Page 1

SAFETY PRECAUTIONS

SERVICE WARNING

Only qualified service technicians who are familiar with safety checks

and guidelines should perform service work. Before replacing parts,

disconnect power source to protect electrostatically sensitive parts. Do

not attempt to modify any circuit unless so recommended by the

manufacturer. When servicing the receiver, use an isolation transformer

between the line cord and power receptacle.

SERVICING THE HIGH VOLTAGE AND CRT

Use EXTREME CAUTION when servicing the high voltage circuits. To

discharge static high voltage, connect a 10K ohms resistor in series with a

test lead between the receiver ground and CRT anode lead. DO NOT lift

the CRT by the neck. Always wear shatterproof goggles when handling

the CRT to protect eyes in case of implosion.

X-RAY RADIATION AND HIGH VOLTAGE LIMITS

Be aware of the instructions and procedures covering X-ray radiation. In

solid-state receivers and monitors, the CRT is the only potential source of

X-rays. Keep an accurate high voltage meter available at all times. Check

meter calibration periodically. Whenever servicing a receiver, check the

high voltage at various brightness levels to be sure it is regulating

properly. Keep high voltage at rated value, NO HIGHER. Excessive high

voltage may cause X-ray radiation or failure of associated components.

DO NOT depend on protection circuits to keep voltage at rated value.

When troubleshooting a receiver with excessive high voltage, avoid close

contact with the CRT. DO NOT operate the receiver longer than

necessary. To locate the cause of excessive high voltage, use a variable

AC transformer to regulate voltage. In present receivers, many electrical

and mechanical components have safety related characteristics which are

not detectable by visual inspection. Such components are identified by a

# on both the schematic and the parts list. For SAFETY, use only

equivalent replacement parts when replacing these components.

GENERAL GUIDELINES

Perform a final SAFETY CHECK before returning receiver to customer.

Check repaired area for poorly soldered connections, and check entire

circuit board for solder splashes. Check board wiring for pinched wires or

wires contacting any high wattage resistors. Check that all control knobs,

shields, covers, grounds, and mounting hardware have been replaced. Be

sure to replace all insulators and restore proper lead dress.

SAFETY CHECKS FIRE AND SHOCK HAZARD

Cold Leakage Checks for Receivers with Isolated Ground

Unplug the AC cord, connect a jumper across the plug prongs, and turn

the power switch on (if applicable). Use an ohmmeter to measure the

resistance between the jumped AC plug and any exposed metal cabinet

parts such as antenna screw heads, control shafts, or handle brackets.

Exposed metal parts with a return path should measure between 1M

ohms and 5.2M ohms. Parts without a return path must measure infinity.

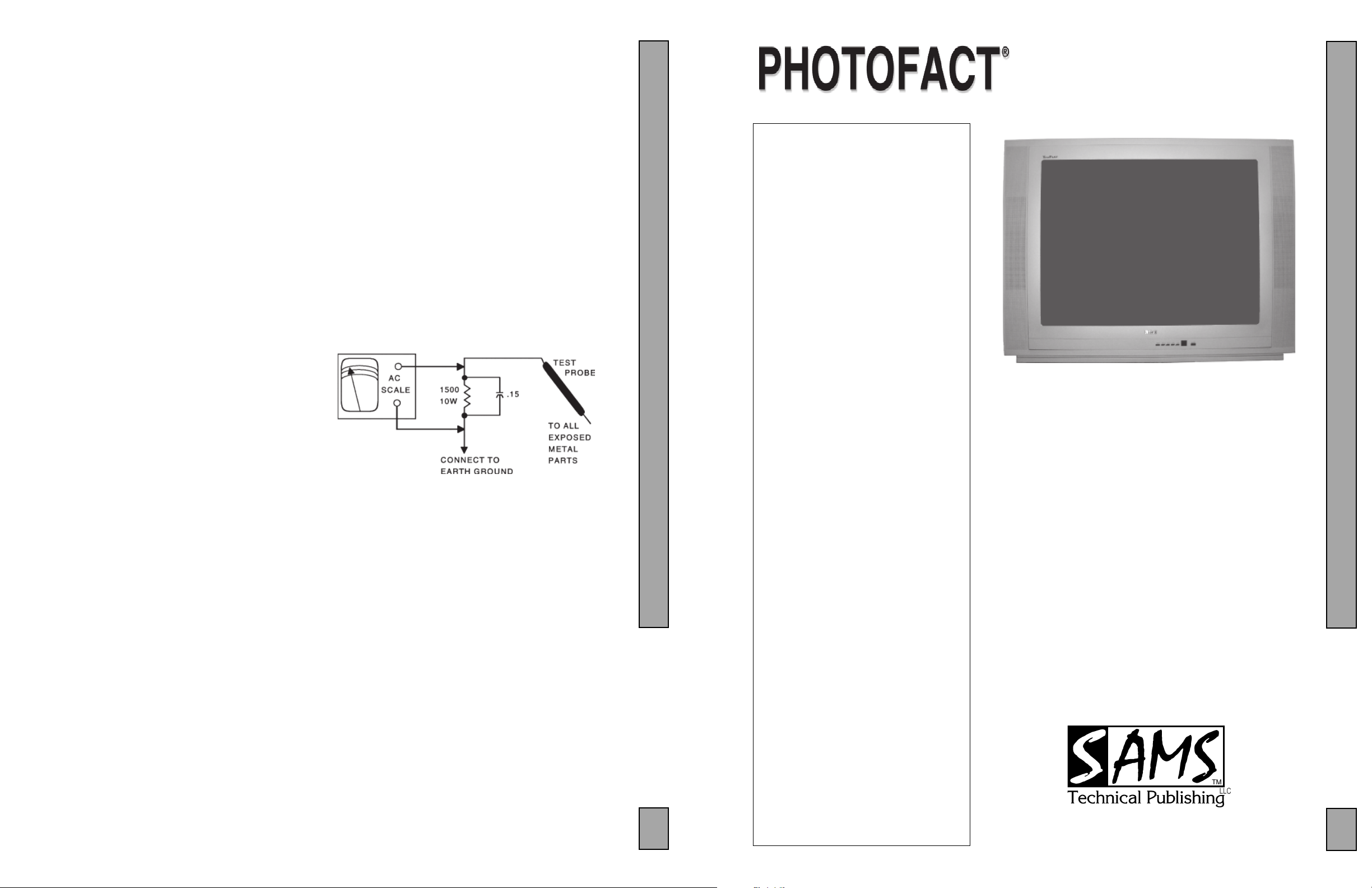

Hot Leakage Current Check

Plug the AC cord directly into an AC outlet. DO NOT use an isolation

transformer. Use a 1500 ohms, 10W resistor in parallel with a .15µF

capacitor to connect between any exposed metal parts on the receiver and

a good earth ground. (See figure below.) Use an AC voltmeter with at

least 5000 ohms per volt sensitivity to measure the voltage across the

resistor. Check all exposed metal parts and measure voltage at each point.

Voltage measurements should not exceed .75VAC, 500µA. Any value

exceeding this limit constitutes a potential shock hazard and must be

corrected. If the AC plug is not polarized, reverse the AC plug and repeat

exposed metal part voltage measurement at each point.

