Instruction Manual

English

Insert Fires

SIENA | ORION | RIALTO | SIRIUS | URANO | IACO

BASIC | SLIM | DUO – BOX

BASIC | SLIM | DUO – BACK BOX

HERA | LOKI | JUNO | HEKA

Mod. 115 – H

Please read this Instruction Manual carefully and keep it for future

reference.

All Solzaima products come with a 2-year warranty.

APPROVED PRODUCT

Thank you for purchasing a SOLZAIMA unit.

Please read this manual carefully and keep it for future reference.

* All our products fulfil the requirements of the European Regulation (Reg

UE 305/2011) and have been certified with the CE conformity trademark;

* SOLZAIMA disclaims responsibility for damages to the unit if it is installed

by non-qualified personnel;

* SOLZAIMA disclaims responsibility for damages to the unit if the rules for

installation and use described in this manual are not followed;

* All local regulations, including those referring to national and European

standards, should be complied with when installing the unit;

* Our Insert Fires have been tested according to standards EN 13229:2001

+ EN 13229:2001/AC:2003 + EN 13229:2001/A1:2003 + EN

13229:2001/A2:2004 + EN 13229:2001/AC:2006 + EN

13229:2001/A2:2004/AC:2006;

* Technical support is normally provided by SOLZAIMA, except in

exceptional cases to be determined by the installer or support technician;

* Whenever you need assistance, you should contact your unit’s supplier or

installer. You should provide its serial number, which is on the identification

plate located on the left side of the ash drawer, as well as on the label on the

back cover of this manual.

Contents:

Solzaima………………………………………………………………. ...... 3

Technical Specifications……………………………………………… ..... 4

Your Unit………………………………………………………………. ...... 9

Components…………………………………………………………….... 12

Installation……………………………………………………………… ... 13

Instructions for Use…………………………………………………… .... 17

Troubleshooting………………………………………………………. .... 26

End of Life……………………………………………………………… ... 27

Sustainability……………………………………………………………... 27

Glossary……………………………………………………………….. .... 28

Warranty……………………………………………………………….. .... 30

1

2

Solzaima

Having first entered the market in 1978, we are a leading specialist company

in the design and manufacture of biomass heating solutions, including insert,

backboiler and free-standing fires.

As a market leader and specialist in the area in which we operate, we put a

premium on the quality of our products to make sure that we satisfy our

customers' needs.

Solzaima is certified in accordance with standards ISO9001:2008 (Quality

Management) and ISO14001:2004 (Environment) and is well aware of its

environmental obligations. In addition, we submit to a demanding testing

regime in order to guarantee top quality and performance across our entire

range of products, in terms of raw materials selection, control of the

manufacturing process, and treatment of all the waste generated. All this to

ensure your home is fitted with solid and reliable equipment.

Technical Specifications

Insert fires are designed to heat their surroundings and are perfect for those

who already own a fireplace and intend on refurbishing it or simply making it

more efficient and cost-effective - such is the case of wall-mounted fires or,

as they are commonly known, "cassettes".

Our stores offer you a range of options to suit the design of your room. The

Back Box and Box units come in Basic, Slim and Duo variants, so you can

find the right model to blend harmoniously into its surroundings without any

need for major alterations, as they do not insert into the wall.

* Technical specifications across the range:

* CE certified

* Average reloading time: ≤ 45 minutos

* Fuel: Dry firewood

* Voltage: 230 V (except Urano/Iaco, Basic/Slim/Duo - Box)

* Frequency: 50 Hz (except Urano/Iaco, Basic/Slim/Duo - Box)

* Power: 2x8.5 W (except Urano/Iaco, Basic/Slim/Duo - Box)

* Type of Equipment: intermittent use

3

4

Table 1 – Technical Specifications for each Unit

W – Width; H – Height

1

Power output is calculated by taking into account a variation of 30% in relation to the rated output.

2

Consumption of firewood, taking into account the range of power outputs.

3

Power output is calculated by taking into account a variation of 30% in relation to the rated output.

4

Consumption of firewood, taking into account the range of power outputs.

Siena

Orion

Rialto

Sirius

Urano

Dimensions

W H W H W H W H W

H

Front (inches/mm)

27.6/

703

26.6

/678

31.6

/803

34.5

/678

35.5

/903

26.6

/678

35.5/

903

26.6

/678

27.6

/703

23.3

/593

Casing (inches/mm)

24.6/

627

23.2

/590

28.6

/727

23.2

/590

32.5

/827

23.2

/590

32.5/

827

23.2

/590

24.6

/627

19.8

/504

Total Depth (inches/mm)

16.7/425

18.2/462

18.2/462

24.5/624

16.7/425

Flue Ø (inches/mm)

Ø 5.9/150 int.

