Page 1

®

ZigBee to Digital Motor Interface (ZBDMI)

DESCRIPTION

The Somfy ZigBee to Digital Motor Interface (ZBDMI) is

a ZigBee routing device that resides as an endpoint

within a designated ZigBee control network. It

receives ZigBee transmissions and converts them

to motor control commands for Somfy’s line of ILT2

(AC) motors, and the Sonesse 30 RS485 (DC) motor.

The interface also receives feedback information

from these motors and distributes it to the ZigBee

network.

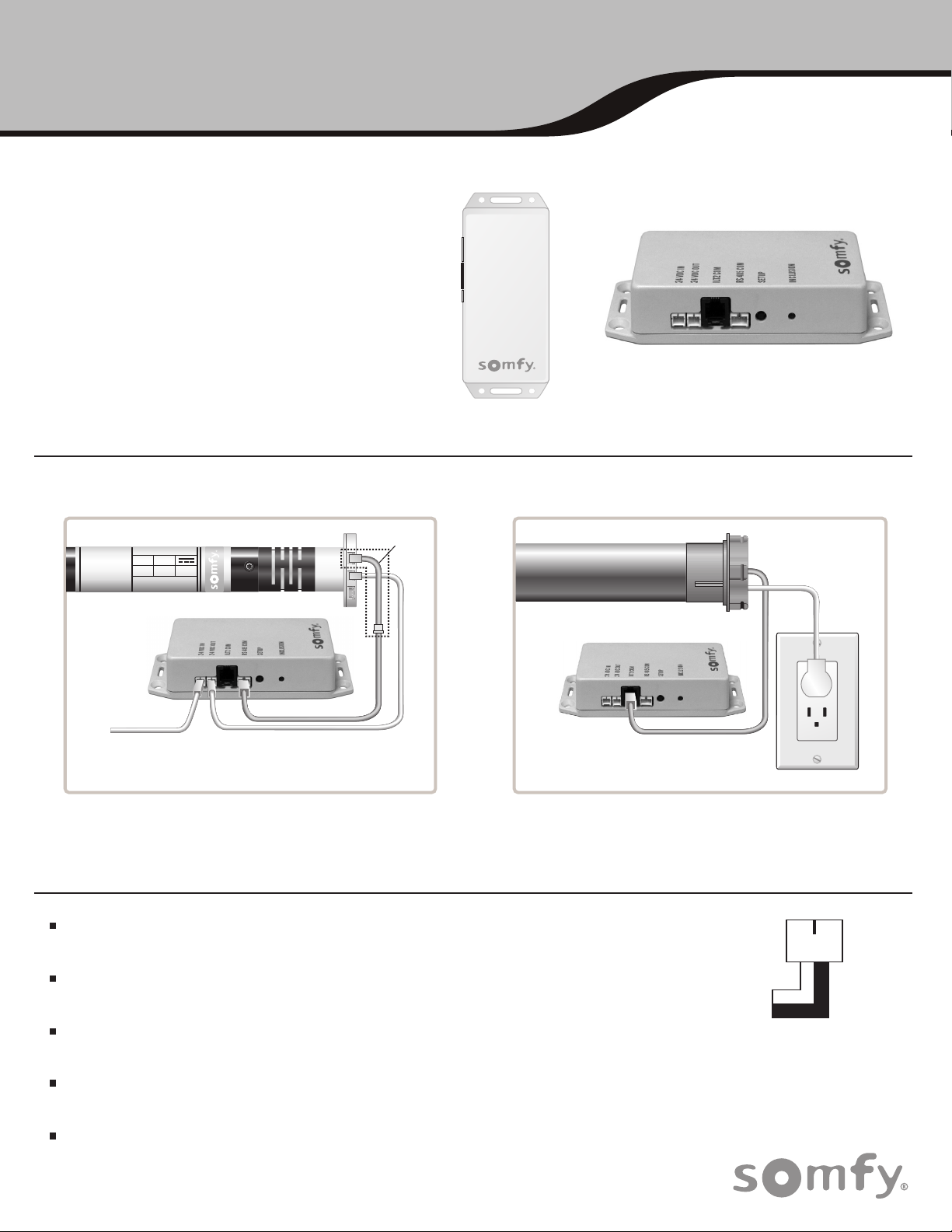

WIRING DIAGRAMS

Typical Sonesse 30 RS485 Motor Connection Typical ILT2 Motor Connection

50 6328 1G0 1

Node ID: 06:00 1E

Sonesse 30 RS485

2Nm 24VDC

28 rpm 0.8A IP 30

Made in USA

SOMFY 74300-France

®

24 VDC IN

24 VDC OUT

ILT2 COM

RS 485 COM

SETUP

INCLUSION

®

ZigBee to Digital Motor Interface

Adaptor

Cable

1870220

*RS485 Com Cable

24V DC in

From Power Supply

* Included with ZigBee to ILT2 Interface

*24V DC to motor

Note: For Sonesse 30 RS485 motors revision H and higher,

the adaptor cable must be used as shown above.

GENERAL REQUIREMENTS

When installing the ZBDMI with a Sonesse 30 RS485 motor, apply +24V DC to the white wire

and -24V DC to the black wire.

When installing the ZBDMI with a Sonesse 50 ILT2 motor, the interface is powerd by the ILT Com

cable once the motor is connected to 120V AC.

The interface must be mounted within thirty (30) feet of each motor head and attached by a Com

cable to its respective modular communication port.

