Page 1

Eddy Series

User’s Guide

Ver 2.1

2008.4.2

Copyright 2007 SystemBase Co., Ltd. All rights reserved.

Tel: 82-2-855-0501 / Fax: 82-2-855-0580

16F Daerung Post Tower-1, Guro-dong, Seoul, Korea

tech@sysbas.com

http://www.sysbas.com/

/

Page 2

Table of Contents

Table of Contents ................................................................... I

Figures.......................................................................................... III

Ta bl es ........................................................................................... IV

Chapter 1. Introduction ......................................................... 1-1

1.1 About this manual.......................................................................1-1

1.2 Who should read this manual .........................................................1-1

1.3 Contents ..................................................................................1-2

1.4 Eddy Documents.........................................................................1-2

1.5 Technical Support .......................................................................1-3

Chapter 2. Getting Started ..................................................... 2-1

2.1 Overview .................................................................................2-1

2.2 Features ..................................................................................2-5

2.3 Package Checklist.......................................................................2-7

2.4 Applications ..............................................................................2-7

Chapter 3. Hardware Description .............................................. 3-1

3.1 Eddy-CPU .................................................................................3-1

3.1.1 Dimensions ................................................................................3-2

3.1.2 Pin Specifications.........................................................................3-3

3.2 Eddy-S1/Pin ..............................................................................3-1

3.2.1 Dimensions ................................................................................3-2

3.2.2 Pin Specifications.........................................................................3-3

3.2.3 Serial Interface Setup....................................................................3-6

3.2.4 Terminal Resistors ........................................................................3-7

3.2.5 Terminal Resistor Installation Guide...................................................3-7

3.3 Eddy-S1/DB9 .............................................................................3-8

3.3.1 Dimensions ................................................................................3-9

3.3.2 Pin Specifications....................................................................... 3-10

3.4 Eddy-S1/DB9-PoE...................................................................... 3-14

3.4.1 Dimensions .............................................................................. 3-15

3.4.2 Pin Specifications....................................................................... 3-16

3.5 Eddy-S2M/Pin .......................................................................... 3-20

3.5.1 Dimensions .............................................................................. 3-21

3.5.2 Pin Specifications....................................................................... 3-22

3.5.3 Eddy-S2M/Pin JIG (Pin-to-DB9 gender).............................................. 3-26

Chapter 4. Integration ........................................................... 4-1

4.1 Connection Guide .......................................................................4-1

I

Page 3

4.2 First-time Bootup ...................................................................... 4-2

4.3 Connecting to Eddy with IP address ................................................. 4-3

4.4 Eddy-S2M/Pin’s MCI & USB Host Port ................................................ 4-6

Chapter 5. Configuration via Web ............................................. 5-1

5.1 Connection .............................................................................. 5-1

5.2 Setup Menu .............................................................................. 5-2

5.3 Network Settings ....................................................................... 5-3

5.4 Serial Settings........................................................................... 5-5

5.5 GPIO Settings ........................................................................... 5-9

5.6 Change Password ...................................................................... 5-11

5.7 Update Firmware...................................................................... 5-13

5.8 Factory Default ........................................................................ 5-15

5.9 Save & Reboot .........................................................................5-16

Chapter 6. Configuration via Telnet ........................................... 6-1

6.1 Connection .............................................................................. 6-1

6.2 View commands ........................................................................ 6-2

6.3 Network commands .................................................................... 6-2

6.4 Serial Commands ....................................................................... 6-3

6.5 GPIO commands ........................................................................ 6-6

6.6 Username/Password Commands ..................................................... 6-6

6.7 System Commands ..................................................................... 6-6

Chapter 7. Appendix ............................................................. 7-1

