Page 1

1

INTRODUCTION

Thank you for purchasing Sonance Symphony®T-series in-wall speakers.

When properly installed your new speakers will give you years of entertainment

pleasure. This manual covers these speaker models: Symphony S625

T, Symphony

S624

T, Symphony S623T, Symphony S622

T, Symphony S621T.

BOX CONTENTS

Your Sonance Symphony speaker box should contain the following items:

(2) Symphony speakers, (2) Plastic paint plugs (installed on fronts of speakers);

(2) Paintable grilles; (1) Mounting cutout template (in packaging)

SPEAKER PLACEMENT

Home Theater Speaker Placement

Left, Center & Right Channels

• Place the left & right speakers on either side of the video screen, anywhere from

6 feet to 10 feet apart and 38 – 42 inches from the floor.

• If possible, locate the left and right speakers at least 18 inches away from the

side walls.

• If possible, locate the center speaker at the same height as the left & right

channel speakers (38 – 42 inches from the floor).

• If you must place the center speaker above or below a video screen, place it

no more than 2 feet above or below the center of the left and right speakers.

This will maintain consistent tonality between all 3 front channel speakers.

• The main listening position should be between 8 and 12 feet away from the

speakers.

Use

Figure 1

as a guide.

Surround Speakers

(5.1-Channel System)

Locate the surround channel

speakers on the side walls

approximately 2 – 6 feet

behind the listening position,

at least 5 feet from the floor.

Use

Figure 2

as a guide.

Surround Speakers

(7.1-Channel System)

• Left & Right Surround

Speakers:

Place the left

and right surround speakers

directly to the sides of the

listening position, at least 5

feet from the floor.

• Surround Back Speakers: Place the surround back speakers in the rear

wall, between 3 feet and 6 feet apart and at least 5 feet from the floor.

Use

Figure 3

as a guide.

Stereo (2-Channel) Placement

• Place the left and right speakers anywhere from 6 feet to 10 feet apart, with

the main listening position as close to midway between the speakers as possible.

• The speakers should be at least 2 feet away from the side walls.

• The main listening position should be between 4 and 10 feet away from the

speakers.

• In most cases pivoting the tweeter of each speaker directly towards the main

listening position will help maximize the stereo soundstage.

Use the left and right speaker placement in

Figure 1

as a guide.

Right Surround

Speaker

Left Surround

Speaker

Left

Front

Speaker

Right

Front

Speaker

Video

Screen

Center

Speaker

Left

Surround Back

Speaker

Right

Surround Back

Speaker

F IGURE 3: SPEAKER P LACEMENT IN A 7.1-CHANNEL S YSTEM

2'

(max.)

18"

From Side

Wall

6' – 10'

Apart

18"

From Side

Wall

F IGURE 1:

L

EFT,CENTER & RIGHT H OME T HEATER S PEAKER P LACEMENT

INSTRUCTION MANUAL

SONANCE SYMPHONY

®

T

IN-WALL SPEAKERS

SAFETY WARNING:

These speakers have FastMount®tabs that prevent the speaker from falling out

of the mounting hole during the installation process.

The edges of the FastMount tabs are very sharp.

Use caution when handling the speaker.

5' – 7'

2' – 6'

F

IGURE 2:

S URROUND S PEAKER

P LACEMENT

Page 2

2

SONANCE SYMPHONY®T

INSTALLING THE SPEAKERS

Before Installation: IR Knockout

All Sonance Symphony T-series speakers have a plug for installing an IR receiver

into the speaker’s front baffle (see

Figure 4

). In systems where the electronics are

placed in an inconvenient location this allows remote controls to be aimed at the

front of the room instead of at the electronics.

The IR plug is in the form of a bolt and retaining nut. To remove the plug, unscrew

the nut (located behind the baffle, see Figure 5) and remove the bolt. The hole

is designed to receive a Sonance OptiLinQ

®

SMR1 or SMR1P Surface-Mount IR

receiver. Insert the IR receiver through the front of the speaker baffle and use the

nut included with the receiver to secure it to the baffle.

