Page 1

AVD-K700P

SERVICE MANUAL

Ver 1.0 2004.06

AVD-K700P is the amplifier, DVD/VIDEO

player and tuner section in HT-V700DP.

• Manufactured under license from Dolby Laboratories. "Dolb y",

"Pro Logic", and the double-D symbol are trademarks of Dolby

Laboratories.

Confidential unpublished works. Copyright 1992 -1997 Dolby

Laboratories. All rightsreserved.

• DTS and DTS Digital Surround are registered trademarks of

Digital Theater Systems, Inc.

SPECIFICATIONS

General

Power requirements AC 120V, 60 Hz

Power consumption 110 W

Dimensions (approx.) 430 x 83 x 376 mm (17 x 3

Mass (approx.) 6.2 kg (13 lb11 oz)

Operating temperature 5˚C to 35˚C (41˚F to 95˚F)

Operating humidity 5 % to 90 %

Signal system NTSC

DVD Section

Laser system Semiconductor laser (Wavelength

Frequency response DVD (PCM 48 kHz): 8 Hz to 22 kHz,

Signal-to-noise ratio More than 80 dB (AUDIO OUT

Harmonic distortion Less than 0.3%

Dynamic range More than 85 dB (AUDIO OUT

Inputs

ANTENNA IN Antenna or CATV input, 75 ohms

VIDEO IN 1 Vp-p 75 ohms, sync negative,

AUDIO IN -6.0 dBm more than 47 kohms,

FM ANTENNAIN FM antenna input, 75 ohms

AM ANTENNAIN AM antenna input, 300 ohms

OPTICAL IN Optical connector x 1

7

/8inches) (W x H x D)

14

DVD : 650 nm, CD : 780nm)

CD: 8 Hz to 20 kHz

jacks)

jacks)

RCA jack x 2

RCA jack (L, R) x 2

3

/8 x

DVD Mechanism T ype DP-7C

VCR Mechanism T ype D-37

Outputs

COMPONENT VIDEO OUT

Audio output (analog audio) 2.0 Vrms (1 KHz, 0 dB), 330 ohms,

VIDEO Section

Maximum recording time SP: 2 HOURS (T-120), EP: 6 HOURS

US Model

Model Name Using Similar Mechanism AVD-K600P

Optical Pick-up Name PVR-502W

VIDEO OUT 1 Vp-p 75 ohms, sync negative

ANTENNA OUT Channel 3 or 4 (Switchable)

Head system 4 heads helical scan azimuth system

Timer 12-hour display type with AM, PM

Tape speed SP: 33.35 mm/sec, EP: 11.12 mm/sec

Tape width 12.7 mm

Rewind time About 150 seconds (T-120)

Antenna 75 ohms (VHF/UHF)

Channel coverage VHF: 2-13, UHF: 14-69, CATV: 1-125

Frequency range 20Hz to 20kHz

Signal-to-noise ratio More than 43dB

Dynamic range More than 85 dB (AUDIO OUT jacks)

Channel separation More than 55 dB (AUDIO OUT jacks)

(Y) 1.0 V (p-p), 75 ohms, negative

sync, RCA jack x 1

(P

B/CB

)/(PR/CR) 0.7 V (p-p), 75 ohms,

RCA jack x 2

RCA jack (L, R) x 1

(T-120)/8 HOURS (T-160)

(4A, A-W, W+1 - W+84, A-5 - A-1)

– Continued on next page –

9-879-041-01

2004F1678-1

© 2004.06

DVD/VCR RECEIVER

Sony Corporation

Home Audio Company

Published by Sony Engineering Corporation

Page 2

AVD-K700P

FM Tuner

Intermediate Frequency

Tuning Range

87.5 - 108.0 MHz

10.7 MHz

AM Tuner

Intermediate Frequency

Tuning Range

530 - 1,720 kHz

450 kHz

AUDIO POWER SPECIFICATION

POWER OUTPUT AND TOTAL

HARMONIC DISTORTION:

With 6 ohm loads, both channels

driven, from 120 - 20,000 Hz; rated

90 watts per channel minimum RMS

power, with no more than 10 % total

harmonic distortion from 250 milli

watts to rated output (USA model

only).

Amplifier

Stereo mode 90 W + 90 W (6Ω at 1 kHz, THD

Surround mode Front: 90 W/ch (6Ω at 1 kHz, THD

Inputs VIDEO 1, VIDEO 2, OPTICAL IN

Design and specifications are subject to change without notice.

10 %)

10 %)

Center*: 90 W (6Ω at 1 kHz, THD

10 %)

Surround*: 90 W/ch (6Ω at 1 kHz,

THD 10 %)

Subwoofer*: 150 W (4Ω at 30 Hz,

THD 10 %)

*

Depending on the sound mode settings

and the source, there may be no sound

output.

Laser component in this product is capable of emitting radiation

exceeding the limit for Class 1.

This appliance is classified as

a CLASS 1 LASER product.

The CLASS 1 LASER

PRODUCT MARKING is

located on the rear exterior.

CAUTION

Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous radiation

exposure.

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be

damaged by heat.

Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270 °C

during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

UNLEADED SOLDER

Boards requiring use of unleaded solder are printed with the leadfree mark (LF) indicating the solder contains no lead.

(Caution: Some printed circuit boards may not come printed with

the lead free mark due to their particular size)

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED LINE

WITH MARK 0 ON THE SCHEMATIC DIAGRAMS AND IN

THE PARTS LIST ARE CRITICAL TO SAFE OPERATION.

REPLACE THESE COMPONENTS WITH SONY PARTS WHOSE

PART NUMBERS APPEAR AS SHOWN IN THIS MANUAL OR

IN SUPPLEMENTS PUBLISHED BY SONY.

: LEAD FREE MARK

Unleaded solder has the following characteristics.

• Unleaded solder melts at a temperature about 40 °C higher

than ordinary solder.

Ordinary soldering irons can be used but the iron tip has to be

applied to the solder joint for a slightly longer time.

Soldering irons using a temperature regulator should be set to

about 350 °C.

Caution: The printed pattern (copper foil) may peel away if

the heated tip is applied for too long, so be careful!

• Strong viscosity

Unleaded solder is more viscou-s (sticky, less prone to flow)

than ordinary solder so use caution not to let solder bridges

occur such as on IC pins, etc.

• Usable with ordinary solder

It is best to use only unleaded solder but unleaded solder may

also be added to ordinary solder.

2

Page 3

AVD-K700P

r

SAFETY CHECK-OUT

After correcting the original service problem, perform the following

safety check before releasing the set to the customer:

Check the antenna terminals, metal trim, “metallized” knobs, screws,

and all other exposed metal parts for AC leakage.

Check leakage as described below.

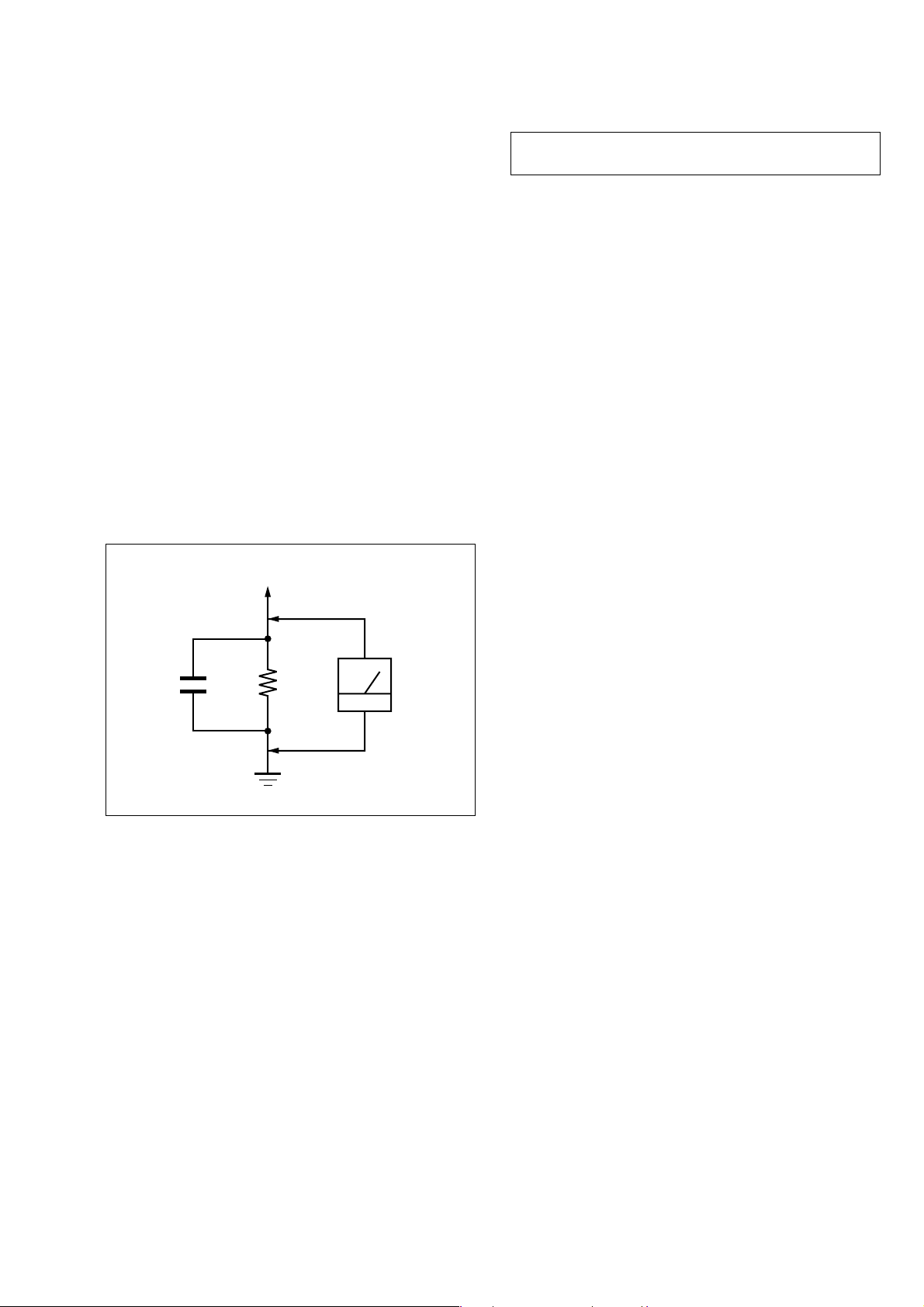

LEAKAGE TEST

The AC leakage from any exposed metal part to earth ground and

from all exposed metal parts to any exposed metal part having a

return to chassis, must not exceed 0.5 mA (500 microamperes.).

Leakage current can be measured by any one of three methods.

1. A commercial leakage tester, such as the Simpson 229 or RCA

WT -540A. Follow the manuf acturers’ instructions to use these

instruments.

2. A battery-operated A C milliammeter . The Data Precision 245

digital multimeter is suitable for this job.

3. Measuring the voltage drop across a resistor by means of a

VOM or battery-operated AC v oltmeter. The “limit” indication

is 0.75 V, so analog meters must have an accurate low-v oltage

scale. The Simpson 250 and Sanwa SH-63Trd are examples

of a passive VOM that is suitable. Nearly all battery operated

digital multimeters that have a 2 V A C range are suitable. (See

Fig. A)

To Exposed Metal

Parts on Set

NOTES ON HANDLING THE OPTICAL PICK-UP

BLOCK OR BASE UNIT

The laser diode in the optical pick-up block may suffer electrostatic

break-down because of the potential difference generated by the

charged electrostatic load, etc. on clothing and the human body.

During repair, pay attention to electrostatic break-down and also

use the procedure in the printed matter which is included in the

repair parts.

The flexible board is easily damaged and should be handled with

care.

NOTES ON LASER DIODE EMISSION CHECK

The laser beam on this model is concentrated so as to be focused on

the disc reflective surface by the objective lens in the optical pickup block. Therefore, when checking the laser diode emission,

observe from more than 30 cm away from the objective lens.

LASER DIODE AND FOCUS SEARCH OPERATION

CHECK

Carry out the “S curve check” in “CD section adjustment” and check

that the S curve waveform is output several times.

AC

0.15 µF

1.5 k

Ω

Earth Ground

voltmete

(0.75 V)

Fig. A. Using an AC voltmeter to check AC leakage.

3

Page 4

AVD-K700P

TABLE OF CONTENTS

1. GENERAL ................................................................... 5

2. ELECTRICAL ADJUSTMENT

2-1. VCR Section Electrical Adjustment ................................ 9

2-2. Electrical Troub leshooting Guide.................................... 10

2-3. DVD & AMP Section

Electrical Troubleshooting Guide.................................... 24

3. MECHANICAL ADJUSTMENT

3-1. Video Mechanism Deck Section ..................................... 32

3-2. Maintenance/Inspection Procedure ................................. 39

4. EXPLODED VIEWS

4-1. Block Diagram – POWER (SMPS) Section-1 – ............. 44

4-2. Block Diagram – POWER (SMPS) Section-2 – ............. 45

4-3. Block Diagram – Y/C Section – ...................................... 46

4-4. Block Diagram – NORMAL AUDIO Section –.............. 47

4-5. Block Diagram – HI-FI Section – ................................... 48

4-6. Block Diagram – SYSTEM Section –............................. 49

4-7. Schematic Diagram – POWER Section-1 – ................... 50

4-8. Schematic Diagram – POWER Section-2 – ................... 51

4-9. Schematic Diagram – SYSTEM Section –..................... 52

4-10. Schematic Diagram – AVCP Section – .......................... 53

4-11. Schematic Diagram – HI-FI/TUNER Section –............. 54

4-12. Schematic Diagram – A/V JACK, SCART Section – .... 55

4-13. Schematic Diagram – KEY/TIMER Section –............... 56

4-14. Schematic Diagram – MPEG & VIDEO Section – ........ 57

4-15. Schematic Diagram – RF & SERVO Section –.............. 58

4-16. Schematic Diagram – AUDIO MICOM Section – ......... 59

4-17. Schematic Diagram – DIGITAL AMP Section – ........... 60

4-18. Schematic Diagram – PWM & CODEC Section – ........ 61

4-19. Schematic Diagram – INTERFACE Section – ............... 62

4-20. Printed Wiring Board – VCR Section –........................... 63

4-21. Printed Wiring Board – DISPLAY Section – .................. 64

4-22. Printed W iring Board

– DVD & AMP Section (Component Side) – ................. 65

4-23. Printed W iring Board

– DVD & AMP Section (Conductor Side) – ................... 66

4-24. Printed Wiring Board – SMPS Section – ........................ 67

4-25. Printed Wiring Board – KEY Section – .......................... 68

5. EXPLODED VIEWS

5-1. Overall Section ................................................................ 69

5-2. DVD Mechanism Deck ................................................... 70

5-3. Front Loading Mechanism Section ................................. 71

5-4. Moving Mechanism Section (1)...................................... 72

5-5. Moving Mechanism Section (2)...................................... 73

6. ELECTRICAL PARTS LIST .................................. 74

4

Page 5

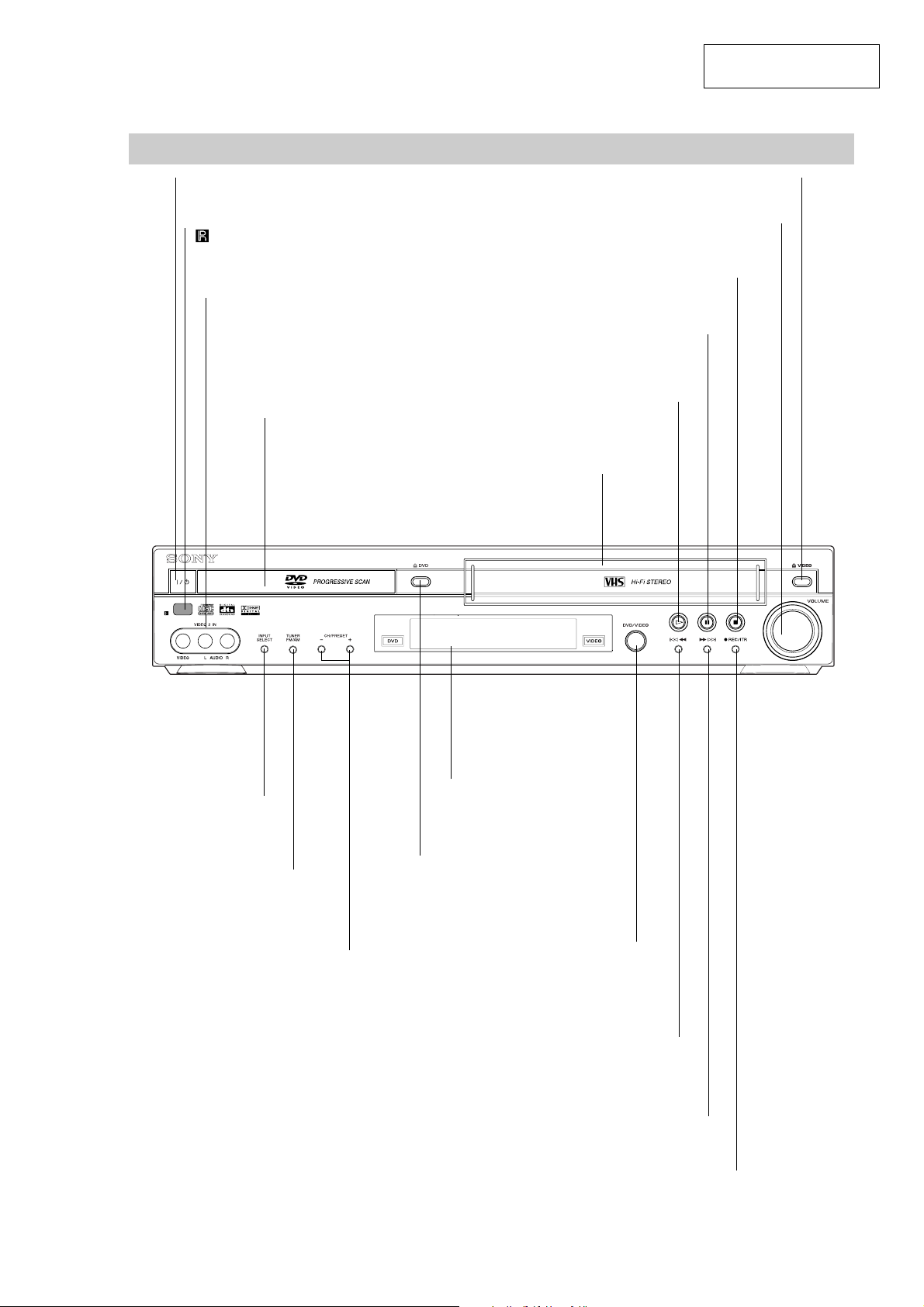

Front Panel

ML

DVD: Go to NEXT chapter/track. Press and hold for a fast forward search.

VIDEO: Advances the tape from STOP mode or for fast forward picture search.

X (PAUSE)

Pause playback or recording

temporarily.

z REC/ITR

To record normally or to activate Instant Timer Recording.