7.1 Firmware Updates...................................................................... 7-1

7.2 Eddy-CPU ................................................................................ 7-3

7.3 Eddy-Serial .............................................................................. 7-4

7.4 Eddy-Memory............................................................................ 7-5

7.5 Ordering Information .................................................................. 7-6

7.6 Package Contents ...................................................................... 7-6

7.7 FCC Statement.......................................................................... 7-7

II

Page 4

Figures

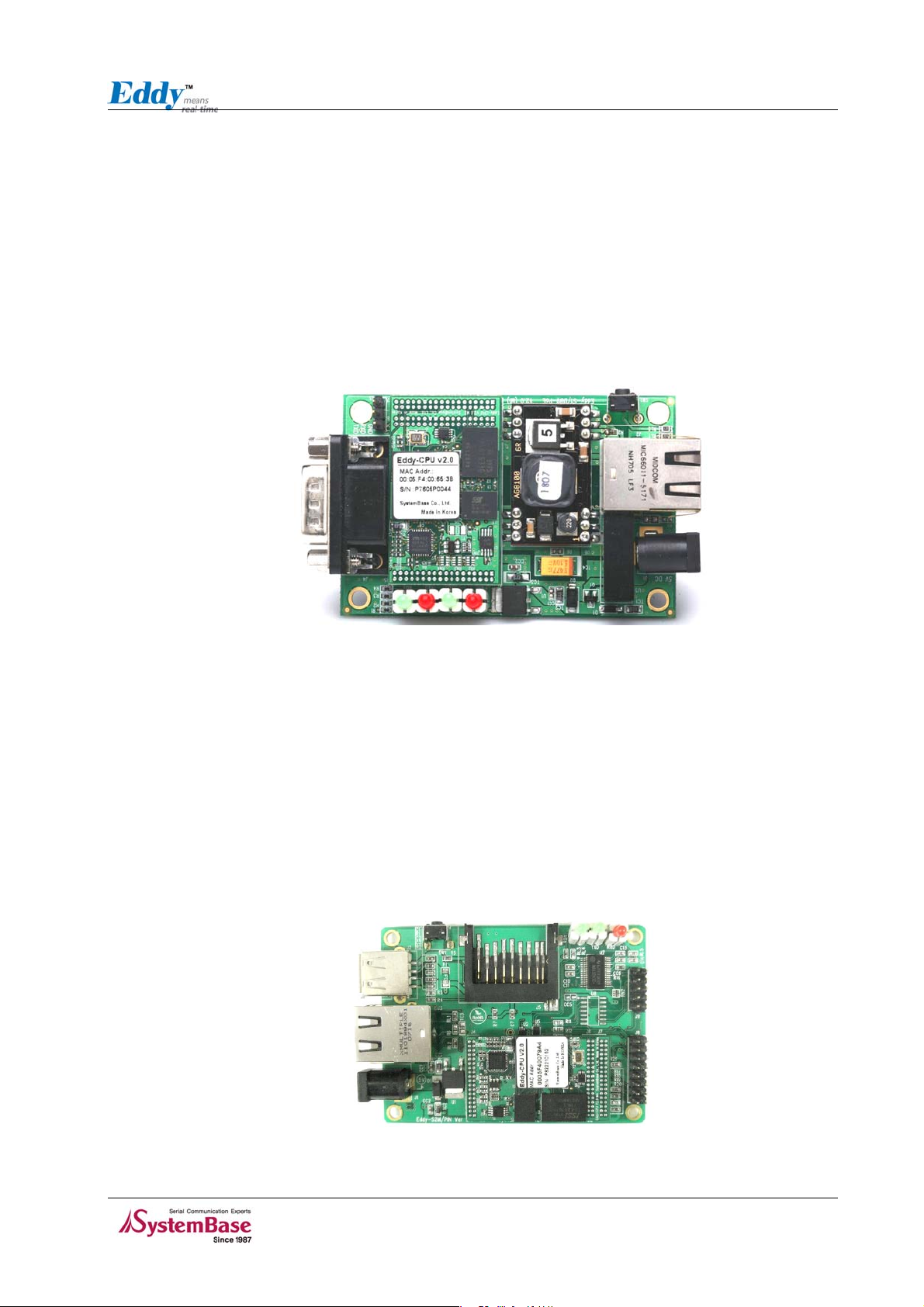

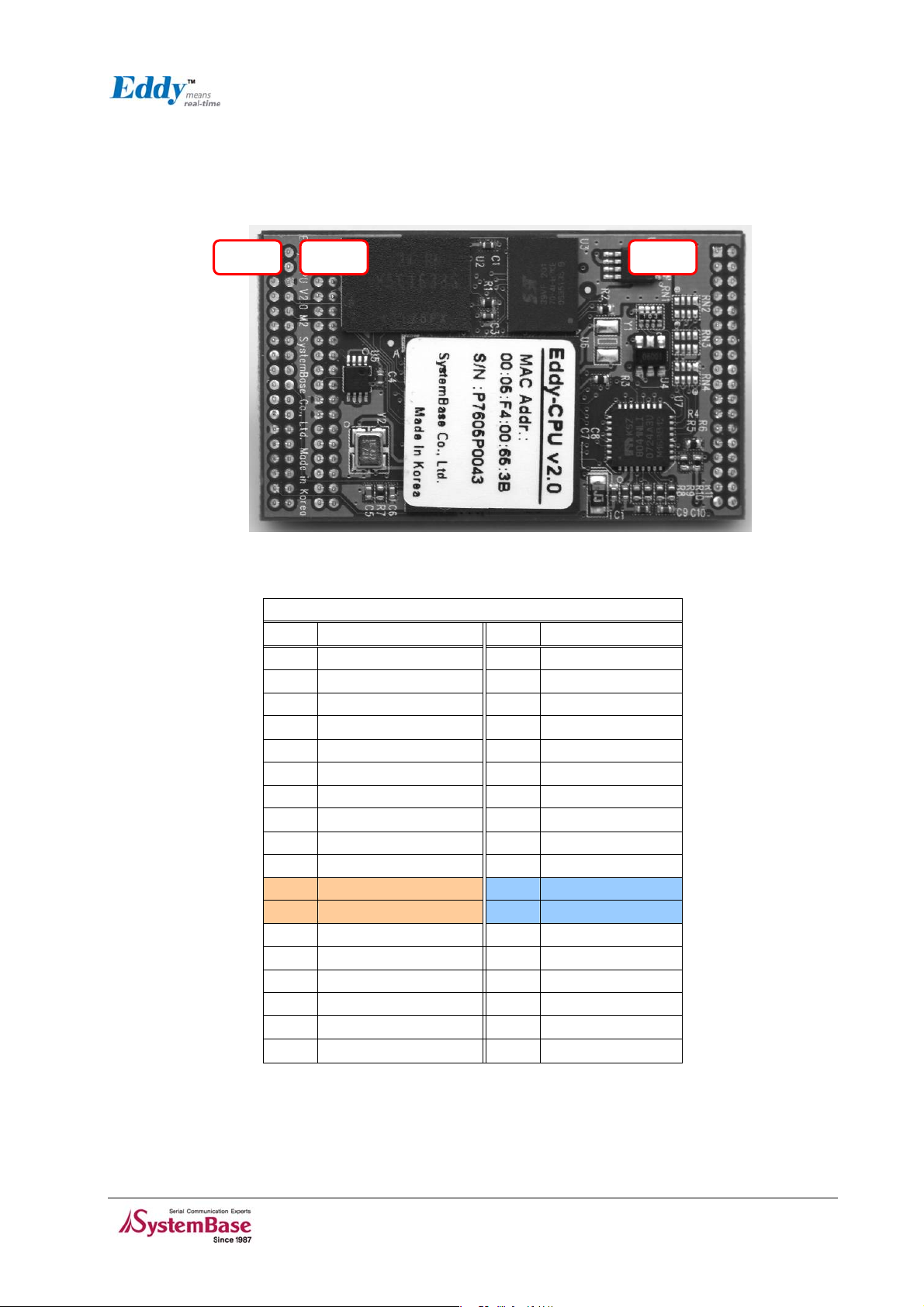

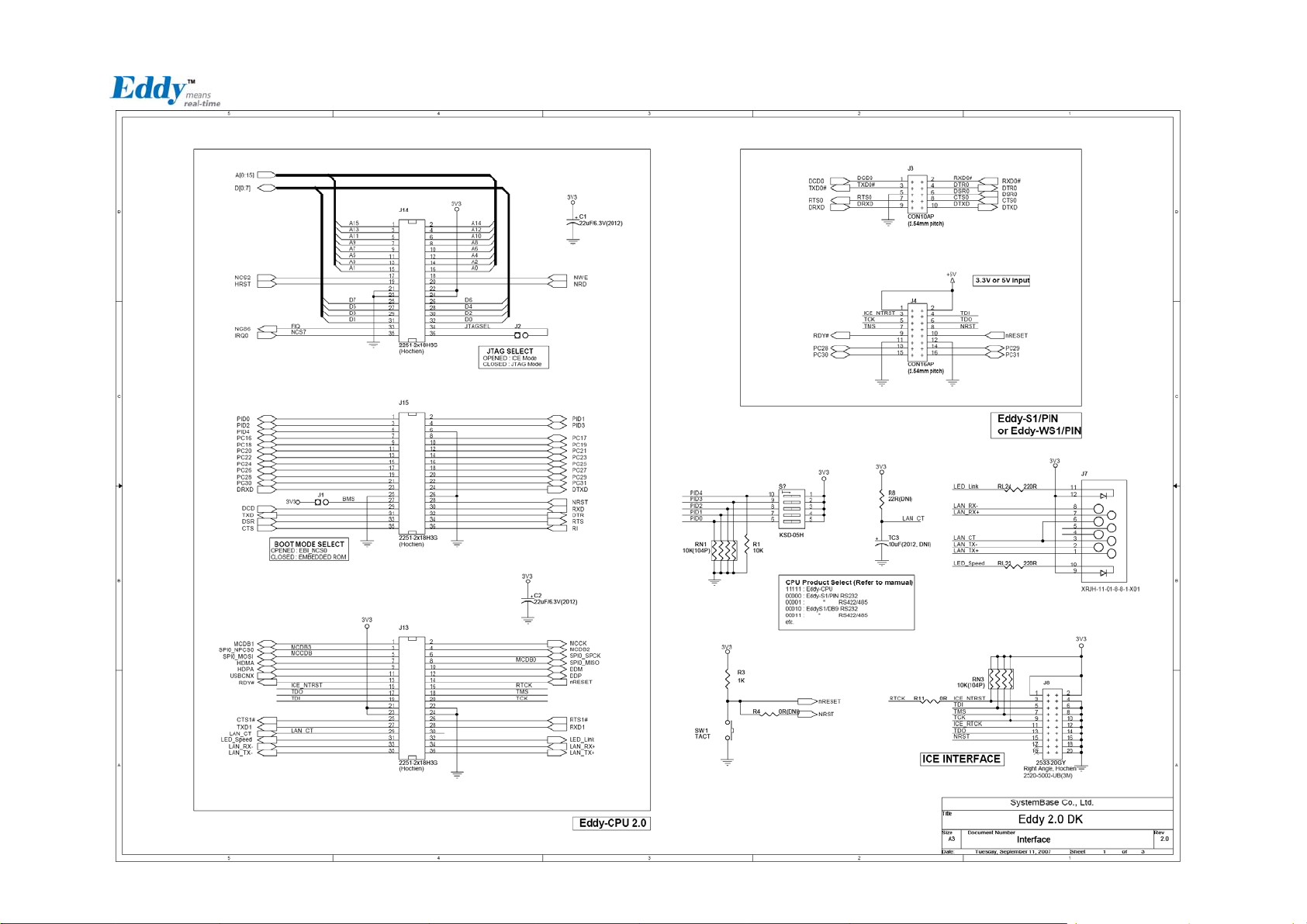

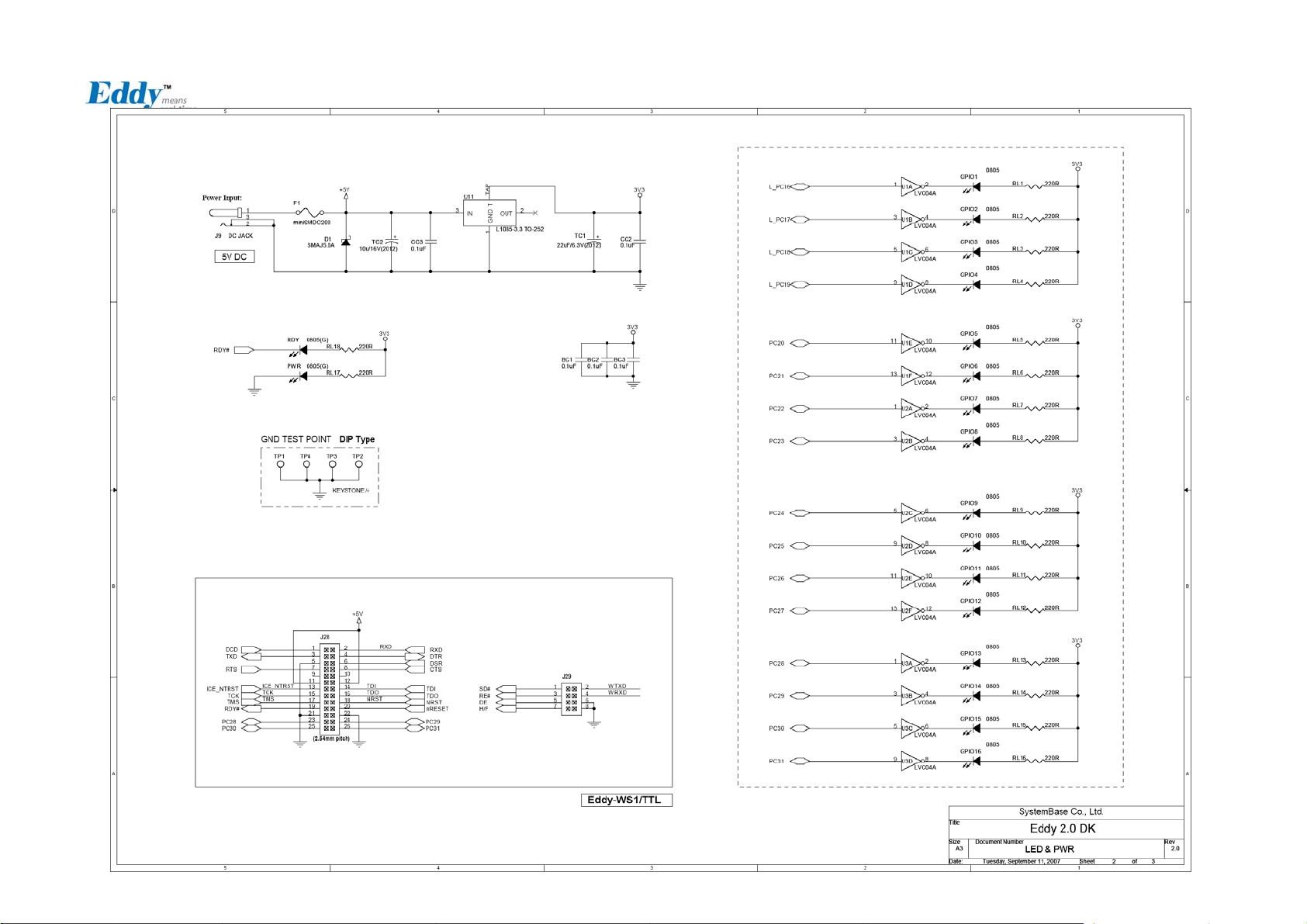

Figure 2-1 Eddy-CPU................................................... 2-1

Figure 2-2 Eddy-S1/Pin ............................................... 2-2

Figure 2-3 Eddy-S1/DB9 ............................................... 2-2

Figure 2-4 Eddy-S1/DB9-PoE ........................................... 2-3

Figure 2-5 Eddy-S2M/Pin .............................................. 2-3

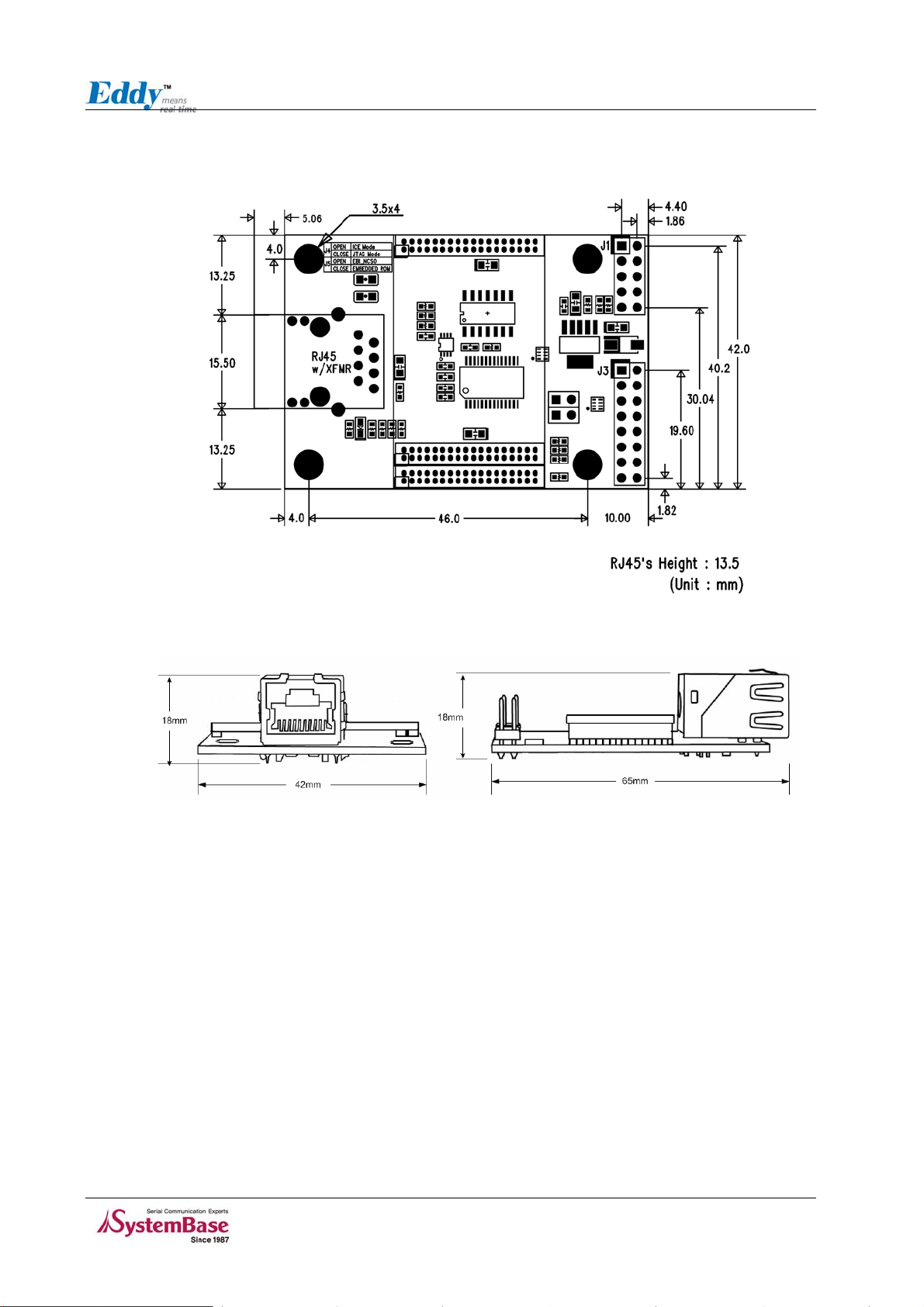

Figure 2-6 Eddy-DK ................................................... 2-4

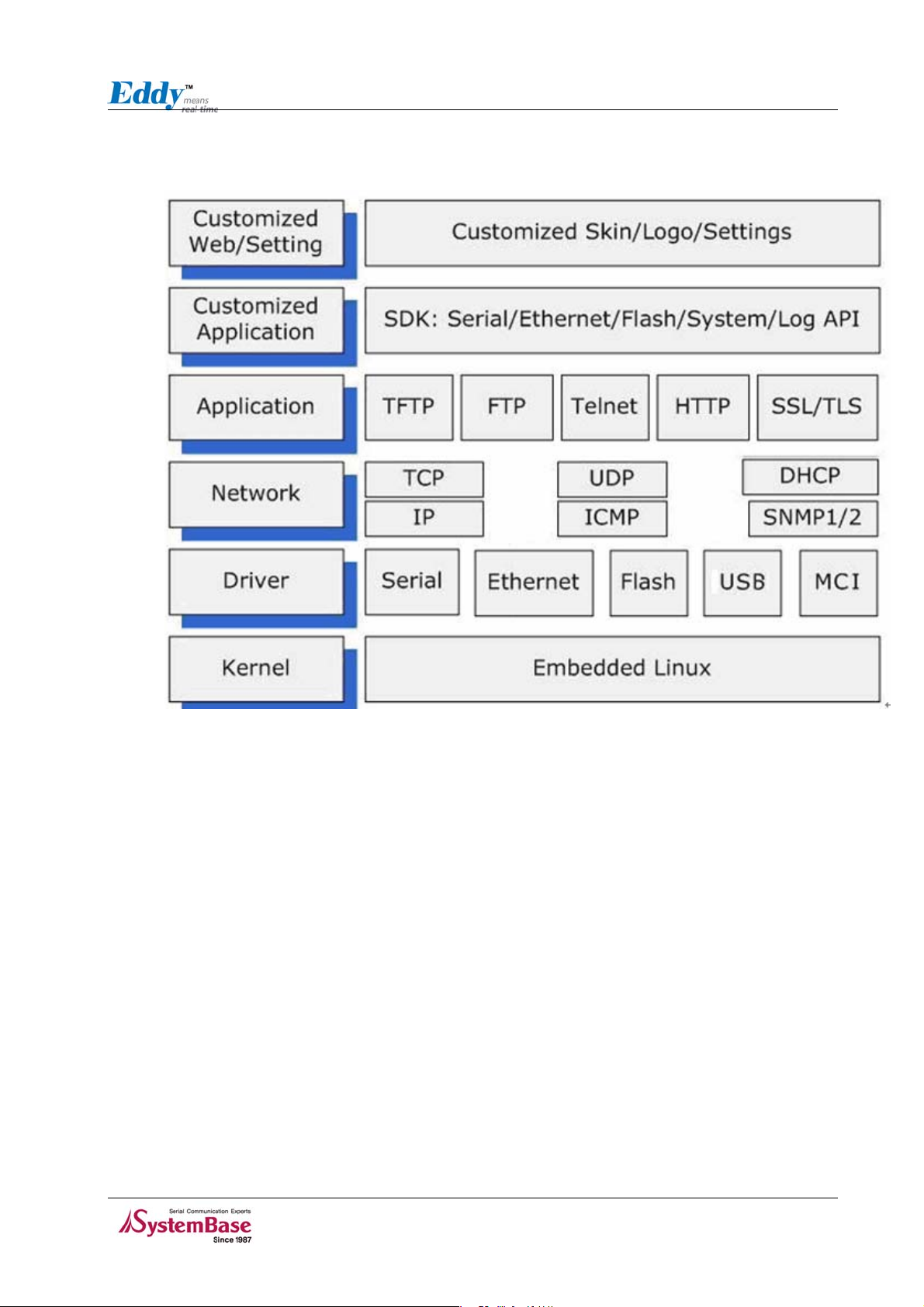

Figure 2-7 Eddy Software Architecture.................................. 2-5

Figure 3-1 Eddy-CPU front and side view ................................ 3-2

Figure 3-2 Pin Spec ................................................... 3-3

Figure 3-3 Eddy-S1/Pin – Product and block diagram...................... 3-1

Figure 3-4 Eddy-S1/Pin Front View ..................................... 3-2

Figure 3-5 Eddy-S1/Pin Side View ...................................... 3-2

Figure 3-6 RS485 Terminal Registor..................................... 3-7

Figure 3-7 Eddy-S1/DB9 – Product Picture and Block Diagram.............. 3-8

Figure 3-8 Eddy-S1/DB9 Front View .................................... 3-9

Figure 3-9 Eddy-S1/DB9 Side View ..................................... 3-9

Figure 3-10 Eddy-S1/DB9-PoE – Product Picture and Block Diagram ......... 3-14

Figure 3-11 Eddy-S1/DB9-PoE Front View................................ 3-15

Figure 3-12 Eddy-S1/DB9-PoE Side View................................. 3-15

Figure 3-13 Eddy-S2M/Pin – Product Picture and Block Diagram ............ 3-20

Figure 3-14 Eddy-S1/DB9-PoE Front View................................ 3-21

Figure 3-15 Eddy-S1/DB9-PoE Side View................................. 3-21

figure 3-16 Eddy-S2M/Pin Pin Spec ..................................... 3-22

figure 3-17 J8 PIN header ............................................. 3-23

figure 3-18 J9 PIN header ............................................. 3-24

figure 3-19 Eddy-S2M/Pin JIG .......................................... 3-26

Figure 4-1 Connecting to the default IP address ......................... 4-3

Figure 5-1 Eddy Login Page............................................ 5-1

III

Page 5

Figure 5-2 Main Page.................................................. 5-2

Figure 5-3 Network Settings Configuration Page ........................... 5-3

Figure 5-4 Serial settings page ......................................... 5-5

Figure 5-5 Eddy-S1/Pin - GPIO Settings Page ............................. 5-9

Figure 5-6 Eddy-CPU - GPIO Settings Page .............................. 5-10

Figure 5-7 Change Password Setting Page............................... 5-11

Figure 5-8 After changing the password ................................ 5-12

Figure 5-9 Update Firmware Setting Page .............................. 5-13

Figure 5-10 Firmware update in progress ............................... 5-14

Figure 5-11 Firmware update complete ................................ 5-14

Figure 5-12 Factory Default Page ....................................... 5-15

Figure 5-13 Save & Reboot Page ........................................ 5-16

Figure 6-1 Connection via Telnet ........................................ 6-1

Figure 7-1 Firmware updates via FTP .................................... 7-1

Figure 7-2 Firmware Update via Telnet ................................... 7-2

Tabl e s

Ta bl e 1 -1 Eddy Documents ............................................ 1-2

Ta bl e 5 -1 Main features of Setup Menu ................................. 5-2

Ta bl e 5 -2 Main features of General Configuration........................ 5-3

Ta bl e 5 -3 Main features for Network Service Configuration ............... 5-4

Ta bl e 5 -4 Main features for Serial Settings .............................. 5-5

Ta bl e 5 -5 Main features for GPIO Settings ............................. 5-10

Ta bl e 5 -6 Main features for Save & Reboot............................. 5-16

Ta bl e 6 -1 def view commands ......................................... 6-2

Ta bl e 6 -2 Network commands ......................................... 6-2

Ta bl e 6 -3 Serial commands ........................................... 6-3

Ta bl e 6 -4 GPIO commands ............................................ 6-6

Ta bl e 6 -5 User/Password configurations ................................ 6-6

Ta bl e 6 -6 System Commands .......................................... 6-6

IV

Page 6

Chapter 1. Introduction

Chapter 1. Introduction

SystemBase Embedded Module lineup is composed of largely three catagories; Eddy-Serial Series,

Eddy-DIO Series and Eddy-CPU Series. This manual focuses on Eddy-Serial and Eddy-CPU Series.

1.1 About this manual

This manual includes all necessary information from installation to operating Eddy Series (Eddy-CPU,

Eddy-S1/Pin, Eddy-S1/DB9, and Eddy-S1/DB9-PoE). Setting Eddy’s configurations, status monitoring,

firmware update, and other administration work are also included, H/W level integration and S/W

setting information can also be found.

1.2 Who should read this manual

This guide is designed for Eddy users and administrators. It is strongly recommended that anyone

trying to apply, use, and maintain Eddy read this document. It will be a great starting point for any

administrator who wants to easily monitor and control Eddy and its connected devices.

1-1

Page 7

Chapter 1. Introduction

1.3 Contents

