Page 1

AR-B1474

INDUSTRIAL GRADE

486DX/DX2/DX4 CPU CARD

User’ s Guide

Edition: 3.1

Book Number: AR-B1474-99.B01

Page 2

Page 3

AR-B1474 User¡¦s Guide

Table of Contents

0. PREFACE....................................................................................................................................................... 0-3

0.1 COPYRIGHT NOTICE AND DISCLAIMER................................................................................................................................0-3

0.2 WELCOME TO THE AR-B1474 SERIAL CPU BOARD.............................................................................................................0-3

0.3 BEFORE YOU USE THIS GUIDE...............................................................................................................................................0-3

0.4 RETURNING YOUR BOARD FOR SERVICE............................................................................................................................0-3

0.5 TECHNICAL SUPPORT AND USER COMMENTS...................................................................................................................0-3

0.6 ORGANIZATION..........................................................................................................................................................................0-4

0.7 STATIC ELECTRICITY PRECAUTIONS....................................................................................................................................0-4

1. OVERVIEW..................................................................................................................................................... 1-1

1.1 INTRODUCTION.........................................................................................................................................................................1-1

1.2 PACKING LIST............................................................................................................................................................................1-2

1.3 FEATURES..................................................................................................................................................................................1-2

2. SYSTEM CONTROLLER ................................................................................................................................ 2-1

2.1 DMA CONTROLLER...................................................................................................................................................................2-1

2.2 KEYBOARD CONTROLLER.........................................................................................................................................................2-1

2.3 INTERRUPT CONTROLLER......................................................................................................................................................2-2

2.3.1 I/O Port Address Map..........................................................................................................................................................2-3

2.3.2 Real-Time Clock and Non-Volatile RAM ............................................................................................................................2-4

2.3.3 Timer....................................................................................................................................................................................2-4

2.3.4 ISA Bus Pin Assignment .....................................................................................................................................................2-5

2.3.5 ISA Bus Signal Description.................................................................................................................................................2-6

2.4 SERIAL PORT.............................................................................................................................................................................2-7

2.5 PARALLEL PORT........................................................................................................................................................................2-9

3. SETTING UP THE SYSTEM............................................................................................................................ 3-1

3.1 OVERVIEW..................................................................................................................................................................................3-1

3.2 SYSTEM SETTING .....................................................................................................................................................................3-2

3.2.1 Serial Port............................................................................................................................................................................3-2

3.2.2 Hard Disk (IDE) Connector (CN1).......................................................................................................................................3-3

3.2.3 Power Connector (J5) .........................................................................................................................................................3-3

3.2.4 FDD Port Connector (CN2).................................................................................................................................................3-4

3.2.5 Parallel Port Connector (CN3)............................................................................................................................................3-4

3.2.6 PC/104 Connector...............................................................................................................................................................3-5

3.2.7 CPU Setting.........................................................................................................................................................................3-7

3.2.8 Memory Setting....................................................................................................................................................................3-9

3.2.9 LED Header (J1, J2 & J4).................................................................................................................................................3-10

3.2.10 Keyboard Connector.....................................................................................................................................................3-10

3.2.11 External Speaker Header (J3)......................................................................................................................................3-11

3.2.12 Reset Header (J7).........................................................................................................................................................3-11

3.2.13 Battery Setting...............................................................................................................................................................3-11

3.2.14 CRT Display Type Select (JP13)..................................................................................................................................3-11

4. INSTALLATION.............................................................................................................................................. 4-1

4.1 OVERVIEW..................................................................................................................................................................................4-1

4.2 UTILITY DISKETTE.....................................................................................................................................................................4-2

4.3 WRITE PROTECT FUNCTION...................................................................................................................................................4-5

4.3.1 Hardware Write Protect.......................................................................................................................................................4-5

4.3.2 Software Write Protect ........................................................................................................................................................4-5

4.3.3 Enable the Software Write Protect......................................................................................................................................4-5

4.3.4 Disable the Software Write Protect.....................................................................................................................................4-5

4.4 WATCHDOG TIMER...................................................................................................................................................................4-6

4.4.1 Watchdog Timer Setting......................................................................................................................................................4-6

4.4.2 Watchdog Timer Enabled....................................................................................................................................................4-7

4.4.3 Watchdog Timer Trigger......................................................................................................................................................4-7

4.4.4 Watchdog Timer Disabled ...................................................................................................................................................4-7

5. SOLID STATE DISK ....................................................................................................................................... 5-1

5.1 OVERVIEW..................................................................................................................................................................................5-1

5.2 SWITCH SETTING......................................................................................................................................................................5-1

5.2.1 Overview..............................................................................................................................................................................5-2

5.2.2 I/O Port Address Select (SW1-1 & SW1-2)........................................................................................................................5-2

5.2.3 SSD Firmware Address Select (SW1-3 & SW1-4).............................................................................................................5-2

5.2.4 SSD Drive Number (SW1-5 & SW1-6) ...............................................................................................................................5-3

5.2.5 ROM Type Select (SW1-7 & SW1-8)..................................................................................................................................5-4

5.3 JUMPER SETTING .....................................................................................................................................................................5-5

5.3.1 SSD BIOS Select (JP7).......................................................................................................................................................5-5

5.3.2 SSD Memory Type Setting (M1 ~ M3 & JP5).....................................................................................................................5-6

0-1

Page 4

AR-B1474 User¡¦s Guide

5.4 ROM DISK INSTALLATION........................................................................................................................................................5-6

5.4.1 UV EPROM (27Cxxx)..........................................................................................................................................................5-6

5.4.2 Large Page 5V FLASH Disk................................................................................................................................................5-8

5.4.3 Small Page 5V FLASH ROM Disk......................................................................................................................................5-9

5.4.4 RAM Disk...........................................................................................................................................................................5-11

5.4.5 Combination of ROM and RAM Disk................................................................................................................................5-12

5.5 INSTALLATION D.O.C..............................................................................................................................................................5-12

5.5.1 Hardware Setting...............................................................................................................................................................5-12

5.5.2 Software Setting................................................................................................................................................................5-13

6. BIOS CONSOLE............................................................................................................................................. 6-1

6.1 BIOS SETUP OVERVIEW ..........................................................................................................................................................6-1

6.2 STANDARD CMOS SETUP........................................................................................................................................................6-2

6.3 ADVANCED CMOS SETUP........................................................................................................................................................6-3

6.4 ADVANCED CHIPSET SETUP...................................................................................................................................................6-5

6.5 POWER MANAGEMENT............................................................................................................................................................6-6

6.6 AUTO-DETECT HARD DISKS....................................................................................................................................................6-7

6.7 PASSWORD SETTING...............................................................................................................................................................6-7

6.7.1 Setting Password.................................................................................................................................................................6-7

6.7.2 Password Checking.............................................................................................................................................................6-7

6.8 LOAD DEFAULT SETTING.........................................................................................................................................................6-7

6.8.1 Auto Configuration with Optimal Setting.............................................................................................................................6-7

6.8.2 Auto Configuration with Fail Safe Setting...........................................................................................................................6-7

6.9 BIOS EXIT....................................................................................................................................................................................6-8

6.9.1 Save Settings and Exit........................................................................................................................................................6-8

6.9.2 Exit Without Saving .............................................................................................................................................................6-8

7. SPECIFICATIONS .......................................................................................................................................... 7-1

8. PLACEMENT & DIMENSIONS ........................................................................................................................ 8-1

8.1 PLACEMENT...............................................................................................................................................................................8-1

8.2 DIMENSIONS ..............................................................................................................................................................................8-2

9. MEMORY BANKS & PROGRAMMING RS-485............................................................................................... 9-1

9.1 USING MEMORY BANK.............................................................................................................................................................9-1

9.2 PROGRAMMING RS-485 ...........................................................................................................................................................9-2

10. SSD TYPES SUPPORTED & INDEX ..........................................................................................................10-1

10.1 SSD TYPES SUPPORTED...................................................................................................................................................10-1

10.2 INDEX....................................................................................................................................................................................10-3

0-2

Page 5

AR-B1474 User¡¦s Guide

0. PREFACE

0.1 COPYRIGHT NOTICE AND DISCLAIMER

September 1995

Acrosser Technology makes no representations or warranties with respect to the contents hereof and specifically

disclaims any implied warranties of merchantability or fitness for any particular purpose. Furthermore, Acrosser

Technology reserves the right to revise this publication and to make changes from time to time in the contents

hereof without obligation of Acrosser Technology to notify any person of such revisions or changes.

Possession, use, or copying of the software described in this publication is authorized only pursuant to a valid

written license from Acrosser or an authorized sublicensor.

(C) Copyright Acrosser Technology Co., Ltd., 1995. All rights Reserved.

No part of this publication may be reproduced, transmitted, transcribed, stored in a retrieval system, or translated

into any language or computer language, in any form or any means, electronic, mechanical, magnetic, optical,

chemical, manual or otherwise, without the prior written consent of Acrosser Technology.

Acrosser, IBM, INTEL, AMD, CYRIX, AMI, MS-DOS, PC-DOS, DR-DOS, X-DOS…are registered trademarks.

All other trademarks and registered trademarks are the property of their respective holders.

This document was produced with Adobe Acrobat 3.01.

