Pellet Insert

Instruction Manual

Models

FIRE 9KW | EARTH 9KW |

WIND 9KW

Read these instructions carefully before installing, using and servicing the unit. The

instruction manual is an integral part of the product.

Mod.814-C

1

Thank you for purchasing a SOLZAIMA appliance.

Please read this manual carefully and keep it for future reference.

* All our products fulfil the requirements of the Construction Products Directive

(Directive 89/106/EEC) and have been approved with the CE conformity mark;

* The Pellet Burning Free Standing Fires are designed according to EN 14785:2008

Standards

* SOLZAIMA disclaims any responsibility for damages to the unit if installed by nonqualified personnel;

* SOLZAIMA is not responsible for any damage to units not installed and used in

compliance to the instructions included in this manual;

* All local regulations, including but not limited to national and European standards,

must be observed when installing, operating and servicing the unit;

* Whenever you need assistance, you should contact the supplier or installer of your

equipment. You should provide the serial number of your stove that is located on the

nameplate on the back of the equipment and on the sticker s glued to the plastic cover

of this manual.

*The technical service must be performed by the unit Installer or Supplier, except on

situations where the assessment performed by the installer or service engineer

determines that SOLZAIMA should be contacted, if required.

Contacts for technical support:

www.solzaima.pt

apoio.cliente@solzaima.pt

Address: Rua dos Outarelos; nº 111;

3750-362 Belazaima do Chão

Águeda - Portugal

2

Table of Contents

1. Package Content ....................................................................................... 4

1.1. Unpacking the insert ............................................................................. 4

2. Safety Precautions .................................................................................... 6

3. Advice on action in the event of a fire in a chimney (including equipment). ...... 7

4. Technical Specifications .............................................................................. 8

5. Installing the Free Standing Pellet Fire ....................................................... 10

6. Installation of optional accessories. ........................................................... 20

7. Intallation requirements ........................................................................... 31

8. Installation for exhaust gas systems: ........................................................ 32

8.1. Installing Without a Chimney ............................................................... 33

8.2. Installation with a Chimney ................................................................. 37

9. Fuel ....................................................................................................... 38

10. Use of the pellet insert ............................................................................. 39

11. Remote Control ....................................................................................... 40

11.1. Infrared Remote Control ................................................................ 40

11.2. Control and Display Panel ............................................................... 40

11.3. Display Information Summary ........................................................ 41

11.3.1. Selecting the Manual or Automatic Mode ..................................... 41

11.3.2. Date and Time ......................................................................... 42

11.3.3. Timer ...................................................................................... 44

11.3.4. Sleep (this menu is displayed only while the unit is operating). .... 48

11.3.5. Info ........................................................................................ 48

11.3.6. Settings Menu .......................................................................... 51

12. Start-up ................................................................................................. 56

12.1. Stop ............................................................................................ 56

12.2. Turning Off the Unit ....................................................................... 56

13. Instruction for installing the frame ............................................................ 57

13.1. Choice of frame ............................................................................. 57

13.2. Installation of the frame on the equipment ....................................... 59

14. Replenishment of pellets .......................................................................... 60

15. Maintenance ........................................................................................... 63

16. Alarm / Failure / Recommendation List....................................................... 71

17. Maintenance Plan and Log ........................................................................ 73

18. Maintenance Guide Label ........................................................................ 77

19. Electrical Diagram of the Free Standing Fire Unit ......................................... 78

3

20. End of life of a pellet insert ....................................................................... 78

21. Warranty ................................................................................................ 78

21.1. Warranty general conditions ........................................................... 79

22. Annexes ................................................................................................. 86

22.1. Flow chart .................................................................................... 86

22.2. Statement of Performance .............................................................. 89

4

1. Package Content

The packaging of the equipment has the following contents:

- Pellet Insert models: Fire 9kW, Earth 9kW or Wind 9kW;

- Handle for opening the door and extracting the equipment;

- Power cable;

- Infrared remote control;

1.1. Unpacking the insert

To unpack the equipment, you must first remove the retractable bag that

surrounds the carton box. Then remove the box by lifting it up and removing

the bag wrapping the insert and the Styrofoam plates.

The insert has a fixed part and a movable part which can be separated. To

separate the two parts, first open the two safety latches under the door, use

the accessory to make it easier to open.

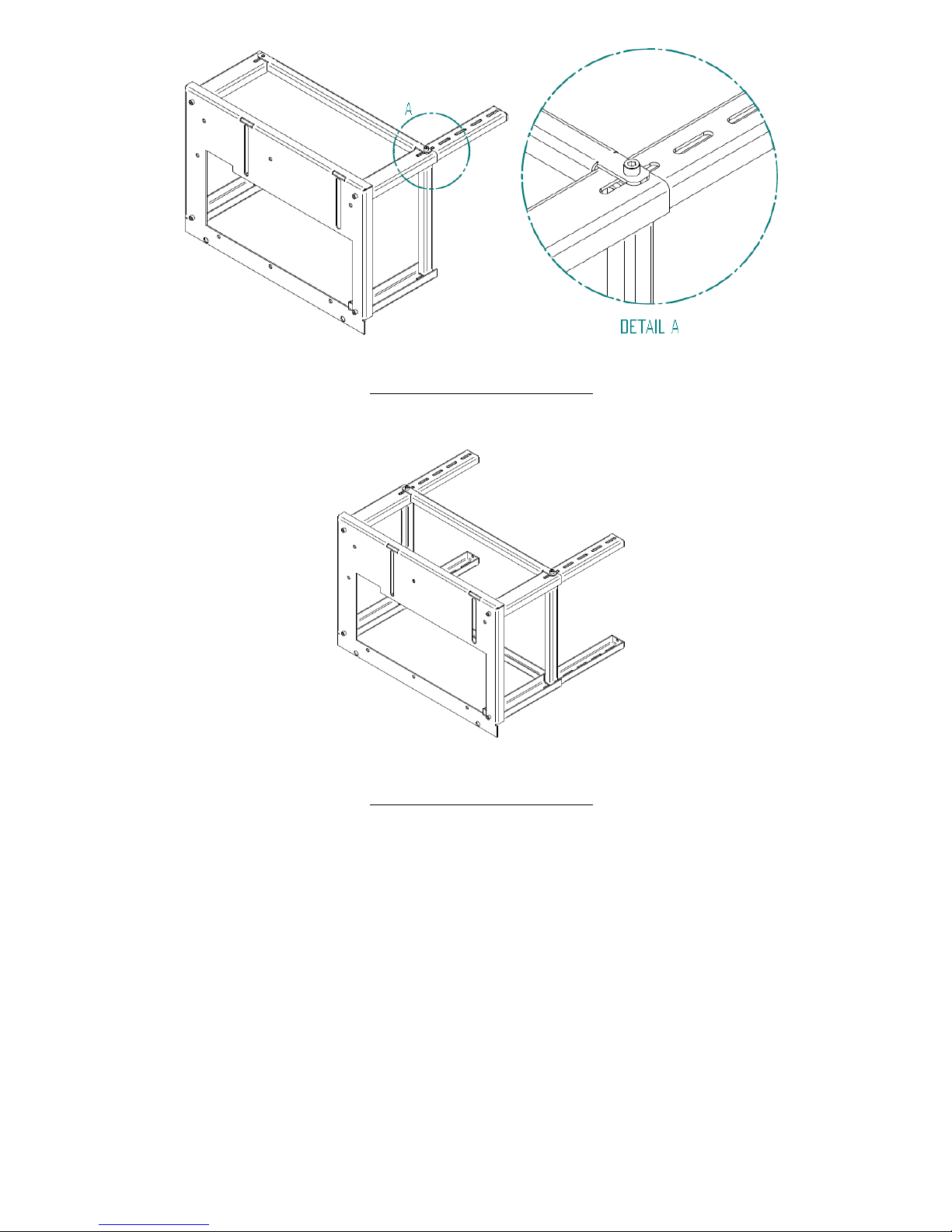

Figure 1 – Open safety latches

5

With the two latches open, use them as pullers to separate the movable part from

the fixed part attached to the pallet.

Notice. When you open the runner system to the limit, you notice a ledge that

locks the moving part, as the ledge passes, the slides are released and the equipment

may fall. You have to be careful that this does not occur. The movable part of the fixed

part is then separated.

The surfaces on which the parts are supported must be protected.

Figure 2 – Separate moving and fixed parts

• With the help of a star wrench PZ2 remove the two screws securing the fixed part

to the pallet, the equipment is thus completely unpacked.

Figure 3 – Separate parts

6

2. Safety Precautions

Make sure you fully read and understand the instructions contained in this manual

before using the pellet insert as a biomass heating unit.

The pellet insert is not intended for use by children or people physically and/or

mentally challenged, or that are inexperienced or unfamiliar with using the unit, except

when under supervision or after receiving proper training.

Do not touch the pellet insert when barefoot or if any part of your body are wet or

humid;

Do not tamper with the safety devices or adjustment features without the

SOLZAIMA SA manufacturer's authorization;

It is prohibited to cover or reduce the size of the ventilation openings of the

installation;

The pellet insert is an equipment that requires air to have a proper combustion, the

possible Airtightness of the place where the equipment is located or the existence of

other sources of air extraction in the house can prevent the correct functioning of the

equipment;

The existence of vents is a requirement for proper combustion;

Please keep the packing materials away from children;

During normal operation, DO NOT open the door of the unit;

Some parts may overheat during normal operation, so the direct contact with hot

parts such as the door handle and glass should be avoided;

Check for the existence of any obstructions to the fume duct before turning on the

unit after a long idle period;

The pellet insert is designed to work inside a protected environment. Safety

systems may be used to turn off the insert. If this happens, contact the after-sales

service and never in any situation disarm the safety systems;

The pellet insert is a biomass heating unit equipped with an electric fume extractor.

The occurrence of a power failure during its use may prevent the fume to be extracted,

consequently causing the room to be filled with smoke. For this reason, a natural fume

extraction system, like a chimney, is recommended;

NEVER turn off an operating Free Standing Pellet Fire unit by disconnecting the

electric plug. The fume extractor on the Free Standing Pellet Fire unit is a powered

feature, so disconnecting the power plug will prevent the extraction of combustion

fumes;

7

The unit must be disconnected from the mains power before any maintenance

procedures can be performed. Please allow the unit to cool down completely before any

maintenance operation (if operating before);

Never touch the interior of the unit without disconnecting it from the power mains.

3. Advice on action in the event of a fire in a chimney

(including equipment).

• Try to put out the fire, without risking your life.

• If you cannot put out the fire within a minute, you should call the fire department.

• Close the doors and windows or partition where the fire has flared.

• Turn off the power and close the gas before leaving your home.

• Once outside, you must wait for the firemen and be ready to give them the

following information: location of the fire, possible materials that are burning and what

they can do to prevent fire progression.

8

4. Technical Specifications

Features

Fire 9kW

Earth 9kW

Wind 9kW

Units

Weight

112

114

116

kg

Height

546

606

546

mm

Width

688

688

688

mm

Depth

573

mm

Diameter of the fume discharge pipe

80

mm

Reservoir capacity

15

kg

Maximum heating capacity

188

m³

Maximum overall thermal power

8,3

kW

Minimum thermal power

3,2

kW

Minimum fuel consumption

0,7

kg/h

Maximum fuel consumption

1,9

kg/h

Rated electrical current

106

W

Electric power at start-up (<10 min.)

350

W

Rated voltage

230

V

Nominal frequency

50

Hz

Thermal yield at rated thermal power

90,1

%

Thermal yield at reduced thermal power

96

%

Max. smoke temperature

154

ºC

Min. smoke temperature

66,3

ºC

CO emissions at rated thermal power

0,01/0,035

%

CO emissions at reduced thermal power

10,35/8,74

%

Combustion gas mass flow

6,3/2,6

g/s

Draught in the chimney

12/10

Pa

Fan Flow

48,2

dB(A)

Table 1 – Technical specifications

Tests were performed using wood pellets with a heating capacity of 4.9 kWh/kg.

The above information was obtained during product homologation tests conducted by

independent laboratories accredited for pellet unit testing.

