PINE RIDGE IV PLAY SYSTEM

lynwood

Bayside

Pine Ridge 3

17½ ft

10 ft

12ft

20'- 6"

8' 0"

20' 6"

3403230

F23230

Effective June 26/09

ASSEMBLY INSTRUCTIONS

Play System dimension with

safety allowance: 32’6” x 20’

8-10 Hrs

Prior to assembly, you MUST read the Owner’s Manual for important safety warnings and details on installing a shock absorbing surface.

This unit’s maximum fall height is 7.5 feet and is intended for a maximum of 7 users, ages 3 to 10 (110 lbs. per child).

For questions, assembly help or assistance with missing or defective parts:

North America

Solowave Design

375 Sligo Rd. West PO Box 10

Mount Forest, Ontario Canada

N0G 2L1

General Inquiries:

Toll Free: 1-877-966-3738

Email: support@solowavedesign.com

United Kingdom

General Inquiries:

Toll Free: 0870 145 2145

Email: info@selwoodproducts.co.uk

Other Countries:

Please refer to label affixed to outside of carton.

The 1-877 number on the Owners Manual &

Safety Instructions is for North America only.

Important Information: Please ensure page is read.

2

ABOUT OUR WOOD

Solowave Design™ uses only Premium playground lumber, ensuring the safest product for your children’s

use. Although great care has been taken in selecting the best quality lumber available, wood is a product

of nature and susceptible to weathering (changes in the aesthetics of the wood). A light sanding may be

required to remove minor splinters. For your information, we have described some changes that may occur

as a result of weathering:

1. Checking Checks are surface cracks in the wood along the grain. 4” x 4” material will

experience more checking than 2”, 1-1/4” or 1” material be cause the surface

and interior moisture content will vary more widely than in thinner wood.

2. Warping Warping refers to any distortion (twisting, cupping) from the true plane that

may take place during weathering.

3. Fading Wood exposed to sunlight, will over time, turn a grey color.

Note: The above changes will not affect the strength of the product.

Due to changes in the climate

What causes weathering?

One of the main reasons for weathering is the

effects of water (moisture); the moisture content

of the wood at the surface is different than the

interior of the wood. As the moisture moves in

or out of the wood (result of climate changes),

the different moisture content causes tension

in the wood, which can result in checking and

or warping.

moisture moves in and out

of the wood

Moisture content will vary

throughout any piece of wood.

How can I reduce the amount of weathering to my Play System?

At the factory we have added water repellent to the stain. This water repellent decreases the amount of water

absorption during rain or snow thus decreasing the tension in the wood. Sunlight will break down the water

repellent, so we recommend applying a water repellent on a yearly basis (see your local stain and paint supplier

for a recommended product). Also if storing the product before installation, make sure you store out of direct

sunlight in a cool dry place.

Will weathering affect the strength of my Play System?

Most weathering is just the normal result of nature and will not affect safe play and enjoyment for your child.

However if you are concerned that a part has experienced a severe weathering problem please call our

consumer relations department for further assistance.

© Solowave Design. All rights reserved.

HELPFUL HINTS

Tools Required

Important Information: Please ensure page is read.

Shovel

Measuring

Tape

Drill (1/8”

3/16” Bit)

Safety

Glasses

Hammer Ratchet 1/2”,

Swing Hangers

Swing hangers must be screwed into the wood

the full length of the shaft, so that the triangular

head is touching the wood (see swing hanger

diagram). Failure to correctly install swing hangers

may result in the hanger itself breaking, or the

hanger becoming dislodged from the wood.

Either circumstance can cause serious injury. Big

Backyard cannot assume any responsibility for

incorrect installation of swing hangers.

(Liquid soap may be used as a lubricant for ease

of installation).

NOTE: Follow proper assembly procedure.

Swing BeamSwing Beam

Swing Hanger orientation for

swing attachment.

Screw Hanger in until

it is snug and flush with

bottom of Swing Beam.

Swing HangerSwing Hanger

7/16” & 9/16”

Level #2 & #3 Phillips

or Robertson

Square

Ruler

Tee - Nuts & Lock washers

Place tee-nut in hole and tap into place with

hammer. Insert the hex bolt through, first the

lock washer and then the flat washer, and feed

through hole. Hand tighten to ensure bolt and

tee-nut connection (this may not be possible due

to coating on hardware, if not use a ratchet), and

then proceed with ratchet. DO NOT over tighten.

Hardware should not crush wood.

NOTE: A 1/4” lock washer and flat washer, are used with

1/4” hex bolt or 5/16” with 5/16”.

Hex Bolt

Lock Washer

Flat Washer

Tee-Nut

Wood

Dowel Installation

Step

Ladder

Warning: For your child’s safety orientate the swing

hangers as shown to ensure your swing will have the proper

swinging motion when installed. Failure to do so could result in

the premature breaking off of the swing hanger or swing chain.

Hardware

When making the selection of 1/4” and 5/16”

hardware, carefully read the instructions in each

step of this manual to ensure the proper hardware

is used.

NOTE: 5/16” Hardware is larger in diameter than 1/4”.

The Swing Triangle Plate has a total of 5 holes,

and they are all used depending on where you are

installing it. When installing the plates, pay close

attention to the holes required. When complete,

the swing end should be angled out (away from

fort) approx. 110˚

NOTE: In the event that the thread of a Hex Bolt is

exposed beyond the tee-nut, please disassemble, add

another flat washer to head of hex bolt and reassemble.

© Solowave Design. All rights reserved.

