Page 1

SONIC 2024/2022

BROADBAND MULTIBEAM ECHOSOUNDERS

Operation Manual V5.0

Revision 002 (05Aug2014)

Part No. 96000001

Page 2

Page 2 of 210

Version 5.0 Rev r002

Date 05-08-2014

Part No. 96000001

Page 3

COPYRIGHT NOTICE

Copyright © 2008, R2Sonic LLC. All rights reserved

Ownership of copyright

The copyright in this manual and the material in this manual (including without limitation the text, artwork, photographs,

images, or any other material in this manual) is owned by R2Sonic LLC. The copyright includes both the print and

electronic version of this manual.

Copyright license

R2Sonic LLC is solely responsible for the content of this manual. Neither this manual, nor any part of this manual, may be

copied, translated, distributed or modified in any manner without the express written approval of R2Sonic LLC.

Permissions

You may request permission to use the copyright materials in this manual by writing to support@r2sonic.com

Authorship

This manual (Sonic 2024/2022 Operation Manual), and all of the content therein, written by:

R2Sonic LLC

5307 Industrial Oaks Blvd, Suite 120

Austin, Texas 78735

USA

Telephone: +1 (512) 891.0000

Version Printing History

• June 2008 Version 1.1/1.2

• July 2008 Version 1.3

• Aug/Sep 2008 Version 1.4

• December 2008 Version 1.5

• June 2009 Version 1.6

• April 2010 Version 2.0

• August 2010 Version 3.0

• April 2011 Version 3.1

• January 2012 Version 4.0

• April 2012 Version 4.1

• February 2014 Version 5.0

R2Sonic LLC reserves the right to amend or edit this manual at any time. R2Sonic LLC offers no implied warranty

concerning the information in this manual. R2Sonic LLC shall not be held liable for any errors within the manual.

Page 3 of 210

Version 5.0 Rev r002

Date 05-08-2014

Page 4

Page 4 of 210

Version 5.0 Rev r002

Date 05-08-2014

Part No. 96000001

Page 5

Table of Contents

1 INTRODUCTION ..................................................................................................................... 19

1.1 Outline of Equipment ............................................................................................................ 19

1.2 How to use this Manual ........................................................................................................ 20

1.2.1 Standard of Measurement ........................................................................................... 20

2 SONIC SPECIFICATIONS .......................................................................................................... 21

2.1 Sonic 2024 System Specification ........................................................................................... 21

2.2 Sonic 2022 System Specification ........................................................................................... 21

2.3 Sonic 2024 Dimensions and Weights .................................................................................... 21

2.4 Sonic 2022 Dimensions and Weights .................................................................................... 22

2.5 Sonic 2024/Sonic 2022 Electrical Interface ........................................................................... 22

2.6 Sonic 2024/2022 Ping Rates (SV = 1500.00m/sec) ............................................................... 22

2.7 Acoustic Centre ..................................................................................................................... 23

3 SONIC 2024/2022 SONAR HEAD INSTALLATION – Surface Vessel ........................................... 25

3.1 Sonic 2024/2022 Receive Module Installation ..................................................................... 25

3.1.1 Mounting the Sonic 2024/2022 Receive Module ......................................................... 26

3.1.2 Receive Module ............................................................................................................ 26

3.1.3 Mounting the Projector ................................................................................................ 27

3.1.4 Correct Orientation of the Sonic 2024 and Sonic 2022 ................................................ 29

3.1.5 Deck Test Prior to Deployment .................................................................................... 29

3.2 Sonar Head Installation Guidelines ...................................................................................... 31

3.2.1 Introduction .................................................................................................................. 31

3.2.2 Over-the-Side mount .................................................................................................... 31

3.2.3 Moon Pool Mount ........................................................................................................ 32

3.2.4 Hull Mount .................................................................................................................... 32

3.2.5 ROV Mounting .............................................................................................................. 32

4 SONIC 2024/2022 SONAR INTERFACE MODULE (SIM) INSTALLATION and INTERFACING ........ 33

4.1 Sonar Interface Module (SIM) .............................................................................................. 33

4.1.1 Physical installation ...................................................................................................... 33

4.1.2 Electrical and Interfacing .............................................................................................. 34

4.1.3 Serial Communication .................................................................................................. 38

Page 5 of 210

Version 5.0 Rev r002

Date 05-08-2014

Page 6

4.1.4 Time and PPS input ....................................................................................................... 38

4.1.5 Motion Input ................................................................................................................. 39

4.1.6 SVP input ....................................................................................................................... 39

5 OPERATION OF THE SONIC 2024/2022 VIA SONIC CONTROL .................................................. 41

5.1 Installing Sonic Control Graphical User Interface ................................................................. 41

5.2 Hot Keys ................................................................................................................................ 41

5.3 Network Setup ....................................................................................................................... 42

5.3.1 Initial Computer setup for Communication .................................................................. 42

5.3.2 Discover Function .......................................................................................................... 43

5.3.3 Configuring Network Communication .......................................................................... 45

5.4 Sensor Setup (Serial and Ethernet Interfacing) ..................................................................... 47

5.4.1 GPS ................................................................................................................................ 47

5.4.2 Motion ........................................................................................................................... 47

5.4.3 Heading ......................................................................................................................... 47

5.4.4 SVP ................................................................................................................................ 48

5.4.5 Message displays .......................................................................................................... 48

5.4.6 Trigger in / Trigger out .................................................................................................. 48

5.5 Sonar Settings (Hotkey: F2) ................................................................................................... 49

5.5.1 Frequency (kHz) ............................................................................................................ 50

5.5.2 Ping Rate Limit .............................................................................................................. 51

5.5.3 Sector Coverage ............................................................................................................ 51

5.5.4 Sector Rotate ................................................................................................................ 52

5.5.5 Minimum Range Gate (m) ............................................................................................. 53

5.5.6 Bottom Sampling ........................................................................................................... 53

5.5.7 Mission Mode ............................................................................................................... 54

5.5.8 IMAGERY ....................................................................................................................... 55

5.5.9 Roll Stabilize .................................................................................................................. 57

5.5.10 Dual Head Mode (Also see Appendix VII, Section 13.9) ............................................... 58

5.5.11 TruePix™, Snippets, Water Column Enable and Intensity Enable ................................. 60

Page 6 of 210

Version 5.0 Rev r002

Date 05-08-2014

Part No. 96000001

Page 7

5.6 Ocean Setting ....................................................................................................................... 61

5.6.1 Absorption: 0 – 200 dB/km .......................................................................................... 61

5.6.2 Spreading Loss: 0 – 60 dB ............................................................................................. 61

5.6.3 Time Variable Gain ....................................................................................................... 62

5.7 Installation Settings .............................................................................................................. 65

5.7.1 Projector Orientation ................................................................................................... 65

5.7.2 Projector Z Offset (m) ................................................................................................... 65

5.7.3 Head Tilt........................................................................................................................ 65

5.8 Status .................................................................................................................................... 66

5.9 Tools ..................................................................................................................................... 69

5.9.1 Engineering ................................................................................................................... 69

5.9.2 Firmware Update .......................................................................................................... 69

5.9.3 Saturation Monitor ....................................................................................................... 71

5.10 Help ....................................................................................................................................... 73

5.10.1 Help Topics ................................................................................................................... 73

5.10.2 Options ......................................................................................................................... 73

5.10.3 Remote Assistance ....................................................................................................... 73

5.10.4 About Sonic Control ...................................................................................................... 74

5.11 Display settings ..................................................................................................................... 75

5.12 Imagery ................................................................................................................................. 76

5.12.1 TruePix™ and Water Column ........................................................................................ 76

5.13 Main Operation Parameters ................................................................................................. 77

5.13.1 Range: 0 – 1200 metres ................................................................................................ 77

5.13.2 RangeTrac™ – Sonic Control automatically sets correct range .................................... 79

5.13.3 Power: 191 – 221 dB ..................................................................................................... 79

5.13.4 Pulse Length: 15µsec – 1000µsec ................................................................................. 79

5.13.5 Gain: 1 – 45 ................................................................................................................... 80

5.13.6 Depth Gates: GateTrac™ .............................................................................................. 80

5.14 Ruler ...................................................................................................................................... 83

5.15 Save Settings ......................................................................................................................... 84

5.16 Operating Sonic Control on a second computer ................................................................... 84

Page 7 of 210

Version 5.0 Rev r002

Date 05-08-2014

Page 8

5.16.1 Two computer setup ..................................................................................................... 84

5.16.2 Changing back to one computer ................................................................................... 85

6 SONIC 2024/2022 THEORY OF OPERATION ............................................................................ 87

6.1 Sonic 2024/2022 Sonar Head Block Diagram ....................................................................... 87

6.2 Sonic 2024/2022 Transmit (Normal Operation Mode) ......................................................... 88

6.3 Sonic 2024/2022 Receive (Normal Operation Mode) ........................................................... 89

6.4 Sonic 2024/2022 Sonar Interface Module (SIM) Block Diagram ........................................... 91

6.4.1 Sonar Interface Module (SIM) Block Diagram ............................................................... 91

7 Appendix I: R2Sonic I2NS Components and Operation ........................................................... 93

7.1 Components .......................................................................................................................... 93

7.2 Connection diagram .............................................................................................................. 94

7.3 Installation ............................................................................................................................ 95

