Page 1

ROOM AIR CONDITIONER

INDOOR UNIT

AS24A2RC

AS18A6RC

AS18A0RCD

SERVICE

OUTDOOR UNIT

US24A2RC

US18A6RC

US18A0RCD

Manual

CONTENTSAIR CONDITIONER

1. Installation

2. Disassembly and Reassembly

3. Troubleshooting

4. Exploded Views and Parts List

5. Refrigerating Cycle Block Diagrams

6. PCB Diagrams

7. Wiring Diagrams

E DB81-00189A(3)

8. Schematic Diagrams

Page 2

1. Installation

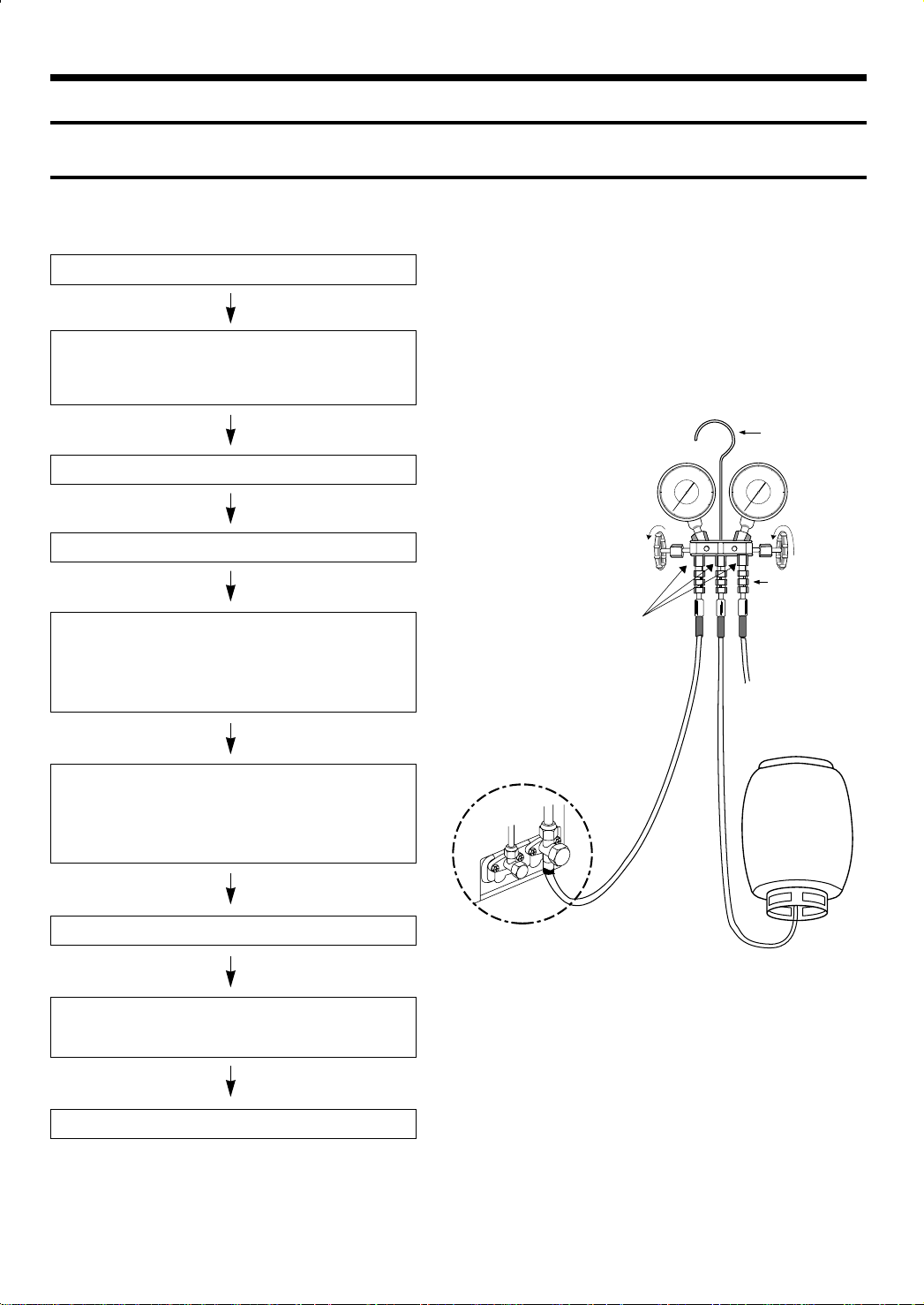

1-1 Refrigerant Refill Procedure

• Refill an air-conditioner with refrigerant when refrigerant has been leaked at installing or using

1. Purge air(for new installation only).

2. Turn the 3-way valve clockwise to close, connect the

pressure gauge(low pressure side) to the service valve,

and open the 3-way valve again.

Suspension hook

3. Connect the tank to refill with Refrigerant

4. Set the unit to cool operation mode.

5. Check the pressure indicated by the pressure

gauge(low pressure side).

* Standard pressure is should be 4.5~5.5kg/cm

regular, high operation mode.

6. Open the refrigerant tank and fill with refrigerant until

the rated pressure is reached.

* It is recommended not to pour the refrigerant in too

quickly, but gradually while operating a pressure valve.

7. Stop operation of the air conditioner.

2

in a

Compound

gauge

For mounting

other and of

hose when

not in use

High

pressure

gauge

Hand

wheel

Finger tight

fittings

Connected to

high pressure

side

Charging

line

R-22

8. Close the 3-way valve, disconnect the pressure gauge,

and open the 3-way valve again.

