Solo 635, 636, 642, 643IP Instruction Manual

9 636 111 english 0/2008

635 / 636 / 642 / 643IP

Instruction manual

Important!

Read this instruction manual carefully before

first operation and strictly observe the safety

regulations!

Chain saw

ENGLISH 2

For USA only

Emissions Control Warranty Statement

The Environmental Protection Agency and Solo are

pleased to explain the emission control system on your

small non-road power equipment engine. In the US

new small non- road engines must be designed, built,

and equipped to meet the Environmental Protection

Agency's standards. Solo must warrant the emission

control system on your small non- road engine for the

period of time listed below provided there has been no

abuse, neglect, or improper maintenance of your small

non-road engine.

Your emission control system includes parts such as

the carburetor, the ignition system, and the exhaust

system.

Where a warrantable condition exists, Solo will repair

your small non-road power equipment engine at no cost

to you including diagnosis, parts, and labor.

Manufacturers Warranty Coverage

Solo's small non-road power equipment engines are

warranted for a period of two years. If any emission

control related part on your engine is defective, the part

will be repaired or replaced by Solo.

Contact Information for Authorized Service Center

Locations, Replacement Parts,

Warranty and Technical Information

Warranty repairs must be completed by a SOLO

Authorized Service Center.

SOLO USA, Inc. 1-800-765-6462

5100 Chestnut Avenu techserv@solousa.com

Newport News, VA 23605

Preface

Dear Customer,

Congratulations for choosing this SOLO quality

product.

The models in this series are particularly high-grade

chainsaws, made in Germany, that are specifically

designed for the multi-faceted demands of the hobby

and leisure market. A high-grade single cylinder twostroke engine with nickel-aluminium-silicon coated

cylinder, designed according to the proven four channel

technology for high performance and low fuel

consumption, guarantees you a high level of

serviceability from your machine.

The automatic chain lubrication system (Ecomatic),

the maintenance-free electronic ignition, the AntiVibration-System for protection at work, the excellent

starting characteristics and the ergonomic design of the

entire machine ensure excellent user comfort and it

makes light of your work. The safety equipment is stateof-the-art and complies with all German and

international safety regulations.

Prior to operating the unit, please read the owner’s

manual carefully, and most importantly, observe all

safety rules.

Observe the maintenance guidelines closely to

ensure the long service life of your equipment.

Your dealer will be glad to assist you with any

questions.

Symbols

The following symbols are used in this manual and on

the product:

Thoroughly read these operating instructions

before undertaking any maintenance,

installation and cleaning steps

Before starting the engine, make sure that you

are wearing a helmet, ear defenders and face

protection.

Switching off the engine

Choke flap:

Cold start position ! pull the lever out

Operation and warm start ! press the lever in

Chain lubrication: symbol above the chain

lubrication tank cap

Fuel mixture: symbol above the fuel mixture

tank cap

Danger! Failure to comply with the

instructions could cause accidents with

potentially life-threatening injuries.

Always wear protective gloves when working

with or on the device.

Always wear safety shoes with non-slip soles.

Chain brake: To block the chain, press the

lever forwards towards the guide bar.

To release the chain again, pull the lever back

towards the front handle.

Caution: Risk of kickback.

Please refer to the notes in chapter

9.“Hazards caused by kickback“

Never smoke near the power tool or where

the equipment is refuelled!

Keep open flames away from the power tool

and the fuel can

- This equipment produces exhaust fumes

and

- fuel vapours are poisonous;

never start or refuel in enclosed spaces

Packaging and disposal

Please keep the original packaging in order to protect

the equipment against transport damage in case you

ever need to ship it or transport it. If the packaging

materials are no longer required then they must be

disposed of properly in accordance with applicable local

regulations. Cardboard packaging materials are raw

materials which can be recycled or reused.

At the end of the equipment’s service life, please make

sure that you dispose of it properly, in accordance with

the official directives and regulations that apply in your

area.

