®

Sonic Meter

Sonic AO

Operating Manual

Important: Do not attempt to operate this instrument without completely reading

this manual and understanding the correct operating procedures.

For online technical support and further information refer to our web site at

www.sonicmeter.com

Rev A-0915

Table of Contents

1. Safety

1.1 Batteries

1.2 Charger

1.3 Meter

1.4 Probe

1.5

Electromagnetic Compatibility

2. Introduction

3. Description

3.1 Sonic Meter

3.2 Keypad

3.3 LCD display

3.4 1 meter cable

3.5 Sonic Meter probe

3.6 Battery Charger

3.7 Batteries

4. Operation

4.1 Changing the batteries

4.2 Resetting the circuit breaker

4.3 Powering up the meter

4.4 Options

4.5 Battery capacity

4.6 Real time reading

4.7 Averaged reading

4.8 Setup

4.9 Powering off the meter

4.10 How to take measurements

5. Appendices

A. Specifications

B. Troubleshooting

C. Parts List

D. Warranty

E. Calibration sheet

1. Safety Issues:

1.1 Batteries:

Sonic Meter

The

(NiMH) batteries rated at 1000mAh. The meter is fault protected against reverse

polarity via a resettable circuit breaker. The meter ships with 8 AAA batteries.

The 4 AAA batteries in the meter were charged at the time of shipping. The other

4 AAA batteries are not charged.

CAUTION: Shorting the batteries (positive terminal connected to negative

terminal) is extremely dangerous and could cause serious injury. Extreme

caution should be used when handling and charging the batteries.

Do not store meter for long periods with the batteries installed. When disposing

of batteries follow all state and local laws.

1.2 Charger:

The battery charger is powered by 120/240Volts AC at 50/60Hz. Use of charger

with any other voltage input will damage the charger and could cause serious

injury.

1.3 Meter:

The

Sonic Meter’s housing is not waterproof. If the meter becomes immersed in

water do not attempt to use it. Do not attempt to repair it. Return the meter to

SyncroCraft® for authorized repair.

1.4 Probe:

The probe attaches to one end of the 1 meter co-axial BNC cable. The other end

of the BNC cable connects to the meter. Never attempt to remove or install the

probe or cable while the meter is powered. Attempting this could cause

voltage surges, possibly damaging the probe or meter.

1.5 Electromagnetic Compatibility:

Sonic Meter

The

approved.

Important: The

device.

Important: Never operate the Sonic Meter

high voltage potentials are not properly contained.

Sonic AO

Sonic AO

Sonic Meter

is powered by 4 AAA Nickel Metal Hydride

complies with EN 61326-1:1997. The meter is CE

Sonic AO

is not designed for use as a medical

Sonic AO

and probe in areas where

NOTE: Please read and understand the entire manual before operating the Sonic

Meter

Sonic AO

.

2. Introduction:

The

Sonic Meter

designed to help maintain the quality and integrity of parts during cleaning cycles

in ultrasonic cleaners.

Ultrasonic cleaners utilize a transducer attached to the tank’s exterior. The

transducer outputs pulsating mechanical energy at high frequencies (ultrasonic),

which cause the liquid in the tank to agitate.

The agitation at this high frequency level is what gives ultrasonic cleaners their

cleaning ability. As the liquid becomes agitated, a phenomenon known as

cavitation takes place. Cavitation is the almost instantaneous formation and

implosion of small bubbles and cavities in the cleaning liquid.

As the liquid cavitates, the minute bubbles and the coincidental implosions cause

the surrounding liquid to impinge forcefully upon the surface areas of the part

being cleaned. The force that the liquid applies to the area of the part is

commonly referred to as the scrub-force.

This scrub-force action takes place throughout the tank. However, the scrub-force

can vary significantly due to the placement of the tank’s transducer and th e

constructive and destructive interference caused by the shape of the tank and parts

being cleaned.

These process variations in scrub-force throughout the tank can be referred to as

hot spots or cold spots in the liquid. Hot and cold spots are locations of high and

low intensity scrub-force relative to a mean value scrub-force. These process

variations can significantly alter the cleanliness or integrity of the parts being

cleaned. Some parts may not have been thoroughly cleaned for the next process,

or the stresses due to the cleaning action may have altered the integrity of the

parts. With the Sonic Meter these process variation situations can be minimized.

With the

Sonic Meter’s slender probe, operators can probe ultrasonic cleaners to

pinpoint areas of optimum intensity in which to place each part. The Sonic

Meter

’s LCD displays the intensity variations. Parts can be varied in their zheight or their x and y positions via an adjustable array fixture. The operator can

determine the location for each part so that all parts are placed in regions of the

same specified pressure reading (scrub-force). Or several readings can be taken

and averaged to determine the mean value pressure of a particular cleaner.

The

Sonic Meter

Sonic AO

The

Sonic AO

Sonic AO

is a pressure sensitive measuring device. It is

measures in units of pounds per square inch (psi).

works with tanks that use frequencies up to 500kHz.