0.2 WELCOME TO THE AR-B1474 SERIAL CPU BOARD

This guide introduces the Acrosser AR-B1474 serial CPU board.

Use the information describes this card’ s functions, features, and how to start, set up and operate your AR-B1474

serial CPU board. You also could find general system information here.

0.3 BEFORE YOU USE THIS GUIDE

If you have not already installed this AR-B1474, refer to the Chapter 3, “Setting Up the System” in this guide.

Check the packing list, make sure the accessories in the package.

AR-B1474 diskette provides the newest information about the card. Please refer to the README.DOC file of

the enclosed utility diskette. It contains the modification and hardware & software information, and adding the

description or modification of product function after manual published.

0.4 RETURNING YOUR BOARD FOR SERVICE

If your board requires servicing, contact the dealer from whom you purchased the product for service information.

If you need to ship your board to us for service, be sure it is packed in a protective carton. We recommend that

you keep the original shipping container for this purpose.

You can help assure efficient servicing of your product by following these guidelines:

1. Include your name, address, telephone and facsimile number where you may be reached during the day.

2. A description of the system configuration and/or software at the time is malfunction.

3. A brief description is in the symptoms.

0.5 TECHNICAL SUPPORT AND USER COMMENTS

User’ s comments are always welcome as they assist us in improving the usefulness of our products and the

understanding of our publications. They form a very important part of the input used for product enhancement

and revision.

We may use and distribute any of the information you supply in any way we believe appropriate without incurring

any obligation. You may, of course, continue to use the information you supply.

If you have suggestions for improving particular sections or if you find any errors, please indicate the manual title

and book number.

Please send your comments to Acrosser Technology Co., Ltd. or your local sales representative.

Internet electronic mail to: webmaster@acrosser.com

0-3

Page 6

AR-B1474 User¡¦s Guide

0.6 ORGANIZATION

This information for users covers the following topics (see the Table of Contents for a detailed listing):

l Chapter 1, “Overview”, provides an overview of the system features and packing list.

l Chapter 2, “System Controller” describes the major structure.

l Chapter 3, “Setting Up the System”, describes how to adjust the jumper, and the connectors setting.

l Chapter 4, “Installation”, describes setup procedures including information on the utility diskette.

l Chapter 5, “Solid State Disk,” describes the various type SSD’ s installation steps.

l Chapter 6, “BIOS Console”, providing the BIOS options setting.

l Chapter 7, Specifications

l Chapter 8, Placement & Dimensions

l Chapter 9, Memory Banks & Programming RS-485

l Chapter 10, SSD Types Supported & Index

0.7 STATIC ELECTRICITY PRECAUTIONS

Before removing the board from its anti-static bag, read this section about static electricity precautions.

Static electricity is a constant danger to computer systems. The charge that can build up in your body may be

more than sufficient to damage integrated circuits on any PC board. It is, therefore, important to observe basic

precautions whenever you use or handle computer components. Although areas with humid climates are much

less prone to static build-up, it is always best to safeguard against accidents may result in expensive repairs. The

following measures should generally be sufficient to protect your equipment from static discharge:

• Touch a grounded metal object to discharge the static electricity in your body (or ideally, wear a grounded

wrist strap).

• When unpacking and handling the board or other system component, place all materials on an antic static

surface.

• Be careful not to touch the components on the board, especially the “golden finger” connectors on the bottom

of every board.

0-4

Page 7

AR-B1474 User¡¦s Guide

1. OVERVIEW

This chapter provides an overview of your system features and capabilities. The following topics are covered:

l Introduction

l Packing List

l Features

1.1 INTRODUCTION

The AR-B1474 is a half size industrial grade CPU card that has been designed to withstand continuous operation

in harsh environments. The total on-board memory for the AR-B1474 can be configured from 1MB to 32MB by

using all 72-pin type DRAM devices.

The 8 layers PCB CPU card is equipped with a IDE HDD interface, a floppy disk drive adapter, 1 parallel port, 2

serial ports, a watchdog timer and a solid state disk. Its dimensions are as compact as 122mm x 185mm. It’ s

highly condensed features make it an ideal cost/performance solution for high-end commercial and industrial

applications where CPU speed and mean time between failure is critical.

The AR-B1474 provides 2 bus interfaces, ISA bus and PC/104 compatible expansion bus. Based on the PC/104

expansion bus, you could easy install thousands of PC/104 module from hundreds venders around the world. You

could also directly connect the power supply to the AR-B1474 on-board power connector in stand alone

applications.

A watchdog timer, which has a software programmable time-out interval, is also provided on this CPU card. It

ensures that the system will not hang-up if a program can not execute normally.

For diskless application, the AR-B1474 provides up to 3MB of bootable ROM, FLASH, or SRAM disk space by

using 64K x 8 to 1M x 8 memory chips.

The AR-B1474 is implemented with M1429 and M1431 chipset incorporate a memory controller, parity generation

and checking, two 8237 DMA controllers, two 8259 interrupt controllers, one 8254 timer/counter, an address buffer

and a data buffer.

A super I/O chip (SMC37C669) is embedded in the AR-B1474 card. It combines functions of a floppy disk drive

adapter, a hard disk drive (IDE) adapter, two serial (with 16C550 UART) adapters and 1 parallel adapter.

The I/O port configurations can be done by setting the BIOS setup program.

As an UART, the chip supports serial to parallel conversion on data characters received from a peripheral device

or a MODEM , and parallel to serial conversion on data character received from the CPU. The UART includes a

programmable baud rate generator, complete MODEM control capability and a processor interrupt system. As a

parallel port, the SMC37C669 provides the user with a fully bi-directional parallel centronics-type printer interface.

This manual has been written to assist you in installing, configuring and running the AR-B1474 CPU card. Each

section is intended to guide you through it’ s procedures clearly and concisely, allowing you to continue to the next

chapters without any difficulty.

1-1

Page 8

AR-B1474 User¡¦s Guide

1.2 PACKING LIST

The accessories are included with the system. Before you begin installing your AR-B1474 card, take a moment to

make sure that the following items have been included inside the AR-B1474 package.

l The quick setup manual

l 1 AR-B1474 all-in-one CPU card

l 1 Keyboard adapter cable

l 1 Parallel port interface cable

l 1 Hard disk drive interface cable

l 1 Floppy disk drive interface cable

l 1 40-pin header for PC/104 adapter

l 1 64-pin header for PC/104 adapter

l 1 Software utility diskettes

NOTE: If there are any discrepancies, please contact your Acrosser distributor immediately.

1.3 FEATURES

The system provides a number of special features that enhance its reliability, ensure its availability, and improve its

expansion capabilities, as well as its hardware structure.

l All-in-one designed 486DX/DX2/DX4 CPU card

l Support 3.3V/5V CPU with voltage regulator

l Support ISA bus and PC/104 bus

l Support 128KB to 512KB second level cache on-board

l Support up to 32MB DRAM on-board

l Support shadow memory and EMS

l Legal AMI BIOS

l IDE hard disk drive interface

l Floppy disk drive interface

l Bi-direction parallel interface

l 2 serial ports with 16C550 UART

l DS12887 or compatible RTC

l Programmable watchdog timer

l Up to 3MB solid state disk (SSD)

l On-board build-in buzzer

l 8 layers PCB

1-2

Page 9

AR-B1474 User¡¦s Guide

2. SYSTEM CONTROLLER

This chapter describes the major structure of the AR-B1474 serial CPU board. The following topics are covered:

l DMA Controller

l Keyboard Controller

l Interrupt Controller

l Serial Port

l Parallel Port

2.1 DMA CONTROLLER

The equivalent of two 8237A DMA controllers are implemented in the AR-B1474 card. Each controller is a fourchannel DMA device that will generate the memory addresses and control signals necessary to transfer

information directly between a peripheral device and memory. This allows high-speed information transfer with less

CPU intervention. The two DMA controllers are internally cascaded to provide four DMA channels for transfers to

8-bit peripherals (DMA1) and three channels for transfers to 16-bit peripherals (DMA2). DMA2 channel 0 provides

the cascade interconnection between the two DMA devices, thereby maintaining IBM PC/AT compatibility.

Following is the system information of DMA channels:

DMA Controller 1 DMA Controller 2

Channel 0: Spare Channel 4: Cascade for controller 1

Channel 1: IBM SDLC Channel 5: Spare

Channel 2: Diskette adapter Channel 6: Spare

Channel 3: Spare Channel 7: Spare

Table 2-1 DMA Channel Controller

2.2 KEYBOARD CONTROLLER

The 8042 processor is programmed to support the serial keyboard serial interface. The keyboard controller

receives serial data from the keyboard, checks its parity, translates scan codes, and presents it to the system as a

byte data in its output buffer. The controller can interrupt the system when data is placed in its output buffer, or

wait for the system to poll its status register to determine when data is available.

Data can be written to the keyboard by writing data to the output buffer of the keyboard controller.

Each byte of data is sent to the keyboard controller in series with an odd parity bit automatically inserted. The

keyboard controller is required to acknowledge all data transmissions. Therefore, another byte of data will not be

sent to keyboard controller until acknowledgment is received for the previous byte sent. The “output buffer full”

interrupt may be used for both send and receive routines.

