3

9-883-885-51

LCD DIGITAL COLOR TV

Page 2

LEVEL

CONFIDENTIAL

3

SERVICE MANUAL

MODEL COMMANDER DESTINATION

KDL-32BX355 RM-YD081 BRAZIL

KDL-40BX455 RM-YD081 BRAZIL

KDL-46BX455 RM-YD081 BRAZIL

AZ3TK

CHASSIS

9-883-885-51

LCD DIGITAL COLOR TV

Page 3

AZ3TK

TABLE OF CONTENTS

SECTION TITLE PAGE

Cautions and Warnings ....................................................................................................................................................................................................4

Safety Check-Out...............................................................................................................................................................................................................6

SECTION 1: DIAGRAMS

1-1. Printed Circuit Boards and Schematic Diagrams Information ............................................................................................................................8

1-2. Block Diagram ....................................................................................................................................................................................................9

1-3. Connector Diagrams ........................................................................................................................................................................................10

A Board Schematic

G Board Schematic

H Board Schematic

SECTION 2: ELECTRICAL PARTS LIST

KDL-32BX355

KDL-40BX455/46BX455

APPENDIX A: ENCRYPTION KEY COMPONENTS

...................................................................................................................................................................................................8

...........................................................................................................................................................................................11

..........................................................................................................................................................................................28

..........................................................................................................................................................................................29

........................................................................................................................................................................31

..................................................................................................................................................................................................31

..................................................................................................................................................................................31

.....................................................................................................................................................A-1

AZ3TK 3

Page 4

AZ3TK

CAUTIONS AND WARNINGS

CAUTION

These servicing instructions are for use by qualied service personnel only. To reduce the risk of electric shock, do not

perform any servicing other than that contained in the operating instructions unless you are qualied to do so.

WARNING!!

An isolation transformer should be used during any service to avoid possible shock hazard, in case of live chassis.

!

SAFETY-RELATED COMPONENT WARNING!!

There are critical components used in LCD color TVs that are important for safety. These components are identied with

shading and

with the part number specied in the parts list to prevent electric shock, re, or other hazard.

NOTE: Do not modify the original design without obtaining written permission from the manufacturer or you will void the

original parts and labor warranty.

!

mark on the schematic diagrams and the parts list. It is essential that these critical parts be replaced only

AZ3TK 4

Page 5

AZ3TK

SETTING UP AND CARRYING THE TV

• Disconnect all cables when carrying the TV.

• Carry the TV with the adequate number of people; larger size TVs require two or more people.

• Correct hand placement while carrying the TV is very important for safety and to avoid damage.

USE CAUTION WHEN HANDLING THE LCD PANEL

When repairing the LCD panel, be sure you are grounded by using a wrist band.

When installing the LCD panel on a wall, the LCD panel must be secured using the 4 mounting holes on the rear

cover.

To avoid damaging the LCD panel:

1. Do not press on the panel or frame edge to avoid the risk of electric shock.

2. Do not scratch or press on the panel with any sharp objects.

3. Do not leave the module in high temperatures or in areas of high humidity for an extended period of time.

4. Do not expose the LCD panel to direct sunlight.

5. Avoid contact with water. It may cause a short circuit within the module.

6. Disconnect the AC power when replacing the backlight (CCFL) or inverter circuit.

(High voltage occurs at the inverter circuit at 650Vrms.)

7. Always clean the LCD panel with a soft cloth material.

8. Use care when handling the wires or connectors of

the inverter circuit. Damaging the wires may cause a

short.

9. Protect the panel from ESD to avoid damaging the

electronic circuit (C-MOS).

10. During the repair, DO NOT leave the Power On for

more than 1 hour while the TV is face down on a

cloth.

CLEANING THE LCD PANEL

CAUTION: When cleaning the TV, be sure to unplug the power cord to avoid any chance of electric shock.

Clean the cabinet of the TV with a dry soft cloth.

Wipe the LCD screen gently with a soft cloth.

; Stubborn stains may be removed with a cloth slightly moistened with a solution of mild soap and warm water.

; If using a chemically pretreated cloth, please follow the instruction provided on the package.

; Never use strong solvents such as a thinner, alcohol or benzine for cleaning.

; Periodic vacuuming of the ventilation openings is recommended to ensure proper ventilation.

; Do Not use paper towels, any type of abrasive pad, rags, rubber or vinyl materials to clean the screen. Using

these materials could easily scratch the screen which may result in permanent damage.

; Do Not use any cleaning product containing alkaline/acid cleaner, scouring powder, or volatile solvent, such as

alcohol, ammonia, benzine, thinner or insecticide. Using any of these harsh cleaners may result in permanent

damage to the screen.

; Do Not spray water or detergent directly onto the TV screen . If liquid drips into the bottom of the screen it may

cause a failure.

AZ3TK 5

Page 6

SAFETY CHECK-OUT

To Exposed Metal

Parts on Set

0.15 µF

Earth Ground

AC

Voltmeter

(0.75V)

AZ3TK

After correcting the original service problem, perform the

following safety checks before releasing the set to the

customer:

1. Check the area of your repair for unsoldered or

poorly soldered connections. Check the entire

board surface for solder splashes and bridges.

2. Check the interboard wiring to ensure that no

wires are “pinched” or touching high-wattage

resistors.

3. Check that all control knobs, shields, covers,

ground straps, and mounting hardware have been

replaced. Be absolutely certain that you have

replaced all the insulators.

4. Look for unauthorized replacement parts,

particularly transistors, that were installed during

a previous repair. Point them out to the customer

and recommend their replacement.

5. Look for parts which, though functioning, show

obvious signs of deterioration. Point them out to

the customer and recommend their replacement.

6. Check the line cords for cracks and abrasion.

Recommend the replacement of any such line

cord to the customer.

7. Check the antenna terminals, metal trim,

“metallized” knobs, screws, and all other exposed

metal parts for AC leakage. Check leakage as

described in “Leakage Test”.

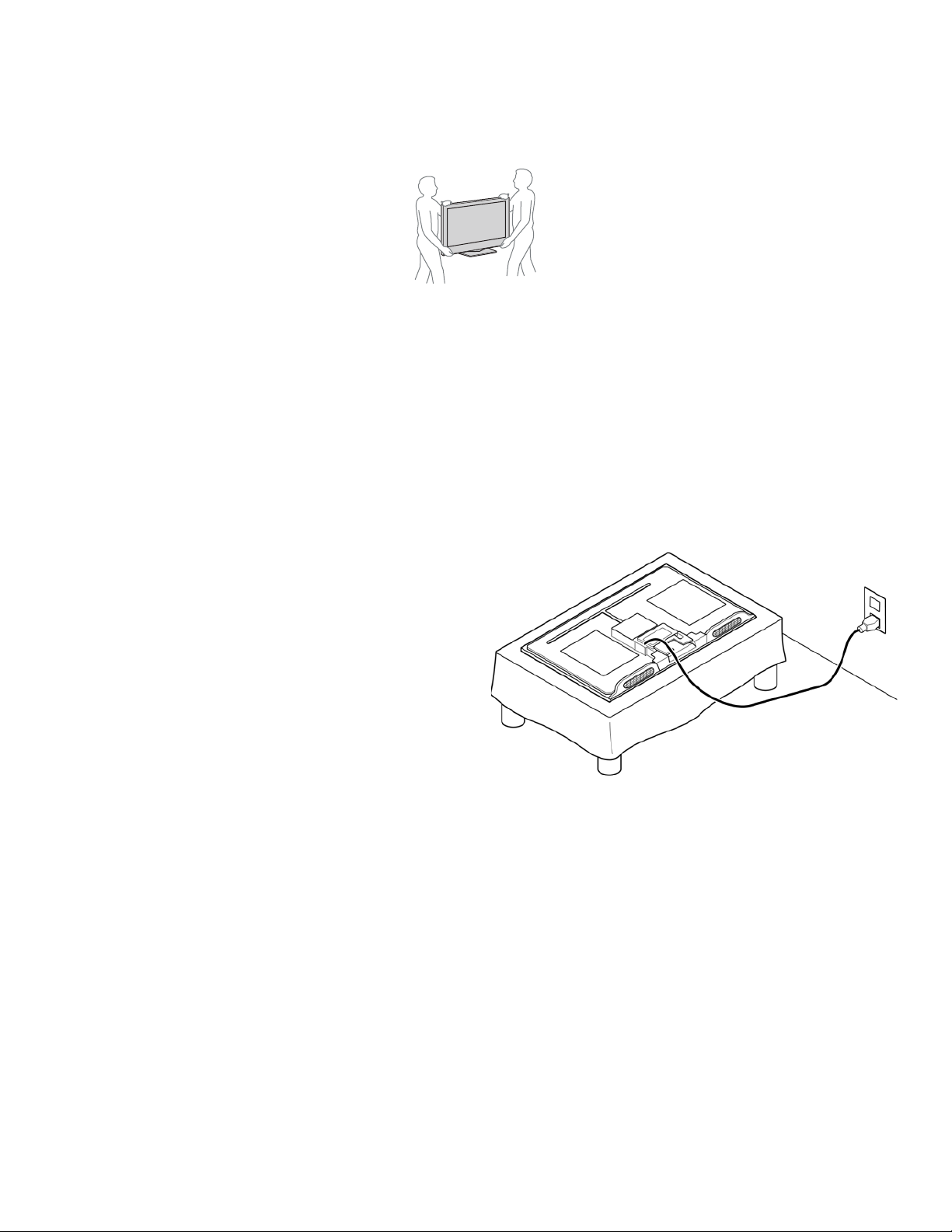

LEAKAGE TEST

The AC leakage from any exposed metal part to earth

ground and from all exposed metal parts to any exposed

metal part having a return to chassis, must not exceed

0.5 mA (500 microamperes). Leakage current can be

measured by any one of three methods.

1. A commercial leakage tester. Follow the

manufacturers’ instructions provided with the

tester.

2. A battery-operated AC milliammeter.

3. Measuring the voltage drop across a resistor

by means of a VOM or battery-operated AC

voltmeter. The “limit” indication is 0.75 V, so

analog meters must have an accurate low

voltage scale. Nearly all battery-operated digital

multimeters that have a 2 VAC range are suitable.

(see Figure A)

Figure A. Use an AC voltmeter to check AC leakage.

