Page 1

KV-25K1

SERVICE MANUAL

MODEL

KV-25K1A

KV-25K1B

KV-25K1D

KV-25K1E

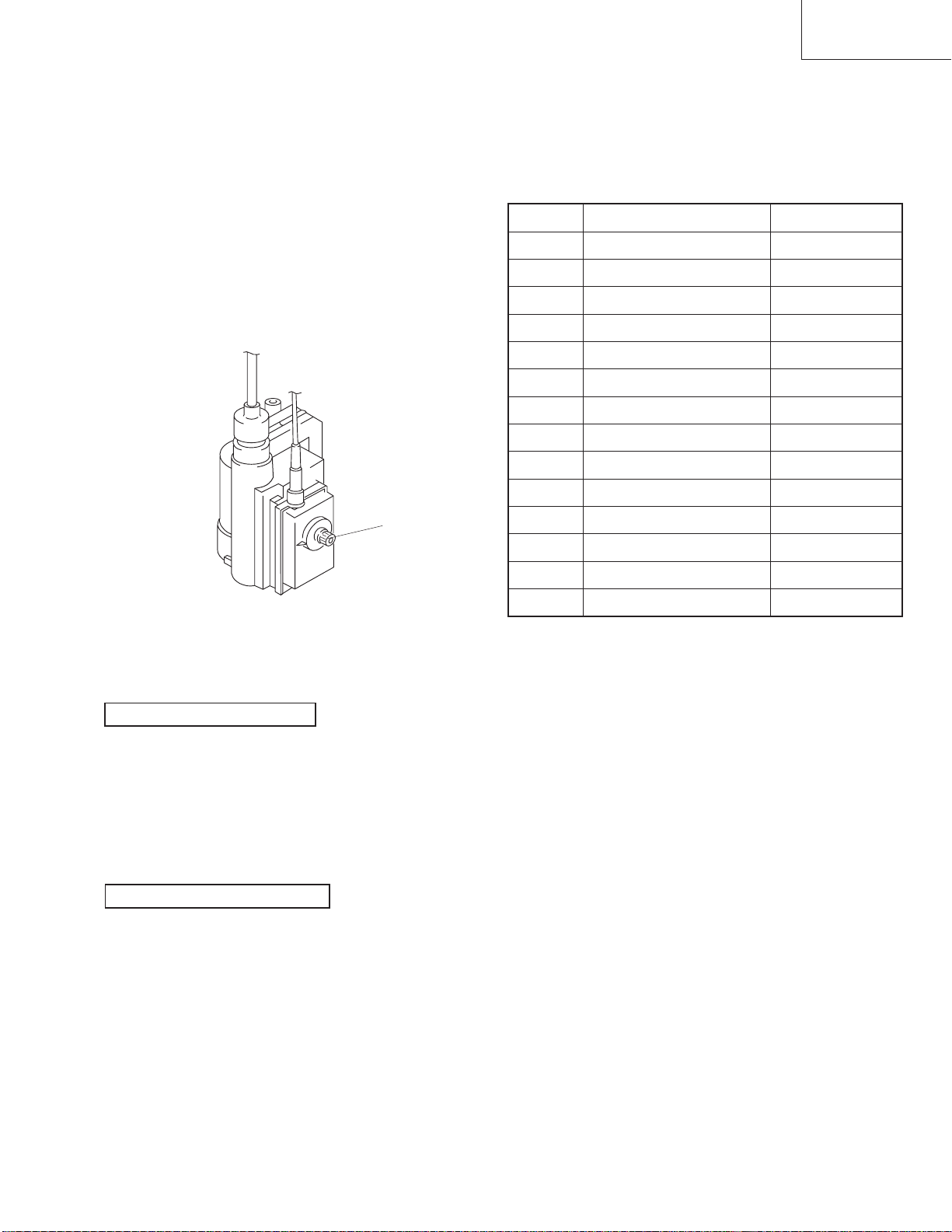

RM-862

RM-862

RM-862

RM-862

DEST.COMMANDER CHASSIS NO.

Italian

French

AEP

Spanish

SCC-K43H-A

SCC-K45H-A

SCC-K41H-A

SCC-K42H-A

MODEL

KV-25K1K

KV-25K1R

KV-25K1U

AE-4

COMMANDER

RM-862

RM-862

RM-862

CHASSIS

DEST.

OIRT

Russian

UK

CHASSIS NO.

SCC-K44J-A

SCC-K44K-A

SCC-K46D-A

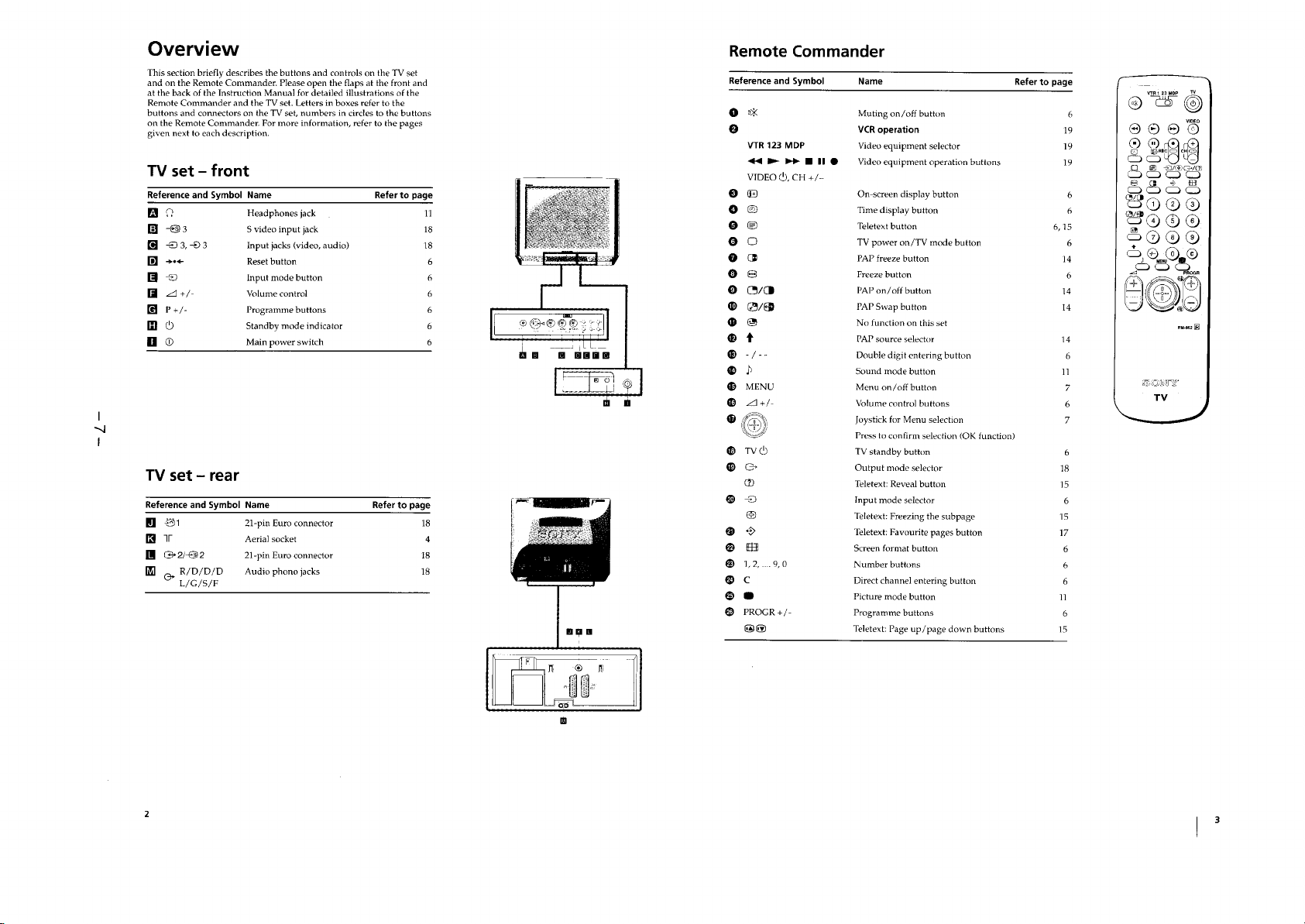

TV

MDP2

3VTR 1

¤

VIDEO

0

( u)

p Pr

+

CH

REC

+

˚

;

_

?

…/

Ú/;

8

;

´8x

´/´

a/Å

A

b

c

≥

MENU

¸

PROGR

RM-862

TRINITRON COLOR TV

R

MICROFILM

R

— 1 —

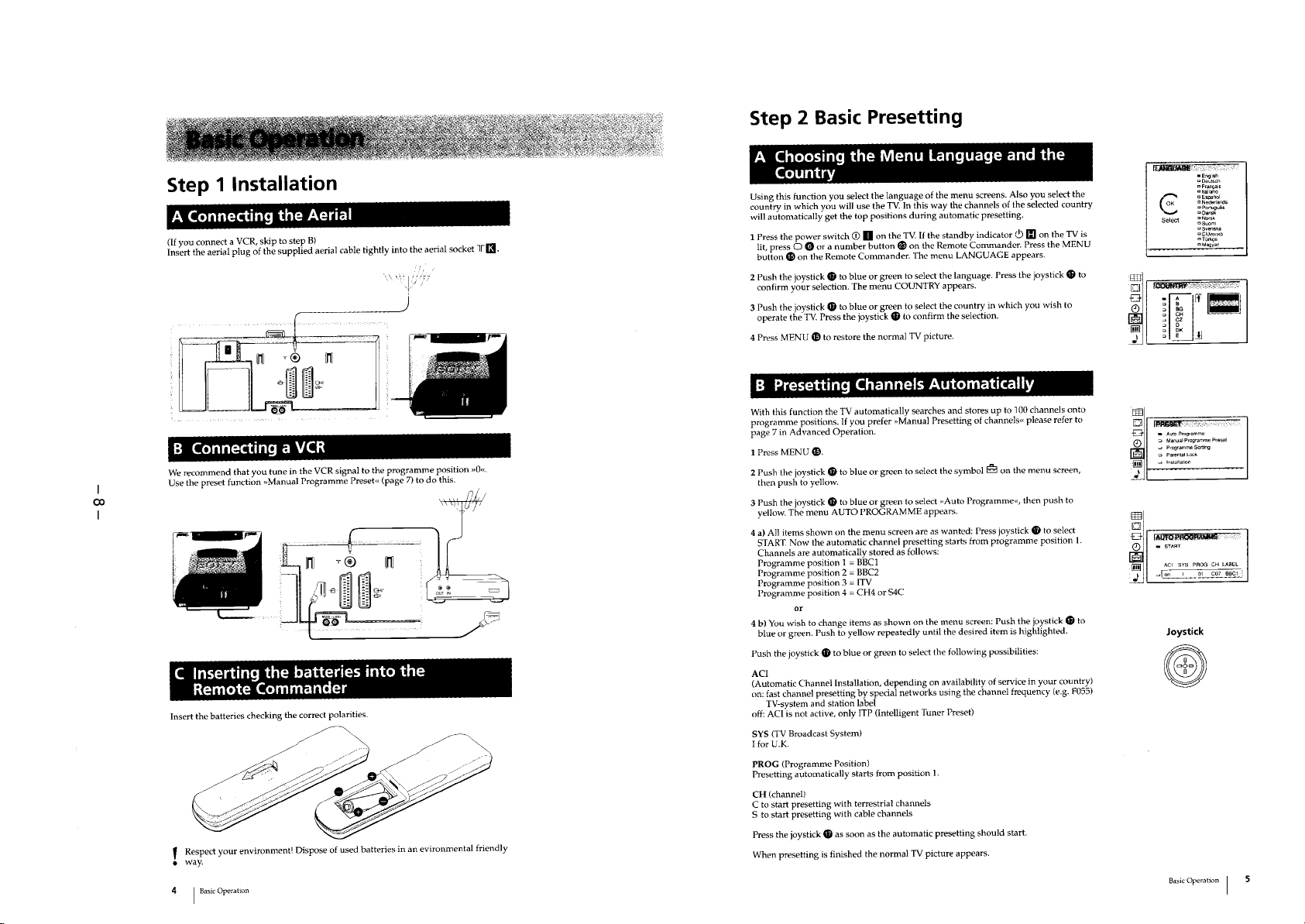

Page 2

KV-25K1

nailatIKD,H/G/B

hcnerFI,L,K/D,H/G/B

metsySruoloCegarevoClennahCmetsySnoisiveleTLEDOMMETI

LAP96-12:FHU)C(2H-A:FHVAILATI

14S-1S:)1(VTELBAC

96E-12E:FHU21E-2E:FHVH/G/B

01U-1U,01M-1M,50S-102:)2(VTELBAC

96R-12R:FHU21R-10R:FHVK/D

06F-12F:FHU01F-20F:FHVL

21E-2E:FHVH/G/BQ-B:ELBAC

96E-12E:FHU

14S-1S:)1(VTELBAC

01U-1U,01M-1M,50S-10S:)2(VTELBAC

96-12:FHU)C(2H-A:FHVAILATI

96B-12B:FHUI

MACES,LAP

34.4/85.3CSTN

)ylnotupnioediv(

MACES,LAP

34.4/85.3CSTN

)ylnotupnioediv(

96E-12E:FHU21E-2E:FHVH/G/BLAP

01U-1U,01M-1M,50S-10S:)2(VTELBAC

96-12:FHU)C(2H-A:FHVAILATI

96B-12B:FHU02R-10R:FHVK/D

96E-12E:FHU21E-2E:FHVH/G/BLAP

01U-1U,01M-1M,50S-10S:)2(VTELBAC

96-12:FHU)C(2H-A:FHVAILATI

96B-12B:FHU02R-10R:FHVK/D

96E-12E:FHU21E-2E:FHVH/G/B

96R-12R:FHU21R-10R:FHVK/D

96E-12E:FHU21E-2E:FHVH/G/B

96R-12R:FHU21R-10R:FHVK/D

LAP

MACES,LAP

34.4/85.3CSTN

)ylnotupnioediv(

MACES,LAP

34.4/85.3CSTN

)ylnotupnioediv(

MACES,LAP

34.4/85.3CSTN

)ylnotupnioediv(

MACES,LAP

34.4/85.3CSTN

)ylnotupnioediv(

34.4/85.3CSTN

)ylnotupnioediv(

PEAK/D,H/G/B

hsinapSK/D,H/G/B

TRIOK/D,H/G/B

NAISSURK/D,H/G/B

KUI 96-12FHU

14S-1S:)1(VTELBAC

14S-1S:)1(VTELBAC

14S-1S:)1(VTELBAC

14S-1S:)1(VTELBAC

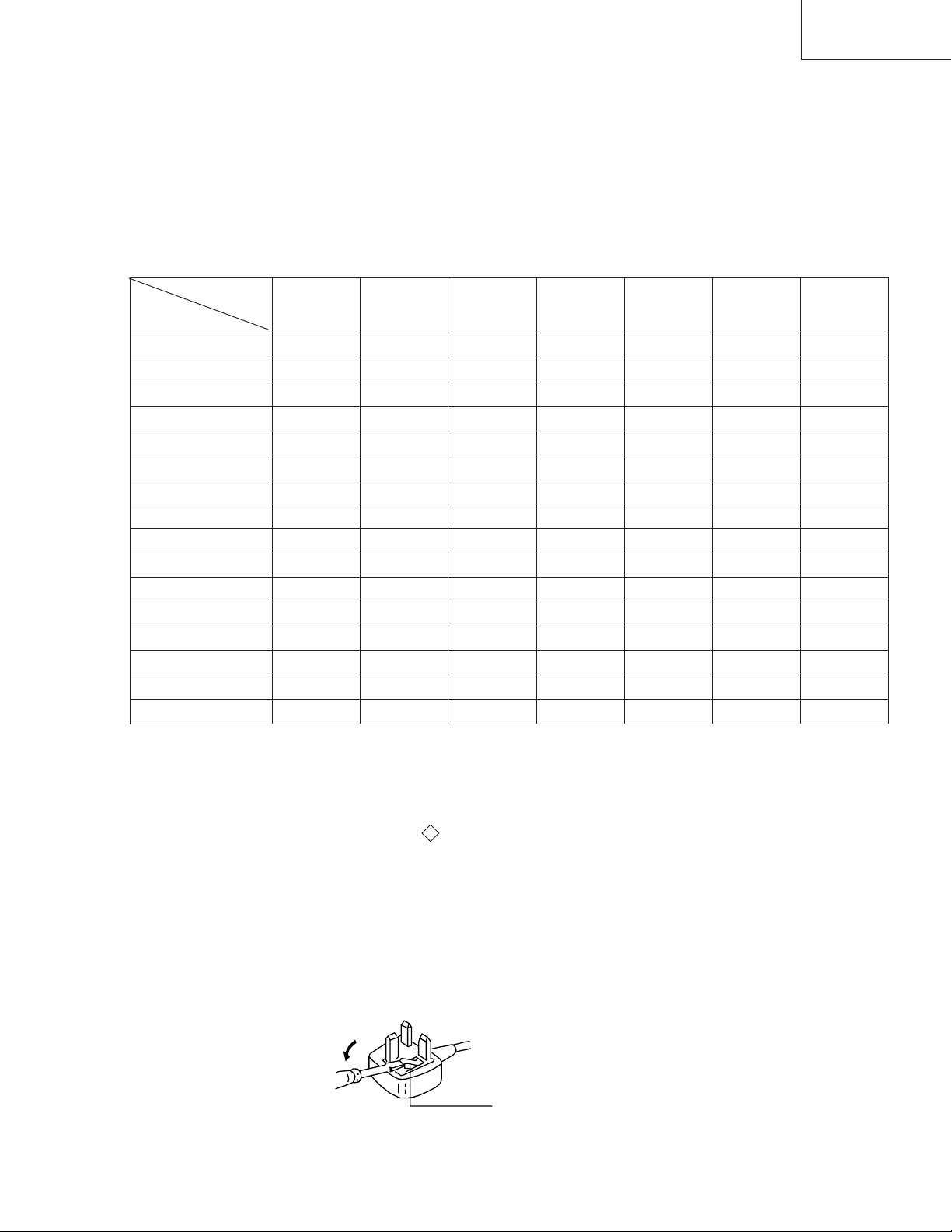

LEDOMA1K52B1K52D1K52E1K52K1K52R1K52U1K52

noitpmusnocrewoP811431431431431431902

Picture Tube Super Trinitron

Approx. 63 cm (25 inches)

