SOMFY Axovia multi Installation Instructions Manual

Wing gate hydraulic actuators – Installation instructions

multi

Mechanical assembly

5012073

2

Table of contents

1

Safety instructions

Standard model

6

Assembly constraints

Specific / standard kits

2

Mechanical kit composition

3

Technical characteristics

4

Pre-assembly checks

5

Assembly process

1

Safety instructions

Make sure that the hazardous areas (crushing, shearing,

wedging) between the driven part and the surrounding fixed

parts due to the opening movement of the driven part are

avoided.

Regularly inspect the state of the gate. Those gates in poor

condition should be repaired, reinforced or even changed prior

to installation. Regularly check that the screws and fastenings of

the Axovia's various components are securely tightened.

Maintain a clearance area of 500 mm at the back of each wing

when the gate is completely open.

Do not clean your Axovia with a high-pressure water flow rate

cleaning appliance.

Disconnect your Axovia from any electricity source while carrying

out cleaning operations or other maintenance operations if the

appliance is controlled automatically.

Never allow children to play near moving gates.

Never allow children to play with fixed control devices.

Always place the remote control devices out of reach of children.

Always keep a watch over your gate while it is moving.

Never handle your Axovia while it is energized or with the

battery.

Wear protective goggles during the drilling phases.

3

2

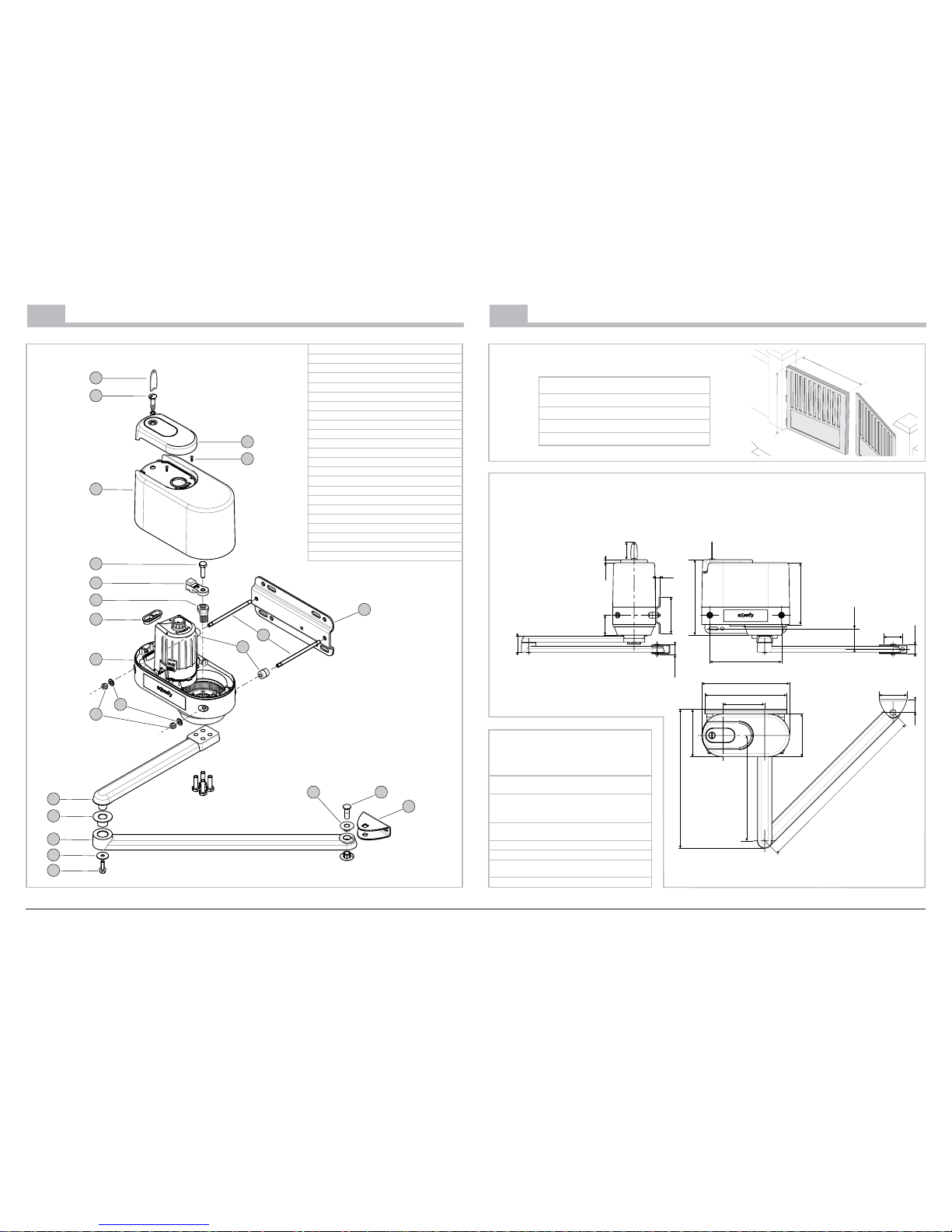

Mechanical kit composition

4

3

11

12

13

2221

23

2

1

5

9

6

7

8

10

16

17

18

19

20

15

14

1 Cover key x2

2 Cover screw x2

3 Guard cover x2

4 Motor cover screw x4

5 Motor cover x2

6 Stop screws + arm x10

7 Opening stop x2

8 Closing stop x2

9 Grommet x2

10 Motor x2

11 Motor/pillar fastening plate x2

12 Fastening stud x4

13 Spacer tube x4

14 Flat washer x4

15 Nut x4

16 Motor arm x2

17 Motor arm / gate arm bush x2

18 Gate arm x2

19 Washer x2

20 Motor arm / gate arm screw x2

21 Gate arm bush x4

22 Long clevis pin for gate arm x2

23 Gate clevis x2

3

Technical characteristics

Maximum dimensions of a gate

H max. height 2 m

L max. width 2 m 50

P max. weight 300 Kg

S max. full surface 4 m

2

H

L

P

Scope

146

360

142

16

44

95

65

620

279

300

245

162

211

258

125

70,5

30,5

36,01

10,5

60

68,5

54,5

474

General overall dimensions (mm)