9

General Measures

Front Back Side Top

Fire 9kW

Earth 9kW

Wind 9kW

Figure 4 – Insertable dimensions to pellets

10

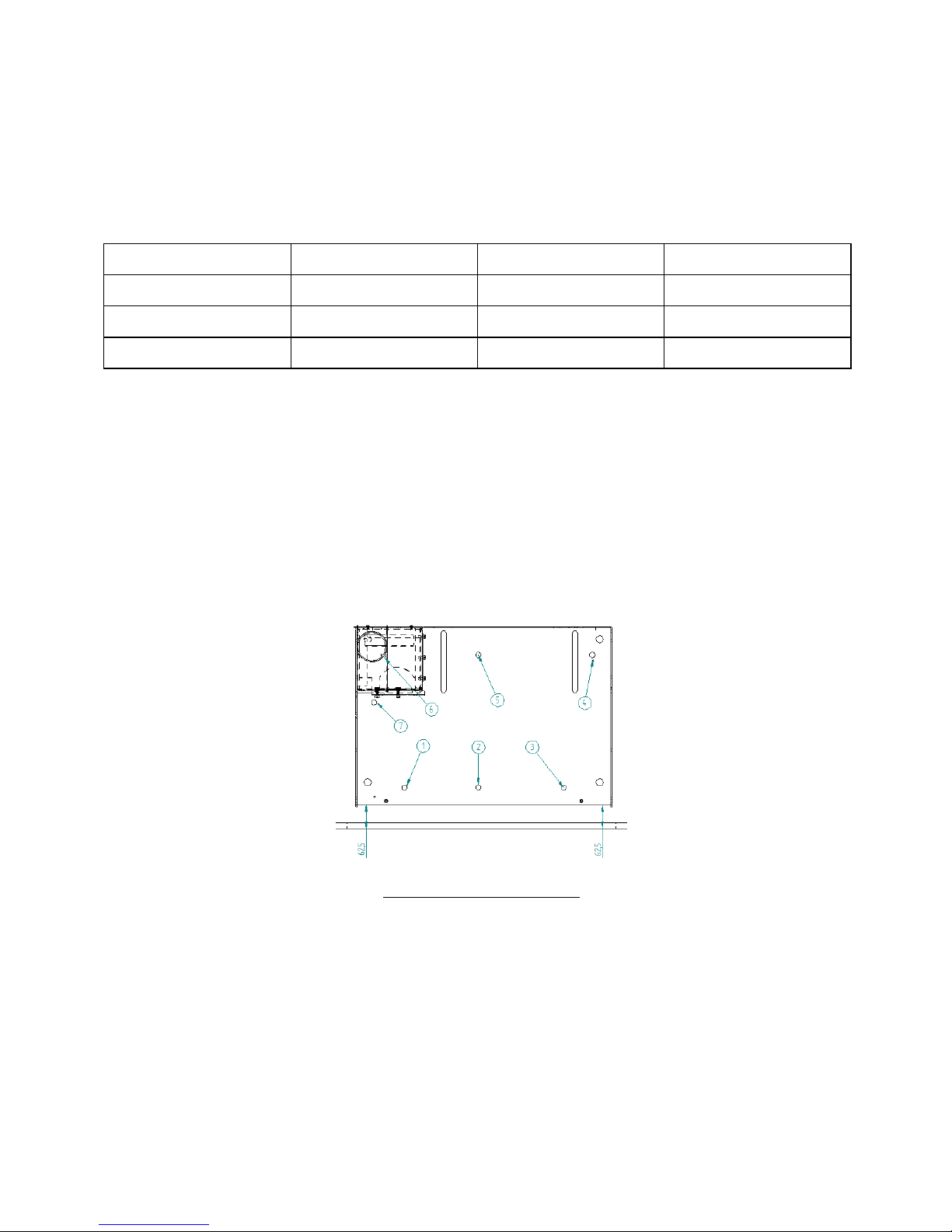

5. Installing the Free Standing Pellet Fire

Before you begin the installation, perform the following actions:

The recommended measures for installing the pellet insert are as follows:

Model

Width (mm)

Height (mm)

Depth (mm)

Fire 9Kw

695

550

550

Earth 9Kw

695

610

550

Wind 9Kw

695

550

550

As can be seen in figure 4 the inserts have finishing frames to cover bigger holes,

giving greater versatility to the insert. There are two different widths, one of 44 mm

and one of 74 mm to finish the equipment’s installation (see point 13).

The surface where the base of the equipment is to be fixed must be leveled and

have the necessary strength to support the entire weight of the equipment and its

subsequent movements to load pellets.

The base of the equipment has 7 holes to attach to the support.

Figure 5 – Fixing base equipment

• As can be seen in Figure 5, a distance of 62.5mm from the base to the front of the

wall must be left (it must be perfectly parallel).

• The equipment has an approximate weight of 100 kg and when it is extracted to the

pellet / maintenance position, it exerts a high force on the base, during installation it is

necessary to use anchoring material suitable for the type of base, soil and wall (In the

case of extending table), recommendations:

11

Material

Type of attachment

Image

Massive (slab, stone)

FMS M8x60 Ø10

Metallic

Massive and non-massive

(brick)

FIP M8x60 Ø10

Chemical

• It is very important that the base where the insert is installed is completely

horizontal.

• If you do not have a base, the optional extendable table is available. This table is a

metal structure that must be fixed to the floor and to the wall. The table can be

adjustable in height between 300 mm (minimum) and 545 mm (maximum), it is very

important to ensure that the top is perfectly horizontal for the correct operation of the

equipment. Together with the extendable table, screws are deliverd to secure the base

of the insert to the table, with the same 7 screws, it is possible to attach the

equipment to an existing base. Instructions given in point 6.

Figure 6 – Optional extendable table

• Connect the 80 mm diameter pipe between the flue gas outlet and the flue outlet to

the outside of the building (eg fireplace) in accordance with the installation drawings.

12

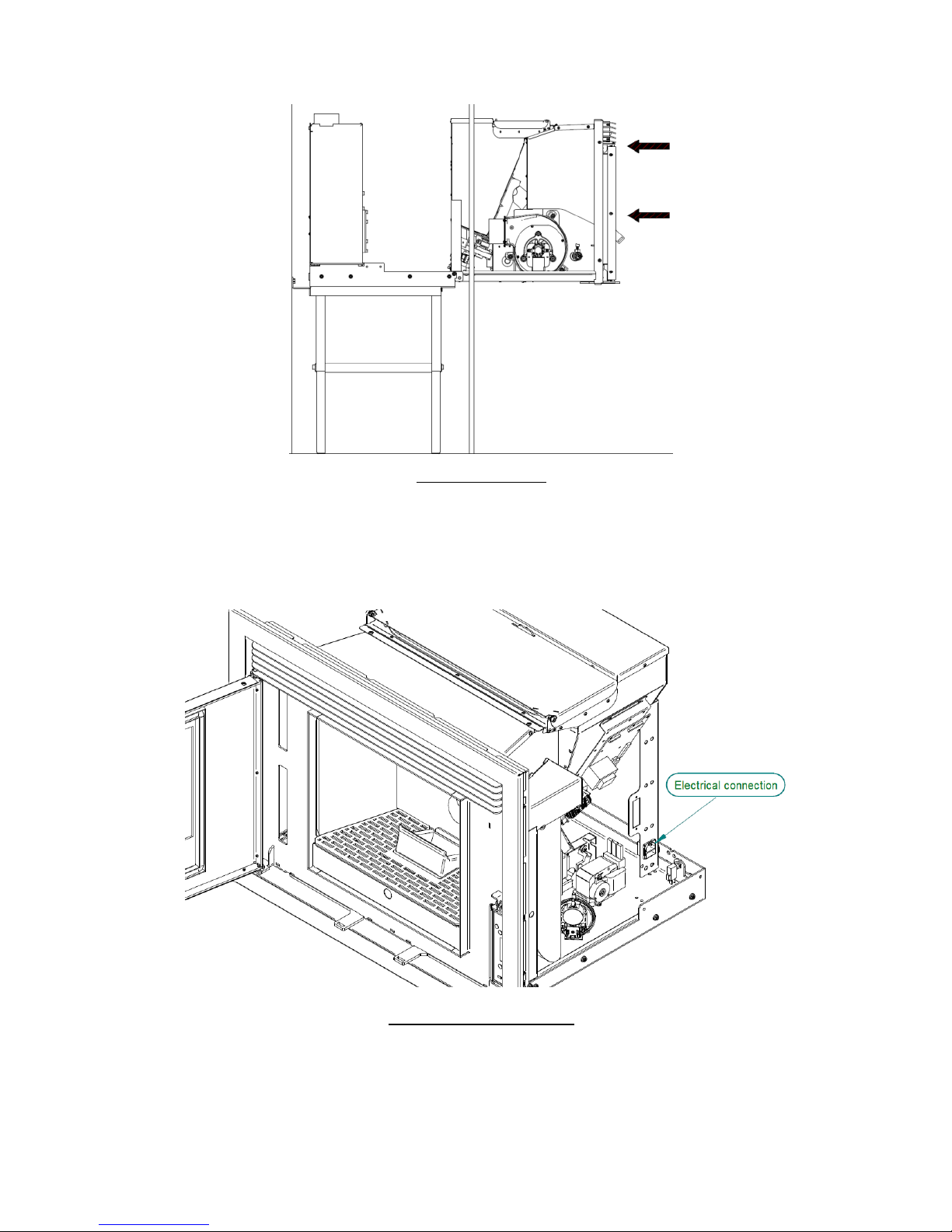

• After securing the base of the equipment and the chimney being installed place the

moving part of the equipment as shown in figure 7.

Figure 7 – Installation

Then do a rotating motion to bring the equipment to the horizontal.

Figure 8 – Installation

Push the movable part to the wall so that it slides on the rails. Check the

correct sliding and that everything is properly attached before continuing with the

intallation. Move the equipment to the end of runner system with open safety latches

13

and once in position, close them to ensure that the equipment is properly placed in the

working position.

Figure 9 – Installation

• Connect the power cord to a 230V 50Hz grounded outlet.

Figure 8 – Electrical connection

• After connecting the power cable to the silo column, it is necessary to attach the

cable to the same column and the base, making sure to leave enough cable length, so

14

that the equipment can make the entire route in the rails (500 mm), without the cable

being stressed or touching the hot parts (Figure 11).

Figure 11 – Electrical connection

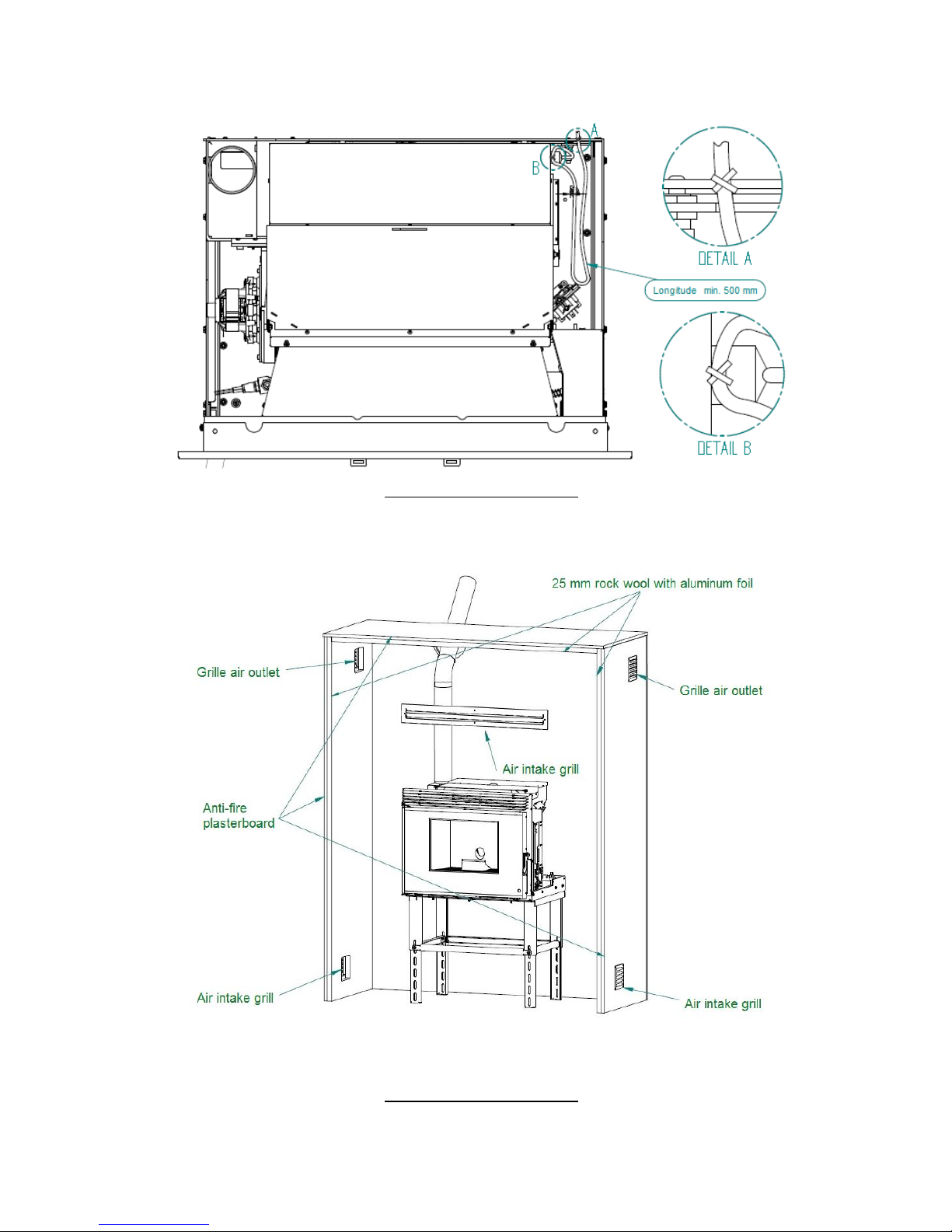

• Standard installation of the insert:

Figure 12 – Electrical connection

15

Instalation WIND 9kW

In case of the Wind 9kW it will be necessary to install the pellet feeding system. To

install this loading system it is necessary to open a 330x330 mm hole.

• The position of the loading system has to maintain a ratio where X is always less than

Y = X * 0.7. (See Figure 13), so that we can ensure that the slope is sufficient so that

the pellets are not trapped in the tube connecting the loading mouth with the top of

the insert structure. The loading mouth can be installed in any of the walls that form

the surroudings where the equipment is installed, either to the right or to the left, as in

the front or rear, if the layout of the house allows it. It is always necessary to respect

the minimum distances X = 390 mm, Y = 275 mm Example: X = 450 mm Y = 450x0.7

= 315 mm (minimum).

• The tube used to attach to the loading mouth and top of the insert chassis must have

an internal diameter of 200mm and must be rigid enough not to deform when the

pellets fall inside. It is recommended to apply flexible aluminum tube.

• To attach the drop tube of the pellets to the loading mouth of the top of the insert

chassis it is recommended to use metal clamps. This type of clamps provides good

clamping and sealing, and it is possible to open or close the clamp when necessary.

Figure 9 – Feeding system installation

16

• The easiest way to install the tube will be to perform the following steps:

1- Using the metal clamp, attach the pre-cut tube with the appropriate size and shape

onto its final position in the loading mouth.

Figure 10 – Installation of the loading tube and metal clamp.

2- Insert the assembly through the hole made in the wall with the above mentioned

measurement 330x330 mm, respecting the dimensions for its positioning indicated

above, it is necessary to fix the loading mouth.

3º- To be fixed to the wall, the loading system has four 6 mm holes in diameter. It is

recommended to use 8mm SX bushings for brick walls with 4.5 or 5.5 bolts and 8mm

HM bushes for plasterboard walls (Pladur) with the corresponding screws.