(Approx. 59 cm picture measured

diagonally) 100˚ deflection

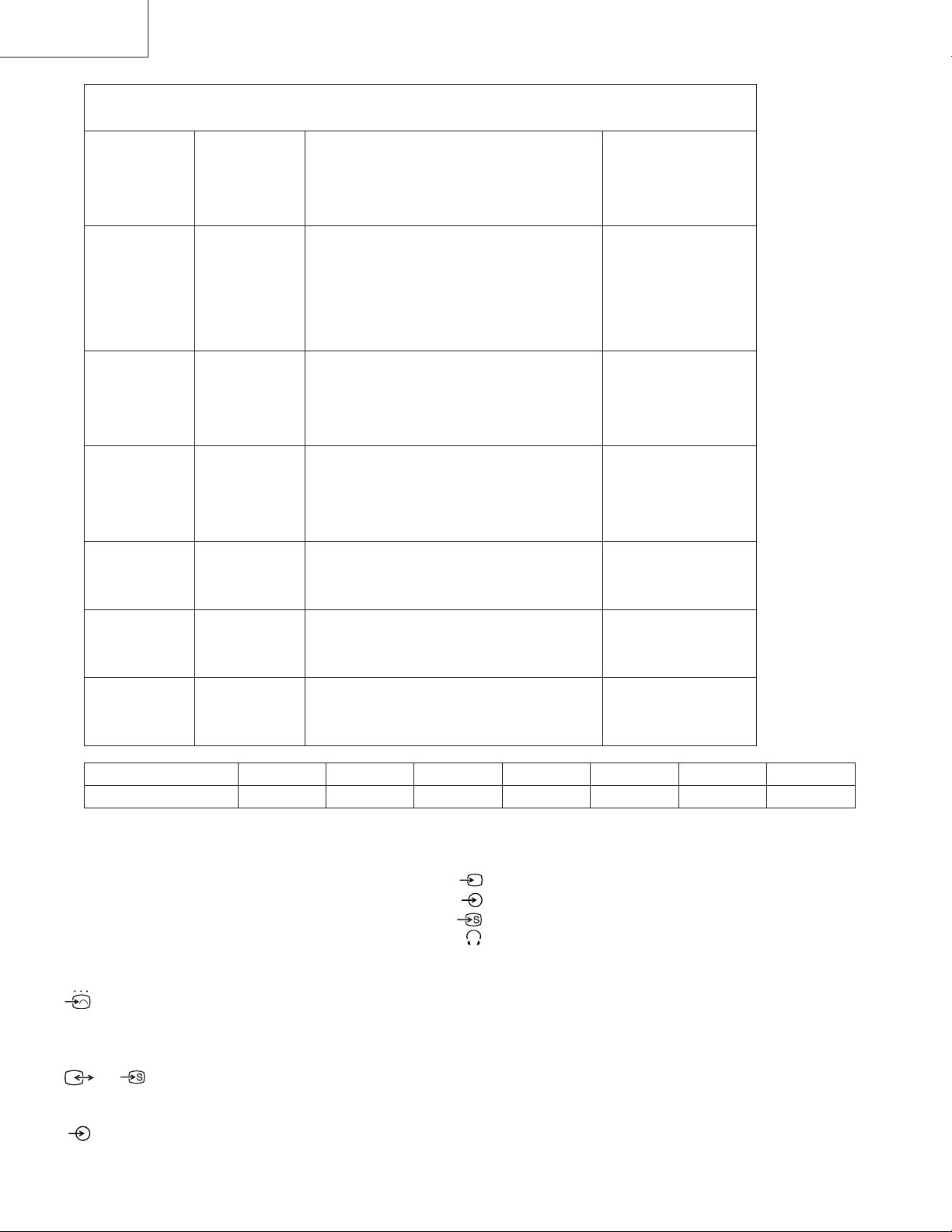

Rear/Front Terminals

[REAR]

21-pin Euro connector (CENELEC standard)

- Inputs for audio and video signals

- Inputs for RGB

- Outputs of TV video and radio signals

2/ 2 21-pin Euro connector

- Inputs for audio and video signals

- Inputs for audio and video signals (selectable)

2 Audio outputs - phono jacks

SPECIFICATIONS

[FRONT]

3 Video input - phono jack

3 Audio inputs - phono jacks

3 S video input - 4 pin DIN

Headphone jack - stereo minijack

Sound output 30Wx2 (music power)

15Wx2 (RMS)

Dimensions 612X515X496mm approx.

Weight Approx. 35.5kg

Supplied accessories RM-862 Remote Commander (1)

R6 batteries (2)

Other features TELETEXT , Fastext

FLOF/TOP text,

NICAM (KV-25K1B/25K1E/25K1U ony)

— 2 —

Page 3

[RM-862]

Remote control system Infrared control

Power requirements 3V dc (2 batteries) R6 (size AA)

Dimensions Approx. 210x56x24 mm (w/h/d)

Weight Approx. 110g

(Not including battery)

Design and specifications are subject to change without

notice.

Model name

A1K52-VKB1K52-VKD1K52-VKE1K52-VKK1K52-VKR1K52-VKU1K52-VK

Item

retliFbmoClatigiDNONONONONONONO

noitcudeResioNlatigiDNONONONONONONO

PIPFFOFFOFFOFFOFFOFFOFFO

PIPMNONONONONONONO

erutciP&erutciPNONONONONONONO

lioCnoitatoRNONONONONONONO

draobpilCNONONONONONONO

)32eniL(9:61otuAFFOFFOFFOFFOFFOFFOFFO

TXTNONONONONONONO

FOLFNONONONONONONO

POTNONONONONONONO

H/G/BmroNNONONONONONOFFO

ImroNFFONOFFOFFOFFOFFONO

K/DmroNNONONONONONOFFO

LmroNFFONOFFOFFOFFOFFOFFO

teserPegaugnaLnailatIhcnerFnamreGhsinapSTRIOTRIOhsilgnE

KV-25K1

WARNING ( KV-25K1U only )

The flexible mains lead is supplied connected to a B.S. 1363 fused

plug having a fuse of 5 AMP capacity. Should the fuse need to be

replaced, use a 5 AMP FUSE approved by ASTA to BS 1362, ie

one that carries the mark.

IF THE PLUG SUPPLIED WITH THIS APPLIANCE IS NOT

SUITABLE FOR YOUR SOCKET OUTLETS IN YOUR HOME.

IT SHOULD BE CUT OFF AND AN APPROPRIATE PLUG FITTED.

THE PLUG SEVERED FROM THE MAINS LEAD MUST BE

DESTROYED AS A PLUG WITH BARED WIRES IS

DANGEROUS IF ENGAGED IN A LIVE SOCKET OUTLET.

When an alternative type of plug is used it should be fitted with a 5 AMP

FUSE, otherwise the circuit should be protected by a 5 AMP FUSE at the

distribution board.

ASA

T

How to replace the fuse.

Open the fuse compartment with the

screwdriver blade

and replace the fuse.

FUSE

— 3 —

Page 4

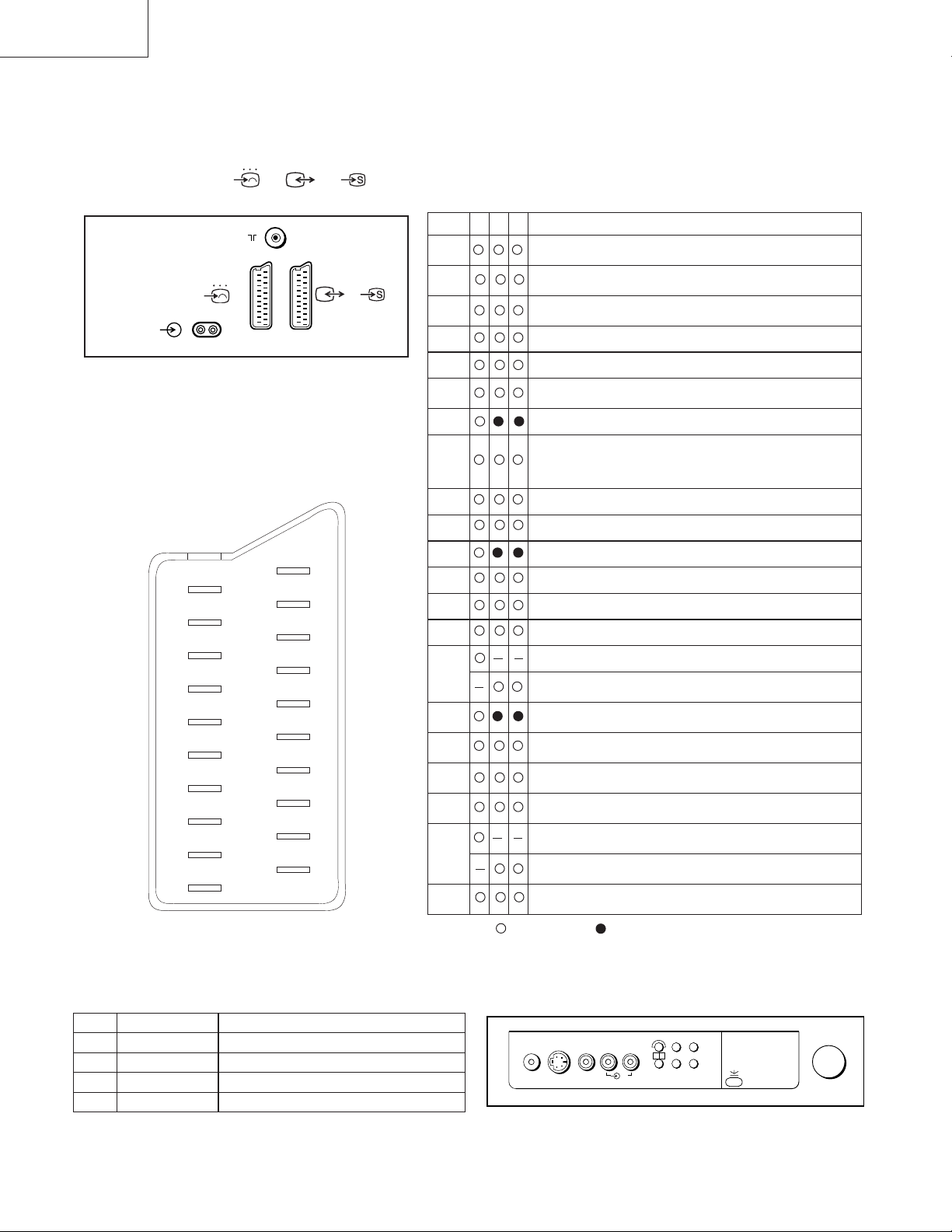

KV-25K1

g

u

2

3

L/G/S/I R/D/D/D

…3

P

Á

-

+

…

q3

U

MONO

)

21 pin connector ( 1, 2/ 2 )

G

1

1

21

19

17

15

13

11

9

7

5

3

1

20

18

16

14

12

10

8

6

4

2

Y2/j

.oNniP 124 langiSleveLlangiS

1

2

2

2/

2

3

4

5

6

7

8

9

01

11

21

31

41

51

61

71

81

91

02

12

Connected

BtuptuooiduA

)thgiR(

BtupnioiduA

)thgiR(

AtuptuooiduA

)tfeL(

)oiduA(dnuorG

)eulB(dnuorG

AtupnioiduA

)tfeL(

tupnieulB7.0 ± evitisop,smho57,Bd3

tcelesnoitcnuF

)lortnocVA(

)neerG(dnuorG

nepO

neerG

nepO

)deR(dnuorG

)gniknalB(dnuorG

tupnideR7.0 ± evitisop,smho57,Bd3

)langisS(

tupniamorc

tupnigniknalB

)langissY(

dnuorG

)tuptuooediV(

dnuorG

)tupnioediV(

tuptuooediV

tupnioediV

tupnioediV

)langisS(Y

dnuorgnommoC

)dliehs,gulp(

Not Connected (Open) * at 20Hz - 20kHz

7.0 ± evitisop,smho57,Bd3

V1 ± ,smho57,Bd3

V1 ± ,smho57,Bd3

V1 ± ,smho57,Bd3

smrV5.0:leveldradnatS

smrV5.0:leveldradnatS

smrV5.0:leveldradnatS

smrV5.0:leveldradnatS

edomVT:)V2-0(etatswoL

smho57:ecnadepmitupnI

*smhok1nahtsseL:ecnadepmituptuO

*smhok01nahteroM:ecnadepmituptuO

*mhok1nahtsseL:ecnadepmituptuO

*mhok01nahtsseL:ecnadepmituptuO

edomtraP:)V21-5.9(etatshgiH

smhok01eroM:ecnadepmitupnI

Fn2nahtsseL:ecnaticapactupnI

)V4.0-0(etatswoL)V3-1(etatshgiH

)Bd01+3-(V3.0:cnysevitisop

)Bd01+3-(V3.0:cnysevitisop

)Bd01+3-(V3.0:cnysevitisop

.oNniPlangiSleveLlangiS

1dnuorG

2dnuorG

3tupni)langisS(YV1 ± Bd01+3-V3.0.cnySevitisop,mho57Bd3

4tupni)langisS(CV3.0 ± .cnySevitisop,mho57Bd3

— 4 —

Page 5

TABLE OF CONTENTS

Section Title PageSection Title Page

KV-25K1

1. GENERAL

Overview ....................................................................

Basic Operation ..........................................................

Advanced Operation ...................................................

Teletext .......................................................................

Optional Equipment ...................................................

Additional Information ...............................................

2. DISASSEMBLY

2-1. Rear Cover Removal ..................................................

2-2. Chassis Assy Removal ...............................................

2-3. Service Position..........................................................

2-4. G Board Removal.......................................................

2-5. A Board Removal.......................................................

2-6. Picture Tube Removal ................................................

Removal and Replacement of

the Main-Bracket Bottom Plates ................................

3. SET-UP ADJUSTMENTS

3-1. Beam Landing ............................................................

3-2. Convergence...............................................................

3-3. Focus ..........................................................................

3-4. Screen (G2), White Balance

(Adjustment in the service mode

with remote commander .............................................

4. CIRCUIT ADJUSTMENTS

4-1. Electrical Adjustments................................................

4-2. Volume Electrical Adjustments..................................

4-3. Test Mode 2:...............................................................

5. DIAGRAMS

7

8

9

13

15

16

17

17

17

17

18

18

19

5-1. Block Diagram (1)......................................................

Block Diagram (2) ......................................................

Block Diagram (3) ......................................................

Block Diagram (4) ......................................................

Block Diagram (5) ......................................................

5-2. Circuit Boards Location .............................................

5-3. Schematic Diagrams and Printed Wiring Boards.......

*A Board ....................................................................

*C Board.....................................................................

*T Board .....................................................................

*B Board.....................................................................

*G Board ....................................................................

*D Board ....................................................................

*VM Board .................................................................

5-4. Semiconductors ..........................................................

5-5. IC Blocks....................................................................

6. EXPLODED VIEWS

20

21

23

6-1. Chassis........................................................................

6-2. Picture Tube ...............................................................

7. ELECTRICAL PARTS LIST ...............................

23

24

28

29

31

33

35

39

41

44

44

49

57

61

67

75

80

85

87

90

91

92

93

SHORT CIRCUIT THE ANODE OF THE PICTURE TUBE AND THE

ANODE CAP TO THE METAL CHASSIS, CRT SHIELD, OR CARBON

PAINTED ON THE CRT, AFTER REMOVING THE ANODE.

AN ISOLATION TRANSFORMER SHOULD BE USED DURING ANY

SERVICE TO AVOID POSSIBLE SHOCK HAZARD, BECAUSE OF

LIVE CHASSIS.

THE CHASSIS OF THIS RECEIVER IS DIRECTLY CONNECTED TO

THE AC POWER LINE.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY SHADING AND MARK ON THE

SCHEMATIC DIAGRAMS, EXPLODED VIEWS AND, IN THE PARTS

LIST ARE CRITICAL FOR SAFE OPERATION. REPLACE THESE

COMPONENTS WITH SONY PARTS WHOSE PART NUMBERS

APPEAR AS SHOWN IN THIS MANUAL OR IN SUPPLEMENTS

PUBLISHED BY SONY.

CAUTION

WARNING !!

!

APRES AVOIR DECONNECTE LE CAP DE L'ANODE, COURTCIRCUITER L'ANODE DU TUBE CATHODIQUE ET CELUI DE

L'ANODE DU CAP AU CHASSIS METALLIQUE DE L'APPAREIL,

OU AU COUCHE DE CARBONE PEINTE SUR LE TUBE CATHODIQUE

OU AU BLINDAGE DU TUBE CATHODIQUE.

AFIN D'EVITER TOUT RISQUE D'ELECTROCUTION PROVENANT

D'UN CHÁSSIS SOUS TENSION, UN TRANSFORMATEUR

D'ISOLEMENT DOIT ETRE UTILISÉ LORS DE TOUT DÉPANNAGE.

LE CHÁSSIS DE CE RÉCEPTEUR EST DIRECTEMENT RACCORDÉ

À L'ALIMENTATION SECTEUR.

ATTENTION AUX COMPOSANTS RELATIFS À LA

LES COMPOSANTS IDENTIFIÈS PAR UNE TRAME ET PAR UNE

MARQUE SUR LES VUES EXPLOSÉES ET LES LISTES DE

PIECES SONT D'UNE IMPORTANCE CRITIQUE PUR LA SÉCURITÉ

DU FONCTIONNEMENT. NE LES REMPLACER QUE PAR DES

COMPOSANTS SONY DONT LE NUMÉRO DE PIÉCE EST INDIQUÉ

DANS LE PRÉSENT MANUEL OU DANS DES SUPPLÉMENTS

PUBLIÉS PAR SONY.

!

ATTENTION

ATTENTION !!

SÉCURITÉ!!

— 5 —

Page 6

Page 7

Page 8

Page 9

Page 10

Page 11

Page 12

Page 13

Page 14

Page 15

Page 16

Page 17

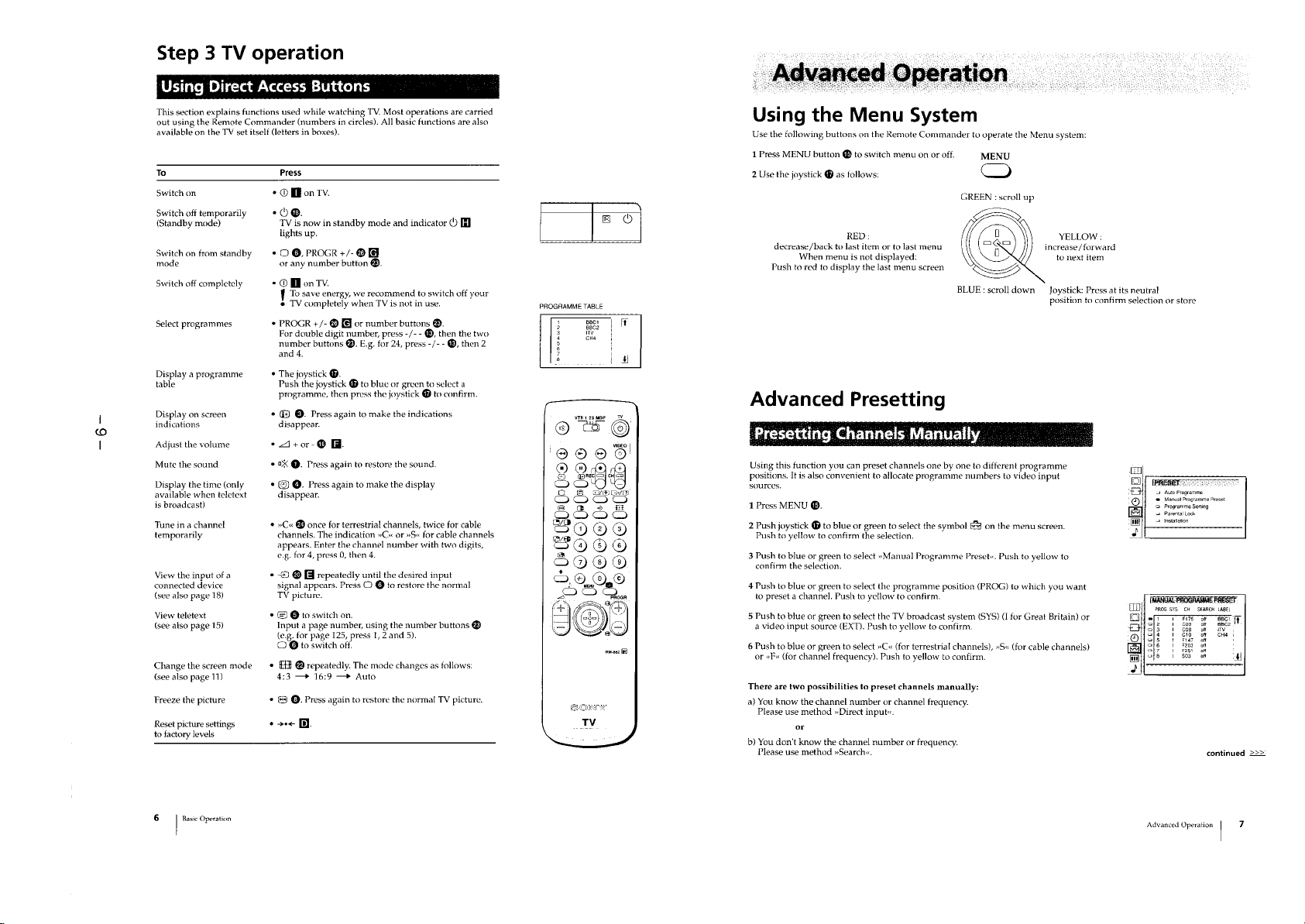

SECTION 2

DISASSEMBLY

— 17 —

2-1. REAR COVER REMOVAL

Rear Cover

2

2-3. SERVICE POSITION

1

Nine screws

(BVTP 4x16)

2-2. CHASSIS ASSY REMOVAL

2-4. G BOARD REMOVAL

Push the claw of the bracket

in the direction of the arrow

and remove.