7.3.1 The IMU and GPS antennas .......................................................................................... 95

7.3.2 INS BNC – TNC Connections .......................................................................................... 95

7.3.3 I2NS DB9 Connections ................................................................................................... 96

7.4 Setup in Sonic Control ........................................................................................................... 97

7.4.1 Network Setup .............................................................................................................. 97

7.4.2 Applanix Group 119 specific to R2Sonic SIMINS ........................................................... 98

7.4.3 Sensor Setup ................................................................................................................. 99

7.4.4 INS Monitor (Alt+I) ........................................................................................................ 99

7.5 Measuring IMU Offsets ....................................................................................................... 101

7.6 I2NS Physical Specifications ................................................................................................ 103

7.7 I2NS Drawings ..................................................................................................................... 105

7.7.1 I2NS IMU ..................................................................................................................... 105

7.7.2 I2NS Sonar Interface Module (SIM) ............................................................................ 106

8 APPENDIX II: Multibeam Survey Suite Components ............................................................. 107

8.1 Auxiliary Sensors and Components ..................................................................................... 107

8.2 Differential Global Positioning System ................................................................................ 107

8.2.1 Installation .................................................................................................................. 107

8.2.2 GPS Calibration............................................................................................................ 108

8.3 Gyrocompass ....................................................................................................................... 109

Page 8 of 210

Version 5.0 Rev r002

Date 05-08-2014

Part No. 96000001

Page 9

8.3.1 Gyrocompass Calibration Methods ............................................................................ 109

8.4 The Motion Sensor .............................................................................................................. 114

8.5 Sound Velocity Probes ........................................................................................................ 115

8.5.1 CTD Probes ................................................................................................................. 116

8.5.2 Time of Flight Probe ................................................................................................... 117

8.5.3 XBT Probes .................................................................................................................. 117

8.6 The sound velocity cast ....................................................................................................... 118

8.6.1 Time of Day ................................................................................................................. 118

8.6.2 Fresh water influx ....................................................................................................... 118

8.6.3 Water Depth ............................................................................................................... 118

8.6.4 Distance ...................................................................................................................... 118

8.6.5 Deploying and recovering the Sound Velocity Probe ................................................. 118

9 APPENDIX III: Multibeam Surveying .................................................................................... 121

9.1 Introduction ........................................................................................................................ 121

9.2 Survey Design ..................................................................................................................... 121

9.2.1 Line Spacing ................................................................................................................ 121

9.2.2 Line Direction .............................................................................................................. 121

9.2.3 Line Run-in .................................................................................................................. 122

9.3 Record Keeping ................................................................................................................... 122

9.3.1 Vessel Record ............................................................................................................. 122

9.3.2 Daily Survey Log .......................................................................................................... 123

10 APPENDIX IV: Offset Measurements .................................................................................... 127

10.1 Lever Arm Measurement – Offsets ..................................................................................... 127

10.2 Vessel Reference System .................................................................................................... 127

10.3 Measuring Offsets .............................................................................................................. 128

10.3.1 Sonic 2024 Acoustic Centre ........................................................................................ 128

10.3.2 Horizontal Measurement ........................................................................................... 128

10.3.3 Vertical Measurement ................................................................................................ 129

11 APPENDIX V: The Patch Test ................................................................................................ 131

11.1 Introduction ........................................................................................................................ 131

11.2 Orientation of the Sonic 2024/2022 Sonar Head ............................................................... 131

Page 9 of 210

Version 5.0 Rev r002

Date 05-08-2014

Page 10

11.3 Patch Test Criteria ............................................................................................................... 132

11.3.1 Latency Test ................................................................................................................ 132

11.3.2 Roll Test ....................................................................................................................... 133

11.3.3 Pitch Test ..................................................................................................................... 134

11.3.4 Yaw Test ...................................................................................................................... 135

11.4 Solving for the Patch Test .................................................................................................... 136

11.5 History ................................................................................................................................. 136

11.6 Basic data collection criteria ............................................................................................... 137

11.7 Patch Test data collection error areas ............................................................................... 137

11.7.1

11.7.2

11.7.3

11.7.4

11.7.5

11.7.6

11.7.7

Positioning

Feature chosen for test

Water depth

Use predefined survey lines

Speed

Vessel line up

Pole variability

.................................................................................................................. 137

.............................................................................................. 137

............................................................................................................... 138

....................................................................................... 138

.......................................................................................................................... 138

.............................................................................................................. 138

............................................................................................................ 138

11.8 Improving the Patch Test and Patch Test results .............................................................. 139

11.8.1

11.8.2

Need to collect sufficient data

Individually solving values

.......................................................................................... 140

................................................................................... 139

11.9 Truthing the patch test ....................................................................................................... 140

12 APPENDIX VI: Basic Acoustic Theory .................................................................................... 141

12.1 Introduction ......................................................................................................................... 141

12.2 Sound Velocity ..................................................................................................................... 141

12.2.1 Salinity ......................................................................................................................... 143

12.2.2 Temperature ............................................................................................................... 143

12.2.3 Refraction Errors ......................................................................................................... 143

12.3 Transmission Losses ............................................................................................................ 144

12.3.1 Spreading Loss ............................................................................................................. 144

12.3.2 Absorption ................................................................................................................... 145

12.3.3 Reverberation and Scattering ..................................................................................... 149

Page 10 of 210

Version 5.0 Rev r002

Date 05-08-2014

Part No. 96000001

Page 11

13 APPENDIX VII: Sonic 2024/2022 Mounting: Sub-Surface (ROV/AUV) .................................... 151

13.1 Installation Considerations ................................................................................................. 151

13.1.1 Ethernet wiring considerations .................................................................................. 152

13.2 Data Rates .......................................................................................................................... 152

13.3 ROV Installation Examples .................................................................................................. 153

13.4 Power Requirements........................................................................................................... 155

13.4.1 Common mode noise rejection .................................................................................. 157

13.4.2 SIM Power connections .............................................................................................. 158

13.5 SIM Installation – ROV ........................................................................................................ 159

13.6 SIM Installation – AUV ........................................................................................................ 160

13.7 SIM Board Physical Installation .......................................................................................... 161

13.8 SIM Stack LED Status Indicators ......................................................................................... 161

13.8.1 SIM Board Dimensional Information .......................................................................... 162

13.8.2 SIM Board Images ....................................................................................................... 163

13.9 Dual Sonar Head ................................................................................................................. 165

13.9.1 Dual Head Installation ................................................................................................ 165

13.9.2 Operation .................................................................................................................... 165

14 APPENDIX VIII: R2Sonic Control Commands ......................................................................... 167

14.1 Introduction ........................................................................................................................ 167

14.2 General Notes ..................................................................................................................... 167

14.2.1 Ethernet Port Numbers .............................................................................................. 167

14.2.2 Type Definitions .......................................................................................................... 167

14.2.3 Command Packet Format ........................................................................................... 167

14.3 Head Commands, Binary Format ........................................................................................ 168

14.4 SIM Commands, Binary Format .......................................................................................... 171

14.5 GUI Commands, Binary Format .......................................................................................... 172

14.6 Command Examples Sent to the Sonar Head and SIM ....................................................... 173

15 APPENDIX IX: R2Sonic Uplink Data Formats ......................................................................... 175

15.1 Introduction ........................................................................................................................ 175

15.2 General Notes ..................................................................................................................... 175

15.3 Port Numbers ...................................................................................................................... 175

Page 11 of 210

Version 5.0 Rev r002

Date 05-08-2014

Page 12

15.4 Type Definitions ................................................................................................................... 175

15.5 Ethernet Data Rates ............................................................................................................ 176

15.6 Bathymetry Packet Format ................................................................................................. 177

15.7 Snippet Format .................................................................................................................... 180

15.8 Water Column (WC) Data Format ....................................................................................... 181

15.9 Acoustic Image (AI) Data Format ........................................................................................ 184

15.10 TruePix™ Data Format ........................................................................................................ 186

15.11 Head Status Format ............................................................................................................ 188

15.12 SIM Status Data Format ...................................................................................................... 190

15.13 Device Status Format .......................................................................................................... 192

15.14 Data Playback Using Bit-Twist ............................................................................................ 193

15.14.1 Introduction ................................................................................................................ 193

15.14.2 Capturing Data ............................................................................................................ 193

15.14.3 Editing Data ................................................................................................................. 194

15.14.4 Data Playback .............................................................................................................. 195

16 APPENDIX X: Drawings ........................................................................................................ 197

Page 12 of 210

Version 5.0 Rev r002

Date 05-08-2014

Part No. 96000001

Page 13

List of Figures

Figure 1: Sonic 2024/2022 Block Diagram ............................................................................................ 19

