Solo 880-12, 880-14, 881-12, 881-14 Instruction Manual

9 880 100 04/2012

880-12 / 880-14 // 881-12 / 881-14

Instruction Manual

Translation of the original instructions

Cut-off machine

A

ttention!

Before first commissioning, read these operating

instructions thoroughly and observe the safety

provisions under all circumstances!

en

ENGLISH 1

Instruction manual cut-off machines 880-12 / 880-14 // 881-12 / 881-14

Translation of the original instructions

Dear customer

thank you for purchasing this quality product from

our company.

For many decades, we have been a producer of

hand-held and back-carried gas powered motor

devices. Each of our motor devices benefits from

this experience in detail today as well.

State-of-the-art production materials in connection

with our know-how warrant a long service life and

high utilisation value of the motor device.

The motor devices of this model line are

particularly high-quality cut-off machines of

German production and designed specifically for

the high demands of professional users. A newly

developed single-cylinder two-stroke highperformance engine with stationary nikasil-coated

cylinder in proven four-channel technology for

great performance at low fuel consumption and

the latest exhaust cleaning technology warrant

high utilisation value of the motor-driven device.

Maintenance-free electronic ignition,

health-protecting anti-vibration system,

patented twin-pipe suction procedure,

vibration system for particularly easy interim

emptying of the air filter during work,

optionally usable water connection with water

supply to the cutting disc to reduce dust when

working,

smart solutions with electronic carburettor control

for simple starting and

ergonomic design and extremely compact build

ensure excellent operating comfort and facilitate

daily work with the motor device.

The safety equipment corresponds to the latest

state of the art and meets all nationally and

internationally relevant safety provisions. Among

others, it comprises:

One-touch stop button

Throttle control lock

Electronic speed limiter

Protective device for the cutting disc

Motor stop facility for maintenance purposes

Before first commissioning, read these operating instructions thoroughly and always

observe all safety provisions and instructions for action.

If you have any further questions after reading these operating instructions, contact your

specialist vendor.

Observe the maintenance guidelines closely to ensure the long service life of your

equipment

ENGLISH 2

Packaging and disposal

Please keep the original packaging in order to protect the equipment against transport damage in case

you ever need to ship or transport it If the packaging materials are no longer required they must be

disposed of properly in accordance with applicable local regulations. Cardboard packaging materials are

raw materials which can be recycled or reused.

At the end of the equipment’s service life, please make sure that you dispose of it in accordance with the

local provisions

Patents

The following patents are pending:

PCT/EP 2011/067574 (separate lubrication)

US13/331,898 (airbox)

The following patents have been granted:

US2010206278A1

US2009007435A1

US2010000846A1

EP2011594A2

EP2011991A2

EP2011992A2

Registered brands and trademarks

solo® and iLube® are registered brands of SOLO Kleinmotoren GmbH.

Any other product and company names named in these operating instructions may be registered brands or

trademarks of the respective manufacture. Use of these names by third parties for their purposes may

injure the rights of the manufacturer. The fact that the ® or ™ sign is missing does not mean that the

designation is a free brand name.

Reservation of changes

In the interest of continuous further development of our motor devices, we must reserve changes to the

delivery scope in form, technology and equipment. For that reason, no claims can be accepted with

reference to text and illustrations in this manual.

Table of Contents

ENGLISH 3

1 Information about these operating instructions ............................................................................... 4

1.1 Notational conventions used in the operating instructions ............................................................ 4

2 Warning, instruction and notice icons ............................................................................................... 4

3 Safety provisions ................................................................................................................................. 6

3.1 Correct use .................................................................................................................................... 6

3.2 General safety notes ..................................................................................................................... 6

3.3 Prescribed work clothing / PPE (Personal Protection Equipment) ................................................ 7

3.4 When fuelling up ........................................................................................................................... 8

3.5 In transport .................................................................................................................................... 8

3.6 During assembly, cleaning, maintenance and repair .................................................................... 9

3.7 Before start-up .............................................................................................................................. 9

3.8 When starting ................................................................................................................................ 9

3.9 During work ................................................................................................................................. 10

4 Power tool description ...................................................................................................................... 11

4.1 Technical data ............................................................................................................................. 11

4.2 Type plate ................................................................................................................................... 11

4.3 Scope of delivery ......................................................................................................................... 12

4.4 Device views and important operating and function parts ........................................................... 12

4.5 Throttle control lock and throttle control ...................................................................................... 14

4.6 Function parts for starting ........................................................................................................... 14

5 Preparing for use ............................................................................................................................... 15

5.1 Installing the cutting discs ........................................................................................................... 15

5.2 Installing cutting discs with 1" inner bore .................................................................................... 16

5.3 Uninstalling the cutting disc ......................................................................................................... 16

5.4 Adjusting protective cowl ............................................................................................................. 17

