Page 1

REVISED

17VC

OPERATION MANUAL

TROUBLESHOOTING MANUAL

CHASSIS

TABLE OF CONTENTS

CIRCUIT DESCRIPTION

D Board (Power Supply Section) ............... 2

D Board (Deflection Section) .................... 11

A Board ................................................... 21

U Board ................................................... 24

GENERAL TROUBLESHOOTING ................ 26

PARTS LEVEL BOARD REPAIR ................. 37

TRINITRON® COLOR COMPUTER DISPLAY

9-978-878-02

- 1 -

Page 2

CIRCUIT DESCRIPTION

f

f

A

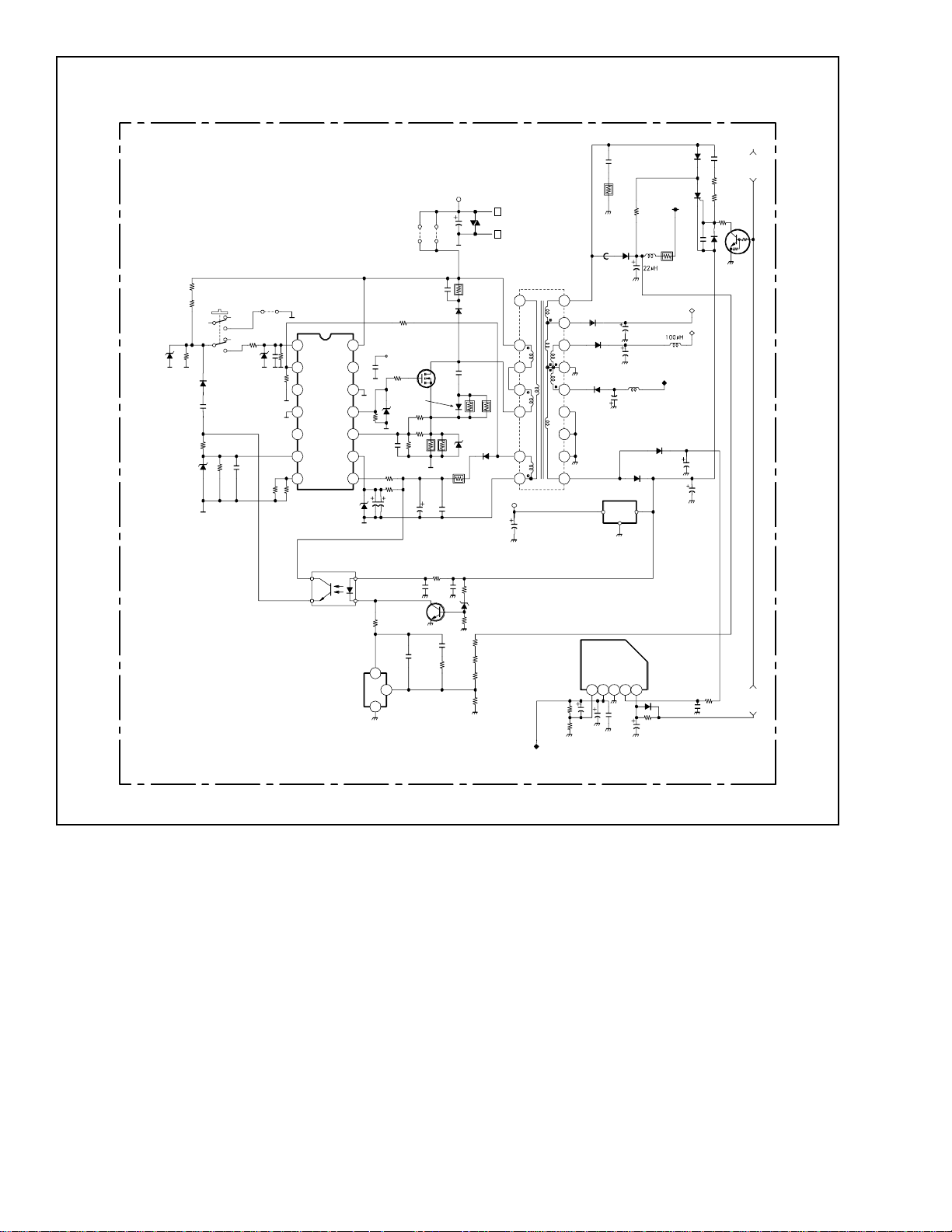

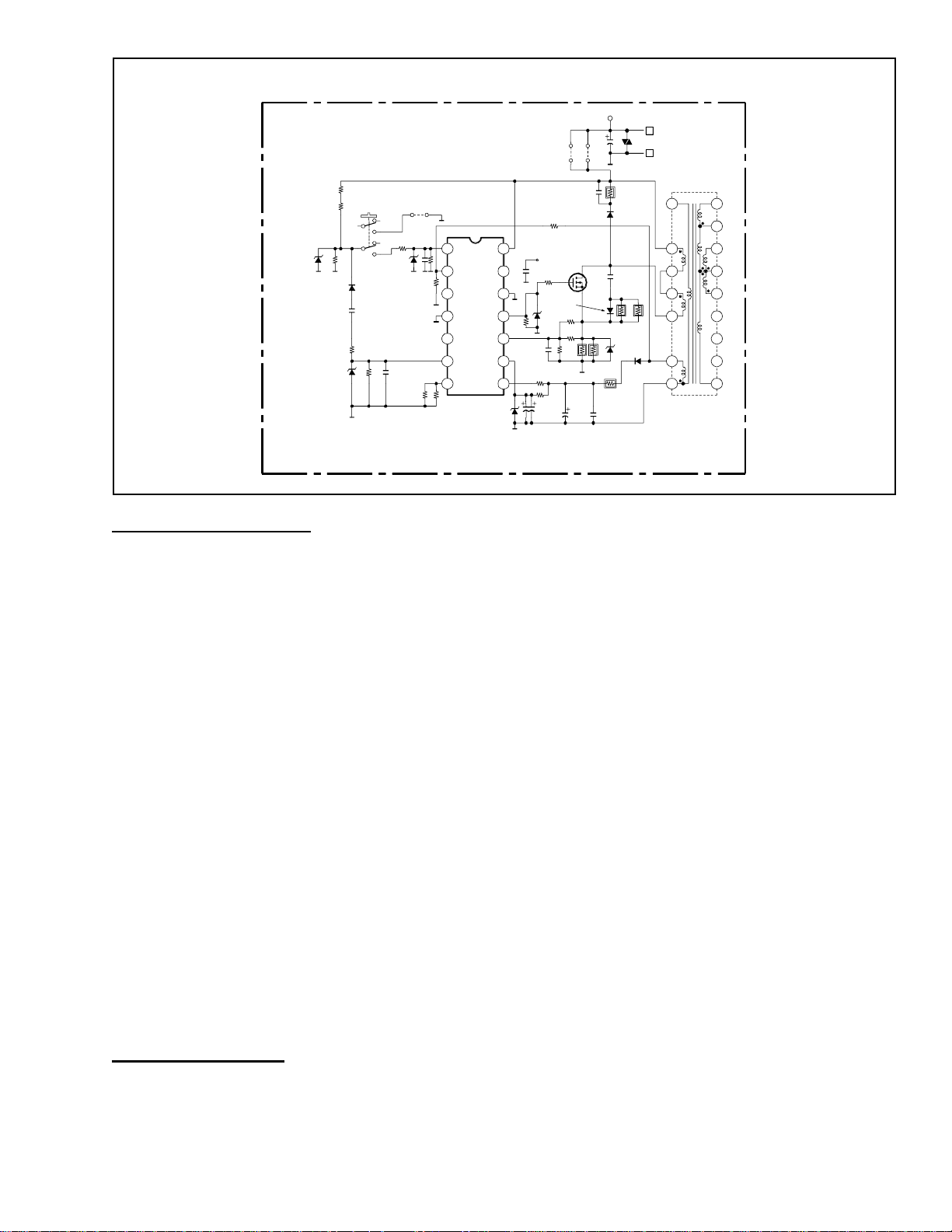

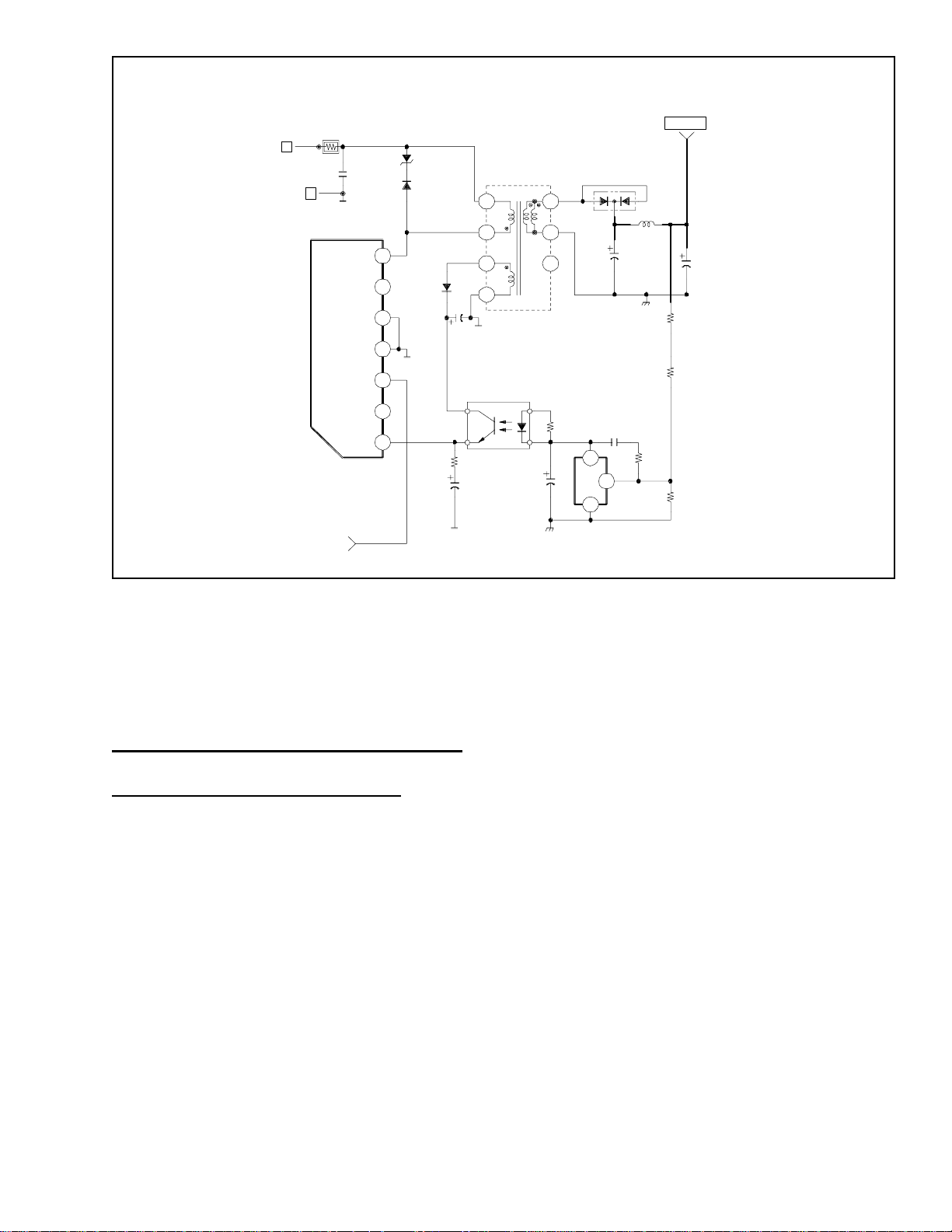

D BOARD POWER SUPPLY SECTION

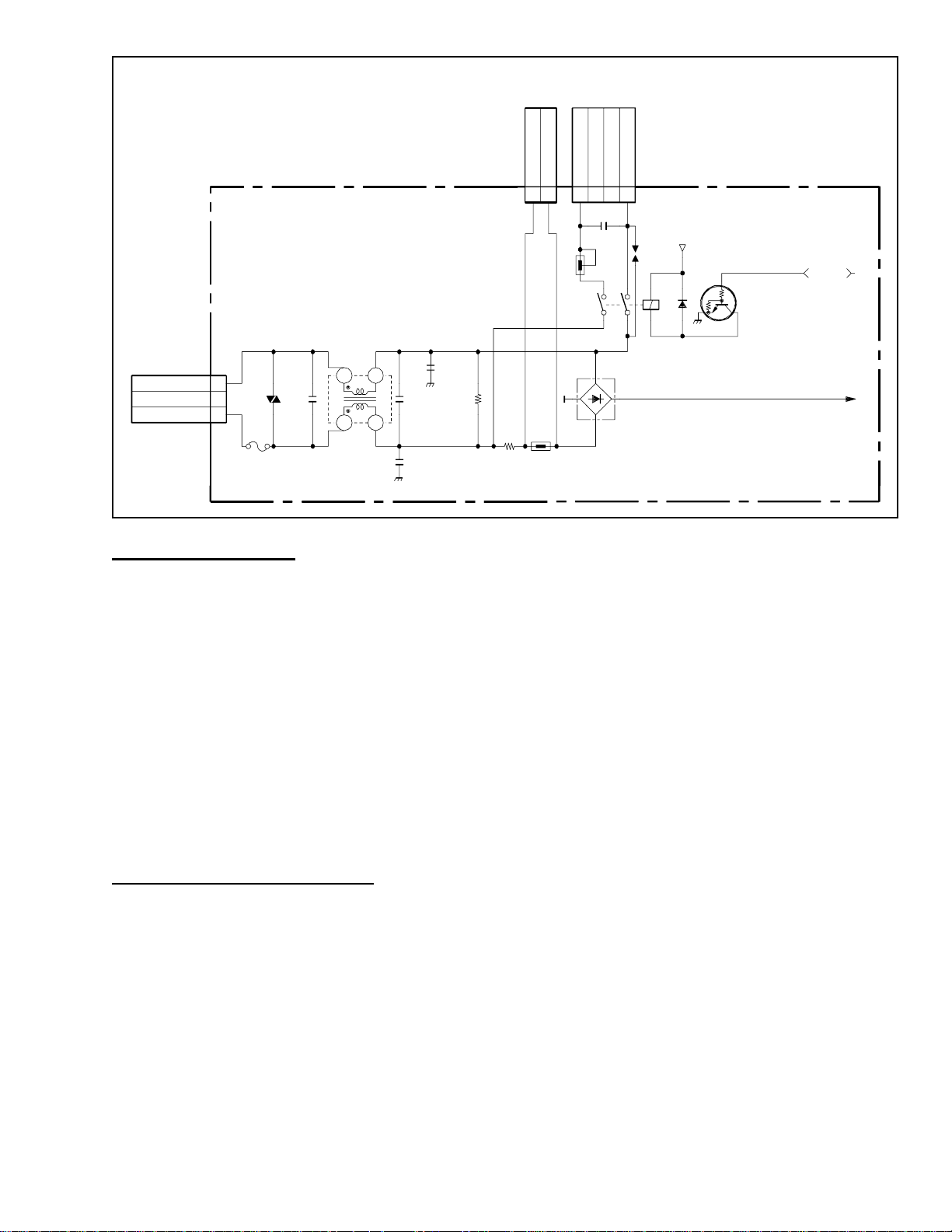

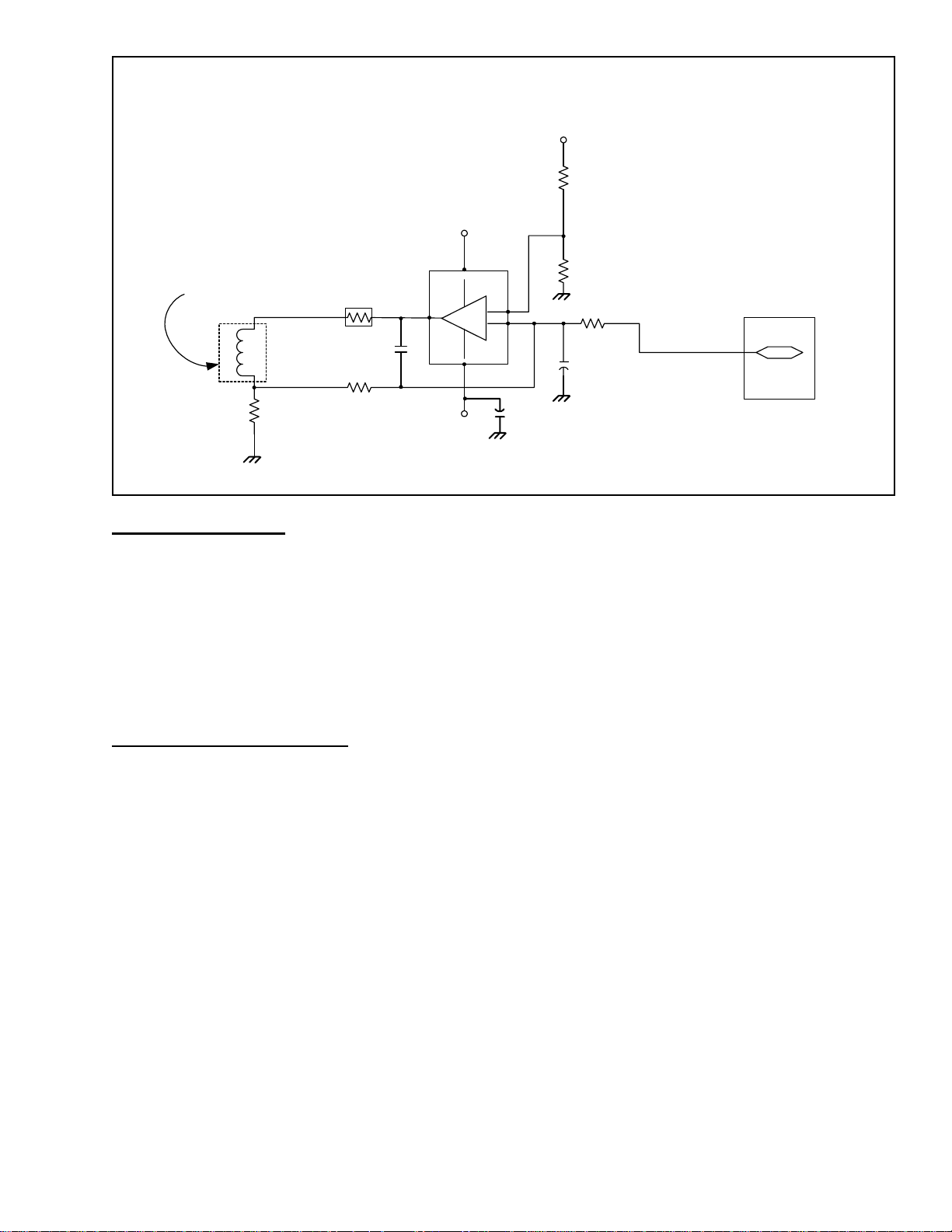

Power Supply Electrical Circuit

The power supply is located on the D Board. It has three modes of operation that are controlled by a microprocessor. The

topology is a discontinuous mode flyback converter with photocoupler feedback for regulating the secondary voltages.

Circuit operation and troubleshooting are explained in the following sections:

Operation Modes Secondary Circuitry

AC Input Protection Circuits

