Page 1

SER VICE MANU AL

AIR CONDITIONER

AF-R100CX

AF-R120CX

S3203AFR12CX/

MODELS

AF-R100CX

AF-R120CX

In the interest of user-safety the air conditioner should be restored to

its original condition and only parts identical to those specified should

be used.

TABLE OF CONTENTS

Page

SPECIFICATIONS .................................................................................................................................................2

WIRING DIAGRAM................................................................................................................................................3

EXTERNAL DIMENSIONS ....................................................................................................................................3

OPERATION INSTRUCTIONS............................................................................................................................. 4

INSTALLATION INSTRUCTIONS ........................................................................................................................ 6

DISASSEMBLING PROCEDURE......................................................................................................................... 8

HOW TO REPAIR REFRIGERATION ................................................................................................................ 12

ELECTRICAL COMPONENT TEST .................................................................................................................... 14

MICROCOMPUTER CONTROL SYSTEM ..........................................................................................................15

TROUBLESHOOTING GUIDE ............................................................................................................................19

COOLING LOAD ESTIMATE FORM ...................................................................................................................24

RUNNING CONDITION .......................................................................................................................................26

PACKING AND ACCESSORIES ......................................................................................................................... 27

REPLACEMENT PARTS LIST ............................................................................................................................28

SHARP CORPORATION This document has been published to be used for after

sales service only.

The contents are subject to change without notice.

1

Page 2

AF-R100CX

AF-R120CX

SPECIFICATIONS

Models AF-R100CX AF-R120CX

Cooling capacity BTU/h 10000 12000

Moisture removal Pints/h 2.7 3.3

ELECTRICAL DATA

Phase Single

Rated frequency Hz 60

Rated voltage Volts 115

Rated current Amps 9.0 11.5

Rated input Watts 1000 1200

Power factor % 97 91

EER BTU/Wh 10.0 10.0

COMPRESSOR

Type (Hermetically sealed rotary type)

Model, Remarks 44R251AC-AJS, 840 W 44B124HX1EF, 1000W

REFRIGERANT SYSTEM

Evaporator Slit fin, Grooved tube, Ø 9.53 mm Hair pin

Condenser Louver fin,

Control O.D. x I.D. x Length x Q'ty(mm)

Capillary tube 2.7 x 1.4 x 400 x 1 Capillary tube 2.7 x 1.2 x 800 x 2

Refrigerant volume R-22(OZ) 18.3(Factory charged) 19.4(Factory charged)

Grooved

tube, 7mm Hair pin

NET DIMENSIONS

Width Height Depth

inches(mm)

22-1/16(560) x 14-3/4(375) x 24-5/16(617)

Net Weight lbs 83 85

GROSS DIMENSIONS

Width Height Depth

inches(mm)

25-25/32(655) x 18-29/32(480) x 27-7/8(708)

Gross Weight lbs 94 96

FAN SYSTEM

Indoor side(Evaporator) Centrifugal fan

Outdoor side(Condenser) Propeller fan

Air flow rate(indoor side) CFM (High/Med/Low) 304 / 254 / 223 (High/Med/Low) 318 / 254 / 219

OTHERS

Safety devices Compressor: Overload relay

Fan motor: Internal thermal protector

Air filter Polypropylene net

Power cord length ft 4.3

Power plug type 125V, 15A

ELECTRICAL PARTS

Running capacitor 250V-60µF 370V-50µF

Fan capacitor

250V-6µF x 2 250V-6µF x 2

Thermistor 15k at 78˚F

Fan motor ARS030ZUEA/SHP(MLA895) ARS030ZUEA/SHP(MLA895)

Overload relay MRA4789-9053 MRA98693-12007

2

Page 3

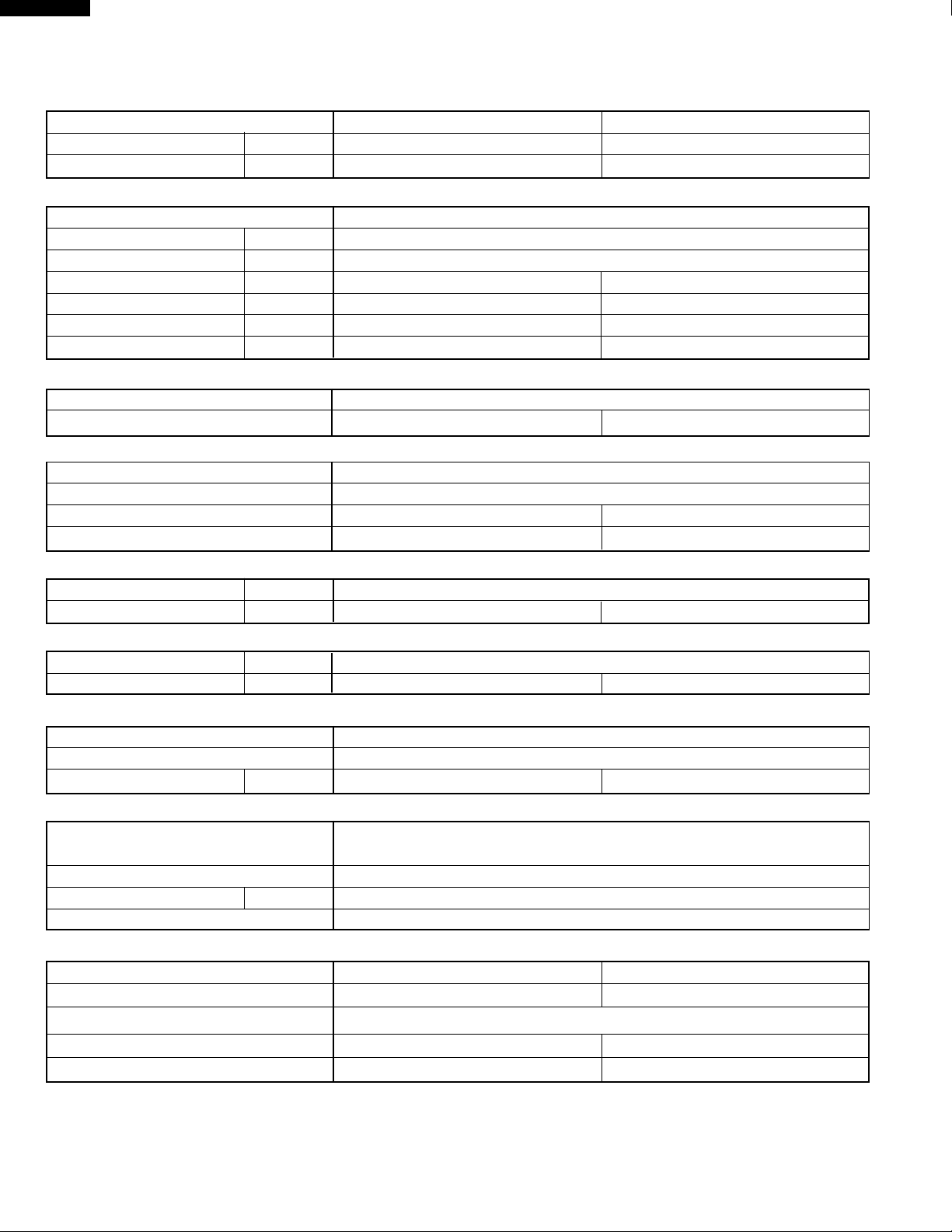

WIRING DIAGRAM

AF-R100CX

AF-R120CX

POWER SUPPLY CORD

115V 60Hz

RUNNING CAPACITOR

RIBBED

AF-R100CX AF-R120CX

250V 60µF 370V 50µF

FAN MOTOR

CAPACITOR

250V 6µF x 2

BL

BL

BK

BL

NON RIBBED

GR

OVERLOAD

PROTECTOR

COMPRESSOR

MOTOR

RUNNING

CAPACITOR

BK

BK

123654

BL

BK

GYREOR

H

THERMAL

PROTECTOR

M.C

A.C

IN

MRY

OUT

BK

BK

C

R

RE

GY

RE

OR

WH

CONNECTOR

WH

M

L

FAN MOTOR

S

WH

GY

8

7

1

3

5

3A 125V

FU1

CONTROL

BOAD UNIT

NR

C1

CNR1

CNR2

CNR3

BCN1

TR

RY1

RY2

RY3

WIRE COLOR

BK

BL

RE

WH

GR

GY

OR

THERMISTOR

CN1

(

ROOM TEMP

YELLOW TH1

CN2

CN3

: BLACK

: BLUE

: RED

: WHITE

: GREEN

: GRAY

: ORANGE

)

BCN2

DISPLAY

BOARD

UNIT

BCN3

Figure W-1

EXTERNAL DIMENSIONS

22-1/16"

38-19/32"

27-5/32"

24-5/16"

5-3/16"

1-3/8"

14-3/4"

16-23/32"

19/32"

3

Page 4

AF-R100CX

AF-R120CX

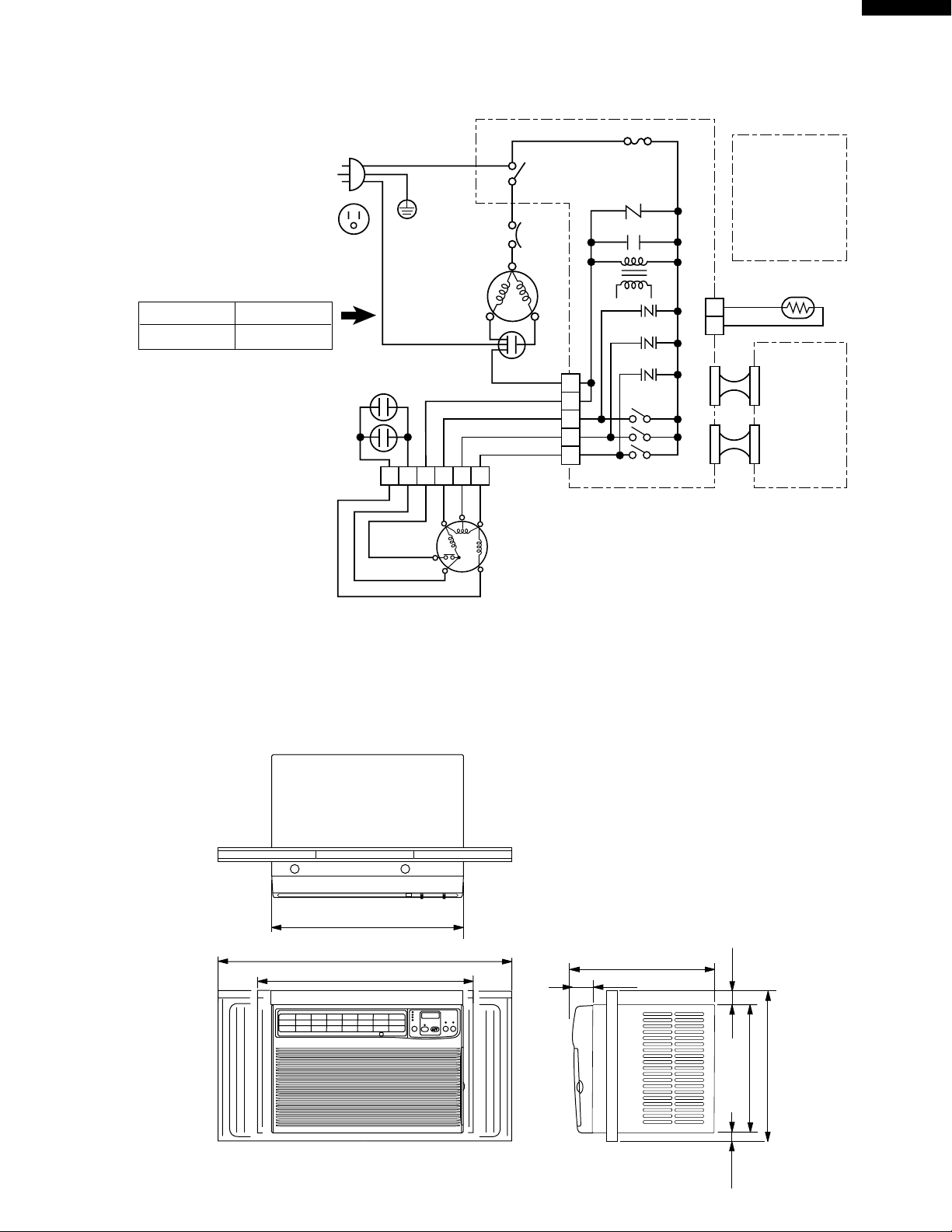

OPERATION INSTRUCTIONS

UNIT

1

Front panel

2

Air inlet (Indoor side)

Louvers

3

Air outlet (Indoor side)

4

5

Exhaust lever

6

Control panel

Cabinet

7

8

Air outlet (Outdoor side)

9

Air inlet (Outdoor side)

10

Filter (Pull the filter handle to the right to remove.)