9. Close the cap of each valve.

1

Page 3

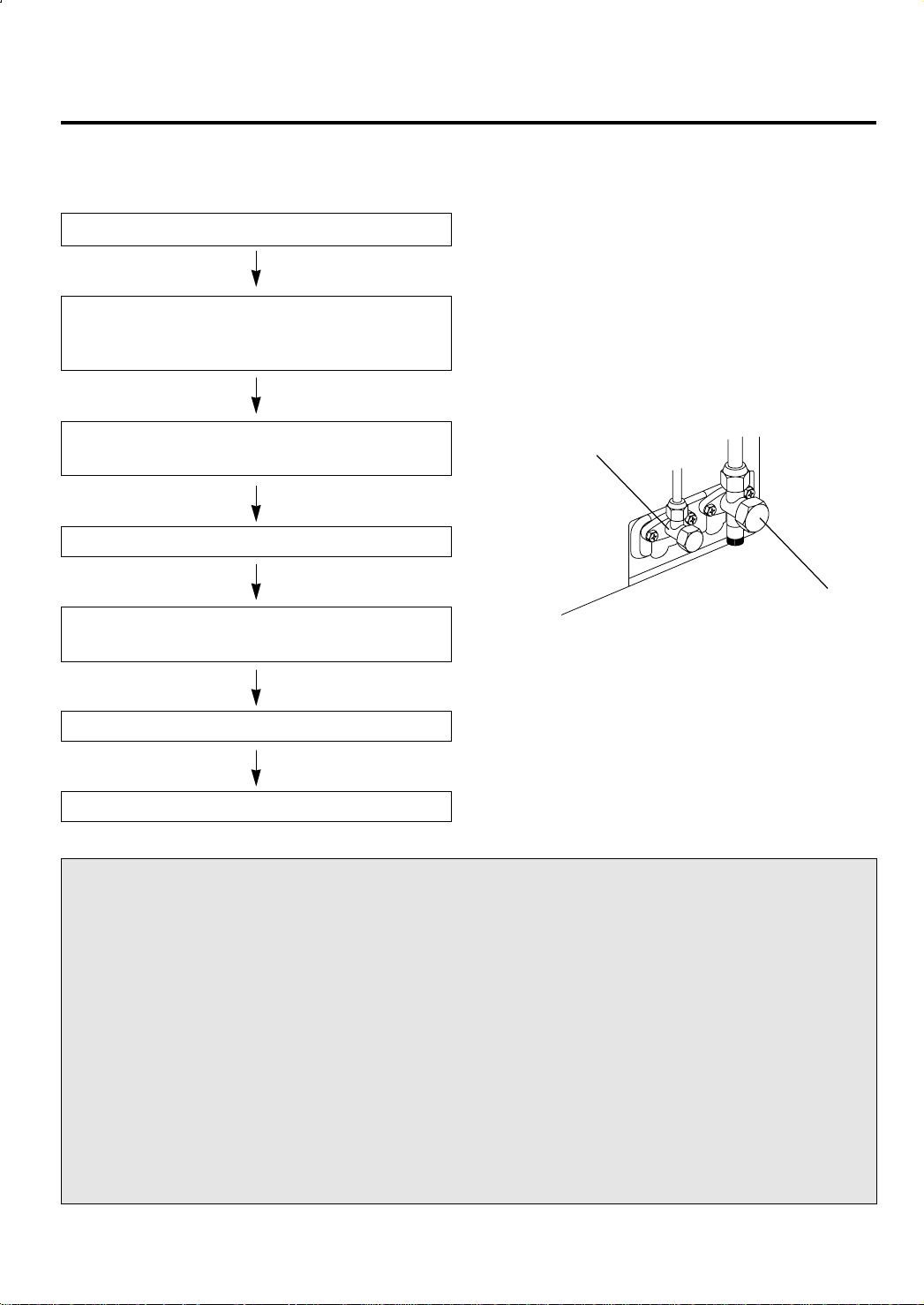

1-2 “Pump down” Procedure

Pump down' shall be carried out when an evaporator is replaced or when the unit is relocated in

another area.

1. Remove the caps from the 2-way valve and the 3-way valve.

2. Turn the 3-way valve clockwise to close and connect

a pressure gauge(low pressure side) to the service valve,

and open the 3-way valve again.

3. Set the unit to cool operation mode.

(Check if the compressor is operating.)

4. Turn the 2-way valve clockwise to close.

5. When the pressure gauge indicates "0" turn the 3-way valve

clockwise to close.

6. Stop operation of the air conditioner.

7. Close the cap of each valve.

Relocation of the air conditioner

• Refer to this procedure when the unit is

relocated.

1. Carry out the pump down procedure

(refer to the details of 'pump down').

2. Remove the power cord.

3. Disconnect the assembly cable from the

indoor and outdoor units.

4. Remove the flare nut connecting the

indoor unit and the pipe.

At this time, cover the pipe of the indoor

unit and the other pipe using a cap or

vinyl plug to avoid foreign material entering.

2-Way Valve

3-Way Valve

5. Disconnect the pipe connected to the outdoor unit.

At this time, cover the valve of the outdoor unit and the other pipe using a cap

or vinyl plug to avoid foreign material

entering.

6. Make sure you do not bend the connection

pipes in the middle and store together

with the cables.

7. Move the indoor and outdoor units to a

new locatioon.

8. Remove the mounting plate for the indoor

unit and move it to a new location.

2

Page 4

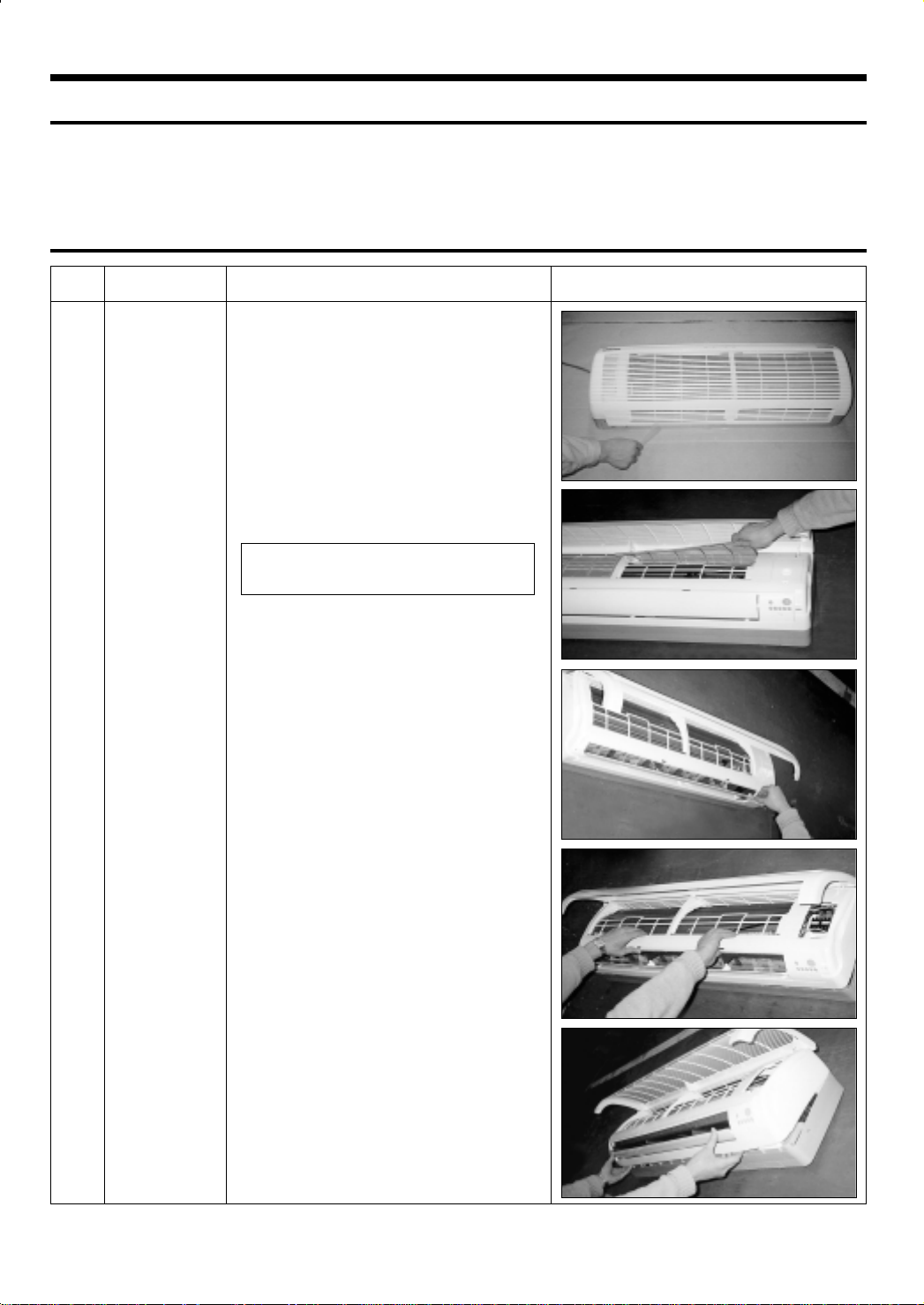

2. Disassembly and Reassembly

Stop operation of the air conditioner and remove the power cord before repairing the unit.

2-1 Indoor Unit

No Parts Procedure Remark

!

Front Grille 1) Stop the air conditioner operation and block the

main power.

2) Seperate tape of front panel upper.

3) Contract the second finger to the left, and right

handle and pull to open the inlet grille.

4) Take the left and right filter out.

* Take the Deodorizing and Electrostatic filter

out. (Optional)

5) Loosen one of the right fixing screw and seperate the terminal cover.

6) Loosen three fixing screws of front grille.

7) Pull the upper left, right and Center of discharge

softly for the outside cover to be pulled out.

8) Pull softly the lower part of discharge and push

it up.

