MI03122-01 09/2015

MANUAL DE INSTRUCCIONES

INSTRUCCIONES PARA EL USO Y EL MANTENIMIENTO, LEA ESTE

MANUAL ANTES DE PONER EN MARCHA EL EQUIPO

INSTRUCTION MANUAL

INSTRUCTIONS FOR THE USE AND MAINTENANCE, READ THIS

MANUAL BEFORE STARTING THE EQUIPMENT

MANUAL DE INSTRUÇÕES

INSTRUÇÕES PARA O USO E MANUTENÇÃO, LEIA ESTE MANUAL

ANTES DE UTILIZAR O EQUIPAMENTO

BEDIENUNGSANLEITUNG

BEDIENUNGS- UND WARTUNGSANLEITUNG, LESEN SIE DIESE

ANLEITUNG VOR INBETRIEBNAHME DES GERÄTES

MANUEL D’INSTRUCTIONS

INSTRUCTIONS POUR L’UTILISATION ET LA MAINTENANCE, LISEZ

CE MANUEL AVANT DE METTRE L’APPAREIL EN MARCHE

ES

EN

FR

DE

PT

ÍNDICE

Introducción 2

Seguridad y protección 2

Descripciones generales 3

Descripción de los elementos del equipo 5

Conexionado de la pinza de masa 6

Conexionado de la antorcha 6

Conexionado del gas 6

Uso de generadores 7

Puesta en servicio Aeroprocess 2000 7

Puesta en servicio Aeroprocess 3200 7

Puesta en servicio Aeroprocess 3220 7

Esquema panel frontal 9

Operativa panel 10

Simbología del display 11

Operativa del menú 12

Operativa soldadura MIG-MAG 13

Operativa soldadura MMA 15

Operativa soldadura TIG 16

Debanadora Aerofeed 5 18

Rodillos 19

Averías 19

Posibles anomalias y soluciones 19

Alarmas y anomalias 20

Instrucciones de mantenimiento 21

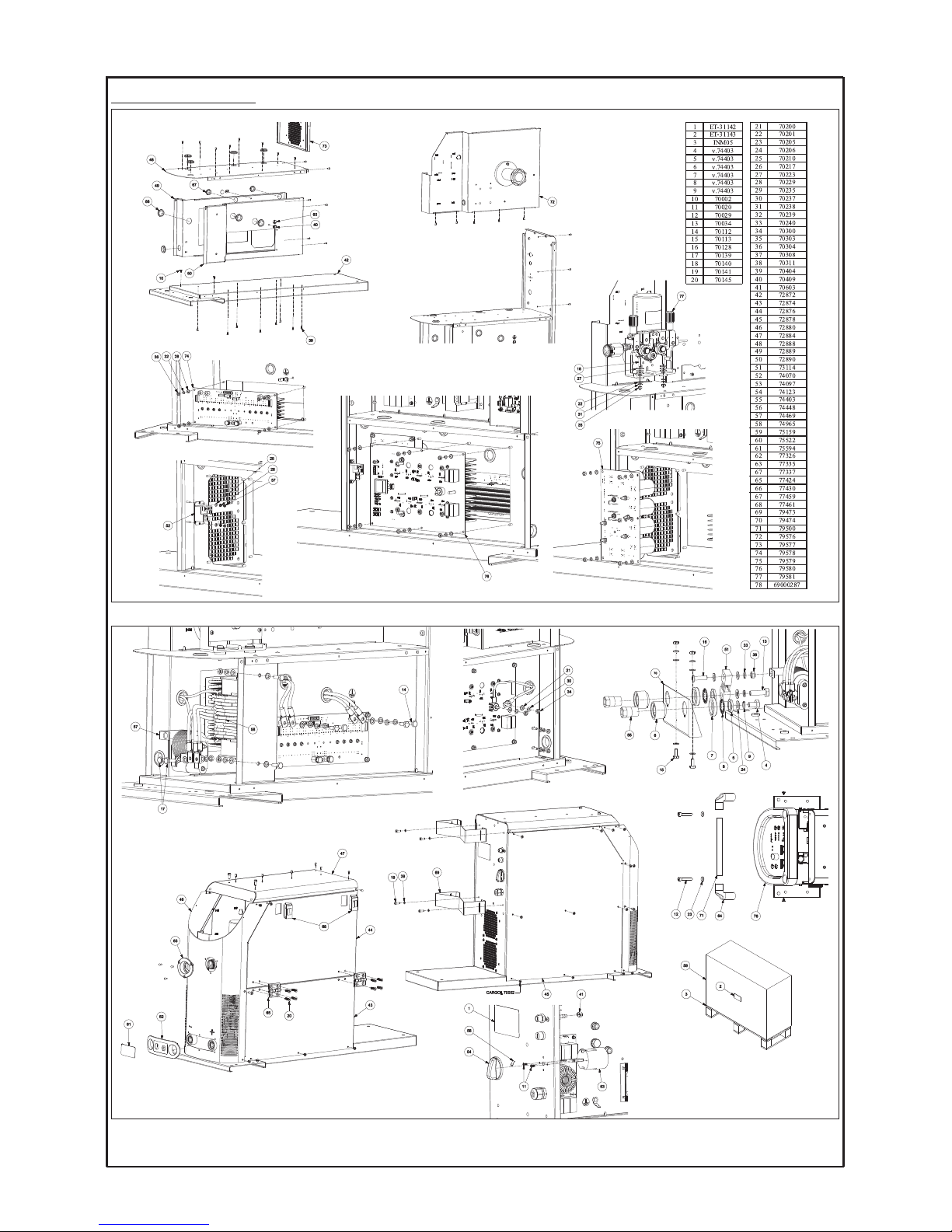

Despieces A1-A2-A3

Esquemas eléctricos A4-A5-A6-A7

Certificado CE A8

Certificado de garantía A9

SOLTER SOLDADURA S.L.

AEROPROCESS

1

INTRODUCCIÓN

Agradecemos la deferencia hacia nuestra marca y esperamos le sea de gran utilidad la máquina de soldar que

acaba de adquirir. El presente manual de instrucciones, contiene las informaciones y las advertencias necesarias

para una correcta utilización dentro de las máximas condiciones de seguridad para el operario. Las máquinas de soldar INVERTER deben ser empleadas por personal experto que conozca y comprenda los riesgos involucrados en la

utilización de las mismas. En caso de incomprensión o duda sobre este manual, rogamos se ponga en contacto con

nosotros. La manipulación interna del equipo conlleva un peligro importante de descarga eléctrica. Rogamos se abstenga de efectuar cualquier manipulación en el aparato (sólo personal técnicamente preparado puede realizarlo). El

f

abricante declina toda responsabilidad por prácticas negligentes en la utilización y/o manipulación.

Este manual debe adjuntarse y conservarse con el modelo de máquina adquirido. Es responsabilidad de las personas que la utilicen y reparen que el producto no deje de cumplir los requisitos de las normas mencionadas.

SEGURIDAD Y PROTECCIÓN

ELECTRICIDAD

El buen funcionamiento de la máquina se asegura con una buena instalación. Verificar que la tensión (V)

de la máquina se corresponde con la de la red. Debe conectarse SIEMPRE la toma de tierra (T).

Personas con elementos eléctricos implantados (MARCAPASOS), no deben utilizar aparatos de esta índole.

PRENDAS PERSONALES

Todo el cuerpo del soldador está sometido a la posible acción de agentes agresivos, por lo que debe

protegerse íntegramente. Usar botas de seguridad, guantes, manguitos, polainas y mandiles de cuero.

PROTECCIÓN CONTRA QUEMADURAS

No tocar nunca con las manos desnudas partes del alambre o el material una vez soldado. Evitar que

las partículas que se desprendan entren en contacto con la piel. No apunte con la antorcha a ninguna

parte del cuerpo.

PROTECCIÓN DE LOS OJOS

Los soldadores y sus ayudantes deben utilizar gafas de seguridad provistas de filtros que detengan las

radiaciones perniciosas para el ojo humano. Usando pantallas especiales es posible observar la zona

de soldadura durante el proceso.

PROTECCIÓN CONTRA INCENDIOS

El proceso de soldadura origina proyecciones de metal incandescente que pueden provocar incendios.

No utilizar la máquina en ambientes con gases inflamables. Limpiar el área de trabajo de todo material

combustible. Proteger especialmente las botellas de gas de acuerdo con los requerimientos que precisen.

PROTECCIÓN DE LAS BOMBONAS DE GAS

Las bombonas que contienen gases de protección han sido rellenadas a altas presiones. Si estas sufren

algún tipo de avería, pueden estallar. Tratar siempre con cuidado las bombonas y soldar lo más lejos

posible de ellas.

AL PROCEDER A SOLDAR DEPÓSITOS CON RESTOS DE MATERIALES INFLAMABLES, EXISTE

UN GRAN RIESGO DE EXPLOSIÓN. ES RECOMENDABLE DISPONER DE UN EXTINTOR LISTO

PARA SU USO.

PERTURBACIONES ELECTROMAGNÉTICAS

Las interferencias electromagnéticas del equipo de soldadura pueden interferir en el funcionamiento de

aparatos sensibles a estas (ordenadores, robots, etc). Asegúrese que todos los equipos en el área de

soldadura sean resistentes a la radiación electromagnética. Para reducir en lo posible la radiación, trabaje con cables de soldadura lo más cortos posibles y, dispuestos en paralelo en el suelo, si es posible.

Trabaje a una distancia de 100 metros o más de equipos sensibles a las perturbaciones. Asegúrese de

tener el equipo de soldadura correctamente puesto a tierra. Si a pesar de todo hay problemas de interferencias, el operador deberá tomar medidas extras como mover la máquina de soldar, usar filtros, usar

cables blindados... para asegurar la no interferencia con otros equipos.

SOLTER SOLDADURA S.L.

AEROPROCESS

2

ES

RECICLADO

En cumplimiento de la normativa Europea 2002/96/EC sobre los desechos de equipos eléctricos y elect

rónicos, el equipo, al final de su vida útil, debe ser depositado en su centro de reciclado local.

DESCRIPCIONES GENERALES

Los equipos de soldadura Aeroprocess están desarollados para ser compatibles con los procesos de soldadura con

electrodo revestido (MMA), TIG y MIG-MAG, destacando su capacidad para soldaduras MIG-MAG con múltiples

combinaciones de materiales y gases de protección. La gama de equipos Aeroprocess está equipada con doble procesador digital de señal, supervisando el estado del arco de soldadura hasta 10000 veces por segundo. Gracias a

esta tecnología, se puede garantizar un arco preciso y fiable bajo cualquier condición de operación. Es posible aplic

arlo de forma universal a cualquier tipo de soldadura de materiales tan diversos como aceros inoxidables, aceros

a

leados, aleaciones de aluminio u otras aleaciones de cobre o titanio.

La gama de equipos Solter Aeroprocess, logra un ajuste ágil gracias a la asistencia de configuración sinérgica de los

parámetros de soldadura MIG-MAG.

Para la soldadura con electrodo revestido (MMA), el equipo está equipado con las funciones de anti-stick, hot-start y

arcforce ajustables. Al emplear estas funciones, el equipo permite soldar eficazmente cualquier tipo de electrodo revestido.

Para la soldadura TIG, el equipo permite la ignición por Lift Arc, control del tiempo de pre-gas y post-gas, y el control

de la rampa de corriente final.

Para soldadura MIG-MAG, el equipo dispone de 28 programas sinérgicos pre-configurados. Además, también están

disponibles las funciones especiales de Burn Back, Hot Start, Crater Filling y temporización para soldadura por puntos.

En la parte posterior del equipo, existe una placa de características que define los parámetros del equipo de soldadura. El diseño de esta placa corresponde a la norma EN 60974-1.

SIGNIFICADO DE LAS INDICACIONES DE LA PLACA DE CARACTERÍSTICAS

EN 60974 Norma internacional de construcción del aparato.

S/N.... Número de serie.

MMA Soldadura con electrodos revestidos.

TIG Soldadura procedimiento TIG.

Uo Tensión secundaria en vacío.

X Factor de servicio %.

I2 Corriente de soldadura (A).

U2 Tensión secundaria con corriente de soldadura (I2).

U1 Tensión nominal de alimentación.

50/60 Hz Frecuencia de red.

IP21 Grado de protección exterior de la máquina.

S Apta para trabajar en lugares con riesgo aumentado.

SOLTER SOLDADURA S.L.

AEROPROCESS

3

SOLTER SOLDADURA S.L.

AEROPROCESS

4

CARACTERÍSTICAS TÉCNICAS

El equipo está diseñado para poder usarse en exteriores. Sin embargo, debe protegerse contra precipitaciones si

está en uso.

PROTECCIÓN

El equipo incorpora todas las protecciones necesarias para garantizar un correcto funcionamiento. Los sensores de

temperatura garantizan que los componentes se mantienen dentro del margen de funcionamiento.

La supervisión del voltaje de alimentación garantiza que el equipo funciona dentro de los márgenes previstos y, en el

caso de sobrepasarlos, se desconectará para evitar posibles anomalías.

CICLO DE TRABAJO Y SOBRECALENTAMIENTO

El ciclo de trabajo es el porcentaje de 10 minutos en el que la unidad puede soldar a la potencia requerida sin sobrcalentarse. En el caso que el equipo se sobrecaliente, la potencia de soldadura se detendrá. Aparecerá en pantalla

una alarma mostrando qué módulo interno es el que se ha sobrecalentado. Los ventiladores funcionarán hasta que

la temperatura interna sea inferior a 40º C. El equipo se rearmará automáticamente al recuperar una temperatura

segura. No obstante, se recomienda esperar un mínimo de 5 minutos para volver a trabajar con normalidad.

Para evitar el sobrecalentamiento, reduzca la potencia de soldadura ajustada y/o la longitud de los cordones que

esté realizando.