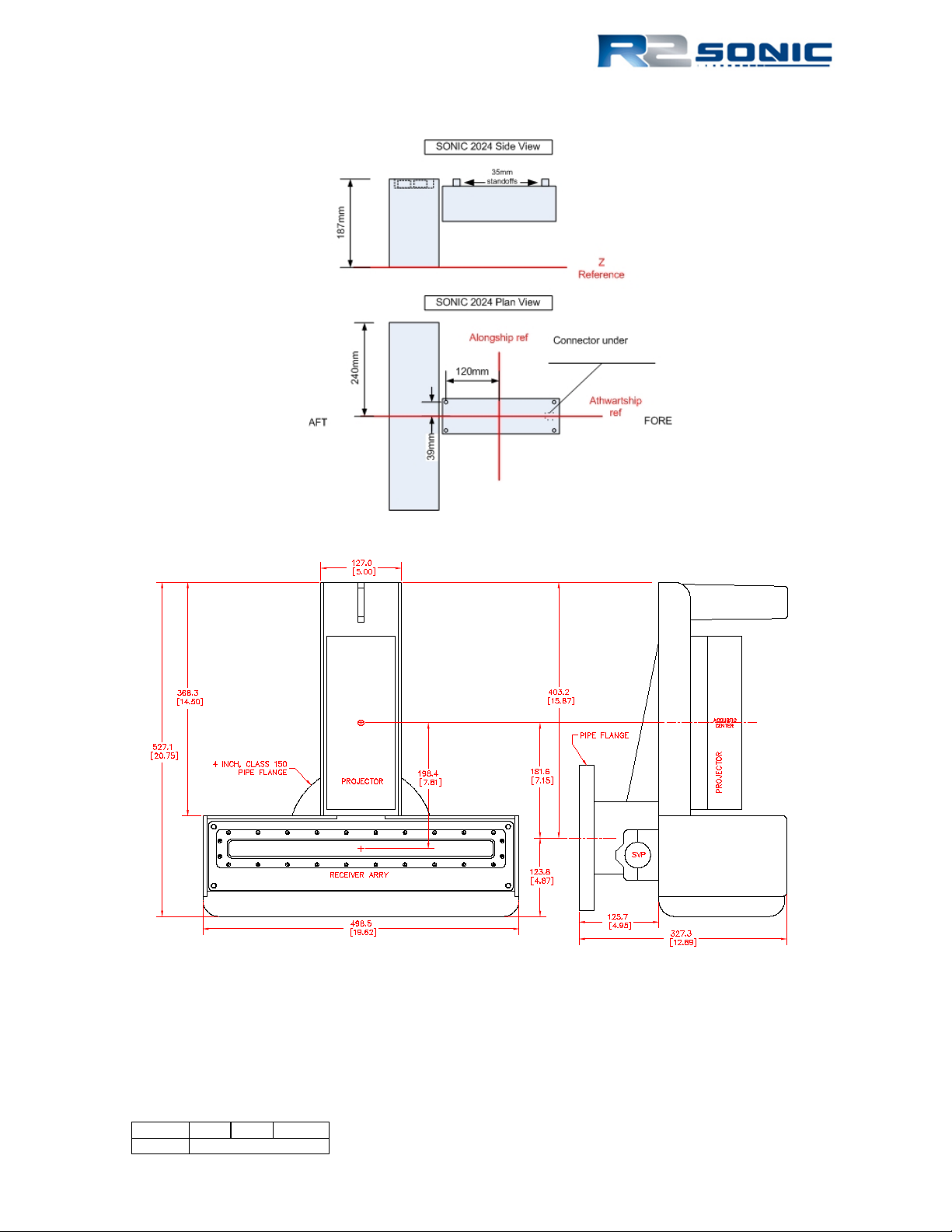

Figure 2: Sonic 2024 Acoustic Centre ................................................................................................... 23

Figure 3: Sonic 2024 Acoustic Centre as Mounted ............................................................................... 23

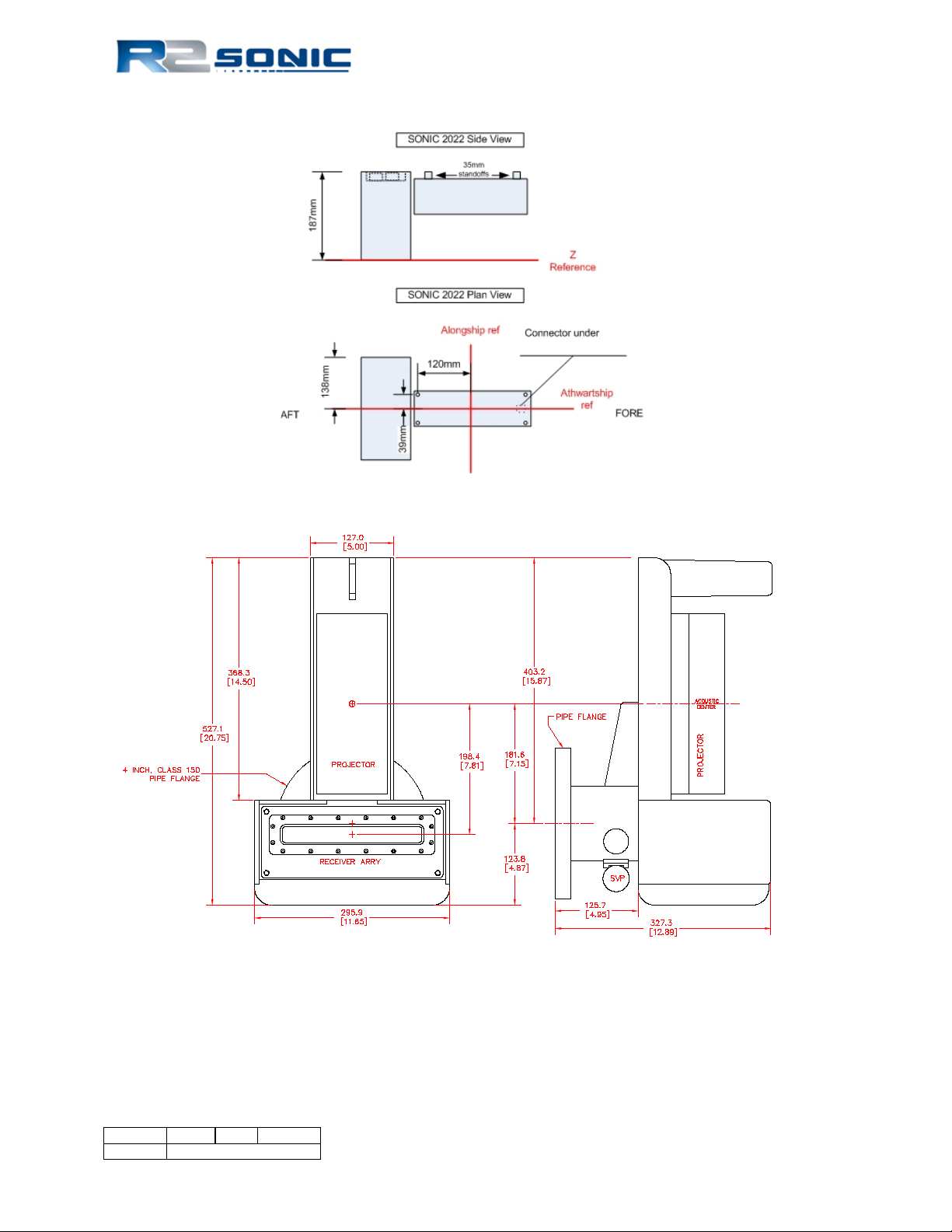

Figure 4: Sonic 2022 Acoustic Centre ................................................................................................... 24

Figure 5: Sonic 2022 Acoustic Centre as Mounted ............................................................................... 24

Figure 6: Sonic 2024 and Sonic 2022 on the mounting frame ............................................................. 25

Figure 7: Top side of Receive Module .................................................................................................. 26

Figure 8: Receive Module Face ............................................................................................................. 26

Figure 9: Seated connectors (Sonic 2024 on left and Sonic 2022 on right) ........................................ 26

Figure 10: Connector wiggle - back and forth NOT up and down ........................................................ 26

Figure 11: Receive Module with cables connected .............................................................................. 27

Figure 12: Sonic 2024 Projector ........................................................................................................... 27

Figure 13: Position the insulating bushing, then wrap threads with Teflon tape, then secure with flat

washer, locking washer and then nut. ................................................................................................. 27

Figure 14: Projector Stand-off .............................................................................................................. 28

Figure 15: Mounting the projector ....................................................................................................... 28

Figure 16: View of the mounted Projector; NB. Connector is facing protective fin ............................. 28

Figure 17: SV Probe mounted in block ................................................................................................. 28

Figure 18: Correct Orientation of the Sonic 2024 and the Sonic 2022 ................................................ 29

Figure 19: Typical over-the-side mount ............................................................................................... 31

Figure 20: Sonar Interface Module (SIM) ............................................................................................. 33

Figure 21: Removal of trim to expose securing holes .......................................................................... 34

Figure 22: SIM Interfacing Physical Connections ................................................................................. 35

Figure 23: SIM Interfacing Guide (from label on top of the SIM) ......................................................... 35

Figure 24: SIM IEC mains connection and deck lead Amphenol connector ......................................... 36

Figure 25: Impulse connector ............................................................................................................... 36

Figure 26: Projector cable configuration .............................................................................................. 37

Figure 27: TTL input/output (PPS and Sync In/Out) schematic ............................................................ 38

Figure 28: Sonic Control Icon on desktop ............................................................................................. 41

Figure 29: Sonic Control 2000 .............................................................................................................. 41

Figure 30: Windows XP Internet Properties ......................................................................................... 42

Figure 31: IP and Subnet mask setup ................................................................................................... 43

Figure 32: Sonic Control Network setup .............................................................................................. 44

Figure 33: Set INS IP ............................................................................................................................. 44

Figure 34: Set IP Time Expired .............................................................................................................. 44