A DVD

Opens or closes

the disc tray.

Remote Sensor

Point the DVD/VCR Receiver remote

control here.

Display window

Shows the current status of the DVD/VCR

Receiver.

Disc Tray (DVD deck)

Insert a disc here.

@ / 1

Switches the DVD/VCR Receiver ON and OFF.

lm

DVD: Go to beginning of current chapter/track or to previous chapter/track.

Press and hold for a fast reverse search.

VIDEO: Rewinds the tape from STOP mode or for fast reverse picture search.

H (PLAY)

To play back a disc or

a recorded tape.

x (STOP)

Stops playback or recording.

INPUT SELECT

Selects the VIDEO

deck’s source

(Tuner, LINE 1 or

LINE 2).

CH/PRESET (+/–)

Scans up or down through

memorized channels or radio

frequencies (stations).

TUNER FM/AM

Selects Radio opera-

tion mode.

VIDEO 2 IN(VIDEO/AUDIO IN (Left/Right))

- Connect the audio/video output of an

external source (Audio system, TV/ Monitor,

another VCR).

- Use the left channel when external source is

MONO.

Video Cassette Compartment (VIDEO deck)

Insert a video cassette here.

A VIDEO

Ejects the tape in the VIDEO deck.

VOLUME

Adjusts sound level of speakers.

DVD/VIDEO

Toggles control

between the DVD deck

and the VIDEO deck.

SECTION 1

GENERAL

AVD-K700P

This section is extracted

from instruction manual.

5

Page 6

AVD-K700P

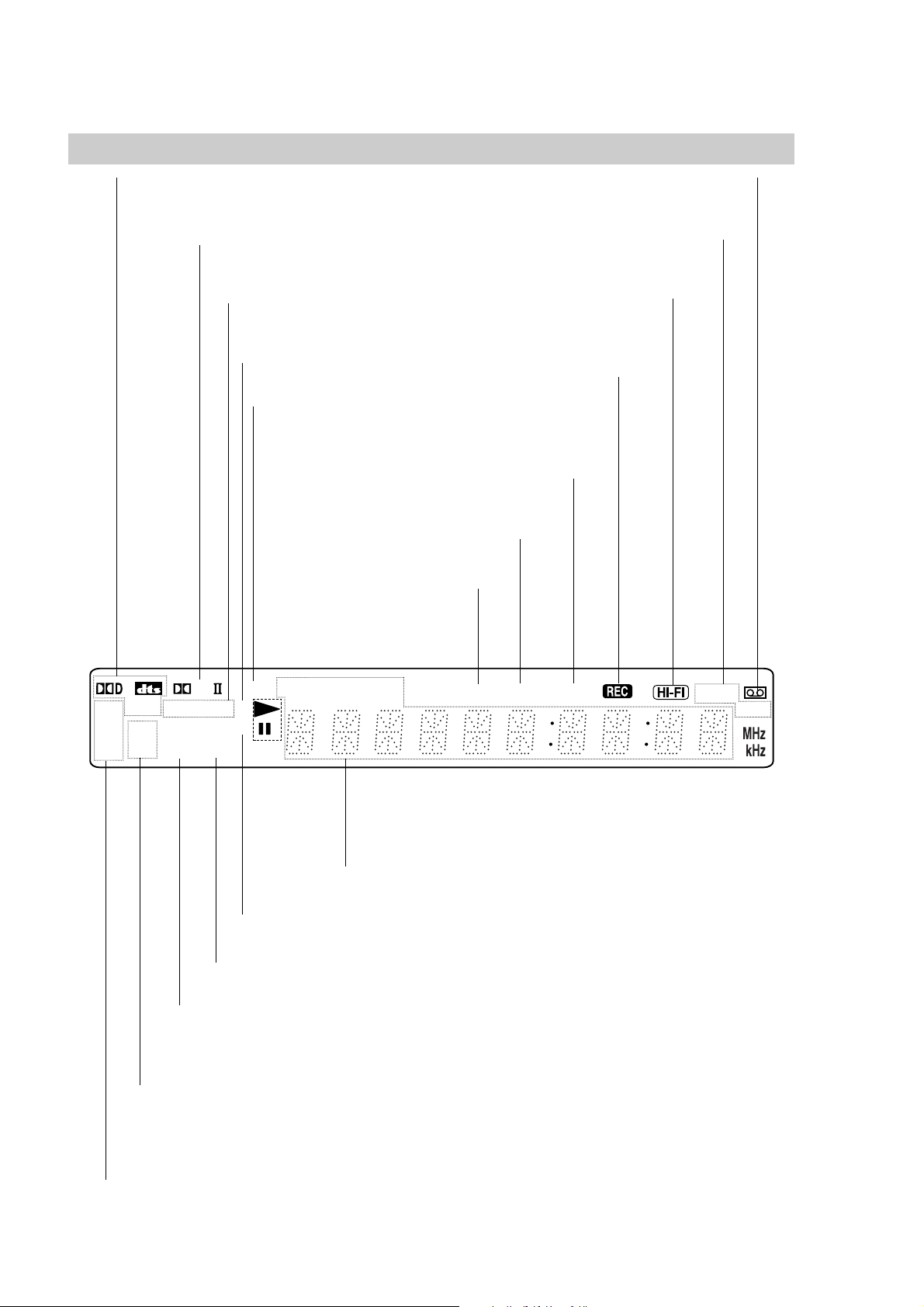

Display Window

Indicates encoding format of the

current disc.

Indicates sound mode is

DOLBY PROLOGIC II.

Indicates repeat mode

Lights when TV mode is

active.

VIDEO DVD/VCR

Receiver is recording.

A cassette is in the VIDEO deck.

SP EP Displays the recording

and playback speed.

HI-FI Indicates the unit is

playing back a tape record-

ed in Hi-Fi.

REC DVD/VCR Receiver

is Recording.

TIMER DVD/VCR Receiver is in

timer recording or a timer recording

is programmed.

TUNED Indicates a AM or FM

broadcast is being received.

ST (STEREO) Indicates a

stereo broadcast is being

received.

PL

PCM

MP3

DVD

VCD

MP3 MP3 disc inserted

DVD DVD inserted.

VCD Video CD inserted

REP 1A - B TV

PROGRESSIVE

PBC

SAP

SHUF PGM

SHUFFLE Random playback active

PBC Indicates PBC On mode

SAP Indicates when a SAP BILINGUAL broadcast

is being received.

VIDEO

PGM Programmed playback active.

TITLE CHAP

Indicates when the Progressive scan playback is in progress.

TRK ST TUNED

Indicates clock, total playing time, elapsed time, chapter number, track

number, channel, radio frequency, volume, channel or current deck

status (Playback, Pause, etc).

TIMER

SP

EP

6

Page 7

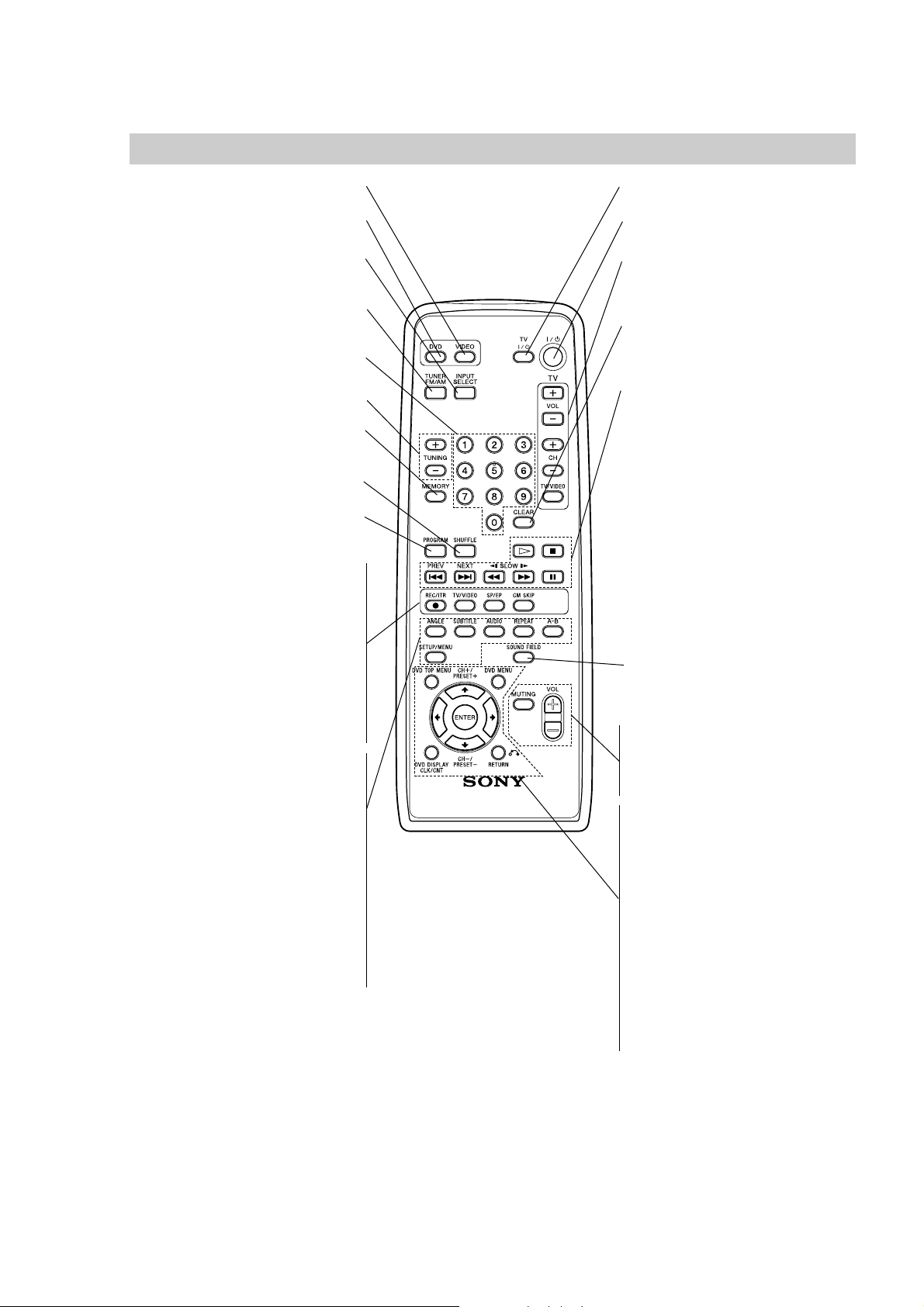

Remote Control

AVD-K700P

VIDEO

Select the output source to VIDEO.

DVD

Sets the output source to DVD.

INPUT SELECT

Selects the VIDEO deck’s source

(L1 OPT, LINE1, LINE2, Tuner).

TUNER FM/AM

Selects the DVD/VCR Receiver’s tuner as

the listening choice. (FM and AM bands)

0-9 numerical buttons

Selects numbered options in a menu.

TUNING (+/–)

To tune in the desired station.

MEMORY

Memorize a radio station frequency into

the tuner.

SHUFFLE

Plays tracks in random order.

PROGRAM

Enters to the program edit mode or exits

from that.

z REC/ITR

Records normally or activates Instant

Timer Recording.

TV/VIDEO

To view channels selected by the VIDEO

tuner or by the TV tuner.

SP/EP

Selects recording speed.

CM SKIP

Fast forwards picture search through 30

seconds of recording.

ANGLE

Selects a DVD camera angle if available.

SUBTITLE

Selects a subtitle language.

AUDIO

Selects an audio language (DVD) or an

audio channel (CD).

REPEAT

Repeat chapter, track, title, all.

A-B

Repeats sequence.

SETUP/MENU

Accesses or returns DVD setup menu

and VIDEO setup menu.

TV @ / 1

Switches TV ON and OFF.

@ / 1

Switches DVD/VCR Receiver ON and OFF.

TV Control Buttons (see page 40)

• VOL +/–: Adjusts TV’s volume.

• CH +/–: Selects TV’s channel.

• TV/VIDEO: Selects the TV’s source.

CLEAR

Removes a track number on the program

menu. To clear preset stations from the

tuner memory.

Playback Control Buttons

• H (PLAY)

Starts playback.

• x (STOP)

Stops playback.

• . (PREV) (DVD mode only)

Go to beginning of current chapter or

track or go to previous chapter or track.

• > (NEXT) (DVD mode only)

Go to next chapter or track.

• m/M (SLOW t/T)

DVD: For picture search or slow playback backward or forward.

VIDEO: Rewinds or advances the tape

in STOP mode or for picture search.

• X (PAUSE)

Pause playback or recording temporarily.

SOUND FIELD

Selects sound mode between AUTO,

PRO LOGIC, PRO LOGIC II (MOVIE,

MUSIC, MATRIX) and 3D SURROUND.

VOL (+/-)

Adjusts speaker volume.

MUTING

Momentarily silence the speaker of the

DVD/VCR Receiver.

DVD TOP MENU

Displays the disc’s Title menu, if available.

DVD MENU

Accesses menu on a DVD disc.

B/b/V/v (left/right/up/down)

Selects an option in the menu.

CH/PRESET(+/–): Selects a program of

VIDEO or Tuner. Adjusts manually the

tape’s picture onscreen.

ENTER

Acknowledges menu selection.

DVD DISPLAY, CLK/CNT

Accesses On-Screen display. Switches

among the clock and tape counter.

RETURN

Returns the setup menu.

Note

This remote control uses the same buttons for VIDEO and DVD

functions (ex. PLAY).

To use the VIDEO, first press the VIDEO button.

To use the DVD, first press the DVD button.

7

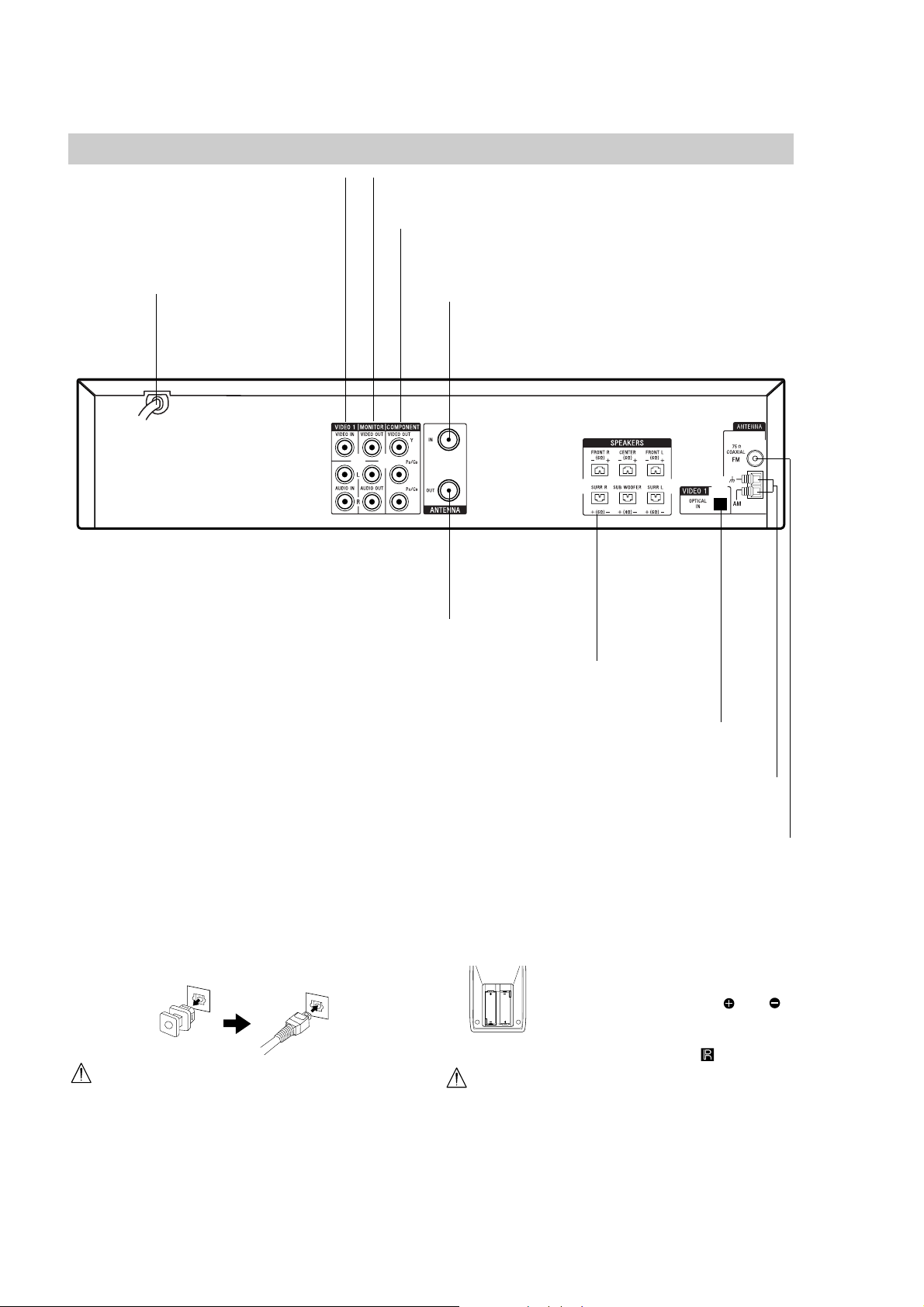

Page 8

AVD-K700P

Rear Panel

VIDEO 1 (VIDEO/AUDIO IN (Left/Right))

Connect the audio/video output of an

external source (Audio system, TV/Monitor,

Another VCR).

AC Power Cord

Plug into the power

source.

ANTENNA OUT (DVD/VIDEO OUT)

Connect to a TV with RF coaxial inputs.

Connect the six supplied speakers to these terminals.

MONITOR (VIDEO / AUDIO OUT (Left/Right))

Connect to a TV with video and audio inputs.

COMPONENT VIDEO OUT (Y P

B/CBPR/CR

(DVD OUT)

Connect to a TV with Y P

B/CBPR/CR

inputs. FOR DVD

VIEWING ONLY.

ANTENNA IN

Connect the VHF/UHF/CATV

antenna to this terminal.

SPEAKERS Connectors

)

Connect to a digital audio output on a digital device.

Dust Protection Cap

Remove the dust protection cap from the OPTICAL IN

jack and connect the optical digital cable (not supplied)

securely so that the configurations of both the cable

and the connector match. Keep the dust protection cap

and always reattach the cap when not using the connector to protect against dust intrusion.

Do not touch the inner pins of the jacks on the rear

panel. Electrostatic discharge may cause permanent

damage to the unit.

OPTICAL IN

AM ANTENNA Connectors

Connect the AM antenna to this terminal.

FM ANTENNA Connectors

Connect the FM antenna to this terminal.

Remote control battery installation

Detach the battery cover on the rear

of the remote control, and insert two

AA

AA

Caution

Do not mix old and new batteries. Never mix different

types of batteries (standard, alkaline, etc.).

R6 (size AA) batteries with and

aligned correctly.

When using the remote control, point

it at the remote sensor on the unit.

