Page 1

AIT Drive

User’s Guide

4-679-249-17(1)

AIT-4 TAPE DRIVE

AITi520

AIT-3 Ex TAPE DRIVE

AITi390

AIT-3 TAPE DRIVE

AITi260

AIT-2 TAPE DRIVE

AITi130

AIT-1 TAPE DRIVE

AITi90

2003 Sony Corporation

Page 2

This document contains proprietary

information which is protected by

copyright.

All rights reserved. No part of this

document may be photocopied,

reproduced or translated to another

language without prior written consent

of Sony.

The information contained in this

document is subject to change without

notice.

SONY MAKES NO WARRANTY

OF ANY KIND WITH REGARD TO

THIS DOCUMENT.

Sony shall not be liable for errors

contained herein, indirect, special,

incidental or consequential damages in

connection with the furnishing,

performance or use of this document.

Your AITi90, AITi130 is assigned a

Model No. ATDNA2 for regulatory

compliance certifications.

Your AITi260 is assigned a Model No.

ATDNA3 for regulatory compliance

certifications.

Your AITi390, AITi520 is assigned a

Model No. ATDNA4 for regulatory

compliance certifications.

The number is indicated on the model

number label on your drive along with

the rated voltage and current.

VORSICHT

Für Kunden in Deutschland

Diese Ausrüstung erfüllt die

Europäischen EMC-Bestimmungen für

die Verwendung in folgender /

folgenden Umgebung(en):

• Wohngegenden

• Gewerbegebiete

• Leichtindustriegebiete

(Diese Ausrüstung erfüllt die

Bestimmungen der Norm EN55022,

Klasse B.)

2

Page 3

IMPORTANT SAFEGUARDS

For your protection, please read these

safety instructions completely before

operating the appliance, and keep this

manual for future reference.

Carefully observe all warnings,

precautions and instructions on the

appliance, or the one described in the

operating instructions and adhere to

them.

USE

Power Sources – This unit should be

operated only from the type of power

source indicated on the marking label.

If you are not sure of the type of

electrical power, consult your dealer or

local power company.

For the unit with a three-wire

grounding type ac plug:

If you are unable to insert the plug into

the outlet, contact your electrician to

have a suitable plug installed. Do not

defeat the safety purpose of the

grounding plug.

AC Power cord: (for AC mains

operating unit only)

The AC power cord should have

appropriate safety approvals or

marking for the country in which the

equipment will be used. Consult your

dealer or local power company.

Cleaning – Unplug the unit from the

wall outlet before cleaning or

polishing it. Do not use liquid

cleaners or aerosol cleaners.

Use a cloth lightly dampened with

water for cleaning the exterior of the

unit.

Object and Liquid Entry – Never

push objects of any kind into the unit

through openings as they may touch

dangerous voltage points or short out

parts that could result in a fire or

electric shock. Never spill liquid of

any kind on the unit.

3

Page 4

INSTALLATION

Water and Moisture – Do not use

power-line operated units near water for example, near a bathtub,

washbowl, kitchen sink, or laundry

tub, in a wet basement, or near a

swimming pool, etc.

Power-Cord Protection – Route the

power cord so that it is not likely to be

walked on or pinched by items placed

upon or against them, paying

particular attention to the plugs,

receptacles, and the point where the

cord exits from the appliance.

Accessories – Do not place the unit on

an unstable cart, stand, tripod, bracket,

or table. The unit may fall, causing

serious injury to a child or an adult,

and serious damage to the unit. Use

only a cart stand tripod, bracket, or

table recommended by the

manufacturer.

Ventilation – The slots and openings

in the cabinet are provided for

necessary ventilation. To ensure

reliable operation of the unit, and to

protect it from overheating, these slots

and openings must never be blocked or

covered.

• Never cover the slots and openings

with a cloth or other materials.

• Never block the slots and openings

by placing the unit on a bed, sofa,

rug or other similar surface.

• Never place the unit in a confined

space, such as a bookcase, or builtin cabinet, unless proper ventilation

is provided.

SERVICE

Damage Requiring Service – Unplug

the unit from the wall outlet and refer

servicing to qualified service

personnel under the following

conditions:

• When the power cord or plug is

damaged or frayed.

• If liquid has been spilled or objects

have fallen into the unit.

• If the unit has been exposed to rain

or water.

• If the unit has been subject to

excessive shock by being dropped,

or the cabinet has been damaged.

• If the unit does not operate normally

when following the operating

instructions. Adjust only those

controls that are specified in the

operating instructions. Improper

adjustment of other controls may

result in damage and will often

require extensive work by a

qualified technician to restore the

unit to normal operation.

• When the unit exhibits a distinct

change in performance - this

indicates a need for service.

Servicing – Do not attempt to service

the unit yourself as opening or

removing covers may expose you to

dangerous voltage or other hazards.

Refer to all servicing to qualified

service personnel.

4

Page 5

Contents

Overview .................................................................................................................. 6

Introduction .............................................................................................................. 7

About AIT Drives ............................................................................................ 7

Precautions .....................................................................................................10

Installation ..............................................................................................................12

SCSI Connection/Setting the SCSI ID ...........................................................12

Option Switches (DIP Switch) .......................................................................13

Mounting Holes..............................................................................................17

Reconfiguring from 5.25" Model to 3.5" Model............................................19

Orientation......................................................................................................20

Attaching and Removing the Dust Cover ...............................................................21

Attaching the Dust Cover ............................................................................... 21

Removing the Dust Cover ..............................................................................23

Operation ................................................................................................................24

Location of 3 LEDs ........................................................................................24

Drive Operation..............................................................................................25

Emergency Tape Removal Procedure ............................................................28

WORM Function ....................................................................................................30

Interface Implementation........................................................................................32

Supported SCSI Messages ............................................................................. 32

Supported SCSI Commands...........................................................................32

Specifications ......................................................................................................... 33

Product Specifications....................................................................................33

Sony Contacts .........................................................................................................35

• Sony cannot accept liability for data written to cartridges lost as a result of using this product.

