Page 1

AVD-K800P

SERVICE MANUAL

Ver 1.2 2004. 09

AVD-K800P is the amplifier, CD/DVD and tuner system in HT-C800DP.

This system incorporates with Dolby* Digital and Dolby Pro Logic (II) adaptive matrix

surround decoder and the DTS** Digital Surround System.

* Manufactured under license from Dolby Laboratories.

“Dolby”, “Pro Logic” and the double-D symbol are trademarks of Dolby Laboratories.

** Manufactured under license from Digital Theater Systems, Inc.

“DTS” and “DTS Digital Surround” are trademarks of Digital Theater Systems, Inc.

SPECIFICATIONS

AUDIO POWER SPECIFICATIONS

POWER OUTPUT AND TOTAL HARMONIC DISTORTION:

Amplifier section

Rated Power Output at Stereo Mode

Reference Power Output

* Depending on the sound field settings and the source, there may be no sound output.

Inputs (Analog) ANALOG IN:

Outputs (Analog) PHONES:

CD/DVD system

Laser Semiconductor laser

Signal format system NTSC/PAL or NTSC

Frequency response (at 2 CH STEREO mode)

Signal-to-noise ratio More than 80 dB

Harmonic distortion Less than 0.03 %

FM tuner section

System PLL quartz-locked digital synthesizer system

Tuning range

North American models: 87.5 – 108.0 MHz (100 kHz step)

Other models: 87.5 – 108.0 MHz (50 kHz step)

Antenna FM wire antenna

Antenna terminals 75 ohms, unbalanced

Intermediate frequency 10.7 MHz

With 6 ohm loads, both channels driven, from 120 – 20,000 Hz; rated 60

watts per channel minimum RMS power , with no more than 0.7 % total

harmonic distortion from 250 milliwatts to rated output (USA model only).

60 W + 60 W (6 ohms, at 1 kHz, THD 0.7 %)

Front: 100 W/ch (6 ohms at 1 kHz, THD 10 %)

Center*: 100 W (6 ohms at 1 kHz, THD 10 %)

Surround*: 100 W/ch (6 ohms at 1 kHz, THD 10 %)

Sub woofer*: 100 W (6 ohms at 100 Hz, THD 10 %)

Sensitivity: 500 mV

Impedance: 50 kilohms

Accepts low- and high-impedance headphones

(DVD: λ = 650 nm)

(CD: λ = 780 nm)

Emission duration: continuous

DVD (PCM): 2 Hz to 22 kHz (±1.0 dB)

CD: 2 Hz to 20 kHz (±1.0 dB)

US Model

Canadian Model

AEP Model

UK Model

E Model

Model Name Using Similar Mechanism NEW

Mechanism T ype

Optical Pick-up Name

AM tuner section

System PLL quartz-locked digital synthesizer system

Tuning range

North American models: 530 – 1,710 kHz (with the interval set at 10 kHz)

European models: 531 – 1,602 kHz (with the interval set at 9 kHz)

Mexican models: 530 – 1,610 kHz (with the interval set at 10 kHz)

Other models: 530 – 1,610 kHz (with the interval set at 10 kHz)

Antenna AM loop antenna

Intermediate frequency 450 kHz

Video section

Inputs Video: 1 Vp-p 75 ohms

Outputs Video: 1 Vp-p 75 ohms

General

Power requirements

North American and Mexican models:

European models: 230 V AC, 50/60 Hz

Other models: 120/220 V AC, 50/60 Hz

Power consumption

Canadian models: 240 VA

Other models: 190 W

Power consumption (at Power Saving Mode):

Dimensions (approx.) 430 × 170 × 450 mm (17 × 6

Mass (approx.) 11.5 kg (25 lb 6 oz.)

Operating temperature 5˚C to 35˚C (41˚F to 95˚F)

Operating humidity 5 % to 90 %

Design and specifications are subject to change without notice.

531 – 1,710 kHz (with the interval set at 9 kHz)

531 – 1,602 kHz (with the interval set at 9 kHz)

Component: Y: 1 Vp-p 75 ohms

120 V AC, 60 Hz

0.5 W

(w/h/d) incl. projecting parts

P

B/CB

P

R/CR

CDM79-DVBU22

DBU-1

: 0.7 Vp-p 75 ohms

: 0.7 Vp-p 75 ohms

7

/8× 17 7/8 inches)

9-877-319-03

2004I16-1

© 2004.09

COMPACT AV SYSTEM

Sony Corporation

Audio Group

Published by Sony Engineering Corporation

Page 2

AVD-K800P

r

Laser component in this product is capable of emitting radiation

exceeding the limit for Class 1.

This appliance is classified as a

CLASS 1 LASER product.

The CLASS 1 LASER

PRODUCT MARKING is

located on the rear exterior.

The following caution

label is located inside

the apparatus.

CAUTION

Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous

radiation exposure.

Notes on chip component replacement

•Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be

damaged by heat.

LEAKAGE

The AC leakage from any exposed metal part to earth Ground and

from all exposed metal parts to any exposed metal part having a

return to chassis, must not exceed 0.5 mA (500 microampers).

Leakage current can be measured by any one of three methods.

1. A commercial leakage tester, such as the Simpson 229 or RCA

WT-540A. Follow the manufacturers’ instructions to use these

instruments.

2. A battery-operated AC milliammeter. The Data Precision 245

digital multimeter is suitable for this job.

3. Measuring the voltage drop across a resistor by means of a

VOM or battery-operated AC voltmeter. The “limit” indication

is 0.75 V, so analog meters must have an accurate low-voltage

scale. The Simpson 250 and Sanwa SH-63Trd are examples of

a passive VOM that is suitable. Nearly all battery operated

digital multimeters that have a 2V AC range are suitable. (See

Fig. A)

To Exposed Metal

Parts on Set

0.15µF

1.5k

Ω

AC

voltmete

(0.75V)

Flexible Circuit Board Repairing

•Keep the temperature of soldering iron around 270˚C

during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

SAFETY CHECK-OUT

After correcting the original service problem, perform the following

safety checks before releasing the set to the customer:

Check the antenna terminals, metal trim, “metallized” knobs, screws,

and all other exposed metal parts for AC leakage. Check leakage as

described below.

Earth Ground

Fig. A. Using an AC voltmeter to check AC leakage.

Unleaded solder

Boards requiring use of unleaded solder are printed with the leadfree mark (LF) indicating the solder contains no lead.

(Caution: Some printed circuit boards may not come printed with

the lead free mark due to their particular size.)

: LEAD FREE MARK

Unleaded solder has the following characteristics.

• Unleaded solder melts at a temperature about 40°C higher than

ordinary solder.

Ordinary soldering irons can be used but the iron tip has to be

applied to the solder joint for a slightly longer time.

Soldering irons using a temperature regulator should be set to

about 350°C.

Caution: The printed pattern (copper foil) may peel away if the

heated tip is applied for too long, so be careful!

• Strong viscosity

Unleaded solder is more viscous (sticky, less prone to flow) than

ordinary solder so use caution not to let solder bridges occur such

as on IC pins, etc.

• Usable with ordinary solder

It is best to use only unleaded solder but unleaded solder may

also be added to ordinary solder.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED LINE WITH

MARK 0 ON THE SCHEMATIC DIAGRAMS AND IN THE PARTS

LIST ARE CRITICAL TO SAFE OPERATION. REPLACE THESE

COMPONENTS WITH SONY PARTS WHOSE PART NUMBERS

APPEAR AS SHOWN IN THIS MANUAL OR IN SUPPLEMENTS

PUBLISHED BY SONY.

2

ATTENTION AU COMPOSANT AYANT RAPPORT

À LA SÉCURITÉ!

LES COMPOSANTS IDENTIFÉS P AR UNE MARQUE 0 SUR LES

DIAGRAMMES SCHÉMA TIQUES ET LA LISTE DES PIÈCES SONT

CRITIQUES POUR LA SÉCURITÉ DE FONCTIONNEMENT. NE

REMPLACER CES COMPOSANTS QUE PAR DES PIÈSES SONY

DONT LES NUMÉROS SONT DONNÉS DANS CE MANUEL OU

DANS LES SUPPÉMENTS PUBLIÉS PAR SONY.

Page 3

AVD-K800P

Part No.

NOTES ON HANDLING THE OPTICAL PICK-UP BLOCK

OR BASE UNIT

MODEL IDENTIFICATION

— BACK PANEL —

The laser diode in the optical pick-up block may suffer electrostatic

break-down because of the potential difference generated by the

charged electrostatic load, etc. on clothing and the human body.

During repair, pay attention to electrostatic break-down and also

use the procedure in the printed matter which is included in the

repair parts.

The flexible board is easily damaged and should be handled with

care.

NOTES ON LASER DIODE EMISSION CHECK

The laser beam on this model is concentrated so as to be focused on

the disc reflective surface by the objective lens in the optical pickup block. Therefore, when checking the laser diode emission,

observe from more than 30 cm away from the objective lens.

LASER DIODE AND FOCUS SEARCH OPERATION

US and E51 models

Canadian model

Mexican model

AEP model

UK model

CHECK

Carry out the “S curve check” in “CD section adjustment” and check

that the S curve waveform is output several times.

•Abbreviation

E51 : Chilean and peruvian models.

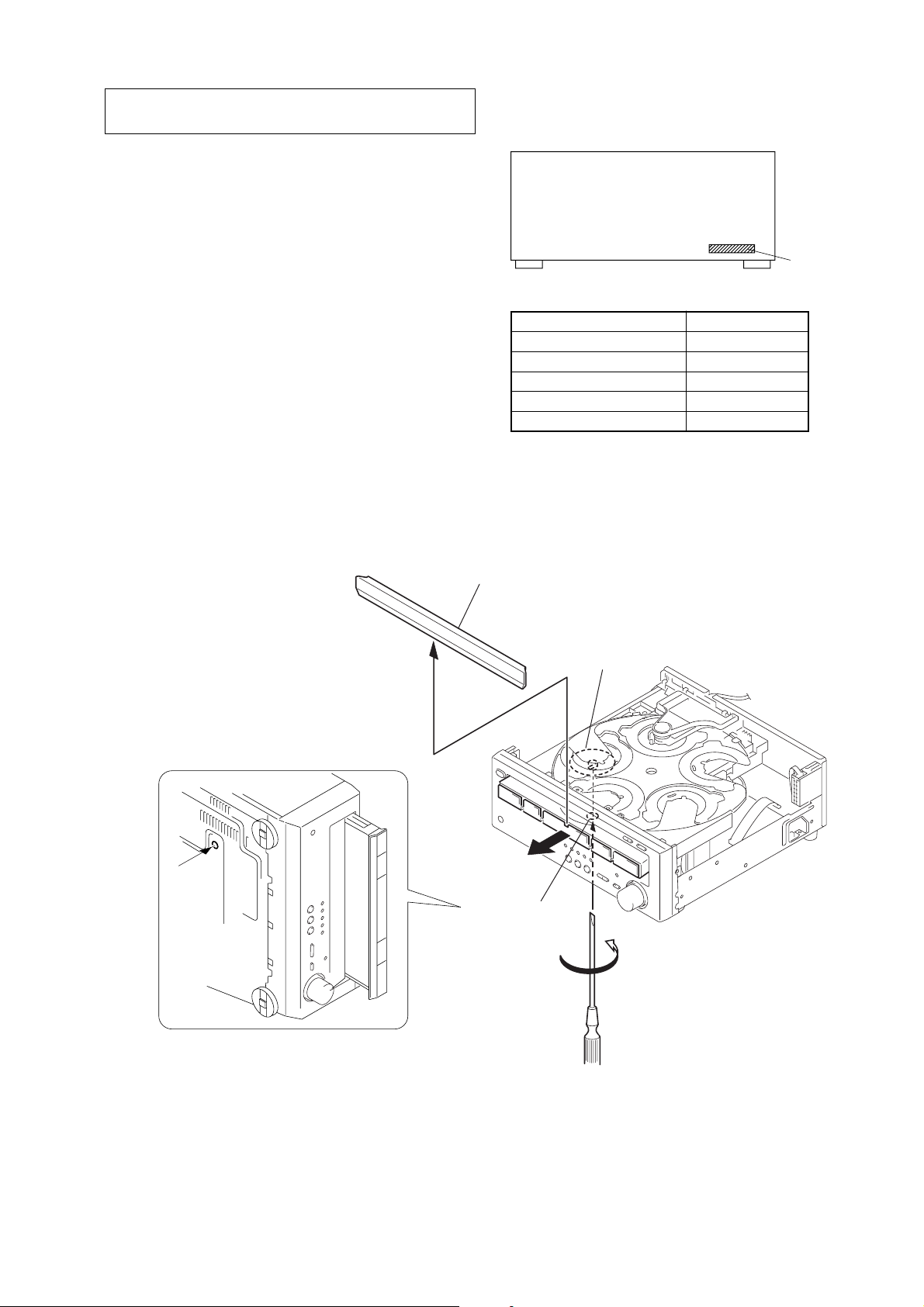

HOW TO OPEN THE DISC TRY WHEN POWER SWITCH TURNS OFF

Model

PARTS No.

4-244-942-0s

4-244-942-1s

4-244-942-2s

4-244-942-3s

4-244-942-4s

3

loading (panel)

2

table

hole of chassis

gear (shaft)

1

Turn the gear (shaft) in the

direction of the arrow.

3

Page 4

AVD-K800P

Ver 1.1

TABLE OF CONTENTS

NOTES ON DMB03 BOARD EXCHANGE

If a DMB03 board is exchanged, “DRIVE AUTO ADJUSTMENT”

may be unable to be performed. In this case, initialize a memory in

the following procedure.

1. Starting Test Mode (see page 17).

2. Press the 2 button of remote commander to set the Drive

Manual Operation (see page 19).

3. Press the 6 button of remote commander to set the Memory

Check (see page 21).

4. Press the [CLEAR] button of remote commander to initialize

a memory.

AUTO SERVO ADJUSTMENT

After parts related to the servo circuit (RF amplifier (IC001), DSP

(IC509), motor driver (IC501), EEPROM (IC903) so on) are

replaced, re-adjusting the servo circuit is necessary. Select “ALL”

at “1. DRIVE AUTO ADJUSTMENT” (Refer to page 18 in TEST

MODE) and adjust DVD-SL (single layer), CD and DVD-DL (dual

layer).

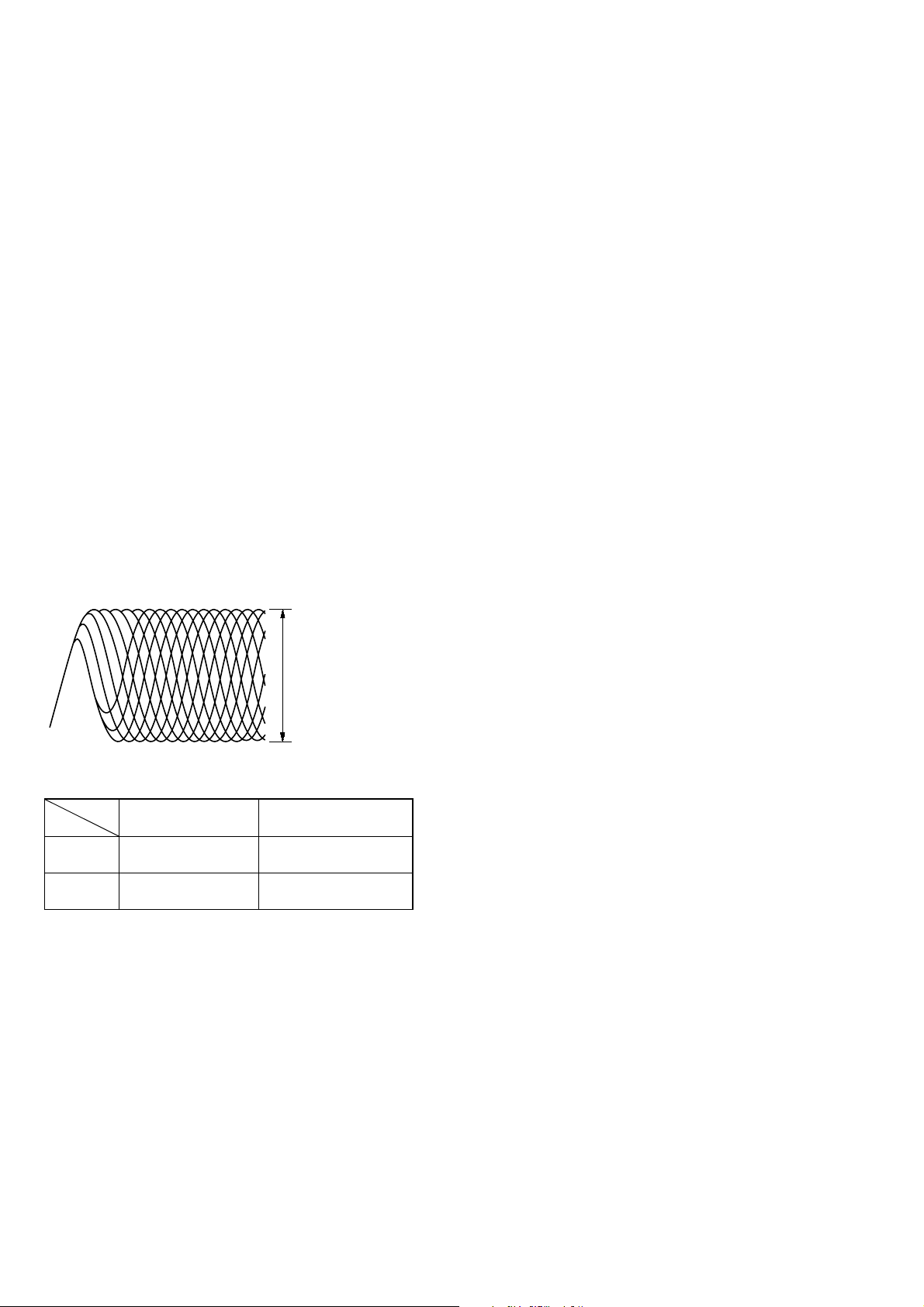

RFMON Level Check

Perform a RFMON level check before exchanging optical pick-up.