ENGLISH 3

Index

Page

1. Safety regulations.....................................................................................................................................4

1.1 Correct use / General safety instructions 4

1.2 Working clothes 4

1.3 Fuelling 5

1.4 When transporting the equipment 5

1.5 Notes on assembly, cleaning, adjustment, maintenance and repairs 5

1.6 Before starting the tool 5

1.7 Starting the tool 6

1.8 When working with the saw 6

2. Specification .............................................................................................................................................7

3. Standard delivery......................................................................................................................................8

4. Designation of important controls and functional parts.......................................................................8

5. Preparing the equipment for use...........................................................................................................10

5.1 Assembly of the guide bar and chain 10

5.2 Adjusting the chain tension 10

6. Refuelling and adding oil to the chain lubrication system .................................................................11

6.1 Fuel information 11

6.2 Mixing ratio 11

6.3 Fuelling 11

6.4 Chain lubrication 11

7. Chain brake .............................................................................................................................................12

8. Starting / Stopping the engine...............................................................................................................12

8.1 Start-up settings 12

8.2 Starting up 13

8.3 Engine will not start: 13

8.4 Switching the engine off:: 13

9. Hazards caused by kickback .................................................................................................................14

10. Using the chainsaw ..............................................................................................................................15

10.1 Application areas 15

10.2 Sawing 15

11. Operating and maintenance information............................................................................................17

11.1 Maintenance and care of the cutting gear 17

11.2 Air Filter Maintenance 18

11.3 Carburettor settings 19

11.4 Maintenance of the chain brake 19

11.5 Vibration damping 19

11.6 Spark plug information 20

11.7 Shutdown and storage 20

11.8 Replacing the fuel filter 20

11.9 Self-help tips 20

11.10 Scheduled maintenance 21

12. Accessories...........................................................................................................................................21

13. Parts subject to wear and tear.............................................................................................................25

14. Guarantee ..............................................................................................................................................25

15. CE Declaration of conformity ..............................................................................................................25

* Permissible cutting gear.........................refer to the last two inside pages of this operating manual

(after the Dutch section)

Information regarding these operating instructions:

Some of the graphic depictions in these operating instructions are schematic illustrations which are not designed to

accurately reflect your specific chainsaw. However, the content is binding in every case.

Safety regulations

ENGLISH 4

1. Safety regulations

1.1 Correct use / General safety instructions

The chainsaw must only be used to cut wood and objects made of wood. The chainsaw must not be used for any

other purposes (chapter 10.1 "Application areas").

Before you start using the saw for the first time, please take the time to carefully read through these

operating instructions, and make sure you keep them in a safe place. At all times the instructions must be

kept available at the place where the saw is being used. The instructions must be read by anybody who works with or

on the device (including for maintenance, care and repairs).

Take special care when using this power tool. By handling the power tool recklessly or without the necessary care

and attention you can put yourself in grave danger. Always work with the utmost care and constantly remind yourself

of the potential dangers and hazards that could occur. Never undertake any work you are not fully comfortable with or

if you are not in a position to fully assess the risks involved. If you are still unsure after reading these operating

instructions, please consult a specialist or enrol in a training course for safe handling and use of the power tool (e.g.

at a specialist forestry training centre).

If you ignore these safety instructions you could be putting your life at risk. Please also make sure that you comply

with all of the health and safety requirements of the professional trade associations.

• When operating in highly flammable vegetation and in areas affected by drought, keep a fire extinguisher handy

(risk of fire).

• You should request and receive instructions from the vendor on the safe operation if you are using this type of

product for the first time.

• Children and young people under 18 years may not work with this power tool, with the exception of young people

over 16 years of age who are being trained under supervision.

• The power tool can be operated easily - even on start-up - by one person. Keep bystanders and animals away

from the working area. When working near thickets, be aware that children and animals may be hidden there.

Immediately stop the machine and the cutter if any person or animal comes close to the working area. The

operator is responsible for any accidents or damage caused to parties or property.

• This machine may only be passed on or lent to third parties if they are familiar with the safe use of this product

and with these instructions. Always supply the manual with the machine.

• Ensure you are rested and in good health when using this machine.