• Sony bears no responsibility for any financial damages, lost profits, or claims made by third

parties arising from the use of this product.

5

Page 6

Overview

The Sony AITi520, AITi390, AITi260, AITi130 and AITi90 drives are

high capacity data storage devices using Advanced Intelligent Tape (AIT)

technology. The AITi260, AITi130 and AITi90 drives achieve high data

reliability through third-level Error Correction Code (second-level Error

Correction Code for the AITi520 and AITi390).

The Sony AITi520, AITi390, AITi260, AITi130 and AITi90 drives store

data on tape using standard formats called AIT (Advanced Intelligent Tape)

and ALDC formats.

6

Page 7

Introduction

About AIT Drives

The AITi520 is an internal AIT drive unit that uses data cartridges

conforming to the AIT-4 format. The AITi390 is an internal AIT drive unit

that uses data cartridges conforming to the AIT-3 Ex format. The AITi260

is an internal AIT drive unit that uses data cartridges conforming to the

AIT-3 format. The AITi130 is an internal AIT drive unit that uses data

cartridges conforming to the AIT-2 format. The AITi90 is an internal AIT

drive unit that uses data cartridges conforming to the AIT-1 format. The

AITi520 supports AIT-4 format. The AITi390 supports AIT-1 (Read only),

AIT-2 (Read only), AIT-3 and AIT-3 Ex formats. The AITi260 supports

AIT-1, AIT-2 and AIT-3 formats. The AITi130 supports AIT-1 and AIT-2

formats. The AITi90 supports only AIT-1 format.

Features

The AIT Drive Unit AITi520 has the following features:

• Supports reading and writing to data cartridges conforming to the AIT-4

format.

• The second-level error correction code guarantees high data reliability

writing to data cartridges conforming to the AIT-4 format.

• Data compression provides 520 gigabytes of storage on SDX4-200C.

The native capacity is 200 gigabytes of storage on SDX4-200C.

• Stored data are automatically checked for compression.

• Ultra 160 SCSI LVD/SE interface is fully supported for host computer

access.

*1

*1

This is assuming 2.6 : 1 compression ratio.

The degree of data compression attained while recording data varies according to

system environment and data type.

7

Page 8

The AIT Drive Unit AITi390 has the following features:

• Supports reading and writing to data cartridges conforming to the AIT-3

and AIT-3 Ex formats.

• Supports reading from data cartridges conforming to the AIT-1 and

AIT-2 formats.

• The second-level error correction code guarantees high data reliability

writing to data cartridges conforming to the AIT-3 Ex format.

• The third-level error correction code guarantees high data reliability

writing to data cartridges conforming to the AIT-1, AIT-2 and AIT-3

formats.

• Data compression provides 390 gigabytes of storage on SDX3X-150C.

The native capacity is 150 gigabytes of storage on SDX3X-150C.

• Stored data are automatically checked for compression.

• Ultra 160 SCSI LVD/SE interface is fully supported for host computer

access.

The AIT Drive Unit AITi260 has the following features:

• Supports reading and writing to data cartridges conforming to the AIT-1,

AIT-2 and AIT-3 formats.

• The third-level error correction code guarantees high data reliability.

• Data compression provides 260 gigabytes of storage on SDX3-100C.

*1

The native capacity is 100 gigabytes of storage on SDX3-100C.

• Stored data are automatically checked for compression.

• Ultra 160 SCSI LVD/SE interface is fully supported for host computer

access.

*1

The AIT Drive Unit AITi130 has the following features:

• Supports reading and writing to data cartridges conforming to the AIT-1

and AIT-2 formats.

• The third-level error correction code guarantees high data reliability.

• Data compression provides 130 gigabytes of storage on SDX2-50C.

The native capacity is 50 gigabytes of storage on SDX2-50C.

• Stored data are automatically checked for compression.

• Wide Ultra SCSI LVD/SE interface is fully supported for host computer

access.

*1

This is assuming 2.6 : 1 compression ratio.

The degree of data compression attained while recording data varies according to

system environment and data type.

8

*1

Page 9

The AIT Drive Unit AITi90 has the following features:

• Supports reading and writing to data cartridges conforming to the AIT-1

format.

• The third-level error correction code guarantees high data reliability.

• Data compression provides 91 gigabytes of storage on SDX1-35C.

*1

The native capacity is 35 gigabytes of storage on SDX1-35C.

• Stored data are automatically checked for compression.

• Wide Ultra SCSI LVD/SE interface is fully supported for host computer

access.

*1

This is assuming 2.6 : 1 compression ratio.

The degree of data compression attained while recording data varies according to

system environment and data type.

9

Page 10

Precautions

Installation

Avoid placing the drive in a location subject to:

– high humidity

– high temperature

– mechanical shock and vibration

– direct sunlight

*

For details, see “Specifications” on page 33.

Operation

• Do not move the drives while they are operating. It may cause

malfunctions.

• Avoid exposing the drives to sudden changes from low to high

temperatures. This may cause condensation to collect inside the drives. If

the ambient temperature should suddenly rise while the drives are turned

on, turn them off and wait at least one hour before turning them back on.