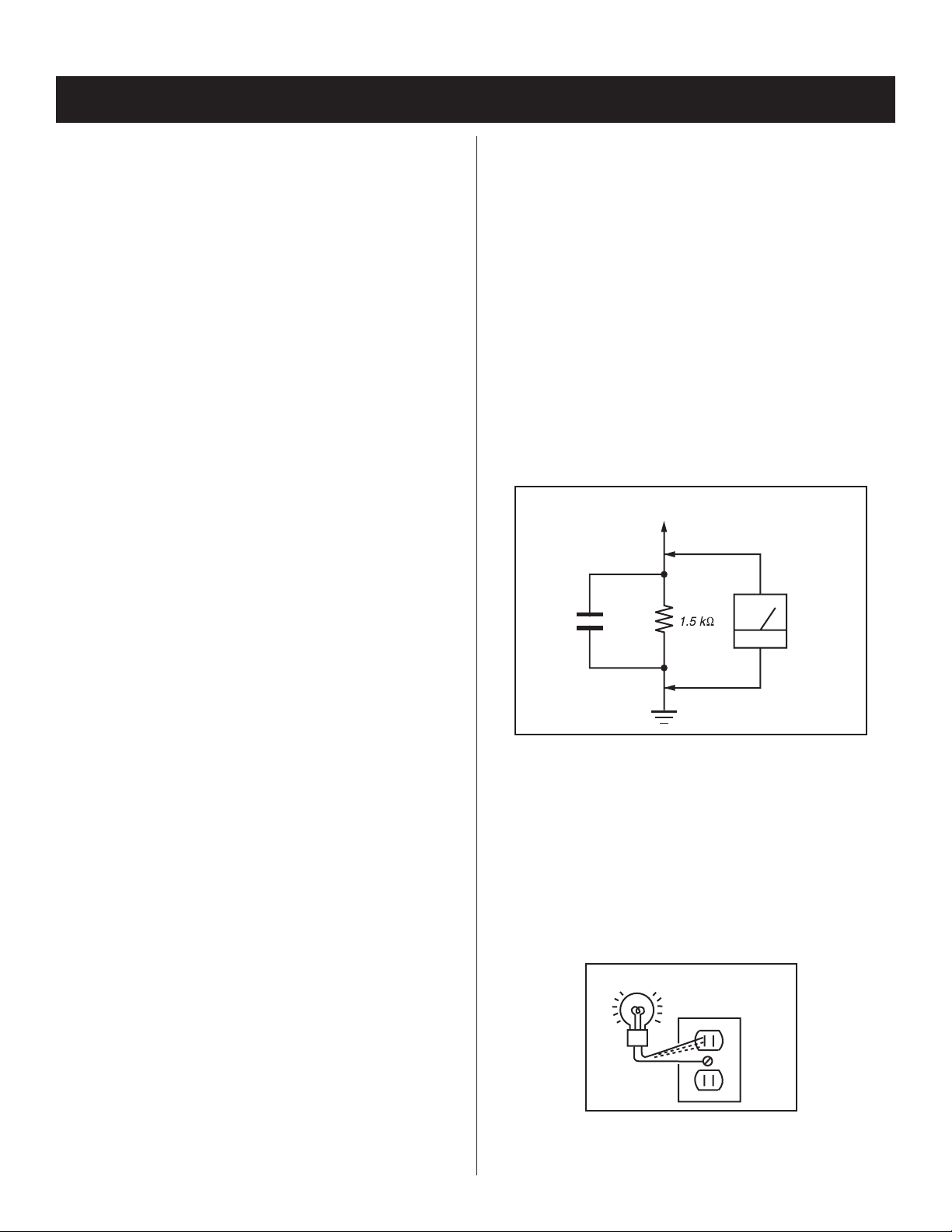

HOW TO FIND A GOOD EARTH GROUND

The cover-plate retaining screw on most AC outlet boxes

is at earth ground. Verify the AC outlet box retaining screw

ground by connecting a 60W to 100W incandescent

(not a neon or uorescent lamp) between the hot side

of the receptacle and the retaining screw. Try both slots,

if necessary, to locate the hot side on the line; the lamp

should light at normal brilliance if the screw is at ground

potential. (see Figure B)

AZ3TK 6

Trouble Light

AC Outlet Box

Figure B. Checking for earth ground.

Page 7

Th

e circuit boards used in these models have been processed using

Lead Free Solder. The boards are identified by the LF logo located

close to the board designation e.g. H1 etc [ see example ]. The

servicing of these boards requires special precautions to be taken as

outlined below.

example

It is strongly recommended to use Lead Free Solder material in order to guarantee optimal quality of new solder joints.

Lead Free Solder is available under the following part numbers :

rebmuntraP retemaiD skrameR

91-500-046-7mm3.0gK52.0

02-500-046-7mm4.0gK05.0

12-500-046-7mm5.0gK05.0

22-500-046-7mm6.0gK52.0

32-500-046-7mm8.0gK00.1

42-500-046-7mm0.1gK00.1

52-500-046-7mm2.1gK00.1

62-500-046-7mm6.1gK00.1

AZ3TK

Due to the higher melting point of Lead Free Solder the soldering iron tip temperature needs to be set to 370 degrees celsius.

This requires soldering equipment capable of accurate temperature control coupled with a good heat recovery characteristics.

AZ3TK 7

Page 8

AZ3TK

SECTION 1: DIAGRAMS

1-1. PRINTED CIRCUIT BOARDS AND SCHEMATIC DIAGRAMS INFORMATION

REFERENCE INFORMATION

All capacitors are in µF unless otherwise noted. pF : µµF 50WV or

less are not indicated except for electrolytics and tantalums.

All electrolytics are in 50V unless otherwise specied.

All resistors are in ohms. kΩ=1000Ω, MΩ=1000kΩ

Indication of resistance, which does not have one for rating

electrical power, is as follows: Pitch : 5mm

Rating electrical power :

1

/4 W in resistance, 1/

W and 1/

10

W in chip resistance.

16

1

/4 W

: nonammable resistor

: fusible resistor

: internal component

: panel designation and adjustment for repair

: earth ground

RESISTOR

: RN METAL FILM

: RC SOLID

: FPRD NONFLAMMABLE CARBON

: FUSE NONFLAMMABLE FUSIBLE

: RW NONFLAMMABLE WIREWOUND

: RS NONFLAMMABLE METAL OXIDE

: RB NONFLAMMABLE CEMENT

: ADJUSTMENT RESISTOR

COIL

: LF-8L MICRO INDUCTOR

Terminal name of semiconductors in silk screen

printed circuit ( )

Device Printed symbol Terminal name

Transistor

1

*

: earth-chassis

Transistor

2

All variable and adjustable resistors have characteristic curve B, unless

3

Diode

Cathode

otherwise noted.

Readings are taken with a color-bar signal input.

Readings are taken with a 10MΩ digital multimeter.

Voltages are DC with respect to ground unless otherwise noted.

Voltage variations may be noted due to normal production

tolerances.

All voltages are in V.

S : Measurement impossibility.

: B+line.

: B-line. (Actual measured value may be different).

: signal path. (RF)

Circled numbers are waveform references.

The components identied by shading and

only with part number specied.

The symbol indicates a fast-blow fuse and is displayed on the component

side of the board. Replace only with fuse of the same rating as marked.

NOTE: The components identied by a red outline and a mark contain condential

information. Specic instructions must be adhered to whenever these components

are repaired and/or replaced.

See Appendix A: Encryption Key Components in the back of this manual.

!

symbol are critical for safety. Replace

Diode

Diode

5

Diode

6

Diode

7

8

Diode

Diode

9

Diode

10

Diode

11

Diode

12

Transistor

13

(FET)

Transistor

14

(FET)

Transistor

15

(FET)

Transistor

16

Transistor

17

Transistor

18

Transistor

19

Transistor

20

Transistor

21

Transistor

22

Transistor

23

Discrete semiconductor

–

(Chip semiconductors that are not actually used are included.)

Anode

Anode

Anode

Anode Cathode

Anode

Anode Anode

Cathode

Cathode

Anode

Anode

Cathode

4

AZ3TK 8

CAPACITOR

: TA TANTALUM

: PS STYROL

: PP POLYPROPYLENE

: PT MYLAR

: MPS METALIZED POLYESTER

: MPP METALIZED POLYPROPYLENE

: ALB BIPOLAR

: ALT HIGH TEMPERATURE

: ALR HIGH RIPPLE

Collector

Base

Collector

Base

Cathode

Cathode

Common

Common

Common

Common

Common

Common

Drain

Drain

C1

E1

C1

E2

C2

B1

E2

C2

Emitter

Emitter

(NC)

(NC)

Cathode

Anode

Cathode

Cathode

Cathode

Anode

Anode

Source

Gate

Source

Gate

Source

Drain

Gate

Emitter

Collector

Base

B1 E1C2

B2 C1E2

B2 E2

B1 C2

B2 E2C1

B1 C2E1

B2 E2

B1 C2E1

B1 E1

C1(B2)

(B2)

E1

E2

C2C1

(B2)

E1

B1

C1

Anode

Circuit

D

G

D

S

B1

B1

B1

B1

B1

B1

D

G

S

S

D

G

S

C2B2C1

E1

E2

C2B2C1

E1

E2

E2B2E1

C1

C2

C2C1(B2)

E2

E2

E2E1(B2)

C1

C2

C2E1(B2)