Degauss Circuit Troubleshooting

Primary Circuitry USB/Audio Power Circuit

Operation Modes

The power supply has four modes of operation, off , active off, suspend/standby and active on. These modes are

related to power savings and are indicated by the front panel LED. Additional indications are failure diagnostics and aging

mode. The table below lists operation mode, condition and LED status.

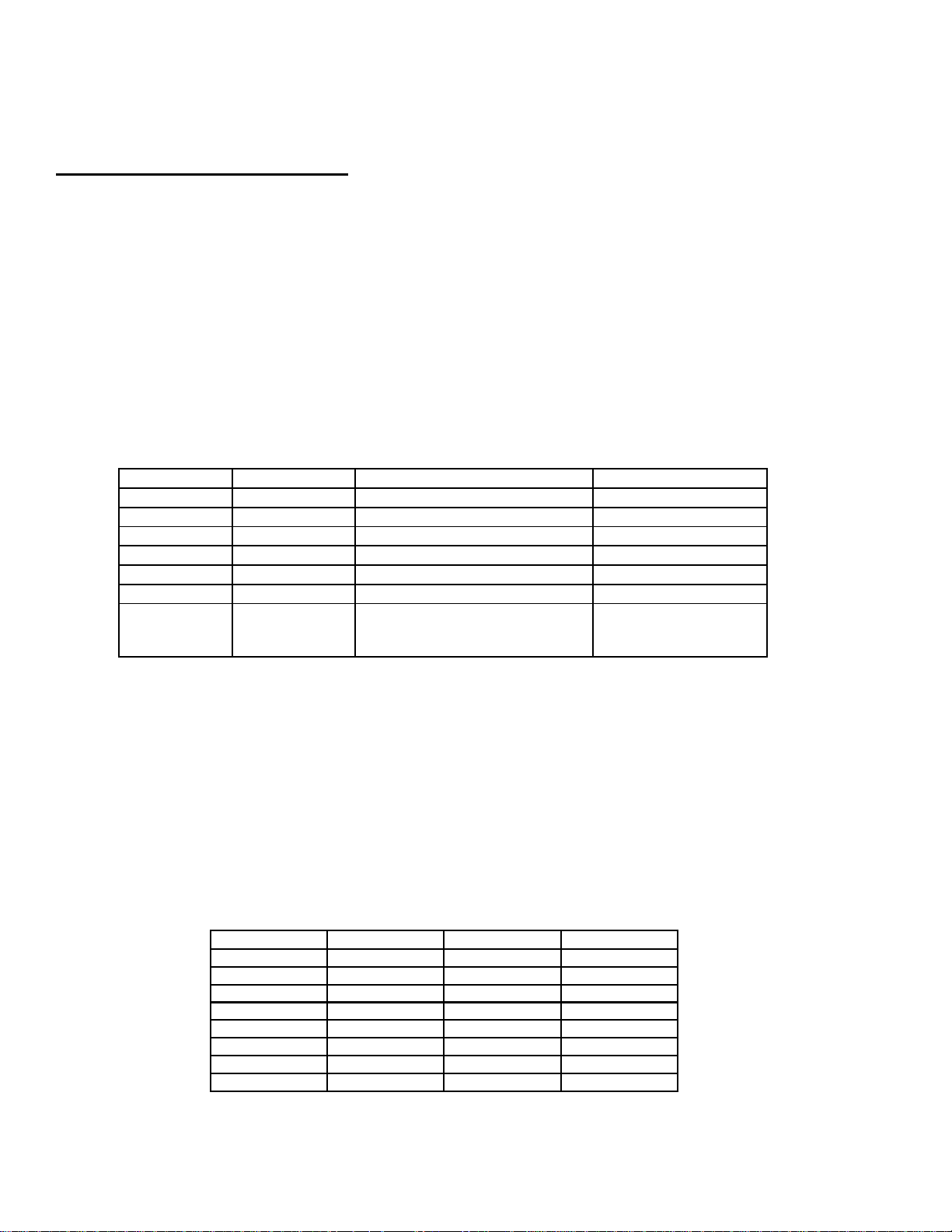

Mode Syncs Condition LED

Off N/A Power Switch Off Off

Active Off No H and/or V Low Power, Heater Off Amber

Active On H and V Present Phase Locked, Normal Operation Green

Failure 1 N/A HV Failure Amber 0.5s<-->Off 0.5s

Failure 2 N/A H Stop, V Stop, S Cap Failure Amber 1.5s<-->Off 0.5s

Failure 3 N/A ABL Failure Amber 0.5s<-->Off 1.5s

Aging/Self Test No H and V Aging Raster or Test Pattern Amber 0.5s<-->Off 0.5s

Green 0.5s<-->Off 0.5s

Amber 0.5s<-->Off 0.5s

Except for power switch off, all modes of operation are controlled by the microprocessor located on the D Board. The

failure modes are detected by the microprocessor and the power supply is forced into active off mode. These functions

are discussed later (Deflection).