Caution;

Assemble the front panel and fix the

hooks of left, right and Center

3

Page 5

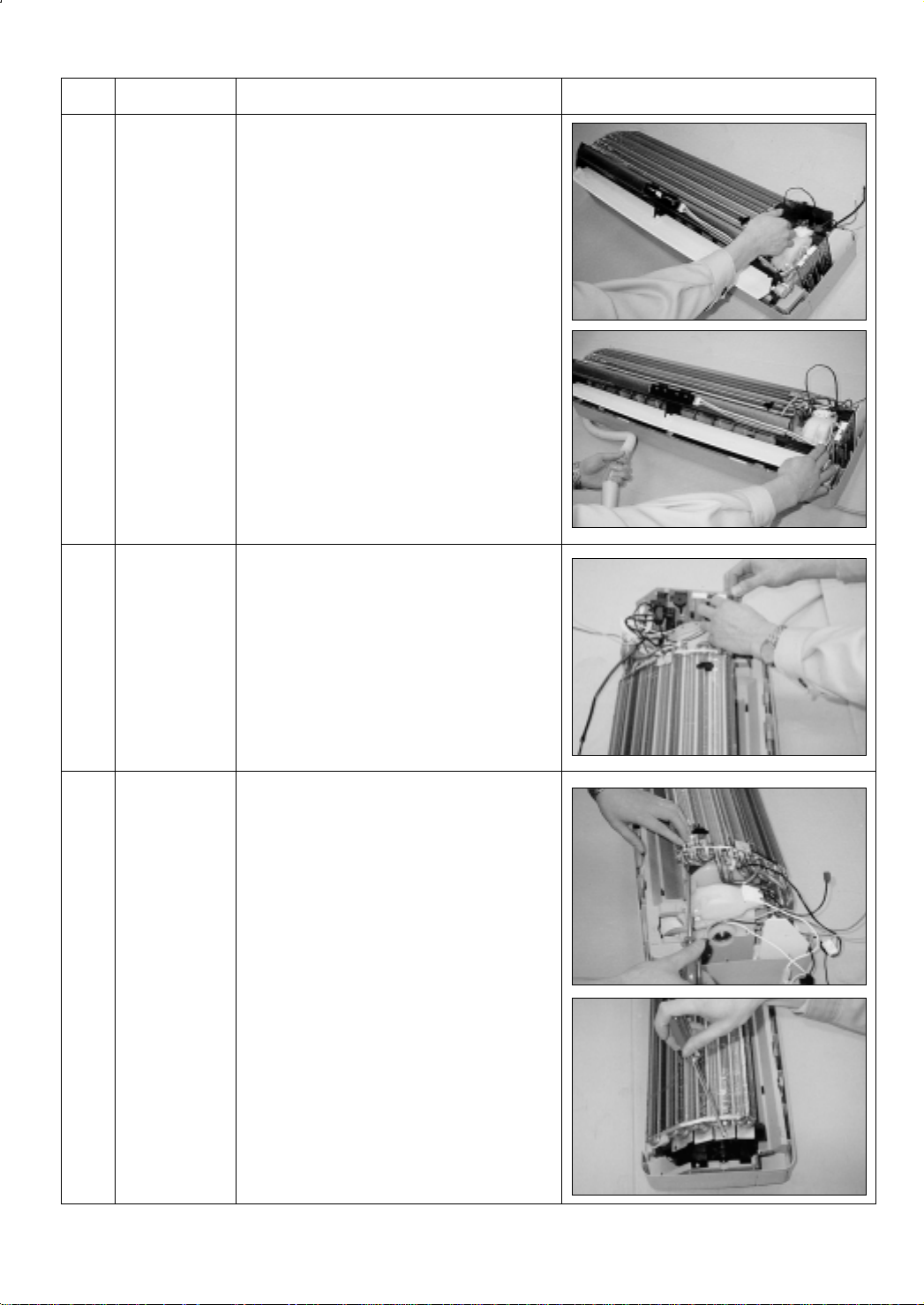

No Parts Procedure Remark

@

#

Ass’y Tray Drain.

Electrical Parts

(Main PCB)

1) Do “1” above.

Separate the drain hose from the extension

drain hose.

2) Take the display PCB out.

(Center of indoor unit)

3) Loosen two fixing screws of left and right

4) Pull tray drain out from the back body.

1) Do “1”, “2”, above

2) Take all the connector of PCB upper side out.

(Inclusion Power cord)

$

Heat Exchanger

3) Separate the outdoor unit connection wire from

the terminal block.

4) Pulling the Main PCB up. it will be taken out.

(Separate the TRANS hook. it before).

1) Do “1” and “2”, “3”, above

2) Loosen two fixing earth screws of right side.

3) Separate the connection pipe.

4) Separate the bush body at the upper side and

holder at the rear side.

5) Loosen the two fixing screws of left side.

6) Lifting the heat exchanger up a little to push the

up side for separation from the indoor unit.

4

Page 6

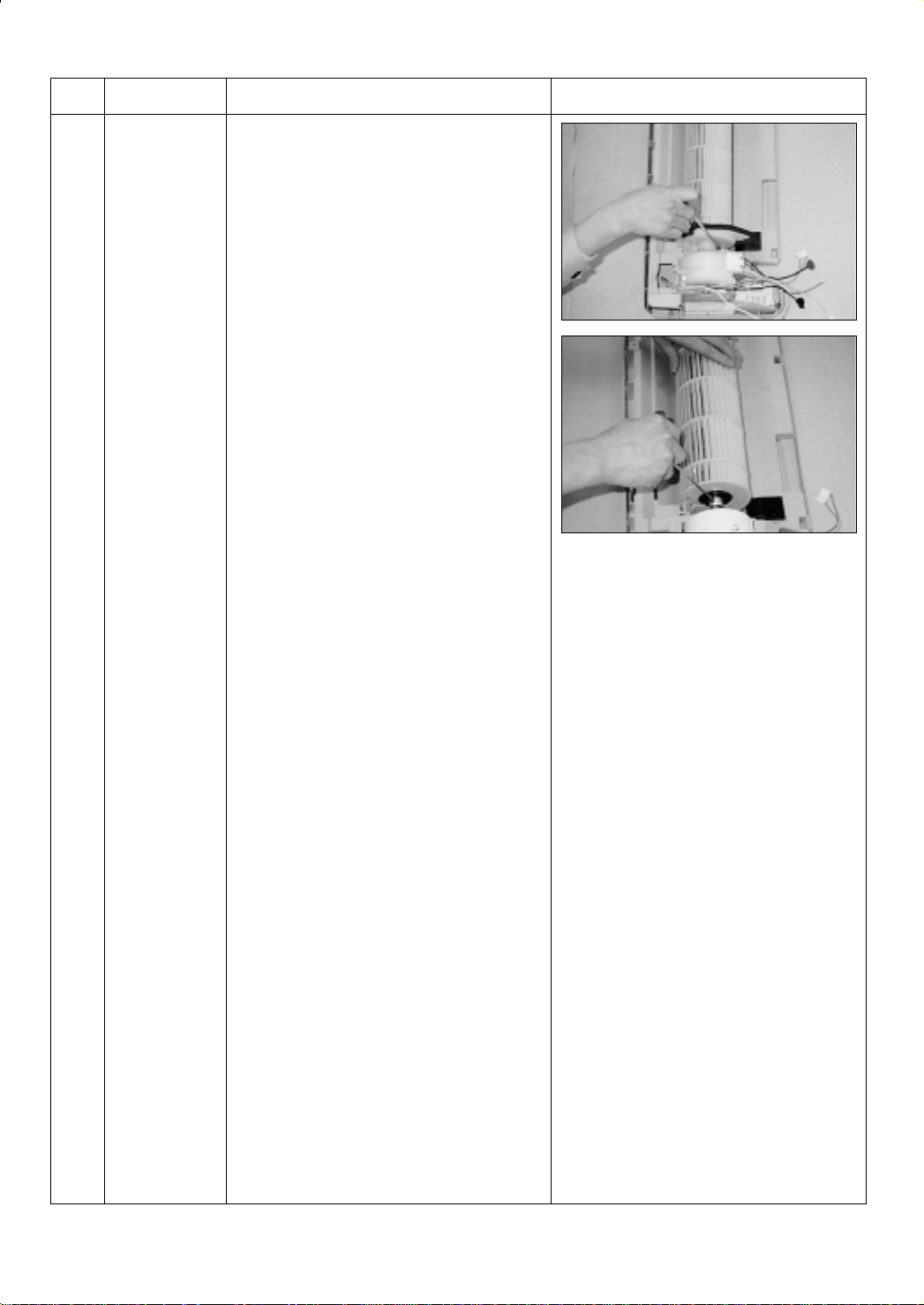

No Parts Procedure Remark

%

Fan Motor and

Cross Fan

1) Do “1” “2” ”3” “4”, above.

2) Loosen the fixing three screws and separate the

motor holder.

3) Loosen the fixing screw of fan motor.

(By use of M3 wrench)

4) Separate the fan motor from the fan.

5) Separate the fan from the left holder bearing.