1. Insert Dowel into provided holes until the

shoulder of tenon is flush to the face of the

Swing Rail or Access Rail or

Ladder Post.

2. Pre-drill a 3 x 1/8” hole through Rail or Post

prior to securing with wood screw. Securing with

screw prior to pre-drilling may lead to cracking

and must be avoided.

3. Secure dowel in place with approprate wood

screws and instructed within manual.

1/8” Drill Bit

Shoulder

Dowel

Tenon

Rail

Wood Identification

4

(Reduced Size Parts)

Before you assemble your fort, please identify and count your boards.

Remember, wood is a product of nature and affected by changes in

weather. Although the wood in this set has been carefully selected, expansion

and contraction may cause slight warping, twisting or

checking of the boards while in the carton. This is a natural

characteristic of wood and

will not

affect the structural integrity of

your set.

Profile dimensions denoted in these instructions are based on wood size before

machining and finishing. Actual size will be smaller.

Nominal

Size

2" x 6"

2" x 4

"

2" x 3"

2" x 2"

5/4

" x 4"

1" x 5"

1" x 6"

Actual

Size

1 3/8" x 5 3/8"

1 3/8" x 3 3/8"

1 3/8" x 2 3/8"

1 1/2" x 1 1/2"

1" x 3 1/2"

5/8" x 4 1/2"

5/8" x 5 3/8"

3660729

(1) Roof Mount (2 x 3 x 23")

(1) SW Roof Mount (2 x 4 x 59-1/4")

3660731

(2) Ground Side (1 x 5 x 56")

(1) Ground Front (1 x 5 x 59-1/4")

(1) Floor Front (2 x 3 x 58-1/4")

(1) Front Top (1 x 4 x 58-1/4")

3660702

3660721

(1) Rope Bottom (1 x 6 x 59-1/4")

3660752

3660730

3660711

(2) Roof Side (1 x 4 x 47-3/4")

(2) Floor End(1 x 6 x 38-1/4")

(2) Ground Diagonal (2 x 3 x 35")

(2) Centre Divider (1 x 4 x 35-3/4")

3660719

3660743

3660304

3660707

(4) CE Gap Board (1 x 4 x 38-3/4")

3620839

(2) Cedar Gap Board (1 x 5 x 35-1/4")

3610710

(1) Floor Back (5/4 x 4 x 59-1/4")

(1) Back Top (1 x 4 x 59-1/4")

(1) Side Joist (2 x 2 x 55")

3660703

3660705

(1) Floor Joist (5/4 x 4 x 58-1/2")

(2) Rock Rail (5/4 x 4 x 51")

3660714

(2) Rock Side (2 x 2 x 49-1/2")

3660704

3660712

3660715

(5) CE Rock Board(1 x 6 x 23-1/2")

3610703

(10) Cedar Floor Board (1 x 5 x 35-1/4")

(Unstained)

(2) CE Wall Board(Unstained) (1 x 6 x 23-1/2")

(4) CE Wall Board(Stained) (1 x 6 x 23-1/2")

3610702

3620702

(1) Lower Chalk Wall (1 x 4 x 31")

(1) Panel Frame (1 x 2 x 25-1/2")

3610621

3660717

3660726

Wood Identification

5

(Reduced Size Parts)

(1) Tarp Front (1 x 4 x 58-1/2")

(1) Top Ridge (2 x 2 x 66")

(2) Seat Table Support (2 x 6 x 16-3/4")

3660701

(1)SW Upright (2 x 4 x 50-1/2")

3664920

(2)SW Post (2 x 4 x 92-1/2")

3664922

(2)Single Beam (2 x 6 x 91-3/4")

3664923

(1) Cafe Seat (5/4 x 6 x 34-1/4")

3610709

3660713

3660753

(2) Table Top (1 x 6 x 34-1/4")

(1)SW Rail Block (2 x 4 x 5-3/8")

3664919

(1)SW Support (5/4 x 4 x 48-1/2")

3664921

3610708

(2) 2 x 2 x 12-1/2" Sl Brace

(1) Top Window (1 x 6 x 23-1/2")

(5) 2 x 2 x 14" Ground Stake

3620701

3650318

3660620

(4) Post (2 x 4 x 83")

3660201

(2) 2 x 4 x 13" Gusset

Component Identification (Reduced Size Parts)

(5) Climbing Rocks

(1) 69 x 58" Canopy

(1) Glider Body

(2) Glider Handles

(1) Rope Ladder

3660771

(4) Triangle

Plate

(1) Slide

(1) 28-1/2"

(2) Belt Swings

with Soft Touch

Rope

Square Chalk Wall

(4) Glider Rope and Chains

HARDWARE IDENTIFICATION

6

Before you start assembling your fort, be sure to sort, identify, and count all of

the hardware.

During Assembly DO NOT fully tighten bolts unless instructed. Fully

tightened bolts may not allow for other hole alignments.

IMPORTANT! Before children use the play center, make sure all

hardware is tightened, all ground stakes are installed, and any

remaining wood, hardware packaging materials are removed

from the play area.

Be careful not to over-tighten hardware as it will crush wood fibers

and result in splintering.