C1

C2

Ver.1.6

G

Page 9

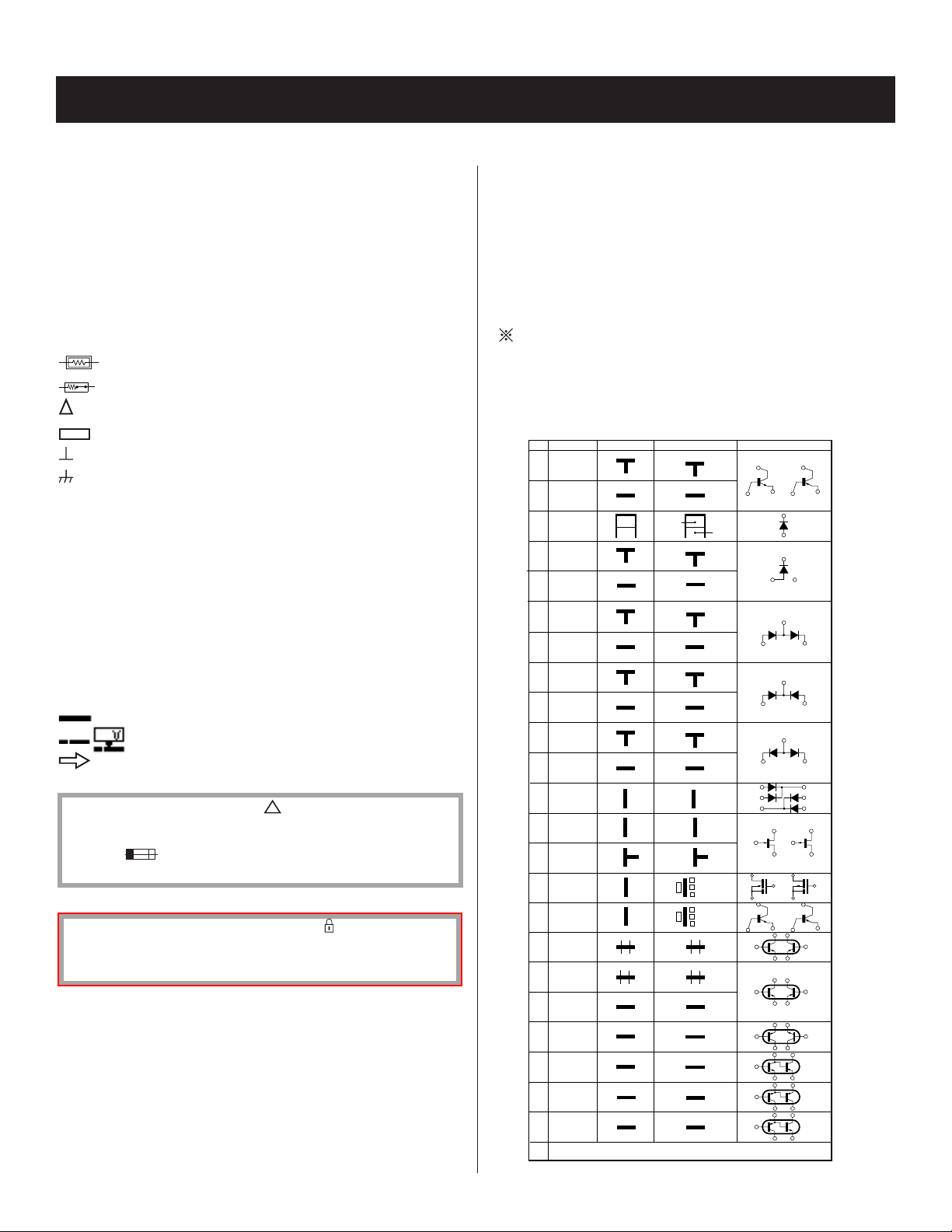

1-2. BLOCK DIAGRAM

AZ3TK

AZ3TK 9

Page 10

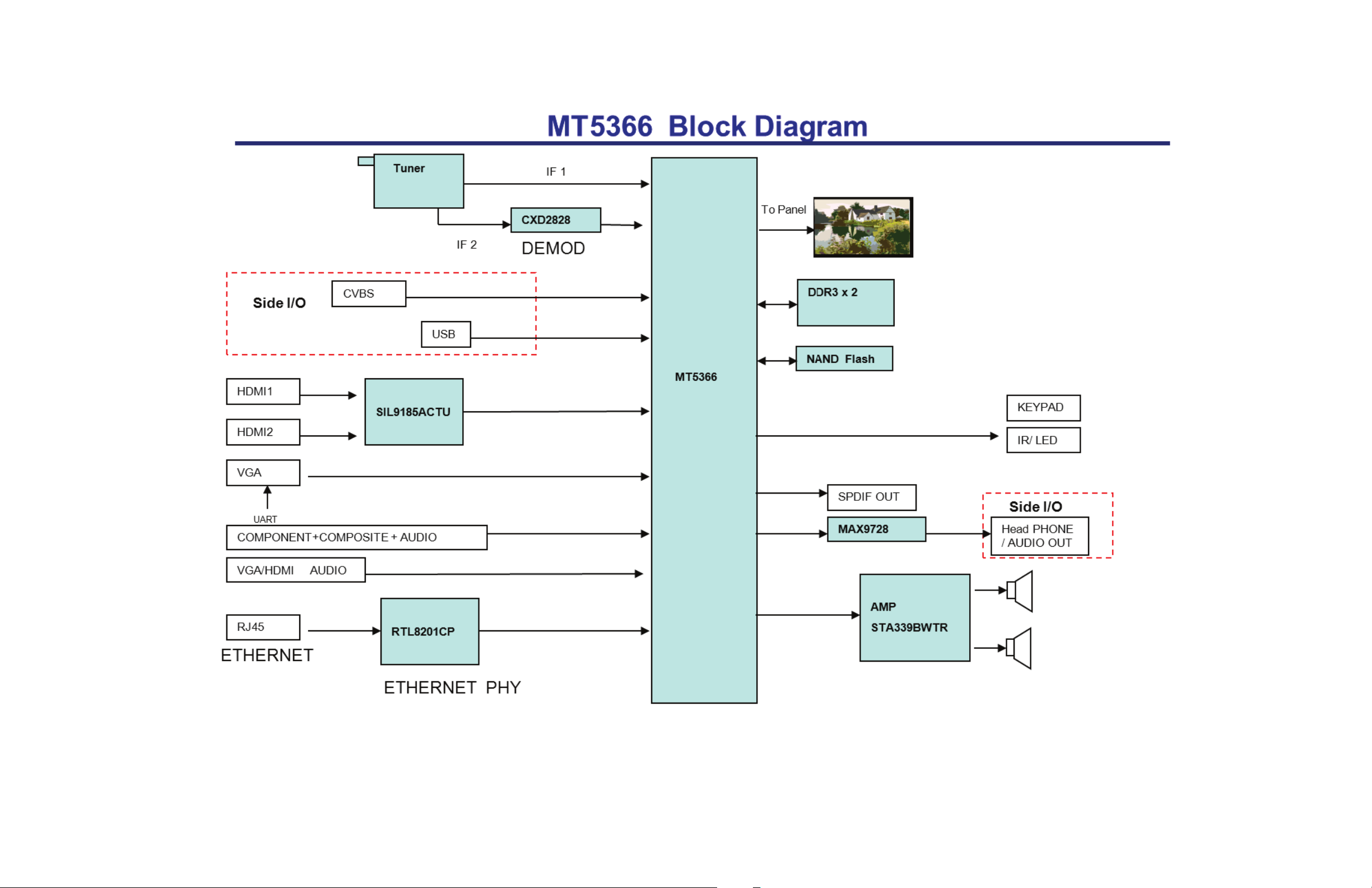

1-3. CONNECTOR DIAGRAMS

Panel

AZ3TK

AC

CN4001

CN201

CN4002

CN4003

CN8001

Main board

Power Board

TCON Board

Key Pad board

IR board

AZ3TK 10

Page 11

A BOARD SCHEMATIC

A

A

B

B

C

C

D

D

E

E

4

4

3

3

2

2

1 1

OPWRSB

BL_DIMMING

BL_ON/OFF

AC_DET

BL_DIMMING

OPWRSB

AC_DET#

INVERTER_DET#

BRIGHT_ADJAC_DET

BL_ON/OFF INVERTER_ON_OFF

BRIGHT_ADJ

INVERTER_ON_OFF

24V

STANDBY_CON

AC_DET#

INVERTER_DET#

3V3SB

AVDD3V3

+5VSB

+5V_SW

+5VSB

VCCK

AVDD3V3

DVDD3V3

VCCK

+12V

3V3SB

+5VSB

AVDD1V2

AVDD3V3

+5V_SW

+5V_SW

3V3SB

VCCK

+5VSB

+24V

DVDD3V3

24V

AVDD1V2

+5VSB

+24V

+12V

OPWRSB9

BL_DIMMING13

BL_ON/OFF13

AC_DET10,13

DVDD3V35,8,9,13,17

3V3SB6,7,9,13

GND3,4,5,6,7,8,9,10,11,12,13,14,16,17

VCCK9,13

AVDD3V34,7,10,11,12,13,14

AVDD1V27,8,9,12,14

+12V14

+5VSB4,5,6,9

+5V_SW5,7,10,12,13,14,16

+24V11

24V13

INVERTER_DET#13

AC_DET 10,13

STANDBY 13

OEM MODEL

Size

Rev

Date

Sheet

of

TPV MODEL

PCB NAME

T P V ( Top Victory Electronics Co . , Ltd. )

Key Component

絬 隔 瓜 絪 腹

FNNSAASN2AC23E

BDBT

1 16Wednesday, December 07, 2011

715G5177-M0D-000-004K

SYSTEM POWER

G5177-M0F-000-004K-1-111114

OEM MODEL

Size

Rev

Date

Sheet

of

TPV MODEL

PCB NAME

T P V ( Top Victory Electronics Co . , Ltd. )

Key Component

絬 隔 瓜 絪 腹

FNNSAASN2AC23E

BDBT

Wednesday, December 07, 2011

715G5177-M0D-000-004K

SYSTEM POWER

G5177-M0F-000-004K-1-111114

OEM MODEL

Size

Rev

Date

Sheet

of

TPV MODEL

PCB NAME

T P V ( Top Victory Electronics Co . , Ltd. )

Key Component

絬 隔 瓜 絪 腹

FNNSAASN2AC23E

BDBT

Wednesday, December 07, 2011

715G5177-M0D-000-004K

SYSTEM POWER

G5177-M0F-000-004K-1-111114

Control Interface

+5V Switch

Detection

INVERTER ON/OFF

H: OFF

L: ON

INVERTER ON/OFF

1.2 x (1+ 0/110) = 1.2V

Bright_Adj

Max:3.3V

Min: 0V

BRIGHT ADJUST

AC Detect

R2

Vout = 0.9x(R1+R2)/R2

R1

MAIN POWER

HI = > POWER_ON

LO = > POWER_OFF

1.149V

MTK

R713

13K OHM +-1%

R713

13K OHM +-1%

CN701

CONN

CN701

CONN

1

2

3

4

5

6

7

8

9

10

11

12

13

14

+

C709

100uF16V

+

C709

100uF16V

+

C704

220uF/16V

+

C704

220uF/16V

R706

100K 1/16W 5%

R706

100K 1/16W 5%

+

C719

100uF16V

+

C719

100uF16V

FB701

120R/6000mA

FB701

120R/6000mA

1

2

U702

G1117-33T63Uf

U702

G1117-33T63Uf

VI

3

VO

2

GND14

4

+

C728

100uF16V

+

C728

100uF16V

Q703

BC847C

Q703

BC847C

F700

5A 32V

F700

5A 32V

C713

100NF

C713

100NF

R704

51K 1/16W 5%

R704

51K 1/16W 5%

R707

2K7 1/16W 5%

R707

2K7 1/16W 5%

C708

10UF 10V

C708

10UF 10V

FB704

120R/6000mA

FB704

120R/6000mA

1 2

C721

3.3nF 50V

C721

3.3nF 50V

R712

3.6K 1%

R712

3.6K 1%

R730

4K7 1/16W 5%

R730

4K7 1/16W 5%

R726

10K 1/16W 5%

R726

10K 1/16W 5%

R714

9K1 1/16W 5%

R714

9K1 1/16W 5%

U703

BD9329EFJ

U703

BD9329EFJ

BST

1

VIN

2

SW

3

GND

4

FB

5

COMP

6

EN

7

SS

8

E-Pad

9

C725

NC/10uF 10V

C725

NC/10uF 10V

R70322K 1/16W 5% R70322K 1/16W 5%

C714

22N 25V

C714

22N 25V

C715

100NF

C715

100NF

Q702

AON4421

Q702

AON4421

D1D2D3G

4

S

5

D6D7D

8

R701

100R 1/16W 5%

R701

100R 1/16W 5%

C726

NC/22UF

C726

NC/22UF

C702

1UF 10V

C702

1UF 10V

R732

0R05 1/4W

R732

0R05 1/4W

R705

1K 1/16W 5%

R705

1K 1/16W 5%

C711

1uF 16V

C711

1uF 16V

R728

100R 1/16W 5%

R728

100R 1/16W 5%

R727

100R 1/16W 5%

R727

100R 1/16W 5%

L701 6.8uH

L701 6.8uH

R715

1K 1/16W 5%

R715

1K 1/16W 5%

R725

10K 1/16W 5%

R725

10K 1/16W 5%

+

C710

100uF16V

+

C710

100uF16V

R729

68K 1/16W 1%

R729

68K 1/16W 1%

C720

1UF 10V

C720

1UF 10V

U705U705

VI

3

VO

2

GND

1

4

4

C727

1UF 10V

C727

1UF 10V

U701

G1084-33TU3Uf

U701

G1084-33TU3Uf

VIN

3

VOUT

2

GND

1

C705

1UF 10V

C705

1UF 10V

+

C718

220uF/16V

+

C718

220uF/16V

C701

100NF

C701

100NF

A-Board

A BOARD SCHEMATIC DIAGRAM (1 OF 16)

AZ3TK

AZ3TK 11

Page 12

A BOARD SCHEMATIC DIAGRAM (2 OF 16)

5

5

4

4

3

3

2

2

1

1

D

D

C

C

B

B

A A

VGA_R_In

VGA_L_In

VSYNC#

VGASCL

VSYNC#

HSYNC#

VGASDA

HSYNC#

VGA11

GRN

VSYNC

HSYNC

RP

BP

SOG

VGACOM

GP

GRN

BLU

BLU

RED

RED

VGA_L_In

VGA_R_In

VGASCL

VGASDA

U0TX

U0RX

U0RX

G_G

VGA_Audio_L_In

VGA_Audio_R_In

VSYNC

HSYNC

BP

SOG

GP

VGACOM

RP

G_G

VGA_5V

U0TX

VGA_5V

VGA_5V

VGA11

VGASDA

VGASCL

+5VSB

VGA_L_In12

VGA_R_In12

VSYNC12

HSYNC12

BP12

SOG12

GP12

VGACOM12

RP12

VGASCL12

VGASDA12

U0TX9

U0RX9

+5VSB2,4,5,6,9

GND2,4,5,6,7,8,9,10,11,12,13,14,16,17

OEM MODEL

Size

Rev

Date

Sheet

of

TPV MODEL

PCB NAME

T P V ( Top Victory Electronics Co . , Ltd. )

Key Component

絬 隔 瓜 絪 腹

FNNSAASN2AC23E

BDBT

2 16Wednesday, December 07, 2011

715G5177-M0D-000-004K

VGA

G5177-M0F-000-004K-1-111114

OEM MODEL

Size

Rev

Date

Sheet

of

TPV MODEL

PCB NAME

T P V ( Top Victory Electronics Co . , Ltd. )

Key Component

絬 隔 瓜 絪 腹

FNNSAASN2AC23E

BDBT

Wednesday, December 07, 2011

715G5177-M0D-000-004K

VGA

G5177-M0F-000-004K-1-111114

OEM MODEL

Size

Rev

Date

Sheet

of

TPV MODEL

PCB NAME

T P V ( Top Victory Electronics Co . , Ltd. )

Key Component

絬 隔 瓜 絪 腹

FNNSAASN2AC23E

BDBT

Wednesday, December 07, 2011

715G5177-M0D-000-004K

VGA

G5177-M0F-000-004K-1-111114

Wake Up TV From Power Saving Mode

VGA SYNC SLICER

VGA CONNECTOR

Audio Input

VGA Audio Input

Near CONN.