INDEXINDEX

INDEX

INDEXINDEX

SET 5303

GridTrace Location

Main Board ....................................... 3

Comb Filter Board ............................3

Important Parts Information ..................... 4

Miscellaneous Adjustments ..................... 1

Parts List ...................................................4

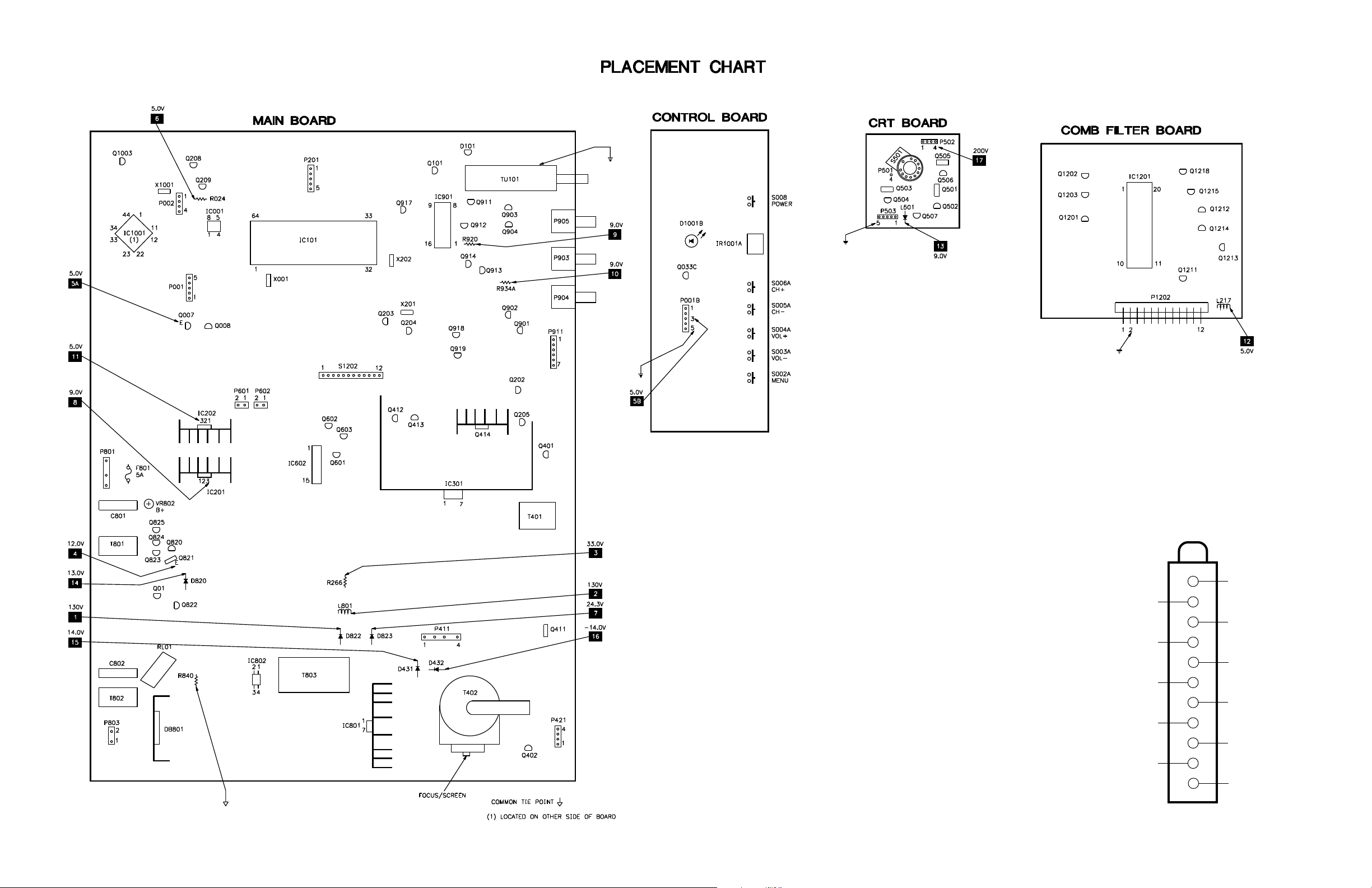

Placement Chart ....................................... 1

Safety Precautions .................................... 1

Schematic Component Location ..............1

Schematic Notes .......................................2

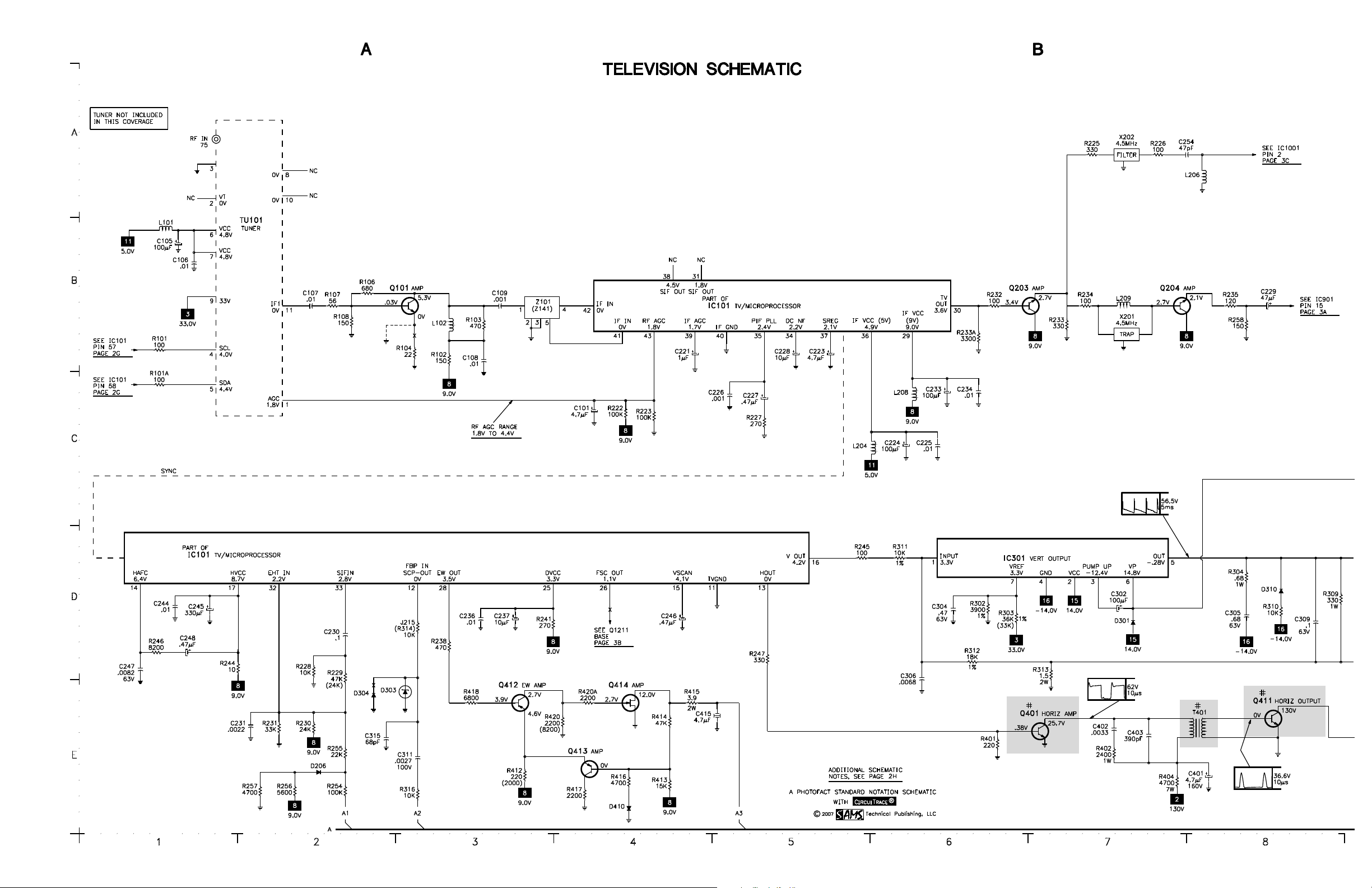

Schematics

Audio ................................................. 3

CRT ................................................... 2

Power Supply .................................... 2

System Control .................................. 2

Television .......................................... 2

Video Switching/Comb Filter ...........3

Service Mode Chart ................................. 1

Test Equipment.........................................3

Tuner Information ....................................1

5303

Technical Service Data

RCA

Model 27V412T (Chassis M134C)

Representative Model

Essential coverage

for servicing a television receiver...

Schematics

The listing of any available replacement part herein in no case constitutes a recommendation, warranty, or guarantee by

SAMS Technical Publishing, LLC as to the quality and suitability of such replacement part. The numbers of the listed parts

have been compiled from information furnished to SAMS Technical Publishing, LLC by the manufacturers of the specific

type of replacement part listed.

Reproduction or use, without express permission, of editorial or pictorial content, in any manner, is prohibited. No patent

liability is assumed with respect to the use of the information contained herein.

© 2007 SAMS Technical Publishing, LLC

9850 E. 30th St.

Indianapolis IN 46229

www.samswebsite.com

Printed in the United States of America 5 4 3 2 1 07PF03424

Page 1 SET 5303

!IBCGC|05303U

5303

MODEL 27V412T (CHASSIS M134C)

For a Complete List of Manuals,

Visit www.samswebsite.com

RCA

Component locations

Parts list

Coverage includes these additional models and chassis:

Models Chassis

24V412T M134C

27V412TYX1 M134C

27V412TYX3 M134C

27V412TYX5 M134C

27V412TYX8 M134C

OCTOBER 2007 SET 5303

5303

4

Page 2

Page 1 SET 5303

MISCELLANEOUS ADJUSTMENTS

HIGH VOLTAGE TEST

High voltage must not be higher than 31.8kV at any beam current.

X RAY PROTECTION TEST

Tune the set to receive a crosshatch signal. Apply an external power supply

to the positive lead of C249 (observe polarity). Slowly increase the voltage

from the supply. The set must shut down and remain off when the voltage

reaches 30V.

B+

Tune the set to receive a crosshatch signal, set the preset picture mode to

normal, and adjust VR802 for 130V ±0.5V at the positive lead of C422.

RF AGC

The RF AGC is factory preset at the time of manufacture for optimum

operation over a wide range of RF signal input conditions and should not

need readjustment, unless there is cable TV adjacent channel interference

