SOMFY Animeo KNX RS485 Operating Manual

Table of content

1

First operation ................................................................................................................................ 3

2

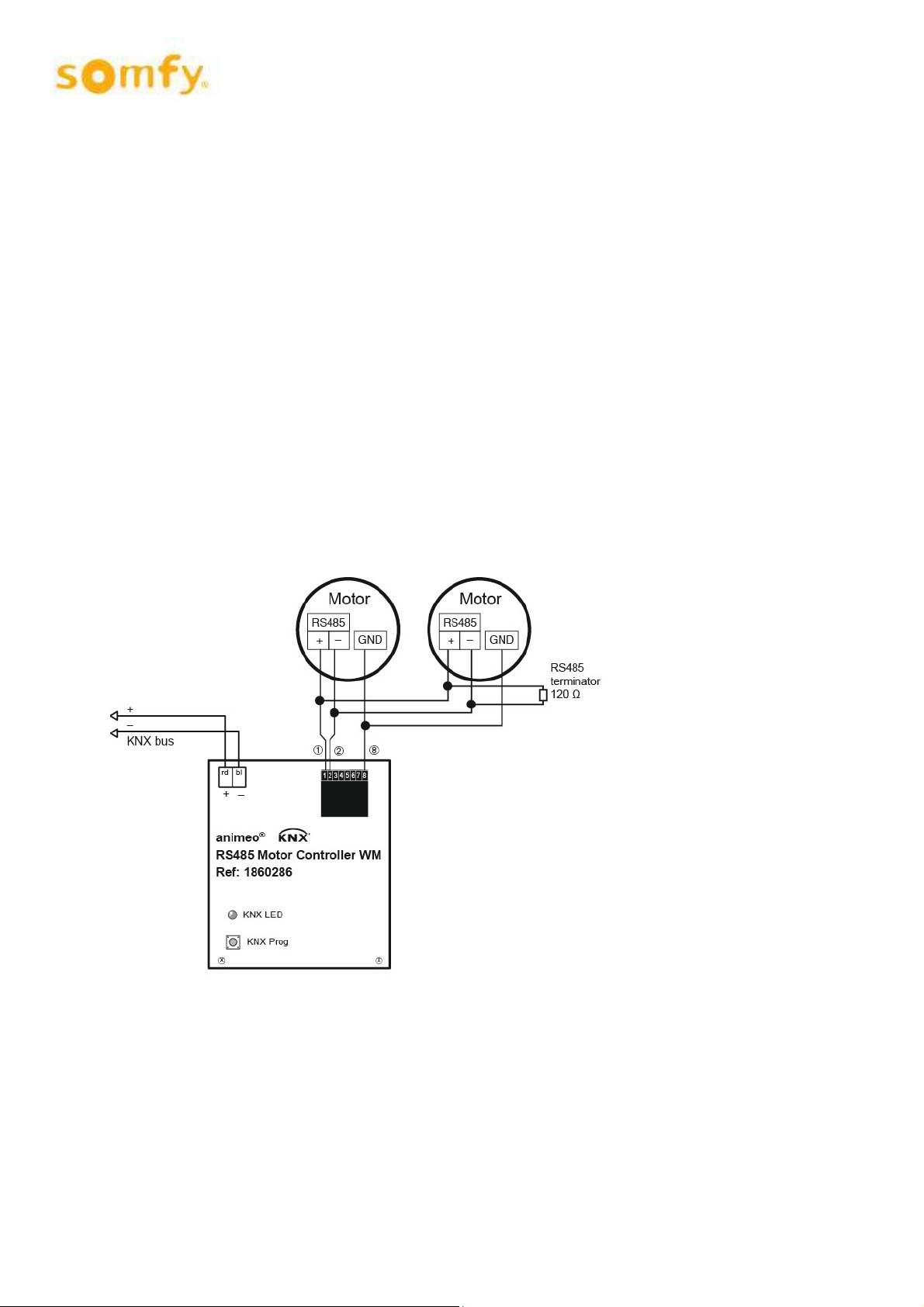

Wiring diagram ............................................................................................................................... 3

3

Communication objects ................................................................................................................ 5

3.1 Object overview...................................................................................................................... 5

3.1.1 List of Objects ........................................................................................................................ 5

4

Parameter ...................................................................................................................................... 19

4.1 Motor Controller settings ...................................................................................................... 19

4.1.1 Menu index card “Motor Controller” ..................................................................................... 19

4.1.2 Menu index card “Motor 1” ................................................................................................... 20

4.2 Group Assignment ............................................................................................................... 24

4.2.1 Menu index card “Group Assignment” ................................................................................. 24

4.2.2 Menu index card “Command Group 1” ................................................................................ 25

5

Technical data .............................................................................................................................. 28

6

General information ..................................................................................................................... 29

7

Appendix ....................................................................................................................................... 30

Different types of motors could be used and connected on the animeo KNX RS485 Motor Con-

troller.

Before connecting motor and Motor Controller make sure that the end limits of the motors have

been set correctly.

Before starting up it is necessary to follow the safety instructions in this manual. SOMFY cannot

be held liable for defects and damages when these have been caused as a result of not following

instructions (wrong installation, incorrect service etc.). Establishing, testing and commissioning of

the equipment is permitted only by a qualified person (in accordance with VDE 0100). Plug in all

connections without voltage. Take precautions against unintentional turning on.

The installation of the Somfy products may occur only at easily accessible places. If maintenance

and repair become hindered by accessibility substantially (e.g. stuck or extensively stuck flooring,

installation behind lamps or behind façades), any originating supplementary costs therein cannot

be charged to the seller.