• Persons under the influence of alcohol or drugs, including prescription drugs, are not allowed to use this

machine, as their ability to quickly react to potential danger may be impaired.

• Never alter, change or modify any safety equipment or functional assemblies on this machine.

• Only use this machine if it is in good, safe condition. Always check the machine prior to use. Risk of accident!

• Only use those accessories and attachments that have been supplied by the manufacturer and that are

expressly approved for attachment.

• The reliability and safe operation of your machine depend on the quality of parts used with the machine. Only use

original spare parts. Original spare parts are identical with genuine production parts and guarantee best quality in

material, dimensions, function and safety. Original parts and accessories are available from your specialist

dealer. Your dealer has been supplied with appropriate documentation to determine the correct parts. Your

dealer is frequently supplied with updates about improvements to the equipment. Please note that the use of

non-original parts will void your warranty.

• Always store the machine in a safe place and in such a way that it will not pose any danger. Stop the engine

when the machine is not used.

Persons who disregard safety instructions, operating or maintenance instructions may be liable for any damage or

consequential losses.

1.2 Working clothes

To prevent injuries, always wear suitable clothing and safety equipment when working with this power tool. This

clothing should be practically oriented to the application (for example a tight fitting work suit), but should not be

confining.

We recommend: SOLO forest and countryside work jacket EN 340 Part no: 99 303 000 + size (2[s] - 6[xxl])

SOLO Outdoor Knee-bree ches Part no: 99 020 95 + size

or SOLO Outdoor dungarees Part no: 99 020 94 + size

Never wear scarves, ties, jewellery or other items of clothing, which might get caught in the equipment, in brush or on

branches. Safely tie back long hair (use a cap, helmet or similar).

Wear safety shoes with a good tread.

We recommend: SOLO leather forest boots Part no: 99 305 10 + size (36 - 48)

Wear protective gloves with non-slip palms.

We recommend: SOLO Forst Part no: 99 390 13 + size (09 / 10 / 12)

Use personal hearing protection and a face protector (e.g. a visor on a safety helmet). Always wear a safety

helmet when working in woods or forests. Falling branches pose a serious risk.

We recommend the SOLO safety helmet with face and hearing protection, order no.: 99 390 1101 (one size)

Safety regulations

ENGLISH 5

1.3 Fuelling

Petrol is very light and highly flammable. Keep away from open flames and never spill fuel. Do not

smoke at the operating site or at and near the refuelling site!

• Stop the engine prior to refuelling.

• Let the engine cool down before refuelling - fire risk!

• Open the tank lid slowly to allow any excess pressure in the tank to be reduced without the risk of petrol spraying

out.

• Fuel may contain substances similar to solvents. Prevent products made from mineral oil coming into contact

with skin and eyes. Wear protective gloves during filling with fuel. Frequently change and clean protective

clothing.

• Avoid breathing in fuel vapour.

• The refuelling site should be well ventilated.

• Avoid any soil spillage of fuel or oil (protection of the environment). Use a suitable mat.

• Immediately clean any spilled fuel on the machine. Change contaminated clothing without delay.

• Always tighten the fuel tank cap firmly by hand without using any tools. The fuel tank cap must not be able to

work itself loose as a result of the vibrations of the engine.

• Check for petrol leaks. Do not start the machine or work with the machine if there is a petrol leak. Life threatening

risk from burns!

• Store fuel and oil in approved and correctly labelled containers

.

1.4 When transporting the equipment

• When carrying the chainsaw for short distances (from one working area to the next), always apply the chain

brake so that the chainsaw is blocked (preferably switch the engine off as well).

• Never carry or transport the power tool while the cutting tool is running.

• When transporting the device over longer distances, always switch the engine off and attach the chain guard.

• To prevent leakage of fuel or oil and damage in general, make sure that the device is secured so that it cannot

fall over when it is transported in vehicles. Check the fuel and chain lubrication tanks for leaks. Ideally you should

drain the tanks prior to transport.

• Always empty the tanks before dispatching the unit.

1.5 Notes on assembly, cleaning, adjustment, maintenance and repairs

• The power tool must not be assembled, maintained, repaired or stored in the vicinity of naked flames.