Figure 35: Command prompt-ipconfig/all ............................................................................................ 45

Figure 36: Sensor communication settings .......................................................................................... 47

Figure 37: Trigger In/Out Options ........................................................................................................ 48

Figure 38: Sonar Operation Settings window ....................................................................................... 49

Page 13 of 210

Version 5.0 Rev r002

Date 05-08-2014

Page 14

Figure 39: Operating Frequency Selection ........................................................................................... 50

Figure 40: UHR frequency available ..................................................................................................... 50

Figure 41: Ping Rate Limit .................................................................................................................... 51

Figure 42: Sector Coverage .................................................................................................................. 52

Figure 43: Sector Rotate ...................................................................................................................... 52

Figure 44: Bottom Sampling Modes .................................................................................................... 53

Figure 45: Example of going from normal to Quad mode ................................................................... 54

Figure 46: Indication of Bottom Sampling Mode ................................................................................. 54

Figure 47: Normal Mission Mode selections ....................................................................................... 54

Figure 48: Mission Mode with the FLS Option installed ...................................................................... 54

Figure 49: Enable Acoustic Image in the wedge display ...................................................................... 55

Figure 50: FLS Wide mode ................................................................................................................... 56

Figure 51: Imagery palette selection in Display Options ..................................................................... 56

Figure 52: Stealth mode single Ping button ......................................................................................... 56

Figure 53: Roll Stabilize ........................................................................................................................ 57

Figure 54: Dual Head Mode ................................................................................................................. 58

Figure 55: Dual Head Mode active ....................................................................................................... 58

Figure 56: Load Settings menu selection ............................................................................................. 59

Figure 57: Loading an .ini file ............................................................................................................... 59

Figure 58: Default dual head Network settings ................................................................................... 59

Figure 59: TruePix™ image of wreck debris and sea grass .................................................................. 60

Figure 60: Ocean Characteristics ......................................................................................................... 61

Figure 61: TVG Curve Concept ............................................................................................................. 62

Figure 62: The angular acoustic wave front will strike each receive element at a different time ...... 64

Figure 63: Installation Settings ............................................................................................................. 65

Figure 64: Status Options ..................................................................................................................... 66

Figure 65: Status Message ................................................................................................................... 66

Figure 66: Real-time Status Window ................................................................................................... 67

Figure 67: Select Tools; Firmware Update ........................................................................................... 69

Figure 68: The Browse button will open the current GUI's directory .................................................. 70

Figure 69: Select correct update .bin file ............................................................................................. 70

Figure 70: A batch file will automatically load the upgrade file .......................................................... 70

Figure 71: The start of a firmware update. A series of dots represents the update progress. .......... 70

Figure 72: Firmware update completed, the window will close automatically and the Update window

will show successful completion .......................................................................................................... 71

Figure 73: Tools | Saturation Monitor ................................................................................................ 71

Figure 74: The Help Menu .................................................................................................................... 73

Figure 75: Installed Options ................................................................................................................. 73

Figure 76: Remote Assistance .............................................................................................................. 73

Figure 77: Remote Assistance window ................................................................................................ 74

Figure 78: About, provides the GUI version ......................................................................................... 74

Page 14 of 210

Version 5.0 Rev r002

Date 05-08-2014

Part No. 96000001

Page 15

Figure 79: Display Settings ................................................................................................................... 75

Figure 80: Imagery Settings .................................................................................................................. 76

Figure 81: Operating parameter buttons ............................................................................................. 77

Figure 82: Range setting represented in the wedge display ................................................................ 78

Figure 83: Graphical concept of the Wedge Display ............................................................................ 78

Figure 84: RangeTrac enabled .............................................................................................................. 79

Figure 85: Transmit Pulse ..................................................................................................................... 80

Figure 86: Enable Gates ........................................................................................................................ 80

Figure 87: Manual and GateTrac selections ......................................................................................... 80

Figure 88: Manually adjust the gate slope ........................................................................................... 81

Figure 89: Gate width tolerance toggle ................................................................................................ 81

Figure 90: GateTrac enabled; Gate min and max control is disabled .................................................. 81

Figure 91: GateTrac: Depth + Slope enabled, manual gate controls are disabled. .............................. 82

Figure 92: GateTrac: Depth + Slope enabled and tracking a steep slope ............................................ 82

Figure 93: Graphical representation of depth gate .............................................................................. 83

Figure 94: Ruler Function ..................................................................................................................... 83

Figure 95: Change in GUI IP .................................................................................................................. 85

Figure 96: SONIC 2024 Sonar Head Block Diagram .............................................................................. 87

Figure 97: Transmit pattern .................................................................................................................. 88

Figure 98: Receive pattern with Transmit pattern ............................................................................... 89

Figure 99: Sonar Interface Module Block Diagram .............................................................................. 91

Figure 100: R2Sonic I2NS Main Components (not including antennas and cables) ............................. 93

Figure 101: GNSS Antennas .................................................................................................................. 93

Figure 102: INS connections ................................................................................................................. 94

Figure 103: INS SIM block diagram ....................................................................................................... 94

Figure 104: INS BNC & TNC Connections .............................................................................................. 95

Figure 105: PPS Out - PPS In ................................................................................................................. 95

Figure 106: Com 1 and Com 2 on SIMINS for POS MV serial data ....................................................... 96

Figure 107: POSView Serial port setup ................................................................................................. 96

Figure 108: Network Settings SIMINS .................................................................................................. 97

Figure 109: Cannot Change IP, waiting on msg 32 ............................................................................... 97

Figure 110: Set IP time expired, cannot change IP ............................................................................... 97

Figure 111: Sensor setup for SIMINS .................................................................................................... 99

Figure 112: INS Monitor ....................................................................................................................... 99

Figure 113: IMU Reference indicators ................................................................................................ 101

Figure 114: POSView Lever Arm setup ............................................................................................... 102

Figure 115: View of installation with the entered offsets .................................................................. 102

Figure 116: IMU Drawing .................................................................................................................... 105

Figure 117: I2NS SIM Drawing ............................................................................................................ 106

Figure 118: Gyrocompass Calibration method 1 ................................................................................ 111

Figure 119: Gyro Calibration Method 2 .............................................................................................. 112

Page 15 of 210

Version 5.0 Rev r002

Date 05-08-2014

Page 16

Figure 120: Gyro Calibration Method 2 example .............................................................................. 113

Figure 121: Idealised concept of Gyro Calibration Method 2 ............................................................ 113

Figure 122: CTD Probe ....................................................................................................................... 116

Figure 123: Time of Flight SV probe ................................................................................................... 117

Figure 124: Deploying a sound velocity probe via a winch or A - Frame ........................................... 120

Figure 125: Rough log, kept during survey operations...does not need to be neat, but must contain

all pertinent information ................................................................................................................... 125

Figure 126: Smooth log; information copied from real-time survey log ........................................... 126

Figure 127: Vessel Horizontal and Vertical reference system ........................................................... 128

Figure 128: Sonic 2024/2022 Acoustic Centre ................................................................................... 128

Figure 129: Sonic 2024/2022 axes of rotation ................................................................................... 131

Figure 130: Latency Data collection ................................................................................................... 132

Figure 131: Roll data collection .......................................................................................................... 133

Figure 132: Roll data collections ........................................................................................................ 133

Figure 133: Pitch data collections ...................................................................................................... 134

Figure 134: Yaw data collection ......................................................................................................... 135

Figure 135: In 1822 Daniel Colloden used an underwater bell to calculate the speed of sound under

water in Lake Geneva, Switzerland at 1435 m/Sec, which is very close to recent measurements. .. 141

Figure 136: Concept of refraction due to different sound velocities in the water column ............... 142

Figure 137: Sound velocity profile ..................................................................................................... 142

Figure 138: Refraction Error indication .............................................................................................. 143

Figure 139: Concept of Spherical Spreading ...................................................................................... 144

Figure 140: Concept of Cylindrical Spreading .................................................................................... 145

Figure 141: Single Head ROV Installation scheme A .......................................................................... 153

Figure 142: Single Head ROV Installation scheme B (Preferred) ....................................................... 153

Figure 143: Dual Head ROV Installation scheme A ............................................................................ 154

Figure 144: Dual Head ROV Installation scheme B (Preferred) ......................................................... 154

Figure 145: Sonic 2024 power supply current waveform. Peak current is 1.770A at 48V. Sonar

settings: pulse width = 100us, Tx Power = 221dB, Freq = 400 kHz. ................................................... 156

Figure 146: Sonic 2022 power supply current waveform. Peak current is 1.340A at 48V. Sonar

setting: pulse width = 100us, Tx Power = 221dB, Freq = 400 kHz. .................................................... 156

Figure 147: Inrush current to 2024 head during power up, 20 ms window. ..................................... 156

Figure 148: Inrush current to the 2024 head during power up, 1 second window. .......................... 157

Figure 149: Power supply choke installation on 48VDC power ......................................................... 157

Figure 150: SIM Controller Power Connections ................................................................................. 158

Figure 151: J6 Connector on SIM Controller board ........................................................................... 158

Figure 152: ROV installation block diagram with the SIM top-side ................................................... 159

Figure 153: ROV installation block diagram with the SIM controller board mounted in the vehicle

electronics bottle and GPS (ZDA or UTC formats) and PPS signals are supplied by top-side equipment