Measurement Point: DMB03 board CN501

13pin (RFMON) — 29pin (AGND)

RFMON signal waveform

VOLT/DIV: 200 mV

TIME/DIV: 500 ns

RFMON level

• Standard value

RFMON level

Standard Value

1.09 ± 0.2Vp-p

1.05 ± 0.2Vp-p

DVD

CD

Test Disc

TDV-520CSO

(J-2501-236-A)

LUV-P01

(4-999-032-01)

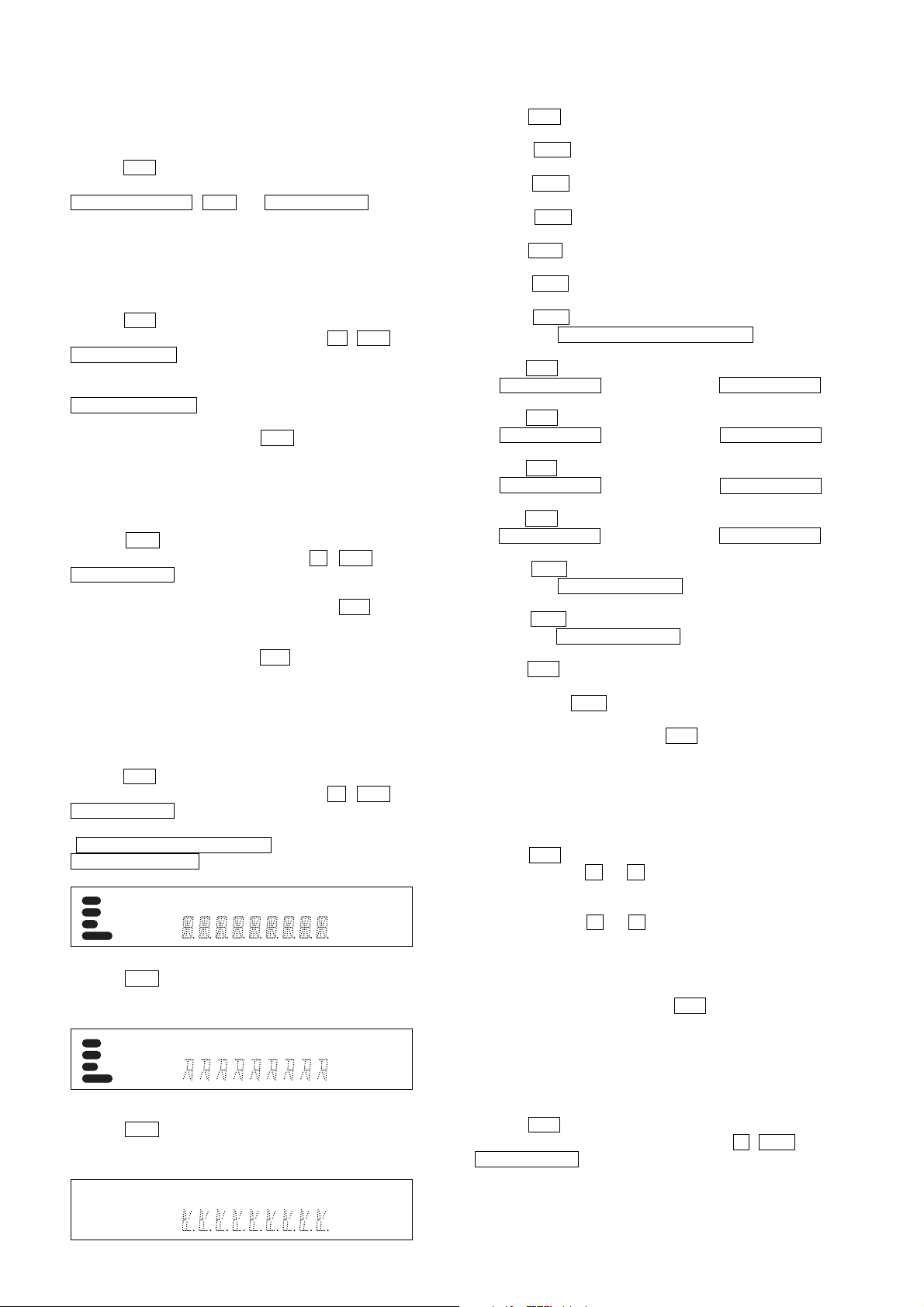

1. GENERAL ·········································································· 5

2. DISASSEMBLY

2-1. Case ··············································································· 7

2-2. Loading (PANEL) ························································· 8

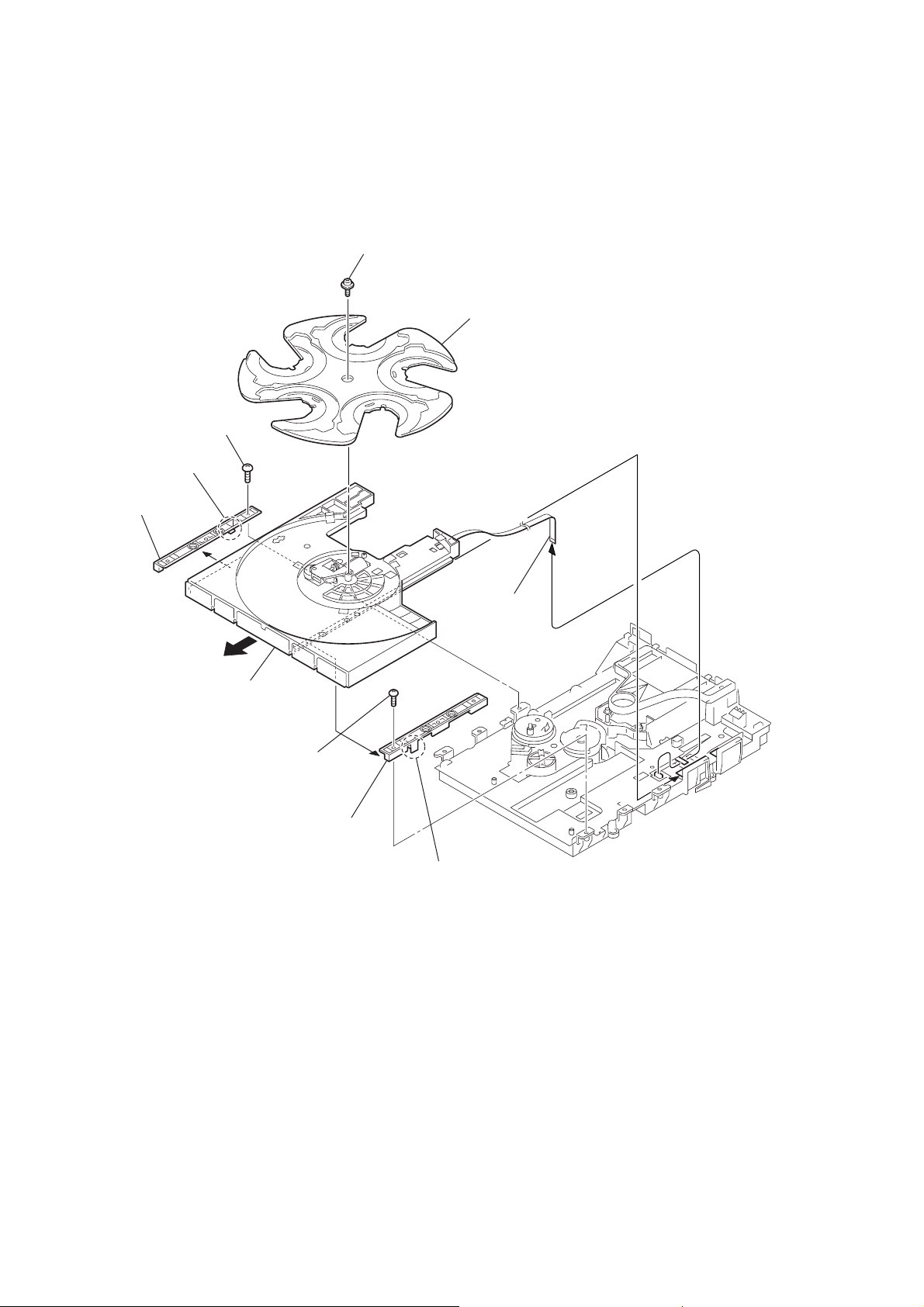

2-3. CD Mechanism Deck (CDM79-DVBU22) ··················· 8

2-4. Front Panel Assy ···························································· 9

2-5. DISPLAY Board, OPEN/CLOSE Board,

POWER SWITCH Board, HP Board ···························· 9

2-6. Tuner Unit (TM301), I/O Board ·································· 10

2-7. DMB03 Board ····························································· 10

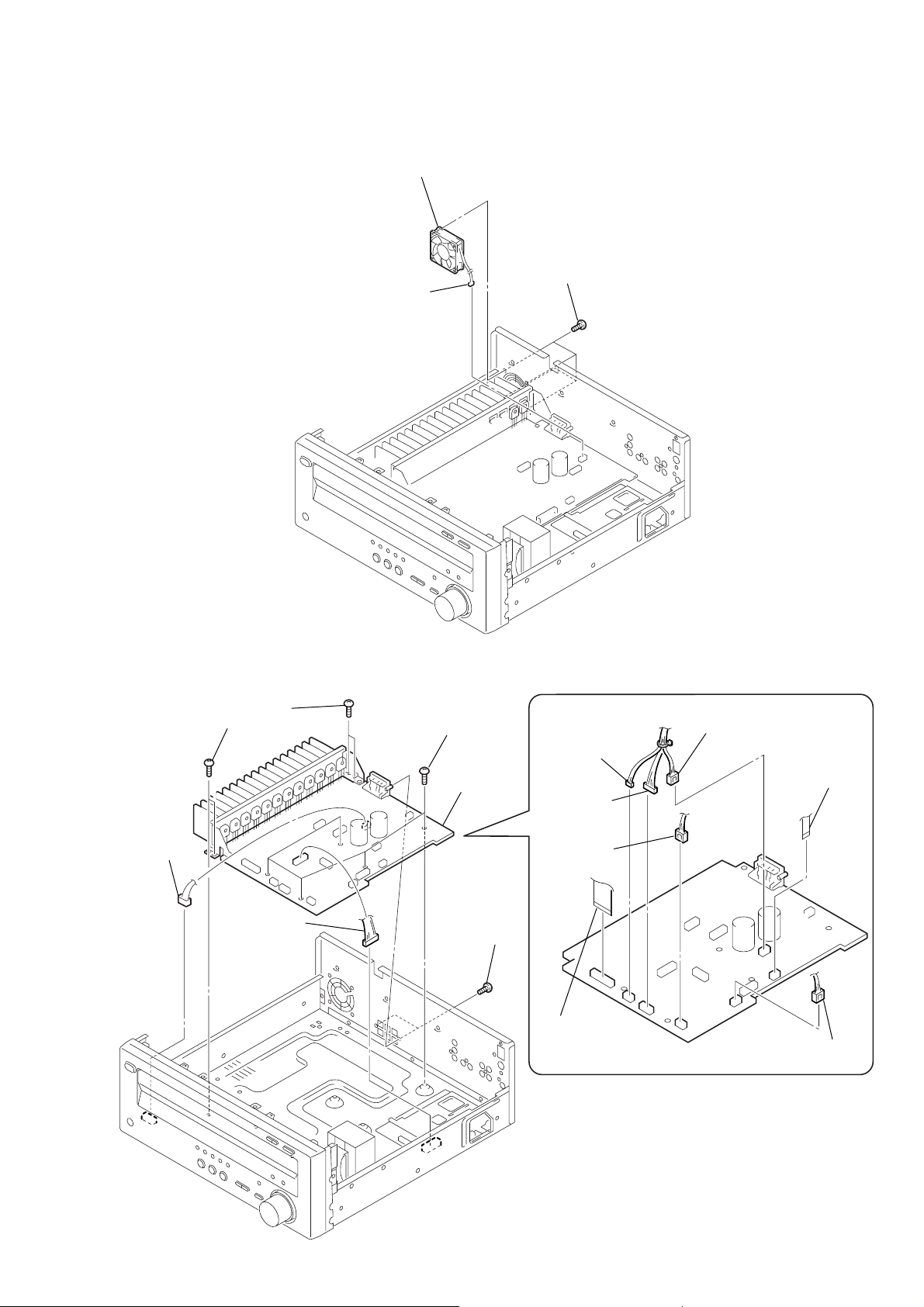

2-8. DC Fan (FAN1) ··························································· 11

2-9. MAIN Board ·······························································11

2-10.Table Assy ··································································· 12

2-11.SE-130 Board ······························································ 13