Aeroprocess 2000 Aeroprocess 3200 Aeroprocess 3220

Voltaje de entrada (U1) 230V +/- 15% 400V +/- 15% 400V +/- 15%

I

ntensidad máxima de entrada (I1 máx)

3

7A

2

2,2A

2

2,2A

Voltaje de soldadura en vacío (U0) 68V 64V 64V

Potencia absorbida max. 9KVA 9KVA 9KVA

Fusible 25A 20A 20A

Rango de regulación MIG-MAG 30-200A 30-320A 30-320A

R

ango de regulación MMA

1

0-200A

1

0-250A

1

0-250A

Rango de regulación TIG 10-220A 10-250A 10-250A

Rendimiento MIG-MAG

200A 45% (40ºC)

2

00A 68% (20ºC)

320A 40% (40ºC)

3

20A 60% (20ºC)

320A 40% (40ºC)

3

20A 60% (20ºC)

Rendimiento MMA

200A 45% (40ºC)

200A 68% (20ºC)

250A 60% (40ºC)

250A 100% (20ºC)

250A 60% (40ºC)

250A 100% (20ºC)

Rendimiento TIG

220A 45% (40ºC)

220A 72% (20ºC)

250A 60% (40ºC)

250A 100% (20ºC)

250A 60% (40ºC)

250A 100% (20ºC)

Hilos utilizables Fe 0,6 - 0,8 - 1,0 - 1,2 0,6 - 0,8 - 1,0 - 1,2 0,6 - 0,8 - 1,0 - 1,2

Hilos utilizables Ss 0,8 - 1,0 - 1,2 0,8 - 1,0 - 1,2 0,8 - 1,0 - 1,2

Hilos utilizables Al 1,0 - 1,2 1,0 - 1,2 1,0 - 1,2

Velocidad máxima del hilo 11m/min 18m/min 18m/min

Rodillos de arrastre 2R 4R 4R

Potencia motor 30W 65W 65W

Tiempo spot máximo 10s 10s 10s

Aislamiento térmico H (180ºC) H (180ºC) H (180ºC)

Grado de protección IP IP23S IP23S IP23S

Ventilación FORZADA FORZADA

FORZADA

Peso 19 Kg 58 Kg 56 Kg

Aeroprocess 2000 Aeroprocess 3200 Aeroprocess 3220

Dimensiones 407x602x285mm 808x935x308 808x935x308

Normas IEC 60974-1 / EC 60974-10

ATENCIÓN

Si se excede el ciclo de trabajo nominal del equipo y se insiste prolongadamente en hacerlo funcionar

(sin darle tiempo a refrigerarse adecuadamente), podría causar una avería importante no cubierta por la

garantía del equipo

ES

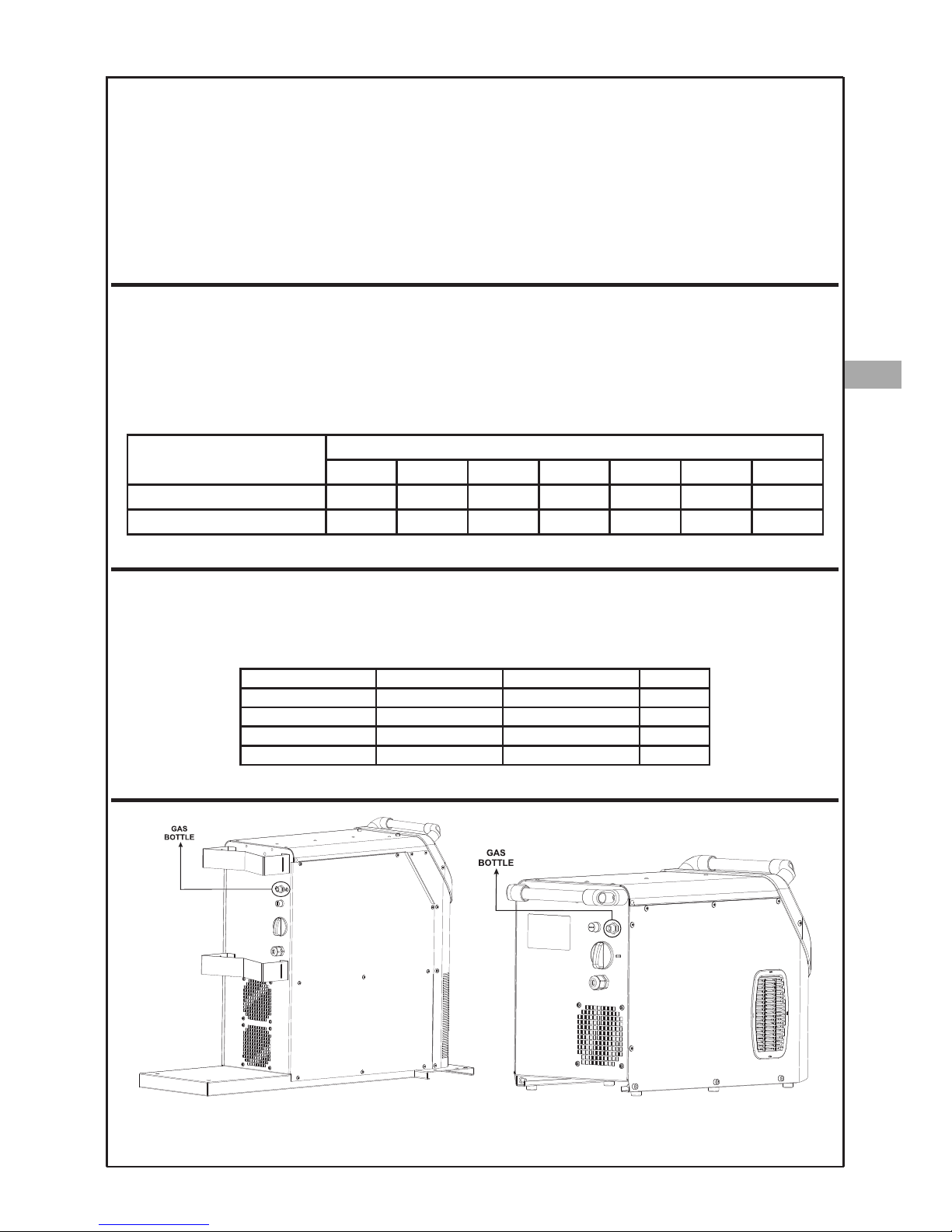

TRANSPORTE E INSTALACIÓN DEL EQUIPO

La posición de transporte del equipo debe ser la indicada en su embalaje. Se debe procurar que el equipo no reciba

n

ingún golpe durante el transporte. El emplazamiento del equipo debe de estar en un lugar seco y ventilado, alejado

de tomas de agua y del puesto de soldadura (para evitar así la entrada de polvo metálico en el interior del equipo).

La máquina deberá conectarse a un cuadro eléctrico, que debe estar compuesto por un interruptor diferencial y un

interruptor automático. El interruptor diferencial protege a las personas de contactos directos o indirectos con partes

e

léctricas. El interruptor automático se debe elegir en función de la placa de características del equipo. Se aconseja

un interruptor con una relación intensidad/tiempo del tipo lenta (curva D), para prevenir falsos disparos.

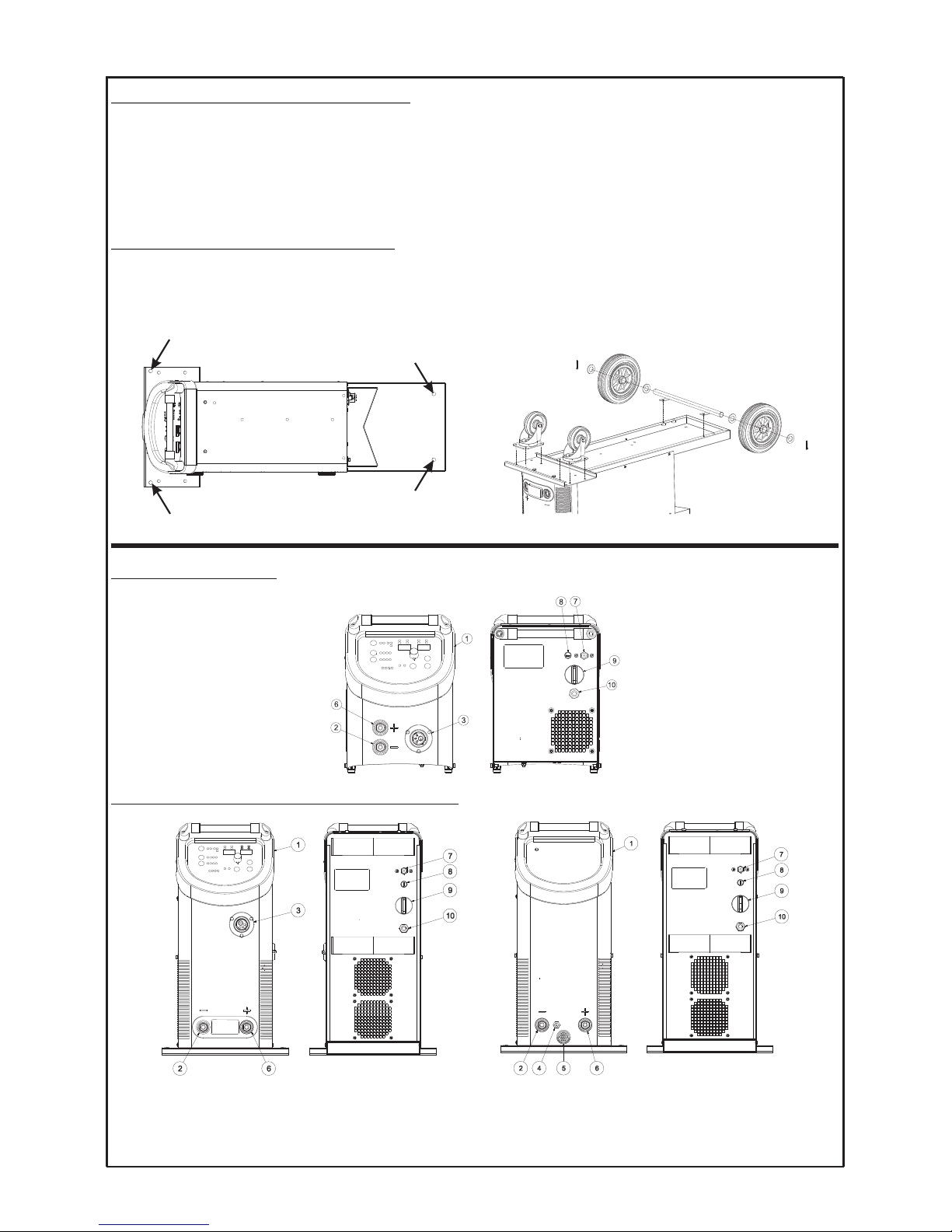

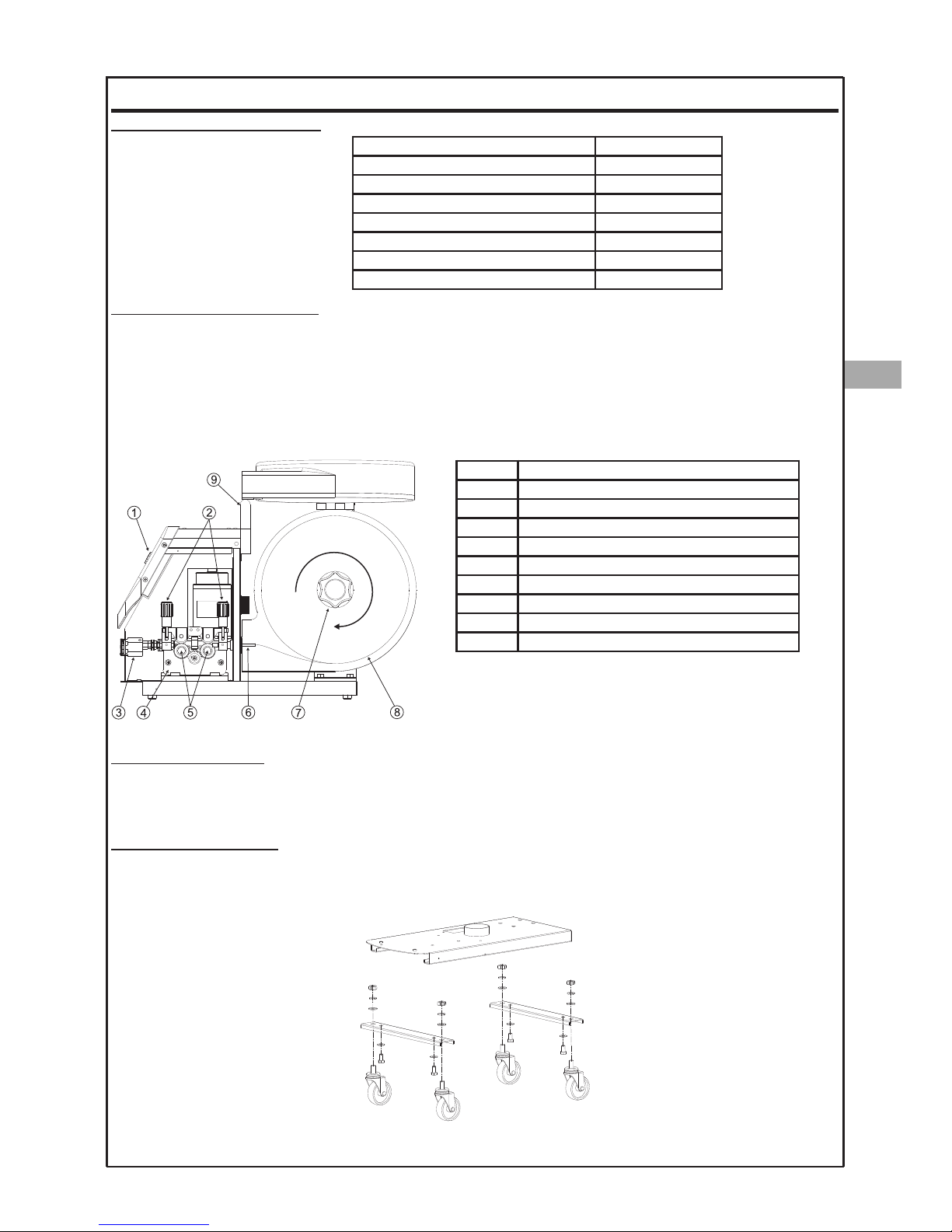

MANIPULACIÓN Y MONTAJE DEL EQUIPO

Para la manipulación y transporte del equipo Aeroprocess 2000, utilice siempre las asas frontal y posterior.

Para mover los equipos Aeroprocess 3200 e 3220, primero debe montar las ruedas delanteras y posteriores con los

r

espectivos tonillos. Para desplazarlos verticalmente, utilice los cáncamos de sujeción que debe atornillar a la base

d

e la unidad, mientras que para desplazarlos horizontalmente, se debe utilizar el asa frontal.