• The engine must be switched off and the stop switch set to "0“ for the duration of all work performed on the guide

bar and saw chain (for assembly, cleaning, maintenance and repairs) (ideally the spark plug connector should be

unplugged as well). Always use protective gloves.

• The power tool requires regular maintenance. Only perform maintenance or repairs yourself if the relevant

operations are covered in the operating instructions. All other work should be performed by an authorised

specialist workshop.

• During maintenance of the silencer or when checking that the silencer is firmly positioned, never touch the

silencer if it is still hot – risk of burns! The silencer gives off extremely large amounts of heat.

• Only genuine replacement parts supplied by the manufacturer must be used for any repairs.

• No changes must be made to the power tool, as this could affect the safety of the device and increase the risk of

accident or injury.

1.6 Before starting the tool

Check the tool every time before starting it to make sure that the complete power tool is operationally safe. The

following points should be checked in addition to the points listed in the operating and maintenance instructions

(chapter 11):

• The stop switch must be easy to switch.

• The throttle control must move freely and return automatically to the idle position. If the throttle control is

operated while the choke lever is pressed in then this must cancel any part throttle stop that is set.

• The guide bar must be firmly secured. Always check that the chain has the correct tension and adjust the tension

if required before starting the tool.

• Also check that the ignition cable and spark plug connector are firmly in place. If there is a loose connection this

can result is sparks which could ignite any escaping fuel/air mixture – fire hazard!

If anything is not as it should be, signs of damage are evident, settings are incorrect or the functional integrity of the

unit is compromised, do not start up the power tool. Instead, have it checked by a specialist workshop.

Safety regulations

ENGLISH 6

1.7 Starting the tool

• When starting the tool, keep a minimum distance of 3 metres to where the tool was refuelled. Never start the

device in an enclosed room.

• Make sure that you have a secure footing on firm ground when starting the tool. Always check that the ground is

level and keep a safe hold of the power tool.

• Perform the start-up routine as described in chapter 8. "Starting the engine / stopping the engine".

• Once the unit has been started, check the idle setting. The cutting blade must be stationary during idling.

• Once it has warmed up, switch the engine off and recheck the chain tension and adjust as required.

1.8 When working with the saw

• The power tool must only be started up if it is fully assembled.

• Work on windfall must only be performed by trained persons.

As soon as the engine is running, it produces toxic exhaust gases which may be colourless and odourless.

Never start up the tool in enclosed spaces. Always make sure that there is sufficient air exchange if you are

working under restricted conditions, such as in a dip or a ditch.

Do not smoke at the place of work or in the close vicinity of the power tool, as this would be an increased fire

hazard.

• Work carefully, deliberately and calmly and do not endanger the safety of others.

- Make sure that visibility and lighting conditions are good.

- Stay within calling distance of others who could help in the event of an emergency.

- Take breaks in good time.

- Be aware of potential sources of danger and take appropriate precautionary measures. Remember that the use

of ear defenders makes it more difficult to hear other sounds. This may also mask sounds warning of imminent

danger or shouts of warning etc.

- Remember that freshly debarked wood is very slippery (bark). Also take care in the wet, when the ground is

slippery, on slopes on uneven terrain.

- Look out for obstacles and hazards that could trip you up, e.g. tree roots, tree stumps and edges. Take special

care when working on slopes. Never work while standing on unstable ground.

- Always hold the power tool firmly with both hands and make sure you have a secure footing on stable ground

at all times.

- Never use the saw above shoulder height and avoid leaning too far forward. Never use the saw while standing

on a ladder, and never climb the tree holding the saw. The only safe way to reach greater heights is to use a

hydraulic lifting cabin.

- Move the chainsaw in such a way that no part of your body would be in the way if the arc of movement of the

saw chain was extended.

- Never touch the ground with the chainsaw while it is running.

- Do not use the saw to prise off or scoop away pieces of wood or other objects.

- Longitudinal cuts should be made at as flat an angle as possible. Special care is required here, as the bumper

spikes cannot engage.