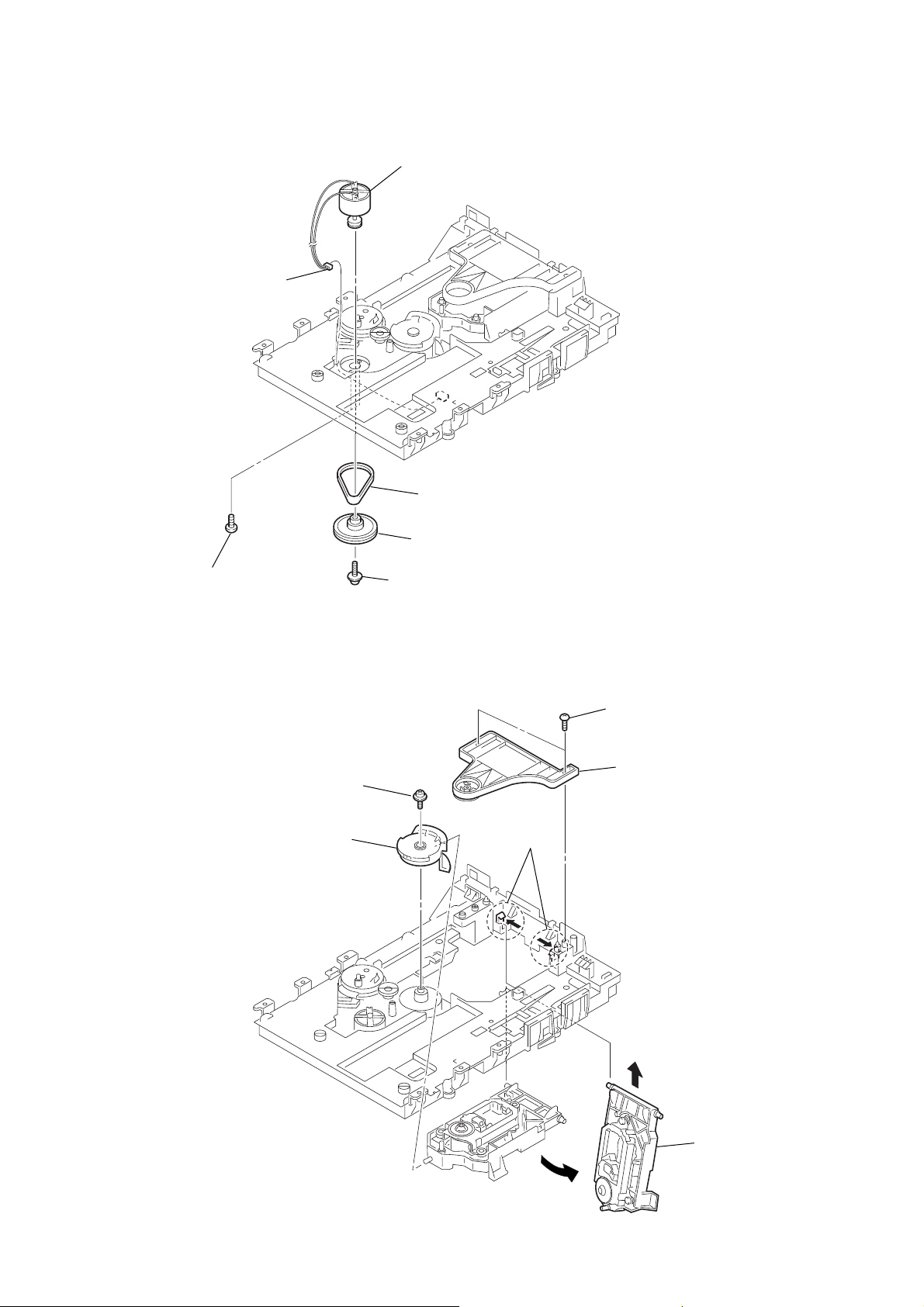

2-12.DC Motor (M001) ······················································· 14

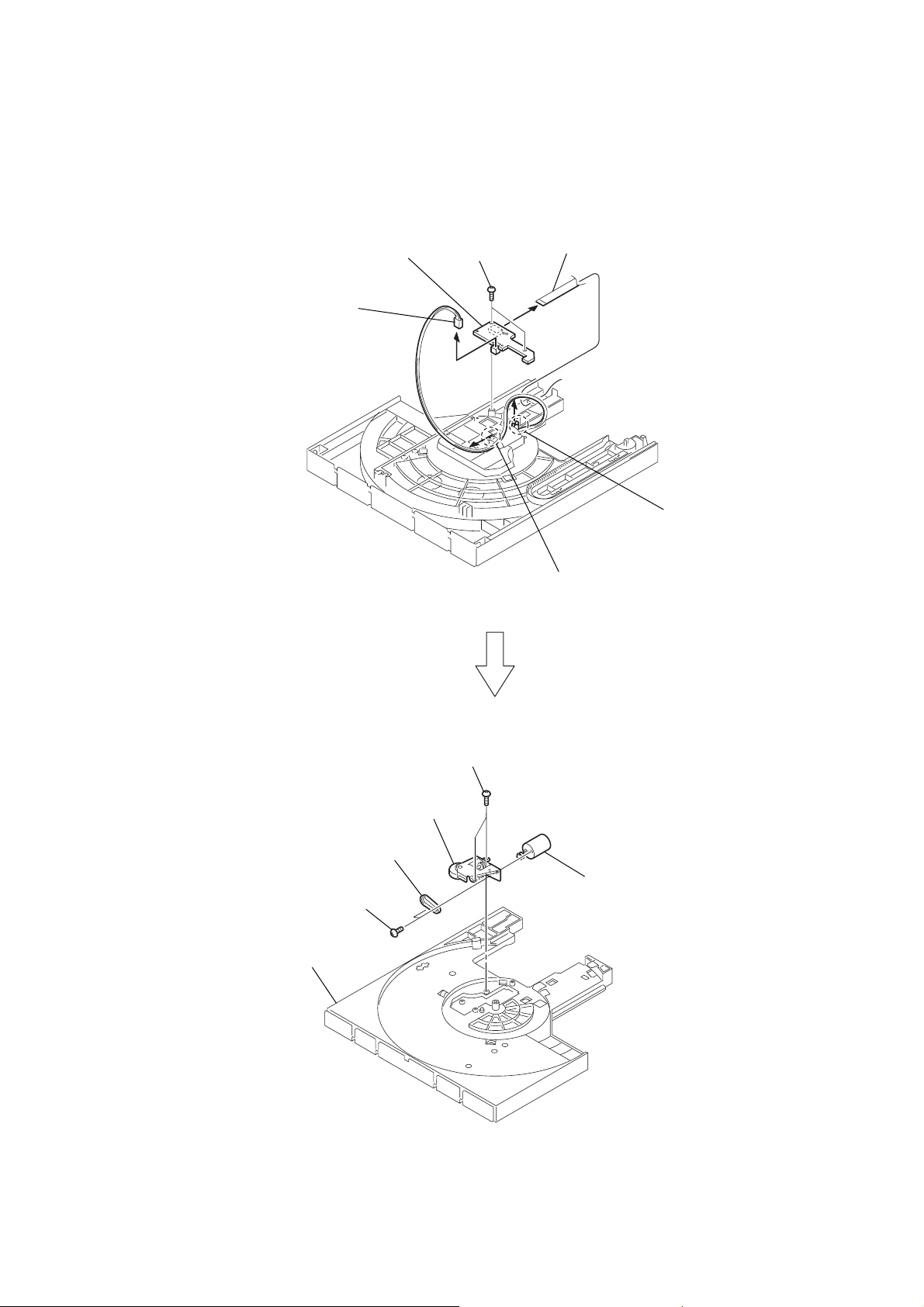

2-13.Pickup Unit Section ····················································· 14

2-14.RF Board ····································································· 15

3. TEST MODE ··································································· 16

4. DIAGRAMS

4-1. Circuit Board Location ················································ 25

4-2. Block Diagrams

— RF SERVO Section — ··········································· 26

— VIDEO Section —·················································· 27

— AUDIO Section — ················································· 28

— AMP Section — ····················································· 29

— POWER Section — ················································ 30

4-3. Printed Wiring Board — RF Section — ······················ 31

4-4. Schematic Diagram — RF Section — ························ 32

4-5. Printed Wiring Board — DMB Section (SIDE A) — · 33

4-6. Printed Wiring Board — DMB Section (SIDE B) — · 34

4-7. Schematic Diagram — DMB Section (1/8) — ··········· 35

4-8. Schematic Diagram — DMB Section (2/8) — ··········· 36

4-9. Schematic Diagram — DMB Section (3/8) — ··········· 37

4-10.Schematic Diagram — DMB Section (4/8) — ··········· 38

4-11.Schematic Diagram — DMB Section (5/8) — ··········· 39

4-12.Schematic Diagram — DMB Section (6/8) — ··········· 40

4-13.Schematic Diagram — DMB Section (7/8) — ··········· 41

4-14.Schematic Diagram — DMB Section (8/8) — ··········· 42

4-15.Printed Wiring Board — I/O Section — ····················· 43

4-16.Schematic Diagram — I/O Section — ························ 44

4-17.Printed Wiring Board — MAIN Section — ················ 45

4-18.Schematic Diagram — MAIN Section (1/3) — ·········· 46

4-19.Schematic Diagram — MAIN Section (2/3) — ·········· 47

4-20.Schematic Diagram — MAIN Section (3/3) — ·········· 48

4-21.Printed Wiring Board

— VOLTAGE SELECTOR, LOADING Section — ··· 49

4-22.Schematic Diagram — LOADING Section — ··········· 50

4-23.Printed Wiring Board — DISPLAY Section — ·········· 51

4-24.Schematic Diagram — DISPLAY Section — ············· 52

4-25. IC Block Diagrams ····················································· 54

4-26. IC Pin Function Description ······································· 61

5. EXPLODED VIEWS

5-1. Case Section ································································ 70

5-2. Front Panel Section ····················································· 71

5-3. Chassis Section···························································· 72

5-4. CD Mechanism Deck Section-1 (CDM79-DVBU22) · 73

5-5. CD Mechanism Deck Section-2 (CDM79-DVBU22) · 74

6. ELECTRICAL PARTS LIST ······································· 75

4

Page 5

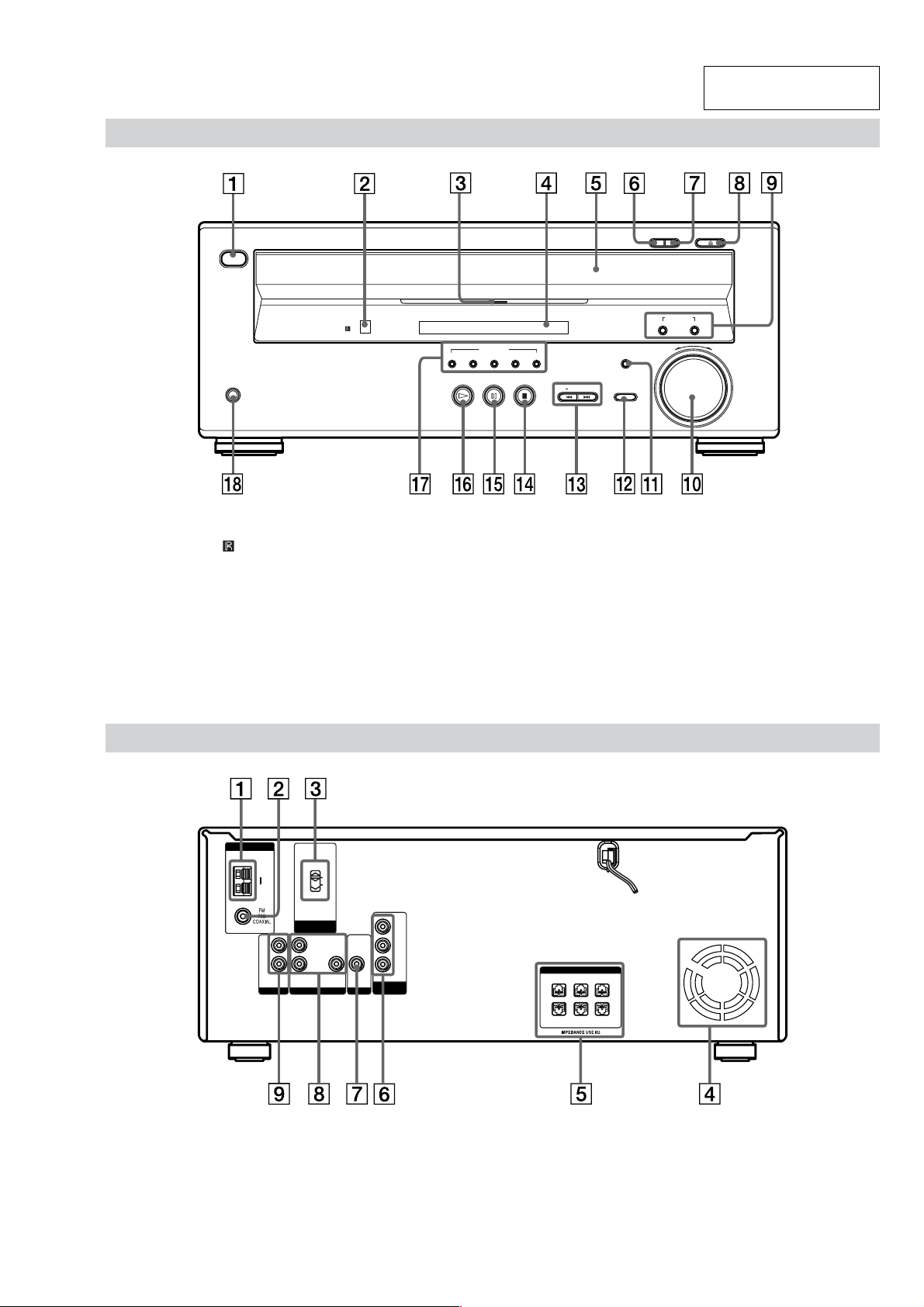

Front Panel

AVD-K800P

SECTION 1

GENERAL

EX-CHANGE DISC SKIP OPEN/CLOSE

?/1

This section is extracted

from instruction manual.

Rear Panel

PHONES

1 ?/1 (power switch) (29)

2

(remote sensor) (18)

3 MULTI CHANNEL DECODING

indicator (49)

4 Front panel display (12)

5 Disc tray (29)

6 EX-CHANGE (30)

7 DISC SKIP (29)

8 A OPEN/CLOSE (29)

MULTI CHANNEL DECODING

DISC SELECT

12345

9 SOUND FIELD +/– (50)

0 MASTER VOLUME control (29, 70)

qa SUB WOOFER LEVEL (69)

qs FUNCTION (29)

qd PRESET +/–, ./> (27, 30)

qf x (stop) (30)

qg S (pause) (30)

qh H (play) (29)

qj DISC SELECT 1 – 5 (29)

qk PHONES jack (29)

SOUND FIELD

–+

+

–

MASTER

SUB WOOFER

VOLUME

LEVEL

+

FUNCTIONPRESET

ANTENNA

AM

y

L

R

AUDIO IN

TV

120V

220V

VOLTAGE

SELECTOR

L

R

AUDIO IN VIDEO IN

VIDEO

VIDEO OUT

MONITOR

Y

PB/

C

P

R

/

C

COMPONENT

VIDEO OUT

B

R

1 AM antenna terminals (22)

2 FM 75Ω COAXIAL antenna jack (22)

3 VOLTAGE SELECTOR (only for

equipped models) (25)

4 Ventilation holes (fan) (74)

5 SPEAKERS jacks (20)

SPEAKERS

FRONT R

FRONT LCENTER

– + – + – +

+–+–+–

SURR R

SUB WOOFER

SURR L

6 COMPONENT VIDEO OUT jacks (24)

7 MONITOR (VIDEO OUT) jack (24)

8 VIDEO (AUDIO L/R IN/VIDEO IN)

jacks (24)

9 TV (AUDIO L/R IN) jacks (24)

5

Page 6

AVD-K800P

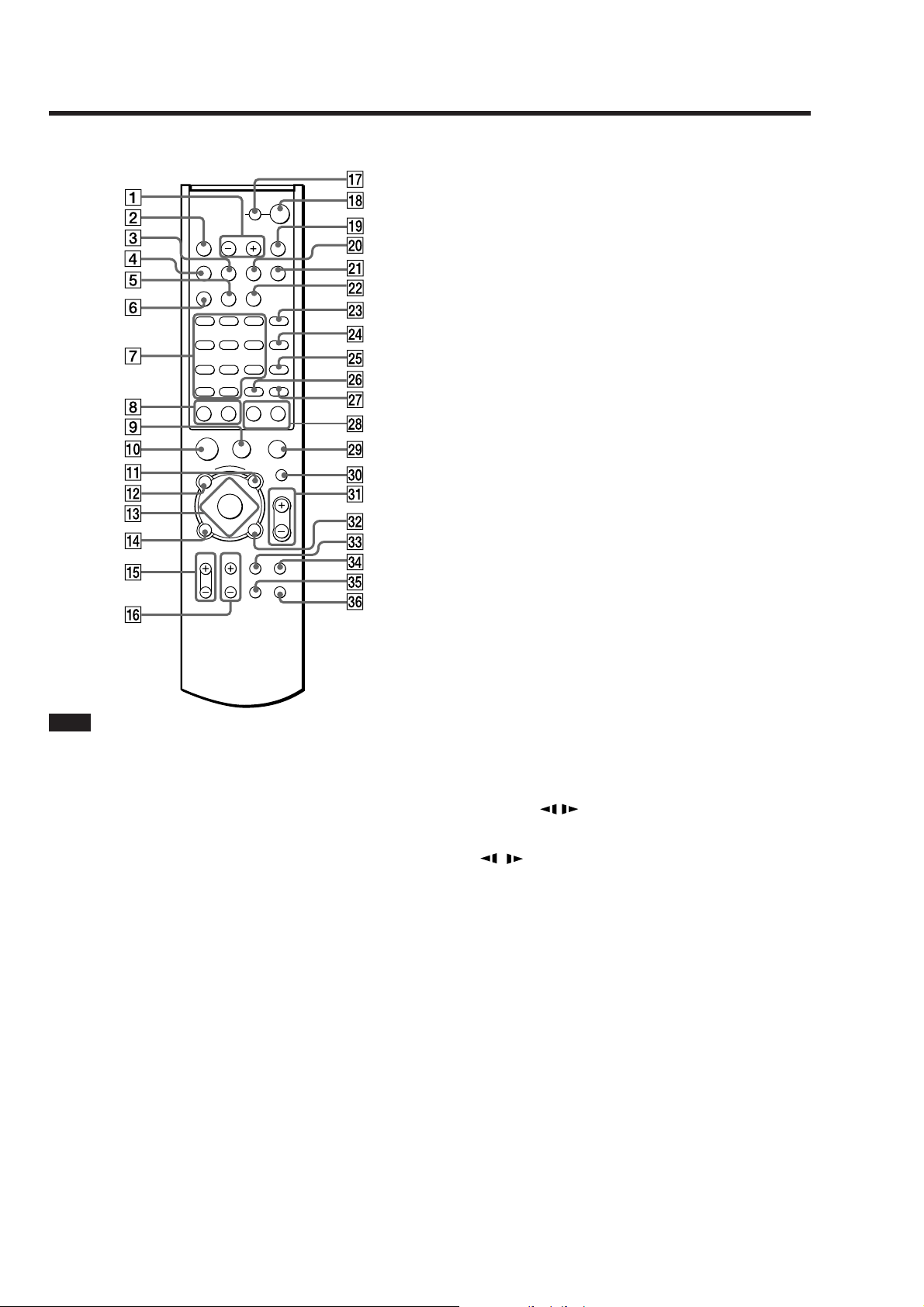

Quick reference for Remote Commander

TV ?/1

MEMORY D. SKIP

TIME

ENTER

m

X

+ MENU

F

g

f

RETURN

VIDEO

SETUP

DVD

DVD

O

TV/

TUNING

y

SLOW

?/1

OPEN/

CLOSE

AUDIO

ANGLE

SUBTITLE

CLEAR

M

y

x

MUTING

VOLUME

BASS

BOOST

DIMMER

SYSTEM STANDBY

SOUND FIELD

FUNCTION

ST/MONO

BAND

PLAY MODE REPEAT

123

456

789

>10

10/0

––++

PRESET

>

.

H

ALBUM

DVD

TOP MENU –

G

DVD DISPLAY

TV VOL TV CH

Note

The remote control of the unit employs command

signals in common with other Sony DVD products.

Thus, depending on the button, other Sony DVD

products may respond.

1 SOUND FIELD +/–

Selects the sound field.

2 FUNCTION

Selects the component you want to use.

3 ST/MONO

Switches monaural or stereo of FM stereo reception.

4 BAND

Selects AM or FM band.

5 REPEAT

Displays the “REPEAT” display on the TV screen.

6 PLAY MODE

Selects program or shuffle play mode.

7 Number buttons

Selects the items of settings.

8 ./>, PRESET +/–

./>: Press to go to the next chapter or track or

to go back to the previous chapter or track.

PRESET +/– : Scan all preset stations.

9 X PAUSE

Pauses playing a disc.

q; H

Plays a disc.

qa DVD MENU/ALBUM +

Displays the DVD menu on the TV screen.

qs DVD TOP MENU/ALBUM –

Displays the title menu on the TV screen.

qd C/X/x/c/ENTER

Selects and executes the items or settings.

qf DVD DISPLAY

Displays the Control Menu display on the TV

screen to set or adjust the items.

qg TV VOL +/–

Adjust the volume of the TV.

qh TV CH +/–

Select preset TV channels.

qj TV [/1 (on/standby)

Turns the TV on and off.

qk [/1 (on/standby)

Turns on and off the power of the system.

ql Z OPEN/CLOSE

Opens or closes the disc tray.

w; MEMORY

Press to store a preset station.

wa D.SKIP

Skips discs.

ws TIME

Displays the playing time of the disc, etc., on the

front panel display.

wd AUDIO

Changes the sound while playing a DVD or VIDEO

CD.

wf ANGLE

Changes the angles when playing a DVD.

wg SUBTITLE

Changes the subtitles when playing a DVD.

wh ENTER

Executes the items or settings.

wj CLEAR

Press to return to the Continuous play, etc.

wk m/M,

/ SLOW, TUNING +/–

m/M (SCAN) : Locate a point while monitoring

the picture while playing disc.

/ (SLOW) : Play a disc in slow motion in the

pause mode.