Before Installation: Retrofit

1. Determine the location for the speaker (see

Speaker Placement

on page 1).

2. Perform an obstruction survey to be certain that there are no studs, conduit,

pipes, heating ducts, pocket doors or air returns in the wall cavity that will

interfere with the speaker.

3. The cutout for all Symphony T speakers is 10

5

/8” (270mm) x 6¾” (171mm).

There must be at least 3

3

/16” (86mm) depth within the wall cavity for the speaker.

4. Position the included cutout template where the speaker is to be located and

pencil an outline on the wall.

• If you are unsure about obstructions, drill a small hole in the center of

the outline and insert a coat hanger wire into the hole to feel-around for

possible obstructions.

5. Cut the mounting hole using a keyhole or drywall saw, and run the speaker

wires from the mounting hole to the amplifier location.

• Consult local building codes before running speaker wires through walls.

Installation

Sonance Symphony T speakers feature exclusive FastMount®tabs and an integral

RotoLock

®

mounting system for quick mounting directly into existing walls.

WARNING: THE EDGES OF FASTMOUNT TABS ARE VERY

SHARP. USE CAUTION WHEN HANDLING THE SPEAKER.

1. Remove the paint plug from the speaker.

2. Run speaker wire from each speaker to the amplifier location.

3. Strip ¼” – ½” of insulation from each speaker lead. Twist the strands or tin

the exposed wire with solder to ensure that there are no stray strands.

(Stray strands that touch each other can cause a short-circuit that can damage

the amplifier.)

4. The speaker’s connector posts are spring-loaded. Push the top of each connector

post down to open the connector and insert the exposed wires into the holes

in the posts.

• The speaker’s positive post is labeled with a red dot; the

negative post is labeled with a black dot. Double-check that you connected

amplifier “+” to speaker “+” and amplifier “–” to speaker “–”.