Subject to technical changes.

animeo KNX RS485 Motor Controller WM 2017-06-30

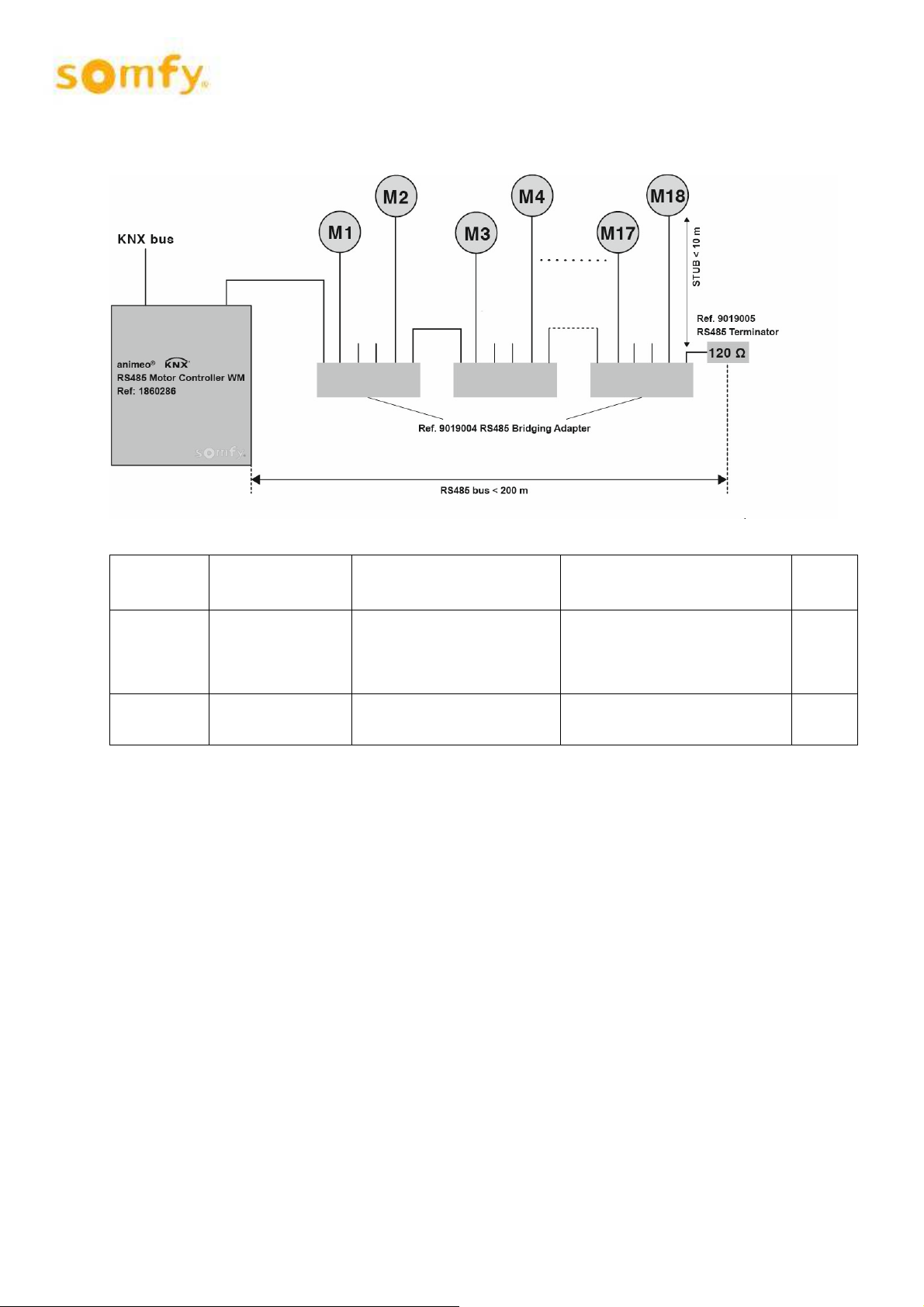

The KNX RS485 is a wall-mounted Motor Controller which enables the

controlling of up to 18 motors. The motors can be controlled either individually or by groups.

RS485 motors can be connected to the RS485 Bridging Adapter, ref.

9019004. Different motor types can be used.

RS485 motors are compatible with

Sonesse50 RS485

LT50 RS485

Sonesse30 RS485

Sonesse50 Ultra DC RS485

Product features:

• Flexible installation: suspended ceiling/raised floor, under window or wall-mounted wiring channels.

• Quick installation and connection of the Motor Controller by plug and play, cable tension relief point

to tighten cables to the housing of the product and daisy chaining of several RS485 motors.

• With the SDN configuration software the motor settings have to be done before configuring via ETS.

• Perfect alignment of the blinds thanks to the increment encoder technology of the RS485 motors.

• The exact position of the blind during movement and when reaching the upper and lower end limits

can be monitored.

• Using a one Byte telegram over the KNX, the blind can be moved to numerous intermediate positions.

animeo KNX RS485 Motor Controller WM . Ref. 5134039A 2/31

animeo KNX RS485 Motor Controller WM 2017-06-30

1 First operation

1. Blinds must be mounted and the upper and lower end limit must be adjusted (s. wiring diagram).

The settings of the motor limits can be done via the use of the SDN configuration software.

2. Link all motors via the RS485 bus and connect them to the Motor Controller.

3. Turn on power supply of the motors.

4. Connect power supply to the Motor Controllers (KNX bus).

5. After a waiting time of ca. 30 seconds all motors can be operated by means of the push buttons

on the Motor Controller.

6. Check end limits and running direction. Can be adjusted later via ETS, if necessary.

7. Create ETS project and download it.

8. After a waiting time of approx. 1 minute after downloading the Motor Controller is ready for opera-

tion.

2 Wiring diagram

, ref. 9019005

animeo KNX RS485 Motor Controller WM . Ref. 5134039A 3/31

animeo KNX RS485 Motor Controller WM 2017-06-30

Connection

to

RS485 bus Modular Jack 8P4C

KNX Bus 2 x 0.8 mm/20 AWG Required, following KNX

Cable Twisted pair Max.

Min.: 4 x 2 x 0.5 mm/24 AWG Required twisted pair shielded,

(RJ45)

impedance 100 Ω (-10 Ω/+30 Ω),

recommended CAT5-FTP,

following Somfy RS485 guidelines

topology guidelines

length

200 m

–

animeo KNX RS485 Motor Controller WM . Ref. 5134039A 4/31

animeo KNX RS485 Motor Controller WM 2017-06-30

3 Communication objects

3.1 Object overview

A maximum of 306 communication objects are available, which however cannot be used at one time.

H Maximum 480 group addresses can be linked.