5

Page 7

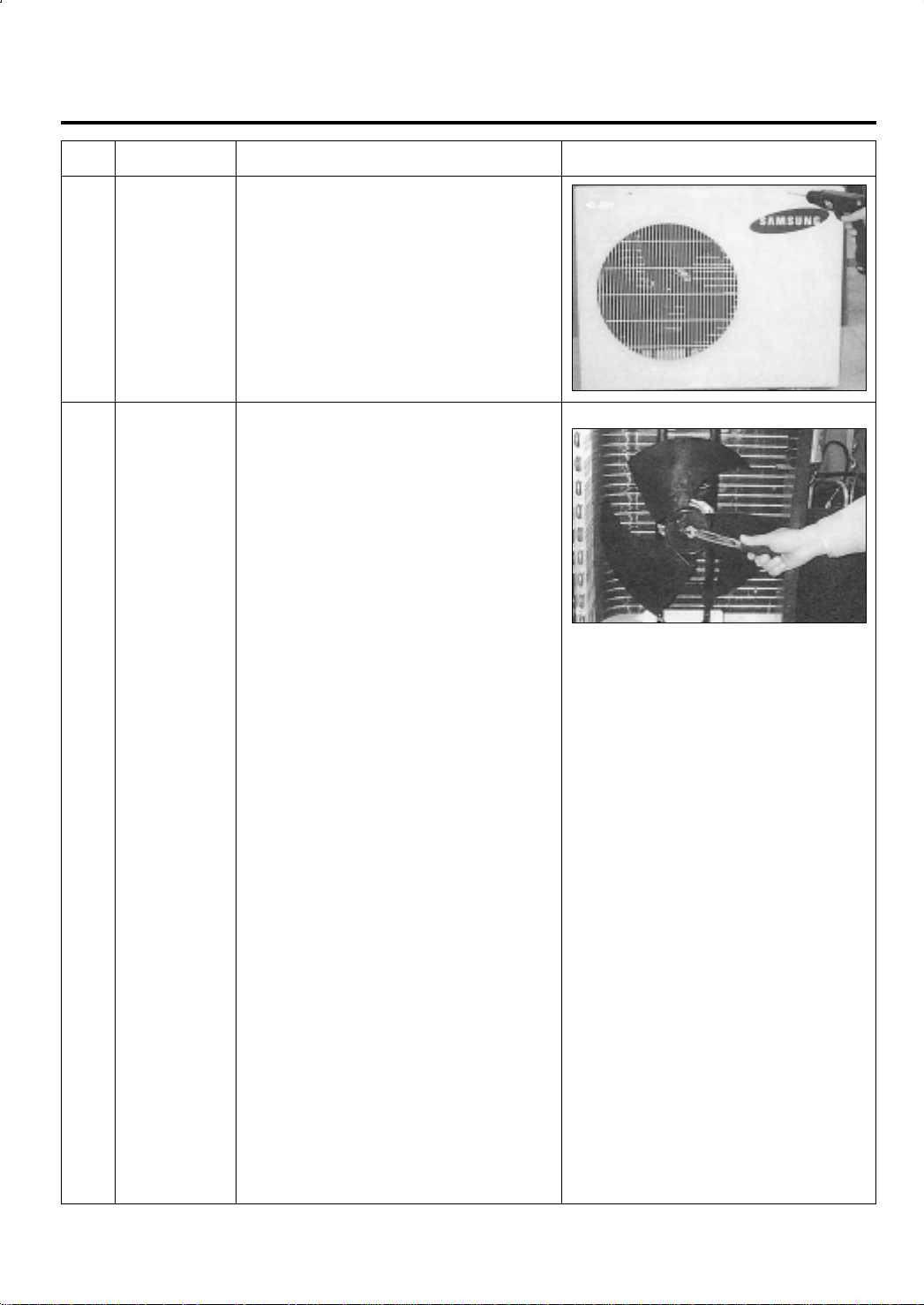

2-2 Outdoor Unit

No Parts Procedure Remark

!

@

Cabinet

Fan Motor &

Propeller Fan

1) Turn off the unit and remove the power cable

2) Remove the top cover.

3) Remove the control box cover.

4) Unplug the ass'y cable.

5) Remove the cabi-side.

6) Remove the cabi-front.

* When you assemble the parts, check if the

each parts and electric connectors are fixed

firmly.

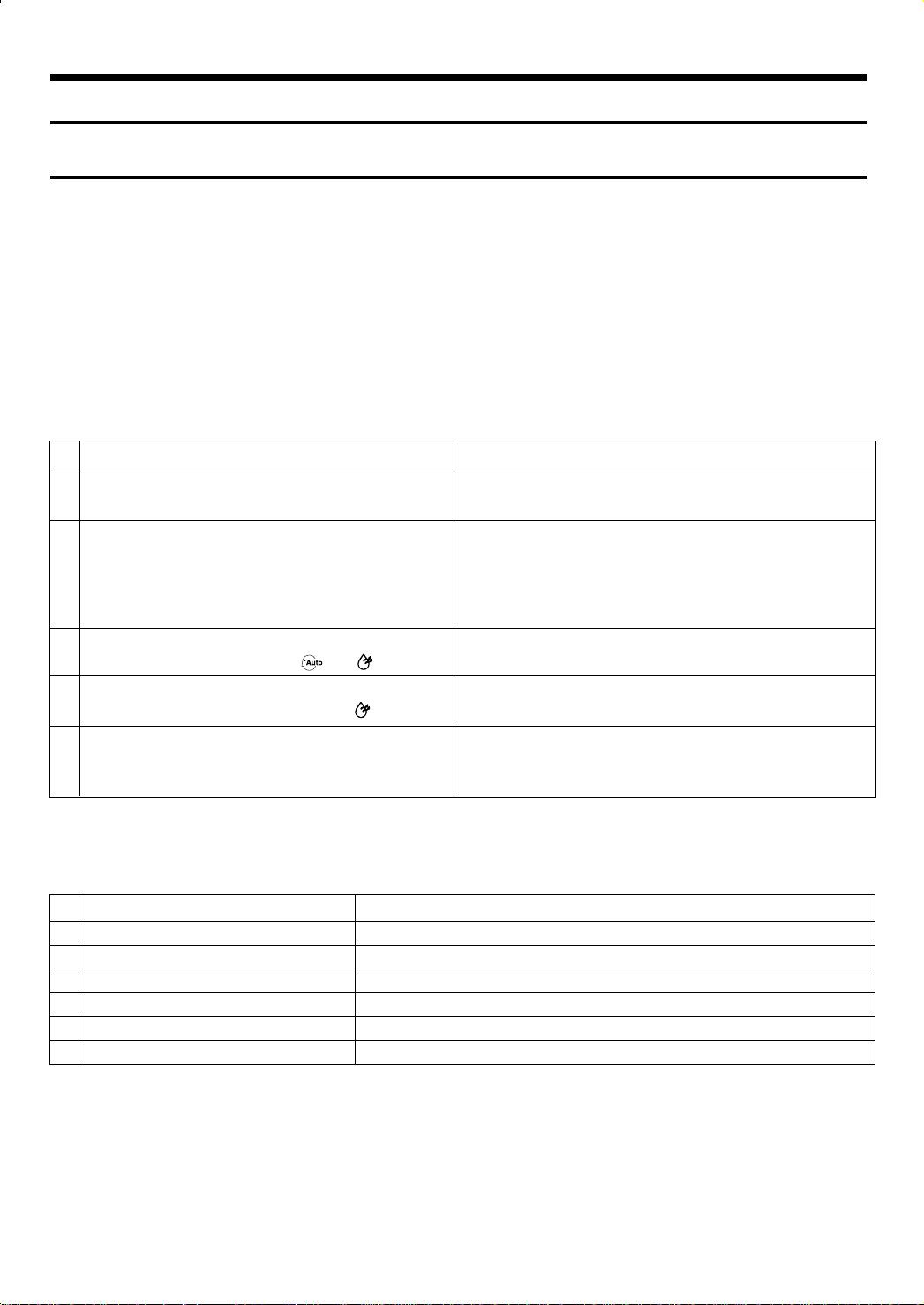

1) Do Procedure 1 above.

2) Remove the nut flange.

(Turn to the right to remove as it is a left turned

screw)

3) Disassemble the propeller fan.