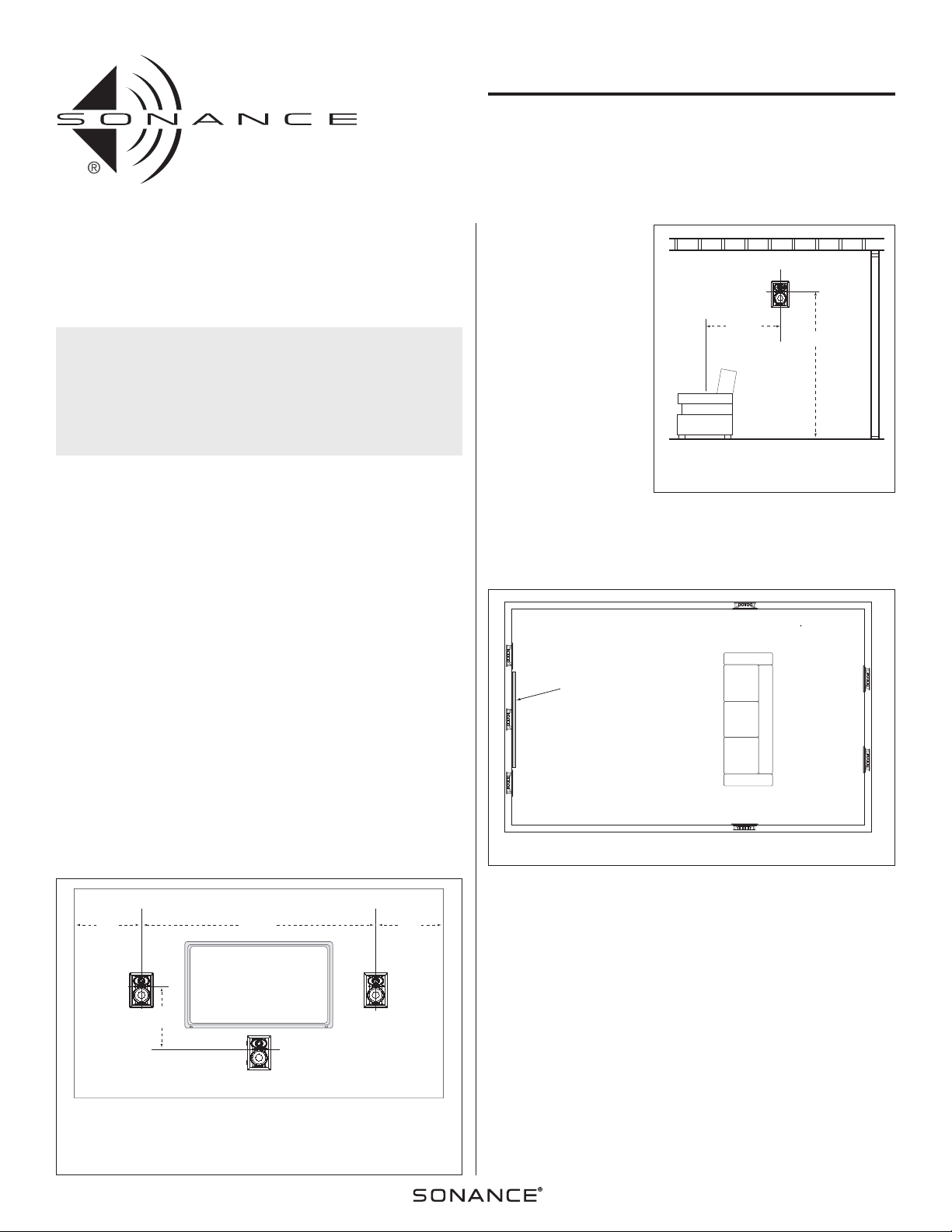

5. Make sure all the RotoLock clamps

are in the full clockwise position

so that they are tucked within the

mounting hole’s border. Insert the

speaker into the hole in the wall

(

Figure 6

). The RotoLock system

can accommodate a maximum wall

material thickness of 1¼”.

• The FastMount tabs will prevent

the speaker from falling out of

the mounting hole, allowing the

installer to let go of the speaker

to pick-up tools or other items

(

Figure 7

).

N

OTE:THEFASTMOUNT TABS

ARE DESIGNED FOR ONE

-

TIME USE ONLY.IF THE

SPEAKER IS REMOVED FROM

THE MOUNTING HOLE THE

F

ASTMOUNT TABS WILL DISCONNECT AND REMAIN INSIDE THE WALL

.