TUNING +/– : Scan all available radio stations.

wl x STOP

Stops playing a disc.

e; MUTING

Mutes the sound.

ea VOLUME +/–

Adjust the SYSTEM volume.

es O RETURN

Press to return to the previously selected screen, etc.

ed TV/VIDEO

Changes the input mode of the TV.

ef BASS BOOST

Adjust the bass tone.

eg DVD SETUP

Displays the setup display on the TV screen to set

or adjust the items.

eh DIMMER

Changes the brightness of the front panel display by

two steps.

6

Page 7

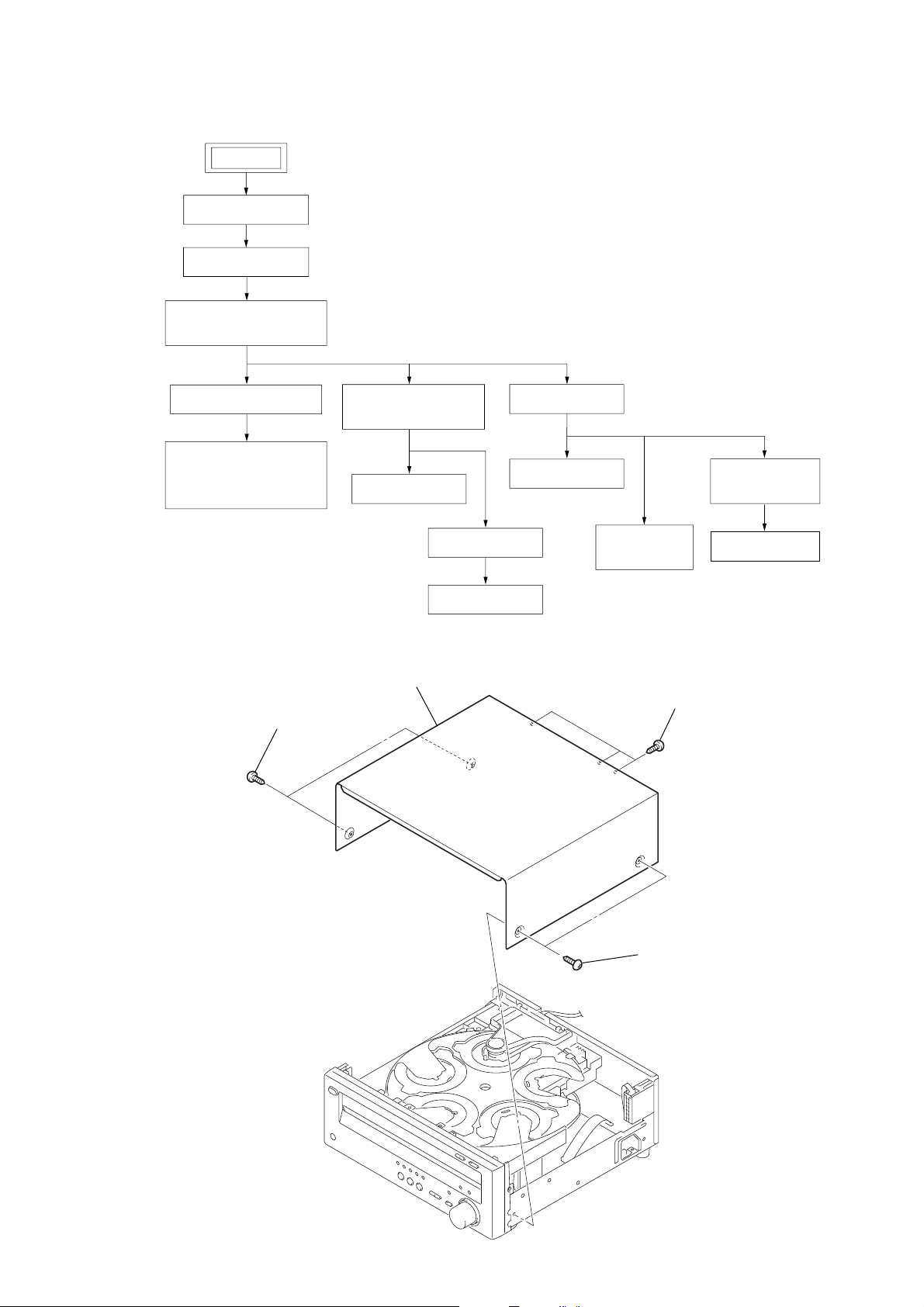

SECTION 2

)

DISASSEMBLY

• The equipment can be removed using the following procedure.

SET

CASE

LOADING (PANEL)

CD MECHANISM DECK

(CDM79-DVBU22)

AVD-K800P

FRONT PANEL ASSY

DISPLAY BOARD,

OPEM/CLOSE BOARD,

POWER SWITCH BOARD,

HP BOARD

Note: Follow the disassembly procedure in the numerical order given.

2-1. Case

2

two screws

(CASE 3 TP2)

TUNER UNIT (TM301),

I/O BOARD

DMB03 BOARD

DC FAN (FAN1)

MAIN BOARD

4

CASE (385)

TABLE ASSY

SE-130 BOARD

DC MOTOR

(M001)

3

three screws

(CASE 3 TP2)

PICKUP UNIT

SECTION

RF BOARD

1

two screws

(CASE 3 TP2

7

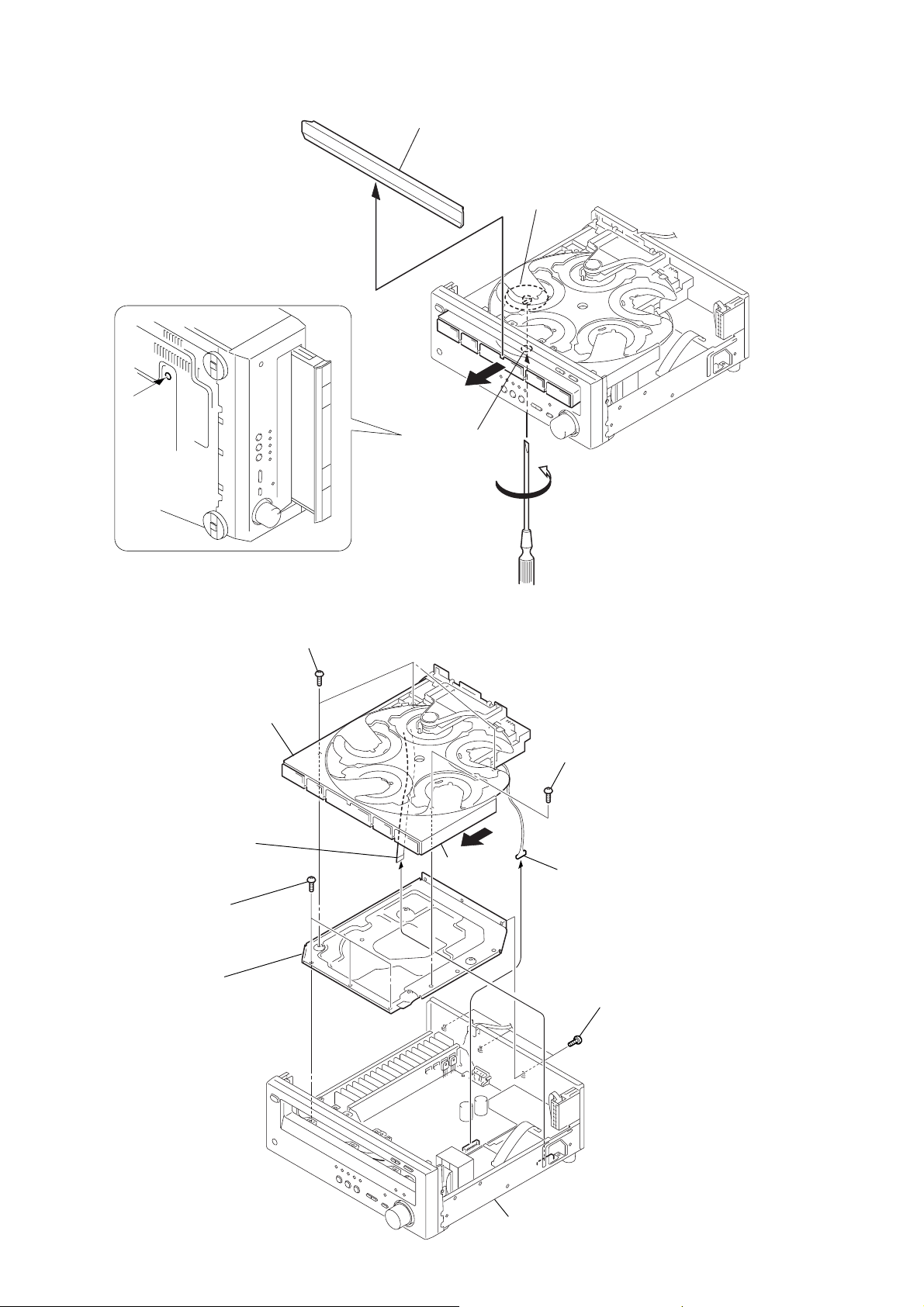

Page 8

AVD-K800P

2-2. Loading (PANEL)

3

loading (panel)

2

table

hole of chassis

gear (shaft)

1

Turn the gear (shaft) in the

direction of the arrow.

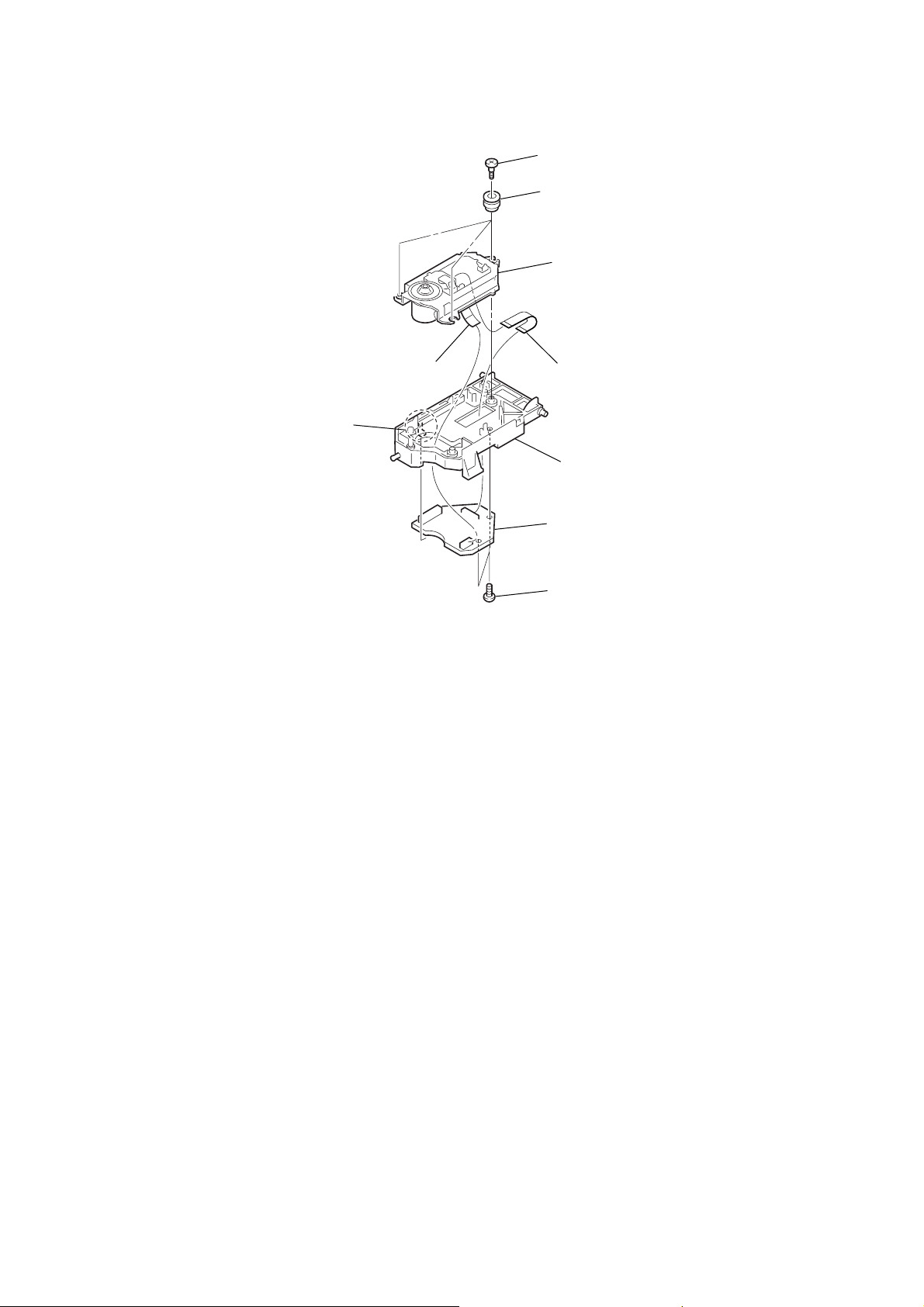

2-3. CD Mechanism Deck (CDM79-DVBU22)

5

three screws

7

CD mechanism deck

(CDM79-DVBU22)

3

flat type wire

(29 core) (CN501)

2

three screws

(BVTP 2.6

8

cdm chassis

×

8)

(BVTP 3

×

8)

table

6

screw

(BVTP 3

4

×

8)

Remove this screw after making

a table slide in the direction of an arrow.

connector (CN906)

1

three screws

×

(BVTP 3

8)

chassis assy

8

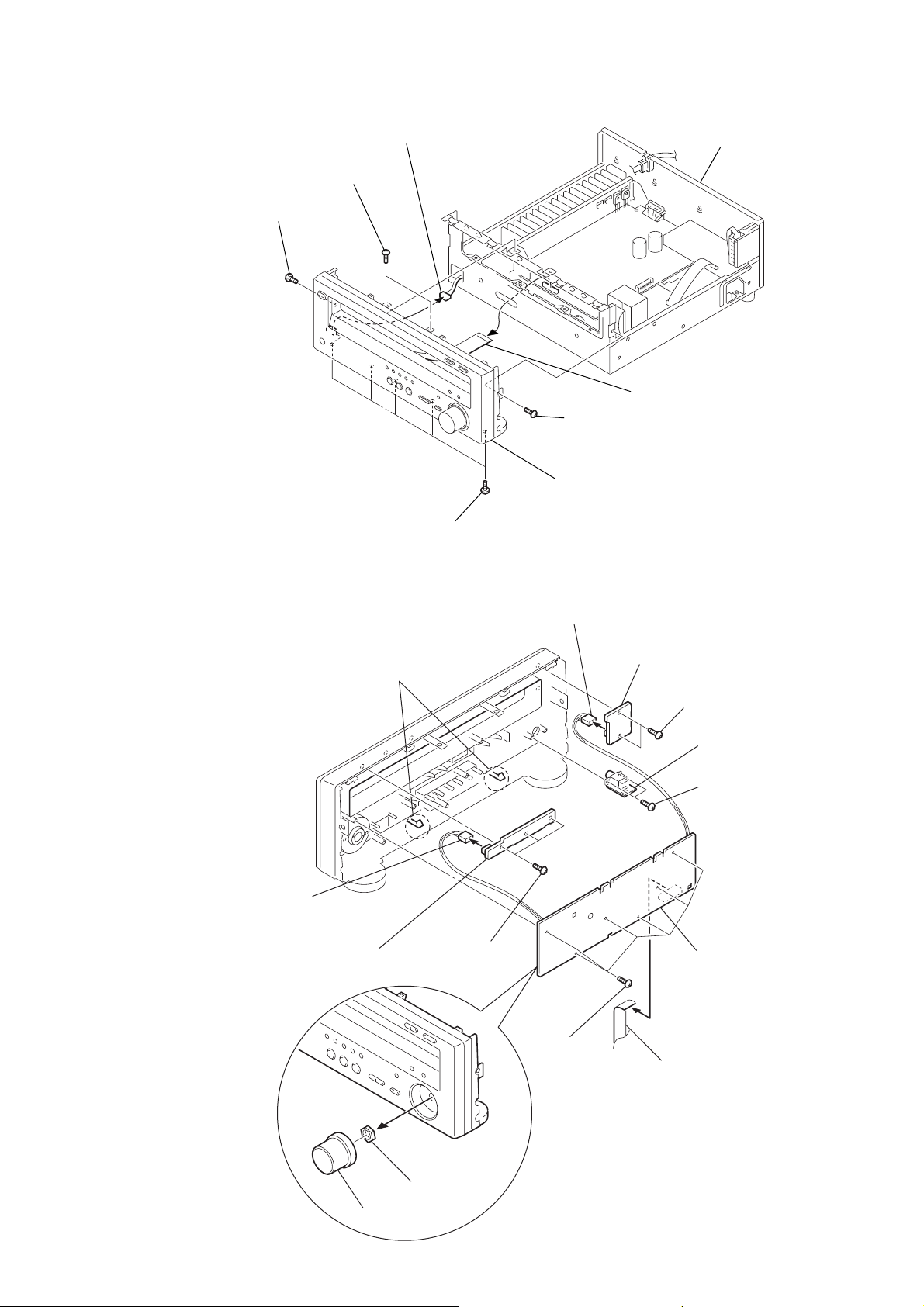

Page 9

2-4. Front Panel Assy

)

2

screw

(+BVTP 2.6

3

two screws

(+BVTP 2.6

×

8)

5

connector (CNP100)

×

8)

1

screw

(+BVTP 2.6

7

front panel assy

chassis assy

6

flat type wire

(25 core) (CNS901)

×

8)

AVD-K800P

4

five screws

(+BVTP 2.6

×

8)

2-5. DISPLAY Board, OPEN/CLOSE Board, POWER SWITCH Board, HP Board

qa

connector (CNP102)

qs

POWER SWITCH board

4

two

claws

8

connector (CNP104)