KV-25K1

Page 18

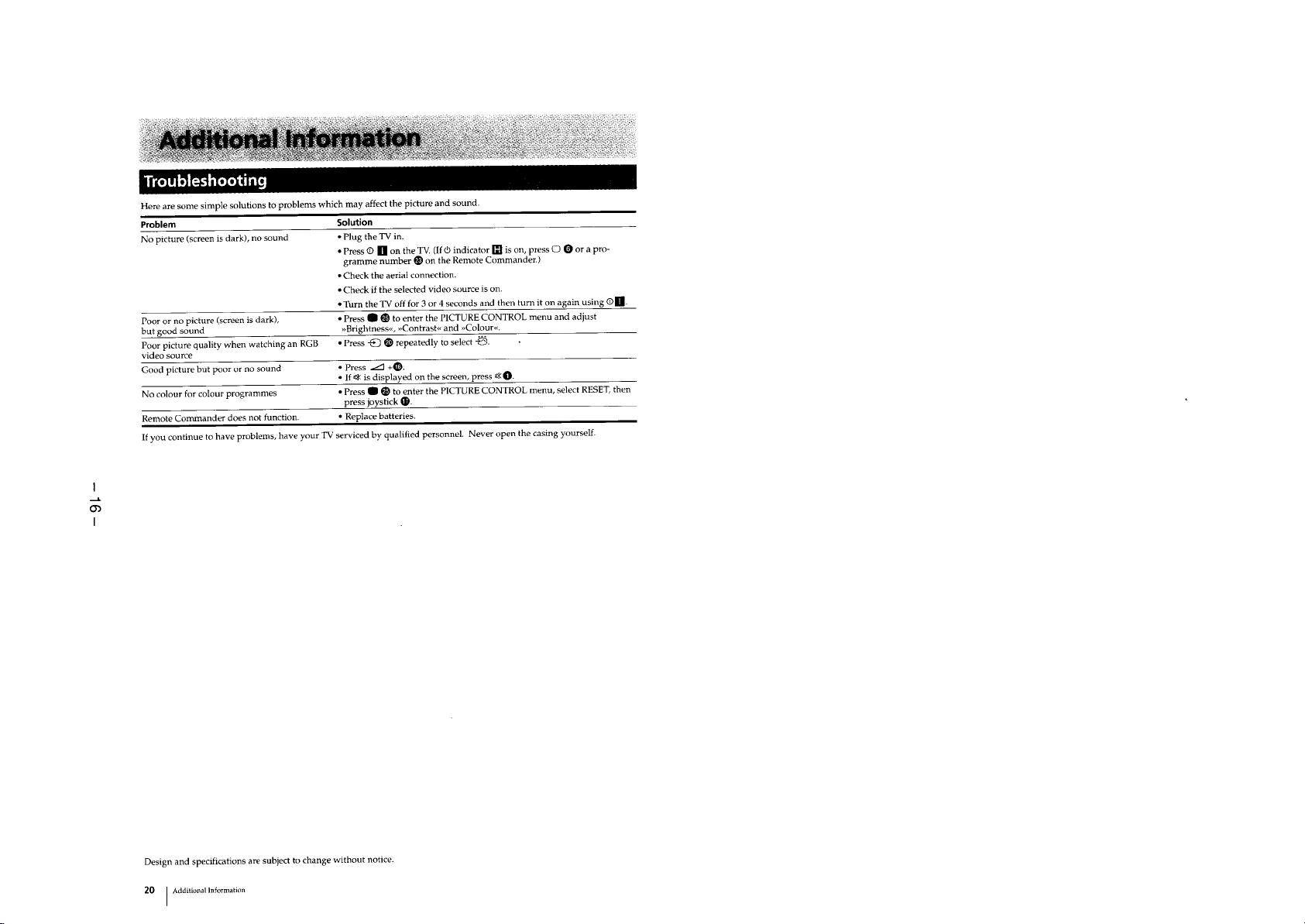

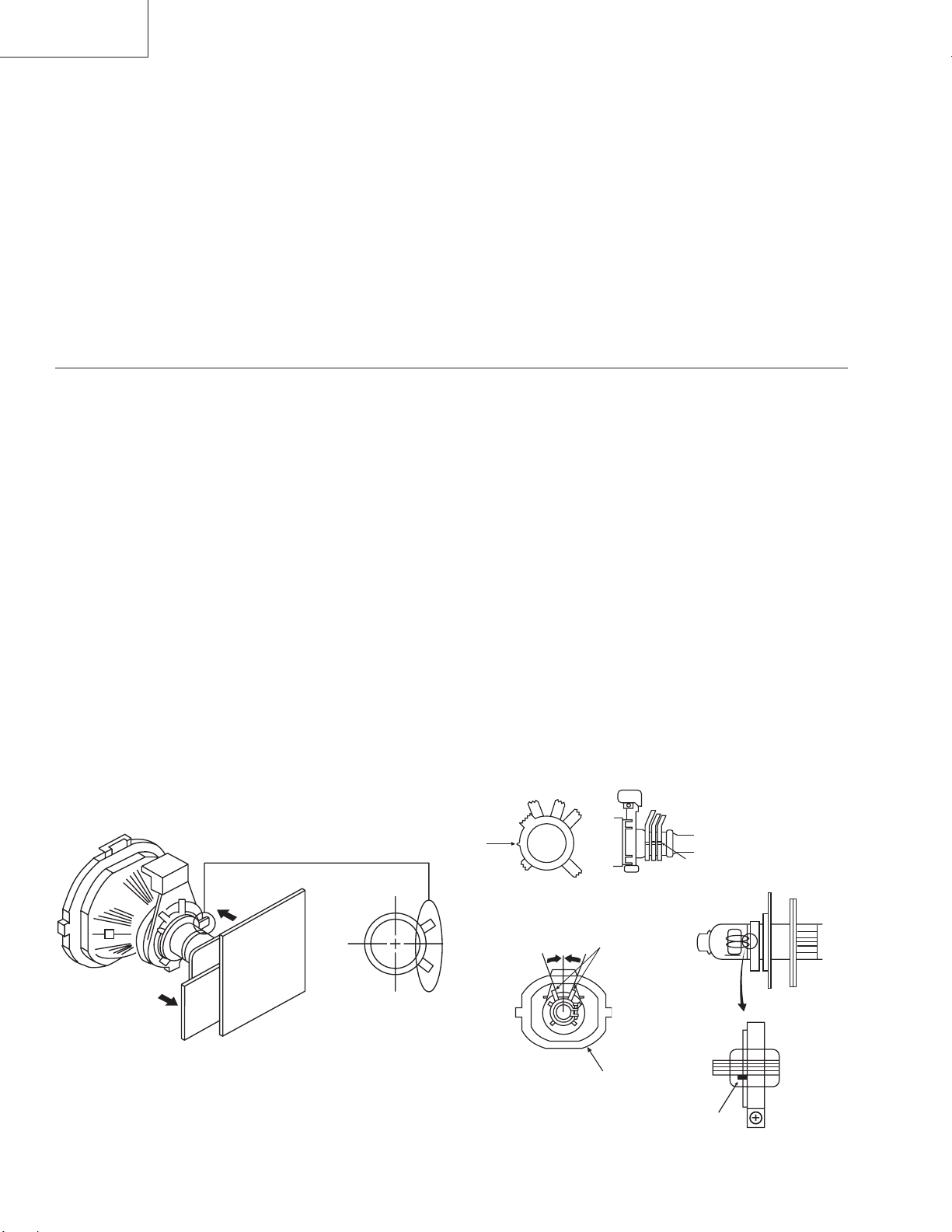

2-5. A BOARD REMOVAL 2-6. PICTURE TUBE REMOVAL

Push the claw of the bracket

in the direction of the arrow

and remove.

Holder DGC

7

Degaussing coil

8

Spring tension

9

KV-25K1

— 18 —

• REMOVAL OF ANODE-CAP

Note:

Short circuit the anode of the picture tube and the anode cap to the metal chassis, CRT shield or

carbon paint on the CRT, after removing the anode.

* REMOVING PROCEDURES.

a

1

Turn up one side of the rubber cap in

the direction indicated by the arrow a

2 Using a thumb pull up the rubber cap

firmly in the direction indicated by the

arrow b

• HOW TO HANDLE AN ANODE-CAP

1

Don't damage the surface of anode-cap with sharp shaped material !

Don't press the rubber hardly not to hurt inside of anode-caps !

2

A metal fitting called as shatter-hook terminal is built into the rubber.

3

Don’t turn the foot of rubber over hardly !

The shatter-hook terminal will stick out or damage the rubber

C board

Speaker

Two Screws

Four tapping screws (M)

b

b

3 When one side of the rubber cap is

separated from the anode button, the

anode-cap can be removed by turning

up the rubber cap and pulling it up in

the direction of the arrow c

c

Anode button

Anode cap

Picture tube

3

13

5

10

4

Chassis

6

Speaker

2

1

Two Screws

14

Neck Assy

11

Deflection

12

Yoke

Cushion

.

Page 19

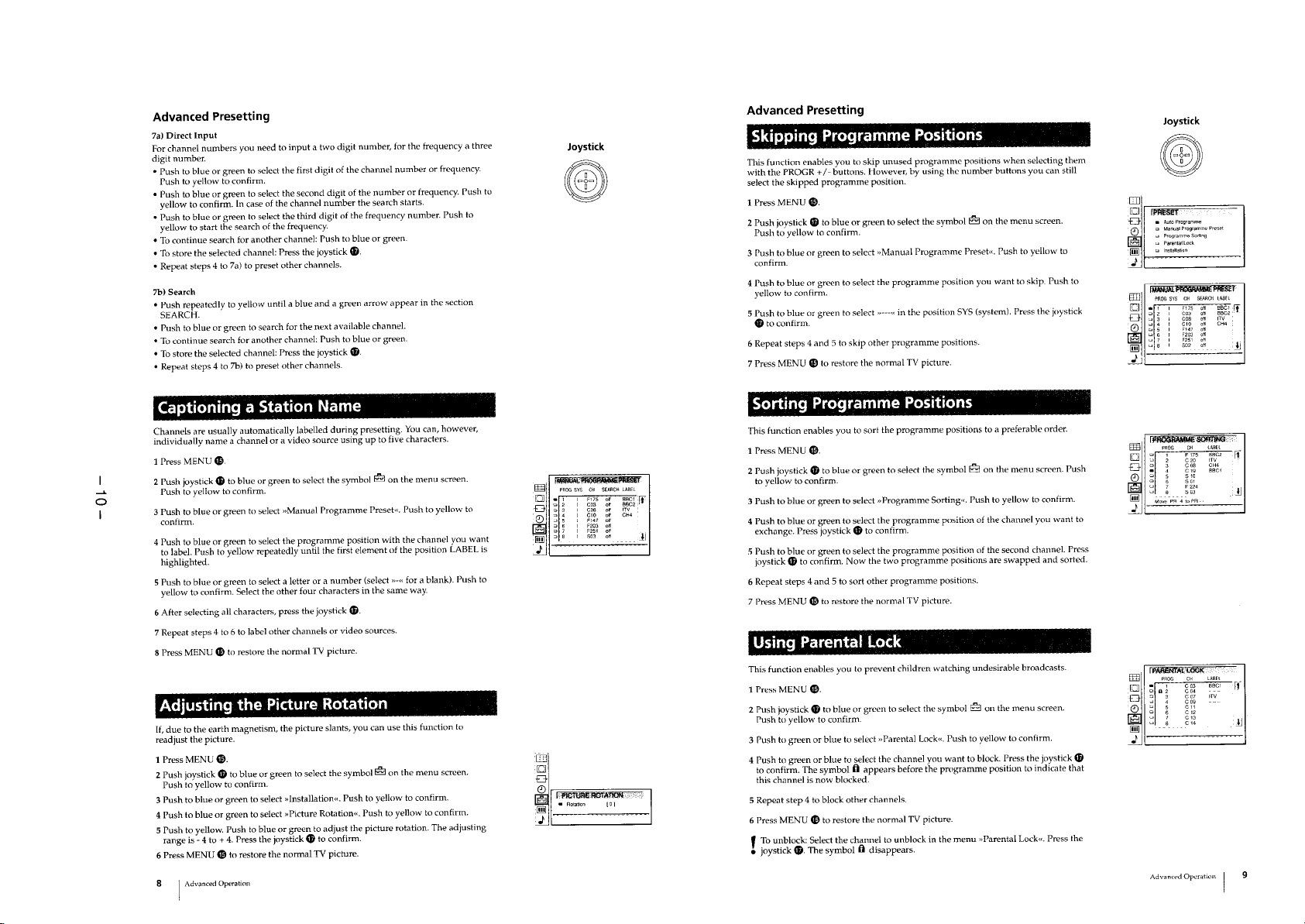

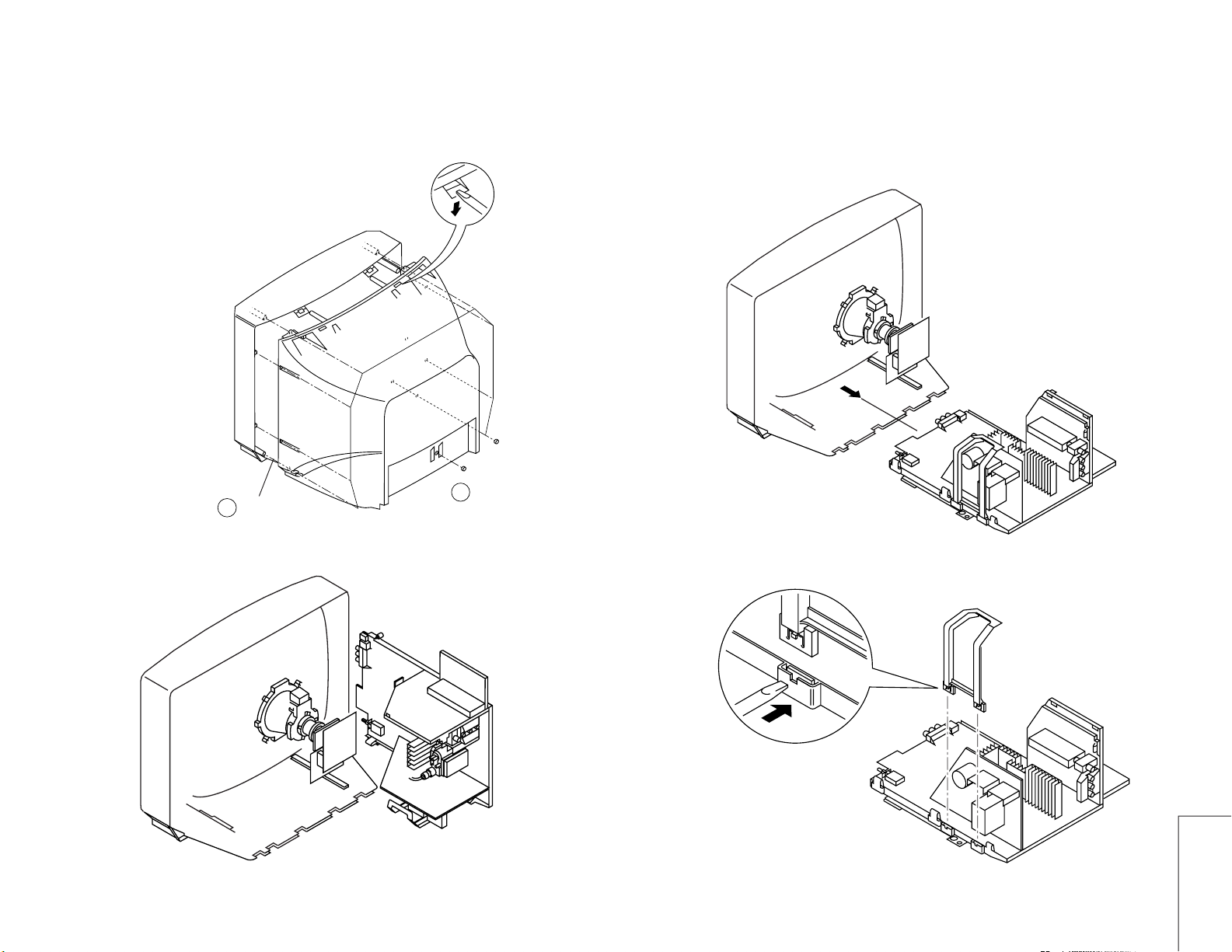

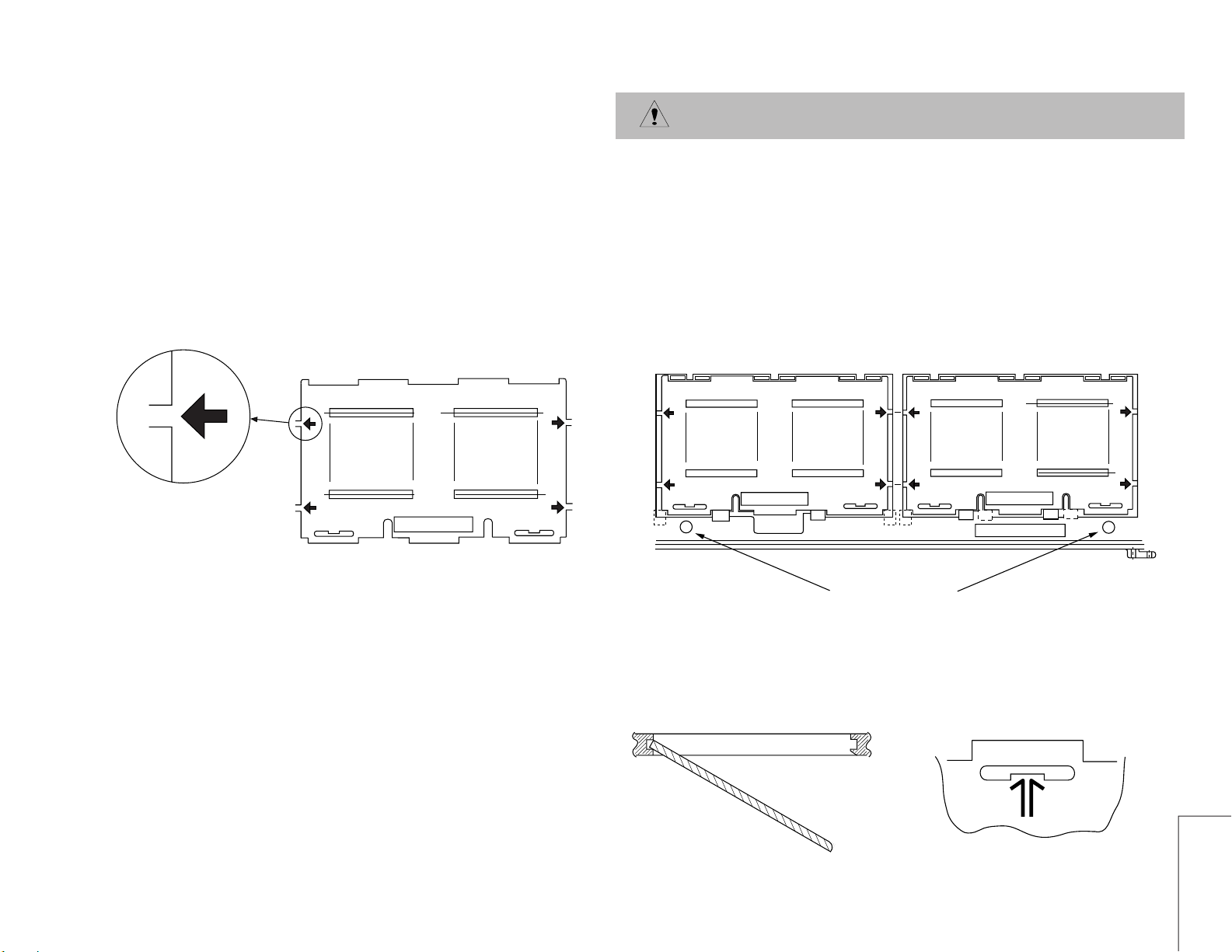

REMOVAL AND REPLACEMENT OF THE MAIN-BRACKET

BOTTOM PLATES.