5.5 Fuelling up ................................................................................................................................... 17

5.6 Adjusting the ribbed belt tension ................................................................................................. 19

5.7 Water connection for wet cutting ................................................................................................. 19

5.8 Relocate cutting device from centre position to outer position .................................................... 20

5.9 Initial commissioning / run-in behaviour ...................................................................................... 22

6 Starting up and switching off the engine ........................................................................................ 23

6.1 Starting process .......................................................................................................................... 23

6.2 Start-up position .......................................................................................................................... 24

6.3 Switching on the engine .............................................................................................................. 24

6.4 Switching off the engine .............................................................................................................. 24

7 Power tool use ................................................................................................................................... 25

7.1 Cutting discs ................................................................................................................................ 25

7.2 Permissible cutting area and danger from kickback or drawing along ........................................ 26

7.3 Working behaviour and working technique ................................................................................. 27

7.4 Cutting metal ............................................................................................................................... 27

7.5 Cutting mineral materials ............................................................................................................ 28

8

Operating and maintenance notes ................................................................................................... 29

8.1 Cleaning and care ....................................................................................................................... 29

8.2 Cleaning the screen filter insert of the connection piece ............................................................. 30

8.3 Idle/carburettor adjustment ......................................................................................................... 31

8.4 Air filter maintenance .................................................................................................................. 32

8.5 Spark plugs check and replacement if required .......................................................................... 33

8.6 Ribbed belt replacement ............................................................................................................. 34

8.7 Fuel filter replacement ................................................................................................................. 35

8.8 Maintenance plan ........................................................................................................................ 36

8.9 Self-aid advice ............................................................................................................................. 37

8.10 Shutting down and storage ......................................................................................................... 38

9 Warranty ............................................................................................................................................. 39

10 Wear parts .......................................................................................................................................... 39

11 EC Declaration of conformity ........................................................................................................... 39

Table of Contents

Information about these operating instructions

ENGLISH 4

These operating instructions are an integral part of the motor device.

They contain important information and instructions for handling the motor device. Always follow

any specified safety regulations and instructions, as they are a prerequisite for ensuring that you

are working safely with the equipment.

These operating instructions must be kept available at the place of use of the equipment at all

times, and they must be read carefully by everybody who works on or with the equipment (including

for maintenance, care and repairs).

These operating instructions must only be used as operating instructions for the motor device 880/881.

Any utilisation of the contents (text and graphics illustrations) – even in excerpts – without our prior written

consent shall be forbidden and may be prosecuted.

Text highlights

Xxxxx Underlined text marks interim headlines.

Xxxxx Text in italics marks advice and notes that facilitate use of the motor device for the user.

1 Xxxxx Numbered text with a black background marks main chapter headlines.

1.1 Xxxx Numbered text with a grey background marks main subchapter headlines.

Xxxxxxx Frames mark especially highlighted sections.

Structure

The operating instructions are structured by numbered main and subchapters. The table of contents on

page 3 shows an overview of the structure.

Header

To make it easier for the user to find the chapters, the header names the main chapter to which the

content on the respective page belongs.

Pictures and diagrams

Some graphical illustrations in these operating instructions are schematic illustrations or principle

illustrations and may not show exactly your device model. The conveyed contents, however, are binding in

any case.

Important: If one or several icons in these operating instructions are centred and directly below a

chapter header the notice applies for the entire chapter.

1 Information about these operating instructions

1.1 Notational conventions used in the operating instructions

2 Warning, instruction and notice icons

W

arning, in

s

D

athr

C

ama

C

aand Alw Alw

W

e

B

e

S

w

S

m

K

e Att

AttNo Att

W

e

D

o

N

e

O

n

Vi

b

N

o

iL

u

Fu

Oil

truction a

n

nger! Failu

eatening in

j

ution! Fail

u

terial dam

a

refully rea

d

before a

n

ays wear

t

ays wear

s

ar safety

g

fore startin

g

itch off the

oking is p

r

ep the po

w

ention: Da

n

ention: Kic

k

tes in cha

p

ention: Da

n

ar breathi

n

not use ci

r

ver contin

u

ly use cutti

rator dial f

o

ise level L

W

be® = Sm

a

el tank.

tank (gree

S

t

d notice ic

o

re to compl

j

uries

re to comp

ge

the opera

t

y cleaning,

he prescri

b

turdy sho

e

loves. This

the engin

e

engine!

ohibited an

er tool and

ger of poi

s

back!