Ø 7.0/180

int.

Ø 7.0/180

int.

Ø 7.8/200

int.

Ø 5.9/150

int.

Rated output (kW)

7

9,5

11

16,5

7

Efficiency (%)

71

71

71

75

71

CO Emissions (13%O2)

(%)

0.2

0.2

0.37

0.26

0.20

CO2 Emissions (%)

8.8

9.7

8.79

11.2

9.7

Average combustion

temperature (ºF/ºC)

802/428

703/373

599/315

696/369

802/428

Combustion flow (g/s)

10

11

10

13

10

Power output1 (kW)

4,9 – 9,1

6,7 – 12,4

7,7 – 14,3

11,6 – 21,5

4,9 – 9,1

Firewood consumption2

(pounds/kg / h)

3.7/1.7 –

6.8/3.1

3.5/1.6 –

6.4/2.9

4/1.8 –

7.5/3.4

7.9/3.6 –

14.5/6.6

3.7/1.7 –

6.8/3.1

Weight (pounds/kg)

172/78

200/91

220/100

268/122

147/67

Maximum heated volume

(m3)

207

279

323

488

207

Energy efficiency rating

Class 1

Class 1

Class 1

Class 1

Class 2

Length Firewood

(inches/mm)

15,7/400

19,6/500

19,6/500

19,6/500

15,7/400

Depression (Pa)

12

12

12

12

12

Box

Iaco

Basic

Slim

Duo

Dimensions

W H W H W H W

H

Front (inches/mm)

31.6/

803

23.3

/593

33.4

/850

36.6

/933

33.4

/850

37

/942

66.9/

1700

36.7

/933

Casing (inches/mm)

28.6/

727

19.8

/504

---

---

---

---

---

---

Total Depth (inches/mm)

18.1/462

23.6/600

23.6/600

23.6/600

Flue Ø (inches/mm)

Ø 7.0/180 int.

Ø 7.8/200

int.

Ø 7.8/200

int.

Ø 7.8/200

int.

Rated output (kW)

9,8

10

10

10

Efficiency (%)

68

75

75

75

CO Emissions (13%O2)

(%)

0.20

0.26

0.26

0.26

CO2 Emissions (%)

9.7

11.2

11.2

11.2

Average combustion

temperature (ºF/ºC)

703/373

696/369

696/369

696/369

Combustion flow (g/s)

11

13

13

13

Power output3 (kW)

6.9 – 12.7

7.0 – 13.0

7.0 – 13.0

7.0 – 13.0

Firewood consumption4

(pounds/kg / h)

5.4/2.45 –

10.1/4.6

3.7/1.7 –

6.8/3.1

3.7/1.7 –

6.8/3.1

3.7/1.7 –

6.8/3.1

Weight (pounds/kg)

176/80

317/144

337/153

383/174

Maximum heated volume

(m3)

290

294

294

294

Energy efficiency rating

Class 2

Class 1

Class 1

Class 1

Length Firewood

(inches/mm)

19,6/500

23,6/600

23,6/600

23,6/600

5

Power output is calculated by taking into account a variation of 30% in relation to the rated output.

6

Consumption of firewood, taking into account the range of power outputs.

7

Power output is calculated by taking into account a variation of 30% in relation to the rated output.

8

Consumption of firewood, taking into account the range of power outputs.

Back Box

Basic

Slim

Duo

Dimensions

W H W H W

H

Front (inches/mm)

33.4

/850

40.5/

1030

33.4

/850

40.7/

1036

66.9/

1700

40.5/

1030

Casing (inches/mm)

---

---

---

---

---

---

Total Depth (inches/mm)

16.9/430

16.9/430

16.9/430

Flue Ø (inches/mm)

Ø 7.0/180

int.

Ø 7.0/180 int.

Ø 7.0/180 int.

Rated output (kW)

11

11

11

Efficiency (%)

71

71

71

CO Emissions (13%O2)

(%)

0.37

0.37

0.37

CO2 Emissions (%)

8.79

8.79

8.79

Average combustion

temperature (ºF/ºC)

599/315

599/315

599/315

Combustion flow (g/s)

10

10

10

Power output5 (kW)

6.4 – 12

6.4 – 12

6.4 – 12

Firewood consumption6

(pounds/kg / h)

3.39/1.54 –

6.3/2.86

3.39/1.54 –

6.3/2.86

3.39/1.54 –

6.3/2.86

Weight (pounds/kg)

279/127

286/130

337/153

Maximum heated volume

(m3)

