Page 1

HISTORY INFORMATION FOR THE FOLLOWING MANUAL:

SERVICE MANUAL

CPD-E240

CPD-E240

US/Canada Model

Chassis No: SCC-L38A-A

17VC

CHASSIS

ORIGINAL MANUAL ISSUE DATE: 1/2002

ALL REVISIONS AND UPDATES TO THE ORIGINAL MANUAL ARE APPENDED TO THE END OF THE PDF FILE.

REVISION DATE REVISION TYPE SUBJECT

1/2002 No revisions or updates are applicable at this time.

TRINITRON® COLOR MONITOR

9-978-885-01

Page 2

Self Diagnosis

Supported model

SERVICE MANUAL

CPD-E240

CPD-E240

US/Canada Model

Chassis No: SCC-L38A-A

17VC

CHASSIS

SPECIFICATIONS

Picture tube 0.24 mm aperture grill pitch (center)

17 inches measured diagonally

90-degree defl ection

Video image area (16.1" maximum viewing image)

Approx. 328 X 242 mm (w/h)

(13 x 9

Resolution Horizontal: Max. 1280 dots

Vertical: Max. 1024 lines

Standard image area Approx. 312 x 234 mm (w/h)

(12

Input signal

Video Analog RGB (75 ohms typical)

0.7 Vp-p, ±5%, Positive

Sync Separate HD/VD,

TTL Polarity Free

External Composite,

TTL Polarity Free (2K ohms impedance)

Sync on Green

3/8

x 9

5/8

inches)

1/4

inches)

Power Consumption 100 W

Defl ection frequency Horizontal: 30 to 75 KHz

Vertical: 48 to 120 Hz

AC input voltage/current 100 to 120 V, 50/60 Hz, 1.7A

220 to 240V, 50/60Hz, 0.9A

Dimensions 402 x 418 x 421 mm (w/h/d)

(15

Mass Approx. 19 kg (41 lb 14 oz.)

Design and specifi cations are subject to change without notice.

7/8

x 16

1/2

x 16

5/8

inches)

9-978-885-01

TRINITRON® COLOR MONITOR

Page 3

TABLE OF CONTENTS

SECTION TITLE PAGE

Power Management.................................................................................................................................. 4

Self Diagnosis Function ............................................................................................................................ 4

Timing SpeciÞ cation.................................................................................................................................. 4

Warnings and Cautions............................................................................................................................. 5

Safety Check Out Instructions .................................................................................................................. 6

1. Disassembly

1-1. Cabinet Removal ............................................................................................................................... 7

1-2. Service Position................................................................................................................................. 7

1-3. A and D Board Removal .................................................................................................................... 8

1-4. Picture Tube Removal ....................................................................................................................... 9

Anode Cap Removal ......................................................................................................................... 9

CPD-E240

2. Safety Related Adjustments

2-1. HV Regulator Check........................................................................................................................ 10

2-2. HV Protector Circuit Check.............................................................................................................. 10

2-3. Beam Protector Check (Software Logic) ......................................................................................... 10

2-4.B+ Voltage Check............................................................................................................................. 10

3. Adjustments

3-1. Landing Rough Adjustment ..............................................................................................................11

3-2. Landing Fine Adjustment..................................................................................................................11

3-3. Convergence Rough Adjustment......................................................................................................11

3-4. Convergence and V. Key (H. TRP) Fine Adjustment........................................................................ 11

3-5. Vertical and Horizontal Position and Size SpeciÞ cation .................................................................. 12

3-6. Focus Adjustment............................................................................................................................ 12

3-7. Digital Convergence Adjustment ..................................................................................................... 13

3-8. Convergence SpeciÞ cation .............................................................................................................. 13

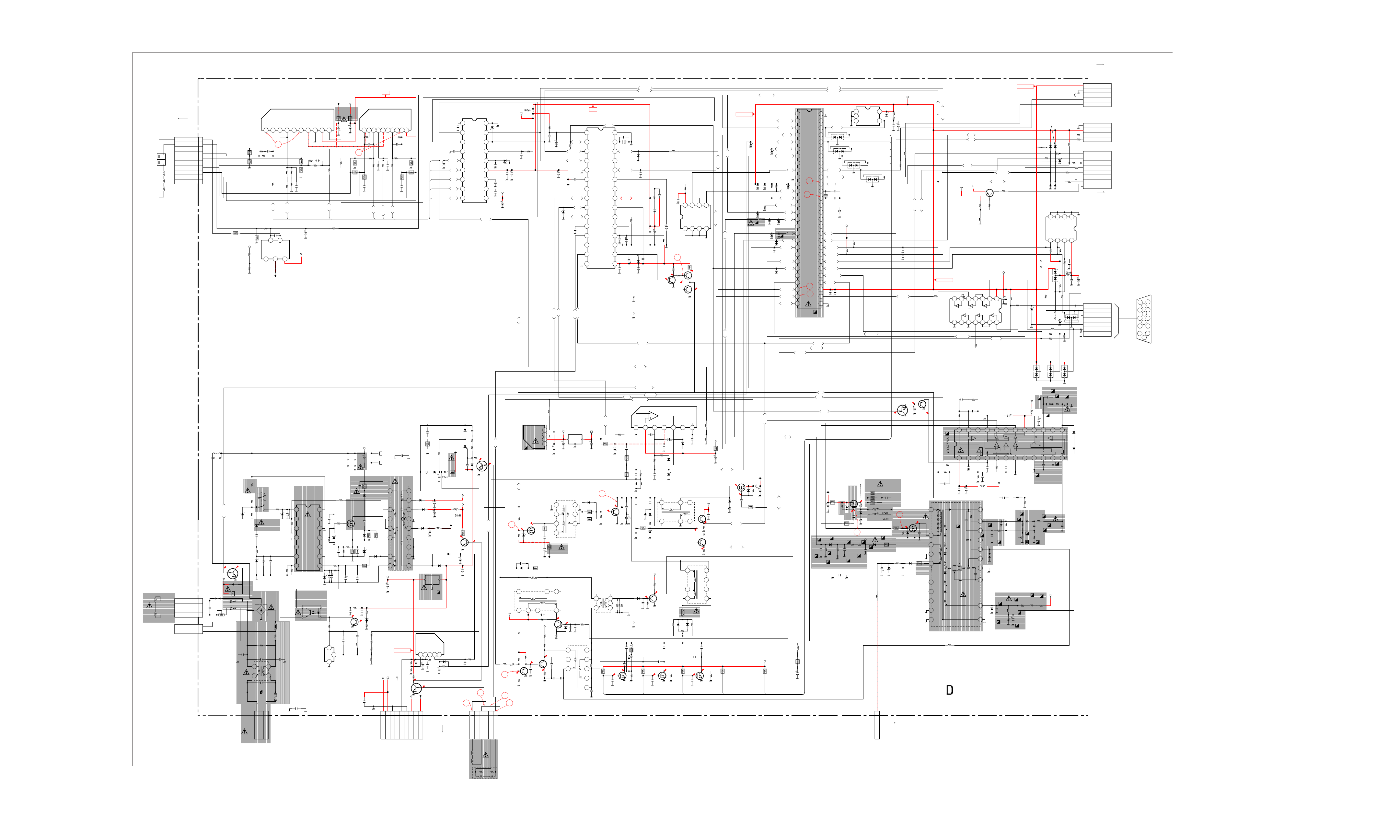

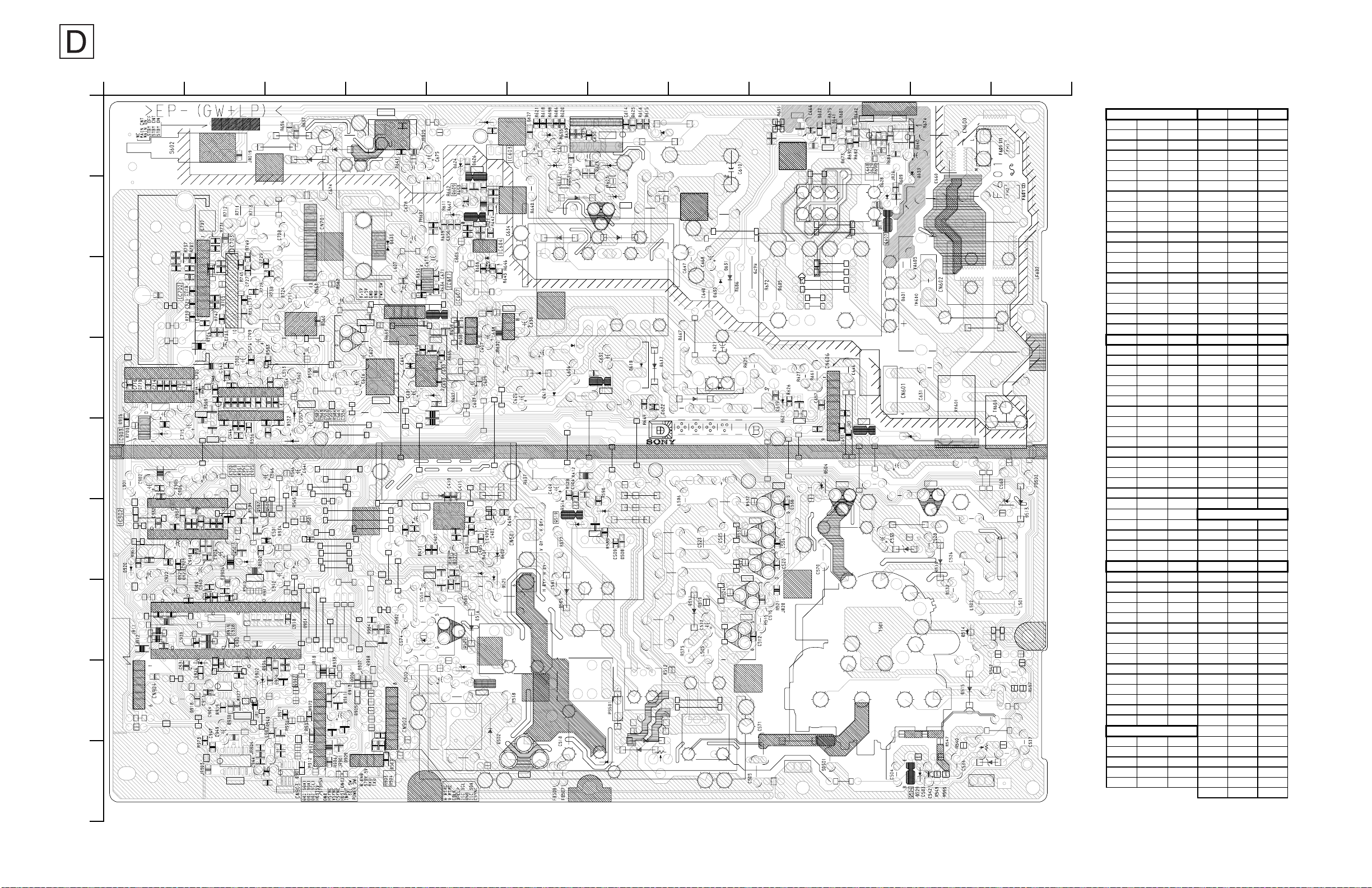

4. Diagrams

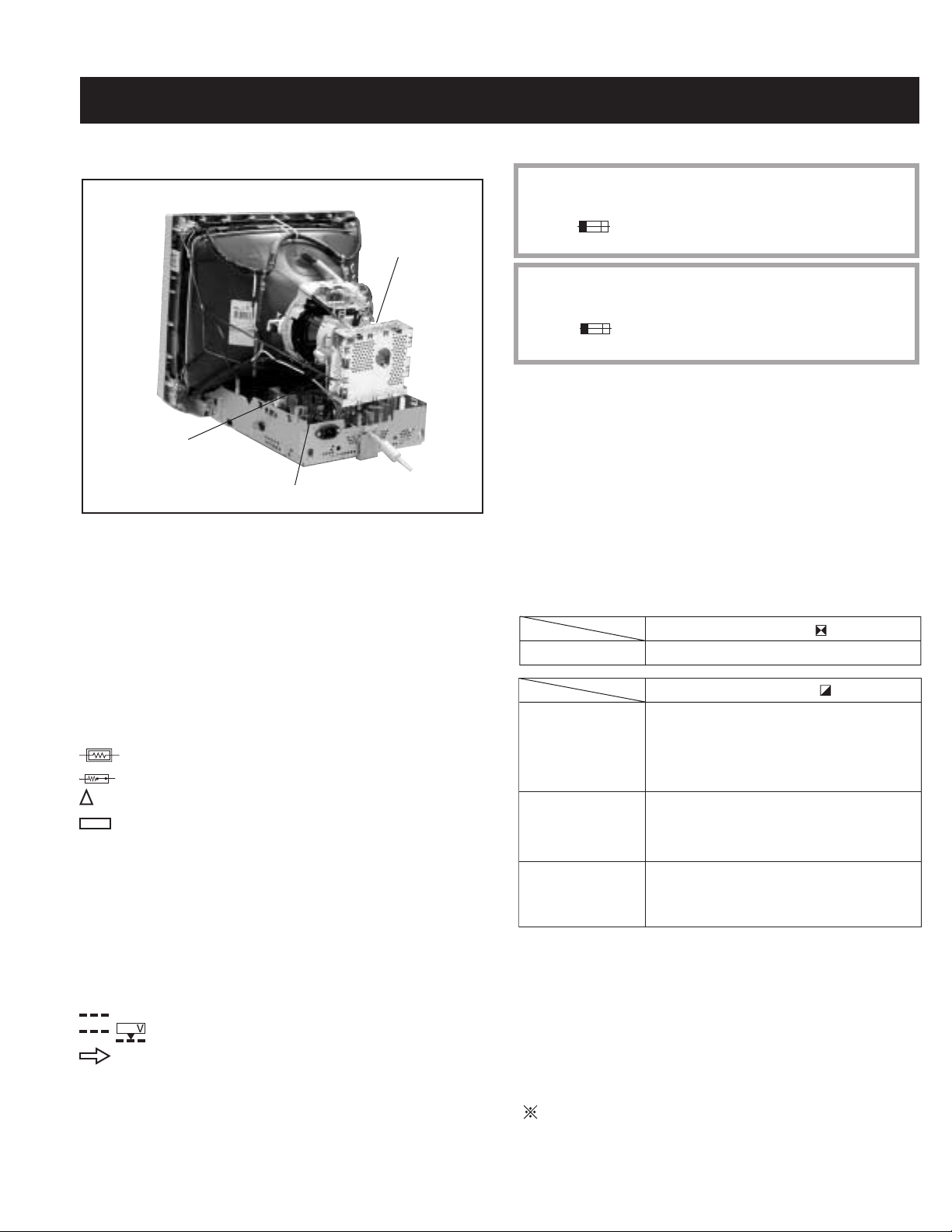

4-1. Circuit Boards Location ................................................................................................................... 14

4-2. Schematic Diagrams And Printed Wiring Boards ............................................................................ 14