- Be careful when cutting wood which has splintered, as sawn off pieces of wood can be torn off and fly off at

high speeds (risk of injury).

• Switch the engine off if you notice any significant changes in the behaviour of the power tool.

• Never touch the silencer while it is hot – risk of burns. Never set down the hot power tool in dried grass or on

other flammable objects. The silencer gives off extremely large amounts of heat (fire hazard).

• Never work with a defective silencer or without a silencer. You risk damaging your hearing and burning yourself

on the device.

First Aid

A first aid box should always be available on-site. Immediately replace any materials you have used:

Note:

Over exposing persons with circulatory problems to vibrations can lead to damage to their nervous system or blood

vessels. The following systems may occur from vibrations to fingers, hands or the wrists: Numbness, itching, pain,

twinges, changes to the colour of the skin or the skin itself. Seek medical advice if you experience any of these

symptoms.

Specification

ENGLISH 7

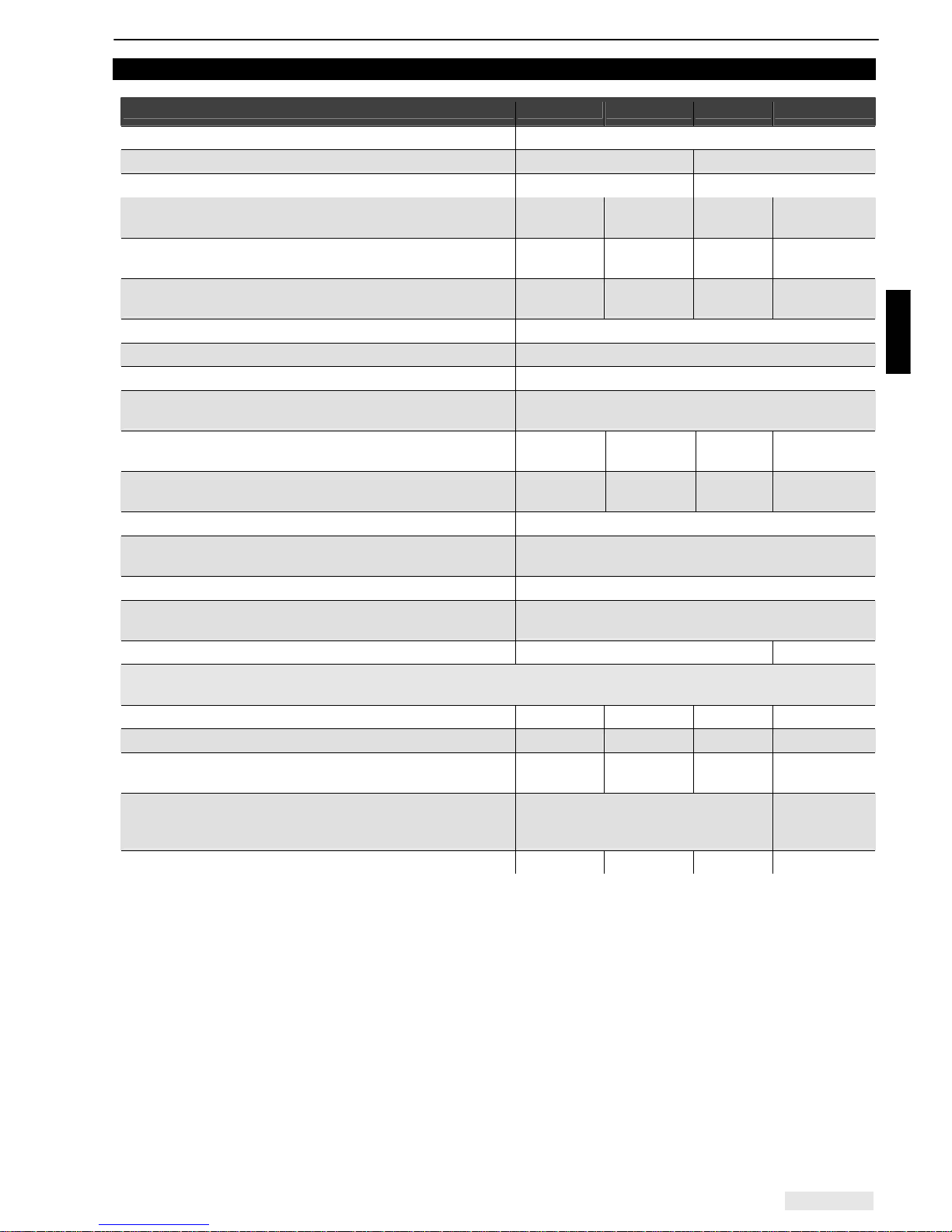

2. Specification

Chain saw 635 636 642 643IP

Engine type SOLO single cylinder two-stroke engine

Engine capacity cm3 36,3 40,2

Bore / stroke mm 38 / 32 40 / 32

Max. power kW

at rpm

1

/

min

1,4

8.500

1,5

8.500

1,8

8.500

2,0

9.000

Max. torque Nm

at rpm /

1

/

min

1,8

7.000

1,8

7.000

2,1

6.500

2,5

6.200

Max. permissible speed

1

/

min

no load with cutter

11.500

± 200

11.500

± 200

12.000

± 200

13.000

± 200

Medium idling speed

1

/

min

2.800± 150

Clutch engagement speed

1

/

min

4200± 150

Fuel tank capacity l 0,37

Fuel mix ratio: with SOLO 2T engine oil

with other two-stroke oils