THESE PARTS ARE ACTUAL SIZE

CLIMBING ROCK BAG

(5)1/4 x 1-1/4"

Pan Bolt

(6) Plastic Tie

(4) 1/4 x 5-1/2" Hex Bolt

(6) 5/16 x 4-1/2" Hex Bolt

(4) 5/16 x 4" Hex Bolt

(2) 5/16 x 2" Hex Bolt

(5) 1/4" Lock

Washer

(5) 3/16" Flat

Washer

(2) Glider Hangers

(Not to Scale)

(5)1/4" Barrel Nut

(No Prongs)

(5) #8 x 1"

Pan Screw

(4) 3/8" Flat Washer

(4) 3/8 x 3" Lag Screw

(4) Swing Hangers

HARDWARE IDENTIFICATION

7

(38) #8 x 1-1/8" Wood Screw

(Actual Size Parts)

(110) #8 x 1-1/2" Wood Screw

(16) #8 x 2-1/2" Wood Screw

(6) #8 x 3" Wood Screw

(1) 1/4 x 1-1/2" Hex Bolt

(19) 1/4 x 2" Hex Bolt

(4) 1/4 x 2-1/2" Hex Bolt

(6) 1/4 x 4" Hex Bolt

(22) #8 x 1/2"

Pan Screw

(14) #12 x 2" Pan Screw

(42)1/4" Lock

Washer

(2) 1/4 x 1-1/4"

Pan Bolt

(22)#8

Flat Washer

(67)1/4" Flat

Washer

(2) #12 x 3/4"

Pan Screw

(6) #12 x 1"

Pan Screw

(42)1/4" T-Nut

(6) #8 x 1/2"

Truss Screws

(2) 1/4 x 4-1/2" Hex Bolt

(4) 1/4 x 5" Hex Bolt

(1) 5/16 x 3" Hex Bolt

(4) 1/4 x 2-1/2" Lag Screw

(13) 1/4 x 3" Lag Screw

(4) 1/4 x 1-1/2" Lag Screw

(4) 5/16 x 1-1/2" Hex Bolt

(8) 5/16" Lock

Nut- Zinc

(2) Corner Brace

(8) 5/16" Flat

Washer-Zinc

(15) 5/16" Lock

Washer

(2) 5/16 x 6" Zinc Hex Bolt

(23) 5/16" Flat

Washer

(15) 5/16" T-Nut

HAVE YOU SORTED, IDENTIFIED, AND COUNTED ALL

8

YOUR HARDWARE, WOOD PIECES AND ACCESSORIES?

THIS WILL ASSIST YOU IN YOUR ASSEMBLY.

WHEN THE PARTS IDENTIFICATION IS COMPLETED,

YOU ARE READY TO START ASSEMBLY.

IF YOU NEED ASSISTANCE CONTACT THE

CONSUMER RELATIONS DEPARTMENT AT

NUMBER LISTED

ON FRONT COVER.

Swing & Slide Wall Assembly

9

For the Slide Wall, assemble Ground Diagonal to Post; Roof Side, Floor End

& Ground Side to Posts; Ground Diangonal to Ground Side.

1

NOTE: For the Swing Wall Assembly, the layout is opposite the Slide Wall,

make sure to repeat the above step.

HARDWARE LIST

2 pcs 1/4 x 5" Hex Bolt

18 pcs 1/4 x 2" Hex Bolt

20 pcs 1/4" T-Nut

24 pcs 1/4" Flat Washer

20 pcs 1/4" Lock Washer

4 pcs 1/4 x 1-1/2" Lag Screw

DO NOT OVER-TIGHTEN HEX BOLTS!

Hardware should not crush wood.

1/4 x 2"

Hex Bolt

2 x 4 x 83"

Posts

1 x 5 x 56"

Ground Side

1 x 4 x 47-3/4"

Roof Side

Slide Wall

1/4 x 5"

Hex Bolt

2 x 3 x 35"

Ground

Diagona

l

WOOD PARTS LIST

2 pcs 2x3x35" Ground Diagonal

2 pcs 1x5x 56" Ground Side

4 pcs 2x4x83" Post

2 pcs 1x6x 38-1/4" Floor End

2 pcs 1x4x 47-3/4" Roof Side

Leave this

hole open

1 x 6 x 38-1/4"

Floor End

1/4 x 1-1/2"

Lag Screw

& 1/4" Flat Washer

Hole is for

1/4 x 2" Hex Bolt

Swing Wall

(Pre-drill with 3/16"

drill bit before

fastening Lag Screw)

Hex Bolt Assembly

Wood Parts

Hex Bolt

Lock Washer

Flat Washer

T-Nut

Tap T-Nut

into the hole.

Lag Screw

Flat Washer

Lag Screw Assembly

Wood Parts

Factory

drilled hole

3/16"

Pre-drill hole

2A

10

1 x 4 x 58¼"

Front Top

Front Wall Assembly

With the aid of helper, attach Floor Front, Ground Front,

Front Top to Walls created in Step 1.

IMPORTANT!

oriented toward the ground & to the right.

Attach Centre Divider to Floor Front &

Front Top. Fasten the Tarp Front to the Roof Sides.

DO NOT OVER-TIGHTEN BOLTS!

Hardware should not crush wood

Make sure that Floor Front holes are

1/4 x 4"

Hex Bolt

#8 x 1½"

Wood Screw

(Pre-drill

with 1/8 Drill)

1 x 4 x 58½"

Tarp Front

(Is thinner than

Floor Joist)

HARDWARE LIST

1 pc 1/4x2" Hex Bolt

2 pcs 1/4x5" Hex Bolt

4 pcs 1/4x4" Hex Bolt

2 pcs 1/4x2-1/2" Lag Screw

8 pcs 1/4" T-Nut

10 pcs 1/4" Flat Washer

8 pcs 1/4" Lock Washer

1 pc 1/4x1-1/4" Pan Bolt

4 pcs #8x1-1/2" Wood Screw

WOOD PARTS LIST

1 pc 1x4x 58-1/2" Tarp Front

1 pc 2 x3x58-1/4" Floor Front

1 pc 1 x5x59-1/4" Ground Front

1 pc 1 x4x58-1/4" Front Top

1 pc 1 x4x35-3/4" Centre Divider

Roof Side

1/4 x 4"

Hex Bolt

Lock Washer

Flat Washer

1/4 x 2½"

Lag Screw

(Pre-drilling

required)

1 x 5 x 59¼"

Ground Front

Middle Hole is

being used in

Hex Bolt Assembly

Note:

the Post

Wood Parts

1/4 x 5"

Hex Bolt

T-NutHex Bolt

Tap T-Nut

into the hole.