For safety reasons, on no account should the plates be removed

and not refitted after servicing.

— 19 —

(1) REMOVING THE PLATES

In the event of servicing being required to the solder side of the D Board printed

circuit, the bottom plates fitted to the main chassis bracket require to be removed.

This is performed by cutting the gates with a sharp wire cutter at the locations

shown and indicated by arrows.

Note : There are 5 plates fitted to the main bracket and secured by 4 or 6 gates.

Only remove the necessary plate to gain access to the circuit board.

FOR SAFETY REASON THIS

PLATE MUST BE REMOUNTED

AFTER CUTTING AND

TAKING AWAY.

Fig 1

(2) REFITTING THE PLATES

Because the plates differ in size it is important that the correct plates are refitted in their

original location.

The plates are identified by markings A-B-C-D-E on their top side.

1. Identify the plate by locating its marking.

2. Turn the plate over noting where the marking is located.

3. Locate the corresponding marking indicated on the main chassis bracket. See Fig 2.

4. Refit the plate as indicated in Fig 3 with the markings located next to each other.

FOR SAFETY REASON THIS

PLATE MUST BE REMOUNTED

AFTER CUTTING AND

TAKING AWAY.

ATTENTION

D

E

Fig 2

FOR SAFETY REASON THIS

PLATE MUST BE REMOUNTED

AFTER CUTTING AND

TAKING AWAY.

ATTENTION

INDEX MARKING

AT BRACKET FRAME

INSERT FROM

THE BOTTOM

SIDE

Fig 3

MAIN BRACKET

In the event of the plates requiring to be

removed at a later stage, this can be achieved

by inserting a screwdriver in the snap-recess

indicated as in Fig 4 and lifting out.

KV-25K1

Fig 4

Page 20

KV-25K1

SECTION 3

SET -UP ADJUSTMENTS

• When complete readjustment is necessary or a new picture

tube is installed, carry out the following adjustments.

• Unless there are specific instructions to the contrary, carry

out these adjustment with the rated power supply.

• Unless there are specific instructions to the contrary, set the

controls and switches as follows.

Contrast............ normal

Brightness ........ normal

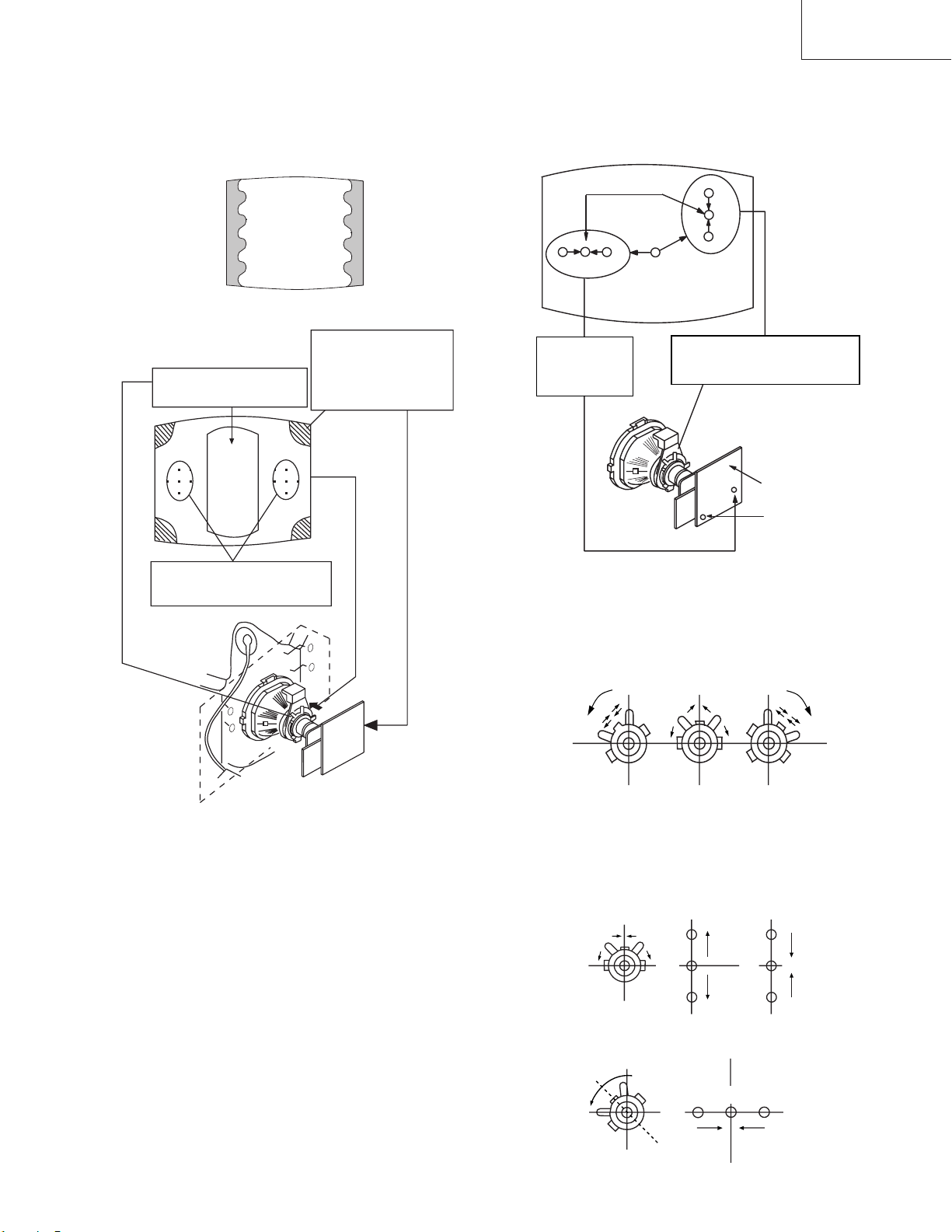

3-1. BEAM LANDING

Preparation:

1. In order to reduce the influence of geomagnetism on the set’s

picture tube face it in an easterly or westerly direction.

2. Switch on the set’s power and degauss with the degausser.

(1) Adjustment of Correction Magnet for Y-Splitting

Axis

1. Input a crosshatch signal from the pattern generator.

2. Picture control is minimum and brightness control is still

normal.

3. Position the neck assy as shown in Fig. 3-2.

4. Move the deflection yoke forward to touch the CRT and it

stands up rightly.

5. Adjust the upper pin and the lower pin symmetrically by

opening or closing the Y-splitting axis correction magnets

on the neck assy.

6. Return the deflection yoke to its original position.

• Carry out the following adjustments in this order:

3-1. Beam landing

3-2. Convergence

3-3. Focus

3-4. White balance

Note:Testing equipment required.

1. Color bar/pattern generator

2. Degausser

3. Vector scope

(2) Landing

Note: Before carrying out the following adjustments adjust the

magnets as indicated below (See Fig.3-3).

1. Input an all-white signal from the pattern generator.

Maximize the picture setting and adjust the brightness setting.

2. Rough-adjust the focus and horizontal convergence.

3. Loosen the deflection yoke screws, align the purity adjustment

knob to the central position. (See Fig. 3-1)

4. Switch from the all-white pattern to an all-green pattern.

5. Move the deflection yoke backwards and adjust with the

purity magnet so that the green is at the center and it aligns

symmetrically. (See Fig. 3-4)

6. Move the deflection yoke forward and adjust so that entire

screen becomes green.

7. Switch the raster signal to red, then to blue and verify the

landing condition.

8. When the position of the deflection yoke has been

determined, fasten the deflection yoke with the screw.

9. If the beam does not land correctly in all the corners, use

magnets to correct it. (See Fig. 3-5)

Y-splitting axis correction magnet

— 20 —

Purity Adjustment

Purity

Deflection yoke

Fig.3-1

Align the bottom edge of the neck

assy with the G3 hole center.

Fig.3-3

Align Pips

on each

magnet

Neck assy

Fig.3-2

Page 21

Green

GRN

Fig.3-4

RED

Red

Blue

BLU

KV-25K1

Center dot

Purity control corrects

this area.

Deflection yoke positioning

corrects these areas

Fig.3-5

Disk magnets or

rotatable disk

magnets correct

these areas (a-d).

H.STAT

convergence

control

RV3701

Screen (G2)

Magnete statico verticale

V.STAT

C Board

RV3702 (H.STAT)

H.STAT convergence

• If the horizontal dots are unable to coincide with the

variable range of the H.STAT convergence, adjust together

with the V.STAT convergence while tracking.

(Adjust the convergence by tilting the V.STAT convergence

or by opening or closing the V.STAT convergence.)

(Open)

(Close)

3-2. CONVERGENCE

(1) Screen center convergence

(Static convergence)

1. Input a dot signal from the pattern generator. Normalize the

picture setting.

2. (Moving horizontally), adjust the H.STAT control so that

the horizontal red, green and blue dots coincide at the

center of screen.

3. (Moving vertically), adjust the V.STAT magnet so that the

vertical red, green and blue points coincide at the center of

screen.

— 21 —

4. Movement of the red, green and blue dots by tilting the

V.STAT magnet and by opening or closing the V.STAT

magnet.

1 By opening or closing the V.STAT magnet, the red, green

and blue points move as shown below

B

G

R

B

G

R

2By rotating the V. STAT magnet counterclockwise, the

red, green and blue dots move as shown below.

B

GR

Page 22

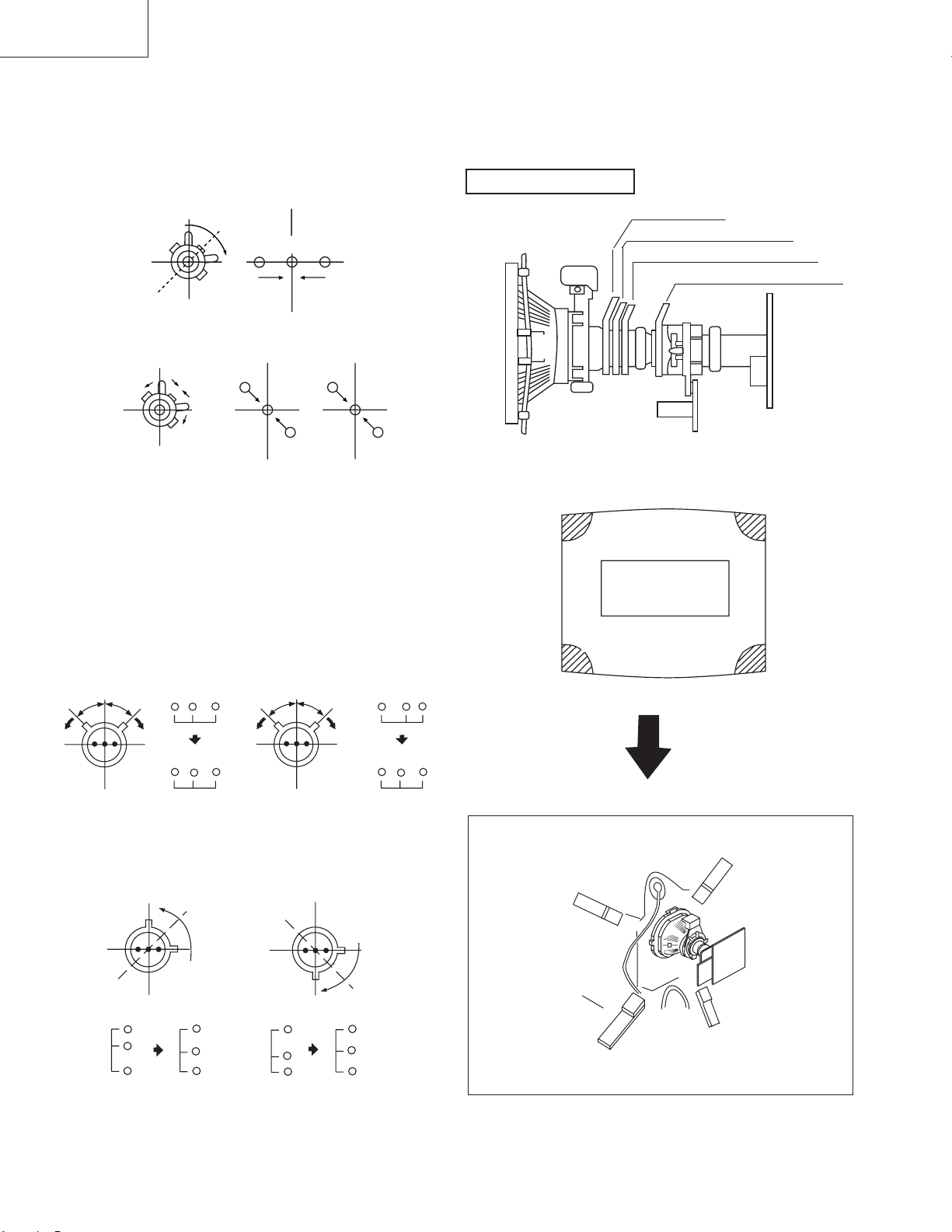

KV-25K1

3By rotating the V.STAT magnet clockwise, the red, green

and blue dots move as shown below.

B

GR

4By opening or closing the V.STAT magnet, the red, green and

blue dots move as shown below.

R

G

B

G

B

R

• If the blue dot does not coincide with the red and green points,

correct the points by using the BMC (Hexapole) magnet.

5Correction for HMC (horizontal mis-convergence) and VMC

(vertical mis-convergence) by using the BMC (Hexapole)

magnet.

1HMC correction by BMC (Hexapole) magnet and movement

of the electronic beam.

HMC correction(A) HMC correction(B)

A < B

RG B

A > B

RGB

Layout of each control

Purity magnet

BMC (Hexapole) magnet

V.STAT convergence magnet

Y-splitting axis correction magnet

Fig.3-5

2. If you are unable to adjust the corner convergence properly,

correct them with the use of permalloys.

a

a—d: angoli dello

a-d: screen-corner

schermo non in

convergence defect

convergenza.

c

c

b

d

d

A = B

RG B

A = B

RG B

2VMC correction by BMC (Hexapole) magnet and movement

of the electronic beam.

VMC correction(A) VMC correction(B)

C < D

C

D

C = D C > D C = D

R

G

B

R

C

G

D

B

R

G

B

R

G

B

— 22 —

b

Permalloy Assy

X-4387-214-1

Convergence adjustment with permalloy

a

d

c

Page 23

KV-25K1

3-3. Focus

1. Receive a television broadcast signal.

2. Normalize the picture setting.

3. Adjust the focus control on the flyback transformer for the

best focus at the center of the screen.

Bring only the center area of the screen into focus,

the magenta-ring appears on the screen. In this case, adjust

the focus to optimize the screen uniformly.

FOCUS

Video Proc. TDA4780

oNmetImetitnemtsujdAtnuomAataD

1TRBLORTNOCRESU

2LOCLORTNOCRESU

3CIPLORTNOCRESU

4EUHLORTNOCRESU

5NIAGR04

6NIAGGjdA

7NIAGBjdA

8FERLVLR13

9FERLVLGjdA

01FERLVLBjdA

11TIMILVRDKAEP55

21AMMAG13

31VEL2=FFOVEL3=NOPCSFFO

41YALEDFFO

3-4. Screen (G2), White balance

(Adjustment in the service mode with

remote commander)

G2 adjustment (RV3701)

1. Input a dot signal from the pattern generator.

2. Set the Picture, Brightness and Colour to minimum.

3. Apply 170V DC from an external power supply to the

R, G and B cathodes of the CRT.

4. While watching the picture, adjust the G2 control

RV3701 [ SCREEN ] on the C board to the point just

before the return lines disappear.

White balance adjustment

1. Receive an all-white signal.

2. Enter into the Service Mode by pressing ' TEST ',

' TEST ' and ' MENU' on the Service Commander.

3. Select ' VIDEO PROC. ' from the on screen menu display

and press OK .

4. The ' VIDEO PROC TDA4780' menu will appear on the

screen.

5. Set picture to MAX.

6. Set the ' R GAIN ' to 25.

7. Adjust the ' G GAIN ' and ' B GAIN ' so that the white

balance becomes optimum.

8. Press the OK button to write the data for each item.

9. Set picture to MIN.

10. Set the ' R LVL REF ' to 31.

11. Adjust ' G LVL REF ', and ' B LVL REF '

with the left and right buttons so that the white balance

becomes optimum.

12. Press the OK button to write the data for each item.

— 23 —

Page 24

KV-25K1

SECTION 4

CIRCUIT ADJUSTMENTS

4-1. ELECTRICAL ADJUSTMENTS

Service adjustment to this model can be performed with the supplied

remote commander, RM-862.

HOW TO ENTER INTO SERVICE MODE

1. Turn on the main power switch of the set while pressing the

PROG + (plus) and PROG

- (minus) buttons on the front panel.

++

VOL PROG

--

Headphone

jack

2. “TT” will appear on the upper right corner of the screen.

3. Press " MENU " on the commander to get the service menu on

screen.