11

Filter handle

12

Power cord

CONTROL PANEL

5

6

4

7

3

8

9

10

2

1

11

12

1

SELECTOR indicator

Receiver window for remote control

2

signal

Display

3

SELECTOR pad

4

TIMER ON/OFF pad

5

6

TIMER indicator

7

TEMPERATURE setting pad

----Lower temp.

----Raise temp.

ENERGY SAVER pad

8

ENERGY SAVER indicator

9

10

POWER ON/OFF pad

11

POWER indicator

COOLING OPERATION

Procedure Pad Display / Indicator

HOW TO OPERATE

1 2 3

HIGH COOL

MED COOL

LOW COOL

FAN ONLY

SELECTOR

TIMER

ON/OFF

4 5 6 7 8 9

F

hr

TEMP

ENERGY

SAVER

POWER

ON/OFF

10 11

1. Touch POWER ON/OFF pad.

• The unit is preset at 74°F and HIGH

COOL. This will show in the display

when the power is first turned on.

2. To turn off the unit, touch POWER ON/

OFF pad again.

POWER

ON/OFF

POWER

ON/OFF

F

hr

• POWER indicator and SELECTOR

indicator (HIGH COOL) will light.

• POWER indicator and SELECTOR

indicator will go off.

4

Page 5

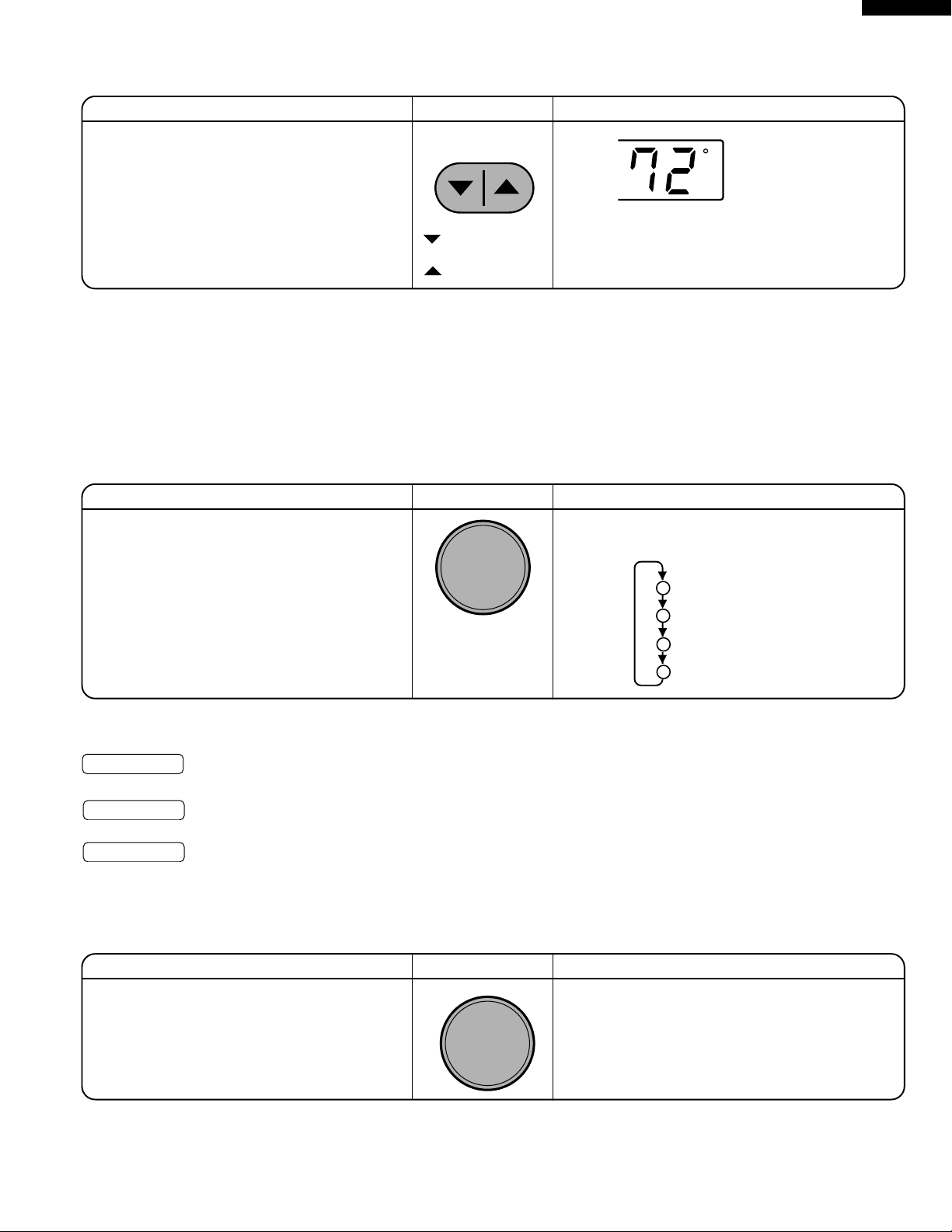

TO CHANGE TEMPERATURE SETTING

MED COOL

LOW COOL

Procedure Pad Display / Indicator

AF-R100CX

AF-R120CX

During cooling operation

TEMP

F

Touch the TEMPERATURE setting pad to

adjust the temperature setting.

• It can be set within the range of

64°F to 86°F.

---Lower temp.

---Raise temp.

• Display will change as you touch the

pad.

hr

The latest temperature setting will be memorized and will appear on the display the next time the unit is

turned on.

NOTE:

In cases of power outages or when the unit is disconnected; when the power is restored or the unit is

plugged in, the unit and display will return to the preset conditions of 74°F and HIGH COOL. The unit will

not automatically turn back on. The user must touch POWER ON/OFF to resume operation.

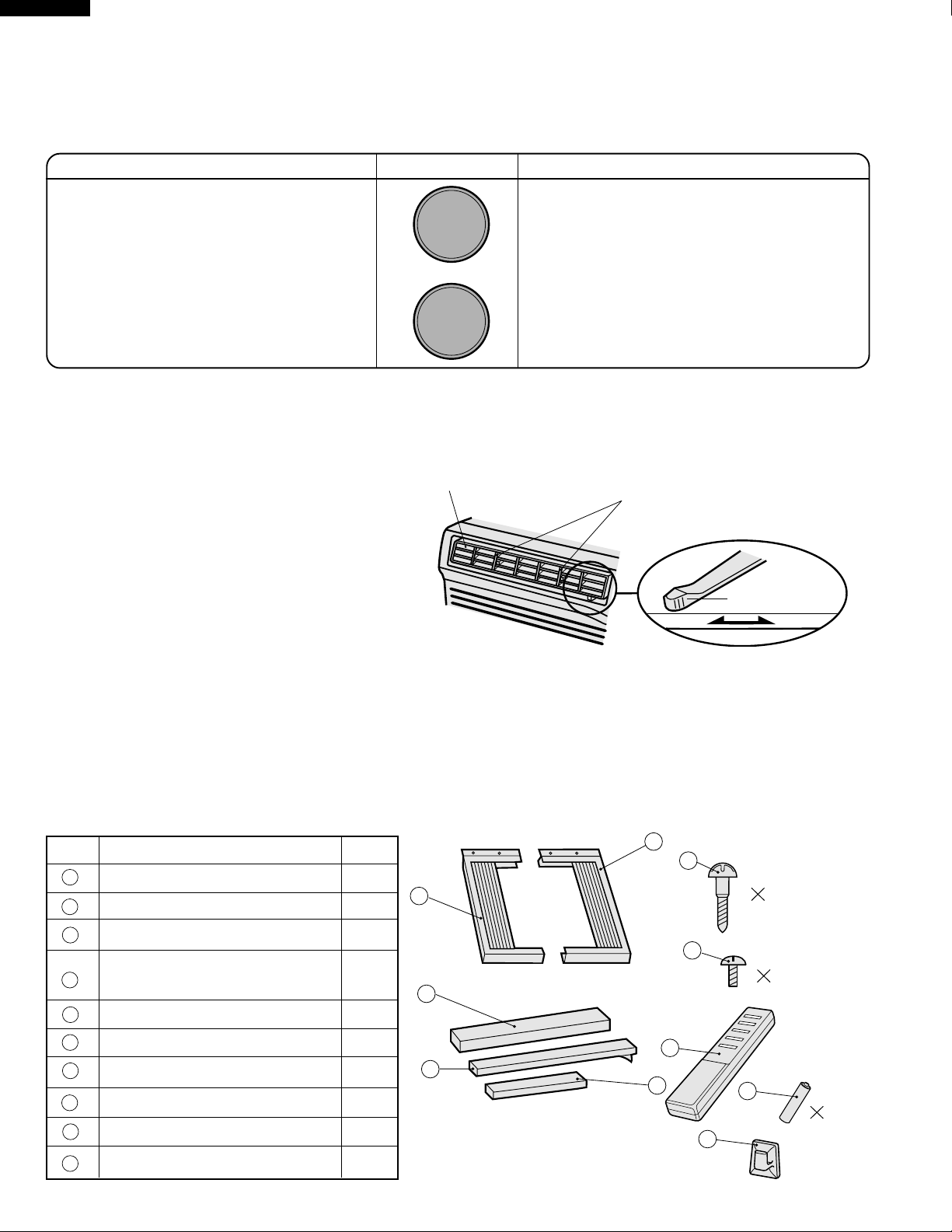

TO CHANGE FAN SPEED

Procedure Pad Display / Indicator

During operation

• SELECTOR indicator will

light in order as you touch.

Touch SELECTOR pad and select

the desired fan speed.

SELECTOR

HIGH COOL

MED COOL

NOTES ON FAN SPEED

HIGH COOL

MED COOL

LOW COOL

Fan and cooling at maximum performance.

Unit is preset to HIGH COOL when first turned on after unit is plugged in.

Fan operates at medium speed; cooling power at medium.

Cooling for sleeping comfort with low fan speed.

FAN ONLY OPERATION

This setting can be used to circulate air whenever cooling is not desired.

The fan will operate at medium speed.

Procedure Pad Display / Indicator

During operation

• SELECTOR indicator FAN ONLY will

light, and the temperature display will

Touch SELECTOR pad and select FAN

ONLY.

SELECTOR

go off. After 5 seconds, the compressor

will stop and the unit will operate in

FAN ONLY mode.

LOW COOL

FAN ONLY

When the unit is turned off, the last fan speed will be stored in memory.

The next time the air conditioner is used, the memorized fan speed will start automatically.

5

Page 6

AF-R100CX

AF-R120CX

ENERGY SAVER

During normal operation, the thermostat automatically controls cooling and the fan runs continuously. When the

ENERGY SAVER is selected, the thermostat automatically controls cooling and the fan automatically stops when

the compressor is not operating. (Fan will stop 30 seconds after the compressor stops.)

Procedure Pad Display / Indicator

During cooling operation

1. Touch ENERGY SAVER pad.

ENERGY

SAVER

• ENERGY SAVER indicator will light.