or picture bending or channel 6 color beats because of excessive RF signal

input, this can occur if the receiver is located too close to the transmitting

tower. The signal should be attenuated at the antenna to reduce the signal

to a satisfactory level.

NOTE: Adjusting the RF AGC to extreme limits of its parameters unusually provides a poor signal to noise ratio.

SCREEN

Tune the set to receive a crosshatch signal, set the preset picture mode to

normal and set all of the picture controls (brightness, contrast, etc) to

midrange. Enter the service mode and preset the menu 1 values. Set RC,

GC, and BC to 80, GD and BD to 40. While still in the service mode, press

the input button on the remote and the vertical will collapse. Adjust the

screen control to produce a dim horizontal line on the CRT.

COLOR TEMPERATURE

Test point Display

Adjust: Menu 1 RC Red Cutoff

Menu 1 GC Green Cutoff

Menu 1 BC Blue Cutoff

Menu 1 GD Green Drive

Menu 1 BD Blue Drive

Set color picture temperature to normal and set all of the picture controls

(brightness, contrast, etc) to midrange. Tune the set to receive a gray scale

stairstep test pattern. Enter the service mode and adjust the values for

cutoff and drive controls to obtain proper color tracking, no tinting of black

and white and shades of gray, and color temperature is 9300 degrees - X =

284, Y = 299.

SUB BRIGHTNESS

Tune the set to receive a gray scale stairstep signal from the A/V inputs. Set

picture color temperature to normal, Set all of the picture controls

(brightness, contrast, etc) to midrange. Enter the service mode and select

menu 5. Adjust the value of BRTC sub brightness to just light the second

dark bar, making sure the first bar stays black.

Test point Display

Adjust: Menu 3 HPOS6 H Position

Menu 3 PARA6 H Parabola

Menu 3 TRAP6 H Trapazoid

Menu 3 HSIZE6 H Size

Menu 3 CNRT6 H Corner Top

Menu 3 CNRB6 H Corner Bottom

Menu 2 HIGHT6 Height

Menu 2 VLIN6 Linearity

Menu 2 VP60 Vertical Center

Menu 2 VSC6 Vert S Correct

NOTE: Confirm correct convergence and purity before adjusting geometry.

Tune the set to receive a circular test pattern to make visual geometry

adjustments. Enter the service mode. Adjust menu 2 and menu 3 values for

the least amount of geometric distortion approximately 7% overscan.

SERVICE MODE

NOTE: Pressing the 1 and input buttons on the remote will shut the set

down if you are in the service mode.

To enter the service mode, press and hold the volume down button on the

set while pressing the info/del button on the remote. Menus 1 thru 10 can

be accessed directly using the remote keypad number buttons. For menu 11

press the 1 and notepad buttons on the remote; menu 12 press the 1 and

caps buttons on the remote; menu 13 press 1 and info/del buttons on the

remote; menu 14 press 1 and sleep buttons on the remote; menu 15 press 1

and calendar buttons on the remote; 16 press 1 and insert buttons on the

remote; menu 17 press 1 and FAV buttons on the remote; menu 18 press 1

and go back buttons on the remote. If any of the service mode menu items

have been adjusted, press the sound button to save the settings, and exit the

service mode.