With the AC cord attached to the monitor and connected to an AC source, the monitor will be off until the power switch is

turned on. When the power switch is turned on, the power supply starts and is in active off mode. The next step is active

on mode. The active off power saving mode is activated by the microprocessor based upon the absence of either H or V

sync. If H and/or V sync signals are not present, the power supply is set to active off mode.

Power supply operation control signals are "Remote Sw", "Power Sw" and "PFC Sw". During active off mode, Remote Sw

and Power Sw are digital low and PFC Sw is digital high. To enter active on mode, the microprocessor sets PFC Sw to

digital low, then 300mS later, Remote Sw and Power Sw are set to digital high.

Output Of

180V (B+) 0V +13V +179V

80V 0V +6V +79V

+15V 0V +1V +15V

-15V 0V -1V -15V

+12V 0V 0V +12V

5V 0V 0V +5V

Heater 0V 0V +6.3V

STBY 5V 0V +5V +5V

Active Of

ctive On

- 2 -

Page 3

AC Input and Degauss

THP600A

THP600

2

0

6

N

C

P

2

DGC1

DGC2

1

0

6

N

C

NC

NC

P

4

1

2

1

0

6

H

T

5

.

4

S

M

R

V

0

2

2

S

O

P

:

2

0

6

F

N

C

0

0

6

P

3

N

1

V

C

N

2

L

3

C

A

6

0

6

1

.

0

2

5

6

F

0

1

5

A

2

5

V

0

L

L

:

T

F

1

2

4

0

7

4

0

V

3

4

6

C

4

3

7

4

0

p

0

2

5

V

0

0

6

6

C

p

0

4

0

7

2

5

0

V

6

R

0

6

C

0

0

2

.

7

2

5

4

5

6

0

k

8

2

/

1

2

W

V

R

:

C

6

0

0

R

T

H

1

3

1

0

W

3

.

4

R

6

Y

0

6

0

.

9

8

4

A

1

2

3

1

3

6

C

2

1

V

1

0

6

G

S

S

E

U

D

G

A

S

1

0

6

1

0

6

2

D

0

T

S

1

-

5

S

D

1

9

2

1

6

D

1

0

0

6

B

S

4

D

L

.

T

C

E

R

C

A

Q

S

E

P

3

4

T

1

-

C

A

T

D

R

D

Y

.

V

A

L

E

R

1. AC Input Section

The AC input section provides EMI filtering, input protection, surge limiting and CRT degauss operation.

EMI Filter

The EMI filter comprises CN600 (inlet with filter), X-capacitors C604 and C605, Y-capacitors C660 and C643 and the

line filter transformer, LF602. Input protection is provided by F601and VA601; surge current limiting by thermistor

TH600 and resistor R600. Degauss is explained in the next section.

Degauss Circuit

The degauss circuit is used to demagnetize the CRT. After power on, the microprocessor located on the D Board sets the

degauss signal to digital high and Q601 turns on relay RY601. This allows AC current into the degaussing coil through

posistor TH601. The current heats up the posistor and the resistance increases, this dampens the current in the degauss

coil to nearly zero. Duration time is approximately 5-6 seconds and the microprocessor then shuts off RY601, which

disconnects the degauss coil from the AC line. This operation should sufficiently demagnetize the CRT.

2. Primary Circuitry Section

IC601

The heart of the primary section is the TEA1504/N2 power supply controller, IC601. The following describes the functions

of each pin.

Pin 1 Vin: This is a MOSFET drain connection internal to IC601, which is connected directly to the DC mains voltage rail.

The startup current source derives power from the DC mains via the Vin pin. It supplies current to charge the Vaux (IC

supply) capacitors C616, C617 and C681 and also provides current to the IC601 control circuitry.

Pin 2 HVS: High voltage safety spacer pin is a no connection.

Pin 3 NC: Connected to primary side DC mains return.

Pin 4 Driver: Outputs the pulse width modulated gate drive for switching transistor Q602. Maximum duty cycle is set

internally at 80%.

- 3 -

Page 4

Pin 5 Isense: Provides cycle by cycle over current protection by turning off pin 4 driver output when Q602 current

exceeds the current limit corresponding to 500mV at pin 5. This pin typically provides 425nS of leading edge blanking time.

The threshold voltage for switch over to low frequency (low power) operation is sensed by pin 5. When the voltage sensed

at pin 5 is below 165mV, IC601 transitions from operating at high frequency (56.5KHz) to low frequency (23.5KHz).

Pin 6 Vaux: IC601 supply pin. An internal current source from IC601 charges the Vaux capacitors C616, C617 and C681

for startup. Once the Vaux capacitors are charged to the startup voltage level (11V), then IC601 starts switching pin 4 driver

output. The Vaux is also supplied by an auxiliary winding from T601 on the primary side once the secondary output voltages

attain their nominal operating voltage values. Pin 6 also provides under voltage lockout detection (8V) and over voltage

protection (14.7V).

Pin 7 DS: Provides the power supply for the driver output (pin 4).

Pin 8 Iref: Controls IC601 internal bias currents, which determines the pulse width modulated switching frequencies.

High frequency is 56.5KHz during active on mode. Low frequency is 23.5KHz during suspend/standby mode.

Pin 9 Vctrl: Feedback voltage for duty cycle control.

Pin 10 NC: No connection.

Pin 11 Gnd: Connected to primary side DC mains return.

Pin 12 NC: No connection.

Pin 13 Dem: Guarantees discontinuous conduction mode operation for the power supply. Verifies that T601 is demagne-

tized by not activating the next gate drive pulse until the primary side auxiliary winding of T601 is lower than the threshold

level of 65mV as detected at pin 13.

Pin 14 OOB: On/Off/Burst mode input signal. A voltage greater than 2.5V enables IC601.

Operation

The power supply is a discontinuous-mode flyback converter with photocoupler feedback for regulating the secondary

voltages. The PWM controls the pulse width of the gate drive.

When AC is applied to the power supply and IC601 pin 14 is greater than 2.5V, start up current is supplied though IC601 pin

1 to IC601 pin 6. Startup voltage is approximately 11V. After start up, the voltage to pin 6 and pin 7 of IC601 is supplied

through D620 connected to T601 pin 1. The first mode of operation is active off mode. The output drive pulse frequency

will be in burst mode operation.

When the power supply enters active on mode, the switching frequency will be 56.5KHz. The Vaux level will be approximately 12.3 volts. OVP threshold is 14.7 volts and UVLO is 8.0 volts. Therefore, if the Vaux voltage is not correct, the

power supply will not operate properly.

Feedback from the secondary side comes through IC603 and IC604, which is connected to IC601 pin 9. (See diagram on

page 5.)

3. Secondary Circuitry Section

The secondary section consists of the following circuits: Rectifier diodes and filters for all output voltages, +5/12 volt

regulators, +5 standby regulator, heater voltage regulator, voltage feedback circuit, active off mode feedback, and protection circuits. This section will describe each circuit and its function.

Secondary Rectifiers

The secondary rectifiers supply the following voltages: 180V (B+) for deflection and video, 80V for video, ±15V for

deflection and regulators, 6.3V for heater regulator, and +5V standby regulator.

- 4 -

Page 5

2

0

C

6

0

p

1

0

0

V

5

0

6

7

p

4

k

V

2

7

6

6

R

0

1

3

5

-

1

V

5

5

6

0

R

)

.

5

7

W

(

J

1

C

6

0

3

3

1

3

6

J

W

0

4

0

)

5

7

.

W

(

J

3

6

1

R

M

.

7

4

W

/

2

1

2

0

R

6

S

M

7

4

.

W

2

1

/

2

1

5

6

R

0

k

8

6

I

P

H

:

C

5

-

D

Z

U

2

3

6

D

B

2

1

7

-

7

T

-

-

Z

J

T

M

1

1

S

S

1

6

5

C

6

0

P

I

C

H

:

8

6

1

R

6

1

R

0

2

2

k

1

P

-

C

R

N

:

C

-

N

R

:

1

D

6

7

-

7

-

-

T

J

T

Z

M

1

9

R

0

J

0

2

6

D

E

-

T

D

6

-

9

0

P

0

.

4

P

I

0

C

H

:

1

4

6

1

C

1

.

0

0

9

3

6

R

I

P

H

C

4

:

B

7

0

4

5

2

6

B

3

1

7

-

1

6

6

1

R

M

.

0

1

9

0

P

H

I

C

:

D

5

T

2

8

6

9

R

k

5

6

P

H

I

C

:

5

6

1

C

2

0

2

.

0

P

H

I

C

:

6

6

0

R

k

7

0

4

B

7

P

-

C

R

N

:

1

0

6

I

C

2

N

4

-

0

1

5

A

E

T

.

G

E

R

W

S

L

O

R

N

T

O

C

4

O

B

O

1

3

M

E

D

1

2

N

C

1

1

R

D

D

N

G

1

0

I

S

N

C

1

V

T

C

R

L

9

E

R

F

I

8

0

6

2

R

k

3

3

P

-

C

N

R

:

J

-

Z

M

T

I

6

L

P

T

O

C

T

O

P

H

C

C

C

R

4

3

E

4

7

6

C

0

p

7

4

0

V

0

5

B

N

I

V

H

E

V

I

N

E

S

A

V

3

6

D

7

-

T

0

6

C

1

D

2

U

P

O

T

N

O

I

4

A

S

O

R

R

O

T

1

H

E

S

V

2

C

N

3

R

4

3

6

0

R

k

.

8

1

C

R

:

E

5

5

0

6

C

0

0

6

8

I

H

:

C

X

U

6

5

6

5

R

0

1

0

D

S

7

8

1

8

-

7

1

6

8

C

7

4

.

V

5

0

3

-

Y

4

E

R

L

L

R

O

1

2

2

6

4

R

0

3

9

P

-

C

R

N

:

3

4

6

0

C

N

A

L

3

1

P

A

M

R

2

1

2

6

C

6

8

0

0

.

0

V

5

2

1

2

R

6

5

k

7

P

I

C

H

:

2

0

Q

6

4

3

8

K

2

S

2

2

6

0

Q

K

I

T

N

A

S

G

.

E

R

W

S

T

U

O

2

1

R

6

2

2

W

4

1

/

4

U

F

D

Z

M

T

p

P

R

6

N

:

R

1

6

6

C

2

2

V

5

2

C

S

2

1

1

6

C

0

p

8

6

I

C

H

:

1

1

C

6

0

2

7

k

2

S

7

6

0

D

2

3

G

0

7

0

7

6

5

R

8

0

6

8

-

1

J

2

3

6

R

3

3

J

Z

T

M

4

6

5

R

4

4

2

1

R

6

9

.

3

0

7

4

0

.

2

2

1

W

1

W

P

-

C

S

R

:

S

R

:

2

6

2

R

2

2

I

P

H

:

C

7

6

1

C

C

2

2

V

2

5

1

7

R

6

0

0

1

P

I

C

H

:

:

3

3

6

C

.

1

0

I

P

H

:

C

4

0

6

Q

1

A

1

3

3

T

R

O

P

3

4

C

6

p

0

7

0

4

P

I

C

H

:

4

3

R

6

P

k

2

8

P

C

N

-

R

:

A

A

0

V

B

B

3

0

A

6

V

0

1

T

6

R

T

S

E

W

5

6

3

R

k

2

2

W

3

S

:

R

6

6

0

D

2

3

G

7

0

0

4

U

F

3

p

1

9

6

R

5

6

6

R

V

5

k

.

1

5

k

.

1

W

2

2

W

S

:

R

R

S

:

6

6

1

D

B

7

.

-

4

7

-

7

T

-

2

D

6

D

1

0

P

G

R

0

4

R

6

1

D

P

R

:

F

8

6

1

1

0

.

T

:

P

5

6

C

6

.

1

0

5

V

2

P

I

C

H

1

1

R

6

2

2

I

P

C

H

:

D

6

-

7

T

J

-

Z

T

M

7

4

R

6

0

k

1

8

0

6

R

k

5

0

1

N

:

R

5

0

R

6

0

k

1

2

N

:

R

4

8

6

R

6

k

.