AV3

Input jacks

AV INPUT

oNmetImetitnemtsujdAtnuomAataD

1TRBLORTNOCRESU

2LOCLORTNOCRESU

3CIPLORTNOCRESU

4EUHLORTNOCRESU

5NIAGR04

6NIAGGjdA

7NIAGBjdA

8FERLVLR13

9FERLVLGjdA

01FERLVLBjdA

11TIMILVRDKAEP55

21AMMAG13

31VEL2=FFOVEL3=NOPCSFFO

41YALEDFFO

51FFUBATADFFO

61XIRTAMCSTNFFO

71VTDHFFO

SECIVEDSECIVED

SECIVEDSECIVED

SECIVED

VTtinI

tsujdAbuS

corPoediV

niaMceDloC

tnoC.tcelfeD

buSceDloC

xoBerutaeF

lA

AD

PIPelgniS

dnuoS

ted32eniL

edisotuA&rednopsimuL,piP

0874ADT

4419ADT

1639ADS

3419ADT

456C78S

0719ADT

0829ADS

8829ADS

4. Push the joystick up (green) or down (blue) on the remote

commander to select the adjustment item.

5. Press the center button to proceed to the next menu.

6. If the adjustment item is 'Video Proc.', push the down button to

move to 'Video Proc.'.

7. The Menu as indicated in Fig 4-3 will appear on the screen.

8. Move the joystick up or down to move to the adjustment item and

press the center (OK) button.

9. Change the data in order to comply with each standard.

81LBSFFFO

91FFOTUCOTUANO

02SID2WSFFFO

122WSFFFO

22SID1WSFFFO

321WSFFFO

42KCALBTPADANO

52V1HGIHYFFO

622DOMFFO

72HCTERTSEULB

82TUOMVFFO

92SBAVRDKAEPNO

03TIMILKAEPTSNCEMITFFO

*

Fig. 4-3 * Switch OFF for White balance Adj and Switch ON for

Shipping Condition

— 24 —

Page 25

SDA9361 (DEFLECT. CONT.)

KV-25K1

oNmetImetitnemtsujdAtnuomAataD

1eziSVjdA

2errtneCVjdA

3ytiraeniLVjdA

4noitcerroCSjdA

5eziSHjdA

6pmAniPjdA

7noitcerroCrenroCpUjdA

8noitcerroCrenroCwoLjdA

9woBVjdA

01esahPniPjdA

11elgnAVjdA

21EDHNO

31RV0

41LBARNO

51siDklBFFO

61qrFeniLx2HF2NO

oNmetImetitnemtsujdAtnuomAataD

92A/D0

03emitklBV82

13emitklBH73

23nacSVtratS0

33esahpklBH16

430htdiwnacSV0

531htdiwnacSV0

63dnaBdrauG0

73nacsdertratS0

83sdleifrebmuN1

93ecalretnInoNINFFO

04deResioNcnysVRNNO

14LBVhtiwCSSNO

24dleif/senilniM0

34dleif/senilxaM0

44pmocTHECFA0

71edoMybdnatSFFO

81lacitreVNO

91tceleSklBESBFFO

02nacStratSESSFFO

12nacSdeRtratSESRSFFO

22draoBdrauGEBGFFO

32elbatemitnacSETSFFO

42noitpadAfleSASNNO

52pmocTHEV

62pmocTHEH

72ertneCH

82tratSMWP

54qerFLLP6

64RCVNO

74edoMneGFFO

84DIWSHNO

94esahpHtnIjdA

05htdiwMWP0

15RCVysioNFFO

25pizlliKFFO

011"52

57"92

001"52

53"92

23

35dr3ctFFO

45ffo4pagdnaBFFO

55ffopagdnaBFFO

65pagdnaB0

0

— 25 —

Page 26

KV-25K1

TDA4780 (VIDEO PROC.)

oNmetImetitnemtsujdAtnuomAataD

1TRBLORTNOCRESU

2LOCLORTNOCRESU

3CIPLORTNOCRESU

4EUHLORTNOCRESU

5NIAGR04

6NIAGGjdA

7NIAGBjdA

8FERLVLR13

9FERLVLGjdA

01FERLVLBjdA

11TIMILVRDKAEP55

21AMMAG13

31VEL2=FFOVEL3=NOPCSFFO

41YALEDFFO

51FFUBATADFFO

61XIRTAMCSTNFFO

71VTDHFFO

81LBSFFFO

91FFOTUCOTUANO

02SID2WSFFFO

122WSFFFO

22SID1WSFFFO

321WSFFFO

42KCALBTPADANO

52V1HGIHYFFO

622DOMFFO

72HCTERTSEULB

82TUOMVFFO

92SBAVRDKAEPNO

03TIMILKAEPTSNCEMITFFO

*

* Switch OFF for White balance Adj and Switch ON for Shipping

Condition

— 26 —

Page 27

KV-25K1

DEFLECTION SYSTEM ADJUSTMENT

V SIZE

1. Enter into the service mode and select 'Deflect cont.'.The

'Deflect cont. SDA9361' adjustment menu will be displayed.

2. Select and adjust each item in order to get an optimum image.

oNmetImetitnemtsujdAtnuomAataD

1eziSVjdA

2errtneCVjdA

3ytiraeniLVjdA

4noitcerroCSjdA

5eziSHjdA

6pmAniPjdA

7noitcerroCrenroCpUjdA

8noitcerroCrenroCwoLjdA

9woBVjdA

01esahPniPjdA

11elgnAVjdA

21EDHNO

31RV0

V POS

V LIN

H SIZE

H PIN CUSH

H TILT

H UP COR

41LBARNO

51siDklBFFO

61qrFeniLx2HF2NO

71edoMybdnatSFFO

81lacitreVNO

91tceleSklBESBFFO

02nacStratSESSFFO

12nacSdeRtratSESRSFFO

22draoBdrauGEBGFFO

32elbatemitnacSETSFFO

42noitpadAfleSASNNO

52pmocTHEV

62pmocTHEH

72ertneCH

82tratSMWP

H LOWER COR

AFC V BOW

AFC V ANGLE

H POS

011"52

57"92

001"52

53"92

23

0

— 27 —

Page 28

KV-25K1

4-2. VOLUME ELECTRICAL ADJUSTMENTS

Sub Brightness Adjustment

1. Enter Service Mode (Device Menu).

2. Select 'SUB ADJUST MENU'.

tnemtsujdabuS

erutciPbuS

ruoloCbuS

ssenthgirBbuS

retneC3/4

retneC-HPAP

tesffO-EWHPAP

SOP-HtxeT/uneM

tesffOBGRTAP

niaGBGRTAP

wodniWgnimarFartxE

3. Adjust the value according to the following advice.

Sub Color Adjustment

1. Input a PAL color bar signal.

2. Connect an oscilloscope to CN3703.

3. Enter into 'SERVICE MODE'.

4. Choose 'SUB ADJUST'.

5. Enter into Sub Color mode.

6. Adjust data so that the right sides of the waveforms are of equal

height.

SAME LEVEL

— 28 —

Page 29

KV-25K1

4-3. TEST MODE 2:

Is available by pressing the Test button twice, OSD “TT” appears. The functions described below are available by pressing the two numbers.

To release the Test Mode 2, press `0' twice, or switch the TV into Standby Mode.

00ffo2edoMtseThctiwS

10muminimoterutcip&ruolocmuminimteS

20)DSOo/w(noitcuderesioNotsseccatceriD

30%03otemulovteS

40)elbaliava99.rPniylnO('edoMecivreS`

50)elbaliava99.rPniylnO('edoMnoitcudorP`

60%08otemulovteS

70

80

90

01deteledsiyrtnehtneT

11)DSOo/w(ecnalabotsseccatceriD

21)DSOo/w(EUHotsseccatceriD

31unemnoitarugifnoC

41noitamrofninoitcudorPfoyalpsiD

51

61atadyromeMrewoPtsaLlautcaevaS

71secruosVAroflebalteserP

81FFO/NOtxeT

91%05otemulovteS

02deteledsiyrtnehtneT

120>-4+>-4-:tsetliocnoitatoR

22yalpsidrotinomrorrednaremitgnitarepO

32)DSOo/w(ssenthgirbbusotsseccatceriD

42)DSOo/w(ruolocbusotsseccatceriD

52yalpsidunemsutatS

62eporuEtseW:noitcelestesretcaractxeT

72eporuEtsaE:noitcelestesretcaractxeT

82hsilgnEKU-eporuE.W:noitcelestesretcaractxeT

92hsikruTeporuEtseW:noitcelestesretcaractxeT

03deteledsiyrtnehtneT

13devreseR

23devreseR

33tsetPIPitluM

43tsetedomotohP

53FFO/NOgnitumoediV

63devreseR

73devreseR

).xam

ssenthgirb&erutcip;.nim.loV(noitidnocgnigA

eudTESEReraseulavgolanA(noitidnocgnippihS

)ffoedomTT,detcelessi1.gorP.gnittesyrotcafot

tesnehwsraeppaunemegaugnaL(teseregaugnaL

)nodehctiwssi

,emuloVsdaer,MVNmorfgnittesyrotcafdaeR

,EUH,tsartnoC,ssenthgirB,ssaB,elberT,ecnalaB

lautcaehtotMORmorfseulavruoloC,ssenprahS

seulavdesu

83)sledom3:4roftoN(tsetedoMneercS

93elbatmargorpteseR

04deteledsiyrtnehtneT

14muminimerutciP

24noybloD

34ffoybloD

44.nimciP+.jdassenthgirBbuSotsseccatceriD

54edomtcetorpotMVNteS

64edomgniteserplennahcRI

74)DSOo/w(noitcelesecruosenohpdaeH

84)DSOo/w(tnemtsujdaOGAotsseccatceriD

94

05deteledsiyrtnehtneT

15tsetebortS

25)ksatwohS(ylnoesulanretnI

35ffo/nolA/rednopsuonimuL

45)DSOo/w(MVotsseccatceriD

55)L.sySylno('ssapwoL`lortnocrecilSXTM

65'noitasnepmocoN`lortnocrecilSXTM

75NOunemecivrestxetageM

85wodniwedocgnimarfllamsXTM

95wodniwedocgnimarfediwXTM

06deteledsiyrtnehtneT

16sevlavtluafedYBLODteS

26elbasidICA

36elbaneICA

ydaerlastcetedetybsihT(etybtsetMVNehtesarE

hctiws,noitcnufsihtgnitcelesretfA.)s'MVNderots

orcimehtybteserpeblliwMVNehT.nodnaffoVT

— 29 —

Page 30

KV-25K1

46sdnammocevalSC2IllateseR

56MVNnisedocrorrederotsteseR

66relortnocbusdnarelortnoclacol+LAProfteseR

76)DSOo/w(emulovenohpdaeHotsseccatceriD

86nosrorreerongI

96ffosrorreerongI

07deteledsiyrtnehtneT

17FFO/NOnoitatorerutciP

27ediwedomYBLOD

37desaercedpetsenoleveltxetBGRtxetageM

47desaercnipetsenoleveltxetBGRtxetageM

57DIkrowtenrofdevreseR

671639ADSrofevlavtluafeD

770829ADSrofeulavtluafeD

87+LAProfseulavtluafeD

974419ADTrofeulavtluafeD

08deteledsiyrtnehtneT

280719ADTrofeulavtluafeD

385817AASrofeulavtluafeD

480874ADTrofeulavtluafeD

584419ADTrofeulavtluafeD

683419ADTrofeulavtluafeD

788829ADSrofeulavtluafeD

88tsae/aissuRtesretcarahctxeT

98tsew/aissuRtesretcarahctxeT

09deteledsiyrtnehtneT

19lamronedomYBLOD

29elbasidPTI

39elbanePTI

49'tfel`ecneuqesesioN

59'ertnec`ecneuqesesioN

69'thgir`ecneuqesesioN

79'dnuorrus`ecneuqesesioN

89'ffo`edomdnuorruS

18xobserutaeFrofseulavtluafeD

99'motnahp`edomYBLOD

— 30 —

Page 31

Page 32

Page 33

Page 34

Page 35

Page 36

Page 37

Page 38

Page 39

Page 40

Page 41

Page 42

Page 43

Page 44

5-4. SEMICONDUCTORS

KV-25K1

BA7046F

BA7046F-T1

MB3793-42PNF

MB3793-42PNF-ER

NJM2240M

85

1

4

( TOP VIEW )

CXA1855Q-T6

25

36

37

48

1

( TOP VIEW )

24

13

12

CXD2044Q-TL

SAA4990H/V2

64 41

65

80

124

( MARKING SIDE VIEW )

40

25

CXD8626Q

5180

81

INDEX

50

LM393P

M5216P

ST24C16FB6

TDA2822M

UPC393C

7

6

8

1

5

2

3

4

LM78L05ACZ

LM78L12ACZ

L78L05ACZ-AP

L78L12ACZ-AP

IN

OUT

GND

MSP3400C-PS-C6-T-ND

MSP3410B-PS-F7-T-ND

SDA30C164-GEG

SDA5273-C126-GEG

9

10

18

26

68

1

( TOP VIEW )

61

433527

M27C4001-15C1

M27C4001-15C1-AE401

PC123F2

PC123FY2

4

3

1

2

PQ05RF21

SDA9288X-A141

TDA8755T-T

32 17

1

( TOP VIEW )

16

STV9379

1

2

3

4

1 : V IN

2 : V OUT

3 : GND

4 : ON/OFF CONTROL

P83C654EBA/560

SDA9280A41

51

52

68

60

52

1

35

34

18

17

( TOP VIEW )

SAA4945H/V1

44

SDA9361

34

44

2333

22

12

1

TC4S66F

TC4S66F-TE85L

1

2

3

4

TDA4665T-T

16

1

( TOP VIEW )

TDA4780/V3

28 15

7

5

9

8

100

130

( TOP VIEW )

31

LM2940CT-9.0

LM2940T-8.0

LM2940T-9.0

L4941BV

TEA7605

IN

OUT

GND

132 30

4

5

( TOP VIEW )

2014

MB814400C-70PJN-ER

26

INDEX

1

( TOP VIEW )

14

13

— 87 —

1

11

29

1

( TOP VIEW )

14

SAA4952WP/V1

20

1

TDA7265

1

TDA7309

( TOP VIEW )

11

11

10

640144

21

7

17

18 28

( TOP VIEW )

39

29

SBX1981-51

Page 45

KV-25K1

TDA9143/N2

TDA9144/N2

TDA9170T

32

1

( TOP VIEW )

17

16

TMS4C2972-26DTR

TMS4C2972-28DTR

36 19

1

( TOP VIEW )

18

CXA1875AM-T4

HEF4053BT

MC14052BDBZ

SN74LS221D

74HCT4046AD/S470

16 9

1

( TOP VIEW )

8

U2860B-BF-PG3

74LVC08D

14 8

1

( TOP VIEW )

7

BC546B

BC556B

BF421L-AMMO

2SC2500-B

2SC2551-O

2SC2551O-TPE2

E

BF871-127

E

DTA144EK

DTA144EK-T146

DTC114EK

DTC114EKA-T146

DTC123EK

DTC123EK-T146

DTC124EKA-T146

DTA144ESA

DTA144ESA-TP

DTC114ESA-TP

DTC144ESA-TP

2SA1175-HFE

2SA733-K

B

C

C

B

DTC144EK

DTC144EK-T146

DTC144EKA-T146

2SA1037K-T-146-R

2SA1162-G

2SC2412K-QR

2SC2412K-T-146-R

C

E

B

2SA933AS-RT

2SA933AS-QRT

2SA933S-RT

2SC1740S-RT

2SC2785-HFE

IRF620

B

C

2SA1837

B

C

2SC2611

2SC2688-LK

2SC3271-N

E

C

2SC3997CA

MARKING SIDE VIEW

2SC4834NP-F09

B

C

E

E

DAN202K

DAN202K-T-146

3

1

2

2

E

3

1

DAP202K

DAP202K-T-146

3

1

2

2

1

3

DA204K

B

DA204K-T-146

3

1

2

S

G

D

BF199

BF199-AMMO

E

C

B

E

IMZ1A-T109

3

2

1

5

4

3

2

3

2

1

D1NL20

D1NL20-TA

B

C

B

C

E

D1NL20-TR

EGP20G

EL1Z

GP08D

GP08DPKG23

2SC4793

4

5

6

6

B

1

C

E

MTZJ-T-77-9.1

MTZJ-T-77-9.1A

R2K-V1

RGP02-20EG23

RGP02-20EL-6394

RGP10GPKG23

RGP15GPKG23

S2LA20F

1SS133T-77

1SS83

1SS83TD

CATHODE

ANODE

— 88 —

Page 46

KV-25K1

D10SC4M

1

1

D4SB60L

D4SB60L-F

RBA-402L

ERC38-06

MA73-TX

S1VB20-S

S1VB40

-

~

~

+

3

2

3

2

MA3030-H(TX)