ITEM SETTING

Menu 1

FAC01

RC 76

GC 86

BC 7B

GD 33

BD 2E

Menu 2

FAC02

HIGHT6 19

VP60 07

VLIN6 0A

VSC6 0A

VBLK6 0A

VCEN6 2B

Menu 3

FAC03

HPOS6 13

PARA6 1C

TRAP6 22

HSIZE6 1F

CNRT6 0A

CNRB6 09

VEHT6 03

HEHT6 03

Menu 4

FAC04

CNTX 7F

CNTN 08

BRTX 20

BRTN 20

COLX 35

COLN 00

TNTX 30

TNTN 30

Menu 5

FAC05

BRTC 3C

COLC 23

COLP 00

SCOL 07

SCNT 06

CNTC 4C

TNTCT 37

TNTCV 37

SERVICE MODE CHART

ITEM SETTING

Menu 6

FAC06

ST3 20

SV3 20

SV4 19

SVD 19

ASSH 07

SHPX 10

SHPN 2A

Menu 7

FAC07

MOD1 60

MOD2 B0

MOD3 70

OPT 36

OPTM1 C1

OPTM2 00

HDCNT 00

HSTOP FF

Menu 8

FAC08

RFAGC 26

BRTS 00

OSD 21

OSDF 53

CCD OSD 4A

CCD OSDF 65

TXCX 1F

RGCN 16

Menu 9

FAC09

V01 46

V25 5A

V50 65

V100 7F

VOLMAX 32

CURTCEN A5

GATE 2A

VOL-OUT 73

Menu 10

FAC10

MODE4 22

MODE5 0B

MODE6 1E

MODE7 C4

MODE8 2D

MODE8 C2

ITEM SETTING

Menu 11

FAC11

MPB STR 43

MPB HMC 0D

MPB HP 07

MPB LP 11

MPB LIM 00

SUB FRE 28

SUB HP 02

VOL MAI 00

Menu 12

FAC12

SVM 05

SVM1 05

OSD2 20

OSDF2 64

PYNX 28

PYNN 18

PYXS 22

PYNS 10

Menu 13

FAC13

CLTM 4F

CLVO 48

CLVS 4F

ABL 27

DCBS 12

FLGO 82

FLG1 0D

Menu 14

FAC14

HAFC 09

AGCC 1C

NOIS 01

ONTM 08

NSHP 1A

PVLVL 80

PLMT 80

ITEM SETTING

Menu 15

FAC15

RC-C FC

GC-C 02

BC-C 00

GD-C FD

BD-C 0A

Menu 16

FAC16

RC-W 04

GC-W 01

BC-W 02

GD-W FB

BD-W E7

YUVGC F7

YUVBC 08

Menu 17

FAC17

D-COL 32

D-BRI 32

D-CON 5A

D-SHP 32

Menu 18

FAC18

S-COL 32

S-BRI 32

S-CON 4B

S-SHP 32

Page 3

SET 5303 Page 1

TUNER INFORMATION

TUNER VOLTAGE CHART

Pin Voltage

(1) AGC 1.8V

(2) VT 0V

(3) GND 0V

(4) SCL 4.0V

(5) SDA 4.4V

(6) VCC 4.8V

(7) VCC 4.8V

(8) NC 0V

(9) 33V 33.0V

(10) NC 0V

(11) IF1 0V

NOTE: Voltages do not change

on different bands.

TUNER TERMINAL GUIDE

(1)

(2)

(3)

(4)

(5)

(6)

(7)

(8)

(9)

(10)

(11)