8

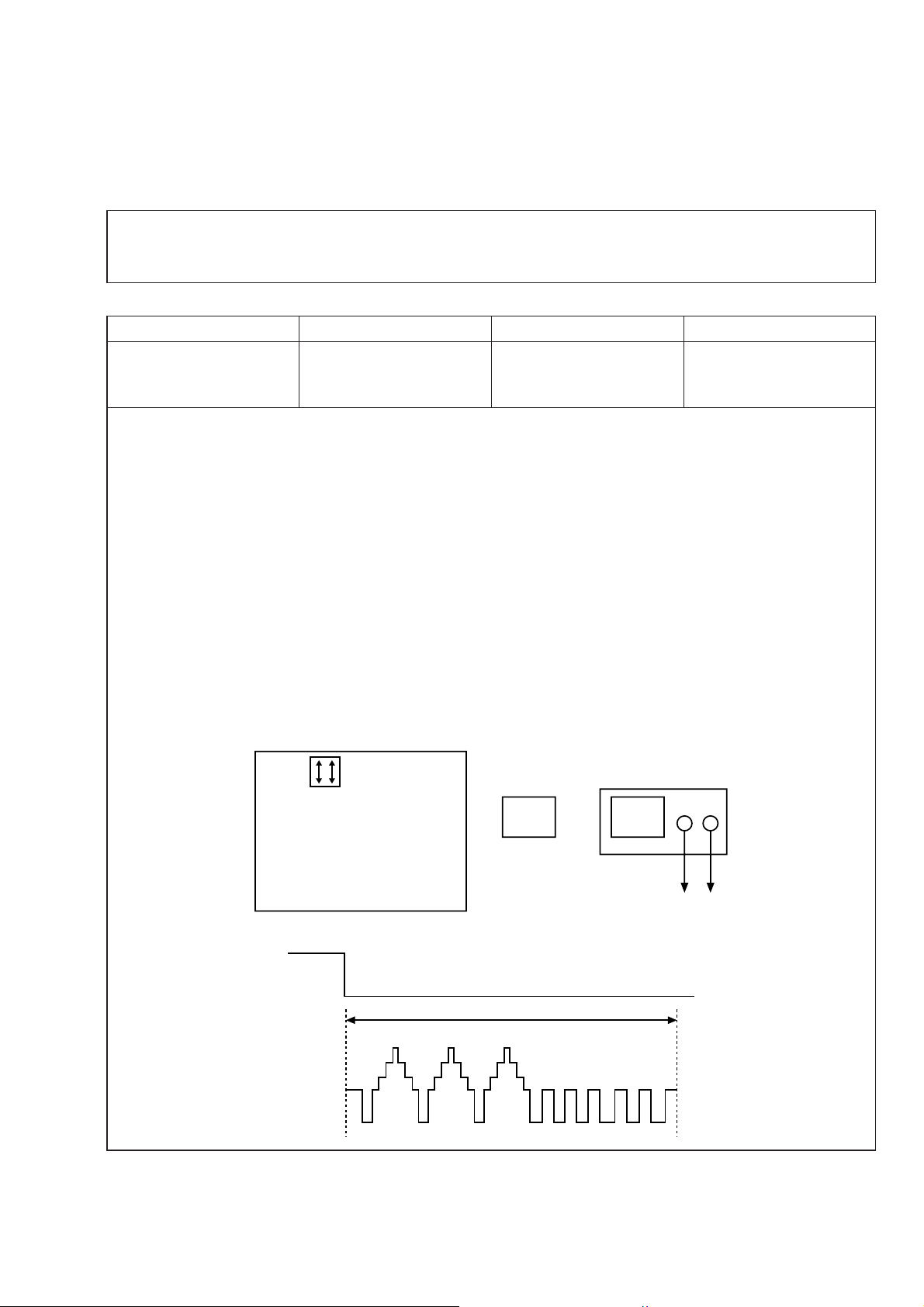

Page 9

SECTION 2

ELECTRICAL ADJUSTMENT

2-1. VCR SECTION ELECTRICAL ADJUSTMENT

1. Servo Adjustment

1) PG Adjustment

• Test Equipment

a) OSCILLOSCOPE

b) NTSC MODEL : NTSC SP TEST TAPE

• Adjustment And Specification

AVD-K700P

MODE

PLAY

MEASUREMENT POINT ADJUSTMENT POINT SPECIFICATION

V.Out

H/SW(W373, W374)

R/C TRK JIG KEY 6.5 ± 0.5H

• Adjustment Procedure

a) Insert the SP Test Tape and play.

b) Press the “O” key on the Remote controller and the “PLAY” key on the Front Panel the same time, the

unit then goes in to Tracking initial mode.

c) Trigger the mixed Combo Video Signal of CH2 to the CH1 H/SW(W373, W374), and then check the dis-

tance (time difference), which is from the selected A(B) Head point of the H/SW(W373, W374) signal to

the starting point of the vertical synchronized signal, to 6.5H ± 0.5H (412µs, 1H=63µs).

Note - Press FRONT CH UP KEY and FRONT PLAYKEYon Deck playback, and it goes in to ATR PRE-

SET. after the SP Test Tape is inserted.

• PG Adjustment Method

a-1) Playback the SP standard tape

b-2) Press the “O” key on the Remote controller and the “PLAY” key on the Front Panel the same time,

Tracking initial mode.

c-3) Repeat the above step(No.b-2), the unit will then finish the PG adjusting automatically.

d-4) Stop the playback, the unit then exits PG adjusting mode after saving the PG data.

• CONNECTION

V.Out

•WAVEFORM

H/SW(W373, W374)

H/SW

Composite

VIDEO

6.5H(412µs)

R/C KEY

OSCILLOSCOPE

CH1 CH2

H/SW

(W373, W374)

V.out

9

Page 10

AVD-K700P

2-2. ELECTRICAL TROUBLESHOOTING GUIDE

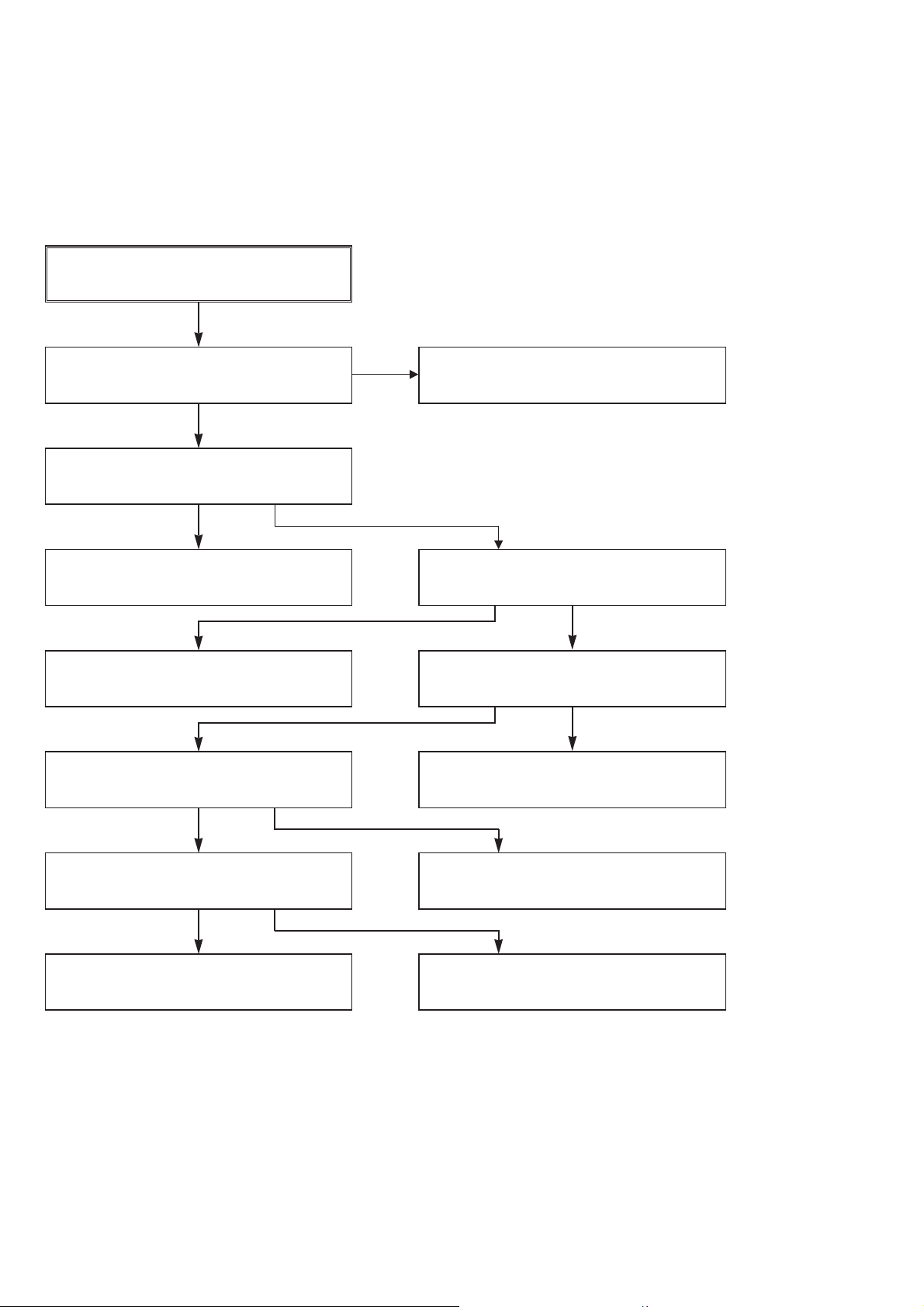

1. Power(SMPS) CIRCUIT

(1) No 5.3VA (SYS/Hi-Fi/TUNER)

NO 5.3VA.

YES

Is the F101 normal?

YES

Is the BD101

NO

NO

Replace the F101.

(Use the same Fuse)

normal?

YES

Is the TH101

normal?

YES

Is Vcc(8.5~21V) sup-

NO

NO

Replace the TH101.

plied to IC104 Pin3?

YES

Check or Replace

the D105.

Replace the

BD101.

Is the D105

normal?

NO

(2) No 12VA (TO CAP, DRUM MOTOR)

NO 12VA.

YES

Is the Vcc(13V) supplied

NO

to (+) terminal in D126?

YES

Check or Replace

the D126.

Check or Replace

the Motor Vcc.

(3) No 5.0V (SYS/Hi-Fi/TUNER)

Is the D129

normal?

YES

Is there about 2.5V

at the IC106 Vref?

YES

Check the Main PCB

5.3VA/5.0V Line short?

NO

NO

Replace the D129.

Replace the IC106.

NO 5.0VA.

YES

Is 5.3VA put into

the Q167 Emitter?

YES

Is the Q169 Base

“H”?

YES

Is about 5V put into

the Q167 Base?

YES

Check or Replace

the Q167/Q169.

NO

NO

NO

5.3VA Line Check.

Check the Power

Control.

Check or Replace the

Q169, R175, R176, R177.

10

Page 11

AVD-K700P

(4) No 5V (TO DVD)

NO 5V.

YES

Is 5.3VA put into

the Q168 Emitter?

YES

Is the Q169 Base

“H”?

YES

Is about 5V put into

the Q168 Base?

YES

Check or Replace

the Q168/Q169

NO

NO

NO

5.3VA Line Check.

Check the Power

Control.

Check or Replace the

Q169, R175, R176, R177.

(5) No 33V (TUNER)

No 33V.

YES

Is Q163 Base “H”?

YES

Check or Replace

Q163, R168, R169.

NO

Check the Power

Control.

(6) No 8V(TO DVD)

NO 8V.

YES

Is Vcc(13V) supplied to

(+) terminal in D126?

YES

Is Vcc(12V) supplied

to IC160 Pin1?

YES

Check or Replace

IC161, C163.

NO

NO

Check or Replace

the D126.

Check or Replace

the D163.

11

Page 12

AVD-K700P

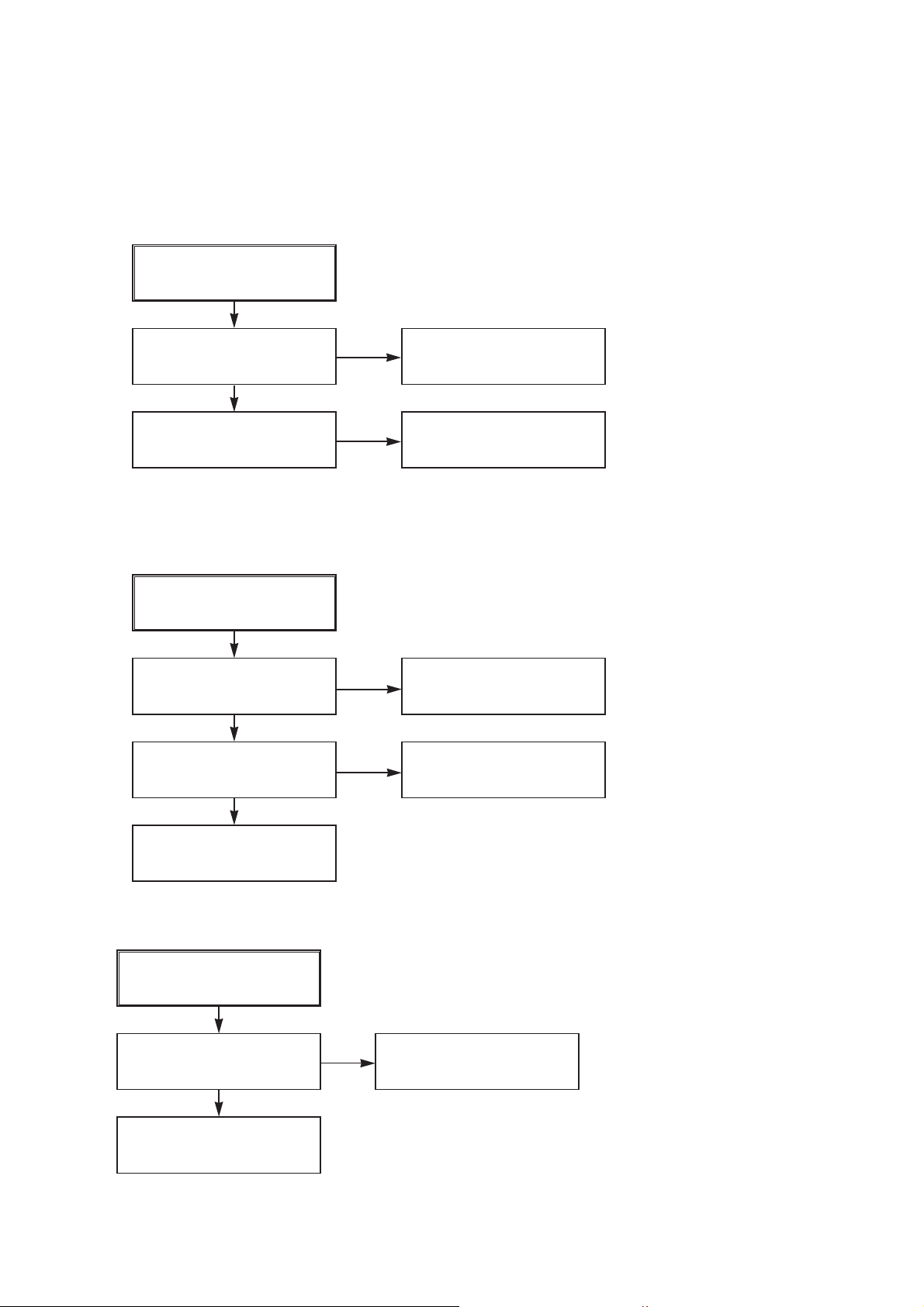

2. SYSTEM/KEY CIRCUIT

(1) AUTO STOP

Auto Stop

YES

Does the SW30 waveform

appear at the IC501

Pin18?

YES

Do the T-UP Reel Pulses

appear at the IC501 Pin80?

YES

Replace the IC501.

NO

NO NO

Check the Drum Motor

signal.

Do T/UP Reel Pulses

appear at the point

between R556 and R536?

YES YES

Replace the T/UP Reel

Sensor (RS501).

(2) The unstable loading of a Cassette tape

The unstable loading of a

Cassette tape

YES

Does 5V appear at the

RS501?

NO

Check the Q160 Power

Circuit.

Is 12V applied to the

PMC01 Pin8?

YES

Does the “H” signal appear

at the IC501 Pin58 during

inserting the CST ?

YES

Does the “L” signal appear

at the IC501 Pin60 during

inserting the CST?

YES

Check the Deck

Mechanism.

Caution :

Auto stop can occur because Grease or Oil has dried up

NO

NO

NO

Check the CST SW and

the peripheral circuitry.

Refer to “SMPS DRUM

12 Volt Trouble Shooting”.

Is 5V applied to the

R531 ?

YES

Refer to SMPS 5.3VA

troubleshooting.

Check the IC501

Pins22, 23, 24, 25.

NO

12

Page 13

3. SERVO CIRCUIT

(1) Unstable Video in PB MODE

Unstable Video in

PB Mode.

YES

Does the Noise level of the

screen change

periodically?

YES

AVD-K700P

Do the CTL pulses appear

at the IC501 Pin97?

YES

Does the CFG waveform

appear at the IC501

Pin87?

YES

On tracking do the CTL

pulses move?

YES

Does the Video Envelope

waveform appear at the

IC501 Pin9?

YES

Replace the IC501.

(2) When the Drum Motor

(2) doesn’t run.

When the Drum Motor

doesn’t run,

Does 12V appear at the

PMC01 Pin8?

NO

NO

NO

NO

Is adjusting the height of

the CTL Head accurate?

Replace the IC501.

Refer to “When the Y signal

doesn’t appear on the

screen in PB Mode”.

Refer to “(2)

No 12VA of Power section”

Do the Drum PWM Pulses

appear at the IC501

Pin76?

YES

Aren’t the foil patterns and

the Components between

IC501 Pin76 and PMC01

Pin12 short?

NO

Readjust the height of the

CTL Head.

NO

Do the DFG Pulses appear

at the PMC01 Pin11?

YES

NO

Replace the Cap M.

YES

Does 2.8V appear at the

PMC01 Pin12?

YES

Check the connector

(PMC01) and the Drum

Motor Ass’y .

NO

Do the DFG Pulses appear

at the IC501 Pin90?

YES

Do the Drum PWM Pulses

appear at the IC501

Pin76?

YES

Aren’t the connecting patterns and the Components

between IC501 Pin76 and PMC01 Pin12 short?

NO

NO

Aren’t the foil patterns and

the Components between

IC501 Pin 90 and PMC01

Pin11 short?

Replace the IC501.

13

Page 14

AVD-K700P

(3) When the Capstan Motor doesn’t run,

When the Capstan Motor doesn’t run,

Does 12VA appear at the PMC01?

YES

Is “DRUM CTL” 2.8V appear at the

PMC01?

YES

Check the PMC01 and the Capstan

Motor Ass’y .

Aren’t the foil patterns and Components

between IC501 Pin77 and PMC01

Pin9 short?

Does the CFG signal come into the

IC501 Pin87?