Other Control Interface

Video Input

VGA Switch

Near MT5366

Near VGA CONN.

I2C

ZD109

VPORT0603100KV05

ZD109

VPORT0603100KV05

12

R107

0R05 1/10W

R107

0R05 1/10W

C116

47pF 50V

C116

47pF 50V

R181

0R05 1/10W

R181

0R05 1/10W

R101

1K 1/16W 5%

R101

1K 1/16W 5%

R143

47K +-1% 1/16W

R143

47K +-1% 1/16W

Q103

BC847C

Q103

BC847C

C119

NC/5PF 50V

C119

NC/5PF 50V

ZD117

VPORT0603100KV05

ZD117

VPORT0603100KV05

12

R133

100R 1/16W 5%

R133

100R 1/16W 5%

R137

100R 1/16W 5%

R137

100R 1/16W 5%

C115

10N 50V

C115

10N 50V

C120

10N 50V

C120

10N 50V

C117

NC/5PF 50V

C117

NC/5PF 50V

ZD112

VPORT0603100KV05

ZD112

VPORT0603100KV05

12

C118

1.5nF 50V

C118

1.5nF 50V

R144

75R 1/16W 1%

R144

75R 1/16W 1%

R125

75R 1/16W 1%

R125

75R 1/16W 1%

R139

47K +-1% 1/16W

R139

47K +-1% 1/16W

R124 0R05 1/16WR124 0R05 1/16W

ZD115

VPORT0603100KV05

ZD115

VPORT0603100KV05

12

R129 0R05 1/16WR129 0R05 1/16W

R122

100R 1/16W 5%

R122

100R 1/16W 5%

R142

47K 1/16W 5%

R142

47K 1/16W 5%

C101

100NF

C101

100NF

CN102

CONN

CN102

CONN

1

2

3

ZD110

VPORT0603100KV05

ZD110

VPORT0603100KV05

1

2

ZD111

VPORT0603100KV05

ZD111

VPORT0603100KV05

12

C126

47pF 50V

C126

47pF 50V

C123

10UF 10V

C123

10UF 10V

ZD114

VPORT0603100KV05

ZD114

VPORT0603100KV05

12

R126

0R05 1/10W

R126

0R05 1/10W

R120

1K 1/16W 5%

R120

1K 1/16W 5%

Q101

BC847C

Q101

BC847C

C125

10UF 10V

C125

10UF 10V

R108

0R05 1/10W

R108

0R05 1/10W

R132

47K 1/16W 5%

R132

47K 1/16W 5%

CN101

D-SUB 15P

CN101

D-SUB 15P

1

6

2

7

3

8

4

9

5

11

12

13

14

15

10

1716

18 19

ZD119

VPORT0603100KV05

ZD119

VPORT0603100KV05

12

C122

10N 50V

C122

10N 50V

R121

10K 1/16W 5%

R121

10K 1/16W 5%

ZD113

VPORT0603100KV05

ZD113

VPORT0603100KV05

12

R127

0R05 1/16W

R127

0R05 1/16W

C121

47pF 50V

C121

47pF 50V

ZD116

VPORT0603100KV05

ZD116

VPORT0603100KV05

1

2

R134

75R 1/16W 1%

R134

75R 1/16W 1%

C124

10N 50V

C124

10N 50V

R141

100R 1/16W 5%

R141

100R 1/16W 5%

A-Board

AZ3TK

AZ3TK 12

Page 13

A BOARD SCHEMATIC DIAGRAM (3 OF 16)

5

5

4

4

3

3

2

2

1

1

D

D

C

C

B

B

A A

PR_IN_1

PB_IN_1

Y_IN_1

YPbPr1R_IN

YPbPr1L_IN

GPIO1

GPIO1

PR1_DET

PR1_DET

AVDD3V3

AVDD3V3

+5VSB

+5VSB

PB0P 12

PR0P 12

Y0P 12

COM0 12

SOY0 12

YPbPr_L_In1 12

YPbPr_R_In1 12

CVBS0P 12

GND2,3,5,6,7,8,9,10,11,12,13,14,16,17

AVDD3V32,7,10,11,12,13,14

GPIO113

+5VSB2,5,6,9

OEM MODEL

Size

Rev

Date

Sheet

of

TPV MODEL

PCB NAME

T P V ( Top Victory Electronics Co . , Ltd. )

Key Component

絬 隔 瓜 絪 腹

FNNSAASN2AC23E

BDBT

3 16Wednesday, December 07, 2011

715G5177-M0D-000-004K

YPBPR

G5177-M0F-000-004K-1-111114

OEM MODEL

Size

Rev

Date

Sheet

of

TPV MODEL

PCB NAME

T P V ( Top Victory Electronics Co . , Ltd. )

Key Component

絬 隔 瓜 絪 腹

FNNSAASN2AC23E

BDBT

Wednesday, December 07, 2011

715G5177-M0D-000-004K

YPBPR

G5177-M0F-000-004K-1-111114

OEM MODEL

Size

Rev

Date

Sheet

of

TPV MODEL

PCB NAME

T P V ( Top Victory Electronics Co . , Ltd. )

Key Component

絬 隔 瓜 絪 腹

FNNSAASN2AC23E

BDBT

Wednesday, December 07, 2011

715G5177-M0D-000-004K

YPBPR

G5177-M0F-000-004K-1-111114

YPbPr1 Video Input

NEARLY CONN.

YPbPr1 Audio Input

R162

56R 1/16W 1%

R162

56R 1/16W 1%

D107

BAV99

D107

BAV99

3

1

2

C139

47pF 50V

C139

47pF 50V

ZD123

VPORT0603100KV05

ZD123

VPORT0603100KV05

12

C127

1.5nF 50V

C127

1.5nF 50V

R4057 100R 1/16W 5%R4057 100R 1/16W 5%

R166

100R 1/16W 5%

R166

100R 1/16W 5%

R158

100R 1/16W 5%

R158

100R 1/16W 5%

R169

47K +-1% 1/16W

R169

47K +-1% 1/16W

R163

56R 1/16W 1%

R163

56R 1/16W 1%

R1152

100R 1/16W 5%

R1152

100R 1/16W 5%

R171

47K +-1% 1/16W

R171

47K +-1% 1/16W

R165

18R 1/16W 5%

R165

18R 1/16W 5%

R153

56R 1/16W 1%

R153

56R 1/16W 1%

C145

10UF 10V

C145

10UF 10V

C1125

47nF 16V

C1125

47nF 16V

C176

100NF

C176

100NF

ZD120

VPORT0603100KV05

ZD120

VPORT0603100KV05

1

2

ZD122

VPORT0603100KV05

ZD122

VPORT0603100KV05

12

R182

0R05 1/10W

R182

0R05 1/10W

R4056

100K 1/16W 5%

R4056

100K 1/16W 5%

ZD118

VPORT0603100KV05

ZD118

VPORT0603100KV05

1

2

C131

47pF 50V

C131

47pF 50V

C135

10N 50V

C135

10N 50V

E

A

B

C

D

CN111

RCA JACK

E

A

B

C

D

CN111

RCA JACK

1

2

3

4

5

6

7

8

9

10

11

12

R150

100R 1/16W 5%

R150

100R 1/16W 5%

R156

100R 1/16W 5%

R156

100R 1/16W 5%

C141

10N 50V

C141

10N 50V

C129

10N 50V

C129

10N 50V

R172 100R 1/16W 5%R172 100R 1/16W 5%

D108

BAS316

D108

BAS316

C143

10UF 10V

C143

10UF 10V

R157

18R 1/16W 5%

R157

18R 1/16W 5%

C134

10N 50V

C134

10N 50V

C140

100N16V

C140

100N16V

R149

18R 1/16W 5%

R149

18R 1/16W 5%

C138

47pF 50V

C138

47pF 50V

A-Board

AZ3TK

AZ3TK 13

Page 14

A BOARD SCHEMATIC DIAGRAM (4 OF 16)

5

5

4

4

3

3

2

2

1

1

D

D

C

C

B

B

A A

CVBS1P

SPDIF_OUT

SIDE_CVBS_IN

SIDE_AudioLIN

SIDE_AudioRIN

AV2_L_In

AV2_R_In

AV2_R_In

CVBS1P

AV2_L_In

USB_DP0

USB_DM0

USB_PWR_EN0

USB_OC_COM

USB_DP0

USB_DM0

CVBS_COM

SPDIF_OUT

USB_OC_COM

USB_PWR_EN0

CVBS_COM

+5V_SW

DVDD3V3

+5V_SW

DVDD3V3

DVDD3V3

+5VSB

+5VSB

AV2_L_In12

CVBS1P12

AV2_R_In12

SPDIF_OUT12

USB_DP014

USB_DM014

USB_PWR_EN013

USB_OC_COM13

+5V_SW2,7,10,12,13,14,16

GND2,3,4,6,7,8,9,10,11,12,13,14,16,17

DVDD3V32,8,9,13,17

CVBS_COM12

+5VSB2,4,6,9

OEM MODEL

Size

Rev

Date

Sheet

of

TPV MODEL

PCB NAME

T P V ( Top Victory Electronics Co . , Ltd. )

Key Component

絬 隔 瓜 絪 腹

FNNSAASN2AC23E

BDBT

4 16Wednesday, December 07, 2011

715G5177-M0D-000-004K

SIDE AV/SPDIF/USB/SIDE HDMI

G5177-M0F-000-004K-1-111114

OEM MODEL

Size

Rev

Date

Sheet

of

TPV MODEL

PCB NAME

T P V ( Top Victory Electronics Co . , Ltd. )

Key Component

絬 隔 瓜 絪 腹

FNNSAASN2AC23E

BDBT

Wednesday, December 07, 2011

715G5177-M0D-000-004K

SIDE AV/SPDIF/USB/SIDE HDMI

G5177-M0F-000-004K-1-111114

OEM MODEL

Size

Rev

Date

Sheet

of

TPV MODEL

PCB NAME

T P V ( Top Victory Electronics Co . , Ltd. )