DESRIPCIÓN DE LOS ELEMENTOS DEL EQUIPO

AEROPROCESS 2000

AEROPROCESS 3200 y AEROPROCESS 3220

SOLTER SOLDADURA S.L.

AEROPROCESS

5

1 - Panel de mando

2 - Conector polo negativo

3 - Euroconector

4

- Conector de gas

5 - Conector de alimentación Aerofeed

6 - Conector polo positivo

7 - Entrada de gas

8

- Fusible fuente de la alimentación control 2A lento

9 - Interruptor principal

10 - Conexión a la red de alimentación

CONEXIONADO DE LA PINZA DE MASA

S

e debe conectar la pinza de masa lo más cerca posible de la pieza a soldar y conectar el otro extremo del cable al

e

quipo (en la posición deseada según la polaridad). La superfície de contacto con la pieza a soldar debe ser la

mayor posible. Asegúrese de que dicha superficie está completamente limpia y libre de pintura y óxido.

La tabla siguiente muestra la sección de cable recomendada por Solter Soldadura según amperaje y ciclo de trabajo

para longitudes inferiores a 25m. Estos datos son como referencia y pueden NO adaptarse a todas las aplicaciones.

Si el cable se sobrecalienta, utilice una sección de cable mayor.

CONEXIONADO DE LA ANTORCHA

Conectar la antorcha MIG en su posición, prestando especial atención a que ésta quede completamente atornillada

al euroconector. Asegúrese de que la antorcha que se va a utilizar es la adecuada según el material, el tipo de refrigeración, los niveles de corriente y el ciclo de trabajo que requiera cada aplicación. Solter dispone de distintas antorchas para adaptarse a las necesidades de cada cliente. Ver tabla a continuación.

CONEXIONADO DEL GAS

Amperaje de soldadura (A)

100 150 200 250 300 350 400

Sección (mm2) para X<60 % 16 25 25 35 50 50 70

Sección (mm2) para X>60 % 16 25 35 50 70 70 90

ANTORCHA REFRIGERACIÓN CICLO TRABAJO REF.

SX-36 4m Aire 270A 60% 56033

SX-36 3m ALU Aire 270A 60% 56077

SX-501 4m Líquida 500A 60% 56075

SX-501 3m ALU Líquida 500A 60% 56078

SOLTER SOLDADURA S.L.

AEROPROCESS

6

ES

Conectar el tubo de gas a la boquilla trasera de la unidad de potencia y el otro extremo del tubo al regulador de caudal de la botella de gas. Asegúrese de que utiliza la mezcla de gas adecuada para el material a soldar. Ajuste el caudal de gas a un valor típico de entre 8 - 10 l/min. Un ajuste del caudal incorrecto puede producir defectos en el

c

ordón de soldadura. Recuerde cerrar la válvula de la botella de gas después de finalizar la soldadura.

USO DE GENERADORES ELÉCTRICOS

Los equipos están preparados para funcionar con un generador eléctrico. No obstante, estos generadores deben

c

umplir una serie de requisitos. Para los equipos trifásicos se recomienda utilizar generadores trifásicos con una potencia constante de al menos 25KVA. Si el generador no tiene la suficiente potencia o el voltaje de salida está fuera

de los límites de trabajo del equipo, podría afectar a la estabilidad del arco de soldadura y, por consiguiente, a la calidad de la unión a soldar. En el caso más desfavorable, puede incluso causar averías en el equipo.

No combine varios equipos de soldadura en un mismo generador. Los cambios súbitos del nivel de carga pueden

afectar a la estabilidad del arco de soldadura.

Ponga en marcha el equipo girando el interruptor ubicado en la parte posterior de la unidad de potencia. Durante la

secuencia de puesta en marcha, el equipo realiza un test interno. Si se detectara alguna anomalía, se mostraría en

el display del panel frontal el correspondiente código asociado a ésta.

Siempre ponga en marcha o pare el equipo mediante el interruptor posterior, NO enchufando o desenchufando el

equipo de la red.

PUESTA EN SERVICIO AEROPROCESS 2000

Conectar la máquina de soldar a un enchufe provisto de toma de tierra. Es obligatorio que la toma de corriente disponga de la conexión de tierra.

La tensión de la red debe encontrarse dentro de los márgenes establecidos por Solter Soldadura (230V ± 15V).

Fuera de estas tensiones, la máquina puede funcionar incorrectamente.

En función del tipo de soldadura a utilizar (MMA, TIG, MIG-MAG), deberá conectar la pinza de masa, la pinza portaelectrodos, la antorcha TIG o la antorcha MIG-MAG.

Seleccionar la polaridad en función del tipo de aplicación y alambre que vaya a utilizar. Para seleccionar dicha polaridad, se debe verificar y/o cambiar las conexiones que se encuentran dentro del compartimento del alambre.

Encender el interruptor del equipo, ubicado en la parte posterior.

PUESTA EN SERVICIO AEROPROCESS 3200

Montar las ruedas delanteras y posteriores en el equipo (ver apartado de manipulación y transporte del equipo).

Conectar el equipo a una red electrica trifásica de 400Vac. Asegurarse de que la potencia de la linea eléctrica será

suficiente para el consumo del equipo. Elegir la polaridad deseada.

En función del tipo de soldadura a utilizar (MMA, TIG, MIG-MAG), deberá conectar la pinza de masa, la pinza portaelectrodos, la antorcha TIG o la antorcha MIG-MAG.

En este modelo no se puede cambiar la polaridad.

Encender el interruptor del equipo, ubicado en la parte posterior.

PUESTA EN SERVICIO AEROPROCESS 3220

1- Montar las ruedas delanteras y posteriores en el equipo (ver apartado de manipulación y transporte del equipo).

2- Posicione y apriete el soporte Aerofeed 5 (56213) a la unidad de potencia (la unidad de potencia ya lleva incorpo-

rados los correspondientes tornillos para sujetar el soporte).

2- Posicione la devanadora encima del soporte Aerofeed 5 (56213).

2- Desatornillar la abrazadera metálica que está detrás del porta bobinas de plástico. Por dentro de esta abrazadera,

debe pasar el cableado de interconexión entre la unidad de potencia y la unidad AEROFEED. Esta abrazadera sujeta y mantiene alineada la conexión.

SOLTER SOLDADURA S.L.

AEROPROCESS

7

3- Realizar todas las conexiones entre el equipo y la devanadora. Deberá seleccionar la polaridad en función del tipo

de alambre que vaya a utilizar. Sin embargo, el tubo de gas y el cable de control, siempre van conectados en el

mismo lugar (1-2). El orden de conexionado es siempre el mismo, primero el cable de potencia, segundo, el conector de gas y, finalmente, el cable de control.

Conexión positiva

Este tipo de conexionado es el más común para los diferentes tipos de alambre. El

cable de potencia, se conecta al polo positivo y la pinza de masa al polo negativo.

Conexión negativa

Este tipo de conexionado es poco frecuente. Se utiliza para alambres de acero tubulares sin gas o con gas del tipo básico. El cable de potencia se conecta al polo

negativo y la pinza de masa al polo positivo.

Se recomienda consultar las especificaciones de polaridad especificadas por el fabricante de alambre, ya que podrían variar.

La devanadora AEROFEED, de serie, incluye el cableado de 1,7m (73368). Si se

desea, está disponible el mismo cableado con 5m (73369) y 10m (73370).

4 - Conectar el cable de masa en la posición deseada.

5 – Conectar la antorcha MIG en su posición.

6 – Conectar el tubo de gas en la parte posterior de la unidad de poténcia.

ATENCIÓN

No conecte directamente la botella de gas a la devanadora, pues ésta no dispone de electroválvula.

Tanto la electroválvula cómo el sensor de presión de gas de protección están ubicados en la unidad de

potencia con el fin de ahorrar en el consumo de gas.

ATENCIÓN

Debe asegurarse que todos los conectores están conectados firmemente y que no puedan presentar pro-

blemas de falsos contactos.

SOLTER SOLDADURA S.L.

AEROPROCESS

8

ES

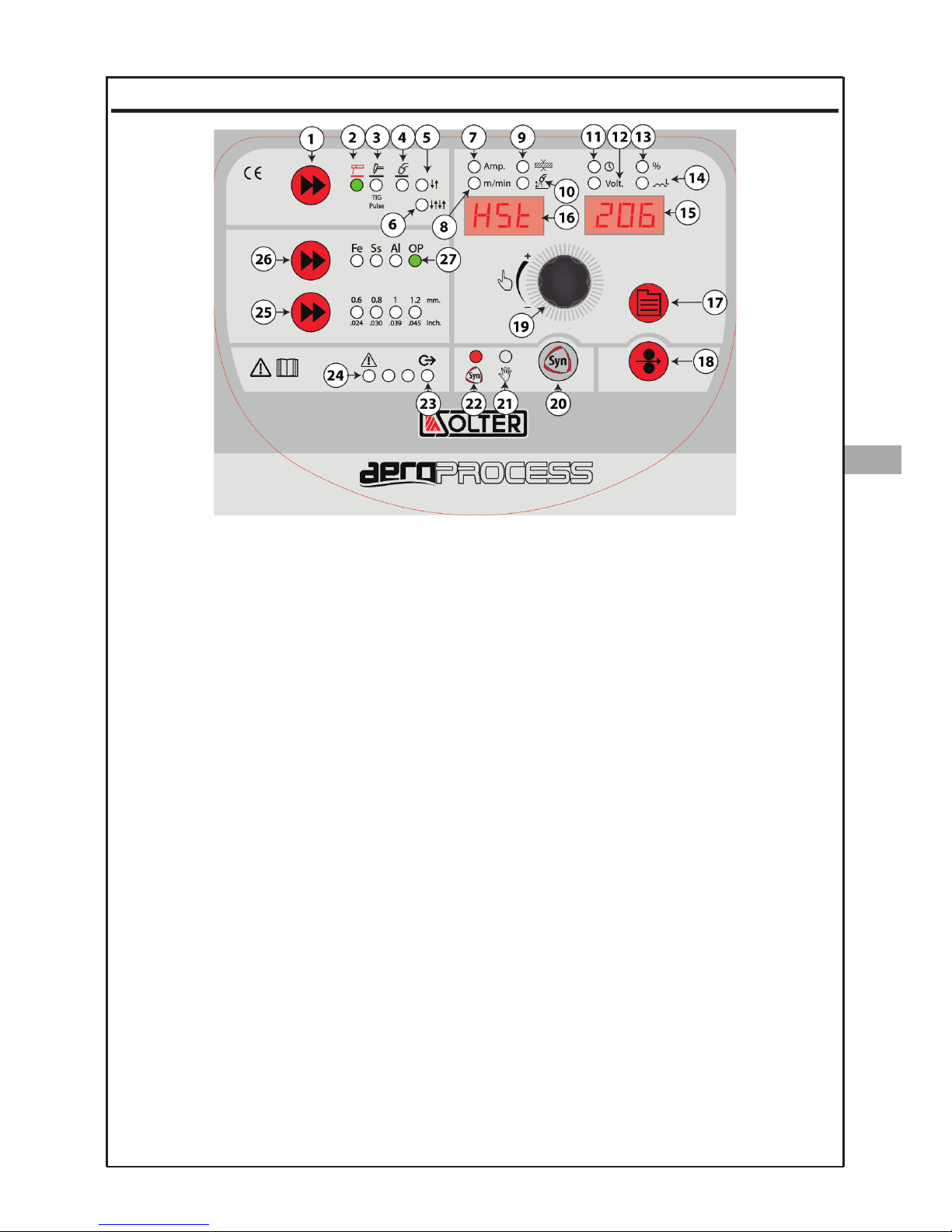

ESQUEMA DEL PANEL FRONTAL

1- Selector del tipo soldadura

2- Modo soldadura MMA

3- Modo soldadura TIG

4- Modo sodadura MIG-MAG

5- Modo 2 tiempos

6- Modo 4 tiempos

7- Amperios

8- Velocidad (m/min)

9- Grosor a soldar

10- Altura del arco

11-Tiempo (0,1s)

12- Voltios

13- Porcentaje

14- Dinámica del arco (inductancia)

15- DISPLAY de valores

16- DISPLAY de parámetros

17- Selector del Menú

18- Pulsador de enhebrado manual

19- Mando principal

20- Selector sinérgico o manual

21- Modo manual

22- Modo sinérgico

23- Salida de potencia activa

24- Anomalía

25- Selector de diámetro del alambre

26- Selector de materiales

27- OP (materiales no estándar)

SOLTER SOLDADURA S.L.