2. To cancel, touch ENERGY SAVER pad

again.

ENERGY

SAVER

• ENERGY SAVER indicator will go off.

NOTE: ENERGY SAVER cannot be set during FAN ONLY mode operation.

TO CHANGE AIR FLOW DIRECTION

Adjust the louvers to change the direction of air flow for uniform and efficient cooling of the room.

Vertical louvers

EXHAUST

If air in your room is stale, set the EXHAUST lever

to the OPEN position. This will exhaust stale air to

the outside. The EXHAUST lever should normally

be kept in the CLOSED position during cooling for

maximum efficiency.

Adjusts LEFT/RIGHT air flow

Horizontal louvers

Adjusts UP/DOWN air flow

EXHAUST Lever

CLOSED OPEN

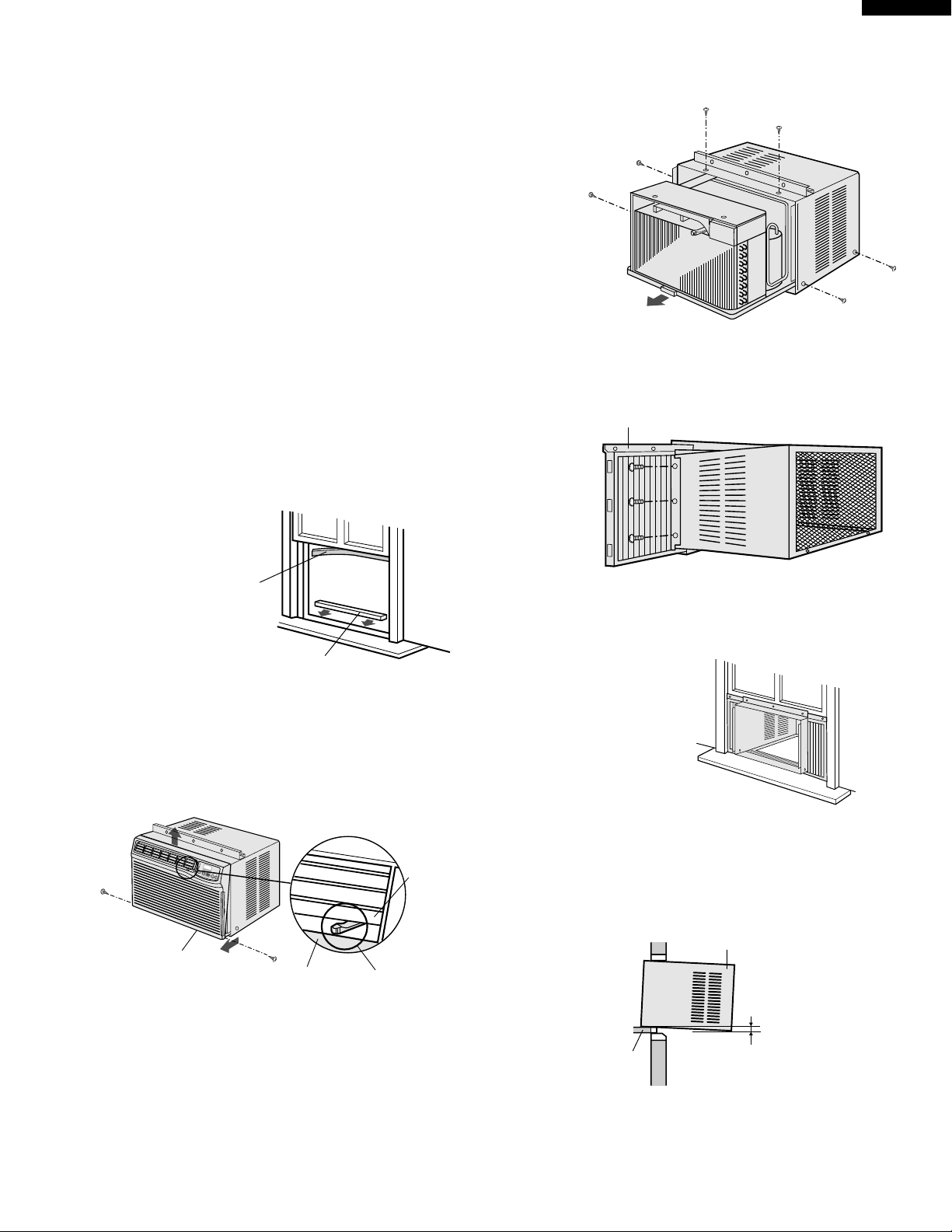

INSTALLATION INSTRUCTIONS

ITEMS PACKED WITH THIS UNIT

No.

1

2

3

4

5

6

7

8

9

10

Right closure assembly 1

Left closure assembly 1

Window sash foam seal 1

Window sash foam seal

(adhesive type)

Bottom gasket 1

Screws(L=1", 25.4mm) 8

Screws(L= 13/ 32", 10mm) 6

Remote control 1

Battery 2

Remote control hook 1

Accessories Q'ty

1

6

2

8

7

1

6

3

8

4

5

9

2

10

6

Page 7

AF-R100CX

AF-R120CX

SUGGESTED TOOLS

1. Screw driver (medium size Phillips)

2. Tape measure or ruler

3. Knife or scissors

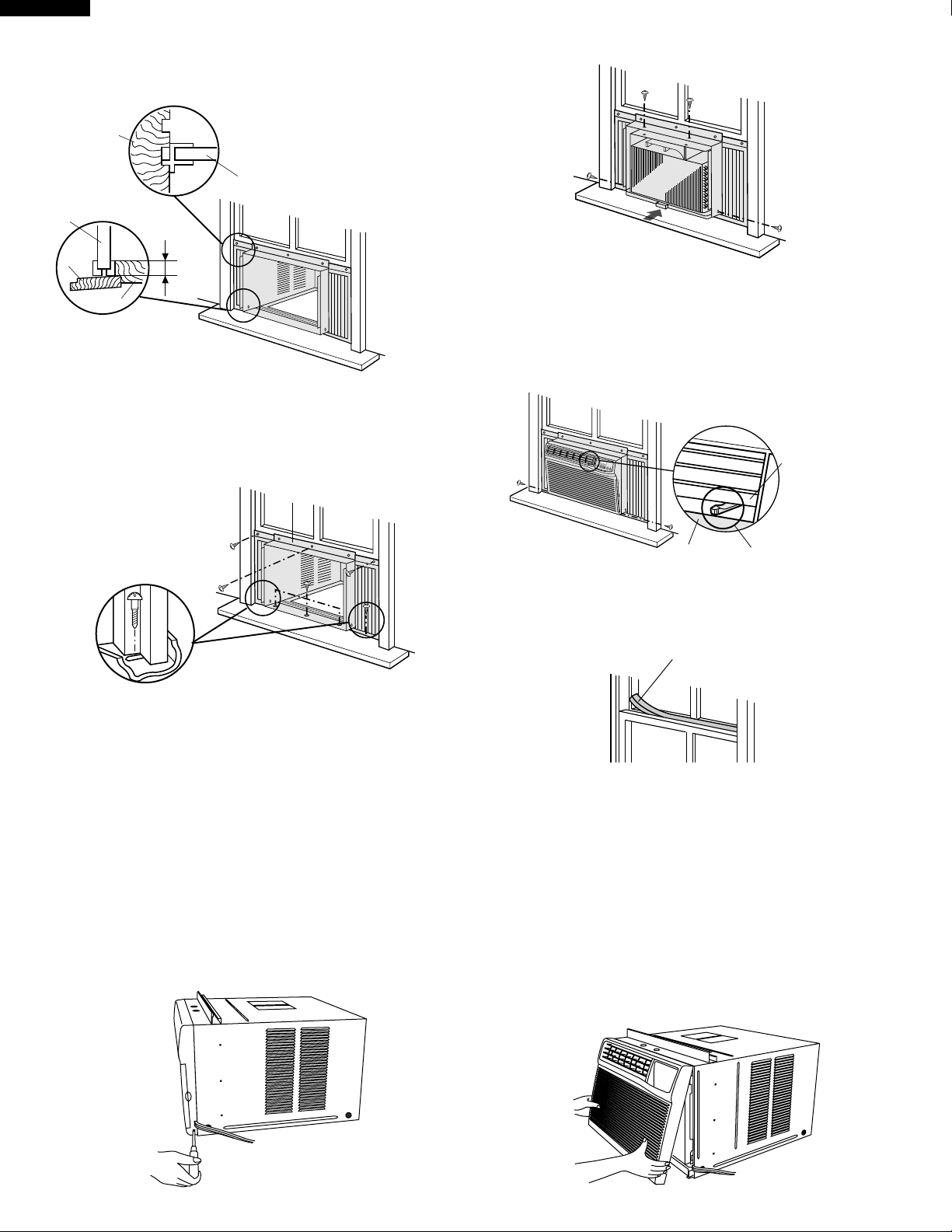

INSTALLATION

These models can also be installed through the wall with

the optional through the wall mounting kit, model AZ80WK. To order this kit either contact your dealer or call

1-800-BE-SHARP.

The wall opening dimensions for through the wall installation

are:

25" (635mm) (W) x 17 -1/ 4 " (438mm) to 17-3/ 4"

(451mm) (H) x 4" (102mm) minimum (D).

Complete instructions are included with the wall mounting

kit.

WARNING: Make sure the unit is turned off and

unplugged before working.

1-1. Cut the window sash foam seal (adhesive type) to the

proper length and attach it to the underside of the

window sash.

1-2. Attach the bottom gasket to the outer side of the

window sill.

CAUTION Do not remove any material (ex.

styrofoam, etc.) from inside the unit.

4. Insert the right closure assembly and the left closure

assembly into the top angle and the bottom channels.

Secure the right and left closure to the cabinet with 6

of the provided screws. (L= 13/ 32 ", 10 mm)

Closure assembly

window sash foam seal

(adhesive type)

bottom gasket

2-1. Unscrew the 2 screws at the corners of the front panel.

Keep them as they will be used later.

2-2. Remove the front panel by pulling the front panel at the

lower corners towards you about an inch.

Next lift it up and pull it towards you.

CAUTION: Take care not to damage the exhaust

lever when removing the front panel.

Horizontal

Louver

Front panel

Front

panel

3-1. Unscrew the 6 stopper screws of the cabinet. Keep

the 4 screws from the top and front , as they will be

used later.

3-2. Slide the chassis out from the cabinet by pulling on the

hand hold located at the bottom center of the chassis.

Exhaust Lever

5. Open the window sash and place the cabinet on the

sill. Close the window sash securely behind the top

angle.If there is space between the bottom channel

and the sill, fill the gap with a thin board or other hard

filler.

WARNING:

At this step, make sure the cabinet is inclined

approximately 1 cm (3/8”) to the back. If the cabinet is

not properly inclined, the water collected in the bottom

tray during operation will not drain properly and may

flow into the room where the air conditioner is installed.

Cabinet

sill

incline backwards about 1cm (3/8")

7

Page 8

AF-R100CX

AF-R120CX

6. Insert the closure assemblies on both sides into the

rails of the jamb.

Jamb

(Left)

Closure assembly

Closure assembly

(Left)

(Left)

Sill

Stool

1/2 inch

(13mm)

7-1. Secure the cabinet to the window stool with 3 screws

(L=1", 25.4 mm), working from the inside of the cabinet.

7-2. Secure the top angle and the closure assemblies to

the window sash with 3 screws (L=1", 25.4 mm).

7-3. Secure the closure assemblies to the sill with 2 screws

(L=1", 25.4 mm).

Top angle

8-1. Slide the chassis back into the cabinet.

8-2. Replace the 4 screws removed in

step 3 to the top

and side of the cabinet .

9-1 Replace the front panel. Slip the exhaust lever through

the opening between the horizontal louver and the

front panel then, hook the cabinet top.

CAUTION:Take care not to damage the exhaust lever with

the front panel.

9-2. Screw the front cabinet on at the bottom corners with

2 screws removed in step 2.