2 x 3 x 58¼"

Floor Front

(Holes are positioned

towards the ground)

Lag Screw

Flat Washer

1/4 x 1¼"

Pan Bolt

1/4 x 2"

Hex Bolt

1 x 4 x 35¾"

Centre Divider

(Pre-drill with 3/16'

drill bit before fastening

Lag Screw)

Lag Screw Assembly

Wood Parts

Factory

drilled hole

3/16"

Pre-drill hole

2B

11

Slide Side Wall

Attach Back Top and Floor Back to Side Walls. Loosely

attach Centre Divider.

Attach Rope Bottom by drilling 1/8" pilot holes using the board

as a guide, first, then attach with Wood Screws. Board should

be oriented with the larger Lag Screw holes toward the top

and the 3 rope holes to the left.

DO NOT OVER-TIGHTEN BOLTS!

Hardware should not crush wood.

1 x 4 x 35-3/4"

Centre Divider

HARDWARE LIST

2 pcs 1/4x4-1/2" Hex Bolt

2 pcs 1/4x4" Hex Bolt

1 pc 1/4x1-1/2" Hex Bolt

1 pc 1/4x1-1/4" Pan Bolt

6 pcs 1/4" T-Nut

8 pcs 1/4" Flat Washer

6 pcs 1/4" Lock Washer

2 pcs #8x2-1/2" Wood Screw

2 pcs 1/4x2-1/2" Lag Screw

WOOD PARTS LIST

1 pc 1x4x59-1/4" Back Top

1 pc 5/4x4x59-1/4" Floor Back

1 pc 1x6x59-1/4" Rope Bottom

1 pc 1x4x35-3/4" Centre Divider

Swing Side Wall

1 x 4 x 59-1/4"

Back Top

5/4 x 4 x 59-1/4"

Floor Back

Rope holes orientated

toward the left

1 x 6 x 59-1/4"

Rope Bottom

1/4 x1-1/4"

Pan Bolt

1/4 x 4"

Hex Bolt

1/4x1-1/2"

Hex Bolt

1/4 x 4-1/2"

Hex Bolt

#8 x 2-1/2" Wood

Screw

1/4 x 2-1/2" Lag Screw

& 1/4" Flat Washer

Fort Floor Assembly

12

Attach Side Joist to Floor Back, using Hex Bolts & tighten.

3

Insert notched Gap Boards flush with Floor Ends & attach

to Floor Front & Side Joist with 1½" long Wood Screws.

Insert Floor Joist under Gap Boards, drill 1/8" pilot holes

on ends using Floor Ends as guides.

Secure with (2) 3" long Wood Screws at each end.

Attach Gap Boards to Floor Joist with 1½" long

#8 x 3"

Wood Screw

These screws repeat

for other side

HARDWARE LIST

4 pcs 1/4x2-1/2" Hex Bolt

4 pcs 1/4" T-Nut

4 pcs 1/4" Flat Washer

4 pcs 1/4" Lock Washer

4 pcs #8x3" Wood Screw

60 pcs #8x1-1/2" Wood Screw

1/8" pilot holes are requiredWood Screws at the centre.

#8 x 1½"

Wood Screw

2 x 2 x 55"

Side Joist

.

WOOD PARTS LIST

2 pcs 1x5x35-1/4" Cedar Gap Board

1 pc 2x2x55" Side Joist

1 pc 5/4x4x58-1/2" Floor Joist

10 pcs 1x5x35-1/4" Cedar Floor Board

1/4 x 2½"

Hex Bolt

Floor Front

1 x 5 x 35¼"

Cedar Gap Board 5/4 x 4 x 58½"

Floor Joist

1 x 5 x 35-1/4"

Cedar Floor Board

Floor Back

#8 x 1½"

Wood Screw

Space (10) Cedar Floor Boards evenly (Approx ½" gap)

Using (5) 1½" long Wood Screws per Floor Board,

attach each board to the Floor Joist underneath.

HARDWARE LIST

13

4

20 pcs #8x1-1/8" Wood Screw

WOOD PARTS LIST

1 pc 1x6x23-1/2" Top Window

4 pcs 1x6x23-1/2" CE Wall Boards

Attach CE Wall boards & Top Window

using (12) Wood Screws, leaving

maximum gap of 3" between deck &

edge of bottom CE Wall board.

Attach CE Wall boards using (8)

Wood Screws as shown.

NOTE: Do not overtighten screws. If screw

tips protrude through, tap them with a

hammer to eliminate the sharp point.

