Sony AA-2W, KV-29FV16A Service Manual

SERVICE MANUAL

MODEL NAME REMOTE COMMANDER DESTINATION CHASSIS NO.

AA-2W

CHASSIS

KV-29FV16A

RM-Y171 Argentina SCC-S34P-A

9-965-908-01

KV-29FV16A

RM-Y171

TRINITRON® COLOR TELEVISION

TABLE OF CONTENTS

SECTION TITLE PAGE

Specifi cations..................................................................................................................................... 3

Warnings and Cautions...................................................................................................................... 4

Safety Check-out ............................................................................................................................... 5

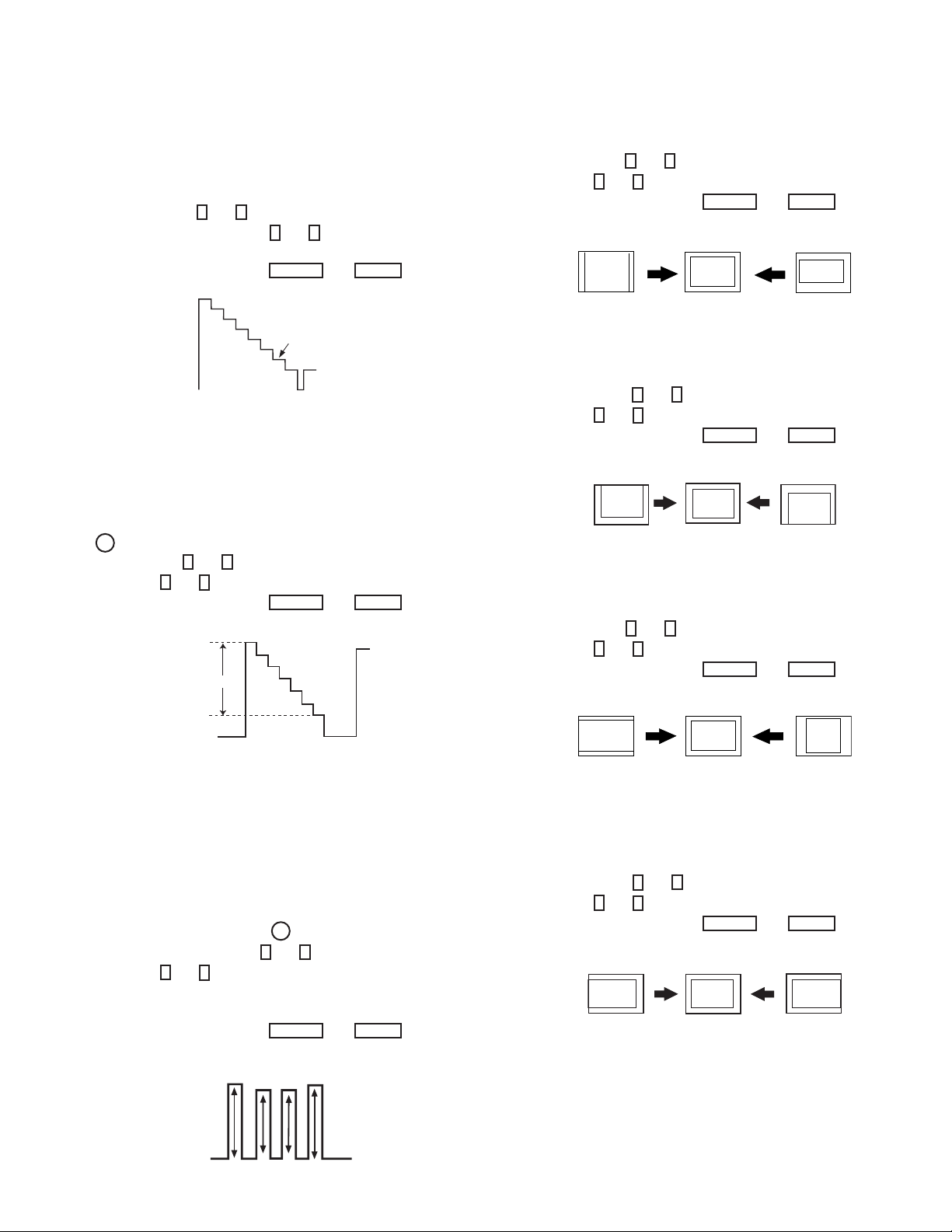

1. Disassembly

1-1. Rear Cover Removal ................................................................................................................. 6

1-2. Chassis Assembly Removal ...................................................................................................... 6

1-3. Service Position......................................................................................................................... 6

1-4. Multi-Button Switch Removal..................................................................................................... 6

1-5. Picture Tube Removal ............................................................................................................... 7

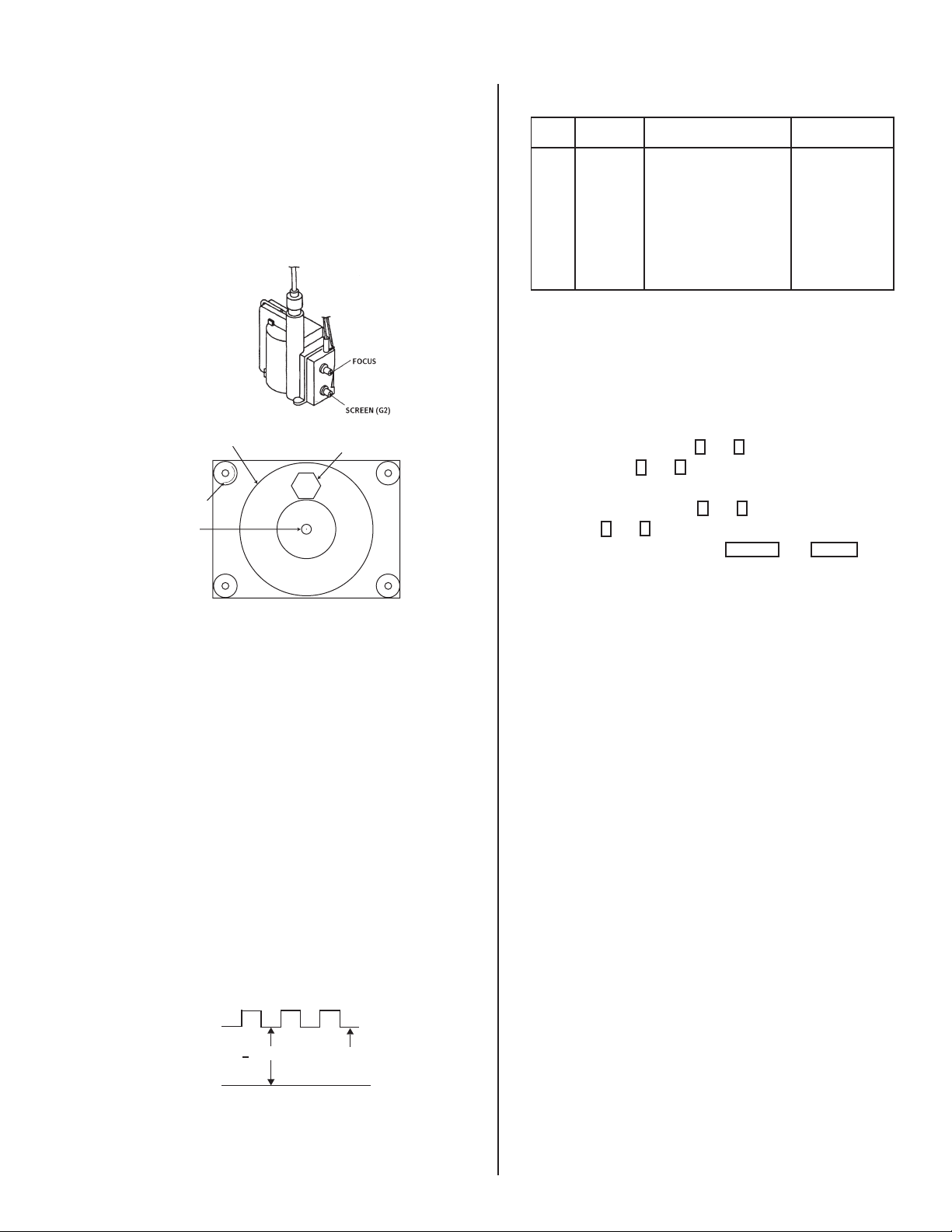

Anode Cap Removal Procedure ........................................................................................................ 7

2. Set-up Adjustments

2-1. Beam Landing ............................................................................................................................ 8

2-2. Convergence .............................................................................................................................. 9

2-3. Focus.........................................................................................................................................11

2-4. Screen (G2) ...............................................................................................................................11

2-5. White Balance Adjustments.......................................................................................................11

KV-29FV16A

3. Safety Related Adjustments

3-1. Hold Down Confi rmation........................................................................................................... 12

3-2. B+ Voltage Confi rmation and Adjustment................................................................................. 12

4. Circuit Adjustments

4-1. Setting the Service Adjustment Mode......................................................................................13

4-2. Memory Write Confi rmation Method ........................................................................................ 13

4-3. Remote Adjustment Buttons and Indicators............................................................................. 13

4-4. A Board Adjustments ............................................................................................................... 19

5. Diagrams

5-1. Circuit Board Location ............................................................................................................. 21

5-2. Printed Wiring Boards and Schematic Diagrams..................................................................... 21

5-3. Diagrams

Block Diagram ......................................................................................................................... 22

A Board.................................................................................................................................... 24

AK Board ................................................................................................................................. 27

C Board.................................................................................................................................... 29

HB Board ................................................................................................................................. 30

HZ Board ................................................................................................................................. 30

HA Board ................................................................................................................................. 31

HX Board ................................................................................................................................. 31

GA Board ................................................................................................................................. 32

UY Main Board ........................................................................................................................ 35

UY PIP Board........................................................................................................................... 36

WA Board................................................................................................................................. 40

5-4. Semiconductors ....................................................................................................................... 42

6. Exploded Views

6-1. Chassis..................................................................................................................................... 43

6-2. Picture Tube Removal .............................................................................................................. 44

7. Electrical Parts List .................................................................................................................................. 45

— 2 —

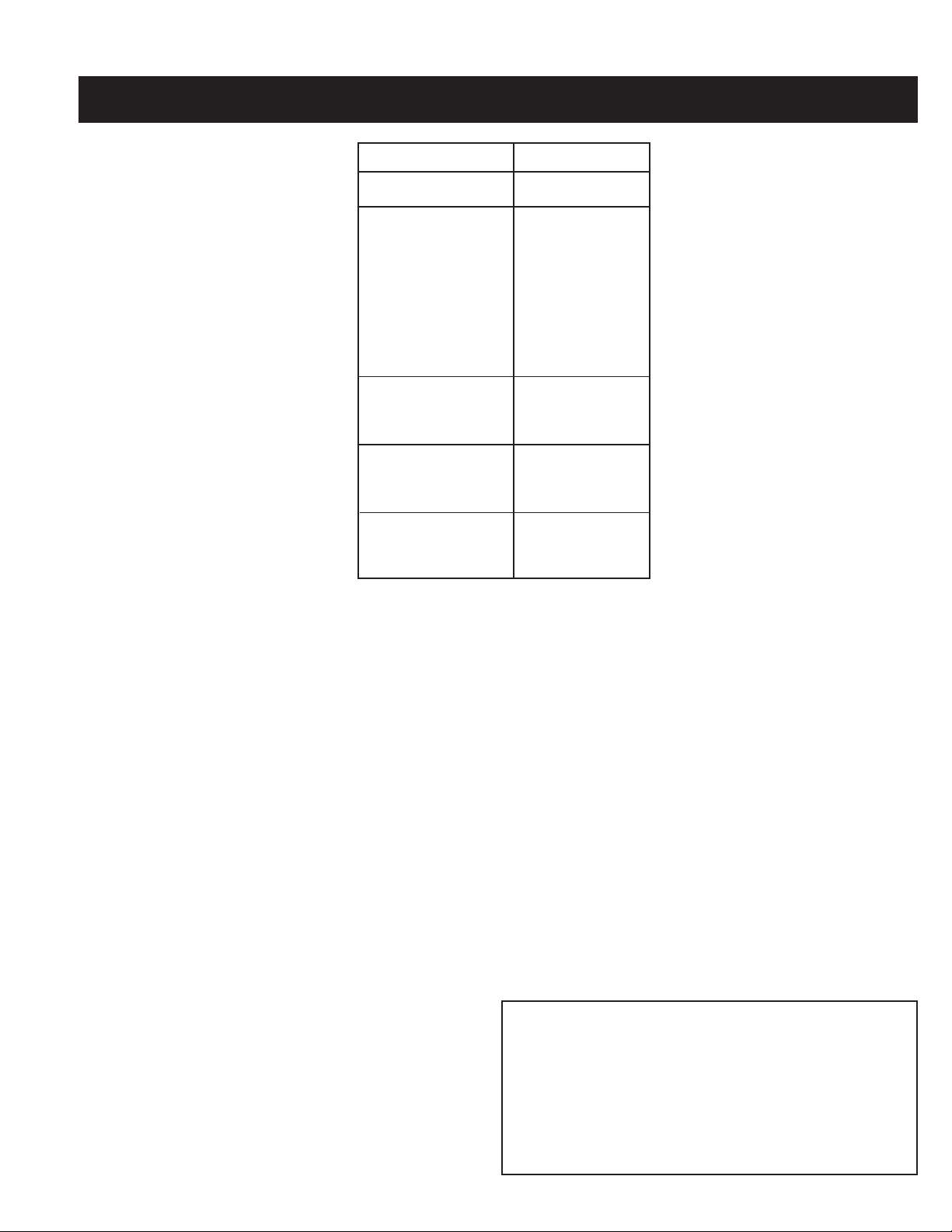

SPECIFICATIONS

KV-29FV16A

KV-29FV16A

Television system

NTSC/PAL-M/PAL-N Color System

Channel coverage

VHF: 2-13/ VHF: 14-69/ CATV: 1-125

Picture tube

Flat Trinitron® tube

Power Requirements

120-220V, 50/60Hz

Number of Inputs/Outputs

Video

S Video

Y,PB, PR

Audio

Audio Out

Monitor Out

S-Link

Speaker Output (W)

Power Consumption (W)

In Use (Max)

In Standby

1)

3

2)

2

3)

1

4)

3

5)

1

1

YES

15W x 2

205W

1W

Dimensions (W x H x D)

mm

762 x 604 x 519 mm

in

30 x 23

Mass

kg

49 kg

lbs

110 lbs

1) 1 Vp-p 75 ohms unbalanced, sync negative

2) Y: 1 Vp-p 75 ohms unbalanced, sync negative

C: 0.286 Vp-p (Burst signal), 75 ohms

3) Y: 1.0 Vp-p, 75 ohms, sync negative;

PB: 0.7 Vp-p, 75 ohms; PR: Vp-p, 75 ohms

m

Vrms (100% modulation), Impedance: 47 kilohms

4) 500

5) More than 408 mVrms at the maximum volume setting (variable)

More than 408 mVrms (fi x); Impedance (output): 2 kilohms

7/8

x 20

1/2

in

Visible screen size

27-inch picture measured diagonally

Actual screen size

29-inch measured diagonally

Antenna

75 ohm external terminal for VHF/UHF

Supplied Accessories

Remote Control RM-Y171

Battery size AA (R6) w/2

Optional Assessories

Connecting Cables:

RK-74A, VMC-810/820830hg, VMC-10HG/30HG,

VMC-720M, VMC-810S/820S, YC-15V/30V,

YC-15/30HG, RK-G69HG, RKC-515HG

AV Cable: VMC-810/820/830 HG

Audio Cable: RKC-515HG

S-LINK Cable: RK-G69HG

Component Video Cable: VMC-10/30 HG

TV Stand: SU-32FD2, SU-36FD2, SU-32XBR2, SU-36XBR2

UV Mixer: EAC-66

Design and specifi cations are subject to change without notice.