If you attempt to operate the drives immediately after a sudden increase

in temperature, malfunctions may occur.

• Turning off the power to the drives while they are writing to tape may

cause the tape to become unreadable. All previously negotiated

parameters will be lost, whenever power to the drives is cycled.

Transportation

• Keep the original packing materials to facilitate safe transportation of the

drive.

• Always remove the tape/media cartridge before moving the drive. After

removing the drive from the computer, repack the drive into its original

packing.

Backup Application

Make sure to use a backup application that is confirmed to operate with an

ISV.

10

Page 11

Usable Cartridges

r

The AITi520 can be used with data cartridges marked with the AIT-4 logo.

The AITi390 can be used with data cartridges marked with the AIT-1 (read

only), AIT-2 (read only), AIT-3 or AIT-3 Ex logo.

The AITi260 can be used with data cartridges marked with the AIT-1, AIT-

2 or AIT-3 logo.

The AITi130 can be used with data cartridges marked with the AIT-1 or

AIT-2 logo.

The AITi90 can be used with data cartridges marked with the AIT-1 logo.

Note

• Be sure to use only the cartridges designed specifically for AIT.

• Do not use anything but AIT cartridges with this system, as doing so can

damage the AIT drive. Although commercially available 8mm videotapes

resemble AIT cartridges in appearance, they have entirely different

specifications and cannot be used.

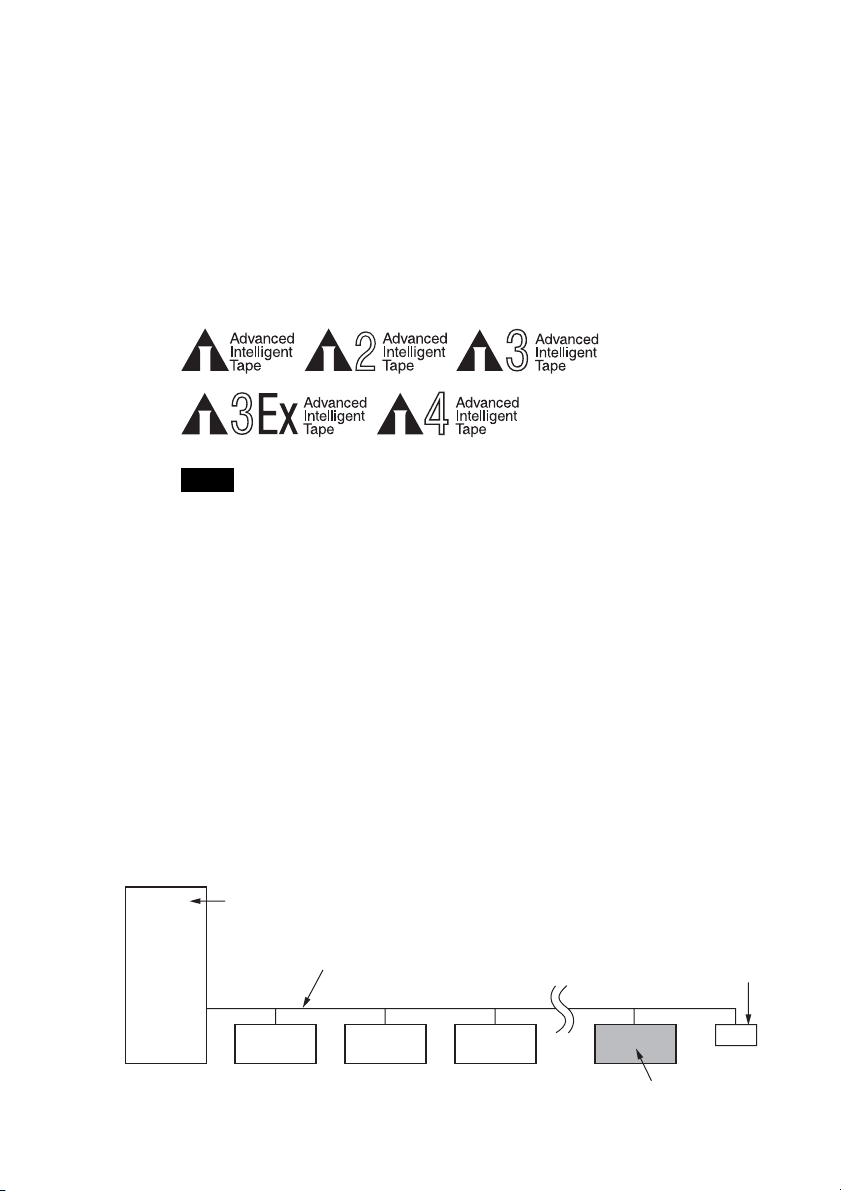

SCSI Termination

The AITi520, AITi390, AITi260, AITi130 and AITi90 conform to the

Microsoft PC97 standard, which requires the internal (naked) drive to be

terminated with an external terminator.

Microsoft PC97 SCSI requirements

SCSI peripherals must not terminate the bus. Both internal and external

cable ends are instead terminated by plug-in connectors.