Figure 11 – Mouthpiece installation

4º After fastening the loading piece, place the finishing frame with the cover. Fix the

frame by tightening the 4 load screws on the wall. The cover has a pin limiting its the

opening, as can be seen in the following figure, with a cut of the base assembly,

finishing ring and loading cover.

17

Figure 12 – Equipment installation

5º- When opening the lid, the inner parts are positioned to facilitate the loading of the

pellets, for this reason it is very important that the cargo mouth is always placed in the

position shown in Figure 16.

6º- As shown in Figure 16, the WIND version has a top chassis attached to the side

columns by means of DIN912 M6 screws and DIN934 nuts. Unscrew without

completely removing the front screws (marked with the letter "A"), the cap rotates

over the rear screws, making the top cover accessible to facilitate attachment of the

flexible tube to the pellet gargle. It is necessary to join the tube leaving the loading

mouth with the cap through a metal clamp, it is necessary to make sure that the tube

has no curves where they can

Accumulate pellets. Finally, place the cover in its original position and fix the screws

again.

18

Figure 13 – Installation of the pellet insert

• The option to install a system to channel the air is only available for the version of

WIND, due to its construction, designed with superior load. To install the system you

must follow the following steps:

1º- Ensure that the fixed part of the insertable pellets is in its definitive place.

2º- The pellet loading tube installation must be carried out in the same way. Add a pipe

to channel the air (aluminum tube 100 mm in diameter) with the grid to be fixed to the

wall. It is recommended to make this union with a metal clamp. The length of the

aluminum tube should be sufficient to reach the air outlet, located on the top of the

chassis. It is necessary to repeat this step to place the second tube.

3º- To access the top of the cover (see Figure 17). It can be observed that the upper

part comes with the installation of 2 air outlets of 100 mm, with a pliers cut the micro

joints to install the tubes for the ducted hot air.

Figure 18 – Insertable pellet installation

19

4º- It is important that the bolts or rivets used to secure the air outlets be fixed from

the bottom up so that a minimum height is allowed inside the insert to not interfere

with the proper extraction of the equipment during maintenance, see Figure 18.

5º- Once the grilles are fitted, the ducted air pipes are attached to them. The use of

metal cable clamps is recommended. It is important to ensure that the air pipes are

not in contact with the exhaust pipe or pellet duct to prevent noise or vibration during

operation of the insert.

• Example of a ducted air installation:

Figure 19 – Equipment installation

• In the installation example (Figure 19), it can be verified that the pipes are placed

to channel the hot air outlet to the room where the insert is installed, but could be

installed to carry hot air to neighboring rooms. The maximum length of pipes without

installing an air extraction box is 3-4m.

• The amount of air flowing to the front of the equipment and that flowsg through the

tubes to channel the hot air can be adjusted using the accessory to open the door and

the safety latches. Put the back part of the accessory between the grate in its central

part as shown in figure 20, you can check that there is a piece that fits perfectly and is

able to rotate and move a deflector that causes the air to be directed towards the Front

or to the air pipes. For safety, there is always a minimum amount of air that has to

20

come out in front of the equipment. After adjusting the position, you must remove the

accessory to keep it cool.

Figure 20 – Equipment installation

6. Installation of optional accessories.

Installing the display outside the equipment.

It is possible to install the display outside the insert. It’s an option that allows the

installation of the display where it is most practicle, up to a maximum length of 30m

using a parallel cable with a 0.75mm2 section. In this way, the operation of the insert

can be controlled without being close to the heat source, even from another division.

This installation requires two additional components: the blind cover for the insert and

the frame to attach the display to the wall. Sufficient cable length must be left so that

the moving part of the equipment can be removed without causing strain on the cable

and does not interfere with the movement of the equipment guides. Steps for

assembly:

Once you have chosen the location where the display will be installed, you should make

a hole in the wall with the help of the plate that will support the display on the back.

Place it next on the wall, making sure it is leveled and with the help of a pencil mark

the hole as shown in the figure.

21

Figure 14 – Installing the display outside the insert

1. Place the outer support plate, making it coincide with the markings done previously

as shown in the figure with the hole, mark the 4 holes where the screws pass.

Figure 15 – Installing the display outside the device

3. With the 5 holes open, the next step is to insert the back support plate to be fixed

from the inside of the wall.

Figure 16 – Installing the display outside the device

4. On the outside, place the front support plate to match the holes previously opened,

insert the screws 4x30mm DIN7991 until it is fully threaded, leaving the two pieces

together and the wall between them.

22

Figure 17 – Installing the display outside the device

5. With all the support fixed to the wall, the display can be placed on the finishing

frame, fixing the display from the front and the box from the rear. We have to connect

the two wires of the display and must take into account that the length must be

enough to be able to remove without creating any problem or tension or interference of

the cable. Finally, the frame must be fitted with the display by attaching the bolts to

the fixing springs as shown in figure 25.

Figure 18 – Installing the display outside the device

Temperature probe installation

• The pellet inserts have a probe to measure the ambient temperature. For a correct

reading of the ambient temperature, this probe must be located on the exterior in a

place where it does not receive direct radiation or hot air from the equipment. It is

sufficient to drill a hole in the wall and fix the box screwed or glued, leaving the end of

the probe inside. Sufficient length of cable must be left so that the moving part of the

equipment can be removed without causing strain on the cable and does not interfere

with the movement of the equipment guides.

23

Figure 19 – Installation of the accessories

Installation of ventilation grille

1. The grate must be installed at the top of the wall where the equipment is installed

to allow the exit of the hot air that accumulates inside the walls, and together with

lower grates allows a natural circulation that will cool the interior walls.

Once you have chosen the place where the grill will be placed, you should drill a hole in

the wall with the help of the plate that will support the back. It should be placed on the

wall making sure that it is level, with the help of a pencil mark the hole as shown in the

figure.

24

Figure 20 – Installation of the accessories

2. The outer support plate is placed making it coincide with the markings done

previously as showed in the figure then mark the 6 holes.

Figure 21 – Installation of the accessories

3. The next step is to place the rear support plate to be fixed from the interior of the

wall

Figure 22 – Installation of the accessories

25

4. On the outside, place the front support plate to match the holes previously opened,

insert the screws 4x30mm DIN7991 until it is fully threaded, leaving the two pieces

together and the wall between them.

Figure 30 – Installation of the accessories

5. Finally you can place the grate on the wall by fitting the bolts into the fixing springs

as shown.

Figure 31 – Installation of the accessories

26

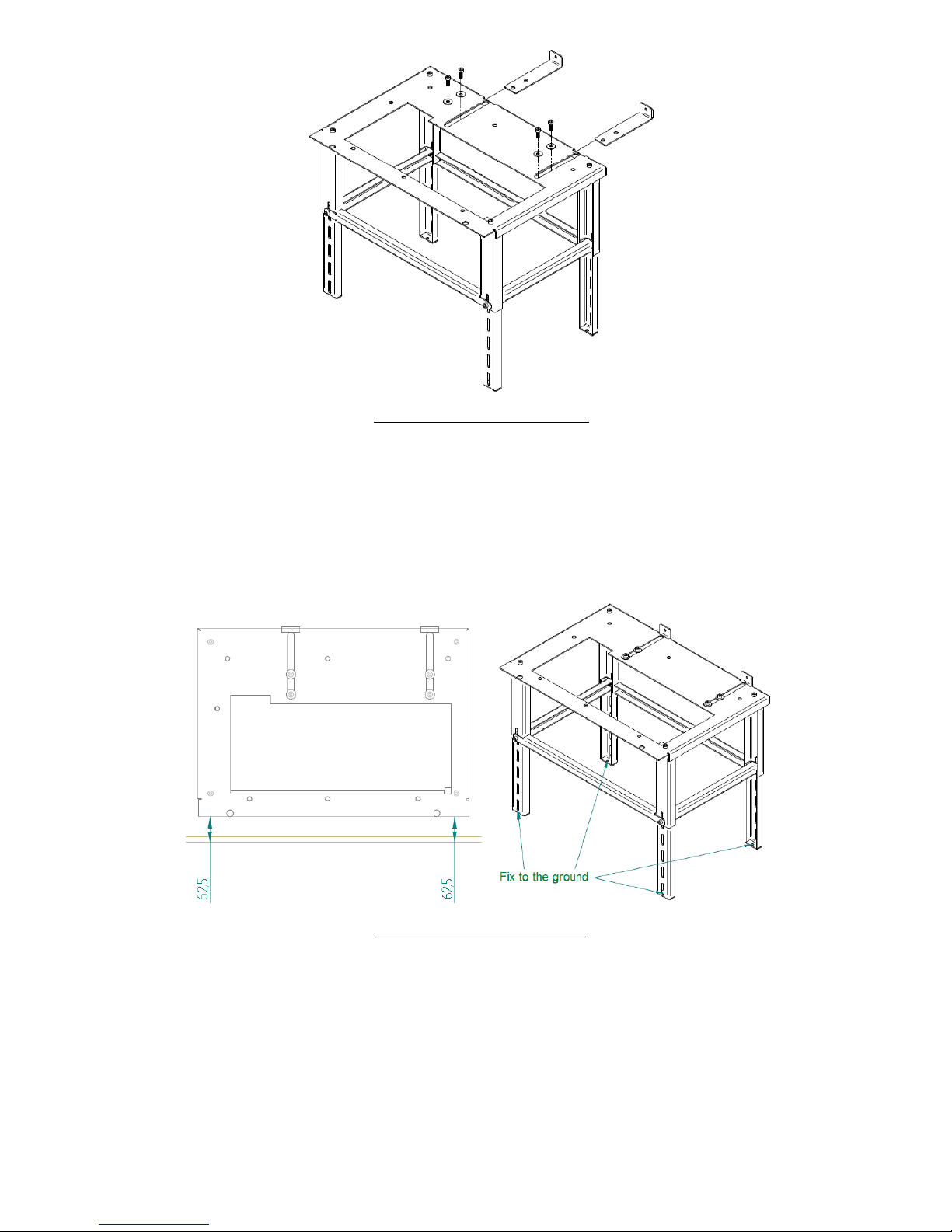

Auxiliary table installation

To perform a root installation. A height adjustable table is available to facilitate the

installation of the equipment. The table is adjustable in height and has 2 components

to regulate the depth and be able to fix it to the the back wall. It also has holes in the

lower legs to facilitate fixation to the floor.

Figure 23 – Auxiliary table installation

It is very important that the table is leveled, both in depth and width, this will facilitate

the extraction of the equipment on the guides and so increasing their life span. To level

the table it is necessary to adjust the legs in height.

The attachment to the wall and to the floor will depend on the material from which

they are made. The fastening must be very firm because the insert has a weight of

about 115 kg, for this reason, the following configurations are recommended according

to the material where the table will be fixed:

Material

Type of attachment

Image

Massive (slab, stone ...)

FMS M8x60 Ø10

Metallic

Massive and non-massive

(brick)

FIP M8x60 Ø10

Chemical

You should select the type of configuration that best suits your needs and use the

proper tools and security measures for the installation.

To assemble the table components you need a 6 mm hex key.

27

The components that make up the table are as follows:

Component drawing

Quant.

Description

19

Screw DIN912 M8x20mm

4

Washers DIN9021 M8

4

Extension for leg

4

Table leg

2

Long locking

2

Short locking

1

Table

2

Fixing brackets

28

1. Protect the surface on which you are going to work. The four legs of the table should

be attached by hand with four DIN912 M8x20mm screws as shown in figure 33.The

rest of the assembly will be easier to perform. As indicated in figure 33.

Figure 24 – Auxiliary table assembbly

2. Place one of the short locks on the inside of one of the leg extensions and insert

between the two leg extensions on one side, as can be seen in the image below. Place

one of the long interlocks on the outside and secure the assembly with a DIN912

M8X20mm bolt. Do not tighten the bolt tightly to make the rest of the assembly easier.

The leg extensions have 5 holes, you must select which to apply as well as the total

height of the table.

29

Figure 254 – Auxiliary table assembly

3. One must repeat the process for the other three legs.

Figure 265 – Auxiliary table assembly

4. Place the two set-squares through the opening on the table and put a screw and

washer in each. Do not tighten the bolts completely, just enough to allow displacement

of the brackets.

30

Figure 27 – Auxiliary table assembly

5. To place the auxiliary table in its final position, remember that the table has to be

installed 62.5 mm from the front wall, as shown in the image. Then mark the four

holes of the legs on the floor, drill the holes, you must use the necessary means of

fixing as indicated previously. At the end the table should be fixed to the floor.

Figure 28 – Auxiliary table assembly

6. You should level the table as accurately as possible with the help of a level. Tighten

all screws with a 6mm umbrako wrench. Move the squares on the back wall and mark

the holes. Remove the brackets, if necessary, remove the screws and remove the

assembly to make it easier to drill holes in the wall. Once done is put the necessary

components to fix, place the brackets in place. Check that the table is level and that it

respects the height of 62.5 millimeters. The screws that secure the table brackets must

be tightened with a 6 mm umbrako table.

31

Before finishing installation check that the table is level if necessary to correct.

Figure 38 – Auxiliary table mounting

7. Intallation requirements

The minimum distances from the pellet insert to flammable surfaces as shown in figure

39.

At the top of the insert it is necessary to keep a minimum distance of 1 m from the

ceiling of the room especially if they contain flammable material in their composition.

The base that supports the insert can not be made of combustible material (eg carpet)

and adequate protection must always be provided.

a) b)

Figure 29 – Minimum distances of all surfaces: a) top view of the installation of the equipment;

b) side view of the equipment installation.

32

¡NOTICE!

Keep combustible and flammable materials at a safe distance. Never less than 5 cm

from insulated surfaces and 1 cm to non-combustible surfaces.

8. Installation for exhaust gas systems:

• The construction of the exhaust pipe must be suitable for the purpose in accordance

with local requirements and in compliance with the regulations in force.

• As shown in figure 40, the exhaust duct must be so arranged that cleaning and

maintenance are ensured by insertion of the inspection points. The insert contains a

registration cover in the smoke box for cleaning.