(•) SRS (SOUND RETRIEVAL SYSTEM)

The (•) SRS (SOUND RETRIEVAL SYSTEM) is manufactured by Sony

Corporation under license from SRS Labs, Inc. It is covered by U.S.

Patent No. 4,748,669. Other U.S. and foreign patents pending.

The word ‘SRS’ and the SRS symbol (•) are registered trademarks of

SRS Labs, Inc. BBE and BBE symbol are trademarks of BBE Sound, Inc.

and are licensed by BBE Sound, Inc. under U.S. Patent No. 4,638,258

and 4,482,866.

— 3 —

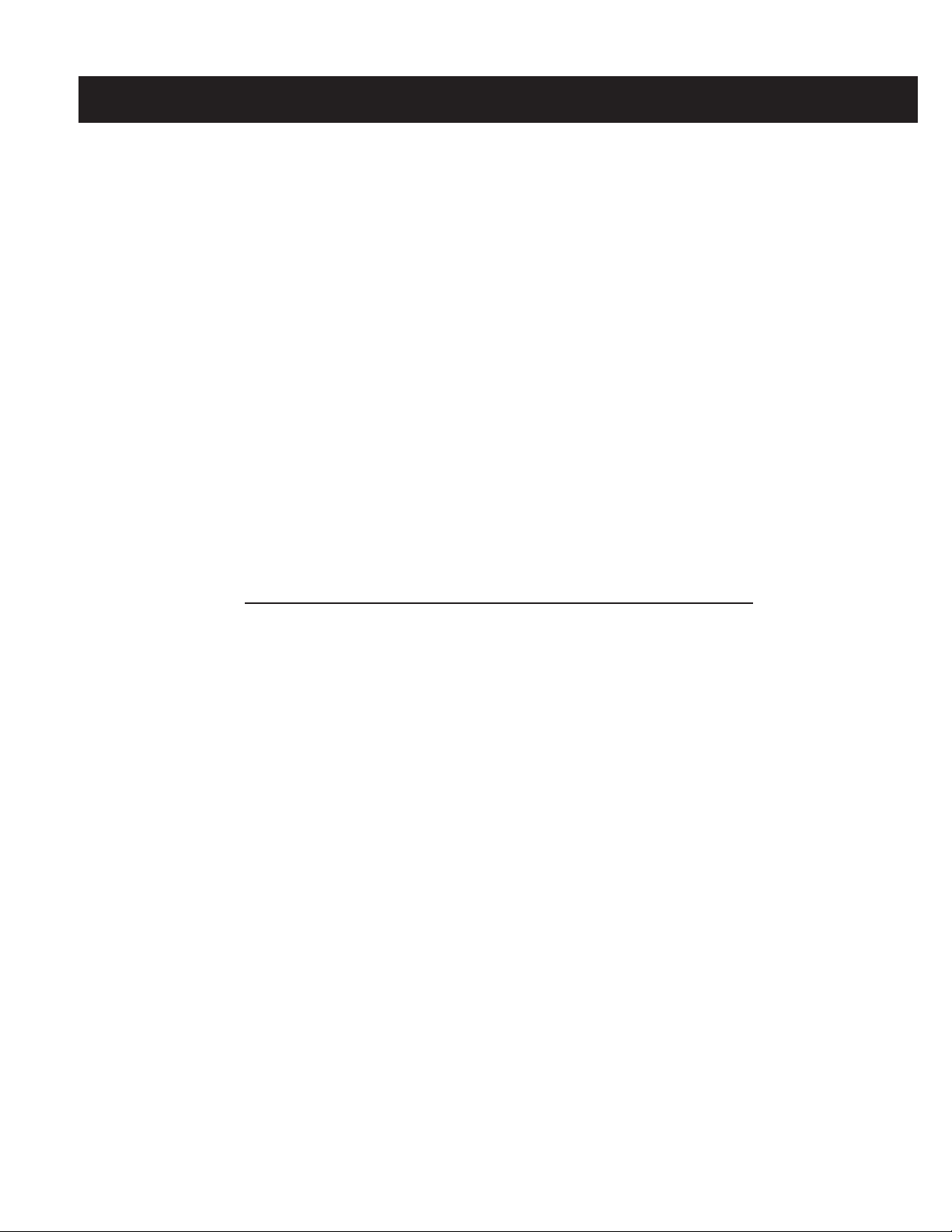

WARNINGS AND CAUTIONS

CAUTION

Short circuit the anode of the picture tube and the anode cap to the metal chassis, crt shield, or carbon painted on the crt, after

removing the anode.

WARNING!!

An isolation transformer should be used during any service to avoid possible shock hazard, because of live chassis. The chassis of

this receiver is directly connected to the ac power line.

! SAFETY-RELATED COMPONENT WARNING!!

KV-29FV16A

Components identifi ed by shading and ! mark on the schematic diagrams, exploded views, and in the parts list are critical for

safe operation. Replace these components with sony parts whose part numbers appear as shown in this manual or in supplements

published by sony. Circuit adjustments that are critical for safe operation are identifi ed in this manual. Follow these procedures

whenever critical components are replaced or improper operation is suspected.

ATTENTION!!

Apres avoir deconnecte le cap de l’anode, court-circuiter l’anode du tube cathodique et celui de l’anode du cap au chassis metallique

de l’appareil, ou la couche de carbone peinte sur le tube cathodique ou au blindage du tube cathodique.

Afi n d’eviter tout risque d’electrocution provenant d’un chássis sous tension, un transformateur d’isolement doit etre utilisé lors de tout

dépannage. Le chássis de ce récepteur est directement raccordé à l’alimentation du secteur.

! ATTENTION AUX COMPOSANTS RELATIFS A LA SECURITE!!

Les composants identifi es par une trame et par une marque ! sur les schemas de principe, les vues explosees et les listes de

pieces sont d’une importance critique pour la securite du fonctionnement. Ne les remplacer que par des composants sony dont

le numero de piece est indique dans le present manuel ou dans des supplements publies par sony. Les reglages de circuit dont

l’importance est critique pour la securite du fonctionnement sont identifi es dans le present manuel. Suivre ces procedures lors de

chaque remplacement de composants critiques, ou lorsqu’un mauvais fonctionnement suspecte.

— 4 —

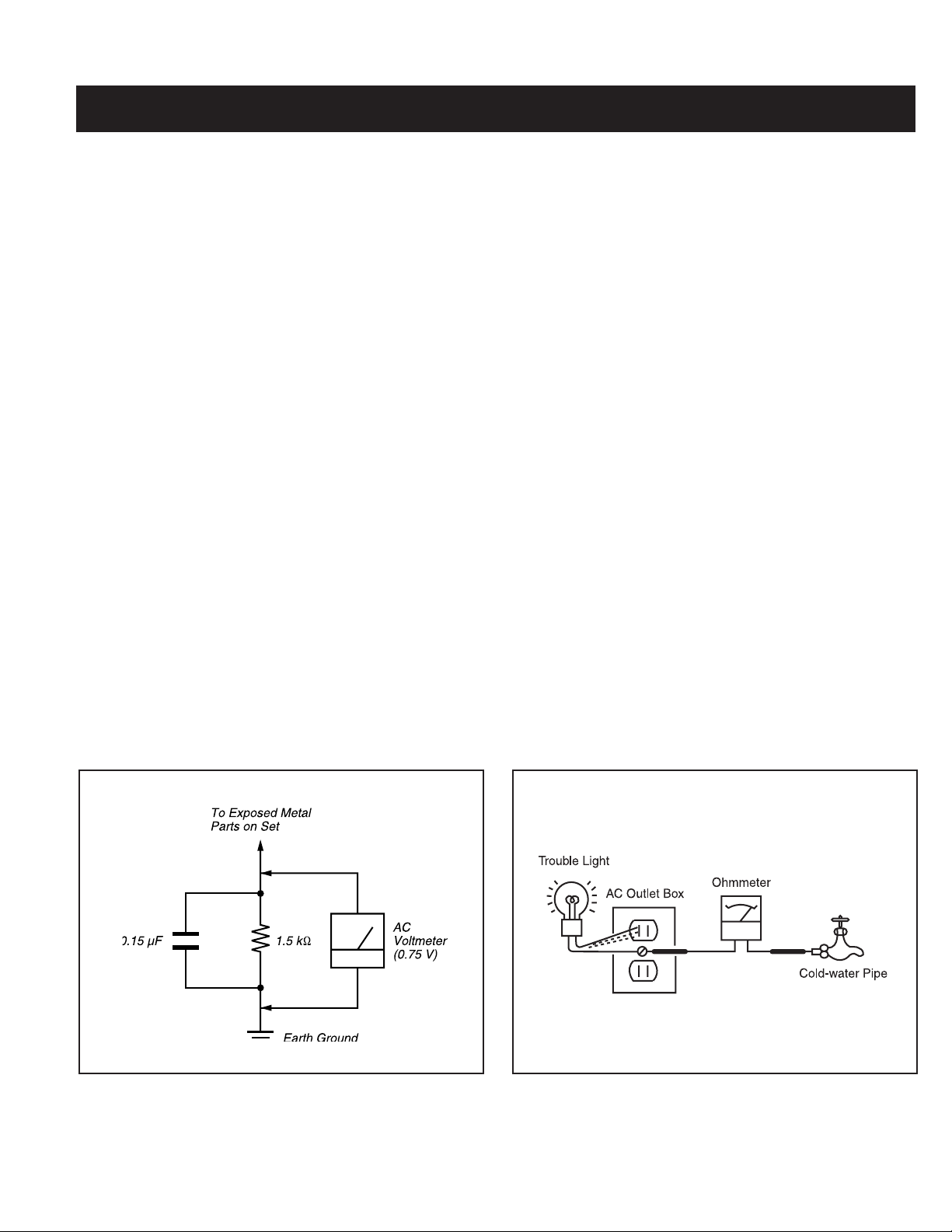

SAFETY CHECK-OUT

KV-29FV16A

After correcting the original service problem, perform the following

safety checks before releasing the set to the customer:

1. Check the area of your repair for unsoldered or poorly soldered

connections. Check the entire board surface for solder splashes and

bridges.

2. Check the interboard wiring to ensure that no wires are “pinched” or

touching high-wattage resistors.

3. Check that all control knobs, shields, covers, ground straps, and

mounting hardware have been replaced. Be absolutely certain that

you have replaced all the insulators.

4. Look for unauthorized replacement parts, particularly transistors,

that were installed during a previous repair. Point them out to the

customer and recommend their replacement.

5. Look for parts which, though functioning, show obvious signs of

deterioration. Point them out to the customer and recommend their

replacement.

6. Check the line cords for cracks and abrasion. Recommend the

replacement of any such line cord to the customer.

7. Check the B+ and HV to see if they are specifi ed values. Make sure

your instruments are accurate; be suspicious of your HV meter if sets

always have low HV.

8. Check the antenna terminals, metal trim, “metallized” knobs, screws,

and all other exposed metal parts for AC leakage. Check leakage

as described below.

Leakage Test

The AC leakage from any exposed metal part to earth ground and from

all exposed metal parts to any exposed metal part having a return to

chassis, must not exceed 0.5 mA (500 microamperes). Leakage current

can be measured by any one of three methods.

1. A commercial leakage tester, such as the Simpson 229 or

RCA WT-540A. Follow the manufacturers’ instructions to use these

instructions.

2. A battery-operated AC milliammeter. The Data Precision 245 digital

multimeter is suitable for this job.

3. Measuring the voltage drop across a resistor by means of a VOM

or battery-operated AC voltmeter. The “limit” indication is 0.75 V,

so analog meters must have an accurate low voltage scale. The

Simpson’s 250 and Sanwa SH-63TRD are examples of passive

VOMs that are suitable. Nearly all battery-operated digital multimeters

that have a 2 VAC range are suitable (see Figure A).

How to Find a Good Earth Ground

A cold-water pipe is a guaranteed earth ground; the cover-plate retaining

screw on most AC outlet boxes is also at earth ground. If the retaining

screw is to be used as your earth ground, verify that it is at ground

by measuring the resistance between it and a cold-water pipe with an

ohmmeter. The reading should be zero ohms.

If a cold-water pipe is not accessible, connect a 60- to 100-watt troublelight (not a neon lamp) between the hot side of the receptacle and the

retaining screw. Try both slots, if necessary, to locate the hot side on the

line; the lamp should light at normal brilliance if the screw is at ground

potential (see Figure B).

Figure A. Using an AC voltmeter to check AC leakage. Figure B. Checking for earth ground.