2-1

Page 10

AR-B1474 User¡¦s Guide

2.3 INTERRUPT CONTROLLER

The equivalent of two 8259 Programmable Interrupt Controllers (PIC) are included on the AR-B1474 card. They

accept requests from peripherals, resolve priorities on pending interrupts in service, issue interrupt requests to the

CPU, and provide vectors which are used as acceptance indices by the CPU to determine which interrupt service

routine to execute.

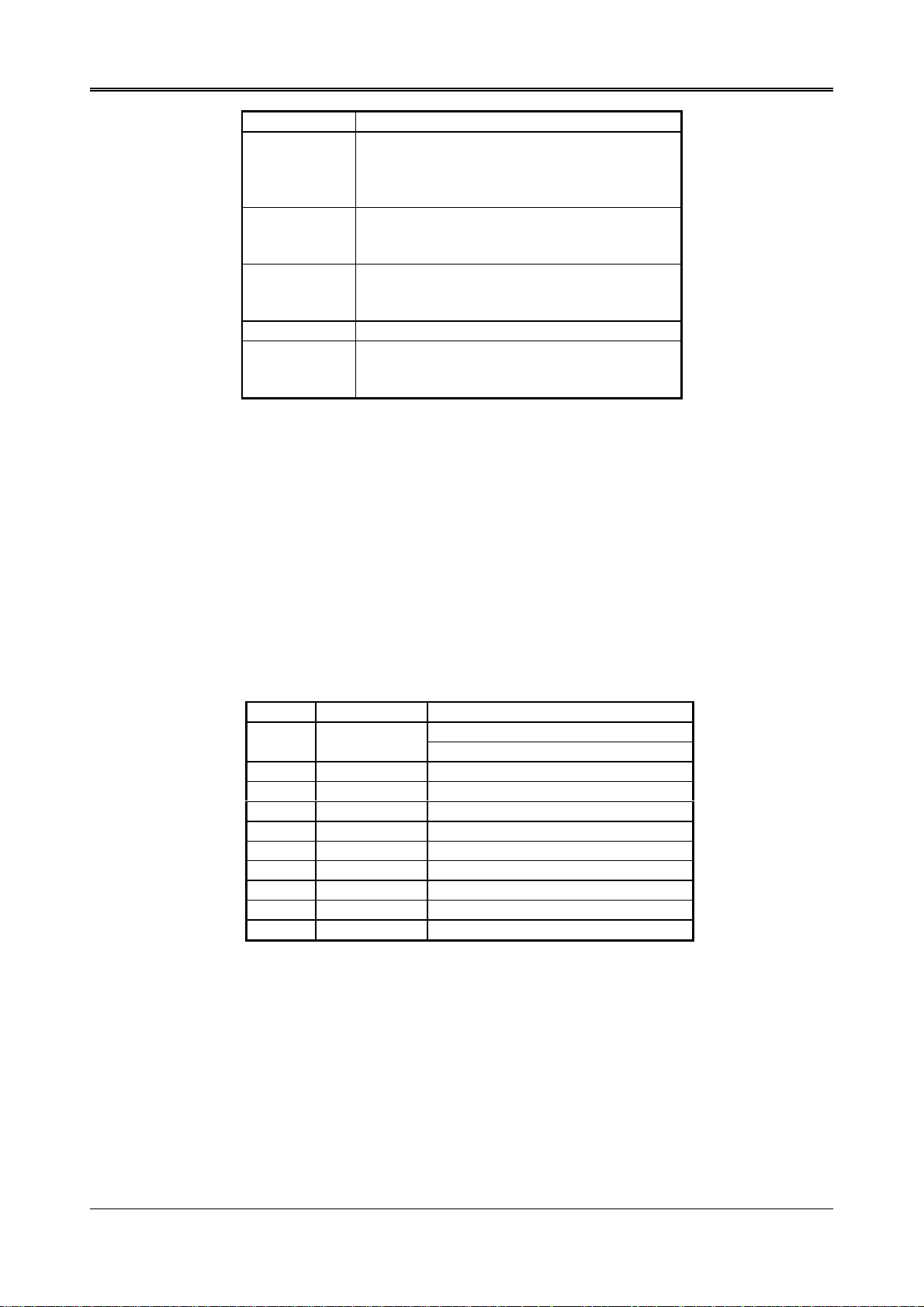

Following is the system information of interrupt levels:

InInterrupt Level

NMI

CTRL1

IRQ 0

IRQ 1

IRQ 2

IRQ 3

IRQ 4

IRQ 5

IRQ 6

IRQ 7

Description

Parity check

CTRL2

System timer interrupt from timer 8254

Keyboard output buffer full

IRQ8 : Real time clock

IRQ9 : Rerouting to INT 0Ah from hardware IRQ2

IRQ10 : Spare

IRQ11 : Spare

IRQ12 : Spare

IRQ13 : Math. coprocessor

IRQ14 : Hard disk adapter

IRQ15 : Spare (Watchdog Timer)

Serial port 2

Serial port 1

Parallel port 2

Floppy disk adapter

Parallel port 1

Figure 2-1 Interrupt Controller

2-2

Page 11

2.3.1 I/O Port Address Map

Hex Range Device

000-01F DMA controller 1

020-021 Interrupt controller 1

022-023 M1429 chipset address

040-04F Timer 1

050-05F Timer 2

060-06F 8042 keyboard/controller

070-071 Real-time clock (RTC), non-maskable interrupt (NMI)

080-09F DMA page registers

0A0-0A1 Interrupt controller 2

0C0-0DF DMA controller 2

0F0 Clear Math Co-processor

0F1 Reset Math Co-processor

0F8-0FF Math Co-processor

170-178 Fixed disk 1

1F0-1F8 Fixed disk 0

201 Game port

208-20A EMS register 0

210-213 SSD

214-215 Watchdog

218-21A EMS register 1

278-27F Parallel printer port 3 (LPT 3)

290-293 SSD

294-295 Watchdog

2E8-2EF Serial port 4 (COM 4)

2F8-2FF Serial port 2 (COM 2)

310-313 SSD

314-315 Watchdog

378-37F Parallel printer port 2 (LPT 2)

380-38F SDLC, bisynchronous 2

390-393 SSD

394-395 Watchdog

3A0-3AF Bisynchronous 1

3B0-3BF Monochrome display and printer port 1 (LPT 1)

3C0-3CF EGA/VGA adapter

3D0-3DF Color/graphics monitor adapter

3E8-3EF Serial port 3 (COM 3)

3F0-3F7 Diskette controller

3F8-3FF Serial port 1 (COM 1)

Table 2-2 I/O Port Address Map

AR-B1474 User¡¦s Guide

2-3

Page 12

AR-B1474 User¡¦s Guide

2.3.2 Real-Time Clock and Non-Volatile RAM

The AR-B1474 contains a real-time clock compartment that maintains the date and time in addition to storing

configuration information about the computer system. It contains 14 bytes of clock and control registers and 114

bytes of general purpose RAM. Because of the use of CMOS technology, it consumes very little power and can be

maintained for long period of time using an internal Lithium battery. The contents of each byte in the CMOS RAM

are listed as follows:

Address Description

00 Seconds

01 Second alarm

02 Minutes

03 Minute alarm

04 Hours

05 Hour alarm

06 Day of week

07 Date of month

08 Month

09 Year

0A Status register A

0B Status register B

0C Status register C

0D Status register D

0E Diagnostic status byte

0F Shutdown status byte

10 Diskette drive type byte, drive A and B

11 Fixed disk type byte, drive C

12 Fixed disk type byte, drive D

13 Reserved

14 Equipment byte

15 Low base memory byte

16 High base memory byte

17 Low expansion memory byte

18 High expansion memory byte

19-2D Reserved

2E-2F 2-byte CMOS checksum

30 Low actual expansion memory byte

31 High actual expansion memory byte

32 Date century byte

33 Information flags (set during power on)

34-7F Reserved for system BIOS

Table 2-3 Real-Time Clock & Non-Volatile RAM

2.3.3 Timer

The AR-B1474 provides three programmable timers, each with a timing frequency of 1.19 MHz.

Timer 0 The output of this timer is tied to interrupt request 0. (IRQ 0)

Timer 1 This timer is used to trigger memory refresh cycles.

Timer 2 This timer provides the speaker tone.

Application programs can load different counts into this timer to generate various sound frequencies.