• Under nominal operating conditions, the drawdown of the combustion gases must

give rise to a depression of 12 Pa, measured 1 meter above the chimney neck.

• The insert can not share the chimney with other equipment.

• Tubes outside the site of use must be double insulated in stainless steel, with an

internal diameter of 80 mm.

• The exhaust pipe can generate condensation, in this case it is advisable to establish

suitable condensate collection systems.

33

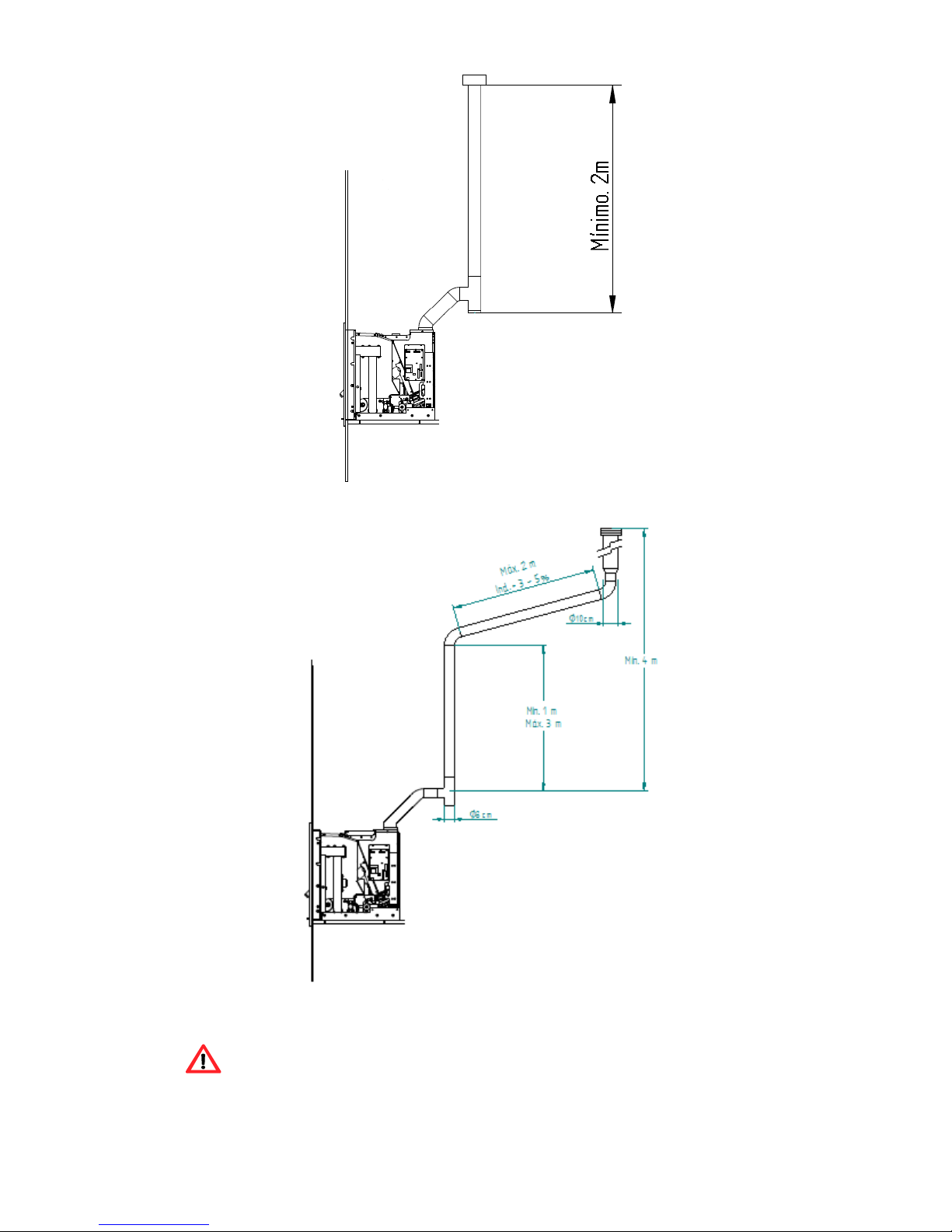

8.1. Installing Without a Chimney

The installation of the pellet insert when there is no chimney should occur, as in figure

40, bringing the exhaust pipe (with a minimum internal diameter of 80 mm) directly

out and above the roof.

Double-walled insulated stainless steel pipes should be used properly to avoid

condensation.

Provide at the base of the tubing a T for periodic inspections and annual maintenance,

as exemplified in figure 40.

Figure 30 – Side view of the installation without chimney, example of the inspection point.

In figure 41, the basic requirements for installing the insert flue are shown.

34

a)

b)

Attention. Do not use 90º curves.

35

c)

Figure 31 – Examples of installations.

Failure to comply with these requirements may prevent the correct operation of

the unit, resulting in warranty void. Be sure to follow all the instructions on the

diagrams.

Free Standing Fires operate with the combustion chamber in draught, which is

why it is absolutely necessary that they include a fume exhaust duct to adequately

extract combustion gases.

Fume duct material: The tubing must consist of 0.5mm thick rigid stainless steel,

with fitting bindings to attach the different sections and accessories.

Insulation: The fume ducts must be double-walled and insulated to make sure the

fumes do not cool down going outwards, which could cause an inadequate circulation

and condensation that may damage the unit.

Output “T-tube”: Always attach to the output of the unit a "T-tube" with a damper.

Chimney Crown: A wind shield termination must be installed to avoid fume back flow.

36

Chimney draught: The Figures below show three standard diagrams, specifying

adequate lengths and diameters. Any other type of installation must guarantee a

draught of 12 Pa (0.12 mbars) measured when hot and at the maximum power.

Ventilation: To get the optimum operation from the unit it is necessary that the

installation location has an air inlet with a minimum section of 100 cm2,

preferably near the back panel of the unit.

If the house is equipped with an air exhaust system (e.g. kitchen extractor

fan), a top ventilation section must be installed, suitable to accommodate the

different air exhaust systems existing in the household. The installation of the

unit on locations near kitchen exhaust fans or fume extractors may prevent

the unit from operating properly. It is recommended that the unit is

disconnected when these extractors are working.

37

8.2. Installation with a Chimney

As shown in figure 34, the installation of the pellet insert brings the exhaust pipe (ᴓ80

mm) directly into the chimney. If the chimney is too large, it is recommended to pipe

the gas outlet with a pipe with a minimum internal diameter of 80 mm.

Provide a "T" for the periodic inspections and the annual maintenance, as shown in

figure 42.

Figure 32 - View installation with chimney.

When atmospheric conditions are so adverse that they cause a significant disturbance

in the drawability of the insertable gases (in particular very strong winds), it is

advisable not to use the insert.

If the equipment is not used for an extended period of time, the user must ensure that

there is no blockage in the chimney tubes prior to lighting.

38

9. Fuel

The Free Standing Pellet Fire operates exclusively with pellets. No other fuel sources

are allowed to be used.

Only use pellets certified by standard EN 14961-2 grade A1 with a diameter of 6mm

and a length of 10-30mm.

The pellets may have a maximum humidity content of 8%. To guarantee a good

combustion, the pellets must maintain these characteristics so it is recommended that

they should be stored in a dry place.

The use of different pellets will reduce the efficiency of the unit and cause deficient

combustion.

Only certified pellets should be used and a sample must be tested before

buying large bulks.

The physicochemical properties of the pellets (namely, calibre, friction, density and

chemical composition) may vary within specific tolerances and across manufacturers.

Please note that this may cause changes to the feeding process and, consequently, the

need for different doses (more or less pellet quantity).

Consequently it may be necessary to adjust the pellets quantity according to its quality,

even if the pellets are certified.

The unit allows for an adjustment of ± 25% the pellet dosage at the start-up

phase and at each power level (please see section 11.3.6 of this manual).

WARNING!

This unit may NOT be used as an incinerator.

39

10. Use of the pellet insert

Recommendations

Before starting up the unit, please check the following:

- Ensure the unit is properly connected to the power mains using the 230V AC power

cable.

Figure 33 – Electrical connection plug

- Check that the pellet hopper is filled. Inside the pellet reservoir is a safety grid to

prevent users from reaching the worm screw.

The unit’s combustion chamber and panel door are made of iron plate

painted with high temperature resistant paint which releases fumes during

the initial burn due to the paint’s curing process. Avoid touching the unit

during its first burn to prevent leaving permanent marks on the paint. The

paint goes through a more plastic phase during the curing process. The curing

of the paint occurs at approximately 300ºC for 30 minutes.

Please make sure the room where the unit is installed has adequate air circulation;

otherwise, the unit will not work properly. For this reason, it is important to check if

there are any other air-consuming heating appliances present in the room (e.g. gas

units, braziers, extractors, etc.); these should not be used simultaneously with the

unit.

40

11. Remote Control

11.1. Infrared Remote Control

Figure 34 – Infrared remote control

The infrared remote control allows the user to turn the unit on and off, control the fan

airflow and increase or decrease the unit's power level.

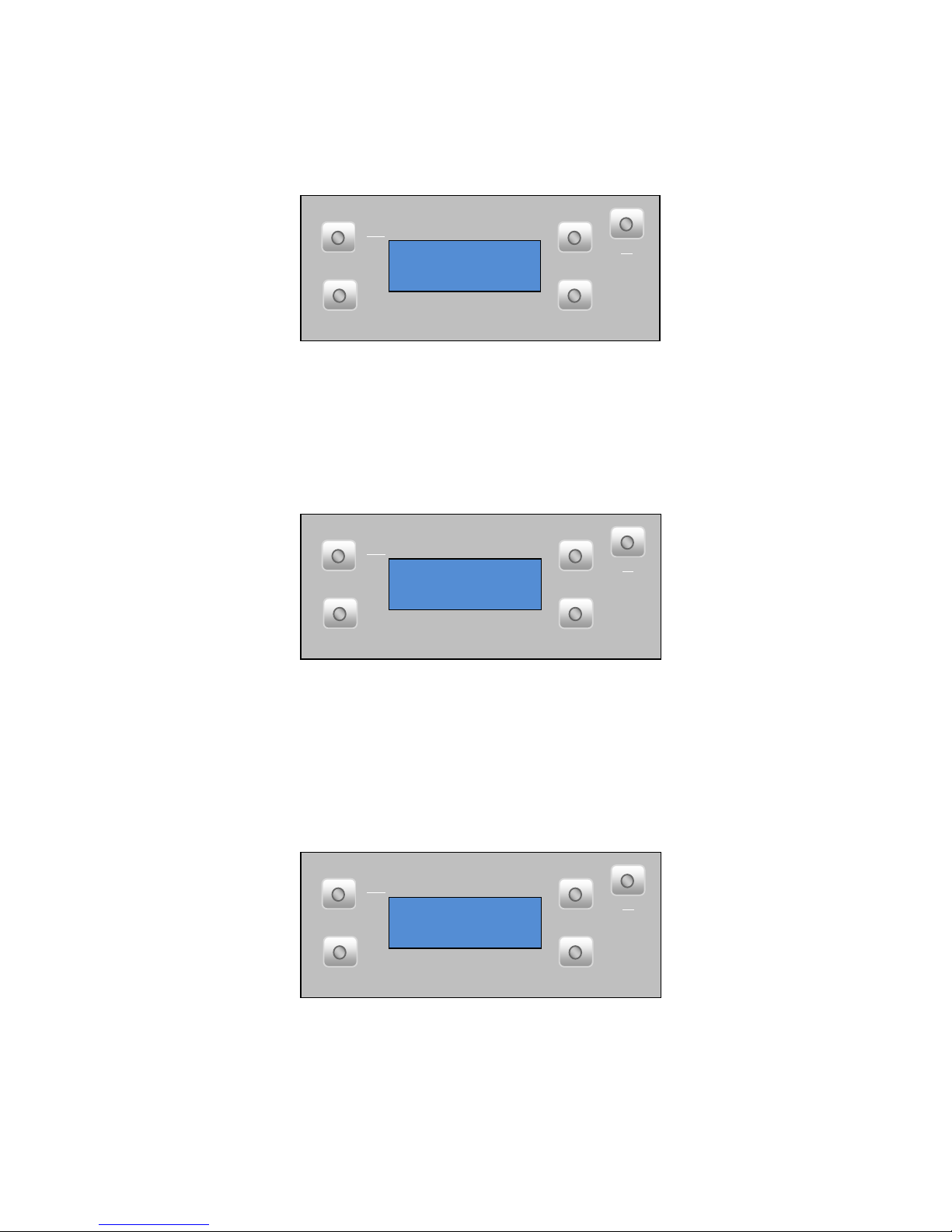

11.2. Control and Display Panel

Figure 35 – Comand and display

.

Figure 36 – Comand keys

ON

OFF

OK

MENU

MODE

ESC

MAN

AUT

20.5ºC 16:03

OFF

a) Key to toggle between

manual and automatic mode

and exit menus (esc).

b) Key to access menus

and confirmation key (ok).

c) Key to start/stop the

unit and reset error

messages.

d) Key to scroll menus to the

left, to increase and reduce

the fan flow and increase or

reduce the set-point

temperature.

e) Key to scroll menus to the

right and increasing and to

reduce the unit's power.

41

11.3. Display Information Summary

11.3.1. Selecting the Manual or Automatic Mode

Menu indicating that the unit power is "off", the room temperature in ºC and Time.

ON

OFF + OK

MENU

MODE

ESC

-

MAN

AUT

20.5ºC 16:03

OFF

Selecting the operating mode: To select the operating mode, press the “Mode” key

to select “Manu” for manual mode or “Auto” for automatic mode.

ON

OFF + OK

MENU

MODE

ESC

-

MAN

AUT

Mode:AUTO Menu

Temp:30ºC Fan:5

Auto mode: In this mode, the unit is turned on at maximum power until reaching a

temperature 1ºC above the selected temperature (set point temperature). After

reaching the selected temperature, the unit switches to the minimum operating power.