— 5 —

SECTION 1: DISASSEMBLY

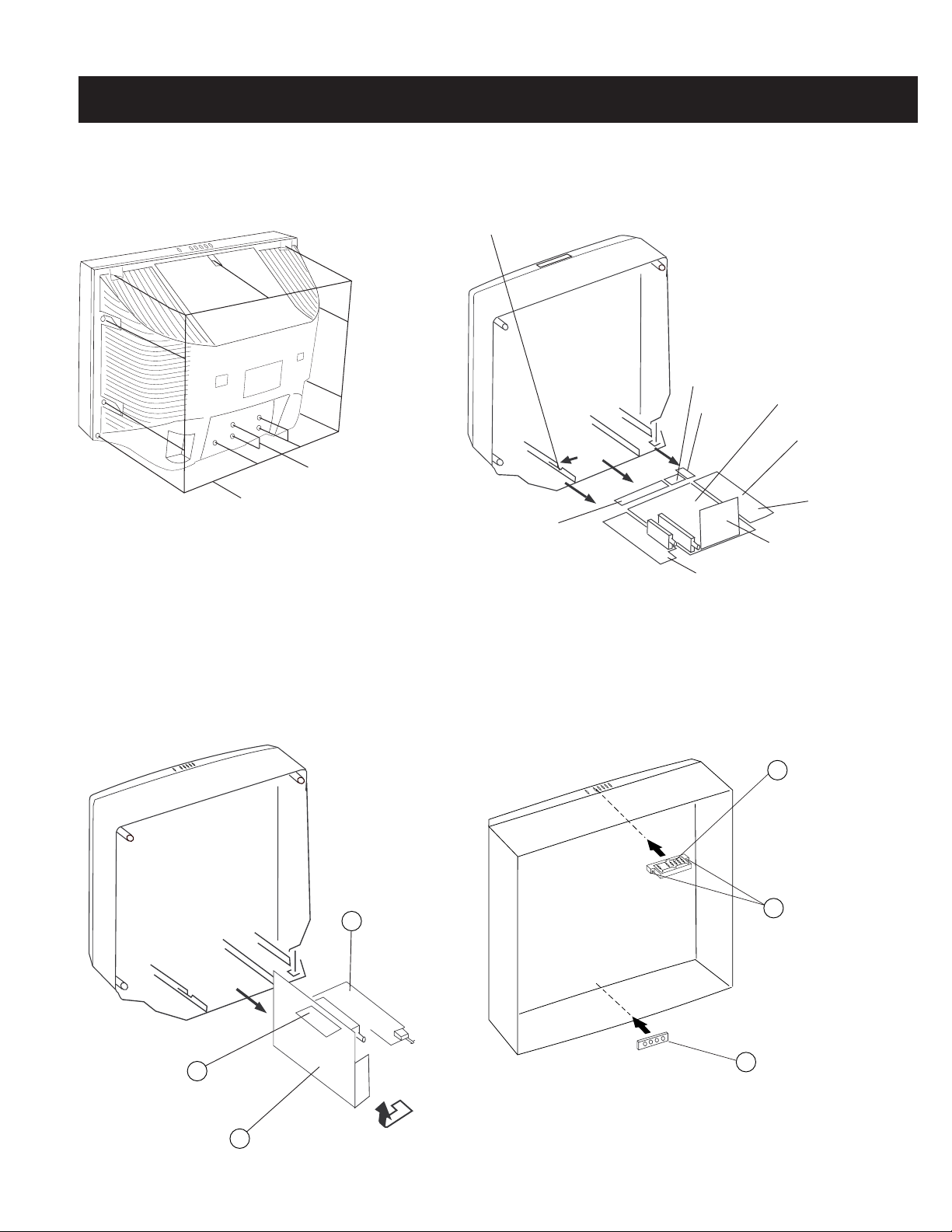

1-1. REAR COVER REMOVAL 1-2. CHASSIS ASSEMBLY REMOVAL

Claw

HB Board

A Board

UY Board

Twelve Screws

(BVTP 4 x 16)

HZ Board

Two Screws

(BVTP 3 x 12)

HA Board

KV-29FV16A

GA Board

Chassis Assembly

AK Board

1-3. SERVICE POSITION 1-4. MULTI-BUTTON SWITCH REMOVAL

Top Multi-Button Switch

1

Two Screws

2

3

GA Board

(+BVTP 4x16)

AK Board

2

1

A Board

— 6 —

Bottom Multi-Button Switch

3

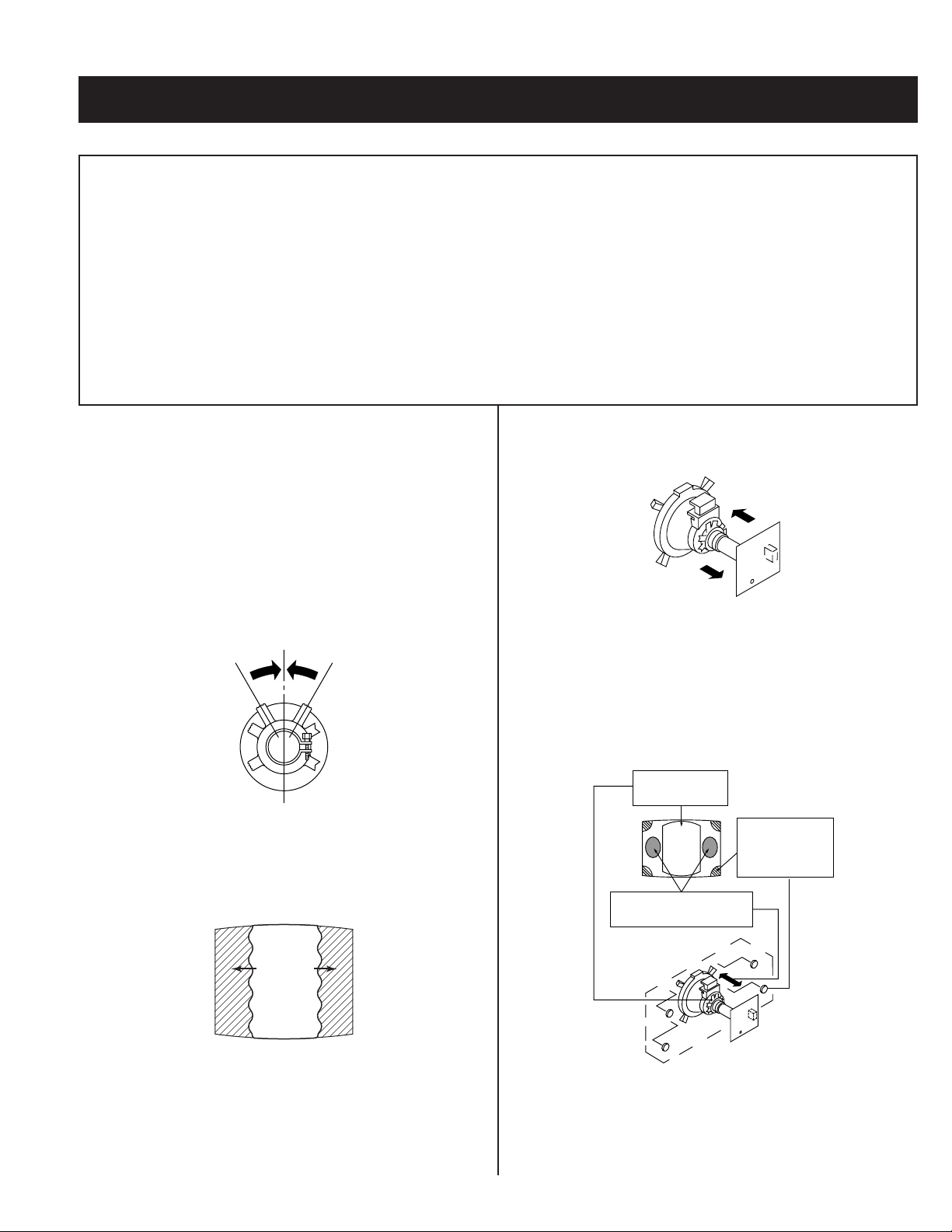

1-5. PICTURE TUBE REMOVAL

WARNING: BEFORE REMOVING THE ANODE CAP

High voltage remains in the CRT even after the power is disconnected. To avoid electric shock,

discharge CRT before attempting to remove the anode cap. Short between anode and CRT

coated earth ground strap.

4

KV-29FV16A

5

3

6

2

10

1

1. Discharge the anode of the CRT and remove the anode cap.

2. Unplug all interconnecting leads from the defl ection yoke, neck

assembly, degaussing coils and CRT grounding strap.

3. Remove the C Board from the CRT.

4. Remove the chassis assembly.

5. Loosen the neck assembly fi xing screw and remove.

6. Loosen the defl ection yoke fi xing screw and remove.

7. Place the set with the CRT face down on a cushion and remove the

degaussing coil holders.

8. Remove the degaussing coils.

9. Remove the CRT grounding strap and spring tension devices.

10. Unscrew the four CRT fi xing screws [located on each CRT corner]

and remove the CRT [Take care not to handle the CRT by the

neck].

9

8

7

ANODE CAP REMOVAL PROCEDURE

WARNING: High voltage remains in the CRT even after the power is disconnected. To avoid electric shock, discharge CRT before attempting to remove

the anode cap. After removing the anode cap, short circuit to either the metal chassis, CRT shield, or carbon painted on the CRT.

REMOVAL PROCEDURES

a

Turn up one side of the rubber cap

inthe direction indicated by arrow a .

b

Use your thumb to pull the rubber

cap fi rmly in the direction indicated

by arrow b .

HOW TO HANDLE AN ANODE CAP

1. Do not use sharp objects which may cause damage to the surface of the anode

cap.

2. To avoid damaging the anode cap, do not squeeze the rubber covering too hard.

A material fi tting called a shatter-hook terminalis built into the rubber.

3. Do not force turn the foot of the rubber cover. This may cause the shatter-hook

terminal to protrude and damage the rubber.

— 7 —

Anode Button

When one side of the rubber cap separates from

the anode button, the anode cap can be removed

by turning the rubber cap and pulling it in the

direction of arrow c .

c

SECTION 2: SET-UP ADJUSTMENTS

KV-29FV16A

The following adjustments should be made when a complete

realignment is required or a new picture tube is installed.

These adjustments should be performed with rated power supply

voltage unless otherwise noted.

The controls and switch should be set as follows unless otherwise

noted:

PICTURE CONTROL: normal

BRIGHTNESS CONTROL: normal

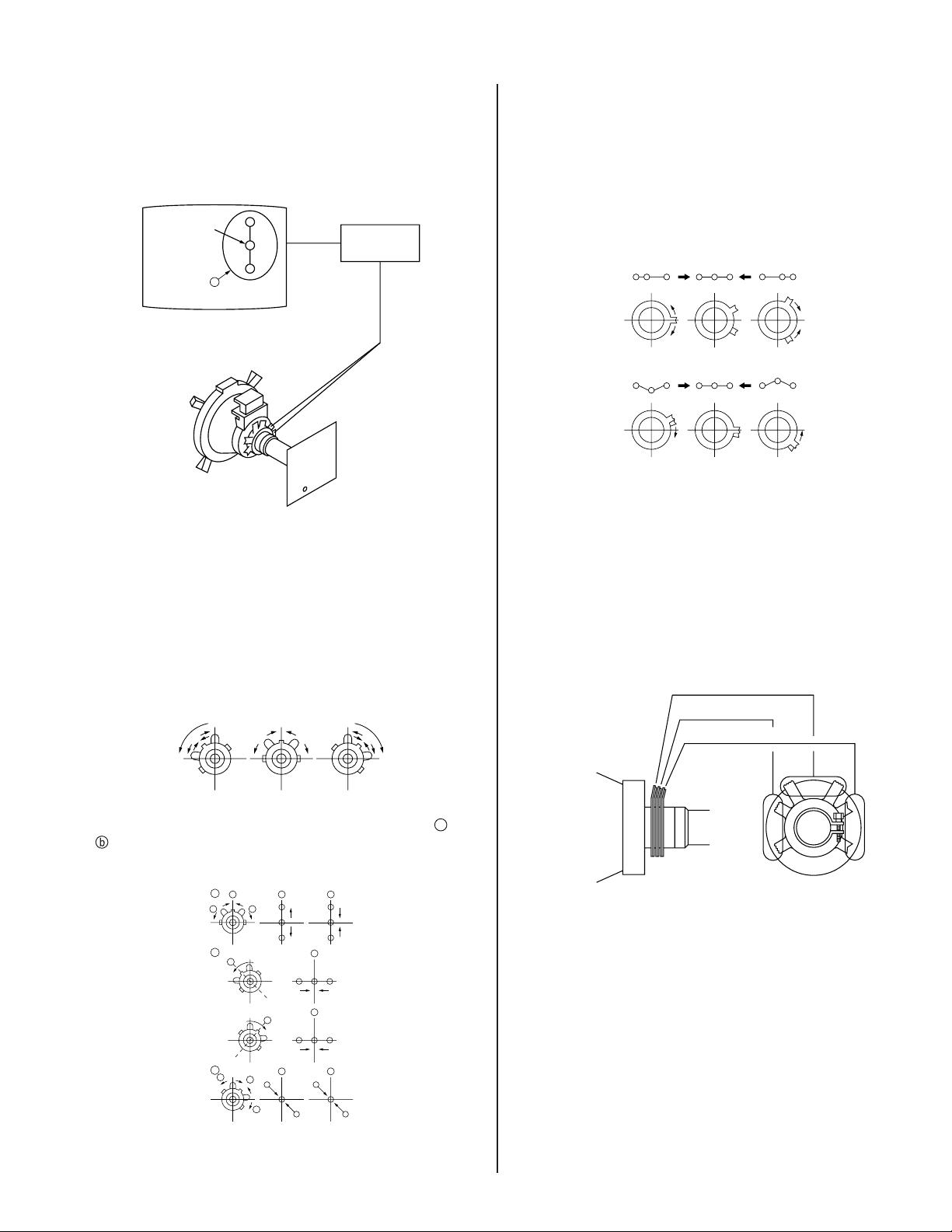

2-1. BEAM LANDING

Preparation:

• Input a white pattern signal.

• Face the picture tube in an East or West direction to reduce the

infl uence of geomagnetism.

NOTE: Do not use the hand degausser; it magnetizes the CRT .

1. Input white pattern from pattern generator.

2. Loosen the defl ection yoke mounting screw, and set the purity control

to the center as shown below:

Perform the adjustments in order as follows:

1. Beam Landing

2. Convergence

3. Focus

4. Screen (G2)/White Balance

Test Equipment Required:

1. Color Bar Pattern Generator

2. Degausser

3. DC Power Supply

4. Digital Multimeter

5. Oscilloscope

6. CRT Analyzer

5. Move the defl ection yoke forward, and adjust so that the entire screen

becomes green.

6. Switch over the raster signal to red and blue and confi rm the

condition.

7. When the position of the defl ection yoke is determined, tighten it with

the defl ection yoke mounting screw.

8. When landing at the corner is not right, adjust by using the disk

magnets.

3. Input green pattern from pattern generator.

4. Move the defl ection yoke backward, and adjust with the purity control

so that green is in the center and red and blue are even on both

sides.

Blue Red

Green

— 8 —

Purity control

corrects this area.

ab

cd

Deflection yoke positioning

corrects these areas.

a

d

Disk magnets or

rotatable disk

magnets correct

these areas(a-d).

b

c

KV-29FV16A

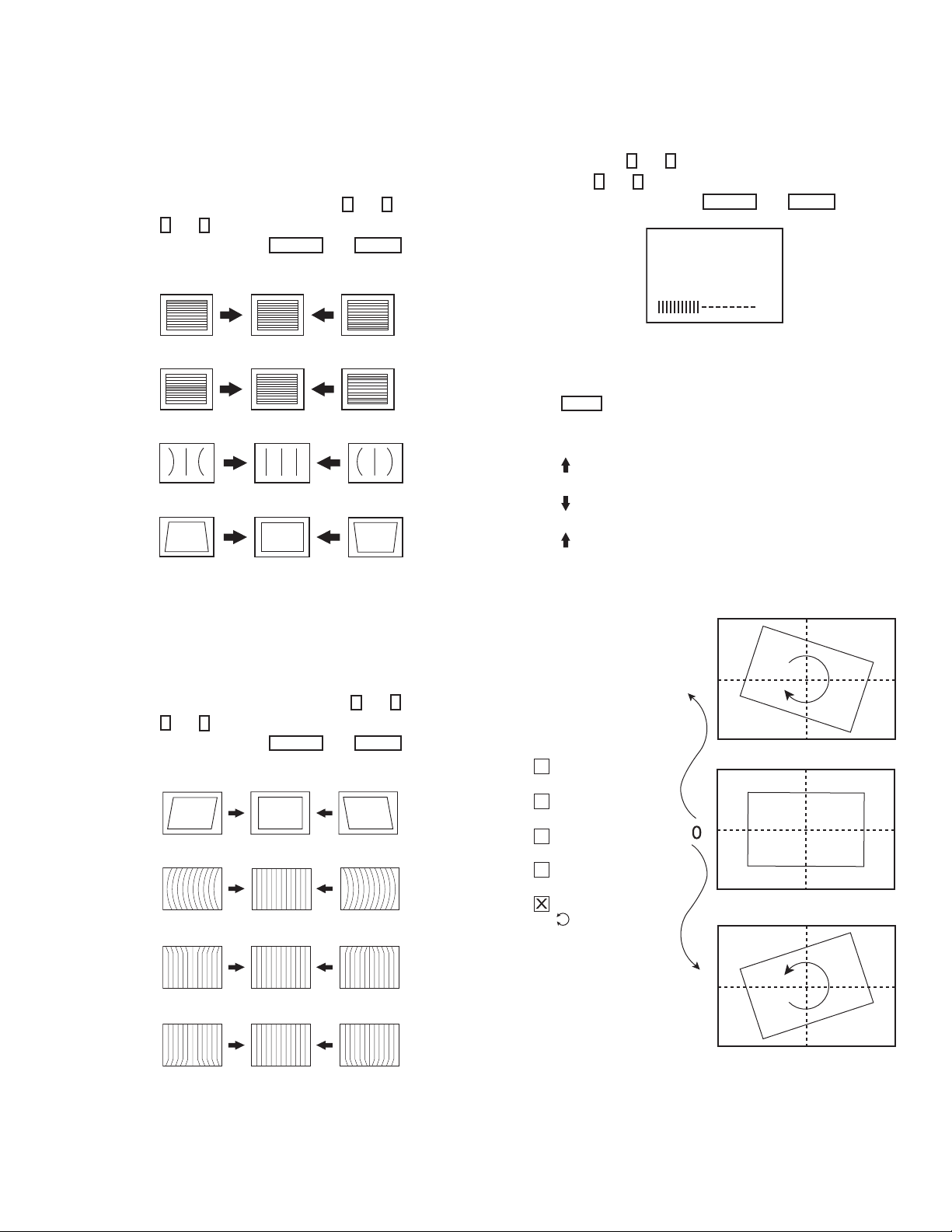

2-2. CONVERGENGE

Preparation:

• Perform FOCUS, V. LIN and V. SIZE adjustments.