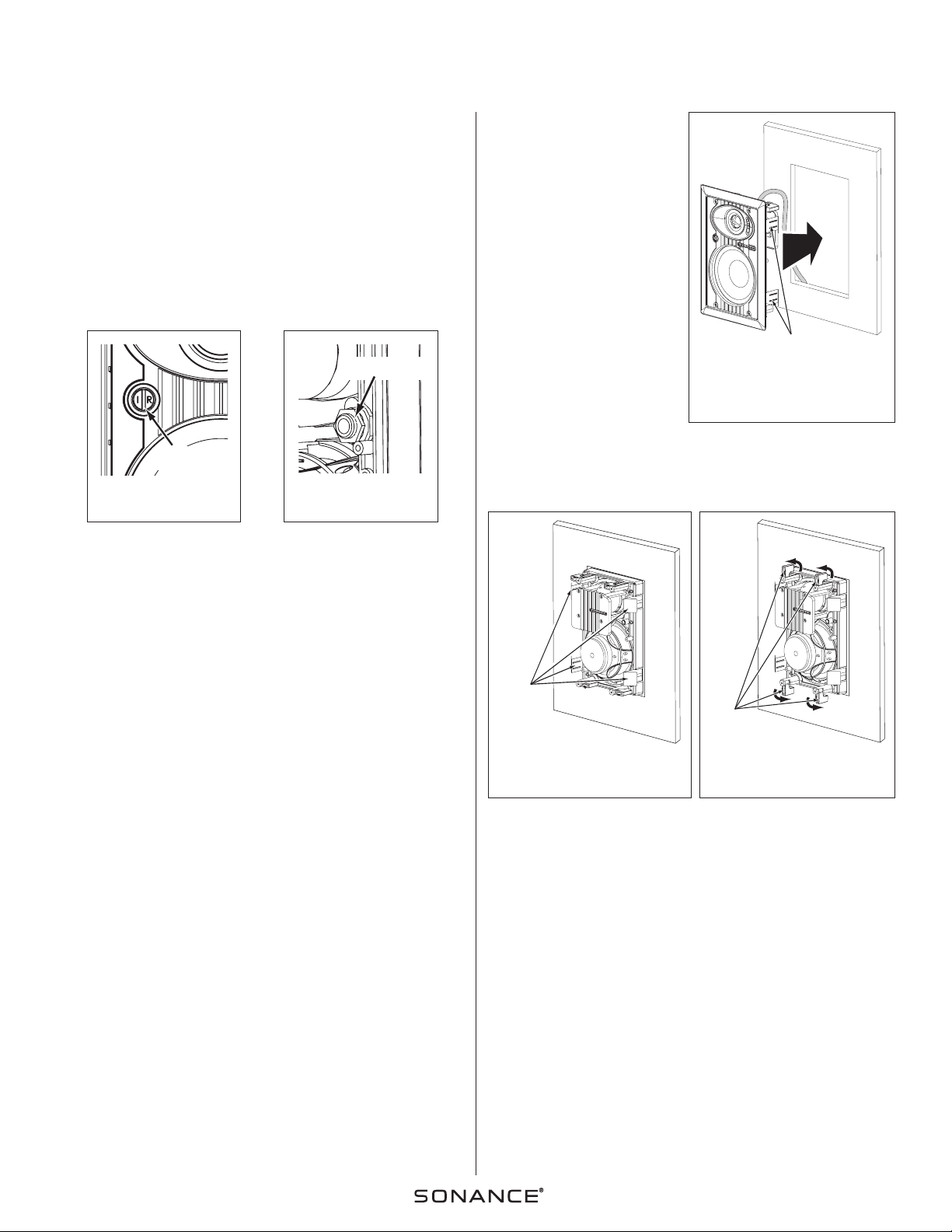

6. Tighten the four screws on the front of the speaker baffle. The RotoLock clamps will

automatically rotate into position and begin clamping the speaker (

Figure 8

).

• When you notice resistance on the screws the speaker has been clamped

successfully.

Important: Always use low-torque settings; NEVER

over-tighten.

N

OTE:THE SPEAKER FLANGE IS DESIGNED TO FLEX AND CONFORM TO

ANY SMALL IMPERFECTIONS IN THE WALL SURFACE

.D

O NOT TIGHTEN

THE SCREWS SO MUCH SO THAT THE FLANGE BOWS

-

OUT

.

7. Attach the grille after the speaker has been installed. Insert about half of the

grille into the groove at the edge of the speaker. Gently fit the remaining half

of the grille by working around the speaker, fitting the grille into the groove

as you go.

N

OTE:YOU CAN ADJUST THE TORQUE APPLIED TO THEROTOLOCK

SCREWS TO ACHIEVE A PROPER GRILLE FIT

.