Horizontal

Louver

Front

Panel

Exhaust Lever

10.Cut the window sash foam seal to the proper length

and seal the opening between the top of the inside

window sash and the outside window sash.

Window sash foam seal

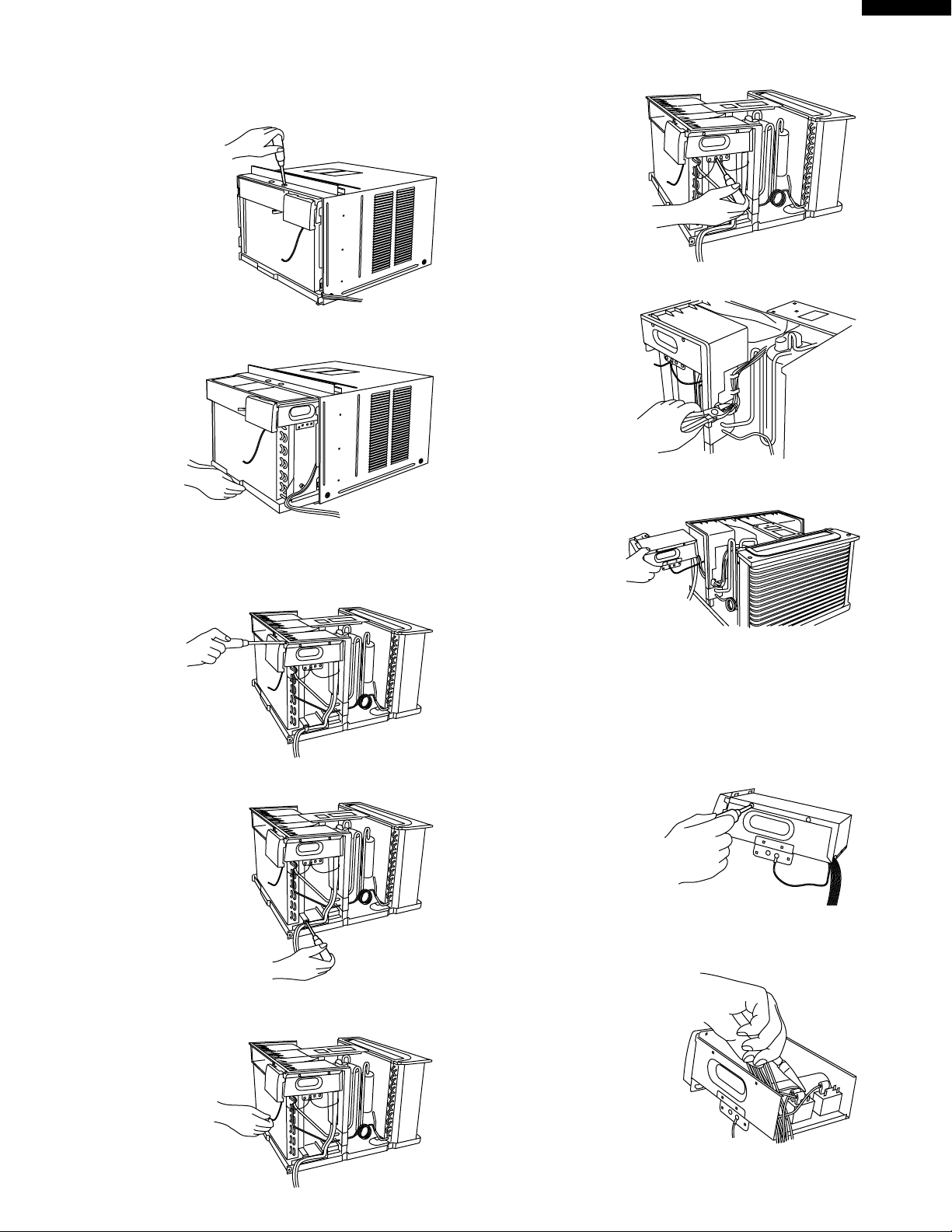

DISASSEMBLING PROCEDURE

CAUTION: DISCONNECT THE ROOM AIR CONDITIONER FROM THE POWER SUPPLY BEFORE ANY SERVICE

1. Unscrew the two screws holding the front panel on each

side.

2. Remove the front panel by pulling it at the lower corner

toward you about 1 inch and next lift up and pull it

toward you.

8

Page 9

AF-R100CX

AF-R120CX

3. Unscrew the four screws holding the cabinet.

Two screws are on top side.

Two screws are on each side.

4. Slide the chassis away from the cabinet by pulling on

each corner of the base pan.

8. Unscrew the one screw holding earth wire .

9. Cut the fixing band holding the wires.

10.Remove the control unit.

5. Unscrew the four screws holding the control unit.

Two screws are on front side.

Two screws are on right side.

6. Unscrew the one screw holding the power supply cord.

11.Unscrew the four screws holding control box cover.

Two are on the right side, one is on the left side, one is

on the back side.

CAUTION: DISCHARGE THE FAN MOTOR CAPACITOR

AND RUNNING CAPACITOR BEFORE

TOUCHING THOSE CAPACITORS OR

OTHER COMPONENTS OR WIRING.

12.Detach each terminals of fan motors by using long-nose

pliers.

7. Unscrew the one screw holding the wire holder.

Pull out thermistor holder.

9

Page 10

AF-R100CX

AF-R120CX

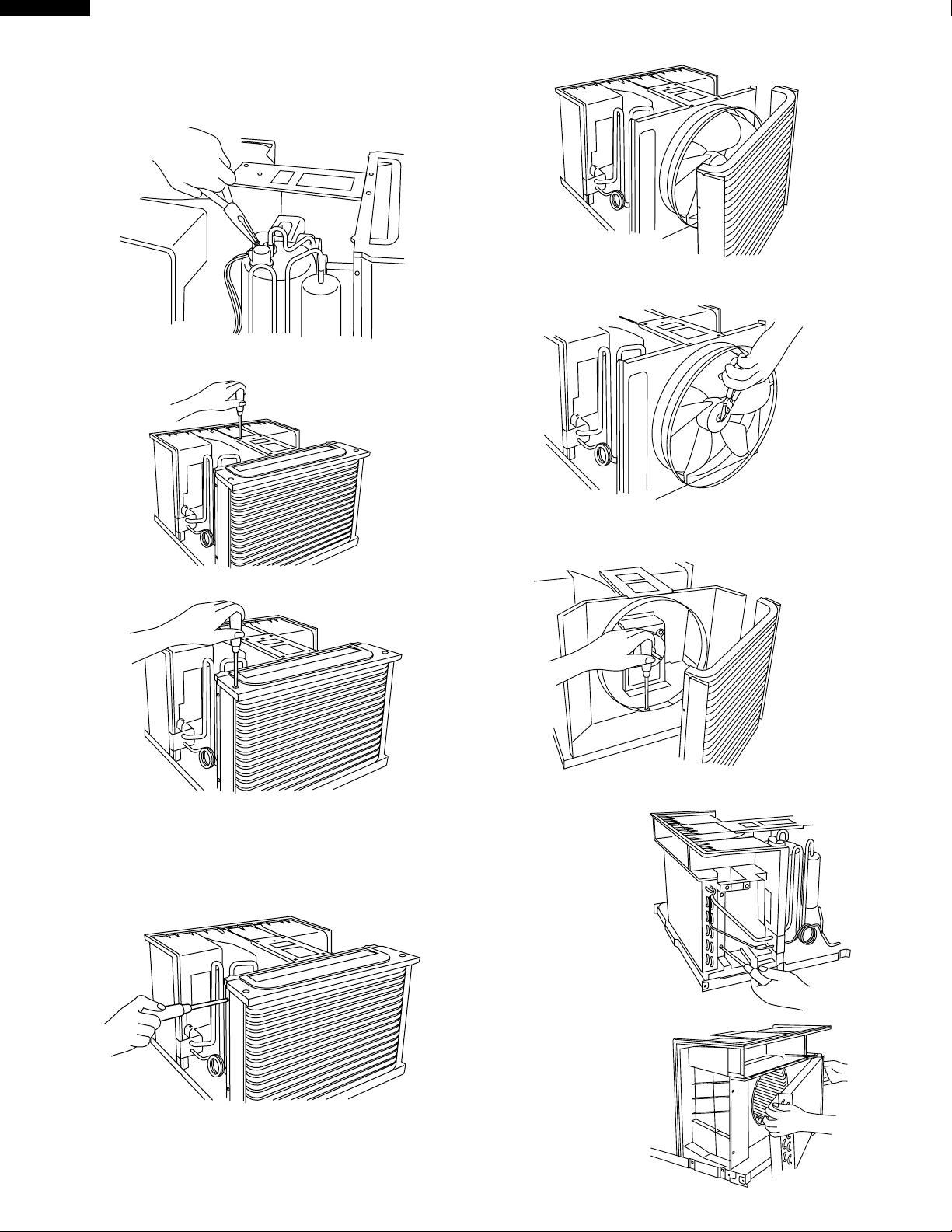

13.Remove the putty and unfasten the one nut at the top of

compressor holding the terminal cover.

Then remove the wiring connector of the compressor

cord.

14.Unscrew the five screws holding the connecting stay.

18.Unfasten the one nut holding propeller fan by rotating it

clockwise. And remove the propeller fan.

15.Unscrew the two screws holding the shroud cover.

16.Unscrew the six screws holding the condenser and

condenser shroud.

Two screws are on the back side.

Four screws are on the each side.

Unscrew the two screws holding the condenser cover .

19.Unscrew the three screws holding condenser shroud.

Note: Seal three female screws with siliconsealer

before re-installing.

20.Unscrew the four screws holding the evaporator.

Two are on left side.

Two are on right side.

17.Remove the condenser by liftting up about 1 inch and

pull it toward you and move to right.

21.Remove the evaporator.

10

Page 11

22.Unscrew the four screws holding the bulkhead.

Three screws are on the each side.

One screw is on the bottom side.

Note: Seal one female screws with siliconsealer

before re-installing.

23.Unscrew the two screws holding the orifice

AF-R100CX

AF-R120CX

27.Unscrew the three screws holding the printed wiring

board.

24.Unfasten the one screw holding the centrifugal fan by

rotating it counterclockwise.

25.Unscrew the one screw holding the fan motor lead wire.

28.Detach terminals by using long-nose pliers.

29.Unscrew the five screws.

Two screws are holding the fan motor capacitors.

One screw is holding the capacitor clamp.

Two screws are holding the transformer.

Unfasten the three spacers of the control box unit.

26.Remove the fan motor by unscrewing the four screws

that have large head holding it with bulkhead.

Note: Torque is 7 - 10 kgf.cm at re-installing.

11

Page 12

AF-R100CX

;;

;;

;;

INNER CONE

TORCH STEM

SILVER ALLOY

Figure 3

Directing Torch Flame to Copper Tubing.

3/8"

AF-R120CX

HOW TO REPAIR REFRIGERATION

Before sealed system work can be preformed a refrigerant recovery EPA and LOCALLY approved certification is

required, additionally, EPA and LOCALLY approved refrigerant recovery equipment is required.

SEALED SYSTEM REPAIR

Sealed system repairs should be properly diagnosed before entering into a repair of the system.

It is important to follow proper procedures when doing a system repair for safety reasons and that the repair will result in a

restoration of the system to proper factory standards.

SAFETY REMINDERS

1) Do not heat any system component with an open flame for any reason.

2) Do not solder until you are sure that all refrigerant has been removed from the system.

3) Do not heat the charging cylinder with an open flame. Use warm water only and do not exceed 125˚F (not too hot to

keep your hand in.)

4) Do not over fill any charging cylinders, as they could explode when over

filled.

5) Use proper wrenches.

6) Use safety goggles when working with refrigerants.

7) Keep a fire extinguisher within easy reach.

8) Watch flame direction when soldering so as not to burn clothing, wiring or

other components.