Sonesse 30 RS485 revision H and higher have a modified RS485 data port that requires the RS485

adaptor cable (part no. 9019192) included with the ZBDMI.

One interface is used for each Somfy Sonesse 50 ILT2 and Sonesse 30 RS485 motor.

ILT Com Cable

+24 VDC

-24 VDC

Page 2

ZIGBEE CERTIFICATION

Certification by the ZigBee Alliance is pending.

NETWORK SETUP

In order for the ZBDMI to become fully operational, all connections must be properly made according to the wiring diagram, and the

electronic limits of the motor must first be set. Please refer to the respective motor instructions on how to set the electronic limits.

Identifying the ZBDMI into a Network

Upon power-up, the INCLUSION LED will turn on for five (5) seconds then turn off. When

1.

the LED turns off, press and release the SETUP button a few times to verify that the motor

moves. This will indicate a good electrical connection between the ZBDMI and the motor.

Disconnecting the ZBDMI from a Network

Select the IDENTIFYcommand on your ZigBee controller.

2.

Press and hold the SETUP button for five (5) seconds to identify the ZBDMI in the network.

3.

Verify that the INCLUSION LED turns on within 10-15 seconds. When the LED is on,

the ZBDMI is identified in the network.

NOTE: If inclusion is unsuccessful, reset the interface according to the factory reset

instructions on the following page and try again.

Select the DISCONNECT command on your ZigBee controller.

1.

The ZBDMI will be disconnected from the network when the INCLUSION LED turns off.

2.

To manually disconnect the ZBDMI from the network, press and hold the SETUP button for five (5) seconds. The ZBDMI will be

3.

disconnected from the network when the INCLUSION LED turns off.

OPERATION BY CONTROLLER

The ZBDMI interface can be operated by 3rd party automation, hand-held and PC based controllers, or manually by pressing the

SETUP button. The following convention is used when operating from either 3rd party automation or controllers:

Light ON = Window Covering UP.

Light OFF = Window Covering DOWN.

Light DIM & BRIGHTEN = Window Covering OPEN at a percentage where 0% = Window Covering CLOSED at its lower limit,

and 100% = Window Covering OPEN at its upper limit.

Lighting percentage values between 0% and 100% = 99 intermediate window covering positions.

MANUAL OPERATION

The SETUP button can be used to manually operate the motor at any time as follows:

Repeatedly pressing and releasing the SETUP button within ½ second will drive the motor in a sequence of UP-STOP-DOWN-STOP.

For example, while the motor is at rest, press and release the SETUP button to drive the motor up. Press and release the SETUP

button again to STOP the motor. Pressing and releasing the SETUP button once more will drive the motor DOWN, and a subsequent

press and release will STOP the motor.

Page 3

FACTORY RESET

Sonesse 30 RS485 Motor

Remove the 24V DC power from the interface.

1.

Press and hold the SETUP button while plugging the 24V DC power back into the interface. Continue holding the SETUP button

2.

until the INCLUSION LED begins to flash.

3.

Upon flashing of the LED, release the SETUP button. The LED will turn off to show that the ZBDMI has been reset.

ILT2 Motor

Unplug the motor’s communication cable from the interface.

1.

Press and hold the SETUP button while plugging the communication cable back into the interface. Continue holding the SETUP

2.

button until the INCLUSION LED begins to flash.

3.

Upon flashing of the LED, release the SETUP button. The LED will turn off to show that the ZBDMI has been reset.

ZBDMI ELECTRICAL SPECIFICATIONS

Voltage Input: Requires Regulated +24V DC.

Voltage Output: Regulated +24V DC, passed through from the Input Voltage.

Power Consumption: 50mA @ 24V DC.

ORDERING INFORMATION

Description Part Number Description Part Number

ZBDMI Interface

1870220

24V DC Plug-in Wall Mount Transformer

1822209

Sonesse 30 RS485 Motor

Sonesse 50 ILT2 Motor (Star head)

Sonesse 50 ILT2 Motor (Round head)

Power Cable (supplied)

Sonesse 30 RS485 Adaptor Cable

CONTACT SOMFY

1000658

1030094

1030077

9016020

9019192

24V DC Plug-in Table Top Transformer

Dry Contact Wall Switch (White)

Dry Contact Wall Switch (Ivory)

Com Cable (supplied)

Somfy Technical Support USA

Monday through Friday 8:00AM – 8:00PM EST

800-647-6639

TechnicalSupport_us@Somfy.com

1822116

1800219

1800220

9016021

Page 4

www.somfysystems.com

SOMFY SYSTEMS, INC.

SOMFY NORTH AMERICAN HEADQUARTERS

121 Herrod Blvd.

Dayton, NJ 08810

P: (800) 22-SOMFY (76639)

NJ: (609) 395-1300

F: (609) 395-1776

FLORIDA

6100 Broken Sound Pkwy. N.W.

Suite 14

Boca Raton, FL 33487

P: (800) 22-SOMFY (76639)

F: (561) 995-7502

CALIFORNIA

15291 Barranca Pkwy

Irvine, CA 92618-2201

P: (800) 22-SOMFY (76639)

F: (949) 727-3775

SOMFY ULC

SOMFY CANADA DIVISION

5178 Everest Drive

Mississauga, Ontario L4W2R4

P: (800) 66-SOMFY (76639)

CN: (905) 564-6446

F : (905) 238-1491

Copyright Somfy Systems, Inc. 4/15

©

P-0020

Loading...

Loading...