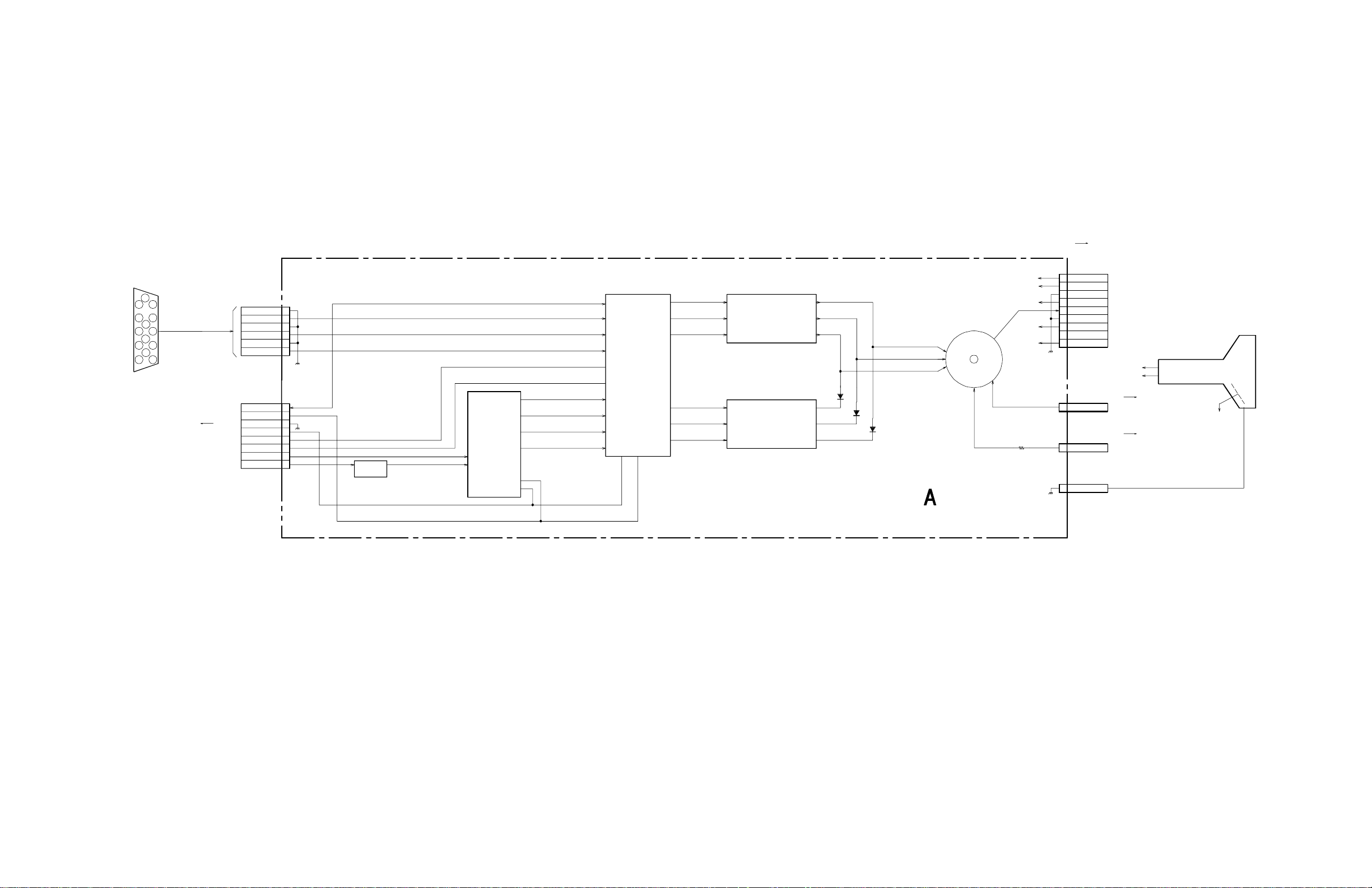

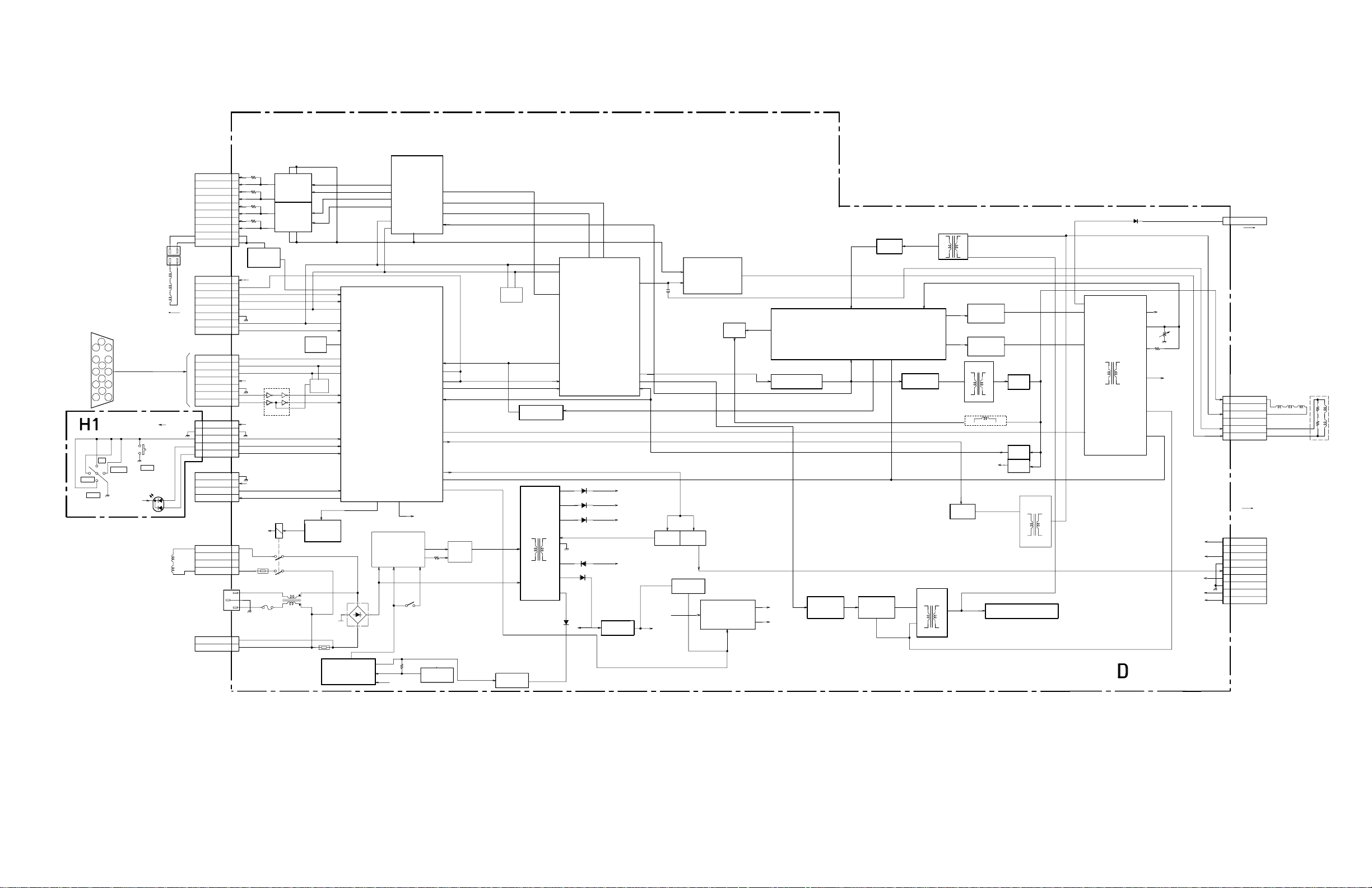

4-3. Block Diagram ................................................................................................................................. 15

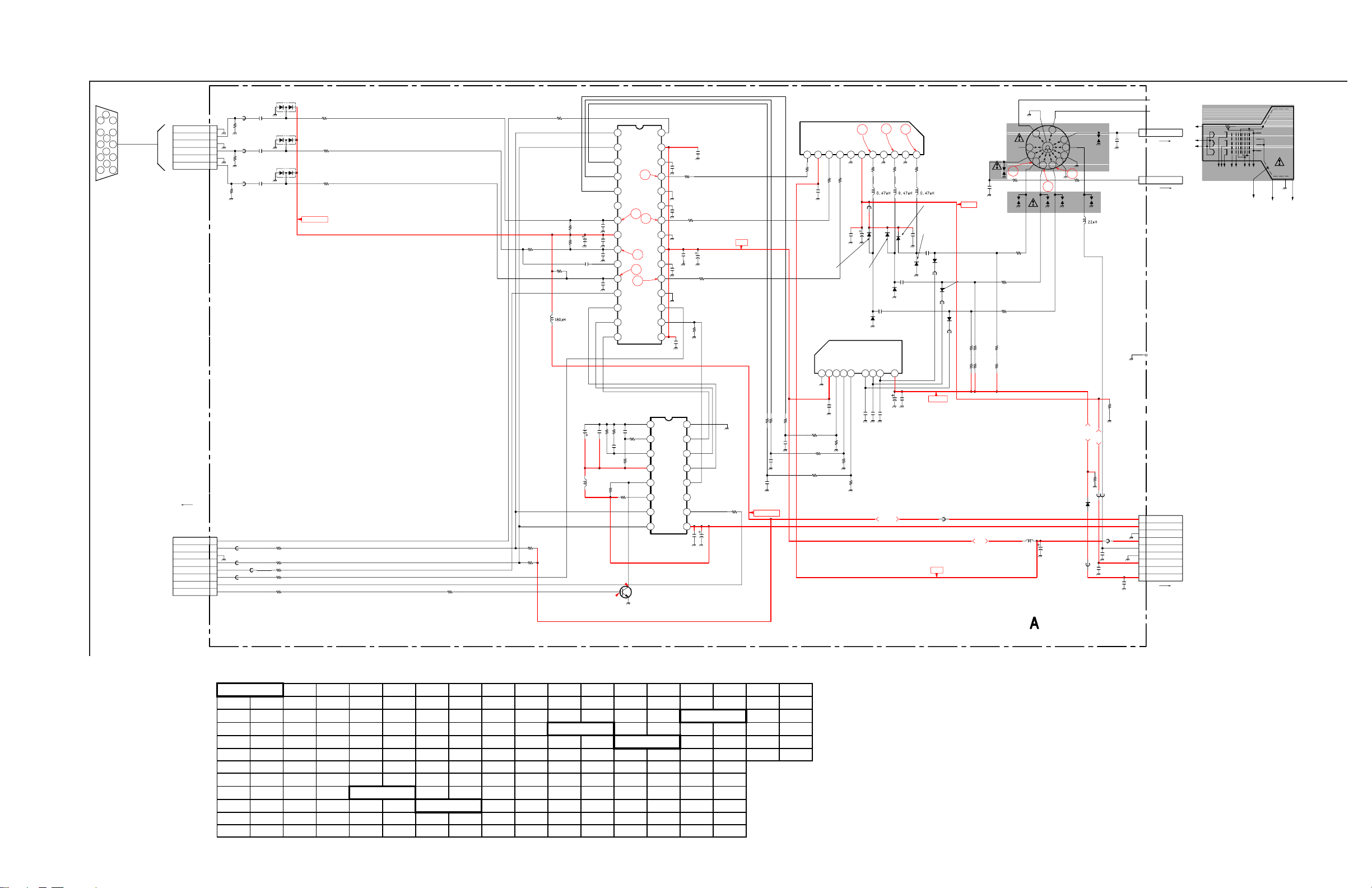

A Board - Schematic Diagram......................................................................................................... 17

D Board - Schematic Diagram ........................................................................................................ 19

H1 Board - Schematic Diagram ...................................................................................................... 23

4-4. Semiconductors............................................................................................................................... 24

5. Exploded Views

5-1. Picture Tube .................................................................................................................................... 25

5-2. Chassis............................................................................................................................................ 26

5-3. Packing Materials ............................................................................................................................ 27

6. Electrical Parts List ....................................................................................................................................... 28

— 3 —

Page 4

CPD-E240

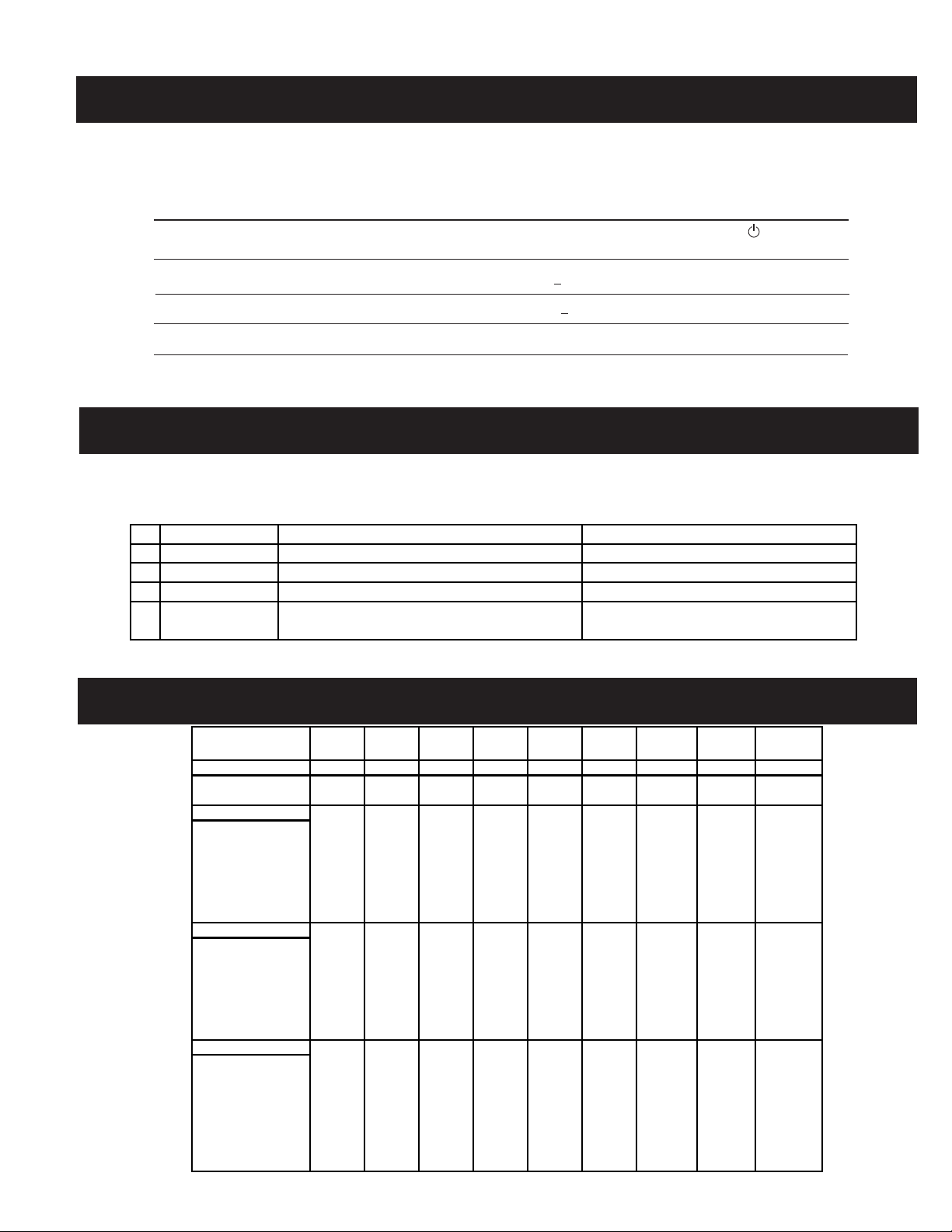

POWER MANAGEMENT

The power saving mode complies with the VESA Display Power Management Signaling standard. Each state of power management shall be activated

by the host computer terminating the appropriate sync signals. Blanking the video must precede termination of the sync signals. The elapsed time

counter shall also be controlled by the host computer. Reactivation of the monitor shall be accomplished from the host computer by re-establishing the

normal sync signal.