• Set BRIGHTNESS control to minimum.

• Input dot pattern.

Center dot

R

G

V.STAT

Magnet

B

VERTICAL AND HORIZONTAL STATIC

CONVERGENCE

1. Adjust V. STAT magnet to converge red, green and blue dots in the

center of the screen (Vertical movement).

Tilt the V. STAT magnet and adjust static convergence to open or

close the V. STAT magnet.

OPERATION OF BMC (HEXAPOLE) MAGNET

The respective dot positions resulting from moving each magnet interact,

so perform adjustment while tracking.

1 Use the V.STAT tabs to adjust the red, green, and blue dots so they

line up at the center of the screen (move the dots in a horizontal

direction).

RG B

RGB RGB

RGB

RGB

RGB

Y SEPARATION AXIS CORRECTION MAGNET

ADJUSTMENT

1. Input cross-hatch pattern, adjust PICTURE to minimum and

BRIGHTNESS to normal.

2. Adjust the defl ection yoke upright so it touches the CRT.

3. Adjust so that the Y separation axis correction magnet on the neck

assembly is symmetrical from top to bottom (open state).

Purity

2. When the V. STAT magnet is moved in the direction of arrow a and

, red, green, and blue dots move as shown below:

1

a

b

2

a

3

b

a

B

b

G

R

b

a

a

R

G

b

a

RG B

b

BG R

B

B

b

B

G

R

b

G

R

V. STAT

BMC (Hexapole)

4. Return the defl ection yoke to its original position.

— 9 —

KV-29FV16A

DYNAMIC CONVERGENCE ADJUSTMENT

Before starting, perform Vertical and Horizontal Static Convergence

Adjustment.

1. Slightly loosen defl ection yoke screw.

2. Remove defl ection yoke spacers.

3. Move the defl ection yoke for best convergence as shown below:

R

B

BGR

G

G

RGB

R

B

RGB

BGR

B

RGB

G

BGR

R

4. Tighten the defl ection yoke screw.

5. Install the defl ection yoke spacers.

R

G

B

RGB RGB

TLH PLATE ADJUSTMENT

Preparation:

• Input crosshatch pattern.

• Adjust Picture Quality to standard, Picture and Brightness to 50%, and

Other to standard.

• Adjust the Horizontal Convergence of red and blue dots by tilting the

TLH plate on the defl ection yoke.

YCH

TLV

XCV

C Board

B R R B

(R)(B) (B)(R)

(TLV)

TLH+

TLH-

TLH Plate

RV1750

V.STAT

SCREEN-CORNER CONVERGENCE

1. Affi x a permalloy assembly corresponding to the misconverged areas:

1. Adjust XCV core to balance X axis.

2. Adjust YCH VR to balance Y axis.

3. Adjust vertical red and blue convergence with V.TILT (TLV VR.)

a

ab

a-d : screen-corner

misconvergence

cd

d

b

4. Adjust Y MAGNET to correct V.BOW Geometery Distortion.

5. Adjust H-TRP to correct H.Trapezoid Geometry Distortion.

After adjusting items 4 and 5, confi rm overall geometry again.

c

H CENTER SW ADJUSTMENT

Before adjusting H Center SW (S501, S502), make sure that HPOS data

is “7”.

Perform adjustments while tracking items 1 and 2.

— 10 —

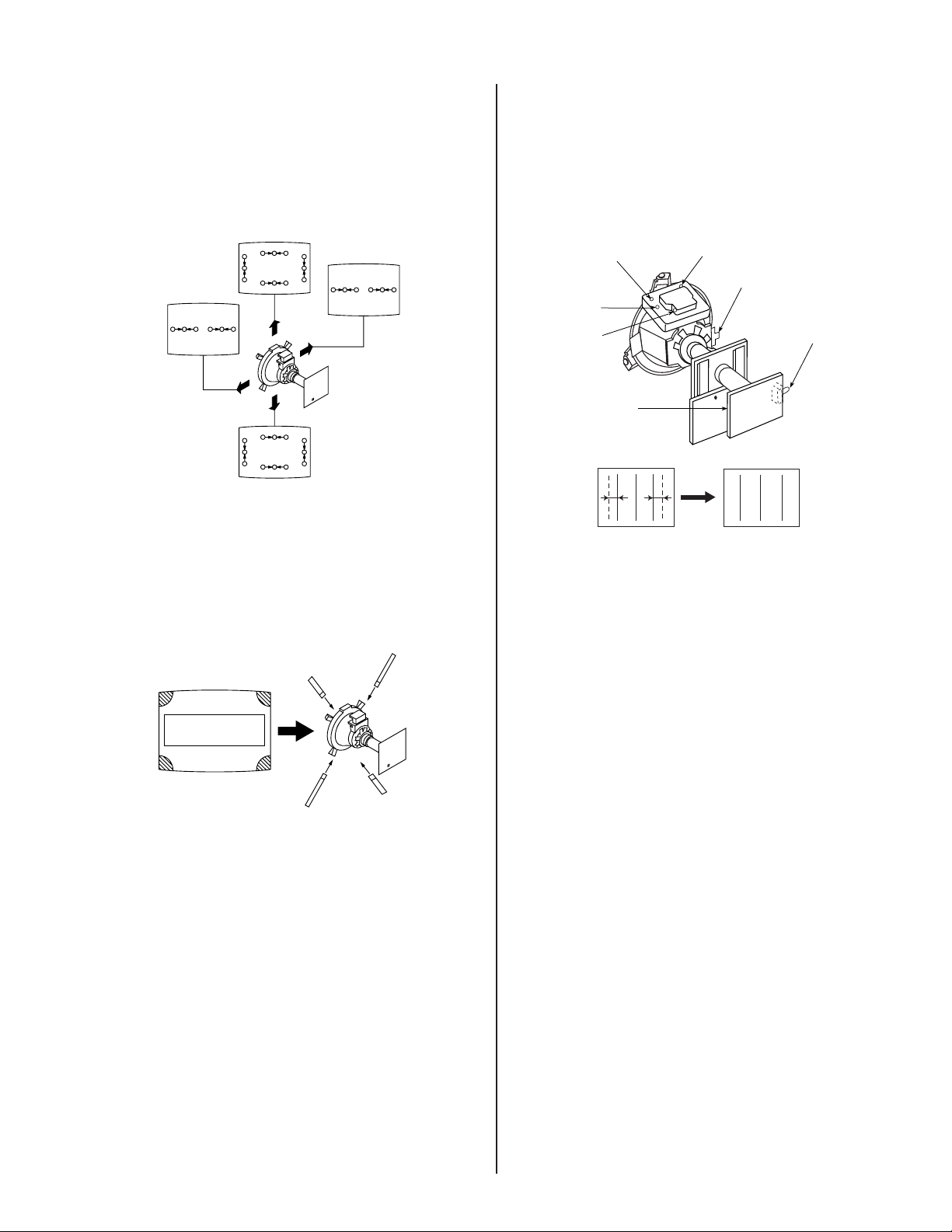

KV-29FV16A

2-3. FOCUS

1. Input monoscope signal.

2. Set user controls to normal.

3. Set video mode to STANDARD.

4. Set the PICTURE to maximum.

5. Adjust at 325 Mark for best center/corner focus balance.

6. Receive an entire white signal. Make sure Magenta Ring is at an

acceptable level.

325 MARK

35

35 MARK

CENTER

CIRCLE

325

2-5. WHITE BALANCE ADJUSTMENTS

then

All Models

31

31

31

7

7

7

7

ENTER

.

NO.

24

25

26

27

28

29

38

Disp.

RDRV

GDRV

BDRV

RCUT

GCUT

BCUT

SBRT

Item

Red Drive

Green Drive

Blue Drive

Red Cut-off

Green Cut-off

Blue Cut-off

Sub Bright

1. Set program palette to STANDARD and push RESET.

2. Input an entire white signal.

3. Set to Service Adjustment Mode.

4. Set the PICTURE and BRIGHT to minimum.

5. Adjust with SBRT if necessary.

6. Set RCUT to “14”.

7. Select GCUT and BCUT with

8. Adjust by pressing

3

and

1

and 4 .

6

for the best white balance.

9. Set the PICTURE and BRIGHT to maximum.

1

10. Select GDRV and BDRV with

6

11. Adjust withg

3

and

for the best white balance.

12. Write into the memory by pressing

and 4 .

MUTING

13. Repeat steps 1-12 for GDR4, BDR4, GCU4 and BCU4 using

Video 4 input.

* Use values from Sub Contrast Adjustments

2-4. SCREEN (G2)

1. Input signal from the pattern generator.

White balance should be adjusted after Sub Contrast because

RDRV is also used in Sub Contrast Adjustment. (See page 19).

2. Set the user controls to NORMAL.

3. Attach the G2-Jig to the C Board.

4. Adjust RCUT, GCUT, BCUT, and SBRT in service mode with an

oscilloscope so that voltages on the red, green, and blue cathodes

are 170 ± 2.0 V DC.

5. Observe the screen and adjust SCREEN (G2) VR to obtain the faintly

visible background of the dot signal.

6. Push the TEST + JUMP (+ Channel) to cut off the signal. The screen

should be bright or dark. Brightness of raster must be increased

when adjusting.

7. Adjust screen VR until the screen is slightly cut off, or scarcely lights

up. A signal cannot be seen when the brightness of the raster is

high.

8. Push the JUMP again to release the cut off.

170 + 2.0 Vdc

GND

170Vdc

pedestal

— 11 —

SECTION 3: SAFETY RELATED ADJUSTMENTS

KV-29FV16A

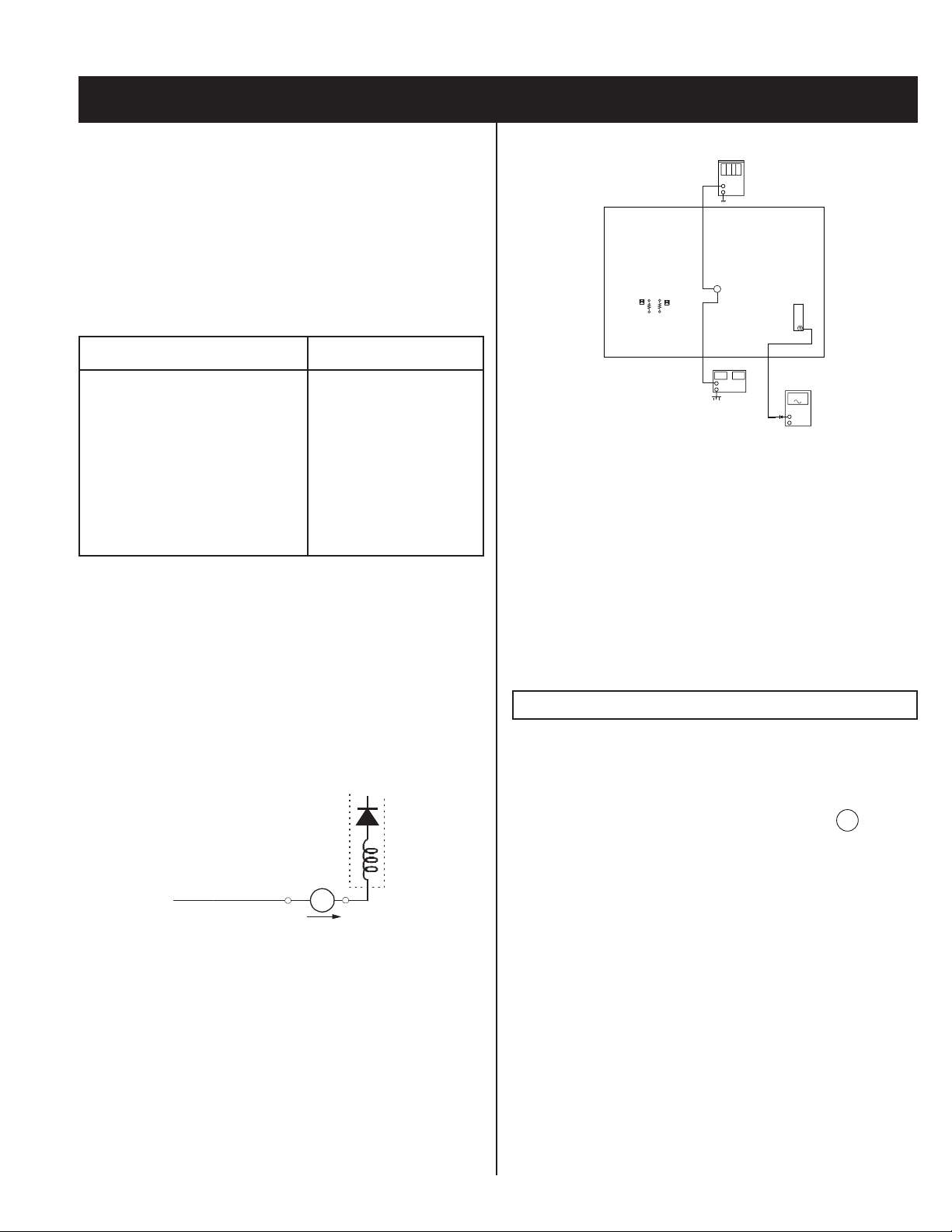

3-1. X R530, R531 CONFIRMATION

METHOD (HOLD-DOWN

CONFIRMATION) AND

READJUSTMENTS

Always perform the following adjustments when replacing the following

components marked with a

Part Replaced (Y)

A BOARD:

C531, C532, D302, D519, D520,

Y

mark on the schematic diagram:

Adjustment (

A BOARD:

R530, R531

X

)

D521, IC355, IC501, Q301, R356,

R359, R361, R529, R530, R531,

R532, R533, R550, T503

GA BOARD

IC6003, R6088

PREPARATION BEFORE CONFIRMATION

1. Turn the POWER switch ON.

2. Input a white signal and set the PICTURE and BRIGHT controls to

maximum.