3.1.1 List of Objects

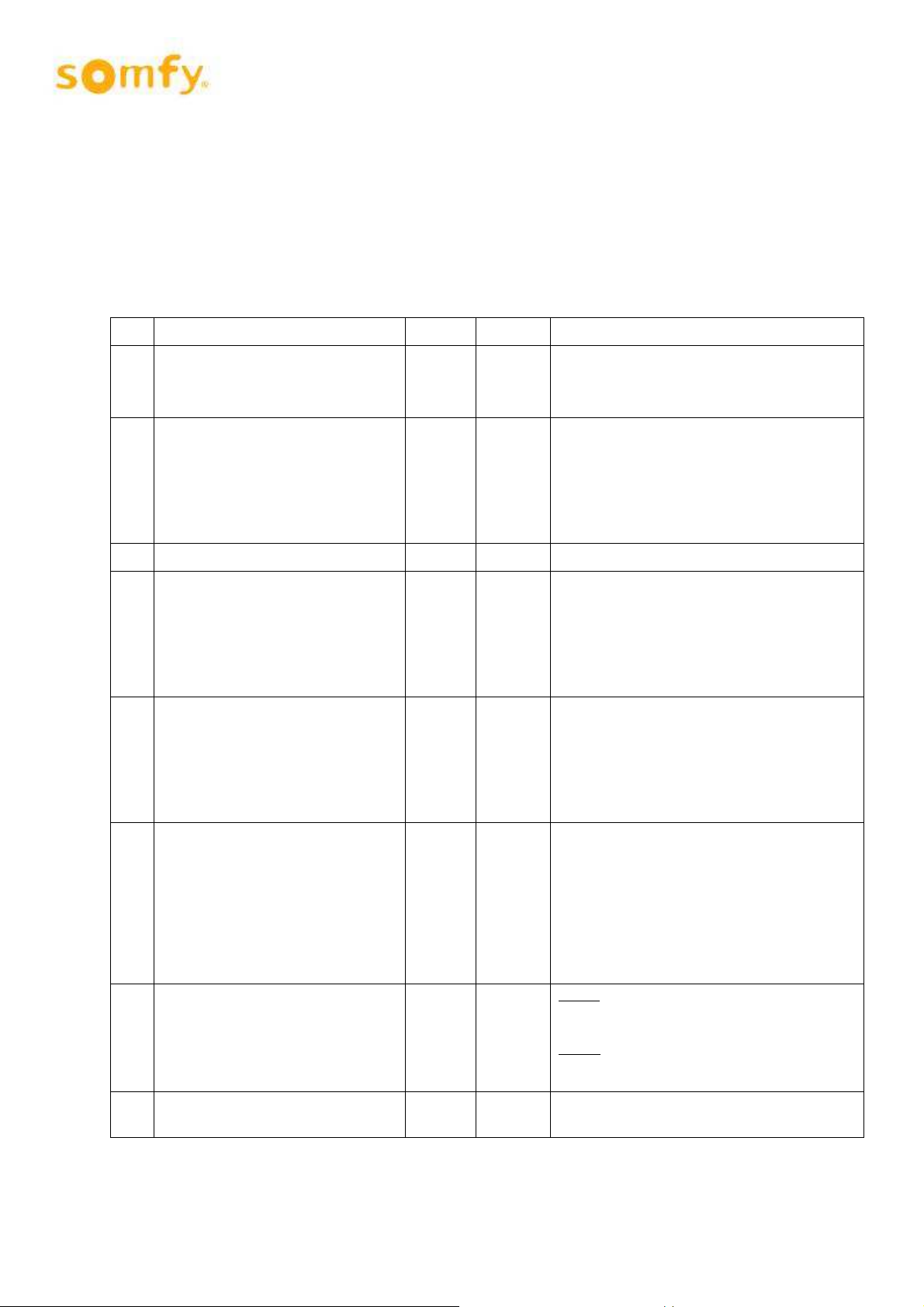

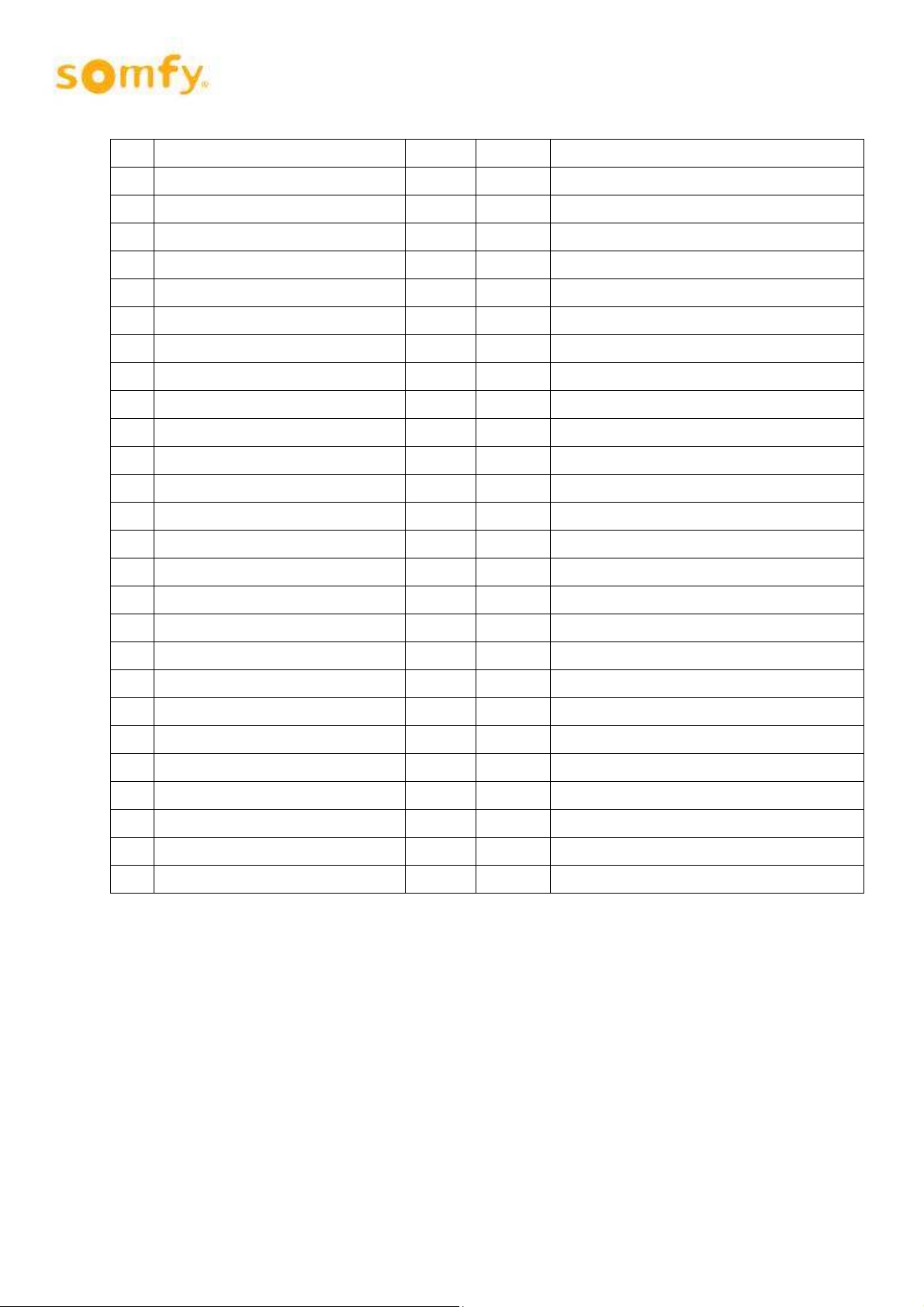

No. Object name Model DPT_ID Description

1 Motor 1 Position Request 1 Bit 1.017

2 Motor 1 Position Feedback 1 Byte 5.001

3 Not used

4 Motor 1 Feedback Upper End 1 Bit 1.001

5 Motor 1 Feedback Lower End 1 Bit 1.001

6 Motor 1 Error Feedback 1 Bit 1.001

7 Motor 1 Identification 4 Bytes 12.*

8 Motor 1 Cycles 4 Bytes 12.001 Read out the number of movement cycles

If a telegram with the value “1” or “0” is received on this communication object, the

current status position is sent on the bus

(object 2).

On this communication object the current

position (UP/DOWN direction) of the blind

is sent to the bus based on the programmed running time. The type of feedback (on demand, status change, cyclic) is

defined in the ETS parameters.

"0" = UP / "100" = DOWN

Over this communication object a telegram

with the value "1" is sent if the upper end

position is reached. When leaving the upper end position of the blind a telegram

with the value "0" is sent. The upper and

the lower end position result from the parameterized running times.

Over this communication object a telegram

with the value "1" is sent after the lower

end position is reached. When leaving the

lower end position of the blind a telegram

with the value "0" is sent. The upper and

the lower end position result from the parameterized running times.

Over this communication object a telegram

is sent if a motor error occurs. An error is

when a move command was sent to the

motor, but the motor does not move.

The sent value of this communication object depends on what has been selected in

the ETS parameters.

• 1/0 (1 = error, 0 = no error) or

• 0/1 (0 = error, 1 = no error)

Write:

0 Motor is winking

1-255 Move to position

Read:

Read out the Motor ID of the connected

RS485 motor

of the motor.