Power consumption Screen Horizontal Vertical Power Recovery time indicator

mode (video) sync signal sync signal consumption

1 Normal operation active yes yes < 100 W -- Green

2 Active-off (3rd mode) blank no* no* < 3 W Approx. 10 sec. Orange

3 Power-off -- -- -- 0 W (approx) -- Off

* In this mode, the signal will appear in one of three ways: The Horizontal Sync Signal alone off, the Vertical Sync Signal

alone off, or both signals off.

SELF DIAGNOSIS FUNCTION

When a failure occurs, the STANDBY/TIMER lamp will ß ash a set number of times to indicate the possible cause of the problem. If there is more than

one error, the lamp will identify the Þ rst of the problem areas.

6WDWXV $UHDRI)DLOXUH /(',QGLFDWLRQ

)DLOXUH +9RU% $PEHUVHFRQG2IIVHFRQG

)DLOXUH +6WRS96WRSRU6&RQQHFWLRQ)DLOXUH $PEHUVHFRQG2IIVHFRQG

)DLOXUH $%/ $PEHUVHFRQG2IIVHFRQG

$JLQJ6HOI7HVW $PEHUVHFRQG2IIVHFRQG

*UHHQVHFRQG2IIVHFRQG

TIMING SPECIFICATION

PRIM E

MODE

MODE 1 2 3 4 5 6 7 8 9

RESOLUTION 640 X 480 640 X 480 720 X 400 800 X 600 800 X 600 832 X 624 1024 X 768 1024 X 768 1280 X 1024

CLOCK 25.175 36 28.322 49.5 56.25 57.283 78.75 94.5 108

HORIZONT AL

H. FREQ 31.469 43.269 31.469 46.875 53.674 49.725 60.023 68.677 63.981

H. TOTAL 31.778 23.111 31.777 21.333 18.631 20.111 16.660 14.561 15.630

H. BLK 6.356 5.333 6.355 5.172 4.409 5.586 3.657 3.725 3.778

H. FP 0.636 1.556 0.636 0.323 0.569 0.559 0.203 0.508 0.444

H. SYNC 3.813 1.556 3.813 1.616 1.138 1.117 1.219 1.016 1.037

H. BP 1.907 2.222 1.907 3.232 2.702 3.910 2.235 2.201 2.296

H. ACTIV 25.422 17.778 25.422 16.162 14.222 14.524 13.003 10.836 11.852

VERTI CAL

V. FREQ 59.940 85.008 70.087 75.000 85.061 74.550 75.029 84.997 60.020

V. TOTAL 16.683 11.764 14.268 13.333 11.756 13.414 13.328 11.765 16.661

V. BLK 1.430 0.670 1.557 0.533 0.578 0.865 0.533 0.582 0.656

V. FP 0.318 0.023 0.381 0.021 0.019 0.020 0.017 0.015 0.016

V. SYNC 0.064 0.069 0.064 0.064 0.056 0.060 0.050 0.044 0.047

V. BP 1.049 0.578 1.112 0.448 0.503 0.784 0.466 0.524 0.594

V. ACTIV 15.253 11.093 12.711 12.800 11.179 12.549 12.795 11.183 16.005

SYNC

EXT (H/V) / POLARITY YES YE S YES YES YES YES YES YES YES

EXT (CS) / POLARITY NO NO NO NO NO NO NO NO NO

INT (G) NO NO NO NO NO NO NO NO NO

SERRATION NO NO NO NO NO NO NO NO NO

SY NC LEVEL TTL TTL TTL TTL TTL TTL TTL TTL TTL

VIDEO

VIDEO LEVEL 0.7 0.7 0.7 0.7 0.7 0.7 0.7 0.7 0.7

SET UP 000000 0 0 0

— 4 —

Page 5

CPD-E240

WARNINGS AND CAUTIONS

CAUTION

Short circuit the anode of the picture tube and the anode cap to the metal chassis, CRT shield, or carbon painted on the CRT, after

removing the anode.

WARNING!!

An isolation transformer should be used during any service to avoid possible shock hazard, because of live chassis. The chassis of this

receiver is directly connected to the AC power line.

! SAFETY-RELATED COMPONENT WARNING!!

Components identiÞ ed by shading and ! mark on the schematic diagrams, exploded views, and in the parts list are critical for safe

operation. Replace these components with sony parts whose part numbers appear as shown in this manual or in supplements published

by sony. Circuit adjustments that are critical for safe operation are identiÞ ed in this manual. Follow these procedures whenever critical

components are replaced or improper operation is suspected.

ATTENTION!!

Apres avoir deconnecte le cap de l’anode, court-circuiter l’anode du tube cathodique et celui de l’anode du cap au chassis metallique de

l’appareil, ou la couche de carbone peinte sur le tube cathodique ou au blindage du tube cathodique.

AÞ n d’eviter tout risque d’electrocution provenant d’un chássis sous tension, un transformateur d’isolement doit etre utilisé lors de tout

dépannage. Le chássis de ce récepteur est directement raccordé à l’alimentation du secteur.

! ATTENTION AUX COMPOSANTS RELATIFS A LA SECURITE!!

Les composants identiÞ es par une trame et par une marque ! sur les schemas de principe, les vues explosees et les listes de pieces

sont d’une importance critique pour la securite du fonctionnement. Ne les remplacer que par des composants sony dont le numero

de piece est indique dans le present manuel ou dans des supplements publies par sony. Les reglages de circuit dont l’importance est

critique pour la securite du fonctionnement sont identiÞ es dans le present manuel. Suivre ces procedures lors de chaque remplacement

de composants critiques, ou lorsqu’un mauvais fonctionnement suspecte.

— 5 —

Page 6

SAFETY CHECK-OUT

CPD-E240

After correcting the original service problem, perform the following

safety checks before releasing the set to the customer:

1. Check the area of your repair for unsoldered or poorly soldered

connections. Check the entire board surface for solder splashes and

bridges.

2. Check the interboard wiring to ensure that no wires are “pinched” or

touching high-wattage resistors.

3. Check that all control knobs, shields, covers, ground straps, and

mounting hardware have been replaced. Be absolutely certain that

you have replaced all the insulators.

4. Look for unauthorized replacement parts, particularly transistors,

that were installed during a previous repair. Point them out to the

customer and recommend their replacement.

5. Look for parts which, though functioning, show obvious signs of

deterioration. Point them out to the customer and recommend their

replacement.

6. Check the line cords for cracks and abrasion. Recommend the

replacement of any such line cord to the customer.

7. Check the B+ and HV to see if they are speciÞ ed values. Make sure

your instruments are accurate; be suspicious of your HV meter if

sets always have low HV.

8. Check the antenna terminals, metal trim, “metallized” knobs,

screws, and all other exposed metal parts for AC leakage. Check

leakage as described below.

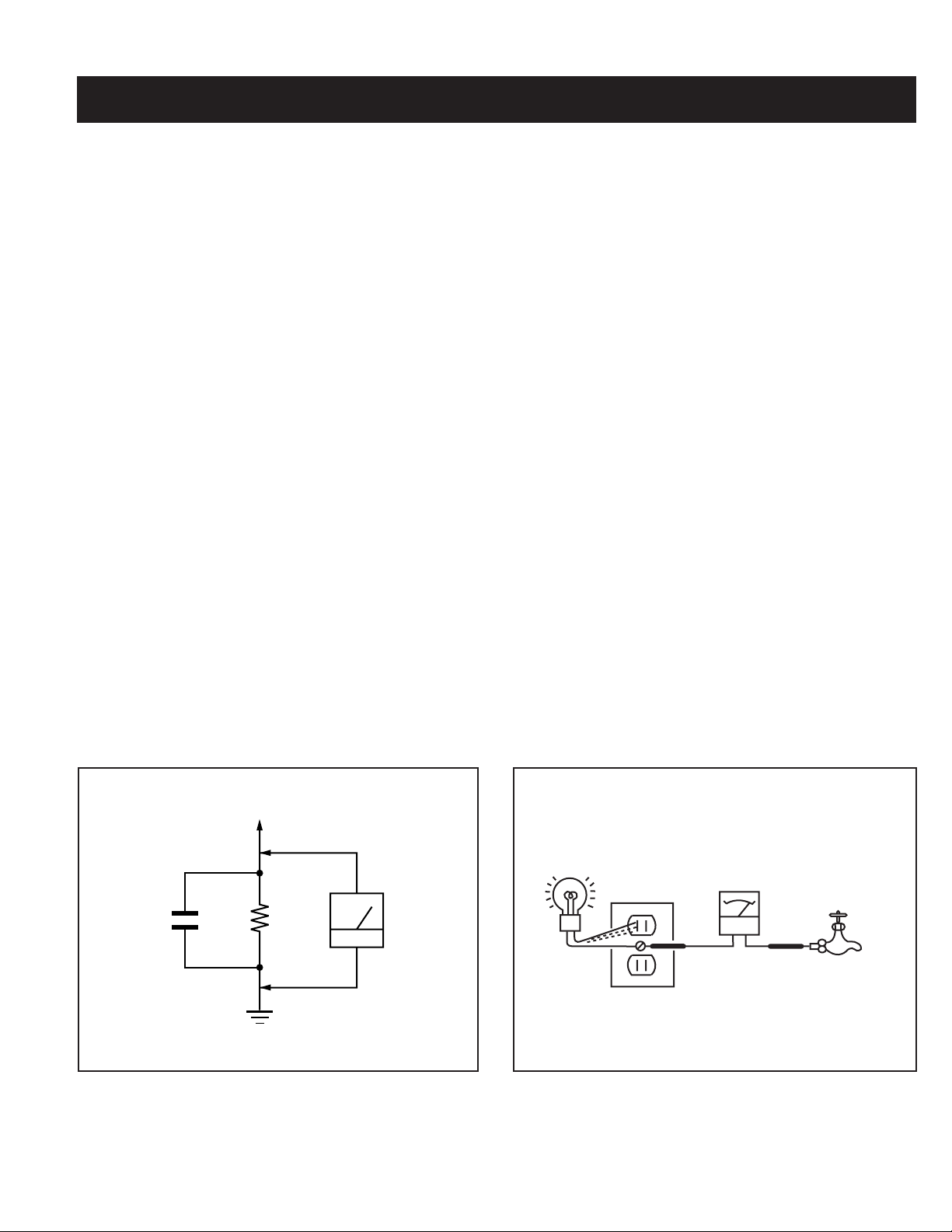

Leakage Test

The AC leakage from any exposed metal part to earth ground and from all

exposed metal parts to any exposed metal part having a return to chassis,

must not exceed 0.5 mA (500 microamperes). Leakage current can be

measured by any one of three methods.

1. A commercial leakage tester, such as the Simpson 229 or RCA

2. A battery-operated AC milliammeter. The Data Precision 245 digital

3. Measuring the voltage drop across a resistor by means of a VOM

How to Find a Good Earth Ground

A cold-water pipe is a guaranteed earth ground; the cover-plate retaining

screw on most AC outlet boxes is also at earth ground. If the retaining

screw is to be used as your earth ground, verify that it is at ground

by measuring the resistance between it and a cold-water pipe with an

ohmmeter. The reading should be zero ohms.

If a cold-water pipe is not accessible, connect a 60- to 100-watt troublelight (not a neon lamp) between the hot side of the receptacle and the

retaining screw. Try both slots, if necessary, to locate the hot side on the

line; the lamp should light at normal brilliance if the screw is at ground

potential (see Figure B).

WT-540A. Follow the manufacturers’ instructions to use these

instructions.

multimeter is suitable for this job.

or battery-operated AC voltmeter. The “limit” indication is 0.75

V, so analog meters must have an accurate low voltage scale.

The Simpson’s 250 and Sanwa SH-63TRD are examples of

passive VOMs that are suitable. Nearly all battery-operated digital

multimeters that have a 2 VAC range are suitable (see Figure A).

To Exposed Metal

Parts on Set

Trouble Light

Ohmmeter

0.15 µF

1.5 K Ω

AC Outlet Box

AC

Voltmeter

(0.75 V)

Earth Ground

Figure A. Using an AC voltmeter to check AC leakage. Figure B. Checking for earth ground.