NO

NO

YES

YES

Refer to “SMPS(CAPSTAN/12Volt)

Trouble Shooting”.

Does the PWM signal appear at the

IC501 Pin77?

NO

Does the CFG signal appear at the

PMC01 Pin1?

NO

Check the Capstan Motor Ass’y.

YES

Does the Capstan PWM signal appear at

the IC501 Pin77?

YES

Aren’t the foil patterns and Components

between IC501 Pin77 and PMC01

Pin9 short?

NO

Aren’t the foil patterns and component

between IC501 Pin87 and PMC01

Pin1 short?

NO

Replace the IC501.

14

Page 15

(4) KEY doesn’t working

KEY doesn’t working.

AVD-K700P

Is 5V applied to the IC501

Pin2, 3?

YES

Does LED or FLD change

when a function button is

pressed?

4. OSD CIRCUIT

(1) No OSD display.

No OSD or F.OSD display.

Is 5.3V applied to the

IC501 Pin53?

YES

Does oscillation occur at

the IC501 Pins44, 45?

YES

NO

NO

NO

NO

Refer to “SMPS 5.3VA

Trouble Shooting”.

Replace the defective

switches.

Refer to “SMPS 5.3VA

Trouble Shooting”.

Check or Replace the pheripheral Circurity.(L511,

R598, C596, C595)

Replace the IC501.

2

C BUS CHECK

(2) I

The I2C waves don’t

come out.

Does Power appear at the

Pull up impedence

(R569, R507)?

YES

Replace the IC501.

NO

Refer to “SMPS 5.3VA

Trouble Shooting”.

15

Page 16

AVD-K700P

5. Y/C CIRCUIT

(1) No Video in EE Mode,

No Video in EE Mode

Does the Video signal

appear at the IC301

Pins28, 30, 32?

YES

Is REG 5.0V applied to the

IC301Pins23, 44, 45, 52, 68,

77?

YES

Does the Video signal

appear at the IC301 Pin26?

NO

NO

NO

Does the Video signal

appear at the IC302

Pins1, 5?

YES

Is there 5V at the IC302

Pin6?

YES

Replace the IC302.

Check the REG 5V Line.

(Power Circuit)

Is I2C BUS signal applied to

the IC301 Pins53, 54, 55?

NO

NO

Check DVD Video Input

(IC602, Pin4), Tuner Video

Input (TU701 Pin16), Line

Video Input (JK601),

respectively.

Check the System Circuit.

(Refer to ‘SYSTEM I

CHECK Trouble Shooting’)

2

C BUS

YES

Does the Video signal

appear at the IC501 Pin52?

YES

Does the Video signal

appear at the IC602 Pin7?

NO

NO

YES

Check the path of the signal between the IC301 Pin

26 and IC501 Pins50, 52.

Is there 5V on the plus

terminal of the C614?

YES

Replace the IC602.

NO

Replace the IC301.

Check the REG 5V Line.

(Power Circuit)

16

Page 17

AVD-K700P

(2) When the Y(Luminance) signal doesn’t appear on the screen in PB Mode,

Is 5V applied to the IC301

Pins23, 44, 45, 52, 68, 77?

Is the Y/C Bus siganl

applied to the IC301

Pins53, 54, 55?

Does the normal RF signal

appear at the IC301 Pin14?

Check the line of the REG

5V Line. (Power Circuit)

Check the System Circuit.

(IC501 Pin18)

Check the V.H.S/W level.

Refer to ‘SYSTEM Y/C

BUS CHECK Trouble

Shooting’.

Is the V.H.S/W signal

applied to the IC301 Pin57?

Does the Rectangular

waveform(5V) appear at

the IC301 Pin57(V.H.S/W)

Clean the Drum.

Check the C324.

Check the R328, R347,

C322, C323.

Does the Y(Luminance)

signal appear at the IC301

Pin20?

Is the Y(Luminance) Video

waveform showed up at the

IC301 Pin22?

Replace the IC301.

NO

YES

YES

YES

YES

YES

YES

YES

NO

NO

NO

NO

NO

NO

17

Page 18

AVD-K700P

(3) When the C(Color) signal doesn’t appear on the screen in PB Mode,

Is 5V applied to the IC301

Pins23, 44, 45, 52, 68, 77?

YES

Does the fsc signal appear

at the IC301 Pins41, 50?

YES

Replace the IC301.

NO

NO

Check the line of the REG

5V Line. (Power Circuit)

Is normal the X301

(3.58MHZ) of oscillation

Frequency?

Does the Color signal

appear at the IC301 Pin48?

YES

Replace the IC301.

NO

NO

Replace the X301.

Check the C342, C341,

R333.

18

Page 19

(4) When the Video signal doesn’t appear on the screen in REC Mode,

YES

YES

YES

YES

YES

YES

NO

NO

YES

YES

YES

YES

YES

Check system part

(V.H/SW)

Replace the IC301.

Check the drum

*OPTION

Pins72, 73, 74(SP)

Pins65, 66, 67(EP)

REC mode

Check the EE mode

NO

Is EE mode normal?

Is color

normal?

A

A

YES YES

Is brightness normal?

Does signal appear at

IC301 Pins41, 50?

NO

Check X301 oscillation

frequency.

YES

Is the brightness signal supplied to IC301 Pins18?

Is 5V supplied to IC301

Pins23, 44, 45, 68, 77?

Check the power of Pins23,

44, 45, 52, 68, 77.

Check the 5V power

NO

NO

NO

NO

NO

Is Y/C Bus applied to

IC301 Pins53, 54, 55?

Check the REG 5V power

Check system part

Do X301 and X-TAL

oscillate?

Check X301.

Is V.H SW supplied to

IC301 Pin57?

Does the FM signal appear

at IC301 Pins73(SP)/

66(EP)?

AVD-K700P

19

Page 20

AVD-K700P

6. Tuner/IF CIRCUIT

(1) No Picture on the TV screen

No picture on the TV

screen

YES

Does the Video signal at

the TU701 Pin16.

YES

NO

Is +33V applied to TU701

Pin14?

YES

Is +5V applied to TU701

Pin3?

YES

Does the Clock signal

appear at TU701 Pin9?

YES

Does the data signal

appear at TU701 Pin10?

YES

Replace Tuner.

NO

NO

NO

NO

Check 33V line.

Check 5V line.

Check the lIC Clock Signal

of µ-COM Pin71.

Check the lIC Data Signal

of µ-COM Pin72.

Does the video signal

appear at IC302 Pin7.

YES

Does the Video signal at

the IC501 Pin 52.

YES

Does the Video signal at

the IC602 Pin 7.

YES

Check the signal flow from IC602

Pin7 to JK601 Pin Video out.

NO

NO

NO

Check the signal flow from

IC501 Pin27.(Pin27 is ‘L’

state in Tuner Mode)

Check the signal from IC301

Pin26 to IC501 Pin50.

Check the signal from IC501 Pin52 to IC602 Pin1 and IC602 Pin2.

(IC602 Pin2 is ‘L’state in VHS mode)

20

Page 21

AVD-K700P

(2) No Sound

No Sound.

Check the Vcc of TU701 Pins3, 14.

YES

Check 5.2V, 33V Line.

NO

Check the Tuner SiF signal at IC801

Pin57.

YES

Check the Audio of IC801 Pins78, 80.

YES

Check the Signal flow from IC801 Pins78,

80 to JK601 Audio out(L), (R)

YES

Check the Tuner SIF of TU701 Pin13.

NO

1. Check the Vcc(5.3VA, 9V) of IC801

Pins3, 5, 36, 54.

2. Check the IIC Clock and Data at IC801

Pins37, 38.

NO

21

Page 22

AVD-K700P

7. Hi-Fi Circuit

A.

Hi-Fi Playback.

No sound

Check the Hi-Fi Selection

Switch and the Tape quality.

YES

Is the RF waveform at

IC801 Pin 23 over 3V

Vp-p?

YES

NO

Is Pin 30 of IC801 over

3.5V ?

YES

Check the Vcc of IC801.

(Pins 3, 15, 32, 46)

YES

NO

YES

Is the Head switching signal

IC801 Pin 39 O.K?

YES

NO

NO

Check power.

Check REC start “H” signal

of µ-COM.

Check IC501 Pin 19.

(Audio Swich 30)

Check IC801 Pin 37(Data),

Pin 38(Clock).

YES

Is IC801 Pin 49(A.Mute)

“High”?

YES

Do Audio signals appear at

IC801 Pin 80(L-CH),

78 (R-CH)?

YES

Check the Contact point

of Audio Output.

Check the connection at

P3D01 if good then

Replace IC801.

NO

Check Ports of µ-COM.

Check A.MUTE port of

µ-COM (Pin High of

IC501).

NO

Replace IC801.

22

Page 23

B.

Hi-Fi REC.

It is impossible to record and playback

Hi-Fi Audio signal.

YES

Check Vcc of IC801. (Pins 3, 15, 32, 46)

AVD-K700P

YES

Check IC801 Pin 37(Data),Pin 38(CLOCK).

YES

Is IC501 Pin 84(A.Mute) “High”?

YES

Are Audio signals present at IC801

Pins 78, 80?

YES

Do FM Audio signals appear at IC801

Pin 26?

YES

Is IC801 Pin 17(REC “H”) “High”?

NO

Check Power.

NO

Check ports of µ-COM.

NO

Check the Port of µ-COM.

NO

Check Audio Input signal Line

(9, 11, 12, 71, 73, 74), Tuner(57).

NO

Replace IC801.

YES

Check the Contact Points of Drum

Connector if good then Replace the Drum.

NO

Check the Port of u-COM.