6

Page 8

3. Troubleshooting

3-1 Items to be checked first

1) The input voltage should be rating voltage 10% range.

The airconditioner may not operate properly if the voltage is out of this range.

2) Is the link cable linking the indoor unit and the outdoor unit linked properly?

The indoor unit and the outdoor unit shall be linked by 6 cables.

Check the terminals if the indoor unit and outdoor unit are properly linked by the same number of

cables.

Otherwise the airconditioner may not operate properly.

3) When a problem occurs due to the contents illustrated in the table below it is a symptom not related to

the malfunction of the airconditioner.

NO

1 The STD operation indication LED blinks when a

power plug of the indoor unit is plugged in for the first time.

2 In a COOL operation mode, the compressor does not

operate at a room temperature higher than the setting

temperature that the INDOOR FAN should operate.

3 Fan speed setting is not allowed in AUTO or DRY mode.

4 Compressor stops operation intermittently in DRY mode.

5 The compressor stops intermittently in a COOL mode or DRY

mode, and fan speed of the indoor unit decreases.

4) Indoor unit observes operation condition of the air conditioner, and displays self diagnosis details on

the display panel.

NO

1 STD LED blinking (1Hz)

2 TIMER LED blinking (1Hz)

3 STD and TIMER LED blinking (1Hz)

4 BIO LED blinking (1Hz)

5 STD, BIO and TIMER LED blinking(1Hz)

6 All LED blinking(1Hz)

Operation of air conditioner

Display

Explanation

It indicates power is on. The LED stops blinking if the operation

ON/OFF button on the remote control unit is pushed.

In happens after a delay of 3 minutes when the compressor is

reoperated. The same phenomenon occurs when a power is on.

As a phenomenon that the compressor is reoperated after a delay of

3 minutes, the indoor fan is adjusted automatically with reference

to a temperature of the air blew

The speed of the indoor fan is set to LL in DRY mode.

Fan speed is 5 steps is selected automatically in AUTO mode.

Compressor operation is controlled automatically in DRY mode

depending on the room temperature and humidity.

The compressor stops intermittently or the fan speed of the indoor

unit decreases to prevent inside/outside air frozen depending on the

inside/outside air temperature.

Self Diagnosis

Restore from power failure (input initial power)

Indoor unit Room sensor Error (open or short)

Indoor unit heat exchanger temperature sensor Error (open or short)

Indoor fan malfunctioning (for spead is Below 450rpm)

EEPROM Error

Option Error (option wasn’t setup or option data error)

7

Page 9

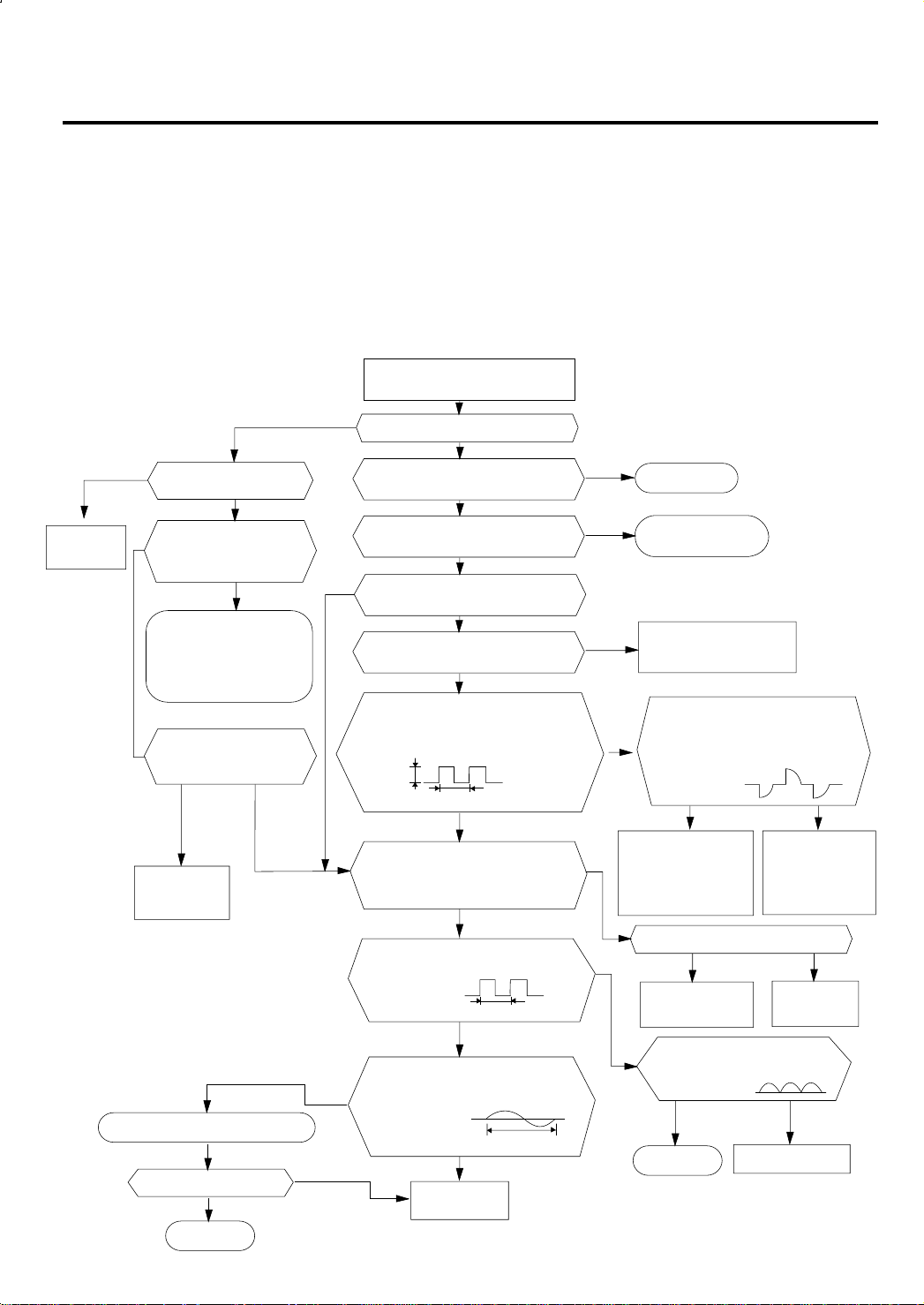

3-2 Fault Diagnosis by Symptom

3-2-1 No Power(completely dead)-Initial diagnosis

1) Checklist :

(1) Is input voltage normal? (rating voltage ±10% range)

(2) Is AC power linked correctly?

(3) Are connections between primary side, secondary side of the power transformer and PCB good.

(4) Is input voltage of DC regulator IC KA7805 (IC02) normal? (11VDC-12.5VDC)

(5) Is output voltage of DC regulator IC KA7805 (IC02) normal? (4.5VDC-5.5VDC)

2) Troubleshooting procedure

Remove power cord and plug in again

in approx. 5 seconds

YES

Replace PCB

display

8

Is DC voltage of PCB

display normal?

NO

Is the rating Voltage ±10%

range applied to the

between #1 and #3 of CN78

NO

•Check linkage between

power cord and

terminal tap

•Check fuse

Is 11~12.5VDC appear in

the input side of the DC

regulator IC KA7805(IC02)?

refer to

replace

PCB module

Replace resonator (X501)

Is operation normal?

YES

OK

NO

NO

YESNO

NO

NO

Is operation lamp blinking?

Does operation start when

run/stop button on the remote

controller unit pushed?

Is transmission display of the remote

controller unit blinking?

Is "beep"sound heard from the main

Is DC voltage of the PCB module

Are voltages of #8 (compressor), and#6

(outdoor fan) of the micom normal? ; 5VDC

Is voltage of #60 (indoor fan) of the micom

DC5V

Is voltage at #33 terminal of the Micom normal?

Is voltage at #18 terminal of the Micom normal?

Is voltage at #52 terminal of the micom

Are voltage at #48 and #49 of the

YES

NO

YES

unit?

YES

normal?

YES

normal?

10ms

NO

YES

normal?

10ms

YES

micom normal?