The set-point temperature can be set between 5 and 40ºC by pressing the "-" key.

The "+" key allows the user to set the fan speed between 1-5 or to automatic

operation.

“Manu” mode”: In this mode, the unit will operate at the speed selected using the "-"

key, ranging between 1 (minimum operating power) and 5 (maximum operating

power)

42

11.3.2. Date and Time

Setting the date: press the Menu key twice until “Data” (Date) is displayed. Press “set”

to see the following menu:

Year

To set the year press “set”. The display starts to flash. Press the “+” or “-” key to

select the desired year and then “ok” to confirm. Press "esc" to return to the "Data"

(Date) menu, then press "+" to scroll to the next menu. The “Mês” (Month) menu is

displayed.

Month

To set the month press “set”. The display starts to flash. Press the “+” or “-” key to

select the desired month and then “ok” to confirm. Press the "+" key to scroll to "Dia

do mês" (Day of the month) menu.

ON

OFF + OK

MENU

MODE

ESC

-

MAN

AUT

esc 4 Set

< Mês >

43

Day of the month

To set the day of the month press “set”; the display starts to flash. Press the “+” or

“-“ key to select the desired day and then press “ok” to confirm. Press the "+" key to

scroll to the "Dia" (Day) menu.

ON

OFF + OK

MENU

MODE

ESC

-

MAN

AUT

esc 30 Set

< Dia Num. >

Day

To set the day of the week press “set”. The display starts to flash. Press the “+” or “-”

key to select the desired day and then “ok” to confirm. Press the "+" key to scroll to

the "Time" (Hour) menu.

ON

OFF + OK

MENU

MODE

ESC

-

MAN

AUT

esc 2a Set

< Dia >

Time

To set the time press “set”; the display starts to flash. Press the “+” or “-“ key to

select the desired time and then press “ok” to confirm. Press the "+" key to go to the

"Minutos" (Minutes) menu.

ON

OFF + OK

MENU

MODE

ESC

-

MAN

AUT

esc 16 Set

< Hora >

44

Minutes

To set the minutes press “set”. The display starts to flash. Press the “+” or “-” key to

select the desired minutes and then “ok” to confirm. Press the “Esc” key to exit.

11.3.3. Timer

The unit is equipped with a timer that allows the unit to be turned on or off at a

specified time.

Activation

To enable the timer press “set”. The “habilitação” (activation) menu is displayed. The

timer may only be activated after setting the configurations, as shown in the following

paragraph.

To activate the Timer mode, press “Set” - the display starts to flash. Press the “+” or

“-" key to select “On” or “Off” and then “Ok” to confirm. Press the "+" key to scroll to

the "Carga Perfil" (Profile Load) menu.

45

There are 10 weekly programmes available on the Timer (see item 17 in the annexes).

The selected programme runs from Monday to Friday and from Saturday to Sunday.

Press “set”; the display starts to flash. Press the “+” or “-“ key to select the desired

programme and then press “ok” to confirm. Press the "+" key to go to menu

"Reiniciado" (Reset).

This menu allows you to delete any programme settings. To do this, press "set". The

"Confirmar?" (Confirm?) prompt appears. Press "set" again to confirm that you want to

delete the settings or "esc" to exit.

ON

OFF + OK

MENU

MODE

ESC

-

MAN

AUT

esc Set

< Reiniciado >

The unit's programmer lets you choose from 6 different programmes for each day of

the week.

To set up programmes “P1” to “P6”, select the desired programme using the “-” and

“+” keys, and press “set” to select. The "P1 Habilitação" (P1 Activation) menu appears.

ON

OFF + OK

MENU

MODE

ESC

-

MAN

AUT

esc Set

< Prog. 1 >

Press "Set" again and when the display starts to flash, press the "+" or "-" keys to

select "On" or "Off". Press "ok" to confirm the selection. Press the "+" key to go to the

"P1 A. Inicio" (P1 A. Start) menu.

46

ON

OFF + OK

MENU

MODE

ESC

-

MAN

AUT

esc On Set

<P1 Habilita >

To set the starting time for Programme P1, press “set”. The display starts to flash.

Press the “+” or “-“ key to select the time and then press “ok” to confirm. Press the

"+" key to go to the "P1 A. Stop" menu.

ON

OFF + OK

MENU

MODE

ESC

-

MAN

AUT

esc 6:15 Set

<P1 H. Inicio >

To set the stopping time for Programme P1, press “set”. The display starts to flash.

Press the “+” or “-“ key to select the time and then press “ok” to confirm. Press the

"+" key to go to the "P1 Temp. (P1 Air Temp.) menu.

ON

OFF + OK

MENU

MODE

ESC

-

MAN

AUT

esc 20:15 Set

<P1 H. Stop >

To set the set point temperature for Programme P1, press “Set”. The display starts

to flash. Press the “+” or “-" key to select the desired temperature, followed by “Ok” to

confirm. Press the "+" key to go to the "P1 Temp. Água” (P1 Water Temp.) menu.

ON

OFF + OK

MENU

MODE

ESC

-

MAN

AUT

esc 18ºC Set

<P1 Temp. Ar >

47

To set the operating power level (1 to 5) of Programme P1, press “Set”. The display

starts to flash. Press the “+” or “-" key to select the desired power level (1 to 5), and

then “Ok” to confirm. Press the "+" key to go to the "P1 Dia" (P1 Day) menu.

To select the days of the week that you want P1 Programme to run, press "set" and

then select the day of the week using the “-” and “+” keys. Press “set”. The display

starts to flash. Select "On" or "Off" using the "-" and "+" keys. Press "ok" to confirm

the selection. Press the "esc" key to go to the "P1 Dia" (P1 Day) menu. Press "esc"

twice and then "+" to access the "Configurações" (Configuration) menu.

Repeat the above steps for programmes P2 to P6.

Note:

- Once the programmes are set, remember to enable them on the

"Habilitações" (Activation) menu.

- There can only be one enabled profile in the Timer, either weekly or daily

(they do not operate simultaneously).

48

11.3.4. Sleep (this menu is displayed only while the unit

is operating).

The "Sleep" menu allows you to setup the time you want the unit to turn off.

ON

OFF + OK

MENU

MODE

ESC

-

MAN

AUT

esc OFF Set

SLEEP

Press "set". The display starts to flash. Select the desired time using the "-" and "+"

keys. After choosing the time, press "ok" to confirm. Press "esc" to return to the menu

and "+" to go to the configuration menu.

ON

OFF + OK

MENU

MODE

ESC

-

MAN

AUT

esc 22:00 Set

SLEEP

11.3.5. Info

This menu contains information on the Free Standing Fire unit. Press "set"; the "Código

de Ficha" (File Code) menu appears.

Software code / Motherboard firmware. Press the "+" key to scroll to the “Código de

Segurança” (Security Code) menu.

49

Software code / Security firmware. Press the "+" key to scroll to the “Código Display”

(Display Code) menu.

ON

OFF + OK

MENU

MODE

ESC

-

MAN

AUT

esc 520420

< ódigo Seguranç >

Software code / Display firmware. Press the "+" key to scroll to the “Código de

Parâmetros” (Parameter Code) menu.

ON

OFF + OK

MENU

MODE

ESC

-

MAN

AUT

esc 500308

< Código Display >

Parameter code. Press the "+" key to scroll to the “Horas de Trabalho” (Operation

hours) menu.

This menu shows the unit's current operating hours.

ON

OFF + OK

MENU

MODE

ESC

-

MAN

AUT

esc 144

< de Funcioname >

50

This menu shows the number of operating hours the unit has registered since its last

servicing.

ON

OFF + OK

MENU

MODE

ESC

-

MAN

AUT

esc 144

< oras de Serviç >

The number of hours at which the next servicing should take place.

This menu shows the phase/status of the free standing fire.

Fume extractor operating speed (rotation per minute).

ON

OFF

+

OK

MENU

MODE

ESC

-

MAN

AUT

esc 49 rpm

< Expulsor Fumos >

Theoretical pellet consumption.

51

Fume temperature.

ON

OFF

+

OK

MENU

MODE

ESC

-

MAN

AUT

esc 18ºC

< emperatura Fum >

Worm drive rotation "On" time.

11.3.6. Settings Menu

To modify the unit's settings, press "Set". The "Língua" ("Language") menu should

then appear, allowing the user to choose a set language.

ON

OFF + OK

MENU

MODE

ESC

-

MAN

AUT

esc Set

< Configurações >

Language

To select the language, press “set”. Using the “+” or “-” keys, select the language (Pt

– Portuguese; Nl – Dutch; Gr – Greek; Tr – Turkish; It – Italian; En – English; Fr –

French; Es – Spanish; De – German). Press "ok" to confirm. Press the "+" key scroll

go to the "Eco" menu.

52

Eco mode

When the “ECO” mode is enabled at the same time as the Thermostat feature, the unit

will operate at maximum power until the thermostat opens contact (NO). The unit then

will operate at minimum power for a preset period of time (Shutdown delay time:

factory setting: 20 minutes). Once the preset time is elapsed, the unit shuts down. At

the start of the Shutdown phase, another timer for a different preset period of time is

triggered (Start-up delay time: factory setting: 20 minutes), that will make the unit

enter the activation phase, when the thermostat closes contact (NC)

Start-up delay time (Delay time On): The delay time that elapses between the

moment the thermostat closes (NC) until the unit is activated.

Shutdown delay time (Delay time Off): The delay time that elapses between the

moment the thermostat opens (OC) until the unit starts to shutdown.

Note: When using the feature for the first time, you must press the On/Off button in

the display. To enable the eco mode, press “set”. The display starts to flash. To activate

the eco mode, press "set". The display starts to flash. Select "On" or "Off" using the "-"

and "+" keys. Press "set" to confirm the selection. Press "esc" to return to the previous

menu and then press "+" to go to the "Iluminação" (Lighting) menu

ON

OFF + OK

MENU

MODE

ESC

-

MAN

AUT

esc Off Set

< Eco >

Lighting

To select lit screen, press “set”. The display starts to flash. Press the "+" or "-" key to

select the time for the screen to light up, or select "On" to keep the light permanently

on. Press “ok” to confirm. Press the "+" key to go to the "Controlo remoto" (Remote

control) menu.

53

ON

OFF + OK

MENU

MODE

ESC

-

MAN

AUT

esc On Set

< Iluminação >

Remote control

This feature enables and disables the remote control, when the user wants to operate

the unit's thermostat remotely. Press "Set" and use the "+" and "-" keys to select the

"On" or "Off" mode. Press "Ok" to confirm. Press the “+” key to go to the “Unidade de

temperatura” (Temperature units) menu.

ON

OFF + OK

MENU

MODE

ESC

-

MAN

AUT

esc On Set

<Controle Remoto>

Note: Some TV remote controls share the same frequency as the unit’s remote control,

possibly influencing the unit's operation. If this is the case, it is recommended to

disable the remote control feature.

Temperature unit (ºC/ºF)

To select ºC / ºF, press “set”. The display starts to flash. Press the “+” or “-” key to

select “ºC”, “ºF” or “Auto”, and then “ok” to confirm. Press the "+" key to go to the

"Combustion recipe" menu.

ON

OFF + OK

MENU

MODE

ESC

-

MAN

AUT

esc Auto Set

< ºC / ºF >

54

Combustion recipe

Press "set" to display the "Combustão receita" (Combustion recipe) menu.

- Pellet

This feature allows the user to increase or decrease by 25% the pellet quantity

during the start-up and power process. Press "set". The display starts to flash.

Press "+" or "-" to increase or decrease (between -10 to +10), as required. Each unit

must be multiplied by 2.5 to obtain the correct percentage. Press “ok” to confirm. Press

the "+" key to go to the "Ar" (Air) menu.

- Air

This feature allows the user to increase or decrease by 25% the rotation speed of

the fume extractor during the start-up and power process. Press “set”. The

display starts to flash. Press the "+" or "-" key to increase or decrease (from -10 to

+10), as required. Each unit must be multiplied by 2.5 to obtain the correct

percentage. Press “ok” to confirm. Press "esc" to return to the "Receita de pellets"

(Pellet recipe) menu and then press "+" to go to the "Carga pellet" (Pellet loading)

menu.

55

Pellet loading

This feature allows you to enable the worm drive to fill the channel when it is empty

to keep the unit running. Press "set"; the "ok" option appears. Press "ok" to activate

the drive; the message "habilitada" (enabled) is displayed. Press "esc" to stop. Press

the "+" key to go to the "Limpeza" (Cleaning) menu.

Cleaning

This feature allows you to clean the burning basket manually. Press "set"; the "ok"

option appears. Press "ok" to start the cleaning procedure; the "Habilitada" (Enabled)

message is displayed. To stop, press "ok". Press the "+" key to go to the "Técnico"

(Technical) menu.

The technical menu is not available to the end user.

56

12. Start-up

After loading the pellets into the deposit (see chapter 13), press and hold the ON/OFF

button for 3s, to start the Free Standing Fire. During the lighting phase, the display will

show the message “Ativação” (Activation) until this phase is completed.

The pellets are fed through the supply channel to the burning basket (combustion

chamber), where they will be ignited using a heat resistor. This process may take 5 to

10 minutes, depending on whether the worm screw used to push through the pellets

has been previously filled with fuel or is empty. Once the ignition phase is completed,

the message "On" appears on the display. The heating power can be adjusted at any

time by pressing the power selection button for approximately 1 second. You can select

from the five pre-set power levels that are available. The selected power is indicated on

the display. The initial power status at each start-up will correspond to the power level

set before the last stop.

Important notice: Before starting up the unit, please check to determine

if the deflector plate is in place.

12.1. Stop

The stop sequence of the unit is started by pressing the ON/OFF button for 3 sec.

The display will show “Desativação” (Disabling) until full completion of this phase.

The extractor will operate until the fume temperature of 64ºC is reached, to guarantee

that all the material has been burnt.

12.2. Turning Off the Unit

The unit should only be disconnected after its full stop. Make sure the “Off” shows on

the display before disconnecting the unit. If necessary, disconnect the power cable

from the mains.