23

Page 24

AVD-K700P

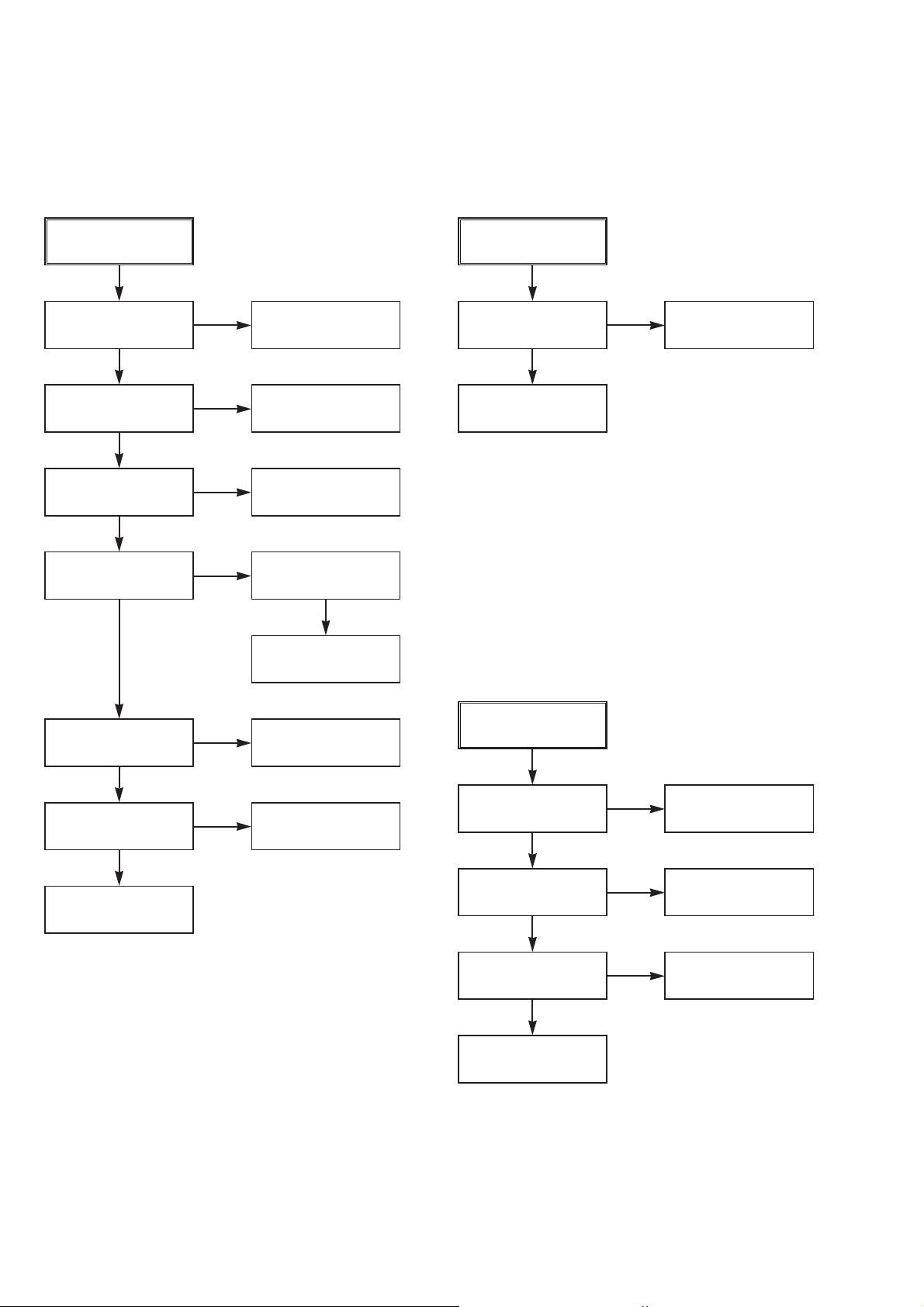

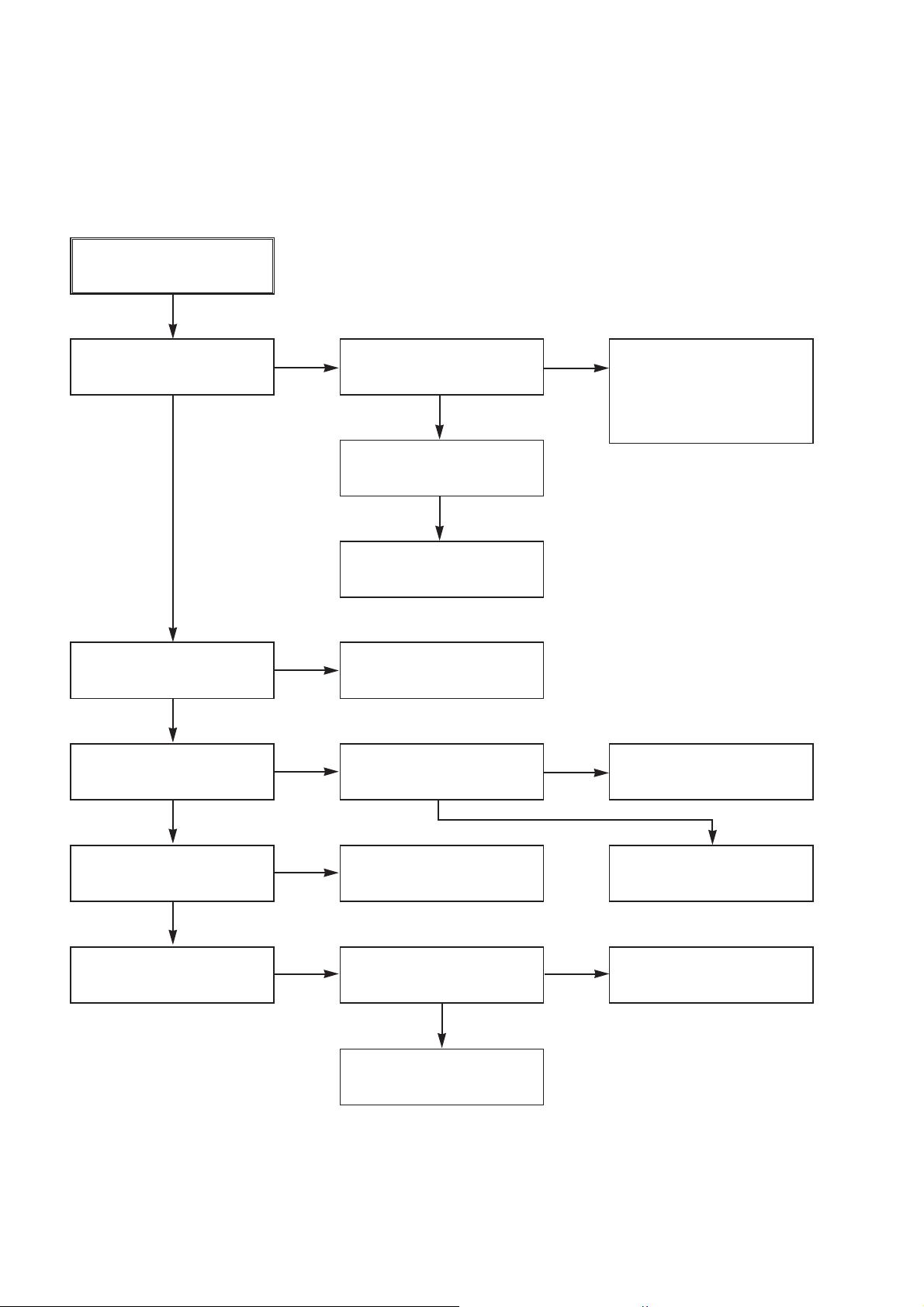

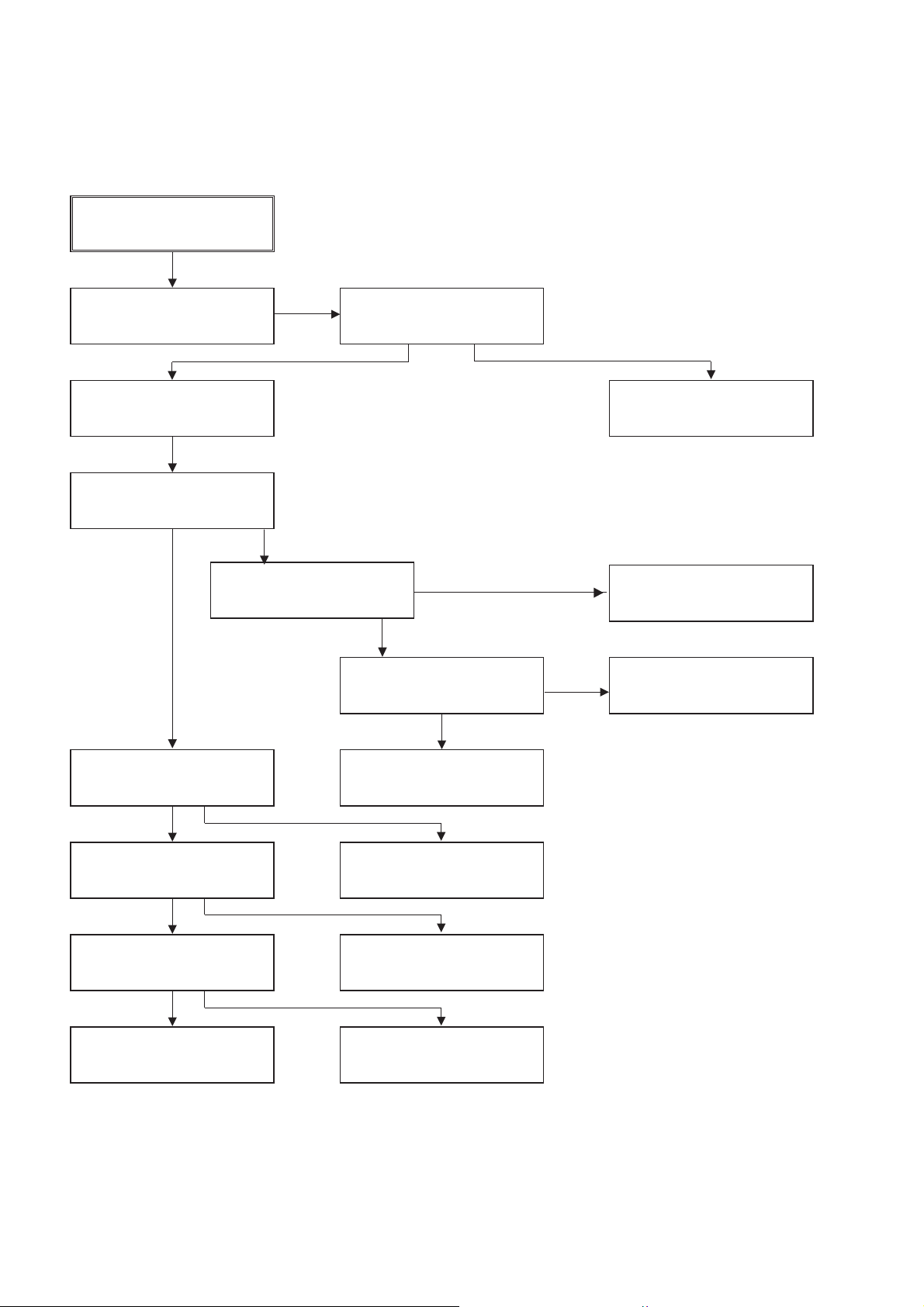

2-3. DVD & AMP SECTION ELECTRICAL TROUBLESHOOTING GUIDE

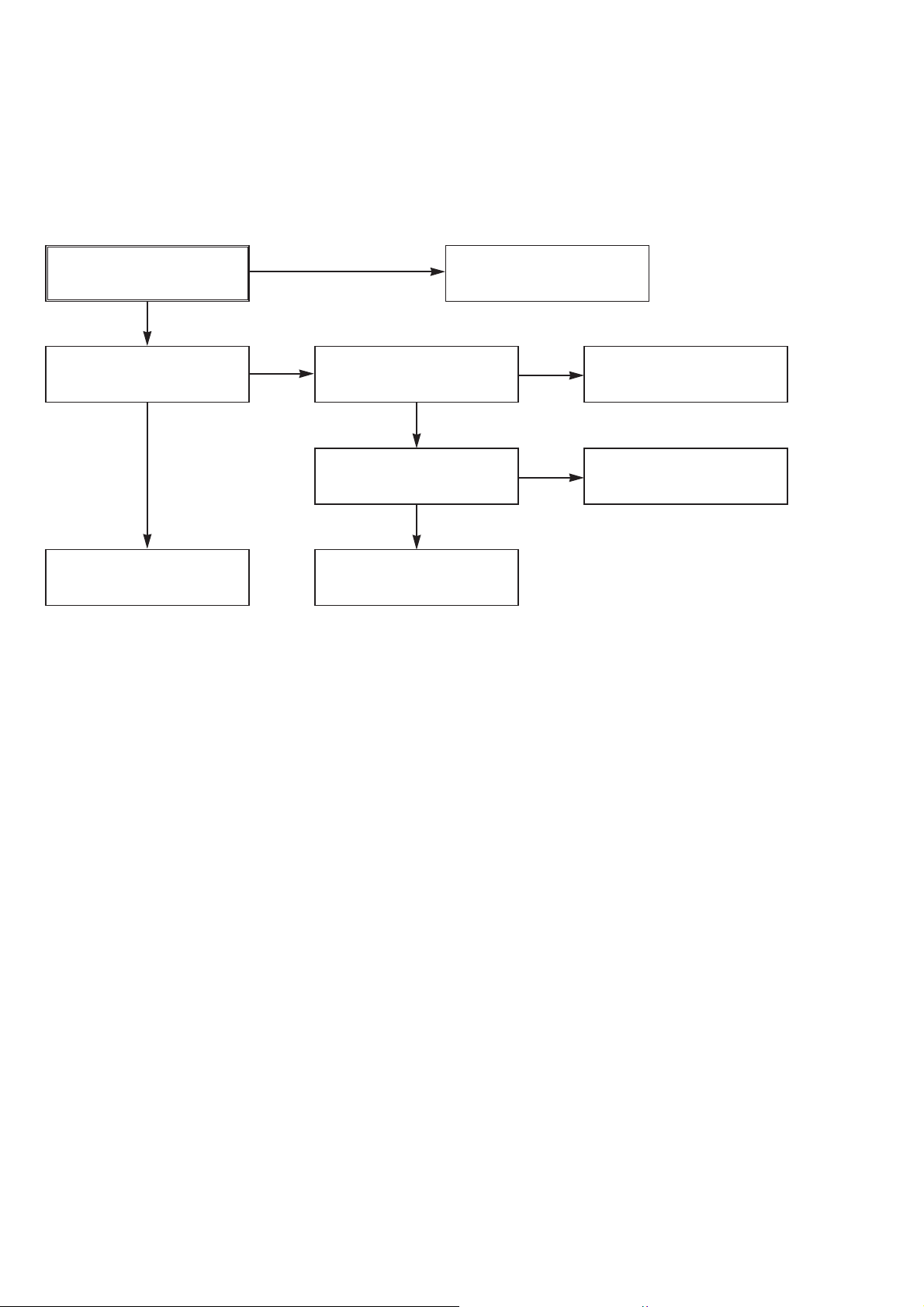

1. System operation flow

Power On

1. 8032 initializes SERVO, DSP & RISC registers

2. Write RISC code to SDRAM

3. Reset RISC

Show LOGO

Yes

SLED Moves to Inner Position

1. Judge whether have disc and disc type

2. Jump to related disc reading procedure

Tray Closed?

No

Tray Close to Closed position

SLED at Inner

Side?

No

Recieve

OPEN/ CLOSE

Key?

Yes

No

1. Execute Pressed Key & IR Key

2. Systemoperati on Routi ne Loop

1. Stop Playback & Open Tray

2. Display tray open message & LOGO

No

Receive

CLOSE Key?

24

Yes

Page 25

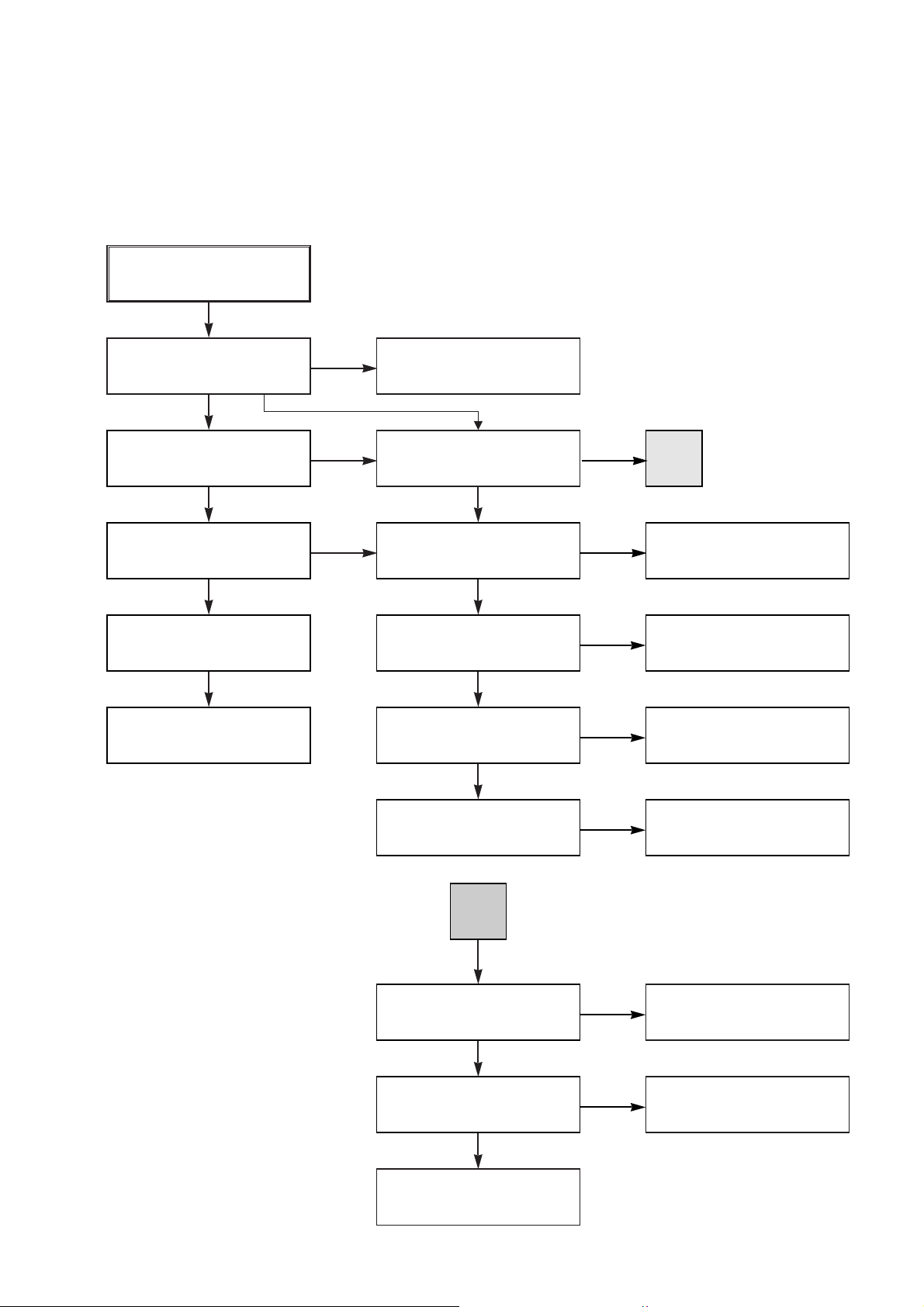

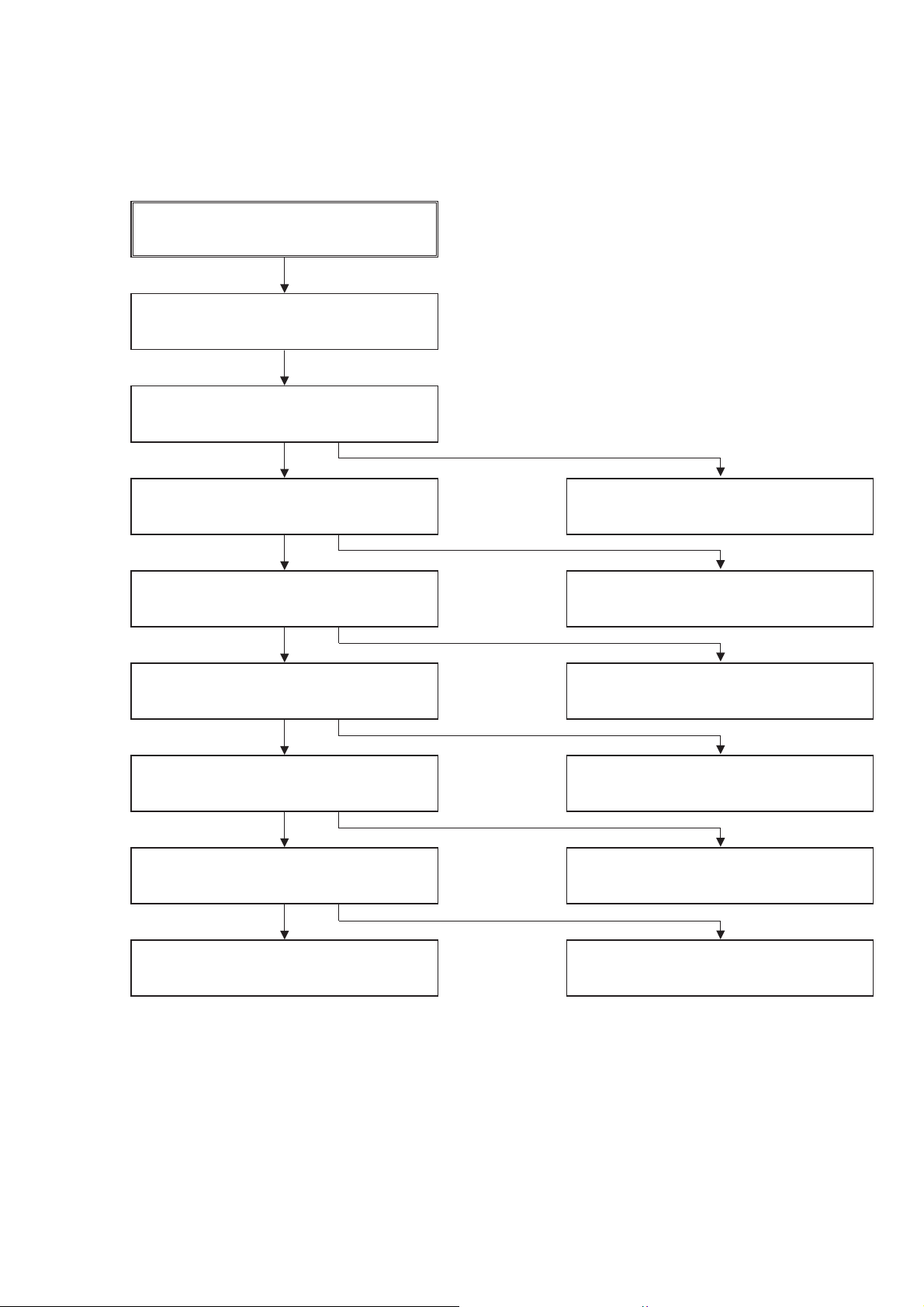

2. Test & debug flow

TEST

AVD-K700P

Check the

AC Voltage

Power PCBA (110V

or 220V)

Yes

Switch on the Power PCBA

Is

the DC Voltage

outputs OK?

(5V, 3.3V, 8V, 12V)

Yes

Is 3.3V and 2.5V DC

outputs normal on main

PCBA?

Yes

Communication between

VCR & DVD is normally?

Yes

No

No

No

No

Check the POWER PART

Check the POWER PART

Check the regulators or diode(D501).

Check the cable connection.

(PDV03)

Connect to PC RS232 Cable and

update the FLASH memory code.

Update

FLASH(IC5A1)

successfully?

Yes

A

No

1. Check 27MHz system clock.

2. Check systemreset circuit.

3. Check FLASH R/Wenable signal PRD,

RWR.

4. Check RS232 SIGNALS.

5. Check FLASH Memory related circuit.

Replace FLASH( IC5A1)