7

9

OPEN / CLOSE board

three screws

(+BVTP 2.6

×

8)

0

two screws

(+BVTP 2.6

qf

qd

6

×

8)

HP board

two screws

(+BVTP 2.6

DISPLAY board

×

8

1

knob (vol)

2

nut

3

six screws

(+BVTP 2.6

×

8)

5

flat type wire

(25 core) (CNS100)

9

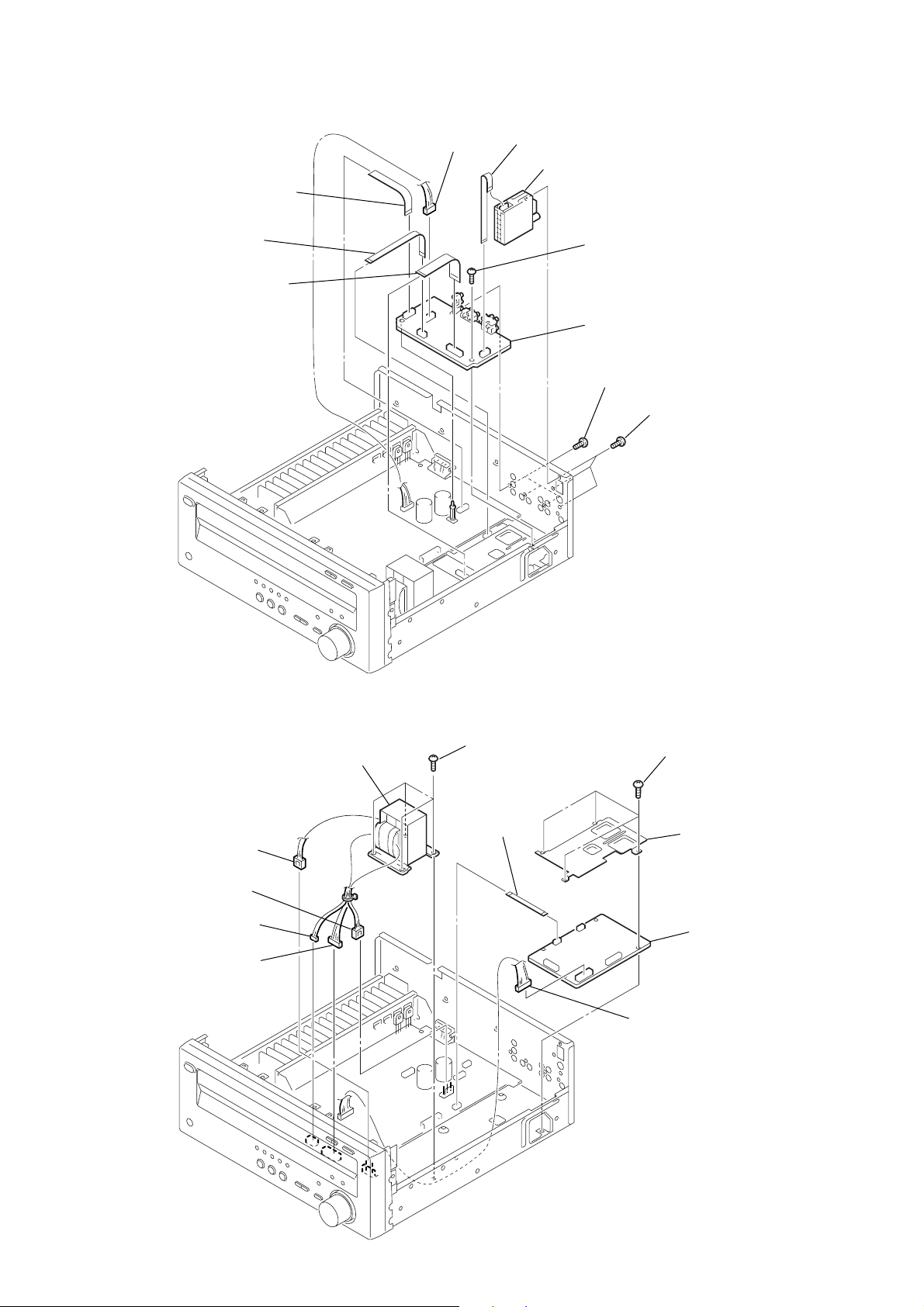

Page 10

AVD-K800P

)

d

2-6. Tuner Unit (TM301), I/O Board

5

wire (flat type) (17 core)

6

wire (flat type) (11 core)

7

wire (flat type) (25 core)

4

connector (CNP3)

1

wire (flat type) (11 core)

3

tuner unit (TM301)

8

screw

(+BVTP 3

q;

I/O board

9

three screws

(+BVTP 3 × 8)

×

8)

2

three screws

(+BVTP 3 × 8

2-7. DMB03 Board

6

connector (CNP902)

7

connector (CN804)

8

connector (CNP905)

9

connector (CNP903)

qa

power transformer

(T901)

q;

four screws

3

wire (flat type)

@

(25 core)

1

four screws

(+BVTP 3

2

heat sink

5

4

connector (CN102)

×

8)

DMB03 boar

10

Page 11

2-8. DC Fan (FAN1)

3

DC fan (FAN1)

2

connector

(CNP801)

1

four screws

(+BVTP 3 × 8)

AVD-K800P

2-9. MAIN Board

qs

four screws

(+BVTP 3

1

connector

(CNP100)

×

6)

2

connector

(CN102)

qa

five screws

(+BVTP 3

qd

MAIN board

q;

two screws

(+BVTP 3

×

8)

×

8)

4

connector

(CNP905)

5

connector

(CNP903)

6

connector

(CNP902)

7

wire (flat type)

(CNS901)

3

connector

(CN804)

9

wire (flat type)

(CNS905)

8

connector

(CNP901)

11

Page 12

AVD-K800P

2-10. T able Assy

4

screw

(+BTP2.6

5

claw

×

1

floating screw

(+PTPWH M2.6)

2

tray

8)

6

plate (guide)

3

table assy

7

screw

(+BTP2.6

plate (guide)

9

×

0

flat type wire

(6 core) (CN002)

8)

8

claw

12

Page 13

2-11. SE-130 Board

1

connector (CN102)

6

SE-130 board

4

two screws

(+BTP 2.6

5

(6 core) (CN101)

×

8)

AVD-K800P

flat type wire

8

two screws

(+P 3

table assy

3

claw

2

claw

7

two screws

(+BTP 2.6

qa

td unit assy

0

td belt

×

3)

×

8)

9

td motor assy

13

Page 14

AVD-K800P

n

2-12. DC Motor (M001)

5

connector

(CN004)

6

DC motor (M001)

4

2-13. Pickup Unit Section

two screws

(+P 2.6 × 4)

3

screw

(+PTPWH M2.6)

4

gear (chuck)

3

belt (loading)

2

gear (loading A)

1

screw

(+PTPWH M2.6)

6

two claws

1

two screws

(+BV B3)

2

chuck assy

14

5

7

8

pickup unit sectio

Page 15

2-14. RF Board

4

flexible flat cable (9 core)

(CN003)

2

claw

6

three step screws (M)

7

three insulators

8

pickup unit

3

flexible flat cable (24 core)

(CN001)

9

holder (BU) assy

AVD-K800P

5

RF board

1

two screws

(+BTP 2.6

×

10)

15

Page 16

AVD-K800P

SECTION 3

TEST MODE

[Version Display Mode]

*The software version is displayed.

Procedure:

1. Press the ?/1 button to turn the set on.

2. To enter the test mode, press the three buttons

INPUT SELECTOR , . and DISC SELECT 1

simultaneously.

3. The message “VER #.##” is displayed for a while.

[Jog V olume Mode]

* Master Volume Check.

Procedure:

1. Press the ?/1 button to turn the set on.

2. To enter the test mode, press the three buttons x , > and

DISC SELECT 5 simultaneously.

3. The message “JOG 0” is displayed.

4. “JOG 0” value increases like +1, +2, +3 ... if rotating the

MASTER VOLUME knob clockwise, or it decreases like

-1, -2, -3, ... if rotating counter-clockwise.

5. To exit from this mode, press the ?/1 button to turn the set

off.

[Key Check Mode]

*Keyboard check.

Procedure:

1. Press the ?/1 button to turn the set on.

2. To enter the test mode, press three buttons x , > and

DISC SELECT 2 simultaneously.

3. In the key check mode, the fluorecent indicator displays

“KEYNUM 0”. Each time a button (without the ?/1 button)

is pressed, “KEYNUM 0” value increases. However, once a

button is pressed, it is no longer taken into account.

4. To exit from this mode, press the ?/1 button to turn the set

off.

[Display T est Mode]

* Fluorescent segments and LEDs are tested when this test is

activated.

Procedure:

1. Press the ?/1 button to turn the set on.

2. To enter the test mode, press the three buttons S , > and

DISC SELECT 3 simultaneously.

3. All segments turn on and all LEDs turn on.

( MULTI CHANNEL DECODING LED (blue),

DISC SELECT 1 to 5 LEDs (green, amber))

SACD

ALL1DISCS

DVD

PROGRAM

u

CD

VIDEO CD

FM AM

SHUFFLEMP3

ANGLE PL II

MULTI PBC

4. Press the > button and confirm the display and all LEDs

turn on.

ST MPEG-2PROGRESSIVEREPEAT1

SMH MONOAUTONTSCTRACKTITLECHAPTER

BASS

BOOST AAC

dB

D

D

kHz

MHz

PCMDIGITALEX

mft.

D

D

DTS

6. Press the > button and confirm all segments and all LEDs

turn off.

7. Press the > button and the message “STRU *.**” is

displayed.

8. Press the > button and the message “DVDU *.**” is

displayed.

9. Press the > button and the message “F/EU *.**” is

displayed.

10. Press the > button and the model name “HT-C800DP” is

displayed.

11. Press the > button and the destination “DEST-***” is

displayed.

12. Press the > button and the message “M_LED ON” is

displayed. The MULTI CHANNEL DECODING LED (blue)

is turned on.

13. Press the > button and the message “4-G 5-A” is displayed.

The DISC SELECT 4 (green) LED and the DISC SELECT 5

(amber) LED are turned on.

14. Press the > button and the message “3-G 4-A” is displayed.

The DISC SELECT 3 (green) LED and the DISC SELECT 4

(amber) LED are turned on.

15. Press the > button and the message “2-G 3-A” is displayed.

The DISC SELECT 2 (green) LED and the DISC SELECT 3

(amber) LED are turned on.

16. Press the > button and the message “1-G 2-A” is displayed.

The DISC SELECT 1 (green) LED and the DISC SELECT 2

(amber) LED are turned on.

17. Press the > button and the message “ALL GREEN” is

displayed. The DISC SELECT 1 to 5 (green) LEDs are turned

on.

18. Press the > button and the message “ALL AMBER” is

displayed. The DISC SELECT 1 to 5 (amber) LEDs are turned

on.

19. Press the > button. All segments turn on and all LEDs turn

on just the same as 3.

20. By pressing the . button, these tests are performed in

reverse order.

21. To exit from this mode, press the ?/1 button to turn the set

off.

[Disc T ray Lock]

The disc tray lock function for the antitheft of an demonstration

disc in the store is equipped.

Setting Procedure:

1. Press the ?/1 button to turn the set on.

2. Press two buttons of x and A simultaneously for five seconds.

3. The message “LOCKED” is displayed and the tray is locked.

Releasing Procedure:

1. Press two buttons of x and A simultaneously for five seconds

again.

2. The message “UNLOCKED” is displayed and the tray is

unlocked.

Note : When “LOCKED” is displayed, the tray lock is not released

by turning power on/off with the ?/1 button.

SACD

DVD

CD

VIDEO CD

ALL1DISCS

PROGRAM

SHUFFLEMP3

MULTI PBC

u

FM AM

ANGLE

STSMHMPEG-2PROGRESSIVEMONOAUTONTSCTRACKTITLECHAPTERREPEAT1

BASS

BOOST AAC

dB

D

D

kHz

MHz

PCMDIGITALEX

mft.

D

D

DTS

PL II

5. Press the > button and confirm the display and all LEDs

turn off.

16

[All Clear Mode]

*The All Clear clears all data including preset data stored in the

RAM to initial conditions. Execute this mode when returning the

set to the customer.

Procedure:

1. Press the ?/1 button to turn the set on.

2. To enter the test mode, press the three buttons S , . and

DISC SELECT 1 simultaneously.

3. The fluorescent indicator tube displays the message “ALL

CLEAR” and the set is reset.

Page 17

AVD-K800P

[DVD OSD TEST MODE]

[GENERAL DESCRIPTION]

The Test Mode allows you to make diagnosis and adjustment easily

using the remote commander and monitor TV. The instructions,

diagnostic results, etc. are given on the on-screen display (OSD).

[STARTING TEST MODE]

1. Press the +/1 button to turn the power on, and set the function

to DVD.

2. While pressing the x and > button, turn the [MASTER

OLUME] knob clockwise to enter the test mode.

3. It displays “SERVICE IN” on the fluorescent indicator tube,

and displays the Test Mode Menu on the monitor screen as

follows. (At the bottom of the menu screen, the model name

and revision number are displayed)

Test Mode Menu

0. Syscon Diagnosis

1. Drive Auto Adjustment

2. Drive Manual Operation

3. Mecha Aging

4. Emergency History

5. Mecha Error History

6. Version Information

7. Video Level Adjustment

Exit: POWER Key

Model :HT-C800DP UC

Revision :x.xx

4. To execute each function, select the desired menu and press its

number on the remote commander (RM-U800).

5. To release from test mode, press the

power off.

+/1 button and turn the

[OPERATING TEST MODE]

0. SYSCON DIAGNOSIS

The same contents as board detail check by serial interface can be

checked from the remote commander operation.

On the Test Mode Menu screen, press [10/0] key on the remote

commander, and the following Check Menu will be displayed.

### Syscon Diagnosis ###

Check Menu

0. Quit

1. All

2. Version

3. EEPROM

4. GPIO

5. SD Bus

6. Video

7. Audio

0-0. Quit

Quit the Syscon Diagnosis and return to the Test Mode Menu.

0-1. All (All items continuous check)

This menu checks all diagnostic items continuously. Normally, all

items are checked successively one after another automatically

unless an error is found, but at a certain item that requires judgment

through a visual check to the result, the following screen is displayed

for the key entry.

• Example display

### Syscon Diagnosis ###

Diag All Check

No.2 Version

2-3. ROM Check Sum

Check Sum = A658

Press NEXT Key to Continue

Press PREV Key to Repeat

For the ROM Check, the check sum calculated by the Syscon is

output, and therefore you must compare it with the specified value

for confirmation.

Following the message, press the [ ] button to go to the next

item, or press the [ ] button to repeat the same operation

again.

To quit the diagnosis and return to Check Menu screen, press the

.

>

[RETURN] key on the remote commander to display Check Menu.

• Error occurred

If an error occurred, the diagnosis is suspended and error is displayed.

Press the [RETURN] key on the remote commander to quit the

diagnosis, or press the [ ] button to repeat the same check where

an error occurred, or press the [ ] button to continue the check

from the item next to faulty item.

General Description of Checking Method

Selecting 2 and subsequent items calls the submenu screen of each

item. And selecting 2 and subsequent items executes respective

menus and outputs the results.

For the contents of each submenu, see “Check Items List” as below.

Check Items List:

0-2. Version

0-2-1. All

0-2-2. Revision

0-2-3. ROM Check Sum

0-2-4. Model Type

0-2-5. Region

0-3. EEPROM Check

0-3-1. Sampling Check

0-3-2. Detail Check

0-4. GP I/O Check

0-5. SD Bus Check

0-6. Video Check

0-7. Audio Check

0-2. Version

0-2-2. Revision

The revision number of ROM (IC206) that the program for

the DVD system processor (IC207) is stored.

0-2-3. ROM Check Sum

The revision number of ROM (IC206) that the program for

the DVD system processor (IC207) is stored.

0-2-4. Model Type

Model name is displayed. (HT-C800DP)

.

>

17

Page 18

AVD-K800P

Ver 1.1

0-2-5. Region

Model destination code is displayed. (2 digits number)

0-3. EEPROM Check

0-3-1. Sampling Check

EEPROM check at every 64 words.

It compares read data with write data of each address. When

there are discrepancies between two data, it displays error.

0-3-2. Detail Check

EEPROM check at every 1 word.

It compares read data with write data of each address. When

there are discrepancies between two data, it displays error.

0-4. GP I/O Check

Pull up/down setting check of the DVD system processor (IC207)

pin 150, 151 and 154 (for clock setting port).

0-5. SD Bus Check

SD bus data check between DVD decoder (IC701) and D-RAM

(IC706).

0-6. Video Check

Output the color bars for video level adjustment.

0-7. Audio Check

Output the test signal (1kHz sine wave) for 5.1 CH test.

1. DRIVE AUTO ADJUSTMENT

On the Test Mode Menu screen, press the [1] key on the remote

commander, and the Adjustment Menu will be displayed.

## Drive Auto Adjustment ##

Adjustment Menu

0. ALL

1. DVD-SL

2. CD

3. DVD-DL

1-1. DVD-SL (single layer)

Test disc: TDV-520CSO (DVD-SL) (Part No. J-2501-236-A)

Press the [1] key on the remote commander and insert a DVD single

layer disc following the message. Then the adjustment will be made

through the steps below, then adjusted values will be written to the

EEPROM.