. 7.2 as of

p

ger of fire

f

g protectio

cular saw

b

e work wit

h

ng discs a

p

r interim e

= 110 d

B

rt lubricati

o

Chap. 5.5,

n cap, mod

arting note

ns used in

y with the i

n

y with the i

ing instruct

maintenan

ed clothin

g

s with goo

d

applies to

a

, put on h

e

ywhere ne

a

fuel canist

e

oning! -

T- P- D

age 26 m

u

rom spark

s

n.

lades.

damaged

proved for

ptying of

t

(A).

n (separat

e

s of page

el 881-12

a

. Chap

.

the operat

structions

nstructions

ions. This

a

ce or asse

m

. Chap.

grip.

all work wit

lmet, ear

d

r the pow

e

rs away fr

o

he power

t

etrol vapo

u

angerous

d

st be obse

.

cutting dis

c

a speed of

he air filte

r

lubricatio

n

17

nd 881-14

)

6, as of p

a

ing instruct

i

could caus

could resu

pplies bef

o

bly work.

3.3, page

7

h or on the

efenders a

r tool and i

n

m naked f

l

ool genera

t

rs are toxi

c

ust emissi

rved under

s.

≥ 4.450 mi

n

. Chap.

, model 88

Chap.

5

ge 23

Warn

ons and o

n

accident

s

t in damag

e

re taking t

h

equipment

nd a visor.

the locati

o

ames.

es exhaus

t

.

ons when

w

all circums

t

-1

.

.4, page

3

1-12 and 8

8

.5, as of p

a

ing, instructi

the equip

m

with pote

n

e to the eq

u

e equipm

e

n where it

gases.

orking.

tances!

2

1-14)

ge 17

on and noti

c

ENG

L

ent:

tially life-

ipment or

o

nt into ope

r

is refuelled

e icons

ISH 5

ther

ation

!

Safety provisions

ENGLISH 6

This power tool must only be used to cut/shorten metals (hot cut) and mineral materials, such as concrete

(cold cutting), each with the cutting discs approved for this material and only for the working situation

indicated in chap. 7 on page 25.

For specifically trained users in rescue missions, other approved cutting discs are also offered that can be

used to cut various composites. These special applications are only permitted to specifically trained users.

This power tool must only be used for outdoor work.

Use of this power tool for any other purpose, such as sawing of wood and to remove/grind off a material

with the side surfaces of the separating disc is forbidden. Impermissible cutting tools, such as saw blades

or knives, must not be installed at the motor device instead of the cutting disc.

Before first commissioning, read these operating instructions thoroughly and keep them safely. They must

be kept available at the place of use of the equipment at all times, and they must be read by everybody

who works on or with the equipment (including for maintenance, care and repairs).

Use this power tool with special care. Work with and at the power tool comprises extreme risks when

proceeding carelessly and improperly. They are specifically based on the high speeds of the cutting disc

and the large forces and torques that the power tool can achieve.

Work with and at the power tool always must be performed carefully and with the greatest care towards all

possible dangers and any possible situations that may occur. Never perform any work processes that you

are not ready for or the risks of which you cannot entirely asses. If you are still unsure after studying these

operating instructions, ask a specialist for help.

The ignition unit of this power tool generates an electromagnetic field in operation. This field may affect the

function of pacers under certain conditions. Persons with a pacer must consult their physician and the

pacer manufacturer before using this power tool.

General information on vibrations: The following symptoms may occur in case of special personal

conditioning, caused by frequent vibration at fingers, hands or wrists: The body parts falling asleep,

tickling, pain, stabbing, changes of the skin tone or skin. If such symptoms are found, see a physician.

Non-observance of the safety notes may be potentially fatal. Comply with the accident prevention

provisions of the professional associations.

For any accidents that may occur, a first aid kit must be present at the workplace at all times. Material

that has been removed must be refilled at once.

Danger of fire from sparks! When working close to easily flammable objects or vegetation, a fire

extinguisher must be provided.

If you are working with this kind of power tool for the first time, have secure handling shown and

explained to you by a specialist.

Children and teens below 18 years of age must not work with this power tool; this does not include

youths older than 16 who are trained under supervision.

The power tool generally must be operated by a person – also when starting up. Keep persons and

animals away from the work area. If a person or animal approaches, the power tool must be stopped at

once. The user is responsible for any injury and property damage he causes.

This power tool must only be lent or passed on to persons who are familiar with this type, its operation

and the operating instructions. Always include these operating instructions.

Only work with this power tool when you are in good shape, rested and healthy.

Persons under the influence of alcohol or drugs, including prescription drugs, are not allowed to use this

machine, as their ability to quickly react to potential danger may be impaired.

3 Safety provisions

3.1 Correct use

3.2 General safety notes

Pd

I

e

C

m

cNt

If materia

authority

f

with the r

e

When cu

t

that the r

e

bars mus

t

provision

s

Never alt

e

Danger o

f

prior to u

s

Only use

approved

cutting to

o

Reliable

o

only gen

u

best qual

i

from you

r

the corre

c

Please n

o

Always s

t

engine.

N

ersons w

h

amage or

c

n order to

p

quipment.