F IGURE

4:

IR P

LUG

F IGURE 5: IR PLUG

R

ETAINING N UT

RotoLock

®

Clamps

FastMount

®

Tabs

FastMount

®

Tab s

F IGURE 6:

I NSERTING THE

S PEAKER

I

NTO THE M OUNTING H OLE

F IGURE 7:

F

ASTM OUNT

®

T ABS

F IGURE 8:TIGHTENING THE

R OTOL OCK C LAMPS

IR Plug

Retaining Nut

Page 3

3

SONANCE SYMPHONY®T

PAINTING THE SPEAKERS

All Sonance Symphony speakers come from the factory fitted with a plastic ‘paint

plug’ that protects the speaker drivers while the mounting flange is being painted.

Paint the grille separately from the speaker. Before painting, carefully remove the

under-grille cloth. It is held in place with a light tacking glue that makes it easy

to remove. Spray the grilles with thinned paint (5 parts thinner to 1 part paint),

being careful not to plug the holes. Too heavy a coat of paint on the grille will

adversely affect the sound of the speaker.

Once the grilles and flange are painted and dry, replace the under-grille cloth,

remove the paint plug from the mounting flange and install the grille.

SPEAKER ADJUSTMENTS

Pivoting Tweeter

All Symphony T-series speakers (except the S621T) have a pivoting tweeter that

allows you to direct sound towards or away from the listening area, depending on

how the speakers are being used:

• If you’re using the speakers in stereo or as the front left/center/right speakers

in a home theater, pivot the tweeter directly towards the listening area. This will

help the sound from the speakers blend into

a solid soundstage even if the speakers are

widely separated.

• If you’re using the speakers as surround

channel speakers in a home theater, you can

create a more diffuse, spacious surround

effect by pointing the tweeters towards a

wall or window, away from the listeners.

To Pivot the Tweeter:

Apply light pressure to the plastic ring around

the outside edge of the tweeter dome, as

shown in

Figure 9

. Do not touch or apply pressure to the tweeter dome.

Tweeter Level Control

The S625T, S624T and S623T have a tweeter level control switch (see

Figure 10

)

that lets you boost or cut the tweeter’s level by 3dB. This allows you to adjust the

speaker’s brightness to better match your listening room or personal taste.

Once you have installed the speakers, listen to a variety of music that you are

familiar with. If the music all tends to

sound too bright or dull, use the Tweeter

Level Control to compensate. If some

recordings sound dull and some sound

bright the speaker is accurately

reproducing differences in the recordings,

and you should leave the control in the

middle (0dB) position.

SPECIFICATIONS

S625T

Tweeter: 1" (25mm) Beryllium dome, Ferrofluid-cooled, pivoting

Woofer: 6½" (165mm) Beryllium cone, rubber surround

Frequency Response: 40Hz – 20kHz ±3dB

Impedance: 6 Ohms nominal; 4 Ohms minimum

Power Handling: 5 watts minimum; 150 Watts maximum

Sensitivity: 90dB SPL (2.83V 1 meter)

Adjustments: ±3dB Tweeter level

Dimensions (W x H x D): 8¼” x 12

3

/16" x 33/8" (210mm x 310mm x 86mm)

Cutout Dim. (W x H): 6¾" x 10

5

/8" (171mm x 270mm)

Shipping Weight: 12 lbs. (5.45kg) Pair

S624T

Tweeter: 1" (25mm) Aluminum dome, Ferrofluid-cooled, pivoting

Woofer: 6½" (165mm) Coated carbon fiber cone, rubber surround

Frequency Response: 43Hz – 20kHz ± 3dB

Impedance: 6 Ohms nominal; 4 Ohms minimum

Power Handling: 5 watts minimum; 140 Watts maximum

Sensitivity: 90dB SPL (2.83V 1 meter)

Adjustments: ±3dB Tweeter level

Dimensions (W x H x D): 8¼” x 12

3

/16" x 33/8" (210mm x 310mm x 86mm)

Cutout Dim. (W x H): 6¾" x 10

5

/8" (171mm x 270mm)