3. Description:

LCD Display

Keypad

Sonic AO

Sonic AO Probe

Figure 1 shows the main components of the Sonic Meter

3.1 Sonic Meter:

The Sonic Meter

housing is made of aluminum with a durable anodized surface. The housing is

not waterproof.

BNC connector

1 meter Cable

Sonic AO

BNC connector

Figure 1

Sonic AO

is packaged in an ergonomic T-shaped housing. The

.

3.2 Keypad:

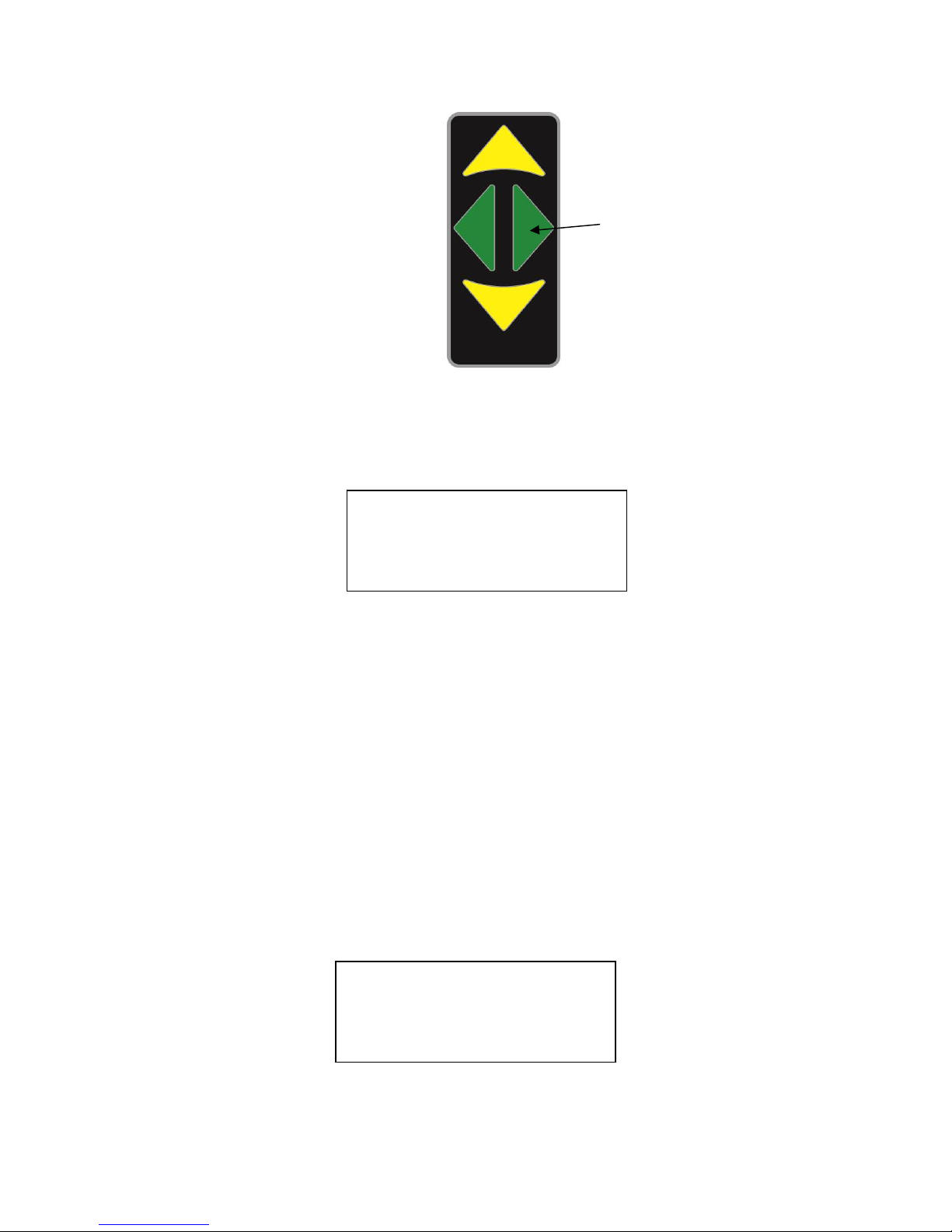

Scroll Up

Scroll Right

Scroll Down Scroll Left

Figure 2

Figure 2 shows the designations of the keypad’s four keys.

The keypad utilizes membrane keys with a color Mylar overlay. There are four

keys that control the meter:

Scroll Up: Color designation is yellow. Used for scrolling up through the menu

choices and increasing input values.

Scroll Down: Color designation is yellow. Used for scrolling down through the

menu choices and decreasing input values.

Scroll Right: Color designation is green. Used for selecting a specific menu

choice and for scrolling right when changing input values.

Scroll Left: Color designation is green. Used for returning back to the previous

menu and for scrolling left when changing input values. By holding this key the

meter will always return to the main Options menu from any other menu.