2-4

Page 13

2.3.4 ISA Bus Pin Assignment

I/O Pin Signal Name Input/Output I/O Pin Signal Name Input/Output

A1 -IOCHCK Input B1 GND Ground

A2 SD7 Input/Output B2 RSTDRV Output

A3 SD6 Input/Output B3 +5V Power

A4 SD5 Input/Output B4 IRQ9 Input

A5 SD4 Input/Output B5 -5V Power

A6 SD3 Input/Output B6 DRQ2 Input

A7 SD2 Input/Output B7 -12V Power

A8 SD1 Input/Output B8 -ZWS Input

A9 SD0 Input/Output B9 +12V Power

A10 IOCHRDY Input B10 GND Ground

A11 AEN Output B11 -SMEMW Output

A12 SA19 Input/Output B12 -SMEMR Output

A13 SA18 Input/Output B13 -IOW Input/Output

A14 SA17 Input/Output B14 -IOR Input/Output

A15 SA16 Input/Output B15 -DACK3 Output

A16 SA15 Input/Output B16 DRQ3 Input

A17 SA14 Input/Output B17 -DACK1 Output

A18 SA13 Input/Output B18 DRQ1 Input

A19 SA12 Input/Output B19 -REFRESH Input/Output

A20 SA11 Input/Output B20 BUSCLK Output

A21 SA10 Input/Output B21 IRQ7 Input

A22 SA9 Input/Output B22 IRQ6 Input

A23 SA8 Input/Output B23 IRQ5 Input

A24 SA7 Input/Output B24 IRQ4 Input

A25 SA6 Input/Output B25 IRQ3 Input

A26 SA5 Input/Output B26 -DACK2 Output

A27 SA4 Input/Output B27 TC Output

A28 SA3 Input/Output B28 BALE Output

A29 SA2 Input/Output B29 +5V Power

A30 SA1 Input/Output B30 OSC Output

A31 SA0 Input/Output B31 GND Ground

Table 2-4 ISA Bus Pin Assignment

AR-B1474 User¡¦s Guide

I/O Pin Signal Name Input/Output I/O Pin Signal Name Input/Output

C1 SBHE Input/Output D1 -MEMCS16 Input

C2 LA23 Input/Output D2 -IOCS16 Input

C3 LA22 Input/Output D3 IRQ10 Input

C4 LA21 Input/Output D4 IRQ11 Input

C5 LA20 Input/Output D5 IRQ12 Input

C6 LA19 Input/Output D6 IRQ15 Input

C7 LA18 Input/Output D7 IRQ14 Input

C8 LA17 Input/Output D8 -DACK0 Output

C9 -MEMR Input/Output D9 DRQ0 Input

C10 -MEMW Input/Output D10 -DACK5 Output

C11 SD8 Input/Output D11 DRQ5 Input

C12 SD9 Input/Output D12 -DACK6 Output

C13 SD10 Input/Output D13 DRQ6 Input

C14 SD11 Input/Output D14 -DACK7 Output

C15 SD12 Input/Output D15 DRQ7 Input

C16 SD13 Input/Output D16 +5V Power

C17 SD14 Input/Output D17 -MASTER Input

C18 SD15 Input/Output D18 GND Ground

Table 2-5 ISA Bus Pin Assignment

2-5

Page 14

AR-B1474 User¡¦s Guide

2.3.5 ISA Bus Signal Description

Name Description

BUSCLK [Output] The BUSCLK signal of the I/O channel is asynchronous to

the CPU clock.

RSTDRV [Output] This signal goes high during power-up, low line-voltage or

hardware reset

SA0 - SA19

[Input / Output]

LA17 - LA23

[Input/Output]

SD0 - SD15

[Input/Output]

BALE [Output] The Buffered Address Latch Enable is used to latch SA0 -

-IOCHCK [Input] The I/O Channel Check is an active low signal which

IOCHRDY

[Input, Open

collector]

IRQ 3-7, 9-12, 14, 15

-IOR

[Input/Output]

-IOW [Input/Output] The I/O write signal is an active low signal which instructs

-SMEMW [Output] The System Memory Read is low while any of the low 1

-MEMR

[Input/Output]

-SMEMW [Output] The System Memory Write is low while any of the low 1

-MEMW

[Input/Output]

DRQ 0-3, 5-7

[Input]

-DACK 0-3, 5-7

[Output]

AEN [output] The DMA Address Enable is high when the DMA

-REFRESH

[Input/Output]

TC [Output] Terminal Count provides a pulse when the terminal count

SBHE

[Input/Output]

The System Address lines run from bit 0 to 19. They are

latched onto the falling edge of "BALE"

The Unlatched Address line run from bit 17 to 23

System Data bit 0 to 15

SA19 onto the falling edge. This signal is forced high

during DMA cycles

indicates that a parity error exist on the I/O board

This signal lengthens the I/O, or memory read/write cycle,

and should be held low with a valid address

The Interrupt Request signal indicates I/O service request

[Input]

attention. They are prioritized in the following sequence :

(Highest) IRQ 9, 10, 11, 12, 13, 15, 3, 4, 5, 6, 7 (Lowest)

The I/O Read signal is an active low signal which instructs

the I/O device to drive its data onto the data bus

the I/O device to read data from the data bus

mega bytes of memory are being used

The Memory Read signal is low while any memory

location is being read

mega bytes of memory is being written

The Memory Write signal is low while any memory

location is being written

DMA Request channels 0 to 3 are for 8-bit data transfers.

DMA Request channels 5 to 7 are for 16-bit data

transfers. DMA request should be held high until the

corresponding DMA has been completed. DMA request

priority is in the following sequence:(Highest) DRQ 0, 1, 2,

3, 5, 6, 7 (Lowest)

The DMA Acknowledges 0 to 3, 5 to 7 are the

corresponding acknowledge signals for DRQ 0 to 3 and 5

to 7

controller is driving the address bus. It is low when the

CPU is driving the address bus

This signal is used to indicate a memory refresh cycle and

can be driven by the microprocessor on the I/O channel

for any DMA channel is reached

The System Bus High Enable indicates the high byte SD8

- SD15 on the data bus

2-6

Page 15

AR-B1474 User¡¦s Guide

Name Description

-MASTER [Input] The MASTER is the signal from the I/O processor which

gains control as the master and should be held low for a

maximum of 15 microseconds or system memory may be

lost due to the lack of refresh

-MEMCS16

[Input, Open

collector]

-IOCS16

[Input, Open

collector]

OSC [Output] The Oscillator is a 14.31818 MHz signal

ZWS

[Input, Open

collector]

The Memory Chip Select 16 indicates that the present

data transfer is a 1-wait state, 16-bit data memory

operation

The I/O Chip Select 16 indicates that the present data

transfer is a 1-wait state, 16-bit data I/O operation

The Zero Wait State indicates to the microprocessor that

the present bus cycle can be completed without inserting

additional wait cycle

Table 2-6 ISA Bus Signal Description

2.4 SERIAL PORT

The ACEs (Asynchronous Communication Elements ACE1 to ACE2) are used to convert parallel data to a serial

format on the transmit side and convert serial data to parallel on the receiver side. The serial format, in order of

transmission and reception, is a start bit, followed by five to eight data bits, a parity bit (if programmed) and one,

one and half (five-bit format only) or two stop bits. The ACEs are capable of handling divisors of 1 to 65535, and

produce a 16x clock for driving the internal transmitter logic.

Provisions are also included to use this 16x clock to drive the receiver logic. Also included in the ACE a completed

MODEM control capability, and a processor interrupt system that may be software tailored to the computing time

required handle the communications link.

The following table is summary of each ACE accessible register

DLAB Port Address Register

Receiver buffer (read)0 base + 0

Transmitter holding register (write)

0 base + 1 Interrupt enable

X base + 2 Interrupt identification (read only)

X base + 3 Line control

X base + 4 MODEM control

X base + 5 Line status

X base + 6 MODEM status

X base + 7 Scratched register

1 base + 0 Divisor latch (least significant byte)

1 base + 1 Divisor latch (most significant byte)

Table 2-7 ACE Accessible Registers

(1) Receiver Buffer Register (RBR)

Bit 0-7: Received data byte (Read Only)

(2) Transmitter Holding Register (THR)

Bit 0-7: Transmitter holding data byte (Write Only)

2-7

Page 16

AR-B1474 User¡¦s Guide

Word Length

(3) Interrupt Enable Register (IER)

Bit 0: Enable Received Data Available Interrupt (ERBFI)

Bit 1: Enable Transmitter Holding Empty Interrupt (ETBEI)

Bit 2: Enable Receiver Line Status Interrupt (ELSI)

Bit 3: Enable MODEM Status Interrupt (EDSSI)

Bit 4: Must be 0

Bit 5: Must be 0

Bit 6: Must be 0

Bit 7: Must be 0

(4) Interrupt Identification Register (IIR)

Bit 0: “0” if Interrupt Pending

Bit 1: Interrupt ID Bit 0

Bit 2: Interrupt ID Bit 1

Bit 3: Must be 0

Bit 4: Must be 0

Bit 5: Must be 0

Bit 6: Must be 0

Bit 7: Must be 0

(5) Line Control Register (LCR)

Bit 0: Word Length Select Bit 0 (WLS0)

Bit 1: Word Length Select Bit 1 (WLS1)

WLS1 WLS0

0 0 5 Bits

0 1 6 Bits

1 0 7 Bits

1 1 8 Bits

Bit 2: Number of Stop Bit (STB)

Bit 3: Parity Enable (PEN)

Bit 4: Even Parity Select (EPS)

Bit 5: Stick Parity

Bit 6: Set Break

Bit 7: Divisor Latch Access Bit (DLAB)

(6) MODEM Control Register (MCR)

Bit 0: Data Terminal Ready (DTR)

Bit 1: Request to Send (RTS)

Bit 2: Out 1 (OUT 1)

Bit 3: Out 2 (OUT 2)

Bit 4: Loop

Bit 5: Must be 0

Bit 6: Must be 0

Bit 7: Must be 0

(7) Line Status Register (LSR)