Page 4

SCHEMATIC COMPONENT LOCATION GUIDE

C008 E26

C01 B17

C021 C24

C022 C24

C025 B24

C026 C23

C027 C26

C028 B23

C029 B24

C030 D26

C031 C26

C032 C26

C033 B26

C034 B26

C041 B26

C043 B26

C070A B25

C101 C4

C104 A23

C105 B1

C106 B1

C107 B2

C108 C3

C109 B3

C209 D16

C210 D16

C211 D15

C211 D15

C212 D15

C213 C10

C214 C11

C216 C12

C217 C11

C218 C13

C219 C12

C220 C12

C221 B4

C223 B5

C224 C6

C225 C6

C226 C5

C227 C5

C228 B5

C229 B8

C230 D2

C231 E2

C233 C6

C234 C6

C235 C14

C236 D3

C237 D3

C238 B9

C239 B10

C241 B10

C242 B9

C243 B10

C244 D1

C245 D1

C246 D4

C247 D1

C248 D1

C249 E15

C250 C12

C251 C11

C254 A7

C260 C22

C261 C24

C262 C24

C263 D23

C264 D24

C266 A23

C280 C14

C281 C14

C301 E23

C302 D7

C303 E23

C304 D6

C305 D8

C306 E6

C308 E22

C309 D8

C311 E3

C315 E2

C401 E8

C402 E7

C403 E7

C411 E9

C412 E9

C413 E9

C414 E9

C415 E4

C419 D10

C422 A23

C431 E22

C432 E24

C433 E21

C435 E21

C441 E22

C442 E23

C443 E15

C451 E13

C501 A30

C502 C30

C503 B30

C504 E23

C505 C31

C506 C24

C508 C31

C509 C24

C624 B46

C625 B46

C626 A44

C627 A44

C630 A44

C631 A44

C634 D46

C661 D45

C801 A17

C802 A18

C803 A19

C804 A19

C804A A19

C805 A19

C805A B18

C806 A20

C807 A20

C810 C19

C811 C19

C812 C19

C813 C18

C814 C19

C815 C20

C820 C21

C821 D22

C822 D22

C826 A21

C827 A22

C828 A21

C829 B19

C830 C21

C831 C22

C832 C22

C833 B23

C834 E18

C835 B17

C836 C18

C840 B20

C902 C33

C903 B34

C904 C42

C905 C42

C908 A34

C909 D41

C910 D41

C911 D24

C912 D24

C913 B34

C914 B34

C915 B44

C916 C44

C924 D33

C925 D33

C926 D35

C927 B45

C928 B45

C929 D24

C930 D24

C1001 E44

C1002 E44

C1004 A43

C1005 A43

C1006 E43

C1008 E44

C1009 E43

C1010 E43

C1011 E44

C1012 B42

C1013 B43

C1014 B42

C1015 A43

C1016 B41

C1017 D42

C1018 E42

C1019 E43

C1023 B44

C1024 C44

C1025 B42

C1031 C43

C1033 C44

C1034 C44

C1035 B42

C1036 B42

C1037 A43

C1038 A43

C1201 B36

C1202 B36

C1203 B36

C1204 B36

C1205 D24

C1206 D24

C1211 D38

C1212 D38

C1213 D39

C1214 D39

C1215 B38

C1216 C38

C1217 C38

C1218 C38

C1219 C38

C1220 B38

C1221 B38

C1222 D39

C1223 D39

C1224 D38

C1225 D38

C1229 D39

C1230 D39

C1231 B39

C1233 C39

C1234 C38

C1235 C38

C1236 B38

D001 D25

D01 B17

D02 B17

D101 A23

D202 B16

D203 C16

D204 B16

D205 C14

D206 E2

D207 C12

D208 E14

D209 E14

D210 E15

D211 C11

D212 C11

D213 C11

D214 C13

D215 D16

D262 E15

D301 D7

D303 E3

D304 E2

D309 D9

D310 D8

D410 E4

D411 E10

D412 E10

D420 E11

D431 E22

D432 E21

D441 E22

D501 C29

D502 C29

D602 D45

D810 C19

D811 C19

D811A C19

D811B C19

D812 C19

D813 C18

D820 D21

D820A D21

D820B D21

D822 A21

D822A A21

D822B A21

D823 C21

D823A C21

D823B C21

D824 B23

D826 E19

D827 C17

D828 C17

D829 C18

D834 B22

D1001A D28

DB801 A19

DEGAUSS A19

F801 A17

IC001 B27

IC101 A26

IC101 B11

IC101 B5

IC101 D1

IC201 C23

IC202 D23

IC301 D6

IC602 A47

IC801 B19

IC802 B18

IC901 A34

IC901 C36

IC1001 A43

IC1201 B38

IR001A A25

J215 D3

J603 E10

J604 E10

J1005 E42

L001 D23

L002 B25

L101 B1

L102 B3

L204 C5

L205 C12

L206 A8

L208 C6

L209 B7

L212 C11

L301 D9

L413 E10

L414 D10

L501 C23

L502 B32

L503 B32

L505 C31

L506 C31

L801 A22

L1001 E43

L1201 B36

L1211 D37

L1212 C37

L1213 D37

L1214 D37

L1215 B38

L1216 C37

L1217 D23

P800 A17

P901 B33

P901 C41

P901 C41

P902 B33

P903 A33

P903 D41

P903 D41

P904 A33

P904 A9

P904 A9

P905 B45

P905 B45

P905 D35

Q007 B23

Q008 D25

Q01 B17

Q033C D28

Q101 B3

Q202 E16

Q203 B6

Q204 B7

Q205 E15

Q208 D16

Q209 D15

Q401 E6

Q402 E14

Q411 E8

Q412 E3

Q413 E4

Q414 E4

Q501 A30

Q502 A30

Q503 C30

Q504 C30

Q505 B30

Q506 B30

Q507 C29

Q601 D45

Q602 D45

Q603 E46

Q820 B22

Q821 B22

Q822 B17

Q823 E19

Q824 E18

Q825 E18

Q901 C42

Q902 C42

Q903 D42

Q904 D42

Q911 D34

Q912 D34

Q913 B44

Q914 B44

Q917 B35

Q918 C27

Q919 C44

Q1003 B41

Q1201 B37

Q1202 B37

Q1203 B37

Q1211 C37

Q1212 E39

Q1213 E39

Q1214 C39

Q1215 C39

Q1218 B39

R001 D26

R003 E27

R004 A26

R005 E25

R006 E26

R01 B17

R02 B17

R010 D27

R023A C25

R024 C23

R024A C25

R025 A27

R025A C25

R026 B27

R026A C25

R027A D25

R030 B23

R031 D25

R032 D25

R033 D25

R033B E28

R033C D27

R0333 C25

R034 D26

R036 C26

R036A C26

R043 C27

R044 B26

R070A B25

R101 B1

R101A C1

R102 C3

R103 B3

R104 B3

R106 B2

R107 B2

R108 B2

R209 D16

R211 D15

R212 D15

R213 D16

R214 B16

R215 C15

R216 B15

R219 C12

R220 C13

R222 C4

R223 C4

R225 A7

R226 A7

R227 C5

R228 D2

R229 E2

R230 E2

R231 E2

R232 B6

R233 B7

R233A B6

R234 B7

R235 B8

R238 D3

R239 C14

R241 D3

R242 B10

R243 B10

R244 D1

R245 D5

R246 D1

R247 D5

R248 B10

R250 E16

R251 E15

R253 E15

R254 E2

R255 E2

R256 E2

R257 E2

R258 B8

R261 E15

R262 C12

R266 A22

R302 D6

R303 D6

R304 D8

R309 D8

R310 D8

R311 D6

R312 D6

R313 D7

R316 E3

R401 E6

R402 E7

R404 E7

R412 E3

R413 E4

R414 E4

R415 E4

R416 E4

R417 E4

R418 E3

R419 D10

R420 E4

R420A E4

R422 D11

R431 E22

R432 E14

R433 E21

R453 E13

R460 E23

R461 A32

R501 A29

R502 A29

R503 A30

R505 C29

R506 C30

R508 C30

R509 C29

R510 B29

R511 B30

R513 B30

R514 D29

R515 C29

R516 B30

R517 C30

R518 A30

R519 A31

R520 C31

R521 B31

R522 D29

R605 D46

R605A D46

R606 D45

R608 A44

R610 D46

R611 B46

R612 A44

R618 E46

R656 D44

R801 A17

R810 B19

R811 B18

R812 C18

R813 C20

R814 C19

R815 C19

R816 D20

R820 D21

R821 A21

R823 C21

R825 D22

R826 B22

R827 B22

R828 E19

R829 B22

R830 C18

R831 B17

R832 E18

R833 C17

R834 C17

R834A C17

R834B C17

R835 C17

R836 E19

R837 E18

R838 E17

R840 B20

R901 C33

R902 B34

R903 B34

R904 C41

R905 A34

R906 C41

R908 A33

R910 D41

R911 D42

R912 D41

R913 D42

R914 B10

R915 A10

R916 C42

R917 C42

R920 D23

R923 D35

R924 B45

R925 B45

R926 B45

R929 C45

R930 D34

R931 D35

R932 B33

R932A D33

R933 D33

R934 B34

R934A D23

R935 D34

R936 D34

R937 D34

R944 C44

R945 C27

R946 B33

R946A B34

R947 B35

R948 B35

R951 D41

R952 D41

R953 C42

R954 C42

R1001 B42

R1002 B42

R1004 D43

R1005 B42

R1006 B41

R1007 B41

R1010 C44

R1011 C44

R1022 B43

R1023 B43

R1201 B36

R1202 B36

R1203 B36

R1204 B37

R1205 B37

R1206 B37

R1207 B37

R1208 B37

R1209 B38

R1211 C38

R1212 C38

R1213 C39

R1215 E39

R1216 E39

R1217 E38

R1218 E39

R1219 E38

R1220 C39

R1221 C39

R1228 B39

R1229 B39

R1232 E39

R1233 C40

R1234 C40

R1236 B37

R1237 B37

RL01 A18

RL01 B18

RT801 A18

RT802 A20

S002A C25

S003A C25

S004A C25

S005A D25

S006A D25

S008 C25

S501 A32

S501 B31

S501 B31

S501 B31

S501 B31

S501 C31

S501 C31

T401 E7

T402 D12

T402 D21

T801 A17

T802 A18

T803 A20

TU101 B2

V801 B32

VR802 C17

W601 A48

W602 B48

X001 C26

X201 B7

X202 A7

X1001 E44

Z101 B3

RCA MODEL 27V412T (CHASSIS M134C)

SET 5303 Page 1

Page 5

Page 2 SET 5303

Page 6

SET 5303 Page 2

Page 7

Page 2 SET 5303

PHILIPS MODEL 32PT5441/37 (CHASSIS L04.1UAA)

Page 8

RCA MODEL 27V412T (CHASSIS M134C)

PHILIPS MODEL 32PT5441/37 (CHASSIS L04.1UAA)