Shipping Weight: 11 lbs. (5.0kg) Pair

S623T

Tweeter: 1" (25mm) Silk dome, Ferrofluid-cooled, pivoting

Woofer: 6½" (165mm) Carbon fiber cone, rubber surround

Frequency Response: 43Hz – 20kHz ±3dB

Impedance: 8 Ohms nominal; 6 Ohms minimum

Power Handling: 5 watts minimum; 135 Watts maximum

Sensitivity: 90dB SPL (2.83V 1 meter)

Adjustments: ±3dB Tweeter level

Dimensions (W x H x D): 8¼” x 12

3

/16" x 33/8" (210mm x 310mm x 86mm)

Cutout Dim. (W x H): 6¾" x 10

5

/8" (171mm x 270mm)

Shipping Weight: 10 lbs. (4.5kg) Pair

S622

T

Tweeter: 1" (25mm) Silk dome, Ferrofluid-cooled, pivoting

Woofer: 6½" (165mm) Polypropylene cone, rubber surround

Frequency Response: 45Hz – 20kHz ±3dB

Impedance: 8 Ohms nominal; 6 Ohms minimum

Power Handling: 5 watts minimum; 125 Watts maximum

Sensitivity: 89dB SPL (2.83V 1 meter)

Adjustments: None

Dimensions (W x H x D): 8¼” x 12

3

/16" x 33/8" (210mm x 310mm x 86mm)

Cutout Dim. (W x H): 6¾" x 10

5

/8" (171mm x 270mm)

Shipping Weight: 10 lbs. (4.5kg) Pair

S621T

Tweeter: ¾" (19mm) Silk dome, Ferrofluid-cooled

Woofer: 6½" (165mm) Polypropylene cone, rubber surround

Frequency Response: 50Hz – 20kHz ±3dB

Impedance: 8 Ohms nominal; 6 Ohms minimum

Power Handling: 5 watts minimum; 100 Watts maximum

Sensitivity: 88dB SPL (2.83V 1 meter)

Adjustments: None

Dimensions (W x H x D): 8¼” x 12

3

/16" x 33/8" (210mm x 310mm x 86mm)

Cutout Dim. (W x H): 6¾" x 10

5

/8" (171mm x 270mm)

Shipping Weight: 9 lbs. (4.1kg) Pair

F IGURE

9:

P

IVOTING THE T WEETER

Tweet er

Level

Control

F IGURE 10:

T WEETER L EVEL C ONTROL

Page 4

TECHNICAL ASSISTANCE AND SERVICE

If you any have questions about the operation or installation of this product, please call our Technical Assistance

Department on any business day at (800) 582-0772 or (949)

492-7777; from 7 a.m. to 5 p.m., PST.

If your speakers should need repair or service, contact your Sonance Authorized

Dealer for help, or use the following procedure:

1. Prior to calling, note the product’s model number, serial number, purchase date,

and the name and address of the dealer where you purchased the product.

2. Contact our Technical Assistance Department at the above number(s) and

describe the problem the unit is experiencing. If applicable, they will issue a

Return Authorization Number.

IMPORTANT: YOU MUST HAVE PRIOR AUTHORIZATION

TO RETURN YOUR SPEAKER TO SONANCE!

3. If you’re directed to return the unit to Sonance for repair, pack the unit in its

original shipping carton. If needed, you can obtain replacement packaging from

us for a small charge. Note: it is best if you place the box into an additional

outer “overcarton” before shipment to minimize a chance of theft in shipment.

Please include a copy of the original bill of sale inside the package.

4. Contact a package delivery company such as United Parcel Service or Federal

Express to arrange prepaid (not collect) shipping. Do not use the U.S. Postal

Service.

IMPORTANT: Freight collect shipments will be refused.

55.. WW rrii ttee tthh ee RRee ttuu rrnn AAuutthhoo rrii zzaa ttiioo nn NNuummbb eerr oonn tt hh ee oouutt ss ii dd ee ooff tt hh ee

sshhii pp ppii nn gg cc aarr ttoo n

n..