........................................................................................................................................................... 159

Page 16 of 210

Version 5.0 Rev r002

Date 05-08-2014

Part No. 96000001

Page 17

Figure 154: ROV installation block diagram with the SIM controller board mounted in the vehicle

electronics bottle. GPS (ZDA or UTC formats) and PPS signals are supplied by the vehicle time

system. ............................................................................................................................................... 159

Figure 155: Typical wiring. GPS (ZDA or UTC formats) and PPS signals are supplied by the vehicle

time system ........................................................................................................................................ 160

Figure 156: SIM Board Stack ............................................................................................................... 160

Figure 157: SIM Stack height .............................................................................................................. 160

Figure 158: SIM Controller Board installation dimensions ................................................................. 162

Figure 159: SIM Stack Outline ............................................................................................................ 162

Figure 160: Assembled SIM Boards .................................................................................................... 163

Figure 161: SIM Boards height ........................................................................................................... 163

Figure 162: Default .ini settings file .................................................................................................... 165

Figure 163: Dual head IP and UDP defaults ........................................................................................ 165

Figure 164: Dual-sonar head ping modes ........................................................................................... 166

Figure 165: Dual Head - Dual SIM external interfacing ...................................................................... 166

Figure 166: Wireshark Capture Options ............................................................................................. 194

Figure 167: Sonic 2024/2022 Projector .............................................................................................. 198

Figure 168: Sonic 2024 Receive Module ............................................................................................ 199

Figure 169: Sonic 2022 Receive Module ............................................................................................ 200

Figure 170: Sonic 2024 Mounting Bracket Drawing 1 ........................................................................ 201

Figure 171: Sonic 2024 Mounting Bracket Drawing 2 ........................................................................ 202

Figure 172: Sonic 2022 Mounting Bracket Drawing 1 ........................................................................ 203

Figure 173: Sonic 2022 Mounting Bracket Drawing 2 ........................................................................ 204

Figure 174: Sonic 2024/2022 Mounting Bracket Flange .................................................................... 205

Figure 175: SIM Box Drawing ............................................................................................................. 206

Figure 176: SIM Stack Outline ............................................................................................................ 207

Figure 177: R2Sonic Deck lead minimum connector passage dimensions ........................................ 208

Figure 178: I2NS IMU Dimensions ...................................................................................................... 209

Figure 179: I2NS SIM Dimensions ....................................................................................................... 210

Page 17 of 210

Version 5.0 Rev r002

Date 05-08-2014

Page 18

List of Tables

Table 1: Metric to Imperial conversion table ....................................................................................... 20

Table 2: System Specification .............................................................................................................. 21

Table 3: Component Dimensions and Mass......................................................................................... 21

Table 4: Electrical Interface ................................................................................................................. 22

Table 5: Ping Rate table ....................................................................................................................... 22

Table 6: Deck Lead Pin Assignment (Gigabit Ethernet and Power) ..................................................... 36

Table 7: DB-9M RS-232 Standard Protocol .......................................................................................... 38

Table 8: SIM DB-9M Serial pin assignment .......................................................................................... 38

Table 9: I2NS Dimensions and Mass .................................................................................................. 103

Table 10: Electrical Specifications ...................................................................................................... 103

Table 11: Gyro Calibration Method 2 computation ........................................................................... 113

Table 12: Absorption Values for Seawater and Freshwater at 400 kHz and 200 kHz........................ 146

Table 13: Operating Frequency - water temperature - absorption ................................................... 148

Table 14: Systems Power Requirements ........................................................................................... 155

Table 15: SIM Gigabit switch speed indicators .................................................................................. 161

List of Graphs

Graph 1: Depth errors due to incorrect roll alignment ..................................................................... 133

Graph 2: Position errors as a result of pitch misalignment; error can be either negative or positive

........................................................................................................................................................... 134

Graph 3: Along track position error caused by 0.5° error in yaw patch test ..................................... 135

Graph 4: Along-track position error caused by 1.0° error in yaw patch test error ............................ 136

Graph 5: Seawater Absorption (Salinity 35ppt) ................................................................................. 147

Graph 6: Freshwater Absorption ....................................................................................................... 147

Page 18 of 210

Version 5.0 Rev r002

Date 05-08-2014

Part No. 96000001

Page 19

1 INTRODUCTION

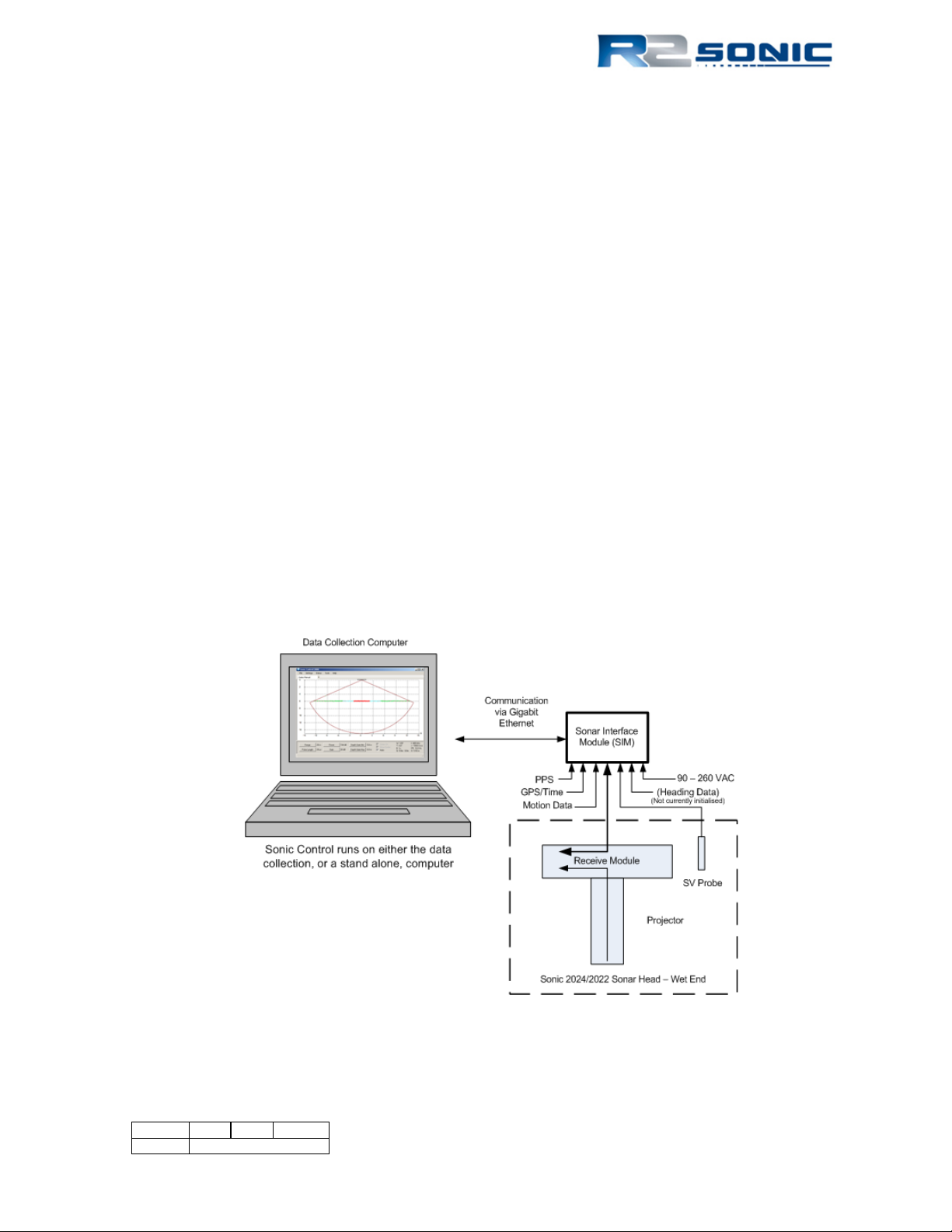

1.1 Outline of Equipment

The R2Sonic Sonic 2024 and Sonic 2022 Multibeam Echosounder (MBES) is based on fifth generation

Sonar Architecture that networks all of the modules and embeds the processor and controller in the

sonar head’s Receive Module to make for a very simple installation. The Sonic Control Graphical

User Interface (GUI) is a simple program that can be installed on any Windows based computer and

allows the surveyor to control the operating parameters of the Sonic 2024/2022. Sonic Control

communicates with the Sonar Interface Module (SIM) via Ethernet. The SIM supplies power to the

sonar head, synchronises multiple heads, time tags sensor data, relays commands to the sonar head,

and routes the raw multibeam data to the customer’s Data Collection Computer (DCC).

The Sonic 2024 and Sonic 2022 work on a user selectable frequency range of 200 kHz to 400 kHz so

it is adaptable to a wide range of survey depths and conditions. The user can adjust the operating

frequency, via the Sonic Control GUI, on the fly, without having to shut down the sonar system or

change hardware or halt recording data. The Sonic 2024/2022 has a user selectable opening angle,

from 10° to 160°, using all 256 beams; the desired opening angle can be selected on the fly without

a halt to data recording. The selected swath angle can also be rotated port or starboard, whilst

recording, to direct the highly concentrated beams towards the desired target. Both the opening

angle and swath rotation can be controlled via the mouse cursor.