267

267

267

Energy efficiency rating

Class 1

Class 1

Class 1

Length Firewood

(inches/mm)

23,6/600

23,6/600

23,6/600

Hera

Loki

Juno

Heka

Dimensions

W H W H W H W

H

Front (inches/mm)

27.6

/703

26.6

/678

31.6

/803

26.6

/678

35.5

/903

26.6

/678

35.5

/903

26.6

/678

Casing (inches/mm)

24.6

/627

23.2

/590

28.6

/727

23.2

/590

32.5

/827

23.2

/590

32.5

/827

23.2

/590

Total Depth

(inches/mm)

17.2/437

18.5/469

18.5/469

24.9/634

Flue Ø (inches/mm)

Ø 5.9/150

int.

Ø 7.0/180

int.

Ø 7.0/180

int.

Ø 7.8/200

int.

Rated output (kW)

7

9,5

11

16,5

Efficiency (%)

71

71

71

75

CO Emissions (13%O2)

(%)

0,2

0,2

0,37

0,26

CO2 Emissions (%)

8,8

9,7

8,79

11,2

Average combustion

temperature (ºF/ºC)

802/428

703/373

599/315

696/369

Combustion flow (g/s)

10

11

10

13

Power output7 (kW)

4,9 – 9,1

6,7 – 12,4

7,7 – 14,3

11,6 – 21,5

Firewood consumption8

(pounds/kg / h)

3.7/1.7 –

6.8/3.1

3.5/1.6 –

6.4/2.9

4/1.8 –

7.5/3.4

7.9/3.6 –

14.5/6.6

Weight (pounds/kg)

172/78

198/90

222/101

271/123

Maximum heated

volume (m3)

207

279

323

488

Energy efficiency rating

Class 1

Class 1

Class 1

Class 1

Length Firewood

(inches/mm)

15,7/400

19,6/500

19,6/500

19,6/500

Depression (Pa)

12

12

12

12

6

Your Unit

BOX Range

BACK BOX Range

BACK BOX also comes in SLIM BACK BOX and DUO BACK BOX variants.

DUO BOX

BASIC BOX

SLIM BOX

Combustion air

intake damper

Door handle

Vermiculite

panels

Firewood box

Smoke outlet

Combustion air

intake damper

Door handle

Firewood box

Forced ventilation

Smoke outlet

Vermiculite panels

8

9

10

BASIC BACK BOX

URANO

URANO with STAINLESS

STEEL FRAME

Combustion air

intake damper

Door handle

Vermiculite panels

Vermiculite panels

SIRIUS

SIRIUS with STAINLESS

STEEL FRAME

Combustion air intake

damper

Door handle

Forced

ventilation

ORION with STAINLESS

STEEL FRAME

Range with optional accessory –

stainless steel or colour-matching frame,

either 1.95in (5cm) or 3.9in (10 cm) wide

ORION

Combustion air

intake damper

Door handle

Forced

Ventilation

Vermiculite

panels

Fig. 1 – Orion, Sirius, Urano, Box, Back Box, Heka and Juno units

Components

* Our insert fires are built entirely of top quality carbon steel plate, with a

thickness of 0.118 inches (3mm) and 0.19 inches (5mm) in the combustion

chamber and 0.019 inches (1.5mm) in the casing. Other parts, such as the

door and ash drawer, use 0.019 inches (1.5mm) and 0.078 inches (2mm)

plates;

* Heat-resistant ceramic glass. Can handle temperatures of up 1382°F

(750°C) in continuous use;

* The combustion chamber is coated with a heat-resistant material known as

vermiculite, a hydrosilicate that can withstand temperatures in the order of

2012°F (1100°C). Its insulating properties allow the unit to take better

advantage of the heat, improve efficiency and provide greater protection for

the steel plate forming the combustion chamber walls, thus prolonging the

life of the equipment.

* Heat-resistant paint for temperature peaks up to 1652°F (900°C) and

operating temperatures in the order of 1112°F (600°C);

* The ash grate is made from a 0.19 inches (5mm) thick plate.

11

12

Vermiculite panels

HEKA with 4 SIDES

FRAME

Combustion air intake

damper

Door handle

Forced

ventilation

HEKA with 3 SIDES

FRAME

HEKA with INTEGRAL

FRAME

GLASS Range

JUNO with 4 SIDES

FRAME

Vermiculite panels

Combustion air intake

damper

Door handle

Forced

ventilation

JUNO with 3 SIDES

FRAME

JUNO with INTEGRAL

FRAME

Installation

Attention: all regulations and standards must be complied with when

installing this stove.