Host Computer Wide SCSI

68p cable

Example of SCSI setup

Te r minato

This drive

11

Page 12

Installation

SCSI Connection/Setting the SCSI ID

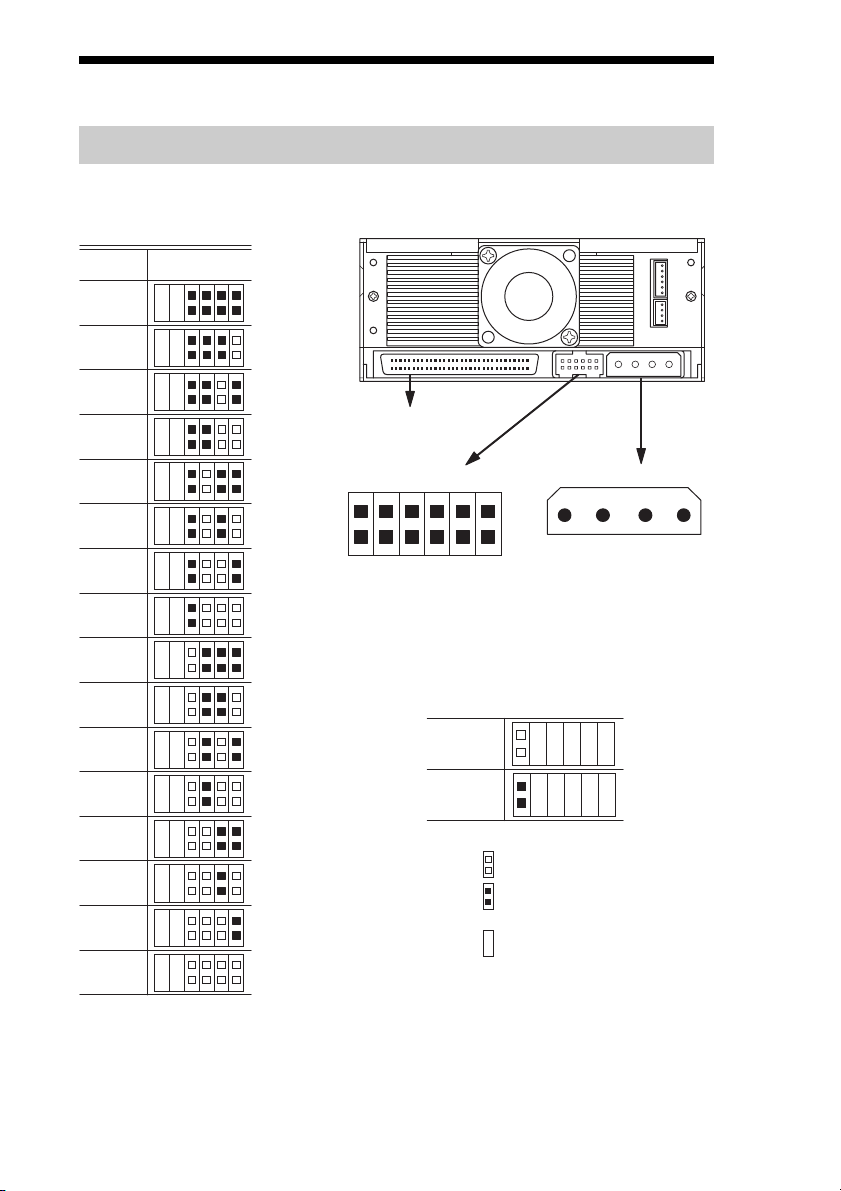

The following figures apply to the AITi520 model.

SCSI ID

210

SCSI ID

0

1

2

3

P.D.

N.C.

3

SCSI 68pin Connector

4

Jumpers

Power Connector

5

5 V

6

7

SCSI ID 3

SCSI ID 2

SCSI ID 1

SCSI ID 0

10

1

8

9

1

Parity Disable

No Connection

Parity

Disable

Enable

12

13

Note :

14

= CLOSED/Jumper

OPEN/Jumper not

=

installed

=

t care

Don’

15

Parity Disable Jumper

Parity check function can be disabled by Jumper. Parity check is disabled

while left end jumper is installed. Parity generate function is always

enabled.

1234

GND GND 12 V

12

Page 13

Option Switches (DIP Switch)

DIP Switch Positions

Default (AITi90, AITi130, AITi260)

ON

OFF

12345678

DIP Switch

1 Drive Mode (OFF)

2 Drive Mode (OFF)

3 Drive Mode (OFF)

4 Drive Mode (OFF)

5 Terminator Power (ON)

6 Periodic Cleaning Req

(OFF)

7 DC Control (1) (ON)

8 DC Control (2) (OFF)

Default (AITi390, AITi520)

ON

OFF

12345678

1 DR (Disaster Recovery)

Mode (OFF)

2 Emulation Mode (OFF)

3 AIT Library Interface Mode

(ON)

4 Reserved (OFF)

5 Terminator Power (ON)

6 Periodic Cleaning Req

(OFF)

7 DC Control (1) (ON)

8 DC Control (2) (OFF)

13

Page 14

DR (Disaster Recovery*) Mode

ON

OFF

12345678

AITi90, AITi130, AITi260

1 Drive Mode (ON)

2 Drive Mode

3 Drive Mode

4 Drive Mode

5 Terminator Power

6 Periodic Cleaning Req

7 DC Control (1)

8 DC Control (2)

*

In Disaster Recovery (DR) Mode, the drive enters the DR Standby Mode

15 seconds after you insert a write-protected tape into the drive, and all

the drive LEDs blink. If you restart the drive while the LEDs are blinking,

it starts as a CD-ROM device.

For details about the Disaster Recovery Mode, refer to the instruction

manual that came with the application software you are using.

Emulation Mode

*

(AITi90, AITi130, AITi260)

ON

OFF

12345678

*

Emulation Mode returns the following in the Product Identification field

of Inquiry of the AITi260.

SDX-700C

*

Emulation Mode returns the following in the Product Identification field

of Inquiry of the AITi130.