5

C

P

N

-

R

:

0

9

6

R

9

k

.

3

P

-

C

N

:

R

N

0

9

1

1

1

7

1

2

3

6

1

5

1

5

6

4

1

7

1

8

1

1

0

3

G

2

Y

B

T

S

0

8

C

6

2

0

2

5

0

B

2

-

1

7

4

1

2

V

5

1

4

C

6

0

0

1

V

6

1

8

6

2

R

k

.

1

9

P

-

C

N

:

R

9

6

4

R

k

.

2

2

P

-

C

R

N

:

V

3

.

6

R

T

E

A

T

H

O

E

0

W

3

1

6

1

D

A

6

U

2

-

M

C

F

0

1

6

F

B

2

1

C

6

4

7

0

V

2

5

C

7

6

1

D

R

6

1

0

G

P

1

1

8

6

D

2

S

1

-

G

N

F

M

2

3

C

6

0

0

1

0

V

5

2

2

2

D

6

S

2

G

1

-

M

N

F

6

0

C

0

0

1

2

5

D

1

0

7

6

I

C

5

T

0

B

A

G

E

R

V

5

O

G

1

J

D

D

T

A

N

U

V

G

O

0

3

C

6

0

.

1

V

0

1

7

3

C

6

6

0

C

0

2

2

7

4

V

6

1

V

1

0

G

0

7

0

4

U

F

D

T

B

5

6

2

R

8

1

0

k

.

2

2

W

/

2

1

7

6

2

R

7

.

4

0

W

/

2

1

2

6

0

L

S

S

1

2

6

2

0

0

1

V

0

0

6

0

L

V

5

1

-

0

6

L

6

0

0

1

3

0

V

1

9

6

D

2

S

1

-

G

N

M

F

4

6

1

D

A

2

T

-

S

6

N

.

3

I

2

0

6

I

C

V

T

-

S

0

A

0

A

B

G

E

R

R

E

A

T

E

H

C

L

C

T

V

C

3

6

0

D

12345

-

2

9

1

S

1

S

1

0

7

R

6

1

2

k

2

I

P

C

H

:

2

6

1

D

6

3

C

B

2

3

1

3

6

9

G

4

1

V

9

6

1

C

2

0

2

.

0

0

P

H

I

:

C

B

1

6

2

D

D

5

T

2

9

-

1

1

V

0

8

V

5

1

4

2

5

C

6

0

0

2

2

5

V

2

2

C

6

0

3

3

6

1

5

.

R

1

T

D

5

:

8

2

6

C

4

7

.

0

5

V

2

I

P

H

:

C

F

W

S

6

6

3

R

R

W

k

7

4

P

W

1

0

6

R

6

k

7

4

W

1

6

6

2

R

k

.

2

2

I

P

H

:

C

3

6

0

Q

K

A

E

1

4

1

C

D

T

R

T

E

A

H

E

W

S

4

0

V

7

9

6

2

.

W

1

S

R

W

S

R

W

P

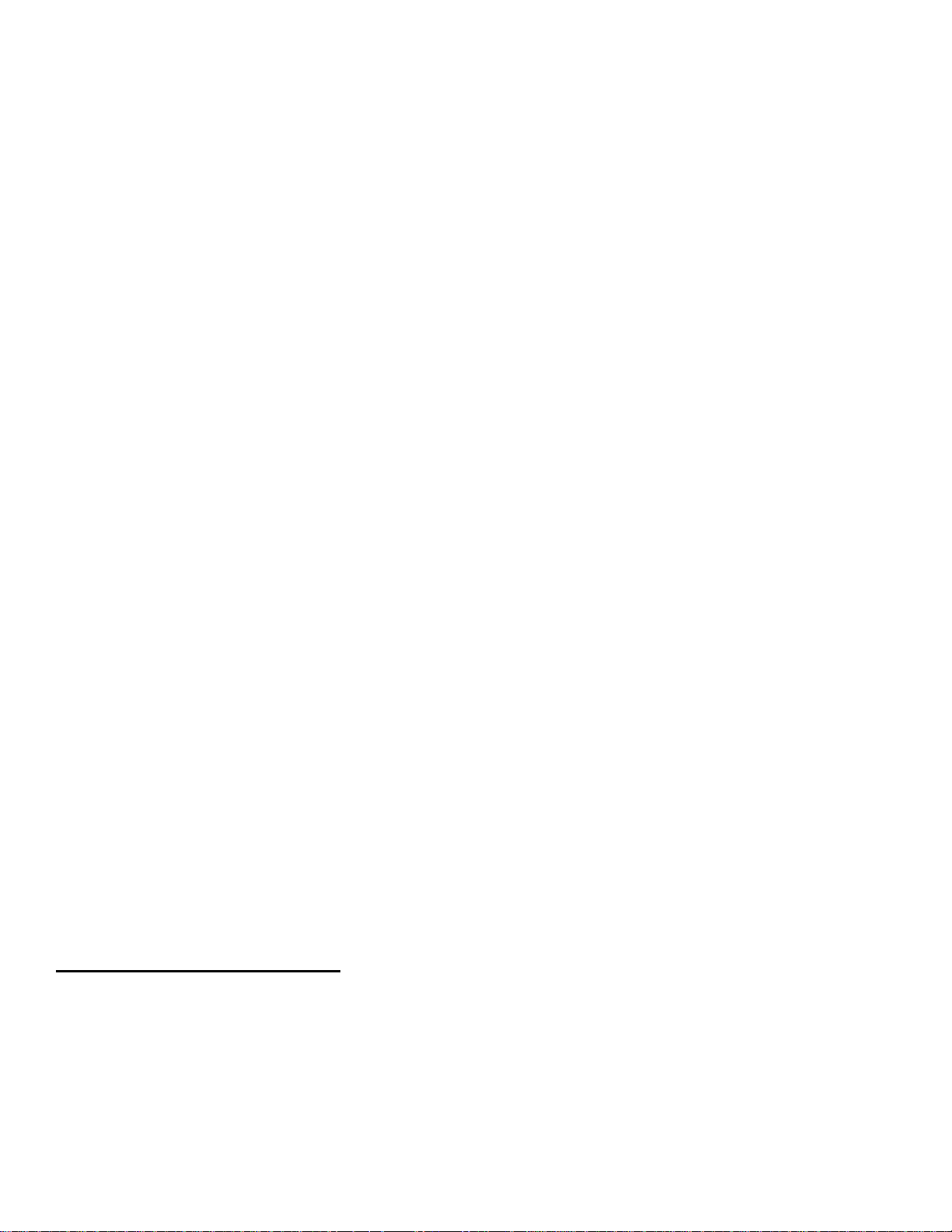

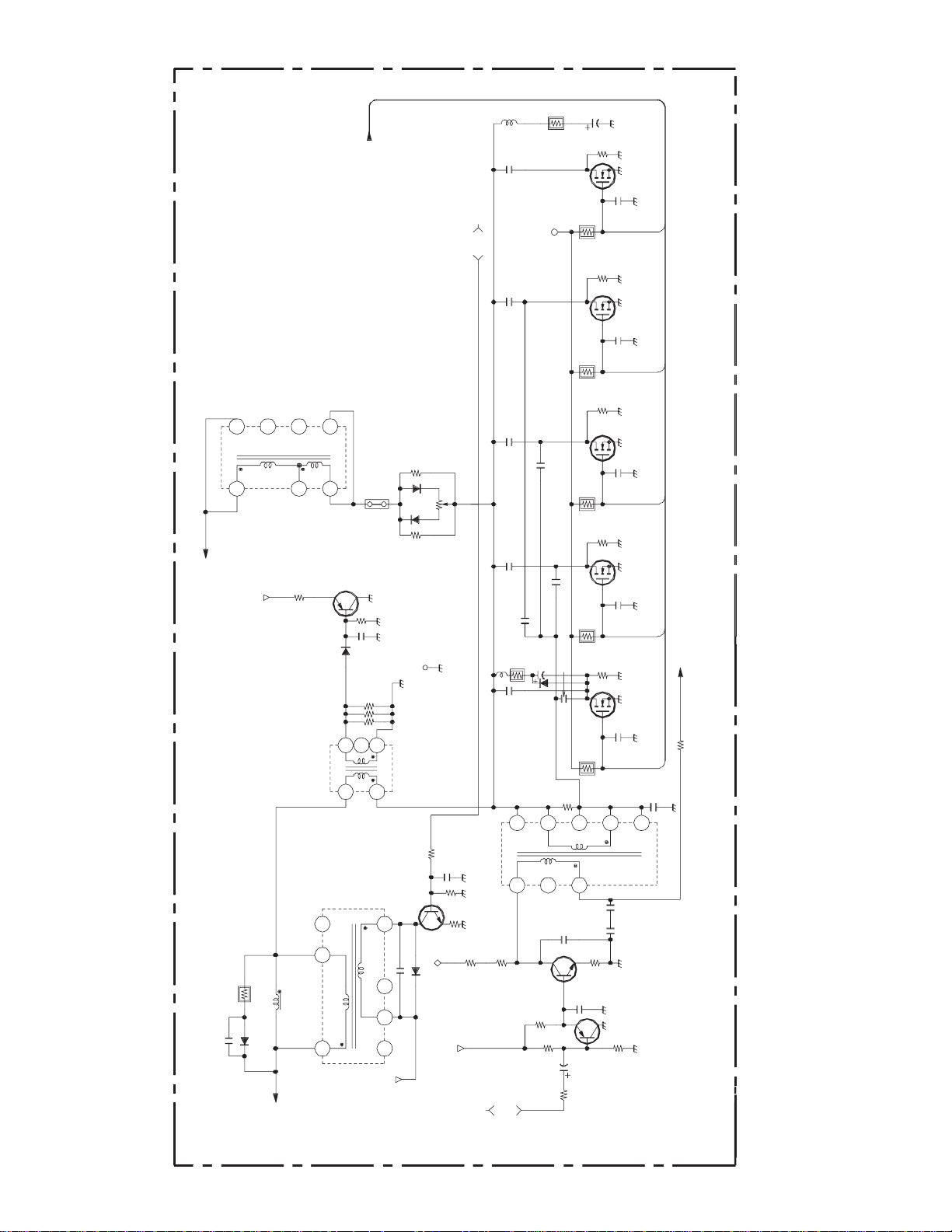

+5/12 Volt Regulator

IC605 is the +12V regulator and IC608 is the +5V regulator. The output voltages are supplied to the microprocessor,

deflection and video circuits. The +15V line provides the input voltage for +12V regulator; the +12V line provides the input

voltage for +5V regulator. During active off mode, the +12V regulator is disabled via Remote Sw and subsequently the 5V

regulator is disabled.

+5V Standby Circuit

IC607 is the standby 5V regulator. In the active on mode the input to the regulator is supplied from T601 winding 14-13.

During the active off mode, the regulator input is supplied from T601 winding 10-13 via D612 and D613. Typical input

voltages to the regulator are active on mode: 9.5V; active off mode: 11.5V.

Heater Voltage Regulator

Heater filament voltage is supplied by T601 winding 14-13 and is regulated by IC602 to 6.3V during active on mode. IC602

output is turned on and off by the Power Sw control line at pin 1, CTL. The output is off during active off mode.

Feedback Circuit

The feedback circuit is divided into two sections. One is for active on mode; the other for active off mode. The following two sections explains the theory and operation.

Active On Mode Feedback

Shunt regulator IC604 regulates the B+ line to 179.2V by sinking current through the opto coupler 1C603 to ground. The

- 5 -

Page 6

Feedback Circuits

2

0

C

6

0

p

1

0

0

V

5

0

6

7

p

4

k

V

2

7

6

6

R

0

1

3

5

-

1

V

5

5

6

0

R

)

.

5

7

W

(

J

1

0

C

6

0

3

3

1

3

6

J

W

W

(

J

3

6

1

R

M

.

7

4

W

/

2

1

2

0

R

6

6

S

M

7

4

.