animeo KNX RS485 Motor Controller WM . Ref. 5134039A 5/31

animeo KNX RS485 Motor Controller WM 2017-06-30

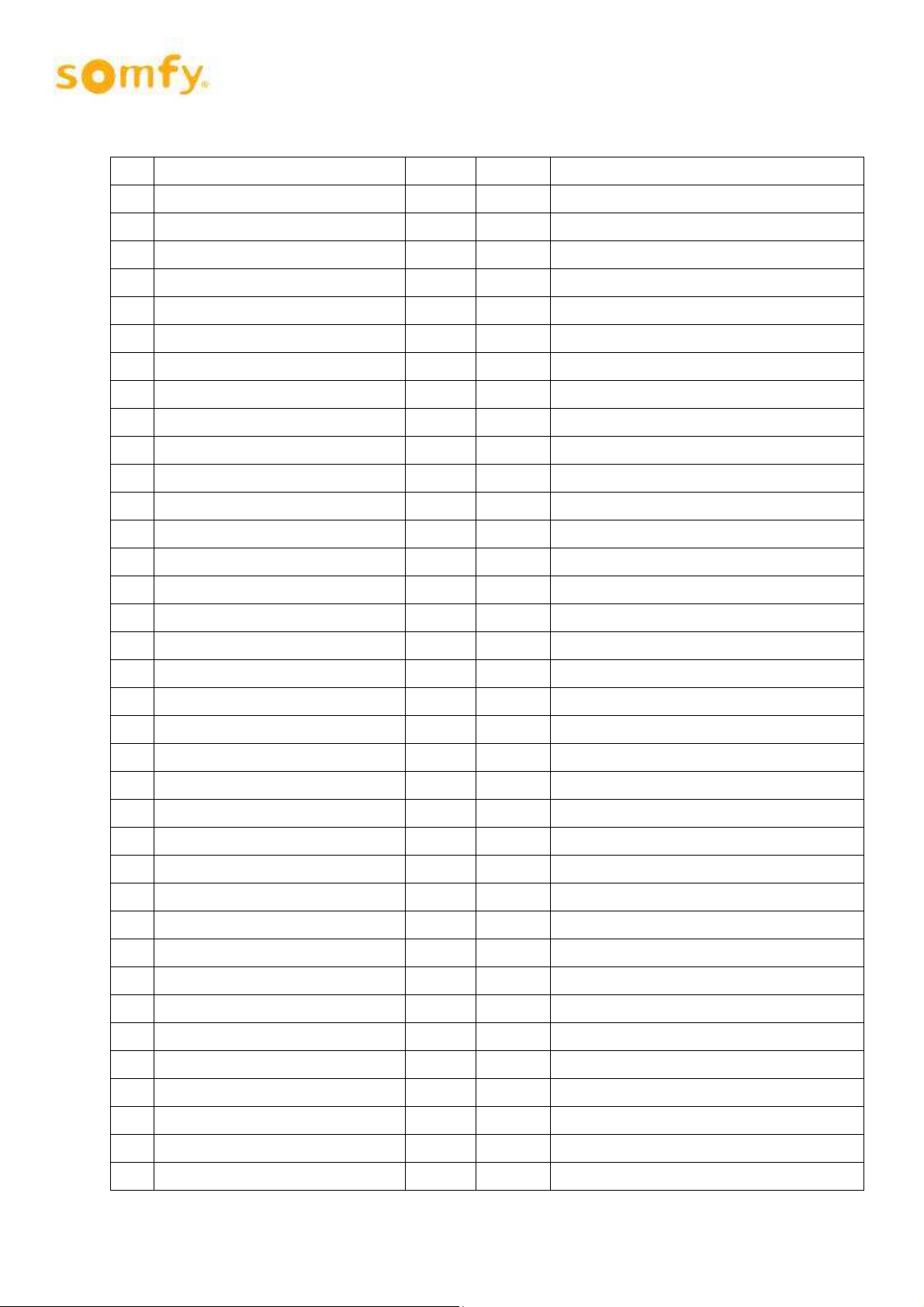

No. Object name Model DPT_ID Description

Motor 2 Position Request

9

1 Bit 1.017 See object description no. 1 for motor 1

10 Motor 2 Position Feedback 1 Byte 5.001 See object description no. 2 for motor 1

11 Not used

12 Motor 2 Feedback Upper End 1 Bit 1.001 See object description no. 4 for motor 1

13 Motor 2 Feedback Lower End 1 Bit 1.001 See object description no. 5 for motor 1

14 Motor 2 Error Feedback 1 Bit 1.001 See object description no. 6 for motor 1

15 Motor 2 Identification 4 Bytes 12.* See object description no. 7 for motor 1

16 Motor 2 Cycles 4 Bytes 12.001 See object description no. 8 for motor 1

Motor 3 Position Request

17

1 Bit 1.017 See object description no. 1 for motor 1

18 Motor 3 Position Feedback 1 Byte 5.001 See object description no. 2 for motor 1

19 Not used

20 Motor 3 Feedback Upper End 1 Bit 1.001 See object description no. 4 for motor 1

21 Motor 3 Feedback Lower End 1 Bit 1.001 See object description no. 5 for motor 1

22 Motor 3 Error Feedback 1 Bit 1.001 See object description no. 6 for motor 1

23 Motor 3 Identification 4 Bytes 12.* See object description no. 7 for motor 1

24 Motor 3 Cycles 4 Bytes 12.001 See object description no. 8 for motor 1

Motor 4 Position Request

25

1 Bit 1.017 See object description no. 1 for motor 1

26 Motor 4 Position Feedback 1 Byte 5.001 See object description no. 2 for motor 1

27 Not used

28 Motor 4 Feedback Upper End 1 Bit 1.001 See object description no. 4 for motor 1

29 Motor 4 Feedback Lower End 1 Bit 1.001 See object description no. 5 for motor 1

30 Motor 4 Error Feedback 1 Bit 1.001 See object description no. 6 for motor 1

31 Motor 4 Identification 4 Bytes 12.* See object description no. 7 for motor 1

32 Motor 4 Cycles 4 Bytes 12.001 See object description no. 8 for motor 1

Motor 5 Position Request

33

1 Bit 1.017 See object description no. 1 for motor 1

34 Motor 5 Position Feedback 1 Byte 5.001 See object description no. 2 for motor 1

35 Not used

36 Motor 5 Feedback Upper End 1 Bit 1.001 See object description no. 4 for motor 1

37 Motor 5 Feedback Lower End 1 Bit 1.001 See object description no. 5 for motor 1

38 Motor 5 Error Feedback 1 Bit 1.001 See object description no. 6 for motor 1

39 Motor 5 Identification 4 Bytes 12.* See object description no. 7 for motor 1

40 Motor 5 Cycles 4 Bytes 12.001 See object description no. 8 for motor 1

Motor 6 Position Request

41

1 Bit 1.017 See object description no. 1 for motor 1

42 Motor 6 Position Feedback 1 Byte 5.001 See object description no. 2 for motor 1

43 Not used

44 Motor 6 Feedback Upper End 1 Bit 1.001 See object description no. 4 for motor 1