57

13. Instruction for installing the frame

13.1. Choice of frame

Before installing the frame, it must be immediately verified that the packaging is

complete and in perfect condition, any damage or lack of components must be

reported before installation.

On this equipment it is possible to install different finishing frames.

To install the frame you must first check that the frame is compatible with the insert:

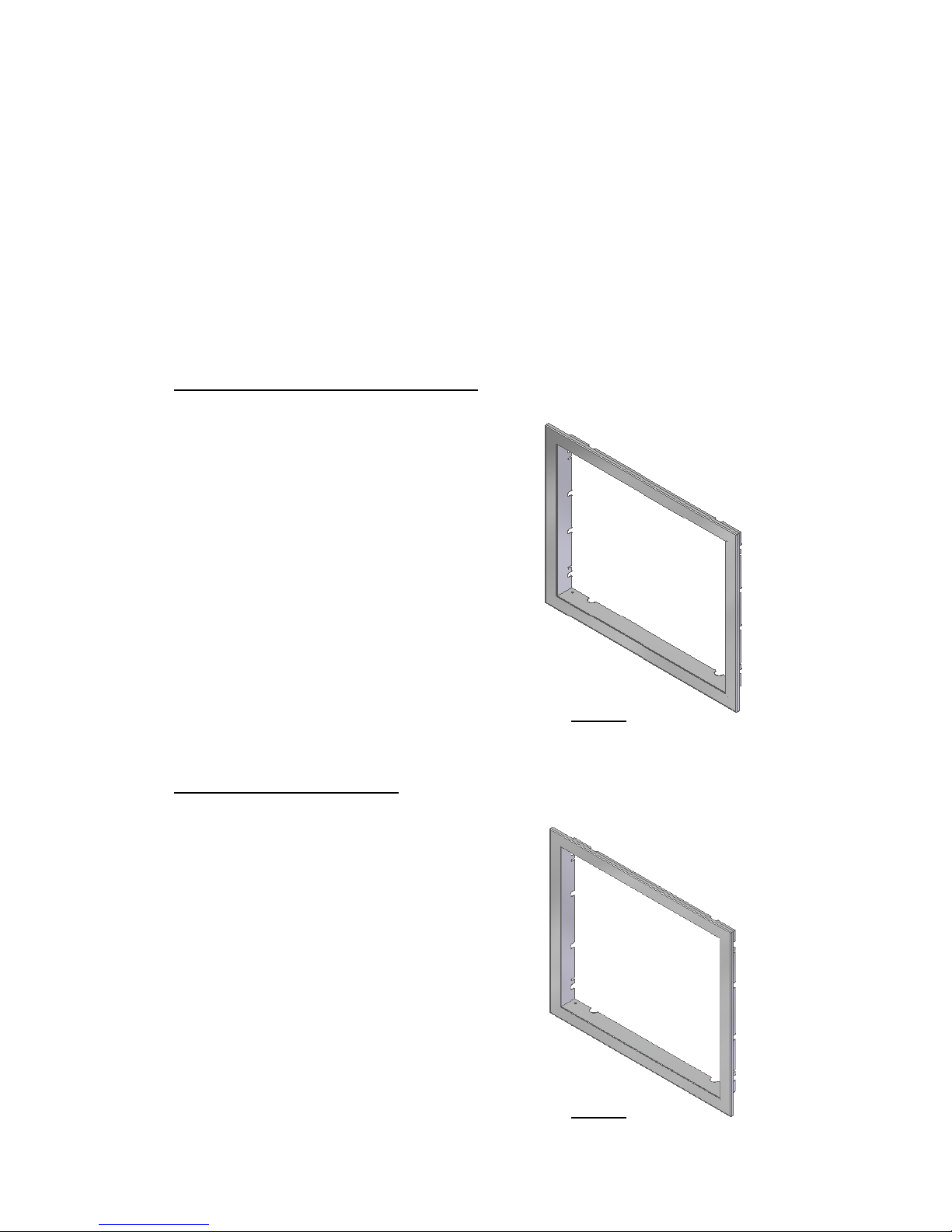

Thin Frame (Fire and Wind 9Kw)

Interior measurements:

685x536mm

Hoop width 44mm

Ref. MO1160N017

Figure 37

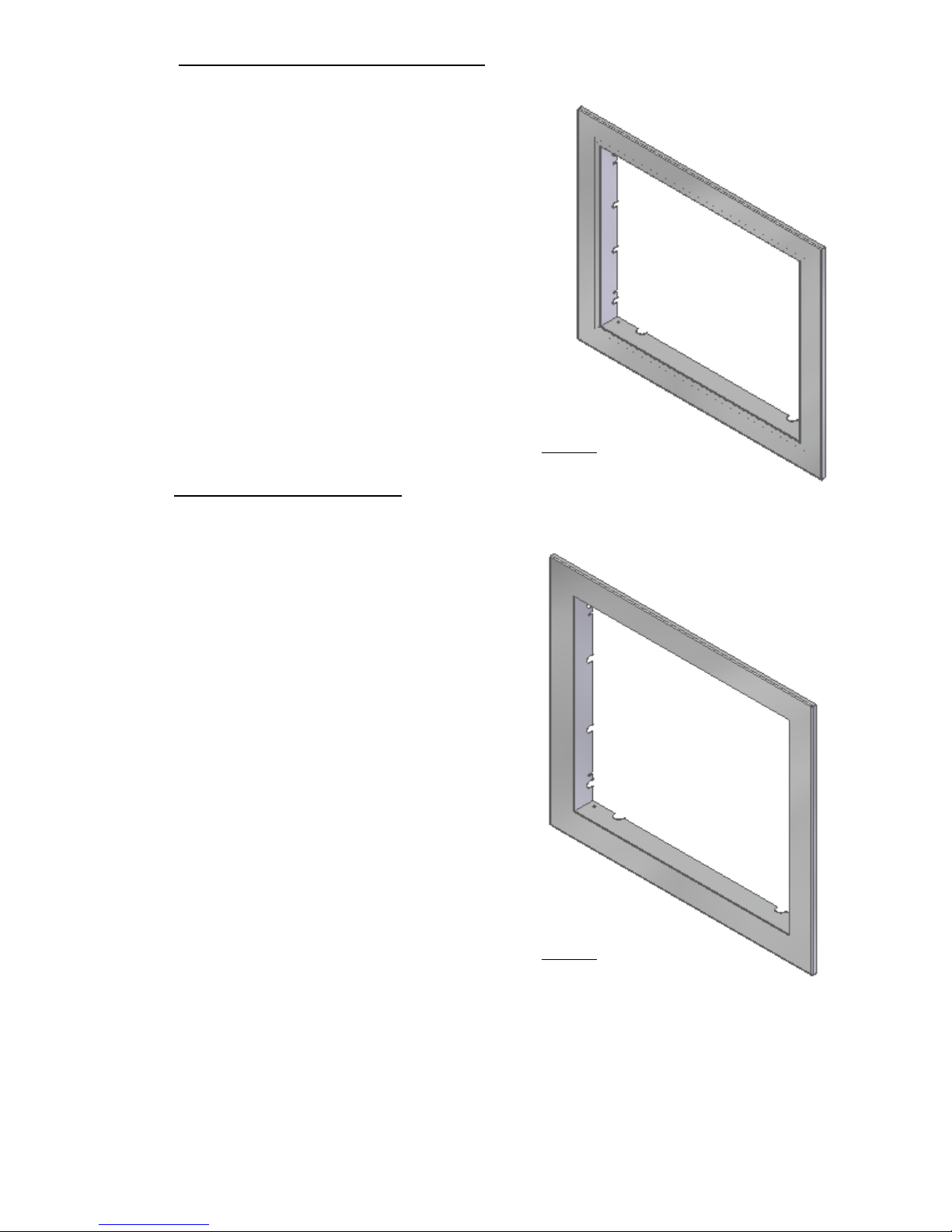

Thin Frame (Earth 9Kw)

Interior measurements:

685x596mm

Hoop width 44mm

Ref. MO1160N015

Figure 38

58

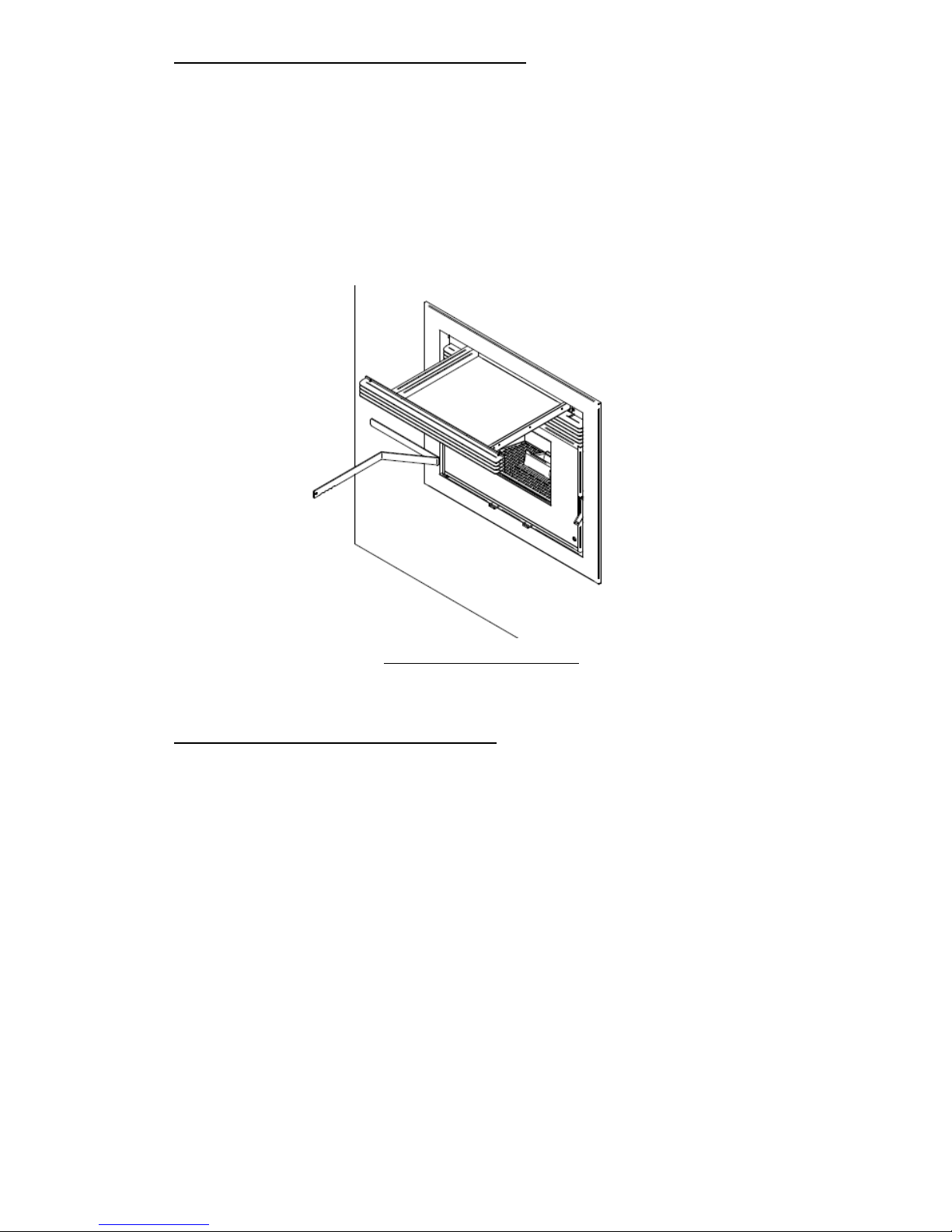

Wide frame (Fire and Wind 9Kw)

Interior measurements:

685x536mm

Hoop width 74mm

Ref. MO1160N018

Figure 39

Wide frame (Earth 9kW)

Interior measurements:

685x596mm

Hoop width 74mm

Ref. MO1160N016

Figure 40

59

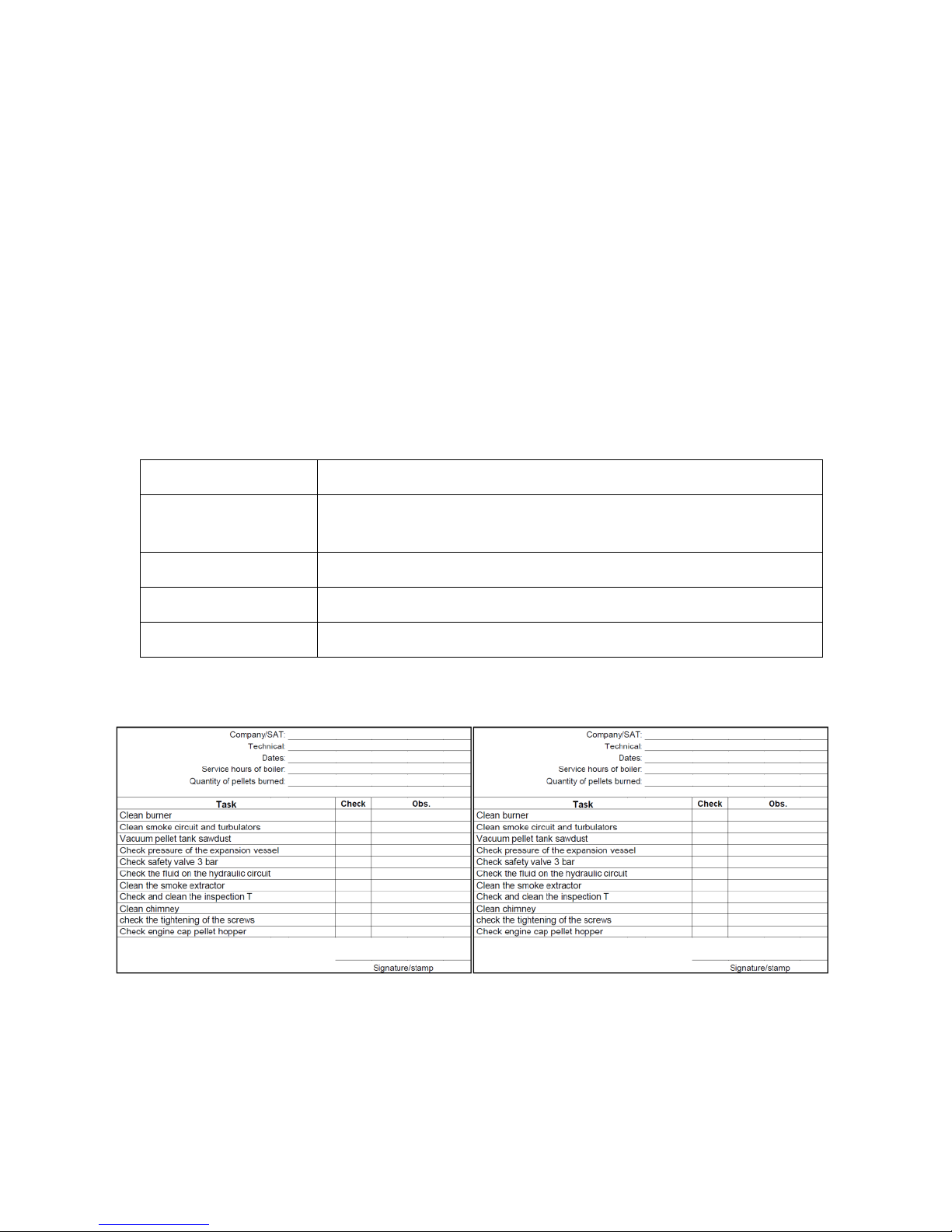

13.2. Installation of the frame on the equipment

With the fixed insert and the tripartite frame prepared, the next step is to assemble the

two. Open the safety catch of the insert, remove the insert to work comfortably. On

each side of the insert we have two screws (Din 967 M4x8mm), it is necessary to

slightly loosen these screws. (See Figure 50).