Chapter 1. Introduction is a preface with general information and introductory notices.

Chapter 2. Getting Started

applications.

Chapter 3. Hardware Descriptions

drawings.

Chapter 4. Integration

time boot-up and status check procedures.

Chapter 5. Configuration via Web

Chapter 6. Configuration via Telnet

connect Eddy via web Telnet.

Chapter 7. Appendix

provides firmware update guides and detailed technical specifications.

gives a brief introduction to Eddy series, including features and

explains the layout and pin specifications with block diagram and

assists you connecting Eddy to serial and network environment. It covers first

provides ways to configure and to connect Eddy via web browser.

provides commands and its explanation to configure and to

1.4 Eddy Documents

The following table summarizes documents included in the Eddy document set.

Table 1-1 Eddy Documents

Document Description

User’s Guide Eddy’s Configuration, and Management Information

Programmer’s application development guide, including in-depth

Programmer’s Guide

Portview User’s Manual

COM Port Redirector

User Manual

Te s t Vi e w

User Manual

General information on Eddy or embedded device servers can be obtained at our website at

http://www.sysbas.com/

Other relevant documents are as follows:

approach to compiling, linking, creating and uploading firmware

API reference is included with a list of available functions

for customized application programming

Guide for SystemBase device server management application

Portview

Guide for SystemBase COM Port Redirector

Guide for SystemBase test program TestView

. Latest documents, software and firmware downloads are available.

1-2

Page 8

Chapter 1. Introduction

Document Description

Eddy Spec Sheet Eddy specifications

An introductory reading for anyone new to embedded device

Eddy White Paper

Eddy Application Notes Various applications of Eddy presented in diagrams and images

All documents are updated promptly, so check for the recent document updates. The contents in

these documents are subject to change without a prior notice.

server, which focuses on background, history, market environment,

and technology

1.5 Technical Support

You can reach our tech support by following 4 ways;

1. Visit the developer’s community at http://www.embeddedmodule.com

tips on Eddy with developers all around the world.

2. Visit us at http://www.sysbas.com/

reviewed and submitted.

3. E-mail our technical support team to tech@sysbas.com

comments are welcomed.

4. Call us at our customer center at 82-2-855-0501 for immediate support.

Our technical support team will kindly help you get over with the problem.

and go to ‘Technical Support’ menu. FAQ and questions can be

. Any kind of inquiries, requests, and

and share information and

1-3

Page 9

Chapter 2. Getting Started

Chapter 2. Getting Started

Welcome to Eddy! This chapter includes Eddy series overview, main and distinctive features, package

contents for each product, and application fields.

2.1 Overview

There are 4 modules in Eddy-Serial Series; Eddy-CPU, Eddy-S1/Pin, Eddy-S1/DB9, and Eddy-S1/DB9-

PoE.

Each module includes default applications for serial and LAN communication, and supports plug-and-

play features. By switching to the custom mode, users can program any application and upload it on

to the module. This application then is executed on the module. In order to write and compile

programmer’s source code, Software Development Kit (SDK) LemonIDE

the Development Kit package. Please refer to Programming Guide and LemonIDE

®

is required. SDK is included in

®

user’s manual

included in the Development Kit for detailed information on the SDK.

SDK is not necessary for users using Eddy in default presettings.

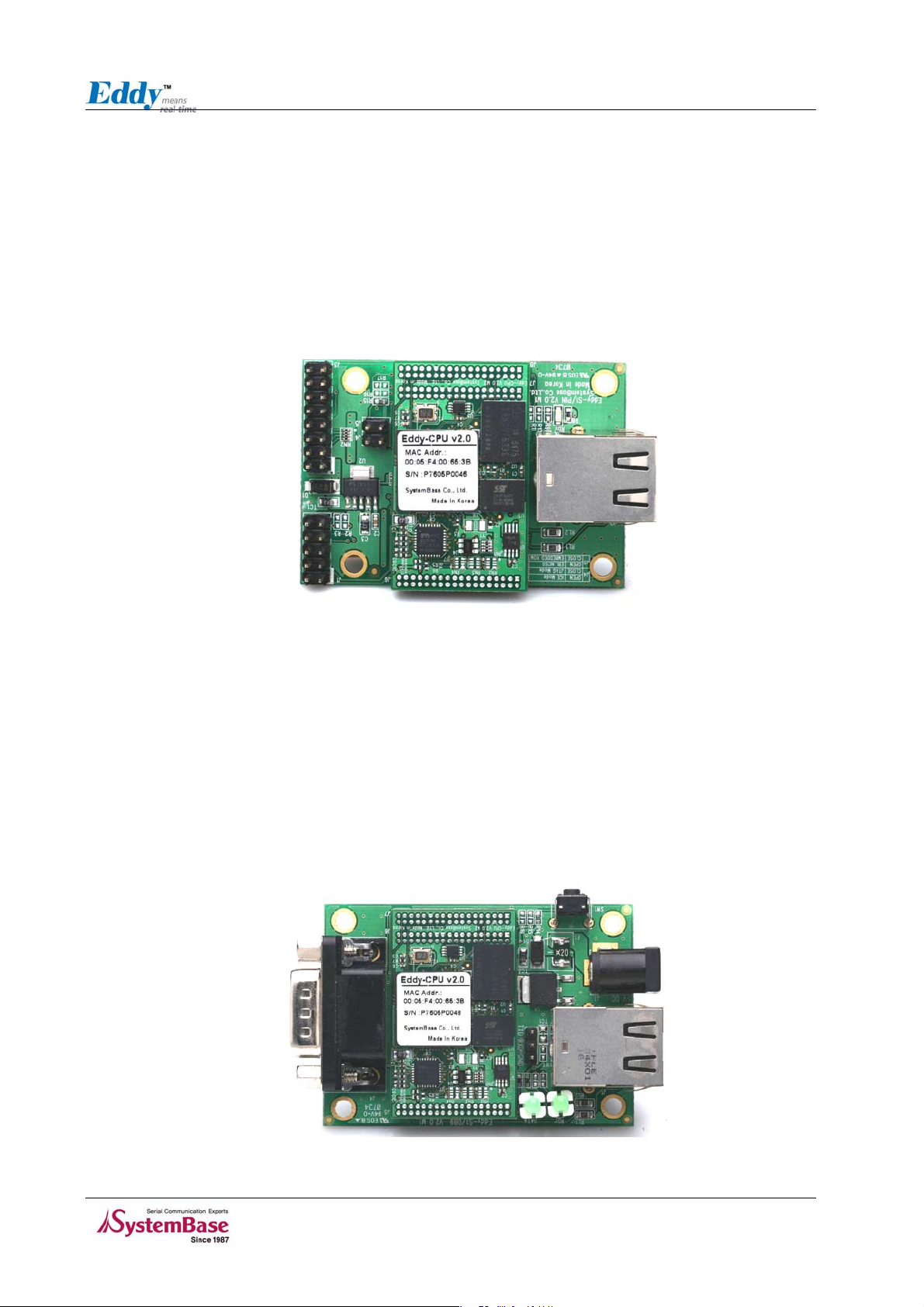

◆ Eddy-CPU

Eddy-CPU is an embedded module based on ATMEL AT91SAM9260-CJ processor with 32MB SDRAM, 4MB

Flash Memory, 1 Ethernet port with 10/100Mbps, 16 bit address / 8 bit data bus interface supporting

external device connection, and maximum 17 programmable IO pins. Programmers can easily

implement RS232/422/485 serial driver or I2C interface with library type example codes and

evaluation kit circuit diagrams.

Eddy-CPU is implemented on a small form factor (42 * 25mm) with on-board memory and integrated

10/100Mbps network interface. Developers can minimize time and cost spent on developing

application products.

Figure 2-1 Eddy-CPU

2-1

Page 10

Chapter 2. Getting Started

◆ Eddy-S1/Pin

RJ-45 Ethernet port is included to provide direct connection to network.

For serial communication, RS232 only or RS422/485 combo interface is available. In the combo

module, RS422/485 setting can be adjusted with software, using web interface.

Acceptable external power input ranges from 3.0 to 5.5V through pin headers.

Please check labeled input voltage on top of the module before supplying power. Improper voltage

feed may damage the module.

Figure 2-2 Eddy-S1/Pin

◆

Eddy-S1/DB9

RJ-45 Ethernet port is included to provide direct connection to network.

For serial communication, RS232 only or RS422/485 combo interface is available through DB9 male

connector. In the combo module, RS422/485 setting can be adjusted with software, using web

interface.

External power input is provided as 5V DC Jack.

Please check labeled input voltage on top of the module before supplying power. Improper voltage

feed may damage the module.

Figure 2-3 Eddy-S1/DB9

2-2

Page 11

Chapter 2. Getting Started

◆ Eddy-S1/DB9-PoE

This module can operate as a powered device (PD), which accepts power input from the twisted pair

Category 5 Ethernet cable as specified in IEEE 802.3af Power-over-Ethernet (PoE) standard.

With an auxiliary 5V DC power jack, power supply can be automatically channeled to 5V adaptor when

PSE (Power Sourcing Equipment) is out of order. Seamless power supply is guaranteed. PSE power can

be used again when the PSE resumes to normal operation.

For serial communication, RS232 only or RS422/485 combo interface is available through DB9 male

connector. In the combo module, RS422/485 setting can be adjusted with software, using web

interface.

Figure 2-4 Eddy-S1/DB9-PoE

◆ Eddy-S2M/Pin

The model supports MCI ( MultiMedia Card Interface) and USB host port.