— 6 —

Cold Water Pipe

Page 7

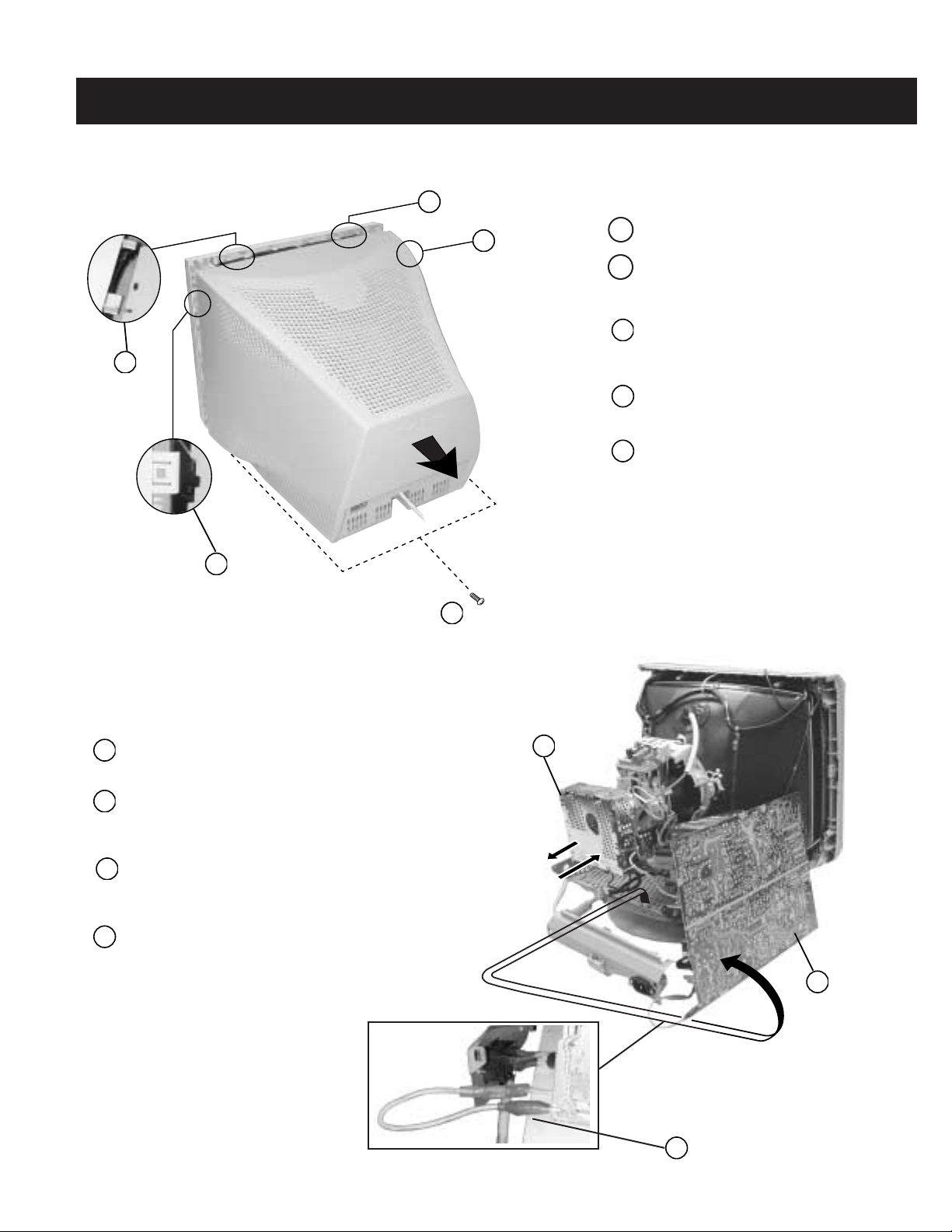

1-1. CABINET REMOVAL

112

CPD-E240

SECTION 1: DISASSEMBLY

4

5

3

Remove (2) Screws (+BVTP 4 x 16)

Release side claw - Insert the tip of a ß athead

screwdriver approximately 0.25" to unlock the

claw.

3

Release top claw - Working from the same

side as the the claw in step 2, insert the tip of

a ß athead screwdriver to unlock the top claw.

4

Release top claw - Repeat Step 3 on the

opposite side.

Release side claw - Repeat Step 2 on the

5

opposite side and gently lift up and then back

to remove the cabinet.

2

1

1-2. SERVICE POSITION

Gently wiggle the A board back and forth to unplug

1

it from the Neck Assembly.

Remove all necessary connections and rotate the D

2

Board and rest it on its side to expose the bottom.

Be sure to reconnect all wires.

Fabricate a temporary ground wire with a male

3

stakon connector on one end and an alligator clip

on the other.

4

Reconnect ground as shown below.

1

2

4

— 7 —

Page 8

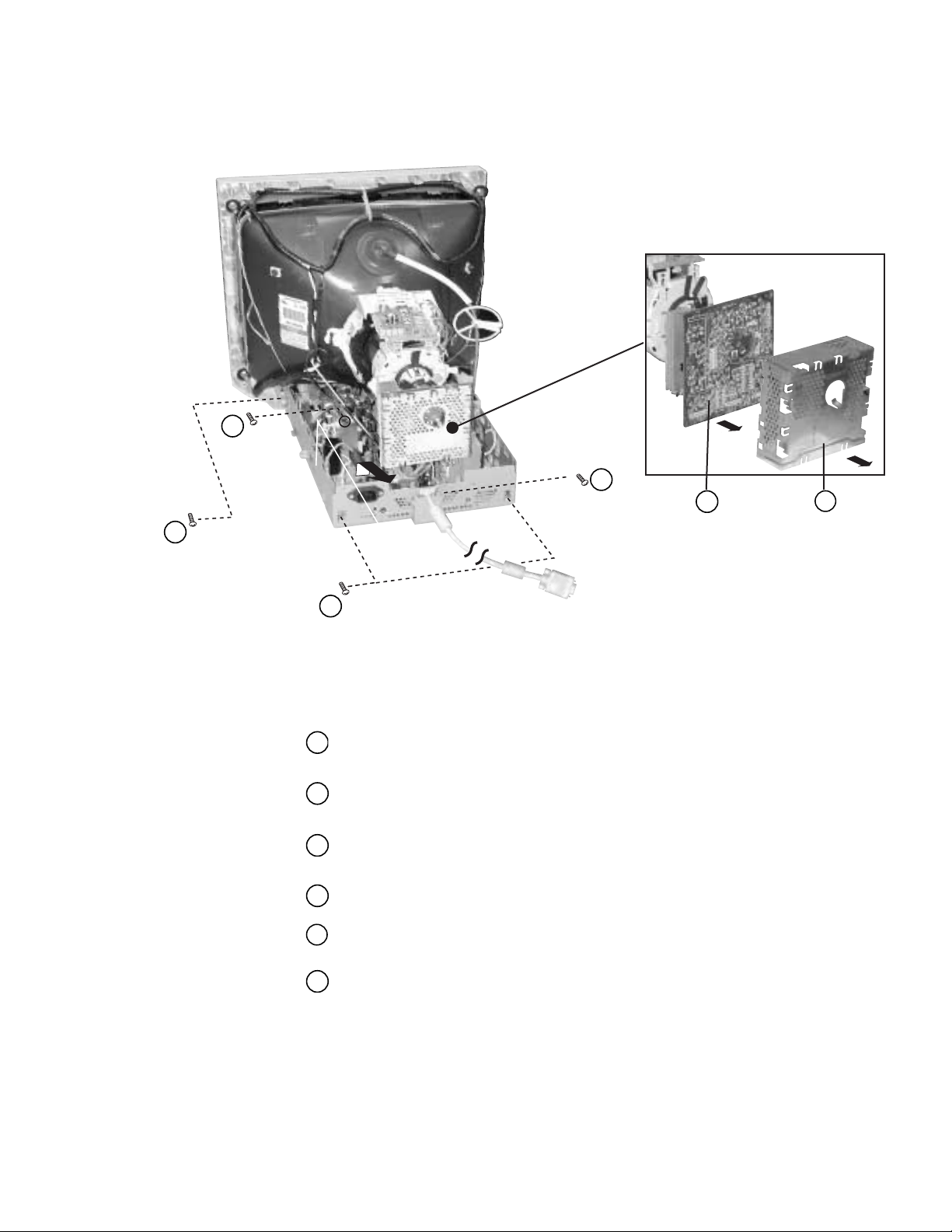

1-3. A & D BOARD REMOVAL

4

CPD-E240

1

6

5

3

2

Remove (1) screw (+BVTP 3 x 8) from the cable holder

1

at the rear of the chassis base to release the cable.

Remove (2) screws (+BVTP 3 x 8) from the rear of the

2

chassis base and remove.

Remove (2) screws (+BVTP 4 x 16) from the chassis

3

base and slide out to remove.

Remove (7) screws (+BVTP 3 x 8) from the D Board.

4

Lift the board up and out to remove.

5

Remove the shield cover from the A board

Gently wiggle the A board back and forth, and pull it to

6

remove.

— 8 —

Page 9

1-4. PICTURE TUBE REMOVAL

CPD-E240

Place the unit face down on a cushion to avoid

1

scratching.

Remove the anode cap.

2

3

Remove (4) screws (Screw (5) Tapping) from

the CRT.

4

Remove the picture tube shield.

Remove the neck assembly.

5

Remove the deß ection yoke.

6

Remove the A board.

7

Remove the demagnetization coil.

8

Remove (2) screws (BVTP 4 x 16) from the

9

chassis assembly and slide out to remove.

5

4

6

7

3

2

8

1

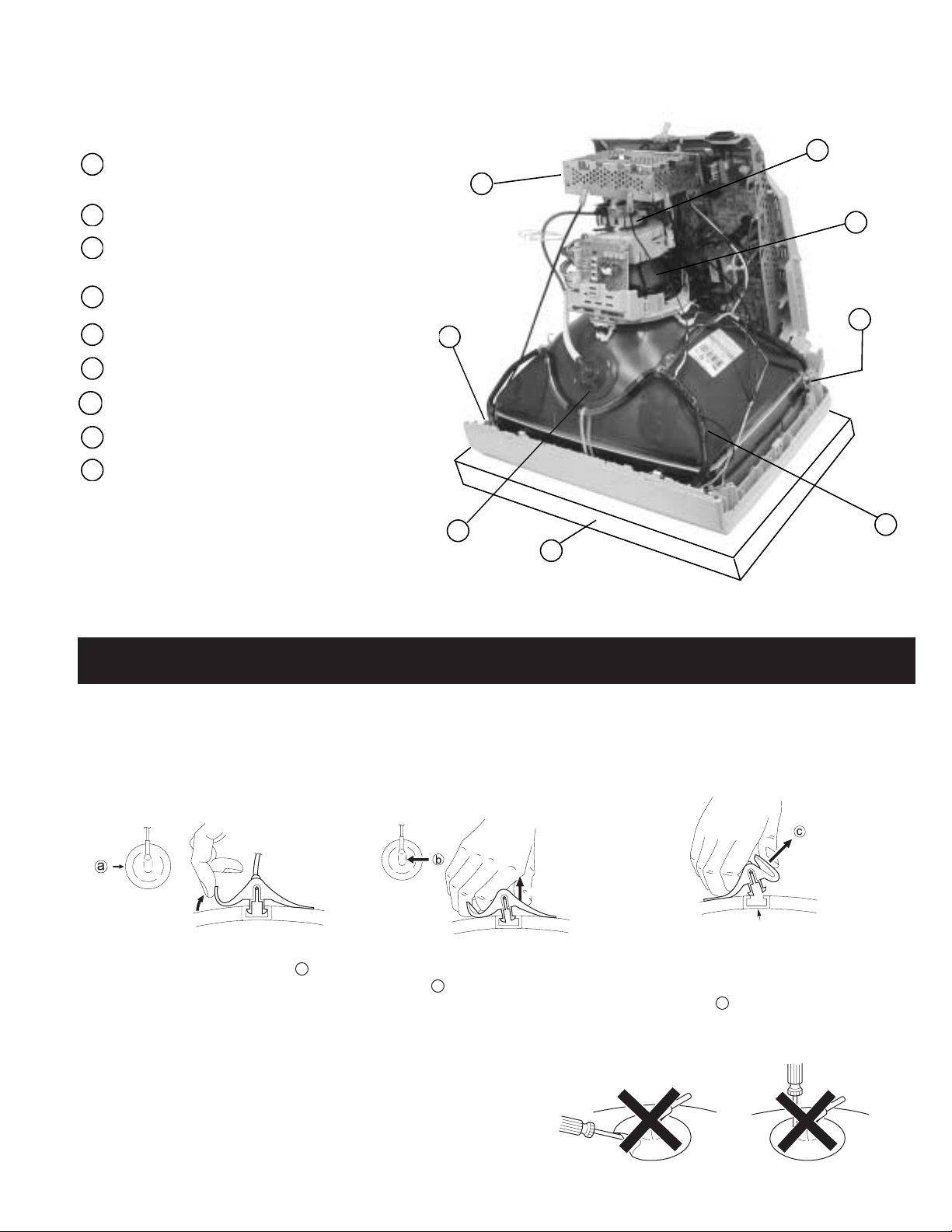

ANODE CAP REMOVAL

WARNING: High voltage remains in the CRT even after the power is disconnected. To avoid electric shock, discharge CRT before attempting to remove

the anode cap. After removing the anode cap, short circuit to either the metal chassis, CRT shield, or carbon painted on the CRT.

REMOVAL PROCEDURES

Anode Button

Turn up one side of the rubber cap

inthe direction indicated by arrow a .

Use your thumb to pull the rubber

cap Þ rmly in the direction indicated

by arrow b .

When one side of the rubber cap separates from

the anode button, the anode cap can be removed

by turning the rubber cap and pulling it in the

direction of arrow c .

HOW TO HANDLE AN ANODE CAP

1. Do not use sharp objects which may cause damage to the surface of the

anode cap.

2. To avoid damaging the anode cap, do not squeeze the rubber covering too

hard. A material Þ tting called a shatter-hook terminalis built into the rubber.

3. Do not force turn the foot of the rubber cover. This may cause the shatter-hook

terminal to protrude and damage the rubber.

— 9 —

Page 10

SECTION 2: SAFETY RELATED ADJUSTMENTS

CPD-E240

When replacing parts shown in the table below, the following

operational checks must be performed as a safety precaution

against X-ray emissions from the unit.

Part Replaced ( )

HV ADJ

HV Regulator

Circuit

HV HOLD

DOWN Circuit

Beam Current

Protector Circuit

Allow the unit to warm up for one minute prior to checking the

following conditions:

D Board T501, IC501, RV501, R540,

R541, R542, R544, R564, R567,

R568, C532, C534, C539, C553,

C554, C555, C556, C558, C561

D Board

D Board

T501, R510, R543, R547, R549,

R552, R595, D515, D517, C540,

C542, C544, IC607, IC901, C951

T501, R545, R546, R548, R550,

R596, R934, C535, C541, IC605,

IC607, IC901

RV501

Part Replaced ( )

2-1. HV REGULATOR CHECK

1. Input white cross hatch signal. (fH = 80 kHz)

2. CONT maximum and BRT center

3. Cut off Screen VR (G2).

4. Input voltage: 120 ± 2 VAC.

5. ConÞ rm that the voltage is within the voltage range shown below:

Standard voltage: 26.0

6. When replacing components identiÞ ed by

the High Voltage.

7. Verify the High Voltage as shown above (26.9 KV

within speciÞ cation. If not, set H. SIZE data at minimum (-127)

and then adjust RV501 on "D" board (Adjustment target = 26.0 KV

± 0.2 KV).

8. After adjusting the High Voltage within speciÞ cation, put the RV

cover on RV501 as shown below and apply sufÞ cient amount of

RTV around RV501.

+ 0.3

- 0.5

KV

, make sure to recheck

+ 0.3

KV) is

- 0.5

2-2. HV PROTECTOR CIRCUIT CHECK

1. ConÞ rm that the voltage between cathode of D517 and GND is

more than 27.0 VDC.

2. Using an external DC Power supply, apply the volt age shown below

between cathode of D517 on "D" and GND, and conÞ rm that the

HV Hold-Down circuit works. (Raster disappears) Apply DC Voltage:

Less than 35.9 VDC.

Check Condition

• Input voltage: 120 ± 2 VAC

• Input signal: (fH =69 kHz), White Cross Hatch

• Controls: CONT (max) & BRT (center)

• B+ Voltage: 179 ± 3.0 VDC

2-3. BEAM PROTECTOR CHECK

(SOFTWARE LOGIC)

1. Using an external current source, apply < 1.55mA between pin

of FBT (T501) and GND, and conÞ rm that the raster fades out.