Clot

h

Whe

n

cann

o

clos

e

heck the i

n

elting ma

t

ontaminat

e

ever wear

he environ

m

Wea

r

Use

p

Eye/

f

Wea

r

Wea

r

Use

b

3.3 Pre

s

ls that may

irst. Work

m

quired sa

f

ting pre-te

n

spective a

t be perfor

m

.

r, change

accidents

!

e.

those acc

e

for attach

m

ls.

peration a

n

ine spare

p

ity in mater

i

specialist

d

t parts. Yo

te that the

ore the ma

ever let th

e

o disregar

d

onsequen

t

revent inju

es should

b

performin

t inflame

b

-meshed li

n

formation

erials like

p

d with fla

m

scarves, ti

e

ent or the

a protecti

v

ersonal h

e

ace protec

t

firm safet

y

protective

reathing p

cribed wo

r

contain as

ust only

b

ety measu

r

sioned an

d

uthorities o

ed in the

p

or modify a

Only use

t

ssories an

d

ent to this

d safety o

f

arts. Origi

n

al, dimensi

ealer. Yo

u

ur dealer i

s

use of non

-

chine in a

s

machine

r

safety ins

t

ial losses.

ries, pleas

e

e tight-fitti

n

g any work

y sparks fl

y

en fabrics

)

in the work

olyester or

mable sub

s

s, jewelle

r

power tool

e helmet d

aring prot

e

ion is man

d

shoes wit

h

gloves wit

h

rotection fo

k clothin

g

estos or o

t

e performe

es.

steel-rein

f

r compone

n

rescribed

o

ny safety e

his machin

e

attachme

n

machine.

O

this machi

al spare p

a

ons, functi

o

r dealer ha

frequently

original pa

afe place

a

un unsupe

r

ructions, o

p

make sur

e

g (no lape

l

, wear a w

o

ing (mater

.

clothes an

d

nylon are

c

tances su

c

or other

c

. Tie back l

o

ing any

w

ction.

atory purs

u

steel toes

non-slip p

a

r dry cuttin

g

/ PPE (P

e

ther toxic s

d upon ap

p

orced con

c

t manufac

t

rder and u

quipment

o

if it is in

g

ts that ha

v

nly cutting

ne also de

p

rts are ide

n

n and saf

e

s been sup

supplied w

rts will void

nd in such

vised!

erating or

that you

w

s), but not

rking suit

o

ials of leat

h

ensure th

ontained i

n

h as petro

l

lothes that

ng hair a

n

ork.

ant to AN

S

and a goo

d

alms.

as protec

t

rsonal Pr

o

ubstances

a

roval and

o

rete pillars,

urers have

nder consi

d

r functional

ood, safe

c

e been su

p

discs appr

o

end on th

e

tical with

g

ty. Original

plied with

a

ith updates

your warr

a

a way that

maintenan

c

ear the pr

e

hindering.

f firm mate

er, cotton

a

at no easil

y

the clothe

s

or similar.

may get c

a

d secure it

I Z 87.1.

grip.

ion from d

u

tection E

q

re to be p

r

nly under

s

observe al

stipulated.

eration of

t

assemblie

s

ondition!

Al

plied by us

ved for thi

s

quality of

t

enuine pro

parts and

a

ppropriate

about imp

r

nty.

it will not p

o

e instructi

o

scribed cl

o

ials with s

u

fter flame-i

flammabl

e

. The wor

k

ught in the

under a he

l

st.

uipment)

ocessed, i

n

upervision

l instructio

n

Cutting of

r

he relevan

t

s of this m

a

ways chec

and that a

r

s machine

he spare p

duction pa

r

ccessorie

s

document

a

ovements

t

se any da

n

ns are liab

thing and

p

fficient fla

m

nhibiting tr

e

materials

a

ing clothe

s

cutting dis

c

lmet.

Safety pr

o

ENG

L

form the r

e

and compl

i

s and stan

einforcem

e

safety

chine.

the mach

i

e expressl

y

must be us

e

rts used.

U

ts and gua

r

are availa

b

tion to det

e

o the equi

p

ger. Stop

t

le for any

rotective

e inhibitio

n

atment or

nd no eas

must nev

e

, at object

s

visions

ISH 7

levant

ance

dards

nt

ne

d as

se

antee

le

rmine

ment.

he

that

heavy

ily

r be

in

Safety provisions

ENGLISH 8

Petrol is highly flammable. Keep distance from open fire and do not spill fuel. Do not smoke at the

workplace or at the site of fuelling!

Always switch off the engine before fuelling.

Danger of fire! Never refuel with the engine still hot!

Always carefully open the tank cap so that any overpressure present can reduce slowly and no fuel will

splash out.

Prevent skin and eye contact with mineral oil products. In case of eye contact, rinse at once with lots of

clear water. In case of persistent irritation, see a doctor immediately!