SET 5303 Page 2

Page 9

Page 3 SET 5303

Page 10

SET 5303 Page 3

Page 11

MAIN BOARD

MAIN BOARD, GRIDTRACE LOCATION GUIDE

C008 B5

C01 L2

C021 C4

C022 C4

C025 B5

C026 B5

C027 D4

C028 E3

C029 E4

C030 E5

C031 E5

C032 E5

C033 E5

C034 E5

C041 D5

C043 D4

C101 A12

C104 A10

C105 A11

C106 A11

C107 A10

C108 B9

C109 B9

C209 A3

C210 A4

C211 A4

C212 A4

C213 B6

C214 B6

C216 B6

C217 B6

C218 B6

C219 B7

C220 B8

C221 B7

C223 C7

C224 B8

C225 B7

C226 C8

C227 B8

C228 C8

C229 D9

C230 C8

C231 D8

C233 D8

C234 D8

C235 D7

C236 D7

C237 D7

C238 D8

C239 E7

C241 D7

C242 C8

C243 D7

C244 D6

C245 E6

C246 D6

C247 D6

C248 D6

C249 G12

C250 H9

C251 H10

C254 B8

C261 G4

C262 H4

C263 G2

C264 F2

C266 J7

C280 E7

C281 E8

C301 I8

C302 I10

C303 I10

C304 H9

C305 I9

C306 J9

C308 I9

C309 L9

C311 L8

C315 J8

C401 I12

C402 J10

C403 I12

C411 L11

C412 L11

C413 K12

C414 L11

C415 H10

C419 J11

C422 L7

C431 M7

C432 M7

C433 L8

C435 M7

C441 O12

C442 O12

C443 O11

C451 P12

C624 I5

C625 I5

C626 I7

C627 I7

C630 H5

C631 H5

C634 H7

C661 G5

C801 I1

C802 M1

C803 O1

C804 O2

C804A N2

C805 O3

C805A N3

C806 P4

C807 P3

C810 O6

C811 O6

C812 P5

C813 P6

C814 P5

C815 O6

C820 L4

C821 K4

C822 K4

C826 L7

C827 K6

C828 L6

C829 M4

C830 L5

C831 K5

C832 K5

C833 L3

C834 K3

C835 M3

C836 M3

C840 N3

C902 F11

C903 D11

C904 F11

C905 E11

C908 D11

C909 C11

C910 C11

C911 E10

C912 E10

C913 D11

C914 D11

C915 F10

C916 F10

C924 B10

C925 B10

C926 B11

C927 B11

C928 B11

C929 C10

C930 C10

C1001 B2

C1002 B2

C1004 B2

C1005 B2

C1006 B2

C1008 B1

C1009 B1

C1010 A1

C1011 B1

C1012 A1

C1013 A1

C1014 A2

C1015 C1

C1016 A2

C1017 D2

C1018 C1

C1019 D1

C1023 D2

C1024 D2

C1025 A2

C1031 C2

C1033 B2

C1034 B2

C1035 C2

C1036 D2

C1037 D1

C1038 D1

D001 E4

D01 L3

D02 L3

D101 A10

D202 B6

D203 A6

D204 A6

D205 E7

D206 F9

D207 B7

D208 E6

D209 E6

D210 G12

D211 H10

D212 H10

D213 H9

D214 D9

D215 A4

D262 H12

D301 I9

D303 J8

D304 J7

D309 J8

D310 J9

D410 G11

D411 K10

D412 K11

D420 O11

D431 M8

D432 L8

D441 O12

D602 G4

D810 P5

D811 O5

D811A O5

D811B O6

D812 P6

D813 P6

D820 L4

D820A K4

D820B L4

D822 L6

D822A L6

D822B L6

D823 L5

D823A L5

D823B L5

D824 H4

D826 J3

D828 M3

D829 M4

D834 K3

DB801 O2

F801 H1

IC001 C4

IC101 C5

IC201 I3

IC202 G3

IC301 J10

IC602 H6

IC801 O7

IC802 N4

IC901 C9

IC1001* C1

J215 G8

J603 H7

J604 G7

J1005 B2

L001 F4

L002 E5

L101 B9

L102 B9

L204 B8

L205 B8

L206 C8

L208 E8

L209 E8

L212 B6

L413 I11

L414 J10

L801 K6

L1001 D2

P001 D3

P201 A6

P411 L9

P421 O12

P601 G4

P602 G4

P801 H1

P803 P1

P903 C12

P904 D12

P905 B12

P911 F12

Q007 E3

Q008 E4

Q01 L3

Q101 A9

Q202 G11

Q203 E8

Q204 E9

Q205 G12

Q208 A4

Q209 B4

Q401 H12

Q402 P12

Q411 L12

Q412 G8

Q413 G9

Q414 H11

Q601 H7

Q602 G6

Q603 H7

Q820 K3

Q821 K3

Q822 M3

Q823 K3

Q824 K3

Q825 J3

Q901 E11

Q902 E11

Q903 C11

Q904 C11

Q911 B10

Q912 C10

Q913 D10

Q914 D10

Q917 C8

Q918 E10

Q919 E10

Q1003 A1

R001 E4

R003 B4

R004 E4

R005 B4

R006 B5

R01 L2

R02 L3

R010 D4

R024 B4

R025 C4

R026 C4

R030 F4

R031 F4

R032 E4

R033 D5

R034 E5

R036 D4

R036A D4

R043 D4

R044 D5

R101 A11

R101A A11

R102 B9

R103 B9

R104 A9

R106 A9

R107 A9

R108 A9

R209 A4

R211 B4

R212 A4

R213 A4

R214 B6

R215 B6

R216 B6

R219 B6

R220 B6

R222 A7

R223 A7

R225 D8

R226 C8

R227 C8

R228 C8

R229 D8

R230 D8

R231 D8

R232 D8

R233 E8

R233A D8

R234 E8

R235 E9

R238 E8

R239 E7

R241 E7

R242 E7

R243 E7

R244 E7

R245 D6

R246 D6

R247 E6

R248 D7

R250 G12

R251 G12

R253 G12

R254 E8

R255 E8

R256 F9

R257 F9

R258 D8

R261 G12

R262 H9

R266 J7

R302 H9

R303 H8

R304 J9

R309 K9

R310 J9

R311 I10

R312 I10

R313 J9

R316 M8

R401 H12

R402 J11

R404 K8

R412 H8

R413 H8

R414 H10

R415 H11

R416 G11

R417 H9

R418 G8

R419 K9

R420 H9

R420A H10

R422 L8

R431 M8

R432 M8

R433 M8

R453 P11

R460 N12

R461 P12

R605 H5

R605A H7

R606 H6

R608 I5

R610 H7

R611 I5

R612 I7

R618 D4

R656 G5

R801 J1

R810 P2

R811 P6

R812 P6

R813 O5

R814 O5

R815 P6

R816 P6

R820 L4

R821 L7

R823 L5

R825 K4

R826 J6

R827 J3

R828 J6

R829 K3

R830 M4

R831 M3

R832 K3

R833 M4

R834 J3

R834A J3

R834B J3

R835 I3

R836 L3

R837 K3

R838 I2

R840 N3

R901 F11

R902 E12

R903 D10

R904 E11

R905 D10

R906 E11

R908 D11

R910 C11

R911 C11

R912 C11

R913 C11

R914 E6

R915 E6

R916 F11

R917 D11

R920 C10

R923 C10

R924 B11

R925 B11

R926 B10

R929 D10

R930 C10

R931 C10

R932 D11

R932A E10

R933 B10

R934 D10

R934A E10

R935 B10

R936 C10

R937 C10

R944 D9

R945 D9

R946 D8

R946A C9

R947 C8

R948 B8

R951 D11

R952 D11

R953 E11

R954 E11

R1001 C2

R1002 D2

R1004 D1

R1005 A1

R1006 A2

R1007 A2

R1010 C2

R1011 B2

R1022 C1

R1023 D1

RL01 M1

RT801 P1

RT802 P3

S1202 F6

T401 J12

T402 N10

T801 K1

T802 N1

T803 N5

TU101 A11

VR802 J2

X001 D5

X201 E8

X202 D8

X1001 B2

Z101 B7

* Located on

other side of

board.