Figure 1: Sonic 2024/2022 Block Diagram

Page 19 of 210

Version 5.0 Rev r002

Date 05-08-2014

Page 20

METRIC

IMPERIAL

10mm (0.010m)

0.39 inches

100mm (0.100m)

3.9 inches

1000mm (1.0 metre)

39.4 inches

100 grams (0.100kg)

3.5 ounces

1000 grams (1.0 kilogram)

2.2 pounds

10° C

50°F

1.2 How to use this Manual

This manual is designed to cover all aspects of the installation and operation of the Sonic 2024 and

Sonic 2022. It is, therefore, recommended that the user read through the entire Operation Manual

before commencing the installation or use of the equipment.

1.2.1 Standard of Measurement

The Metric system of measurement is utilised throughout this manual; this includes temperature in

degrees Celsius.

Table 1: Metric to Imperial conversion table

Page 20 of 210

Version 5.0 Rev r002

Date 05-08-2014

Part No. 96000001

Page 21

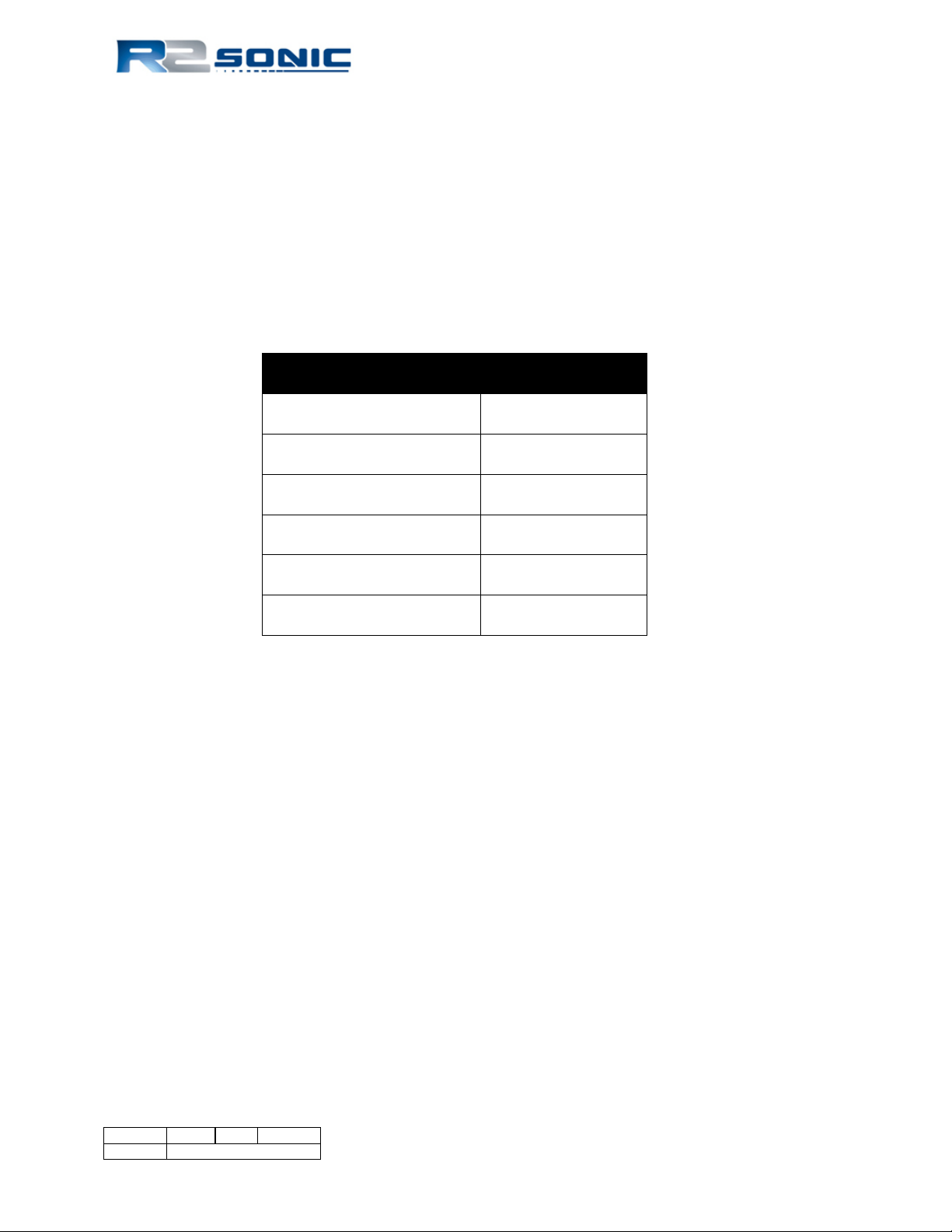

2 SONIC SPECIFICATIONS

System Feature

Specification

Frequency

400kHz / 200kHz

Beamwidth – Across Track (at nadir)

0.5°@ 400kHz / 1.0° @ 200kHz

Beamwidth – Along Track (at nadir)

1.0° @ 400kHz / 2.0° @ 200kHz

UHR Beamwidth (at nadir)

0.3° Across Track x 0.6° Along Track

Number of Beams

256

Swath Sector

10° to 160° (user selectable)

UHR Swath Sector

10° to 60° (user selectable)

Maximum Slant Range

1200 metres

Pulse Length

15µSec – 1000µSec

Pulse Type

Shaped Continuous Wave (CW)

Depth Rating

100 metres (3000 metres optional)

Operating Temperature

-10° C to 40° C

Storage Temperature

-30° C to 55° C

System Feature

Specification

Frequency

400kHz / 200kHz

Beamwidth – Across Track (at nadir)

1.0°@ 400kHz / 2.0° @ 200kHz

Beamwidth – Along Track (at nadir)

1.0° @ 400kHz / 2.0° @ 200kHz

UHR Beamwidth (at nadir)

0.6° Across Track x 0.6° Along Track

Number of Beams

256

Swath Sector

10° to 160° (user selectable)

UHR Swath Sector

10° to 60° (user selectable)

Maximum Slant Range

1200 metres

Pulse Length

15µSec – 1000µSec

Pulse Type

Shaped Continuous Wave (CW)

Depth Rating

100 metres (3000 metres optional)

Operating Temperature

-10° C to 40° C

Storage Temperature

-30° C to 55° C

Component

Dimensions (L x W x D) / Dry Weight

Receiver Module

480mm x 109mm x 190mm / 12.9kg

Projector

273mm x 108mm x 86mm / 3.3kg

Sonar Interface Module (SIM)

280mm x 170mm x 60mm / 2.4kg

I2NS Sonar Interface Module (SIM)

280mm x 170mm x 126.4mm / 4.2kg

Receive module and Projector mass in water

5.9kg (Fresh)

2.1 Sonic 2024 System Specification

Table 2: System Specification

2.2 Sonic 2022 System Specification

2.3 Sonic 2024 Dimensions and Weights

Table 3: Component Dimensions and Mass

Page 21 of 210

Version 5.0 Rev r002

Date 05-08-2014

Page 22

Component

Dimensions (L x W x D) / Dry Weight

Receiver Module

276mm x 109mm x 190mm / 7.7kg

Projector

273mm x 108mm x 86mm / 3.3kg

Sonar Interface Module (SIM)

280mm x 170mm x 60mm / 2.4kg

I2NS Sonar Interface Module (SIM)

280mm x 170mm x 126.4mm / 4.2kg

Receive module and Projector mass in water

4.0kg (Fresh)

Item

Specification

Mains Power

90 – 260 VAC; 45 – 65 Hz

Power Consumption (SIM and Sonar Head)

75 Watt (Sonic 2022: 54 Watt)

Power Consumption (Sonar Head Only)

50W avg.; 90W Peak (Sonic 2022: 35W avg.; 70W

Peak)

Integrated Inertial Navigation System (I2NS)

38.4W (SIM and IMU with Antennas)

Uplink/Downlink

10/100/1000Base-T Ethernet

Data Interface

10/100/1000Base-T Ethernet

Sync IN/OUT

TTL

GPS Timing

1PPS; RS232 NMEA

Auxiliary Sensors

RS232 / Ethernet

Deck Cable Length

15 metre (optional to 50 metres)