3. Confi rm that the voltage of more than 23.0 VDC appears between

TP85 and ground on the A Board.

4. Using a Variac, apply AC input voltage: 120 ± 2.0 VAC.

5. Input a white signal and verify that the I ABL is within the sepcifi ed

range: 1730.0 ± 100µA, +B = 135.0 ± 1.0 V DC.

At AC input: 120.0 ± 2.0 V AC.

T503

FBT

ammeter

3.0 mA DC

range

ABL

+

-

A

I ABL

digital

+

-

multimeter

R531

R530

DC Power Supply

TP85

+

-

T503

FBT

ammeter

3mA DC range

A

+

-

Lower than 24.78 ± (-0.1) V DC.

At AC input 120.0 ± 2.0 V AC.

8. A BOARD - CONDUCTOR SIDE: Confi rm that a voltage appears

between TP85 and ground of more than 21.0 V DC.

3-2. B+ VOLTAGE CONFIRMATION AND

ADJUSTMENT

Always perform the following adjustments when replacing the following

components, which are marked with

the GA Board:

GA BOARD: IC6003, R6088

1. Using a Variac, apply AC input voltage: 130 ± 2.0 VAC

2. Input a monoscope signal.

3. Set the PICTURE control and the BRIGHT control to initial reset

value.

4. Confi rm the voltage of GA Board CN6007 between pin

is less than 135.0 ± 1.5 V DC.

5. If step 4 is not satisfi ed, replace the R6088 on GA Board and repeat

the above steps.

Y

on the schematic diagram on

1

to ground

6. Record the voltage between TP 85 and ground.

7. Using an external DC power supply, apply voltage between TP85 and

ground. Increase the voltage gradually and confi rm that the hold

down works (raster disappears) at lower than the voltage recorded

in Step 6.

— 12 —

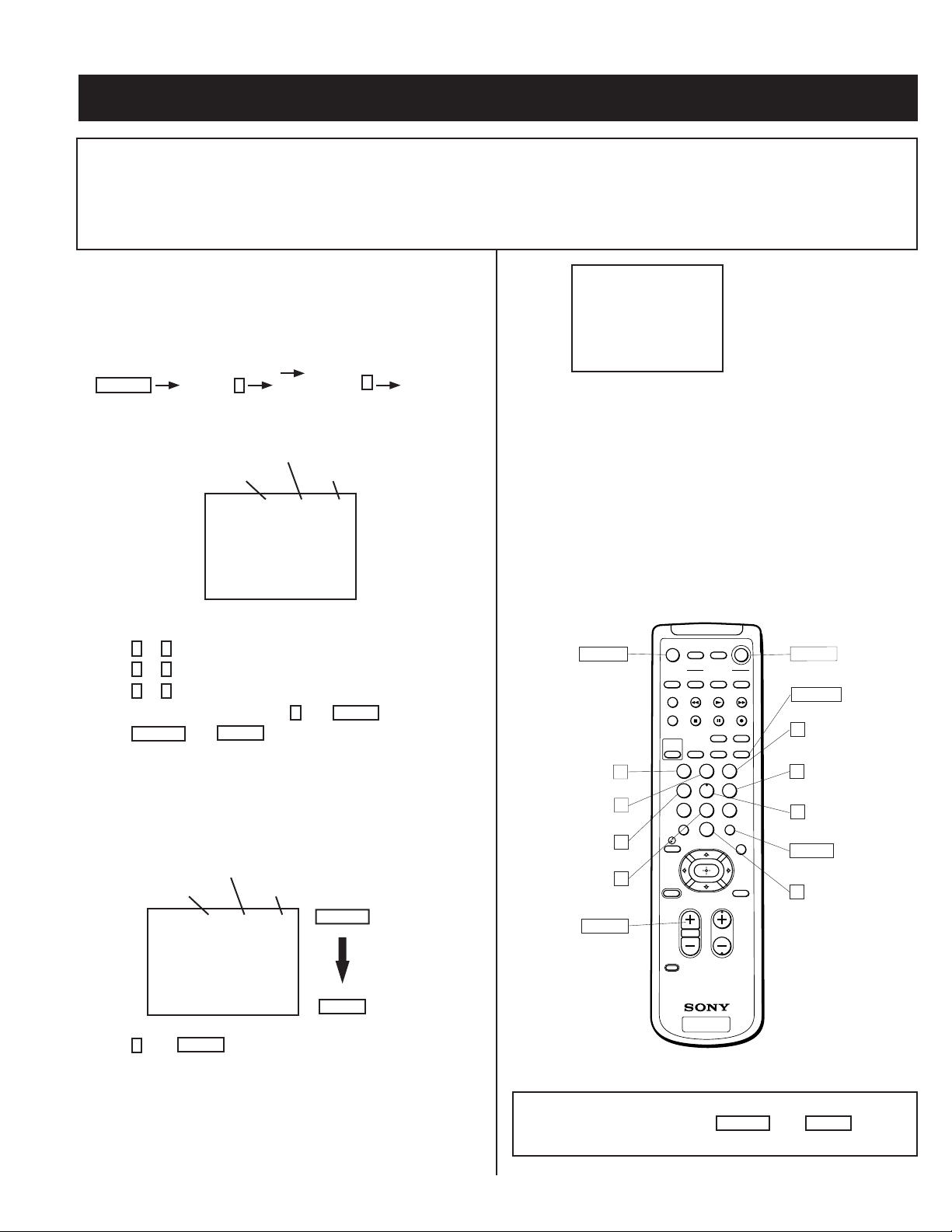

SECTION 4: CIRCUIT ADJUSTMENTS

ELECTRICAL ADJUSTMENTS BY REMOTE COMMANDER

Use the Remote Commander (RM-Y171) to perform the circuit adjustments in this section.

Test Equipment Required: 1. Pattern generator 2. Frequency counter 3. Digital multimeter 4. Audio oscillator

KV-29FV16A

4-1. SETTING THE SERVICE ADJUSTMENT

MODE

1. Standby mode (Power off).

2. Press the following buttons on the remote commander within a

second of each other:

DISPLAY

Channel 5 Sound Volume

+

Power

SERVICE ADJUSTMENT MODE IN

Register Item

Device Item Data Item

SERVICE VP VPOS 30

1000 0

3. The CRT displays the item being adjusted.

4. Press 2 or 5 on the Remote Commander to select the device item.

5. Press

6. Press

7. To recover the latest values, press

8. Press

1

or 4 on the Remote Commander to select the item.

3

or 6 on the Remote Commander to change the data.

0

ENTER

MUTING

then

then

ENTER

to write into memory**.

.

Note: If the NVM is replaced, perform this test and reset. Then

download from microprocessor to NVM to prevent loss of

picture.

SERVICE ADJUSTMENT MODE MEMORY

Register Item

Device Item Data Item

SERVICE VP VPOS 30

1000 0

MUTING

Green

SERVICE WRITE

1000 0000

Factory original setting

10. Turn set off and on to exit.

4-2. MEMORY WRITE CONFIRMATION

METHOD

1. After adjustment, pull out the plug from the AC outlet, then replace the

plug in the AC outlet again.

2. Turn the power switch ON and set to Service Mode.

3. Call the adjusted items again to confi rm they were adjusted.

4-3. REMOTE ADJUSTMENT BUTTONS AND

INDICATORS

VTR/DVD

FREEZE

SLEEP

SAT/CABLE

FUNCTION

SAT/CABLE

SWAP PIP

AUDIO

CHVOL

ENTER

POWER

TV/VIDEO

TV/VIDEOANT

DISPLAYMTS/SAP

GUIDE

RM-Y171

TV

TV

POWER

(Service mode)

DISPLAY

(Service mode)

3

(Data up)

6

(Data down)

5

(Device item down)

ENTER

(Write into memory)

0

(Read out of memory)

(Write into memory)

MUTING

1

(Item up)

2

(Device item up)

4

(Item down)

8

(Initialize)

VOL (+)

(Service mode)

MUTING

VTR/DVD

SYSTEM

OFF

TV/VTR

+

CH

POSITION

Ð

PICTURE

MODE

1 2 3

4 5 6

7 809

JUMP

TV/SAT

RESET MENU

CODE SET

Red

9. Press

then

8

ENTER

ENTER

on the Remote Commander to initialize.

Note: Carry out this step when adjusting IDs 0 to 4 and when

replacing IC102.