W

2

1

/

2

1

5

6

R

0

k

8

6

I

P

H

:

C

5

T

-

D

Z

2

6

D

7

7

T

-

-

Z

J

T

M

U

3

B

2

1

-

D

1

1

S

S

1

6

5

C

6

0

P

I

C

H

:

8

6

1

R

0

6

1

R

0

2

2

k

1

P

-

C

R

N

:

C

-

N

R

:

0

1

D

6

7

-

7

-

-

T

J

T

Z

M

1

9

R

0

J

0

2

D

E

-

0

6

-

9

P

.

4

P

I

0

C

H

:

1

4

6

1

C

1

.

0

0

9

3

6

R

I

P

H

C

4

:

B

7

0

4

5

2

6

B

3

1

7

-

1

6

6

1

R

M

.

0

1

9

P

H

I

C

:

D

5

T

2

8

6

9

R

k

5

6

P

H

I

C

:

5

6

1

C

2

0

2

.

0

P

H

I

C

:

6

6

0

R

k

7

0

4

B

7

P

-

C

R

N

:

1

0

6

I

C

2

N

4

-

0

1

5

A

E

T

.

G

E

R

W

S

L

O

R

N

T

O

C

4

N

I

V

OOB

1

3

HVS

M

E

D

1

2

C

N

N

C

1

1

E

R

RIV

D

D

N

G

1

0

E

ENS

I

S

N

C

1

X

A

U

V

VCT

R

L

9

D

S

REF

I

8

0

6

2

R

k

3

3

8

3

6

D

P

-

C

N

R

:

1

8

-

7

7

-

T

J

-

Z

M

T

0

3

6

C

I

-

Y

4

1

D

2

6

L

P

T

E

R

L

U

P

O

O

C

T

O

P

H

L

R

O

T

N

C

O

C

C

R

4

3

4

6

0

C

I

A

L

3

1

4

A

S

A

M

O

R

R

R

E

R

7

C

:

4

7

6

C

0

p

7

4

0

V

0

5

B

6

O Q

T

1

I

ATS

H

E

2

1

R

6

2

2

2

W

4

1

/

3

4

U

F

D

Z

M

T

4

3

6

0

R

k

.

8

1

C

R

:

5

5

0

6

C

0

p

0

6

8

I

P

H

:

C

6

R

6

5

6

5

R

N

:

R

0

1

0

7

1

6

6

C

2

2

V

5

2

1

6

8

C

7

4

.

V

5

0

1

2

C

S

2

2

6

4

R

0

3

9

P

-

C

R

N

:

1

1

6

C

0

p

8

6

I

C

H

:

3

N

1

P

2

0

V

4

0

)

5

7

.

1

2

6

C

6

8

0

0

.

0

V

5

2

1

2

6

5

k

P

I

H

2

0

Q

6

4

3

8

K

2

S

2

2

0

K

N

G

.

E

R

W

S

T

U

O

1

C

6

0

2

7

V

k

2

S

7

6

0

D

2

3

G

0

7

0

7

6

5

R

8

0

6

8

-

1

J

2

3

6

R

3

3

J

-

Z

T

M

4

6

5

R

4

4

2

1

R

6

9

.

3

0

2

2

7

4

0

.

1

W

P

-

C

1

W

S

R

:

S

R

:

2

6

2

R

2

2

I

P

H

:

C

7

6

1

C

2

6

2

C

0

V

2

5

:

C

1

7

R

6

0

0

1

P

I

C

H

:

:

3

3

6

C

.

1

0

I

P

H

:

C

4

0

6

Q

1

A

1

3

3

T

R

O

P

3

4

C

6

p

0

7

0

4

P

I

C

H

:

4

3

R

6

P

k

2

8

P

C

N

-

R

:

A

A

B

B

3

0

A

6

V

0

1

T

6

R

T

S

E

W

5

6

3

R

k

2

2

W

3

S

:

R

6

6

0

D

2

3

G

7

0

0

4

U

F

3

p

1

9

6

R

5

6

6

R

5

k

.

1

5

k

.

1

W

2

2

W

S

:

R

R

S

:

6

6

1

D

B

7

.

-

4

7

-

7

T

0

2

D

6

G

D

1

0

P

G

R

0

4

R

6

1

D

P

R

:

F

8

1

1

.

T

P

C

5

6

6

.

1

0

5

V

2

P

I

C

H

1

1

R

6

2

2

I

P

C

H

:

D

6

-

7

T

J

-

Z

T

M

7

4

R

6

0

k

1

8

0

6

R

k

5

0

1

N

:

R

5

0

R

6

0

k

1

2

N

:

R

4

8

6

R

6

k

.

5

C

P

N

-

R

:

0

9

6

R

9

k

.

3

P

-

C

N

:

R

N

0

9

1

1

1

7

1

2

3

6

1

5

1

5

6

4

1

7

1

8

1

1

3

2

Y

B

T

S

0

8

6

2

0

2

5

0

B

2

-

1

7

4

1

2

V

5

1

4

C

6

0

0

1

V

6

1

8

6

2

R

k

.

1

9

P

-

C

N

:

R

9

6

4

R

k

.

2

2

P

-

C

R

N

:

V

3

.

6

R

T

E

A

T

H

O

E

0

W

3

1

6

1

D

A

6

U

2

-

M

C

F

0

1

6

F

B

2

1

C

6

4

7

0

V

2

5

C

7

6

1

D

R

6

1

0

G

P

1

1

8

6

D

2

S

1

-

G

N

F

M

2

3

C

6

0

0

1

0

V

5

2

L

2

2

D

6

S

2

G

1

-

M

N

F

6

0

C

0

0

1

2

5

D

1

0

7

6

I

C

5

T

0

B

A

G

E

R

V

5

O

G

1

J

D

D

T

A

N

U

V

G

O

0

3

C

6

0

.

1

V

0

1

7

3

C

6

6

0

C

0

2

2

7

4

V

6

1

V

1

0

G

0

7

0

4

U

F

D

T

B

5

6

2

R

8

1

0

k

.

2

2

W

/

2

1

7

6

2

R

7

.

4

0

W

/

2

1

2

6

0

L

S

S

1

2

6

2

0

0

1

V

0

0

6

0

L

V

5

1

-

0

6

6

0

0

1

3

0

V

1

9

6

D

2

S

1

-

G

N

M

F

4

6

1

D

A

2

T

-

S

6

N

.

3

I

2

0

6

I

C

V

T

-

S

0

A

0

A

B

G

E

R

R

E

A

T

E

H

C

L

C

T

V

C

3

6

0

D

12345

-

2

9

1

S

1

S

1

0

7

R

6

1

2

k

2

I

P

C

H

:

2

6

1

D

6

3

C

B

2

3

1

3

6

9

G

4

1

V

9

6

1

C

2

0

2

.

0

0

P

H

I

:

C

B

1

6

2

D

D

5

T

2

9

-

1

1

V

0

8

V

5

1

4

2

5

C

6

0

0

2

2

5

V

2

4

2

C

6

0

0

3

3

V

6

1

5

.

R

6

1

1

T

D

5

:

8

2

6

C

4

7

.

0

5

V

2

I

P

H

:

C

F

W

S

6

6

3

R

R

W

k

7

4

P

W

1

0

6

R

6

k

7

4

W

1

6

6

2

R

k

.

2

2

I

P

H

:

C

3

6

0

Q

K

A

E

1

4

1

C

D

T

R

T

E

A

H

E

W

S

7

9

2

.

W

S

R

W

S

R

W

P

reference voltage at IC604 pin 1 determines the sink current into pin 3. The reference voltage is set to 2.5 volts by

resistor divider R608, R650, R648, and R609. Since the B+ is connected to the resistor divider, any change in B+ voltage

is detected at the reference terminal. The shunt regulator will either increase or decrease the current into pin 3 in order

to decrease or increase the B+ voltage respectively and try to maintain the reference voltage to 2.50 volts. IC603 biases

it's phototransistor accordingly and drives IC601 pin 9 (Vctrl) which changes the duty cycle at IC601 pin 4 (driver) to

regulate the B+ voltage at 179.2V.

Active Off Mode Feedback

Power Sw control line is low (heater off) during active off mode and respectively Q603 is off. Voltage pulses from T601 pin

10 flow through C620, R636, and R660 triggering the gate of thyristor D613. D613 turns on effectively shorting the B+ rail

to the standby 5V regulator input; current flows from T601 pin 10 through D612 and D613 to the standby 5V regulator input.

When the standby 5V regulator input is increased to approximately 12.7V it forward biases zener diode D605 turning on

Q604 and sinks current through IC603 to ground. The standby 5V input supplies this current to IC603 pin 1. IC603 biases it's

phototransistor and drives current through D609 into IC601 pin 14 (OOB) triggering burst mode operation. IC601 pin 4

(driver) is pulled low turning off switching transistor Q602. T601 pin 1 (auxiliary winding) feedback pulses are discontinued and IC601 pin 6 (Vaux) decreases to 8V. IC601 internal current source then charges pin 6 (Vaux) to the startup voltage

level (11V) which starts switching pin 4 driver output. The feedback cycle is then repeated. The burst repetition rate is

approximately every 110mS and when IC601 pin 4 is switching its frequency is 23.5KHz.

- 6 -

Page 7

J

Z

M

T

4. Protection Circuits

Protection Circuits

-

V

5

5

3

1

5

0

6

R

)

5

.

7

(

W

J

0

1

6

C

0

3

3

3

1

6

W

J

7

(

W

J

3

1

6

R

M

7

.

4

W

2

/

1

2

0

6

R

4

1

6

R

8

6

C

:

3

6

2

D

B

1

2

-

7

7

-

T

-

0

6

S

M

7

.

W

2

/

2

5

1

k

0

P

I

H

5

T

E

-

D

Z

U

6

D

9

1

S

1

S

1

5

6

6

C

0

P

I

H

C

:

8

1

6

R

0

1

6

R

0

2

2

k

1

P

C

-

N

R

:

P

C

-

N

R

:

0

6

1

D

4

-

7

-

7

T

-

Z

J

T

M

9

1

0

R

J

2

D

-

0

-

.

P

I

H

C

:

0

1

4

1

6

C

1

0

.

0

3

9

6

R

4

6

1

9

2

7

P

I

H

C

:

B

0

7

4

5

2

3

B

1

-

7

6

1

6

R

M

0

.

1

P

I

H

C

:

8

9

6

R

D

T

5

k

6

5

P

I

H

C

:

5

1

6

C

2

2

0

.

0

P

I

H

C

:

6

0

6

R

k

0

7

4

P

C

-

N

R

:

B

1

6

0

C

I

2

-

N

4

5

0

1

E

A

T

.

E

G

R

S

W

L

R

O

T

N

C

O

4

N

I

V

B

O

O

1

3

E

D

1

2

C

N

1

1

N

G

1

0

C

N

1

C

V

9

R

I

8

0

2

6

R

k

3

3

P

C

-

N

R

:

1

S

V

H

M

2

C

N

3

R

E

V

I

R

D

D

4

E

S

N

E

S

I

5

X

U

A

V

L

R

T

6

S

D

F

E

7

8

6

3

D

8

1

7

-

7

T

-

-

J

T

Z

M

6

R

7

H

C

:

7

4

6

C

p

0

7

4

V

0

0

5

B

0

6

Q

O

T

N

I

S

T

A

E

H

2

1

6

R

2

2

W

4

/

1

0

4

F

U

D

6

Z

J

T

M

3

0

6

R

k

8

.

1

C

R

:

0

5

6

C

p

0

0

8

6

P

I

H

C

:

2

6

R

5

5

6

R

2

-

N

R

:

0

0

1

6

R

2

H

C

:

6

1

6

C

2

2

V

5

2

1

8

6

C

7

.

4

V

0

5

V

0

0

4

)

5

.

2

1

6

C

8

6

0

.

0

V

0

5

2

1

2

k

5

P

I

2

0

Q

6

3

4

2

8

K

2

S

2

K

.

G

R

E

S

W

T

O

U

1

6

C

0

7

2

k

2

S

7

0

D

6

3

G

2

7

0

7

5

6

R

8

0

1

8

-

3

2

6

R

3

3

-

J

T

Z

M

4

5

6

R

4

4

1

6

R

9

3

.

0

7

4

.