YES

Replace

micom

100ns

;

0VDC

;

5VDC

NO

YES

NO

NO

YES

NO

Normal

Refer to remote control

unit fault diagnosis

Refer to Replace PCB

module.

Are voltages at RY71(Compressor)

and RY72 (Outdoor fan)

Is voltage at SS71(indoor fan)

YES

Check connections

compressor, outdoor

fan and indoor fan.

Is output voltage of ICO2 normal?(DC5V)

YES

Refer to replace PCB

module

Is voltage output terminal of

D101~D105(IN4007) normal?

YES

OK

normal? ; DC12V

NO

Replace

RY71, RY72

and SS71

NO

Replace ICO2

NO

Replace IN4007

Page 10

3-2-2 When the Indoor Unit Fan Does Not Operate. (Initial Diagnosis)

1) Checklist :

(1) Is the indoor unit fan motor properly connected with the connector (CN73)?

(2) Is the AC voltage correct?

(3) Is HALL IC in indoor fan motor properly connected with the connector (CN43)?

(4) Is the running capacitor properly connected with the solder part of the PCB?

2) Troubleshooting procedure

After unplugging out the power cord should

Does the operating lamp(Green) blink?

Does the Solid State Relay(SS71) work

properly?

+

SS71+

PCB CN73

pin3, pin5

be reconnected within five seconds.

YES

YES

Test rod location

-

SS71-

YES

Is the supply voltage of the fan

motor sufficient?

Test rod location

Condition

Fan operate

12V

Normal

Voltage

Normal

voltage

.

= AC 180V

.

NO

NO

NO

Check as in the procedur “NO power parts”

Refer to page 8.

Microcomputer is out of order.

PCB is

out of order.

Refer to replace

PCB module

YES

Fan motor

is out of order.

MF-C is out of order

Replace MFC

Fan motor

should be replaced.

9

Page 11

3-2-3 When the Outdoor Unit Does Not Operate. (Initial Diagnosis)

1) Checklist :

(1) Is input voltage normal?(rating voltage ±10% range)

(2) Is the set temperature of the remote control higher than room temperature in COOL mode?

(3) Is the POWER IN connector (CN78) linked correctly?

(4) Is the outdoor unit properly connected with the TERMINAL BLOCK connector(5P)?

2) Troubleshooting procedure

After unplugging out the power cord should be recon-

nected within five seconds.

Does the operating lamp blink

YES

Does the timer lamp blink during operation ?

NO

Is the power relay RY71 operated by adjusting the room

temperature?

Test rod location Normal

+ - Condition Voltage

IC06 Pin #6 GND RY71 ON DC 4.8V

NO

Is the rating Voltage ±10% range applied relay between

CN78 ! and #.

NO

YES

YES

PCB and

Room tem-

perature

sensorshould

be checked.

!

!

NO

#

Check as in the procedure "No Power parts"

Room temperature sensor is

PCB is out of order.

Power relay is

out of order

Refer to page 8.

out of order

@

Power relay should be

Refer to replace

PCB module

replaced.

10

YES

!@

NO

Is the room sensor normal register?

(25°C → 10KΩ)

50˚F 68˚F 86˚F

17.96kΩ 12.09kΩ 8.3kΩ

YES

#

Outdoor unit is

out of order.

Page 12

3-2-4 When the UP/DOWN Louver Motor Does Not Operate. (Initial Diagnosis)

1) Checklist :

(1) Is input voltage normal? (rating voltage ±10% range)

(2) Is the UP/DOWN louver motor properly connected with the connector (CN61)?

2) Troubleshooting procedure

Remove power cord and plug in again in approx. 5 seconds.

NO

Is operating lamp blinking?

YES

Y

Does operation start when swing button of the remote

control unit pushed?

NO

N

Voltage at pin #1-#4 of micom (ICO4)

change?(Squarewave)

YES

Y

Volatge at pin #16, #15 of IC06, #10, #11 of IC05 (KID65003)

change?(Squarewave)

YES

Y

N

Check as in the procedure "No Power

parts". Refer to page 8.

YES

NO

NO

Y

N

N

Driver IC05 (KID65003) is faulty.

Normal

Micom (IC04) is faulty.

UP/DOWN louver motor is faulty.

11

Page 13

3-2-5 If Operation By Remote Control Unit Is Impossible. (Initial Diagnosis)

1) Troubleshooting procedure

Remove power cord and plug in again approx. 5 Seconds

Is operation lamp blinking?

YES

“ “ sound heard from the indoor unit when ON/OFF

button on the remote control unit pushed?

NO

Voltage of battery less than 2.5V (Remote Control Unit)?

NO

LCD display status of REMOCON normal?

YES

Transmission display lamp ( ) blinking when ON/OFF

button on the remote control unit pushed?

YES

Voltage at PIN #30 of Remocon Micom change?

YES

Voltage at collecter of Q601 or Q602 change?

YES

NO

Check as in the procedure “NO Power parts”.

Refer to page 8.

YES

YES

NO

NO

NO

NO

Q601(C4375Y) or Q602(C1623Y) is faulty.

Normal

Replace battery.

LCD is faulty.

Replace button.

Micom is faulty.

IR LED(CL-1L5EU) is faulty.

12

Voltage at pin #26 of micom (IC04) change (INDOOR UNIT)?

YES

Micom (IC04) is faulty.

NO

Receiver module is faulty.

Page 14

3-3 Replace PCB module

3-3-1 Replace PCB module

Replace the PCB module

Check the connection and plug in

Remove power cord

Does al display lamp blink or STD lamp blink?

YES

Refer to set up the Model option

NO

Replace another PCB module

13

Page 15

4. Exploded Views and Parts List

1

2

4

5

7-1

6

6-1

20

10-3

10-1

10-2

21

14

16

1112

13

9

8

13-1

17

18

19

10

15

7-2

3-2

3-3

3-1

3

7

4-1 Indoor Unit

14

Page 16

■ Parts List

No.

1

2

3

3-1

3-2

3-3

4

5

6

6-1

7

7-1

7-2

8

9

10

10-1

10-2

10-3

11

12

13

13-1

14

15

16

17

18

19

20

21

CODE NO

DB64-00127A

DB63-30150C

DB74-10101C

DB61-10164B

DB74-10082A

DB74-10081A

DB63-00091A

DB64-00130A

DB93-00311C

DB63-00115A

DB94-00099B

DB31-10153B

DB66-00104A

DB96-01125B

DB96-01125H

DB67-00058A

DB90-00884B

DB90-00433Z

DB61-00601A

DB65-10108A

DB65-00039H

DB65-00068C

DB31-10151D

DB94-00040J

DB94-40003A

DB94-40007A

PD-SH302C-01

PD-SH302C-03

DB32-00027B

DB61-10163A

DB94-00107A

DB90-00434A

DB70-10663A

DB63-00227A

DB70-00115A

Description Specification

GRILLE AIR INLET

GUARD AIR FILTER

CLEANER FILTER ASS´Y

CASE-CLEANER FILTER

DEODORIZING FILTER

CLEANER FILTER

COVER TERMINAL

FRONT PANEL

ASS´Y PCB DISPLAY

COVER DISPLAY

ASS´Y TRAY DRAIN

ASS´Y STEPING MOTOR

BLADE-H

ASS´Y EVAP

ASS´Y EVAP

SPACER-EVAP

ASS´Y HOLDER MOTOR(24K)

ASS´Y HOLDER MOTOR(18K)

HOLDER MOTOR

CLIP EARTH WIRE

TERMINAL BLOCK ASS´Y

TERMINAL BLOCK ASS´Y

MOTOR FAN IN

ASS´Y-CROSS FAN

RUBBER BEARING

BEARING MOTOR

ASS´Y MAIN PCB

ASS´Y- MAIN-PCB

ASS´Y-TERMISTOR

CASE CONTROL

ASS´Y BACK BODY

ASS´Y HOLDER PIPE

PLATE HANGER

COVER-TERMINAL BLOCK

PLATE-KNOCKOUT

HIPS

PP

ASS’Y

PP

POLYESTER/CARBON

POLYESTER/COTTON

ABS(V0)

HIPS

ASS’Y

ABC(BLK)

ASS´Y

MP24S

ABS

PLATE1.2(5/8”)

SLIT1.5(1/2”)

PVC

ASS’Y

ASS’Y

PP(Vo)

SECC

6P, 25A

6P, 25A

IIC-9430SKF7A

ø95 x L

CR(BLK)

ASS’Y

PD-SH30ZC-01

PD-SH30ZC-03

103AT

ABS(VO)

HIPS

ASS’Y

SGCC-M

ABS

SGCC-M

Q’TY

AS24A2RC AS18A6RC AS18A0RCD

1

2

1

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

2

1

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

2

1

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

15

Page 17

1

2

3

4

7

16

6

5

8

18

13

12

13-1

15-1

15-2

15-3

15-5

15

15-4

15-6

14-2

10

9

14-1

14

12-2

12-1

11

4-2 Outdoor Unit

4-2-1 24K BTU

17

17-1 17-2

16

Page 18

■ Parts List

No.