RANGE

PING RATE

2 - 7

60.0

10

55.4

15

39.4

20

30.6

25

25.0

30

21.1

35

18.3

40

16.1

50

13.0

70

9.4

100

6.7

150

4.5

200

3.4

250

2.7

300

2.3

400

1.7

450

1.5

500

1.4

700

1.0

1000

0.7

1200

0.6

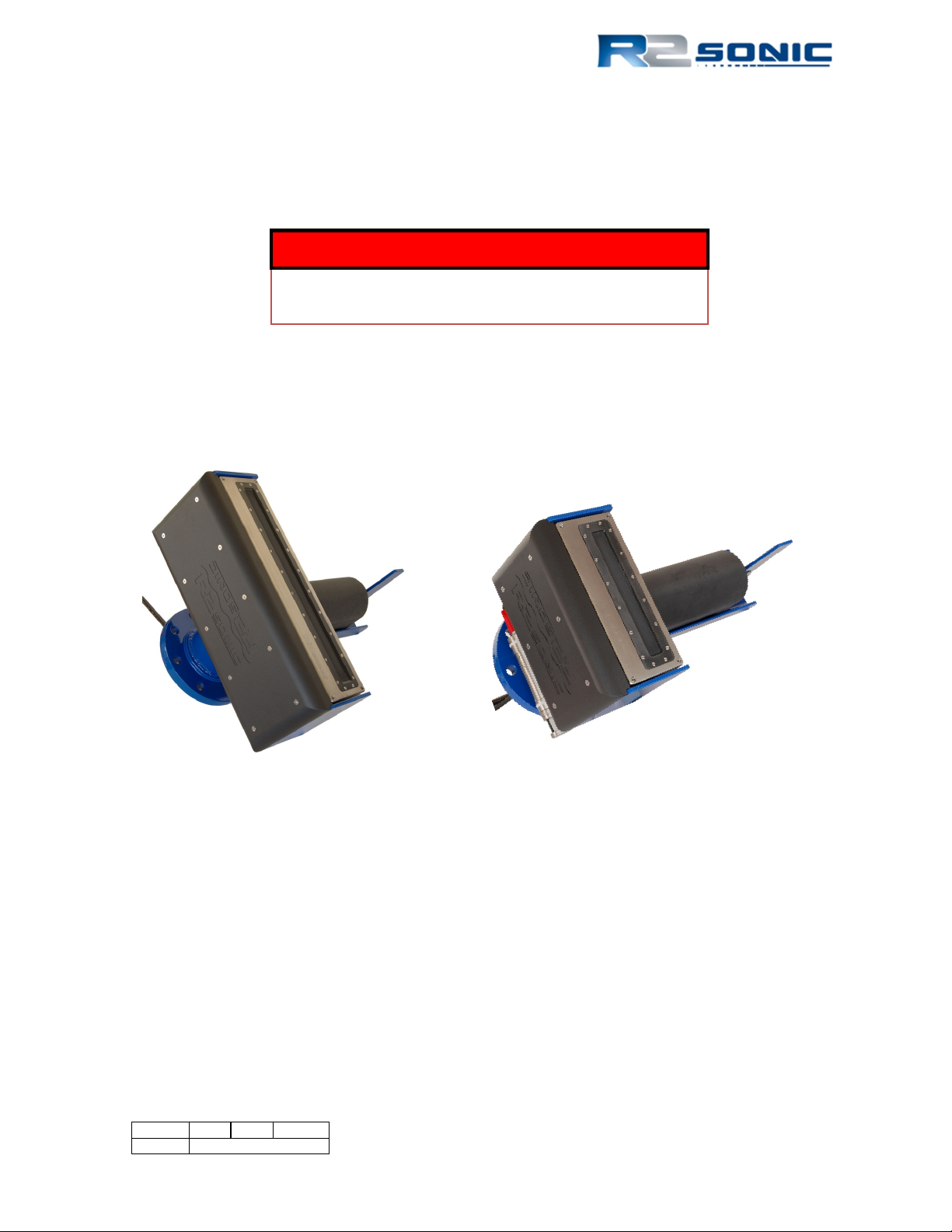

WARNING

THE RECEIVE MODULE IS FILLED WITH

PRIOR TO OPERATION.

2.4 Sonic 2022 Dimensions and Weights

2.5 Sonic 2024/Sonic 2022 Electrical Interface

Table 4: Electrical Interface

2.6 Sonic 2024/2022 Ping Rates (SV = 1500.00m/sec)

OIL THAT WILL FREEZE TO A SOLID AT

-10°C. STORAGE BELOW THIS

TEMPERATURE (TO -30°C) IS POSSIBLE IF

THE HEAD IS SLOWLY THAWED OUT

Table 5: Ping Rate table

Page 22 of 210

Version 5.0 Rev r002

Date 05-08-2014

Part No. 96000001

Page 23

2.7 Acoustic Centre

Figure 2: Sonic 2024 Acoustic Centre

Figure 3: Sonic 2024 Acoustic Centre as Mounted

Centre of Flange to Alongship offset = 0.182m (0.597ft)

Top of Flange to Z reference = 0.327m (1.073ft)

Page 23 of 210

Version 5.0 Rev r002

Date 05-08-2014

Page 24

Figure 4: Sonic 2022 Acoustic Centre

Figure 5: Sonic 2022 Acoustic Centre as Mounted

Centre of Flange to Alongship offset = 0.182m (0.597ft)

Top of Flange to Z reference = 0.327m (1.073ft)

Page 24 of 210

Version 5.0 Rev r002

Date 05-08-2014

Part No. 96000001

Page 25

3 SONIC 2024/2022 SONAR HEAD INSTALLATION – Surface Vessel

WARNING

DECK LEAD MINIMUM BEND RADIUS =

150MM

The Sonic 2024/2022 can be installed on an over-the-side pole, through a moon pool, or as a

permanent hull mount. The light weight, small size, and low power consumption makes the Sonic

2024/2022 ideal for underwater vehicle (ROV and AUV) installations.

3.1 Sonic 2024/2022 Receive Module Installation

The Sonic 2024/2022 sonar head is mounted on the standard R2Sonic mounting frame as shown

below.

Figure 6: Sonic 2024 and Sonic 2022 on the mounting frame

If the Sonic 2024/2022 sonar head is not pre-mounted, the following guidelines must be followed

for proper operation of the system.

• The Receive Module is orientated with the narrow part of the face towards the projector

(see above).

• The projector is orientated with the connector towards the end with the protective fin.

• The Projector must be mounted with the correct 35mm standoffs in place.

Page 25 of 210

Version 5.0 Rev r002

Date 05-08-2014

Page 26

Sonic 2022

Sonic 2024

Sonic 2022

Sonic 2024

When inserting or removing

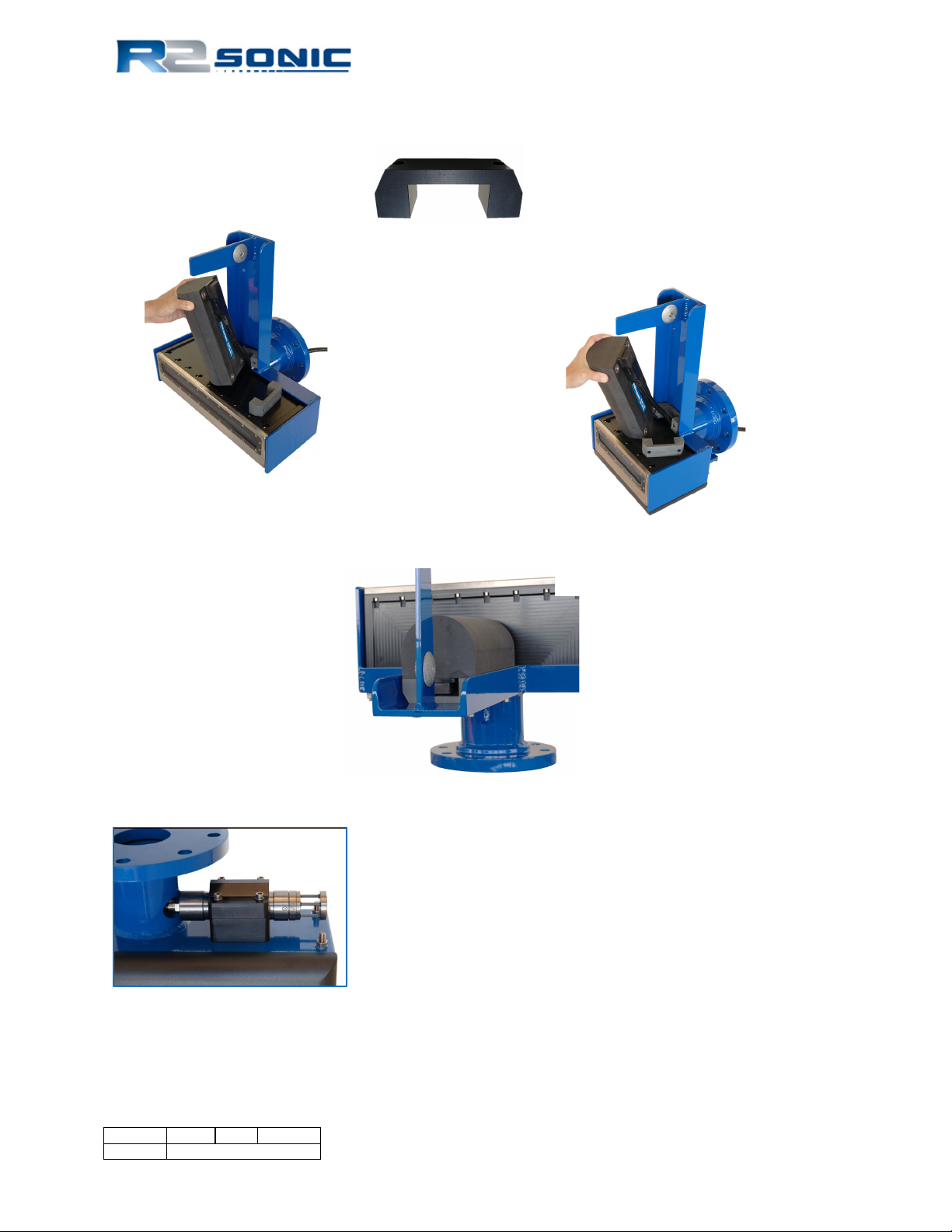

3.1.1 Mounting the Sonic 2024/2022 Receive Module

Figure 7: Top side of Receive Module

Figure 8: Receive Module Face

3.1.2 Receive Module

The Receive Module has two connectors; the female connector is for the Projector cable, the male

connector is for the deck lead that goes to the SIM. There is a securing ‘ear’ on top of the Receive

Module to secure the cables with a cable tie or other similar securing methods. Seat the 0.439m

projector cable first. A light spray of silicone lubricant (3M Silicone Lubricant, 3M ID: 62-4678-4930-

3) will aid in seating the connectors. Silicone grease is never to be used. The deck lead passes

through the hydrophone pole and then through the flange opening. Seat the deck lead after seating

the projector cable. ENSURE that all connections are tight with no visible gaps.