SDX-500C

*

Emulation Mode returns the following in the Product Identification field

of Inquiry of the AITi90.

SDX-400C

AITi390, AITi520

1 DR (Disaster Recovery) Mode (ON)

2 Emulation Mode

3 AIT Library Interface Mode

4 Reserved

5 Terminator Power

6 Periodic Cleaning Req

7 DC Control (1)

8 DC Control (2)

1 Drive Mode (ON)

2 Drive Mode (ON)

3 Drive Mode (ON)

4 Drive Mode (ON)

5 Terminator Power

6 Periodic Cleaning Req

7 DC Control (1)

8 DC Control (2)

14

Page 15

Emulation Mode* (AITi390, AITi520)

ON

OFF

12345678

*

Emulation Mode returns the following in the Product Identification field

of Inquiry of the AITi520.

SDX-700C

*

Emulation Mode returns the following in the Product Identification field

of Inquiry of the AITi390.

SDX-700C

Cleaning Request Mode

Periodic cleaning requests can be enabled by a DIP switch.

ON

OFF

1 DR (Disaster Recovery)

Mode

2 Emulation Mode (ON)

3 AIT Library Interface Mode

4 Reserved

5 Terminator Power

6 Periodic Cleaning Req

7 DC Control (1)

8 DC Control (2)

12345678

AITi90, AITi130, AITi260

1 Drive Mode

2 Drive Mode

3 Drive Mode

4 Drive Mode

5 Terminator Power

6 Periodic Cleaning Req (ON)

7 DC Control (1)

8 DC Control (2)

When switch 6 is ON, cleaning requests are enabled. When enabled, the

“CLEANING REQUEST” LED on the front panel lights after every 100

hours of operation.

When this LED lights, clean the drive with a cleaning cartridge.

Note

To maintain the drive in optimum condition in environments affected by dust and other

contaminants, we recommend keeping cleaning requests enabled.

AITi390, AITi520

1 DR (Disaster Recovery) Mode

2 Emulation Mode

3 AIT Library Interface Mode

4 Reserved

5 Terminator Power

6 Periodic Cleaning Req (ON)

7 DC Control (1)

8 DC Control (2)

15

Page 16

Terminator Power Control DIP switch

This DIP switch determines whether terminator power is supplied to the

SCSI bus. To enable terminator power, set position 5 [Terminator Power]

switch to ON.

Data Compression Control DIP switch

Data compression can be selected by DIP switches. Data compression is

enabled when position 7 [DC Control (1)] is ON. Control by host can be

disabled when position 8 [DC Control (2)] is ON.

16

Page 17

Mounting Holes

The following figures apply to the AITi520 models. However, the locations

of the mounting holes for the other models are the same.

For 3.5" Standard Height

_

+

4.8 0.5mm

_

+

[0.19" 0.02"]

_

+

41.2 0.5mm

_

+

[1.62" 0.02"]

_

+

7.6 0.5 mm [0.3" 0.02"]

6-M3 (depth 2.5mm [0.10"] max.)

6-M3 (depth 2.5mm [0.10"] max.)

_

+

_

+

_

+

_

+

90.0 0.3mm [3.54" 0.01"]

60.0 0.3mm

[2.36" 0.01"]

_

+

_

+

21.0 0.3mm

[0.83" 0.01"]

_

+

_

+

_

+

7.4 0.6mm [0.29" 0.02"]

_

+

_

+

9.8 0.6 mm

[0.39" 0.02"]

_

+

_

+

155.0 0.5mm [6.10" 0.02"]

_

+

94.0 0.5mm [3.70" 0.02"]

_

+

101.6 0.5mm [4.00" 0.02"]

_

+

_

+

_

+

_

+

42.0 0.3mm

[1.65" 0.01"]

70.0 0.3mm [2.76" 0.01"]

_

+

_

+

_

+

_

+

31.0 0.3mm

[1.22" 0.01"]

17

Page 18

For 5.25" Half Height

7.0mm

[0.28"]

_

+

_

+

79.2 0.3mm [3.12" 0.01"]

_

+

9.9 0.5mm

_

[0.39" 0.02"]

+

_

+

21.8 0.5mm

_

+

[0.86" 0.02"]

_

+

41.2 0.5mm

_

+

[1.62" 0.02"]

_

+

7.6 0.5 mm [0.3" 0.02"]

6-M3

_

+

_

+

_

+

_

+

_

+

79.2 0.3mm [3.12" 0.01"]

_

+

_

+

47.5 0.3mm

[1.87" 0.01"]

_

+

_

+

_

+

155.0 0.5mm [6.10" 0.02"]

42.0 0.3mm

[1.65" 0.01"]

70.0 0.3mm [2.76" 0.01"]

_

+

_

+

_

+

_

+

9.8 0.6 mm

[0.39" 0.02"]

_

+

7.4 0.6mm [0.29" 0.02"]

_

+

31.0 0.3mm [1.22" 0.01"]

_

+

94.0 0.5mm [3.70" 0.02"]

139.6 0.5mm [5.50" 0.02"]

146.0 0.5mm [5.75" 0.02"]

149.0 0.5mm [5.87" 0.02"]

4-M3

_

+

_

+

79.2 0.3mm [3.12" 0.01"]

_

+

_

+

47.5 0.3mm

[1.87" 0.01"]

_

+

_

+

_

+

_

+

_

+

_

+

_

+

_

+

18

Page 19

Reconfiguring from 5.25" Model to 3.5" Model

You can reconfigure the 5.25" model to the 3.5" model yourself.