AEROPROCESS

9

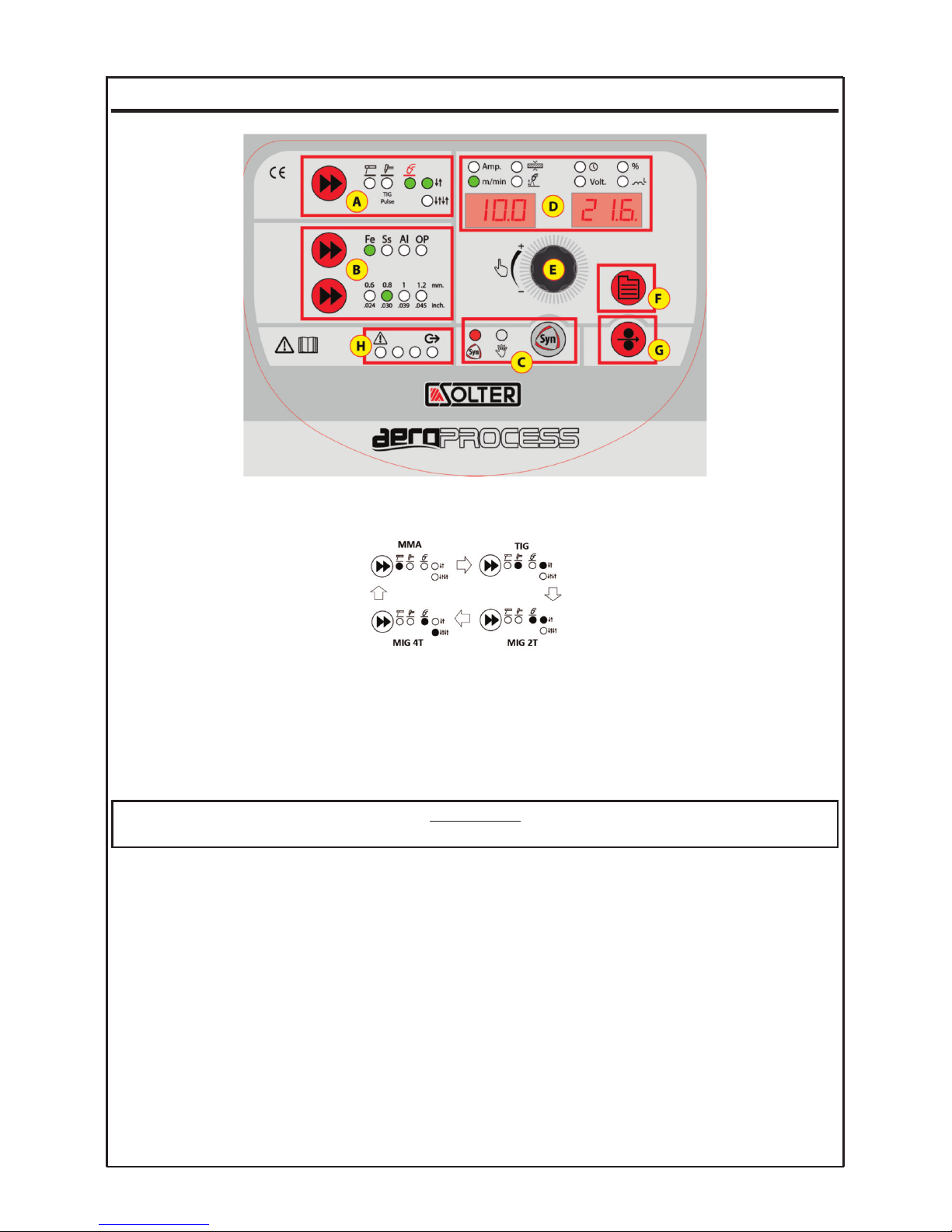

OPERATIVA PANEL

A- Selector del tipo de soldadura: Nos permite seleccionar entre los diferentes tipos de soldadura del equipo. El se-

lector es secuencial y a cada pulsación se seleccionará un nuevo tipo de soldadura (vea la siguiente imagen).

B- Selectores de material y diámetro del alambre: Sólo disponibles en modo MIG. Nos permite seleccionar entre las

diferentes opciones de materiales (consultar el adhesivo situado en la tapa para más detalles). Al realizar un cam-

bio de material o diámetro, siempre se activará el modo SYN.

C- Selector de modo sinérgico (automático) o manual: Para una óptima calidad de soldadura, se recomienda selec-

cionar el modo sinérgico (en este modo, la tensión de soldadura siempre es la adecuada para la velocidad que seleccionemos, permitiendo un pequeño ajuste con el parámetro de altura de arco). En modo MANUAL, podemos

ajustar independientemente la tensión de soldadura y la velocidad del alambre.

D- Panel indicador principal: En ésta pantalla se indicaran todos los valores que seleccionemos (variables de soldadura, opciones del menú, así como los valores de corriente y tensión del proceso de soldadura).

E- Selector principal: Con este selector podremos seleccionar opciones del menú y ajustar los valores de los diferentes parámetros. El valor que se puede modificar siempre aparece en modo parpadeo.

F- Pulsador del menú: Con este pulsador podremos entrar y salir del menú del equipo. Para desplazarse o modificar

una opción del menú, utilizaremos el selector E.

G- Pulsador de enhebrado: Sólo válido para el modo MIG. Nos permite enhebrar el alambre en la antorcha al preparar el equipo. Al pulsarlo, aparece en la pantalla la indicación inc y la velocidad de enhebrado (que podremos modificar con el selector E).

H- Indicador de las anomalías o estados del equipo: En él aparecen varias indicaciones (alarmas, sobretemperatura

o equipo trabajando).

ATENCIÓN

En modo MANUAL se podría ajustar el equipo de tal forma que el proceso de soldadura no sea el ade-

cuado.

SOLTER SOLDADURA S.L.

AEROPROCESS

10

ES

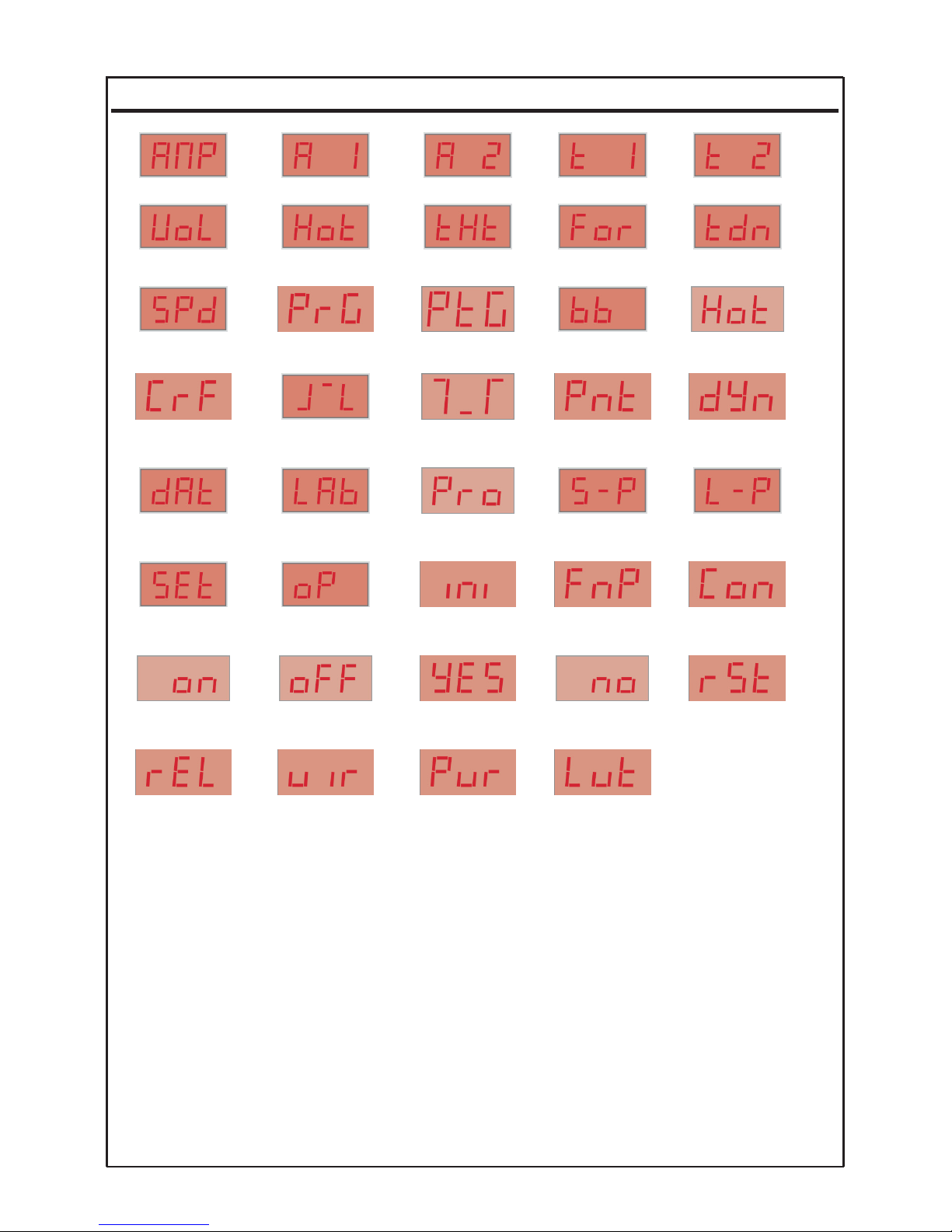

SIMBOLOGÍA DEL DISPLAY

Amperios Amperios I1en TIG Amperios I2en TIG Tiempo de I1 en TIG Tiempo de I2 en TIG

Voltaje de soldadura

C

orriente Hot-start en

MMA

T

iempo Hot-start en

MMA

C

orriente Force-arc

en MMA

T

iempo de la rampa

de bajada en TIG

Velocidad del alambre

en MIG

Tiempo pre-gas en

TIG / MIG

Tiempo post-gas en

TIG / MIG

Burn-back en MIG

Corriente Hot-start en

MIG

Rellenado de crater

en MIG

Tiempo de soldadura

en MIG

Tiempo de repetición

en MIG

Control de

penetración en MIG

Dinámica de la

soldadura en MIG

Menú de datos Tiempo trabajado Acceso a programas

Guardar programa

en la memoria

Recuperar programa

de la memoria

Ajuste de parámetros

del proceso

Número de programa

seleccionado

Inicialización de

parámetros de fábrica

Funciones de

programa

Consumo de alambre

Función activada Función desactivada Confirmar Anular

Reset del contador de

consumo de alambre

Versión de software

Versión de software

de la interfaz usuario

Versión de software

de la unidad potencia

Versión SYN en

MIG-MAG

SOLTER SOLDADURA S.L.

AEROPROCESS

11

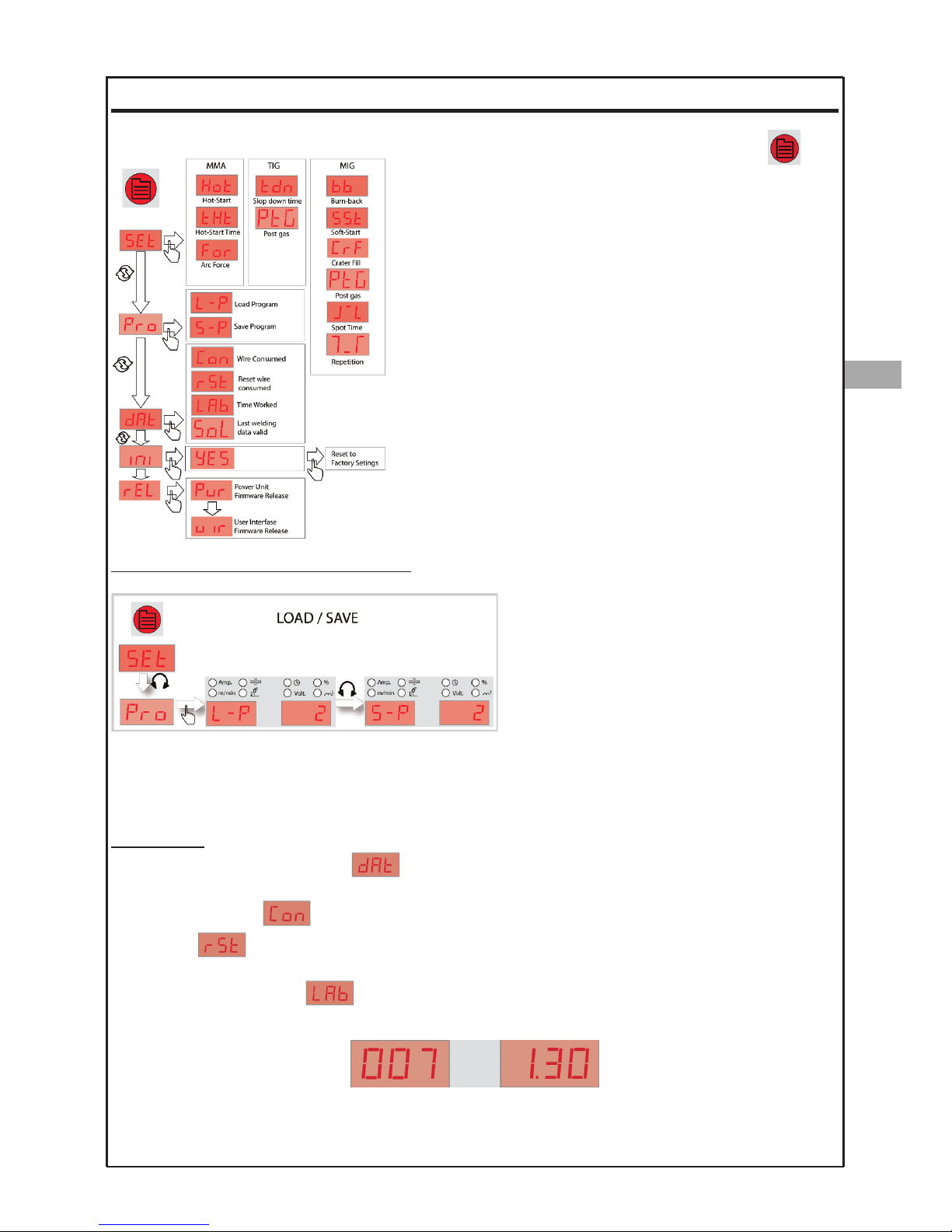

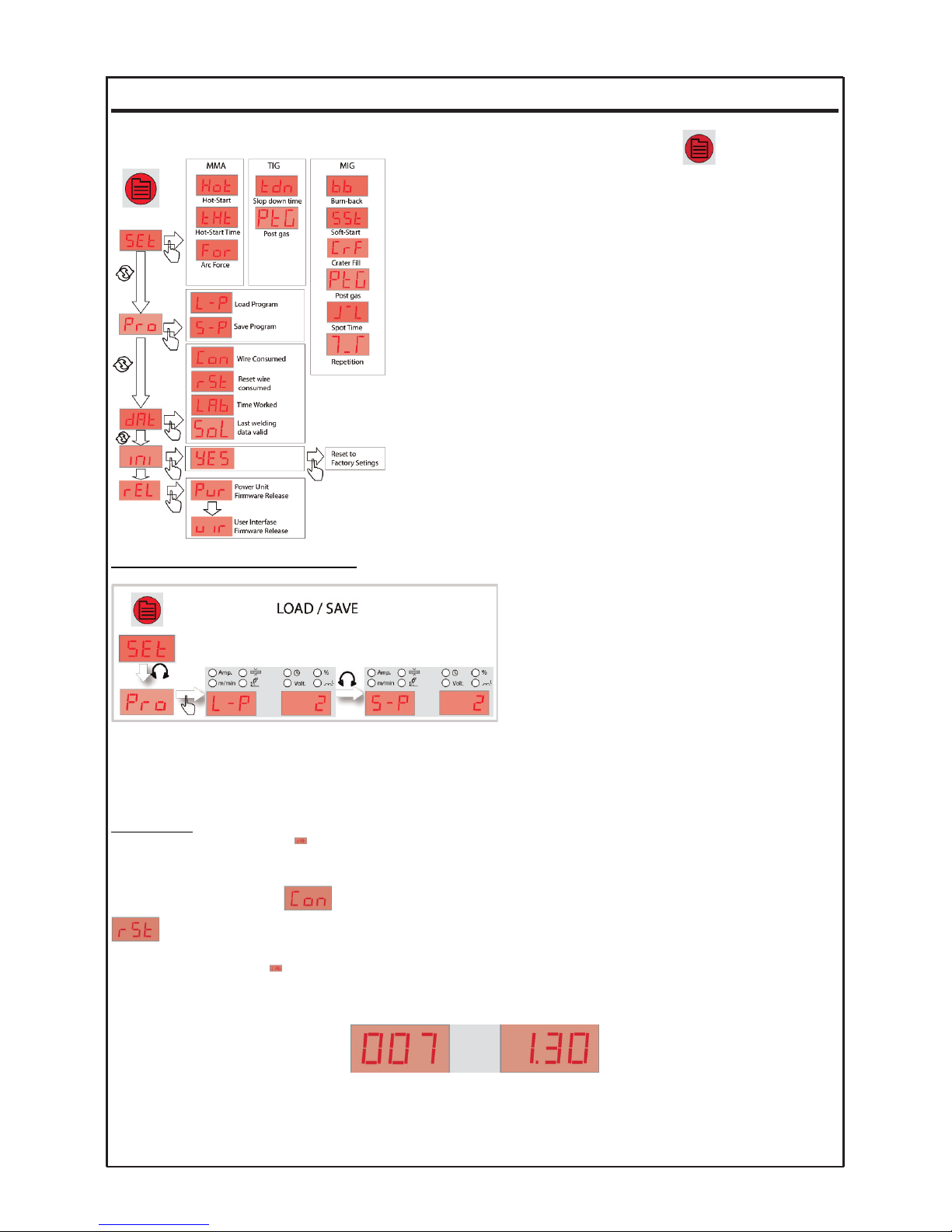

OPERATIVA DEL MENÚ

Para acceder al menú del equipo pulsaremos la tecla (17) .