The MultiMedia Card Interface (MCI) supports the MultiMedia Card (MMC) Specification V3.11, the SD

Memory Card Specification V1.0.

The USB Host Port integrates a root hub and transceivers on downstream ports. It provides sev-eral

high-speed half-duplex serial communication ports at a baud rate of 12 Mbit/s. Up to 127 USB devices

For two serial communication, RS232 only or RS422/485 combo interface is available through PIN

type connector. In the combo module, RS422/485 setting can be adjusted with software, using web

interface.

Figure 2-5 Eddy-S2M/Pin

2-3

Page 12

Chapter 2. Getting Started

◆

Eddy Development Kit (Eddy DK)

Eddy Development Kit (Eddy DK) helps programmers to test and customize their own Eddy applications

easily, with 1 piece of Eddy-S1/Pin module included in the package. The kit includes evaluation board,

all necessary connectors, and programming environment with documentations and guidelines. Please

refer to Programming Guide included in the Development Kit for detailed information on the DK.

Figure 2-6 Eddy-DK

2-4

Page 13

Chapter 2. Getting Started

◆ Eddy Software Architecture

Figure 2-7 Eddy Software Architecture

2.2 Features

Various features of Eddy make it a universal yet distinctive embedded solution.

Below lists main features of Eddy Serial Series. Others will explicitly appear throughout this guide.

z Premium-level hardware with ARM9 180MHz CPU, 4MB Flash, and 32MB SDRAM

z Selectable RS232 only or RS422/485 combo interfaces

z MMC and SDcard interface

z USB host port

z Max 921.6Kbps serial speed

z Max 8Mbps MCI speed

z Max 8Mbps USB Full speed

z Program and run your own application

z SystemBase SDK and API support for application programming (included in Development Kit)

z Small size to fit in to any hardware

2-5

Page 14

Chapter 2. Getting Started

z 10/100Mbps Ethernet port (auto MDIX)

z SystemBase COM Port Redirector for better adaptability

z Extensive configuration and monitoring with Portview

z Firmware upload with Web, FTP, and TFTP

z Configuration with Web, Telnet, SNMP, and Portview

z Various customizing options

z Standard Linux environment for openness in executable applications

z Multiple Programmable IO pins for customized applications

2-6

Page 15

Chapter 2. Getting Started

2.3 Package Checklist

Eddy package is composed of following components. Make sure every component is included with your

package.

◆ Eddy Package Contents

All module packages include a module and a CD with utilities and documents.

Module 1pc (Eddy-S1/Pin, Eddy-S1/DB9, Eddy-S1/DB9-PoE, Eddy-S2M/Pin)

CD-ROM (Utilities and documents)

2.4 Applications

Eddy can be applied to many practical applications in various fields. Some are presented below.

◆ Factory / Industrial Automation

PLC, Robot arms, Human-Machine Interface, Warehouse rails

Medical instruments, Inspection equipment controllers

Alarming units

◆ Home Appliances / Electronic Devices

Power controller, Gaming machines

Scales, Gas detection units, Water & pollution metering devices

Data collection and distribution units

◆ Financial / Building Automation

Card readers, Barcode scanners, Kiosks, Point-Of-Sale related devices

Serial printers, Cash registers, Credit card authorization terminals

Biometric detection units, Security devices

◆ OEM Device Server Distributors

OEM device server with distributor’s own case & brand

Ready-to-go device or customized application / setup mode can be inserted

2-7

Page 16

Chapter 3. Hardware Description

Chapter 3. Hardware Description

This chapter provides Eddy’s hardware information, including block diagram, layout, pin specifications,

dimensions and other hardware-related issues.

3.1 Eddy-CPU

Ethernet port is provided as pin headers, and the transformer and RJ-45 connector should be manually

implemented by users. (RJ-45 connector with embedded transformer, normally called LAN-Mate or

MAC Jack, can be used as a simpler approach.

16 bit address / 8 bit data bus provides flexibility in external peripheral connectivity and up to 16

programmable IO can be used on user’s side.

Chip Selects

Chip select signal Typical Slave Device Address Range Size

NCS0 Flash ROM 0x10000000~x107FFFFF 4MB

NCS2 0x30000000~

NCS6 0x60000000~

NCS7

Eddy-CPU Operating Conditions

Parameter Symbol Min Typ Max Units

Supply Voltage Vcc 3.0 3.3 3.6 VDC

Supply Current Icc

Operating ambient

temperature

Application

dependent

0x70000000~

-40

T

A

300

85

mA

℃

3-1

Page 17

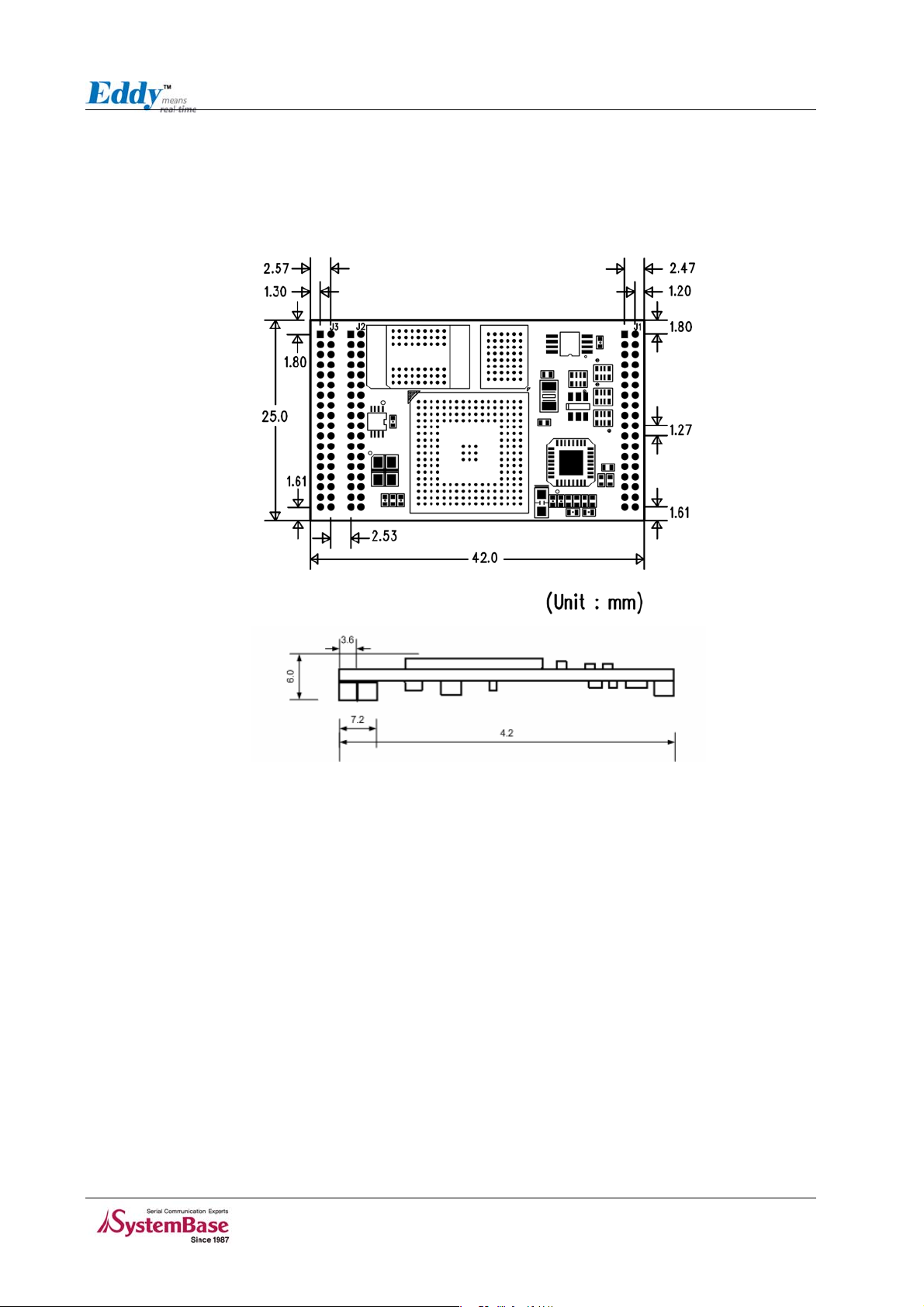

3.1.1 Dimensions

Dimensions of Eddy-CPU are shown below.

Chapter 3. Hardware Description

Figure 3-1 Eddy-CPU front and side view

3-2

Page 18

Chapter 3. Hardware

Description

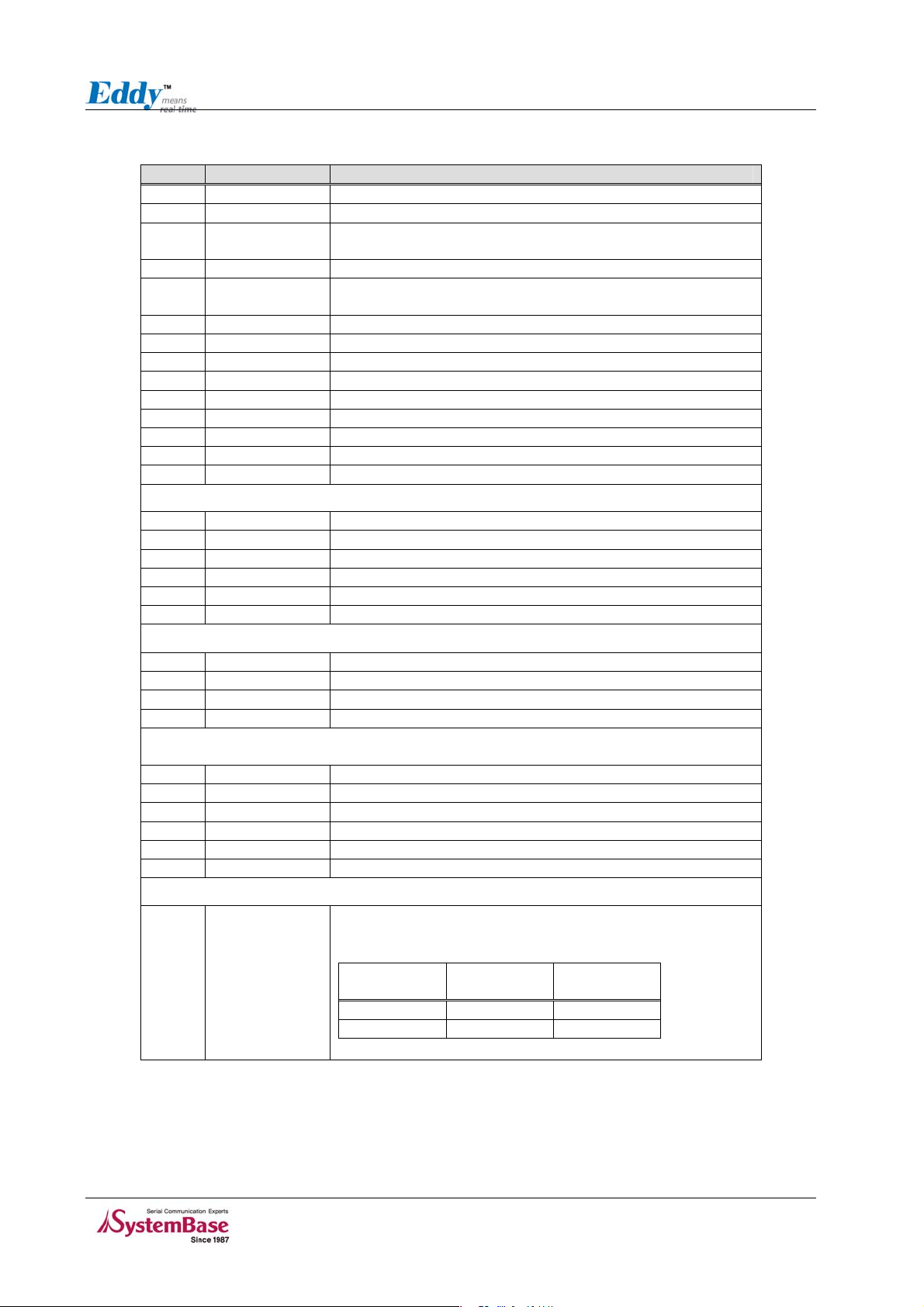

3.1.2 Pin Specifications

Pin specifications are presented below.

J1 Pin J3 Pin J2 Pin

Figure 3-2 Pin Spec

J1 Specifications

Pin Desc. Pin Desc.