Figure 41 - Locating the screws to attach the frame to the insert

Insert the frame, aligning the insertable bolts with the frame flaps, insert the frame,

line up in front of the insert and tighten the screws again to secure the rim (See Figure

51). Place the insert in its operating position and close the two safety latches, if the

wall is sensitive to marks it is recommended to leave 1 or 2 mm distance between the

rim and the wall.

60

Figure 42 – Installing the frame

VERY IMPORTANT: You should always read the instruction manual of the

equipment before proceeding with its installation.

14. Replenishment of pellets

Depending on the type of insert, refueling will be done in one of the following ways:

Insertable with replenishment by extraction of the body.

If the refueling is by extraction the first thing we should know is we can never refuel

with the equipment in operation.

It must always be replenished when the insert is completely disconnected, because

when extracting the insert from the operating position the smoke extractor is

disconnected from the smoke box and this can cause smoke to flow out to the room

where it's installed.

To refill disconnect the equipment, open the located safety latches under the door.

Using these latches, remove the equipment completely (figure 53).

61

Figure 43 – Extraction of the insert to refuel

At the top of the equipment we can see the lid of the pellet tank. We open completely

by rotating until it touches the front (figure 54).

After refueling, close the cover and put the insert into its working position, finally close

the safety latches.

Figure 44 – Pellet Reservoir Lid Opening

62

Insertable with refill per load drawer.

This charging system can be used with the equipment in operation, but always with

care as you will be close to sources of heat.

To refill the tank open the cargo drawer by pulling the upper grate completely. Pour the

pellets into the drawer and with the aid of the accessory the pellets should be pushed

to the back of the drawer. The pellets will fall into the tank. When the pellets stop

falling and begin to accumulate in the drawer stop loading.

Figure 45 – Drawer for refuelling

Insertable with top-load refueling.

This top loading system can be used with the equipment in operation because it does

not interfere with the normal operation of the insert and depending on where the

loading mouth is placed it will not be near the heat source, you can observe the

installation of this system in the Point 4. The installation of the equipment is restricted

to the height and distance to install the respective loading mouth. The mouth can be

installed on the right, left, forward or, if possible, evenly distributed through the back

of the equipment. To load the pellets simply open the loading door, the door has stops

that will open the door in a certain position to facilitate loading, causing a ramp effect

for the pellets to enter the tube into the tank. When checking that the pellets are about

to reach the loading mouth, do not put more and you should close the door.

63

Figure 46 – Loading head for refueling

15. Maintenance

Maintenance is a work of overhaul and mainly cleaning. The periods marked in this

manual are indicative and the dirt on the equipment varies greatly according to usage

and fuel.

Note: Before performing any cleaning, it is imperative that the insert is off and

sufficiently cold in order to avoid accidents.

Daily Maintenance

The insertable pellet requires strict maintenance. The main care is the regular cleaning

of the ashes in the pellet burning chamber. This can be done in a practical way through

the aid of a simple vacuum cleaner. The cleaning operation must be performed after

each firing of approximately 30 kg of pellets.

To perform this maintenance, you must open the door with the aid of the accessory.

Clean the drawer and the grate. Then remove the burner and empty the ashes.

64

Figure 47 – Opening of the door

Weekly Maintenance

Open the door, clean the debris that may be on the grate before removing it, remove

the grate, drawer and burner (Figure 58) and vacuum the ashes. Make sure all burner

holes are clear, clean the inside of the insert. Finally, put the components in reverse

order.

Figure 48 – Weekly cleaning

65

Additional Cleaning

Every 600-800 kg of pellets, an additional cleaning should be carried out.

Open the door, clean the debris that may be on the grate before removing it, remove

the grate, drawer and burner, once removed, remove the baffle plate, which is on top

of the combustion chamber (figure 59).

Figure 49 – Removal of the baffle plate

Remove the vermiculite plates lining the inside of the combustion chamber, first

remove the sides and then the back. This shows the parts separating the combustion

chamber from the smoke passage (Figure 60).

Figure 50 – Combustion chamber separators

Using a nº5 hex wrench, remove the two DIN912 M6x12 screws securing the lower

spacers (Figure 61). Once removed, the top separators are easily removed, the smoke

66

passage in the rear of the combustion chamber should be cleaned using a vacuum

cleaner and a vacuum cleaner to clean the combustion chamber, the top-floor heat

exchanger, The ash basket area and the lower part of the combustion chamber.

Figure 51 – Fume passage cleaning and cast iron heat exchanger

Cleaning the Glass

Allow the unit to cool down completely before cleaning the glass. For cleaning, use a

specific product following the instructions of the label. Avoid contact between the

product and rope gasket and painted metal parts of the unit, as this may cause

oxidation. The rope gasket is fixed with glue so any contact with water or any other

liquids must be avoided.

Figure 52 – Incorrect cleaning of the glass

67

Figure 53 – Cleaning the glass: Applying liquid to the cloth

Figure 54 – Cleaning the glass: Cleaning the glass with the cloth

Annual cleaning

For the next cleaning task, it is necessary to remove the insert. With the door closed,

open the two safety latches located under the door using the accessory (figure 65).

On the left side of the equipment you can access the smoke extractor, as shown in

figure 65.

68

Figure 55 – Smoke extractor view

The smoke extractor is located on the left side of the equipment, it’s mainly composed

of two parts, the body and the motor. To clean the extractor it is necessary to remove

the cap with the motor, remove the screws as shown in Figure 66 with a Phillips

screwdriver (PH2). You can use a brush and a vacuum cleaner to remove any dirt from

the extractor walls and propellers.

Figure 56 – Smoke extractor view

69

The second part of the cleaning requires the complete removal of the moving part of

the equipment. The first thing to do is to disconnect the power cord and the

connections if there is external probe or chrono-thermostat.

We remove the equipment from its fixed base. At the rear of the fixed base, to the left

we have the smoke box that is connected to the chimney. On the front there is a red

silicone gasket that is responsible for making the connection between the extractor and

the smoke box, it must be checked that this gasket is in good condition. The joint can

not have cracks or cuts and must be flexible, if it is not in good condition it is

necessary to replace. The smoke box on the right side has a fixed cover with screws 6

DIN912 M6x12 (see figure 67), it is necessary to remove this cover to gain access to

the inside of the box and clean (see figures 68).

Figure 57 – Smoke box cover

Inside the box there are two smoke deflectors, positioned as shown in figure 68, to

carry out a proper cleaning it is necessary to remove them.

70

Figure 58 – Smoke box cover

To remove the baffles, you first have to remove 2 M6x20 DIN 912 screws as shown in

figure 69. Clean the inside of the smoke box and replace the

baffles.

Figure 59 – Smoke box deflectors

Finally, replace all the parts in reverse order of their disassembly, finally close the

safety locks under the door.

NOTICE! The frequency of maintenance tasks depends on the quality of

the pellets.

71

16. Alarm / Failure / Recommendation List

Table 2 - List of alarms

Important notice: when triggered, all the alarms above cause the machine to

shutdown. The alarm must be reset and the unit restarted. To reset the unit, press the

“On/Off” button for 10 seconds until the alarm sounds.

Alarm

Code Troubleshooting

Ignition failure

A01

Maximum time 2400 s

- the worm drive channel is empty - restart the unit

- resistance burnt – replace resistance

- burning basket incorrectly installed

- Locked worm - unlock

- Smoke temperature ñ exceeded the value

defined in the captivation

No flame or insufficient

quantity of pellets

A02

Temperature under :

- 40 °C (Air Version)

- 43 °C (Douro 24 kW);

- 50 ºC (Douro 17 kW)

- Pellet reservoir is empty

Pellet drum temperature

is too high

A03

110 °C

- the fan is not working – call for assistance

- faulty thermostat - call for assistance

- faulty ventilation of the unit

Fume temperature is too

high

A04

Over 230 °C (Air

version);

Over 260 °C (Water

version)

- the fan is not working or is working at a low

speed - increase level to the maximum (if the

problem persists, call for assistance)

- Insufficient extraction

- Excess pellets - Faulty smoke sensor

Pressure regulator alarm

A05

Door open, draught too

low or extractor fault for

60 sec

- close the door and clear the error message on

the faulty pressure switch

- obstruction of the exhaust pipe or faulty extractor

Air mass sensor

A06

40 lpm Delta for 3600 s

- Piping with insufficient draft or obstructed tubing

The door is open

A07

Door open for 60

seconds

- close the door - clear the error message

- Faulty air mass sensor

Fume extractor failure

A08

Connection failure

- check connection

- Check that the fan is not blocked

Fume probe failure

A09

Connection failure

- check connection

Pellet resistor failure

A10

Connection failure

- check connection

- Faulty resistance

Worm drive failure

A11

Connection failure

- check connection

- Failed worm motor

Pellet level sensor alarm

A15

- check connection

Water pressure out of

operating range *

A16

- check connection

- Check pressure in the hydraulic circuit

- Adjust pressure (1 bar) in the hydraulic circuit

(working range 0.5 to 2.8 bar)

Excess water

temperature *

A18

- check connection

- Check that the pump is working

- Bleed hydraulic circuit

- Check that the heat sinks are open

72

- Failures

Failures

“Service” (Maintenance)

Air sensor failure

The door is open

Air temperature probe failure

Table 3 - List of failures

Important notice: A “service” warning on the display (maintenance due) indicates

that the unit has exceeded 2100 operating hours. In this case, the client must perform

the unit's maintenance procedure (following the instruction on the Technical Manual).

Once this procedure is completed the hour meter may be reset, to clear the waning

message. This message does not impact the normal operation of the unit. It is simply a

warning.

Important notice: The errors can be reset only when the error information is

flashing on the display. To reset the error, press the ”Mode” button once while

displaying the error.

WARNING!

In case of an emergency, turn off the unit by following the normal shutdown procedure.

WARNING!

THE UNIT BECOMES HOT DURING OPERATION SO CARE MUST BE TAKEN

ESPECIALLY WHEN HANDLING THE DOOR GLASS AND DOOR HANDLE.