animeo KNX RS485 Motor Controller WM . Ref. 5134039A 6/31

animeo KNX RS485 Motor Controller WM 2017-06-30

No. Object name Model DPT_ID Description

45 Motor 6 Feedback Lower End 1 Bit 1.001 See object description no. 5 for motor 1

46 Motor 6 Error Feedback 1 Bit 1.001 See object description no. 6 for motor 1

47 Motor 6 Identification 4 Bytes 12.* See object description no. 7 for motor 1

48 Motor 6 Cycles 4 Bytes 12.001 See object description no. 8 for motor 1

Motor 7 Position Request

49

1 Bit 1.017 See object description no. 1 for motor 1

50 Motor 7 Position Feedback 1 Byte 5.001 See object description no. 2 for motor 1

51 Not used

52 Motor 7 Feedback Upper End 1 Bit 1.001 See object description no. 4 for motor 1

53 Motor 7 Feedback Lower End 1 Bit 1.001 See object description no. 5 for motor 1

54 Motor 7 Error Feedback 1 Bit 1.001 See object description no. 6 for motor 1

55 Motor 7 Identification 4 Bytes 12.* See object description no. 7 for motor 1

56 Motor 7 Cycles 4 Bytes 12.001 See object description no. 8 for motor 1

Motor 8 Position Request

57

1 Bit 1.017 See object description no. 1 for motor 1

58 Motor 8 Position Feedback 1 Byte 5.001 See object description no. 2 for motor 1

59 Not used

60 Motor 8 Feedback Upper End 1 Bit 1.001 See object description no. 4 for motor 1

61 Motor 8 Feedback Lower End 1 Bit 1.001 See object description no. 5 for motor 1

62 Motor 8 Error Feedback 1 Bit 1.001 See object description no. 6 for motor 1

63 Motor 8 Identification 4 Bytes 12.* See object description no. 7 for motor 1

64 Motor 8 Cycles 4 Bytes 12.001 See object description no. 8 for motor 1

Motor 9 Position Request

65

1 Bit 1.017 See object description no. 1 for motor 1

66 Motor 9 Position Feedback 1 Byte 5.001 See object description no. 2 for motor 1

67 Not used

68 Motor 9 Feedback Upper End 1 Bit 1.001 See object description no. 4 for motor 1

69 Motor 9 Feedback Lower End 1 Bit 1.001 See object description no. 5 for motor 1

70 Motor 9 Error Feedback 1 Bit 1.001 See object description no. 6 for motor 1

71 Motor 9 Identification 4 Bytes 12.* See object description no. 7 for motor 1

72 Motor 9 Cycles 4 Bytes 12.001 See object description no. 8 for motor 1

Motor 10 Position Request

73

1 Bit 1.017 See object description no. 1 for motor 1

74 Motor 10 Position Feedback 1 Byte 5.001 See object description no. 2 for motor 1

75 Not used

76 Motor 10 Feedback Upper End 1 Bit 1.001 See object description no. 4 for motor 1

77 Motor 10 Feedback Lower End 1 Bit 1.001 See object description no. 5 for motor 1

78 Motor 10 Error Feedback 1 Bit 1.001 See object description no. 6 for motor 1

79 Motor 10 Identification 4 Bytes 12.* See object description no. 7 for motor 1

80 Motor 10 Cycles 4 Bytes 12.001 See object description no. 8 for motor 1