Bit 0: Data Ready (DR)

Bit 1: Overrun Error (OR)

Bit 2: Parity Error (PE)

Bit 3: Framing Error (FE)

Bit 4: Break Interrupt (BI)

Bit 5: Transmitter Holding Register Empty (THRE)

Bit 6: Transmitter Shift Register Empty (TSRE)

Bit 7: Must be 0

2-8

Page 17

(8) MODEM Status Register (MSR)

Bit 0: Delta Clear to Send (DCTS)

Bit 1: Delta Data Set Ready (DDSR)

Bit 2: Training Edge Ring Indicator (TERI)

Bit 3: Delta Receive Line Signal Detect (DSLSD)

Bit 4: Clear to Send (CTS)

Bit 5: Data Set Ready (DSR)

Bit 6: Ring Indicator (RI)

Bit 7: Received Line Signal Detect (RSLD)

(9) Divisor Latch (LS, MS)

LS MS

Bit 0: Bit 0 Bit 8

Bit 1: Bit 1 Bit 9

Bit 2: Bit 2 Bit 10

Bit 3: Bit 3 Bit 11

Bit 4: Bit 4 Bit 12

Bit 5: Bit 5 Bit 13

Bit 6: Bit 6 Bit 14

Bit 7: Bit 7 Bit 15

AR-B1474 User¡¦s Guide

Table 2-8 Serial Port Divisor Latch

2.5 PARALLEL PORT

(1) Register Address

Table 2-9 Registers’ Address

Desired Baud Rate Divisor Used to Generate 16x Clock

300 384

600 192

1200 96

1800 64

2400 48

3600 32

4800 24

9600 12

14400 8

19200 6

28800 4

38400 3

57600 2

115200 1

Port Address Read/Write Register

base + 0 Write Output data

base + 0 Read Input data

base + 1 Read Printer status buffer

base + 2 Write Printer control latch

(2) Printer Interface Logic

The parallel portion of the SMC37C669 makes the attachment of various devices that accept eight bits of parallel

data at standard TTL level.

2-9

Page 18

AR-B1474 User¡¦s Guide

(3) Data Swapper

The system microprocessor can read the contents of the printer’ s Data Latch through the Data Swapper by reading

the Data Swapper address.

(4) Printer Status Buffer

The system microprocessor can read the printer status by reading the address of the Printer Status Buffer. The bit

definitions are described as follows:

1234567 0

X X X

-ERROR

SLCT

PE

-ACK

-BUSY

Figure 2-2 Printer Status Buffer

NOTE: X presents not used.

Bit 7: This signal may become active during data entry, when the printer is off-line during printing, or when the

print head is changing position or in an error state. When Bit 7 is active, the printer is busy and can not

accept data.

Bit 6: This bit represents the current state of the printer’ s ACK signal. A 0 means the printer has received the

character and is ready to accept another. Normally, this signal will be active for approximately 5

microseconds before receiving a BUSY message stops.

Bit 5: A 1 means the printer has detected the end of the paper.

Bit 4: A 1 means the printer is selected.

Bit 3: A 0 means the printer has encountered an error condition.

(5) Printer Control Latch & Printer Control Swapper

The system microprocessor can read the contents of the printer control latch by reading the address of printer

control swapper. Bit definitions are as follows:

1234567 0

X X

STROBE

AUTO FD XT

INIT

SLDC IN

IRQ ENABLE

DIR(write only)

Figure 2-3 Bit’ s Definition

NOTE: X presents not used.

Bit 5: Direction control bit. When logic 1, the output buffers in the parallel port are disabled allowing data driven

from external sources to be read; when logic 0, they work as a printer port. This bit is write only.

Bit 4: A 1 in this position allows an interrupt to occur when ACK changes from low state to high state.

Bit 3: A 1 in this bit position selects the printer.

Bit 2: A 0 starts the printer (50 microseconds pulse, minimum).

Bit 1: A 1 causes the printer to line-feed after a line is printed.

Bit 0: A 0.5 microsecond minimum highly active pulse clocks data into the printer. Valid data must be present

for a minimum of 0.5 microseconds before and after the strobe pulse.

2-10

Page 19

AR-B1474 User¡¦s Guide

3. SETTING UP THE SYSTEM

This section describes pin assignments for system’ s external connectors and the jumpers setting.

l Overview

l System Setting

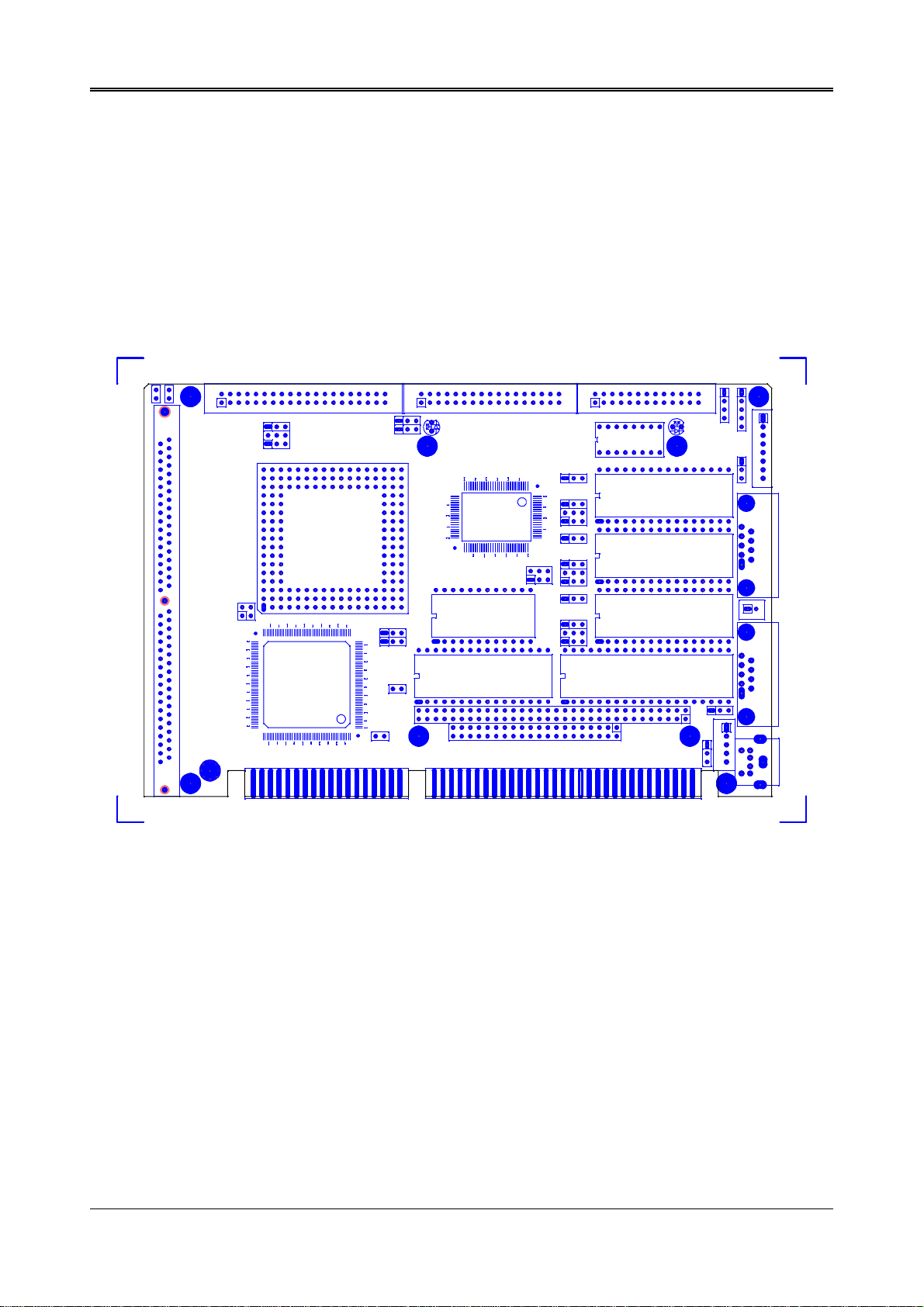

3.1 OVERVIEW

The AR-B1474 is a half size industrial grade CPU card that has been designed to withstand continuous operation

in harsh environments. The total on-board memory for the AR-B1474 can be configured from 1MB to 32MB by

using all 72-pin type DRAM devices.

CN4

U27

CN3

U8

U12

U18

H7

H15

JP13

J4J3

JP3

JP11

J8

H19H18

J2J1

H4

SIMM1 DB1

JP8

1

H16

CN1 CN2

U13

JP15

JP1

JP12

J7

CN6

JP14

JP2

U20

BUS1 BUS2

LED1 LED2

H6

U7

JP9

JP10

H14

CN6

U17

U26

JP6

P5

P6

JP5

P7

P8

JP7

P9

P10

SW1

JP4

H5

J5

J6

DB2

CN5

Figure 3-1 AR-B1474 Placement

3-1

Page 20

AR-B1474 User¡¦s Guide

3.2 SYSTEM SETTING

Jumper pins allow you to set specific system parameters. Set them by changing the pin location of jumper blocks.