1 Remove the 2 screws for each side rail.

2 Take the side rail off.

Side Rail (L)

Side Rail (R)

19

Page 20

Orientation

10

10

10

10 10

10

10

10

20

Page 21

Attaching and Removing the Dust Cover

Attaching the Dust Cover

1 Align the dust cover’s hinge clips (one on each side) with the

pins of the drive bezel.

• The dust cover should be positioned so that the magnets

on the cover’s back face the drive bezel.

*

This magnet does not affect the tape of the cartridge.

• Holding the dust cover at an angle as shown in the figure below,

set the hinge clips on top of the bezel pins, positioning them so that

they bracket the pins.

*

21

Page 22

2 Press down at an angle on each side in turn until you hear

the hinge clips click into place.

Caution

Do not press the dust cover in horizontally from the front. Doing so

could cause the dust cover to break.

3 Close the dust cover.

This completes attachment of the dust cover.

22

Page 23

Removing the Dust Cover

1 Open the dust cover.

2 Holding the dust cover at both corners, carefully raise the

dust cover.

The dust cover hinge clips and drive bezel pins uncouple.

Note

We recommend that you use the drive with the dust cover.

23

Page 24

Operation

Location of 3 LEDs

There are three LED indicators (TAPE MOTION LED, CLEANING

REQUEST LED, REPLACE TAPE LED) and an EJECT button on the

front panel of the unit.

Front Panel (for 3.5" Standard Height)

Advanced

Intelligent

Tape

LED

TAPE

MOTION

CLEANING

REQUEST

REPLACE

TAPE

EJECT button

LED Indication for Drive Status

The LED indicators are defined as follows.

LED

TAPE CLEANING REPLACE

MOTION REQUEST TAPE

Independent Independent Tape Loaded

Independent Independent Tape Access in Progress (write/read)

Independent Independent Tape Access in Progress (others)

Independent Independent Cleaning is requested

Independent Independent Cleaning is Not Completed

Independent Independent Media Error Occurred

H/W Error Occurred

on

Slow

1 pulse (0.9 sec on/0.3 sec off)

Fast

1 pulse (0.3 sec on/0.3 sec off)

Sense

24

Page 25

Drive Operation

Loading a Cartridge

Note

While setting the data cartridge, do not turn off the host computer. This

may cause a malfunction or damage data.

1 Turn on the host computer. Check that the drive’s TAPE

MOTION LED, CLEANING REQUEST LED and REPLACE

TAPE LED go off.

2 Open the dust cover.

3 Set the AIT data cartridge orientation as shown here and

insert it into the data cartridge slot.

By inserting the data cartridge to the extent, it is automatically set in

the drive and the TAPE MOTION LED lights.

25

Page 26

Unloading a Cartridge

The cartridge can be removed from the AITi520, AITi390, AITi260,

AITi130 and AITi90 either in response to a SCSI Unload Command, or by

pressing the EJECT bottom.

By pressing EJECT button, the tape is rewound and the cartridge ejected

from the slot.

Write-protecting a Cartridge

Cartridges can be write-protected by sliding the tab on the back of the

cartridge. In this state, data can be read from the tape but not written onto it.

AIT-1 AIT-2

AIT-3

AIT-3 Ex

AIT-4

Using your fingernail, push the switch in the

direction of the arrow to protect the tape from

writing or accidental erasure.

Return the switch to its original position to

re-enable writing.

26

Page 27

Using a Cleaning Cartridge

To keep the AIT drive in top condition, clean the drive unit as needed using

a cleaning cartridge with the AIT logo. When the drive unit needs cleaning,

the CLEANING REQUEST indicator lights. (For the AITi390 and the

AITi520, use the AITi390 and the AITi520 cleaning cartridge respectively.)

Use the cleaning cartridge made exclusively for each model.

Cleaning cartridge to use

AITi520 SDX4-CL

AITi390 SDX3X-CL

AITi260, AITi130, AITi90 SDX1-CL

How to Clean

1 Load the cleaning cartridge into the AIT drive.

Cleaning starts automatically.

2 Cleaning takes about 15 seconds and the cartridge is

automatically ejected when finished (AITi90, AITi130,

AITi260).

Cleaning takes from a few seconds to a minute for the

AITi390 and the AITi520, * and the cartridge is automatically

ejected when finished.

* The cleaning time varies depending on the condition of the drive (AITi390,

AITi520).

Caution

Do not rewind the cleaning cartridge and reuse it. When you reach the

end of the cartridge, dispose it and buy a new cleaning cartridge with

the AIT logo.

27

Page 28

Storage Precautions

• Keep cartridges in their cases when not in the drives.

• Avoid storing cartridges in dusty locations, in direct sunlight, near heaters

or air conditioners, or in humid locations.

• Do not place cartridges on dashboards or in car storage trays.

Emergency Tape Removal Procedure

1 Remove the drive from the chassis or enclosure to allow

access to the bottom of the drive.

2 Remove the drive’s top cover.

3 Locate the small opening in the bottom of the drive and

insert the tip of a precision screwdriver so that the Loading

motor shaft can be rotated.

4 Rotate the motor shaft clockwise to bring the threading

mechanism back to the initial position.

28

Reel motor

Loading motor

Emergency Tape Removal Procedure

Page 29

Caution

Stop rotating the motor shaft immediately, when Guide B gets to the

area below the line C-C (This line is defined by 2 circular tape guide

surfaces of the cartridge). Otherwise, the gear of the drive can be

damaged.

A

Tape guide surface Tape guide surface

C

Detail A

Guide B

The Initial Position of the Threading Mechanism

Cartridge

5 Before the manual ejection procedure, tape slack must be

removed in order to prevent tape damage. Rotate the gear

mechanism located on the bottom of the drive

counterclockwise to tighten the tape.