9) Solder in a well ventilated area. If a high concentration of freon is present,

an open flame will create phosgene gas which can be harmful.

GOOD FIT

PROPER

JOINT FIT

CLEARANCE

.001"TO .003"

POOR FIT

PROPER SOLDERING

Joint clearances should be maintained so that the brazing alloy will flow

between the closely mated surfaces rather than forming large fillets.

This films make the strongest joints, capillary attraction also work best with

close tolerance.

The best clearance is between 0.001" to 0.003", the amount of lap will be

approximately 3/8" depending on the swaging tool used. (Figure 1.)

CLEANING TUBING

To make a sound, leak tight joint, the brazing alloy when raised to brazing

temperature, must wet and flow freely over the entire surface of the tubing in

the joint area.

To assure this, the tubing surfaces must be free of all dirt, grease, oil and

oxides otherwise the alloy will not wet and flow properly over any surface with

these elements present. Cleaning can be done with an abrasive cloth or steel

wool. Never blow into the tubing because this will introduce a lot of moisture

into the system. Open tubing joints should be covered if exposed for long

periods of time.

PROPER FLUXING

Flux is necessary when using silver solder; it is not required when using silfos

on copper to copper joints.

To do a good job the flux should cover the tube surface completely. Be careful

not to introduce any flux inside the tubing.

Fluxing should be done after the tubing is mated together and just before

brazing is done. Do not allow it to dry out.

When brazing, the flux should become entirely liquid and clear, like water. The

temperature will be at 1100˚F and only a little more heat will allow the alloy

to flow freely into the joint.

Joint Clearance.

Figure 1

EMERY CLOTH

KEEP TUBE IN

DOWNWARD POSITION

Cleaning Tubing.

Figure 2

12

Page 13

AF-R100CX

AF-R120CX

HEATING THE TUBING

Direct the torch flame so that the larger tube receives most of the heat. Silver

solder flows at 1200˚F and silfos flows at 1300˚F.

Heat all around the tubing.

The flame is composed of two cones, a smaller inner cone (pale blue) in color and

a much larger outer cone. The hottest part of the flame is at the tip of the inner

cone. The flame should be directed at the joint with the tip of the cone just touching

OUTER CONE

HOTTEST PART

OF FLAME

INNER CONE

the surface of the tubing. Figure 3 and 4.

TORCH STEM

Composition of Torch Flame.

Figure 4

DEHYDRATING SEALED SYSTEM

Many servicers feel that since air conditioners run with evaporator temperatures above 33˚F, moisture will not present a

problem. Nothing is further from the truth. Oxygen in moisture plus the heat produced during compression will react with the

refrigerant oil to produce harmful acids in the system which will break down motor winding insulation, create sludge and pit

component parts, reducing efficiency of the air conditioner and shortening the life of compressors.

There it becomes mandatory that good dehydrating practices be adhered to at all times.

Proper hook up procedures as shown in Figure 5 must be used in order to pull and good vacuum from the system.

The use of a good vacuum pump is very important so that the boiling point of any water in the system will be lowered to a

point where it will vaporize and be expelled from the system in the form of vapor.

Type of evacuation methods

1. Piston Type Compressor No good.

System parts must be above 110 ˚F.

2. Rotary Vacuum Pump Disavantages.

Low CFMC. 4 oil gets dirty.

3. Single State Vacuum Pump will not clean oil.

Oil must be changed often.

TO RELATED SERVICE

VALVE OR PROCESS

TUBES OF THE UNIT.

ELECTRIC

VACUUM

GAUGE

LARGE DIAMETER

BRAIDED VACUUM

HOSES

HIGH VACUUM

MANIFOLD

DIAL-CHARGE

CHARGING CYLINDER

LOW SIDE

GAUGE

HIGH SIDE

GAUGE

4. Two Stage Vacuum Pump will reach 50 microns.

First stage is below atmospheric pressure.

Moisture is removed into second stage which works up

to atmospheric pressure thus keeping oil clean.

Manometer cannot be read to 1/2 mm. Micron gauge

reads from 25,400 microns to 0.

HIGH VACUUM PUMPHook up for Evacuation and charging

Figure 5

It becomes clear that good equipment and maintained properly must be used in order to remove air and moisture from the

system.

When a vacuum of 1,000 to 500 microns is reached, block off the vacuum pump from the system.

This is done by closing the value between the pump and system. If the micron gauge does not increase above 1,000, the

system is free of moisture and no leak exists. If the micron gauge increases to higher levels moisture or a leak exists.

LEAKS

Several methods are used to detect leaks in systems.

Electronic Leak Detectors are very sensitive and are able to detect leaks down to 1/2 ounce per year.

A good electronic leak detector is generally far better in locating very small leaks.

Halide Torch be sure the room is free from refrigerant vapors. Watch the flame for the slightest change in color.

13

Page 14

AF-R100CX

AF-R120CX

A very faint green indicates a small leak. The flame will be unmistakably changed to green or purple when large leaks

are encountered. To simplify leak detection pressurize the system to approximately 75 lbs.

Some leaks can be located by a visual inspection of the system components and solder joints and if oil is found at any

given location it generally is a sign that a leak exists at that point due to the fact that flame does carry oil with it travels

through the system.

Soap Bubbles

Liquid detergents can sometimes assist in finding small leaks by brushing detergent on the suspect area and

watching for bubbles. Before applying detergent be sure that the system is pressurized.

Tap line devices are permissible for diagnosis only they are not suitable when evacuating the system. After the diagnosis

has been made they must be removed so that the system will be restored to a hermeticly sealed condition.

ELECTRICAL COMPONENT TEST

RUNNING CAPACITOR AND FAN CAPACITOR

CAUTION:DISCHARGE THE RUNNING CAPACITOR AND FAN CAPACITOR BEFORE TOUCHING CAPACITOR

OR WIRING.

(1) Discharge capacitor by shorting terminals.

(2) Take the wires off the capacitor terminals.

(3) Set the selector switch of a volt-ohm-meter(or a tester) on the resistance range.

(4) Connect the probes to the capacitor terminals and watch the indicator swing.

The indicator does not swing at all ..... Open.

The indicator swings but does not return ..... Shorted.

The indicator swings, then returns a moment later ..... Good.

FAN CAPACITOR

RUNNING CAPACITOR

INSULATION TEST

Check the resistance between the terminals and case.

Reading must be more than 10M at DC 500V.

OVERLOAD RELAY

Check continuity between terminals with volt-ohm-meter.

INSULATION TEST

Check resistance between terminals and the relay case.

Reading must be more than 10M at DC 500V.

COMPRESSOR

(1) Take the wires off compressor terminals.

(2) Set selector switch of volt-ohm-meter on the resistance range.

(3) Put the probes on the terminals of the compressor and check continuity between each terminal.

INSULATION TEST

Check the resistance between the terminals and the copper tube.

Reading must be more than 10M at DC 500V.

14

Page 15

MICROCOMPUTER CONTROL SYSTEM

AF-R100CX

AF-R120CX

1. Temperature control characteristic

1-1 COOL operation

In the “COOL” mode, the thermostat circuit is controlled

by two thermostat lines (C1, C2).

C1

C2

Room temperature (°F)

86

84

64

62

64 86

Preset temperature (°F)

("THERMO" switch)

Figure Y-1

2. Operation mode

2-1 COOL operation

The compressor turns on or off, at thermostat lines C1

and C2. The fan motor is also controlled with the

compressor.

States 1 & 3

States 2

1

: Compressor ON

: Compressor OFF

3

C1

3. Fan speed

Fan speeds are given by the fan motor, “H”, “M” and

“L”, which are available in the following operation

mode.

Table Y-1

Selector Fan motor

HIGH COOL H

MED COOL M

LOW COOL L

FAN ONLY M

4. 12-hours timer

4-1 OFF-TIMER operation

Set the delay timer during operation.

The unit will turn off automatically according to your

setting. Timer duration can be set by 0.5 hours to

maximum 12 hours. Up to 9.5 hours, you can set by 0.5

hours increments and from 10 to 12 hours, by 1 hour

increment.

If you touch button “POWER ON/OFF” during OFFTIMER operation, then the unit turns off and OFFTIMER operation is cancelled.

4-2 ON-TIMER operation

Set the delay timer when unit is not operating.

The unit will turn on automatically according to your

setting. Timer duration can be set by 0.5 hours to

maximum 12 hours. Up to 9.5 hours, you can set by

0.5 hours increments and from 10 to 12 hours, by 1

hour increment.

If you touch button “POWER ON/OFF” during ONTIMER operation, then the unit turns on and ON-TIMER

operation is cancelled.

ON-TIME and OFF-TIME display will count down the

remaining time.

from 0.5 to 9.5 ..... 0.5 hours

from 10 to 12 ....... 1 hour

Room temperature (°C)

Room temperature transition

Preset temperature (°C)

Figure Y-2

2-2 FAN ONLY operation

The fan motor always turns on.

C2

5. Energy saver

During normal operation, the thermostat automatically

controls cooling and the fan runs continuously whenever

the air conditioner is in operation.

When the ENERGY SAVER is set, the thermostat

2

automatically controls cooling and the fan automatically

stop when compressor is not operating. (Fan will stop

in 30 seconds after the compressor stops.)

ON

Compressor

ON

Fan

OFF

OFF

30 seconds

Figure Y-3

15

Page 16

AF-R100CX

AF-R120CX

6. Safety start

When you turn the air conditioner OFF and restart again soon, wait at least 3 minutes before the cooling operation

starts.

7. Test mode

Keep pushing both buttons “POWER ON/OFF” and “ " ” and supply the power, the system will go to the test mode.

In this mode, the output operation is switched by pushing buttons. Normal outputs are shown in Table Y-2.

Table Y-2

No.

0

1

2

3

4

5

6

7

8

9

Push key

(Switch)

LED1

Plug in the power supply

cord while pushing

POWER ON/OFF key

and (down) key.

SLECTOR (SW3)

SLECTOR (SW3)

SLECTOR (SW3)

POWER "ON/OFF" (SW4)

UP (SW5)

DOWN (SW6)

TIMER (SW2)

ENERGY SAVER (SW1)

POWER ON/OFF

by the Remote control

Input-check Output-check

TH1

Open/Short check

Indicator by LED2

8.8

0.1

0.1

0.1

0.2

0.3

0.4

0.5

0.6

0.6

= Thermistor check included, = Thermistor check not included

T(˚C) T(˚F) R(k )

0 32.0 49.33 1.17

1 33.8 46.86 1.21

2 35.6 44.53 1.26

3 37.4 42.33 1.31

4 39.2 40.25 1.36

5 41.0 38.29 1.41

6 42.8 36.44 1.46

7 44.6 34.68 1.51

8 46.4 33.02 1.56

9 48.2 31.45 1.61

10 50.0 29.96 1.67

11 51.8 28.55 1.72

12 53.6 27.22 1.78

13 55.4 25.96 1.83

14 57.2 24.76 1.89

15 59.0 23.62 1.94

16 60.8 22.56 2.00

17 62.8 21.52 2.05

18 64.4 20.55 2.11

19 66.2 19.63 2.17

20 68.0 18.76 2.22

LED lighting

HIGH

MED

LOW

FAN

POWER

TIMER

COOL

COOL

COOL

ONLY

[LED2]

[LED3]

[LED4]

TH: OK

TH: OK

TH: OK

TH: OK

TH: OK

TH: OK

TH: OK

TH1: OPEN/SHORTcheck( =OK) Comp.: Not output

[LED5]

ON/OFF

[LED6]

ENERGY

SAVER

[LED7]

[LED8]

FAN

COMP

output

output

OFF OFF

LOW OFF

MED OFF

HIGH OFF

OFF OFF

LOW OFF

MED OFF

HIGH OFF

OFF OFF

LOW OFF

All LEDs lighting

FAN output check

Key operation check

Remote control operation

check (Receive)

Table Y-3

V(volts)

T(˚C) T(˚F) R(k ) V(volts)

21 69.8 17.93 2.28

22 71.6 17.14 2.33

23 73.4 16.39 2.39

24 75.2 15.68 2.44

25 77.0 15.00 2.50

26 78.8 14.36 2.55

27 80.6 13.74 2.61

28 82.4 13.16 2.66

29 84.2 12.60 2.71

30 86.0 12.07 2.77

31 87.8 11.57 2.82

32 89.6 11.09 2.87

33 91.4 10.63 2.93

34 93.2 10.19 2.98

35 95.0 9.78 3.03

36 96.8 9.38 3.08

37 98.6 9.00 3.13

38 100.4 8.64 3.17

39 102.2 8.30 3.22

40 104.0 7.97 3.27

Check item

and Remark

V ....... Input the voltage of microcomputer (No. 10-port).