Motor 11 Position Request

81

1 Bit 1.017 See object description no. 1 for motor 1

animeo KNX RS485 Motor Controller WM . Ref. 5134039A 7/31

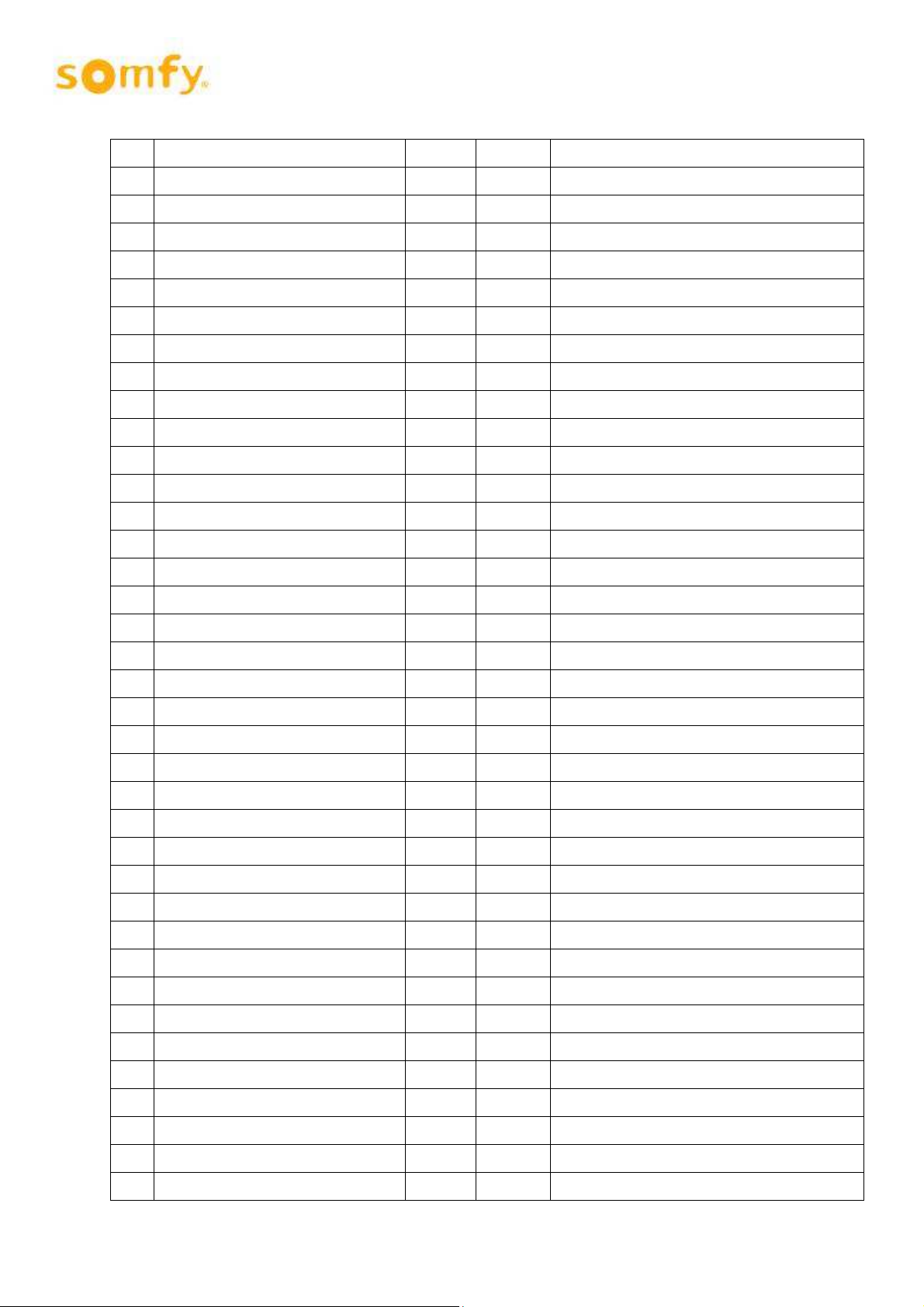

animeo KNX RS485 Motor Controller WM 2017-06-30

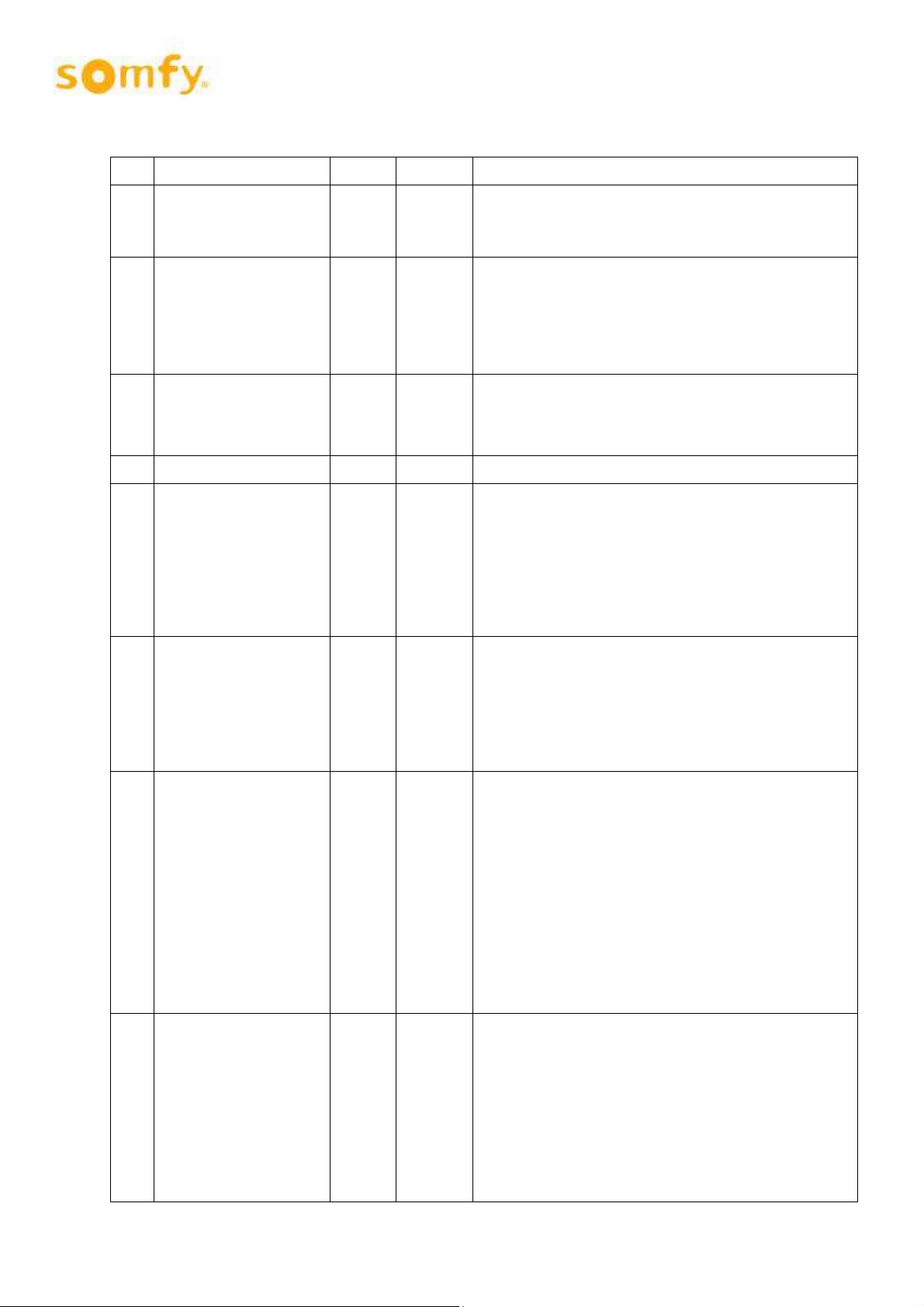

No. Object name Model DPT_ID Description

82 Motor 11 Position Feedback 1 Byte 5.001 See object description no. 2 for motor 1

83 Not used

84 Motor 11 Feedback Upper End 1 Bit 1.001 See object description no. 4 for motor 1

85 Motor 11 Feedback Lower End 1 Bit 1.001 See object description no. 5 for motor 1

86 Motor 11 Error Feedback 1 Bit 1.001 See object description no. 6 for motor 1

87 Motor 11 Identification 4 Bytes 12.* See object description no. 7 for motor 1

88 Motor 11 Cycles 4 Bytes 12.001 See object description no. 8 for motor 1

Motor 12 Position Request

89

1 Bit 1.017 See object description no. 1 for motor 1

90 Motor 12 Position Feedback 1 Byte 5.001 See object description no. 2 for motor 1

91 Not used

92 Motor 12 Feedback Upper End 1 Bit 1.001 See object description no. 4 for motor 1

93 Motor 12 Feedback Lower End 1 Bit 1.001 See object description no. 5 for motor 1

94 Motor 12 Error Feedback 1 Bit 1.001 See object description no. 6 for motor 1

95 Motor 12 Identification 4 Bytes 12.* See object description no. 7 for motor 1

96 Motor 12 Cycles 4 Bytes 12.001 See object description no. 8 for motor 1

Motor 13 Position Request

97

1 Bit 1.017 See object description no. 1 for motor 1

98 Motor 13 Position Feedback 1 Byte 5.001 See object description no. 2 for motor 1

99 Not used

100 Motor 13 Feedback Upper End 1 Bit 1.001 See object description no. 4 for motor 1

101 Motor 13 Feedback Lower End 1 Bit 1.001 See object description no. 5 for motor 1

102 Motor 13 Error Feedback 1 Bit 1.001 See object description no. 6 for motor 1

103 Motor 13 Identification 4 Bytes 12.* See object description no. 7 for motor 1

104 Motor 13 Cycles 4 Bytes 12.001 See object description no. 8 for motor 1

Motor 14 Position Request

105

1 Bit 1.017 See object description no. 1 for motor 1

106 Motor 14 Position Feedback 1 Byte 5.001 See object description no. 2 for motor 1

107 Not used

108 Motor 14 Feedback Upper End 1 Bit 1.001 See object description no. 4 for motor 1

109 Motor 14 Feedback Lower End 1 Bit 1.001 See object description no. 5 for motor 1

110 Motor 14 Error Feedback 1 Bit 1.001 See object description no. 6 for motor 1

111 Motor 14 Identification 4 Bytes 12.* See object description no. 7 for motor 1

112 Motor 14 Cycles 4 Bytes 12.001 See object description no. 8 for motor 1

Motor 15 Position Request

113

1 Bit 1.017 See object description no. 1 for motor 1

114 Motor 15 Position Feedback 1 Byte 5.001 See object description no. 2 for motor 1