25

Page 26

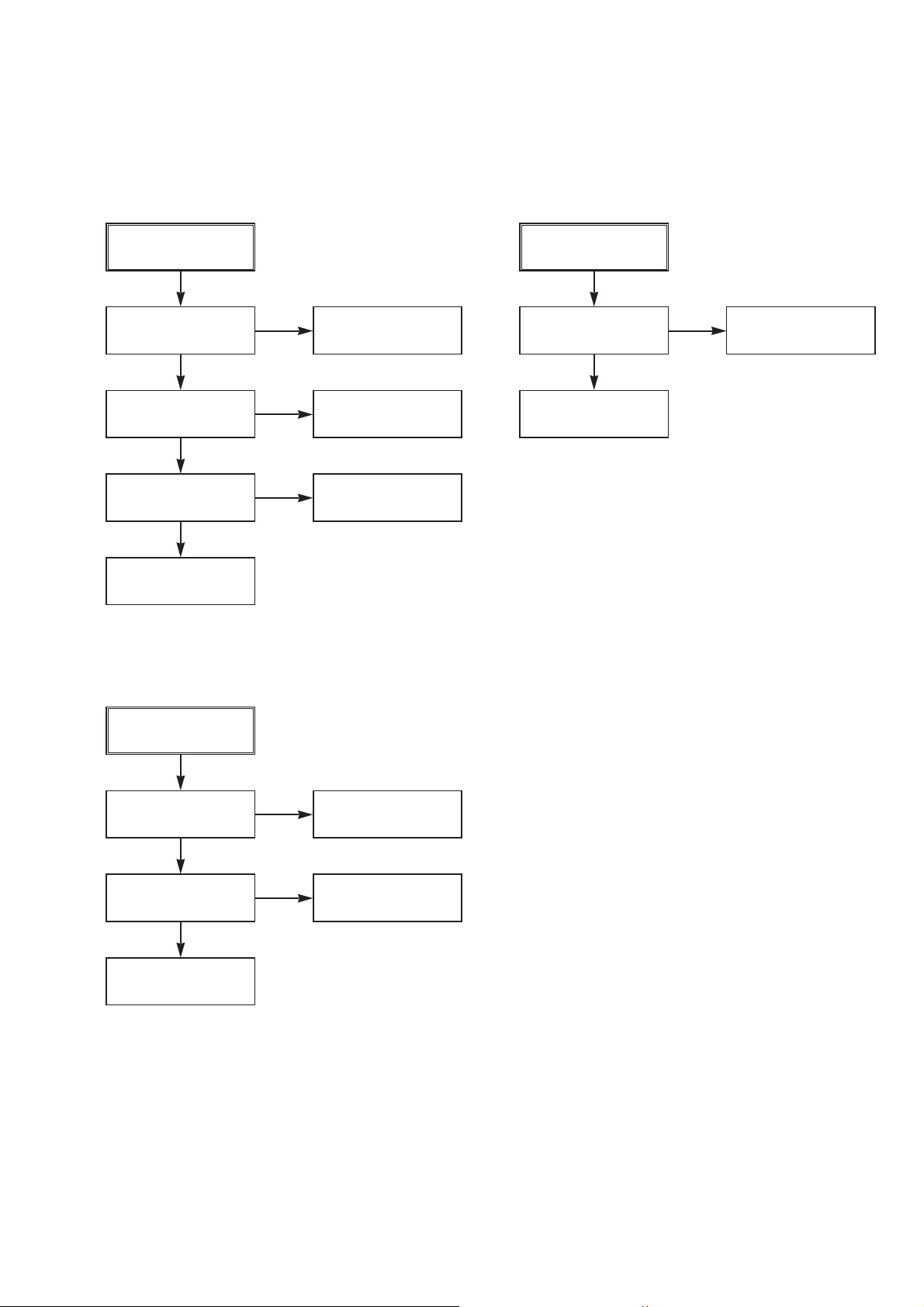

AVD-K700P

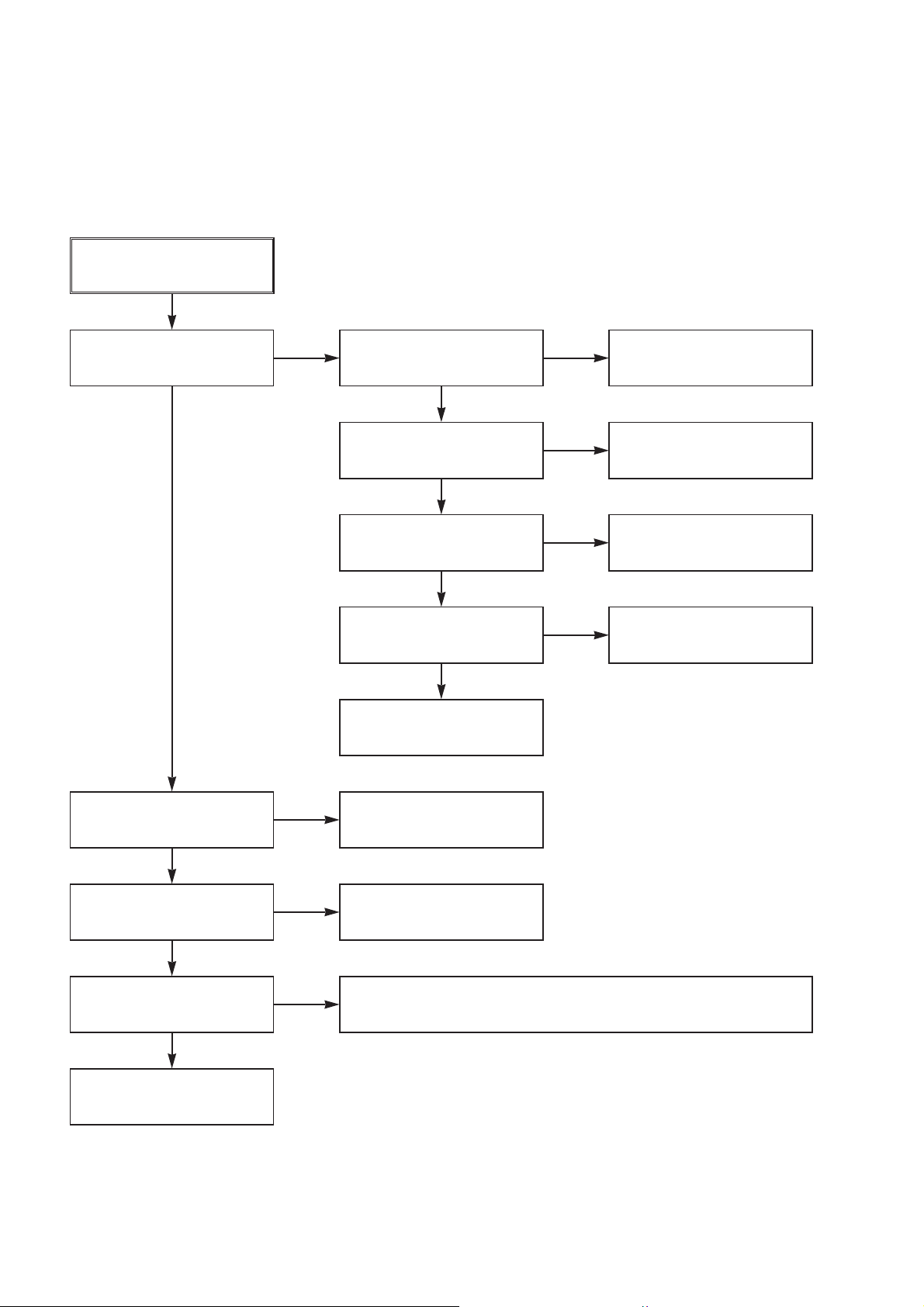

A

RESET or Power On.

Show LOGO?

YES

NO NO

Flash

Memory operates

properly?

YES

SDRAM

works properly?

NO

YES

MT1379

VIDEO outputs

properly?

NO

YES

Have

TV signal output?

NO

YES

Check AV cable

connection to TV set .

Check connection lines between FLASH

& MT1379 and the FLASH access time

whether is sui table or not.

Check connection lines between

SDRAM(IC502,IC503) & MT1379 and the

SDRAM is damaged.

Check the related circuit of MT1379.

(IC501 PIN 161,166, 168 check)

Check the filtering and amp circuit of

TV signal .(IC507)

Does

Tray move inside

when it is not at

closed position?

YES

B

NO

Normal

TROUT & TRIN

signals?

YES

Normal

TRCLOSE &

TROPEN signal?

YES

Normal

LOAD+ & LOAD-

signal ?

YES

Check the cable connection between

main PCBA and loader. (MECHA)

NO

NO

NO

Check the load OPEN &

CLOSE switch

Check the Tray control IO pins

on MT1376 & MT1379.

Check the Tray control amplifying

circuit on Motor driver.(IC402)

26

Page 27

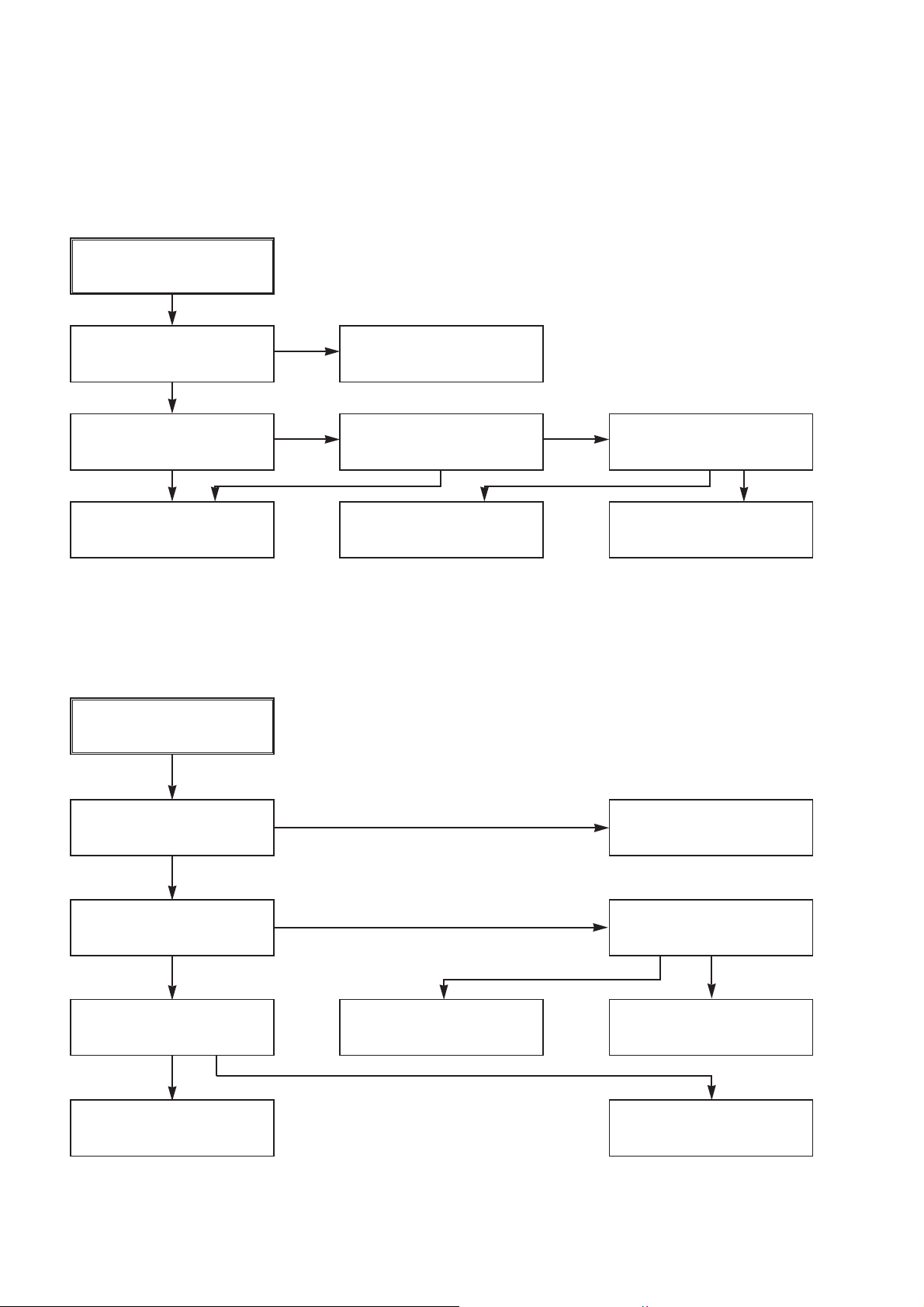

B

Does

the SLED move

to inner side when it is at

outer position?

No

Motor Driver STBY

Pin is High?

No

AVD-K700P

Check the connection line of

STBY signal .

Do not put in disc and tray

close.

Yes

Motor Driver STBY

Pin is High?

Yes

SL+ and SL- output

properly?

Yes

Check the cable connection

with MECHA.

No

No

OKYes

Check the related circuit of

FMSO.

Check the amp circuit on

motor driver.

Optical

Lens has movements

for searching

Focus?

Yes

C

Proper FOSO outputs

to motor driver?

Yes

Proper F+

& F- outputs?

Yes

Check cable connect of the

pick-up head.

NoNo

No

Check FOSO connection on

MT1379 and motor driver.

Check the amp circuit on

motor driver.

27

Page 28

AVD-K700P

C

Laser turns on when

reading disc?

Yes

Disc ID is correct?

Yes

Does spindle rotate?

No

No

No

LD01 or LD02 output

properly?

Yes

Collector

voltage of power

transistor is OK?

(Q404, Q405)

Yes

Check cable connection between

transistor output and pick-up head.

Proper RFL signal

on MT1336?

Yes

Check the RFL connection

between MT1336 and MT1379.

Proper

DMSO signal on

MT1379

No

No

No

No

Check the laser power circuit

on MT1336 and connecting to

power transistor. (Q404, Q405)

Check the related circuit on

laser power transi stor

Check the related circuit

on MT1336 RFL signal .

Check DMSO related

circuit on MT1379.

D

Yes

Yes

SP+ & SP- output

properly?

Yes

Check the cable connection

between spindle and main PCBA.

No

Check the spindle control

amp circuit of motor driver.

28

Page 29

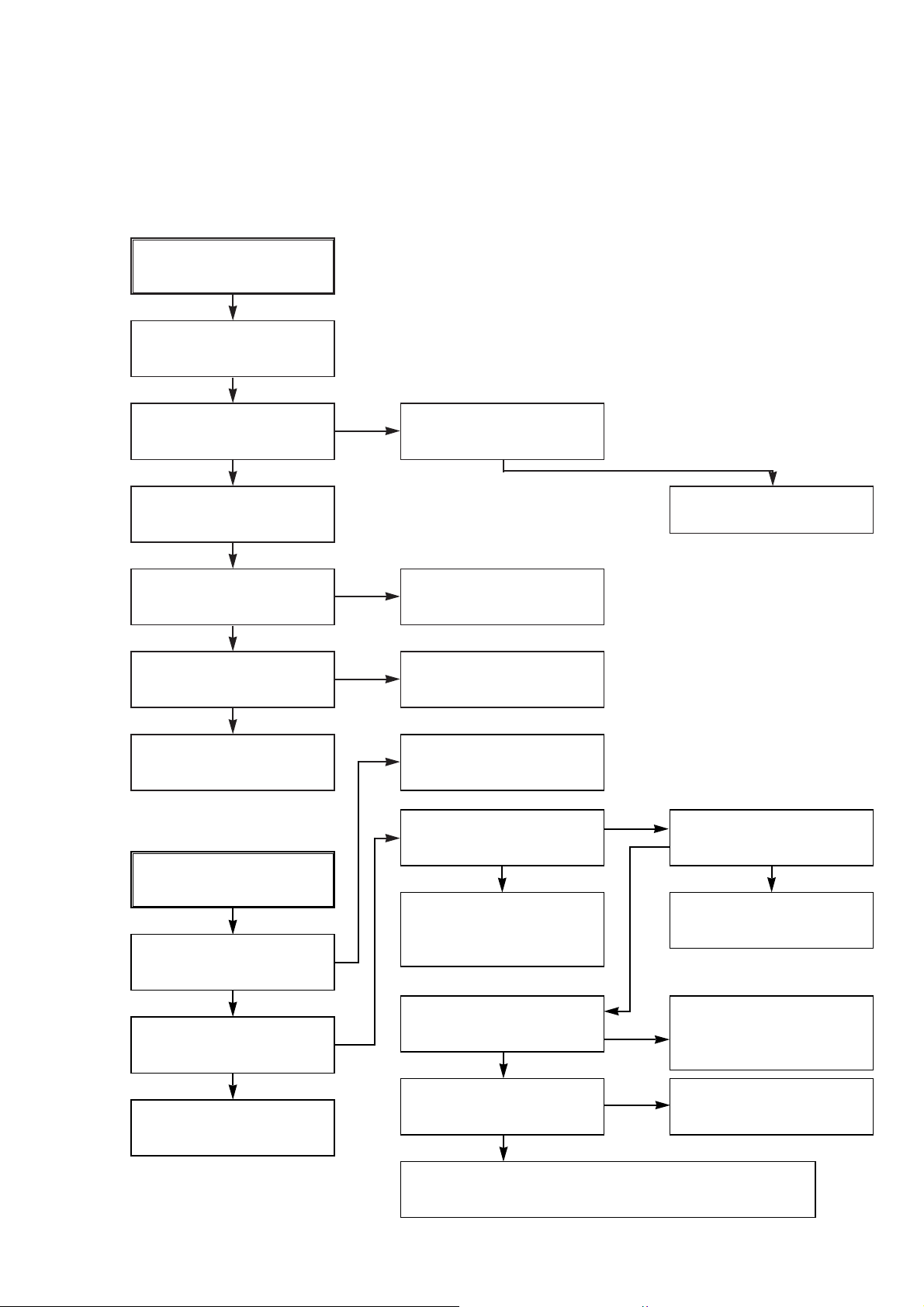

D

AVD-K700P

Yes

Focus ON OK?

Yes

Track On OK?

Yes

No No

Check FEO connection

between MT1336 and MT1379

Proper

signals on A, B, C,

D of MT1336

Yes

Proper FEO signal

on MT1336?

Yes

Proper FEO signal

on MT1336?

Yes

Properly TRSO signal

on MT1379?

Yes

No

NoNo

No

Check connections between

MT1336 and pick-up head.

Check the related circuit

on MT1336 FEO sugnal .

Check the related

circuit on MT1336

Check the TRSO connection

on MT1379 and motor dirver.

Disc is play?

Yes

E

No

T+ & T- output

properly?

Yes

Check cable connection on

pick-up head.

Check RF signal waveform.

No

Check the tracking control

amp circuit on motor driver.

29

Page 30

AVD-K700P

E

Normal

Audio output

when disc playback?

YES YES

TEST END

NO

Audio

DAC received

correct data stream?

Normal

Audio DAC

out? (IC206)

YES

Check Audio filter, amplify, mute

circuit. (IC205 Application circuit)?

NO

NO

Check connection between MT1379

& Audio DAC. (Check ARCK, ALRCK

ACKL, ASDAT3)

Check the related circuit of

Audio DAC. (Check Audio

out Pins 8, 5)