(

Stained)

INSIDE VIEW SHOWN

1 x 6 x 23-1/2"

Top Window

#8 x1-1/8"

Wood Screw

1 x 6 x 23-1/2"

CE Wall Board

Stained

INSIDE VIEW SHOWN

1 x 6 x 23-1/2"

CE Wall Board

Stained

#8 x1-1/8"

Wood Screw

11" MIN

Gap between

deck and bottom

board can not

exceed 3"

5

14

HARDWARE LIST

2 pcs #8x1-1/8" Wood Screw

4 pcs #8x1-1/2" Wood Screw

12 pcs #8x1/2" Pan Screw

12 pcs #8 Flat Washer

WOOD PARTS LIST

1 pc 1x2x25-1/2" Panel Frame

1 pc 1x4x31" Lower Chalk Wall

ACCESSORY LIST

1 Chalk Wall (Tarp)

Attach Panel Frame and Lower Chalk Wall with

(4) Wood Screws. Drill pilot holes with a 1/8" drill bit,

using the boards as guides.

Lower Chalk Wall should butt up under Panel Frame

end. Next, attach the Lower Chalk Wall from the inside

with (2) Wood Screws into the divider from the inside.

Hang Chalk Wall with graphics facing inside, and

attach with (10) Pan Screws (#8 Flat Washers)

from the outside. With the remaining (2) Pan Screws

(#8 Flat Washers), attach to the divider from the inside.

Important! Loosen the bolts from the Centre Divider to

slide tarp between. Tighten bolts.

1 x 2 x 25½"

Panel Frame

1 x 4 x 31"

Lower Chalk Wall

Gap between deck

and bottom can not

exceed 3 inches.

#8x 1-1/8"

Wood Screw

#8 x 1/2"

Evenly space

Pan Screws.

Attach through

Chalk Wall hem.

#8 x 1½"

Wood

Screw

Chalk Wall

(Tarp)

6A

15

5/4 x 4 x 51"

*Pre-drill pilot holes, with a 1/8" drill bit and evenly space the

drilled holes as shown in the Side View.

Using (3)Pan Screws per Rock Rail, attach(2) Rock Sides to

the (2) Rock Rails.

2 x 2 x 49-1/2"

Rock Sides

Rock Rails

Tops mount

to Fort

HARDWARE LIST

6 pcs #12x2" Pan Screw

28 pcs #8x1-1/2" Wood Screw

WOOD PARTS LIST

2 pcs 5/4x4x51" Rock Rail

2 pcs 2x2x49-1/2" Rock Side

5 pcs 1x6x23-1/2" CE Rock Board

2 pcs 1x6x23-1/2" CE Wall Board

(

unstained)

6B

#8 x 1½"

Wood Screw

Front View

R.Side View

Roughly 20"

#12 x 2"

Pan Screw

(Pre-drill pilot holes)

*Evenly space the Rock Boards in between both CE Wall Boards.

Using (4) Wood Screws per board, attach (5) CE Rock Boards &(2) CE Wall Boards

to the Rock Rails.

Alternate Rock Boards as desired. Holes in middle of board

MUST be oriented to the top of the Climbing Wall for proper mounting of Rocks.

Mount screws from edge

NOTE: Start at top and

attach top board ¼"

below mounting holes.

3/4"

1 x 6 x 23½"

CE Rock Boards

1 x 6 x 23½"

CE Wall Boards

(Unstained)