1 MCDB1 2 MCCK

3 MCDB3(SPI0_NPCS0)

5 MCCDB(SPI0_MIOSI) 5 SPI0_SPCK

7 HDMA 8 SPI0_MISO

9 HDPA 10 DDM

11 USBCNX 12 DDP

13 RDY# 14 nRESET

15 NTRST 16 RTCK

17 TDO 18 TMS

19 TDI 20 TCK

21 3.3V

23 3.3V

25 CTS1 26 RTS1

27 TXD1 28 RXD1

29 NC 30 NC

31 LED_Speed 32 LED_link

33 LAN_RX- 34 LAN_RX+

35 LAN_TX- 36 LAN_TX+

J1

4 MCDB2

22 GND

24 GND

3-3

Page 19

Chapter 3. Hardware Description

J1 Pin Description

Pin No Name Description

1 MCDB1 Multimedia Card Slot B Data

2 MCCK Multimedia Card Clock

MCDB3

3

(SPI0_NPCS0)

4 MCDB2 Multimedia Card Slot B Data

MCCDB

5

(SPI0_MOSI)

6 SPI0_SPCK SPI Serial Clock

7 HDMA USB Host Port A Data 8 SPI0_MISO SPI Master In Slave Out

9 HDPA USB Host Port A Data +

10 DDM USB Device Port Data 11 USBCNX Used when implementing USB Device Port

12 DDP USB Device Port Data +

13 RDY# Output signal for CPU operation status

14 nRESET Microcontroller Reset input

15 NTRST Test Reset Signal

16 RTCK Return Test Clock

17 TDO Test Data Out

18 TMS Test Mode Select

19 TDI Test Data In

20 TCK Test Clock

21 3.3V 3.0V to 3.6V power input

22 GND Ground

23 3.3V 3.0V to 3.6V power input

24 GND Ground

SPI Master Out Slave In

Power Supplies

Multimedia Card Slot B Data

SPI Peripheral Chip Select 0

Multimedia Card Slot B Command

ICE and JTAG

Universal Synchronous Asynchronous Receiver Transmitter USART1

25 CTS1 USART1 Clear To Send

26 RTS1 USART1 Request To Send

27 TXD1 USART1 Transmit Data

28 RXD1 USART1 Receive Data

29 NC No Connection

30 NC No Connection

Ethernet 10/100

LAN connection speed

31 LED_Speed

Speed Pin State LED

Definition

10Base-T H OFF

100Base-TX

L ON

3-4

Page 20

Chapter 3. Hardware

22

24

36

Description

LAN connection status

Link/Activity

32 LED_link

33 LAN_RX- Physical receive or transmit signal (- differential)

34 LAN_RX+ Physical receive or transmit signal (+ differential)

35 LAN_TX- Physical transmit or receive signal (- differential)

36 LAN_TX+ Physical transmit or receive signal (+ differential)

No Link H OFF

Link L ON

Activity Toggle Blinking

Pin State LED

Definition

J2 Specifications

Connect USB cable to J1 while the jumper is connected to J2, so that applications can be compiled,

linked, created, and uploaded to the Eddy-CPU module. (Please refer to Programmer Guide for more

information.)

J2

Pin Desc. Pin

1 A15 2 A14

3 A13 4 A12

5 A11 5 A10

7 A9 8 A8

9 A7 10

11 A5 12

13 A3 14

15 A1 16

17 NCS2 18

19 HRST 20

21 GND

23 GND

25 D7 26

27 D5 28

29 D3 30

31 D1 32

33 NCS6(FIQ) 34

35 IRQ0(NCS7)

Desc.

A6

A4

A2

A0

NWE

NRD

3.3V

3.3V

D6

D4

D2

D0

JTAGSEL

VDDBU

3-5

Page 21

Chapter 3. Hardware Description

26

J2 Pin Description

Pin No Name Description

1~16 A[15:0] Address Bus 0~15

17 NCS2

18 NWE External device Write Enable signal, active low

19 HRST External device Reset signal, active high

20 NRD External device Read signal

21, 23 GND Ground

22, 24 3.3V 3.0V to 3.6V power input

25~32 D[7:0] Data Bus

33 NCS6/FIQ

34 JTAGSEL

35 NCS7/IRQ0

36 VDDBU

External device Chip Select signal, 256MB memory area

addressable, active low

- External device Chip Select signal, 256MB memory area

addressable, active low

- Fast Interrupt Input

JTAG boundary scan can be used by connecting pin34 and 36.

This pin should not be connected when using ICE(In-Circuit

Emulator) or in normal operation status.

- External device Chip Select signal, 256MB memory

addressable, active low

- External Interrupt Input

JTAG boundary scan can be used by connecting pin34 and 36.

This pin should not be connected when using ICE(In-Circuit

Emulator) or in normal operation status.

J3 Specifications

J3

Pin Desc. Pin

1 PID0 2 PID1

3 PID2 4 PID3

5 PID4 6 GND

7 GPIO1 8 GPIO2

9 GPIO3 10

11 GPIO5 12

13 GPIO7 14

15 GPIO9 16

17 GPIO11 18

19 GPIO13 20

21 GPIO15 22

23 DRXD 24

25 GND

27 BMS 28

29 DCD 30

31 TXD 32

33 DSR 34

35 CTS 36

Desc.

GPIO4

GPIO6

GPIO8

GPIO10

GPIO12

GPIO14

GPIO16

DTXD

GND

NRST

RXD

DTR

RTS

RI

3-6

Page 22

Chapter 3. Hardware

Description

J3 Pin Description

Pin No Name Description

1-5 PID[4:0]

6, 25,

26

7~22 GPIO[1:16]

23 DRXD Debug Receive Data

24 DTXD Debug Transmit Data

27 BMS

28 NRST External device Reset signal, active low signal

29 DCD USART0 Data Carrier Detection

30 RXD USART0 Receive Data

31 TXD USART0 Transmit Data

32 DTR USART0 Data Terminal Ready

33 DSR USART0 Data Set Ready

34 RTS USART0 Request To Send

35 CTS USART0 Carrier To Send

36 RI USART0 Ring Indicator

GND Ground

Universal Synchronous Asynchronous Receiver Transmitter USART0

Product ID only used by the manufacturer.

Please do not work on these pins.

General Purpose In/Out signal

Development Kit’s LED adjustable

Pin State LED

Definition

H ON

Boot Mode Select signal

BMS = 1, Boot on Embedded ROM

BMS = 0, Boot on External Memory

L OFF

Debug Unit - DBGU

Reset/Test

3-7

Page 23

Chapter 3. Hardware Description

3-1

Page 24

Chapter 3. Hardware Description

3-2

Page 25

Chapter 3. Hardware Description

\

3-3

Page 26

Chapter 3. Hardware Description

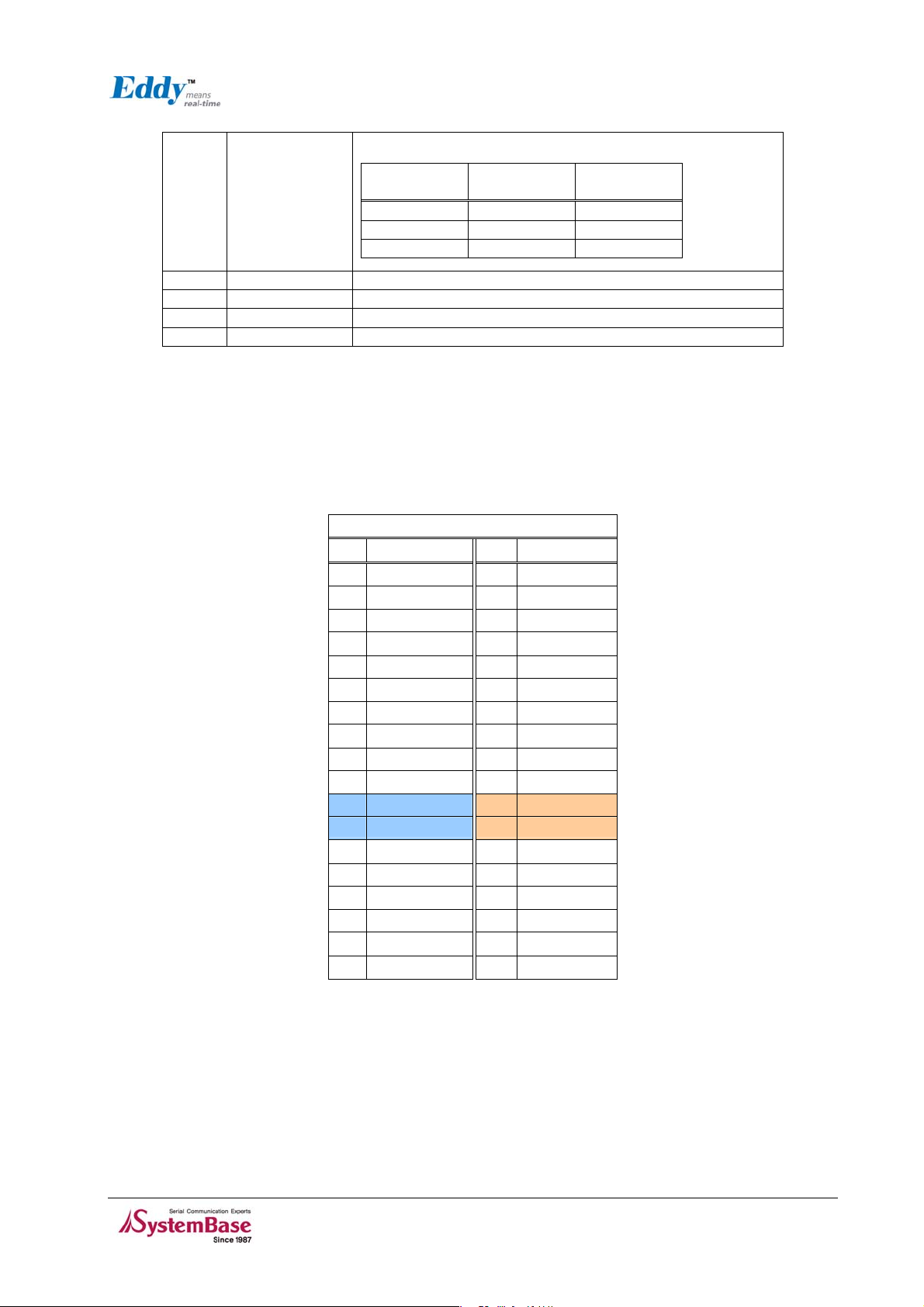

3.2 Eddy-S1/Pin

Ethernet LAN port is in RJ-45 form factor to provide direct network connection. One serial port is

provided in pin header interface, supporting either RS232 only or RS422/485 combo. Pins can be

connected to any kind of external serial interface of user’s preference.

Figure 3-3 Eddy-S1/Pin – Product and block diagram

3-1

Page 27

3.2.1 Dimensions

Chapter 3. Hardware Description

Figure 3-4 Eddy-S1/Pin Front View

Figure 3-5 Eddy-S1/Pin Side View

3-2

Page 28

Chapter 3. Hardware Description

3.2.2 Pin Specifications

Pin Specification and its usages are as follows.

J3

RJ-45

J1

◆ J1

Serial 10-pin header connector

◇ J1 : RS232

Pin Signal Description

1 DCD Data Carrier Detection (Input)

TXD

GND

RTS

NC

10

RXDDCD

2

DTR

DSR

6

CTS

8

NC

1

34

5

7

9

2 RXD Receive Data (Input)

3 TXD Transmit Data (Output)

4 DTR Data Terminal Ready (Output)

3-3

Page 29

Pin Signal Description

5 GND Ground

6 DSR Data Set Ready (input)

7 RTS Request to Send (Output)

8 CTS Clear to Send (Input)

9, 10 NC No Connection

◇ J1 : RS422 Full Duplex

Pin Signal Description

2 RXD+ Receive differential data positive (Input)

3 TXD+ Transmit differential data positive (Output)

6 RXD- Receive differential data negative (input)

Chapter 3. Hardware Description

7 TXD- Transmit differential data negative (Output)

◇ J1 85 Half : RS4 Duplex

Pin Signal Description

3 TRX+ Transmit/Receive differential data positive

7 TRX- Transmit/Receive differential data negative

◆

J3

6-pin header connector

1

VCC

NTRST

TCK TDO

TMS NRST

RDY# nRESET10

GND GND12

GPIO0

GPIO2

1

5

7

9

11

13

15 16 GPIO3

2

43

6

8

VCC

TDI

GPIO114

3-4

Page 30

Chapter 3. Hardware Description

Pin Signal Description

1,2 VCC 3.0 ~ 5.5V DC input

3 NTRST Test Reset Signal

4 TDI Test Data In

5 TCK Test Clock

6 TDO Test Data Out

7 TMS Test Mode Select

8 NRST Reset signal for external devices

Ready indicator (Active low output)

Processor status can be indicated, when connected as below.

9 RDY#

Connection to external reset switch (Input)

As reset logic is built-in, this pin can be connected directly to the

10 nRESET

11 GND Ground

switch without any additional circuit. When pressing the switch

for more than 5 seconds (low input), factory default settings are

restored.

12 GND Ground

13 GPIO0 Programmable I/O 0 (user-defined I/O)

14 GPIO1 Programmable I/O 1 (user-defined I/O)

15 GPIO2 Programmable I/O 2 (user-defined I/O)

16 GPIO3 Programmable I/O 3 (user-defined I/O)

3-5

Page 31

◆ RJ-45 Ethernet

Pin Signal Description

1 TXD+ Physical transmit or receive signal (+ differential)

2 TXD- Physical transmit or receive signal (- differential)

Chapter 3. Hardware Description

3 RXD+ Physical receive or transmit signal (+ differential)

6 RXD- Physical receive or transmit signal (- differential)

LED Description

Left Green

(LAN_Speed)

Right Yellow

(LAN_LINK)

Speed Pin State

10Base-T H OFF

100Base-TX L ON

Link/Activity Pin State

No Link H OFF

Link L ON

Activity Toggle Blinking

LAN connection speed

LED Definition

LAN connection status

LED Definition

3.2.3 Serial Interface Setup

Eddy supports RS232 only or RS422/485 combo by hardware. In combo modules, RS422/485 interface

can be configured by software.

3-6

Page 32

Chapter 3. Hardware Description

3.2.4 Terminal Resistors

Terminal Resistors are installed in RS422 or RS485 communication to prevent noise and distortion of

long distance data transfer. They help by matching impedance in communication line, and normally

120 ohm resistors are used. The decision to use terminal resistor lies with the user, and one may

choose to either install or not install terminal resistors in RS422 or RS485 mode. Installation can be

done by connecting RX+ and RX- pin on J1 pin header to the resistor if in RS422 mode, or TRX+ and

TRX- pin in RS485 mode.