Page 3 SET 5303

SET 5303 Page 3

Page 12

COMB FILTER BOARD

TEST EQUIPMENT

Test equipment listed by participating manufacturer illustrates

typical or equivalent equipment used by Sams engineers to obtain

measurements. This equipment is compatible with most types used

by field service technicians.

Equipment Sencore No.

Oscilloscope SC3100

Generators

RGB CM2125

Multiburst Signal VG91

Color Bar VG91

TV Stereo VG91

Digital VOM SC3100

Frequency Meter SC3100

Hi-Voltage Probe HP200

Accessory Probes TP212

Isolation Transformer PR570

Capacitance Analyzer LC102

CRT Analyzer CR7000

AC Leakage Tester PR570

Inductance Analyzer LC102

Flyback Yoke Tester TVA92

Field Strength Meter SL753

Transistor Tester TF46

Horizontal Analyzer HA-2500

Video Analyzer VG91, TVA92

RCA MODEL 27V412T (CHASSIS M134C)

COMB FILTER BOARD, GRIDTRACE LOCATION GUIDE

C1201 F7

C1202 G2

C1203 H7

C1204 H6

C1205 B5

C1206 B6

C1211 F2

C1212 F2

C1213 F3

C1214 F3

C1215 F4

C1216 G5

C1217 F5

C1218 G6

C1219 F6

C1220 D6

C1221 D5

C1222 D4

C1223 D5

C1224 D3

C1225 D4

C1229 E1

C1230 E1

C1231 C1

C1233 B3

C1234 F6

C1235 E6

C1236 F3

IC1201 E2

L1201 G7

L1211 F1

L1212 H5

L1213 H6

L1214 D2

L1215 C5

L1216 E5

L1217 B6

P1202 F7

Q1201 H4

Q1202 G2

Q1203 H3

Q1211 C6

Q1212 B3

Q1213 A5

Q1214 B4

Q1215 C3

Q1218 C2

R1201 F7

R1202 H7

R1203 H5

R1204 G4

R1205 H2

R1206 H3

R1207 H1

R1208 H1

R1209 G3

R1211 E6

R1212 E6

R1213 D4

R1215 A6

R1216 A7

R1217 A4

R1218 B4

R1219 A3

R1220 D3

R1221 B1

R1228 D1

R1229 B1

R1232 B5

R1233 B1

R1234 A1

R1236 B5

R1237 C6

SET 5303 Page 3

Page 13

Page 4 SET 5303

PARTS LIST

Item No. Type No. Mfr. Part No. Notes

D001 5.1HSB 268334 -

D01, 02 1N4148 266885 -

D101 (1) CW574CD 266892 -

D101 (2)(3)(4)(5) UPC574J 270921 -

D202 Thru

D206 1N4148 266885 -

D207 - 266890 -

D208 1N4148 266885 -

D209 - 268335 -

D210 - 268336 -

D211, 12 1N4148 266885 -

D213 - 266888 -

D214, 15 1N4148 266885 -

D262 1N4148 266885 -

D301 1N4001 266883 -

D303 - 266891 -

D304 FR104 266880 -

D309 BZV85-C51 268337 -

D310 1N4148 266885 -

D410 1N4148 266885 -

# D411 (1) BY228 266879 -

# D411 (2)(3)(4)(5) - 271009 -

# D412 FR104 266880 -

D420 (4)(5) 1N4001 266883 -

D420 (1)(2)(3) FR104 266880 -

D431, 32 FR104 266880 -

D441 FR104 266880 -

D501, 02 1N4148 266885 -

D602 1N4148 266885 -

D810, 11 FR104 266880 -

D812 1N4148 266885 -

D813 - 266890 -

# D820 RU4YX 268338 -

D822 RU4AM 268339 -

D823 (1)(6) RU4YX 268338 -

D823 (2)(3)(4)(5) SR3100 270876 -

D824 1N4001 266883 -

D826 - 266891 -

D827 1N4148 266885 -

D828 BZX79B6V2 270380 -

D829 1N4148 266885 -

D834 - 268340 -

D1001A - 268440 -

Item No. Type No. Mfr. Part No. Notes

DB801 D3SB60 268341 -

IC001 MC24-08P 266906 -

IC101 (1) TMPA8859CSNG 268344 -

IC101 (2)(3)(4)(5) TCL-A27V02-T0 270923 -

IC201 (1)(6) L7809CV 266912 -

IC201 (2)(3)(4)(5) L7809 270922 -

IC202 (1)(6) L7805CV 257704 -

IC202 (2)(3)(4)(5) L7805CV 270856 -

IC301 STV8172 270381 -

IC602 TDA7266SA 268347 -

IC801 STRW6735 268348 -

# IC802 PS2561L1-1V 268349 -

IC901 4052 268350 -

IC1001 MSPP3425G 268343 -

IC1201 TC90A49P 268345 -

J310 1N4148 266885 -

L501 1N4148 266885 -

Q007 2SC1815Y 266579 -

Q008 2SA1015Y 266899 -

Q01 - 268364 -

Q033C 2SC1815Y 266579 -

Q101 2SC3779D 266902 -

Q202, 03, 04 2SC1815Y 266579 -

Q205 2SA1015Y 266899 -

Q208 2SA817AY 266603 -

Q209 PDTC124ES 266897 -

# Q401 2SC2482 266900 -

Q402 2SC1815Y 266579 -

# Q411 3DD3402 268428 -

Q412, 13 2SA1015Y 266899 -

Q414 IRF630MFP 268367 -

Q501 2SC4544 208434 -

Q502 2SC1815Y 266579 -

Q503 2SC4544 208434 -

Q504 2SC1815Y 266579 -

Q505 2SC4544 208434 -

Q506 2SC1815Y 266579 -

Q507 2SA562TM-O 268369 -

Q601 2SC1815Y 266579 -

Q602 2SA1015Y 266899 -

Q603 PDTC124ES 266897 -

Q820 - 268370 -

Q821 2SC4544 208434 -

Page 14

PARTS LIST continued

SET 5303 Page 4

Item No. Type No. Mfr. Part No. Notes

Q822 Thru

Q825 2SC1815Y 266579 -

Q901 Thru

Q904 2SC1815Y 266579 -

Q911 2SC1815Y 266579 -

Q912 2SA1015Y 266899 -

Q913, 14, 17 2SC1815Y 266579 -

Q918, 19 PDTC124ES 266897 -

Q1003 2SC1815Y 266579 -

Q1201 2SC1815Y 266579 -

Q1202 2SA1015Y 266899 -

Q1203 2SC1815Y 266579 -

Q1211 2SA1015Y 266899 -

Q1212 2SC1815Y 266579 -

Q1213, 14 2SK362-Y 268365 -

Q1215, 18 2SA1015Y 266899 -

R212 1N4148 266885 -

Item No. Function/Rating Mfr. Part No. Notes

# C411 .0039 5% 1.6kV 268312 -

.0036 5% 1.6kV 268311 -

.0033 5% 1.6kV 268449 -

# C412 .0082 5% 1.6kV 268436 -

.0068 5% 1.6kV 268424 -

# C413 .027 5% 400V 270395 -

.022 5% 400V 268313 -