(A jumper block is a small plastic-encased conductor that slips over the pins.) To change a jumper setting, remove

the jumper from its current location with your fingers or small needle-nosed pliers. Place the jumper over the two

pins designated for the desired setting. Press the jumper evenly onto the pins. Be careful not to bend the pins.

We will show the locations of the AR-B1474 jumper pins, and the factory-default setting.

CAUTION: Do not touch any electronic component unless you are safely grounded. Wear a grounded wrist strap

or touch an exposed metal part of the system unit chassis. The static discharges from your fingers can

permanently damage electronic components.

3.2.1 Serial Port

(1) RS-485 Adapter Select (JP3 & JP11)

JP3 and JP11 can be set independently. JP3 selects COM-A port and JP11 selects COM-B port.

JP3 -- COM-A

1

2

3

Reserved for Acrosser's

RS-485 adapter used only

Figure 3-2 JP3: RS-485 Adapter Select for COM-A

1

2

3

RS-232C

(Factory Preset)

JP11 -- COM-B

1 2 3

Reserved for Acrosser's

RS-485 adapter used only

Figure 3-3 JP11: RS-485 Adapter Select—COM-B

1 2 3

RS-232C

(Factory Preset)

(2) RS-232 Connector (DB1 & DB2)

There are two serial ports with EIA RS-232C interface on the AR-B1474. COM-A and COM-B use two on-board Dtype 9-pin male connectors (DB1 & DB2). If you want to configure the serial port, please refer to the BIOS

configuration.

DB1 (COM A)

DB2 (COM B)

3-2

5 GND

5 GND

9-RI

4-DTR

4-DTR

8-CTS

3 TXD

3 TXD

7-RTS

2 RXD

2 RXD

6-DSR

1-DCD

Figure 3-4 DB1 & DB2: RS-232 Connector

1-DCD

9-RI

8-CTS

7-RTS

6-DSR

Page 21

AR-B1474 User¡¦s Guide

6 +12VDC

3.2.2 Hard Disk (IDE) Connector (CN1)

A 40-pin header type connector (CN1) is provided to interface with up to two embedded hard disk drives (IDE AT

bus). This interface, through a 40-pin cable, allows the user to connect up to two drives in a “daisy chain” fashion.

To enable or disable the hard disk controller, please use BIOS Setup program to select. The following table

illustrates the pin assignments of the hard disk drive’ s 40-pin connector.

2

1

Figure 3-5 CN1: Hard Disk (IDE) connector

Pin Signal Pin Signal

1 -RESET 2 GROUND

3 DATA 7 4 DATA 8

5 DATA 6 6 DATA 9

7 DATA 5 8 DATA 10

9 DATA 4 10 DATA 11

11 DATA 3 12 DATA 12

13 DATA 2 14 DATA 13

15 DATA 1 16 DATA 14

17 DATA 0 18 DATA 15

19 GROUND 20 Not used

21 Not Used 22 GROUND

23 -IOW 24 GROUND

25 -IOR 26 GROUND

27 Not Used 28 BALE

29 Not Used 30 GROUND

31 IRQ14 32 -IOCS16

33 SA 1 34 Not used

35 SA 0 36 SA 2

37 -CS 0 38 -CS 1

39 HD LED A 40 GROUND

Table 3-1 HDD Pin Assignment

40

39

3.2.3 Power Connector (J5)

J5 is 8-pin power connector. Using the J5, you can connect the power supply to the on board power connector for

stand alone applications directly.

J5

1 GND

2 +5VDC

3 +5VDC

4 GND

5 GND

7 -12VDC

8 -5VDC

Figure 3-6 J5: Power Connector

3-3

Page 22

AR-B1474 User¡¦s Guide

3.2.4 FDD Port Connector (CN2)

The AR-B1474 provides a 34-pin header type connector for supporting up to two floppy disk drives.

To enable or disable the floppy disk controller, please use BIOS Setup program to select.

2

1

Figure 3-7 CN2: FDD Port connector

Pin Signal Pin Signal

1-33(odd) GROUND 18 -DIRECTION

2 -Reduce Write Current 20 -STEP OUTPUT PULSE

4 Not used 22 -WRITE DATA

6 Not used 24 -WRITE ENABLE

8 -INDEX 26 -TRACK 0

10 -MOTOR ENABLE A 28 -WRITE PROTECT

12 -DRIVE SELECT B 30 -READ DATA

14 -DRIVE SELECT A 32 -SIDE 1 SELECT

16 -MOTOR ENABLE B 34 -DISK CHANGE

Table 3-2 FDD Pin Assignment

34

33

3.2.5 Parallel Port Connector (CN3)

To use the parallel port, an adapter cable has been connected to the CN3 (26-pin header type) connector. This

adapter cable is included in your AR-B1474 package. The connector for the parallel port is a 25-pin D-type female

connector.

2

1

Parallel Port Connector

26

25

14

1

25

13

D-Type Connector

Figure 3-8 CN3: Parallel Port Connector

CN3 DB-25 Signal CN3 DB-25 Signal

1 1 -Strobe 2 14 -Auto Form Feed

3 2 Data 0 4 15 -Error

5 3 Data 1 6 16 -Initialize

7 4 Data 2 8 17 -Printer Select In

9 5 Data 3 10 18 Ground

11 6 Data 4 12 19 Ground

13 7 Data 5 14 20 Ground

15 8 Data 6 16 21 Ground

17 9 Data 7 18 22 Ground

19 10 -Acknowledge 20 23 Ground

21 11 Busy 22 24 Ground

23 12 Paper Empty 24 25 Ground

25 13 Printer Select 26 -- No Connect

Table 3-3 Parallel Port Pin Assignments

3-4

Page 23

3.2.6 PC/104 Connector

AR-B1474 User¡¦s Guide

(1) 64-Pin PC/104 Connector Bus A & B (CN6)

64

63

-IOCHCK ---

IOCHRDY---

Figure 3-9 CN6: 64-Pin PC/104 Connector Bus A & B

64-Pin PC/104 Connector

SD7 --SD6 --SD5 --SD4 --SD3 --SD2 --SD1 --SD0 ---

AEN --SA19 --SA18 --SA17 --SA16 --SA15 --SA14 --SA13 --SA12 --SA11 --SA10 ---

SA9 ---

SA8 ---

SA7 ---

SA6 ---

SA5 ---

SA4 ---

SA3 ---

SA2 ---

SA1 ---

SA0 ---

GND ---

A1

A2

A3

A4

A5

A6

A7

A8

A9

A10

A11

A12

A13

A14

A15

A16

A17

A18

A19

A20

A21

A22

A23

A24

A25

A26

A27

A28

A29

A30

A31

A32

CN6

1 2

B1

--- GND

B2

--- RSTDRV

B3

--- +5 VDC

B4

--- IRQ9

B5

--- -5 VDC

B6

--- DRQ2

B7

--- -12 VDC

B8

--- -ZWS

B9

--- +12 VDC

B10

--- KEY

B11

--- -SMEMW

B12

--- -SMEMR

B13

--- -IOW

B14

--- -IOR

B15

--- -DACK3

B16

--- DRQ3

B17

--- -DACK1

B18

--- DRQ1

B19

--- -REFRESH

B20

--- BUSCLK

B21

--- IRQ7

B22

--- IRQ6

B23

--- IRQ5

B24

--- IRQ4

B25

--- IRQ3

B26

--- -DACK2

B27

--- TC

B28

--- BALE

B29

--- +5 VDC

B30

--- OSC

B31

--- GND

B32

--- GND

2

B

A

1

(2) 40-Pin PC/104 Connector Bus C & D (CN4)

39

40

SBHE ---

LA23 --LA22 --LA21 --LA20 --LA19 --LA18 --LA17 ---

-MEMR ---

-MEMW ---

SD10 --SD11 --SD12 --SD13 --SD14 --SD15 ---

40-Pin PC/104 Connector

GND ---

C1

C2

C3

C4

C5

C6

C7

C8

C9

C10

C11

SD8 --SD9 ---

C12

C13

C14

C15

C16

C17

C18

C19

KEY ---

C20

CN4

1 2

D1

--- GND

D2

--- -MEMCS16

D3

--- -IOCS16

D4

--- IRQ10

D5

--- IRQ11

D6

--- IRQ12

D7

--- IRQ15

D8

--- IRQ14

D9

--- -DACK0

D10

--- DRQ0

D11

--- -DACK5

D12

--- DRQ5

D13

--- -DACK6

D14

--- DRQ6

D15

--- -DACK7

D16

--- DRQ7

D17

--- +5 VDC

D18

--- -MASTER

D19

--- GND

D20

--- GND

1

C

D

2

Figure 3-10 CN4: 40-Pin PC/104 Connector Bus C & D

3-5

Page 24

AR-B1474 User¡¦s Guide

(3) PC/104 ISA Bus Signal Description

Name Description

BUSCLK [Output] The BUSCLK signal of the I/O channel is asynchronous

RSTDRV [Output] This signal goes high during power-up, low line-voltage or

SA0 - SA19

[Input / Output]

LA17 - LA23

[Input/Output]

SD0 - SD15

[Input/Output]

BALE [Output] The Buffered Address Latch Enable is used to latch SA0

-IOCHCK [Input] The I/O Channel Check is an active low signal which

IOCHRDY

[Input, Open collector]

IRQ 3-7, 9-12, 14, 15

[Input]

-IOR

[Input/Output]

-IOW [Input/Output] The I/O write signal is an active low signal which instructs

-SMEMR [Output] The System Memory Read is low while any of the low

-MEMR

[Input/Output]

-SMEMW [Output] The System Memory Write is low while any of the low

-MEMW

[Input/Output]

DRQ 0-3, 5-7 [Input] DMA Request channels 0 to 3 are for 8-bit data transfers.