6 After the tape slack has been removed, continue to turn the

Loading motor shaft located on the bottom of the drive

clockwise with a precision screwdriver until the tape

cartridge is lifted out of the drive mechanism and is ejected.

7 Return the drive to Sony for repair.

C

29

Page 30

WORM Function

The AITi520, AITi260 and AITi130 support the WORM function. This

section explains the WORM function.

What is “WORM”?

“WORM” is an acronym for “Write Once Read Many”, a function that

allows data to be written to the same place on a tape only once, but permits

that data to be read from the tape for any number of times. The AITi520,

AITi260 and AITi130 support WORM cartridges. When a WORM

cartridge is used with an application that supports the WORM function,

data that has been written to a tape can not be accidentally deleted or

overwritten.

A WORM drive operates in the same manner as a non-WORM drive when

used with a non-WORM cartridge (henceforth referred to as “regular

cartridge”).

The operation of a WORM drive and a non-WORM drive differs according

to the type of cartridge that is being used.

Tape Drive Cartridge

Non-WORM drive

WORM drive

Regular Cartridge

(without WORM logo)

Read/Write Enabled

Read/Write Enabled

WORM Cartridge

(with WORM logo)

Waiting for Eject

Read/Append-Write Enabled

WORM Cartridges

WORM cartridges can be distinguished from regular cartridges by their

WORM logo and red shutters.

AIT-2 WORM cartridge: SDX2-50W

AIT-3 WORM cartridge: SDX3-100W

AIT-4 WORM cartridge: SDX4-200W

30

Red

WORM logo

Page 31

How to Write Data onto a WORM Cartridge

As with a regular cartridge, there is no limit on how many times data can be

read from a WORM cartridge. When writing data to a WORM cartridge,

the data can not be written to a portion of the tape that has already been

written.

When writing data onto a WORM cartridge, it is appended after data that

has already been written onto the cartridge. Accordingly, move to the EOD

area before writing data onto the cartridge.

SCSI Commands Supported by the WORM Drive

The WORM drives support the same SCSI commands that are supported by

non-WORM drives. However, if an attempt is made to write to a portion of

a tape where data has already been written, the following error information

is returned:

“Sense Key = 07, ASC = 27h, ASCQ = 00: Persistent Write Protect” or

“Sense Key=03, ASC=27h, ASCQ=04: Write Position Error.”

AIT WORM-compliant Software

To find out whether your backup application is AIT WORM compliant,

contact the manufacturer of the software.

Notes

• Sony cannot accept liability for data written onto a WORM cartridge that

is lost as a result of using this unit.

• Sony accepts no responsibility for any financial damages, lost profits, or

claims made by third parties arising from the use of this product.

31

Page 32

Interface Implementation

Supported SCSI Messages

Abort

Bus Device Reset

Command Complete

Disconnects

Extended Message

– Synchronous Data Transfer

Request

– Wide Data Transfer Request

– Parallel Protocol Request

(AITi260, AITi390, AITi520)

Supported SCSI Commands

Erase

Inquiry

Load/Unload

Locate

Log Sense

Log Select

Mode Select

Mode Sense

Persistent Reserved IN

Persistent Reserved OUT

Prevent Allow Medium Removal

Read

Read Attribute

(AITi390, AITi520)

Read Block Limits

Read Buffer

Read Position

Receive Diagnostic Result

Release Unit

(AITi90, AITi130, AITi260)

Release (6) (AITi390, AITi520)

Release (10) (AITi390, AITi520)

32

Identify ( w/&w/o Disconnect )

Ignore Wide Residue

Initiator Defected Error

Message Parity Error

Message Reject

No Operation

Restore Pointer

Save Data Pointer

Report Density Support

Report Device Identifier

(AITi390, AITi520)

Report Luns

Request Sense

Reserve Unit

(AITi90, AITi130, AITi260)

Reserved (6) (AITi390, AITi520)

Reserved (10) (AITi390, AITi520)

Rewind

Seek Block

(AITi90, AITi130, AITi260)

Send Diagnostic

Set Device Identifier (AITi390, AITi520)

Space

Test Unit Ready

Verify

(AITi90, AITi130, AITi260)

Write

Write Attribute (AITi390, AITi520)

Write Buffer

Write Filemarks

Page 33

Specifications

Product Specifications

Dimensions (not including bezel and protruding parts)

3.5" 5.25"

Height 41.2 mm (1.62 in) 41.2 mm (1.62 in)

Width 101.6 mm (4.0 in) 146.0 mm (5.75 in)

Depth 155.0 mm (6.1 in) 155.0 mm (6.1 in)

Altitude

Operating 0 to 3048 m (0 to 10,000 ft.)

Acoustic Noise (A) curve weight

Streaming Write/Read less than 35 dB (A)

Insert/Eject less than 60 dB (A)

Note

The sound-meter on (A) scale is located 1m (3.3 ft.) in front of the center of the

drive front panel.

Mass

AITi390, AITi520 AITi260 AITi130 AITi90

3.5" 780 g (27.5 oz.) 780 g (27.5 oz.) 740 g (26.1 oz.) 740 g (26.1 oz.)

5.25" 1010 g (35.6 oz.) 1050 g (37.0 oz.) 970 g (34.2 oz.) 970 g (34.2 oz.)