1. Combustion air and gas circulation

* This type of stove should be installed in a well-ventilated area. Any air

intake grilles should be placed in locations that are not liable to become

blocked;

* Additional air inlets may be needed if the stove is used in simultaneous

with other devises that require an air supply. The installer should evaluate

the situation according to the overall air flow requirements;

* Use of this unit at the same time as other heating devices that require an

air supply may necessitate additional air inlets. The installer should assess

the situation in light of total air flow requirements;

* Under normal operating conditions, the combustion gas flow should create

a draught of 12 Pa one metre above the throat of the flue. For proper

installation, at least 78.7 inches (2 metres) of metal flue tube with the same

diameter as the unit's smoke outlet should be fitted vertically above the unit.

After this section, sections of tubing with a maximum angle of 45° may be

used;

Figures 2 and 3 illustrate correct and incorrect angles for installing a bend.

45º45º

Fig. 2 – Correct angle for bends Fig.3 – Incorrect angle for bends

* A single-walled tube installed on the outside of a building results in the

condensation of water vapour in the combustion gases. We therefore

recommend the use of a double – walked insulated pipe;

* The flue outlet should allow for good air circulation and be placed at least

23.6 inches (60cm) above the top of any obstacle located within a distance

of 9.8 feet (3m);

* The same flue should not be used for more than one unit or open fireplace.

With shared chimneys, each flue should reach its outlet independently and

these should be at the same level to ensure that the air circulation expels the

gases;

* Brick chimneys should not be too wide, as the smoke will cool as it

disperses, reducing the draft. In case of draft problems, a revolving chimney

cowl can be installed;

45º45º45º

13

14

2. Installation location requirements

* The unit should stand on a masonry hearth made of refractory bricks or

another type of non-combustible material;

* It is recommended for insert fires to be insulated with insulating material

with a thickness of 1.57 inches (40mm) and a density of 154 pounds

(70kg)/m3 (except for the Back Box and Box ranges, in their Basic, Slim and

Duo variants). All units should be installed at least 15.7 inches (400mm)

from combustible materials;

* Combustible materials should not be installed close to the walls of the unit;

* The floor on which the unit will stand must be able to support a permanent

load of 2.2 pounds (1kg)/cm². If the load capacity of the floor is insufficient, a

solid plate can be used to distribute the load over an area larger than the

unit’s base;

* The building’s air intake grilles should not be obstructed;

* There should be a gap of around 0.19 inches (5mm) between the unit and

ornamental stones, to allow room for the metal to expand. These should also

be installed so as to allow the unit to be removed without causing damage, if

the need arises; This recommendation does not apply to the Back Box and

Box ranges, in their Basic, Slim and Duo variants.

* Ensure that the opening in the wall is of an appropriate size to house the

unit;

* Materials/objects placed in front of the unit, as well as behind in the case of

the Box range, should be able to withstand the heat radiated from the glass

of the door(s), so should not be combustible;

* Refractory cement or other refractory material should be applied on the

chimney walls;

* The use of wood finishings may increase the risk of fire. Therefore, we

recommend the use of adequate insulation or that wood not be used at all.