DVD Single Layer Disc Adjustment Steps:

1. Sled tilt reset

2. Disc check memory SL

3. Wait 300 msec

4. Set disc type SL

5. LD on

6. Spindle start

7. Wait 1 sec

8. Focus servo on 0

9. Auto track offset adjust

10. CLVA on

11. Wait 500 msec

12. Tracking on

13. Wait 1 sec

14. Sled on

15. Check CLV on

16. Auto LFO adjust

17. Auto focus offset adjust

18. Auto tilt position adjust

19. Auto focus gain adjust

20. Auto focus offset adjust

21. EQ boost adjust

22. Auto loop filter offset adjust

23. Auto track gain adjust

Search Check

24. 32 track jump forward

25. 32 track jump reverse

26. 500 track jump forward

27. 500 track jump reverse

28. All servo stop

29. EEP copy loop filter offset

Exit: RETURN

Normally, [10/0] is selected to adjust DVD (single layer), CD and

DVD (dual layer) in this order. But, individual items can be adjusted

for the case where adjustment is suspended due to an error. In this

mode, the adjustment can be made easily through the operation

following the message displayed on the screen.

The disc used for adjustment must be the one specified for

adjustment.

1-0. ALL

Press the [10/0] key on the remote commander, and the servo set

data in EEPROM will be initialized. Then, 1. DVD-SL disc, 2. CD

disc and 3. DVD-DL disc are adjusted in this order.

Each time one disc was adjusted, it is ejected. Replace it with the

specified disc following the message. You can finish the adjustment

by pressing the [RETURN] button on the remote commander.

Note: During adjustment of each disc, the measurement for disc type judg-

ment is made. As automatic adjustment does not judge the disc

type unlike conventional models, take care not to insert wrong type

discs. Also, do not give a shock during adjustment.

1-2. CD

Test disc: LIV-P01 (CD) (Part No. 4-999-032-01)

Press the

following the message. Then the adjustment will be made through

the steps below, then adjusted values will be written to the EEPROM.

CD Adjustment Steps

[2] key on the remote commander and insert a CD disc

1. Sled tilt rest

2. Disc check memory CD

3. Wait 500 msec

4. Set disc type CD

5. LD on

6. Spindle start

7. Wait 500 msec

8. Focus servo on 0

9. Auto track offset adjust

10. CLVA on

11. Wait 500 msec

12. Tracking on

13. (TC display start)

14. Wait 1 sec

15. Jitter display start

16. Sled ON

17. Check CLV on

18. Auto loop filter offset adjust

19. Auto focus offset adjust

20. Auto focus gain adjust

18

Page 19

AVD-K800P

Ver 1.1

21. Auto focus offset adjust

22. EQ boost adjust

23. Auto LFO Adjust

24. Auto track gain adjust

Search Check

25. 32Tj forward

26. 32Tj reverse

27. 500Tj forward

28. 500Tj reverse

29. All servo stop

1-3. DVD-DL (dual layer)

Test disc: TDV-540C (DVD-DL) (Part No. J-2501-235-A)

Press the

layer disc following the message. Then the adjustment will be made

through the steps below, then adjusted values will be written to the

EEPROM.

DVD Dual Layer Disc Adjustment Steps:

Layer 1 Adjust

Layer 0 Adjust

[3] key on the remote commander and insert a DVD dual

1. Sled tilt reset

2. Disc check memory DL

3. Wait 500 msec

4. Set disc type DL

5. LD on

6. Spindle start

7. Wait 1 sec

8. Focus servo on 0

9. Auto track offset adjust

10. CLVA on

11. Wait 500 msec

12. Tracking on

13. Wait 500 msec

14. Sled on

15. Check CLV lock

16. Auto loop filter offset adjust, Auto focus adjust

17. Auto focus gain adjust

18. Auto focus offset adjust

19. EQ boost adjust

20. Auto loop filter offset adjust

21. Auto Track Gain Adjust

Search Check

22. 32 track jump forward

23. 32 track jump reverse

24. 500 track jump forward

25. 500 track jump reverse

26. Focus jump (L1 t L0)

27. Auto track offset adjust L0

28. CLVA on

29. Wait 500 msec

30. Tracking on

31. Wait 500 msec

32. Sled on

33. Check CLV lock

34. Auto focus filter offset adjust

35. Auto Focus Adjust

36. Auto focus gain adjust

37. Auto focus offset adjust

38. EQ boost adjust

39. Auto Loop Filter Offset

40. Auto track gain adjust

Search Check

41. 32 track jump forward

42. 32 track jump reverse

43. 500 track jump forward

44. 500 track jump reverse

Layer Jump Check

45. Layer jump (L0 ? L1)

46. Layer jump (L1 ? L0)

47. All servo stop

2. DRIVE MANUAL OPERATION

Note: This mode is used for design, and not used in service fundamen-

tally.

On the Test Mode Menu screen, press the [2] key on the remote

commander, and the Operation Menu will be displayed. For the

manual operation, each servo on/off control and adjustment can be

executed manually.

## Drive Manual Operation ##

Operation Menu

1. Disc Type

2. Servo Control

3. Track/Layer Jump

4. Non EEPROM Write Adjust

5. EEPROM Write Adjust

6. Memory Check

7. Disc Check Memory

8. Error Rate Display

9. SACD Water Mark

Exit: RETURN

In using the manual operation menu, take care of the following

points. These commands do not provide protection, thus requiring

correct operation. The sector address or time code field is displayed

when a disc is loaded.

Note:

1. Set correctly the disc type to be used on the Disc Type screen.

2. In case of an alarm, immediately press the x button to stop the

servo operation, and press the +/1 button to turn the power

off.

Basic operation:

(controllable from front panel or remote commander)

+/1 :Power OFF (release the Test Mode)

x : Servo stop

A : Stop and eject/Loading

[RETURN] : Return to Operation Menu or Test

Mode Menu

>.

[ ], [ ] :Transition between sub modes of menu

[1] to [9], [10/0] : Selection of menu items

Cursor o/

O

: Increase/Decrease in manually

adjusted value

19

Page 20

AVD-K800P

2-1. Disc Type

Disc Type

Disc Type Select

1. Disc Type Auto Check

2. Set Disc Type DVD

3. Set Disc Type CD

4. Set Disc Type Hybrid

Exit: RETURN

2-1-1. Disc Type Auto Check

1) Press the [1] key on the remote commander to display the Disc

Type Auto Check screen.

2) Insert a disc and press the [ENTER] key on the remote

commander.

3) It judges the type of inserted disc automatically and displays

the disc type and so on as below.

Disc Type Auto Check

Disc Type xx

Layer xx

Mirr Time xx

Mirr Count xx

FZC Count xx

PI Reference xx

PI Peak xx

2-1-3. Disc Type CD

It sets up so that it may judge as a disc type of specification of the

disc with which the set was inserted.

[1]: CD disc (normal speed, 12 cm)

[2]: CD disc (double speed, 12 cm)

[3]: CD disc (normal speed, 8 cm)

[4]: CD disc (double speed, 8 cm)

[5]: CD-RW disc (normal speed, 12 cm)

[6]: CD-RW disc (double speed, 12 cm)

[7]: CD-RW disc (normal speed, 8 cm)

[8]: CD-RW disc (double speed, 8 cm)

2-1-4. Disc Type Hybrid

It sets up so that it may judge as a disc type of specification of the

disc with which the set was inserted.

[1]: SACD Hybrid disc (SACD layer, 12 cm)

[2]: SACD Hybrid disc (CD layer, normal speed, 12 cm)

[3]: SACD Hybrid disc (CD layer, double speed, 12 cm)

[4]: SACD Hybrid disc (SACD layer, 8 cm)

[5]: SACD Hybrid disc (CD layer, normal speed, 8 cm)

[6]: SACD Hybrid disc (CD layer, double speed, 8 cm)

2-2. Servo Control

Note: Be sure to perform the disc type setup before performing this item.

Servo Control

1.LD off R.Sled FWD

2.Focus off L.Sled REV

3.SPDL off U.Sled Reset

4.CLVA off D.Sled Limit

5.Trk. off

6.Sled off

7.Fcs.Srch off

8.Fcs.OppL off

ENTER.Execute

Exit: RETURN

Disc Type : CD, DVD or Hybrid (SACD)

Layer : SINGLE, DUAL or HYBRID

Mirr Time : Mirror time of between disc surface and record

surface when disc type judgment. (hexadecimal

number)

Mirr Count : The number of times which mirror counts between

disc surface and record surface when disc type

judging.

FZC Count : The number of times which focus zero cross points

of each layer when lens down.

PI Reference: The average of PI reference voltage. (hexadecimal

number)

PI Peak : PI peak level voltage. It performs only when disc

type judgment is successful. (hexadecimal number)

2-1-2. Disc Type DVD

It sets up so that it may judge as a disc type of specification of the

disc with which the set was inserted.

[1]: DVD single layer disc (12 cm)

[2]: DVD dual layer disc (0 layer, 12 cm)

[3]: DVD dual layer disc (1 layer, 12 cm)

[4]: DVD-RW disc (12 cm)

[5]: DVD single layer disc (8 cm)

[6]: DVD dual layer disc (0 layer, 8 cm)

[7]: DVD dual layer disc (1 layer, 8 cm)

[8]: DVD-RW disc (8 cm)

0.All Servo Off

Exit: RETURN

On this screen, the servo on/off control necessary for replay is

executed. Normally, turn on each servo from 1 sequentially and

when CLVA is turned on, the usual trace mode becomes active. In

the trace mode, DVD sector address or CD time code is displayed.

This is not displayed where the spindle is not locked.

The spindle could run overriding the control if the spindle system is

faulty or RF is not present. In such a case, do not operate CLVA.

[1] LD : Turn on/off the laser.

[2] Focus : Search the focus and turn on the focus.

[3] SPDL : Turn on/off the spindle.

[4] CLVA : Turn on/off normal servo of spindle servo.

[5] Trk. : Turn on/off the tracking servo.

[6] Sled : Turn on/off the sled servo.

[7] FCS. Srch : Turn on/off the focus search.

[8] FCS. OppL : Turn on/off the focus search to another

(opposite) layer of designated layer in Disc

Type setting. (dual layer disc only)

[10/0] : All servo off.

[R] Sled FWD (right cursor) : Move the sled forward.

[L] Sled REV (left cursor) : Move the sled reverse.

[U] Sled FWD (up cursor) : Reset the sled.

[D] Sled REV (down cursor): Limit in the sled.

20

Page 21

AVD-K800P

2-3. Track/Layer Jump

Track/Layer Jump

1. 1Tj FWD R.Lj L0>L1

2. 1Tj REV L.Lj L1>L0

3.500Tj Fine FWD U.Fj L0>L1

4.500Tj Fine REV D.Fj L1>L0

5.10kTj Dirc FWD

6.10kTj Dirc REV

7.20kTj Dirc FWD

8.20kTj Dirc REV

0. All Servo Off

Exit: RETURN

On this screen, track jump, etc. can be performed. Only for the DVD

dual layer disc, the focus jump and layer jump are displayed in the

right field

[1] 1Tj FWD : 1 track jump forward.

[2] 1Tj REV : 1 track jump reverse.

[3] 500Tj FWD: 500 track jump (fine search)forward.

[4] 500Tj REV : 500 track jump (fine search) reverse.

[5] 10kTj FWD: 10k track jump (direct search) forward.

[6] 10kTj REV : 10k track jump (direct search) reverse.

[7] 20kTj FWD: 20k track jump (direct search) forward.

[8] 20kTj REV : 20k track jump (direct search) reverse.

[10/0] : All servo off.

2-4. Non EEPROM Write Adjust

2-5. EEPROM Write Adjust

EEPROM Write Adjust

1. Focus Offset

2. Focus Gain

3. Trk. Offset Coarse

4. ——————

5. Trk. Gain

6. EQ Boost

0.All Servo Off

Exit: RETURN

On this screen, each item can be adjusted automatically. Select the

desired number

selected item is adjusted automatically.

[1] to [10/0] from the remote commander, and

[1] Focus Offset: Adjusts focus offset.

[2] Focus Gain : Adjusts focus gain.

[3] TRK. Offset : Adjusts tracking offset of the RF amp

(IC001) side.

[5] TRK. Gain : Adjusts track gain.

[6] EQ Boost : Adjusts amount of boost of equalizer.

[10/0] : All servo off.

2-6. Memory Check

Display images are shown as follows, and all two screens are able

to switch by theOkey (UP) or okey (DW).

Non EEPROM Write Adjust

1. Focus Offset

2. Focus Gain

3. Trk. Offset Coarse

4. Trk. Offset Fine

5. Trk. Gain

6. EQ Boost

0.All Servo Off

Exit: RETURN

On this screen, each item can be adjusted manually. Select the desired

number

setting for the selected item will be displayed, then increase or

decrease numeric value with theOkey or okey. This value is

stored in the EEPROM. If CLV has been applied, the jitter is

displayed for reference for the adjustment.

[1] to [10/0] from the remote commander, and current

[1] Focus Offset: Adjusts focus offset.

[2] Focus Gain : Adjusts focus gain.

[3] TRK. Offset : Adjusts tracking offset of the RF amp

(IC001) side.

[4] TRK. Offset : Adjusts tracking offset of the DSP (IC401)

side.

[5] TRK. Gain : Adjusts track gain.

[6] EQ Boost : Adjusts amount of boost of equalizer.

[10/0] : All servo off.

EEPROM Data 1/2 CD SL L0 L1

Focus Gain xx xx xx xx

Trk. Gain xx xx xx xx

Focus Offset xx xx xx xx

Trk. Offset xx xx xx xx

EQ. Boost xx xx xx xx

PI Level xx xx -- -Fcs. Balance -- xx -- -Jitter xx xx xx xx

Mirror Time xx xx xx -FE Level -- xx -- -Traverse Lv1. -- xx -- -Next:DW Default:CLR Exit:RET

EEPROM Data 2/2 CDRW DVDRW

Focus Gain xx xx

Trk. Gain xx xx

Focus Offset xx xx

Trk. Offset xx xx

EQ. Boost xx xx

Next:UP Default:CLR Exit:RET

On this screen, current servo adjusted data stored in the EEPROM

are displayed. The adjusted data are initialized by pressing the

[CLEAR] key, but be careful that they are not recoverable after

initialization.

Before clearing the adjusted data, make a note of the set data. This

screen will also appear if [0]-All is selected in the Drive Auto

Adjustment. In this case, default setting cannot be made.

21

Page 22

AVD-K800P

2-7. Disc Check Memory

Disc Check Memory

1. SL Disc check

2. SL Disc check

3. SL Disc check

Exit: RETURN

On this screen, measure the mirror time of chucked disc, and write

to the EEPROM.

2-8. Error Rate Display

Error Rate Display

ERR Address

C1 Err Now xxxxxxxx xxxxxxxx

Max xxxxxxxx xxxxxxxx

Avg xxxxxxxx

C2 Err Now xxxxxxxx xxxxxxxx

Max xxxxxxxx xxxxxxxx

Avg xxxxxxxx

Start: ENTER Stop: Return

On this screen, measure and display the error rate.

3. MECHA AGING

On the Test Mode Menu screen, selecting [3] executes the aging of

the mechanism deck.

### Aging Test MENU ###

Pls use over 40min. CD

**

Operation Menu

1. Open/Close Test

Exit: RETURN

1) On the Aging Test MENU screen, press the [1] key on the

remote commander to display the Open/Close Test screen.

2) Insert discs and press the [ENTER] key on the remote

commander.

3) It starts the aging.

During aging, the disc number, operating status and repeat cycle

are displayed. Aging can be aborted at any time by pressing

the x key. After the operation is stopped, press the x key or

**

[RETURN] key aging to return to the Aging Test MENU.

4. EMERGENCY HISTORY

On the Test Mode Menu screen, selecting [4] displays the

information such as servo emergency history.

The history information from last 1 up to 10 can be scrolled with

theOkey orokey. Also, specific information can be displayed

by directly entering that number with ten keys.

### EMG. History ###

Laser Hours CD xxxxhxxm

DVD xxxxhxxm

a. bb xx xx xx xx xx xx xx

xx xx xx xx xx xx xx xx

a. bb xx xx xx xx xx xx xx

xx xx xx xx xx xx xx xx

Select:1-9 Scroll:UP/DOWN

(1.Latest EMG.) Exit: RETURN

xxxxhxxm: The laser on total hours. Data below minutes are

omitted.

a. : Error number.

bb : Error code.

xx : Not used.

• Clearing History Information

Clearing laser hours:

Press the

Then both CD and DVD data are cleared.

Clearing emergency history:

Press the [DVD TOP MENU] and [CLEAR] keys in this order.

Initializing set up data:

Press [DVD MENU] and [CLEAR] keys in this order.

The data have been initialized when “Set Up Initialized”

message is displayed. The EMG. History screen will be restored

soon.

[DVD DISPLAY] and [CLEAR] keys in this order.

22

Page 23

AVD-K800P

• Code list of Emergency History

10: Communication to RF AMP (IC001) failed.

11: Each servo for focus, tracking, and spindle is unlocked.

12: Check sum error of EEPROM (IC204).

14: Communication to servo DSP (IC509) failed, or servo DSP

(IC509) is faulty.

15: Communication to DVD decoder (IC701) failed, or DVD

decoder (IC701) is faulty.

20: Initialization of sled servo failed. It is not placed in the ini-

tial position.

23: Sled servo operation error.

24: Made a request to move the sled servo to wrong position.

30: Tracking balance adjustment error.

31: Tracking gain adjustment error.

33: Focus bias adjustment error.

34: Focus gain adjustment error.

35: Equalizer adjustment error.

40: Focus servo does not operate.

41: With a DVD dual layer disc, focus jump failed.

50: CLV (spindle) servo does not operate.

51: Spindle does not stop.

60: Made a request to seek nonexistent address.

61: Seek error of retry more than regulated times.

70: Control data could not be read.

80: Disc reading failed.

5. MECHA ERROR HISTORY

On the Test Mode Menu screen, selecting [5] displays the information

of mechanism deck error history.

The history information from last 1 up to 8 can be scrolled with

theOkey orokey. Also, specific information can be displayed

by directly entering that number with ten keys.