Figure 9: Seated connectors (Sonic 2024 on left and Sonic 2022 on right)

the connector, use a left to

right or back and forth

movement and never an up

and down movement.

Page 26 of 210

Version 5.0 Rev r002

Date 05-08-2014

Part No. 96000001

Figure 10: Connector wiggle - back and forth NOT up and down

Page 27

Figure 12: Sonic 2024 Projector

Sonic 2024

Sonic 2022

SV Probe block is secured, via screws, though the underside of the mounting frame

Figure 11: Receive Module with cables connected

Prior to mounting the Receive Module, the block that holds the sound velocity probe must be

secured through the underside of the mounting bracket. Next, mount the Receive Module in the

mounting frame. This can be most easily done by putting the receive module face on a piece of

cardboard or other material and then lowing the mounting frame down with the threaded bolts

passing through the mounting frame. The threads, of the securing bolts, after passing through the

frame, must be wrapped with 2 wraps of Teflon™ tape. This is to prevent galling where the nut will

freeze on the bolt. Do not tighten beyond 17Newton metre (150 pound-inch or 12.5 pound-foot).

Figure 13: Position the insulating bushing, then wrap threads with Teflon tape, then secure with flat washer, locking

washer and then nut.

3.1.3 Mounting the Projector

The projector is secured to the frame with two, 35mm stand offs. The

stand-offs allow room for the Projector to Receive Module cable to be

run. A 6mm drive hex screw secures the projector through the standoff. The Projector’s connector faces towards the protection fin.

Connect the 0.439m interconnect cable’s female end to the Projector’s

male bulk head connector. When the connectors are mated, there

should be no visible gap between them. A very light spray of silicon

lubricant will aid seating the connector.

Page 27 of 210

Version 5.0 Rev r002

Date 05-08-2014

Page 28

Sonic 2024

Sonic 2022

Figure 14: Projector Stand-off

Figure 15: Mounting the projector

Figure 16: View of the mounted Projector; NB. Connector is facing protective fin

Figure 17: SV Probe mounted in block

Page 28 of 210

Version 5.0 Rev r002

Date 05-08-2014

Part No. 96000001

Page 29

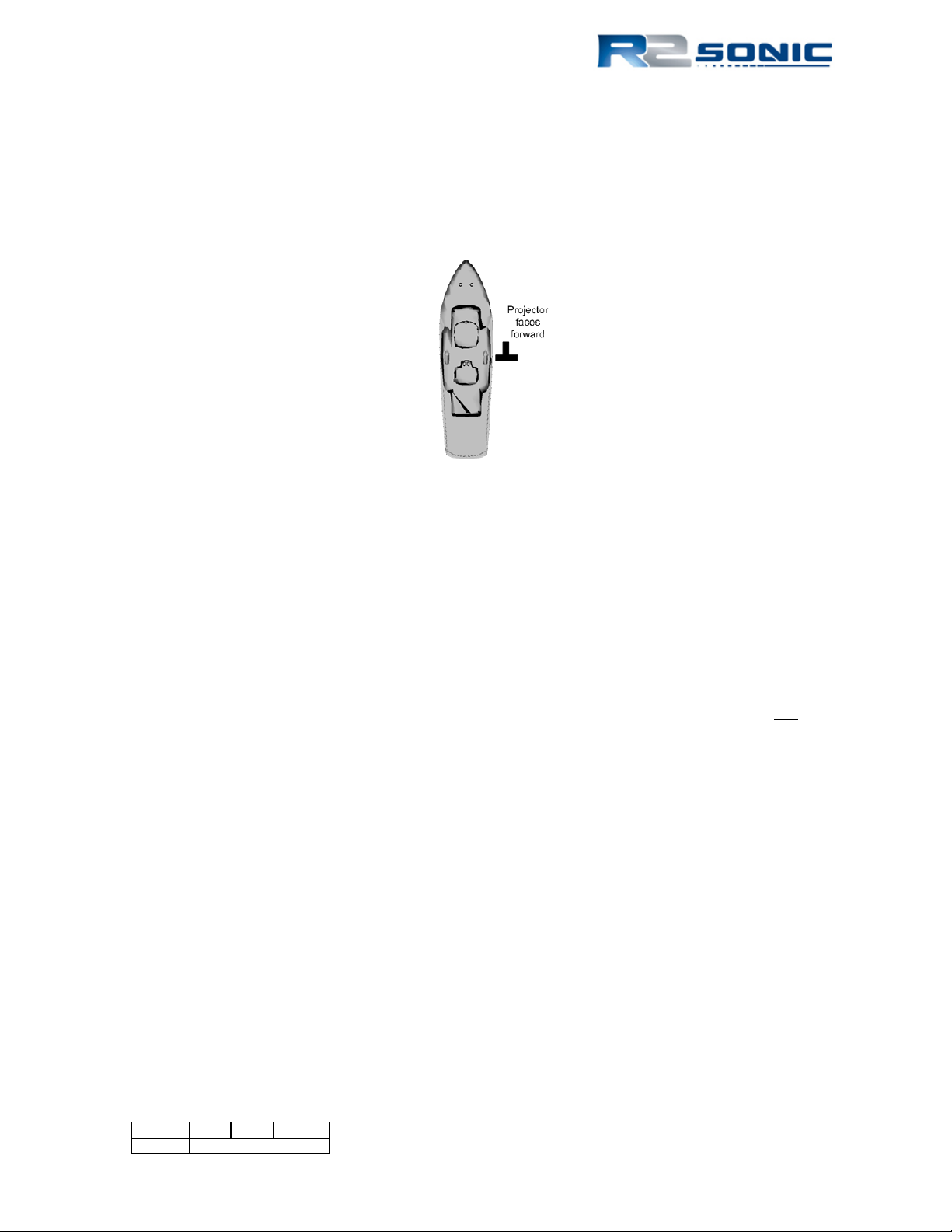

3.1.4 Correct Orientation of the Sonic 2024 and Sonic 2022

The Sonic 2024/2022 is designed to be installed with the projector facing forward, or towards the

bow. However, if the installation requires the projector to face aft, in Sonic Control, the user can

select the orientation to projector aft and this will re-orientate the data output to reflect the

projector orientation.

Figure 18: Correct Orientation of the Sonic 2024 and the Sonic 2022

3.1.5 Deck Test Prior to Deployment

It is highly recommended that the operation of the sonar be verified prior to putting the sonar or

vessel into the water. The deck test will test both the receiver and the transmitter.

3.1.5.1 Communications test

The first test is to ensure that computer, running Sonic Control, can communicate with both the

sonar head and the SIM.

• Make sure that Sonic Control is installed in the root directory on the computer and not

under ProgramFiles nor on the desktop

• Make sure all firewalls are off

• Make sure all virus checkers are disabled

• Verify the IP4 configuration for the network card being used for the sonar

• Make sure that the files, in the Sonic Control directory, are not Read-only, or otherwise

protected by the operating system

3.1.5.2 Receiver rub test

This tests the receiver and the receive elements

• Turn transmit power off by positioning the cursor over the Power button, then Shift + left

mouse button; this will set transmit power to 0

• Reduce the range

• Turn Acoustic Imagery on (under Settings | Displays)

• Increase Gain to 30

Page 29 of 210

Version 5.0 Rev r002

Date 05-08-2014

Page 30

• Have someone rub the receiver face, slowly, with their hand, along the face of the receiver.

Noise will be seen, in the display, that will correspond to the rubbing

• If noise is not seen, try adjusting range or gain

• If noise is not seen, check the Impulse connector, on the receiver

3.1.5.3 Transmitter test

This tests that the transmitter is transmitting

• Have someone position their ear close to the projector

• Set ping rate (Settings | Sonar settings) to 2 Hz

• Set pulse width to 100µsecs

• Slowly bring up Power

• A distinct ‘click’ should be heard at the 2 Hz ping rate

• If no clicking is heard, increase pulse width and power

• If no clicking is heard, check the projector cable connection

• If no clicking is heard, open the Status window and check TX voltage (V); voltage should

increase / decrease with increase / decrease in Power

3.1.5.4 Problems with Deck Test

If there are any issues, with the Deck Test, please contact R2Sonic Support immediately. R2Sonic

Support can be contacted via email: R2Support@R2Sonic.com

; telephone/SMS: +1.805.259.8142;

Skype: chaswbrennan

Page 30 of 210

Version 5.0 Rev r002

Date 05-08-2014

Part No. 96000001

Page 31

3.2 Sonar Head Installation Guidelines

Figure 19: Typical over-the-side mount

3.2.1 Introduction

The proper installation of the Sonic 2024/2022 sonar head is critical to the quality of data that will