15

15

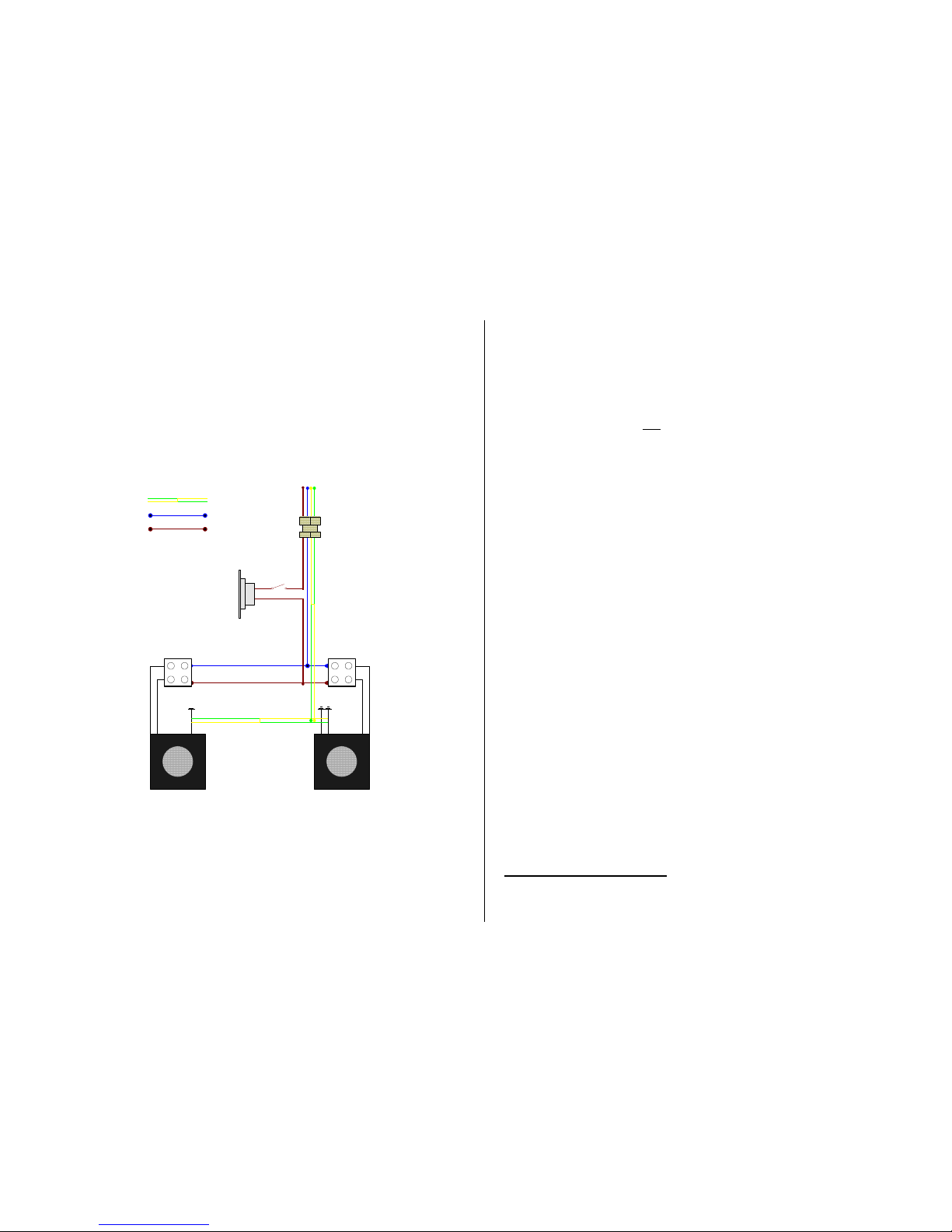

3. Forced Ventilation

* Units that are equipped with forced ventilation include 2 ventilators, with a

power of 8.5 W and a pulsating air flow of 67 m3/h each, connected in

parallel through a thermostat according to the circuit diagram below.

Fig.4 – Circuit diagram

Attention: all three wires in the power feed cable – earth, neutral and live – should be

connected. We take no responsibility for any damage resulting from non-compliance with this

warning.

* The electrical components should always be connected to the power

supply;

* The cable used for the electrical connection should be silicon-coated and

heat-resistant to 356°F (180°C). If the power feed cable is damaged, it

should only be replaced by a qualified technician;

* You should take care to not lay the cable where it may be crushed;

* The electrical installation should incorporate means to switch the unit off,

with a minimum separation of 0.118 inches (3mm) between the contacts,

pursuant to the applicable legislation in force.9

Instructions for Use

Attention: all regulations and standards must be complied with when

installing this unit.

1. Fuel

* Only firewood should be used in this type of unit. It may not be used as an

incinerator, nor should other materials such as coal, painted wood,

varnishes, thinners, liquid fuels, glues or plastics be used. Also avoid

burning common combustible materials such as cardboard and straw.

* The firewood should have a low water content (less than 20%) in order to

ensure efficient combustion and avoid creosote build-up in the smoke duct

and on the glass;

* See Table 2, which lists some of the types of wood that can be used in

these units;

9

We recommend the use of a 30 mA differential switch and a 0.5 A circuit breaker for the unit’s

electrical installation.

16

17

TERMOSTATO

TERRA

NEUTRO

FASE

VENTILADOR VENTILADOR

JUNÇÃO CERÂMICA

JUNÇÃO CERÂMICA

CERRA-CABOS

TERRA

TERRA

EARTH

NEUTRAL

LIVE

CERAMIC TERMINAL BLOCK

CERAMIC TERMINAL BLOCK

EARTH

EARTH

VENTILATOR

VENTILATOR

CABLE-CLAMP

THERMOSTAT

Table 2 – List of types of firewood that may be used in SOLZAIMA fires, their geographical

distribution and calorific value/reactions.

Common

Name

Scientific

name

Distribution

(total: 18 districts)

Characteristics

Smoke

Heat

Lighting

Combustion

Speed

Hardness

Pine

Pinus

Europe, except

Finland; Northern

Sweden and

Norway.