3.3 LCD Display:

The LCD is a character based, high contrast display made up of 4 lines by 20

characters. Information is displayed in a menu driven format where selections are

made by scrolling to the desired selection point with the keypad.

3.4 1 meter cable:

The 1m BNC cable connects the meter to the probe.

Never attempt to remove or install the probe or cable while the meter is

powered on. Surges in voltage could damage the probe or meter.

3.5 Sonic Meter Probe:

The probe is made of 304 stainless steel with a BNC connector at the top of the

probe and the sensing transducer at the bottom. Each probe has a unique

sensitivity value associated with the sensing transducer. The sensitivity value is

input into the meter’s memory via the keypad. The top of the probe is engraved

with a serial number that distinguishes it from other Sonic Meter probes. For

example, if an operator were to switch the probe from the meter with another

probe, the operator would need to power off the meter, switch the probes, power

up the meter and then go into the Setup menu and change the probe’s sensitivity.

This procedure is explained in detail in section 4.8.

3.6 Battery charger:

The battery charger can only be used to charge Nickel Metal Hydride (NiMH)

type rechargeable batteries. Do not charge NiCd batteries or mix other

batteries with NiMH batteries.

The battery charger should only be powered by 120/240Volts AC at 50/60Hz.

The plug type is NEMA 5-15.

3.7 Batteries:

The Sonic Meter

Sonic AO

ships with 8 AAA Nickel Metal Hydride (NiMH)

batteries. The meter uses 4 AAA NiMH batteries rated 1.2V/800mAh or higher.

The batteries should reach full charge in 5hrs or less.

Do not attempt to charge these batteries with any other charger than the unit

shipped with the meter.

4. Operation:

4.1 Changing the Batteries

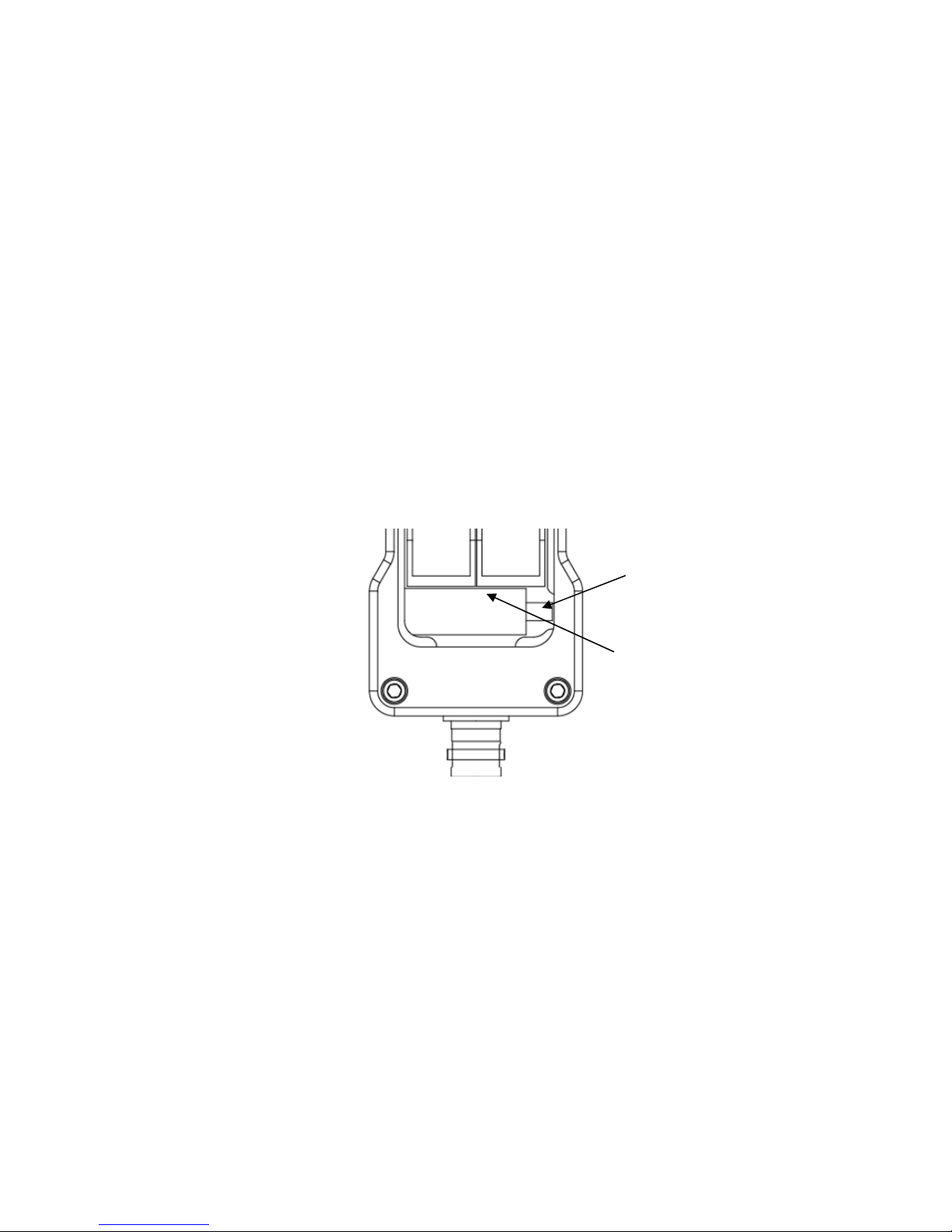

#6-32 Phillips Screw

Phillips Screwdriver

Battery Cover

4X AAA Batteries

Retaining Tab

Figure 3

Figure 3 shows how the 4 AAA batteries are removed.