6C

16

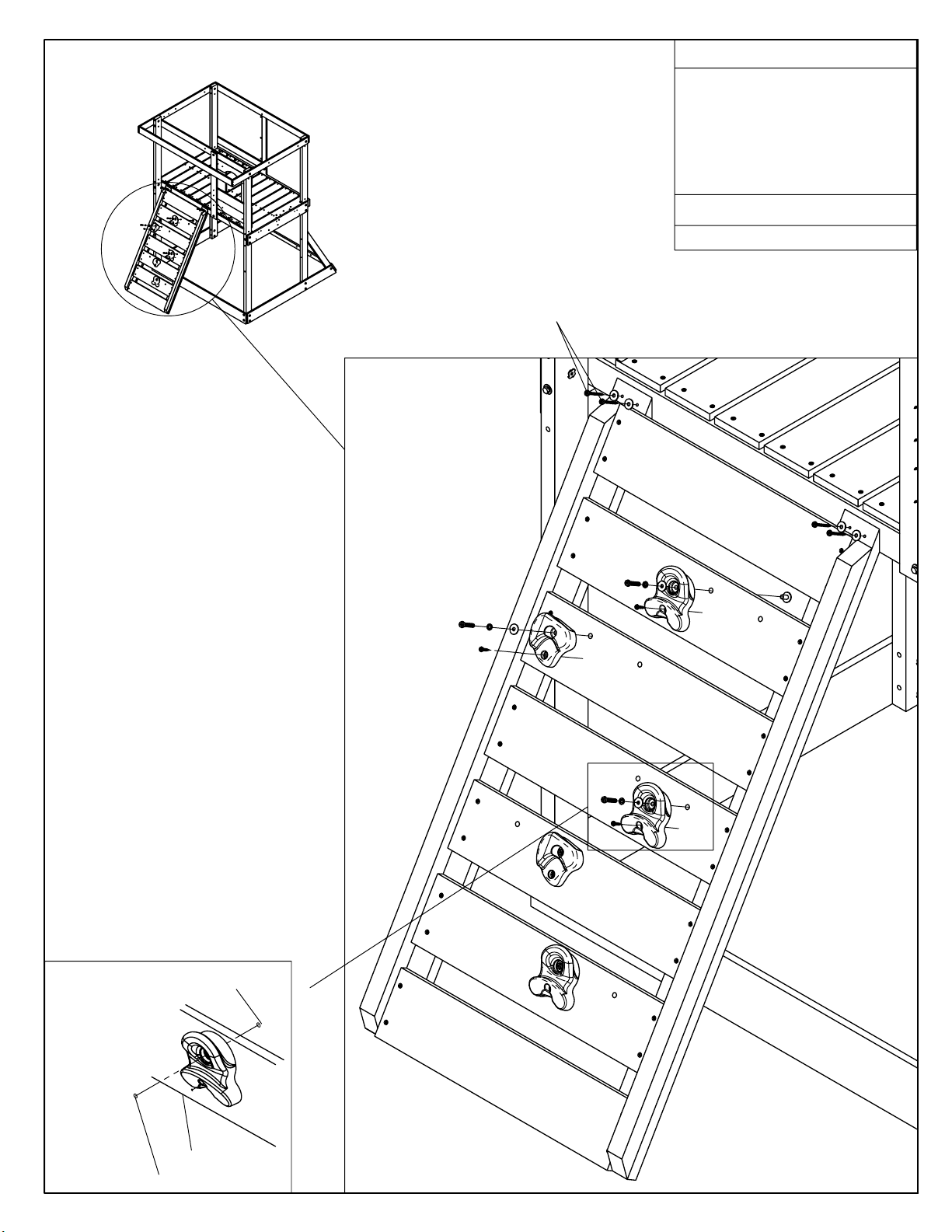

Center Rock Wall in opening at front of Fort.

Drill 1/8" pilot holes then attach with

(4) 2" Long Pan Screws (3/16" Flat Washers).

Attach rocks in desired locations with

Pan Bolts, lock washers, flat washers,

& Barrel Nuts. The #8 x 1" Pan Screw is used to

prevent rock from spinning. Attach

directly below the pan bolt as per Detail A.

#12 x 2" Pan Screw

& 1/4" Flat Washer

HARDWARE LIST

5 pcs 1/4x1-1/4" Pan Bolt

5 pcs 1/4" Barrel-Nut

5 pcs 3/16" Flat Washer

5 pcs 1/4" Lock Washer

5 pcs #8x1" Pan Screw

4 pcs #12x2" Pan Screw

4 pcs 1/4" Flat Washer

ACCESSORY LIST

5 Rocks

DETAIL A

1/4 x 1-1/4"

Pan Bolt

1/4" Lock Washer

3/16" Flat Washer

1/4" Barrel Nut

(No Prongs)

#8 x 1"

Pan Screw

7A

17

Attach Gussets

•Drill 3/16" pilot holes into the swing side posts, using the Gusset

hole as a guide. Fasten, using (1) Lag Screw with flat washer.

•Using (3) 1-1/2" Wood Screws per side, attach the Gussets to the

Floor End through the factory drilled holes.

IMPORTANT! Make sure that the fort wall is square before mounting

the lag screws.

#8 x 1-1/2"

Wood Screw

2 x 4 x 13"

Gusset

WOOD PARTS LIST

2 pcs 2x4x13" Gusset

1 pc 2x3x59¼" Roof Mount

1 pc 2x4x59¼" Sw Roof Mount

HARDWARE LIST

1 pc 5/16x3" Hex Bolt

2 pcs 5/16x4" Hex Bolt

3 pcs 5/16" Lock Washer

3 pcs 5/16" Flat Washer

3 pcs 5/16" T-Nut

6 pcs #8x1½" Wood Screw

2 pcs 1/4x3" Lag Screw

2 pcs 1/4" Flat Washer

Attach Roof & SW Mount

7B

•Using (1) 3" long Hex Bolt, attach the Roof Mount to the Roof Side

of the slide wall, as shown below.

•Using (2) 4" long Hex Bolt, attach the SW Roof Mount to the Floor

End & Roof Side of the swing wall, as shown below.

2 x 3 x 23"

5/16 x 3"

Hex Bolt

Slide Side

1/4 x 3" Lag Screw

& 1/4 Flat Washer

Roof Mount

Swing Side

5/16 x 4"

Hex Bolt

2 x 4 x 59¼"

SW Roof Mount

8A

18

Swing End Assembly

•Fasten the Triangle Plates to the insides of the Single Beams.

•Attach (1) 1/4 x 5½" Hex Bolts to each end of each beam.

NOTE: These bolts are required for strength, they do not attach to

anything but the beams.

•Place the Sw Rail Block at the centre & in between the beams.

Fasten with bolts.

A

WOOD PARTS LIST

2 pcs 2x6x91¾" Single Beam

2 pcs 2x4x92½" Sw Post

1 pc 2x4x50½" Sw Upright

1 pc 2x4x5 3/8" Sw Rail Block

1 pc 5/4x4x48½" Sw Support

HARDWARE LIST

4 pcs 1/4x5½" Hex Bolt

4 pcs 1/4" Flat Washer

4 pcs 1/4" Lock Washer

4 pcs 1/4" T-Nut

2 pcs 5/16x4" Hex Bolt

4 pcs 5/16x4½" Hex Bolt

4 pcs 5/16x1½" Hex Bolt

10 pcs 5/16" Flat Washer

10 pcs 5/16" Lock Washer

10 pcs 5/16" T-Nut

ACCESSORY LIST

4 Triangle plates

5/16 x 1½"

Hex Bolt

Sw Rail Block

2 x 4 x 5 3/8"

DETAIL A

Fort Side

5/16 x 1½"

Hex Bolt

•Fasten (2) Sw Posts to the Sw Upright, then attach

the Sw Support to the Sw Posts & Upright.