En el display aparecerá la primera opción del menu SET. Desde este

punto, con el selector principal (19) seleccionaremos el menú desea

do.

Una vez aparece la opción deseada, pulsaremos el selector principal

p

ara acceder a los diferentes parámetros del menú seleccionado,

pudiendo realizar la consulta del valor o modificarlo (pulsar el selector principal para poder modificarlo (modo parpadeo) + pulsar de

nuevo el pulsador principal para confirmar el nuevo valor). Para

abandonar el menú desde cualquier posición, utilizaremos la tecla

17.

La modificaciones realizadas se guardarán automaticamente y serán

vigentes hasta que no se modifiquen. Si queremos guardar los datos

en un programa determinado, se deberá proceder según la operativa

de las memorias de programas.

GESTIÓN DE LA MEMORIA DE PROGRAMAS

El equipo permite guardar en memoria cualquier

tipo de programa con todos los datos, tanto principales como secundarios.

Para gestionar la lectura/escritura de estos programas, debemos seleccionar el menú programa (entrar en el modo menú y seleccionar “Pro”). Ahora

podemos seleccionar entre la opción de recuperar

un programa (L-P) o guardar un programa (S-P).

Una vez seleccionada la opción deseada, seleccionaremos el número de programa para posteriormente validar la

opción con el mando selector.

Los datos recuperados se pueden modificar y se guardarán como programa actual, pero en ningún caso se modificará el programa de la memoria, quedando a salvo de modificaciones accidentales.

MENÚ DATOS

Entrar en el modo menú y seleccionar . En este menú, tenemos la posibilidad de leer los datos de consumo

de alambre del equipo y el de las horas de trabajo.

El consumo de alambre se visualizará en m y cm. Este valor lo podemos resetear en cualquier momento

con la opción del menú. El valor es acumulativo hasta un valor máximo de 600m en el que se resetea automáticamente.

El dato de las horas de trabajo se visualiza en horas y minutos (hhhh.mm) y no puede ser reseteado. Este

contador se incrementa con el tiempo de soldadura real.

Ejemplo: 71h 30 minutos

SOLTER SOLDADURA S.L.

AEROPROCESS

12

ES

INICIALIZACIÓN DE LOS DATOS

Todos los datos del programa de trabajo se pueden reiniciar al valor de fábrica, lo cual será útil para corregir problem

as ocasionados por parámetros modificados involuntariamente.

Para proceder a la inicialización, deberemos entrar en el menú y seleccionar ini. Al pulsar el mando selector, se reiniciaran todos los datos del programa de trabajo.

INFORMACIÓN DE LA VERSIÓN DEL SISTEMA

En la opción del menú , podremos obtener la información de la versión de nuestro equipo.

indica la versión de la unidad de potencia y la versión del panel operador.

OPERATIVA SOLDADURA MIG

Para prácticamente todos los tipos de materiales, la conexión será con el negativo en la pieza y el positivo en la antorcha, a excepción de los alambres tubulares sin aportación de gas (OP 130, OP131, OP132 y OP133) que será

con la polaridad invertida (solo válido para el modelo AEROPROCESS 2000 y 3220)

Sistema de arrastre

Se deberá preparar el sistema de arrastre con las opciones adecuadas al material que utilizaremos. Deberemos colocar los rodillos adecuados para el material en uso y ajustar la presión de los rodillos al mínimo para que el alambre

sea arrastrado con fuerza, pero pueda patinar si hay una obstrucción en la guía de alimentación del alambre.

Siga el siguiente procedimiento para el correcto ajuste de la presión de los rodillos:

1- Pulse el botón de enhebrado hasta que el alambre de soldadura salga por la antorcha.

2- Afloje la presión de los rodillos hasta el mínimo (indicado en el tensor con el número 1).

3- Coloque la antorcha en un angulo de 45º con la tobera a unos 5cm de una superficie de madera.

4- Pulse el botón de enhebrado para que el alambre salga sobre la superficie de madera.

5- Incremente la presión de los rodillos hasta que el alambre deje de patinar y pueda avanzar. En ese punto, dé

media vuelta más en el tensor de ajuste.

6- En el caso de que el alambre siempre patinara, aún con el tensor al máximo, indicaría que existe un problema en

el sistema de arrastre. Deberían comprobarse la guía del alambre (sirga), el ajuste del freno, el estado de la punta

de contacto y el desgaste de los rodillos.

También se deberá preparar la antorcha con los consumibles adecuados al material en uso, esto incluye, utilizar una

punta y una guía específica para la sección del alambre en uso. Para aluminios se requiere una guia de teflón o grafito. No se recomiendan antorchas de longitudes superiores a tres metros. Para longitudes de antorchas superiores,

se aconseja utilizar una antorcha con motor en el extremo del tipo “PUSH PULL”. Es importante conectar firmemente

la antorcha a la devanadora para evitar el sobrecalentamiento o caídas de voltaje.

Para soldaduras de aluminio, debe retirarse la guía de salida del euroconector, y la guía interna de teflón o grafito de

la antorcha, debe llegar hasta los rodillos de arrastre.

Colocaremos la bobina del alambre en el soporte previsto para ésta, de manera que, en funcionamiento, la bobina

gire en el sentido de las agujas del reloj. Asegúrese de que ninguna parte sobresalga de la bobina de alambre. Utilice el adaptador SOLTER 56125 para bobinas de 150mm de diámetro. El extremo del alambre deberá limarse para

que se deslice correctamente y no pueda quedarse bloqueado o estropear la guía. Ajuste el freno de manera que la

bobina no continue girando cuando el motor se detenga. Una presión excesiva en el freno puede provocar que el

motor de arrastre patine, causando defectos en la soldadura. Este freno está ubicado en el interior del soporte de la

bobina del alambre. Finalmente, coloque la tuerca firmemente para fijar la bobina al porta bobinas. Hacer pasar el

alambre por los rodillos del motor de forma que éste entre 10cm dentro de la sirga de la antorcha y posteriormente

cerrar el anclaje de los rodillos. Durante el proceso de soldadura, la puerta de aceso al motor de arrastre y la tapa

del porta bobinas deben permancer cerradas.

ATENCIÓN

No se borrarán los datos de ningún programa guardado en la memoria.

SOLTER SOLDADURA S.L.

AEROPROCESS

13

Gas de protección

Para cada tipo de material, deberemos conectar el gas de protección adecuado. Un gas no adecuado puede provocar una soldadura incorrecta o un funcionamiento anómalo del equipo.

Enhebrado del alambre

C

olocaremos el rodete del alambre en el soporte previsto para éste, de manera que entre lo más recto posible en el

sistema de arrastre (utilizar el adaptador SOLTER ref. 56125 para rodetes de 150mm). El freno debe ajustarse de

m

anera que no gire suave, ya que podría ocasionar un enredo del alambre al parar de traccionar. El extremo del

a

lambre deberá limarse para que se deslice correctamente y no pueda quedarse enganchado o estropear la guia.

Colocar el alambre en el sistema de arrastre de forma que entre unos 10cm dentro de la antorcha y cerrar los rodillos. Retirar la punta de contacto de la antorcha para garantizar un enhebrado sin problemas. Utilizar el botón de enhebrado del panel para completar el proceso. Se puede ajustar la velocidad de enhebrado con el selector principal.

Selección del modo de soldadura MIG

El equipo permite trabajar en diferentes modos MIG.

2T: Soldadura mientras mantenemos el pulsador.

4T: La primera pulsación inicia la soldadura, en la segunda pulsación la finaliza efectuando el llenado

del cráter (crater filling) mientras se mantenga pulsada la antorcha.

Modo SPOT y SPOT con repetición

Solo se puede seleccionar en modo 2T (se deberá activar en el menú SET). Manteniendo el pulsador, el equipo realizará un tiempo de soldadura definido por el parámetro correspondiente.

Todos estos modos pueden funcionar en manual o sinérgico.

Crater filling (rellenado del crater). Esta opción estará activa solamente en modo 4T. Al activar el pulsador de la antorcha para parar, el equipo reducirá la velocidad del alambre para realizar la función de crater filling, mientras lo tengamos pulsado.

Modo Manual

Este modo solo se recomienda para personal experimentado en la soladura MIG. El ajuste es totalmente manual y

deberá conocerse las características de velocidad y tensión de soldadura para el material utilizado.

Modo sinérgico

En este modo deberemos especificar en el equipo el tipo de material, grosor del alambre y gas de protección que

vamos a utilizar. Una vez configurado el equipo, éste se irá ajustando automáticamente según la velocidad de alambre que especifiquemos, suministrando en cada posición las características adecuadas al proceso.

Para la selección del material, tenemos dos opciones. La primera serian todos los materiales habituales con los

gases habituales, esta selección se realiza con las teclas 27 y 28. Para los materiales o gases no tan habituales, debemos seleccionar el programa OP y escoger el programa adecuado de la tabla de programas.

Ajustes en modo sinérgico

En modo sinérgico siempre ajustaremos como parámetro principal la velocidad del alambre. Éste parámetro determina la potencia de la soldadura y deberá ser el adecuado para el proceso. El mínimo y máximo de este parámetro

viene determinado por el material utilizado.

Otro parámetro que podemos ajustar es el offset. Éste determina la altura del arco de soladura. Los valores posibles

son de +10 a -10 siendo su valor óptimo de 0.

El tercer parámetro que podemos ajustar es la dinámica de la soldadura (inductancia). Éste parámetro afectará al

acabado final del cordón, así como a las proyecciones que puedan generarse. El ajuste posible es de +10 a -10

siendo el valor recomendable 0.

Selección del material a soldar y gas de protección

Es importante que antes de iniciar la soldadura tengamos seleccionado el material que utlizaremos. Para los materiales más habituales, Acero con Ar CO2 (15 - 25%), Inoxidable 316 / 308 / 304 con Ar CO2 (2%) y aluminio 53XX

con Ar, podemos realizar la selección directamente con los indicadores del frontal. Para combinaciones de gases no

tan habituales u otros materiales, se deberá seleccionar un programa en la opción OP. En el interior de la puerta del

alimetador de alambre, puede consultar los programas sinérgicos para soldadura MIG disponibles.

ATENCIÓN

Los componentes del sistema de arrastre son piezas sometidas al desgaste. Para obtener una calidad

ó

ptima de soldadura, el mantenimiento del sistema de arrastre es fundamental.

SOLTER SOLDADURA S.L.

AEROPROCESS

14

ES

Diagrama operativa del panel en modo MIG sinérgico con materiales no habituales

Para los materiales no habituales, deberemos selecc

ionar la opción OP en el selector de materiales e introducir el número de programa que corresponde al

material, diámetro del alambre y gas que deseamos.

Este número de programa está indicado en la tabla

a

dherida en la tapa del equipo.

Parámetros adicionales

Para el ajuste del comportamiento del equipo tenemos una serie de parámetros

adicionales ajustables desde el menú SET.

Burn-back: Determina el retroceso del alambre al finalizar la soldadura.

Soft-Start: Determina la rampa de aceleración del alambre al principio de la sol-

dadura y nos ayudará a calibrar el arranque del mismo.

Crf: Ajuste del relleno del cráter final (Crater Filling). Al finalizar el cordón de sol-

dadura, especilmente a potencias elevadas, puede aparecer un cráter que mediante esta función se puede rellenar con una menor potencia de soldadura.

PtG: Tiempo de post-gas. Determina el tiempo que se suministrara gas después

de finalizar la soldadura. Los valores posibles son de 0,1 a 5,0 segundos.

PrG: Tiempo de pre-gas. Tiempo en que se suministra gas antes de iniciar la soldadura.

Tiempo de SPOT: Determina el tiempo de soldadura de un punto. Sólo será activo si tenemos seleccionado un valor de tiempo. En la posición OFF está desactivado. La función de soldadura por puntos sólo es compatible en modo 2T.

Tiempo de repetición del SPOT: Tiempo de pausa antes de iniciar una nueva

soldadura en SPOT. Con el selector en OFF no hay repetición. La repetición del

tiempo de soldadura se realizará mientras tengamos apretado el pulsador de la

antorcha. Si el tiempo de SPOT no está activado, éste ajuste no tiene ningún efecto.

OPERATIVA SOLDADURA MMA

Conectar la pinza porta-electrodos y pinza de masa según indicaciones del electrodo que utilizemos (utilizar los bornes dinse (+ y -) del exterior del equipo).

Seleccionar el modo MMA. Una vez está seleccionado el modo MMA, podremos ajustar el amperaje de soldadura

deseado.

SOLTER SOLDADURA S.L.