Key Component

絬 隔 瓜 絪 腹

FNNSAASN2AC23E

BDBT

Wednesday, December 07, 2011

715G5177-M0D-000-004K

SIDE AV/SPDIF/USB/SIDE HDMI

G5177-M0F-000-004K-1-111114

Side AV(CVBS)Video & Audio input

Side AV Video & Audio

Near MT5366

SPDIF

Near Connector

HI = > POWER ON

EQUAL LENGTH and DIFFERENTIAL

IMPEDANCE 90ohm

USB PORT 0

LO = > POWER OFF

USB

OPTICAL

SPDIF OUT

LO=> OC

HI = > NORMAL

0.7~1.5A

CN603

CONNNECTOR

CN603

CONNNECTOR

GND

1

VCC

2

VIN

3

R175

100R 1/16W 5%

R175

100R 1/16W 5%

R177

47K +-1% 1/16W

R177

47K +-1% 1/16W

1234

CN103

CONN

1234

CN103

CONN

1

2

3

4

65

C150

10UF 10V

C150

10UF 10V

R176

47K +-1% 1/16W

R176

47K +-1% 1/16W

R180

4K7 1/16W 5%

R180

4K7 1/16W 5%

C137

100NF

C137

100NF

R178

10K 1/16W 5%

R178

10K 1/16W 5%

C149

1UF 10V

C149

1UF 10V

C153

100N16V

C153

100N16V

R174

75R 1/16W 1%

R174

75R 1/16W 1%

U112

G5250M1T1U

U112

G5250M1T1U

OUT

1

GND

2

OC

3

EN

4

IN

5

C675

1UF 10V

C675

1UF 10V

ZD130

VPORT0603100KV05

ZD130

VPORT0603100KV05

1

2

R173

100R 1/16W 5%

R173

100R 1/16W 5%

C147

47nF 16V

C147

47nF 16V

+

C152

100uF16V

+

C152

100uF16V

C699

100NF

C699

100NF

ZD128

VPORT0603100KV05

ZD128

VPORT0603100KV05

1

2

C148

47pF 50V

C148

47pF 50V

R179

100R 1/16W 5%

R179

100R 1/16W 5%

R699

33R 1/16W 5%

R699

33R 1/16W 5%

D106

BAS316

D106

BAS316

ZD127

VPORT0603100KV05

ZD127

VPORT0603100KV05

12

ZD129

VPORT0603100KV05

ZD129

VPORT0603100KV05

1

2

R183

0R05 1/10W

R183

0R05 1/10W

D105

BAV99

D105

BAV99

3

1

2

C151

10UF 10V

C151

10UF 10V

A

B

C

CN128

CONN

A

B

C

CN128

CONN

1

2

3

4

5

6

7

A-Board

AZ3TK

AZ3TK 14

Page 15

A BOARD SCHEMATIC DIAGRAM (5 OF 16)

5

5

4

4

3

3

2

2

1

1

D

D

C

C

B

B

A A

RR1XC-

RR1X2-

RR1X0+

RR1X1-

RR1X0-

RR1X2+

RR1X0-

RR1XC+

RR1X1+

RR1X2+

RR1XC+

RR1X2-

RR1XC-

RR1X0+

RR1X1+

RR1X1-

RR1X1-

HPD1

RR1X0+

RR1X2-

RR1XC+

DDC_SCL1

DDC_SDA1

RR1XC-

RR1X0-

RR1X1+

RR1X2+

RR2X1-

HEC-

HPD2

RR2X0+

RR2X2-

RR2XC+

DDC_SCL2

DDC_SDA2

RR2XC-

RR2X0-

RR2X1+

RR2X2+

CEC_A2

OPWR2_5V

RR2X1+

RR2X0-

RR2X1-RR2X1-

DDC_SCL2

RR2X0+

RR2X2+

RR2XC+

DDC_SCL2

RR2XC+

RR2X0-

RR2XC-

RR2X2+

RR2XC+

RR2X0+

OPWR2_5V

RR2X2-

RR2X1+

RR2X2-

RR2X1+

RR2X0+

CEC_A2

RR2X2+

RR2X1-

RR2XC-

RR2XC-

DDC_SDA2

HPD2

RR2X2-

RR2X0-

DDC_SDA2

OPWR1_5V

DDC_SDA1

DDC_SCL1

RR1X2+

RR1X0+

RR1XC-

RR1XC+

RR1X1-

RR1X2-

HPD1

RR1X0-

RR1X1+

DDC_SDA1

CEC_A1

CEC_A1

DDC_SCL1

OPWR1_5V

OPWR2_5V

3V3SB

3V3SB

OPWR1_5V

OPWR1_5V

+5VSB

RR1X2+7

RR1X1+7

RR1XC-7

RR1X1-7

DDC_SCL17

RR1X2-7

HPD17

RR1X0+7

RR1X0-7

RR1XC+7

DDC_SDA17

RR2X2+7

RR2X1+7

RR2XC-7

RR2X1-7

DDC_SCL27

RR2X2-7

HPD27

RR2X0+7

RR2X0-7

RR2XC+7

DDC_SDA27

HD_CEC 7

GND2,3,4,5,7,8,9,10,11,12,13,14,16,17

OPWR2_5V7

3V3SB2,7,9,13

OPWR1_5V7

+5VSB2,4,5,9

OEM MODEL

Size

Rev

Date

Sheet

of

TPV MODEL

PCB NAME

T P V ( Top Victory Electronics Co . , Ltd. )

Key Component

絬 隔 瓜 絪 腹

FNNSAASN2AC23E

BDBT

5 16Wednesday, December 07, 2011

715G5177-M0F-000-004K

HDMI CONNECTOR

G5177-M0F-000-004K-1-111114

OEM MODEL

Size

Rev

Date

Sheet

of

TPV MODEL

PCB NAME

T P V ( Top Victory Electronics Co . , Ltd. )

Key Component

絬 隔 瓜 絪 腹

FNNSAASN2AC23E

BDBT

Wednesday, December 07, 2011

715G5177-M0F-000-004K

HDMI CONNECTOR

G5177-M0F-000-004K-1-111114

OEM MODEL

Size

Rev

Date

Sheet

of

TPV MODEL

PCB NAME

T P V ( Top Victory Electronics Co . , Ltd. )

Key Component

絬 隔 瓜 絪 腹

FNNSAASN2AC23E

BDBT

Wednesday, December 07, 2011

715G5177-M0F-000-004K

HDMI CONNECTOR

G5177-M0F-000-004K-1-111114

HDMI 2

HDMI 1

100ohm differential impedance

for TMDS traces.

100ohm differential impedance

for TMDS traces.

FB502 300OHMFB502 300OHM

1

2

U506

NC/RClamp0524P.TCT

U506

NC/RClamp0524P.TCT

IN1

1

IN2

2

GND

3

IN3

4

IN4

5

OUT4

6

OUT3

7

GND

8

OUT2

9

OUT1

10

ZD504

VPORT0603100KV05

ZD504

VPORT0603100KV05

1 2

R508 47K 1/16W 5%R508 47K 1/16W 5%

R511 47K 1/16W 5%R511 47K 1/16W 5%

R509 47K 1/16W 5%R509 47K 1/16W 5%

U507

NC/RClamp0524P.TCT

U507

NC/RClamp0524P.TCT

IN1

1

IN2

2

GND

3

IN3

4

IN4

5

OUT4

6

OUT3

7

GND

8

OUT2

9

OUT1

10

R501

27K 1/16W 5%

R501

27K 1/16W 5%

R510 47K 1/16W 5%R510 47K 1/16W 5%

ZD503

VPORT0603100KV05

ZD503

VPORT0603100KV05

1 2

U504

NC/RClamp0524P.TCT

U504

NC/RClamp0524P.TCT

IN1

1

IN2

2

GND

3

IN3

4

IN4

5

OUT4

6

OUT3

7

GND

8

OUT2

9

OUT1

10

C502

100N16V

C502

100N16V

CN503

HDMI CONN

CN503

HDMI CONN

SHELL1

20

SHELL2

21

D2+

1

D2 Shield

2

D2-

3

D1+

4

D1 Shield

5

D1-

6

D0+

7

D0 Shield

8

D0-

9

CK+

10

CK Shield

11

CK-

12

CE Remote

13

NC

14

DDC CLK

15

DDC DATA

16

GND

17

+5V

18

HP DET

19

SHELL4

23

SHELL3

22

SHELL5

24

SHELL6

25

SHELL7

26

U505

NC/RClamp0524P.TCT

U505

NC/RClamp0524P.TCT

IN1

1

IN2

2

GND

3

IN3

4

IN4

5

OUT4

6

OUT3

7

GND

8

OUT2

9

OUT1

10

FB501 300OHMFB501 300OHM

1

2

ZD506

VPORT0603100KV05

ZD506

VPORT0603100KV05

1 2

ZD502

NC/VPORT0603100KV05

ZD502

NC/VPORT0603100KV05

1

2

CN502

HDMI CONN

CN502

HDMI CONN

SHELL1

20

SHELL2

21

D2+

1

D2 Shield

2

D2-

3

D1+

4

D1 Shield

5

D1-

6

D0+

7

D0 Shield

8

D0-

9

CK+

10

CK Shield

11

CK-

12

CE Remote

13

NC

14

DDC CLK

15

DDC DATA

16

GND

17

+5V

18

HP DET

19

SHELL4

23

SHELL3

22

SHELL5

24

SHELL6

25

SHELL7

26

D501

BAS316

D501

BAS316

ZD505

VPORT0603100KV05

ZD505

VPORT0603100KV05

1 2

C503

100N16V

C503

100N16V

A-Board

AZ3TK

AZ3TK 15

Page 16

A BOARD SCHEMATIC DIAGRAM (6 OF 16)

5

5

4

4

3

3

2

2

1

1

D

D

C

C

B

B

A A

HD_CEC

OSCL1

RR1X1-

RR2X2+

RR2XC+

RR1XC+

RR2X1+

RR1X2-

RR2X2-

RR2X0-

RR1X0-

RR2X1-

RR1X0+

RR2X0+

RR2XC-

RR1XC-

RR1X2+

HPD1

HPD2

RR1X1+

OSDA1

DDC_SCL1

DDC_SDA1

M_RX1_1B

M_RX1_2B

M_RX1_2

HDMI_HPD

AVDD33_HDMI

M_RX1_1

AVDD33_HDMI

AVDD12_HDMI

M_RX1_C

AVDD12_HDMI

M_RX1_0

M_RX1_0B

M_RX1_CB

HDMI_CEC

HD_CEC

HDMI_CEC

SPDIF_OUT

HEC-

HDMISW_RST#

HDMI_SCL

HDMI_SDA

HDMISW_SCL#

M_RX1_2B

HDMI_SCL

DDC_SCL1

M_RX1_0

RR2X1-

DDC_SDA2

RR1X0+

RR2XC+

HDMISW_RST#

RR1X2+

M_RX1_0B

HDMI_SDA

RR2X0+

RR2X2+

RR1X0-

HPD1

RR1X2-

HDMISW_SCL#

M_RX1_1

RR2X2-

HPDIN

DDC_SDA1

M_RX1_C

RPWR2_5V

RR1X1-

M_RX1_1B

HPD2

RPWR1_5V

M_RX1_CB

RR1X1+

M_RX1_2

RR2X1+

DDC_SCL2

RR2XC-

RR2X0-

HDMISW_SDA#

RPWR1_5V

RPWR2_5V

TPWR

TPWR

HDMISW_SDA#

HDMI_HPD

DDC_SCL2

DDC_SDA2

RR1XC+

RR1XC-

OPWR1_5V

OPWR2_5V

AVDD3V3

AVDD1V2

AVDD1V2

AVDD3V3

+5V_SW

+5VSB

3V3SB

AVCC1V8

3V3SB_9185

3V3SB_9185

AVCC1V8

3V3SB_9185

AVCC1V8

DVDD1V8

AVCC1V8

AVCC1V8

AVCC1V8

3V3SB_9185

3V3SB_9185

AVCC1V8

AVCC1V8

3V3SB_9185

3V3SB_9185

DVDD1V8

DVDD1V8

3V3SB_9185

AVCC1V8

AVCC1V8

DVDD1V8

3V3SB_9185

3V3SB_9185

3V3SB

OPWR1_5V6

OPWR2_5V6

OSDA19,11,13

OSCL19,11,13

RR1XC+6

RR1X0-6

RR1X1+6

RR2X1+6

HPD26

RR2XC+6

RR1XC-6

RR1X2+6

RR2XC-6

RR2X2+6

RR2X2-6

RR2X0+6

RR2X1-6

RR1X1-6

HPD16

RR2X0-6

RR1X2-6

RR1X0+6

HD_CEC6

DDC_SDA16

DDC_SCL16

DDC_SCL26

DDC_SDA26

AVDD3V32,4,10,11,12,13,14

AVDD1V22,8,9,12,14

+5V_SW2,5,10,12,13,14,16

+5VSB2,4,5,6,9

GND2,3,4,5,6,8,9,10,11,12,13,14,16,17

3V3SB2,6,9,13

SPDIF_OUT5,12

HPD26

OSCL1 9,11,13

OPWR1_5V6

OPWR2_5V6

OSDA1 9,11,13

OEM MODEL

Size

Rev

Date

Sheet

of

TPV MODEL

PCB NAME

T P V ( Top Victory Electronics Co . , Ltd. )