115 Not used

116 Motor 15 Feedback Upper End 1 Bit 1.001 See object description no. 4 for motor 1

117 Motor 15 Feedback Lower End 1 Bit 1.001 See object description no. 5 for motor 1

118 Motor 15 Error Feedback 1 Bit 1.001 See object description no. 6 for motor 1

animeo KNX RS485 Motor Controller WM . Ref. 5134039A 8/31

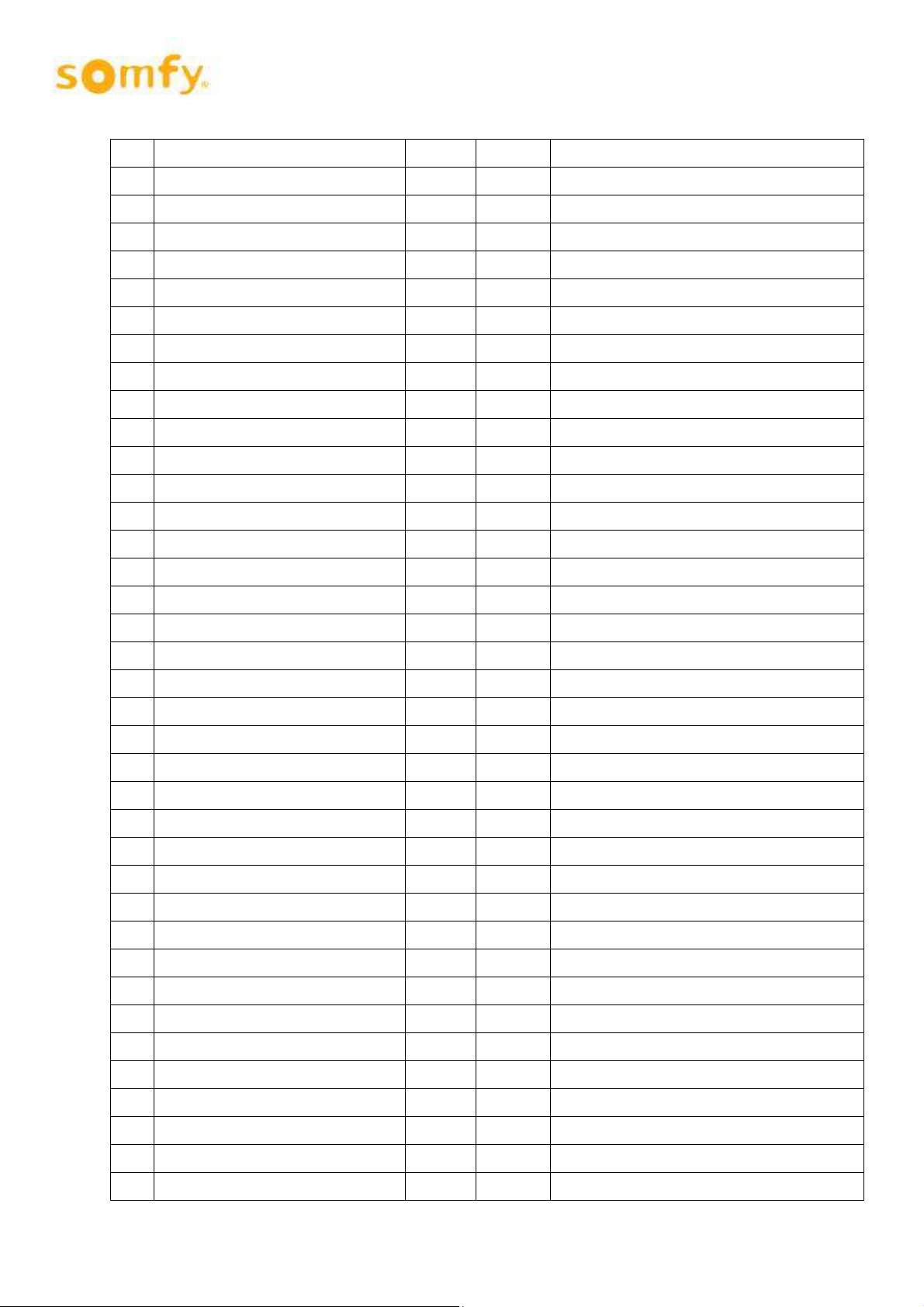

animeo KNX RS485 Motor Controller WM 2017-06-30

No. Object name Model DPT_ID Description

119 Motor 15 Identification 4 Bytes 12.* See object description no. 7 for motor 1

120 Motor 15 Cycles 4 Bytes 12.001 See object description no. 8 for motor 1

Motor 16 Position Request

121

122 Motor 16 Position Feedback 1 Byte 5.001 See object description no. 2 for motor 1

123 Not used

124 Motor 16 Feedback Upper End 1 Bit 1.001 See object description no. 4 for motor 1

125 Motor 16 Feedback Lower End 1 Bit 1.001 See object description no. 5 for motor 1

126 Motor 16 Error Feedback 1 Bit 1.001 See object description no. 6 for motor 1

127 Motor 16 Identification 4 Bytes 12.* See object description no. 7 for motor 1

128 Motor 16 Cycles 4 Bytes 12.001 See object description no. 8 for motor 1

Motor 17 Position Request

129

130 Motor 17 Position Feedback 1 Byte 5.001 See object description no. 2 for motor 1

131 Not used

1 Bit 1.017 See object description no. 1 for motor 1

1 Bit 1.017 See object description no. 1 for motor 1

132 Motor 17 Feedback Upper End 1 Bit 1.001 See object description no. 4 for motor 1

133 Motor 17 Feedback Lower End 1 Bit 1.001 See object description no. 5 for motor 1

134 Motor 17 Error Feedback 1 Bit 1.001 See object description no. 6 for motor 1

135 Motor 17 Identification 4 Bytes 12.* See object description no. 7 for motor 1

136 Motor 17 Cycles 4 Bytes 12.001 See object description no. 8 for motor 1

Motor 18 Position Request

137

138 Motor 18 Position Feedback 1 Byte 5.001 See object description no. 2 for motor 1

139 Not used

140 Motor 18 Feedback Upper End 1 Bit 1.001 See object description no. 4 for motor 1

141 Motor 18 Feedback Lower End 1 Bit 1.001 See object description no. 5 for motor 1

142 Motor 18 Error Feedback 1 Bit 1.001 See object description no. 6 for motor 1

143 Motor 18 Identification 4 Bytes 12.* See object description no. 7 for motor 1

144 Motor 18 Cycles 4 Bytes 12.001 See object description no. 8 for motor 1

1 Bit 1.017 See object description no. 1 for motor 1

animeo KNX RS485 Motor Controller WM . Ref. 5134039A 9/31

animeo KNX RS485 Motor Controller WM 2017-06-30

No. Object name Model DPT_ID Description

Command Group 1

153

Up/Down

Command Group 1

154

Dedicated Stop

155 Command Group 1

Position

156 Not used

1 Bit 1.008

1 Bit 1.017 If the end product is in a full moving process, it stops

1 Byte 5.001