Little

High

Easy

Fast

Soft

Cork Oak

(+)

Quercus

suber

Southern Europe

Little

Very

High

Easy

Regular

Hard

Eucalyptus

Eucalyptu

s

Mediterranean

Region

Lot

Regu

lar

Difficult

Slow

Hard

Holm Oak

(+)

Quercus

ilex

Southern Europe

Little

Very

High

Difficult

Slow

Hard

Olive tree

Olea

Mediterranean

Region

Little

Very

High

Difficult

Slow

Hard

Oak

Quercus

Across Europe

Little

High

Difficult

Slow

Hard

Ash

Fraxinus

Across Europe

Regula

r

High

Difficult

Slow

Hard

Birch

Betula

Across Europe

Little

Very

High

Easy

Fast

Soft

Beech

Fagus

Europe, except

Iberian Peninsula

and Northern

Europe, including

United Kingdom.

Little

High

Difficult

Slow

Hard

Elm

Ulmus

Across Europe

Regula

r

High

Difficult

Slow

Hard

Maple

Acer

Across Europe

Little

Regu

lar

Regular

Slow

Soft

Poplar

Populus

Across Europe

Little

High

Easy

Fast

Soft

Chestnut

Castanea

Across Europe

Regula

r

High

Difficult

Slow

Hard

(+): greatest commercial availability

1.1 Power

The power of your unit indicates its heating capacity, i.e. the energy your unit

transfers from the firewood to your home (usually measured in kW) and is

directly related to the amount of firewood that you place in it.

The rated output is the measure of a standard load of firewood when tested

in laboratories during a certain amount of time.

The power output is a manufacturer's recommendation from tests to the

equipment with firewood loads within a reasonable operation range. This

power output range will present different firewood consumptions per hour.

1.2 Energy Efficiency and Performance Ratings

Implementing solutions that seek to achieve greater energy efficiency allows

for substantial reductions in energy needs, and thus reduces our current

dependence on fossil fuels and other non-renewable sources of energy.

Energy efficiency enables you to make large savings from both an economic

and an environmental point of view.

As a result of Solzaima's commitment towards the equipment's efficiency,

most of our products are classified as efficiency class 1, i.e., with an

efficiency rate equal to or greater than 70%.

18

19

A 70% efficiency rate means that 70% of the energy contained in the

firewood is used to warm your home or, in other words, you are able to

produce the same amount of energy with much less firewood.

*in accordance with EC classification standards for insert fires.

A Solzaima 5kW stove with an efficiency rate of 75%, i.e. efficiency class 1,

will consume approximately 3.5 pounds (1.6kg) of firewood per hour to warm

a 389 sq ft room (35m2).

Typically, a traditional fireplace has an efficiency rate of approximately 10%,

which means it will consume about 26.5 pounds (12kg) of firewood to

produce the same 5kw necessary to warm the same 389 sq ft room (35m2).

2. First Use

* Ask the installer to light the unit to ensure that all is functioning correctly;

* The stove’s paint is cured by the heat when it is first used, which may give

rise to additional smoke. If this happens, you should ventilate the room by

opening external windows and doors.

EFFICIENCY RATING*

EFFICIENCY RATE*

(fire door closed)

70 %

60% < 70 %

50% < 60 %

30% < 50 %

FIREWOOD CONSUMED IN ONE HOUR TO WARM APPROXI MATELY

389 SQ FT (35 m2) WI TH A 5kW UNIT

A traditional fireplace with an

efficiency rate of 10% consumes

26.5 pounds (12kg) of firewood

A fireplace equipped with a simple

fire (class 4) and providing an

efficiency rate of 30% consumes 8.8

pounds (4kg) of firewood

A fire with an efficiency rate of 50%

(class 3) consumes 5.3 pounds

(2.4kg) of firewood

A Solzaima fire with an efficiency

rate of 75% (class 1) consumes only

3.5 pounds (1.6kg) of firewood

1

2

3

4

1

2

3

4

20

21

3. Normal Use

a) Open the combustion air regulator on the door;

b) Place some pine cones (preferably) on the ash grate;

c) Place some kindling wood on top, piled horizontally;

d) The lighting period is over when the unit has reached a constant

temperature. You should then regulate the combustion air intake;

* You should check that there is sufficient ventilation in the room where the

stove is installed, otherwise it will not work properly. For this reason, you

should check if there are any other heating devices which consume air

during operation (e.g. gas-fired equipment, braziers, etc). We recommend

against using these devices all at once;

* The air for combustion is drawn from the surrounding room, consuming

oxygen. You should check that ventilation grilles and other devices for

allowing air to enter from outside remain unobstructed;

* You should only open the door during reloading. Normal conditions of use

require the door to remain closed;

* Reload before the previous load has burnt completely, in order to make it

easier for the combustion to continue;

* When reloading with firewood, open the door slightly and wait a little while

to allow a good draft, and only then open the door completely.