16

Page 17

CA1: 1000pF x 8 (CAPACITOR ARRAY)

RA1: 10kΩ x 8 (RESISTOR ARRAY)

IF NOT SPECIFIED 1/5W, ±5% (RESISTOR)

IF NOT SPECIFIED 50V 1000pF (CAPACITOR)

IF NOT SPECIFIED 1SS133T-72 (DIODE)

: INDICATED POSITION IS FUNCTION TEST POINT

SW1: ENERGY SAVER

SW2: TIMER

SW3: SELECTOR

SW4: POWER

SW5: UP-KEY

SW6: DOWN-KEY

NO INSERT PART

C13 16V 10µF

R22 10k(F)

CA1: 1000pF x 8

RA1: 10kΩ x 8

LED2

,

LED3, LED4, LED5 GREEN

COLOR

LED7, LED8

YELLOW

LED6

LED10

RED

ORANGE

R11 ~ R18

150Ω x 8

LED2 COOL/H

LED3 COOL/M

LED4 COOL/L

LED5 FAN

LED6 ON/OFF

LED7 TIMER

LED8 ENERGY

SAVER

HEATSINK

POWER SUPPLY

115V AC

60Hz

FAN MOTOR

CAPACITOR

250V 6µF x 2

RUNNING CAPACITOR

AF-R100CX AF-R120CX

250V 60µF 370V 50µF

GRAY

RED

ORANGE

WHITE

CONNECTOR

BL

BL

BK

RE

OR

WH

GY

BK

GY

RE

GR

WH

123654

L

BK

BL

M

MA

H

FAN

MOTOR

25˚C

TH1(15k)

ROOM

Temp

YELLOW

CN1

CNR1 - CNR3

C13 C14

16V

10µ

R22

R10

15K(F)

-5V

Q2, Q3, Q4

KRA106M

(DTA143ZS)

D7 D6

D5D8

COMP

MRY

RY1

RY2

RY3

FAN H

FAN M

FAN L

12V

R9

10K

++

RY1

RY2

RY3

CNR1

CNR2

CNR3

BCN1

671

3

5

RUNNING

CAPACITOR

GRAY

RS

C

COMPRESSOR

MOTOR

OVERLOARD

PROTECTOR

MRY

3A

125V

FU1

C1

D1

D3 D4

D2

C2 C3 C4 C5 C6 C7

C8

0V

Q5

R2

15K

250V

0.1µF

NR

271

TR

D1 - D4

ZD1

HZ4A-2

25V

0.1µ

25V

47µ

25V

0.1µ

25V

0.1µ

25V

1000µ

25V

0.1µ

10V

100µ

KRA101M

(DTA143ES)

COM

79L05

OUT

IN

5V

12V

R1

22K

Q6

KRC101M

(DTC143ES)

R3

10K

C10

C9

16V

0.01µ

R4

20k

5V

Q7: KRA106M

(DTA143ZS)

Q1: KRA105M

(DTA123JS)

Q7

R8

2.7K

BZ

Q1

Q2

Q3

Q4

OSC

5V

4MHz

C11

16V

10µ

C12

25V

0.1µ

5V

C20

C21

C22

CN2

7654321

BCN2

5V

Q8

Q9

Q10

Q8 ~ Q10

KRA222M

(DTB123EA)

IC4

C18

16V

10µ

C17

PHOTO

DETECTOR

UNIT

E/SAVER

SW1

SW2

SW3

SW4

SW5

SW6

D10

D11

D12

D13

D14

D15

TIMER

SELECTOR

POWER

UP-KEY

QWN-KEY

R12

R11

R13

R14

R15

R16

R17

R18

LED1

1

9

10

18

CN3CA1 BCN3

5V

RA1

IC1

5V

TMP47C443N

1X V

HOLD

R92

R91

R90

R83

INT1

R81

INT2

R63

R62

R61

R60

R53

X

RESET

R70

R71

R72

R40

R41

R42

R43

R50

R51

R52

V

OUT dd

IN

SS

28272625242322212019181716

15

2345678

9

1011121314

TEST

5V

R20

R21

10K

10K

10K 10K

10K

R5

C15

C19 16V 10µF

C16

R7

R6

IN OUT

COM

7812

D17

+++

BL

BK

IC3

IC2

432

1

2134567

8

88

+

+

+

AF-R100CX

AF-R120CX

Electronic Control Circuit Diagram

17

Page 18

AF-R100CX

AF-R120CX

COOL/ H

COOL/ M

COOL/ L

FAN

R1

D4

LED2

GREEN

LED3

GREEN

GREEN

LED4

LED5

GREEN

SELECTOR

R4

Q6

C3

C2

D3

QPWBFB376JBZZ

C18

C17

R14

SW3

D12

JP15

14

CN1

C9

B

C

E

JP14

C14

IC2

IN

D17

C4

D1

D2

C5

IC4

OUT

IC3

JP1

JP33

JP32

YELLOW

LED7

TIMER

SW2

JP16

TIMER

CA1

OUT

COM

DPWBFA193JBKZ

18

JP34

JP35

1

LED1

JP25

JP24

R13

SW6

D11

JP17

DWN-KEY

94V0

R

QPWBFB376JBZZ

ZD1

R9

CB

R2

DPWBFAA193JBKZ

JP36

14

R10

C10

JP6

R3

15

CN3

JP2

IC1

RA1

18

1

10

JP36

JP37

JP38

9

JP27

JP26

R17

SW5

D15

UP-KEY

8888 8

AE2A

AE2B

Q5

TEST

28

JP5

R21

R5

R20

C15

CN2

7

C22

R6

D8

7

JP12

B

C

E

OSC

B

C

Q8

JP28

R16

D14

VB

V0

V0

B

C

Q7

E

JP11

E

JP4

RY2

BCN2

JP40

JP39

BCE

JP29

JP10

JP7

Q2

E

C21

C20

D7

JP19

JP18

R8

B

Q3

5V

GND

1

BCE

BCE

YELLOW

LED8

JP20

ENERGY

SAVER

SW1

E/SAVER

B

E

Q4

JP8

C12

D6

8

Q9

E

JP9

12V

C11

Q10

R12

D10

BZ

B

Q1

D5

BCN3

R18

R11

JP30

JP31

RED

LED8

JP22

JP23

R15

ON/OFF

SW4

D13

JP21

POWER

COMP

POWER CORD

OUT

IN

1

MRY

C6

VB

V0

AE2A

8888 8

V0

AE2B

C7

R

94V0

JP3

C16

R7

Printed Wiring Board

C19

RY3

8

(GRAY)

18

CNR3

BCN3

(FAN MOTOR)

CNR2

CNR1

1

(RED)

RY1

C1

FU1

NR

125V 3A

Page 19

AF-R100CX

AF-R120CX

No cooling

(Operation not at all.)

Measure the power supply

voltage at receptacle.

120V(over 100V)

Is it sufficient current capacity

of power equipment ?

Is it small wiring for power

supply equipment ?

sufficient

Is plug disconnecting ?

connecting

Check the power supply cord.

OK

under 100V

The house fuse or circuit

breaker open ?

open

Is it proper current capacity of the

house fuse or the circuit breaker ?

not proper

Change the house fuse and

the circuit breaker turn on.

insufficient

Ask the power supply

company for check.

disconnecting

Connect plug properly.

imperfect contact

Change the power supply cord.

TROUBLESHOOTING GUIDE

not open.

Ask the power supply

proper

company for check.

Check the fuse on PWB ass'y.

OK

Measure the secondary

voltage of transformer.

over 14V(AC)

Measure the voltage between

-12V and GND on PWB ass'y.

OK(12V, DC)

Measure the voltage between

-5V and GND on PWB ass'y.

OK(5V, DC)

If unit operate, dose the house

fuse or the circuit breaker open ?

NO

open

Change the fuse on PWB ass'y.

under 14V(AC)

NG

NG

Change PWB ass'y.

YES

Measure the insulation

resistance of compressor.

OK(over 10MΩ)

Measure the insulation

resistance of fan motor.

OK(over 10MΩ)

NG(under 10MΩ)

Change the compressor.

NG(under 10MΩ)

Change the fan motor.

Checking complete.

Can the Compressor operate ?

can operate

19

can't operate

Change the compressor.

Page 20

AF-R100CX

AF-R120CX

No cooling

(Fan operate but the

compressor doesn't operate.)

Measure the power

supply voltage at

receptacle.

120V(over 100V)

I

s it sufficient current

capacity of power

equipment ?

Is it small wiring for power

supply equipment ?

sufficient

Measure the current in

compressor circuit.

current

Check the

overload relay.

OK

Check the

running capacitor.

OK

under 100V

Ask the power supply

company for check.

insufficient

Ask the power supply

company for check.

no current

imperfect contact

Change the

overload relay.

NG

Change the running

capacitor.

Check the

overload relay.

short

Is the connector

disconnecting ?

connecting

Check the compressor

relay.(MRY on PWB)

OK

open

Change the

overload relay.

disconnecting

Connect properly.

NG

Change PWB ass'y.

Measure the resistance

of compressor coil.

OK

Is there high heat

source near the unit.

there isn't

Is the outdoor

temperature too high ?

under 43ûC

Check the outdoor heat

exchanger.

not dirty

NG

Change the compressor.

there is

Remove the high heat

source or stop.

over 43ûC

Avoid sun light and

ventilate well for outdoor

heat exchanger.

dirty

Clean them with steam

cleaner or another method.

Check the thermister.

OK

NG

Change the thermistor.

Checking method for the compressor relay.

(MRY on PWB)

Turn off the

power supply.

Measure the

resistance of its coil.

OK(160Ω at 20ûC)

Turn on the power

supplty as operating the

compressor.

Measure the

voltage to its coil.

OK(12V, DC)

OK

NG

NG

NG

Can the compressor

operate ?

can operate

Checking complete.

can't operate

Change the compressor.

20

Page 21

No cooling

(The compressor operate but

the fan motor doesn't operate)

AF-R100CX

AF-R120CX

crack at the solder part

Repair with over solder. Connect the connector

Check BNC1 on PWB

ass'y

OK

Check the fan motor

capacitor.

OK

Measure the resistance

of compressor coil.

OK

Is the fan locked ?

disconnecting the connector

properly.

NG

Change the fan motor

capacitor

NG

Change the fan motor.

locked

Is the fan touched to

another parts ?

no touch

Change the fan motor.

touch

Change fan or another

parts, or adjust.

The compressor doesn't

turn off.

Check the thermister

connector.

OK

Check the thermister

resistance.

OK

Check the compressor

relay.

OK

Checking complete.

Checking complete

disconnecting

Connect the connector

properly.

NG

Change the thermister.

NG

Change PWB ass'y.

Checking method for the compressor relay.

(MRY and PWB)

Turn off the power

supply.

Measure the contact

resistance.

open

OK NG

short

21

Page 22

AF-R100CX

AF-R120CX

Insufficient cooling(Both compressor and compressor operate)

Check the temperature setting.

OK

too high

Set the lower temperature.

Check the air filter.

not dirty

Is there high heat source or

any object restricting heat

radiation near the unit.

there isn't

Check doors and windows.

close

Check the outdoor and indoor

heat exchanger.

not dirty

Calculate heat load wit using

Cooling load estimate form.