Temperature and Humidity Range

Temperature

Operating 5 ˚C to 40 ˚C (∆T<10 ˚C/h)

(41 ˚F to 104 ˚F (∆T<18 ˚F/h))

Non-Operating (mech.) – 40 ˚C to 70 ˚C (∆T<20 ˚C/h)

(– 40 ˚F to 158 ˚F (∆T<36 ˚F/h))

Non-Operating (tape) – 40 ˚C to 45 ˚C (∆T<20 ˚C/h)

(– 40 ˚F to 113 ˚F (∆T<36 ˚F/h))

33

Page 34

Humidity

Operating 20 to 80% RH, non-condensing

Non-Operating (mech.) 5 to 95% RH (∆RH<30%/h)

Non-Operating (tape) 20 to 80% RH (∆RH<30%/h)

Maximum wet bulb temperature :

26 ˚C (78.8 ˚F)

Maximum wet bulb temperature :

45 ˚C (113 ˚F)

Air-cooling Requirement

Surrounding temperature < 40 ˚C (104 ˚F)

Clean air flow is recommended to minimize the possibility of data loss.

Power Requirements

AITi390, AITi520

Voltage Max Ripple

5 V +/– 5 % 100 mVp-p 1.5 A 2.5 A

12 V +/– 10 % 150 mVp-p 0.75 A 3.0 A

AITi260

Voltage Max Ripple

5 V +/– 5 % 100 mVp-p 1.6 A 1.9 A

12 V +/– 10 % 150 mVp-p 0.5 A 1.2 A

Typical Maximum

Typical Maximum

Current

Current

AITi130

Voltage Max Ripple

5 V +/– 5 % 100 mVp-p 1.1 A 1.4 A

12 V +/– 10 % 150 mVp-p 0.4 A 1.2 A

AITi90

Voltage Max Ripple

5 V +/– 5 % 100 mVp-p 1.1 A 1.4 A

12 V +/– 10 % 150 mVp-p 0.4 A 1.2 A

Typical Maximum

Typical Maximum

Current

Current

34

Page 35

Sony Contacts

For further information, please contact:

Sony Electronics Inc., Tape Storage Solutions (USA)

URL: http://www.storagebysony.com

Sony of Canada Ltd., AV/IT Marketing Group

Computer Peripherals Product Marketing

115 Gordon Baker Road Toronto, Ontario, M2H 3R6 Canada

TEL: (416) 499-1414 or (1) 800-961-7669

FAX: (416) 499-8541

Sony Business Europe

URL: http://www.sonyisstorage.com/

Electronics Devices Marketing (Singapore)

(A division company of Sony Electronics (S) Pte. Ltd.)

Enterprise Storage Solutions Dept.

2 International Business Park, #01-10 Tower One, The Strategy,

Singapore 609930

TEL: 65-6544-8000 FAX: 65-6544-7390

Sony Corporation of Hong Kong Ltd.

Computer Peripheral Sales & Marketing Division

Electronic Devices Marketing Hong Kong

45/F, The Lee Gardens, 33 Hysan Avenue, Causeway Bay, Hong Kong

TEL: (852) 2909-1008 FAX: (852) 2909-2001

Sony Corporation of Hong Kong Ltd. Beijing Rep. Office

Computer Peripheral Div.

Full Link Plaza Tower A 11/F., No.18 Chaoyangmenwai Ave., Beijing

100020 P.R.C.

TEL: 86-10-6588-0633 FAX: 86-10-6588-0855

URL: http://www.sony.com.cn/ed/cp/ait/

Sony Corporation of Hong Kong Ltd.,

Electronic Devices Marketing Hong Kong

Computer Peripherals Sales & Marketing Div.

8/F, One Corporate Avenue, 222 Hu Bin Road. Luwan District,

Shanghai. P.R.C. Postcode 200021

TEL: 86-21-6121-6878

URL: http://www.sony.com.cn/ed/cp/ait/

35

Page 36

Sony Brasil Ltda.

Rua Inocéncio Tobias, 125, Barra Funda

São Paulo-SP, Brasil 01144-000

TEL: (55) 11-2196-9000 FAX: (55) 11-2196-9186

URL: http://www.sonybrasil.com.br

Sony Australia Limited

33-39 Talavera Rd.

NORTH RYDE, NSW 2113

TEL: 1300-13-7669 FAX: 02-9870-5864

e-mail: CIC-customerissues@ap.sony.com

Sony New Zealand

Akoranga Business Park

NORTH SHORE, AUCKLAND

TEL: 0800-76-6969 FAX: 09-308-9300

e-mail: CIC-customerissues@ap.sony.com

Sony Chile Ltda

Av. Kennedy 8017, Las Condes, Santiago, Chile

TEL: (02) 210-6000 FAX: (02) 210-5417

Sony Taiwan Limited

Optical Devices Storage Dept. Data Storage Section

5F, 145 Changchun Road, Taipei 104, Taiwan

TEL: 886-2-2522-7920 FAX: 886-2-2522-2153

Sony Korea Corporation EDMK CP Sales & Marketing Team

34F, ASEM Tower, World Trade Center, 159-1, Samsung-Dong,

Kangnam-Ku, Seoul, 135-798, Korea

TEL: 82-2-6001-4249 FAX: 82-2-6001-4115

URL: http://www.sony.co.kr/cp/

Sony Gulf FZE Computer Display & Peripheral Div.

P.O.BOX 16871, Jebel Ali, Dubai, U.A.E.

TEL: 971-4-8815488 or 8816912 FAX: 971-4-8817210 or 8816259

Sony Marketing of Japan

Business Solution Dept. Server Solution Marketing Section

URL: http://www.sony.co.jp/STORAGE

36

Page 37

Loading...

Loading...