### Mecha Error History ###

aa: Initialization is completed or not.

FF : Complete.

other number : Not complete.

bb: Operating status of mechanism deck at an error occurred.

(lod sq jcp)

00 : Initializing.

10 to 15 : Open operating.

16 to 19 : Kicking cause open failed.

1A to 1F : Open operating.

20 to 27 : Complete the open operation.

28 : No disc and complete the open operation.

29 to 2F : Complete the open operation.

30 to 3F : Close requesting.

40 to 4F : Open requesting.

50 to 5F : Close operating.

60 to 6F : Complete the chucking operation.

80 to 8F : Complete the release operation.

(BU is home position)

90 to 9F : BU down operating.

A0 to AF : Opening/closing the shutter. Or stationary state in

open/close the shutter is enablement.

B0 to BF : BU up requesting.

C0 to CF : BU down requesting.

D0 to DF : BU upping.

E0 to EF : No disc checking in disc loading.

cc: Operating status of mechanism deck at an error occurred.

(lod oq jcp)

00 : Complete the operation.

10 to 1F : Open operating.

20 to 2F : Close operating.

30 to 3F : Release operating.

60 to 6F : Chucking operating.

70 to 7F : Kicking operating.

80 to 8F : Returning the BU to home position. (after kicking)

1. aa bb cc xx xx xx xx xx

2. aa bb cc xx xx xx xx xx

3. aa bb cc xx xx xx xx xx

4. aa bb cc xx xx xx xx xx

5. aa bb cc xx xx xx xx xx

6. aa bb cc xx xx xx xx xx

7. aa bb cc xx xx xx xx xx

8. aa bb cc xx xx xx xx xx

Scroll:UP/DOWN

(1.Latest Err.) Exit: RETURN

23

Page 24

AVD-K800P

6. VERSION INFORMATION

On the Test Mode Menu screen, selecting [6] displays the ROM

version and region code.

The parenthesized hexadecimal number in version field is checksum

value of ROM.

## Version Information ##

IF con. Ver.x. xx

SYScon. Ver.x. xx (xxxx)

Model HT-C800DP

Region 0x

Config xxxxxxxx

Front End Ver.x.xx

Exit: RETURN

IF con. : The version of system controller (IC901) on the MAIN

board.

SYScon. : The version of DVD system processor (IC207).

Front End: The version of mechanism controller (IC901).

7. VIDEO LEVEL ADJUSTMENT

On the Test Mode Menu screen, selecting [7] displays color bars

for video level adjustment. During display of color bars, OSD

disappears but the menu screen will be restored if pressing the

[RETURN] key.

24

Page 25

d

d

SECTION 4

D

DIAGRAMS

AVD-K800P

4-1. Circuit Board Location

POWER SWITCH BOARD

HP BOARD

MAIN BOARD

DISPLAY BOARD

OPEN/CLOSE BOARD

SE-130 BOARD

RF BOARD

VOLTAGE SEL BOARD

MD-94 BOARD

I/O BOARD

DMB03 BOAR

THIS NOTE IS COMMON FOR PRINTED WIRING BOARDS AND SCHEMATIC DIAGRAMS.

(In addition to this, the necessary note is printed in each block.)

For schematic diagrams.

Note:

• All capacitors are in µF unless otherwise noted. pF: µµF

50 WV or less are not indicated except for electrolytics

and tantalums.

• All resistors are in Ω and 1/

specified.

f

•

• C : panel designation.

• A : B+ Line.

• B : B– Line.

•Voltages and waveforms are dc with respect to ground

•Voltages and wavef orms are dc with respect to ground in

•Waveforms are taken with a oscilloscope.

• Circled numbers refer to waveforms.

• Signal path.

•Abbreviation

: internal component.

Note:

The components identified by mark 0 or dotted

line with mark 0 are critical for safety.

Replace only with part

number specified.

under no-signal (detuned) conditions.

service mode.

Voltage variations may be noted due to normal production tolerances.

no mark : STOP

F : AUDIO

J : CD PLAY

c : DVD PLAY

d : TUNER

L : VIDEO

r : COMPONENT VIDEO

e : VIDEO/TV AUDIO IN

I : SACD PLAY

CND : Canadian model.

E51 : Chilean and peruvian models.

MX : Mexican model.

: Impossible to measure

∗

4

W or less unless otherwise

Note:

Les composants identifiés par

une marque 0 sont critiques

pour la sécurité.

Ne les remplacer que par une

piéce portant le numéro

spécifié.

For printed wiring boards.

Note:

• X : parts extracted from the component side.

a

•

• b : Pattern from the side which enables seeing.

(The other layers' patterns are not indicated.)

Caution:

Pattern face side: Parts on the pattern face side seen from

(SIDE A) the pattern face are indicated.

Parts face side: Parts on the par ts face side seen from

(SIDE B) the parts face are indicated.

: Through hole.

• Indication of transistor

C

Q

CEB

These are omitte

EB

These are omitte

2525

Page 26

AVD-K800P

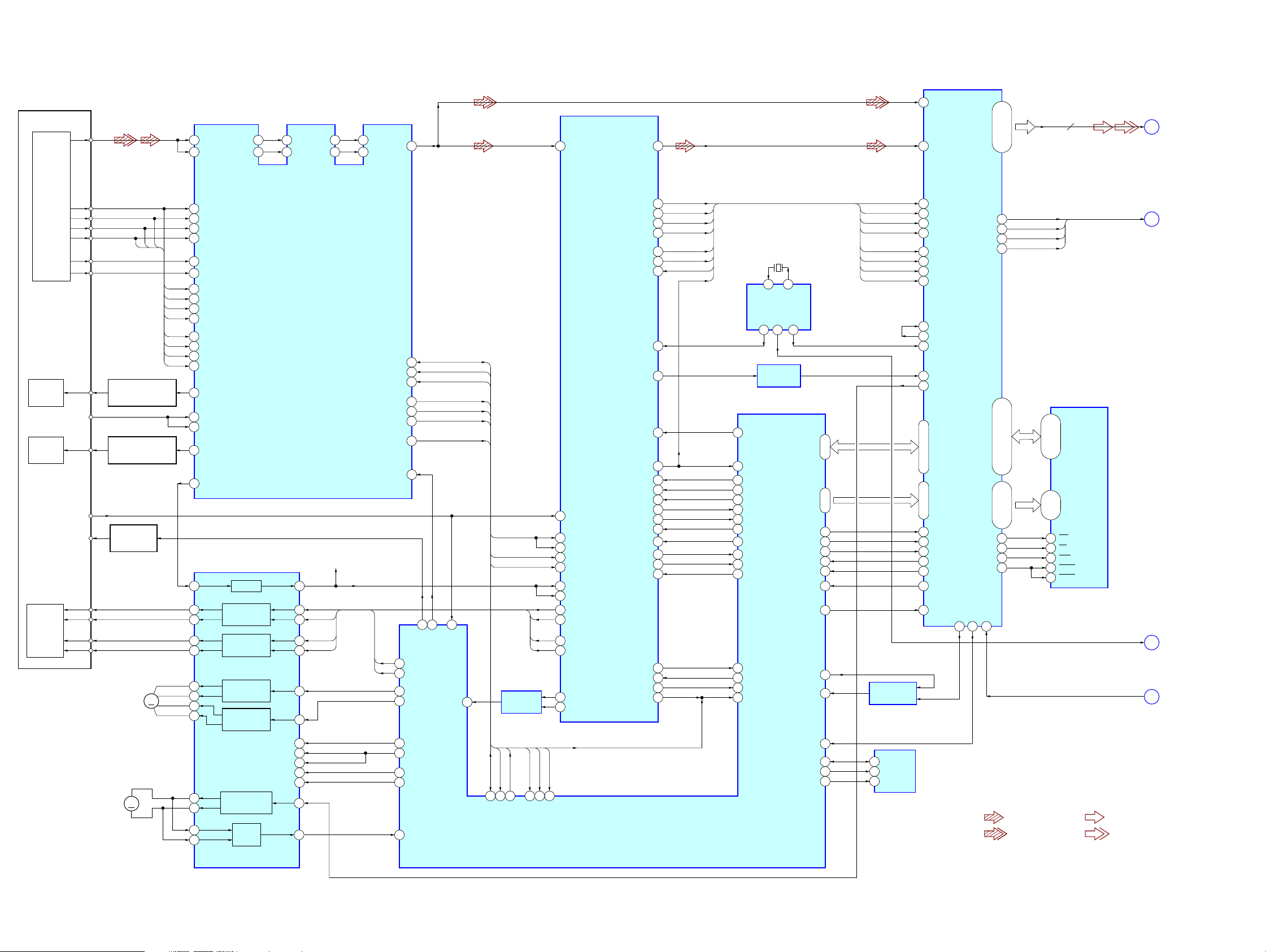

4-2. Block Diagrams — RF SERVO Section —

RF

1

63

DVDRFP

RFSIN

ATOP

ATON

117

RFIN

8

FNP

62

61

AIP

59

AIN

60

FNN

535254

DIP

55

DIN

RFAC

57

50

RFAC

PCMD

66

160

MDAT

32, 30, 27, 24

HDB0 – HDB7

44, 41, 39, 35,

SD0 – SD7

A

VIDEO

SECTION

DETECTOR

OPTICAL PICK-UP

BLOCK

(TDP022W)

LASER

CD LD

DIODE

(FOR CD)

LASER

DVD LD

DIODE

(FOR DVD)

INLIM

FCS+

FCS–

2AXIS

DEVICE

FOCUS/

TRACKING

COIL

TRK+

TRK–

A

B

C

D

F

E

PD

SW

AUTOMATIC POWER

CONTROL (FOR CD)

AUTOMATIC POWER

CONTROL (FOR DVD)

LASER DIODE

(SPINDLE)

Q901

SELECT

(SLED)

MM

D

Q002

Q001

CBA

MM

A2

3

B2

4

C2

5

D2

6

18

CD E

17

CD F

B

12

A

A

11

B

D

10

C

C

9

D

B

16

CD A

A

15

CD B

D

14

CD C

C

13

CD D

22

CDLD

24

CDPD

DVDPD

23

DVDLD

21

V125

36

FOCUS/TRACKING COIL DRIVER,

SPINDLE, SLED MOTOR DRIVER

36 48

37 1

34 3

35 4

32

31

30

29

27

28

47

46

IC501

BUFFER

FOCUS COIL

DRIVE

TRACKING COIL

DRIVE

SLED MOTOR

DRIVE

SLED MOTOR

DRIVE

SPINDLE MOTOR

DRIVE

BUFFER

IC001

CD/DVD/SACD RF AMP,

FOCUS/TRACKING ERROR AMP

4042

7

10

MUTE12

MUTE34

MUTE5

TSD-M

39

19

20

21

22

13

45

POWER SAVE

AVC

(1.65V)

FF

FR

TF

TR

SDATA

SCLK

SDEN

MIRR

LDON

FF

FR

47

46

48

39

TE

40

FE

42MNTR

27

26

7

FCS_JMP_1

8

FCS_JMP_2

44

SLED_B

43

SLED_A

97

A8

60

MUTE_2D

63

SP_ON

73

TSD-M

62

FG

28

76 31

LDSEL

LD_ON

SLED

DATA_RF

CLK_RF

SDEN

MIRR

INLIM

61

TE

FE

PI

TE

FE

PI

CLK_RF

DATA_RF

82

83

SDCLK_RF

SDATA_RF

IC503

AMP

SDEN

2

SDEN

BCK

LRCK

C2PO

WDCK

WFCK

SBSO

EXCK

IC509

CD DECODER,

DIGITAL SERVO PROCESSOR

XTAI

MDP

MD2

SCOR

DATA

CLOK

XLAT

SSTP

26

41

TE

40

SE

FE

39

43

RFDC

VC

38

CE

42

FF

33

FFDR

FR

34

FRDR

TF

31

TFDR

TR

32

TRDR

SFDR

29

SRDR

30

MIRR

PI

FE

TE

67PI66

65

FE

TE

IC901 (1/2)

MECHANISM

CONTROLLER

SENS

SQSO

SQCK

XRST

LOCK

GFS

MUTE

COUT

SCLK

FOK

MIRR

LRCK

65

C2PO

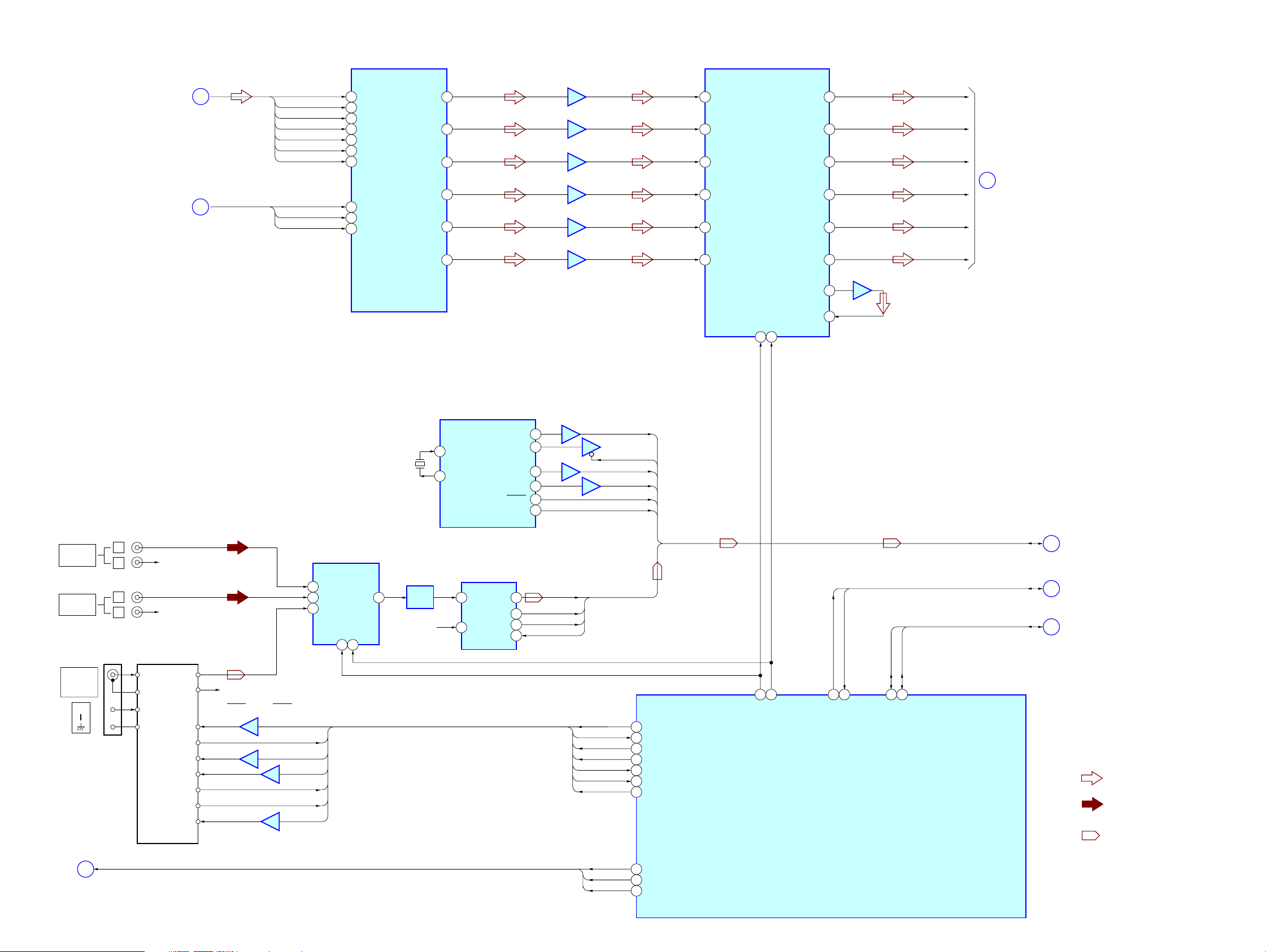

14

GSCOR

17

WFCK

10

SBSO

79

EXCK

80

SCOR

IC906

CLOCK

GENERATOR

13 3

71

3

26

49

50

27

9

52

54

98

75

71

59

30

72

74

29

IC703 (2/2)

DOCTRL/

ISBTEST

SCOR

DATA_CD

CLOK_CD

LAT_CD

SENS_CD

SQSO

SQCK

XDRST

LOCK_CD

GFS_CD

MUTE_CD

COUT_CD

SCLK_CD

FOK_CD

MIRR

25

63

15

4

6

5

7

76

77

2

24

13

3

19

8

22

20

7 8

XTI

SO3

MO1

27M

BUFFER

X902

27MHz

XTO

SO2

10

XRD

XWR

XCS_DVD

INIT0_DVD

INIT1_DVD

GFS_DVD

XRST_1882

SCK_DSD

MNT1

SDA_EEP

SCL_EEP

WP_EEP

JIT

14-21

D0 – D7

89-96

A0 – A7

85

84

12

22

23

58

25

45

64

6

5

100

99

BCLK

67

BCLK

LRCK

C2PO

GSCOR

WFCK

SBSO

EXCK

SCOR

IC703 (1/2)