1 : 50

1 : 25

Fuel consumption at max. power

ISO 7293

kg

/

h

0,7

0,7

0,8

0,8

Specific consumption at max. power

ISO 7293

g

/

kWh

500

490

470

410

Capacity of the chain lubrication oil tank l 0,19

Carburettor All-position diaphragm carburettor with primer and

integrated fuel pump

Air filter, two part Flow filter insert and large volume foam filter

Ignition Electronically controlled magneto ignition,

maintenance free

Sprocket teeth 6 7

In determining the following values regarding the acceleration of vibrations and sound, the different operating

conditions were weighted in accordance with the current standards

Sound pressure leve L

Peq

EN ISO 22868 dB(A) 100 100 101 101

Sound power level L

Weq

EN ISO 22868 dB(A) 105 105 107 107

Weighted effective acceleration a

hv,eq

DIN ISO 22867

Handle r.h. side / handle l.h. side m/s

2

9,1 / 7,4

9,1 / 7,4 7,9 / 4,8

7,5 / 4,5

Dimensions Height/ Width/ Length

cutting length of the guide bar 35 cm (14’’) mm

cutting length of the guide bar 38 cm (15’’) (643IP) mm

250/ 220/ 720

---

---

250/ 220/ 750

Weight without tank contents, guide bar and chain kg 4,2 4,2 4,1 4,1

Build year of the power tool ! refer to the type plate on the power tool (Chapter 4, "

Designation of important

controls and functional parts ").

Permissible cutting gear and the corresponding cutting lengths ! refer to the last two inside pages of this operating

manual (after the Dutch section)

Standard delivery ; Designation of important controls and functional parts

ENGLISH 8

3. Standard delivery

• Chainsaw – basic unit (without guide bar and saw chain)

• Guide bar

• Saw chain

• Chain guard

• Tool: Combination tool (spark plug spanner with screwdriver), plus additional screwdriver