If a telegram with the value "0" is received on this

communication object, the appropriate blind goes up.

If a telegram with the value "1" is received, the appropriate blind goes down.

with the receipt of a telegram on the object, regardless of whether a telegram with the value "0" or "1" is

received. If the end product is in passive state, then

with the receipt of a telegram on this communication

object no action is executed.

If this communication object receives a telegram, the

appropriate blind will go into the position which is defined by the received value.

"0" = UP "100" = DOWN

157 Command Group 1

Move to IP1

158 Command Group 1

Move to IP2

159 Command Group 1

Security low prio

1 Bit 1.008 If a telegram with the value "1" is received on this

communication object, the blind goes to the intermediate position 1 which was configured by local switch

or parameterized in the ETS parameters. The last position which has been configured is active. Receiving

a telegram with the value "0" on this communication

object the appropriate blind goes to the upper end

position.

1 Bit 1.008 If a telegram with the value "1" is received on one of

these communication objects, the corresponding

blind moves to the intermediate position 2 parameterized in the ETS parameters. Receiving a telegram

with the value "0" on one of these communication objects, the corresponding blind moves to the upper

end position.

1 Bit 1.001 If a telegram with the value "1" is received on this

communication object, the blind goes to the position

which was parameterized in the ETS parameters.

When the communication object receives a telegram

with value "0" no action will be executed. Only with

the selection "Restore previous position after security

(Yes)" in the ETS parameters this action will be executed on the blind. If this communication object is active through a telegram with the value "1" and if then

on the communication object 160 (security position,

high priority) a telegram with value "1" is received, the

blind will move to the position configured in the ETS

parameters (security position, high priority).

160 Command Group 1

Security high prio

animeo KNX RS485 Motor Controller WM . Ref. 5134039A 10/31

1 Bit 1.001 If a telegram with the value "1" is received on this

communication object, the blind goes to the position

which was parameterized in the ETS parameters.

When the communication object receives a telegram

with value "0" no action will be executed. Only with

the selection " Restore previous position after security (Yes)" in the ETS parameters this will be executed in the blind. If an object for security position,

low priority is active ("1"), the blinds will go to the parameterized position for the low priority.

Loading...

Loading...