-DACK 0-3, 5-7

[Output]

AEN [output] The DMA Address Enable is high when the DMA

-REFRESH

[Input/Output]

TC [Output] Terminal Count provides a pulse when the terminal count

SBHE [Input/Output] The System Bus High Enable indicates the high byte SD8

to the CPU clock.

hardware reset

The System Address lines run from bit 0 to 19. They are

latched onto the falling edge of "BALE"

The Unlatched Address line run from bit 17 to 23

System Data bit 0 to 15

– SA19 onto the falling edge. This signal is forced high

during DMA cycles

indicates that a parity error exist on the I/O board

This signal lengthens the I/O, or memory read/write cycle,

and should be held low with a valid address

The Interrupt Request signal indicates I/O service request

attention. They are prioritized in the following sequence :

(Highest) IRQ 9, 10, 11, 12, 13, 15, 3, 4, 5, 6, 7 (Lowest)

The I/O Read signal is an active low signal which

instructs the I/O device to drive its data onto the data bus

the I/O device to read data from the data bus

1mega bytes of memory are being used

The Memory Read signal is low while any memory

location is being read

1mega bytes of memory is being written

The Memory Write signal is low while any memory

location is being written

DMA Request channels 5 to 7 are for 16-bit data

transfers. DMA request should be held high until the

corresponding DMA has been completed. DMA request

priority is in the following sequence:(Highest) DRQ 0, 1,

2, 3, 5, 6, 7 (Lowest)

The DMA Acknowledges 0 to 3, 5 to 7 are the

corresponding acknowledge signals for DRQ 0 to 3 and 5

to 7

controller is driving the address bus. It is low when the

CPU is driving the address bus

This signal is used to indicate a memory refresh cycle

and can be driven by the microprocessor on the I/O

channel

for any DMA channel is reached

- SD15 on the data bus

3-6

Page 25

AR-B1474 User¡¦s Guide

Others CPU

Others CPU

Name Description

-MASTER [Input] The MASTER is the signal from the I/O processor which

gains control as the master and should be held low for a

maximum of 15 microseconds or system memory may be

lost due to the lack of refresh

-MEMCS16

[Input, Open collector]

-IOCS16

[Input, Open collector]

OSC [Output] The Oscillator is a 14.31818 MHz signal

-ZWS

[Input, Open collector]

Table 3-4 PC/104 ISA Bus Pin Assignment

The Memory Chip Select 16 indicates that the present

data transfer is a 1-wait state, 16-bit data memory

operation

The I/O Chip Select 16 indicates that the present data

transfer is a 1-wait state, 16-bit data I/O operation

The Zero Wait State indicates to the microprocessor that

the present bus cycle can be completed without inserting

additional wait cycle

3.2.7 CPU Setting

The AR-B1474 accepts many types of microprocessor, such as INTEL/AMD/CYRIX 486DX/DX2/DX4. All of these

CPUs include an integer processing unit, floating-point processing unit, memory-management unit, and cache.

They can give a two to ten-fold performance improvement in speed over the 386 processor, depending on the

clock speeds used and specific application. Like the 386 processor, the 486 processor includes both segmentbased and page-based memory protection schemes. Instruction processing time is reduced by on-chip instruction

pipelining. By performing fast, on-chip memory management and caching, the 486 processor relaxes requirements

for memory response for a given level of system performance.

(1) AMD DX2-80 CPU Select (JP1)

AMD DX2-80

Figure 3-11 JP1: AMD DX2-80 CPU Select

(2) CPU Voltage Select (JP2)

Figure 3-12 JP2: CPU Voltage Select

(3) AMD 4X CPU (5x86) Select (JP15)

JP1

1 2 31 2 3

JP2

1 3 5 1 3 5

3.3V 5V

1 2 3

JP15

1 2 31 2 3

1 2 3

AMD CPU

Figure 3-13 JP15: AMD 4X CPU (5x86) Select

3-7

Page 26

AR-B1474 User¡¦s Guide

(4) CPU Clock Select (JP6 & JP9)

For different type of CPUs, the clock generator and clock divisor need to be set by JP6 and JP9. The clock base is

selected by JP6, JP9 is used to select single or half clock system. We recommend that you refer the following

table for setting the CPU clock.

1 2 3

1 2 3

1X

JP9

1 2 3

1 2 3

2X

Factory Preset

Figure 3-14 JP9: CPU System Clock Multiplier Select

Pin Definition

6

1-2 A

3-4 B

5-6 C

12345

BA C

Table 3-5 JP6: CPU Base Clock

CPU Type

DX-25, DX2-50,

DX4-75

DX-33, DX2-66,

DX4-100, 5X86133

DX-40, DX2-80,

DX4-120

DX-50 50MHZ 50MHz 1X Close Close Close

CPU

Clock

25MHz 50MHz 1X Close Open Open

33.3MHz 33.3MHz 1X Close Open Close

40MHz 40MHz 1X Close Close Open

Base

Clock

JP9

Table 3-6 CPU Clock Setting

JP6

A B C

Note

Factory

Preset

3-8

Page 27

AR-B1474 User¡¦s Guide

3.2.8 Memory Setting

(1) Cache RAM Size Select (JP8)

The AR-B1474 can be configured to provide a write-back or write-through cache scheme and support 128KB to

512KB cache systems. A write-back cache system may provide better performance than a write-through cache

system. The BIOS Setup program allows you to set the cache scheme either write-back or write-through, either

the internal cache selection.

The AR-B1474 needs four 32Kx8 SRAM chips to construct 128KB cache. To construct 256KB cache, four 64Kx8

SRAM chips are needed. Four 128Kx8 SRAM chips will provide 512KB cache.

JP8 JP8 JP8

3 4

3 4

3 4

1 2

128KB

1 2

256KB

1 2

512KB

(Factory Preset)

Figure 3-15 JP8: Cache RAM Size Select

(3) DRAM Configuration

There is one 32-bit memory bank on the AR-B1474 card. It can be one-side or double-side SIMM (Single-Line

Memory Modules) which is designed to accommodate 256Kx36 bit to 8Mx36 bit SIMMs. This provides the user

with up to 32MB of main memory. The 32-bit SIMM (without parity bit) also can be used on AR-B1474 card. There

are six on-board memory configurations available. Please refer to the following table for details:

SIMM1 Total Memory

256KX32(X36) 1MB

512KX32(X36) 2MB

1MX32(X36) 4MB

2MX32(X36) 8MB

4MX32(X36) 16MB

8MX32(X36) 32MB

Table 3-7 DRAM Configuration

3-9

Page 28

AR-B1474 User¡¦s Guide

3.2.9 LED Header (J1, J2 & J4)

(1) External Power LED & Keyboard Lock Header (J4)

1 Power LED+

2 Not Used

3 Power LED4 Key-Lock+

5 Key-Lock-

Figure 3-16 J4: Power LED & Key Lock Header

(2) HDD LED Header (J1)

12LED+

Figure 3-17 J1: HDD LED Header

(3) Watchdog LED Header (J2)

LED-

1 LED+

2 LED-

Figure 3-18 J2: Watchdog LED Header

3.2.10 Keyboard Connector

(1) 6-Pin Mini DIN Keyboard Connector (CN5)

CN5 is a 6-pin Mini-DIN connector. This keyboard connector is PS/2 type keyboard compatible. An PC/AT

compatible keyboard can be used by connecting the provided adapter cable CN5 and keyboard.

1 DATA

1

2 Not Used

3 GND

4 VCC

5 CLOCK

3 4

5

6 Not Used

Figure 3-19 CN5: Keyboard Connector

(2) AUX. Keyboard Connector (J8)

A PC/AT compatible keyboard can be used by connected the provided adapter cable between J8 and the

keyboard. The pin assignments of J8 connector are as follows:

2

6

CN5 (Front View)

3-10

J8

1 CLOCK

2 DATA

3 Not Used

4 GND

5 VCC

Figure 3-20 J8: AUX. Keyboard Connector

Page 29

3.2.11 External Speaker Header (J3)

Besides the on board buzzer, you can use an external speaker by connecting J3 header directly.

J3

1 Speaker+

2 Speaker3 Speaker4 Speaker-

Figure 3-21 J3: External Speaker Header

3.2.12 Reset Header (J7)

J7 is used to connect to an external reset switch. Shorting these two pins will reset the system.

1 Reset+

2 Reset-

1 2

Figure 3-22 J7: Reset Header

3.2.13 Battery Setting

AR-B1474 User¡¦s Guide

(1) Battery Charger Select (JP4)

1 2 3 1 2 3

Non chargeableRechargeable

Factory-Default Setting

Figure 3-23 JP4: Battery Charger Select

(2) External Battery Connector (J6)

J6 allows users to connect an external 4.5 to 6 VDC battery to the AR-B1474 if the on-board battery is empty.