— 13 —

TV

RM-Y171

** WARNING: Do NOT turn off the power or remove the AC cord

immediately after pressing

MUTING

then

ENTER

. Wait at

least 10 seconds

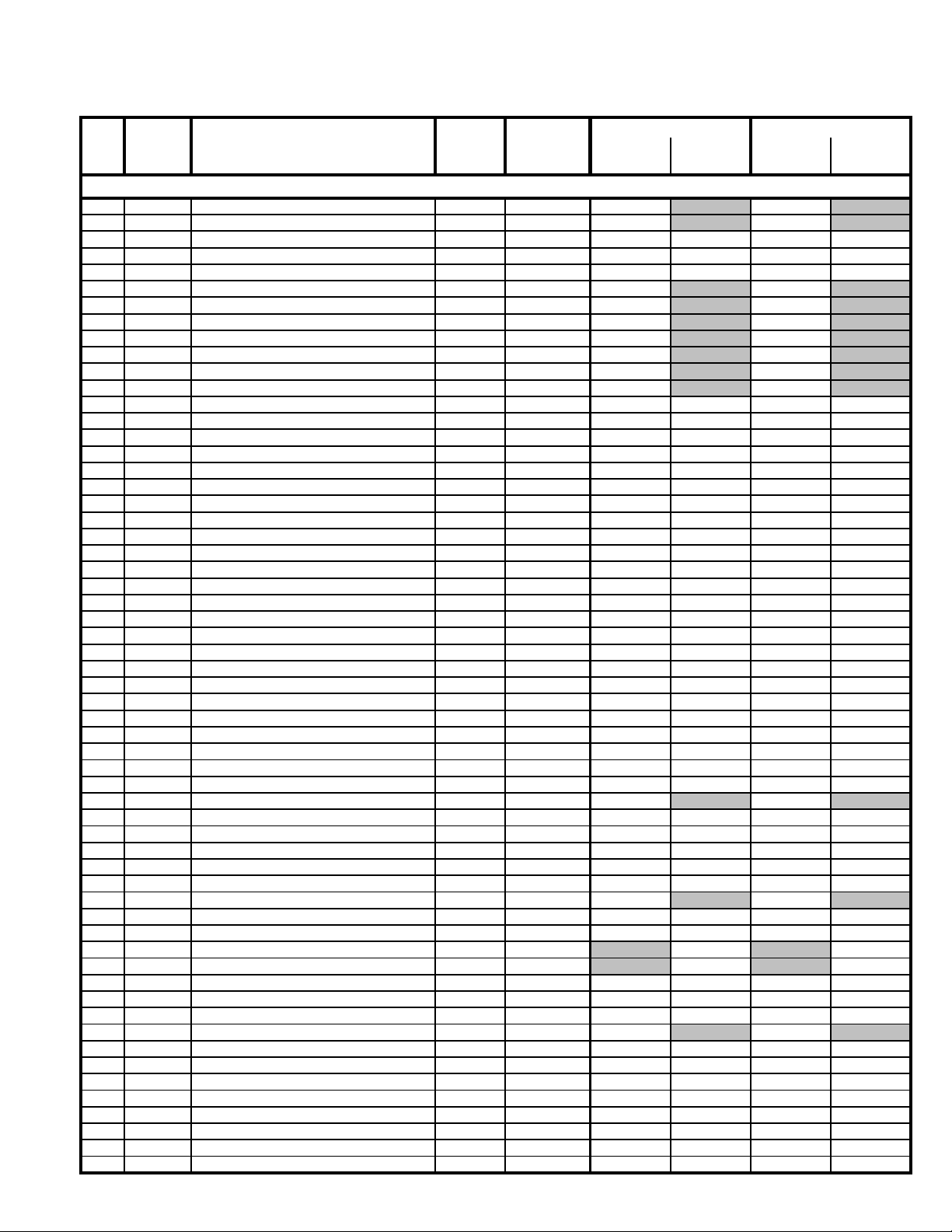

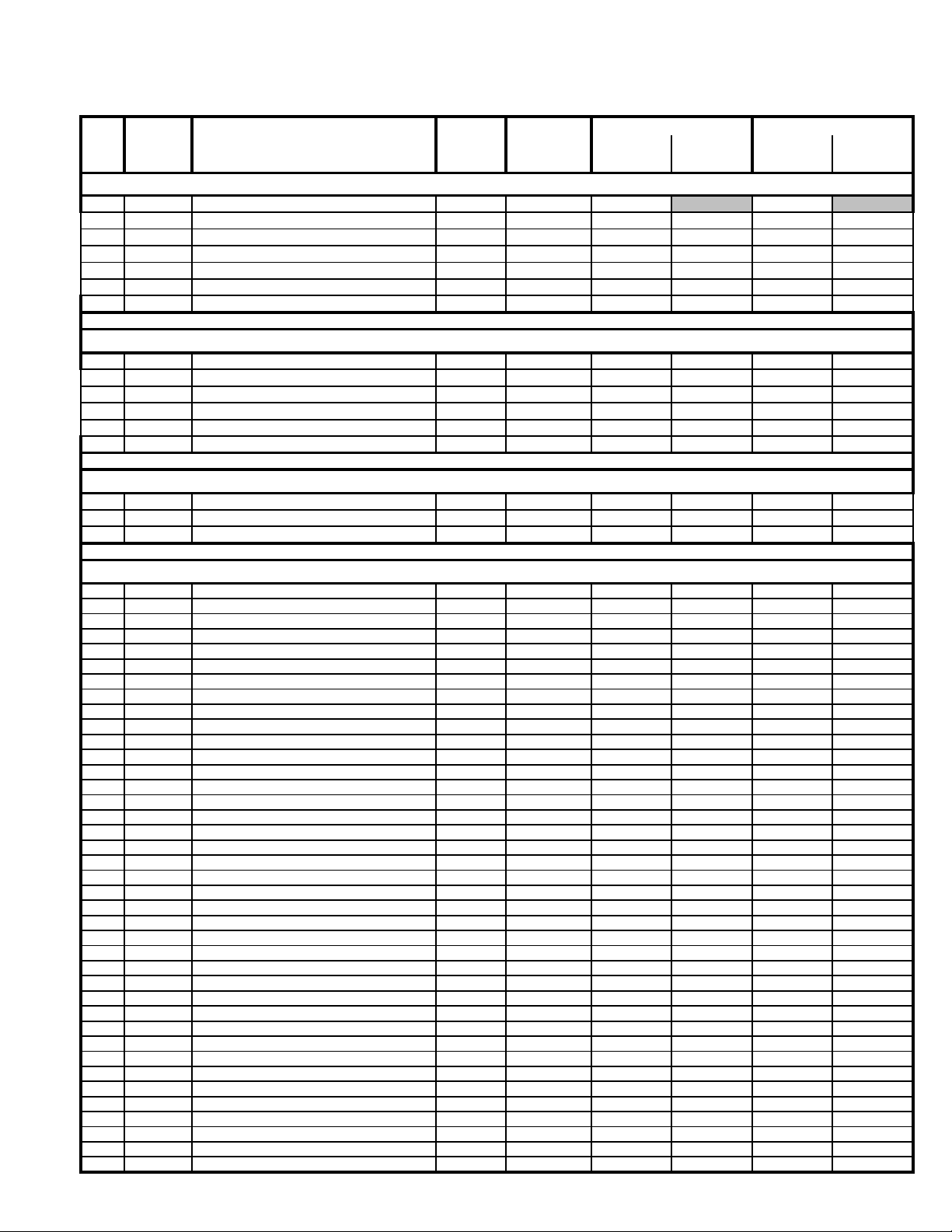

SERVICE DATA

V

V

KV-29FV16A

No. Initial Data Average Data

Name

DescriptionRegister

Range

Adj/FixData

NTSC

PAL-M

PAL-N

TV/AUX

S/VIDEO 1-3

VIDEO 4

NTSC

PAL-M

PAL-N

TV/AUX

S/VIDEO 1-3

VIDEO 4

P CXA2135S

1 HPOS Horizontal Position Adjust 0-31 Fix 7 7

2 HSIZ Horizontal Amp Adjust 0-31 Fix 10 10

3 VBOW VRT Line Bowing Adjust 0-15 Fix6666

4 VANG VRT Line Bow Slant Adjust 0-15 Fix5555

5 TRAP Horizontal Trapezoid Adjust 0-15 Fix6666

6 PAMP Horizontal Pin Distort Adjust 0-63 Fix 32 32

7 UCPN Upper Pin 0-63 Fix 36 36

8 LCPN Lower Pin 0-63 Fix 36 36

9 VSIZ Vertical Amplitude Test 0-63 Fix 0 0

10 VPOS Vertical Position Test 0-63 Fix 31 31

11 VLIN Vertical Linearity Adjust 0-15 Fix 7 7

12 VSCO S-Correction 0-15 Fix 7 7

13 VZOM 16:9 CRT Z Mode On/Off 0,1 Fix0000

14 EHT VRT High Volt Correction 0-15 Fix4444

15 ASP Aspect Ratio Control 0-63 Fix47474747

16 SCRL 16:9 CRT Z Mode Tran Scroll 0-63 Fix31313131

17 HBSW HBLK SW 0,1 Fix1111

18 LBLK Left Screen H Blk Control 0-15 Fix15151515

19 RBLK Right Screen H Blk Control 0-15 Fix0000

20 HDW H Drive Pulse Width 0,1 Fix0011

21 EWDC EW/DC Adjust 0,1 Fix0000

22 LVLN Screen Bottom VRT Lin Adjust 0-15 Fix0000

23 UVLN Screen Top VRT Lin Adjust 0-15 Fix0000

24 RDRV R Output Drive Control 0-63 Adj 31 31 31 31

25 GDRV G Output Drive Control 0-63 Adj 31 31 31 31

26 BDRV B Output Drive Control 0-63 Adj 31 31 31 31

27 RCUT R Output Cutoff Control 0-15 Adj 7777

28 GCUT G Output Cutoff Control 0-15 Adj 7777

29 BCUT B Output Cutoff Control 0-15 Adj 7777

30 RDR4 Video 4 R Output Drive Control 0-63 Adj 31 31 31 31

31 GDR4 Video 4 G Output Drive Control 0-63 Adj 31 31 31 31

32 BDR4 Video 4 B Output Drive Control 0-63 Adj 31 31 31 31

33 RCU4 Video 4 R Output Cutoff Control 0-15 Adj 7777

34 GCU4 Video 4 G Output Cutoff Control 0-15 Adj 7777

35 BCU4 Video 4 B Output Cutoff Control 0-15 Adj 7777

36 SHUE Sub Hue 0-31 Adj 7 7 15 15

37 SCOL Sub Color 0-31 Adj 15 15

38 SBRT Sub Brightness 0-63 Fix15151515

39 RON R Output On/Off 0,1 Fix1111

40 GON G Output On/Off 0,1 Fix1111

41 BON B Output On/Off 0,1 Fix1111

42 AXPL Axis Pal 0,1 Fix0000

43 CBPF Chroma BPF On/Off 0,1 Fix 1 1

44 COFF Color On/Off 0,1 Fix0000

45 KOFF Set Color Killer 0,1 Fix0000

46 SSHP Sub Sharpness 0-15 Fix 7 7

47 SHPF Sharpness Circuit F0 0,1 Fix 1 1

48 PREL Pre/Over-Shoot Switching 0,1 Fix1111

49 Y-DC DC Trans Radio Switching 0,1 Fix1111

50 ABLM ABL Mode Switching 0,1 Fix1111

51 YDEL Y Delay Time Control 0-15 Fix 7 7

52 NCOL No Color ID 0,1 Fix1111

53 FSC FSC Out On/Off 0,1 Fix1111

54 K-ID Killer ID 0,1 Fix1111

55 HOSC H VCO Oscillation Frequency 0-15 Fix7777

56 VSS V Sync Slice Level 0,1 Fix0011

57 HSS H Sync Slice Level 0,1 Fix0011

58 HMSK H Mask 0,1 Fix1111

59

TMS Select Signal VTIM Pin 0-3 Fix0000

— 14 —

f

T

S

V

e

e

V

y

c

g

g

A

g

g

A

K

K

g

K

g

V

VTRR

V

V

V

t

g

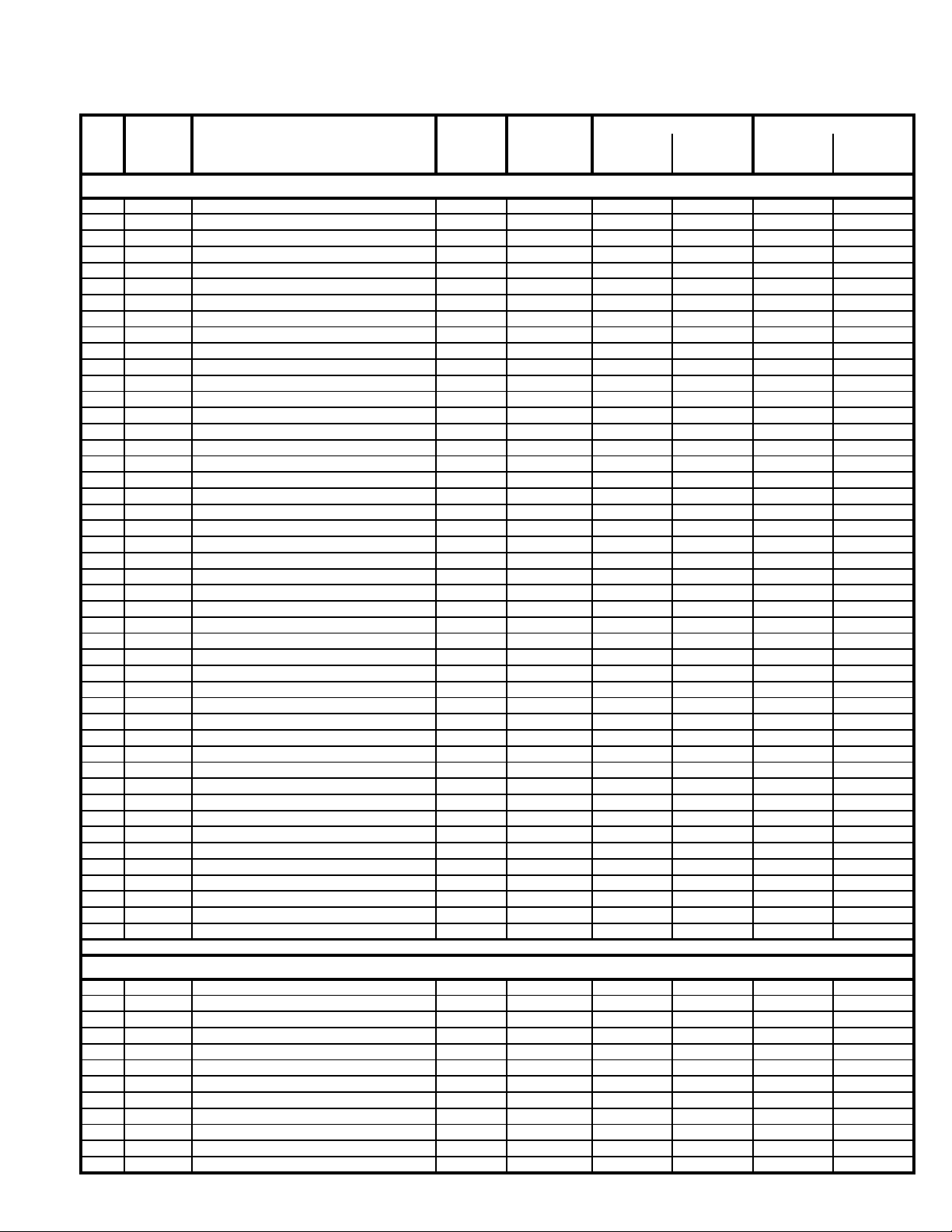

SERVICE DATA (CONT.)

KV-29FV16A

No. Register

Name

VP CXA2135S

60 AFC AFC Loop Gain 0-3 Fix 0 0

61 FIFR Field Frequency 0-3 Fix3311

62 REFP REFP 0,1 Fix0000

63 VBSW VBW 0-3 Fix0000

64 BMOF Blk Off 0,1 Fix0000

65 AGN2 Aging 2 0,1 Fix0000

66 YSHU Hue for YUV Models 0-63 Fix 31 31 31 31

Description Data

Range

continued

Adj/Fix Initial Data Average Data

NTSC

PAL-M

PAL-N

TV/AUX

S/VIDEO 1-3

VIDEO 4

NTSC

PAL-M

PAL-N

S/VIDEO 1-3

VIDEO 4

TV/AUX

AP BH3868

67 BBLP BBE Low Pass 0-15 Fix0055

68 BBHP BBE High Pass 0-15 Fix0033

69 SVOL Sub Volume 0-15 Fix0077

70 SBAL Sub Balance 0-15 Fix7777

71 SBAS Sub Bass 0-15 Fix7755

72 STRE Sub Treble 0-15 Fix7755

AP TDA7467

73 SPCA SRS/Space Attenuation 0-63 Fix0000

74 CENA SRS/Center Attenuation 0-63 Fix0000

75 INPA Input Attenuation 0-127 Fix3333

3D UPD64081

76 HHDS HH Of

77 COU

78 YAP

79 NSDS Adaptiv

80 MSS Adaptiv

81 DYC Hi Impedence

82 EXAD Ext Ad Selected

83 PECS Standard

84 EXCS Use CSI Just in Case

85 CPP

86 HDP H Phase +/- 0µ sec

87 CDL Y/C Dela

88 DYCO Y Movin

89 DYG

90 DCCO C Movin

91 DCG

92 YNR

93 YNRI Effect Small

94 YNRL Noise Limit

95 CNR

96 CNRI Effect Small

97 CNRL CNR Limit

98 ID1O ID 1 Throu

99 ID1W 4:03

100 ID1N Normal

101 CL

102 ST1S Monitor Out

103 ST0S Monitor Out

104 WSC Corin

105

106

107 LDSR Frame

108 PWRE PWRE

109 PDRE PDRE

110 PBRE PBRE

111

112

113 TEST Tes

114 YPFT Y Peakin

Gain 1/BPF On

Comp/Y Eaking On

TB = 1.25 VPP

+/- 0µ se

Y Moving Gain

C Moving Gain

Effect Small

Effect Small

Low Fix

TRH H Non Standard DET

H Non Standard DET

APGV Apacon Gain

API

Apacon

Corin

Corin

h

0-3

0-3

0-3

0-3

0-3

0-3

0,1

0-3

0-3

0-3

0-7

0-7

0-15

0-15

0-15

0-15

0,1

0,1

0-3

0,1

0,1

0-3

0,1

0,1

0,1

0,1

0-3

0-3

0-3

0-3

0-3

0-3

0,1

0-7

0-15

0-7

0-31

0,1

0-3

Fix1111

Fix3333

Fix3333

Fix0000

Fix0000

Fix2222

Fix1111

Fix0000

Fix1111

Fix0000

Fix3333

Fix4444

Fix2222

Fix 10 10 10 10

Fix2222

Fix9999

Fix1111

Fix0000

Fix1111

Fix1111

Fix0000

Fix1111

Fix0000

Fix0000

Fix0000

Fix1111

Fix0000

Fix1111

Fix1111

Fix1111

Fix1111

Fix2222

Fix0000

Fix4444

Fix8888

Fix3333

Fix 10 10 10 10

Fix0000

Fix3333

— 15 —

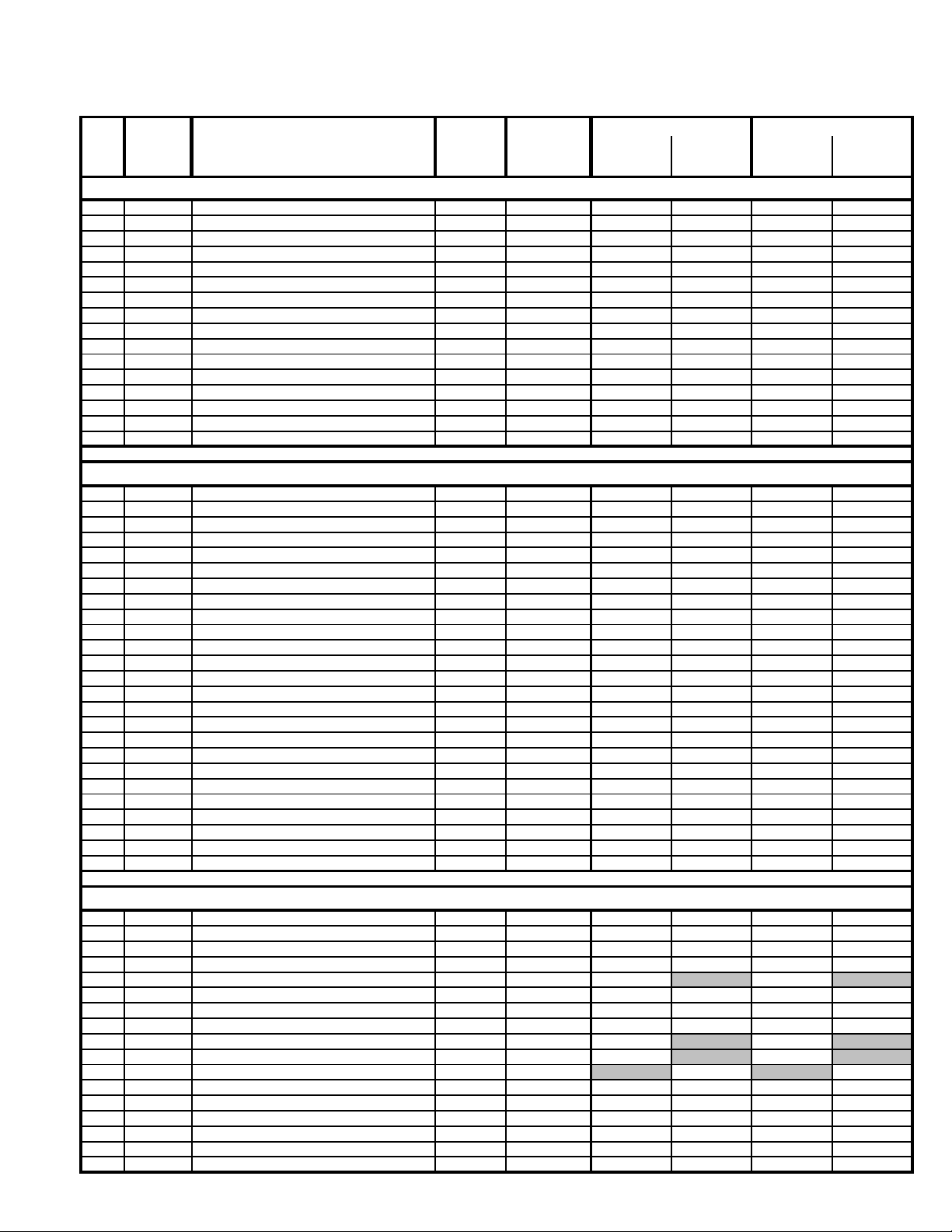

SERVICE DATA (CONT.)