1

2

3

4

5

6

7

8

9

10

11

12

12-1

12-2

13

13-1

14

14-1

14-2

15

15-1

15-2

15-3

15-4

15-5

15-6

16

17-1

17-2

18

CODE NO

DB90-00652P

DB90-20210A

DB67-50074A

DB60-20020A

DB31-00027F

DB95-20147A

DB94-50039C

DB96-01917A

DB90-40176B

DB64-60160B

DB90-10616D

DB95-10339F

DB73-10008A

DB60-00028A

DB96-10637B

DB62-40055F

DB96-10635A

DB62-31842B

DB62-40039C

DB93-00680K

3501-001184

2501-001194

DB65-00040B

DB95-90026B

3601-000236

2501-000389

DB72-50622A

DB60-30010A

DB60-30010D

DB96-10670A

Description Specification Remark

Q’TY

US24A2RC

ASS’Y CABI FRONT

ASS’Y-BASE OUT

FAN-PROPELLER

BOLT SPECIAL

MOTOR FAN OUT

ASS’Y-MOTOR B/K

ASS’Y-PARTITION

ASS’Y-CONDENSER

ASS’Y-COVER-CONTROL

CABI SIDE OUT

ASS’Y-CABI UPPER

COMPRESSOR

GROMMET ISOLATOR

NUT WASHER

ASS’Y SUCTION

PACKED V/V 15.88"

ASS’Y-TUBE CAPI

TUBE CAPI(C)

PACKED V/V 6.35"

ASS’Y CONTROL OUT

POWER-RELAY

COMPOR CAPACITOR

TERMINAL BLOCK

SPARK KILLER

FUSE

MOTOR CAPACITOR

CLOTH SOUND

NUT FLANGE 6.35"

NUT FLANGE 15.88"

TUBE-DISCHARGE

SC-90073T

SC-90073T

AS+G/F20%

M8 L25

OSME-906SRC

SGCC-M

SGCC-M

ASS’Y

ABS(V5)

SC-90073T

SC-90073T

H29B26UABCA

CR

M8

ASS’Y

20LT/MIN

ASS’Y

ID 1.7 x 900 x 2

6.35 INCH

ASS’Y

UZ 2A BB220

35µFx450VAC

8P/35A

-

2A, 250V

4µF x 450VAC

G3771BD

G3771BD

-

1

1

1

1

1

1

1

1

1

1

1

1

4

4

1

1

1

1

1

1

1

1

1

1

1

1

2

2

1

17

Page 19

4-2-2 18K BTU(US18A✳RCD)

2

3

5

13-1

13

12-1

12-2

12

12-4

18

14

14-1

9

10

15-5

15-3

15-2

15-1

15-6

15-4

15

12-3

4

1

11

6

7

16

8

17

17-1 17-2

18

Page 20

15

14

10

9

12-2

12-1

13

13-1

18

5

3

2

4

11

1

6

7

16

8

12-4

12-3

15-2

15-1

15-3

15-5

15-4

15-6

12

If you need a receiver, install it at this point.

(The capacity is 255cc)

4-2-2 18K BTU(US18A✳RCD)

17

17-1 17-2

19

Page 21

■ Parts List

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

13-1

14

14-1

15

15-1

15-2

15-3

15-4

15-5

15-6

16

17-1

17-2

18

CODE NO

DB90-00652K

DB90-00653K

DB90-20210B

DB90-20160H

DB67-50063A

DB60-20020A

DB31-10119H

DB31-00056D

DB61-20008C

DB94-00080A

DB94-00165A

DB96-01914A

DB96-01523B

DB90-40176B

DB90-60160B

DB90-10671L

DB90-00429A

DB90-10613D

48B190IV1EH

48D190IU1EH

DB96-00504A

DB96-01726A

DB62-40074C

DB62-00898B

DB96-00502B

DB96-10640B

DB62-40039B

DB93-01167B

DB93-00673N

3501-001184

2501-001238

DB65-00040B

DB95-90026B

3601-000236

2301-001370

DB72-50615A

DB60-30010A

DB60-30010D

DB60-30010C

DB96-00503A

DB96-01738A

Description Specification

ASS’Y-CABI FRONT

ASS’Y-CABI FRONT

ASS’Y-BASE OUT

ASS’Y-BASE OUT

FAN-PROPELLER

BLOT SPECIAL

MOTOR FAN OUT

MOTOR FAN OUT

MOTOR B/K BASE

ASS’Y-PARTITION

ASS’Y-PARTITION

ASS’Y-CONDENSER

ASS’Y-CONDENSER

COVER-CONTROL

ASS’Y-CABI BACK

ASS’Y-CABI BACK

ASS’Y-CABI UPPER

ASS’Y-CABI UPPER

COMPRESSOR

COMPRESSOR

ASS’Y-SUCTION

ASS’Y-SUCTION

PACKED V/V 12.7"

PACKED V/V 12.7"

ASS’Y-TUBE CAPI

ASS’Y-TUBE CAPI

PACKED V/V 6.35"

ASS’Y-CONTROL OUT

ASS’Y-CONTROL OUT

POWER RELAY

CAPACITOR COMP

TERMINAL BLOCK

SPARK KILLER

FUSE

CAPACITOR MOTOR

CLOTH SOUND

NUT FLARE 6.35"

NUT FLARE 15.88"

NUT FLARE 15.88"

TUBE-DISCHARGE

TUBE-DISCHARGE

SC-90073T

SC-90073T

SC-90073T

SC-90073T

AS+G/F20%

ASS035ZTEE

ASS030ZTEC

SGCC-M

ABS(V5)

SC-90073T

SC-90073T

48B190IV1EH

48D190IU1EH

10LT/MIN, 1/2"

10LT/MIN, 1/2"

6.35 INCH

UZ 2A BB220

40uFx450VAC

8P, 35A

2A, 250V

2.5uFx450VAC

C3771BD

C3771BD

C3771BD

M8L25

ASS’Y

ASS’Y

ASS’Y

ASS’Y

ASS’Y

ASS’Y

ASS’Y

ASS’Y

ASS’Y

ASS’Y

ASS’Y

ASS’Y

-

-

-

-

Q’TY

US18A6RC US18A0RCD

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

-

-

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

20

Page 22

4-2-3 PCB Box

4

1

2

5

3

■ Parts List

No

1

2

3

4

5

Description

ASS’Y MAIN PCB

ASS’Y THERMISTOR

ASS’Y PCB DISPLAY

CASE CONTROL

COVER DISPLAY

Specification

PD-SH30ZC-03

103AT 240/240

ASS’Y

ABS

ABS

Q’TY

1

1

1

1

1

Remark

21

Page 23

MEMO

22

Page 24

5. Refrigerating Cycle Block Diagram

INDOOR UNIT

Heat

exchanger

(Evaporator)

OUTDOOR UNIT

Capillary tube

1

T

Liquid side

Cross fan

2

T

Gas side

2-way valve

3-way valve

Compressor

Heat

exchanger

(Condenser)

Propeller fan

Cooling

Gas leak check point

Refrigerating cycle temperature and pressure

STD Pressure Piping Temp(°F) Use Temp. Condition(°F)

MODEL Operating Condition (psi)