DETAIL B

Swing End

5/16 x 4"

Hex Bolt

Sw Upright

2 x 4 x 50 1/2"

1/4 x 5½"

Hex Bolt

5/16 x 4½"

Hex Bolt

B

Single Beam

2 x 6 x 91 3/4"

DETAIL C

Sw Support

5/4 x 4 x 48½"

C

5/16 x 4½"

Hex Bolt

Sw Posts

2 x 4 x 92 1/2"

8B

19

Attach Swing & Glider Hangers

•Attach (4) Swing Hangers to the Single Beams. Stagger

hangers 2 per beam.

•Using (2) lag screws per hanger, attach the Glider Hanger to

the underside of the beams. Align the holes of the hangers

with the beam holes.

Note: Glider Hangers are fastened to the holes in Single Beam

closest to the fort side.

Front View

Stagger the

Swing Hangers

HARDWARE LIST

4 Swing Hangers

2 Glider Hangers

4 pcs 3/8x3" Lag Screw

4 pcs 3/8" Flat Washer

To install Swing

Hangers, screw in

until flush with beam.

Use liquid soap as

a lubricant for ease

of installation.

IMPORTANT!

Swing Side

triangle plate hole

uses this

CAUTION!

Lag Screws and washers

must be

fastened tight

to the Glider Hangers

and the Single Beams

3/8 x 3" Lag Screw

& 3/8 Flat Washer

Glider Hangers

IMPORTANT!

Fort Side uses this

triangle plate hole

MOVE THE FORT TO ITS FINAL LOCATION & TIGHTEN ALL

20

8C

HEX BOLTS FROM PREVIOUS STEPS

•With the aid of a helper,

frame.

secure Single Beam to the Swing Post

Single Beam

5/16"

Lock Washer 5/16" T- Nut

5/16 x 4½"

Hex Bolt

HARDWARE LIST

2 pcs 5/16x4½" Hex Bolt

2 pcs 5/16x2" Hex Bolt

6 pcs 5/16" Flat Washer

2 pcs 5/16" Lock Washer

2 pcs 5/16" T-Nut

2 pcs 5/16" Lock Nut-zinc

5/16 x 2"

Hex Bolt

Triangle

Plate

5/16" Lock Nut

zinc

5/16"

Flat Washer

*CONNECT SWING ASSEMBLY TO SWING MOUNT FROM INSIDE THE

FORT, HAVING A HELPER HOLD THE SINGLE BEAMS IN POSITION.

INSIDE FORT VIEW

5/16 x 4½"

Hex Bolt

5/16"

Lock Washer

Triangle Hole Layout

CORRECT

INCORRECT

Triangle Hole Layout

CORRECT

INCORRECT

5/16" T- Nut

5/16" Lock Nut

zinc

5/16 x 2"

Hex Bolt

5/16" Flat

SW Roof MountWasher

9A

21

Roof & Wall Assembly

•Using (2) #8 x 3" Wood Screws, fasten into ends of Roof

Mounts using holes in Top Ridge as a guide.

•Using (16) #8 x 1-1/8" Wood Screws, attach (4) CE Gap

Boards to the Fort-Swing Side, space evenly between Roof

Mount & Post each side.

WOOD PARTS LIST

6 pcs #8x1/2" Truss Screw

16 pcs #8x1-1/8" Wood Screw

2 pcs #8x3" Wood Screw

2 pcs Corner Brace

HARDWARE LIST

Rock Wall and Swing Beam

removed for clarity!

1 x 4 x 38-3/4"

CE Gap Board

#8 x 1-1/8"

Wood Screw

1 pc 2x2x66" Top Ridge

4 pcs 1x4x38-3/4" CE Gap Board

2 x 2 x 66"

Top Ridge

#8 x 3"

Wood Screw

Roof Side

Tarp Front Corner Brace

with hardware

Insert (2) Corner Braces at the corners where the Roof Sides

meet the Tarp Front and fasten with (3) #8 x 1/2" Truss Screws

per corner. (Make sure the Corner Braces are positioned

according to the drawing).

9B

22

Centre and hang Canopy over Roof Ridge & attach (2) pan screws

with washers on the top of roof. Stretch Canopy to the front &

attach with (4) evenly spaced screws with washers at the hem.

Do the same at the back.

HARDWARE LIST

10 pcs #8x1/2"Pan Screw

10 pcs #8"Flat Washer

ACCESSORY LIST

1 Canopy

#8 x 1/2" Pan Screw

#8 Flat Washer

10

Loosen bolt

to get tarp

underneath

A. Pull rope through holes at top

and tie a knot under deck. Spacing

between top rung and edge of

board must be greater than 9-1/2"

B. Pull rope through hole at bottom

and tie knot, making sure that

spacing between rung and edge of

board is greater than 9-1/2".

C. IMPORTANT!

tighten loose rope ends at top of

rope ladder, and cut excess Plastic

Ties, making sure to round the sharp

edges.

Plastic Ties.

Keep rope tight to remove slack

Keep 1" space between

use (6)plastic ties

B

HARDWARE LIST

6 Plastic Ties

ACCESSORY LIST

1 Rope Ladder

A

1"

C

Make sure this

knot is tight to

the Floor Back

before attaching

Plastic Ties.

View from under Fort

Must be greater

than 9-1/2"

11A

23

1/4 x 3"

Lag Screw

Attach Seat/Table Supports on the inside

of the Fort Posts on the slide side. Drill (2) pilot

holes approximately 18" up from the ground then

attach only (2) 1/4 x 3" Lag Screws (1/4" Washer)

through center holes of Supports.

Drill 1/8" holes into Supports using Seat as guide.