KV-29FV16A

No. Register

Name

3D UPD64081

Description Data

Range

continued

Adj/Fix Initial Data Average Data

NTSC

PAL-M

PAL-N

TV/AUX

S/VIDEO 1-3

VIDEO 4

NTSC

PAL-M

PAL-N

TV/AUX

S/VIDEO 1-3

VIDEO 4

115 YPFG Y Peaking Gain 0-15 Fix 10 10 10 10

116 V1PS Line Comb Dot H 0-3 Fix2222

117 VEGS Line Comb Dot V 0-3 Fix2222

118 CC3N C Width 0,1 Fix0000

119 C0HS C Delay On 0,1 Fix0000

120 CLPH Y-Ad Clamp Test 0,1 Fix0000

121 SEL2 DC Sensitivity Small 0,1 Fix0000

122 SEL1 DY Sensitivity Small 0,1 Fix0000

123 YHCO Coring Small 0-3 Fix2211

124 YPCO Coring On 0,1 Fix0000

125 ED20 Standard 0,1 Fix1111

126 OVST Standard 0,1 Fix0000

127 CSHD Standard 0,1 Fix0000

128 KCTT Standard 0-3 Fix0000

129 SHT1 Standard 0,1 Fix0000

130 SHT0 Standard 0,1 Fix0000

131 VCT Standard 0,1 Fix0000

132 OTT Standard 0,1 Fix0000

133 CGAT Standard 0,1 Fix0000

134 CGGT Standard 0,1 Fix0000

135 CGFT Standard 0,1 Fix0000

136 CGT Standard 0,1 Fix0000

137 HPLL Standard 0,1 Fix1111

138 BPLL Burst PLL Fast 0,1 Fix0000

139 FSCF Burst Gain Large 0,1 Fix0000

140 PLLF PLL Loop Gain Large 0,1 Fix1111

141 KILR Killer Lever 0-15 Fix3333

142 HSSL H Slice Level 0-15 Fix 12 12 12 12

143 VSSL V Slice Level 0-15 Fix8888

144 BGPS Start Burst Gate 0-15 Fix4444

145 BGPW Width of Burst Gate 0-15 Fix 10 10 10 10

146 ADCL ADC Clock 0-3 Fix3333

147 ADPD Adc Power Down On 0,1 Fix1111

148 ADLT Standard 0,1 Fix0000

149 NRZO Check On 0,1 Fix0000

150 FSCO Level Check On 0,1 Fix0000

151 VTVH Normal 0-3 Fix0000

152 TST2 Standard 0,1 Fix0000

153 HMEM Use CSI Just in Case 0,1 Fix1111

154 HINV Polarity of Reset 0,1 Fix1111

155 HTMG Field Memory Address 0,1 Fix0000

156 HCP HH Carrier Phase 0-15 Fix7777

157 TST3 Test 0,1 Fix0000

158 HHMG HH Moving Gain 0,1 Fix1111

159 HHFG HH Off 0-3 Fix0000

160 HHTG Max HH 0-15 Fix5555

PI TA1226N

161 SHPR Picture Improvement Sharpness 0-127 Fix 59 59 59 59

162 BLAD Picture Improvement Black Area Det. 0-3 Fix0000

163 SRTS Picture Improvement SRT Start Pos 0-3 Fix3333

164 YNR Picture Improvement YNR 0,1 Fix1111

165 GIRE Picture Improvement Gamma Start 0-3 Fix3333

166 DAC1 Picture Improvement DAC1 0,1 Fix1111

167 DAC2 Picture Improvement DAC2 0,1 Fix0000

168 GCUR Picture Improvement Gamma Curve 0,1 Fix0000

169 BLKC Picture Improvement Black Compen. 0,1 Fix1111

170 TEST Picture Improvement Test 0-3 Fix3333

171 RS Picture Improvement RS 0-7 Fix0000

172 RTC Picture Improvement RTC 0-7 Fix4444

— 16 —

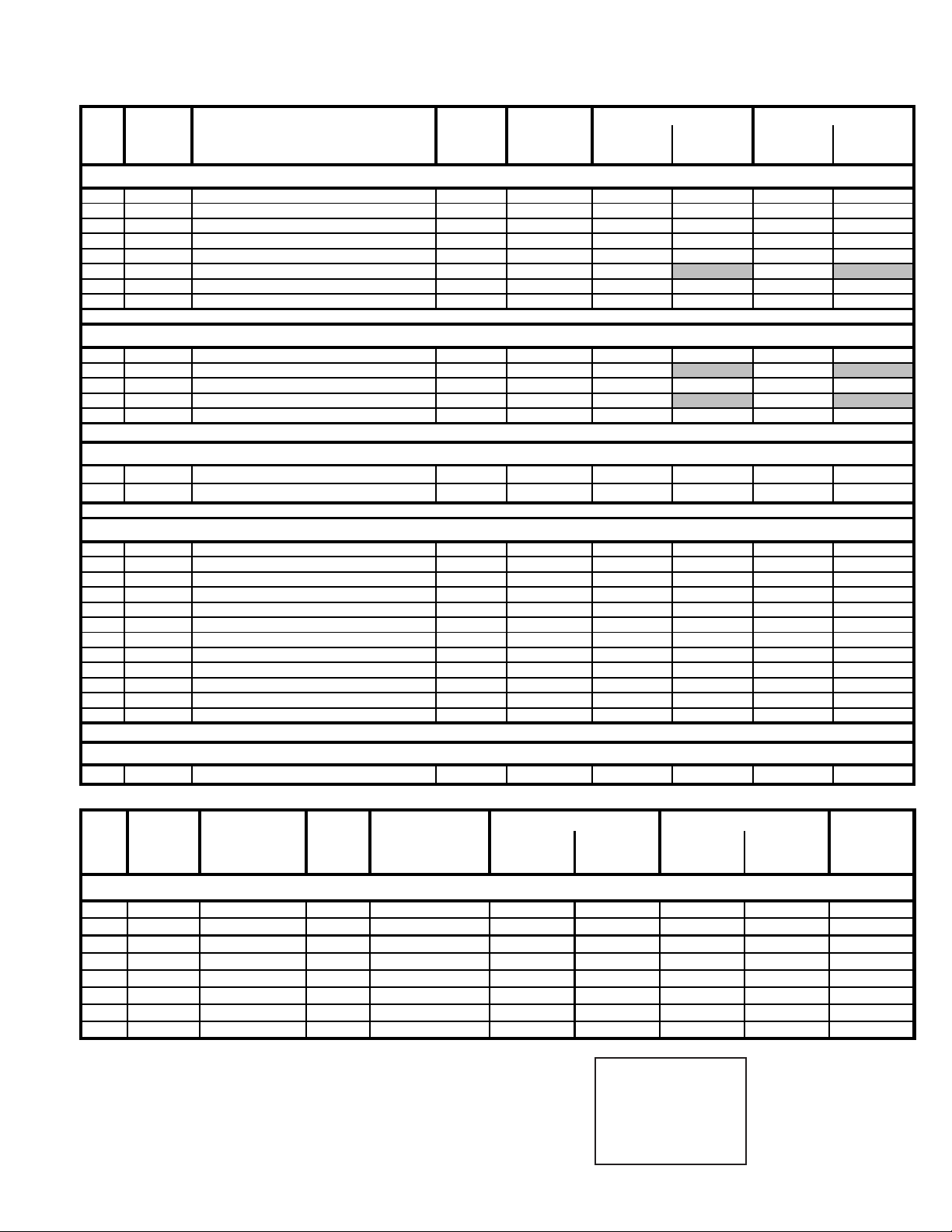

SERVICE DATA (CONT.)

t

y

W

y

W

y

p

y

W

y

W

y

y

y

TDy

t

y

t

TDy

t

YDy

y

y

f

0Dy

0

y

y

(

(

(

y

(

)

(

)

(

)

(

)

(

(

(

0

(

2

(

(

(

(

(

(

(

T

C

A

J

R

KV-29FV16A

No. Register

Description Data

Name

DC CXA2060

173 DCSF Dynamic Convergence DC Shif

174 UYBW D

175 LYBW D

176 HAMP D

177 UCBW D

178 LCBW D

179 UMBH D

180 LMBH D

181 PWM D

182 HTL

183 UTLD D

184 LTL

185 HDT

186 TOFF D

187 DAC

188 DAC1 D

namic Convergence Upper YBO

namic Convergence Lower YBO

namic Convergence H. Am

namic Convergence H. CBO

namic Convergence L. CBO

namic Convergence U. MBH

namic Convergence L. MBH

namic Convergence PWM

namic Convergence H. Til

namic Convergence U. Til

namic Convergence L. Til

namic Convergence H. Dut

namic Convergence Tilt Of

namic Convergence DAC

namic Convergence DAC1

SP SDA9288

189 PYSD P in P (Seimens) YS Dela

190 PIPH P in P

191 PIPV P in P

192 PYDL P in P

193 PIFX P in P Inset Fixed

194 PPFX P in P Parent Fixed

195 PCLI P in P CLISW

196 PAMS P in P AMSEC

197 PHDL P in P

198 PMVD P in P

199 PIVD P in P

200 PCON P in P

201 FRMY P in P

202 CHRI P in P

203 CHRO P in P

204 MAT

205 MAT1 P in P

206 MAT

207 IPER P in P

208 IPEB P in P

209 PCPS P in P

210 PCPF P in P

211 PSEL P in P

212 PPLL P in P

213 PVNR P in P

Seimens) H-Position

Seimens) V-Position

Seimens) Y-Dela

Seimens) H-Pulse Delay (Ins

Seimens) V-Pulse Delay (Mn

Seimens) V-Pulse Delay (Ins

Seimens) Contrast Lvl (Ins

Seimens) Frame Y

Seimens) Chroma Input Pol.

Seimens) Chroma Output Pol.

P in P (Seimens) MAT0

Seimens) MAT1

P in P (Seimens) MAT2

Seimens) Pedestal R-Y

Seimens) Pedestal B-Y

Seimens) CLP & HSIDEL

Seimens) CLP Cycles

Seimens) SELDOWN

Seimens) PLL Filter

Seimens) VSP Pulse Noise R.

Range

0-63

0-63

0-63

0-63

0-63

0-63

0-63

0-63

0-63

0-63

0-63

0-63

0-3

0,1

0-255

0-255

0-15

0-127

0-63

0-7

0-3

0-3

0,1

0,1

0-15

0-31

0-31

0-15

0-15

0,1

0,1

0,1

0,1

0,1

0-15

0-15

0,1

0,1

0,1

0-3

0,1

Adj/Fix Initial Data Average Data

NTSC

PAL-M

PAL-N

TV/AUX

S/VIDEO 1-3

VIDEO 4

NTSC

PAL-M

PAL-N

TV/AUX

S/VIDEO 1-3

VIDEO 4

Fix32323232

Fix31313131

Fix31313131

Fix23232323

Fix14141414

Fix14141414

Fix 15 15 15 15

Fix 15 15 15 15

Fix 63 63 63 63

Fix63636363

Fix63636363

Fix63636363

Fix3333

Fix1111

Fix 255 255 255 255

Fix 255 255 255 255

Fix2222

Fix 78 78 78 78

Fix 18 18 18 18

Fix0000

Fix0000

Fix0000

Fix1111

Fix0000

Fix15151515

Fix11111111

Fix18181818

Fix3333

Fix 10 10 10 10

Fix0000

Fix0000

Fix1111

Fix0000

Fix1111

Fix0000

Fix0000

Fix0000

Fix0000

Fix1111

Fix0000

Fix0000

IC CXA2019

214 IDPX

215 ICOL Color

216 ISHP Sharpness

217 ISCO Sub Chroma Decoder Sub Cont

218 ISCL Sub Chroma Decoder Sub Color

219 ISHU Sub Chroma Decoder Sub Hue

220 ITO

Sub Chroma Decoder Tot On

221 ITRP Sub Chroma Decoder Trap On

222 IAFC AF

223 ITR

Sub Chroma Decoder CTRAP AD

224 ICD2 Sub Chroma Decoder CD Mode2

225 ISF0 SHP-F0

226 IYD

Sub Chroma Decoder Y Drive

227 IVPE Sub Chroma Decoder V Ped

228 IUPE Sub Chroma Decoder U Ped

229 IRVP Sub Chroma Decoder RV Ped

230 IRUP Sub Chroma Decoder RU Ped

0,1

0-63

0-15

0-15

0-15

0-15

0,1

0,1

0-3

0-15

0,1

0,1

0-31

0-15

0-15

0-15

0-15

— 17 —

Fix0000

Fix38383838

Fix 10 10 10 10

Fix7777

Fix 8 8

Fix7777

Fix0000

Fix1111

Fix 1 1

Fix 7 7

Fix 1 1

Fix1111

Fix 24 24 24 24

Fix0000

Fix0000

Fix9999

Fix7777

KV-29FV16A

y

n

t

y

r

t

y

y

g

y

K

Y

y

y

y

y

y

y

y

SERVICE DATA (CONT.)