• These Operating Instructions

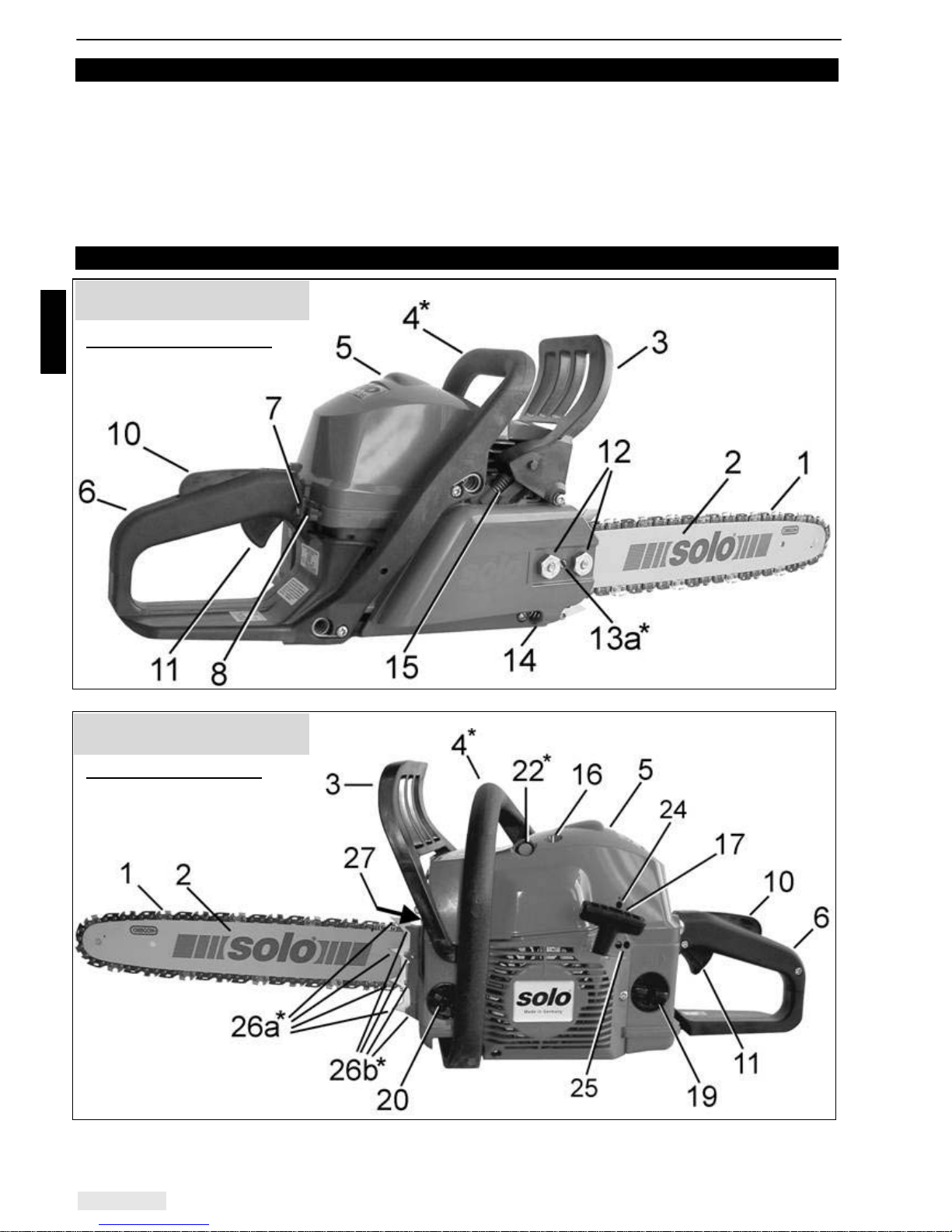

4. Designation of important controls and functional parts

View: profile from the right

View: profile from the left

Fig. 1a

(

Depending on the version

)

Fig. 1b

(Depending on the version)