0

2

W

1

W

1

P

C

S

R

:

S

R

:

2

2

2

P

I

7

1

6

C

2

2

6

C

V

5

2

0

:

ABA

B

3

0

6

A

V

5

3

6

R

k

2

2

W

3

S

R

:

0

6

6

D

3

G

2

7

0

0

4

F

U

3

p

9

1

6

R

6

5

6

R

V

k

5

.

1

k

5

.

1

W

2

W

2

S

R

:

S

R

:

1

6

6

D

B

.

7

4

7

-

7

-

T

2

0

6

D

3

2

D

G

0

P

1

G

R

0

4

6

R

1

D

R

P

F

:

8

1

1

.

T

P

1

0

6

T

T

R

S

W

E

N

9

7

6

5

4

1

2

0

1

1

1

2

1

3

1

5

1

6

1

7

1

8

1

4

1

The following are protection circuits: OCP, OVP, UVLO and secondary short circuits. OCP is pulse by pulse and is performed

on the primary side. OVP detects excessive output voltages. UVLO detects output under voltages. The following will explain

the operation of these functions.

OCP

OCP is activated if there is too much current passing through the switching power MOSFET, Q602. This condition will

occur if either the B+ line or 80 volt line is shorted.

R614 and R654 are the current sense resistors. Current through these resistors will produce a positive voltage. R623,

R624, R657 and C650 provide a voltage divider and filter to IC601 pin 5 (Isense). If the voltage level exceeds 0.5 volts, the

IC does pulse by pulse current limit and the output voltages are reduced. This condition can be audible and characterized by

a chirping sound.

OVP and UVLO

The OVP and UVLO functions are detected by IC601 pin 6 (Vaux). Vaux is typically 12.3V. In the event the regulation control

loop were to fail, the output voltages would either increase or decrease; then Vaux would increase or decrease respectively

via T601 transformer coupling. IC601 pin 6 will detect an OVP at 14.7V and UVLO at 8V turning off the driver output and

initiating a low dissipation safe-restart mode.

Secondary Short Circuits

Safe operation during secondary short circuits is provided by the demag function of IC601 pin 13. Demag protection

reduces the switching frequency, thereby reducing the input power level and providing safe operation. Demag also

provides a soft start function during startup gradually increasing the switching frequency until fixed frequency operation

is attained.

5. Troubleshooting

Warning

Before attempting to fix the power supply, safety should be considered first. Never connect test probes to the primary side

circuits, unless proper isolation has been installed. If isolation for the AC mains is not present, serious harm can occur.

Never assume you are safe.

- 7 -

Page 8

Caution: C610 has a Slow Voltage Discharge

If the front panel power on/off button is switched to the off position prior to the AC mains input power being removed from

the monitor, then electrolytic capacitor C610 discharges with a long time constant. When the monitor cabinet cover and/or

EMI shield are removed, making the D board circuitry accessible during servicing or repair by qualified personnel, the

following procedure is recommended: Always remove the AC mains input power from the monitor prior to switching the

front panel on/off button to the off position. The AC mains input power should be removed from the monitor for a minimum of 30 seconds before the front panel on/off button is switched to the off position.

Caution: Do NOT Touch IC610 Component Tab or Heat Sink

IC610 component tab has an electrical voltage potential equivalent to the primary side return (approximately AC mains

input voltage potential). If IC610 heat sink insulator pad and/or shoulder washer busing are damaged or not assembled

correctly, then the IC610 heat sink will have an electrical voltage potential equivalent to primary side return (approximately

AC mains input voltage potential).

No Power

In the event that the monitor does not turn on, first verify input power is applied to CN600 and the front panel power button

is turned on; then check F601. If F601 is blown, the primary side circuitry should be checked. If the fuse is not blown, then

check the secondary side circuitry, especially the protection circuits. If these circuits are causing a no power symptom, the

problem can be more readily found.

AC Input and Degauss Circuit Trouble Shooting

For no power or nonoperating power supply, the AC input circuitry should be checked. Open or short circuit elements will

cause non-operation. Check F601, CN600, D601, R600, TH600 and R605 on the D Board. Check the front panel power

button for continuity.

If all elements are correct, check whether F601 breaks when power is applied and the power button is closed. If the fuse

does blow, there probably is a component shorted in the prmary circuitry.

The degauss will malfunction if CN601 is not connected. One problem could be loss of degauss signal from the microprocessor. This can be verified by using the manual degauss command found in the OSD menu. If the signal does not appear at

Q601 base, then it is possible that the microprocessor does not function correctly or standby 5V is not functioning.

The second step is to place a short across the AC terminals of RY601 for less than two seconds. If degauss operates then

check Q601 and RY601. If degauss does not work, check TH601 for an open condition and C631 for a short condition.

Primary Section

Three main areas can diagnose primary circuit failures. These are IC601, Q602 and Feedback system.

Visible checks of these areas will aid in finding problems. The following will discuss each section.

IC601

First apply AC to the monitor and check IC601 pin 4 output. If the output on pin 4 is not present, there could be problems

with Q602 and related parts or pin 14 could be less than 2.5 volts. Further, check Vaux level at pin 6. If it less than 11V,

the IC could be in safe-restart mode. If the voltage is very low, there could be a short on any of the IC pins. In reference

to ground, check the impedance of pin 1, 8 and 14. If any of these pins are shorted, replace the IC and check components

connected to the related pins. Take care that C616, C617 and C681 are fully discharged before replacing the IC.

Q602

The switching transistor can be damaged in various ways. These are related to voltage, current and temperature.

Check whether the transistor is shorted across drain and source terminals. If there is a short, F601, R605, R614, R654,

R623, R624, R657 and C650 should be checked. Additional components to check are D608, R603, R612 and IC601. If

Q602 is shorted, all these parts should be replaced.

Failure of a secondary rectifier diode can also cause Q602 to fail. Check 180V and 80V diodes for open or short

conditions. There is also a clamp circuit, which is used to clip the turn off spike found on Q602 drain. If the clamp

circuit is broken, it can cause Q602 failures. Check D606, C612 and R635. Also check the snubber circuit components

C613, D607, R619 and R656.

Secondary Circuit

Failure in the secondary circuits can be categorized by rectifier diodes, regulators, feedback loops and protection circuits.

- 8 -

Page 9

These sections are interrelated and failure in one can affect another. Consequently, some failures will also affect the

primary circuitry.

Rectifier Section

Rectifier diode failures are not common, but do occur. Deflection, video and high voltage circuitry failures contribute to

diode damage. In the event a voltage is not present, check for shorts to ground, open or short diodes.

+5/12 Volt Regulator

If +12V or +5V output line is not available or the wrong voltage, IC605 or IC608 may be damaged. Before replacing

either IC, check for shorts or damaged parts along the output lines. If +12 volt does not appear, check the Remote Sw

signal from IC901 pin 6.

Standby 5V Circuit

Failure of this circuit can be affected by IC607. In case the circuit does not work properly, check D605, D614, R611 and

Q604. If these components are good, check the remaining circuit parts. Another possible influence can be the heater

circuit. Since both the standby 5V and heater voltages are produced by T6-1 winding 13-14.

Heater Voltage Regulator

This circuit may be affected by R697 or D619. If these parts are good, check the regulator output for a short to ground.

Shorts can occur on the video board. In the case of Power Sw signal.

Feedback Circuit

Problems with feed back can cause power supply shut down and low or high output voltages. First determine whether the

power supply is operating in active off, active on modes or not at all.

The power supply can be stuck in active off mode. The Remote Sw signal, Q603, Q604, D605 and IC603 can affect this

condition. Likewise, if the power supply is always in active on mode, the same items should be checked, along with

D612, D613, D621, C619, C620, R626, R636 and R660.

Checking for voltages at IC603 pins 1 and 2, IC604 pins 1 and 3 can solve more difficult problems. Additionally, IC603

pins 3 and 4, and IC601 pin 9 should be checked. If there are problems with these devices, 180V or standby 5V line, the

feedback systems will not work correctly. Also check the protection circuits.

Protection Circuits

OCP occurs when there is excessive current through Q602. Failures with Q510, Q507 or the video section could cause

this condition. These areas should be checked. OCP condition can also occur if R614 or R654 are open; if R623 or

R657 are shorted; or if R624 is open.

OVP usually occurs when the feedback loop is open, or loss of standby 5V. Isolate the OVP trigger condition, by first

checking the operation of the feedback loop.

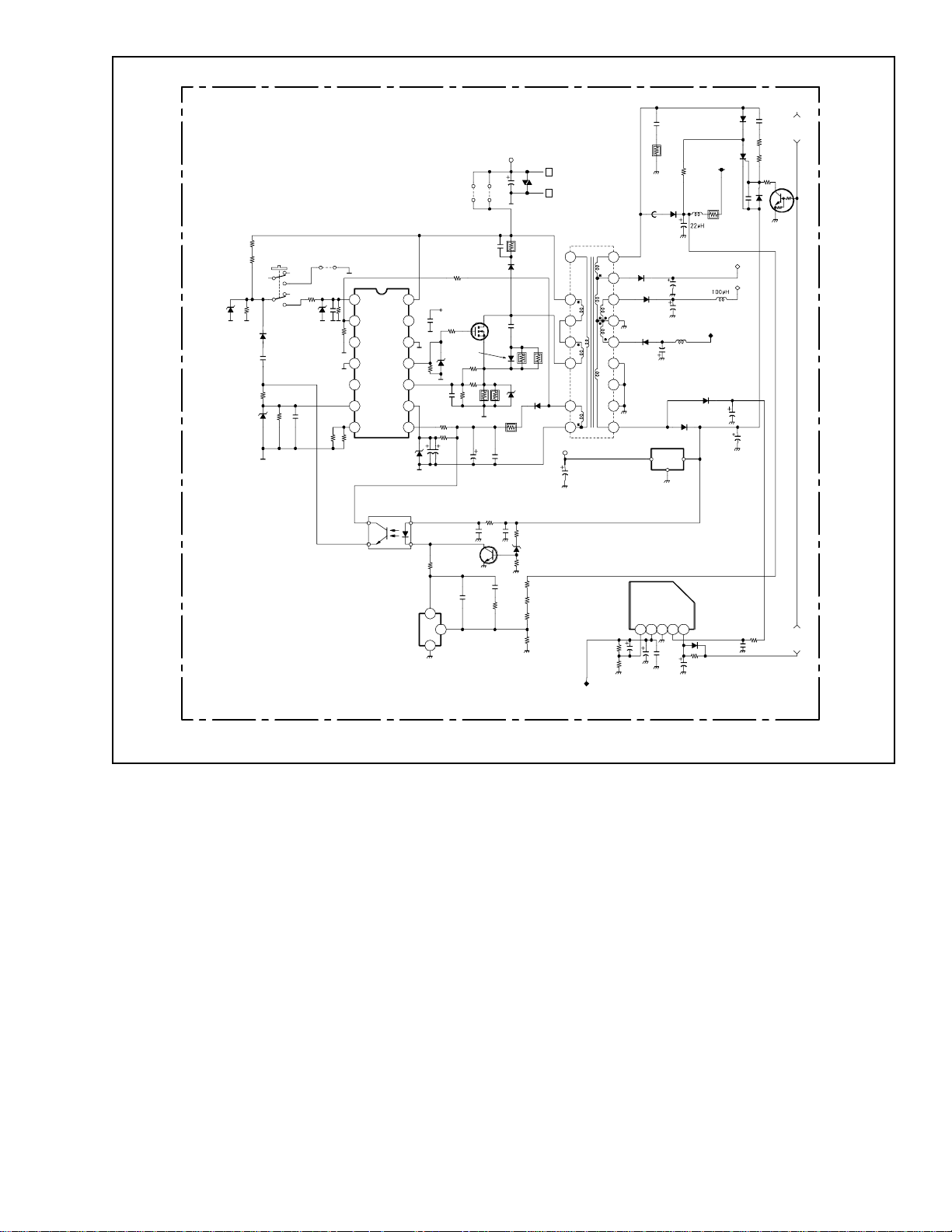

6. USB/Audio Power Circuit

CAUTION: Do not touch IC610 component tab or heat sink. The IC610 component tab has an electrical voltage

potential equivalent to the primary side return (approximately AC mains voltage potential). If the IC610 heat sink insulator

pad and/or shoulder washer bushing are damaged or not assembled correctly, then the IC610 heat sink will have an electrical

voltage potential equivalent to the primary side return (approximately AC mains voltage potential).