With a Phillips screwdriver, unscrew the 6-32 Phillips screw from the back of the

meter. Lift the battery cover out from the meter. Remove the 4 AAA NiMH

batteries, and replace with 4 charged batteries. Make certain that you replace the

batteries into their sockets with the correct polarity. The polarity is clearly

marked on the bottom of each battery socket. Reinstall the battery cover with the

retaining tab positioned first in the bottom of the meter before securing the cover.

If the batteries are installed with the incorrect polarity, one of three situations will

be evident:

1. One of the 4 batteries was installed with the incorrect polarity.

Observation: The meter will power on, but the battery percentage will not be

displayed, and keypad keys will not function. Reinstall the battery correctly.

2. Two or three batteries were installed with the incorrect polarity.

Observation: The meter will not power on. Reinstall the batteries correctly.

3. All four batteries were installed with the incorrect polarity.

Observation: The 0.63Amp circuit breaker will disengage power. The meter

will not power on. Remove all four batteries. Reset the circuit breaker.

Reinstall the batteries correctly.

4.2 Resetting the circuit breaker

Push white tab to the right

to reset circuit breaker

0.63 Amp Circuit Breaker

Figure 4

Figure 4 shows the circuit breaker located at the bottom of the meter just below

the battery housing.

Remove the battery cover. With a small thin screwdriver, carefully push the

small white tab of the circuit breaker to the right. A small click will sound when

the reset tab has been moved all the way to the right. The circuit breaker is now

reset.

The most probable reason for setting off the circuit breaker would be incorrectly

installed batteries.