Table of

characteristics

Frequency of

manœuvres

40 cycles/day

Automatic obstacle

detector

Complies with the NF EN

60335-2-103 standard

with AX24 cabinet

Operating temperature -15˚C to +55˚C

Thermal protection

Yes by means of the AX24

Protection index IP 54

Motor power supply

outlets

24 VDC

Power per motor 130 W

4

4

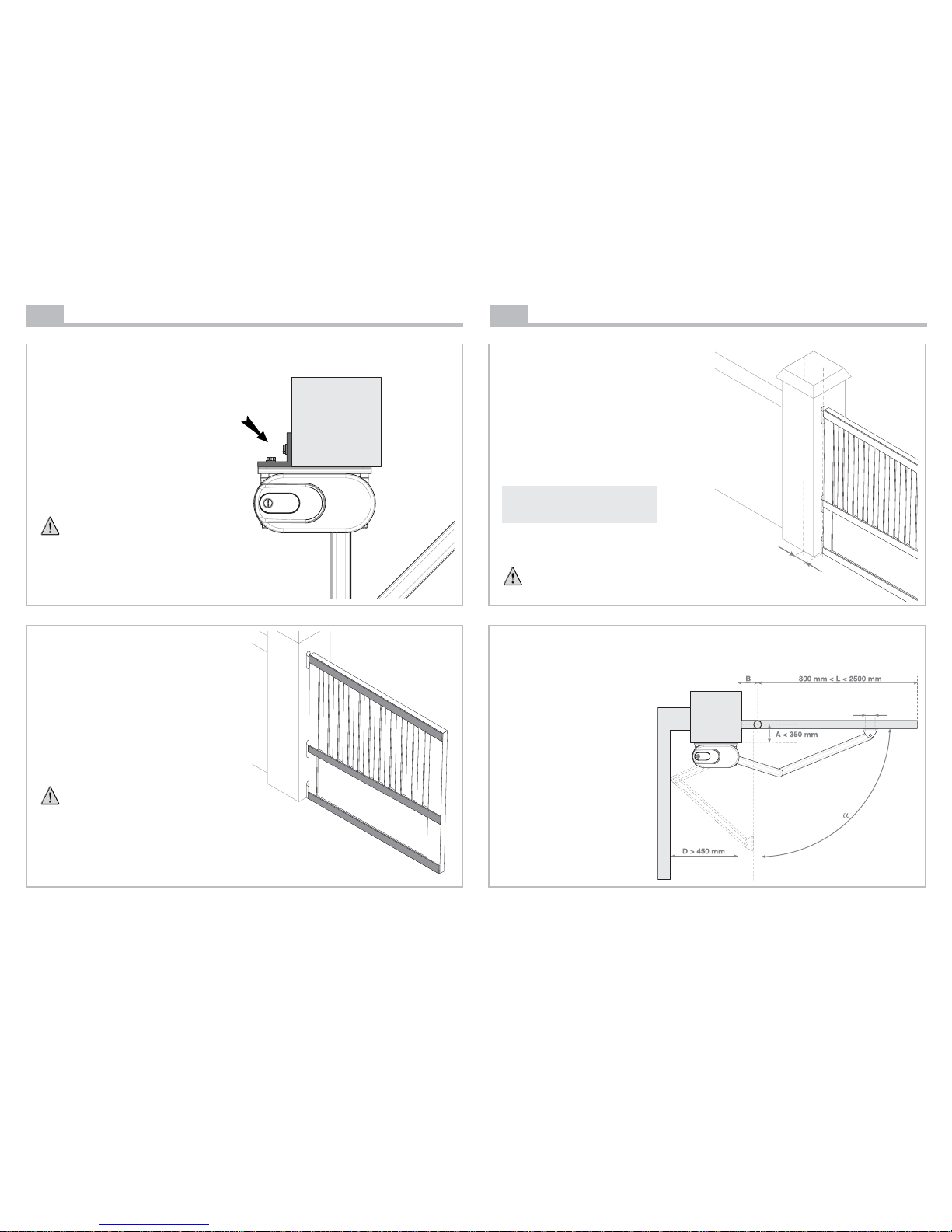

Pre-assembly checks

When one of the motor support plate

fastening holes is either in empty

space or near the angle of the pillar,

it is absolutely essential to add a

reinforcement bracket (not

supplied).

For an opening > 90°, the

dimension of the pillar should

be 40 cm; otherwise, you MUST use

a bracket.

Pillar reinforcement bracket

If the gate does not have any wings,

provide for metal backing plates

(e.g. 40x40 mm and 4 mm thick) to

fasten the wing clevis.

For a large wing ( > 2 m ) or in

a windy region, SOMFY

recommends installation of an

electric lock.

Wing brace

5

Assembly process

The AM vertical axis gives the

position of the motor/pillar

fastening plate.

B is the distance between the

gudgeon and the AM axis.

B depends on the a opening angle

of the wing:

If

αα

≤ 90˚ B = 70 mm min

If

αα

> 90˚ B = 150 mm

Mark out the AM axis.

Check that the open wing does

not knock against the motor.

B

AM

Locating axis markout

To be on the safe side, check

distance D: distance

between the AM axis and

the first obstacle on the side

opposite the wing (quoin)

D ≥ 450 mm.

Distance L should be

beween 800 mm and

2500 mm.