MA3033-L

MA3033L-TX

MA3056M-TX

MA3062M-TX

RD5.6M-B2

3

+

-

~

~

SLA-570KT3F

1

2

NC

23

1

ANODE

CATHODE

MA3051L-TX

CATHODE

CATHODE

ANODE

ERD08M-15

CATHODE

ANODE

ESAC39M-06CF38

ANODE

MTZJ-T-77-13B

MTZJ-T-77-15B

MTZJ-T-77-2.2A

MTZJ-T-77-33C

MTZJ-T-77-39C

MTZJ-T-77-5.6B

MTZJ-T-77-9.1B

MTZJ-13B

RD12SB2

UDZ-TE-17-12B

MTZJ-33C

MTZJ-39C

RD15ES-B2

RD5.6ESB2

RD9.1ESB2

1SS119-25

1SS119-25TD

CATHODE

ANODE

ANODE

3

2

1

1

2

3

CATHODE

— 89 —

Page 47

Page 48

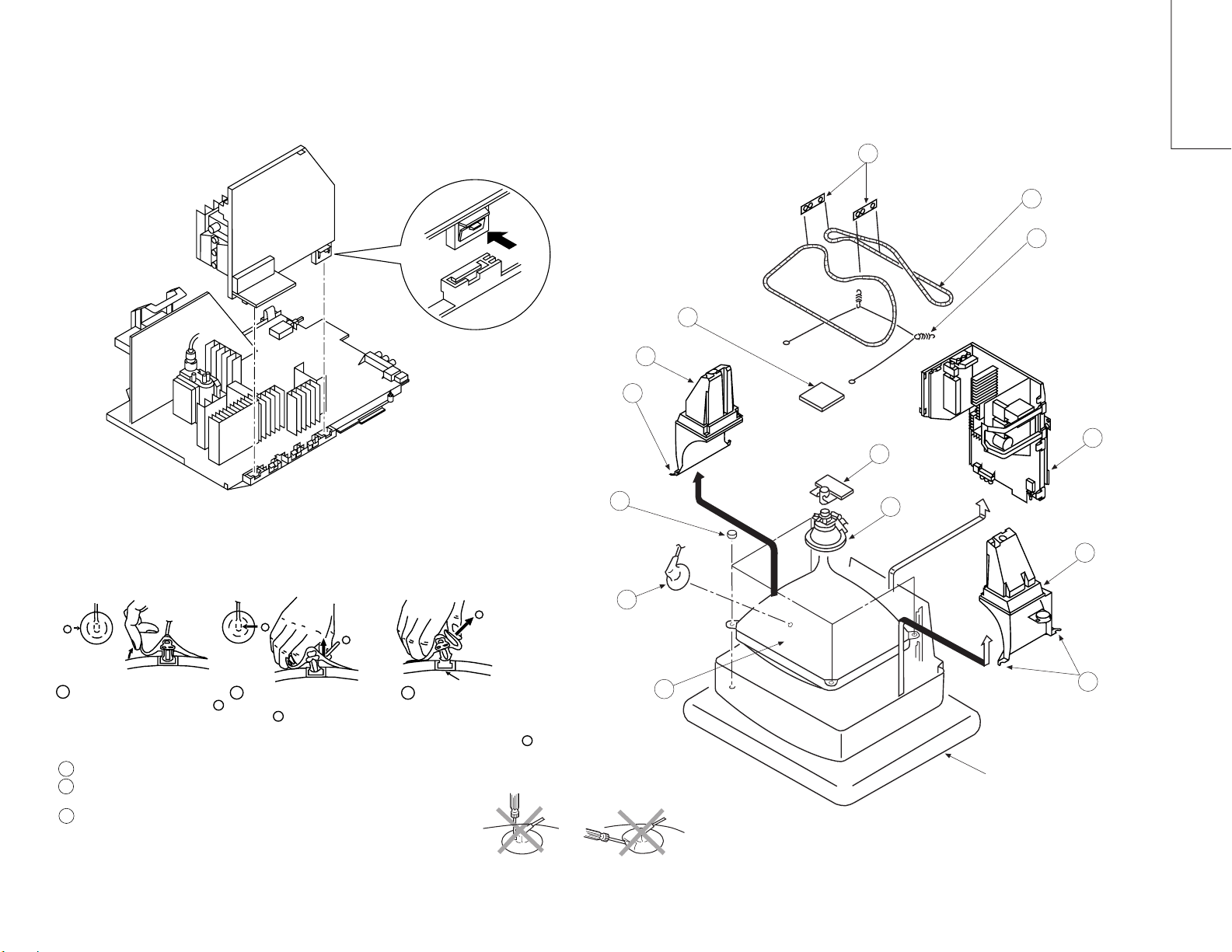

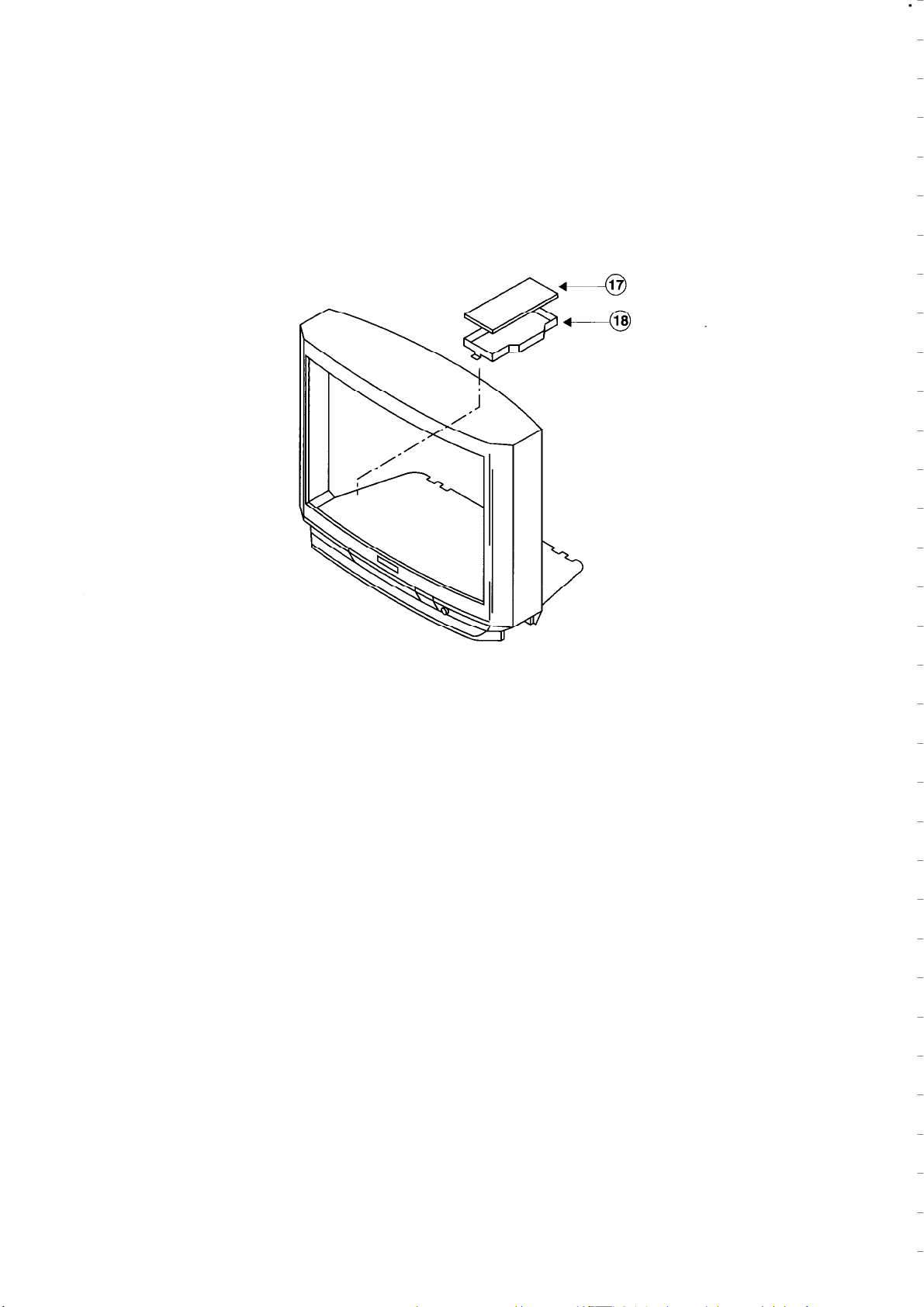

SECTION 6

EXPLODED VIEWS

NOTE :

• Items with no part number and no description are not stocked because they

are seldom required for routine service.

• The construction parts of an assembled part are indicated with a collation

number in the remarks column.

• Items marked " * " are not stocked since they are seldom required for

routine service. Some delay should be anticipated when ordering these

items.

The components identified by

shading and marked are critical

for safety.

Replace only with the part number

specified.

KV-25K1

Les composants identifies par une

trame et une marque sont

critiques pour la securite.

Ne les remplacer que par une piece

portant le numero specifie.

6-1. CHASSIS

14

13

1

12

16

11

10

7

8

9

6

5

4

15

3

2

REF NO PART NO DESCRIPTION REMARK

1 1-571-433-21 SWITCH, PUSH (AC POWER)

2 *4-203-457-01 BRACKET, MAIN

3 1-751-680-11 CORD, POWER (WITH NOISE FILTER)

2.5A/250V KV-25K1A/25K1B/25K1D/

25K1E/25K1K/25K1R

1-776-204-11 CORD, POWER (FILTER) KV-25K1U

4 *4-202-531-01 AC CORD LOCK (SC)

5 *A-1640-259-A D BOARD, COMPLETE

6 1-453-222-11 TRANSFORMER ASSY, FLYBACK

(NX-4003/U2B4)

7 *A-1636-024-A G BOARD, COMPLETE

8 *4-203-613-01 SUPPORTER, G

9 1-693-338-21 TUNER (TUVIF) (AEP)

(KV-25K1A/25K1D/25K1E/25K1K/25K1R)

1-693-340-21 TUNER (TUVIF) (FR) (KV-25K1B)

1-693-339-21 TUNER (TUVIF)(UK) (KV-25K1U)

REF NO PART NO DESCRIPTION REMARK

10 *A-1632-601-A A BOARD, COMPLETE (KV-25K1A/25K1D)

*A-1632-604-A A BOARD, COMPLETE (KV-25K1B)

*A-1632-602-A A BOARD, COMPLETE (KV-25K1E)

*A-1632-605-A A BOARD, COMPLETE (KV-25K1K)

*A-1632-606-A A BOARD, COMPLETE (KV-25K1R)

*A-1632-603-A A BOARD, COMPLETE (KV-25K1U)

11 *4-203-612-01 BRACKET, A-B

12 *A-1632-093-A B BOARD, COMPLETE

13 *A-1652-042-A T BOARD, COMPLETE (KV-25K1A/25K1D/

25K1E/25K1K/25K1R)

*A-1652-044-A T BOARD, COMPLETE (KV-25K1B)

*A-1652-047-A T BOARD, COMPLETE (KV-25K1U)

14 4-203-537-01 BRACKET, J-K-T

15 X-4200-307-1 COVER, ASSY REAR

16 4-039-358-01 SCREW (4X16), (+) BV TAPPING

— 91 —

Page 49

KV-25K1

6-2. PICTURE TUBE

73

67

51

74

75

76

77

68

70

72

69

71

58

57

62

60

64

59

61

72

63

65

65

66

52

53

56

54

51 X-4200-306-1 BEZNET ASSY 52-56

52 4-047-464-01 CATCHER PUSH

53 4-203-693-11 DOOR, CONTROL

54 4-203-692-01 WINDOW, ORNAMENTAL

55 4-203-704-01 BUTTON, POWER

56 4-202-964-01 SPRING

57 8-733-254-05 PICTURE TUBE (SD-269) (M60LCS60X)

58 8-451-474-11 DEFLECTION YOKE (Y25GXCB)

59 8-733-243-51 ITC

60 1-452-509-41 NECK ASSY PICTURE TUBE (NA-308)

61 *A-1644-080-A VM BOARD, COMPLETE

62 *A-1638-105-A C BOARD, COMPLETE

63 4-369-318-31 SPRING, TENSION

64 1-406-807-11 COIL DEGAUSSING

55

The components identified by

shading and marked are critical

for safety.

Replace only with the part number

specified.

REF NO PART NO DESCRIPTION REMARKREF NO PART NO DESCRIPTION REMARK

65 4-203-390-01 CUSHION, DGC

66 4-202-745-01 HOLDER, D.G.C. (25")

67 1-505-484-11 SPEAKER (2.6CM)

68 1-505-674-11 SPEAKER MID RANGE (8CM)

69 4-039-358-01 SCREW (4X16),(+) BV TAPPING

70 1-505-673-11 SPEAKER WOOFER (10CM)

71 4-039-890-01 SCREW (4X20),(+) BV TAPPING

72 4-039-355-11 SCREW (4X12),(+) BV TAPPING

73 4-308-870-00 CLIP, LEAD WIRE

74 1-452-032-00 MAGNET, DISK; 10MM Ø

75 1-452-094-00 MAGNET, ROTATABLE DISK; 15MM Ø

76 X-4387-214-1 PERMALLOY ASSY, CORRECTION

77 3-701-007-00 BAND, BINDING

71

68

70

69

67

Les composants identifies par une

trame et une marque sont

critiques pour la securite.

Ne les remplacer que par une piece

portant le numero specifie.

— 92 —

Page 50

The components identified by

shading and marked are critical

for safety.

Replace only with the part number

specified.

Les composants identifies par

une trame et une marque sont

critiques pour la securite.

Ne les remplacer que par une piece

portant le numero specifie.

SECTION 7

ELECTRICAL PARTS LIST

REF.NO. PART NO. DESCRIPTION REMARKREF.NO. PART NO. DESCRIPTION REMARK

KV-25K1

When indicating parts by reference

number, please include the board

name.

CAPACITORS COILS

MF : mF , PF : mmF MMH : mH , µH : mH

• Items marked " * " are not stocked since

they are seldom required for routine

service. Some delay should be anticipated

when ordering these items.

• All variable and adjustable resistors

have characteristic curve B, unless

otherwise noted.

RESISTORS

• All resistors are in ohms

B

*A-1620-093-A B BOARD, COMPLETE

*****************

< CAPACITOR >

C407 1-126-969-11 ELECT 220MF 20% 50V

C408 1-164-004-11 CERAMIC CHIP 0.1MF 10% 25V

C409 1-162-638-11 CERAMIC CHIP 1MF 16V

C410 1-162-638-11 CERAMIC CHIP 1MF 16V

C411 1-162-638-11 CERAMIC CHIP 1MF 16V

C412 1-163-037-11 CERAMIC CHIP 0.022MF 10% 50V

C413 1-163-037-11 CERAMIC CHIP 0.022MF 10% 50V

C414 1-164-005-11 CERAMIC CHIP 0.47MF 25V

C418 1-164-004-11 CERAMIC CHIP 0.1MF 10% 25V

C419 1-164-004-11 CERAMIC CHIP 0.1MF 10% 25V

C420 1-164-004-11 CERAMIC CHIP 0.1MF 10% 25V

C421 1-162-568-11 CERAMIC CHIP 0.33MF 10% 16V

C422 1-162-638-11 CERAMIC CHIP 1MF 16V

C427 1-126-963-11 ELECT 4.7MF 20% 50V

C428 1-164-004-11 CERAMIC CHIP 0.1MF 10% 25V

C429 1-163-225-91 CERAMIC CHIP 28PF 5% 50V

C430 1-163-225-91 CERAMIC CHIP 8PF 5% 50V

C431 1-164-004-11 CERAMIC CHIP 0.1MF 10% 25V

C432 1-164-004-11 CERAMIC CHIP 0.1MF 10% 25V

C433 1-164-004-11 CERAMIC CHIP 0.1MF 10% 25V

C434 1-163-117-00 CERAMIC CHIP 100PF 5% 50V

C435 1-163-145-00 CERAMIC CHIP 0.0015MF 5% 50V

C438 1-164-004-11 CERAMIC CHIP 0.1MF 10% 25V

C439 1-126-964-11 ELECT 10MF 20% 50V

C440 1-126-964-11 ELECT 10MF 20% 50V

C441 1-163-037-11 CERAMIC CHIP 0.022MF 10% 50V

C442 1-162-587-11 CERAMIC CHIP 0.039MF 10% 25V

C443 1-164-004-11 CERAMIC CHIP 0.1MF 10% 25V

C444 1-164-004-11 CERAMIC CHIP 0.1MF 10% 25V

C445 1-164-004-11 CERAMIC CHIP 0.1MF 10% 25V

C446 1-163-125-00 CERAMIC CHIP 220PF 5% 50V

C449 1-164-004-11 CERAMIC CHIP 0.1MF 10% 25V

C450 1-164-004-11 CERAMIC CHIP 0.1MF 10% 25V

C451 1-164-004-11 CERAMIC CHIP 0.1MF 10% 25V

C452 1-163-103-00 CERAMIC CHIP 27PF 5% 50V

C453 1-164-004-11 CERAMIC CHIP 0.1MF 10% 25V

C454 1-162-568-11 CERAMIC CHIP 0.33MF 10% 16V

C455 1-126-964-11 ELECT 10MF 20% 50V

C457 1-164-232-11 CERAMIC CHIP 0.01MF 10% 50V

• F : nonflammable

REF.NO. PART NO. DESCRIPTION REMARKREF.NO. PART NO. DESCRIPTION REMARK

C1800 1-126-963-11 ELECT 4.7MF 20% 50V

C1801 1-126-963-11 ELECT 4.7MF 20% 50V

C1802 1-163-141-00 CERAMIC CHIP 0.001MF 5% 50V

C1803 1-126-964-11 ELECT 10MF 20% 50V

C1804 1-164-004-11 CERAMIC CHIP 0.1MF 10% 25V

C1805 1-164-489-11 CERAMIC CHIP 0.22MF 10% 16V

C1806 1-110-501-11 CERAMIC CHIP 0.33MF 10% 16V

C1807 1-126-963-11 ELECT 4.7MF 20% 50V

C1808 1-163-125-00 CERAMIC CHIP 220PF 5% 50V

C1809 1-163-125-00 CERAMIC CHIP 220PF 5% 50V

C1810 1-162-638-11 CERAMIC CHIP 1MF 16V

C1811 1-163-989-11 CERAMIC CHIP 0.033MF 10% 25V

C1812 1-163-989-11 CERAMIC CHIP 0.033MF 10% 25V

C1813 1-164-489-11 CERAMIC CHIP 0.22MF 10% 16V

C1814 1-163-125-00 CERAMIC CHIP 220PF 5% 50V

C1815 1-163-125-00 CERAMIC CHIP 220PF 5% 50V

C1816 1-126-963-11 ELECT 4.7MF 20% 50V

C1817 1-164-004-11 CERAMIC CHIP 0.1MF 10% 25V

C1818 1-164-004-11 CERAMIC CHIP 0.1MF 10% 25V

C1819 1-163-097-00 CERAMIC CHIP 15PF 5% 50V

C1823 1-164-004-11 CERAMIC CHIP 0.1MF 10% 25V

C1824 1-164-004-11 CERAMIC CHIP 0.1MF 10% 25V

C1825 1-126-964-11 ELECT 10MF 20% 50V

C1826 1-164-004-11 CERAMIC CHIP 0.1MF 10% 25V

C1827 1-164-004-11 CERAMIC CHIP 0.1MF 10% 25V

C1828 1-163-117-00 CERAMIC CHIP 100PF 5% 50V

C1829 1-163-097-00 CERAMIC CHIP 15PF 5% 50V

C1830 1-164-004-11 CERAMIC CHIP 0.1MF 10% 25V

C1831 1-163-125-00 CERAMIC CHIP 220PF 5% 50V

C1832 1-164-232-11 CERAMIC CHIP 0.01MF 10% 50V

C1833 1-126-964-11 ELECT 10MF 20% 50V

C1834 1-164-004-11 CERAMIC CHIP 0.1MF 10% 25V

C1835 1-164-489-11 CERAMIC CHIP 0.22MF 10% 16V

C1836 1-110-501-11 CERAMIC CHIP 0.33MF 10% 16V

C1839 1-126-963-11 ELECT 4.7MF 20% 50V

C1840 1-162-638-11 CERAMIC CHIP 1MF 16V

C1841 1-163-989-11 CERAMIC CHIP 0.033MF 10% 25V

C1842 1-163-989-11 CERAMIC CHIP 0.033MF 10% 25V

C1843 1-164-489-11 CERAMIC CHIP 0.22MF 10% 16V

C1846 1-126-963-11 ELECT 4.7MF 20% 50V

C1847 1-164-004-11 CERAMIC CHIP 0.1MF 10% 25V

C1848 1-164-004-11 CERAMIC CHIP 0.1MF 10% 25V

The components identified by

shading and marked are critical

for safety.

Replace only with the part number

specified.

Les composants identifies par

une trame et une marque sont

critiques pour la securite.

Ne les remplacer que par une piece

portant le numero specifie.

— 93 —

Page 51

KV-25K1

B

The components identified by

shading and marked are critical

for safety.

Replace only with the part number

specified.

Les composants identifies par

une trame et une marque sont

critiques pour la securite.

Ne les remplacer que par une piece

portant le numero specifie.