Regularly change and clean protective clothes.

Avoid breathing in fuel vapour.

The refuelling site should be well ventilated.

Avoid any soil spillage of fuel or oil (protection of the environment). Use a suitable mat.

Immediately clean any spilled fuel on the machine. Change contaminated clothing without delay.

Always tighten the fuel tank cap firmly by hand without using any tools. Tank caps are equipped with an

overturning protection and must be turned closed until a clear "skipping".

The fuel tank cap must not be able to work itself loose as a result of the vibrations of the engine.

Danger to life from burns! Observe leaks. Do not start up and work when fuel is escaping.

Fuels and oil must only be stored in properly and correctly labelled containers.

Before carrying the power tool (even across short distances from one working area to the next), always

switch off the engine and wait until the cutting disc has stopped. Carry the power tool by the top handle

and have the cutting disc point backwards.

Danger of burns! Do not touch the hot muffler.

Never carry or transport the power tool with the cutting disc running.

To avoid spilling of fuel and oil and to prevent damage, the power tool must be secured against tipping

when transporting it in vehicles. Check the tanks for fuel and oil for tightness. We recommend that the

tanks be emptied before transport.

Empty the tanks before shipping.

Advice: We recommend that you keep the original packaging in order to protect the equipment against

transport damage in case you ever need to ship it or transport it.

3.4 When fuelling up

3.5 In transport

Bo

The pow

e

Before a

s

to "0" an

d

Only the

i

Wear pro

t

The pow

e

own that

a

other wo

r

Danger o

f

tight fit.

Only perf

o

Danger o

f

safety!

efore any

perating a

n

Stop dial

The throt

t

to operat

e

locked).

The cutti

n

Danger o

f

result in

s

In case o

f

not be st

a

Only use

Keep at l

e

rooms.

Observe

s

power to

o

Perf

o

Check th

e

3.6 Duri

n

3.7 Bef

o

3.8 Wh

e

r tool mus

t

sembly, cl

e

the cuttin

g

dle speed

s

tective glo

v

r tool requ

i

re describ

k must onl

y

burns! Do

rm repair

s

accident

a

start, chec

k

d mainten

a

and one-to

u

le control

m

the throttl

e

g disc mu

s

fire! Igniti

o

parks whic

irregulariti

rted. In su

c

the power

t

ast 3 metr

e

ecure and

l.

rm the sta

r

idle settin

g assem

b

re start-u

p

n starting

not be as

s

aning, mai

disc must

etting mu

s

es for any

w

res regular

ed in these

be perfor

m

not touch

t

with origin

nd injury!

N

the entire

nce notes

ch stop b

u

ust move

f

control w

i

t be attach

e

n cable an

h could ign

es, recogni

h cases, h

ool if it is i

n

s distanc

e

firm hold

w

ting proce

s

g after star

t

ly, cleani

n

embled, m

a

ntenance a

have stop

p

t be perfor

m

ork.

maintenan

operating i

ed by spe

c

he muffler

w

al spare pa

o modifica

power tool

( chap.

8

tton must

b

reely and r

thout push

i

d firmly to

d spark plu

te any esc

a

sable dam

a

ave the po

w

completel

y

from the f

u

hen startin

s as descri

ing. The c

u

g, mainte

n

intained, r

e

nd repair,

a

ed.

ed with th

ce. Only p

e

nstructions

ialist work

s

hile it is s

t

rts.

tions are p

e

for operati

o

, page 29)

e easy to

o

eturn auto

m

ng (unlock

i

the spindl

e

g connecto

ping fuel/

a

ge, impro

p

er tool ins

assembl

e

elling site

w

g up. Alwa

y

bed in cha

p

tting disc

m

ance an

d

paired or

s

lways turn

engine ru

rform suc

h

and that y

o

hops auth

o

ill hot – no

t

rmitted at

t

nally safe

c

check the

perate.

atically to

ng) the thr

o

.

r must be f

i

ir mixture!

er settings

pected by

s

d condition

hen starti

n

s start up

o

. 6 on pag

e

ust stand

s

repair

tored in th

e

off the eng

i

nning.

maintena

n

u conside

r

rised by u

s

even for

m

he power t

ondition. I

n

following it

e

he idle po

s

ttle control

rmly in pla

c

or limited f

u

pecialist w

o

.

g. Never s

t

n level gro

23.

till in idle

m

vicinity of

ine; the sto

ce and rep

yourself s

k

.

aintenanc

e

ool, becau

s

addition t

o

ms:

ition. It mu

lock (throt

t

e. Loose c

nction, th

e

rkshops a

u

tart the ma

c

und and s

e

ode.