Description Data

Name

IC CXA2019

231 IDCT Sub Chroma Decoder DC Tran

232 IRYD Sub Chroma Decoder RY Drive

233 IPRE Sub Chroma Decoder Pre Over

234 IRUD Sub Chroma Decoder RU Drive

235 IRVD Sub Chroma Decoder RV Drive

236 IDLV Sub Chroma Decoder Dela

237 ISCR Sub Chroma Decoder SCP BGR

238 ISCF Sub Chroma Decoder SCP BGF

continued

Range

0-7

0-31

0-3

0-31

0-31

0-3

0-3

0-3

Adj/Fix Initial Data Average DataNo. Register

NTSC

PAL-M

PAL-N

Fix4466

Fix 19 19 19 19

Fix1111

Fix8888

Fix8888

Fix 0 0

Fix1111

Fix1111

TV/AUX

S/VIDEO 1-3

VIDEO 4

NTSC

PAL-M

PAL-N

TV/AUX

S/VIDEO 1-3

VIDEO 4

DA CXA1315

239 IDPX D/A Converter N-S Correctio

240 ICOL Color

241 ISHP Sharpness

242 ISCO Sub Chroma Decoder Sub Cont

243 ISCL Sub Chroma Decoder Sub Color

0-63

0-255

0-255

0-31

0-31

Fix 32 32 32 32

Fix 120 120

Fix 120 120 120 120

Fix 15 15

Fix 1 1 15 15

D1 CXD2085

244 XJGL XJGLK 0,1 Fix0000

245 LNJ1 LNJ1 0,1 Fix0000

CC CXP85856A

246 CRIL CCD CRI Pulse Compare Data Low

247 CFLD CCD Caption Fixed-Field Count

248 CCDI CCD No CCD Interrup

249 CRIP CCD CRI & Parit

250 CRIT CCD CRI Time Constan

251 CSB1 CCD S

252 CSB2 CCD S

253 CREP CCD CRI Si

254 CDSD CCD Data Start Dela

255 CCDS CCD Caption Data Threshold

256 CHMK CCD P8-HMAS

257 CHS

CCD P8-HSYC

nc Slice Bias 1

nc Slice Bias 2

Erro

nal End Position

0-15

0-15

0-7

0-7

0-3

0-3

0-7

0-256

0-31

0-31

0-63

0-255

Fix2222

Fix5555

Fix3333

Fix4444

Fix0000

Fix3333

Fix4444

Fix 142 142 142 142

Fix8888

Fix9999

Fix 42 42 42 42

Fix 136 136 136 136

OP CXP85856A

258 DISP OSD Position 0-63 Fix1111

No. Register

Name

Description Data

Range

Adj/Fix Initial Data Average Data ID

NTSC

PAL-M

PAL-N

TV/AUX

S/VIDEO 1-3

VIDEO 4

NTSC

PAL-M

PAL-N

TV/AUX

S/VIDEO 1-3

VIDEO 4

ID MAP

259 IDCT NVM ID 0

260 IRYD NVM ID 1

261 IPRE NVM ID 2

262 IRUD NVM ID 3

263 IRVD NVM ID 4

264 IDLV NVM ID 5

265 ISCR NVM ID 6

266 ISCF NVM ID 7

0-7

0-31

0-3

0-31

0-31

0-3

0-3

0-3

Fix by model 89 89 63 63 31

Fix b

model 55 55 55 55 63

Fix b

model 175 175 175 175 175

Fix b

model 96 96 64 64 192

Fix b

model 203 203 251 251 251

Fix b

model 181 181 181 181 181

Fix b

model 66666

Fix b

model 9900112

SERVICE IDO WRITE

Note: Items 1-266 show

adjustment order

— 18 —

KV-29FV16A

4-4. A BOARD ADJUSTMENTS

SUB BRIGHT ADJUSTMENT

1. Set to Service Adjustment Mode.

2. Input a grey scale pattern signal.

3. Set the PICTURE to minimum, and BRIGHT to normal.

white

1

and 4 .

3

and 6 so that the stripe second

MUTING

second from the right

black

then

ENTER

.

4. Select SBRT with

5. Adjust SUB BRIGHT level with

from the right is faintly visible.

6. Write into memory by pressing

SUB CONTRAST ADJUSTMENT (RDRV)

1. Input a 75% color-bar signal.

2. Set to: VIDEO mode = Standard, COLOR = Minimum, PICTURE =

100%, GON = 0 (OFF), BON = 0 (OFF)

3. Set to Service Adjustment Mode and connect an oscilloscope to pin

of CN351 on the A Board.

1

4

3

and

1

.

and

6

for: 1.85 ± 0.05 Vp-p.

MUTING

White

1.85 ± 0.05Vp-p

then

ENTER

.

4. Set RDRV with

5. Adjust with

6. Write into memory by pressing

V. SIZE ADJUSTMENT (VSIZ)

1. Input a monoscope signal.

2. Set to Service Adjustment Mode.

4

3

and

1

3. Select VSIZ with

4. Adjust with

5. Write into memory by pressing

.

and

6

for the best vertical size.

MUTING

then

ENTER

V. SIZE

V. POSITION ADJUSTMENT (VPOS)

1. Input a monoscope signal.

2. Set to Service Adjustment Mode.

4

3

and

1

6

.

and

for the best vertical center.

MUTING

then

ENTER

3. Select VPOS with

4. Adjust with

5. Write into memory by pressing

V. POSITION

H. SIZE ADJUSTMENT (HSIZ)

1. Input a monoscope signal.

2. Set to Service Adjustment Mode.

4

3. Select HSIZ with

4. Adjust with 3 and

5. Write into memory by pressing

H. SIZE

1

.

and

6

for the best horizontal size.

MUTING

then

ENTER

.

.

.

Black

SUB HUE, SUB COLOR ADJUSTMENT

(SHUE, SCOL, 4SHU, 4COL)

Note: SCOL and SHUE are for all other inputs (NTSC/PAL M/PAL N)

4SHU and 4COL are for Video 4 input (NTSC/PAL M/PAL N)

1. Input a 75% color-bar signal.

2. Set to Service Adjustment Mode and set: VIDEO mode = Standard,

PICTURE = 100%, COLOR = 50%, HUE = 50%.

3. Connect an oscilloscope to Pin

4. Select SHUE and SCOL with

3

6

5. Adjust with

6. Write SHUE data one step down from even condition to NVM.

SCOL is adjusted by SHUE compensation.

7. Write into memory by pressing

8. Repeat Steps 1-7 for 4SHU and 4COL.

and

for the V1 = V4 (SCOL) and V2 = V3 (SHUE).

V1

3

of CN351 on the A Board.

4

1

V2 V3

.

and

MUTING

V4

then

ENTER

.

H. POSITION ADJUSTMENT (HPOS)

HPOS Range is from 0~15.

1. Input a monoscope signal.

2. Set to Service Adjustment Mode.

4

3

and

1

6

.

and

for the best horizontal center.

MUTING

then

ENTER

3. Select HPOS with

4. Adjust with

5. Write into memory by pressing

H. POSITION

.

— 19 —

KV-29FV16A

V LINEARITY (VLIN), V CORRECTION (VSCO),

PIN AMP (PAMP) AND TRAPEZIUM (TRAP)

ADJUSTMENTS

1. Input a cross-hatch signal.

2. Set to Service Adjustment Mode.

4

3. Select VLIN, VSCO, PAMP, and TRAP with

3

6

4. Adjust with

5. Write into memory by pressing

and

for the best picture.

MUTING

V LINEARITY(VLIN)

VS CORRECTION (VSCO)

PIN AMP (PAMP)

TRAPEZIUM (TRAP)

1

then

and

ENTER

.

.

OSD POSITION ADJUSTMENT (DISP)

1. Input a color-bar signal.

2. Set to Service Adjustment Mode.

4

3

and

1

3. Select DISP with

4. Adjust with

5. Write into memory by pressing

.

and

6

for the bar center.

MUTING

SERVICE

1000 0000

then

AFC 0

ENTER

.

ROTATION COIL ADJUSTMENT

1. Input a monoscope signal.

2. Push

3. Select the “Set-up” mode.

4. Select “Tilt Correction”. Confi rm that number (0) color changes to red.

5. Push

+5 and the picture rotates clockwise.

6. Push

to -5 and the picture rotates counter-clockwise.

7. Push

on the Remote (RM-Y171).

MENU

(+) on the Remote. Confi rm that the number increases up to

(-) on the Remote. Confi rm that the number decreases down

(+) on the Remote. Return the value to 0.

V ANGLE (VANG), V BOW (VBOW), UPPER

UPPER PIN (UCPN) AND LOW PIN (LCPN)

ADJUSTMENTS

1. Input a cross-hatch signal.

2. Set to Service Adjustment Mode.

4

then

1

and

ENTER

.

.

3. Select VANG, VBOW, UCPN, and LCPN with

3

6

4. Adjust with

5. Write into memory by pressing

and

for the best picture.

MUTING

V ANGLE (VANG)

V BOW (VBOW)

UPPER PIN (UCPN)

LOW PIN (LCPN)

SET-UP

+5

Channel Set-up

Favorite Channel

Video Label

Language: English

Tilt Correction

Menu

-5

— 20 —

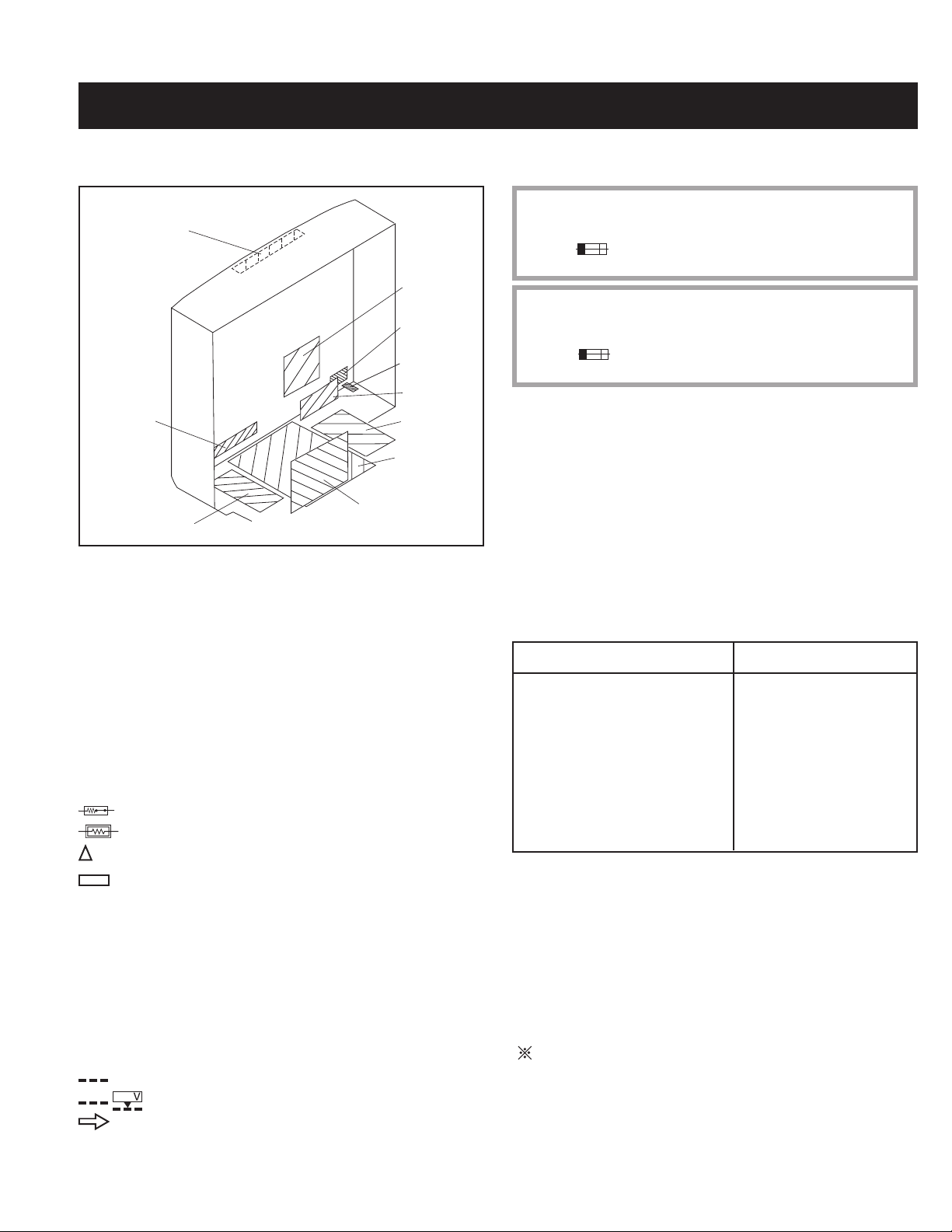

5-1. CIRCUIT BOARDS LOCATION

HX Board

SECTION 5: DIAGRAMS

The components identifi ed by shading and ! symbol are critical for safety. Replace

only with part number specifi ed.

The symbol indicates a fast operating fuse and is displayed on the component

side of the board. Replace only with fuse of the same rating as marked.

C Board

Les composants identifi es par un trame et une marque

HB Board

securite. Ne les remplacer que par une piece portant le numero specifi e.

KV-29FV16A

!

sont critiques pour la

HZ Board

WA Board

HA Board

AK Board

GA Board

A Board

UY Board

5-2. PRINTED WIRING BOARDS AND

SCHEMATIC DIAGRAMS INFORMATION

All capacitors are in µF unless otherwise noted. pF : µµF 50WV or less

are not indicated except for electrolytics and tantalums.

All electrolytics are in 50V unless otherwise specifi ed.

All resistors are in ohms. KΩ=1000Ω, MΩ=1000kΩ

Indication of resistance, which does not have one for rating

electrical power, is as follows: Pitch : 5mm

Rating electrical power :

1

/

W in resistance, 1/

4

W and 1/

10

8

: nonfl ammable resistor.

: fusible resistor.

: internal component.

: panel designation and adjustment for repair.

All variable and adjustable resistors have characteristic curve B, unless

otherwise noted.

Readings are taken with a color-bar signal input.

Readings are taken with a 10MΩ digital multimeter.

Voltages are DC with respect to ground unless otherwise noted.

Voltage variations may be noted due to normal production tolerances.

All voltages are in V.

S : Measurement impossibillity.

: B+line.

: B-line. (Actual measured value may be different).

: signal path. (RF)

Circled numbers are waveform references.

1

/

W

4

W in chip resistance.

Le symbole

fusible de meme yaleur, comme maque.

indique une fusible a action rapide. Doit etre remplace par une

The components identifi ed by X in this basic schematic diagram have

been carefully factory-selected for each set in order to satisfy regulations

regarding X-ray radiation. Should replacement be necessary, replace

only with the value originally used (Refer to Safety Related Adjustments

on page 12).

When replacing components identifi ed by

Y

, make the necessary

adjustments as indicated. If the results do not meet the specifi ed value,

change the component identifi ed by

X

and repeat the adjustment until

the specifi ed value is achieved.

When replacing the parts listed in the table below, it is important to

perform the related adjustments.

Part Replaced (Y) Adjustment (X)

A BOARD:

C531, C532, D302, D519, D520,

A BOARD:

R530, R531

D521, IC355, IC501, Q301, R356,

R359, R361, R529, R530, R531,

R532, R533, R550, T503

GA BOARD

IC6003, R6088

REFERENCE INFORMATION

RESISTOR

: RN METAL FILM

: RC SOLID

: FPRD NONFLAMMABLE CARBON

: FUSE NONFLAMMABLE FUSIBLE

: RW NONFLAMMABLE WIREWOUND

: RS NONFLAMMABLE METAL OXIDE

: RB NONFLAMMABLE CEMENT

: ADJUSTMENT RESISTOR

COIL

: LF-8L MICRO INDUCTOR

CAPACITOR

: TA TANTALUM

: PS STYROL

: PP POLYPROPYLENE

: PT MYLAR

: MPS METALIZED POLYESTER

: MPP METALIZED POLYPROPYLENE

: ALB BIPOLAR

: ALT HIGH TEMPERATURE

: ALR HIGH RIPPLE

— 21 —

Loading...

Loading...