73

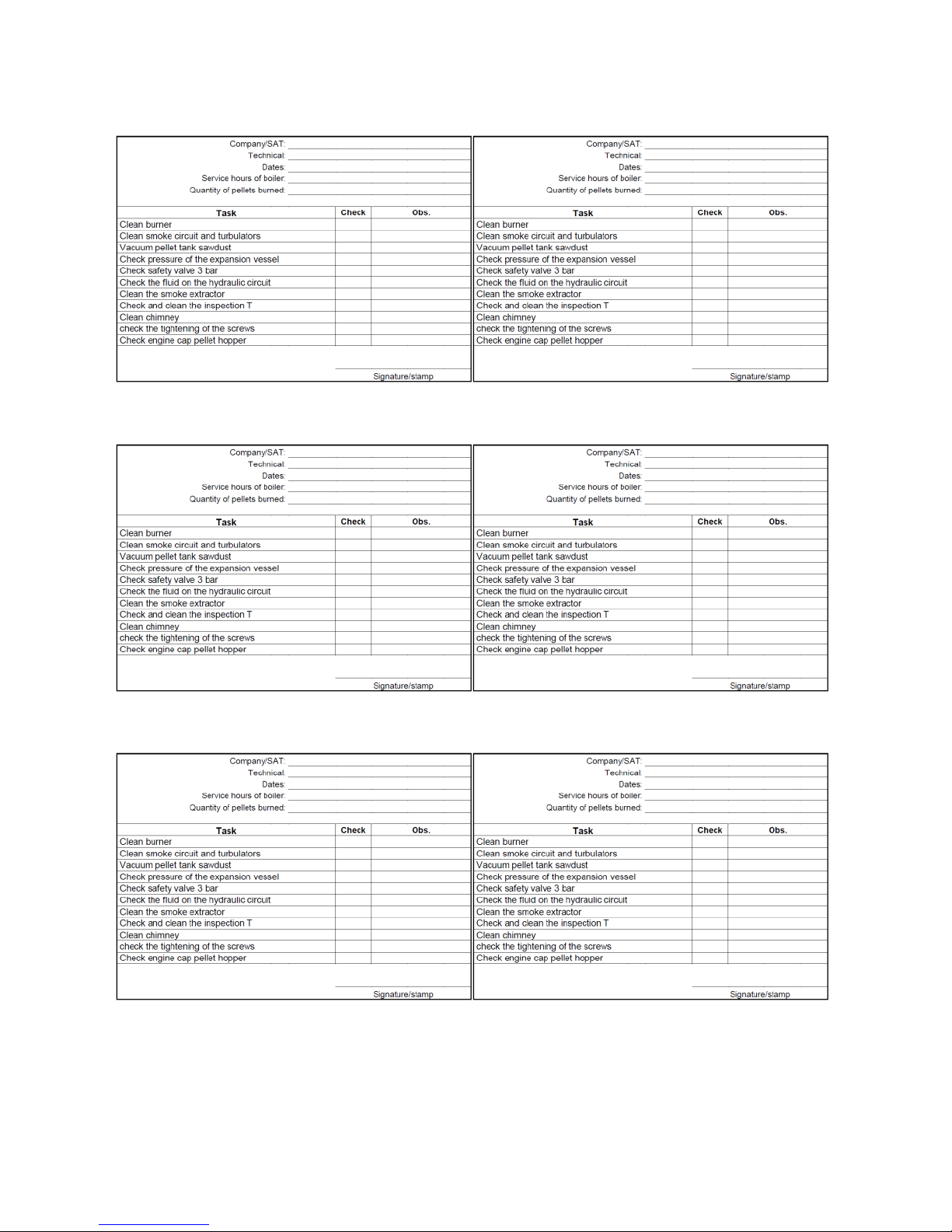

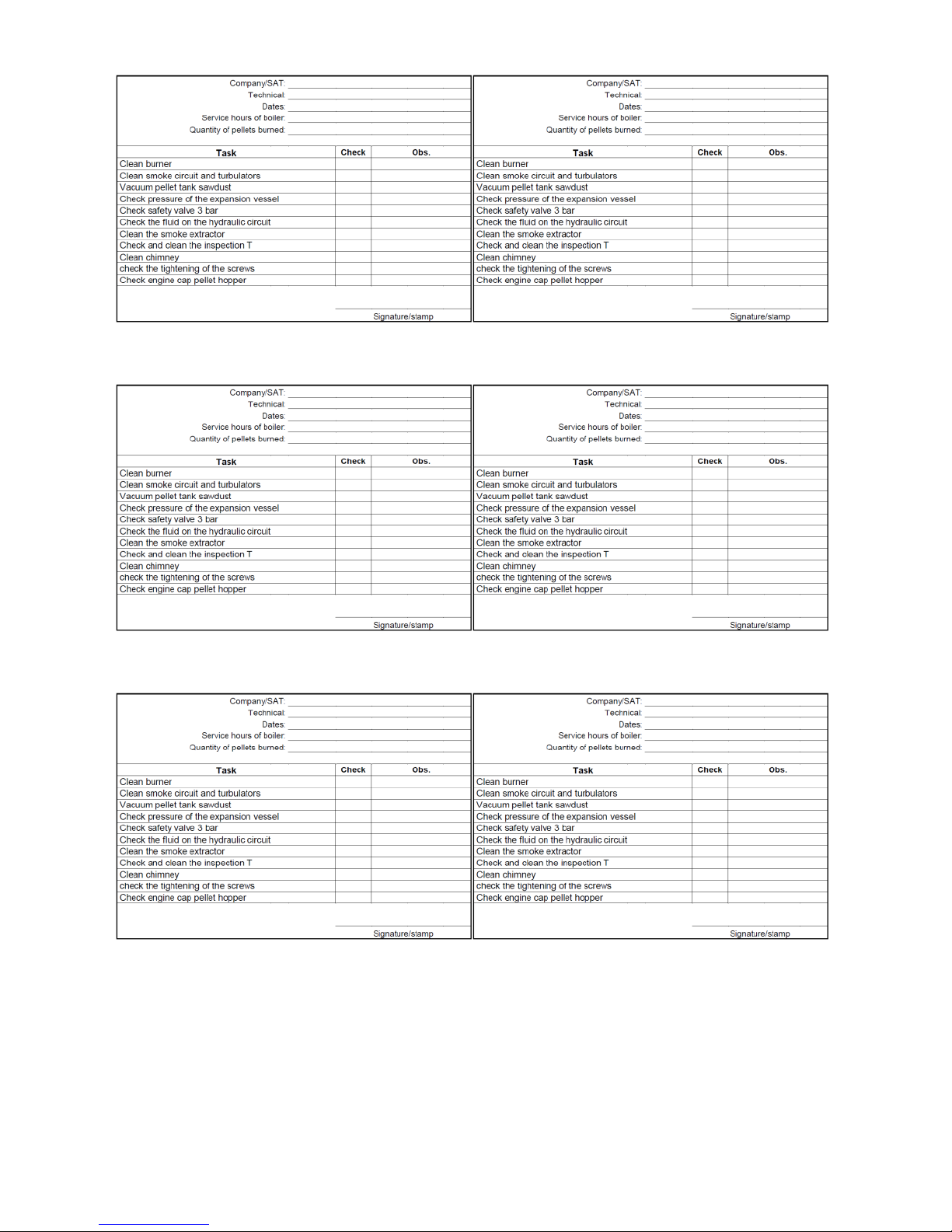

17. Maintenance Plan and Log

To ensure the proper operation of the unit, maintenance operations must be

performed, as described in Chapter 10 of this Instruction Manual or in the Maintenance

and Cleaning Guide. There are specific maintenance tasks that must be performed by

authorised technicians only. Please contact the person responsible for installing the

unit. To make sure the warranty remains valid, the maintenance operations performed

on this unit must comply with the frequency requirement specified in the manual, and

the service technician must fill and sign the maintenance log.

Client data:

Name:

Address:

Telephone:

Model:

Serial number:

74

75

76

77

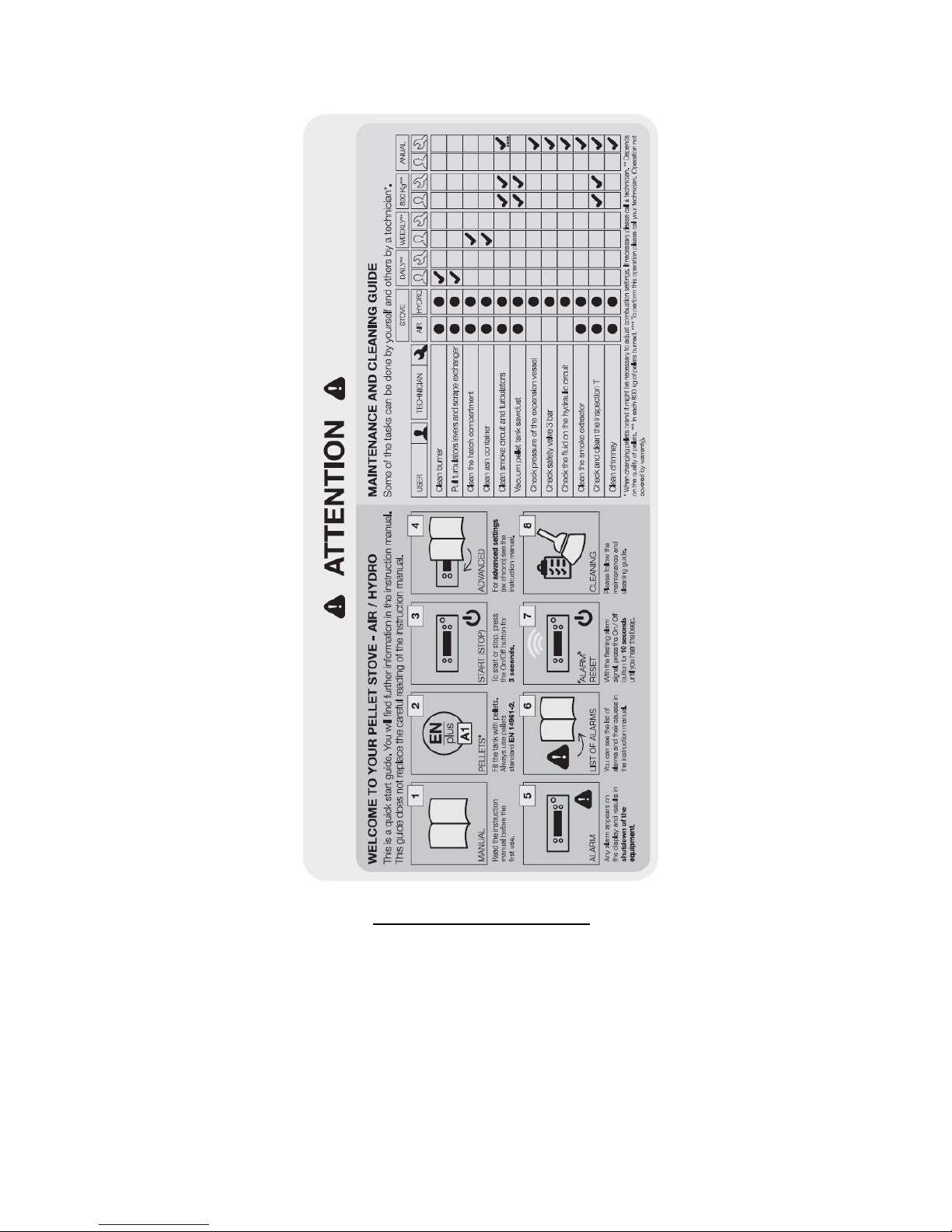

18. Maintenance Guide Label

Figure 60 – Maintenance guide label

Note: The safety warnings sticker label is attached from factory to the unit’s pellet lid,

in the Portuguese language. Attached to the manual you will find other language

versions of the sticker labels (Spanish, English, French and Italian). If necessary,

remove the Portuguese language label and replace it with the label in your country’s

language.

78

19. Electrical Diagram of the Free Standing Fire Unit

Figure 61 – Electrical diagram

20. End of life of a pellet insert

Approximately 90% of the materials used to manufacture these units are recyclable,

contributing towards a reduced environmental impact and a more sustainable planet.

End-of-life units should be processed by licensed waste operators. We recommend

contacting your local council to ensure the unit is collected and handled pursuant to

any legal requirements.

21. Warranty

This model requires that the unit is subject to start-up for the warranty to be to

activated. The start-up service can only be performed by technical services authorised

by the manufacturer. This is mandatory before the unit reaches 100 service hours. The

final user is responsible for any expenses related to the start-up service.

79

21.1. Warranty general conditions

1. Company name of the Manufacturer

SOLZAIMA S.A.

www.solzaima.pt

apoio.cliente@solzaima.pt

Address: Rua dos Outarelos; nº 111;

3750-362 Belazaima do Chão

Águeda - Portugal

This document does not constitute a voluntary warranty provided by SOLZAIMA S.A.

for any products manufactured and marketed by SOLZAIMA (hereinafter called

“Product(s)”). The purpose of this document is to provide the client with guidelines on

how to effectively activated the legal warranty that is standard to any consumer

Product (hereinafter “Warranty”). Naturally, this document does not impact any

warranty legal rights the Buyer may have, arising from the Product purchase contract.

2. Identification of the Warranted Product

The use of the warranty service is based on the assumption that, through the proper

means, the Client has previously sent the correct warranted Product information to

SOLZAIMA S.A. including the Product information as described on in the proof of

purchase and on the Product’s specification plate (model and serial number).

3. Warranty Conditions for the Product

3.1 A SOLZAIMA S.A. is liable towards the Buyer for the non-compliance of the Product

with the sale and purchase contract, within the following timeframes:

3.1.1 For 24 months from the Product’s delivery date, in case the Product is applied to

domestic use;

3.1.2 For 6 months from the Product’s delivery date, in case the Product is applied to

professional use;

3.2 To claim his rights and provided the deadline mentioned above is not exceeded, the

Buyer must denounce in writing to SOLZAIMA S.A. the Product’s non-compliance within

80

the following deadline:

3.2.1 Within 60 (sixty) days from the date the non-compliance was detected, in case

the Product is applied to domestic use;

3.2.2 Within 30 (thirty) days from the date the non-compliance was detected, in case

the Product is applied to professional use;

3.3 During the Warranty period specified under clause 3.1 above (to make sure the

Warranty is valid), any Product servicing operations must be exclusively performed by

the manufacturer’s technical services representative. All servicing under the scope of

this Warranty shall be performed from Monday to Friday within the working hours and

calendar legally established in each region.

3.4 Any service request must be sent to SOLZAIMA S.A. Customer Service via the

following email: apoio.cliente@solzaima.pt. Upon the technical servicing of the Product,

the Buyer must provide the technician with a document certifying the Product is in the

Warranty Period, namely the proof of purchase or other document supporting the

purchase. In any case, the document certifying that the Product is in the Warranty

Period must include the identification of the Product (as per clause 2 above) and the

date of purchase Alternatively, and to make the Product Warranty valid, the Client may

provide the PSR - the certifying document of the unit start-up (when applicable).

3.5 The Product must be installed by a specialized technician, qualified to install the

Product in compliance with the regulations applicable in the Client's geography, namely

those regarding the chimney, as well as other applicable regulations concerning water

supply, power supply and/or other utilities related to the use of the equipment or

sector, as described in the Instruction Manual. This Warranty shall be void in case of

non-compliance of the Product installation with the manufacturer’s specifications

and/or any applicable law in force. Should be Product be installed on the exterior of a

building, it must be protected from weather conditions, namely rain and wind. In this

case, it may be necessary to protect the unit with a cabinet or a protection box

properly ventilated.

3.6 The units cannot be installed in locations with chemicals agents in the atmosphere,

in saline or high humidity environments. The combination of these agents with oxygen

(air) may cause the quick corrosion of the combustion chamber to . In these

81

environments, it is recommended that the units are protected with proper anticorrosion

products, specially between periods of usage. We recommend the application of