COMPARATOR

5

SDA

6

SCL

7

WP

158

BCLK

163

LRCK

155

C2PO

146

GSCOR

151

WFCK

148

SBIN

147

EXCK

150

SCOR

DVD DECODER

167

XTAL

169

XTL2

170

XTL1

137

MDIN2

135

SPO

D0 – D7

172-176, 1, 2, 4

A0 – A7

5, 7, 9-14

17

XRD

18

XWR

19

XCS

20

XINT0

21

XINT1

107

GFS

164

XRST

IC903

EEPROM

XHWR

HDRQ

HDB8

XHRD

IC701

MDB0 – MDB9,

XMWR

XMOE

XRAS

XCAS

APE0

MNT1

109

92

• SIGNAL PATH

48

46

26

49

MDBA – MDBF

99, 101, 102, 104-106

66-69, 71, 73-75, 96, 97,

89, 91

MA0 – MA9

79, 80, 82-87,

76

94

78

95

XHAC

53

: CD

: DVD

XDCK, XSAK, SDEF, XSHD

XDCK

XSAK

SDEF

XSHD

2-5, 7-10,

I/O0 – I/O15A0 – A9

41-44, 46-49

IC706

16Mbit

D-RAM

27-32

21-24,

17

WE

33

OE

18

RAS

34

UCAS

35

LCAS

27M

XSRQ-ZIVA

: AUDIO

: VIDEO

B

C

D

VIDEO

SECTION

VIDEO

SECTION

VIDEO

SECTION

2626

Page 27

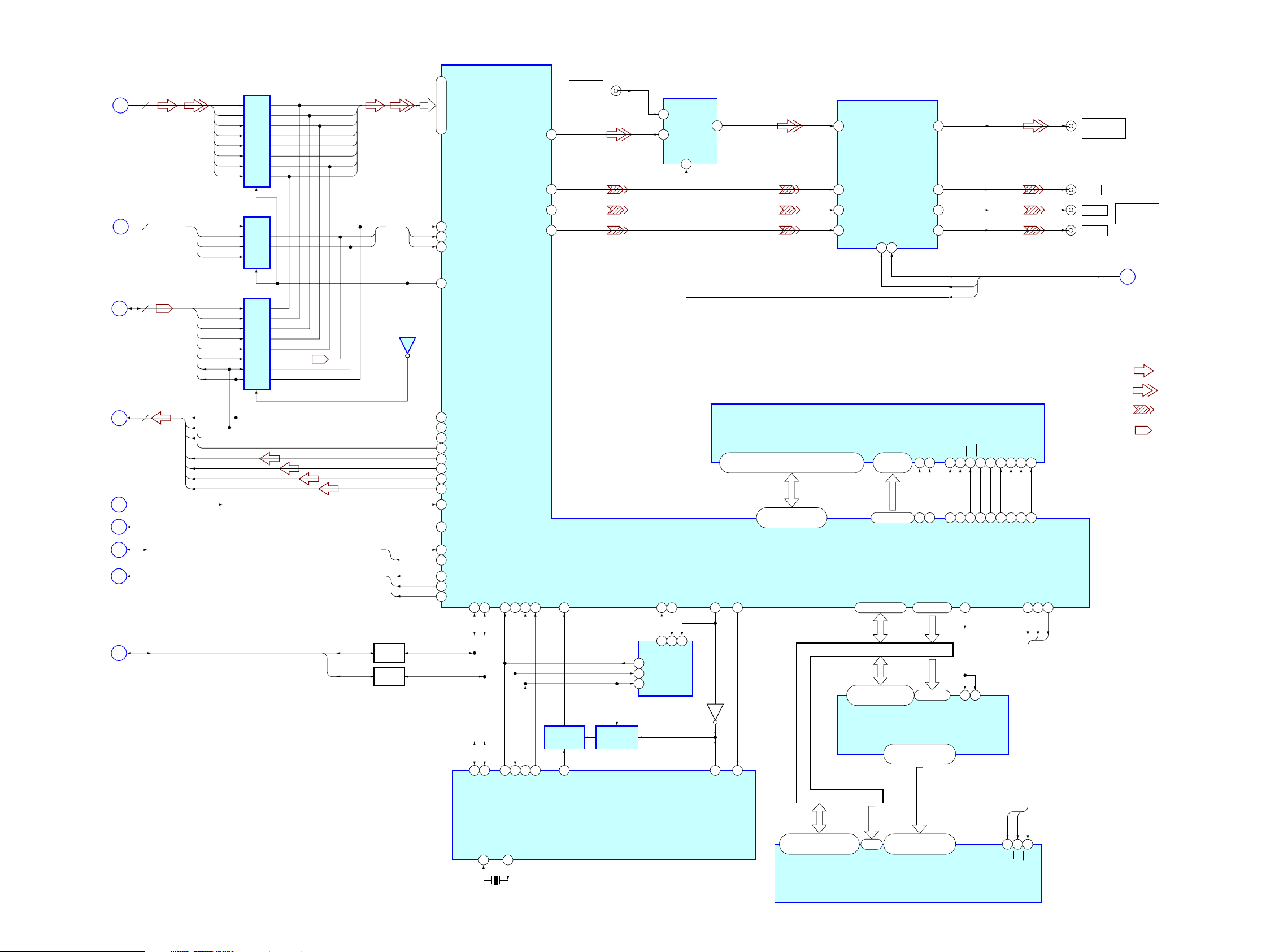

— VIDEO Section —

AVD-K800P

RF SERVO

SECTION

RF SERVO

SECTION

AUDIO

SECTION

AUDIO

SECTION

RE SERVO

SECTION

RE SERVO

SECTION

AUDIO

SECTION

AUDIO

SECTION

8

A

4

B

10

E

7

F

27M

C

XSRQ_ZIVA

D

SYS RESET, MUTE REQ

G

MDI, MC, ML

H

XSAK

SDEF

XDCK

XSHD

RERR

AES3_DATA

AES3_LRCK

AES3_BCK

NVERR

ADC_DATA

BCK

LRCK

LRCK-ZIVA

BCK-ZIVA

XCK

XCK I/O SEL

DATA0

DATA1

DATA2

DATA3

SD0

SD1

SD2

SD3

SD4

SD5

SD6

SD7

IC256

D-FF

IC258

D-FF

IC259

D-FF

AV0

AV1

AV2

AV3

AV4

AV5

AV6

AV7

XDCK#

XSAK#

SDEF#

IC255

SYS RESET

MUTE REQ

MDI

MC

ML

177-174, 171-168

SDDATA0 – SDDATA7

SDCLK

183

SDEN

179

SDERROR

182

INT/EXT

192

LRCK

148

BCK

149

XCK

147

XCK_I/O_SEL

106

DATA0(DM)

150

DATA1(FLR)

151

DATA2(SLR)

152

DATA3(CSW)

153

XIN

139

SDREQ

178

RESET

202

MREQ

110

MDI

143

MC

144

ML

145

161

I2C_DA

I2C_CL

160

186

DRVTX

DRVRX

187

VDAC_0

VDAC_2

VDAC_3

VDAC_4

DRVCLK

185

184

HIRQ1

J302 (1/2)

VIDEO

VIDEO IN

V

131

Y/G

125

CB/R

122

CR/B

119

VIDEO INPUT

SELECTOR

1

V_IN

3

DVD

IC1302

SW1

2

OUT

IC1301

VIDEO AMP, 75Ω DRIVER

7

4

VIN

12

CYIN

14

CBIN

16

CRIN

3

MUTE1

MUTE2

15

VOUT

CYOUT

CBOUT

CROUT

VOUT

31

CYOUT

25

CBOUT

22

CROUT

19

COMP MUTE

V-MUTE

VSW2

COMP MUTE, V-MUTE, VSW2

J302 (2/2)

MONITOR

VIDEO OUT

Y

PB/CB

PR/CR

J301

COMPONENT

VIDEO OUT

AUDIO

J

SECTION

• SIGNAL PATH

: AUDIO

: VIDEO

: COMPONENT VIDEO

DRVRDY

188

HIRQ2

WRITE_CTRL(ZIVA_E2P)

116

165

DQ0 – DQ31 A0 – A11

2,4,5,7,8,10,11,13,74,76,77,79,80,82,83,85,31,

33,34,36,37,39,40,42,45,47,48,50,51,53,54,56

57-60, 64-71, 75-78,

81-84, 88-95, 99-102

MD0 – MD31

IC207

DVD SYSTEM PROCESSOR

RST_SPC

CS_(ZIVA_E2P)

191

162

IC203

128Mbit SD-RAM

25-27,

60-66,24,21

42-33, 45, 46

MA0 – MA11

22, 19-14, 11-3 2, 207, 206

BS0

22

23

48

47

BA0

HA1 – HA3HAD0 – HAD15

BS1

BA1

68

56

CLK

20

49

MCLK

190

CS

17

53

MCS0

ALE

WE

19

51

MWE

RAS

18

52

MRAS

CAS

16

62

MCAS

DQM0

DQM1

71

28

73

86

MDQM0

MDQM1

DQM2

DQM3

59

97

MDQM2

MDQM3

HCS0

195

27

WEH.UDS

HREAD

25

: TUNER

AUDIO

SECTION

I2CDATA, I2CCLK

I

I2CDATA

I2CCLK

Q904

SWITCH

Q903

SWITCH

78

79

I2C_SIO

41 40

I2C_SCL

EXTAL

X901

20MHz

34

SO_ZIVA

XTAL

33

SI_ZIVA

35

36

SCK_ZIVA

IC904

FLIP-FLOP

37

DRVIRQ

DRVRDY

MECHANISM CONTROLLER

IC902

SWITCHING

IC901 (2/2)

6

5

4

DO

DI

SK

IC204

EEPROM

1 8

R/B

WC

HAD0 – HAD15 HA1 – HA3

3

CS

Q202

32

38

RST

CS_ZIVA

HAD0 – HAD15

29,31,33,35,38,40,42,44,

30,32,34,36,39,41,43,45

DQ0 – DQ15

DATA & ADDRESS BUS

HAD0 – HAD15 HA1 – HA3

55, 54, 52, 51,

49-47, 45-40, 38-36

1D1 – 1D10, 2D1 – 2D6

DATA & ADDRESS BUS

HA1 –

HA3

25-23

A0 – A2

34, 33, 31

2D7 – 2D9

1Q1 – 1Q10, 2Q1 – 2Q9

2, 3, 5, 6, 8-10, 12-17,

19-21, 23, 24, 26

22-18, 8-1, 48,

17, 16, 9, 10, 13

A3 – A21

IC206

PROGRAMMABLE ROM

56 29

BUS INTERFACE

HA4 –HA22

ADDRESS BUS

1LE

2LE

IC216

CEWEOE

CE

OE

WE

26

28OE11

CE

WE

2727

Page 28

AVD-K800P

— AUDIO Section —

VIDEO

SECTION

VIDEO

SECTION

IC302

D/A CONVERTER

IC1310

AMP

F

H

DATA0

DATA1

DATA2

DATA3

LRCK-ZIVA

BCK-ZIVA

XCK

MDI

MC

ML

31

DATA4

45

DATA1

46

DATA2

47

DATA3

41

LRCK

40

BCK

38

SCKI

34

MDI

35

MC

36

ML

VOUT1

VOUT2

VOUT3

VOUT4

VOUT5

VOUT6

FL

14

FR

13

SL

12

SR

11

C

10

SW

9

21

67

IC1311

AMP

21

67

IC1309

AMP

21

67

44

INFLA

43

INFRA

47

INSLA

46

INSRA

48

INCA

45

INSWA

IC1312

SOUND PROCESSOR

DA

CL

13 14

L OUT

R OUT

SL OUT

SR OUT

C OUT

SW OUT

SR

SW

FL

FR

SL

AMP

K

SECTION

C

29

31

23

25

21

27

IC1307

2

CO

3

CI

HPF

J304 (1/2)

AUDIO IN

J304 (2/2)

AUDIO IN

VIDEO

SECTION

VIDEO

TV

FM

75Ω

COAXIAL

AM

COMP MUTE, V-MUTE, VSW2

J

L

R

L

R

FM/AM TUNER PACK

FM ANT

GND

AM ANT

GND

R-CH

R-CH

TM301

STEREO

L-CH

R-CH

ST-DI

ST-DO

CLK

TUNED

MUTE

IC372

DIGITAL AUDIO

INTERFACE

22

DATAO

19

IC352

DOUT

LRCK

SYSCLK

ERROR

BCK

CKOUT

BCK

LRCK

AUDIO

15

14

13

16

20

21

10

2

24

R-CH

XIN

1

XOUT

A/D CONVERTER

1

VINL

5

VINR

X372

12.288MHz

IC1303

AUDIO INPUT

SELECTOR

1

INA1

3

INB1

5

INC1

22 23

R-CH

IC1304

BUFFER

CE

TUN_DI

TUN_DO

TUN_CLK

TUN_LATCH

TUNED

STEREO

TUN_MUTE

14

OUT1

DA

CL

IC1313

AMP

ADC_DATA

BCK

LRCK

XCK

IC333

BUFFER

AES3_DATA

XCK_I/O_SEL

AES3_LRCK

TUN_DI

TUN_DO

TUN_CLK

TUN_LATCH

TUNED

STEREO

TUN_MUTE

AES3_BCK

NVERR

RERR

73

87

1

2

69

72

11

TUNDI

TUNDO

TUN_CLK

TUN_LATCH

TUNED

STEREO

TUN_MUTE

47 48

VOL_CLK

VOL_DATA

MUTE REQ

SYS RESET

4 94

M_REQ

ZIVA_RST

AES3_BCK, AES3_LRCK, NVERR, RERR,

I2CCLK

I2CDATA

3 5

I2C_CLK

I2C_DATA

AES3_DATA, XCK_I/O_SEL,

ADC_DATA, BCK, LRCK, XCK

SYS RESET, MUTE REQ

I2CDATA, I2CCLK

VIDEO

E

SECTION

VIDEO

G

SECTION

VIDEO

I

SECTION

• R-ch is omitted due

to same as L-ch.

• SIGNAL PATH

: AUDIO

: VIDEO/TV

AUDIO IN

: TUNER

IC901 (1/3)

COMP MUTE

V-MUTE

VSW2

27

COMP-MUTE

28

VIDEO-MUTE

46

VSW2

SYSTEM CONTROLLER

2828

Page 29

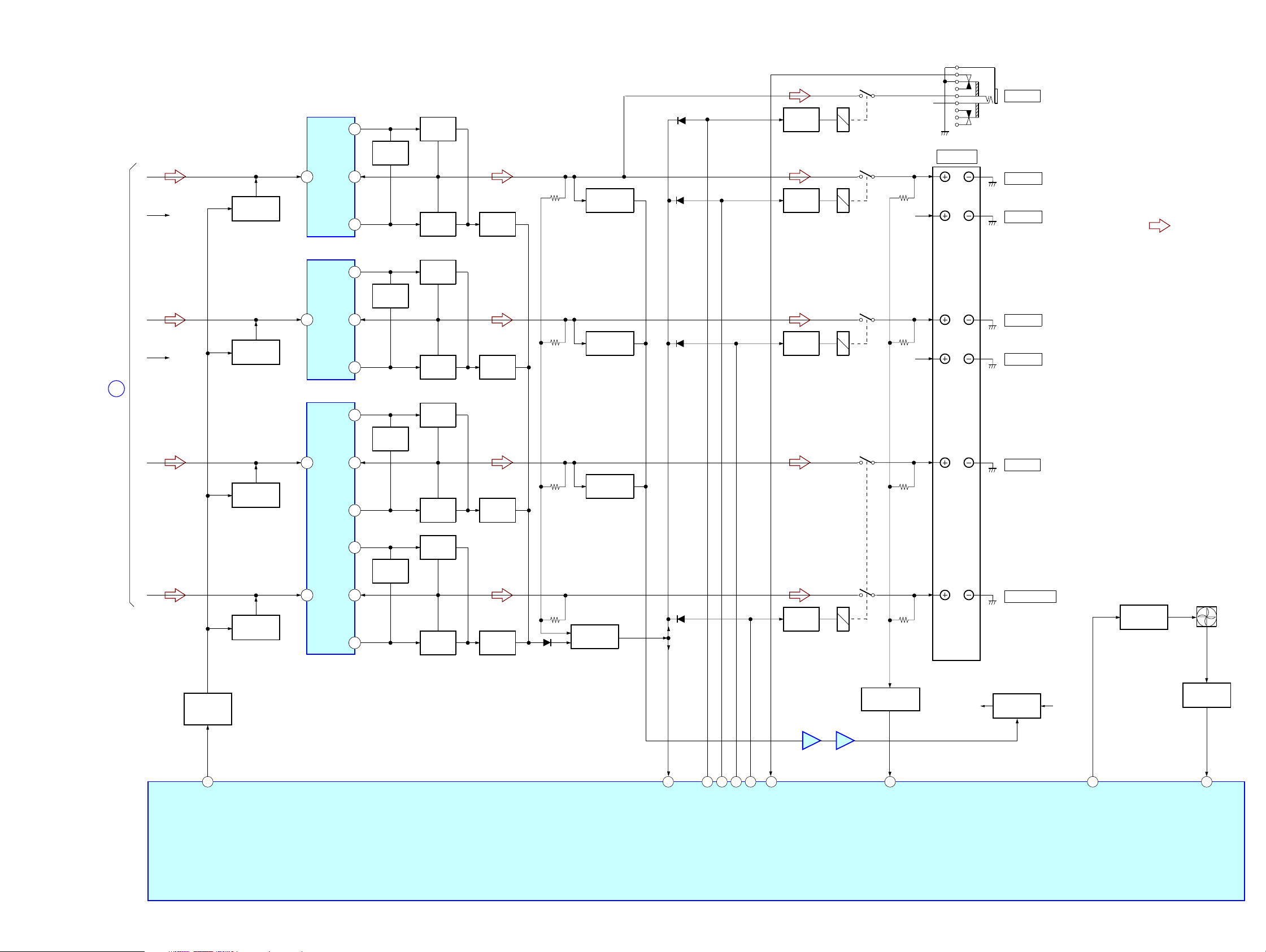

— AMP Section —

FL

FR R-CH

Q591

MUTING

IC500

POWER AMP

+V OUT2

8

IN2

-V OUT2

IC600

POWER AMP

+V OUT2

NF2

AVD-K800P

J100

PHONES

FRONT L

FRONT R

• R-ch is omitted due