* Use of the stove is not recommended when weather conditions are so bad

that the draught is seriously affected (particularly when there are very strong

winds).

3.1 Optional Accessories

* The stove is supplied with three/four frame elements or a full frame and

accompanying components to attach them to the wall.

* The Sirius, Siena, Orion, Rialto, Urano and Iaco models offer a choice of

frame designs to best suit the room where the unit is to be installed.

* The following frames are available:

a) stainless steel, either 1.95in (5cm) or 3.9in (10cm) wide;

b) full colour-matching frame, either 1.95in (5cm) or 3.9in (10cm) wide;

c) 3 or 4 separate colour-matching frame sides.

4. Additional Outlets

* There are 2 outlets (each 3.9 inches (100mm) in diameter) on the top

surface of the unit, which may be used by removing the covers and adapting

ducts to direct the warm air to other rooms; this does not apply to the Box

and Back Box ranges, in their Basic, Slim and Duo variants;

* If the warm air duct always runs upwards, there is no need for a forced

system. If it is for distributing the heat, you should install an aspirator to force

the air to circulate. In this case, it should be installed as plumb over the unit

as possible, so the thermostat can detect the rising heat immediately;

22

23

* An air outlet grille should be placed in each room and all the ducts should

be well insulated;

* If you are interested in this form of heating, we recommend you contact a

specialised installer.

5. Safety

* The ventilators should always be connected to the power supply;

* You should take care to not lay the cable where it may be crushed;

* The exposed metal parts reach high temperatures - 212°F (100°C) on the

door and 140°F (60°C) on the frame. The door handle does not reach

temperatures above 113°F (45°C). Do not touch the hotter areas;

* You should use a glove or other protection if you have to touch the unit

when it is in operation;

* In case of fire in the flue, immediately close the door of the unit and

the combustion air intake damper;

* If there is a power cut, resulting in the ventilators cutting out when the unit

is in operation, close the combustion air intake and do not load the unit with

any more firewood. Keep the door closed.

6. Cleaning and Maintenance

* You should remove ash from the drawer on a regular basis (after the unit is

switched off), so that the combustion air can enter through the ash grate

unobstructed;

* The window should be cleaned with a suitable product,10 by following the

instructions for use and not allowing the product to come into contact with

the sealing ring and painted metal parts, which could trigger oxidation. The

sealing ring is glued, so should not be moistened with water or cleaning

products. If it becomes detached, it can be reattached with contact glue after

cleaning the groove with fine sandpaper;

* We advise you to clean the flue and flue throat (at the exit of the unit) at

least once a year, removing the baffle plate to do so;

* If you do not use the unit for a prolonged period, check to make sure that

the flue pipes are clear before lighting it;

* The stove should be cleaned using a dry cloth.

10

Seek advice from your supplier/installer.

24

25

Troubleshooting

Problem

Solution

Glass gets dirty

. Check moisture of firewood

. Increase burn intensity by opening the

combustion air intake regulator slightly

Excessive draft

. Close the combustion air intake damper

. Contact the installer

Weak draft, causing smoke

to be expelled into the

room

. Check that the flue is clear of obstructions

. Clean the flue

. There may be exceptional weather

conditions

Weak fire

. Check moisture of firewood and opening of

the combustion air damper

. Check entry of air into the room

Ventilation stopped

working

. Check possible obstruction of ventilators

. Check and/or reconnect power supply

. The stove may not be hot enough to make

the ventilators switch on

Ventilation working but

flow is weak

. Clean all dust, ash or other residue that may

have accumulated in the ventilator grilles

Problems associated with

the weather

. Contact the installer

End of Life

* Around 90% of the materials used in the manufacture of these units is

recyclable, thus helping to reduce environmental impact and contributing to

the sustainable development of the planet;

* End-of-life units should be taken to licensed waste operators. We advise

you to contact your local council for collection.

Sustainability

* Solzaima designs solutions and equipment "moved" by biomass as their

primary energy source. This is our contribution for the sustainability of our

planet – an economically viable and environmentally-friendly alternative,

following environmental best management practices to ensure an efficient

carbon cycle management.

* Solzaima cares about being up to date with and assessing the existing

forest area while efficiently responding to energetic demands, with a

constant watch on biodiversity and natural wealth, critical aspects to the

quality of life in our planet.