REF.NO. PART NO. DESCRIPTION REMARK

C1849 1-163-105-00 CERAMIC CHIP 33PF 5% 50V

C1850 1-163-245-11 CERAMIC CHIP 56PF 5% 50V

C1852 1-164-695-11 CERAMIC CHIP 0.0022MF 5% 50V

C1853 1-163-121-00 CERAMIC CHIP 150PF 5% 50V

REF.NO. PART NO. DESCRIPTION REMARK

C1935 1-163-097-91 CERAMIC 15PF 5% 50V

C1937 1-163-103-00 CERAMIC CHIP 27PF 5% 50V

C1947 1-164-004-11 CERAMIC CHIP 0.1MF 10% 25V

C1948 1-164-004-11 CERAMIC CHIP 0.1MF 10% 25V

C1952 1-163-235-11 CERAMIC CHIP 22PF 5% 50V

C1854 1-164-005-11 CERAMIC CHIP 0.47MF 16V

C1856 1-163-105-00 CERAMIC CHIP 33PF 5% 50V

C1857 1-163-101-00 CERAMIC CHIP 22PF 5% 50V

C1858 1-163-989-11 CERAMIC CHIP 0.033MF 10% 25V

C1953 1-216-204-00 METAL GLAZE 1.8K 5% 1/8W

C1954 1-163-235-11 CERAMIC CHIP 22PF 5% 50V

C1955 1-216-204-00 METAL GLAZE 1.8K 5% 1/8W

C1859 1-164-005-11 CERAMIC CHIP 0.47MF 16V

< CONNECTOR >

C1860 1-126-961-11 ELECT 2.2MF 20% 50V

C1861 1-163-097-00 CERAMIC CHIP 15PF 5% 50V

C1862 1-163-097-00 CERAMIC CHIP 15PF 5% 50V

C1864 1-163-125-00 CERAMIC CHIP 220PF 5% 50V

C1866 1-126-964-11 ELECT 10MF 20% 50V

CN412 *1-564-513-11 PLUG, CONNECTOR 10P

CN417 *1-564-596-11 PLUG, CONNECTOR 15P

CN419 *1-564-512-11 PLUG, CONNECTOR 9P

CN1810 *1-564-512-11 PLUG, CONNECTOR 9P

CN1811 *1-900-901-85 CONNECTOR ASSY, MICRO 8P

C1867 1-164-004-11 CERAMIC CHIP 0.1MF 10% 25V

C1868 1-164-004-11 CERAMIC CHIP 0.1MF 10% 25V

CN1815 *1-564-512-11 PLUG, CONNECTOR 9P

C1869 1-164-004-11 CERAMIC CHIP 0.1MF 10% 25V

C1870 1-164-004-11 CERAMIC CHIP 0.1MF 10% 25V

< DIODE >

C1871 1-164-004-11 CERAMIC CHIP 0.1MF 10% 25V

D401 8-719-914-43 DIODE DAN202K

C1872 1-164-004-11 CERAMIC CHIP 0.1MF 10% 25V

C1873 1-164-004-11 CERAMIC CHIP 0.1MF 10% 25V

C1874 1-164-004-11 CERAMIC CHIP 0.1MF 10% 25V

C1875 1-164-004-11 CERAMIC CHIP 0.1MF 10% 25V

D402 8-719-914-43 DIODE DAN202K

D403 8-719-028-00 DIODE MA3033-L

D410 8-719-401-63 DIODE MA3062M-TX

D411 8-719-914-43 DIODE DAN202K

C1876 1-163-243-11 CERAMIC CHIP 47PF 5% 50V

D412 8-719-914-43 DIODE DAN202K

C1877 1-163-243-11 CERAMIC CHIP 47PF 5% 50V

D415 8-719-914-43 DIODE DAN202K

C1878 1-164-004-11 CERAMIC CHIP 0.1MF 10% 25V

C1879 1-164-004-11 CERAMIC CHIP 0.1MF 10% 25V

< FERRITE BEAD >

C1880 1-164-004-11 CERAMIC CHIP 0.1MF 10% 25V

C1881 1-164-004-11 CERAMIC CHIP 0.1MF 10% 25V

FB401 1-414-234-11 INDUCTOR, FERRITE BEAD

FB402 1-414-234-11 INDUCTOR, FERRITE BEAD

C1882 1-164-004-11 CERAMIC CHIP 0.1MF 10% 25V

C1883 1-164-004-11 CERAMIC CHIP 0.1MF 10% 25V

C1884 1-164-004-11 CERAMIC CHIP 0.1MF 10% 25V

FB403 1-414-234-11 INDUCTOR, FERRITE BEAD

FB404 1-414-234-11 INDUCTOR, FERRITE BEAD

FB405 1-414-234-11 INDUCTOR, FERRITE BEAD

C1885 1-164-004-11 CERAMIC CHIP 0.1MF 10% 25V

C1886 1-164-004-11 CERAMIC CHIP 0.1MF 10% 25V

FB406 1-414-234-11 INDUCTOR, FERRITE BEAD

FB407 1-414-234-11 INDUCTOR, FERRITE BEAD

C1887 1-164-004-11 CERAMIC CHIP 0.1MF 10% 25V

C1889 1-164-004-11 CERAMIC CHIP 0.1MF 10% 25V

C1890 1-126-964-11 ELECT 10MF 20% 50V

FB1801 1-414-234-11 INDUCTOR, FERRITE BEAD

FB1802 1-414-234-11 INDUCTOR, FERRITE BEAD

FB1803 1-414-234-11 INDUCTOR, FERRITE BEAD

C1891 1-164-004-11 CERAMIC CHIP 0.1MF 10% 25V

C1892 1-164-004-11 CERAMIC CHIP 0.1MF 10% 25V

FB1804 1-414-234-11 INDUCTOR, FERRITE BEAD

FB1805 1-414-234-11 INDUCTOR, FERRITE BEAD

C1893 1-164-004-11 CERAMIC CHIP 0.1MF 10% 25V

C1894 1-164-004-11 CERAMIC CHIP 0.1MF 10% 25V

C1895 1-163-241-11 CERAMIC CHIP 39PF 5% 50V

FB1806 1-414-234-11 INDUCTOR, FERRITE BEAD

FB1808 1-414-234-11 INDUCTOR, FERRITE BEAD

FB1809 1-414-234-11 INDUCTOR, FERRITE BEAD

C1898 1-164-004-11 CERAMIC CHIP 0.1MF 10% 25V

C1899 1-163-097-00 CERAMIC CHIP 15PF 5% 50V

FB1810 1-414-234-11 INDUCTOR, FERRITE BEAD

FB1811 1-216-295-91 CONDUCTOR, CHIP

C1904 1-163-145-00 CERAMIC CHIP 0.0015MF 5% 50V

C1910 1-126-964-11 ELECT 10MF 20% 50V

C1912 1-164-004-11 CERAMIC CHIP 0.1MF 10% 25V

FB1812 1-216-295-91 CONDUCTOR, CHIP

FB1813 1-216-295-91 CONDUCTOR, CHIP

FB1815 1-216-295-91 CONDUCTOR, CHIP

C1913 1-163-229-11 CERAMIC CHIP 12PF 5% 50V

C1916 1-216-043-91 METAL GLAZE 560 5% 1/10W

< ENCAPSULATED FILTER >

C1919 1-164-004-11 CERAMIC CHIP 0.1MF 10% 25V

C1921 1-163-105-00 CERAMIC CHIP 33PF 5% 50V

C1924 1-164-004-11 CERAMIC CHIP 0.1MF 10% 25V

C1925 1-164-004-11 CERAMIC CHIP 0.1MF 10% 25V

C1926 1-164-004-11 CERAMIC CHIP 0.1MF 10% 25V

C1927 1-164-004-11 CERAMIC CHIP 0.1MF 10% 25V

FL1801 1-233-767-11 FILTER

FL1803 1-415-940-11 DELAY LINE

FL1807 1-236-071-11 ENCAPSULATED COMPONENT

FL1808 1-236-071-11 ENCAPSULATED COMPONENT

FL1809 1-236-071-11 ENCAPSULATED COMPONENT

< IC >

C1928 1-164-004-11 CERAMIC CHIP 0.1MF 10% 25V

C1931 1-164-004-11 CERAMIC CHIP 0.1MF 10% 25V

C1932 1-163-275-11 CERAMIC CHIP 0.001MF 5% 50V

C1933 1-136-479-11 FILM 0.001MF 1% 100V

IC402 8-759-275-36 IC TDA4780/V3

IC403 8-759-421-42 IC SDA9361

IC1801 8-759-257-59 IC TDA8755T-T

IC1803 8-759-439-27 IC TMS4C2972-28DTR

IC1804 8-759-439-64 IC HEF4053BT

— 94 —

Page 52

The components identified by

shading and marked are critical

for safety.

Replace only with the part number

specified.

Les composants identifies par

une trame et une marque sont

critiques pour la securite.

Ne les remplacer que par une piece

portant le numero specifie.

REF.NO. PART NO. DESCRIPTION REMARKREF.NO. PART NO. DESCRIPTION REMARK

KV-25K1

B

IC1805 8-759-439-64 IC HEF4053BT

IC1806 8-759-439-64 IC HEF4053BT

IC1807 8-759-439-64 IC HEF4053BT

IC1808 8-759-439-62 IC SAA4990H/V2

IC1809 8-759-460-49 IC SDA9280B21

IC1810 8-759-438-66 IC CXD8626Q

IC1811 8-759-257-59 IC TDA8755T-T

IC1812 8-759-444-24 IC 74HCT4046AD/S470

IC1813 8-759-426-57 IC 74HCT4046AD

IC1814 8-759-438-64 IC SAA4952WP/V1

IC1815 8-759-444-24 IC 74HCT4046AD/S470

IC1816 8-759-444-25 IC P83C654EBA/560

IC1817 8-759-439-27 IC TMS4C2972-28DTR

IC1819 8-759-991-41 IC LM78L05ACZ

IC1823 8-759-991-41 IC LM78L05ACZ

IC1824 8-759-991-41 IC LM78L05ACZ

IC1825 8-759-234-77 IC TC4S66F

IC1831 8-759-439-26 IC SN74LS221D

< COIL >

L401 1-408-429-00 INDUCTOR 470UH

L402 1-408-429-00 INDUCTOR 470UH

L407 1-410-999-11 INDUCTOR CHIP 3.3UH

L1801 1-410-435-21 INDUCTOR 220UH

L1802 1-410-435-21 INDUCTOR 220UH

L1803 1-408-403-00 INDUCTOR 3.3UH

L1804 1-408-409-00 INDUCTOR 10UH

L1805 1-410-999-11 INDUCTOR CHIP 3.3UH

L1806 1-216-295-91 CONDUCTOR, CHIP

L1808 1-408-403-00 INDUCTOR 3.3UH

JR418 1-216-295-91 CONDUCTOR, CHIP

JR420 1-216-295-91 CONDUCTOR, CHIP

JR421 1-216-295-91 CONDUCTOR, CHIP

JR422 1-216-295-91 CONDUCTOR, CHIP

JR423 1-216-295-91 CONDUCTOR, CHIP

JR424 1-216-295-91 CONDUCTOR, CHIP

JR426 1-163-117-00 CERAMIC CHIP 100PF 5% 50V

JR1801 1-216-295-91 CONDUCTOR, CHIP

JR1802 1-216-295-91 CONDUCTOR, CHIP

JR1803 1-216-295-91 CONDUCTOR, CHIP

JR1804 1-216-295-91 CONDUCTOR, CHIP

JR1805 1-216-295-91 CONDUCTOR, CHIP

JR1806 1-216-295-91 CONDUCTOR, CHIP

JR1807 1-216-295-91 CONDUCTOR, CHIP

JR1808 1-216-295-91 CONDUCTOR, CHIP

JR1809 1-216-295-91 CONDUCTOR, CHIP

JR1810 1-216-295-91 CONDUCTOR, CHIP

JR1811 1-216-295-91 CONDUCTOR, CHIP

JR1812 1-216-295-91 CONDUCTOR, CHIP

JR1840 1-216-295-91 CONDUCTOR, CHIP

JR1841 1-216-295-91 CONDUCTOR, CHIP

JR1843 1-216-295-91 CONDUCTOR, CHIP

JR1875 1-216-295-91 CONDUCTOR, CHIP

JR1878 1-216-295-91 CONDUCTOR, CHIP

JR1879 1-216-295-91 CONDUCTOR, CHIP

JR1880 1-216-295-91 CONDUCTOR, CHIP

JR1881 1-216-295-91 CONDUCTOR, CHIP

JR1882 1-216-295-91 CONDUCTOR, CHIP

JR1883 1-216-295-91 CONDUCTOR, CHIP

JR1890 1-216-295-91 CONDUCTOR, CHIP

L1810 1-410-426-11 INDUCTOR 39UH

L1811 1-216-295-91 CONDUCTOR, CHIP

L1812 1-408-403-00 INDUCTOR 3.3UH

L1813 1-216-295-91 CONDUCTOR, CHIP

L1814 1-408-403-00 INDUCTOR 3.3UH

L1901 1-410-426-11 INDUCTOR 39UH

JR1893 1-216-295-91 CONDUCTOR, CHIP

JR1894 1-216-295-91 CONDUCTOR, CHIP

JR1901 1-216-295-91 CONDUCTOR, CHIP

JR1904 1-216-029-00 METAL GLAZE 150 5% 1/10W

JR1905 1-216-295-91 CONDUCTOR, CHIP

JR1910 1-216-295-91 CONDUCTOR, CHIP

L1902 1-410-426-11 INDUCTOR 39UH

L1903 1-414-170-11 INDUCTOR CHIP 100UH

R408 1-216-065-00 METAL GLAZE 4.7K 5% 1/10W

R409 1-216-057-00 METAL GLAZE 2.2K 5% 1/10W

< TRANSISTOR >

R439 1-216-093-00 METAL GLAZE 68K 5% 1/10W

R443 1-216-025-91 METAL GLAZE 100 5% 1/10W

Q411 8-729-901-06 TRANSISTOR DTA144EK

R444 1-216-025-91 METAL GLAZE 100 5% 1/10W

Q412 8-729-901-06 TRANSISTOR DTA144EK

Q413 8-729-920-74 TRANSISTOR 2SC2412K-QR

Q415 8-729-900-53 TRANSISTOR DTC114EK

Q416 8-729-920-74 TRANSISTOR 2SC2412K-QR

R445 1-216-025-91 METAL GLAZE 100 5% 1/10W

R446 1-216-025-91 METAL GLAZE 100 5% 1/10W

R447 1-216-025-91 METAL GLAZE 100 5% 1/10W

R448 1-216-043-91 METAL GLAZE 560 5% 1/10W

Q1801 8-729-216-22 TRANSISTOR 2SA116-2G

R449 1-216-049-91 METAL GLAZE 1K 5% 1/10W

Q1802 8-729-901-01 TRANSISTOR DTC144EK

Q1804 8-729-901-01 TRANSISTOR DTC144EK

Q1805 8-729-216-22 TRANSISTOR 2SA116-2G

Q1807 8-729-216-22 TRANSISTOR 2SA116-2G

R450 1-216-099-00 METAL GLAZE 120K 5% 1/10W

R451 1-216-101-00 METAL GLAZE 150K 5% 1/10W

R452 1-216-073-00 METAL GLAZE 10K 5% 1/10W

R453 1-216-017-91 METAL GLAZE 47 5% 1/10W

Q1808 8-729-901-01 TRANSISTOR DTC144EK

R454 1-216-017-91 METAL GLAZE 47 5% 1/10W

Q1809 8-729-901-01 TRANSISTOR DTC144EK

Q1810 8-729-901-01 TRANSISTOR DTC144EK

Q1812 8-729-920-74 TRANSISTOR 2SC2412K-QR

Q1813 8-729-900-53 TRANSISTOR DTC114EK

R455 1-216-063-91 METAL GLAZE 3.9K 5% 1/10W

R456 1-216-097-91 METAL GLAZE 100K 5% 1/10W

R457 1-216-099-00 METAL GLAZE 120K 5% 1/10W

R458 1-216-049-91 METAL GLAZE 1K 5% 1/10W

< RESISTOR >

JR406 1-216-295-91 CONDUCTOR, CHIP

JR407 1-216-295-91 CONDUCTOR, CHIP

JR408 1-216-295-91 CONDUCTOR, CHIP

JR409 1-216-049-91 METAL GLAZE 1K 5% 1/10W

JR417 1-216-295-91 CONDUCTOR, CHIP

R459 1-216-049-91 METAL GLAZE 1K 5% 1/10W

R463 1-216-049-91 METAL GLAZE 1K 5% 1/10W

R465 1-216-073-00 METAL GLAZE 10K 5% 1/10W

R466 1-216-049-91 METAL GLAZE 1K 5% 1/10W

R467 1-216-041-00 METAL GLAZE 470 5% 1/10W

R468 1-216-025-91 METAL GLAZE 100 5% 1/10W

— 95 —

Page 53

KV-25K1

B

The components identified by

shading and marked are critical

for safety.

Replace only with the part number

specified.

Les composants identifies par

une trame et une marque sont

critiques pour la securite.

Ne les remplacer que par une piece

portant le numero specifie.