30

Page 31

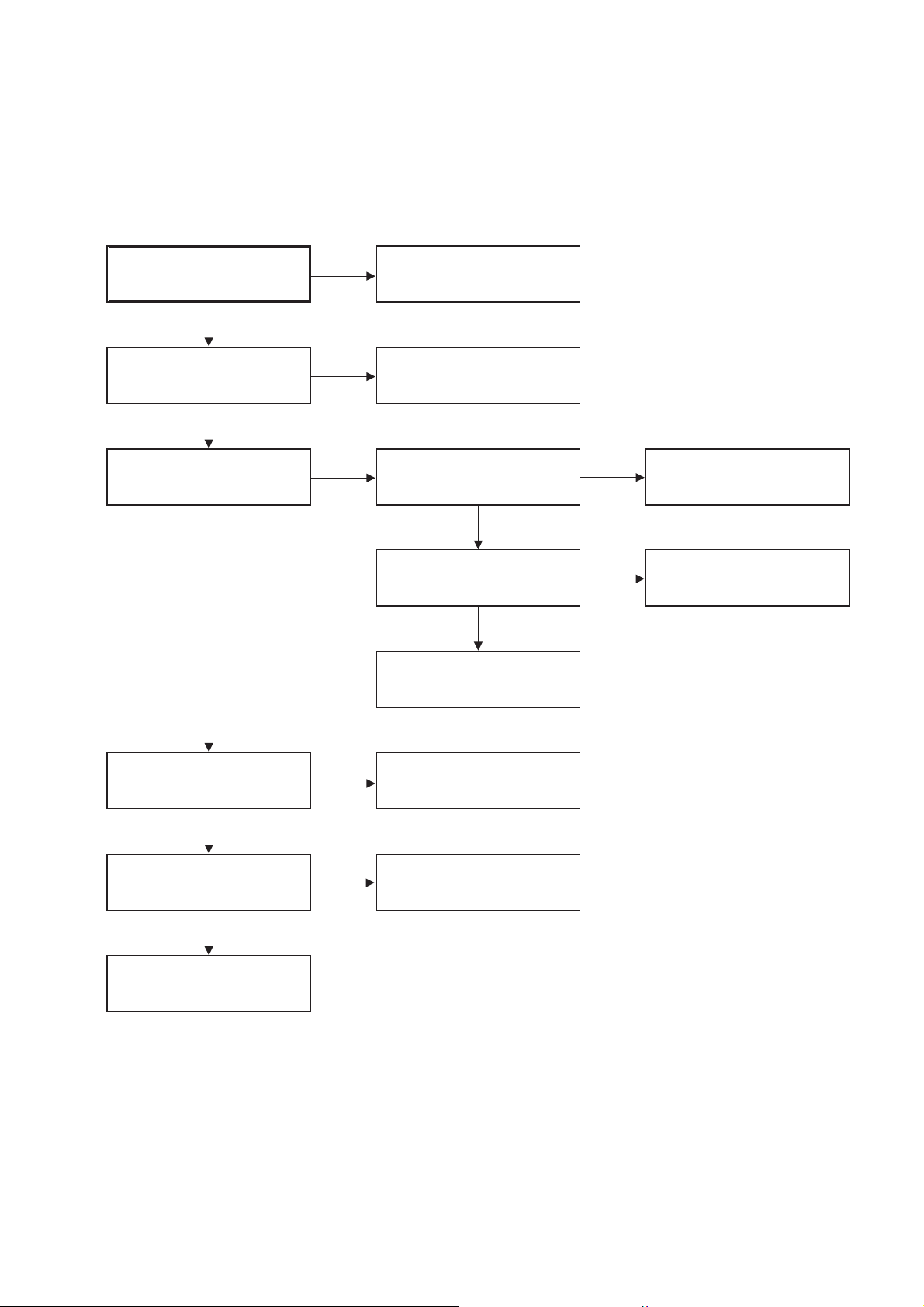

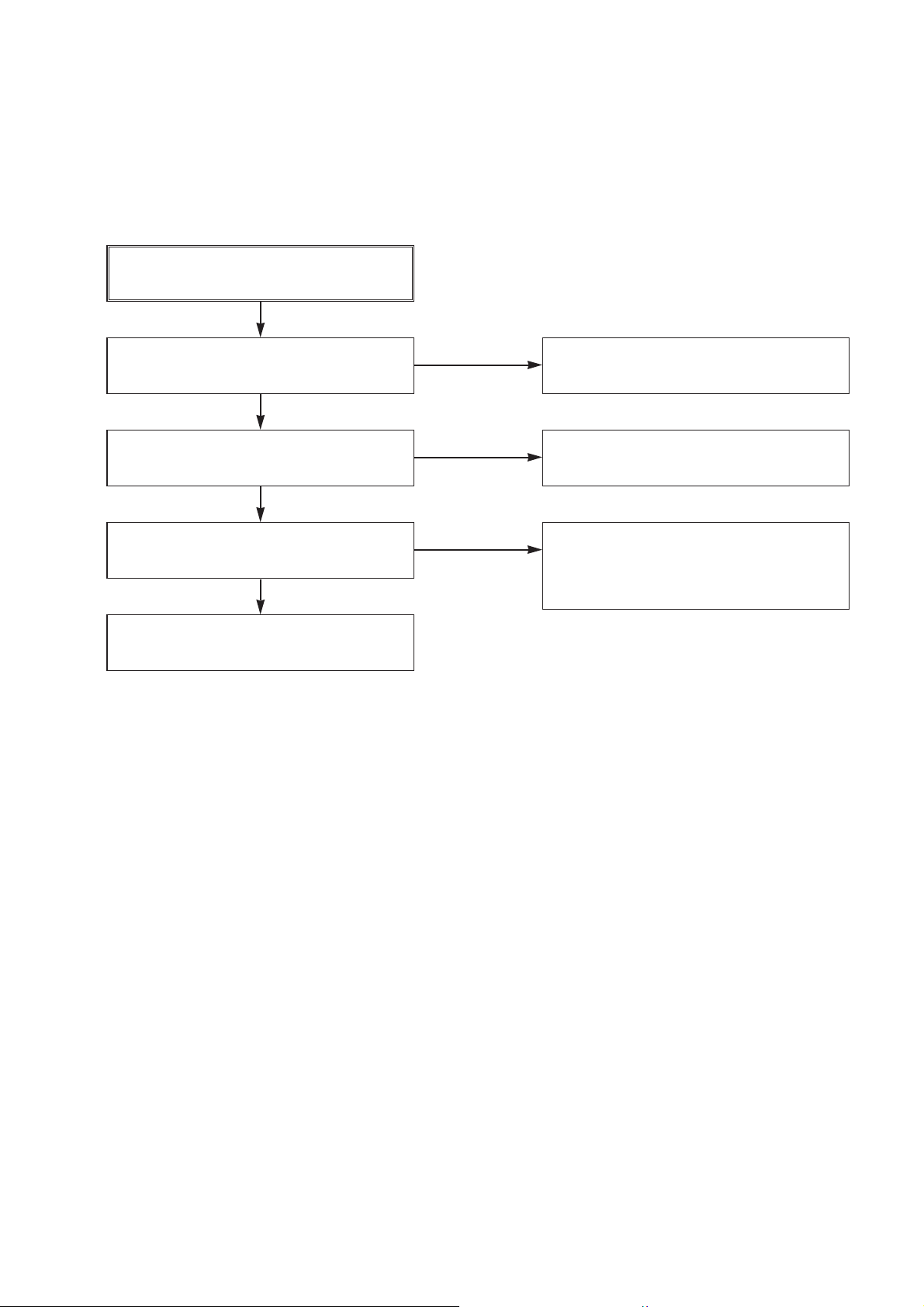

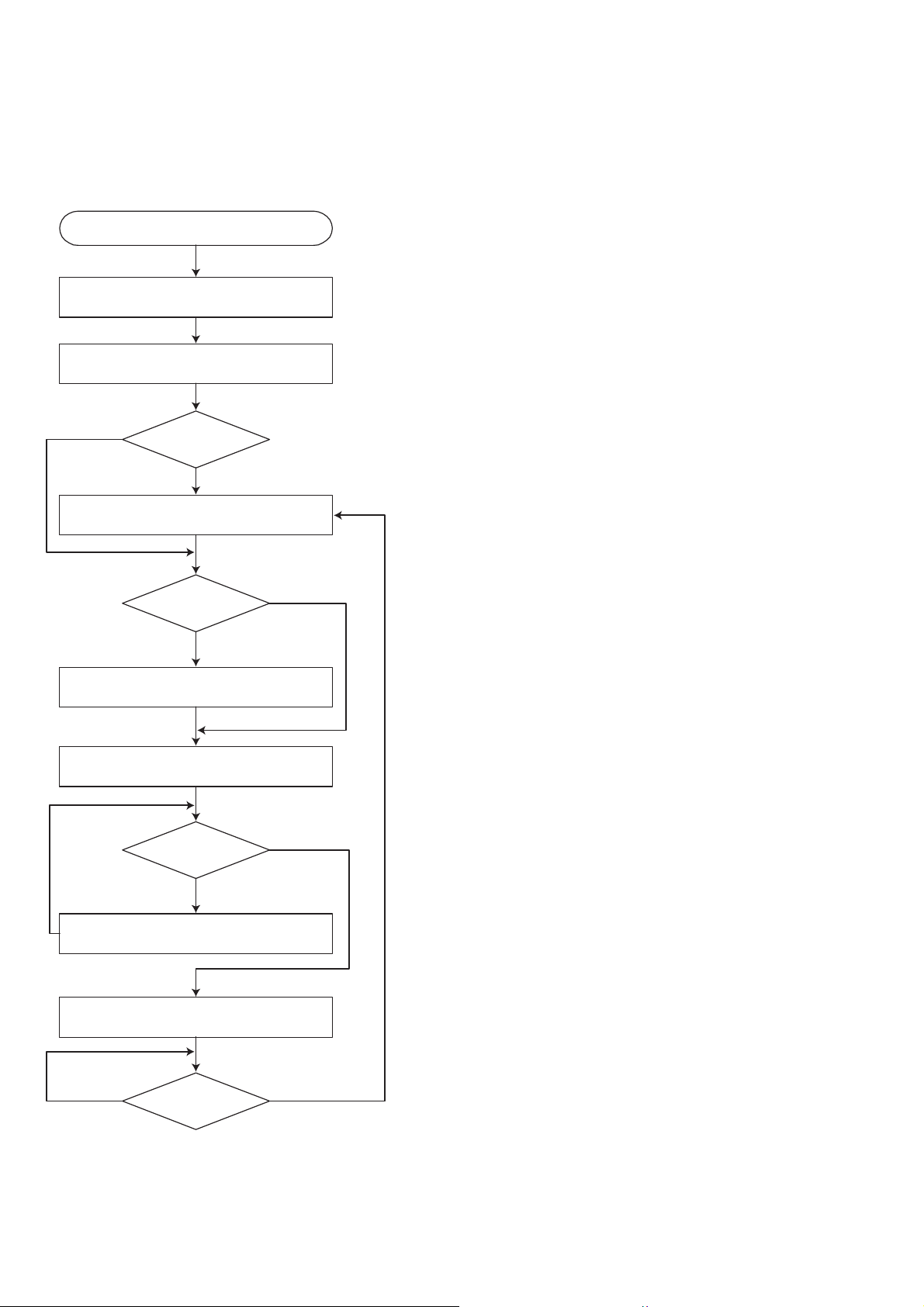

3. AUDIO µ-COM Circuit(DVD & AMP)

POWER ON

AVD-K700P

Does CD/DVD appear

at FLT?

YES YES

Does Loading appear

at FLD?

YES

Does no Dise or Time

appear at FLD?

YES

YES

Check if DVD an Audio

Micom Insert is OK.

YES

Check Power.

YES

Check DVD Module.

NO NO

NO

Does it appear DVD Error

at FLD?

NO

Check Connector (DVV01)

if is normally.

Check power part of Main

B/D.

NO

Check oscillator of X101.

Check if PN102 is high.

YES

YES

YES

YES

NO

NO

NO

NO

NO

Does CD/DVD appear

at FLT?

Reconnet it.

Refer to SMPS.

Refer to oscillator Circuit.

Check DVD Reset

Waveform.

OK

Check SMPS.

YES

Check if IC101 Pin53

is high.

YES

Check if IC101 Pin9, 36,

59 is high(5V).

YES

Check if IC101 Pin49

is high.

YES

Replace IC101.

NO

NO

NO

Check IC101 Reset

Waveform.

Check 3.3V line.

Check Power dection

Circuit.

31

Page 32

AVD-K700P

MECHANICAL ADJUSTMENT

3-1. VIDEO MECHANISM DECK SECTION

• Fixtures and Tools for Service

SECTION 3

1. Cassette Torque Meter

SRK-VHT-303(Not SVC part)

Part No:D00-D006

30

0

S

-

T

250

H

V

-

200

K

R

150

S

S

R

K

VIDEO

CASSETTE

H

V

T

-

-

K

T

R

0

TORQUE

S

50

0

M

ETER

VHT-303

50

100

150

200

250

30

0

4. Torque gauge adaptor

Part No:D09-R001

2. Alignment tape

Part No NTSC:DTN-0001

PAL:DTN-0002

5. Post height adjusting driver

Part No:DTL-0005

3. Torque gauge

600g.Cm ATG

Part No:D00-D002

6. + Type driver (ø5)

32

Page 33

AVD-K700P

1. Mechanism Assembly Mode Check

Purpose of adjustment : To make tools normally operate by positioning tools accurately.

Fixtures and tools used VCR (VCP) status Checking Position

• Blank Tape (empty tape)

1) Turn the VCR on and take the tape out by pressing the

eject button.

2) Separate both top cover and plate top, and check both

the hole (A) of gear cam and the hole (A ’) of chassis correspond (Fig. C-2).

3) If it is done as in the paragraph 2): Turn the gear cam as

in No.2) after mantling the motor assembly L/D.

• Eject Mode

(with cassette withdrawn)

CHECK DIAGRAM

• Mechanism and Mode Switch

4) Undo the screw fixing the deck and the main frame, and

separate the deck assembly. Check both the hole (A) of

gear cam and the hole (A’) of chassis correspond (Fig.

C-1).

5) Check the mode S/W on the main P.C. board locates at

a proper position as in (B) of the Fig. (C-1).

6) Connect the deck to the main P.C. board and perform all

types of test.

Gear Cam

(C)

Gear Drive

(B)

Mode S/W

BOTTOM VIEW

TOP VIEW

Fig. C-1

Fig. C-2

Correspondence of the gear cam hole (O)

and the gear drive hole (O)

Motor Assembly L/D

Gear Cam

(A')

(A)

Chassis Hole

Gear Cam Hole

33

Page 34

AVD-K700P

2. Previous Preparation for Deck Adjustment

(Preparation to load the VCR (VCP) with cassette tape not inserted)

1) Take the power cord from the consent.

2) Separate the top cover and the plate assembly top.

3) Insert the power cord into again.

4) Turn the VCR (VCP) on and load the cassette while pushing the lever stopper of the holder assembly CST backward. In this case, clog both holes on the housing

rail part of chassis to prevent detection of the end sensor.

3. Torque Measuring

Purpose of Measuring : To measure and check the reel torque on the take-up part and the

supply part that performs basic operation of the VCR (VCP) for

smoothly forwarding the tape.

Measure and check followings when the tape is not smoothly

wound or the tape velocity is abnormally proceeded:

If doing so, proceeding to the stop mode is done. In this

status, input signals of all modes can be received.

However, operation of the Rewind and the Review is

impossible since the take-up reel remains at stop status

and so cannot detect the reel pulse (however, possible for

several seconds).

VCR (VCP) status Measuring methodFixtures and tools used

• Torque Gauge

(600 g.cm ATG)

• Torque Gauge Adaptor

• Cassette Torque Meter

SRK-VHT-303

• Play (FF) or Review

(REW) Mode

• Try to operate the VCR (VCP) per mode with the

tape not inserted (See ‘2. Prior Preparation for

Deck Adjustment).

• Measure after adhering and fixing the torque

gauge adaptor to the torque gauge (Fig. C-3-1)

• Read scale of the supply or take-up part of the

cassette torque meter (Fig. C-3-2).

Item

Fast forward Torque

Rewind Torque

Play Take-Up Torque

Review Torque

Fast Forward

Rewind

Play

Review

Mode Instruments Reel Measured Measuring Value

Torque Gauge

Torque Gauge

VHT-303

VHT-303

Take-Up Reel

Supply Reel

Take-Up Reel

Supply Reel

NOTE

Adhere the torque gauge adaptor to the torque gauge for measuring the value.

• Cassette Torque Meter (SRK-VHT-303)• Torque Gauge (600g.cm ATG)

Torque Gauge

Torque Gauge

Adaptor

More than 400g°cm

More than 400g°cm

40~100g°cm

120~210g°cm

300

S

-

T

250

H

V

-

200

K

R

150

S

SRK

V

ID

E

O

C

A

H

S

V

T

-

-

S

K

T

E

R

T

0

T

T

S

E

O

50

R

0

Q

M

E

T

E

R

V

H

T

-

3

0

3

50

U

E

100

150

200

250

300

34

Reel Table

Fig. C-3-2Fig. C-3-1

Page 35

Adjustment Procedure

1) Travel the tape and check the bottom surface of the

tape travels along with the guide line of the lower drum.

2) If the tape travels toward the lower part of guide line on

the lower drum, turn the guide roller height adjusting

screw to the left

3) If it travels to the upper part, turn it to the right.

4) Adjust the height of the guide roller to ensure that the

tape is guided on the guide line of the lower drum at the

inlet/outlet of the drum. (Fig. C-4-1)

Fig. C-4-1

GUIDE ROLLER

HEIGHT

ADJUSTMENT SCREW

ADJUSTMENT DIAGRAM

Purpose of adjustment : To ensure that the bottom surface of the tape can travel along with

the tape lead line of the lower drum by constantly and adjusting

and maintaining the height of the tape.

4. Guide Roller Height Adjustment

Fixtures and tools used VCR (VCP) status Adjustment position

• Post Height Adjusting

Driver

• Play or Review Mode

• The guide roller height adjusting screw on the

supply guide roller and the take-up guide roller

4-1. Prior Adjustment

1) Play the standard test tape after connecting the probe of

oscilloscope to the RF envelope output point and the

head switching output point.

2) Tracking control (playback) : Locate it at the center

(Set the RF output to the maximum value via the tracking control when such adjustment is completed after the

drum assembly is replaced.)

3) Height adjusting screw: Flatten the RF waveform.

(Fig. C-4-2)

4) Move the tracking control (playback) to the right/left.

(Fig. C-4-3)

5) Check the start and the end of the RF output reduction

width are constant.

CAUTIONS

There must exist no crumpling and folding of the tape due

to excess adjustment or insufficient adjustment.

Fig. C-4-2

Fig. C-4-2

P2 POST ADJUSTMENT

P3 POST ADJUSTMENT

CH-1 CH-2

RF ENVELOPE OUTPUT POINT

HEAD RF SWITCHING OUTPUT POINT

Flatten the waveform by

lightly turning the

guide roller height adjustment screw.

When turning the tracking

control to both sides.

OSCILLOSCOPE

When the tracking control

locates at the center.

Waveform

Connection Diagram

Fixtures and tools used

Measuring tools and

connection position

VCR (VCP) status Adjustment position

• Oscilloscope

• Standard test tape

• Post height adjusting

driver

• CH-1: PB RF Envelope

• CH-2: NTSC : SW 30Hz

PAL: SW 25Hz

• Head switching output

point

• RF Envelope output

point

• Play the standard test

tape.

• Guide roller height

adjusting screw

4-2. Fine Adjustment

AVD-K700P

35

Page 36

AVD-K700P

5. Audio/Control (A/C) Head Adjustment

Purpose of adjustment : To ensure that audio and control signals can be recorded and

played according to the contract tract by constantly maintaining

distance between tape and head, and tape tension between the P3

post and the P4 post.

5-1. Prior Adjustment (performed only when no audio output appears in play of the standard test tape)

Fixtures and tools used VCR (VCP) status Adjustment position

• Blank Tape

(Empty Tape)

• Driver (+) Type ø 5

• Play the blank tape

(empty tape).

Adjustment Procedure/Adjustment Diagrams

1) Basically use the A/C head assembly adjusted as in

SPEC.

2) Check there is crumpling and folding of the tape around

the A/C head. If it is, Turn and adjust the tilt adjusting

screw to ensure that the tape corresponds to the bottom

guide of the P4, and recheck the tape path after proceeding play for 4-5 seconds.

8.3

A/C Head Base

• Tilt adjusting screw (C)

• Height adjusting screw (B)

• Azimuth adjusting screw (A)

3) Where the tape bottom is not equal to Fig. C-5-3, Adjust

the height by using the height adjusting screw (B) and

then readjust it by using the tilt adjusting screw (C).

CAUTIONS

Always check the height of the A/C head since most ideal

height of A/C head can be obtained when the bottom part

of the tape is away 0.2 ~ 0.25mm from the bottom part of

the A/C head.

A/C Head

P4

Tape

0.2~0.25mm

Tape

Azimuth

Adjustment

Screw(A)

36

Fig. C-5-1

X-Value Adjustment

Hole

Fixed Screw

A/C Head Assembly

Fig. C-5-2

Fig. C-5-3

Tilt Adjustment

Screw(C)

Height Adjustment

Screw(B)

Page 37

AVD-K700P

Adjustment Procedure

1) After releasing the auto tracking, lightly turn the fixing

screw. Turn the (+) type driver (Ø 3 ~ Ø 4) on the X-distance adjusting hole to the right or left. Adjust the RF

envelope level to the maximum point and then fix the fixing screws.

2) For the 31mm head, adjust it with the SP tape recorded

in the width of 31mm since the head travels on the tape

track only for SP with the width of 58mm.

5-2. Tape Path Check between Pinch Roller and

Take up Guide (Check in the Rev Mode)

1) Check the tape pass status between the pinch roller and

the take-up guide.(Check there is crumpling of the tape

pass and folding of the take-up guide.)

1) (1) When holding of the take-up guide bottom occurs

Turn the tilt adjusting screw (C) clockwise and travel it

stably to ensure there is no crumbling or folding of the

tape.

1) (2) When holding of the take-up guide top occurs

Turn the tilt adjusting screw (C) anti-clockwise and

travel it stably to ensure there is no crumbling or folding of the tape.

1) 2) Check there is folding of the tape at the bottom or top

of the take-up guide in cutting-off the REV mode

CAUTIONS

If the RF waveform is changed after adjusting the A/C head,

perform fine adjustment to ensure the RF waveform is flattened.

Adjustment Procedure

1) Connect the probe of Oscilloscope to the audio output

jack.

2) Ensure that Audio 1KHz, 7KHz output is flattened at the

maximization point by adjusting the Azimuth adjusting

screw (A).

Fig. C-5-4

Fixtures and tools used Connection position VCR (VCP) status Adjustment position

• Oscilloscope

• Standard test tape

(only for SP)

• Driver (+) Type Ø 4

• Audio Output Jack • Play the standard test

• Tape, 1KHz, 7KHz.