Key Component

絬 隔 瓜 絪 腹

FNNSAASN2AC23E

BDBT

6

16

Wednesday, December 07, 2011

715G5177-M0D-000-004K

HDMI SWITCH

G5177-M0F-000-004K-1-111114

OEM MODEL

Size

Rev

Date

Sheet

of

TPV MODEL

PCB NAME

T P V ( Top Victory Electronics Co . , Ltd. )

Key Component

絬 隔 瓜 絪 腹

FNNSAASN2AC23E

BDBT

Wednesday, December 07, 2011

715G5177-M0D-000-004K

HDMI SWITCH

G5177-M0F-000-004K-1-111114

OEM MODEL

Size

Rev

Date

Sheet

of

TPV MODEL

PCB NAME

T P V ( Top Victory Electronics Co . , Ltd. )

Key Component

絬 隔 瓜 絪 腹

FNNSAASN2AC23E

BDBT

Wednesday, December 07, 2011

715G5177-M0D-000-004K

HDMI SWITCH

G5177-M0F-000-004K-1-111114

HDMI 3

HDMI 2

HDMI 1

PCB LAYOUT: Place all decoupling capacitors (0.1uf)as close to the pin

as possible.

( 17 mA )

( 61 mA )

Analog Power

MT5366

DEL R505

U502

G1117T63Uf

U502

G1117T63Uf

VIN

3

GND

1

VOUT

2

TH

4

R529 0R05 1/16WR529 0R05 1/16W

C512

100NF

C512

100NF

C556

100N16V

C556

100N16V

R522

120R 1% 1/10W

R522

120R 1% 1/10W

C510

10UF 10V

C510

10UF 10V

R520

NC/100K 1/16W 5%

R520

NC/100K 1/16W 5%

R524

56R 1/10W 1%

R524

56R 1/10W 1%

R523

0R05 1/16W

R523

0R05 1/16W

C509

100NF

C509

100NF

R556

0R05 1/10W

R556

0R05 1/10W

R534

0R05 1/10W

R534

0R05 1/10W

R515

10K 1/16W 5%

R515

10K 1/16W 5%

R525

NC/100K 1/16W 5%

R525

NC/100K 1/16W 5%

C506

100NF

C506

100NF

R519

0R05 1/16W

R519

0R05 1/16W

C508

100NF

C508

100NF

C514

1UF 10V

C514

1UF 10V

R502

NC/0R05 1/16W

R502

NC/0R05 1/16W

C525

100NF

C525

100NF

R514

10K 1/16W 5%

R514

10K 1/16W 5%

R513 4K7 1/16W 5%R513 4K7 1/16W 5%

C526

100NF

C526

100NF

C505

10UF 10V

C505

10UF 10V

MT5366GSNG

U401G

MT5366GSNG

U401G

PWR5V

AD6

HDMI_CEC

AB6

HDMI_HPD

AC6

HDMI_SCL

AC5

HDMI_SDA

AB5

AVDD33_HDMI

AE1

AVDD12_HDMI

AA6

AVSS33_HDMI

AC4

RX_0

AE3

RX_0B

AD3

RX_1

AE4

RX_1B

AD4

RX_2

AE5

RX_2B

AD5

RX_C

AE2

RX_CB

AD2

C523

10UF 10V

C523

10UF 10V

FB504

220R/2000mA

FB504

220R/2000mA

1

2

R516

10K 1/16W 5%

R516

10K 1/16W 5%

R533

NC/10K 1/16W 5%

R533

NC/10K 1/16W 5%

C527

100NF

C527

100NF

C528

100NF

C528

100NF

FB507

220R/2000mA

FB507

220R/2000mA

1

2

R530 0R05 1/16WR530 0R05 1/16W

C529

100NF

C529

100NF

C530

100NF

C530

100NF

C507

100NF

C507

100NF

C501

1uF 25V

C501

1uF 25V

R548

10K 1/16W 5%

R548

10K 1/16W 5%

R503 0R05 1/16WR503 0R05 1/16W

C515

1UF 10V

C515

1UF 10V

C531

100NF

C531

100NF

C555

100N16V

C555

100N16V

C524

10UF 10V

C524

10UF 10V

R560

0R05 1/10W

R560

0R05 1/10W

FB506

220R/2000mA

FB506

220R/2000mA

1

2

R512

1K 1/16W 5%

R512

1K 1/16W 5%

C518

10UF 10V

C518

10UF 10V

C504

10UF 10V

C504

10UF 10V

C516

1uF 16V

C516

1uF 16V

U501

SiI9185ACTU

U501

SiI9185ACTU

TX2+

1

TX2-

2

AGND

3

TX1+

4

TX1-

5

AVCC18

6

TX0+

7

TX0-

8

AGND

9

TXC+

10

TXC-

11

ExtSWING

12

RESET#

13

LSDA/PSEL0

14

LSCL/PSEL1

15

HPD0

16

AVCC18

17

R0XC-

18

R0XC+

19

AGND

20

R0X0-

21

R0X0+

22

AVCC33

23

R0X1-

24

R0X1+

25

AGND

26

R0X2-

27

R0X2+

28

AVCC18

29

DSDA0

30

DSCL0

31

RPWR0

32

DVDD18

33

DGND

34

I2CSEL/INT

35

HPD1

36

AVCC18

37

R1XC-

38

R1XC+

39

AGND

40

R1X0-41R1X0+42AVCC3343R1X1-44R1X1+45AGND46R1X2-47R1X2+48AVCC1849DSDA150DSCL151RPWR152CEC_D53CEC_A54AVCC3355HPD256AVCC1857R2XC-58R2XC+59AGND

60

R2X0-

61

R2X0+

62

AVCC33

63

R2X1-

64

R2X1+

65

AGND

66

R2X2-

67

R2X2+

68

AVCC18

69

DSDA2

70

DSCL2

71

RPWR2

72

DVDD18

73

DGND

74

TEST

75

HPDIN

76

TSDA

77

TSCL

78

TPWR/I2CADDR

79

AGND

80

C511

100NF

C511

100NF

A-Board

AZ3TK

AZ3TK 16

Page 17

A BOARD SCHEMATIC DIAGRAM (7 OF 16)

5

5

4

4

3

3

2

2

1

1

D D

C

C

B

B

A

A

RCLK0#

RCLK0 CLK0

CLK0#

CLK1#

RCLK1#

CLK1

RCLK1

RVREF4

B_A10

RVREF2

RDQ7

B_BA1

B_CAS#

RDQ2

RDQM0

B_CKE

B_RST#

B_A0

CLK0#

B_A1

B_A5

B_BA0

B_A11

CLK0

B_BA2

B_RAS#

RDQS0#

RDQ9

B_A3

RDQ0

B_A7

B_WE#

RVREF1

B_A6

RDQ3

RDQ4

RDQS0

B_A12

RDQ13

RDQ8

RDQ6

RDQM1

RDQ14

B_CS#

B_ODT

RDQ11

B_A9

RDQ12

B_A8

B_A4

B_A13

RDQ1

RDQ15

RDQ5

RDQS1#

B_A2

RDQS1

RDQ10

RCLK1

RDQS0

RDQS0#

RDQS2

RDQS1#

RDQS2#

RCLK0#

RCLK1#

RDQS3

RVREF5

RDQM3

AVDD12_MEMPLL

RDQM2

RCLK0

RDQS1

MEMTP

RDQM0

RDQS3#

RDQM1

MEMTN

RVREF3

1_BA2

1_WE#

1_A1

1_A9

1_CS#

1_A0

1_A13

1_BA1

1_A8

1_A4

1_ODT

1_CKE

1_A12

1_A7

1_A3

1_A11

1_CAS#

1_A6

1_BA0

1_A2

1_A10

1_RAS#

1_A5

RDQ5

RDQ27

RDQ29

RDQ26

RDQ12

RDQ17

RDQ16

RDQ6

RDQ22

RDQ8

RDQ15

RDQ28

RDQ21

RDQ23

RDQ7

RDQ13

RDQ4

RDQ25

RDQ20

RDQ18

RDQ10

RDQ3

RDQ9

RDQ0

RDQ24

RDQ19

RDQ30

RDQ14

RDQ2

RDQ11

RDQ1

RDQ31

1_RST#

1_A10

A_BA1

1_RAS#

1_A3

1_A1

1_BA0

A_BA0

B_A0

1_A11

1_BA1

B_RAS#

B_A1

1_A2

1_BA0

1_A7

1_A8

B_A3

1_WE#

1_WE#

1_A11

A_CS#

B_A8

B_A5

B_A2

B_CAS#

1_A0

B_A11

A_RST#

A_A7

B_BA0

1_ODT

1_RST#

B_BA1

B_A12

1_A12

1_RST#

B_BA2

1_A13

A_WE#

B_ODT

1_BA1

1_A6

1_A5

B_RST#

B_CKE

1_A8

B_CS#

B_A9

B_WE#

1_CAS#

B_A10

1_CS#

1_A3

B_A6

A_A8

A_A5

1_A4

1_A7

1_CKE

B_A7

B_A4

B_A13

1_CS#

1_A5

1_BA2

A_A11

A_A3 1_A9

RVREF5

AVDD12_MEMPLL

RVREF2

RVREF1

ZQ1

1_DDRV_N9

1_DDRV_C1

1_DDRV_H9

1_DDRV_N9

1_DDRV_H9

1_DDRV_F1

1_DDRV_R1

1_DDRV_C1

1_DDRV_R9

1_DDRV_N9

1_DDRV_H9

1_DDRV_F1

1_DDRV_R9

1_DDRV_R1

1_DDRV_C1

A_ODT

RDQS3

RDQ31

A_BA1

A_CKE

A_A4

RDQS2#

A_A13

RDQS2

RDQM2

CLK1#

RDQ28

A_RAS#

RDQ17

A_BA2

RVREF4

A_A1

A_A12

RDQ25

RDQ23

A_A3

A_BA0

RDQ30

A_A2

A_A6

A_A0

RDQ18

RDQ20

RDQ19

RDQ27

A_CS#

RDQ22

RVREF3

CLK1

A_A5

RDQ24

RDQS3#

RDQ16

A_A10

A_CAS#

A_RST#

A_A9

A_A8

RDQ21

A_A7

RDQ29

A_WE#

A_A11

RDQ26

RDQM3

ZQ2

2_DDRV_N1

2_DDRV_C1

2_DDRV_R1

2_DDRV_A8

2_DDRV_F1

2_DDRV_H9

2_DDRV_A8

2_DDRV_H92_DDRV_N1

2_DDRV_C1

2_DDRV_F1

2_DDRV_C9

2_DDRV_N1

2_DDRV_H9

2_DDRV_C1

2_DDRV_R1

2_DDRV_N1

2_DDRV_A8

2_DDRV_H9

2_DDRV_C9

2_DDRV_C9

2_DDRV_C9

1_A4

A_A13

A_RAS#

A_A4

1_A9

A_ODT

1_A6

1_ODT

A_CAS#

1_A1

1_CKE

A_A6

A_A1

1_RAS#

1_A2

1_A12

1_BA2

A_A0

1_CAS#

A_CKE

A_A12

A_A9

A_A2

1_A10

A_A10

1_A0

1_A13

A_BA2

DDRV

DDRV

DDRV

DDRV

DDRV

DDRV

DDRV

DVDD3V3

DDRV

AVDD1V2

DDRV

DDRV

DDRV

DDRV

DVDD3V3

AVDD1V2

DDRV

DDRV

GND2,3,4,5,6,7,9,10,11,12,13,14,16,17

AVDD1V22,7,9,12,14

DVDD3V32,5,9,13,17

OEM MODEL

Size

Rev

Date

Sheet

of

TPV MODEL

PCB NAME

T P V ( Top Victory Electronics Co . , Ltd. )