# C414 .0076 5% 1.6kV 268314 -

.0082 5% 1.6kV 268436 -

.0056 5% 1.6kV 270396 -

.0072 5% 1.6Kv 268450 -

C415 4.7µF 20% 50V NP 268315 -

# C419 .47 5% 400V 268425 -

.51 5% 400V 270402 -

.56 5% 400V 270927 -

.33 5% 400V 268397 -

C505 .001 10% 2kV 268322 -

# C801, 02 .22 20% 250VAC 270379 -

.22 20% 275VAC 266326 -

C804 .0047 +80% -20% 250VAC 266984 -

# C804A 470pF 10% 400VAC 266983 -

C805 .0047 +80% -20% 250VAC 266984 -

# C805A 470pF 10% 400VAC 266983 -

C815 .0015 10% 2kV 268330 -

Item No. Function/Rating Mfr. Part No. Notes

C826 470pF 10% 2kV 268439 -

# C840 .0022 20% 400VAC 266982 -

C1001, 02 3.3pF ±.25pF 50V NPO 266971 -

D811A, B Ferrite Bead 267016 -

D820A, B Ferrite Bead 268283 -

D822A, B Ferrite Bead 268283 -

D823A, B Ferrite Bead 268283 -

# DEGAUSS (1) Degaussing 268431 -

# DEGAUSS (2)(3)(4)(5) Degaussing 263503 -

# DEGAUSS (6) Degaussing 268466 -

# F801 Fuse 268342 5Amp

F801A, B Fuse Holder 267064 For F801

IR001A Receiver 270382 Remote

J603, 04 2.2µH 270398 -

J1005 22µH 267008 -

L001 Ferrite Bead 270407 -

L002 10µH 267010 -

L101 47µH 268351 -

L102 1µH 267007 -

L204, 05 06, 08 22µH 267013 -

L209, 12 10µH 267010 -

L301 Ferrite Bead 268352 -

L413 600µH 268353 -

# L414 (1)(2)(4)(6) 24µH 270399 -

# L414 (3)(5) 18µH 268427 -

L501 1N4148 266885 -

L502 10µH 267011 -

L503 (1)(2)(3)(4)(5) 5.6µH 268355 -

L503 (6) 10µH 267011 -

L505, 06 Ferrite Bead 267016 -

L801 100µH 267012 -

L1001 22µH 267008 -

L1201 10µH 267010 -

L1211 Thru

L1215 10µH 267010 -

L1216 .6µH 267009 -

L1217 10µH 267010 -

# P800 (1)(6) Line Cord 268396 Polarized

# P800 (2)(3)(4)(5) Line Cord 268457 Polarized

P901 Jack 267046 Assembly

P902 Jack 268360 Video Input

P903 Jack 268360 Assembly

P904 Jack 268361 Assembly

Page 15

PARTS LIST continued

Item No. Function/Rating Mfr. Part No. Notes

P905 Jack 268360 Assembly

R302 3900 1% 1/4W 268381 -

R303 36K 1% 1/4W 268429 -

33K 1% 1/4W 268382 -

R311 10K 1% 1/4W 268385 -

R312 18K 1% 1/4W 268386 -

R404 4700 5% 7W 268390 -

# R516, 17, 18 15K 2W - -

4700 5% 1/6W 266282 -

# R801 1M 20% 1/2W 266940 -

R820 Fuse 268410 5Amp, 250VAC

R821, 23 Fuse 268411 3Amp, 250VAC

R827 4700 5% 5W 268413 -

R834A 6800 1% 1/4W 176634 -

R834B 390 1% 1/4W 266595 -

R835 120K 1% 1/2W 268414 -

# R840 8.2M 1W 266941 -

# RL01 Relay 268417 Degaussing

# RT801 (1)(6) PTC 268418 -

# RT801 (2)(3)(4)(5) PTC 270926 -

# RT802 NTC 266357 -

S002A Switch 267136 Menu

S003A Switch 267136 Volume -

S004A Switch 267136 Volume +

S005A Switch 267136 Channel -

S006A Switch 267136 Channel +

S008 Switch 267136 Power

# S501 Socket 266290 CRT

# T401 Horizontal Drive 266291 -

# T402 (7) Horizontal Output 268419 -

# T801, 02 Line Filter 268420 -

# T803 Power 268421 -

TU101 Tuner 270388 TEDH9-251A

# V801 CRT - -

VR802 330 B+ 270389 -

2000 B+ - -

W601, 02 (1) Speaker 270373 16 Ohms, 8W

W601, 02 (6) Speaker 268472 16 Ohms, 5W

W601, 02 (2)(3)(4)(5) Speaker 271001 60mm X 125mm, 16 Ohms

X001 Crystal 266315 8MHz

X201 Trap 266318 4.5MHz

X202 Filter 266317 4.5MHz

X1001 Crystal 268423 18.432MHz

Item No. Function/Rating Mfr. Part No. Notes

Z101 Filter 266319 SAW

PC Board (4) 270963 Comb Filter

PC Board (2)(5) 270959 CRT

PC Board (3)(4) 270964 CRT

PC Board (2)(3)(4)(5) 270958 IR Receiver

PC Board (2)(3)(4)(5) 270961 Keyboard

PC Board (2)(3)(4)(5) 270962 Side

PC Board (3)(5) 260967 Yoke Adapter

Spacers 267049 Yoke Positioning (3 Used)

Transmitter (2)(3)(4)(5) 265714 Remote, RCR130TB1

Transmitter (1)(6) 270372 Remote

# For SAFETY use only equivalent replacement part.

(1) Used in model 27V412T.

(2) Used in model 27V412TYX1.

(3) Used in model 27V412TYX3.

(4) Used in model 27V412TYX5.

(5) Used in model 27V412TYX8.

(6) Used in model 24V412T.

(7) Screen and focus controls are part of T402.

Important Parts Information

n Parts not listed in the parts list are commonly available at your local electronics parts retailer.

n The parts listed here are those not usually available from a well-stocked supply cabinet or bin.

n On the parts lists, safety items are marked with a # to remind you that only exact replacements are recommended for

these items.

n When ordering parts, state the model number, part number, and description.

Obtaining Parts

Many of these parts are available from your local Sams authorized distributor or the manufacturer of the equipment. Call

Sams for the name of your nearest distributor:

800-428-7267

Page 4 SET 5303

Page 16

RCA MODEL 27V412T (CHASSIS M134C)

RCA MODEL 27V412T (CHASSIS M134C)

SET 5303 Page 4

Loading...

Loading...