Attach Seat with (4) 1/4 x 3" Lag Screws (1/4" Washer)

and tighten.

Pivot seat down 90 degrees, then

tighten Lag Screws attached to Posts.

5/4 x 6 x 34-1/4"

Cafe Seat

WOOD PARTS LIST

2 pcs 2x6x16¾" Seat Table Support

1 pc 5/4x6x34¼" Cafe Seat

HARDWARE LIST

6 pcs 1/4x3" Lag Screw

6 pcs 1/4" Flat Washer

Fort Post

Lag Screw

Flat Washer

2 x 6 x 16-3/4"

Seat/Table Supports

Lag Screw Assembly

Use factory drilled

holes as guides &

drill 3/16" pilot holes.

Factory drilled hole

11B

24

Make sure the seat is level and under the fort.

Children seated at the table should be facing out.

using the (4) remaining factory holes Drill 1/8" holes

as guides. Holes should be centered on the Post.

Secure with the (4) 1/4 x 3" Lag Screws (1/4" Flat Washer)

and tighten.

Secure CE Table Tops with (8) #8 x 1-1/2" Wood Screws.

WOOD PARTS LIST

2 pcs 1x6x34-1/4" CE Table Top

HARDWARE LIST

4 pcs 1/4x3" Lag Screw

4 pcs 1/4" Flat Washer

8 pcs #8x1-1/2" Wood Screw

#8 x 1-1/2"

Wood Screw

Supports

1 x 6 x 34-1/4"

CE Table Top

1/4 x 3" Lag Screw

with 1/4" Flat Washers

12

25

Mount slide to deck, centred on opening.

First drill 1/8" pilot holes through deck into centre of

Slide Brace and attach with screws

Note: Place slide in the centre of the

platform as shown.

#12 x 1" middle screw fastens to the floor joist.

#12 x 1"

Pan Screw

WOOD PARTS LIST

2 pcs 2x2x12-1/2" Sl Brace

HARDWARE LIST

4 pcs #12x2" Pan Screw

1 pc #12x1" Pan Screw

ACCESSORY LIST

1 Slide

#12 x 2"

Pan Screw

Slide

2 x 2 x 12-1/2"

Sl Brace

Floor Joist

(Hidden)

#12 x 2" Pan Screw

fastens through

deck and into

SL Brace on both

sides.

13

26

Stakes Installation

•Use a scrap wood piece in between the top of the Ground Stake &

the Sledge Hammer to protect the stake from damage.

•Stakes are to be secure to the posts and the ground.

•Firmly anchor unit to ground before use.

•Check for looseness, re-secure and replace if necessary.

•

DO NOT USE CONCRETE OR OTHER MATERIALS FOR ANCHORING STAKES!

•Drive Ground Stakes into the ground, making sure that the ground is

firm underneath the stakes.

•Using (2) Wood Screws, attach each stake to the corresponding

post as shown below.

WOOD PARTS LIST

5 pcs 2x2x14" Ground Stakes

HARDWARE LIST

10 pcs #8x2-1/2" Wood Screw

Drive 2 x 2 x 14"

Ground Stakes into

firm soil and attach to

SW Posts, Post, Ground

Diagonal using (2)

screws each.

Drive one Stake

and attach to

back of Rock Wall.

Sample Ground Stake Installation

Drill Pilot

Holes. Use

Stake as

guide.

#8 x 2-1/2"

Wood Screw

Ground level

(Drive stake10½"

into ground)

14

27

5/16 x 3¾"

Eyebolt

5/16 Flat

Washers-zinc

5/16 Lock

Nut-zinc

5/16 x 6"

Hex Bolt

5/16 Flat

Washers

ACCESSORY LIST

1Glider Seat

4 Glider Ropes with Chain

2 Glider Handles

2 Belt Swings

HARDWARE LIST

2 pcs 5/16x6" Hex Bolt

4 pcs 5/16" Flat Washer

8 pcs 5/16" Flat Washer-zinc

6 pcs 5/16" Lock Nut-zinc

•Assemble Glider Handles to Seat as shown with

6" Hex Bolt, two Flat Washers and one

Zinc Lock Nut. Tighten the Zinc Lock Nut until the

bolt threads are flush. Repeat for other Handle.

•Attach the Glider Eyebolts to the Glider

Handles using the hardware as shown.

DO NOT over tighten the Nut. Overtightening

can damage the Glider and cause it to collapse

during use. Check assembly frequently making

sure that the nut stays in place. Replace

hardware if it loosens repeatedly.

Hang swings from Swing Hangers using the chains

at the top to adjust heights accordingly.

Glider Seat

IMPORTANT! Before playing, check that all

hardware is tightened correctly and no bolt

threads are protuding. To prevent these sharp

edges, we have provided extra flat washers that

can be added to eliminate this condition.

Periodically, check hardware and tighten if

required. Add an additional washer if the bolt

threads start to protrude.

Glider Handle

ATTENTION

28

*During peak play season, periodically check

and re-tighten all hex bolts, lag screws, and wood screws

to ensure safety. Do not over-tighten to avoid crushing

wood.

*Thoroughly read instructions and the owners manual

before using play center.

*Maintain assembly instructions for future reference.

FILL THIS OUT BEFORE YOU DISCARD YOUR CARTONS.

YOU WILL NEED THIS INFORMATION IF YOU CALL

CONSUMER RELATIONS DEPARTMENT.

PRODUCT NUMBER:

DATE STAMP:

(BOX No. 1)

(BOX No. 2)

(BOX No.3)

(BOX No. 4)

Loading...

Loading...