OK

Check rotating direction of

centrifugal fan.(to clockwise)

OK

Check changing fan speed

properly.

OK

dirty

Clean the air filter.

there is

Remove the high heat

source or stop.

open

Doors and windows

must be kept closed.

dirty

Clean them with steam

cleaner or another method.

Undersized air conditioner

Change unit to proper

sized air conditioner.

NG

NG

Check the fan motor connector.

OK

Measure the resistance

of fan motor coil.

OK

NG

NG

Change the fan motor.

Connect properly.

Is the outdoor temperature

too high ?

under 40ûC

Check the thermister.

OK

Measure temperature difference

between inlet and outlet air at indoor.

over 10ûC

Checking complete.

over 40ûC

NG

Avoid sun light and ventilate well for

outdoor heat exchanger.

Change the thermister.

under 10ûC

Is frost sticking to capillary tube ?

Or is indoor heat exchanger no cold ?

NO

YES

Is the refrigerant leaked ?

NO

The capillary tube restrict,

and change the capillary tube.

Measure the emperature

difference between discharge

tube and suction tube.

temperature difference

YES

Repair leakage and recharge

the refrigerant.

No temperature difference

The compressor is defective.

Change the compressor.

22

Page 23

Excessive vibration

or Abnormal noise

AF-R100CX

AF-R120CX

At fan only mode,

Excessive vibration

or Abnormal noise

NO

YES

Check the air filter

Check rotating

direction of centrifugal

fan.(to clockwise)

Is the fan deformed or

broken.

Is loosened screw

and nut fixing fan ?

not dirty

OK

OK

OK

dirty

Clean the air filter.

NG

Check the fan motor

connector.

Measure the resistance

of fan motor coil.

deform or broken

Change the fan

loosened

Tighten up.

OK

OK

NG

Connect properly.

NG

Change the fan motor.

Is each screws

loosened ?

OK

Is pipe touching to

another parts.

OK

Check mounting of

compressor.

OK

Check compressor

noise and vibration.

OK

Checking complete

Checking complete

loosen

Tighten up

touching

Repair with adjusting

shape of pipes.

NG

Repair mounting or

change compressor

cushion.

too big

Change compressor.

23

Page 24

AF-R100CX

AF-R120CX

COOLING LOAD ESTIMATE FORM

INSTRUCTIONS FOR USING COOLING LOAD ESTIMATE FORM FOR ROOM AIR CONDITIONERS

(AHAM PUB. NO. RAC-1)

A. This cooling load estimate form is suitable for estimating the cooling load for comfort air conditioning installations

which do not require specific conditions of inside temperature and humidity.

B. The form is based on an outside design temperature of 95˚F dry bulb and 75˚F wet bulb. It can be used for areas in

the continental United States having other outside design temperature by applying a correction factor for the

particular locality as determined from the map.

C. The form includes "day" factors for calculating cooling loads in rooms where daytime comfort (such as living rooms,

offices, etc.).

D. The numbers of the following paragraphs refer to the correspondingly numbered item on the form:

1. Multiply the square feet of window area for each exposure by the applicable factor. The window area is the area

of the wall opening in which the window is installed. For windows shaded by inside shades or venetian blinds, use

the factor for "Inside Shades". For windows shades by outside awnings or by both outside awnings and inside

shades (or venetian blinds), use the factor for "Outside Awnings". "Single Glass" includes all types of single

thickness windows, and "Double Glass" includes sealed air space types, storm windows, and glass block. Only

one number should be entered in the right-hand column for item 1, and this number should represent only the

exposure with the largest load.

2. Multiply the total square feet of all windows in the room by the applicable factor.

3a. Multiply the total length (linear feet) of all walls exposed to the outside by the applicable factor. Doors should be

considered as being part of the wall. Outside walls facing due north should be calculated separately from outside

walls facing other directions. Walls which are permanently shaded by adjacent structures should be considered

as being "North Exposure". Do not consider trees and shrubbery as providing permanent shading. An insulated

frame wall or a masonry wall 8 inches or less in thickness is considered "Light Construction". An insulated frame

wall or a masonry wall over 8 inches in thickness is considered "Heavy Construction".

3b. Multiply the total length (linear feet) of all inside walls between the space to be conditioned and any unconditioned

spaces by the given factor. Do not include inside walls which separate other air conditioned rooms.

4. Multiply the total square feet of roof or ceiling area by the factor given for the type of construction most nearly

describing the particular application. (Use one line only.)

5. Multiply the total square feet of floor area by the factor given. Disregard this item if the floor is directly on the

ground or over a basement.

6. Multiply the number of people who normally occupy the space to be air conditioned by the factory given. Use a

minimum of 2 people.

7. Determine the total number of watts for lights and electrical equipment, except the air conditioner itself, that will

be in use when the room air conditioning is operating. Multiply the total wattage by the factor given.

8. Multiply the total width (linear feet) of any doors or arches which are continually open to an unconditioned space

by the applicable factor.

NOTE: Where the width of the doors or arches is more than 5 feet, the actual load may exceed the calculated

value. In such cases, both adjoining rooms should be considered as a single large room, and the room air

conditioner unit or units should be selected according to a calculation made on this new basis.

9. Total the loads estimated for the foregoing 8 items.

10. Multiply the sub total obtained in item 9 by the proper correction factor, selected from the map, for the particular

locality. The result is the total estimated design cooling load in BTU per hour.

E. For best results a room air conditioner unit or units having a cooling capacity rating(determined in accordance with the

NEMA Standards Publication for Room Air Conditioners, CN 1-1960) as close as possible to the estimated load

should be selected. In general, a greatly oversized unit which would operate intermittently will be much less

satisfactory than one which is slightly undersized and which would operate more nearly continuously.

F. Intermittent loads such as kitchen and laundry equipment are not included in this form.

24

Page 25

AF-R100CX

HEAT GAIN FROM QUANTITY

FACTORS

DAY

BTU/Hr

(Quantity

x Factor)

1. WINDOWS: Heat gain from sun.

Southeast

Northeast

South

Southwest

Southeast

West

Northwest

North

sq ft

sq ft

sq ft

sq ft

sq ft

sq ft

sq ft

No

Shades

Inside

Shades

Outside

Shades

(Area a

Factor)

60

80

75

75

110

150

120

0

25

40

30

35

45

65

50

0

20

25

20

20

30

45

35

0

Use

only

the

largest

load

Use

only

only

These factors are for single glass only. For glass block, multiply the above factors

by 0.5: for double-glass or storm windows, multiply the above factors by 0.8.

2. WINDOWS: Heat gain by conduction.

(Total of all windows)

Single glass

Double glass or glass block

sq ft

sq ft

sq ft

sq ft

sq ft

sq ft

sq ft

sq ft

ft

ft

ft

ft

watts

30

60

30

19

12

20

30

14

7

8

3

3

3

5

600

300

Light Construction Heavy Construction

x x x x x x x x x x

(Item 9) x (Factor from Map) =

3. WALLS: (Based on linear feet of wall.)

4. ROOF OR CEILING: (Use one only.)

5. FLOOR: (Disregard if floor is directly

on ground or over basement.)

6. NUMBER OF PEOPLE:

7. LIGHTS AND ELECTRICAL

EQUIPMENT IN USE

8. DOORS AND ARCHES

CONTINUOUSLY OPENED TO

UNCONDITIONED SPACE:

(Linear feet of width.)

9. SUB-TOTAL

10. TOTAL COOLING LOAD:

(BTU per hour to be used for selection

of room air conditioner(s).)

a. Outside walls

Noth exposure

Other than North exposure

b. Inside Walls (between conditioned

and unconditioned spaces only)

a. Roof, uninsulated

b. Roof, 1 inch or more insulation

c. Ceiling, occupied space above.

d. Ceiling, insulated with attic space

above

e. Ceiling, uninsulated, with attic space

above

FARGO

EUGENE

RENO

SACRAMENT

FRESNO

LAS VEGAS

PHOENIX

PUEBLO

WICHITA

SAN ANTONIO

GREEN BAY

BIRMINGHAM

ATLANTA

COLUMBIA

ROCHESTER

ALBANY

NEW HAVEN

AF-R120CX

25

Page 26

AF-R100CX

AF-R120CX

RUNNING CONDITION

Note:

1. Select mode of the Running Condition of a Room Air Conditioner.

SELECTOR................................................HIGH COOL

TEMPERATURE.................................................... 64°F

2. Data of Performance Curve is measured between 40RH% and 70RH%.

If you measure the Room Air Conditioner above or below this rating, the data may miss the range of the performance

curve.

3. Outlet air temp. is influenced by the method of measurement. Measurement examples are shown.

4. Use power input data when checking the Running Condition.

RUNNING CONDITION FOR

MODEL AF-R100CX

PERFORMANCE CURVE

1100

1000

900

800

700

600

10

9

8

7

Line current(Amp.) Power input (Wa tt)

6

35

(96)

30

(88)

25

(77)

20

(68)

15

(59)

10

Outlet air temp. C ( F)

(50)

25 30 35 40

(77) (86) (96)

Outside air temp. C( F)

(104)

RUNNING CONDITION FOR

MODEL AF-R120CX

PERFORMANCE CURVE

1500

1400

1300

1200

1100

1000

900

800

13

12

11

10

Line current(Amp.) Power input (Wa tt)

9

30

(88)

25

(77)

20

(68)

15

(59)

10

(50)

5

Outlet air temp. C ( F)

(41)

25 30 35 40

(77) (86) (96)

Outside air temp. C( F)

(104)