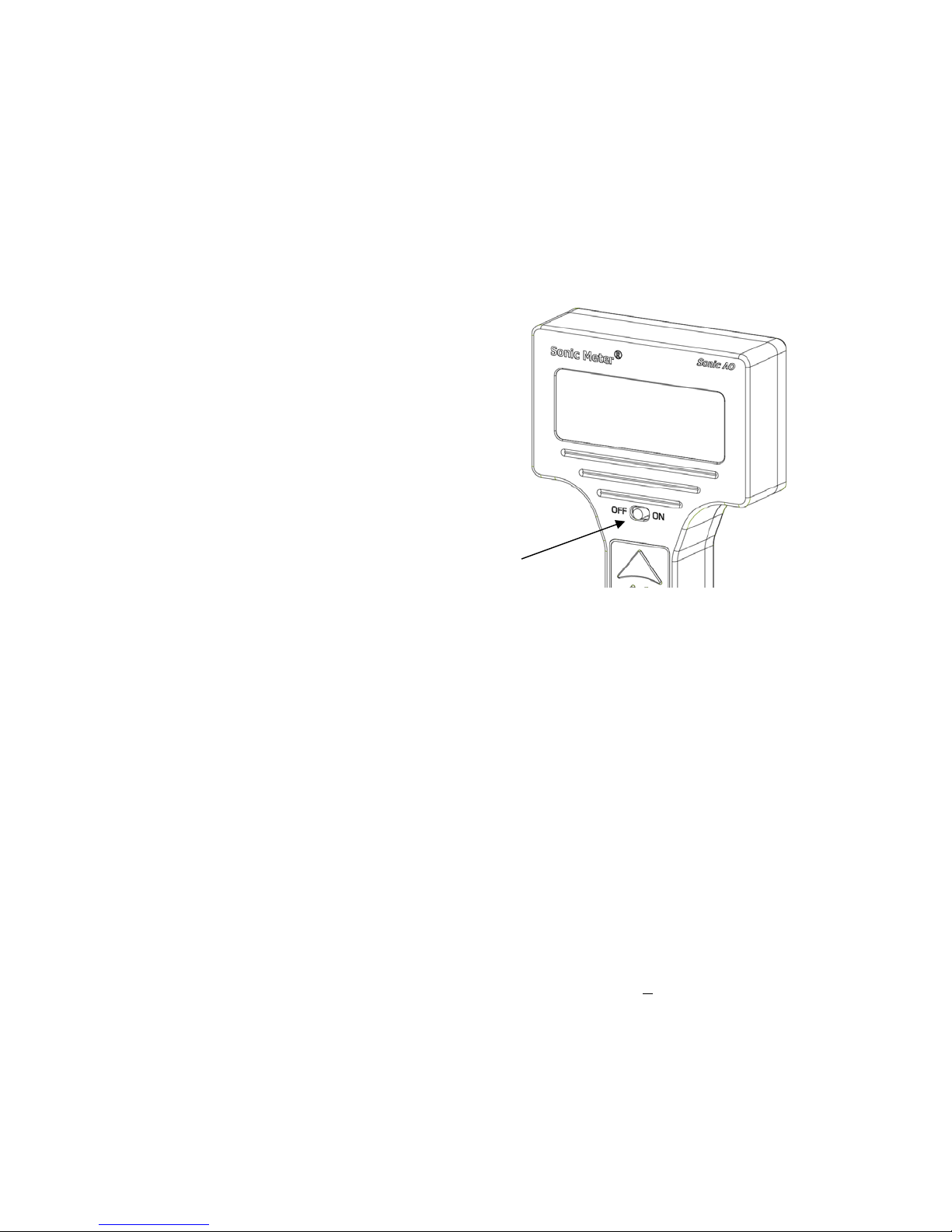

4.3 Powering up the meter

Options: Batt.=100%

→1. Real time reading

2. Averaged reading

3. Setup

To power the meter on, move the Power Switch to the right as shown in Figure 5.

Note: Before taking measurements, wait approximately 1 minute after

powering up the meter. Waiting 1 minute allows the probe to come to full

charge.

4.4 Options menu (main menu)

The Options menu will appear on the LCD after powering up the meter as shown

in the upper left of Figure 5. The Options menu displays the batteries capacity and

three option selections: 1. Real time reading; 2. Averaged reading; and 3. Setup.

4.5 Battery capacity

The battery’s capacity is displayed in percent. As the battery decreases in

voltage, this value decreases. For NiMH batteries, this value will gradually drop

until about 40%. After this point, the NiMH batteries drop off quickly. With

continuous use, the meter will run approximately 5 hours.

4.6 Real time reading

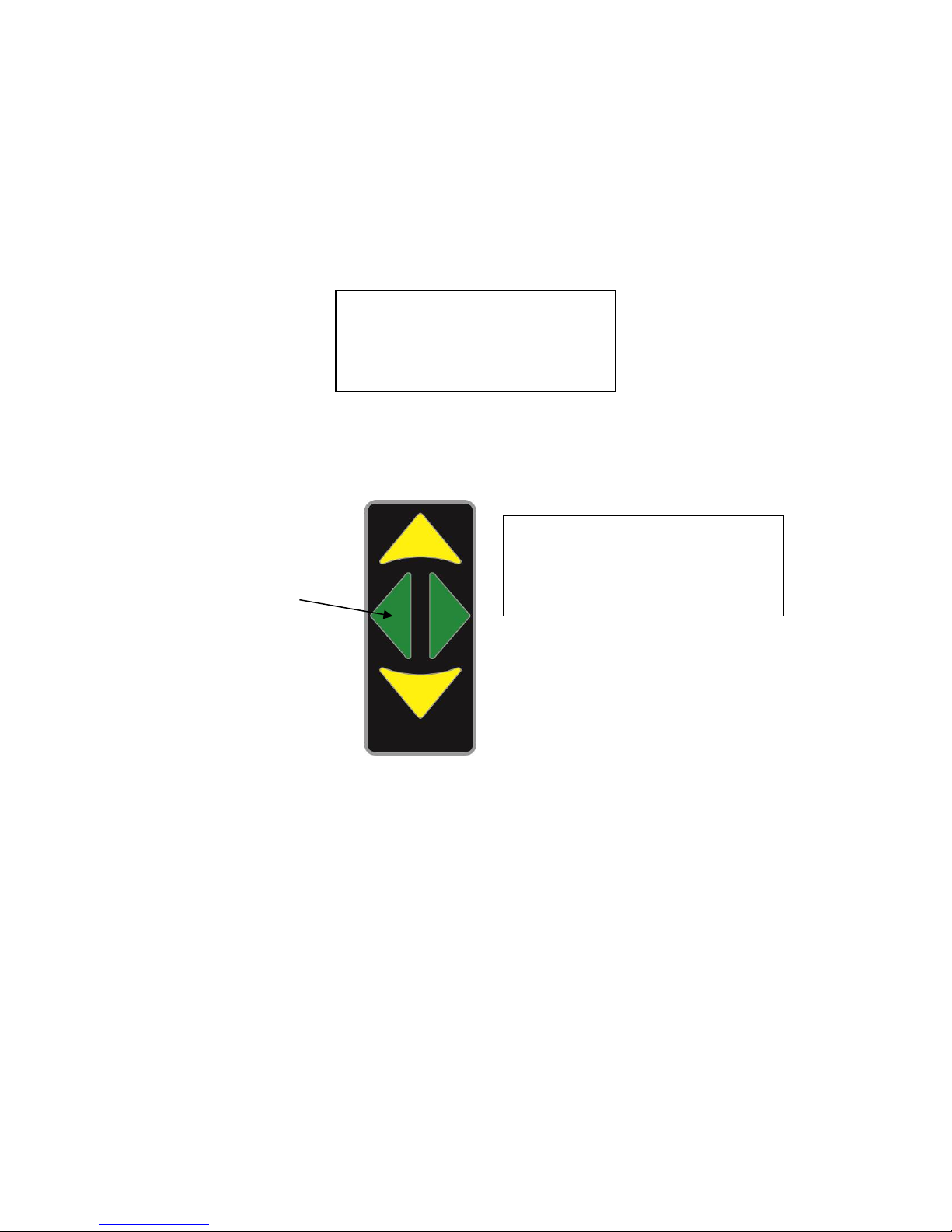

In Figure 5, the Options menu displays the selection arrow at the 1

Note: the 1st position (Real time reading) is always the default position of the

selection arrow when entering the Options menu.