B

A < 350 mm

65

D > 450 mm

800 mm < L < 2500 mm

Required clearance

5

5

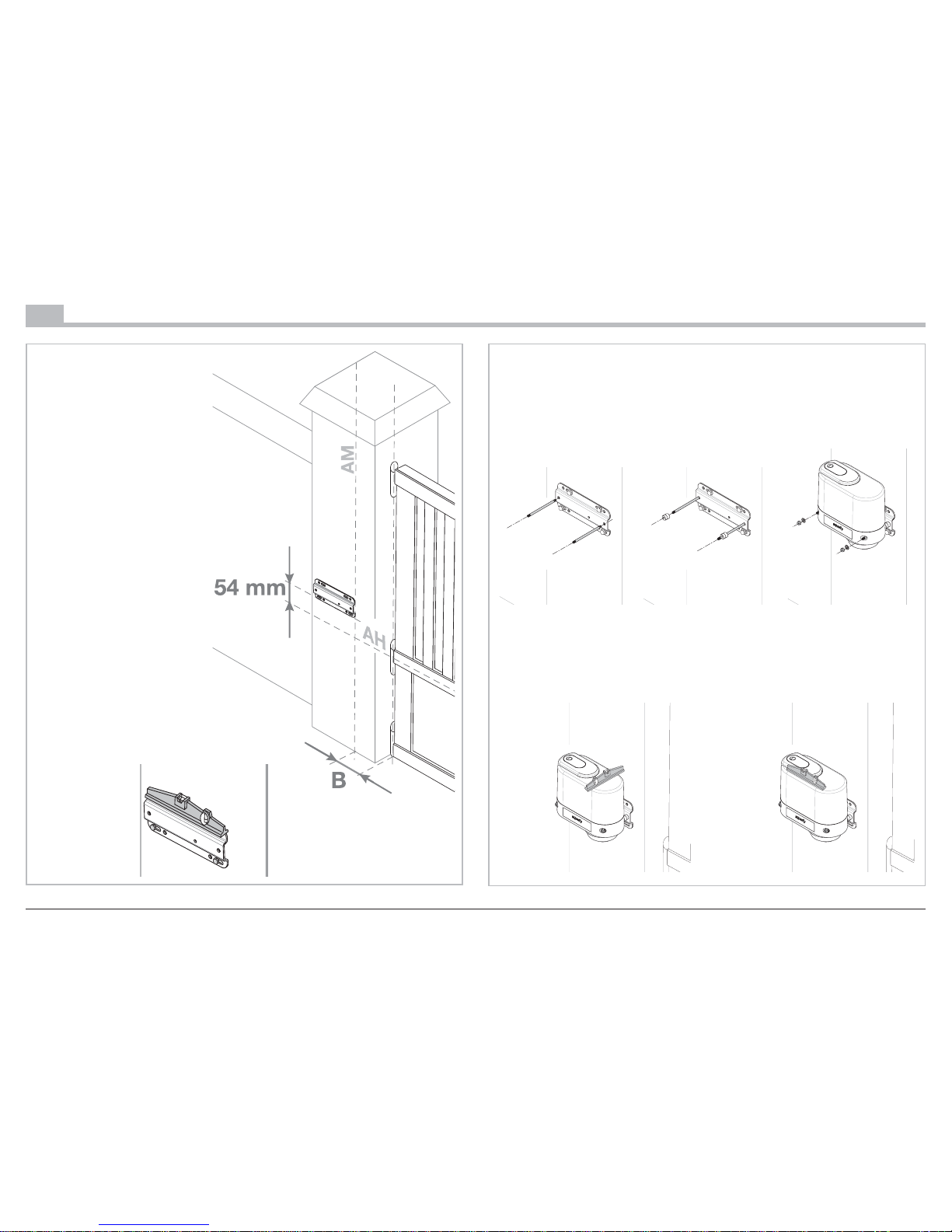

Assembly process

Mark out a horizontal axis

(AH) in the middle of the

brace, perpendicular to the

wing's axis of rotation.

Extend this axis onto the

pillar as far as the

intersection with AM.

Gate with no brace: if the

gate has no no brace, place

the motors at approx. 1/3 of

the height of the wings

starting from the ground.

In addition, you will be

required to provide for

brackets for fastening the

clevises (see page 4).

Place the motor/pillar

fastening plate at a distance

of 54 mm above AH.

Mark out the drilling points

and drill them: to improve

adjustment, use the round

holes to make your mark,

drill, then turn the fastening

plate over and fix using the

oblong holes.

Check that the

plate is in a

perfectly

horizontal

position.

Mounting the fastening plate

1.

Mount the fastening

gudgeons on the pillar

fastening plate, screw

them as far as the

thread will go.

2. Slide the spacers

onto the fastening

gudgeons.

3. Position and

fasten the motor.

Check that it is in a perfectly horizontal position:

Mounting the motor on the plate

Loading...

Loading...