Check Condition

• Input voltage: 120 ± 2 VAC

• Input signal : (fH = 69 kHz), White Cross Hatch

• Controls: CONT (max) & BRT (center)

2-4. B+ VOLTAGE CHECK

1. Input white cross hatch (fH = 69 kHz) signal.

2. CONT (max) & BRT (center).

3. Input voltage: 110 ± 10 VAC.

Note: Use NF power supply or make sure that dis tortion factor is

3% or less.

4. ConÞ rm that the voltage is within the range shown below:

Standard voltage: 179 ± 3.0 VDC

104

RV501

— 10 —

Page 11

CPD-E240

R

SECTION 3: ADJUSTMENTS

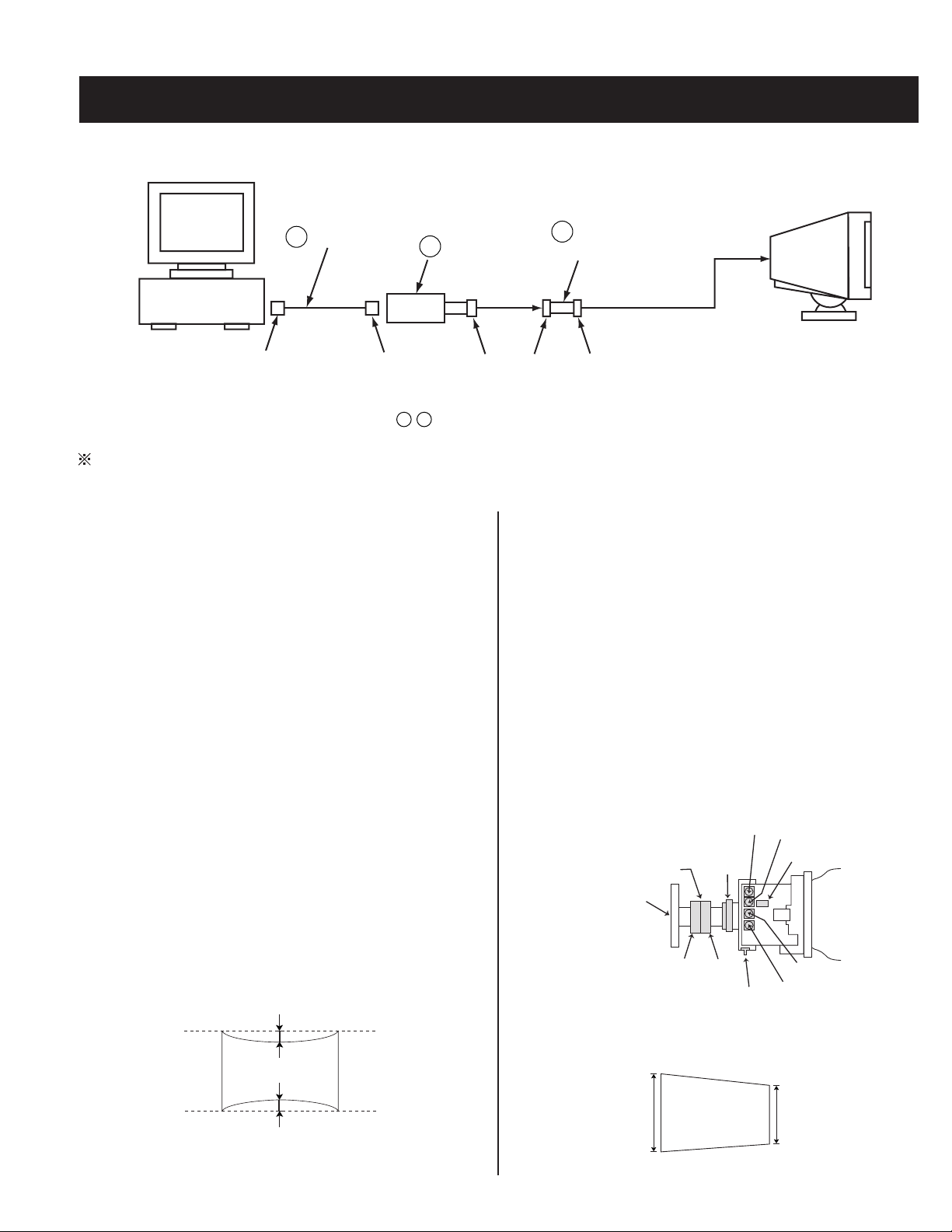

Connect the communication cable of the connector located on the D board on the monitor. Run the service software and then follow the instructions

3-702-691-01

1

1-690-391-21

A-150-919-A

2

Interface Unit

3

Connector Attachment

IBM at Computer

as a Jig

D-Sub

(9 Pin [female])

* The Parts above ( ) are necessary for DAS Adjustment.

Allow a 30 minute warm-up period prior to making the following

adjustments:

Mini Din

(8 Pin)

4 Pin

-

1

3

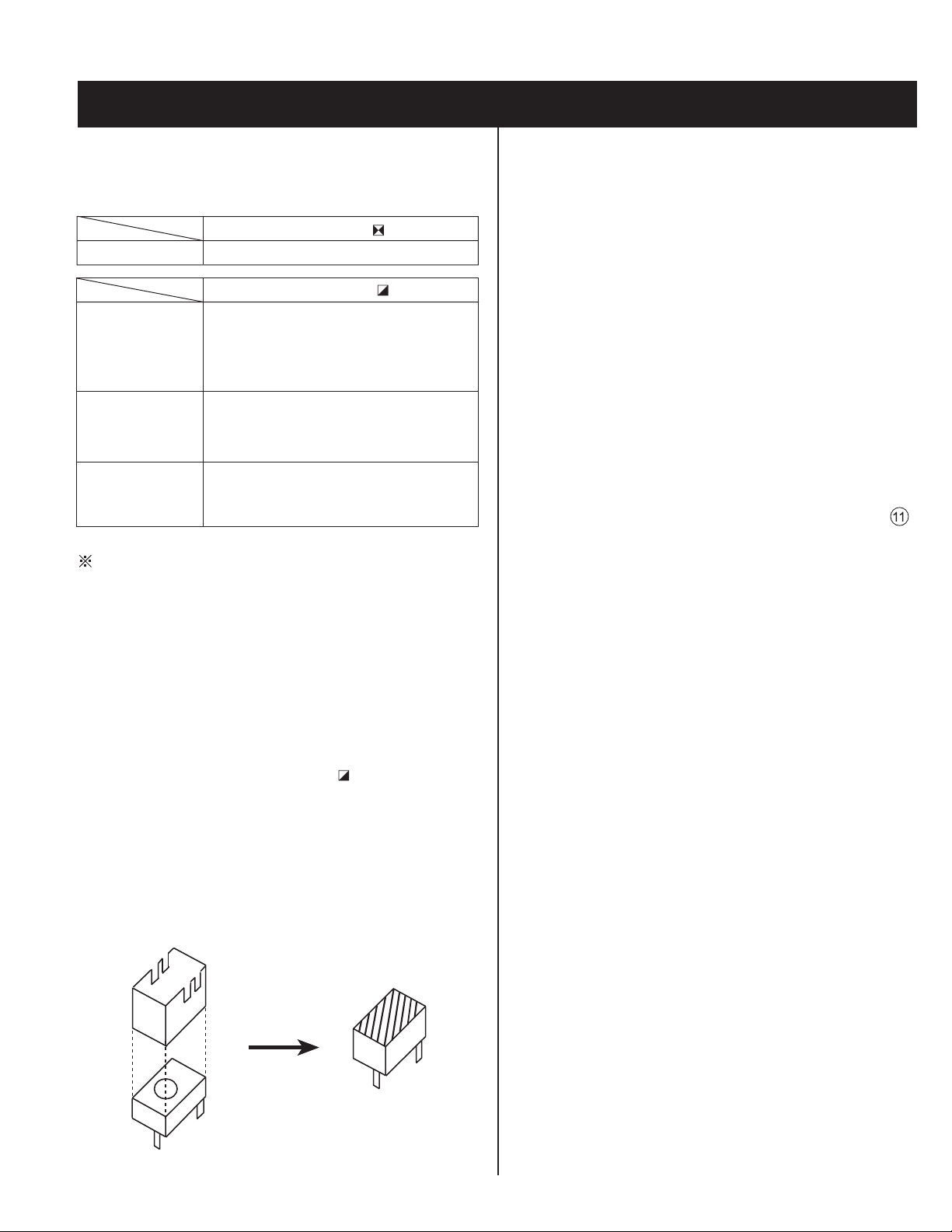

3-1. LANDING ROUGH ADJUSTMENT

1. Display the all white pattern.

2. Adjust the contrast to maximum value.

3. Display the plain green pattern.

4. Slide the DY back and roughly adjust the plain green pattern with

the purity magnet so that it is centered on the screen.

5. Moving the DY forward, adjust so that an entire screen be comes

pure green.

6. Adjust the tilt of DY and tighten lightly with a clamp.

3-2. LANDING FINE ADJUSTMENT

To BUS CONNECTOR

4 Pin

12. If the corner landing is out of speciÞ cation, use a disk magnet for

13. If disk magnets were used, perform an auto degauss.

14. Remove the wobbling coil and sensor.

15. Fix the purity magnet on DY with white paint.

4 Pin

the landing correction.

3-3. CONVERGENCE ROUGH ADJUSTMENT

1. Enter the white crosshatch signal.

2. Roughly adjust the horizontal (H.STAT) and vertical (V.STAT)

convergence at four-pole magnet.

3. Roughly adjust HMC and VMC at six-pole magnet.

1. Place the monitor in the Helmholtz coil.

2. Set TLH plate to zero position.

3. Display plain green pattern.

4. Degauss CRT face and iron parts with degauss equipment or handdegausser.

5. Perform auto degauss.

6. Attach a wobbling coil to the speciÞ ed position of CRT neck.

7. Put the sensor of landing checker to CRT face.

8. Adjust purity, DY position and DY tilt.

9. Tighten DY screw.

10. Perform auto degauss.

11. Adjust top and bottom pin by pitching DY up and down with two

wedges so that [a] is equal to [b].

[a]

[b]

— 11 —

3-4. CONVERGENCE AND V. KEY (H. TRP)

FINE ADJUSTMENT

H-TRP VR

Purity

6-pole

Mg

Magnet

4-pole

Mg

Neck Ass'y

A Board

1. Display crosshatch pattern with green lines and black Þ eld.

2. Adjust V. Key (=H. Trapezoid) with H-Trp VR so that [a] is equal

to [b].

[a]

TLV VR

TLH Plate

XCV VR

DY

YCV VR

TB Pin V

[b]

CRT

Page 12

3. Adjust the TB Pin with TB Pin VR.

m

m

TB Pin Movement

16. Adjust V.TILT with TLV VR.

TLV Movement

CPD-E240

R

B

B

R

4. Adjust V.SIZE with "VSIZE".

5. Change "CONV_SW" to "0" and "MCR2" to "153".

6. Display crosshatch pattern with red and blue lines and black Þ eld.

7. Adjust H.STAT and V.STAT with 4 pole magnet. Use 4 pole magnet,

not "HSTAT" and "VSTAT".

4 Pole Magnet

1

2

1

2

R

1

2

1

2

1

B

R

B

R

B

R

B

2

1 2

R

B

R

B

8. Display crosshatch pattern with white lines and black Þ eld.

9. Adjust HMC and VMC with 6 pole magnet.

6 Pole Magnet

2

G

1

2

G

1

17. If necessary, repeat steps 3-14 to make the optimum condition for

the entire screen.

18. Fix 4-pole magnet, 6-pole magnet, TLH plate and XCV VR with

white paint.

Zero Position Neck Ass'y

Purity

4-Pole Mg

6-Pole Mg

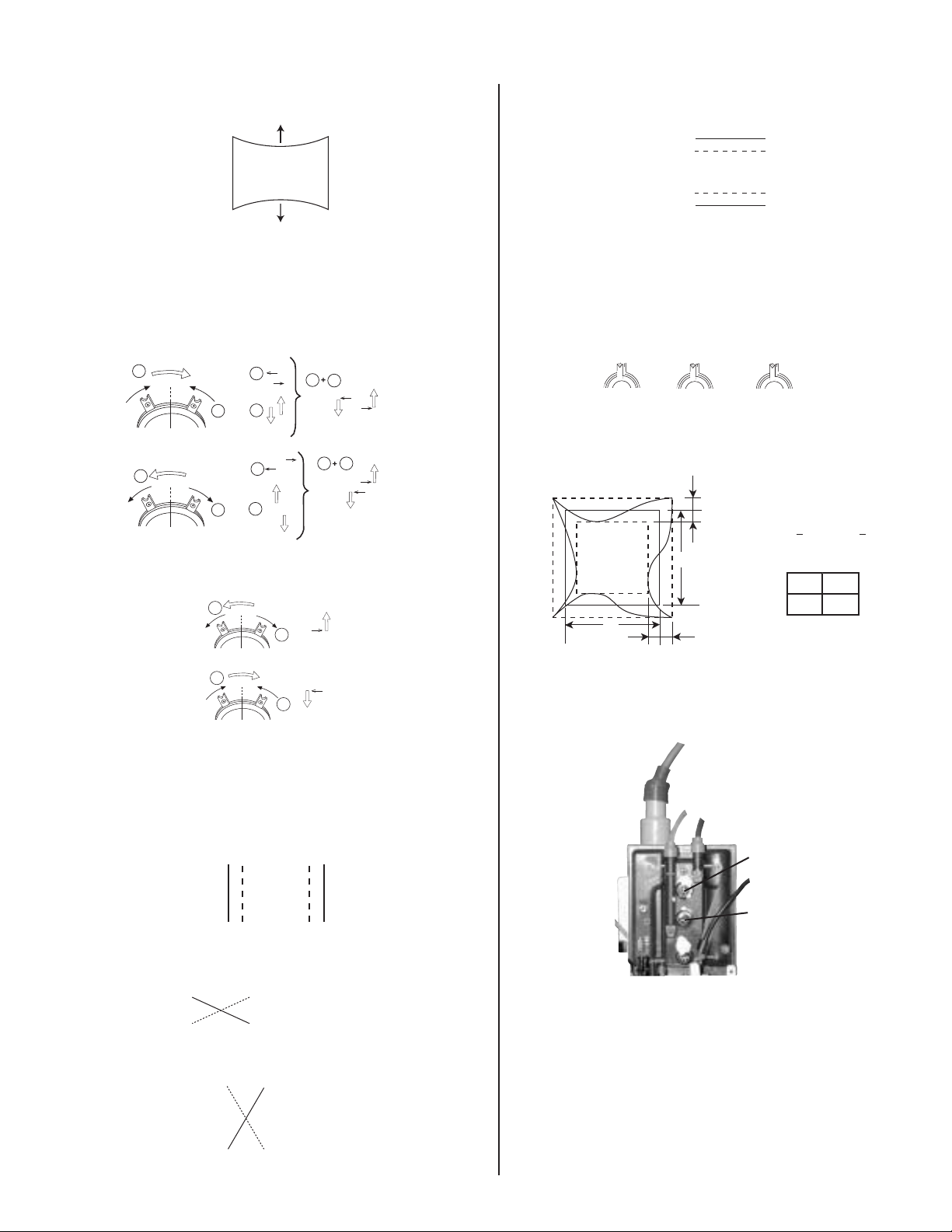

3-5. VERTICAL AND HORIZONTAL POSITION

AND SIZE SPECIFICATION

a

fH > 60 kHz fH < 60 kHz

a = 2.0 mm 2.4 m

A

b = 2.0 mm 2.4 m

A

B

234 312

B

b

3-6. FOCUS ADJUSTMENT

1. Adjust focus (V) and focus (H) for optimum focus.

10. Display crosshatch pattern with red and blue lines and black Þ eld.

11. If necessary, repeat steps 5-8.

12. Change "CONV_SW" to "6".

13. Adjust H.TILT with TLH plate.

TLH Movement

R B B R

14. Adjust XCV with XCV VR.

XCV Movement

B

15. Adjust YCH with YCH VR.

YCH Movement

R

B

R

Focus (V)