AEROPROCESS

15

Para el modo MMA existen una serie de parámetros adicionales que se

pueden ajustar accediendo al menú SET.

H

ot Start MMA: Nivel de corriente de inicio para arco con electrodo reves-

tido. El valor está referido en tanto por ciento respecto a la corriente nominal. Un valor entre el 100 y el 150 % ayuda a una mejor penetración del

material al iniciar el cordón.

Tiempo de Hot-start MMA: Tiempo durante el que se aplicará el Hot-Start.

Configurable entre 0 y 2,5s

Force-arc MMA: Regula la intensidad en cortocircuito máxima para ayudar

a la transferencia de material. Un valor alto ayuda a prevenir que el electrodo pueda pegarse a la pieza y mejora la calidad de soldadura para electrodos de tipo celulósicos o aleaciones de

a

luminio.

L

a función hot-start permite entregar una potencia inicial ligeramente superior para mejorar el cebado y facilitar la

creación del baño de fusión. Ésta función permite reducir el riesgo de que puedan aparecer defectos de fusión al

principio del cordón de soldadura.

Los equipos Aeroprocess 2000, 3200 y 3220 disponen de la función arc-force. Está función asiste la transferencia de

material del electrodo revestido ajustando la intensidad en corto circuito. Si se produce un corto circuito prolongado

durante más de un segundo, se activa la función de anti-stick (el equipo deja de suministrar potencia para permitir

despegar el electrodo).

OPERATIVA SOLDADURA TIG

Para la soldadura en modo TIG o TIG arco pulsado, se deberá utilizar una antorcha TIG ref. 06131 conectada en el

euroconector (sólo para aeroprocess 2000 o 3220) o el adaptador ref. 56210 (todos los modelos) para antorchas

TIG SR17 o SR26, en este caso, se conectará la antorcha directamente a los bornes externos. Se deberá utilizar

gas Argón 100%.

La polaridad la antorcha debe ser negativa (deberemos cambiar la polaridad de ésta si se trata de un equipo Aeroprocess 2000 o connectar la antorcha al negativo si se trata de una Aeroprocess 3200 o 3220). La pieza siempre se

conectará al positivo.

Seleccionar el modo TIG.

El equipo sólo permitirá el ajuste de la

corriente de soldadura. Los demás parametros se deberán ajustar en el

menú SET.

Parámetros ajustables en modo TIG:

Tdn: Tiempo de la rampa de bajada de la corriente de soldadura al finalizar

el cordón (en décimas de segundos).

PtG: Tiempo de post-gas. Determina el tiempo que se suministrará gas

después de finalizar la soldadura.

Para los modelos Aeroprocess 2000, 3200 y 3220, la ignición del arco para procesos TIG se realiza mediante contacto. Presione ligeramente el electrodo con la pieza a soldar (1), presione el pulsador de la antorcha y espere entre

1 y 2 segundos (comenzará a fluir el gas de protección y se calentará ligeramente el electrodo de tungsteno para

permitir la ignición del arco (2)). Levante lentamente el electrodo de la pieza girando la antorcha de manera que la

tobera permanezca en contacto con la pieza a soldar (3). El arco se iniciará y el amperaje se incrementará hasta el

nivel ajustado previamente (4).

ATENCIÓN

Para realizar el cambio de polaridad y/o connectar/desconnectar accesorios, apague el equipo y espere

unos segundos. Asegúrese de apretar los bornes interiores (Aeroprocess 2000) y exteriores (resto de

equipos) firmemente para evitar que se sobrecalienten.

SOLTER SOLDADURA S.L.

AEROPROCESS

16

ES

Selección del modo de soldadura TIG

El equipo permite trabajar en diferentes modos TIG.

2T: Soldadura mientras mantenemos el pulsador.

4T: Durante la primera pulsación, se efectuará la secuencia de ignición del arco y el equipo generará

una corriente inicial (predeterminada como la mitad de la configurada). Al soltar el pulsador, se mantendrá el arco de

soldadura con el nivel establecido. Al pulsar de nuevo el pulsador, se realizará la rampa de bajada hasta un valor

igual a la mitad del configurado y se mantendrá éste nivel de corriente hasta dejar de presionar el pulsador.

Se recomienda utilizar electrodos de tungsteno con Torio (rojo), Cerio (gris) o Lanthano (oro).

La punta del electrodo debe afilarse con forma de cono. De esta forma, el arco será mas estable y la energia se podrá

concentrar más en la raíz de la soldadura. En función del amperaje a utilizar, se recomienda afilar mas o menos el electrodo.

En función del amperaje al que vaya a soldar, se recomienda un diámetro de electrodo, una tobera y un caudal de gas

específicos. Siga la siguiente tabla de referencia como guía.

Si utiliza una antorcha con potenciómetro de regulación, puede variar el ajuste del amperaje de soldadura (desde el

valor nominal programado en el panel frontal hasta el valor mínimo de operación del equipo). Ésto permite con un

solo mando reducir o aumentar el ajuste de corriente de soldeo de todos los parámetros asociados a la intensidad

nominal.

ATENCIÓN

No trate de encender el arco rascando el electrodo como si se tratara de una cerilla.

Rango Amperaje (A) Electrodo (mm) Tobera (mm) Caudal de gas (l/min)

10 - 60 1,0 6,5 / 8,0 5 - 6

60 - 120 1,6 6,5 / 8,0 / 9,5 6 - 7

120 - 170 2,0 8,0 / 9,5 7 - 8

170 - 220 2,4 9,5 / 11,0 8 - 9

220 - 350 3,2 11,0 / 12,5 9 - 10

300 - 420 4 16 10 - 12

SOLTER SOLDADURA S.L.

AEROPROCESS

17

DEVANADORA AEROFEED5

CARACTERÍSTICAS TÉCNICAS

DESCRIPCIONES GENERALES

La unidad de alimentación de alambre es el dispositivo que hace que el alambre pase por el tubo de contacto de la pistola para fundirse en el arco. Los equipos MIG-MAG disponen de un sistema para variar la velocidad de avance del

alambre, así como de una válvula magnética para regular el paso del gas.

Un motor transmite la potencia a los rodillos de arrastre, de manera que éstos desplazan el alambre desde la bobina

a la punta de contacto de la antorcha. Los rodillos en contacto son normalmente uno plano y otro con bisel. El bisel es

en forma de V para materiales duros como aceros, en forma de U para materiales blandos como el aluminio y ranurados para aceros tubulares. Es imprescindible seleccionar el rodillo de acuerdo con el diámetro y material del alambre

en uso.

ASA DE TRANSPORTE

Siempre que desee manipular la unidad Aerofeed, utilice el asa de transporte. Dicha asa debe utilizarse en caso que

quiera colgar en alto la devanadora. El asa de la unidad debe estar aislada eléctricamente de la estructura metálica

de la cuál será suspendida.

KIT RUEDAS AEROFEED

Para montar el KIT ruedas (56206), primero debe retirar los 4 pies de nylon de la parte inferior de la unidad, montar

las ruedas a los 2 soportes y atornillar éstos a la base de la devanadora. No vuelva a utilizar los pies de nylon para

atornillar los soportes, utilice los tornillos metálicos suministrados con el kit.

C

ARACTERÍSTICAS TÉCNICAS

A

EROFEED 5

Tensión de entrada (U1) 24V DC

Intensidad máxima 500A DC

Diámetros de hilo aplicables De 0,6 a 1,2mm

V

elocidad máxima del hilo

1

8m/min

Rendimiento 60%

Grado de protección IP IP23C

Peso 15Kg

Nº Descripción

1 Panel de control

2 Ajuste de presión de los rodillos

3 Euroconector

4 Motor de arrastre

5 Rodillos de arrastre

6 Guía del alambre

7 Fijación y freno de la bobina de alambre

8 Bobina de alambre

9 Asa de transporte

SOLTER SOLDADURA S.L.

AEROPROCESS

18

ES

RODILLOS

AVERÍAS

En el caso de producirse algún tipo de avería que represente un peligro para las personas, equipo y/o entorno, deberá desconectarse el equipo de inmediato y asegurarse de que no se pueda volver a conectar si no se ha solucionado la causa que la ha provocado. Las averías solo deben ser eliminadas por personal cualificado, teniendo en

cuenta las indicaciones de seguridad del equipo.

POSIBLES ANOMALÍAS Y SOLUCIONES

RODILLOS MATERIAL 2000 3200 3220

0

,6 - 0,8 Ranura V

F

e, SS,CuSi, CuAl

5

6105

- 5

5606

0,8 - 1,0 Ranura V Fe, SS,CuSi, CuAl 56106 55600 1,0 - 1,2 Ranura V Fe, SS,CuSi, CuAl 55986 55601 55607

1,2 - 1,6 Ranura V Fe, SS,CuSi, CuAl - 55602 55608

0,8 - 1,0 Ranura U Al 55987 55612 1,0 - 1,2 Ranura U Al 55988 55603 55609

1,2 - 1,6 Ranura U Al - - 55610

0,8 - 1,0 Ranura Estriada Flux Core, Metal Core 56116 -

-

1

,0 - 1,2 Ranura Estriada

F

lux Core, Metal Core

5

5989

5

5604

5

5611

1,2 - 1,6 Ranura Estirada Flux Core, Metal Core - 55605 55613

ANOMALÍA POSIBLE CAUSA

No se pone en marcha el equipo

Verificar si hay tensión en la toma de corriente.

Interruptor defectuoso.

Apagar el equipo o desconectarlo durante 1 minuto, volver a intentar la

puesta en marcha.

Circuito electrónico defectuoso.

Piloto de anomalía iluminado

Apagar el equipo un minuto y ponerlo en marcha de nuevo. Si el error

persiste, contactar con el servicio técnico.

Piloto de sobretemperatura iluminado

Máquina sobrecalentada y en fase de enfriamiento. Espere a que la

máquina se recupere.

Piloto de salida parpadea

El equipo ha detectado que el pulsador de la antorcha estaba pulsado

al arrancar el equipo o al recuperarse de un paro por temperatura.

Suelte el pulsador de la antorcha y/o pedal.

El alambre no sale correctamente

Verificar que el sistema de arrastre gira correctamente.

Freno del carrete demasiado apretado.

Accesorios del sistema de arrastre incorrectos.

Antorcha o consumibles en mal estado

El alambre no sale a la velocidad deseada

En el inicio de la soldadura el alambre siempre sale a una velocidad

mínima. Verificar que el sistema de arrastre funciona correctamente

con el enhebrado manual.

No sale gas de protección

Verificar que hay gas en la botella.

Verificar que el ajuste de caudal es correcto.

Antorcha taponada y/o perforada.

Válvula de gas defectuosa.

El arco no es estable y el alambre

choca con la pieza.

Verificar si el material que utilizamos se corresponde con el que hemos

seleccionado.

Verificar que tenemos los consumibles y rodillos adecuados al material

utilizado.

SOLTER SOLDADURA S.L.

AEROPROCESS

19

ALARMAS Y ANOMALIAS

No se inicia el arco

L

a toma de corriente de la pieza no hace contacto.

Conexión incorrecta del equipo (polaridad).

Cables de soldadura en mal estado.

Inicio del arco incorrecto

Conexiones electricas defectuosas.

Pieza sucia y/o oxidada.

A

justes incorrectos.

Poca penetración

Baja intensidad de soldadura.

Velocidad excesiva al soldar.

P

olaridad invertida.

Poros en la soldadura

Poco caudal de gas o gas inadecuado.

Consumibles de la antorcha defectuosos.

Salpicaduras

Exceso de intensidad de soldadura.

Ajuste de la dinámica incorrecta.

Posición de soldadura incorrecta.

Programa de soldadura incorrecto.

Arco inestable

Pieza con óxido o mal preparada para soldar. Revisar el contacto de la

pinza de masa y los consumibles de la antorcha

Programa de soldadura inadecuado

Nº ERROR CAUSA SOLUCIÓN

Er 1

Datos de la memoria

corruptos

Éste error se recupera automáticamente. Se cargarán los datos por

defecto. Enviar el equipo al servicio técnico para una puesta a

punto.

Er 2

Error de la memoria

interna

Este error se recupera automáticamente y el equipo puede seguir

funcionando.

Er 3

Error en la memoria

de datos

El equipo carga un juego de parámetros por defecto y puede seguir

funcionando.

Er 4

Error en la comunica-

ción con la potencia

Apagar el equipo un minuto y volver a ponerlo en marcha. Si el

error persiste, anotar el valor del segundo display y consultar al

servicio técnico.

Er 5

Placa control poténcia

no compatible

Se ha encontrado una placa de control no compatible o ha dejado

de funcionar. Substitúyala.

Er 6

Error de la memoria in-

terna

Memoria de datos no operativa, substituya el panel operador.

Er 10

Sobrecalentamiento

Tensión de alimenta-

ción incorrecta

Esperar que el equipo se enfríe.

Verificar la tensión de entrada del equipo

SOLTER SOLDADURA S.L.

AEROPROCESS

20

ES

INSTRUCCIONES DE MANTENIMIENTO

Se recomienda una supervisión periódica del equipo. Antes de realizar cualquier operación de mantenimiento, desc

onecte el equipo de la red de alimentación y manténgala durante la operación de mantenimiento. Reduzca los pla-

zos de mantenimiento aconsejados ante condiciones de uso severas.