Safety pr

o

ENG

L

naked fla

m

p dial must

air work on

illed for. A

n

or to chec

e this may

the notes

t not be p

o

le control

onnection

c

power uni

t

thorised b

y

hine in clo

curely hold

visions

ISH 9

es.

be set

your

y

k it for

impair

in the

ssible

an

must

us.

sed

the

Safet

y

ENG

L

In ad

d

with t

h

Da

n

invi

s

nar

r

air

e

Inc

r

Se

c

inv

o

Ch

e

–

–

–

–

Th

e

Wh

e

Wo

r

–

–

–

–

–

–

–

–

–

–

Swi

Da

n

Da

n

fla

m

Da

nNev

3.9

provisions

ISH 10

ition to the

e motor d

e

ger of poi

s

ible and o

d

ow situati

o

xchange

a

eased dan

g

ure the wo

r

lved and

w

ck the site

Spark form

explosive

g

No electric

a

Objects th

a

environme

n

Prepare th

e

work piec

e

n working

k carefully

,

Ensure go

o

A

lways re

m

Put in wor

k

Be attentiv

e

Consider t

h

announce

d

Observe tri

A

lways hol

d

Never cut

s

Guide the

p

Only proce

objects wit

h

Do not use

tch off the

e

ger of bur

n

ger of fire!

mable obj

e

ger of hea

r

er work wi

t

During w

o

safety pro

v

vice:

oning! Onc

ourless. N

ns, trough

s

nd that no

t

er of fire!

D

rkplace ag

a

earing pro

t

of deploy

m

ation durin

g

ases of liq

u

l lines mu

s

t may fall

o

t first.

workplac

e

to be cut

m

in resident

i

considera

t

d sight an

d

ain within

c

ing breaks

towards

p

at use of

h

anger ma

y

pping dan

g

on to the

tanding on

ower tool

s

ss the wor

k

the cuttin

g

the power

ngine wh

e

s! Do not t

o

Muffler rad

cts.

ing damag

h defectiv

e

rk

isions alre

a

e the engin

ever start t

h

or ditches

.

oxic gase

s

o not smo

inst accid

e

ective clot

h

ent for pos

cutting m

e

ids, or ea

s

t be place

d

ff or topple

so that se

ust be fre

e

al areas, o

b

ely and cal

light cond

alling dist

a

in time.

ossible da

n

earing prot

also be m

ers and ob

power tool

a ladder.

o that no

b

piece to b

e

disc runn

i

tool to leve

n the pow

e

uch the m

iates enor

m

e and burn

s

muffler or

w

dy listed, t

e is runnin

g

e power t

o

Only work

may accu

m

ke at the w

o

ntal acces

s

es must b

e

sible dang

e

ans that

w

ily flamma

b

in the are

a

over durin

g

cure backi

n

of foreign

serve the

mly and do

itions.

nce of oth

e

ger sourc

e

ction limit

s

issed.

tacles. Ne

with both h

ody part is

cut with th

ng.

r off and s

h

r tool start

s

ffler while

ous heat.

N

!

ithout mu

f

he followin

g

, the pow

e

ol in close

d

here when

ulate.

orkplace –

by third p

a

present w

i

rs.

ork must n

e

le objects.

to be cut.

work mu

s

g away is

p

bodies su

c

noise prote

not endan

g

r persons

w

s and take

perceptio

n

ver work o

n

ands and

a

located in

t

e cutting di

ovel away

to behave

it is still ho

t

ever put t

h

fler.

safety pr

o

r tool prod

u

rooms. S

p

it is absol

u

not even in

rties, e.g.

w

thin 30 me

t

ver be pe

r

t be secur

e

ossible.

h as scre

w

ction provi

s

er any oth

ho may a

d

the corres

p

of sound

s

unstable

u

lways ens

u

he extend

e

sc running;

objects.

noticeably

.

e hot pow

e

visions als

o

ces toxic

e

ecial dang

e

tely certain

the proxim

ith warnin

g

res around

formed clo

s

d or remov

s, nails or

s

ions.

er persons

.

minister fi

r

onding pr

e

. Signal so

u

ndergroun

d

re a safe a

d swivel ra

never tou

c

differently.

r tool into

d

apply wh

e

xhaust tha

t

er also ap

p

that there

ity of the p

o

signs. On

the workin

e to poten

t

ed from th

e

tones.

st aid in e

m

ventive m

e

nds, calls,

ds.

nd firm sta

n

nge of the

c

h the floor

o

dry grass

o

n working

may be

lies in

is sufficien

t

wer tool.

ly persons

g area.

ially

working

ergencies.

asures.

etc. that

ce.

utting disc

r other

r on

.