Focus (H)

— 12 —

Page 13

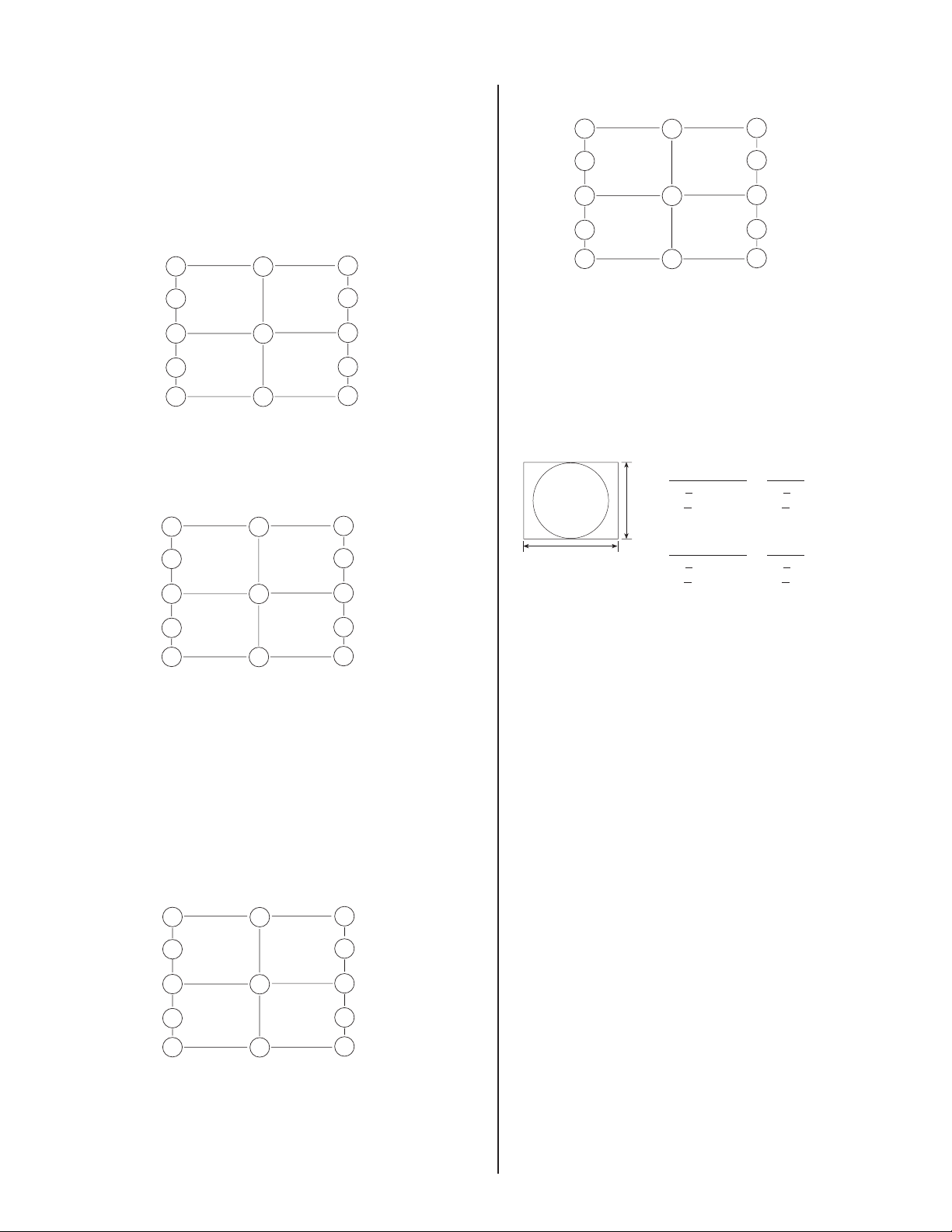

3-7. DIGITAL CONVERGENCE ADJUSTMENT

Convergence (Low) Mode

1. Adjust the H.STAT and V.STAT with "HSTAT" and "VSTAT".

2. Change "CONV_SW" to "7".

A. Horizontal Convergence

MBH-T-L-LO

CBH-T-LO

9

17

YBH-T-LO

5

10

CBH-T-R-LO

18

MBH-T-R-LO

B. Vertical Convergence

CCV-T-L-HI

MCV-T-L-HI

XBV-L-HI

MCV-B-L-HI

CCV-B-L-HI

13

21

3

23

15

V STAT-T-HI

7

8

V STAT-B-HI

Adjust each misconvergence point in sequence.

V STAT-HI

14

CCV-T-R-HI

22

MCV-T-R-HI

4

XBV-R-HI

24

MCV-B-R-HI

16

CCV-B-R-HI

CPD-E240

APH-L-LO

MBH-B-L-LO

CBH-B-L-LO

1

HSTAT

19

11

6

YBH-B-LO

2

APH-R-LO

20

MBH-B-R-LO

12

CBH-B-R-LO

Adjust each misconvergence point in sequence.

B. Vertical Convergence

CCV-T-L-LO

MCV-T-L-LO

XBV-L-LO

MCV-B-L-LO

CCV-B-L-LO

13

21

3

23

15

V STAT-T-LO

7

V STAT

8

V STAT-B-LO

14

CCV-T-R-LO

22

MCV-T-R-LO

4

XBV-R-LO

24

MCV-B-R-LO

16

CCV-B-R-LO

Adjust each misconvergence point in sequence.

2. Repeat the procedure of A and B so that the convergence of the

entire screen is within the speciÞ cation.

2. Repeat the procedure of A and B so that the convergence of the

entire screen is within the speciÞ cation.

3. Change "MCR2" to "170".

3-8. CONVERGENCE SPECIFICATION

B

A

312 mm

A Zone:

Primary Mode Others

234 mm

H: < 0.25mm H: < 0.3mm

V: < 0.25mm V: < 0.3mm

B Zone:

Primary Mode Others

H: < 0.3mm H: < 0.4mm

V: < 0.3mm V: < 0.4mm

Convergence (High) Mode

1. Adjust the H.STAT and V.STAT with "HSTAT-HI" and "VSTAT-HI".

A. Horizontal Convergence

YBH-T-HI

CBH-T-HI

MBH-T-L-HI

APH-L-HI

MBH-B-L-HI

CBH-B-L-HI

9

17

1

19

11

5

HSTAT-HI

6

YBH-B-HI

10

CBH-T-R-HI

18

MBH-T-R-HI

2

APH-R-HI

20

MBH-B-R-HI

12

CBH-B-R-HI

Adjust each misconvergence point in sequence.

— 13 —

Page 14

4-1. CIRCUIT BOARDS LOCATION

CPD-E240

SECTION 4: DIAGRAMS

The components identiÞ ed by shading and ! symbol are critical for safety. Replace

only with part number speciÞ ed.

A Board

H1 Board

D Board

4-2. PRINTED WIRING BOARDS AND

SCHEMATIC DIAGRAMS INFORMATION

All capacitors are in µF unless otherwise noted. pF : µµF 50WV or less

are not indicated except for electrolytics and tantalums.

All electrolytics are in 50V unless otherwise speciÞ ed.

All resistors are in ohms. KΩ=1000Ω, MΩ=1000kΩ

Indication of resistance, which does not have one for rating electrical

power, is as follows: Pitch : 5mm

Rating electrical power :

1

/

W in resistance, 1/

4

W and 1/

10

W in chip resistance.

8

: nonß ammable resistor.

: fusible resistor.

: internal component.

: panel designation and adjustment for repair.

All variable and adjustable resistors have characteristic curve B, unless

otherwise noted.

Readings are taken with a color-bar signal input.

Readings are taken with a 10MΩ digital multimeter.

Voltages are DC with respect to ground unless otherwise noted.

Voltage variations may be noted due to normal production tolerances.

All voltages are in V.

S : Measurement impossibillity.

: B+line.

: B-line. (Actual measured value may be different).

: signal path. (RF)

Circled numbers are waveform references.

1

/

W

4

The symbol

side of the board. Replace only with fuse of the same rating as marked.

Les composants identiÞ es per un trame et une marque

securite. Ne les remplacer que par une piece portant le numero speciÞ e.

Le symbole indique une fusible a action rapide. Doit etre remplace par une

fusible de meme yaleur, comme maque.

indicates a fast operating fuse and is displayed on the component

!

sont critiques pour la

The components identiÞ ed by X in this basic schematic diagram

have been carefully factory-selected for each set in order to

satisfy regulations regarding X-ray radiation. Should replacement be

necessary, replace only with the value originally used.

When replacing components identiÞ ed by

Y

, make the necessary

adjustments as indicated. If the results do not meet the speciÞ ed value,

change the component identiÞ ed by

X

and repeat the adjustment until

the speciÞ ed value is achieved. (See Page 10)

When replacing the parts listed in the table below, it is important to

perform the related adjustments.

Part Replaced ( )

HV ADJ

RV501

Part Replaced ( )

HV Regulator

Circuit

D Board T501, IC501, RV501, R540,

R541, R542, R544, R564, R567,

R568, C532, C534, C539, C553,

C554, C555, C556, C558, C561

HV HOLD

DOWN Circuit

D Board

T501, R510, R543, R547, R549,

R552, R595, D515, D517, C540,

C542, C544, IC607, IC901, C951

Beam Current

Protector Circuit

D Board

T501, R545, R546, R548, R550,

R596, R934, C535, C541, IC605,

IC607, IC901

REFERENCE INFORMATION

RESISTOR

: RN METAL FILM

: RC SOLID

: FPRD NONFLAMMABLE CARBON

: FUSE NONFLAMMABLE FUSIBLE

: RW NONFLAMMABLE WIREWOUND

: RS NONFLAMMABLE METAL OXIDE

: RB NONFLAMMABLE CEMENT

: ADJUSTMENT RESISTOR

COIL

: LF-8L MICRO INDUCTOR

CAPACITOR

: TA TANTALUM

: PS STYROL

: PP POLYPROPYLENE

: PT MYLAR

: MPS METALIZED POLYESTER

: MPP METALIZED POLYPROPYLENE

: ALB BIPOLAR

: ALT HIGH TEMPERATURE

: ALR HIGH RIPPLE

— 14 —

Page 15

4-3 DIAGRAMS BLOCK DIAGRAM (1/2)

0

1

5

5

1

4

4

1

8

3

3

1

7

2

2

1

6

1

1

1

R

O

T

C

E

N

N

O

C

B

U

S

N

-

I

D

P

5

1

N

A

L

I

N

S

I

G

R

D

A

O

B

D

O

T

2

0

9

N

C

2

C

0

3

N

G

B

D

N

1

E

L

U

B

2

D

N

G

G

3

E

E

R

N

G

4

G

R

D

N

5

R

D

E

6

9

0

3

N

C

8

C

N

Y

S

C

A

D

S

C

I

I

7

6

D

N

G

L

C

S

C

I

I

5

4

P

L

C

P

B

K

L

B

C

3

2

R

V

T

C

R

C

R

R

H

T

1

CPD-E240

D

R

A

O

B

D

O

T

6

0

6

N

C

4

0

3

N

V

5

+

S

Y

B

T

V

5

+

0

0

3

C

N

C

Y

S

7

N

I

-

B

9

-

G

N

I

1

1

N

I

-

R

P

R

2

1

8

1

5

D

I

C

0

0

3

0

1

B

L

F

V

5

B

L

F

W

S

6

0

0

Q

H

4

1

D

S

O

-

G

3

1

D

S

O

-

B

2

1

K

L

S

B

O

-

D

7

A

D

S

8

S

L

C

5

1

D

S

O

-

R

O

S

1

4

1

3

1

7

1

E

L

P

C

M

A

C

I

K

L

B

-

D

R

S

O

D

S

O

-

G

D

B

S

O

-

B

-

K

D

L

S

O

S

L

C

S

D

1

2

2

O

-

T

R

U

4

2

T

G

U

O

-

7

2

T

U

B

O

-

A

M

P

-

0

1

0

5

G

R

K

B

-

4

G

K

B

-

G

3

G

B

K

B

-

A

8

N

I

-

R

C

R

T

D

R

I

V

9

-

G

N

I

1

1

-

B

N

I

3

N

I

-

R

4

-

G

N

I

5

N

I

-

B

E

0

2

I

C

0

F

F

A

M

P

C

U

T

O

I

C

0

0

4

5

T

U

O

-

R

3

T

U

O

-

G

1

-

T

B

U

O

7

T

U

-

R

O

8

T

U

O

-

G

9

T

U

O

-

B

J

0

0

1

4

7

R

K

8

G

K

9

B

K

(

V

H

G

1

G

2

3

0

1

)

E

O

I

D

V

2

1

+

V

0

8

+

8

1

V

+

0

C

V

5

+

T

9

S

Y

B

V

5

+

8

G

D

N

7

1

+

V

2

6

1

H

5

G

D

N

4

8

V

0

+

3

C

N

2

V

+

0

8

1

1

1

O

O

O

T

J

D

R

O

B

A

A

0

6

3

N

C

1

V

3

3

-

N

1

C

0

3

1

K

2

.