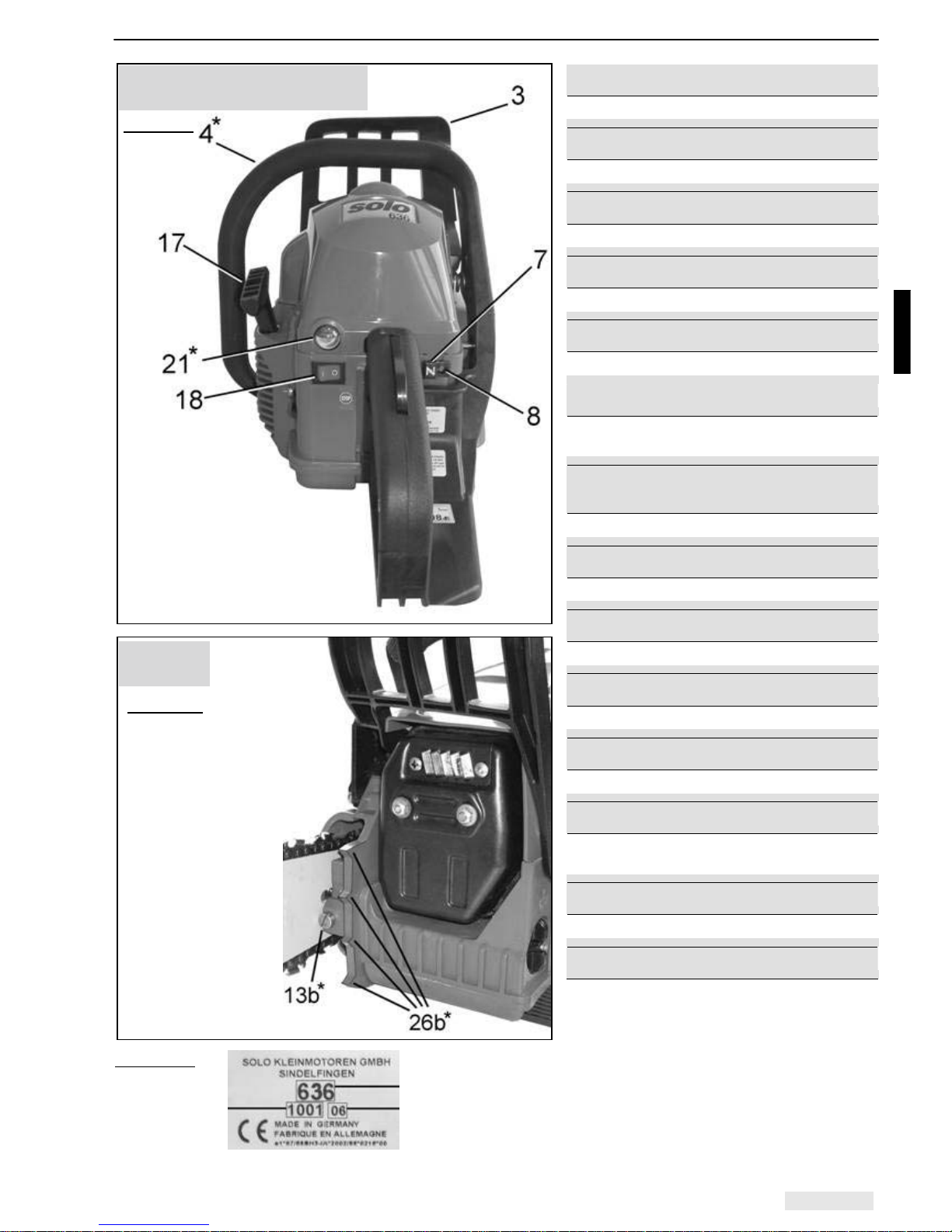

Designation of important controls and functional parts

ENGLISH 9

View: rear

View: front

-

Type plate:

Type designation

Serial number Build year (06 !2006).

.

Fig. 1c

(Depending on the version)

Fig. 1d

(635)

1. Chain

2. Guide bar

3. Hand protection

4*. Front handle

5. Cowl

6. Rear handle

7. Choke

8. Part throttle control pin

10. Throttle control lock

11. Throttle control

12. Retaining nuts for the rail cover

13a*. Chain tensioning bolt on the side

(636, 642, 643IP)

13b*. Chain tensioning bolt in front

(635)

14. Chain guard

15. Chain brake release spring

16. Hood fixing screw

17. Starter handle

18. Stop switch

19. Fuel tank cap

20. Chain lubrication oil tank cap

21*. Primer (636, 642, 643IP only)

22*. Decompression valve (636, 642 only)

24. Idling stop screw T

25. Carburettor adjusting screws (H / L)

(for use by a specialist workshop only)

26a*. Bumper spikes metal (643IP)

26b*. Bumper spikes (635, 636, 642)

27. Exhaust

*

Depending on the version

Loading...

Loading...