• Azimuth Adjusting

Screw (A)

• Height Adjusting Screw

(B)

5-3. Fine Adjustment (Azimuth Adjustment)

1KHz

A: Maximum

7KHz

B: Minimum

Fig. C-6

Fixtures and tools used Connection position VCR (VCP) status Adjustment position

• Oscilloscope

• Standard test tape

(only for SP)

• Driver (+) Type Ø 4

• CH-1: PB RF Envelope

• CH-2: NTSC ; SW 30Hz

PAL:SW 25Hz

• Head switching output

point

• RF Envelope output

point

• Play the standard test

tape.

6. X-distance Adjustment

Left

X-distance Adjusting Hole

Tilt Adjusting Screw (C)

Fixing Screw

Height Adjusting

Screw (B)

Right

Grove of Base A/C

Purpose of adjustment : To maintain compatibility with other VCR (VCP).

RF ENVELOPE OUTPUT POINT

HEAD RF SWITCHING OUTPUT POINT

OSCILLOSCOPE

Connection Diagram

CH-2CH-1

Azimuth

Adjustment

Screw(A)

37

Page 38

AVD-K700P

7. Adjustment after Drum Assembly (Video Heads)

Purpose of adjustment : To adjust and stabilize the height change, X-distance change, etc

depending on the guide roller after assembling the drum.

Fixtures and tools used Connection position VCR (VCP) status Adjustment position

• Oscilloscope

• Standard test tape

(only for SP)

• Post Height Adjusting

Driver

• Driver (+) Type Ø 5

• CH-1: PB RF Envelope

• CH-2: NTSC : SW 30Hz

PAL:SW 25Hz

• Head switching output

point

• RF Envelope output

point

Checking/Adjustment Procedure

1) Play the blank tape (empty tape) and check whether the

guide roller crumbles or wrinkles the tape and adjust it if

necessary.

2) Check that the RF envelope output waveform is flat, and

adjust the height of the guide roller while playing the

standard test tape.

3) Adjust the switching point.

4) Check the RF envelope output is the maximum when

the tracking control locates at the center. If not maximum, set up to ensure that RF envelope output

becomes the maximum by turning the (+) type driver (Ø

3 ~ Ø 4) on the base A/C groove.

• Play the blank tape.

• Play the standard test

tape.

Connection Diagram

RF ENVELOPE OUTPUT POINT

HEAD RF SWITCHING OUTPUT POINT

Waveform

V1/V MAX = 0.7

V1/V MAX = 0.8

RF ENVELOPE OUTPUT

• Fine adjustment of

guide roller

• Switching Point

• Tracking Preset

• X-distance

OSCILLOSCOPE

CH-2CH-1

V2V1V1

8. Check of Traveling Device after Deck Assembly

8-1. Audio, RF Normalization Time (Locking Time) Check in Play after CUE or REV

Fixtures and tools used Measuring standard Connection position VCR (VCP) status

• Oscilloscope

• 6H 3KHz Color Bar

Standard Test tape

• Stop Watch

• RF Locking Time: Within

5 seconds

• Audio Locking Time :

Within 10 seconds

• CH-1: PB RF Envelope

• CH-2: Audio output

• RF Envelope output

point

• Play the 6H 3KHz

Color Bar Standard

Test tape.

• Audio output jack

Checking Procedure

1) Check that locking time of the RF and Audio waveform is

fallen within the measuring standard in conversion of the

play mode from the CUE or the REV mode.

2) Readjust the paragraph 5 and 6 if it deviates from the

standard.

8-2. Check of Tape Curl and Jam Status

Fixtures and tools used Fixtures and tools used Fixtures and tools used

• T-160 Tape

• T-120 Tape

Checking Procedure

1) Check there is no abnormality of every traveling post

status.

2) There must be no abnormal operation of the counter in

• There must be no jam or curl at the

first, middle and end position of tape.

occurrence of folding of the bottom tape. There must be

not abnormality of audio signal in damage of the top tape.

3) If there is abnormality, readjust the adjustment paragraph 4 and 5.

• Travel the tape at the position

of its first and end.

38

Page 39

3-2. MAINTENANCE/INSPECTION PROCEDURE

1. Checking Points prior to Repair

Following abnormal phenomena may be repaired by

removal of foreign materials and oil supply. Check oiling is

required at the checking set or cleaning status is complete.

Determine that necessity of checking and repair the set

exists after checking the using period of the set together

with the user. In this case, followings must be checked:

AVD-K700P

Phenomena

Color beat Pollution of Full-Erase Head o

S/N, Color Faded Pollution of Video Head o

Horizontal, Vertical Jitte o

Poor Sound, Low Sound o

No tape wound or tape

wound loosely.

FF or REW impossible,

or slow turning

Tape loosely wound in

REV or Unloading

Checking Points and

Cause

Pollution of Video Head or

Tape Transport System

Pollution of Audio/Control

Head

Pollution of Pinch Roller or

Belt Capstan Belt

Deterioration of Clutch

Assembly D37 Torque

Pollution of Drum and

Traveling Device

Replace-

ment

o

o

Fig. C-9-3

CAUTIONS

If operation of the position with (O) mark is abnormal even

after removing cause, replace it with substitute product since

it shows damage or wearing.

F/E Head

Video Head

A/C Head

Pinch Roller

Belt Capston

Clutch

Assembly A37

Fig. C-9-1 TOP VIEW

Fig. C-9-2 BOTTOM VIEW

* No. (1) ~ (12) shows sequence that the tape moves from the supply reel to the take-up reel.)

(3) F/E Head

(5) Drum Assembly

(Video Head)

(4) Base Assembly P2

(2) Tension Post

(1) Supply Reel

(6) Base Assembly

P3

(7) A/C Head

(8) P4 Post

(10) Pinch Roller

(11) Take-up Guide

Post

(9) Capstan Shaft

(12) Take-up Reel

Fig. C-9-3 Tape Transport System

39

Page 40

AVD-K700P

2. Essential Check and Repair

Recording density of the video is far higher than the audio.

Therefore video parts are very precise so as to allow only

error of 1/1000mm or so in order to maintain compatibility

with other videos.

If one of these parts is polluted or old, same phenomena will

appear as they are damaged.

To maintain clear screen, regular check, replacement of old

and damaged parts and oil supply, etc are essential.

3. Regular Check and Repair

Check and repair schedule is not constant since they vary

depending on method that the consumer uses video and

environment where the video is installed at.

However, for the video used by common household, good

screen will be maintained if regular check and repair per

1,000 hour is performed. The following chart shows relationship between using time and checking time:

Table 1

Time

Requiring

Checking

Average

hours used

per day

One hour

Two hours

Three hours

About

1 year

About

18 months

About

3 years

4. Tools for Check and Repair

(1) Grease: Floil G-3114 (KANTO) or equivalent grease

(Green)

(2) Grease: Kanto G-754, PL-433 (Yellow)

(3) Alcohol (Isopropyl Alcohol)

(4) Cleaning Patch (cloth)

5. Maintenance Process

5-1) Removal of Foreign Material

(1) Removal of foreign material from video head (Fig. C-9-4)

Firstly try to use a cleaning tape.

(1) Use a cleaning patch if foreign materials are not removed

with the cleaning tape due to severe dirty of the head.

Soak the cleaning patch in alcohol and put it to the head

tip. Smoothly turn the drum (turning cylinder) to the right

or left (In this case, the cleaning patch must not be

moved vertically).

(1) After completely drying the head, test the traveling status

of the tape.

(1) If alcohol (Isopropyl Alcohol) remains at the video head,

the tape may be damaged when this solution touches

with the head surface.

Never use a cloth bar (commercial sale)

(2) Wipe the tape transport system and the drive system

with the cleaning patch soaked in alcohol (Isopropyl

Alcohol) when removing foreign materials from them.

1) The part touched with the traveling tape is called as

tape transport system. The drive system consists of

parts to travel the tape.

(2) 2) Care must be exercised so that unreasonable force

to change the pattern will be applied to the tape transport system during removal of foreign materials.

40

Cleaning Patch

(Cloth)

Soak alcohol

(Isopropyl Alcohol).

Drum

(Turning Cylinder)

Head Tip

Smoothly turn the drum (turning

cylinder) touching the soft surface

to the head tip surface.

Fig. C-9-4

Page 41

AVD-K700P

5-2) Grease Applications

(1) Grease Application Method

Apply grease by using a cloth swab or brush. Care must

be exercised so that excess quantity should not be

used. If the excessive quantity is applied, wipe it with

the gauze soaked in alcohol (Isopropyl Alcohol).

NOTE: POSITION OF GREASE APPLICATION

(2) Regular Grease Application

Apply grease to the designated application position

every 500 hour.

5

4

2

1

3

(1) Inner Side Surface and Top

Surface of Loading Path

(2) Stable Adhesion Part of Base

P2, P3

(3) Arm Pinch Shaft

(4) Gear Wheel Shaft

(5) Reel S. T. Shaft

(1) (2) (3) (4): KG-684G

(Green)

(5): PL-433 (Yellow)

Cam Part

(PL-433.Yellow)

Gear Part

(PL-433.Yellow)

Boss Part Side Wall

(PL-433.Yellow)

Gear Part Side Application

(PL-433.Yellow)

Cam Part Side Application

(KG-684G.Green)

Gear Sector Gear Cam

Base Loading Gear Drive

Inner Surface of

Guide Rail

(KG-684G.Green)

Chassis (L) Chassis (R)

Gear Part

1

2

3

4

6

5

7

(1) Inner Side Surface and Top

Surface of Loading Path

(2) Stable Adhesion Part of Base

P2, P3 Coil

(3) Gear Cam Shaft

(4) Gear Drive Shaft

(5) Clutch Shaft Groove

(6) Guide Part on the Plate Slider

Side Wall (Left)

(7) Guide Part on the Plate Slider

Side Wall (Right)

(1) (2) (3) (4) (5) (6) (7): KG684G (Green)

Chassis (TOP)

Chassis (Bottom)

Cam Part

(KG-684G , GREEN)

Cam Part

(KG-684G , GREEN)

Gear Rack F/L

Lever, Brake Driving Cam Part

Side Wall Guide Part

Lever F/R Driving Part

Side Wall Guide Part

Lever, Spring Driving Part

Lever Tension Driving Cam Part

Gear Sector Driving Part

Plate Slider

41

Page 42

AVD-K700P

Lever, F/R, Base, Tension GEAR AY, P2 & P3

LEVER, F/R

Clutch Contact Part

(PL-433, Yellow)

Tension Arm Party

Hinge Part (PL-433, Yellow)

BASE, TENSION

PL-433

42

Page 43

SECTION 4

d

d

DIAGRAMS

AVD-K700P

THIS NOTE IS COMMON FOR PRINTED WIRING BOARDS AND SCHEMATIC DIAGRAMS.

(In addition to this, the necessary note is printed in each block.)

For schematic diagrams.

Note:

• All capacitors are in µF unless otherwise noted. (p: pF)

50 WV or less are not indicated except for electrolytics

and tantalums.

• All resistors are in Ω and 1/

specified.

• f : internal component.

Note: The components identified by mark 0 or dotted line

with mark 0 are critical for safety.

Replace only with part number specified.

4

W or less unless otherwise

For printed wiring boards.

Note:

• b : Pattern from the side which enables seeing.

(The other layers' patterns are not indicated.)

Caution:

Pattern face side: P arts on the pattern face side seen from

(Conductor Side) the pattern face are indicated.

Parts face side: Parts on the parts face side seen from

(Component Side) the parts face are indicated.

• Indication of transistor

C

Q

CEB

These are omitte

These are omitte

EB

MEMO

AVD-K700P

4343

Page 44

AVD-K700P

4-1. BLOCK DIAGRAM – POWER (SMPS) SECTION-1 –

BD101

BD101

PSW01

T101

!

32VA

NC

LINE FILTER

BLOCK

( C101, C102,

L101, L102 )

!

V101

!

F101

C103

DRIVE & S/W BLOCK

QUASI-RESONANT BLOCK

( IC101, R114, R115, C123, C107,

BC101, D108, R101, D102, R102,

D103, R106, ZD102, Z101, C108,

R104, C109, C110)

DRIVE & S/W BLOCK

SOFT-START BLOCK

( R107, R108, C121, R105,

C120, C119, ZD1103, D105,

R111, BC102 )

SNUBBER

BLOCK

( R110, C115,

D104, C117 )

IC102

IC103

T102

!

RECTIFER & SMOOTHING

NC

BLOCK

( D122, C131, R131,

C132, C133, C135, L122 )

PWR SENSE

FEED-BACK

BLOCK

( R122, R121, C136,

R123, R124, R125,

R126 )

!

PWR SENSE

BLOCK

( R184, R185 )

PSV01

FD(+)

FD(-)

-29VA

33VA

13VA

3.8VA

5.3VA

F102

RECTIFIER &

SMOOTHING

BLOCK

(D123, C130, ZD121, R127)

RECTIFIER &

SMOOTHING

BLOCK

( D125, R129, C138 )

RECTIFIER & SMOOTHING

BLOCK

( D124, C137, R128 )

RECTIFIER & SMOOTHING

BLOCK

( D126, C140, L122, C141 )

RECTIFIER & SMOOTHING

BLOCK

( D127, C142, L123, C146 )

PW101

!

BL

BR

(WH)

(BK)

NOTES) Symbol denotes AC ground.

NOTES) Symbol denotes DC chassis ground.

AVD-K700P

C113C114

!!

C122

!

!

IC105

RECTIFIER & SMOOTHING

BLOCK

( D129, C144, L124, C147 )

FEED-BACK

BLOCK

( R132, R133, C148,

R134, R135, R136,

R137 )

IC106

4444

Page 45

4-2. BLOCK DIAGRAM – POWER (SMPS) SECTION-2 –

33VT BLOCK

(Q163, R168,

R169, R170)

AVD-K700P

TO SYS

FD(+)

TO SYS

FD(-)

TO SYS

-29VA

3.3V BLOCK

(IC161, C164)

TO TU

33V

FD(+)

FD(-)

-29VA

GND

33VA

GND

13VA

GND

3.8VA

3.8VA

GND

5.3VA

5.3VA

GND

GND

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

8V BLOCK

(IC160, D163,

C163, R161)

9V BLOCK

(Q162, R171, ZD163)

3.3V BLOCK

(IC163, C177)

3.5V BLOCK

(IC162, D165, C172)

5V BLOCK

(Q168, R178, R179,

R180, C169)

5.2V BLOCK

(Q167, C168, R175,

R176, R177)

1

2

3

4

5

6

7

8

9

10

11

12

TO SYS

5.3VA

PVD01

5.3VA

5.0V

8V

GND (M)

9V

GND (A)

3.3V

5V

GND

3.5V

A.GND

D.GND

AVD-K700P

PVS01

REG 5V

(Q166, C166, C167,

R174, ZD161)

TO TU/SYS/ Hi-Fi

PWR CTL BLOCK

(Q169, C170, R181,

R182, R183)

5.2V

FROM µ-COM

PWR CTL 'H'

TO A VCP

REG 5V

4545

Page 46

AVD-K700P

4-3. BLOCK DIAGRAM – Y/C SECTION –

(PB Mode)

EP PB 'A'

EP PB 'B'

SP PB 'B'

SP PB 'A'

64

65

67

72

74

59 58 57 55 54 53

ACC

DET

ENV

DET

AUDIO

MUTE

HA SW

C-ROT

RF-SW

IN

P

P

P

P

Y/C ENA

Y/C DATA

Y/C CLOCK

MAIN

C-LPF

CONV

4.21M

BPF

SUB

CONV

3.58M

BPF2

ACC

AMP

ACC

DET

FM

AGC

CLAMP

DOUBLE

LIMFMDEM

PB

FM-EQ

LPF

Y

3.58M

BPF1

YNR

COMB

CNC

SUB

LPF

MAIN

DE-EM

CCD

Y/C

MIX

OUT

CLAMP

VCA

CLAMP

6dB

(REC Mode)

V. H/SW55Y/C ENA

57

39

IN

37

36

EP REC

66

34

69

70

73

26

SP REC

V.OUT

22

21

B

R

R

DECODER

C-LPF

Y/C DATA

Y/C CLOCK

54

53 51 50 49 48 47

SERIAL

BGA

MAIN

BPF

SUB

B-UP

AMP

ACC

AMP

ACC

DET

DETAIL

ENH

NL

EMPHA

CONV

4.21M

CONV

X-TAL

3.58MHZ

320FH

VCO

REC

APC

CLAMP

MAIN

EMPHA

FM

MOD

REC

FM-EQ

REC

AFC

SLDVX01

OUT

39

38

CLAMP

LPF

CCD

VCA

CLAMP

3.58M

BPF1

YNR

COMB

Y

VIDEO

AGC

37

IN

36

34

IC302

SW

BLOCK

32

30

28

TU/LINE1

DVD

LINE2

V.OUT

26

22

21

4.7K

B

20

AVD-K700P

4646

Page 47

4-4. BLOCK DIAGRAM – NORMAL AUDIO SECTION –

1) EE Mode 2) PB Mode 3) REC Mode

MOD. OUT

A. OUT (R)

A. OUT (L)

2

IC301

LA71206M

DET

ALC

76

80

78

IC801

10

LA72670M

OUTPUT

SELECTOR

IC301

LA71206M

DET

ALC

76

9

REC

10

AVD-K700P

AMP

IC801

LA72670M

TU701

TUNER

NORMAL

AUDIO

OUT

6

SIF

DE MOD

57

13

SIF

4

RF_MOD

INPUT

SELECT

2

1

A_IN

OUTPUT

SELECT

9

71

117312

REAR JACK

LINE AUDIO(L) IN

LINE AUDIO(R) IN

78

A. OUT (R)

80

A. OUT (L)

74

DVD AUDIO

IC301

LA71206M

EQ

410

AMP

AMP

53

55 54

(System)

DATA

From u-COM

CLOCK

ENA

NORMAL

IC801

LA72670M

TU701

TUNER

AUDIO

OUT

6

SIF

DE MOD

13 57

SIF

4

RF MOD.

INPUT

SELECT

1 2

A_IN

OUTPUT

SELECT

9

71

LINE AUDIO(L) IN

LINE AUDIO(R) IN

78

A. OUT (R)

80

A. OUT (L)

AVD-K700P

REAR Jack

5

6

N.A.IN

R/P HEAD

4

EQ

3

2

REAR Jack

4747

Page 48

AVD-K700P

4-5. BLOCK DIAGRAM – HI-FI SECTION –

DVD AUDIO

REAR JACK

FRONT

AUDIO INPUT

BLOCK

SIF

DVD A.IN 'L'

DVD A.IN 'R'

AV1 A.IN 'L'

AV1 A.IN 'R'

AV2 A.IN 'L'

AV2 A.IN 'R'

57

12

74

11

73

9

71

A

B

DEMO

DULATE

INPUT

SELECT

IC801

LA72670M

Hi-Fi/

REC

24

26 27

Hi-Fi REC