V

1

7

0

3

N

C

1

N

G

D

D

R

A

O

B

D

O

T

0

1

5

N

C

D

R

A

O

B

D

O

T

T

B

F

P

E

T

U

R

E

T

U

B

I

C

V

H

)

T

B

T

F

(

O

— 15 —

2

O

F

1

K

B

L

>

V

1

C

7

-

<

0

7

-

5

8

1

8

9

-

8

9

Page 16

BLOCK DIAGRAM (2/2)

R

O

T

C

N

E

N

O

C

B

S

U

-

D

N

I

5

P

1

1

0

A

N

I

N

L

I

S

G

5

1

5

4

4

1

8

3

3

1

7

2

2

1

6

1

1

1

L

E

A

N

P

N

T

R

O

F

1

S

U

P

I

R

F

T

E

L

N

O

W

D

U

E

N

M

T

H

G

7

0

0

1

S

V

5

+

Y

T

B

S

D

R

A

O

B

A

O

T

9

0

N

3

C

1

0

0

1

N

C

V

5

+

B

Y

T

S

3

0

0

C

G

D

CPD-E240

T

R

O

L

V

-

C

O

C

N

O

1

0

N

7

C

P

8

0

1

-

4

Y

C

9

+

4

Y

C

-

8

3

Y

C

7

+

3

Y

C

6

-

2

Y

C

5

+

2

Y

C

-

4

1

Y

C

+

3

1

Y

C

-

N

I

O

T

A

T

O

R

2

1

+

O

N

I

T

A

T

O

R

2

0

9

N

C

C

R

T

R

H

C

R

T

R

V

K

L

B

C

P

L

C

P

B

L

C

S

C

I

I

N

D

G

A

D

S

C

I

I

C

N

Y

S

C

3

0

9

N

C

D

1

N

G

T

S

O

H

1

A

D

S

C

D

D

1

L

C

S

C

D

D

V

5

Y

B

T

S

V

/

5

T

S

O

H

N

D

G

C

Y

N

S

H

C

N

Y

S

V

V

5

Y

B

T

S

5

D

N

G

4

Y

E

K

3

D

E

R

D

E

L

2

N

R

G

D

E

L

1

1

0

9

N

C

N

D

G

D

V

5

+

B

Y

T

S

X

D

R

X

D

T

1

0

N

6

C

2

C

G

D

N

C

N

C

1

C

G

D

A

C

I

N

2

0

6

N

C

0

0

6

P

H

T

0

A

0

6

P

H

T

4

A

T

O

R

5

C

I

M

O

R

F

1

5

2

5

Q

2

3

4

5

6

7

8

1

2

3

+

4

Y

B

T

S

5

6

7

4

0

9

C

N

+

Y

B

T

S

5

4

3

2

1

1

2

Y

B

T

S

3

4

V

2

1

+

1

2

3

4

2

1

6

4

9

S

1

6

D

1

O

N

I

T

2

0

V

5

I

N

N

C

Y

S

0

C

8

9

I

V

5

V

5

+

7

C

O

N

V

O

U

T

3

I

C

7

0

3

2

V

O

U

T

C

O

N

5

I

C

7

0

2

4

3

2

3

N

O

I

T

T

A

O

R

6

4

K

N

A

L

B

C

2

2

P

M

A

L

C

P

B

6

3

K

L

C

7

3

A

T

A

D

8

2

C

N

Y

-

S

C

5

4

E

T

S

R

E

0

4

C

9

I

0

6

9

I

C

V

.

L

O

M

P

R

E

A

G

E

D

0

6

Q

F

T

L

2

0

6

F

T

E

E

S

R

3

3

I

C

P

4

3

L

C

S

D

C

D

5

3

A

D

S

C

D

D

0

3

C

N

Y

-

S

H

0

2

N

C

Y

S

-

V

5

1

4

B

P

8

4

5

A

P

7

4

6

A

P

8

3

D

X

R

9

3

D

D

X

T

S

S

U

1

-

C

A

6

D

R

E

P

L

U

O

C

O

T

H

O

P

L

O

R

T

N

C

O

C

C

R

3

0

6

C

I

N

0

1

I

C

7

T

U

O

C

T

I

A

T

S

-

V

9

O

C

I

T

A

T

S

-

H

8

6

T

U

O

V

N

C

O

-

V

T

U

O

V

N

C

O

-

H

7

6

1

A

D

S

7

1

L

C

S

F

E

.

R

V

5

C

P

U

1

I

C

9

0

E

T

O

M

R

E

S

S

U

A

G

E

4

S

-

0

S

3

5

-

9

4

7

N

V

I

1

C

E

T

R

1

0

2

1

T

N

T

O

C

G

E

R

W

-

S

R

I

D

1

0

6

C

I

N

S

E

I

T

R

L

C

N

V

1

9

2

0

6

S

4

V

3

1

E

F

.

R

V

T

U

N

I

2

N

I

S

V

-

3

N

I

O

S

P

V

4

1

N

.

I

D

H

T

O

U

R

E

F

F

B

U

1

2

Q

3

A

D

S

4

L

C

S

3

M

O

R

P

E

5

0

9

C

I

3

2

K

C

O

L

5

2

R

C

R

T

V

6

2

T

U

-

O

V

7

2

T

U

-

O

H

2

3

B

F

H

8

1

1

B

P

4

3

A

D

5

4

A

D

6

1

B

3

P

6

F

F

O

/

O

N

P

A

C

-

S

O

E

N

G

A

H

C

G

E

R

-

W

S

4

V

E

5

E

S

B

O

O

4

5

T

U

O

2

0

6

Q

T

C

E

T

O

R

P

0

4

6

Q

M

A

O

R

R

R

3

E

4

0

6

I

C

2

F

R

E

-

V

D

2

K

C

L

O

8

2

N

I

-

V

6

2

N

I

-

H

K

C

O

L

C

N

Y

S

4

2

5

Q

,

2

5

2

Q

T

R

S

0

1

6

T

P

1

N

I

S

.

V

V

I

D

.

V

8

W

A

S

.

V

N

T

R

O

L

E

F

.

C

O

I

C

9

0

2

1

7

U

T

O

.

H

2

1

F

E

D

.

V

4

1

Y

L

F

H

.

V

0

1

8

0

V

8

V

1

5

R

E

T

E

A

H

W

S

0

3

6

Q

V

5

1

-

V

2

1

V

5

1

+

G

E

R

V

5

V

2

1

C

I

V

5

7

0

6

V

-

O

U

7

1

Y

B

T

S

Q

T

N

I

+

4

C

I

N

I

-

1

R

E

T

A

E

H

G

E

R

2

0

6

C

I

4

L

R

T

N

C

5

0

6

5

,

1

N

I

I

5

1

0

T

U

O

4

B

G

E

-

R

H

5

Q

R

,

2

E

V

1

V

2

C

6

0

5

,

6

0

L

A

B

S

I

D

0

2

O

1

0

2

G

8

E

B

E

I

V

R

.

D

H

0

5

Q

,

1

5

0

Q

,

3

0

9

Q

V

2

+

1

T

U

O

5

V

+

T

U

O

P

W

M

-

C

I

I

D

R

-

H

2

F

U

F

B

5

5

0

Q

0

1

7

2

5

3

+

C

O

N

T

1

0

5

E

V

2

H

P

4

8

P

M

A

-

F

D

V

4

0

5

Q

O

F

E

R

3

1

E

V

I

D

R

.

H

1

5

Q

T

S

H

5

0

T

5

T

F

2

1

8

1

+

2

P

O

3

B

9

1

O

2

B

U

T

O

1

S

T

F

D

3

0

5

T

G

R

E

-

V

H

3

0

5

Q

T

U

O

-

V

H

0

1

5

Q

T

D

H

4

0

5

T

3

0

L

5

N

C

O

T

N

I

P

H

C

T

I

W

9

1

Q

5

T

U

.

O

H

7

0

Q

5

T

U

O

H

8

0

Q

5

1

9

0

T

U

O

H

1

5

2

Q

5

T

C

L

6

5

0

T

G

E

N

A

H

C

A

P

C

-

S

5

1

4

Q

,

1

3

Q

5

,

1

2

5

Q

B

1

5

0

T

V

H

T

R

C

O

T

1

0

5

R

V

D

A

R

O

B

A

O

T

V

S

1

3

0

N

C

V

0

1

8

+

V

0

8

+

V

2

1

+

5

V

+

V

5

+

Y

T

B

S

E

R

O

W

P

(

R

V

E

O

N

C

9

9

-

)

E

C

E

N

G

F

2

K

O

B

L

C

>

7

V

1

1

8

<

-

8

8

0

5

-

7

0

5

1

N

C

V

3

3

-

1

D

R

A

O

B

A

O

T

6

0

3

N

C

1

0

5

C

N

+

Y

D

H

6

C

N

5

-

Y

D

H

4

C

N

3

-

Y

D

V

2

+

Y

D

V

1

D

R

A

O

B

A

O

T

4

0

3

N

C

6

0

6

N

C

V

0

8

+

1

1

C

N

2

V

0

8

+

3

4

N

D

G

1

H

5

V

1

2

+

6

7

N

D

G

8

V

5

+

V

5

+

B

Y

T

9

S

2

— 16 —

Page 17

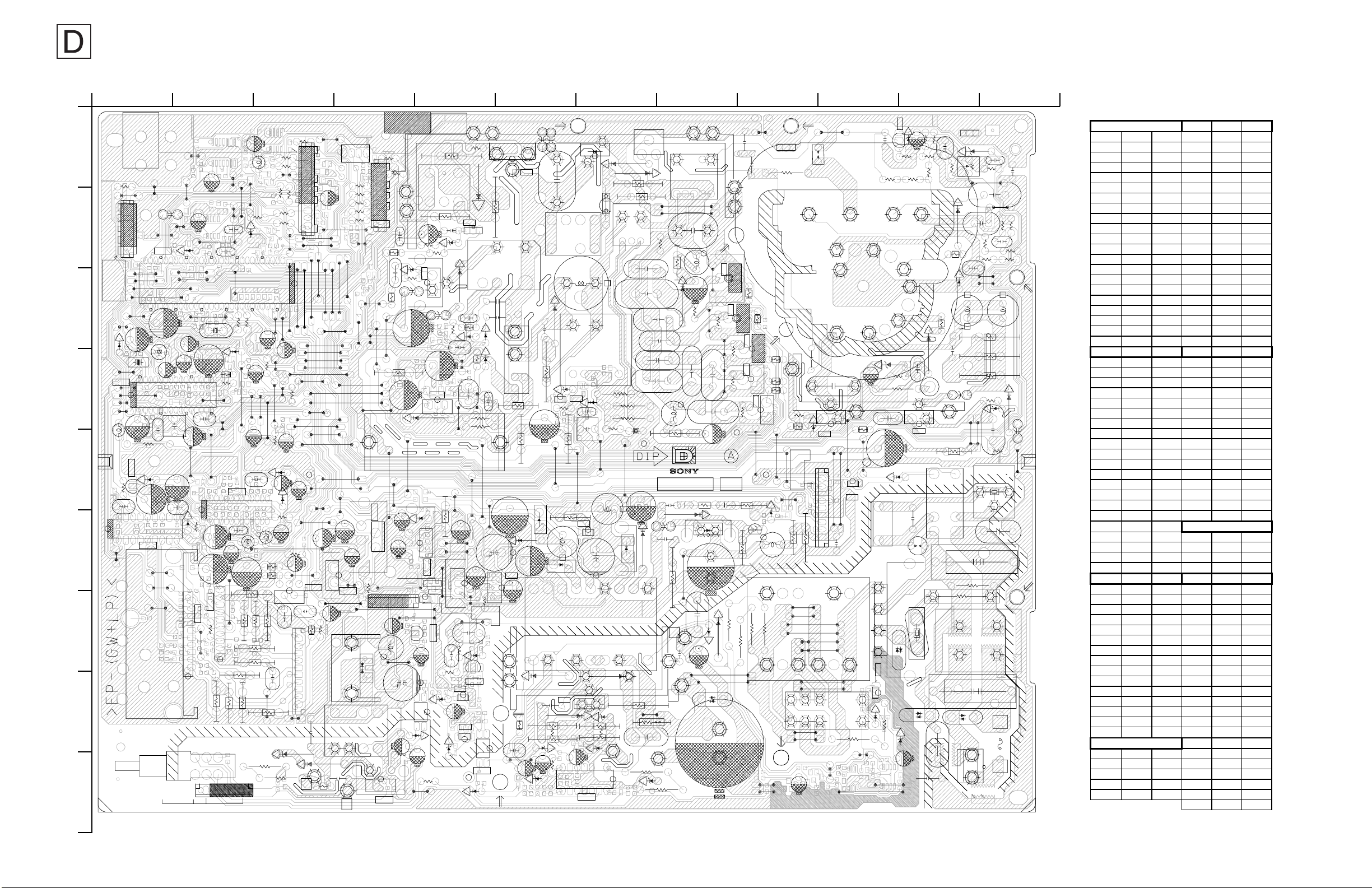

A BOARD SCHEMATIC DIAGRAM

CPD-E240

A

—

B

—

C

—

D

—

E

—

F

—

G

1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16

1

3

1

D

5

1

1

-

6

2

2

S

1

P

.

T

R

O

P

1

5

3

C

2

0

3

B

F

1

.

0

0

V

5

2

P

I

H

C

:

P

I

H

C

:

0

1

5

5

1

4

4

1

8

3

3

1

7

2

2

1

6

1

1

1

O

R

C

T

E

N

N

C

O

B

S

U

D

-

I

N

P

1

5

I

N

L

A

G

N

S

I

2

0

3

C

N

6

P

B

.

G

N

D

1

2

E

B

L

U

D

G

.

G

N

3

4

G

R

E

E

N

R

.

G

N

D

5

6

E

D

R

T

O

D

B

O

A

R

D

C

N

9

0

2

9

0

N

3

C

P

8

Y

C

N

C

S

8

S

I

D

I

A

C

7

G

N

D

6

C

L

I

I

C

S

5

L

B

P

P

C

4

C

B

L

K

3

R

C

R

T

V

2

R

C

1

H

R

T

B

1

1

2

1

6

3

R

5

7

1

6

2

R

2

B

F

5

7

0

H

C

:

1

6

1

R

1

B

F

0

5

7

H

C

:

0

1

0

B

F

9

0

0

B

F

F

0

.

7

5

1

0

B

F

D

5

1

1

-

2

6

2

P

S

1

.

O

T

R

P

1

5

2

C

1

.

0

V

5

2

P

I

H

C

:

B

1

1

1

D

2

0

P

I

2

0

P

I

6

1

0

B

M

M

1

5

1

-

2

6

2

P

S

1

.

O

T

R

P

1

5

1

C

1

.

0

V

5

2

P

I

H

C

:

B

7

4

1

2

0

R

7

4

0

2

0

R

M

M

0

.

5

0

1

8

1

0

R

7

1

0

0

R

1

0

1

6

0

0

R

0

3

3

R

5

7

P

I

H

C

:

0

3

2

R

0

1

P

I

H

C

:

0

3

1

R

5

7

P

I

H

C

:

5

V

S

T

B

Y

R

C

:

R

.

2

C

P

I

H

C

:

P

I

H

C

:

P

I

H

C

:

0

P

I

H

C

:

0

P

I

H

C

:

0

2

5

0

R

k

0

1

P

I

H

C

:

:

R

2

C

:

0

3

0

R

k

1

8

1

S

D

2

S

C

3

B

4

G

5

R

6

G

2

7

B

2

1

3

C

9

1

3

R

M

1

I

H

C

:

8

1

2

5

7

H

2

0

2

I

H

2

0

2

.