26

27

Glossary

* Ampere (A): SI unit of measurement of electric current

* bar: unit of pressure equal to exactly 100,000 Pa. This pressure is very close to

standard atmospheric pressure.

* cal (calorie): equal to the amount of heat required to increase the temperature of

one gram of water by one degree centigrade.

* Groove: housing for the sealing ring.

* cm (centimetres): unit of measurement.

* CO (carbon monoxide): Lightly flammable, colourless, odourless and very

dangerous gas, due to its toxicity.

* CO2 (carbon dioxide): Gas needed by plants on the one hand for photosynthesis,

and emitted into the atmosphere on the other, contributing to the greenhouse effect.

* Combustion: a process that releases energy. Combustion is basically a chemical

reaction that requires three things in order to take place: fuel, oxidant and ignition

temperature.

* Oxidant: chemical substance that feeds combustion (essentially oxygen) and is

essential for it to take place.

* Fuel: anything that can undergo combustion, in this case wood.

* Creosote: chemical compound created by combustion. This compound is

sometimes deposited on the glass and flue of an insert fire.

* Circuit breaker: Electromechanical device that protects a given electrical

appliance.

* Energy Efficiency: capacity to generate large quantities of heat with the least

amount of energy possible, causing the least environmental impact and reducing the

energy budget.

* CO Emissions: emission of carbon monoxide gas into the atmosphere.

* CO Emissions (13% O2): carbon monoxide content corrected for 13% of O2.

* Differential Switch: protects people and property against earthing failures,

preventing electric shocks and fires.

* kcal (Kilocalorie): multiple unit of measurement of calories. Equivalent to 1,000

calories.

* kW (Kilowatt): Unit of measurement equal to 1,000 watts.

* mm (millimetres): unit of measurement.

* mA (milliampere): unit of measurement of electric current.

* Pa (Pascal): standard SI unit of pressure and tension. This unit is named after

Blaise Pascal, eminent French mathematician, physicist and philosopher.

* Calorific Value: also known as specific combustion heat. Represents the quantity

of heat released when a certain quantity of fuel is completely burned. Calorific value

is expressed in calories (or kilocalories) per unit of weight of fuel.

* Rated output: Electric power consumed by an energy source. Measured in watts.

* Nominal heat output: heating capacity, i.e. the heat energy the unit transfers from

energy present in the firewood – measured for a standard load of firewood over a

given period of time.

* Power output: a manufacturer's recommendation from tests on the equipment with

firewood loads within a reasonable operating range. This power output range will

present different firewood consumptions per hour.

* Plumb: vertically above the installation.

* Efficiency: expressed as a percentage of “useful energy” that can be extracted

from a given system, taking into account the “total energy” of the fuel used.

* Ignition temperature: temperature above which the fuel can enter into combustion.

* Heat-resistant: resistant to high temperatures and thermal shock.

* Ceramic glass: Highly resistant ceramic material produced through controlled

crystallisation of vitreous materials. Used widely in industrial applications.

* W (Watt): SI unit of power.

28

29

Warranty

* All SOLZAIMA units have a 2 (two) year warranty from the date the invoice

was issued. In order for your warranty to be valid, you must keep the invoice

or receipt of purchase throughout the warranty period.

;

* The warranty applies only to defects in materials or manufacture;

* The unit's components – ventilators, thermostats, terminals, electric cables,

etc. have a 2 (two) year warranty;

* SOLZAIMA is happy to replace defective elements free of charge, following

analysis and verification by a qualified agent/installer.

* Exclusions:

* Fracture of the glass due to misuse of the unit does not fall within the

scope of this warranty; the chances of natural fracture of the glass are

minimal, as this would only be possible due to overheating. The glass can

withstand temperatures of 1382°F (750°C) in constant operation, as well as

temperature peaks of 1562°F (850°C) – temperatures which are never

reached during normal operation;

* The type of fuel used and how the unit is handled are not within

SOLZAIMA’s control, so the parts in direct contact with the flame – the ash

grate, comb and baffle plate – are not covered by this warranty;

* The vermiculite and sealing ring are not included in the warranty;

* The installer bears full responsibility for all problems and/or defects

resulting from the installation process;

* Costs associate with moving, transport, labour, packaging, disassembly

and immobilisation of the unit incurred during warranty operations shall be

borne by the purchaser;

* Any malfunctioning caused by mechanical or electrical parts not supplied

by SOLZAIMA and which are prohibited under the instructions governing

heating appliances are not covered by this warranty;

* SOLZAIMA disclaims responsibility for damages caused by the use of any

fuel other than firewood.

30

31

Loading...

Loading...