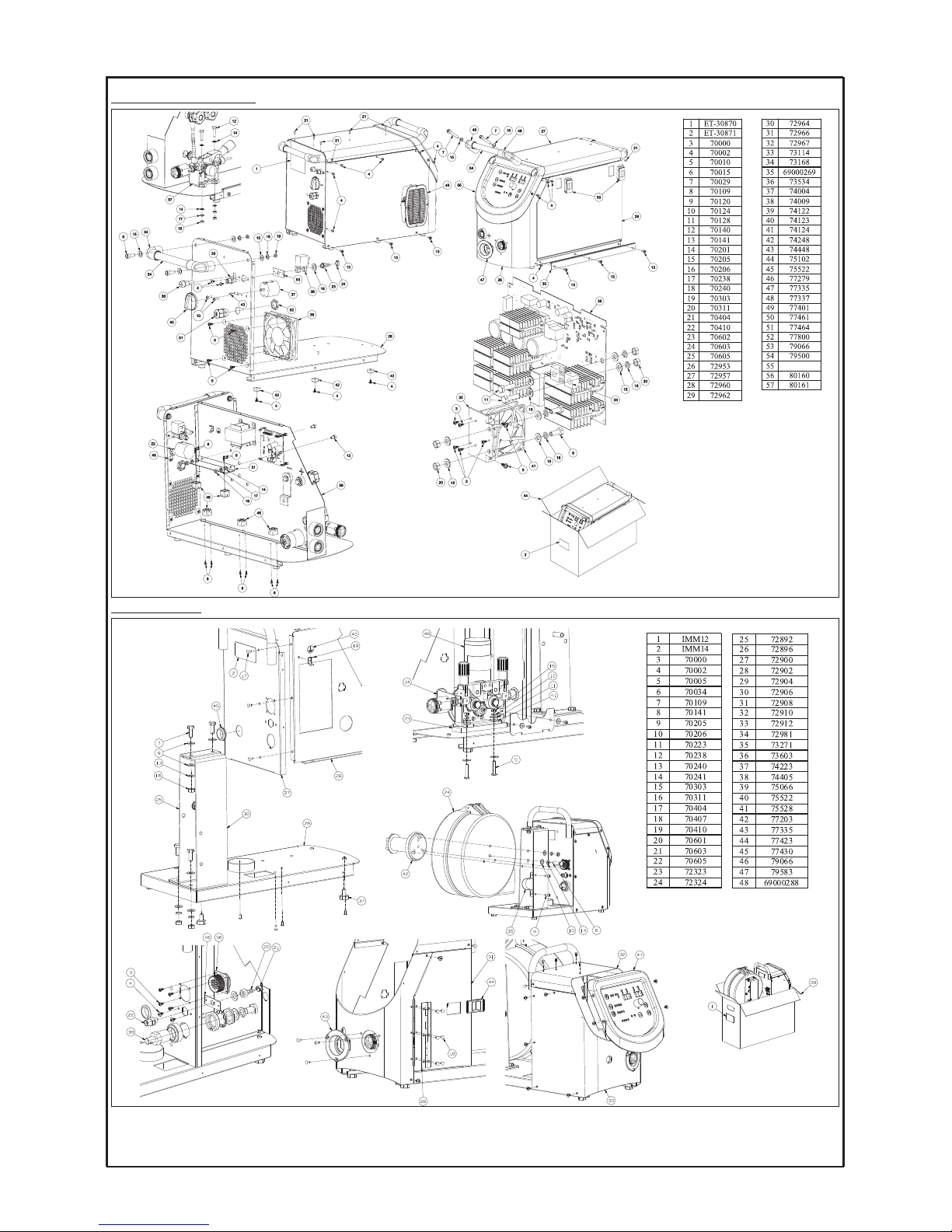

DESPIECES

Aeropocess 2000 (A1)

Aerofeed 5 (A1)

Aeroprocess 3200 (A2)

Aeroprocess 3220 (A3)

ESQUEMAS ELÉCTRICOS

AEROPROCESS 3200 (A4)

AEROPROCESS 3220 (A5)

AEROPROCESS 2000 (A6)

AEROFEED 5 (A7)

INTERVALO ACCIÓN

Semanalmente

Verifique el estado de los cableados y accesorios externos.

S

ubstituya componentes desgastados en la antorcha

L

impie y apriete las conexiones eléctricas del circuito de soldadura

Limpie la unidad de arrastre con aire comprimido.

Trimestral

Sople el túnel de ventilación con aire a presión (seco) desde la toma de ventilación frontal.

No remueva el envolvente de protección durante el soplado.

Desmonte todas las rulinas de la unidad de arrastre (se deberán limpiar de polvo y suciedad, y engrasarlas ligeramente).

Anual

Efectúe una revisión completa según especifica la norma para equipos de soldadura

EN-60974. Dirijase a su distribuidor.

ATENCIÓN

La manipulación de partes internas del equipo debe realizarse únicamente por personal cualificado.

Existe riesgo de choque eléctrico al contactar con partes activas. NO debe operar sin las tapas debida-

mente colocadas. Antes de acceder al interior del equipo, desconéctelo de la alimentación y espere como

mínimo 5 minutos antes de realizar cualquier operación de mantenimiento.

SOLTER SOLDADURA S.L.

AEROPROCESS

21

INDEX

Introduction 2

Security and protection 2

General descriptions 3

Description of the items of equipment 5

Connection of the earth clamp 6

Connection of the torch 6

Gas connection 6

Use of electric generators 7

Commissioning of Aeroprocess 2000 7

Commissioning of Aeroprocess 3200 7

Commissioning of Aeroprocess 3220 7

Front panel layout 9

Operating the front panel 10

Symbology of the display 11

Operating the menu 12

MIG-MAG welding operations 13

MMA welding operations 15

TIG welding operations 16

Aerofeed 5 wire feeder 18

Rollers 19

Faults 19

Possible anomalies and solutions 19

Alarms and anomalies 20

Maintenance instructions 21

Exploded drawings A1-A2-A3

Schematics A4-A5-A6-A7

CE certificate A8

Certificate of guarantee A9

SOLTER SOLDADURA S.L.

AEROPROCESS

1

EN

INTRODUCTION

Thank you for choosing our brand. We hope that the welding machine you have purchased will serve you well. This

instruction manual contains the necessary information and warnings for correct use within the maximum operator safety conditions. INVERTER welding equipment must be used by expert personnel who know and understand the

risks involved in the use of this equipment. If you have any doubt or queries concerning this manual, please, contact

us. Internal manipulation of the equipment involves the risk of electric shocks. We request you not to carry out any

manipulation of the equipment (only technically trained personnel can do this). The manufacturer denies all responsibility for negligent practices in the use or manipulation of this machine. This manual must be kept with the equipment

p

urchased. It is the responsibility of those persons who use and repair this machine to comply with the requirements

of the above mentioned regulations.

SECURITY AND PROTECTION

ELECTRICITY

A good and safe installation is essential to ensure the optimum performance of this equipment. Make

sure that the unit is connected to the correct supply voltage.

The equipment must ALWAYS have an adequate grounded (earth) connection.

Electromagnetic fields may interfere with the operation of several electrical and electronic devices such

as pacemakers. We highly recommend people with such devices to avoid using this kind of equipment.

PERSONAL CLOTHING

The entire body of the welder is subject to possible contact with aggressive agents, so it must be totally

protected. Use safety boots, gloves, oversleeves, gaiters and leather aprons.

BURN PROTECTION

Never touch parts of the wire or the material with your bare hands once soldered. Avoid skin contact with

airborne particles. Do not point the torch at any part of the body.

EYE PROTECTION

Welders and their assistants must use safety masks or goggles with filters which stop harmful radiation

entering the eyes. Use special screens to observe the welding area during the process.

FIRE PROTECTION

The welding process produces flying incandescent metal parts which may cause fires. Do not use the

machine in areas where there may be inflammable gases. Clean the working area of all inflammable material. Pay special attention to the protection of the gas cylinders in accordance with the necessary requirements.

PROTECTION FOR GAS CYLINDERS

Cylinders containing shielding gas, store their contents at high pressure. If these cylinders suffer any

form of damage, they may explode. Always treat these cylinders with care and weld as far away from

them as possible.

WELDING IN TANKS WHICH MAY CONTAIN THE TRACES OF INFLAMMABLE MATERIALS INSIDE,

INVOLVES A HIGH RISK OF EXPLOSION. WE RECOMMEND KEEPING AN EXTINGUISHER READILY AVAILABLE FOR USE.

ELECTROMAGNETIC DISTURBANCES

Electromagnetic interferences produced by welding equipment may interfere in the operation of equipment which is sensitive to this kind of interference (computers, robots etc). Ensure that all the equipment

in the welding area is resistant to electromagnetic radiation. In order to reduce radiation as much as possible, work with welding wires as short as possible and placed in parallel on the floor if possible. Work at

a distance of 100 metres or more from equipment which is sensitive to disturbances. Ensure that the machine equipment is correctly earthed. If there are still interference problems despite having taken the

above described precautionary measures, the operator must take extra measures such as moving the

welding machine, using filters, using protected cables... to ensure that interference with other equipment

does not occur.

RECYCLING

In compliance with European Directive 2002/96/EC on waste electric and electronic equipment, this

equipment must be deposited in your local recycling centre at the end of its useful life.

SOLTER SOLDADURA S.L.

AEROPROCESS

2

GENERAL DESCRIPTIONS

Aeroprocess welding machines have been developed to support MMA, TIG and MIG-MAG welding processes; with a

n

otable capacity for MIG-MAG welding with multiple combinations of materials and shielding gases.

T

he range of Aeroprocess machines is equipped with dual digital signal processor, monitoring the status of the wel-

d

ing arc up to 10000 times per second. Thanks to this technology, the equipment can ensure an accurate and reliable arc under all operating conditions. It can be applied universally to any type of welding of various materials such

as stainless steels, alloy steels, aluminium alloys or other copper or titanium alloys.

The range of Solter Aeroprocess equipments allows rapid setting with the assistance of synergic configuration of

MIG-MAG parameters.

For MMA welding, the machine is equipped with adjustable anti-stick, hot-start and arc-force features. Thanks to

t

hese features, you can weld effectively with any type of coated electrodes.

For TIG welding, the equipment allows Lift Arc ignition, pre and post gas timing, and end current ramp control.

For MIG-MAG welding, the equipment has 28 pre-set synergic programs. In addition, there are also available the

special features of Burn Back, Hot Start, Crater Filling and timing for spot welding.

On the back of the machine, there is a nameplate of the welding machine parameters. This plate is designed in accordance with the EN 60974-1 Standard.

MEANING OF THE INDICATIONS ON THE SPECIFICATIONS PLATE

EN 60974 International Standard for welding equipment.

S/N.... Serial number.

MMA MMA welding.

TIG TIG welding.

Uo No-load welding voltage.

X Duty Cycle %.

I2 Welding current (Amps).

U2 Test voltage for welding current (I2).

U1 Mains voltage.

50/60 Hz Frequency of the mains

IP21 IP protection class.

S Suitable for working in places with increased risks.

SOLTER SOLDADURA S.L.

AEROPROCESS

3

EN

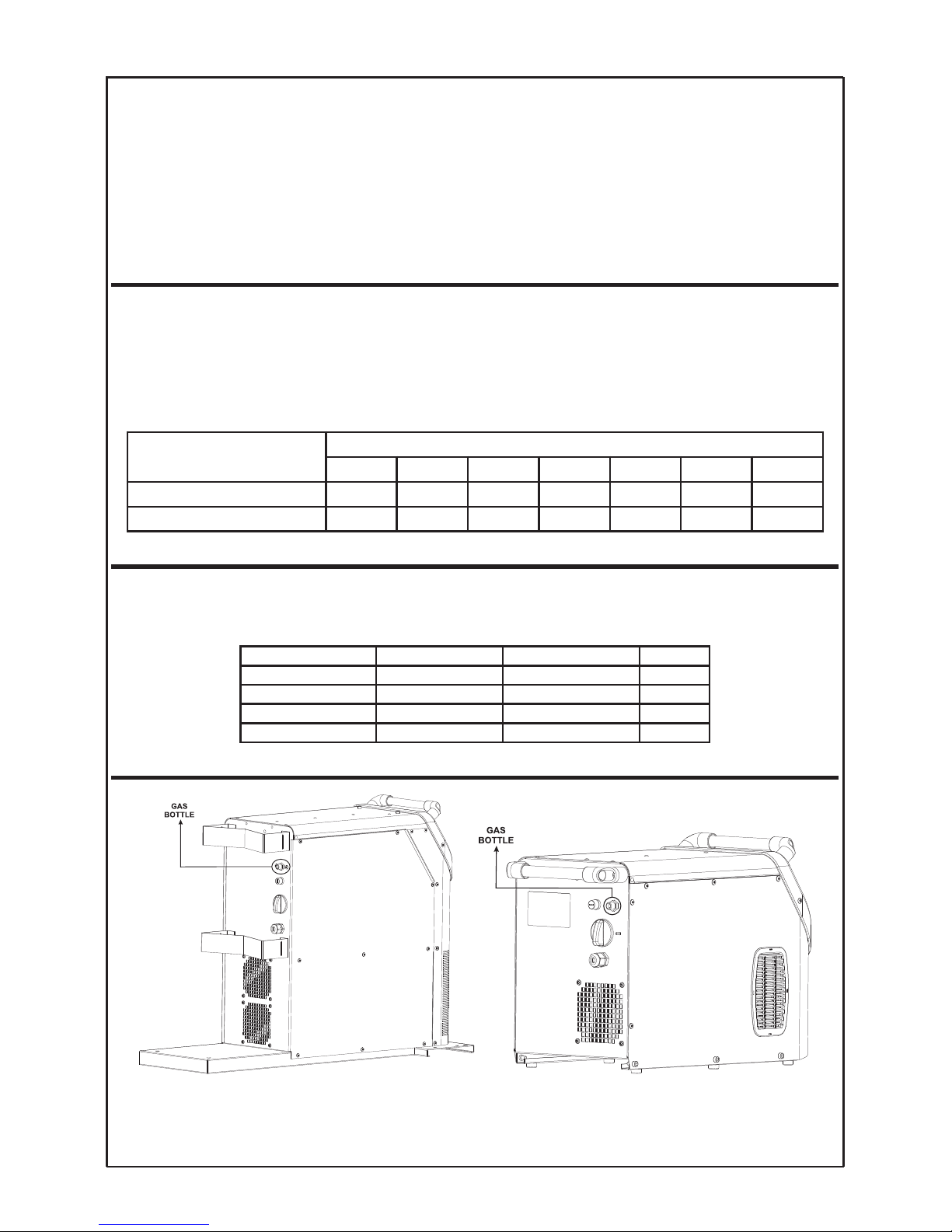

TECHNICAL SPECIFICATIONS

The machine is designed to be used outdoors. However, it should be protected from rainfall while it’s in use.

PROTECTION

The machine features all necessary protective measures to ensure proper operation. Temperature sensors ensure

that the components are kept within the operating range.

Monitoring of the supply voltage ensures that the machine operates within expected ranges and, in case of exceeding them, is disconnected to prevent possible anomalies.

OPERATING CYCLE AND OVERHEATING

The operating cycle is the percentage of 10 minutes during which the unit can weld at the required power without

overheating. If machine becomes overheated, the welding power will stop. The screen will display an alarm showing

which internal module is the one that has been overheated. The fans turn until the internal temperature is below

40°C. The machine will automatically reset when it reaches a safe temperature again. However, it is recommended to

wait at least 5 minutes before starting to work normally again.