Key Component

絬 隔 瓜 絪 腹

FNNSAASN2AC23E

CDBT

7 16Wednesday, December 07, 2011

715G5177-M0D-000-004K

DDR3 DRAM

G5177-M0F-000-004K-1-111114

OEM MODEL

Size

Rev

Date

Sheet

of

TPV MODEL

PCB NAME

T P V ( Top Victory Electronics Co . , Ltd. )

Key Component

絬 隔 瓜 絪 腹

FNNSAASN2AC23E

CDBT

Wednesday, December 07, 2011

715G5177-M0D-000-004K

DDR3 DRAM

G5177-M0F-000-004K-1-111114

OEM MODEL

Size

Rev

Date

Sheet

of

TPV MODEL

PCB NAME

T P V ( Top Victory Electronics Co . , Ltd. )

Key Component

絬 隔 瓜 絪 腹

FNNSAASN2AC23E

CDBT

Wednesday, December 07, 2011

715G5177-M0D-000-004K

DDR3 DRAM

G5177-M0F-000-004K-1-111114

Damping and Termination for CLK

RVREF_as closed to U403 RVREF_as closed to U403

Near MT5366 NEAR DRAMNEAR DRAMNear MT5366

Damping and Termination for CLK

DDR#2 Bottom Side

Main Chip Bottom Side

MT5366 DE-CAP.