The USB/Audio power supply circuit is a flyback converter that uses an integrated power mosfet and switch mode pwm

control IC (IC610). The circuit consists of IC610, T602, D633, PH601, IC611 and associated circuitry. Start up is

initiated when C675, connected to the CONTROL pin 1 is charged via a high voltage current source internal to IC610.

When CONTROL pin 1 reaches 5.8V, the control circuitry and mosfet are activated and a 10mS soft-start begins. The

typical mosfet DRAIN pin 7 switching frequency is 130 KHz with a ±4KHz jitter. The feedback loop consists of shunt

regulator IC611 and optocoupler PH601 that will regulate the secondary side output voltage at 6.5V and provide feedback

current to CONTROL pin 1. During normal operation, T602 bias winding pins 3-4 provide the charging current to maintain

CONTROL pin 1 at 5.8V; additionally the CONTROL pin 1 charging current that is regulated by IC611 and PH601 controls

the mosfet duty cycle to provide closed loop regulation.

The front panel power button controls the on/off function for the USB/Audio power circuit. When the power button is in

the OFF position, the MULTIFUNCTION pin 3 is shorted to CONTROL pin 1, turning off the power circuit. When the

power button is in the ON position, the MULTIFUNCTION pin 3 is shorted to primary side DC mains return, which enables

the power circuit.

- 9 -

Page 10

2

1

S Cap Sws

H Deflection Circuit

TO:

180V

H Lin and

Ringing Circuit

12V

C575

FB506

5

R581

3

D518

Q521

T505

Q520

B+CHOP

R582

HST

3

C574

HDY-

4

HDY-

3

1

D516

L503

HOC

FB504

T504 HDT

1

H DY+

2

8

H DY+

1

1

2

6

TO: IC901 #32 pin

H FLY

Q508

D502

4

IC902 #14 pin

C521

C518

D506

R518

R517

R513

Q511

C522

Q507

H-OUT

C510

FB507

R522

R511

FB508

-15V

C543

R551

C563

20

3

R553

Out

H Reg

IN

H Def

IN

HD

PWM IC501

IN

H SHAPE

IC902

E/W PIN #9

8

2

R569

R584

R583

C582

- 10 -

C576

12V

12V

R504

R933

CN801

R509

C502

Q501

R594

Q903

HD output pin #17

IC902

R508

D501

Q502

Page 11

1

8

2

3

4

5

6

1

2

4

3

1

2

3

1

2

3

4

5

6

7

C

6

7

0

C

6

7

1

C

6

7

2

C

6

7

3

C

6

7

5

C

6

7

6

C

6

7

7

D

6

3

3

D

6

3

4

D

6

3

5

D

6

3

6

I

C

6

1

0

I

C

6

1

1

L

6

0

7

P

H

6

0

1

R

6

3

0

R

6

3

1

R

6

3

2

R

6

3

4

R

6

3

9

R

6

4

1

R

6

5

1

T

6

0

2

*

*

*

*

*

*

*

*

*

*

*

*

P

O

W

E

R

S

U

P

P

L

Y

C

O

N

T

R

O

L

I

C

*

E

R

R

O

R

A

M

P

*

*

C

O

N

T

R

O

L

*

*

*

*

*

*

*

*

S

R

T

D

F

S

M

C

A

B

+

6

.

5

V

To SW 602

USB/Audio Power Circuit

A voltage clamp to limit the peak voltage on DRAIN pin 7 is provided by D635 and D636. Bypass capacitor C677 is

utilized to improve high frequency noise immunity.

IC610 provides the following protection functions: a 10mS soft-start function, a cycle-by-cycle peak current limit function, a shutdown/auto-restart function if an out of regulation condition occurs and an over temperature protection function.