Only the SRAM disk will sink the battery current. If no SRAM chip will be used, no battery is needed. The battery

charger on AR-B1474 does not source charge current to the external battery which connects on J6.

1 Battery+

2 Battery-

1 2

Figure 3-24 J6: External Battery Connector

3.2.14 CRT Display Type Select (JP13)

JP13

1

2

3

MONO/EGA/VGA DisplayColor Display

Figure 3-25 JP13: CRT Display Type Select

1

2

3

Factory-Default Setting

3-11

Page 30

Page 31

AR-B1474 User¡¦s Guide

4. INSTALLATION

This chapter describes the procedure of the installation. The following topics are covered:

l Overview

l Utility Diskette

l Write Protect Function

l Watchdog Timer

4.1 OVERVIEW

This chapter provides information for you to set up a working system based on the AR-B1474 CPU card. Please

read the details of the CPU card’ s hardware descriptions before installation carefully, especially jumpers setting,

switch setting and cable connection.

Follow steps listed below for proper installation:

Step 1 : Read the CPU card’ s hardware description in this manual.

Step 2 : Install any DRAM SIMM onto the CPU card.

Step 3: Install the EPROMs, FLASHs ro SRAMs on the memory sockets.

Step 4 : Set jumpers and switch.

Step 5 : Make sure that the power supply connected to your passive CPU board is turned off.

Step 6 : Plug the CPU card into a free AT-bus slot or PICMG slot on the backplane and secure it in place with

a screw to the system chassis.

Step 7 : Connect all necessary cables. Make sure that the FDC, HDC, serial and parallel cables are

connected to pin 1 of the related connector.

Step 8 : Connect the hard disk/floppy disk flat cables from the CPU board to the drives. Connect a power

source to each drive.

Step 9 : Install a MDA, CGA, EGA or VGA display card in your system.

Step 10 : Plug the keyboard into the keyboard connector.

Step 11 : Turn on the power.

Step 12: Configure your system with the BIOS Setup program then re-boot your system.

Step 13: If the CPU card does not work, turn off the power and read the hardware description carefully again.

Step 14: If the CPU card still does not perform properly, return the card to your dealer for immediate service.

4-1

Page 32

AR-B1474 User¡¦s Guide

4.2 UTILITY DISKETTE

To support the AR-B1474 solid state disk’ s operations, the following programs or files has been provided on the

accompanying utility diskette:

(1) PGM1474.EXE

PGM1474.EXE PGM1474.EXE is used to program the 12V FLASH EPROM after the ROM pattern files are

generated by RFG.EXE The PGM1474.EXE can also program the correctness of the ROM

pattern files onto 5V FLASH EPROM (start from MEM1) or SRAM for testing the ROM pattern

files.

To execute PGM1474.EXE, the main menu will be displayed on your screen. There are 8 options on the main

menu.

Quit to DOS

Quits and exits to the DOS.

OS Shell

Exits from PGM1474 temporarily to the DOS prompt. Type EXIT to return to PGM1474 main menu.

Load ROM File

If this option is used, the PGM1474 will prompt you for the ROM pattern file name. This option is useful if

you have not previously entered a ROM pattern file name or if you wish to use a different ROM pattern file.

The PGM1474 will check and display the ROM file name, ROM file size, (FLASH) memory capacity and the

number of ROM pattern files that will be loaded and copied onto the (FLASH) memory chips.

Verify Memory

If ROM pattern files were loaded without error, this option instructs PGM1474 to verify the contents of

(FLASH) memory chips with the current ROM pattern files.

Program Memory

If there are no mistakes in your ROM pattern file, then this menu option will erase (FLASH) memory, write

the current ROM pattern files onto (FLASH) memory and verify data that was just written to (FLASH)

memory, using the ROM pattern files.

Memory Type/Mfr.

Before you program the (FLASH) memory chips, make sure that the FLASH’ s type and manufactory match

the one shown on the main menu. Otherwise, you can use this option to select the proper type and

manufacture and instruct the program to use a right programming algorithm.

Select PGM Chips

Normally the PGM1474 will program all ROM pattern files onto the FLASH memories with the ROM pattern

files just loaded. But you can use this option to select which memory chips that you want to program and

which memory chips need to be skipped. The PGM1474 will only program the selected chips when writing

data to the FLASH memory. This is very useful when some of the memory chip were verified and

programmed previously.

Select FLASH PLSCNTs

If the 12V FLASHs have been programmed several times, please select the <Slowest> FLASH PLSCNT

mode instead of <Standard> mode. In the <Slower> or <Slowest> mode, PGM1474.EXE will retry more

times to program data onto the 12V FLASHs correctly.

The default setting is <Slowest> mode.

4-2

Page 33

AR-B1474 User¡¦s Guide

(2) WD1474.EXE

WD1474.EXE This program demonstrates how to enable and trigger the watchdog timer. It allows you to

test the <TIMES-OUT & RESET> function when the watchdog timer is enabled.

(3) WP1474.EXE

WP1474.EXE This program demonstrates how to enable and disable software write protected function. It

also shows the current protect mode of write or read only memory.

(4) BU1474.EXE

BU1474.EXE BU1474.EXE is used to update the SSD BIOS conveniently if the SSD BIOS need to be

revised. This program will erase the BIOS ROM and reprogram with revised BIOS.

(5) RFG.EXE

RFG.EXE This program is used to generate ROM pattern files in a binary format. Each ROM pattern file

has the same size as the FLASH or EPROM and can be easily programmed on to the FLASH

with on-board programmer or on to EPROM with any EPROM programmer. If you have

specified a DOS drive in the *.PGF file, RFG will generate bootable ROM pattern files for the

EPROM or FLASH disk. The RFG supports the following DOS: MS-DOS, PC-DOS, DR-DOS,

and X-DOS.

NOTE: If you want to use AR-B1474 with any DOS which is not supported by RFG, please send your requirement

to Acrosser Technology Co., Ltd. or contract with your local sales representative.

The RFG.EXE provided in the utility diskette is a program that converts the files you list in the PGF and convert

them into ROM pattern file. The RFG will determine how many EPROMs are needed and generate the same

number of ROM pattern files. These ROM pattern files are named with the name assigned by the ROM_NAME in

the PGF and the extension names are *.R01, *.R02….etc. To generate ROM pattern files.

The ROM File Generator main menu will be displayed on the screen. There are 7 options on the main menu. They

serve the following functions:

Quit to DOS

Quits and exits to the DOS

OS Shell

Exits from the RFG temporarily to the DOS prompt. Type <EXIT> to return to the RFG main menu.

Load PFG File

If this option is used, the RFG will prompt you for the PGF file name. This option is useful if you have not

previously entered a PGF name or you wish to use a different PGF file. The RFG will check and display the

PGF filename, ROM pattern file name, EPROM capacity, DOS version and the number of ROM pattern files

that will be generated.

Type Current PGF File

This option instructs the RFG to use the DOS type command to display the contents of the current PGF file.

Generate ROM File(s)

If there is no mistake in your *.PGF file, then this menu option will generate ROM pattern files. The number

of ROM pattern file generated by the RFG will depend on the total capacity needed by your files. For

instance, if 3 files are generated, then you will need to use 3 EPROMs (The size depends upon the number

4-3

Page 34

AR-B1474 User¡¦s Guide

stated in your PGF). The ROM pattern files will have the same file names, but will have different extension

names. For example:

TEST.R01, TEST.R02, TEST.R03…etc.

Display Error in PGF File

This option displays errors that were detected in your PGF.

Help to PGF File

This option gives information on how to write a PGF file and how to generate ROM pattern files. An

example PGF is also included.

Move the reverse video bar to <Generate ROM File(s)> then press [ENTER]. The ROM pattern file is a

binary file. The file size will be the same size as the EPROM that you assigned in the PGF. For example, if

you are using 128KX8 EPROM memory chips, then the size of ROM patterns file will be 131072 bytes. For

other chips the file size will be:

64KX8 EPROM----65536 bytes

256KX8 EPROM—262144 bytes

512KX8 EPROM---524288 bytes

1MX8 EPROM -----1048576 bytes

(6) RFGDEMO.PGF

RFGDEMO.PGF This file provides a sample PROGRAM GROUP FILE which illustrates how to create ROM

pattern files correctly.

The PGF is an ASCII text file that can be created by using any text editor, word processor or DOS <COPY CON>

command. The PGF lists what files will be copied and if DOS is going to be copied. This file can have any DOS

filename, but the extension name must be *.PGF. For example, followings are valid filenames.

RFGDEMO.PGF

MYRFG.PGF

MSDOS.PGF

….

An examples of the *.PGF file is as follow.

ROM_NAME=TEST1 ; ROM pattern file name is TEST1

;The output file names will be TEST1.R01, TEST1.R02..etc.

DOS_DRIVE=C: ; DOS system drive unit is drive C:

;If user does not want to copy DOS

;system files onto the ROM disk

;write as DOS_DRIVE=NONE

ROM_SIZE=128 ;128 means 128KX8 (27C/29F010) EPROM size used

;256 means 512KX8 (27C/29F020) EPROM size used