Page 1

ASSEMBLY INSTRUCTIONS

FOR ADJUSTABLE FLAT PANEL WALL MOUNT

This product is designed to mount flat panel televisions weighing up to 132lbs/60kgs to a vertical wall with

maximum flat panel wall mount installing hole dimensions 75.5cm (width) x 48cm (height). It allows you to

effortlessly tilt your new television up or down without using tools.

Maximumsupport width

Before installing our wall mount product,

please make sure your unit installing hole

dimensions is covered in product maximum

supported range.

Maximumsupport

highwall mount

installinghole

Safety Warning:

Be careful to make sure there are no missing or defective parts.

Never use defective parts.

Improper installation may cause damage or serious injury.

Note The included hardware is for mounting on walls with wood stud construction.

If you are uncertain about the nature of your wall, consult an expert.

Please consult your hardware or installation professional for proper mounting to other types or walls.

The supplied hardware is not for steel.

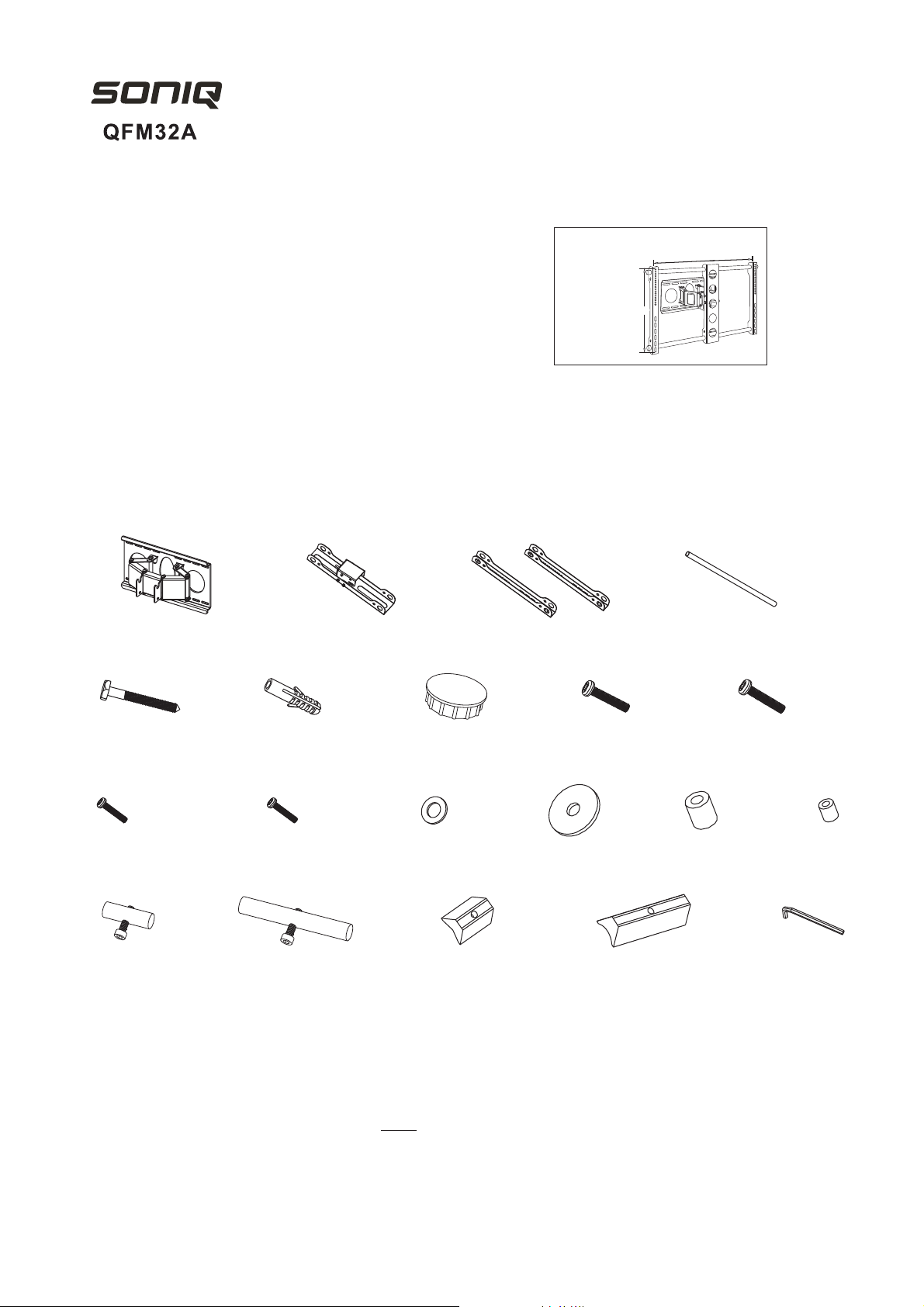

SUPPLIED PARTS:

wallmount installing hole

75.5cm

48cm

bx: Arm Assembly 1 c: Monitor Brackets x2a Wall Plate x: 1

e: 61/4x2.5"Lag Bolt x f: 6Concrete Anchor x h: M8 Machine Screw

j: 4M5x30 Machine Screw x k: M4x30 Machine Screw x4

p: Axle Pin & Safety Bolt x4

1a.BRICK,SOLID CONCRETE AND CONCRETE BLOCK MOUNTING:

wall. Three in the top row of slots and three more in the bottom row. Make sure these holes are level and there is at least 150mm between any

two holes. Pre-Drill these holes with a 10mm masonry bit to at least 60mm in depth. Insert a Concrete Anchor (f) into each of these holes, PreDrill these holes with a 5mm flush with the concrete surface even if there is a layer of drywall or other material in front. Attach the to

the wall using 6 Lag bolts (e) and 6 M4 / M5 Washer (m).

WARNING :Tighten Lag Bolts (e) only until Lag Bolt Washer (l) is pulled firmly against the Wall Plate (a).DO NOT OVERTIGHTEN THE

BOLTS!

1b. MOUNTING THE WALL PLATE: be mounted to two wood studs.

adjacent studs. It is a good idea to verify where the studs are located with an awl or thin nail shown in diagram 1-A. Pre-drill a 3mm deep hole

at the desired height in each stud using a 4mm drill bit. Make sure these holes are in the center area of the studs and level with each other.

Use the as a template to mark the location of the second hole in each stud. Pre-drill these two holes using the 4 drill bit as well.

Wall plate

Attach the to the wall using for the four Lag Bolts (e). Make sure the is oriented so the flat surface in the center of the

plate in against the wall shown in diagram 1-B.

Wall Plate Wall Plate

q : Axle Pin & Safety Bolt 2x

The (a) Use a high quality stud sensor to locate two

wall plate

g: Plastic Cover x4

l: Lag Bolt Washer x10

r4: Vise Assembly (small) x

Use the (a) as a template to mark 6 hole locations on the

MUST

M8x25 x4 and M8x40 x4

m: M4/M5 Washer x12

s2: Vise Assembly (big) x

Wall Plate

d: 1”Diameter Tube 2x

i: x4M6x30 Machine Screw

n: Plastic Spacer x4

o: Plastic Spacer x4

t: Allen Key(2)