With the selection arrow still at the 1st position, press and release the Right Scroll

key as shown in Figure 6

ON/OFF

Power Switch

Figure 5

st

position.

Scroll Right

Figure 6

The following screen will appear on the LCD as shown below in Figure 7.

Pressure=###.##psi

Low < ###.##psi

High > ###.##psi

Figure 7

The real time pressure (psi) is displayed along with the operator’s specified Low

and High range limits as shown above in Figure 7.

The Low and High range limits are input into the meter’s non-volatile memory at

the Setup stage, which will be explained in section 4.8 Setup.

The Low range limit indicator is a “<” symbol that is displayed in the upper lefthand corner. Refer to Figure 8. This indicator appears when the pressure reading

is less than the acceptable Low range limit value XXX.XXpsi. At 0.00psi this

symbol is not displayed.

For example: If the Low range limit is < 15.00psi and the actual pressure reading

=14.99psi, then the Low range limit indicator “<” will be displayed in the upper

left-hand corner of the LCD as shown below in Figure 8.

< Pressure= 14.99psi

Low < 15.00psi

High > ###.##psi

Figure 8

The High range limit indicator is a “>” symbol that is displayed in the upper right-

p

hand corner. Refer to Figure 9. This indicator appears when the pressure reading

is more than the acceptable High range limit value XXX.XXpsi.

For example: If the High range limit is > 25.00psi and the actual pressure reading

equals 25.01psi, then the High range limit indicator “>” will be displayed in the

upper right-hand corner of the LCD as shown below in Figure 9.

Pressure= 25.01psi >

Low < ###.##psi

High > 25.00psi

Figure 9

Return back to the Options menu at anytime by pressing and releasing the Left

scroll key as shown below in Figure 10.

Options: Batt.=100%

→1. Real time reading

2. Averaged reading

Scroll Left

3. Setu

Figure 10

4.7 Averaged readings

p

Options: Batt.=100%

1. Real time reading

→2. Averaged reading

3. Setu

At the Option menu, scroll down to 2nd position as shown above in Figure 11. If

the meter is not at the Option menu press and hold the Scroll Left key.

With the selection arrow at the 2nd position, press and release the Scroll Right key

to select the Averaged reading option. The following menu will appear as shown

below in Figure 12.

Figure 11

Pressure=###.##psi

→1. Begin readings

2. Samples=##

3. Interval=##.##sec

Scroll Left

Scroll Down

Figure 12

The first line displays the real time pressure. The real time pressure is displayed

so that the operator can position the probe in the cleaner before taking an

averaged reading. Below the real time pressure, the Averaged readings menu

displays three selections: 1. Begin readings; 2. Samples= XX; and 3.

Interval=XX.XXsec.

Selection 1 will initiate the averaging of the pressure based on the number of

pressure reading samples and the time interval. Selection 2 will allow the user to

select the number of samples. Selection 3 will allow the user to select the time

interval per sample.

Before taking an average reading of the pressure, selections 2 and 3 will need to

be setup.

Start by changing the Samples value. Press the yellow Scroll Down key once so

that the selection arrow is on 2. If you passed selection 2, you can either press

the yellow Scroll Up key or keep pressing the Scroll Down key until the selection

indicator is at selection 2 as shown below in Figure 13.

Pressure=###.##psi

1. Begin readings

→2. Samples=#0

3. Interval=##.##sec

Figure 13

With the selection indicator at the 2nd position, press and release the Scroll Right

key. An underscored flashing cursor will appear in the ones digit of the Samples

value as shown above in Figure 13.

The number of samples can range from 0 to 40.

With the cursor still in the ones digit, use the yellow Scroll Up or Scroll Down

buttons to change this number. When the desired ones digit is set, press and

release the Scroll Left key once. The underscored cursor will now be positioned

in the tens digit as shown below in Figure 14. Once again, use the Scroll Up or

Scroll Down keys to change this number.

Pressure=###.##psi

1. Begin readings

→2. Samples=10

3. Interval=##.##sec

Figure 14

When the desired number is set for the tens digit, press and release the Scroll Left

key once to return the selection arrow to the 2nd position. The value will

automatically be saved in non-volatile memory.

rd

To set the time interval between sampling, scroll down to the 3

position with

yellow Scroll Down key as shown below in Figure 15

Pressure=###.##psi

1. Begin readings

2. Samples=10

→3. Interval=##.#8sec

Figure 15

With the selection indicator at the 3rd position, press and release the Scroll Right

key. An underscored flashing cursor will appear in the hundredths digit of the

Samples value as shown in above Figure 15.

