Solo 425, 475, 435, 485, 473D Instruction Manual / Spare Parts List

...

9 452 161 english 05/2006

425 / 475 // 435 / 485 // 473D / 473P

Instruction manual /

Spare parts list

Attention!

Read this instruction manual carefully before first

operation and strictly observe the safety

regulations! At using the sprayer wear protective

gloves, goggles and breathing protection.

Backpack Sprayer

ENGLISH 2

Congratulations on the purchase of your new

SOLO Sprayer. We thank you for your wise choice and

are confident that you will be very happy with it.

The use of modern materials in conjunction with

SOLO Know-How over many decades guarantee

customer satisfaction with millions of SOLO machines

in all countries of the world.

In the best interest of continued technological

progress we reserve the right to change design and

configuration of any product without prior or other

notice. Therefore, please note that text and illustrations

of this manual are not to be considered binding and do

not constitute a basis for legal or other claims.

1. Safety

• Do not operate the sprayer while persons

(especially children) or animals are in close vicinity.

The operator is responsible for any damage or harm

to third parties.

• When using plant protection equipment and while

working with plant protection chemicals of any kind,

always observe the Safety Precautions prescribed

by the chemical manufacturer. The operator is to

observe Personal Safety Regulations (Safety

Clothing).

• Heavily dilute (approx. 1:10) surplus spray fluid left

over after treatment of field or garden, and spray the

solution over the area you have already treated.

• After every use and especially after the end of the

spraying season, clean and flush the sprayer, tank

as well as all parts which come in contact with

chemicals.

• Residues of plant protection chemicals may lead to

corrosion and damage of the sprayer.

• Clean and service wear parts such as nozzles,

filters,

gaskets and seals.

• Never clean nozzles with hard objects.

• Any remaining excess spray solution can be

heavilydiluted (approx. 1:10 ratio) and applied over

the already treated area.

• Damaged parts should be replaced without delay.

Always use Original Parts.

• Always release all pressure in the tank or spray line

before commencing service or maintenance work

on the machine.

We recommend the SOLO horticultural equipment

cleaner in 500 ml bottles; part no. 49 00 600

• When removing the spray tube from the machine

always point the end of the tube away from yourself.

• For safety reasons, the sprayer should not be used

forth application of:

o aggressive liquids (sanitizers, disinfectants and

preservatives)

o liquids above 40 °C temperature

o flammable liquids with a flashpoint below 55 °C

2. General Information

The SOLO Pressure Sprayer is designed for the

application of approved plant protection chemicals in

agriculture, horticulture, viticulture and forestry. All

Accident Prevention Regulations and all generally

recognized Safety Precautions are to be adhered to.

Spray solutions other than approved plant protection

materials may only be used if any detrimental effect to

the machine or harm to persons, animals and

environment can be excluded. For the operator and

possibly the chemical manufacturer to test the material

resistance to certain chemicals, the product

manufacturer will provide details of the type of

materials used for the Pressure Sprayer. Any

unauthorized modification or changes made to the

Pressure Sprayer will automatically exclude liability

claims against the manufacturer.

3. Check list for completeness

• 1 piece Pressure Sprayer (assembled with Pressure

tube and handle )

• 1 piece LX-lever

o 2 pieces disc 16,5 x 24 x 1

o 1 piece Screw M8 x 30

o 1 piece disc 8,4

o 1 piece nut M8

• 1 piece spray tube (complete assembled)

• 1 piece Tank Lid

• 1 piece Pressure Tank Plug with O-Ring 16 x 3 (not

Model 473)

• 1 piece Operators Manual

• 1 piece Hollow Cone Nozzle with Swirl Plate and

Gasket

• 1 pc. each symbolic label for

container content: herbicide,

fungicide and insecticide.

NOTE:

Affix the appropriate label to identify

the container content.

PLEASE NOTE:

Never pour different agents at the same time into the

container. Before using a different agent, thoroughly

clean out the container and all parts in contact with the

spray agent, then flush with plenty of water. We

recommend the SOLO horticultural equipment cleaner

in 500 ml bottles; part no. 49 00 600

ENGLISH 3

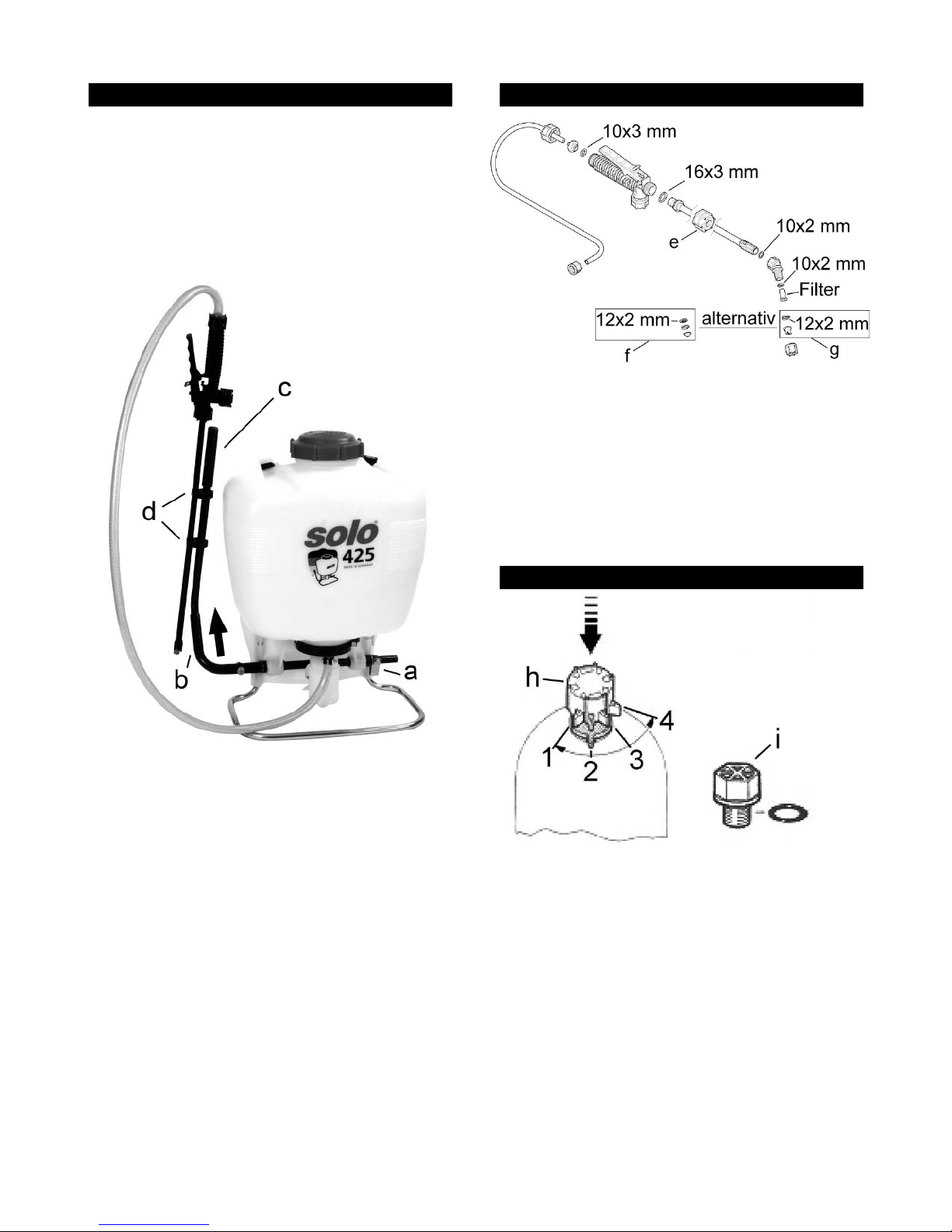

4. Assembly

The Sprayer is assembled except for the pump lever

which can be attached to either side. (discharge hose

and lever grip already fitted) 1-off lever grip (LX lever

model). The pressure sprayer is supplied with fittings

for assembly of the lever grip (LX lever) preattached on

the left-hand side (facing towards the tank inscription).

If you prefer the lever grip (LX lever) to be mounted on

the opposite side, reposition the safety clips (a) on the

r.h. side.

When fitting the LX lever, the retaining tube (b) of the

LX lever should be facing upwards and back (facing

towards the tank inscription).

If you prefer the lever grip (LX lever) to be mounted on

the opposite side, reposition the safety clips (a) on the

r.h. side.

To store the device, raise the pump handle (C) of the

LX lever in the retaining tube (b) and suspend the

spray tube in both clips (d).

To work the pump handle (c),lower it again in the

retaining tube (b).

The spray tube is connected to the shut-off valve by

means of screw cap.

5. Correct choise of

The spray tube is connected to the shut-off valve by

means of screw cap (e).

For the treatment of shrubs, bushes and trees (three

dimensional distribution) we recommend the use of the

hollow cone nozzle (f) . For area treatment (two

dimensional distribution) we recommend the use of a

flat spray nozzle (g).

For the treatment of tall bushes or trees, a brass tree

lance (150cm length) is available as an accessory (part

no. 49 00528).

6. Pressure adjustment

To regulate the output quantity/ droplet size, the spray

pressure can be adjusted in steps from 1-4 bar.

The pressure is adjusted prior to filling the tank by

turning the adjuster cap (h) on top of the pressure tank.

After any pressure in the pressure tank has been

released via the shutoff valve, press down adjuster cap

and locate the selected pressure marker tooth over the

tooth on the pressure tank.

Should spray pressure in excess of 4 bar be required

we recommend to replace the pressure valve with the

pressure plug (i)(part no. 42 00 215) which is supplied

with the unit. Release any pressure in the pressure

tank first before replacing the valve. A spanner width of

24 mm is required.

Loading...

Loading...