Wall Plate

Page 2

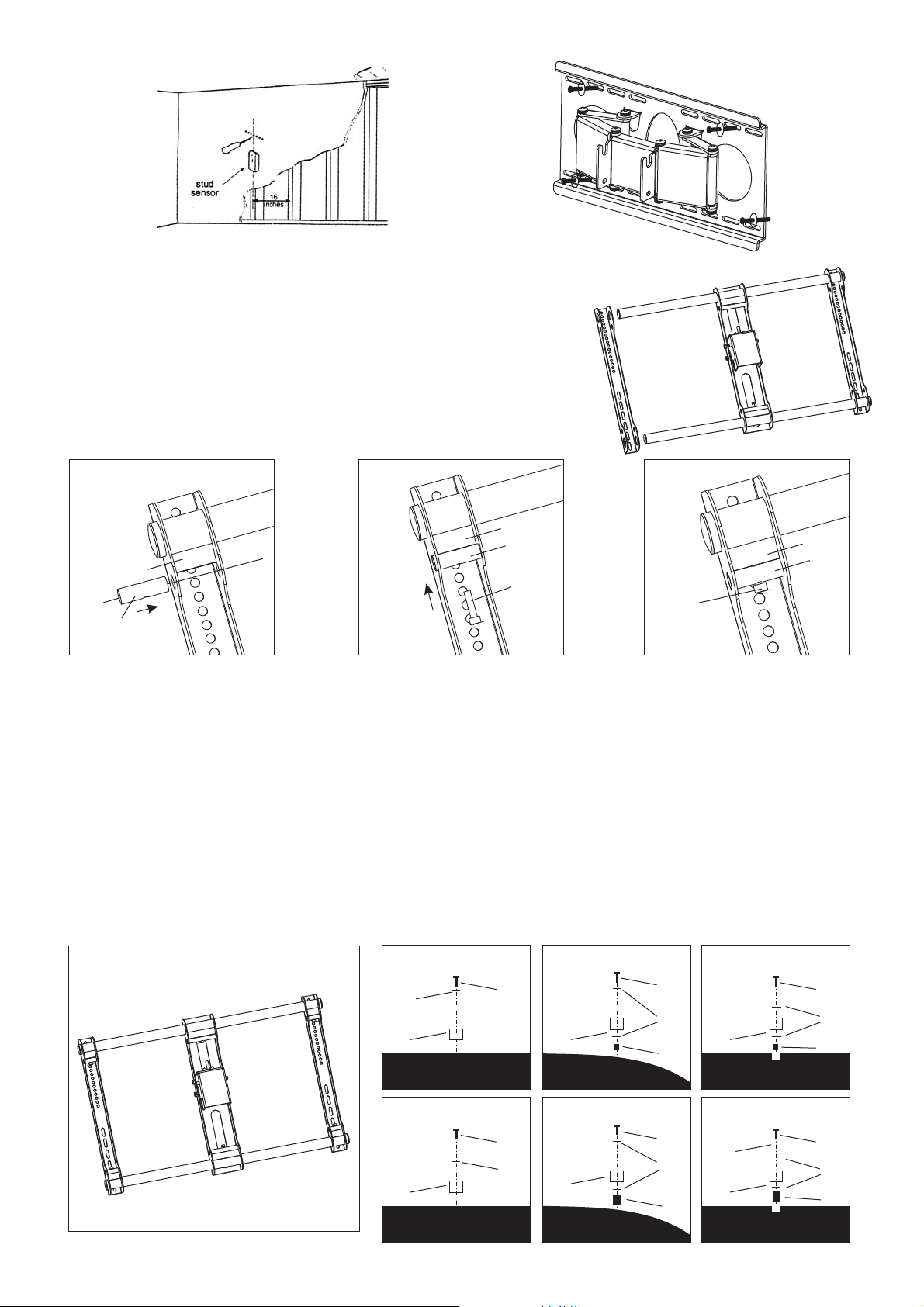

Diagram 1-A Diagram 1-B

2.Assembly the monitor bracket: As shown in diagram 2, put two 1” diameter Tube through

Arm Assembly (b) and monitor bracket (c) in turn, pay attention to getting the section of TV Rail

with round hole upward and the one with slot downward .Then according to Diagram 3-A,

place Vise Assembly (small) Monitor Bracker TV Rail (c), put Axle pin (short) through the

round hole on monitor brackets and fit the arc face tightly against iameter tube, then as

(c)

1” d

shown in Diagram 3-B, put M6 Safety Bolt through Axle pin and screw in Visa Assembly. The

effect at the end of installation is shown in Diagram (3-C).Attention:do not tighten the screw at

this time so as to let monitor brackets smoothly slide on Diameter Tube.

1”

The tubes must extend beyond the outside edges of both monitor brackets and the Allen bolt in

all 6 vise assemblies must be tightened for the installation to be safe!

r

p

r

M6 safety Bolt

Diagram2

r

p

p

M6 safety Bolt

Diagram3-A Diagram3-B Diagram3-C

3.Attach the monitor bracket to the television:

3a.Select the television mounting hardware:

provided bolts is the correct diameter, Two

Always make sure the television is unplugged before threading any bolt into the back panel,

Locate the threaded inserts on the back of your flat panel television. Determine which of the

lengths in each of the following diameter are provided: M4,M5,M6,and M8. The shorter bolts are to be used if the back your television is flat. The

longer blots are designed to be used with either the M4/M5 Spacer (o) or the M6/M8 Spacer (n) on televisions with curved or recessed backs. The

long bolts are only to be used without a spacer in rare cases when the threaded in serts are deeply recessed inside the frame of the television.

3b.

Diagram 4 shows the orientation of the monitor brackets on the back of the television. Each Monitor Bracket (c) must be held in place by 2 bolts.

Make sure both monitor brackets are level with each other by selecting the same hole in the bottom half of each bracket and adjust the arm

assembly in the center of the TV. If you determined that your television requires either the M4(k) or M5(j) diameter look at the diagrams 5 through 7

and select the one that best represents the shape of the back of your television and the arm assembly in the center of the back of TV. If

youdetermined that your television requires either the M6(l) or M8(h) diameter bolts, look at diagrams 8 through 10 and select the one that best

represents the shape of the back of your television.

WARNING: DO NOT LAY THE TELEVISION FACE DOWN ON THE GLASS, lean it up against a wall or other solid surface. Lying the

television down on the glass may cause permanent damage.

WARNING : Threaded bolts carefully into your television by hard before tightening, If feel resistance, remove the bolt immediately!

Diagram 5-Flat Back TV with M4/

M5 Machine Screws

m

c

j,k

Diagram 6-Curved Back TV with

M4/M5 Machine Screws

j,k

m

c

o

Diagram 7-Recessed Back TV with

M4/M5 Machine Screws

j,k

m

c

o

Diagram4

Diagram 8-Flat Back TV with M6/

M8 Machine Screws

h,i

l

c

Diagram 9-Curved Back TV with

M6/M8 Machine Screws

h,i

l

C

n

Diagram 10-Recessed Back TV with

M6/M8 Machine Screws

q

c

h,i

l

n

Page 3

4.Hang the TV onto the wall plat: after Monitor Brackets are mounted on the TV, lift the TV with its back to the wall plate and hang

it on the wall plate as shown in Diagram 11,For the big TVs two persons may be required to do this .After the TV is hung on the wall

plate securely, tighten the screw (u) into the screw hole on the arm assembly (b) according to Diagram12 to get both Arm

assembly and wall plate jointed together.

Diagram11 Diagram12

Loading...

Loading...