The time interval between samples can range from 0.01 to 99.99 seconds.

Pressure=###.##psi

1. Begin readings

2. Samples=10

→3. Interval=##.28sec

Figure 16

With cursor still in the hundredths digit, use the yellow Scroll Up or Scroll Down

buttons to change this number. When the desired hundredths digit is set, press

and release the Scroll Left key once. The underscored cursor will now be

positioned in the tenths digit as shown above in Figure 16. Once again, use the

Scroll Up or Scroll Down keys to change this number. Repeat this step for the

ones and tens digits. When the desired number is set for the ones and tens digits,

press and release the Scroll Left key once to return to the selection arrow at the

3rd position. The value will automatically be saved in non-volatile memory.

When the number of samples and time interval parameters are set to the desired

values, scroll up to the 1st position (Begin readings) by pressing and releasing the

yellow Scroll Up key twice. To execute the averaging process, press and release

the Scroll Right key once. The following screen prompt will appear as shown

below in Figure 15. This screen will remain for the duration of the averaging.

The index (number of samples) of the average will count down each of the

readings and be displayed in the upper left-hand corner as shown below in Figure

17.

#

* Averaging Data *

After the averaging process has been completed, the following screen will display

the average pressure value as shown in Figure 18.

To return to the averaging screen press the Scroll Left key once. To return to the

options screen, press the Scroll Left key again.

Figure 17

Average = ###.##psi

←exit

Figure 18

4.8 Setup

p

p

From the Options menu, scroll down to the 3rd option as shown below in Figure

19.

Options: Batt.=100%

1. Real time reading

2. Averaged reading

→3. Setu

Figure 19

With the selection indicator at the 3rd position, press and release the Scroll Right

key. The Setup menu will appear as shown below in Figure 20.

Instrument Setup:

→1. Limits

2. Median

3. Probe Setu

Figure 20

Options 1 and 2 are used for setting up the low and high range limits that were

explained in section 4.6. The low and high range limits are calculated as follows:

low range = median(value) – limits(value)

high range = median(value) + limits(value)

Example: median = 25, limits = +5. The low and high range limits will be 20 and

30 psi, respectively.

st

Now set the limits. With the selection indicator at the 1

position, press and

release the Scroll Right key.

The following limits setup screen will appear as shown below in Figure 21.

Old value=XXX.XXpsi

Enter a new limit:

New value=XXX.XXpsi

To exit scroll left

The cursor will appear underscored and flashing in the hundredths position of the

“New Value”. By using the yellow Scroll Up/Down keys, each digit can be

Figure 21

changed. To move to the next digit use the Left Scroll key. The cursor can

always be moved to the previous digit by using the Right Scroll key. After the

last digit (hundreds) has been set, push the Left Scroll key once to return to the

Setup menu. Values are automatically saved.

Now set the median. At the Setup menu, with the selection indicator at the 2nd

position (Median), press and release the Scroll Right key.

The following median setup screen will appear as shown in below in Figure 22.

Old value=XXX.XXpsi

Enter a new median:

New value=XXX.XXpsi

To exit scroll left

Figure 22

Use the same procedure to setup the median as was previously used for setting up

the limits.

Now set the probe sensitivity.

Each probe sold with each Sonic Meter

of this, the probe sensitivity value will have to be changed whenever the probe is

switched among meters or a probe has been replaced due to damage. If this is

not done, the accuracy of the measured value will change by a small amount. The

serial number of each probe is engraved at the top of the probe. The sensitivity

and serial number for each probe is recorded in the Calibration Sheet (packaged

with the meter). If more than two meters are used at the same location,

occasionally check to make sure the probes are matched with their corresponding

meters.

At the Setup menu, with the selection indicator at the 3rd position (Probe), press

and release the Scroll Right key.

The following median setup screen will appear as shown in below in Figure 23.

Old value=XXX.XXpsi

Enter sensitivity:

New value=XXX.XXpsi

To exit scroll left

®

has a unique sensitivity value. Because

Figure 23

Use the same procedure to setup the probe sensitivity as was previously used for

setting up the limits and median. Refer to Appendix E for the probe’s sensitivity

value.

4.9 Powering off the meter

To power off the meter, simply move the ON/OFF switch to the left as shown in

Figure 24.

ON/OFF

Power Switch

Figure 24

4.10 How to take measurements

Follow the manufacturer’s operating procedures before operating ultrasonic

cleaners: set the proper degas and temperature settings before taking any readings.

Quick real time pressure readings:

The real time reading mode allows for a quick estimate of the pressure at a

particular point. This is useful for checking pressure levels during the process of

cleaning.

Note: the pressure indicates the actual cleaning scrub-force at a particular

location.