I

H

9

1

2

R

M

1

P

I

I

H

C

:

9

1

1

R

M

1

P

I

H

C

:

7

0

0

L

4

k

P

8

k

P

F

p

2

1

P

9

0

0

C

0

0

0

1

V

0

1

P

C

1

0

.

0

7

4

0

C

7

4

V

5

2

2

0

0

L

0

8

0

1

0

C

0

2

C

:

B

C

1

4

0

0

C

:

B

0

C

.

0

H

C

:

B

+

5

1

.

V

5

P

I

H

2

5

H

1

C

5

1

6

4

1

0

I

G

9

2

1

F

p

C

Y

N

S

0

1

P

I

I

N

R

1

1

2

1

F

p

A

M

L

C

2

1

S

O

B

3

1

O

S

G

4

1

S

O

R

5

1

X

C

:

2

0

0

R

4

0

0

R

0

C

k

8

.

1

0

6

5

0

0

1

P

I

H

C

:

P

I

H

C

:

H

C

:

B

P

R

8

C

:

4

4

0

C

p

0

0

1

P

I

H

C

:

B

:

1

5

0

R

k

1

P

I

H

C

:

1

0

0

R

0

P

I

H

C

:

2

4

.

2

0

.

0

3

A

N

C

Y

S

C

.

9

2

L

B

C

C

V

8

2

G

K

B

B

H

S

/

6

7

2

K

G

B

T

O

U

B

6

2

K

G

B

N

D

G

B

5

2

G

H

S

/

3

5

4

2

N

I

T

O

U

G

3

2

V

N

D

G

G

N

I

2

2

G

C

V

C

2

N

I

1

2

1

R

H

/

S

B

0

2

4

O

R

U

T

P

9

1

D

N

G

R

D

8

1

L

K

B

D

7

1

0

C

0

L

K

B

D

S

O

D

0

0

C

I

6

0

A

2

A

-

R

E

P

2

4

p

0

P

I

3

0

0

k

2

.

P

I

H

5

0

0

R

k

0

3

3

P

I

H

C

Q

2

C

2

S

U

B

:

2

C

:

B

6

1

R

C

C

V

1

S

A

7

M

P

3

0

0

C

I

P

2

0

6

D

9

X

C

S

D

O

:

A

S

S

V

1

O

C

V

2

_

R

P

R

3

_

G

A

D

D

V

4

_

B

B

L

F

H

5

_

D

S

O

S

S

6

A

D

S

7

C

S

L

8

6

0

0

K

2

1

4

E

R

F

F

9

4

0

C

1

.

0

V

5

2

P

I

H

C

:

B

4

0

1

C

1

.

0

V

5

2

P

I

H

C

:

B

7

1

3

R

6

5

4

0

2

C

1

.

0

V

5

2

P

I

H

C

:

B

7

1

2

R

6

5

2

1

0

C

1

.

0

V

5

2

P

I

H

C

:

B

C

4

0

3

C

1

.

0

V

5

2

P

I

H

C

:

1

1

R

6

5

0

5

1

.

V

5

P

I

H

9

0

0

R

k

0

1

P

I

H

C

:

6

1

S

S

V

5

1

D

S

O

4

1

D

S

O

3

1

D

S

O

2

1

K

L

B

1

1

T

N

I

0

1

B

L

F

V

2

0

C

7

4

5

2

9

D

D

V

2

9

0

C

1

0

.

0

P

I

H

C

:

B

1

2

V

7

0

0

0

7

4

V

6

1

7

P

P

C

C

-

-

N

N

R

R

:

:

k

k

2

2

.

.

8

8

6

0

3

R

6

k

2

.

8

6

0

0

1

P

C

-

N

R

:

2

R

R

5

0

1

C

1

.

0

V

5

2

P

I

H

C

:

B

5

0

2

C

1

.

0

V

5

2

P

I

H

C

:

B

5

0

3

C

1

.

0

V

5

2

P

I

H

C

:

B

4

1

0

R

0

0

1

P

I

H

C

:

2

V

Y

5

V

S

T

B

S

A

N

I

I

B

_

V

B

1

101

4

0

3

R

2

2

P

I

H

C

:

P

I

H

4

C

0

:

2

R

5

1

0

C

2

2

1

.

0

V

5

2

P

I

H

C

:

B

4

0

D

1

8

2

S

H

S

I

O

T

C

E

T

O

P

R

:

D

N

G

123457891

3

5

0

C

1

.

0

V

5

2

P

I

H

C

:

B

7

0

1

R

k

1

P

C

-

N

R

:

0

1

R

1

.

9

-

N

R

:

7

0

2

R

k

1

P

C

-

N

R

:

7

0

3

R

k

1

P

C

-

N

R

:

7

N

N

3

I

I

C

D

_

_

C

N

G

G

R

V

6

7

8

9

4

0

1

R

2

2

P

I

H

C

:

4

1

0

C

7

4

V

0

0

1

1

1

0

C

1

.

0

V

0

0

1

4

2

0

D

2

8

S

H

S

N

O

N

I

T

E

C

T

R

O

P

:

0

5

1

D

2

8

S

S

H

O

N

I

C

T

E

O

T

R

P

:

0

4

0

I

C

7

5

9

D

2

8

H

P

M

A

F

F

-

O

T

C

U

:

T

U

N

N

N

O

I

I

C

I

_

_

_

C

_

G

V

R

B

R

2

0

1

C

1

.

0

V

0

5

2

S

P

M

:

C

2

8

k

P

C

2

R

.

9

-

N

R

:

:

8

0

k

1

P

C

8

0

3

R

k

1

.

9

P

C

-

N

R

:

9

T

T

U

2

1

U

O

D

D

O

_

N

N

_

R

G

G

G

4

5

1

1

1

R

1

1

2

R

0

0

1

0

0

1

D

R

P

F

:

D

R

P

F

:

5

0

2

5

L

0

1

L

3

0

0

B

F

6

3

0

C

p

0

0

0

1

V

0

0

5

6

0

2

C

1

.

0

V

0

5

2

S

P

M

:

D

2

S

S

H

C

T

E

O

P

R

:

6

0

1

C

1

.

0

V

0

5

2

S

P

M

:

T

T

U

U

O

O

B

_

_

+

G

B

1

4

5

0

C

8

1

0

C

1

.

0

2

.

2

V

0

5

2

V

0

5

2

S

P

M

:

2

0

3

C

1

.

0

V

0

5

2

S

P

M

:

2

0

2

1

.

0

V

0

5

S

P

M

V

5

+

Y

B

T

S

2

0

C

0

I

T

T

5

4

1

2

L

M

U

O

_

B

123

5

0

8

2

I

T

T

U

P

U

T

O

O

E

D

V

I

:

1

1

3

R

0

0

1

D

R

P

F

:

5

0

3

L

4

0

D

3

8

2

S

H

S

N

I

O

T

E

C

T

O

P

R

:

5

0

D

3

2

8

S

S

H

N

I

O

T

C

T

E

O

P

R

:

6

0

3

C

1

.

0

V

0

5

2

S

P

M

:

6

0

D

3

8

S

S

H

M

L

A

C

:

1

0

3

B

F

N

O

B

F

1

0

1

B

F

+

1

8

0

V

8

0

0

B

F

)

5

(

W

J

2

V

1

5

3

0

C

7

4

0

0

.

0

V

k

2

B

:

8

0

V

+

2

P

6

0

D

2

8

2

S

S

H

P

M

L

A

C

:

6

1

0

D

1

0

2

2

8

S

H

S

P

A

M

L

:

C

9

0

2

R

9

0

1

R

k

0

7

4

k

0

7

4

P

I

H

C

:

P

I

H

C

:

2

0

2

R

2

0

1

R

k

0

7

4

k

0

7

4

P

I

H

C

:

P

I

H

C

:

V

2

1

+

R

G

1

1

G

0

1

1

0

0

G

S

0

1

4

6

0

R

)

5

1

(

W

J

1

0

3

G

S

1

5

3

R

7

4

W

2

/

1

E

G

R

U

S

:

1

5

2

R

7

4

W

2

/

1

E

G

R

U

S

:

1

5

1

R

7

4

W

2

/

1

E

G

R

U

S

:

9

0

3

R

k

0

7

4

P

I

H

C

:

2

0

3

R

k

0

7

4

P

I

H

C

:

2

1

2

1

V

C

3

1

2

1

1

0

1

2

9

8

B

K

9

G

K

8

1

0

0

L

)

5

(

W

J

(

1

0

J

0

3

G

1

3

1

G

3

4

H

4

5

H

5

6

7

R

K

6

R

K

2

1

7

8

4

0

R

1

1

S

M

2

.

2

W

1

1

0

1

G

S

1

0

2

G

3

3

0

R

k

0

3

3

1

0

0

D

9

1

3

R

1

S

6

1

0

C

7

4

V

5

2

F

B

0

0

5

)

O

E

D

I

V

3

0

0

C

p

0

0

0

1

V

0

0

5

3

0

0

G

S

2

0

0

G

S

5

0

0

L

2

3

0

R

k

0

0

1

P

I

H

C

:

V

0

8

V

1

0

+

8

+

FB001

FB004

6

0

0

B

F

1

0

0

C

p

0

0

0

1

V

0

0

5

B

2

0

0

C

p

0

0

0

1

V

0

0

5

3

1

0

C

p

0

0

0

1

V

0

0

5

B

:

F

B

T

M

R

O

F

B

T

F

O

M

F

R

6

0

N

3

C

G

1

1

T

O

D

C

C

1

1

.

2

K

T

O

D

F

3

0

N

C

P

1

N

C

T

L

(

S

T

B

9

8

+

5

V

D

N

G

7

2

1

+

6

1

H

5

D

N

G

4

+

8

0

3

C

N

2

+

1

8

1

T

O

D

C

V

C

R

V

9

1

H

B

O

A

R

D

1

0

N

5

0

1

3

N

E

W

N

V

B

O

A

R

D

B

T

2

G

B

K

R

K

M

G

G

K

1

G

0

R

U

E

I

P

C

T

U

T

B

E

4

G

V

H

T

O

T

O

B

O

D

A

R

D

O

A

B

A

7

3

0

C

N

7

0

4

3

P

9

H

T

W

)

E

Y

P

Y

5

V

V

V

V

0

D

B

O

A

R

0

6

N

6

R

D

—

A BOARD IC VOLTAGE LIST

,&

SLQ YROW

1&

SLQYROW

SLQ YROW

SLQ YROW

SLQYROW1&

$OOYROWDJHVDUHLQ9

,&

,&

,&

SLQ YROW

,&

,&

— 17 —

D

A

R

O

B

>

A

C

7

V

1

<

1

-

0

8

5

8

8

-

9

7

-

9

Page 18

A

[VIDEO]

CPD-E240

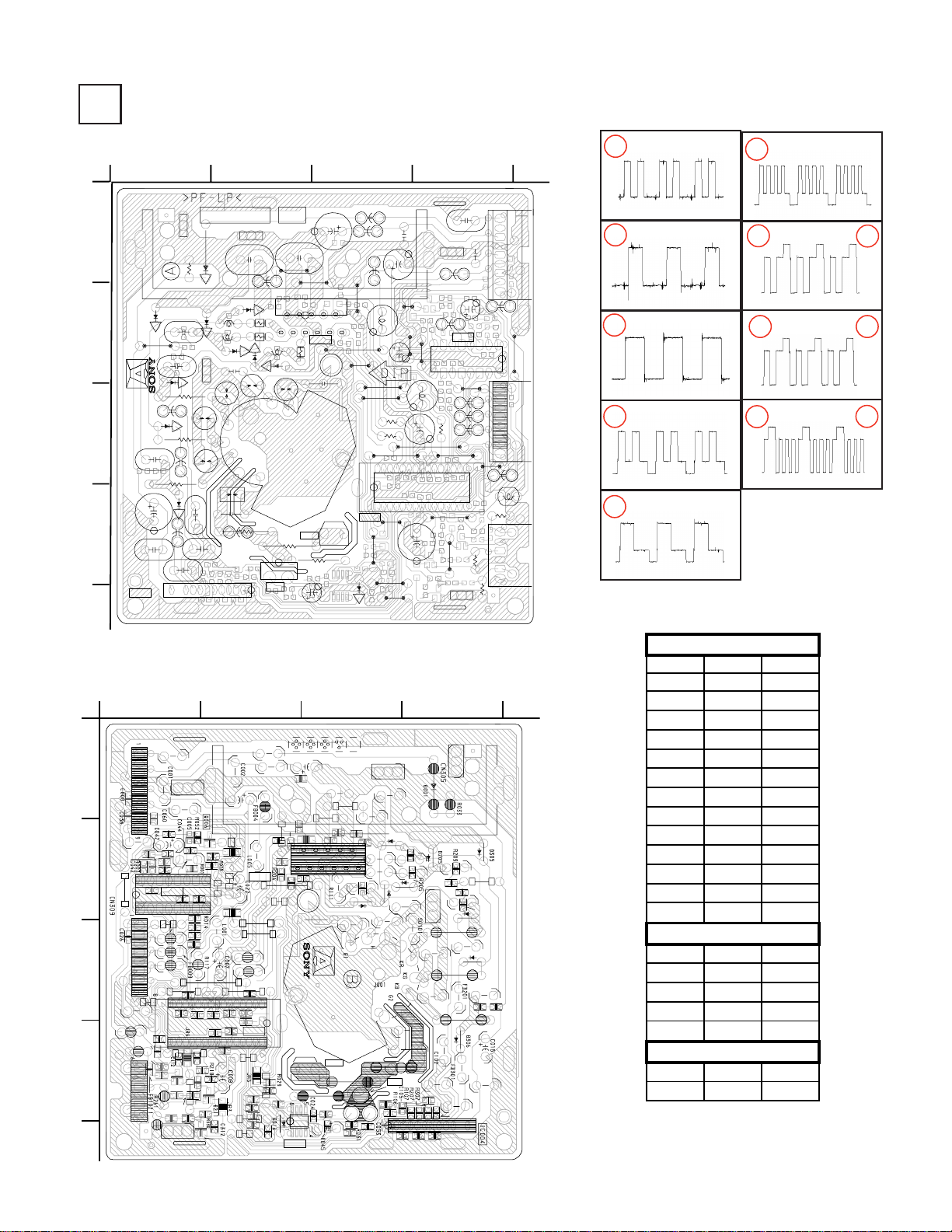

A BOARD WAVEFORMS

COMPONENT SIDE

1

1

-

A

A

5

0

3

B

C

D

D

3

J

2

W

1

5

1

R

1

0

1

B

F

6

0

2

D

1

5

2

R

6

0

3

C

F

B

1

5

3

R

8

1

0

C

3

B

F

4

5

0

C

1

1

C

I

0

0

4

CONDUCTOR SIDE

1

C

N

0

3

4

+

1

8

0

V

N

C

+

8

0

V

A

G

N

D