26

Page 27

Top pad F

PACKING AND ACCESSORIES

Closure ass'y

4

Top pad B

3

AF-R100CX

AF-R120CX

Packing case

2

Bag

Bottom pad ass'y

1

27

Page 28

AF-R100CX

AF-R120CX

REPLACEMENT PARTS LIST

REF. NO. PART NO. DESCRIPTION Q'TY CODE

CABINET AND UNIT PARTS

1- 1 CMOTLA895JBEZ Fan motor 1 BN

1- 2 DCHS-A442JBTA Base pan ass’y [AF-R100CX] 1 BC

1- 2 DCHS-A440JBTA Base pan ass’y [AF-R120CX] 1 BC

1- 3 DCAB-A094JBTA Cabinet ass’y 1 BF

1- 4 PSEL-B150JBE0 Cabinet seal 2 AD

1- 5 HPNLCA770JBFA Control panel 1 AF

1- 6 PSEL-C059JBEZ Evaporator insulator 1 AD

1- 7 LANG-A459JBWZ Conecting stay 1 AC

1- 8 LANG-A355JBTA Top inst. Angle 1 AP

1- 9 LHLD-A482JBFZ Thermistor holder 1 AE

1-10 CLEV-A035JBKZ Damper ass’y 1 AE

1-11 NFANPA092JBFZ Propeller fan 1 AV

1-12 NFANSA030JBFZ Centrifugal fan 1 AU

1-13 PFILMA116JBEB Air filter 1 AN

1-14 PFPFPB466JBE0 Insulator 2 AC

1-15 PKESPA082JBTA Condenser shroud 1 AV

1-16 PKESPA083JBFA Orifice 1AQ

1-17 LBND-A046JBE0 Wire fixing band 1 AE

1-18 LCOV-A002JBF0 Shroud cover 1 AM

1-19 PCOV-A320JBP0 Motor cover 1 AC

1-20 PSEL-C057JBEZ Tube insulator 1 AD

1-21 LANG-A356JBTA Bottom inst. Angle 1 AE

1-22 PSKR-A207JBFA Bulkhead 1 BA

1-23 PSRA-A120JBFZ Drain tray 1 AE

1-24 TLAB-C206JBRZ Energy card [AF-R100CX] 1 AC

1-24 TLAB-C205JBRZ Energy card [AF-R120CX] 1 AC

1-25 TSPC-E052JBRZ Name badge [AF-R100CX] 1 AC

1-25 TSPC-E051JBRZ Name badge [AF-R120CX] 1 AC

1-26 GWAKPA136JBFB Louver duct 1 AH

1-27 GWAKPA135JBFB Front panel 1 AT

1-28 TLABBA110JBRA SHARP badge 1 AB

1-29 LANGAA038JBFB Left closure frame 1 AK

1-30 LANGAA039JBFB Right closure frame 1 AK

1-31 PPLTPA013JBFB Closure 2AL

1-32 PSPRCA010JBE0 Spring 1AD

1-33 TLABKA564JBE0 Number card 1 AC

1-34 PFPFPB446JBE0 Insulator 1 AC

1-35 CWAK-C095JBKZ Front panel ass’y 1 AX

1-36 MJNTPA074JBFB Louver link 2 AC

1-37 MLOV-A252JBFB Vertical louver A 4 AB

1-38 MLOV-A253JBFB Vertical louver B 2 AC

1-39 PSEL-B360JBE0 Cabinet insulator 1 AB

1-40 PSEL-C064JBEZ Drain tray insulator 1 AC

1-41 PSEL-B361JBE0 Cabinet insulator 2 AE

1-42 PSEL-B367JBE0 Cabinet insulator 2 AC

1-43 PSEL-B516JBE0 Base pan insulator 2 AC

1-44 PFPFPB443JBE0 Insulator 1 AC

1-45 PSEL-C063JBEZ Bulkhead insulator 1 AC

1-46 PSEL-B519JBE0 Angle insulator 1 AD

1-47 PSEL-C056JBEZ Motor seal 1 AE

1-48 LHLDW0367JBE0 Wire holder 1 AA

1-49 LHLDW0368JBE0 Wire holder 1 AA

1-50 PFPFPB528JBE0 Panel insulator 1 AD

1-51 PSEL-A432JBE0 Damper insulator 1 AC

1-52 PFPFPB611JBE0 Insulator 1 AG

1-53 PSEL-B532JBE0 Damper insulator 1 AB

1-54 PSEL-B394JBE0 Panel insulator 1 AB

1-55 PSEL-B560JBE0 Damper insulator 1 AB

1-56 LANG-A507JBWZ Fan motor angle 1 AH

1-57 HPNLCA771JBEA Decoration panel 1 AM

1-58 PSEL-B366JBE0 Panel insulator 1 AD

1-59 PSEL-C104JBEZ Insulator 1 AB

1-60 PSEL-C105JBEZ Cabinet insulator 1 AE

1-61 LHLDW0363JBE0 Wire holder 1 AA

1-62 PSHE-A191JBEZ Sheet 1AE

1-63 LHLD-A356JBE0 Wire holder [AF-R120CX] 1 AE

28

Page 29

AF-R100CX

AF-R120CX

REF. NO. PART NO. DESCRIPTION Q'TY CODE

CONTROL BOX PARTS

2- 1 LBNDKA078JBWZ Capacitor clamp [AF-R100CX] 1 AD

2- 1 LBNDKA096JBWZ Capacitor clamp [AF-R120CX] 1 AC

2- 2 LPLTMA128JBW0 Control box cover 1 AK

2- 3 DPLT-A047JBW0 Cont. box angle ass’y 1 AS

2- 4 QACC-A263JBZZ Power supply cord 1 AT

2- 5 RH-HXA011JBZZ Thermistor 1 AL

2- 6 QW-VZD104JBE0 Lead wire 1 AD

2- 7 QW-IZA037JBZZ Lead wire [AF-R100CX] 1 AS

2- 7 QW-IZA036JBZZ Lead wire [AF-R120CX] 1 AS

2- 8 RC-HZA256JBE0 Fan motor capacitor 2 AM

2- 9 RC-HZA435JBZZ Running capacitor [AF-R100CX] 1 AY

2- 9 RC-HZA407JBZZ Running capacitor [AF-R120CX] 1 AY

2-10 TLABCB579JBRZ Wiring diagram [AF-R100CX] 1 AA

2-10 TLABCB377JBRZ Wiring diagram [AF-R120CX] 1 AC

2-11 DPWBFA193JBKZ Control board unit 1 BC

2-12 PSPA-A084JBE0 Spacer 2AC

2-13 PSPA-A085JBE0 Spacer 1AC

2-14 QFS-AA048JBE0 Fuse 1AB

2-15 LBND-A042JBE0 Wire fixing band 4 AC

CYCLE PARTS

3- 1 PCMPRA360JBEZ Compressor [AF-R100CX] 1 CB

3- 1 PCMPRA359JBEZ Compressor [AF-R120CX] 1 CC

3- 2 PPIPCF657JB1Z Discharge tube [AF-R100CX] 1 AP

3- 2 PPIPCF655JB1Z Discharge tube [AF-R120CX] 1 AR

3- 3 PPIPCF656JB1Z Suction tube [AF-R100CX] 1 AP

3- 3 PPIPCF654JB1Z Suction tube [AF-R120CX] 1 AS

3- 4 RHOG-A199JBZZ Overload relay [AF-R100CX] 1 AU

3- 4 RHOG-A198JBZZ Overload relay [AF-R120CX] 1 AT

3- 5 DCON-A166JBKZ Condenser ass’y [AF-R100CX] 1 BT

3- 5 DCON-A167JBKZ Condenser ass’y [AF-R120CX] 1 BT

3- 6 PEVA-A429JBEZ Evaporator [AF-R100CX] 1 BP

3- 6 PEVA-A424JBEZ Evaporator [AF-R120CX] 1 BQ

3- 7 GLEG-A103JBE0 Compressor cushion [AF-R100CX] 3 AG

3- 7 GLEG-A105JBE0 Compressor cushion [AF-R120CX] 3 AF

3- 8 PSEL-B161JBE0 Gasket washer [AF-R100CX] 1 AH

3- 9 PCOV-A371JBE0 Terminal cover [AF-R100CX] 1 AF

3- 9 PCOV-A321JBE0 Terminal cover [AF-R120CX] 1 AR

3-10 PSEL-B160JBE0 Terminal gasket [AF-R100CX] 1 AH

3-10 PSEL-A971JBE0 Terminal gasket [AF-R120CX] 1 AN

3-11 DCPY-A235JBKZ Capillary tube ass’y [AF-R100CX] 1 AT

3-11 DCPY-A234JBKZ Capillary tube ass’y [AF-R120CX) 1 AW

3-12 MSPR-A129JBE0 Cycle spring 1 AD

3-13 PGUM-0034JBE0 Damper rubber 1 AF

3-14 MSPR-A114JBE0 Protector spring [AF-R100CX] 1 AF

3-14 MSPR-A136JBE0 Protector spring [AF-R120CX] 1 AF

3-15 LPLTMA114JBW0 Condenser stay 2 AH

ACCESSORY PARTS

4- 1 TINSEA320JBRZ Operation manual 1 AD

4- 2 PSEL-A349JBE0 Window insulator 1 AE

4- 3 PSEL-A350JBE0 Window insulator 1 AD

4- 4 PSEL-B365JBE0 Window insulator 1 AD

4- 5 TCAD-A351JBEZ Consummer card 1 AB

4- 6 DX-BZA027JBK0 Screws kit 1 AE

4- 7 CRMC-A526JBEZ Remote control 1 AT

4- 8 LHLD-A389JBFB Controller holder 1 AE

4- 9 SSAKAA017YDE0 Bag 1AC

4-10 UBATUA027JBE0 Battery pack 1 AE

PACKING PARTS

5- 1 CPADBA688YDK0 Top pad ass’y 1 AL

5- 2 CPADBA009JBK0 Bottom pad ass’y 1 AT

5- 3 SPAKCA986JBEZ Packing case [AF-R100CX] 1 AX

5- 3 SPAKCA985JBEZ Packing case [AF-R120CX] 1 AX

5- 4 SSAKHA314YDE0 Protect 1AD

5- 5 PPAK-A007JBE0 Inner packing 1 AG

5- 6 TLABMA309JBRZ Feature card 1 AB

5- 7 SSAKAA053YDE0 Bag 1AB

29

Page 30

AF-R100CX

AF-R120CX

REF. NO. PART NO. DESCRIPTION Q'TY CODE

SCREWS AND NUTS

6- 1 XTTSD40P12000 Tapping screw 22 AA

6- 2 LX-BZA236JBE0 Special screw 1 AC

6- 3 XHTSD40P08000 Tap tight screw 8 AA

6- 4 LX-NZA148JBE0 Special nut [AF-R100CX] 1 AD

6- 4 LX-NZA136JBE0 Special nut [AF-R120CX] 1 AL

6- 5 LX-HZA001JBE0 Special screw 6 AB

6- 6 XCTSD40P10000 Tapping screw 19 AA

6- 7 LX-NZA074JBE0 Special nut 1 AB

6- 8 LX-NZA028JBE0 Special nut 3 AB

6- 9 XTPSD40P08000 Tapping screw 3 AA

6-10 XCTSD40P06000 Tapping screw 16 AA

6-11 XBPSD40P12J00 Machine screw 2 AB

6-12 LX-CZA038WRE0 Special screw 6 AA

6-13 XHTSD40P10000 Tap tight screw 2 AA

6-14 XTPSD40P12000 Tapping screw 2 AA

HOW TO ORDER REPLACEMENT PARTS

To have your order filled promptly and correctly, please furnish the following information.

CONTROL BOX PARTS

A

B

1-5

1-57

1. MODEL NUMBER 2. REF. NO.

3. PART NO. 4. DESCRIPTION

23456

6-3

6-3

6-13

2-8

A

6-3

2-10

2-2

6-3

B

2-11

2-14

6-3

2-1

6-9

2-9

2-7

C

2-3

2-4

C

6-11

2-4

D

6-14

2-12

23456

2-13

2-6

6-1

6-3

30

2-15

D

Page 31

AF-R100CX

AF-R120CX

1

23456

CABINET PARTS

1-28

1-60

5-1

1-33

1-46

5-2

6-1

1-3

5-7

2-4

6-12

6-10

6-6

1-25

1-18

1-42

6-6

1-14

1-41

6-5

6-12

1-4

6-6

1-21

6-5

6-7

6-6

1-15

6-5

1-23

6-6

1-34

1-40

1-11

6-6

1-43

6-12

6-12

6-1

1-43

1-52

6-1

A

5-3

B

C

1-24

5-4

1-8

D

A

B

1-2

C

D

6-5

1-19

1-49

1-63

6-5

6-6

1-17

1-1

1-56

1-47

1-22

1-20

1-56

1-45

1-48

1-59

E

6-1

F

6-6

1-4

1-31

E

1-29

1-30

4-2

4-3

1-42

4-1

1-41

6-12

1-39

6-6

6-1

4-10

1-14

4-7

F

4-6

4-4

4-5

6-1

6-1

4-8

5-5

1-13

1-7

4-9

G

1-35

1-36

1-38

1-37

1-26

1-54

6-6

1-10

1-53

1-55

1-38

1-62

1-51

6-1

1-6

G

1-37

1-12

6-2

1-16

H

H

1-32

1-50

1-58

1-27

5-6

123456

31

Page 32

AF-R100CX

AF-R120CX

1

A

B

C

6-1

D

E

CYCLE PARTS

3-6

2-6

6-3

1-61

6-1

23456

6-1

6-4

3-14

3-4

6-10

3-7

6-10

3-3

3-11

1-44

6-8

2-7

3-5

3-2

3-9

3-10

3-15

6-10

6-4

3-14

3-4

2-7

3-8

3-9

3-10

3-13

3-12

3-1

1-9

2-5

AF-R100CX

A

B

C

D

E

1-44

6-10

3-5

3-6

6-1

3-11

1-61

1-9

2-5

3-12

3-1

6-1

6-1

3-7

6-10

3-3

6-8

3-2

3-15

6-10

F

G

H

F

3-13

G

6-1

2-6

6-3

H

AF-R120CX

123456

32

'02 SHARP CORP. (2S0.85E) Printed in U.S.A.

Loading...

Loading...