3.2.5 Terminal Resistor Installation Guide

◆ RS422

Install terminal resistors at each end (terminal)

RS422 Dev ice A

TXD+

TXD-

RXD+

RXD-

When using RS422 Point to P oint Mode

Terminal REG

120R

120R

Terminal REG

RS422 Dev ice B

RXD+

RXD-

TXD+

TXD-

RS422 Master Device

TXD+

TXD-

RXD+

RXD-

When us ing RS422 Multi-Drop Mode

120R

Terminal REG

RS422 Slave Dev ice A

RXD+

RXD-

TXD+

TXD-

RS422 Slave Dev ice B

RXD+

RXD-

TXD+

TXD-

RS422 Slave Dev ice N

120R

Terminal REG

RXD+

RXD-

TXD+

TXD-

◆ RS485

Install terminal resistors only at each end (not in the middle ones in Multi-Drop structure)

RS485 Device D

TRXD-

TRXD+

TRXD-

TRXD+

RS485 Device G

Terminal REG

TRXD-

TRXD+

120R

RS485 Device N

RS485 Device A

TRXD-

120R

Terminal REG

RS485 Device B

TRXD-

TRXD+

RS485 Device E

RS485 Device C

TRXD-

TRXD+

TRXD-

TRXD+

RS485 Device F

Figure 3-6 RS485 Terminal Registor

TRXD+TRXD+

TRXD-

3-7

Page 33

Chapter 3. Hardware Description

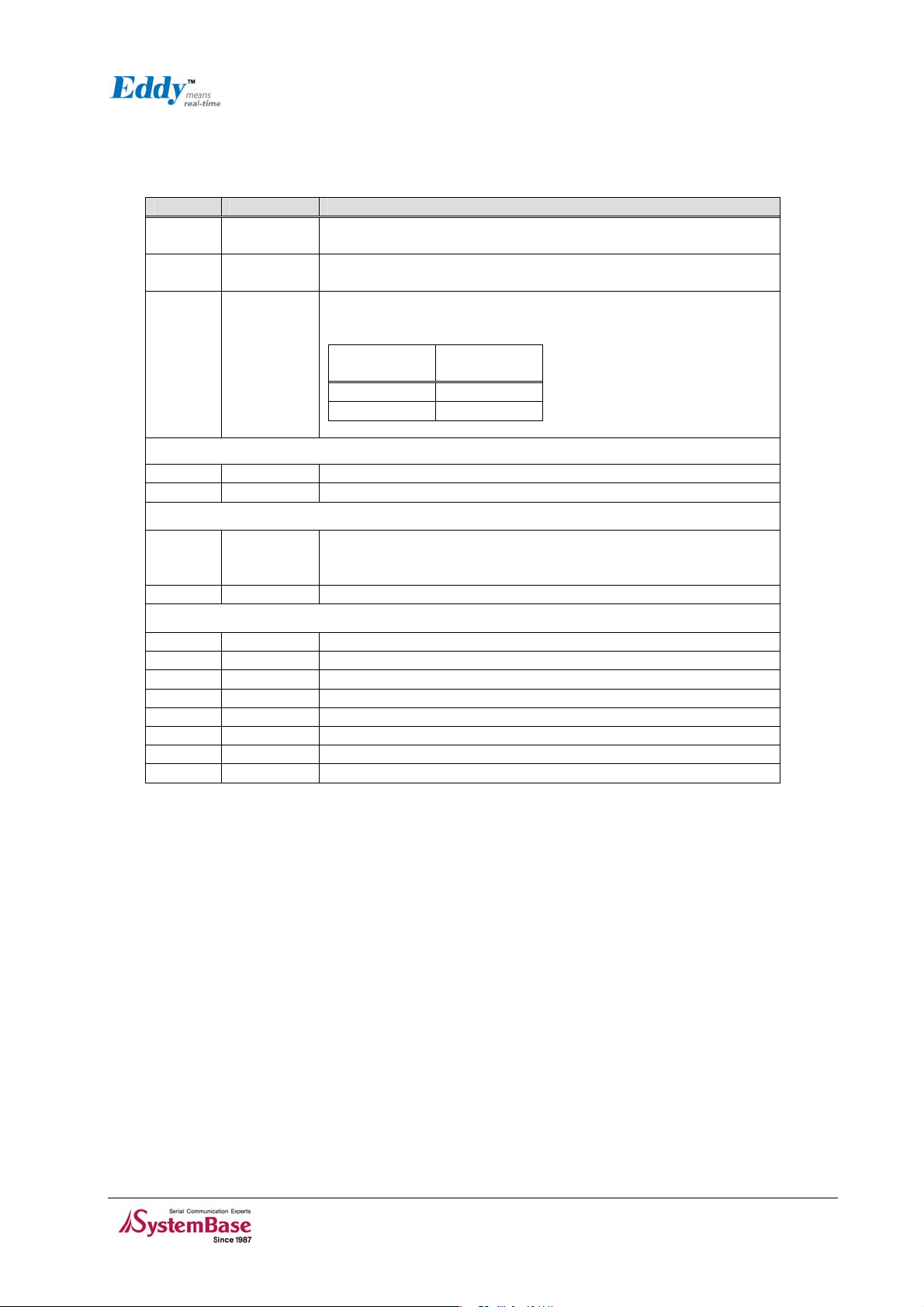

3.3 Eddy-S1/DB9

Ethernet LAN port is in RJ-45 form factor to provide direct network connection. Unlike other modules,

this model can be applied without any connection interface.

For serial communication, RS232 only or RS422/485 combo interface is available through DB9 male

connector. In the combo module, RS422/485 setting can be adjusted with software, using web

interface.

RJ45

w/LED & XFMR

RDY

DATA

32MB

SDRAM

4MB Flash

Eddy-CPU

RESET

5V PWR

Regulator

Ethernet

10/100M

GPIO

16ea

ARM926EJ-S

PoE PD Module

200MIPS

Serial Driver

DB-9M

RS-232 or RS422/485

Figure 3-7 Eddy-S1/DB9 – Product Picture and Block Diagram

3-8

Page 34

Chapter 3. Hardware Description

3.3.1 Dimensions

Figure 3-8 Eddy-S1/DB9 Front View

Figure 3-9 Eddy-S1/DB9 Side View

3-9

Page 35

3.3.2 Pin Specifications

Pin Specification and its usages are as follows

DB9

Chapter 3. Hardware Description

Reset switch

Power Jack

RJ-45

LED

◆ Power JACK

Contact Polarity

Center +5VDC ± 5%(over 400mA )

Outer Ground

3-10

Page 36

Chapter 3. Hardware Description

◆ DB9

Serial Connector

◆ RS232

Pin Signal Description

1 DCD Data Carrier Detection (Input)

2 RXD Receive Data (Input)

3 TXD Transmit Data (Output)

4 DTR Data Terminal Ready (Output)

5 GND Ground

6 DSR Data Set Ready (input)

7 RTS Request to Send (Output)

8 CTS Clear to Send (Input)

9 RI Ring Indicator (Input)

◆ RS485 Half Duplex

Pin Signal Description

3 TRX+ Transmit/Receive differential data positive

7 TRX- Transmit/Receive differential data negative

3-11

Page 37

◆ RS422 Full Duplex

Pin Signal Description

2 RXD+ Receive differential data positive (Input)

3 TXD+ Transmit differential data positive (Output)

6 RXD- Receive differential data negative (input)

7 TXD- Transmit differential data negative (Output)

◆ LED

Pin Signal Description

1 READY Indicates the processor status

2 DATA LED ON when serial data is transmitted

◆ RJ-45 Port

Chapter 3. Hardware Description

Pin Signal Description

1 TXD+ Physical transmit or receive signal (+ differential)

2 TXD- Physical transmit or receive signal (- differential)

3 RXD+ Physical receive or transmit signal (+ differential)

6 RXD- Physical receive or transmit signal (- differential)

LED Description

Left Green

(LAN_Speed)

Speed Pin State

10Base-T H OFF

100Base-TX L ON

LAN connection speed

LED Definition

3-12

Page 38

Chapter 3. Hardware Description

Pin Signal Description

LAN connection status

Right Yellow

(LAN_LINK)

Link/Activity Pin State

No Link H OFF

Link L ON

Activity Toggle Blinking

LED Definition

3-13

Page 39

Chapter 3. Hardware Description

3.4 Eddy-S1/DB9-PoE

This module can operate as a powered device (PD), which accepts power input from the twisted pair

Category 5 Ethernet cable as specified in IEEE 802.3af Power-over-Ethernet (PoE) standard.

With a backup 5V DC power jack, power supply can be automatically channeled to 5V adaptor when

PSE (Power Sourcing Equipment) is out of order. Seamless power supply is guaranteed. PSE power can

be used again when the PSE is in normal operation.

For serial communication, RS232 only or RS422/485 combo interface is available through DB9 male

connector. In the combo module, RS422/485 setting can be adjusted with software, using web

interface.

Figure 3-10 Eddy-S1/DB9-PoE – Product Picture and Block Diagram

3-14

Page 40

Chapter 3. Hardware Description

3.4.1 Dimensions

Figure 3-11 Eddy-S1/DB9-PoE Front View

Figure 3-12 Eddy-S1/DB9-PoE Side View

3-15

Page 41

3.4.2 Pin Specifications

Pin Specification and its usages are as follows.

Chapter 3. Hardware Description

LED

Power Jack

RJ-45

Reset Switch

◆ Power JACK

DB9

Contact Polarity

Center +5VDC ± 5%(400mA or above)

Outer Ground

3-16

Page 42

Chapter 3. Hardware Description

◆ DB9

Serial Connector

◆ RS232

Pin Signal Description

1 DCD Data Carrier Detection (Input)

2 RXD Receive Data (Input)

3 TXD Transmit Data (Output)

4 DTR Data Terminal Ready (Output)

5 GND Ground

6 DSR Data Set Ready (input)

7 RTS Request to Send (Output)

8 CTS Clear to Send (Input)

9 RI Ring Indicator (Input)

◆ RS485 Half Duplex

Pin Signal Description

3 TRX+ Transmit/Receive differential data positive

7 TRX- Transmit/Receive differential data negative

3-17

Page 43

◆ RS422 Full Duplex

Pin Signal Description

2 RXD+ Receive differential data positive (Input)

3 TXD+ Transmit differential data positive (Output)

6 RXD- Receive differential data negative (input)

7 TXD- Transmit differential data negative (Output)

◆ LED

Pin Signal Description

1 POWER LED ON when power is on

2 TXD LED ON when serial data is transmitted

Chapter 3. Hardware Description

3 RXD LED ON when serial data is received.

4 READY

Indicates the processor status

3-18

Page 44

Chapter 3. Hardware Description

◆ RJ-45 Port(w/PoE PD Functionality)

Pin Signal Description

1 TXD+ Physical transmit or receive signal (+ differential)

2 TXD- Physical transmit or receive signal (- differential)

3 RXD+ Physical receive or transmit signal (+ differential)

4 Vin+ PSE positive connection

5 Vin+ PSE positive connection

6 RXD- Physical receive or transmit signal (- differential)

7 Vin- PSE negative connection

8 Vin- PSE negative connection

LED Description

Left Green

(LAN_Speed)

Right Yellow

(LAN_LINK)

Speed Pin State

10Base-T H OFF

100Base-TX L ON

Link/Activity Pin State

No Link H OFF

Link L ON

Activity Toggle Blinking

LAN connection speed

LED Definition

LAN connection status

LED Definition

3-19

Page 45

Chapter 3. Hardware Description

3.5 Eddy-S2M/Pin

This model supports MCI ( MultiMedia Card Interface) and USB host port.

The MultiMedia Card Interface (MCI) supports the MultiMedia Card (MMC) Specification V3.11 and the

SD Memory Card Specification V1.0.

The USB Host Port integrates a root hub and transceivers on downstream ports. It provides several

high-speed half-duplex serial communication ports at a baud rate of 12 Mbit/s, up to 127 USB devices.

Two serial ports are provided in PIN connector form. Two types of model are available where the

standard models supports RS232 and combo models supports RS422/RS485. RS422 and RS485 is

software selectable, and can be adjusted through web browser interface.

Figure 3-13 Eddy-S2M/Pin – Product Picture and Block Diagram

3-20

Page 46

Chapter 3. Hardware Description

3.5.1 Dimensions

Figure 3-14 Eddy-S1/DB9-PoE Front View

Figure 3-15 Eddy-S1/DB9-PoE Side View

3-21

Page 47

3.5.2 Pin Specifications

Pin Specification and its usages are as follows.

Reset Switch

Chapter 3. Hardware Description

MCI slot

LED

USB Host

RJ-45

Power Jack

◆ Power JACK

J9 PIN

J8 PIN

figure 3-16 Eddy-S2M/Pin Pin Spec

Contact Polarity

Center +5VDC ± 5%(400mA or above)

Outer Ground

3-22

Page 48

Chapter 3. Hardware Description

figure 3-17 J8 PIN header

◇ J8 : RS232

Pin Signal Description

1 DCD Data Carrier Detection (Input)

2 RXD Receive Data (Input)

3 TXD Transmit Data (Output)

4 DTR Data Terminal Ready (Output)

5 GND Ground

6 DSR Data Set Ready (input)

7 RTS Request to Send (Output)

8 CTS Clear to Send (Input)

9,10 NC No Connection

◇ J8 : RS422 Full Duplex

Pin Signal Description

2 RXD+ Receive differential data positive (Input)

3 TXD+ Transmit differential data positive (Output)

6 RXD- Receive differential data negative (input)

7 TXD- Transmit differential data negative (Output)

◇ J8 : RS485 Half Duplex

Pin Signal Description

3 TRX+ Transmit/Receive differential data positive

7 TRX- Transmit/Receive differential data negative

3-23

Page 49

◆ J9

16-pin header connector

figure 3-18 J9 PIN header

Pin Signal Description

1, 2 VCC 3.0~5.5V DC input

Chapter 3. Hardware Description

3 RXD Receive Data (Input)

4 TXD Transmit Data (Output)

5 RTS Request to Send (Output)

6 CTS Clear to Send (Input)

7,8 NC No Connection

Ready indicator (Active low output)

Processor status can be indicated, when connected as below.