DDR3#1

MT5366

NEAR BRANCH

Damping for DDR#2 ADDR/CMD

NEAR BRANCH

Damping for DDR#1 ADDR/CMD

U401B

U402

DRAM POWER DDRV

RVREF_as closed to MT5363

AV1V2_MEMPLL

DDR#1 Bottom Side

RVREF_as closed to U402

RVREF_as closed to U402

U403

DDR3#2

For Layout

0603

FROM MTK

1.533V

R475

0R05 1/4W

R475

0R05 1/4W

C4007

10uF

C4007

10uF

R404

0R05 1/16W

R404

0R05 1/16W

RP405 200R

RP405 200R

1

2

3

4

8

7

6

5

RP400 200RRP400 200R

1

2

3

4

8

7

6

5

C404

100N16V

C404

100N16V

R412

1K 1/16W 1%

R412

1K 1/16W 1%

C428

100N16V

C428

100N16V

R419

1K 1/16W 1%

R419

1K 1/16W 1%

RP402 200R

RP402 200R

1

2

3

4

8

7

6

5

RP411 200R

RP411 200R

1

2

3

4

8

7

6

5

C413

100N16V

C413

100N16V

C407

100N16V

C407

100N16V

C405

100N16V

C405

100N16V

U403

H5TQ1G63DFR-H9C

U403

H5TQ1G63DFR-H9C

VDD_0

B2

NC_0

J1

VSS_0

A9

VSSQ_0

B1

UDQS#

B7

VDDQ_0

A1

DQU6

B8

VSSQ_1

B9

UDM

D3

UDQS

C7

VSSQ_2

D1

DQU7

A3

VDDQ_1

A8

DQU1

C3

VDDQ_2

C1

VDDQ_3

C9

DQU0

D7

VDDQ_4

D2

DQU4

A7

VSSQ_3

D8

DQU3

C2

DQU2

C8

VSSQ_4

E2

DQU5

A2

VDD_1

D9

NC_1

J9

VSS_1

B3

VSSQ_5

E8

LDQS#

G3

VDDQ_5

E9

DQL6

G2

VSSQ_6

F9

LDM

E7

LDQS

F3

VSSQ_7

G1

DQL7

H7

VDDQ_6

F1

DQL1

F7

VDDQ_7

H2

DQL0

E3

VDDQ_8

H9

DQL4

H3

VSSQ_8

G9

DQL3

F8

DQL2

F2

BA2

M3

DQL5

H8

VDD_5

N1

VREFDQ

H1

VSS_2

E1

VSS_5

J8

CK

J7

VDD_2

G7

CKE

K9

WE#

L3

RAS#

J3

CK#

K7

ODT

K1

RESET#

T2

BA0

M2

BA1

N8

CAS#

K3

CS#

L2

A10/AP

L7

A1

P7

A2

P3

A0

N3

VDD_3K2VSS_3

G8

A3

N2

A5

P2

A6

R8

A4

P8

A7

R2

A9

R3

A11

R7

A8

T8

VSS_4

J2

VDD_4

K8

A12/BC#

N7

NC_3

L9

ZQ

L8

NC_2

L1

VREFCA

M8

NC_4

M7

NC

T3

NC_6

T7

VSS_6

M1

VSS_7

M9

VSS_8

P1

VSS_9

P9

VSS_10

T1

VSS_11

T9

VDD_6

N9

VDD_7

R1

VDD_8

R9

R413

1K 1/16W 1%

R413

1K 1/16W 1%

C424

100N16V

C424

100N16V

R428

0R05 1/4W

R428

0R05 1/4W

RP401 200RRP401 200R

1

2

3

4

8

7

6

5

R409

0R05 1/10W

R409

0R05 1/10W

C425

10uF

C425

10uF

C403

100N16V

C403

100N16V

C416

100N16V

C416

100N16V

C408

1uF 25V

C408

1uF 25V

R417

1K 1/16W 1%

R417

1K 1/16W 1%

C432

100N16V

C432

100N16V

C434

100N16V

C434

100N16V

R410

1K 1/16W 1%

R410

1K 1/16W 1%

R476

0R05 1/4W

R476

0R05 1/4W

R411

1K 1/16W 1%

R411

1K 1/16W 1%

R464

0R05 1/10W

R464

0R05 1/10W

C426

100N16V

C426

100N16V

R403

1K 1/16W 1%

R403

1K 1/16W 1%

R425

0R05 1/10W

R425

0R05 1/10W

R455

0R05 1/4W

R455

0R05 1/4W

RP408 200R

RP408 200R

1

2

3

4

8

7

6

5

R4054

120R 1% 1/10W

R4054

120R 1% 1/10W

R408

0R05 1/10W

R408

0R05 1/10W

R458

0R05 1/10W

R458

0R05 1/10W

C418

100N16V

C418

100N16V

C472

10uF

C472

10uF

C427

100N16V

C427

100N16V

R435

0R05 1/10W

R435

0R05 1/10W

RP410 200R

RP410 200R

1

2

3

4

8

7

6

5

C414

100N16V

C414

100N16V

TP401

TP401

C400

100N16V

C400

100N16V

C423

100N16V

C423

100N16V

R414

1K 1/16W 1%

R414

1K 1/16W 1%

C421

100N16V

C421

100N16V

C449

100N16V

C449

100N16V

R405527R 1/10W 1% R405527R 1/10W 1%

C406

100N16V

C406

100N16V

R400

240 OHM +-5% 1/16W

R400

240 OHM +-5% 1/16W

C431

100N16V

C431

100N16V

U402

H5TQ1G63DFR-H9C

U402

H5TQ1G63DFR-H9C

VDD_0

B2

NC_0

J1

VSS_0

A9

VSSQ_0

B1

UDQS#

B7

VDDQ_0

A1

DQU6

B8

VSSQ_1

B9

UDM

D3

UDQS

C7

VSSQ_2

D1

DQU7

A3

VDDQ_1

A8

DQU1

C3

VDDQ_2

C1

VDDQ_3

C9

DQU0

D7

VDDQ_4

D2

DQU4

A7

VSSQ_3

D8

DQU3

C2

DQU2

C8

VSSQ_4

E2

DQU5

A2

VDD_1

D9

NC_1

J9

VSS_1

B3

VSSQ_5

E8

LDQS#

G3

VDDQ_5

E9

DQL6

G2

VSSQ_6

F9

LDM

E7

LDQS

F3

VSSQ_7

G1

DQL7

H7

VDDQ_6

F1

DQL1

F7

VDDQ_7

H2

DQL0

E3

VDDQ_8

H9

DQL4

H3

VSSQ_8

G9

DQL3

F8

DQL2

F2

BA2

M3

DQL5

H8

VDD_5

N1

VREFDQ

H1

VSS_2

E1

VSS_5

J8

CK

J7

VDD_2

G7

CKE

K9

WE#

L3

RAS#

J3

CK#

K7

ODT

K1

RESET#

T2

BA0

M2

BA1

N8

CAS#

K3

CS#

L2

A10/AP

L7

A1

P7

A2

P3

A0

N3

VDD_3K2VSS_3

G8

A3

N2

A5

P2

A6

R8

A4

P8

A7

R2

A9

R3

A11

R7

A8

T8

VSS_4

J2

VDD_4

K8

A12/BC#

N7

NC_3

L9

ZQ

L8

NC_2

L1

VREFCA

M8

NC_4

M7

NC

T3

NC_6

T7

VSS_6

M1

VSS_7

M9

VSS_8

P1

VSS_9

P9

VSS_10

T1

VSS_11

T9

VDD_6

N9

VDD_7

R1

VDD_8

R9

C415

100N16V

C415

100N16V

R466

0R05 1/4W

R466

0R05 1/4W

C410

NC/0.1uF 50V

C410

NC/0.1uF 50V

R406

100R 1/16W 5%

R406

100R 1/16W 5%

MT5366GSNG

U401B

MT5366GSNG

U401B

RDQ6//RDQ0

D13

RDQ0//RDQ1

D12

RDQ1//RDQ2

E13

RDQ7//RDQ3

D11

RDQ4//RDQ4

D14

RDQ5//RDQ5

E12

RDQ3//RDQ6

E14

RDQ2//RDQ7

E11

RDQ13//RDQ8

B10

RDQ11//RDQ9

B15

RDQ10//RDQ10

A10

RDQ12//RDQ11

A15

RDQ15//RDQ12

C11

RDQ9//RDQ13

C15

RDQ8//RDQ14

C10

RDQ14//RDQ15

C14

RDQ22//RDQ16

G5

RDQ23//RDQ17

J5

RDQ17//RDQ18

H5

RDQ16//RDQ19

J4

RDQ20//RDQ20

H4

RDQ21//RDQ21

K4

RDQ19//RDQ22

G4

RDQ18//RDQ23

K3

RDQ26//RDQ24

J1

RDQ27//RDQ25

D2

RDQ29//RDQ26

J2

RDQ28//RDQ27

C1

RDQ31//RDQ28

H3

RDQ25//RDQ29

D1

RDQ24//RDQ30

J3

RDQ30//RDQ31

E2

RDQS0//RDQS0

B13

RDQS0_//RDQS0_

A13

RDQS1//RDQS1

A12

RDQS1_//RDQS1_

B12

RDQS2//RDQS2

F2

RDQS2_//RDQS2_

F1

RDQS3//RDQS3

G1

RDQS3_//RDQS3_

G2

RDQM0//RDQM0

C12

RDQM1//RDQM1

C13

RDQM2//RDQM2

G3

RDQM3//RDQM3

E1

RCLK0//RCLK0

A9

RCLK0_//RCLK0_

B9

RCLK1//RCLK1

K1

RCLK1_//RCLK1_

K2

RBA2//RRESET_

C6

AVDD12_MEMPLL

H9

AVSS12_MEMPLL

H10

MEMTP

D8

MEMTN

C8

RCAS_//RA0

C4

RA6//RA1

F9

RBA0//RA2

C5

RA5//RA3

A7

RA4//RA4

F8

RBA1//RA5

D5

RA13//RA6

D7

RA10//RA7

A6

NC//RA8

E6

RA3//RA9

B7

RA12//RA10

E8

RA11//RA11

F7

RA0//RA12

D6

RA1//RA13

B6

RCKE//RWE_

B4

RODT//RODT

A3

RRAS_//RCAS_

B3

RWE_//RCS_

A4

RCS_//RRAS_

A2

RA9//RCKE

D9

RA8//RBA0

E7

RA2//RBA1

E9

RA7//RBA2

C7

RVREF

E3

VCC2IO

C16

VCC2IO

B16

VCC2IO

A16

VCC2IO

F15

VCC2IO

E15

VCC2IO

D15

VCC2IO

H14

VCC2IO

H13

VCC2IO

K8

VCC2IO

J8

VCC2IO

H8

VCC2IO

B1

VCC2IO

F6

DVSS

L5

VCC2IO

E5

DVSS

L4

VCC2IO

D4

DVSS

L3

VCC2IO

C3

VCC2IO

B2

VCC2IO

A1

DVSS

L6

DVSS

K6

DVSS

C9

DVSS

F11

DVSS

F12

DVSS

E10

DVSS

J6

DVSS

F10

DVSS

H11

DVSS

K7

DVSS

H12

VCC2IO

C2

VCC2IO

D3

VCC2IO

E4

VCC2IO

F5

VCC2IO

G6

VCC2IO

F14

RP404 200R

RP404 200R

1

2

3

4

8

7

6

5

TP400

TP400

C4006

10uF

C4006

10uF

RP407 200R

RP407 200R

1

2

3

4

8

7

6

5

+

C409

220uF/16V

+

C409

220uF/16V

C433

100N16V

C433

100N16V

C412

100N16V

C412

100N16V

R416

0R05 1/4W

R416

0R05 1/4W

RP409 200R

RP409 200R

1

2

3

4

8

7

6

5

C411

10uF

C411

10uF

R407

100R 1/16W 5%

R407

100R 1/16W 5%

U415U415

VIN

3

VOUT

2

ADJ/GND

1

R405

0R05 1/16W

R405

0R05 1/16W

R442

0R05 1/10W

R442

0R05 1/10W

C419

100N16V

C419

100N16V

R402

1K 1/16W 1%

R402

1K 1/16W 1%

R401

240 OHM +-5% 1/16W

R401

240 OHM +-5% 1/16W

C4008

100N 50V

C4008

100N 50V

C402

100N16V

C402

100N16V

C420

100N16V

C420

100N16V

R415

1K 1/16W 1%

R415

1K 1/16W 1%

RP403200R

RP403200R

1

2

3

4

8

7

6

5

C417

100N16V

C417

100N16V

R451

0R05 1/10W

R451

0R05 1/10W

C422

100N16V

C422

100N16V

C430

100N16V

C430

100N16V

R418

0R05 1/10W

R418

0R05 1/10W

RP406 200R

RP406 200R

1

2

3

4

8

7

6

5

C429

100N16V

C429

100N16V

R453

0R05 1/10W

R453

0R05 1/10W

C401

100N16V

C401

100N16V

A-Board

AZ3TK

AZ3TK 17

Page 18

A BOARD SCHEMATIC DIAGRAM (8 OF 16)

5

5

4

4

3

3

2

2

1

1

D

D

C

C

B

B

A A

JTDO

OXTALI

JTMS

JTCK

JTDI

JTRST#

ORESET#

SYS_EEPROM_WP

OSCL2

POCE1#

AVDD33_XTAL_STB

JTDO

OXTALO

U1TX

PDD1

OSDA2

PDD3

POWE#

PDD7

OSDA2

OSCL2

PDD2

U0TX

AVDD10_LDO

POOE#

PDD6

PACLE

U0RX

OIRI

AVDD12_PLL

PDD4

OSCL0

PAALE

OXTALI

PARB#

JTDI

OSDA0

OPWRSB

OSCL1

PDD5

OSDA1

PDD0

AVDD33_REG_STB

JTMS

ORESET#

JTRST#

U1RX

JTCK

Flash_WP#

OSCL0

OSDA0

U1RX

U1TX

U0TX

U0RX

AVDD33_XTAL_STB

AVDD33_REG_STB

OSCL1

OSDA1

FSRC_WR

AVDD12_PLL

OSCL1

OSDA1

SYS_EEPROM_WP

OPWRSB

AOSDATA1

OPCTRL4

OPCTRL5

OPCTRL5

OPCTRL4

U0RX

U0TX

OIRI

PDD5

POCE1#

PAALE

PDD3

PARB#

PACLE

PDD2

Flash_WP# PDD1

PDD7

PDD0

POWE#

PDD4POOE#

PDD6

OSDA2

OSCL2

OXTALO

AOSDATA1

DVDD3V3

3V3SB

3V3SB

AVDD1V2

VCCK

DVDD3V3

DVDD3V3

DVDD3V3

DVDD3V3

DVDD3V3

DVDD3V3

DVDD3V3

3V3SB

DVDD3V3

DVDD3V3

DVDD3V3

VCCK

VCCK

DVDD3V3

DVDD3V3

+5VSB

3V3SB

VCCK

AVDD1V2

DVDD3V3

DVDD3V3

DVDD3V3

+5VSB

3V3SB

+5VSB2,4,5,6

3V3SB2,6,7,13

VCCK2,13

DVDD3V32,5,8,13,17

AVDD1V22,7,8,12,14

GND2,3,4,5,6,7,8,10,11,12,13,14,16,17

OSDA17,11,13

OSCL17,11,13

OPWRSB2

SYS_EEPROM_WP13

OPCTRL513

OPCTRL413

AOSDATA112

U0TX3

U0RX3

OIRI13

OSDA215

OSCL215

OEM MODEL

Size

Rev

Date

Sheet

of

TPV MODEL

PCB NAME

T P V ( Top Victory Electronics Co . , Ltd. )

Key Component

絬 隔 瓜 絪 腹

CNYSAASN2AC04E

BDBT

8 16Wednesday, December 07, 2011

715G5177-M0C-000-004K

FLASH/XTAL/JTAG/UART

G5177-M0C-000-004K-1-110902

OEM MODEL

Size

Rev

Date

Sheet

of

TPV MODEL

PCB NAME

T P V ( Top Victory Electronics Co . , Ltd. )

Key Component

絬 隔 瓜 絪 腹

CNYSAASN2AC04E

BDBT

Wednesday, December 07, 2011

715G5177-M0C-000-004K

FLASH/XTAL/JTAG/UART

G5177-M0C-000-004K-1-110902

OEM MODEL

Size

Rev

Date

Sheet

of

TPV MODEL

PCB NAME

T P V ( Top Victory Electronics Co . , Ltd. )

Key Component

絬 隔 瓜 絪 腹

CNYSAASN2AC04E

BDBT

Wednesday, December 07, 2011

715G5177-M0C-000-004K

FLASH/XTAL/JTAG/UART

G5177-M0C-000-004K-1-110902

RESET Circuit

27MHz CRYSTAL

JTAG Port

SYSTEM EEPROM

I2C ADDRESS "A0"

HI = > WP

LO = > WRITE

STRAPPING

( 42 mA )

E-Fuse

( 13 mA )( 10 mA )

UART Port 1

FOR CODE DOWNLOAD AND DEBUG

UART Port 0

3rd I2C

2nd I2C

Control Interface

NAND Flash

Default 2G bit NAND Flash used

256MB

U401A

U409

U408

CN406

R437

10K 1/16W 5%

R437

10K 1/16W 5%

C448

27PF 50V

C448

27PF 50V

R420 4K7 1/16W 5%R420 4K7 1/16W 5%

C446

100N16V

C446

100N16V

R445

4K7 1/16W 5%

R445

4K7 1/16W 5%

C438

100pF 50V

C438

100pF 50V

R429

4K7 1/10W 5%

R429

4K7 1/10W 5%

R432

4K7 1/16W 5%

R432

4K7 1/16W 5%

R424

4K7 1/16W 5%

R424

4K7 1/16W 5%

TP402

TP402

C440

NC/10uF 10V

C440

NC/10uF 10V

C445

100N16V

C445

100N16V

R423

4K7 1/16W 5%

R423

4K7 1/16W 5%

C453

100N16V

C453

100N16V

R439

10K 1/16W 5%

R439

10K 1/16W 5%

R461

0R05 1/10W

R461

0R05 1/10W

R434

4K7 1/16W 5%

R434

4K7 1/16W 5%

R454 10K 1/16W 5%R454 10K 1/16W 5%

R426

10K 1/10W

R426

10K 1/10W

C455

100N16V

C455

100N16V

R448

4K7 1/16W 5%

R448

4K7 1/16W 5%

R433

4K7 1/16W 5%

R433

4K7 1/16W 5%

R430

4K7 1/10W 5%

R430

4K7 1/10W 5%

U409

AT24C128C-SSHM-T

U409

AT24C128C-SSHM-T

A0

1

A1

2

A2

3

GND

4

SDA

5

SCL

6

WP

7

VCC

8

C435

100N16V

C435

100N16V

X400

27MHz

X400

27MHz

1

2

C456

100N16V

C456

100N16V

R431

4K7 1/10W 5%

R431

4K7 1/10W 5%

MT5366GSNG

U401A

MT5366GSNG

U401A

JTCK

R4

JTDI

T1

JTDO

R3

JTMS

T3

JTRST_

T2

OSDA1

U4

OSCL1

U3

XTALI

AE19

XTALO

AD19

AVDD33_XTAL_STB

AC18

AVSS33_XTAL_STB

AE18

AVDD12_PLL

AB15

AVSS12_PLL

AA17

OPWRSB

AB9

ORESET_

Y8

OIRI

AC8

DVSS

H6

DVSS

M9

DVSS

W19

DVSS

Y19

DVSS

W20

DVSS

Y20

DVSS

N9

DVSS

L12

DVSS

L13

DVSS

L14

DVSS

P9

DVSS

R10

DVSS

M11

DVSS

M12

DVSS

M13

DVSS

M14

DVSS

M15

DVSS

M16

DVSS

N11

DVSS

N12

DVSS

N13

DVSS

N14

DVSS

N15

DVSS

N16

DVSS

P11

DVSS

P12

DVSS

P13

DVSS

P14

DVSS

P15

DVSS

P16

DVSS

R11

DVSS

R12

DVSS

R13

DVSS

R14

DVSS

K12

DVSS

K13

DVSS

M10

DVSS

N10

DVSS

P10

U0TX

AB8

U0RX

AC7

U1RX

U2

U1TX

U1

POWE_

J19

POOE_

K21

POCE1_

K22

POCE0_

J21

PDD7

K23

PDD6

L23

PDD5

L24

PDD4

L25

PDD3

K20

PDD2

K19

PDD1

L22

PDD0

M23

PARB_

J20

PACLE

J24

PAALE

J25

VCCK

M1

VCCK

M2

VCCK

M3

VCCK

M4

VCCK

M5

VCCK

M6