Power tool description

ENGLISH 11

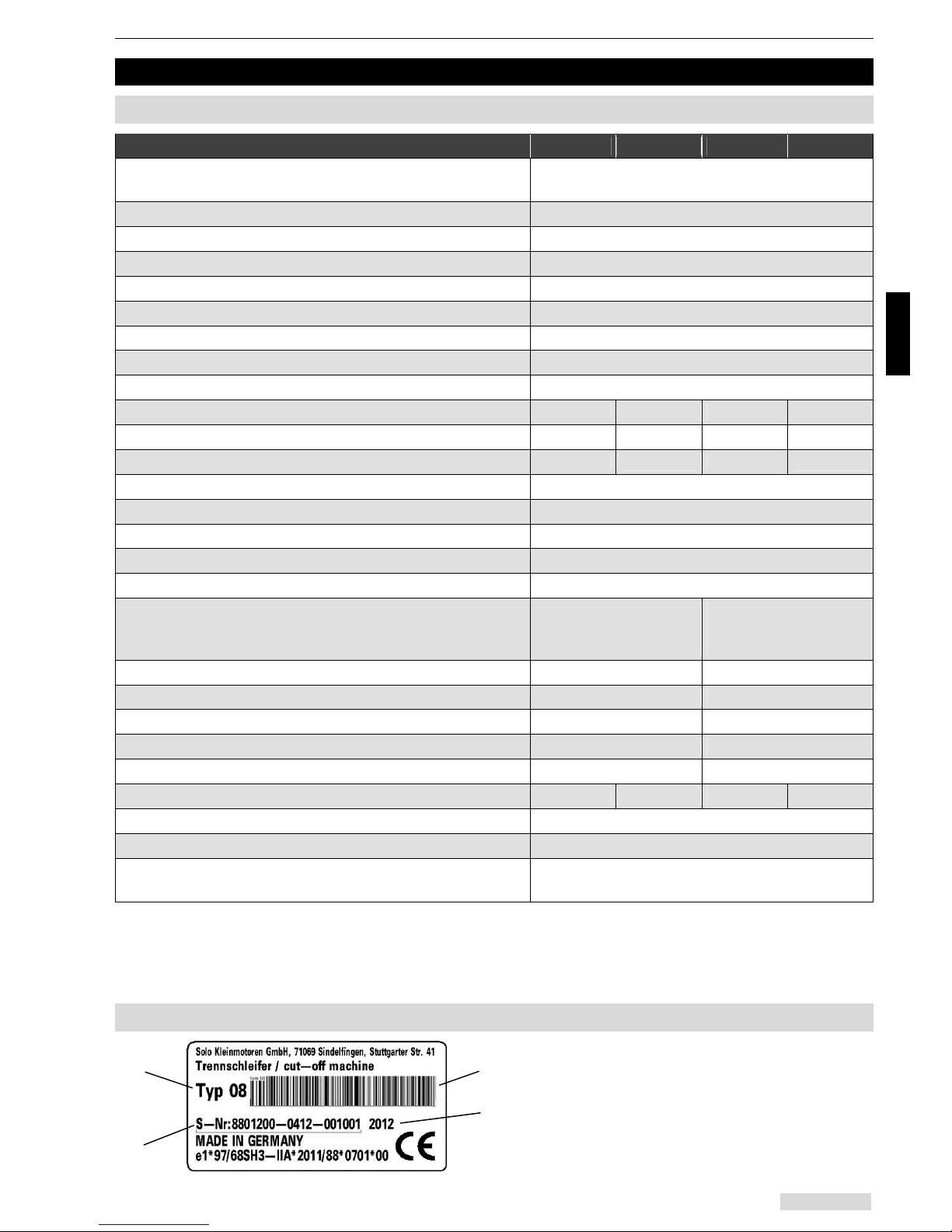

Model 880-12 881-12 880-14 881-14

Motor Single-cylinder two-stroke motor,

four-channel flushing

Engine capacity cm3 81

Bore Ø / stroke mm 52 / 38

Max. power at rpm kW / 1/

min

4.0 / 9,300

Max. torque at rpm Nm / 1/

min

4.8 / 7,000

Max. permissible speed

1

/

min

9,500 ±200 (no load with cutting disc)

Idling speed

1

/

min

2,600 ±200

Clutch engagement speed

1

/

min

4,800 ±200

Fuel tank capacity l 0,9

Oil tank capacity l --- 0.32 --- 0.32

Fuel mix ratio oil: petrol 1:50 --- 1:50 ---

Electronically controlled separate lubrication ---

---

Fuel consumption at max. power (ISO 7293)

kg

/h 1.75

Specific consumption at max. power (ISO 7293)

g

/

kWh

460

Carburettor, with primer Position-independent, electronically controlled

Air filter Paper / fleece

Ignition Electronic digital ignition with index

Cutting disc Diameter ″ / mm

Bore diameter

Tightening torque of the attachment screw Nm

12 / 300

20 mm or 1"

30 ±2

14 / 350

20 mm or 1"

30 ±2

Minimum flange outer diameter mm 100 100

Spindle diameter mm 20 20

Maximum spindle rpm

1

/

min

4,450 4,450

Cutting depth, max. mm 100 125

Dimensions Height / width / length mm 430 / 267 / 750 430 / 267 / 775

Weight without tank content, without cutting disc kg 10.1 10.4 10.2 10.5

Sound level

1,2

L

Pe

q

(EN ISO 19432 Annex B) dB(A) 98

Sound power level

1,2

L

We

q

(EN ISO 19432 Annex B) dB(A) 108

Weighted effective acceleration

1,3

a

hv,eq

(EN ISO 19432 Annex C)

rear handle / top handle m/s2

4.5 / 6.0

1

In determining the following values regarding the acceleration of vibrations and sound, the different operating

conditions were weighted in accordance with the current standards.