9 RDY#

Connection to external reset switch (Input)

As reset logic is built-in, this pin can be connected directly to the

10 nRESET

11 GND Ground

12 GND Ground

switch without any additional circuit. When pressing the switch

for more than 5 seconds (low input), factory default settings are

restored.

13 GPIO0 Programmable I/O 0 (user-defined I/O)

14 GPIO1 Programmable I/O 1 (user-defined I/O)

15 GPIO2 Programmable I/O 2 (user-defined I/O)

16 GPIO3 Programmable I/O 3 (user-defined I/O)

3-24

Page 50

Chapter 3. Hardware Description

◇ J9 : RS422 Full Duplex

Pin Signal Description

3 RXD+ Receive differential data positive (Input)

4 TXD+ Transmit differential data positive (Output)

5 RXD- Receive differential data negative (input)

6 TXD- Transmit differential data negative (Output)

◇ J9 : RS485 Half Duplex

Pin Signal Description

4 TRX+ Transmit/Receive differential data positive

5 TRX- Transmit/Receive differential data negative

◆ RJ-45 포트

Pin Signal Description

1 TXD+ Physical transmit or receive signal (+ differential)

2 TXD- Physical transmit or receive signal (- differential)

3 RXD+ Physical receive or transmit signal (+ differential)

6 RXD- Physical receive or transmit signal (- differential)

LED Description

Left Green

(LAN_Speed)

Speed Pin State

10Base-T H OFF

100Base-TX L ON

LAN connection speed

LED Definition

3-25

Page 51

Pin Signal Description

LAN connection status

Right Yellow

(LAN_LINK)

Link/Activity Pin State

No Link H OFF

Link L ON

Activity Toggle Blinking

3.5.3 Eddy-S2M/Pin JIG (Pin-to-DB9 gender)

Eddy-S2M/Pin JIG is provided as a Pin-to-DB9 gender for Eddy-S2M/Pin module. Eddy-S2M/Pin JIG is

used for connections to DB9 interfaces. It can also be used as Eddy-S2M/Pin module’s GPIO status

checker through its LEDs.

Eddy-S2M/Pin JIG is included in Eddy-S2M/Pin package and is not sold separately.

◆ Eddy-S2M/Pin JIG (DB9 to PIN connector)

Chapter 3. Hardware Description

LED Definition

figure 3-19 Eddy-S2M/Pin JIG

Serial Connector

3-26

Page 52

Chapter 3. Hardware Description

◆ RS232

Pin Signal Description

1 DCD Data Carrier Detection (Input)

2 RXD Receive Data (Input)

3 TXD Transmit Data (Output)

4 DTR Data Terminal Ready (Output)

5 GND Ground

6 DSR Data Set Ready (input)

7 RTS Request to Send (Output)

8 CTS Clear to Send (Input)

9 RI Ring Indicator (Input)

◆ RS485 Half Duplex

Pin Signal Description

3 TRX+ Transmit/Receive differential data positive

7 TRX- Transmit/Receive differential data negative

◆ RS422 Full Duplex

Pin Signal Description

2 RXD+ Receive differential data positive (Input)

3 TXD+ Transmit differential data positive (Output)

6 RXD- Receive differential data negative (input)

7 TXD- Transmit differential data negative (Output)

◆ LED

LED Signal Description

1 GPIO0 Programmable I/O 1 (user-defined I/O)

2 GPIO1 Programmable I/O 2 (user-defined I/O)

3-27

Page 53

Chapter 3. Hardware Description

LED Signal Description

3 GPIO2 Programmable I/O 3 (user-defined I/O)

4 GPIO3 Programmable I/O 4 (user-defined I/O)

Processor status can be indicated, when connected as

5 READY

below.

3-28

Page 54

Chapter 4. Integration

Chapter 4. Integration

This chapter explains how you can make Eddy to communicate. It deals with LAN and pin header

connection guides for Eddy to operate together with the target serial device.

Follow these steps to connect Eddy to the device and network.

4.1 Connection Guide

1) LAN

In order to connect Eddy to network, you need to use RJ45 Ethernet port. It supports both 10Mbps and

100Mbps Ethernet connection (auto-sensing). Since Eddy’s LAN port supports MDIX function, you can

either connect cross LAN cable or direct LAN cable. Plug one end of a LAN cable to Eddy and the other

end to a hub, switch, or any other network device that can provide you with network access.

2) Pin Header

For those models with pin header interface, it is important that you clearly understand which pins you

are to connect and how you connect them. For pin specifications, please refer to Chapter 3. Hardware

Description. Please note that not all pins must be used. You can selectively connect only those pins

relevant to your application.

3) DB9

For Eddy-S1/DB9, you can simply connect Eddy to the destination serial device with a DB9 cable. For

pin specifications, please refer to Chapter 3.

4-1

Page 55

Chapter 4. Integration

4.2 First-time Bootup

First of all, please make sure the power input you supply to the module is corresponding with the

Eddy model that you have. If an appropriate power input has been successfully supplied, Eddy will

power on and start booting. For those models that require power input through pins (this will leave

out DB9 models), you can notice that there are two Power In pins per serial port. It is a good practice

to connect both power pins to the power supply for more stability in operation.

Although there is no power LED to check the status, you can check by LEDs on the RJ45 Ethernet port.

LED status operation is described in Chapter 3. Hardware Description

simply use a 5V DC power adaptor. In models with Pin Header, issue 3.3 ~ 5V power input.

An IP address is required to access Eddy’s web interface or telnet command-line configuration tool. By

factory default, Eddy is assigned a static IP address. After the initial connection, you can either

manually assign a different IP address or set Eddy to automatically get an IP address from a DHCP

server. While this depends on your network environment and policy, it is strongly recommended that

you assign Eddy with a unique static IP.

. In models with DB9, you can

4-2

Page 56

Chapter 4. Integration

4.3 Connecting to Eddy with IP address

In order to view current Eddy’s settings or modify them, you need to make a Web or Telnet connection

to Eddy. IP address is required information to make a connection.

There are two ways you can know the current IP address of Eddy.

First is to use a built-in, alias IP address of “10.10.1.1”.

Second is to use “Detector” application provided in the Utility & Documents CD. This application

allows searching for Eddy modules on the network.

◆

The factory default IP address: 192.168.0.223

Eddy’s default IP address is set to 192.168.0.223. In order to connect with this address, you need to

change network configurations so that your PC can connect to the IP 192.168.0.223. Please refer to an

example below, and note that values don’t necessarily have to be identical to the example below.

Figure 4-1 Connecting to the default IP address

4-3

Page 57

Chapter 4. Integration

◆

Factory default alias IP address: 10.10.1.1

In case you configure Eddy to use DHCP to obtain an IP address automatically, you might find it hard to

know the IP address to connect to. To provide users with an easier way to know the current IP address,

Eddy has a fixed alias IP that is always accessible. Use the address below whenever you cannot find

out Eddy’s IP address.

In order to connect with this address, you need to change network configurations so that your PC can

connect to the IP 10.10.1.1. Please refer to an example below, and note that values do not necessarily

have to be identical to the example below.

Figure 4-2. Connecting to alias IP address

◆ Connection via Detector

By running the Detector program in the Utility & Documents CD included in the Eddy package, you can

dynamically search for all Eddy modules on the network and connect to any module. (For more

information on Detector, please refer to the Portview manual in the Utility & Documents CD included

in the Eddy package)

4-4

Page 58

Chapter 4. Integration

After running Detector, click Search button on the top-left to display all Eddy modules on the network.

Select the module that you would make a connection to, and click Telnet or Web to connect to the

module via Telnet or Web, respectively.

Figure 4-3 Detector Layout

If Eddy module is not on the same network as the PC you are working on, use “IP Configure” button to

temporarily assign an IP address that you would like to make a Web or Telnet connection to. If you

assign a temporary IP address to Eddy, you need to to change the IP address and restart in Web or

Telnet.

Figure 4-4 Setting Eddy with temporary IP address

Now you are ready to connect to Eddy! There are three options to configure Eddy.

1) Web

You can easily configure Eddy with web interface, accessible from any web browser. For more

information, please refer to

2) Telnet

You can configure Eddy with commands after accessing Eddy through Telnet. For more information,

Chapter 5. Configuration via Web

.

please refer to Chapter 6. Configuration via Telnet

3) Portview

You can use a Windows-based utility Portview from SystemBase to monitor Eddy. For more information

on using the utility for your administration purpose, please refer to Portview User Guide.

.

4-5

Page 59

4.4 Eddy-S2M/Pin’s MCI & USB Host Port

y

The following contents outline the usage of Eddy-S2M/Pin’s MCI & USB Host Port.

Using MCI slot

MMC and SDCards can be used through MCI slot.

Please note that MCI and SDCard must be inserted before power is induced to Eddy-S2M/Pin module.

MMC or SDCards are automatically recognized as a new disk space in " /tmp/mmc " folder. If memory

card is not inserted to the MCI slot, " /tmp/mmc " folder will not be created.

To check memory card’s current disk space information, type in "du -sk /tmp/mmc" or "df /tmp/mmc"

commands via telnet. Following example displays status of a memory card with 1GB memory storage

capacity.

Chapter 4. Integration

Eddy login: edd

Password:

# pwd

/tmp

# ls

ifstate login.pw thttpd.log wtmp

login.id mmc thttpd.pid

# du -sk /tmp/mmc

16 /tmp/mmc

# df /tmp/mmc

Filesystem Size Used Available Use% Mounted on

/dev/mmcblk0p1 970.1M 1.5M 968.6M 0% /tmp/mmc

#

Using USB host port

An USB memory stick or USB hub can be attached to Eddy-S2M/Pin module’s USB host port. If other

USB devices are to be attached to this port, device drivers for the devices must be first created and

loaded to Eddy-S2M/Pin module using Eddy-DK.

Following example displays procedures for USB memory stick usage.

z Insert the USB memory stick to USB host port and connect telnet.

z Type in "fdisk -l " or "ls -al /dev/sd* " command to check USB memory stick is properly

inserted.

z Create a folder using “mkdir /tmp/usb” command.

z Mount "/tmp/usb" folder using "mount -t vfat /dev/sda1 /tmp/usb" command.

z Always unmount USB memory stick with "umount <mounted folder> " command,

before removing USB memory stick from USB host port.

If more than one USB memory stick is connected using a USB hub, each memory stick would be

4-6

Page 60

Chapter 4. Integration

y

recognized as /dev/sdb1, /dev/sdc1, /dev/sdd1…. Each device must be mounted for proper use.

Following displays an example of two USB memory stick connection with a hub.

Eddy login: edd

Password:

# fdisk -l

Disk /dev/sda: 4068 MB, 4068474880 bytes

51 heads, 50 sectors/track, 3116 cylinders

Units = cylinders of 2550 * 512 = 1305600 bytes

Device Boot Start End Blocks Id System

/dev/sda1 1 3117 3973116 b Win95 FAT32

Disk /dev/sdb: 1020 MB, 1020788736 bytes

32 heads, 63 sectors/track, 988 cylinders

Units = cylinders of 2016 * 512 = 1032192 bytes

Device Boot Start End Blocks Id System

/dev/sdb1 * 1 989 996750+ 6 FAT16

Partition 1 has different physical/logical endings:

phys=(987, 31, 63) logical=(988, 30, 30)

# ls -al /dev/sd*

brw-rw---- 1 root root 8, 0 Jan 1 00:04 /dev/sda

brw-rw---- 1 root root 8, 1 Jan 1 00:04 /dev/sda1

brw-rw---- 1 root root 8, 2 Jan 1 00:04 /dev/sdb

brw-rw---- 1 root root 8, 3 Jan 1 00:04 /dev/sdb1

# ls -al

drwxrwxrwt 3 root root 200 Jan 1 00:00 .

# pwd

/tmp

# mkdir usb1

# mkdir usb2

# mount -t vfat /dev/sda1 usb1

# mount -t vfat /dev/sdb1 usb2

# df /tmp/usb*

Filesystem Size Used Available Use% Mounted on

/dev/sda1 3.8G 3.2G 547.3M 86% /tmp/usb1

/dev/sdb1 973.1M 217.6M 755.5M 22% /tmp/usb2

#

4-7

Page 61

Chapter 5. Configuration via Web

Chapter 5. Configuration via Web

5.1 Connection

Open your favorite web browser and enter the IP address of Eddy to access Eddy’s web manager. Once

you are successfully connected, the following front page will show up. You need to enter appropriate

username and password to login. Please note that this username and password is used as

authentication method for Telnet as well.

◆ Factory default username: eddy

◆ Factory default password: 99999999

TM

Figure 5-1 Eddy Login Page

5-1

Page 62

Chapter 5. Configuration via Web

5.2 Setup Menu

If login process is successful, you will see a web manager’s main page, showing summary of your

device. On the left, you will see a setup menu, and you can navigate through these options.

Figure 5-2 Main Page

Main features of Setup Menu are as follows.

Table 5-1 Main features of Setup Menu

Menu Descriptions

Summary View a summary of Eddy.

Network Settings Configure network connection settings.

Serial Settings

GPIO Settings Configure programmable I/O pins.

Change Password Change ID and password for both Web and Telnet interface.

Update Firmware Update Eddy’s firmware.

Factory Default Restore all the factory default settings.

Save & Reboot Save the configurations and reboot Eddy.

Configure detailed operation environment for serial

communication.

5-2

Page 63

Chapter 5. Configuration via Web

5.3 Network Settings

Configure general network environment and network management. After changing values, you need to

click ‘Submit’ button. Then you will see the same page with modified values. Please note that you

have to ‘Save & Reboot’ in order to see these changes in effect. Changes will be discarded if you do

not save current settings.