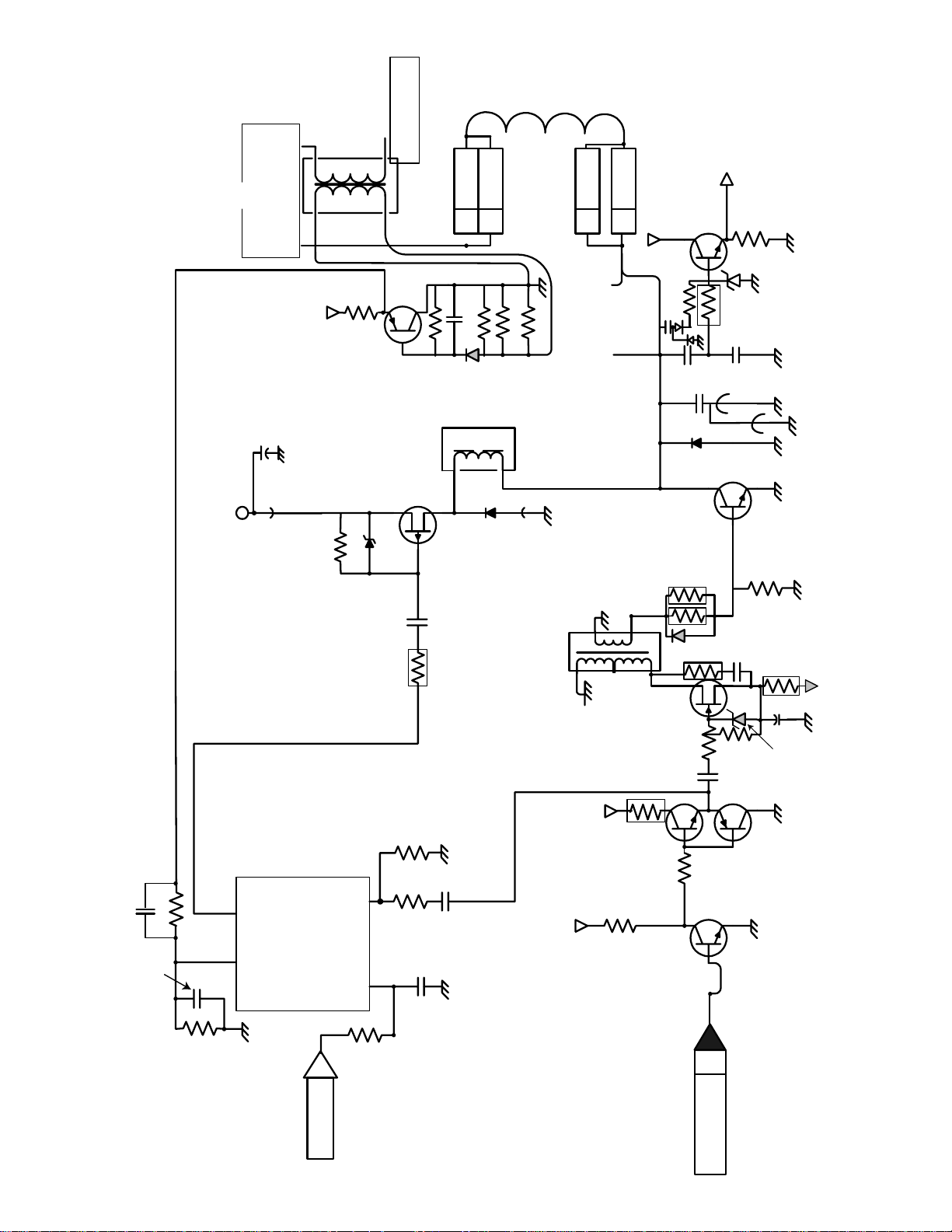

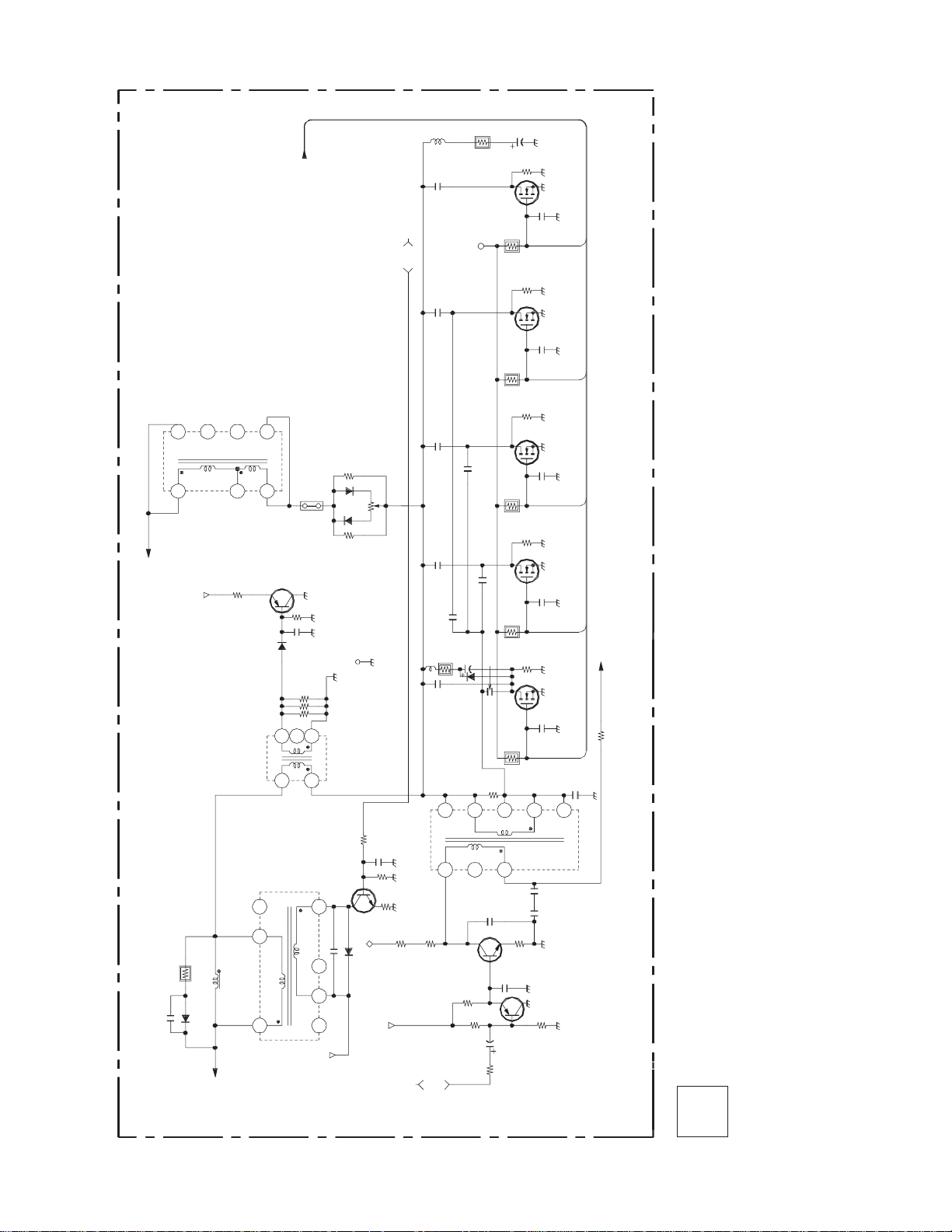

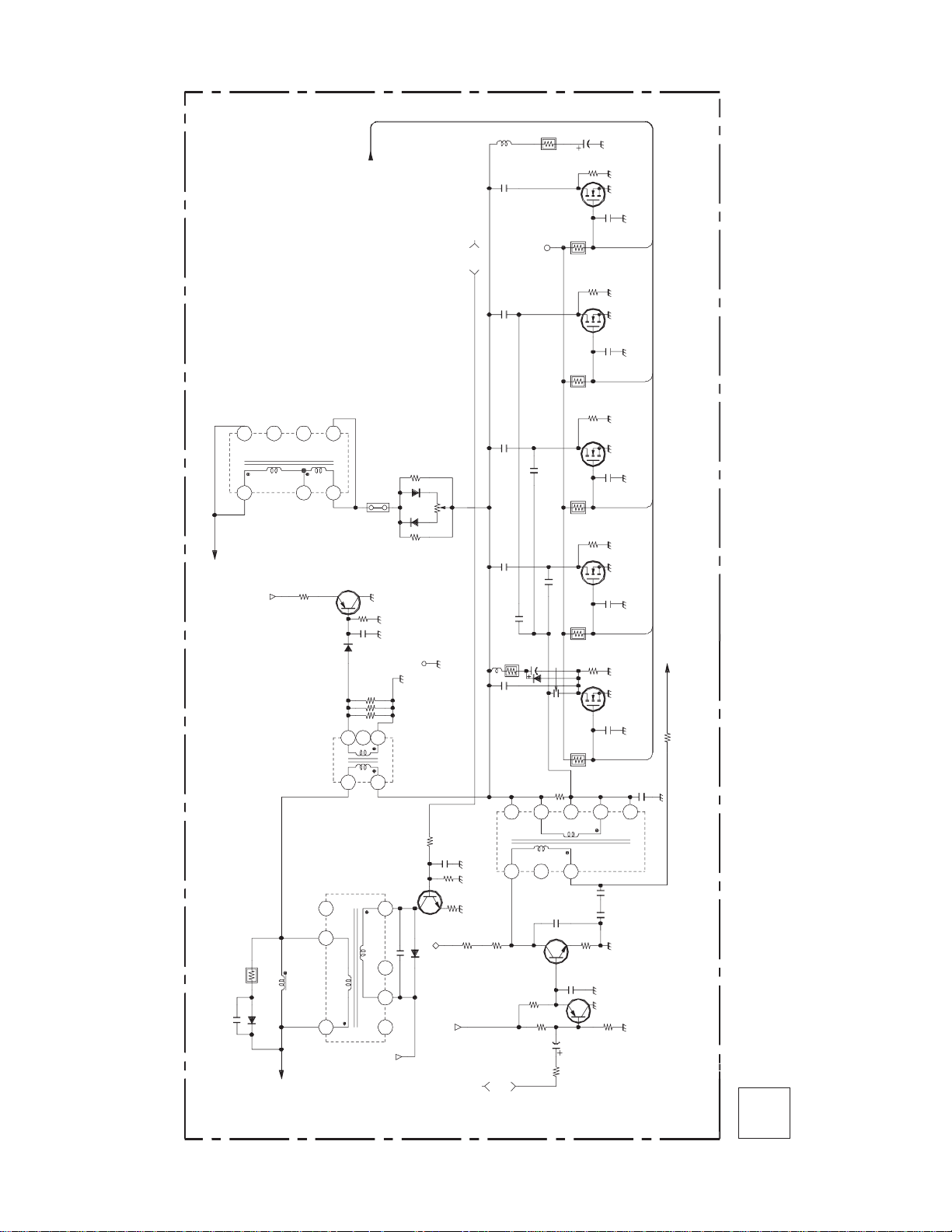

D BOARD DEFLECTION SECTION

1. Horizontal Deflection Circuit

Overview

These circuit drive the DY (Deflection Yoke) for Horizontal Deflection. The H size and H shape control (IC501 and around)

is included in this page as well.

H Drive, H Out, Feedback

+12Vp-p HD pulse is generated by the inverter Q903 using the Jungle IC902 H. out pin #17. And switch Q511 through A

push-pull amplifier (Q501 and Q502) buffers. The drive current which introduced in HDT (T504) by this switching will

drive Q507 (H out Tr) and 1000V pulse appears on collector. D506 is the "Damper Diode" which avoid the negative pulse

and discharge the energy for next Horizontal Drive. Q508 is the buffer for the "H BLK" feed back to Jungle IC 902 H. FLY

pin #14 and it will be the reference of phase / jitter control of Jungle. HST (T505) is to sense the deflection current

through DY. The voltage appeared on secondary side will be the feed back for H Size/Shape control.

H Size/Shape control

HD pulse also triggering the H Size/Shape control IC501 pin #8. IC501 is "PWM IC" and it controls H and HV B+

chopper duty. H Shape and H size information is already included and coming from Jungle IC902 E/W pin #9. It will be

supplied to IC501 pin #2. H reg output pin #20 is switching pulse of Q520 (B+ chopper). The energy supplement from

180V to H Def circuit (through L503 HOT) is controlled by the duty of this pulse. The H Shape input and feedback

voltage from T505 are compared by error amp (in IC501) and H Reg out pulse duty is controlled to keep the level of

these two the same.

- 11 -

Page 12

H

6

m

0

2

8

5

.

7

L

2

5

3

5

&

1

0

2

9

5

C

,

I

1

5

M

,

O

0

R

5

F

,

9

4

S

N

I

P

0

C

1

C

5

H

L

7

8

1

+

Y

O

D

T

H

V

2

1

5

6

6

0

U

2

7

5

0

0

4

R

2

3

L

5

N

D

1

1

0

D

3

P

k

9

I

7

8

H

.

5

C

4

R

:

1

9

5

R

5

W

T

0

E

S

5

N

H

T

5

4

S

P

U

0

1

W

K

A

1

7

2

3

5

0

Q

1

A

S

2

D

T

5

2

2

1

-

5

9

D

1

1

S

S

1

W

0

N

4

5

R

/

1

:

1

3

2

9

0

2

3

2

2

7

L

/

5

5

4

1

R

N

D

W

1

S

D

P

0

C

k

9

-

2

5

N

2

R

R

:

1

7

T

0

1

P

.

5

:

0

C

6

W

0

N

1

4

5

R

5

/

1

:

R

1

2

W

N

0

9

4

5

R

5

/

:

1

R

1

5

4

1

4

1

#

0

9

N

C

I

I

P

N

I

L

H

R

2

E

W

0

0

2

T

0

5

/

1

N

V

1

R

E

C

H

3

0

0

P

L

C

H

m

2

.

2

5

0

5

L

R

7

V

9

P

4

0

2

P

0

5

0

:

.

C

4

0

7

5

V

P

4

0

2

P

0

5

0

:

.

C

4

0

2

V

3

1

1

P

8

0

2

3

.

P

0

5

5

5

0

:

.

2

C

C

0

V

7

6

P

1

0

2

P

5

5

.

:

2

0

C

P

P

:

V

0

8

0

6

4

5

C

7

4

0

.

0

D

W

5

0

2

R

7

2

7

0

7

P

.

/

5

1

5

F

4

1

R

C

:

V

2

4

P

A

8

0

1

P

T

5

.

5

:

1

0

2

-

C

1

0

5

4

D

L

N

1

D

5

P

k

8

I

2

2

H

P

.

5

C

1

6

I

2

R

:

0

0

H

.

5

C

0

C

:

A

1

9

1

1

6

T

W

0

5

T

6

3

5

C

E

3

Q

L

N

C

S

2

5

7

7

S

0

W

7

R

0

3

5

:

1

R

p

1

V

0

8

k

0

5

1

2

C

2

8

C

W

0

L

E

5

N

H

L

U

0

5

2

0

L

5

N

D

1

D

O

T

0

1

Y

D

H

3

2

1

V

2

1

B

W

S

P

2

I

H

-

C

V

:

0

B

7

2

1

.

0

E

T

8

9

5

0

0

5

5

5

3

C

D

S

S

1

P

k

1

6

I

8

7

H

.

5

C

6

R

:

4

N

9

1

R

3

5

:

R

k

5

k

6

N

N

0

6

0

0

R

R

3

5

3

5

:

:

3

R

3

R

R

Q

P

-

M

4

A

A

0

1

5

5

4

F

k

Q

0

9

0

D

5

1

3

.

R

C

V

S

2

V

2

1

2

2

1

0

#

9

C

N

I

I

P

V.DF

2

0

5

R

V

3

2

7

0

7

k

N

.

3

5

5

W

0

S

2

R

0

/

:

1

1

V

5

Y

B

T

S

V

P

0

P

5

:

2

D

5

R

k

2

P

1

5

F

R

:

P

P

:

V

0

5

2

5

1

P

.

P

0

:

0

V

3

0

5

5

C

2

8

6

0

.

0

V

1

0

1

5

5

2

C

2

7

1

.

5

4

R

4

7

p

V

4

0

0

0

B

3

0

5

3

5

C

P

k

1

C

0

0

-

0

5

N

2

C

R

:

1

0

5

R

R

6

2

5

2

C

5

:

R

E

G

2

N

3

6

A

S

3

1

H

3

5

C

K

Q

S

P

2

A

C

D

6

R

k

3

P

1

5

F

R

:

5

k

3

6

5

5

R

D

3

R

k

3

P

1

5

F

R

:

3

k

2

6

5

5

R

4

k

2

6

5

5

R

D

1

R

k

2

P

1

5

F

R

:

5

k

1

1

5

R

3

S

P

1

8

I

0

3

H

.

5

C

0

C

:

B

0

S

N

R

:

E

G

2

N

S

3

A

5

3

H

1

3

C

5

K

Q

S

P

2

A

C

S

P

1

6

I

0

3

H

.

5

C

0

C

:

B

1

S

N

R

:

E

G

N

8

S

A

9

2

H

0

1

C

2

5

K

Q

P

S

2

A

C

P

S

1

0

I

0

2

H

.

5

C

0

C

:

B

2

S

N

R

:

E

G

S

8

N

9

3

A

0

1

H

2

5

C

K

Q

S

P

2

A

C

S

P

1

5

I

0

1

H

.

5

C

0

C

:

B

9

M

1

1

5

R

S

4

1

5

Q

P

1

2

I

0

1

H

.

5

C

0

C

:

B

D

R

7

P

0

F

5

:

C

2

5

T

3

S

1

B

#

F

N

O

I

T

P

E

G

8

N

9

A

0

H

2

C

K

S

P

2

A

C

)

S

8

5

3

1

5

(

R

W

J

4

S

8

V

1

0

.

0

0

4

1

T

3

F

0

D

5

:

T

8

1

F

V

7

p

k

5

0

2

1

C

5

V

p

0

k

0

5

1

2

C

k

7

N

7

0

R

.

5

:

P

2

R

1

3

I

0

0

H

.

5

C

0

C

:

B

7

R

3

5

E

0

0

F

1

5

F

A

Q

U

S

B

2

P

3

C

k

0

0

-

0

1

5

N

1

R

R

0

0

1

:

(BOARD)

D

H. LINEARITY AND RASTER DISTORTION CORRECTION CIRCUIT

- 12 -

Page 13

H

6

m

0

2

8

5

.

7

L

2

5

3

5

&

1

0

2

9

5

C

,

I

1

5

M

,

O

0

R

5

F

,

9

4

S

N

I

P

0

C

1

C

5

H

L

7

8

1

+

Y

O

D

T

H

V

2

1

5

6

6

0

U

2

7

5

0

0

4

R

2

3

L

5

N

D

1

1

0

D

3

P

k

9

I

7

8

H

.

5

C

4

R

:

1

9

5

R

5

W

T

0

E

S

5

N

H

T

5

4

S

P

U

0

1

K

A

1

7

2

3

5

0

Q

1

A

S

2

D

T

5

2

2

1

-

5

9

D

1

1

6

S

1

S

5

1

R

W

0

N

4

5

R

/

1

:

1

3

4

2

9

0

2

3

2

7

L

5

5

4

R

N

D

W

1

S

D

P

0

C

k

9

-

2

5

N

2

R

R

:

1

7

T

0

1

P

.

5

:

0

C

W

0

N

4

5

R

/

1

:

1

2

W

N

0

9

4

5

R

5

/

:

1

R

1

5

1

4

1

#

0

9

N

C

I

I

P

N

I

L

H

R

2

E

W

0

0

2

T

0

5

/

1

N

V

1

R

E

C

H

W

2

/

1

3

0

0

P

L

C

H

m

2

.

2

5

0

5

L

R

7

9

V

P

4

0

2

P

0

5

0

:

.

C

4

0

7

5

V

P

4

0

2

P

0

5

0

:

.

C

4

0

2

V

3

1

1

P

8

0

2

3

.

P

0

5

5

5

0

:

.

2

C

C

0

V

7

6

P

1