REF.NO. PART NO. DESCRIPTION REMARK

R469 1-216-025-91 METAL GLAZE 100 5% 1/10W

R470 1-216-055-00 METAL GLAZE 1.8K 5% 1/10W

R473 1-216-081-00 METAL GLAZE 22K 5% 1/10W

R477 1-216-057-00 METAL GLAZE 2.2K 5% 1/10W

R483 1-216-063-91 METAL GLAZE 3.9K 5% 1/10W

R484 1-216-049-91 METAL GLAZE 1K 5% 1/10W

R487 1-216-295-91 CONDUCTOR, CHIP

R488 1-216-107-00 METAL GLAZE 270K 5% 1/10W

R491 1-216-107-91 METAL GLAZE 270K 5% 1/10W

R499 1-216-025-91 CARBON 100 5% 1/4W

R1801 1-216-051-00 METAL GLAZE 1.2K 5% 1/10W

R1802 1-216-049-91 METAL GLAZE 1K 5% 1/10W

R1803 1-216-049-91 METAL GLAZE 1K 5% 1/10W

R1804 1-216-053-00 METAL GLAZE 1.5K 5% 1/10W

R1805 1-216-049-91 METAL GLAZE 1K 5% 1/10W

R1806 1-216-051-00 METAL GLAZE 1.2K 5% 1/10W

R1807 1-216-049-91 METAL GLAZE 1K 5% 1/10W

R1808 1-216-025-91 METAL GLAZE 100 5% 1/10W

R1810 1-216-076-00 METAL GLAZE 13K 5% 1/10W

R1811 1-216-025-91 METAL GLAZE 100 5% 1/10W

R1812 1-216-033-00 METAL GLAZE 220 5% 1/10W

R1813 1-216-045-00 METAL GLAZE 680 5% 1/10W

R1814 1-216-031-00 METAL GLAZE 180 5% 1/10W

R1815 1-216-037-00 METAL GLAZE 330 5% 1/10W

R1816 1-216-295-91 CONDUCTOR, CHIP

R1817 1-216-037-00 METAL GLAZE 330 5% 1/10W

R1818 1-216-037-00 METAL GLAZE 330 5% 1/10W

R1819 1-216-073-00 METAL GLAZE 10K 5% 1/10W

R1820 1-216-029-00 METAL GLAZE 150 5% 1/10W

R1821 1-216-023-00 METAL GLAZE 82 5% 1/10W

REF.NO. PART NO. DESCRIPTION REMARK

R1855 1-216-057-00 METAL GLAZE 2.2K 5% 1/10W

R1856 1-216-057-00 METAL GLAZE 2.2K 5% 1/10W

R1857 1-216-057-00 METAL GLAZE 2.2K 5% 1/10W

R1858 1-216-057-00 METAL GLAZE 2.2K 5% 1/10W

R1859 1-216-017-91 METAL GLAZE 47 5% 1/10W

R1860 1-216-001-00 METAL GLAZE 10 5% 1/10W

R1861 1-216-295-91 CONDUCTOR, CHIP

R1864 1-216-071-00 METAL GLAZE 8.2K 5% 1/10W

R1865 1-216-295-91 CONDUCTOR, CHIP

R1866 1-216-089-91 METAL GLAZE 47K 5% 1/10W

R1867 1-216-075-00 METAL GLAZE 12K 5% 1/10W

R1868 1-216-089-91 METAL GLAZE 47K 5% 1/10W

R1869 1-216-049-91 METAL GLAZE 1K 5% 1/10W

R1870 1-216-049-91 METAL GLAZE 1K 5% 1/10W

R1871 8-216-069-91 METAL GLAZE 6.8K 5% 1/10W

R1878 1-216-295-91 CONDUCTOR, CHIP

R1879 1-216-049-91 METAL GLAZE 1K 5% 1/10W

R1880 1-216-085-00 METAL GLAZE 33K 5% 1/10W

R1881 1-216-065-00 METAL GLAZE 4.7K 5% 1/10W

R1882 1-216-085-00 METAL GLAZE 33K 5% 1/10W

R1885 1-216-049-91 METAL GLAZE 1K 5% 1/10W

R1886 1-216-295-91 CONDUCTOR, CHIP

R1888 1-216-021-00 METAL GLAZE 68 5% 1/10W

R1890 1-216-295-91 CONDUCTOR, CHIP

R1891 1-216-295-91 CONDUCTOR, CHIP

R1892 1-216-295-91 CONDUCTOR, CHIP

R1893 1-216-295-91 CONDUCTOR, CHIP

R1894 1-216-047-91 METAL GLAZE 820 5% 1/10W

R1895 1-216-067-00 METAL GLAZE 5.6K 5% 1/10W

R1896 1-216-059-00 METAL GLAZE 2.7K 5% 1/10W

R1822 1-216-049-91 METAL GLAZE 1K 5% 1/10W

R1823 1-216-051-00 METAL GLAZE 1.2K 5% 1/10W

R1824 1-216-049-91 METAL GLAZE 1K 5% 1/10W

R1826 1-216-053-00 METAL GLAZE 1.5K 5% 1/10W

R1827 1-216-049-91 METAL GLAZE 1K 5% 1/10W

R1828 1-216-051-00 METAL GLAZE 1.2K 5% 1/10W

R1829 1-216-049-91 METAL GLAZE 1K 5% 1/10W

R1830 1-216-025-91 METAL GLAZE 100 5% 1/10W

R1831 1-216-081-00 METAL GLAZE 22K 5% 1/10W

R1832 1-216-065-00 METAL GLAZE 4.7K 5% 1/10W

R1833 1-216-295-91 CONDUCTOR, CHIP

R1835 1-216-073-00 METAL GLAZE 10K 5% 1/10W

R1836 1-216-089-91 METAL GLAZE 47K 5% 1/10W

R1837 1-216-089-91 METAL GLAZE 47K 5% 1/10W

R1838 1-216-075-00 METAL GLAZE 12K 5% 1/10W

R1839 1-216-079-00 METAL GLAZE 18K 5% 1/10W

R1840 1-216-059-00 METAL GLAZE 2.7K 5% 1/10W

R1841 1-216-295-91 CONDUCTOR, CHIP

R1842 1-216-115-00 METAL GLAZE 560K 5% 1/10W

R1843 1-216-037-00 METAL GLAZE 330 5% 1/10W

R1844 1-216-081-00 METAL GLAZE 22K 5% 1/10W

R1845 1-216-065-00 METAL GLAZE 4.7K 5% 1/10W

R1846 1-216-077-00 METAL GLAZE 15K 5% 1/10W

R1848 1-216-025-91 METAL GLAZE 100 5% 1/10W

R1849 1-216-001-00 METAL GLAZE 10 5% 1/10W

R1850 1-216-057-00 METAL GLAZE 2.2K 5% 1/10W

R1897 1-216-065-00 METAL GLAZE 4.7K 5% 1/10W

R1898 1-216-065-00 METAL GLAZE 4.7K 5% 1/10W

R1899 1-216-059-00 METAL GLAZE 2.7K 5% 1/10W

R1900 1-216-065-00 METAL GLAZE 4.7K 5% 1/10W

R1901 1-216-059-00 METAL GLAZE 2.7K 5% 1/10W

R1902 1-216-059-00 METAL GLAZE 2.7K 5% 1/10W

R1903 1-216-059-00 METAL GLAZE 2.7K 5% 1/10W

R1904 1-216-059-00 METAL GLAZE 2.7K 5% 1/10W

R1905 1-216-059-00 METAL GLAZE 2.7K 5% 1/10W

R1906 1-216-059-00 METAL GLAZE 2.7K 5% 1/10W

R1907 1-216-059-00 METAL GLAZE 2.7K 5% 1/10W

R1908 1-216-059-00 METAL GLAZE 2.7K 5% 1/10W

R1909 1-216-059-00 METAL GLAZE 2.7K 5% 1/10W

R1910 1-216-059-00 METAL GLAZE 2.7K 5% 1/10W

R1911 1-216-059-00 METAL GLAZE 2.7K 5% 1/10W

R1912 1-216-059-00 METAL GLAZE 2.7K 5% 1/10W

R1914 1-216-059-00 METAL GLAZE 2.7K 5% 1/10W

R1915 1-216-661-11 METAL CHIP 2.7K 0.50% 1/10W

R1920 1-414-170-11 INDUCTOR CHIP 100UH

R1921 1-216-295-91 CONDUCTOR, CHIP

R1922 1-216-025-91 METAL GLAZE 100 5% 1/10W

R1927 1-216-295-91 CONDUCTOR, CHIP

R1928 1-216-115-91 METAL GLAZE 560K 5% 1/10W

R1933 1-163-103-00 CERAMIC CHIP 27PF 5% 50V

R1934 1-216-115-00 METAL GLAZE 560K 5% 1/10W

R1940 1-216-025-91 METAL GLAZE 100 5% 1/10W

R1851 1-216-057-00 METAL GLAZE 2.2K 5% 1/10W

R1852 1-216-057-00 METAL GLAZE 2.2K 5% 1/10W

< CRYSTAL >

R1853 1-216-057-00 METAL GLAZE 2.2K 5% 1/10W

R1854 1-216-057-00 METAL GLAZE 2.2K 5% 1/10W

X401 1-767-343-21 VIBRATOR, CRYSTAL

X1801 1-579-175-11 VIBRATOR, CERAMIC

— 96 —

Page 54

The components identified by

shading and marked are critical

for safety.

Replace only with the part number

specified.

Les composants identifies par

une trame et une marque sont

critiques pour la securite.

Ne les remplacer que par une piece

portant le numero specifie.

REF.NO. PART NO. DESCRIPTION REMARKREF.NO. PART NO. DESCRIPTION REMARK

KV-25K1

A

*A-1632-601-A A BOARD,COMPLETE (KV-25K1A/25K1D)

****************

*A-1632-604-A A BOARD,COMPLETE (KV-25K1B)

****************

C163 1-163-009-11 CERAMIC CHIP 0.001MF 10% 50V

C164 1-164-232-11 CERAMIC CHIP 0.01MF 10% 50V

C165 1-164-346-11 CERAMIC CHIP 1MF 16V

C166 1-163-251-11 CERAMIC CHIP 100PF 5% 50V

*A-1632-602-A A BOARD,COMPLETE (KV-25K1E)

****************

*A-1632-605-A A BOARD,COMPLETE (KV-25K1K)

****************

*A-1632-606-A A BOARD,COMPLETE (KV-25K1R)

****************

C167 1-164-222-11 CERAMIC CHIP 0.22MF 25V

C170 1-164-232-11 CERAMIC CHIP 0.01MF 10% 50V

C171 1-164-232-11 CERAMIC CHIP 0.01MF 10% 50V

C200 1-163-251-11 CERAMIC CHIP 100PF 5% 50V

C201 1-163-243-11 CERAMIC CHIP 47PF 5% 50V

*A-1632-603-A A BOARD,COMPLETE (KV-25K1U)

****************

C202 1-164-506-11 CERAMIC CHIP 4.7MF 16V

C203 1-164-004-11 CERAMIC CHIP 0.1MF 10% 25V

< CAPACITOR >

C204 1-162-568-11 CERAMIC CHIP 0.33MF 10% 16V

C205 1-164-506-11 CERAMIC CHIP 4.7MF 16V

C101 1-164-004-11 CERAMIC CHIP 0.1MF 10% 25V

C206 1-164-004-11 CERAMIC CHIP 0.1MF 10% 25V

C102 1-164-004-11 CERAMIC CHIP 0.1MF 10% 25V

C103 1-163-251-11 CERAMIC CHIP 100PF 5% 50V

(KV-25K1B)

C105 1-126-965-11 ELECT 22MF 20% 50V

C207 1-110-501-11 CERAMIC CHIP 0.33MF 10% 16V

C208 1-110-501-11 CERAMIC CHIP 0.33MF 10% 16V

C209 1-110-501-11 CERAMIC CHIP 0.33MF 10% 16V

C210 1-110-501-11 CERAMIC CHIP 0.33MF 10% 16V

C111 1-124-907-11 ELECT 10MF 20% 50V

C211 1-163-133-00 CERAMIC CHIP 470PF 5% 50V

C112 1-164-346-11 CERAMIC CHIP 1MF 16V

C114 1-164-346-11 CERAMIC CHIP 1MF 16V

C116 1-104-664-11 ELECT 47MF 20% 16V

C117 1-163-017-00 CERAMIC CHIP 0.0047MF 10% 50V

C212 1-163-133-00 CERAMIC CHIP 470PF 5% 50V

C213 1-164-004-11 CERAMIC CHIP 0.1MF 10% 25V

C214 1-164-506-11 CERAMIC CHIP 4.7MF 16V

C215 1-164-506-11 CERAMIC CHIP 4.7MF 16V

C118 1-104-664-11 ELECT 47MF 20% 16V

C216 1-164-004-11 CERAMIC CHIP 0.1MF 10% 25V

C119 1-163-017-00 CERAMIC CHIP 0.0047MF 10% 50V

C120 1-124-907-11 ELECT 10MF 20% 50V

C121 1-164-299-11 CERAMIC CHIP 0.22MF 10% 25V

C122 1-164-346-11 CERAMIC CHIP 1MF 16V

C217 1-124-907-11 ELECT 10MF 20% 50V

C218 1-124-907-11 ELECT 10MF 20% 50V

C219 1-163-131-00 CERAMIC CHIP 390PF 5% 50V

C220 1-163-131-00 CERAMIC CHIP 390PF 5% 50V

C126 1-104-664-11 ELECT 47MF 20% 16V

C221 1-163-275-11 CERAMIC CHIP 0.001MF 5% 50V

C127 1-163-017-00 CERAMIC CHIP 0.0047MF 10% 50V

C128 1-104-664-11 ELECT 47MF 20% 16V

C129 1-163-017-00 CERAMIC CHIP 0.0047MF 10% 50V

C130 1-163-133-00 CERAMIC CHIP 470PF 5% 50V

C222 1-163-275-11 CERAMIC CHIP 0.001MF 5% 50V

C223 1-163-275-11 CERAMIC CHIP 0.001MF 5% 50V

C224 1-163-275-11 CERAMIC CHIP 0.001MF 5% 50V

C227 1-165-320-11 CERAMIC CHIP 0.47MF 10% 16V

C131 1-164-346-11 CERAMIC CHIP 1MF 16V

C228 1-165-320-11 CERAMIC CHIP 0.47MF 10% 16V

C132 1-163-133-00 CERAMIC CHIP 470PF 5% 50V

C133 1-164-346-11 CERAMIC CHIP 1MF 16V

C134 1-124-907-11 ELECT 10MF 20% 50V

C135 1-164-299-11 CERAMIC CHIP 0.22MF 10% 25V

C229 1-164-004-11 CERAMIC CHIP 0.1MF 10% 25V

C230 1-164-506-11 CERAMIC CHIP 4.7MF 16V

C231 1-163-087-00 CERAMIC CHIP 4PF 0.25PF 50V

C232 1-163-087-00 CERAMIC CHIP 4PF 0.25PF 50V

C136 1-124-907-11 ELECT 10MF 20% 50V

C233 1-163-243-11 CERAMIC CHIP 47PF 5% 50V

C137 1-164-506-11 CERAMIC CHIP 4.7MF 16V

C138 1-124-907-11 ELECT 10MF 20% 50V

C139 1-164-346-11 CERAMIC CHIP 1MF 16V

C140 1-164-506-11 CERAMIC CHIP 4.7MF 16V

C234 1-163-243-11 CERAMIC CHIP 47PF 5% 50V

C303 1-164-004-11 CERAMIC CHIP 0.1MF 10% 25V

C304 1-164-004-11 CERAMIC CHIP 0.1MF 10% 25V

C305 1-164-004-11 CERAMIC CHIP 0.1MF 10% 25V

C141 1-164-506-11 CERAMIC CHIP 4.7MF 16V

C306 1-164-004-11 CERAMIC CHIP 0.1MF 10% 25V

C143 1-163-113-00 CERAMIC CHIP 68PF 5% 50V

C144 1-163-237-11 CERAMIC CHIP 27PF 5% 50V

(KV-25K1B)

(KV-25K1B)

C307 1-164-004-11 CERAMIC CHIP 0.1MF 10% 25V

C308 1-164-004-11 CERAMIC CHIP 0.1MF 10% 25V

C309 1-164-004-11 CERAMIC CHIP 0.1MF 10% 25V

C310 1-164-004-11 CERAMIC CHIP 0.1MF 10% 25V

C145 1-163-249-11 CERAMIC CHIP 82PF 5% 50V

C311 1-164-004-11 CERAMIC CHIP 0.1MF 10% 25V

(KV-25K1B)

C146 1-164-346-11 CERAMIC CHIP 1MF 16V

C150 1-164-004-11 CERAMIC CHIP 0.1MF 10% 25V

C151 1-164-004-11 CERAMIC CHIP 0.1MF 10% 25V

C312 1-164-004-11 CERAMIC CHIP 0.1MF 10% 25V

C313 1-164-004-11 CERAMIC CHIP 0.1MF 10% 25V

C314 1-164-004-11 CERAMIC CHIP 0.1MF 10% 25V

C315 1-164-004-11 CERAMIC CHIP 0.1MF 10% 25V

C152 1-124-907-11 ELECT 10MF 20% 50V

C316 1-164-004-11 CERAMIC CHIP 0.1MF 10% 25V

C153 1-110-501-11 CERAMIC CHIP 0.33MF 10% 16V

C154 1-110-501-11 CERAMIC CHIP 0.33MF 10% 16V

C155 1-164-004-11 CERAMIC CHIP 0.1MF 10% 25V

C156 1-164-506-11 CERAMIC CHIP 4.7MF 16V

C317 1-164-004-11 CERAMIC CHIP 0.1MF 10% 25V

C318 1-164-182-11 CERAMIC CHIP 0.0033MF 10% 50V

C319 1-164-182-11 CERAMIC CHIP 0.0033MF 10% 50V

C320 1-165-320-11 CERAMIC CHIP 0.47MF 10% 16V

C157 1-164-506-11 CERAMIC CHIP 4.7MF 16V

C321 1-164-506-11 CERAMIC CHIP 4.7MF 16V

C159 1-164-505-11 CERAMIC CHIP 2.2MF 16V

C160 1-163-251-11 CERAMIC CHIP 100PF 5% 50V

C162 1-164-346-11 CERAMIC CHIP 1MF 16V

C322 1-164-506-11 CERAMIC CHIP 4.7MF 16V

C323 1-164-506-11 CERAMIC CHIP 4.7MF 16V

— 97 —

Page 55

KV-25K1

A

The components identified by

shading and marked are critical

for safety.

Replace only with the part number

specified.

Les composants identifies par

une trame et une marque sont

critiques pour la securite.

Ne les remplacer que par une piece

portant le numero specifie.

REF.NO. PART NO. DESCRIPTION REMARK

C324 1-164-004-11 CERAMIC CHIP 0.1MF 10% 25V

REF.NO. PART NO. DESCRIPTION REMARK

C1323 1-164-232-11 CERAMIC CHIP 0.01MF 10% 50V

C325 1-164-004-11 CERAMIC CHIP 0.1MF 10% 25V

C1324 1-164-232-11 CERAMIC CHIP 0.01MF 10% 50V

C332 1-164-232-11 CERAMIC CHIP 0.01MF 10% 50V

C333 1-164-004-11 CERAMIC CHIP 0.1MF 10% 25V

C334 1-164-232-11 CERAMIC CHIP 0.01MF 10% 50V

C335 1-164-004-11 CERAMIC CHIP 0.1MF 10% 25V

C1325 1-164-232-11 CERAMIC CHIP 0.01MF 10% 50V

C1326 1-164-232-11 CERAMIC CHIP 0.01MF 10% 50V

C1327 1-164-232-11 CERAMIC CHIP 0.01MF 10% 50V

C1328 1-164-232-11 CERAMIC CHIP 0.01MF 10% 50V

C336 1-164-004-11 CERAMIC CHIP 0.1MF 10% 25V

C1329 1-164-232-11 CERAMIC CHIP 0.01MF 10% 50V

C337 1-110-501-11 CERAMIC CHIP 0.33MF 10% 16V

C338 1-164-004-11 CERAMIC CHIP 0.1MF 10% 25V

C339 1-164-232-11 CERAMIC CHIP 0.01MF 10% 50V

C340 1-164-232-11 CERAMIC CHIP 0.01MF 10% 50V

C1330 1-164-004-11 CERAMIC CHIP 0.1MF 10% 50V

C1331 1-164-232-11 CERAMIC CHIP 0.01MF 10% 50V

C1332 1-164-004-11 CERAMIC CHIP 0.1MF 10% 25V

C1333 1-164-232-11 CERAMIC CHIP 0.01MF 10% 50V

C341 1-164-232-11 CERAMIC CHIP 0.01MF 10% 50V

C1334 1-164-004-11 CERAMIC CHIP 0.1MF 10% 25V

C342 1-164-004-11 CERAMIC CHIP 0.1MF 10% 25V

C343 1-164-232-11 CERAMIC CHIP 0.01MF 10% 50V

C344 1-164-232-11 CERAMIC CHIP 0.01MF 10% 50V

C345 1-164-004-11 CERAMIC CHIP 0.1MF 10% 25V

C1335 1-164-232-11 CERAMIC CHIP 0.01MF 10% 50V

C1350 1-163-017-00 CERAMIC CHIP 0.0047MF 10% 50V

C1360 1-163-133-00 CERAMIC CHIP 470PF 5% 50V

C1361 1-104-663-11 ELECT 33MF 20% 16V

C346 1-164-505-11 CERAMIC CHIP 2.2MF 16V

C1401 1-164-004-11 CERAMIC CHIP 0.1MF 10% 25V

C347 1-164-505-11 CERAMIC CHIP 2.2MF 16V

C350 1-164-506-11 CERAMIC CHIP 4.7MF 16V

C351 1-164-506-11 CERAMIC CHIP 4.7MF 16V

C355 1-163-231-11 CERAMIC CHIP 15PF 5% 50V

C1402 1-163-231-11 CERAMIC CHIP 15PF 5% 50V

C1403 1-163-231-11 CERAMIC CHIP 15PF 5% 50V

C1404 1-164-182-11 CERAMIC CHIP 0.0033MF 10% 50V

C1405 1-164-004-11 CERAMIC CHIP 0.1MF 10% 25V

C356 1-163-231-11 CERAMIC CHIP 15PF 5% 50V

C1406 1-164-004-11 CERAMIC CHIP 0.1MF 10% 25V

C357 1-163-241-11 CERAMIC CHIP 39PF 5% 50V

C1001 1-164-506-11 CERAMIC CHIP 4.7MF 16V

C1002 1-164-506-11 CERAMIC CHIP 4.7MF 16V

C1003 1-164-506-11 CERAMIC CHIP 4.7MF 16V

C1407 1-164-004-11 CERAMIC CHIP 0.1MF 10% 25V

C1409 1-165-320-11 CERAMIC CHIP 0.47MF 10% 16V