To avoid overheating, reduce the adjusted welding power or the length of the welds.

Aeroprocess 2000 Aeroprocess 3200 Aeroprocess 3220

Input voltage (U1) 230V +/- 15% 400V +/- 15% 400V +/- 15%

M

aximum input current (I1 máx)

3

7A

2

2,2A

2

2,2A

No-load voltage (U0) 68V 64V 64V

Max. absobed power 9KVA 9KVA 9KVA

Fuse 25A 20A 20A

Mig-Mag regulation range 30-200A 30-320A 30-320A

M

MA regulation range

1

0-200A

1

0-250A

1

0-250A

TIG regulation range 10-220A 10-250A 10-250A

Mig-Mag duty cycle

200A 45% (40ºC)

2

00A 68% (20ºC)

320A 40% (40ºC)

3

20A 60% (20ºC)

320A 40% (40ºC)

3

20A 60% (20ºC)

MMA duty cycle

200A 45% (40ºC)

200A 68% (20ºC)

250A 60% (40ºC)

250A 100% (20ºC)

250A 60% (40ºC)

250A 100% (20ºC)

TIG duty cycle

220A 45% (40ºC)

220A 72% (20ºC)

250A 60% (40ºC)

250A 100% (20ºC)

250A 60% (40ºC)

250A 100% (20ºC)

Usable wires of Fe 0,6 - 0,8 - 1,0 - 1,2 0,6 - 0,8 - 1,0 - 1,2 0,6 - 0,8 - 1,0 - 1,2

Usable wires of Ss 0,8 - 1,0 - 1,2 0,8 - 1,0 - 1,2 0,8 - 1,0 - 1,2

Usable wires of Al 1,0 - 1,2 1,0 - 1,2 1,0 - 1,2

Maximum feeding speed 11m/min 18m/min 18m/min

Rollers 2R 4R 4R

Power of the motor 30W 65W 65W

Maximum spot time 10s 10s 10s

Temperature protection class H (180ºC) H (180ºC) H (180ºC)

IP protection class IP23S IP23S IP23S

Ventilation FORCED FORCED

FORCED

Weight 19 Kg 58 Kg 56 Kg

Aeroprocess 2000 Aeroprocess 3200 Aeroprocess 3220

Dimensions 407x602x285mm 808x935x308 808x935x308

Standards IEC 60974-1 / EC 60974-10

ATTENTION

If the nominal operating cycle of the machine is exceeded and the equipment is forced to work for too

long (without being allowed to cool properly), this could cause significant damage not covered by the

guarantee.

SOLTER SOLDADURA S.L.

AEROPROCESS

4

TRANSPORT AND INSTALLATION OF THE WELDING MACHINE

The transport position must be as indicated on the packaging. Impacts should be avoided during transport of the mac

hine. The machine must be located in a dry and well-ventilated area, away from water outlets and from the welding

station (to prevent metal dust entering the welding machine). The machine must be installed on a horizontal surface

with a maximum gradient of 10°. The machine must be connected to an electrical box, which should consist of a circuit breaker and an automatic switch. The circuit breaker protects people from direct or indirect contacts with electric

al parts. The automatic switch must be chosen according to the equipment nameplate. A switch with an

intensity/time ratio of the slow type (D curve) is recommended to prevent false triggering.

HANDLING AND ASSEMBLY OF THE MACHINE

To handle and move the Aeroprocess 2000 equipments, always use the front and rear handles.

To handle and move the Aeroprocess 3200 and 3220 equipments, firstly you have to assemble the front and the rear

w

heels (using their respective screws). To move them vertically, use the eyebolts that have to be screwed to the base

o

f the unit. To move them horizontally, you must use the front handle.

DESCRIPTION OF THE ITEMS OF EQUIPMENT

AEROPROCESS 2000

AEROPROCESS 3200 and AEROPROCESS 3220

SOLTER SOLDADURA S.L.

AEROPROCESS

5

EN

1 - Control panel

2 - Negative pole connector

3 - Euroconnector

4

- Gas connector

5 - Aerofeed connector

6 - Positive pole connector

7 - Gas input

8

- 2A Fuse (control)

9 - Main switch

10 - Mains connection

CONNECTION OF THE EARTH CLAMP

T

he earth clamp must be connected as close as possible to the workpiece and the other side of the cable must be

c

onnected to the machine (in the desired position according with the polarity). The contact surface with the workpiece

should be as large as possible. Make sure that the surface is completely clean and free of paint and rust.

The following table shows the cable section, recommended by Solter Soldadura, according to amperage and operating cycle for lengths of less than 25m. These data are for reference and may NOT suit all applications. If the cable

overheats, use a larger cable section.

CONNECTION OF THE TORCH

Connect the MIG torch in its position taking special care to ensure it is tightly screwed. Make sure that the torch is

going to be used is suitable for the current levels and operating cycle that the application requires. You can use an

air-cooled or water-cooled torch. Solter has different torches to suit the needs of each customer. See table below.

GAS CONNECTION

Welding current (A)

100 150 200 250 300 350 400

Section (mm2) for X<60% 16 25 25 35 50 50 70

Section (mm2) for X>60% 16 25 35 50 70 70 90

TORCH REFRIGERATIÓN DUTY CICLE REF.

SX-36 4m Air 270A 60% 56033

SX-36 3m ALU Air 270A 60% 56077

SX-501 4m Liquid 500A 60% 56075

SX-501 3m ALU Liquid 500A 60% 56078

SOLTER SOLDADURA S.L.

AEROPROCESS

6

Connect the gas tube to the rear nozzle of the power unit and the other end of the tube to the gas cylinder flow regulator. Be sure to use the proper gas mixture for the material to be welded. Set the gas flow rate to a typical value of 8

- 10 l/min. A wrong flow setting can cause defects in the weld bead. Remember to close the gas bottle valve when

y

ou finish welding.

USE OF ELECTRIC GENERATORS

The equipments are prepared to work with an electric generator. However, these generators must meet certain requir

ements. It is recommended to use three-phase generators with a constant power of at least 25KVA. If the generator

does not have enough power or the output voltage is outside the machine’s operating limits, this could affect the stability of the welding arc and, therefore, the quality of the weld joint. In the worst case, it may even cause damage to

the machine.

Do not use more than one welding machine with the same generator. Sudden changes in charge level may affect the

stability of the welding arc.

S

tart the machine by turning the switch on the back of the power unit. During the start up sequence, the equipment

performs an internal test. If a fault is detected, the associated code will appear on the front panel display.

Always start or stop the machine using the rear switch, NOT by plugging or unplugging it from the mains

COMMISSIONING OF AEROPROCESS 2000

Connect the welding machine to a socket with earth wire (the plug must have an earth connection).

Make sure that the voltage is within the range of 230Vac +/- 15%. Outside this voltage range, the machine may mal-

function.

Depending on the type of welding that is going to be used (MMA, TIG, MIG-MAG), you must connect the earth

clamp, the electrode holder clamp, TIG torch or MIG-MAG torch.

Select the polarity depending on the type of application and the wire that is going to be used. To select this polarity,

verify and/or change the connections that are inside the wire coil compartment.

Turn the switch located on the back of the machine.

COMMISSIONING OF AEROPROCESS 3200

Assemble the front and rear wheels on the equipment (see section handling and assembly of the machine).

Connect the machine to a three-phase 400Vac mains. Make sure that the power of the mains is enough for the consumption of the equipment. Select the desired polarity.

Depending on the type of welding that is going to be used (MMA, TIG, MIG-MAG), you must connect the earth

clamp, the electrode holder clamp, TIG torch or MIG-MAG torch.

In this model, the polarity can not be changed.

Turn the switch located on the back of the machine.

COMMISSIONING OF AEROPROCESS 3220

1- Assemble the front and rear wheels on the equipment (see section handling and assembly of the machine).

2- Position and fasten the bracket for Aerofeed 5 (56213) to the power unit (the power unit has the screws incorpora-

ted to fasten the bracket).

2- Position the winder above the Aerofeed 5 bracket (56213).

2- Unscrew the metal bracket behind the plastic rolls holder. Through this bracket, you must pass the interconnecting

wiring between the power unit and the AEROFEED unit. This clamp secures and maintains the connection aligned.

SOLTER SOLDADURA S.L.

AEROPROCESS

7

EN

3- Make all connections between the equipment and the winder. You must select the polarity depending on the type

of wire that you will use. However, gas tube and control cable always have to be connected in the same place (1-2).

The order of connection is always the same, the power cord first, second, the gas connector and finally, the control

cable.

Positive connection

This type of connection is the most common for different types of wire. The power

cable is connected to the positive pole and the earth clamp to the negative pole.

Negative connection

This type of connection is less frequent. It is used for tubular steel wires without

gas or with gases of basic type. The power cable is connected to the negative pole

and the earth clamp to the positive pole.

You are recommended to see the polarity specifications given by the wire manufacturer, as these may vary.

The standard AEROFEED winder comes with a 1.7m cable (73368). If desired, the

same cable is available with lengths of 5m (73369) and 10m (73370).

4 - Connect the ground cable to the desired position.

5 – Connect the MIG torch in its position.

6 – Connect the gas tube at the rear part of the power unit.

ATTENTION

Do not connect the gas cylinder directly to the wire feeder, as it has no solenoid. The solenoid and the

shielding gas pressure sensor are located in the power unit in order to save gas consumption.

ATTENTION

Ensure that all connectors are securely connected and that they may not present problems of false

contacts.

SOLTER SOLDADURA S.L.

AEROPROCESS

8

FRONT PANEL LAYOUT

1- Selector of welding type

2- MMA welding mode

3- TIG welding mode

4- MIG - MAG welding mode

5- 2T mode

6- 4T mode

7- Amps visualization

8- Speed in m/min.

9- Welding thickness

10- Arc height

11-Time (0,1s)

12- Volts visualization

13- Percentage (%)

14- Arc dynamics (inductance)

15- Values display

16- Parameters display

17- Menu selector

18- Button of manual feeding

19- Main selector

20- Synergic or manual selector

21- Manual mode

22- Synergic mode

23- Power output activated

24- Anomaly

25- Wire diameter selector

26- Standard materials selector

27- OP (Non-standard materials)

SOLTER SOLDADURA S.L.

AEROPROCESS

9

EN

OPERATING THE FRONT PANEL

A - Selector of welding type: This button lets you choose between the different types of welding offered by the ma-

chine. The selector is sequential, so each time the button is pressed, a new type of welding is selected (see next picture)

B - Selectors of material and wire diameter: Only available in MIG mode. This buttons let you select between different

material options (see the sticker on the inside of the winder for details). When you change material or diameter,

the SYN mode is always activated by default.

C - Selector of synergic (automatic) mode or manual mode: For optimum welding quality, you are recommended to

select the synergic mode (in this mode, the welding voltage is always right for the speed you select, allowing a little

adjustment of arc height parameter). In MANUAL mode, you can adjust the welding voltage and speed independently.

D - Main panel displays: These displays show all the values selected (welding variables, menu options, and the current and voltage values of the welding process).

E - Main selector: With this selector you can select menu options and set the values of the different parameters. The

value that can be modified always appears in flashing mode.

F - Menu button: With this button you can enter and exit the advanced parameter setting menu.To move or change a

menu option, use the selector E.

G- Button of manual feeding: Only available in MIG mode. It allows us to thread the wire into the torch to prepare the

equipment. When pressed, the indication "inc" and the threading speed (which may change with the E selector) are

displayed.

H - Machine status indicator: This part displays several indications (alarms, overheating or machine operating)

ATTENTION

In MANUAL mode, the machine could be set in a non proper way.

SOLTER SOLDADURA S.L.

AEROPROCESS

10

SYMBOLOGY OF THE DISPLAY

Amps Amps I1in TIG Amps I2in TIG Time I1 in TIG Time I2 in TIG

W

elding

voltage

H

ot-start

current in MMA

H

ot-start time

in MMA

F

orce-arc current

in MMA

T

IG slope down

time

Wire feed speed

in MIG

Pre-gas time

in TIG / MIG

Post-gas time

in TIG / MIG

Burn-back

in MIG

Hot-start current

in MIG

Crater Filling

in MIG

Welding time

in MIG

Repetition time

in MIG

Penetration control

in MIG

Arc dynamics

in MIG

Data menu Worked time Program access

Save program

in memory

Load program

from memory

Menu for welding

parameters

Number of selected

program

Factory

settings

Program

Functions

Consumed

wire

Enabled

function

Disabled

function

Confirm Cancel

Reset of the consu-

med wire counter

Software version

Firmware release

of the user interface

Power unit

firmware release

MIG-MAG SYN

database version

SOLTER SOLDADURA S.L.

AEROPROCESS

11

EN

OPERATING THE MENU

To access the machine menu press key (17) .

The first option of SET menu is displayed. From this point, with the

main selector (19), select the desired menu.

Once the desired option appears, press the main selector to access

the different parameters of the selected menu, allowing to check the

v

alue or change it (press the main selector to modify the value (flashing mode) + press again the main selector to confirm the new

value). To exit the menu from any position, use the 17 key.

The changes made are automatically saved and will be in effect until

they are changed. If we want to save the data in a given program,

proceed according to the operation of the program memories.

PROGRAM MEMORY MANAGEMENT

The machine can store any program in memory

with all data, both primary and secondary.

To manage the reading/writing of these programs,

select the program menu (enter menu mode and

select "Pro"). After that, you can choose between

the options “read a program (L-P)” or “save a program (S-P)”. Having selected the option, select the

program number with the main selector and confirm

the action by pressing the same selector.

The recovered data can be edited and will be saved as the current program, but the original program in the memory

will not be changed, being safeguarded from accidental changes.

DATA MENU

Enter menu mode and select . In this menu, we have the possibility to read the wire consumption data and

the worked hours of the machine.

The wire consumption data will be displayed in m and cm. You can reset this value at any moment using the

option from the menu. If you don’t reset the value manually, this value will be reset automatically when it arri-

ves to 600m.

The operating time value is displayed in hours and minutes (hhhh.mm) and cannot be reset. The value on

this time meter increases with the real welding time.

Example: 71h 30 minutes

SOLTER SOLDADURA S.L.

AEROPROCESS

12

RESETTING PARAMETERS TO DEFAULT VALUES

All operating program data can be reset to the default value, which is useful for correcting problems caused by unint

entionally altered parameters.