3-Way Valve DB WB DB WB

T1 T2

Standard 57~71 46~54 46~54 80 67 95 75

AS24A2RC Cooling Max over load - - - 80 67 115 75

Low temp - - - 67 57 67 57

Standard 64~78 50~54 50~54 80 67 95 75

AS18A6RC Cooling Max over load - - - 80 67 115 75

Low temp - - - 67 57 67 57

Standard 64~78 50~54 50~54 80 67 95 75

AS18A0RCD Cooling Max over load - - - 80 67 115 75

Low temp - - - 67 57 67 57

Indoor Outdoor

23

Page 25

6. PCB Diagrams

6-1 Main PCB(PD-SH30ZC-03)

24

Page 26

■ Parts List

No. Design-Location Description Specification Q’TY

1 C103 C-CERAMIC,DISC 2.2nF,20%,400V,Y5U,TP,12. 1

2 C702 C-FILM,MPPF 100nF,10%,275V,BK,18x6x12,15 1

3 CR71 C-FILM,MPPF 2000nF,+10-5%,450V,BK,38x18x 1

4 C701 C-FILM,MPEF 220NF,10%,275V,BK,26.5X8.5X1 1

5 RY71,72,74 RELAY-MINIATURE 12VDC,200MW,3000MA,1FORM 3

6 SS71 SSR 12Vdc,-,2A,1mS,1mS 1

7 IC04 IC MICOM S3C8469(SDIP) 1

8 IC02 IC-VOLT REGU KA7805A,TO-220AB,1A,0/125C, 1

9 TN11 TRANS 2UEW0.30/2UEW0.45,1.5KV,1KHz,-,7Pi 1

10 FT71 CHOKE-COIL LSA-05230P,AC250V,2A,30.5x22x3 1

11 BZ61 BUZZER CBE2220BA,STICK,-,-,-,-,-,-,- 1

12 F701 FUSE FST,250V,3.15A,20MM,VDE,50T-03 1

13 F701 HOLDER-FUSE FH-51H,7.5A,-,-,-,-,- 1

14 D101,102,103,104 DIODE-RECTIFIER 1N4007,1000V,1A,DO-41,TP 4

15 D105 DIODE-RECTIFIER UG2B,100V,2A,DO-204AC,TP 1

16 ZD12 DIODE-ZENER DIODE-ZENER;MTZ3.6A,3.6V,3.455-3.695V,50 1

17 ZD13 DIODE-ZENER DIODE-ZENER;MTZJ11B,11V,10.5-11.05V,500m 1

18 ZD11 DIODE-TVS DIODE-TVS;ST02D-200,185/200/215V,200W,DO 1

19 Q603 TR-SMALLSIGNAL TR-SMALL SIGNAL;KSA708-Y,PNP,800mW,TO-92 1

20 Q401,601,602 TR-SMALL SIGNAL TR-SMALL SIGNAL;KSC945,NPN,250mW,TO-92,T 3

21 Q901,902 TR-DIGITAL TR-DIGITAL;KSR2002,PNP,300MW,10K/10K,TO- 2

22 Q201 TR-DIGITAL TR-DIGITAL;KSR1002,NPN,300MW,10K/10K,TO- 1

23 PC11 PHOTO-COUPLER PHOTO-COUPLER;TR,50-600%,200mW,DIP-4,ST 1

24 PC12 PHOTO-COUPLER PHOTO-COUPLER;TR,20-300%,200mW,DIP-4,ST 1

25 IC01 IC-PWM CONTROLLER IC-PWM CONTROLLER;255,DIP,8P,300MIL,PLAS 1

26 VA71,72 VARISTOR 560V,2500A,17.5x7.5mm,TP 2

27 R405,406 R-CARBON 330ohm,5%,1/8W,AA,TP,1.8x3.2mm 2

28 R104,105 R-CARBON 220OHM,5%,1/4W,AA,TP,2.4X6.4MM 2

29 R101 R-CARBON 470OHM,5%,1/4W,AA,TP,2.4X6.4MM 1

30 R206,501,502,601,604,606,902 R-CARBON 10KOHM,5%,1/8W,AA,TP,1.8X3.2MM 7

31 R201,207,208,401,403,408,603,605,608 R-CARBON 1KOHM,5%,1/8W,AA,TP,1.8X3.2MM 9

32 R910,911,912,913 R-CARBON 3.3KOHM,5%,1/8W,AA,TP,1.8X3.2MM 4

33 R102,103 R-CARBON 330KOHM,5%,1/4W,AA,TP,2.4X6.4MM 2

34 R106,901 R-CARBON 4.7KOHM,5%,1/8W,AA,TP,1.8X3.2MM 2

35 R607 R-CARBON 560OHM,5%,1/4W,AA,TP,2.4X6.4MM 1

36 R402 R-CARBON 6.8KOHM,5%,1/8W,AA,TP,1.8X3.2MM 1

37 R602 R-CARBON(S) 1KOHM,5%,1/2W,AA,TP,2.4X6.4M 1

38 R202,203 R-METAL OXIDE(S) 51Kohm,5%,2W,AA,TP,4x12 2

39 R404,407 R-METAL 6.8Kohm,1%,1/8W,AA,TP,1.8x3.2m 2

40 C203,204,401 C-CERAMIC,MLC-AXIAL 10nF,+80-20%,25V,Y5V 3

41 C404,903 C-CERAMIC,MLC-AXIAL 1nF,10%,50V,Y5P,TP,1 2

42 C102,104,107,109,114,116,117,118,201, C-CERAMIC,MLC-AXIAL 100nF,+80-20%,50V,Y5 14

202,402,403,501,901

43 C105 C-AL 1000uF,20%,25V,GP,TP,10x20,5 1

44 C601 C-AL 47uF,20%,50V,GP,TP,6.3x11,2.5 1

45 C108 C-AL 470uF,20%,25V,GP,TP,10x16,5 1

46 C101,110 C-AL 6.8uF,20%,450V,GP,TP,10x16mm,5 2

47 X501 RESONATOR-CERAMIC 4MHz,0.5%,TP,10.0x5.0x 1

48 F702 FUSE-RADIAL LEAD 250V,1A,TIME-LAG,-,8.5x 1

49 CN78 CONNECTOR-HEADER 1WALL,3P/5P,1R,3.96mm,S 1

50 CN71 CONNECTOR-HEADER 1WALL,3P/5P,1R,3.96mm,S 1

51 CN73 CONNECTOR-HEADER 1WALL,3P/5P,1R,3.96mm,S 1

52 CN91 CONNECTOR-HEADER BOX,10P,1R,2.5mm,STRAIG 1

53 CN43 CONNECTOR-HEADER BOX,3P,1R,2.5mm,STRAIGH 1

54 CN41 CONNECTOR-HEADER BOX,4P,1R,2.5mm,STRAIGH 1

55 CN61 CONNECTOR-HEADER BOX,6P,1R,2.5mm,STRAIGH 1

56 IC07 IC-MASK ROM 93LC56B,8BIT,-,DIP,8P,-,-,- 1

57 IC03 IC-RESET KA7533,DIP,-,-,-,-,- 1

58 IC06 IC-DRIVE KID65003AP,DIP,16P,STICK,TR-AR 2

59 L101 COIL CHOKE 5.0mH,-,8.0*11.0,-,-,PE-M10 1

60 WIRE-SO COPPER PI0.6,SN,T,52MM,TAPING_WI 35

61 PCB-MAIN PD-SH30ZC-00,FR-1,-,-,T1.6,W197 1

25

Page 27

7. Wiring Diagrams

7-1 Indoor Unit

■ AS24A2RC/AS18A0RCD ■ AS18A6RC

26

Page 28

7-2 Outdoor Unit

■ US24A2RC/US18A0RCD

DIAGRAM-OUTDOOR

MARK NAME MARK NAME

PR POWER RELAY TB 1, 2 TERMINAL BLOCK

C1 CAPACITOR FM1 FAN MOTOR

F FUSE(2A, 250V~) S SPARK KILLER

■ US18A6RC

DIAGRAM-OUTDOOR

MARK NAME MARK NAME

PR POWER RELAY TB1, 2 TERMINAL BLOCK

F FUSE(2A, 250V~) FM1 FAN MOTOR

S SPARK KILLER

27

Page 29

8. Schematic Diagrams

8-1 Indoor Unit

2928

Page 30

MEMO

30

Page 31

MEMO

31

Page 32

MEMO

32

Page 33

ELECTRONICS

Loading...

Loading...