Figure 5-3 Network Settings Configuration Page

Main features for General Configuration is as follows.

Table 5-2 Main features of General Configuration

Menu Default Descriptions

Device

Name

Line Type Static IP

IP Address 192.168.0.223

Eddy

Current IP address Eddy is assigned to.

Name of the current device

IP obtaining method for Eddy’s network connection.

(When line type is Static IP, manually enter an

appropriate IP address. When line type is DHCP, current

IP is displayed, but it is not editable.)

5-3

Page 64

Chapter 5. Configuration via Web

Current subnet mask Eddy is assigned to.

(When line type is Static IP, manually enter an

Subnet

Mask

255.255.255.0

appropriate subnet mask.When line type is DHCP,

current subnet mask is displayed, but it is not

editable.)

Current default gateway Eddy is assigned to

(When line type is Static IP, manually enter an

Gateway 192.168.0.254

appropriate default gateway. When line type is DHCP,

current default gateway is displayed, but it is not

editable.)..

DNS 168.126.63.1 DNS (Domain Name Service) IP address

Main features for Network Service Configuration are as follows.

Table 5-3 Main features for Network Service Configuration

Menu Default Descriptions

Set the IP address and the port number of the PC

Portview

IP / Port

0.0.0.0 / 4000

where Portview is installed. For more information on

Portview, please refer to the Portview User Manual.

DDNS

(Username/

203.32.117.1

Password)

SNMP Disable

Telnet Service Enable

FTP Service Enable

Web Service Enable

LemonIDE

Target Agent

Disable

If IP is set to 0.0.0.0, this feature is disabled

Register DDNS server’s IP address for DDNS service.

DDNS service used in Eddy is supported by

http://ddns.nu

default ID is eddy and default password is 99999999

if you want to used this ,you should register your own

in http://ddns.nu

Enable or disable SNMP(Simple Network Management

Protocol) support

▪MIB-II (RFC 1213): System, Interface, IP, ICMP, TCP, UDP

▪MIB-I (RFC 1317): Serial Interface

Enable or disable Telnet service.

If disabled, you cannot connect to Eddy via Telnet.

Enable or disable FTP service.

If disabled, you cannot connect to Eddy via FTP.

Enable or disable Web service.

If disabled, you cannot connect to Eddy via Web.

Enable or disable remote debugging function used by Eddy

development environment, LemonIDE®..

For more information, please refer to LemonIDE user

manual in the SDK CD included in Eddy-DK package.

5-4

Page 65

Chapter 5. Configuration via Web

5.4 Serial Settings

You can set the communication and operation environment for the serial port. After changing values,

you need to click ‘Submit’ button. Then you will see the same page with modified values. Please note

that you have to ‘Save & Reboot’ in order to see these changes in effect. Changes will be discarded if

you do not save current settings.

Figure 5-4 Serial settings page

Serial communication settings for Eddy-S1/Pin, S1/TTL, S2/Pin are as follows.

Table 5-4 Main features for Serial Settings

Menu Default Descriptions

▪Eddy-S1/Pin, S1/DB9, S1/DB9-PoE

Only RS232 interface supported. Fixed. (Default: RS232)

▪Eddy-S1/Pin-C, S1/DB9-C, S1/DB9-PoE-C

Interface

RS232 or

RS422

RS422 or RS485 interface is supported. By software, you can select

one of these interfaces. (Default: RS422)

▪Eddy-CPU

User decides the serial interface, meaning Web or Telnet

configuration is not possible. For more information on interface

5-5

Page 66

Chapter 5. Configuration via Web

Menu Default Descriptions

configuration, please refer to Chapter 3. Hardware Description.

Select the operation protocol, which the serial port would use.

▪Disable

Do not use this port.

▪COM

Use the serial port of Eddy as the COM ports of Windows

2000/XP/2003/Vista operated PC.

▪TCP Server

Eddy works as a socket server, waiting for the client connection on

the network.

Socket number for awaiting connections can be set in ‘Local

socket port’ field.

All data between the socket and the serial port is transferred

untouched after the socket connection is established.

▪TCP Client

Eddy acts as a socket client in this mode. It tries to connect to the

server IP address and the socket number assigned when a certain

server waits for connection on the network.

All data between the socket and the serial port is transferred

untouched after the socket connection is established.

Operation

Mode

COM

(Win200x

/XP)

▪TCP Broadcast

Eddy works as a server, accepting up to 5 simultaneous

connections from socket clients.

Data transmitted from Eddy is broadcast to each socket client.

▪TCP Multiplex

Eddy works as a server, accepting up to 5 simultaneous

connections from socket clients. The difference between TCP

Broadcast and TCP Multiplex is that Multiplex allows each socket

to communicate exclusively. That is, serial data in response are

only transferred to the sender socket.

▪UDP Server

Eddy works as a UDP server, waiting for UDP connection from the

client on the network.

Socket number for awaiting connections can be set in ‘Local

socket port’ field.

Once a UDP packet is received to the socket that waits for the

connection, the data is transmitted to the serial port. The data

input from the serial port is put into UDP packets, which

eventually are sent to the client.

▪UDP Client

When the data is input to the serial port, UDP packets are sent

using the preset IP address and the socket number of the server.

5-6

Page 67

Chapter 5. Configuration via Web

Menu Default Descriptions

Local

Socket Port

Port Alias Port1 Port alias name for convenience. 16 Characters at maximum.

Baud Rate 9600 bps

Data Bits 8

Stop Bits 1

Parity None

Flow

Control

Device

Typ e

Remote IP

Address /

Port

Keepalive 0 sec

4001

None

DataOnly

0.0.0.0 /

4000

Set the socket number for the port. TCP server and UDP server

operation mode makes use of this port for awaiting network

socket connections.

Set communication speed.

(Options: 150, 300, 600, 1200, 2400, 4800, 9600, 19200, 38400,

57600, 115200, 230400, 460800, 921600 bps)

Set the number of bits in each character size.

(Options: 5, 6, 7, 8)

Set the number of stop bits..

(Options: 1, 2)

Set parity bit check scheme..

(Options: None, Odd, Even)

Set the flow control scheme.

(Options: None, Xon/Xoff, RTS/CTS)

Set the signal line checking method for the device to be

connected to the given serial port.

If the mode is set to Data Only, only Txd, Rxd, and Gnd signal lines

are used in inter-device communication. If the mode is set to

Modem Signals, all modem signals except RI(Ring Indicator) are

asserted, tested, and used in communication.

(Options: Data Only, Modem Signals)

When the Operation Mode is either TCP Client or UDP Client, set

the IP address and the socket number to connect to..

After a certain amount of time passes without any communication

after the socket connection between the given serial port and the

server is established, automatically disconnect the socket

connection. Valid from 0 to 32767.

For example, if the operation mode is set to TCP Server and Alive

Check Time is configured to 10, TCP Server will listen for the

client’s connection and eventually establish a connection. Since

the check time is 10 seconds, the server will wait for 10 seconds

until the client connected to it sends any packet. If there is no

data for 10 seconds, server will quit the connection and return to

the listening state. This option is helpful in preventing

communication obstacles that occur when either Eddy or the

client quits unexpectedly (i.e. Sudden black out, reboot, LAN

cable cut, etc.). In these cases, the other part of communication

might not recognize the failure of its partner. Such

misunderstanding can cause communication errors.

If the value is set to 0, this function is disabled. Once connected

socket will be retained until explicitly disconnected.

(Only applies to TCP Client, TCP Server, TCP Broadcast, and TCP

Multiplex operation modes.)

5-7

Page 68

Menu Default Descriptions

This needs to be set when consecutive data from the given serial

port needs to be transmitted to socket at once.

If 100 bytes of character string are to be transmitted from the

serial device and bypass is set to Disable, Eddy waits until the

entire 100 bytes are received. The maximum size to be

transmitted at once is 1500 bytes.

Bypass Enable

Port Login Disable

Passive

Username

Passive

Password

conuser

99999999

Eddy waits in idle state for 5-byte incoming interval, calculated by

the communication speed after the last incoming data. If no data

is received during this time, Eddy transmits all remaining data to

the server in one packet.

If set to Enable, however, few bytes’ pieces are transmitted right

away in a packet, therefore multiple packets sent to the server.

This helps in real-time communication, but might cause

tremendous traffic on the network.

When the Operation Mode is set to TCP Server, ask for the

username and password when the client tries to connect

(Options: Enable, Disable)

When the Operation Mode is set to TCP Server, set the username

to ask for. 32 Characters at maximum.

When the Operation Mode is set as TCP Server, set the password to

ask for. 32 Characters at maximum.

Chapter 5. Configuration via Web

5-8

Page 69

Chapter 5. Configuration via Web

5.5 GPIO Settings

Configure operation mode and value for each Programmable I/O pins.

Eddy includes GPIO pins that output 3.3V or detect 3.3V signals.

Eddy-CPU has 16 pins, Eddy-S1/Pin has 4 pins, but Eddy-S1/DB9 and Eddy-S1/DB9-PoE models do not

have any GPIO pins.

You can detect either any 3.3V signals from external device, or output 3.3V signal to the external

device. You can also program a customized GPIO application, and you can implement it with the SDK

included in the Eddy development kit.

After changing values, you need to click ‘Submit’ button. Then you will see the same page with

modified values. Please note that you have to ‘Save & Reboot’ in order to see these changes in effect.

Changes will be discarded if you do not save current settings.

Different Eddy modules support different port number of GPIOs. Eddy Web server automatically senses

connected Eddy module and its supported GPIO ports and displays it on the Web.

If no GPIO is present in the current model, GPIO settings page is not available.

Figure 5-5 Eddy-S1/Pin - GPIO Settings Page

5-9

Page 70

Chapter 5. Configuration via Web

Figure 5-6 Eddy-CPU - GPIO Settings Page

Table 5-5 Main features for GPIO Settings

Menu Default Descriptions

Set current pin’s I/O mode. When in output mode, 3.3V output can

Mode Output

Value High

be controlled. When in input mode, any 3.3V from outside can be

detected (Options: Output, Input)

Set current pin’s output value. (This option only applies to output

mode pins)

If the value is High, 3.3V is output through the port.

(Options: High / Low)

5-10

Page 71

Chapter 5. Configuration via Web

5.6 Change Password

Change Web/Telnet access username and password. After changing values, you need to click ‘Submit’

button. Then you will see the same page with modified values. Please note that you have to ‘Save &

Reboot’ in order to see these changes in effect. Changes will be discarded if you do not save current

settings.

◆ Default user id : eddy

◆ Default password : 99999999

Figure 5-7 Change Password Setting Page

5-11

Page 72

Chapter 5. Configuration via Web

Figure 5-8 After changing the password

5-12

Page 73

Chapter 5. Configuration via Web

5.7 Update Firmware

Firmware is an application embedded in Flash memory of Eddy. Set the location of the firmware file

to update, using the ‘Browse…‘ button. The selected firmware will be transferred to Eddy when you

click ‘Start Update’. After the transmission is complete, Eddy will be automatically restarted to

operate with the new firmware.

Figure 5-9 Update Firmware Setting Page

5-13

Page 74

Chapter 5. Configuration via Web

Figure 5-10 Firmware update in progress

Figure 5-11 Firmware update complete

5-14

Page 75

Chapter 5. Configuration via Web

5.8 Factory Default

Restore all the configuration parameters to the factory default values. Clicking on ‘Restore Factory

Defaults’ button will delete all current settings and restore settings to the initial status. Eddy will

automatically reboot.

You cannot turn back the decision once you select this option.

◆ The factory default IP address of Eddy : 192.168.0.223

Figure 5-12 Factory Default Page

5-15

Page 76

Chapter 5. Configuration via Web

5.9 Save & Reboot

This option saves changes to the Flash memory and restarts the system to let the changes to take

place in the operation.

Figure 5-13 Save & Reboot Page

Main features for Save & Reboot are as follows

Table 5-6 Main features for Save & Reboot

Menu Descriptions

Save and Reboot ‘Save & Reboot’ reboots Eddy after saving changes to Flash memory.

‘Reboot Only’ option just reboots Eddy without saving changes. This

Reboot without Saving

option can be used to rollback the changes you have mistakenly

made.

5-16

Page 77

Chapter 6. Configuration via Telnet

Chapter 6. Configuration via Telnet

6.1 Connection

Open your telnet client and enter Eddy’s IP address to connect. You need to enter appropriate

username and password to login. Please note that this username and password is used as

authentication method for Web as well. This means if username or/and password has been modified

from the telnet interface, modified values have to be entered to connect to web, and vice versa.

◆ Factory default username : eddy

◆ Factory default password : 99999999

Figure 6-1 Connection via Telnet

[def] command - you can view or configure Eddy’s settings

[help] command - you can see help for [def] command

After changing values, you can see modified values with ‘def view’ commands. But be careful

because these values are not in effect unless you issue a ‘def save’ command. Changes will be

discarded if you do not save current settings.

6-1

Page 78

Chapter 6. Configuration via Telnet

6.2 View commands

Commands related to View are as follows.

Table 6-1 def view commands

Commands Descriptions

def view Show all information about Eddy.

def view server Show network and device server’s settings.

def view port Show serial port settings.

def view gpio Show GPIO pin settings.

def help Show command list and help.

6.3 Network commands

Configure general network environment and network management.

Table 6-2 Network commands

Commands Default Descriptions

def mac

<Mac Address>

def line

[ip / dhcp]

def ip

<IP Address>

def mask

<Subnet mask>

def gateway

<Gateway

address>

00:05:f4:00:20:

57

Static IP IP obtaining method for Eddy’s network connection.

192.168.0.223

255.255.255.0

192.168.0.1

Register Eddy’s MAC address.