2

Insecurity K purs. to EC directive 2006/42/EC: 2.5 dB(A)

3

Insecurity K purs. to EC directive 2006/42/EC: 2 m/s2

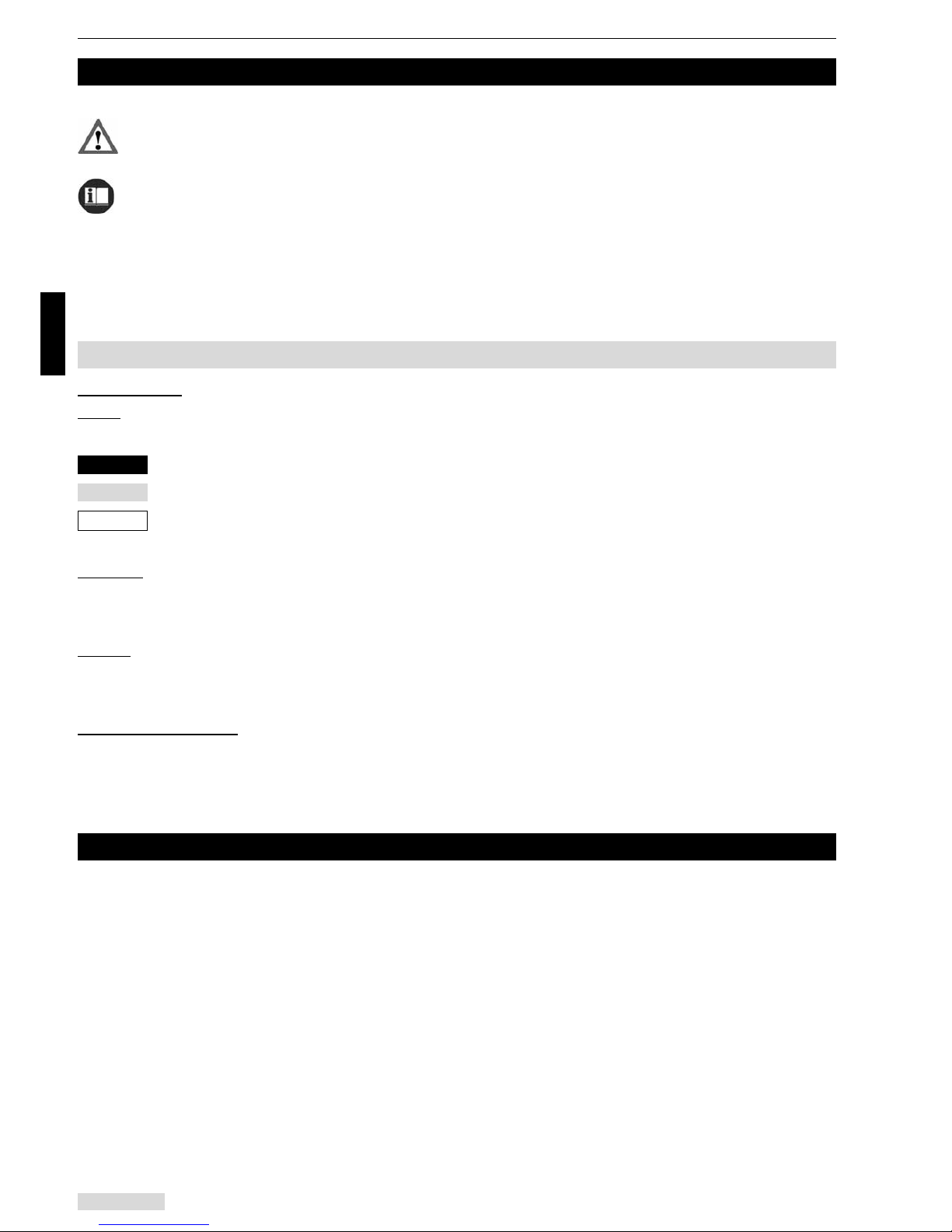

a: Type designation

b: Serial number

c: Bar code

d: Year of build

4 Power tool description

4.1 Technical data

4.2 Type plate

d

a

b

c

Loading...

Loading...