Begin probing the tank with the meter in real time reading mode. Notice the

fluctuations in the readings. The readings usually fluctuate + 3 psi for most tanks,

but can fluctuate higher depending on your tank and the shape of the part sitting

inside of it.

Average pressure:

For precise pressure readings, set the meter in averaged reading mode. Averaged

reading mode is useful for determining the pressure levels of a particular point or

the tanks overall output

For a good starting point, set the number of samples to 10, and the interval to 1

second. These settings will average 10 samples over a 10second period.

With the meter still in averaged reading mode, take 10 to 20 readings throughout

the tank (more readings for lager tanks). Make sure to hold the probe steady

while taking each average. Write down each reading. Then average these

readings to get an overall pressure value for the tank.

Note: The more readings taken, the more accurate will be the overall average of

the tank’s output. If mapped at different depths, a clear picture of the distribution

can be determined. Additional methods for increased repeatability involve

readings at tightly held locations using some sort of grid plate located over the

tank with locating holes. Also including multiple depths by using a lock collar

along the body of the probe tube is very helpful.

Factors that determine the tanks pressure output:

Pressure levels can vary by as much as +10psi each time a different set of

measurements is taken.

The factors that determine this variance are:

• Degas time

• Tank temperature

• Part geometry

• Probe position

Degas the tank according to the manufacturer’s specifications. The degas time is

usually 15-20 minutes

Some tanks have a heat setting so that temperature can be controlled. Follow the

manufacturer’s specifications. Usually by the time the tank is degassed, the

temperature has stabilized.

Part geometry: the shape of a part can cause a change in the pressure output. The

part’s shape can cause constructive and destructive interference.

Probe position is critical. Within only a few millimeters, the pressure can vary

significantly (this variance differs by tank type). This is due to nodes of high and

low pressure that develop within the liquid. For the highest level of precision, the

probe should be held in some type of fixture that allows for x, y and z positions.

5. Appendices:

A. Specifications

Bandwidth: up to 500kHz

Pressure reading: 0-130psi, accuracy < 3% error. Determined over the entire

working range.

Temperature Operating Range: -65 to 250 F or –55 to 120 C

Performance: Real time reading samples pressure every 50msec. Averaged

reading can sample 0-40 readings at sample intervals of 10msec to 99.99sec.

Accuracy: The Sonic Meter

analog signal coming from the probe’s transducer. The precision of the meter

is +0.03psi.

Battery life (hours): The Sonic Meter

150mA/hour. The NiMH batteries are rated at 800 to 1000mAh. For

continuous use, the meter will run approximately 5 hours before batteries will

need to be recharged.

B. Troubleshooting

Meter fails to power on:

1. Batteries need to be recharged.

2. Batteries were improperly installed. (refer to section 4.1)

3. Circuit breaker has tripped. (refer to section 4.1 and 4.2)

4. Circuit fault unknown (return to Authorized Dealer)

Meter fails to power off:

1. Circuit fault unknown (return to Authorized Dealer

Pressure reads zero when tanks are on:

1. Cable has a line break.

*measure impedance of cable: 1-5ohms acceptable

*replace cable if impedance is above 5 ohms

2. Probe fault unknown (return to Authorized Dealer)

3. Meter fault unknown (return to Authorized Dealer)

C. Parts list

1. Meter: # Sonic AO-meter

Sonic AO

uses a 12bit ADC to digitize the

Sonic AO

consumes current at a rate

2. Probe: # Sonic AO-probe

3. Cable: # Sonic AO-cable

4. Case: # Sonic AO-case

5. Manual: # Sonic AO-manual

6. Battery charger: # Sonic AO-charger

7. Batteries: # Sonic AO-battery

D. Warranty

The manufacturer, SyncroCraft®, LLC, warrants the Sonic Meter

AO

against defects in materials and workmanship for a period of 12

Sonic

months from the date of shipment to the original purchaser.

SyncroCraft®, LLC will, at its option, repair or replace products that

prove to be defective.

The foregoing warranty shall not apply to defects resulting from improper

use or modification.

No other warranty is expressed or implied. SyncroCraft®, LLC

specifically disclaims warranties of merchantability and application for a

particular purpose

For warranty repair, SyncroCraft®, LLC will incur shipping cost.

For repairs not covered under this warranty, return shipping cost must be

paid before shipping this instrument to SyncroCraft®, LLC.

E. Authorized Dealers

For Sales or Service in the United States, North and South America, or Europe

contact:

SyncroCraft®, LLC

16225 Camino del Sol

Los Gatos, CA 95032

Tel: (408)438-0597

e-mail: syncrocraft@comcast.net

URL: http://www.sonicmeter.com

For Sales or Service in Asia contact:

Shinka Industry Co., Ltd.

Asahi-tamagawa building 2F, 1-636 Maruko-dori, Nakahara-ku, Kawasaki,

211-0006 Japan

Tel: +81-44-589-6367

Fax: +81-44-589-6368

e-mail: sk@shinka-sangyo.co.jp

URL: http://www.shinka-sangyo.co.jp

Loading...

Loading...