6. Ship the packaged unit to:

Q

UALITYASSURANCEDEPARTMENT

S

ONANCE

212 A

VENIDAFABRICANTE

SANC

LEMENTE

, CA 92672-7531

LIMITED LIFETIME WARRANTY COVERAGE

(U.S. ONLY)

S

ONANCE WARRANTS TO THE ORIGINAL RETAIL PURCHASER ONLY THAT

THIS

S

ONANCE PRODUCT WILL BE FREE FROM DEFECTS IN MATERIALS

AND WORKMANSHIP

,

PROVIDED THE SPEAKER WAS PURCHASED FROM A

S

ONANCEAUTHORIZEDDEALER

.

Defective products must be shipped, together with proof of purchase, prepaid

insured to the Authorized Sonance Dealer from whom they were purchased, or to

the Sonance factory at the address listed on this instruction manual.

Freight collect shipments will be refused. It is preferable to ship this product in

the original shipping container to lessen the chance of transit damage. In any case,

the risk or loss or damage in transit is to be borne by the purchaser. If upon

examination at the factory or Authorized Sonance Dealer it is determined that the

unit was defective in materials or workmanship at any time during this warranty

period, Sonance or the Authorized Sonance Dealer will, at its option, repair or

replace this product at no additional charge, except as set forth below. If this

model is no longer available and can not be repaired effectively, Sonance, at is

sole option, may replace the unit with a current model of equal or grater value.

In some cases where a new model is substituted, a modification to the mounting

surface may be required. If mounting surface modification is required, Sonance

assumes no responsibility or liability for such modification. All replaced parts and

product become the property of Sonance. Products replaced or repaired under this

warranty will be returned to the original retail purchaser, within a reasonable time,

freight prepaid.

This Warranty does not include service or parts to repair damage caused by accident, disaster, misuse, abuse, negligence, inadequate packing or shipping procedures,

commercial use, voltage inputs in excess of the rated maximum of the unit, or

service, repair or modification of the product which has not been authorized or

approved by Sonance. This Warranty also excludes normal cosmetic deterioration

caused by environmental conditions. This Warranty will be void if the Serial Number

on the product has been removed, tampered-with or defaced. This Warranty is in

lieu of all other expressed warranties. If the product is defective in materials or

workmanship as warranted above, the purchaser’s sole remedy shall be repair or

replacement as provided above. In no event will Sonance be liable for any incidental or consequential damages arising out of the use or inability to use the

product, even if Sonance or an Authorized Sonance Dealer has been advised of the

possibility of such damages, or for any claim by any other party.

Some states do not allow the exclusion or limitation of consequential damages, so

the above limitation and exclusion may not apply. All implied warranties on the

product are limited to the duration of this expressed Warranty. Some states do not

allow limitation on the length of an implied warranty. If the original retail purchaser resides in such a state, this limitation does not apply.

EXCLUSIONS AND LIMITATIONS

The warranty set forth above is in lieu of all other warranties, express or implied,

of merchantability, fitness for a particular purpose, or otherwise. The warranty is

limited to Sonance products registered herein and specifically excludes any damage to loudspeakers and other allied or associated equipment which may result for

any reason from use with this product. Sonance shall, in no event, be liable for

incidental or consequential damages arising from any breach of this warranty or

otherwise. This warranty gives you specific legal rights, and you may have other

rights which vary from state to state.

©2007 Sonance. All rights reserved. Sonance, Sonance Symphony, RotoLock and FastMount are registered trademarks of Dana Innovations.

Due to continuous product improvement, all features and specifications are subject to change without notice. For the latest Sonance product specification information visit

our website: www.sonance.com

212 Avenida Fabricante • San Clemente, CA 92672-7531 USA • (800) 582-7777 or (949) 492-7777 • FAX: (949) 361-5151 • Technical Support: (800) 582-0772

www.sonance.com

33-4338 06/07

Loading...

Loading...